Packaging film material processing device

A processing device and packaging film technology, applied in recycling technology, presses, plastic recycling, etc., can solve the problems of low space utilization, waste space, not easy to compress and fold, etc., to improve environmental conditions, simple structure, easier processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

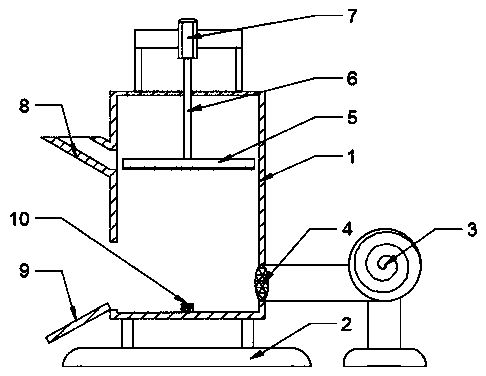

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] A packaging film material processing device, comprising a box body (1), a base (2), a pouring port (8), a discharge port (9), and the pouring port (8) is obliquely opened on the box body and arranged on the upper side of the box body, The box body (1) is suspended on the base (2), and the box body (1) is made of steel, square, hollow, and the inner wall is covered with fireproof and heat-resistant material fireproof cotton; the discharge port (9) is set on The lower side of the box (1) is designed as a full opening on one side, which is equivalent to the lower half of the box on this side being movable when the box is opened, and the box (1) and the discharge port (9) are opened The upper part of the plate connection is provided with a lock, and the lower part is provided with a hinge, which can be opened outward; the upper end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com