Self-priming vane pump

A vane pump, self-priming technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve the problems of long time, low running speed, low sealing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is merely exemplary in nature and does not limit the disclosure and its application or uses.

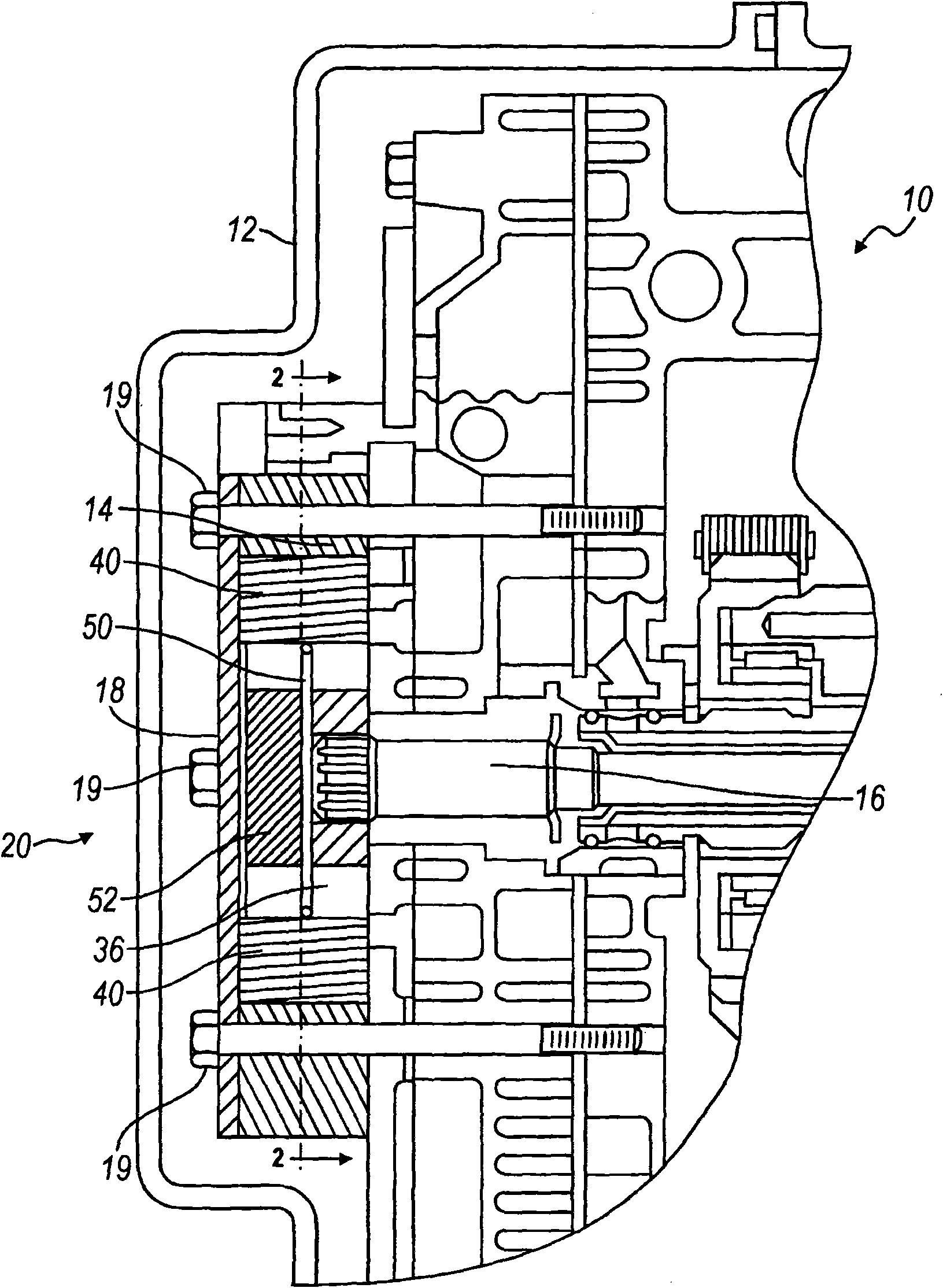

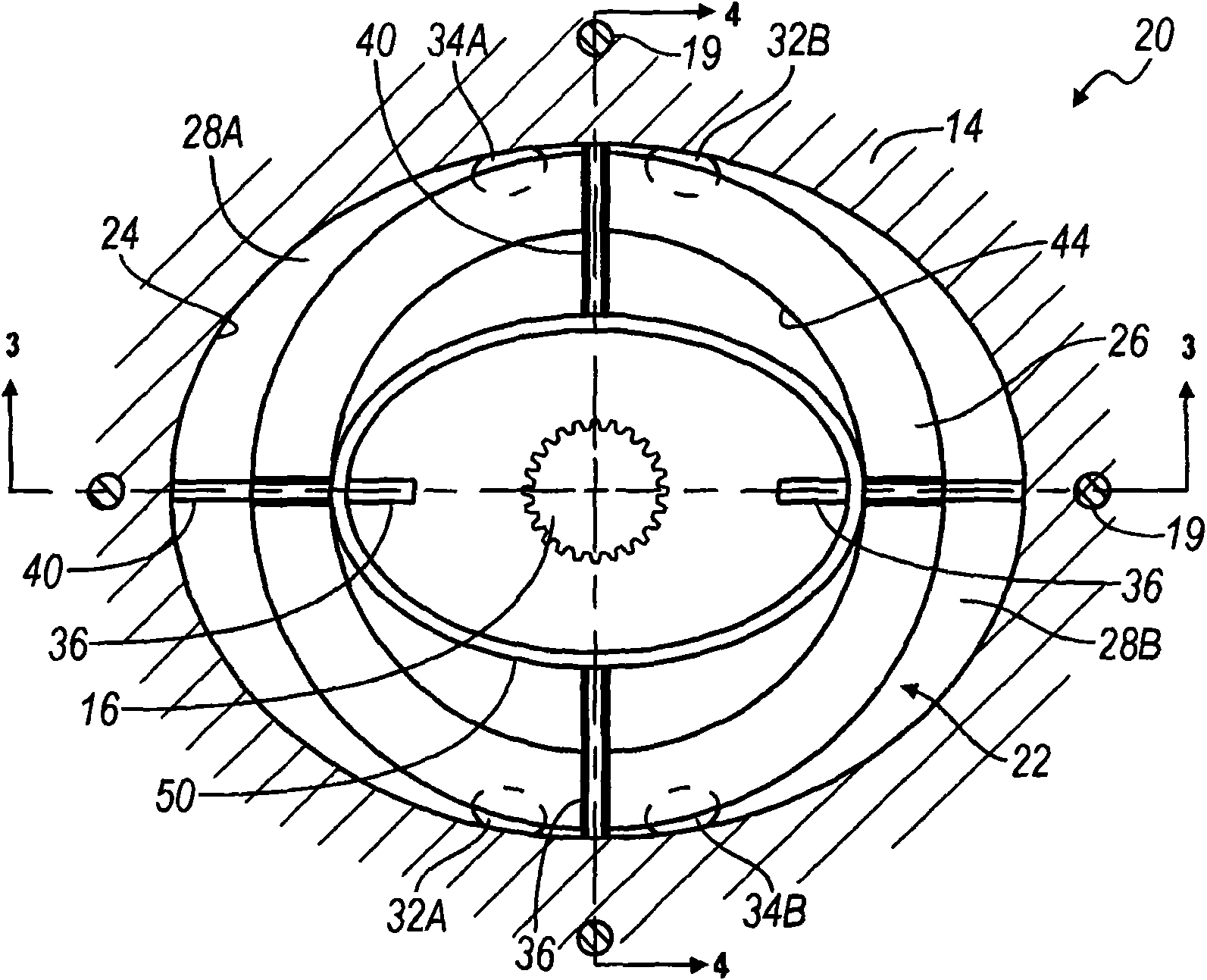

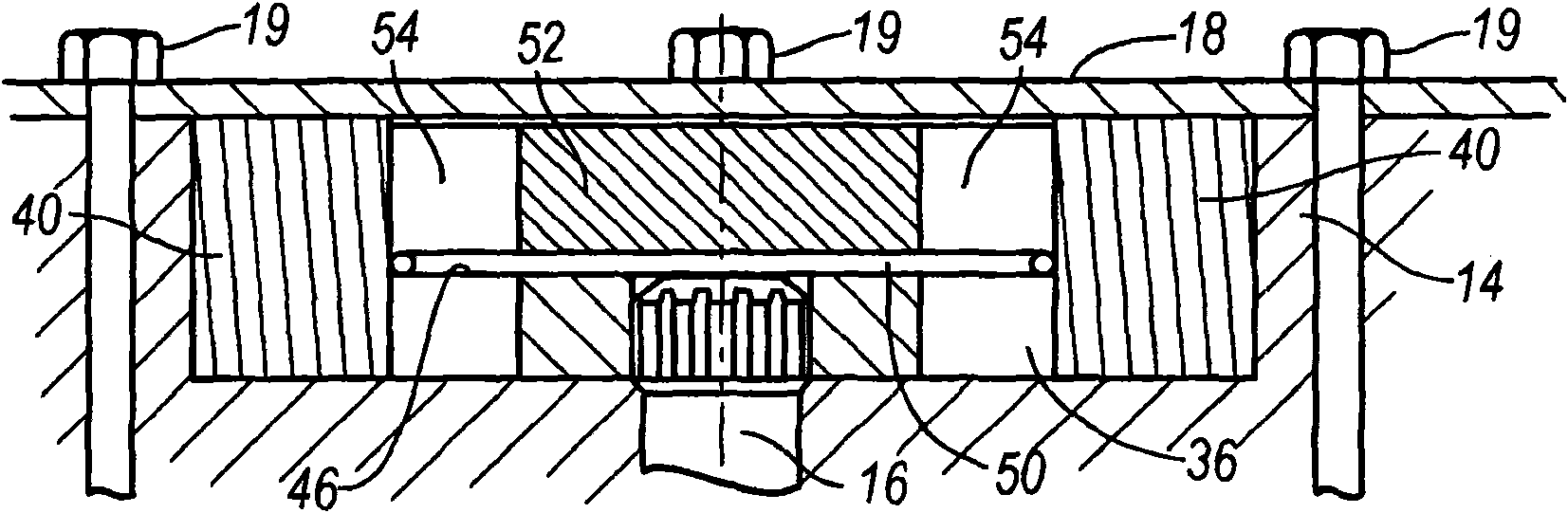

[0021] refer to figure 1 , shows a portion of an automatic transmission incorporating the present invention, generally indicated by reference numeral 10 . The automatic transmission 10 includes a housing 12, figure 1 Part of it is shown in . Housing 12 encloses and protects various components of automatic transmission 10 , such as vane pump housing 14 and drive shaft 16 supported in vane pump housing 14 . A front plate 18 , held by suitable fasteners such as bolts 19 , closes the front side of the vane pump housing 14 . Drive shaft 16 drives a vane pump 20 incorporating the present invention. Vane pump 20 draws hydraulic fluid or oil from an oil sump (not shown) in transmission housing 12 and provides this hydraulic fluid or oil under pressure to various control circuits and devices (not shown) of automatic transmission 10 . ) and bearings, clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com