Wheel bearing sealing device

A technology of wheel bearings and sealing devices, which is applied in bearing assembly, bearings, axles, etc., can solve problems such as muddy water ingress, sealing device damage, sealing member fastening force and follow-up ability degradation, etc., so as to improve the sealing performance and eliminate the sealing performance The effect of the change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] One embodiment of the present invention will be described with reference to the drawings.

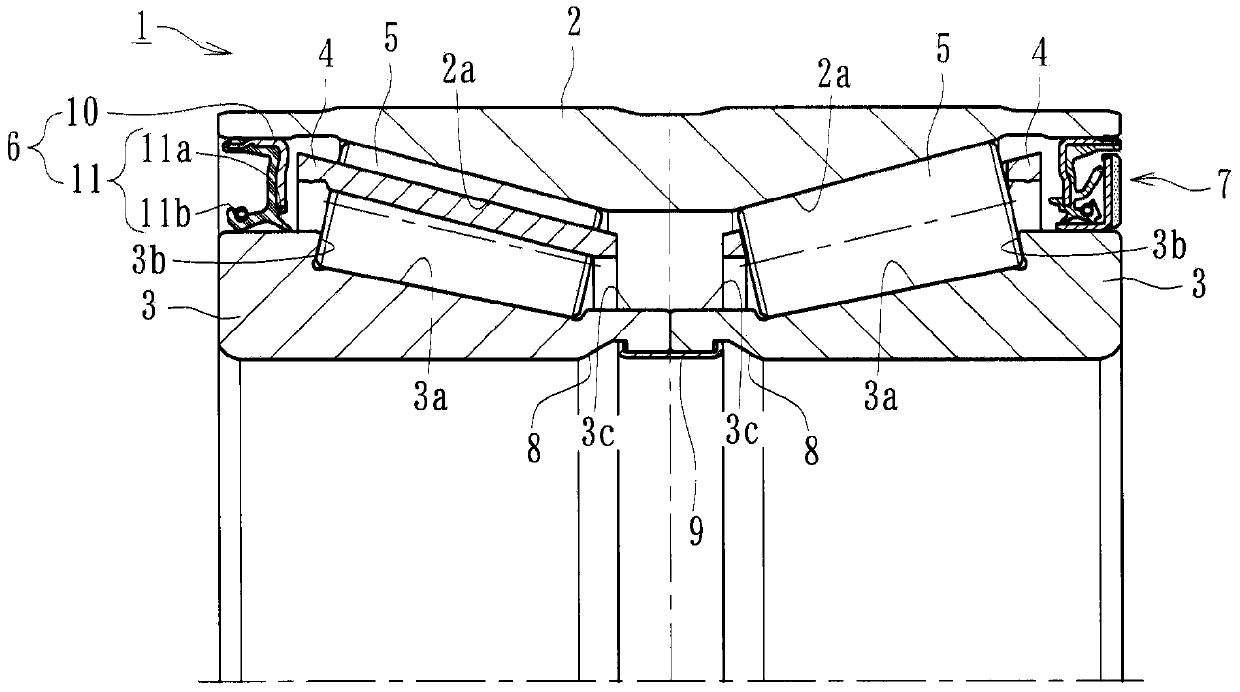

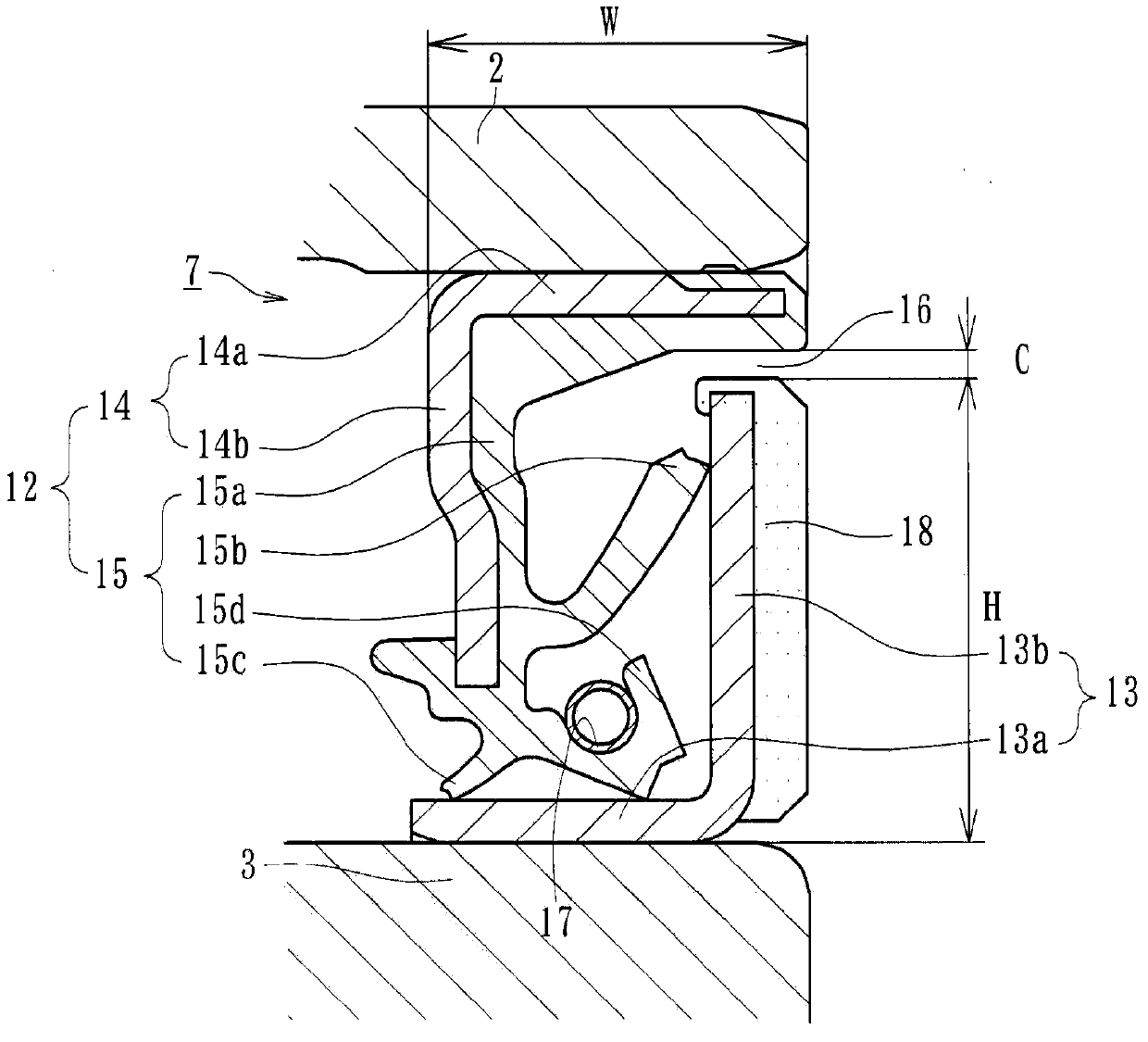

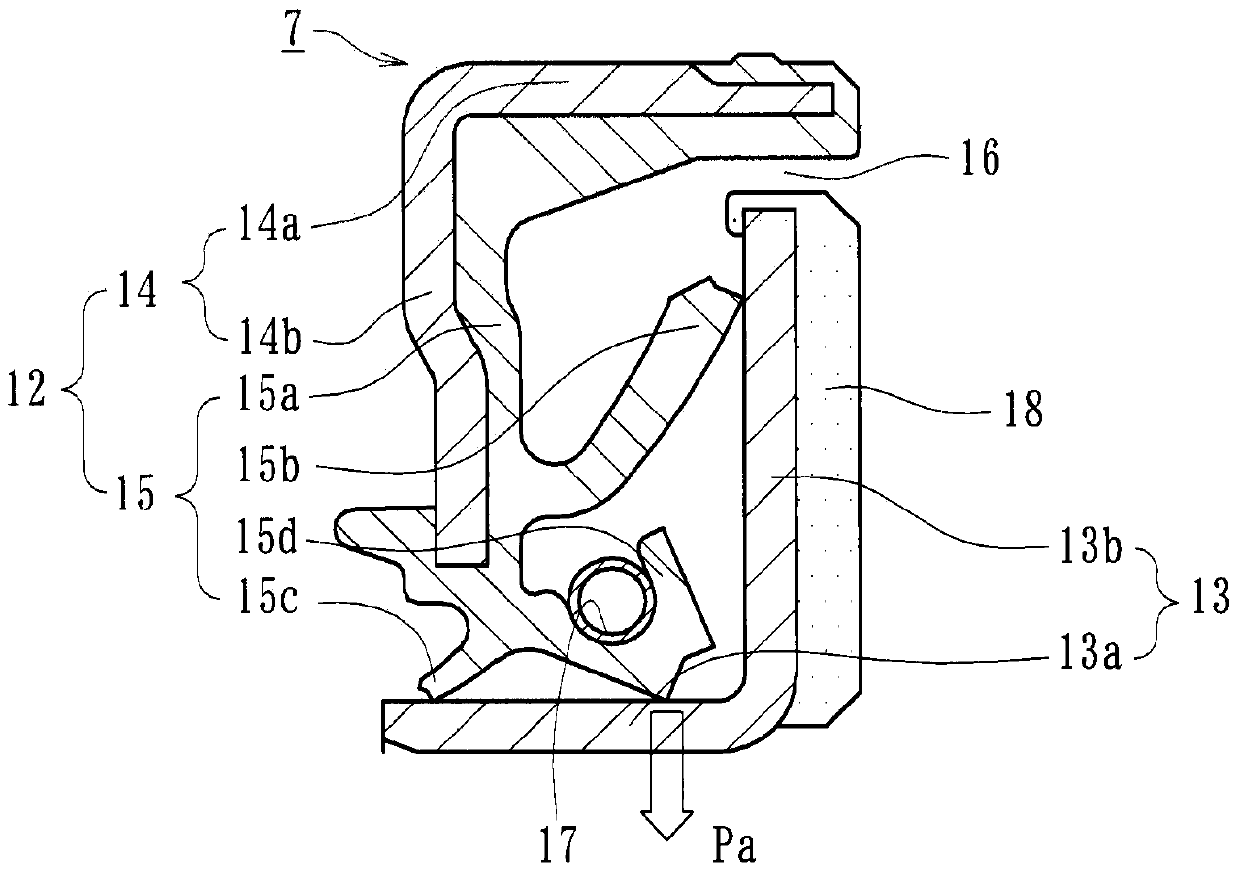

[0036] figure 1 is a longitudinal section of an embodiment of the wheel bearing sealing device of the present invention; figure 2 yes figure 1 A partially enlarged view showing a sealing device; image 3 is showing figure 2 An explanatory diagram of the total fastening force of the sealing device; Figure 4 is an explanatory diagram showing the fastening force under the condition that the dust lip is not provided with a clamping coil spring; Figure 5 is a graph showing the measurement results of the fastening force of the radial lip under a severe environment at normal temperature; and Figure 6 It is a graph showing the measurement results of the fastening force of the radial lip in a severe environment of low temperature. In the description of this specification, the outer side of the sealing device when installed on the vehicle is referred to as "outer side" ( fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com