Gas shield device for argon arc welding of titanium material

A technology of argon arc welding and gas shielding, which is used in devices for supplying/removing shielding gas, arc welding equipment, welding equipment, etc., which can solve the problem of blue and gray weld color, uneven gas dispersion, and poor weld pool protection. and other problems, to achieve uniform gas dispersion, increase the number of shunt holes, and good welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

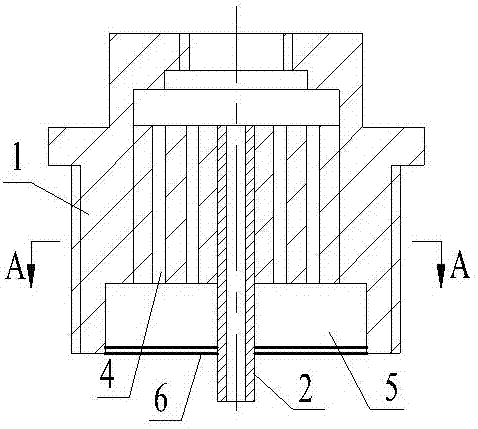

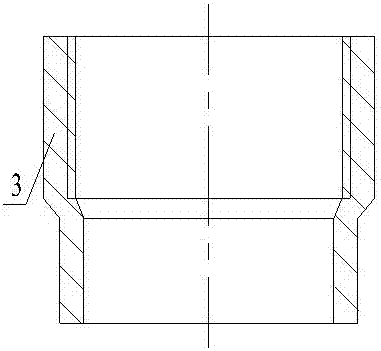

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

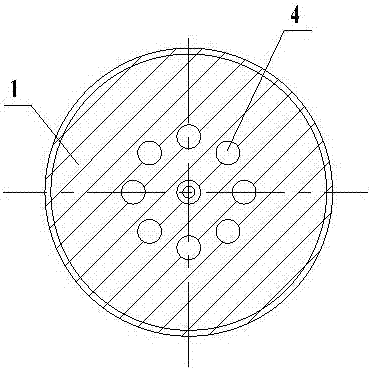

[0013] Such as Figure 1 to Figure 3 As shown, the titanium argon arc welding gas shielding device includes nozzle 1, porcelain nozzle 2 and conductive nozzle 3. Centering on the contact tip 3, there are eight shunt holes 4 arranged in a ring shape, and the end of the nozzle 1 is a protective cover structure with a cavity 5 inside. Increase the number of round holes for diversion, increasing the original 3 to 8, the round holes are more densely arranged, and there are 2 layers of 200-mesh stainless steel wire mesh 6 at the end of the nozzle to make the gas disperse more evenly and the air flow It is more stable and plays a better protective role...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com