LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of composite building template

A technology of LFT-D and building formwork, which is applied in the field of building formwork forming technology, can solve the problems of no building formwork data disclosure, failure to ensure uniform mixing of glass fibers, and inability to flexibly and accurately control the weight of glass fiber added, so as to avoid high costs , the effect of length guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

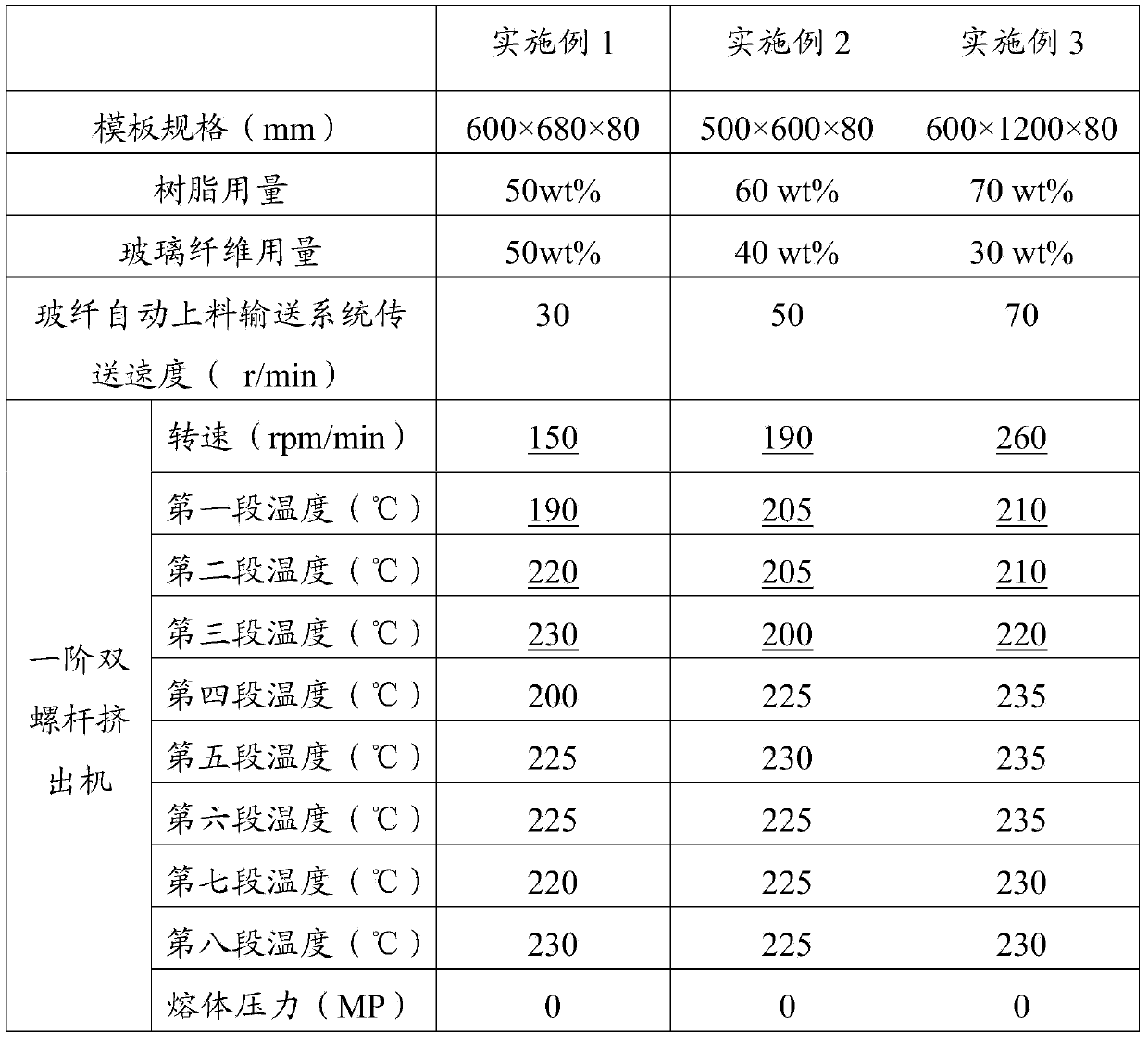

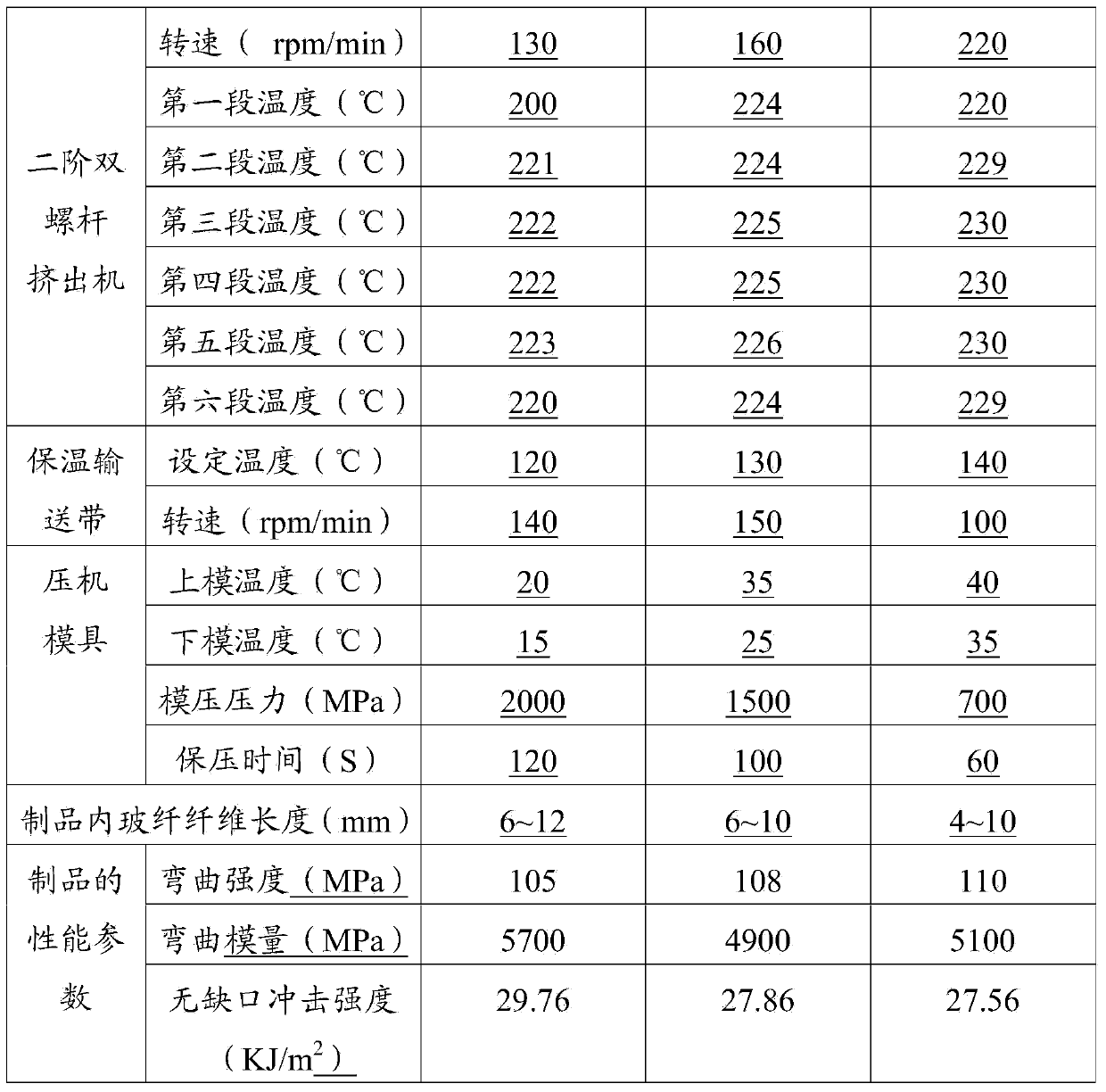

Examples

Embodiment Construction

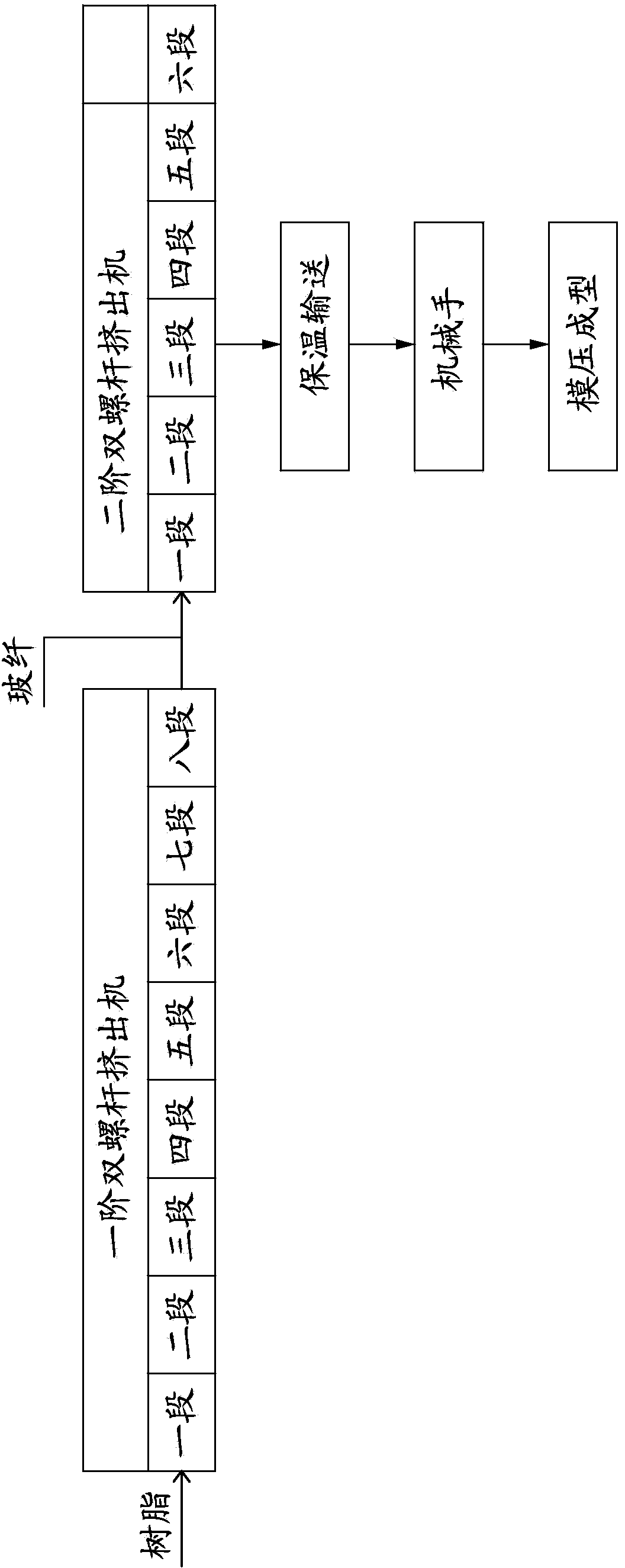

[0023] like figure 1 Shown, the LFT-D molding process of composite building formwork of the present invention comprises

[0024] Step 10. The resin is quantified from the vacuum feeding system to the vector weighing system according to the weight of the template, and then enters the first-stage twin-screw extruder for heating and melting, and then enters the second-stage twin-screw extruder at the same time as the glass fiber at the feed port of the second-stage twin-screw extruder. The screw extruder performs mixing and plasticization, and the weight ratio of the resin to the glass fiber is: 50-70 wt% of the thermoplastic resin and 30-50 wt% of the glass fiber.

[0025] Among them, the glass fiber is sent to the glass fiber metering and cutting device through the glass fiber automatic feeding and conveying system, cut and added to the resin melt according to the set length of 24-25mm, and is subjected to a secondary process by the shearing action of the resin melt. The lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com