Patents

Literature

125results about How to "Strong coherence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

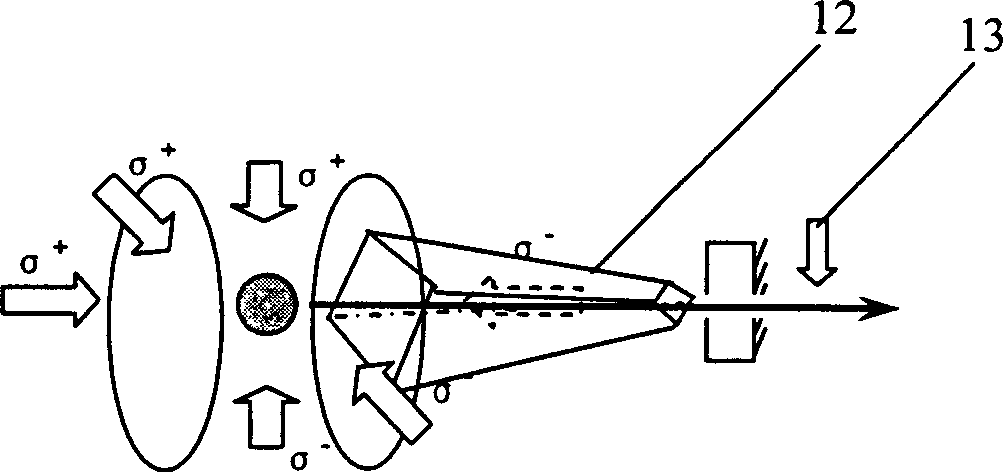

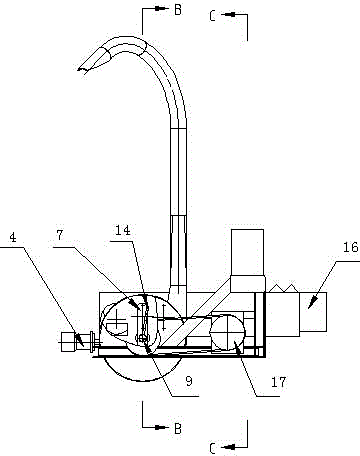

Laser link communication-measurement composite system

InactiveCN106911381AIncrease profitReduce weightOptical rangefindersFree-space transmissionTelecommunications linkBeam splitter

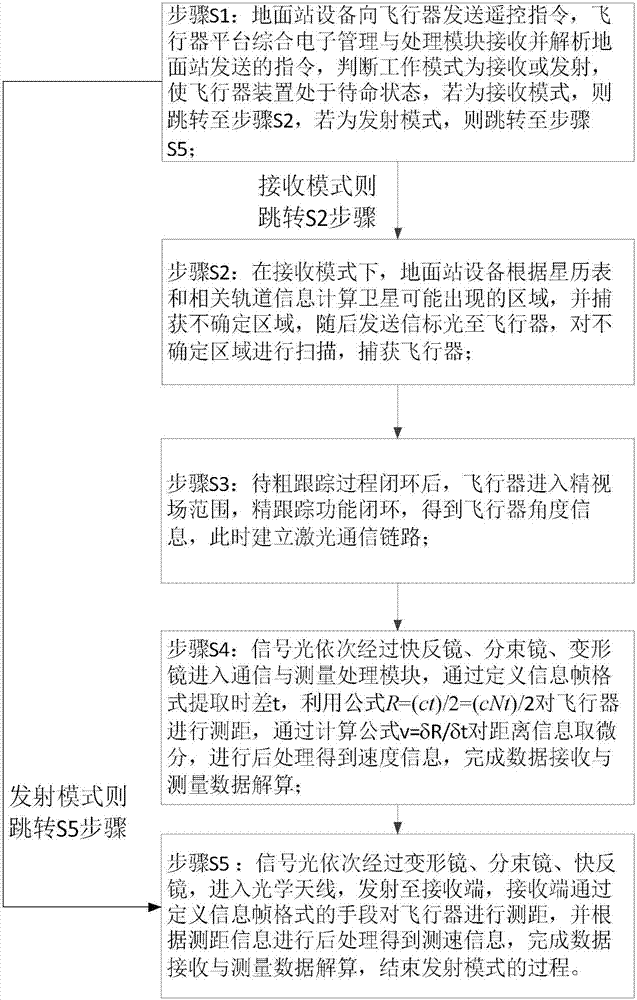

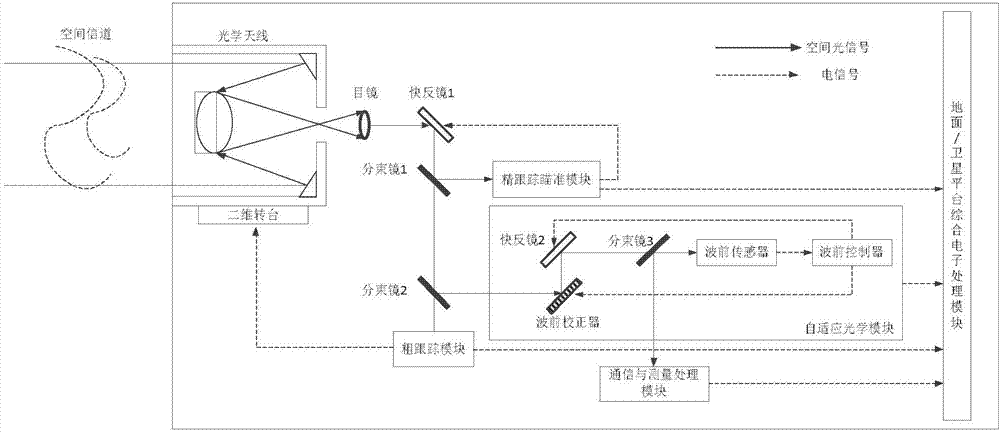

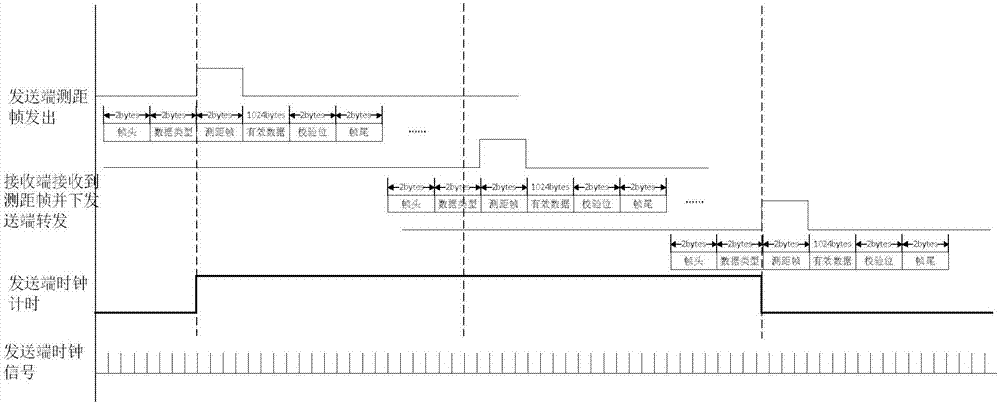

The invention discloses a laser link communication-measurement composite system. Through adoption of the laser link communication-measurement composite system, the payload weight, size and power consumption can be lowered. The laser link communication-measurement composite system is implemented by the following technical scheme: an optical antenna transmits a comprehensive optical signal to a rapid reflecting mirror through an eye lens at a transmitting end; reflected light splits a light beam of the comprehensive optical signal into two paths through a beam splitter; one path is transmitted into another beam splitter through the beam splitter to transmit the light beam into a coarse tracking module in order to extract a target position coarse miss distance, and a control voltage is applied to a two-dimensional turntable according to an embedded control algorithm; the other path of comprehensive optical signal is introduced into the field range of a fine tracking module through the beam splitter, and transmitted into the fine tracking module to extract a target position fine miss distance, the overall offset of fine field light spots is controlled, the light spots are introduced into the center of a fine tracking field to obtain target angle information, and the extracted target position fine miss distance is transmitted into a ground / satellite platform comprehensive electronic management and processing module to finish target capture and an aiming function and establish a communication link.

Owner:10TH RES INST OF CETC

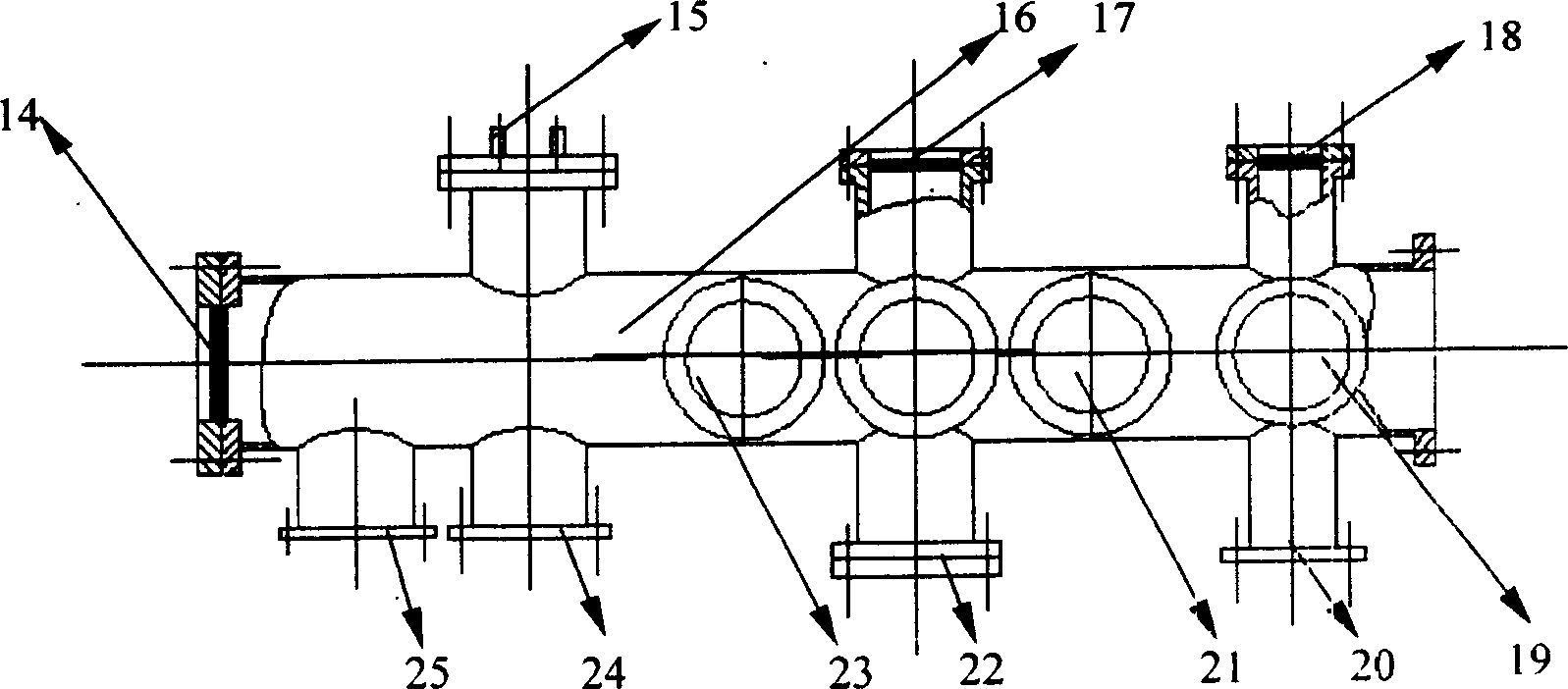

Cold atomic beam producing method and device

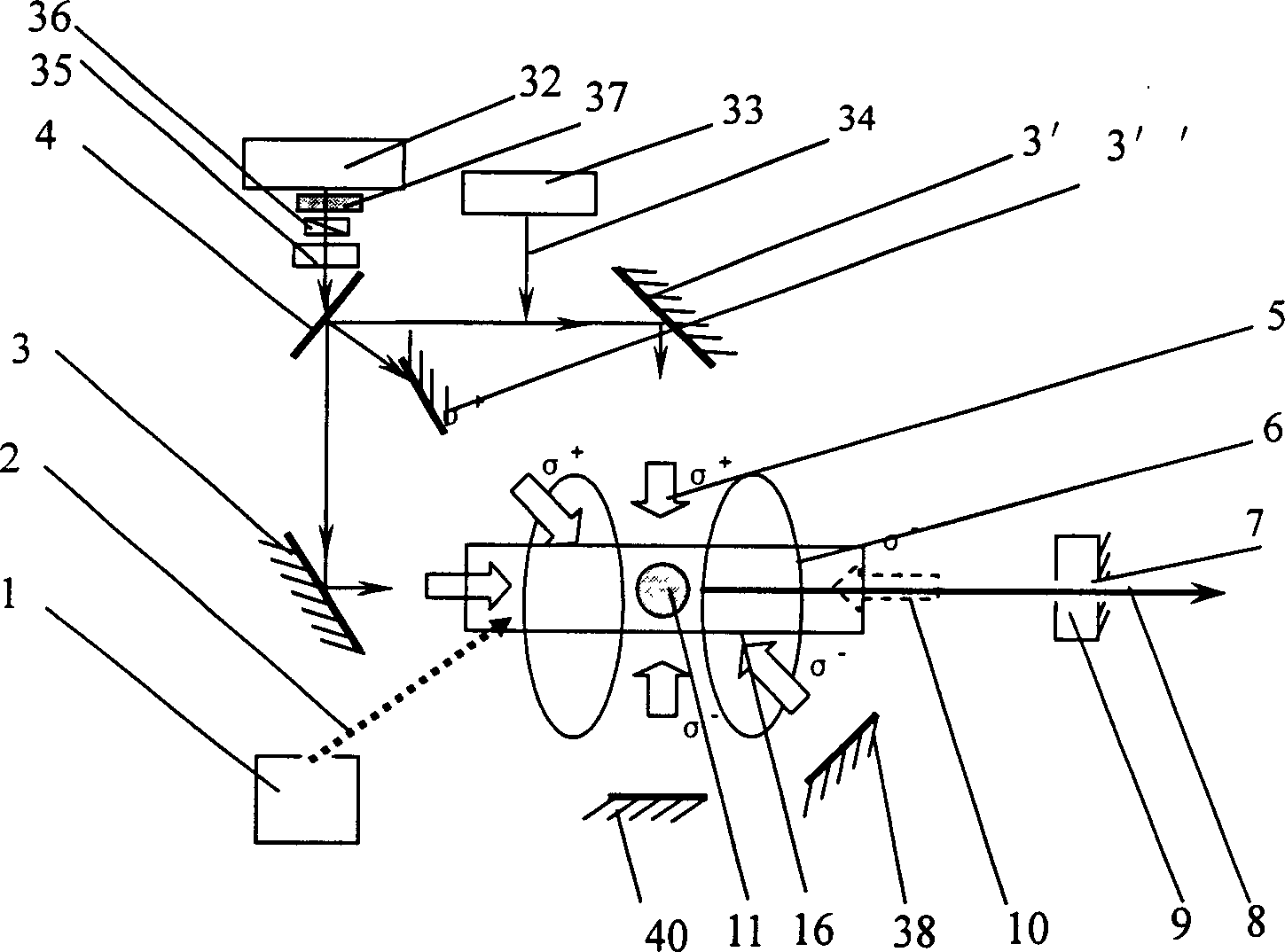

This invention relates to a method and device for generating cold atomic beam. Said method includes heating hot atom source in vacuum chamber to form atomic saturated vapor pressure atmosphere, cooling hot atom by three-D MOT to below 200uk and trapped to form cold atomic cloud, by the quarter wave plate reflection mirror in MOT the laser radiation pressure being unbalanced to make cold atom emitting along said direction, four tape arranged straight line set with contrary current direction is set in atom beam emission direction, which makes the atom emitted to forward to obtain cold atom beam with low speed, large flux and small transverse speed, laser beam vertical with atom beam set in the direction of cold atom emitting for atom beam state preparation to realize state concordant emitted cold atom beam.

Owner:TSINGHUA UNIV

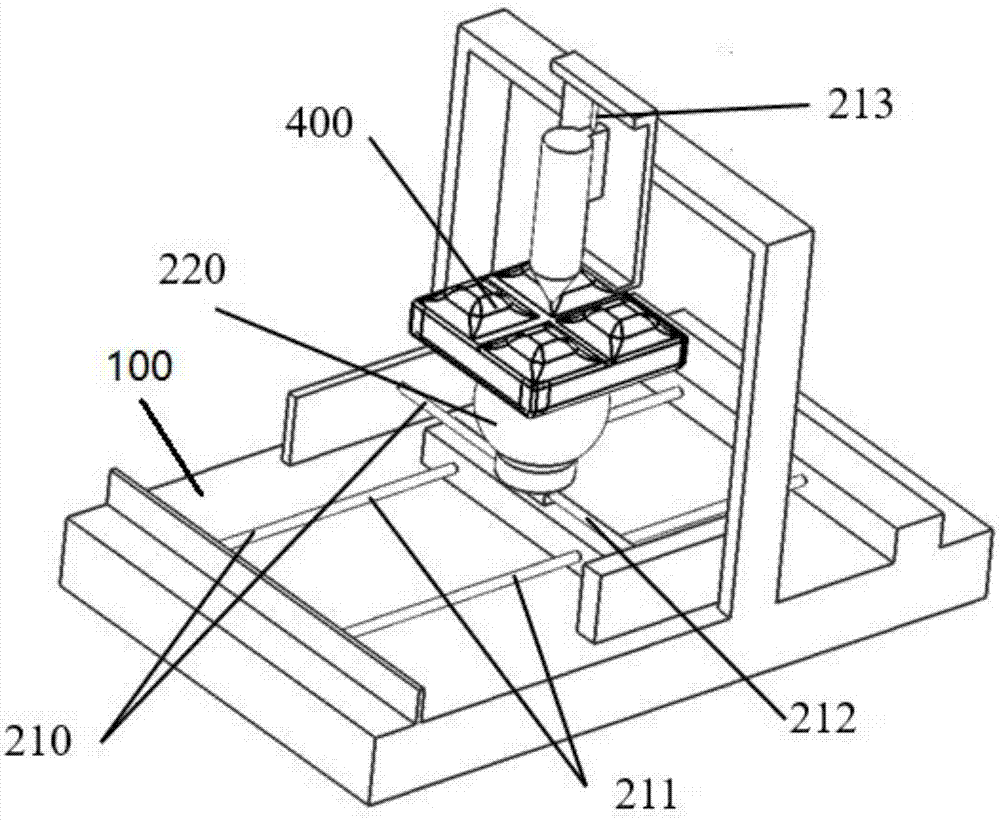

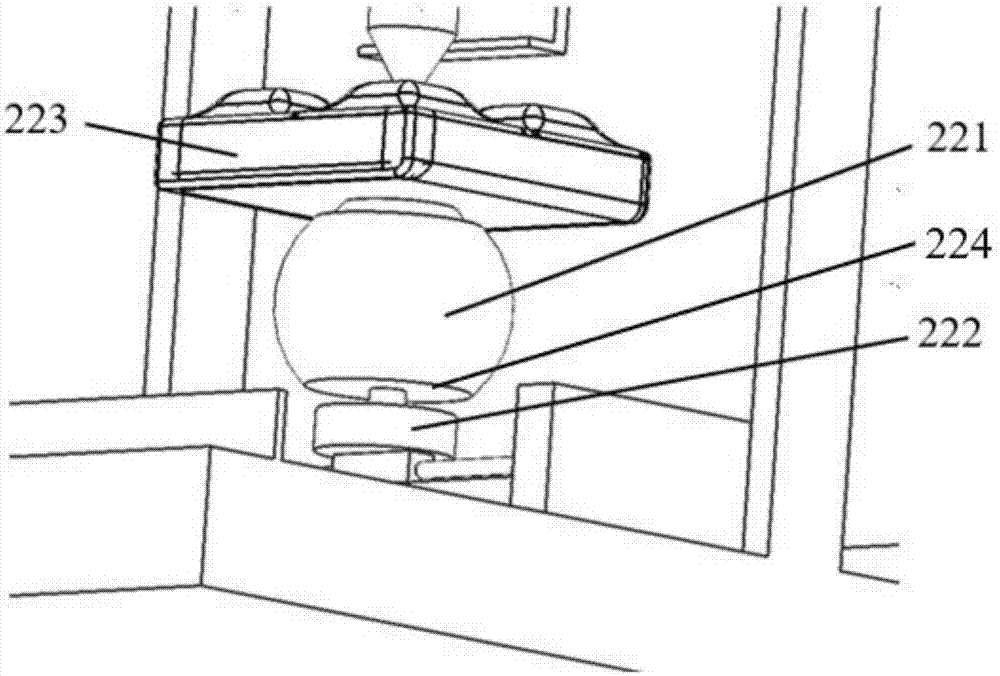

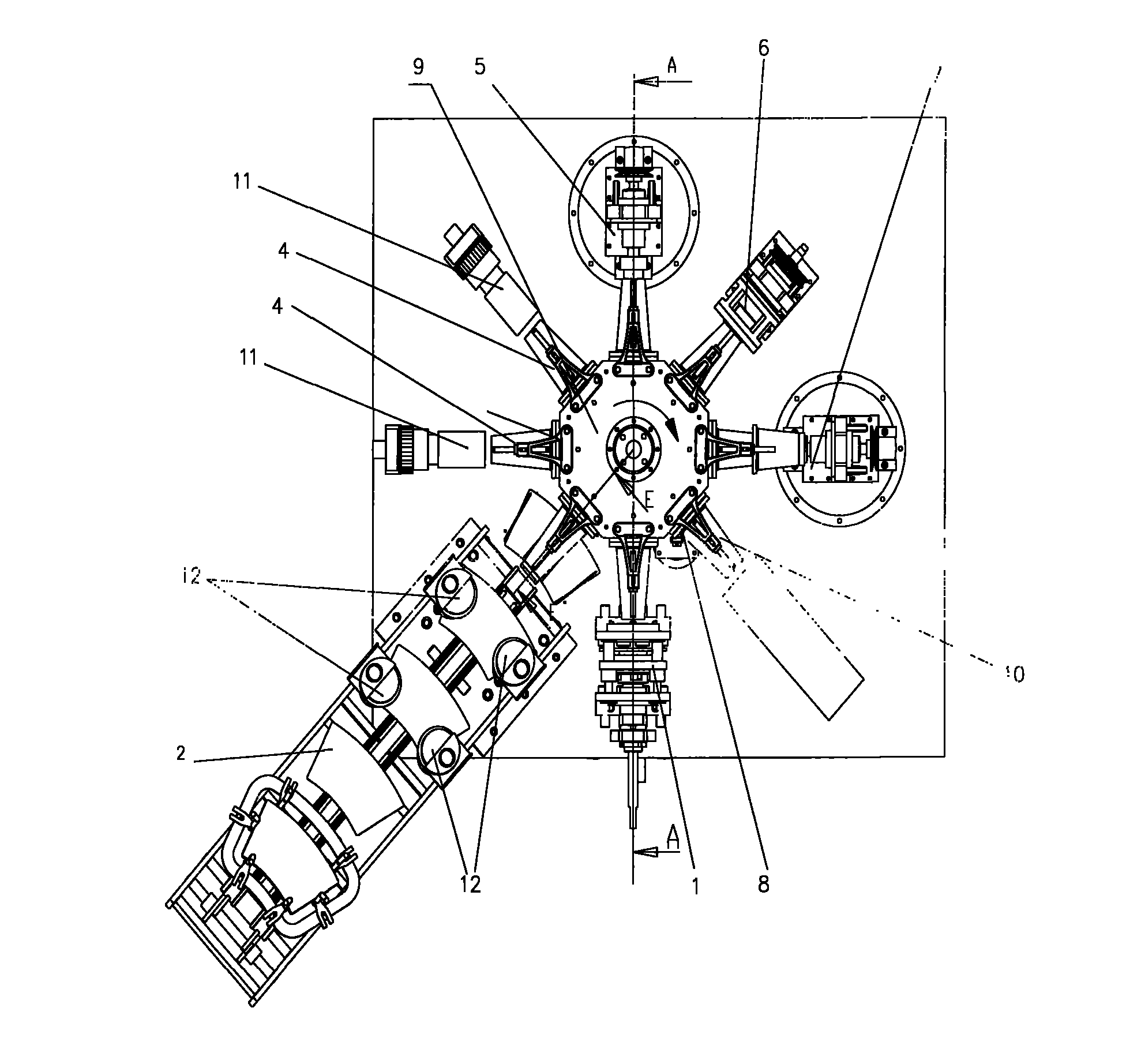

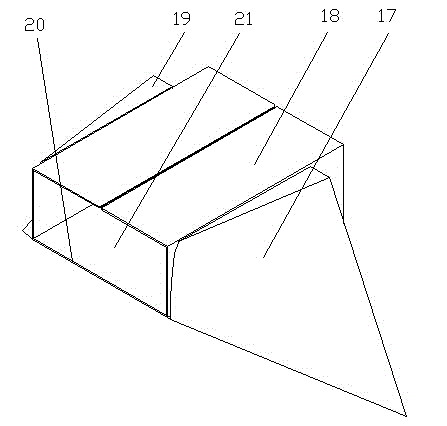

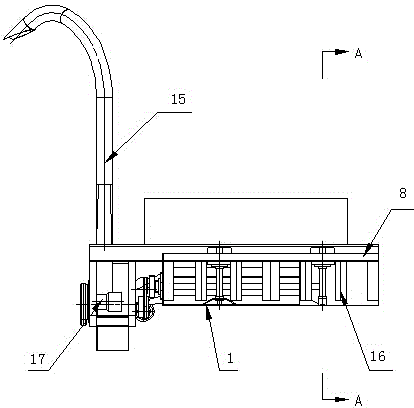

Complex surface circuit conformal spray printing method and equipment

ActiveCN107512083AOmit vector transformationSteady ejectionDuplicating/marking methodsTypewritersManufacturing cost reductionComputer module

The invention belongs to the field of electric fluid dynamics spray printing, and discloses a complex surface circuit conformal spray printing method and equipment. The equipment comprises a spherical motor module, a translation module and a conformal spray printing module. The translation module drives the spherical motor module to move in an X-axis direction and a Y-axis direction in a plane; the conformal spray printing module comprises a spray head part and an electric signal part; the spray head part moves up and down so as to realize a freedom degree of a Z-axis direction; the electric signal part applies voltage on an ink fluid and an electrode ring in an ink cartridge; the spherical motor module rotates around the X-axis direction, the Y-axis direction and the Z-axis direction so as to realize six-degree-of-freedom motion of an object to be spray-printed; a curve surface base plate is grounded, so that the electric potential of the object to be sprayed-printed is zero; and the voltage applied in the ink fluid is higher than the voltage applied in the electrode ring, so that a gradient electric potential difference is formed on the ink fluid, the electrode ring and the object to be spray-printed. Through the complex surface circuit conformal spray printing method and the equipment provided by the invention, a conformal patterning electric spray-printing process of a complex surface is realized, an application range of the electric spray-printing process is improved, the manufacturing cost is reduced, and the printing accuracy is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

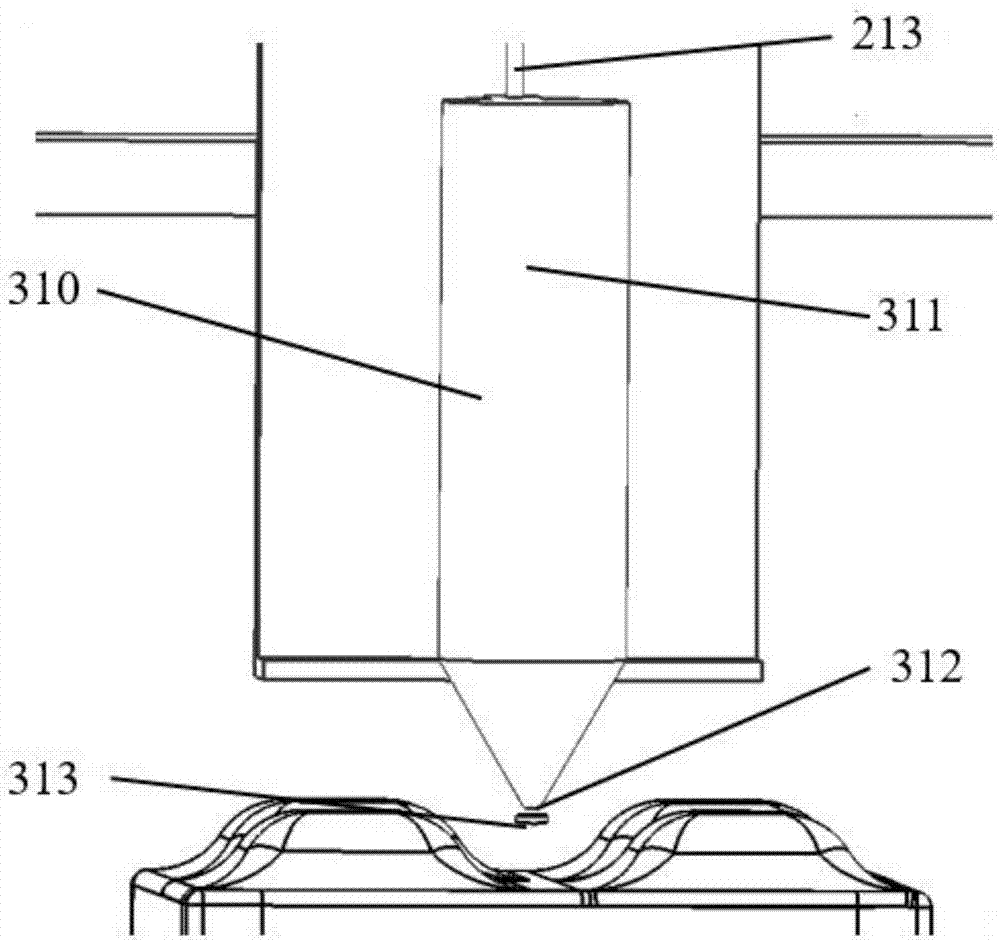

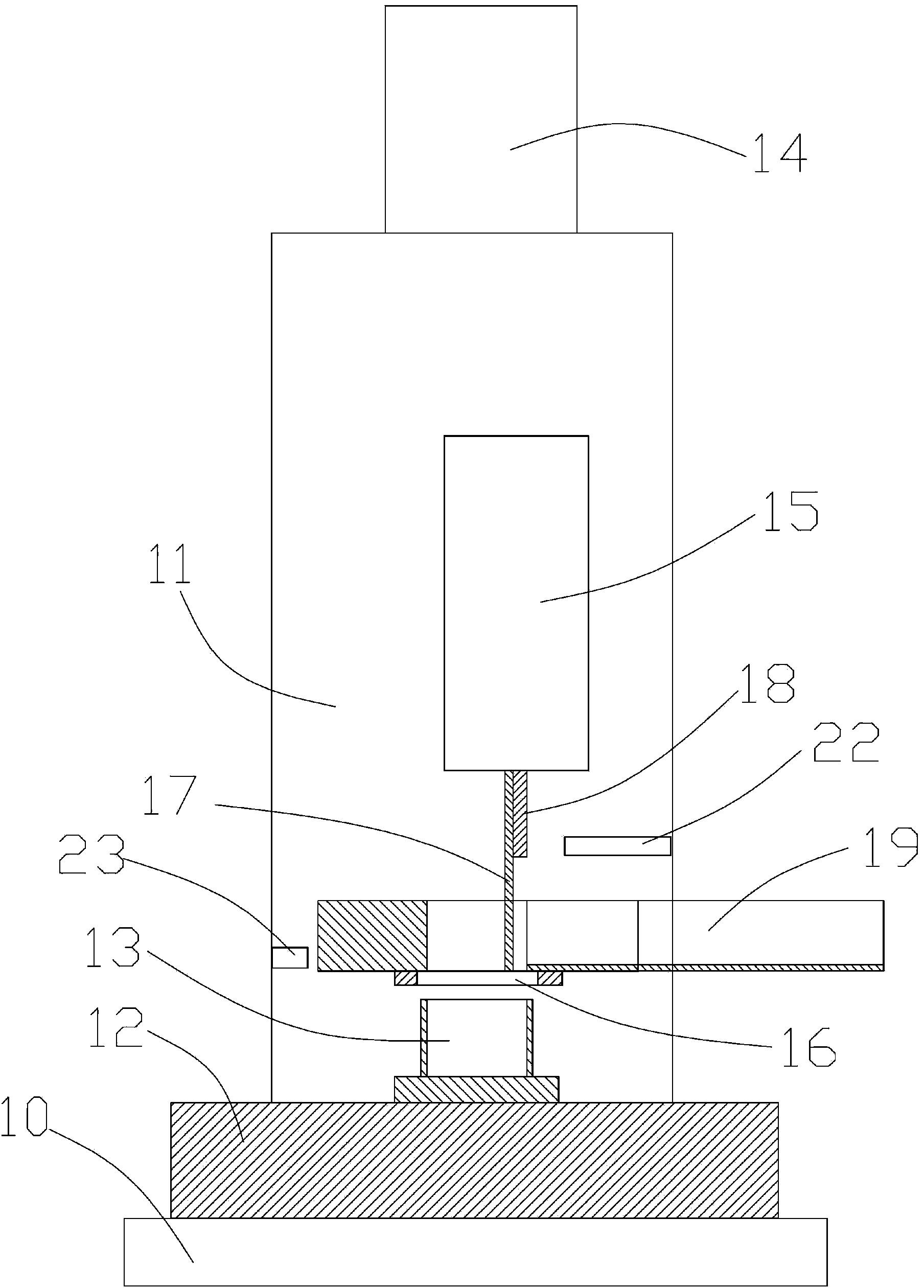

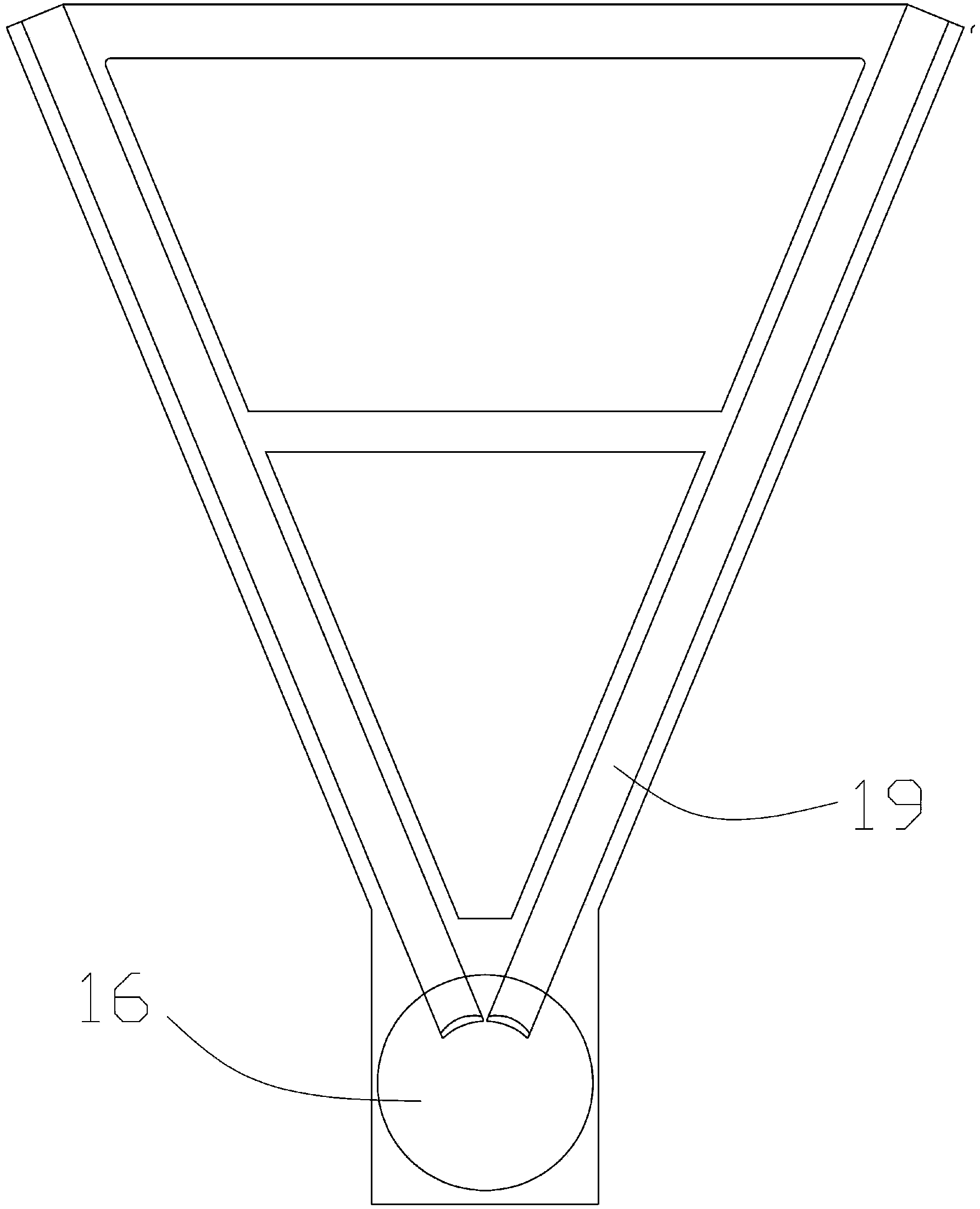

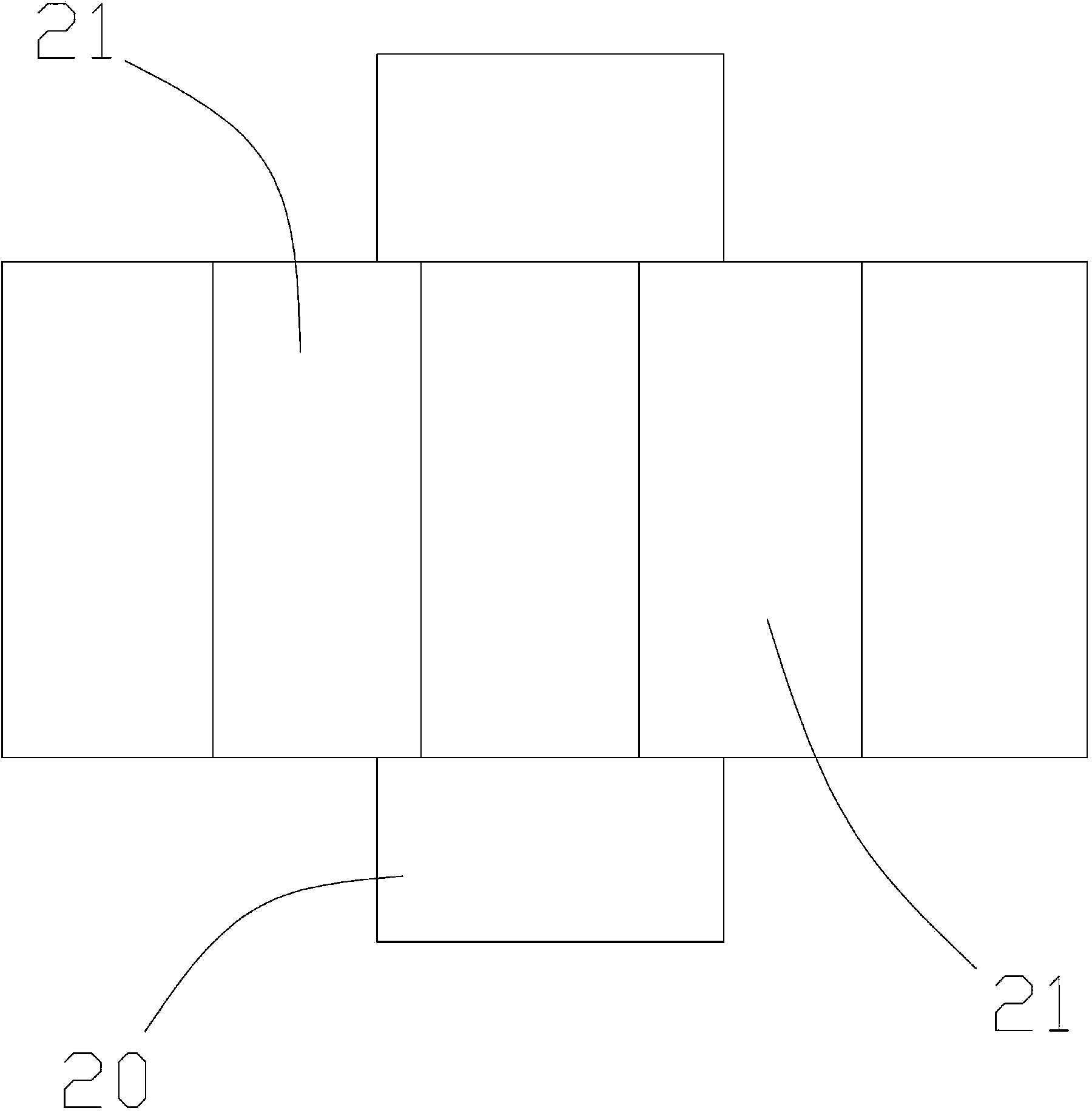

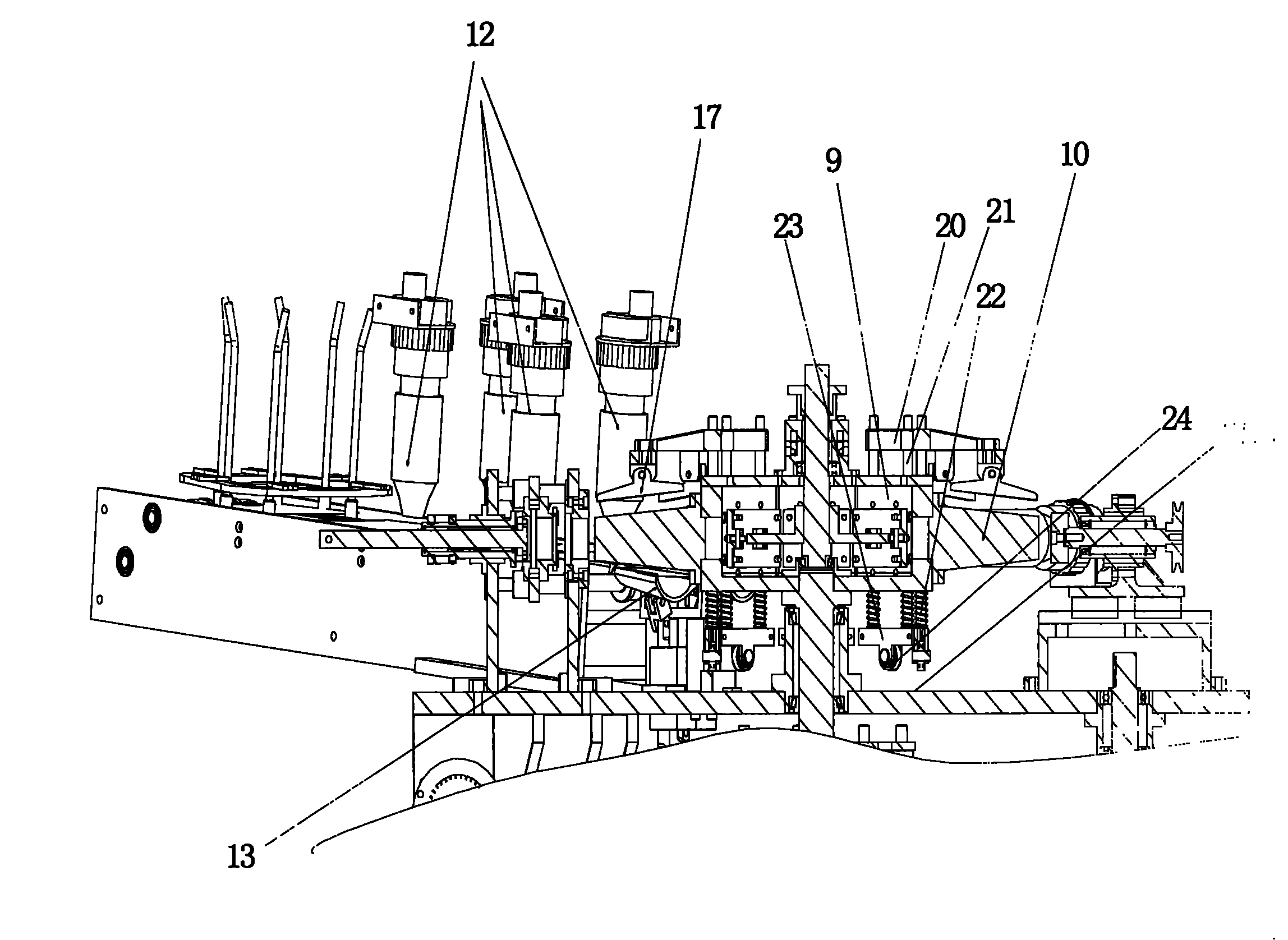

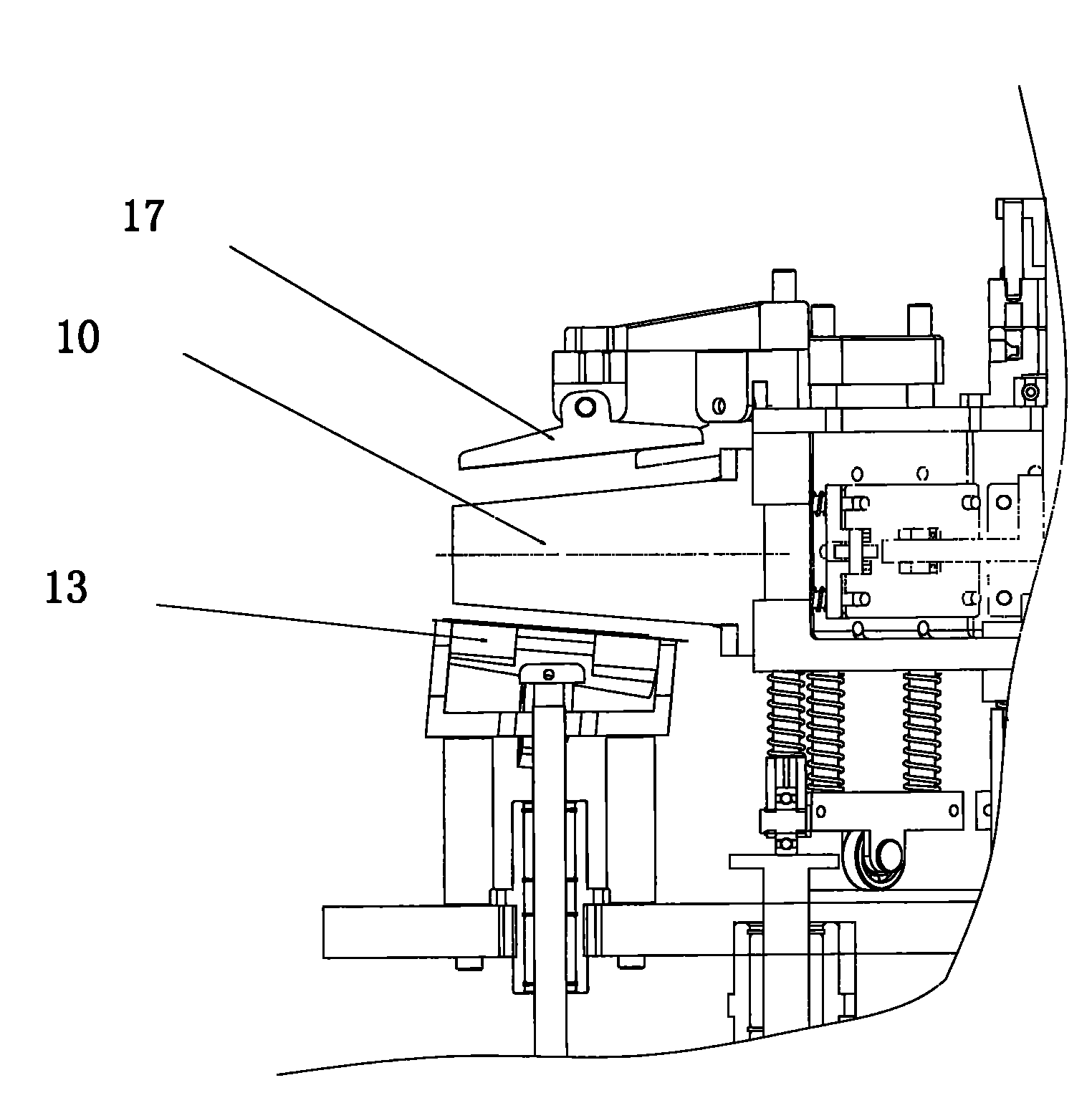

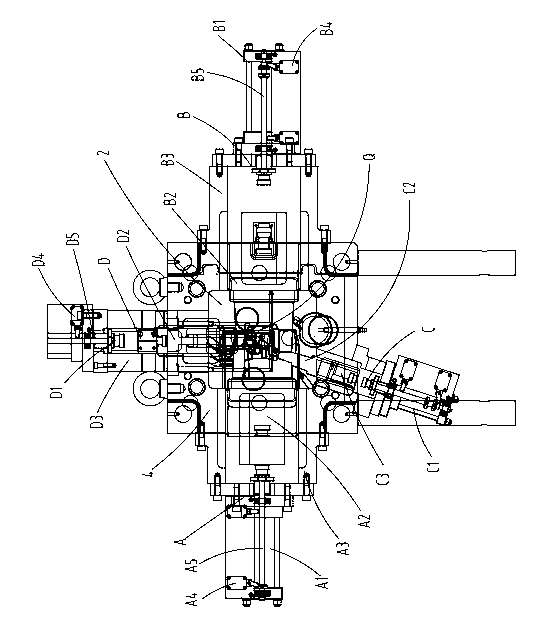

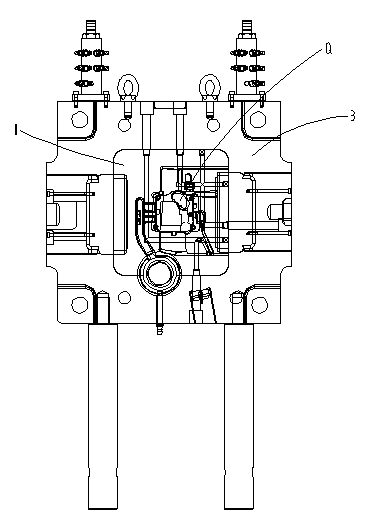

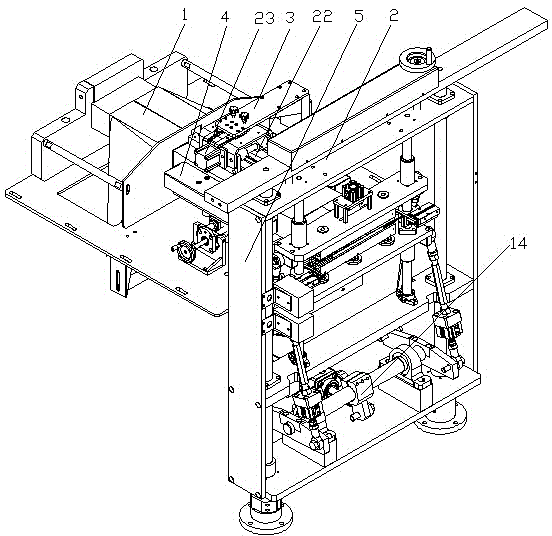

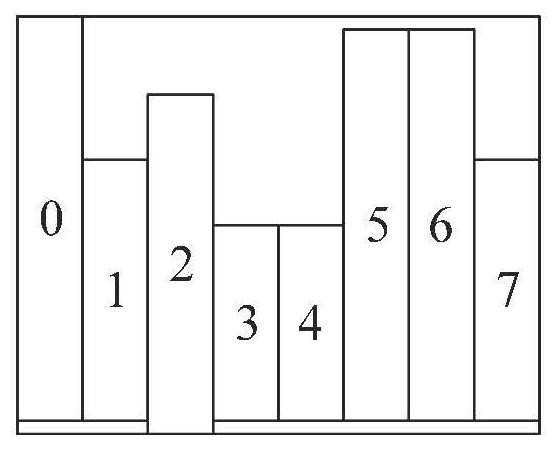

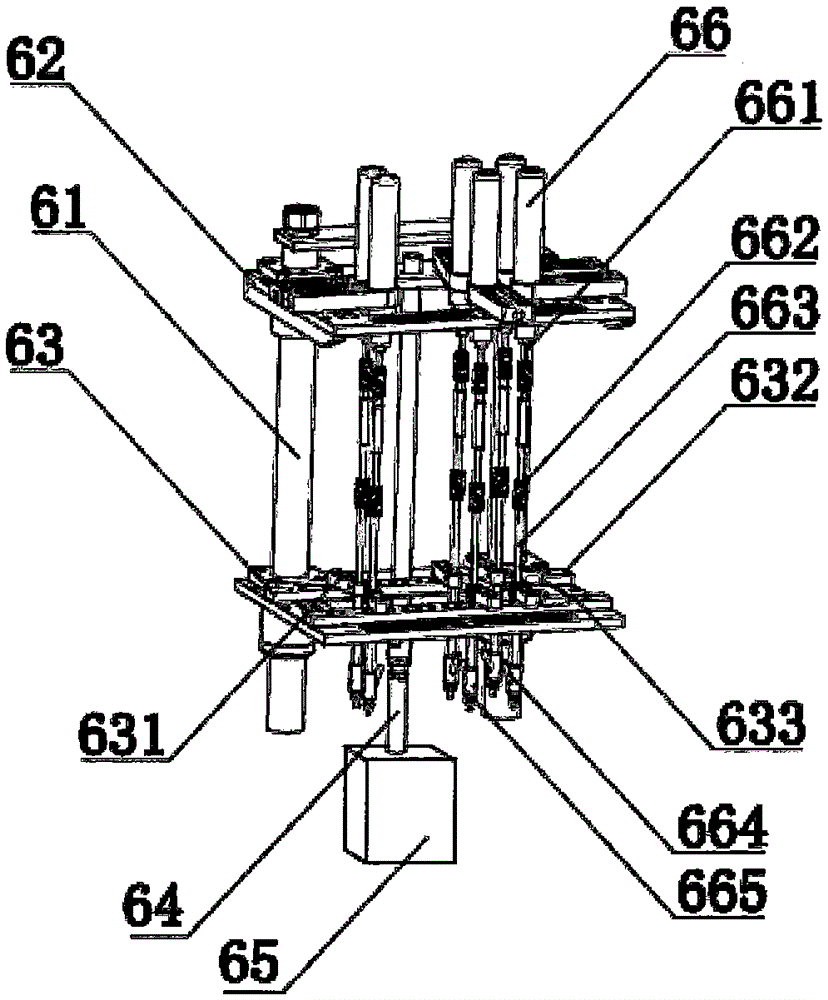

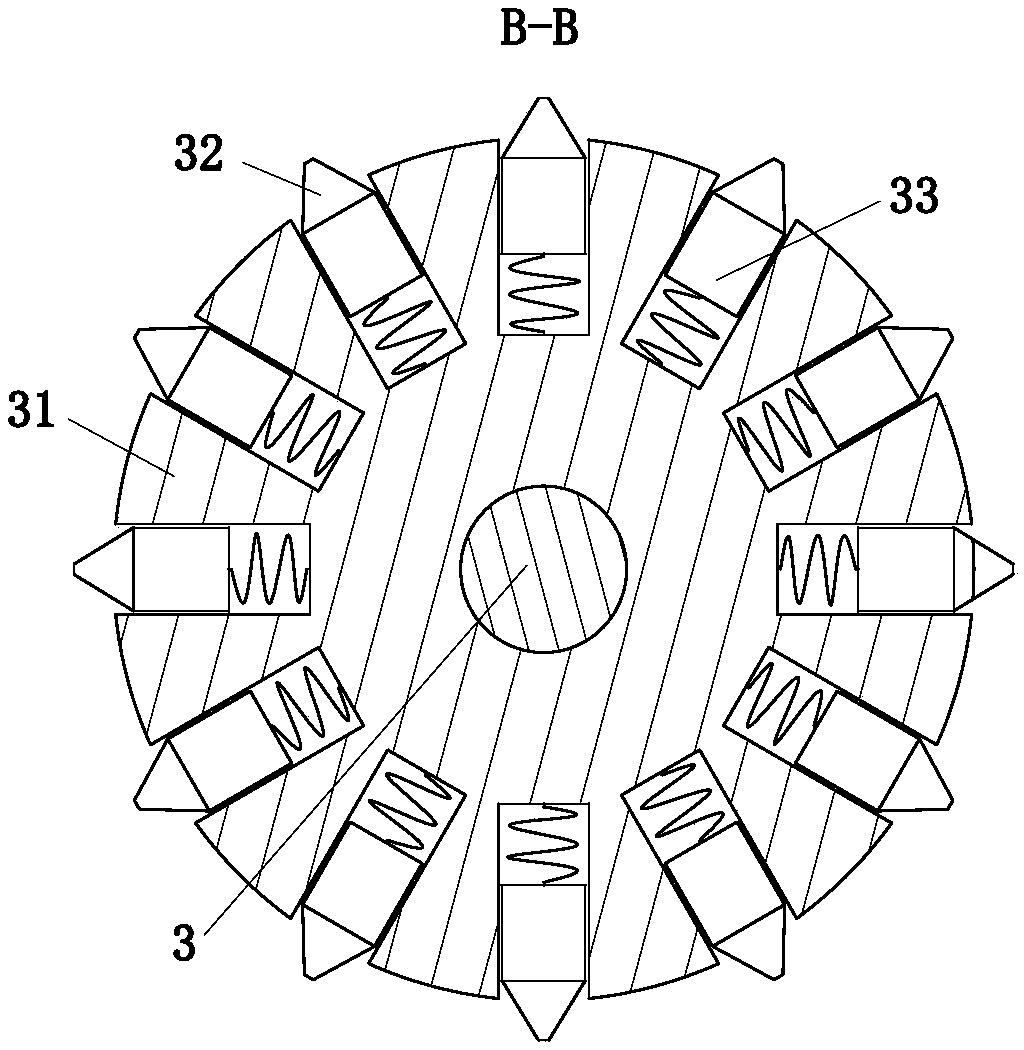

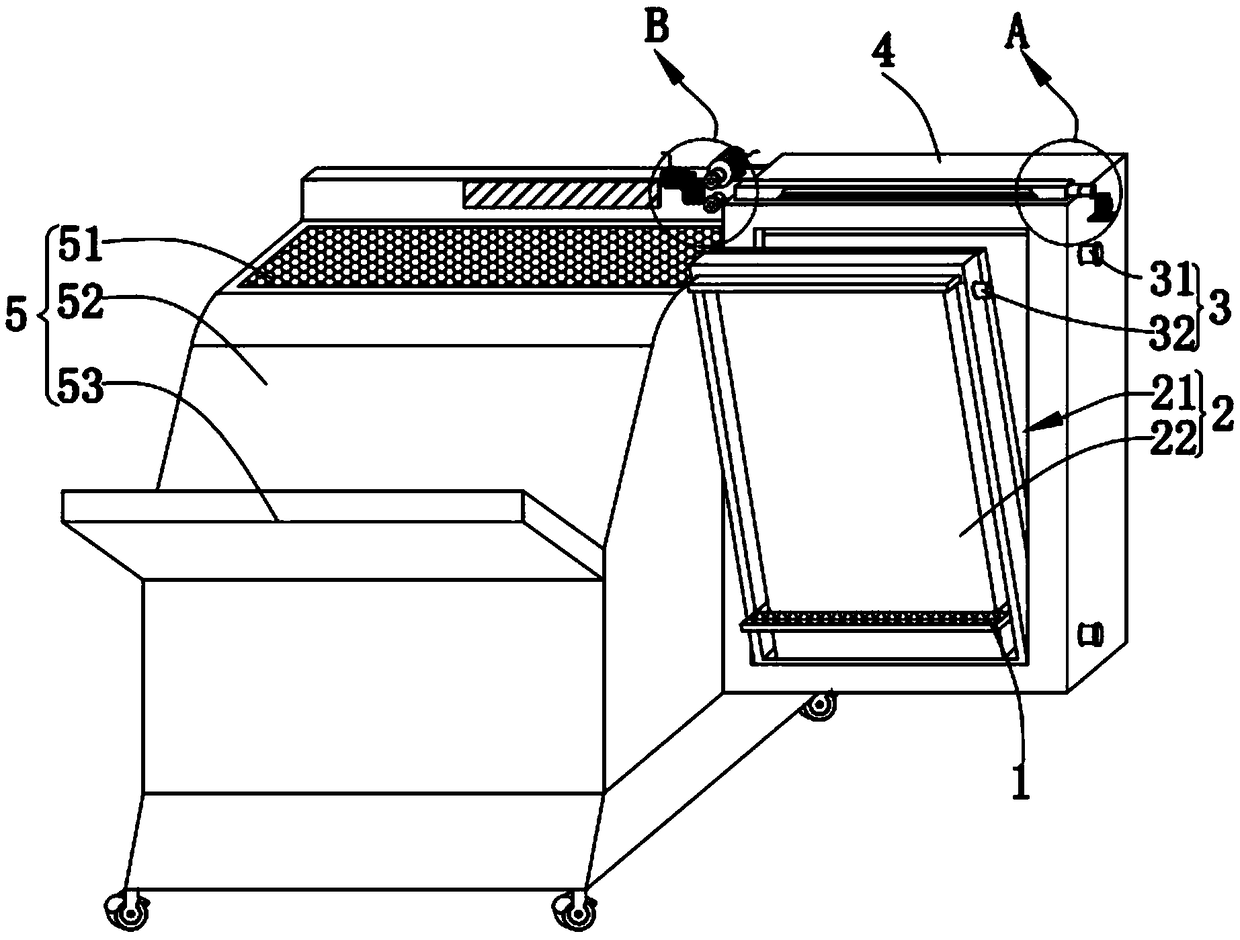

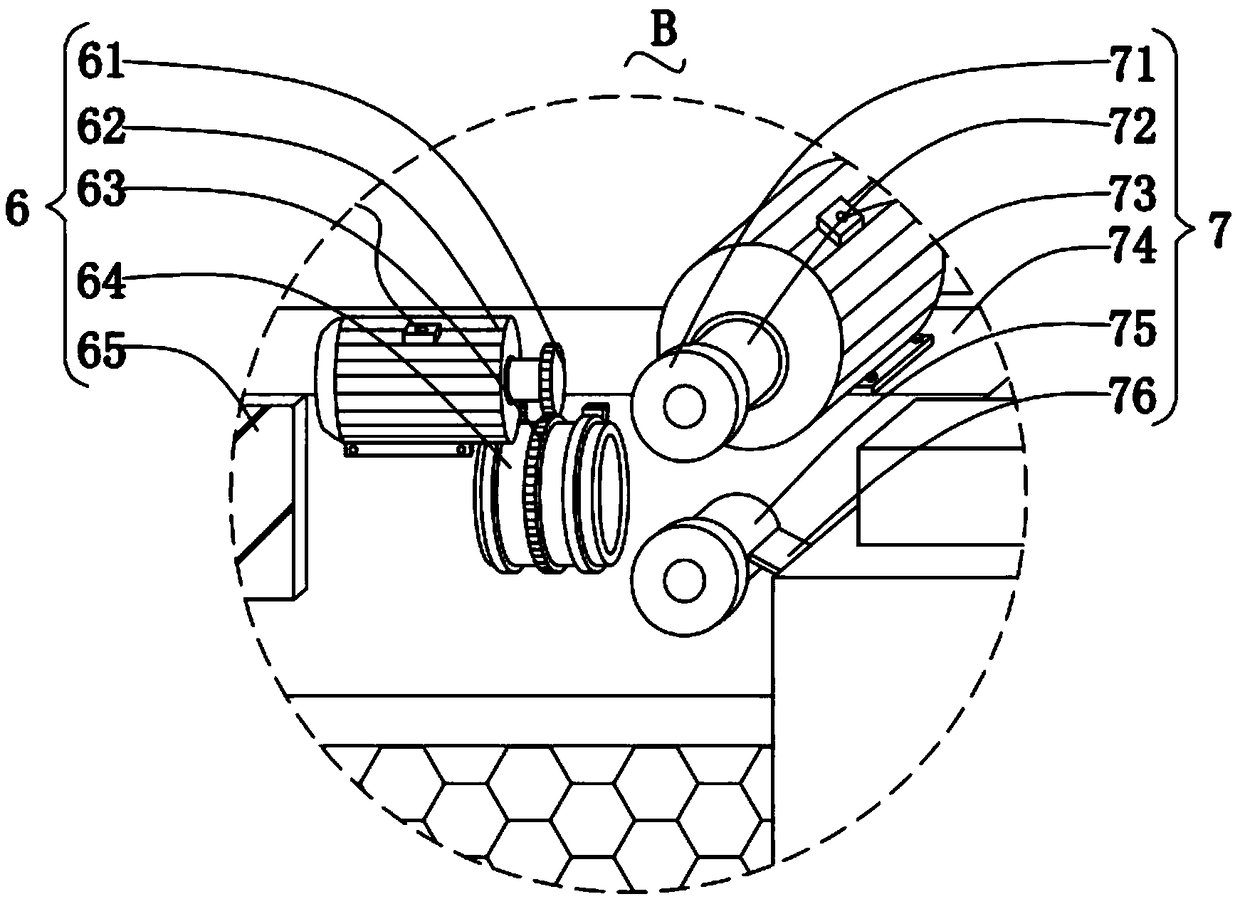

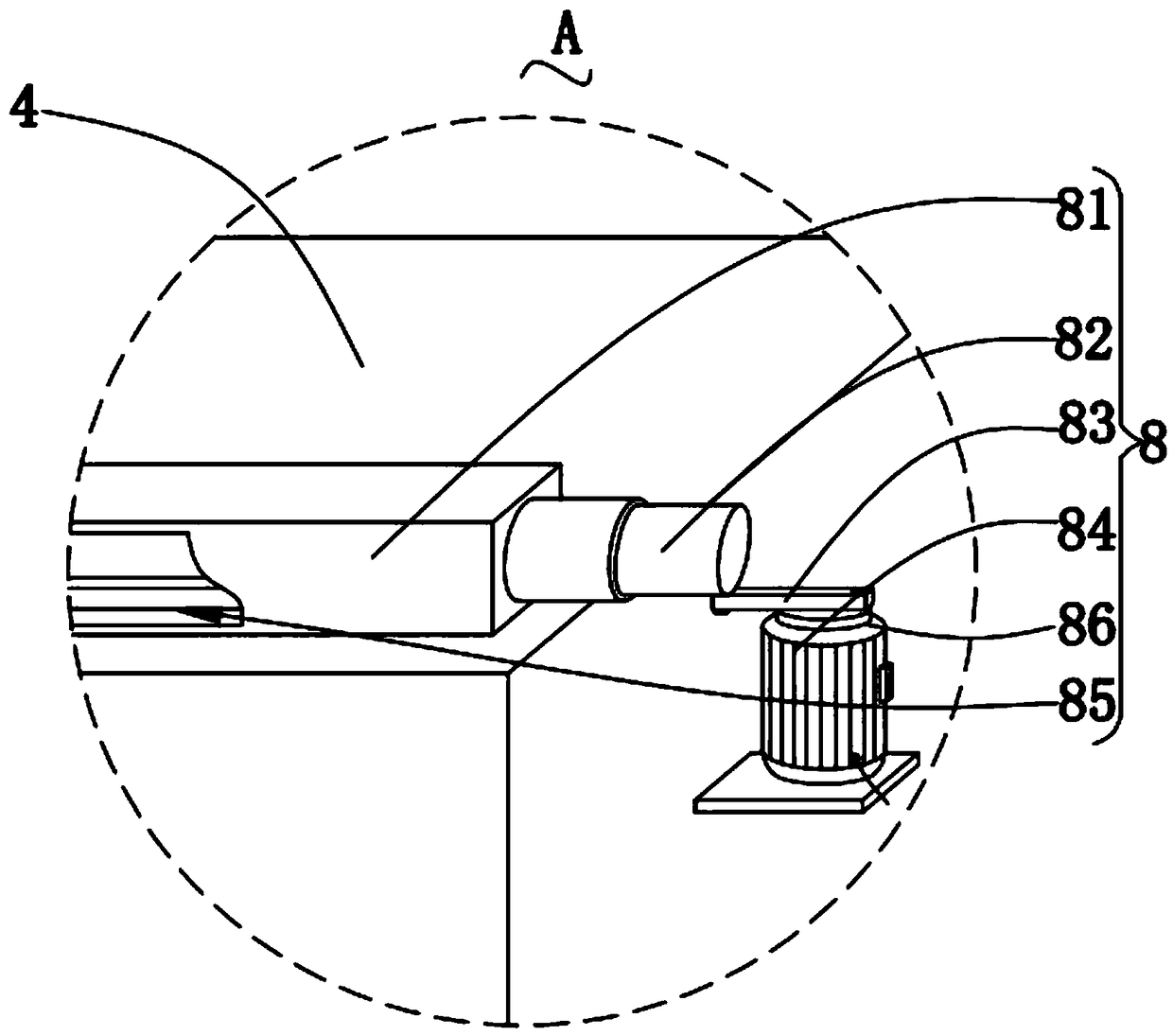

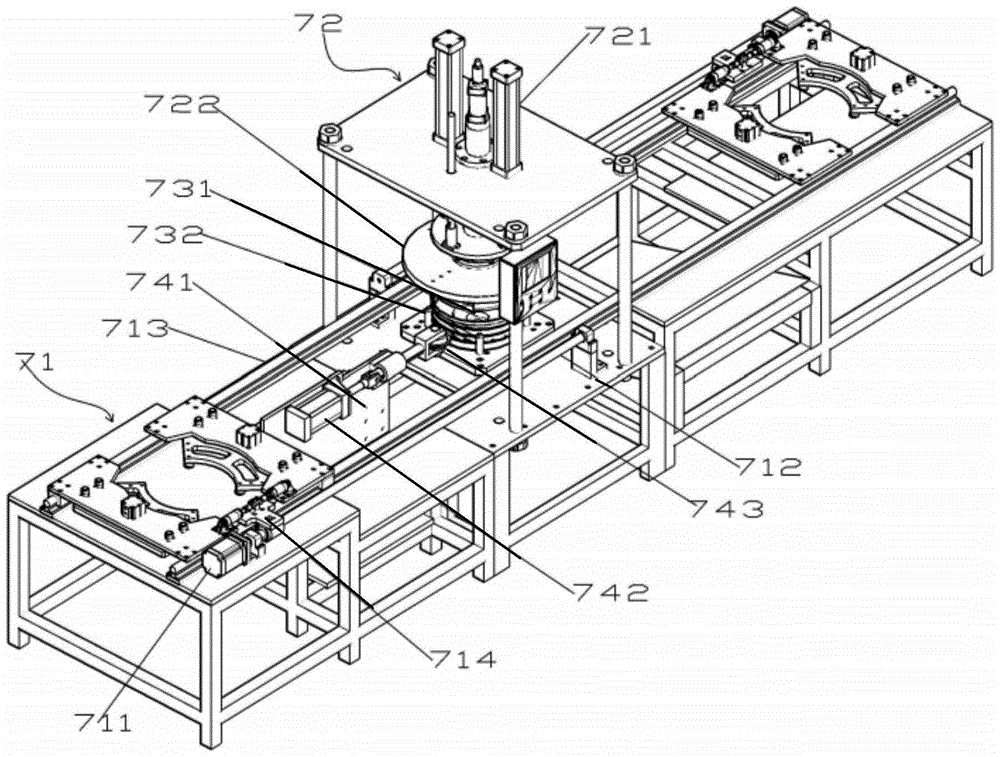

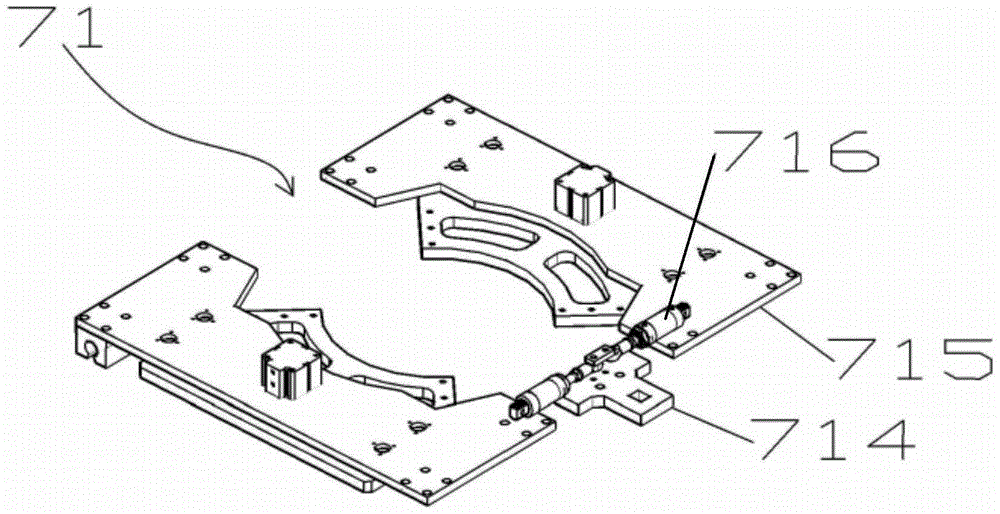

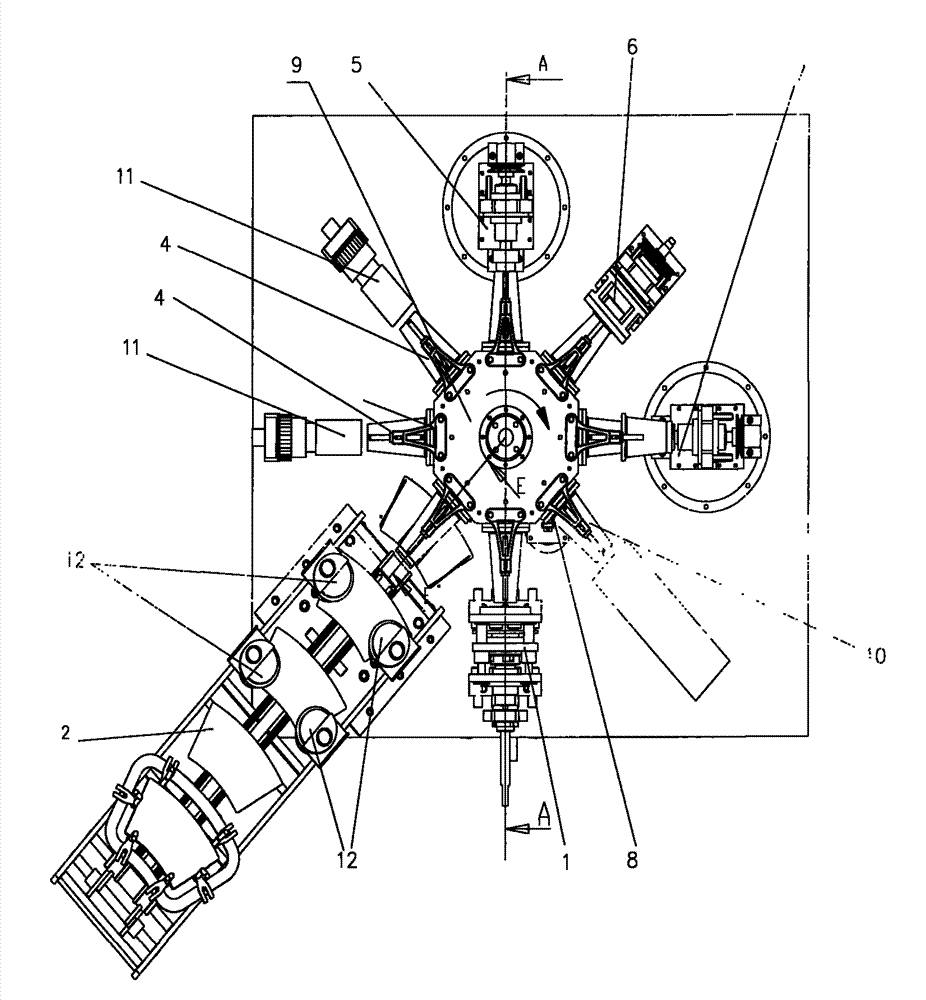

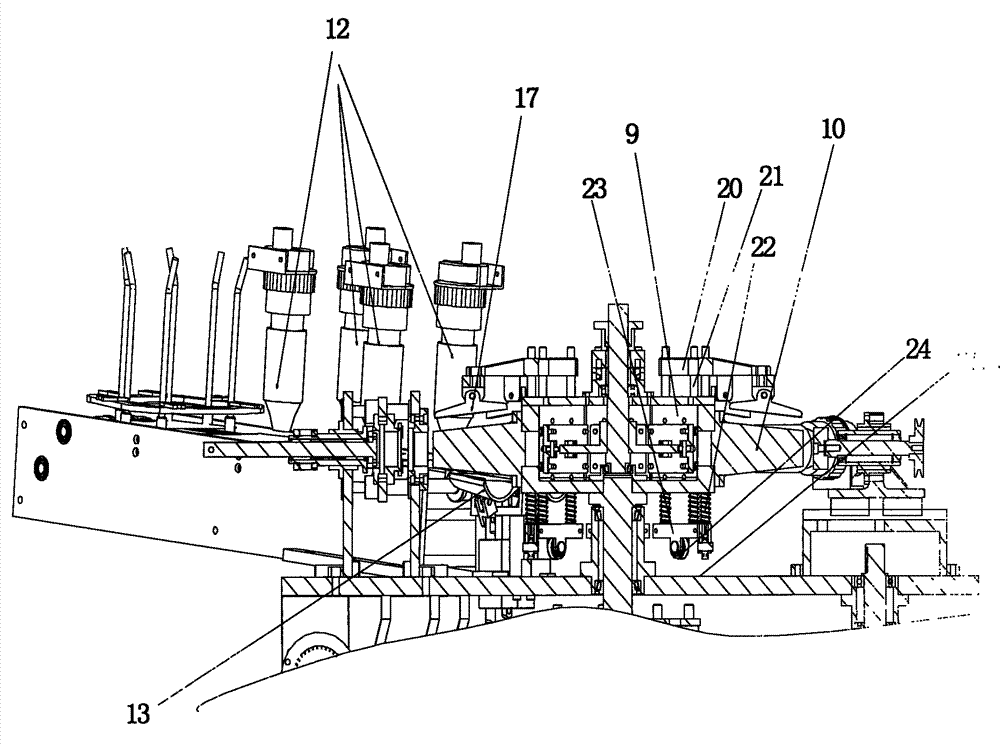

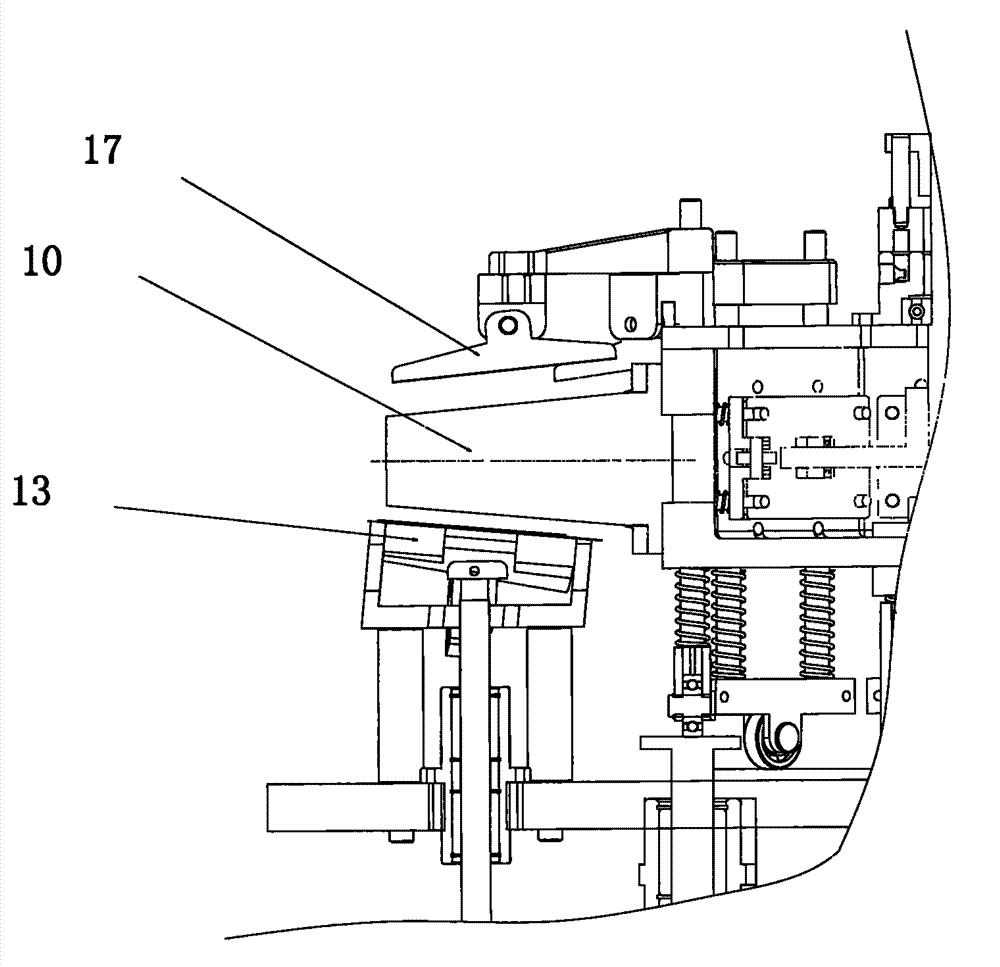

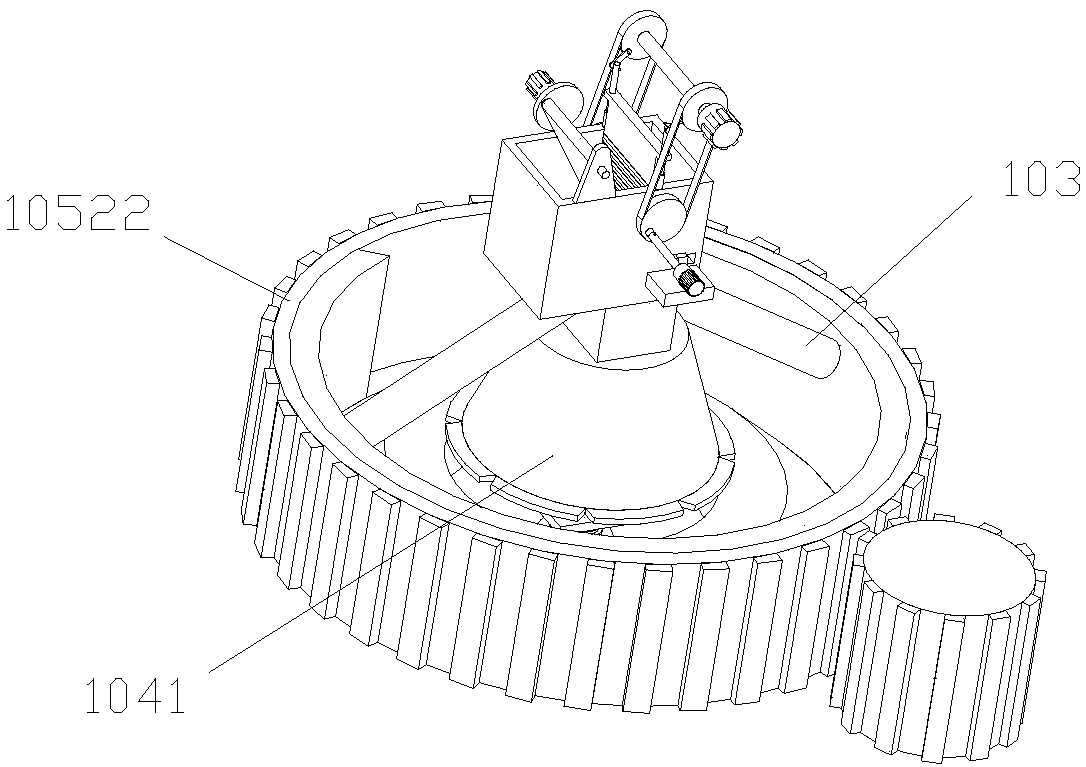

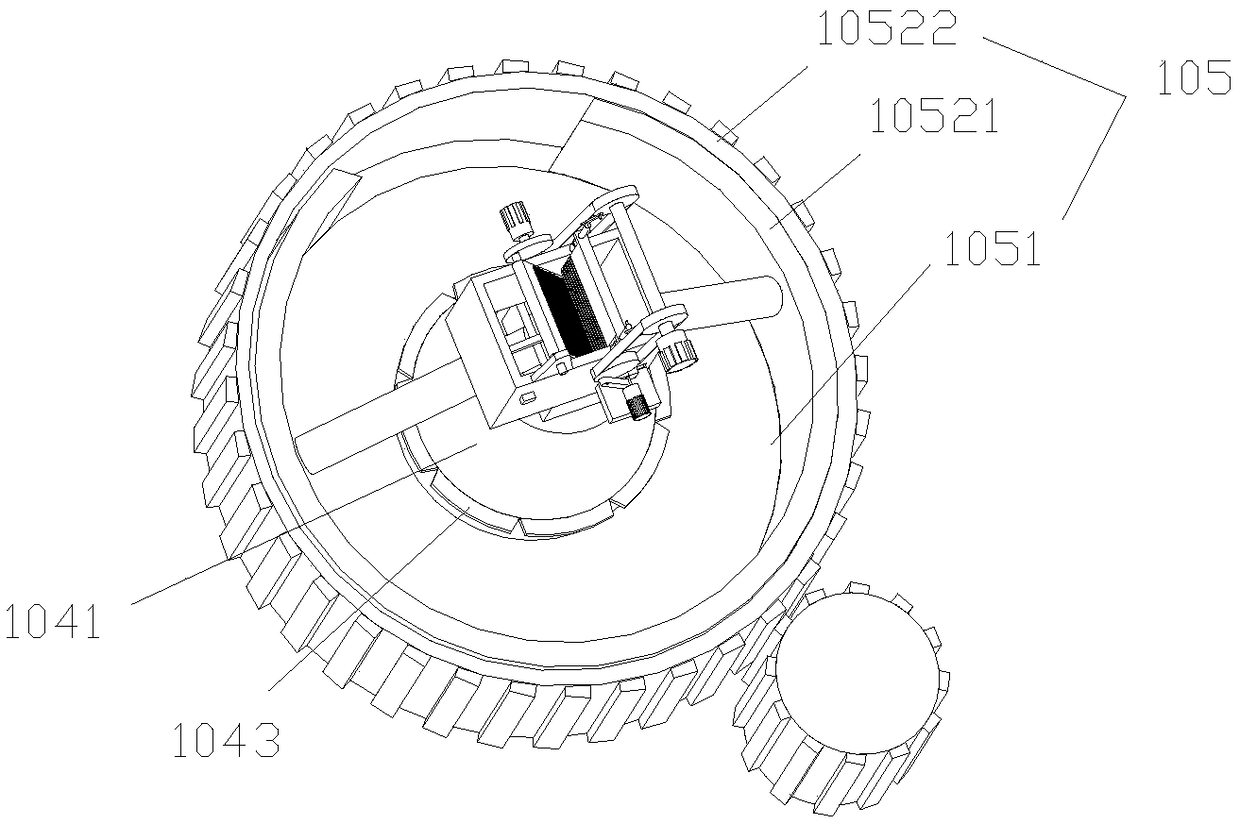

Automation equipment for installing motor rotor magnetic steel sheets

ActiveCN103944325AStrong coherenceAutomate installationManufacturing stator/rotor bodiesMagnetic polesEngineering

The invention particularly relates to automation equipment for installing motor rotor magnetic steel sheets, and belongs to the technical field of motor accessory machining equipment. The automation equipment comprises a base, a dividing device and a guide rail are arranged on the base, a sheet inserting mechanism and a power device I for driving the sheet inserting mechanism to slide along the guide rail are arranged on the guide rail, the sheet inserting mechanism comprises a power device II and a butting base, a feeding assembly is arranged on the power device II, a feeding groove for storing the magnetic steel sheets is formed in the butting base, and the butting base is located between the dividing device and the power device II. The automation equipment achieves automated installation, saves manpower, reduces workload, is high in magnetic steel sheet separation and insertion continuity, simplifies installation steps, is stable, achieves insertion of a plurality of magnetic steel sheets, is distinct in magnetic pole, increases the production efficiency and the product percent of pass, and is simple in structure, convenient to operate and low in manufacturing cost.

Owner:台州市速普机电有限公司

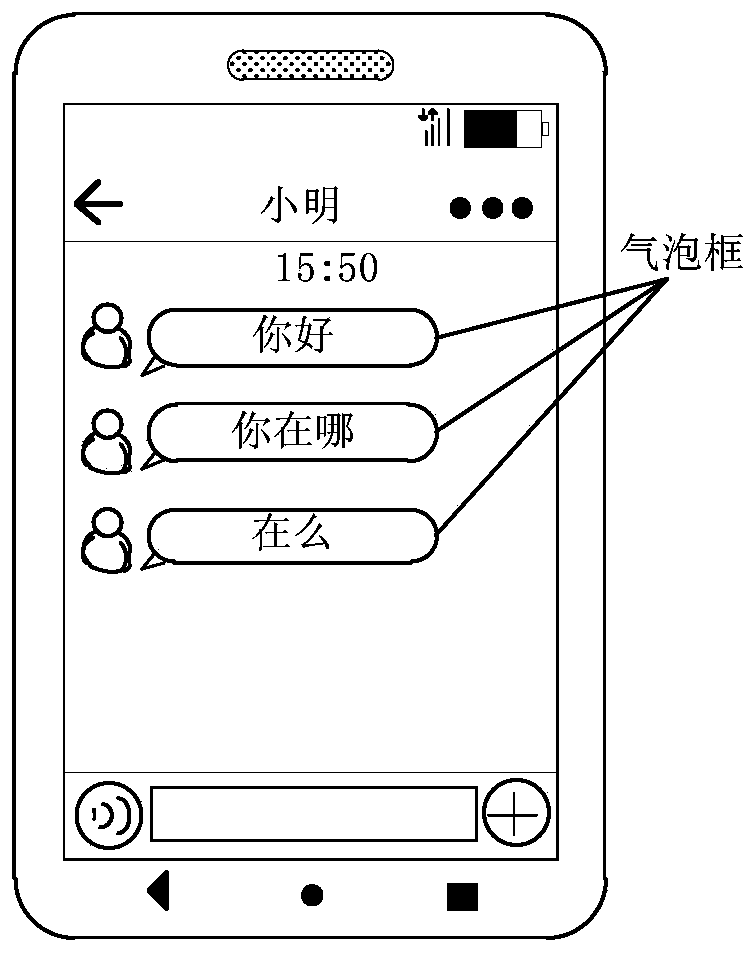

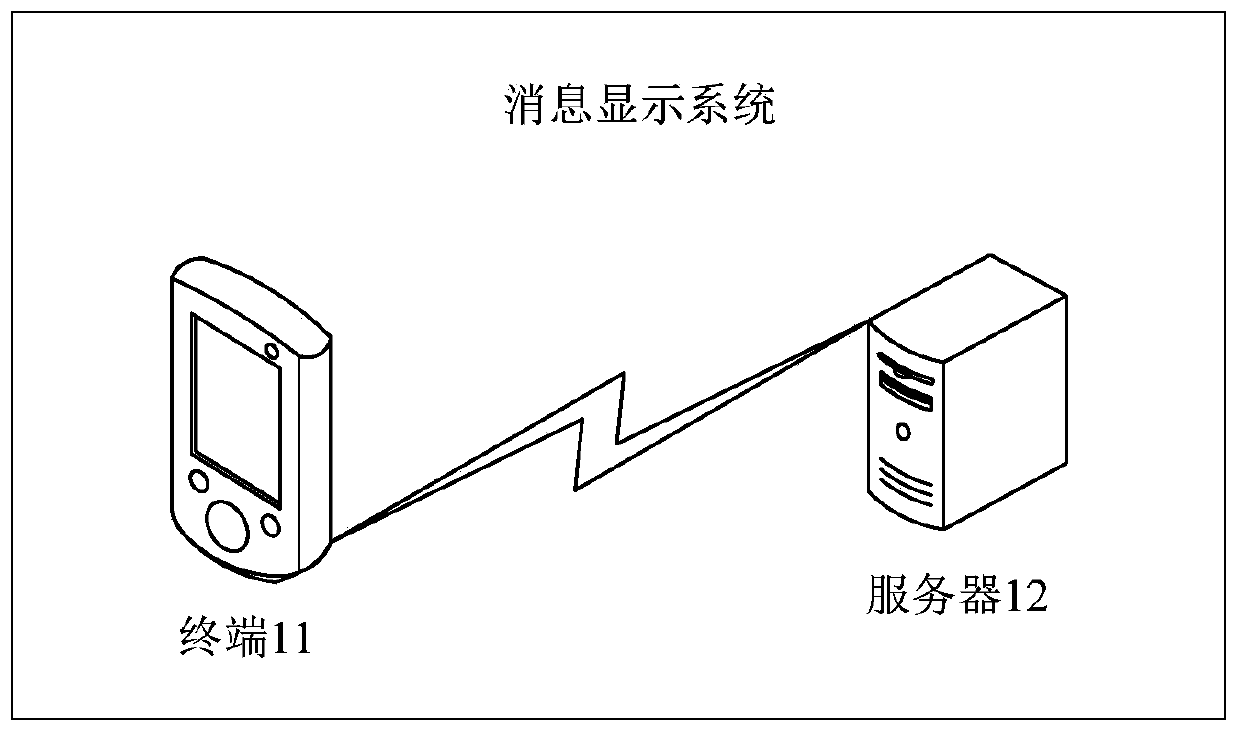

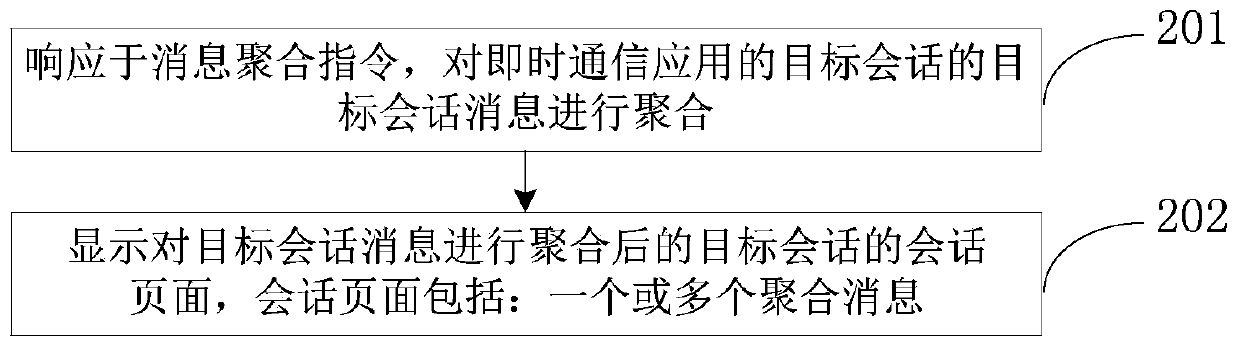

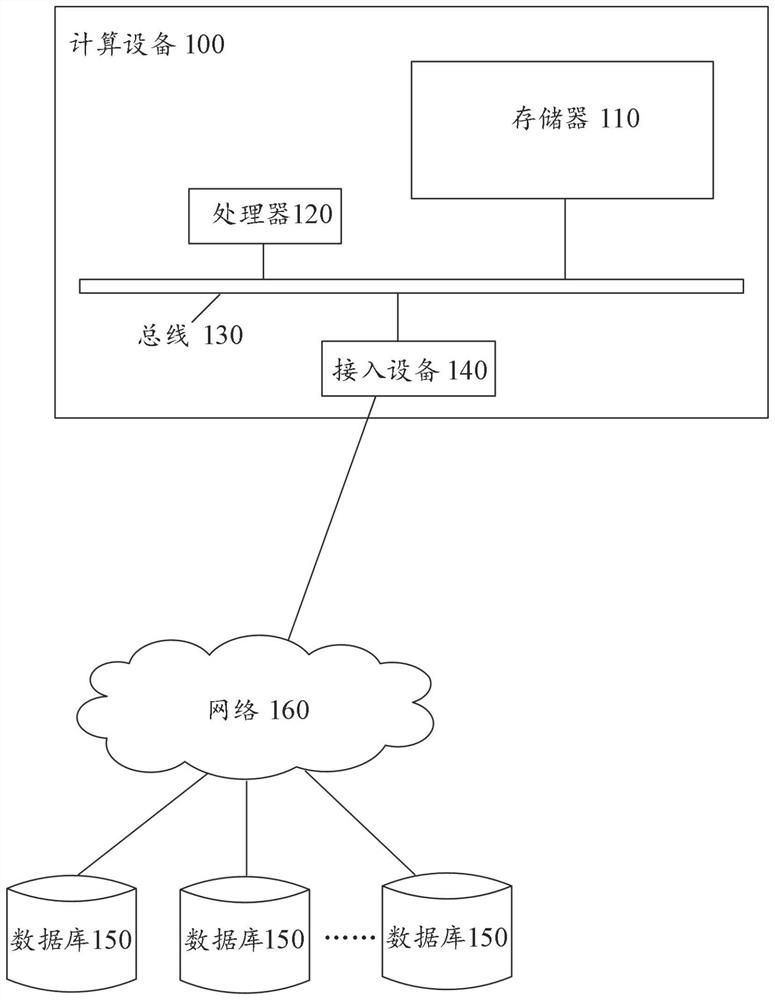

Message display method and device

ActiveCN111555961AImprove the efficiency of viewing messagesImprove experienceProgram loading/initiatingData switching networksDisplay deviceInstant messaging

The invention relates to a message display method and device, relates to the field of communication, increases message content displayed on a session page of an instant messaging application, and improves the space utilization rate of the session page. The message display method comprises: aggregating a target session message of a target session of an instant messaging application by a message display device in response to a message aggregation instruction; wherein the target session message comprises one or more groups of messages to be aggregated, one group of messages to be aggregated comprises continuous N messages of one account, and N is a positive integer; and displaying a session page of the target session after the target session message is aggregated, the session page comprising:one or more aggregated messages, and one aggregated message comprising a message content included in a corresponding group of messages to be aggregated.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Paper cup machine

The invention discloses an improved invention of a paper cup machine, which is mainly characterized in that the machine body comprises a rotating disc, wherein the periphery of the rotating disc is provided with a horizontal cup mould, a bounding press block is arranged on the position of the horizontal cup mould, when the rotating disc rotates, the cup mould sequentially passes through each station making paper cups, the rolling bottom and the hemming of the invention are formed at one step, and more important, when all the stations work, the cup is always in the bonding state on the cup mould, so that the edge of the heated paper cup has enough time to cool when being bounded, and the paper cup is firmly bounded. The invention has strong movement coherence, can make over 100 paper cups per minute, and can reach the purpose of making the paper cups at a high speed.

Owner:ZHEJIANG NEW DEBAO MACHINERY

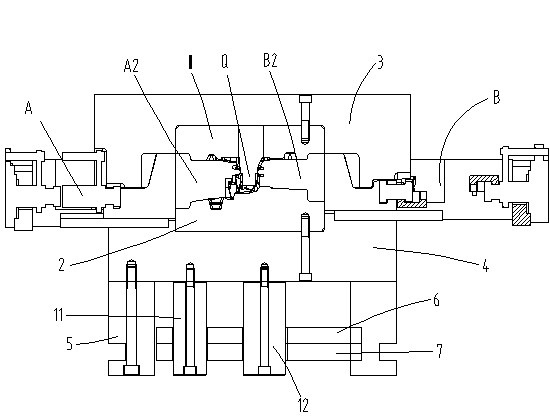

Metal pouring die of hydraulic core pulling structure

ActiveCN103273047AExtended service lifeImprove rigidityFoundry mouldsFoundry coresEngineeringAutomation

The invention discloses a metal pouring die of a hydraulic core pulling structure. The metal pouring die comprises an upper die frame, a lower die frame, an upper die core and a lower die core, wherein the upper die frame and the lower die frame are vertically fastened, the upper die core is embedded on the bottom face of the upper die frame, the lower die core is embedded on the top face of the lower die frame, the upper die core and the lower die core form a forming cavity of the metal pouring die when being vertically matched, a first-side core pulling component and a second-side core pulling component are allocated on the left side and the right side of the lower die frame respectively, and a third-side core pulling component and a fourth-side core pulling component are allocated on the front side and the rear side of the lower die frame respectively. According to forming complexity of the metal pouring die, the core pulling components are independently allocated on four sides of the die, so that the metal pouring die is reasonable in design, flexible to operate and suitable for convenient manufacturing of different models. The core pulling components are driven by hydraulic oil, so that the metal pouring die is high in automation degree, direct in control, high in working efficiency and low in labor cost. The metal pouring die is controlled by travel switches, and core pulling strokes are designed to be adjustable, so that the metal pouring die is convenient and fast to operate and wide in application range.

Owner:NINGBO HUASHUO MOLDING & MACHINE

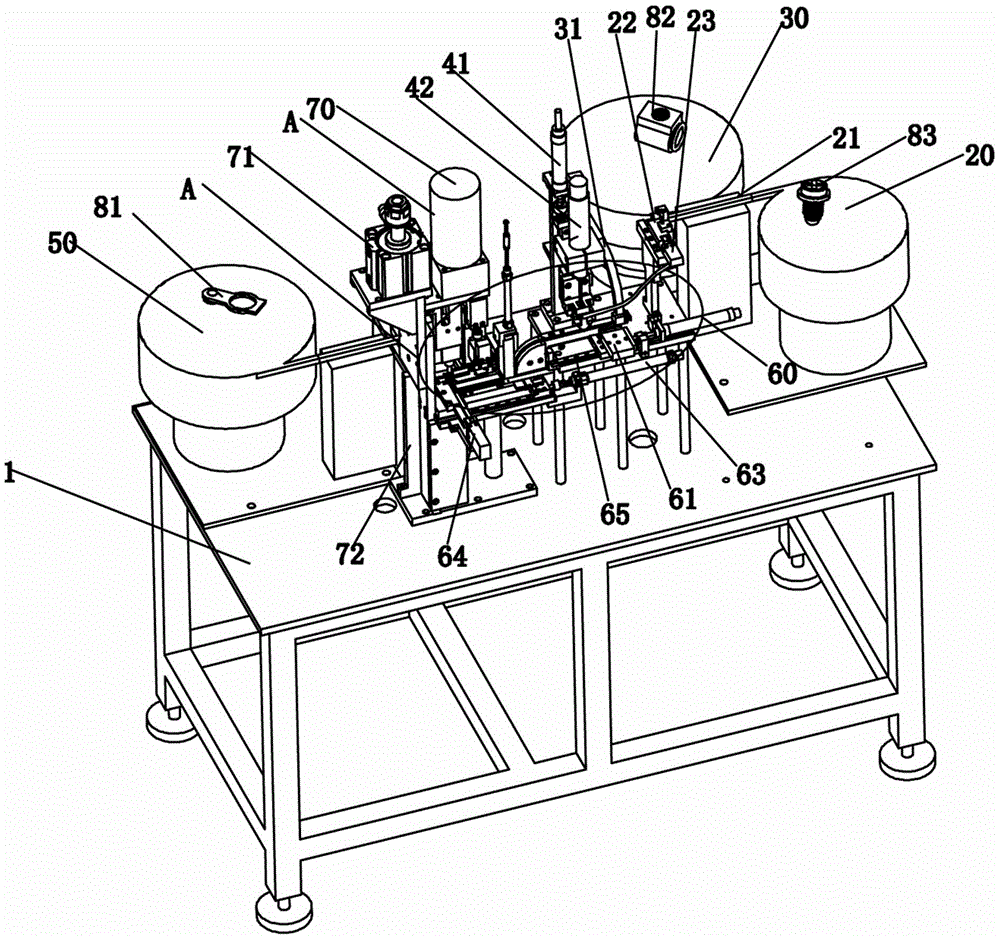

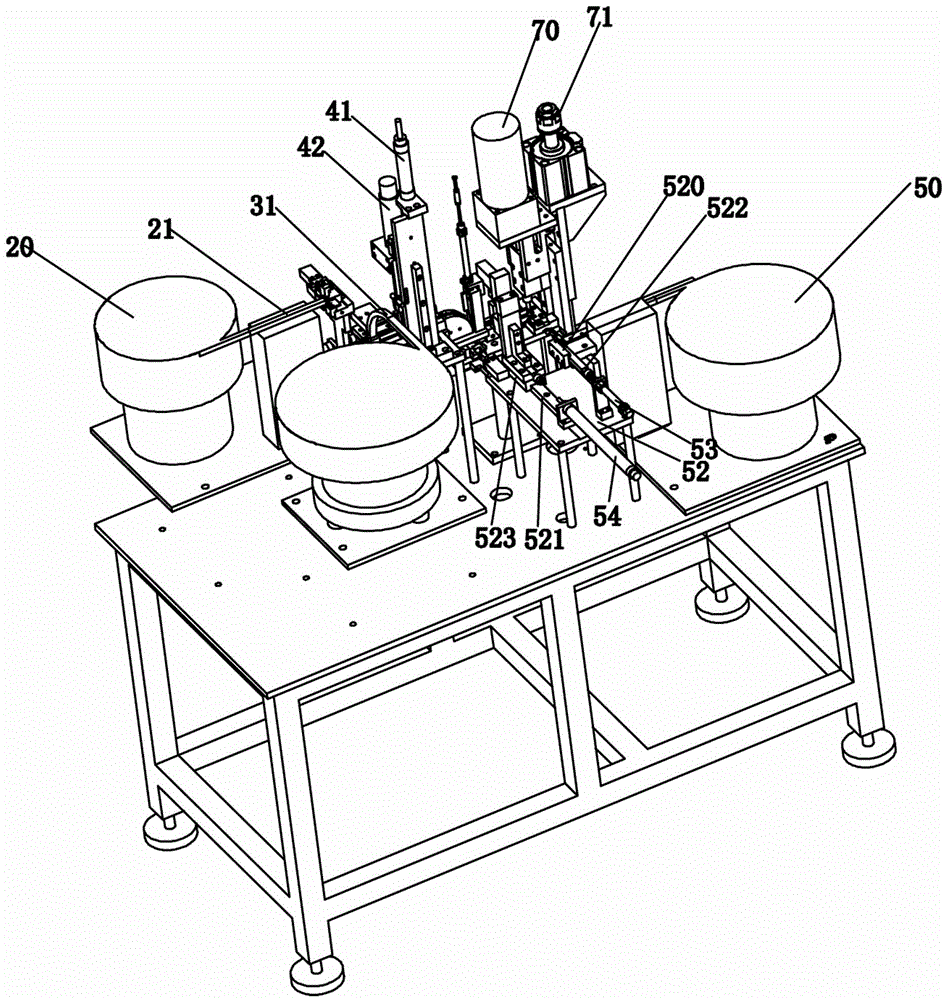

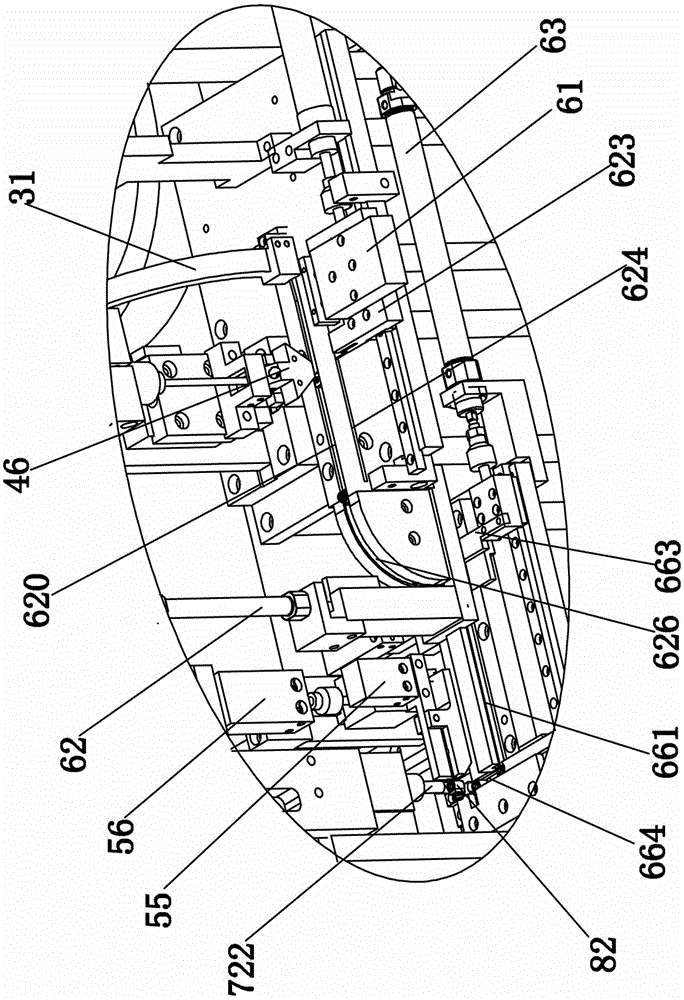

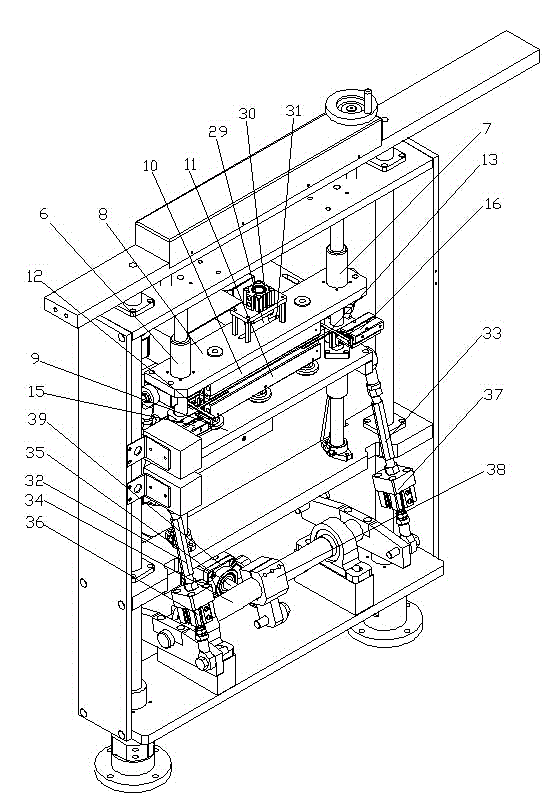

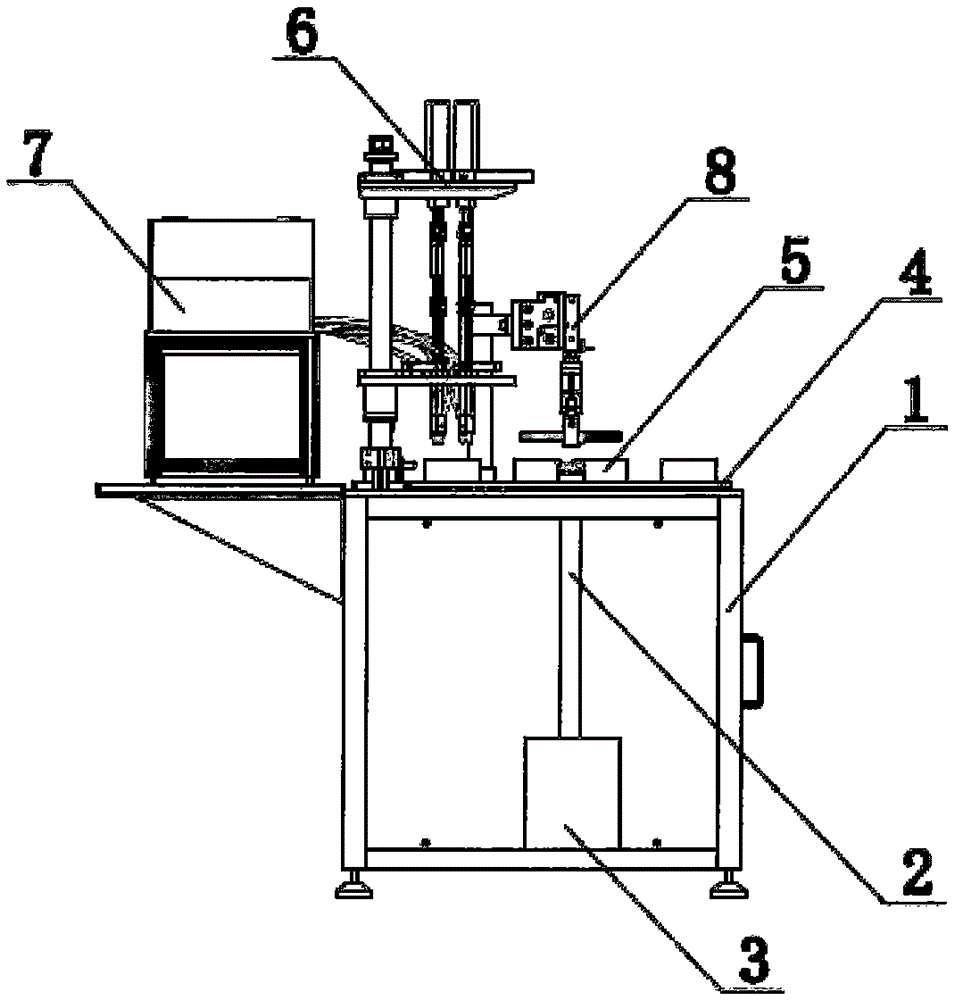

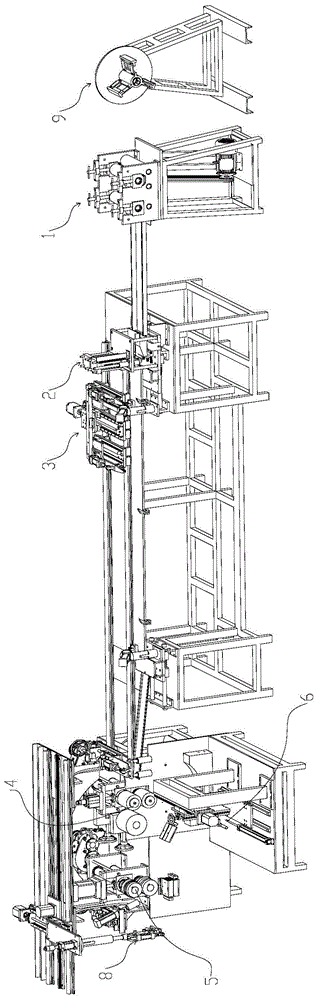

Full-automatic screw locking and sheet riveting feeding machine used for wiring terminal of switch socket

ActiveCN105563084ARealize automatic feedingNo manual operationMetal working apparatusMetal sheetMetal

The invention relates to a full-automatic screw locking and sheet riveting feeding machine used for a wiring terminal of a switch socket. According to the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention, a screw, a metal column and a metal sheet are separately conveyed to a screw turning mechanism through a screw feeding mechanism, a metal column feeding mechanism, a metal sheet feeding mechanism and a material conveying mechanism, and the metal column is screwed up with the screw, and then, the metal column screwed up with the screw is conveyed to a sheet riveting mechanism through the material conveying mechanism for sheet riveting, therefore automatic operation of automatic feeding, automatic screw turning, automatic sheet riveting and the like is realized, so the full-automatic screw locking and sheet riveting feeding machine disclosed by the invention is capable of realizing full-automatic operation from feeding to screw locking to sheet riveting to discharge in a whole process of feeding, screw locking and sheet riveting without manual operation, therefore manual labor is greatly saved, production cost is reduced, and production efficiency is greatly increased.

Owner:FOSHAN SHUNDE MEIZHIMEI APPLIANCE MFG CO LTD

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

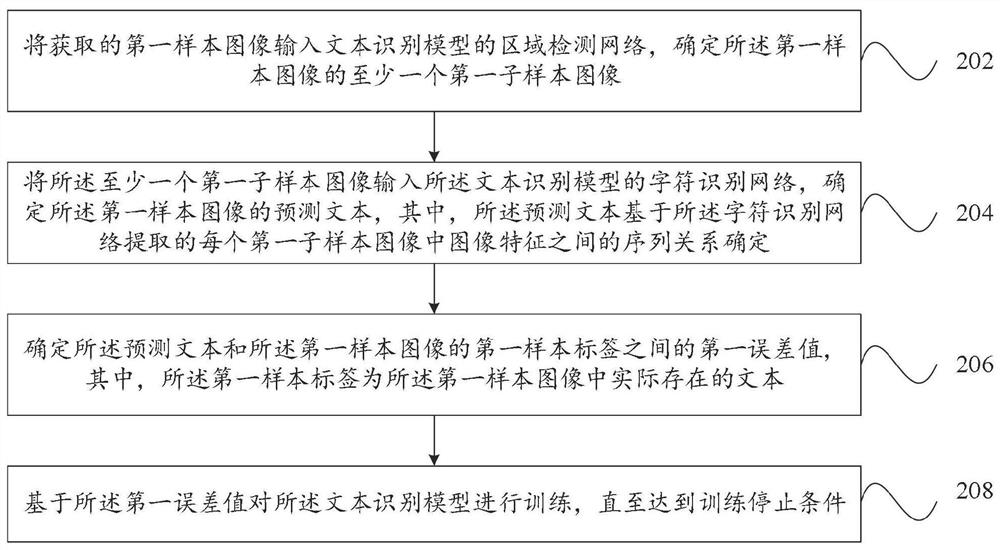

Text recognition model training method and device and text recognition method and device

PendingCN113111871AImprove training efficiencyImprove accuracyCharacter and pattern recognitionNeural architecturesText recognitionSample image

The invention provides a text recognition model training method and device and a text recognition method and device.The text recognition model training method comprises the steps of inputting an obtained first sample image into a region detection network of a text recognition model, and determining at least one first sub-sample image of the first sample image; inputting the at least one first sub-sample image into a character recognition network of a text recognition model, and determining a prediction text of the first sample image, the prediction text being determined based on a sequence relationship between image features in each first sub-sample image extracted by the character recognition network; determining a first error value between the predicted text and a first sample label of the first sample image, wherein the first sample label is a text actually existing in the first sample image; and training the text recognition model based on the first error value until a training stop condition is reached. According to the method, the accuracy of the obtained predicted text is higher, and the training efficiency of the text recognition model can be improved.

Owner:BEIJING KINGSOFT DIGITAL ENTERTAINMENT CO LTD +1

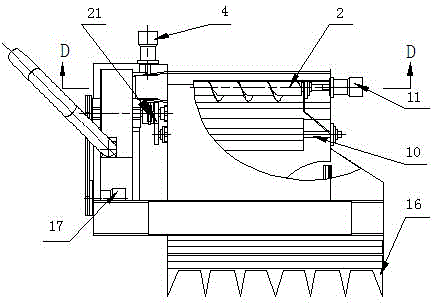

Green belt trimming device with recovery device

InactiveCN104641956AEfficient recyclingRecycled recycling worksHedge trimming apparatusCuttersTool bitEngineering

The invention discloses a green belt trimming device with a recovery device. The green belt trimming device comprises a box body, wherein horizontal rotating cutter heads are arranged at the front side of the box body, a driving device used for driving the rotating cutter heads to rotate is arranged between the box body and the horizontal rotating cutter heads, a spiral conveying device is arranged at the back side of the box body, the rotating cutter heads throw materials to be trimmed to an input opening of the spiral conveying device inside the box body, an output opening of the spiral conveying device is connected with and arranged at the outer side of the box body, and the recovery device is used for recovering trimmed materials. During the green belt trimming, moving equipment drives the trimming device to forwards move, the driving device drives the horizontal rotating cutter heads to fast rotate and trim the green belt, the trimmed materials can be fast thrown to the bottom end of the box body through the horizontal rotating cutter head, and can be conveyed to the input opening of the spiral conveying device, the recovery device is designed, the effective recovery on the trimmed materials is realized, the environment pollution is avoided, and in addition, the potential safety hazards of trimmed materials on running vehicles can be eliminated.

Owner:TAIAN INST OF AGRI MACHINERY SCI SHANDONG PROV

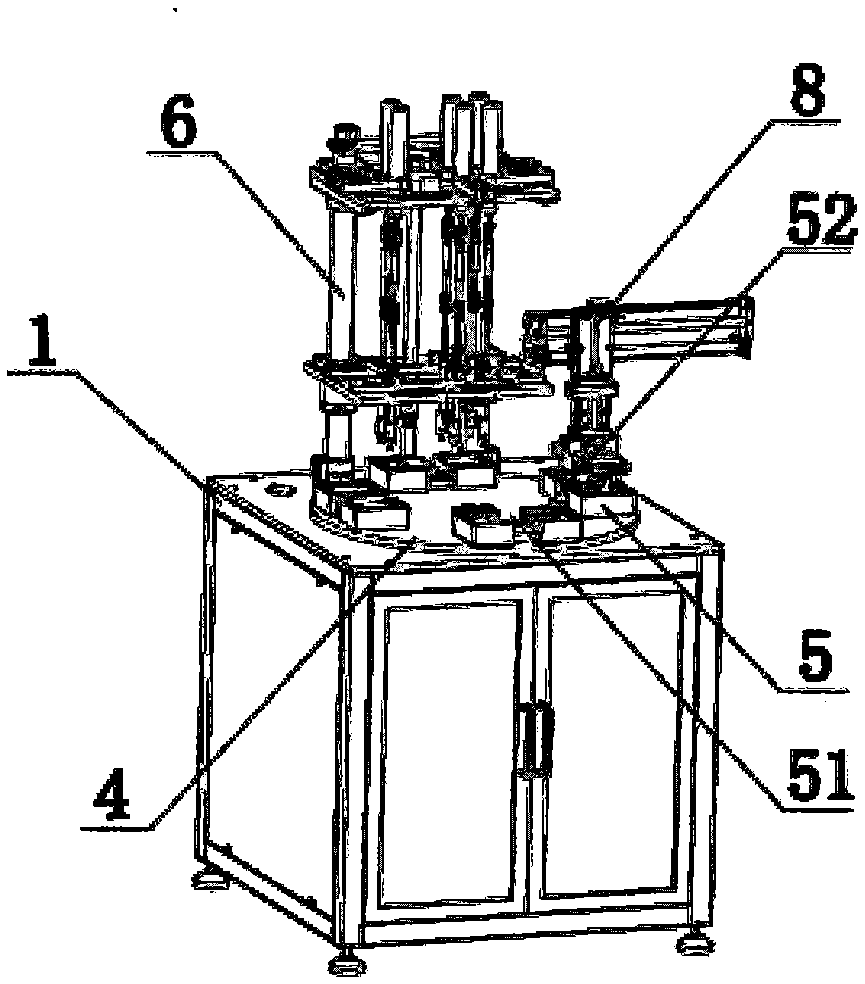

Fully-automatic screw locking machine

ActiveCN105345449AStrong coherenceEasy to manage and useMetal working apparatusEngineeringFully automatic

The invention discloses a fully-automatic screw locking machine which comprises a rack. The fully-automatic screw locking machine is characterized in that the middle part of the rack is vertically provided with a main shaft; the lower end of the main shaft is taken into the rack and is connected with a primary motor; the upper end of the main shaft extends out of the rack and is connected with a rotary plate; the main shaft is just connected with the bottom of the center of the rotary plate; a plurality of mould boxes with equal-arc-length spacing among one another, which surround the center of the rotary plate, are arranged on a loop line on the rotary plate; an automatic screw locking assembly is arranged on a position, above one mould box, at the side of the rotary plate; the automatic screw locking assembly is connected with an automatic screw supply assembly; and the side of the rotary plate is provided with an automatic product removing assembly, which is arranged at a next-step inlet position of the automatic screw locking assembly, in a rotary direction of the rotary plate. The fully-automatic screw locking machine is not great in integral dimension, small in floor space, convenient to use and control, high in continuous working consistency, and high in efficiency and precision in work.

Owner:ZHEJIANG OUGE AUTOMATION TECH CO LTD

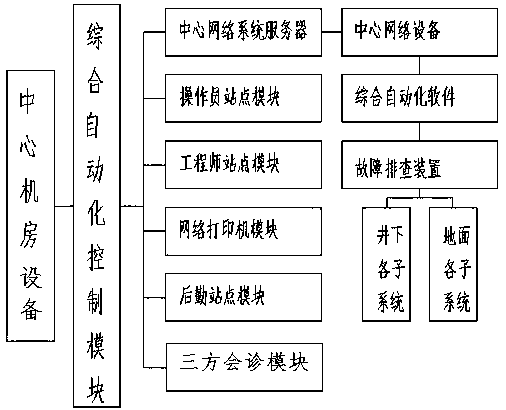

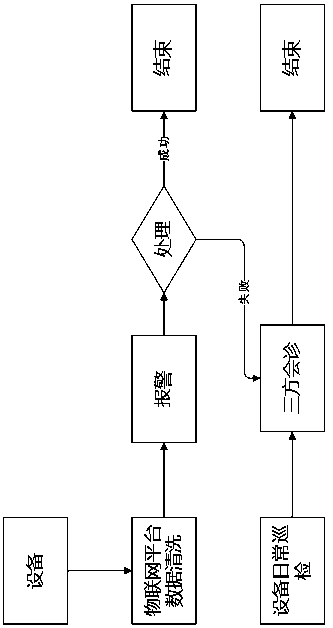

Mining equipment operation data transmission, intelligent early warning and remote consultation analysis system and method

ActiveCN110351356AReduce missed detectionRealize zero inventory productionTelevision system detailsDatabase management systemsComputer printingThe Internet

The invention relates to a mine equipment operation data transmission, intelligent early warning and remote consultation analysis system and method. Central machine room equipment is connected with acentral network system server, an operator station module, an engineer station module, a network printer module,a logistics station module and a three-party consultation module through a comprehensiveautomatic control module, wherein the central network system server is connected with the central network equipment, comprehensive automation software is arranged in the central network equipment, the central network equipment is connected with the troubleshooting equipment through the comprehensive automation software, and troubleshooting equipment is installed at the position of a point to be detected of each underground subsystem and each ground subsystem; full-life-cycle management of the equipment is realized; remote consultation of equipment performance, establishment of a mining main equipment database, establishment of a database integrated control platform, real-time sharing of data on the internet, realization of online resource sharing of experts, manufacturers and use units, cancelling of maintenance classes, improvement of production efficiency, cancelling of night shift, realization of zero-inventory production of mines and reduction of production and operation costs.

Owner:内蒙古智能煤炭有限责任公司

Building construction method

InactiveCN109098370AHollowing will not happenNo crackingCovering/liningsEmulsionArchitectural engineering

The invention discloses a building construction method. The building construction method comprises the following steps: step 1) preparation before construction; step 2) detection of water content on abase layer surface of a building wall; step 3) base layer treatment; step 4) putty repairing; step 5) puttying, wherein puttying should be carried out twice on the base layer of a building wall, andafter putty brushed twice is dry, step 6) is carried out; step 6) brushing emulsion paint, wherein the emulsion paint needs to be brushed twice like puttying in step 5. According to the construction method for brushing the emulsion paint on a building wall, a brushing process is simple, a brushing sequence is carried out according to characteristics of the emulsion paint, after brushing of the emulsion paint, hollowing and cracking can be avoided, brushing consistency is high, before brushing of the emulsion paint, the base layer surface of the wall body is cleaned and repaired repeatedly, then two layers of putty are brushed, and thus, the sprayed emulsion paint is stable in structure, and cannot drop easily.

Owner:台山市河朗新型环保建材有限公司

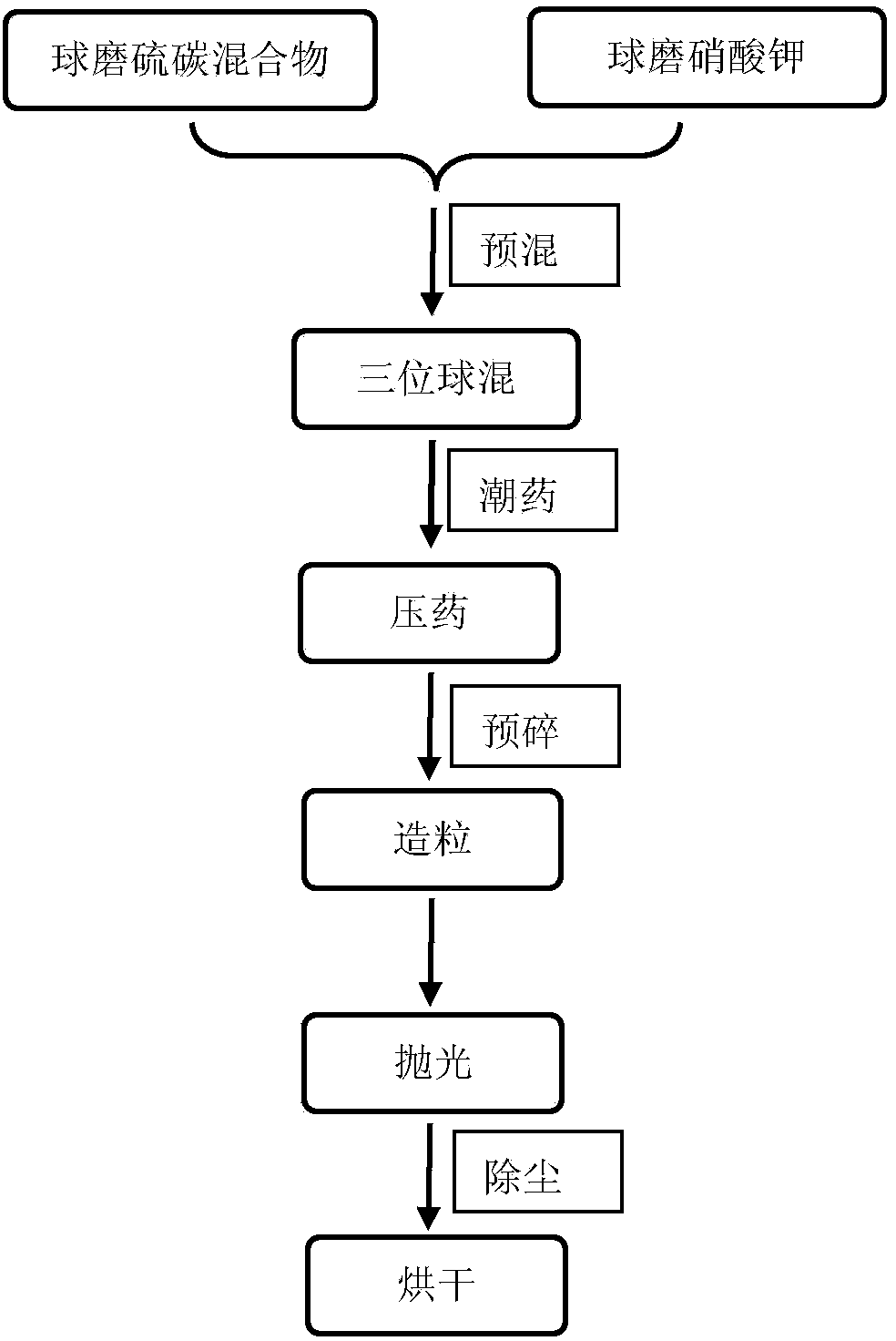

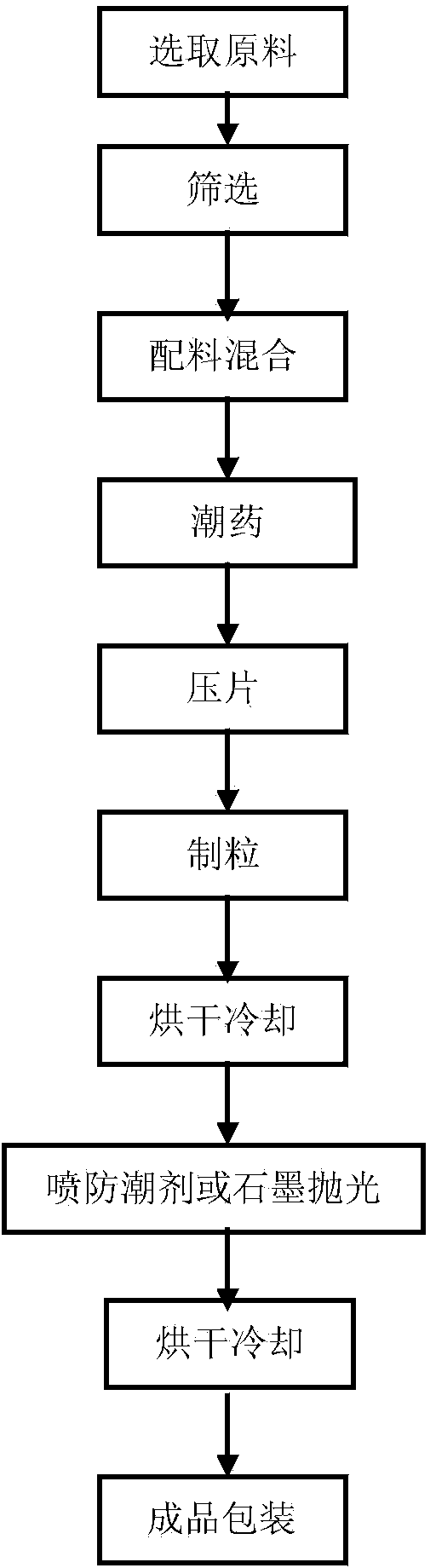

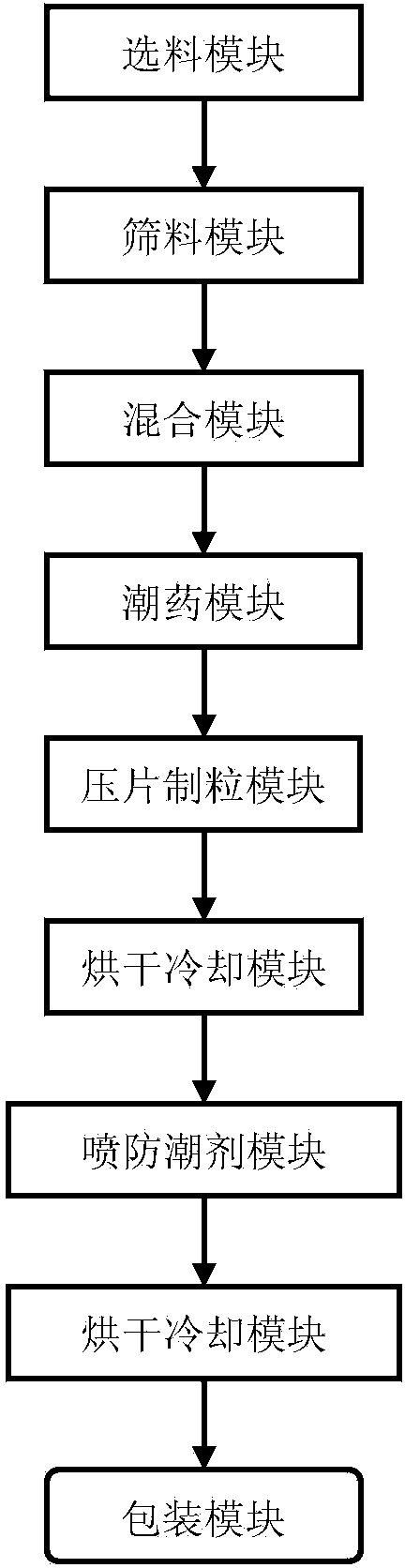

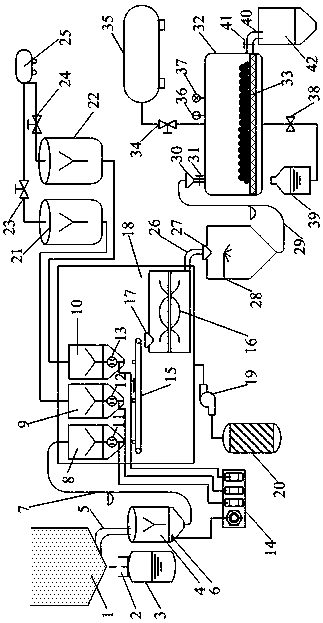

Process and system for manufacturing military nitre or black gunpowder

InactiveCN104030864ASimple contentEasy to operateExplosive working-up apparatusInorganic oxygen-halogen salt explosive compositionsHigh densityPyrotechnic composition

The invention discloses a process for manufacturing military nitre or black gunpowder. The process for manufacturing the military nitre or black gunpowder comprises the following steps: 1) selecting raw materials; 2) respectively screening the raw materials by virtue of a sieve more than 100 meshes; 3) batching and mixing, namely batching the screened single raw material, placing the batched raw materials into an automatic pyrotechnic composition mixing machine, and mixing for 3-5 minutes until the raw materials are uniformly mixed; 4) moistening medicine and carrying out continuous tabletting, pelletizing and sorting; 5) drying and cooling, namely drying gunpowder particles obtained in step 4) by virtue of an infrared ray optical wave pipe or a hot air channel and then cooling the gunpowder particles; 6) spraying a moisture-proof agent or polishing, namely placing the gunpowder particles in step 5) into a moisture-proof agent spraying tank, spraying a proper amount of a moisture-proof agent, spraying while the moisture-proof agent spraying tank is rotated, uniformly covering or polishing, so that a moisture-proof effect is realized; 7) drying, cooling and packaging the medicine particles sprayed with the moisture-proof agent in step 6). The invention also discloses a system for manufacturing the military nitre or black gunpowder. The process and system for manufacturing the military nitre or black gunpowder have the advantages of easy operation, implementation of pipeline process control, low labour cost, high production efficiency, low labour intensity, high safety coefficient, high density of the produced gunpowder particles and good follow-up using effect.

Owner:浏阳市工业园浏河机械厂

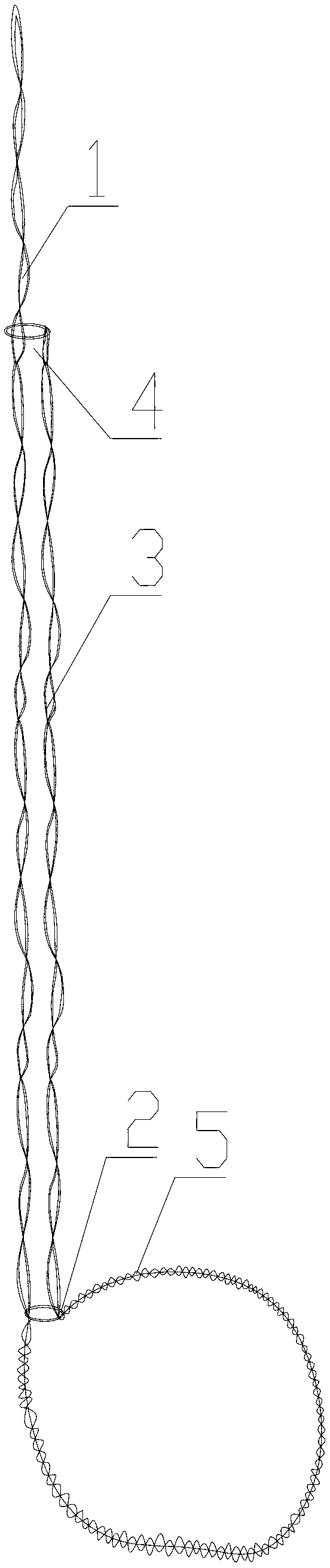

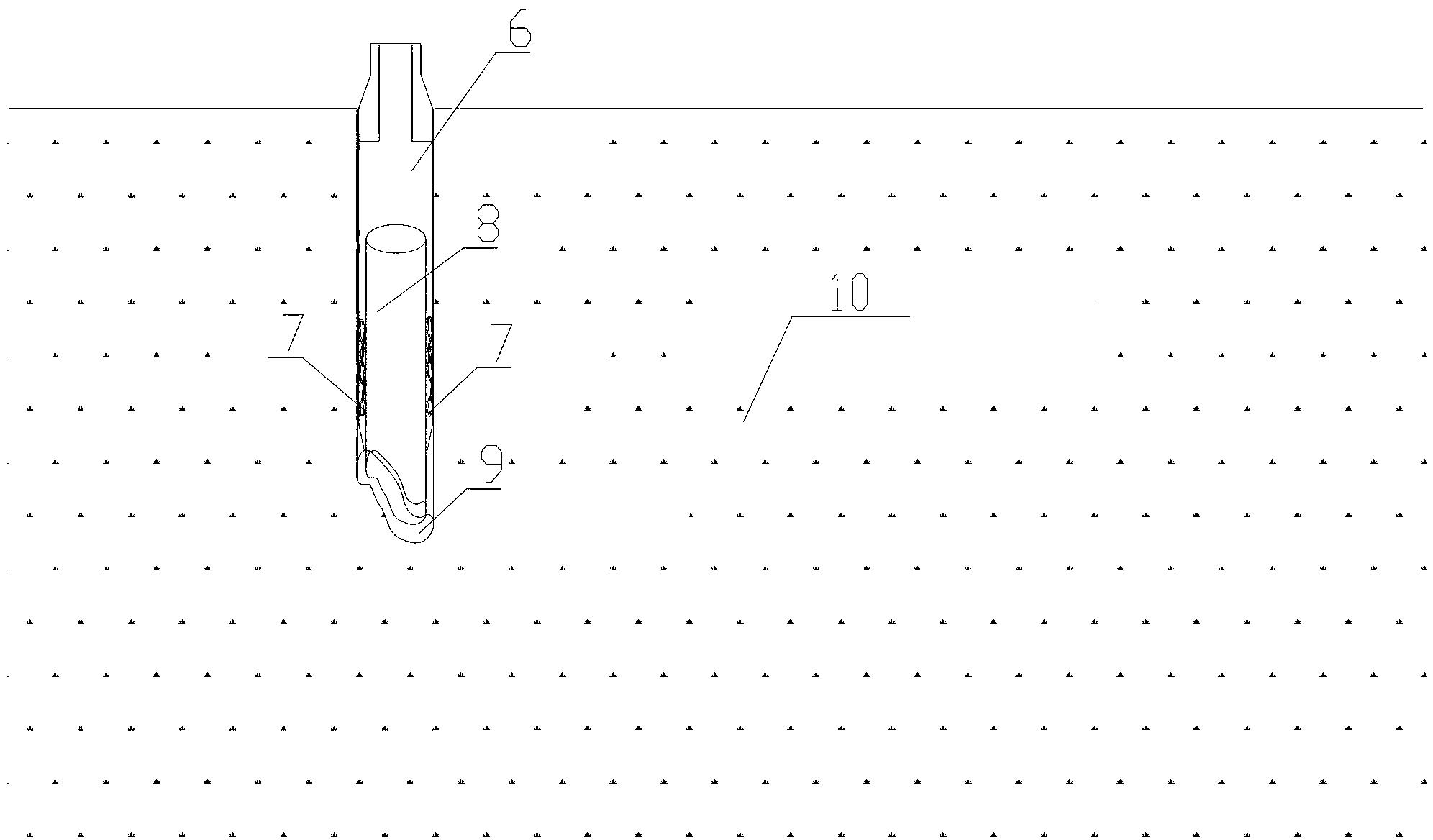

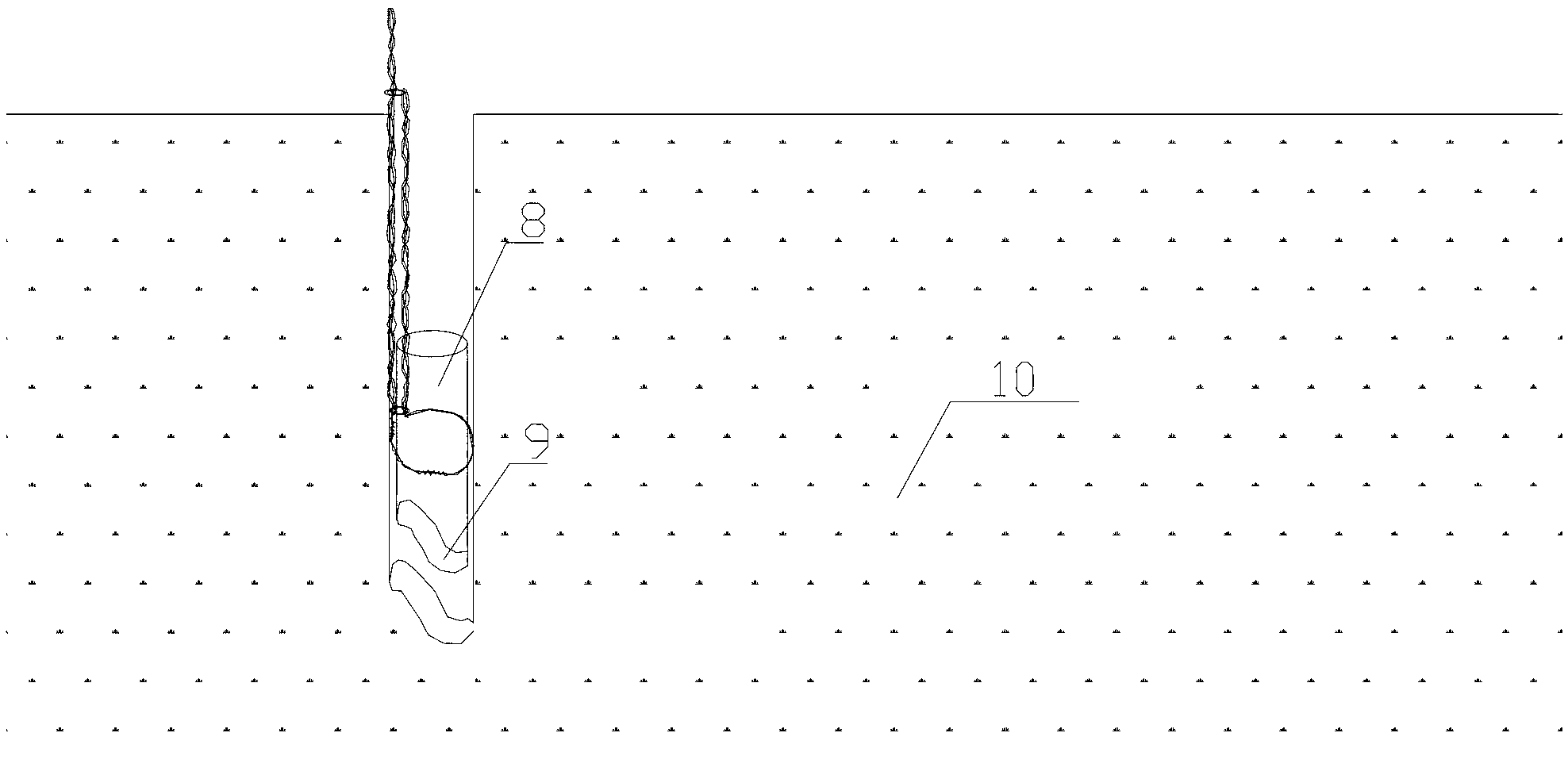

High efficiency coring method for portable drilling machine in integral hard rock

ActiveCN103306623ADamage Fracture RealizationStrong targetingConstructionsCore removalRock coreHigh integrity

The invention relates to a high efficiency coring method for a portable drilling machine in an integral hard rock. The invention solves the technical difficult problems of high wear speed of a drilling tool and low coring rate which are caused by the case that when the portable drilling machine drills in the hard rock with high integrity, the root of a rock core is usually difficult to cut off or is difficult to successfully take out after being cut off. The invention adopts the scheme that the high efficiency coring method comprises the following steps: a, on a superficial layer of the earth surface, where a rock core to be taken is positioned, drilling a blind hole by the drilling machine and clearing away the broken rock core in the blind hole; b, lengthening a drill rod on the drilling machine in the step a and continuously drilling towards the lower layer on the basis of the blind hole; c, lifting up the drilling machine in the step b to form a gap between the inner wall of a hollow drill bit and the rock core; d, filling a filler in the gap in the step c; e, starting the drilling machine to enable the root of the rock core to be broken, shutting down the drilling machine and taking out the drill rod and the hollow drill bit; f, placing in-hole positioning imaging equipment into the blind hole to carry out positioning and recording on a damaged and cracked position of the rock core in the blind hole; g, taking out the in-hole positioning imaging equipment in the blind hole; h, placing deep hole rock core extracting equipment into the blind hole and taking out a rock core sample.

Owner:NANJING UNIV

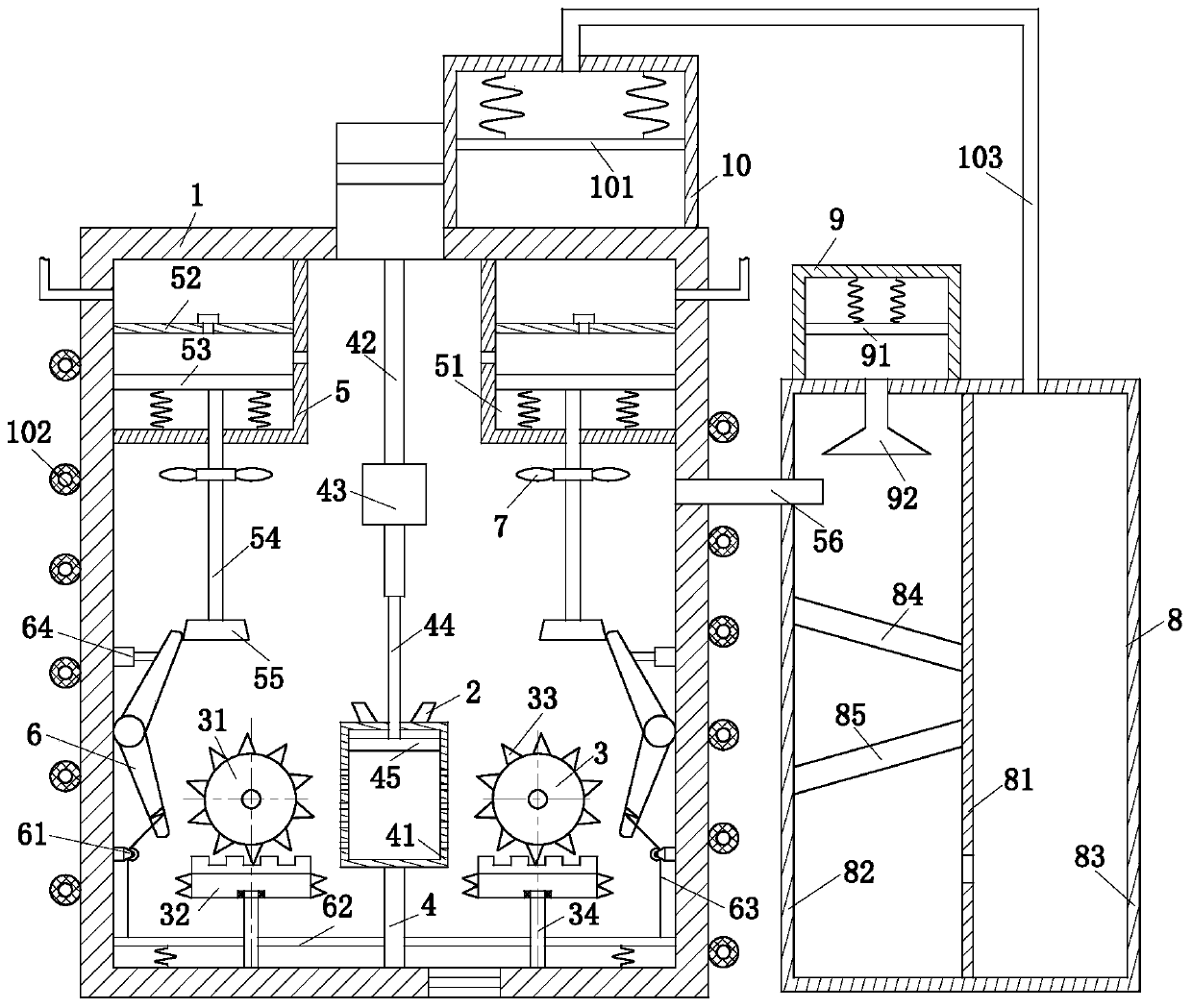

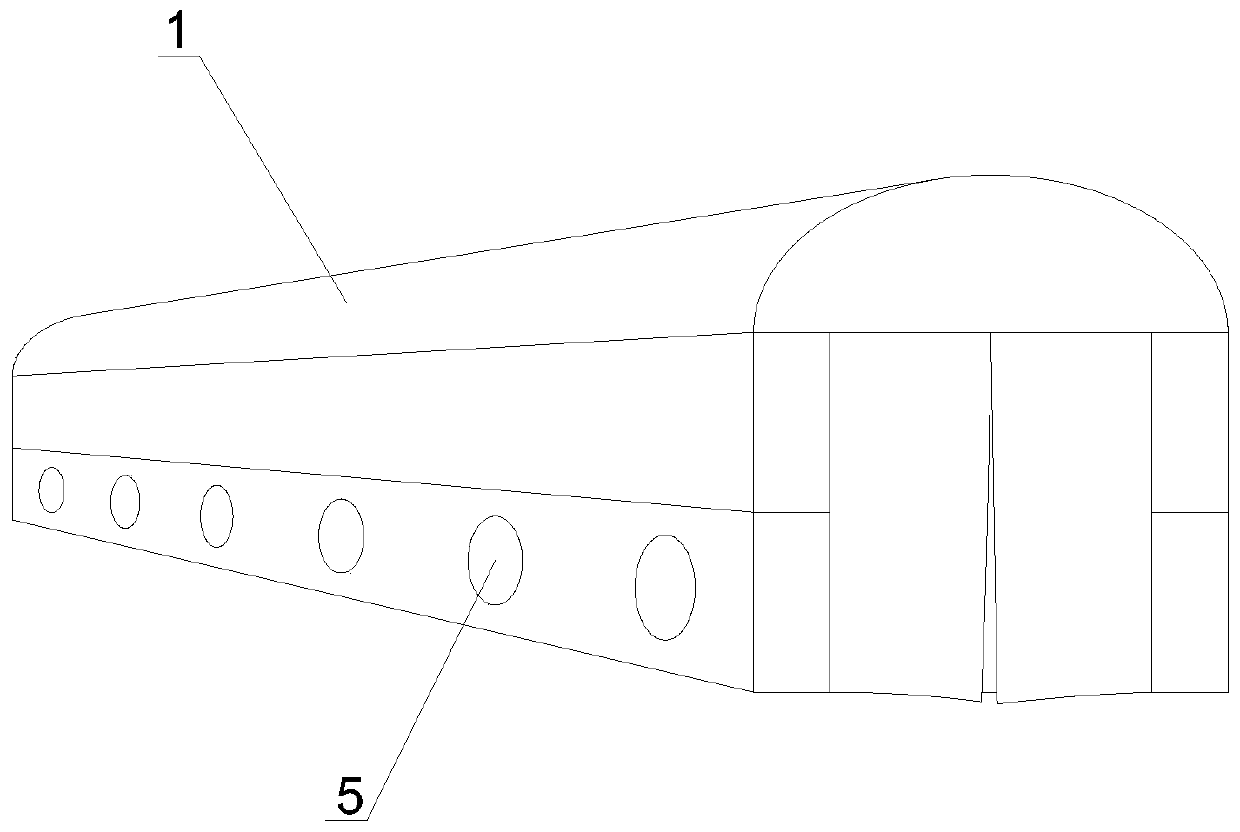

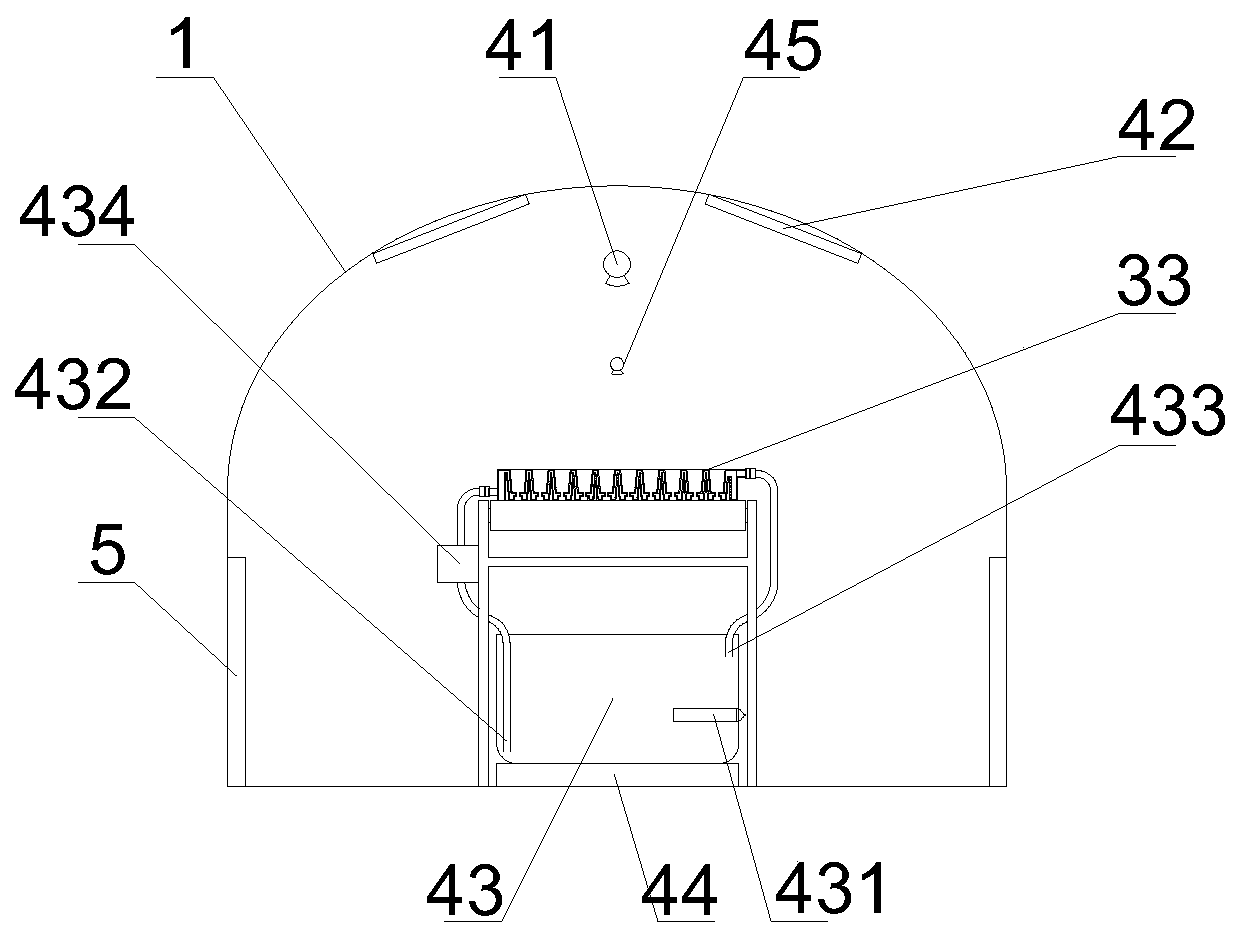

High-efficiency garbage incineration treatment device

ActiveCN109737422AImprove efficiencyStrong coherenceIncinerator apparatusEngineeringUtilization rate

The invention belongs to the technical field of garbage treatment, and particularly relates to a high-efficiency garbage incineration treatment device. The high-efficiency garbage incineration treatment device comprises a incineration box, a motor, a feeding port, a discharging port, an igniter and a controller, wherein electric valves are both arranged in the feeding port and the discharging port, the motor is fixedly connected to the side wall of the incineration box, and the output end of the incineration box penetrates through the side wall of the incineration box and extends into the incineration box; a crushing unit is arranged in the incineration box, the crushing unit comprises a first crushing wheel and a second crushing wheel, wherein the first crushing wheel and the second crushing wheel are symmetrically arranged by taking the center line in the vertical direction of the incineration box as the reference, crushing teeth are all arranged on the outer rings of the first crushing wheel and the second crushing wheel; and a heat collecting unit is arranged above the crushing unit. The high-efficiency garbage incineration treatment device is novel in structure,, heat generated by garbage incineration and waste gas can be utilized while the efficiency of garbage incineration is improved, so that the utilization rate of resources is improved.

Owner:徐州诚凯知识产权服务有限公司

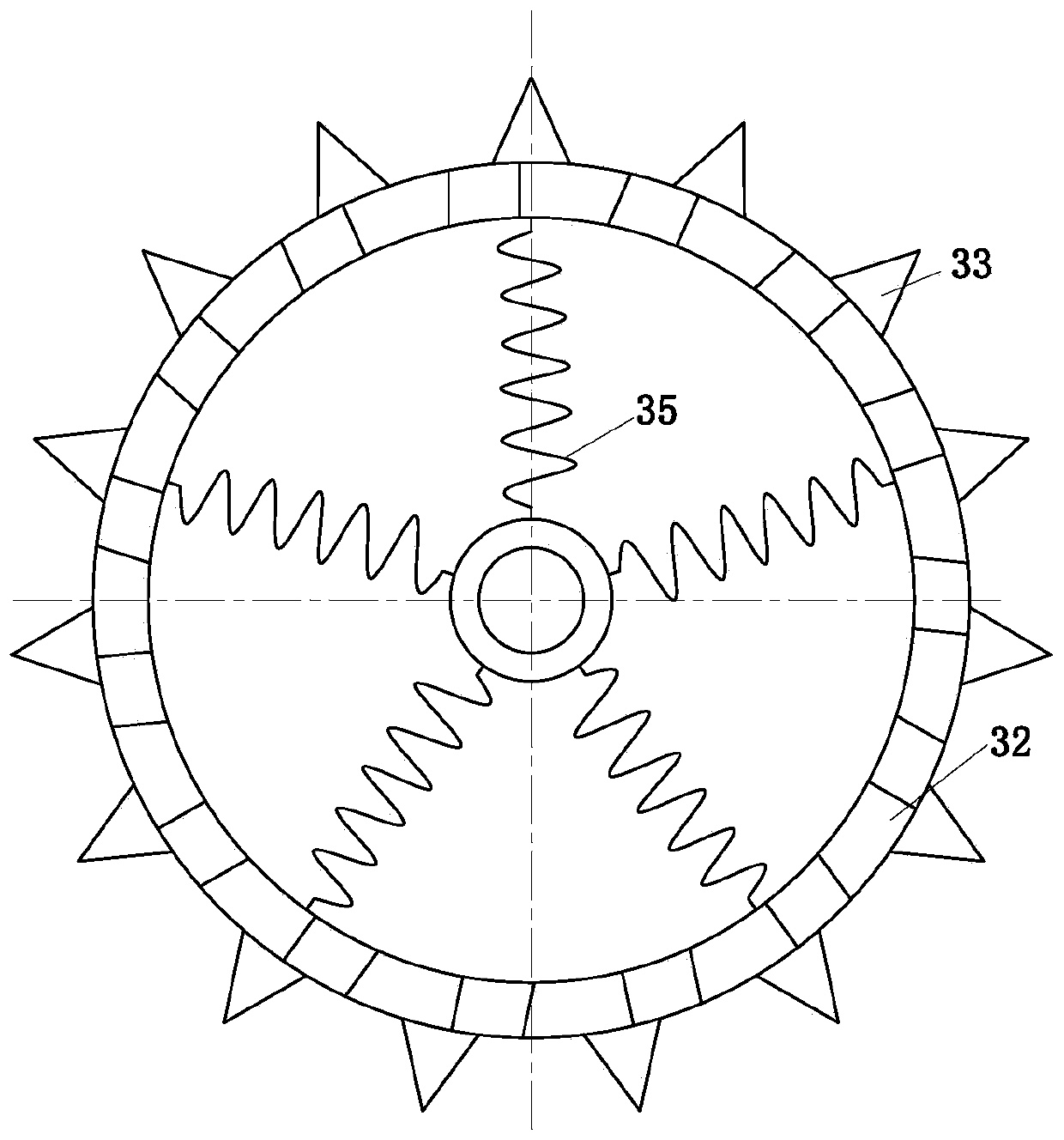

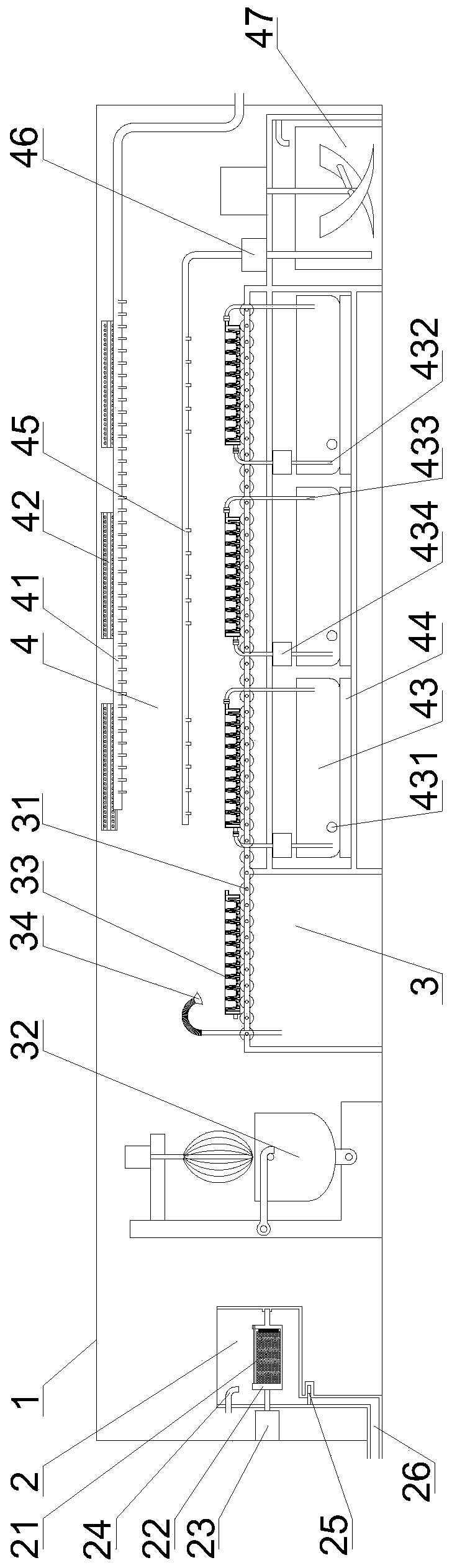

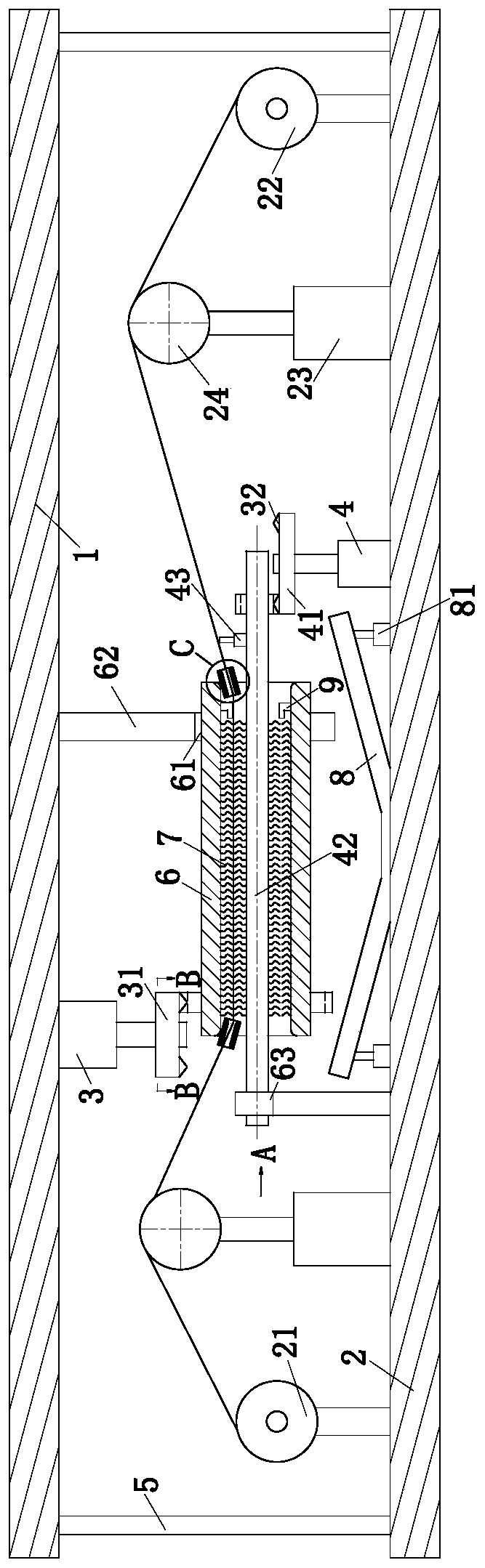

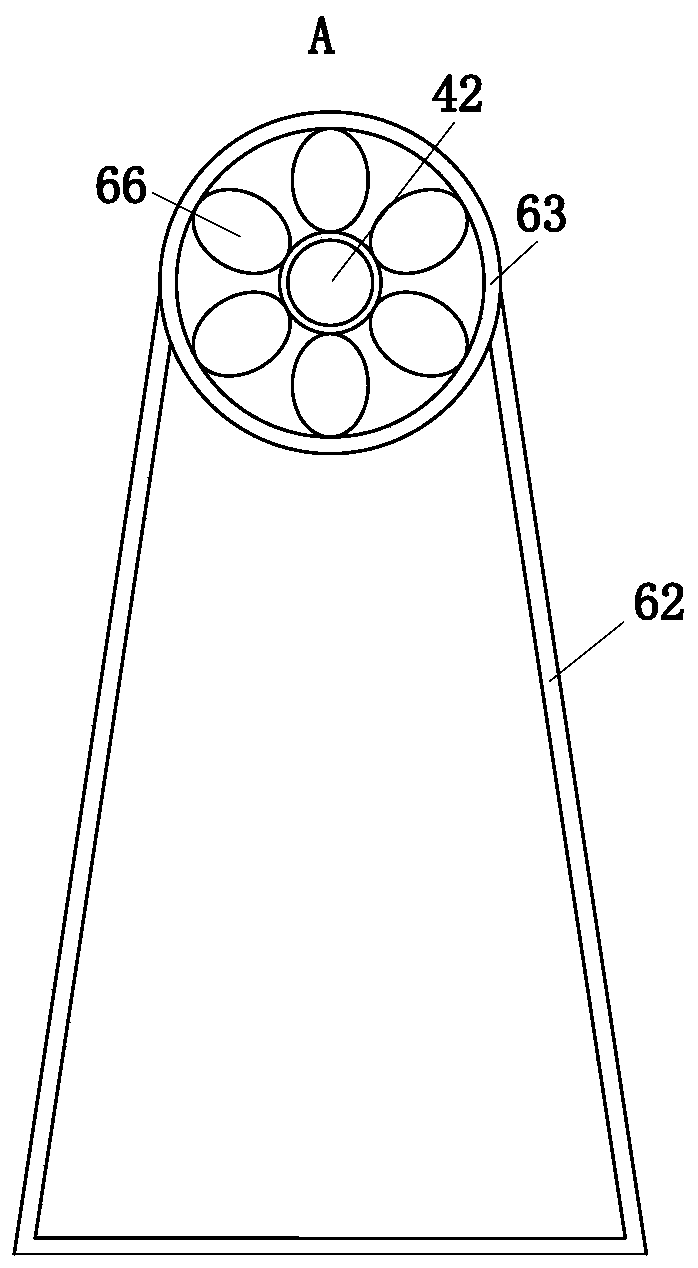

Friction type steel wire surface oxide skin automatic cleaning device

InactiveCN109676502AReduce vibrationImprove stabilityGrinding carriagesGrinding machinesSurface oxidationRotated tooth

The invention belongs to the technical field of steel wire surface treatment equipment and particularly discloses a friction type steel wire surface oxide skin automatic cleaning device. The frictiontype steel wire surface oxide skin automatic cleaning device comprises an upper base, a lower base, a first motor, a second motor, a steel wire and a controller. A first rotating disc is connected tothe output end of the first motor in a sleeving manner. Rotating teeth are uniformly arranged at an outer ring of the first rotating disc. The first rotating disc is internally uniformly provided withgrooves. The grooves correspond to the rotating teeth in position. A guiding block is arranged at the bottom of each rotating tooth. Each guiding block is connected with the corresponding groove through a spring. Each rotating tooth is of a hollow structure and is made of a rubber material. The bottom of the second motor is fixedly connected with the lower base. A second rotating disc is connected to the output end of the second motor in a sleeving manner. The second rotating disc is the same as the first rotating disc in structure. A solid tube is arranged above the second rotating disc andsleeved with a gear. The gear is engaged with the second rotating disc for transmission. The friction type steel wire surface oxide skin automatic cleaning device is simple in structure, environmentally friendly and free of pollution; and through mechanism cooperation, oxide skin on the surface of the steel wire can be removed.

Owner:程郎

Aluminum bar polishing device

ActiveCN109015145AEasy to joinReduce laborRevolution surface grinding machinesGrinding feedersMechanical engineering

The invention relates to the field of aluminum bar polishing, in particular to an aluminum bar polishing device. The aluminum bar polishing device comprises two guiding structures, a first driving structure, a flaw detection structure, a second driving structure, a third driving structure, a pushing rod, a supporting frame, a fixing structure and a sliding structure. A clamping plate is in buckledconnection with a fixing box through a fixing mechanism, the clamping plate is fixedly connected with a material box for storing aluminum bars relative to the side walls of the fixing box; by pressing a pedal plate, a jacking plate presses downwards, a first spring shrinks, and the aluminum bars not polished are added into the material box conveniently; after the clamping plate is buckled on theside walls of the fixing box, a limiting plate is pulled out, thus the first spring stretches, and the jacking plate moves upwards to convey the aluminum bars at the top of the material box into a stock box; a feeding mechanism is connected with a power source to push the aluminum bars to a material entering mechanism for material entering, thus the labor capacity of workers is decreased, and theworking comfort degree is increased; and the aluminum bars are automatically conveyed after reaching the interior of the material entering mechanism, conveying and polishing are conducted simultaneously through cooperation of the material entering mechanism and a polishing mechanism, and thus continuity is high.

Owner:江苏神铸智能科技有限公司

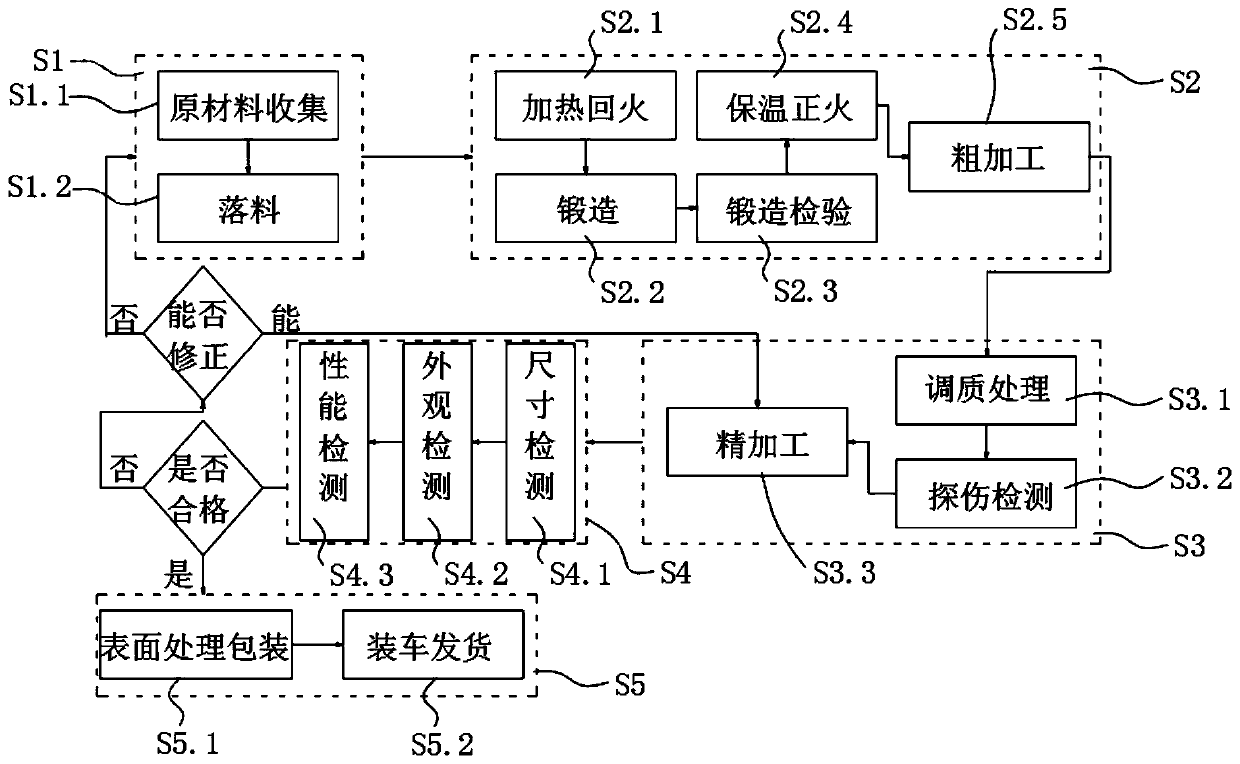

Engineering machinery part production line

InactiveCN111300071AReduce lossStrong coherenceOther manufacturing equipments/toolsMachine partsEconomic benefits

The invention discloses an engineering machinery part production line. The line involves a material collecting and machining procedure, a part rough machining procedure, a part finish machining procedure, a part quality detecting procedure and a packaging and transporting procedure, wherein the material collecting and machining procedure, the part rough machining procedure, the part finish machining procedure, the part quality detecting procedure and the packaging and transporting procedure are conducted in the same workshop. According to the production line, the production processes are highin consistency, the efficiency can be improved, the energy loss can be reduced, a part is roughly machined into a rough machined part, the finish machining allowance is reserved, finish machining is conducted after thermal refining to produce the standard part, in the whole production process, the machining quality and standard of the workpiece are tracked and detected many times, the non-standardpart is reworked and removed in time, standardized finish machining is facilitated, unnecessary machining operation is avoided, the yield is increased, the defective rate is reduced, and economic benefits are improved.

Owner:CHANGSHA LEIFENG HEAVY FORGING

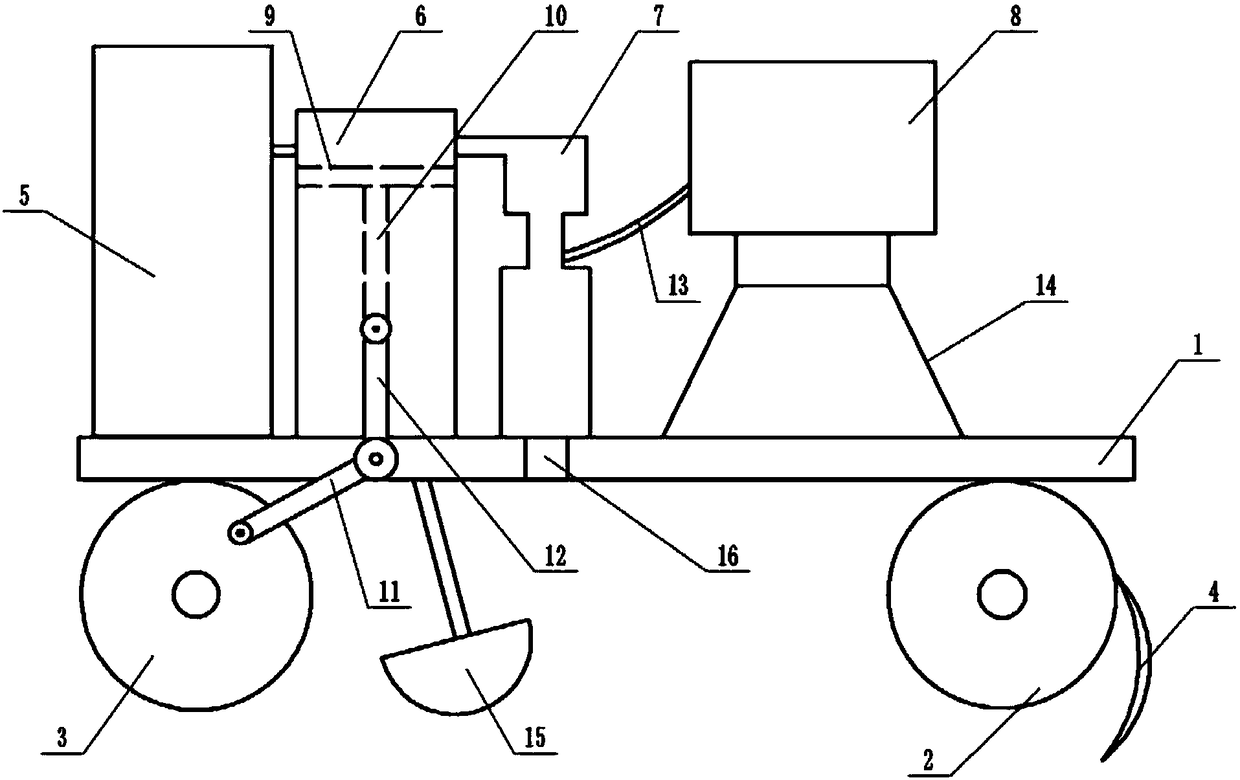

Organic cauliflower growing device

InactiveCN108112306AAvoid Growth VariationsStrong structural stabilityLiquid seeding techniquesPlantingAgricultural engineeringRapeseed

The invention relates to the field of vegetable growth and in particular discloses an organic cauliflower growing device. The device comprises a seeding trolley, wherein front wheels and rear wheels are arranged on the seeding trolley; pit blades are hinged onto the front wheels; a water tank, a watering vat, a water seed mixing chamber and a rapeseed placement chamber are sequentially arranged onthe seeding trolley from the rear to the front; the watering vat is communicated with the water tank; the water seed mixing chamber is communicated with the watering vat; the rapeseed placement chamber is communicated with the water seed mixing chamber; a discharging hole is formed in the bottom of the rapeseed placement chamber; a piston plate is connected to the interior of the watering vat ina sliding manner; a piston rod is arranged on the piston plate; a first rotating rod is hinged onto the rear wheel; a second rotating rod is hinged between the first rotating rod and the piston rod; the middle section of the water seed mixing chamber protrudes inwards; and a rapeseed inflow channel is formed between the protrusion part and the lower end of the rapeseed placement chamber. The device is high in structural stability and high in integration degree, operations of seeding and watering can be completed while digging holes, and the phenomenon that non-uniform vegetable growth is caused by non-uniformity produced by manual seeding and digging is avoided.

Owner:重庆市永旺种子有限公司

Fully automatic apron equipment all-in-one machine

ActiveCN104942604BIncrease distanceStrong coherenceOther manufacturing equipments/toolsEngineeringRight-to-left

Owner:GUANGZHOU DEYA MACHINERY MFG

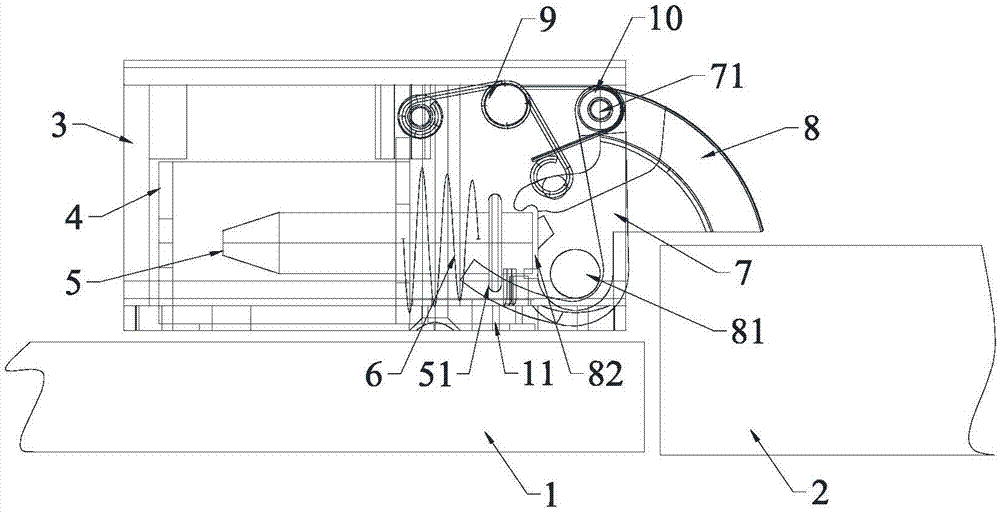

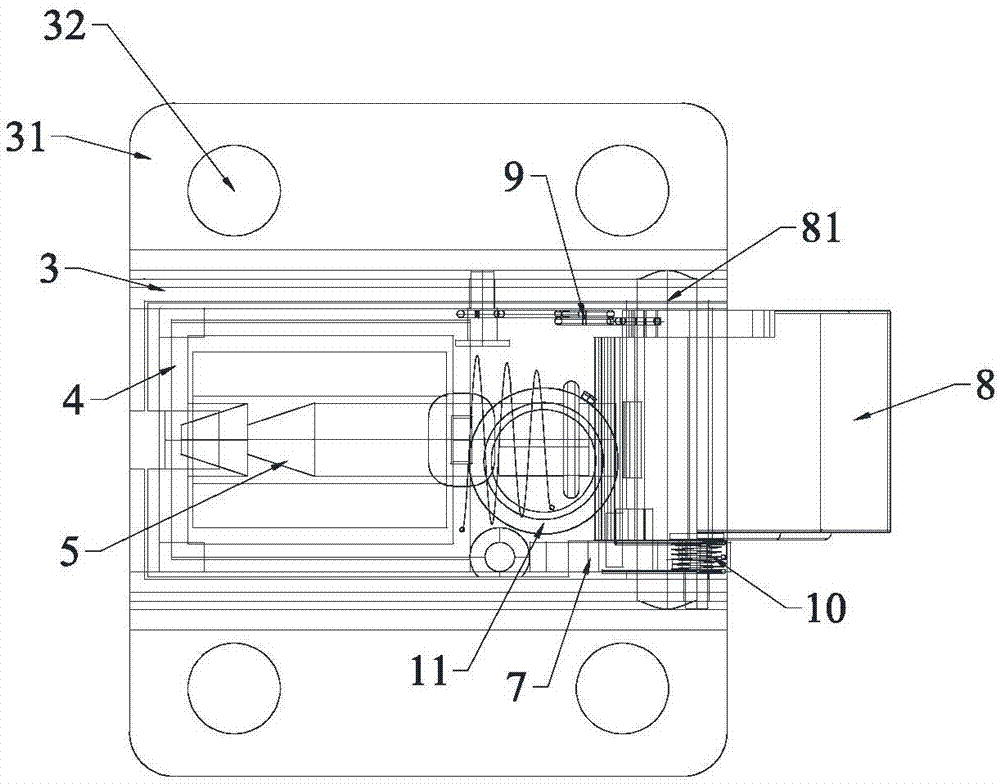

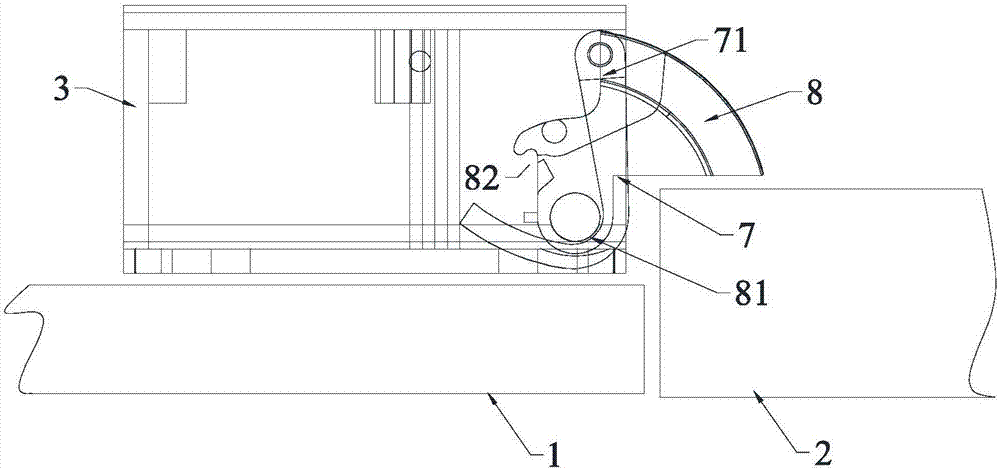

Electronic lock and application of access control system of electronic lock

PendingCN107355139AGuaranteed StrengthEnsure safetyNon-mechanical controlsControl theoryMechanical engineering

The invention discloses an electronic lock and application of access control system of electronic lock and is mounted on the edge of the door body by a lock box. An electromagnet, a self-locking mechanism and a locking tab are provided in the lock box. The electromagnet is arranged on the one side of the locking tab. The other side of the locking tab is correspondingly provided with a door frame. One end of the self-locking mechanism is connected to one end of the locking tab. The other end of the self-locking mechanism is located in the lock box. The electromagnet can do back and forth movement relative to the locking tab. When the door opens, the electromagnet is controlled by electric power to move a certain distance away from the direction of the locking tab and is free from the restriction of the locking tab. When the door body is pulled, the door frame forces the locking tab to rotate at a certain angle in the forward direction of a first rotating shaft, and the door can be opened. Meanwhile, the self-locking mechanism rotates the lock box out with the opening angle of the door. When the door closes, the door frame first touches the self-locking mechanism. The self-locking mechanism rotates the front end of the self-locking mechanism and meets the tail of the locking tab. The locking tab is rotated through the first rotating shaft to complete the closing action. The electronic lock and the application of access control system of electronic lock have the advantages of simple structure, strong generality, safety and convenience.

Owner:佛山市奇点安防科技有限公司

Paper cup machine

The invention discloses an improved invention of a paper cup machine, which is mainly characterized in that the machine body comprises a rotating disc, wherein the periphery of the rotating disc is provided with a horizontal cup mould, a bounding press block is arranged on the position of the horizontal cup mould, when the rotating disc rotates, the cup mould sequentially passes through each station making paper cups, the rolling bottom and the hemming of the invention are formed at one step, and more important, when all the stations work, the cup is always in the bonding state on the cup mould, so that the edge of the heated paper cup has enough time to cool when being bounded, and the paper cup is firmly bounded. The invention has strong movement coherence, can make over 100 paper cups per minute, and can reach the purpose of making the paper cups at a high speed.

Owner:ZHEJIANG NEW DEBAO MACHINERY

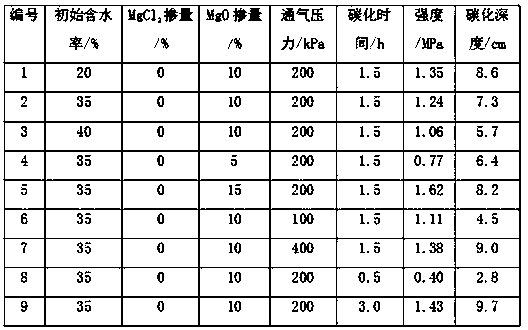

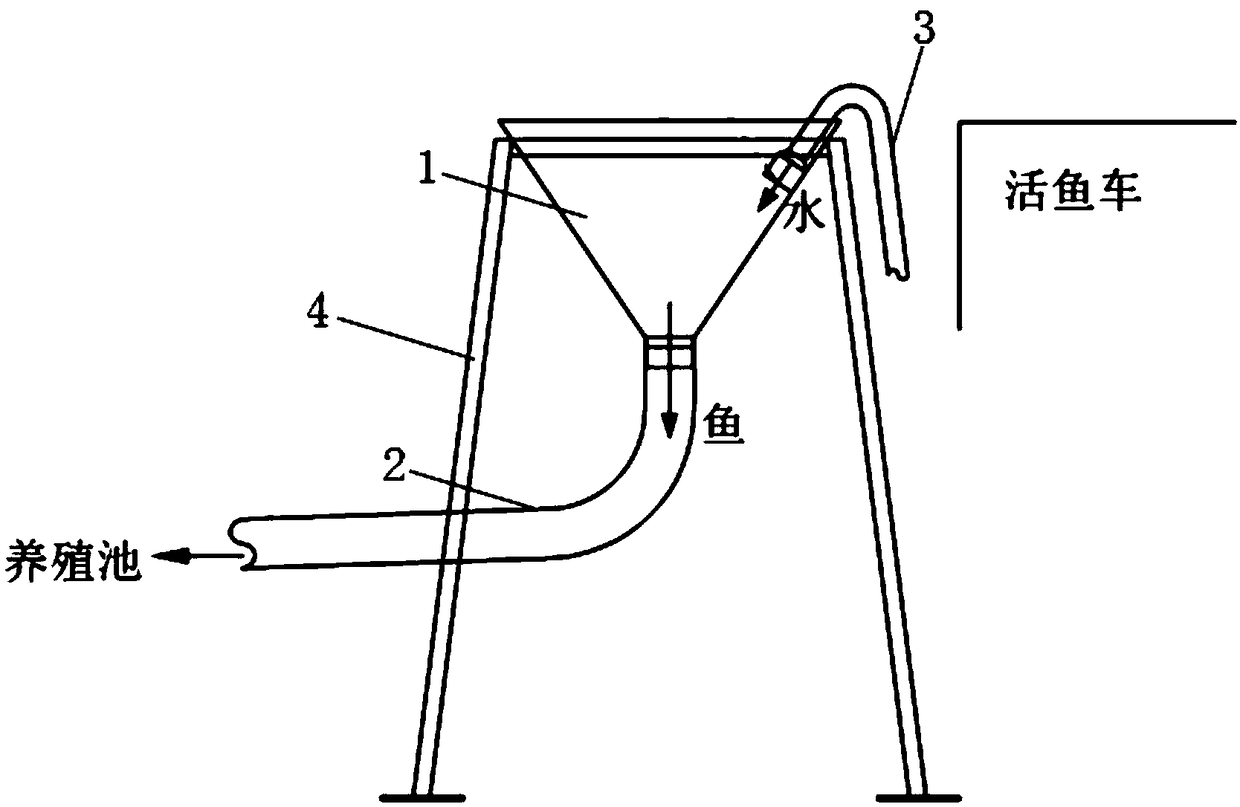

Treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide

ActiveCN108128991AAdjust dosage in real timeGuaranteed work efficiencyFixation/solidifcation sludge treatmentProcess orientedSludge

The invention discloses a treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide. The system comprises a pretreatment device, a curing agent supply device, a uniform mixing device, a granulation device, a carbonization device and a collection device. Through the sequential working of the devices, the sufficient blending of silt and a curing and the quick carbonization of a magnesium oxide cured silt granule are completed; thus, the problems of the difficult carbonization and curing of high-water-content and low-permeability silt / sludge soil are solved; multiple sensors particularly arranged in the system are cooperatively used; the supply quantity of the curing agent can be regulated through actually measuring a water content; the particle size of the granule and the pressure of carbon dioxide are regulated according to the property of the soil; the work efficiency is greatly improved; all the devices are more systematized and process-oriented; milldust and the carbon dioxide can be absorbed in the use process of the devices; the secondary pollution is avoided; the carbonized granule of the silt, generated after the devices finish working, is high in hardness and high in shear strength, and can be used as a filling material for a roadbed, an airport runway, engineering backfilling and the like, and the treatment system has great engineeringconstruction significance for the reutilization of silt / sludge in engineering.

Owner:SOUTHEAST UNIV

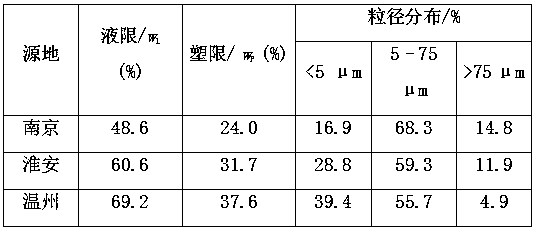

Method for unloading fry into pond

InactiveCN109479768AShorten pool timeStrong coherenceClimate change adaptationPisciculture and aquariaWater dischargeWater quality

The invention provides a method for unloading fry into a pond. The method includes the following steps that 1, after a live fish transport vehicle arrives at the scene, the water temperature and dissolved oxygen concentration of one fish tank is measured, the state of the fry is observed, and unloading work starts; 2, water is extracted from an aquaculture pond into the fish tank, until water in the fish tank is completely changed by water in the aquaculture pond; 3, a drainage valve at the bottom of the fish tank is switched on, and 1 / 3 of the water is discharged; 4, fry conveying equipment is assembled and placed near the live fish transport vehicle; 5, a submersible pump is turned on, water is injected into a conical container, a hand-held fishing net is used for catching the fry and putting the fry in the conical container, and the fry then enters a fish pipe with the water flow and finally reaches the aquaculture pond; 6, with fry catching, water discharge continues until all fryare caught; 7, when the fish tank is unloaded, the water quality of the fish tank is determined and water is changed, and unloading work of all the fish tanks is completed in turn. The method adopts uninterrupted pipeline transportation, each link has strong coherence, and the time of unloading fry into the pond can be shortened.

Owner:上海耕海渔业有限公司 +1

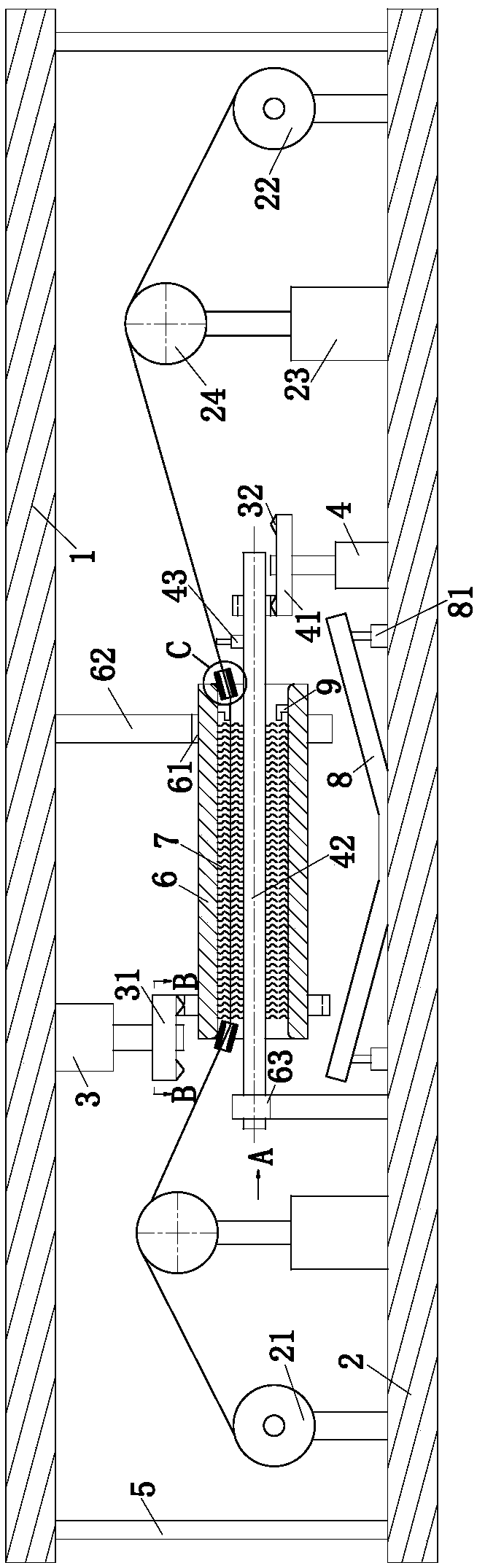

Crushing production line device and crushing method for processing waste concrete recycled aggregates

The invention discloses a crushing production line device for processing waste concrete recycled aggregates. The crushing production line device successively comprises a three-level crushing machine,a pre-crushing disc assembly, a centrifugal crushing blanking apparatus and a pin-roll lamination crushing apparatus according to the sequence of a technological process; the three-level crushing machine is used for crushing the concrete blocks with no iron impurities and non-iron impurities for three times, the pre-crushing disc assembly is used for centrifugally pre-crushing agglomerates and blocks in the crushed particles, and the centrifugal crushing blanking apparatus is used for secondarily crushing the pre-crushed particles and intermittently blanking the secondarily crushed particles;and the pin-roll lamination crushing apparatus is used for vertically extruding the secondarily crushed particles and also rolling crushing the particles. The crushing production line device of the invention has the advantages that the raw material can be crushed in various manners, the equipment integration degree is high, the raw material can be thoroughly crushed, the crushing efficiency is high, the smashing effect is good, the aggregate recycling rate of the recycled concrete is improved, the smashing effect is good, and the aggregate recycling rate of the recycled concrete can be improved.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

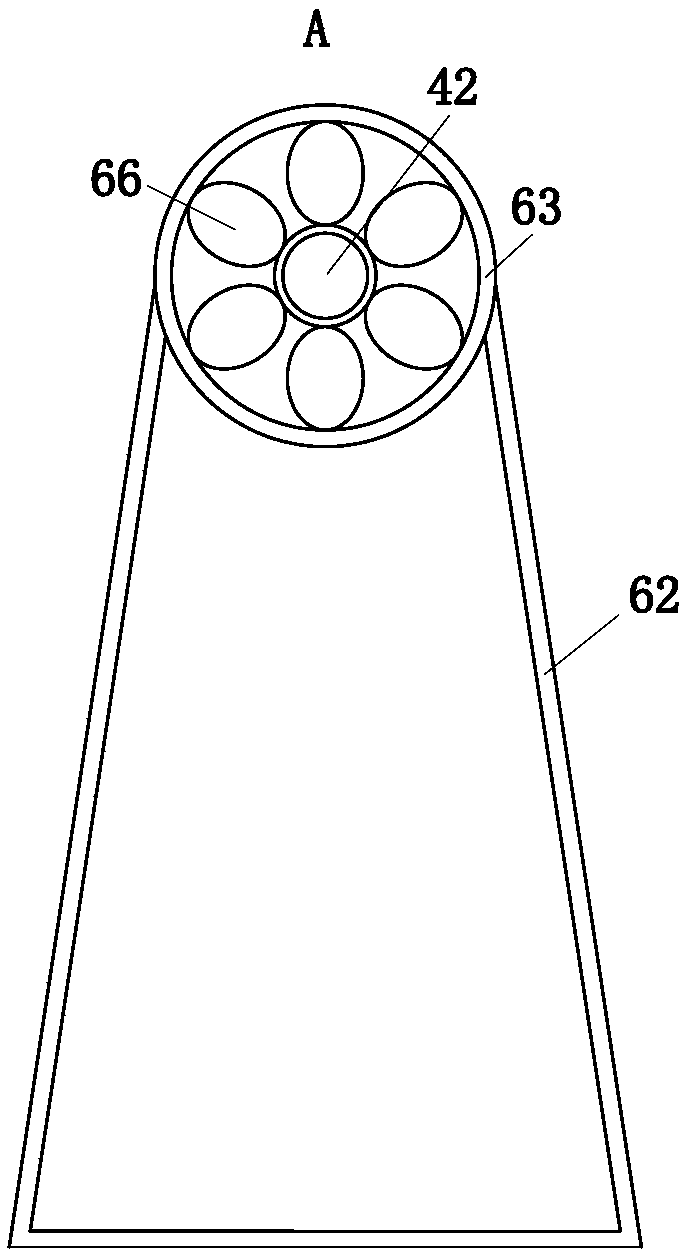

Method and device for industrial cultivation of rubber grass seedlings

ActiveCN110012755AEarly rootingWell developed root systemManure treatmentClimate change adaptationDiseaseInsect pest

The invention discloses a method and device for industrial cultivation of rubber grass seedlings, with an aim to solve problems that due to unsuitable climate and soil environment, the growth rate andsurvival rate of the rubber grass seedlings are low, the root system of plants is not developed, the survival rate of transplanting in the later stage is low and the like. Through the cultivation device of the rubber grass seedlings and artificial simulation of seed growth environment, the characteristics of seed germination and seedling growth law of rubber grass are accorded with, the technicalmethod is established to maintain soil temperature, humidity and sufficient light and effectively improve the growth rate and survival rate of the rubber grass seedlings, the cultivated rubber grassseedlings are good in growth, leaves are thick green and shiny, the root system is developed, no diseases and insect pests are caused, and a wide range of application and popularization value is achieved.

Owner:新疆农业科学院农作物品种资源研究所 +1

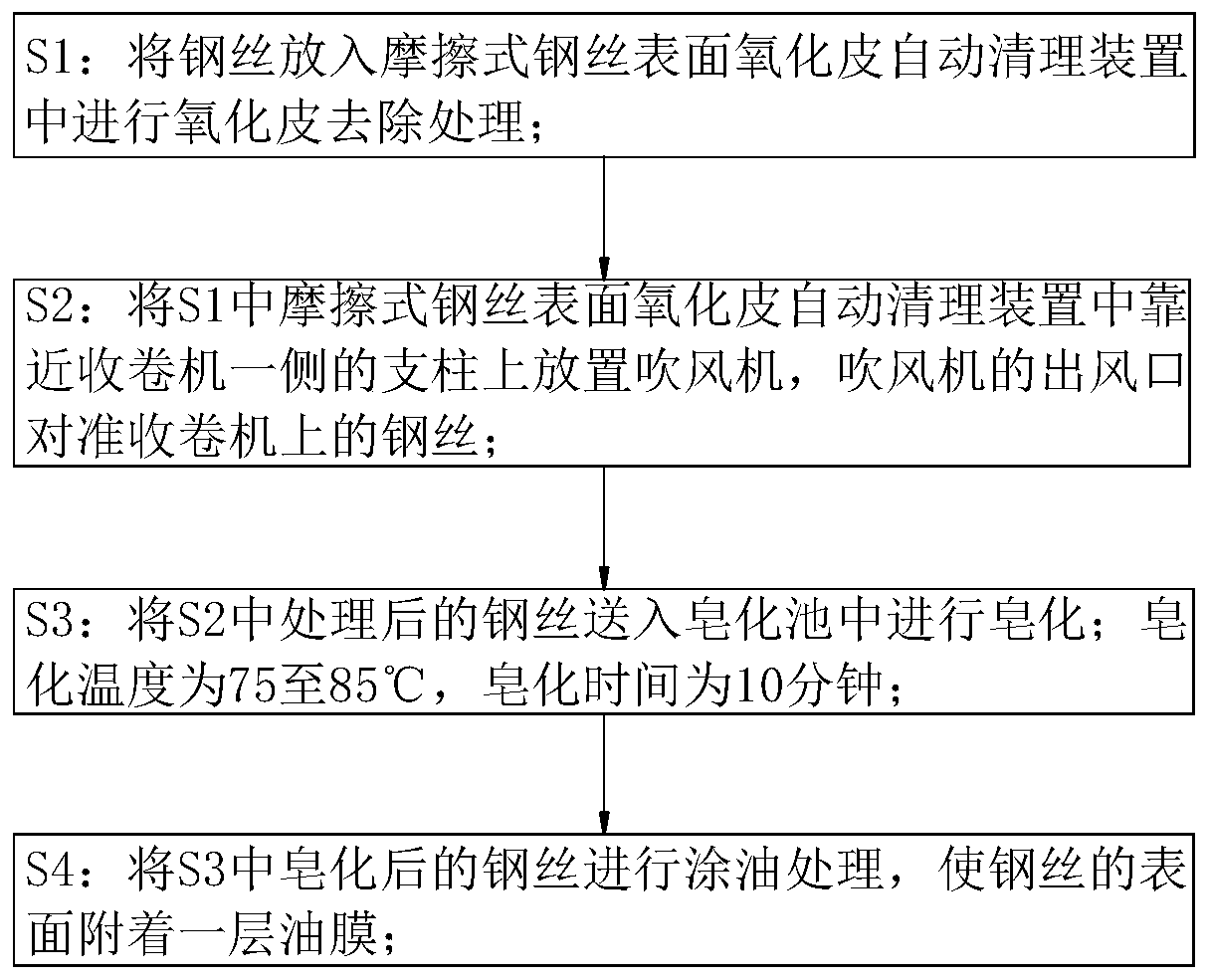

Process for removing oxide skin of steel wire surface

PendingCN109746806AExtended service lifeThe process steps are simpleMetallic material coating processesGrinding machinesSurface oxidationProtection layer

The invention belongs to the technical field of steel wire surface treatment and particularly relates to a process for removing oxide skin of a steel wire surface. The process for removing the oxide skin of the steel wire surface comprises the steps that a steel wire is put into a friction type automatic removing device for the oxide skin of the steel wire surface so that oxide skin removal treatment can be conducted; a blower is placed on a supporting column, close to the side of a rolling machine, in the friction type automatic removing device for the oxide skin of the steel wire surface, and an air outlet of the blower is aligned with the steel wire in the rolling machine; the treated steel wire is conveyed to a saponification pool so that saponification can be conducted; and oiling treatment is conducted on the saponified steel wire. The process for removing the oxide skin of the steel wire surface is simple in steps; the oxide skin of the steel wire surface can be removed, and inaddition, a protective layer can be applied on the steel wire surface; and the service life of steel wire is prolonged.

Owner:程郎

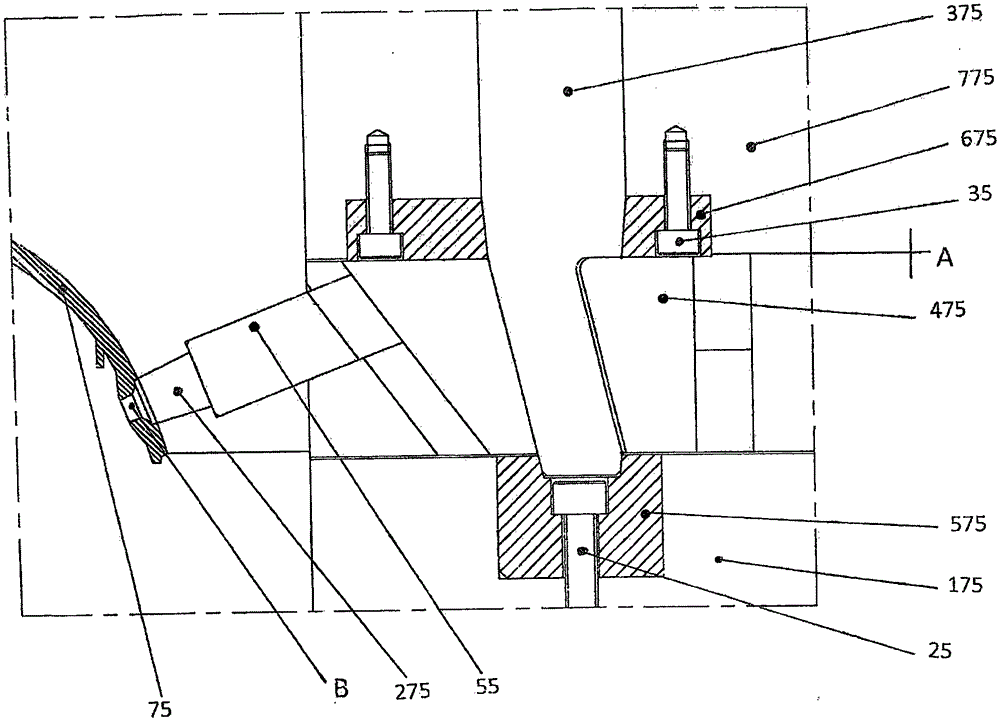

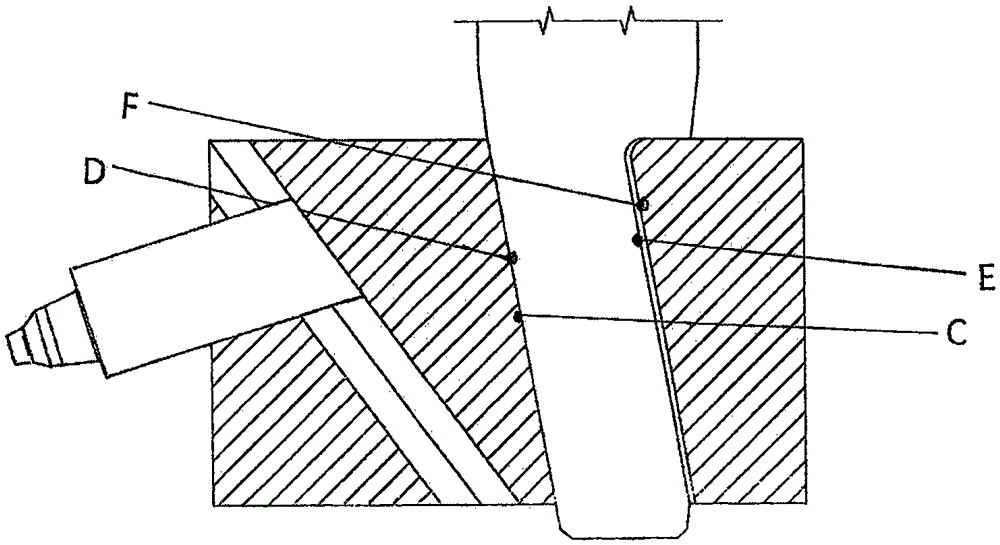

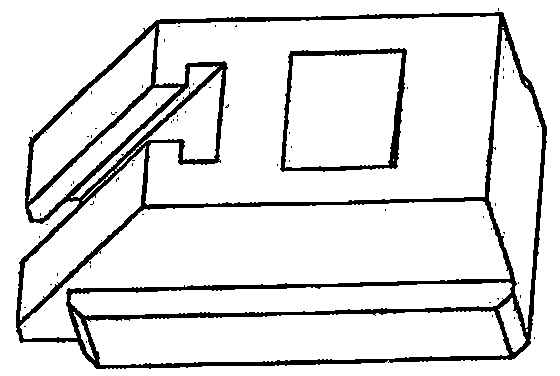

Mechanism for driving core pulling of inclined mold core through sliding block

The invention relates to a mechanism for driving core pulling of an inclined mold core through a sliding block. The mechanism is formed by the sliding block (475), a dog-leg cam (375), a molding sliding block (55) and a molding mold core (275); T-shaped bosses are arranged on the two side faces of the sliding block (475), a square inclined through hole is formed in the center of the sliding block (475), a slope is arranged on the left side of the sliding block (475), a T-shaped groove is formed in the arranged slope, the sliding block (475) is installed in a concave T-shaped groove formed in a movable mold plate (175), the molding sliding block (55) is installed in the concave T-shaped groove formed in the left side of the sliding block (475), a concave-convex T-shaped groove is formed in the right side of the molding sliding block (55) and is in slide clearance fit with the concave T-shaped groove in the slope of the sliding block (475), and the molding mold core (275) is connected to the left side of the molding sliding block (55) in a fastening manner.

Owner:牟维军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com