Base plate device of industrial water jet machine

A water spray machine and base plate technology, applied in the direction of the spray device, can solve the problems of easy deformation, etc., and achieve the effect of convenient maintenance, strong practicability, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

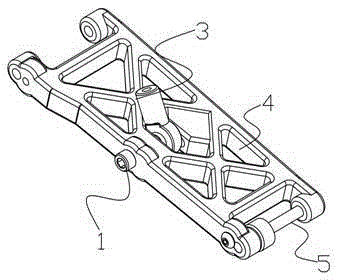

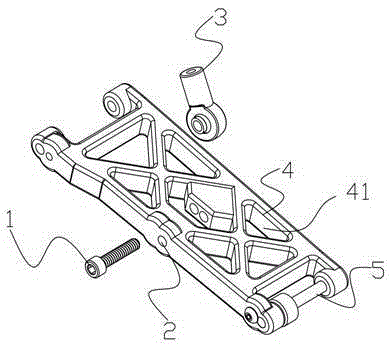

[0014] Such as figure 1 , figure 2 As shown, the industrial water spray machine bottom plate device of the present invention includes a rectangular mounting base plate 4, which is provided with a heat dissipation grid array composed of heat dissipation grids 41, and a side wall of the mounting base plate 4 is provided with a The fixed screw hole 2 is provided with a connecting bolt 1, the head of the connecting bolt 1 is provided with a movable faucet 3, and the tail of the mounting base plate 4 is provided with a rotatable fixed shaft 5.

[0015] The faucet 3 is made of stainless steel, and the mounting substrate 4 is made of aluminum alloy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com