Forming and sealing method for food packaging

A food packaging and sealing technology, applied in packaging sealing/fastening, packaging, transportation packaging and other directions, can solve the problems of poor sealing effect, complex forming and sealing, low forming and sealing efficiency, etc., to improve packaging and sealing efficiency and sealing effect. Good, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

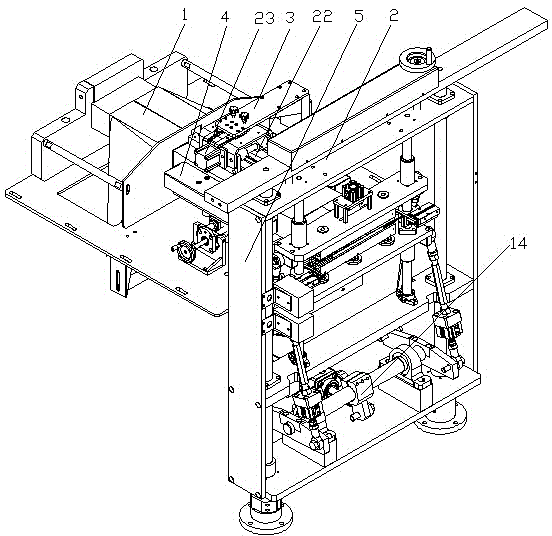

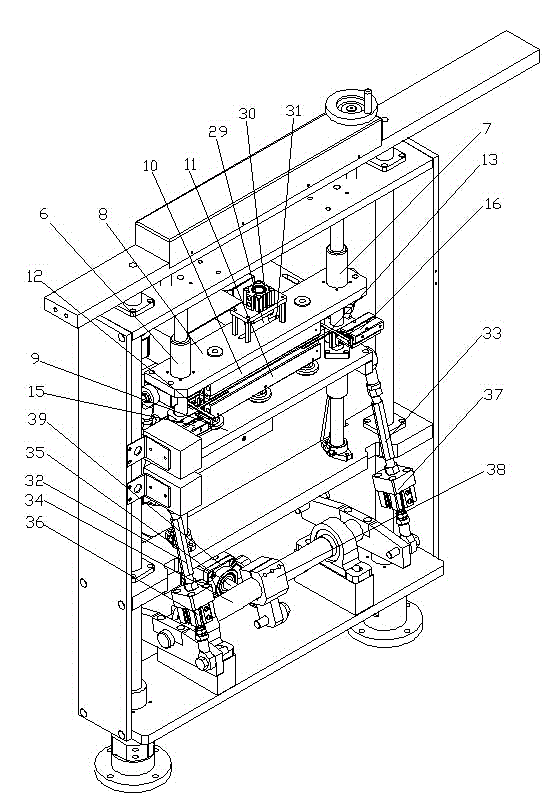

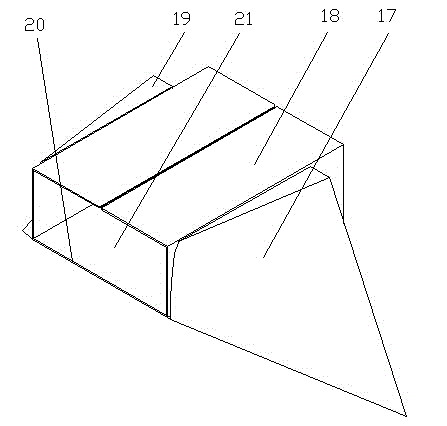

[0035] see figure 1 , a method for forming and sealing food packaging, comprising successively a bag forming step, a longitudinal sealing step and a horizontal sealing step, the bag forming step is to fold the whole roll of packaging film into a square film bag by the bag forming part 1; the horizontal sealing step The front end of the vertically sealed square film bag filled with materials is cornered and heat-sealed through the knife-sealing corner part 2, and the rear end of the square film bag is cut off first, and then corners are cornered and heat-sealed to obtain the finished product.

[0036] This embodiment is the most basic implementation mode. In the bag forming step and the longitudinal sealing step, the bag forming parts and the longitudinal sealing parts of the prior art can be used, and the film bag conveying parts of the prior art can be used in the film bag conveying process. The whole roll of packaging film is folded into a square film bag by the bag form...

Embodiment 2

[0038] see figure 1 , a method for forming and sealing food packaging, comprising successively a bag forming step, a longitudinal sealing step and a horizontal sealing step, the bag forming step is to fold the whole roll of packaging film into a square film bag by the bag forming part 1; the horizontal sealing step The front end of the vertically sealed square film bag filled with materials is cornered and heat-sealed through the knife-sealing corner part 2, and the rear end of the square film bag is cut off first, and then corners are cornered and heat-sealed to obtain the finished product.

[0039] In the longitudinal sealing step, the middle sealing part 3 is used to seal the square film bag containing the materials in the middle.

[0040] This embodiment is a preferred implementation mode. The longitudinal sealing step is to seal the square film bag containing the material in the middle through the middle sealing part, which can adjust the regularity of the packaging mater...

Embodiment 3

[0042] see figure 1 , a method for forming and sealing food packaging, comprising successively a bag forming step, a longitudinal sealing step and a horizontal sealing step, the bag forming step is to fold the whole roll of packaging film into a square film bag by the bag forming part 1; the horizontal sealing step The front end of the vertically sealed square film bag filled with materials is cornered and heat-sealed through the knife-sealing corner part 2, and the rear end of the square film bag is cut off first, and then corners are cornered and heat-sealed to obtain the finished product.

[0043] In the longitudinal sealing step, the middle sealing part 3 is used to seal the square film bag containing the materials in the middle.

[0044] A film bag conveying step is also arranged between the longitudinal sealing step and the horizontal sealing step. The film bag conveying step is to form an adsorption on the square film bag containing materials after the film bag negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com