Novel machine oil magnetizing filtering device

A new type of engine oil technology, applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of inability to disassemble and assemble, complicated operation steps, scattered, etc., to achieve simple disassembly and assembly, Simple operation steps, protection from damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

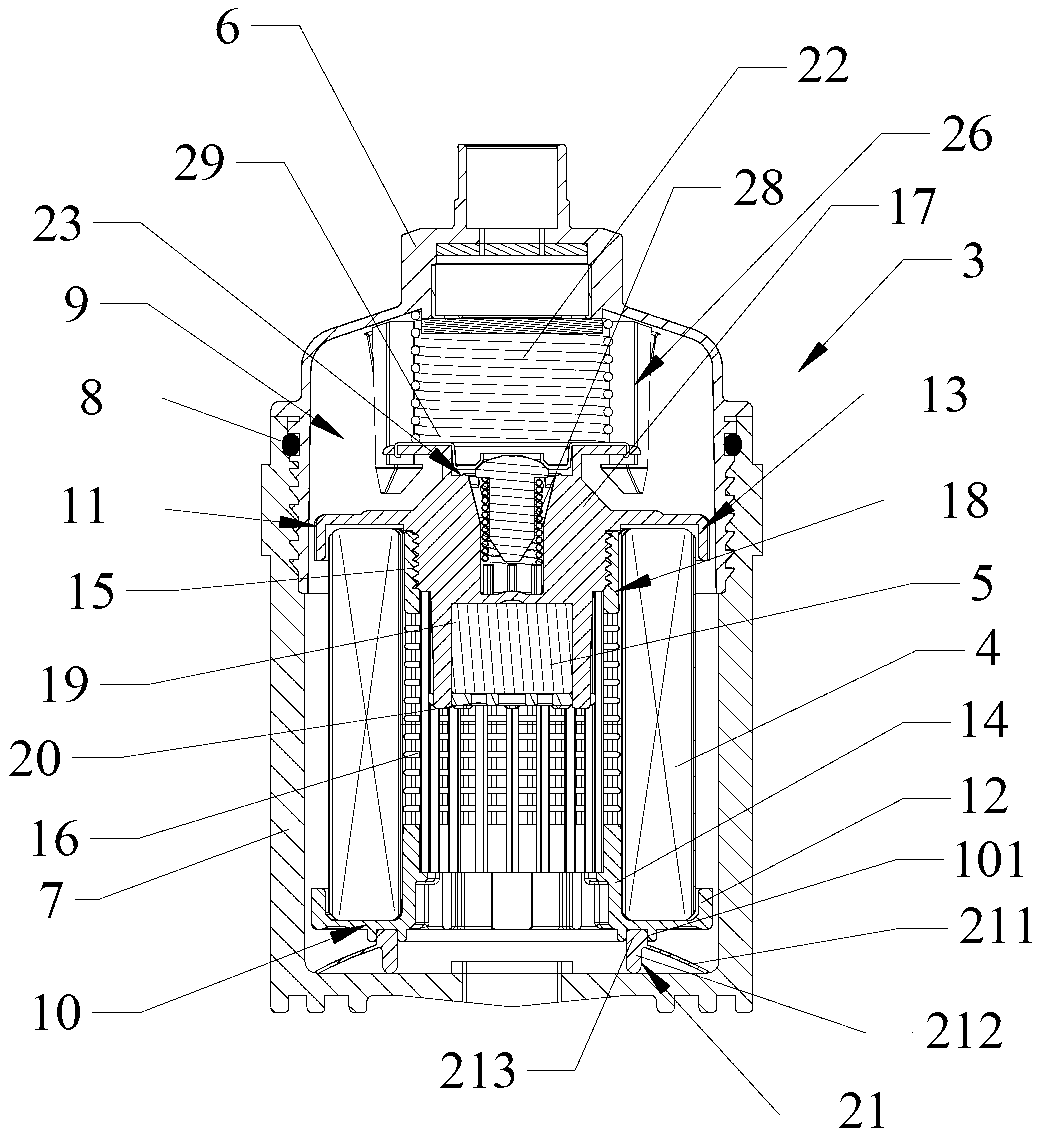

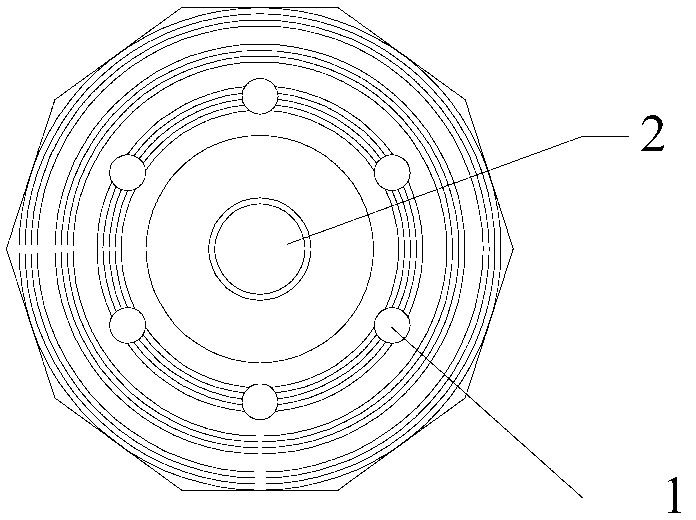

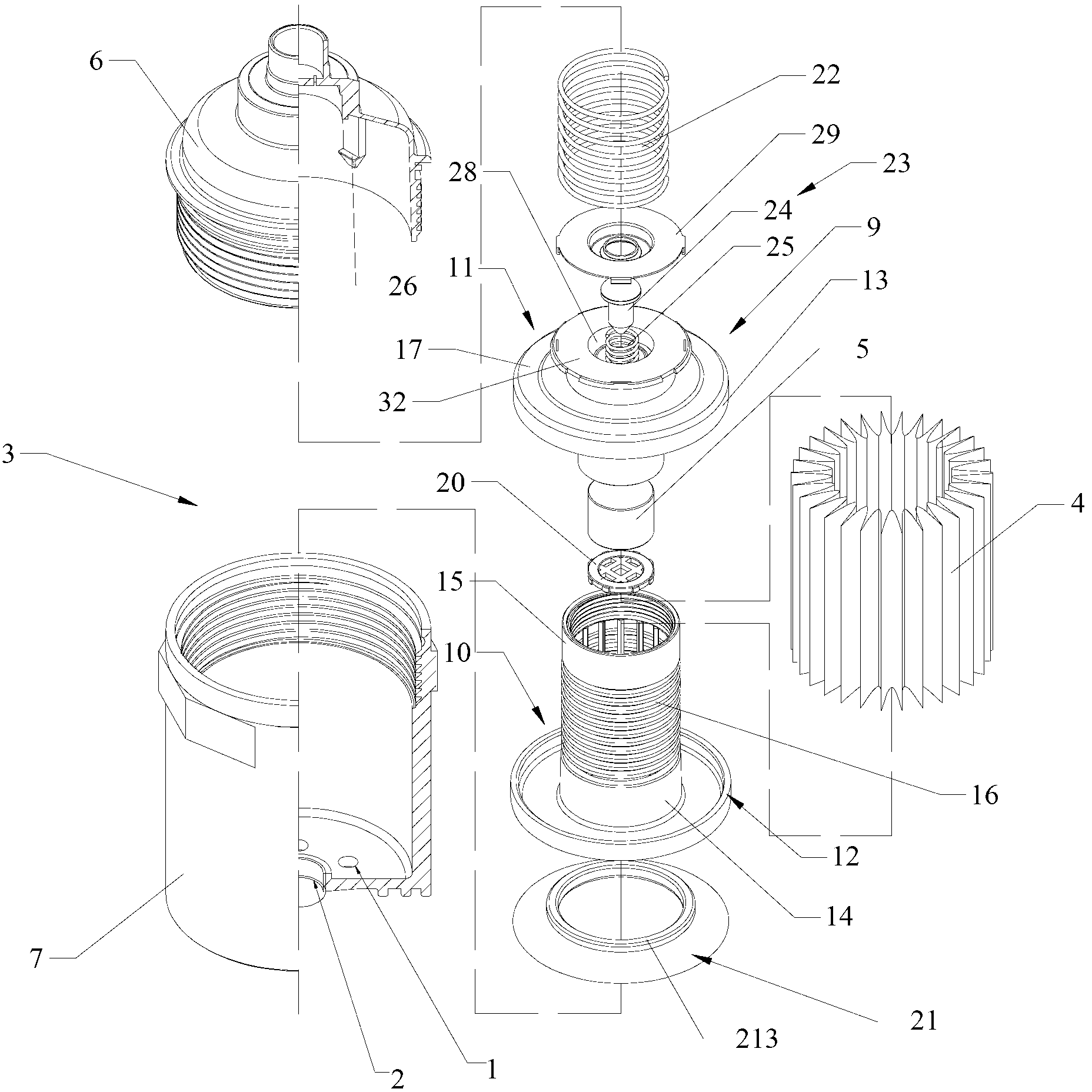

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A specific embodiment of the present invention see Figures 1 to 6 .

[0035] Such as figure 1As shown, the oil magnetized filter of the embodiment of the present invention includes a housing 3 having an oil inlet hole 1 and an oil outlet hole 2, which is arranged in the housing 3 and is located between the oil inlet hole 1 and the oil outlet The filter element 4 between the oil holes 2, and the magnet 5 arranged in the housing 3. The housing 3 includes a cover housing 6 and a base housing 7 that are detachably sealed and engaged, the cover housing 6 is provided with a cover housing thread, and the base housing 7 is provided with a base housing thread, A sealing ring 8 is provided between the screw thread of the cover shell and the screw thread connection part of the base shell to realize the detachable sealing engagement connection of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com