Viscosity reduction stirrer on lower portion of pump

A technology of agitator and oil pump, which is applied to mixers with rotary stirring devices, chemical instruments and methods, and production of fluids, etc. Simple structure and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

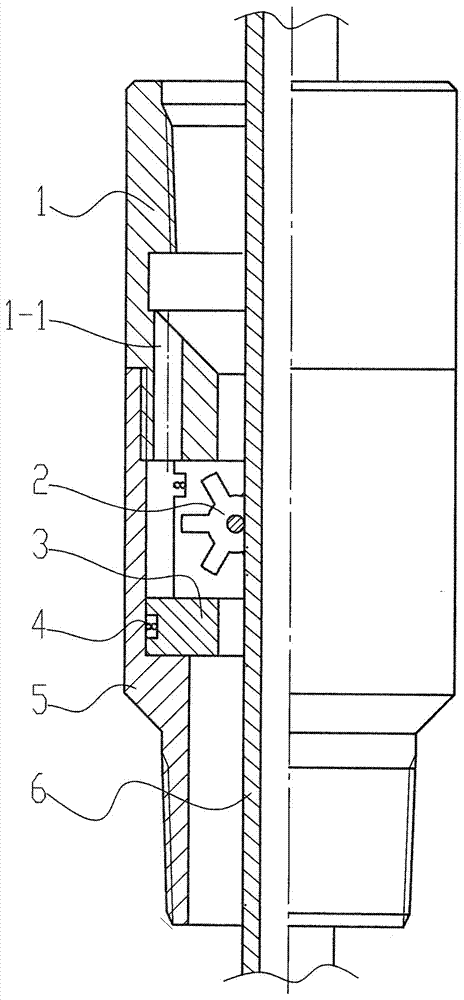

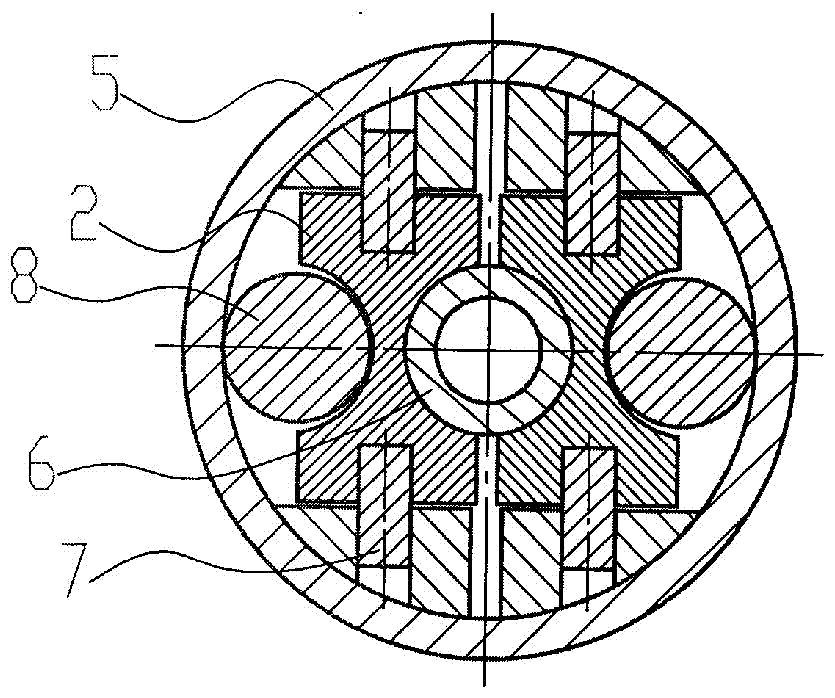

[0011] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

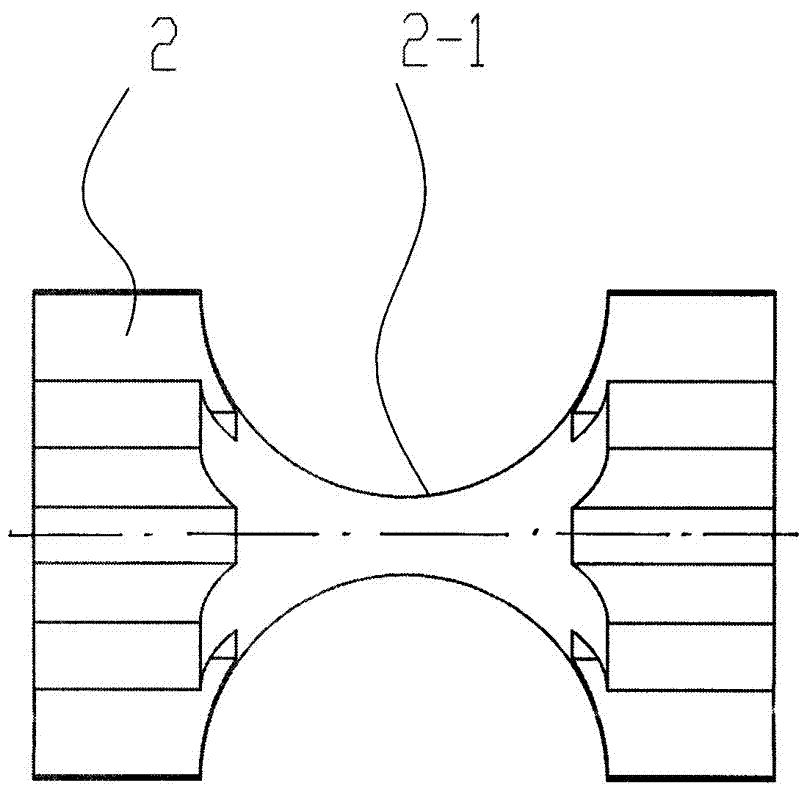

[0012] As can be seen from the figure, the embodiment of the present invention includes an upper joint 1, an impeller 2, an impeller frame 3, a hoop spring 4, a lower joint 5, a hollow rod 6, and an axle 7. Movement, horizontally drill a fixed axle hole 3-1 on the semi-cylindrical impeller frame 3, set up an impeller groove 3-2 on the semi-cylindrical impeller frame 3, and open hoop spring grooves at the upper and lower ends of the semi-cylindrical impeller frame 3 3-3, the middle of the impeller 2 is a hyperbolic cylinder 2-1, the arc radius of the hyperbolic cylinder 2-1 matches the outer wall of the hollow rod 6 (so that they can be in close contact with each other), There are blades 2-2 at both ends of the impeller 2, and a rotating shaft hole 2-3 (blind hole) is drilled on both ends of the impeller 2. The two rotating shaft holes 2-3 drilled on both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com