Patents

Literature

85results about How to "Steady ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine droplet ejecting device and ink jet recording apparatus using the same

The fine droplet ejecting device includes a ejection unit having an ejection port, and for continuously ejecting fine droplets by applying an electrostatic force to a solution or ink having an electrical charge containing at least fine particles and a medium, a deflecting unit for deflecting the fine droplets ejected from the ejection unit based on a control signal and a recovering unit for recovering either one of the fine droplets flying straight after being ejected from the ejection unit and the fine droplets having a flight direction deflected by the deflecting unit. The ejection unit may further include a resolution enhancing unit for deflecting the fine droplets in a direction different from the flight direction deflected by the deflecting unit. The device can eject the fine droplets stably at high speed, and can reduce a cost. The ink jet recording apparatus uses the fine droplet ejecting device.

Owner:FUJIFILM CORP

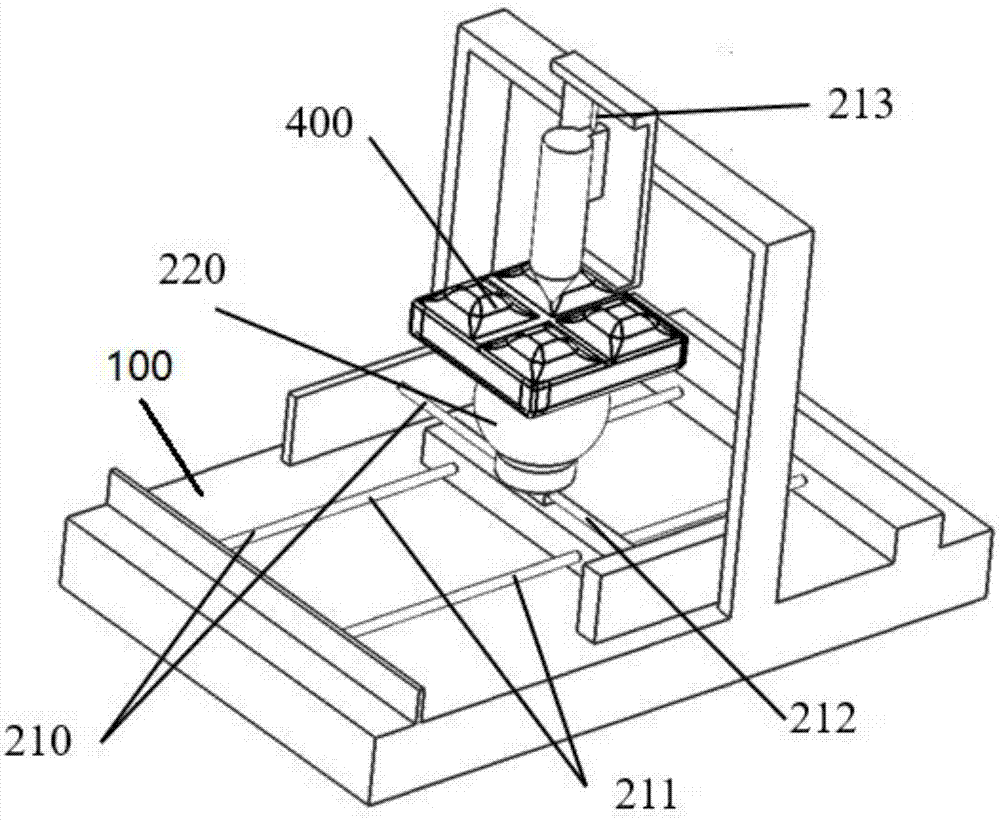

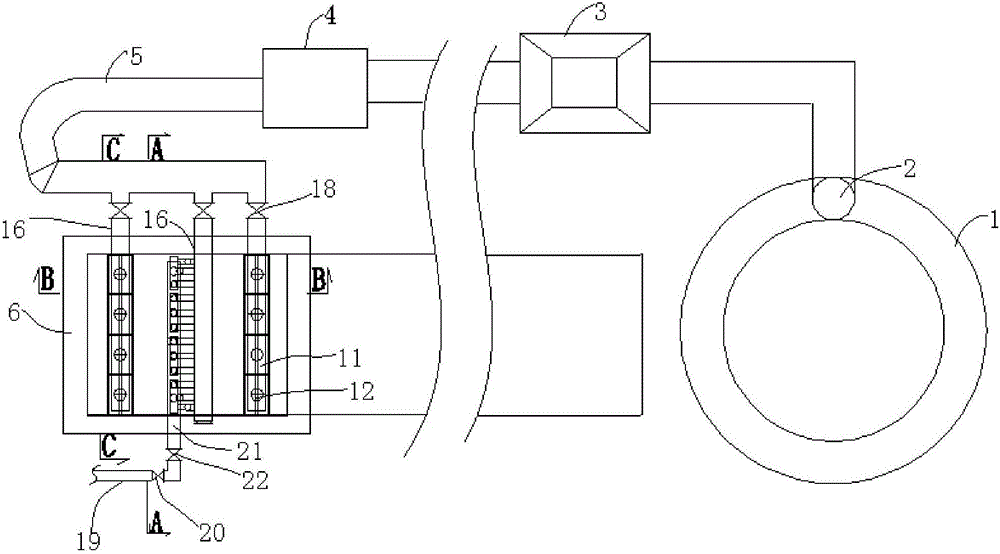

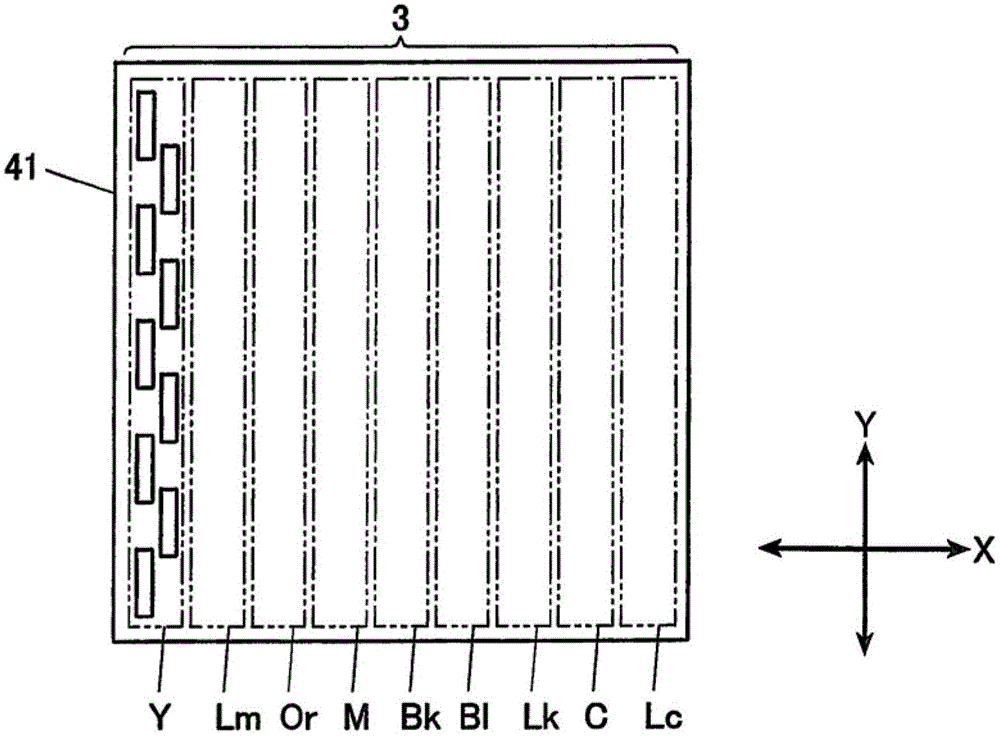

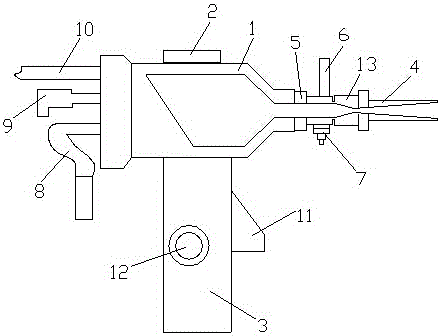

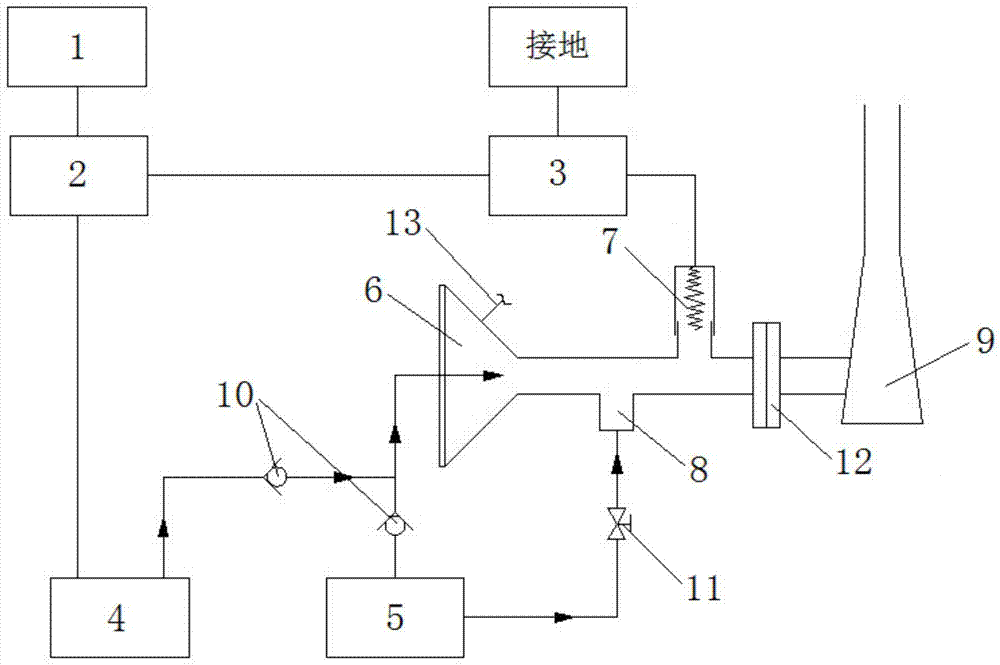

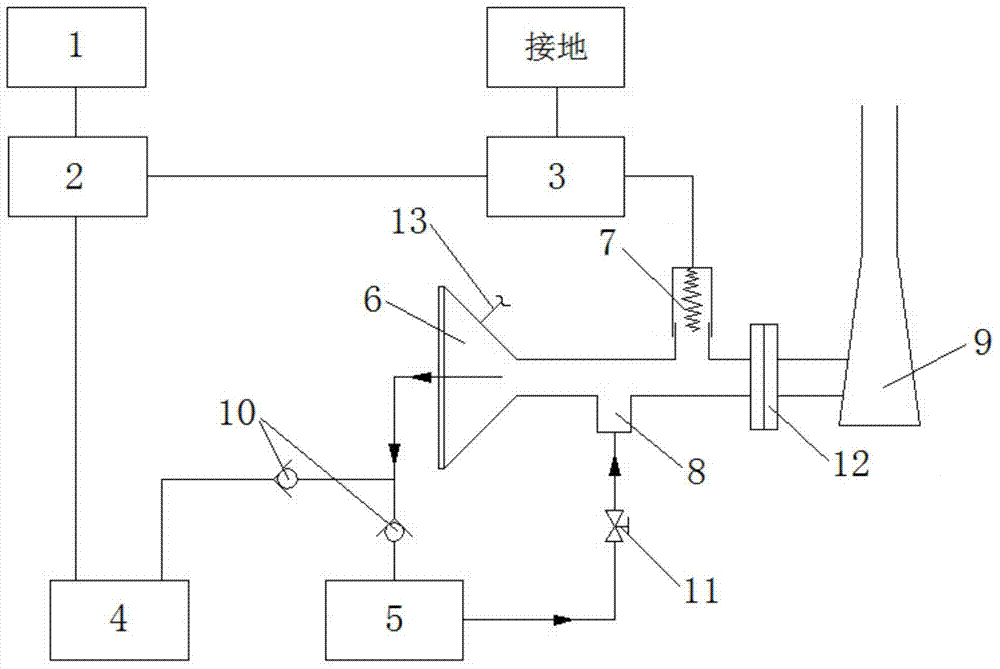

Complex surface circuit conformal spray printing method and equipment

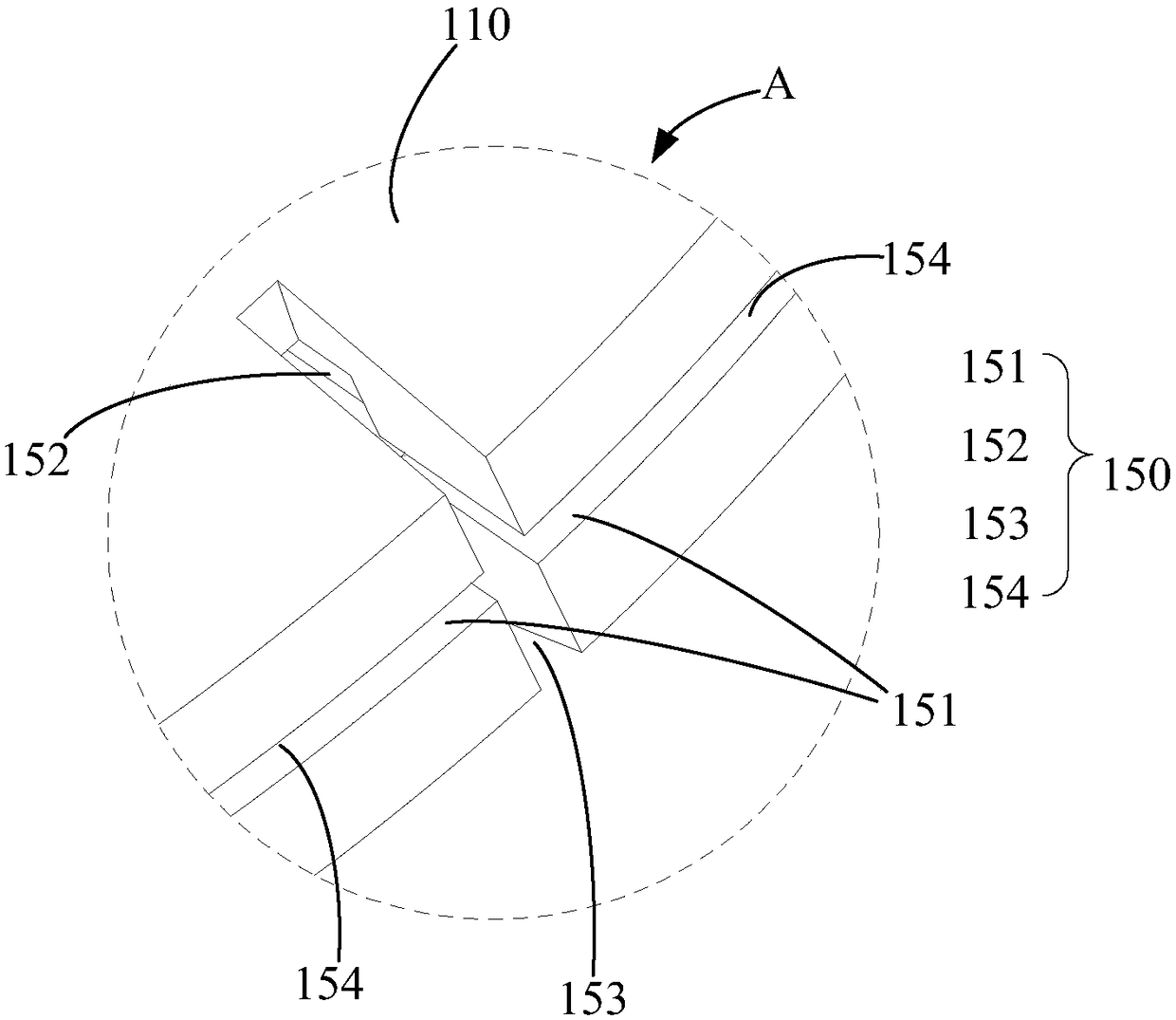

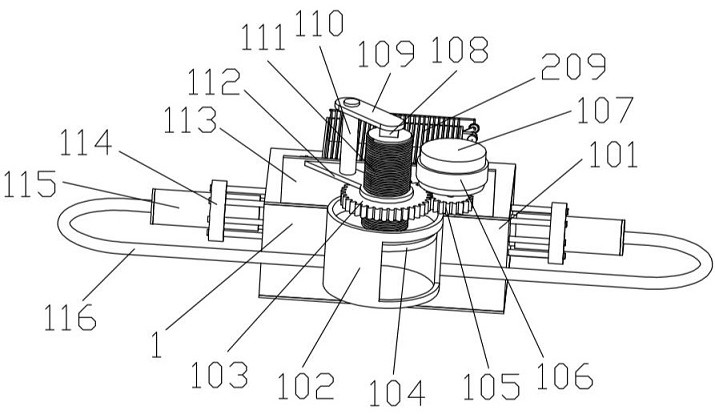

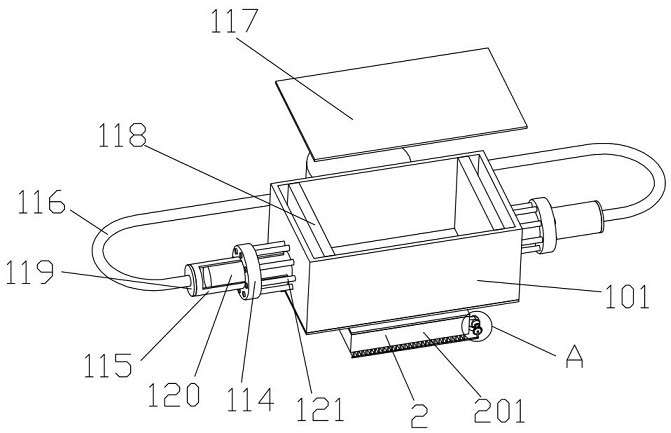

ActiveCN107512083AOmit vector transformationSteady ejectionDuplicating/marking methodsTypewritersManufacturing cost reductionComputer module

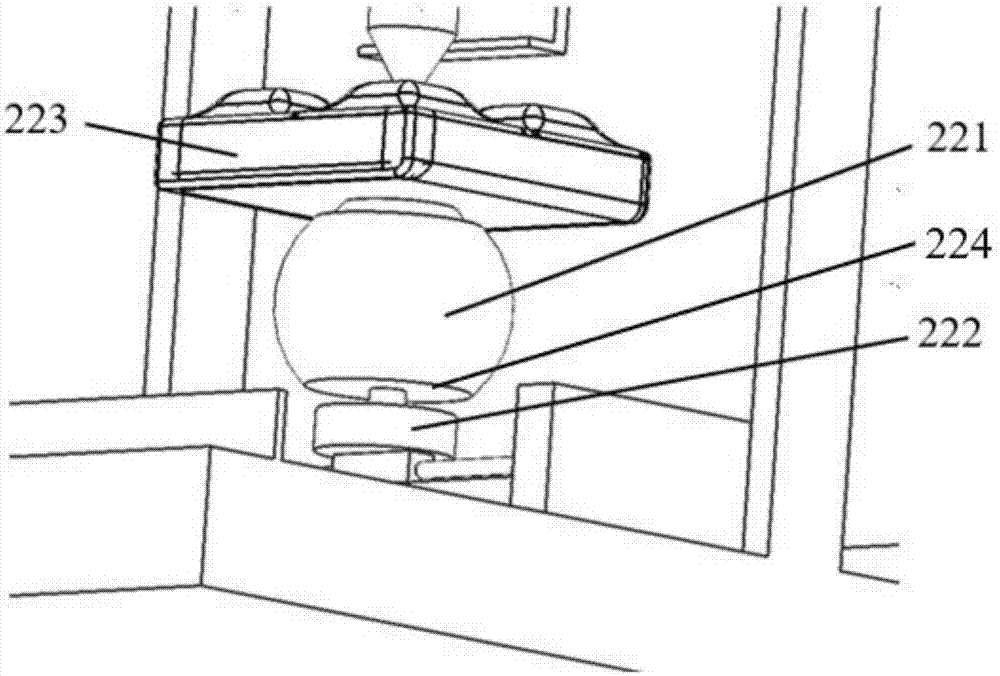

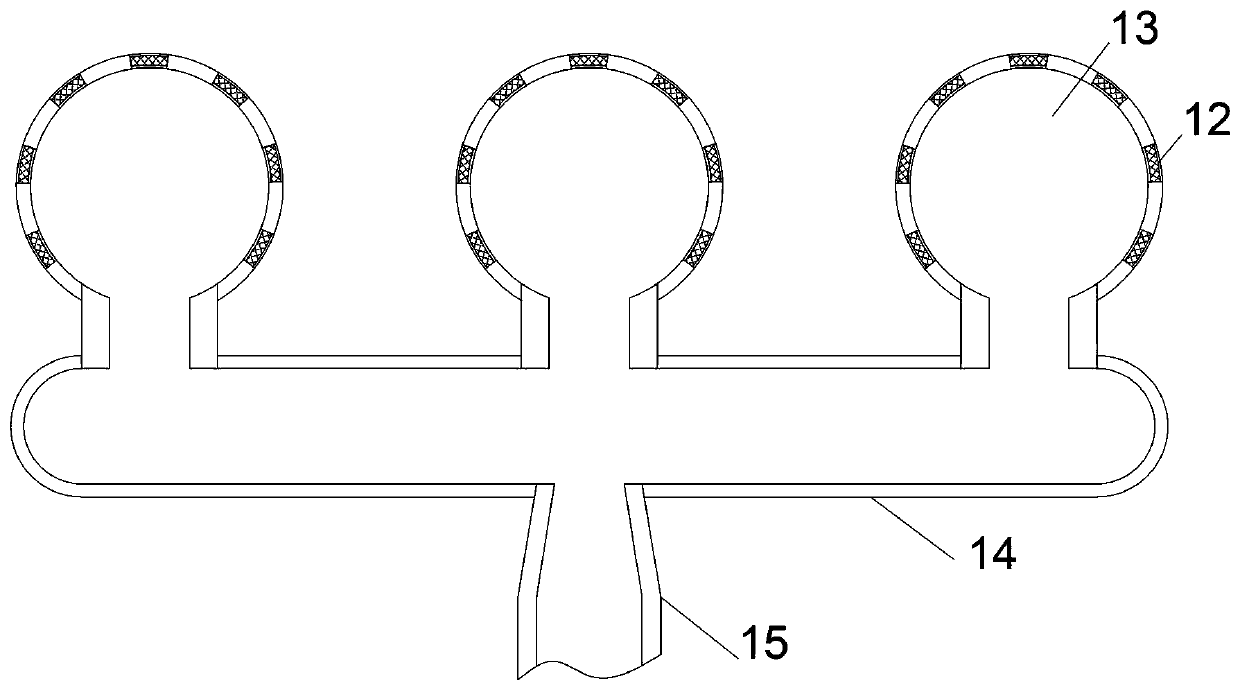

The invention belongs to the field of electric fluid dynamics spray printing, and discloses a complex surface circuit conformal spray printing method and equipment. The equipment comprises a spherical motor module, a translation module and a conformal spray printing module. The translation module drives the spherical motor module to move in an X-axis direction and a Y-axis direction in a plane; the conformal spray printing module comprises a spray head part and an electric signal part; the spray head part moves up and down so as to realize a freedom degree of a Z-axis direction; the electric signal part applies voltage on an ink fluid and an electrode ring in an ink cartridge; the spherical motor module rotates around the X-axis direction, the Y-axis direction and the Z-axis direction so as to realize six-degree-of-freedom motion of an object to be spray-printed; a curve surface base plate is grounded, so that the electric potential of the object to be sprayed-printed is zero; and the voltage applied in the ink fluid is higher than the voltage applied in the electrode ring, so that a gradient electric potential difference is formed on the ink fluid, the electrode ring and the object to be spray-printed. Through the complex surface circuit conformal spray printing method and the equipment provided by the invention, a conformal patterning electric spray-printing process of a complex surface is realized, an application range of the electric spray-printing process is improved, the manufacturing cost is reduced, and the printing accuracy is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

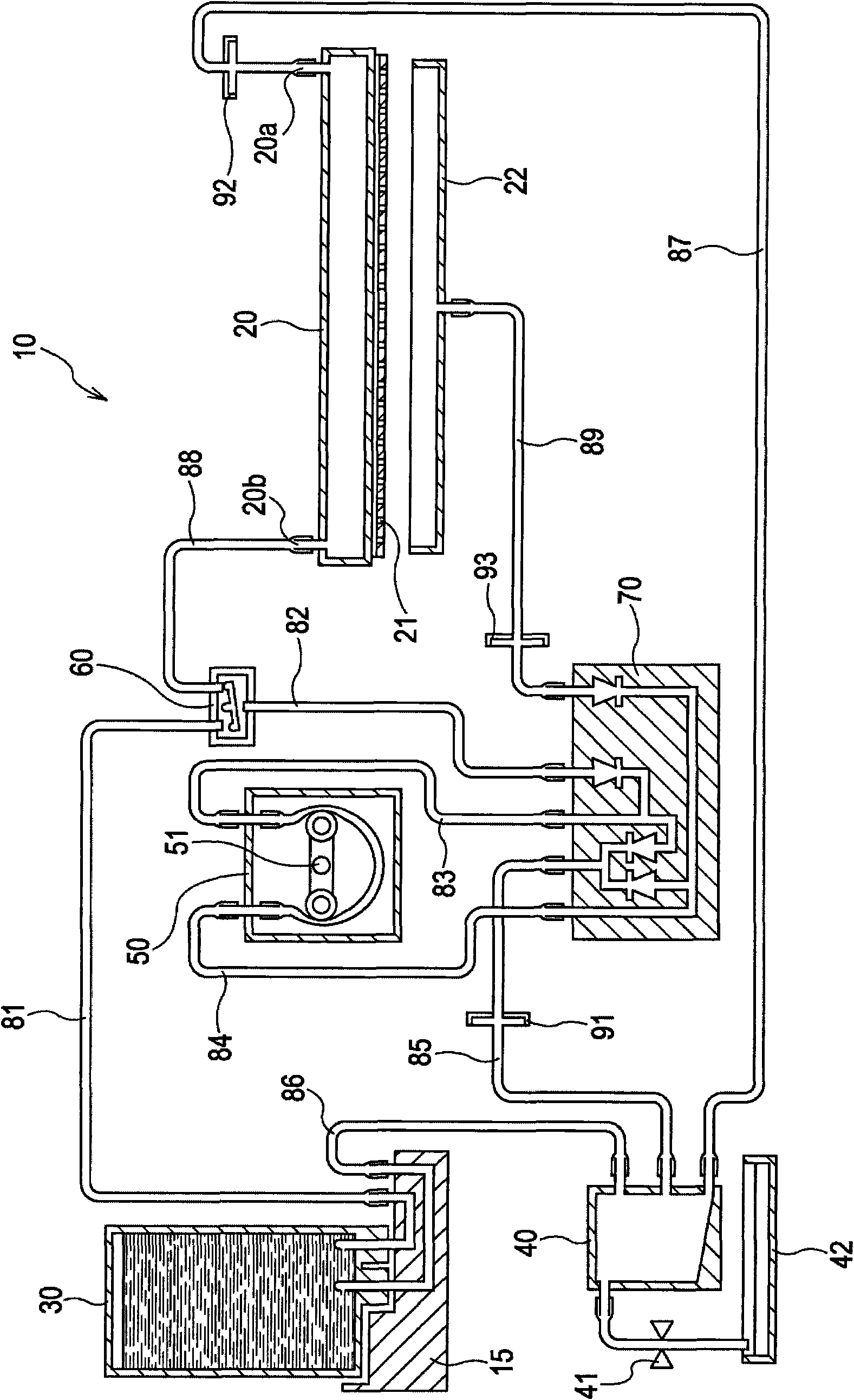

Liquid supplying device, liquid discharging device, and method of controlling liquid discharging device

The present invention discloses a liquid supplying device, a discharging device and a method of controlling the liquid discharging device, the liquid supplying device includes a liquid tank storing liquid that is supplied to a consumption object that consumes the liquid, a transfer pump for transferring the liquid stored in the liquid tank, an auxiliary tank temporarily storing the liquid transferred by the transfer pump before supplying the liquid to the consumption object, and a return pipe disposed so as to return the liquid to the liquid tank from the auxiliary tank when an amount of the liquid stored in the auxiliary tank becomes greater than or equal to a certain amount.

Owner:SONY CORP

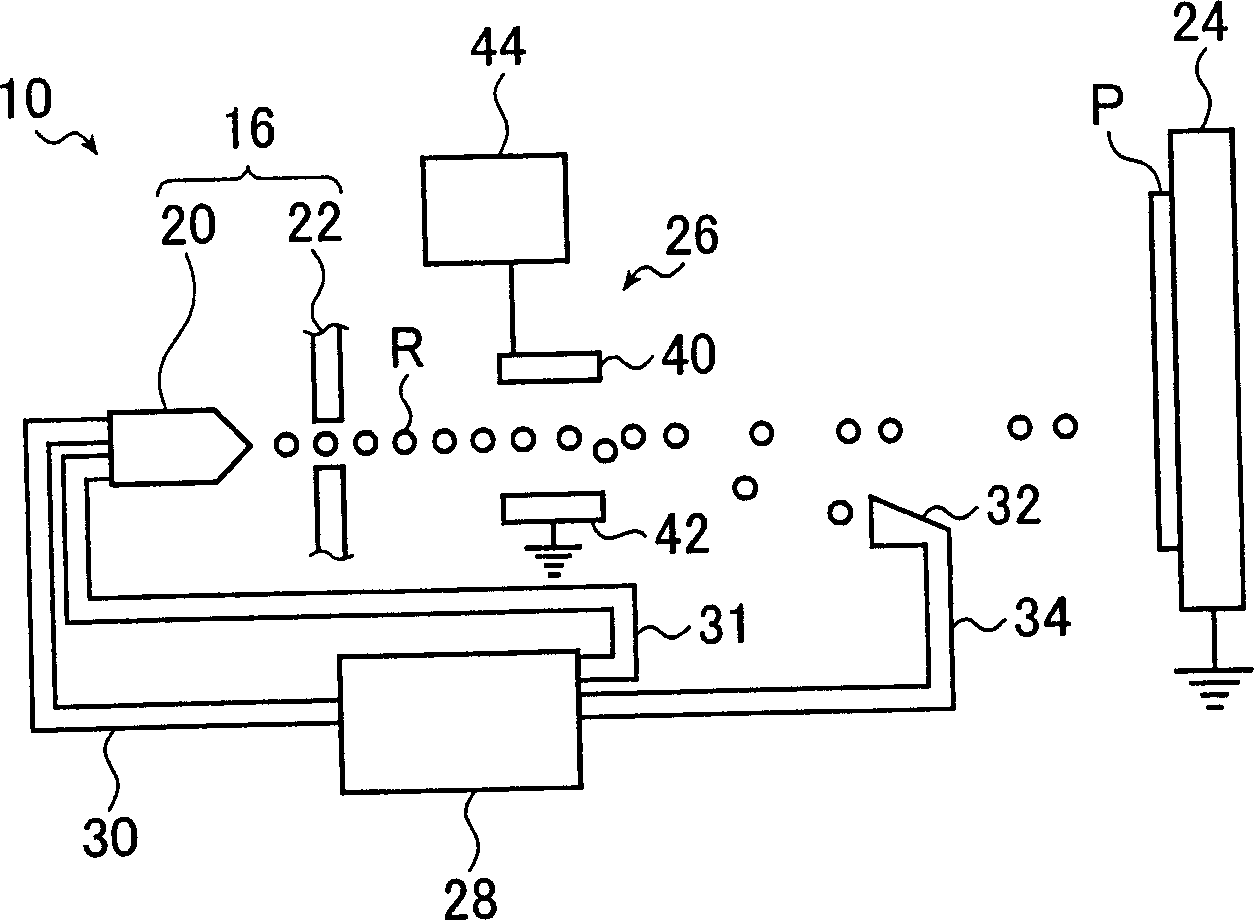

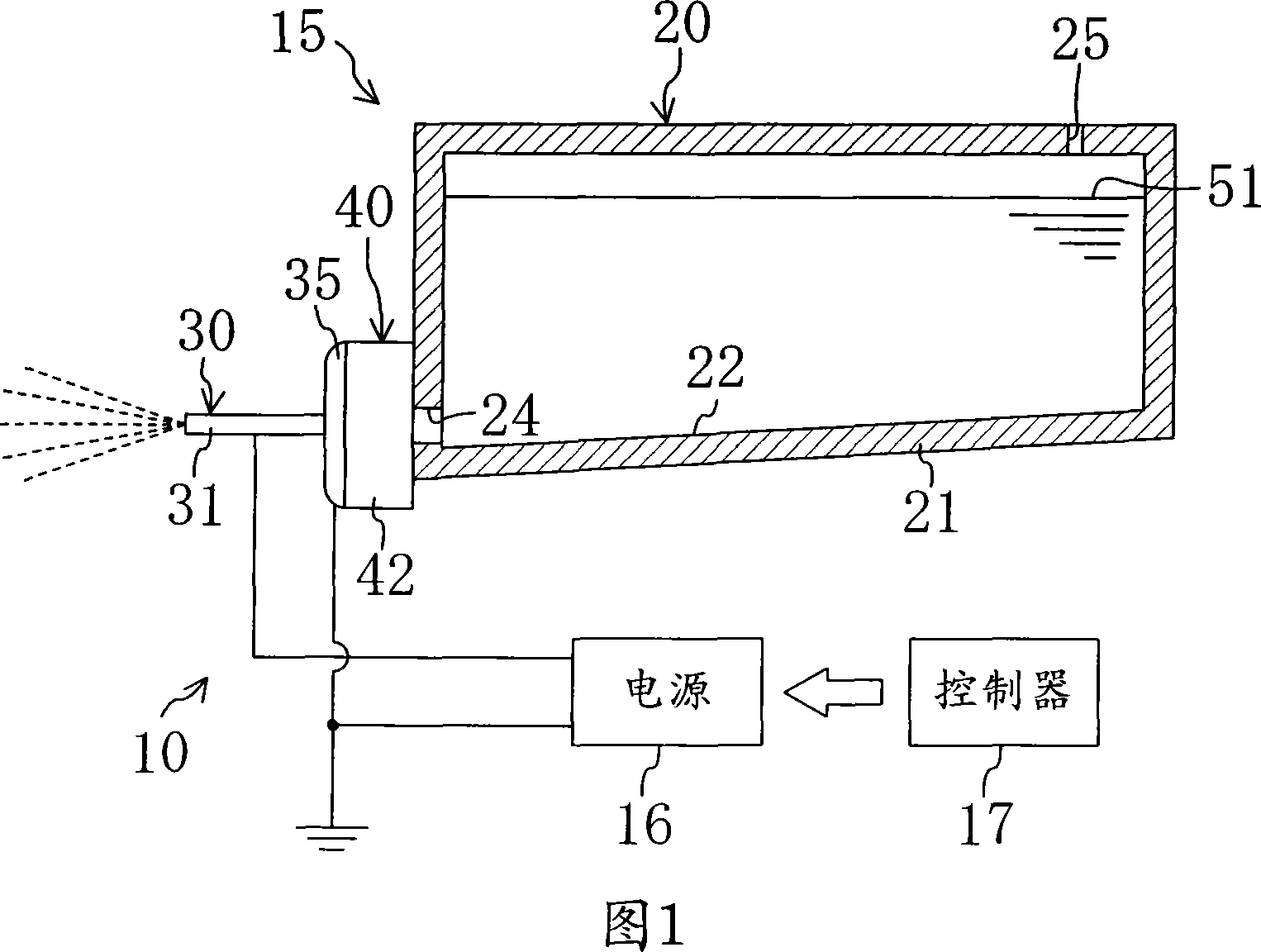

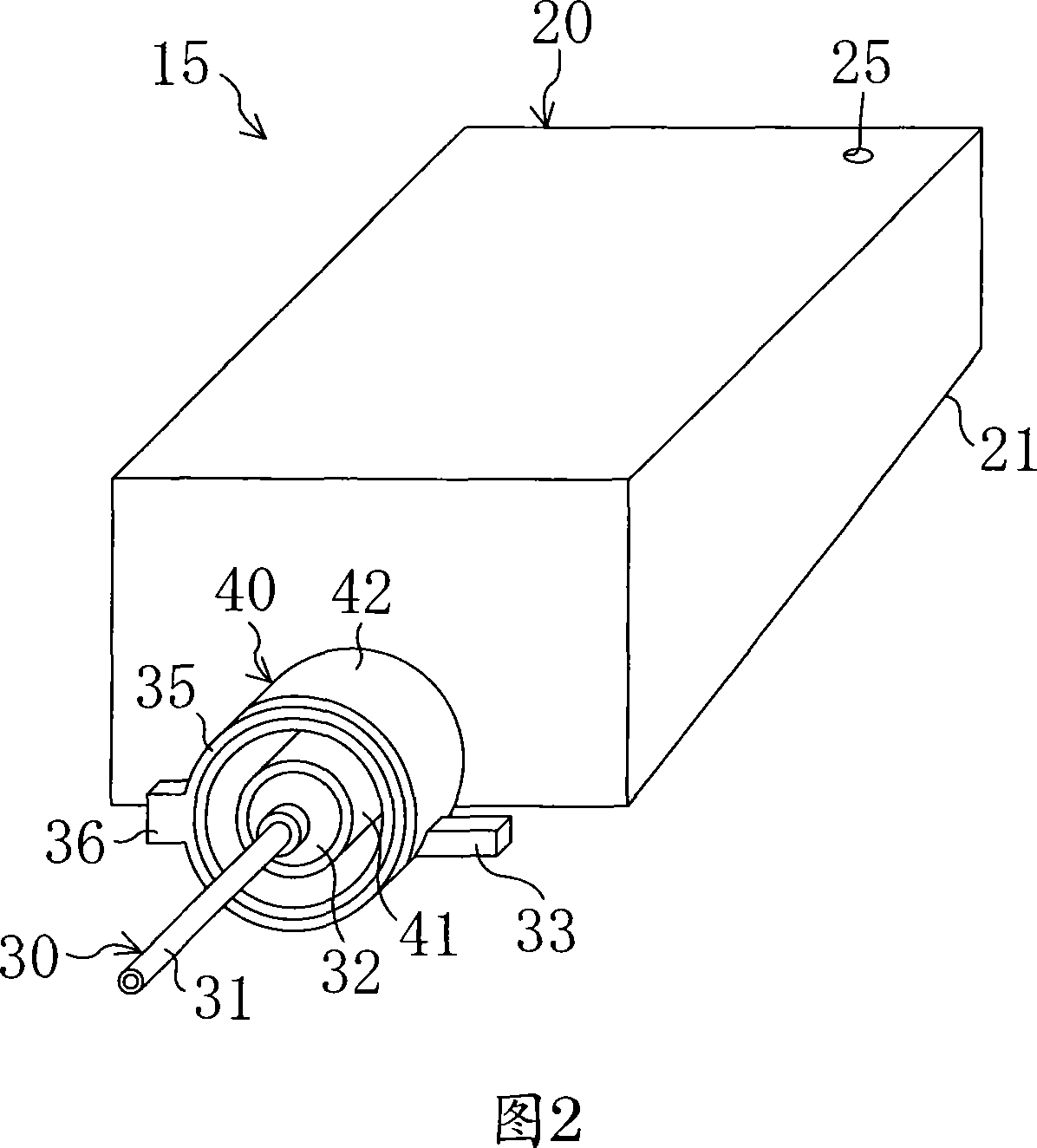

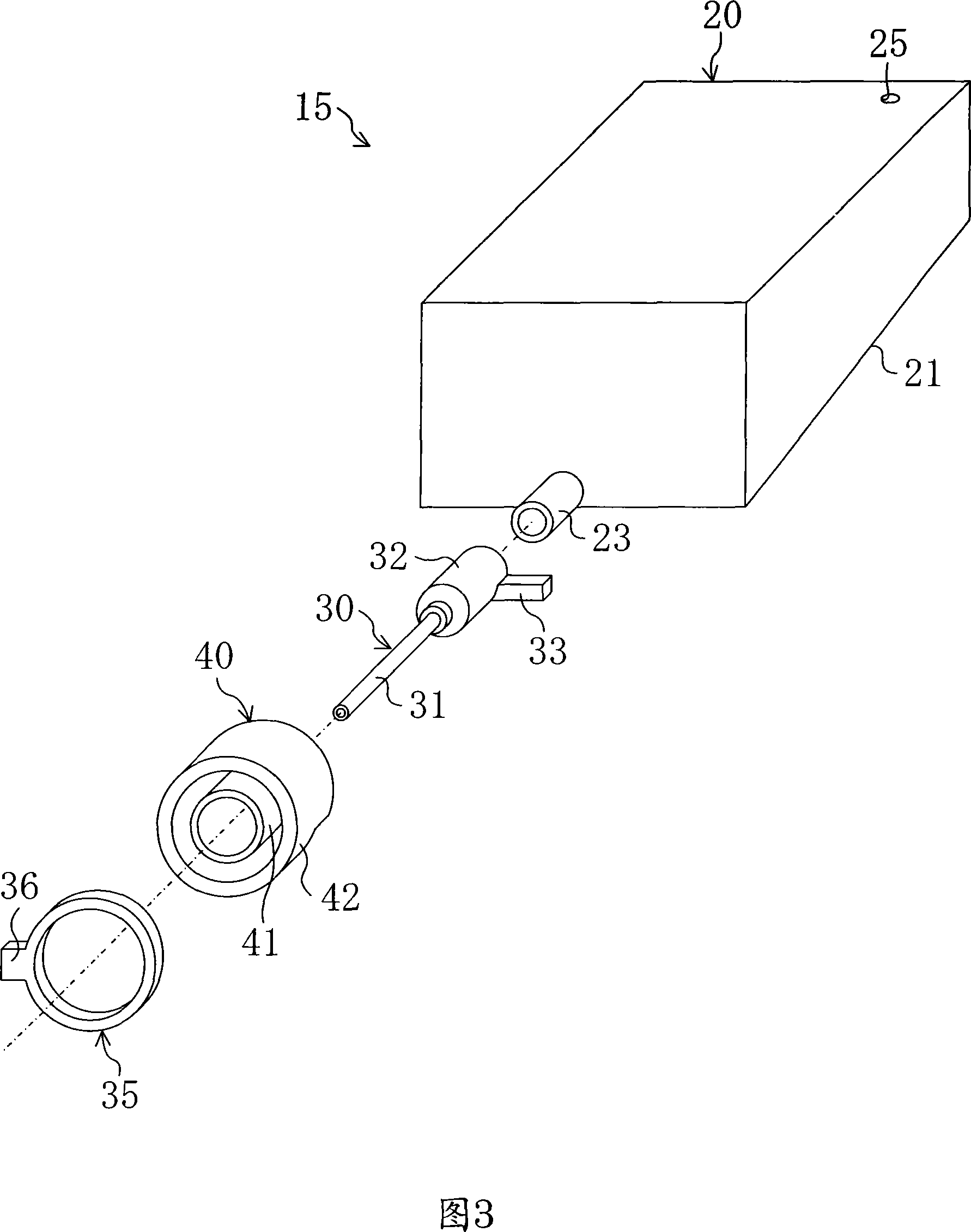

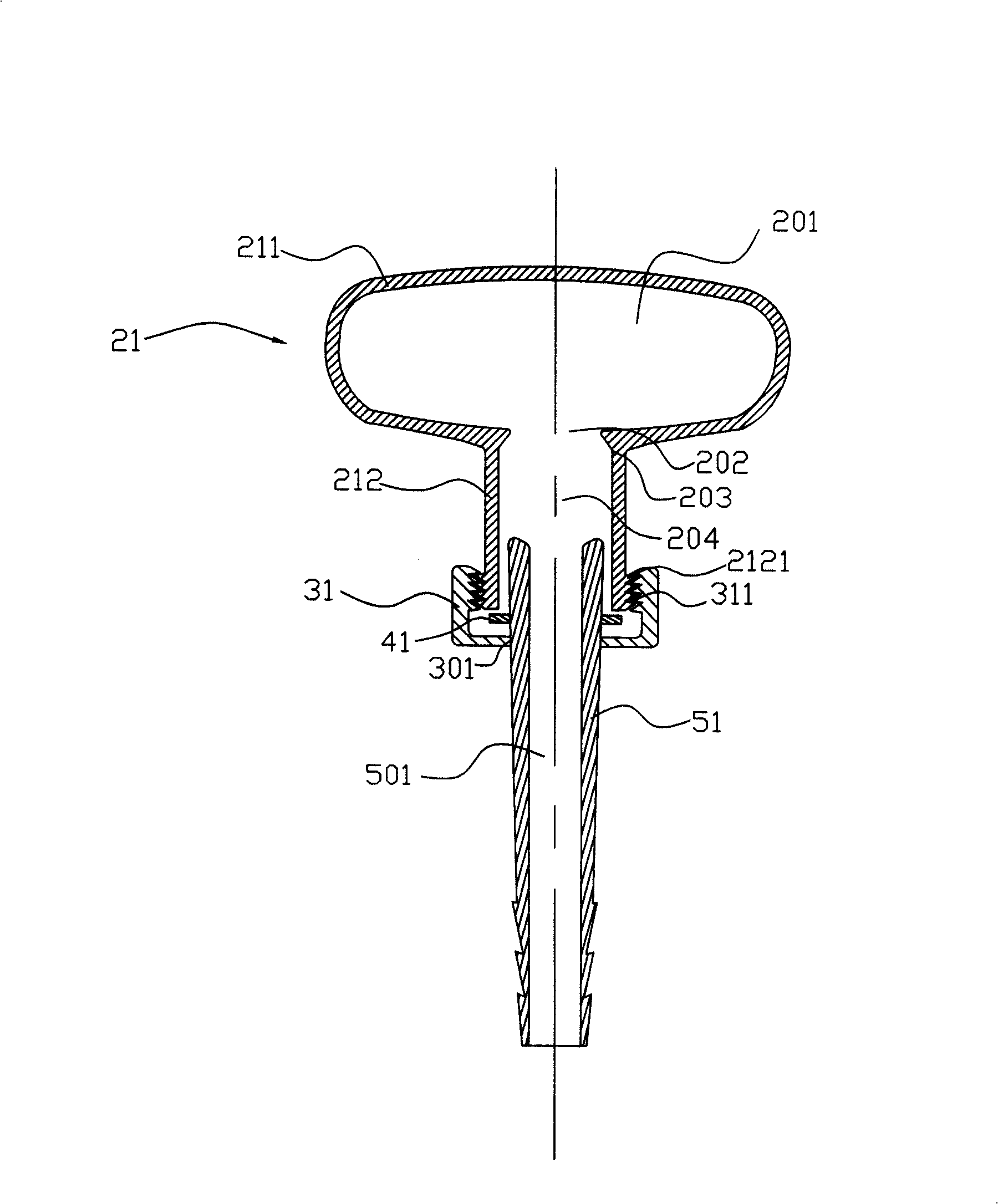

Electrostatic spray apparatus

InactiveCN101068623APrevent outflowSimple structureLiquid spraying plantsMedical atomisersSpray nozzleAqueous solution

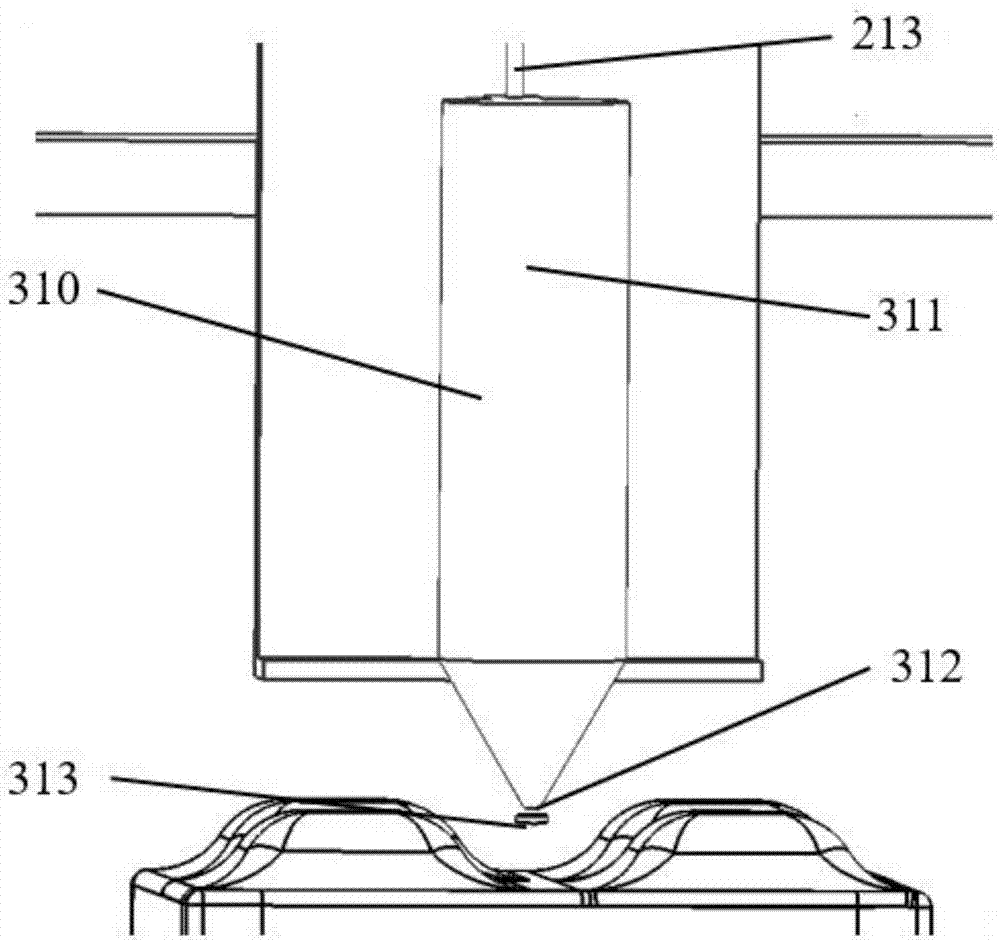

An electrostatic spray device (10) has a spray cartridge (15), an electric power source (16), and a controller (17). In the spray cartridge (15), a nozzle unit (30) is provided at the lower part of a solution tank (20). A spray nozzle (31) of the nozzle init (30) is positioned below the liquid level (51) in the solution tank (20). There is a head difference between the tip of the spray nozzle (31) and the liquid level (51) in the solution tank (20), and an aqueous solution in the solution tank (20) is supplied into the spray nozzle (31) by the head difference. When a voltage is applied to the spray head (31) by the power source (16), the aqueous solution is sprayed from the tip of the spray nozzle (31).

Owner:DAIKIN IND LTD

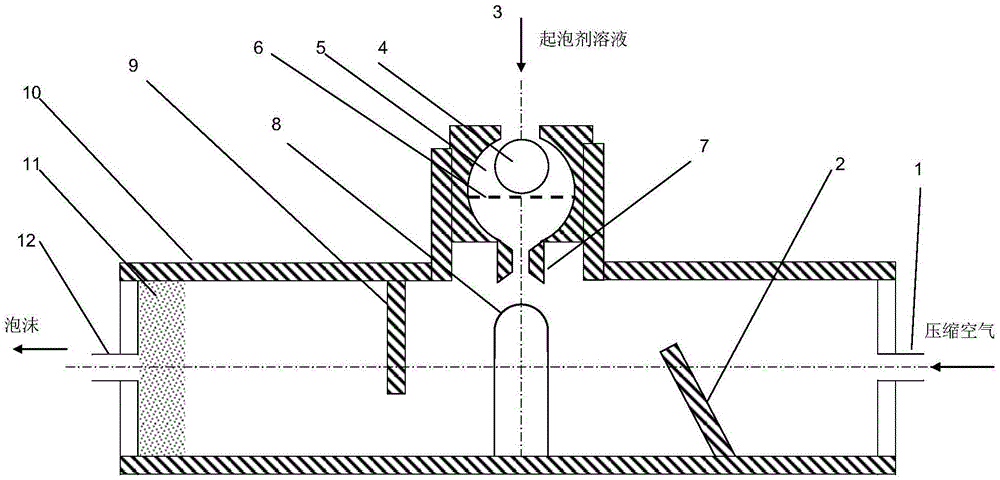

Foam generator

ActiveCN105521720AQuality improvementImprove accelerationFlow mixersTransportation and packagingFoaming agentMaterials science

A foam generator is provided. According to a foam generation principle, after air enters a foam generator cavity body, for avoiding conditions of single-phase outflowing of a foaming agent and uneven foaming as much as possible, firstly, a spray nozzle structure arranged at the cavity body is utilized for transforming pressure energy of a foaming agent solution at an inlet into kinetic energy to a greater extent; the foaming agent solution is dispersed and atomized by an atomizer after being sprayed; compressed air and the atomized foaming agent solution are fully mixed and then flow to a foam outlet of the foam generator; a dense metal filter screen arranged at the foam outlet ensures that the foaming effect is further improved, and the problem that the air or the foaming agent flows out of the foam generator in a single phase manner does not exist.

Owner:XI'AN PETROLEUM UNIVERSITY

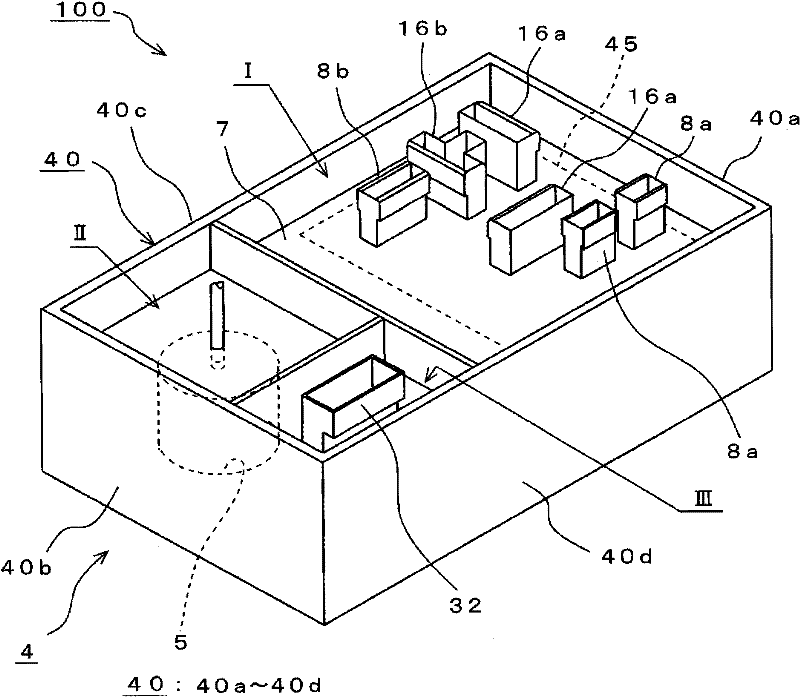

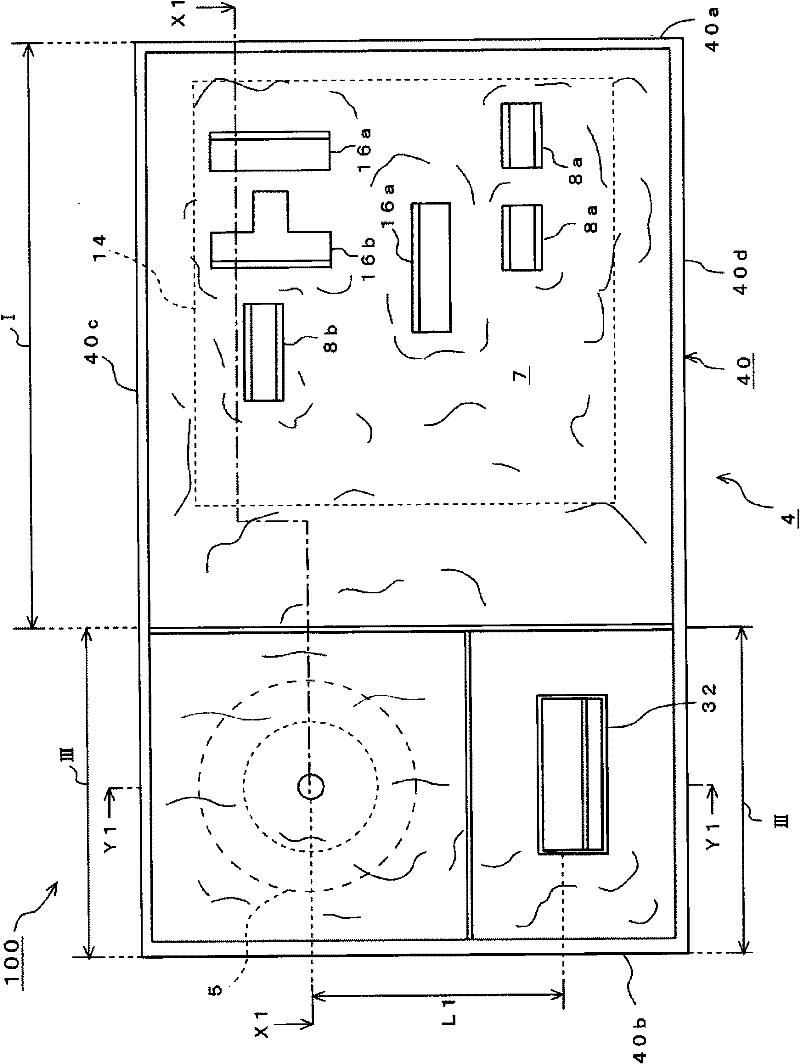

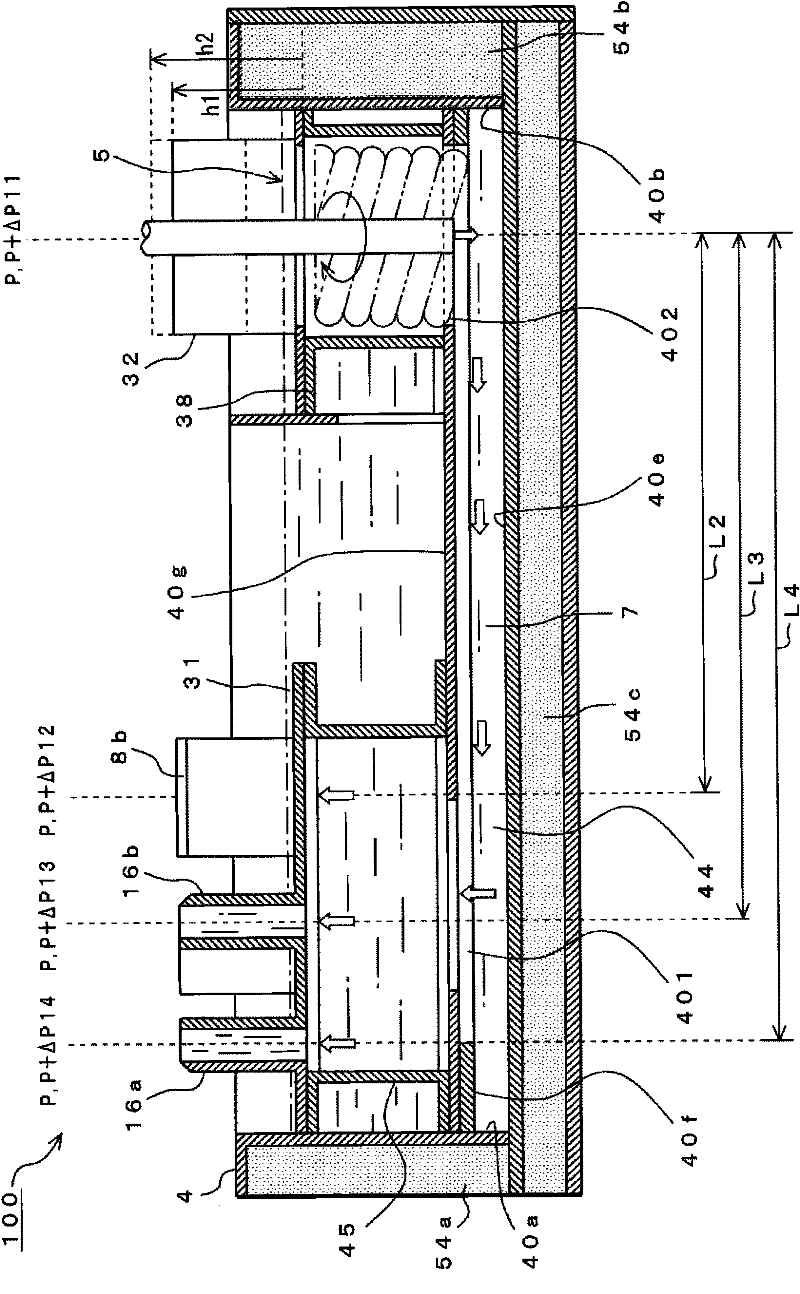

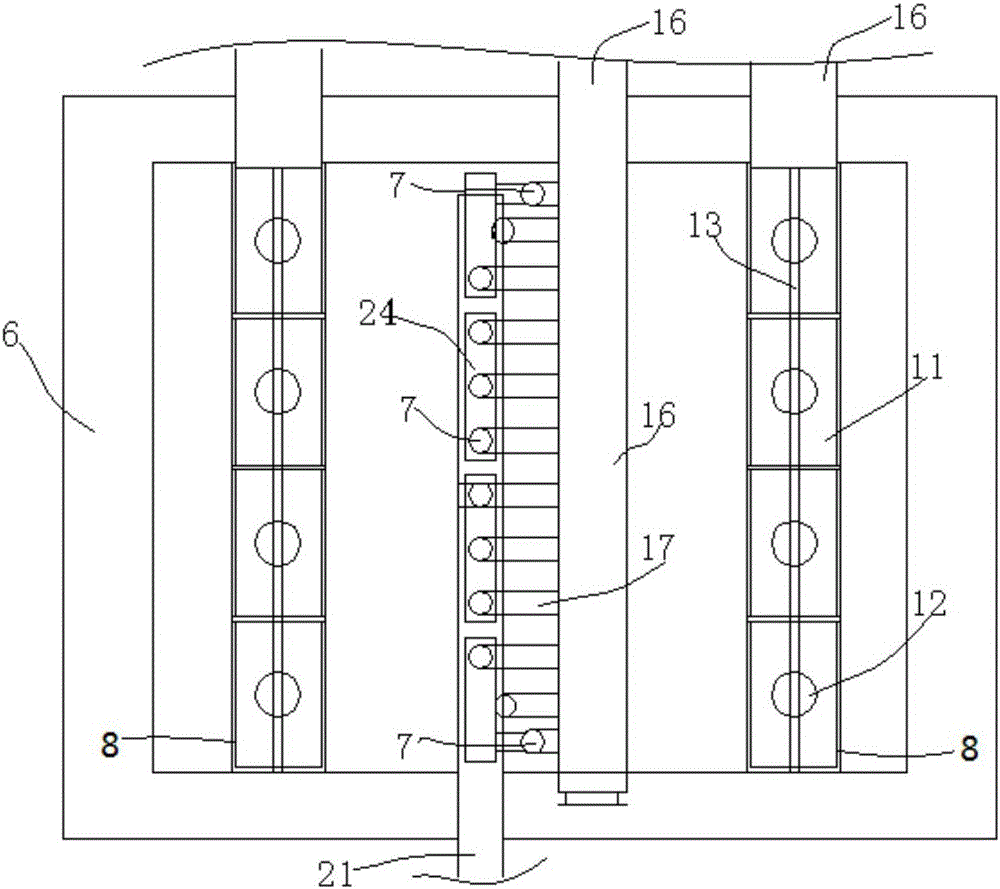

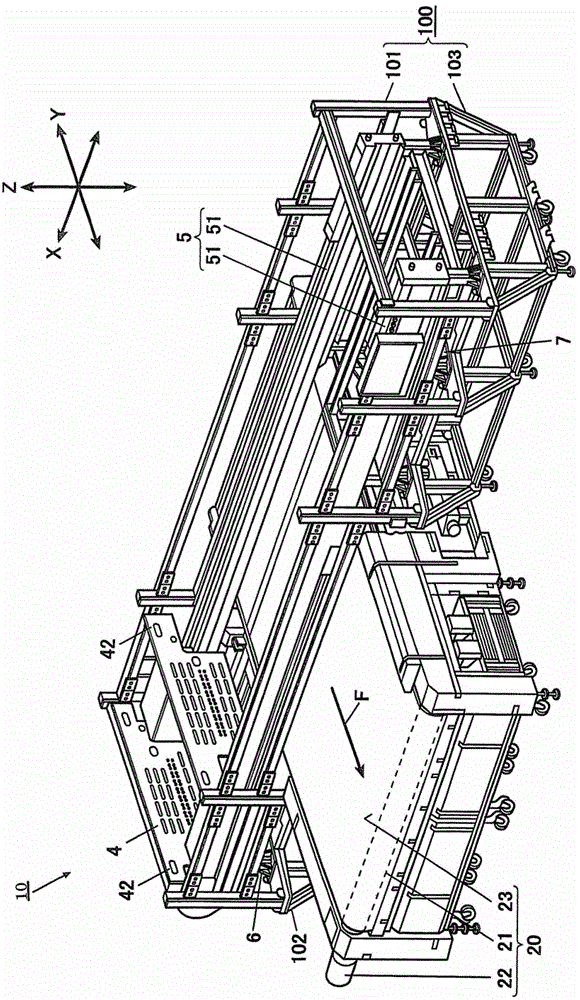

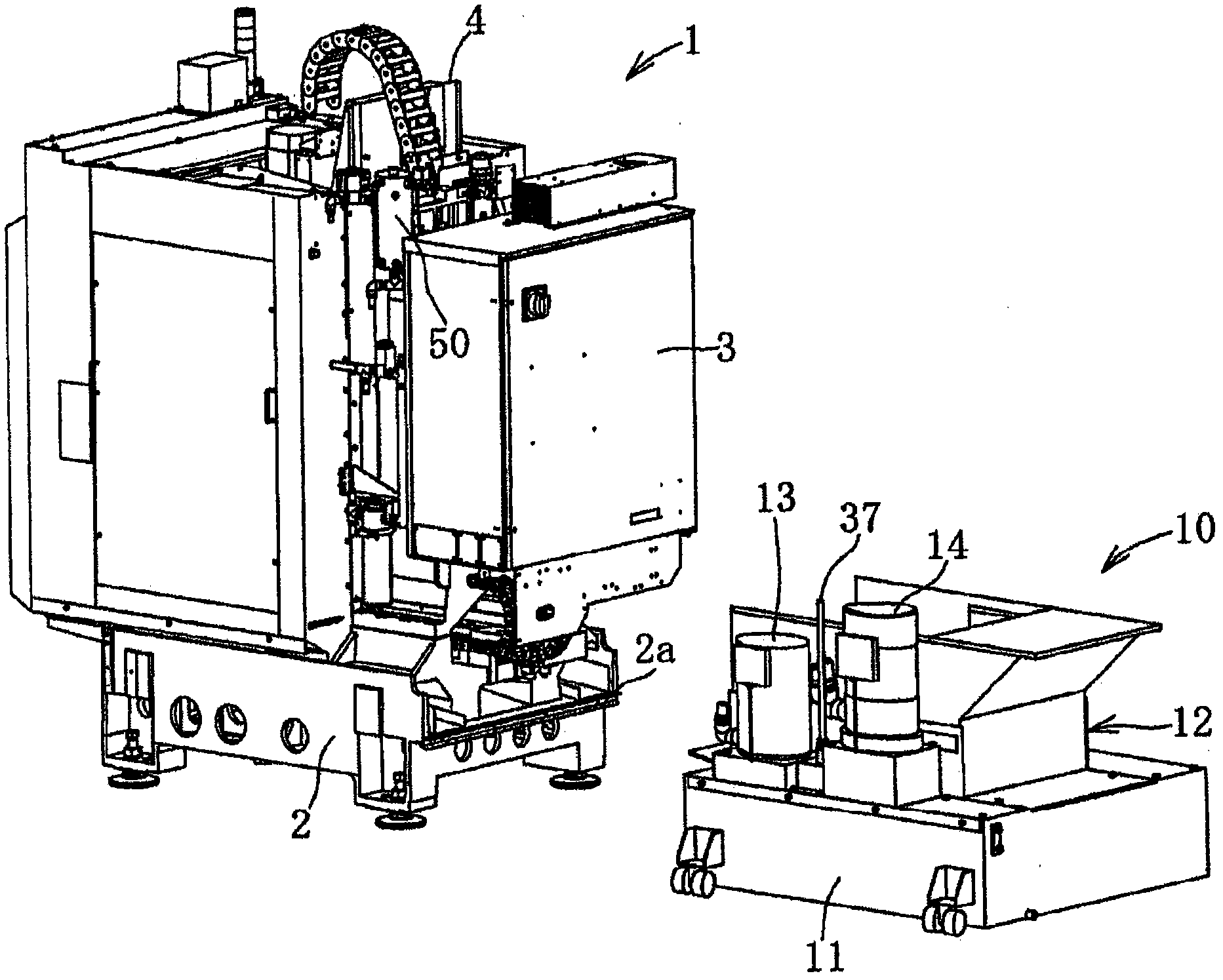

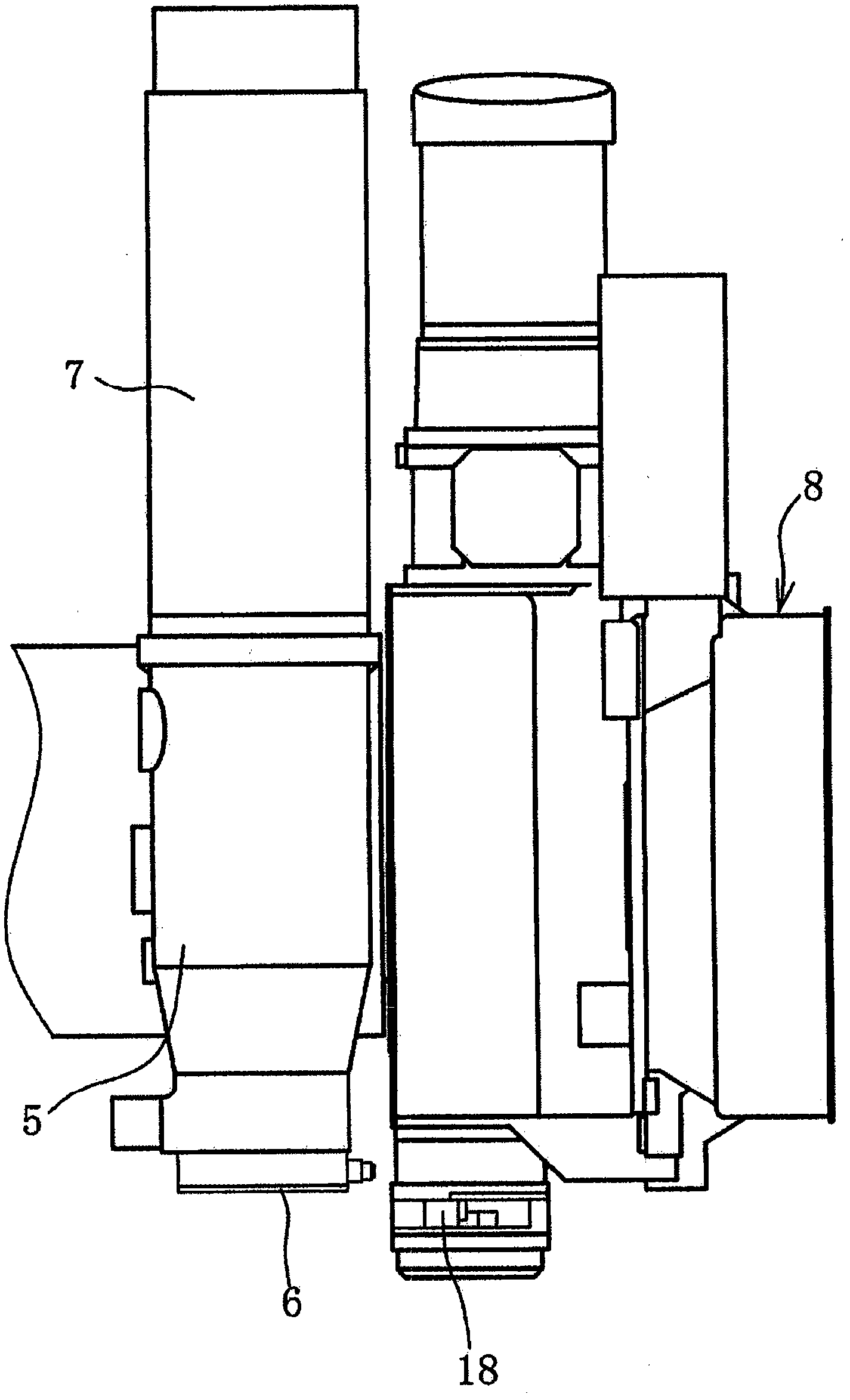

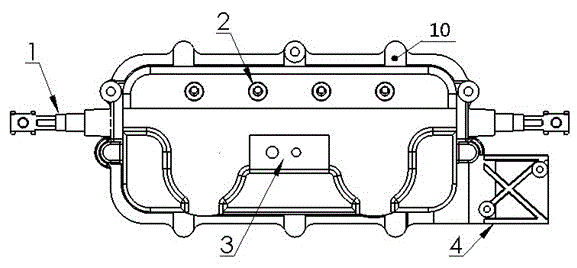

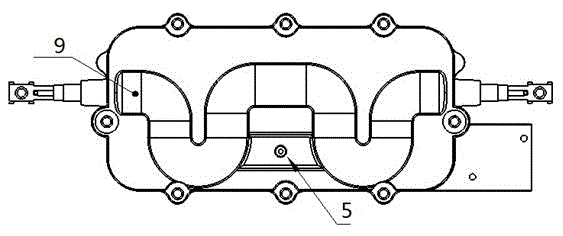

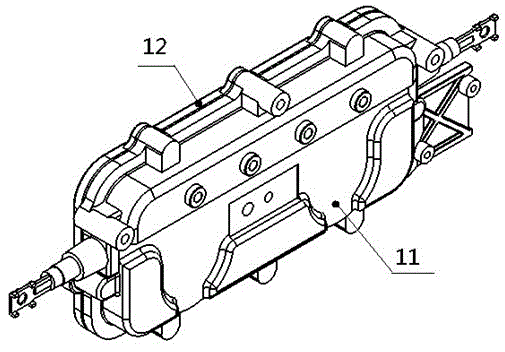

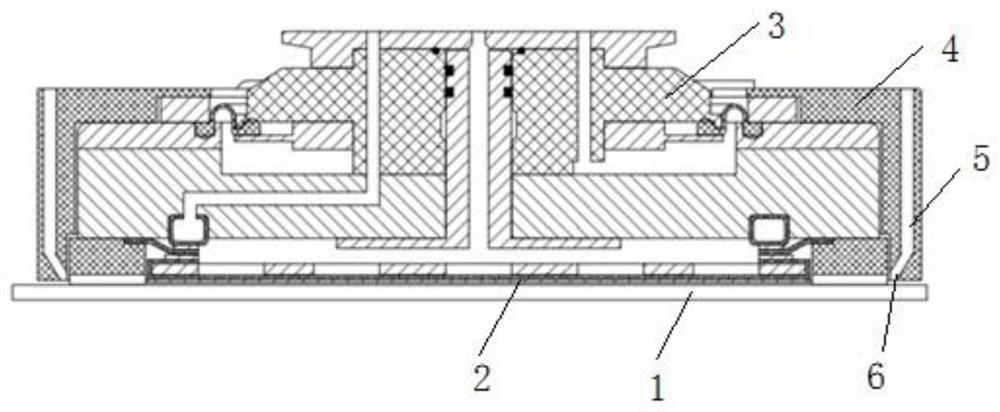

Localized jet soldering device and partial jet soldering method

ActiveCN102365910AControllable speedHighly stablePrinted circuit assemblingMetal working apparatusSpray nozzleEngineering

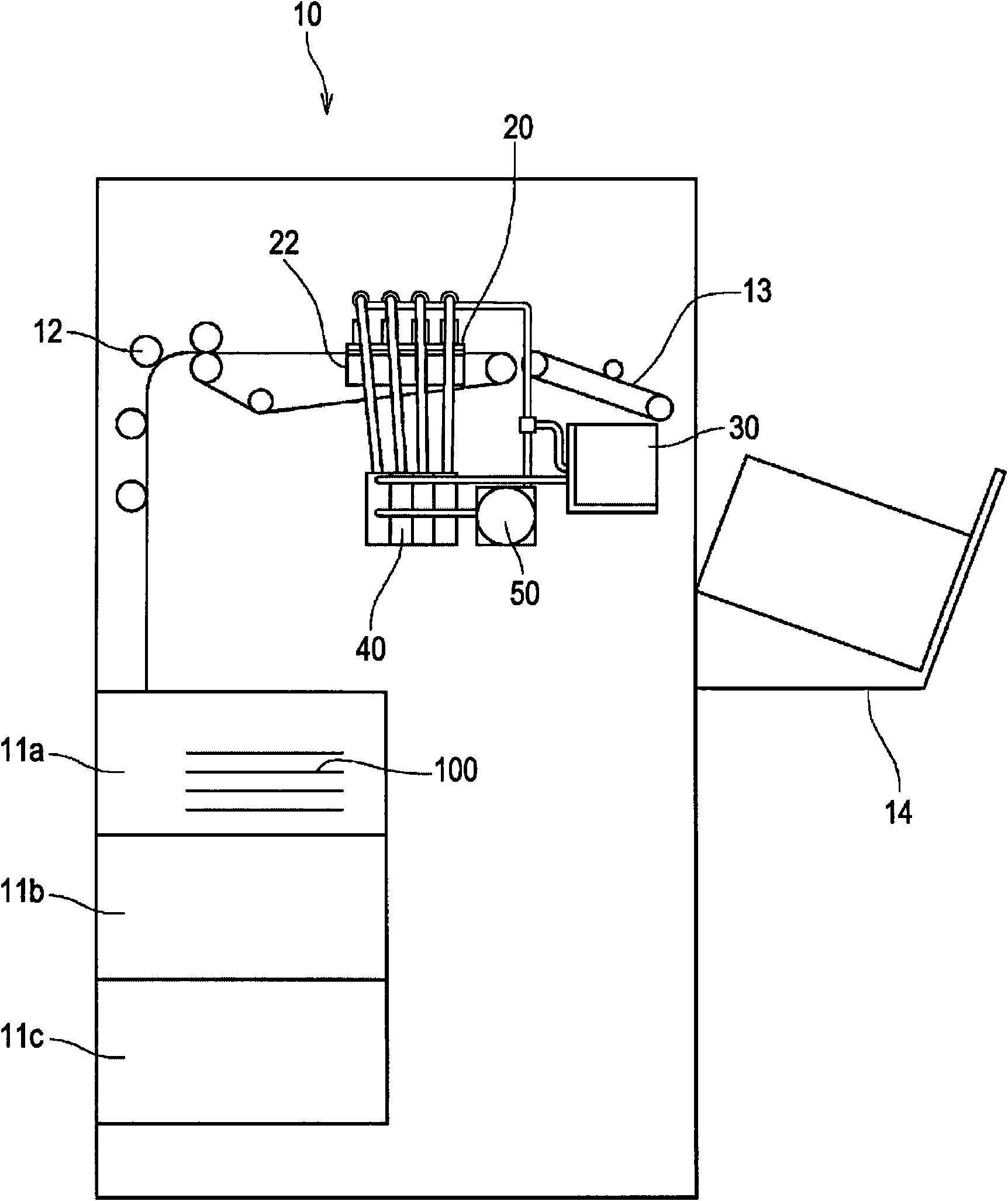

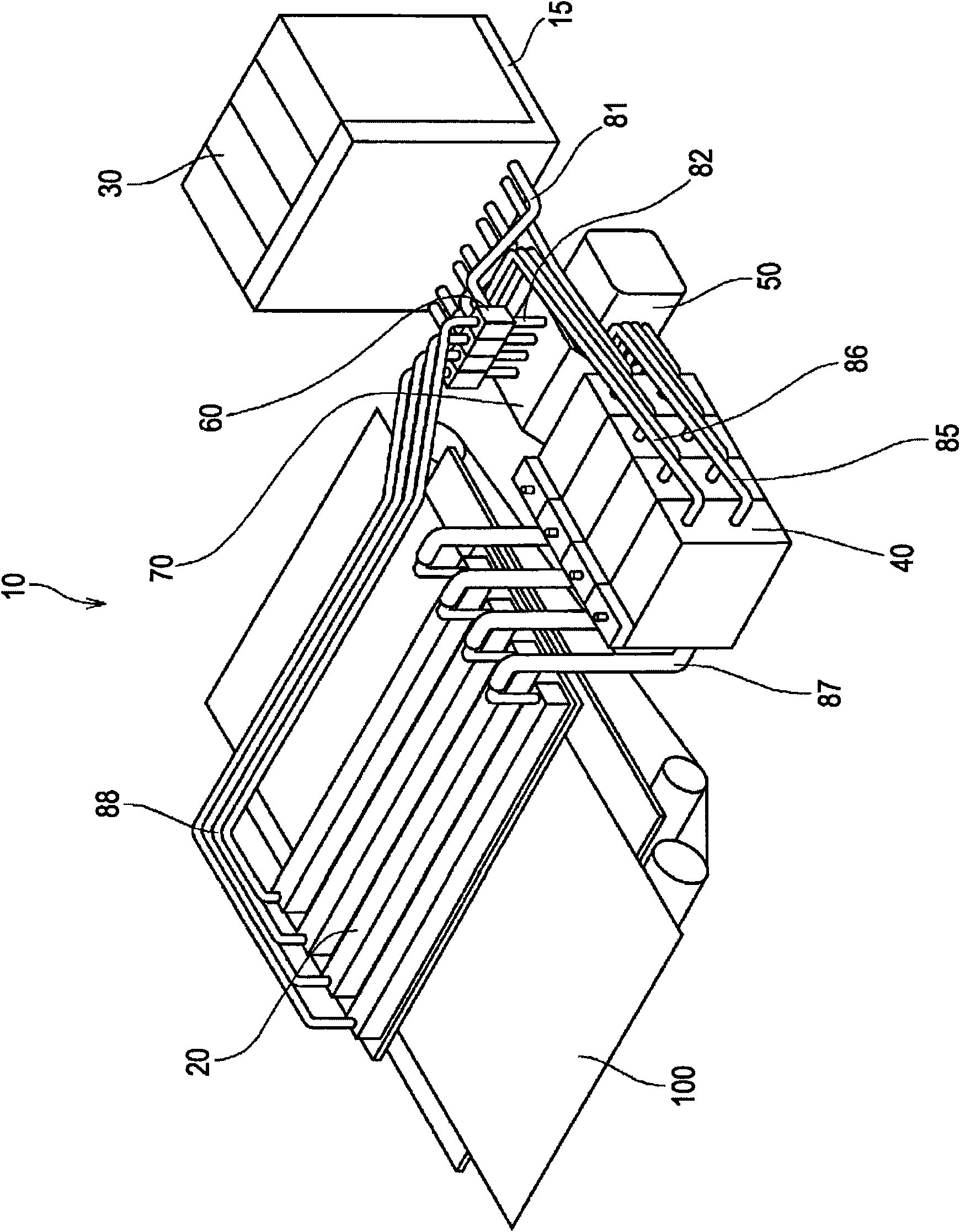

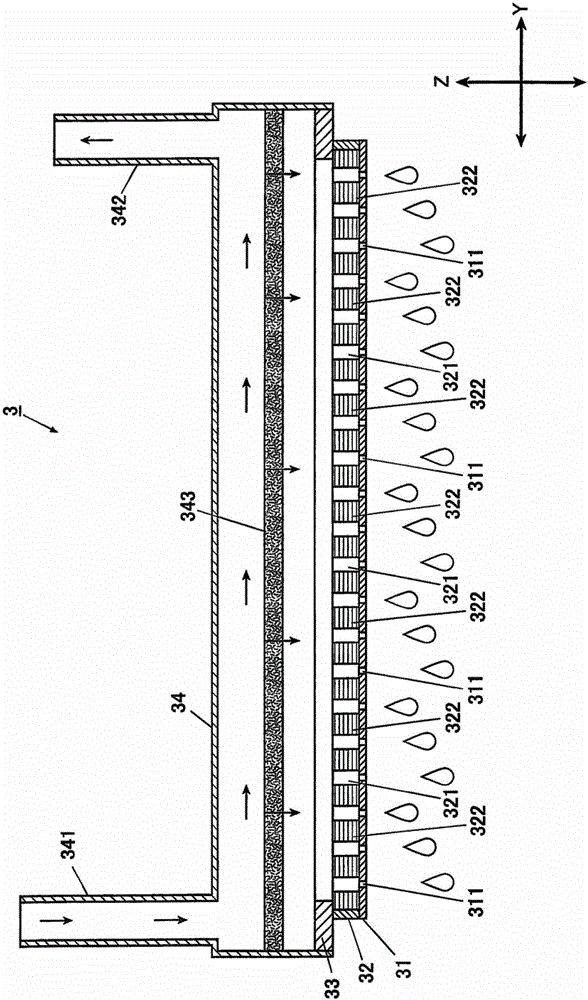

Even when a nozzle with a small aperture is used in a localized jet solder tank, molten solder can be jetted locally and stably into a component mounted member, without lowering the rotational frequency of a pump in said localized jet solder tank which is difficult to set. As shown in figure 3, the localized jet automatic soldering device (100) is provided with a solder tank (4), which has a nozzle base (44) and contains molten solder (7); a pump (5), which brings the molten solder (7) in the solder tank (4) to a predetermined pressure, and supplies said solder (7) to the nozzle base (44); a plurality of nozzles (8a, etc.) with a predetermined solder ejection area connected to the nozzle base (44), and which eject the molten solder (7) supplied by the pump (5) at a predetermined pressure,such that said solder (7) builds up due to surface tension; and a dummy nozzle (32) connected to the nozzle base (44) with a solder ejection area larger than that of said nozzles (8a, etc.), and which ejects molten solder (7) supplied by the pump (5) at a predetermined pressure. The dummy nozzle (32) is disposed at a location closer to the pump (5) than the abovementioned nozzles (8a, etc.).

Owner:SENJU METAL IND CO LTD

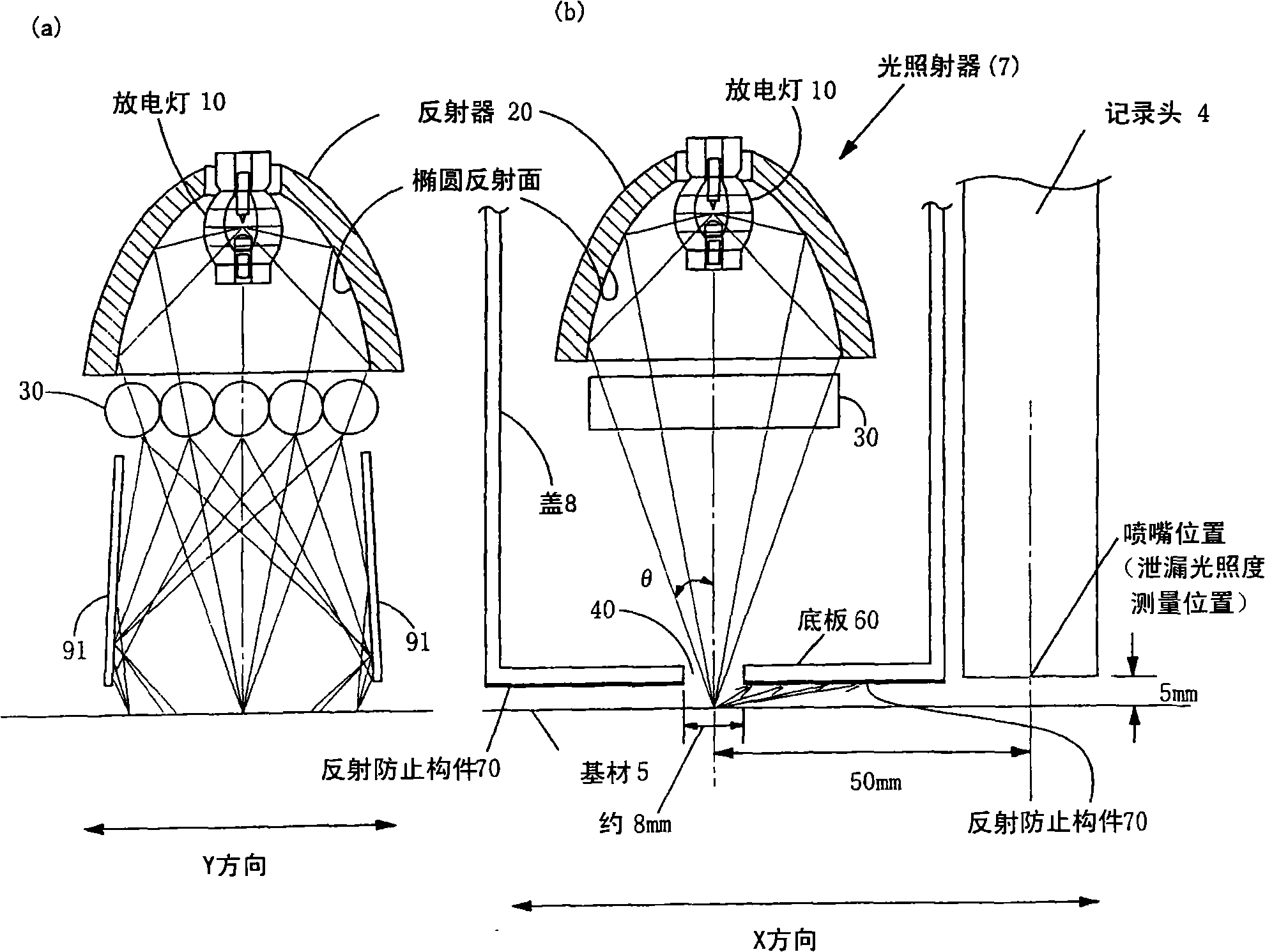

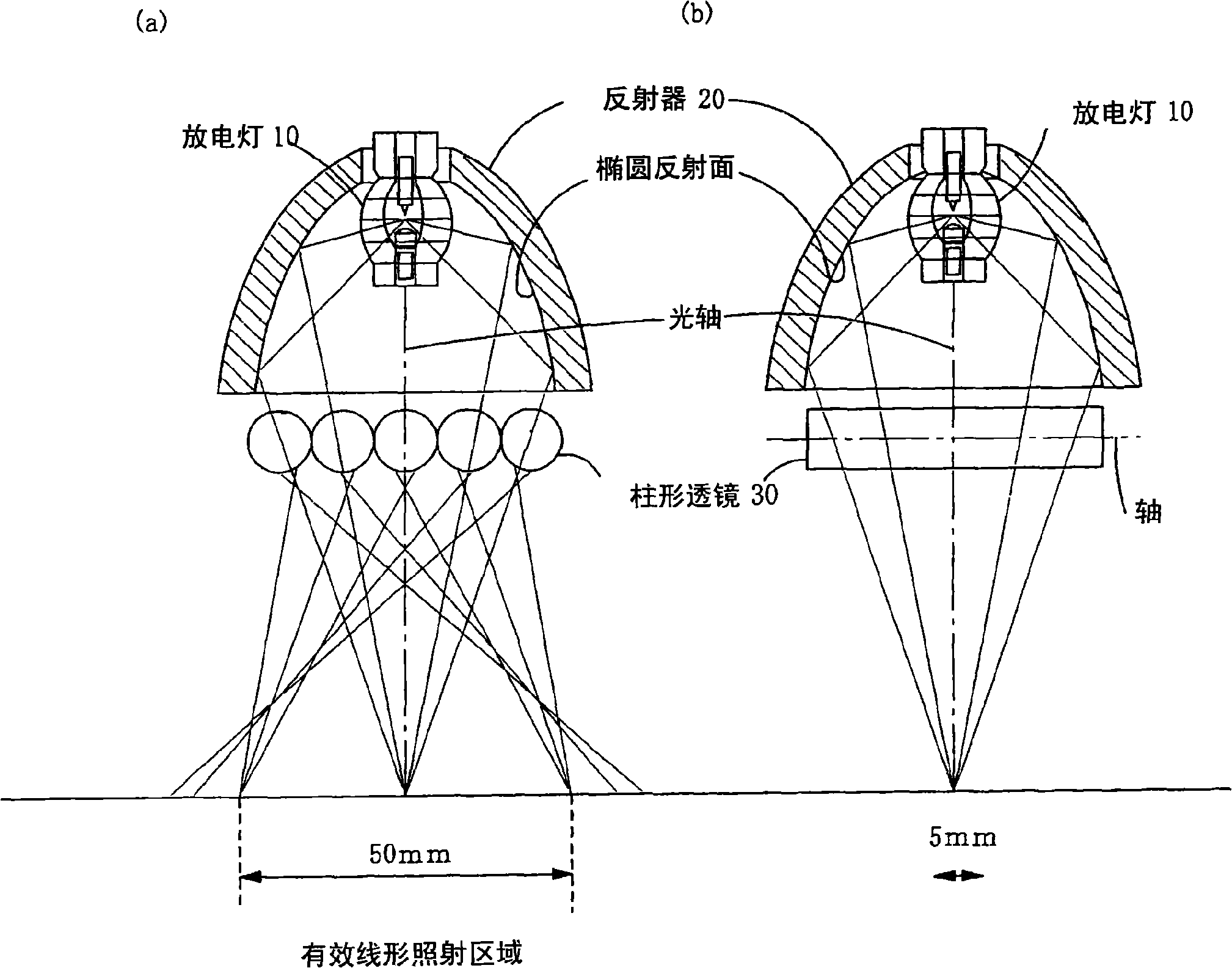

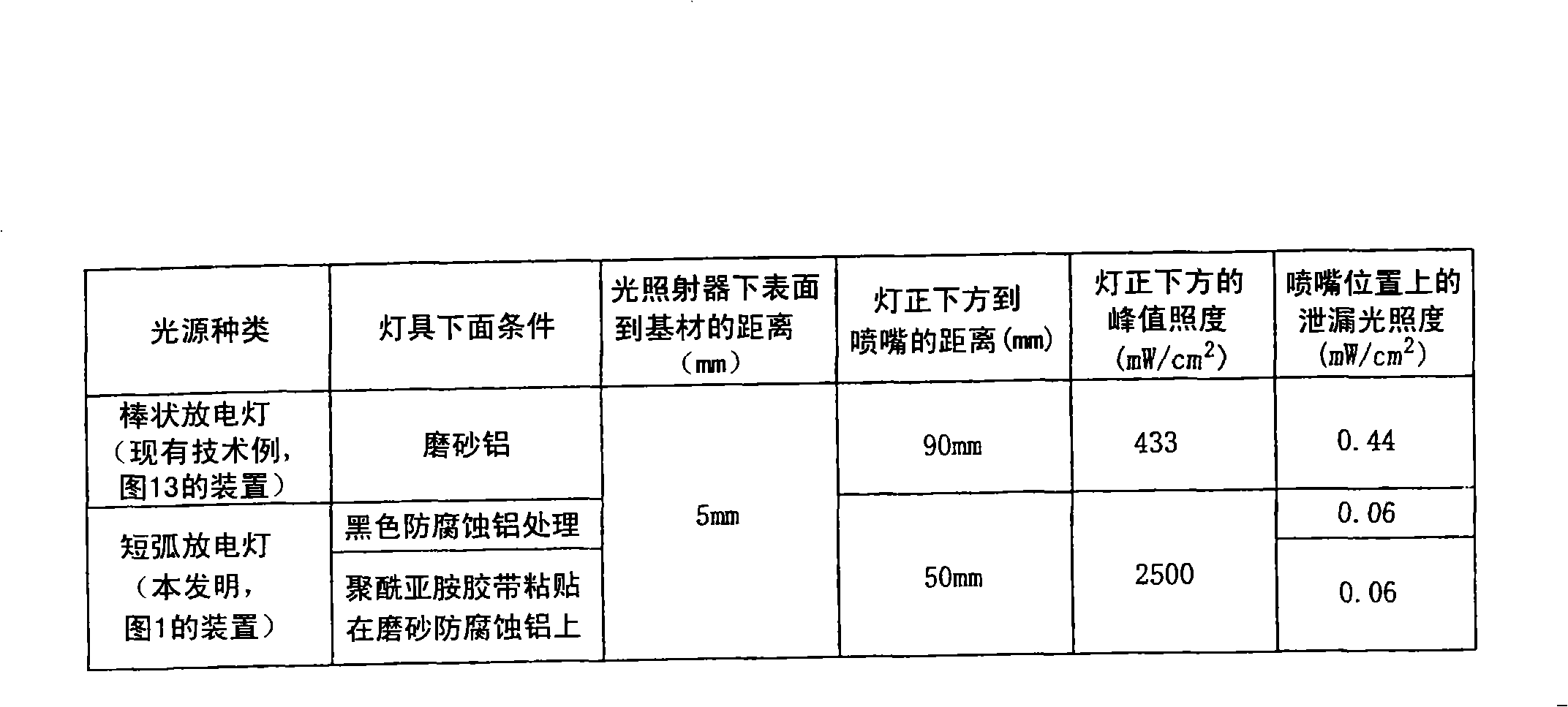

A light irradiator and a printer using the light irradiator

InactiveCN101357533AAvoid absorptionLess quantityGas discharge lampsTypewritersOptoelectronicsPhysics

The invention relates to an optical irradiator and a printer using the same, to prevent clogging of a nozzle of a printing head, a light irradiator for an ink jet printer is composed of a short arc type discharge lamp (10) and optical elements used for linearly condensing light from the lamp (10), e.g., an elliptic light condensing mirror (20) and a rod lens (30) in order to linearly condense light emitted from the lamp onto a substrate (5). A slit-type light outlet (40) is provided on a bottom plate (60) of a housing (8) so that the direct light from the lamp cannot reach places on the substrate (5) in the vicinity of the nozzle (4) of a printing head (4), and antireflection material (70) is provided on the surface of the bottom plate (60) facing the substrate (5) so that the light emitted from the light irradiator and reflected by the substrate (5) can be absorbed by the antireflection material (70).

Owner:USHIO DENKI KK

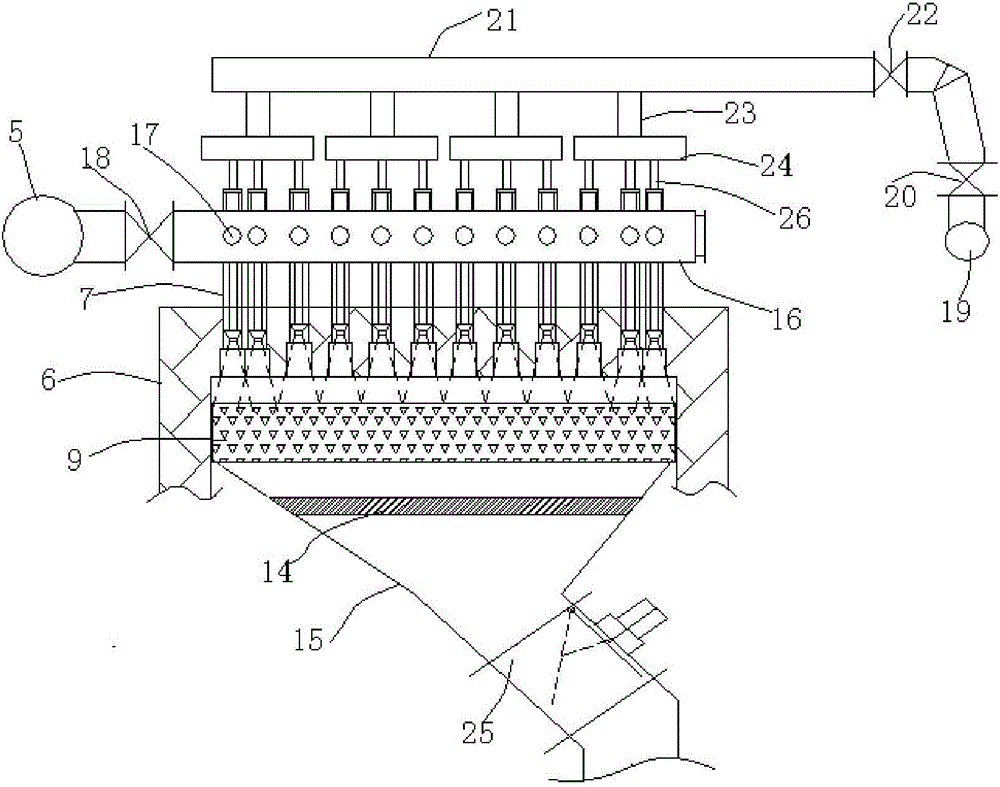

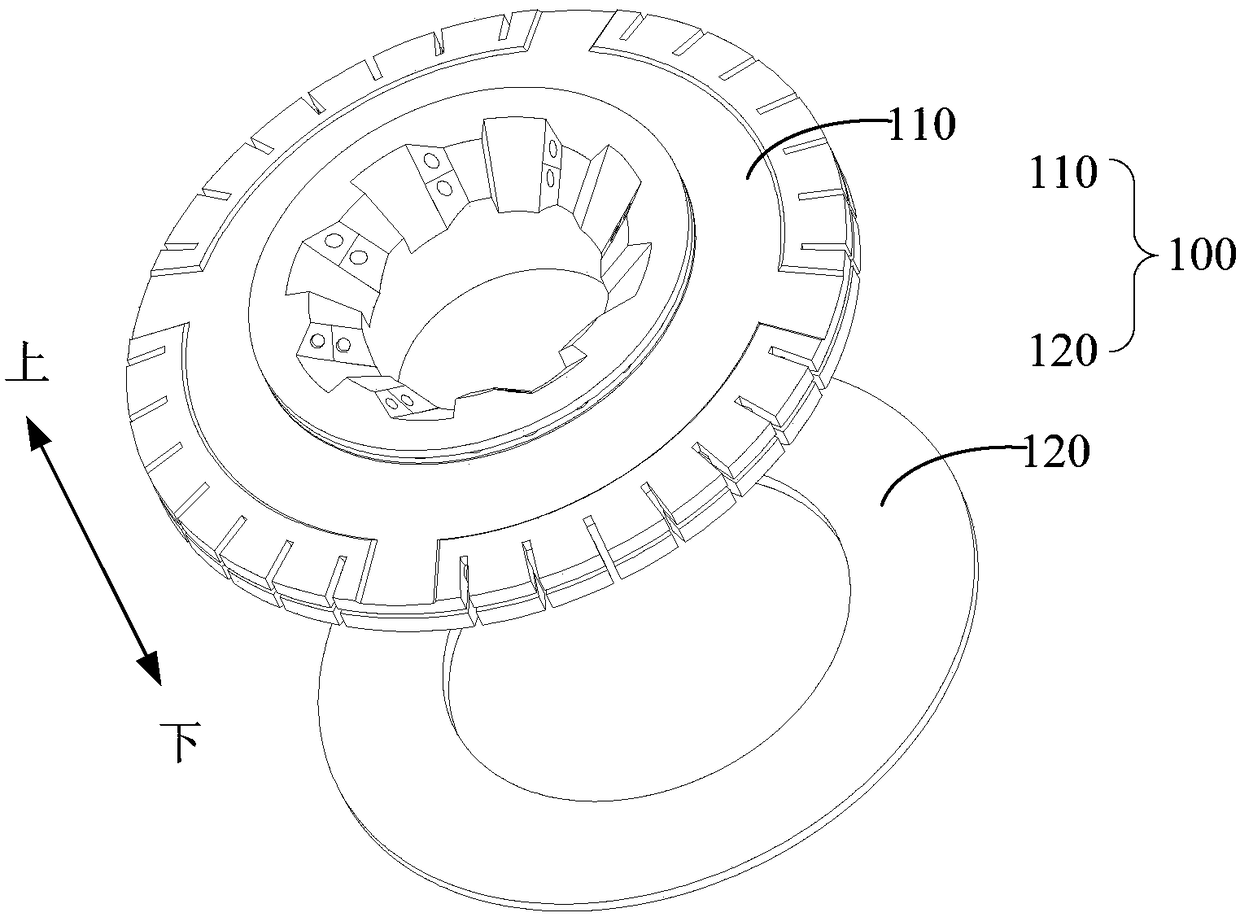

Igniting device and ignition method for sintering

ActiveCN106440811AImprove distributionBalanced sinter ignition qualityFuel lightersFurnace typesEngineeringEnergy conservation

The invention discloses an igniting device and an ignition method for sintering and belongs to the field of iron smelting of a blast furnace. The igniting device disclosed by the invention comprises an ignition furnace, a gas charging pipe and a hot air charging pipe; a row of burner nozzles are arranged on a part, at an ignition section of the ignition furnace, of the furnace top; the middle burner nozzles are arranged linearly; the burner nozzles close to the two sides of a sintering machine trolley are arranged in an arc shape; each burner nozzle communicates with the gas charging pipe and the hot air charging pipe respectively; the parts, at the front end and the rear end of the ignition section, of the furnace top are each provided with an isolation chamber; each isolation chamber communicates with the hot air charging pipe; an air box is arranged at the bottom of the ignition furnace, wherein a retarder is arranged inside the air tank under the burner nozzles. The igniting device disclosed by the invention has the advantages of optimizing distribution of an igniting fuel on an overall sintering material surface, balancing the ignition quality of sintering materials at all positions of a sintering machine, improving the quality of sintered ore products, also enhancing the ignition effect, reducing consumption of the igniting fuel and satisfying the production process requirements on energy conservation and environmental protection.

Owner:MAANSHAN IRON & STEEL CO LTD

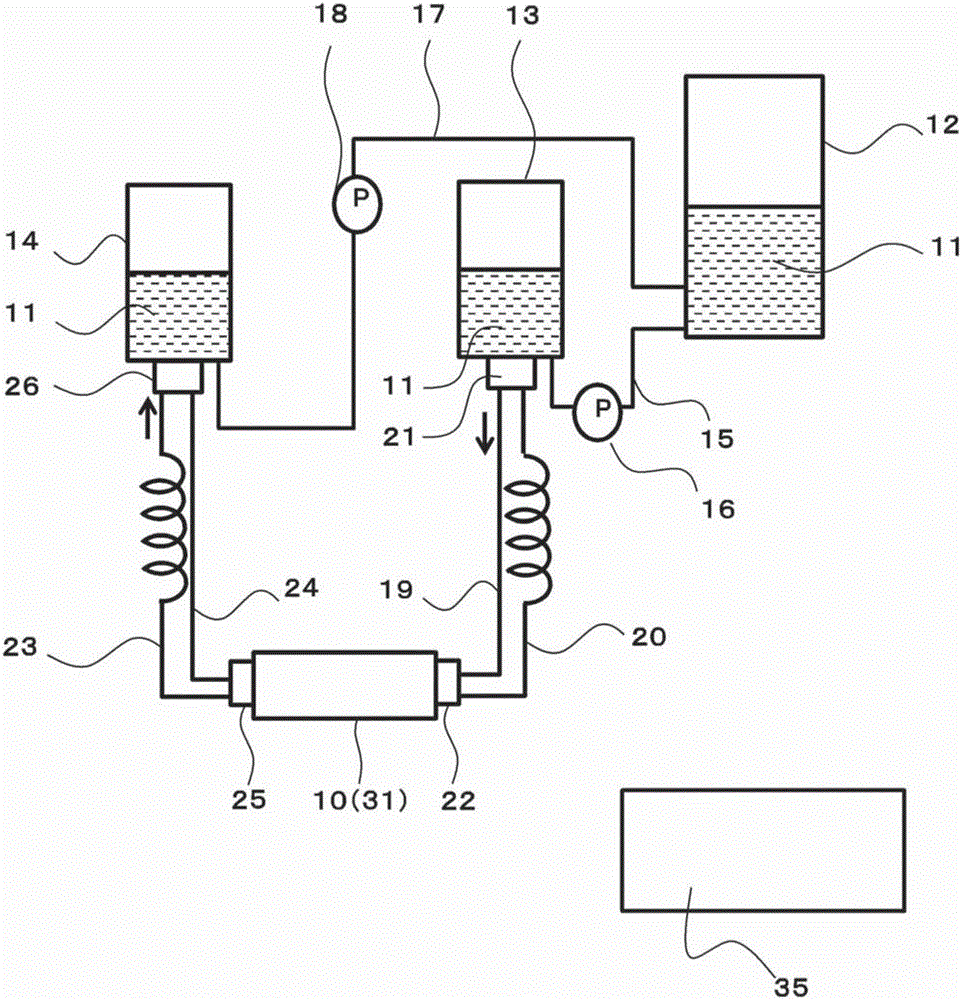

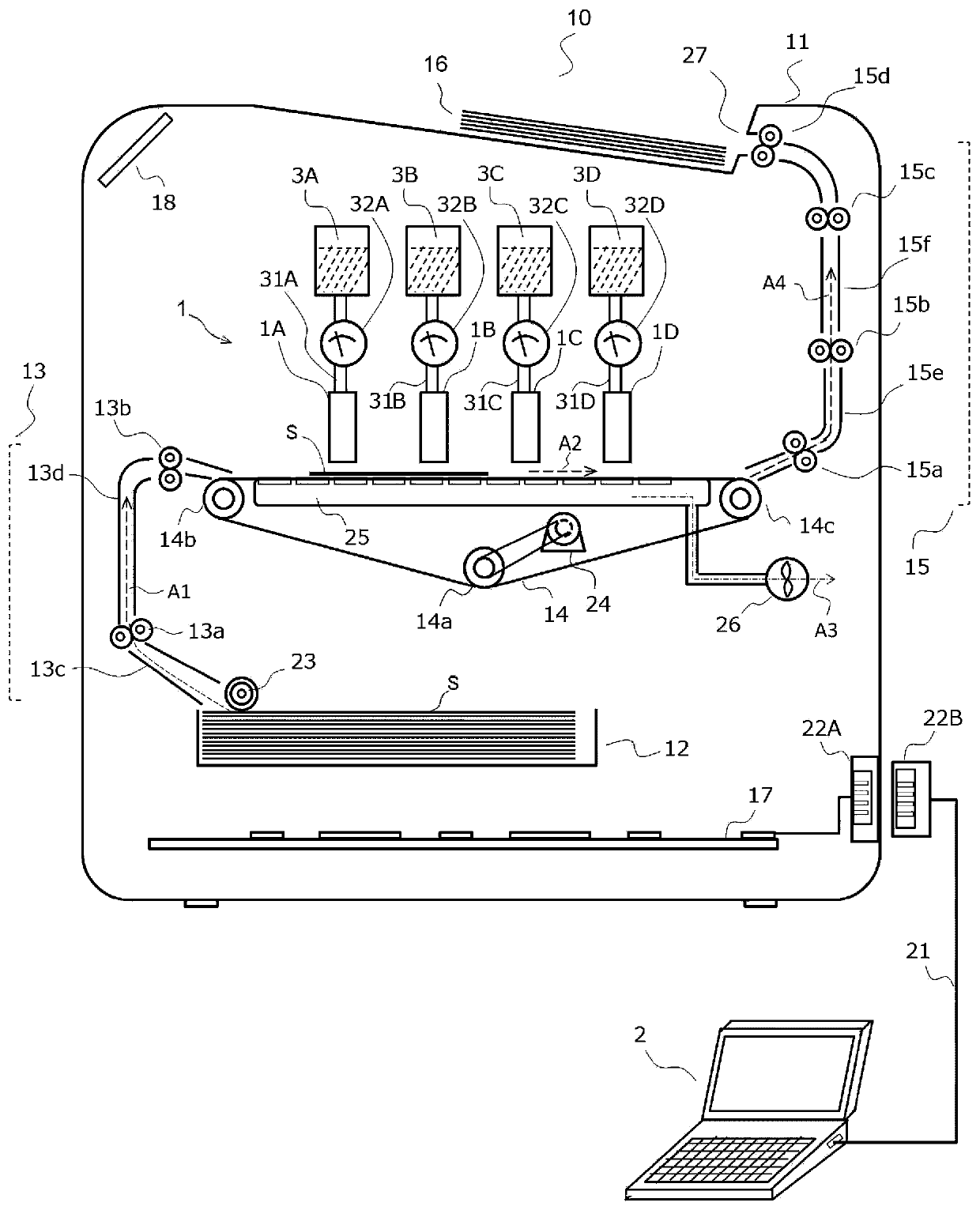

Ink supply device and ink supply method for inkjet recording apparatus

ActiveCN103057272AAvoid situations where actions are interruptedQuick switchPrintingAir bubbleWaste management

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

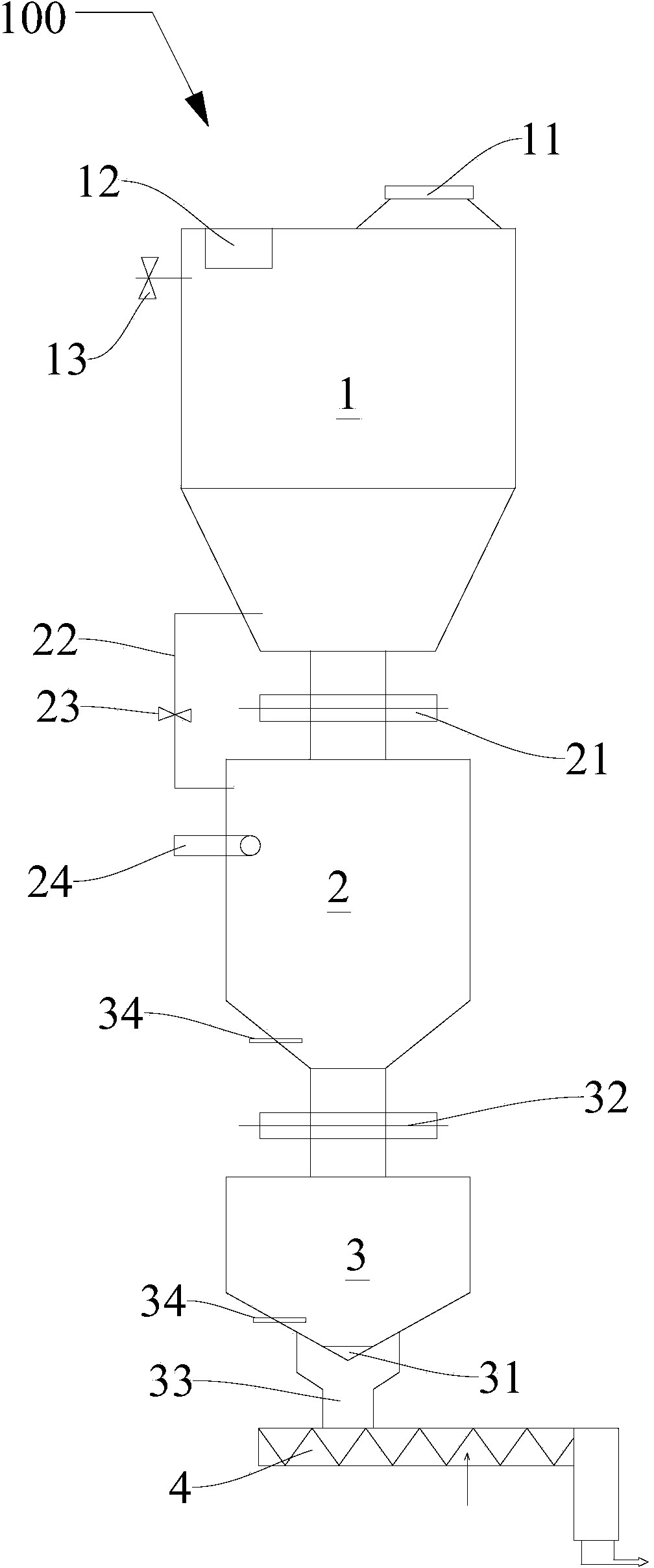

Continuous scab removal sand feeding device and titanium white chlorination production device with same

The invention discloses a continuous scab removal sand feeding device and a titanium white chlorination production device with the same. The continuous scab removal sand feeding device comprises a charging material tank with a charging hole, a pressure release valve and a sensor for detecting the material capacity, a middle material tank arranged at the downstream part of the feeding material tank, and a feeding material tank which is arranged at the downstream part of the middle material tank and is provided with a discharging hole, wherein a first discharging valve for connecting the charging material tank with the middle material tank and disconnecting the charging material tank from the middle material tank is arranged between the charging material tank and the middle material tank; a discharging adjustment device for adjusting the material conveying quantity is arranged at the discharging hole; a second discharging valve for connecting the middle material tank with the feeding material tank and disconnecting the middle material tank from the feeding material tank is arranged between the middle material tank and the feeding material tank. According to the continuous scab removal sand feeding device disclosed by the embodiment of the invention, the scab removal sand conveying quantity can be accurately adjusted, and scab removal sand can be continuously and stably discharged.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

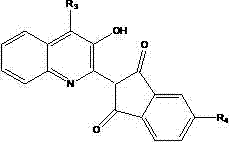

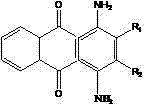

Surfactant for uncoated thermal transfer ink, uncoated thermal transfer ink and preparation method of surfactant

The invention discloses and provides a surfactant for an uncoated thermal transfer ink, the uncoated thermal transfer ink and a preparation method of the surfactant. The surfactant for the uncoated thermal transfer ink is capable of reducing the cost of thermal transfer paper, reducing the usage amount of ink, and improving the heat transfer rate and the color concentration of the ink. The uncoated thermal transfer ink is prepared from the following raw materials in parts by weight: 20-40 parts of non-azo disperse dyes, 5-40 parts of an organic solvent, 1-10 parts of a surfactant, 0.05-1 part of a pH modifier, 0.05-1 part of a buffering agent, 0.01-0.3 part of a preservative, 0.1-1 part of an emulsifier, 0.05-1 part of a chelating agent and 20-50 parts of water; the surfactant is a polyoxyethylene polyoxypropylene copolymer; the preparation method of the uncoated thermal transfer ink comprises the following steps: firstly, stirring an organic solvent mixed with water; adding the surfactant, stirring for 30 minutes to be full and uniform; adding the pH modifier, the buffer agent, the preservative, the emulsifier and the chelating agent, stirring for 30 minutes to be full and uniform; adding the non-azo disperse dyes, stirring for 2 hours to be full and uniform; and filtering with 1.0micron of filter membrane, thus obtaining the thermal transfer ink.

Owner:珠海欣威科技有限公司

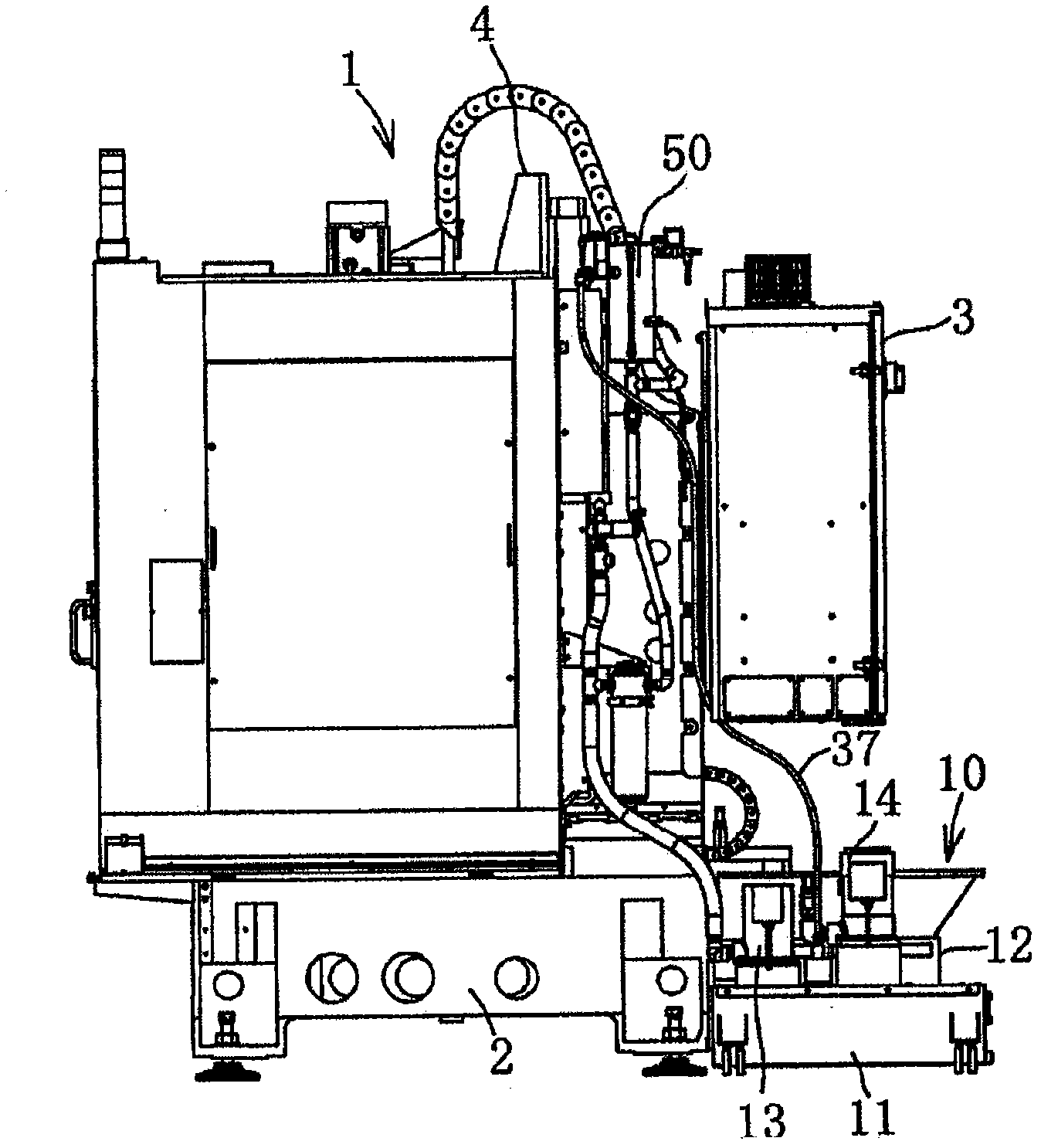

Tool cleaning device

ActiveCN102049702AImprove responsivenessSteady ejectionMaintainance and safety accessoriesEngineeringNozzle

The invention provides a tool cleaning device which comprises an accumulating part at the middle of a cleaning fluid path. The accumulating part accumulates the cleaning fluid flowing in the cleaning fluid path. The tool cleaning device comprises a pressurization path for pressurizing the interior of the accumulating part. When a tool and a tool retainer are cleaned, the cleaning fluid in the accumulating part is sprayed out from a cleaning fluid jet nozzle. A great amount of cleaning fluid is sprayed out from the cleaning fluid jet nozzle with less resistance. When the cleaning is completed,the closing of a feed flow valve arranged at the cleaning fluid path is later than the closing of a pressurization valve arranged at the pressurization path. The cleaning fluid jet nozzle continues to inject after the releasing of pressurization. The tool and the tool retainer can be cleaned reliably by the cleaning fluid from the cleaning fluid jet nozzle. The tool cleaning device can effectively prevent the poor installation of the tool and the tool retainer.

Owner:BROTHER KOGYO KK

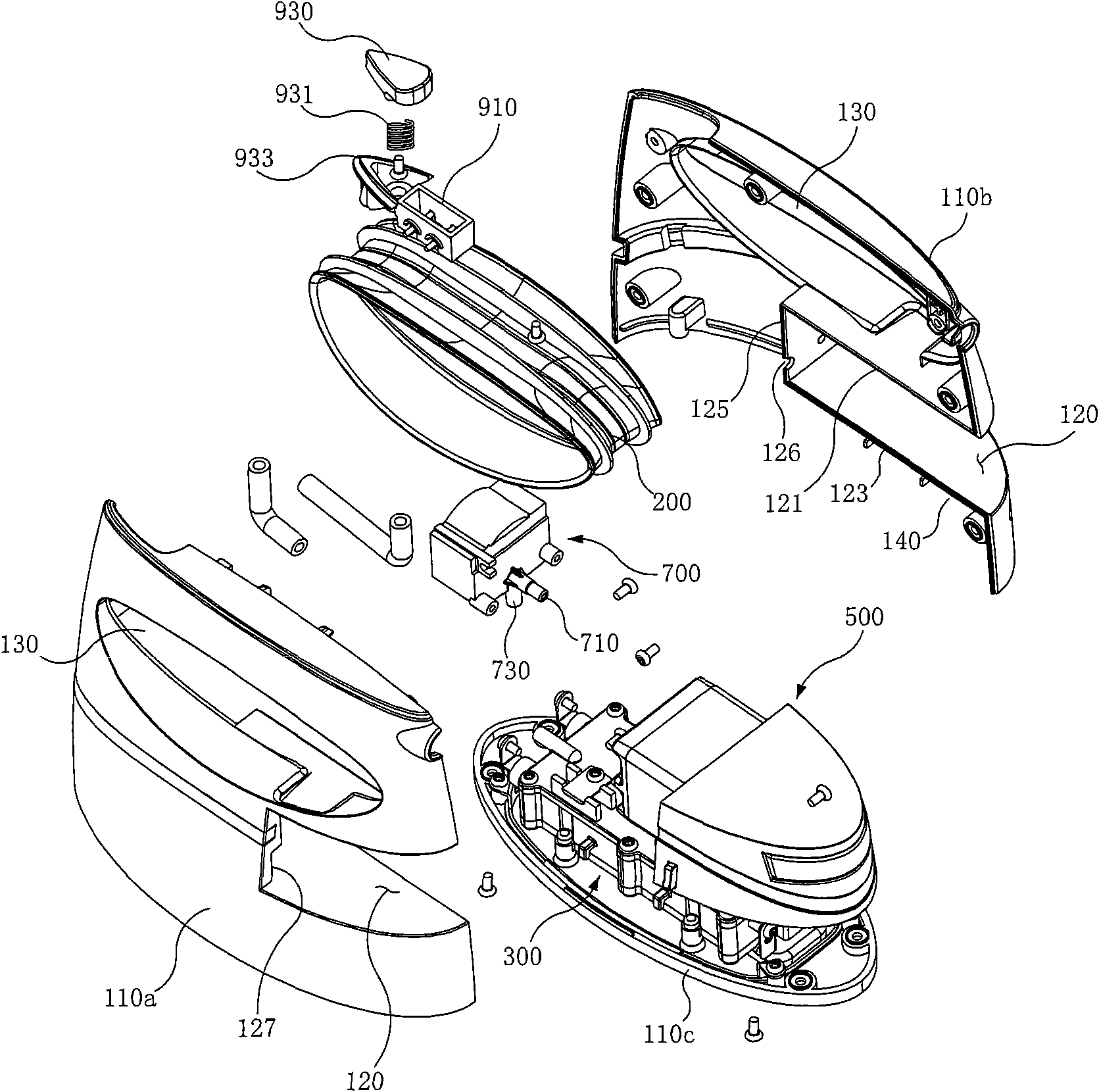

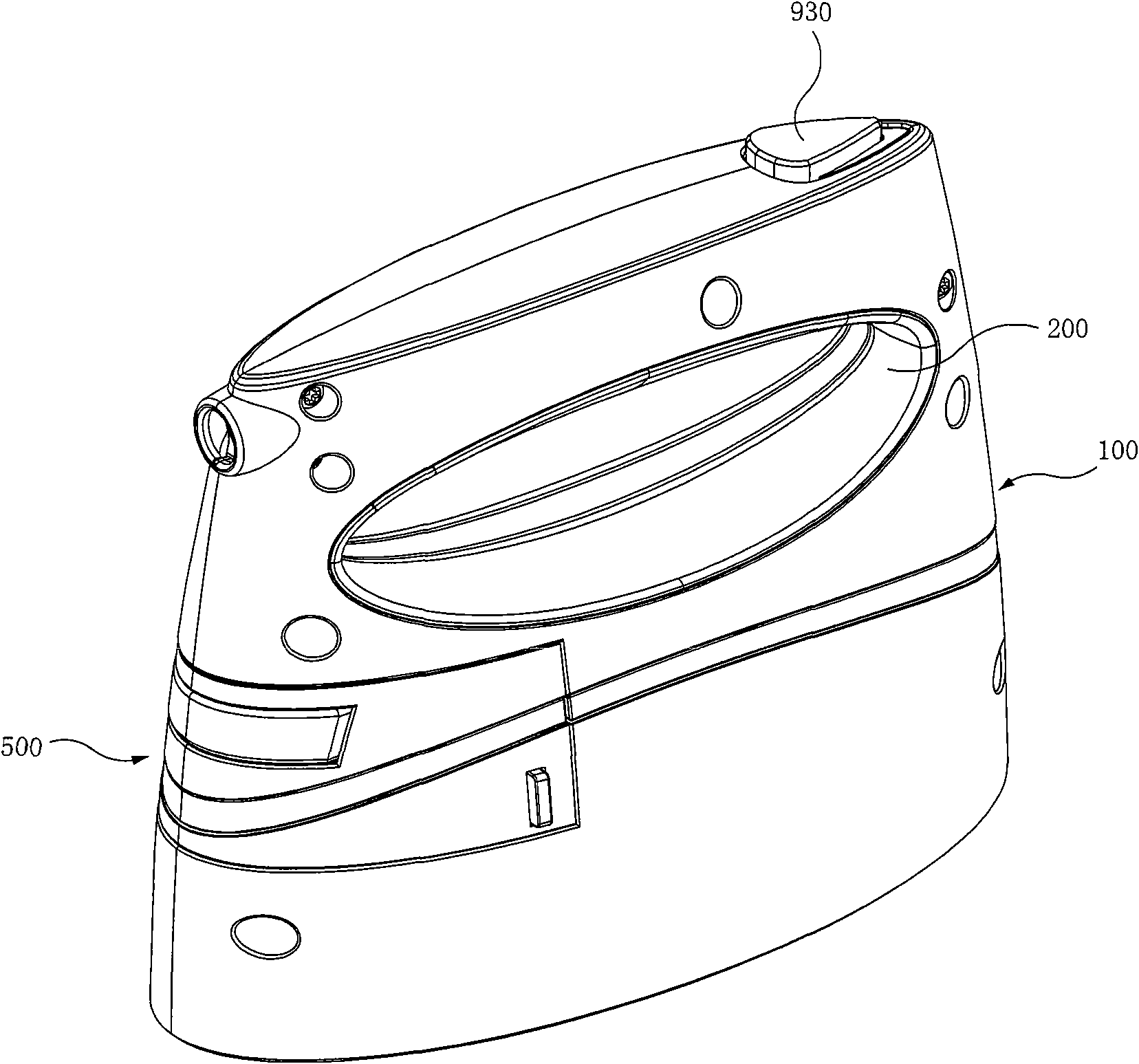

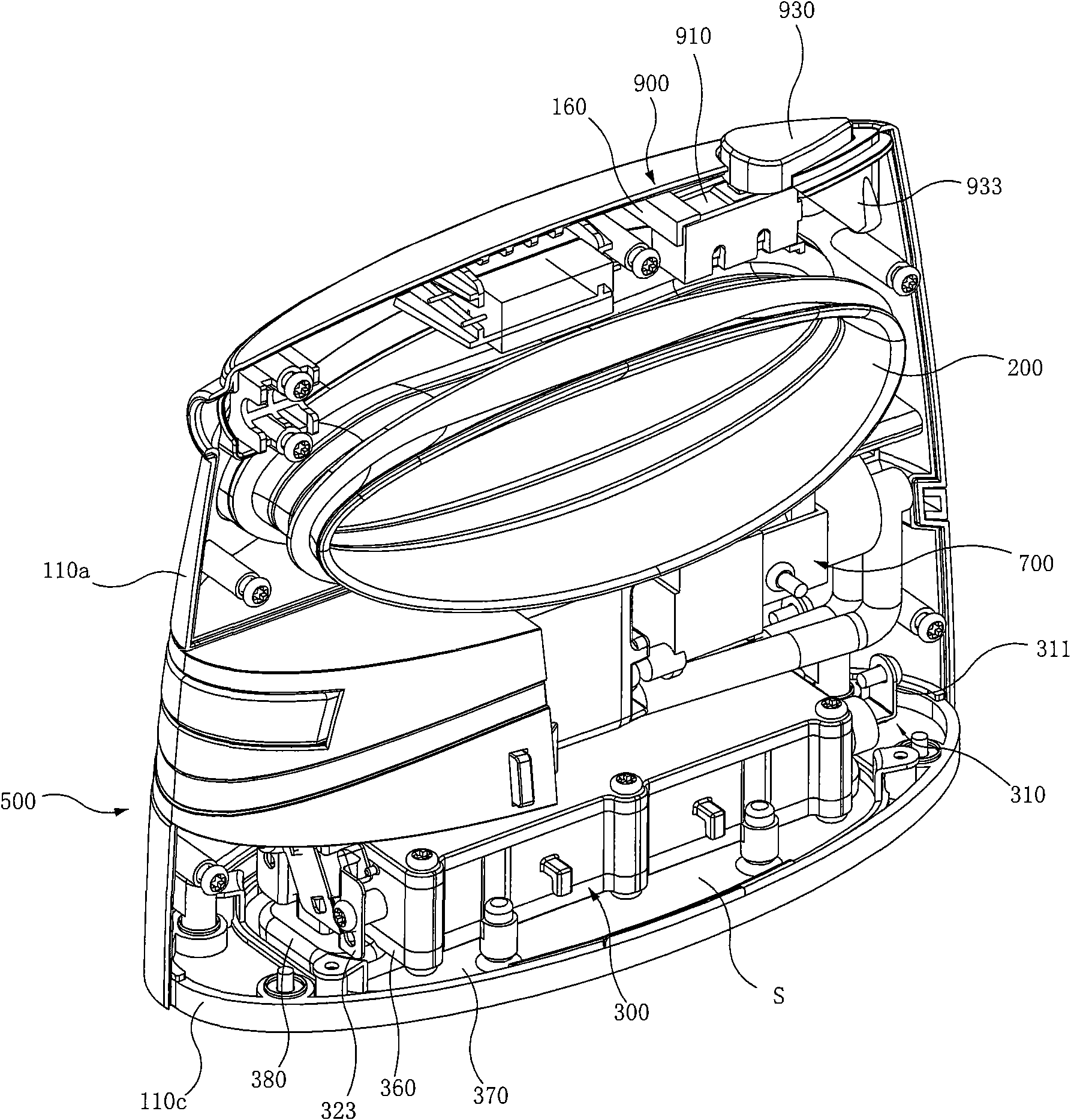

Electric steam iron

InactiveCN101880954AImprove assembly efficiencySteady ejectionIroning padsHand ironEngineeringWater tanks

The present invention relates to an electric steam iron, including a water tank module for storing water, a rapid heater module for injecting the water stored in the water tank module in steam, an electric pump for pumping the water stored in the water tank module to the rapid heater module, a handle, and a control part for controlling the rapid heater module and the electric pump, also including a housing for mounting the water tank module, the electric pump, the rapid heater module and the handle. The handle and the electric pump are assembled to the housing, such that the assembly efficiency of accessories may be improved, and steam injection function is optimized due to stability of the electric pump.

Owner:SUZHOU HAAN TECH +1

steam generator

The invention provides a steam generator, which comprises a heating shell, wherein the heating shell is provided with a water inlet and an air outlet; a W-shaped heating pipe is arranged in the inner cavity of the heating shell; an airflow guide baffle is arranged on the inner wall of the heating shell; the W-shaped heating pipe and the airflow guide baffle are arranged in an overlapping mode. According to the steam generator disclosed by the invention, the thermal efficiency of the device is higher due to the structural design of an inner runner and the inner design of the heating shell, the temperature of the ejected steam is higher, and the airflow of the ejected steam is guaranteed. Meanwhile, the device has the advantages of smaller size, light weight, wider application range and lower cost.

Owner:QINGDAO YUNLU ENERGY TECH

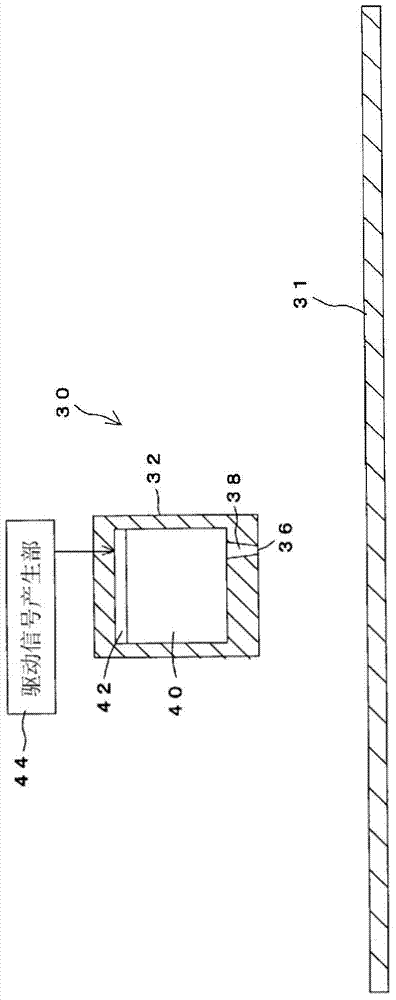

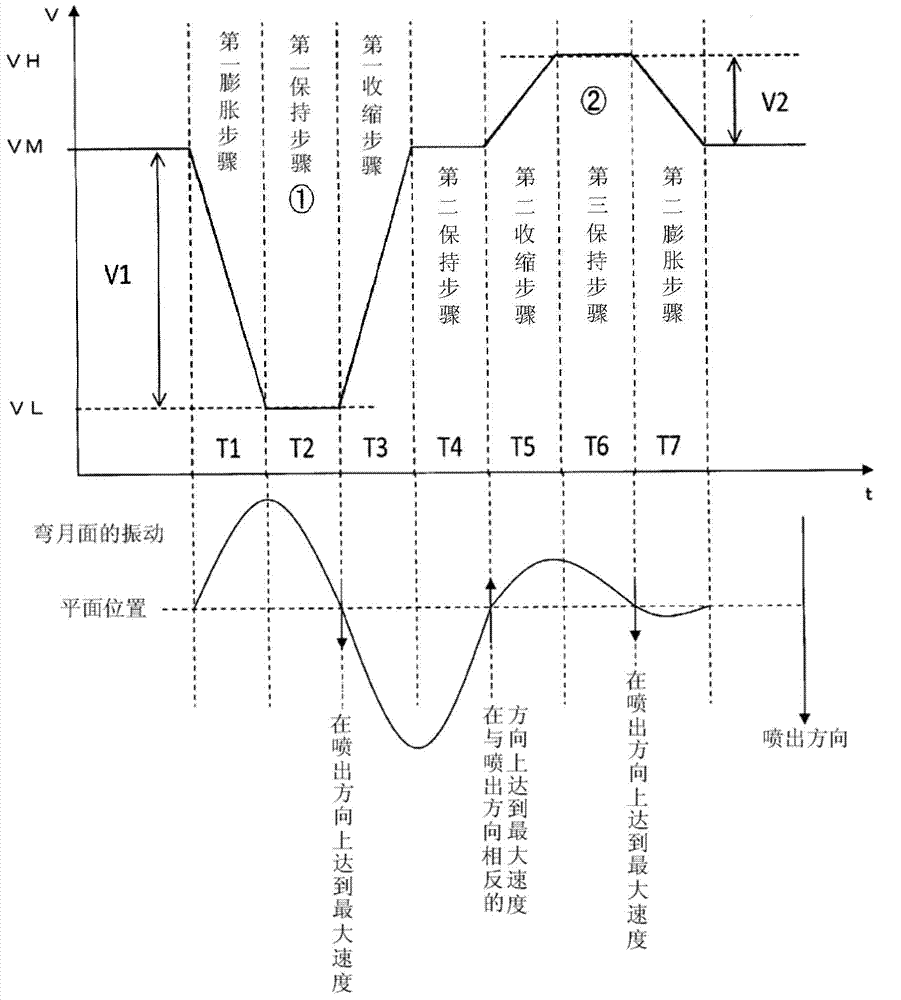

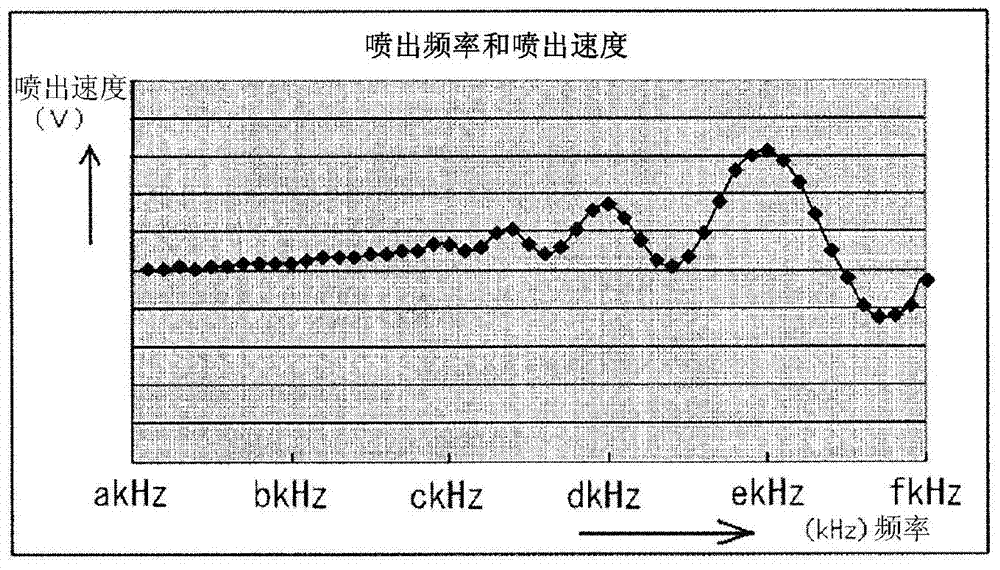

Inkjet recording device

Provided is an inkjet recording device that, no matter what sort of ink the ink is, prevents residual oscillation of the ink, thereby preventing permeation of the ink at an opening section, and can stably cause the continuous discharge of the ink. The inkjet recording device (30) is equipped with: a recording head (32) at which a nozzle (38) is formed having a pressure chamber (40), which houses ink, and an opening section (36) that causes the discharge of ink and interconnects with the pressure chamber (40); a piezoelectric element (42) configuring a portion of the pressure chamber (40); and a drive signal generation unit (44) that inputs a drive signal to the piezoelectric element (42), altering the volume of the pressure chamber (40). The drive signal generation unit (44) generates the drive signal in a manner so as to cause the execution of: a first expansion step for causing the expansion of the pressure chamber (40); after the first expansion step, a first contraction step for causing the contraction of the pressure chamber to cause the discharge of ink; and after the first contraction step, a second contraction step for causing the contraction of the pressure chamber at a timing at which a meniscus is pulled in the reverse direction from the direction of discharge. The drive signal output by the drive signal generation unit (44) is set in a manner so that the electrical potential at the endpoint of the second contraction step is positioned in a range on the reverse side from the electrical potential at the starting point of the first expansion step, and is set in a manner so that the electrical potential at the starting point of the first expansion step is approximately the same as the electrical potential at the starting point of the second contraction step.

Owner:MIMAKI ENG

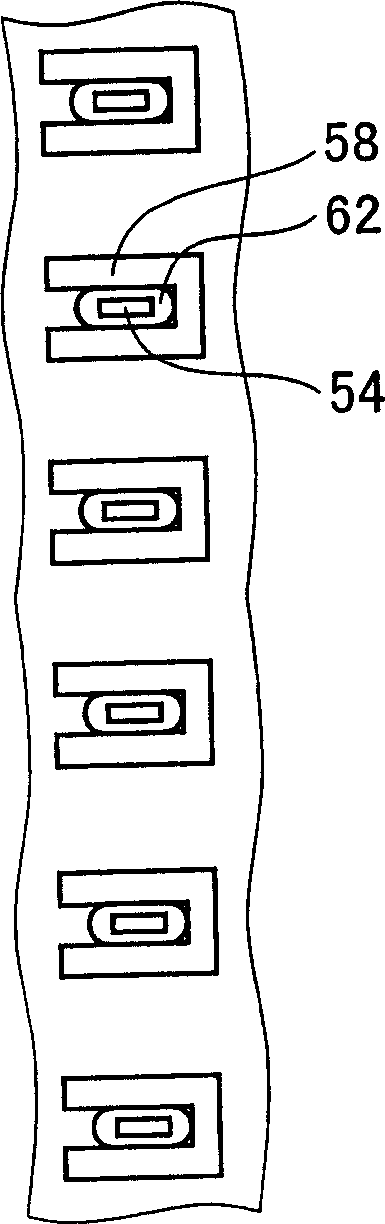

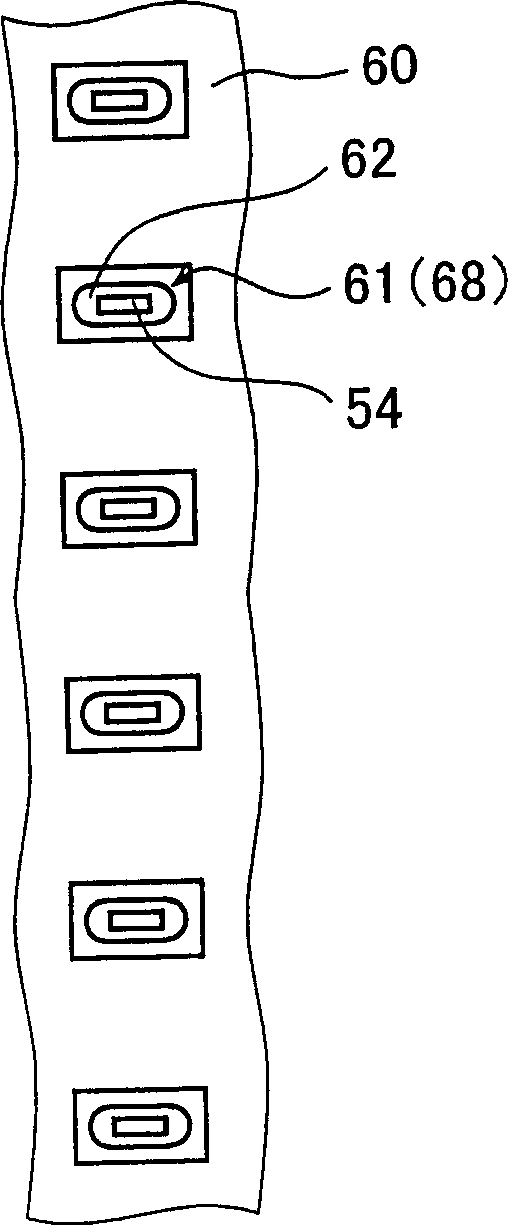

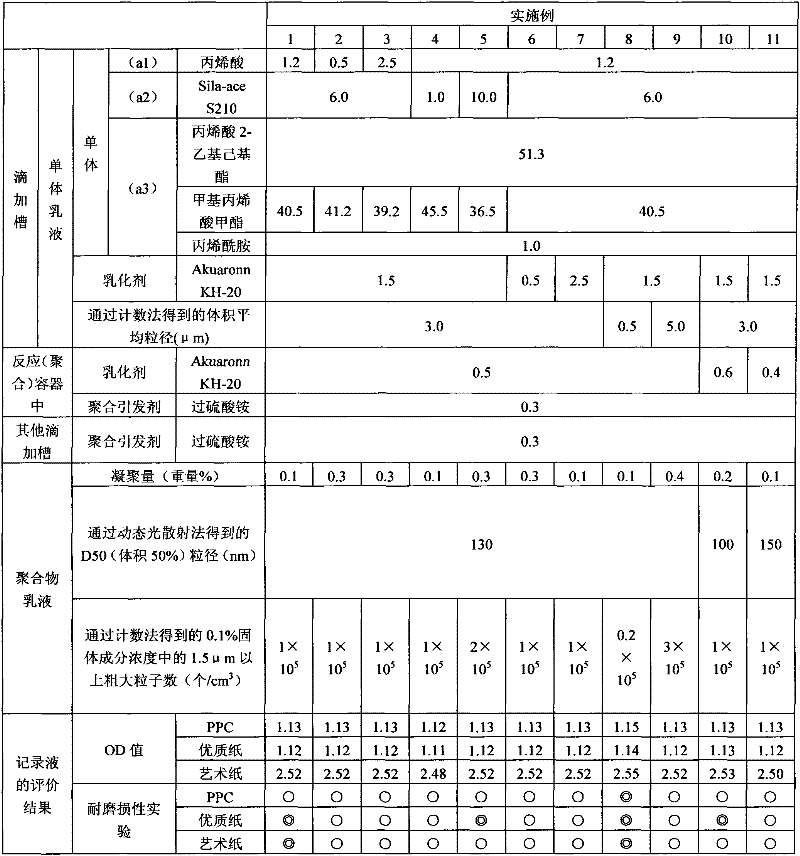

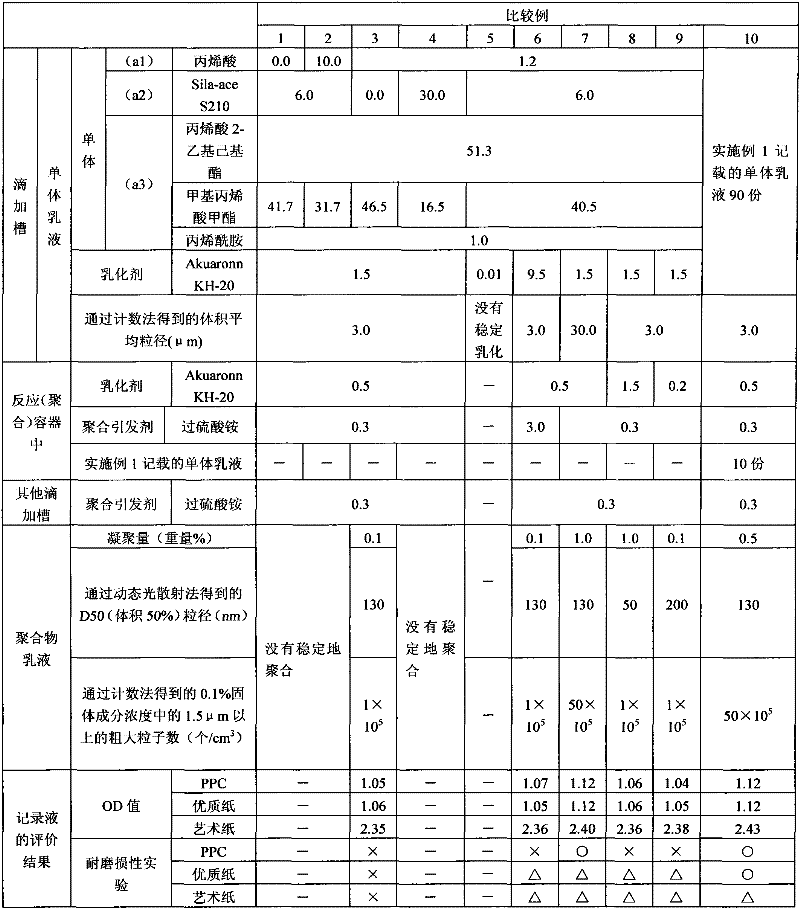

Polymer emulsion and aqueous inkjet recording liquid containing the polymer emulsion

InactiveCN102272168AImprove blockageSteady ejectionDuplicating/marking methodsInksOptical densityWear resistance

Provided is a pigmented aqueous inkjet recording liquid with which clogging of a nozzle is improved and stable discharge is possible, with said aqueous inkjet recording liquid having excellent properties-in particular, an optical density (OD) value and wear resistance-which are required of an inkjet recording liquid. This aqueous inkjet recording liquid is a polymer emulsion which is obtained by using specific amounts of an emulsifier, water, and an aqueous polymerization initiator to radical-polymerize a radical-polymerizable unsaturated monomer (a), for which a radical-polymerizable unsaturated monomer (a2) having a specific amount of an alkoxysilyl group is an essential component; wherein said recording liquid contains a pigment and a polymer emulsion in which, according to the particle counting method, the number of 1.5 [mu]m or larger ultra-coarse particles in the polymer emulsion when converted to a solid content concentration 0.1% is 5.0*105 / cm3.

Owner:TOYO INK SC HLDG CO LTD

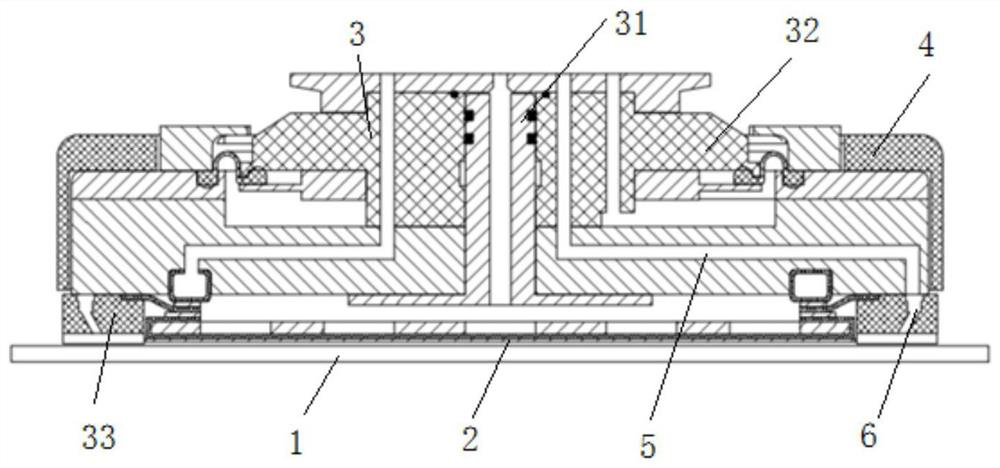

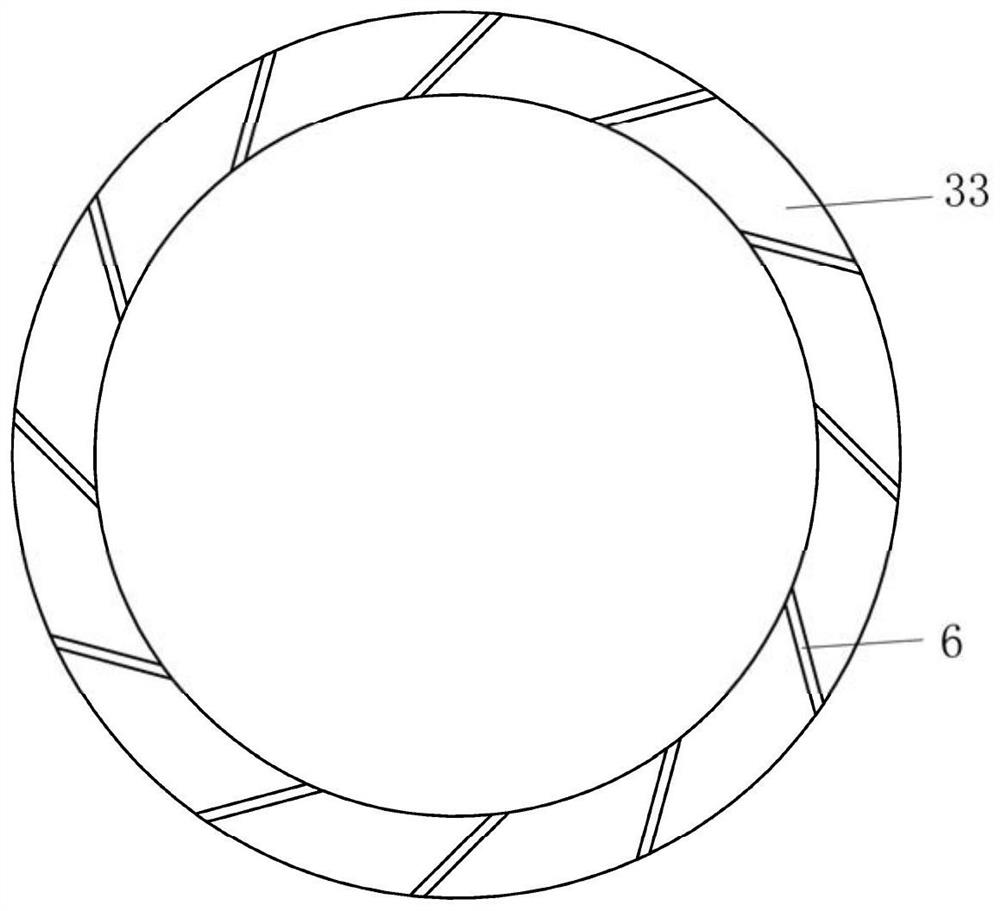

Polishing device and chemical mechanical planarization equipment

ActiveCN111958479AGuaranteed stabilitySteady ejectionLapping machinesWork carriersEngineeringMechanical engineering

The invention relates to the technical field of semiconductor equipment, in particular to a polishing device and chemical mechanical planarization equipment. The polishing device comprises a main bodyand a protective cover arranged outside the main body, an infusion assembly is located in the main body and / or the protective cover, the infusion assembly is provided with at least one liquid outlet,and liquid sprayed from the liquid outlet is uniformly distributed on the contact area of a polishing pad. The polishing device and chemical mechanical planarization equipment can improve the surfaceuniformity of a wafer.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

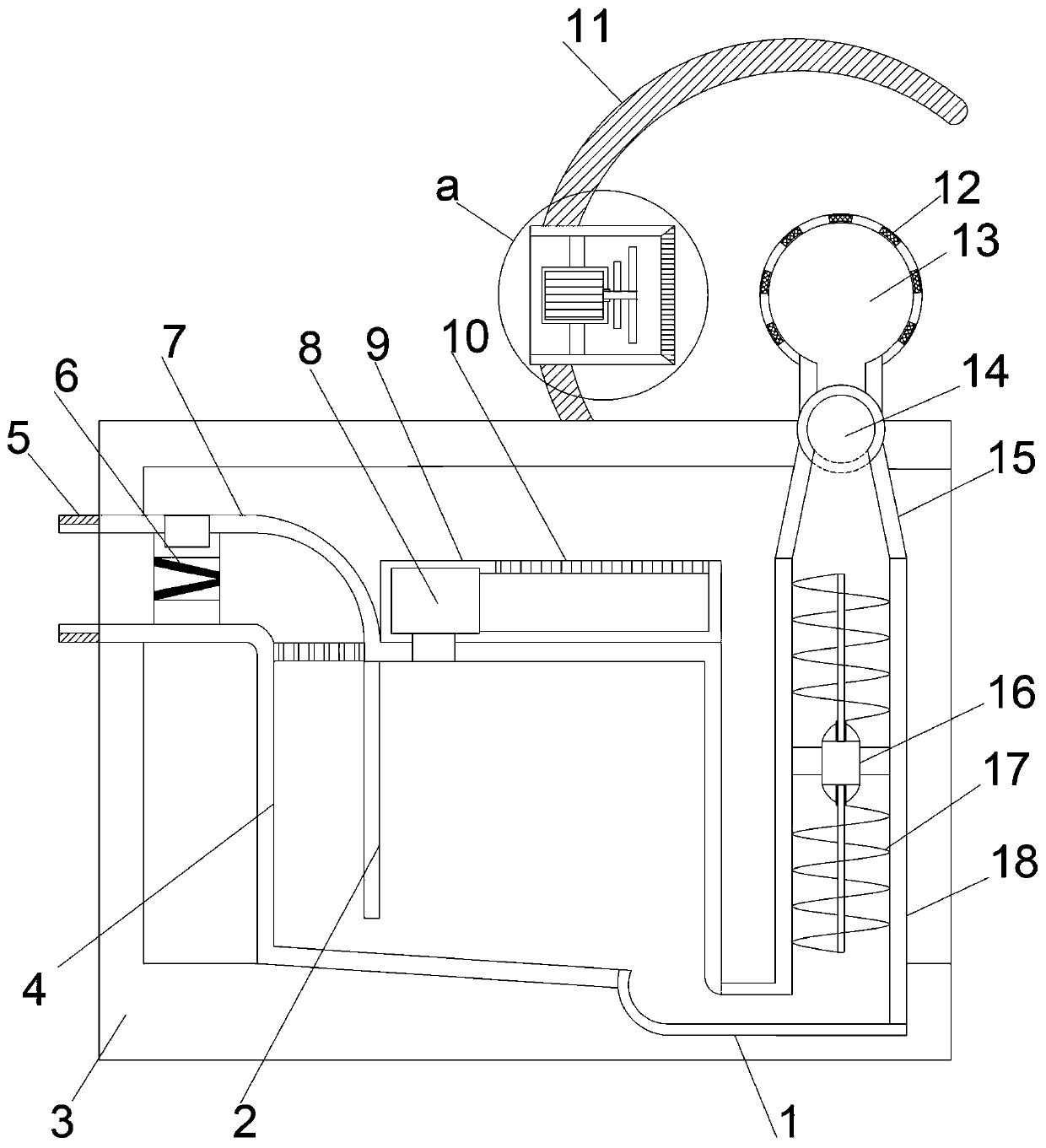

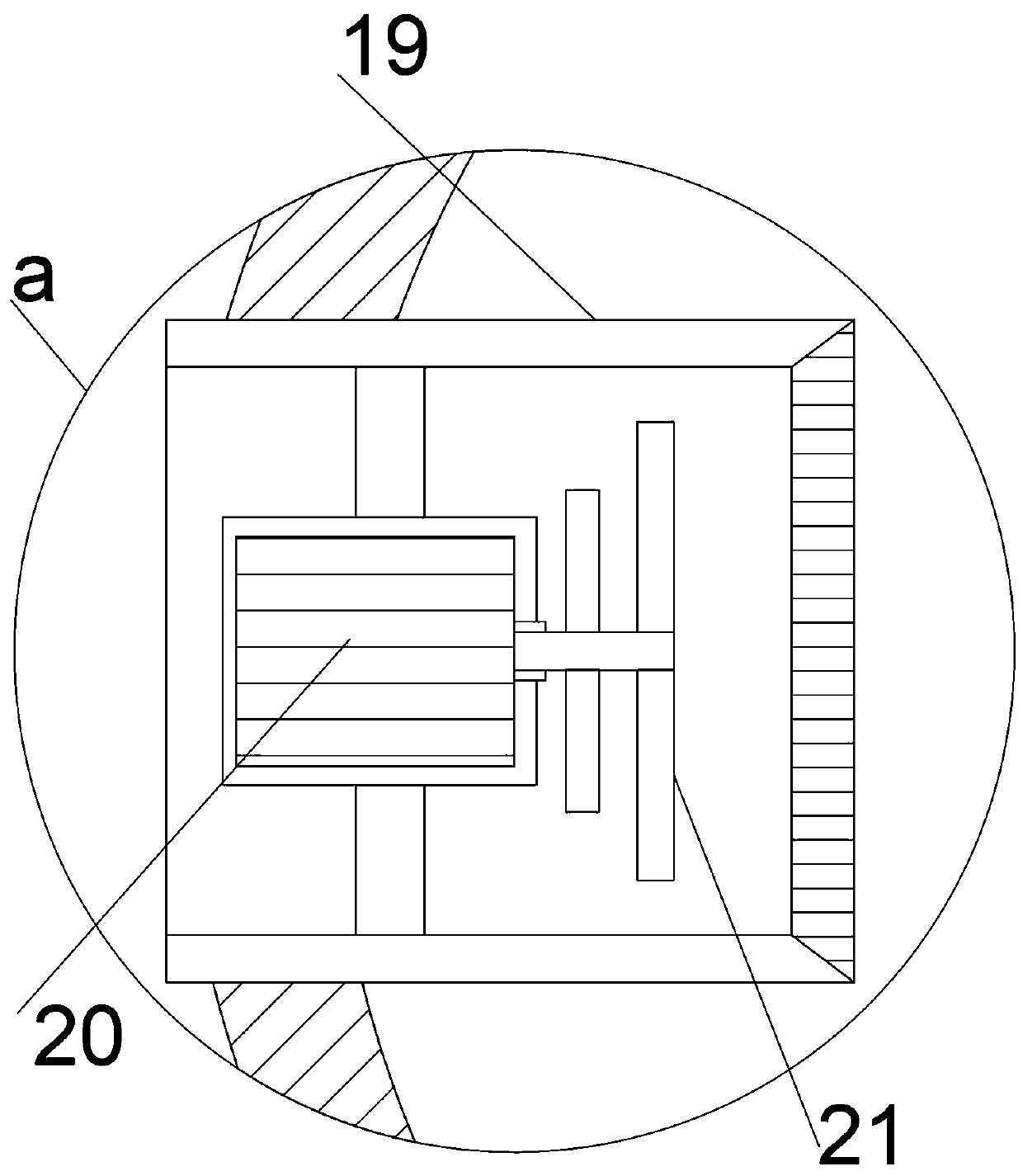

Non-heating environment-friendly humidification device

ActiveCN109520057ASteady diversionSteady ejectionLighting and heating apparatusAir humidification systemsEngineeringInlet flow

The invention relates to the field of environment-friendly humidification equipment, in particular to a non-heating environment-friendly humidification device. A vertically-arranged support installingbarrel is included. An inclined bottom flow guiding installing barrel is arranged at the middle position in the support installing barrel. The upper left end of the inclined bottom flow guiding installing barrel leftwards stretches out of the support installing barrel through an arc connecting pipe to be provided with a water inlet flow guiding pipe, and the part, on the right side of the inclined bottom flow guiding installing barrel, of the support installing barrel is internally and vertically upwards provided with a pressurizing flow guiding pipe through a U-shaped flow guiding pipe, andstable flow guiding of water energy is achieved through one-way flow guiding. Through two-level pressurizing, water is stably atomized and sprayed out, and the non-heating environment-friendly humidification device is suitable for high-fineness atomization sprayer work. Multi-set atomization is synchronously conducted, the atomization area is wide, and the atomization efficiency is high. Through active air blowing and flow guiding, atomized small liquid drops are rapidly guided out, and the atomization and humidification area is wider. Since the diameter of the atomized small liquid drops is obviously smaller than that of atomization equipment used at present, the atomized small liquid drops are rapidly evaporated for air humidification after being blown out, heating for humidification isnot needed, and energy saving and high efficiency are achieved.

Owner:YANCHENG DONGFANG TIANCHENG MACHINERY

Ink printing pretreatment solution

InactiveCN103790040AHas a cohesive effectInhibition of soakingDyeing processAlkaline earth metalSprayer

The invention discloses a pretreatment solution for pretreating a textile before ink printing, which contains water, alkali earth metal ionic compound and crosslinkable polyurethane, wherein the glass transition temperature of the crosslinkable polyurethane particles is lower than -20 DEG C, the particle size obtained by a light scattering process is greater than 300nm and smaller than 800nm, and the crosslinking degree for high-polymer particles (tetrahydrofuran insoluble substances, residue level) at 25 DEG C is higher than 40%. The pretreatment solution can enable the printing chroma of the textile to reach 50 or so, which is 25% higher than the prior art. Meanwhile, by using the pretreatment solution, the adhesive force of the ink on the textile is increased, and the ink spraying stability of the sprayer is higher.

Owner:WUXI VISION PRO

Dust collection box and steam vacuum cleaning machine using the same

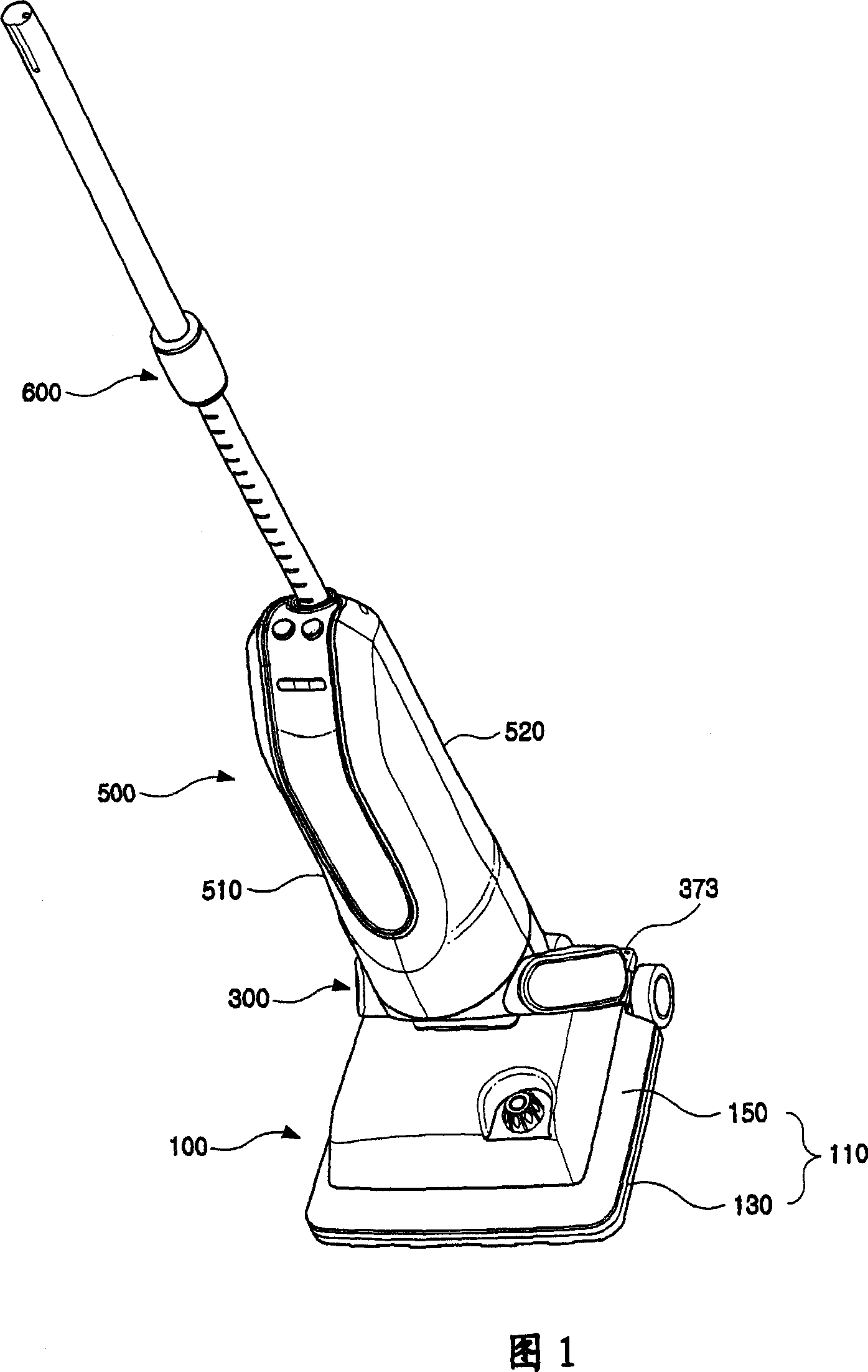

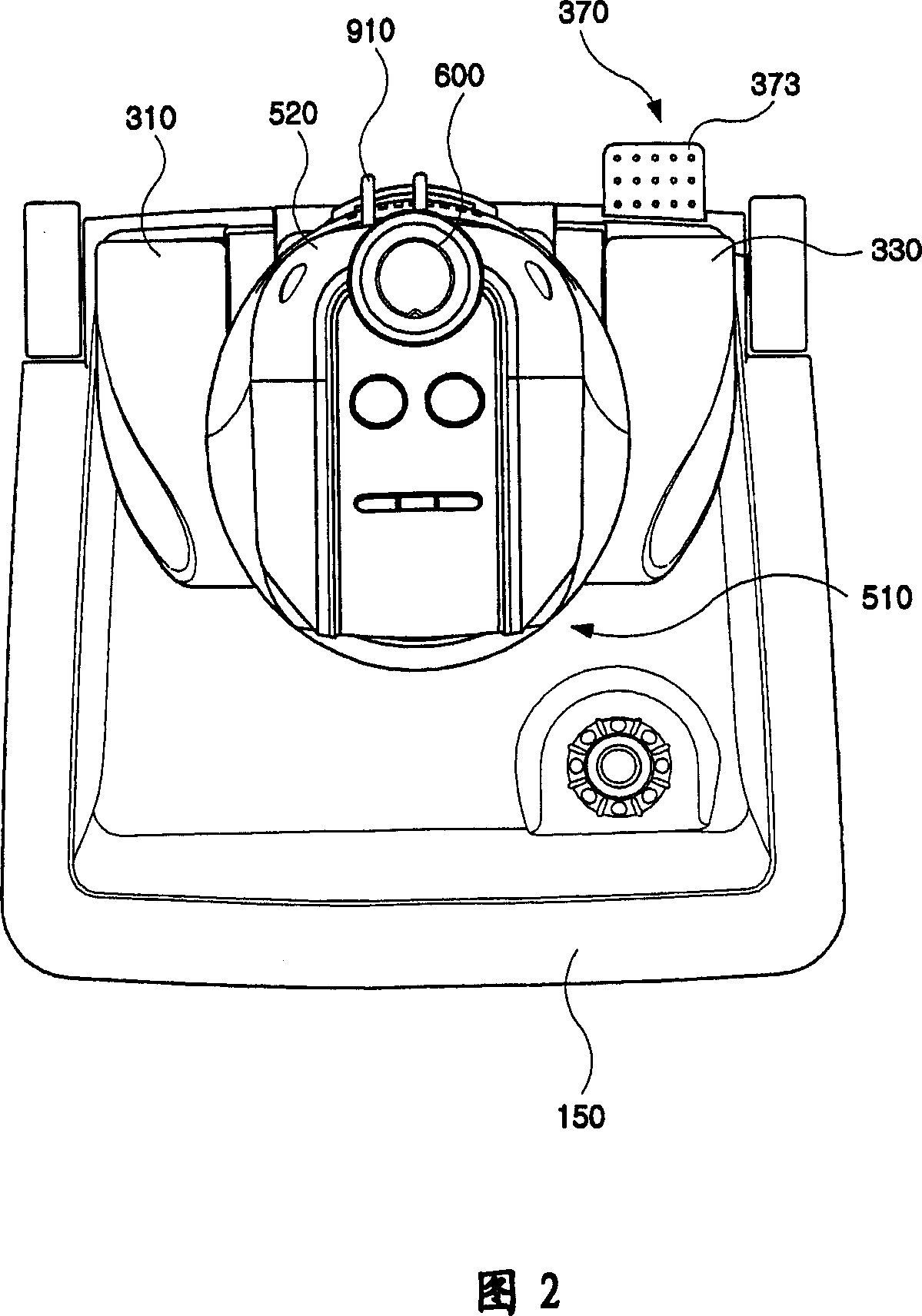

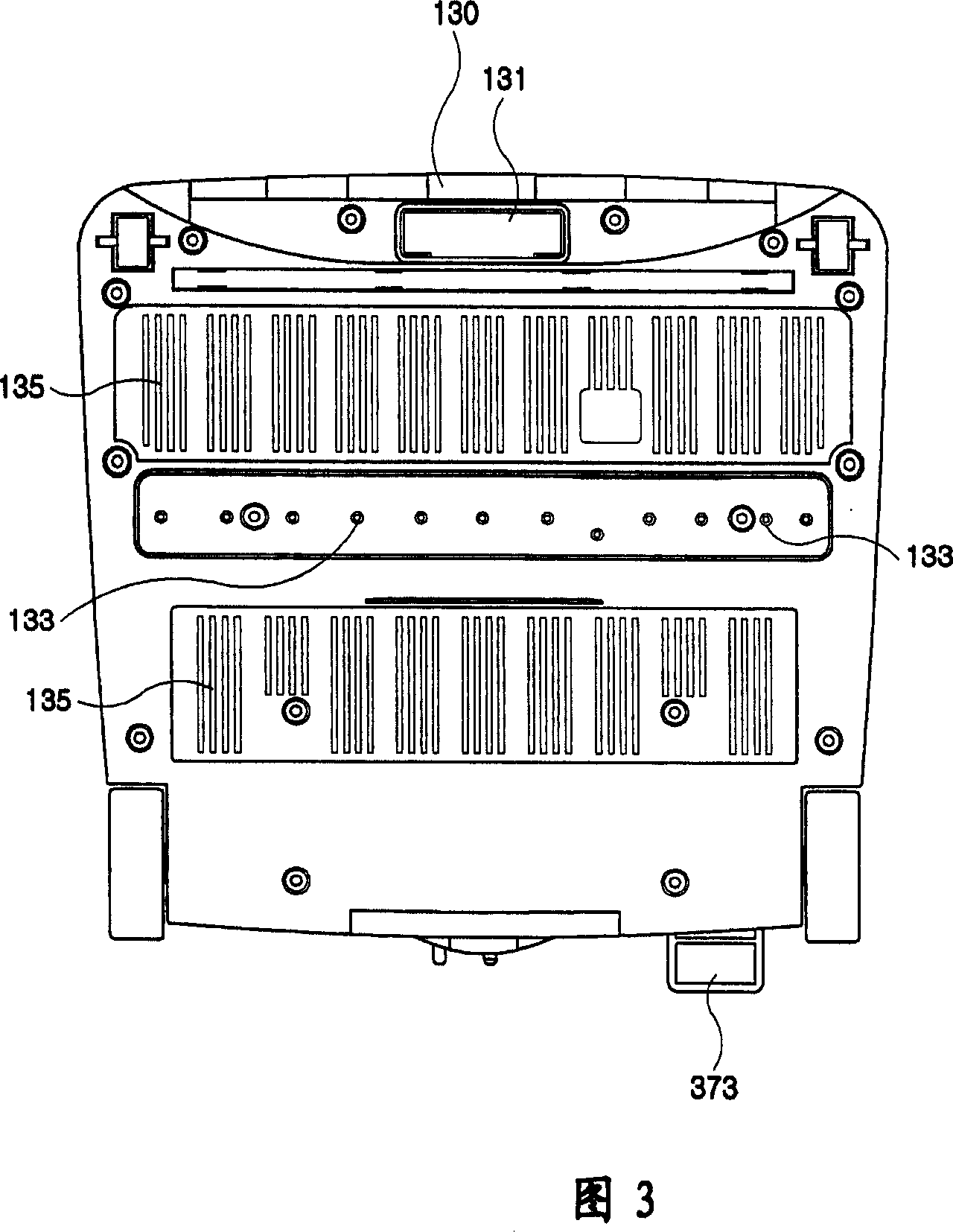

InactiveCN1957821APrevent splashPrevent backflowSuction filtersCarpet cleanersBackflowWaste management

A dust collection box is provided for comprising a dust collection housing which has an inlet orifice and an outlet orifice, an inlet chamber which is arranged inside the dust collection housing and connects with the inlet orifice, an outlet chamber which is arranged inside the dust collection housing and connects with the outlet orifice, a separating wall arranged inside the dust collection housing dividing the inlet chamber from the outlet chamber, a filter means which is provided to open or close the dust collection housing on the upper of the housing and filter the air in the inlet chamber which is supplied to the outlet chamber. The dust collection box provided in this invention is comprised of a dust collection housing having an inlet orifice and an outlet orifice, an inlet chamber and an outlet chamber arranged inside the housing, a separating wall for dividing the inlet chamber and outlet chamber, a filter means for filtering the air in the inlet chamber and supplying the filtered air to the outlet chamber. By applying this structure of present invention, splash or backflow of dust or water can be well prevented.

Owner:韩京姬

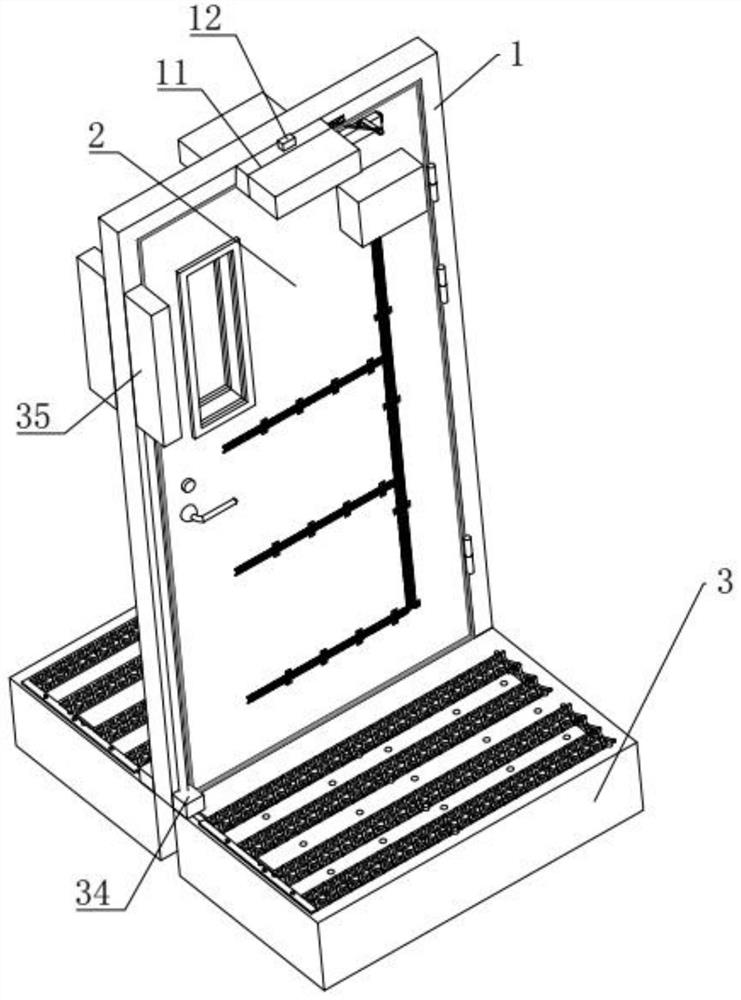

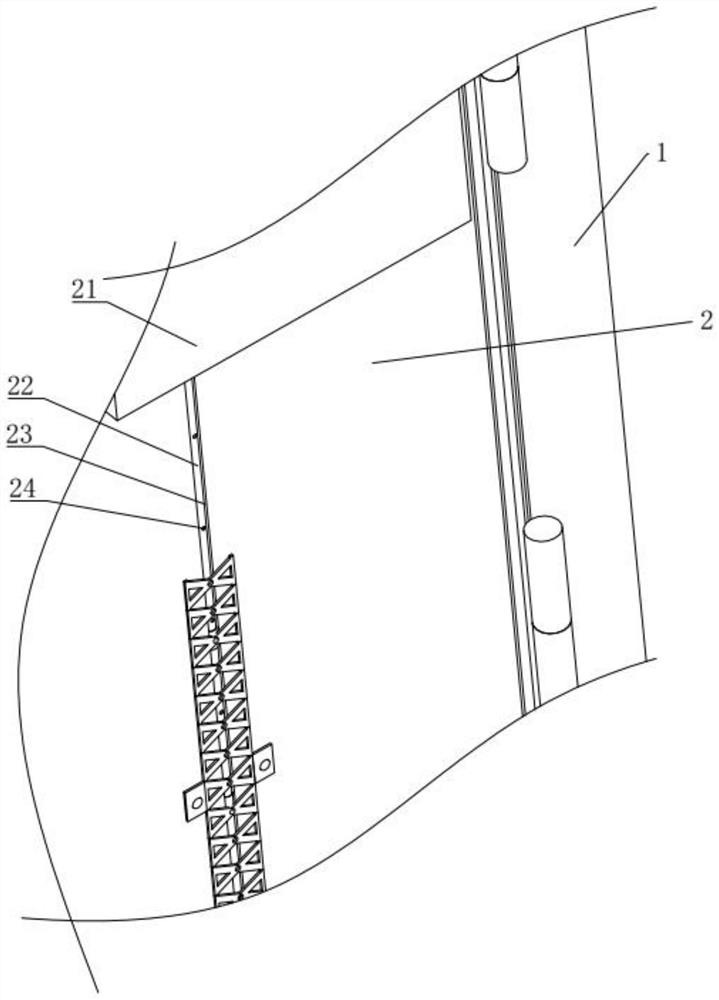

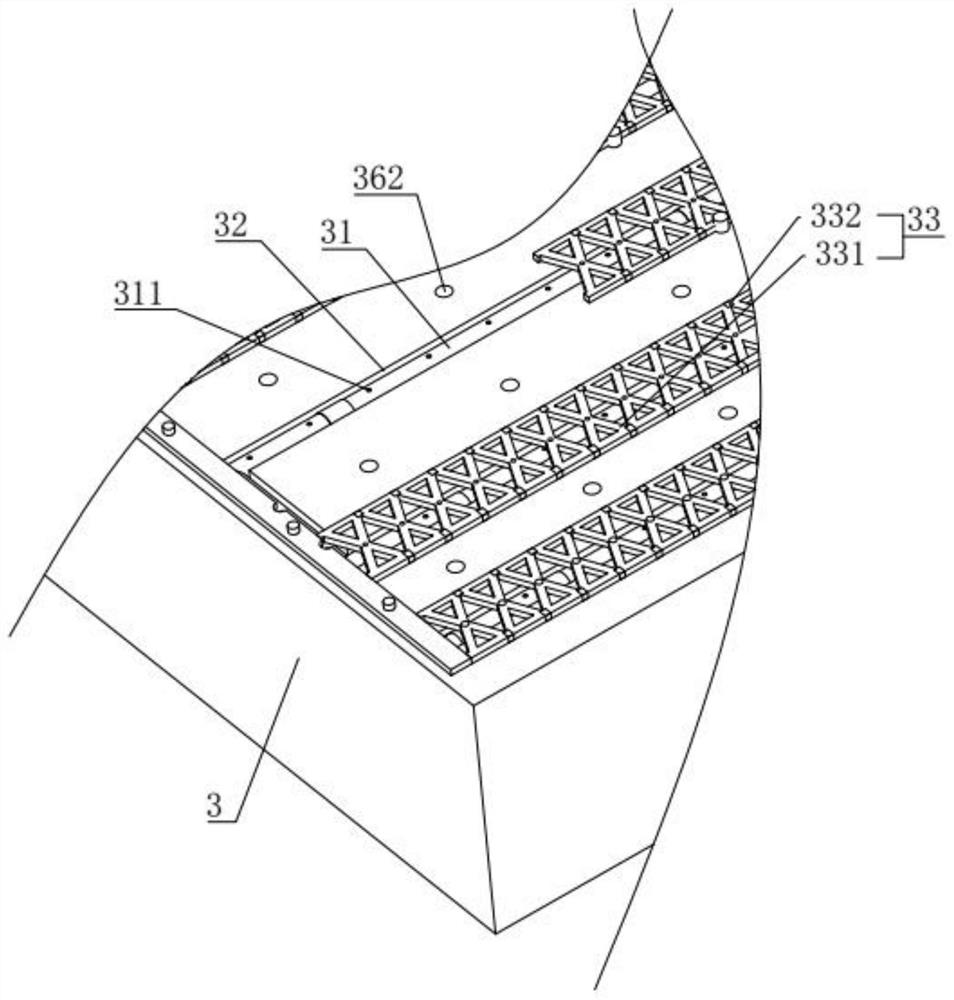

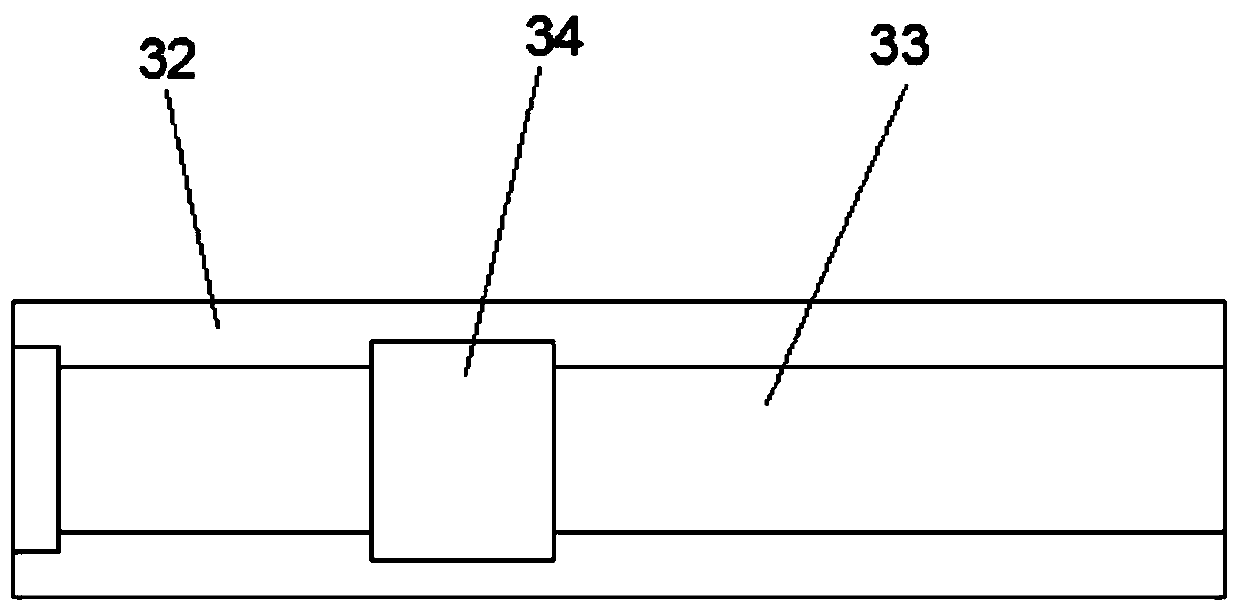

A fire door for easy escape

ActiveCN109723334BEasy to transport waterReduce fireFireproof doorsFire rescueWater storageWater storage tank

A fire door easy to escape, comprising a fire door frame (1) and a fire door board (2) which is hingedly connected to the fire door frame (1). The two sides at the lower end of the fire door frame (1) are provided with placement blocks (3) on the ground, respectively, and the upper surfaces of the placement blocks (3) are flush with the surface of the ground; the upper surface of each placement block (3) is provided with placement grooves (32) for placing first drainage pipes (31) and first fixing pieces (33) for limiting the first drainage pipes (31) in the placement grooves (32); water pumps (34) are provided on the first drainage pipes (31), water inlets of the water pumps (34) are connected to water storage tanks (35) disposed on the fire door frame (1) and arranged in the height direction of the fire door frame (1), and a plurality of water spraying holes (311) are formed on the side of the first drainage pipes (31) facing the openings of the placement grooves (32). The fire door is able to effectively reduce fire around fire door, and escape of people is facilitated.

Owner:陈滨

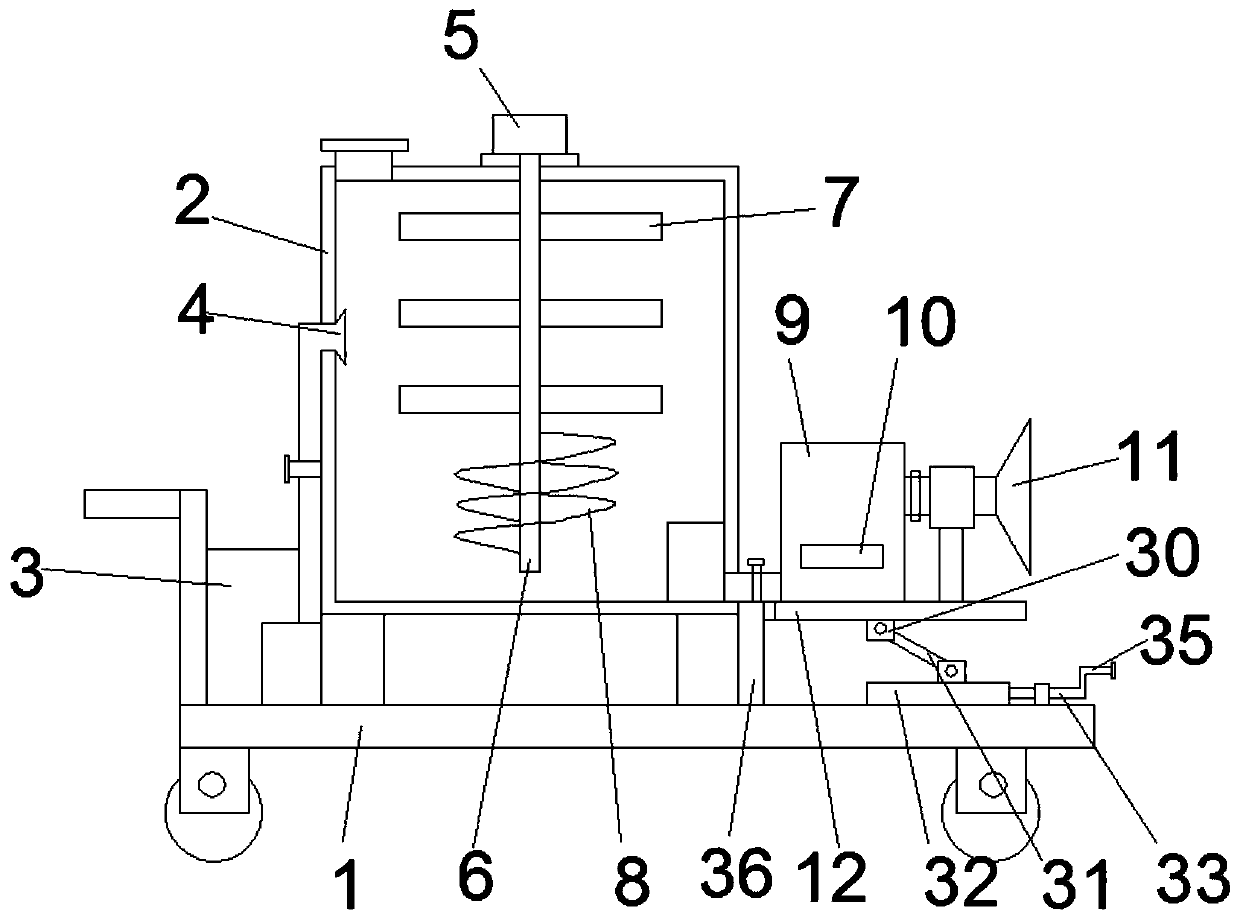

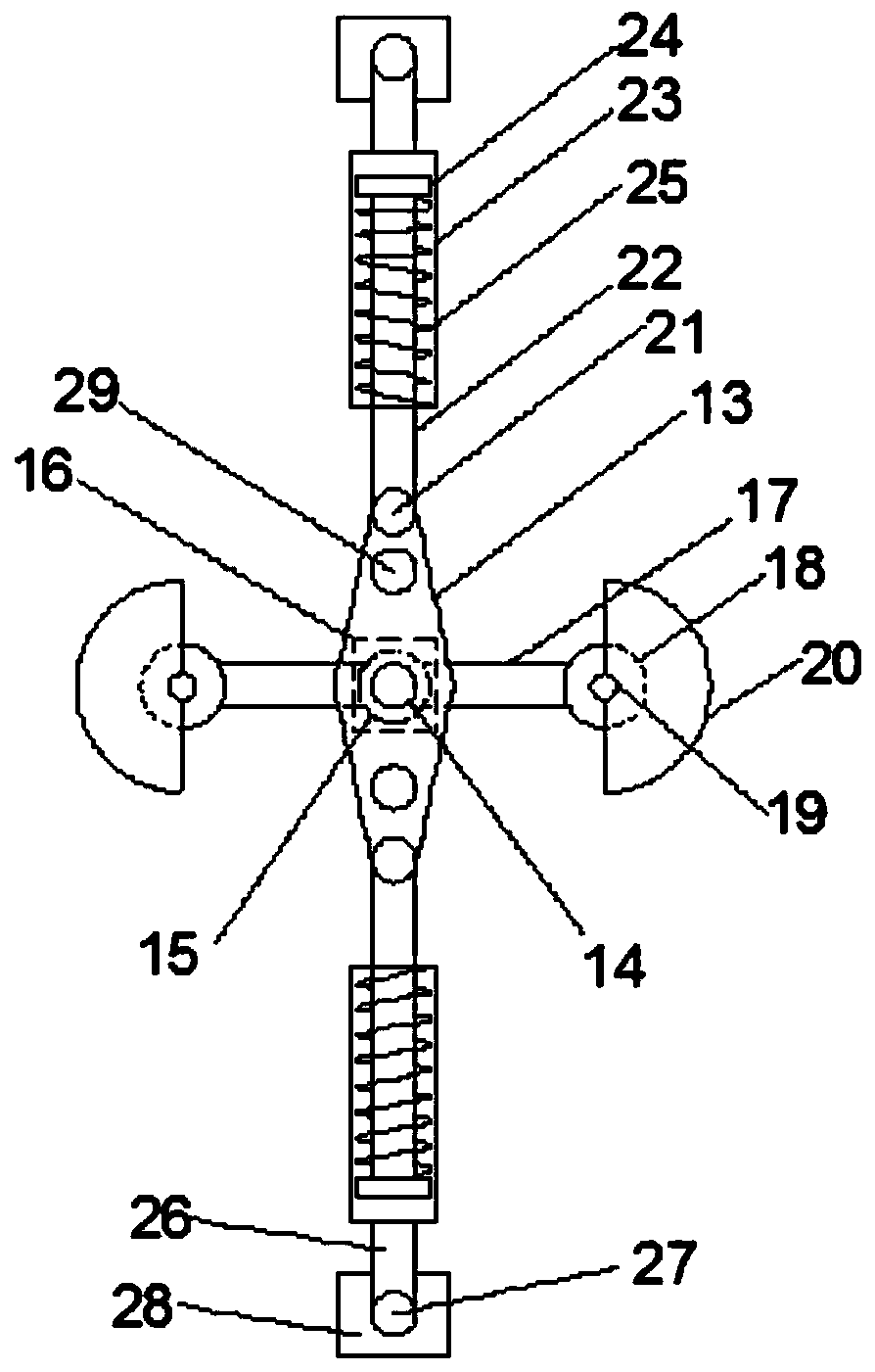

Agricultural planting pesticide spraying device convenient to adjust and uniform in spraying

InactiveCN110959593AEasy to adjustSpray evenlyTransportation and packagingRotary stirring mixersAgricultural scienceAgricultural engineering

The invention discloses an agricultural planting pesticide spraying device convenient to adjust and uniform in spraying. The agricultural planting pesticide spraying device comprises a base, a supporting column is fixedly arranged at the top of the base, a mixing box is fixedly arranged at the top of the supporting column, a water tank is placed on the base and located on one side of the mixing box, a first water pump is arranged in the water tank, a water inlet pipe is connected to the top of the first water pump, the end, away from the first water pump, of the water inlet pipe penetrates through the mixing box and extends into the mixing box to be connected with a water spraying head, a pesticide adding opening is formed in the top of the mixing box, a stirring motor is fixedly arrangedon one side of the pesticide adding opening, the output end of the stirring motor is connected with a stirring shaft, one end of the stirring shaft penetrates through the mixing box and extends into the mixing box to be symmetrically and fixedly provided with stirring paddles, and a propeller is arranged on the outer side of the stirring shaft and located below the stirring paddles. The agricultural planting pesticide spraying device has the beneficial effects that pesticide spraying is carried out through the pesticide spraying head, traditional manual operation is replaced, and the working efficiency is greatly improved.

Owner:杨克伟

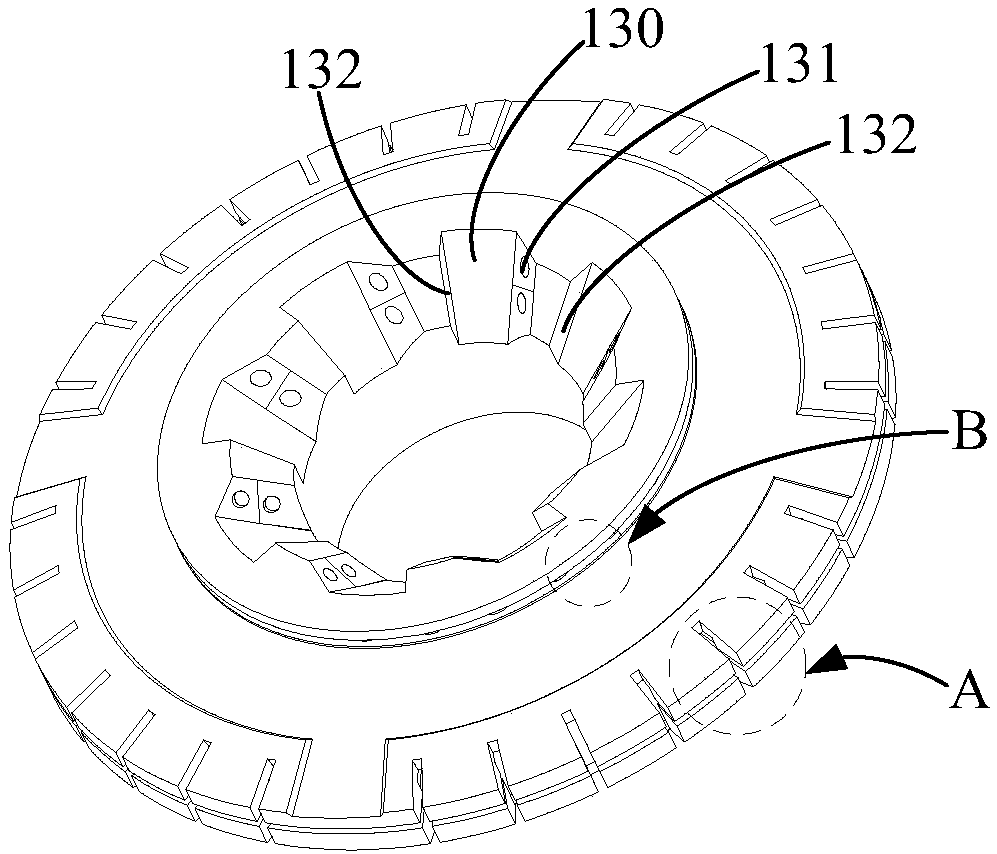

Burner cap, burner and burning cooking tool

ActiveCN108443882AIncrease in sizePrevent flashbackStoves/ranges topsGaseous fuel burnerEngineeringFuel gas

The invention discloses a burner cap, a burner and a burning cooking tool. The burner cap is provided with a fuel gas chamber, a gas inlet hole which communicates with the fuel gas chamber and a fuelgas pipeline, and burning fire holes which communicate with the fuel gas chamber, wherein each burning fire hole comprises an outer circle fire hole which is positioned in the circumferential edge ofthe burner cap; each outer circle fire hole comprises a circumferential flame stabilizing groove which is circumferentially formed along the burner cover, and an upper flame stabilizing groove which is positioned above the circumferential flame stabilizing groove; and each circumferential flame stabilizing groove communicates with the corresponding upper flame stabilizing groove. According to thetechnical scheme, the burner cap has the advantages that the fuel gas burning efficiency is greatly improved; and meanwhile, the flame stability is effectively improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

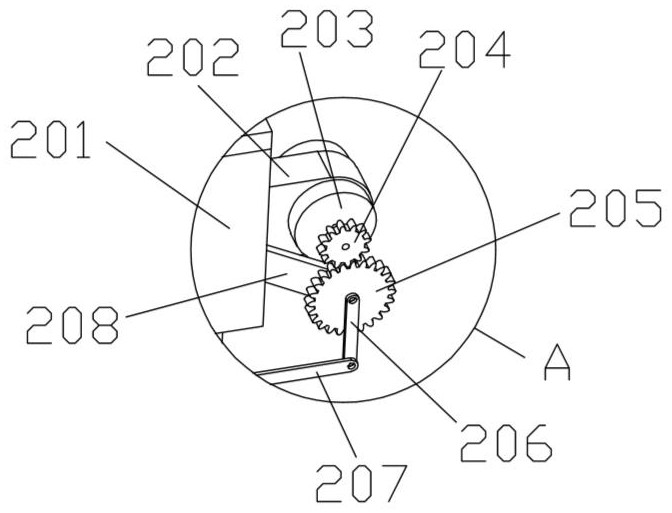

Aerial fire extinguishing equipment for unmanned aerial vehicle

ActiveCN111632302ASteady ejectionAdjust the direction of ejectionFire rescueMarine engineeringGear wheel

Owner:张家界中科网商集团有限公司

Temperature-adjustable strain spray gun

InactiveCN105660177AKeep aliveKeep access mixCultivating equipmentsMushroom cultivationEngineeringAtmospheric pressure

The invention discloses a temperature-adjustable strain spray gun. The temperature-adjustable strain spray gun comprises a gun cylinder, a heating component, a handle and a nozzle; the heating component is arranged on the gun cylinder, the handle is arranged on the lower portion of the gun cylinder, the handle is fixedly connected with the gun cylinder, the nozzle is arranged at the front end of the gun cylinder, a nut is arranged at the tail end of the nozzle, the nozzle is in thread connection with the gun cylinder through the nut, the nozzle is provided with a temperature sensor and a bacterial powder injection connector, an infusion tube, a pressure sensor and a compression tube are arranged at the rear end of the gun cylinder, the infusion tube and the compression tube are in seamless connection with the gun cylinder, a starting switch and an air pressure adjusting knob are arranged on the handle, the starting switch is communicated with the infusion tube, and the air pressure adjusting knob is communicated with the compression tube. The temperature-adjustable strain spray gun is simple in structure, convenient to operate, capable of effectively adjusting the temperature and concentration of bacterial liquid, and the good biological activity of stains is kept.

Owner:中山安荞生物科技有限公司

Ink printing pretreatment solution

The invention discloses a pretreatment solution for pretreating a textile before ink printing, which contains water, alkali earth metal ionic compound and crosslinkable polyurethane, wherein the alkali earth metal ionic compound is a Ca-Ba halide mixture. The pretreatment solution can enable the printing chroma of the textile to reach 60 or so, which is 50% higher than the prior art. Meanwhile, by using the pretreatment solution, the adhesive force of the ink on the textile is increased, and the ink spraying stability of the sprayer is higher.

Owner:WUXI VISION PRO

Ignition system for smoke sprayers

ActiveCN104115808ASteady ejectionCooperate accuratelyInsect catchers and killersCombustion chamberFuel tank

The invention discloses an ignition system for smoke sprayers and belongs to the technical field of the smoke sprayers. The ignition system comprises a power supply, an ignition switch, an igniter, an oil tank, a carburetor, a sparking plug, an oil spray nozzle, a combustion chamber and an air pump, wherein the igniter and the air pump are electrically connected with the power supply respectively through the ignition switch, the igniter is electrically connected with the sparking plug, the air pump is respectively connected with the oil tank and the carburetor through air pipes, and check valves are respectively arranged on main paths of the air pipes and branch paths connected with the oil tank. The oil tank is connected with the oil spray nozzle through an oil supply pipe, and an oil supply valve is arranged on the oil supply pipe. The carburetor is connected with the combustion chamber, and the sparking plug and the oil spray nozzle are arranged on a connection pipe between the carburetor and the combustion chamber. By means of the air pump, pressurization of the oil tank is achieved, and air required by ignition is provided. Fuel oil is sprayed out stably under action of positive pressure, mixed fuel oil and the sparking plug are matched accurately, the success rate of ignition is high, and ignition operation is convenient and efficient. Meanwhile, continuous and stable operation of the smoke sprayers is achieved.

Owner:史文军 +1

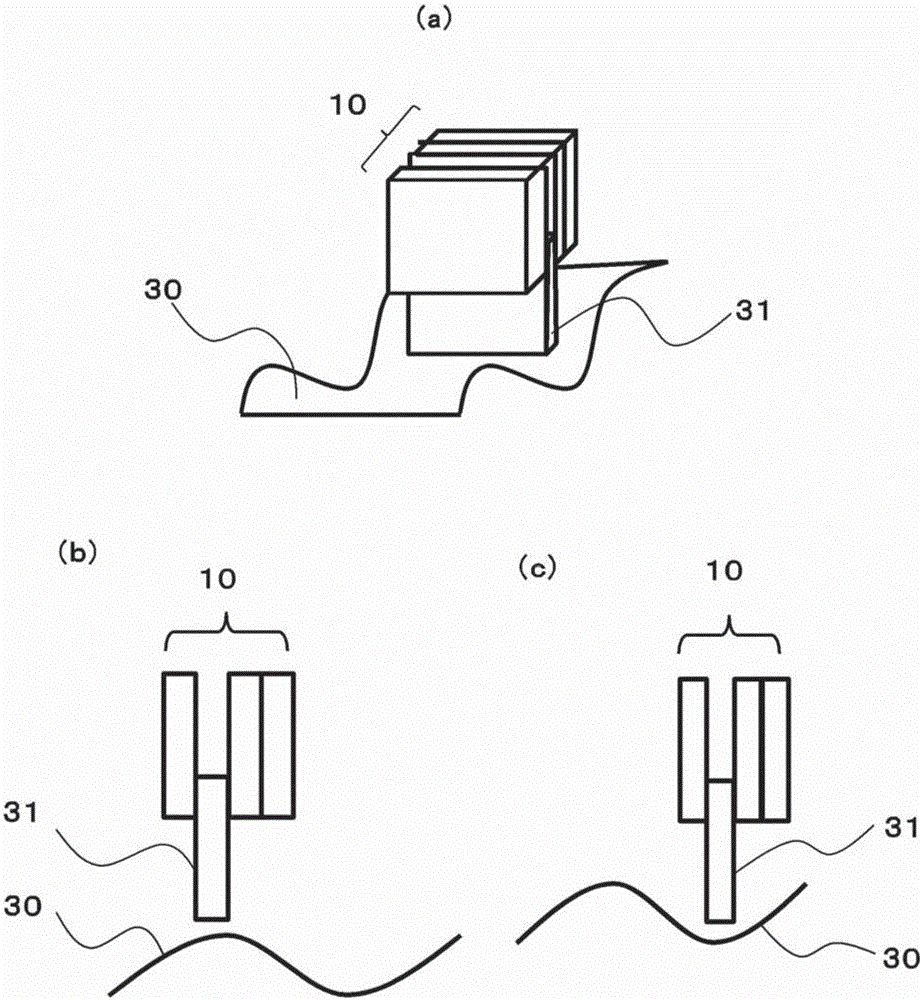

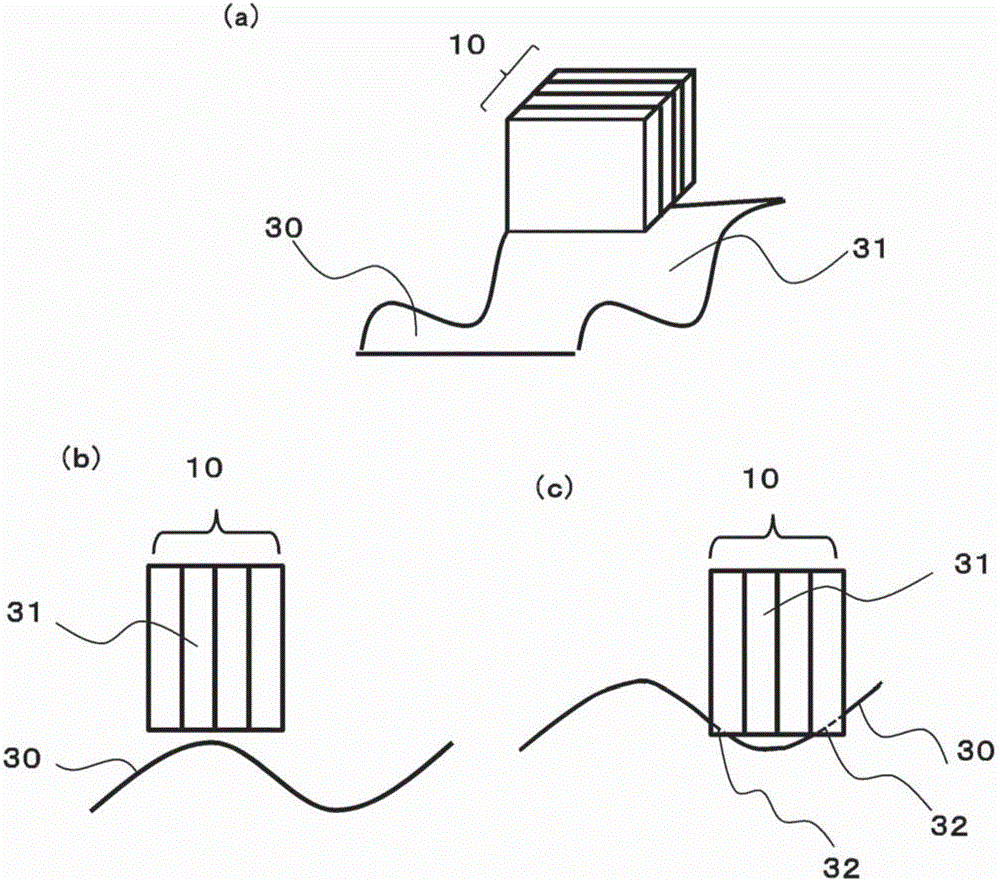

Inkjet device and inkjet method

The invention provides an inkjet device and an inkjet method. The inkjet apparatus has a plurality of spraying heads which spray ink as any of the spraying heads is lowered so as to form a specified pattern at a structure body which has larger concanves and convexes. In order to stably spray ink, the spraying heads are configured to have stable ink flow therein by, as the spraying heads are lowered, performing selection among 2 pipe paths which connect an ink feeding groove and the spraying heads and 2 pipe paths which connect a recycling groove and the spraying heads, the ink feeding groove supplying ink to the spraying heads, and the recycling groove recycling ink from the spraying heads.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Vapour spraying nozzle of ironing machines

The invention discloses a steam jet of an ironing machine, comprising a nozzle body in which a steam chamber is arranged and a handle connected with the nozzle body; a steam receiver is arranged above the steam jet; a steam channel is arranged between the steam receiver and the steam chamber; the cross-sectional area of the steam receiver is larger than the cross-sectional area of the steam channel; the steam receiver can lead the water droplet contained in the steam flowing through the steam receiver to be evaporated partially, and part of the water droplet is separated and flow back to the ironing machine, thus leading the steam ejected by the steam jet to be more stable without leaving watermarks or water stain on clothes.

Owner:陈金勇

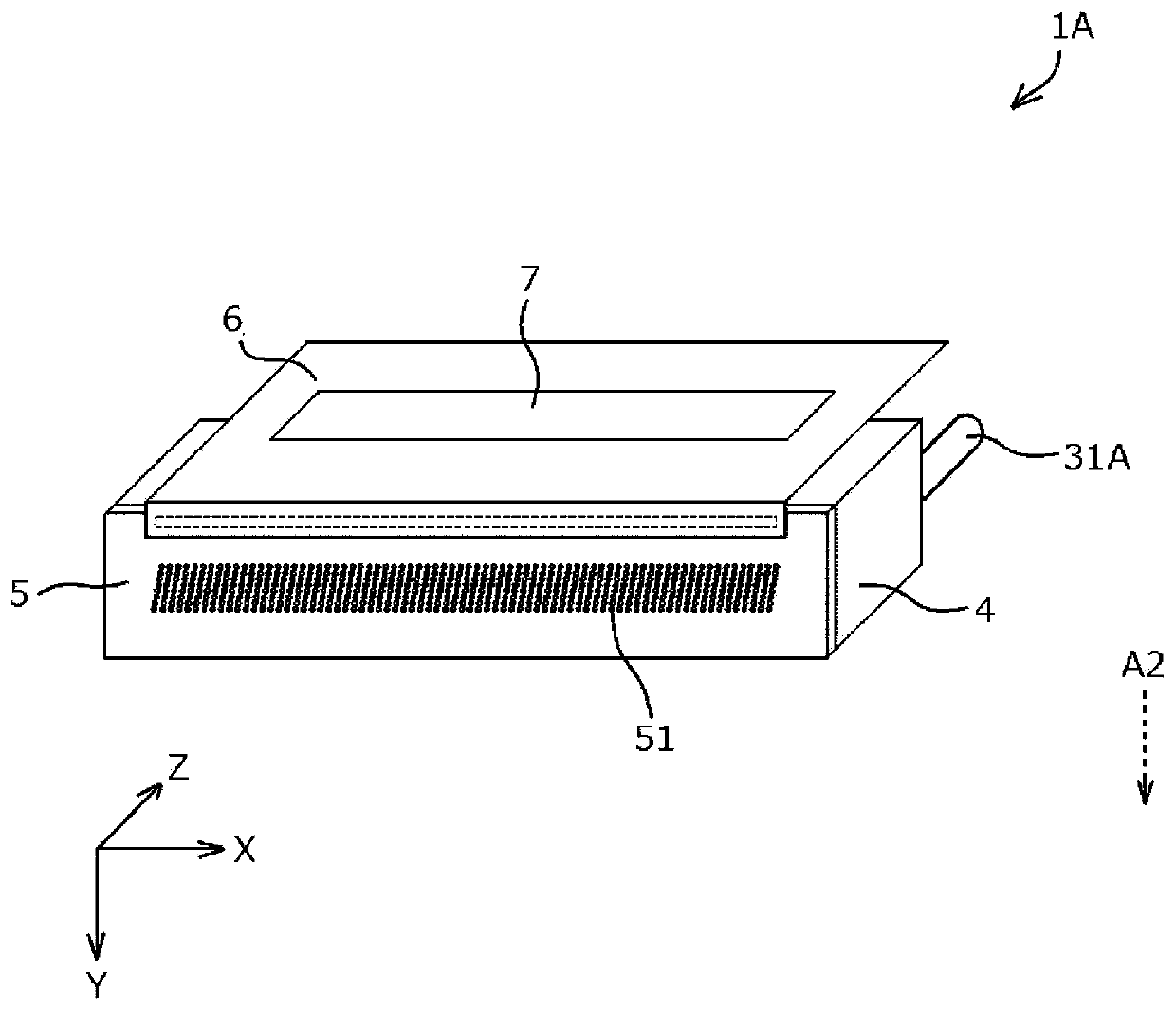

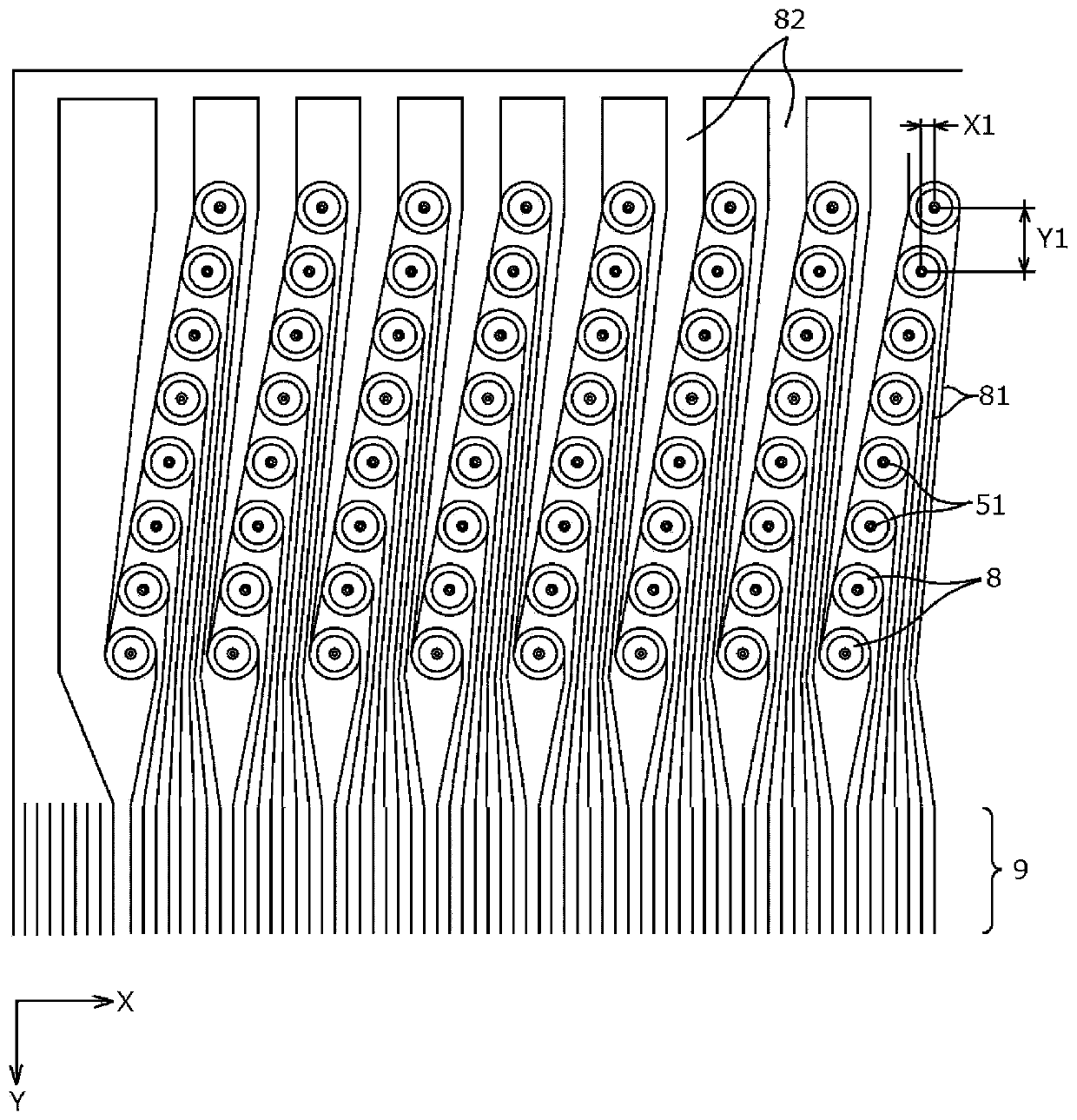

Liquid ejection device and multi-nozzle liquid ejection device

The invention provides a liquid ejection device and a multi-nozzle liquid ejection device that can suppress the crosstalk of inerference of motions of an actuator and performs stable liquid ejection.According to one embodiment, a liquid ejection device 1A includes a nozzle plate 5, an actuator 8, a liquid supply unit 2, a waveform generation circuit 301, a waveform allocation circuit 302, and a drive signal output circuit. A plurality of nozzles 51 for ejecting liquid is arranged in the nozzle plate. The actuator is provided in each of the nozzles. The waveform generation circuit generates plural kinds of drive waveforms with different generation start timings. The waveform allocation circuit can set the drive waveform among plural kinds of drive waveforms and the actuator of the nozzle to be allocated. The drive signal output circuit drives the actuator with the allocated drive waveform.

Owner:TOSHIBA TEC KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com