Patents

Literature

70 results about "Garter spring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A garter spring is a coiled steel spring that is connected at each end to create a circular shape, and is used in oil seals, shaft seals, belt-driven motors, and electrical connectors. Compression garter springs exert outward radial forces, while extension garter springs exert inward radial forces. The manufacturing process is not much different from the creation of regular coiled springs, with the addition of joining the ends together. Like most other springs, garter springs are typically manufactured with either carbon steel or stainless steel wire.

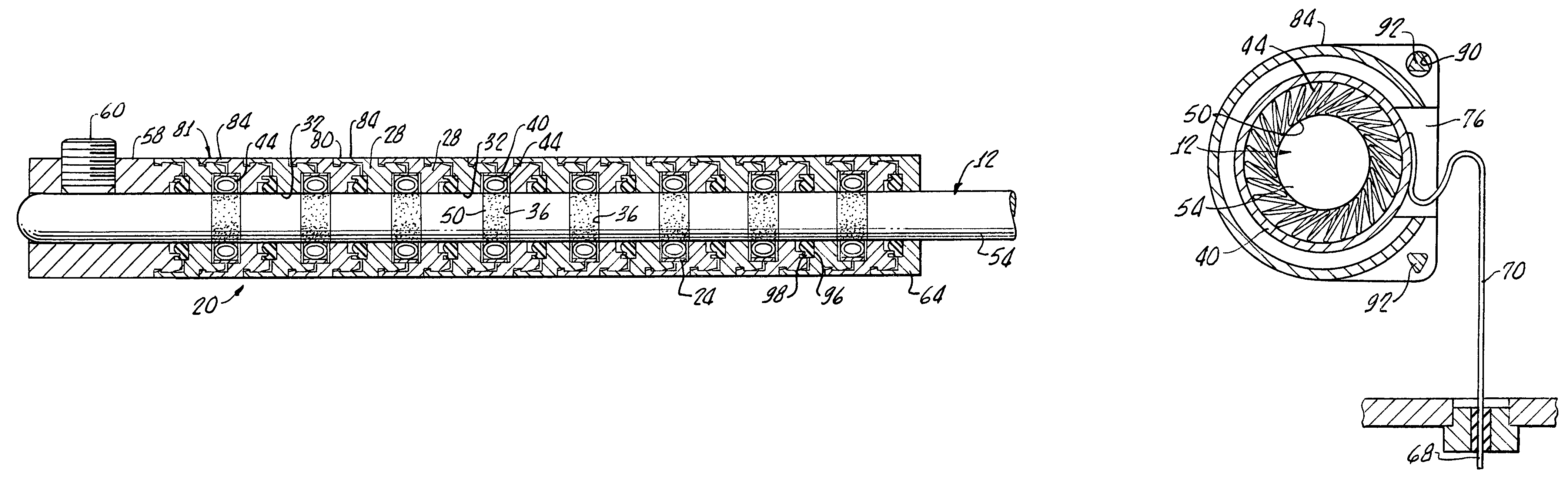

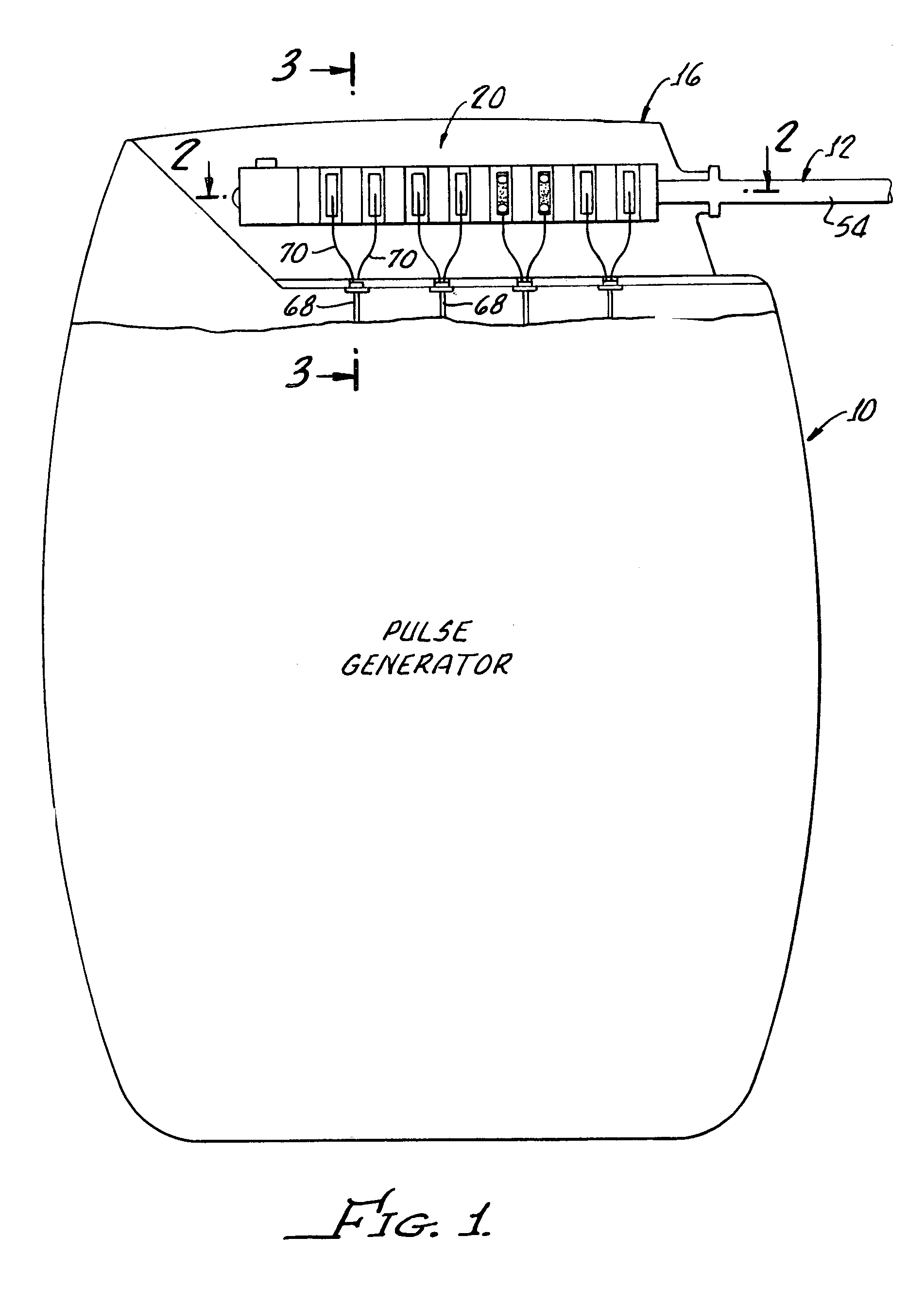

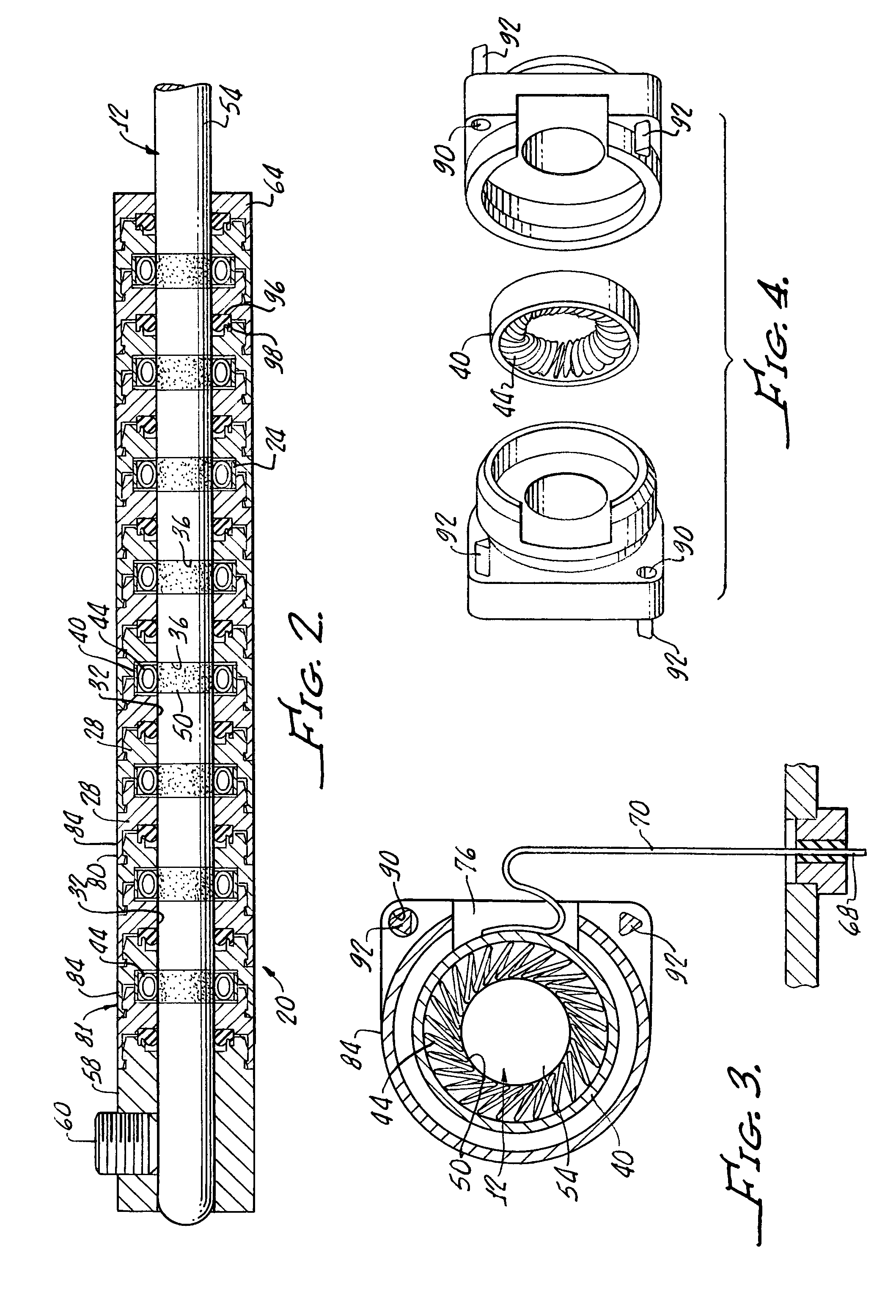

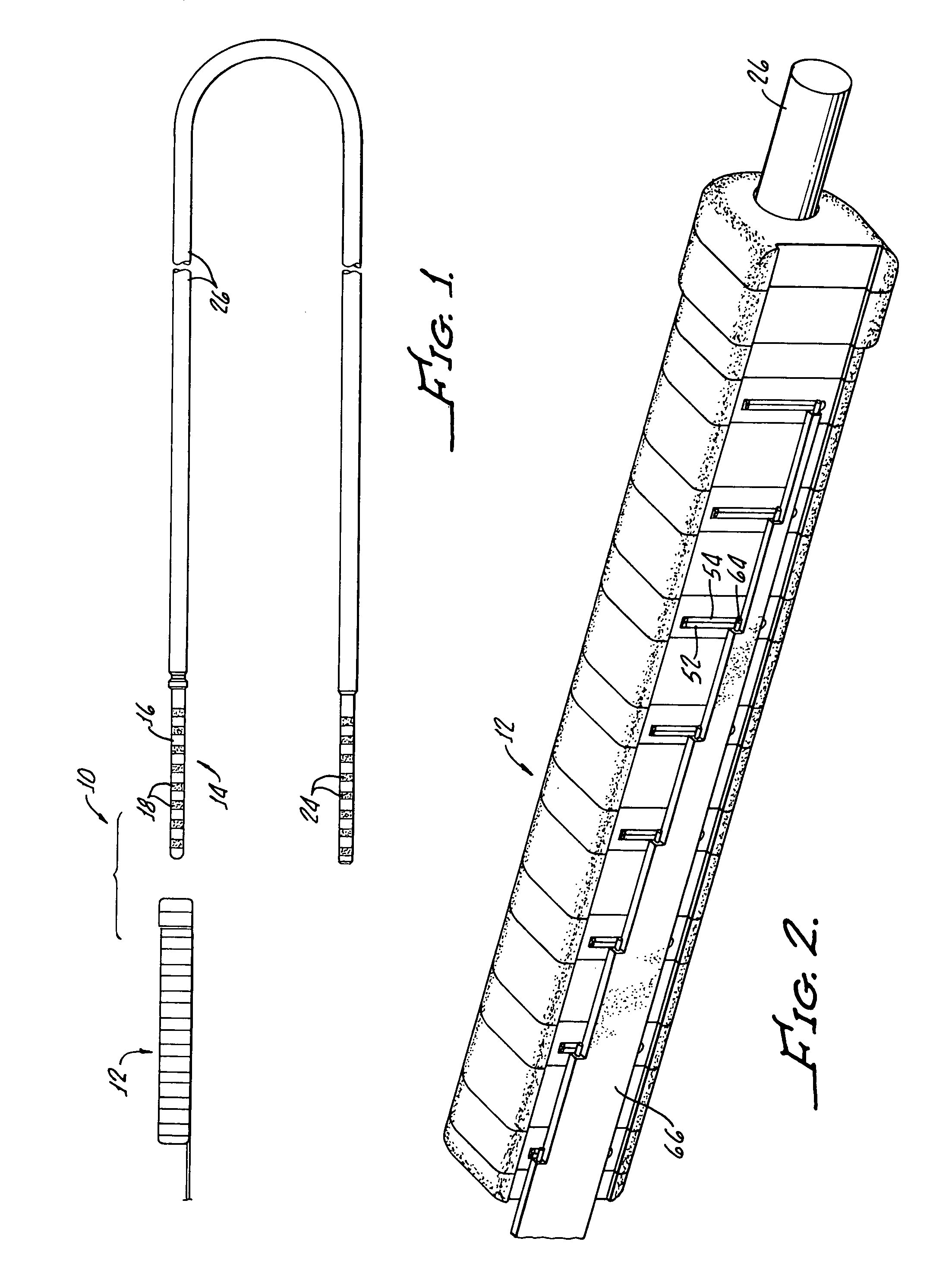

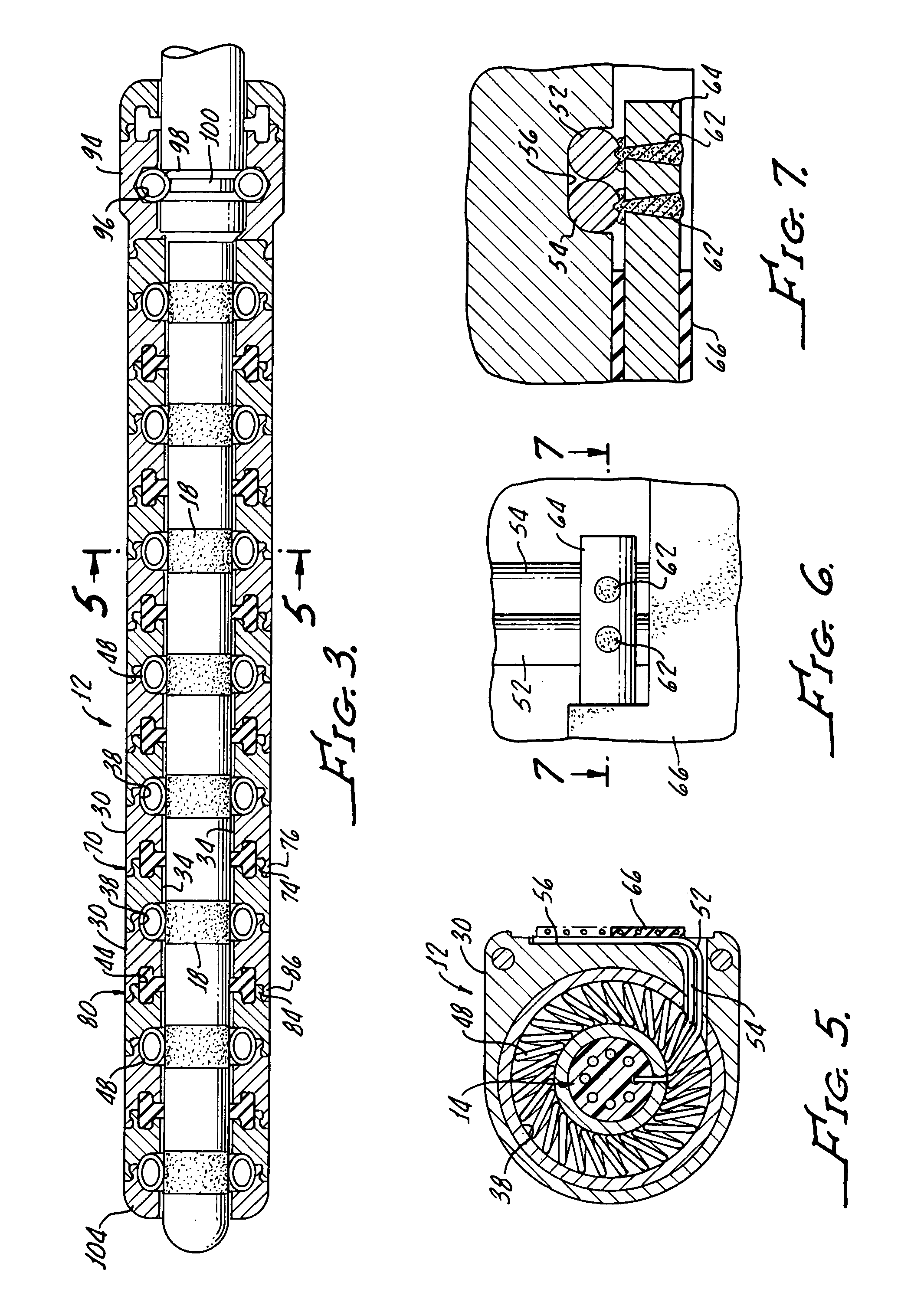

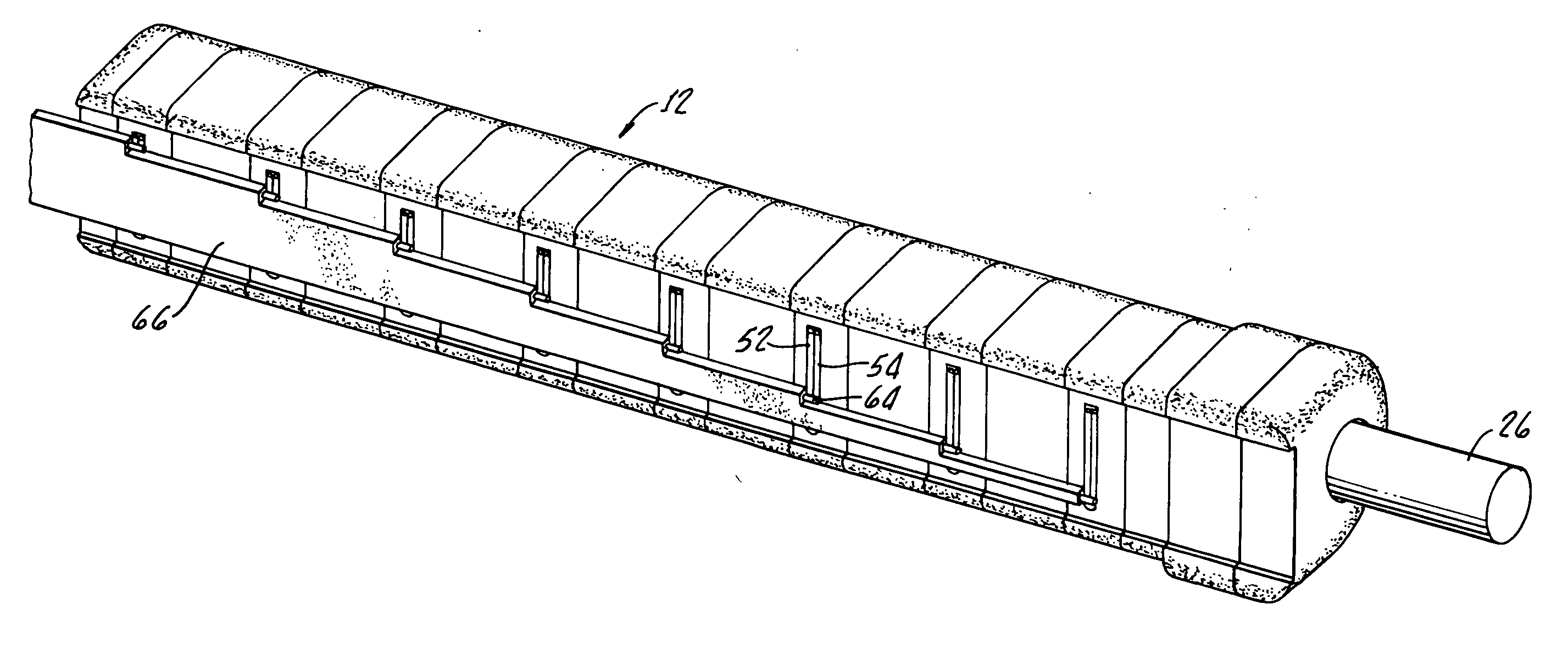

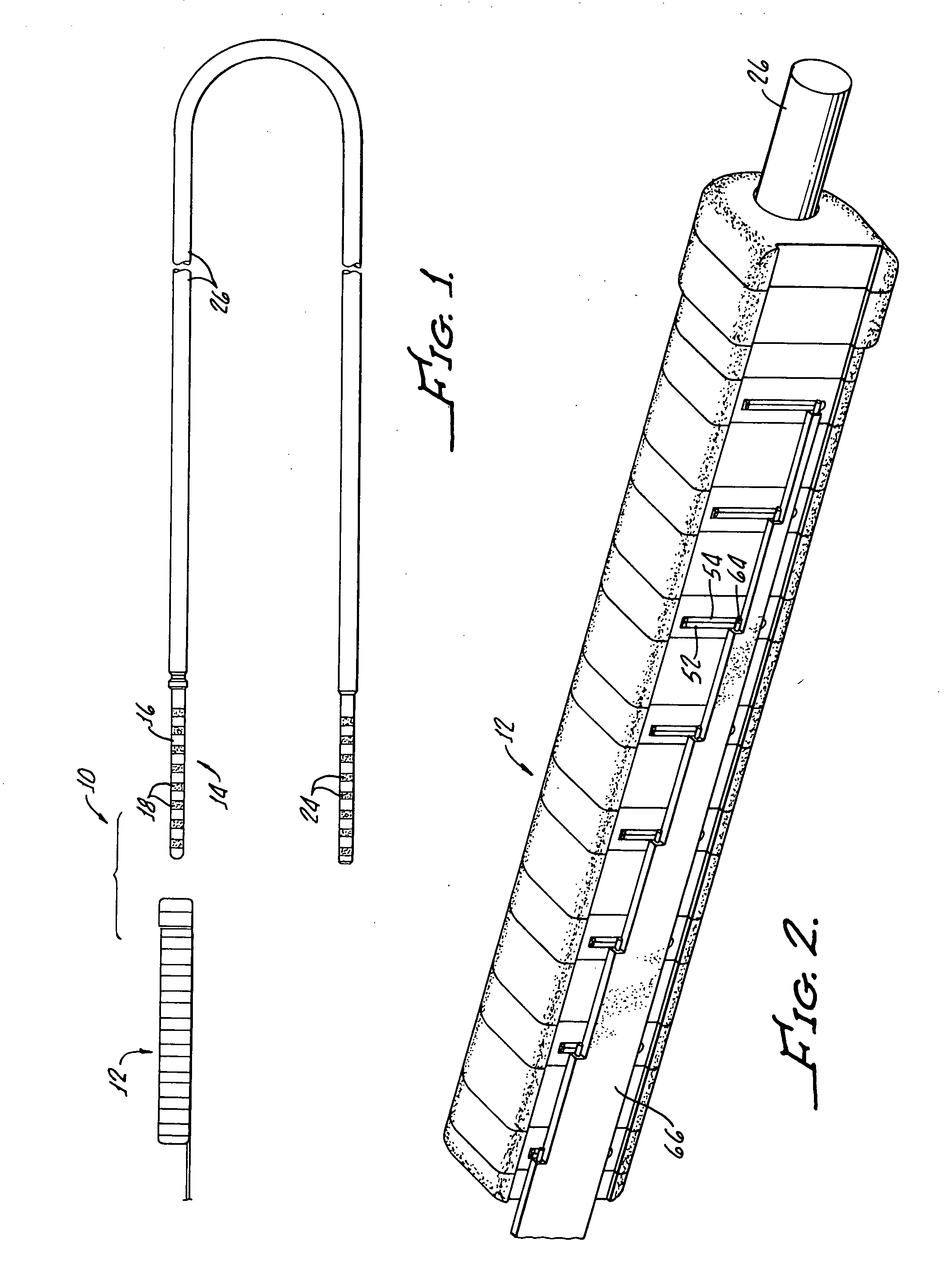

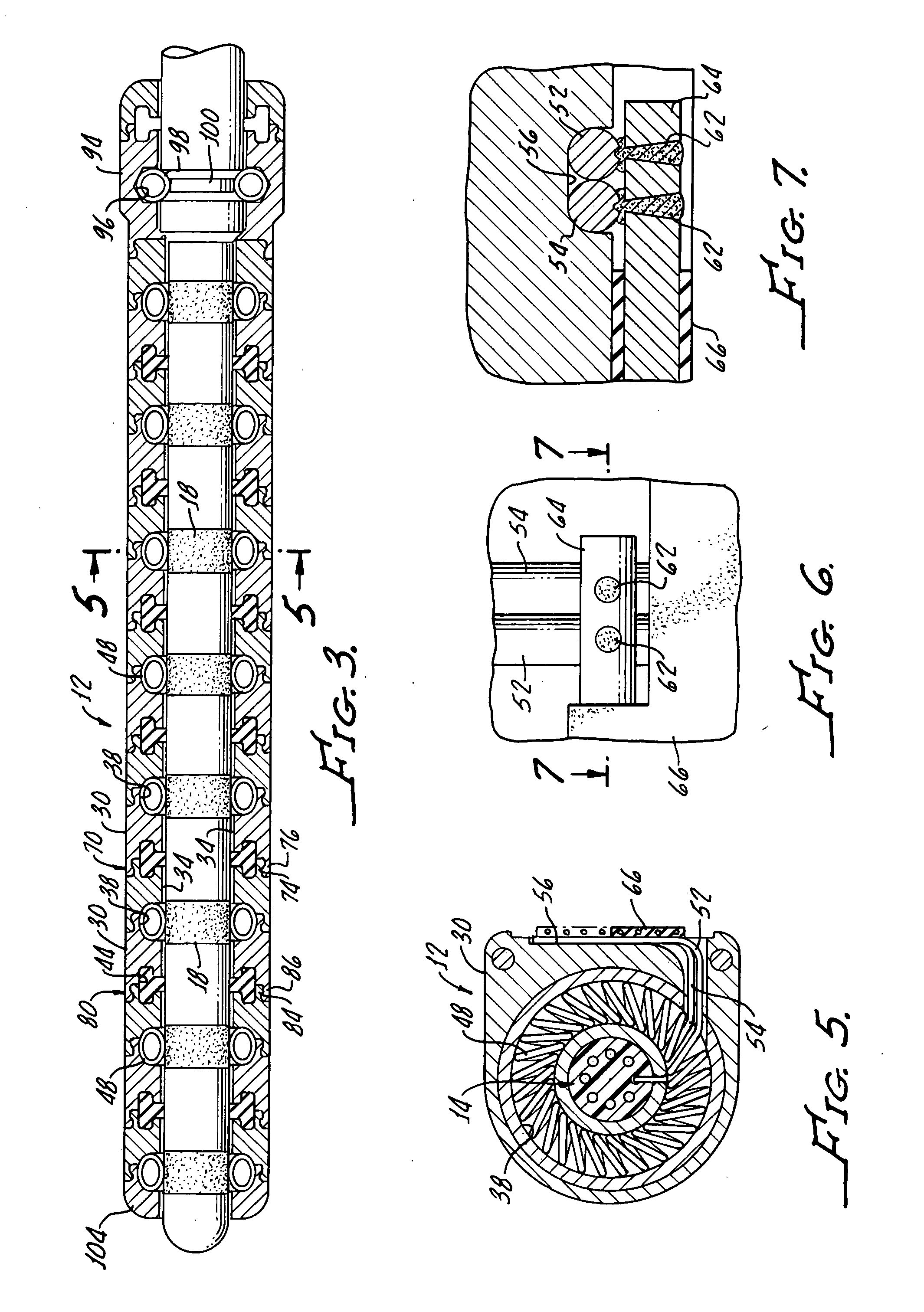

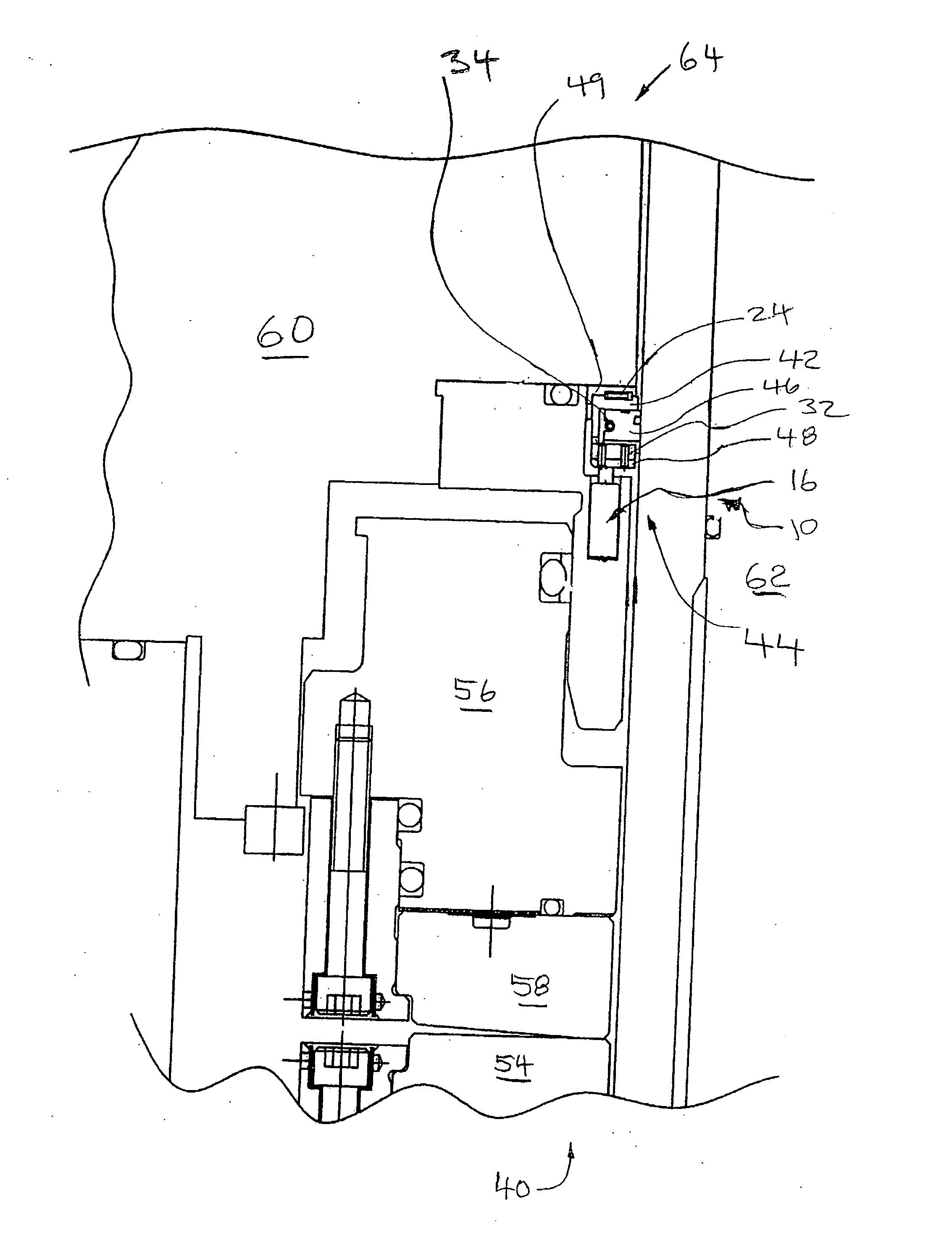

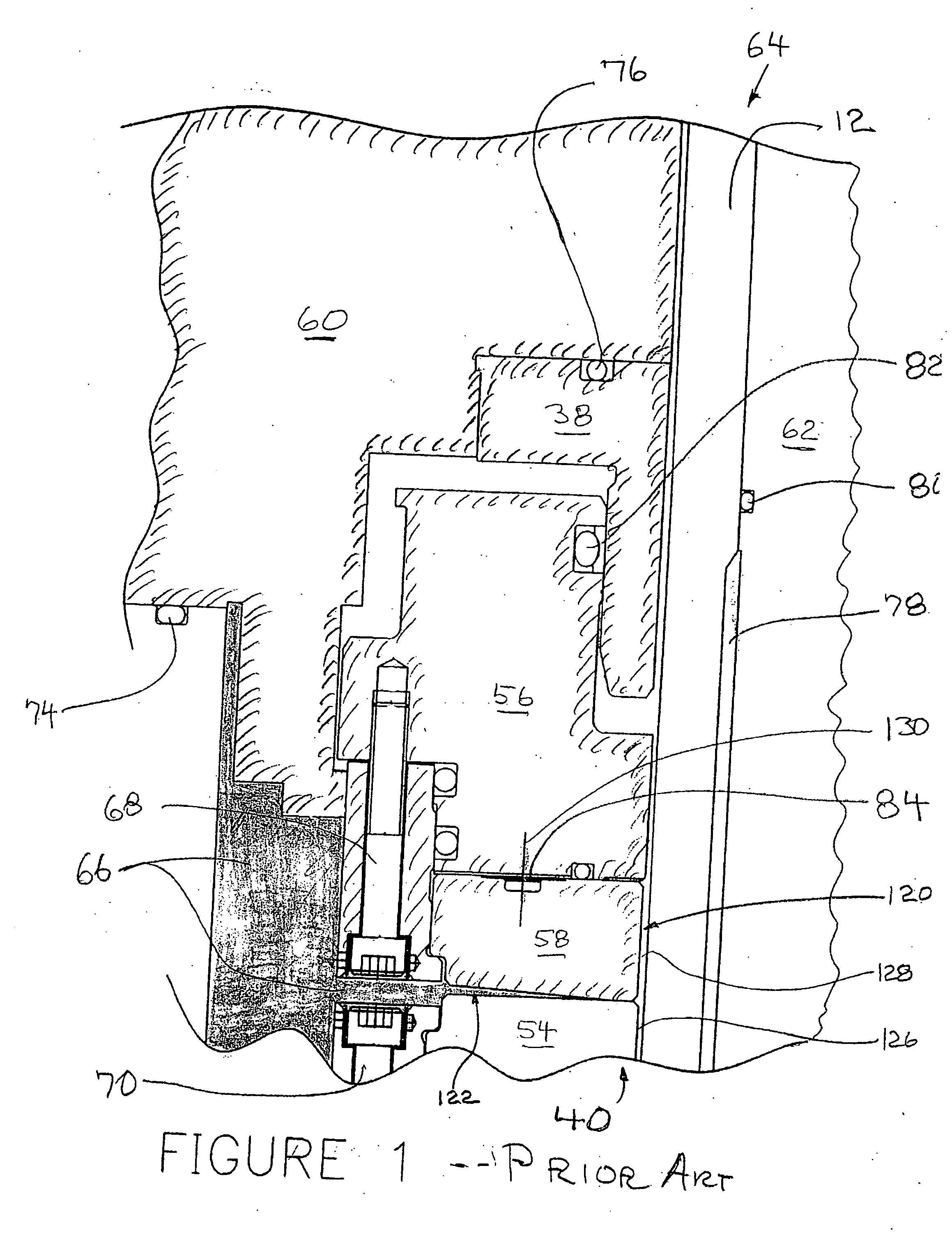

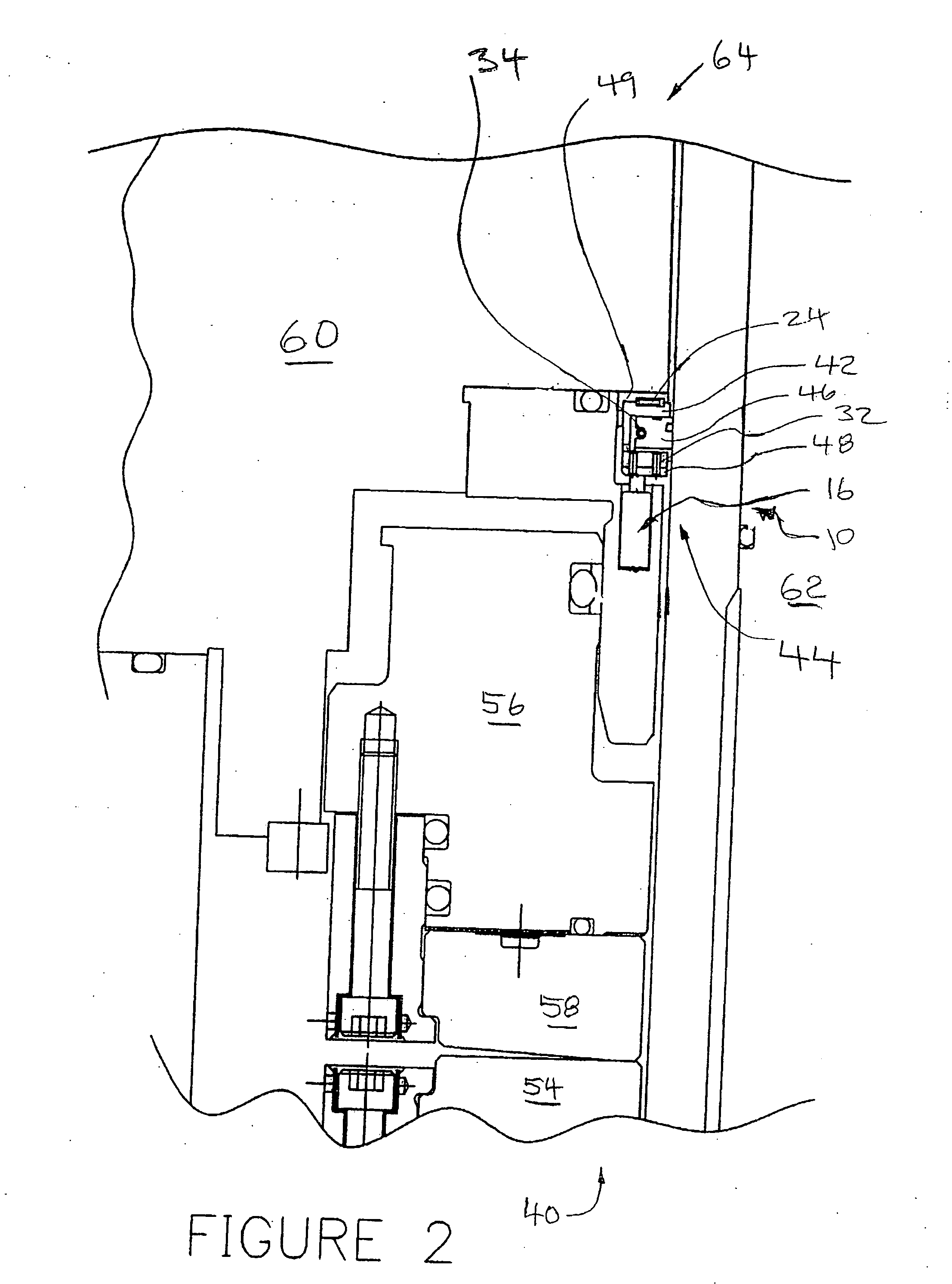

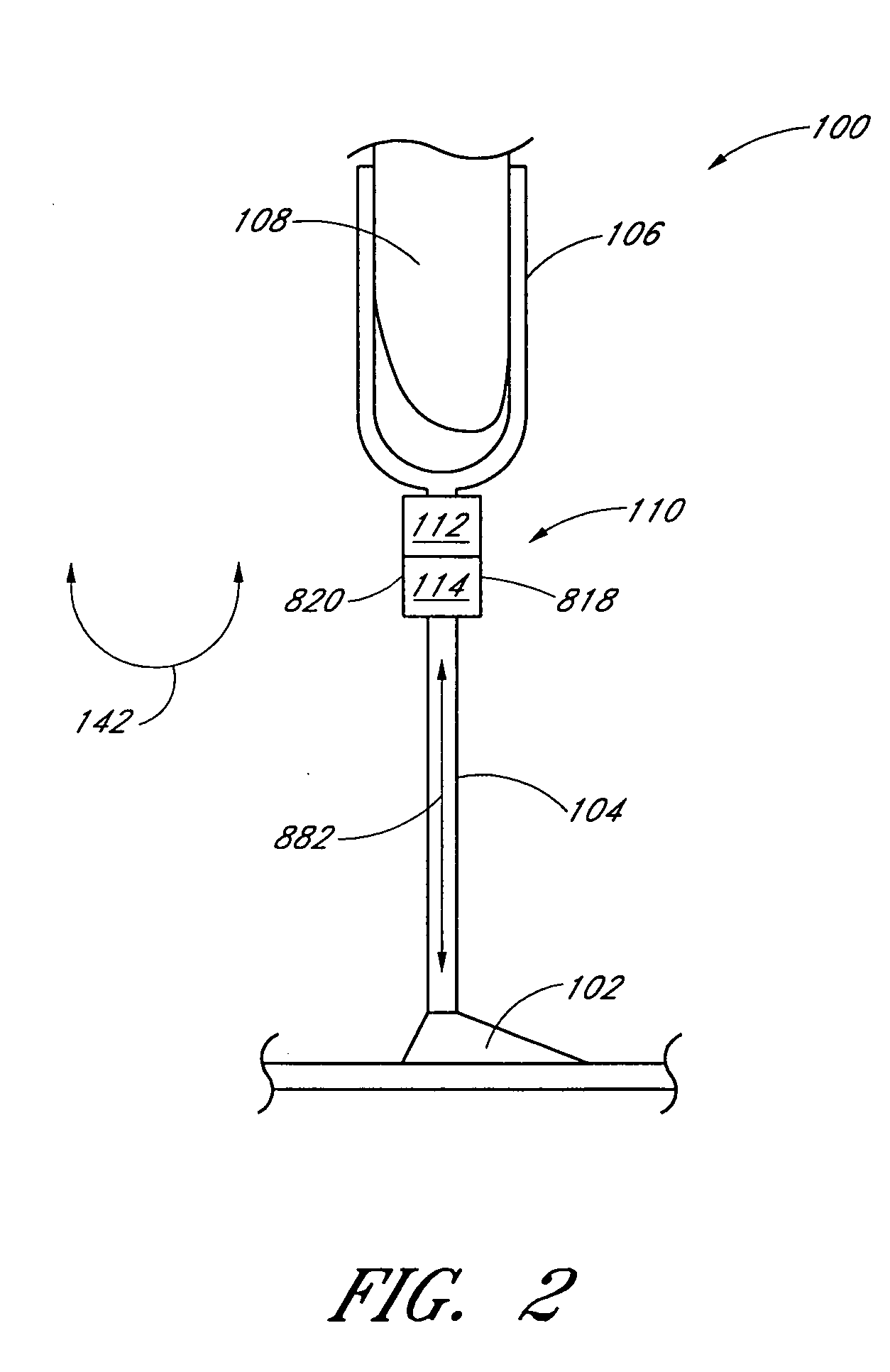

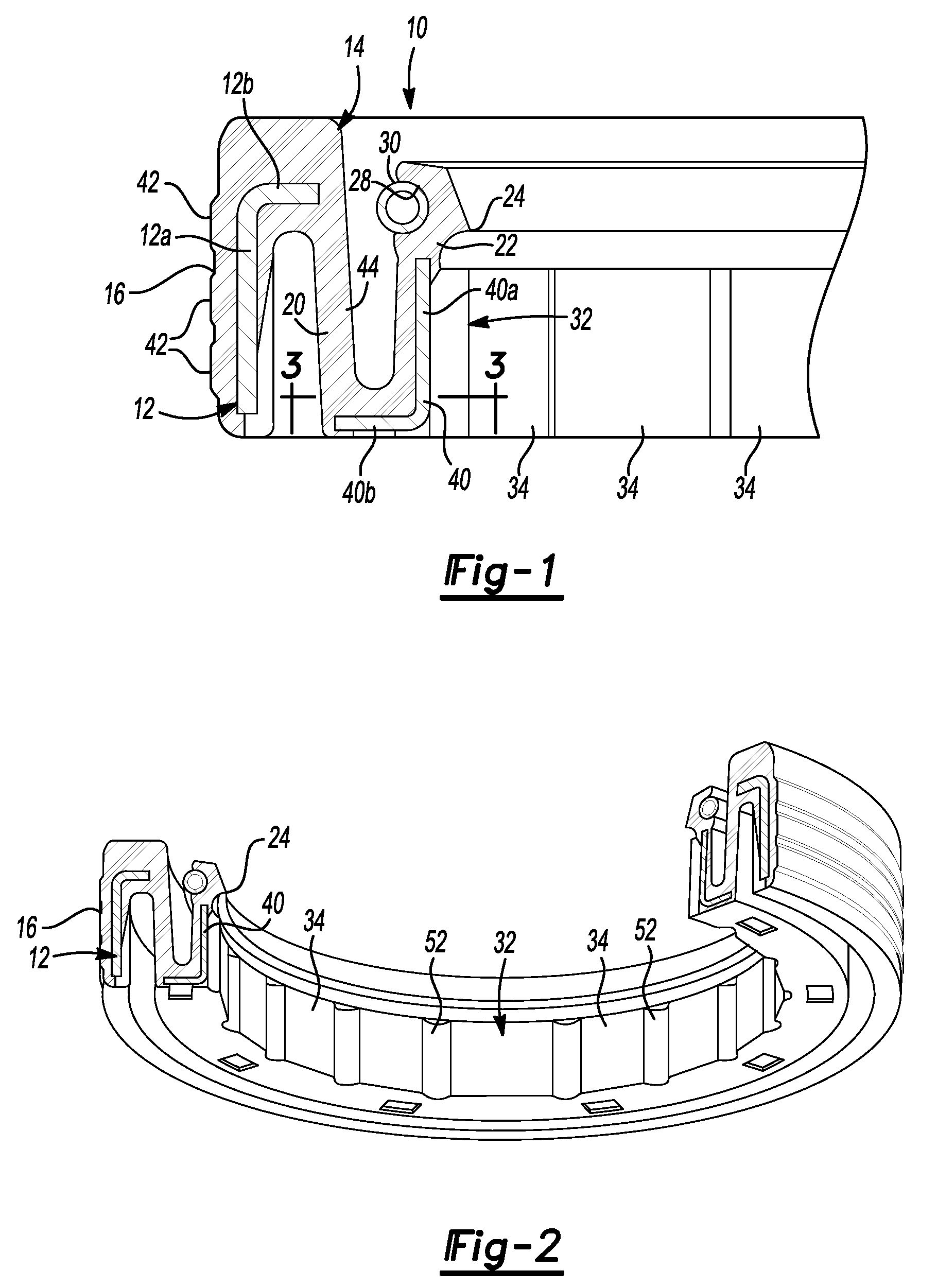

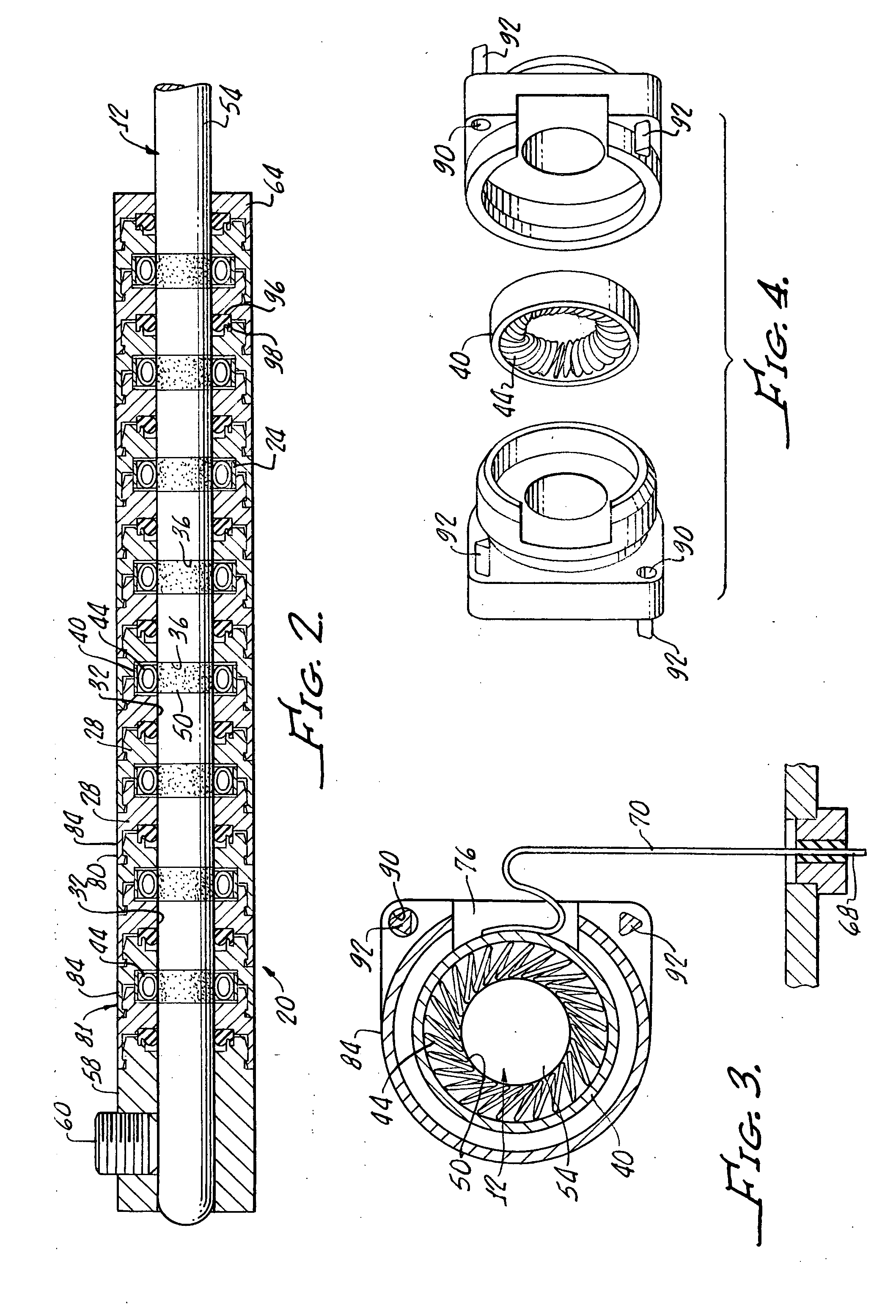

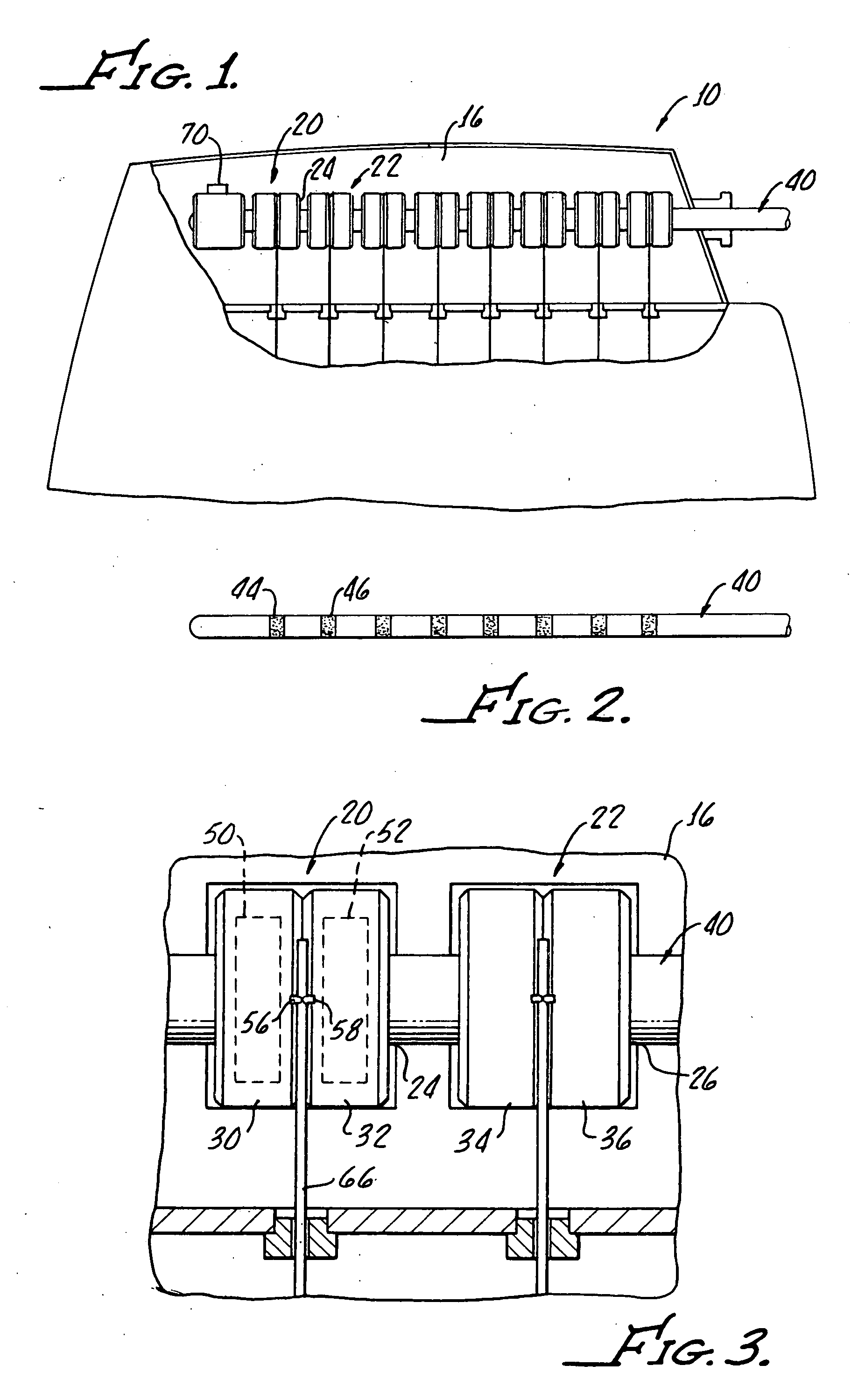

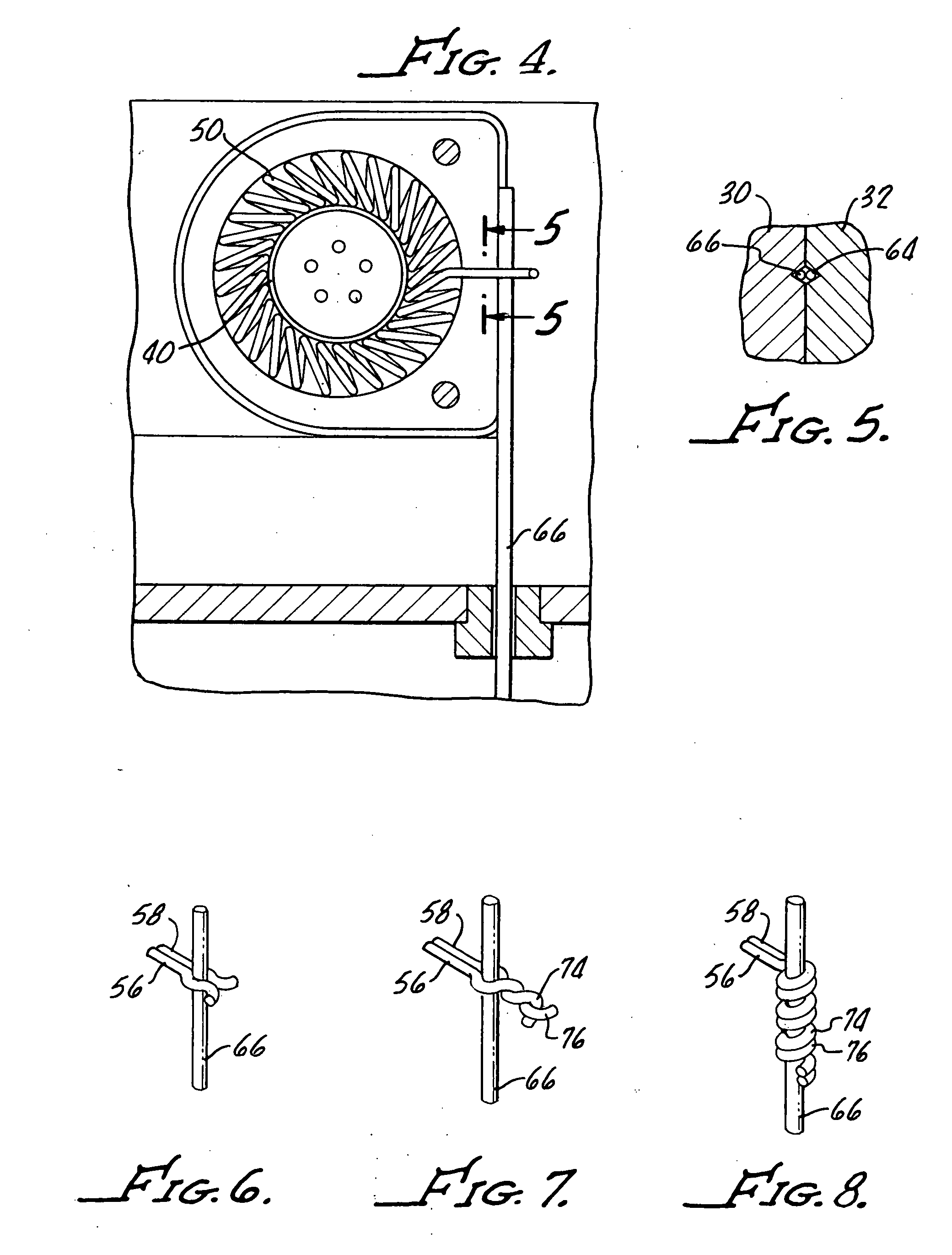

Electrical conductive path for a medical electronics device

ActiveUS7195523B2Reliable contactLow costElectrotherapyCoupling contact membersEngineeringGarter spring

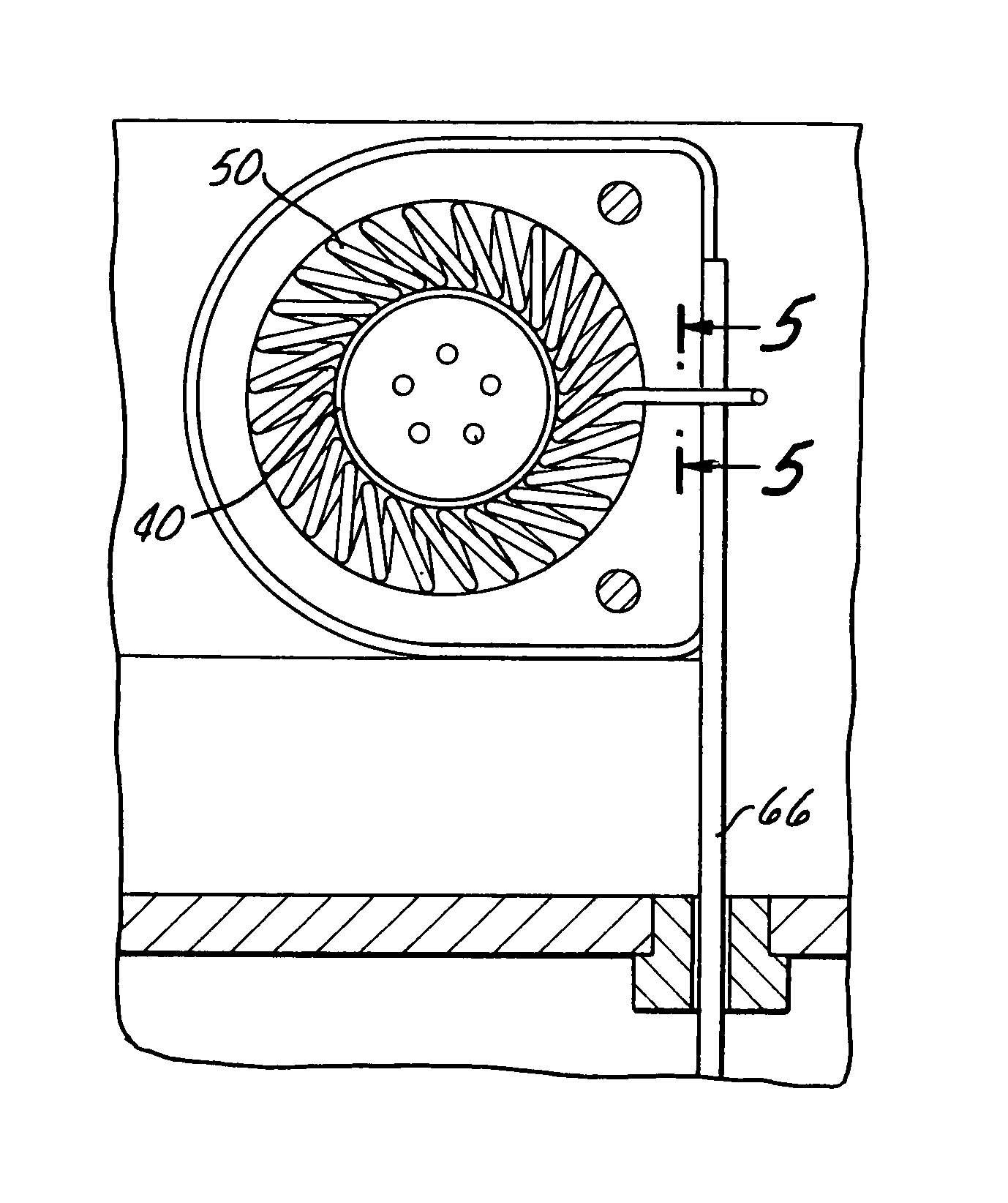

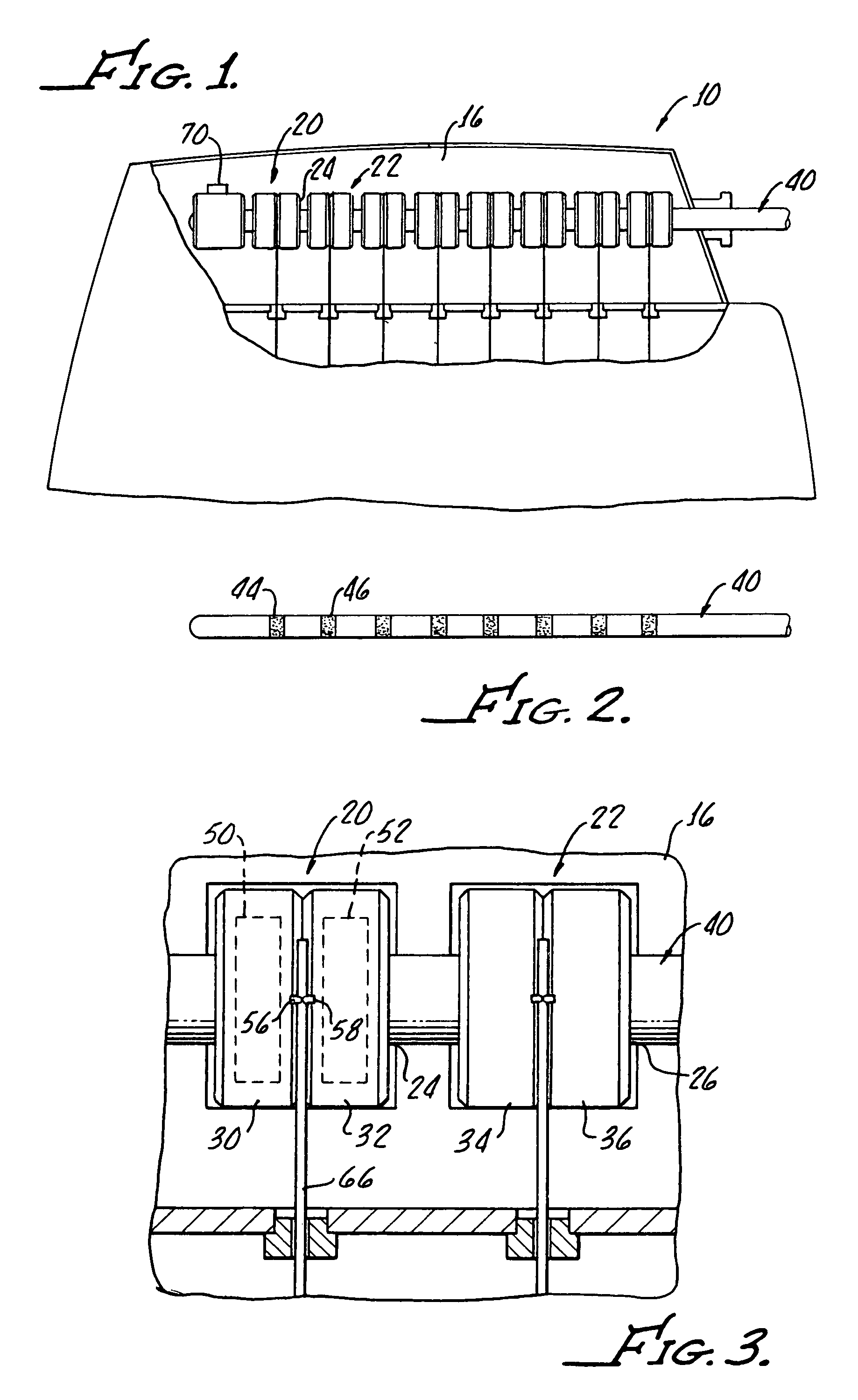

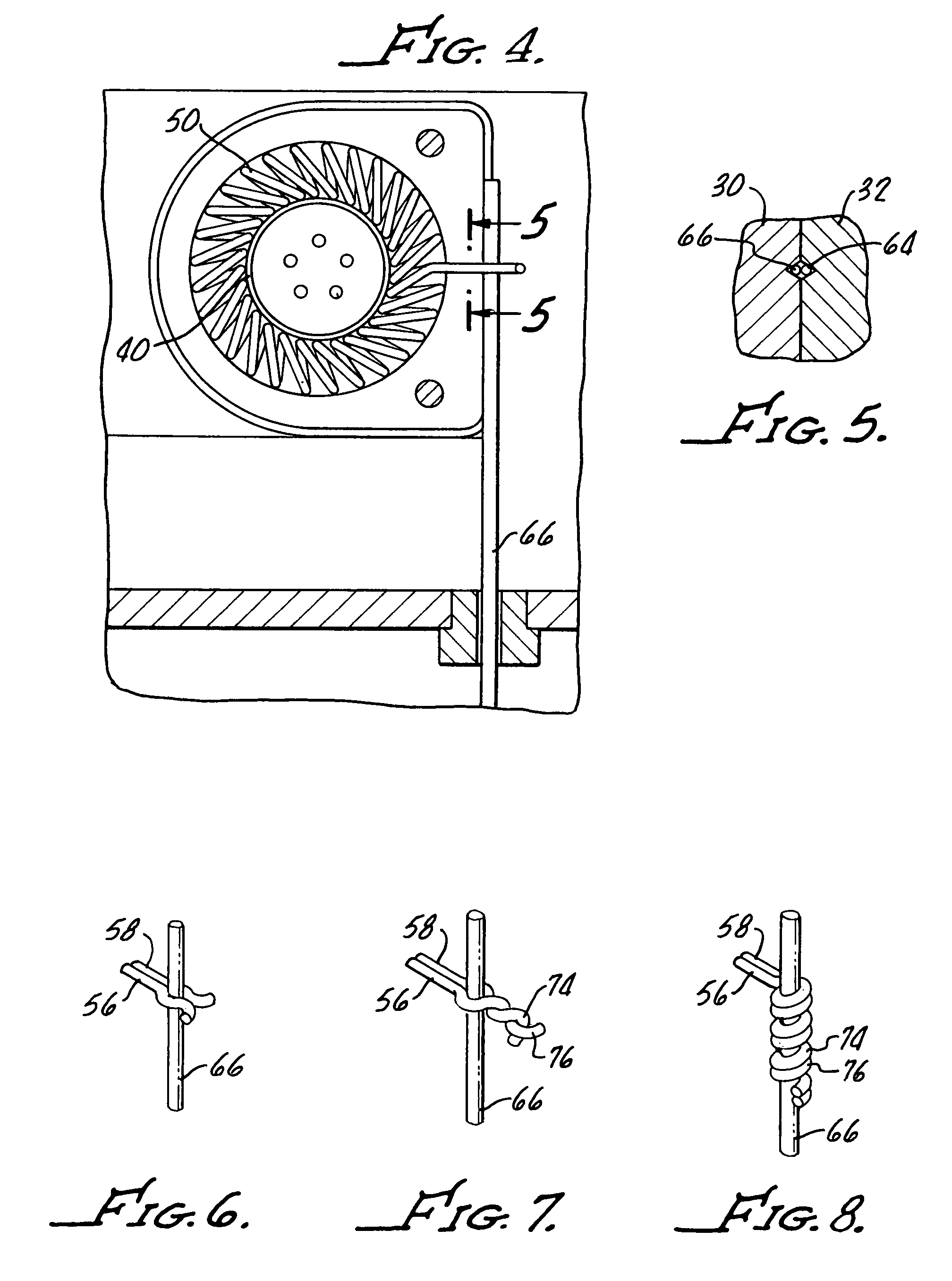

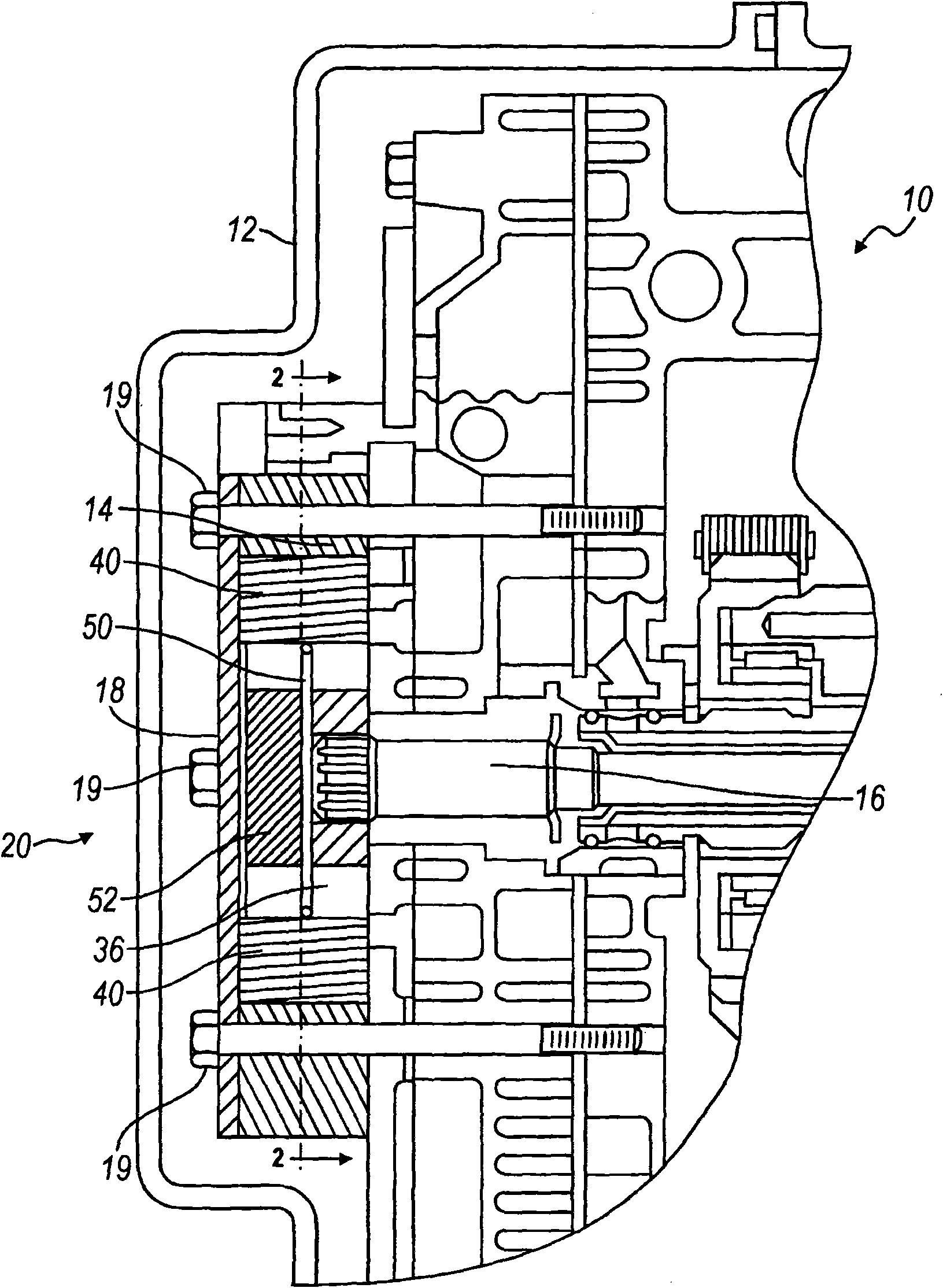

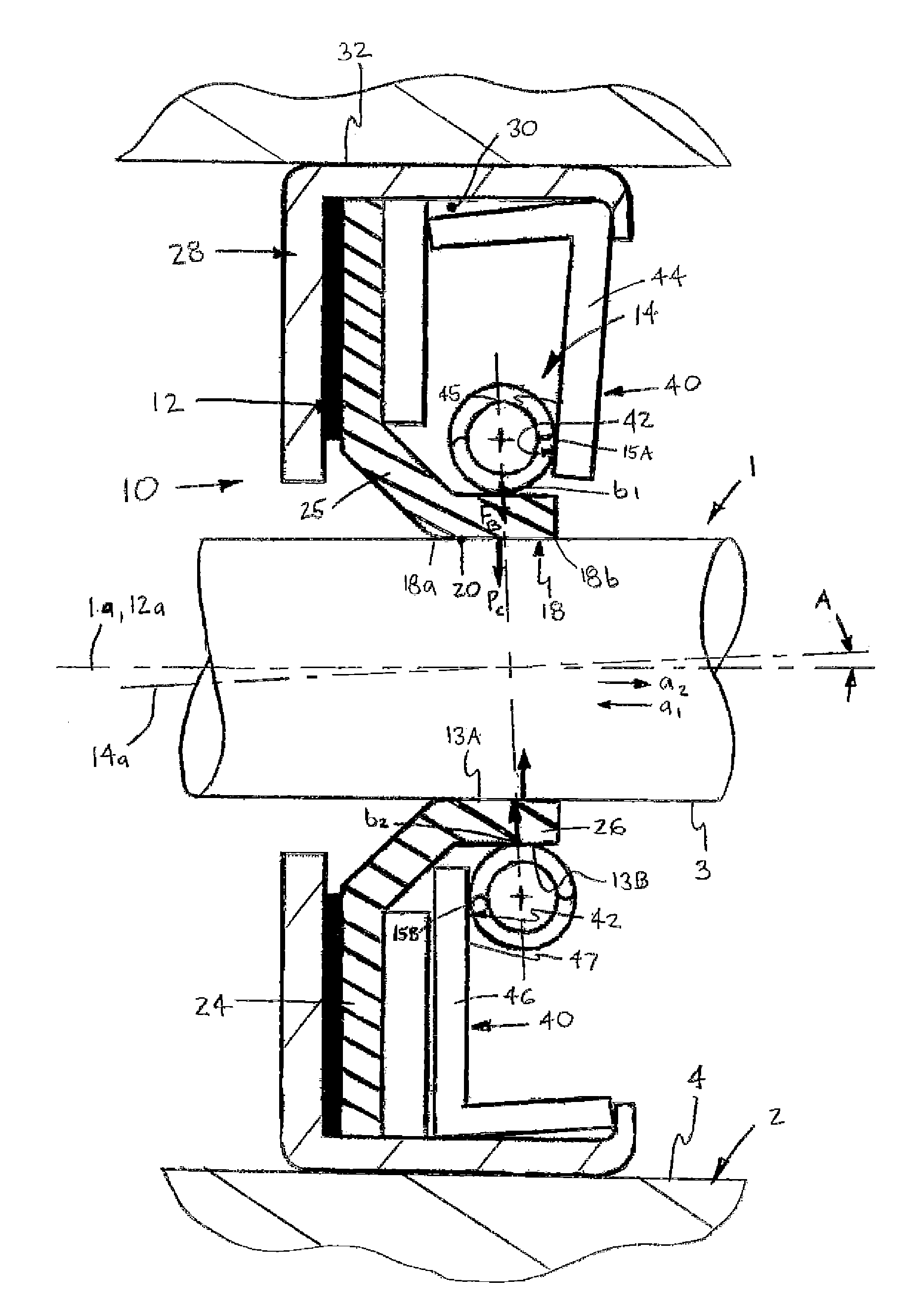

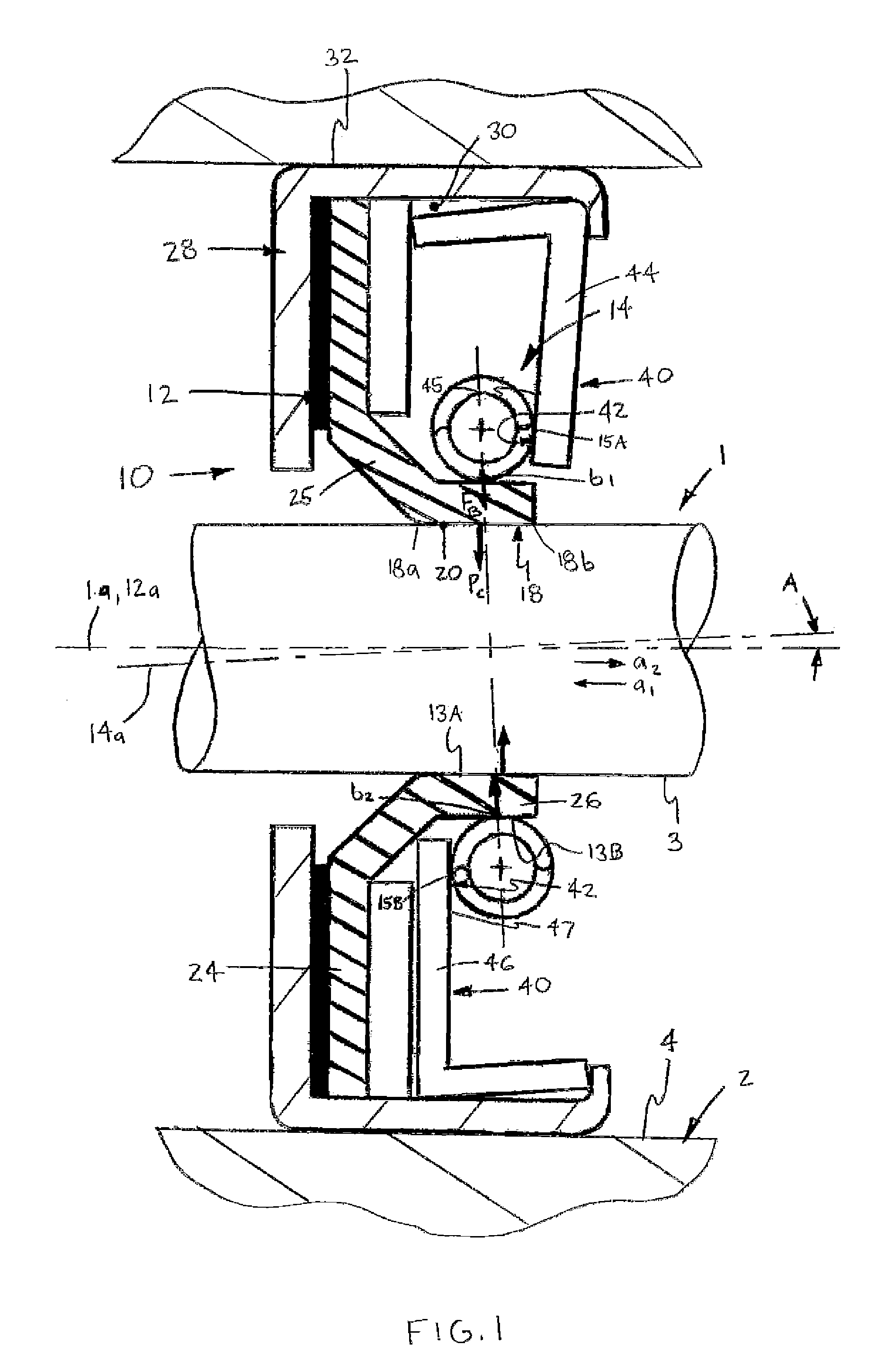

An electrical conductive path for medical electronic device generally includes a plurality of stackable molded non-conductive housing with each housing having a bore therethrough alignable with adjacent housing bores. The adjacent housings and define any combination when stacked, spaced apart slots for receiving a plurality of electrically conductive spring rings. A plurality of electrically conducting garter springs are disposed within corresponding spring rings and a cable is provided including wires attached to corresponding spring rings.

Owner:BAL SEAL ENG CO INC

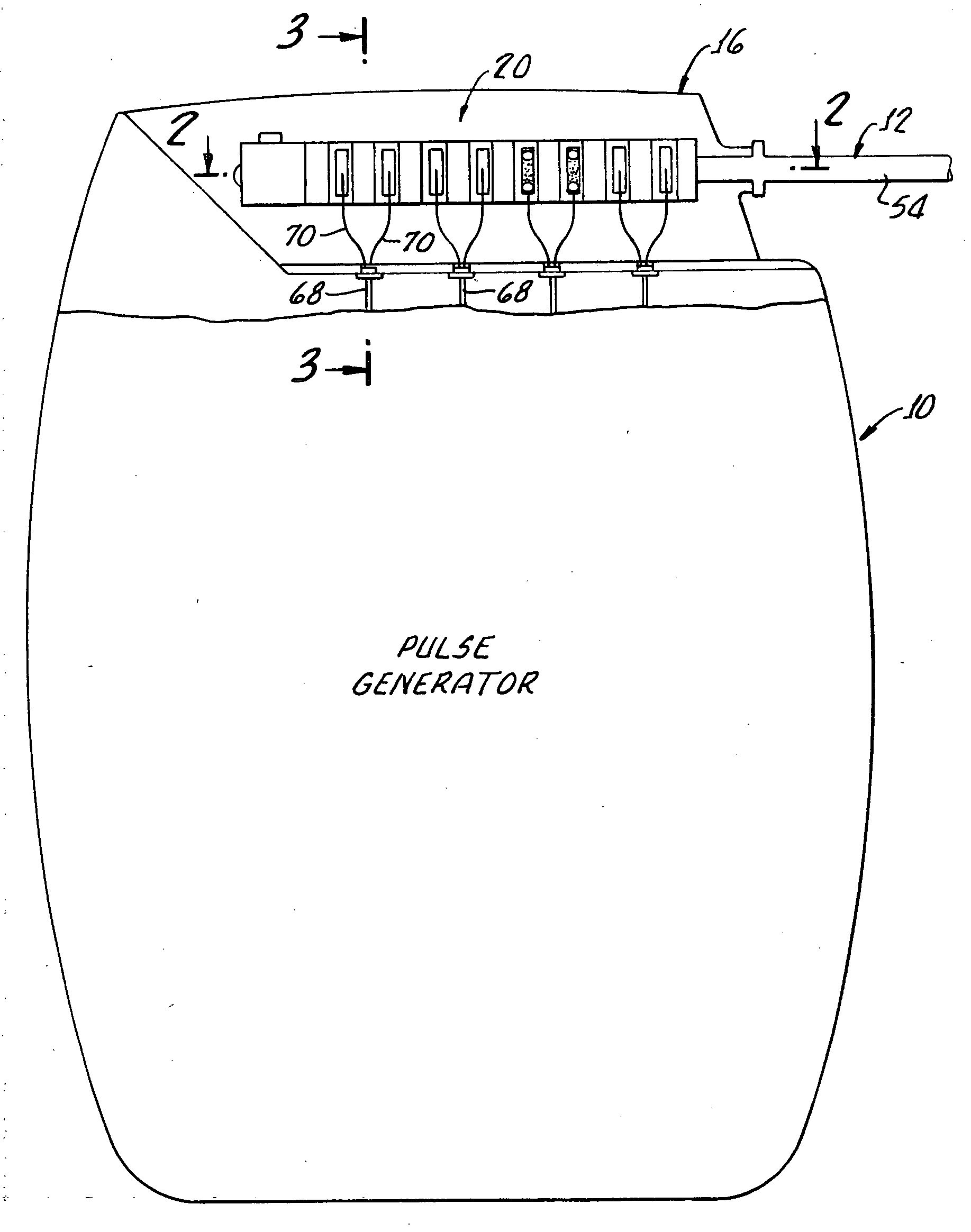

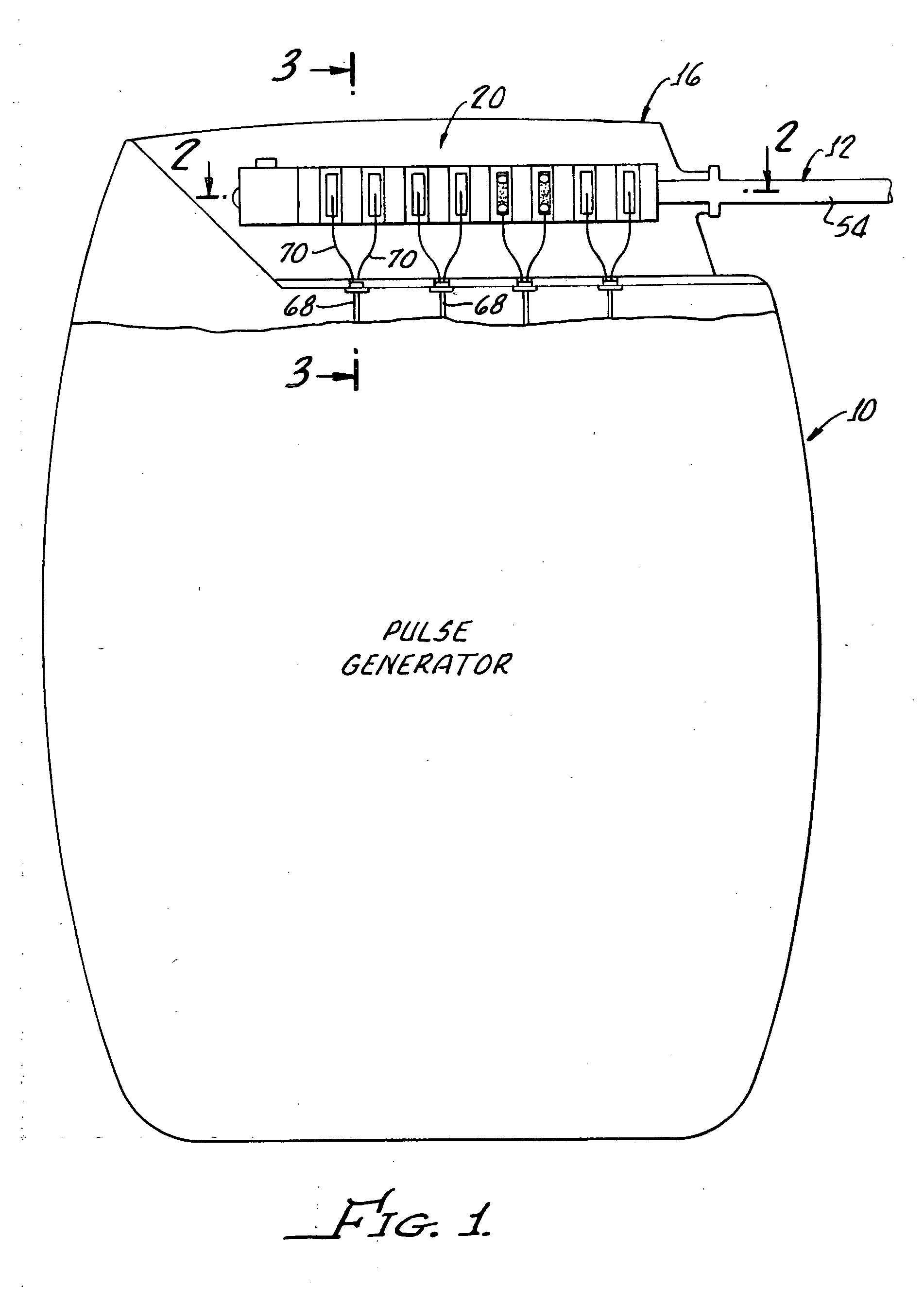

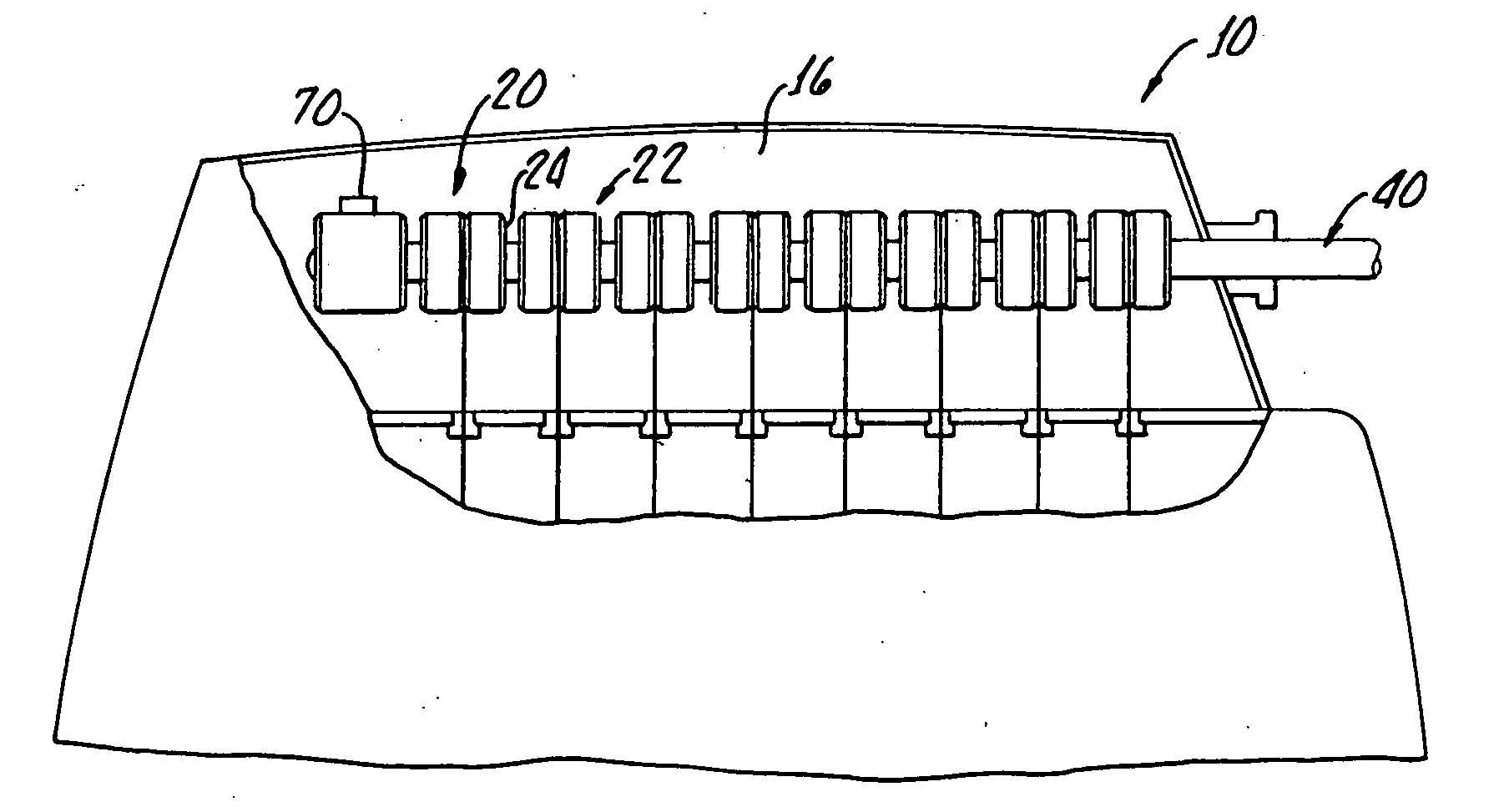

Stackable assembly for direct connection between a pulse generator and a human body

A stackable electrical connector assembly includes a plurality of contact housings with each housings having a bore therethrough alignable with adjacent housing bores. The adjacent housings define, in combination, spaced apart radial spring grooves. A plurality of electrically conducting garter springs are disposed in corresponding spring grooves with each spring including a lead extending to an exterior of adjacent housings. A cable having a plurality of wires is provided with each wire attached to a corresponding lead. The housings are modular enabling the contacts to provide a different number of terminal connections.

Owner:BAL SEAL ENG CO INC

Stackable assembly for direct connection between a pulse generator and a human body

A stackable electrical connector assembly includes a plurality of contact housings with each housings having a bore therethrough alignable with adjacent housing bores. The adjacent housings define, in combination, spaced apart radial spring grooves. A plurality of electrically conducting garter springs are disposed in corresponding spring grooves with each spring including a lead extending to an exterior of adjacent housings. A cable having a plurality of wires is provided with each wire attached to a corresponding lead. The housings are modular enabling the contacts to provide a different number of terminal connections.

Owner:BAL SEAL ENG CO INC

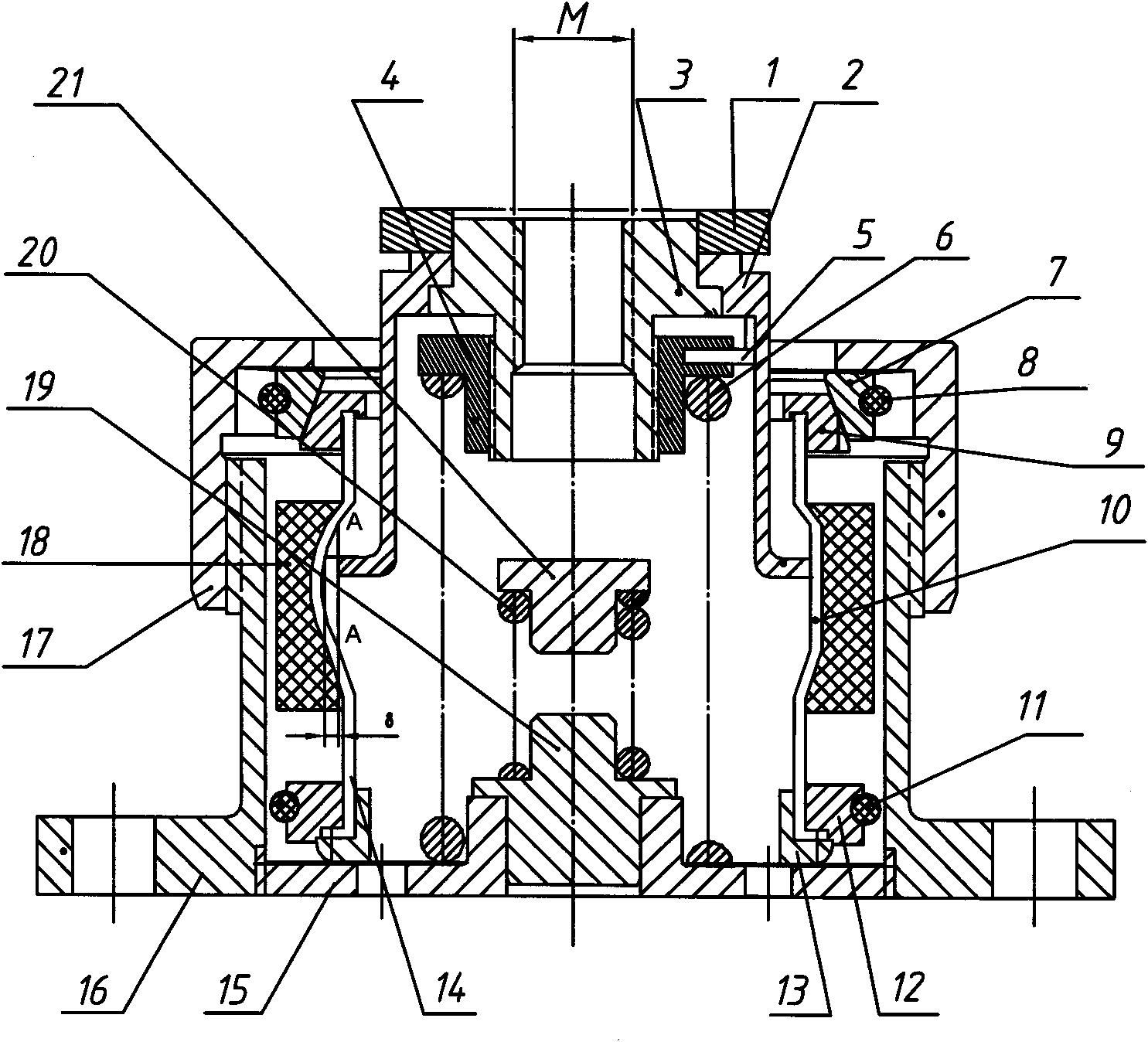

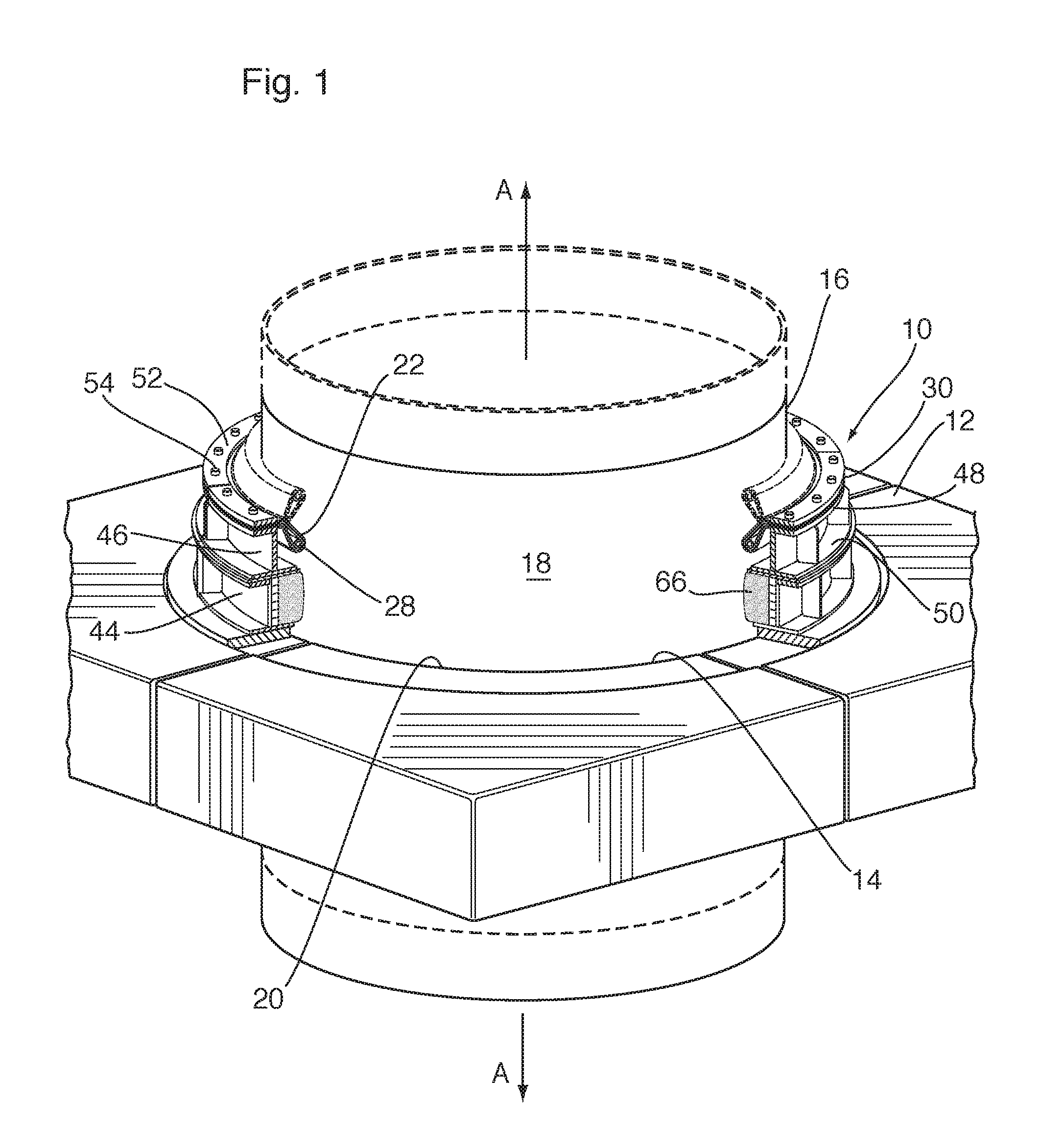

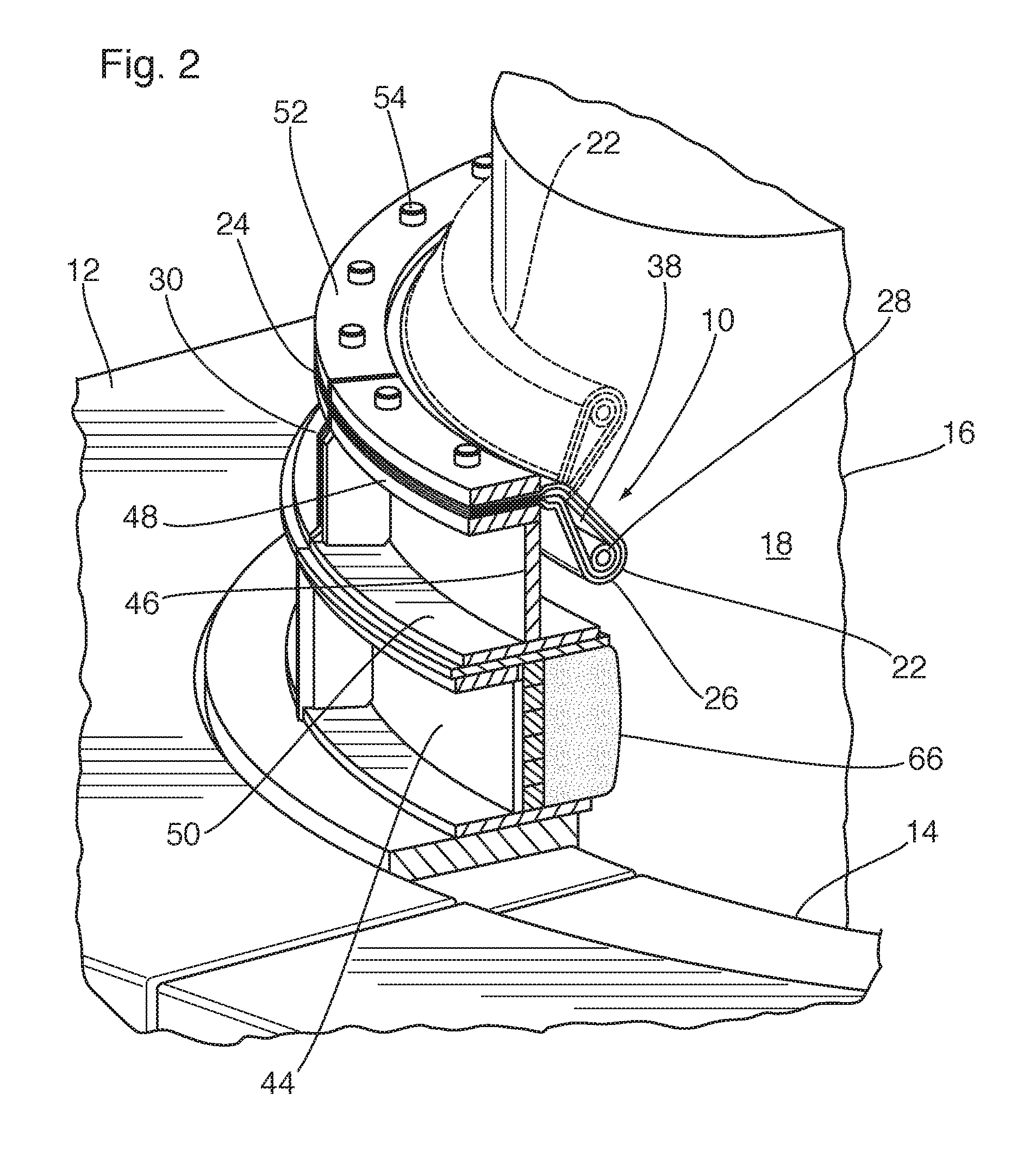

Shutdown seal for reactor coolant pump

InactiveUS20070140877A1Big impactMinimal effectSpecific fluid pumpsEngine sealsCoolant flowProcess failure

A thermally actuated shutdown seal provides a shutdown seal usable in a pump having a primary seal assembly positioned circumferentially about a rotating shaft for separating a region of high pressure coolant fluid from the shaft. The shutdown seal includes a two-piece interlocked housing which encompasses carbon graphite ring segments positioned circumferentially about the shaft, a garter spring and a series of compression springs. The replaceable insert with machined recess contains the shutdown seal assembly and is biased axially with a wave spring and held with the annular recess by a closure ring. The seal is designed with coolant fluid flow directly in contact with such ring segments and specially designed paths around the ring segments during normal pump operation. The seal requires a thermally actuated means for moving the two-piece interlocked housing axially into a blocking position within the coolant flow path to shutdown and minimize fluid flow bypassing the ring segments and between the ring segments and the pump shaft, upon occurrence of a process failure in the facility served by the pump and consequent temperature rise of the fluid being pumped.

Owner:STEIN SEAL +1

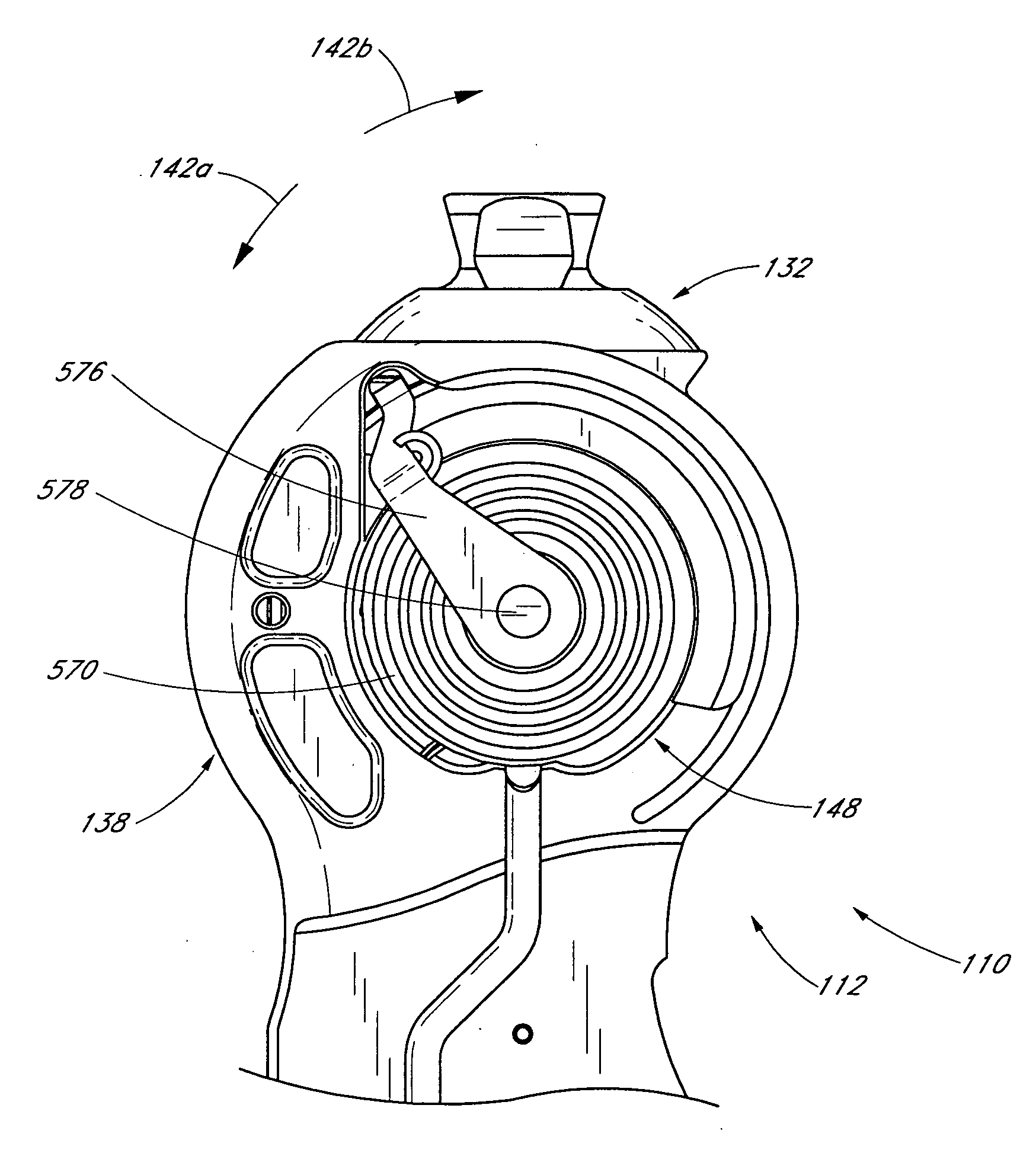

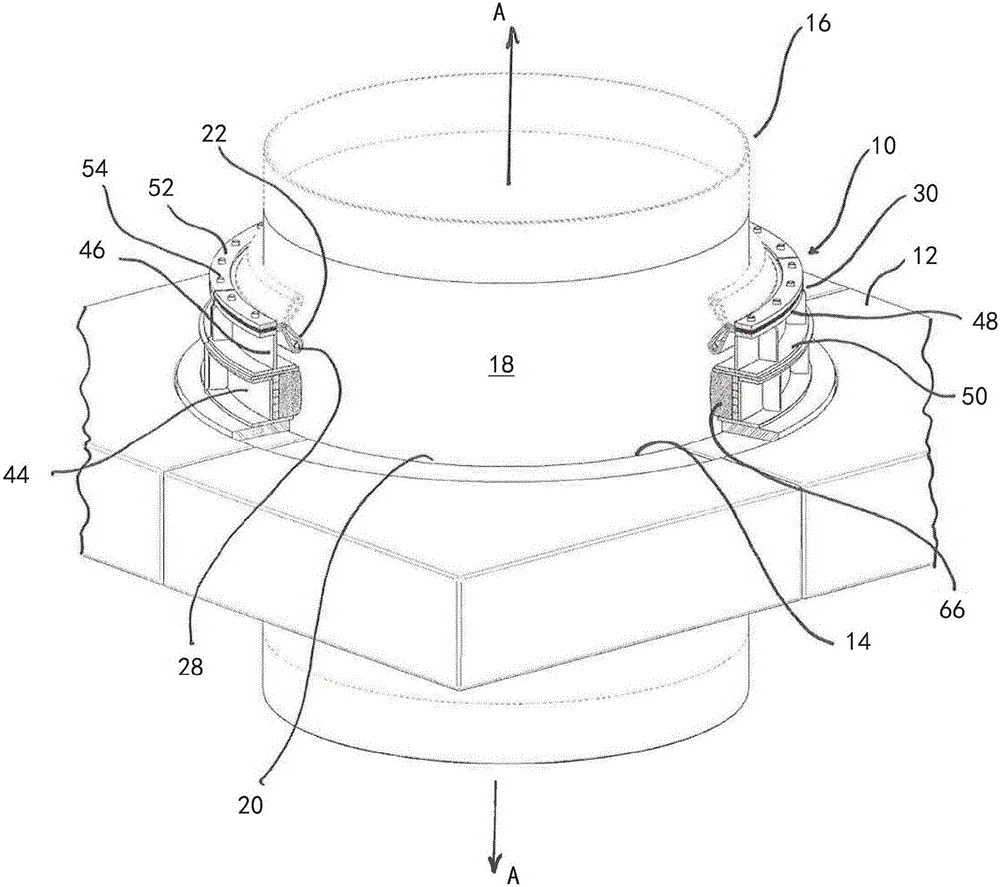

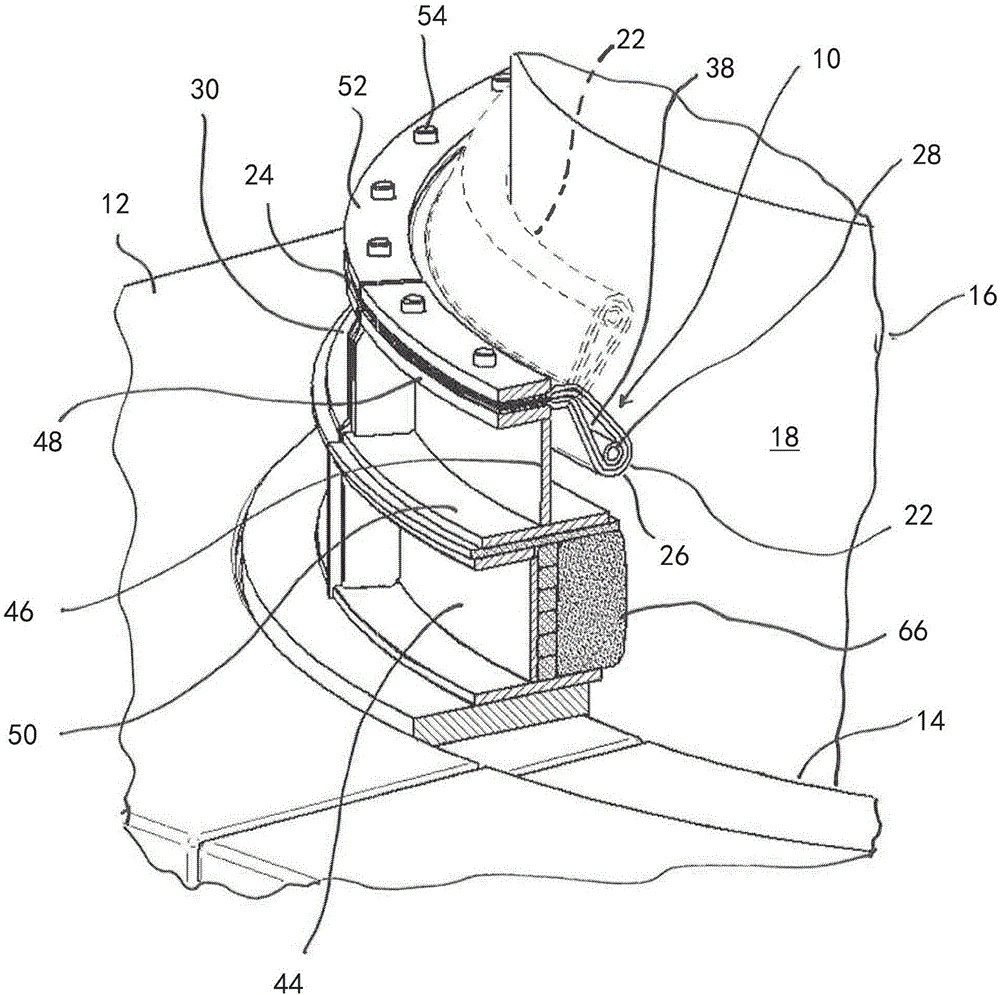

Dynamic seals for a prosthetic knee

The invention in some embodiments relates to a dynamic seal for a prosthetic knee. The dynamic seal in one embodiment is utilized to seal a magnetorheological fluid comprising a liquid and solid particles within a chamber of the knee. The dynamic seal embodiments are specially configured with a pre-loaded tensioned garter spring which has a coil spacing that is at least as large as the size of the particles or maximum size of the particles in the magnetorheological fluid. Desirably, this allows the magnetorheological fluid particles to flow in and out of the dynamic seal without clogging the seal and advantageously provides for a reliable dynamic seal.

Owner:OSSUR HF

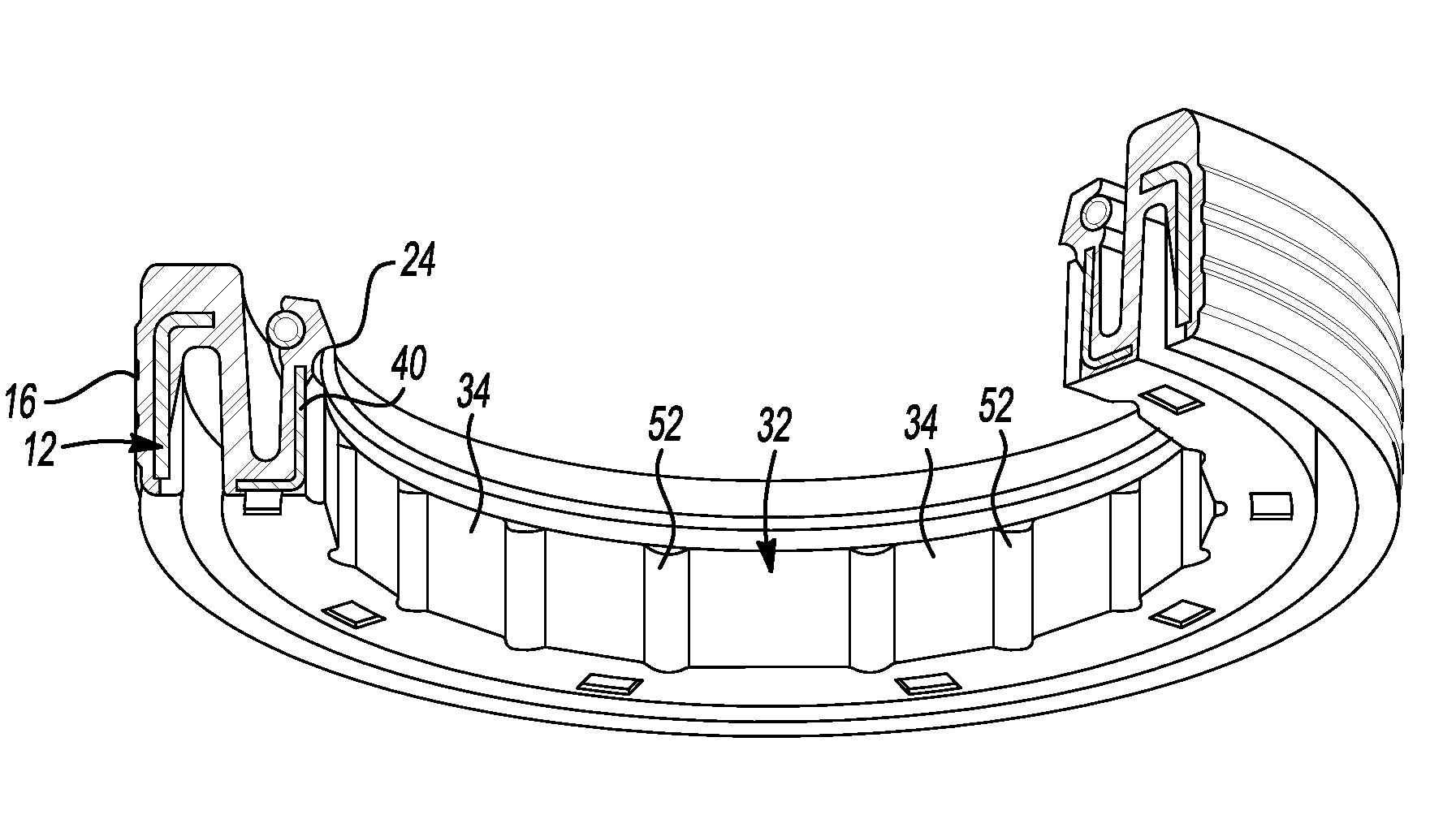

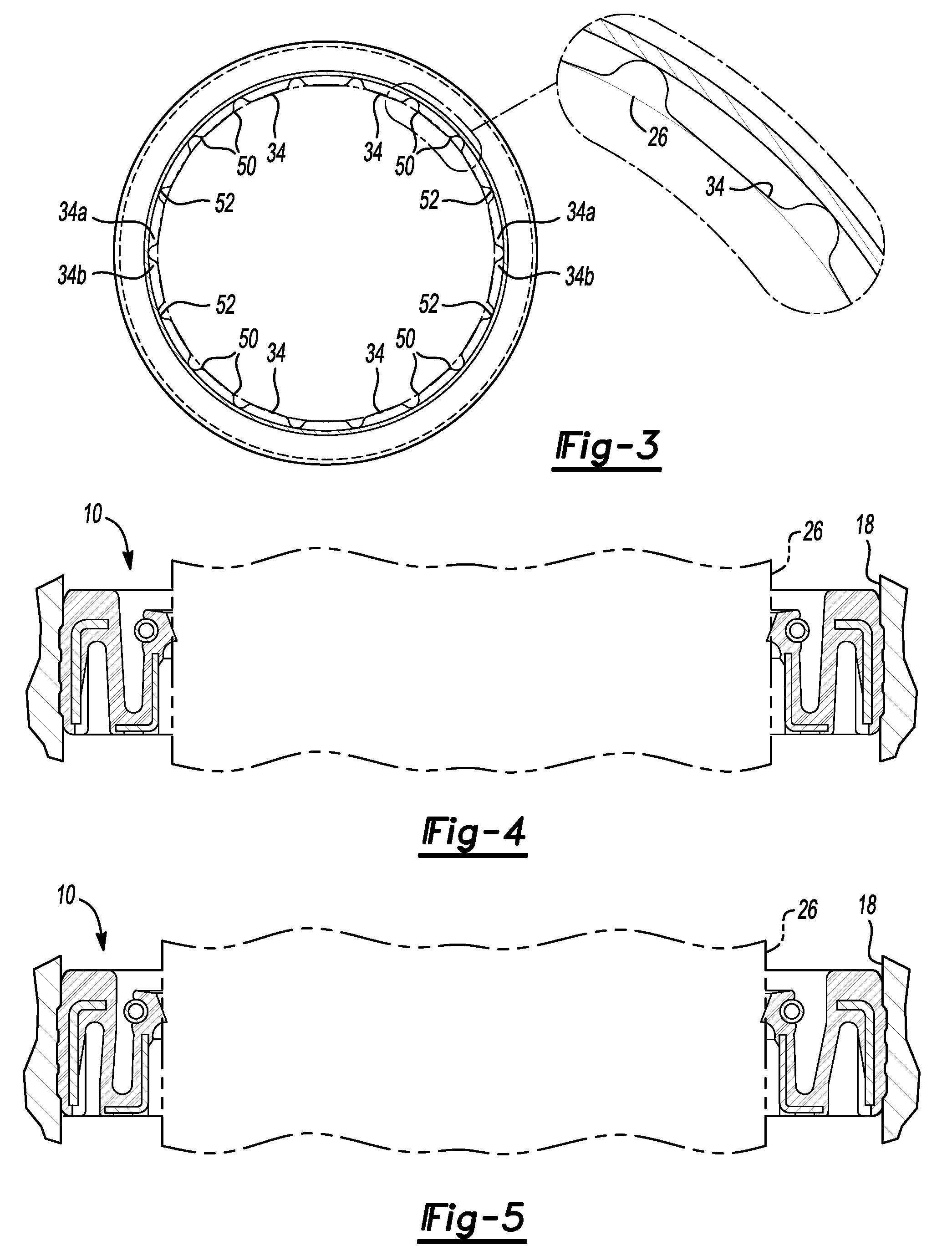

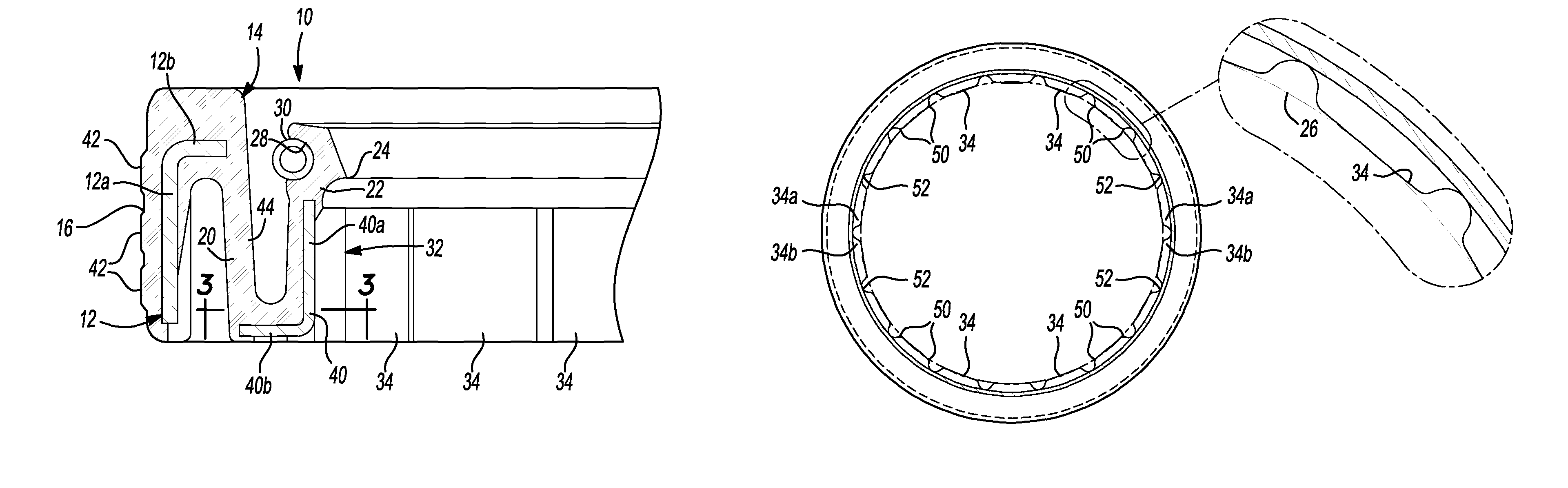

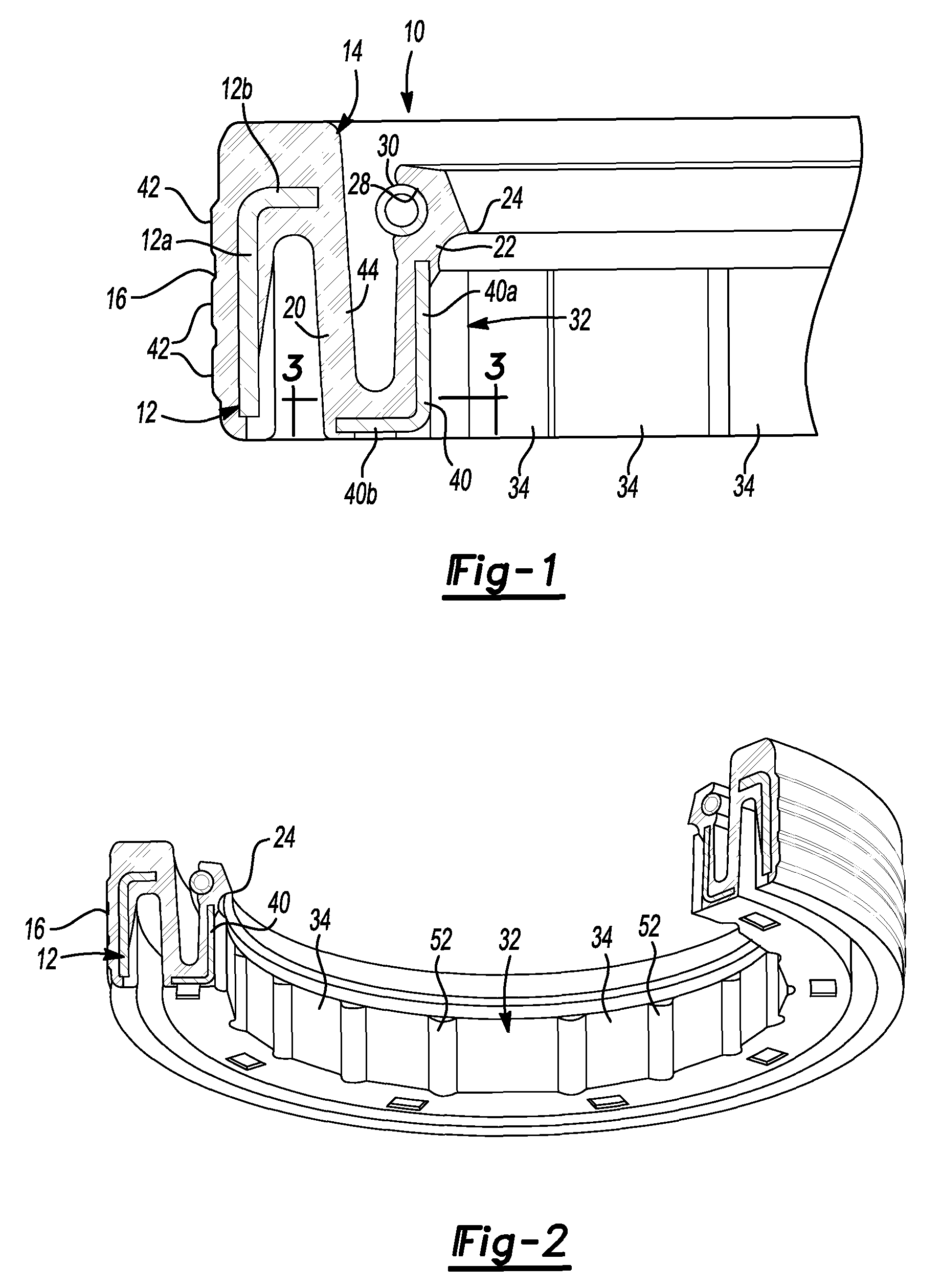

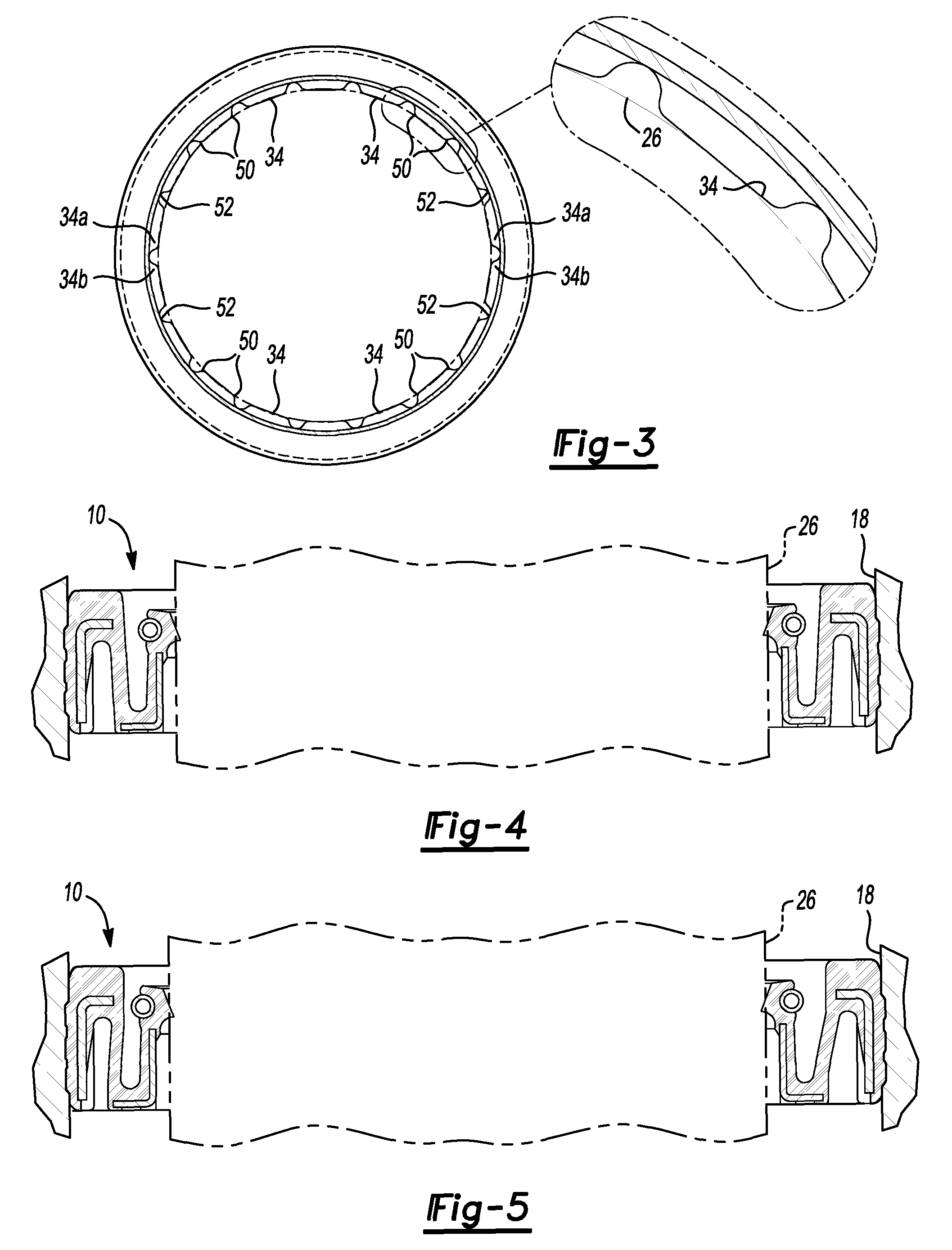

Radial Shaft Seal with Large Radial Offset Accommodation

A radial shaft seal is provided for accommodating large radial offset of the shaft relative to a housing. The seal includes an annular retainer insert provided for engaging the seal to a fixed housing. An annular elastomeric seal body is molded to the retainer insert and includes flexible axially extending portion extending from an inner surface of the retainer insert. A seal portion extends axially from a radially inward end of the radially inwardly extending portion and includes a seal lip with a garter spring disposed radially outward of the sealing lip and an elastomeric bearing surface disposed adjacent to the sealing lip. The bearing surface includes a plurality of raised pads adapted to engage the shaft. The pads each include a rounded edge on lateral sides thereof for encouraging the creation of a lubricating film between the pads and shaft. The pads are lubricated by direct exposure to the fluid being sealed.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

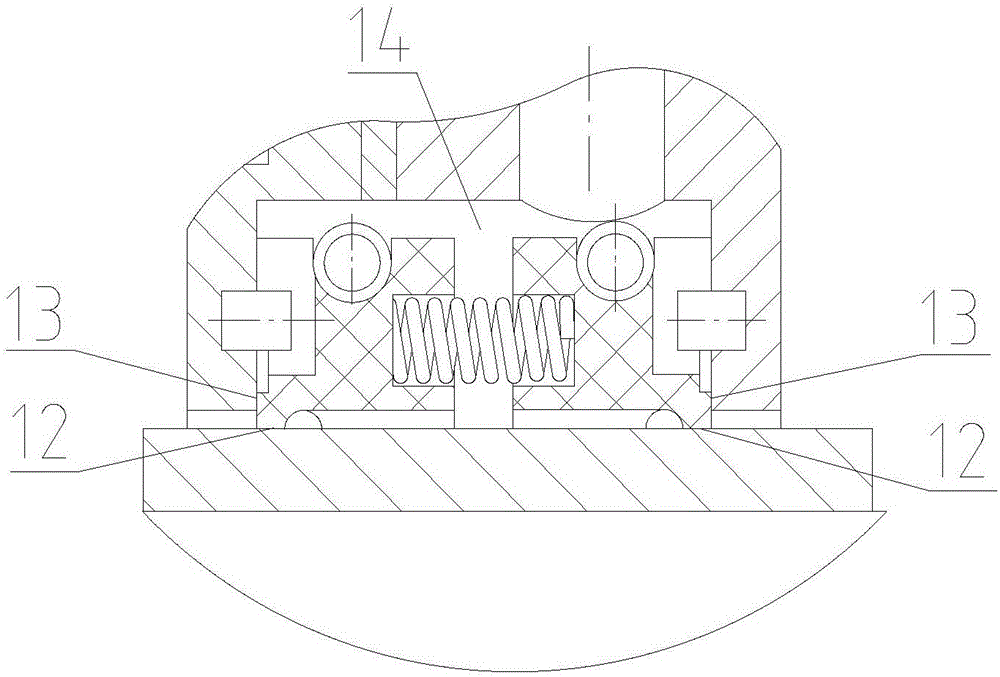

Vibration isolation buffer for resisting strong impact

ActiveCN101865235AImprove buffering effectWon't scatterNon-rotating vibration suppressionInertia effect dampersEngineeringVibration isolation

The invention discloses a vibration isolation buffer for resisting strong impact. In the vibration isolator, a base sleeve is used as a main frame, and the base sleeve is internally provided with a main spring module, a damp buffer spring module and a connecting structure module. A circle of buffer mesh pad is filled between the inner circle of the base sleeve and a straight reed and a bent reed of the damp buffer spring module to form an elastic garter spring. When the buffer is subjected to greater horizontal impact force, the buffer mesh pad can enhance the buffering effect and restrain the straight reed and the bent reed, thereby the straight reed and the bent reed can not separate from a hold-down mechanism to scatter. In addition, a vertical buffer spring is additionally arranged, therefore, when a main spring makes displacement under vertical impact force and contacts the buffer spring, the buffer spring can counteract part of the impact force, and when the impact force disappears, the buffer spring can provide help for the resetting of the main spring.

Owner:南京捷诺环境技术有限公司

Electrical conductive path for a medical electronics device

ActiveUS20060047322A1Dimensionally accurateDimensionally consistentElectrotherapyCoupling contact membersEngineeringGarter spring

An electrical conductive path for medical electronic device generally includes a plurality of stackable molded non-conductive housing with each housing having a bore therethrough alignable with adjacent housing bores. The adjacent housings and define any combination when stacked, spaced apart slots for receiving a plurality of electrically conductive spring rings. A plurality of electrically conducting garter springs are disposed within corresponding spring rings and a cable is provided including wires attached to corresponding spring rings.

Owner:BAL SEAL ENG CO INC

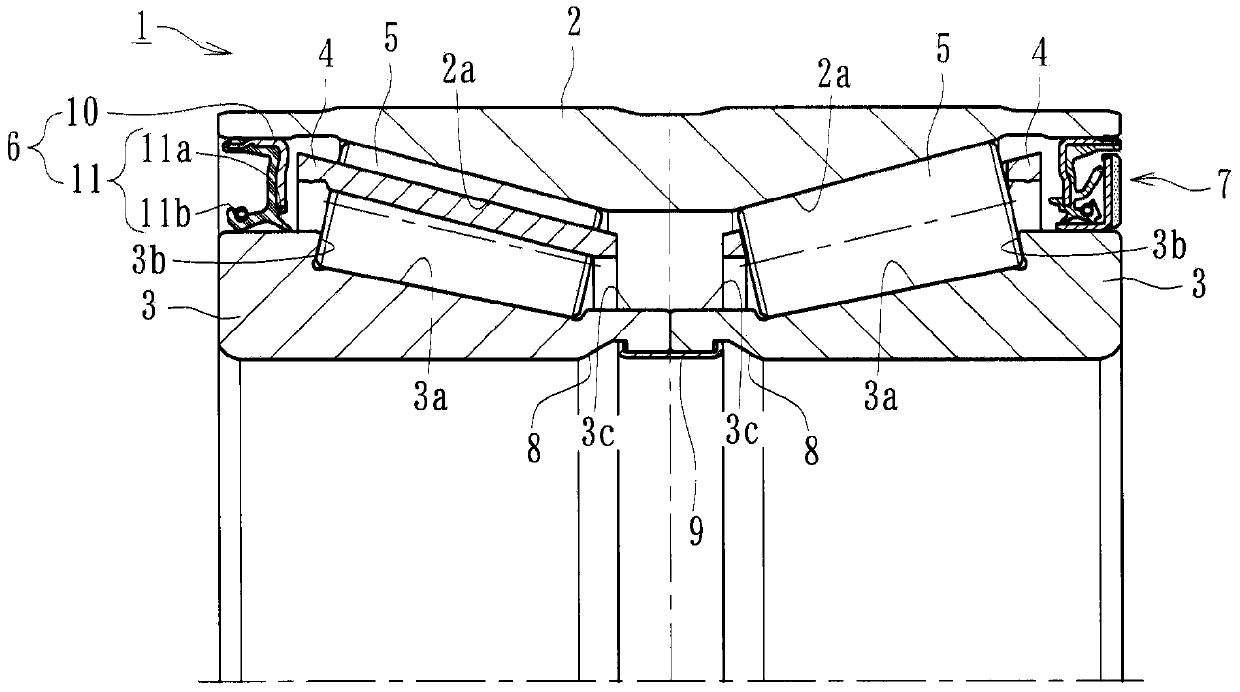

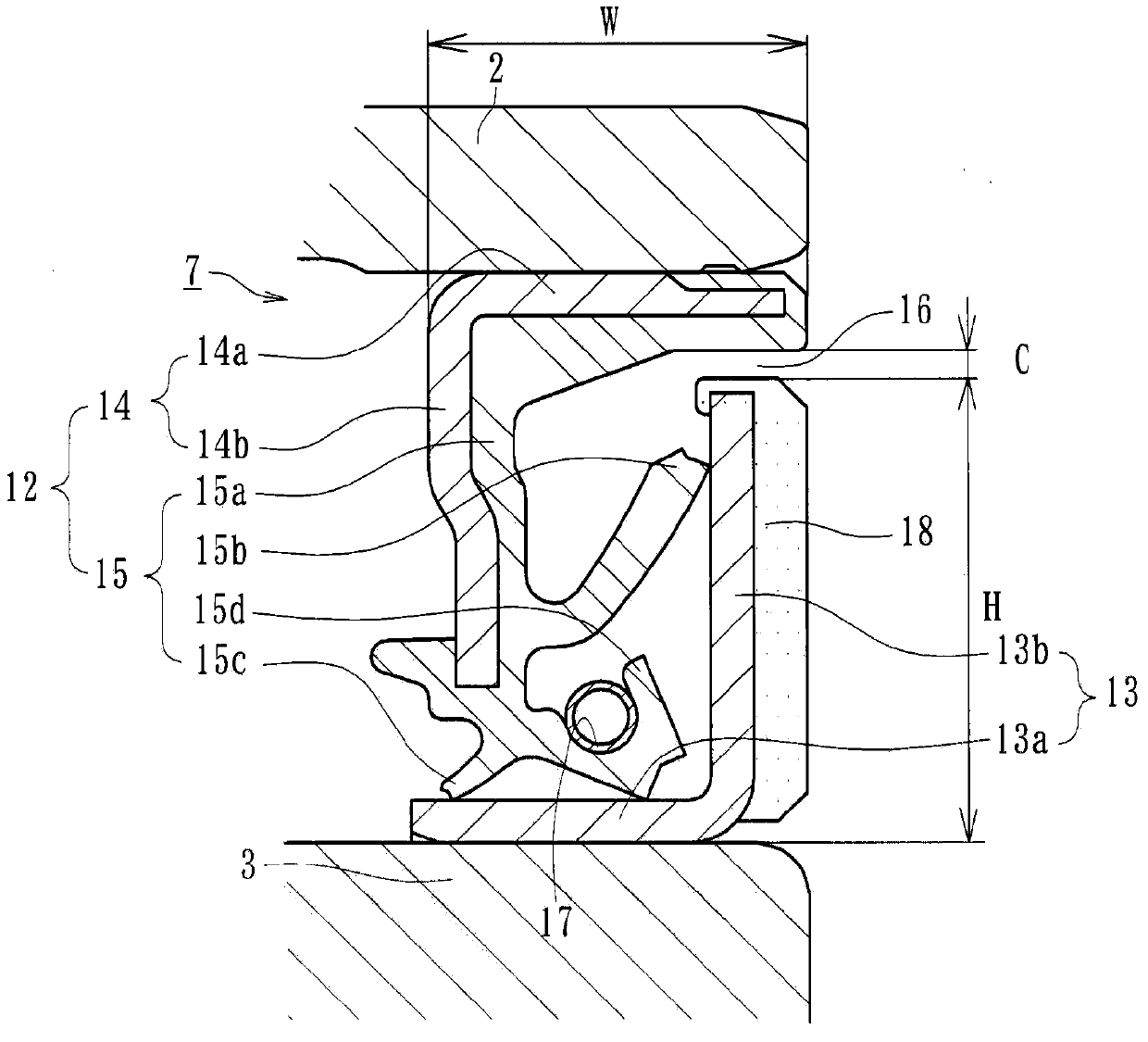

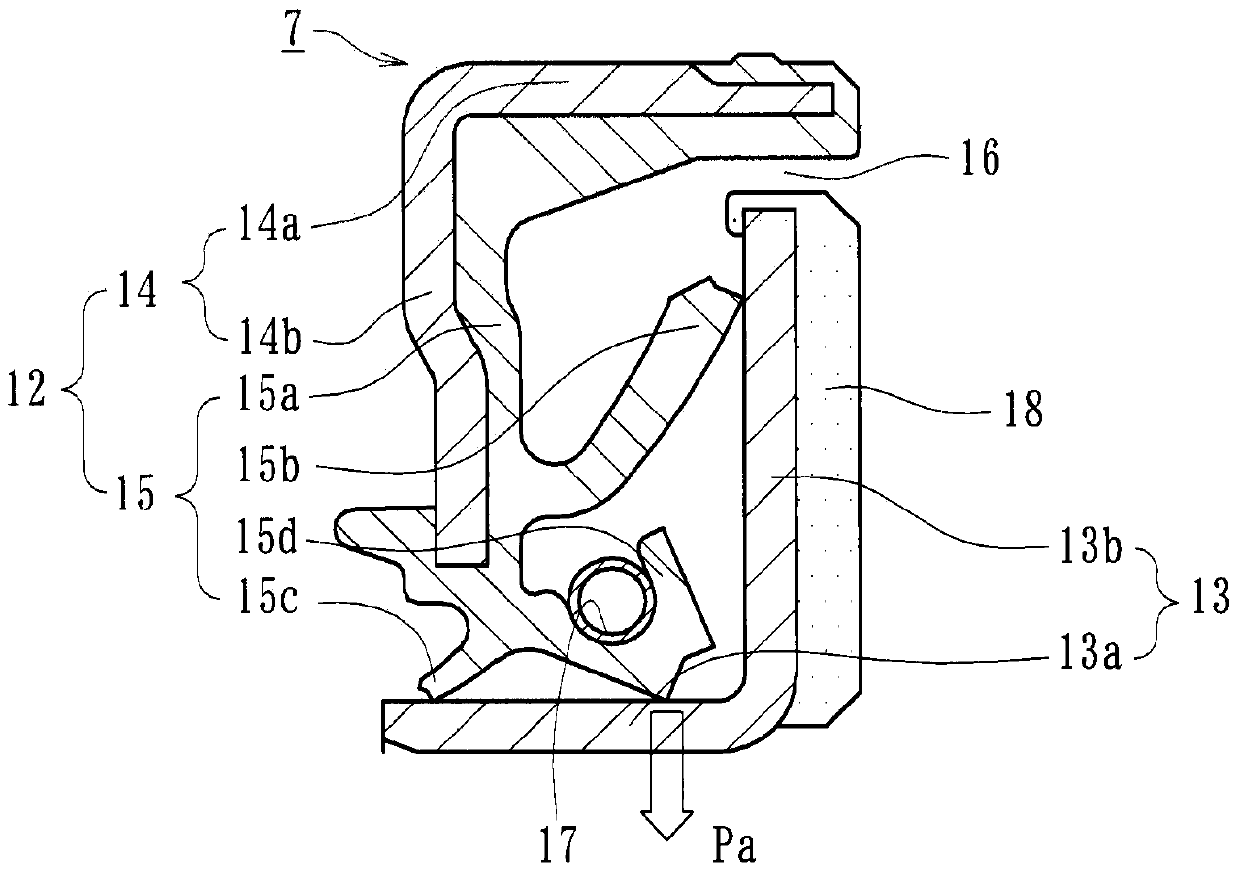

Wheel bearing sealing device

ActiveCN104220768AEliminates changes in tightnessImprove sealingEngine sealsRoller bearingsVulcanizationEngineering

Provided is a wheel bearing sealing device that sets the optimum specification based on the tension force of a radial lip in a pack seal and improves the sealing performance in low-temperature environments and muddy water environments. The wheel bearing sealing device comprises a seal plate (12) constituted by a seal member (15) bonded to a cored bar (14) through adhesion by vulcanization, and a slinger (13) that includes a cylindrical portion (13a) and a vertical plate portion (13b) extending outward in the radial direction. The seal member (15) includes a side lip (15b) which extends outward at an angle in the radial direction and slides against the vertical plate portion (13b) via axial-direction interference, and a radial lip that is formed in a bifurcated shape on an inner diameter side of the side lip (15b) and is constituted by a grease lip (15c) and a dust lip (15d) slide-contacting the cylindrical portion (13a) via radial-direction interference. A garter spring (17) is mounted on the dust lip (15d), and the tension force is set to be 50% or higher of the entire tension force while the tension force in a state where there is no garter spring (17) is set to be at least 3N.

Owner:NTN CORP

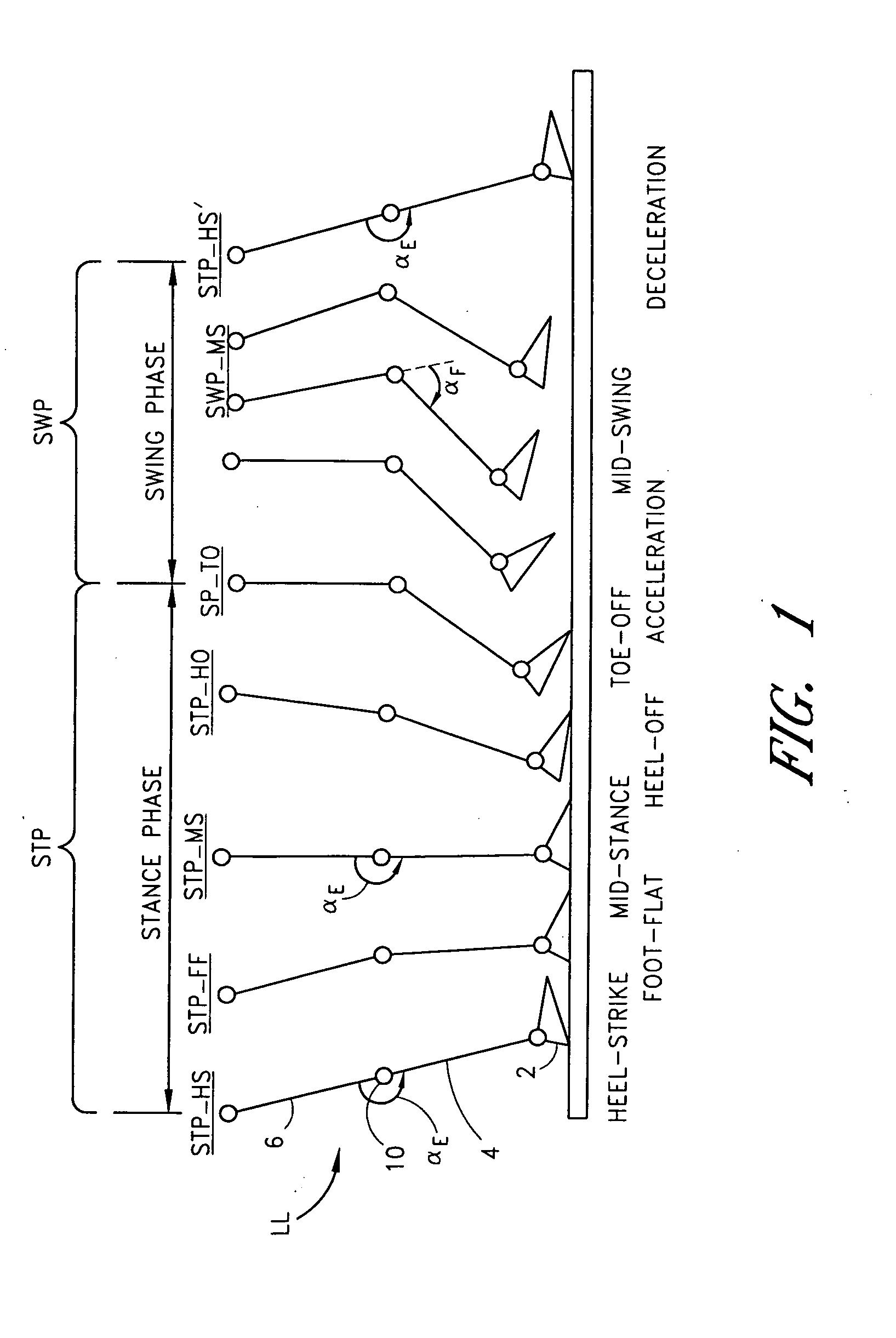

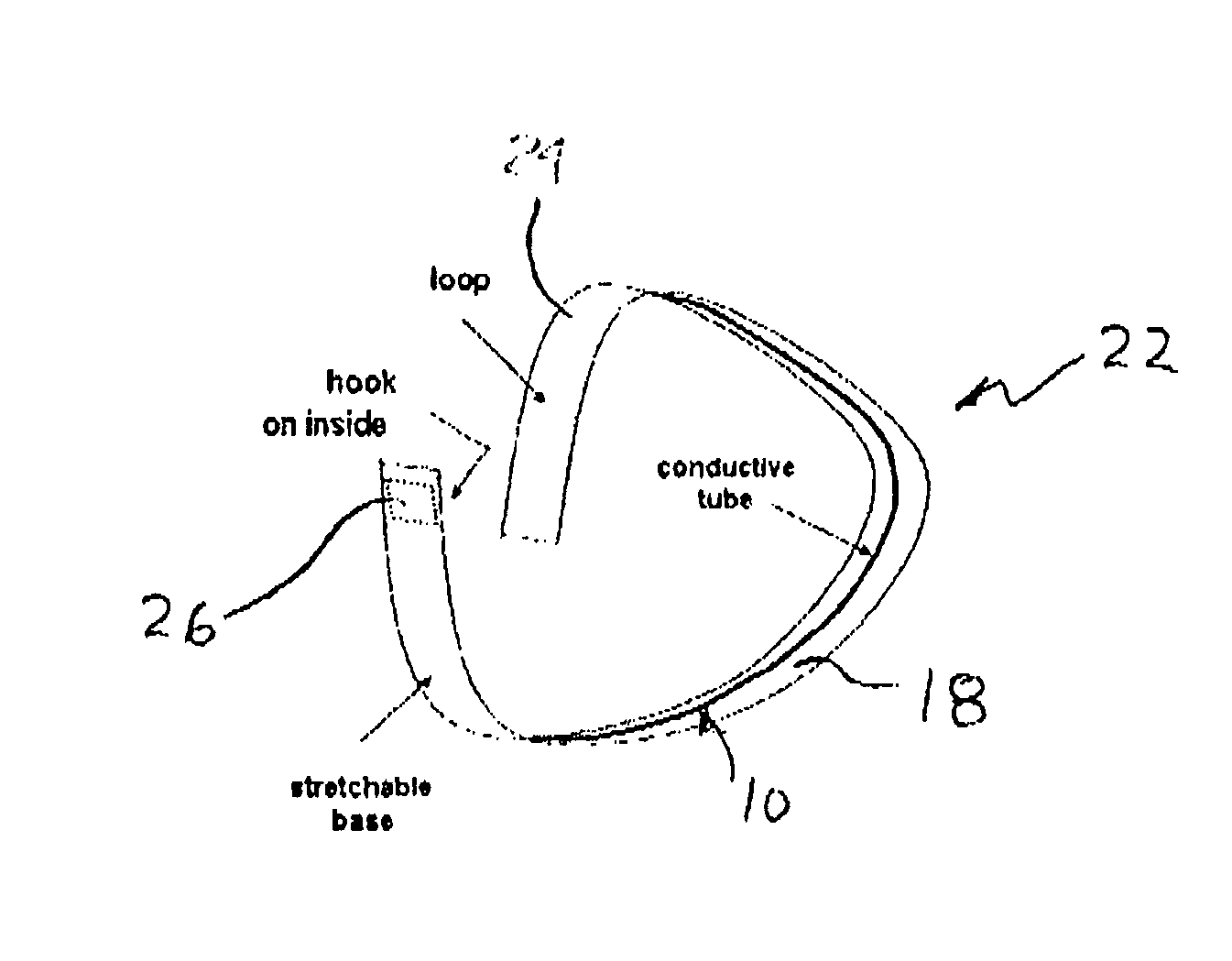

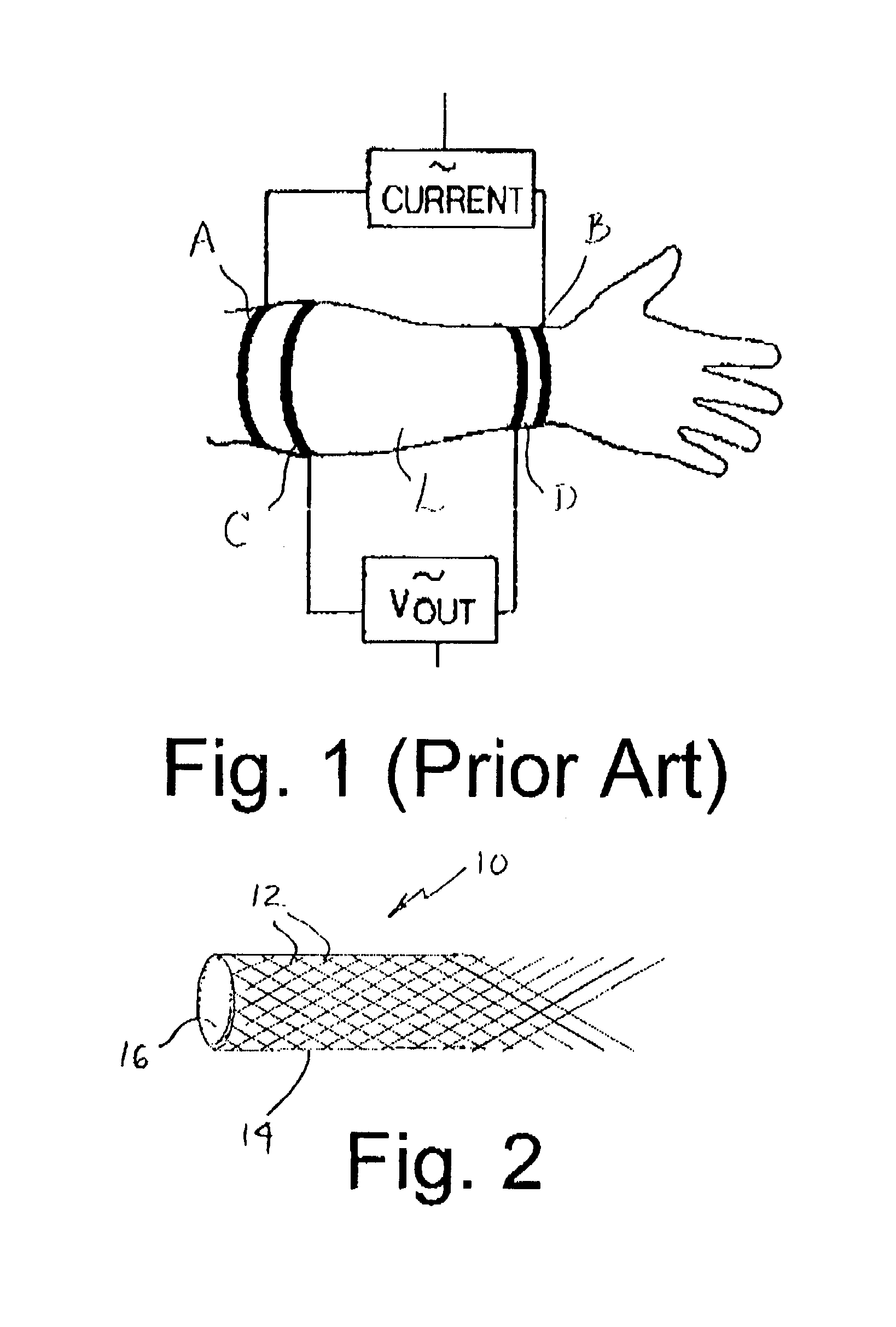

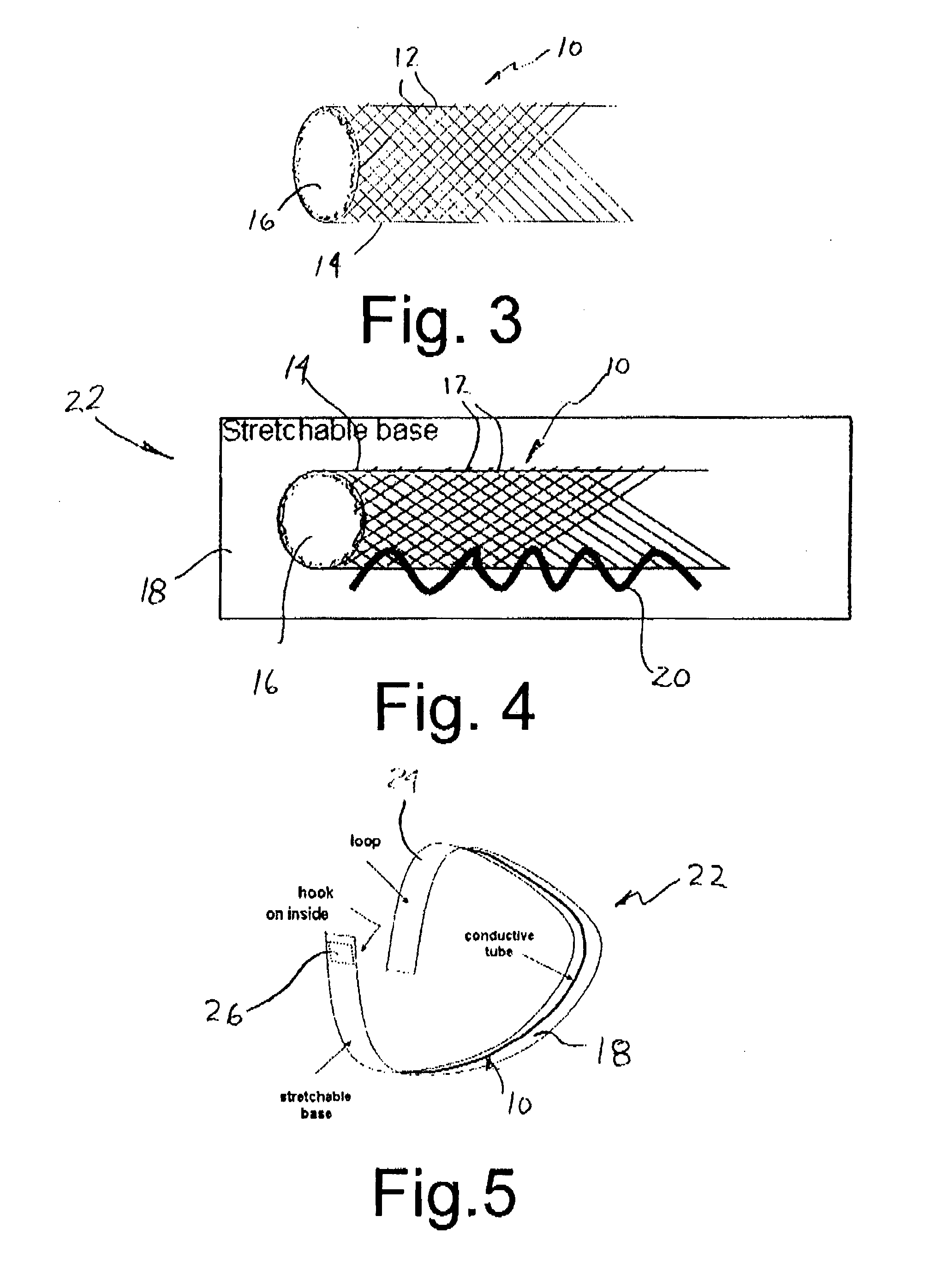

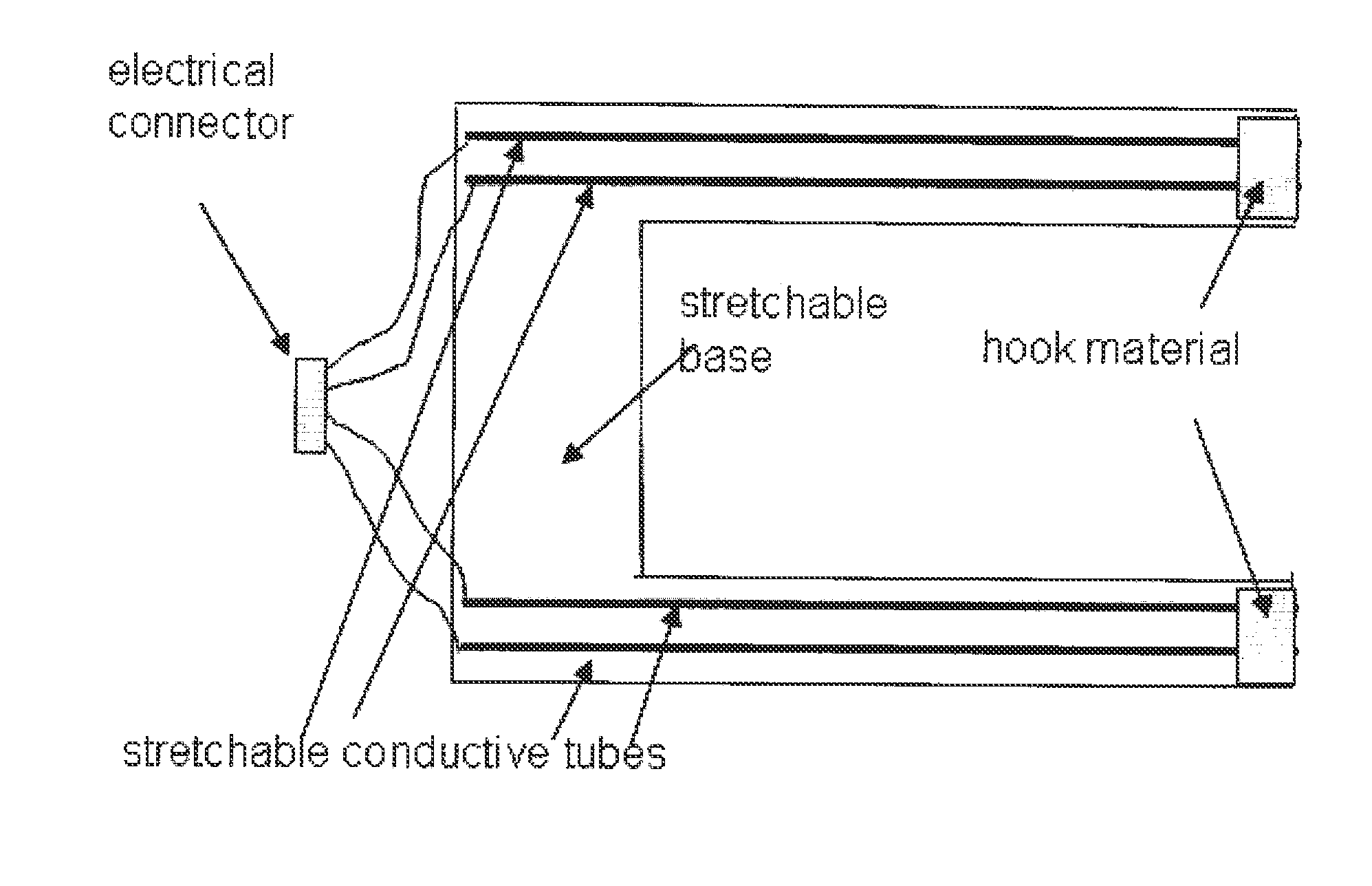

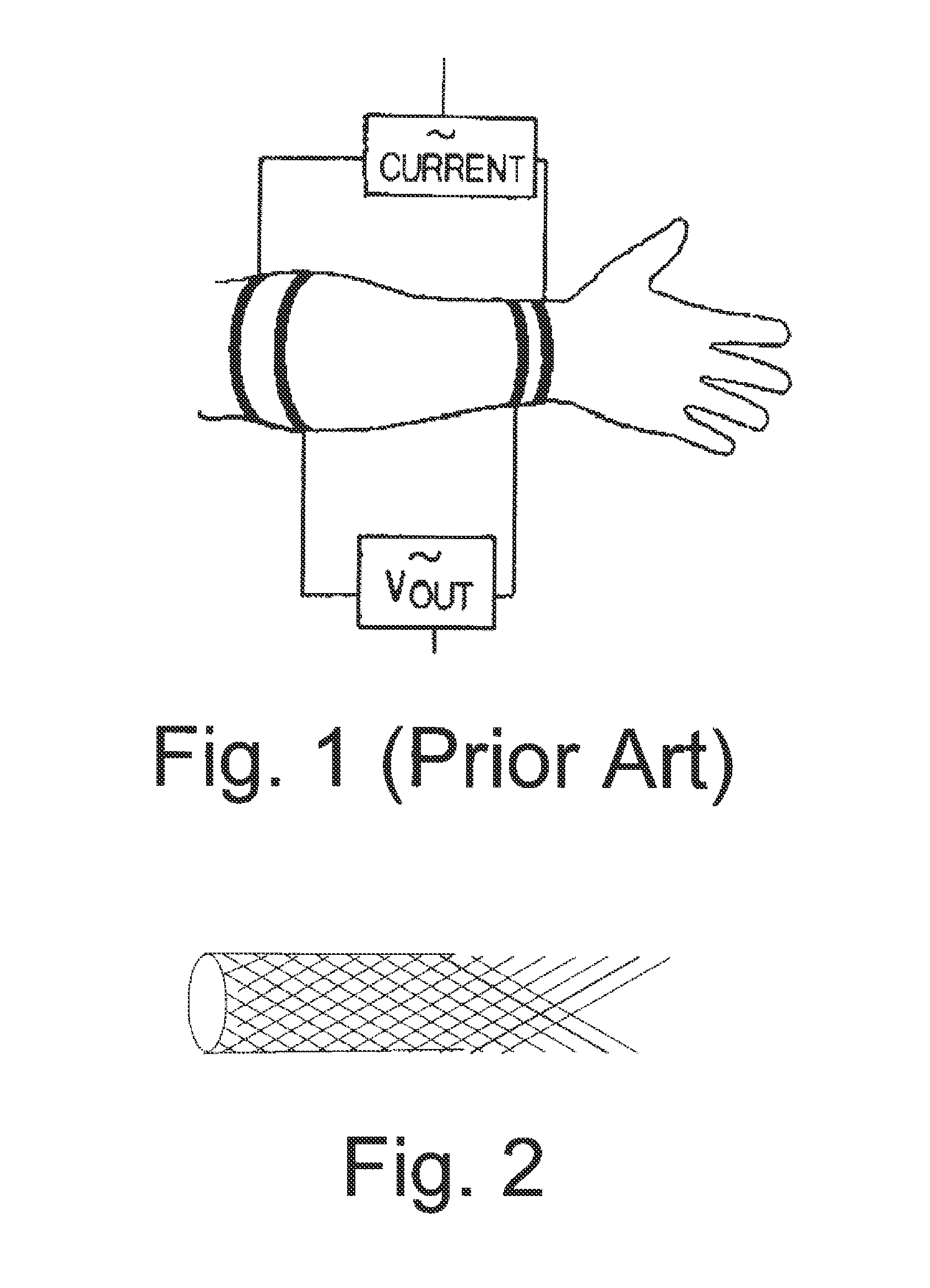

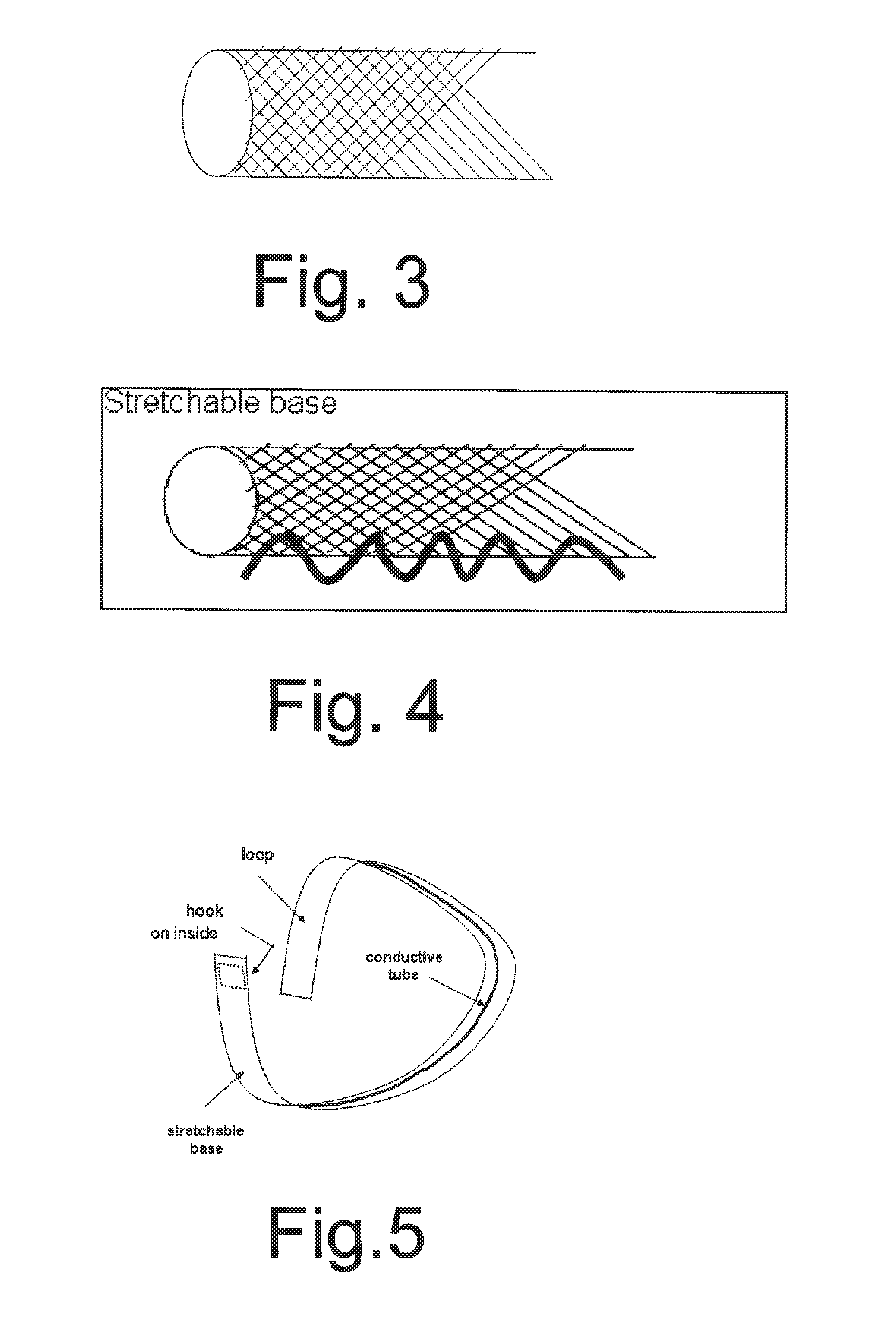

Stretchable electrode and method of making physiologic measurements

ActiveUS8019401B1Easy to useReliable low impedanceCatheterDiagnostic recording/measuringElectrical conductorElastic substrate

A stretchable electrode for use in physiologic measurements on a human body, such as peripheral impedance plethysmography, is disclosed. One embodiment of the stretchable electrode comprises an uninsulated stainless steel wire braid formed into a tubular conductor surrounding an elastic core and attached to an elastic substrate or base. Other embodiments of the stretchable electrode include a garter spring, a flat braided or woven conductor and an undulating wire. The electrode is placed about a limb of a human body and elastically stretched so that the conductor is in substantially continuous circumferential electrical contact with the skin of the limb. A method of attaching the stretchable electrode to the limb of a human body is also disclosed.

Owner:SMITHMARKS INC

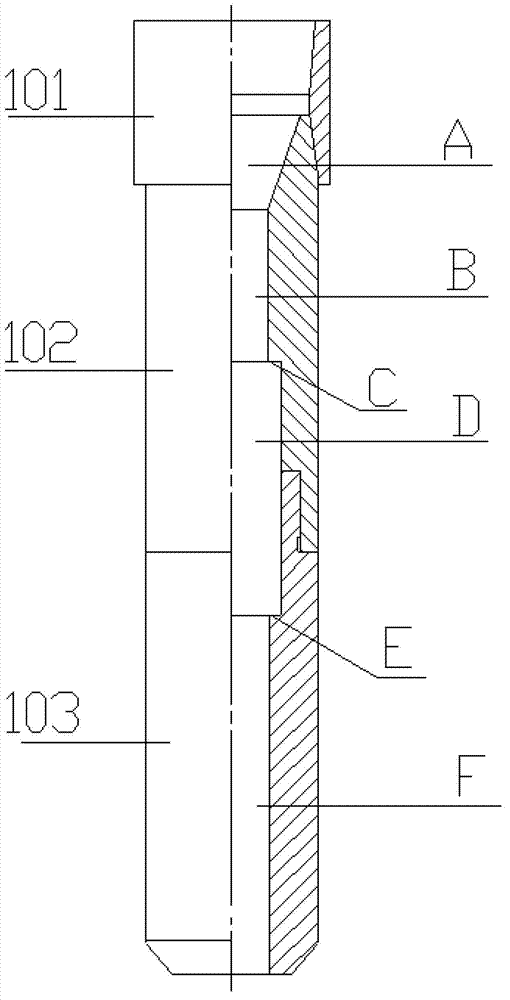

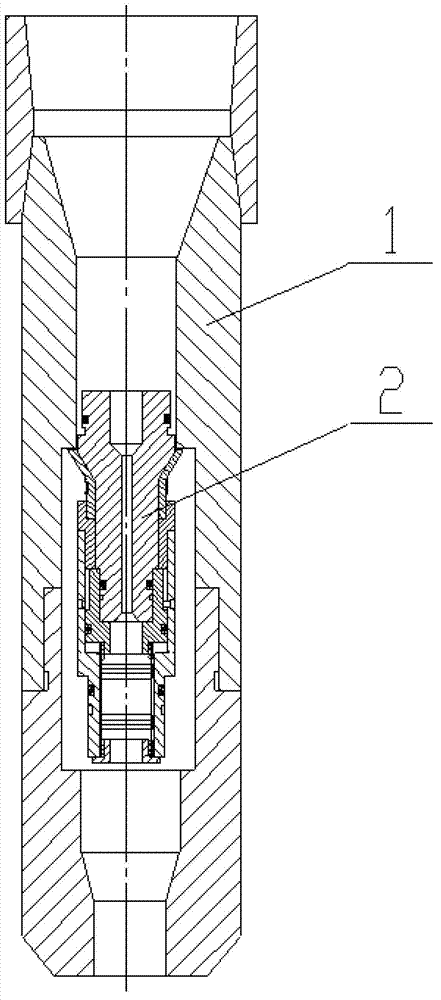

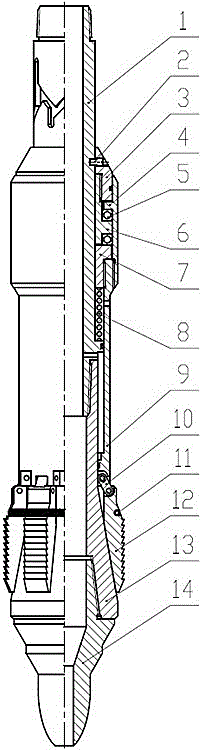

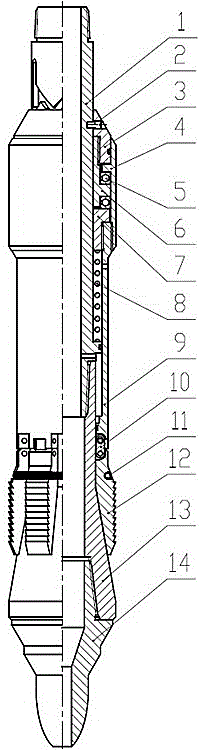

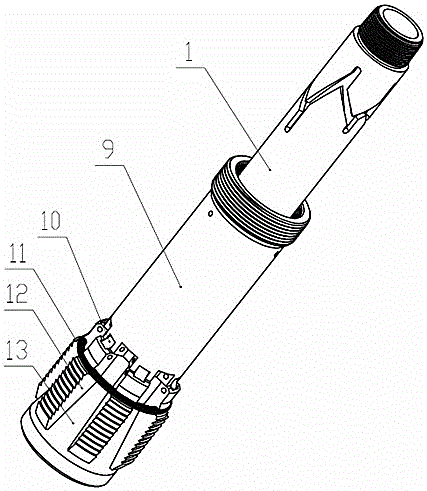

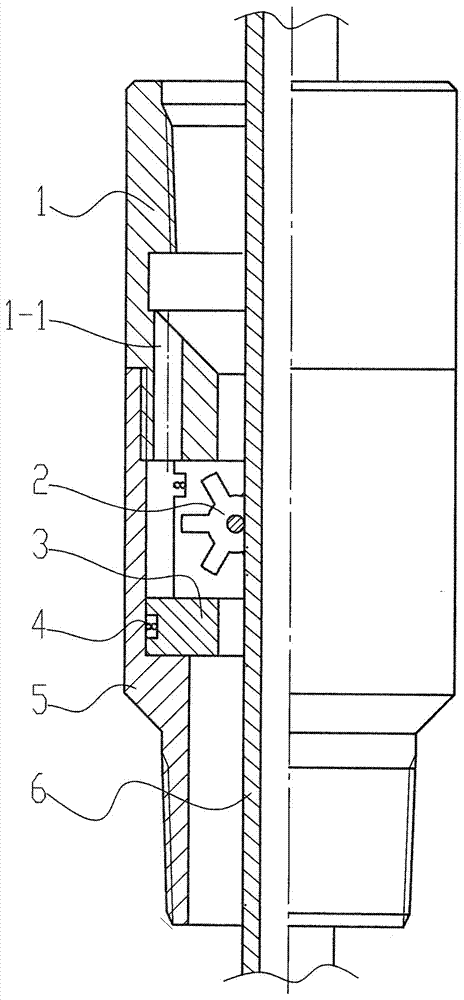

Horizontal well logging anti-lift unlocking device

The invention discloses a horizontal well logging rod and tube delivery tappet anti-lift unlocking device, which is applied to instrument delivery of horizontal well logging of an oilfield. The anti-lift unlocking device consists of a hanging anti-lift shell and an anti-lift device, wherein the hanging anti-lift shell consists of a coupling, an anti-lift body and a hanging body; the anti-lift device consists of an anti-lift cone, an anti-lift slip ring, a garter spring, a slip seat, a piston body, a positioning pin, a tension spring, a piston limiting cylinder and a tension spring plug; the anti-lift cone is provided with a conical surface; the anti-lift slip ring and the garter spring are combined and then are sleeved on the conical surface on the anti-lift cone; the lower part of the anti-lift slip ring is arranged in a mounting groove in the upper part of the slip seat; the upper part of the piston limiting body is used for placing the piston body; the positioning pin is arranged in a threaded hole in the piston limiting body; and the tension spring plug is blocked at the lower end of the piston limiting body under the acting force of the tension spring. The anti-lift unlocking device has the effects of reliable anti-lift property, capability of providing delivery capacity of 3 tons and smooth unlocking.

Owner:PETROCHINA CO LTD

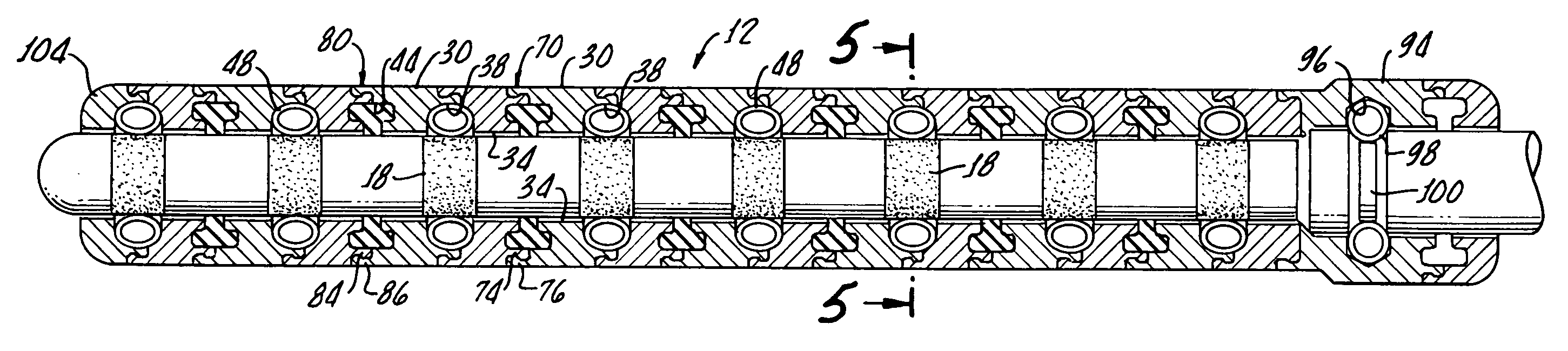

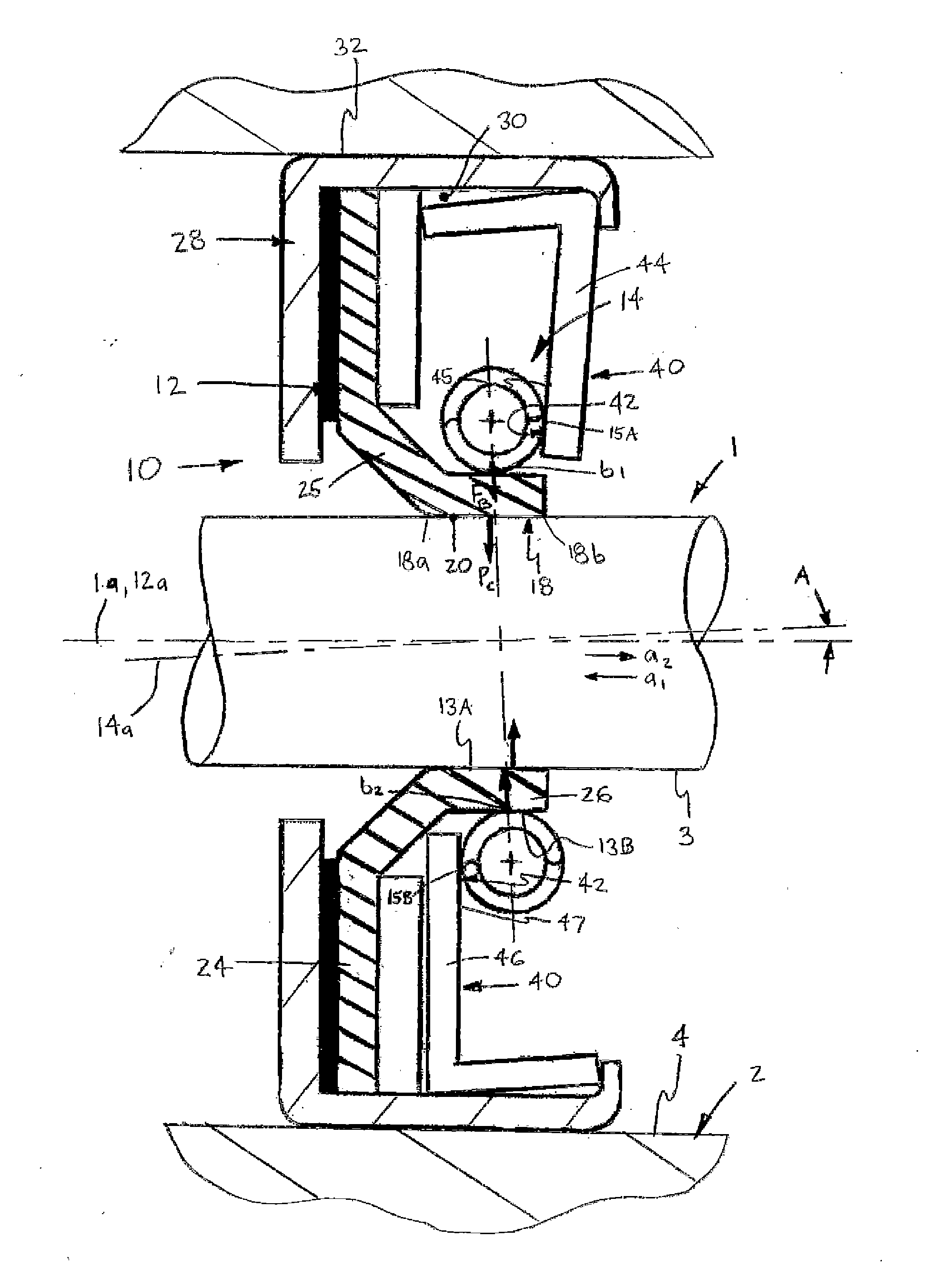

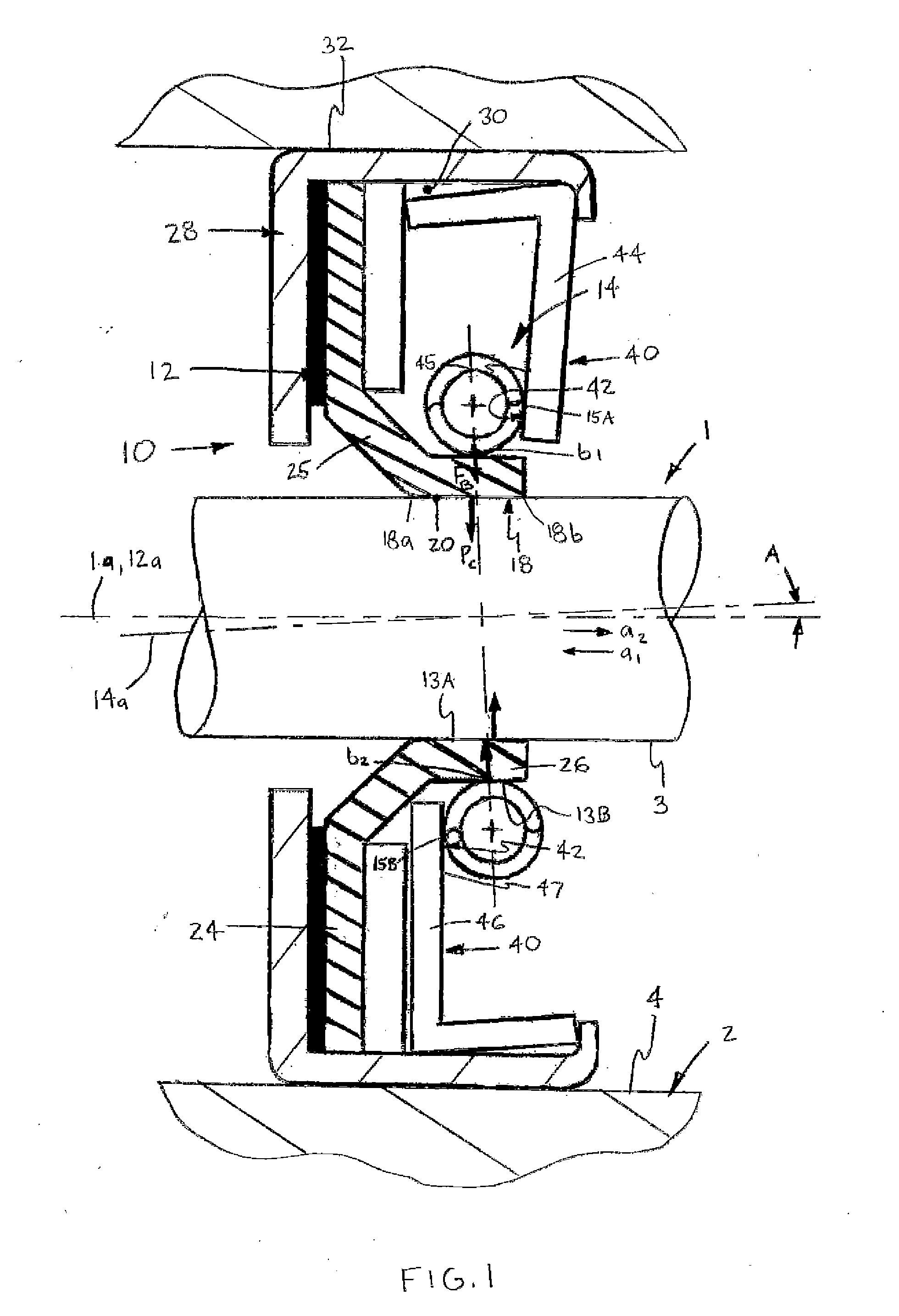

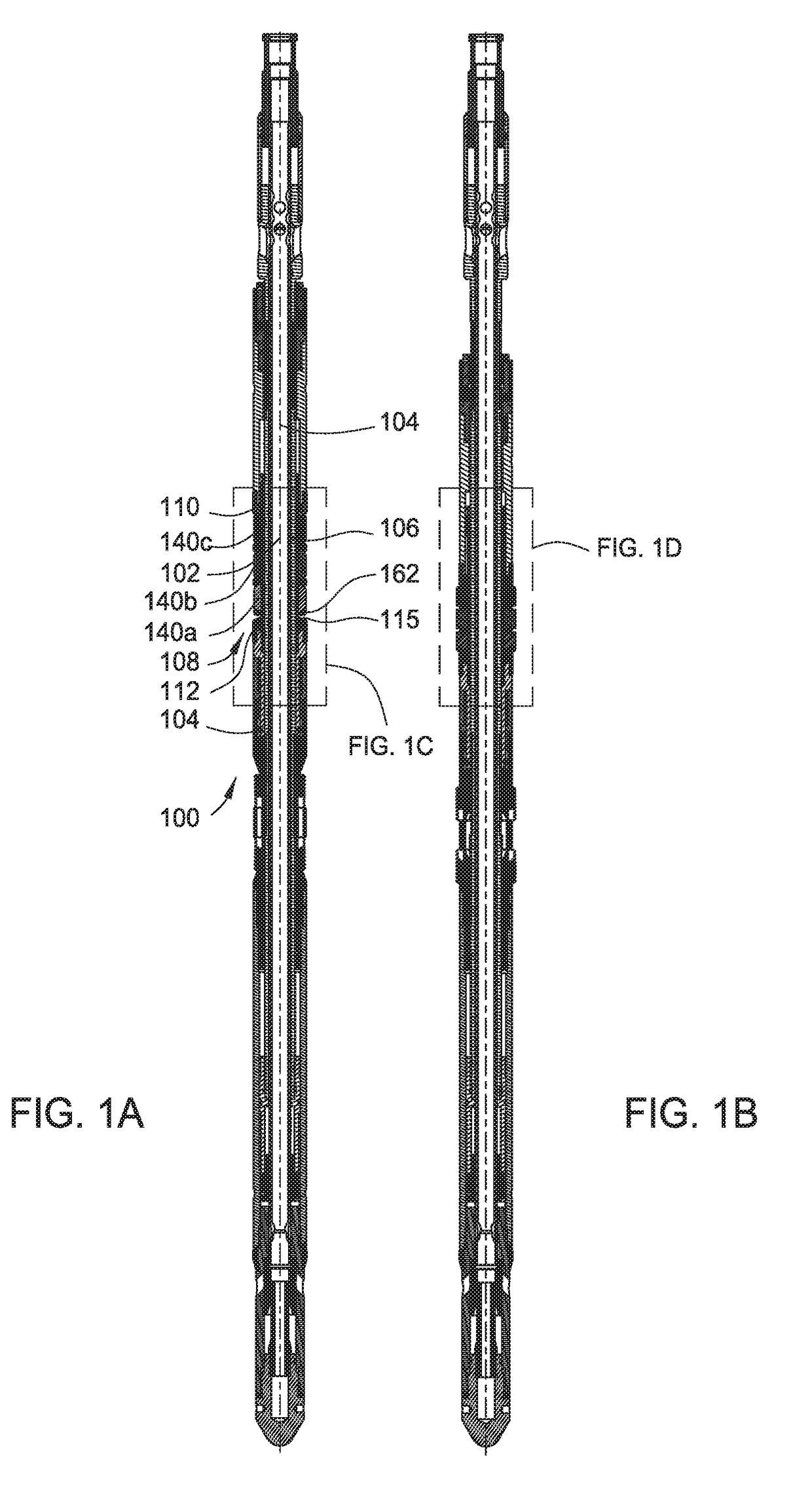

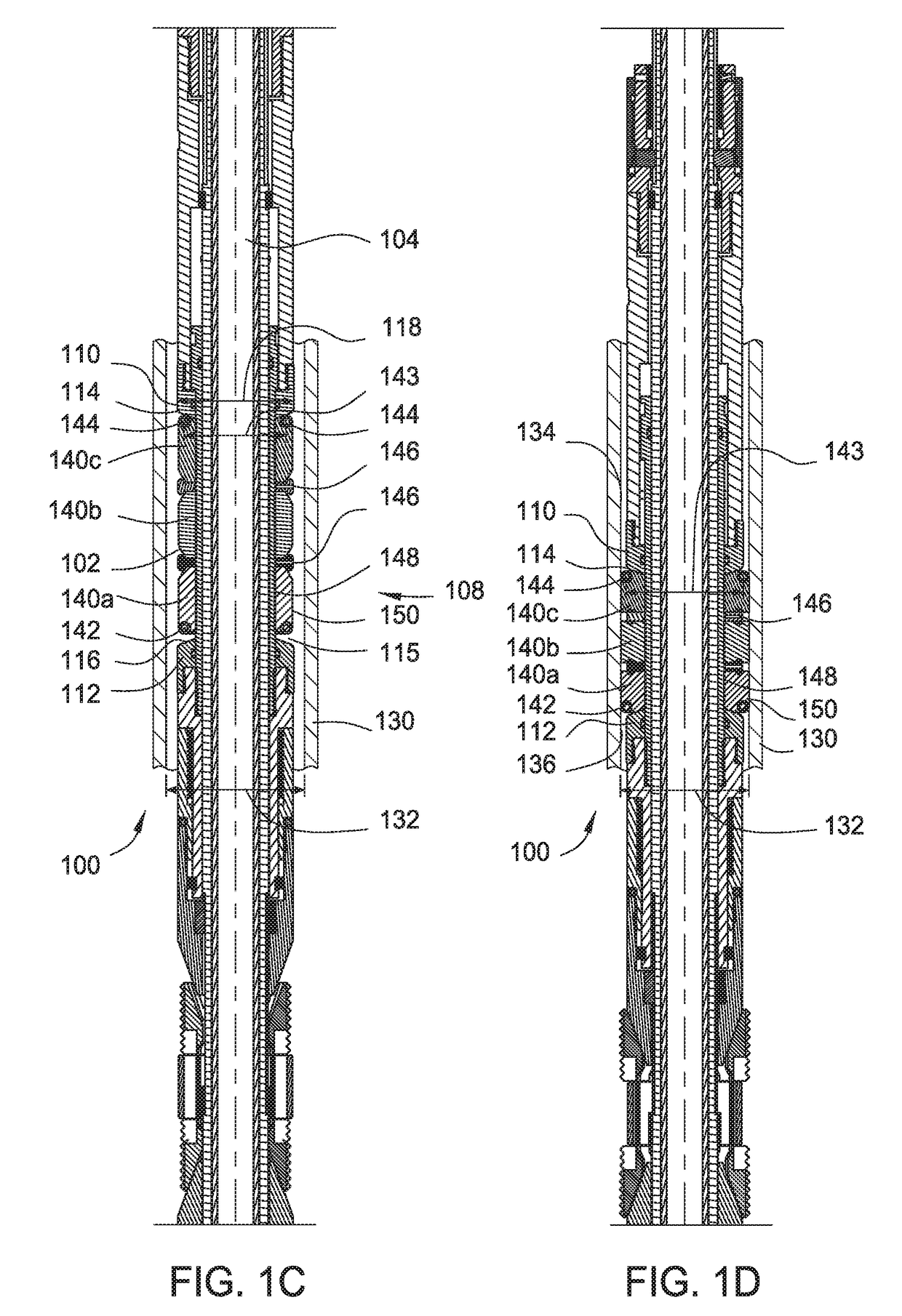

Pigtail spring contacts for implanted medical devices

Spring contact apparatus for an implantable medical device includes a plurality of nonconductive housing with each housing having a bore therethrough alignable with adjacent housing bores and assembled in spaced apart pairs with adjacent radial accesses to adjacent housing chambers. A plurality of electrically conductive garter springs are provided with the pairs of garter springs being disposed in corresponding adjacent housing chambers and each spring having a pigtail lead extending through a corresponding axis. The pairs of adjacent pigtail leads extending from adjacent axes are of sufficient length for a combined attachment to a corresponding pulse generator lead.

Owner:BAL SEAL ENG CO INC

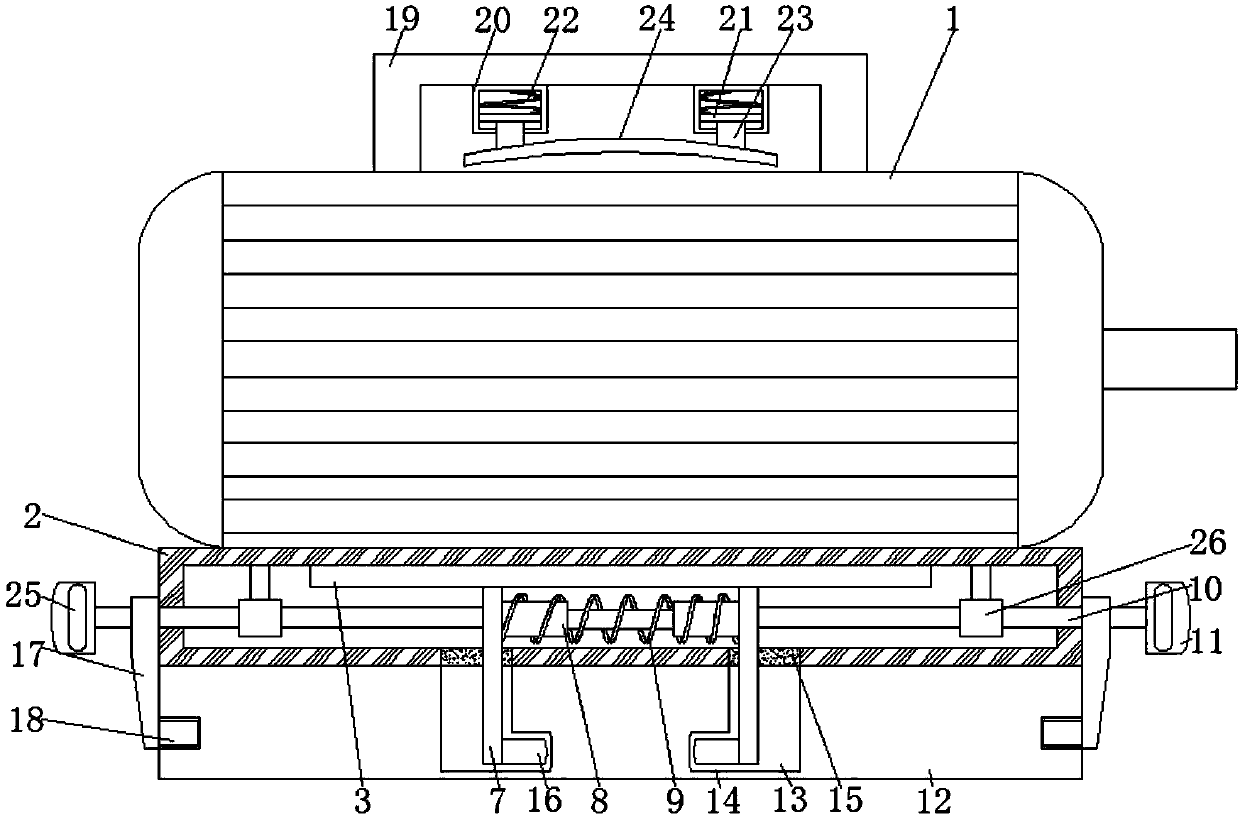

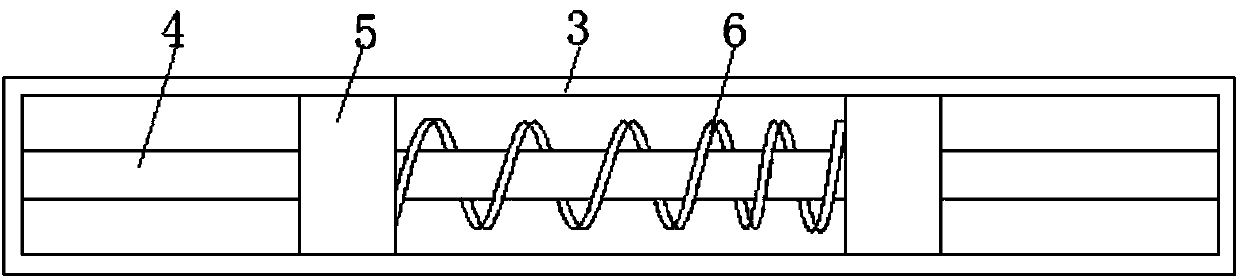

Energy-saving motor convenient for installation

InactiveCN107800224AEasy to installAvoid distortionSupports/enclosures/casingsEngineeringGarter spring

The invention discloses an energy-saving motor that is easy to install, comprising an energy-saving motor, the bottom of the energy-saving motor is fixedly connected with a base, the base is a hollow structure, the top of the inner wall of the base is fixedly connected with a slide rail, and the slide rail A slide bar is plugged inside, and two sliders are slidably connected in the slide rail, and the two sliders are respectively sleeved on both sides of the surface of the slide bar, and an extrusion spring is sleeved on the slide bar. Both ends of the extrusion spring are respectively fixedly connected to opposite sides of the two sliders, and the bottoms of the two sliders are fixedly connected to vertical plates. Through the improvement of the block, when the two pull plates are pulled backwards, the block can be separated from the slot, the two pull plates are released, and the block can be made to move again under the action of the elastic force of the extrusion spring and the clamping spring. Quickly snap into the card slot, so that the energy-saving motor can be quickly installed, and the use of shock-absorbing springs and pistons can make the grip plate have a certain shock-absorbing effect and avoid damage to the opponent.

Owner:魏靖靖

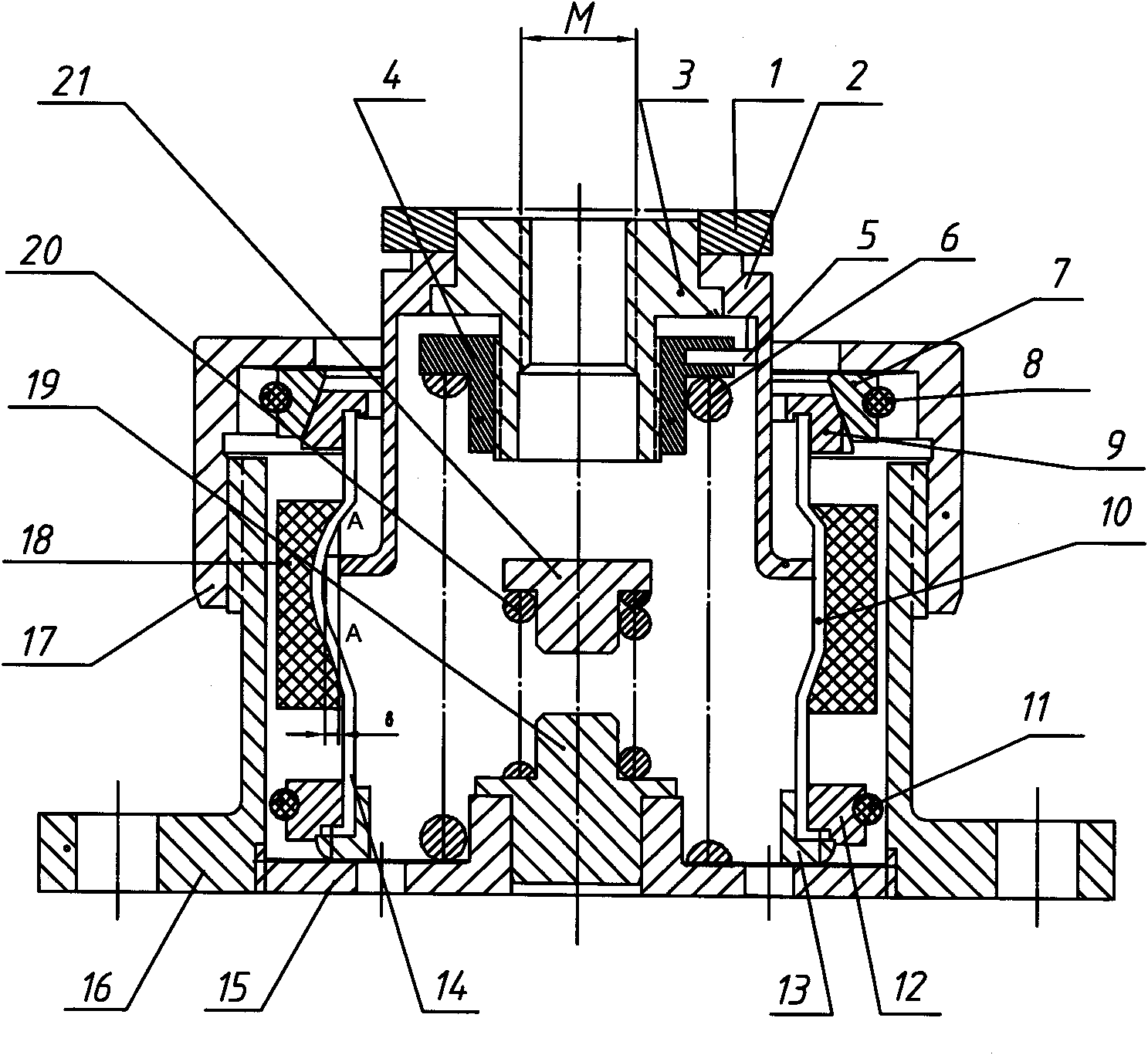

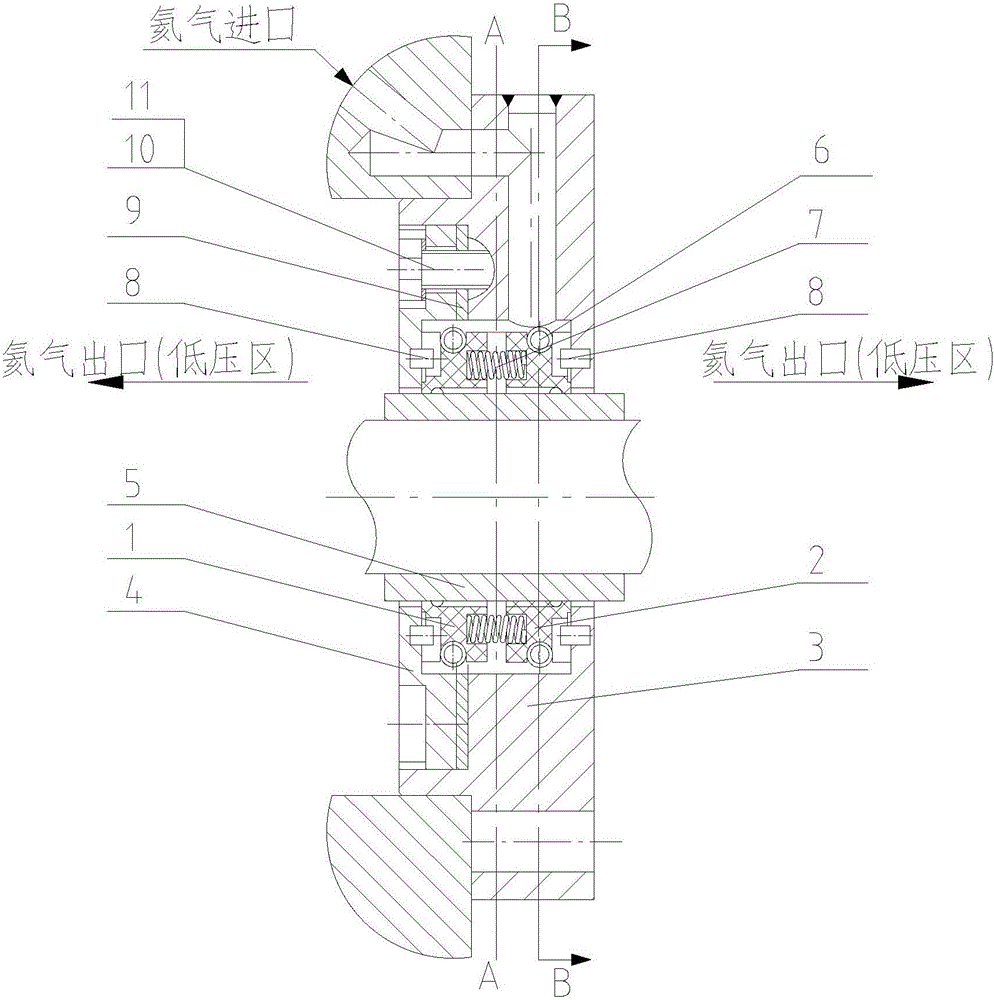

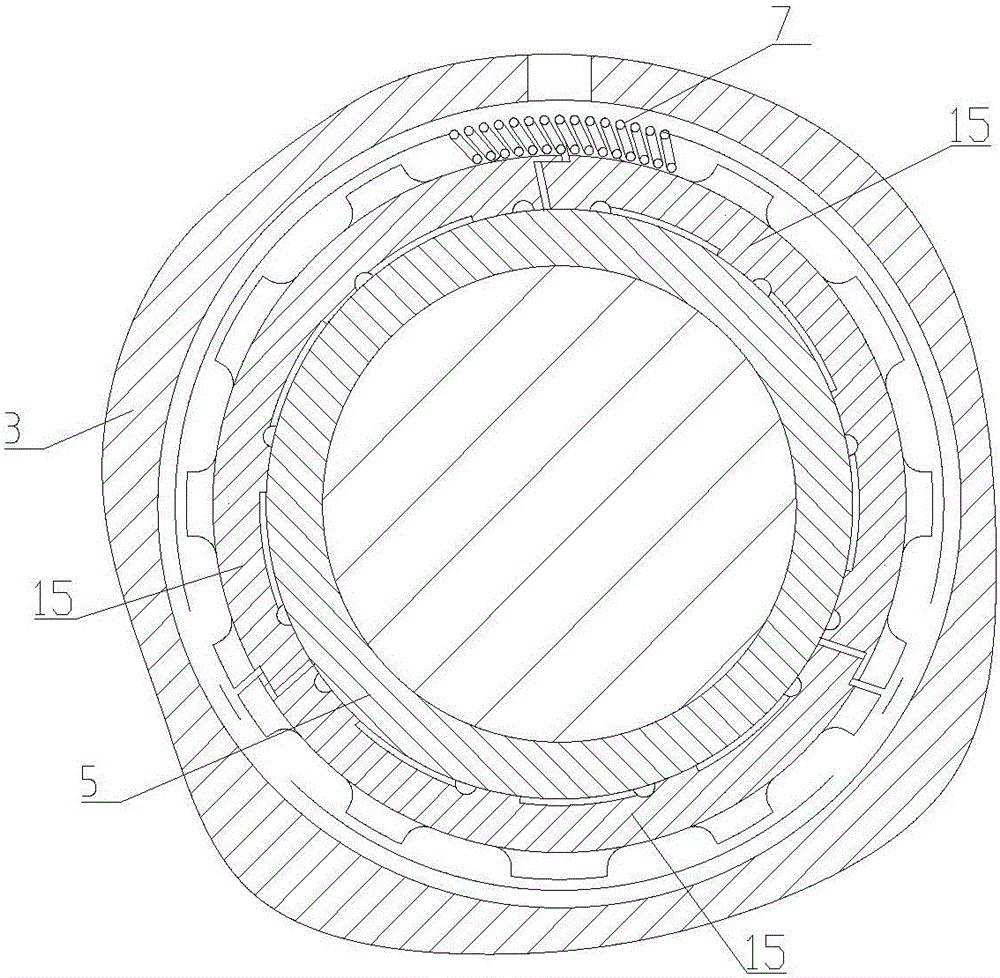

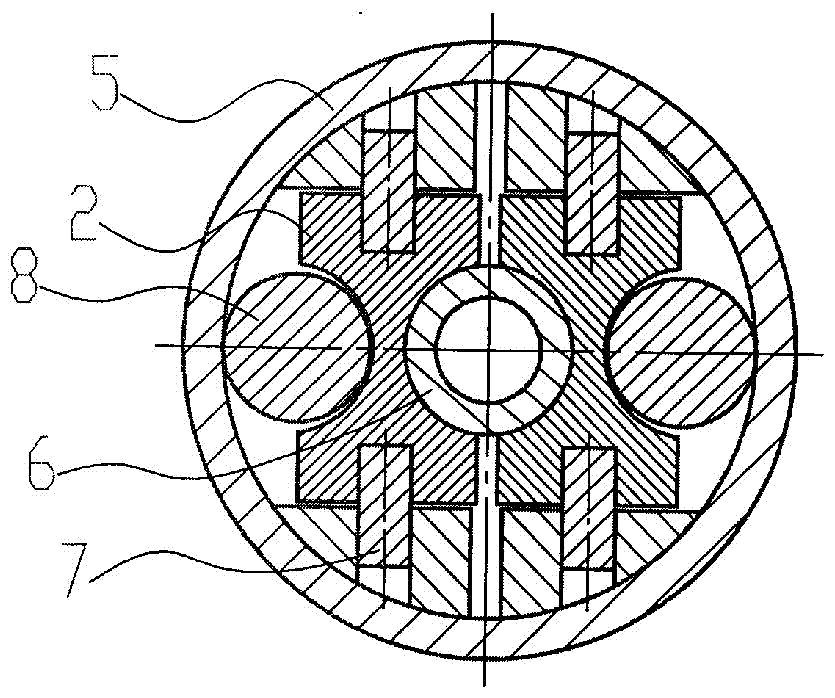

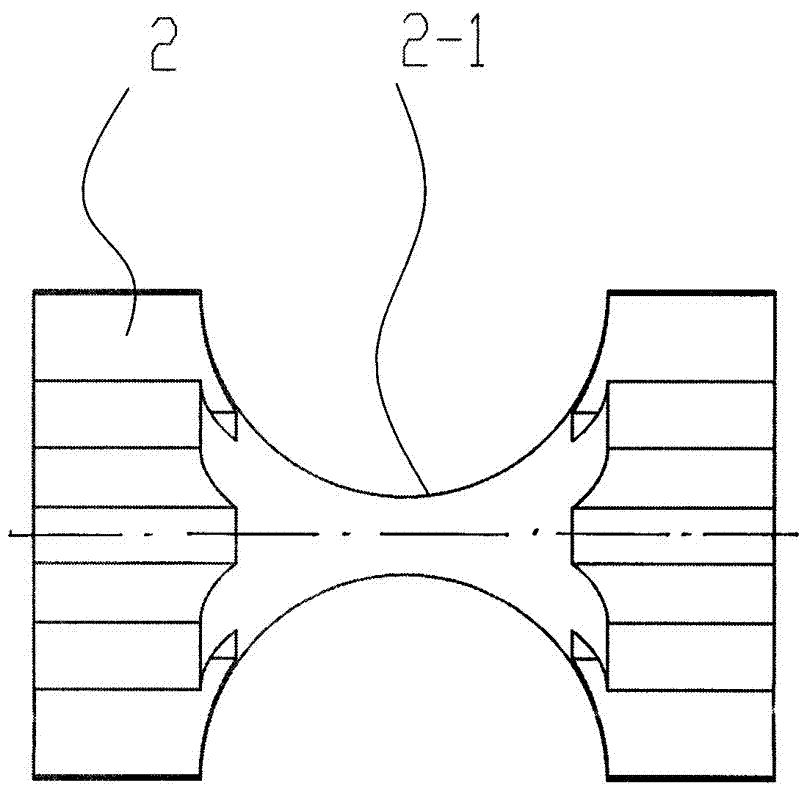

Circumferential sectioned helium sealing device for oxygen turbine pump of hydrogen oxygen engine

The invention discloses a circumferential sectioned helium sealing device for an oxygen turbine pump of a hydrogen oxygen engine. According to the circumferential sectioned helium sealing device, a circumferential sectioned sealing ring I and a circumferential sectioned sealing ring II are placed in a cavity formed by a cover plate and a sealing shell; sealing shaft sleeves are placed in rings of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II; the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II are oppositely placed and pre-tensioned by virtue of pre-tensioning springs; and each of the circumferential sectioned sealing ring I and the circumferential sectioned sealing ring II is formed by connecting a plurality of fan-shaped arc sections with the same structure end to end, and constrained on an excircle surface through garter springs. According to the circumferential sectioned helium sealing device, each sealing ring is composed of the plurality of fan-shaped arc sections, a hydrodynamic groove structure is introduced, and a hydrodynamic effect of a sealing clearance fluid is adequately utilized, thus the helium sealing device reliably works under an extremely small clearance, and a low leakage amount is maintained.

Owner:BEIJING AEROSPACE PROPULSION INST

Retrofittable severe duty seal for a shaft

A unitary sleeve lip seal can be used to provide permanently lubricated sealed bearings in severe service conditions such as the track pins of track-driven vehicles and agricultural equipment. The seal has a labyrinthine exclusion path and multiple dust lips contacting the sleeve in addition to the main sealing lip. A garter spring encircling the main sealing lip may enable the seal to operate at moderately elevated pressures. The sleeve has a radial flange at the outermost end. Elastomeric lips extend between the sleeve flange and a faceplate that terminates the outside end of the seal housing. The seal is packed with water-resistant grease and can, when installed in association with grease-packed bearings can create a permanently lubricated bearing / shaft assembly that requires no re-greasing. Resilient coatings both protect the sleeve and case and also improve leak resistance, especially when the seal is retrofitted onto shafts that have been damaged. The design provides a seal having performance that is comparable to that of dual cone face seals at a much lower cost and in a much smaller assembly. Seals made according to this design can easily be made in standard sizes that can serve as direct replacements for previously available seals.

Owner:DICHTOMATIK AMERICAS

Slip type hydraulic control inner fishing tool

InactiveCN105863544ASalvage is efficient and reliableDownload is validCleaning apparatusCoiled tubingThrust bearing

The invention relates to a slip type hydraulic control inner fishing tool for fishing underground pipe tools and pipe falling objects in the oil and gas well development process. The slip type hydraulic control inner fishing tool can effectively achieve recycle of the underground pipe tools and fishing operation for the gas falling objects. According to the technical scheme, the upper end of an upper barrel is in screwed connection with a coiled tubing, the upper end of a conical barrel is in screwed connection with the lower end of the upper barrel, the lower end of he conical barrel is in screwed connection with the upper end of a guiding shoe, one end of a connecting rod is hinged to the upper end of a slip, the other end of the connecting rod is hinged to a hinge support at the lower end of a sleeve, a garter spring is installed an arc groove in the outer side of the slip, a spring is installed on a protruding step on the lower portion of the upper barrel, a bearing pedestal and two thrust bearings are integrally arranged in an inner cavity of a thrust shell, one end of a siding pin is in screwed connection with a rotary sealing cover threaded counter bore, and the other end of the sliding pin is inserted into a sliding groove rail on the upper portion of the upper barrel. The slip is hydraulically controlled to be stretched in the radial direction, and it is ensured that fishing is efficient and reliable; slip stretching and retraction can be controlled unlimited times according to operation requirements.

Owner:SOUTHWEST PETROLEUM UNIV

Sleeve seal for electric furnace electrodes

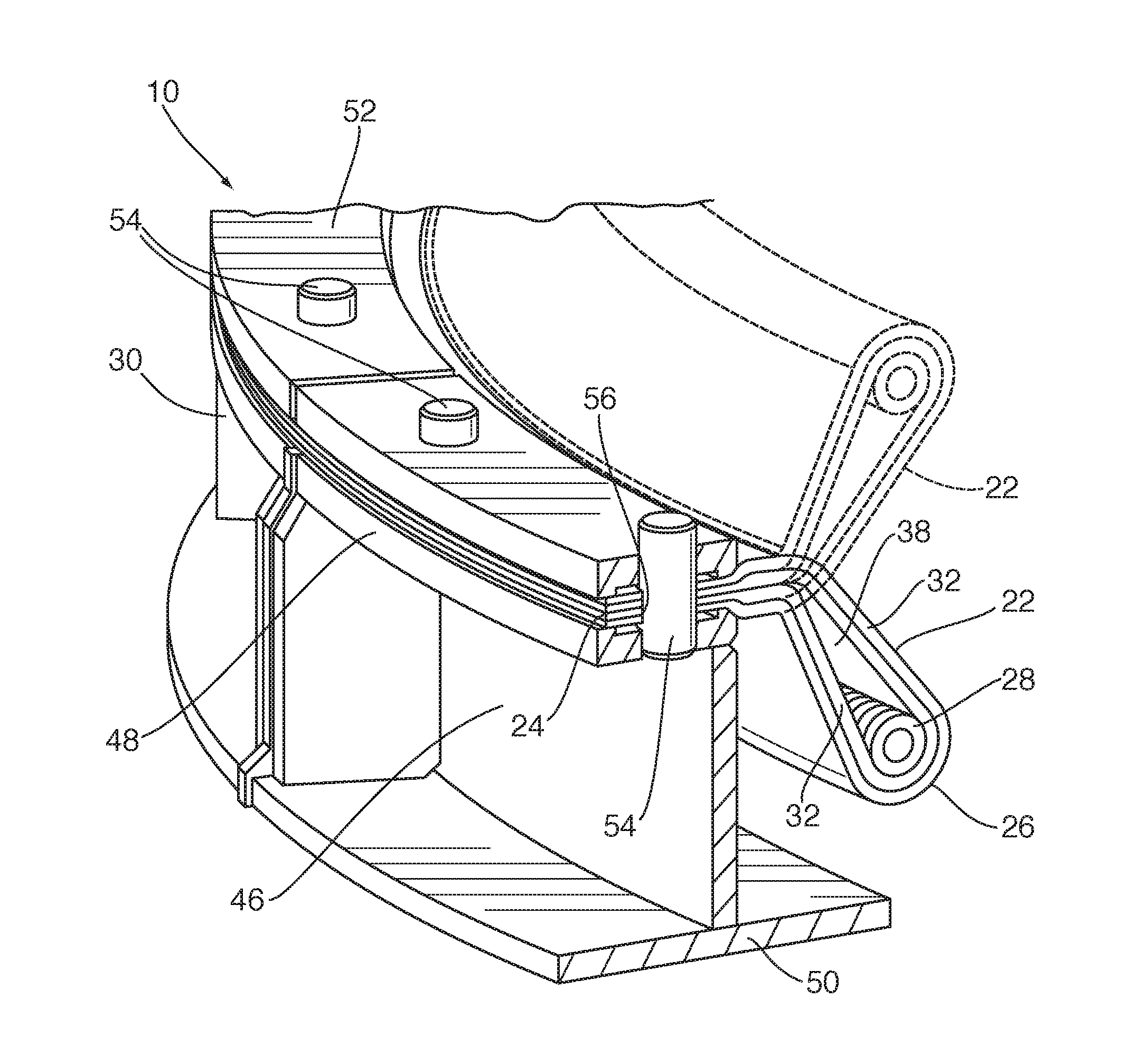

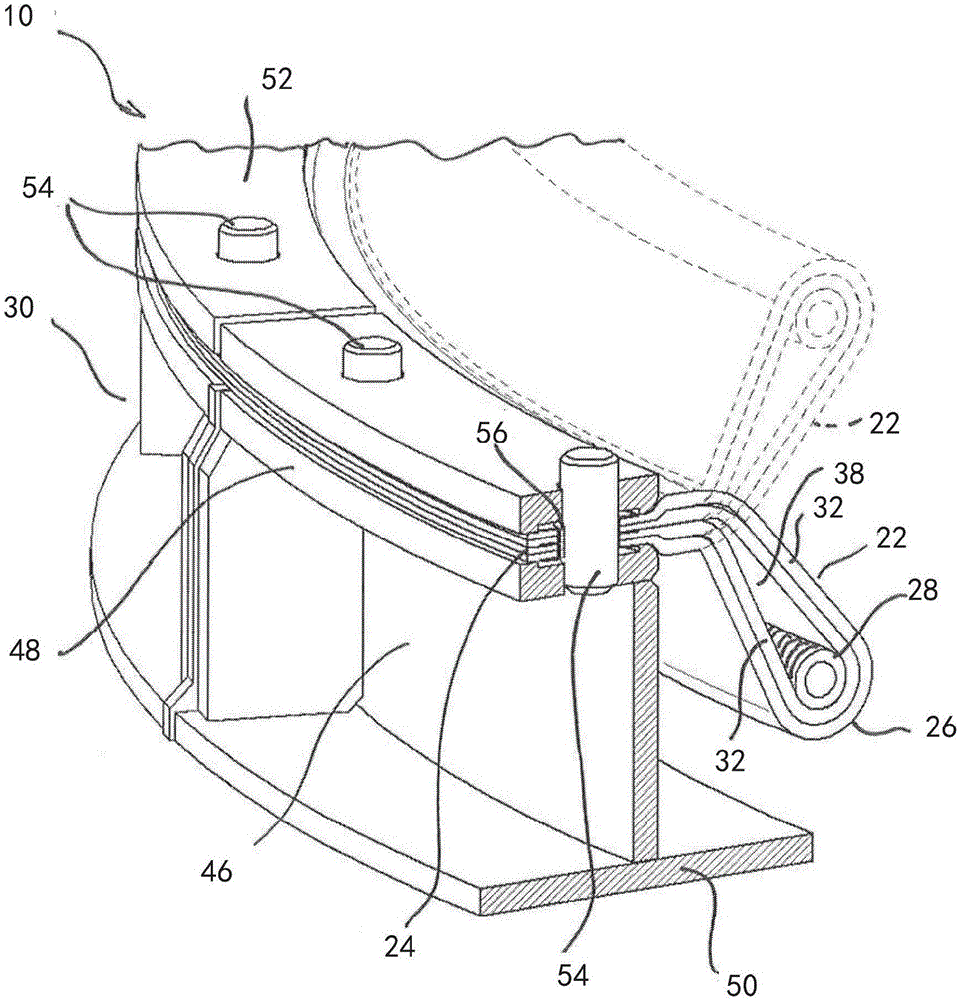

ActiveUS20170051831A1Increase flexibilityReduce compressionEngine sealsElectric discharge heatingGarter springMechanical engineering

A highly flexible sealing arrangement designed to seal high-temperature furnace ports, particularly the electrode port of an electric furnace. The seal comprises an annular support member fixed to a flexible sealing member and employs the use of a garter spring to uniformly apply the desired amount of seal compression. The arrangement and flexibility of the sealing member allows the seal to adapt itself to the wide range of operating and upset conditions that typically exist for a furnace electrode seal. Frictional wear on the seal may be greatly reduced as the design inherently allows for a much lower amount of seal compression to be applied, furthermore, the seal is able to move axially which can significantly reduce wear caused by electrode regulation.

Owner:HATCH LTD

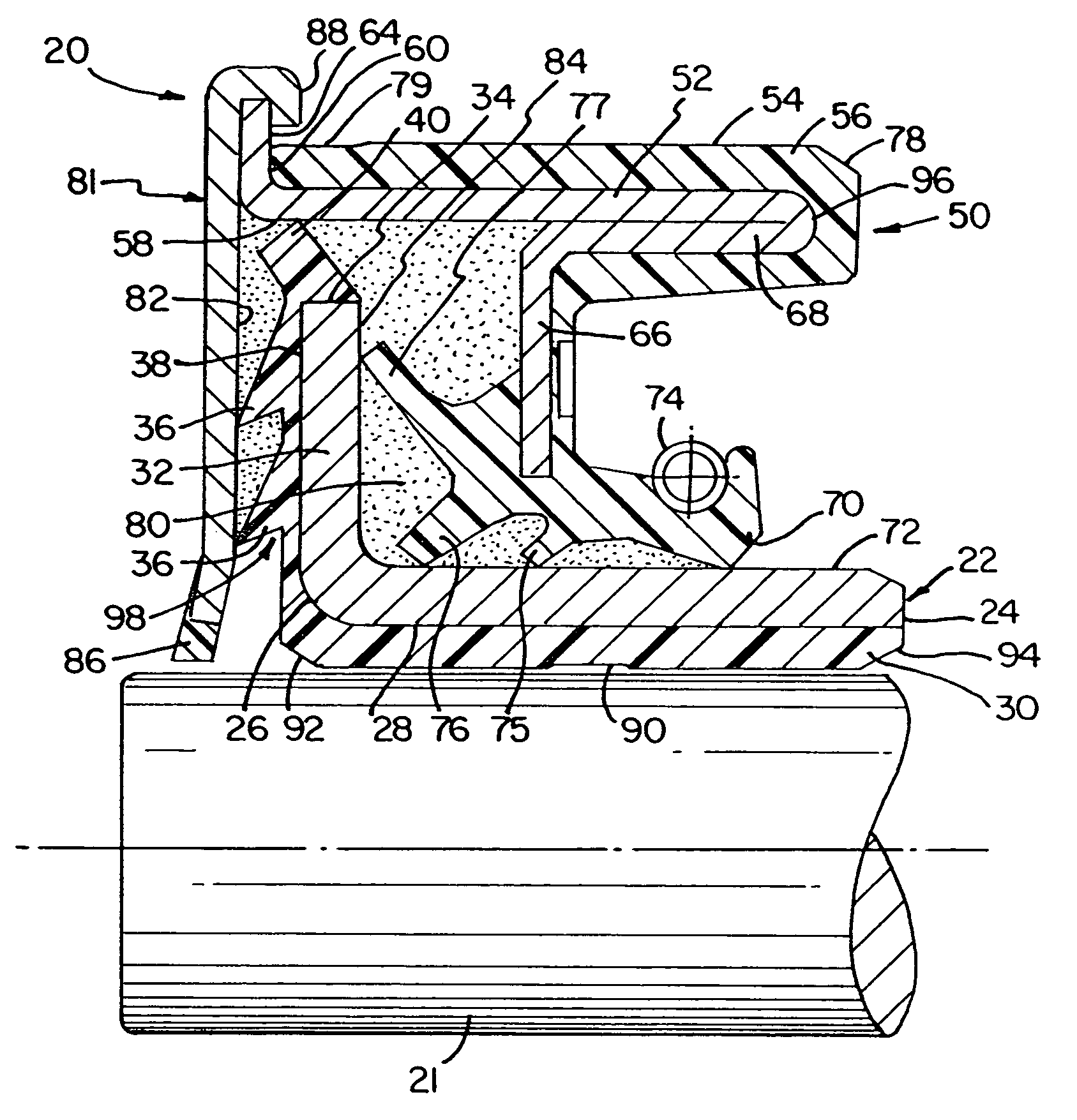

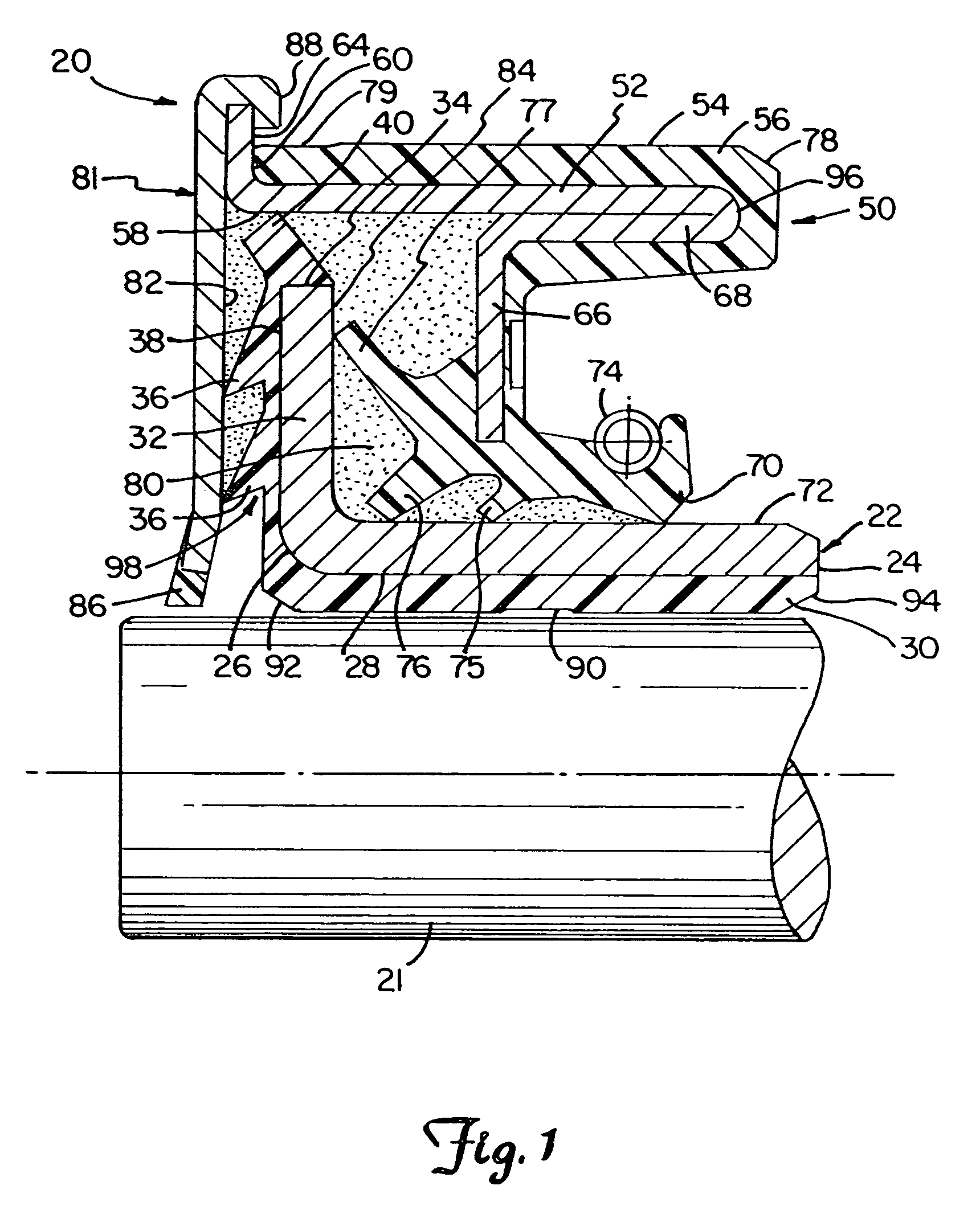

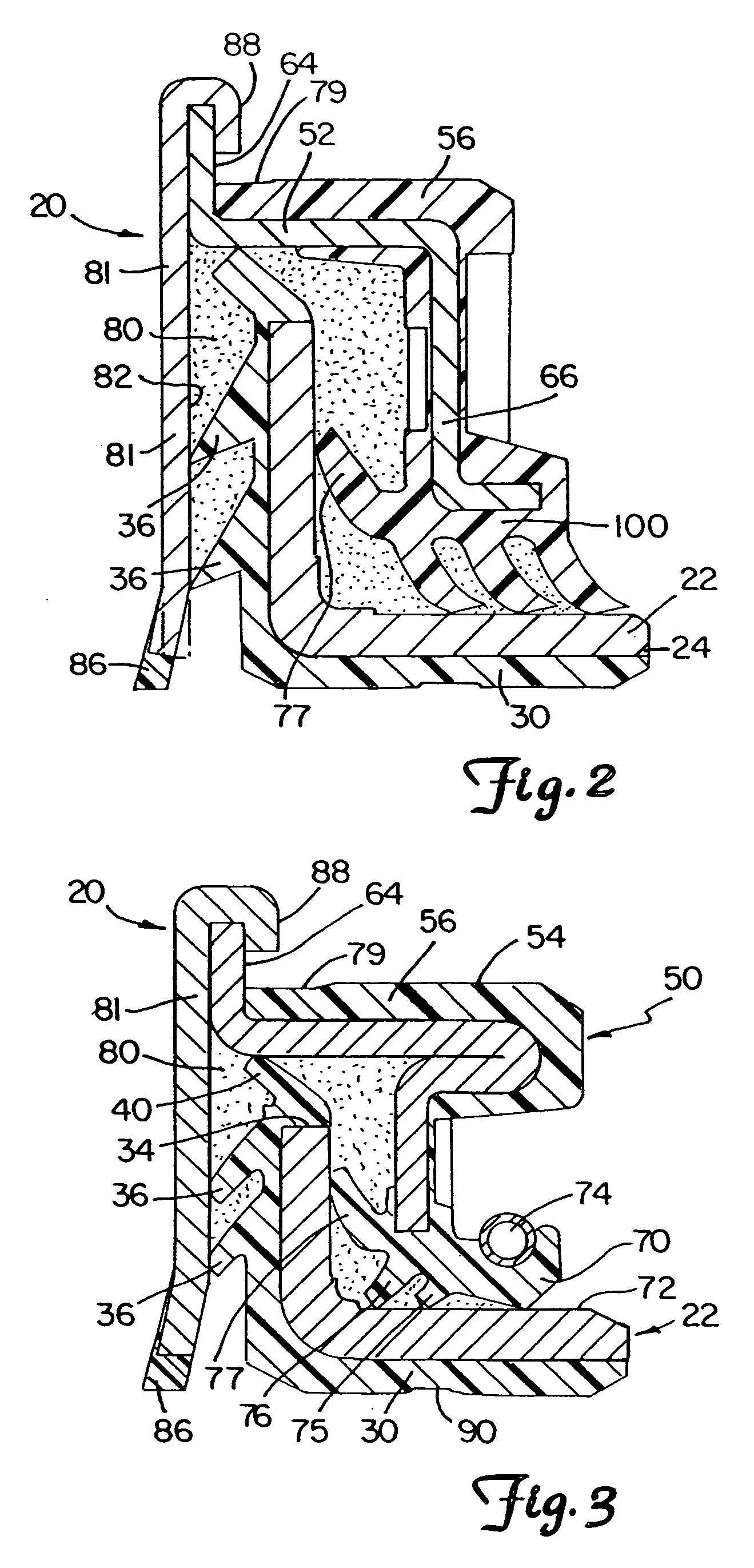

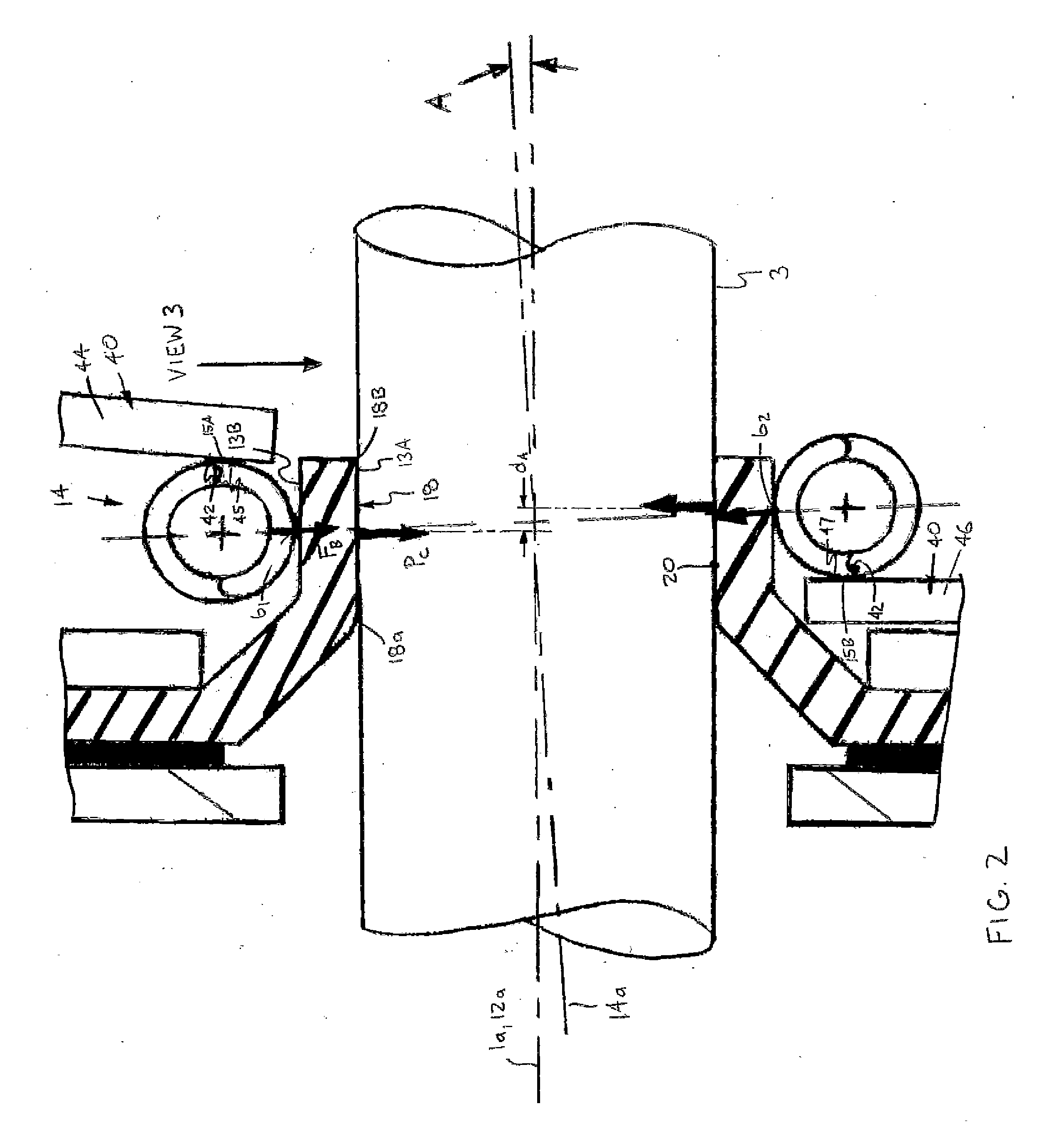

Pumping Seal Assembly with Angled Spring

InactiveUS20110316235A1Inhibit migrationAccounting for variationEngine sealsPiston ringsContact pressureDirect substance

A seal assembly is for sealing a space between a housing and a shaft rotatable about a central axis. The seal assembly includes a seal body connectable with the housing and having an inner circumferential sealing surface. The sealing surface has opposing axial ends and is slidably contactable with the shaft outer surface to define a sealing interface. An annular biasing member, preferably a garter spring, is disposed about a portion of the seal body and has a centerline. The biasing member exerts a biasing force directed radially inwardly toward the centerline, such that the seal exerts a contact pressure on the shaft. Further, the biasing member is angularly positioned on the seal body such that the contact pressure extends axially along the shaft axis to direct substances entering the sealing interface toward a proximal axial end of the sealing surface when the shaft rotates about the central axis.

Owner:AB SKF

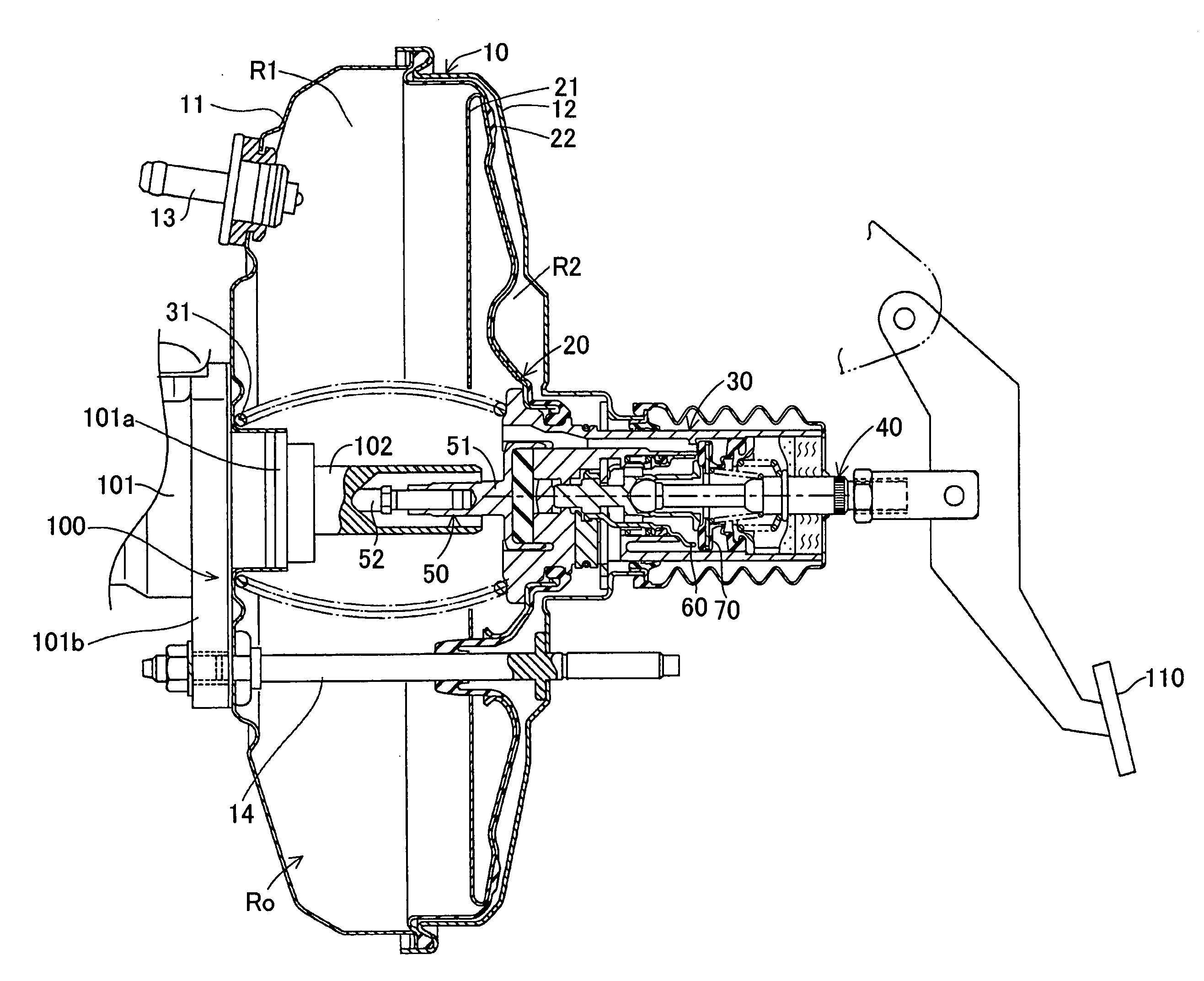

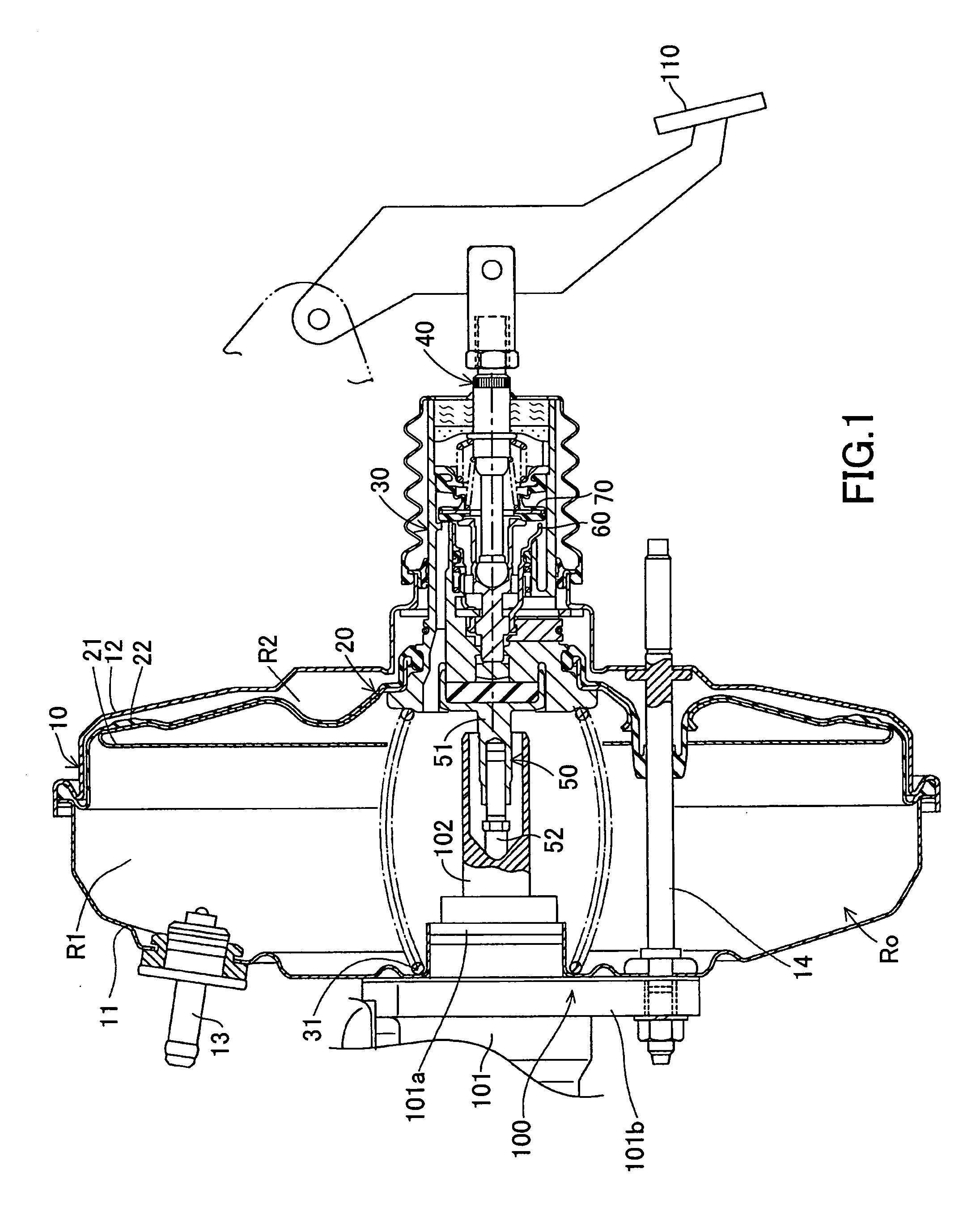

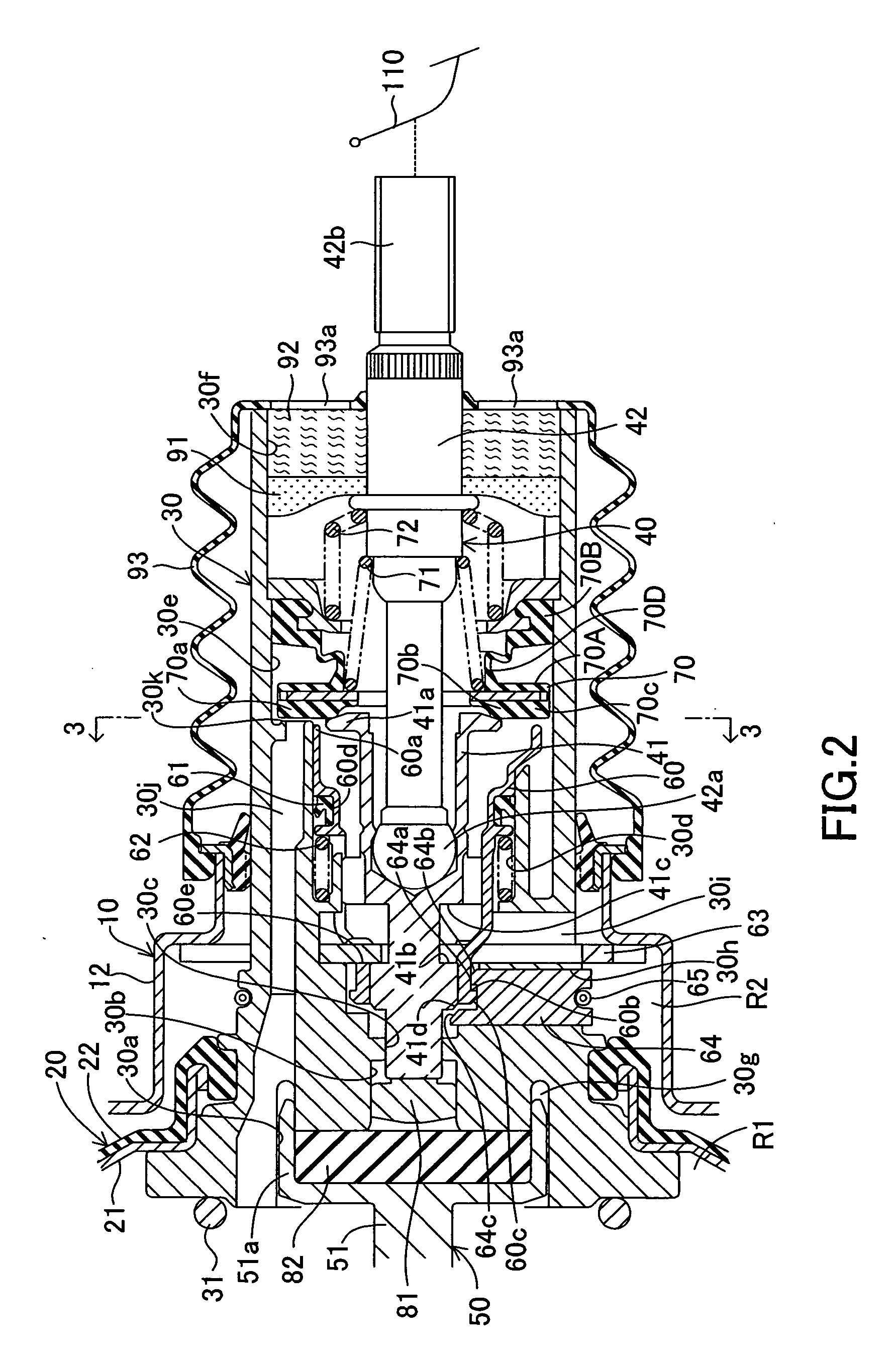

Negative pressure type booster

InactiveUS20050092167A1High strengthSimple configurationBraking action transmissionServomotorsSpool valveGarter spring

A negative pressure type booster includes a power piston, a slide valve, and a holding mechanism, among others, and assists a driver during emergency braking. The holding mechanism is adapted to hold the slide valve at a predetermined frontward position, and includes a latch member that is mounted to the power piston in such a manner as to be linearly movable in a radial direction, and a garter spring for biasing the latch member radially inward. The latch member has a hook that can be engaged with and disengaged from a hook provided on the slide valve. When a plunger moves frontward relative to the power piston by a quantity greater than a predetermined value, a push slope provided on the plunger pushes a passive slope provided on the latch member radially outward, whereby the hook of the latch member is disengaged from the hook of the slide valve.

Owner:ADVICS CO LTD

Pigtail spring contacts for implanted medical devices

Spring contact apparatus for an implantable medical device includes a plurality of nonconductive housing with each housing having a bore therethrough alignable with adjacent housing bores and assembled in spaced apart pairs with adjacent radial accesses to adjacent housing chambers. A plurality of electrically conductive garter springs are provided with the pairs of garter springs being disposed in corresponding adjacent housing chambers and each spring having a pigtail lead extending through a corresponding axis. The pairs of adjacent pigtail leads extending from adjacent axes are of sufficient length for a combined attachment to a corresponding pulse generator lead.

Owner:BAL SEAL ENG CO INC

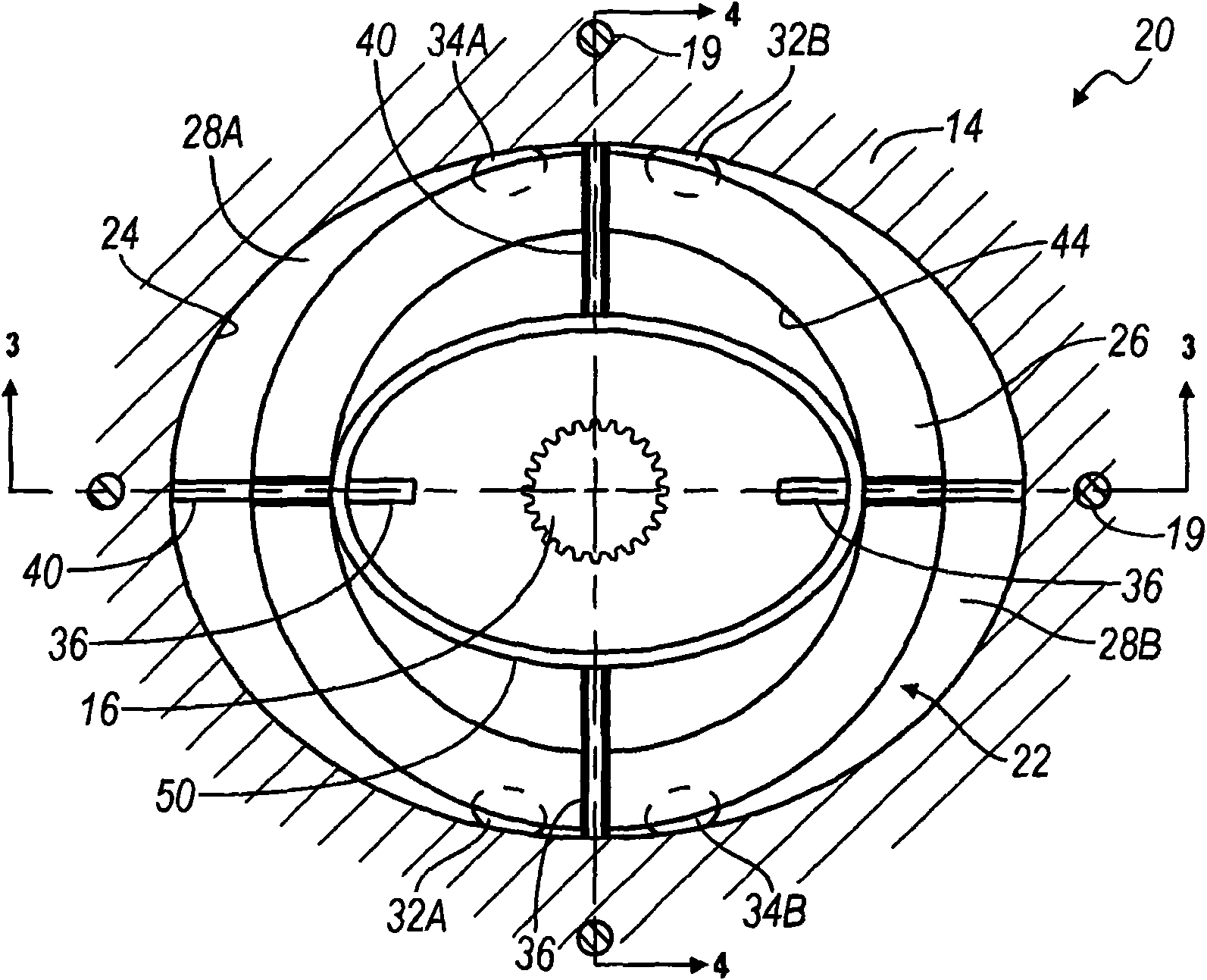

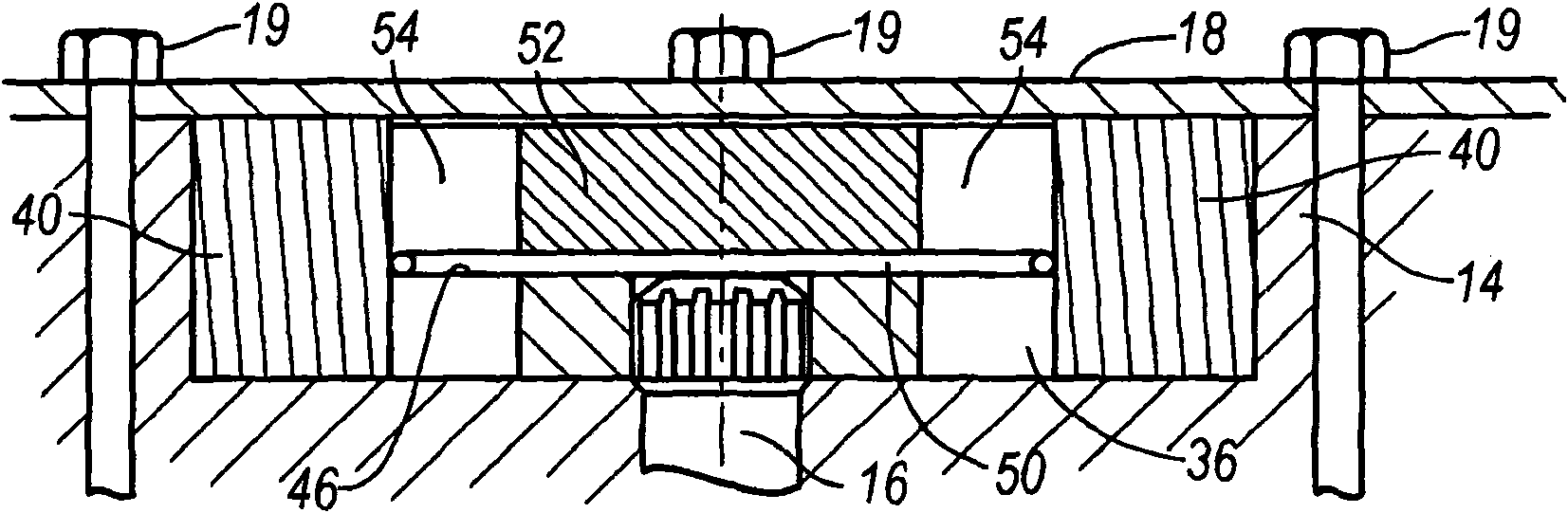

Self-priming vane pump

A self-priming vane pump includes a cylindrical rotor disposed in a cavity in a housing including inlet and outlet ports. The rotor defines a plurality of axially extending slots which each receive one of a like plurality of vanes. A garter spring or similar resilient annulus is disposed within the rotor and provides a radially outwardly directed force on the vanes which maintains their contact with the cavity walls during pump start-up and rapidly self-primes the pump. The spring or annulus rests against a shoulder within the hollow rotor and is retained therein by a pressed in collar.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pumping seal assembly with angled spring

InactiveUS8328201B2Inhibit migrationAccounting for variationEngine sealsPiston ringsContact pressureDirect substance

A seal assembly is for sealing a space between a housing and a shaft rotatable about a central axis. The seal assembly includes a seal body connectable with the housing and having an inner circumferential sealing surface. The sealing surface has opposing axial ends and is slidably contactable with the shaft outer surface to define a sealing interface. An annular biasing member, preferably a garter spring, is disposed about a portion of the seal body and has a centerline. The biasing member exerts a biasing force directed radially inwardly toward the centerline, such that the seal exerts a contact pressure on the shaft. Further, the biasing member is angularly positioned on the seal body such that the contact pressure extends axially along the shaft axis to direct substances entering the sealing interface toward a proximal axial end of the sealing surface when the shaft rotates about the central axis.

Owner:AB SKF

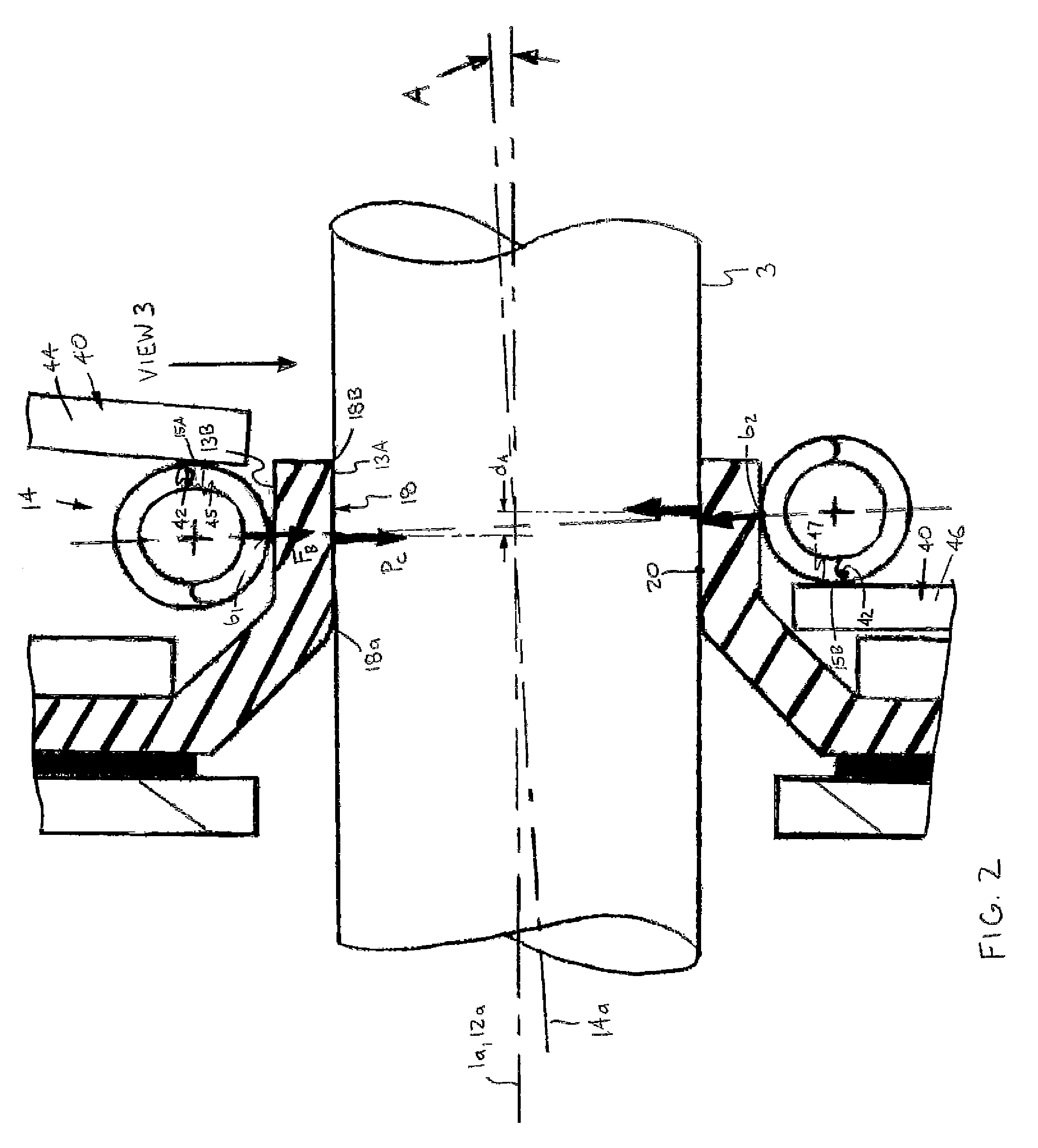

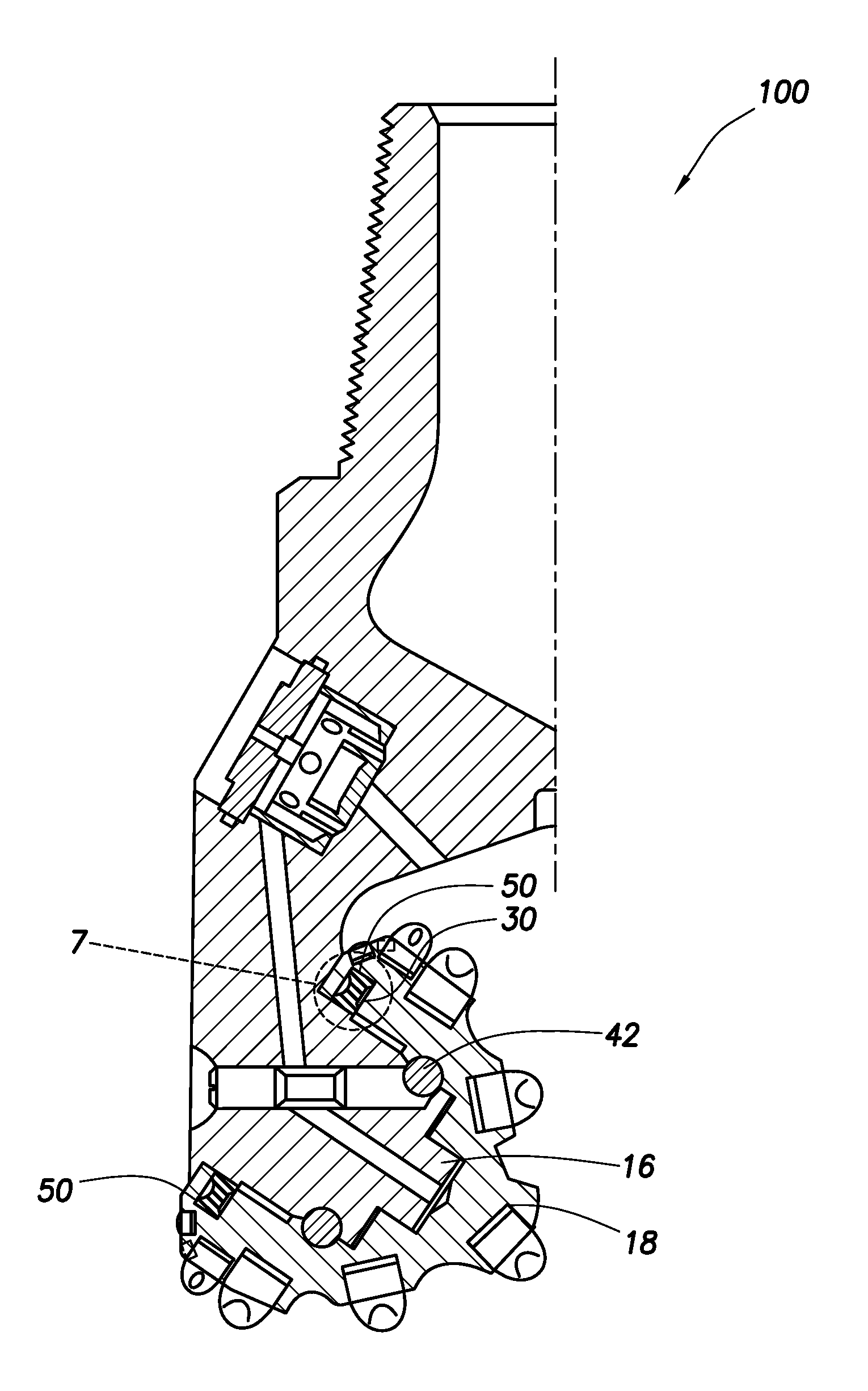

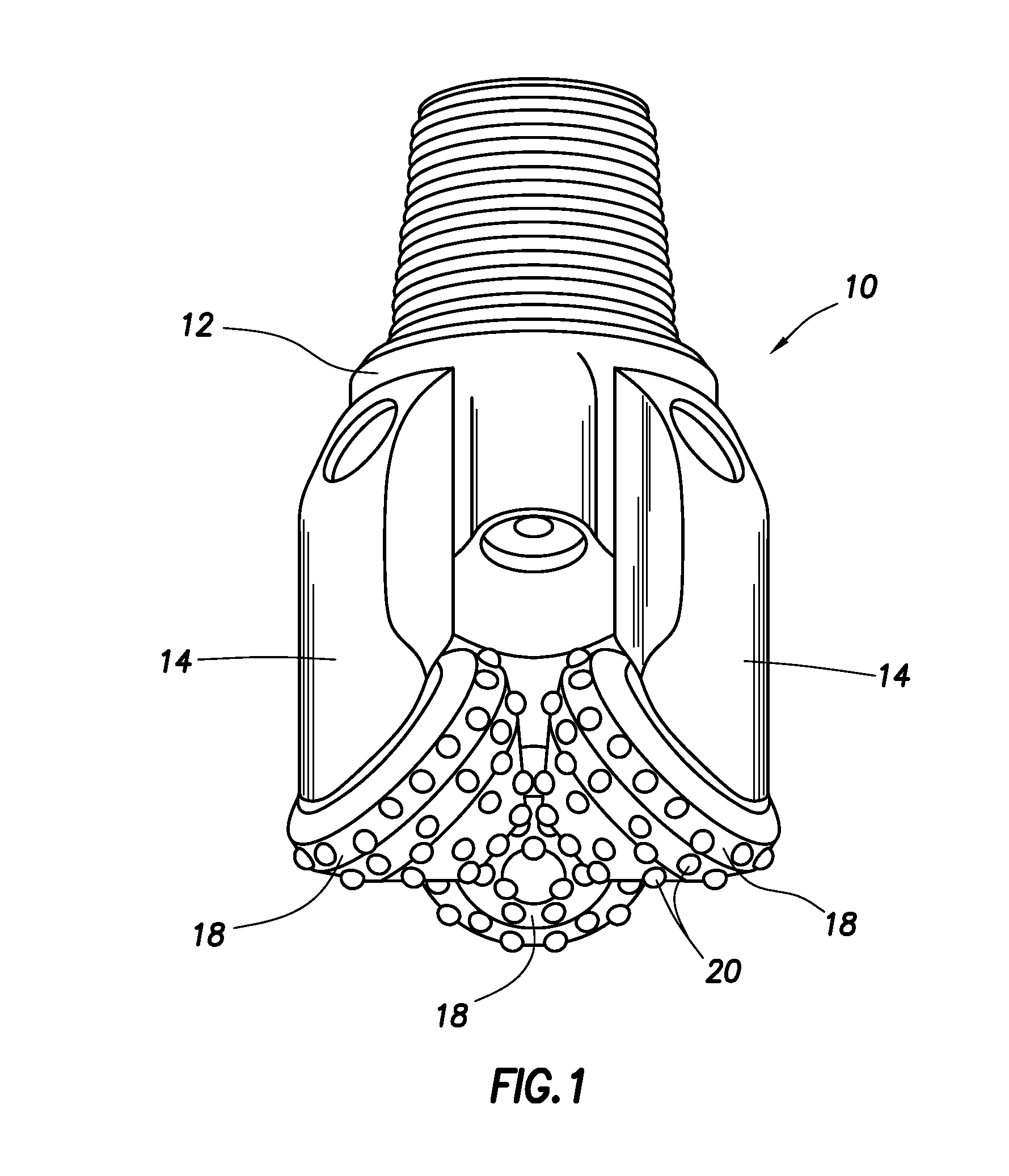

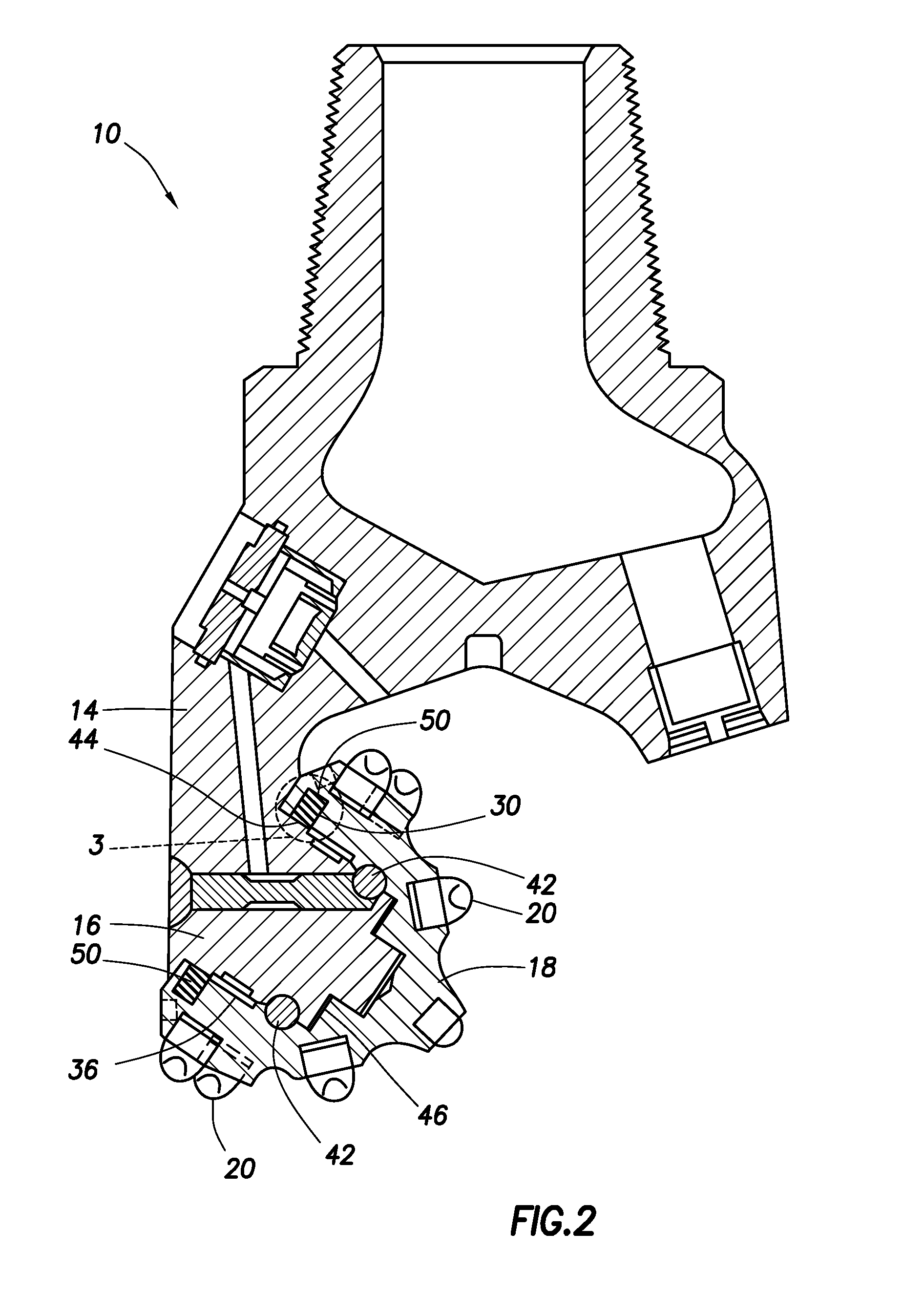

Drill bit seal and method of using same

A seal for a rolling cutter drill bit is provided. The seal has a ring shaped seal body having an inside diameter and an outside diameter, and a mud lobe and a grease lobe extending from the inside diameter of the seal body. The seal body has an asymmetrical, longitudinal cross-section such that, when positioned in a seal groove of the drill bit and compressed therein under downhole pressure, the mud lobe and grease lobe are maintained in contact with a seal land of the seal groove. The seal body may be provided with a garter spring and / or a textured pattern.

Owner:NAT OILWELL VARCO LP

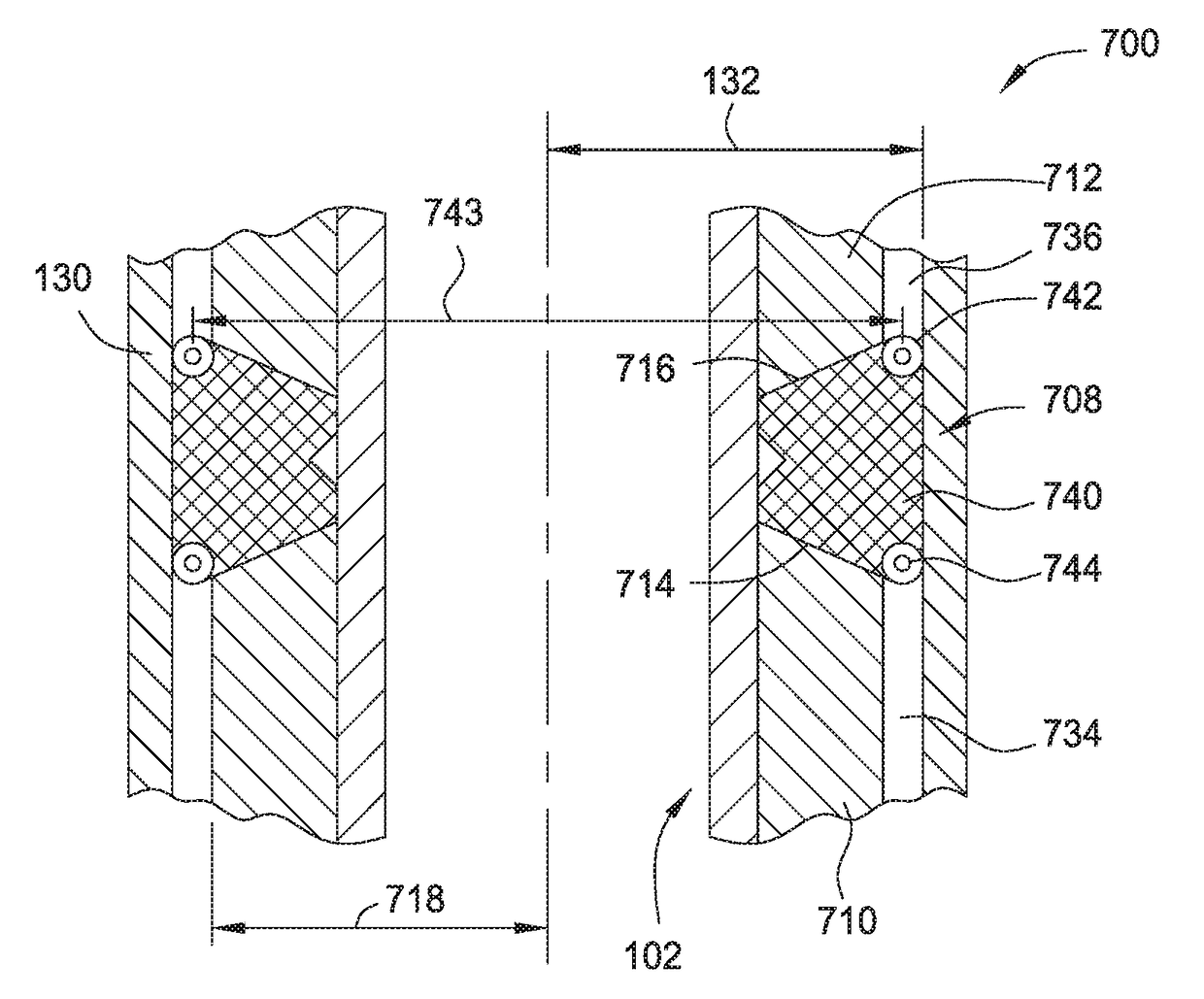

Anti-extrusion barrier for packing element

Embodiments of the present disclosure generally relate to an anti-extrusion device used in a packer or a bridge plug. The anti-extrusion device includes a garter spring and a support assembly having a ring shaped body disposed in an entire circumference of an inner volume of the garter spring. The ring shaped body expands with expansion of the garter spring while maintaining a continuous ring.

Owner:WEATHERFORD TECH HLDG LLC

Viscosity reduction stirrer on lower portion of pump

PendingCN107489408AReduce viscosityGood viscosity reduction effectTransportation and packagingRotary stirring mixersImpellerEngineering

Disclosed is a viscosity reduction stirrer on the lower portion of a pump. Fixing impeller shaft holes are transversely drilled in semicircular cylinder impeller frames, impeller grooves are formed in the semicircular cylinder impeller frames, and garter spring grooves are formed in the upper and lower ends of the semicircular cylinder impeller frames. Hyperbolic type columns are arranged in the middles of impellers. Blades are arranged at the two ends of the impellers. Rotating impeller shaft holes are drilled in the two end faces of the impellers. The impellers are placed in the impeller grooves and mounted on the impeller frames through impeller shafts inserted into the fixing impeller shaft holes and the rotating impeller shaft holes. The two impeller frames provided with the impellers are closed, a garter spring is mounted in each of the two garter spring grooves of the impeller frames, thus the impeller frames are made into a whole and then placed in the upper portion of a lower connector. The lower portion of an upper connector is connected with the upper portion of the lower connector. A hollow rod is inserted into the upper connector and penetrates through the lower connector. The inner sides of the two impellers are closely attached to the hollow rod so that the hollow rod can drive the impellers to rotate. Viscosity reduction agents injected from the hollow rod and well liquid can be stirred at the impellers when flowing upwards together, so that the viscosity reduction agents and the well liquid are uniformly mixed.

Owner:张秀梅

Sleeve seal for electric furnace electrodes

A highly flexible sealing arrangement designed to seal high-temperature furnace ports, particularly the electrode port of an electric furnace. The seal comprises an annular support member fixed to a flexible sealing member and employs the use of a garter spring to uniformly apply the desired amount of seal compression. The arrangement and flexibility of the sealing member allows the seal to adapt itself to the wide range of operating and upset conditions that typically exist for a furnace electrode seal. Frictional wear on the seal may be greatly reduced as the design inherently allows for a much lower amount of seal compression to be applied, furthermore, the seal is able to move axially which can significantly reduce wear caused by electrode regulation.

Owner:HATCH LTD

Radial shaft seal with large radial offset accommodation

Owner:FREUDENBERG NOK GEN PARTNERSHIP

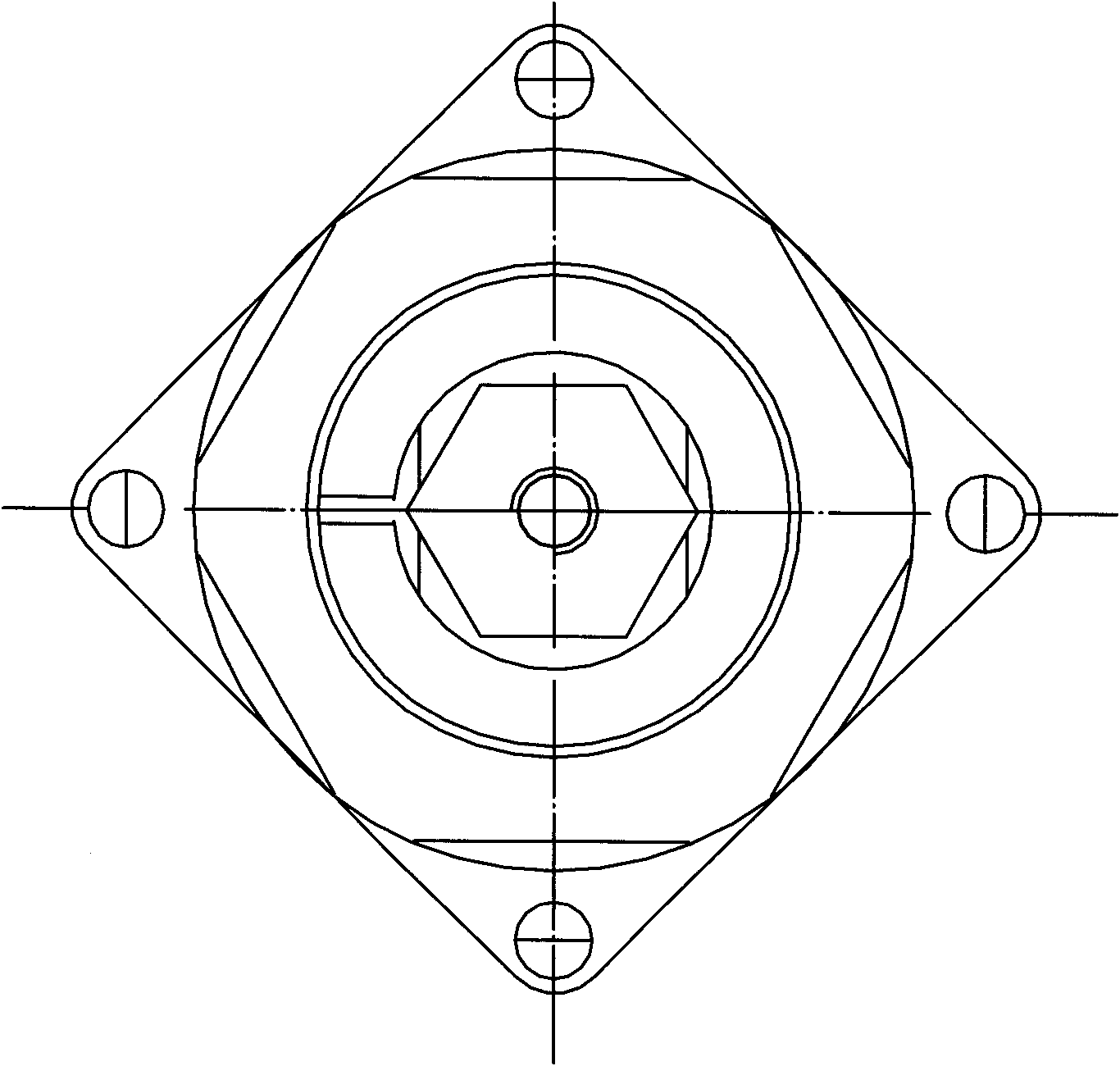

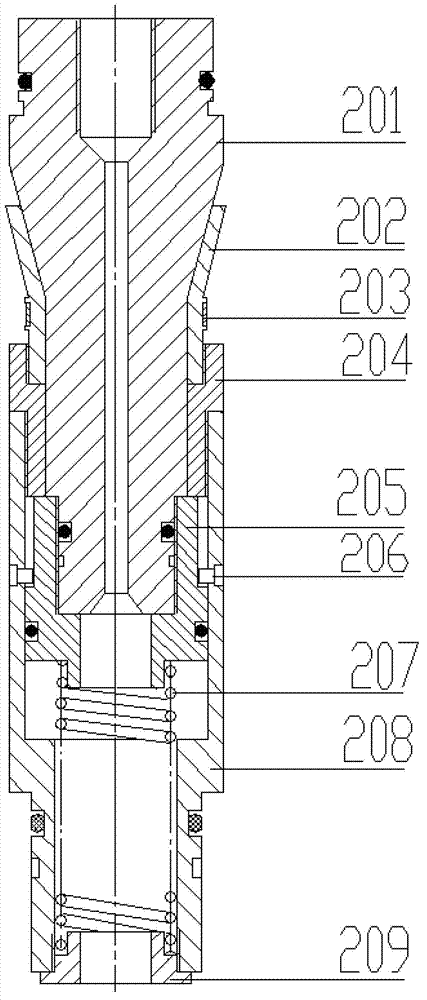

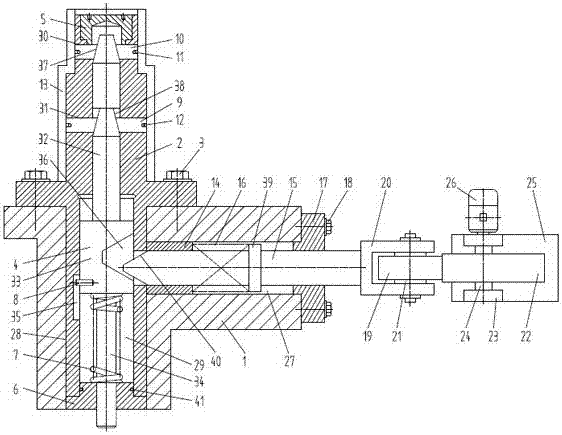

Centering and clamping device for stepped sleeve

PendingCN106914762AAchieve releaseEasy loading and unloadingPositioning apparatusGrinding work supportsEngineeringCam

The invention provides a centering and clamping device for a stepped sleeve, and belongs to the technical field of machining. The centering and clamping device comprises a slide bar and a wedge post, wherein the slide bar is arranged on a slide bar sliding chute of a supporting shaft seat in an upward / downward sliding way through a guide segment; an anti-rotation pin shaft is inserted into an anti-rotation guide groove; upper centering and clamping blocks are arranged on upper centering grooves of the supporting shaft seat in a radial sliding way; the inner sides of the upper centering and clamping blocks fit upper conical rings on centering segments of the slide bar; upper garter springs are arranged on the three upper centering and clamping blocks in an encircling way; lower centering and clamping blocks are arranged on lower centering grooves of the supporting shaft seat in a radial sliding way; the inner sides of the lower centering and clamping blocks fit lower conical rings on the centering segments of the slide bar; lower garter springs are arranged on the three lower centering and clamping blocks in an encircling way; the wedge post is arranged on a guide sliding sleeve in a leftward / rightward sliding way; a V-shaped wedge block is arranged at the left end of the wedge post; a cam fits a support roller. By adopting the centering and clamping device, centering and clamping of the stepped sleeve are realized rapidly, and the stepped sleeve is convenient for charging and discharging.

Owner:TONGXIANG BAIBAO E COMMERCE CO LTD

Stretchable electrode and method of making physiologic measurements

InactiveUS20110251470A1Reliable low impedanceGood electrical contactSensorsBlood characterising devicesElectrical conductorElastic substrate

A stretchable electrode for use in physiologic measurements on a human body, such as peripheral impedance plethysmography, is disclosed. One embodiment of the stretchable electrode comprises an uninsulated stainless steel wire braid formed into a tubular conductor surrounding an elastic core and attached to an elastic substrate or base. Other embodiments of the stretchable electrode include a garter spring, a flat braided or woven conductor and an undulating wire. The electrode may be placed about a limb of a human body and elastically stretched so that the conductor is in substantially continuous circumferential electrical contact with the skin of the limb. A method of attaching the stretchable electrode to the limb of a human body is also disclosed.

Owner:SMITHMARKS INC

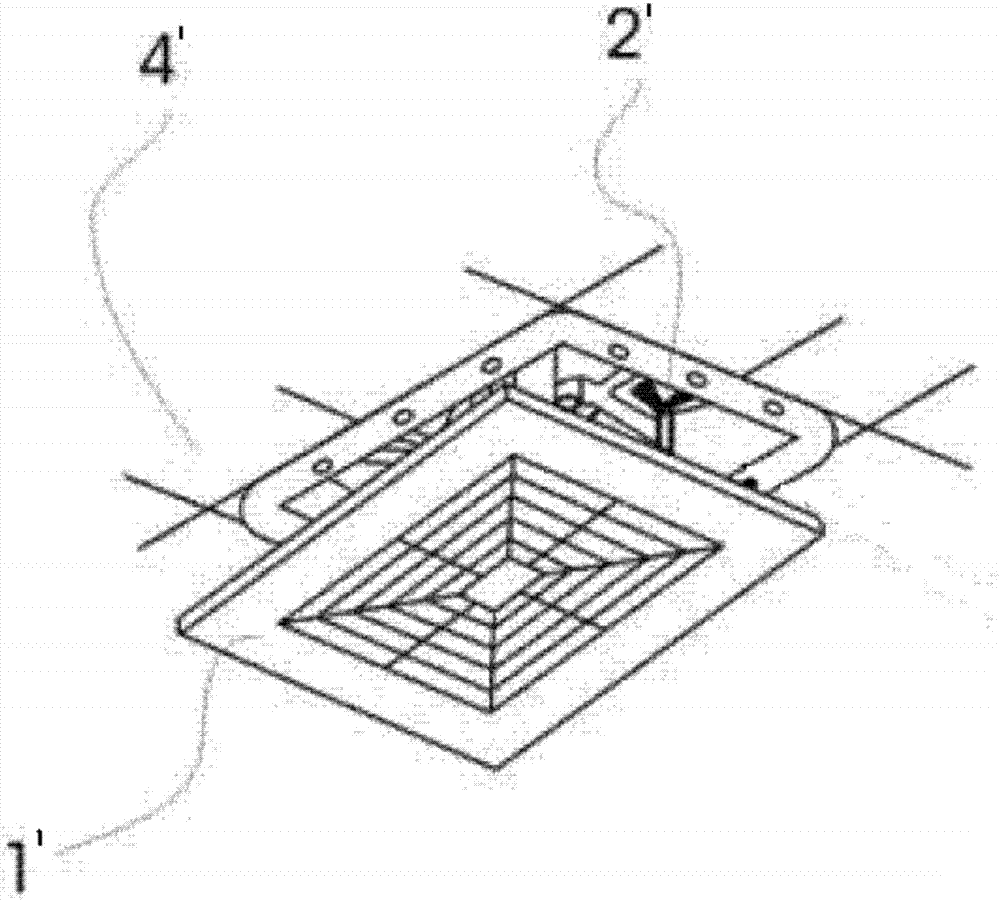

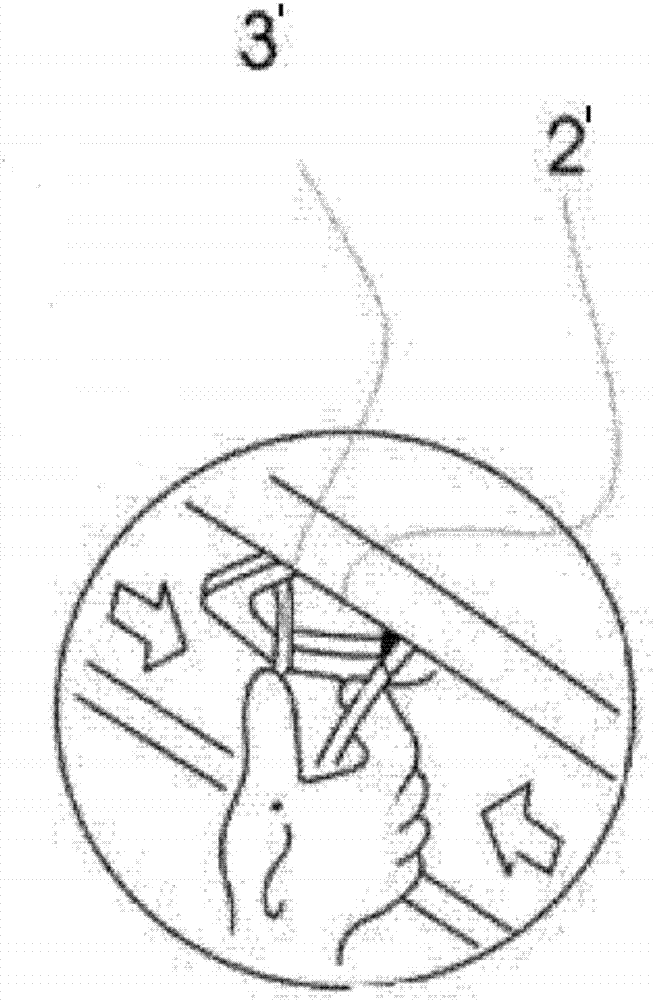

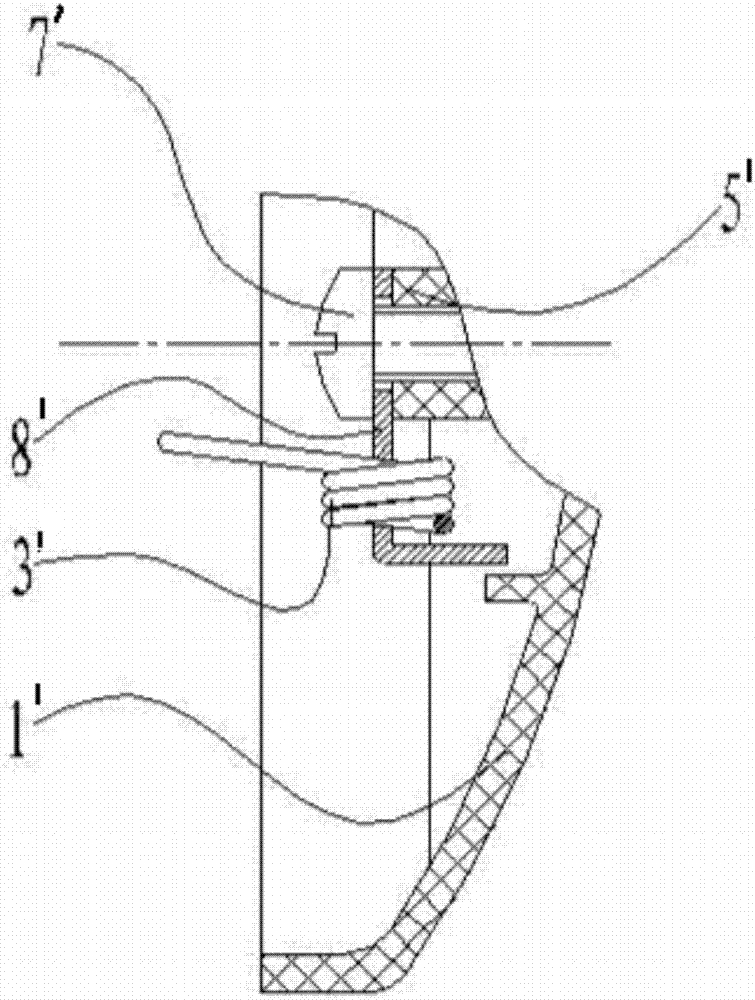

Anti-drop mounting mechanism of ventilator panel

PendingCN106931579AEasy to installReduce processLighting and heating apparatusHeating and ventilation casings/coversEngineeringStructural engineering

The invention relates to an anti-drop mounting mechanism of a ventilator panel. The anti-drop mounting mechanism of the ventilator panel comprises a garter spring, a blocking arm and a ventilator panel. The garter spring comprises a spring ring and strips extending from two ends of the spring ring in the radial direction. A suspension arm transversally stretches out of the ventilator panel, and the spring ring is sleeved on the suspension arm; the blocking arm is arranged to block the end the suspension arm, the blocking arm comprises a supporting part which vertically stretches out of ventilator panel, the top end of the supporting part is higher than the suspension arm, a suspension part transversally stretches out of the top end of the supporting part in an opposite direction as the suspension arm, the suspension part partially overlaps with the portion of the suspension arm in the vertical direction, and thus a channel the spring ring can penetrate through is formed. By adoption of the mounting structure, no auxiliary tool is needed. The blocking arm and the suspension arm apply stress to each other to prevent the garter spring from getting loose simply; what's more, the suspension part of the blocking arm can serve as a second suspension arm to fasten the spring ring even if the spring ring slips out of the suspension arm.

Owner:GUANGDONG NEDFON INDOOR AIR SYST TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com