Automobile sealing strip trimming device

A technology of automobile sealing strip and cutting device, applied in the field of machinery, can solve the problems of increased material cost, inclined section, increased labor cost, etc., and achieve the effect of ensuring safety, smooth section and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are preferred embodiments of the present invention, but do not limit the protection scope of the present invention.

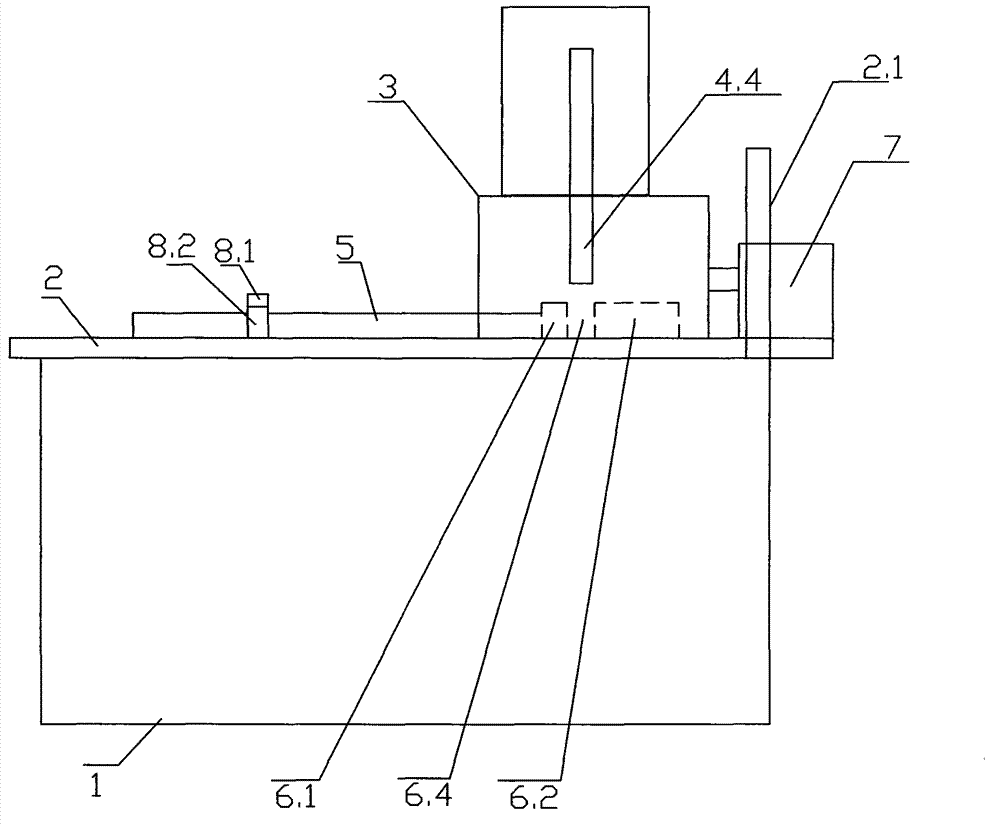

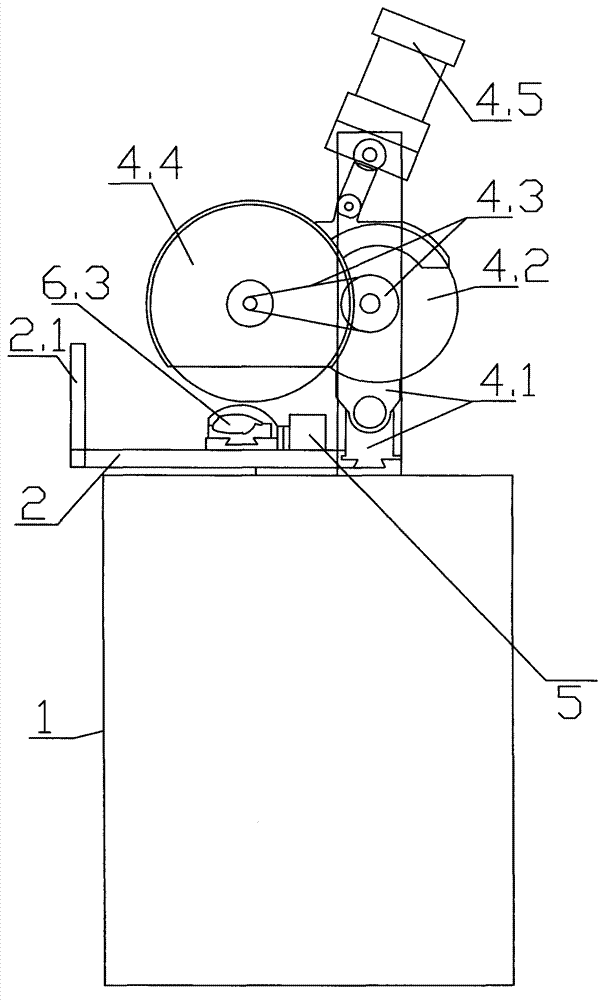

[0016] refer to figure 1 , figure 2 As shown in the figure, an automobile weather strip cutting device of the present invention includes a frame 1, a worktable 2, a cutting assembly, a guide assembly, a measuring assembly and a limit assembly. The worktable 2 is slidably fitted on the frame 1 to cut The assembly is fixedly connected to the workbench 2, the guide assembly is detachably installed on the workbench 2 and is located below the cutting assembly, the measurement assembly is fixed on the workbench 2, and the limit assembly is detachably installed on the measurement assembly. figure 2 The protective cover 3 is not shown in the figure.

[0017] A handle 2.1 is fixed on the workbench 2 . Used to pull the table 2 to move on the frame 1.

[0018] The cutting assembly is provided with a protective cover 3 outside, the protective cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com