Anti-drop mounting mechanism of ventilator panel

An installation mechanism and ventilation fan technology, applied in the field of ventilation fans, can solve the problems of high cost, time-consuming and laborious, and achieve the effects of eliminating the process of screwing, stable structure, and convenient and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

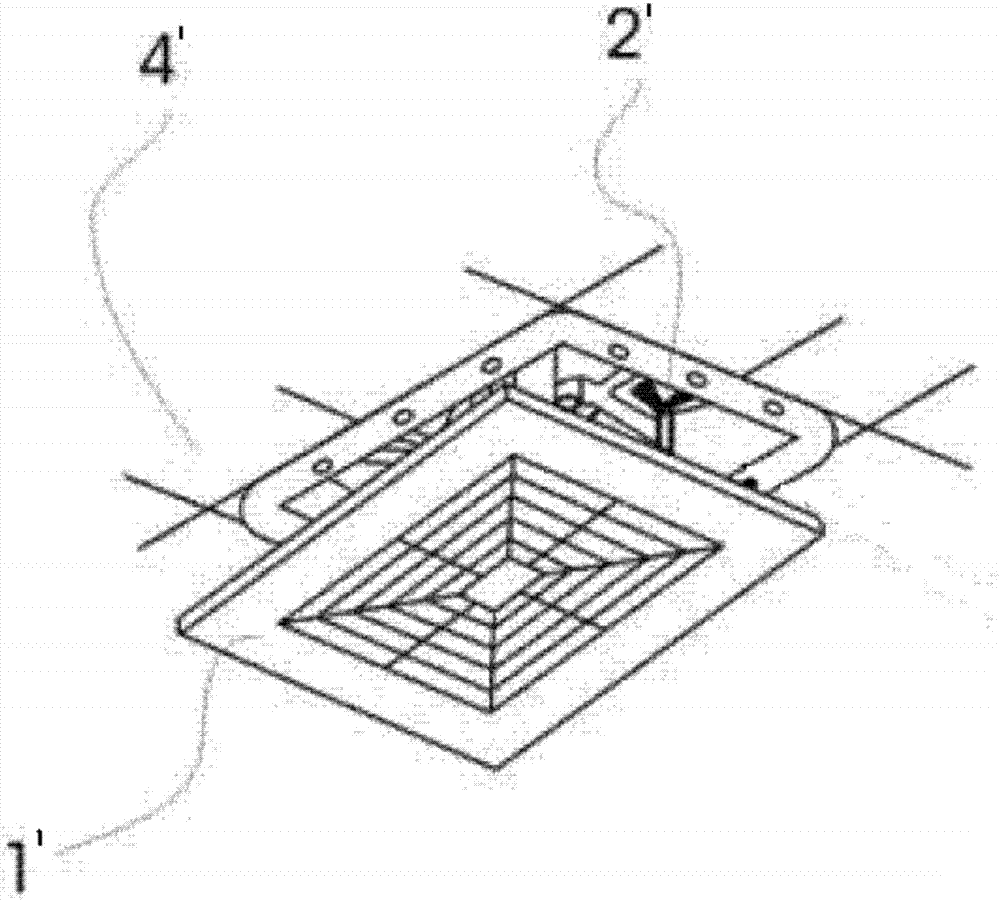

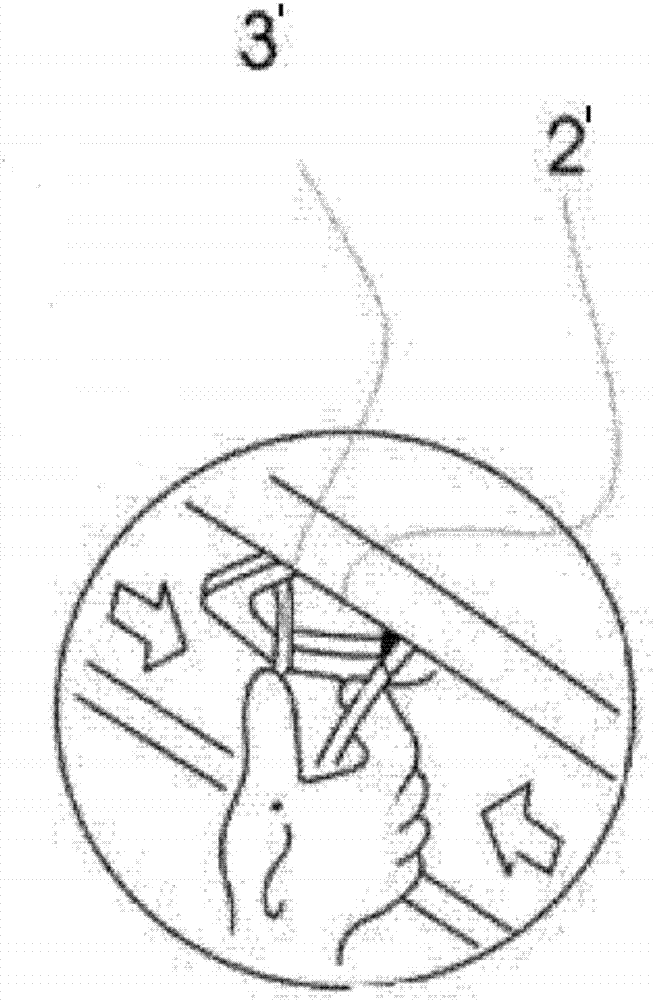

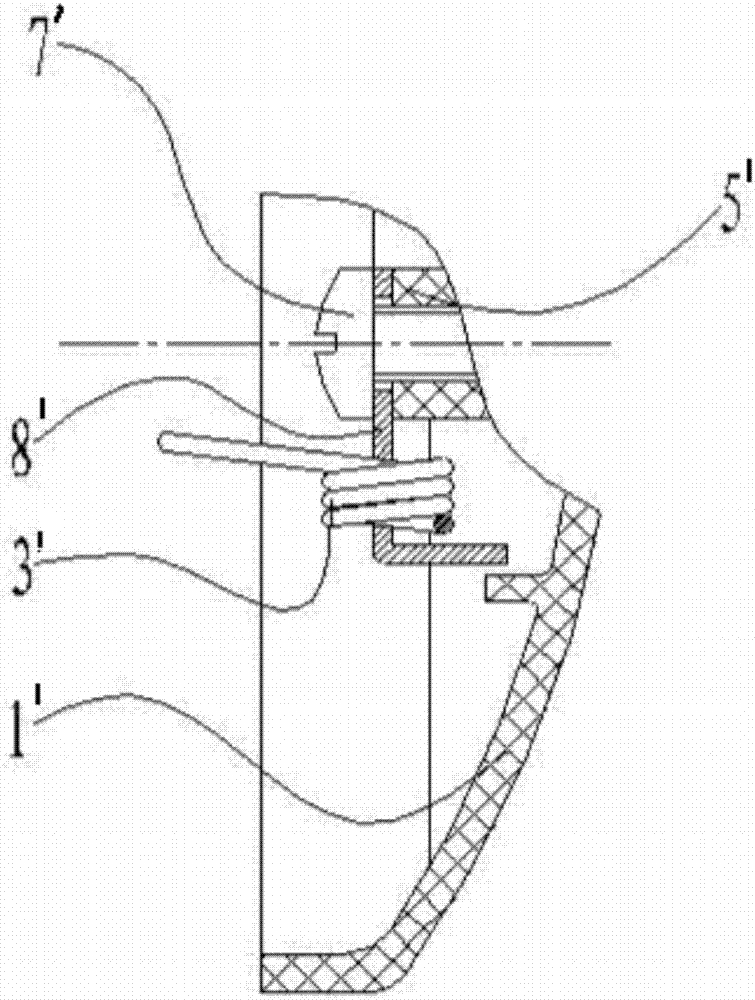

[0022] like Figure 4 , Figure 5 and Image 6 as shown, Figure 4 It is a structural schematic diagram of the installation mechanism of the anti-falling ventilation fan panel of the present invention, Figure 5 It is a cross-sectional view of the installation mechanism of the anti-falling ventilation fan panel of the present invention, Image 6 It is a structural schematic diagram of the clamping spring.

[0023] An anti-falling ventilation fan panel installation mechanism, including a clamping spring 1 and a ventilation fan panel 2, the clamping spring 1 includes a spring ring 11 and clip strips 12 extending from the radial ends of the spring coil 11, the ventilation fan panel 2 The suspension arm 3 extends horizontally from the top, and the spring ring 11 of the clamping spring 1 can be inserted into the suspension arm 3, and then the clip strips 12 protruding from the two ends of the spring ring 11 are inserted into the preset card position of the ceiling and Clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com