Double-split-flow turbine steam-inlet diversion structure

A split turbine and steam inlet technology, which is applied in the direction of blade support components, stators, engine components, etc., can solve the problems of poor stability and reliability of steam axial split flow, high loss, unstable aerodynamic boundary of steam vortex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

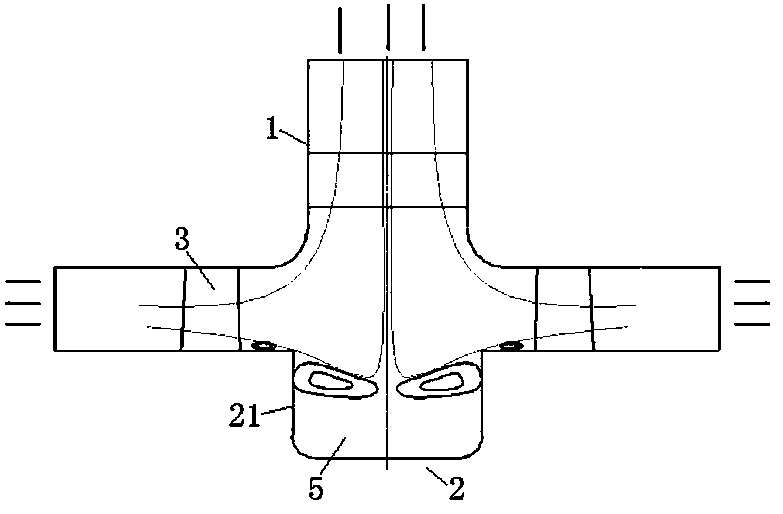

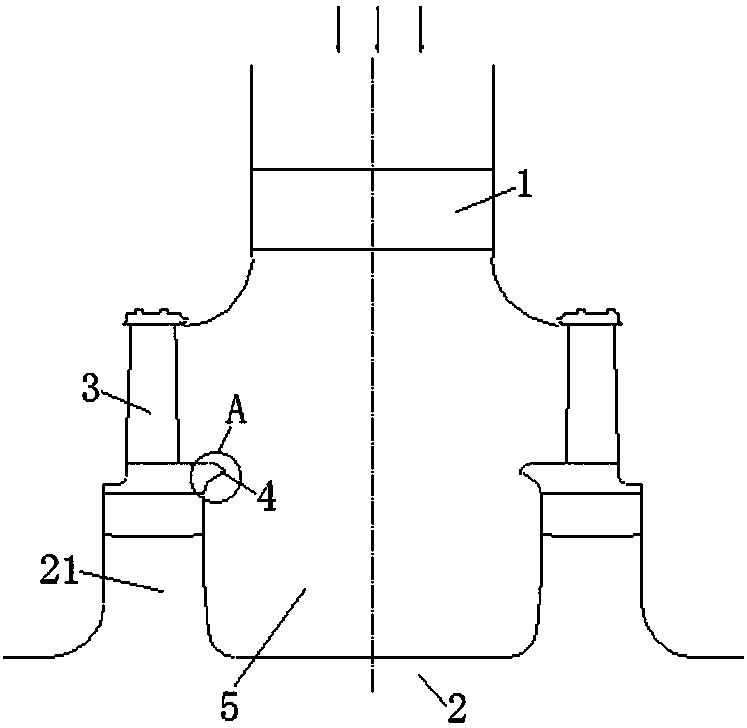

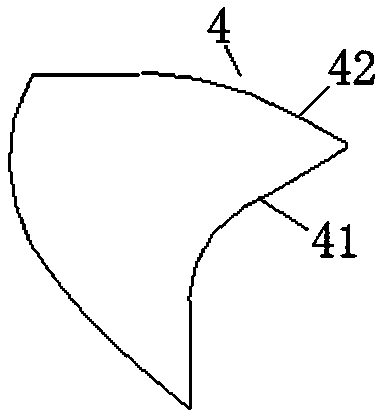

[0013] The invention relates to turbine technology, in particular to a steam inlet diversion structure of a double split flow turbine. Below in conjunction with the accompanying drawings of the description - that is figure 2 , image 3 and Figure 4 The technical content of the present invention is described in detail and specifically.

[0014] see figure 2 , image 3 and Figure 4 As shown, the present invention includes a first-stage vane 1 and a wheeled rotor 2 that are assembled together correspondingly.

[0015] Wherein, the first-stage stationary vane 1 is a radial-flow stationary vane.

[0016] The two sides of the part of the wheel rotor 2 corresponding to the first-stage stationary blade 1 have radially protruding impellers 21 for assembling the moving blades 3 , and the positive and negative first-stage moving blades 3 are correspondingly assembled on their corresponding on the rim of the impeller 21.

[0017] The split cavity 5 is enclosed between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com