Full-automatic screw locking and sheet riveting feeding machine used for wiring terminal of switch socket

A fully automatic, screw-locking technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to guarantee the consistency of screw installation torque, the inability to ensure the accuracy of screw installation, and the huge labor costs of production enterprises. Strong continuity of continuous work, saving manpower, and high locking precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

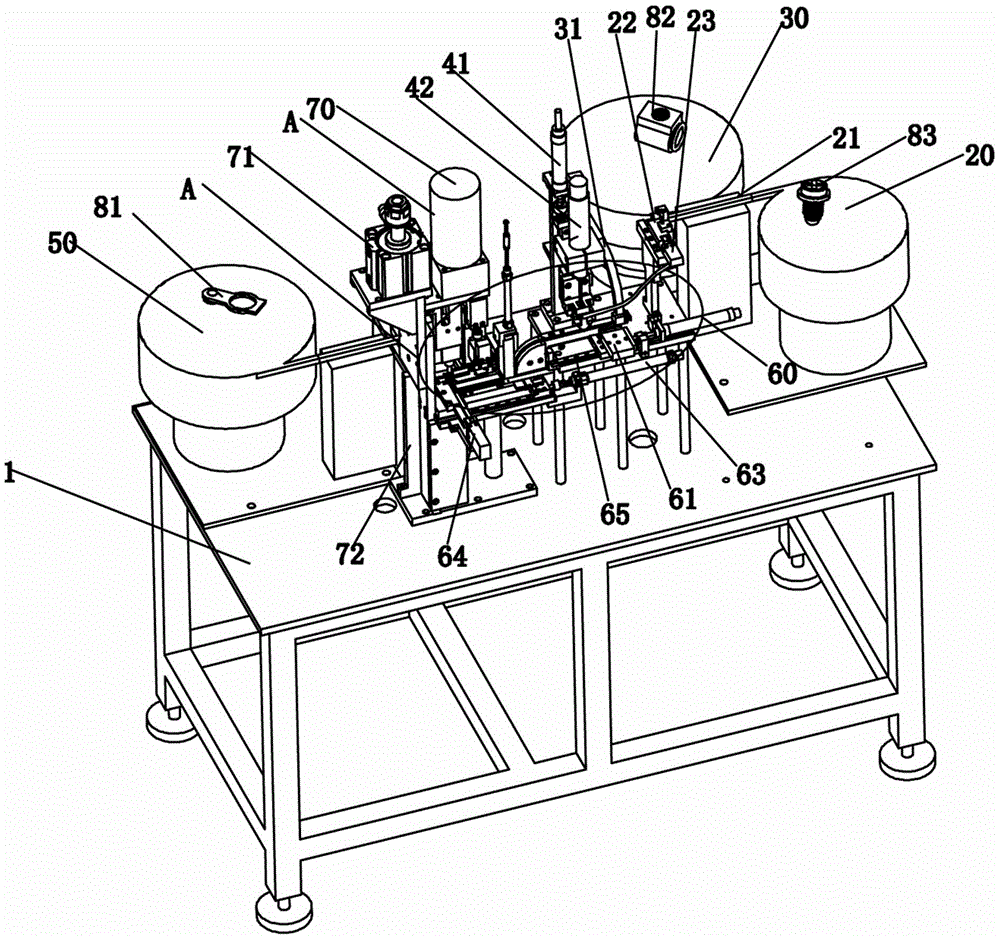

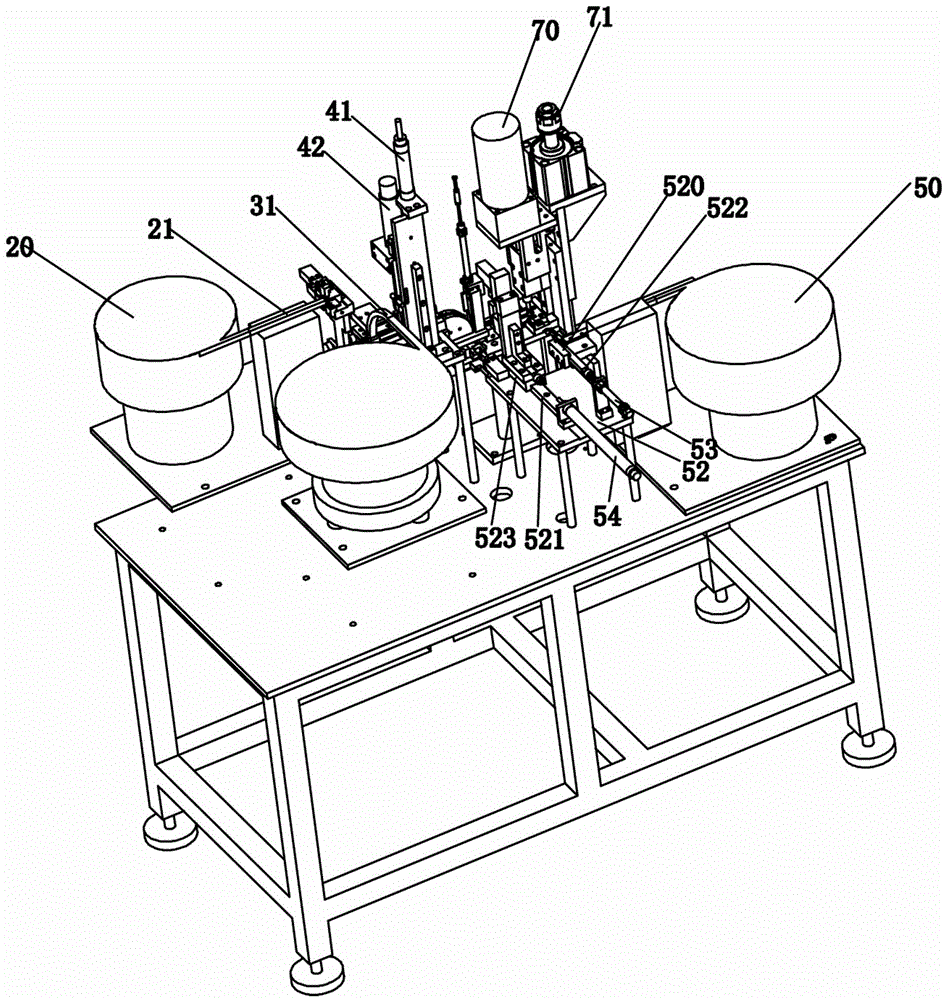

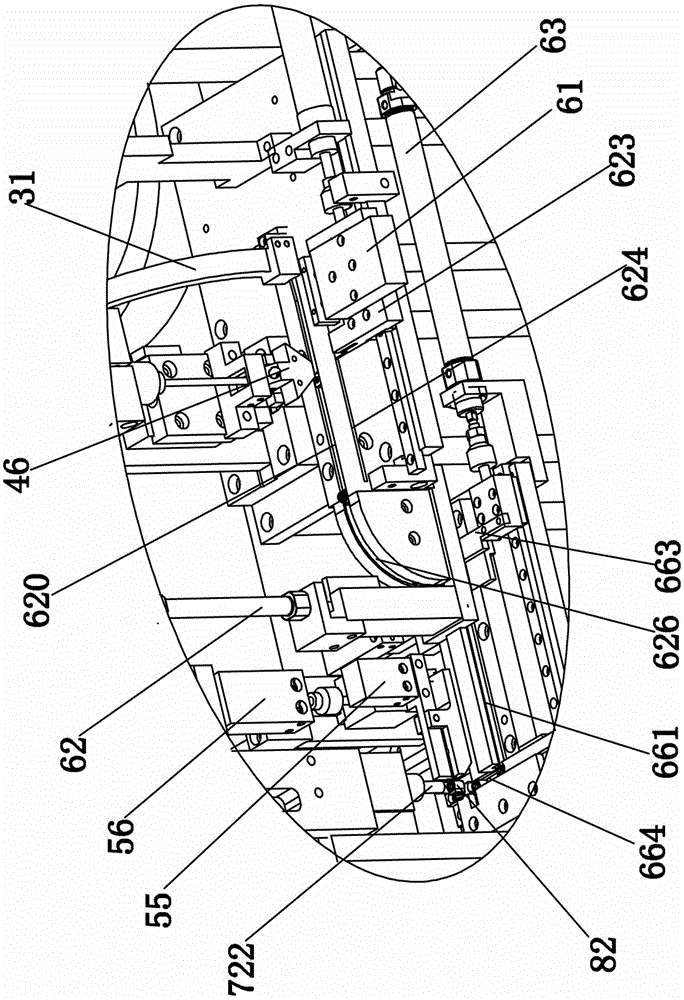

[0041] see Figure 1 to Figure 14As shown, a fully automatic locking screw riveting chip feeder for switch and socket terminals includes a workbench 1; it is arranged on the workbench 1 and is used to deliver the screw 83 to the screw feeding mechanism 2 of the screwing mechanism 4; On the workbench 1, it is used to transport the metal column 82 to the metal column feeding mechanism 3 below the screw mechanism 4; on the workbench 1, it is used to transport the metal sheet to the metal sheet feeding mechanism 5 of the riveting mechanism 7 for stamping ; Set on the workbench 1, it is used to twist the screw 83 so that the metal column 82 is screwed together with the screw screw mechanism 4; it is set on the workbench 1, and is used to transport the metal column 82 with the screw 83 screwed together The feeding mechanism 6 for the riveting mechanism 7; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com