Patents

Literature

303results about How to "Won't scatter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

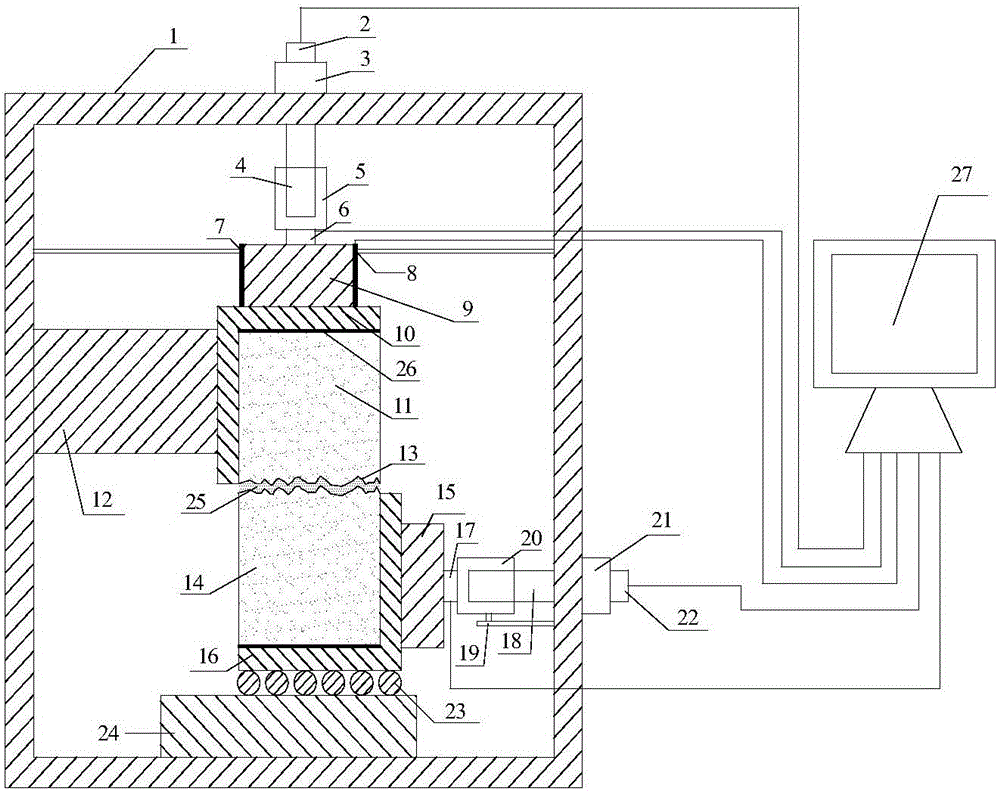

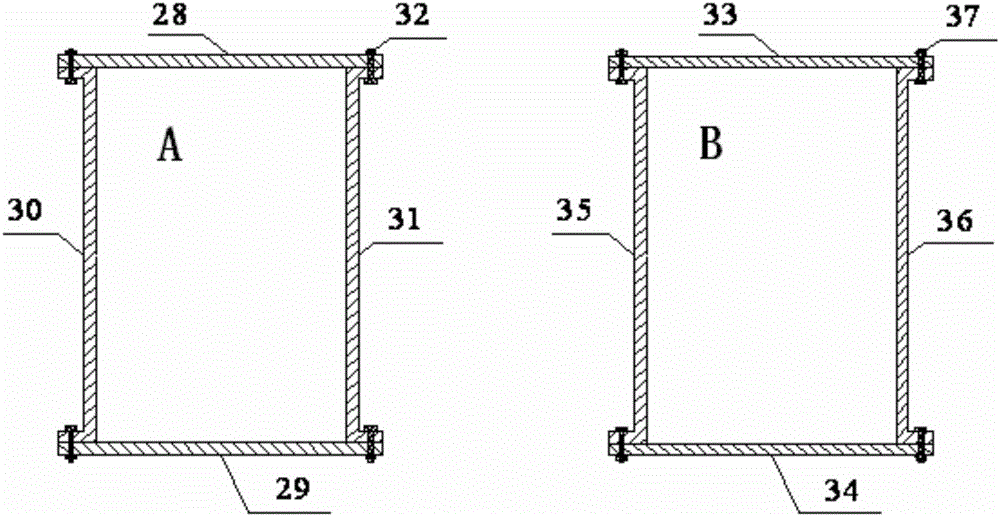

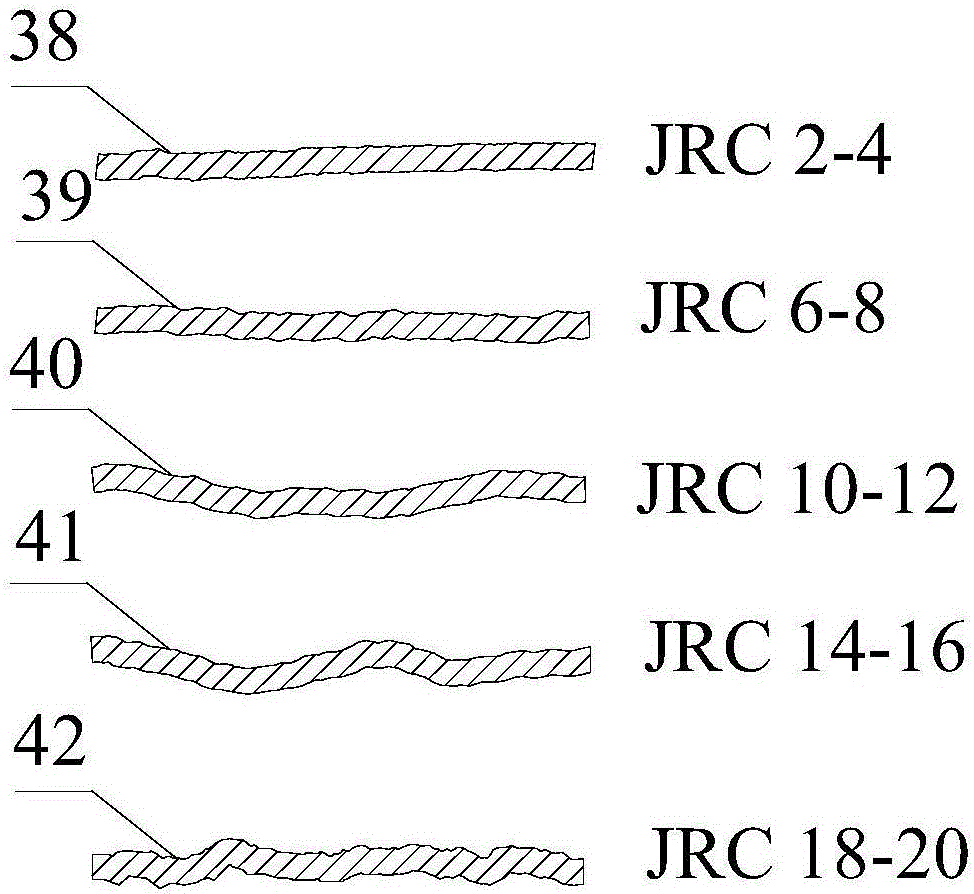

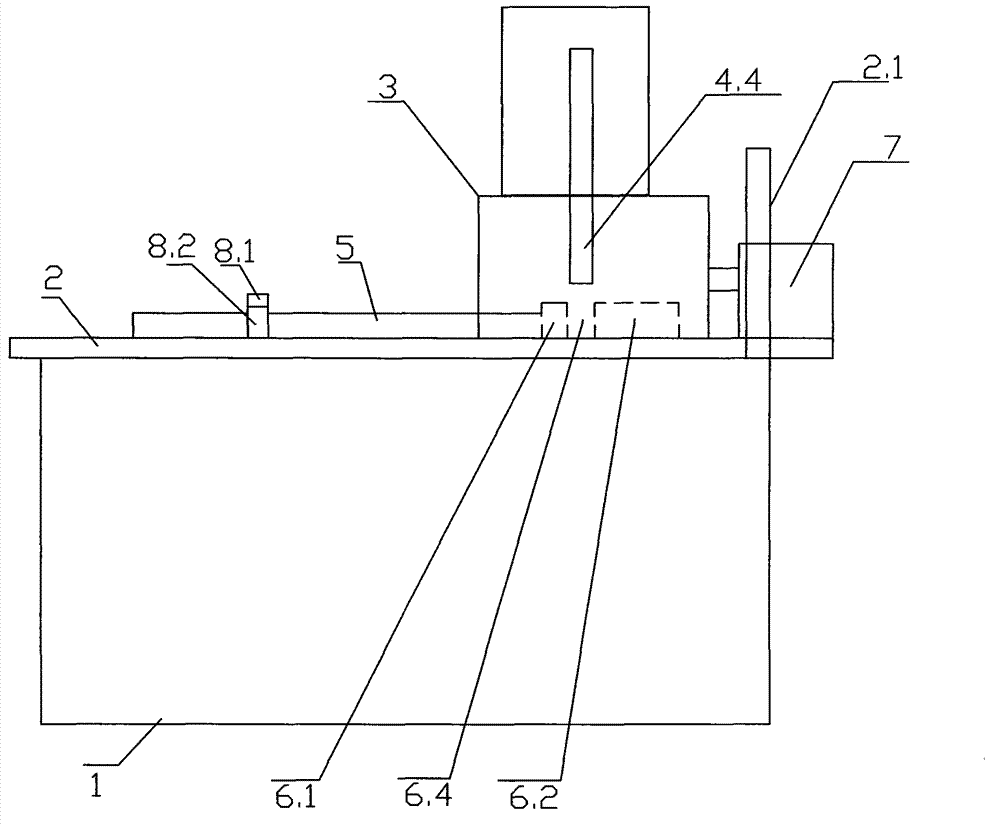

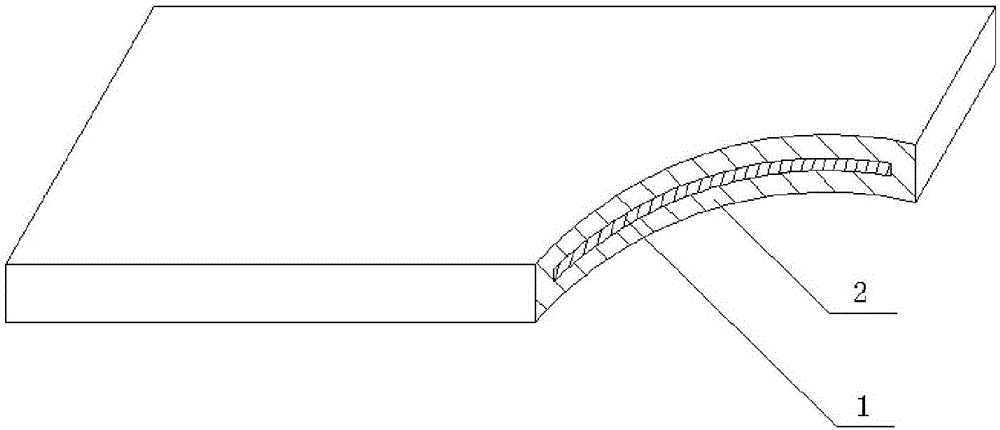

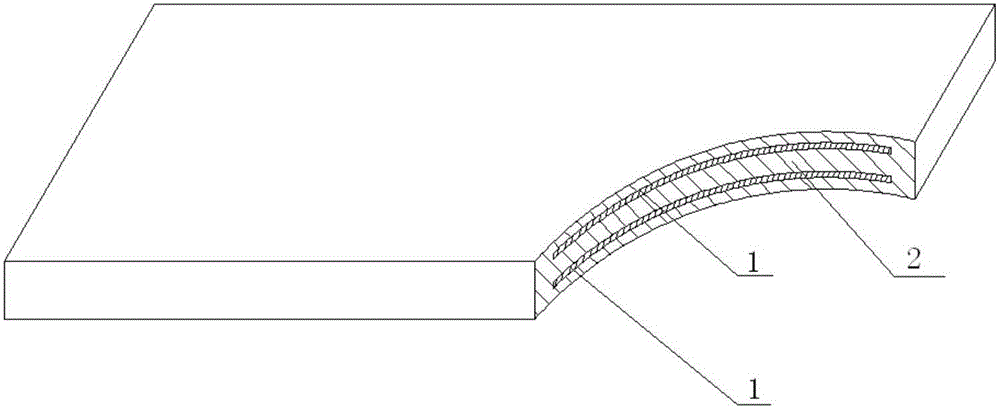

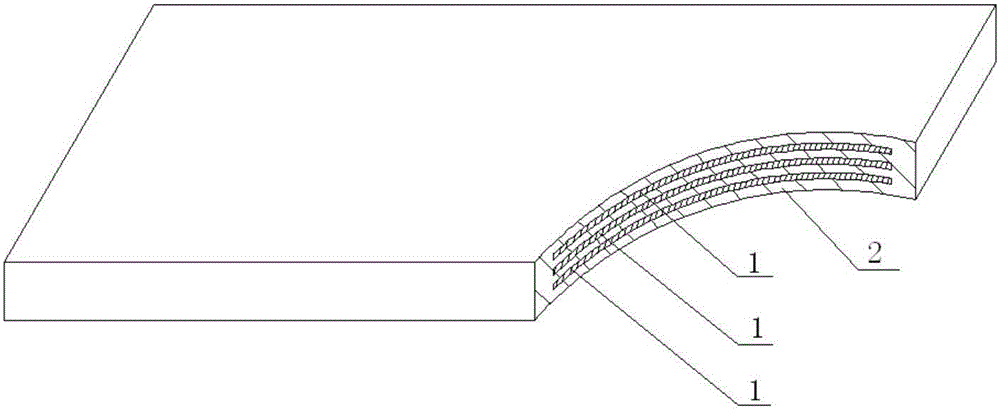

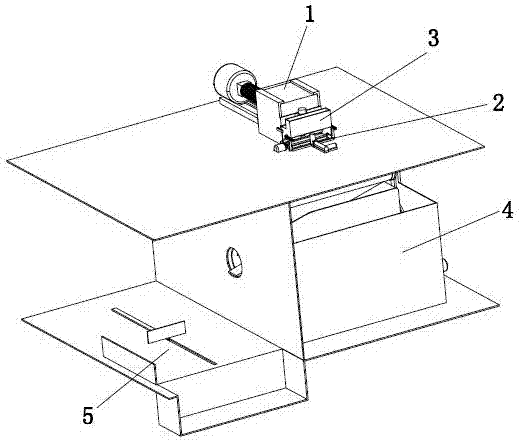

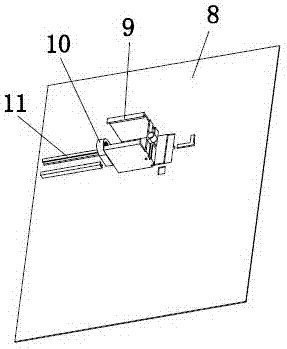

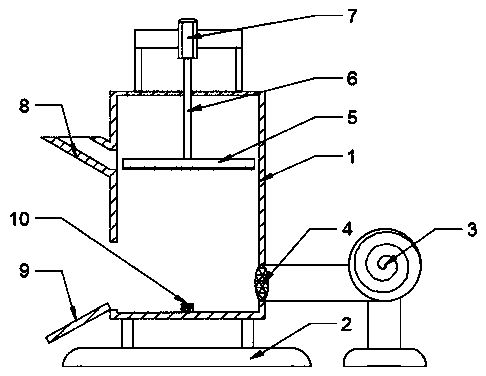

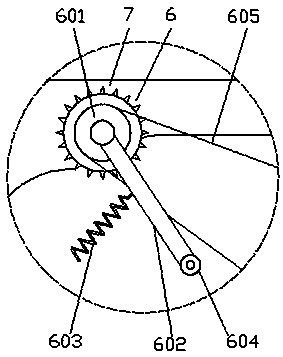

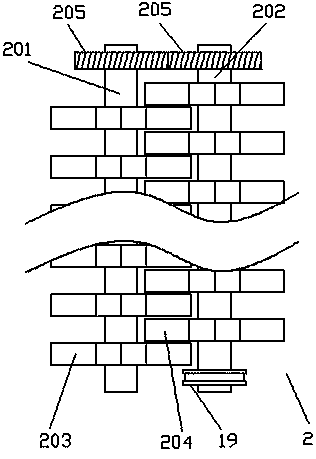

Device and method for preparing rock-like material structural plane and utilizing rock-like material structural plane to shearing test

ActiveCN106092695ASimple installation and disassemblyWon't scatterPreparing sample for investigationMaterial strength using steady shearing forcesStructure of the EarthData acquisition

The invention relates to a device and method for preparing a rock-like material structural plane and utilizing the rock-like material structural plane to a shearing test. The device comprises a test part manufacturing system, a test part system, a loading system and a data acquisition system. The device provided by the invention can realize preparation of the rock-like material structural plane and a weak intercalated layer structural plane containing different fillers, and researches on shearing properties of the structural plane can be realized.

Owner:HUNAN UNIV OF SCI & TECH

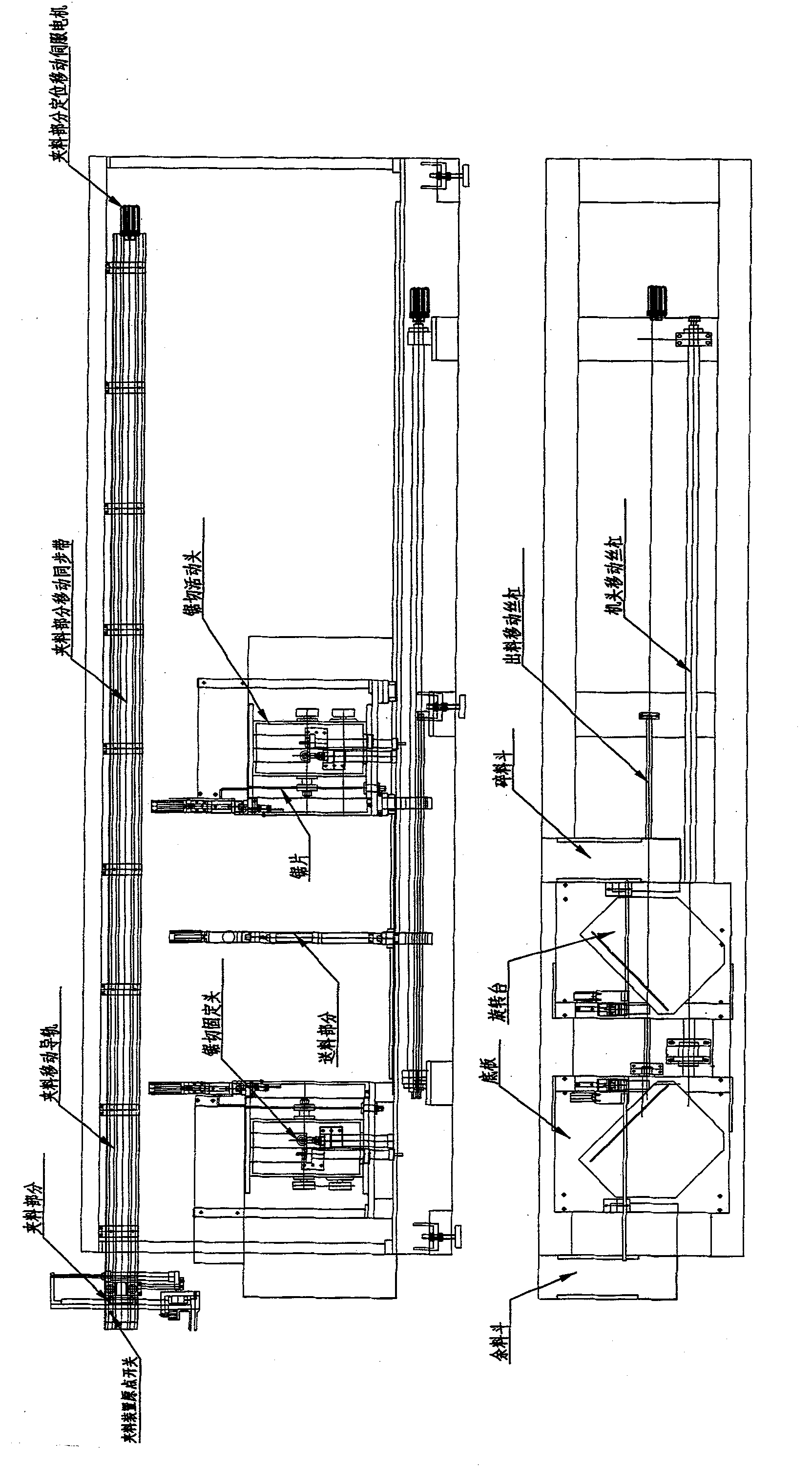

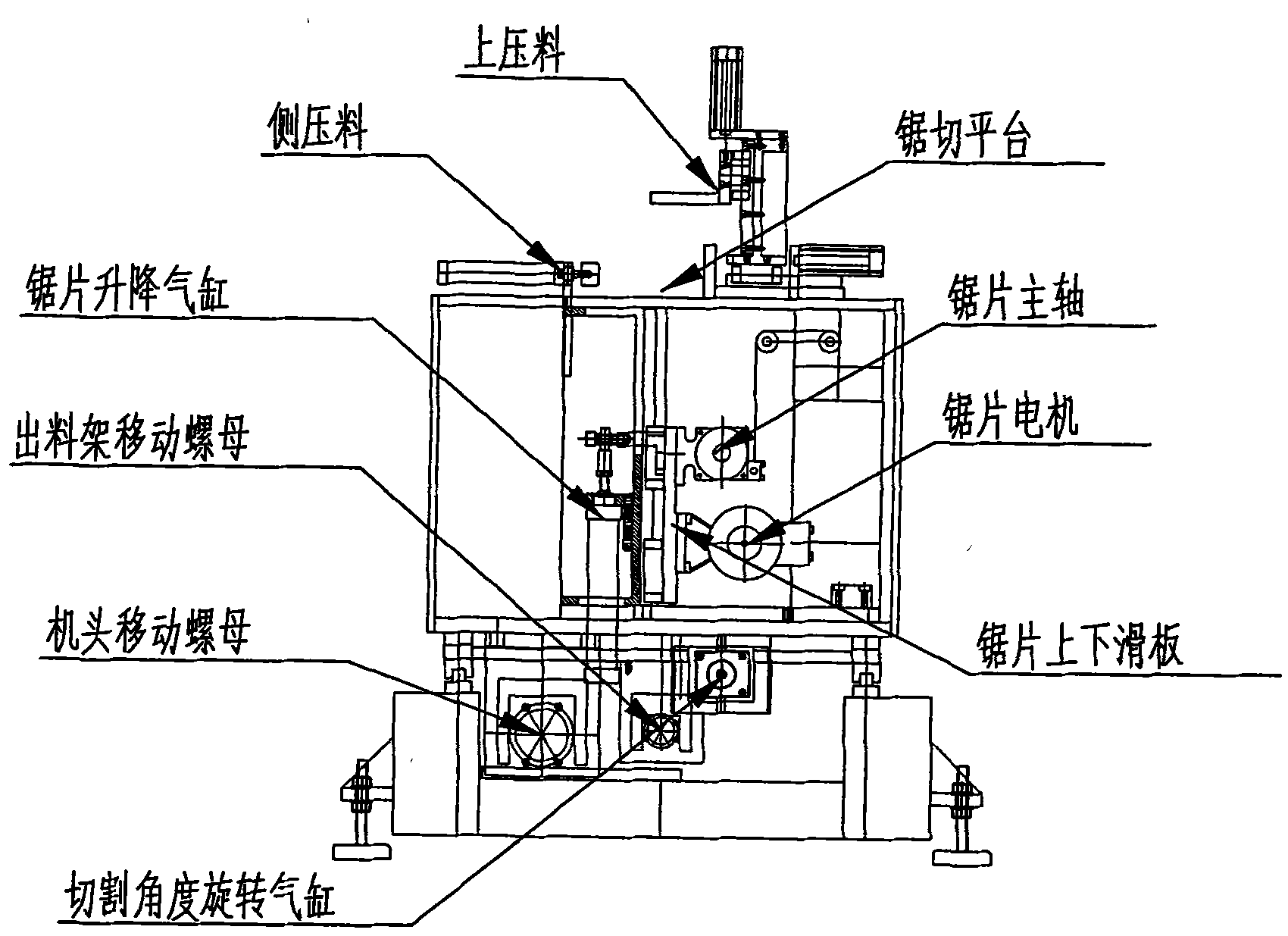

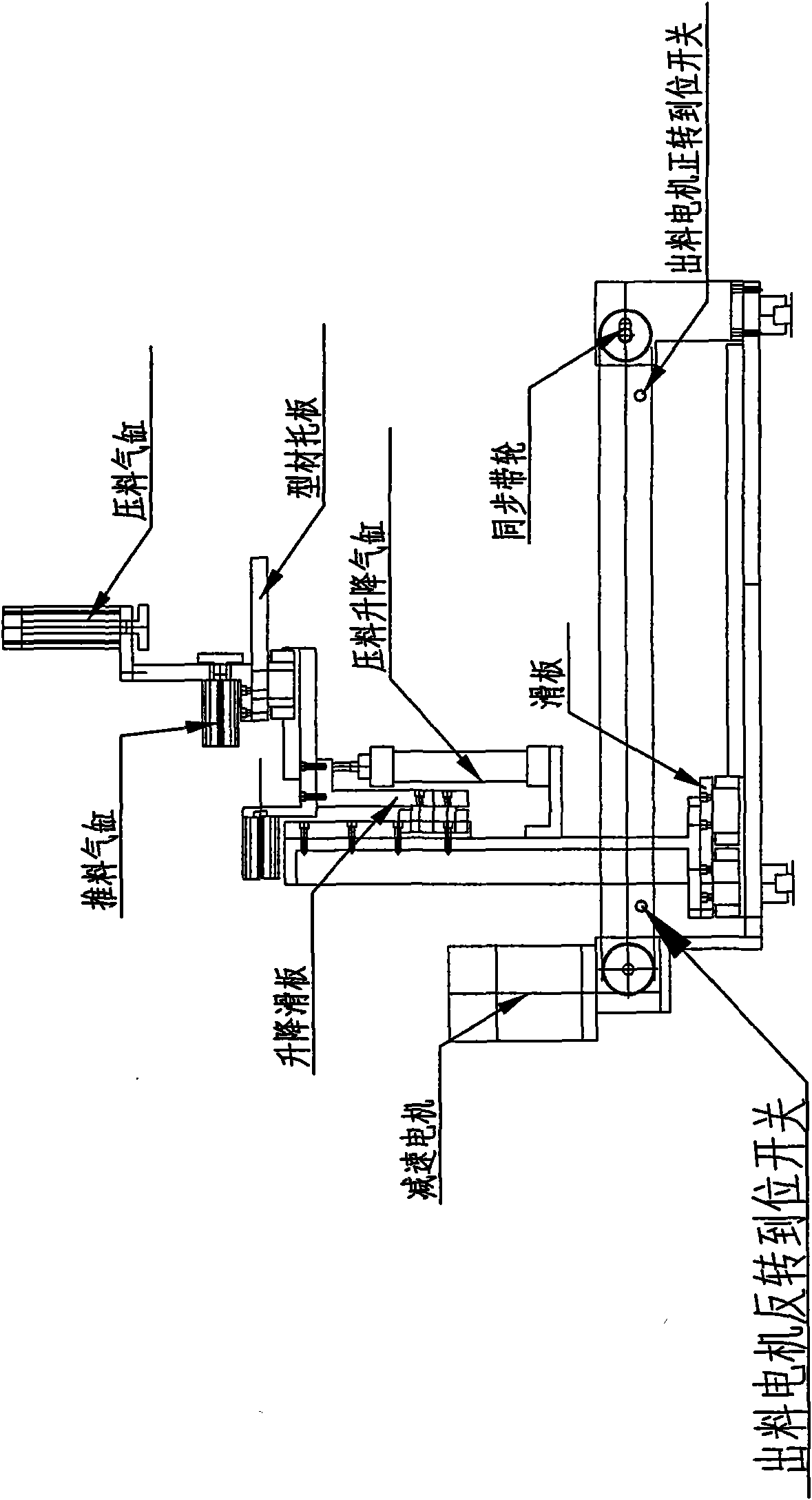

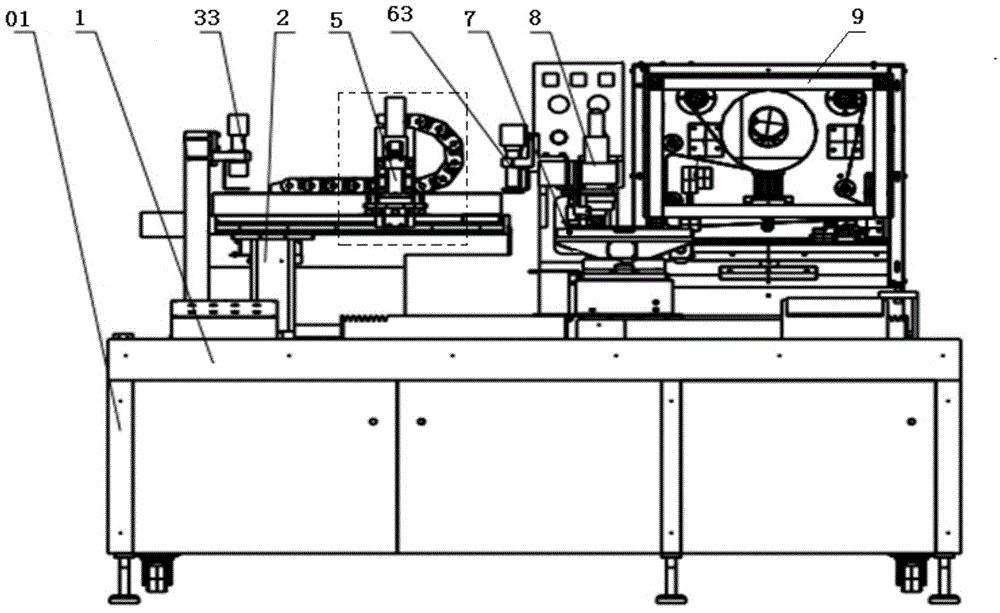

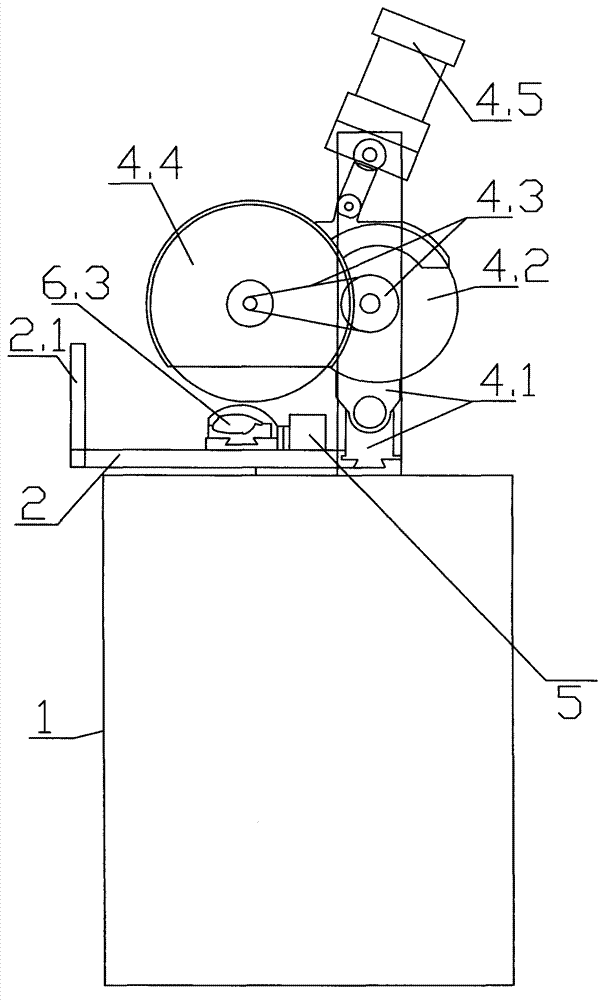

Numerical control double-headed sawing center for aluminum profiles

InactiveCN102101200AWon't scatterRealize humanized designMetal sawing devicesMetal sawing accessoriesNumerical controlSlide plate

The invention discloses a numerical control double-headed sawing center for aluminum profiles, which comprises a machine head up and down sawing part and an automatic loading part, wherein the machine had up and down sawing part mainly comprises a moving sawing machine head and a fixed sawing machine head, which are arranged on a frame, and a sawing platform arranged on top plates of the sawing machine heads, and the moving sawing machine head does horizontal motion under the action of a machine head screw rod through a machine head slide rail; a saw blade pillar is arranged on a baseplate of the sawing machine heads through a rotating baseplate, and the saw blade pillar can rotate around a centering shaft connected on the rotating baseplate; the saw blade pillar is connected with a sliding plate through a saw blade slide rail, a saw blade motor and a saw blade main shaft, which are connected through a belt, are fixedly arranged on the sliding plate, and a saw blade is arranged on the saw blade motor; and the sliding plate is connected with a telescopic rod of a lifting cylinder of the saw blade. Manual intervention is not required during the cutting process, the cutting process is automatically completed, a fundamental plane of the cut profile is large, the discharge is steady, the sawing is smooth, the fundamental plane does not need to be turned over when entering into the next corner combination process step, the processing errors are reduced, and the working efficiency is improved.

Owner:ANYANG JIAMING MACHINERY

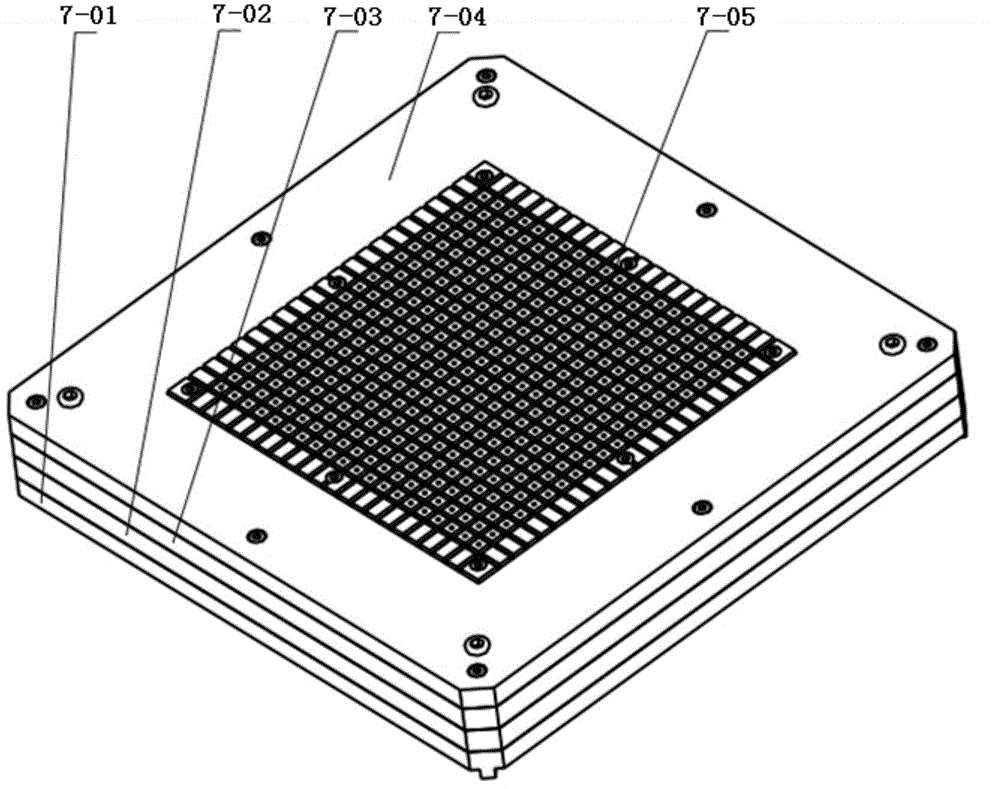

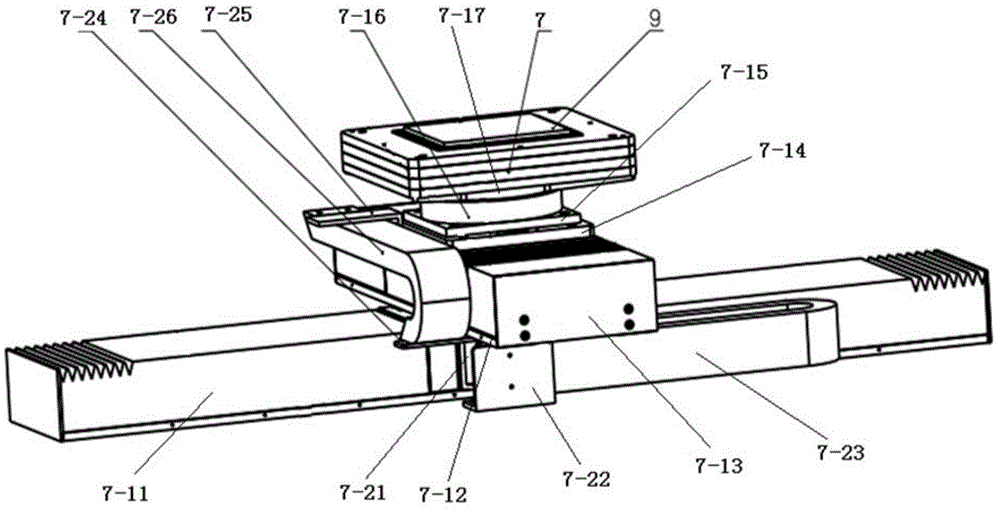

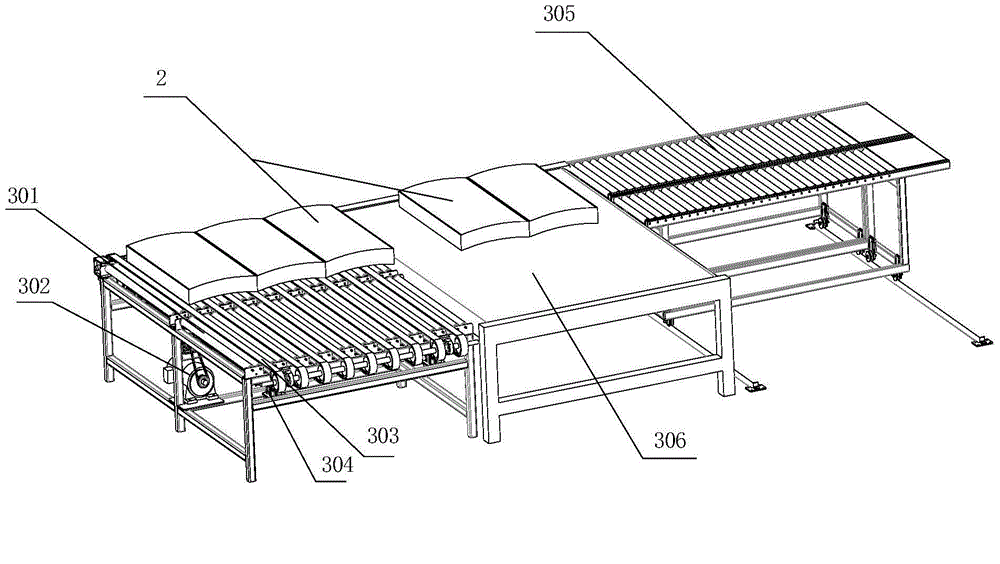

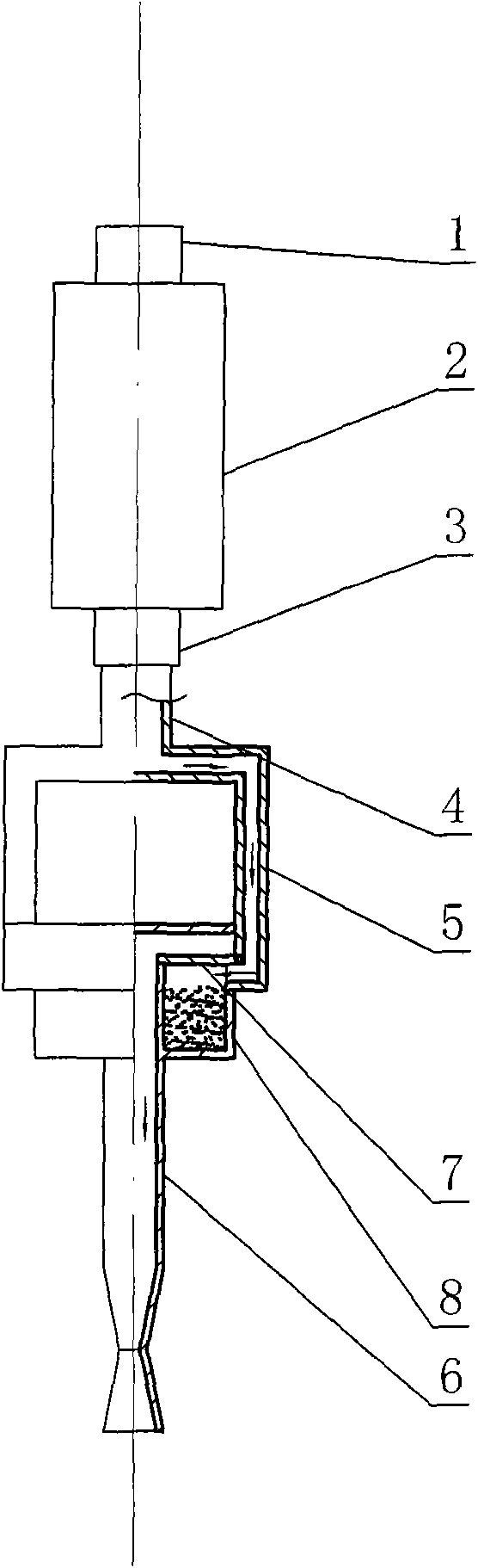

Laser cutting equipment for stainless steel chip

ActiveCN104084697AGuaranteed Position AccuracyPick up accuratelyMetal working apparatusLaser beam welding apparatusManipulatorLaser cutting

The invention relates to laser cutting equipment for a stainless steel chip. A loading platform device of the laser cutting equipment can carry out Y-direction straight-line motion on a platform base, and the stainless steel chip is placed on the loading platform device. A primary positioning camera is installed above the loading platform device, and used for primary positioning of the stainless steel chip. A loading mechanical hand can carry out X-direction straight-line motion and Y-direction straight-line motion on a loading base and is used for picking the stainless steel chip and placing the stainless steel chip to a suction platform. The suction platform can carry out X-direction straight-line motion, Z-direction straight-line motion and rotary motion on the platform base. A fine positioning camera is fixedly arranged above the suction platform on the platform base and used for adjusting the position of the suction platform to achieve fine positioning of the stainless steel chip. A laser cutting system and a film pasting device are fixed to the platform base and used for achieving cutting and film pasting of the stainless steel chip. The laser cutting equipment is high in integration degree, high in production efficiency, good in cutting quality and capable of well meeting the requirement for producing stainless steel chips on a large scale.

Owner:CHANGSHUN GUANGHUA MICRO ELECTRONICS EQUIP ENG CENT

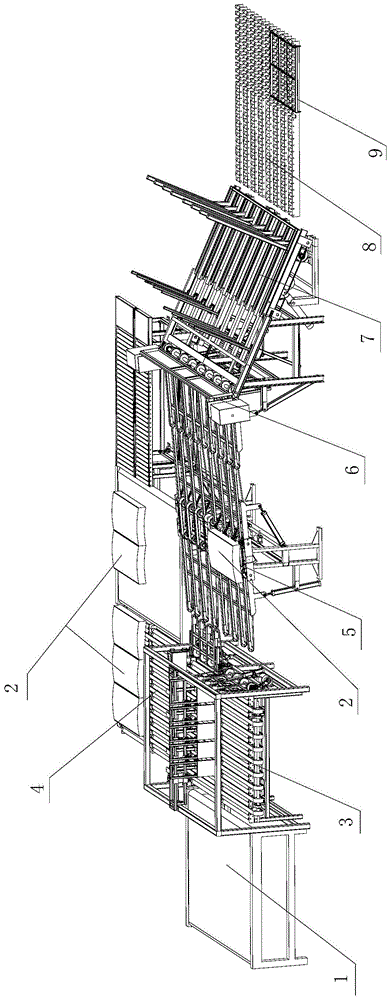

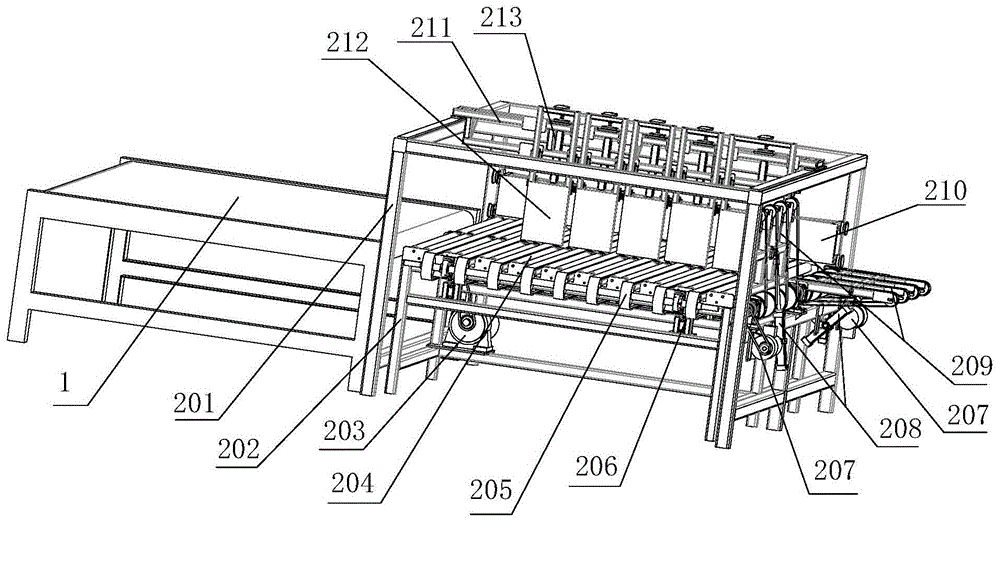

Corrugated paperboard turning and stacking discharging production line and control method thereof

InactiveCN104944195ASimple structureEasy to operatePile receiversArticle deliveryProduction linePaperboard

The invention discloses a corrugated paperboard turning and stacking discharging production line and a control method thereof. The production line comprises a paperboard separating and pushing device, an interlock-type turning device, a temporary storing and moving device, a stacking righting device and a paperboard stack conveying device which are sequentially connected with one another. Corrugated paperboards of the discharging production line are conveyed to the interlock-type turning device through a conveyor belt, every two corrugated paperboards are stacked through the interlock-type turning device, the stacked corrugated paperboard units are conveyed to the temporary storing and moving device which erects each corrugated paperboard unit, after multiple corrugated paperboard units are stacked into a group, the temporary storing and moving device conveys the corrugated paperboard unit groups to the stacking righting device which turns the corrugated paperboard unit groups by 90 degrees and conveys the corrugated paperboard unit groups to the paperboard stack conveying device, paperboard stack trays are arranged in the paperboard stack conveying device, and the corrugated paperboard unit groups are placed in the paperboard stack trays. The corrugated paperboard turning and stacking discharging production line and the control method thereof have the advantages of being simple in structure, easy to operate and high in automation degree.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +2

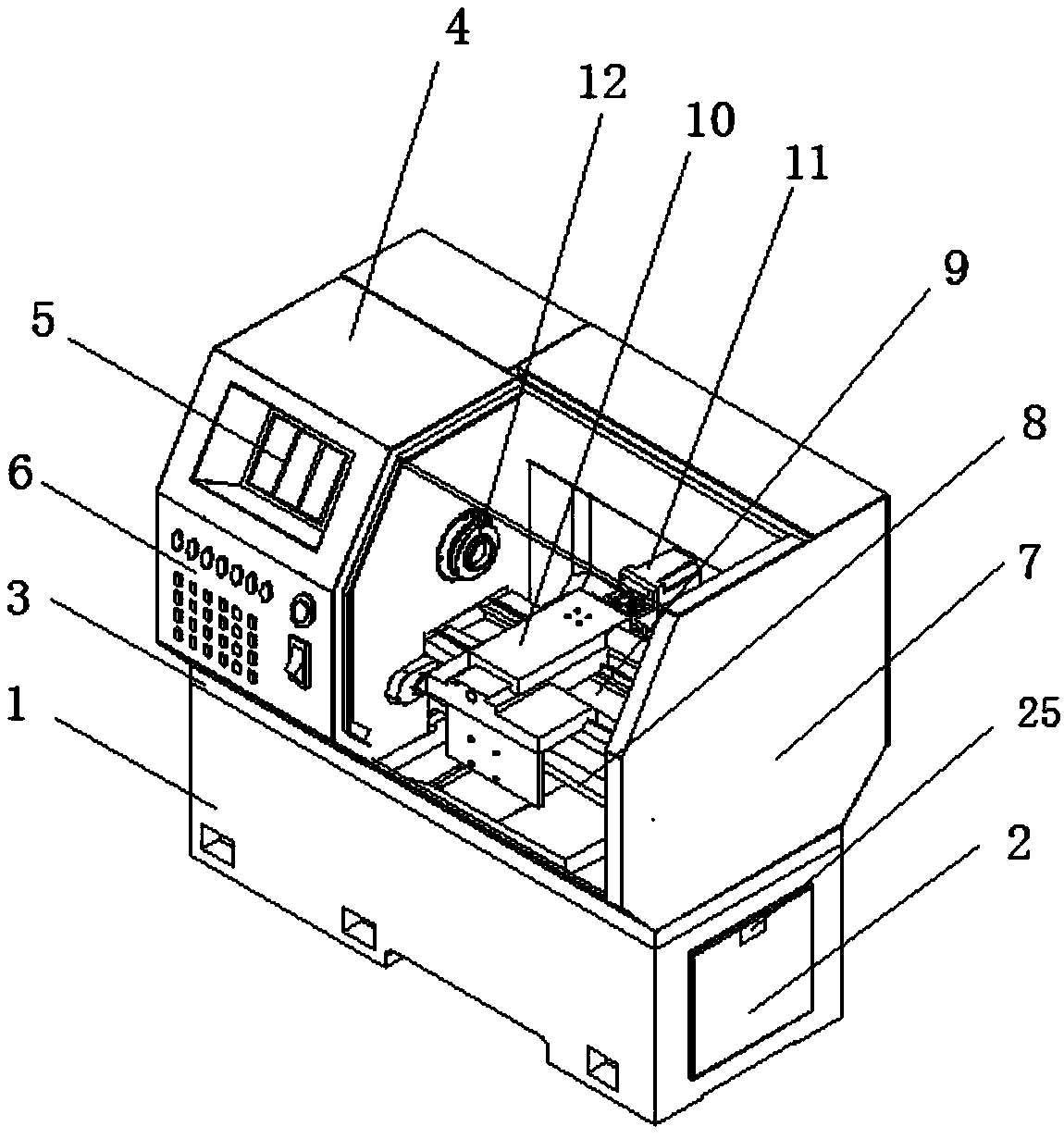

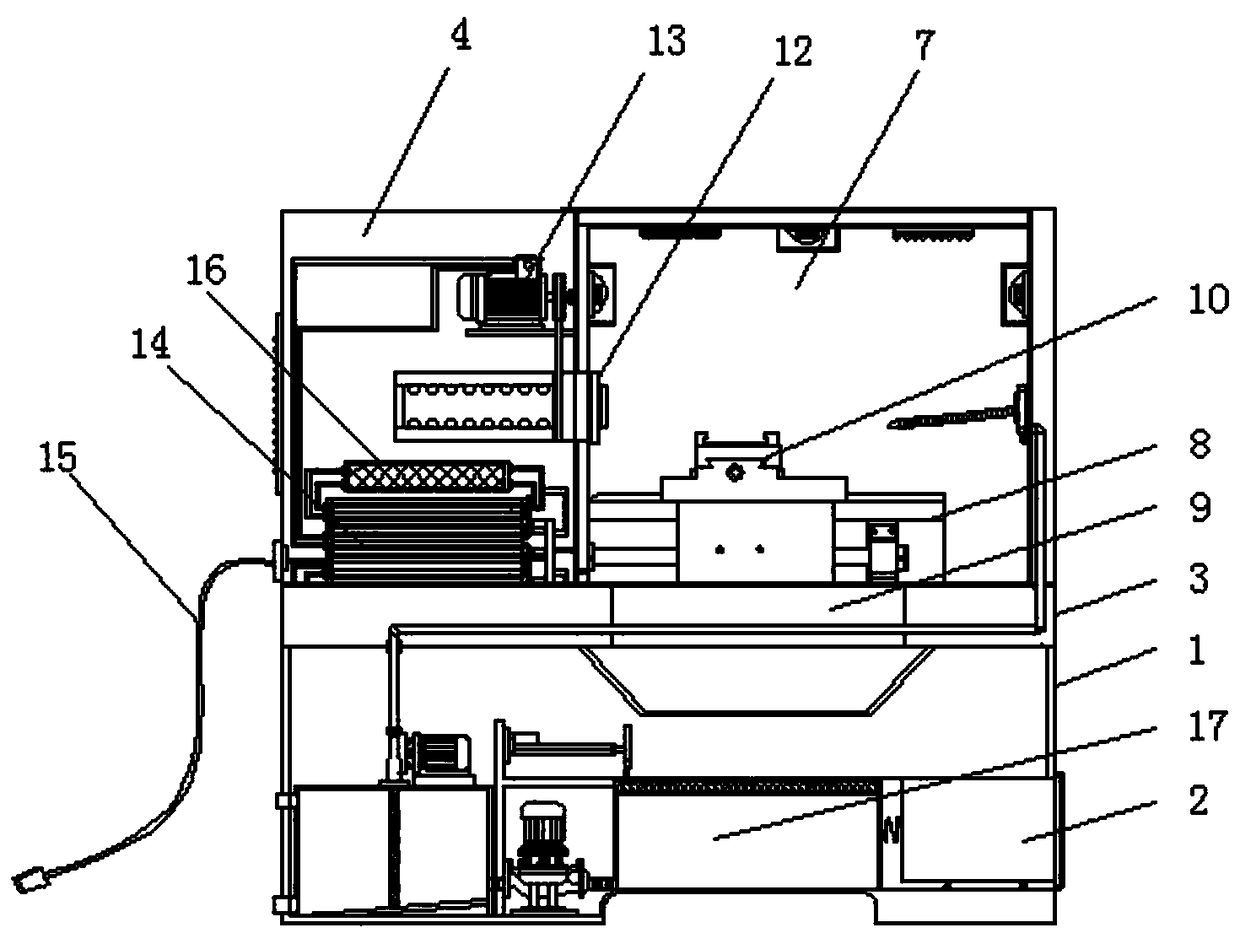

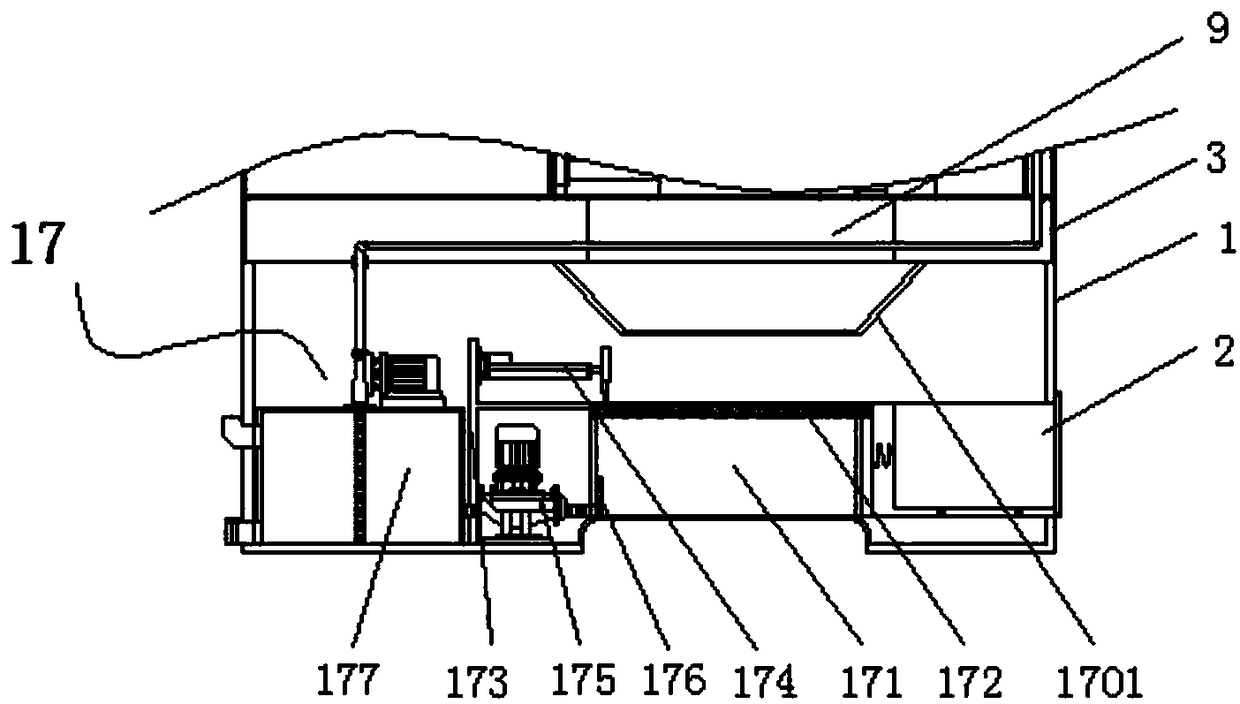

Numerical control lathe capable of recycling cutting fluid

ActiveCN109454494AAccurate collectionWon't scatterMaintainance and safety accessoriesNumerical controlMicrocomputer

The invention discloses a numerical control lathe capable of recycling cutting fluid. The numerical control lathe comprises a bottom box, a display screen, a processing chamber, a workbench, a first motor, a cutting fluid recycling device, a first camera, a second camera, a third camera and a light, wherein a waste box is arranged at the right end of the bottom box; a connection seat is welded tothe upper end of the bottom box; the cutting fluid is collected by a recycling tank through the filtration of a first filter screen; at the same time, iron filings are pushed into the waste box by a pushing mechanism so that the cutting fluid cannot be wasted and the iron filings cannot be scattered and can be convenient to remove subsequently; the collected cutting fluid is pumped into a liquid collecting tank by a first liquid suction pump through a second filter screen and is pumped by a second liquid suction pump to be conveyed to a hydrojet pipe to spray, so that after recycling, the effect of reusing is achieved; the first camera, the second camera and the third camera monitor processing conditions in a processing chamber in real time; and after being processed by a single chip microcomputer, the processing conditions are displayed on the display screen so that the worker can observe the processing conditions in real time.

Owner:SUZHOU CHANGHENG PRECISION METAL DIE CASTING

Automobile sealing strip trimming device

InactiveCN103085095AGuaranteed lengthKeep healthyMetal working apparatusPhysical healthWaste material

The invention discloses an automobile sealing strip trimming device which comprises a machine frame, an operating platform, an incising assembly, a guide assembly, a measuring assembly and a limiting assembly. The operating platform is in slide fit with the machine frame, the incising assembly is fixedly connected with the operating platform, the guide assembly is installed on the operating platform in a dismantle mode and arranged below the incising assembly, the measuring assembly is fixed on the operating platform, and the limiting assembly is installed on the measuring assembly in a dismantle mode. The measuring assembly is combined with the limiting assembly, the situation that the length of material strip obtained through incision conforms to demands can be guaranteed. At the same time, an incision groove is formed by a left guide block and a right guide block on the guide assembly, a sealing strip is cut off at the position of the incision groove by a cutting blade of the incising assembly, and the situations that the cross section of the material strip is smooth and does not incline can be guaranteed. Waste materials and dust produced in the process of cutting the material strip are collected by a cleaner, and cannot scatter on the ground and pollute the air. Physical health of workers is guaranteed. The automobile sealing strip trimming device belongs to the technical filed of machinery.

Owner:JIANXIN ZHAOS GRP CORP

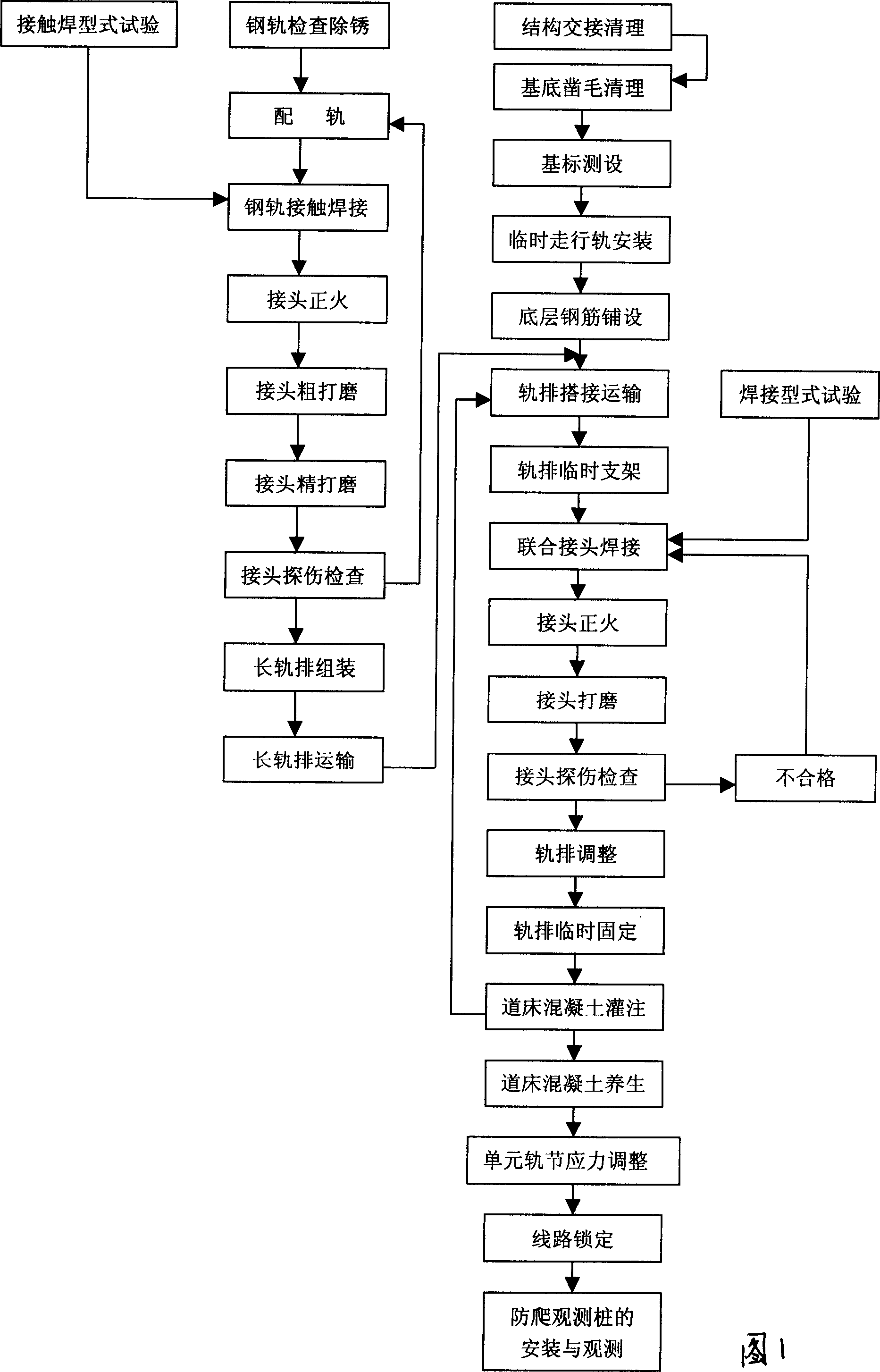

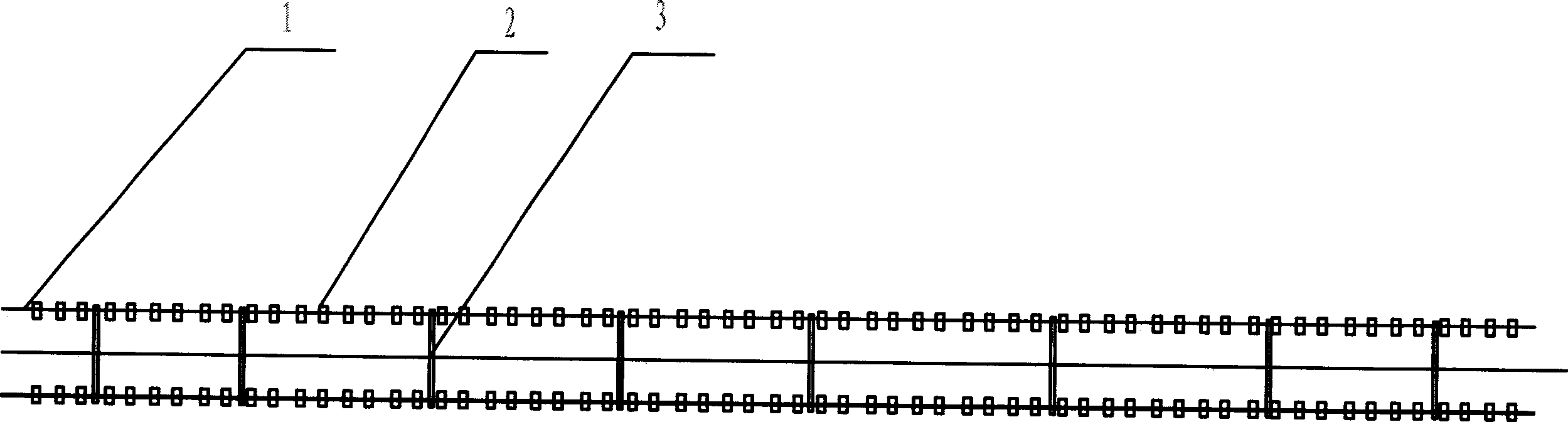

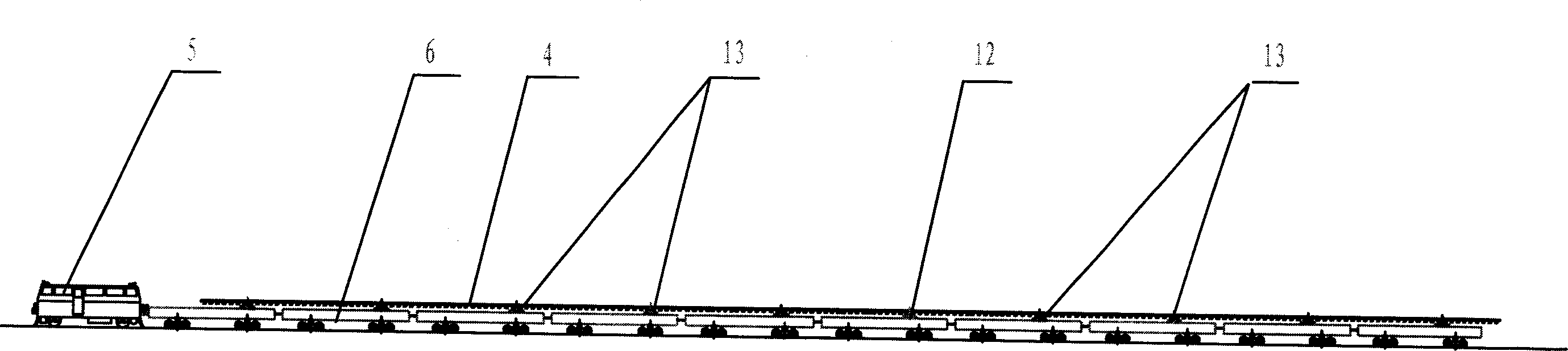

Short-sleeper long-lump integrated ballast bed seamless track construction method

ActiveCN1804216AReduce labor intensityReduce pollutionRailway track constructionAssembly lineShort-sleeper

The invention relates to a method for constructing short sleeper long rail row integrated seamless track, which welds at least three standard steel rails into long rail bar on the base ground and combines two long rail bars with short sleeper, fasteners, and steel rail into long rail row; uses light rail towing vehicle to move the long rail row into construction site and uses gantry cranes to move the long rail row to the mounting position to be adjusted, welded and temporary fixed; then processes railway bed irrigation and rail temperature fixing. The inventive method can transform traditional processes which should be completed inside the hole or light way construction site to the rail laying base; and it can utilizes assembly-line operation which can improve the rail row mounting quality, reduce the labor force, reduce the environmental pollution, shorten the construction period, confirm the welding quality between rails, avoid arranging the welding interface on the sleeper and confirm the shape of curve. In addition, since it utilizes mechanical integrated suspending and mounting inside the hole, it can accelerate the construction plan. The invention can mount, transport and weld the long rail with at least 125m length in one time.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

Preformed solder containing soldering flux and preparation method thereof

ActiveCN107433400AWon't hurtWon't scatterWelding/cutting media/materialsSoldering mediaThermal bridgeIngot

The invention relates to the technical field of materials for electronic device welding and specifically discloses a kind of performed solder containing soldering flux and a preparation method thereof. The performed solder containing the soldering flux comprises a soldering material and the soldering flux wrapped in the soldering material; the mass percent of the soldering material is 95%-99.9%, and the mass percent of the soldering flux is 0.1%-5%. The preparation method of the performed solder containing the soldering flux comprises the steps of preparing the soldering flux; smelting and casting an ingot of the soldering material; conducting charging and extruding the ingot of the soldering material into a preform body; rolling the perform body into a material strap; and cutting the material strap. By adopting the performed solder provided by the invention, the deficiencies of dipping the liquid soldering flux and externally applying the solid soldering flux are made up; the soldering flux can reduce the surface tension of the molten soldering material, facilitates wetting and spreading of the performed solder, promotes welding, prevents secondary oxidation of the performed solder and has an auxiliary heat conduction effect as a thermal bridge. By means of the performed solder containing the soldering flux, the welding quality is effectively improved, the good welding effect is achieved, the stability of the welding process can be guaranteed, and the production efficiency can be improved.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

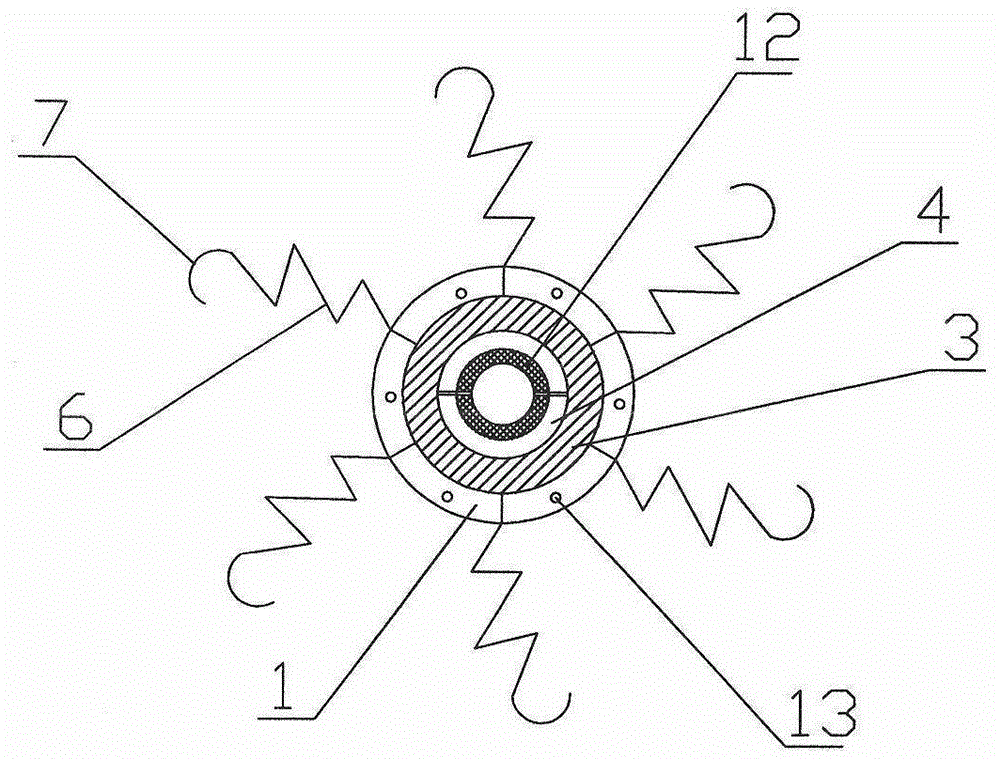

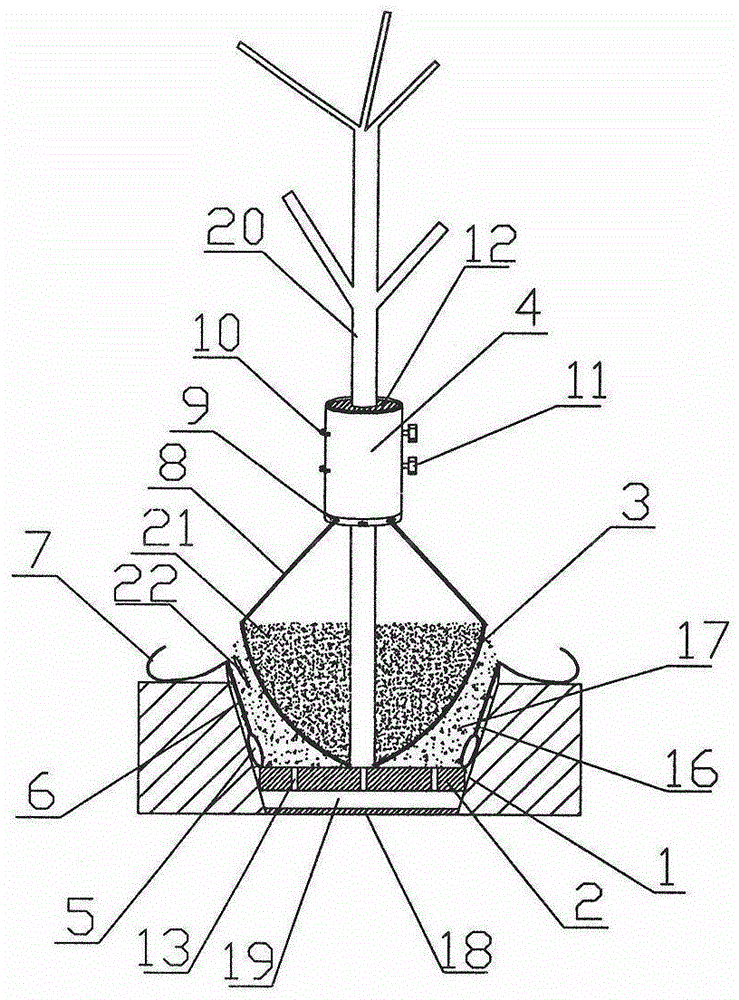

Precious landscape tree transplanting device and transplanting method adopting same

The invention discloses a precious landscape tree transplanting device and a transplanting method adopting the same. The precious landscape tree transplanting device is arranged in cooperation with a tree well and comprises a bottom plate, a wrapping part and a hoisting hoop. The bottom plate is arranged in the tree well and provided with lifting rings, lifting hooks are connected to the lifting rings through lifting ropes, and the lifting hooks are arranged outside the tree well. The wrapping part is movably laid on the bottom plate and provided with wrapping ropes. The hoisting hoop is clamped on a trunk, multiple connecting holes are formed in the lower end of the hoisting hoop, and the wrapping ropes are connected with the connecting holes. The precious landscape tree transplanting device and the transplanting method adopting the same are especially suitable for temporary planting of trees with the diameters being 100-400 mm before field planting, roots of the trees do not need to be cut off in transplanting, the rootstock systems of the trees are not damaged, mud at the roots of the trees forms balls without scattering in transplanting, transplanting is convenient, and the tree survival rate is very high.

Owner:GUANGZHOU GREENING CO

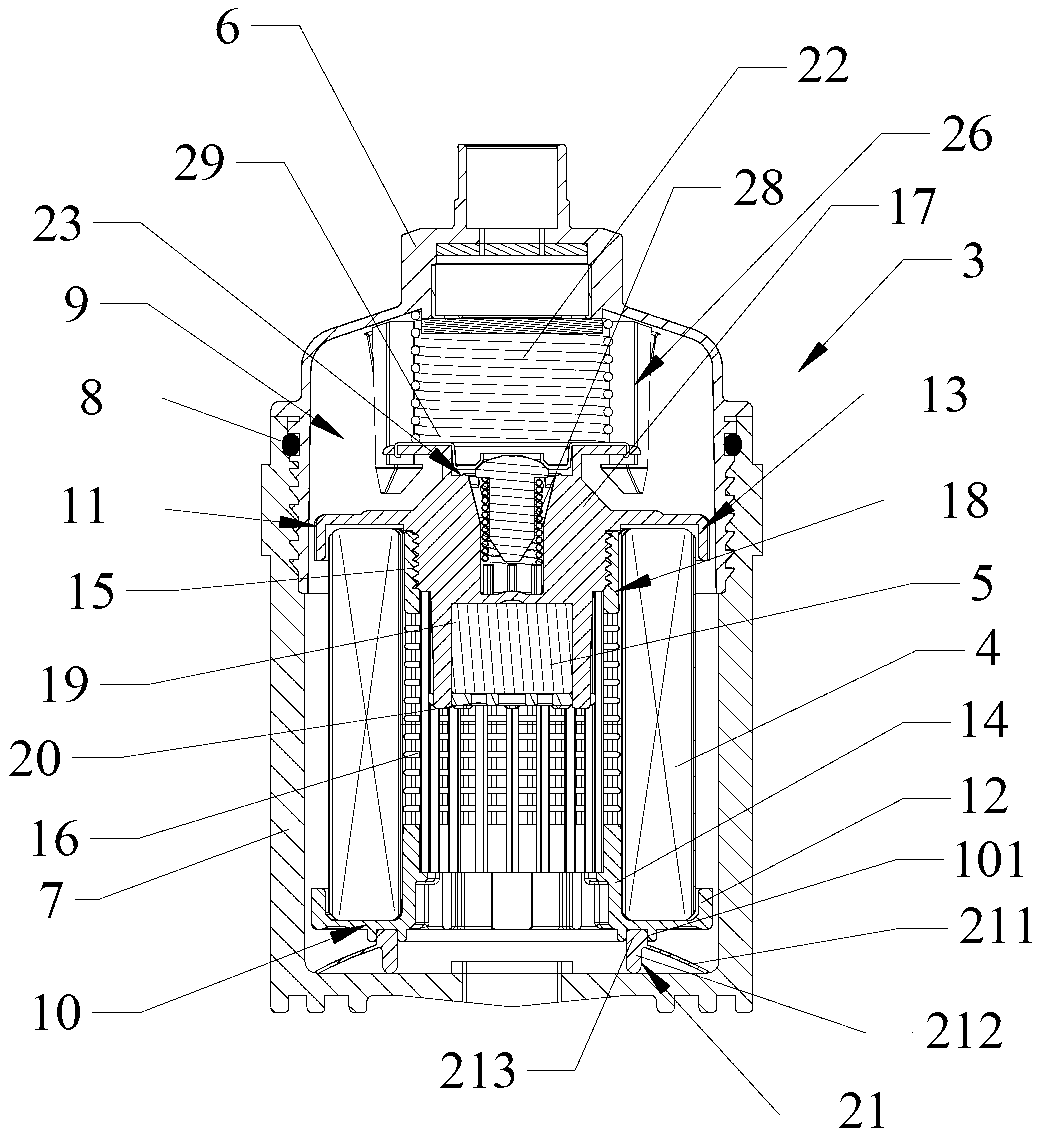

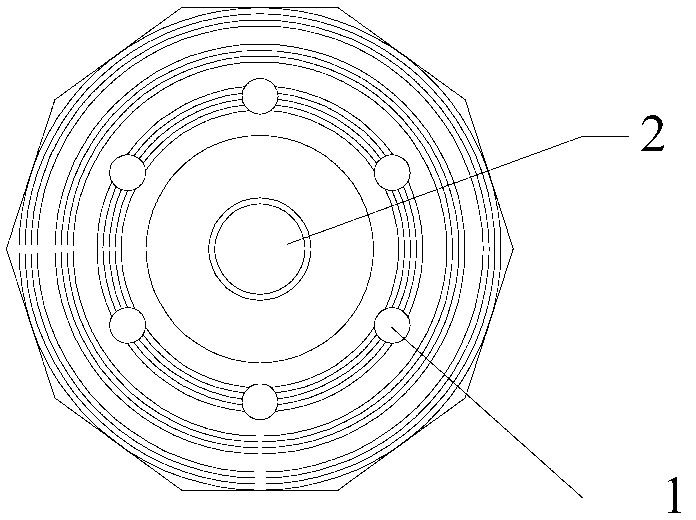

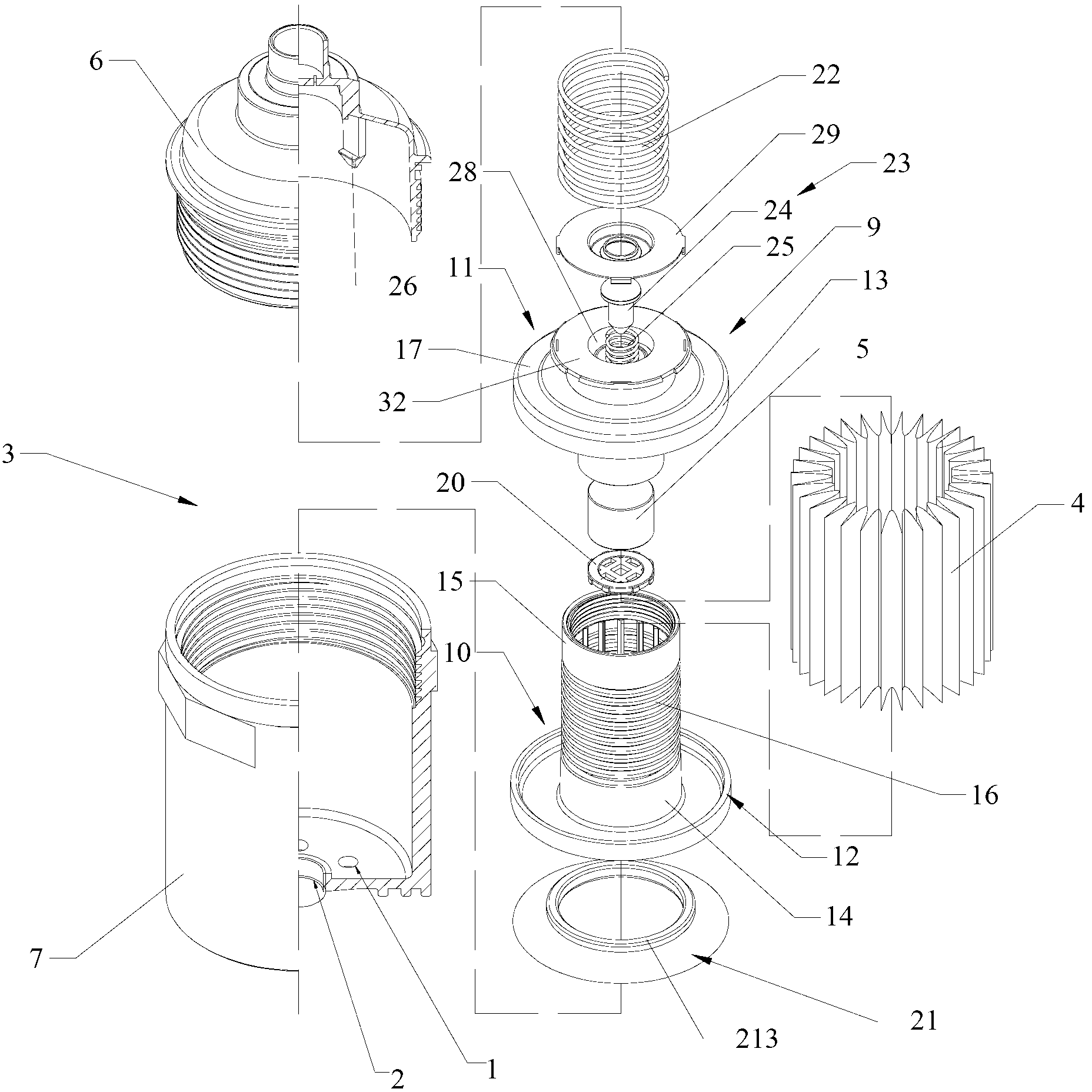

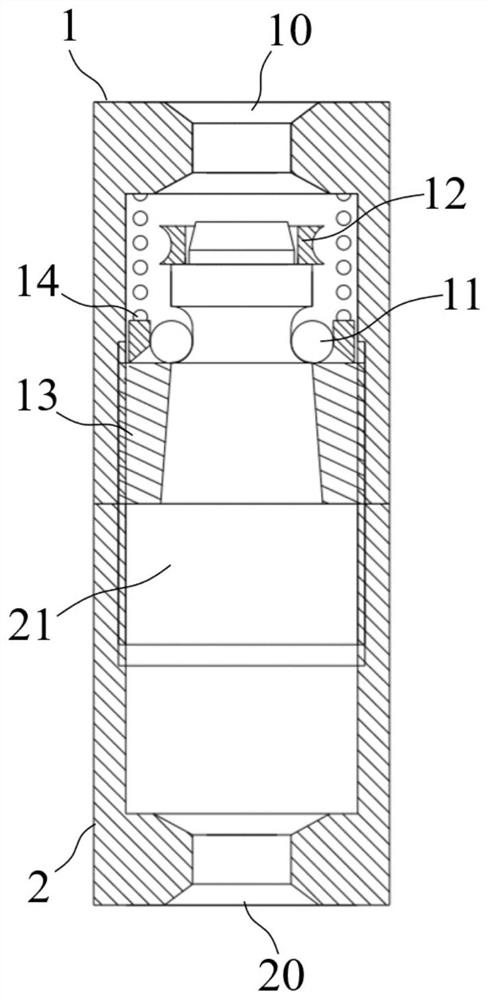

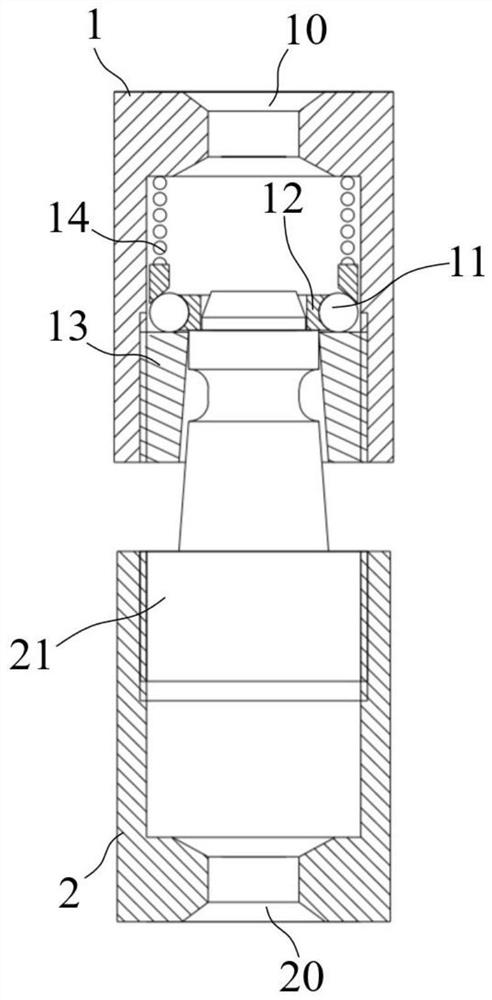

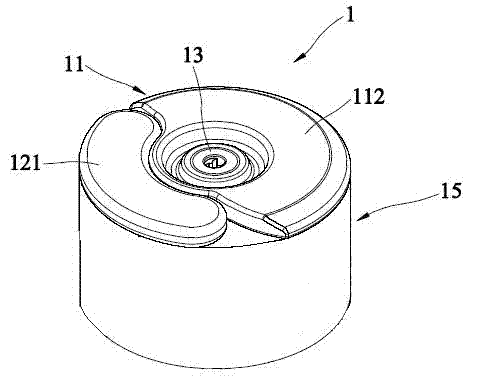

Novel machine oil magnetizing filtering device

InactiveCN103061849AEasy to operateWon't scatterPressure lubricationLubricant mounting/connectionPetroleum engineeringFilter element

The invention relates to a novel machine oil magnetizing filtering device. The novel machine oil magnetizing filtering device comprises a shell, a filtering element and a magnet, wherein the shell has an oil inlet hole and an oil outlet hole, the filtering element is arranged in the shell and is positioned between the oil inlet hole and the oil outlet hole, and the magnet is supported by a support member in the shell. As the support member is connected with the shell, when the novel machine oil magnetizing filtering device provided by the invention needs maintenance operation, the support member and the filtering element which are assembled into a whole can be separated from the shell of the base only by detaching the shell of a cover, then a support is detached, so that the operations of replacing the filtering element and washing the magnet can be conveniently carried out, conversely, after maintenance, the filtering device can be conveniently assembled. With the novel machine oil magnetizing filtering device provided by the invention, the accurate locating of the filtering element and the magnet can be realized, and the effect of the filtering device is guaranteed; and through well-designed integral structure, the supporting effect can be realized, and meanwhile, assembling and disassembling can be conveniently carried out, thus facilitating follow-up maintenance operation.

Owner:杭州睿能电子科技有限公司

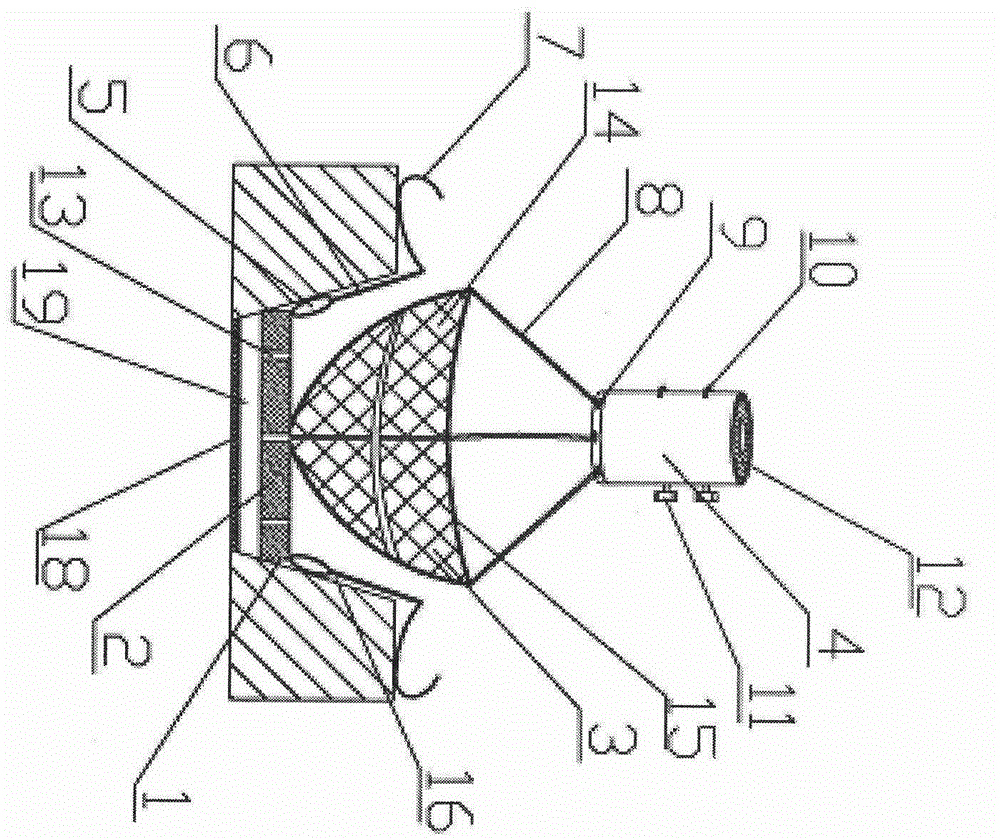

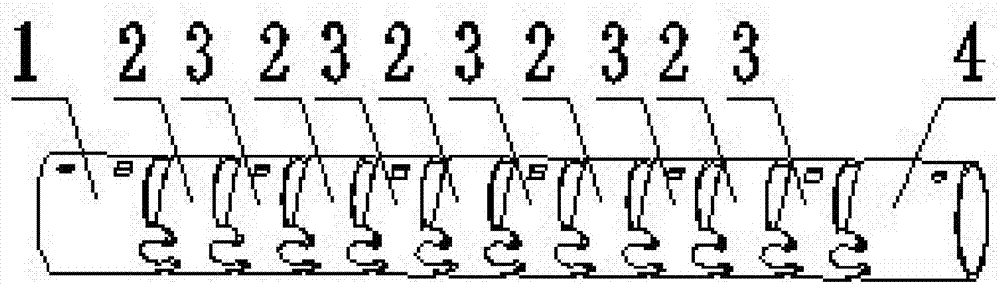

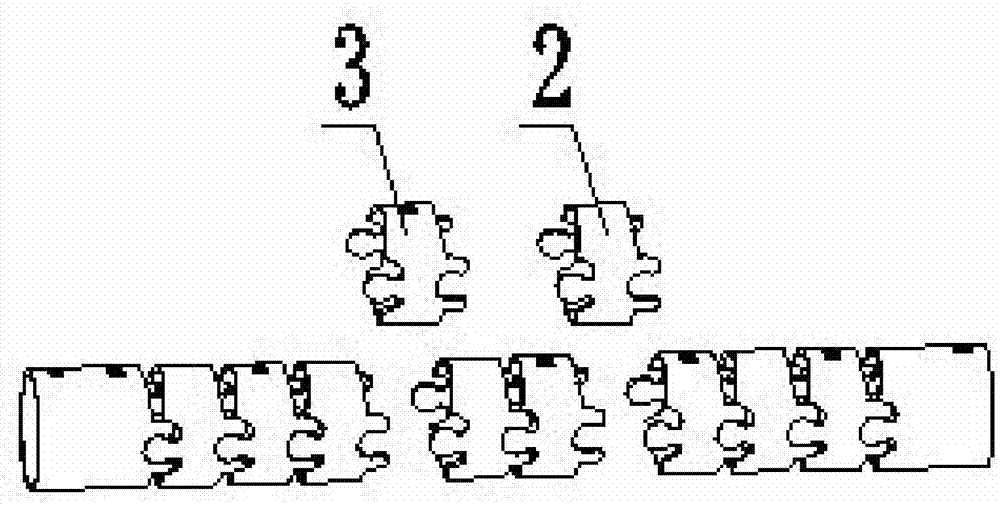

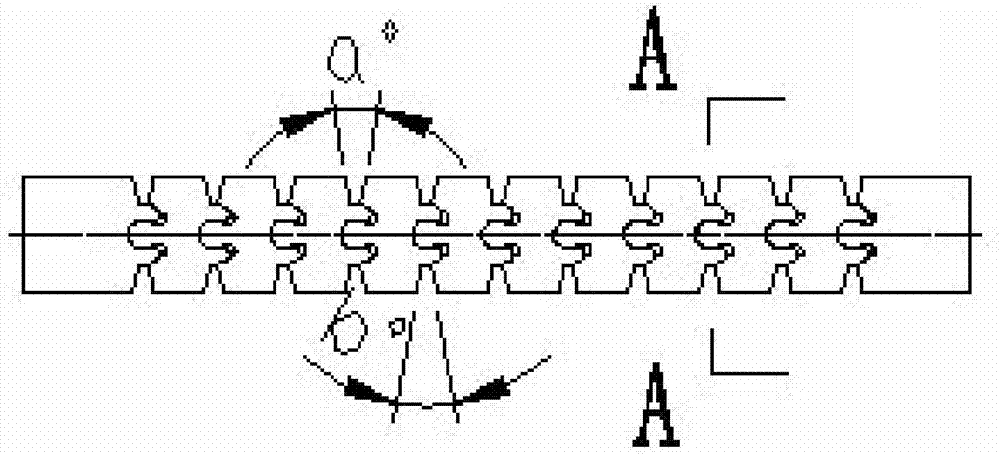

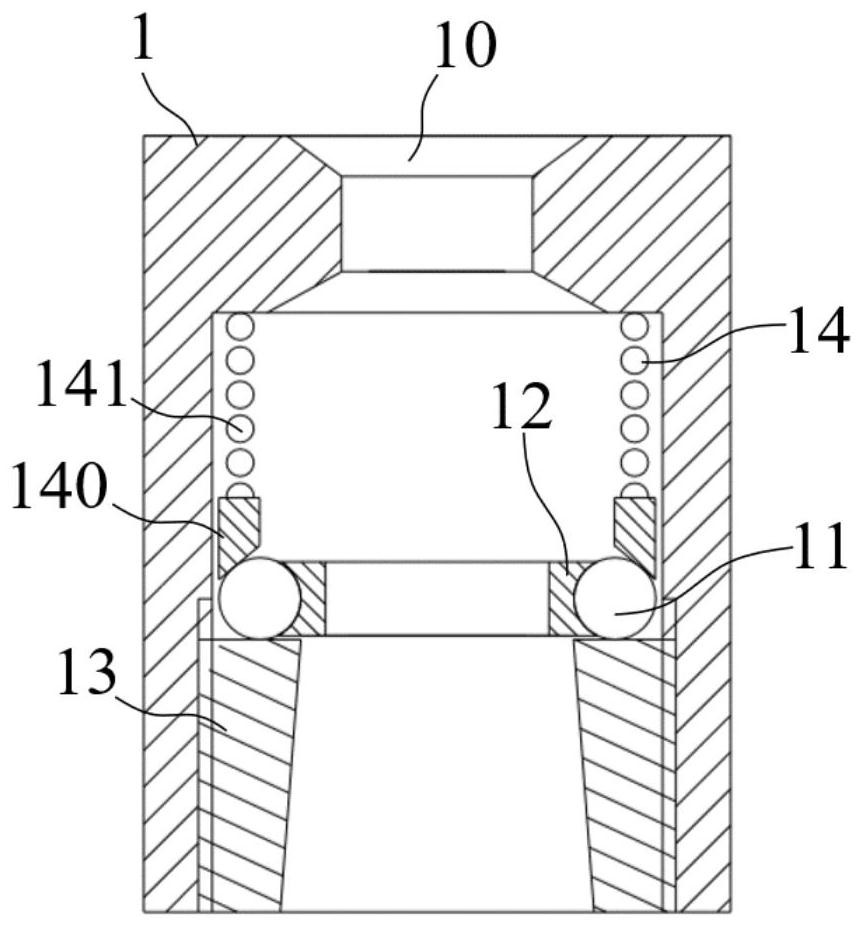

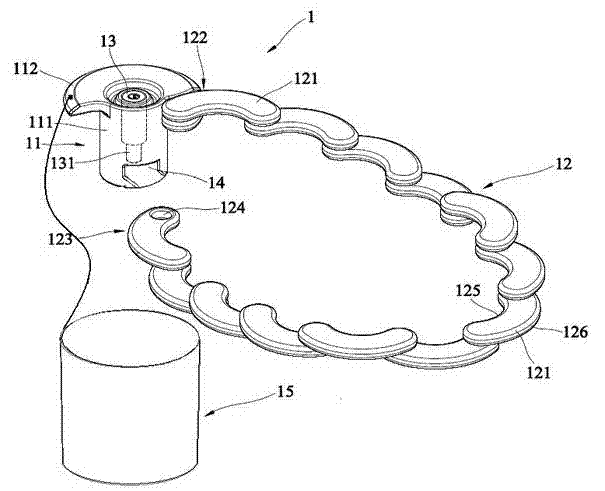

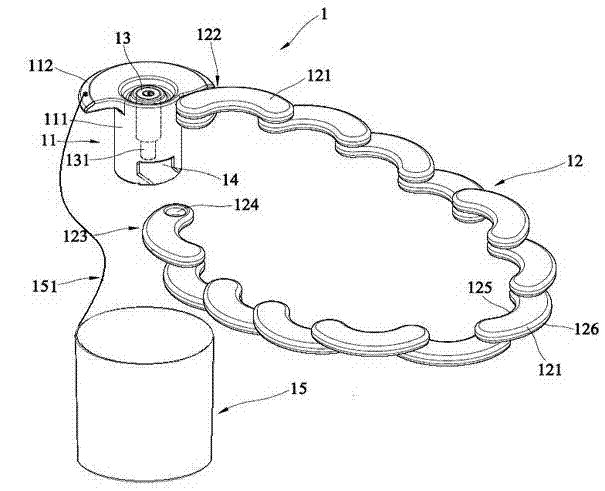

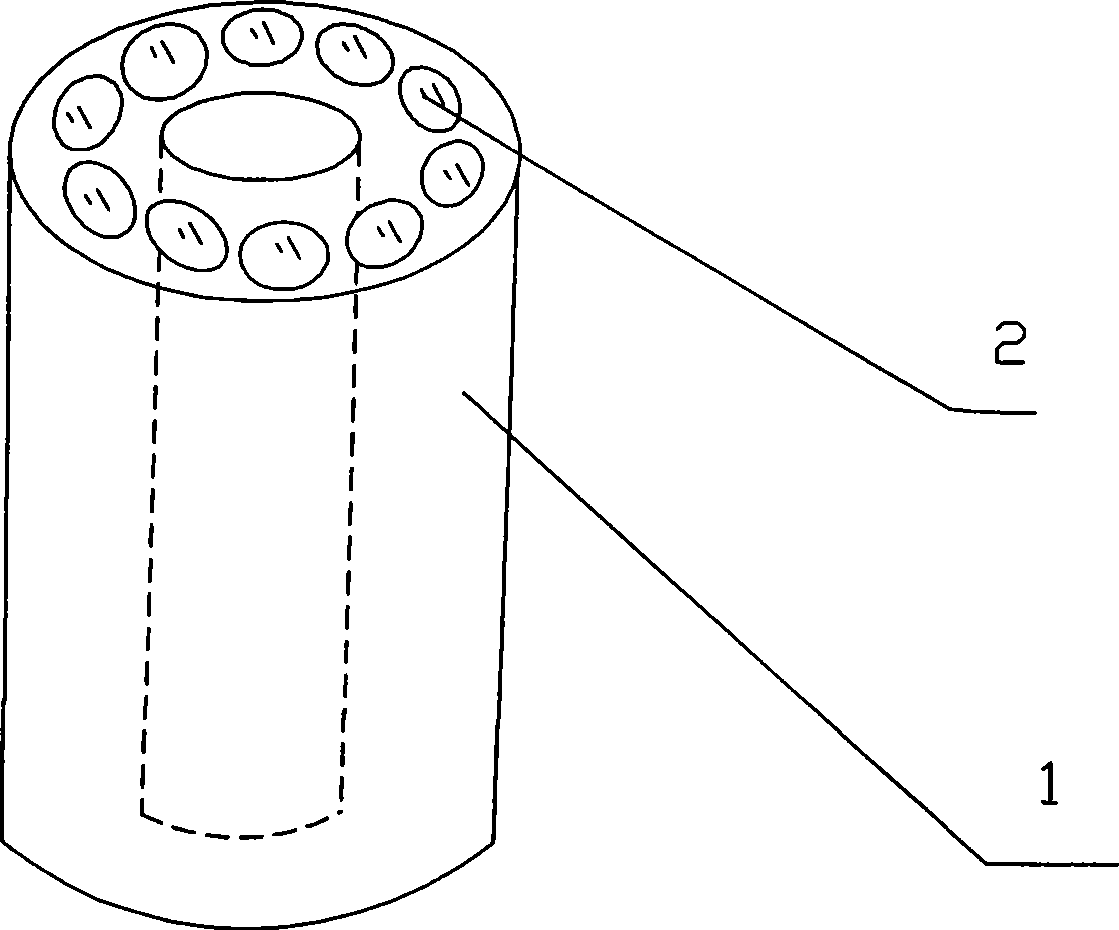

Rivet-free snake bone assembly for endoscope

The invention discloses a rivet-free snake bone assembly for an endoscope. The rivet-free snake bone assembly comprises a head end section and a rear section, and n sets of middle sections are arranged between the head end section and the rear section; each middle section is composed of a first middle section and a second middle section; n first middle sections and n second middle sections are arranged between the head end section and the rear section at intervals; the head end section and the first middle sections, the first middle sections and the second middle sections, and the second middle sections and the rear section are connected through two connecting sets of snap ring hinge structures; one engaging lug of one part can rotate relative to a connecting groove of a part connected with the engaging lug; two engaging lugs of the same part form a rotation center, and thus the snake bone assembly bends. By means of the rivet-free snake bone assembly for the endoscope, through the connecting sets of the snap ring hinge structures, connection of adjacent parts is achieved, cut corners are formed at the two sides of each connecting set, which guarantees that the snake bone can flexibly rotate, and guarantees that all units of the snap ring hinge cannot scatter, thus a rivet structure is omitted, and the production efficiency is greatly improved.

Owner:上海成运医疗器械股份有限公司

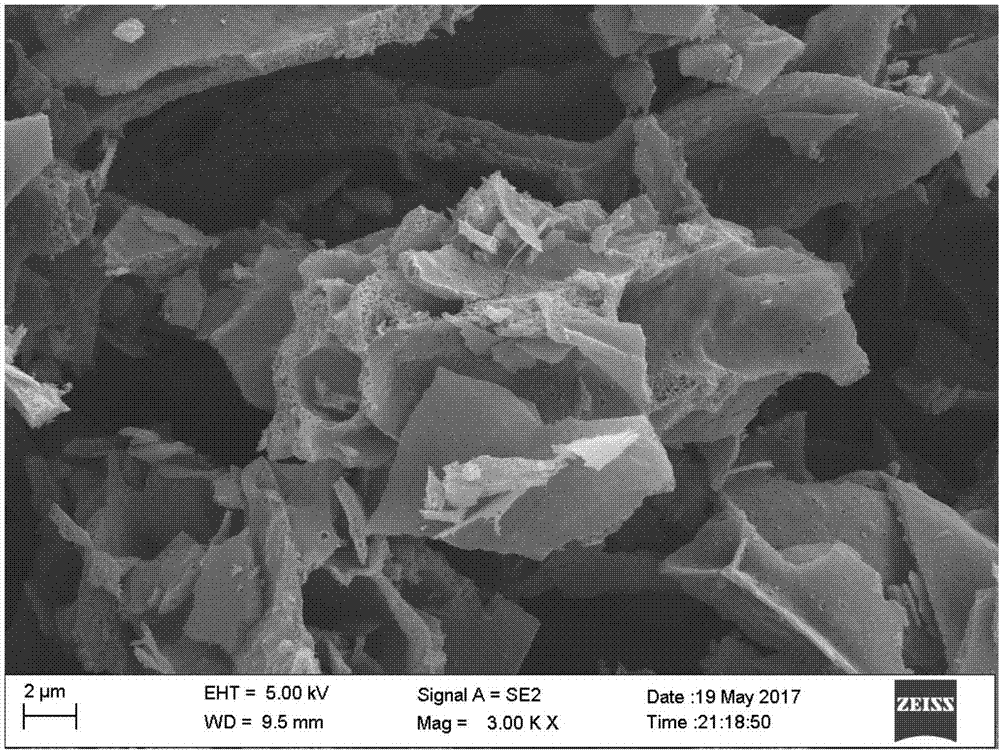

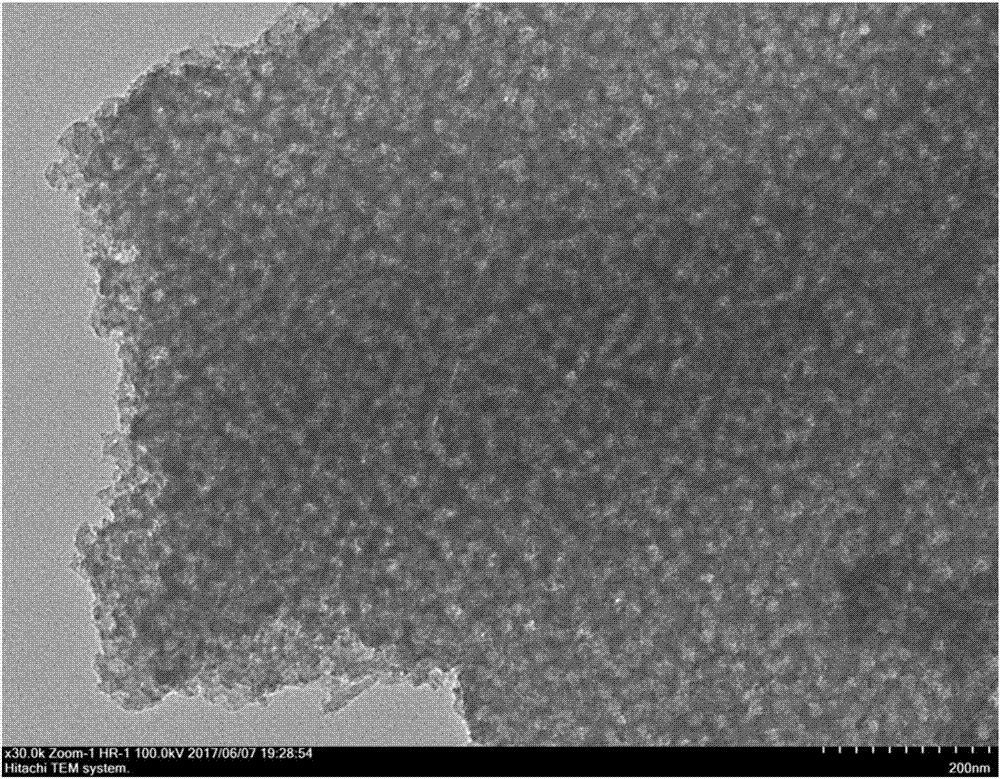

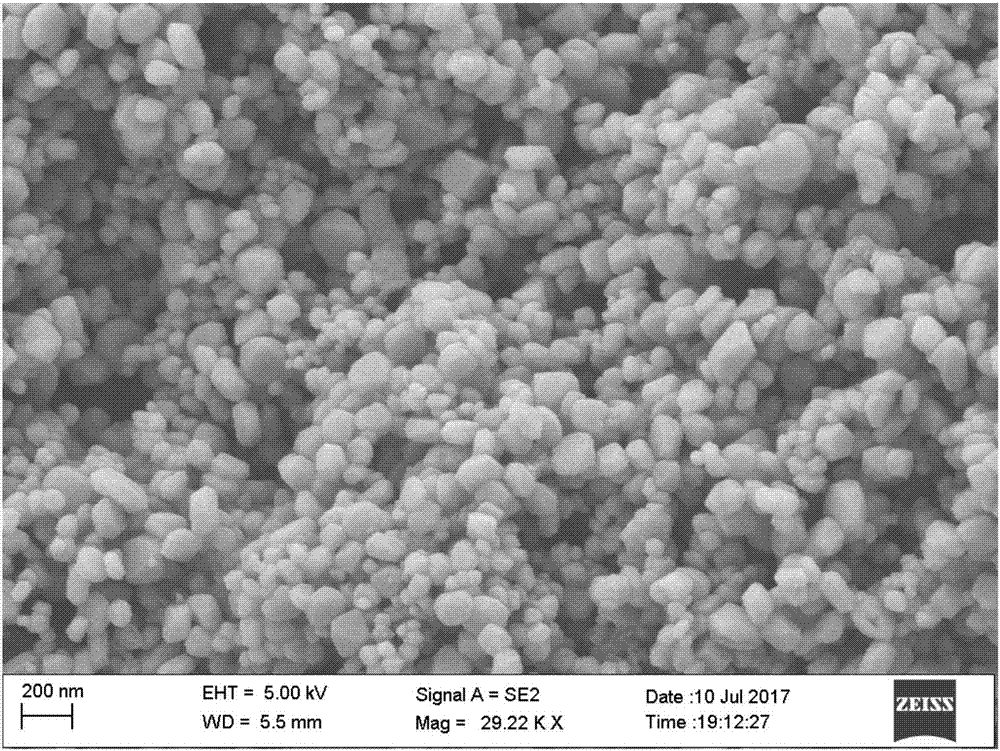

Preparation method of Co-Al active material coated nickel-cobalt-aluminum ternary layered positive electrode material

InactiveCN110165163AStable lattice structureImprove performanceCell electrodesSecondary cellsLithium compoundCobalt

The invention discloses a preparation method of a Co-Al active material coated nickel-cobalt-aluminum ternary layered positive electrode material. The method comprises the steps: employing LDH as a coating material precursor, and coating the surface of an NCA ternary material precursor with the coating material precursor; mixing lithium salt with the NCA ternary material precursor, and performinghigh-temperature calcination to prepare the nickel-cobalt-aluminum ternary layered positive electrode material. According to the material, the outer layer of the NCA ternary material is coated with anLi-Co-AlO2 coating layer which has certain electrochemical activity, so the performance of the battery is improved under the condition that the capacity of the battery is not lost. A Co-Al lithium compound has a more stable lattice structure and has a positive effect on the cycling stability of the material. Besides, in the lattice structure of the compound, some defect vacancies can be reservedin the structure due to the mutual doping influence of the compound, so that electron conduction and ion diffusion are facilitated, and the rate capability of the battery is improved. The method is simple to operate, novel in strategy and obvious in effect.

Owner:TIANNENG SAFT ENERGY JOINT CO

Wet-processing brake gasket and producing method thereof

InactiveCN103133578AIncrease stickinessWon't scatterOther chemical processesFriction liningFiberWarm water

The invention provides a wet-processing brake gasket. The wet-processing brake gasket is characterized by comprising, by mass, 15-17% of resin, 6-12% of fibers, 10-20% of water residues, 15-25% of bentonite, 2-7% of antifriction agent, 15-30% of fillers and 15-25% of hot water. Friction materials produced by the wet-processing brake gasket are long and thin in friction performance and stable in friction coefficient, product friction can be lowered, production environment can be improved, and dust pollution can be reduced.

Owner:LIAONING JIUTONG FRICTION MATERIALS

Automatic cooking machine for fried bread sticks

ActiveCN106889129ANovel ideaSimple structureOil/fat bakingBaking plantsEngineeringMechanical engineering

The invention relates to an automatic cooking machine for fried bread sticks. The machine is characterized by comprising a blank making device, a blank drawing and stretching device, a cooking device and a discharging device which are connected in a cooperative mode. By the cooperation of the blank making device, the blank drawing and stretching device, the cooking device and the discharging device, all processes are automatically completed from slicing, flour spreading, blank pressing, automatic drawing and stretching to fried bread stick cooking and discharging, and it is only needed to regularly feed a dough box and a flour box and replace the oil in an oil tank, so that automated operation of cooking the fried bread sticks is achieved, and automatic vending of the fried bread sticks is achieved if combined with a vending machine.

Owner:朱景建

Modified silica sol, fireproof liquid, composite fireproof glass as well as preparation method and application thereof

ActiveCN112320807AStrong adhesionHigh bonding strengthFireproof paintsSilicon compoundsOrageneOrganic polymer

The invention belongs to the technical field of inorganic nano materials, and particularly relates to modified silica sol, fireproof liquid, composite fireproof glass and a preparation method and application thereof. The preparation method of the modified silica sol comprises the following steps: 1) mixing silica sol to be modified with a silane coupling agent and reacting; and 2) mixing an organic polymer containing a reaction group with the material obtained in the step 1) and reacting to obtain the modified silica sol. The modified silica sol is prepared by the preparation method and is used for preparing the fireproof liquid, and the obtained fireproof liquid is high in crosslinking density and good in adhesive force.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +2

Preparation method for MOF derived oxide coated NCA high nickel ternary cathode material

InactiveCN110061224AEasy to operateInnovative designCell electrodesSecondary cellsMass ratioMetal-organic framework

The invention discloses a preparation method for an MOF derived oxide coated NCA high nickel ternary cathode material and belongs to the technical field of a lithium ion battery. The preparation method comprises the steps of (1), preparing corresponding metal organic frameworks (MOFs) containing specific metal elements; (2), mixing an NCA high nickel ternary cathode material with the specific MOFsaccording to a mass ratio, and carrying out ball milling, thereby enabling the MOFs to be attached to the surface of the NCA high nickel ternary cathode material uniformly; and (3), calcining the material in air, thereby changing a coating material from the MOFs to MOF derived oxides, and obtaining a final product. According to the method, through utilization of features of the nano-material MOFs, a coating layer is kept at a nano-level, so the surface of the material is protected, side reaction due to direct contact with electrolyte is reduced, and battery performance of the cathode materialis improved. The method is novel and convenient and is obvious in effect.

Owner:TIANNENG SAFT ENERGY JOINT CO

Preparation method of magnetic activated carbon and magnetic activated carbon prepared thereby

InactiveCN107159123AImprove adsorption capacityNo secondary pollutionCarbon compoundsOther chemical processesCelluloseActivated carbon

The invention discloses a preparation method of magnetic activated carbon and magnetic activated carbon prepared thereby; the preparation method of the magnetic activated carbon having high specific surface area comprises the steps of preparing cellulose sol, lyophilizing in vacuum, pyrolytically activating at high temperature, ultrasonically blending and loading, hydrothermally carbonizing at low temperature and magnetizing, and the other steps. Compared with the prior art, the preparation method has the advantages that the magnetic activated carbon prepared via multiple techniques has larger specific surface and richer pore structure than traditional activated carbon, also has magnetism evenly distributed, and is better than traditional single activated carbon materials in terms of adsorbing heavy metals in industrial wastewater and domestic wastewater.

Owner:HEFEI UNIV OF TECH

Packaging film material processing device

The invention discloses a processing device special for chips and waste materials of plastic packaging film materials such as PE through design. The device comprises a box body, a pouring opening, a gland, a gland handle, a hot air blower and a discharging opening, plastic thin film processing leftover materials are poured into the box body through the pouring opening, firstly, a pressing plate isutilized to press the plastic thin film processing leftover materials, when the special thickness is achieved, the hot air blower is started so as to heat the waste materials, the waste materials areheated to deform and contract, and finally the waste materials are contracted to be quite small in volume under the continuous pressure of the gland. According to the processing device, the fluffy waste materials with the large volume of the plastic thin film materials are arranged into the small block volume of waste materials through the device so that the situation that the waste materials arein disorder and then are scattered everywhere can be avoided, and then the processing device has the huge effect in the aspects of optimizing the environment and clean and tidy production.

Owner:嘉兴市科邦医用包装有限公司

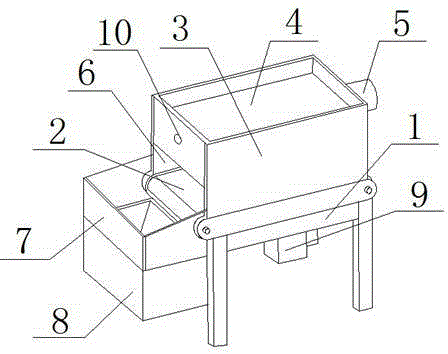

Automatic weighing device used for tea production line

InactiveCN106672586AWon't scatterSimple and fast operationConveyor partsProduction lineDisplay device

The invention discloses an automatic weighing device used for a tea production line. The automatic weighing device comprises a rack, a conveying device, a feeding box, a turning device, a driving motor, a discharging port, baffles, a hopper, a controller, a rotating shaft, first cover plates, a turning plate, gravity sensors, springs and second cover plates. The turning device comprises the rotating shaft and the turning plate, one end of the rotating shaft is connected to the driving motor, and the other end of the rotating shaft is installed on the feeding box. The heights of the baffles are higher than that of the discharging port. A display device is arranged on the rack, the weight of materials on the turning plate can be directly displayed by the display device, and meanwhile, relevant parameters can be preset on the display device. The controller controls the conveying device, the driving motor and the display device. The automatic weighing device used for the tea production line is easy and convenient to operate and simple in structure, time and labor are saved, the problems that manual weighing is troublesome, the working process is complex, and working efficiency is low are solved, and the automatic weighing device is suitable for application and promotion.

Owner:HENGYANG ZHIYUAN AGRI TECH

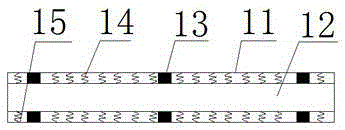

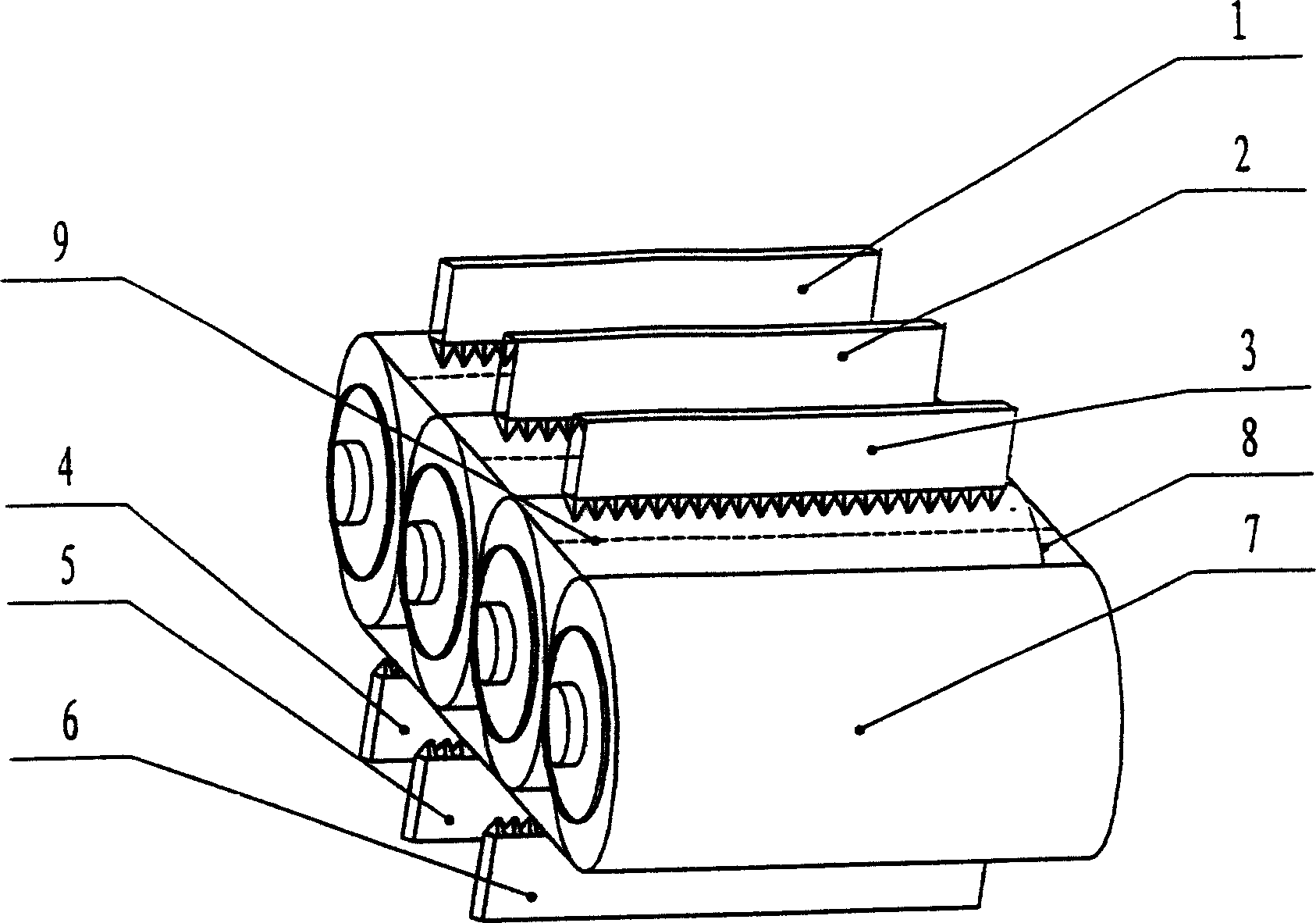

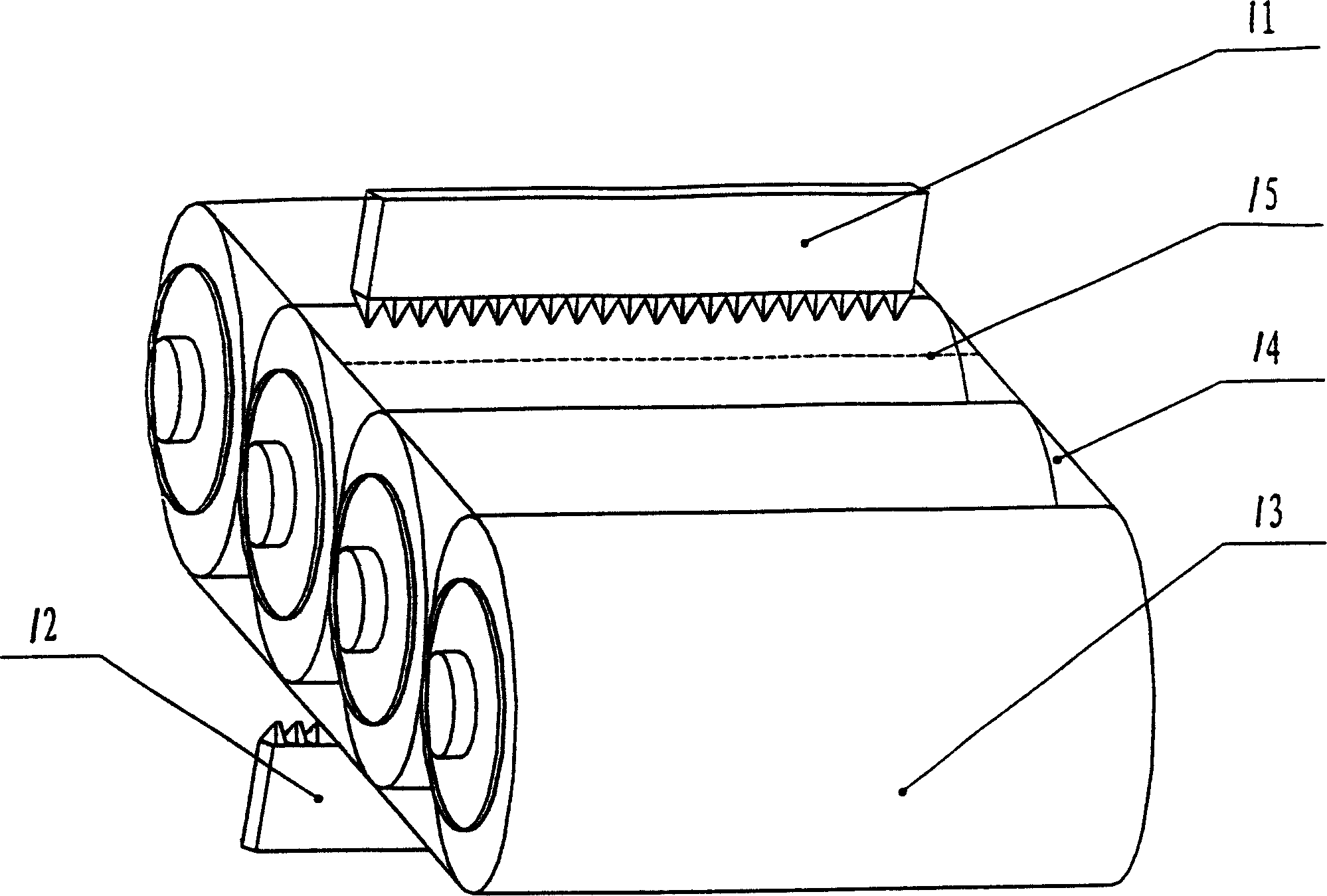

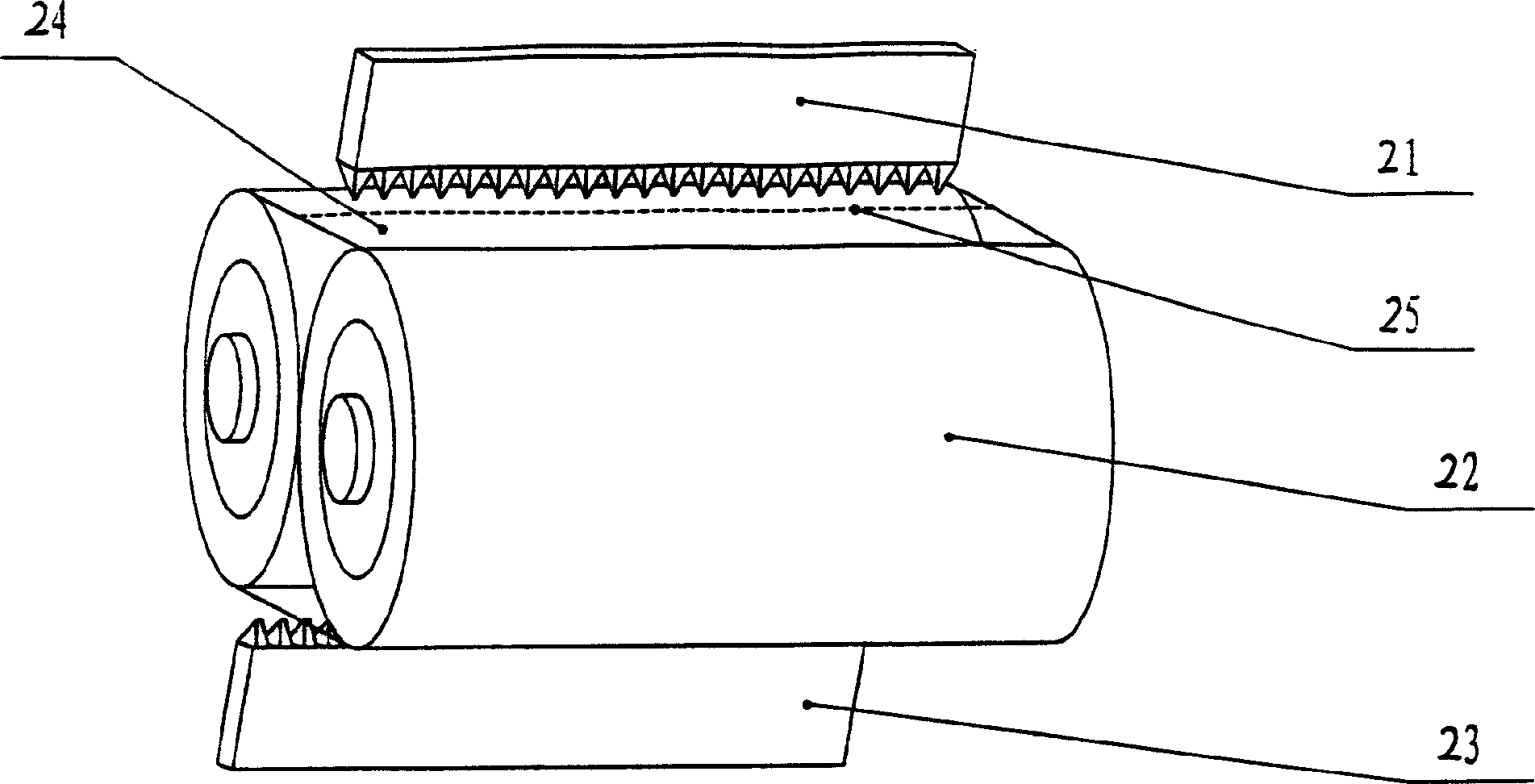

Cylindrical product tearable package, its manufacturing method and its special cutting knife

InactiveCN1513736ARapid productionImprove product qualityRigid containersContainers with multiple articlesEngineeringParallel arrangement

A package able to be torn away for the cylindrical goods features that multiple cylindrical goods arranged parallelly can be packed by a thermoshrinking film on which there are detaching lines. A special cutter with multiple toothed cutting edges is used to cut said packing film along said detaching lines for tearing away the film and getting a cylindrical goods.

Owner:FUJIAN NANPING NANFU BATTERY

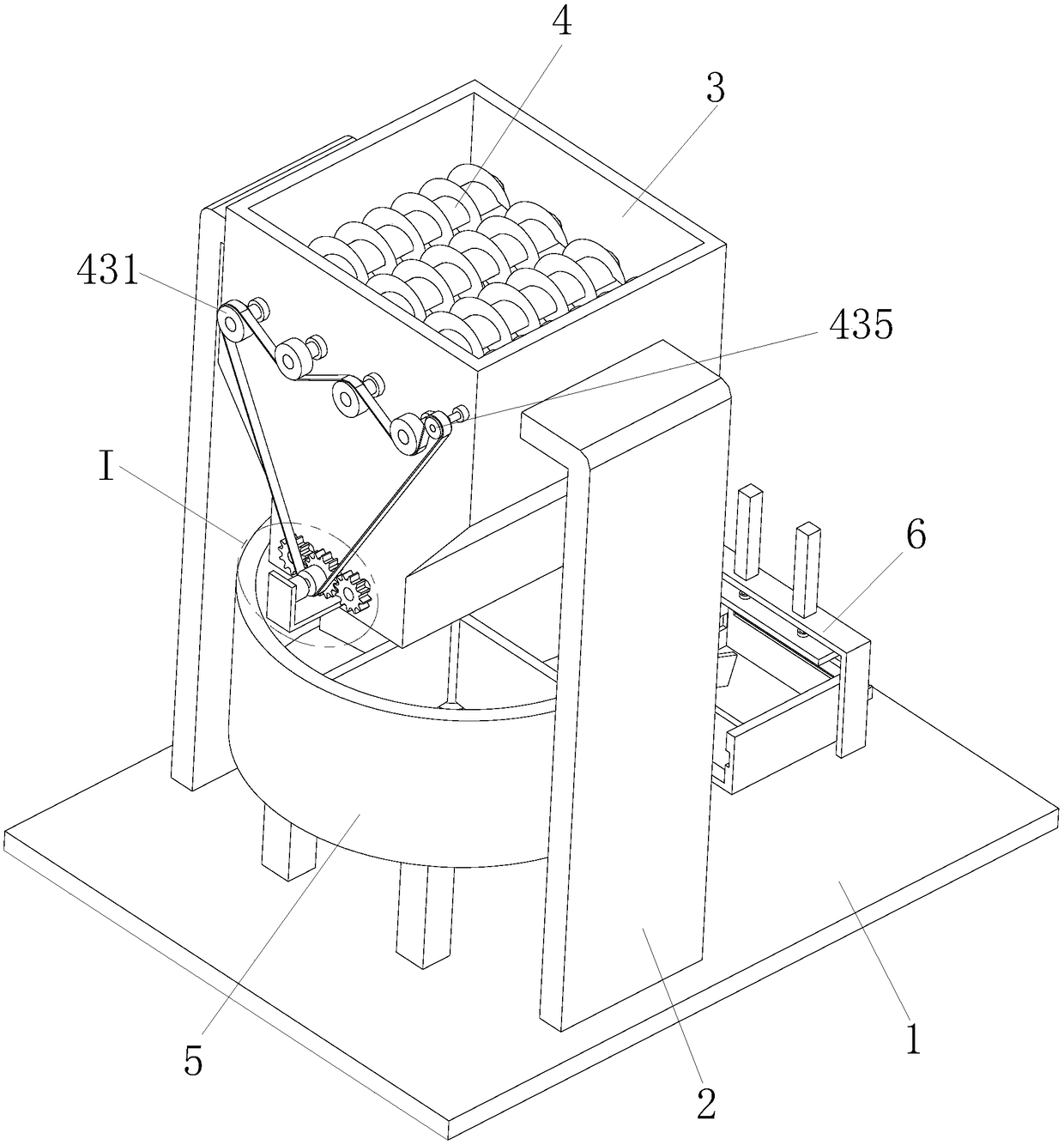

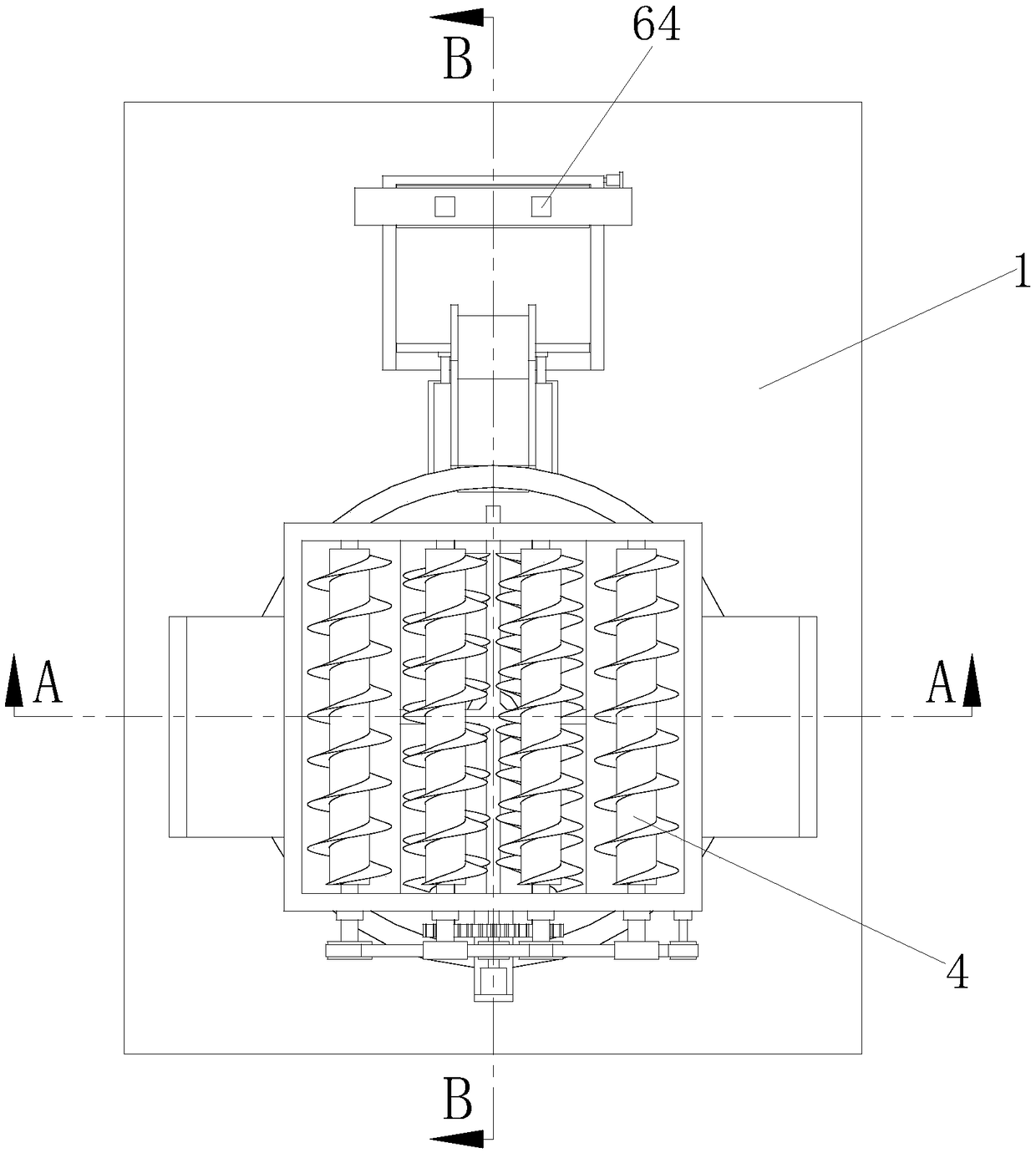

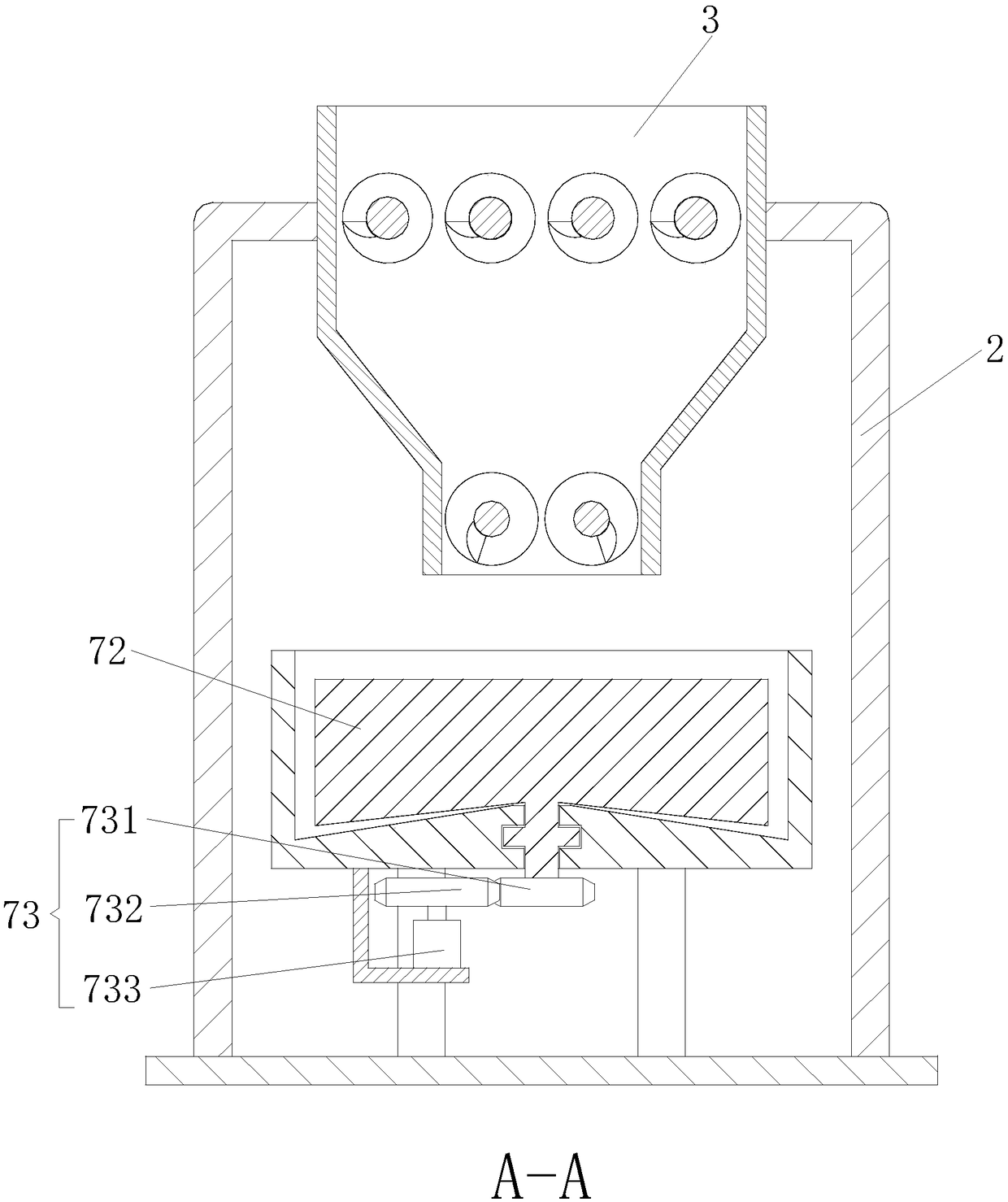

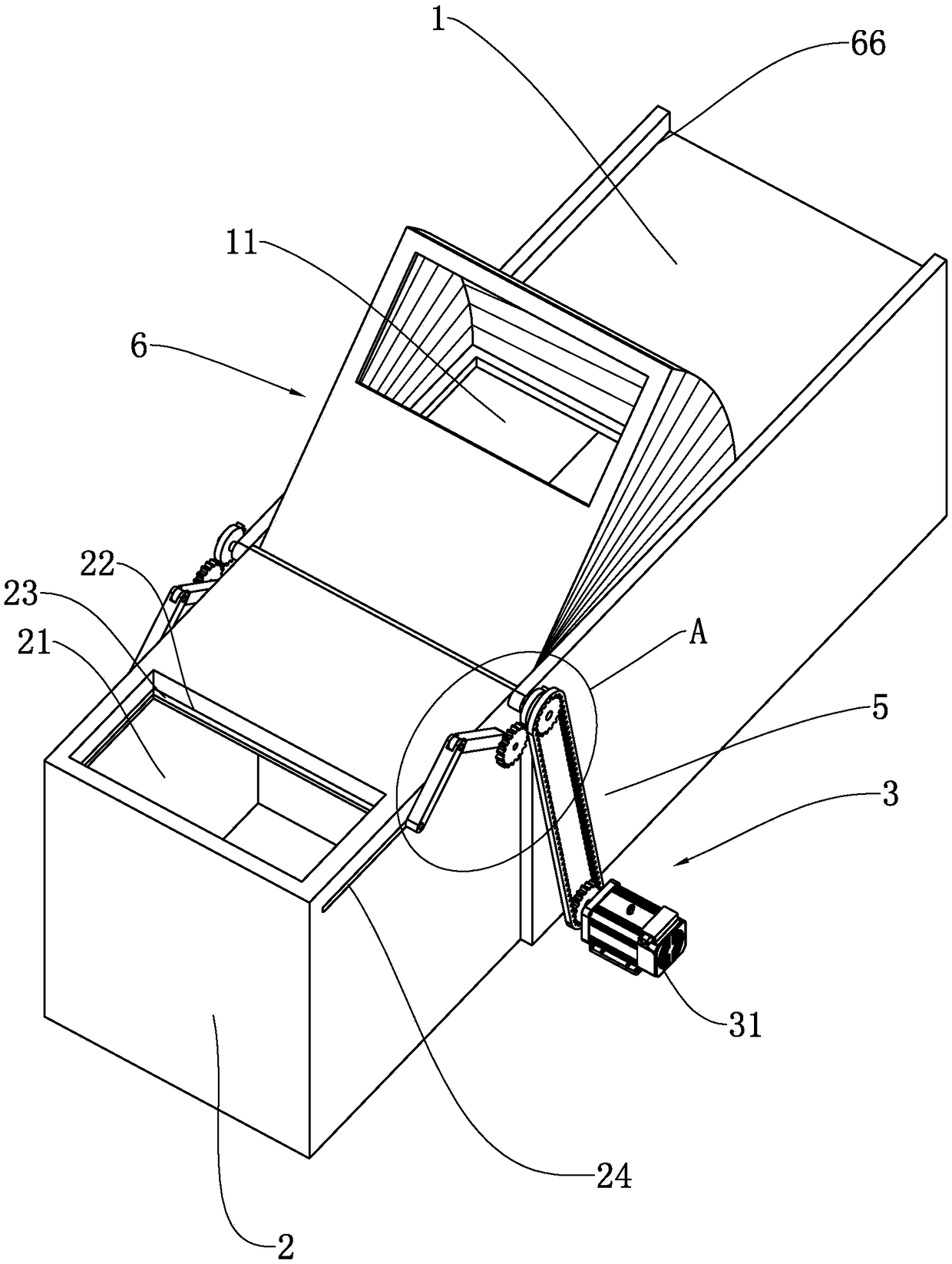

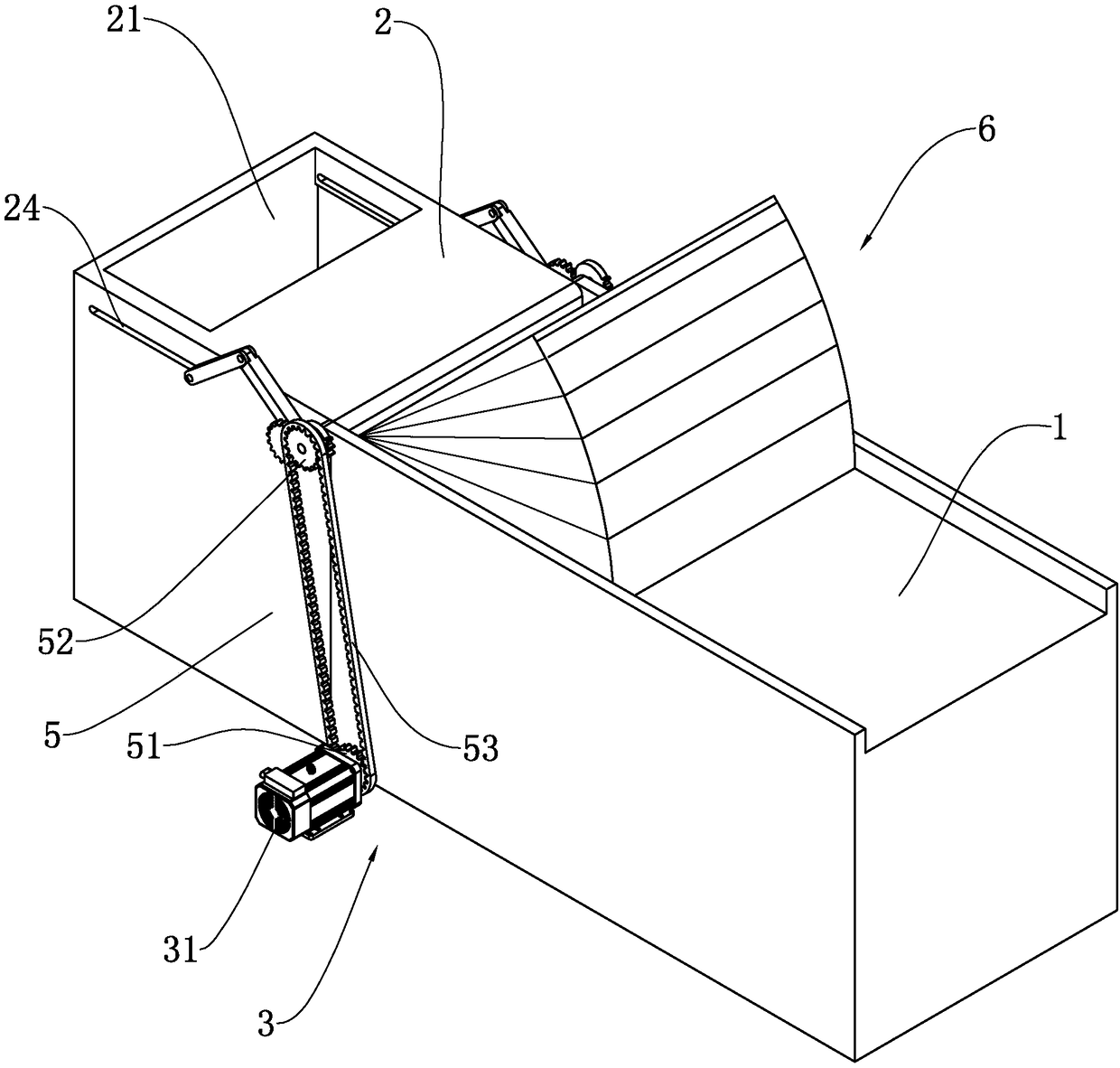

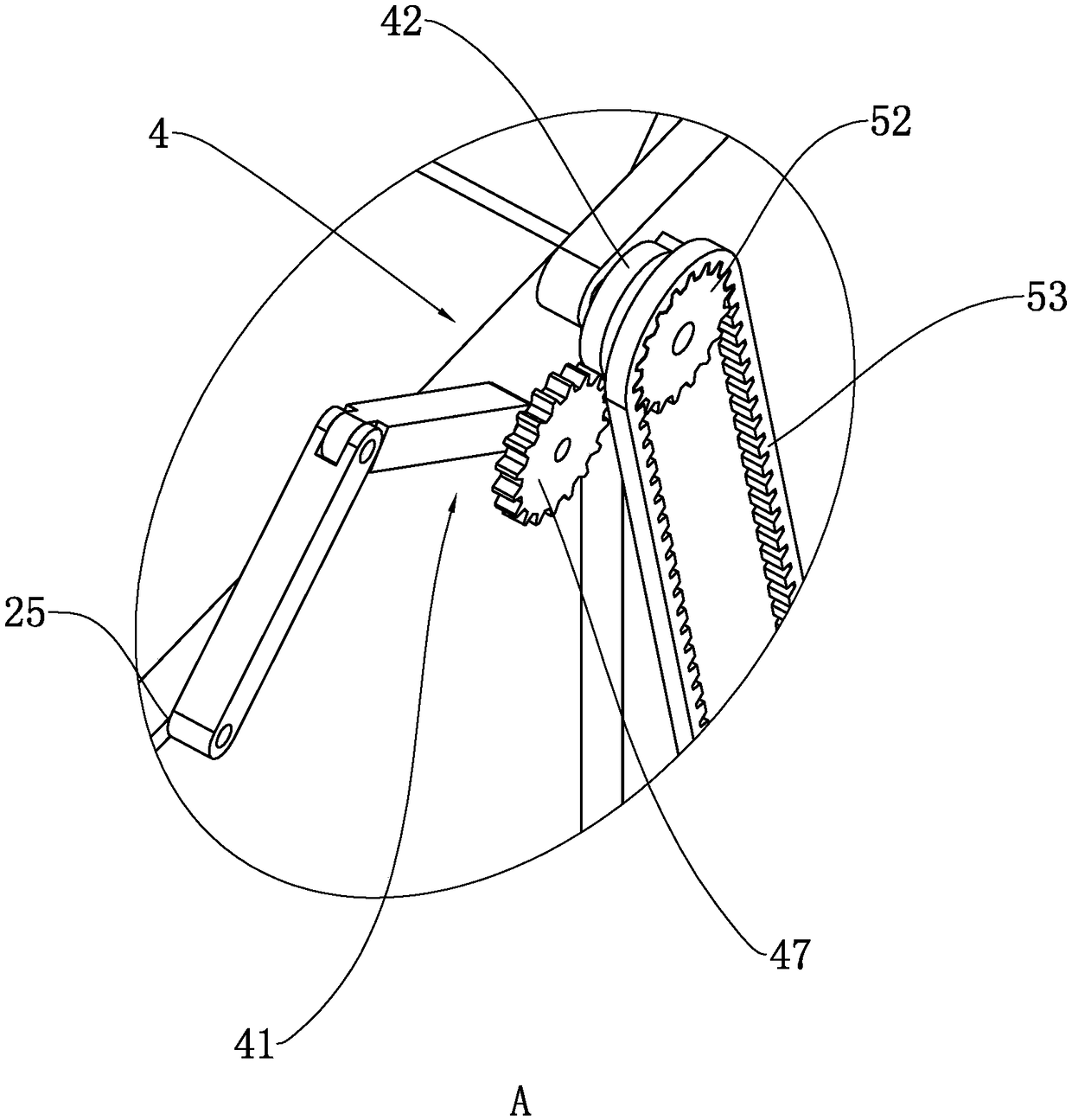

Straw pulverizing compressor

InactiveCN109076799AGuaranteed forming rateWon't scatterCuttersBundling machine detailsHydraulic cylinderEngineering

The invention relates to a straw pulverizing compressor. The compressor comprises a bottom plate and an installing frame installed on the bottom plate, a pulverizing box is fixed to the installing frame, a pulverizing mechanism which can perform multi-layer pulverizing is installed in the pulverizing box, collecting mechanisms used for collecting straw powder are distributed between the bottom plate and the pulverizing box, and a bundling mechanism which is used for bundling the straw powder is installed on the bottom plate. According to the straw pulverizing compressor, multi-layer pulverizing is conducted by the cooperation of first and second pulverizing knives to improve pulverizing efficiency, the first and second pulverizing knives are cooperatively driven to rotate synchronously through a chain wheel transmission mechanism and gear transmission, energy is saved, the working efficiency is improved, pulverizing time is saved, bundling is cooperatively conducted through multiple groups of shaping plates and hydraulic cylinders to ensure the shaping rate of straw powder, and it is ensured that the straw powder does not scatter after being shaped to make packaging and stacking convenient..

Owner:无为县黄姑农机专业合作社

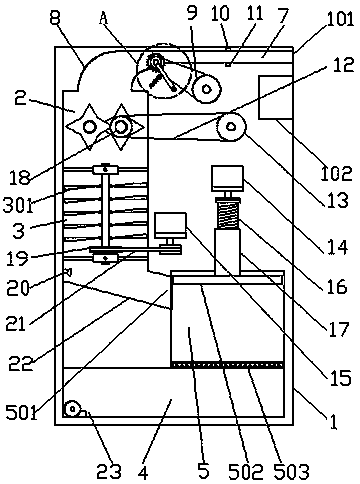

Automatic-compression paper shredder

The invention discloses an automatic-compression paper shredder, and belongs to the technical field of paper shredder equipment. The invention provides the technical scheme points that according to the device, a paper sheet is cut into thin strips through a cutting mechanism, so that a shredding mechanism arranged below and rotating at high speed can finely shred the thinly shredded paper strips conveniently through a blade; in addition, a low-power motor drives a compression mechanism to achieve a better paper scrap compression effect; paper scraps are firstly sprayed with the right amount ofwater through an atomizing spray head so as to be softened and easily stressed and shaped, a drive motor A rotates conveniently, the rotation motion is converted into the linear motion through a spiral rotary rod and a threaded sleeve, a pressing plate is driven to push so as to compress and form the smashed paper scraps, and the paper scraps can be adhered together and cannot be scattered aftermoisture volatilization so as to be convenient to store, recycle and carry subsequently.

Owner:深圳市奥科杰环保材料科技有限公司

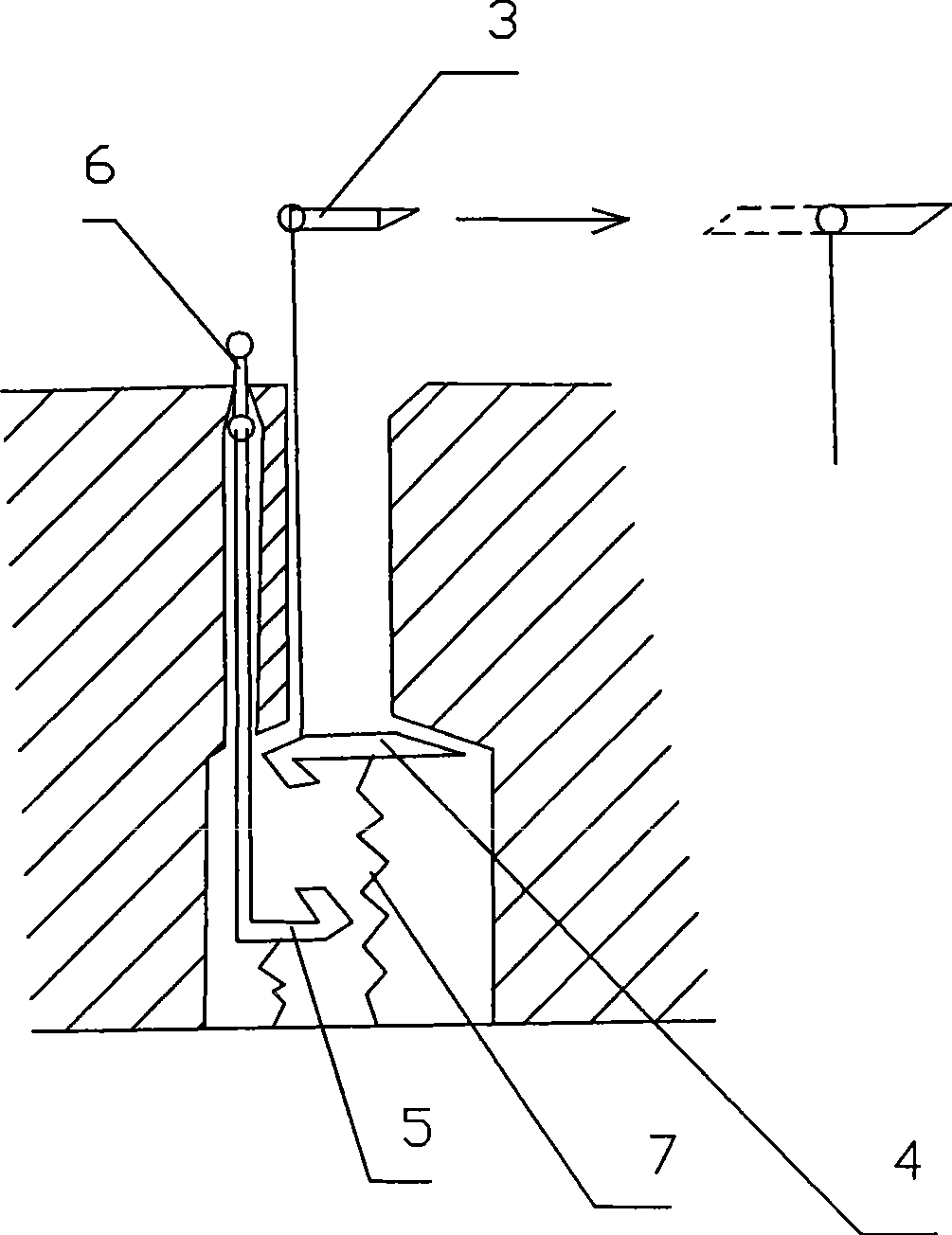

Steel ball self-locking mechanical connecting device and connecting method

The invention discloses a steel ball self-locking mechanical connecting device and method, and belongs to the technical field of buildings. The steel ball self-locking mechanical connecting device comprises an upper joint and a lower joint, and further comprises steel balls, a supporting ring, a limiting piece, a supporting piece, a plug and an arc-shaped groove, wherein the steel balls are arranged in the upper joint; the steel balls are arranged in the circumferential direction of the outer side face of the supporting ring; the limiting piece is used for limiting the downward falling trend of the supporting ring; the supporting piece is used for providing downward and centripetal force for the steel balls; one end of the plug is connected with the upper end in the lower joint, and the other end of the plug extends out of the upper end of the lower joint; the arc-shaped groove is of a groove structure formed in the side wall of the extending end of the plug in the circumferential direction; and after the upper joint and the lower joint abut against each other, the plug penetrates through the limiting piece and jacks up the supporting ring, and the steel balls enter the arc-shapedgroove under the acting force of the supporting piece. The device is easy to assemble, structures are matched with each other after assembly, automatic triggering and locking can be achieved after theupper joint and the lower joint abut against each other under the action of gravity, triggering is easy and convenient, rigid limitation is formed between the steel balls and the rigid plug arc-shaped groove after triggering, and stable and effective anti-drawing acting force is provided for a precast pile after connection.

Owner:XUZHOU NORMAL UNIVERSITY

Complete equipment for garbage transfer

InactiveCN109250372AReduce the burden onWon't scatterRefuse receptaclesRefuse transferringElectric machineryEngineering

The invention relates to the field of garbage treatment, in particular to complete equipment for garbage transfer. The equipment aims at solving the problem that when poured into a garbage compressiondevice from a storage box, garbage is scattered to the ground. The equipment is characterized by comprising a garbage compression device provided with a first feeding port, a storage box and a driving device, a second feeding port matched with the first feeding port is formed in the top of the storage box, a storage groove is formed in the side wall of the second feeding port, and a sealing platefor sealing the second feeding port is slidingly connected to the interior of the storage groove; the driving device comprises a motor, a start-stop mechanism for converting a rotation pair of the motor to a sliding pair for driving the sealing plate to slide along the storage groove and a continuous track mechanism for driving the storage box to rotate. According to the complete equipment for garbage transfer, through the design of the sealing plate, the second feeding port can be sealed, and accordingly the garbage cannot be scattered to the ground when poured in.

Owner:杭州俊盛机电有限公司

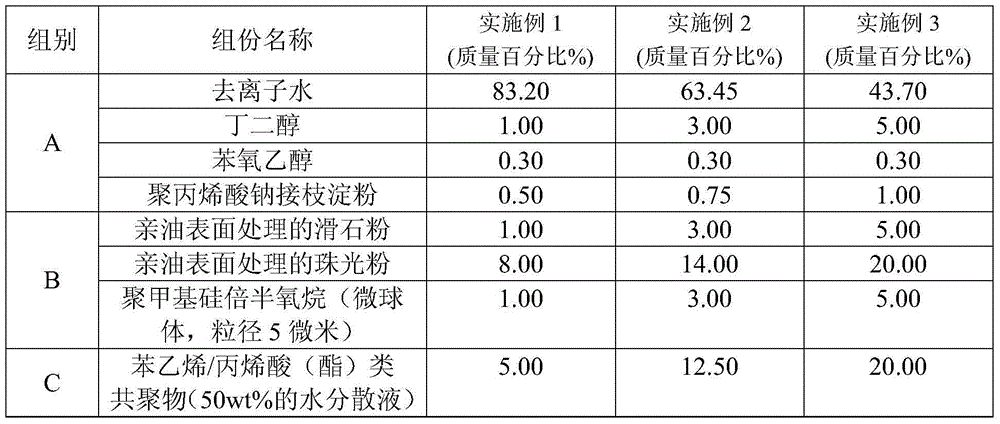

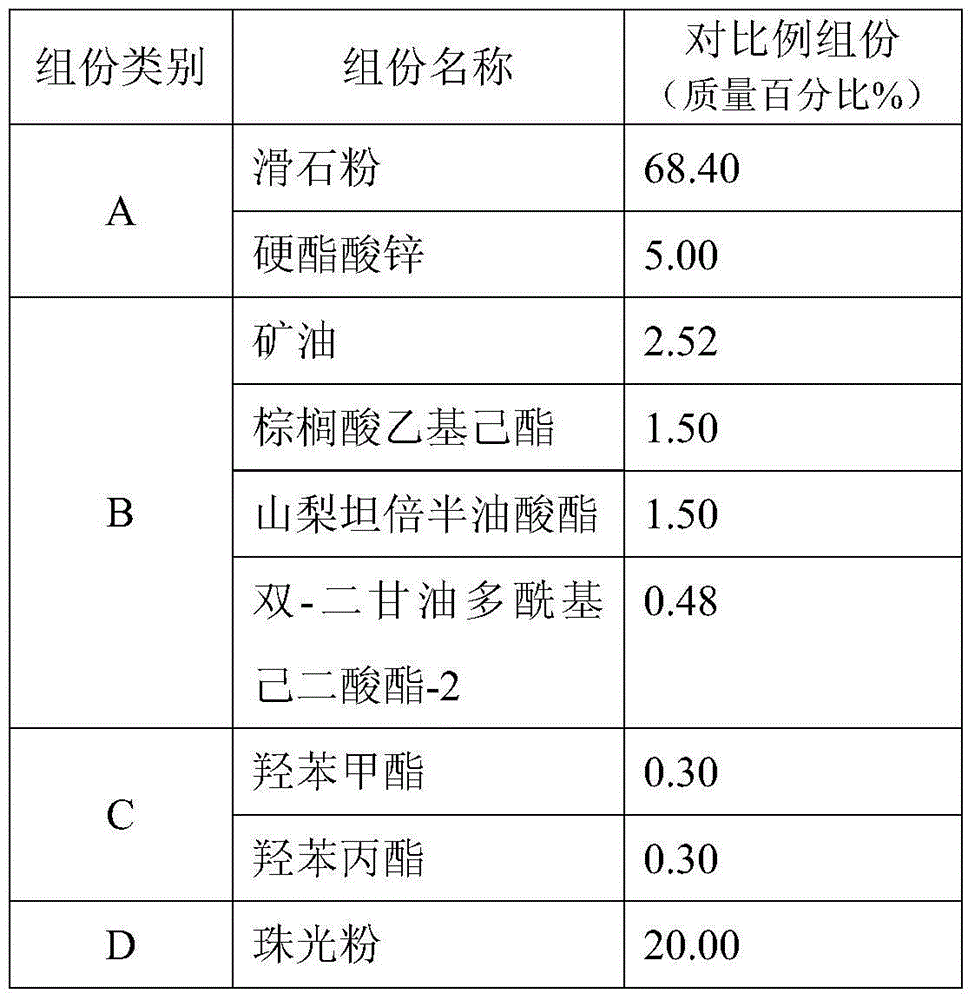

Refreshing and durable mousse eye shadow and preparation method thereof

InactiveCN104606073AStrong adhesionNot easy to take off makeupCosmetic preparationsMake-upSodium polyacrylateFilm-forming agent

Owner:GUANGZHOU SHEENCOLOR COSMETICS CO LTD

High/low-temperature multifunctional long-lifespan high-performance glass antifogging agent

InactiveCN101659855AStrong water absorptionGood anti-fog effectOther chemical processesRevolutions per minuteSolvent

The invention relates to a glass antifogging agent, in particular to a formulation and a manufacturing technique for a high / low-temperature multifunctional long-lifespan high-performance glass antifogging agent. The formulation is characterized by comprising the following components (in percentage by weight): 1, 3 to 30 percent of gelatin; 2, 50 to 69 percent of phosphoric acid; 3, 20 to 30 percent of isopropanol; 4, 0 to 10 percent of formaldehyde; 5, 0 to 10 percent of glycerol; and 6, 0 to 19 percent of ethylene glycol. The manufacturing technique comprises the following steps: adding materials 2 and 3 to a container and evenly stirring to form solvent A; putting a material 1, namely the gelatin, into the solvent A and allowing the gelatin to absorb enough solvent A to swell, be completely soft and have no hard heart; slowing heating the gelatin during water bath to dissolve the gelatin; using a stirrer to continuously stir the gelatin at a speed of 50 revolutions per minute till the gelatin is completely dissolved; keeping the constant temperature of gelatin solution and adding materials 4, 5 and 6 in turn pro rata; stirring and mixing evenly; and obtaining a finished product of the antifogging agent. The product can have good antifogging effects in a wide temperature range between 30 DEG C below zero and 100 DEG C.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Chain lock

The invention relates to a chain lock, which comprises a lock body provided with a lock hole, a chain tape, a lock screw mechanism, a shaft lever and a shaft lever sleeve, wherein the chain tape comprises a first end and a second end, wherein the first end is fixedly connected with the lock body, and the second end is inserted into the lock hole; the lock screw mechanism is arranged on the lock body and comprises a locking position and a lock bolt, wherein the locking position is used for controlling the second end to be locked on the lock body, and the lock bolt is used for releasing the second end to an unlocking position; the lock body is provided with the shaft lever, and the chain tape is wound and wrapped on the outer circumference of the shaft lever in the unlocking state; the shaft lever sleeve is a barrel structure with an open upper end, and in the unlocking state, the shaft lever sleeve is sleeved outside the shaft lever and matched with the upper end surface of the shaft body. The chain lock disclosed by the invention has a simple structure, achieves a good reception effect by winding the chain tape on the outer circumference of the shaft lever and adopting a fixing way of the shaft lever sleeve, ensures that the received chain tape cannot hang down, and is attractive in appearance.

Owner:SINOX LOCKKUNSHANCO LTD

Cigarette case

InactiveCN103395567AEasy to carryWon't scatterContainers for flexible articlesPackaging cigaretteEngineeringPackaging Case

The invention discloses a cigarette case, relates to the field of cigarette cases, and solves the technical problem of inconvenience of storing cigarette butts and cigarette ash in the prior art. The cigarette case comprises a case body, a case cover and a storage bag. The storage bag is a flame retardant tinfoil bag used for holding the cigarette butts and cigarette ash so as to protect the environment. The flame retardant tinfoil bag is convenient to carry, and the cigarette butts and the cigarette ash inside the bag cannot scatter when the bag is sealed.

Owner:HUZHOU JIHE PACKAGE PROD

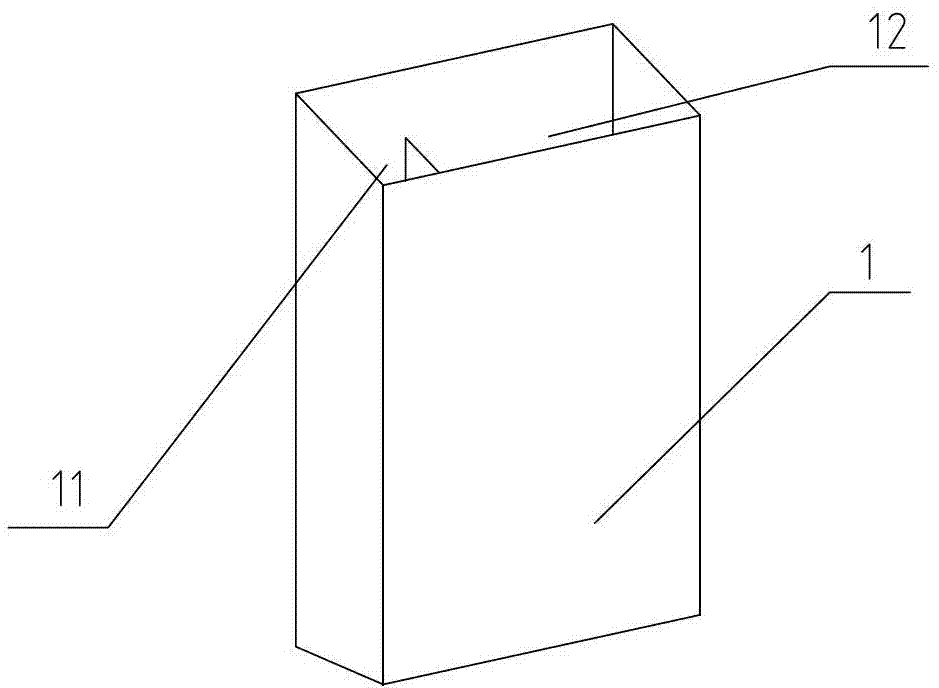

Elastic pen container

The invention discloses an elastic pencil vase, which belongs to the technical field of manufacturing pencil vases. The pencil vase comprises a cylindrical barrel body, wherein the cylindrical barrel body is provided with at least three pencil holes, as well as a small cylinder which is formed by arcs connected with the pencil holes and is coincide with a central axis of the cylindrical barrel body; each pencil hole is formed by two parts; the aperture of a lower part is larger than that of an upper part; a tray is arranged in a hole of the lower part; the tray is connected with a pencil hole plug in an orifice; an identification layer is arranged on the pencil hole plug; the bottom surface of the tray is fixed on the bottom of the barrel body through a spring; one end of the tray is provided with a hook which is matched with a hook-shaped structure on button under the tray; the button passes through a cylindrical hole on one side of one pencil hole and protrudes out of the surface of the barrel body; and the lower surface of the button is fixed on the barrel body through the spring. The elastic pencil vase has the cylindrical barrel body which is provided with a plurality of holes for placing pencils, and has the advantages of simple operation, taking-using convenience and the like.

Owner:崔静

Pneumatic pollen transmission device

InactiveCN101658130AReduce volumeHigh alignmentPlant genotype modificationAgricultural engineeringEngineering

The invention relates to a garden tool, in particular to a pneumatic pollen transmission device which comprises a one-way air inlet valve, an air chamber, a one-way air outlet valve, a main pipe, sidepipes, a spray pipe, a cover plate and a pollen hopper, wherein the bottom of the air chamber is connected with the one-way air outlet valve, the lower end of which is connected with the main pipe, and the lower end of the main pipe is communicated with the two reverse L-shaped side pipes with the opposite directions; the lower ends of the two side pipes are respectively connected and communicated with two sides of the cylindrical pollen hopper with a closing top end; and the pollen hopper is internally provided with the elastic cover plate used for sealing the lower half part of the pollen hopper. The pneumatic pollen transmission device has higher alignment performance and pollination success rate, and can be operated by a single hand.

Owner:CHENGDU JUNFENG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com