Surface runoff rate measuring and separating flow sampling device

A technology of flow measurement and surface runoff, which is applied in the field of agricultural environment, can solve the problems of loss of representativeness of water in runoff pools, large area of construction projects, and large area of runoff pools, etc., to achieve easy cleaning and maintenance, simple construction, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

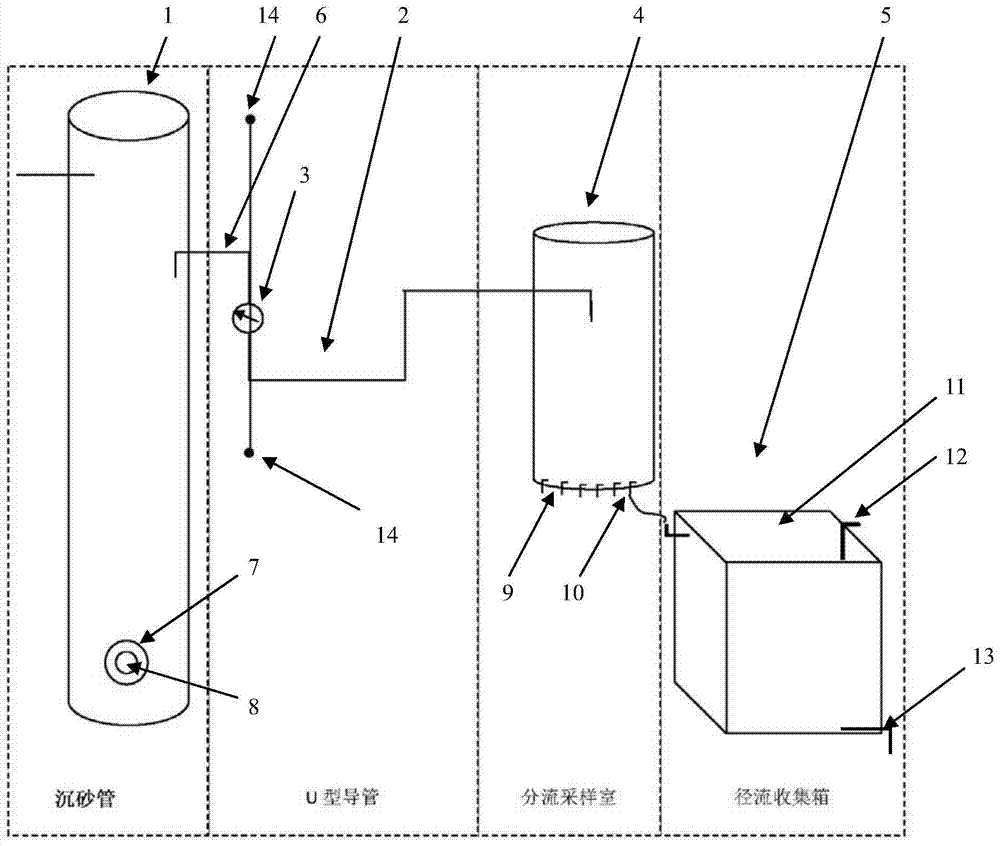

[0020] refer to figure 1 , a surface runoff flow measurement and diversion sampling device, including a sand settling pipe 1, a U-shaped conduit 2, a water meter 3, a diversion sampling chamber 4 and a runoff collection box 5, and the sand settling pipe 1 is provided with a water outlet , the water outlet is provided with a water level positioning pipe 6, and the water level positioning pipe 6 communicates with one side of the U-shaped conduit 2, and a water meter 3 is arranged on one side of the U-shaped conduit 2, and the U-shaped conduit 2 The other side is connected with the split flow sampling chamber 4, and the runoff collection box 5 is provided with a water inlet, and the water inlet communicates with the bottom of the split flow sampling chamber.

[0021] The sand settling pipe 1 is a cylindrical watertight container with a diameter of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com