Hydraulically controlled internal and external two-way compression packer

A packer, two-way technology, applied in the direction of sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of unreliable diversion of inner and outer pipes, unsmooth backwash well, cumbersome construction procedures, etc., to achieve The effect of simplifying the operation procedure and water injection string, meeting the requirements of well flushing and reducing the operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

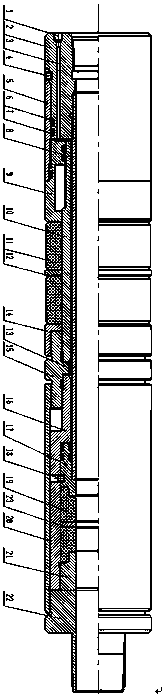

[0022] Embodiment 1: The outer setting mechanism includes an outer rubber cylinder 11, an outer piston 9, and an outer support sleeve 10. The outer piston 9 and the outer rubber sleeve 11 are sequentially sleeved on the outer wall of the outer support sleeve 10 from top to bottom, and the outer The piston and the outer rubber tube are in axial contact, and the outer wall of the upper end of the outer piston is connected to the upper connection sleeve 5 , and the upper connection sleeve is temporarily fixed with the upper joint 1 by the upper shear pin 4 . The upper joint is provided with a separate upper hydraulic channel 3 that penetrates up and down and communicates with the outer piston. An outer adjustment ring 14 is arranged between the lower end of the outer rubber tube and the bridging joint 15. A central pipe 8 is arranged inside the outer support sleeve. The upper end of the central pipe is connected to the upper joint 1, and the middle passage leading to the inner set...

Embodiment 2

[0023] Embodiment 2: On the basis of Embodiment 1, the upper end of the inner rubber tube is connected to the piston in a stepped end face, and the lower end of the inner rubber tube and the upper end of the adjustment ring are also connected in a stepped end face. The inner wall of the inner piston is provided with an inner ring limiter, and the lower end of the central tube is fixed on the inner ring limiter. There can be multiple outer rubber tubes with outer spacer rings 12 arranged between them, and multiple inner rubber tubes can be set with inner spacer rings 23 with each other.

[0024] In short, in the present invention, the upper joint 2 is provided with a pressure transmission hole 1 and an upper hydraulic passage 3, the inside of the upper joint is threaded with the central pipe 8, the outer part of the upper joint is threaded with the upper connecting sleeve 5, and the upper joint The sleeve is threadedly connected with the outer piston 9, the outer support sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com