Test device and method for impulse blowing jet stream included angle and jet stream declination angle

A technology of pulse injection and testing device, which is applied to measurement devices, fluid devices, instruments, etc., can solve the problems of inability to guarantee the length of the entire filter bag, damage to the filter bag, uneven cleaning of the filter bag, etc., and achieve enhanced cleaning. Ash effect, prolong service life, protect filter bag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

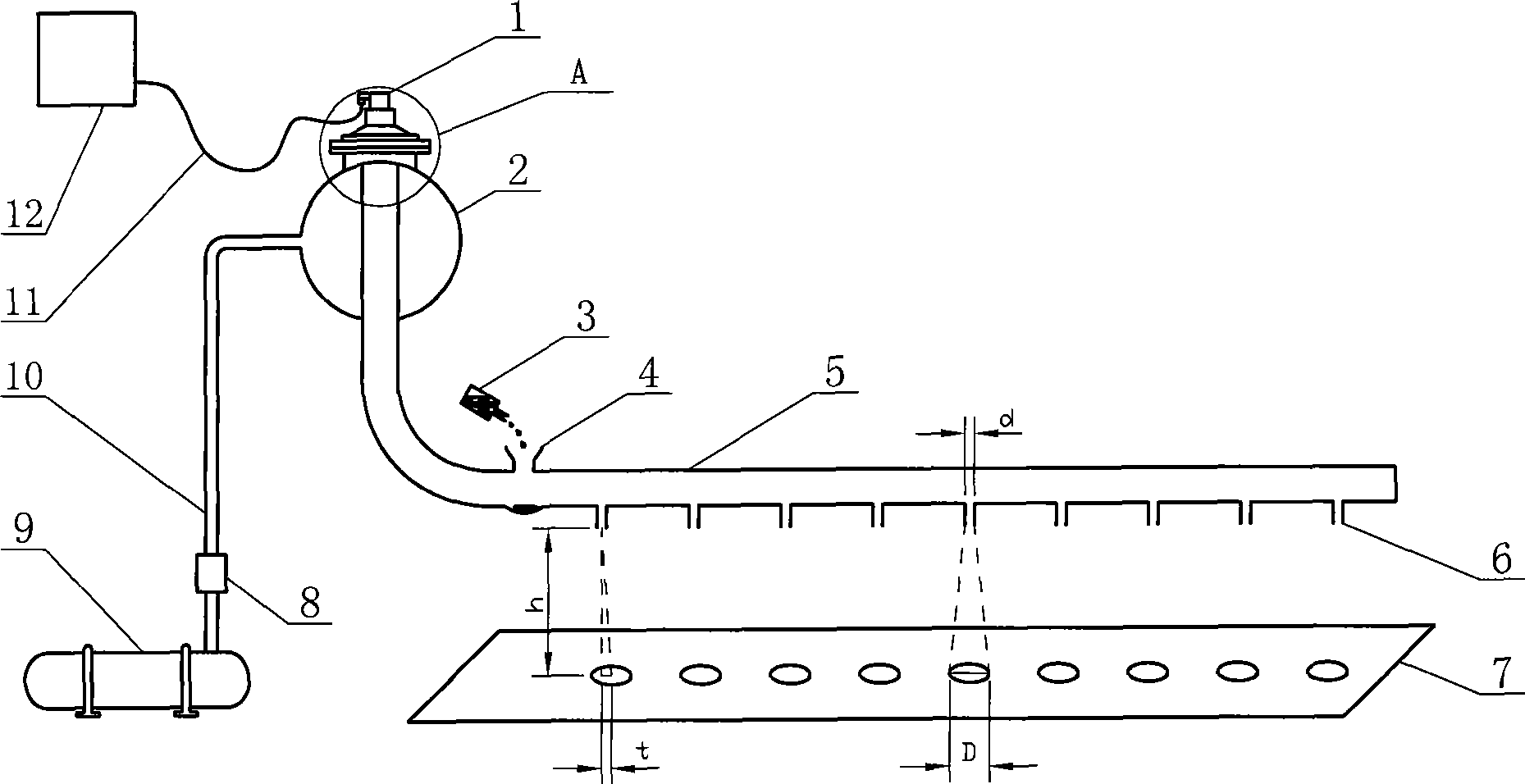

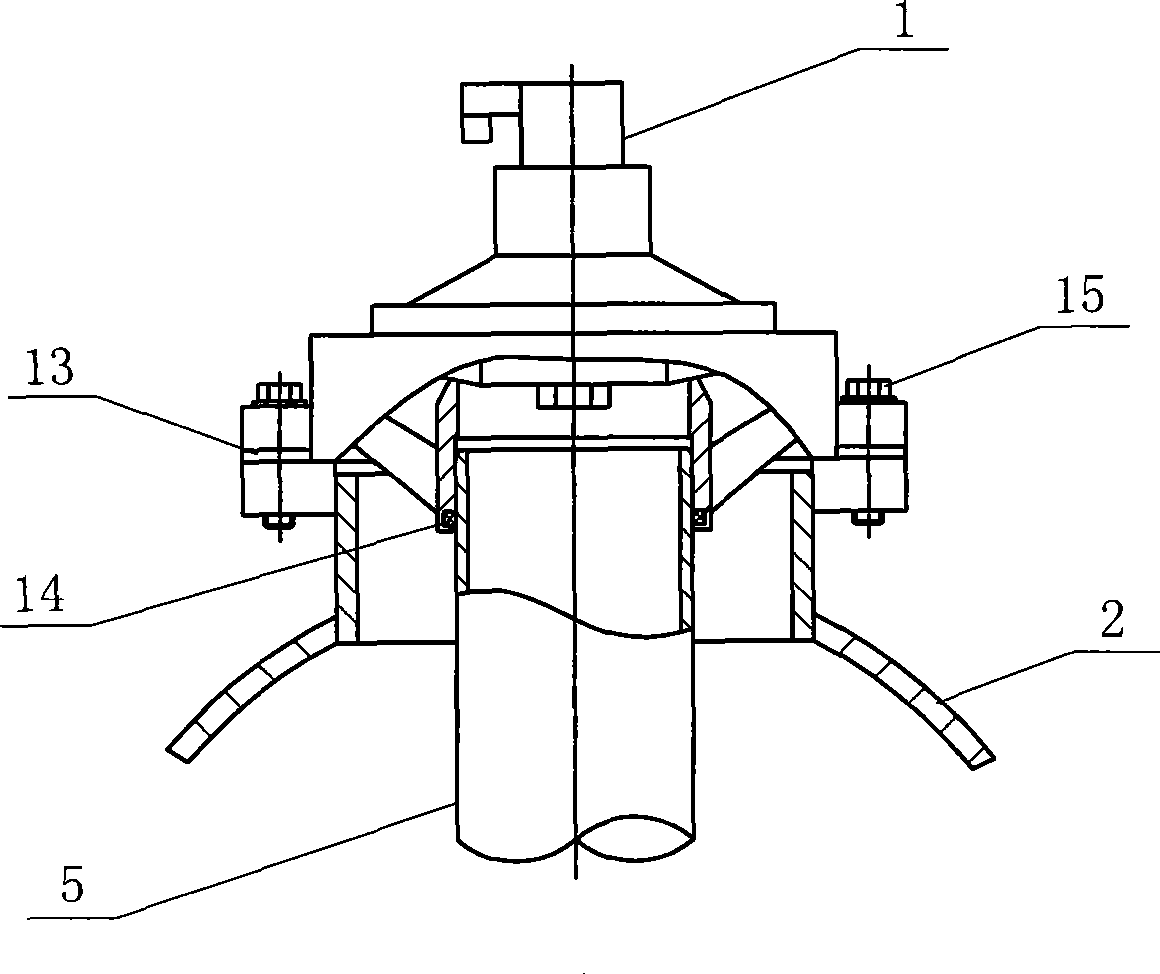

[0014] combine figure 1 , figure 2 As shown, a test device for pulse jet angle and jet deflection angle includes a pulse jet device, a pulse valve 1 is installed on an air bag 2, a gasket 13 is placed in the middle, and is tightened and fixed with a fastener 15 , the pulse valve 1 is connected to the pulse controller 12 through the wire 11, the left side of the air bag 2 is connected to the air source processor 8 and the air compressor 9 through the pipeline 10 in turn, and the blowing pipe 5 is connected to the pulse valve 1 after passing through the air bag 2 , sealed by the sealing ring 14 in the pulse valve 1, nine nozzles 6 are arranged on the blowing pipe 5, and a filling port 4 is arranged on the left side of the nozzles 6 on the blowing pipe 5, directly below the blowing pipe 5 An image screen 7 is provided.

[0015] A method for testing the included angle of the pulse-jet jet and the deflection angle of the jet. First, the injection pipe 5 is injected with a color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com