Fixed-length cutting device for stainless steel tube

A technology for cutting devices and stainless steel pipes, which is applied in positioning devices, feeding devices, manufacturing tools, etc., can solve the problems of reducing the working speed of cutting machines and increasing error rates, and achieves compact and reasonable structural design, convenient operation and use, and convenient positioning and pressing tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

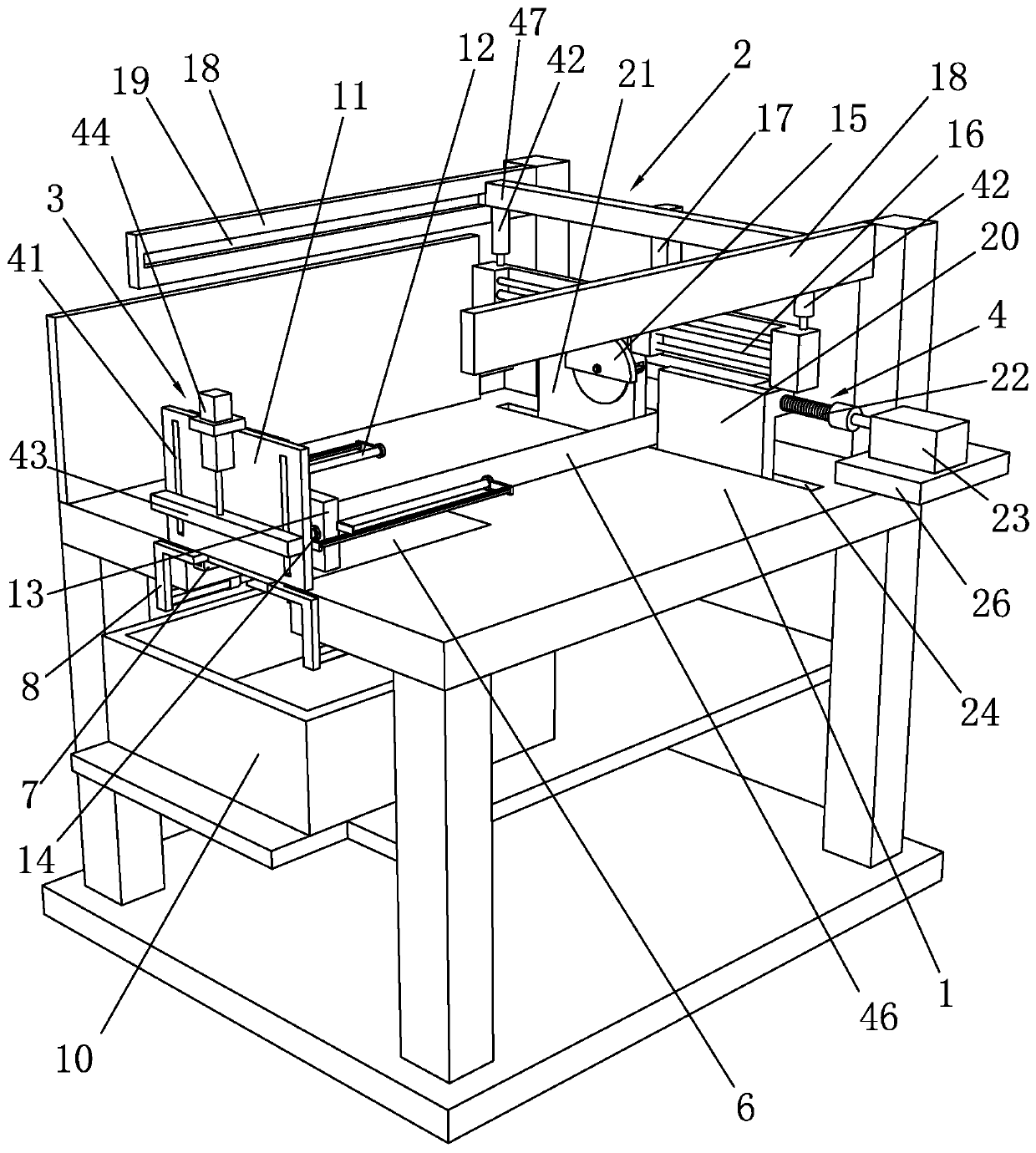

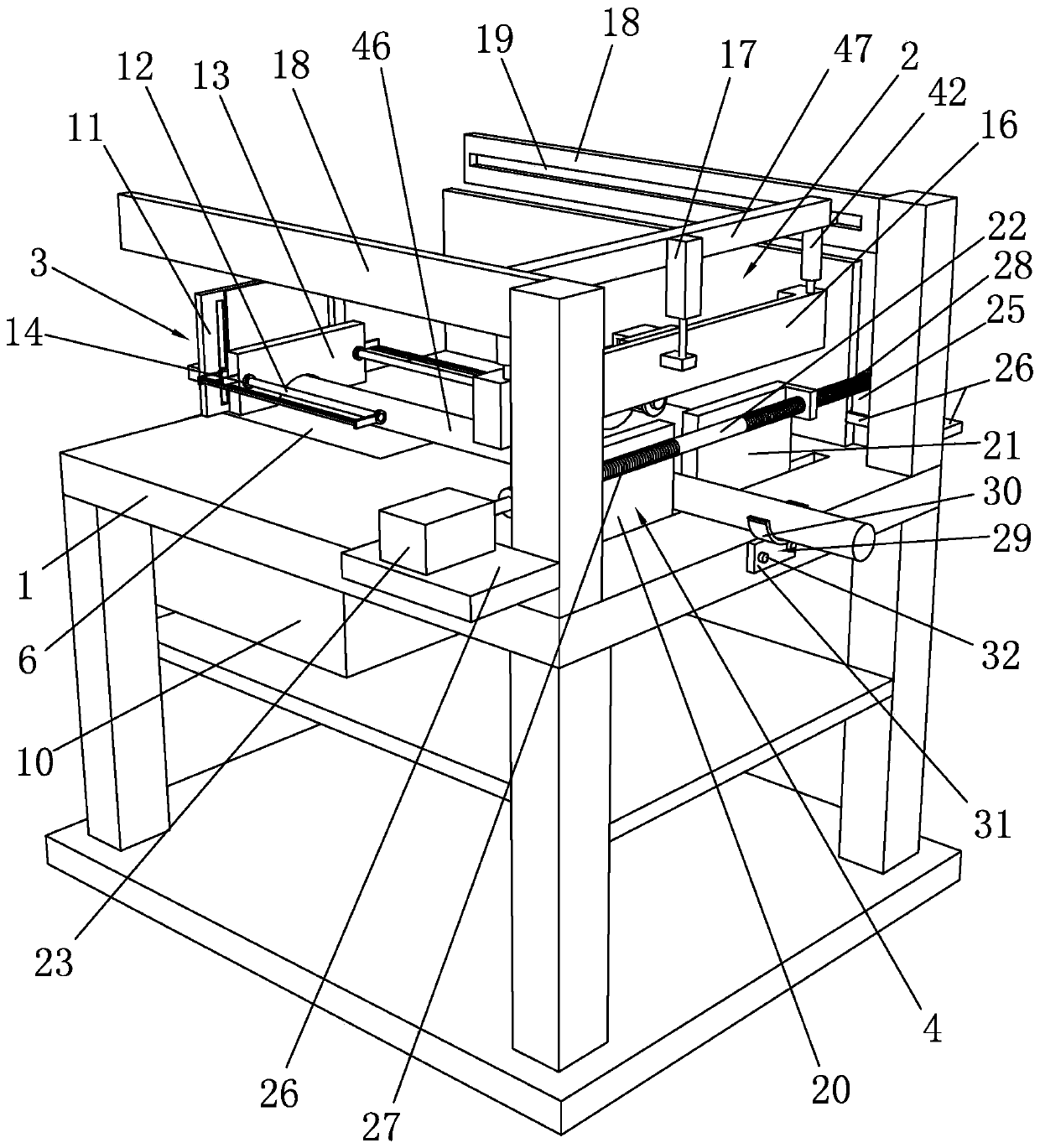

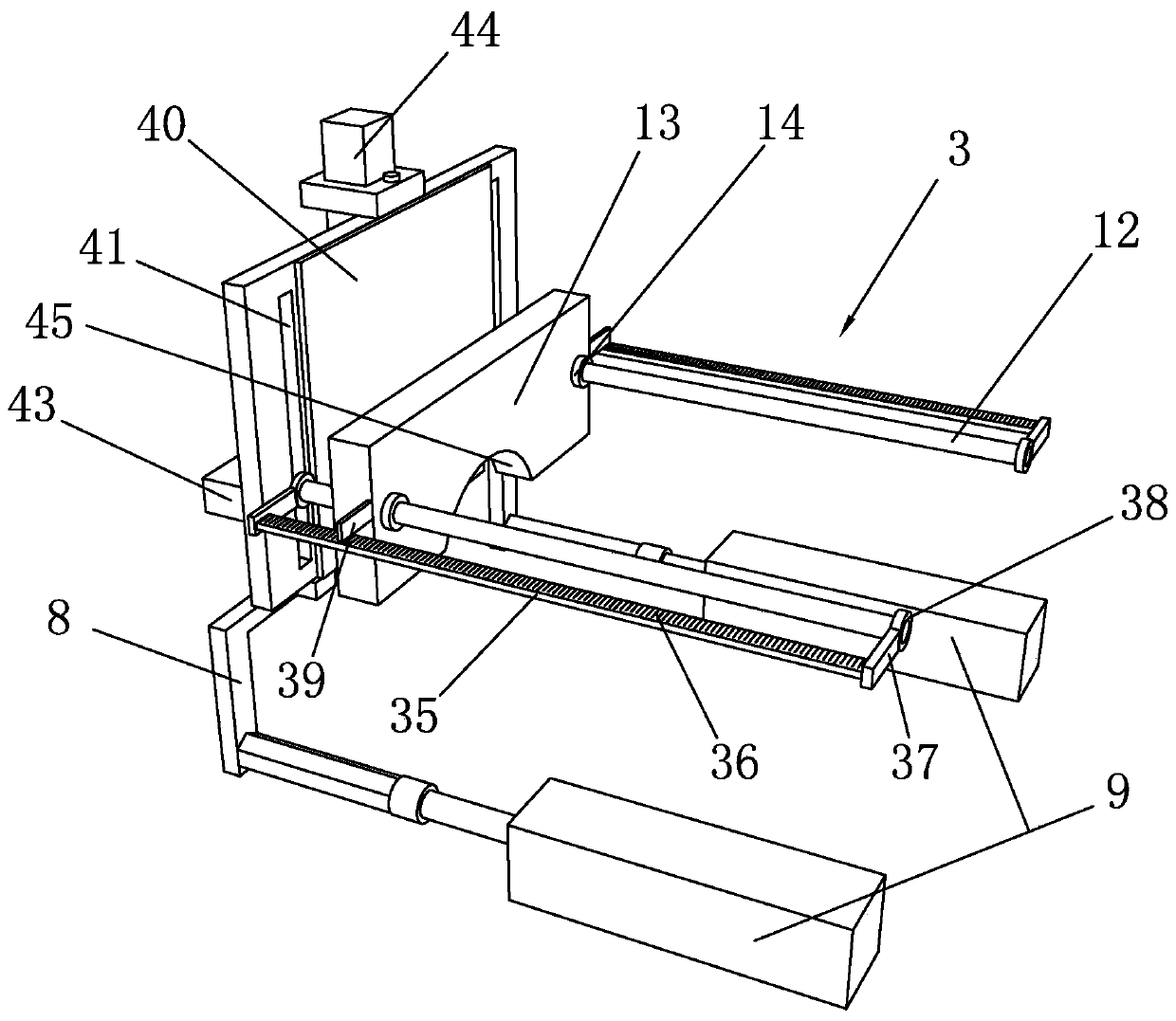

[0027] Such as Figure 1 to Figure 5 As shown, it is a fixed-length cutting device for stainless steel pipe 46 according to the present invention, which includes a cutting table 1 and a cutting head group 2. The cutting head group 2 is located on the cutting table 1, and the center of the right end of the cutting table 1 is provided with an arc Bracket 29, arc-shaped bracket 29 comprises arc-shaped guide ring 30 and connecting plate 31, and arc-shaped guide ring 30 and connecting plate 31 are integrally formed structure, and the place horizontal plane of the lowest point on the arc-shaped surface of arc-shaped guide ring 30 and The top surface of the cutting table 1 is flush, the connecting plate 31 is fixedly connected with the cutting table 1 by the fixing screw 32, the design of the arc bracket 29 can facilitate the initial positioning of the stainless steel pipe 46, when the stainless steel pipe 46 is put into the cutting table 1 , first ensure that one end of the stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com