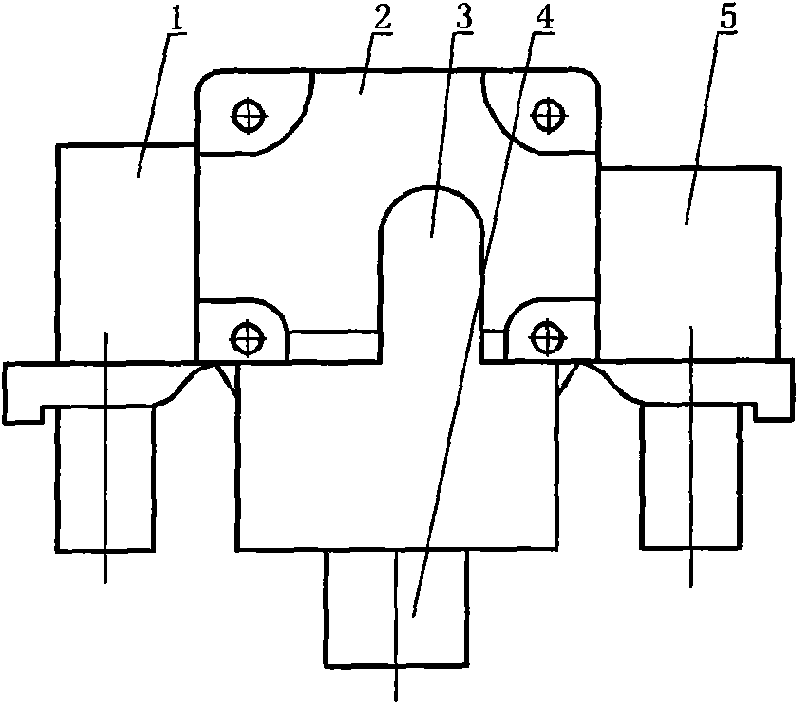

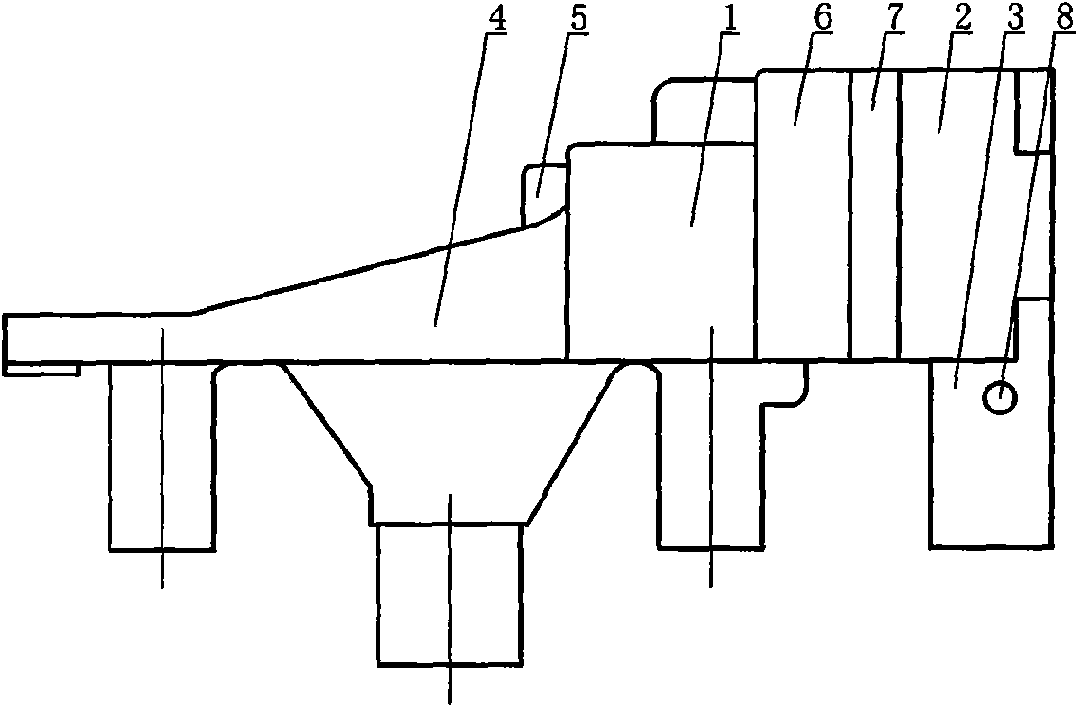

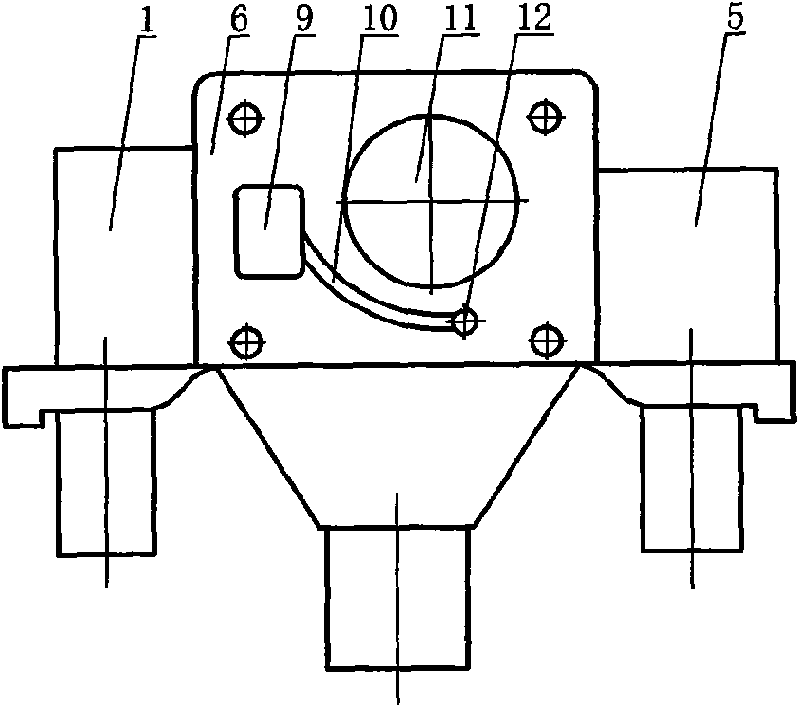

Cylinder body structure of compressor

A compressor cylinder block and cylinder block technology, applied in the field of compressors, can solve problems such as unsatisfactory requirements, achieve scientific and reasonable structural design, reduce air flow pulsation, and reduce pulsation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0022] A compressor cylinder structure, in which a connection seat 6, a crankshaft hole 13, a first-stage high-pressure buffer chamber 1, and a second-stage high-pressure buffer chamber 5 are formed on the upper part of the cylinder base 4, and four corners of the lower bottom of the cylinder base Mounting columns (without labels) are respectively made, the crankshaft hole is made at the upper middle position of the cylinder base and extends downward to the bottom, the above-mentioned two high-pressure buffer chambers are respectively arranged on both sides of the connecting seat, and a piston hole is made on the end surface of the connecting seat 11. The connecting seat is fixed coaxially with the cylinder head 2 through the valve plate 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com