Patents

Literature

595results about How to "Expand the market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

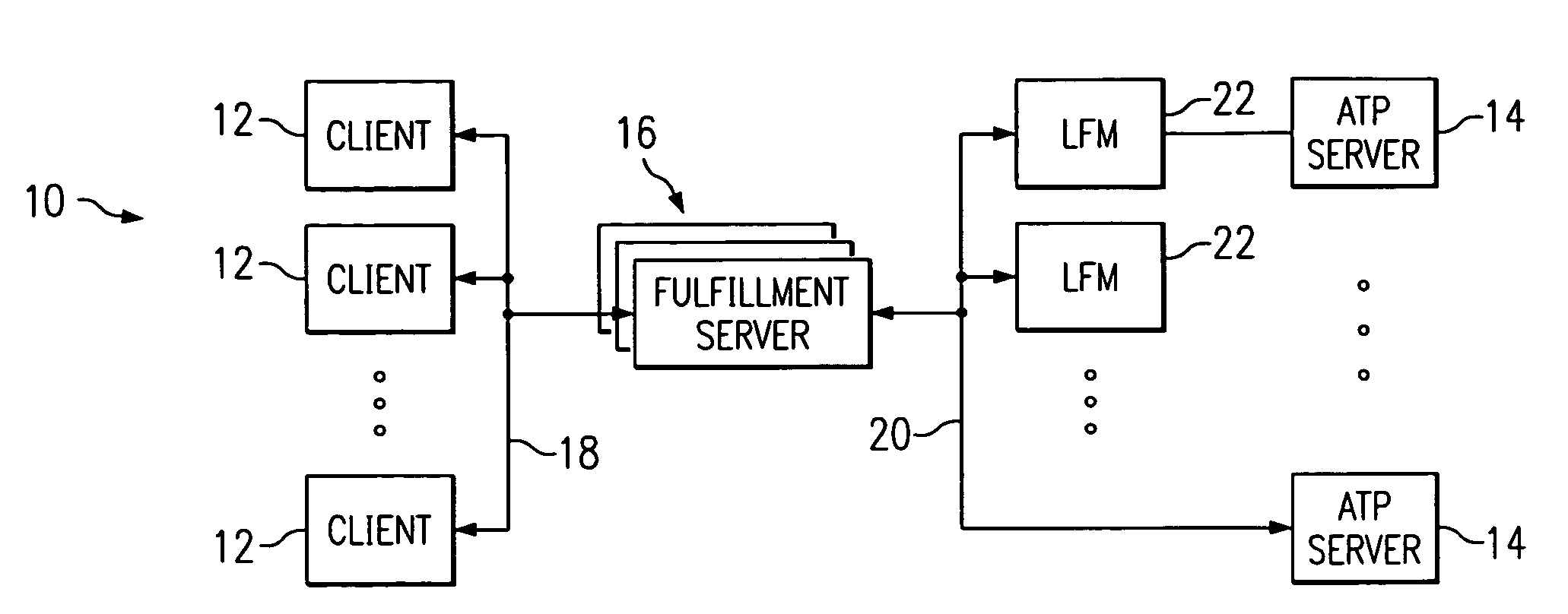

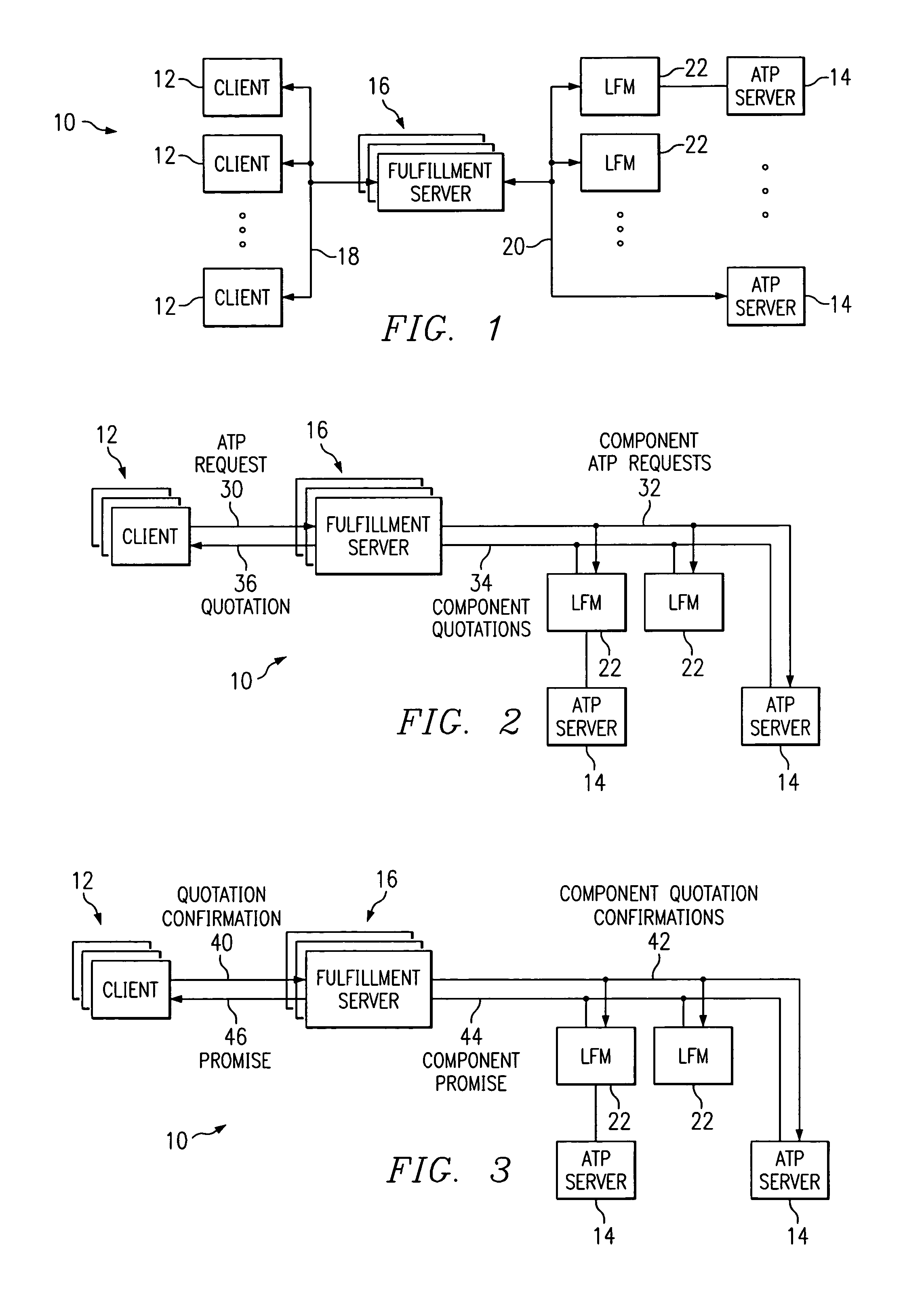

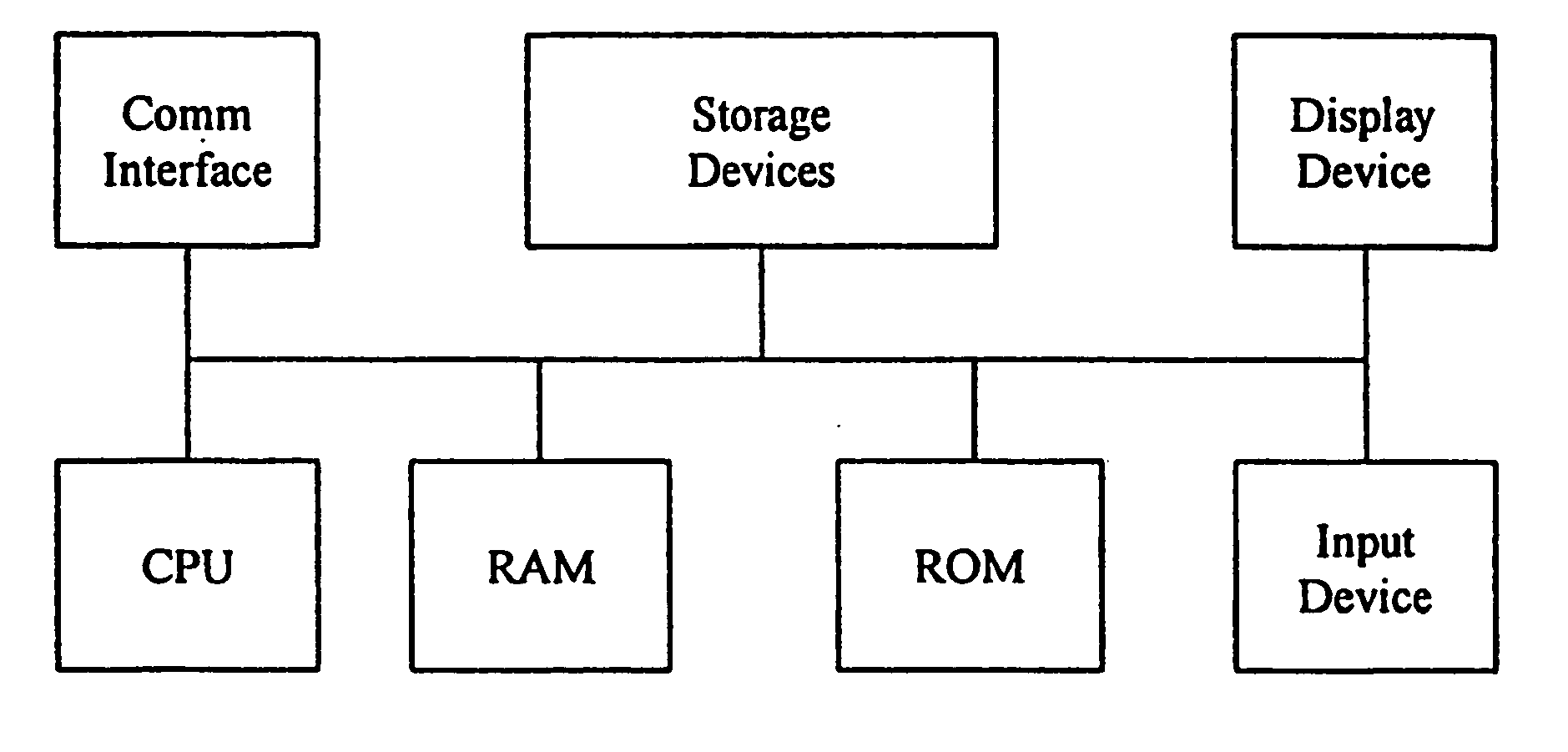

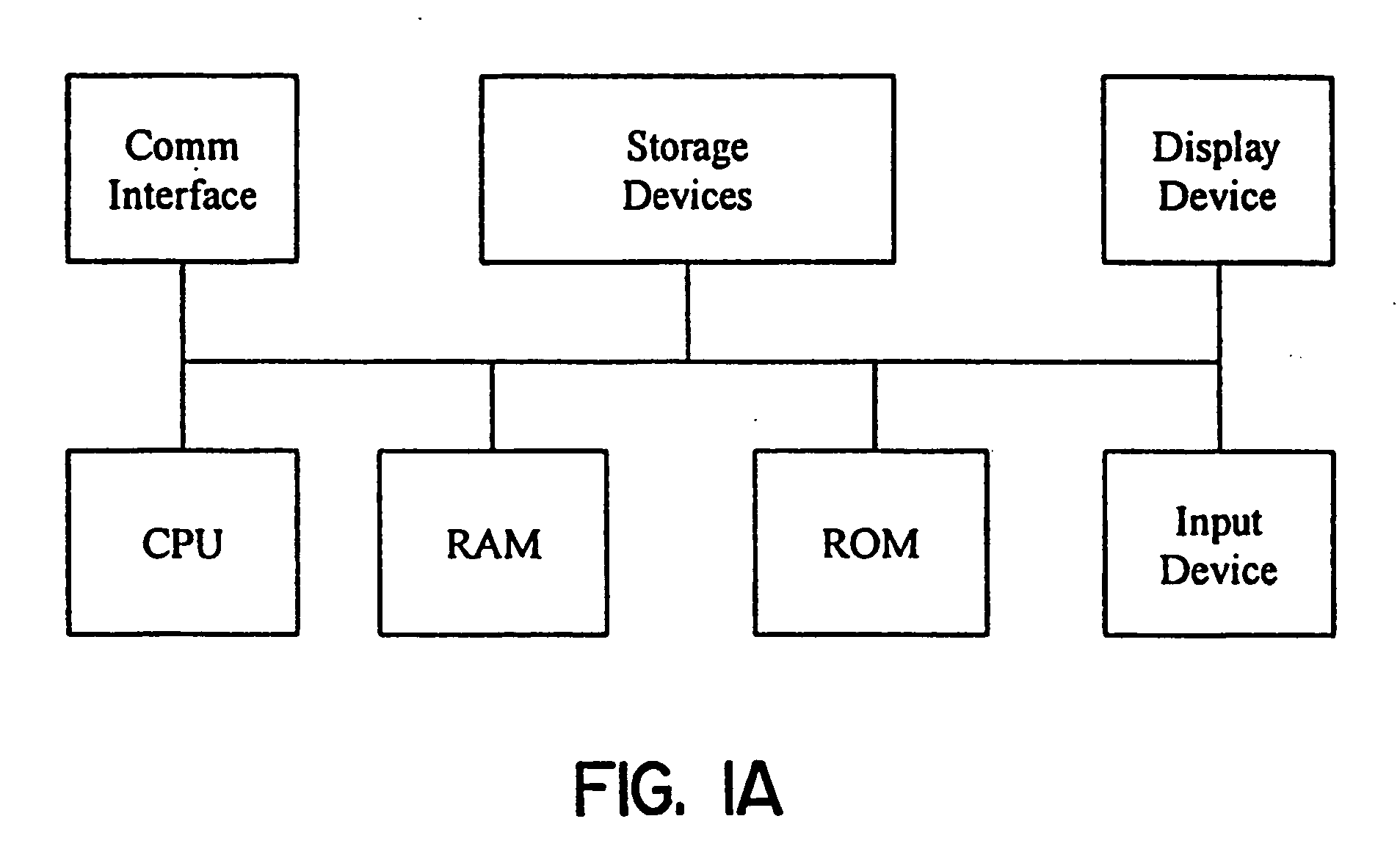

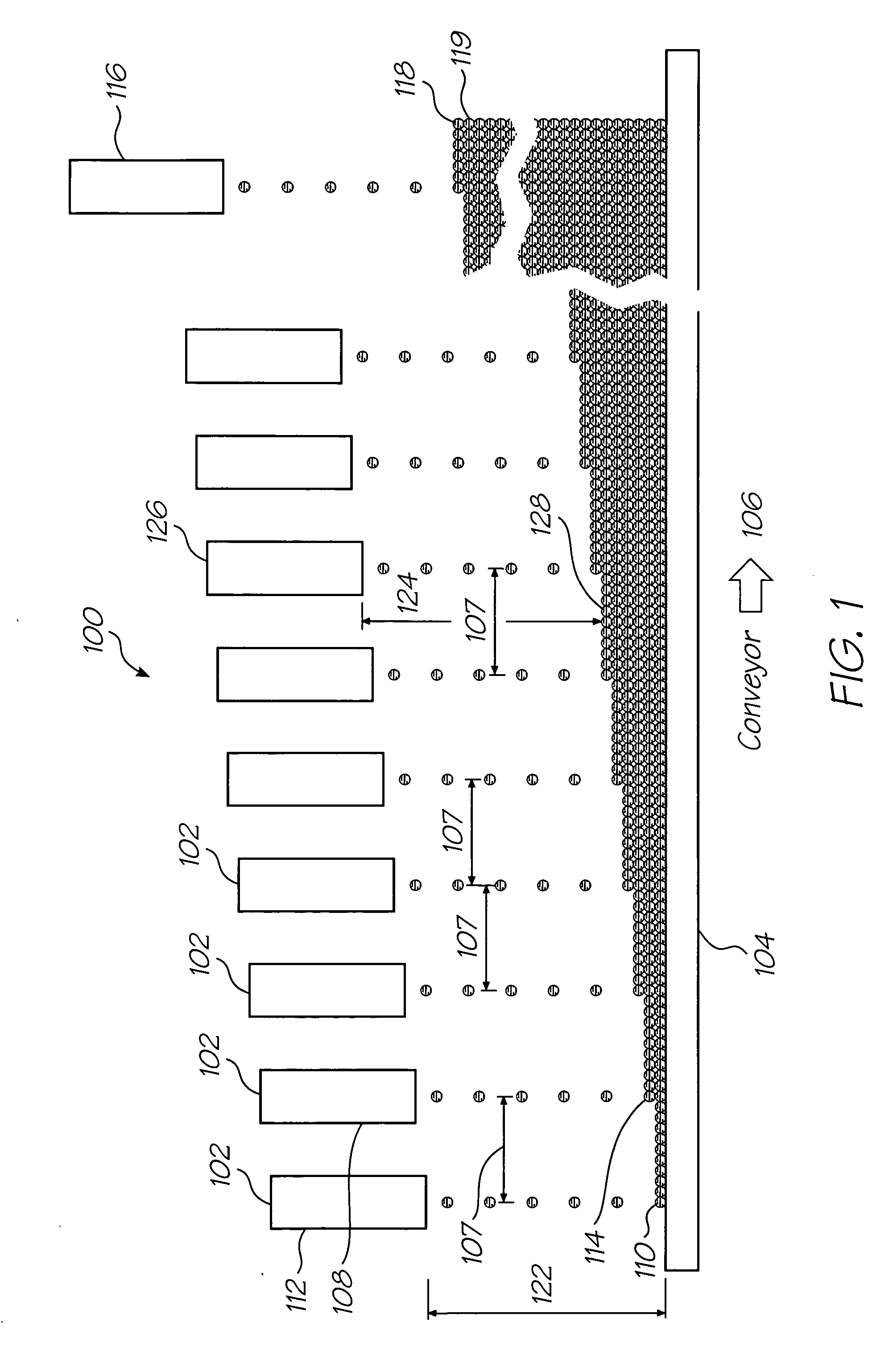

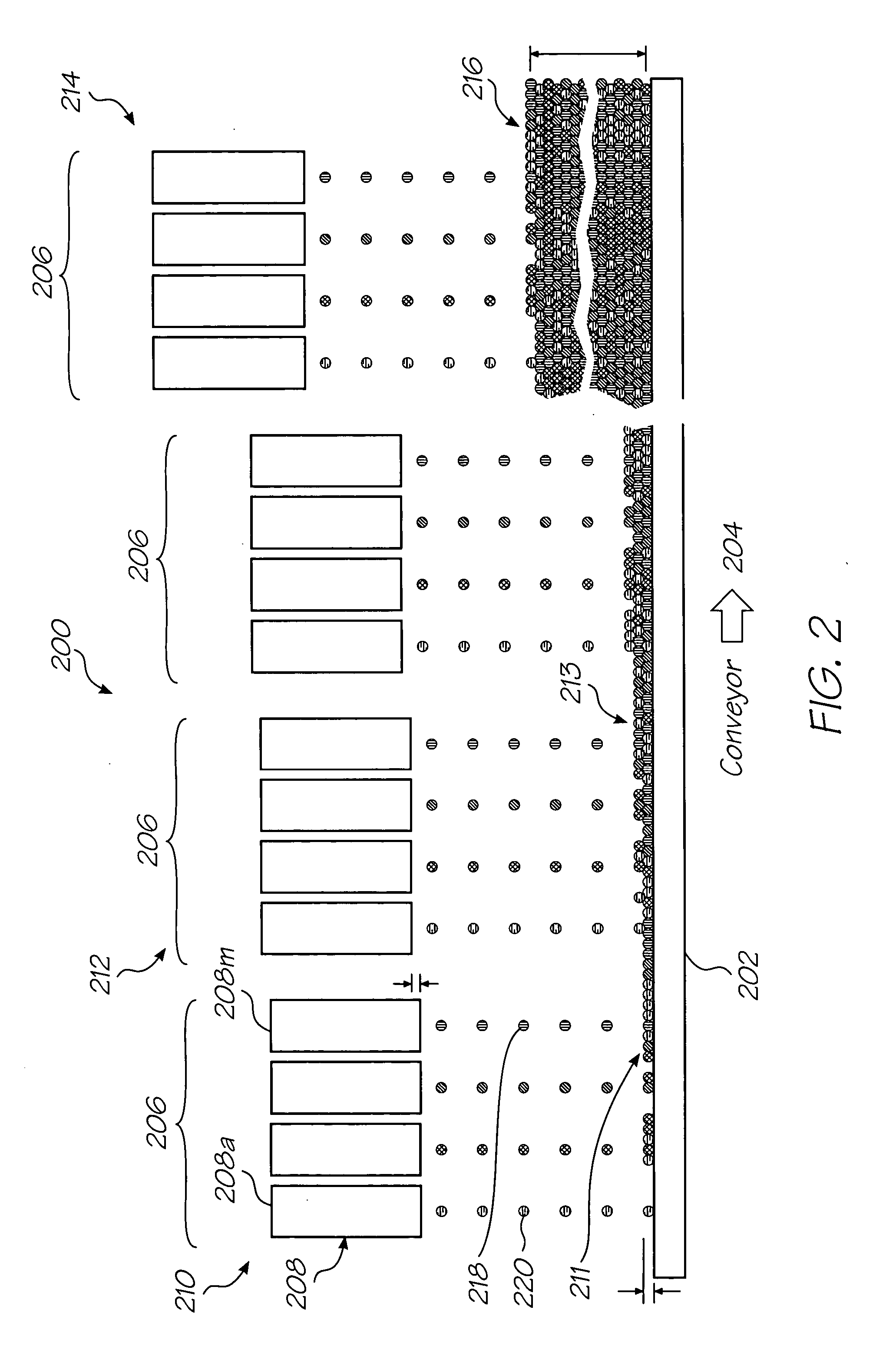

Fulfillment management system for managing ATP data in a distributed supply chain environment

ActiveUS7249044B2Disadvantages and and reduced eliminatedEnvironment reduced eliminatedMultiprogramming arrangementsBuying/selling/leasing transactionsLine itemComputer science

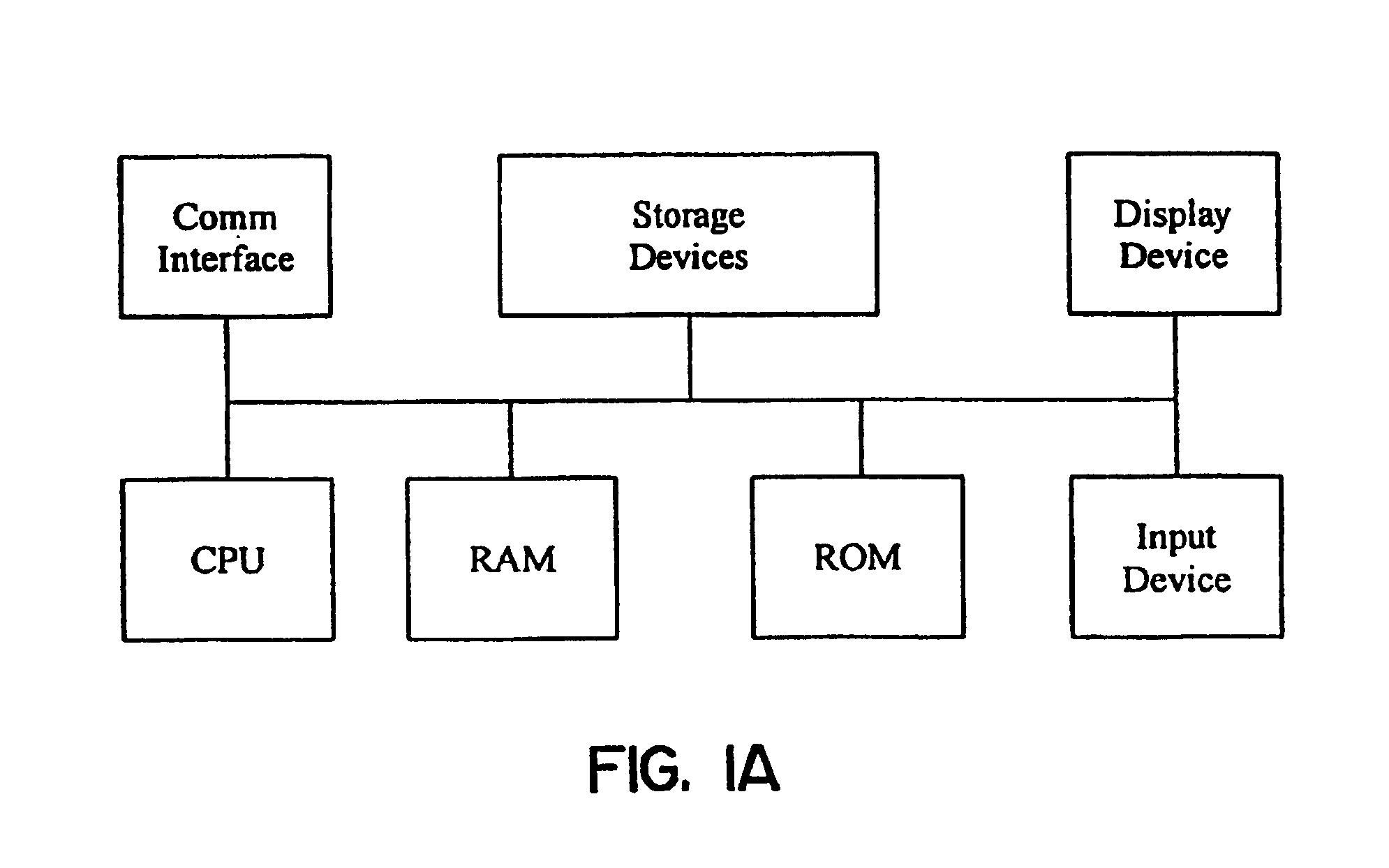

A fulfillment management system includes a database operable to store product availability information associated with at least one product. The fulfillment management system also includes one or more processors collectively operable to receive at least one component available-to-promise (ATP) request. Each component ATP request corresponds to a particular ATP request line-item for a desired product. The one or more processors are also operable to retrieve at least a portion of the product availability information associated with the desired product from the database for each component ATP request, determine an ATP response for each component ATP request using the retrieved product availability information, generate a component quotation for each component ATP request according to the corresponding ATP response, and communicate the component quotation for consolidation with other component quotations.

Owner:BLUE YONDER GRP INC

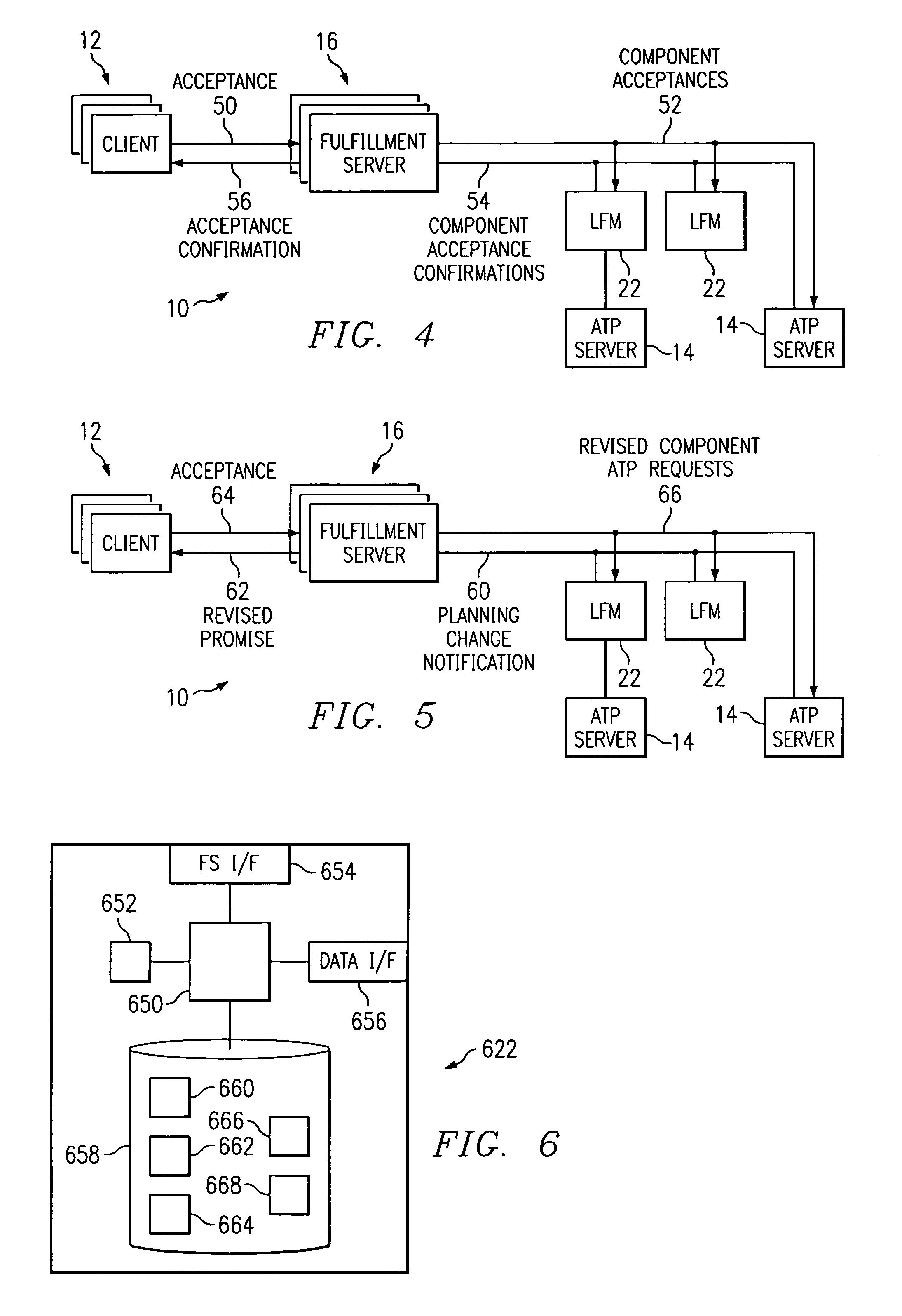

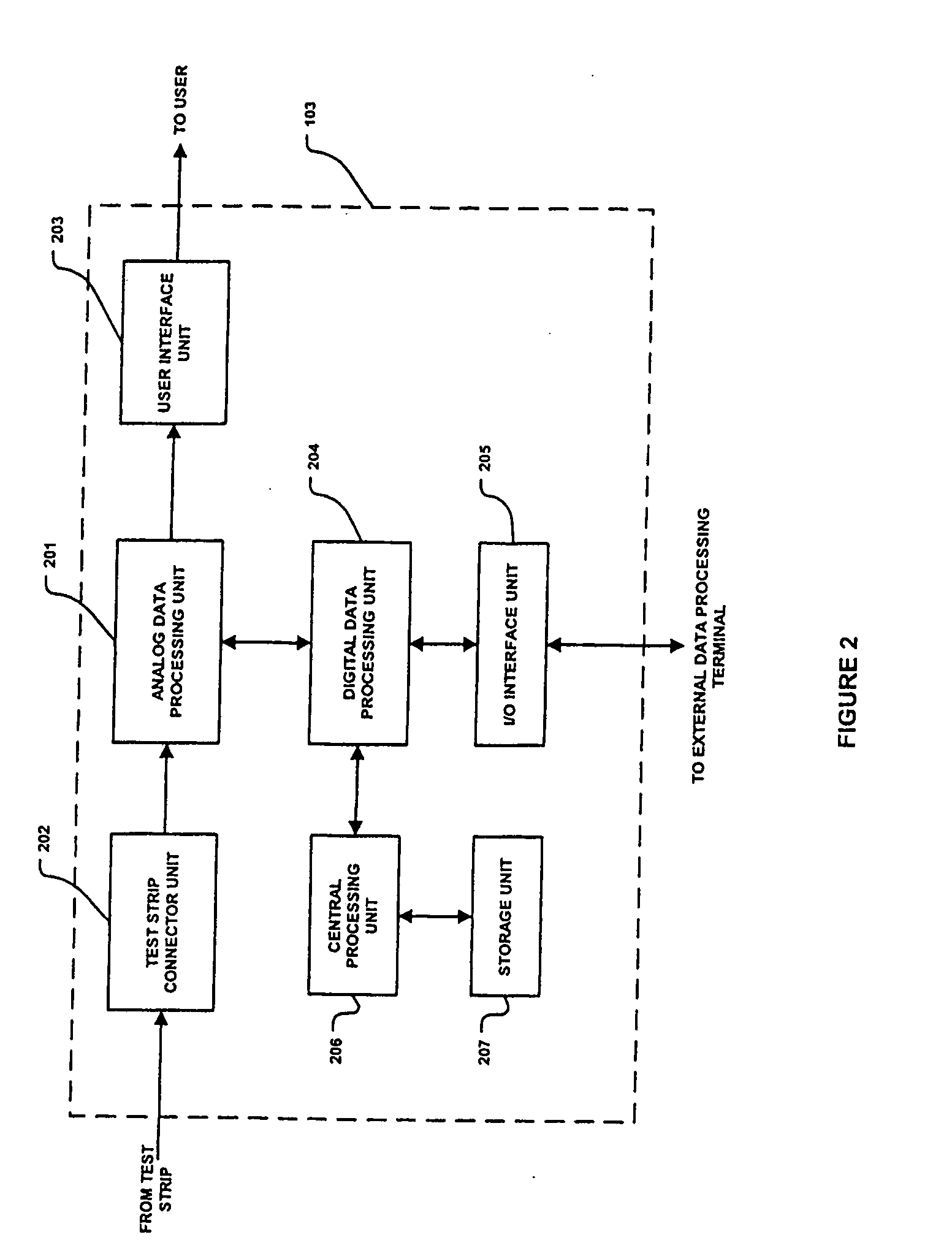

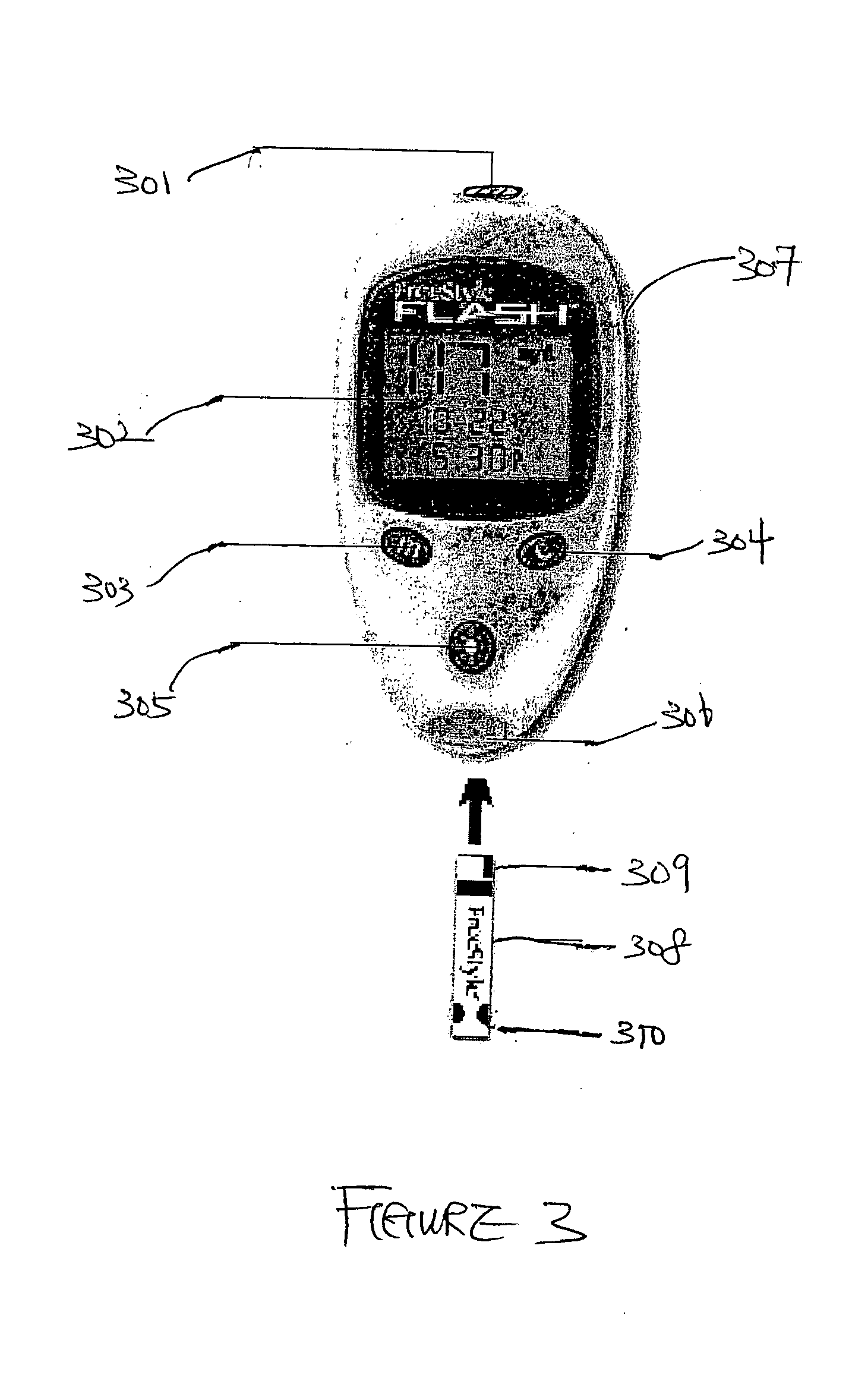

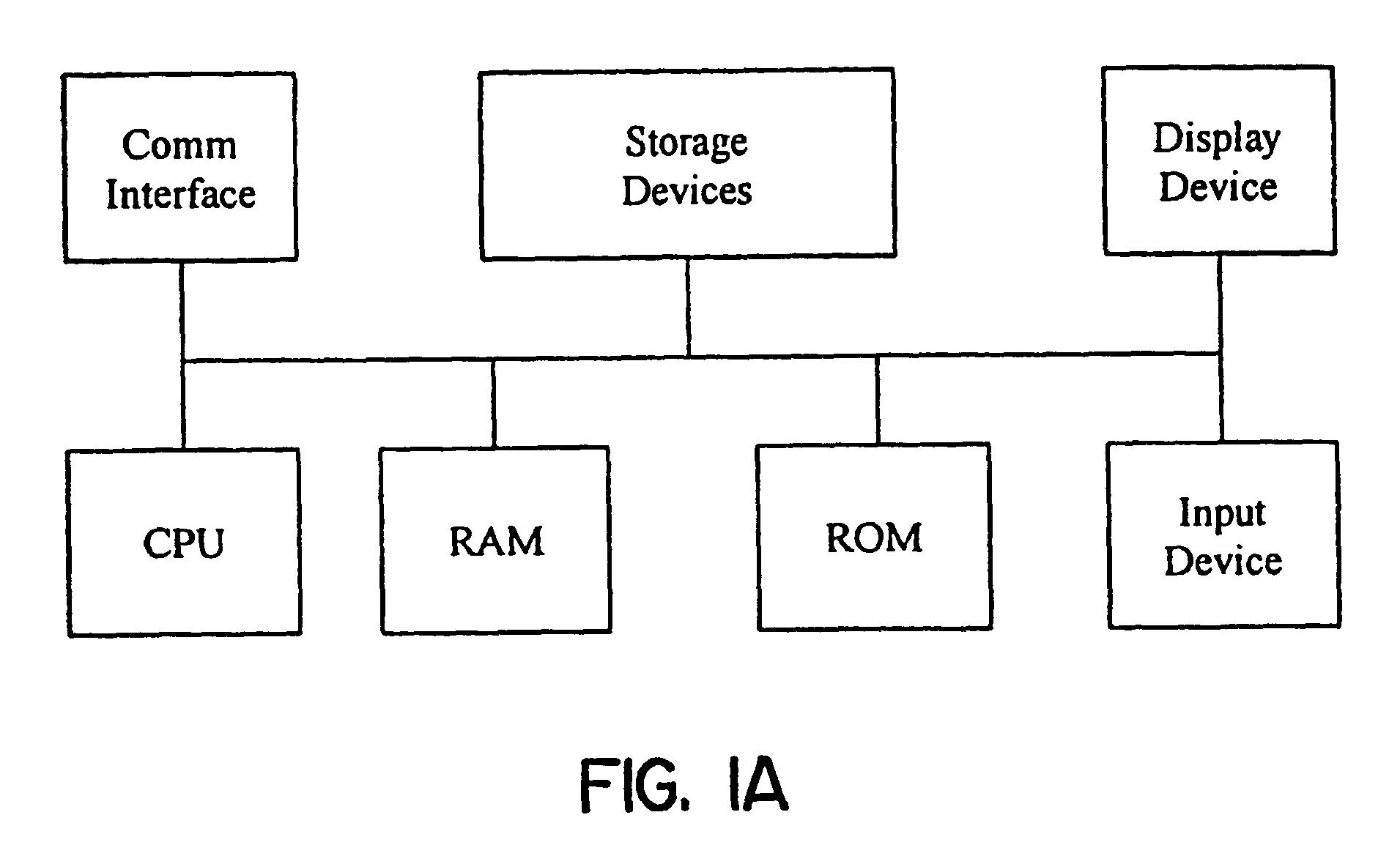

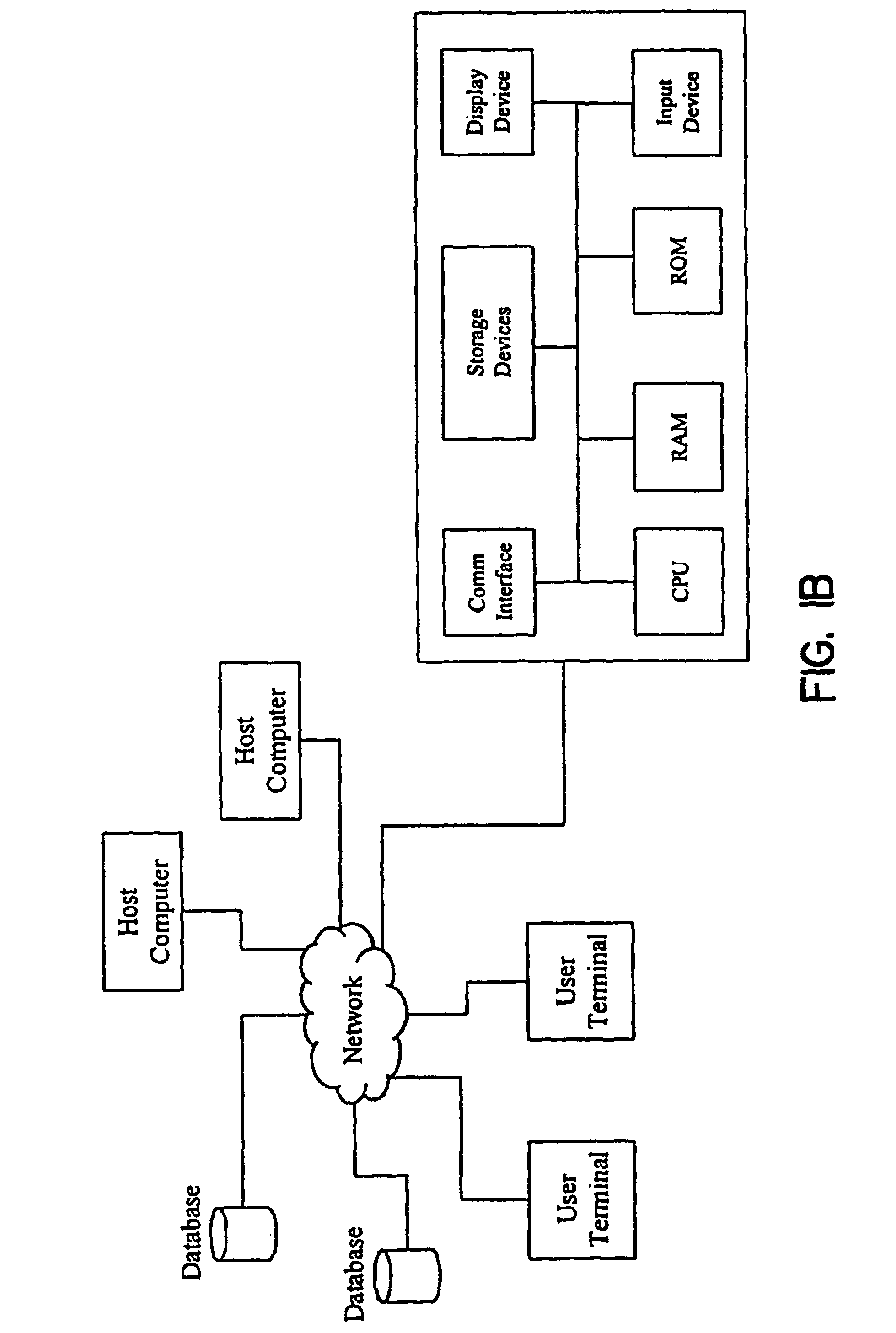

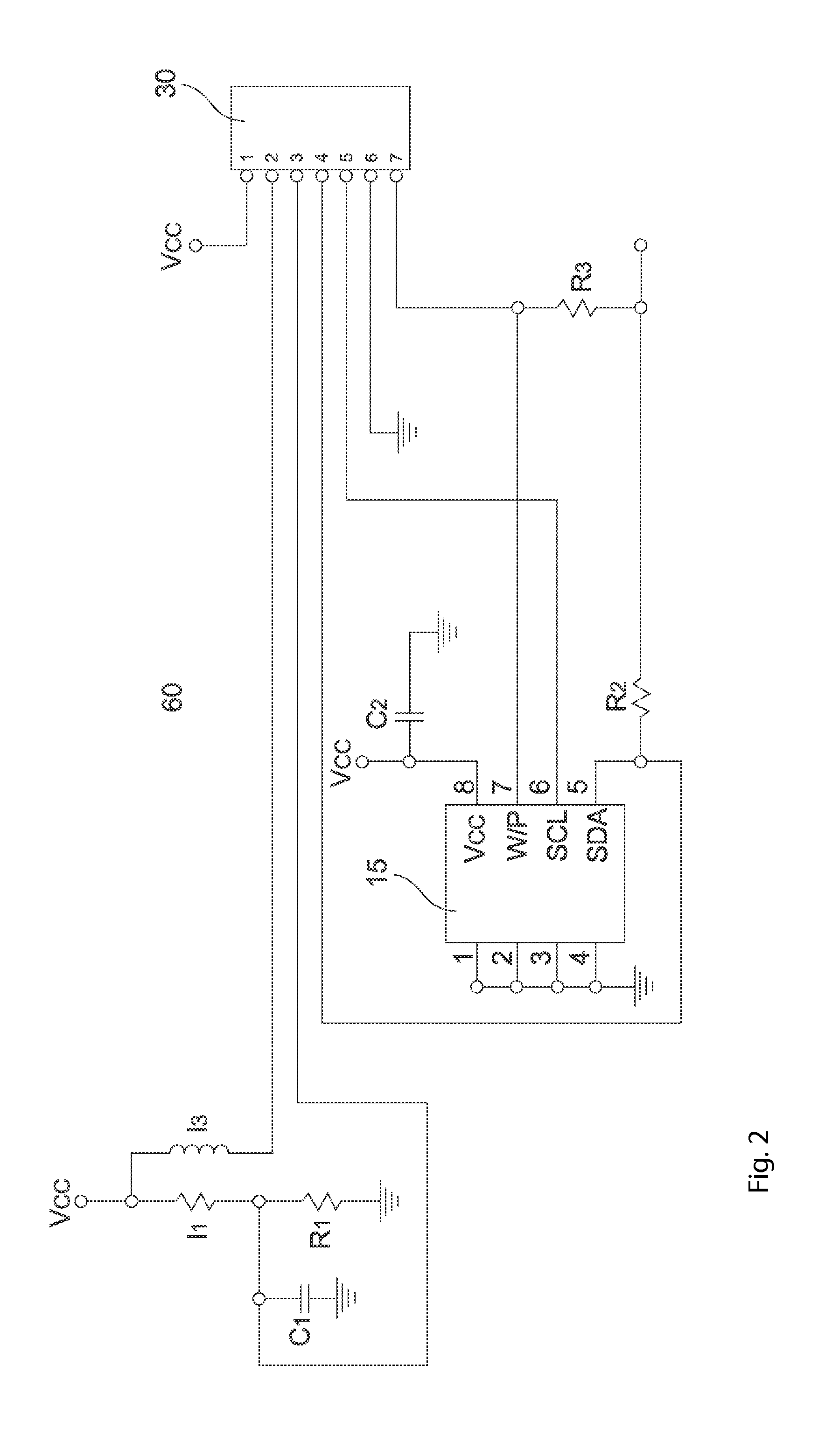

Method and apparatus for providing power management in data communication systems

ActiveUS20050009126A1Good for healthEarly detectionBioreactor/fermenter combinationsBiological substance pretreatmentsCommunications systemBlood glucose meters

A blood glucose meter having a compact housing, a display unit disposed on the housing, the display unit including a display light source to illuminate the display unit,an input unit disposed on the housing, the input unit configured to provide input functions for the blood glucose meter, and a power source provided within the housing for providing power to the blood glucose meter, where the housing includes a port integrated on said housing configured to receive a blood glucose test strip, and corresponding methods of measuring blood glucose meter is provided.

Owner:ABBOTT DIABETES CARE INC

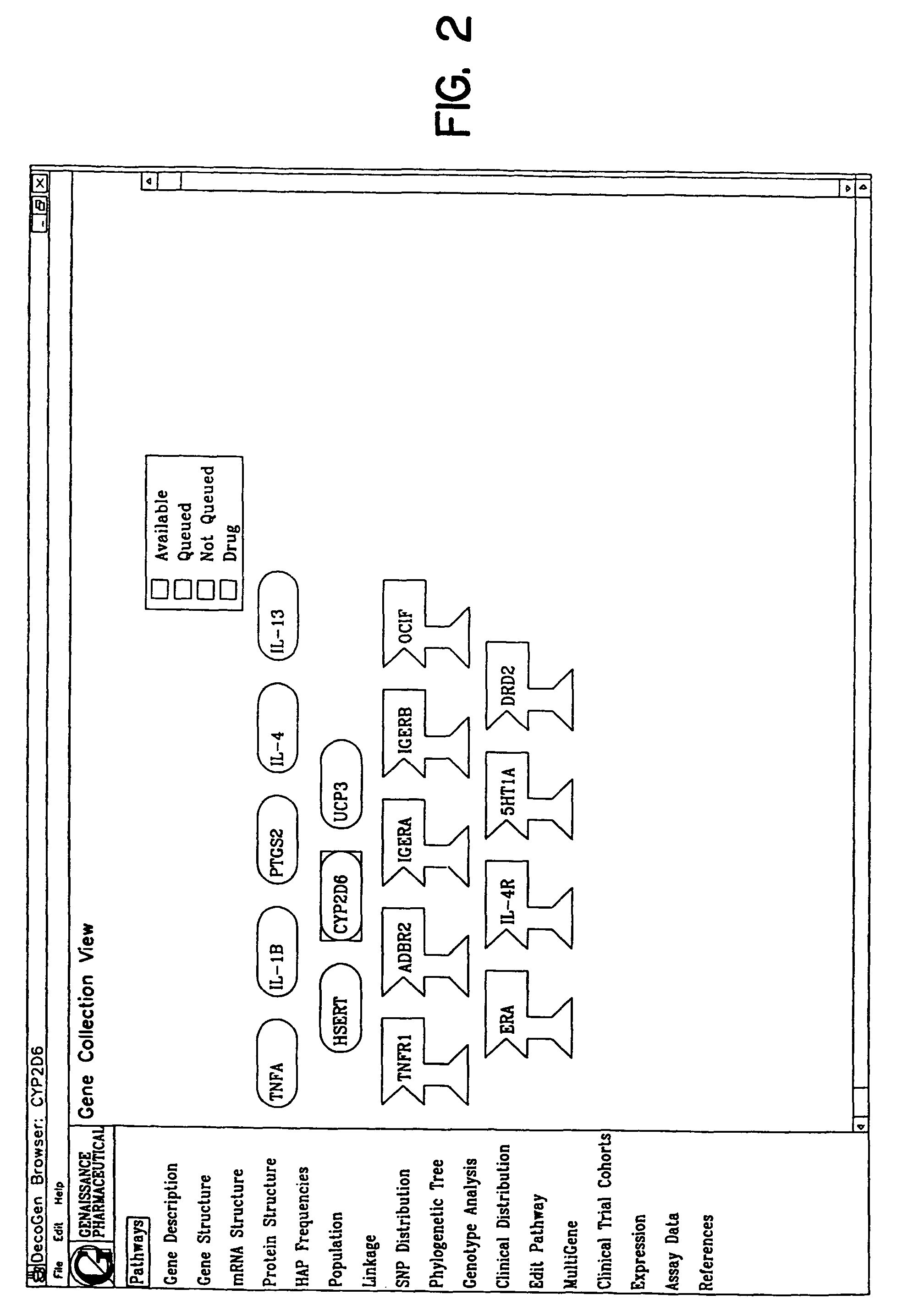

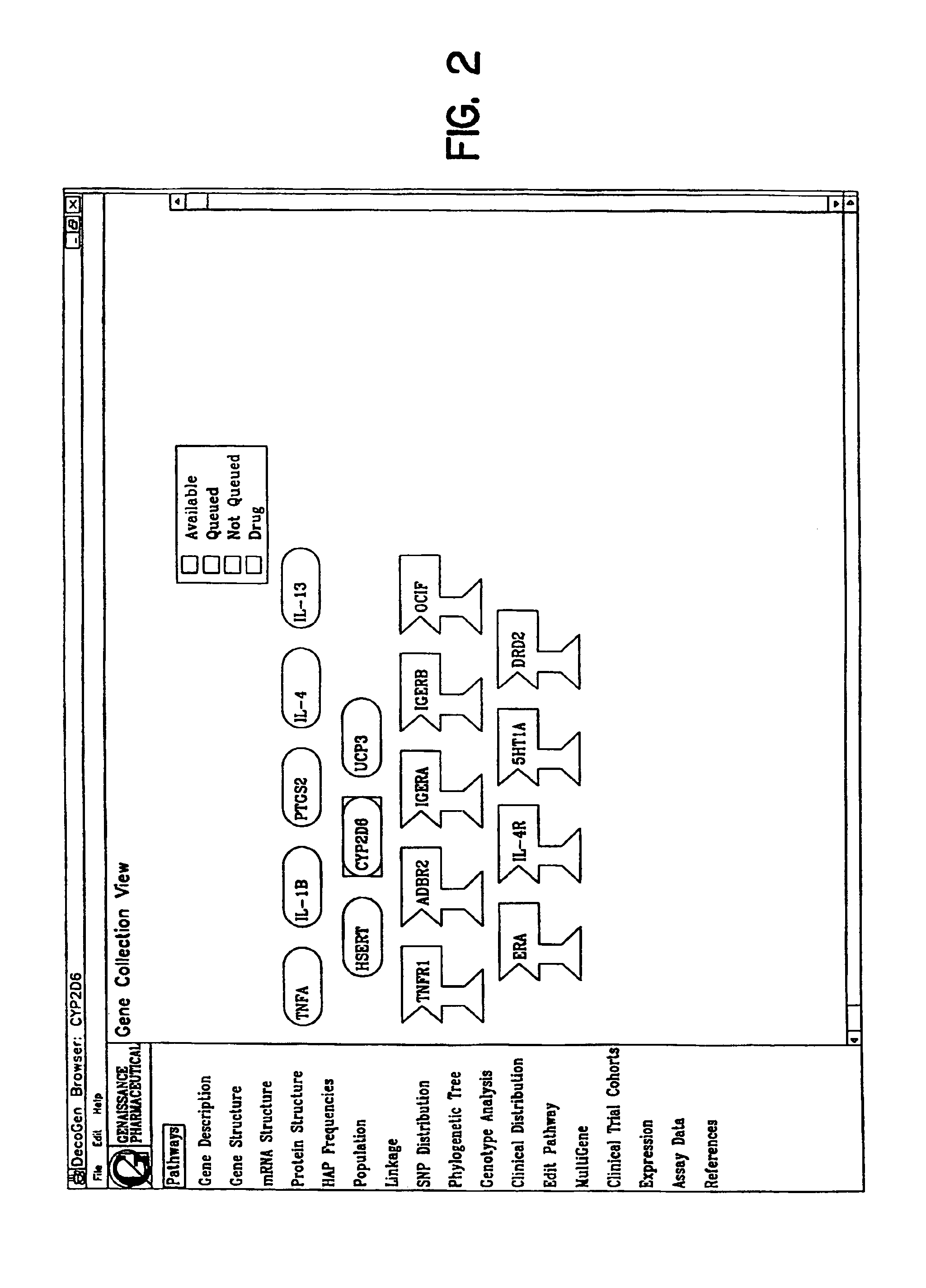

Methods for obtaining and using haplotype data

InactiveUS7058517B1Shorten the timeReduce effortMicrobiological testing/measurementProteomicsPopulationS genotyping

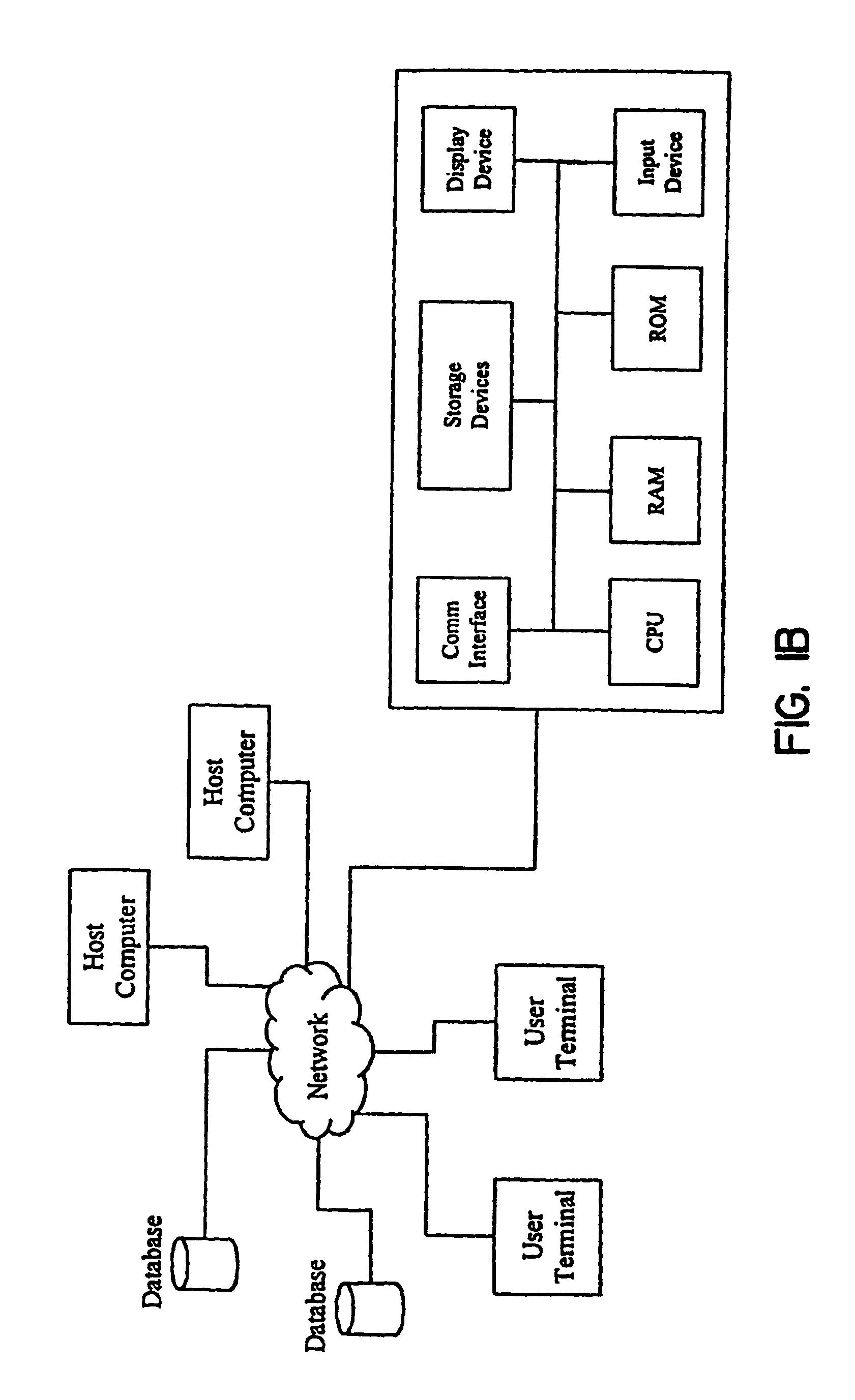

Methods, computer program(s) and database(s) to analyze and make use of gene haplotype information. These include methods, program, and database to find and measure the frequency of haplotypes in the general population; methods, program, and database to find correlation's between an individual's haplotypes or genotypes and a clinical outcome; methods, program, and database to predict an individual's haplotypes from the individual's genotype for a gene; and methods, program, and database to predict an individual's clinical response to a treatment based on the individual's genotype or haplotype.

Owner:GENAISSANCE PHARMA INC

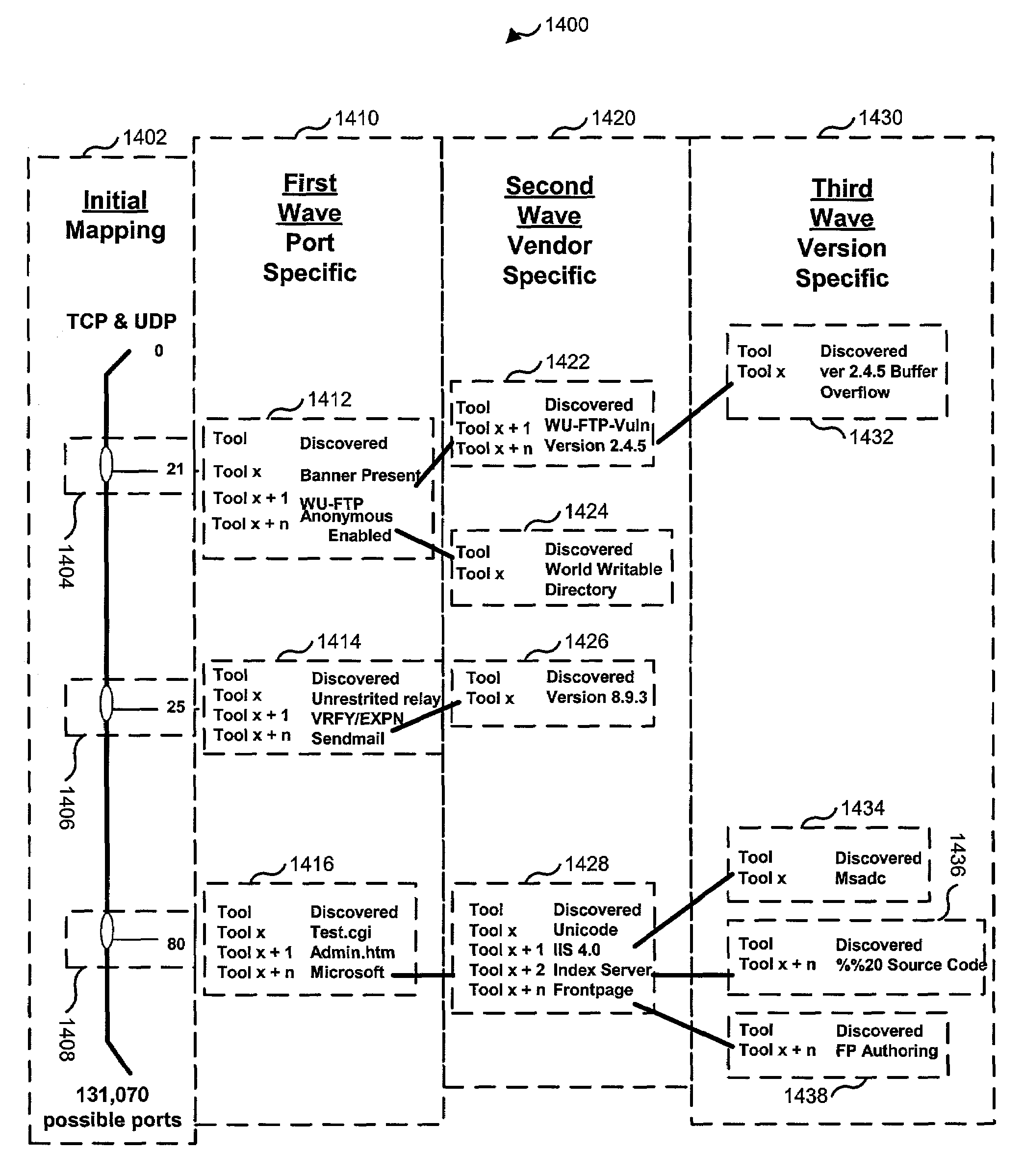

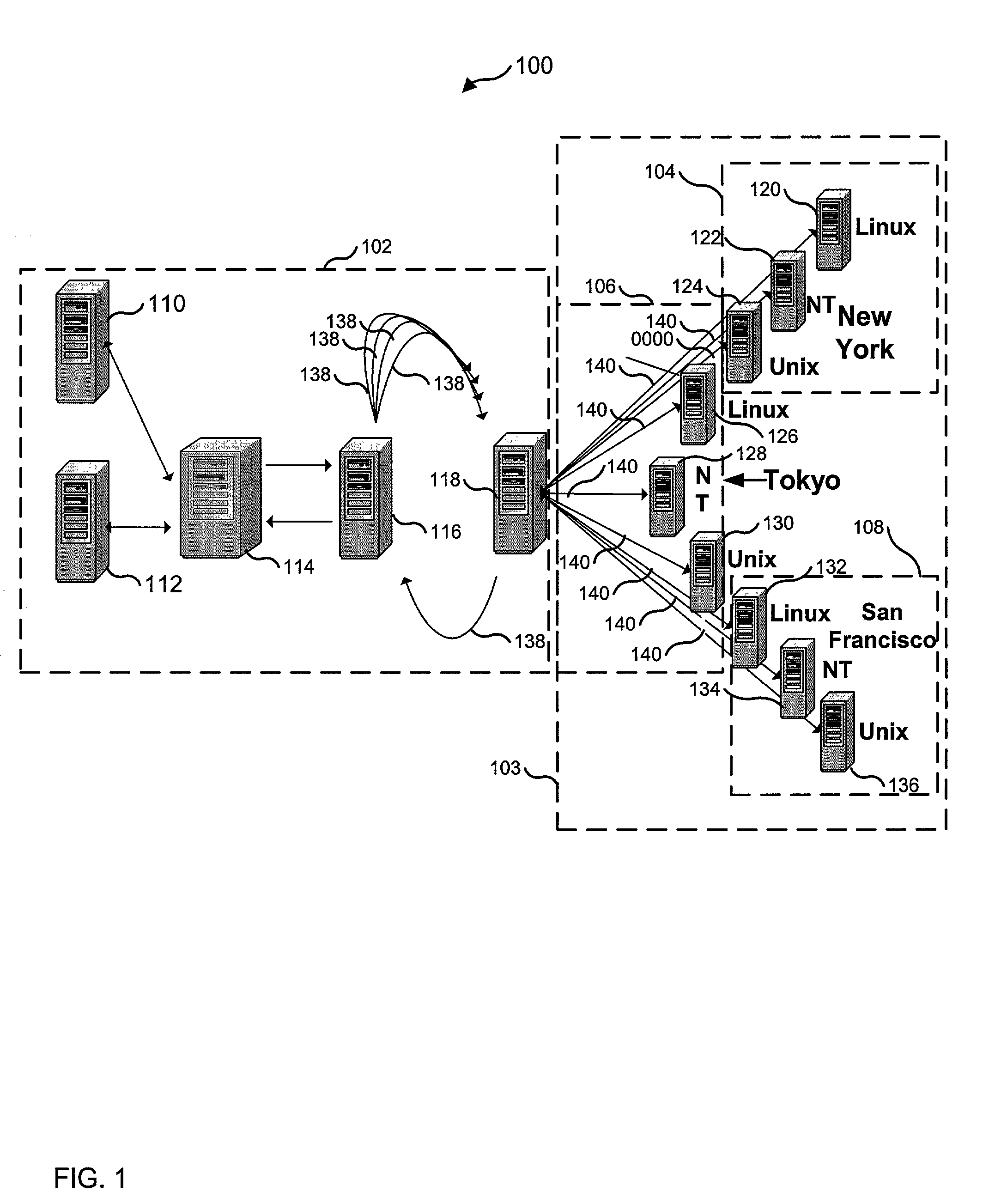

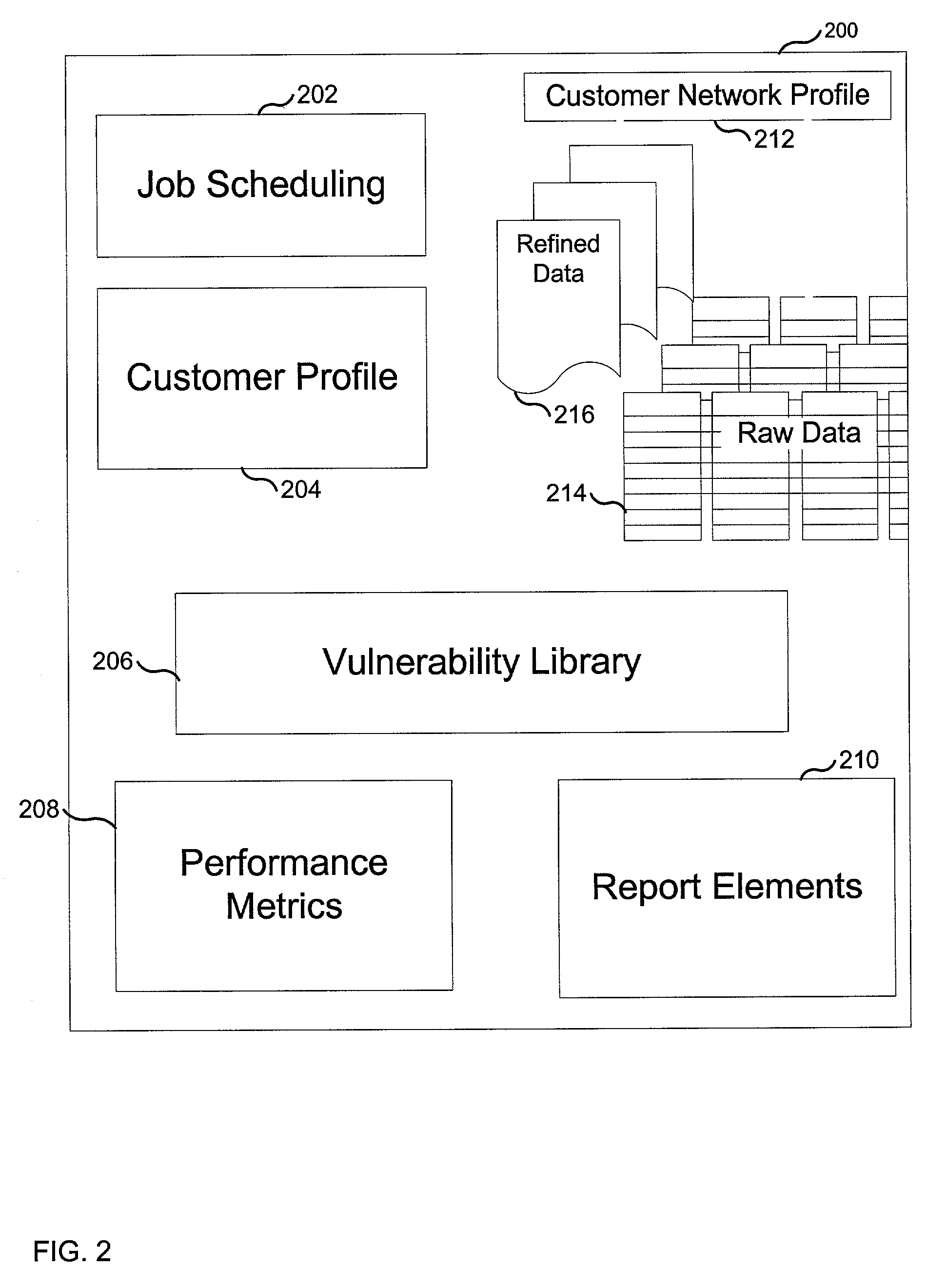

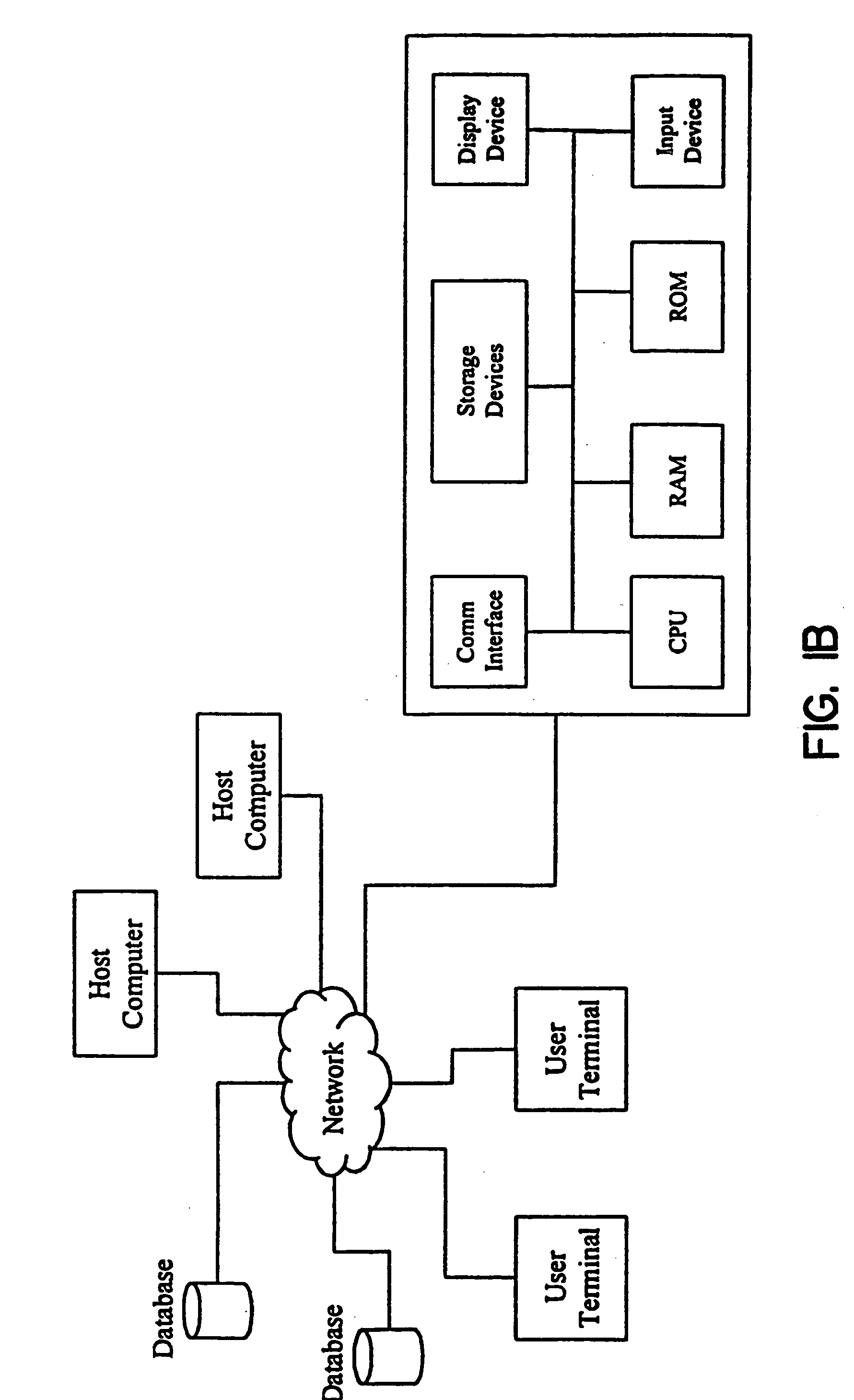

Network security testing

ActiveUS7325252B2Improve viewing effectShort working hoursMemory loss protectionError detection/correctionSecurity solutionWork period

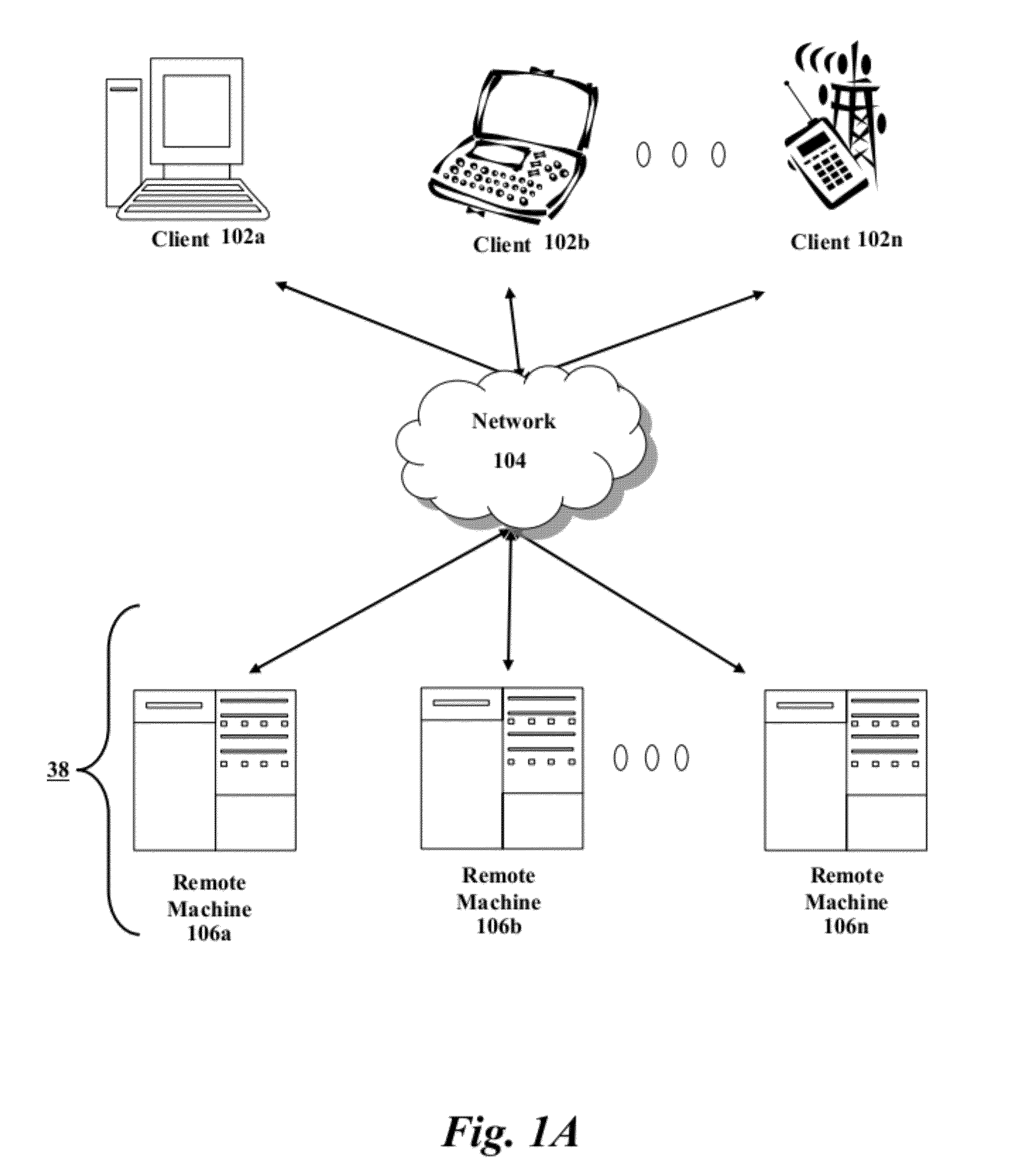

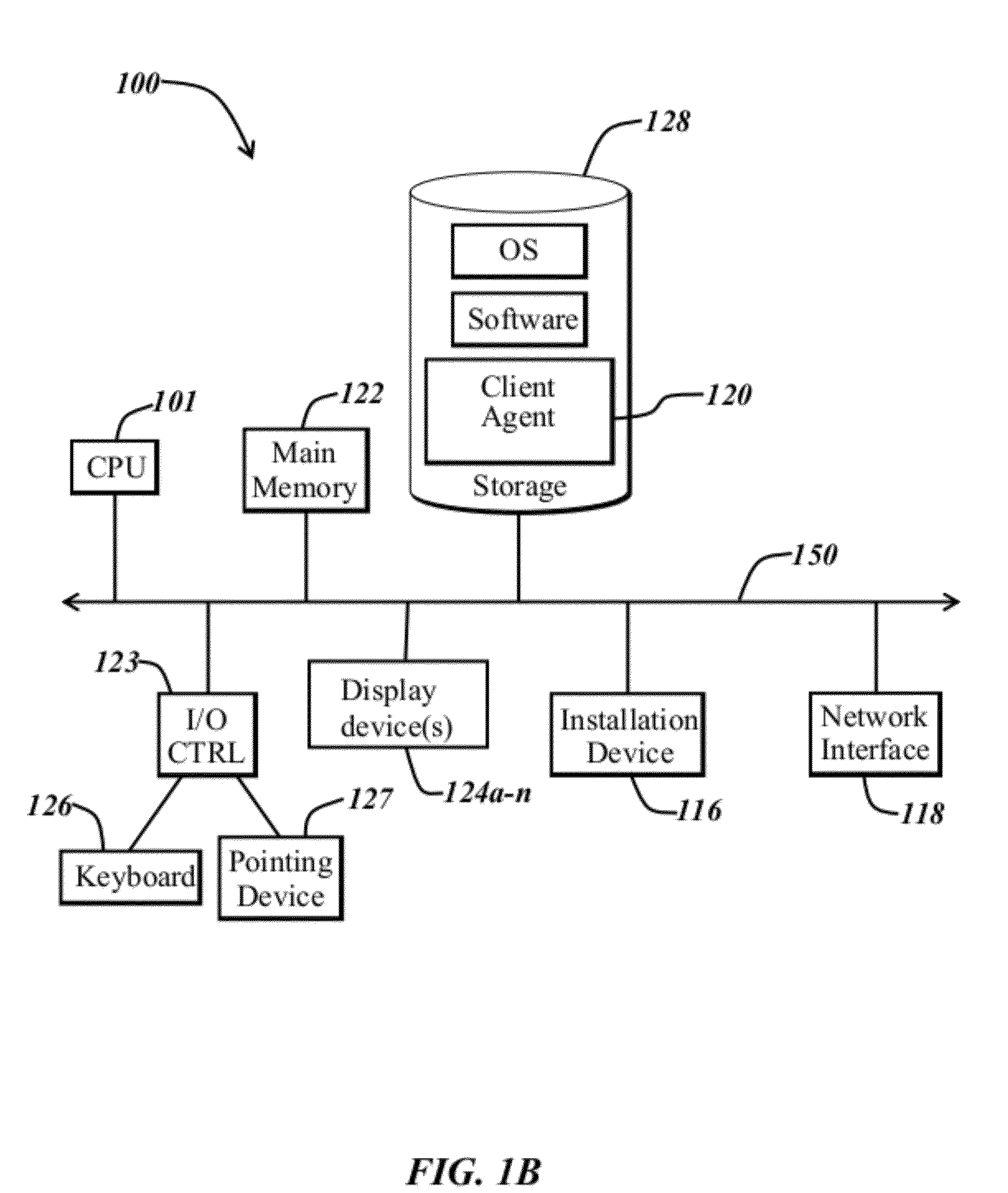

To answer the security needs of the market, a preferred embodiment was developed. A preferred embodiment provides real-time network security vulnerability assessment tests, possibly complete with recommended security solutions. External vulnerability assessment tests can emulate hacker methodology in a safe way and enable study of a network for security openings, thereby gaining a true view of risk level without affecting customer operations. Because this assessment can be performed over the Internet, both domestic and worldwide corporations benefit. A preferred embodiment's physical subsystems combine to form a scalable holistic system that can be able to conduct tests for thousands of customers any place in the world. The security skills of experts can be embedded into a preferred embodiment systems and automated the test process to enable the security vulnerability test to be conducted on a continuous basis for multiple customers at the same time. A preferred embodiment can reduce the work time required for security practices of companies from three weeks to less than a day, as well as significantly increase their capacity. Component subsystems typically include a Database, Command Engine, Gateway, multiple Testers, Report Generator, and an RMCT.

Owner:ALERT LOGIC

Methods for obtaining and using haplotype data

InactiveUS6931326B1Accurate predictionReduce costs and risksMicrobiological testing/measurementProteomicsHaplotypeS genotyping

Methods, computer program(s) and database(s) to analyze and make use of gene haplotype information. These include methods, program, and database to find and measure the frequency of haplotypes in the general population; methods, program, and database to find correlation's between an individual's haplotypes or genotypes and a clinical outcome; methods, program, and database to predict an individual's haplotypes from the individual's genotype for a gene; and methods, program, and database to predict an individual's clinical response to a treatment based on the individual's genotype or haplotype.

Owner:PGXHEALTH

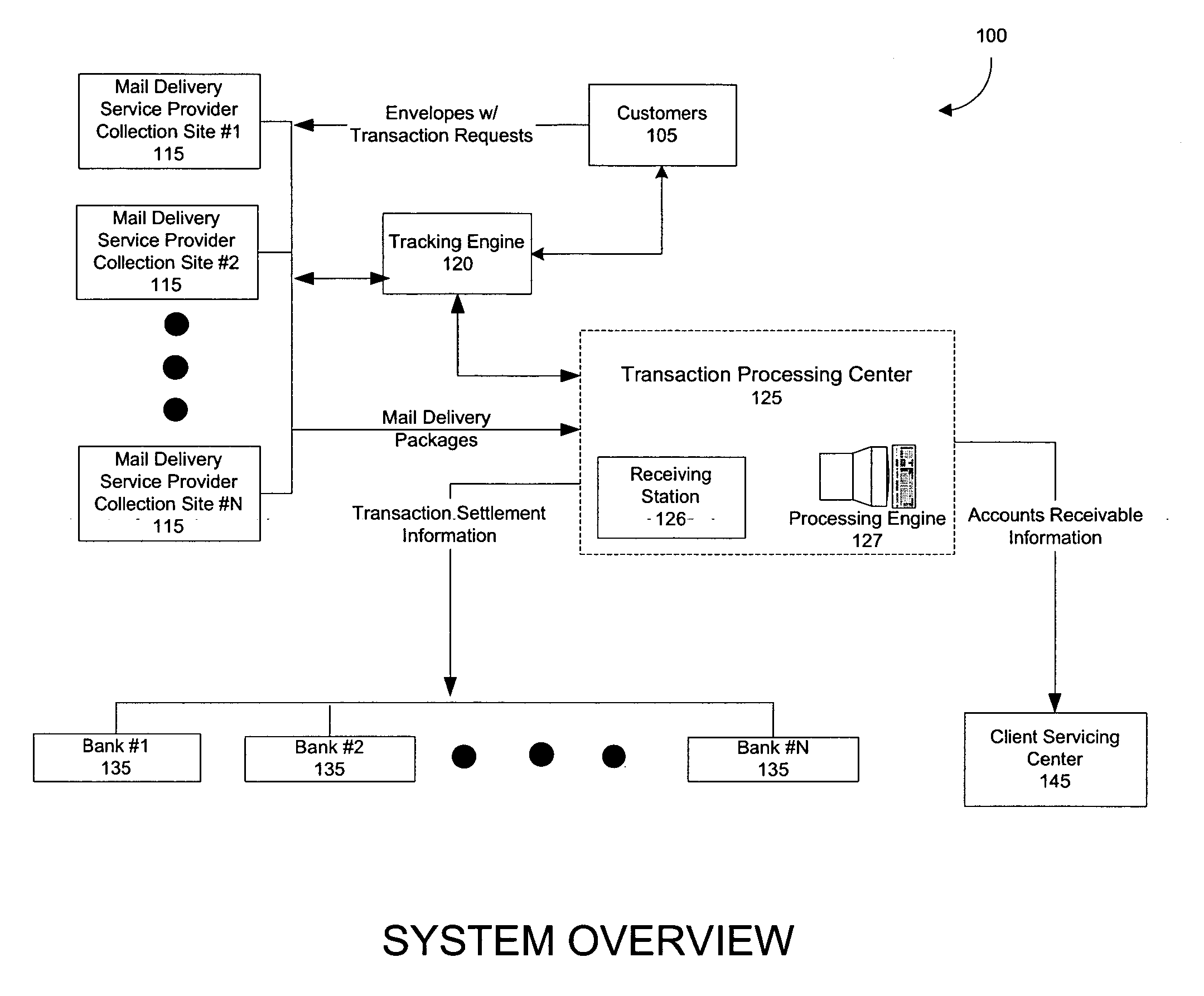

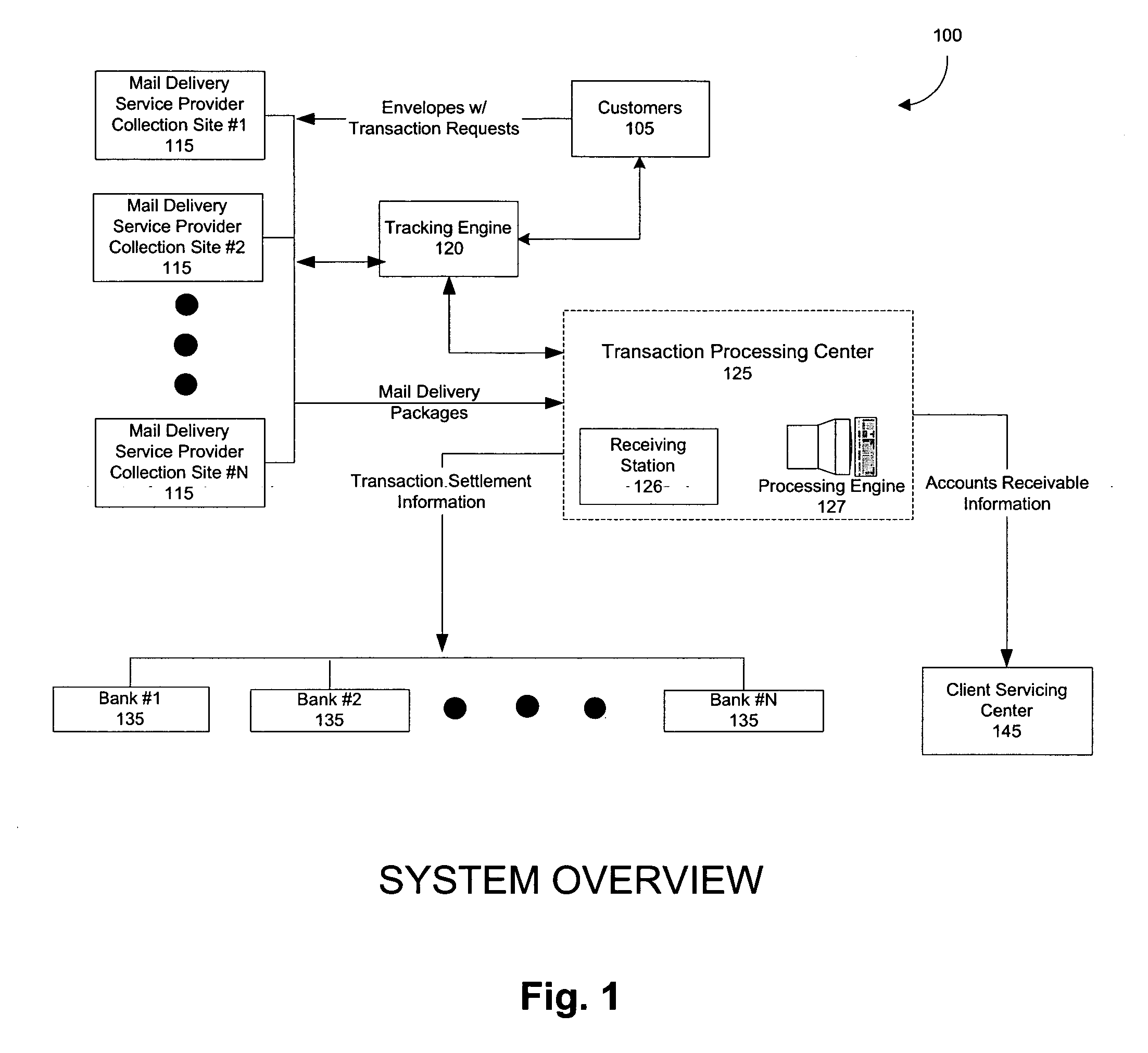

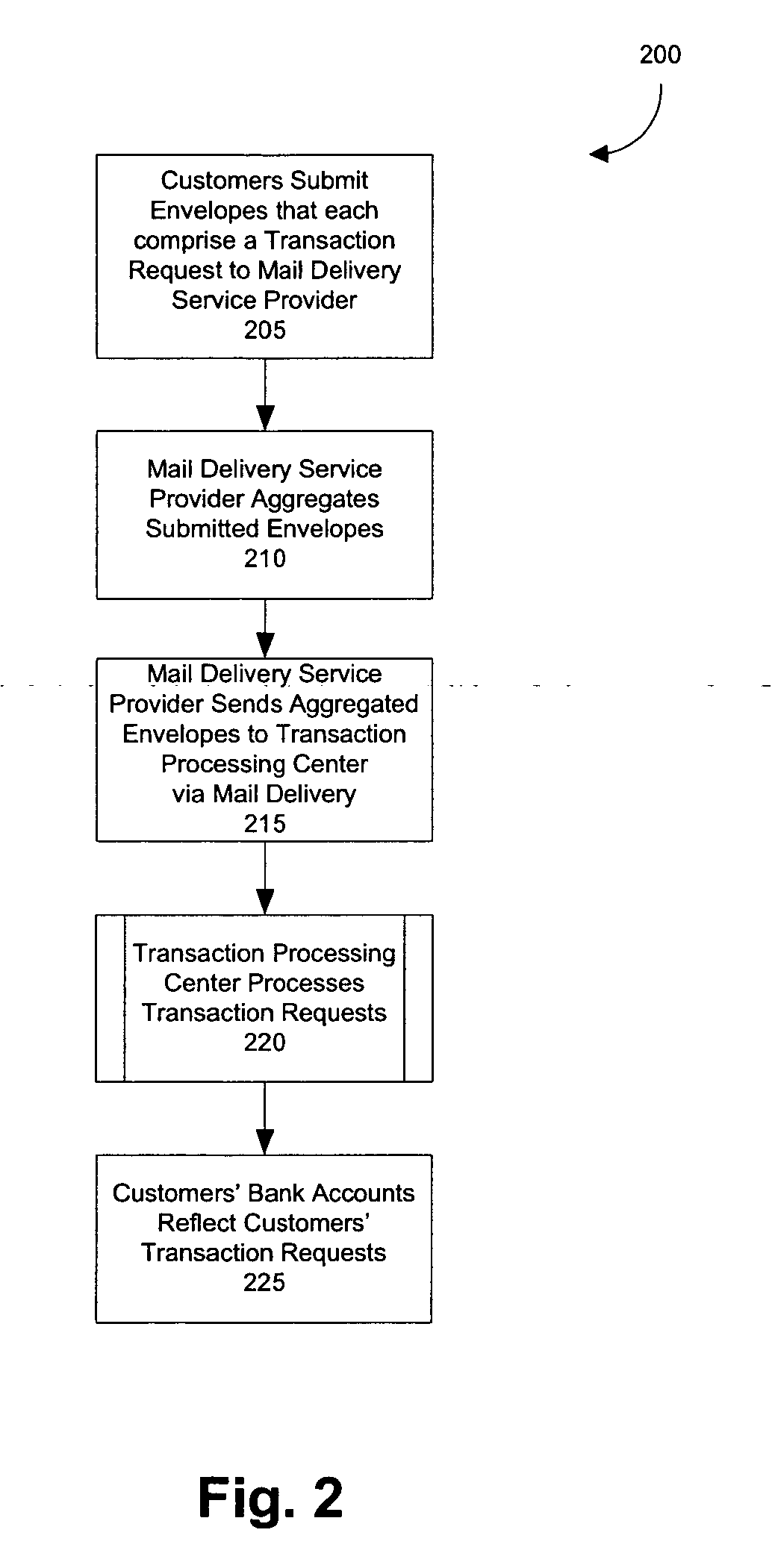

Method and system for processing a financial transaction

InactiveUS20060208059A1Convenient and efficient and cost-effectiveExpand the marketComplete banking machinesFinanceFinancial transactionDatabase

Convenient, efficient, and cost-effective processing of a financial transaction. Banking customers can drop-off financial transaction requests at any of a plurality of geographically dispersed collection sites that operate on behalf of an expedited mail delivery service. Each collection site can aggregate received transaction requests into a package to be delivered to a transaction processing center via expedited mail delivery. Each transaction request can be contained within an envelope. Utilizing unique identifying insignias on each envelope and package, the location of each envelope and package can be tracked during the expedited mail delivery. Upon receipt, the transaction processing center can process each transaction request.

Owner:NETBANK

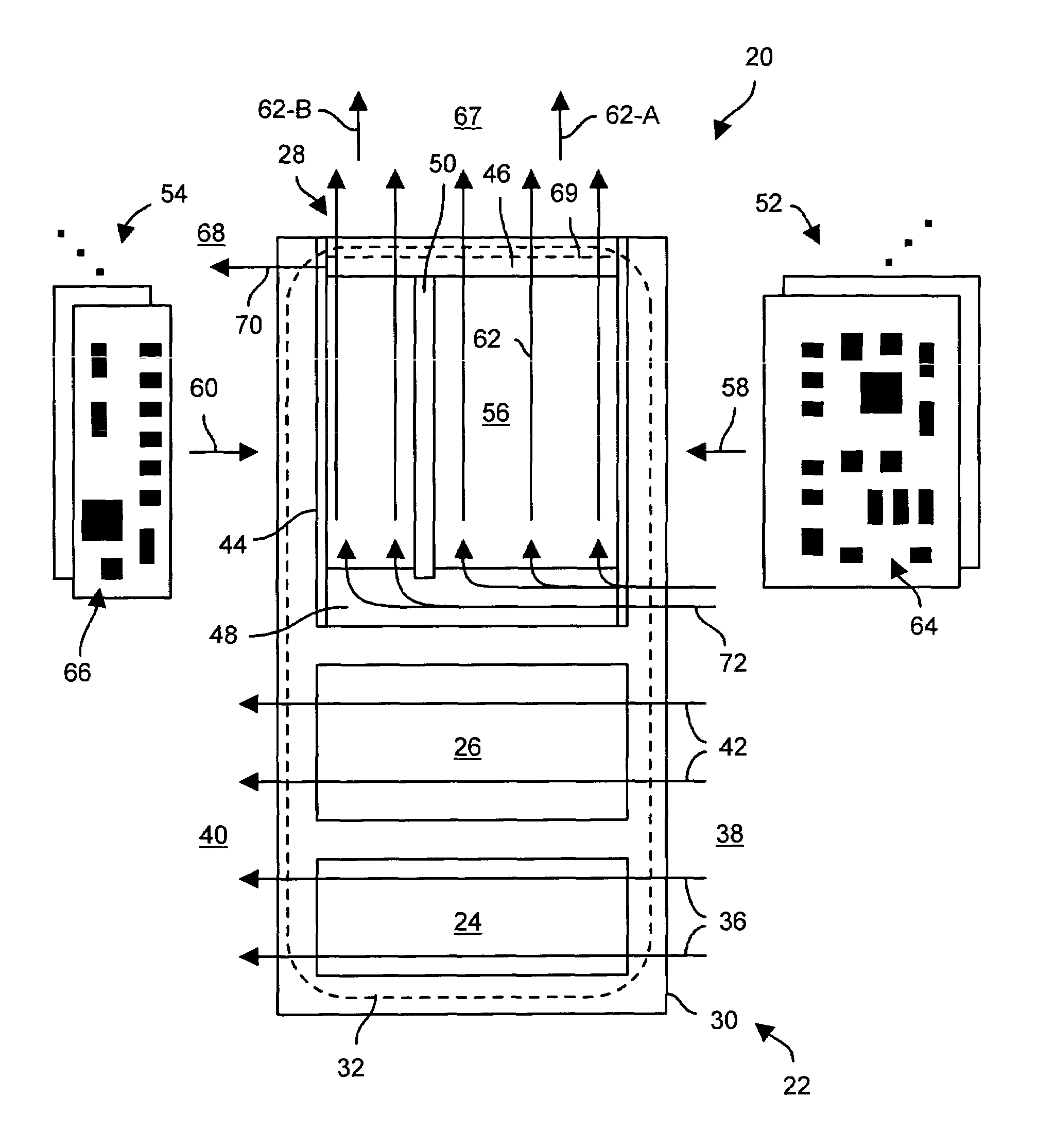

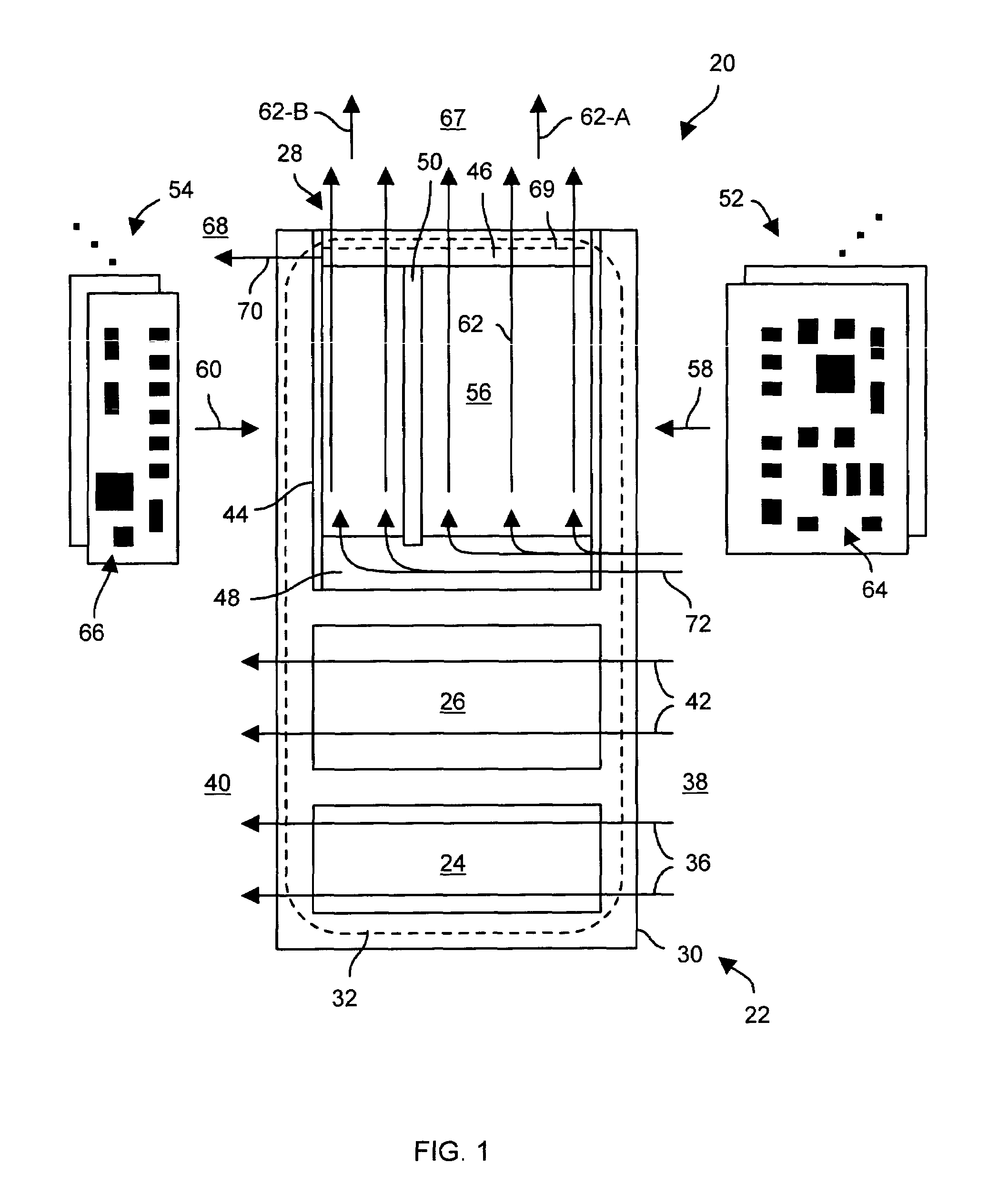

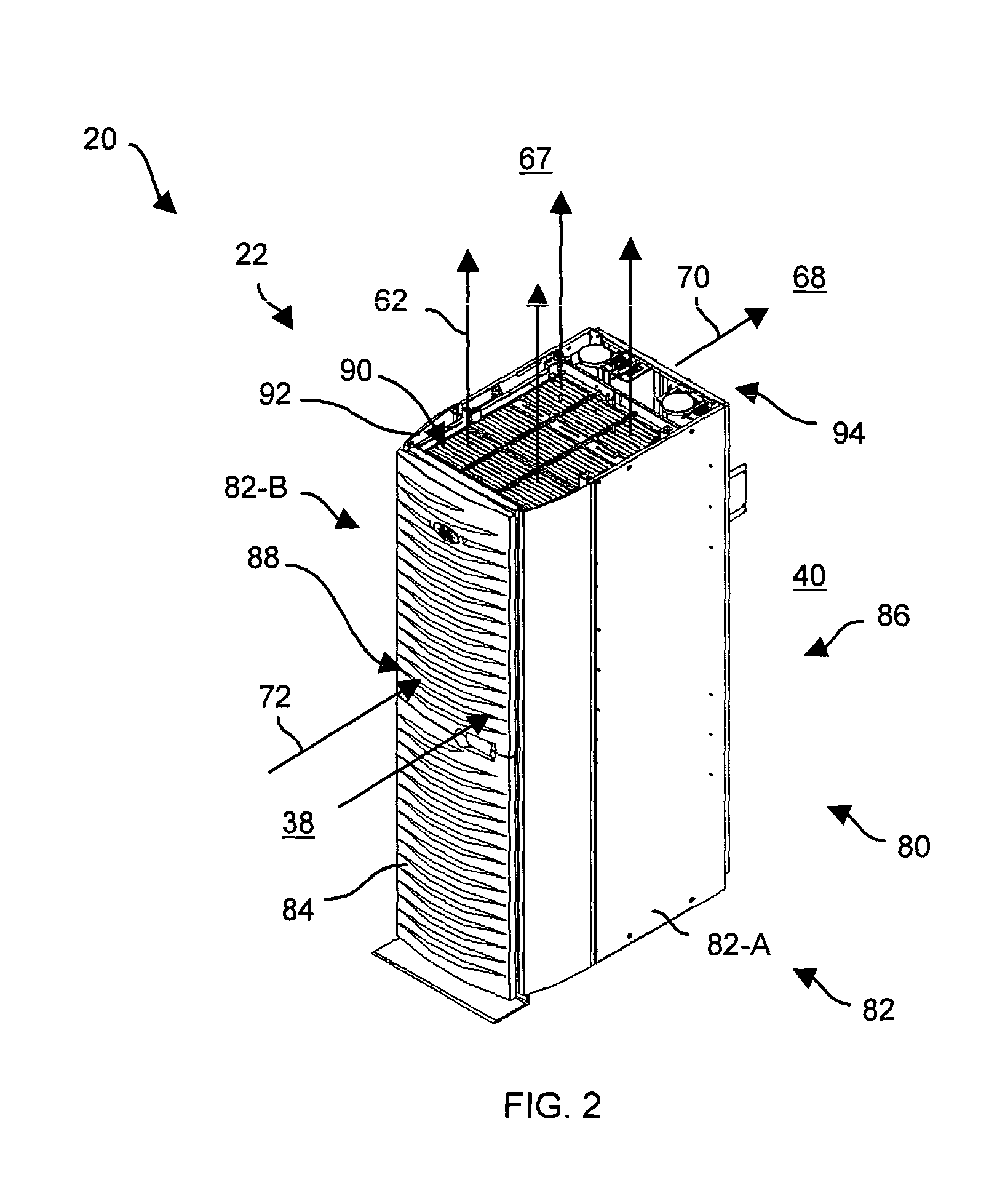

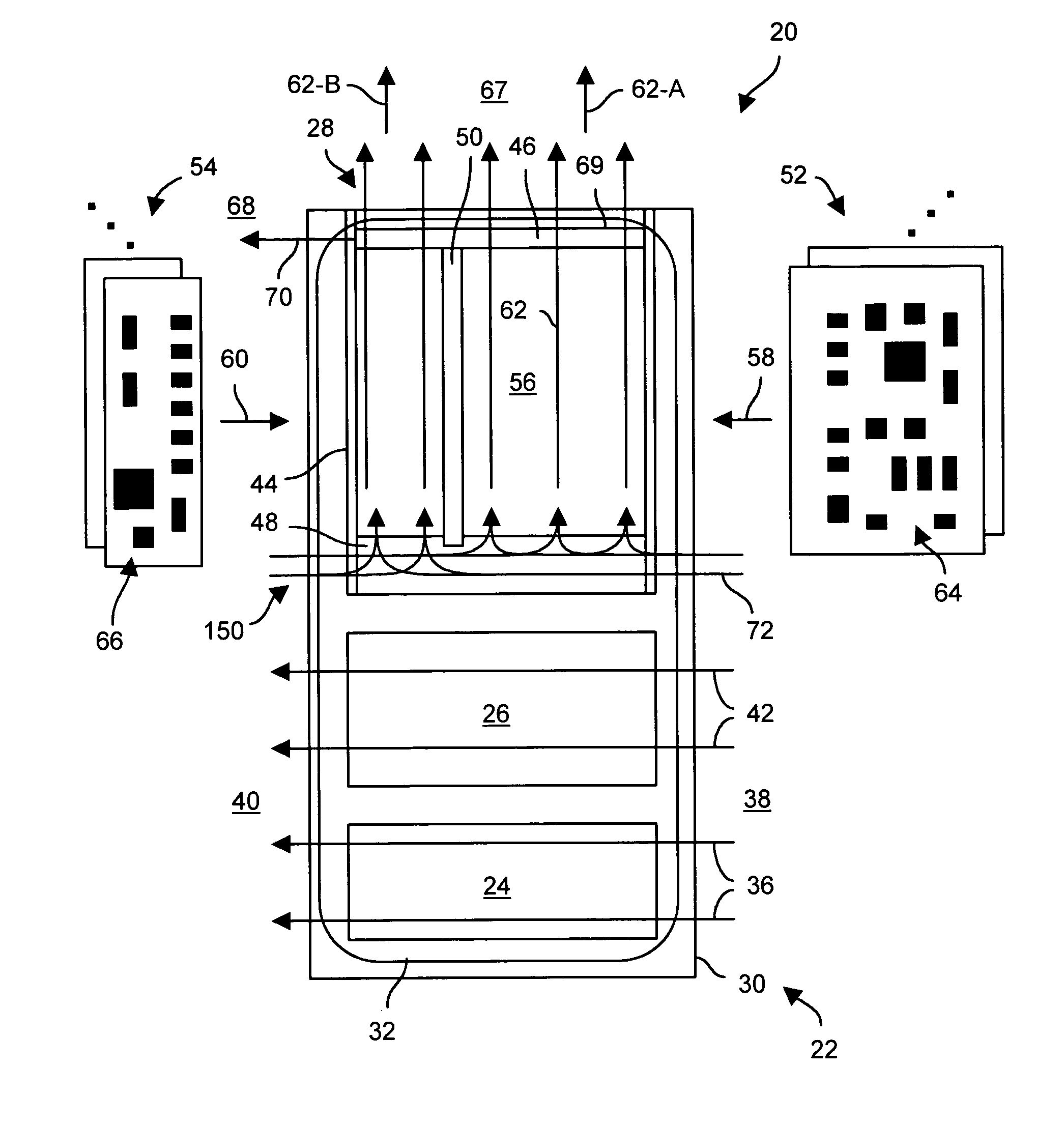

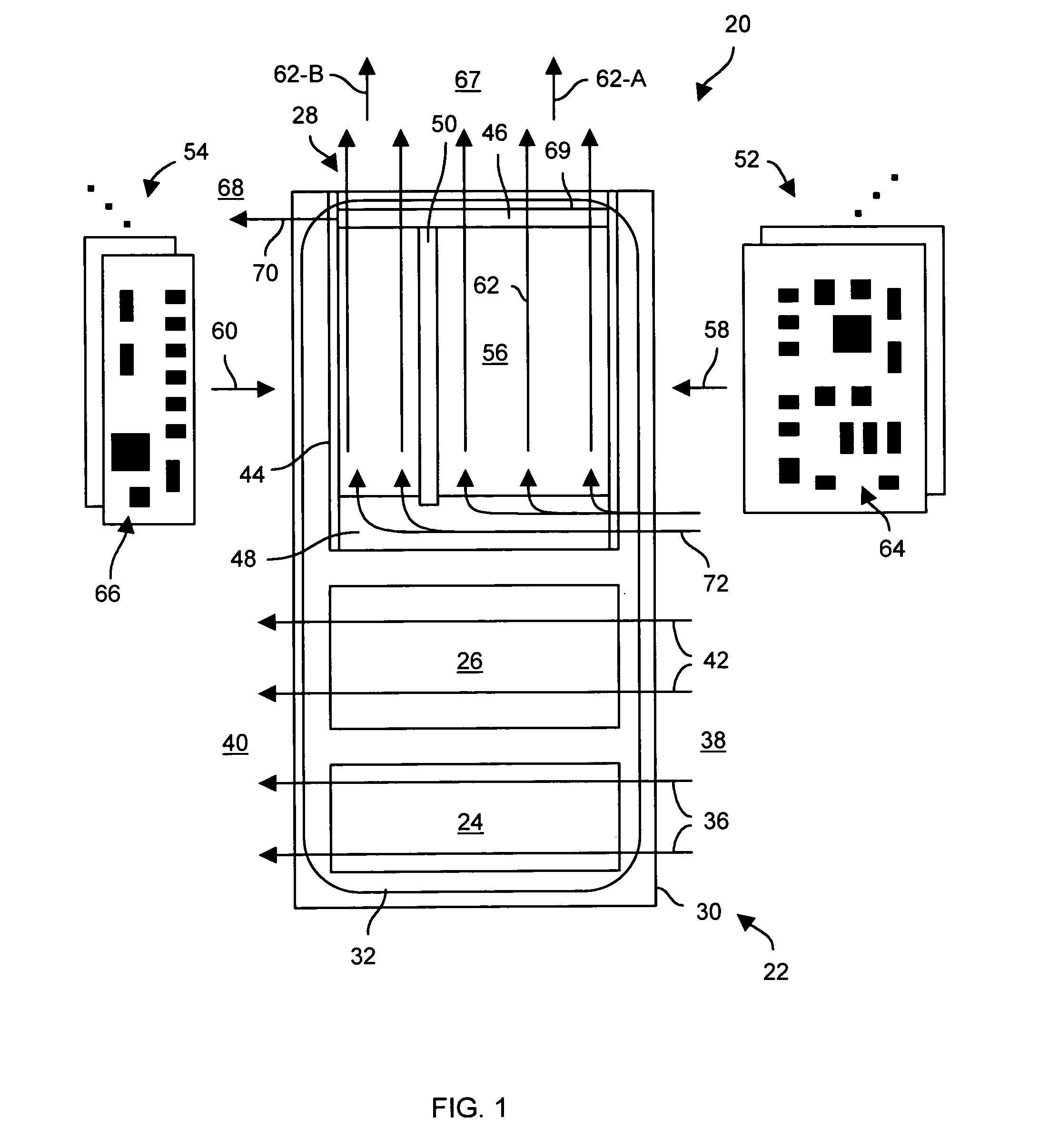

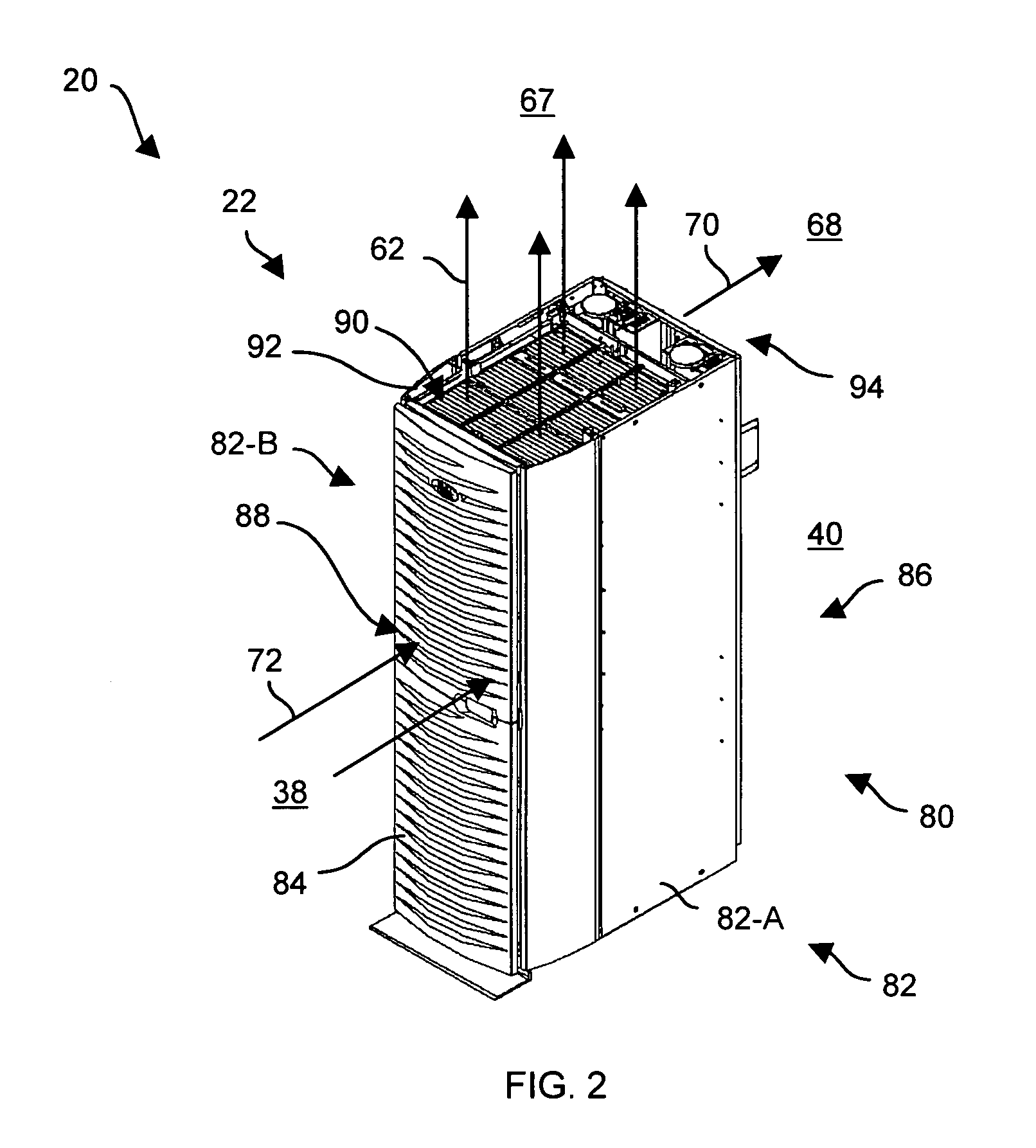

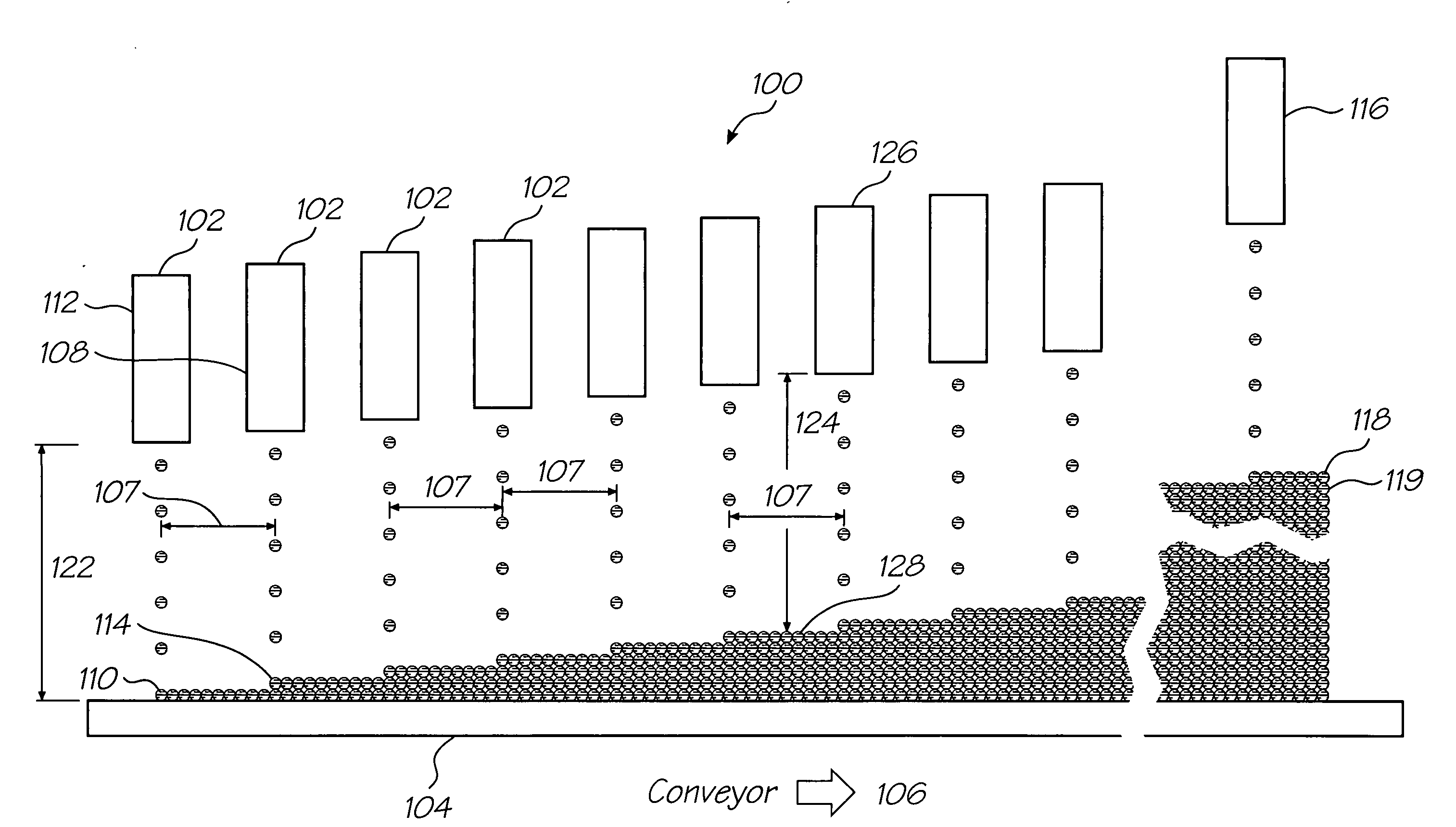

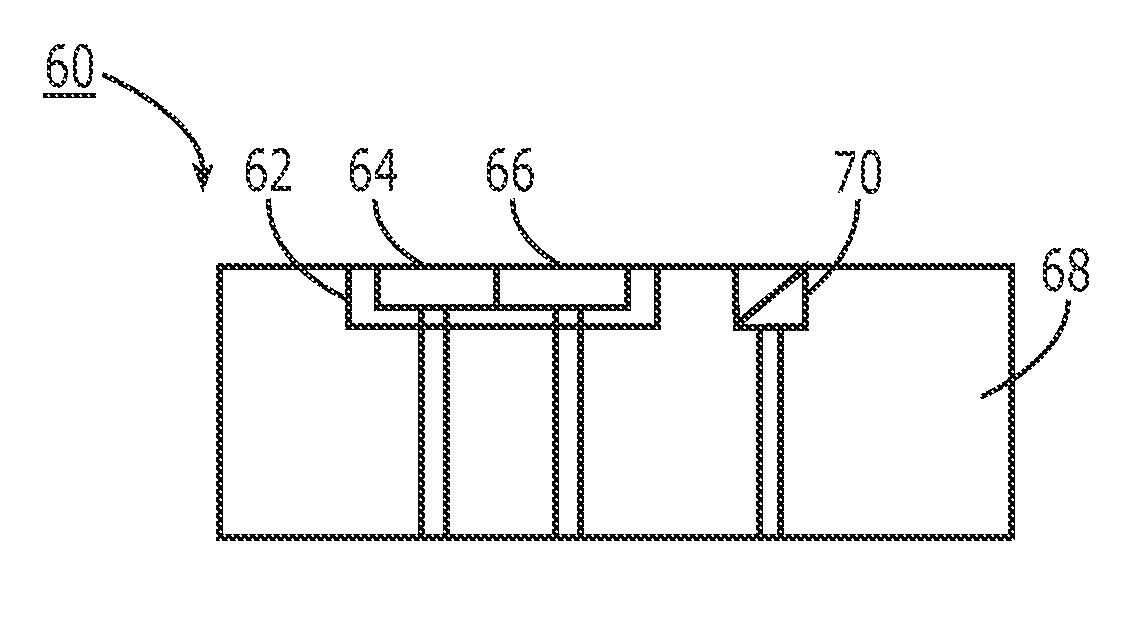

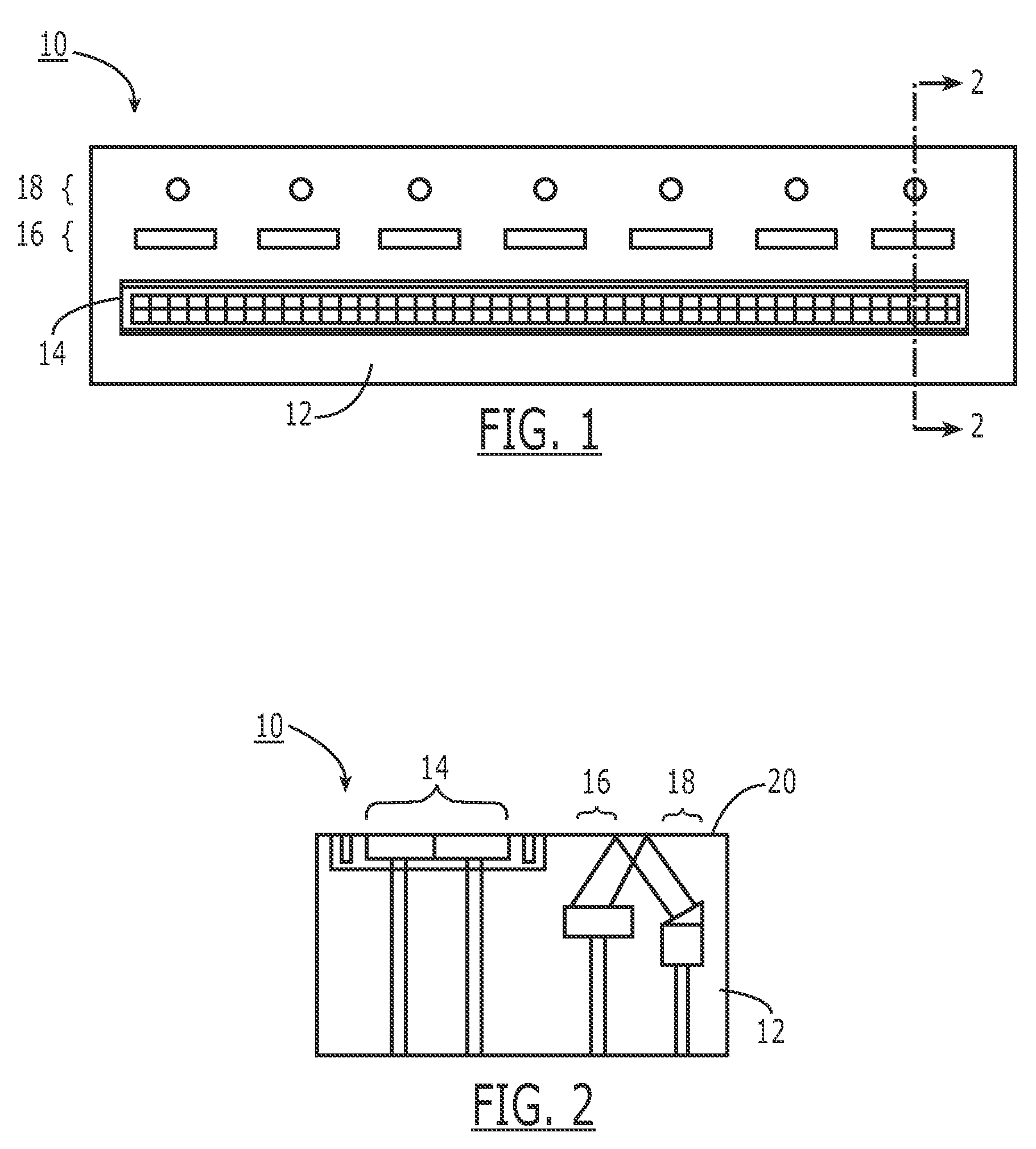

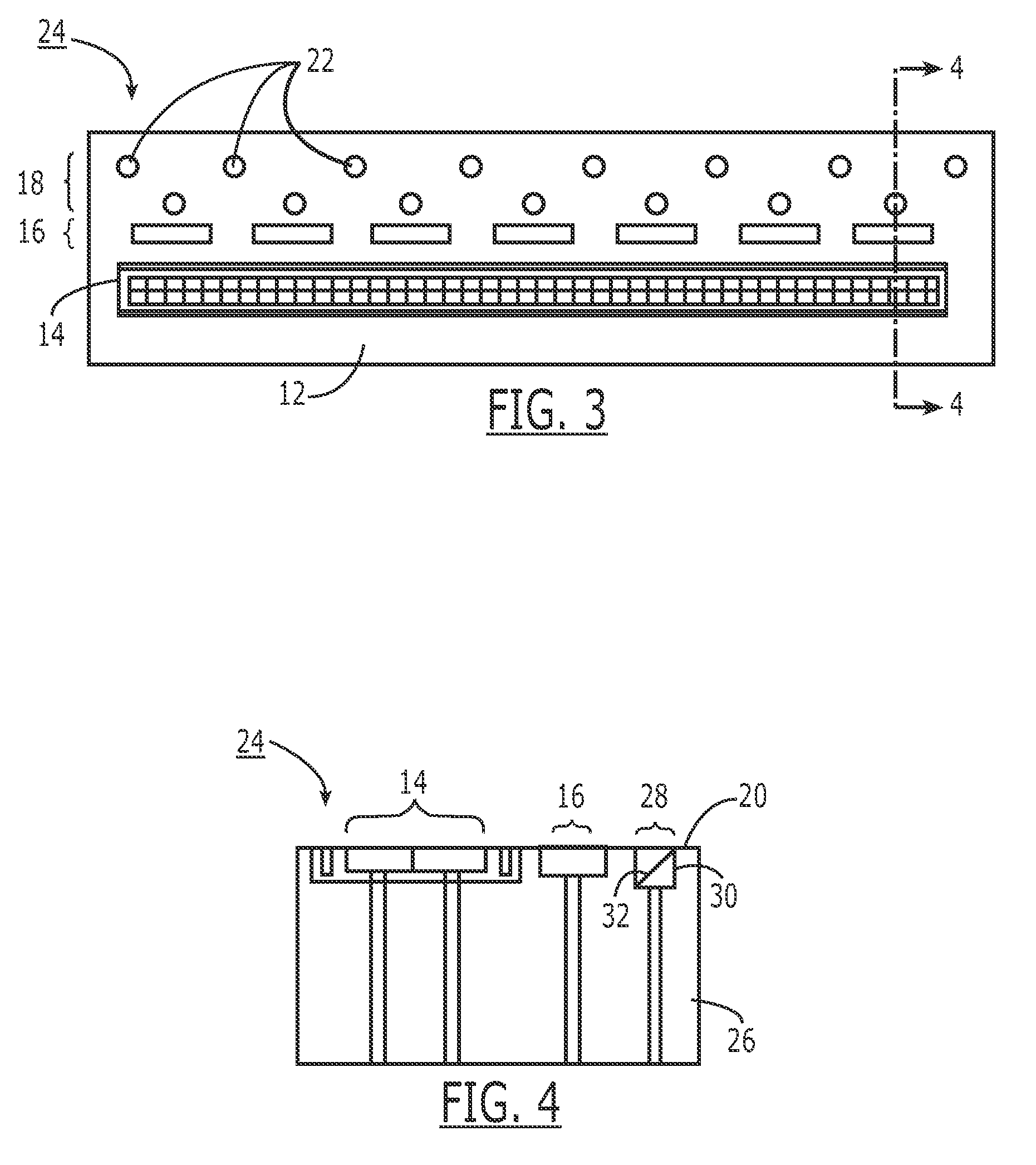

Techniques for cooling a set of circuit boards within a rack mount cabinet

ActiveUS6987673B1Expand marketSufficient coolingDigital data processing detailsFurniture partsAirflowEngineering

A data storage subsystem is configured to mount within a rack mount cabinet. The data storage subsystem includes a housing configured to mount to a set of vertical rails of the rack mount cabinet, a set of circuit boards configured to install in a vertically aligned manner within the housing to define a set of vertically oriented channels within a central space defined by the set of vertical rails of the rack mount cabinet, and a fan assembly configured to mount to the set of vertical rails in a position above the housing to generate a vertical air stream through the set of vertically oriented channels and to exhaust the vertical air stream to an external location above the rack mount cabinet. The vertical air stream enables robust heat removal from the set of circuit boards even if the rack mount cabinet does not reside in a cold-isle environment.

Owner:EMC IP HLDG CO LLC

Methods for obtaining and using haplotype data

InactiveUS20050191731A1Accurate predictionReduce costs and risksData visualisationBiostatisticsHaplotypeCrowds

Methods, computer program(s) and database(s) to analyze and make use of gene haplotype information. These include methods, program, and database to find and measure the frequency of haplotypes in the general population; methods, program, and database to find correlation's between an individual's haplotypes or genotypes and a clinical outcome; methods, program, and database to predict an individual's haplotypes from the individual's gen type for a gene; and methods, program, and database to predict an individual's clinical response to a treatment based on the individual's genotype or haplotype.

Owner:JUDSON RICHARD S +3

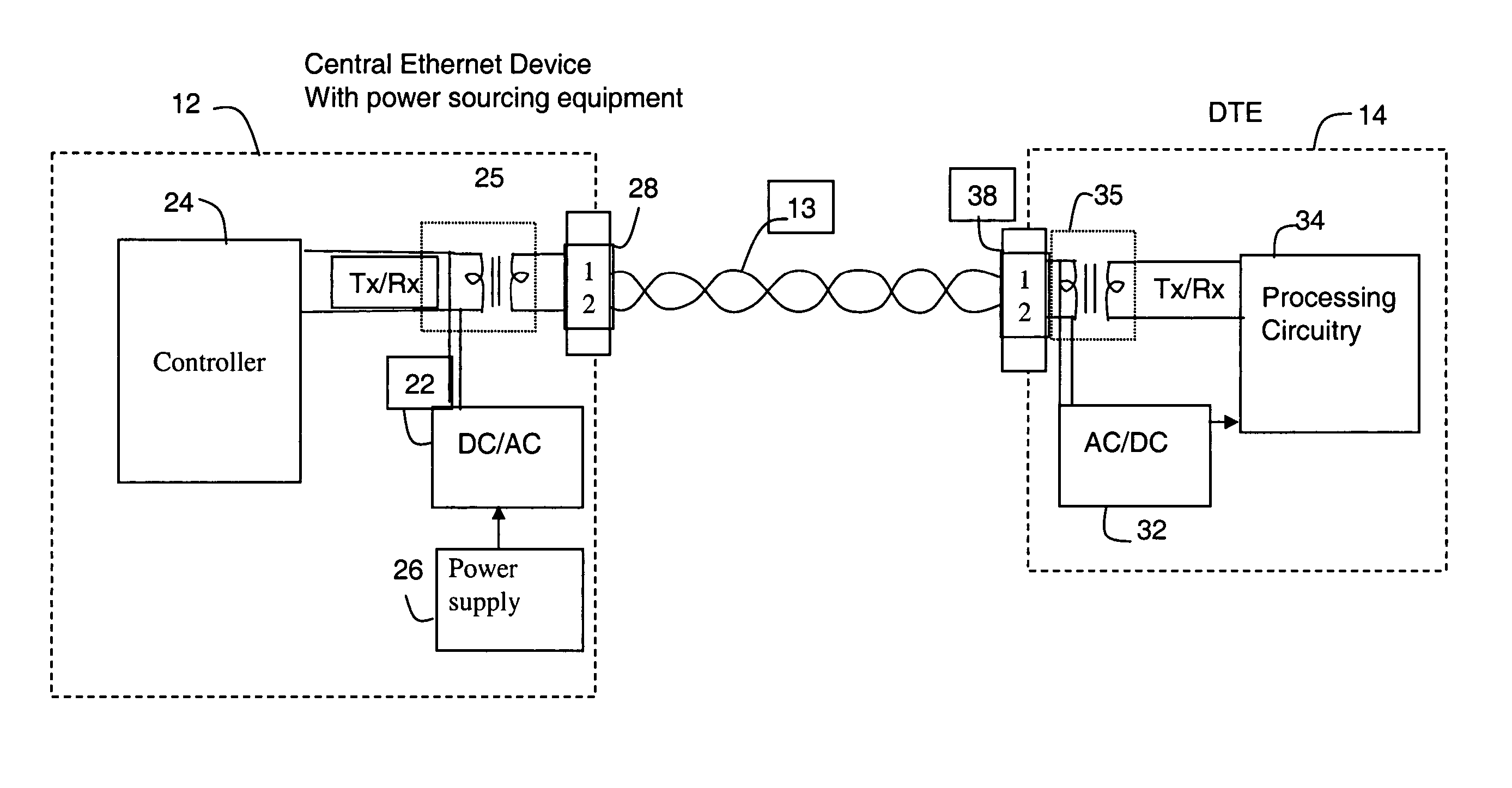

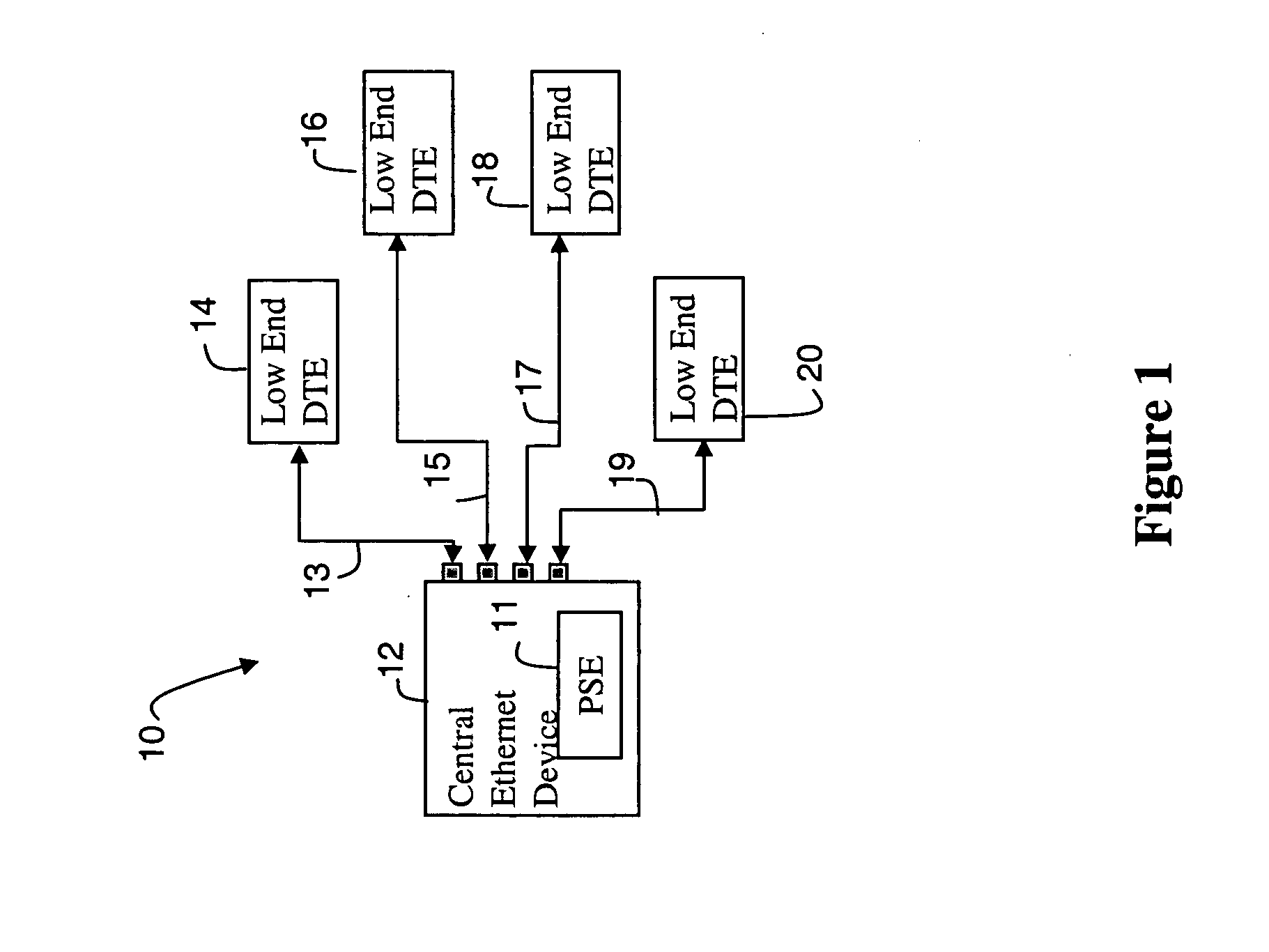

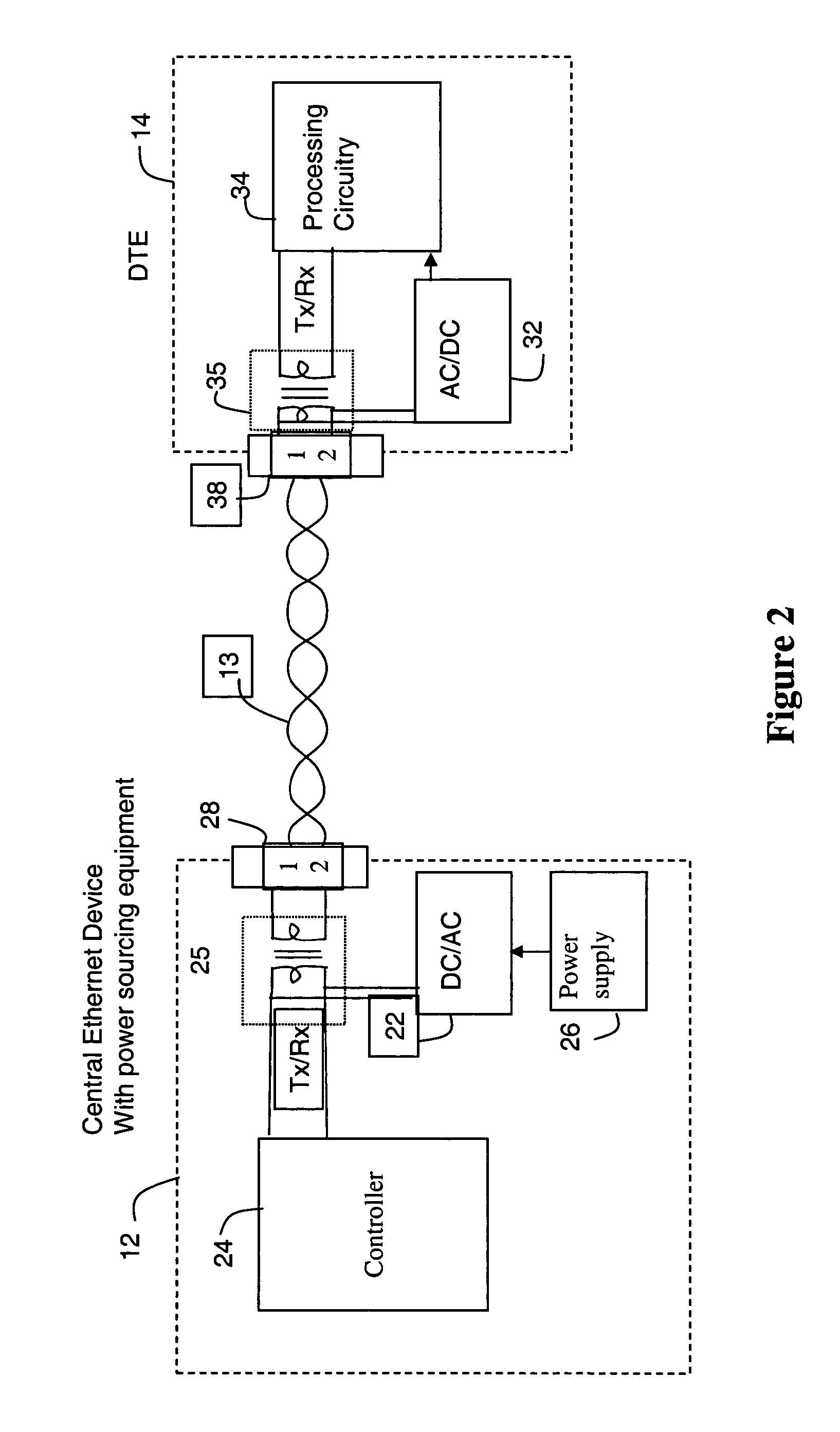

Ultra low cost ethernet architecture

InactiveUS20050078700A1Low costExpand the marketMultiplex system selection arrangementsData switching by path configurationDistributed powerEthernet communication

A low cost mechanism that may be used to extend Ethernet capability to low end devices provides sufficient capacity to support Ethernet communications using only a single twisted pair medium. Because only a single twisted pair is used, the overall cost, complexity and size associated with the integrating Ethernet functionality into an end device is reduced. A distributed power system delivers power to a Data Terminal Equipment (DTE) device over the single twisted pair medium. With such an arrangement, Ethernet capability and power may be simultaneously delivered to low end devices at a reduced cost.

Owner:RPX CLEARINGHOUSE

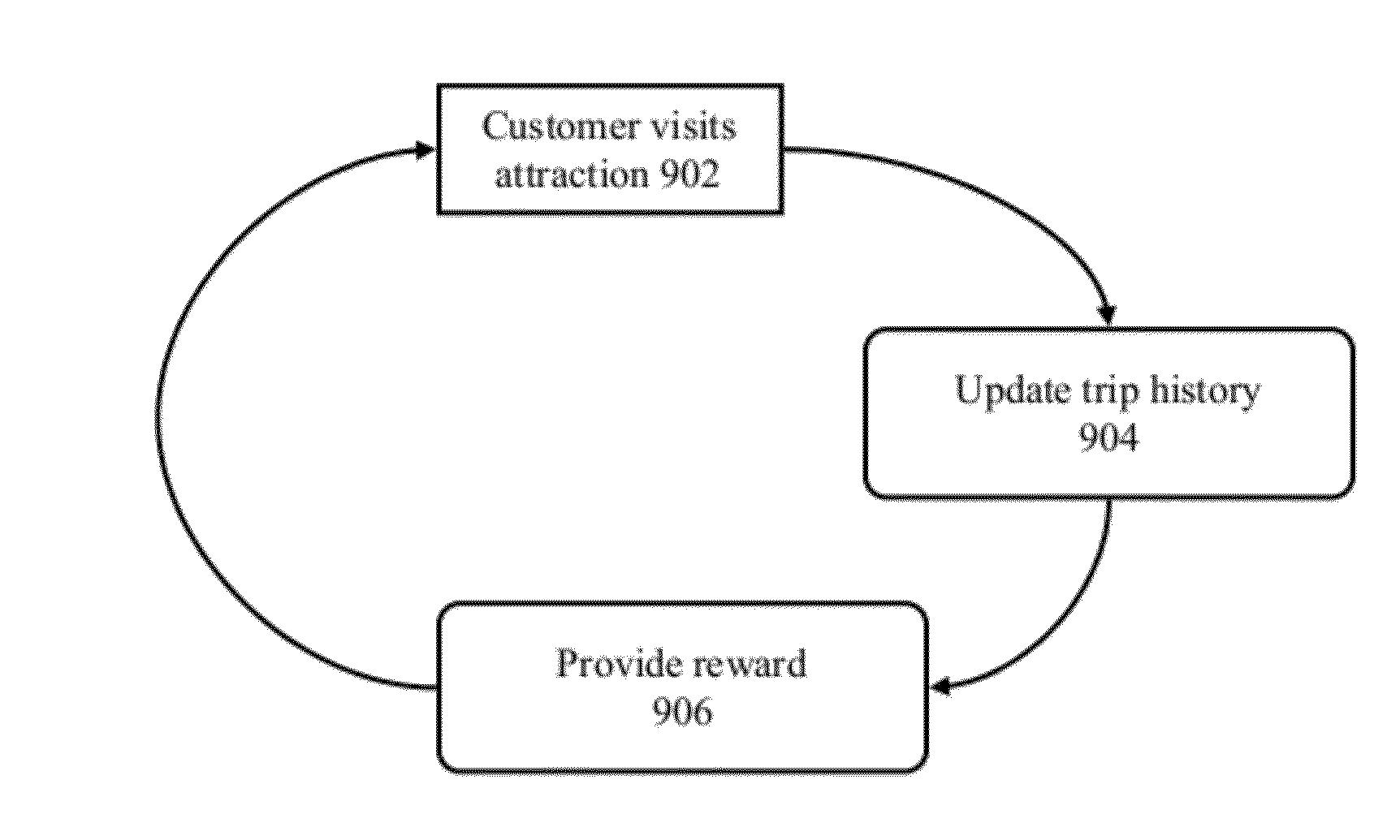

Systems and methods for location-based marketing for attraction access

ActiveUS20120323691A1Improve analysisEnhanced reportingReservationsPayment architectureReal-time computingAnalyser

Owner:SMART DESTINATIONS

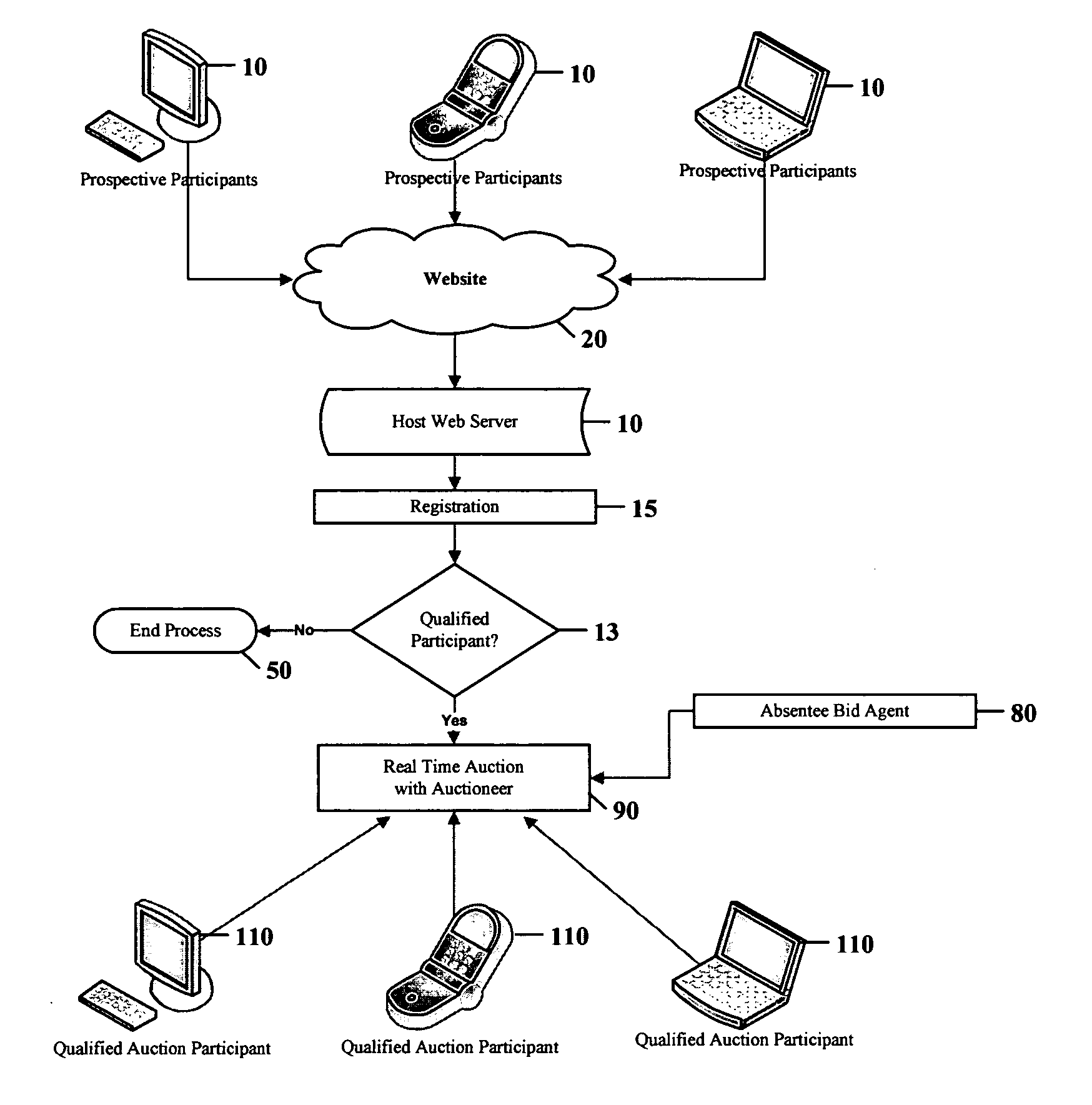

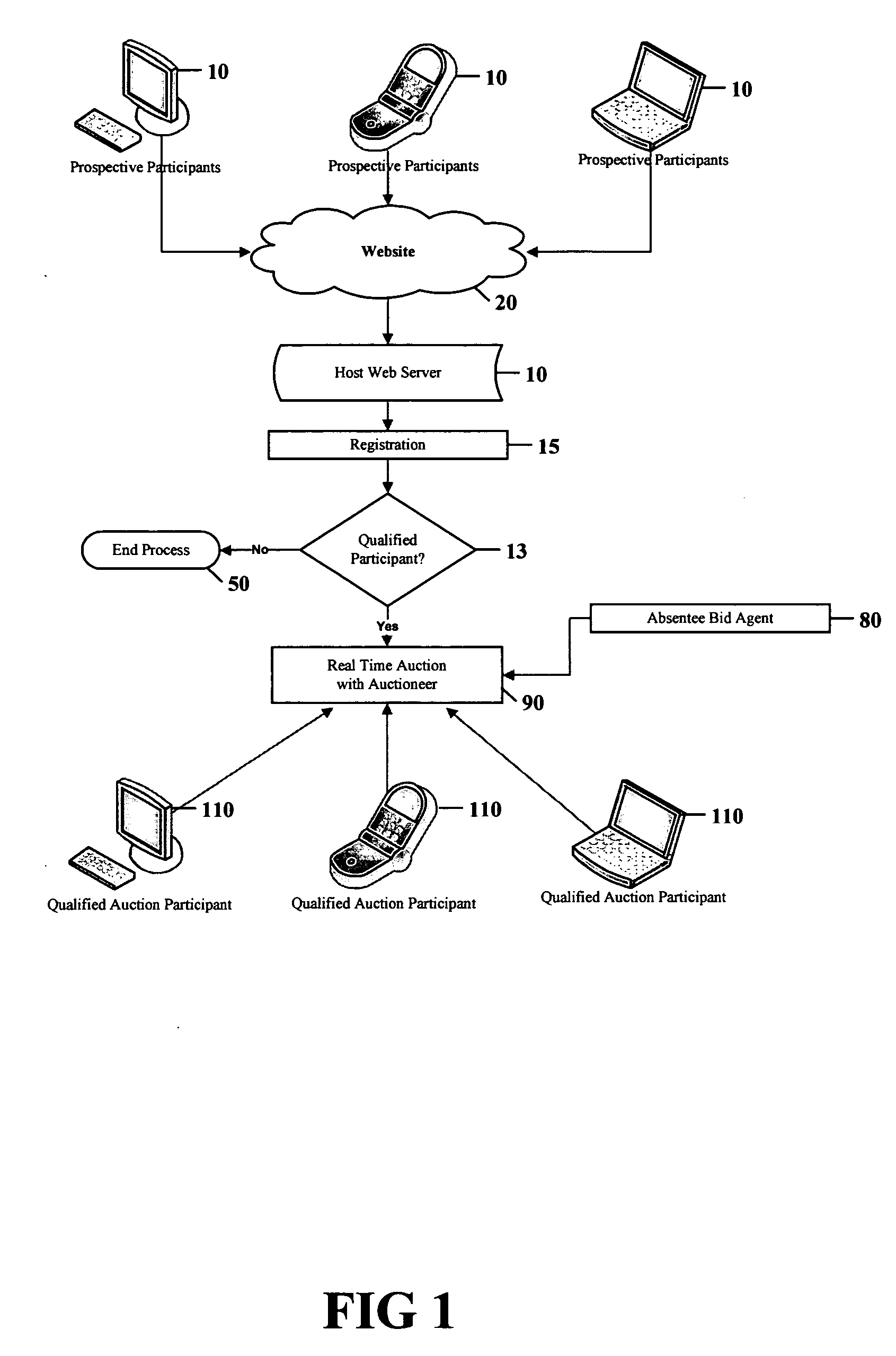

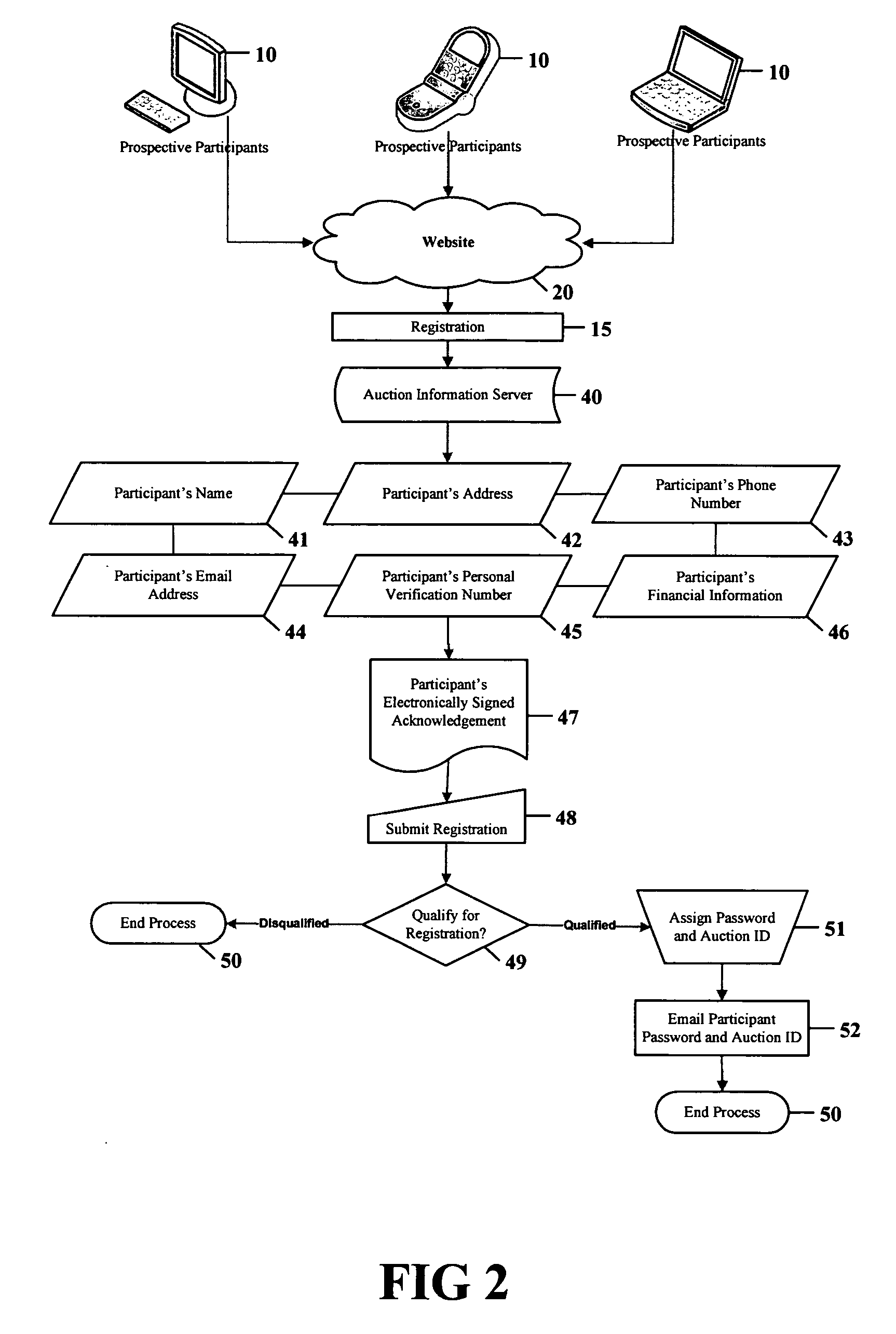

Real-time, interactive, competitive method of on-line auction utilizing an auctioneer

Owner:NASSIRI NICK

Techniques for cooling a set of circuit boards within a rack mount cabinet

InactiveUS7187547B1Expand the marketReliable and robust heat removalDigital data processing detailsDrawersComputer hardwareVertical alignment

A data storage subsystem is configured to mount within a rack mount cabinet. The data storage subsystem includes a housing configured to mount to a set of vertical rails of the rack mount cabinet, a set of circuit boards configured to install in a vertically aligned manner within the housing to define a set of vertically oriented channels within a central space defined by the set of vertical rails of the rack mount cabinet, and a fan assembly configured to mount to the set of vertical rails in a position above the housing to generate a vertical air stream through the set of vertically oriented channels and to exhaust the vertical air stream to an external location above the rack mount cabinet. The vertical air stream enables robust heat removal from the set of circuit boards even if the rack mount cabinet does not reside in a cold-isle environment.

Owner:EMC IP HLDG CO LLC

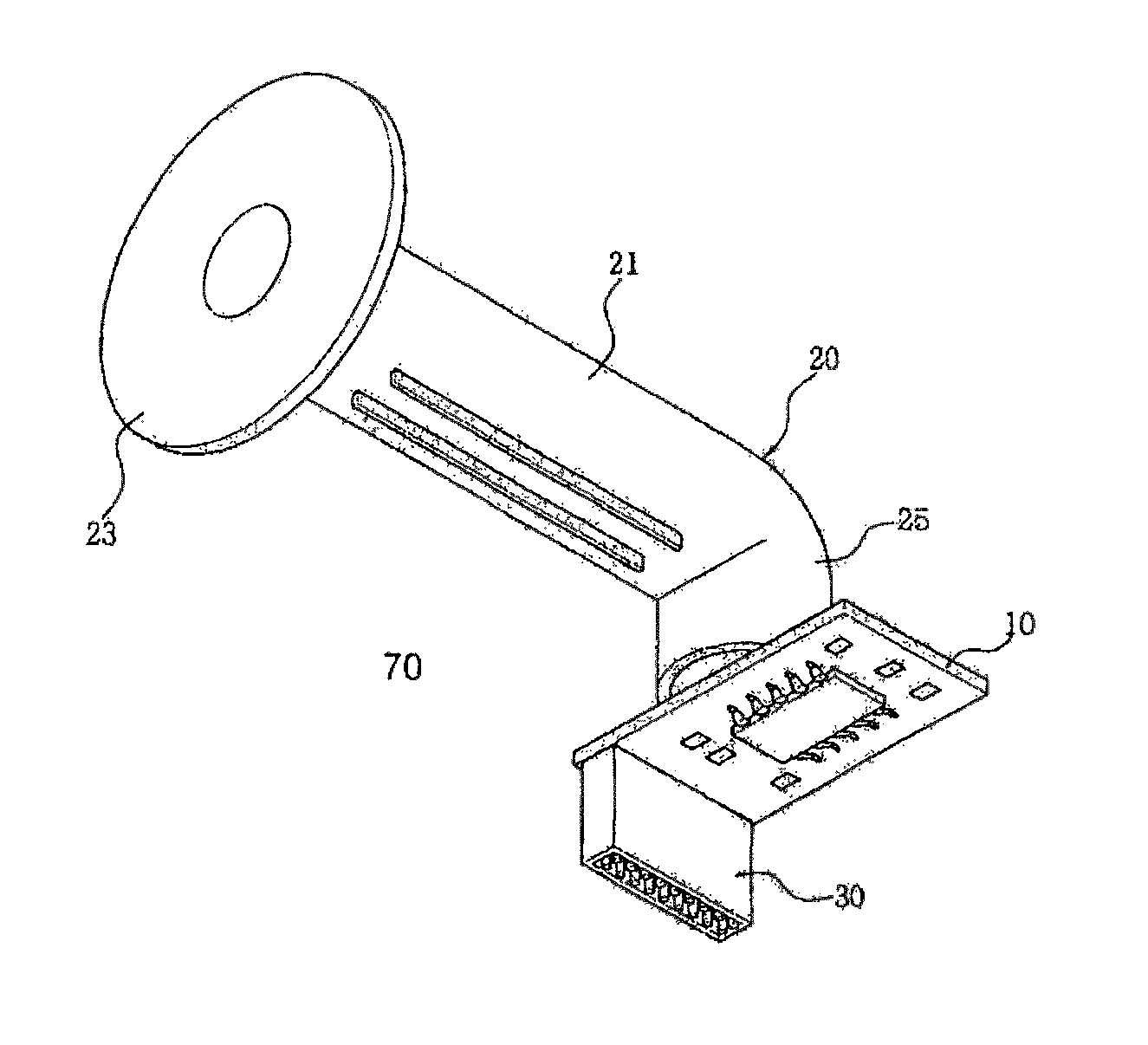

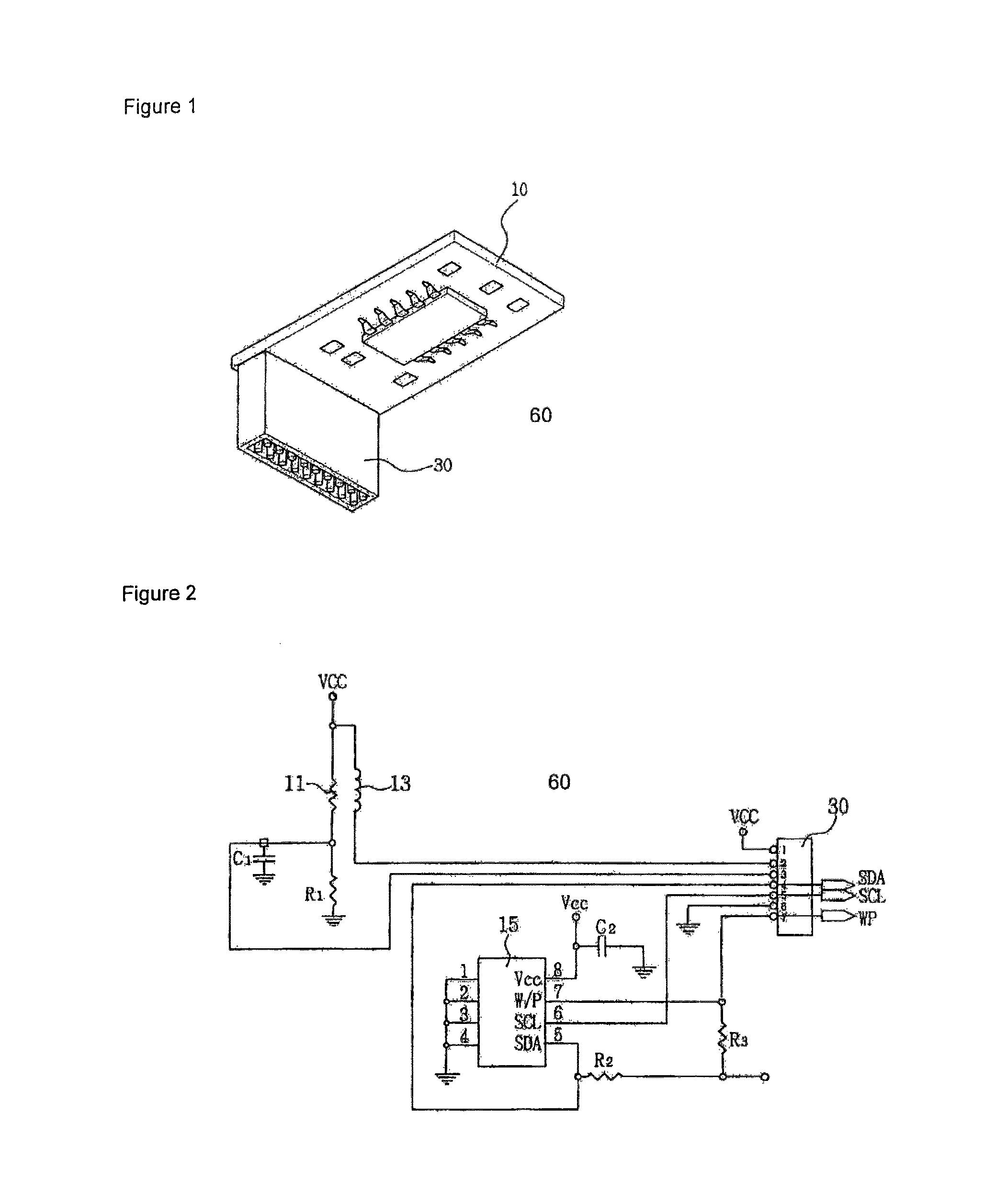

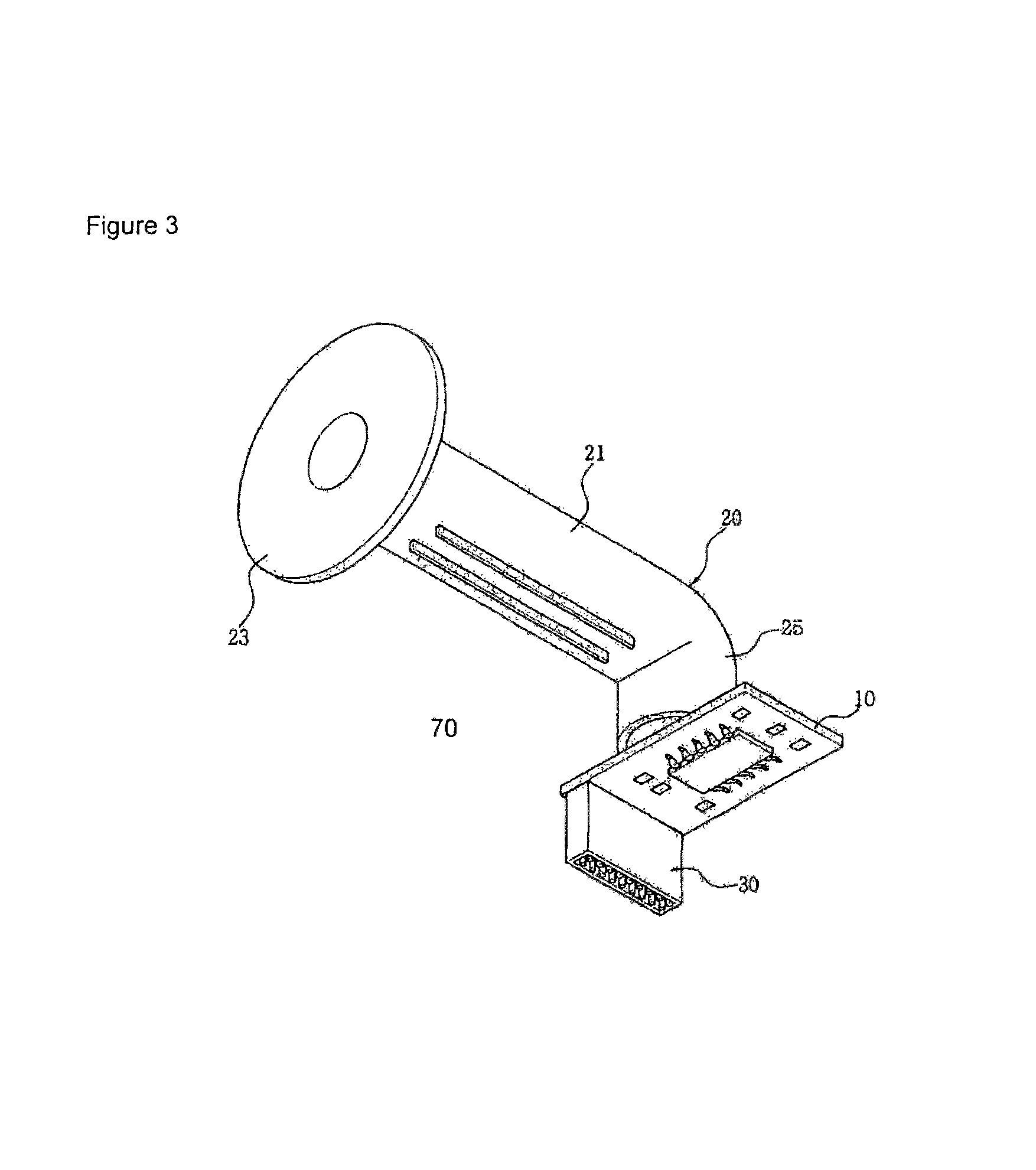

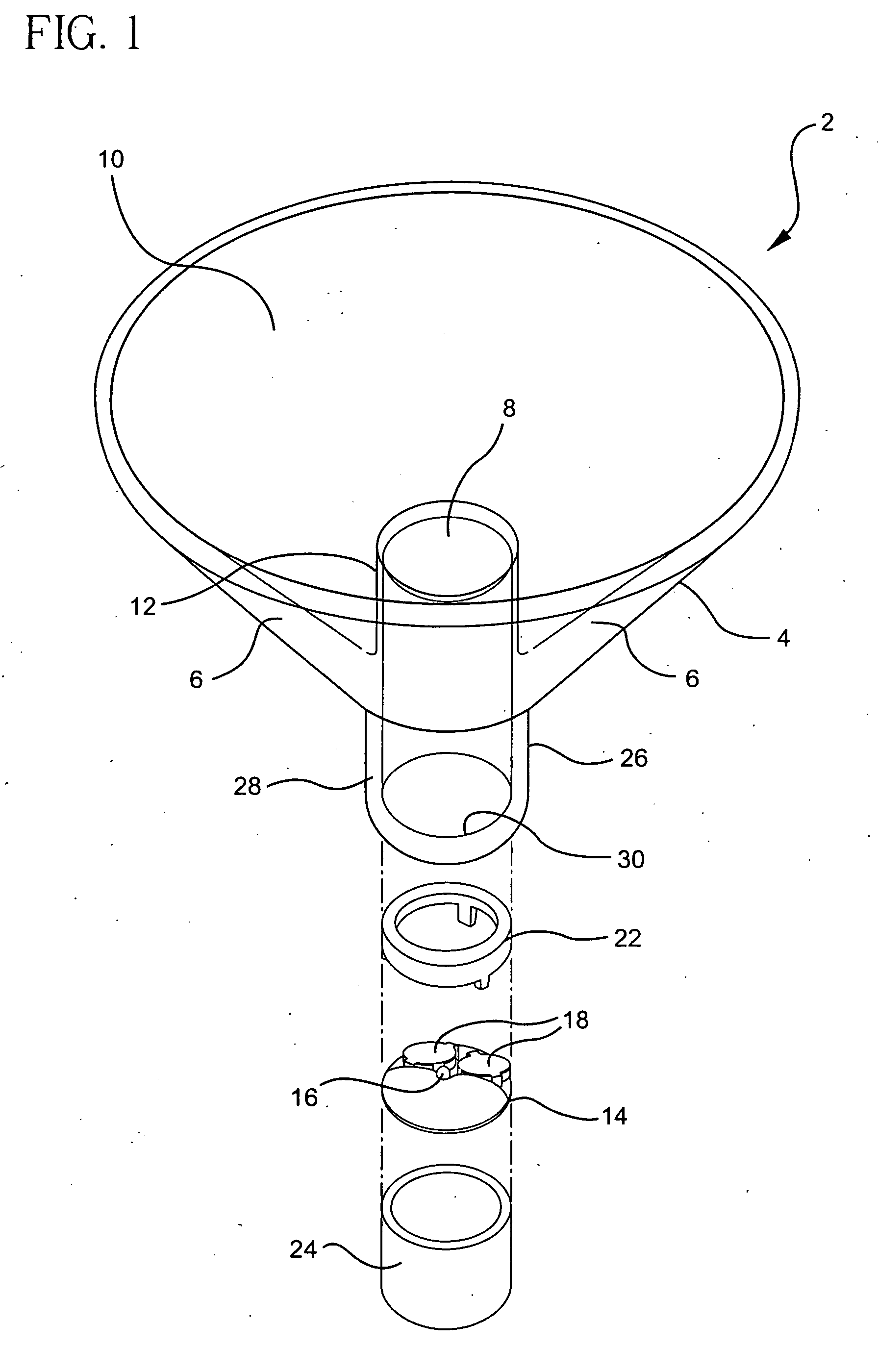

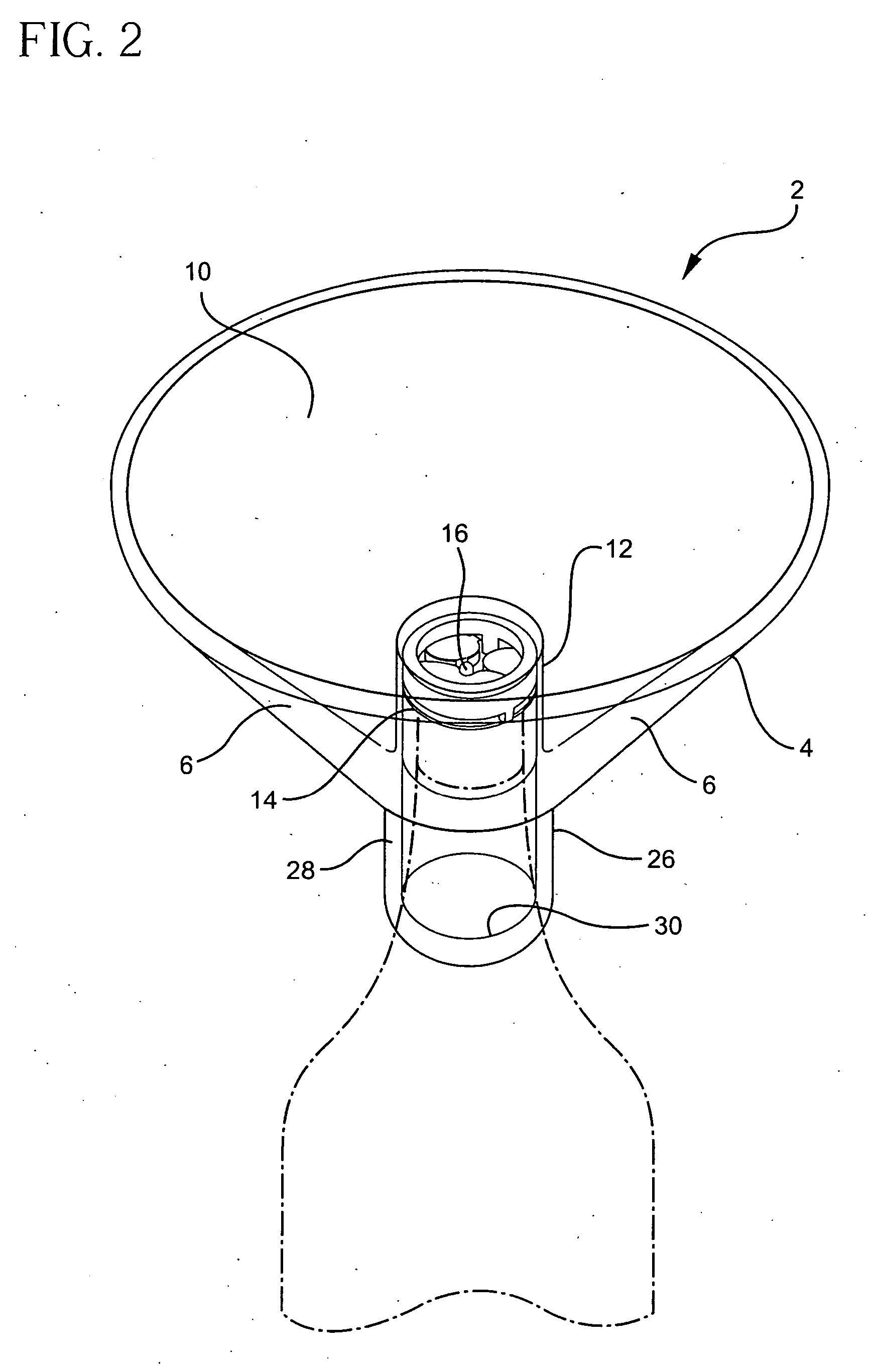

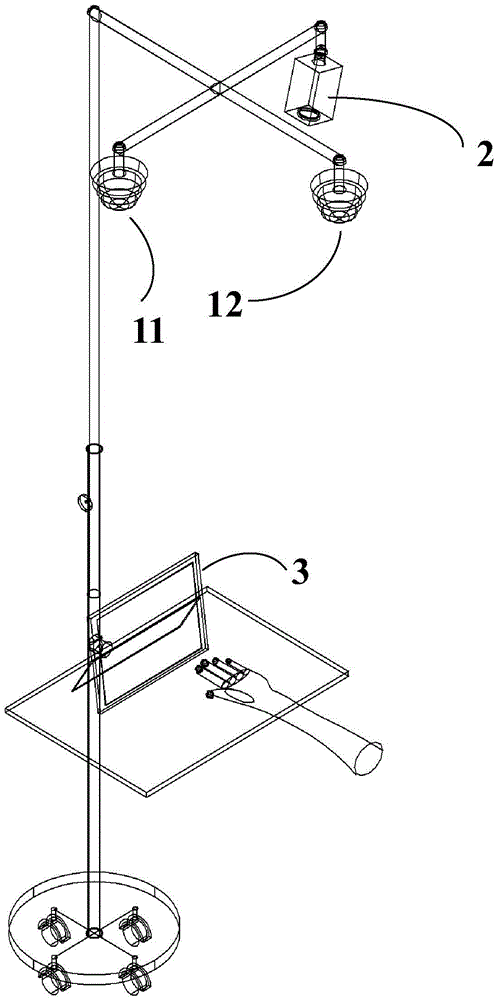

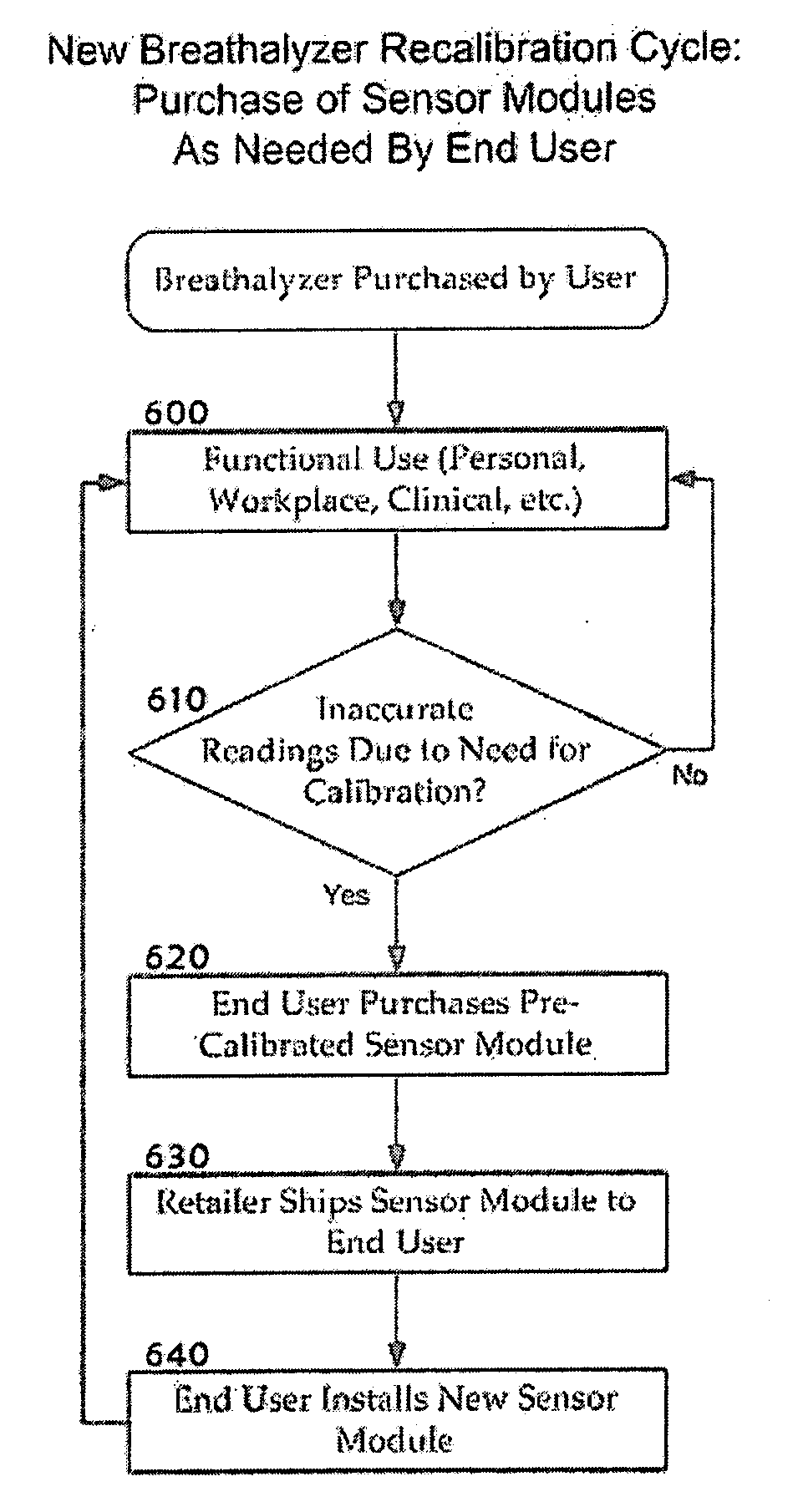

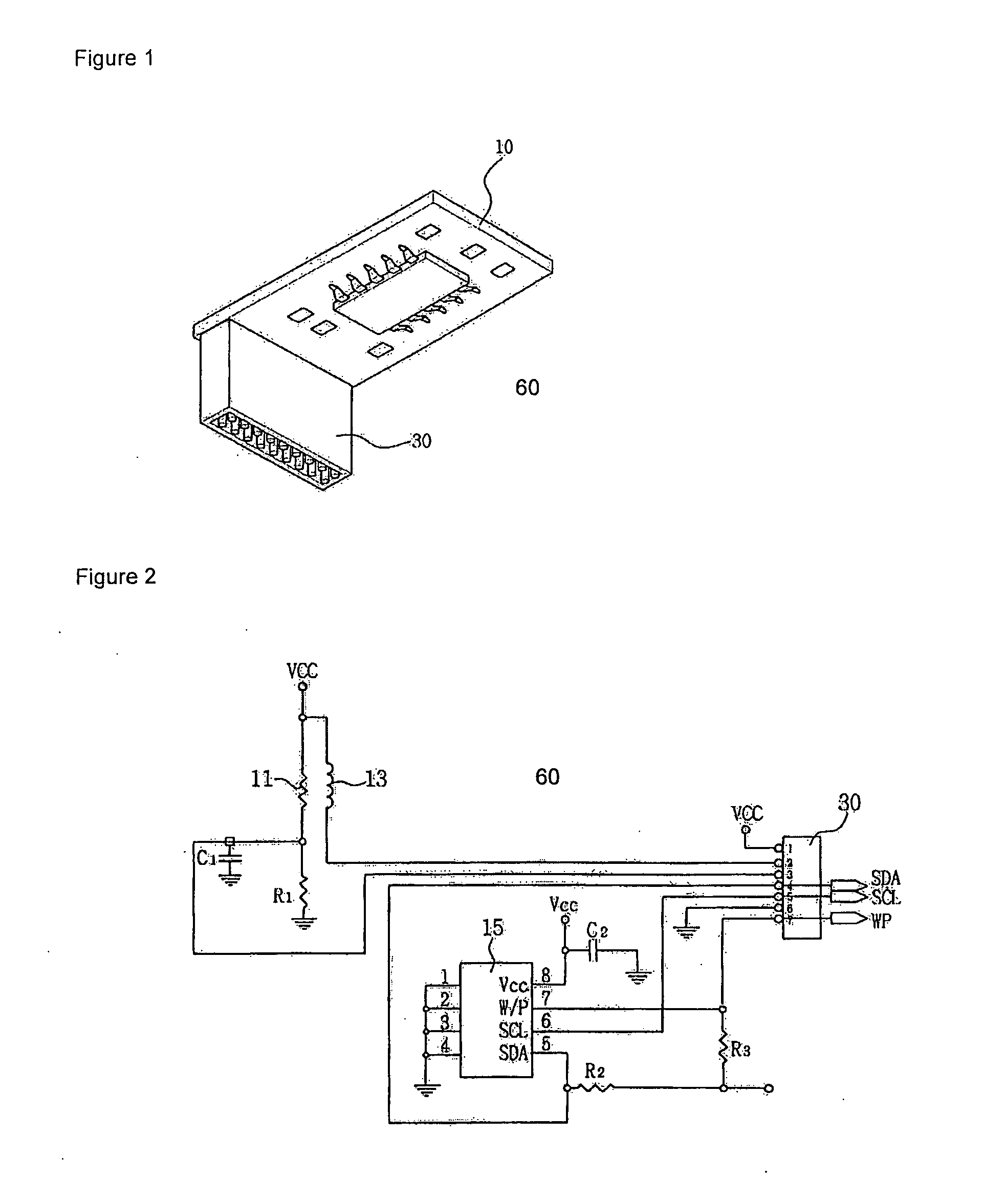

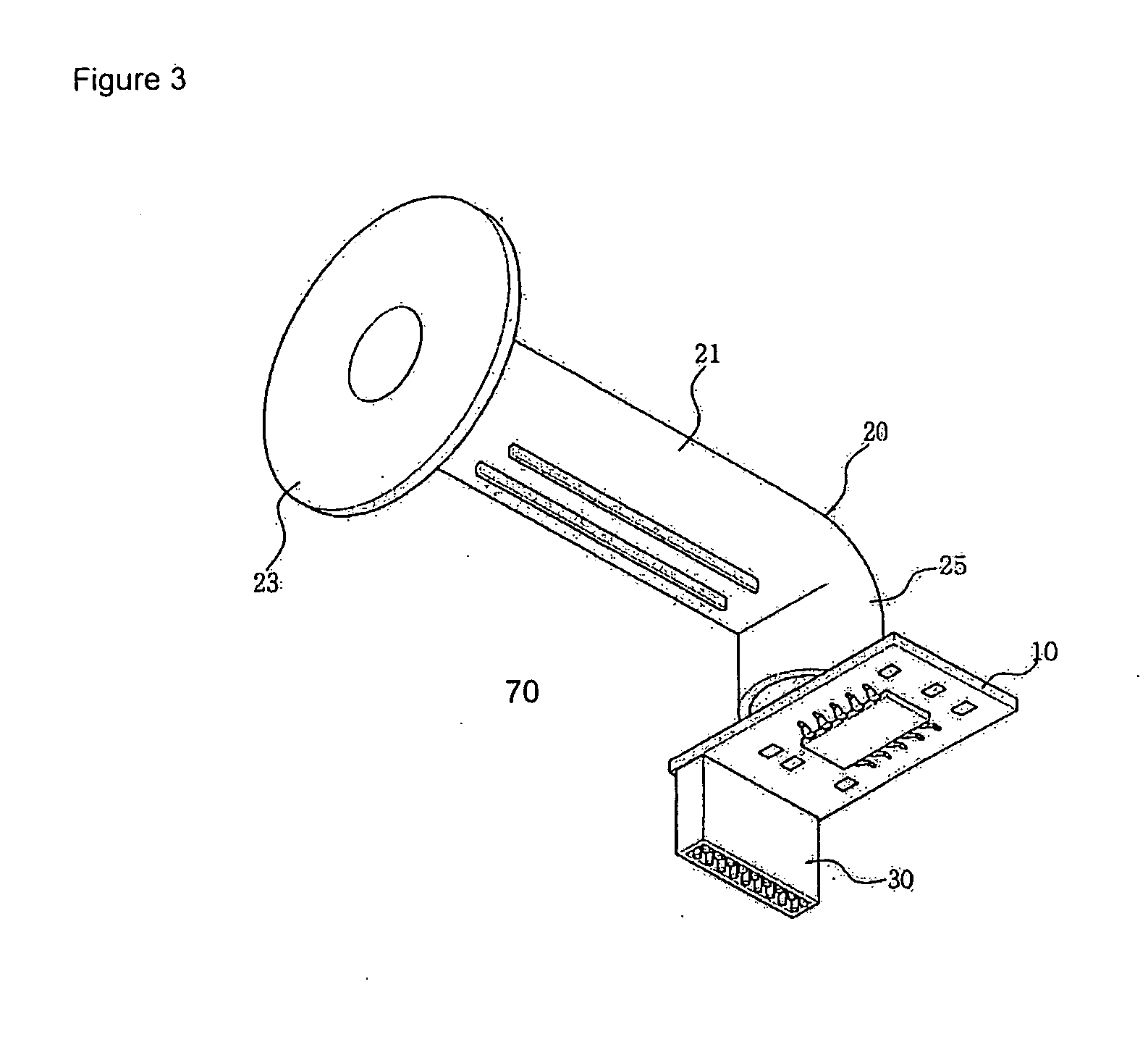

Pre-calibrated replaceable sensor module for a breath alcohol testing device

ActiveUS7841224B2Shorten the timeReduce utilizationMaterial analysis by optical meansMaterial resistanceEnvironmental healthAir sample

Owner:AK GLOBALTECH

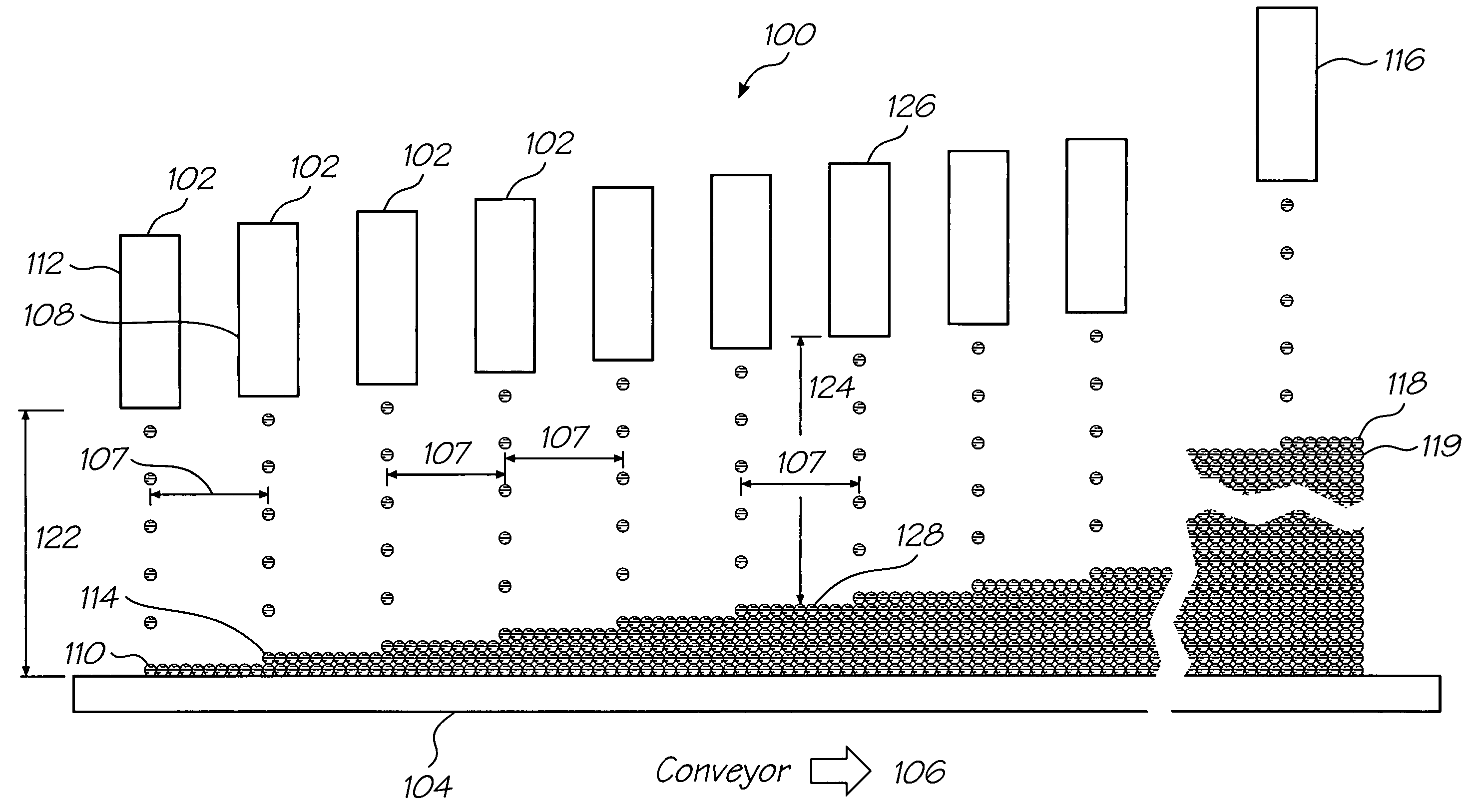

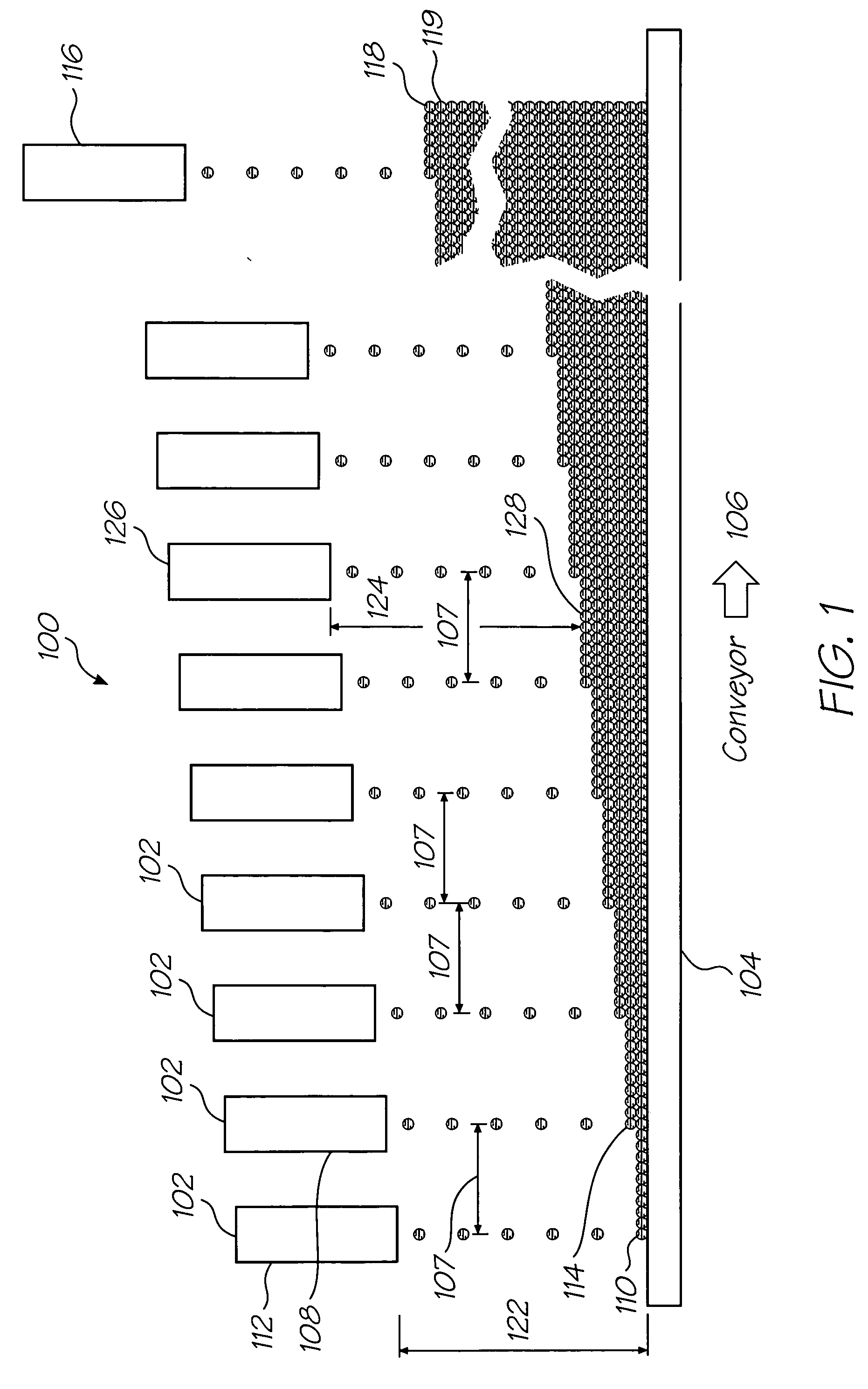

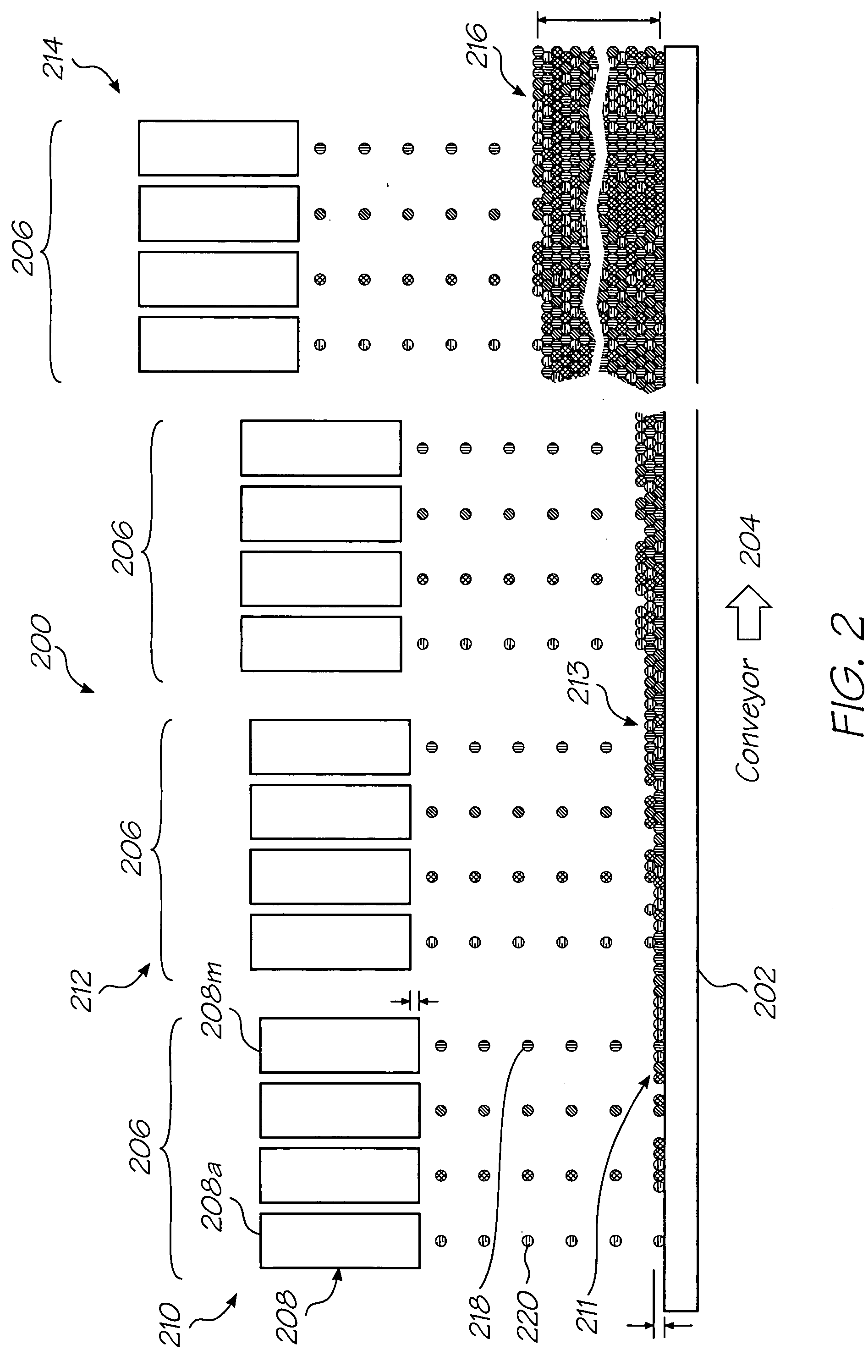

3-d product printing system

InactiveUS20040141018A1Increased substrate speedIncrease speedAdditive manufacturing apparatusLiquid surface applicatorsManufacturing engineeringSoftware engineering

Owner:SILVERBROOK RES PTY LTD

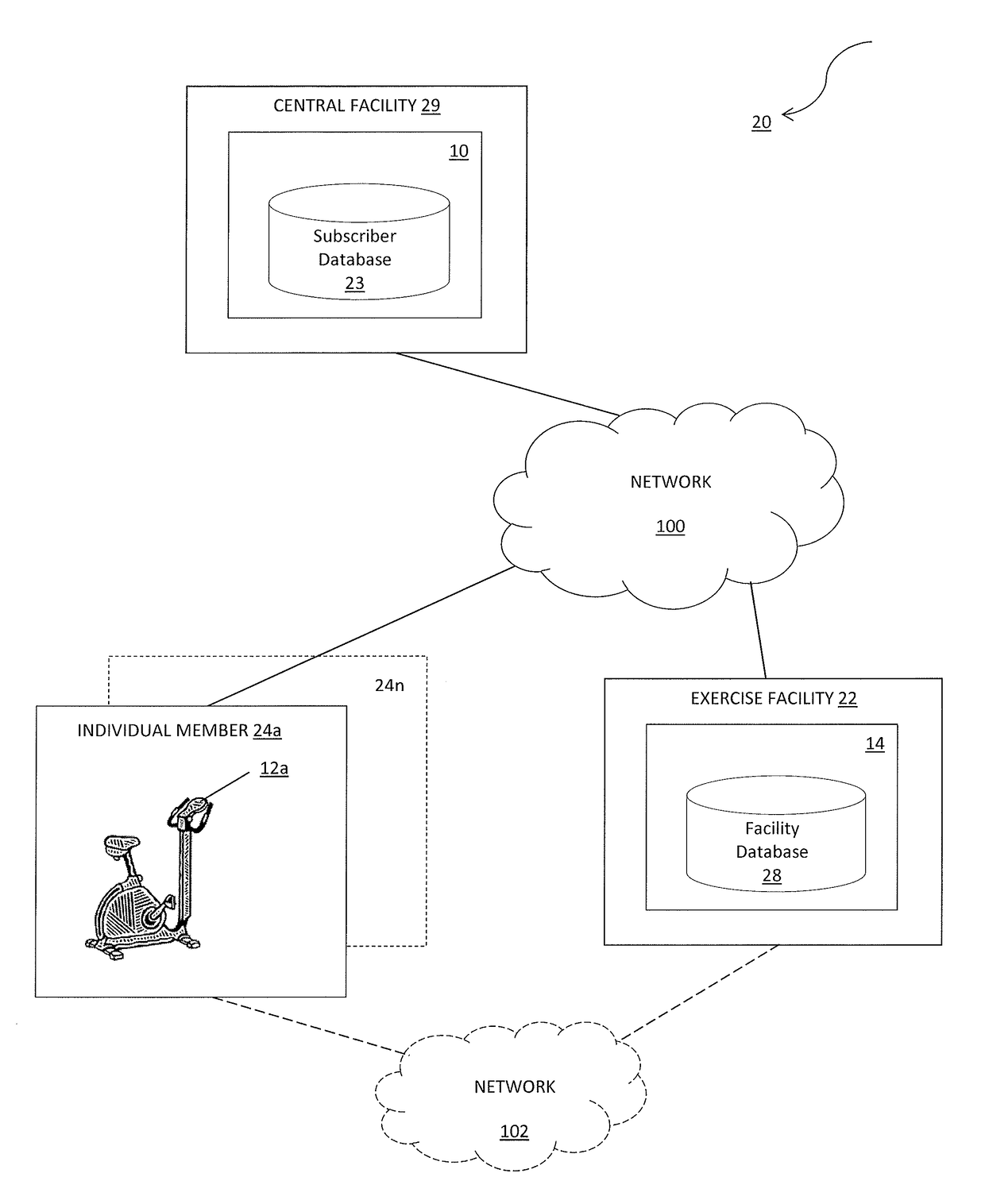

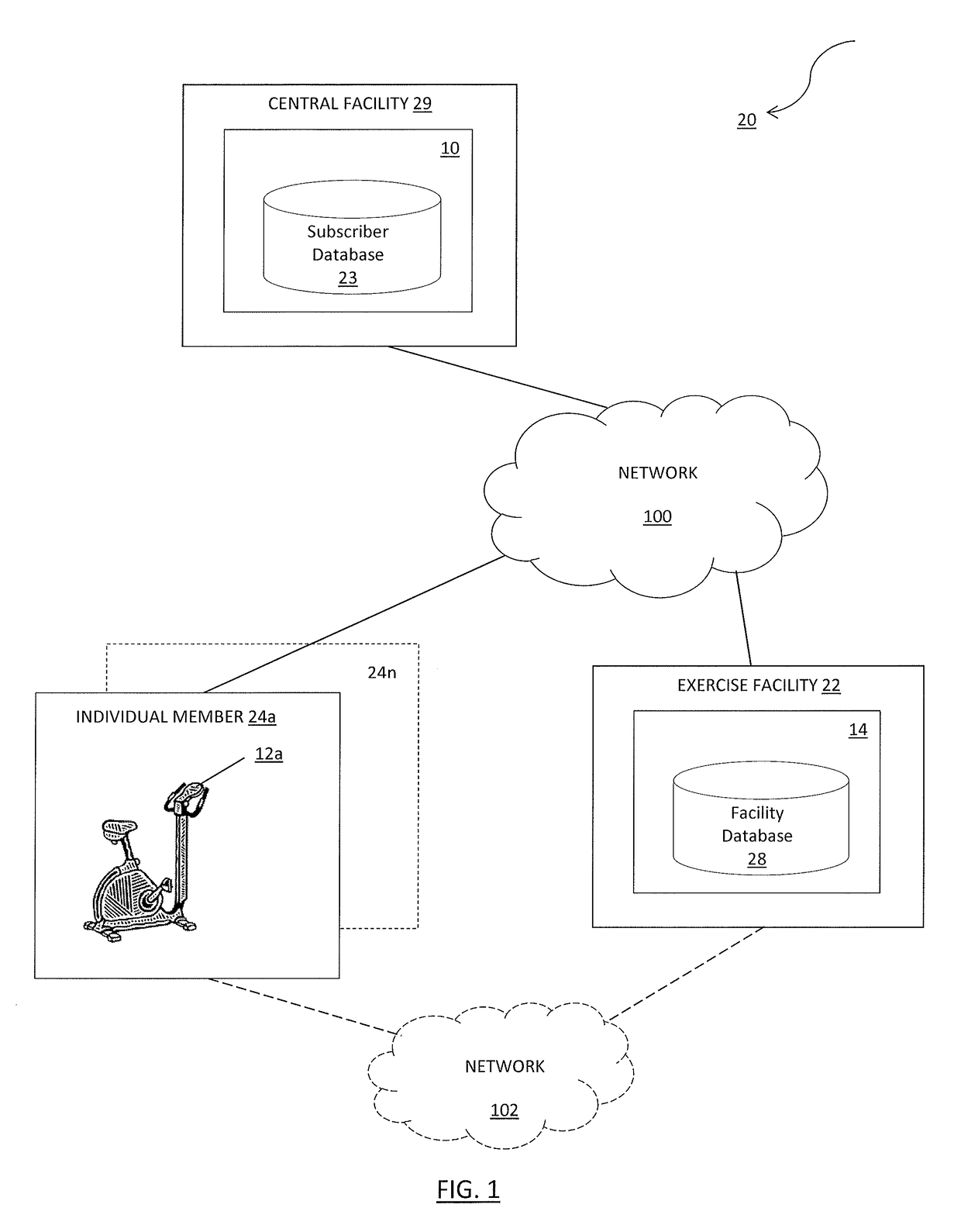

Synchronized exercising and singing

ActiveUS9975002B2Improve performanceIncrease the number ofPhysical therapies and activitiesElectrophonic musical instrumentsData streamDisplay device

A computer-implemented method and system facilitating a karaoke performance while exercising during an individual exercise session or group exercise class are disclosed. An indication of a song to be performed during the session or exercise class is received. At least one computer-readable karaoke file corresponding to the song is retrieved. The at least one computer-readable karaoke file may comprise common data elements, at least two independent karaoke data streams and exercise-related data elements. From a first class participant a selection of a first data stream of the at least two independent karaoke data streams is received. From a second class participant a selection of a second data stream of the at least two independent karaoke data streams is received. The presentation of the common data elements and the exercise-related data elements on a display common to the first and the second class participants is directed. The presentation of the first karaoke data stream on a display unique to the first class participant is directed. The presentation of the second karaoke data stream on a display unique to the second class participant is directed. The presentation of the common data elements, the exercise-related data elements, the first data stream and the second data stream may be synchronized.

Owner:PINKERTON ROSS PHILIP

Technique for producing Jinhuaqianliang tea (flower coil tea)

ActiveCN101352191AQuality improvementUniform qualityPre-extraction tea treatmentCooking & bakingThirst

The technology for producing golden flower Qianliang tea (Hua-juan tea) is characterized in that the technology comprises the process steps as follow: plucking criteria-water removing in high temperature-rolling and shaping-pile-fermentation-dry and adding incense-stems picking and sieving-matching and pile-classificaition and weighting-steam softening-moisture detection-adpressing and sizing-premilary test and baking-cultivating golden flower-aerationagitation. The technology is an improved deep processing technology. The processes of the pile-fermentation and the cultivating golden flower ensure that the appearance of the products is ooiu colour, the interior is brown, and even distributed beneficial organism (namely, golden flower)-eurotium cristatum is clearly saw, the shangse is bright red, the taste is pure and aromatic, and the flower is aromatic, and has the health care functions of promoting sleeping, invigorating stomach and promoting digestion, relaxing bowel, slaking thirst and helping produce saliva, antidiabetics, lowering blood pressure, curing bloated, cuing laxness, etc. The technology fully actives microelements such as vitamins contained in tea, mineral composition, 18 amino acid, protein, glucide, folic acid, catchol which are beneficial to human health and easily absorbed, and the cultivation of golden flower has substantial transformation on tea polyphenols, caffeine, and theophylline that are transferred into elements that are beneficial to human health, all ages, expand market, have high cultural value, provide collection opportunity for black tea lovers.

Owner:湖南省安化县晋丰厚茶行有限公司

Dynamically configured 3-d object creation system

ActiveUS20040141025A1Increase speedIncrease substrate speedLiquid surface applicatorsConfectionerySecondary layerLayer wise

A three dimensional object creation system that prints objects layer by layer, the system including a plurality of printheads, the system printing at least part of each of multiple layers simultaneously, the system configured to enable at least one first printhead that is initially configured to print at least part of a first layer to be dynamically reconfigured to print at least part of a second layer.

Owner:3D SYST INC

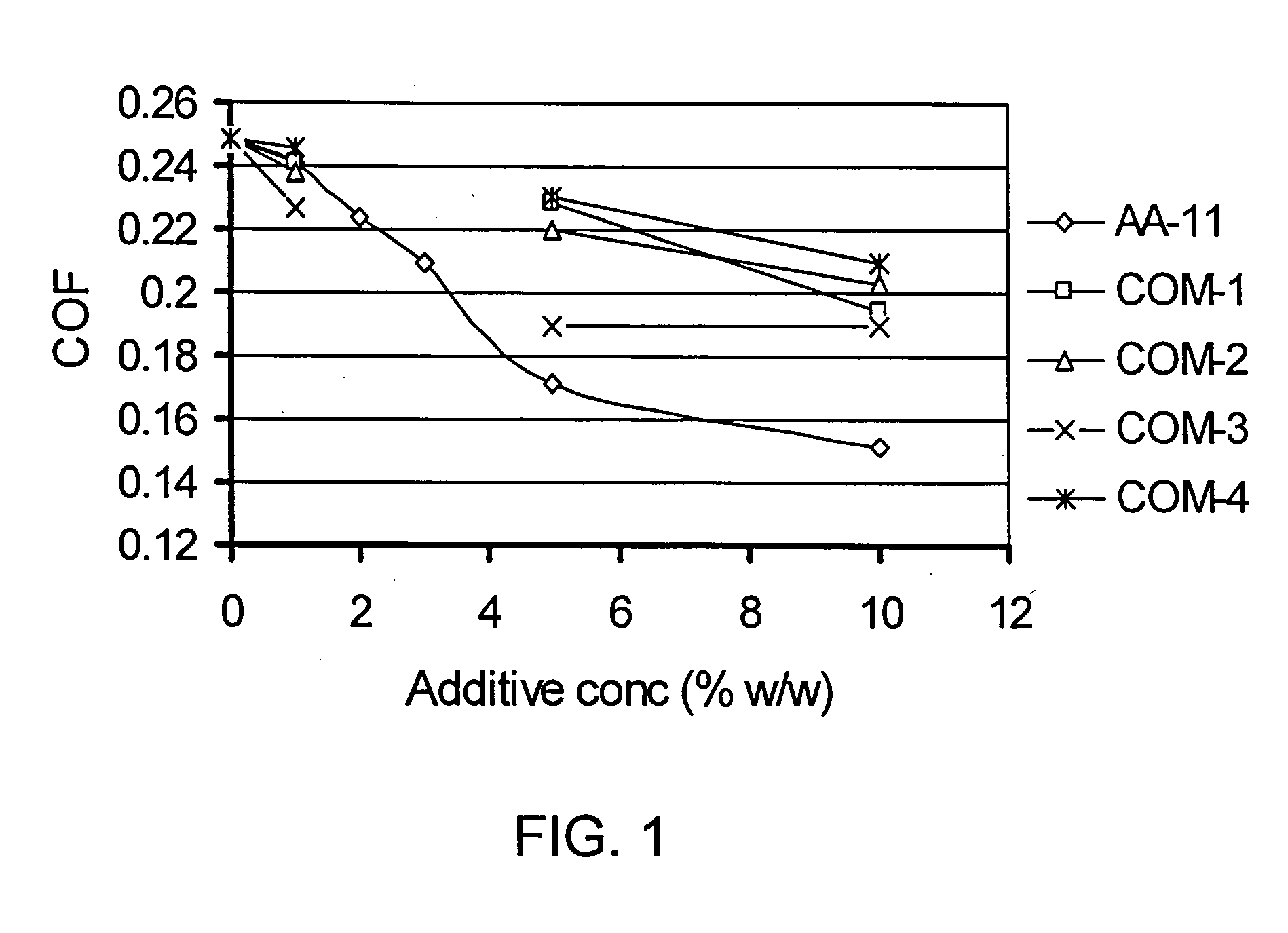

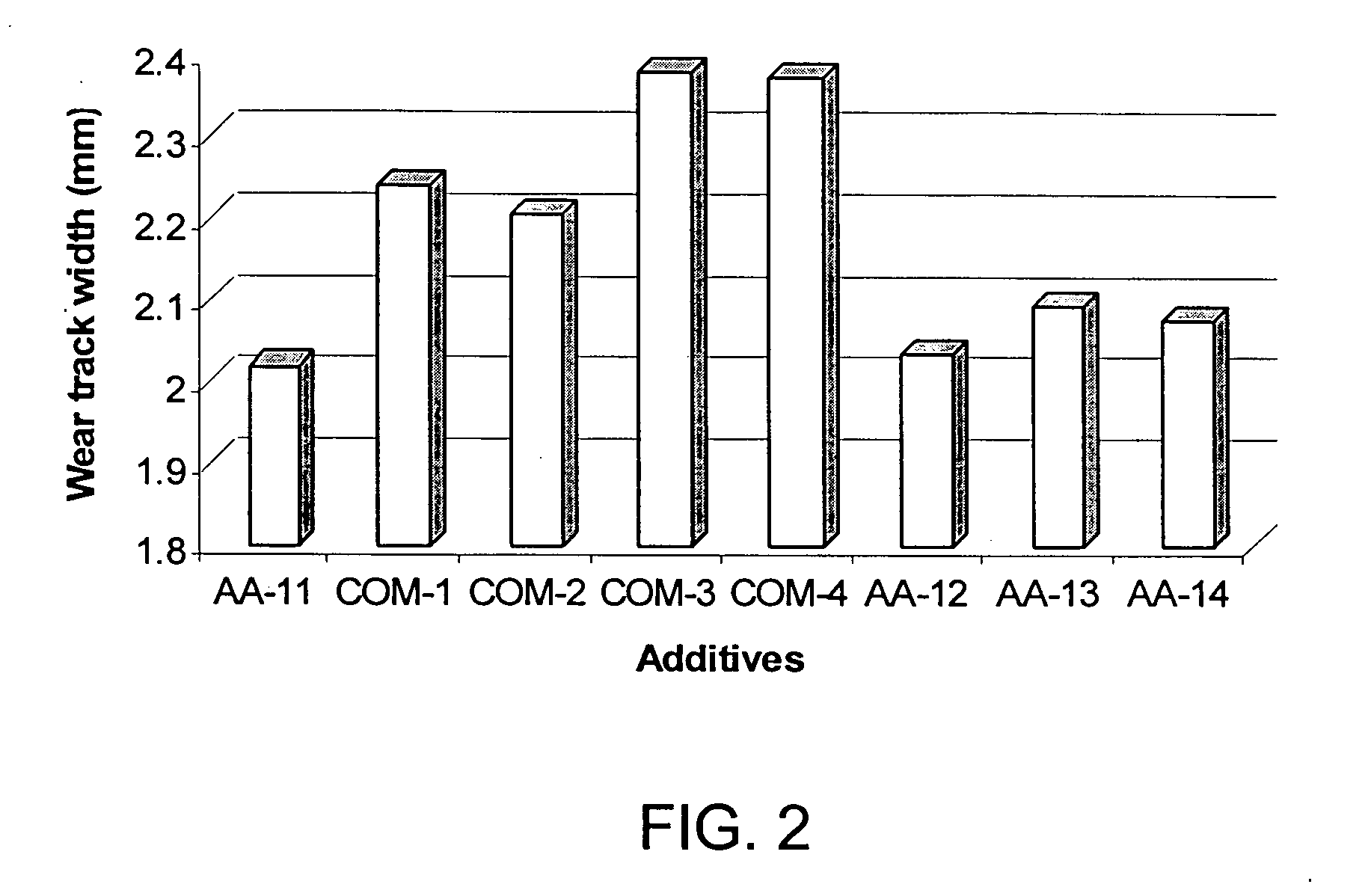

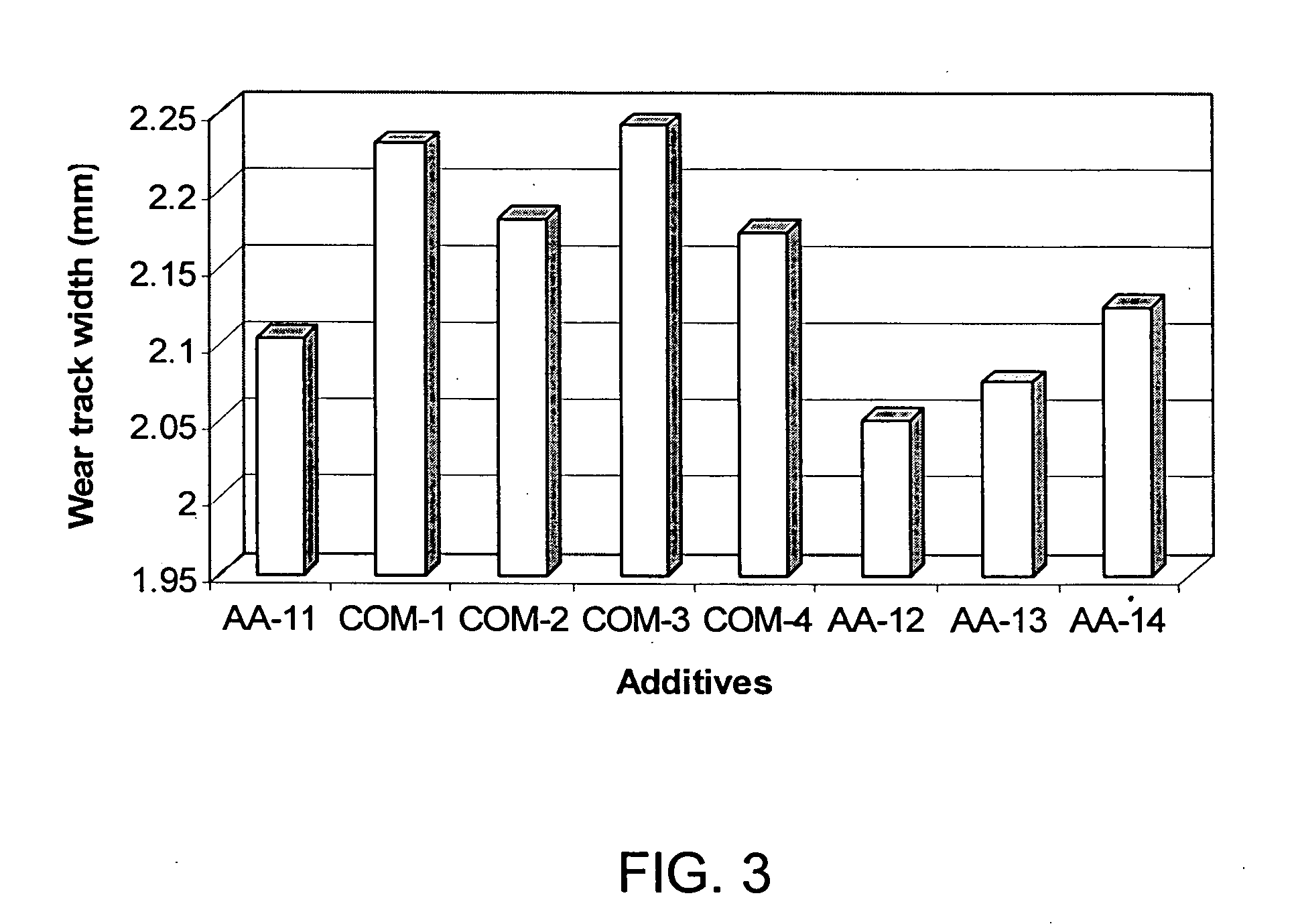

Poly(hydroxy thioether) vegetable oil derivatives useful as lubricant additives

InactiveUS20060009365A1Expand the marketReduce demandOrganic compound preparationSurface-active detergent compositionsThiolVegetable oil

A novel class of chemically-modified vegetable oils is prepared by reacting epoxidized triglyceride oils with thiols. The resultant poly(hydroxy thioether) derivatives have utility as antiwear / antifriction additives for environmentally-friendly industrial oils and automotive applications.

Owner:US SEC AGRI +1

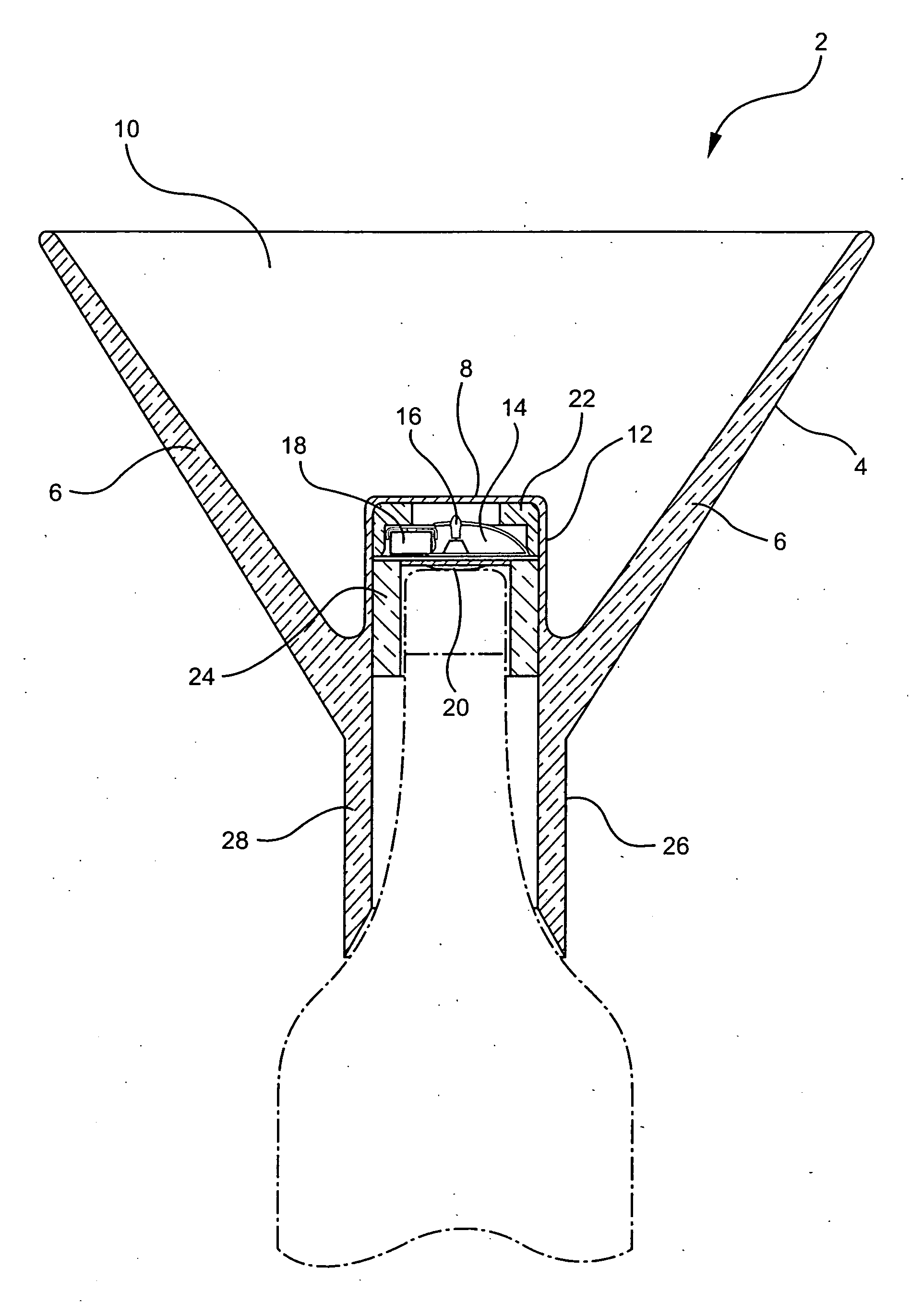

Lighted vessel for attachment to bottle

InactiveUS20060273087A1Improve drinking experienceExpand the marketCapsContainer decorationsEngineeringBottle

Owner:CRAWFORD ROSS B

Panada composition for flour-coating meat food capable of being frozen and pre-fried by microwave and products produced by the composition

The invention relates to a panada composition used for pre-fried flour-coated meat ware and the pre-fried flour-coated meat ware made of the panada composition, which comprises flour, soybean protein, soybean lecithin, maltodextrin, and guar gum. The pre-fried flour-coated meat ware made of the panada composition and the preparation method in the invention can still retain great crispness after refrigeration and freezing and then reheating by microwave; therefore, the processing of the pre-fried flour-coated meat ware is simplified and facilitated, is conducive to expanding the market occupation, and generate tremendous economic gains.

Owner:FUJIAN ANJOY FOODS CO LTD +4

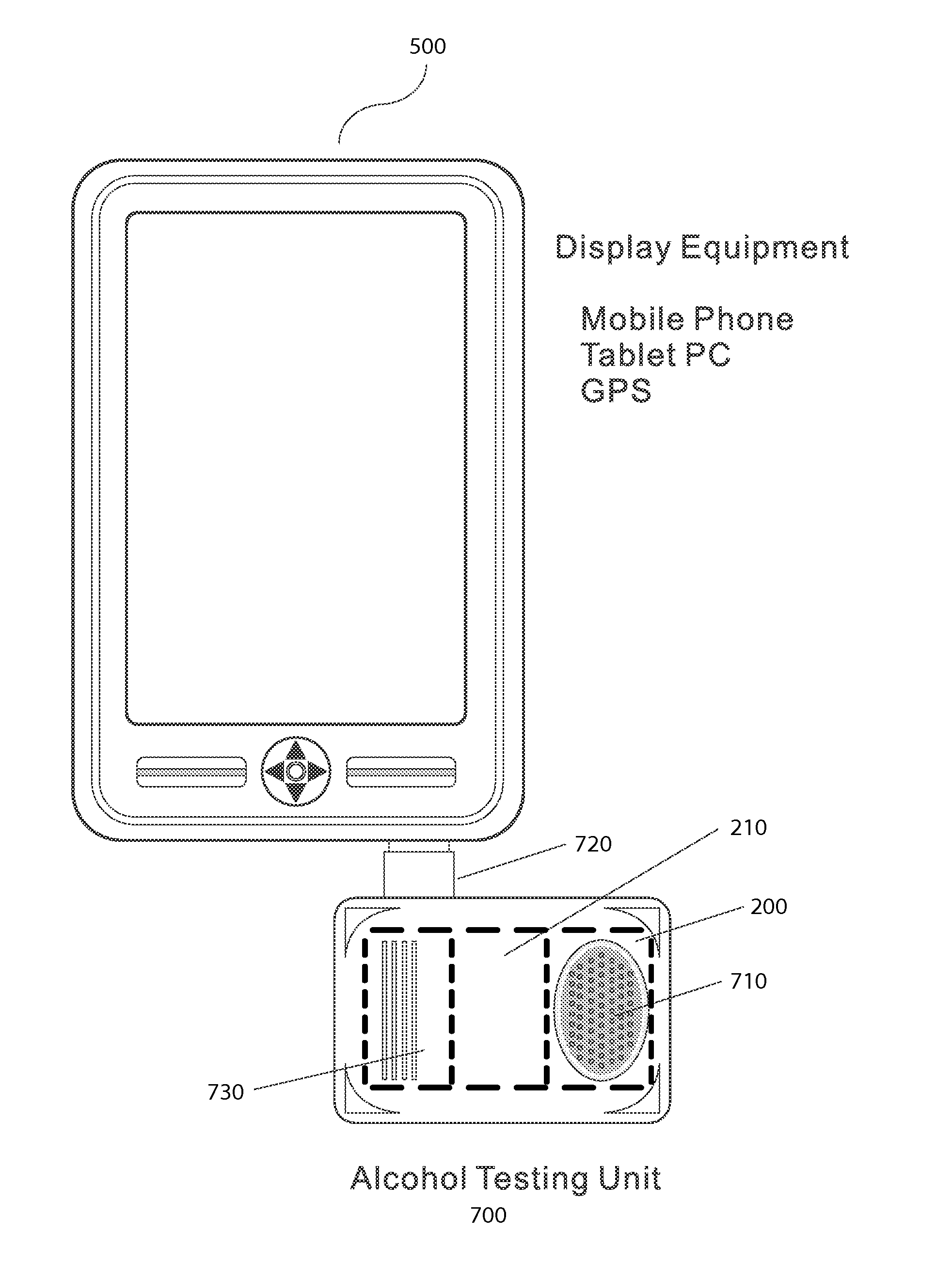

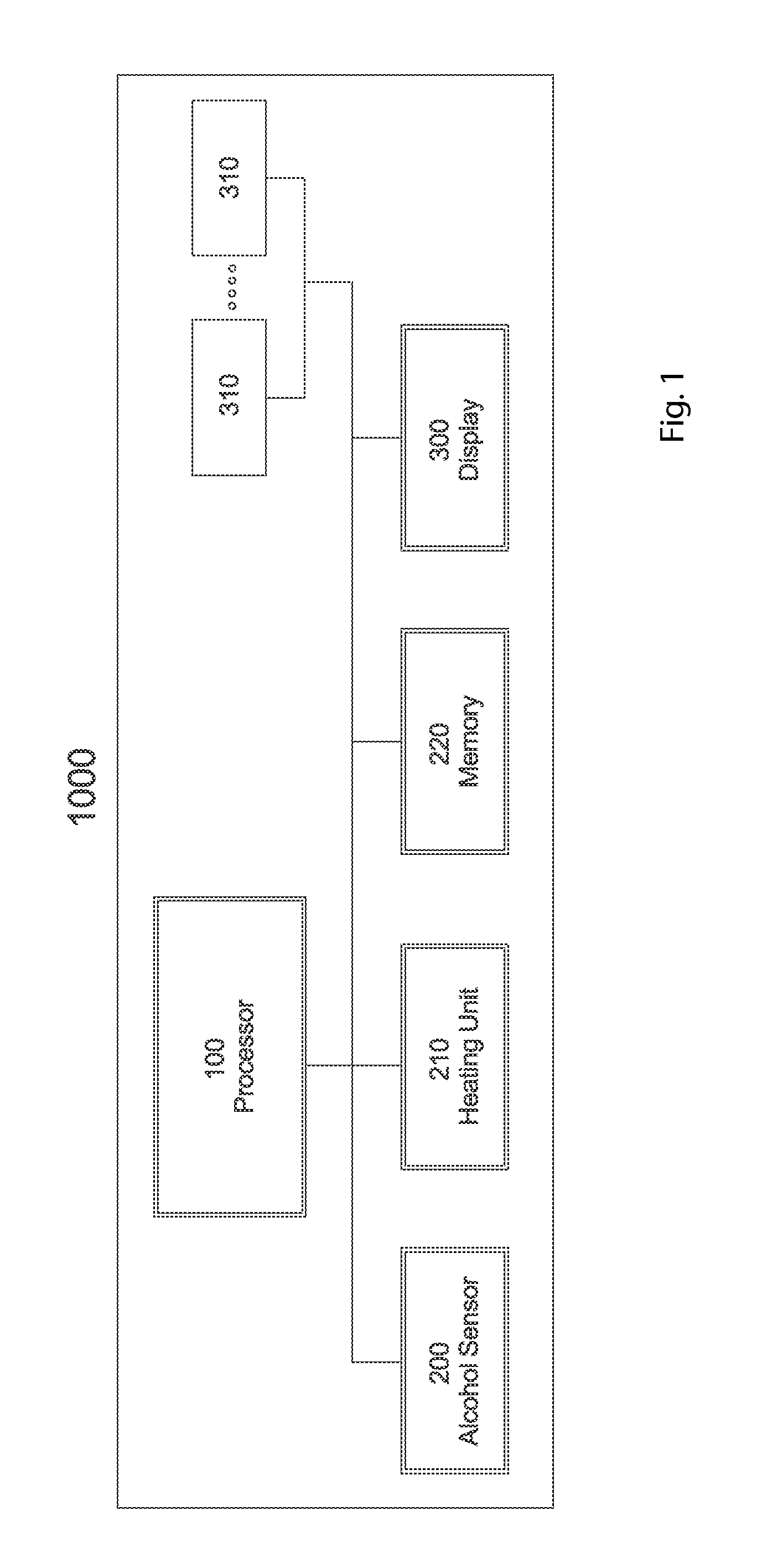

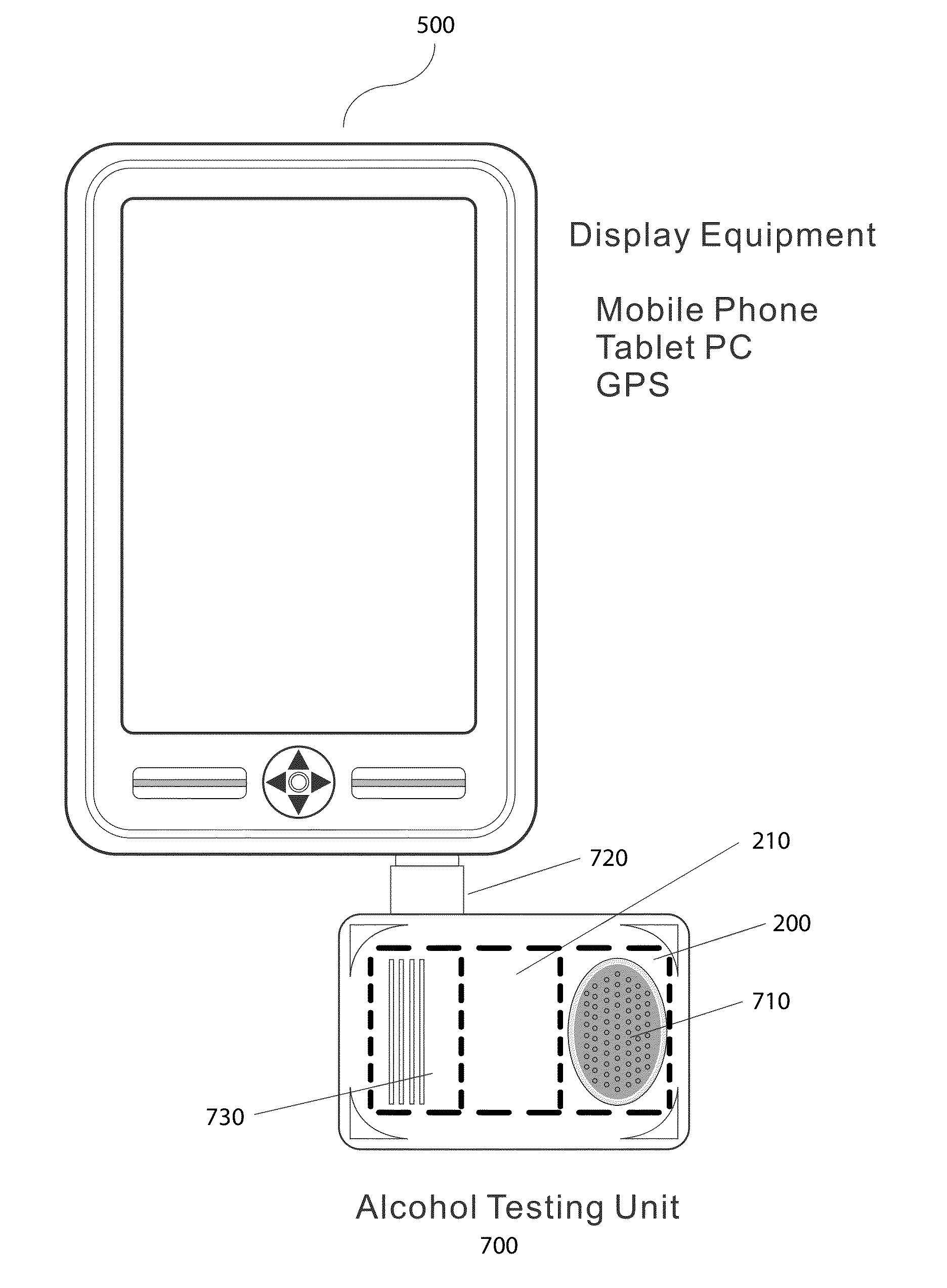

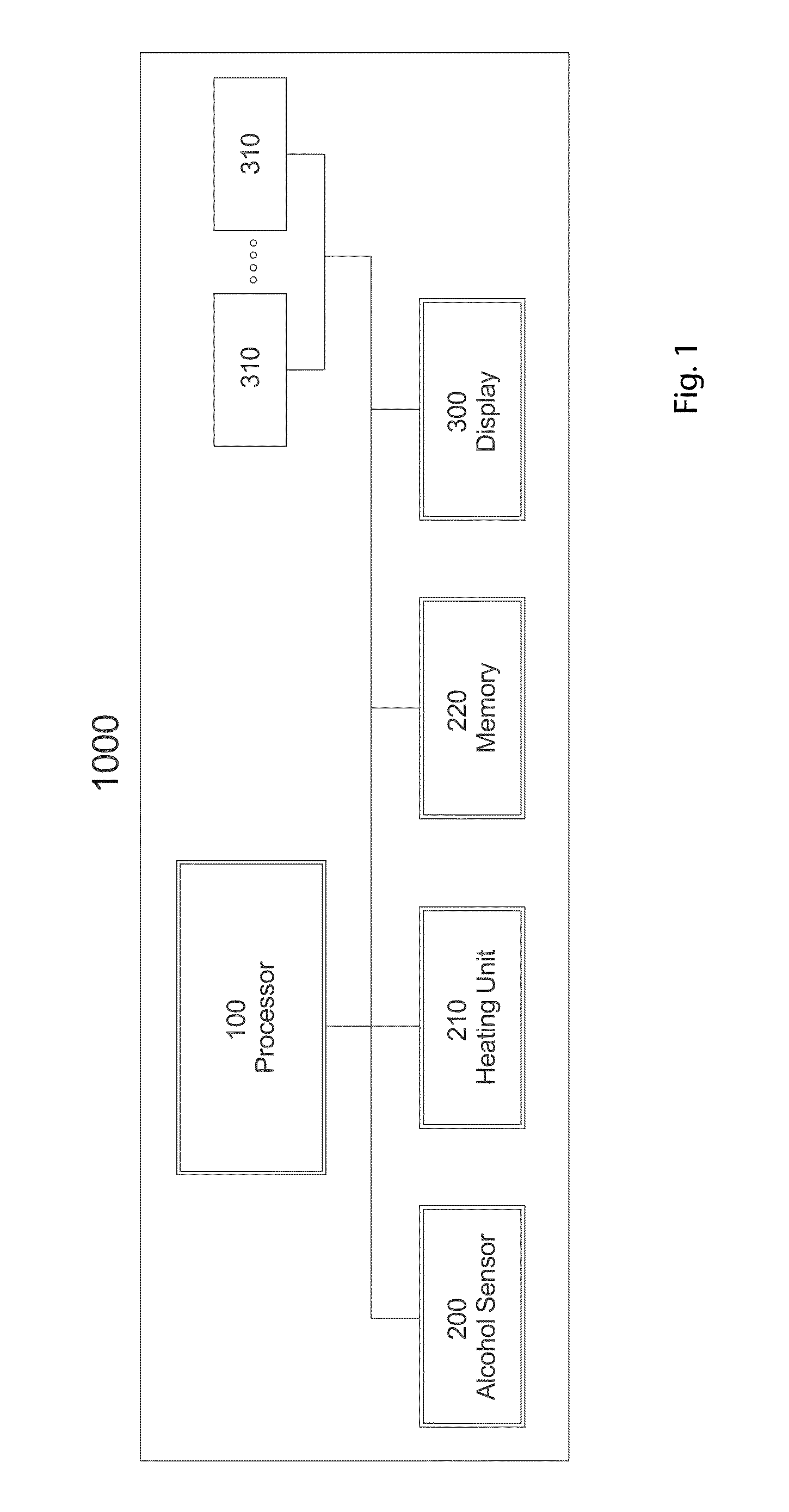

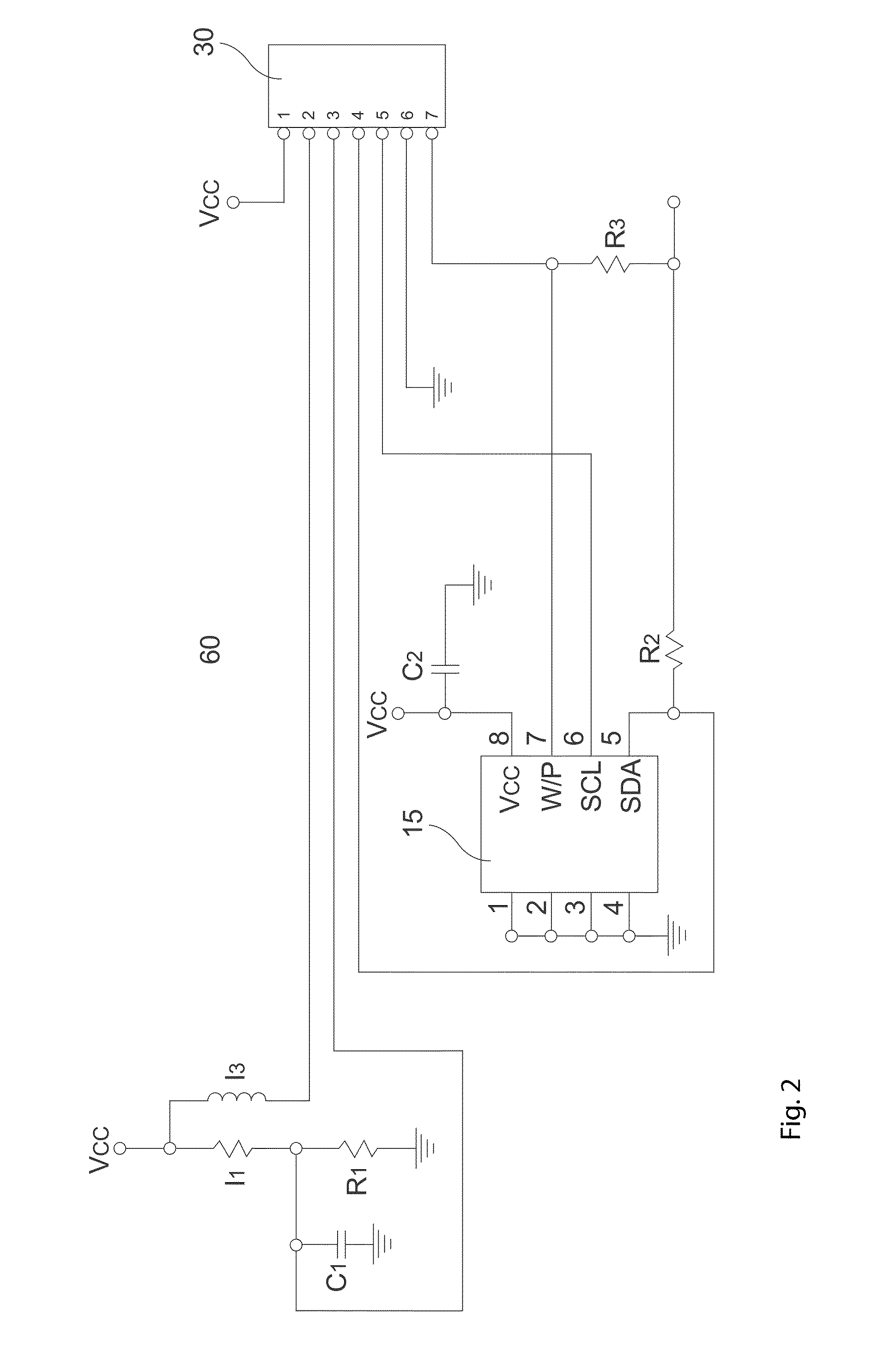

Calibrating breathalyzer

ActiveUS20130282321A1Expand the marketEasy to replaceTesting/calibration apparatusSpeed measurement using gyroscopic effectsStart timeDisplay device

The calibrating breathalyzer comprises an alcohol sensor, a non-volatile memory, a processing unit or processor, a display and a housing to house these components. The processing unit can calibrate the breathalyzer using the user's body as a simulator based on the user's metabolism rate, type and amount of alcohol consumed by the user. The processing unit determines a sample time to receive a breath sample from the user based on a time to a predetermined calibration point from the drinking start time calculated using the user's metabolism rate and the determined maximum alcohol level. The BAC % measurement based on the user's breath sample at the sample time is used as a reference point in calibrating the breathalyzer.

Owner:AK GLOBALTECH

Hybrid multi-sensor biometric identification device

ActiveUS8073204B2Expand the marketElectric signal transmission systemsDigital data processing detailsProximity sensorAnti spoofing

Owner:APPLE INC

Human body characteristic visualization device and method

InactiveCN105534694AAcupoint labeling is intuitiveHigh precisionDevices for locating reflex pointsEducational modelsHuman bodyVisual space

The invention provides a human body characteristic visualization device. The human body characteristic visualization device is capable of visualizing non-dominant human body characteristics in the various parts of a human body and even in the whole body, so that the intuitive location of an observer is achieved and the position and morphology information of the non-dominant characteristics of the human body are mastered; specifically, the human body characteristic visualization device comprises a three-dimensional scanning device which, together with a visualization device, defines a visual space, and a data processing device which is stored with human body characteristic information and is used for processing the three-dimensional information in a human body detected part acquired by the three-dimensional scanning device, so that the visualization device is controlled within the visual space, and the matched visual human body characteristic information is released from the body surface region of the human body detected part.

Owner:SHANGHAI HUAJUN TECH CO LTD

Calibrating breathalyzer

ActiveUS9020773B2Shorten the timeReduce utilizationTesting/calibration apparatusSpeed measurement using gyroscopic effectsStart timeDisplay device

The calibrating breathalyzer comprises an alcohol sensor, a non-volatile memory, a processing unit or processor, a display and a housing to house these components. The processing unit can calibrate the breathalyzer using the user's body as a simulator based on the user's metabolism rate, type and amount of alcohol consumed by the user. The processing unit determines a sample time to receive a breath sample from the user based on a time to a predetermined calibration point from the drinking start time calculated using the user's metabolism rate and the determined maximum alcohol level. The BAC % measurement based on the user's breath sample at the sample time is used as a reference point in calibrating the breathalyzer.

Owner:AK GLOBALTECH

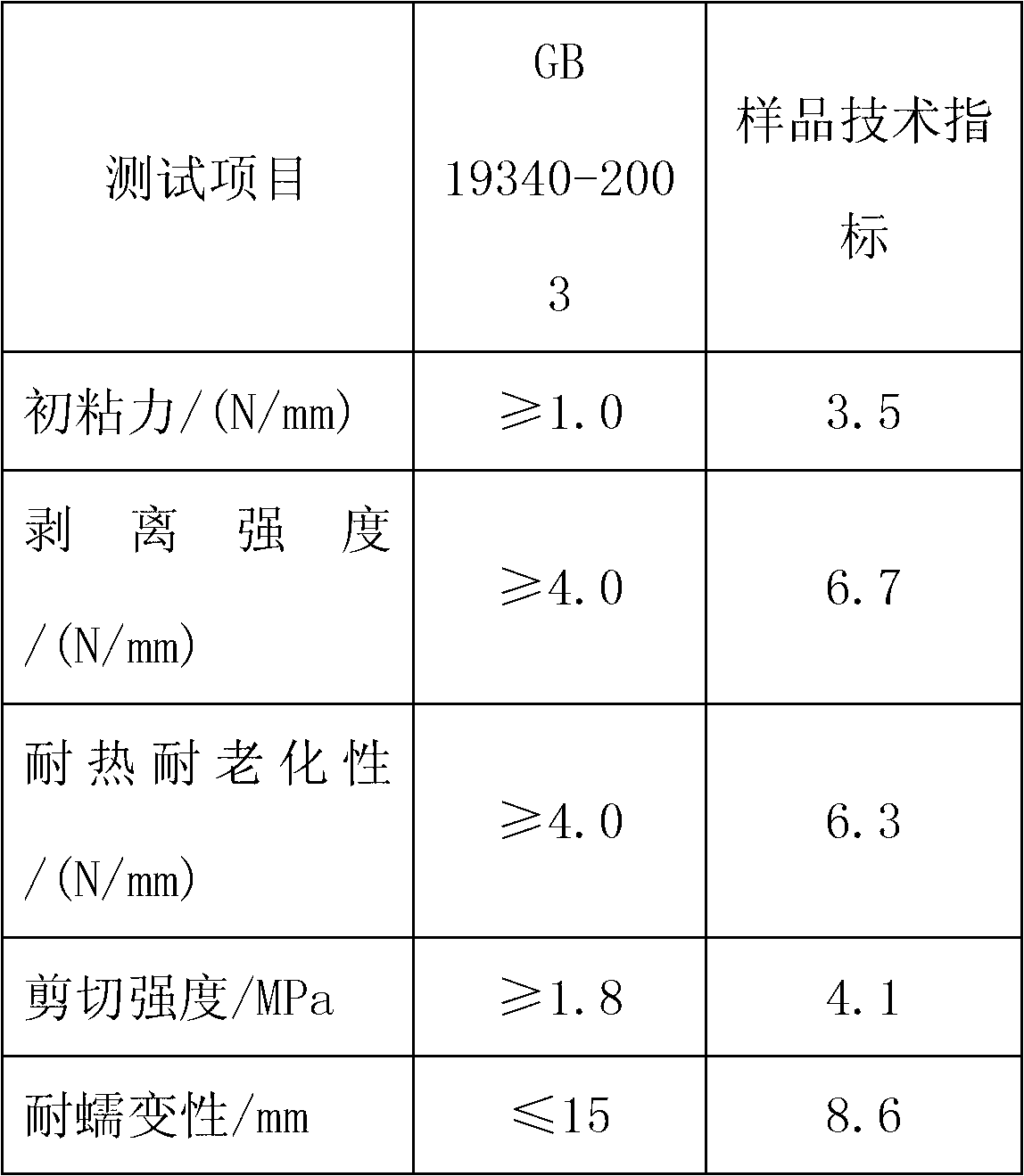

High-solid-content aqueous adhesive for shoes and preparation method thereof

InactiveCN102827570AHigh solid contentIncrease drying speedMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesAdhesiveSolid content

The invention discloses a high-solid-content aqueous adhesive for shoes and a preparation method thereof. The aqueous adhesive is prepared from an aqueous resin and a deionized water-emulsified polyurethane prepolymer, wherein the polyurethane prepolymer is synthesized from isocyanate, polylol, a hydrophilic chain extender, a crosslinking agent and a neutralizing agent. The preparation method comprises the following steps of: preparing a polyurethane prepolymer through pre-polymerizing and neutralizing processes; and preparing the aqueous adhesive for a high-solid-content shoe by using an aqueous resin in cooperation with deionized water emulsification. The aqueous adhesive for shoes disclosed by the invention has the advantages of high solid content, low cost, excellent performance and the like.

Owner:SHAANXI UNIV OF SCI & TECH

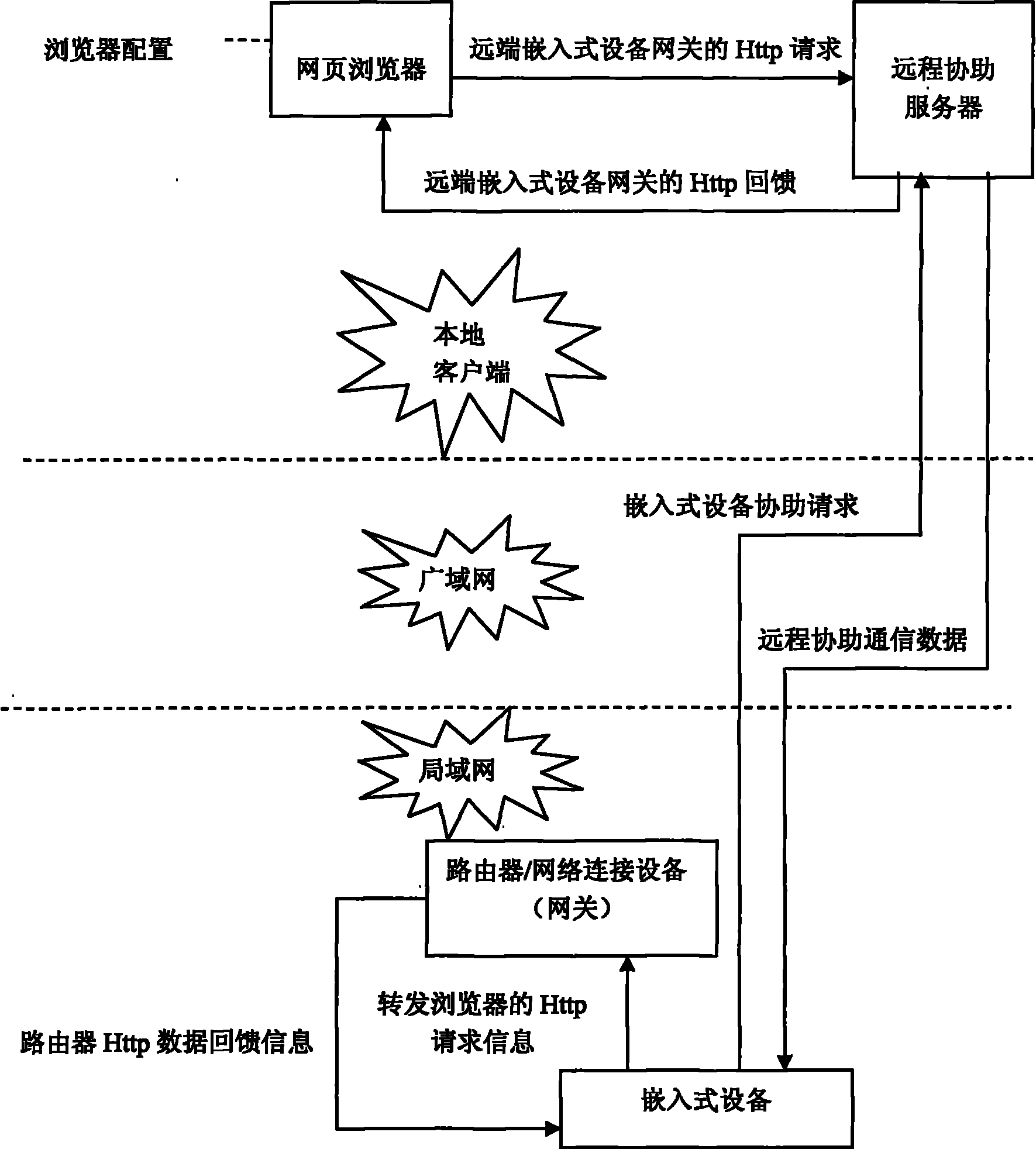

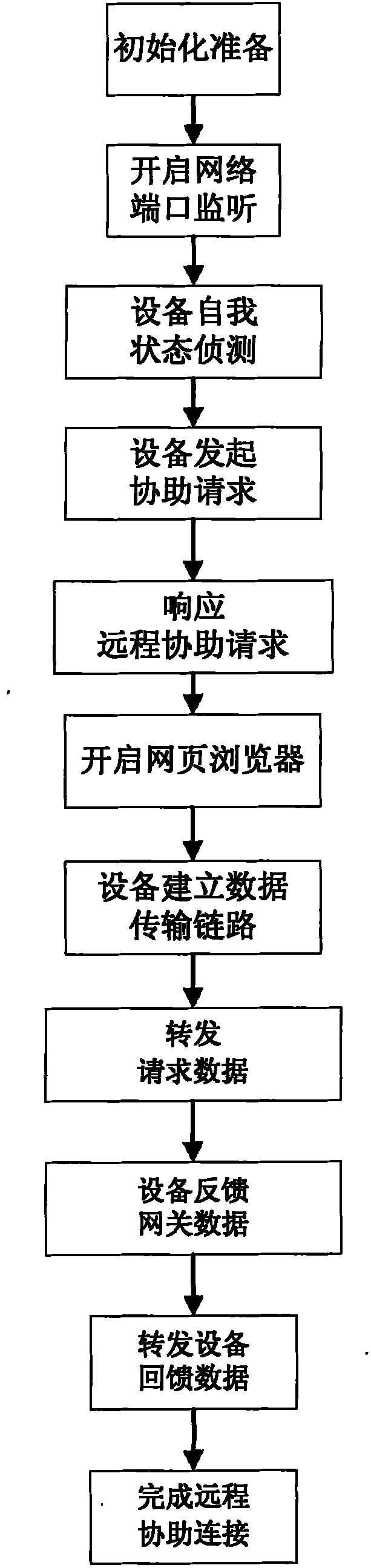

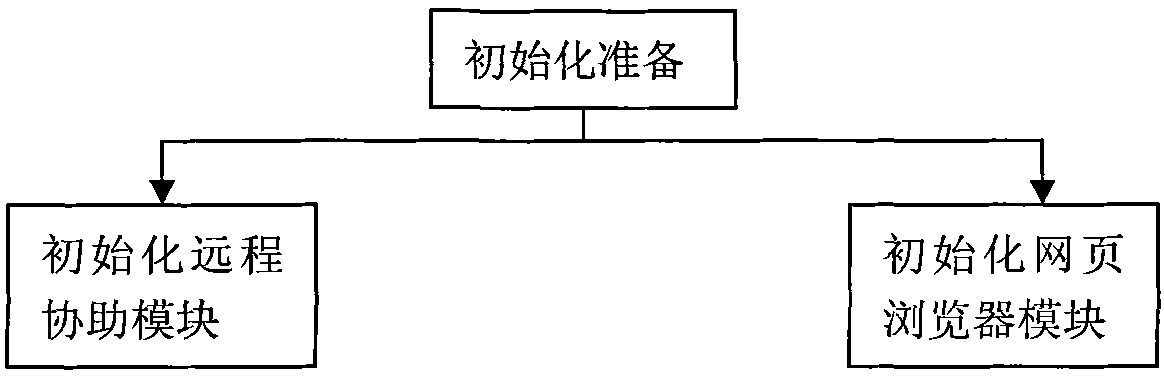

Remote assistance service method aiming at embedded operation system

The invention provides a communication control method and in particular discloses a remote assistance service method aiming at an embedded operation system. According to the method, a remote assistance server is enabled to access and configure a router in the front end of a far-end embedded device through the network data transmission and exchange by using an HTTP (hyper text transport protocol) assistance agent service technology and a reverse active connection technology, thus the embedded device is changed as a serviceable network terminal device, and more embedded devices can be easily changed as the serviceable network terminal device in the network. Compared with the general remote assistance method, the remote resistance service method provided by the invention can be used for greatly reducing the expenditure of manpower and financial resource; and meanwhile, the puzzle and trouble in installing and using the embedded device is reduced, and the market and prospect of the embedded device development is spread and extended in the future.

Owner:FUITHER TECH

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

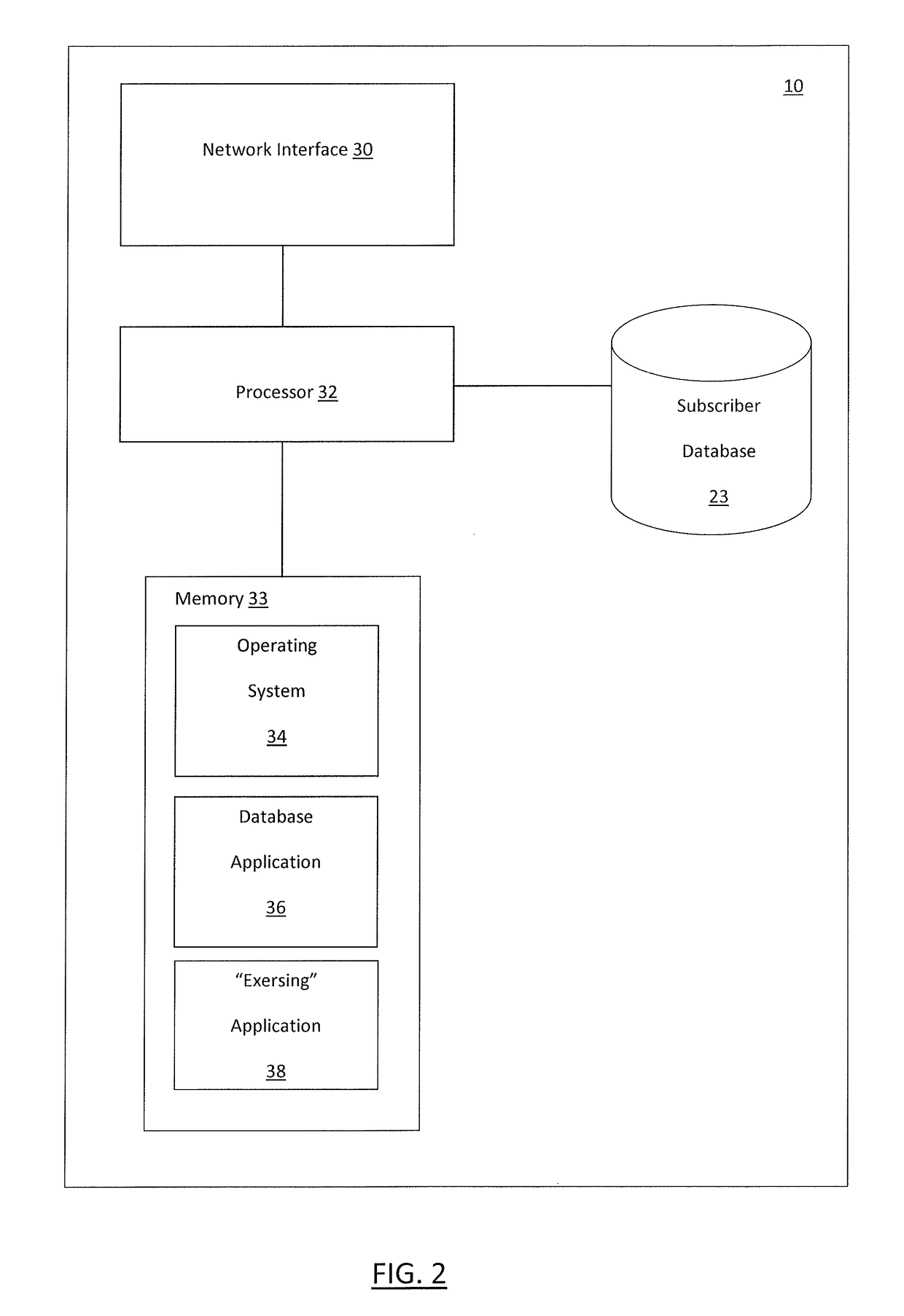

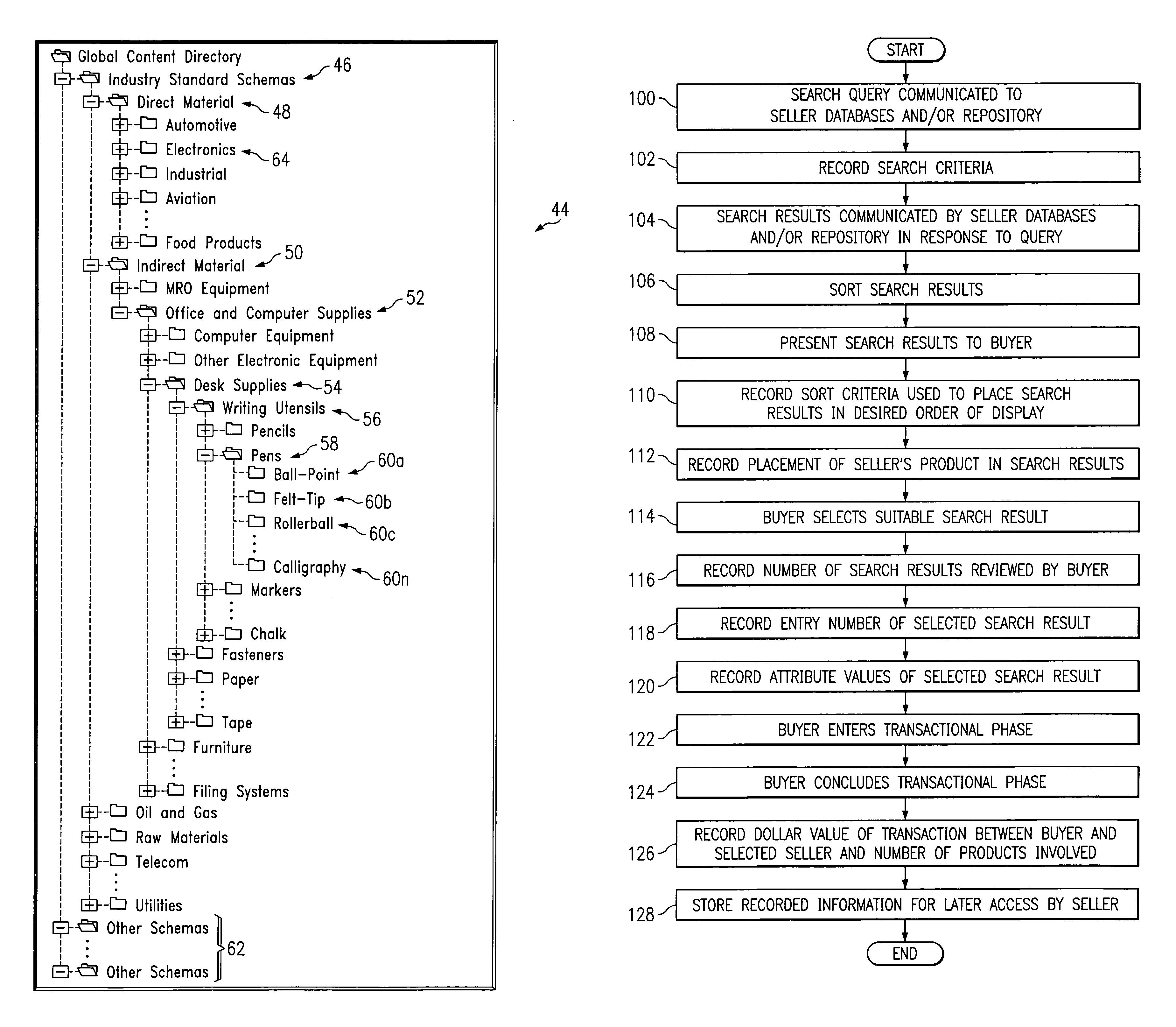

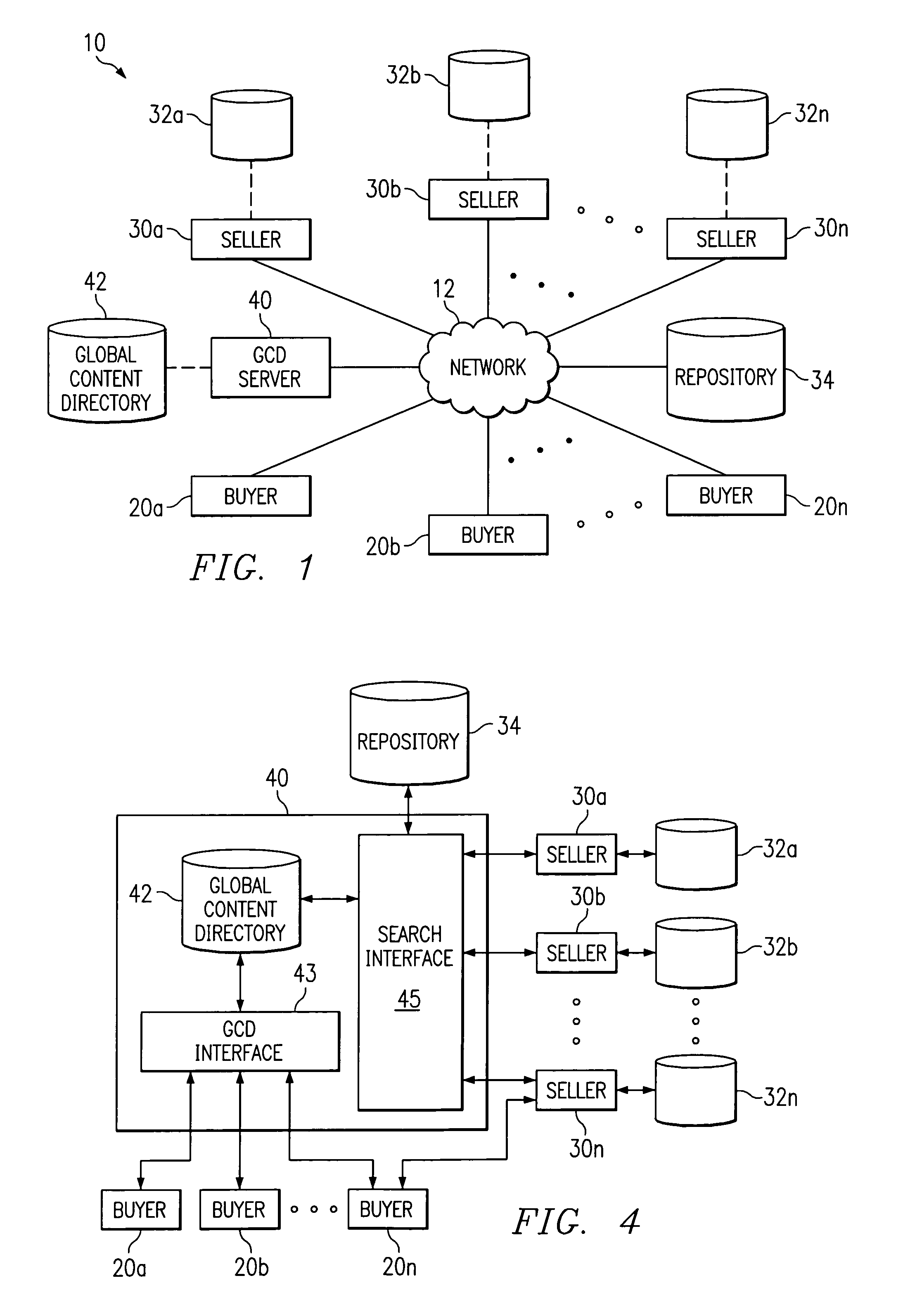

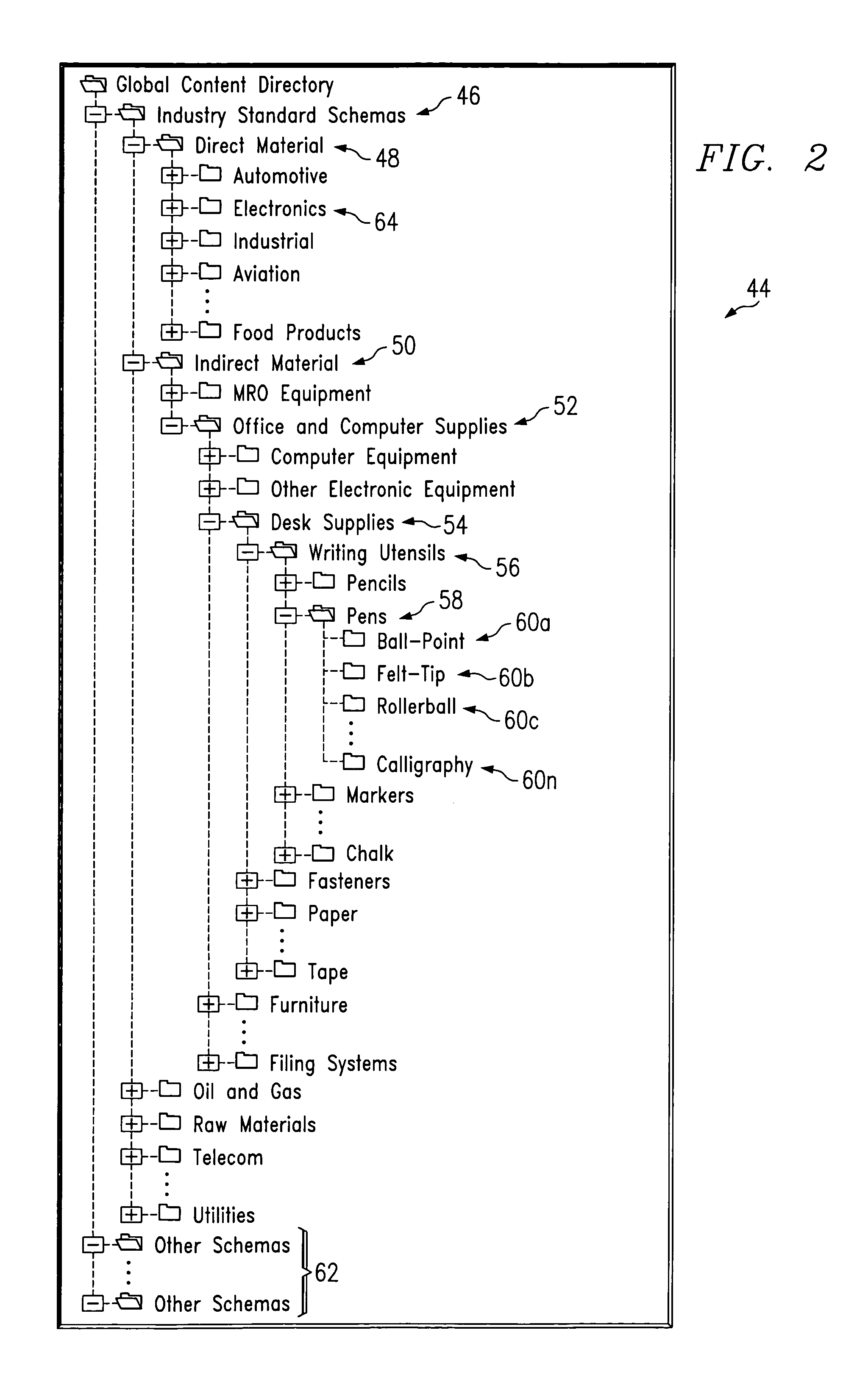

Providing market feedback associated with electronic commerce transactions to sellers

InactiveUS7330829B1Disadvantages and reduced eliminatedEfficient modificationMarket data gatheringE-commerceInformation retrieval

An electronic commerce system (10) providing market feedback to sellers includes a server (40) operating on one or more computers. The server (40) records query information associated with a search query for a buyer (20) of one or more databases containing product data. The server (40) also records presentation information associated with presentation of multiple search results to the buyer (20), each search result including data for a product matching one or more search criteria specified in the search query, the search results including one or more search results reflecting product data for a particular seller (30). The server (40) also records selection information associated with selection by the buyer (20) of a particular search result from among the multiple search results. The server (40) also provides at least some of the recorded query information, presentation information, or selection information to the particular seller (30) to allow the particular seller (30) to assess one or more aspects of its product data relative to product data of other sellers (30).

Owner:JDA SOFTWARE GROUP

Pre-calibrated replaceable sensor module for a breath alcohol testing device

ActiveUS20070193335A1Shorten the timeReduce utilizationWithdrawing sample devicesMaterial resistanceEnvironmental healthAir sample

The present invention describes a replaceable breath alcohol sensor module that can be replaced with a new pre-calibrated breath alcohol sensor module or re-calibrated. The breath alcohol sensor module requiring calibration can be removed from the body of a Breath Alcohol Testing Device (commonly called “breathalyser” or “breathalyzer”). The breath alcohol sensor module can be separately calibrated for accurate calculation of “percent blood alcohol concentration” (% BAC) based on breath air samples and then re-installed into the breath alcohol tester or the old breath alcohol sensor module can be replaced with a new pre-calibrated breath alcohol sensor module. The present invention improves upon and / or replacing the current method of re-calibration at a breathalyzer service center.

Owner:AK GLOBALTECH

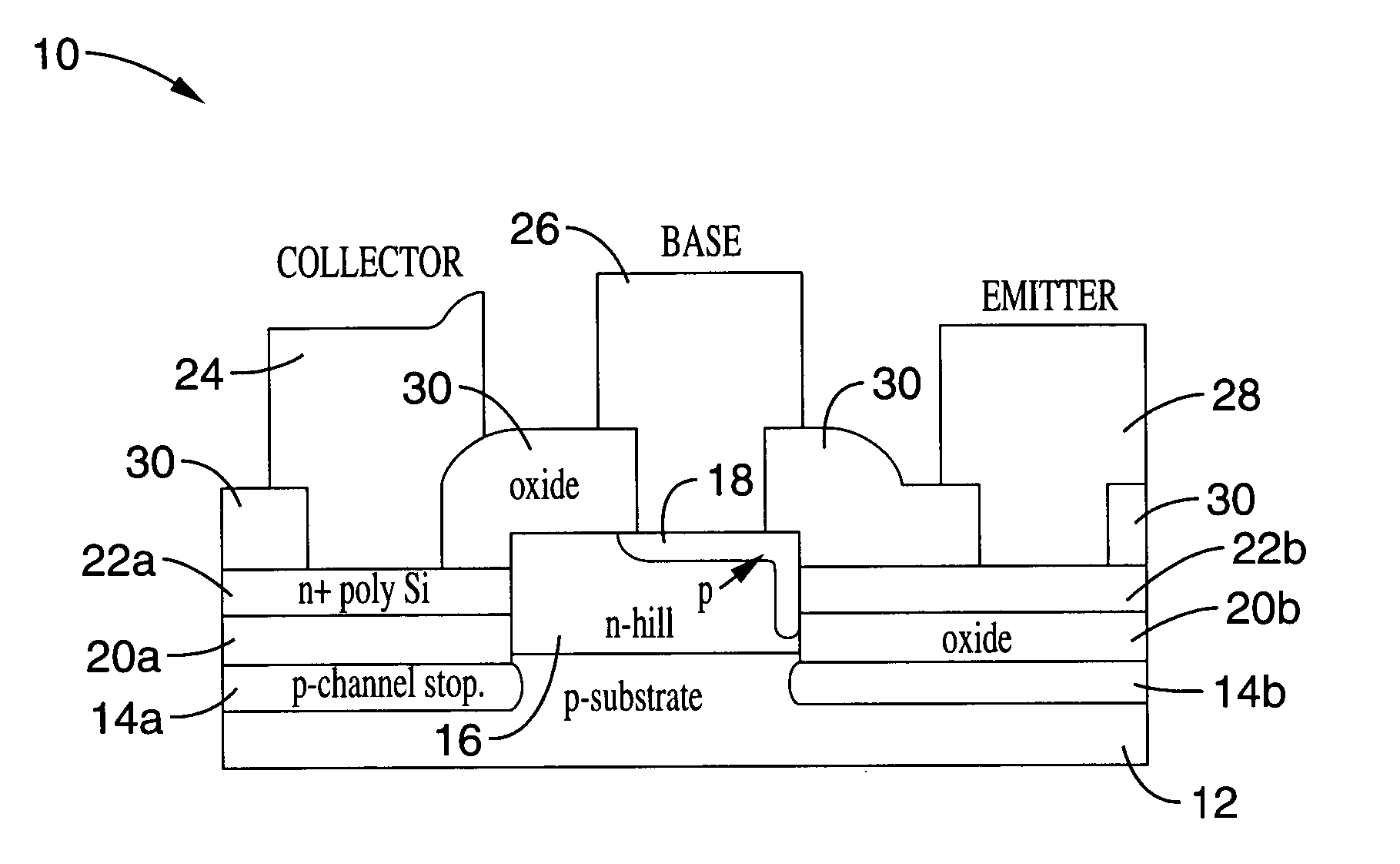

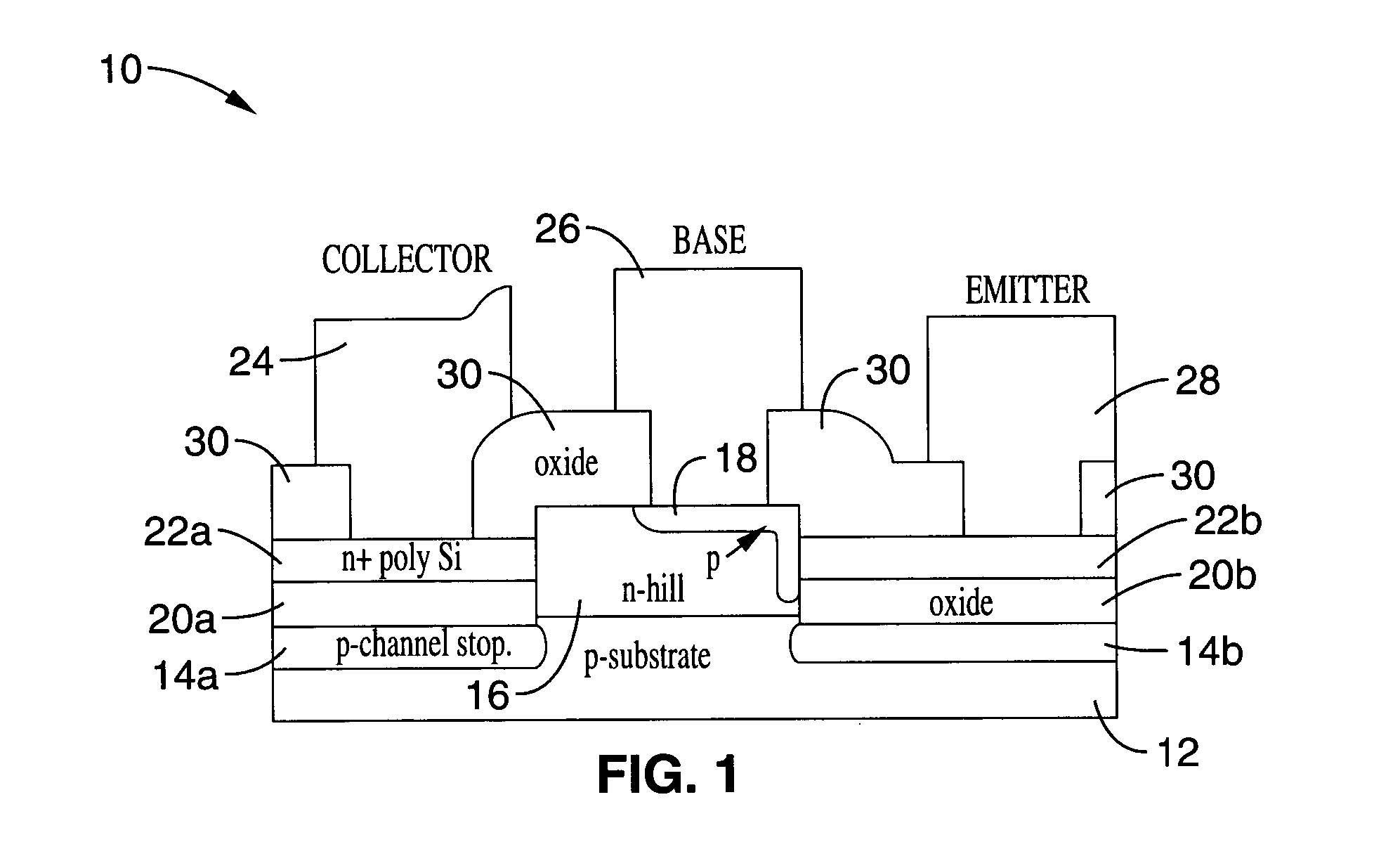

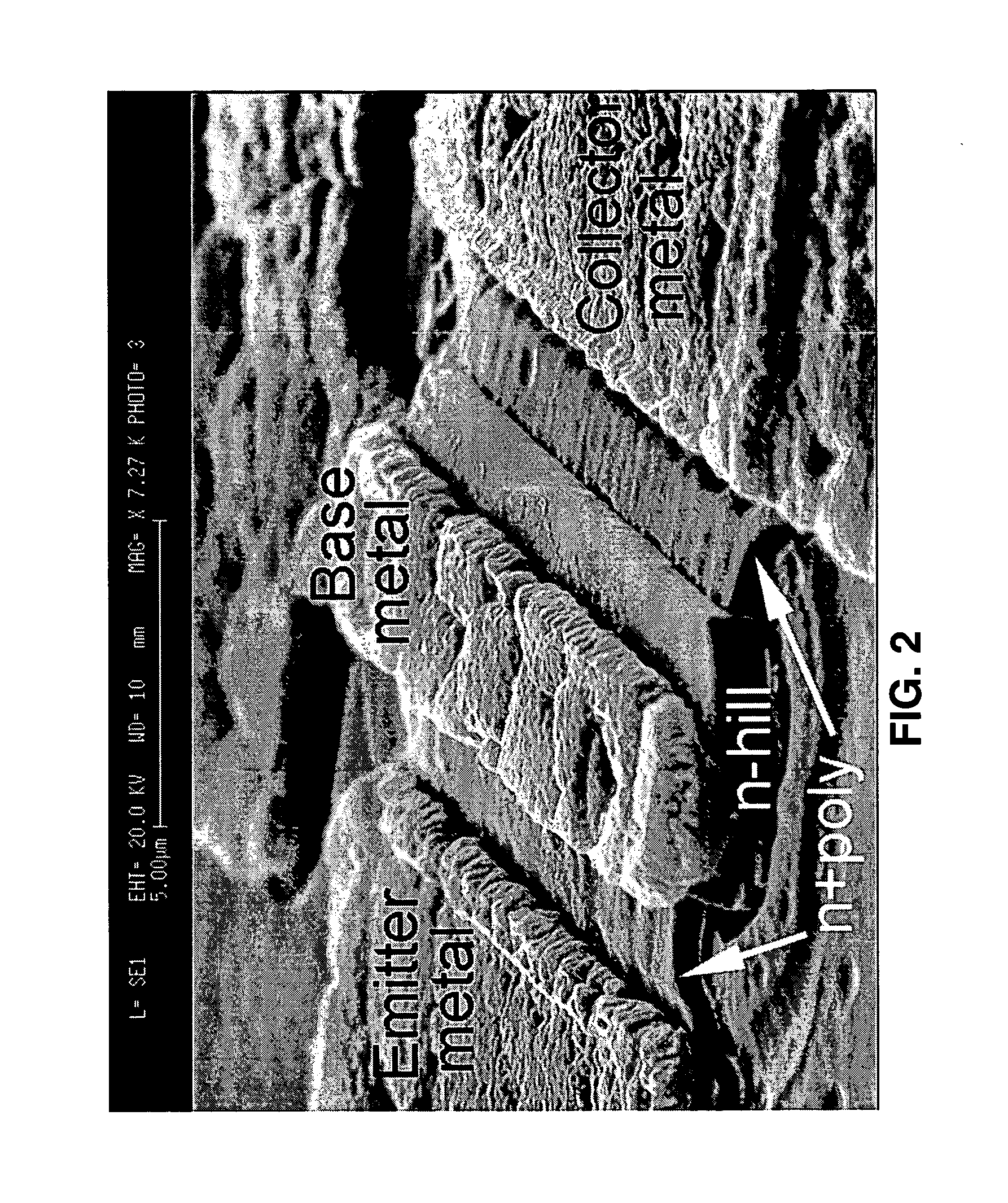

Horizontal current bipolar transistor and fabrication method

InactiveUS20050040495A1Small area of chip surfaceHigh bulk densitySemiconductor/solid-state device manufacturingSemiconductor devicesVolumetric Mass DensityIntegrated circuit

A bipolar transistor structure for use in integrated circuits where the active device is processed on the sidewall of an n-hill so that the surface footprint does not depend on the desired area of active device region (emitter area). This structure, which is referred to as a Horizontal Current Bipolar Transistor (HCBT), consumes a smaller area of chip surface than conventional devices, thereby enabling higher packing density of devices and / or the reduction of integrated circuit die size. The device is fabricated with a single polysilicon layer, without an epitaxial process, without demanding trench isolation technology, and with reduced thermal budget. Fabrication requires fewer etching processes and thermal oxidations than in conventional devices.

Owner:RGT UNIV OF CALIFORNIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com