High-solid-content aqueous adhesive for shoes and preparation method thereof

A water-based adhesive with high solid content technology, applied in adhesives, carboxyl rubber adhesives, monocarboxylate copolymer adhesives, etc., to achieve excellent low temperature resistance, high bonding strength, and broaden the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

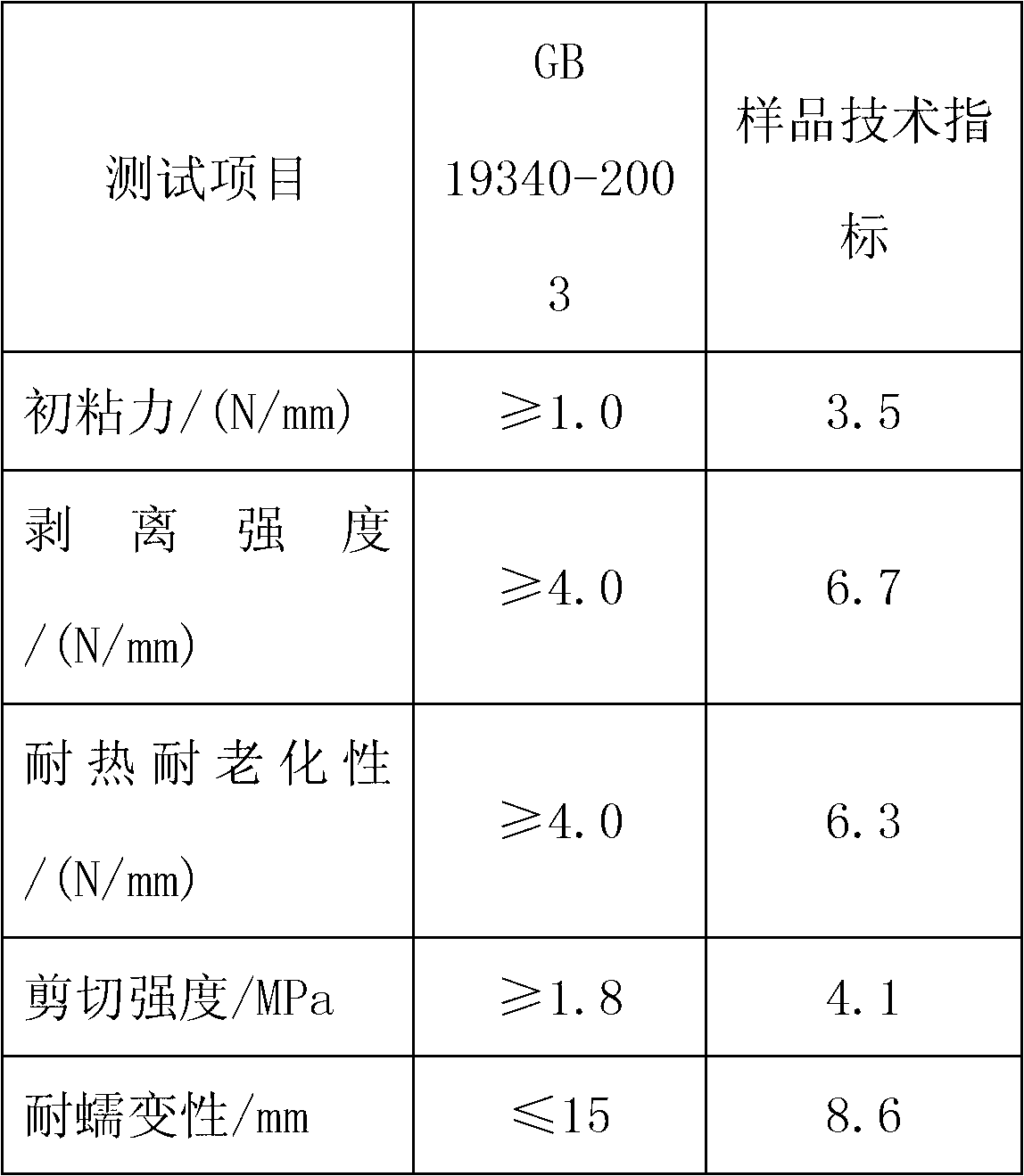

Examples

Embodiment 1

[0024] 1) Take 4% isocyanate, 10% polyol, 3% hydrophilic chain extender, 1.0% crosslinking agent, 0.8% neutralizing agent, 0.1% catalyst, 50% water-based resin by weight percentage Emulsion, 3% solvent, the balance is deionized water;

[0025] 2) Prepolymerization: Add polyols and isocyanates into the reaction kettle, raise the temperature to 70°C, then add the catalyst, and react for 3 hours;

[0026] 3) Chain extension: add a hydrophilic chain extender and a cross-linking agent at 70°C for 2 hours;

[0027] 4) Neutralization: Add neutralizer after cooling down to 30°C;

[0028] 5) Emulsification: Add deionized water and water-based resin emulsion to it under high-speed stirring to emulsify and stir evenly to obtain a water-based adhesive for shoes with high solid content.

[0029] Wherein, the isocyanate is isophorone diisocyanate;

[0030] The polyol is polycaprolactone diol with a number-average relative molecular mass of 1000-3000;

[0031] The hydrophilic chain exten...

Embodiment 2

[0038] 1) Including 8% isocyanate, 15% polyol, 5% hydrophilic chain extender, 0.8% crosslinking agent, 0.9% neutralizing agent, 0.2% catalyst, 60% water-based resin by weight percentage Emulsion, 1% solvent, the balance is deionized water;

[0039] 2) Prepolymerization: Add polyols and isocyanates into the reaction kettle, raise the temperature to 90°C, then add the catalyst, and react for 1 hour;

[0040] 3) Chain extension: add a hydrophilic chain extender and a cross-linking agent at 90°C for 1 hour;

[0041] 4) Neutralization: Add neutralizer after cooling down to 40°C;

[0042] 5) Emulsification: Add deionized water and water-based resin emulsion to it under high-speed stirring to emulsify and stir evenly to obtain a water-based adhesive for shoes with high solid content.

[0043] Among them, the isocyanate is hexamethylene diisocyanate.

[0044] The polyol is a polycarbonate diol with a number-average molecular mass of 1000-3000;

[0045] The hydrophilic chain extend...

Embodiment 3

[0052] 1) By weight percentage, it includes 7% isocyanate, 20% polyol, 1% hydrophilic chain extender, 1.2% crosslinking agent, 1.1% neutralizer, 0.3% catalyst, 45% water-based resin Emulsion, 5% solvent, the balance is deionized water;

[0053] 2) Prepolymerization: Add polyols and isocyanates into the reactor, raise the temperature to 75°C, then add catalyst, and react for 2 hours;

[0054] 3) Chain extension: add a hydrophilic chain extender and a cross-linking agent at 75°C for 1.5 hours;

[0055] 4) Neutralization: Add neutralizer after cooling down to 33°C;

[0056] 5) Emulsification: Add deionized water and water-based resin emulsion to it under high-speed stirring to emulsify and stir evenly to obtain a water-based adhesive for shoes with high solid content.

[0057] Wherein, the isocyanate is a mixture of isophorone diisocyanate and hexamethylene diisocyanate;

[0058] The polyol is a polyethylene adipate diol with a number-average molecular weight of 1000-3000;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com