Patents

Literature

548results about How to "Improve sealing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

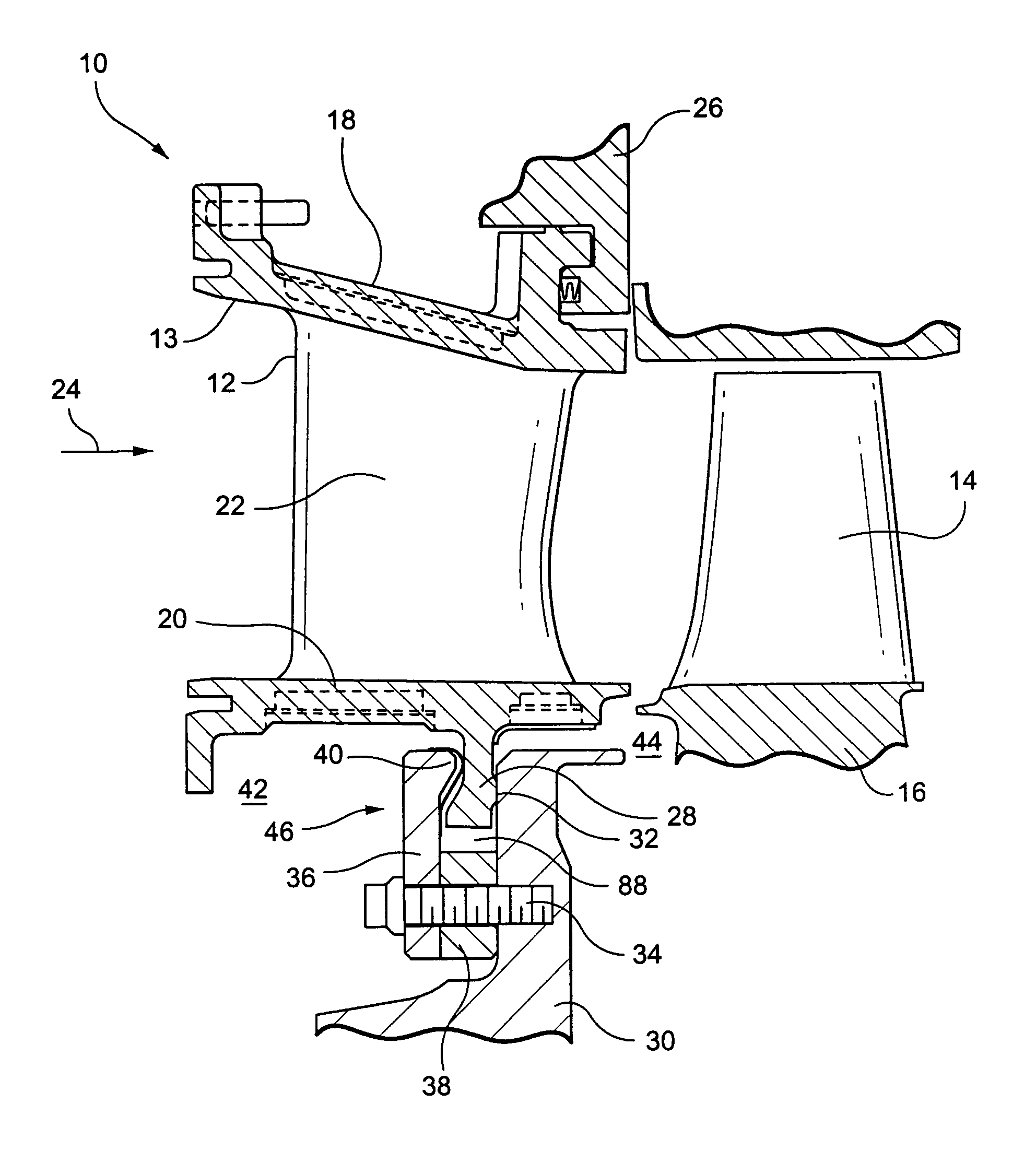

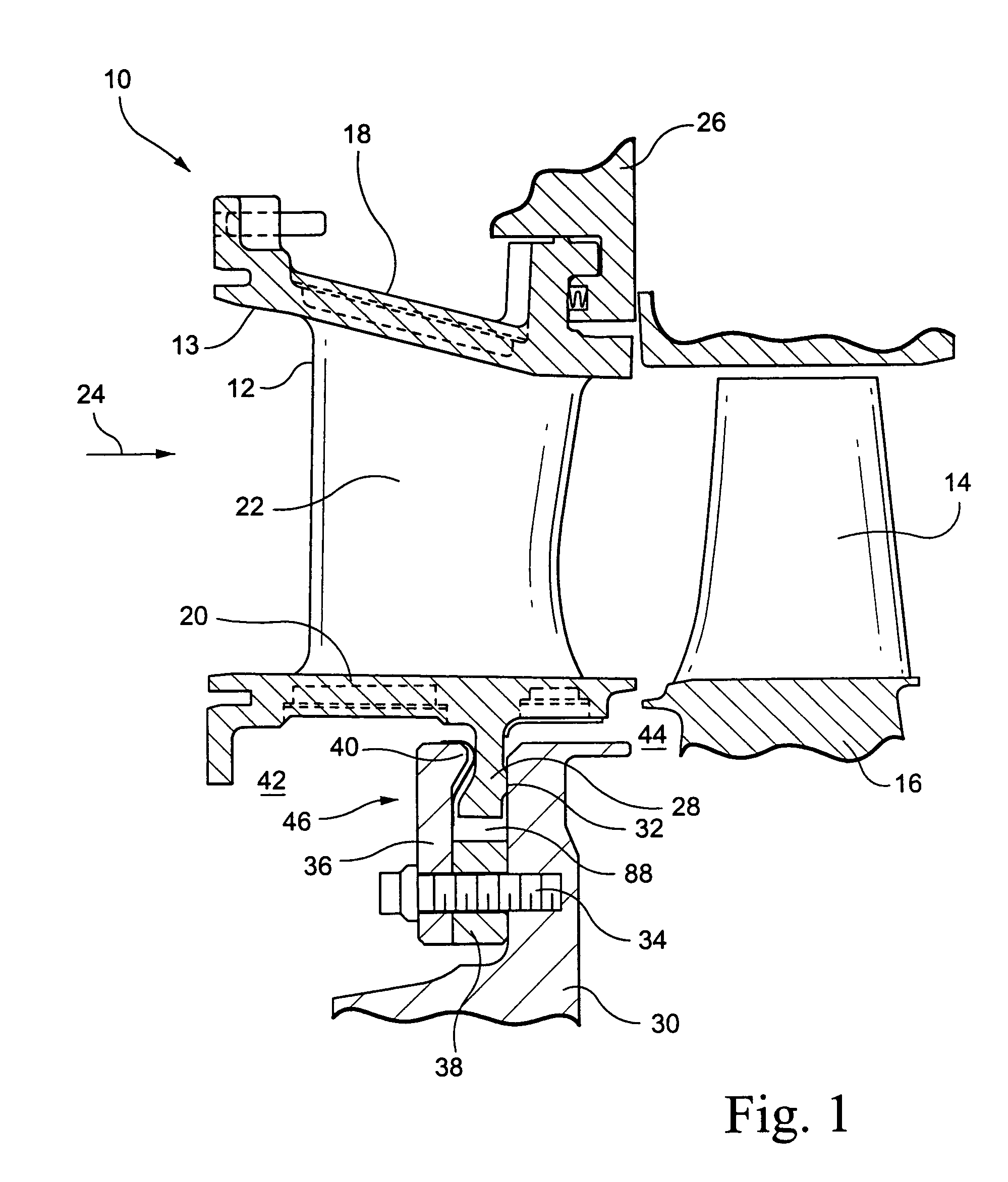

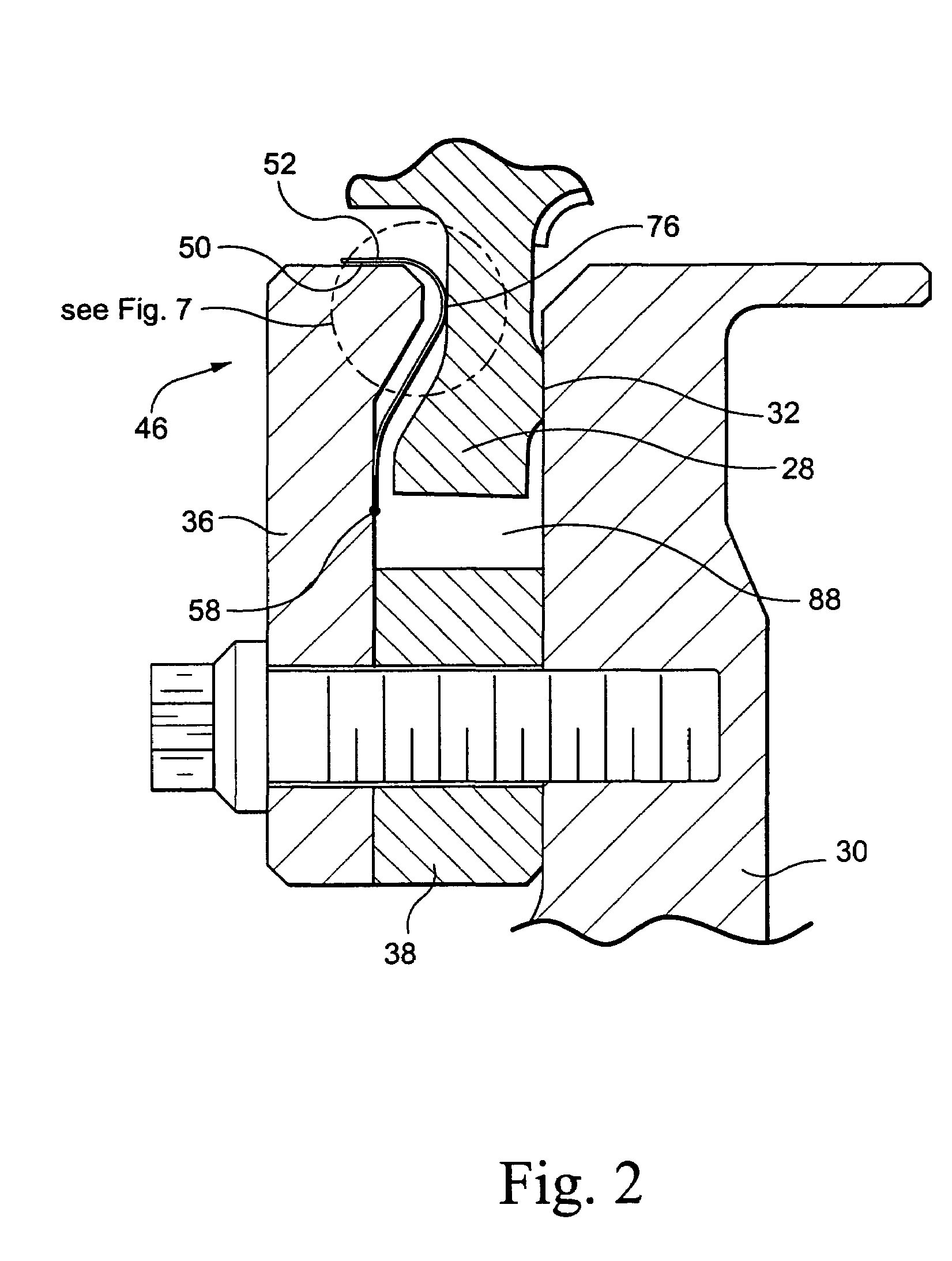

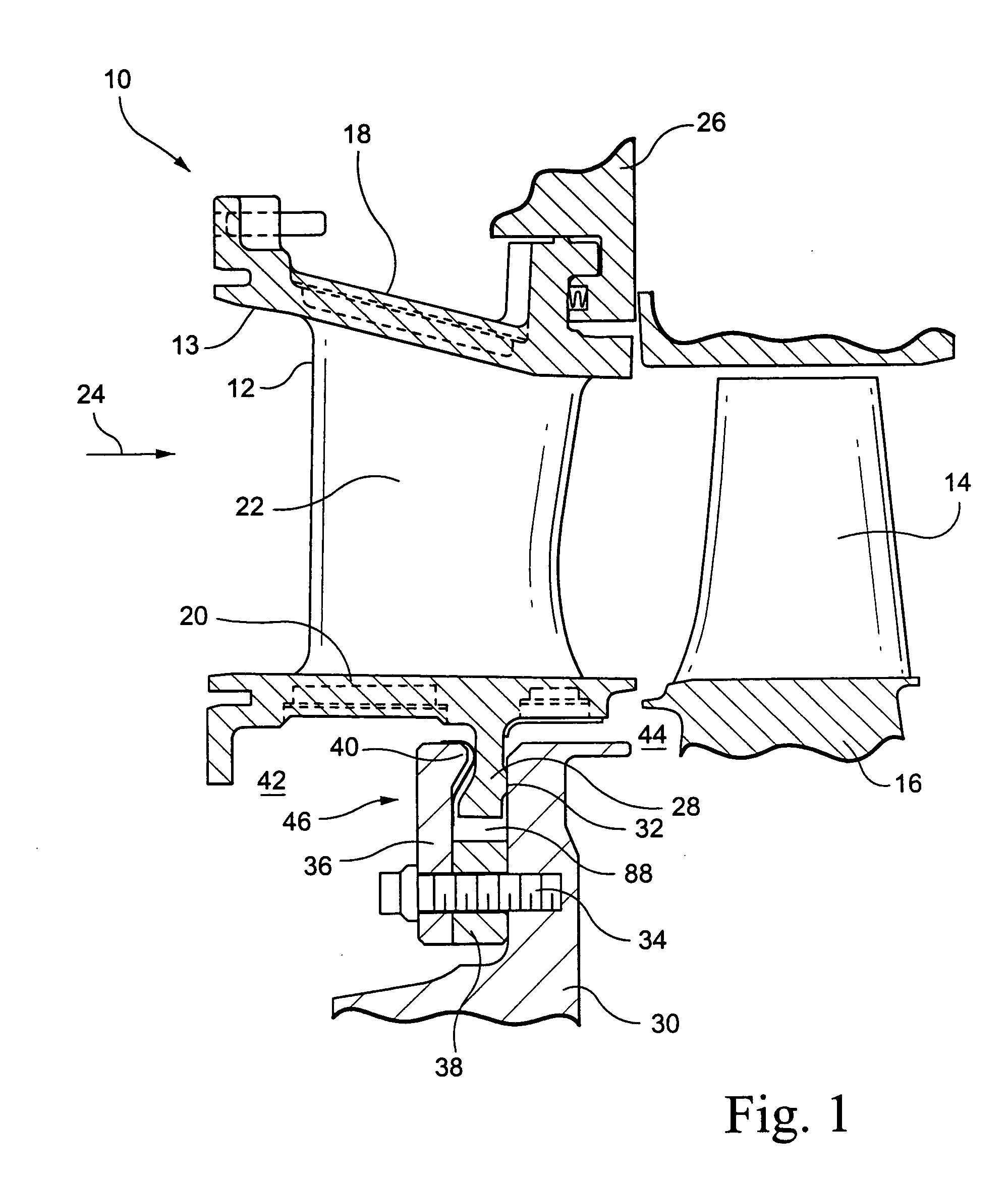

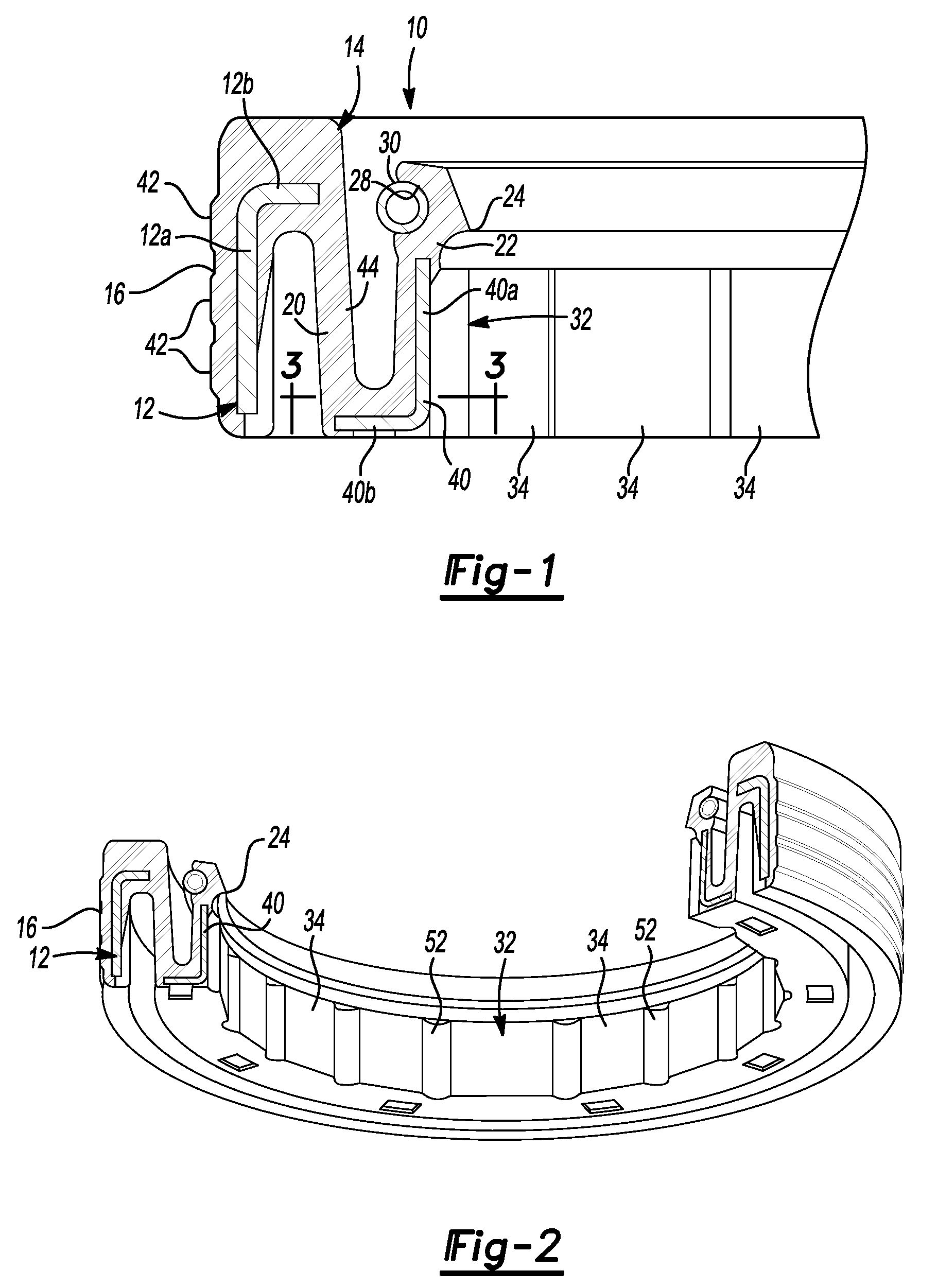

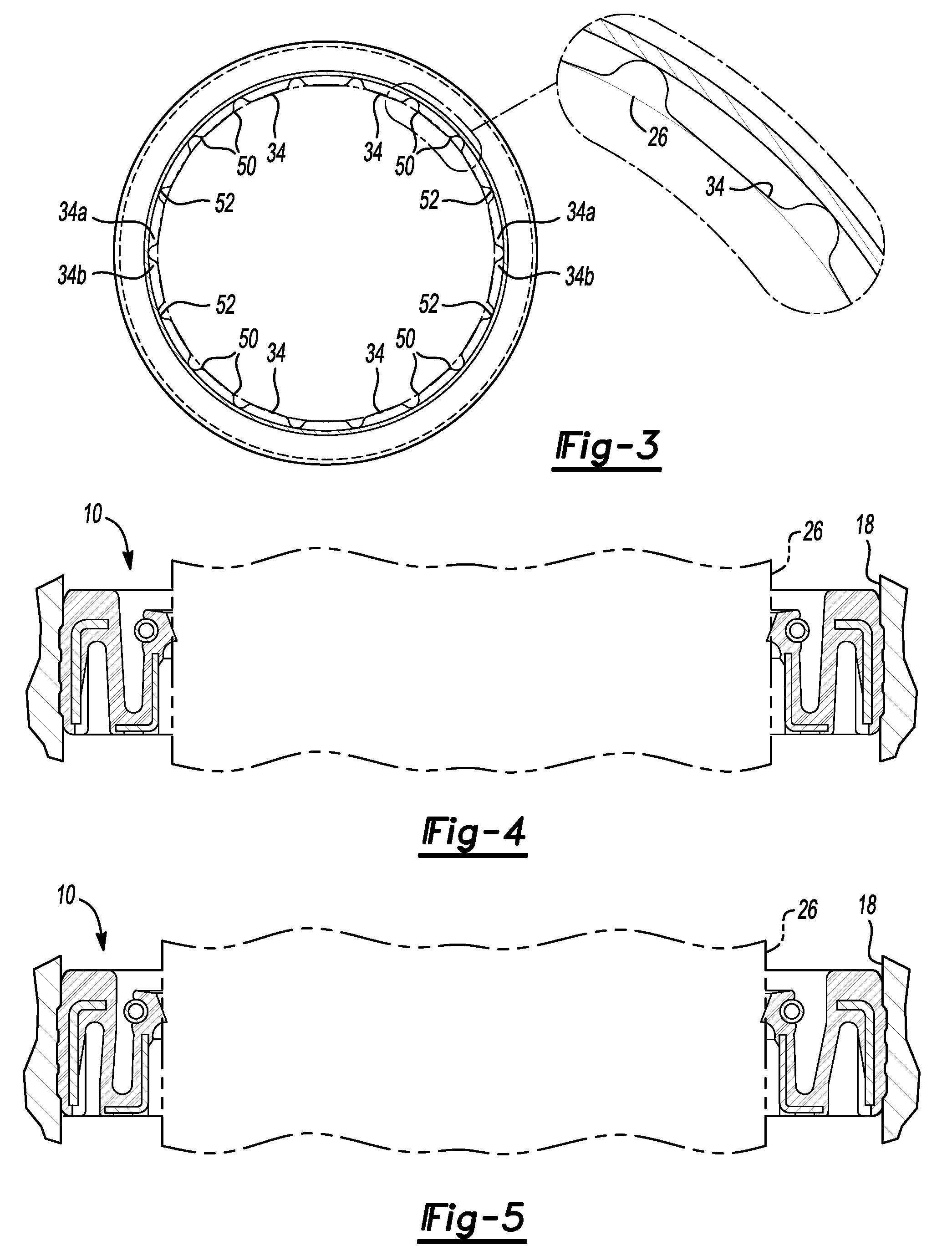

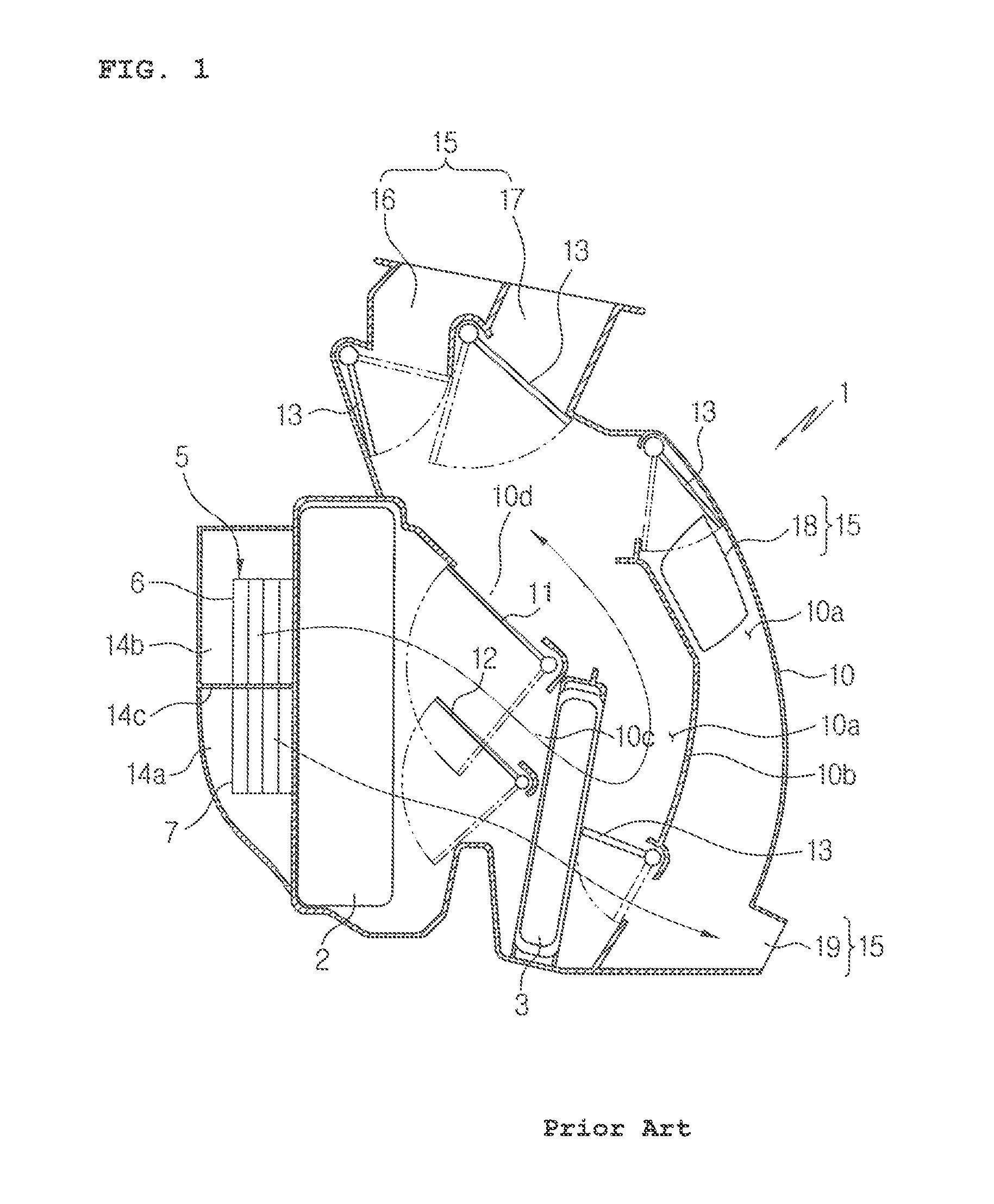

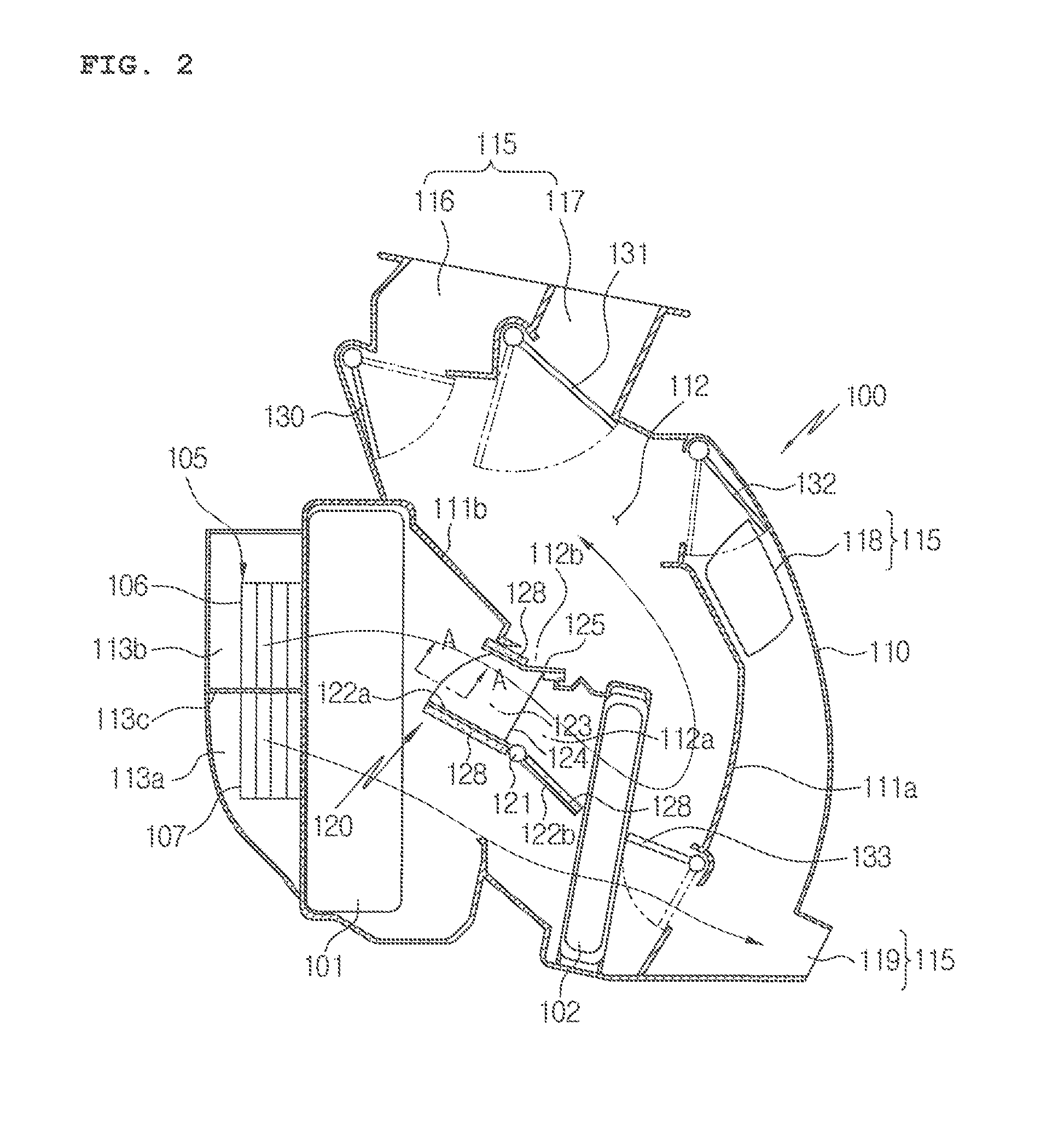

System for sealing an inner retainer segment and support ring in a gas turbine and methods therefor

InactiveUS7094026B2Improve engine efficiencyReduce leakagePump componentsStatorsLeakage flowGas turbines

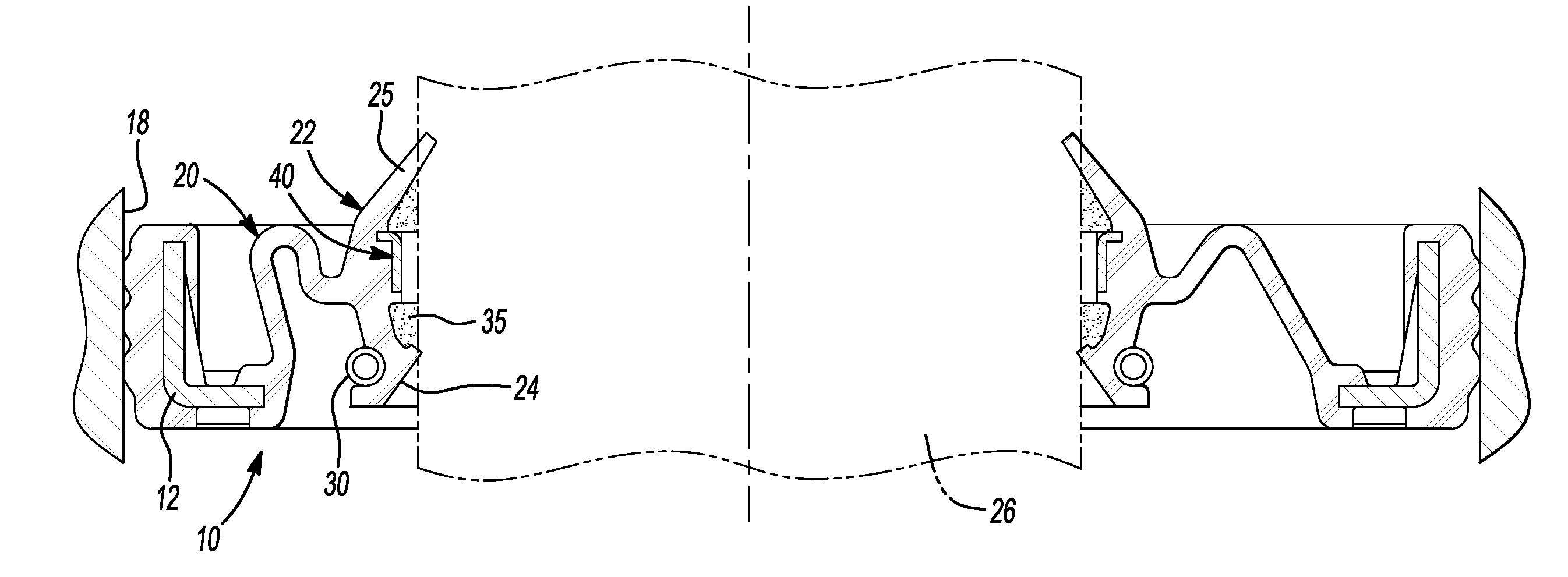

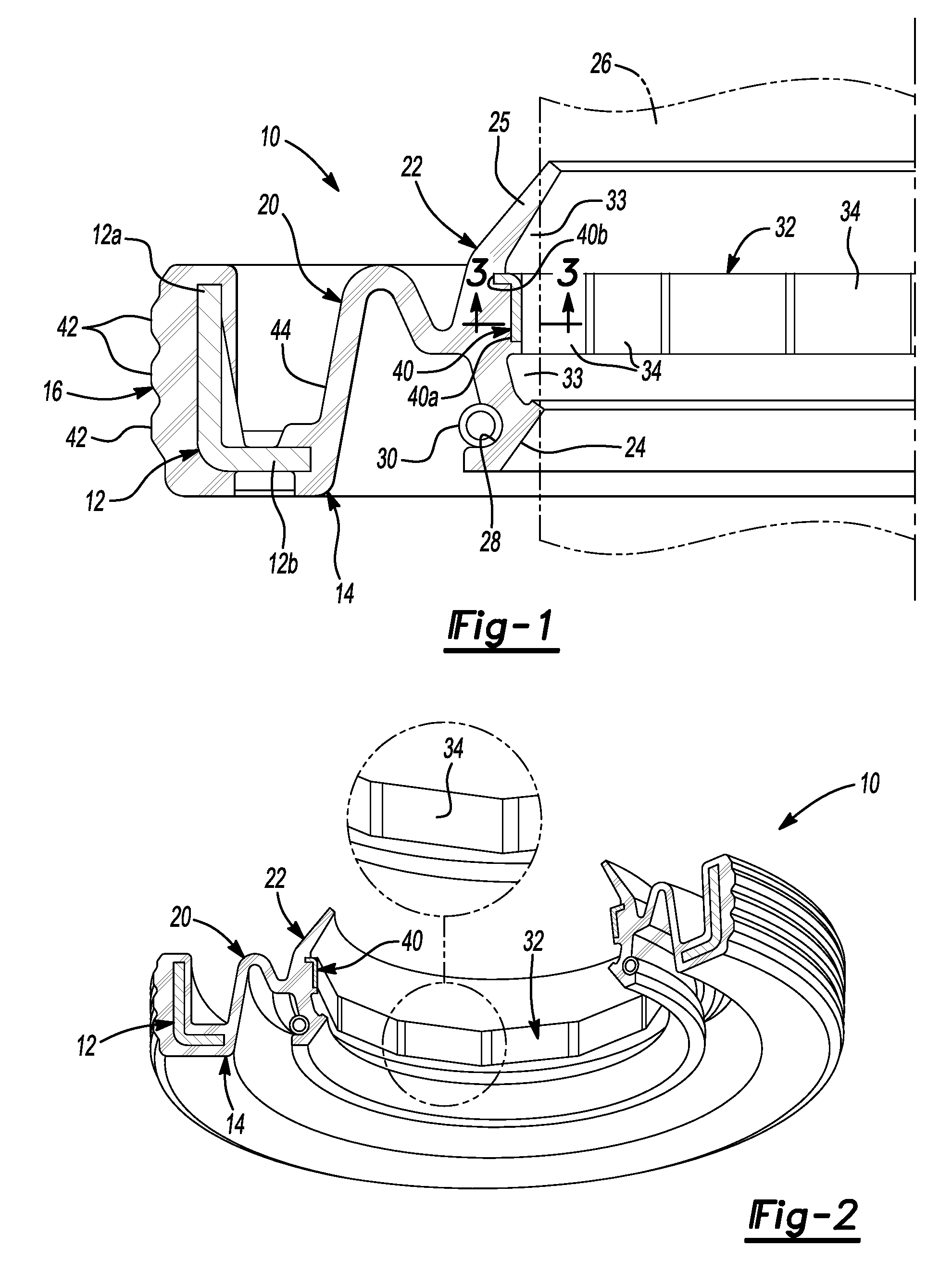

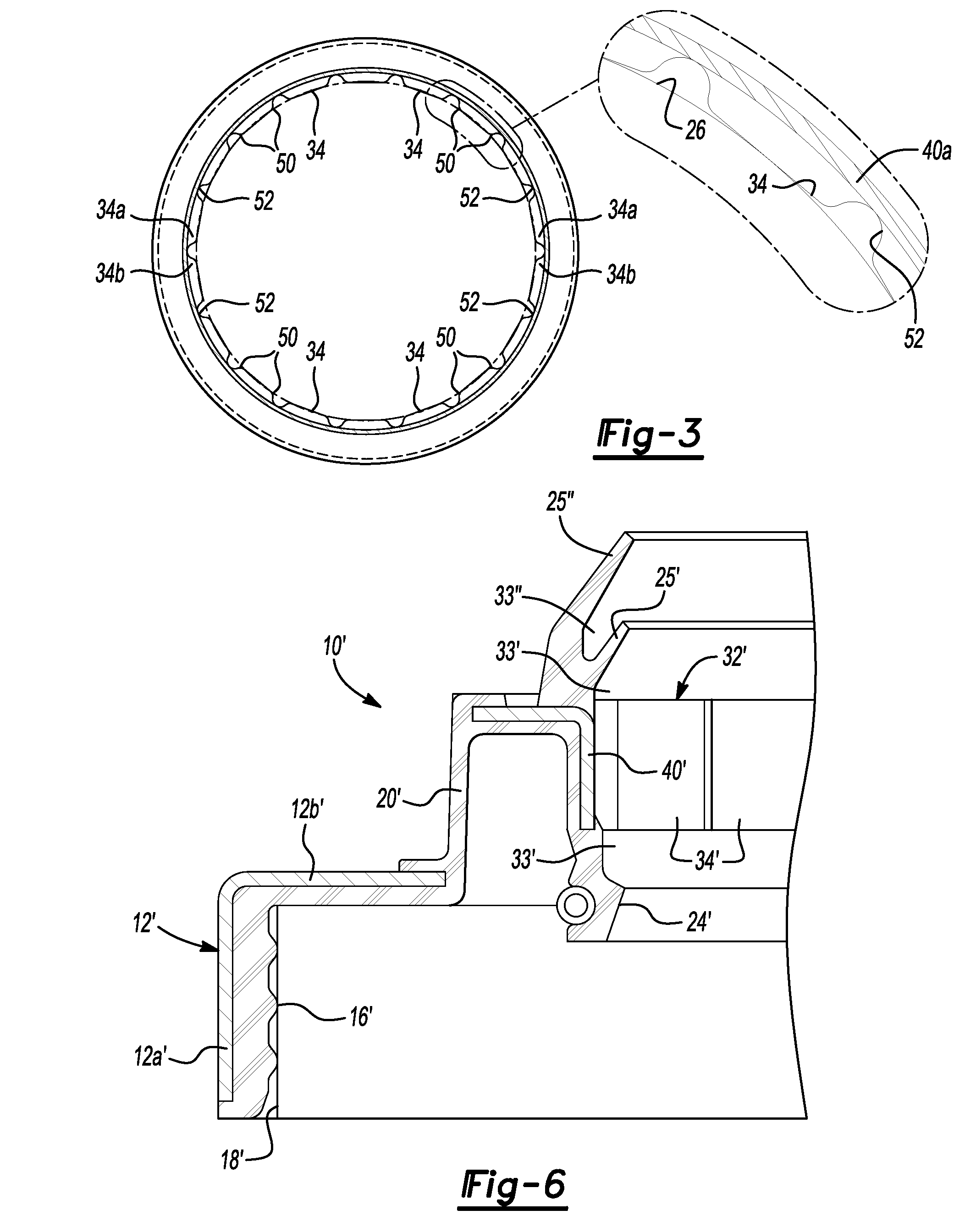

Arcuate seal layers conforming with one another are disposed between inner retainer segments and inner rails of nozzle segments of a gas turbine. The layers are secured to the aft axial face of the segments and project radially outwardly to seal against the forward axial faces of the rails. The rear axial faces of the rails have chordal seals for sealing against the forward axial faces of the support rings. The seal layers have radial cuts misaligned with one another in an axial direction to preclude leakage flows through gaps formed by the cuts. Arcuate spacers are staggered circumferentially with the arcuate retainer segments whereby an intermediate pressure plenum is formed between the finger seals and chordal seals.

Owner:GENERAL ELECTRIC CO

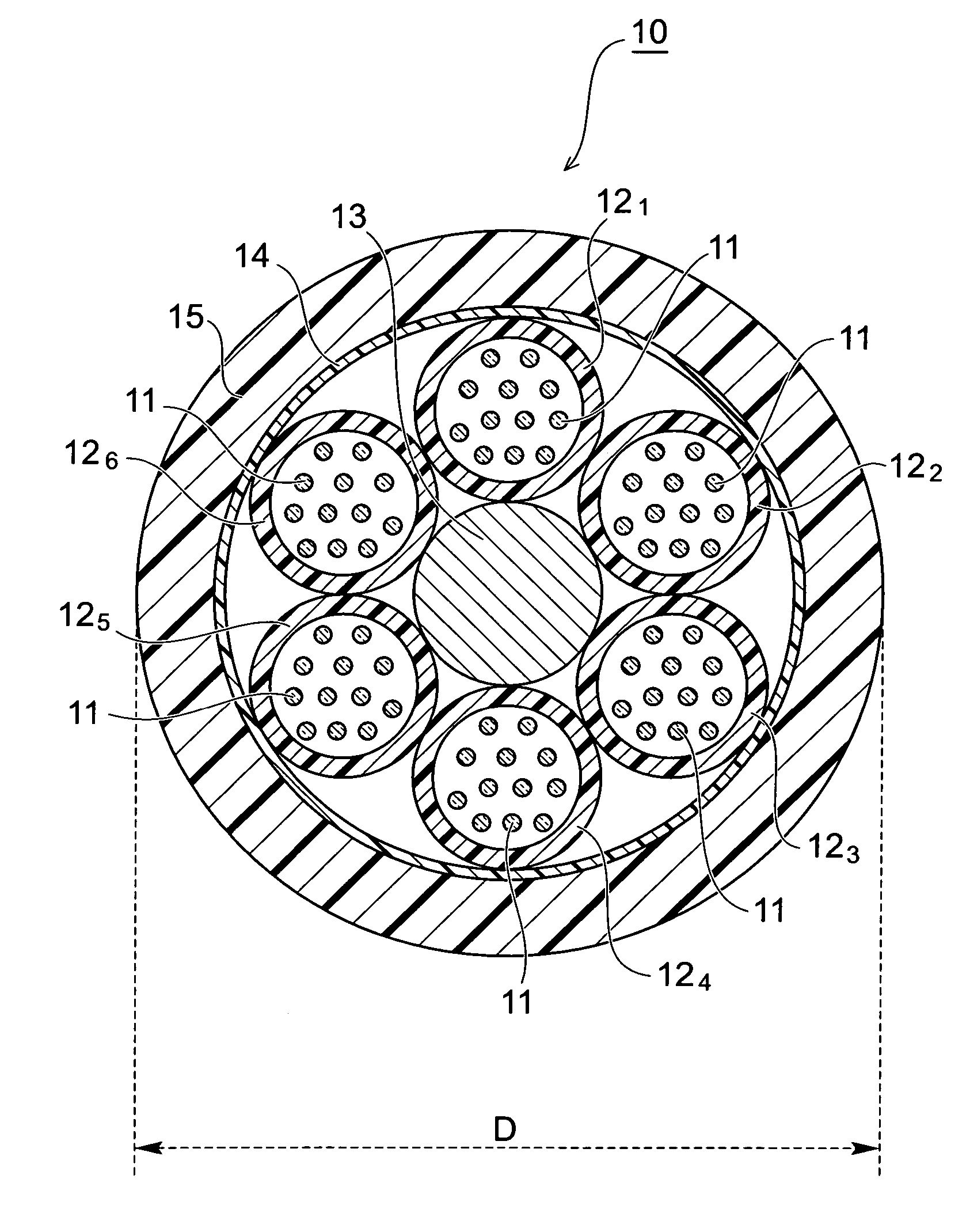

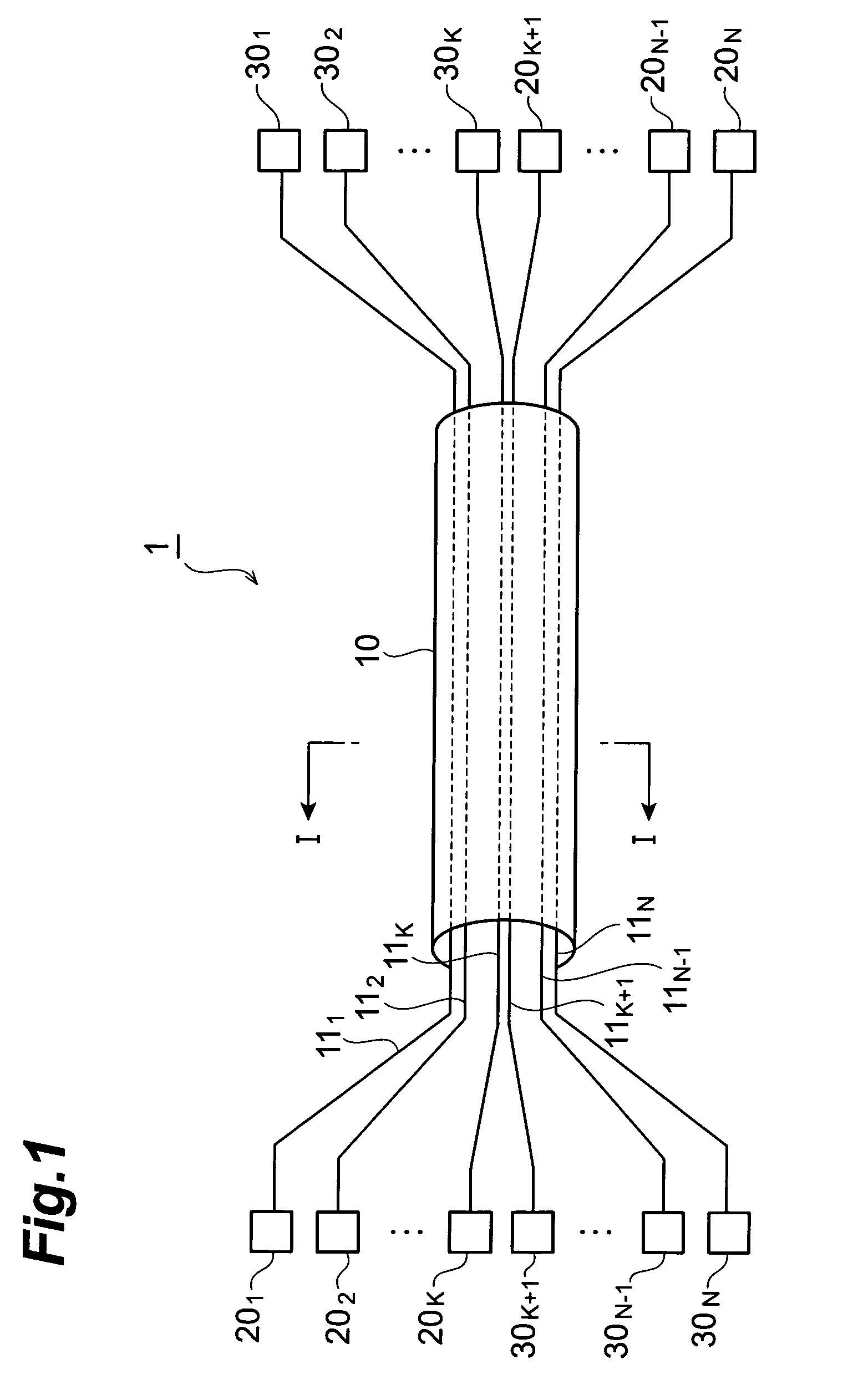

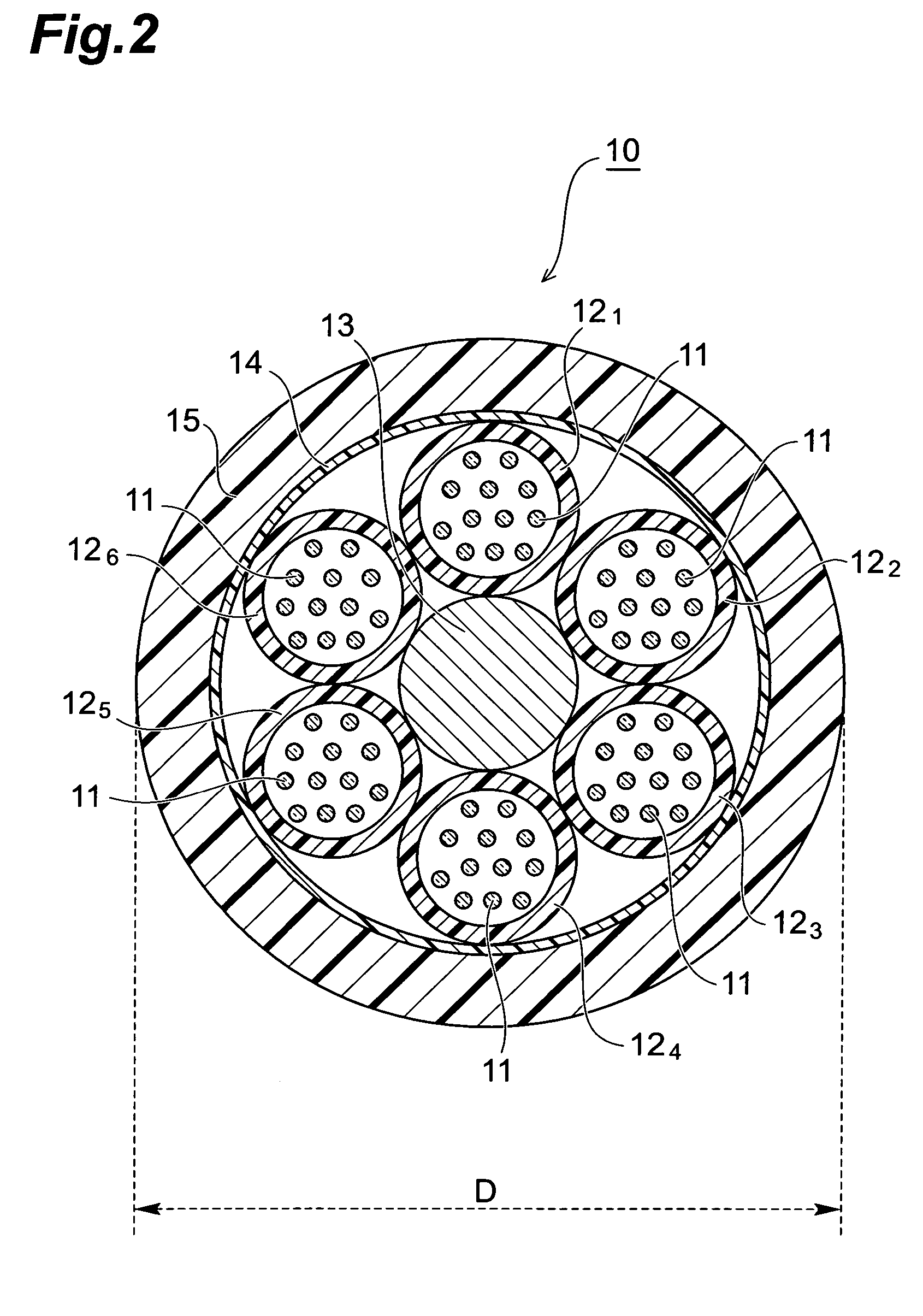

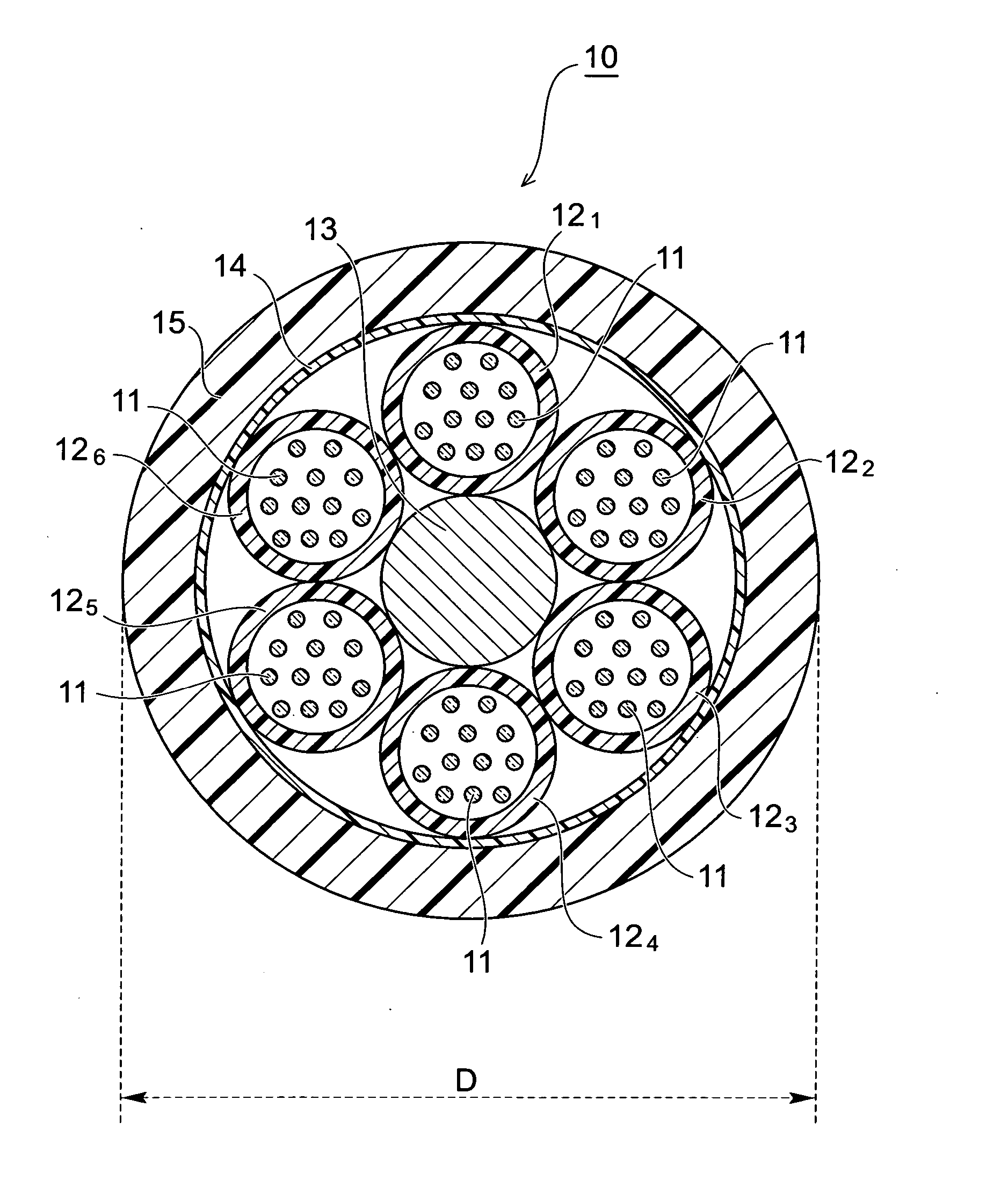

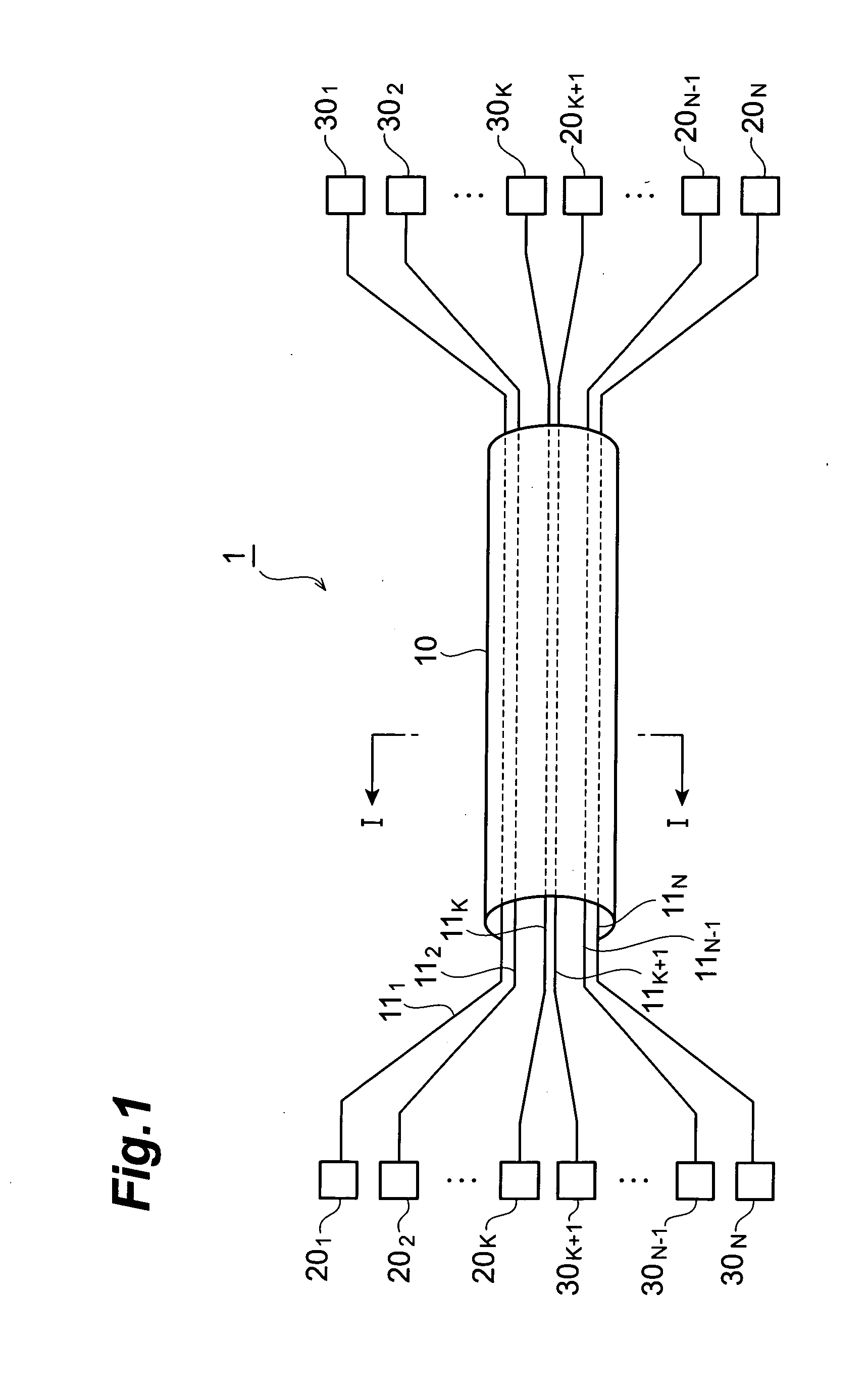

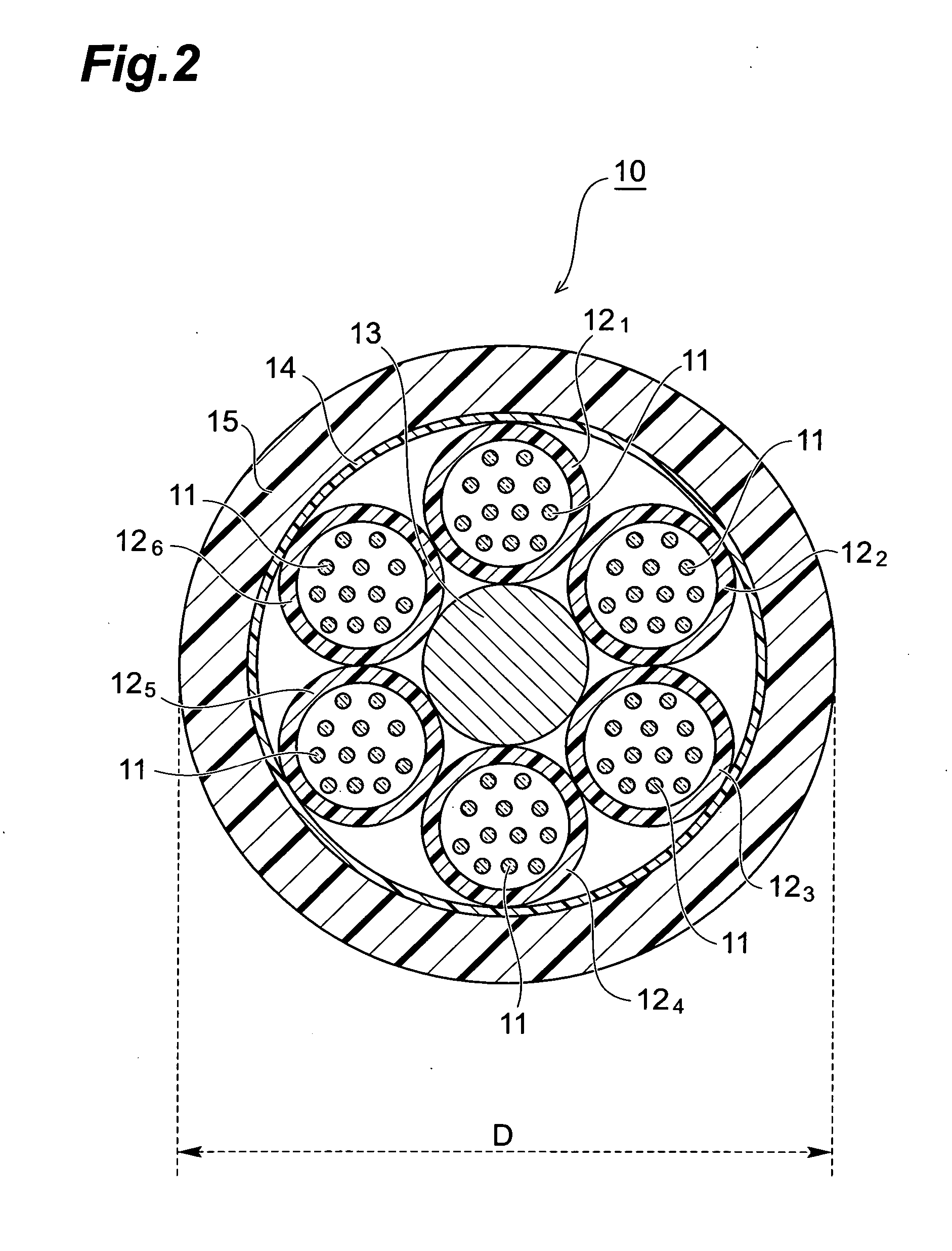

Optical cable

ActiveUS7321709B2Reduce the overall diameterImprove sealing efficiencyFibre mechanical structuresFiberEngineering

An optical cable according to the present invention relates to an optical cable having a construction to enable reduction of a cable outer diameter, and / or improvement of contained efficiency of coated optical fibers while an increase of transmission loss in each coated optical fiber is suppressed. The optical cable has a loose-tube type of structure constructed by: a tension member; a plurality of tubes stranded together around the tension member; and an outer sheath covering the outer periphery of the plurality of tubes. One or more coated optical fibers are contained in each tube. A ratio of A / B is 6.3 or more but 7.0 or less, where each coated optical fiber has a mode field diameter A in a range of 8.6±0.4 μm at a wavelength of 1.31 μm, and where a fiber cutoff wavelength thereof is B μm.

Owner:SUMITOMO ELECTRIC IND LTD +1

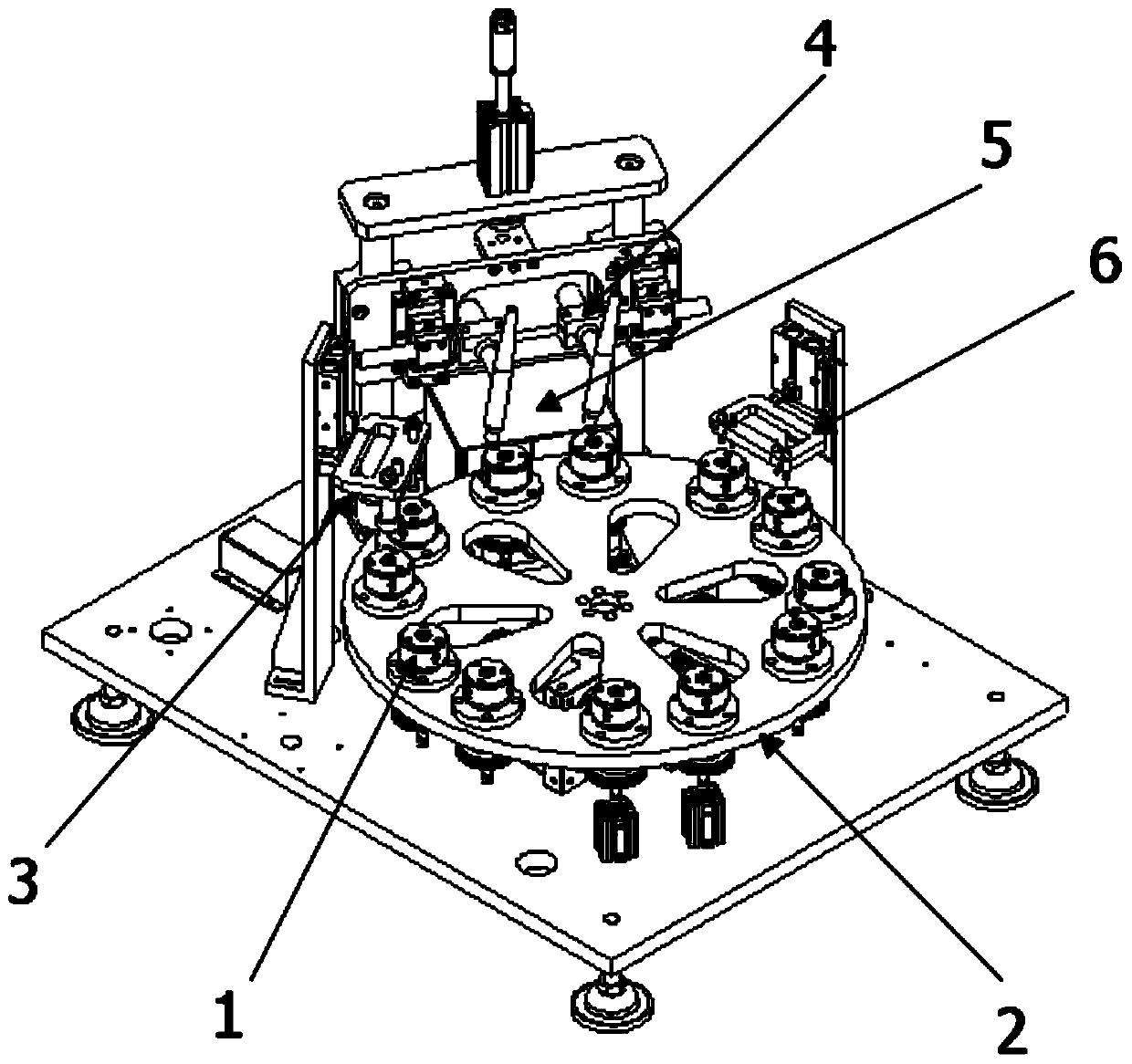

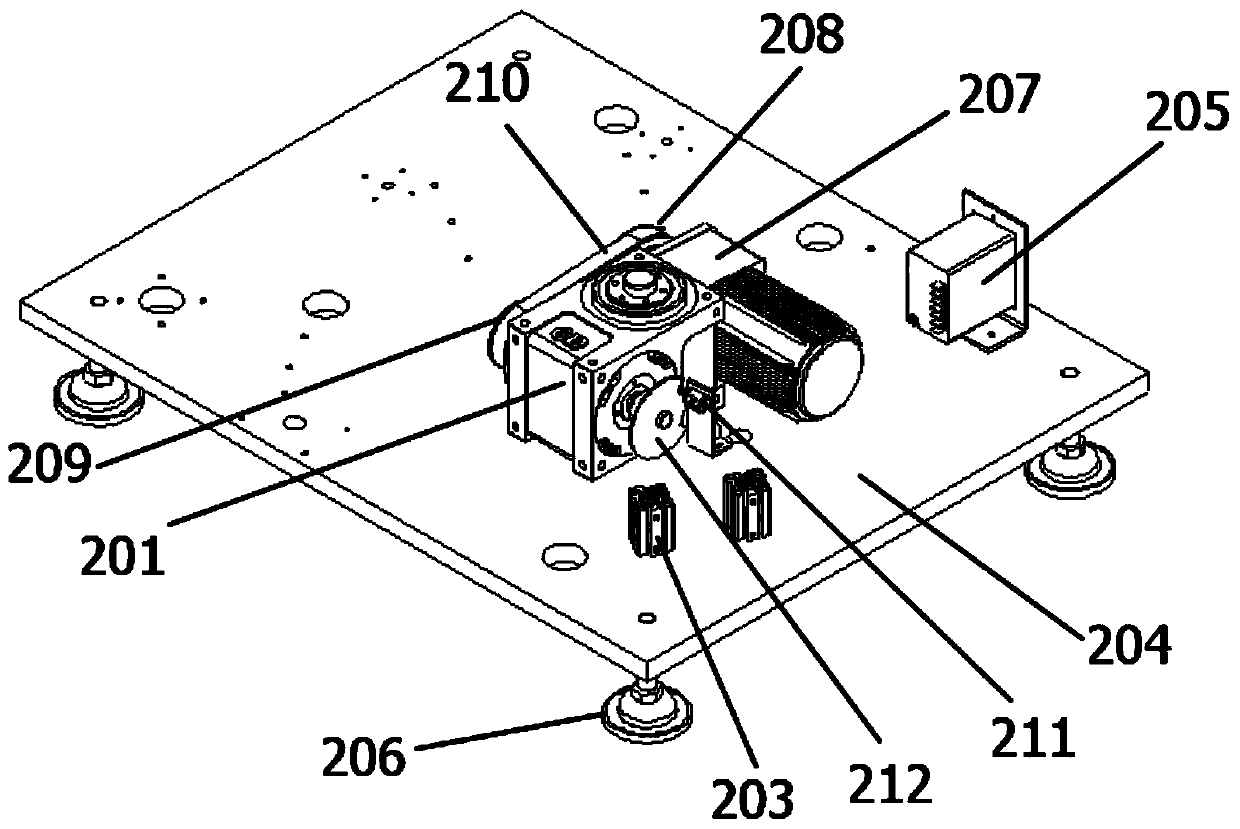

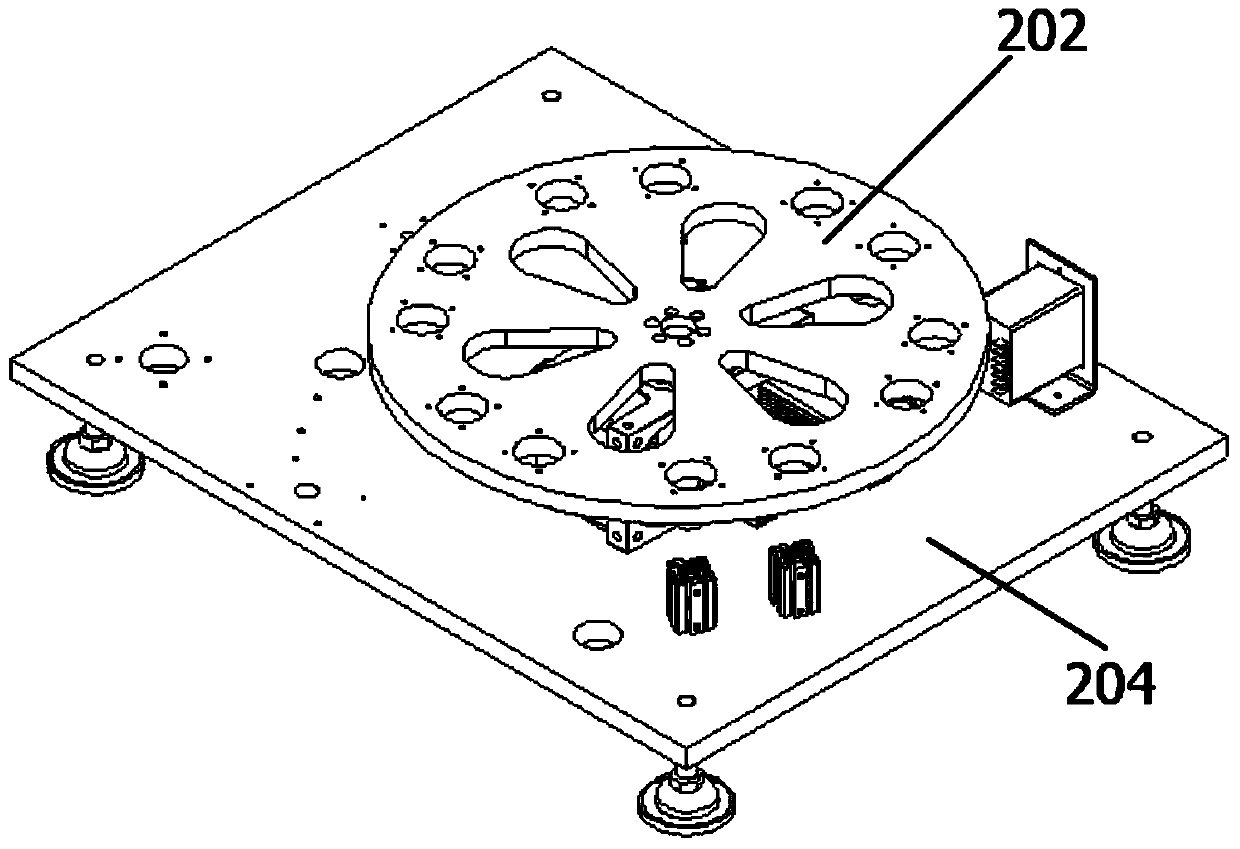

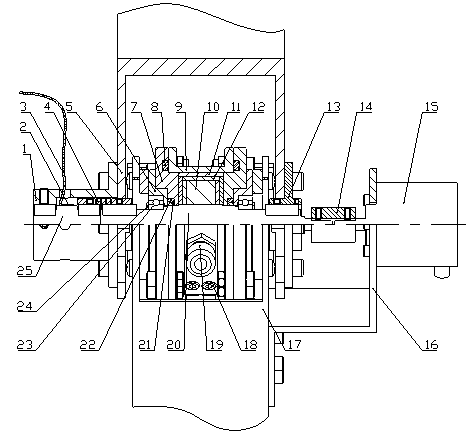

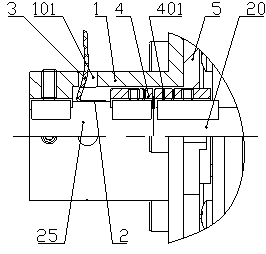

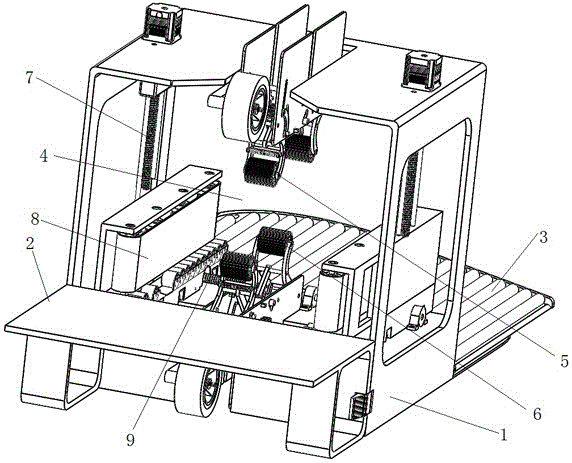

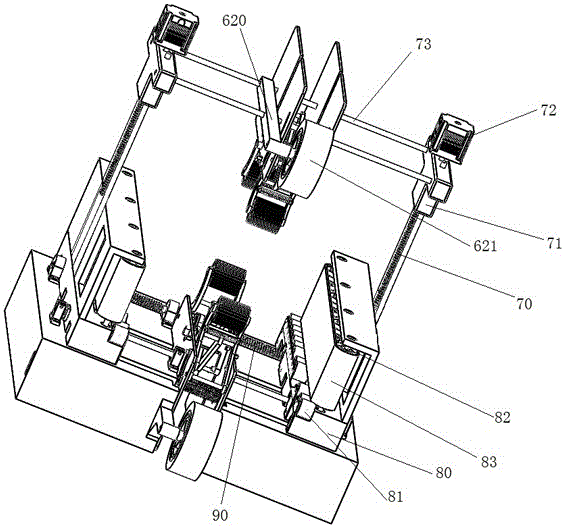

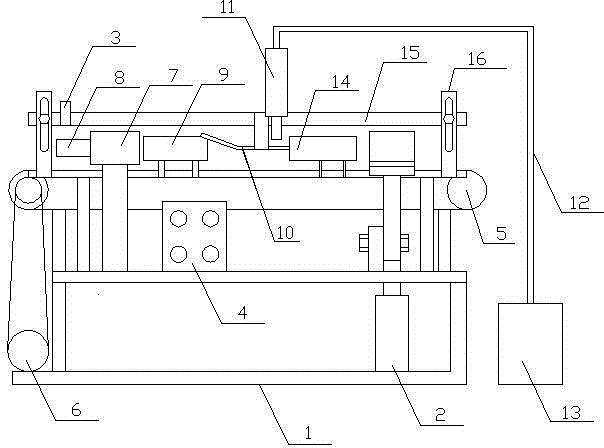

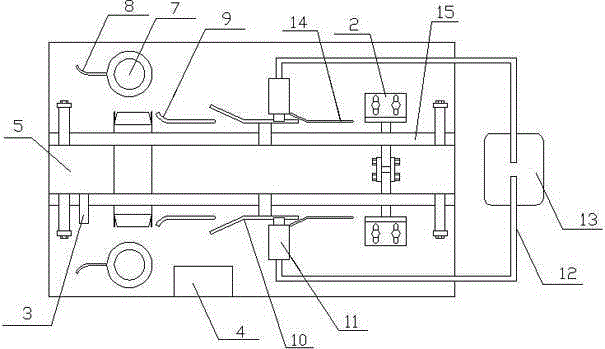

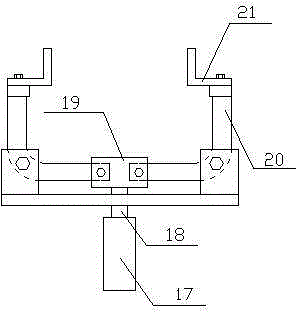

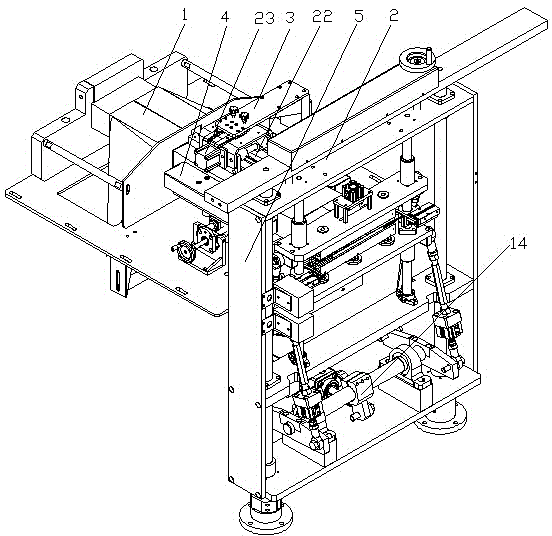

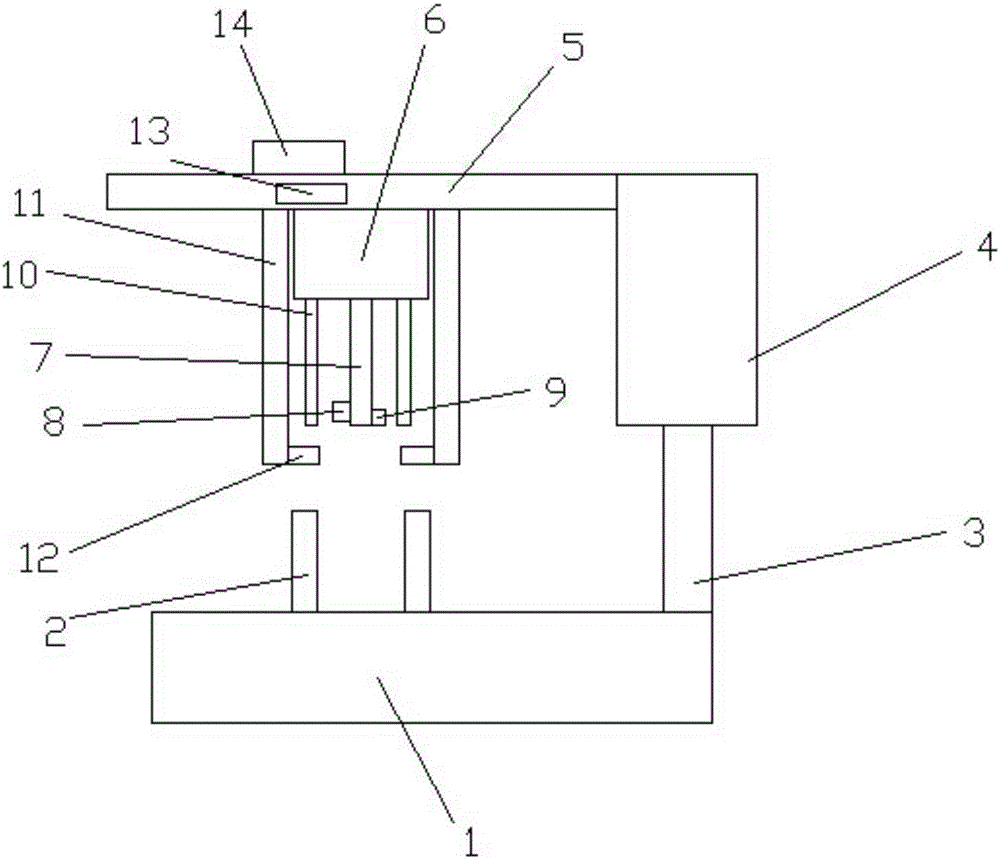

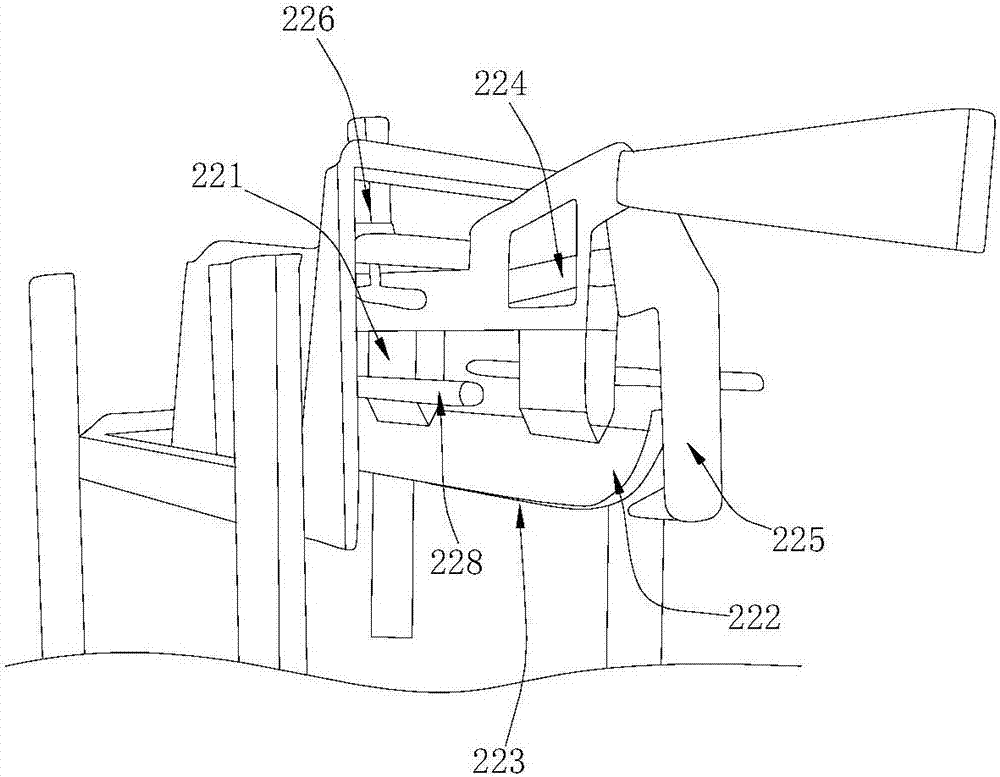

Automatic battery welding device

ActiveCN103769718AImprove sealing efficiencyImprove yieldWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention relates to an automatic battery welding device. The automatic battery welding device mainly comprises a battery clamp (1), a station switching mechanism (2), a battery pressing mechanism (3), a battery welding mechanism (4) and a clamp rotating mechanism (5). A battery is placed in the battery clamp, and the battery clamp rotates on a circular disk for one round to finish welding and sealing of the battery. By means of the automatic battery welding device, existing pure manual battery casing welding modes can be replaced, the problem of low producing efficiency in welding of a manual battery steel casing and an end cover group is solved, producing costs of the battery are lowered, the producing efficiency is increased, and defects in the prior art are overcome.

Owner:RAMWAY NEW ENERGY CO LTD

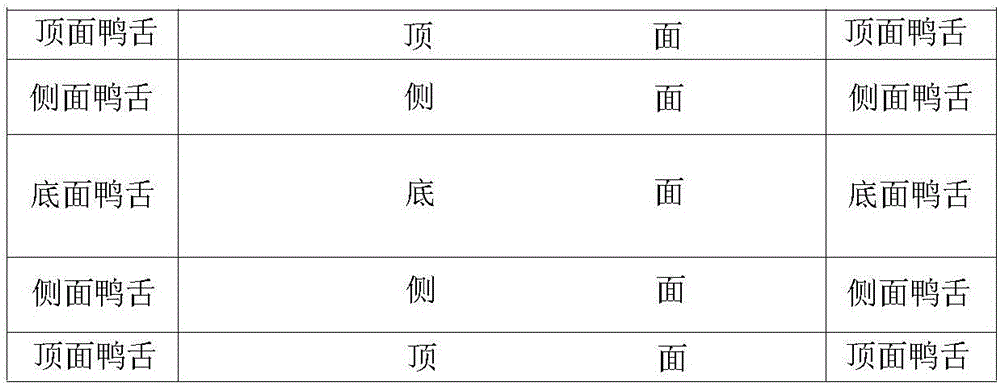

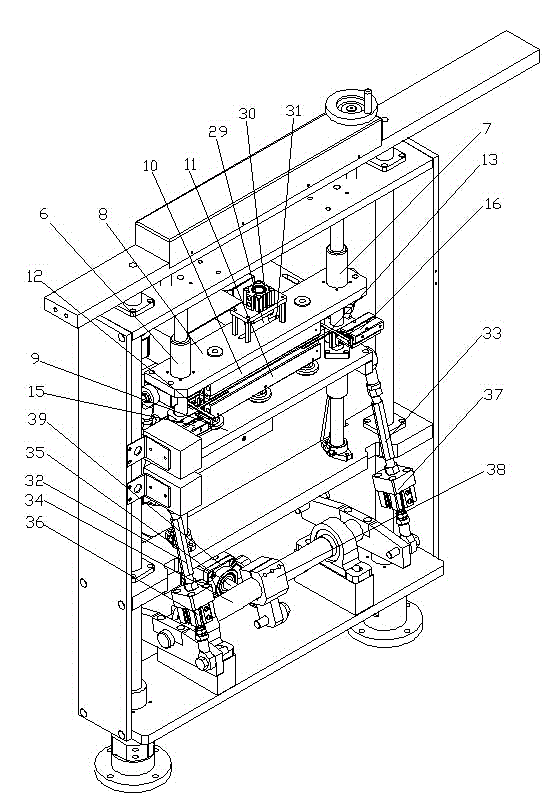

Automatic package machine for corrugated cartons with different lengths

InactiveCN105730772AHigh conveying precisionModerate delivery speedWrapper twisting/gatheringCartonEngineering

The invention discloses an automatic package machine for corrugated cartons with different lengths. The automatic package machine comprises a rack. An initial material position containing area, a wrapping forming area and a carton sealing area are sequentially arranged on the rack in the carton conveying direction. A material conveying device is arranged below the initial material position containing area. A carton containing area is arranged in the wrapping forming area. A top face folding mechanism, a front end folding system and a tail end folding system are arranged in the carton containing area. A side face folding mechanism is arranged below the carton containing area. Each of the front end folding mechanism and the tail end folding mechanism comprises a side face duck tongue folding mechanism, a top face duck tongue folding mechanism and a bottom face duck tongue folding mechanism. A plurality of powerless transmission rollers are arranged in the carton sealing area in the length direction of the carton sealing area. A two-end carton sealing mechanism, a length direction carton sealing system and a width direction carton sealing system are arranged in the carton sealing area in the carton conveying direction. By means of the automatic package machine, packaging of carton type products of different specifications and different sizes can be achieved, and the application range is wide.

Owner:SHANDONG UNIV OF SCI & TECH

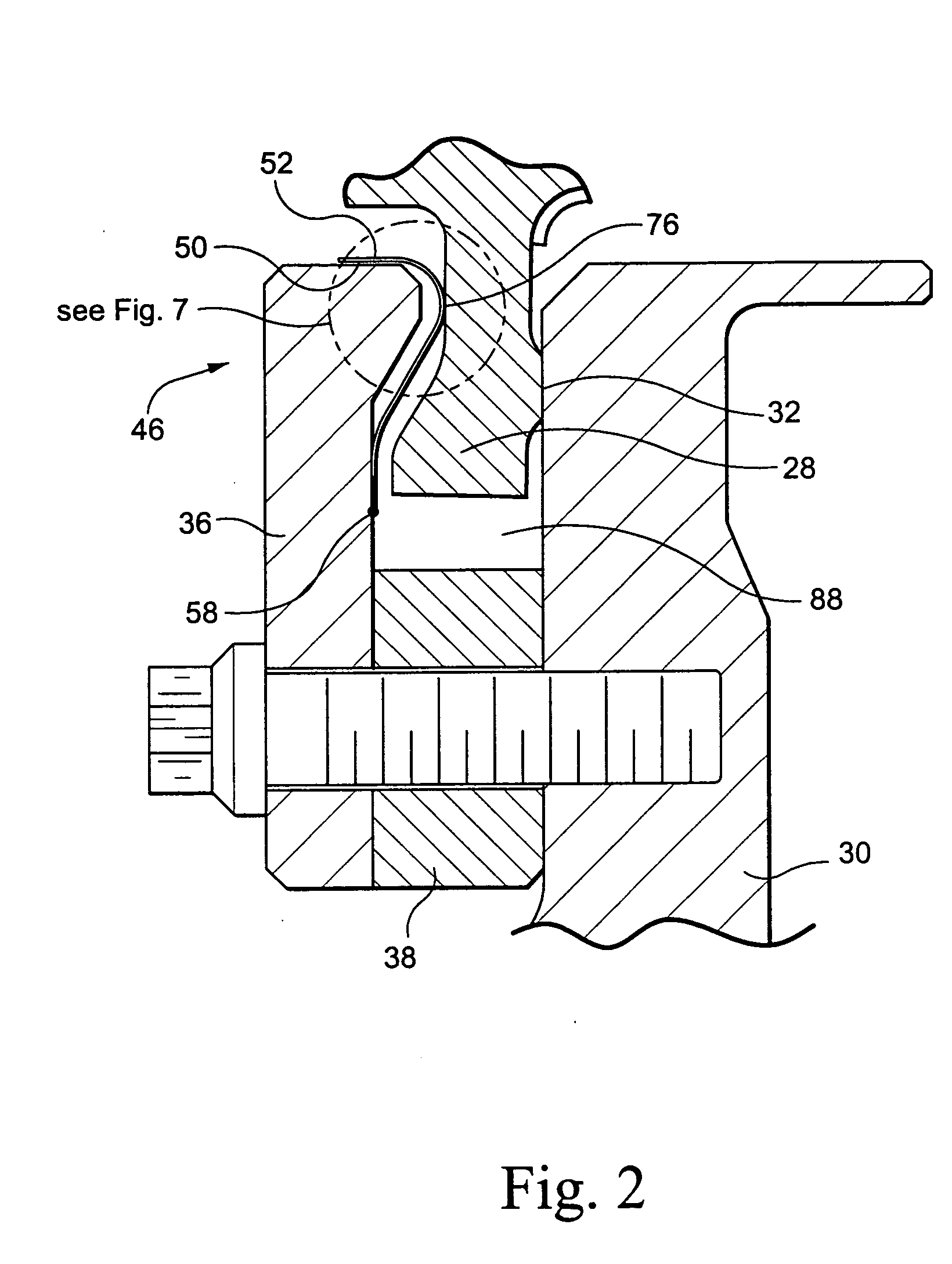

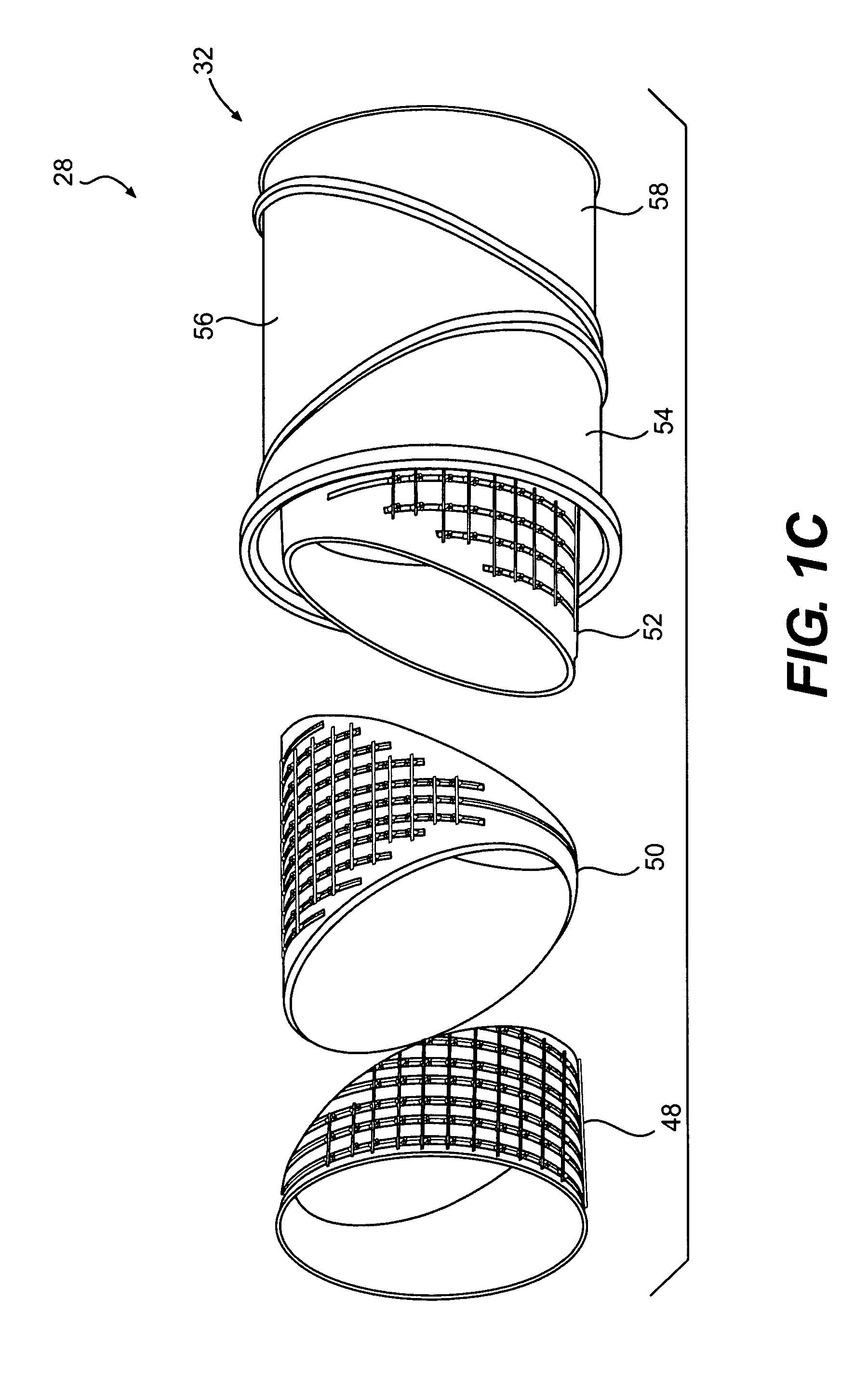

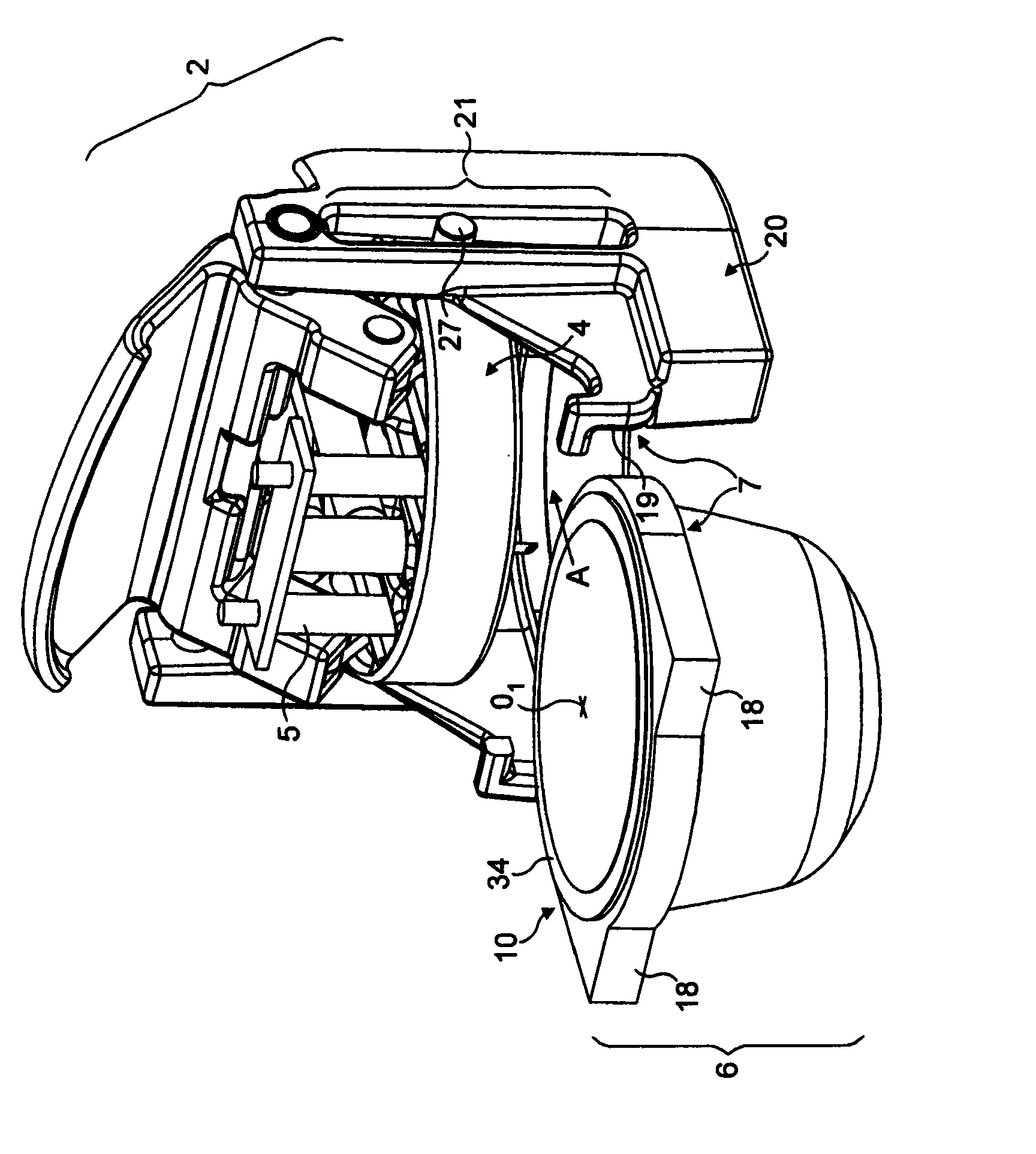

Prelubricated Multi-Lipped Radial Shaft Seal With Large Radial Offset Accommodation

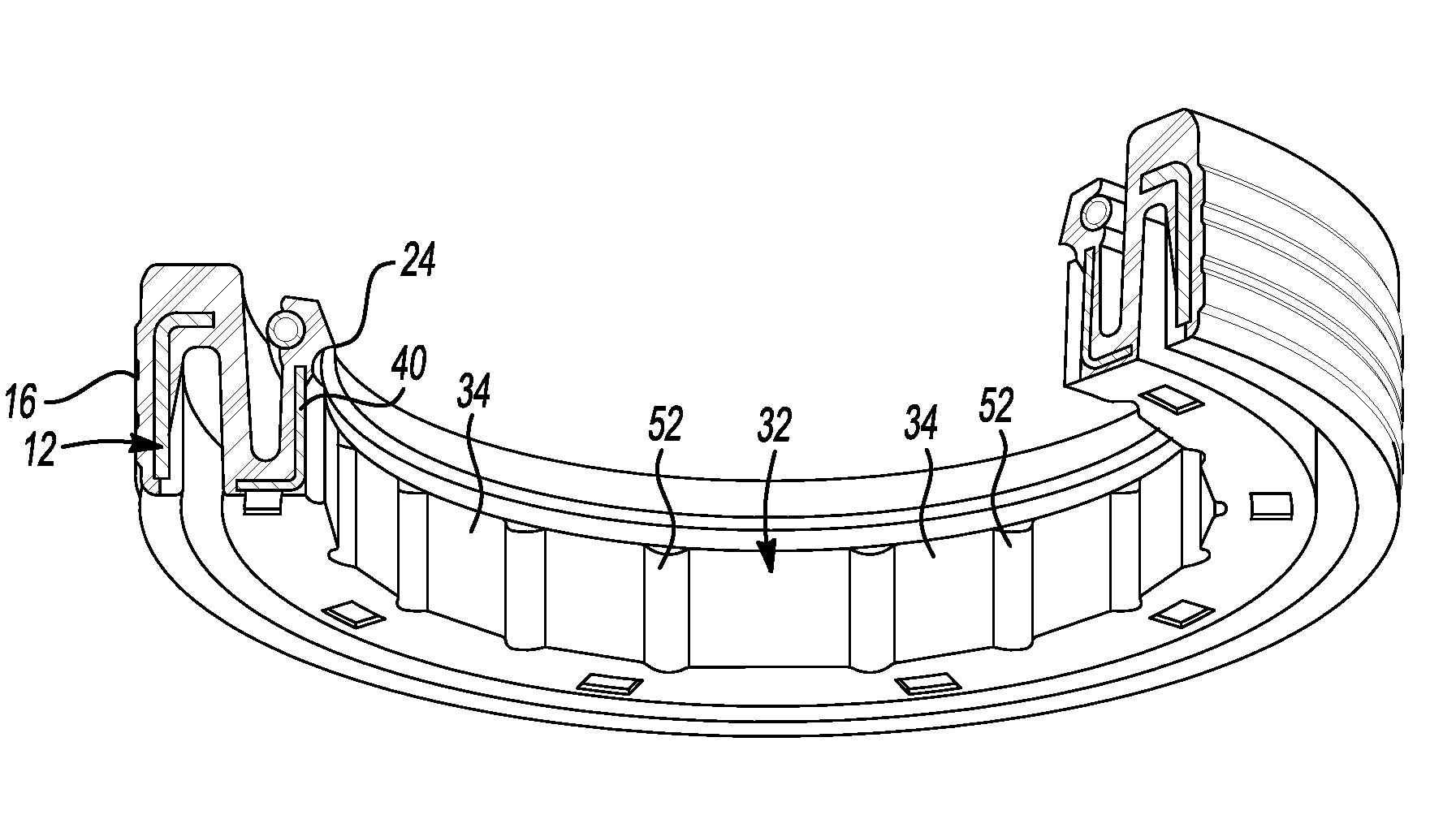

InactiveUS20080284110A1Easy to carryImprove sealing efficiencyEngine sealsEngineeringBearing surface

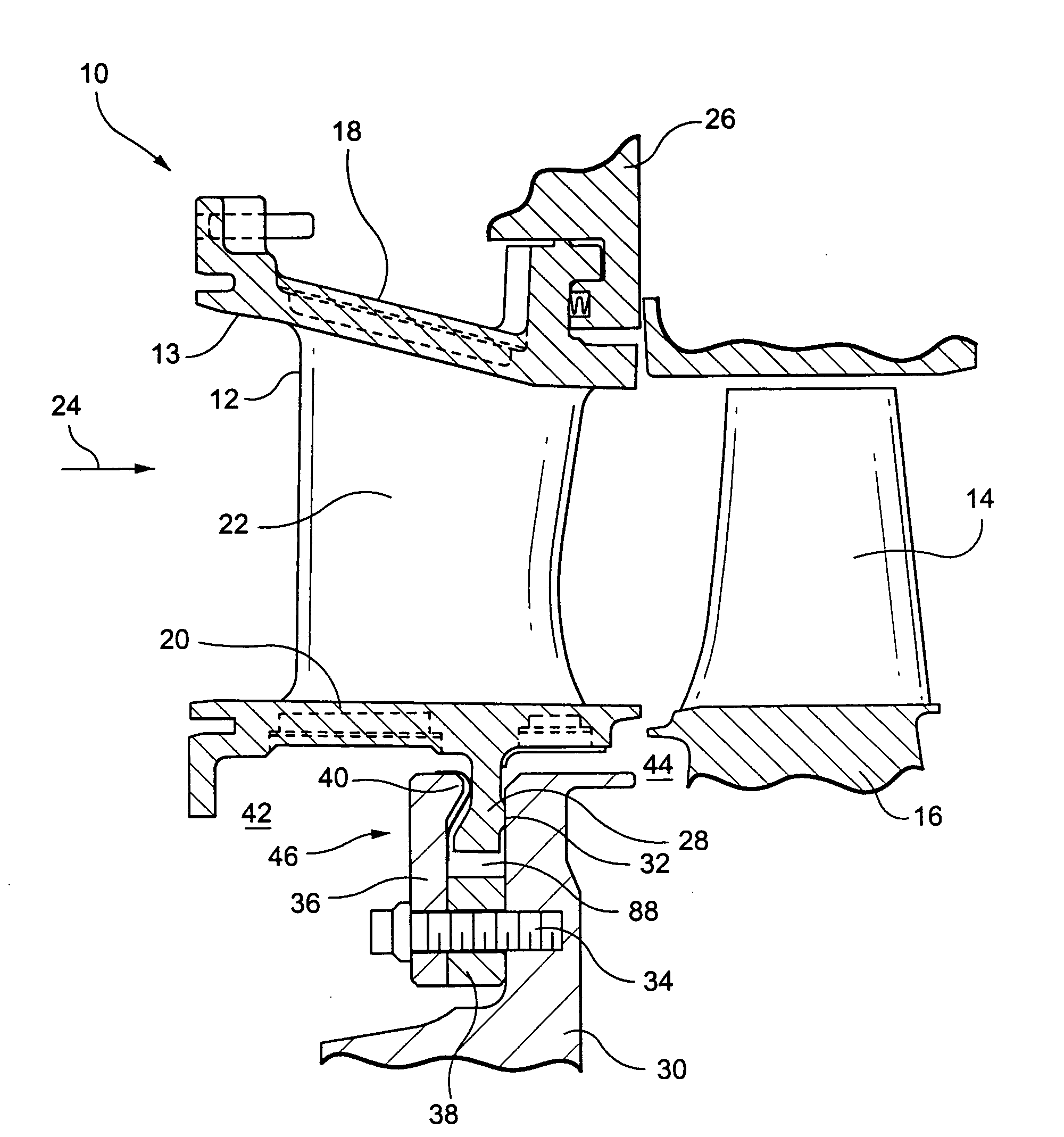

A radial shaft seal is provided for accommodating large radial offset of the shaft relative to a housing. The seal includes an annular retainer insert provided for engaging the seal to a fixed housing. An annular elastomeric seal body is molded to the retainer insert and includes a flexible axially extending portion extending from an inner surface of the retainer insert. A seal portion extends from a radially inward end of the flexible portion and includes first and second seal lips and an elastomeric bearing surface disposed between the first and second sealing lips. The bearing surface includes a plurality of raised pads adapted to engage the shaft. The pads each include a rounded edge on lateral sides thereof for encouraging the creation of a lubricating film between the pads and shaft. The pads are lubricated by a lubricant disposed in a lubricant chamber disposed between the first and second seal lips.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

System for sealing an inner retainer segment and support ring in a gas turbine and methods therefor

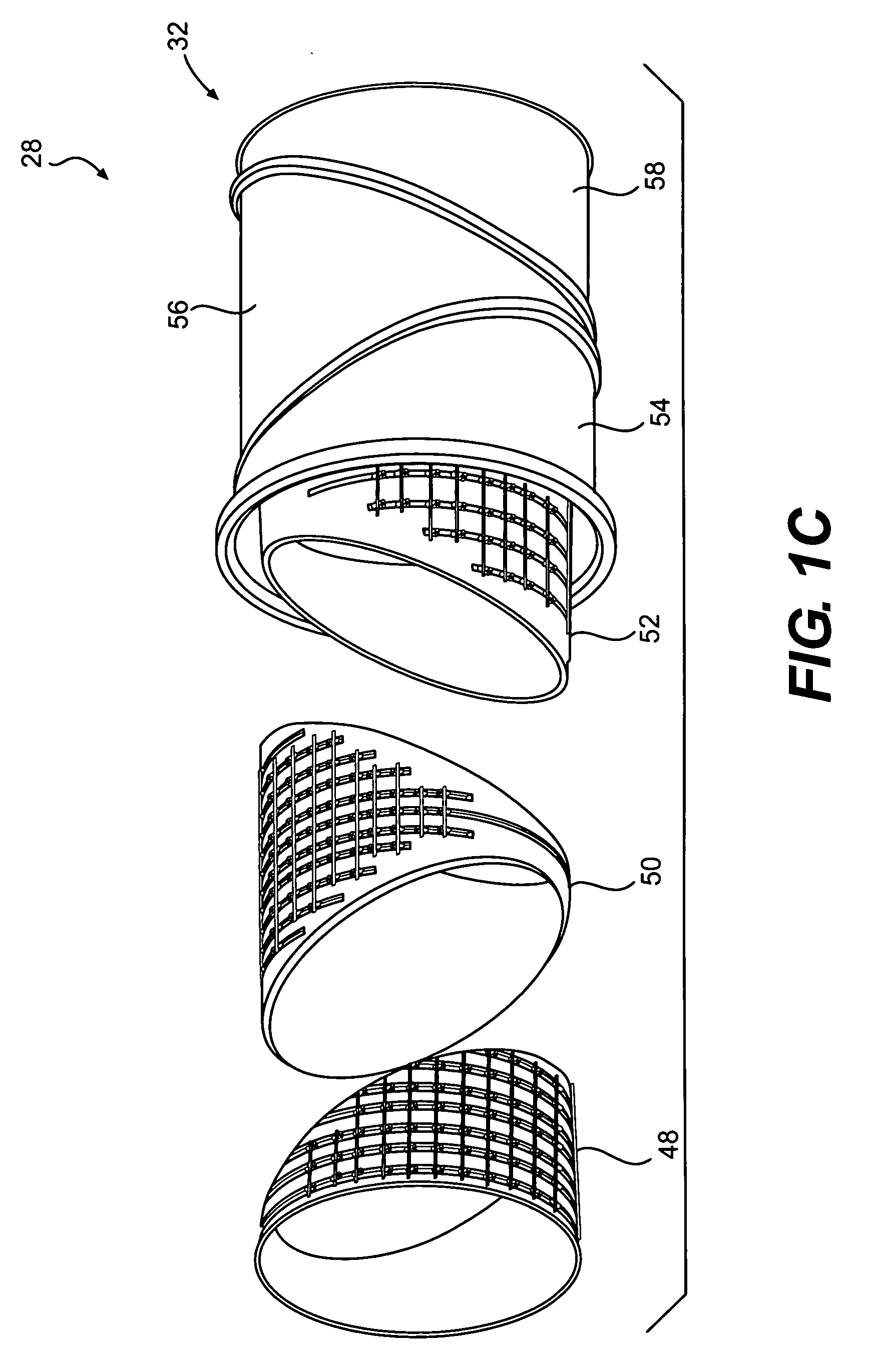

InactiveUS20050244267A1Improve sealingIncreasing turbine engine efficiencyPump componentsStatorsLeakage flowGas turbines

Arcuate seal layers conforming with one another are disposed between inner retainer segments and inner rails of nozzle segments of a gas turbine. The layers are secured to the aft axial face of the segments and project radially outwardly to seal against the forward axial faces of the rails. The rear axial faces of the rails have chordal seals for sealing against the forward axial faces of the support rings. The seal layers have radial cuts misaligned with one another in an axial direction to preclude leakage flows through gaps formed by the cuts. Arcuate spacers are staggered circumferentially with the arcuate retainer segments whereby an intermediate pressure plenum is formed between the finger seals and chordal seals.

Owner:GENERAL ELECTRIC CO

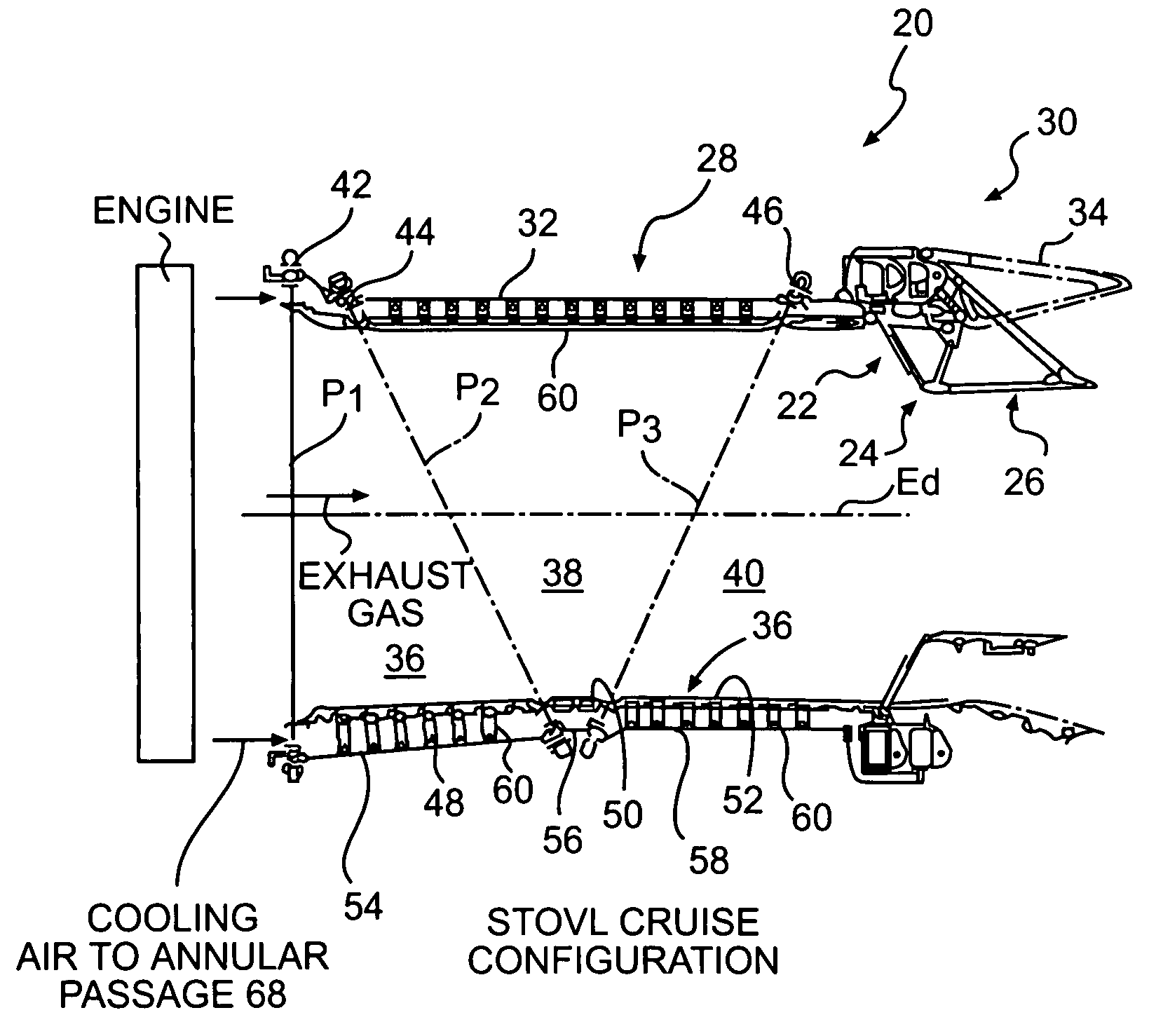

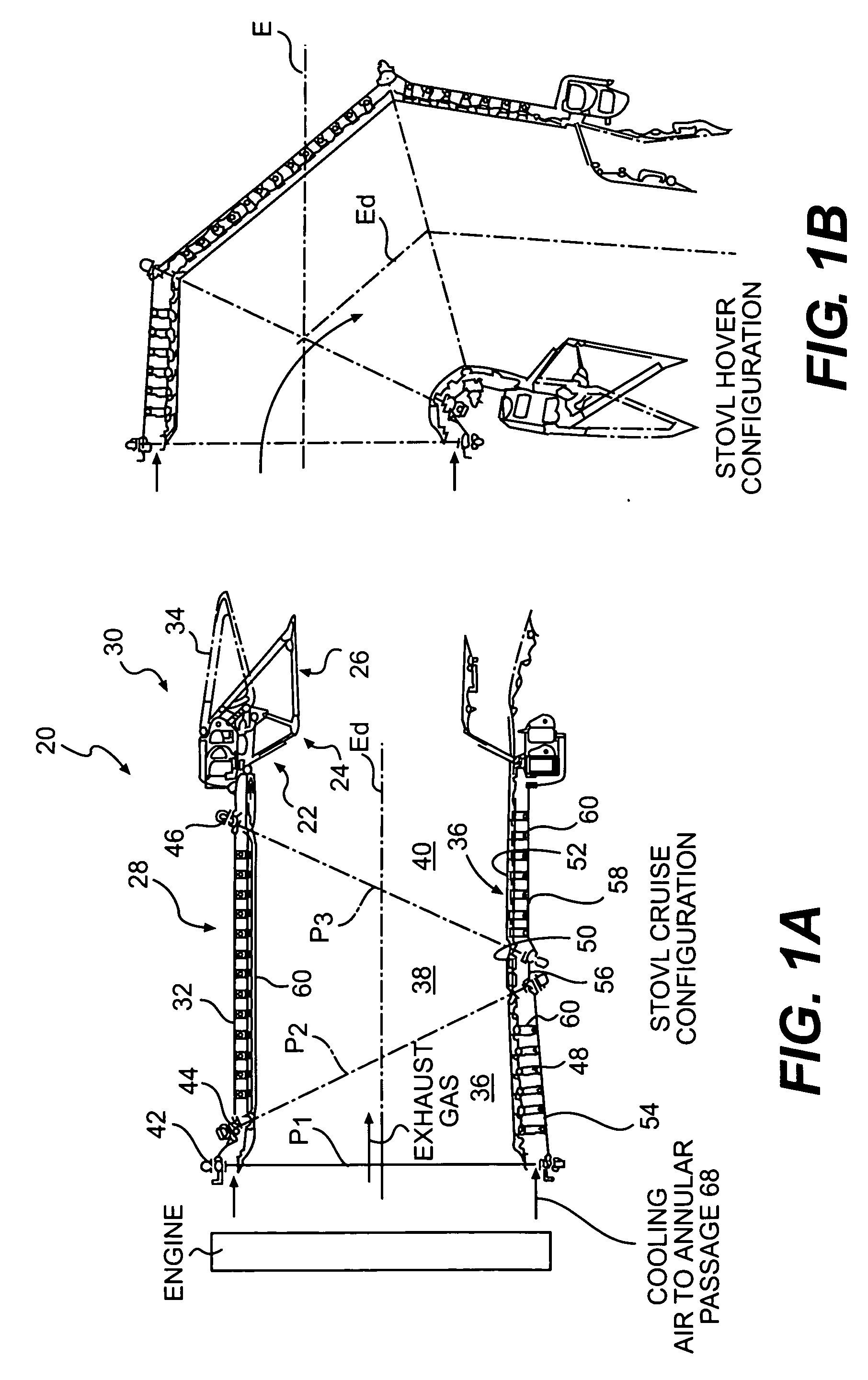

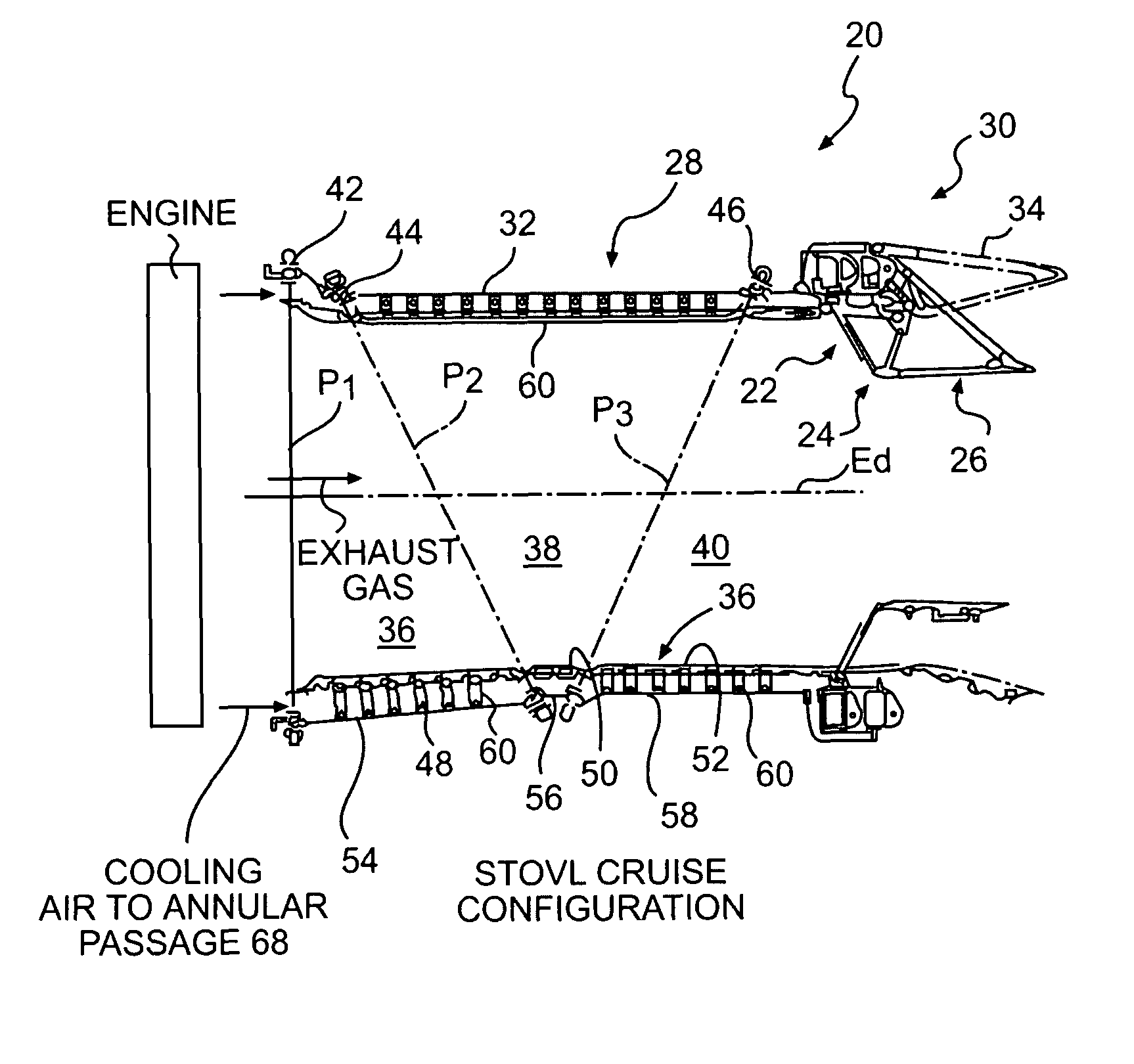

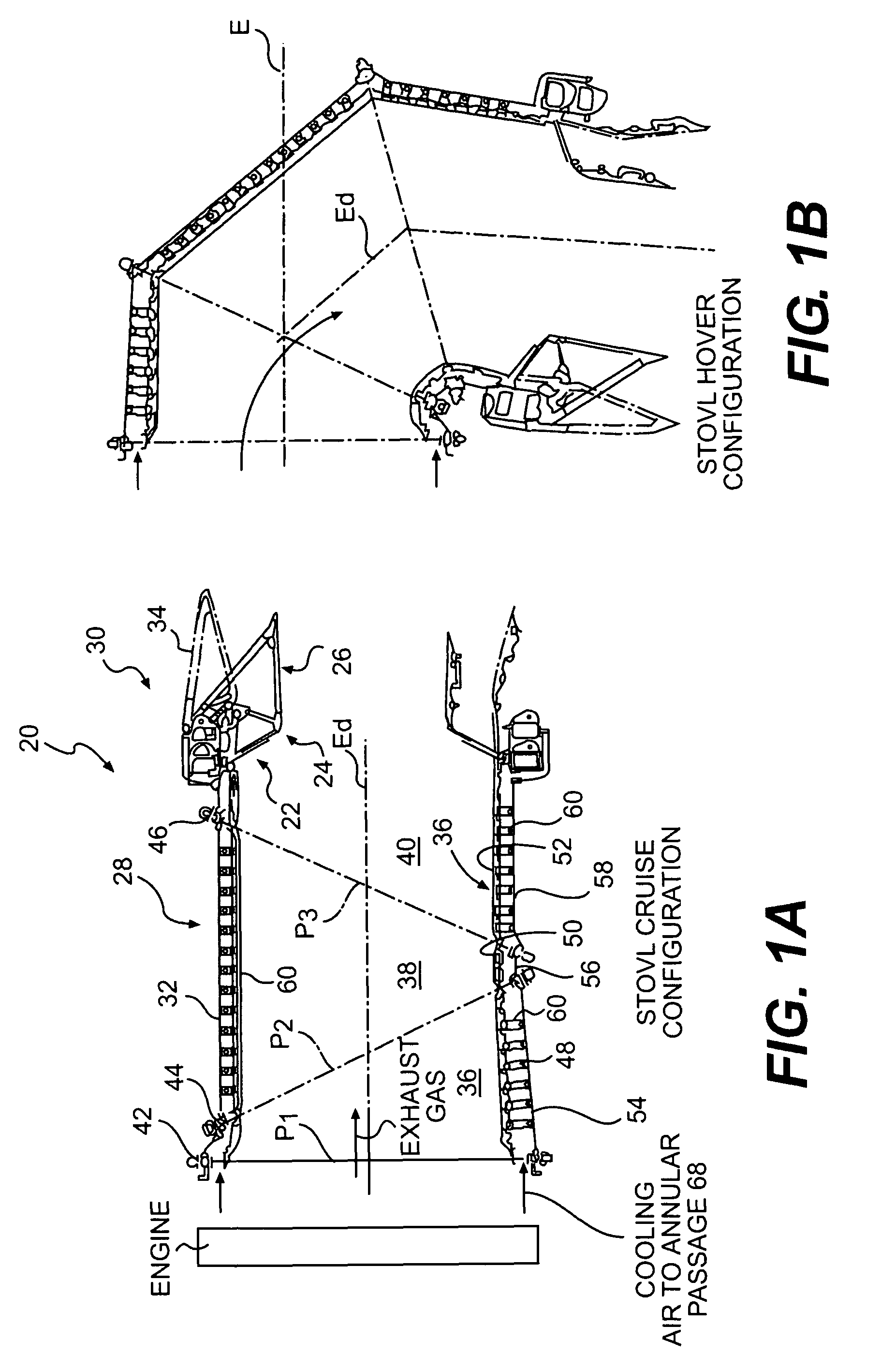

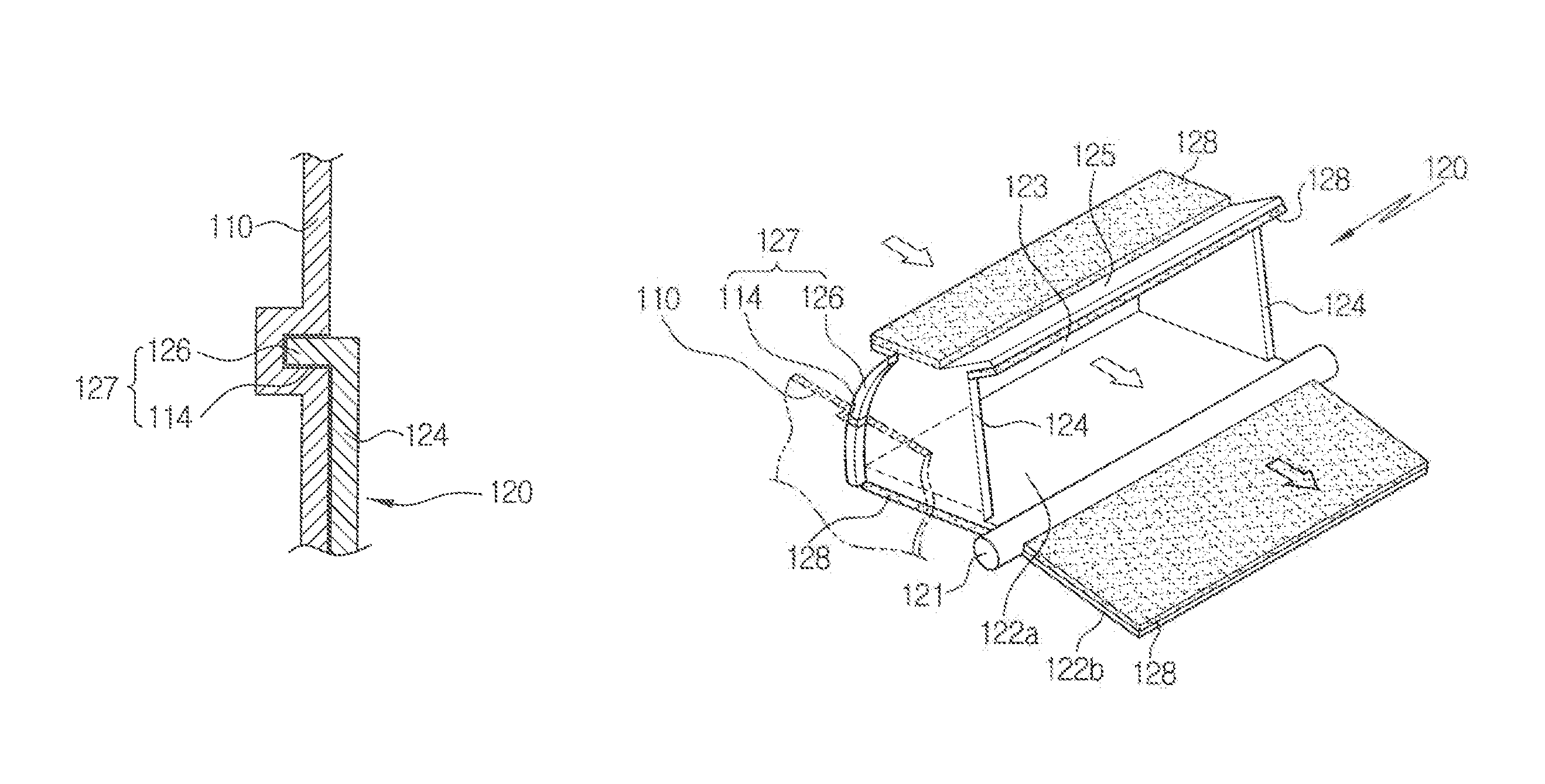

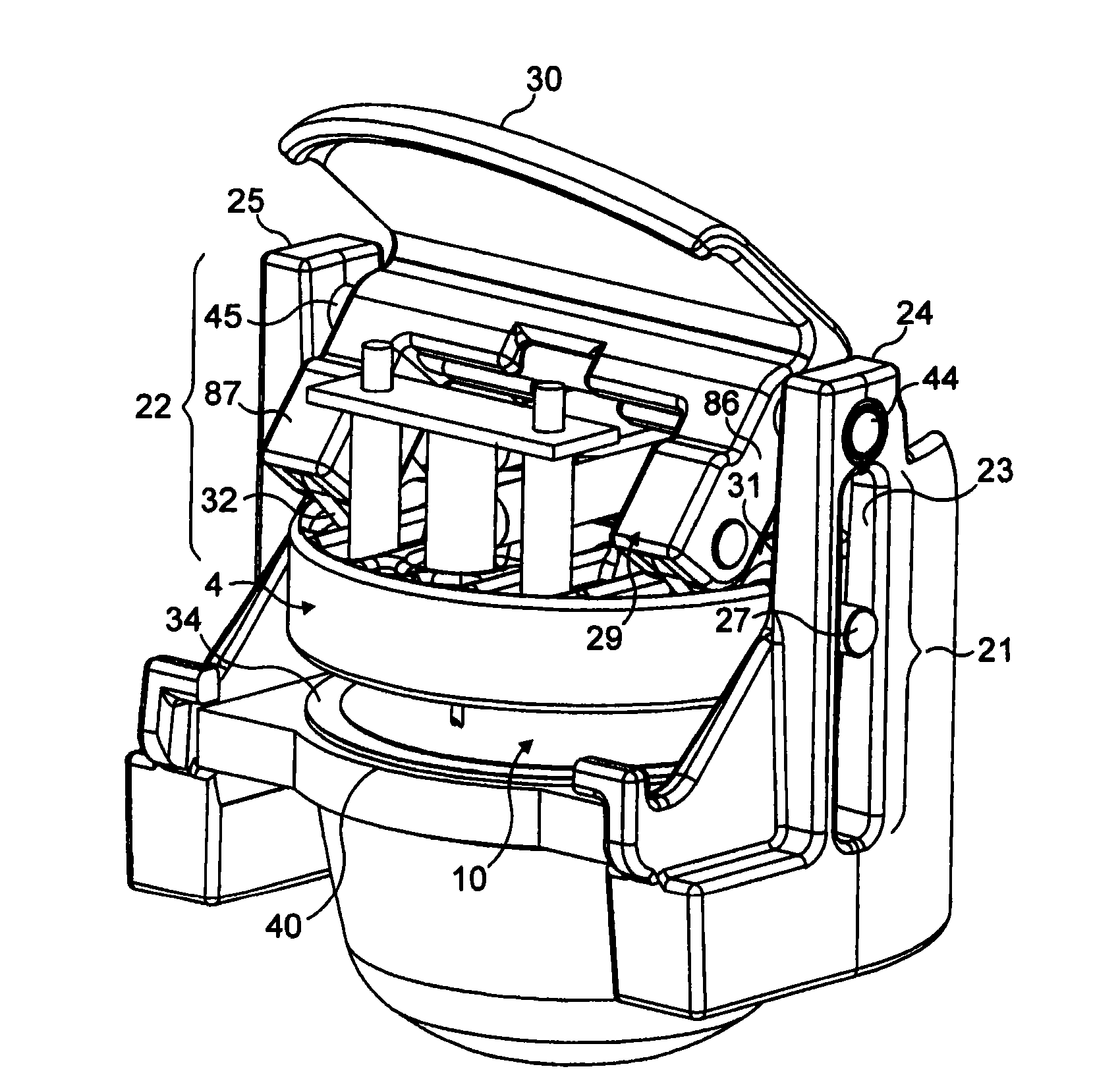

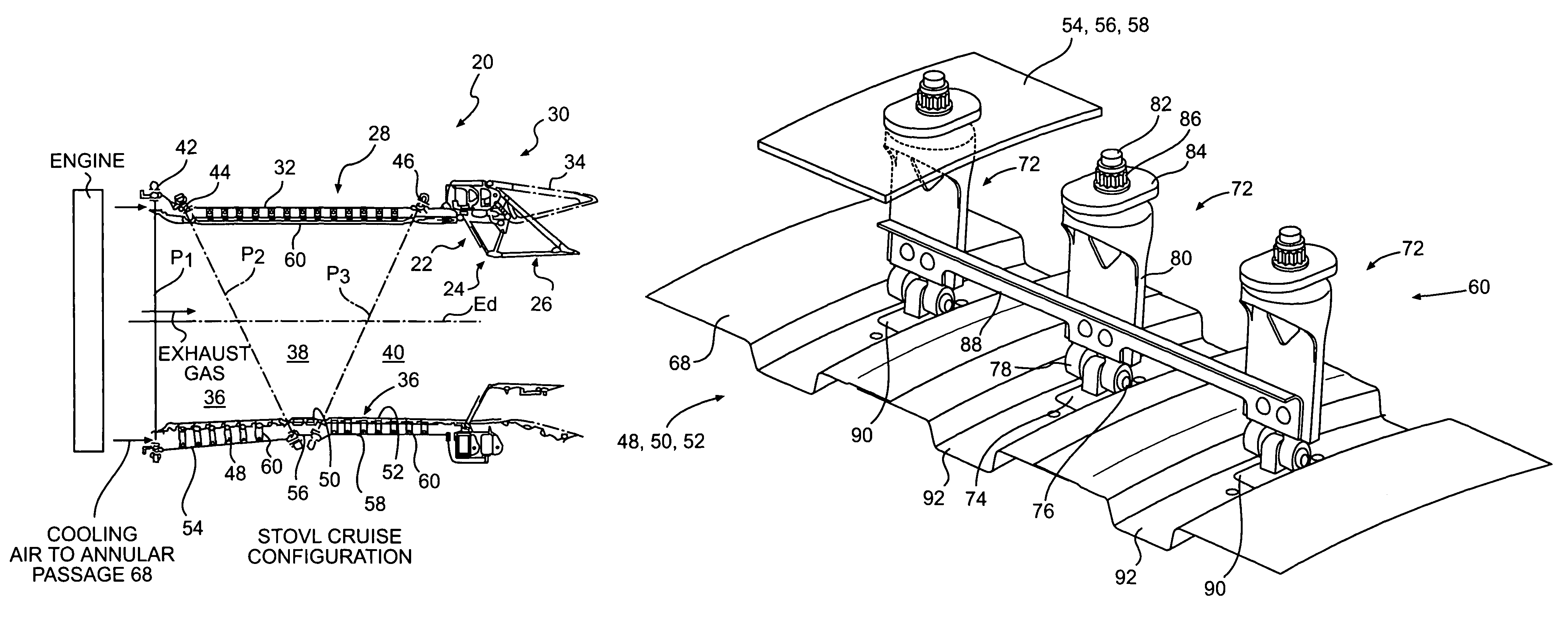

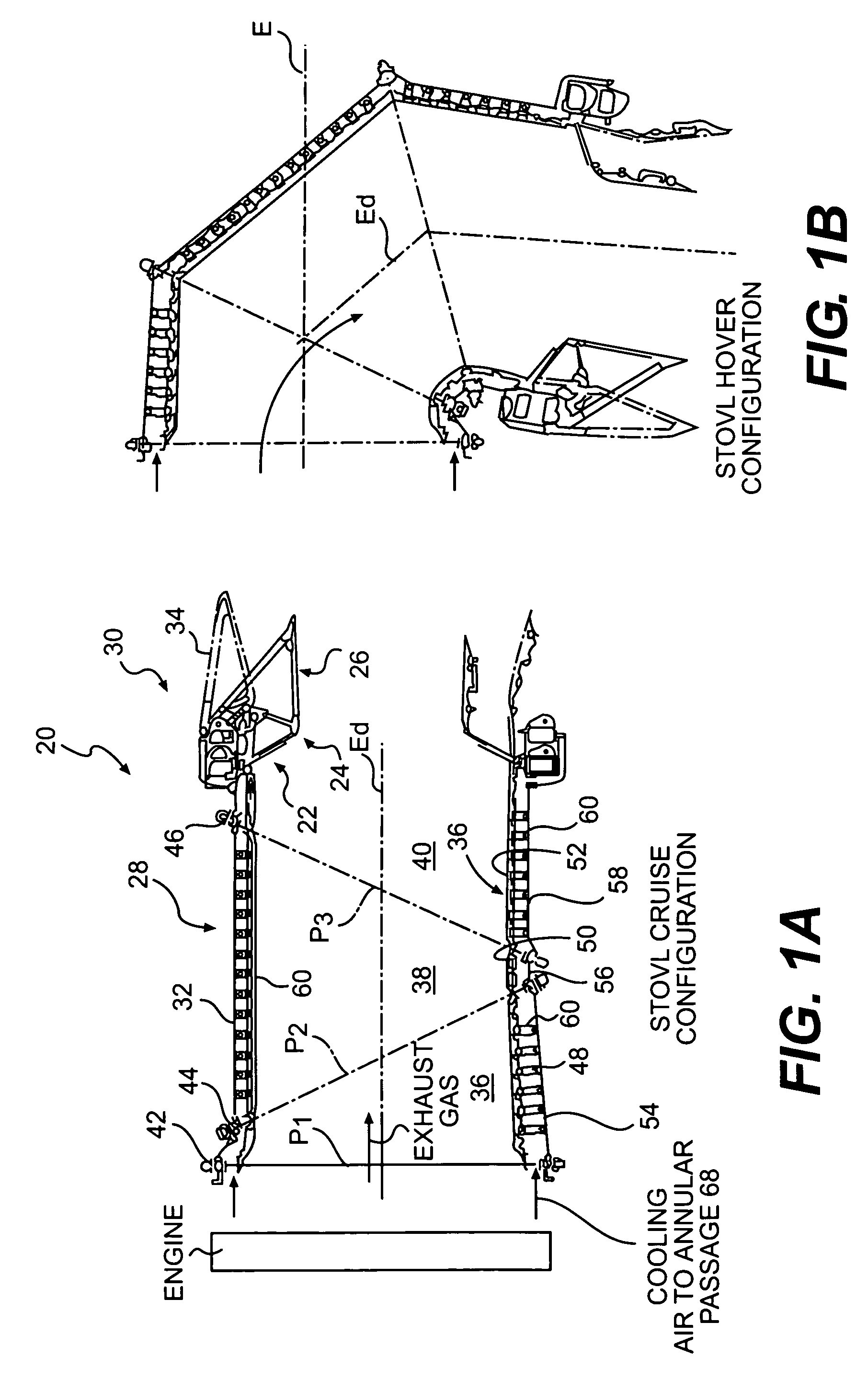

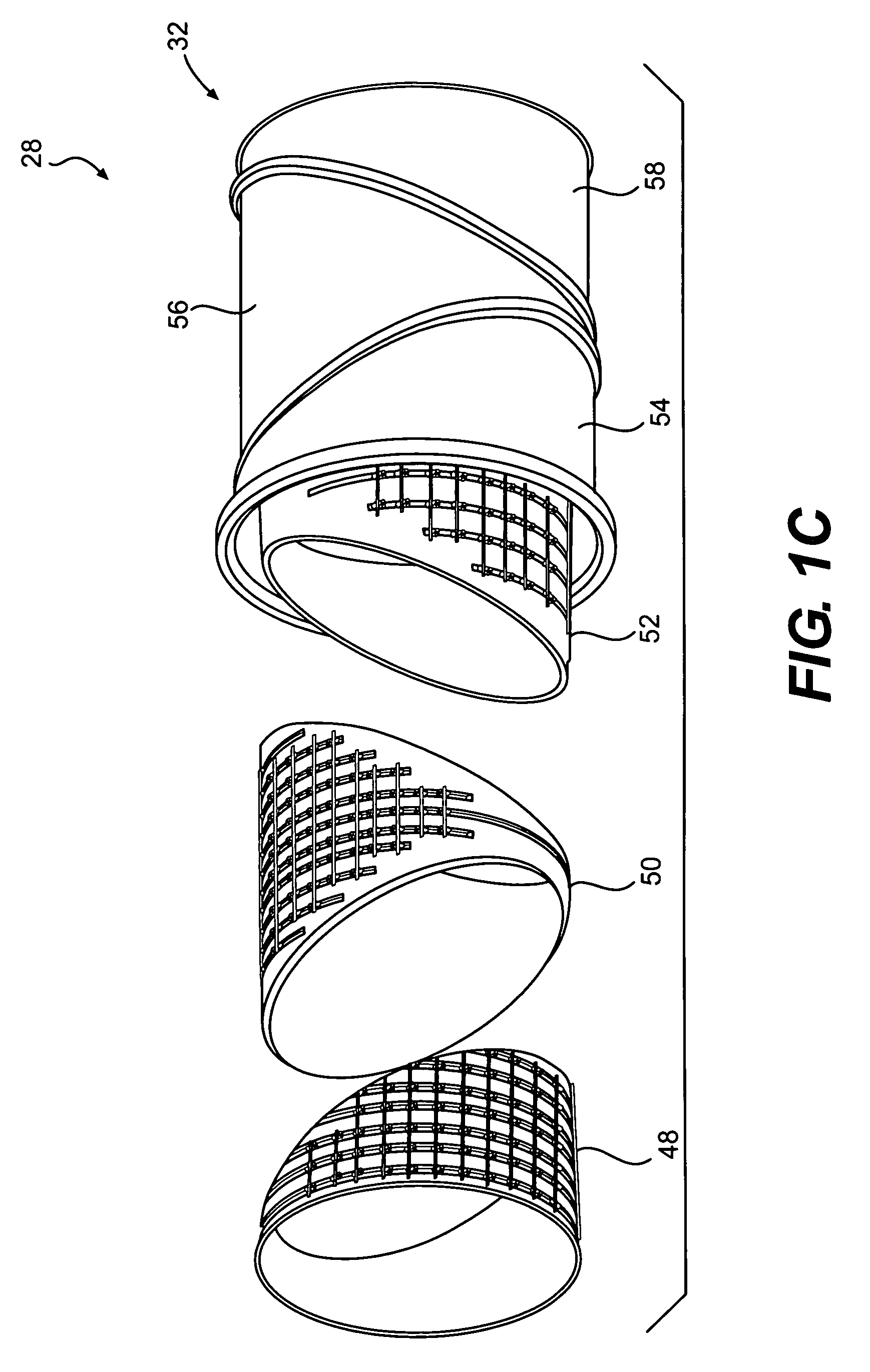

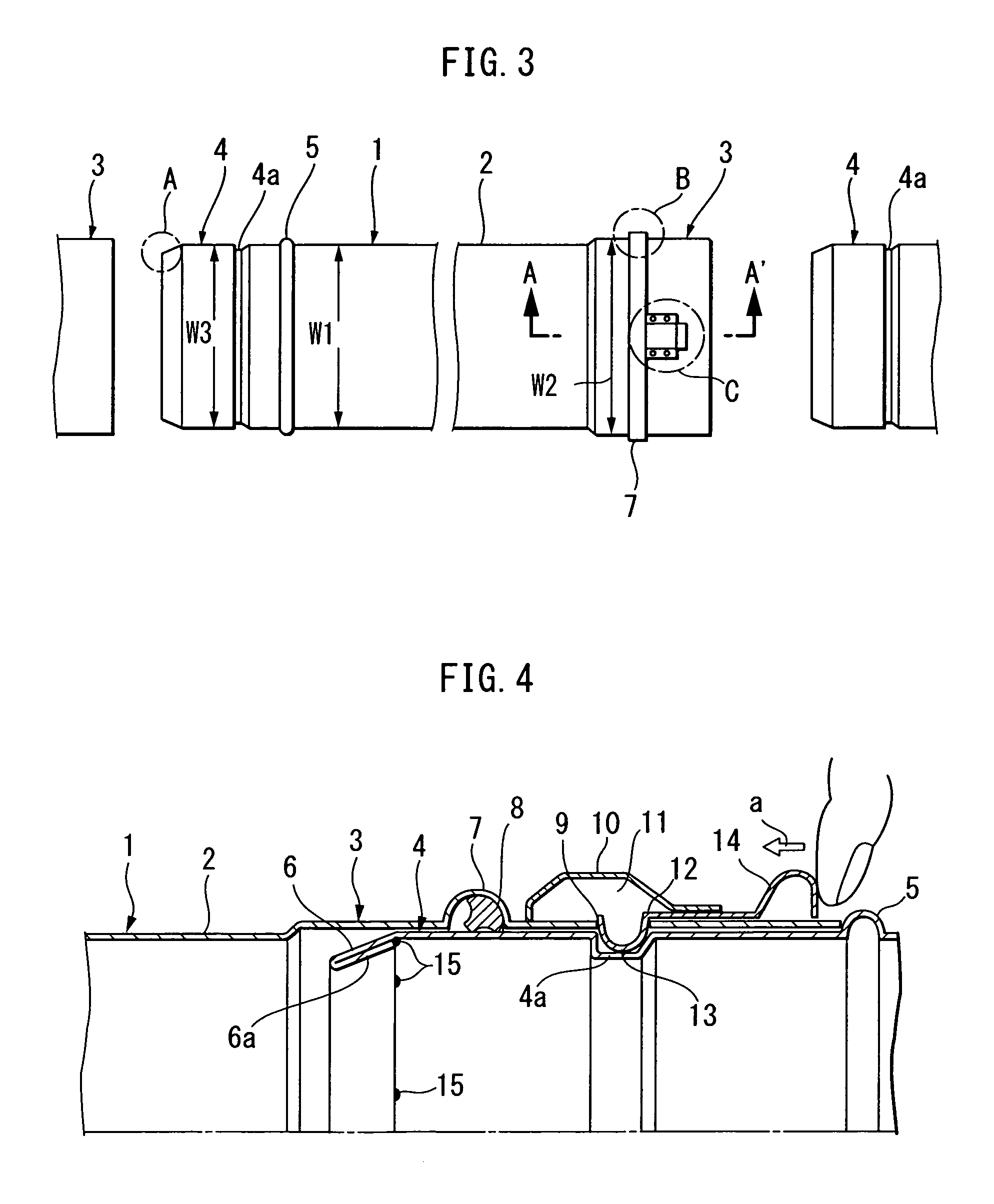

Low profile attachment hanger system for a cooling liner within a gas turbine engine swivel exhaust duct

InactiveUS20080022689A1Minimize the numberImprove sealing efficiencySpraying apparatusGas turbine plantsLimited accessGas turbines

An exhaust duct assembly includes a cooling liner spaced apart from an exhaust duct case that articulate for use in a short take off vertical landing (STOVL) type of aircraft. The cooling liner assembly is attached to the exhaust duct case through a foldable attachment hanger system. The foldable attachment hanger system provides a low profile (foldable up / down) for a limited access installation envelope typical of a three bearing swivel duct (3BSD) which rotates about three bearing planes to permit transition between a cruise configuration and a hover configuration. In this way, each cooling liner segment may be formed as a complete cylindrical member requiring joints only between the swivelable duct sections.

Owner:UNITED TECH CORP

Radial Shaft Seal with Large Radial Offset Accommodation

A radial shaft seal is provided for accommodating large radial offset of the shaft relative to a housing. The seal includes an annular retainer insert provided for engaging the seal to a fixed housing. An annular elastomeric seal body is molded to the retainer insert and includes flexible axially extending portion extending from an inner surface of the retainer insert. A seal portion extends axially from a radially inward end of the radially inwardly extending portion and includes a seal lip with a garter spring disposed radially outward of the sealing lip and an elastomeric bearing surface disposed adjacent to the sealing lip. The bearing surface includes a plurality of raised pads adapted to engage the shaft. The pads each include a rounded edge on lateral sides thereof for encouraging the creation of a lubricating film between the pads and shaft. The pads are lubricated by direct exposure to the fluid being sealed.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

Optical cable

ActiveUS20070104429A1Reduce outer diameterIncrease in transmission lossFibre mechanical structuresTension memberMode field diameter

An optical cable according to the present invention relates to an optical cable having a construction to enable reduction of a cable outer diameter, and / or improvement of contained efficiency of coated optical fibers while an increase of transmission loss in each coated optical fiber is suppressed. The optical cable has a loose-tube type of structure constructed by: a tension member; a plurality of tubes stranded together around the tension member; and an outer sheath covering the outer periphery of the plurality of tubes. One or more coated optical fibers are contained in each tube. A ratio of A / B is 6.3 or more but 7.0 or less, where each coated optical fiber has a mode field diameter A in a range of 8.6±0.4 μm at a wavelength of 1.31 μm, and where a fiber cutoff wavelength thereof is B μm.

Owner:SUMITOMO ELECTRIC IND LTD +1

Normal-temperature sealer for anodic oxide film of aluminum and aluminum alloy and sealing method thereof

InactiveCN101665970AQuick sealImprove sealing efficiencySurface reaction electrolytic coatingTetramineDodecylsulfonic acid

The invention provides a normal-temperature sealer for an anodic oxide film of aluminum and aluminum alloy. The sealer is characterized by comprising the following components in concentration (g / L): Ni<2+>0.8-1.3, F<-> 0.4-0.8, triethanolamine 0.1-5.0, hexamethylene tetramine 0.1-1.0, sodium dodecanesulphonate0.001-0.1, bloom inhibitor 0.01-2.0 and the balance of water. The invention also discloses a sealing method for the sealer. Compared with the prior art, the sealer has the advantages of low cost, easy preparation, easy operation, and great improvement on the surface anti-pollution ability, the anti-corrosion property and the electric insulativity of the anodic oxide film of the aluminum alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

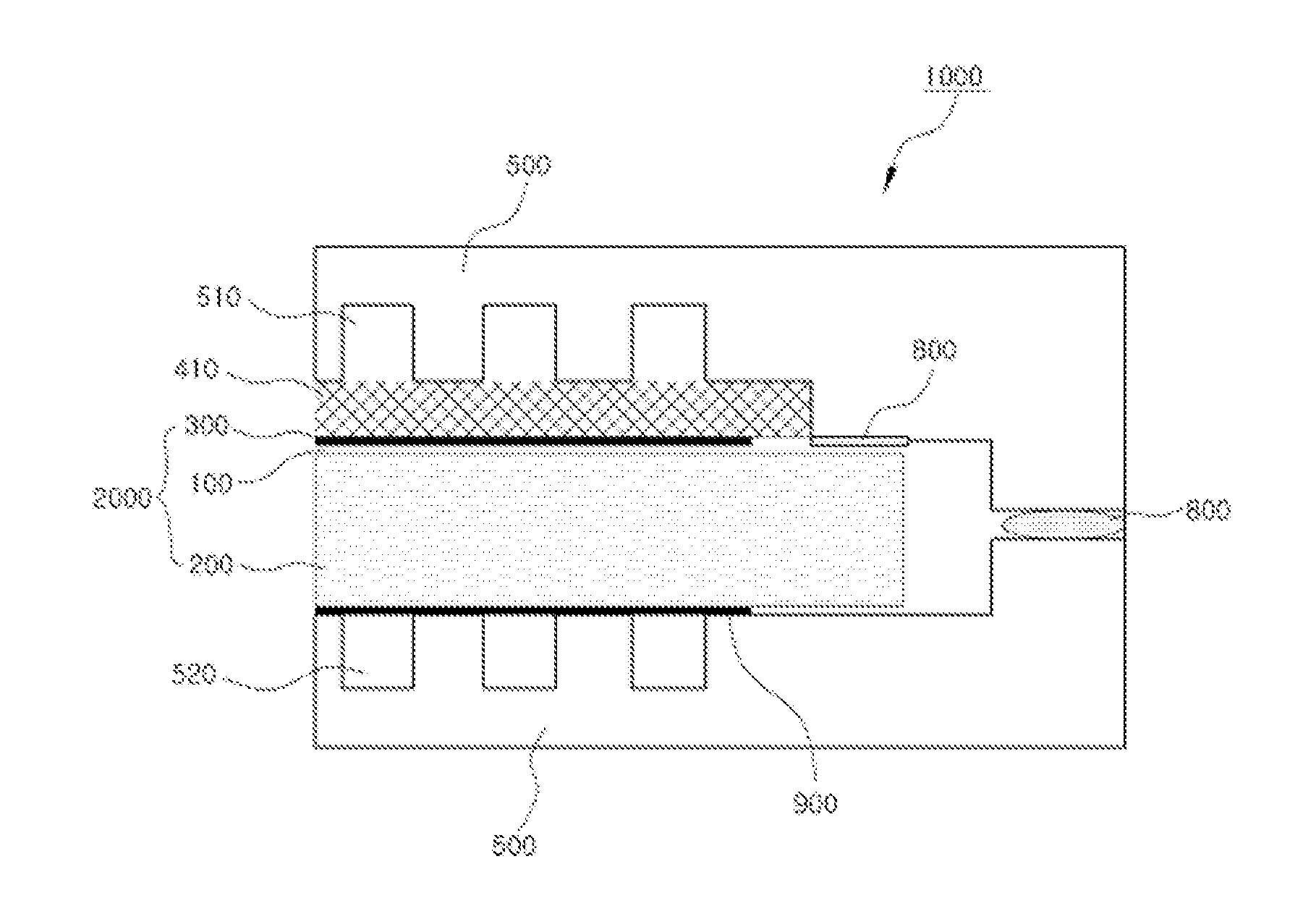

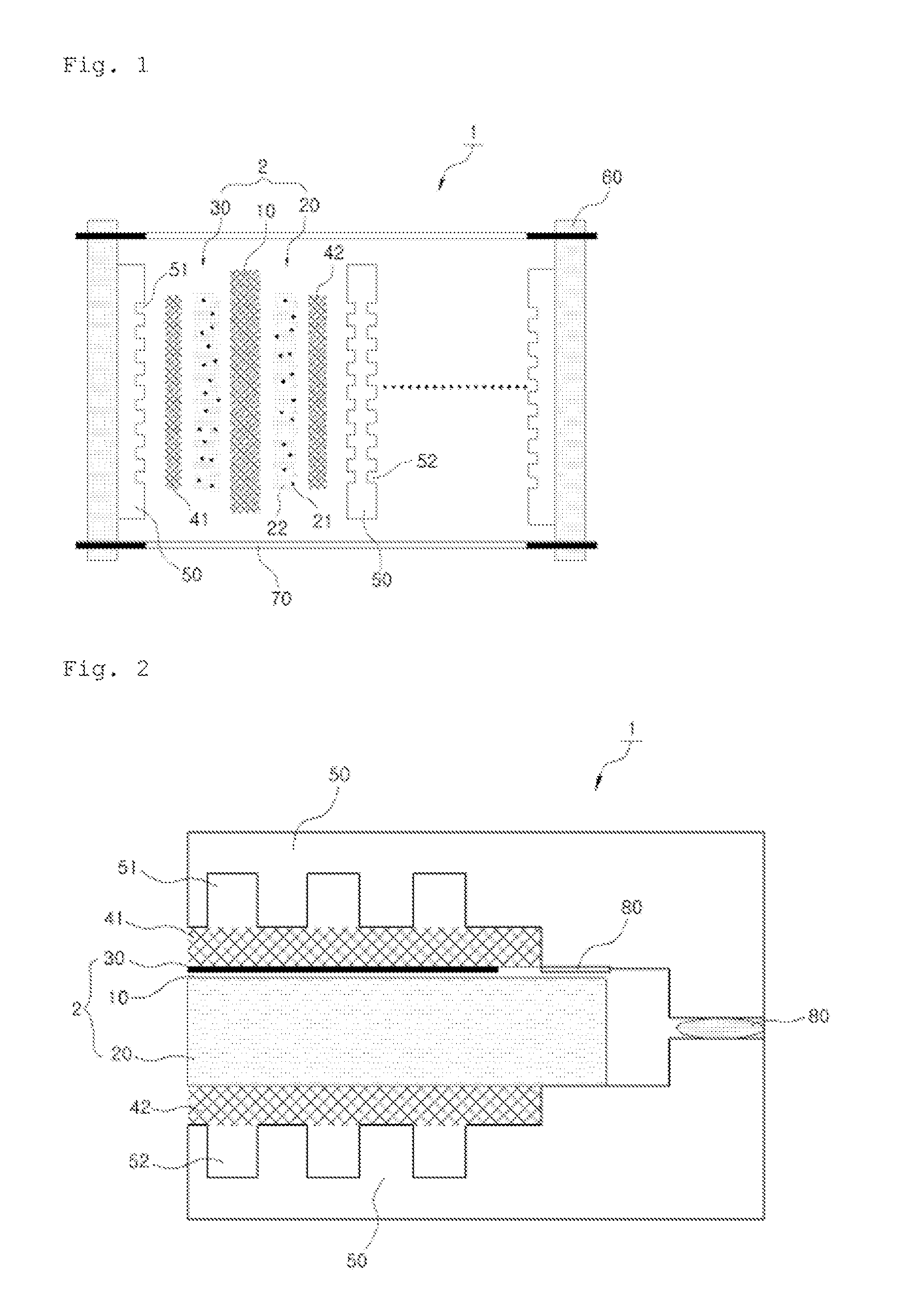

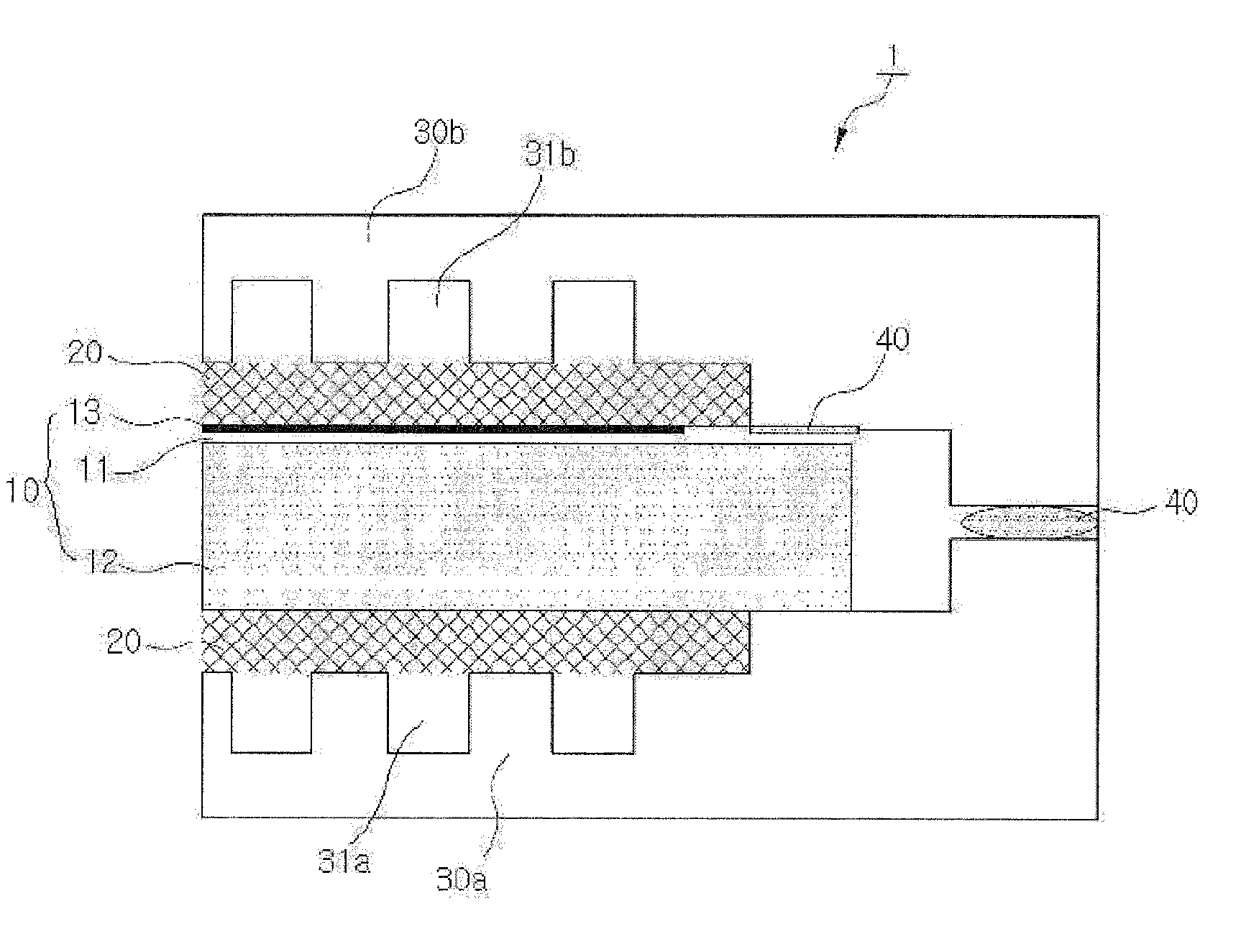

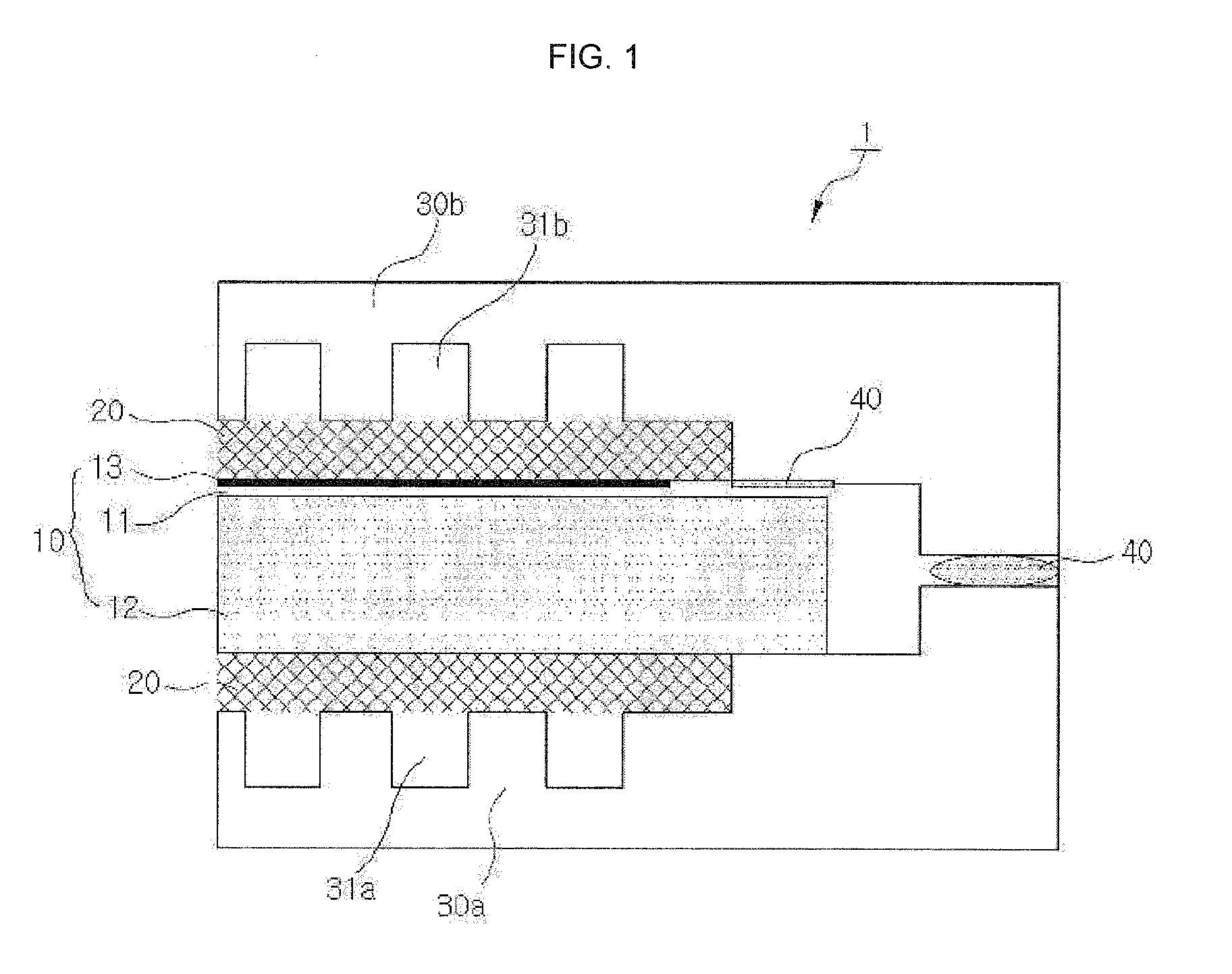

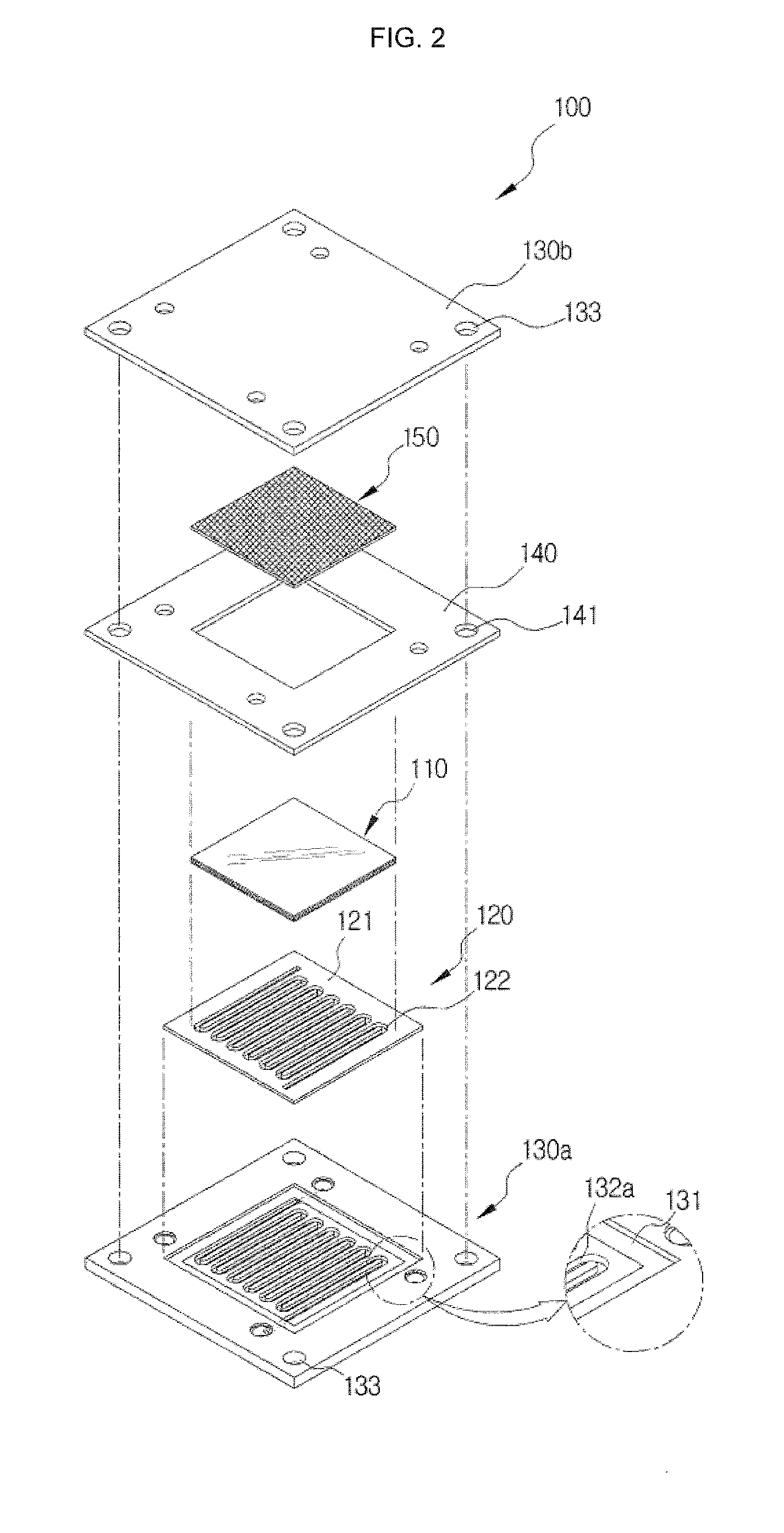

Combination Structure Between Single Cell and Interconnect of Solid Oxide Fuel Cell

InactiveUS20090035635A1Improve sealing efficiencyHigh mechanical strengthFuel cells groupingSolid electrolyte fuel cellsFuel cellsSlurry

The present invention relates to a combination structure of a solid oxide fuel cell between an electrode and an interconnect in which the electrode and interconnect are sinter-joined to each other by using slurry in a status that a conventional current collector is excluded, thereby improving a strength and a sealing efficiency. The combination structure between a single cell and an interconnect of a solid oxide fuel cell which comprises electrolyte, and an anode and a cathode which are respectively contacted with both sides of the electrolyte; and an interconnect which are formed at both sides of the single cell and has a cathode passage for supplying air to the cathode and an anode passage for supplying fuel to the anode, is characterized by that one or both sides of the single cell are directly combined with the interconnect.

Owner:KOREA ADVANCED INST OF SCI & TECH

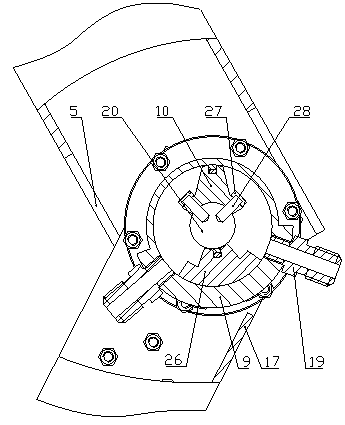

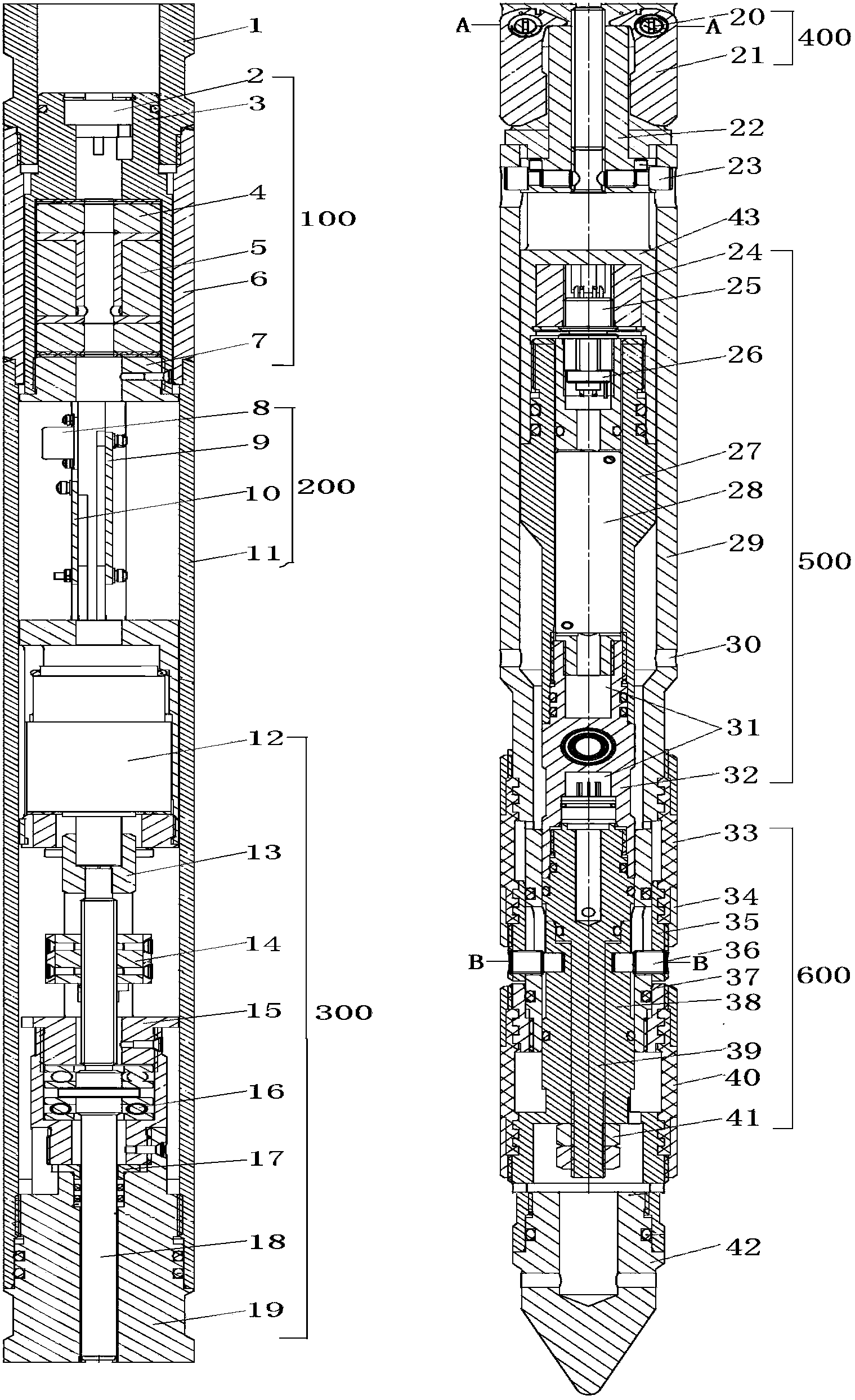

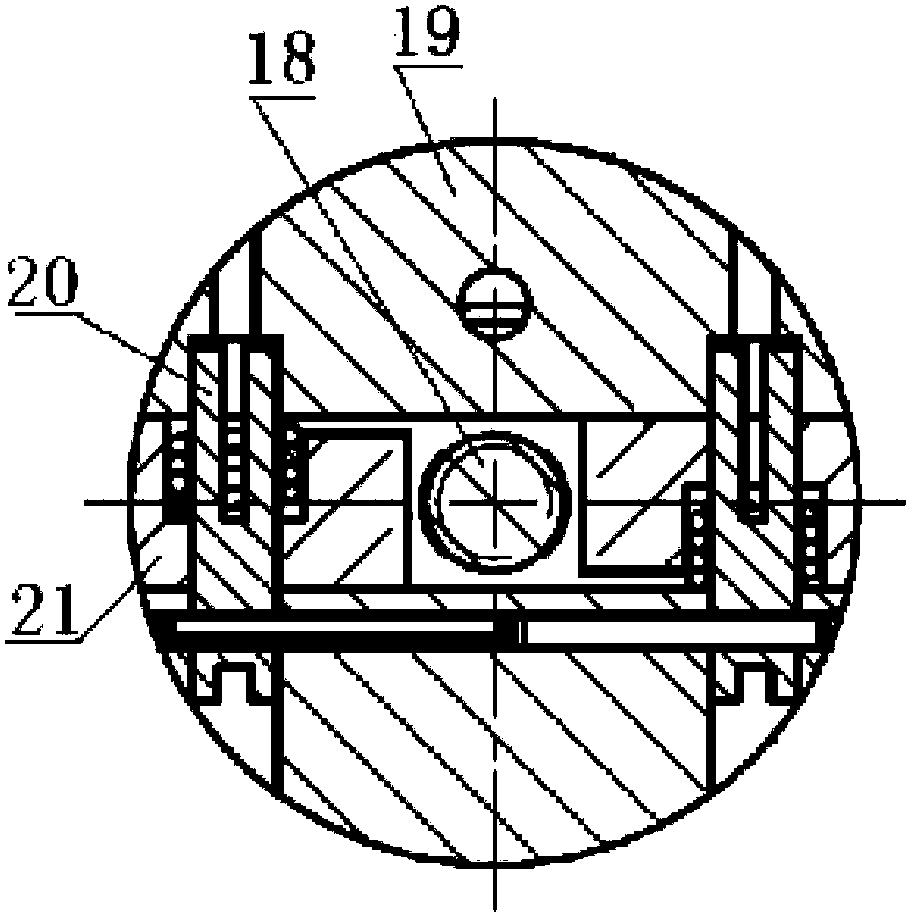

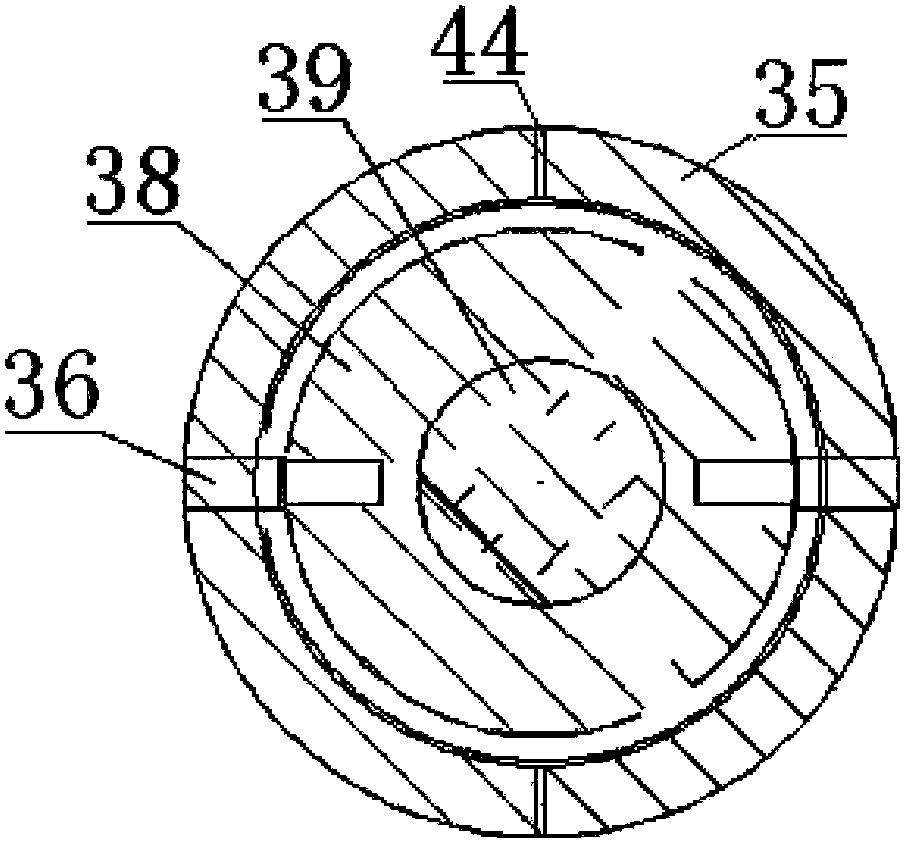

Robot joint rotating hydraulic cylinder with torque and angle feedback functions

InactiveCN103711741AIncreased torque densityHigh densityJointsFluid-pressure actuatorsHydraulic cylinderCoupling

The invention discloses a robot joint rotating hydraulic cylinder with torque and angle feedback functions. The robot joint rotating hydraulic cylinder comprises an open type sealed hydraulic oscillating cylinder, a torque sensing module and an angular displacement sensing module, wherein the open type sealed hydraulic oscillating cylinder comprises an oscillating cylinder output shaft, an elastic retainer ring, a bearing, a shaft sleeve, an outward leakage radial O-shaped sealing ring, an outward leakage O-shaped polytetrafluoroethylene ring, an open type cylinder cover, a leakage axial O-shaped sealing ring, a cylinder body, a fixed blade, a movable blade, an inward leakage polytetrafluoroethylene bar, an inward leakage sealing bar and an oil inlet and outlet channel connecting piece; the torque sensing module comprises an elastic shaft coupling, a torque detection shaft, a strain gauge, a torque detection signal line, a torque transmission flange, a torque transmission and support dual-purpose flange and a larger leg; the angular displacement sensing module comprises a shaft coupling, an encoder bracket, an encoder and a smaller leg. The hydraulic cylinder can provide large torques, is simple in structure, and is easy and convenient to control. Meanwhile, a modular structure is adopted, thereby realizing torque feedback and angle feedback functions.

Owner:SOUTHEAST UNIV

Low profile attachment hanger system for a cooling liner within a gas turbine engine swivel exhaust duct

ActiveUS7975488B2Minimize the numberImprove sealing efficiencyEfficient propulsion technologiesGas turbine plantsLimited accessGas turbines

An exhaust duct assembly includes a cooling liner spaced apart from an exhaust duct case that articulate for use in a short take off vertical landing (STOVL) type of aircraft. The cooling liner assembly is attached to the exhaust duct case through a foldable attachment hanger system. The foldable attachment hanger system provides a low profile (foldable up / down) for a limited access installation envelope typical of a three bearing swivel duct (3BSD) which rotates about three bearing planes to permit transition between a cruise configuration and a hover configuration. In this way, each cooling liner segment may be formed as a complete cylindrical member requiring joints only between the swivelable duct sections.

Owner:RTX CORP

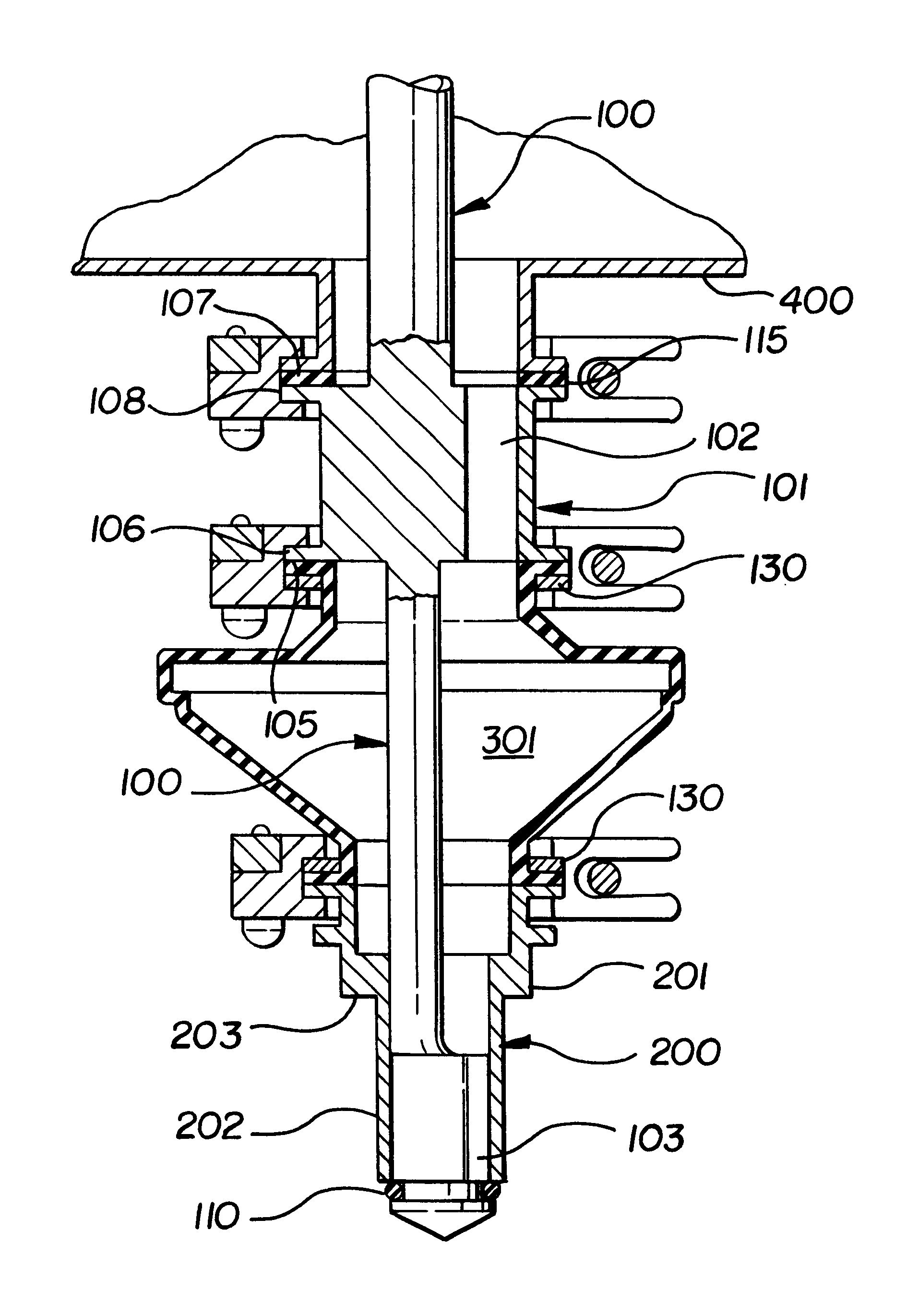

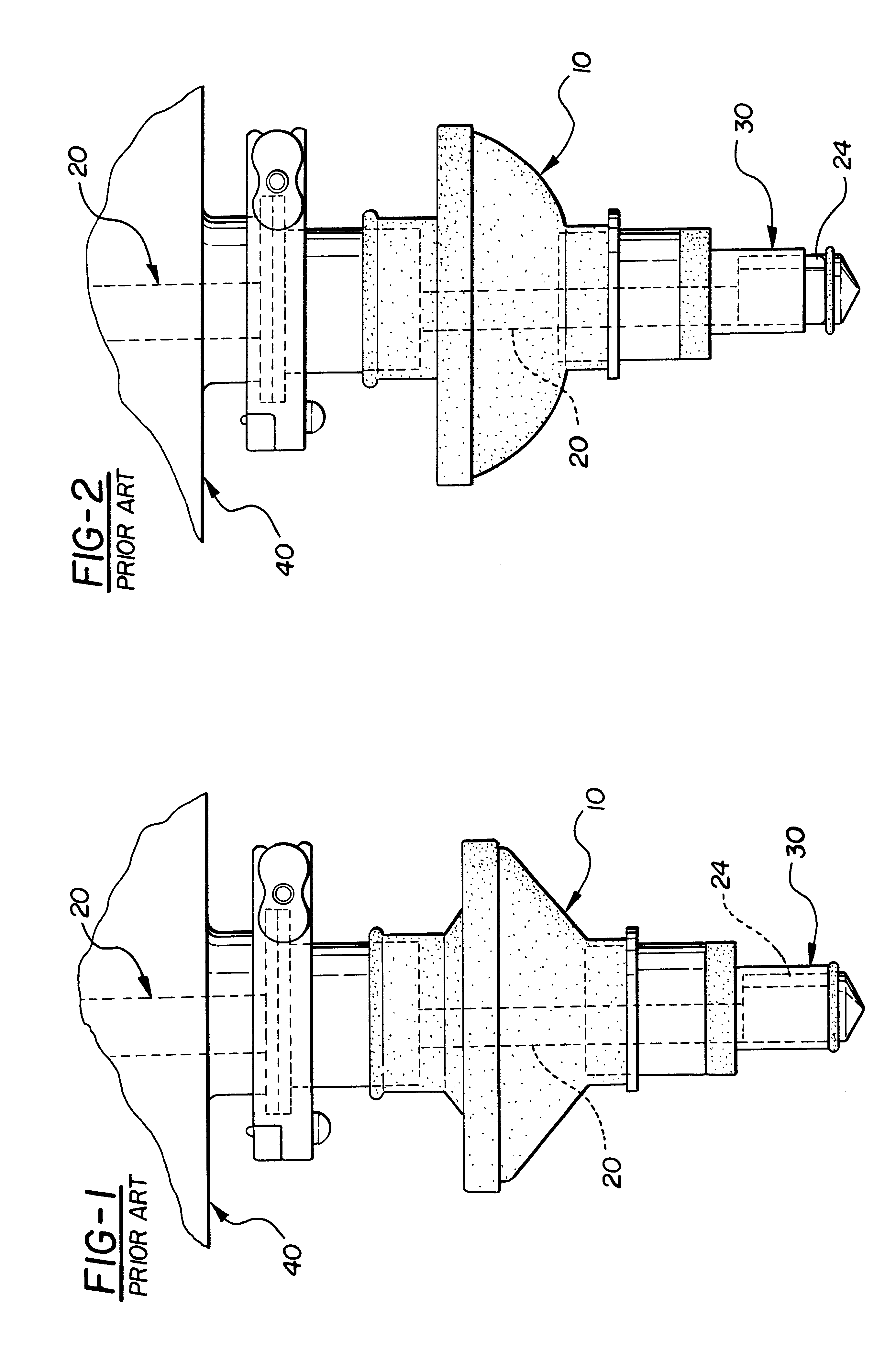

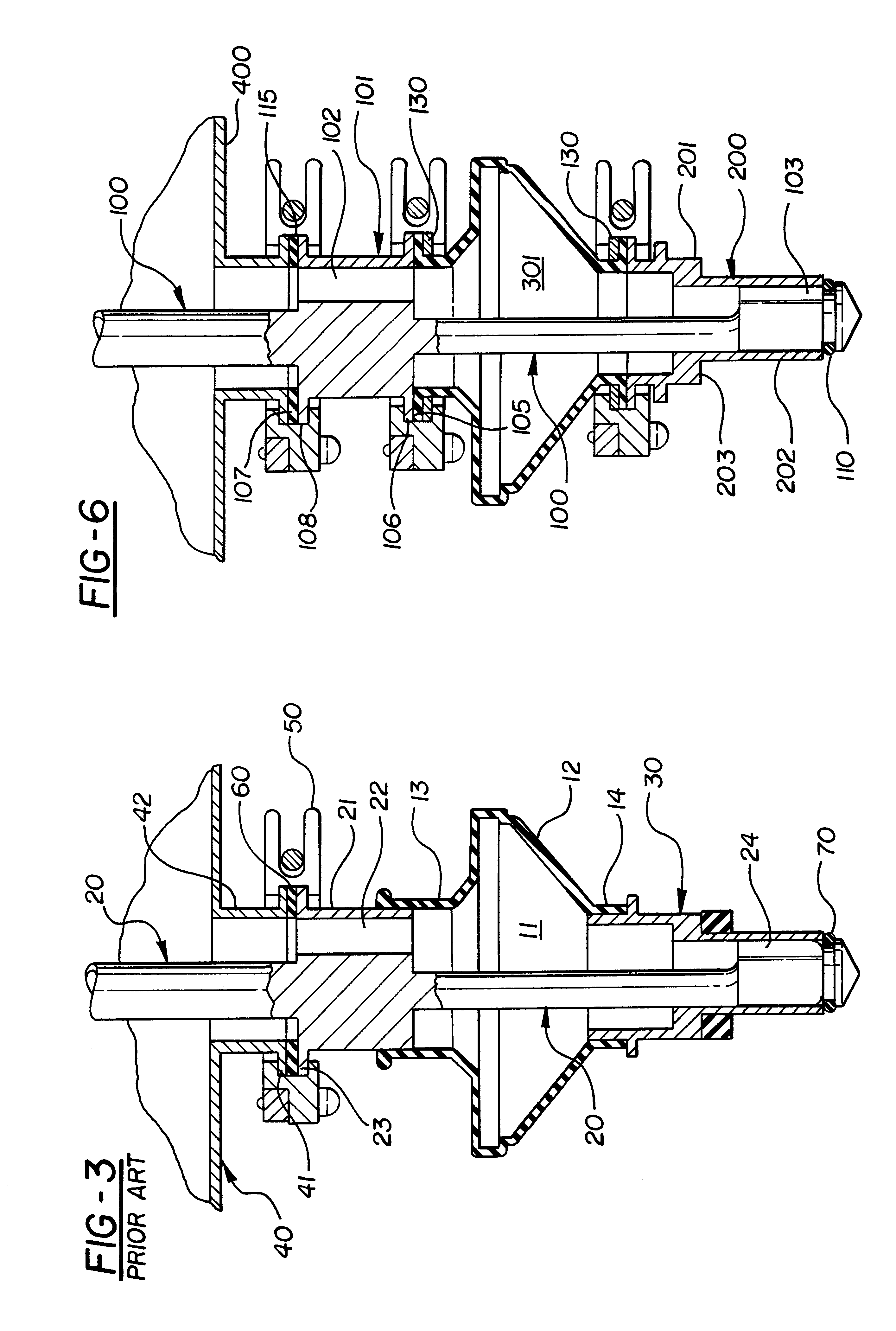

Fluid-dispensing valve for a container-filling apparatus

InactiveUS6253811B1Improve securityImprove sealing efficiencySolid materialLiquid materialNozzleEngineering

A fluid-dispensing valve for a container-filling apparatus comprises a vent tube having an axial mating surface; a nozzle positionable over and axially moveable in relation to the vent tube to define open and closed conditions of the fluid-dispensing valve, the nozzle including an axial mating surface; a biasing member for biasing the nozzle in a closed condition of the fluid-dispensing valve, the biasing member having a fluid passageway therethrough, and further including at least two axial mating surfaces, one axial mating surface axially abutting with an axial mating surface of each of the vent tube and nozzle to define an axially mated condition of the fluid-dispensing valve; and one or more members for maintaining the vent tube, nozzle, and biasing member in the axially mated condition of the fluid-dispensing valve.

Owner:FILLER SPECIALTIES

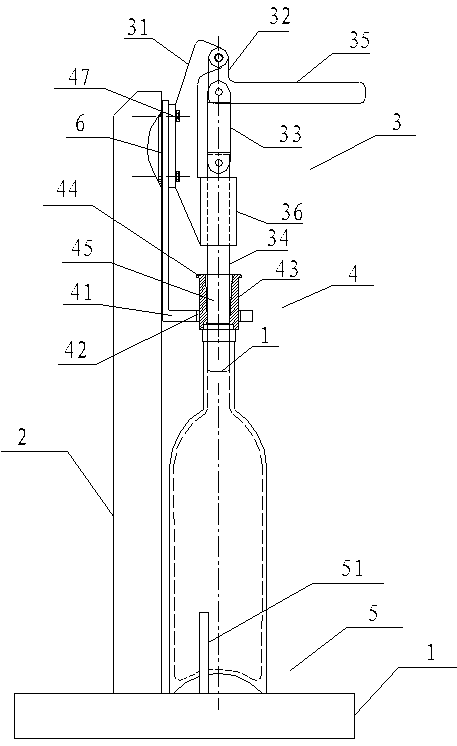

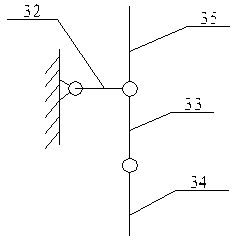

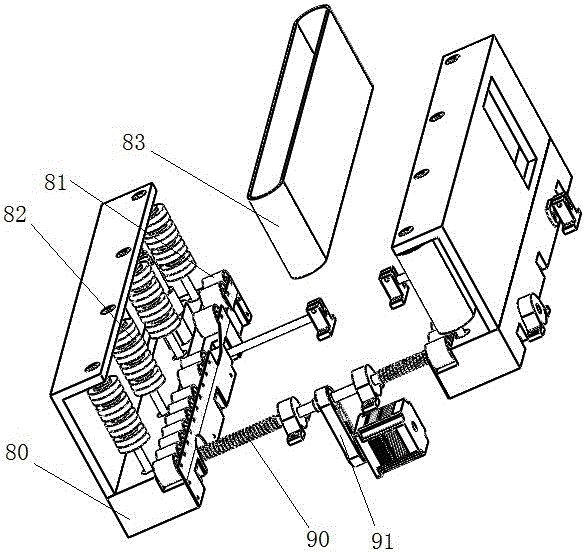

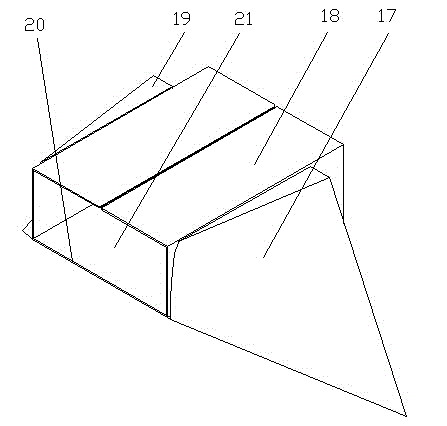

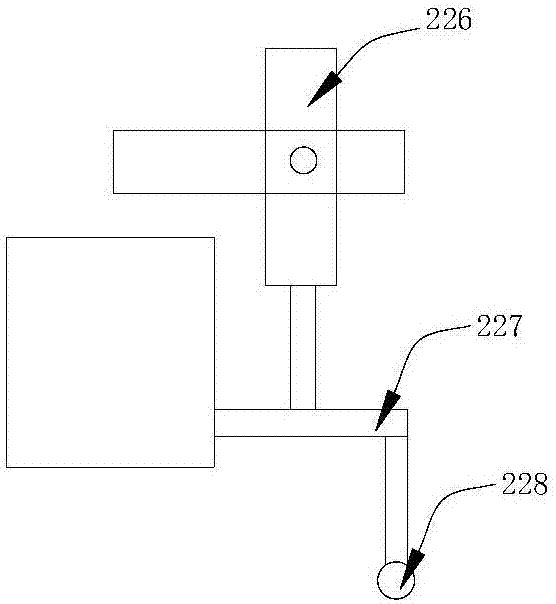

Cork pressing device

InactiveCN103159151AQuick compressionGuaranteed to press in correctlyThreadless stopper insertionEngineeringMechanical engineering

The invention discloses a cork pressing device. The cork pressing device comprises a support base plate and a support vertical plate, wherein the support base plate and the support vertical plate are mutually perpendicular. The support vertical plate is provided with a cork pressing mechanism, and a cork guide mechanism arranged below the cork pressing mechanism. The support base plate is provided with a locating mechanism used for fixing objects to be pressed. Centers of the cork pressing mechanism, the cork guide mechanism and the locating mechanism are collinear. The cork pressing mechanism is a crank-link mechanism. The support vertical plate is further provided with a slotted hole used for adjusting the height of the cork pressing mechanism. By rotating a crank, a cork can be pressed fast, operation is simple and convenient, much time and labor do not need to be consumed, and sealing efficiency is improved. By arranging the cork guide mechanism, the cork can be pressed correctly. Meanwhile, by arranging the locating mechanism, the objects to be pressed can be located accurately. By arranging the slotted hole used for adjusting the height of the cork pressing mechanism in the support vertical plate, adjustment can be carried out according to the height of the objects to be pressed. The cork pressing device is strong in genenrality.

Owner:苏州微纳过滤设备有限公司

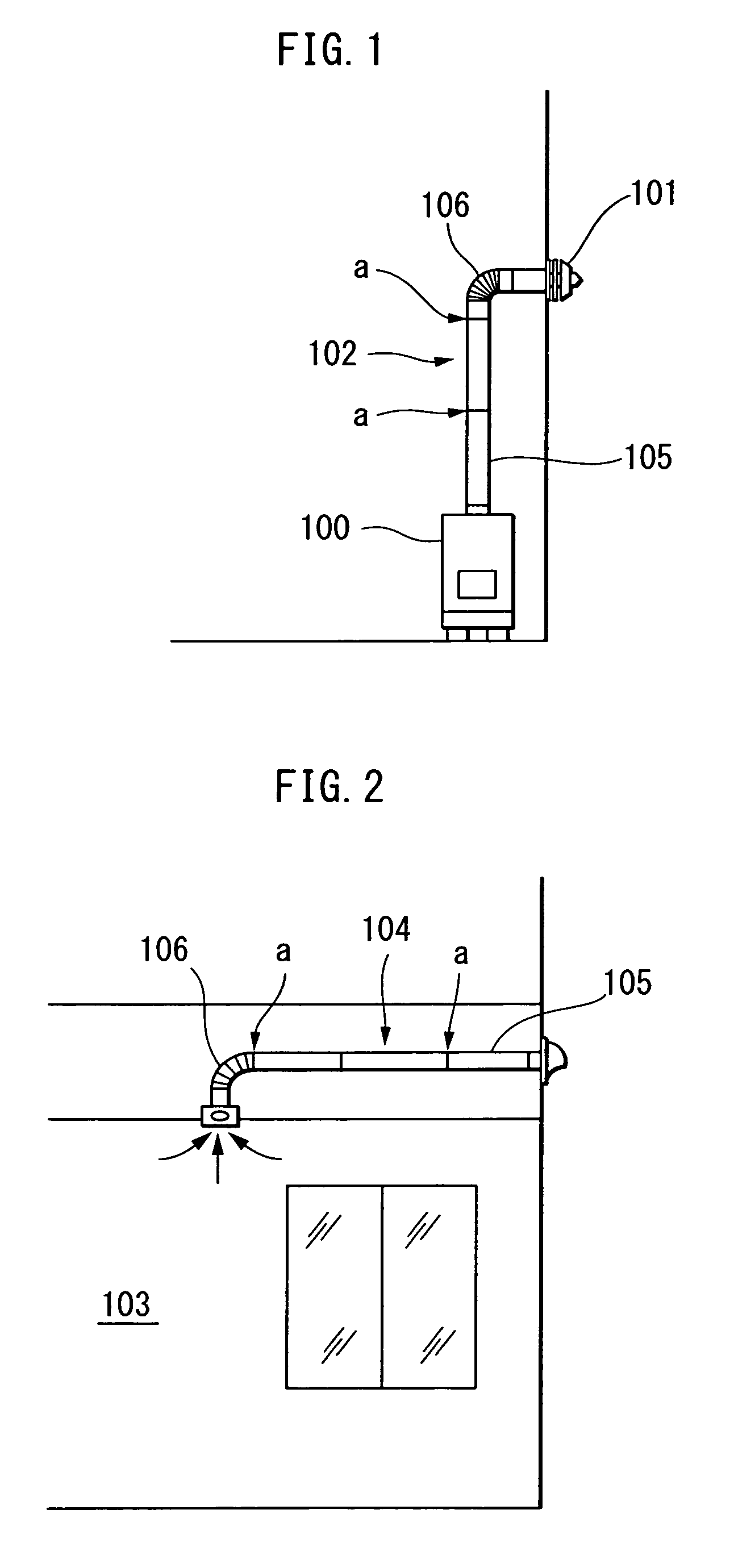

Vehicular air conditioner having two-layered air flow

ActiveUS8544533B2Easy to adjust temperatureEasy to operateAir-treating devicesRailway heating/coolingTemperature controlControl theory

An air conditioner for vehicles having a two layer air flow structure which uses one temperature control door for adjusting the temperature and serving as a partition wall for the two-layer air flow structure.

Owner:HANON SYST

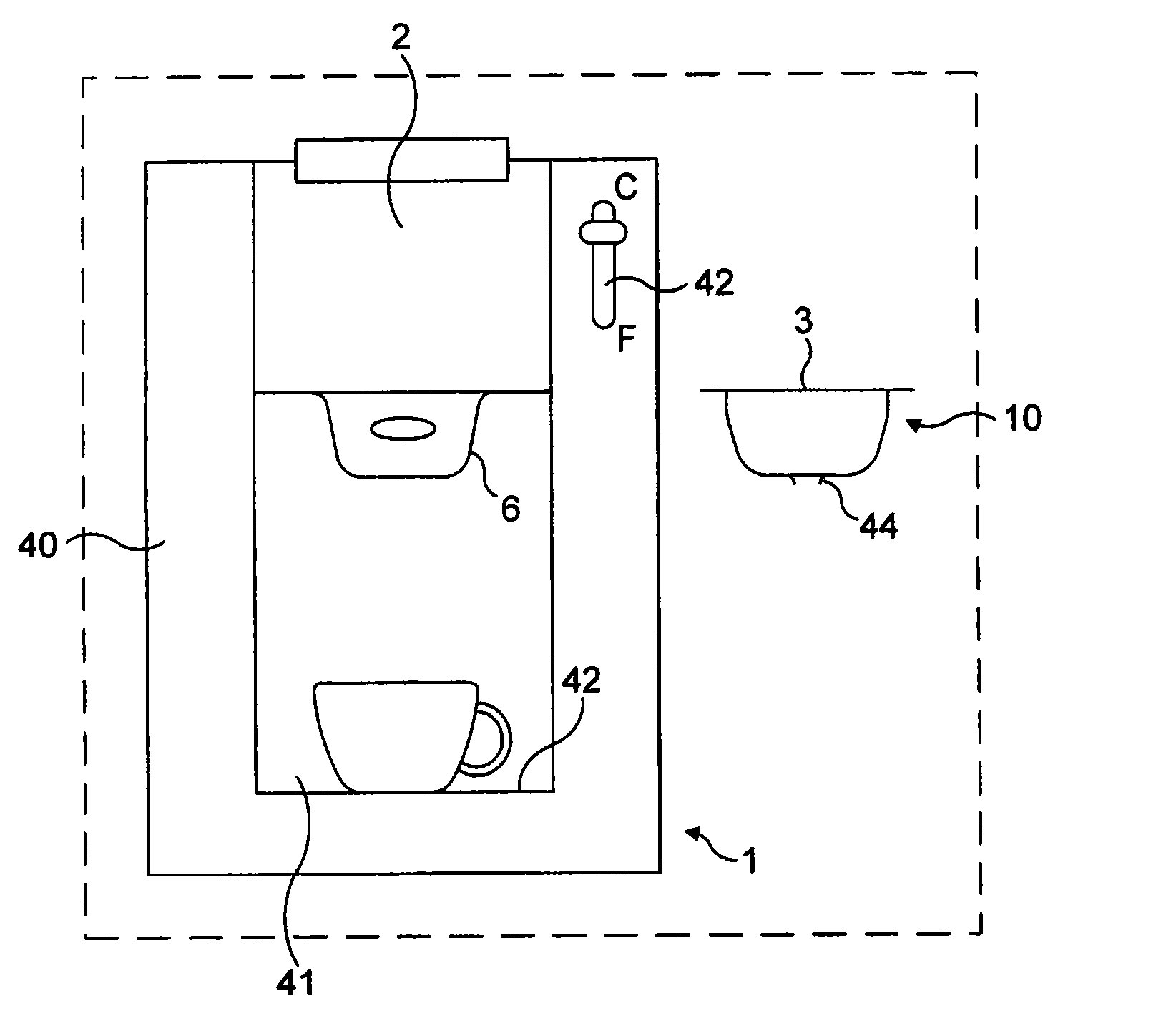

Device for preparing a liquid beverage from a cartridge

ActiveCN101668461AImprove sealingImprove solubilityBeverage vesselsThin material handlingBiomedical engineeringFluid supply

The device has a capsule holder receiving and supporting a capsule and detachable from a pressurized fluid supply unit. An injection unit (5) is provided through an injection support i.e. disc, of thesupply unit, and movable in engagement to the capsule. An elastic ring (16) is associated with the injection unit for carrying out local and direct sealing between the injection unit and an injectionwall of the capsule. An activation system applies a locking effort of the supply unit against a support side (40) of the capsule holder and an edge (34) of the capsule. An independent claim is also included for a method for reducing liquid resurgence or gas-liquid mixture through an injection point of a capsule.

Owner:NESTEC SA

Electric direct reading test sealing checking tool

The invention discloses an electric direct reading test sealing checking tool, which is designed for realizing the direct-reading type electric sealing checking of an underground packer of a separate injection well and improving the test efficiency and reliability. The electric direct reading test sealing checking tool consists of an upper joint, a magnetic positioning device (a coil assembly, magnetic steel and the like arranged in a sheath), an integrated controller (a power supply module connected with a control framework, a main control panel, motor, a magnetic positioning plate and the like), a motive power transmission mechanism (a motor connected with a lead screw, a position limiting slide block, a thrust slide block and the like), a positioning mechanism (a positioning claw connected with a middle joint), a pressure data collector (comprising a thrust slide block, a pressure sensor and the like) and a test sealing device (upper and lower rubber tubes connected with a sleeve, a mandrel and the like) through sequential connection. The electric direct reading test sealing checking tool has the advantages that the real-time observation sealing checking effect is realized in a ground direct reading mode, the sealing checking efficiency is high, the rubber tube packing and unpacking are controlled in an electric way, the sealing checking success rate is high, the magnetic positioning device is utilized for realizing the precise positioning, the positioning claw can open and withdraw at any time according to the instructions, and the goal of completing the test sealing checking in all layer positions through once well descending can be realized.

Owner:PETROCHINA CO LTD

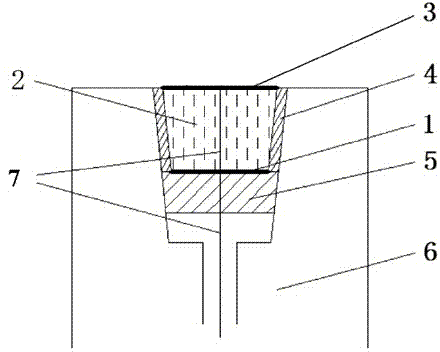

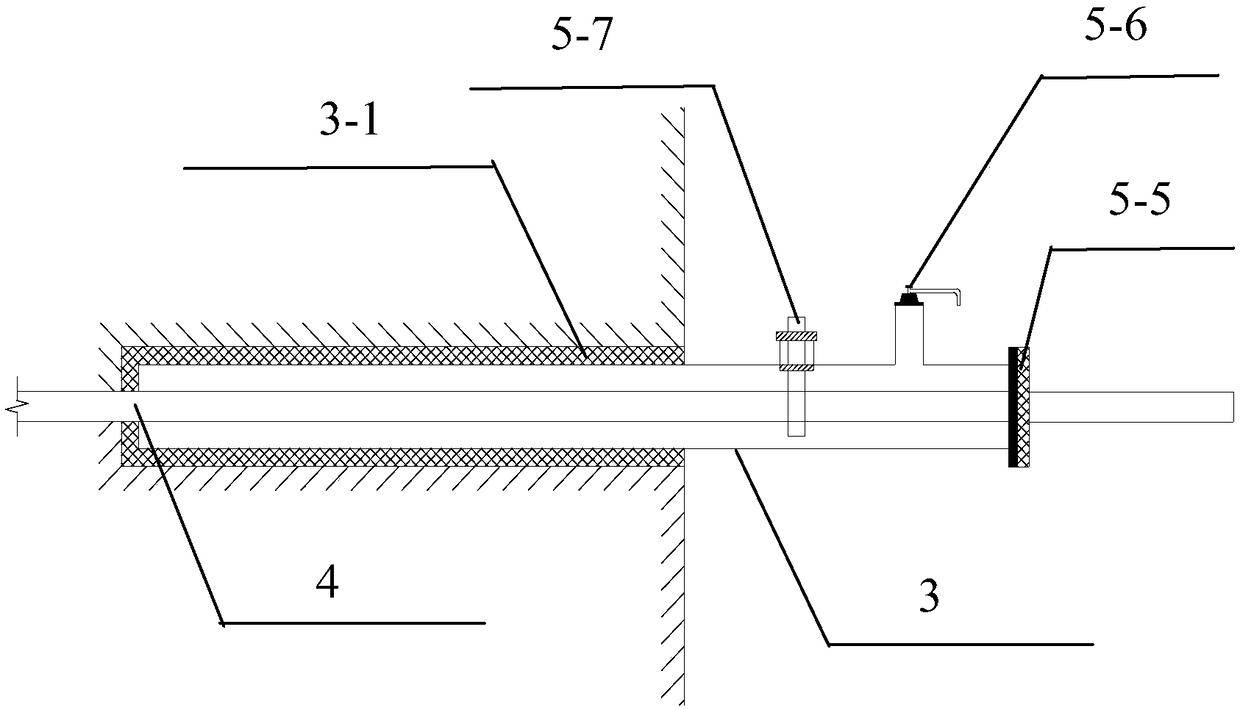

Platinum electrode for high-temperature high-pressure hydrothermal system and preparation method thereof

ActiveCN104749234AGood mechanical strength at high temperatureModerate hardnessMaterial electrochemical variablesPlatinumOptoelectronics

The invention discloses a platinum electrode for a high-temperature high-pressure hydrothermal system and a preparation method of the platinum electrode. The platinum electrode is composed of a substrate (6), a circular truncated cone shaped high-temperature insulating mat (5), a high-temperature insulating taper sleeve (4), a circular truncated cone shaped high-temperature insulating ceramic (2), an inert metal sheet (1), a spongy inert metal layer (3) and an electrode lead wire (7), wherein one end of the substrate is provided with a taper hole and the other end of the substrate is provided with an axis through hole; the convergent end of the taper hole is provided with the circular truncated cone shaped high-temperature insulating mat, the divergent end of the taper hole is provided with the high-temperature insulating taper sleeve and the circular truncated cone shaped high-temperature insulating ceramic, the electrode lead wire and the spongy inert metal layer are arranged on the axis and the large circular surface of the circular truncated cone shaped high-temperature insulating ceramic, and the inert metal sheet is arranged between the circular truncated cone shaped high-temperature insulating mat and the circular truncated cone shaped high-temperature insulating ceramic. Compared with the existing various high-pressure hydrothermal platinum electrodes, the platinum electrode solves the difficult problems that the existing cold-sealing type platinum electrode at home and abroad has poor stability and reliability and the hot-sealing type platinum electrode cannot be used in a high-pressure hydrothermal environment at higher than 400 DEG C.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Low profile attachment hanger system for a cooling liner within a gas turbine engine swivel exhaust duct

InactiveUS7814753B2Minimize the numberImprove sealing efficiencySpraying apparatusGas turbine plantsLimited accessGas turbines

An exhaust duct assembly includes a cooling liner spaced apart from an exhaust duct case that articulate for use in a short take off vertical landing (STOVL) type of aircraft. The cooling liner assembly is attached to the exhaust duct case through a foldable attachment hanger system. The foldable attachment hanger system provides a low profile (foldable up / down) for a limited access installation envelope typical of a three bearing swivel duct (3BSD) which rotates about three bearing planes to permit transition between a cruise configuration and a hover configuration. In this way, each cooling liner segment may be formed as a complete cylindrical member requiring joints only between the swivelable duct sections.

Owner:UNITED TECH CORP

Quick automatic box sealer and box sealing method thereof

The invention relates to a quick automatic box sealer and a box sealing method thereof; the quick automatic box sealer comprises a frame, and a feed plate and a discharge plate connected to the front and rear ends of the frame; a sealing passage is extended in the middle of the frame from front to rear, an upper core and a lower core arranged in the middle of the sealing passage in top-bottom correspondence manner, the upper core and the lower core are staggered in front-rear manner, the upper core is arranged on the frame through a height adjusting mechanism, the left and right of the lower core are provided with belt conveying mechanisms along the sealing passage, the two belt conveying mechanisms are arranged on two sides of the lower core in opposing manner and are driven in sync by a two-way screw mechanism, a pressure sensor is arranged on the upper surface of the feed plate, a first proximity switch is arranged at the lower end of the front of the upper core, and the front ends of the two belt conveying mechanisms are provided with second proximity switches respectively. The quick automatic box sealer and the box sealing method thereof have the advantages that the sealing passage can adapt to the height and width of a box, and the box is sealed automatically and quickly through the cooperation of the upper and lower cores.

Owner:胡宇航

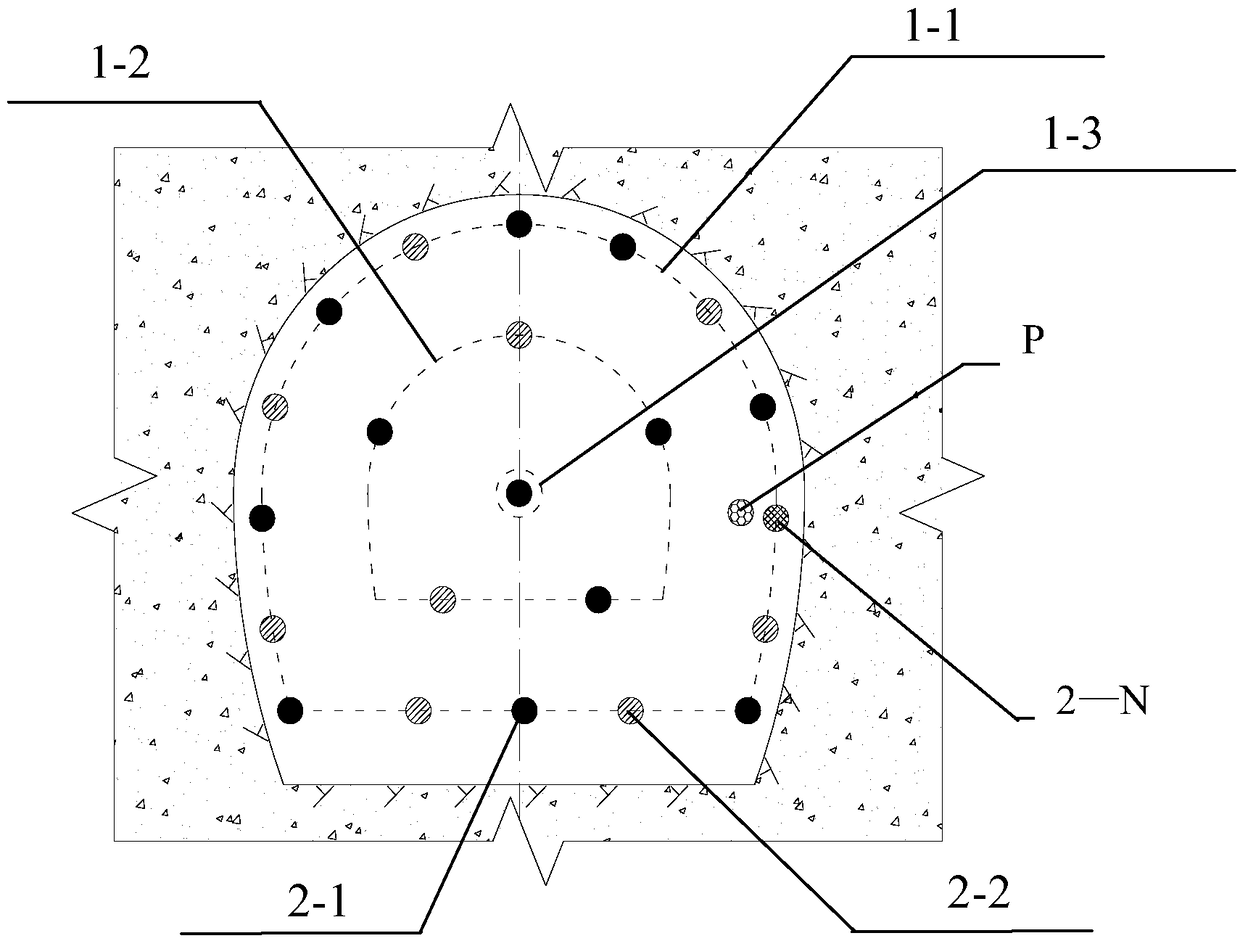

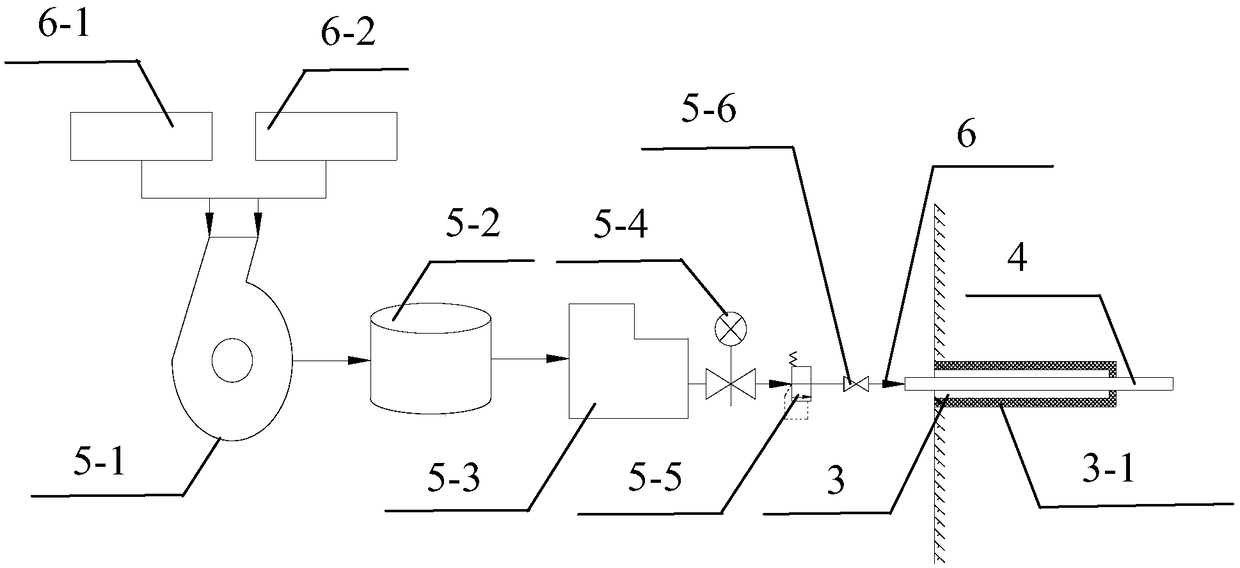

Advanced pre-grouting construction method using HSC grouting materials

InactiveCN108756898AReduce disturbanceReduce processing timeUnderground chambersTunnel liningSafety riskBuilding construction

The invention discloses an advanced pre-grouting construction method using HSC grouting materials. The advanced pre-grouting construction method using the HSC grouting materials comprises the steps that a drilling ring is marked on a tunnel face; the hole site of a grouting hole is marked on the drilling ring; holes are drilled at the hole site to form the grouting hole; installation is carried out in the grouting hole; a grouting pipe is inserted in an orifice pipe; a grouting system is installed; and HSC grouting fluid is injected into the grouting pipe for advanced pre-grouting and other steps. The advanced pre-grouting construction method using the HSC grouting materials fundamentally solves the water inrush problem in the construction of a subsurface tunnel and can ensure the safety of the whole construction process. Compared with other construction methods in the prior art, the whole construction process is in a safe, stable, rapid and high-quality controllable state, the construction efficiency is improved, safety risks and construction costs are reduced, and the construction process is easy to operate and control.

Owner:CHINA RAILWAY SIXTH GROUP +1

Packaging box sealing mechanism

InactiveCN105000222ASimple structureEnsure the quality of the boxWrapper twisting/gatheringEngineeringPosition sensor

The invention discloses a packaging box sealing mechanism, and belongs to the field of packaging equipment. The packaging box sealing mechanism comprises a support, a conveying mechanism, box sealing mechanisms, a reinforcing mechanism, a position sensor and a control box. The conveying mechanism is horizontally arranged on the support. The box sealing mechanisms are arranged at the portions, on the two sides of the conveying mechanism, of the support. Each box sealing mechanism comprises an edge lug folding and sealing mechanism, an upper lug folding and sealing mechanism, a glue injection mechanism and a lower lug sealing plate. The reinforcing mechanism comprises a lifting air cylinder, a piston rod, a supporting plate, a connecting plate and a reinforcing clamping plate. The position sensor is arranged at the portion, on one side of a conveyor belt, of the support. The control box is fixed to the support and connected with a conveying motor, a rotating motor, a lifting air cylinder and a glue injection cylinder. The packaging box sealing mechanism is simple in structure, convenient to operate and capable of rapidly and efficiently sealing packaging boxes containing packaging bags automatically; the places to which glue is stuck are reinforced through the reinforcing mechanism; the packaging box sealing quality is ensured, the labor intensity of workers is lowered, and the production requirement is met.

Owner:张欣雨

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

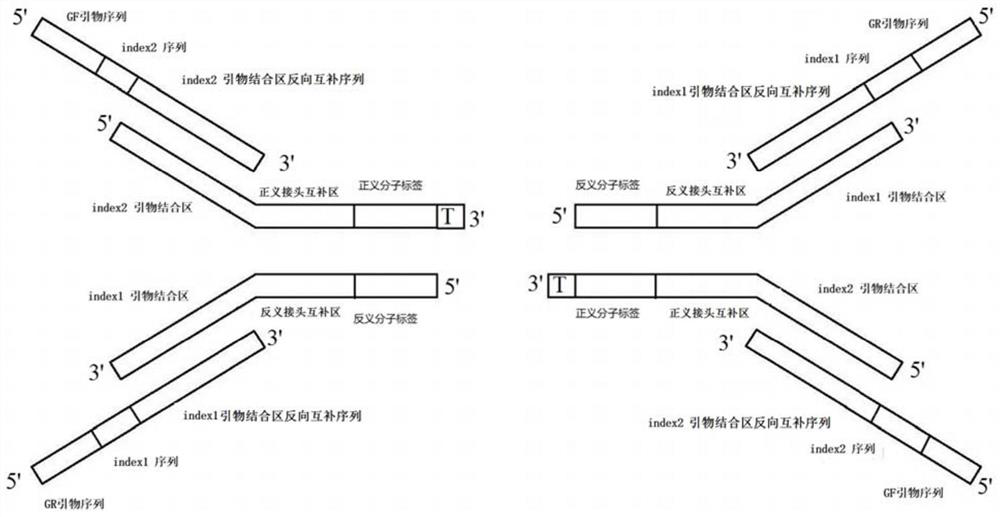

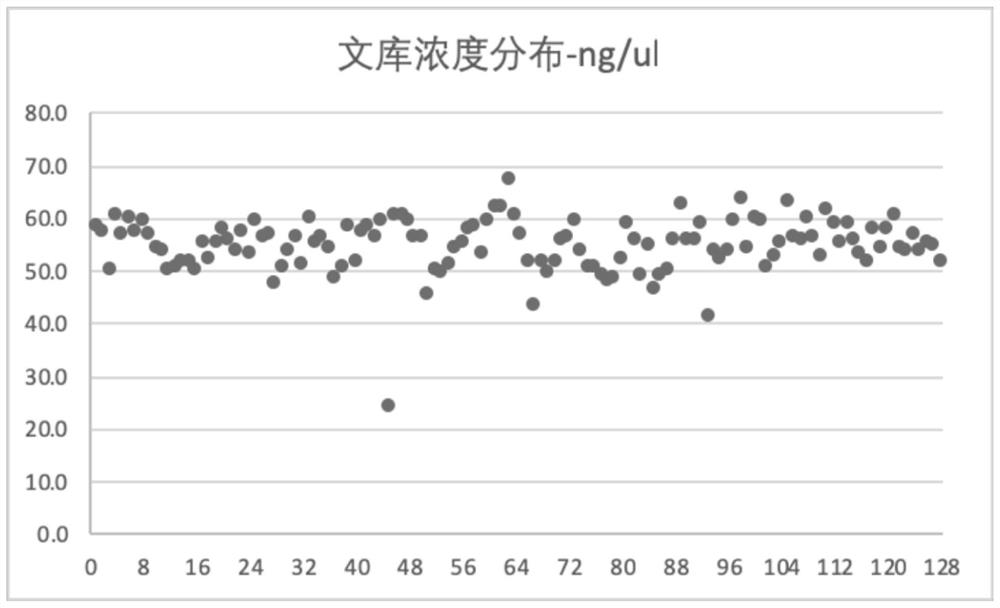

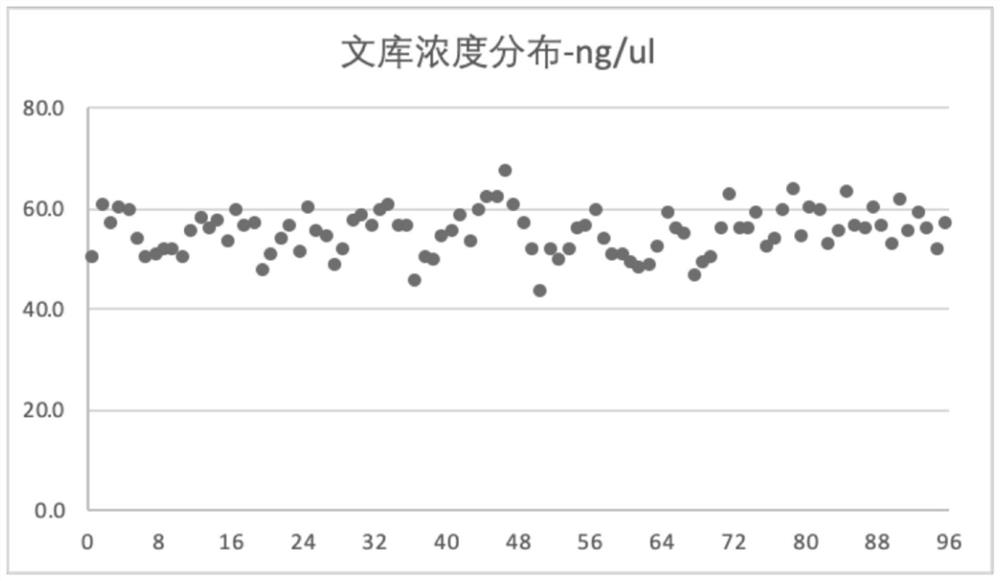

Short joint, double-index joint primer and double-index library building system of gene sequencer

InactiveCN112626189AUniformity of Amplification EfficiencyFragment transformation efficiency uniformityNucleotide librariesMicrobiological testing/measurementBase JEngineering

The invention provides a short joint, a double-index joint primer and a double-index library building system of a gene sequencer. The short joint comprises two partially complementary joint oligonucleotide chains: including a joint oligonucleotide chain 1 and a joint oligonucleotide chain 2, wherein the joint oligonucleotide chain 1 sequentially comprises an index 2 primer binding region, a positive-sense joint complementary region, a positive-sense molecular tag and a protruding base T from the 5' end to the 3 'end; and the joint oligonucleotide chain 2 sequentially comprises an antisense molecular tag, an antisense joint complementary region and an index1 primer binding region from the 5' end to the 3 'end. The fragment conversion efficiency, the amplification efficiency uniformity between index combinations, the capture efficiency uniformity and the data yield stability of the double-index library system constructed by using the short joint are remarkably superior to those of an existing double-index library system.

Owner:北京吉因加医学检验实验室有限公司 +1

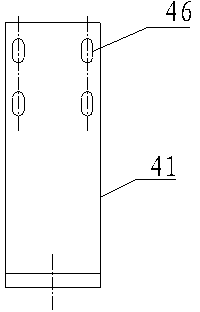

Vacuumizing plastic bag sealing machine

InactiveCN106144013AHigh degree of automationImprove sealing efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPressure sensor

The invention relates to a vacuum-pumped plastic bag sealing machine, which includes an operation table, on which two symmetrical limit plates and a cylinder are arranged, the upper end of the cylinder is connected with a lower pressing block, one side of the lower pressing block is connected with a cross bar, and the lower end of the cross bar is Connect the vacuum pump. The lower end of the vacuum pump is equipped with a vacuum head and a fixture. The vacuum head is equipped with an infrared sensor and a pressure sensor. There are symmetrical support rods on both sides of the vacuum pump. The support rod passes through the drive device and the cross bar. The lower ends are slidingly connected, and the opposite sides of the lower ends of the two support rods are symmetrically provided with sealing strips. The midpoint between the vacuum head and the two limit plates is on the same straight line. The device, the pressure sensor, the cylinder and the driving device are all respectively connected with the controller. The present invention has a relatively high degree of automation and can vacuumize the plastic bag before sealing.

Owner:SUZHOU SHENGBAIWEI PACKAGE EQUIP

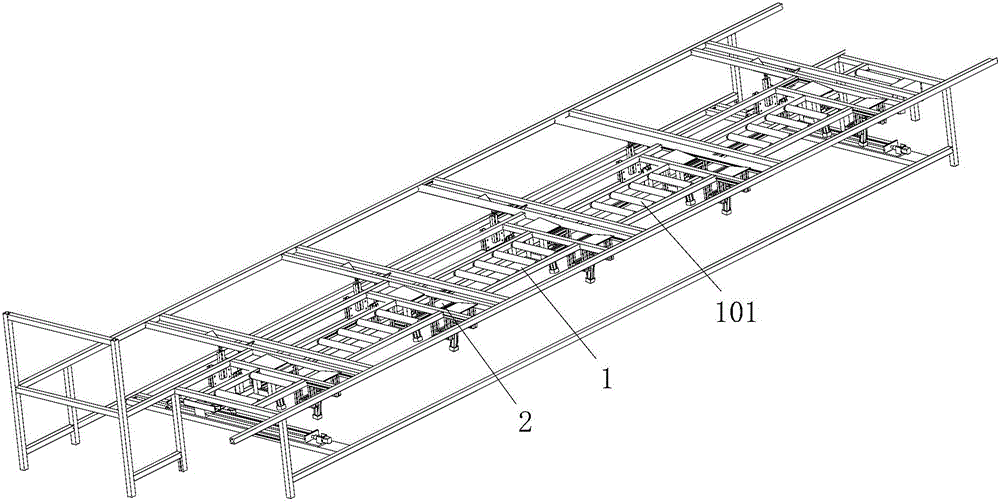

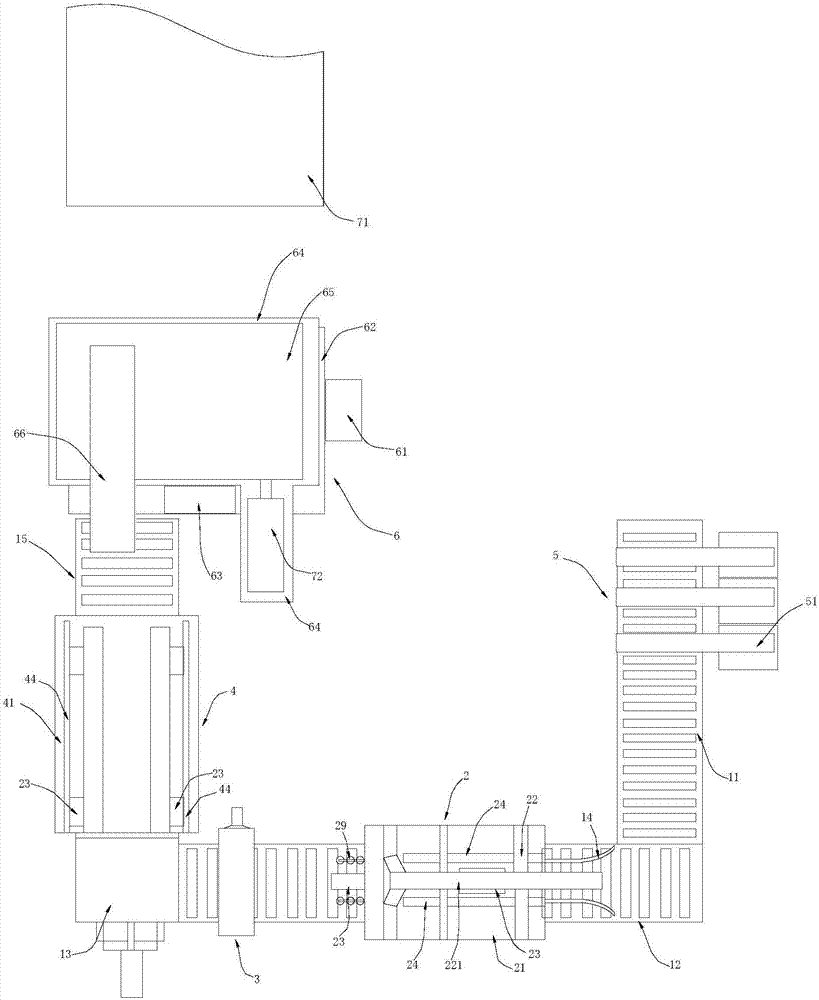

Intelligent packaging production line

InactiveCN107187675AFree laborFully automatedWrapper twisting/gatheringBinding material applicationProduction lineCarton

The invention relates to the field of production lines and discloses an intelligent packaging production line. The intelligent packaging production line comprises a feed rail, a product sorting mechanism, a cover detaching and carton sealing mechanism, a binding mechanism, an end corner glue sealing mechanism, a carton stacking mechanism and a conveying warehousing mechanism. The product sorting mechanism, the cover detaching and carton sealing mechanism, the binding mechanism, the end corner glue sealing mechanism, the carton stacking mechanism and the conveying warehousing mechanism are arranged in the feed direction of the feed rail sequentially. The cover detaching and carton sealing mechanism comprises a rack main body, a cover detaching frame arranged on the rack main body, a carton sealing assembly arranged on the rack main body, and two side conveying belts. The intelligent packaging production line can sort products automatically, cartons are subjected to cover folding, carton sealing, binding and end corner glue sealing procedures, automatic stacking and conveying warehousing are achieved, thus industrial automation is achieved, worker labor force is liberated, carton sealing efficiency is improved, and carton sealing quality is ensured.

Owner:DAKANG HLDG GROUP

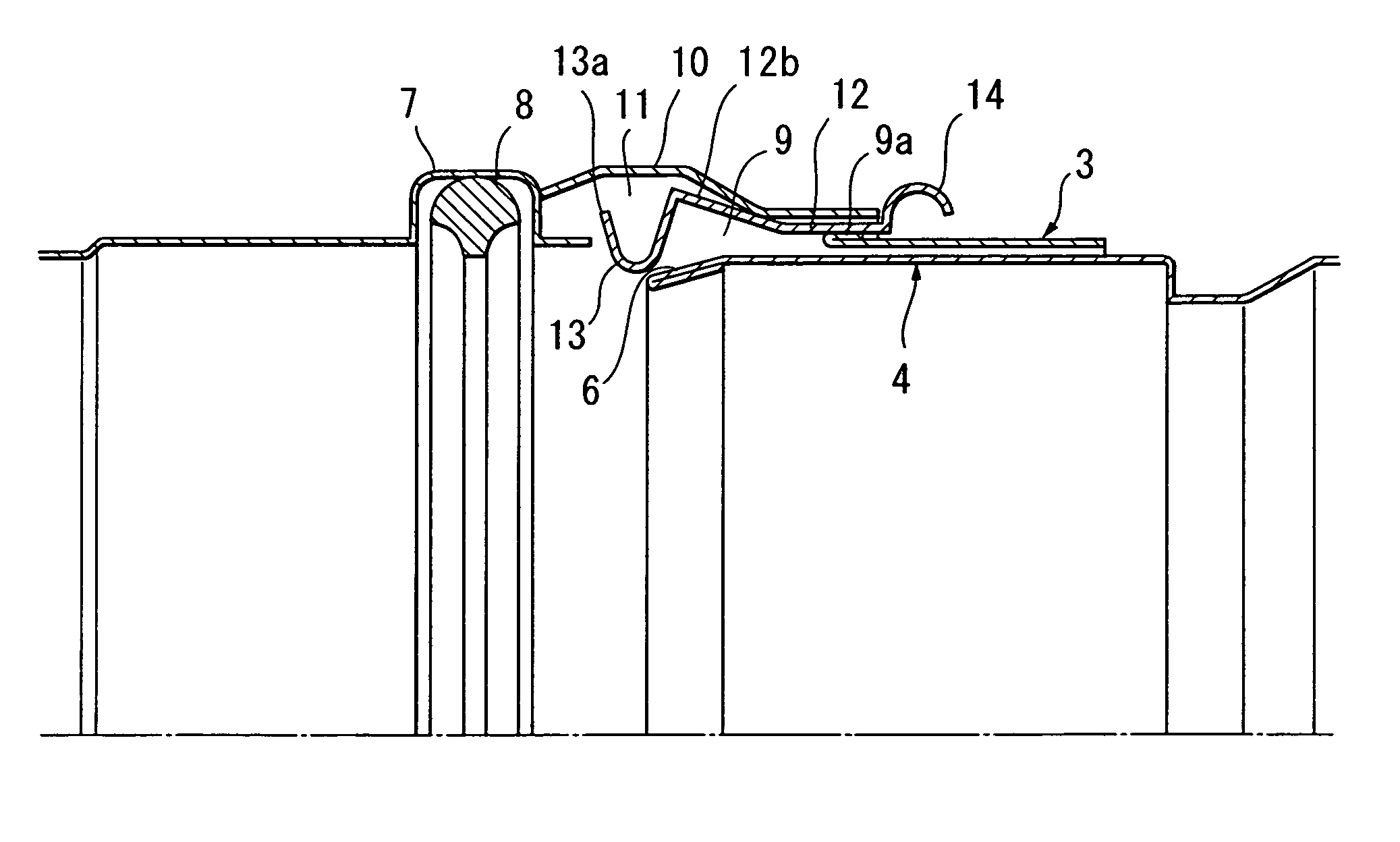

Supply and exhaust pipe

ActiveUS7347224B2Buckling strength at the edge is doubledImprove bending strengthSleeve/socket jointsFluid pressure sealed jointsFlexural strengthEngineering

In order to provide a supply and exhaust pipe comprising a drop-off prevention mechanism, particularly effective for pipes with a large diameter, to increase bending strength and sealing efficiency, formation of a hemmed section A at an top edge of an insert portion 4 can eliminate the occurrence of buckling and increase bending strength. Furthermore, an O-ring for sealing can improve sealing efficiency and also can make itself follow a deformation of the pipe by forming it into a mushroom shape to establish close contacts to the pipe at two points, namely a neck 8b and a part of the circumference 8c of a cap 8a. Furthermore, a drop-off prevention mechanism of the pipe has a wide sliding piece 12, and an arc 17 with a curvature adapted to the curvature of the pipe is formed on the lower surface of the sliding piece 12, to stabilize its sliding.

Owner:TOKYO GAS RENOVATION CO LTD

Inter-slit temporary plugging agent and preparation method thereof

InactiveCN105778877AImprove short-term temperature resistanceImprove toughnessDrilling compositionChloridePotassium sulfate

The invention provides an inter-slit temporary plugging agent and a preparation method thereof. The inter-slit temporary plugging agent consists of the following components in percentage by mass: 37.625-48.375% of polyacrylamide, 35-45% of natural polyurethane, 6-8% of a sulfonate surfactant and 10-12% of urea. The preparation method comprises the step of initiating polymerization and crosslinking of acrylamide to generate a mixed crosslinking system of polyacrylamide and natural polyurethane by taking an acrylamide monomer, natural polyurethane, the sulfonate surfactant and urea as raw materials, potassium sulfate as an initiating agent, isopropanol as a chain transfer agent, and aluminum chloride as a crosslinking agent. The temporary plugging agent has nontoxic and harmless raw materials, has the characteristics of low cost, simple process, strong capability of forming filter cakes at high temperature, high plugging efficiency and strong plugging effect, and does not generate residues after being completely dissolved, so that the temporary plugging agent is suitable for inter-slit temporary plugging of high-temperature formation breakdown, and is an environment-friendly temporary plugging agent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

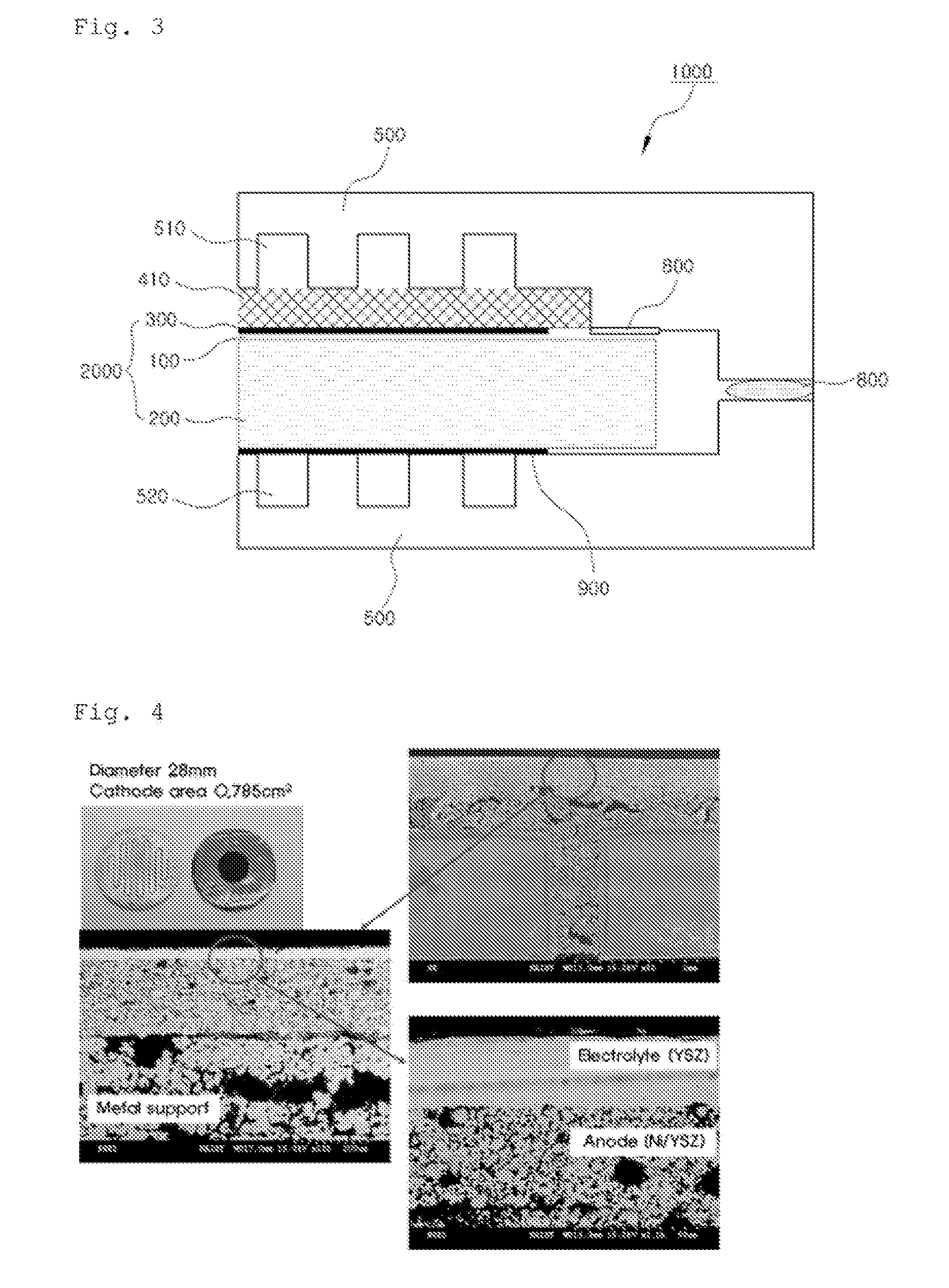

Metal support and solid oxide fuel cell including the same

InactiveUS20100062302A1Increased durabilityAvoid mixingFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsNuclear engineering

Disclosed are a metal support for a solid oxide fuel cell and the solid oxide fuel cell including the metal support. The metal support is coupled to a separator of the solid oxide fuel cell by welding and supports one surface of a unit cell comprising a fuel electrode, an air electrode, and an electrolyte layer interposed between the fuel and air electrodes, wherein the metal support is in the form of a plate and has a welding portion welded to the separator on the outer circumference thereof and a hollow portion surrounded by the welding portion to allow a fuel gas or air to flow therethrough. The use of the metal support increases the mechanical strength of the solid oxide fuel cell, resulting in improved durability and extended service life of the solid oxide fuel cell. In addition, the metal support ensures a smooth flow of the fuel gas or air, resulting in an increase in the sealing efficiency and energy production efficiency of the solid oxide fuel cell.

Owner:KOREA ADVANCED INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com