Vacuumizing plastic bag sealing machine

A vacuuming, plastic bag technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of no vacuuming, lack of automation performance, etc., and achieve the effect of high sealing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

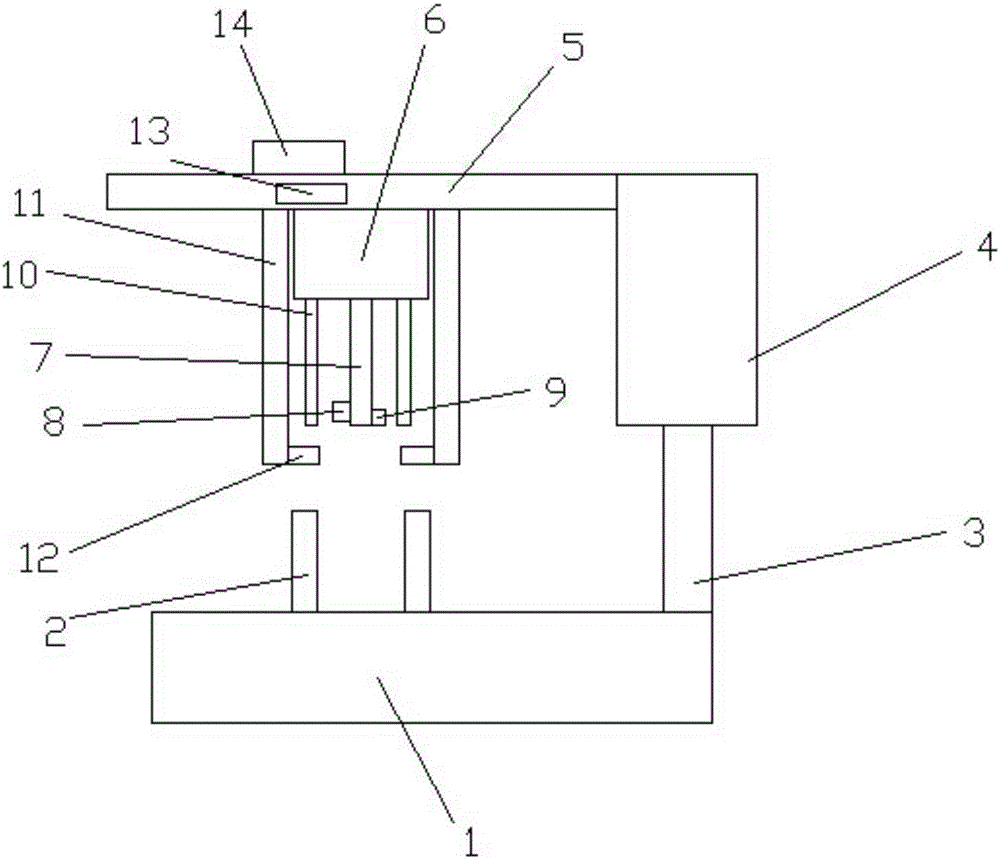

[0018] figure 1 The vacuum-pumped plastic bag sealing machine shown includes an operating table 1, which is provided with two symmetrical limit plates 2 and a cylinder 3. The upper end of the cylinder 3 is connected to the lower pressing block 4, and one side of the lower pressing block 4 is connected to the cross bar. 5. The lower end of the cross bar 5 is connected to the vacuum pump 6, and the lower end of the vacuum pump 6 is provided with a vacuum head 7 and a clamp 10. The vacuum head 7 is provided with an infrared sensor 8 and a pressure sensor 9, and the vacuum pump 6 is provided on both sides. There are symmetrical support rods 11, and the support rods 11 are slidingly connected with the lower ends of the cross bar 5 through the driving device 13. The opposite sides of the lower ends of the two support rods 11 are symmetrically provided with sealing strips 12, and the vacuum head 7 and the two limit plates 2 The midpoint between them is on the same straight line, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com