Carton loading mechanism

A carton and outer carton technology, applied in the field of carton packing mechanism, can solve the problems of low production efficiency and low degree of automation, reduce volume and occupy space, improve speed and efficiency, and facilitate and flexible packing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

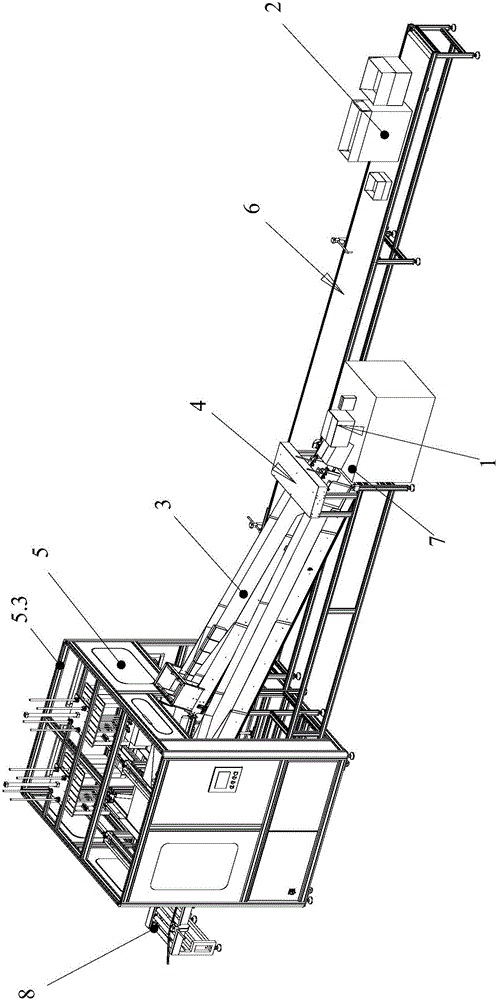

[0040] Such as Figure 1 to Figure 6 As shown, the carton packing mechanism of the present invention is used to arrange the cartons 1 into the outer box 2; the carton packing mechanism includes:

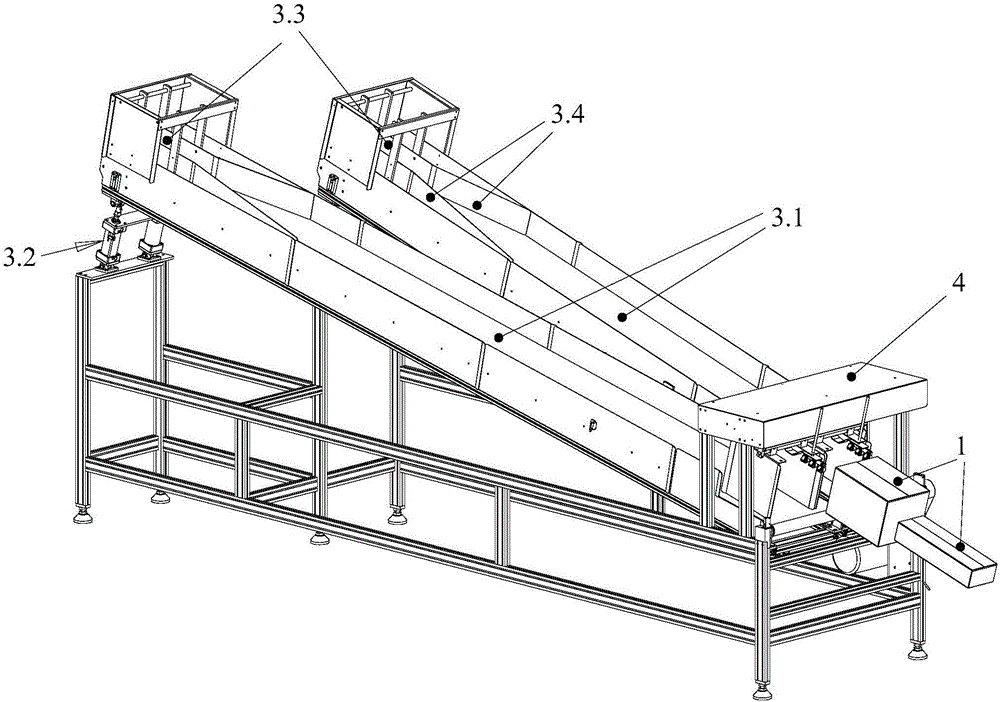

[0041] The carton conveying device 3 with two conveying channels 3.1 is used to arrange and guide the conveying according to the number of rows / columns of the cartons 1 preset in the outer box 2;

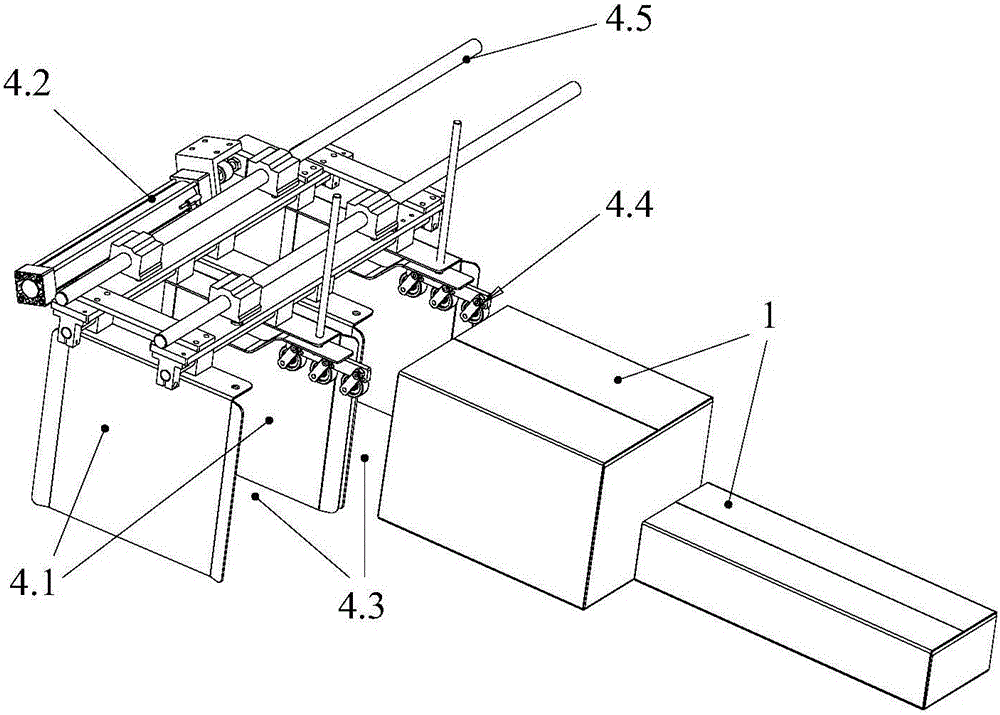

[0042] One end is connected to the mechanism inlet 7, and the other end is movably connected to the two conveying channels 3.1. The distribution device 4 is used to move the cartons 1 conveyed from the single mechanism inlet 7 and transport them to the carton conveying device 3. 2 transmission channels 3.1;

[0043] The box packing device 5 connected to the outlet of the carton conveying device 3 is used to form the cartons 1 into rows / columns one by one according to the preset arrangement, and then form layers row / column, and then pack the arranged whole layer of cartons 1 Load the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com