Water distribution device and water-consuming system with same

A water divider and water outlet technology, which is applied in branch pipelines, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of increasing the difficulty of on-site installation and installation efficiency, and achieve stable and reliable product structure and easy assembly and connection. , the effect of stable diversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

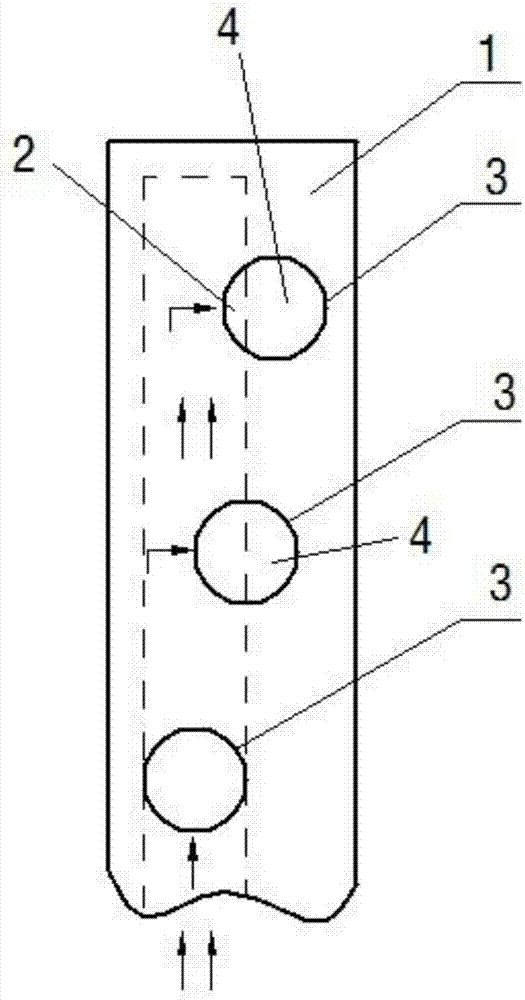

[0045] figure 1 A specific embodiment of the applicant's water separator is shown, which is the same as the traditional water separator in that it also includes a water separator housing 1, and a water inlet chamber is formed in the water separator housing 1 2. The outer surface of the water distributor housing 1 is provided with a plurality of ( figure 1 Only 3) water outlet holes 3 are shown in . Obviously, the water outlet hole 3 has an outer end far away from the water inlet chamber 2 and an inner end close to the water inlet chamber 2 .

[0046] The key improvement of this embodiment is that the above-mentioned three water outlet holes 3 all have the same hole type and diameter, and the inner ends of the two water outlet holes 3 are provided with a water retaining member 4 that partially blocks the water outlet section of the water outlet holes .

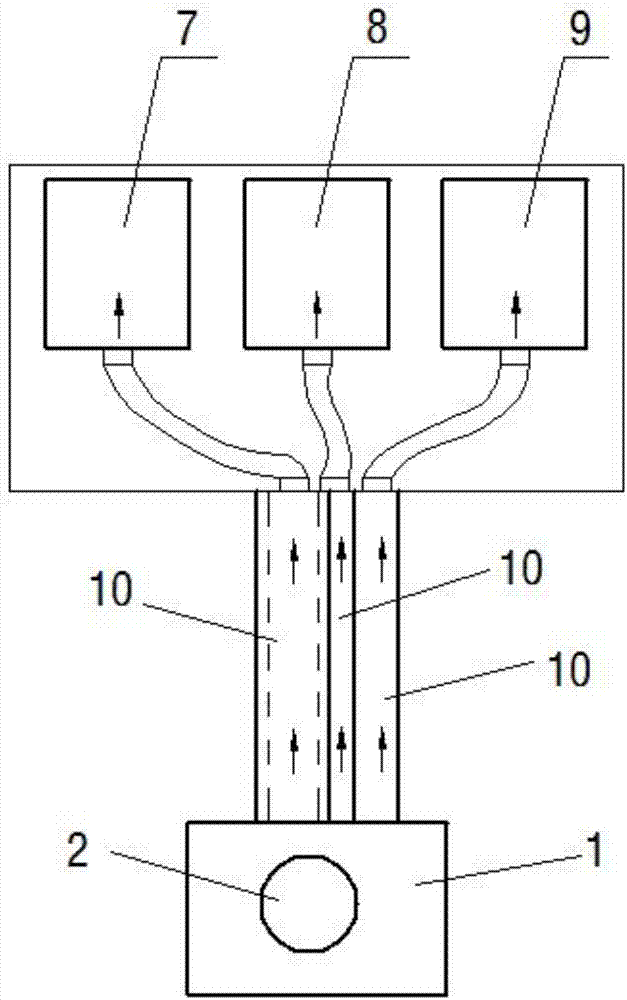

[0047] figure 2 It shows a specific application example of this kind of water divider in a certain water system. In the ...

Embodiment 2

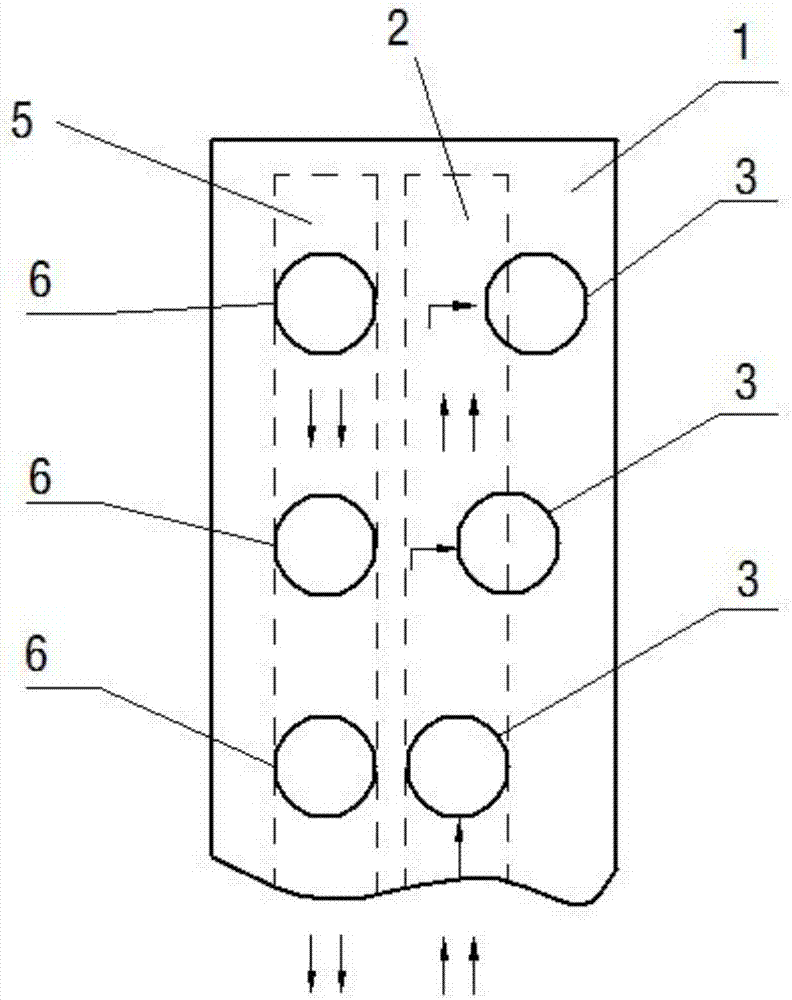

[0055] image 3 Shows the second specific embodiment of the applicant's water separator, Figure 4 A specific application example of the water separator of this embodiment in another water system is shown.

[0056] The structure of the water separator in this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that: the water inlet chamber 2 is also formed in the water separator housing 1 and the water return chamber 5 is isolated from each other, and the water separator housing 1 offers three backwater holes 6 communicating with the aforementioned backwater chamber 5 . And the aforementioned water return hole 5 also has the same hole shape and hole diameter as the three water outlet holes 3 . In this way, the water diversion joint connected to the water return hole 5 and the water diversion joint connected to the water outlet hole 3 can adopt exactly the same specifications.

[0057] refer to Figure 4 As shown, the three water ...

Embodiment 3

[0060] Figure 5 A third specific embodiment of the applicant's water separator is shown, Figure 6 A specific application example of the water separator of this embodiment in the third water system is shown.

[0061] The structure of the water distributor in this embodiment is basically the same as that of the second embodiment above, the difference is that the water retaining member 4 adopts a completely different structural form, specifically: the water retaining member 4 arranged at the inner end of the water outlet hole 3 is a set The baffle plate structure of a plurality of small holes, the outer contour of this baffle plate completely blocks the water outlet cross-section at the inner side of the water outlet hole 3, and only leaves the small holes provided on it for water flow to flow out. Those water retaining members 4 with a large number of small holes and a large total area of the small holes have larger water outlet flow rates of the corresponding water outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com