Method for preparing magnesium sulfate from anthraquinone waste acid

A technology of anthraquinone waste acid and magnesium sulfate, applied in the direction of magnesium sulfate, etc., can solve the problems of reduced yield, longer process flow, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, the concentration of the dilute sulfuric acid solution is 50wt%.

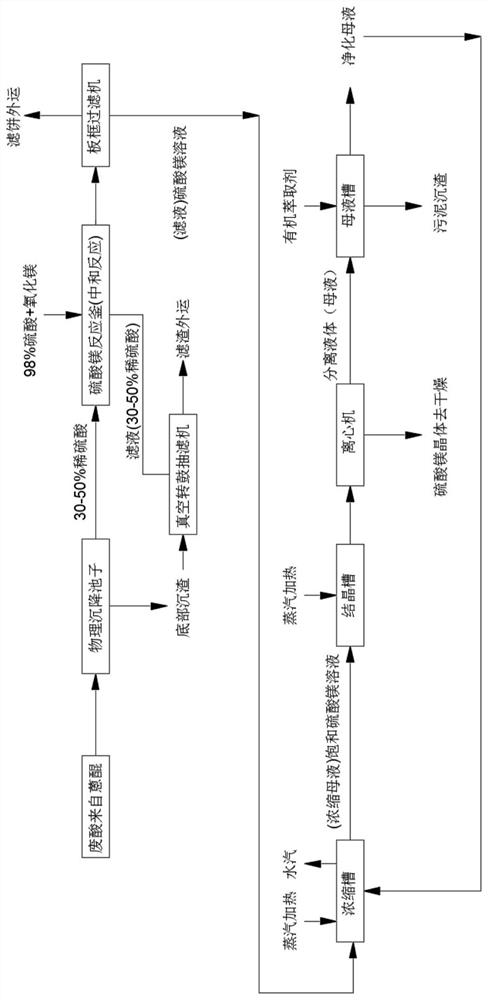

[0024] Such as figure 1 Shown, a kind of method utilizing anthraquinone spent acid to prepare magnesium sulfate comprises the following steps:

[0025] S1, passing anthraquinone waste acid into a physical settling tank for static separation to obtain dilute sulfuric acid solution and sediment. In this step, there are two physical settling tanks, one for use and the other for standby;

[0026] S2. The sediment is separated from solid and liquid through a vacuum drum suction filter, wherein the filtrate is returned to the dilute sulfuric acid solution, and the filter cake is sent out;

[0027] S3, dilute sulfuric acid solution, magnesium oxide and 98wt% concentrated sulfuric acid are mixed and reacted to obtain a solid-liquid mixture, and the solid-liquid mixture is subjected to solid-liquid separation to obtain magnesium sulfate mother liquor and filter cake, and the filter cake is se...

Embodiment 2

[0032] In this embodiment, the concentration of the dilute sulfuric acid solution is 40wt%.

[0033] A kind of method utilizing anthraquinone spent acid to prepare magnesium sulfate comprises the following steps:

[0034] S1, passing anthraquinone waste acid into a physical settling tank for static separation to obtain dilute sulfuric acid solution and sediment. In this step, there are two physical settling tanks, one for use and the other for standby;

[0035] S2. The sediment is separated from solid and liquid through a vacuum drum suction filter, wherein the filtrate is returned to the dilute sulfuric acid solution, and the filter cake is sent out;

[0036] S3, mixed reaction of dilute sulfuric acid solution, magnesium oxide and 98wt% concentrated sulfuric acid to obtain a solid-liquid mixture, the solid-liquid mixture is subjected to solid-liquid separation to obtain magnesium sulfate mother liquor and filter cake, and the filter cake is sent out; Magnesium mother liquor ...

Embodiment 3

[0040] In this embodiment, the concentration of the dilute sulfuric acid solution is 40wt%.

[0041] A kind of method utilizing anthraquinone spent acid to prepare magnesium sulfate comprises the following steps:

[0042] S1, passing anthraquinone waste acid into a physical settling tank for static separation to obtain dilute sulfuric acid solution and sediment. In this step, there are two physical settling tanks, one for use and the other for standby;

[0043] S2. The sediment is separated from solid and liquid through a vacuum drum suction filter, wherein the filtrate is returned to the dilute sulfuric acid solution, and the filter cake is sent out;

[0044] S3, dilute sulfuric acid solution, magnesium oxide and 98wt% concentrated sulfuric acid are mixed and reacted to obtain a solid-liquid mixture, and the solid-liquid mixture is subjected to solid-liquid separation to obtain magnesium sulfate mother liquor and filter cake, and the filter cake is sent out;

[0045] S4. Usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com