Liquid ejection device and multi-nozzle liquid ejection device

A nozzle type, nozzle technology, applied in the printing device, printing and other directions, can solve the problem of unstable ink ejection and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

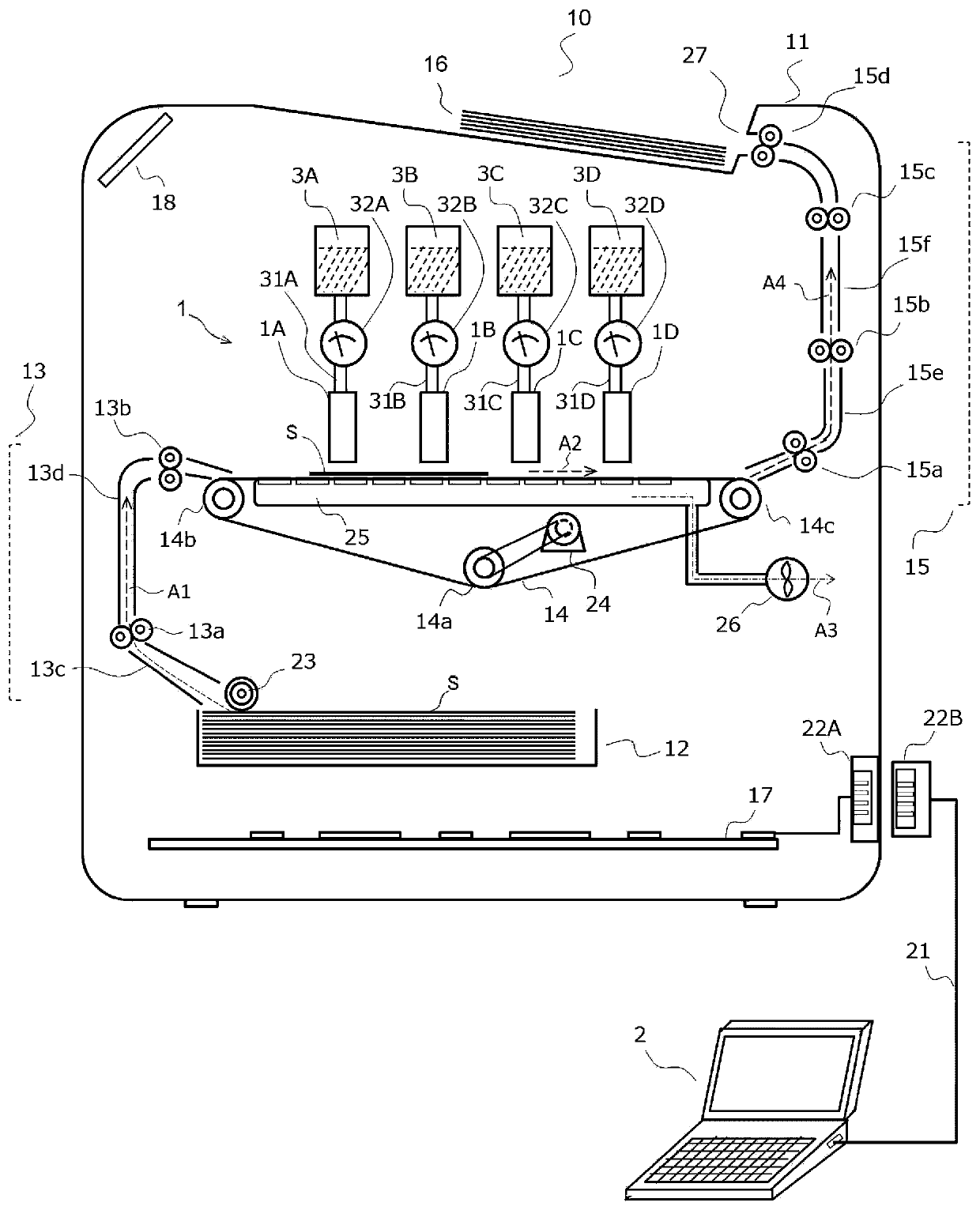

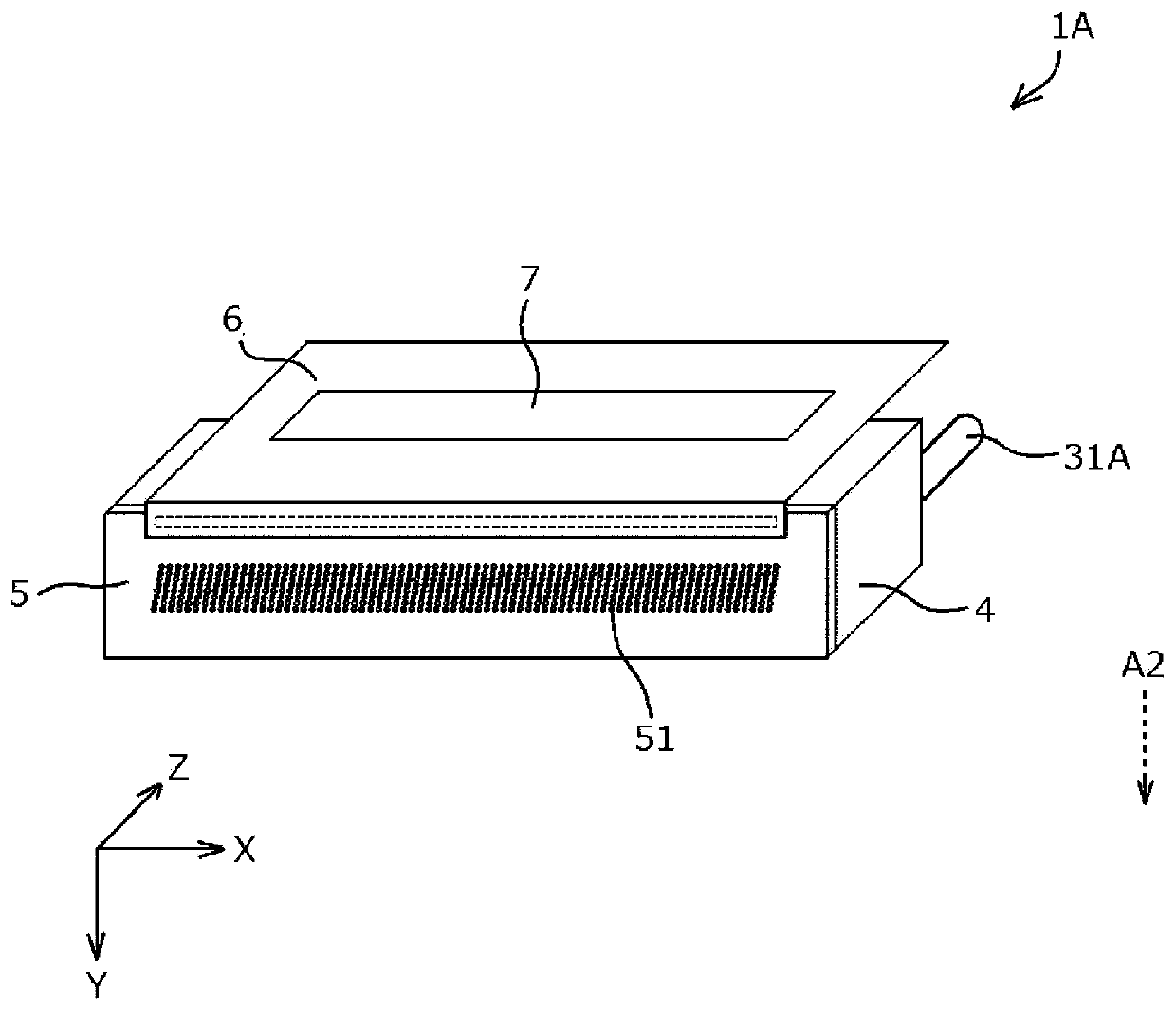

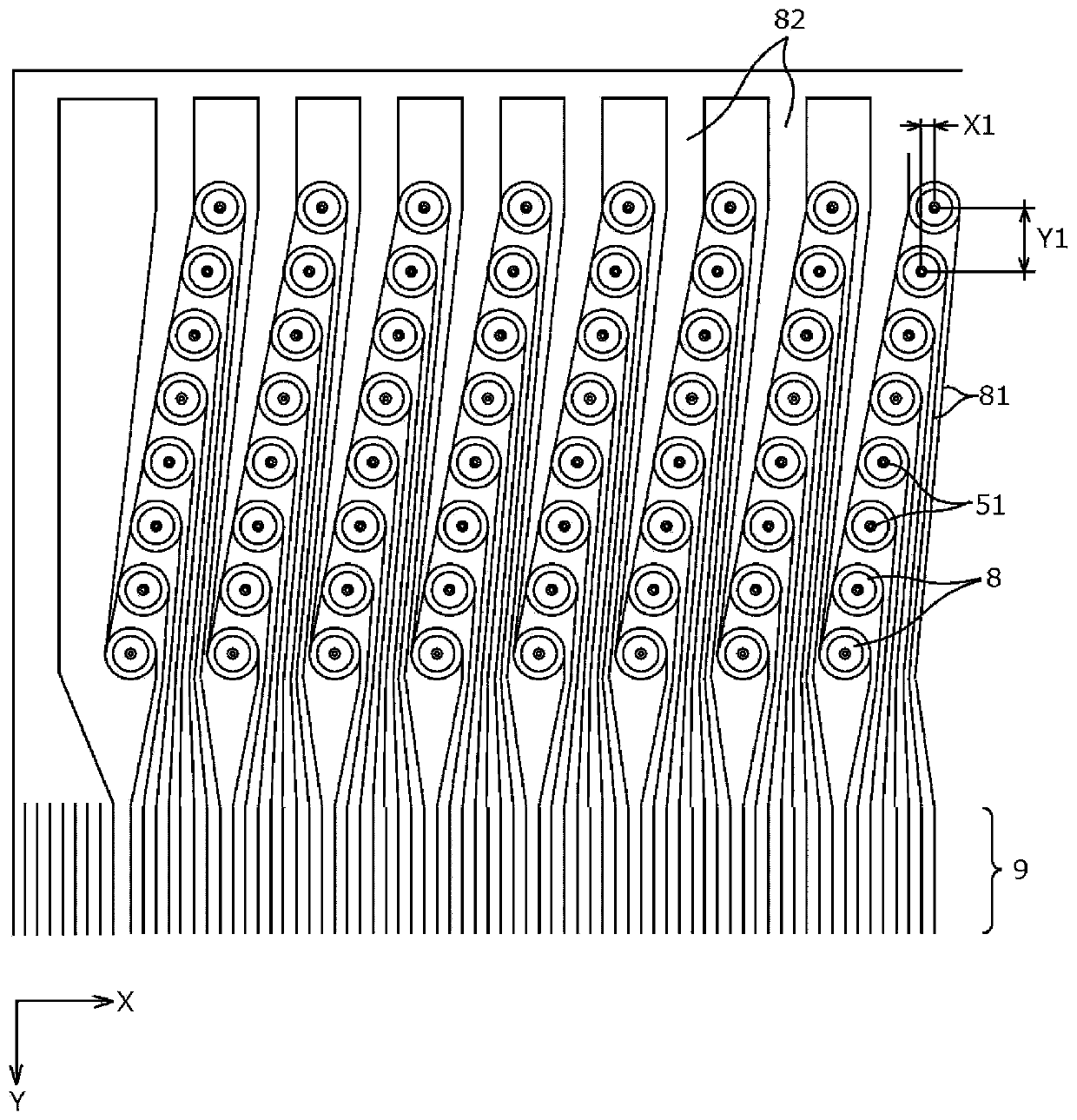

[0043] An inkjet printer 10 that prints an image on a recording medium will be described as an example of an image forming apparatus equipped with the liquid ejection device 1 according to the embodiment. figure 1 A schematic configuration of the inkjet printer 10 is shown. The inkjet printer 10 includes, for example, a box-shaped casing 11 as an outer package. Inside the casing 11, a cassette 12 for accommodating a sheet S as an example of a recording medium, an upstream transport path 13 for the sheet S, a conveyor belt 14 for transporting the sheet S taken out from the cassette 12, and a direction transport Inkjet heads 1A to 1D that eject ink droplets from the sheet S on the belt 14 , a downstream conveyance path 15 of the sheet S, a discharge tray 16 , and a control board 17 . An operation unit 18 as a user interface is provided on the upper side of the casing 11 .

[0044] The image data printed on the sheet S is generated by, for example, the computer 2 as an external...

no. 2 approach

[0123] Next, a liquid ejection device according to a second embodiment will be described. Figure 31 A longitudinal cross-sectional view of an inkjet head 101A as an example of a liquid ejection device is shown. The inkjet head 101A has the same configuration as the inkjet head 1A illustrated in the first embodiment except that the pressure chamber (individual pressure chamber) 41 is omitted and the nozzle plate 5 communicates directly with the common ink chamber 42 . Therefore, for Figure 4For the same configuration, the detailed description thereof will be omitted by assigning the same reference numerals.

[0124] Figure 31 The illustrated inkjet head 101A is also driven by generating and driving waveforms having different start timings for allocation of all channels. In this case as well, it is possible to realize a multi-nozzle type inkjet head capable of canceling out the crosstalk applied to channels of interest for the reasons described above.

[0125] That is, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com