Patents

Literature

32results about How to "Convenient for initial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fixed-length cutting device for stainless steel tube

ActiveCN109719570ACompact and reasonable structure designEasy to useMeasurement/indication equipmentsFeeding apparatusEngineeringLength measurement

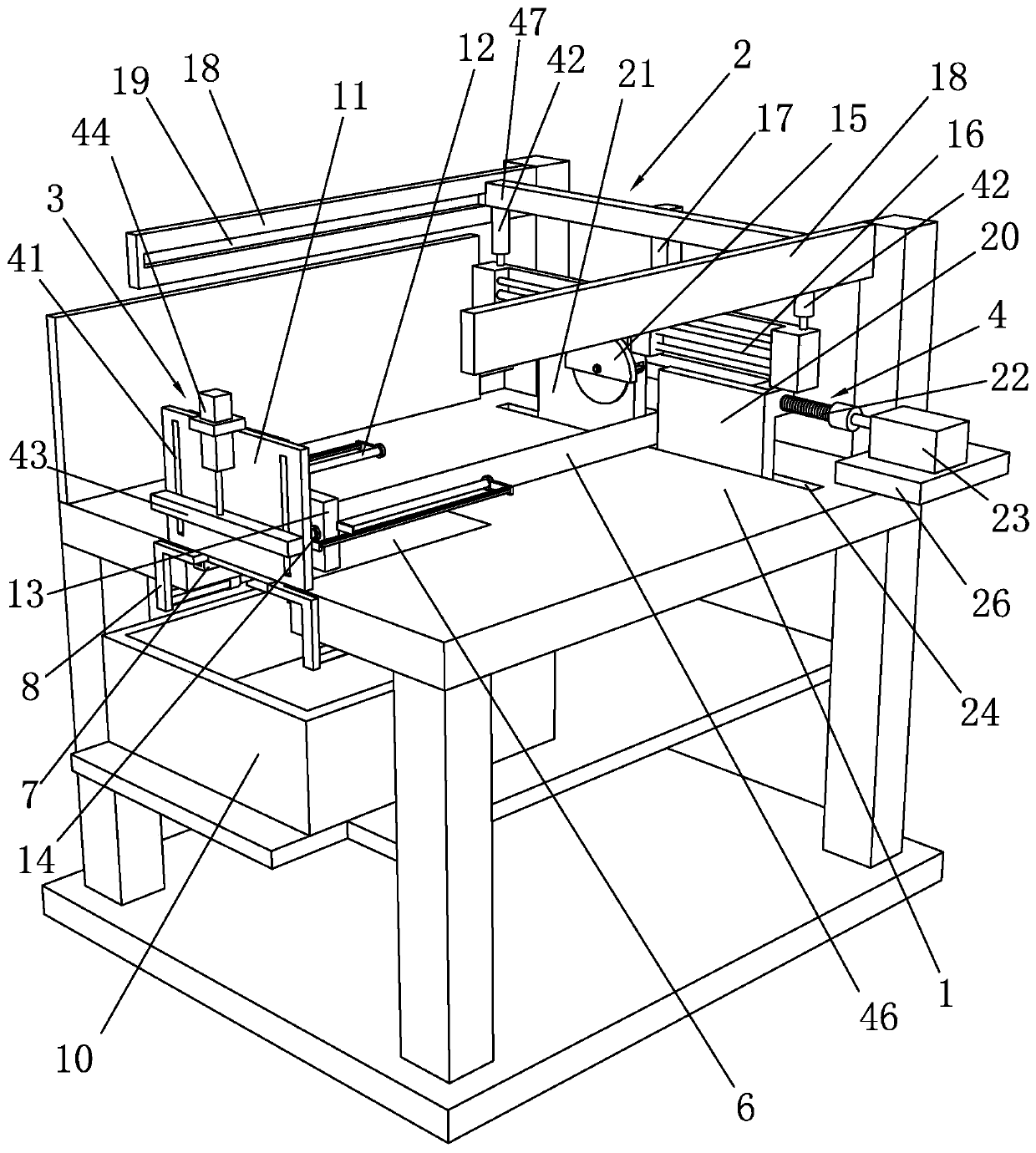

The invention discloses a fixed-length cutting device for a stainless steel tube. The fixed-length cutting device for a stainless steel tube comprises a cutting platform and a cutting head group, andfurther comprises a length determining assembly and a clamping assembly; the left side end of the cutting platform is provided with an opening groove, a cutting panel is arranged in the opening groove, and a material collecting box is arranged under the cutting panel; and the length determining assembly comprises a fixed side plate, positioning screws and a positioning pressing plate, the fixed side plate is located over the left end of the opening groove and fixedly connected with the top face of the cutting platform, the positioning screws are symmetrically arranged on the front side and theback side of the fixed side plate, and the two ends of the positioning pressing plates are arranged on the two positioning screws in a sleeving mode separately. According to the fixed-length cuttingdevice for the stainless steel tube, the structure is simple, the practicability is high, operation is easy, use is convenient, not only can the cutting rate and the cutting precision of the stainlesssteel tube be improved, but also the cutting length standard can be guaranteed every time only through one time of cutting length measurement, the manual labor intensity is effectively reduced, the error rate brought by each time of manual measurement is decreased, and resources and the cost are saved.

Owner:ANHUI KINGWE PIPE IND

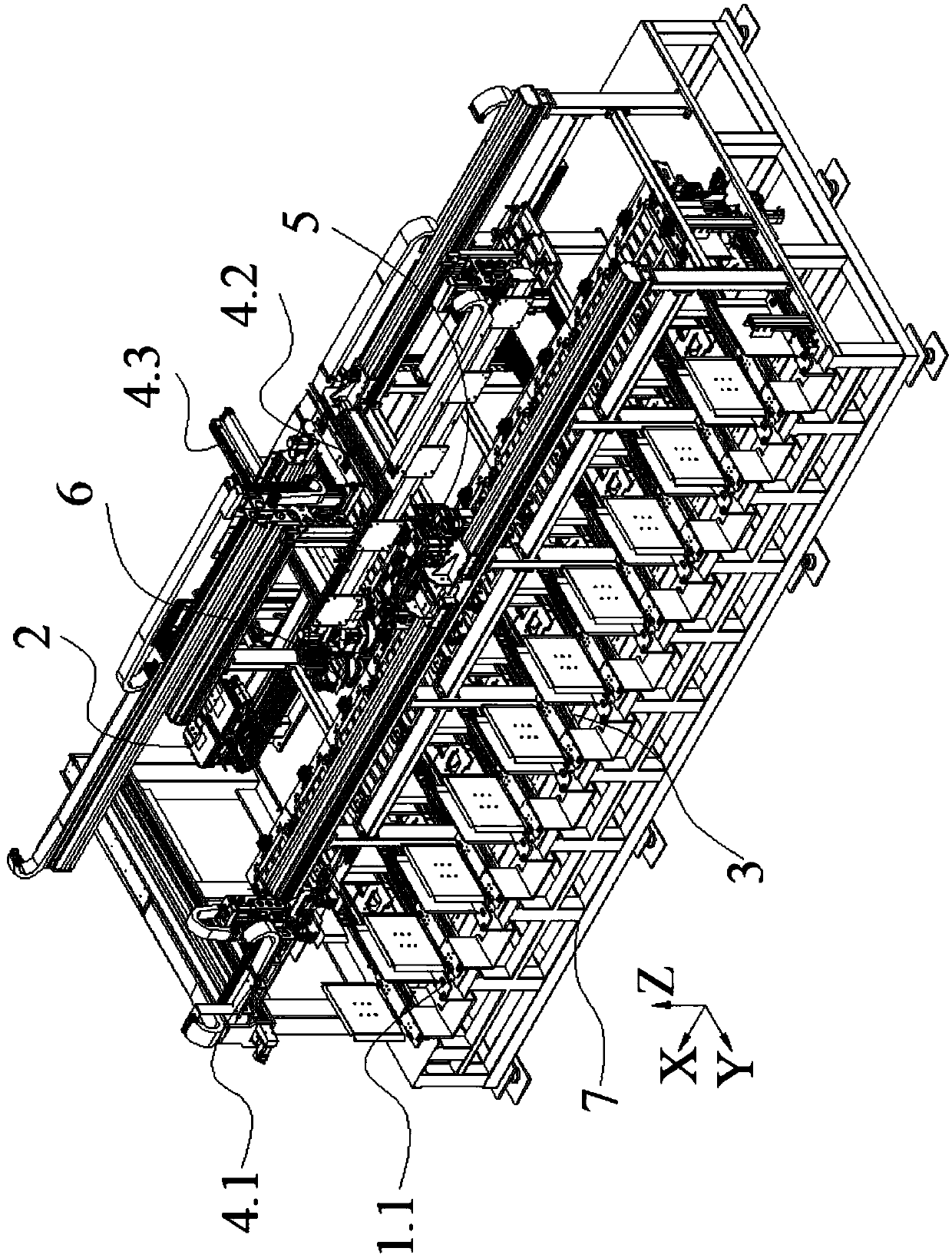

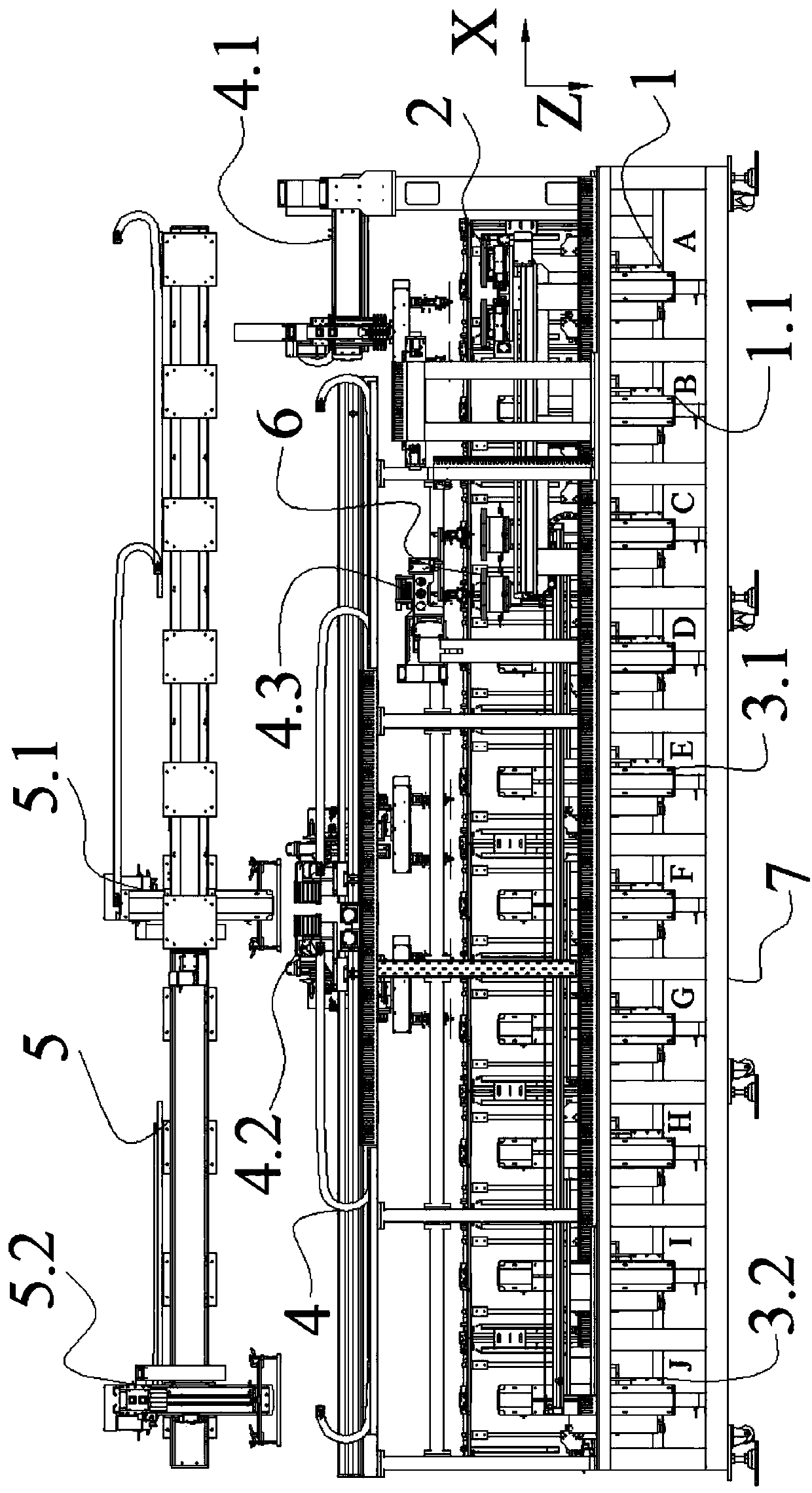

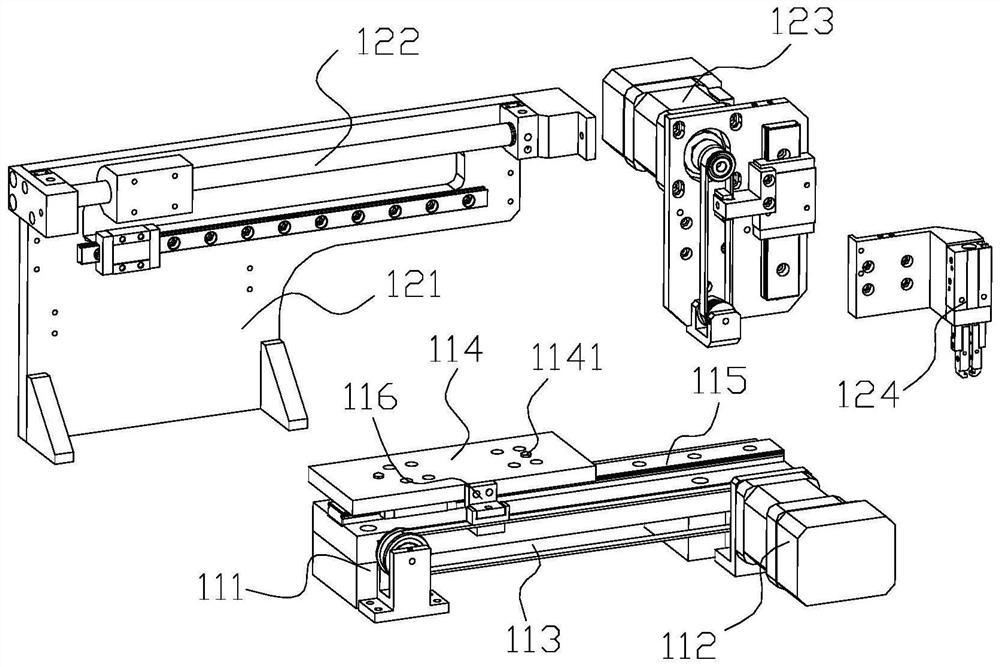

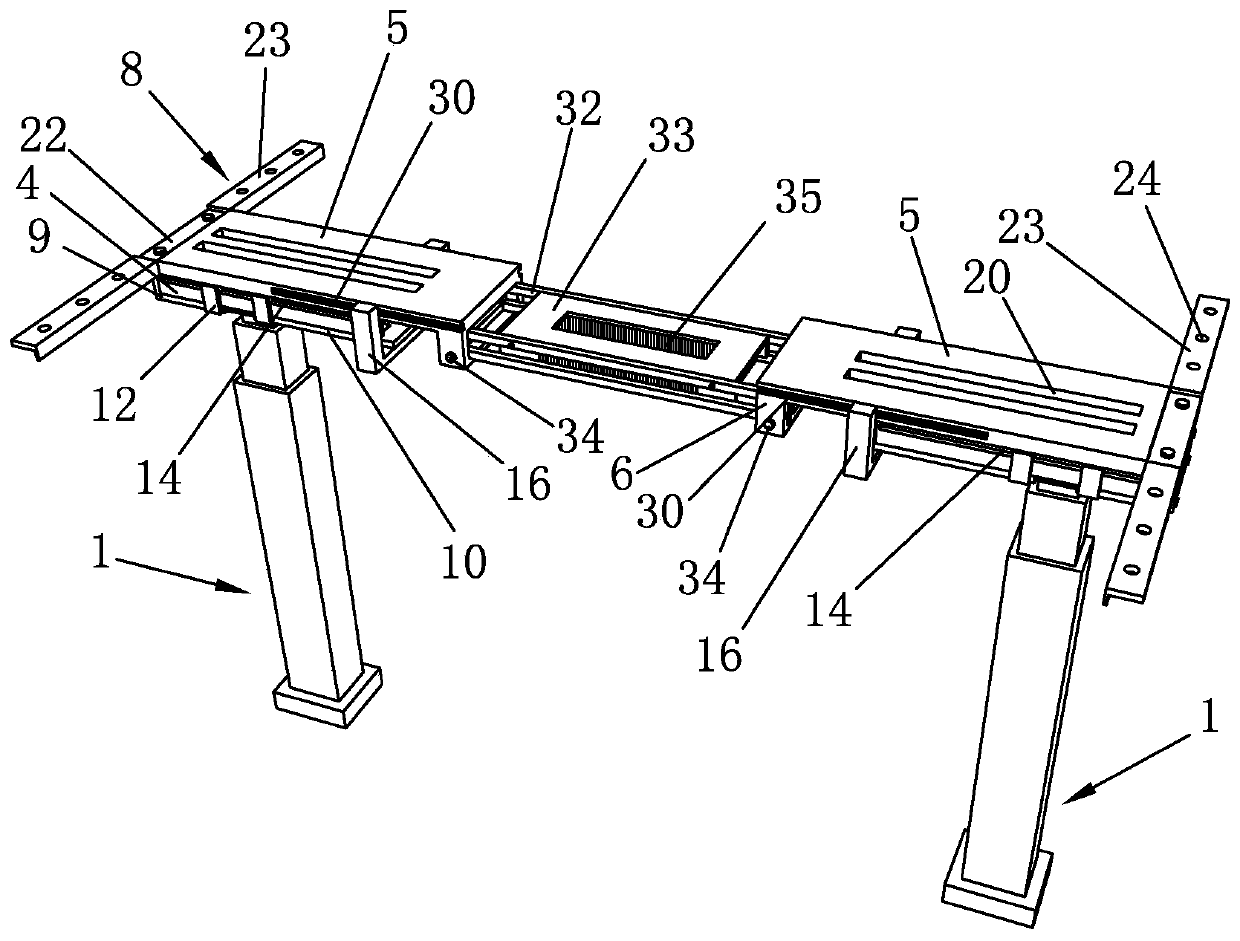

Panel grading device

PendingCN107855285AHigh degree of automationImprove efficiencySortingEngineeringElectrical and Electronics engineering

The invention relates to the technical field of display panel detection, in particular to a panel grading device. The panel grading device comprises a grade judgment position and a charging device, and is characterized in that the charging device comprises a feeding device, a discharging device, a panel taking and placing device and a tray taking and placing device, wherein the feeding device comprises a plurality of feeding positions which are sequentially arranged in the X direction; the feeding device is used for carrying trays for containing panels; the discharging device is adjacent to the feeding device and comprises first discharging positions and a plurality of second discharging positions; the first discharging positions and the second discharging positions are sequentially arranged in the X direction; the discharging device is used for carrying the trays; the panel taking and placing device is arranged on the upper portion of the grading device and used for transferring the panels between the feeding device, the grade judgment position and the discharging device; the tray taking and placing device is arranged above the feeding device and the discharging device and used for transferring the trays on the feeding device onto the discharging device. The panel processing device provided by the invention is reasonable in structure design, compact in arrangement and capableof rapidly achieving discharging, feeding and classifying of the panels.

Owner:KUSN JINGXUN ELECTRONICS TECH

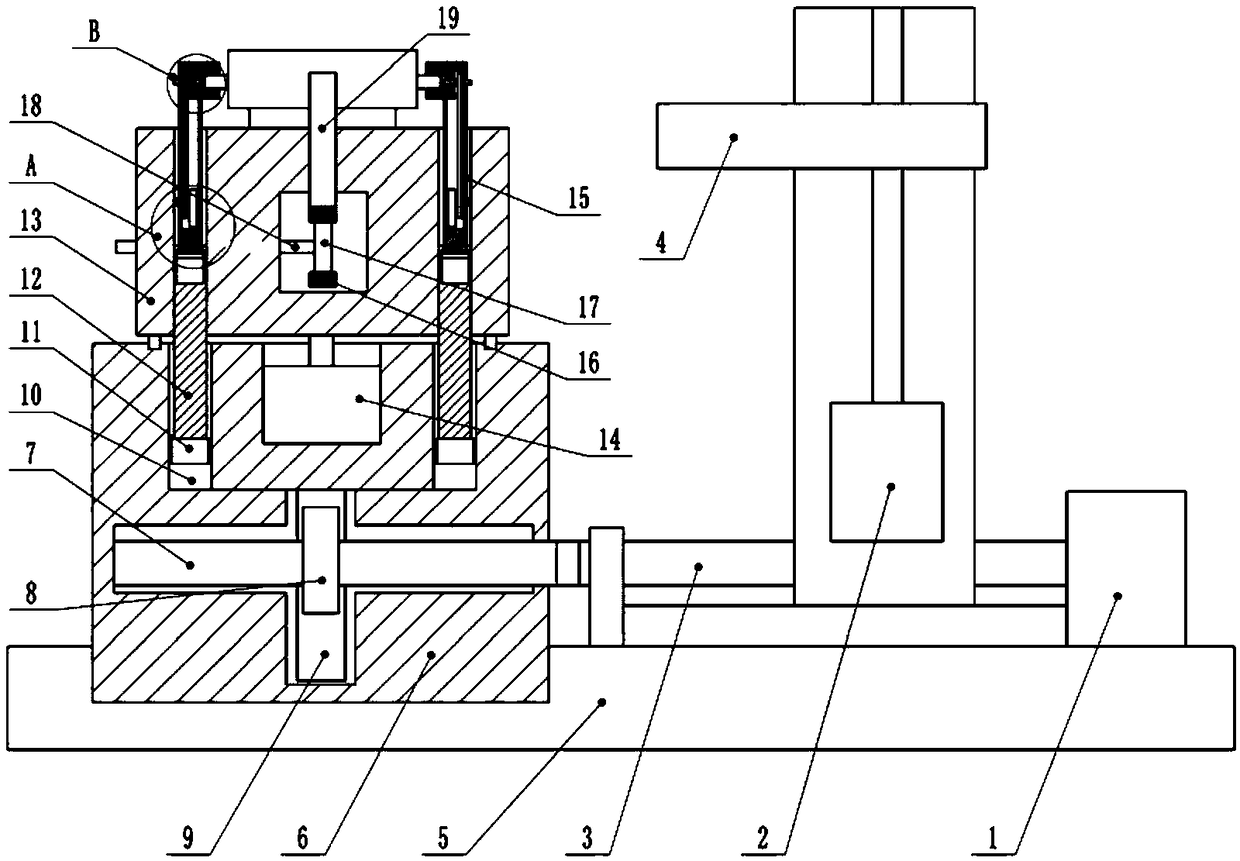

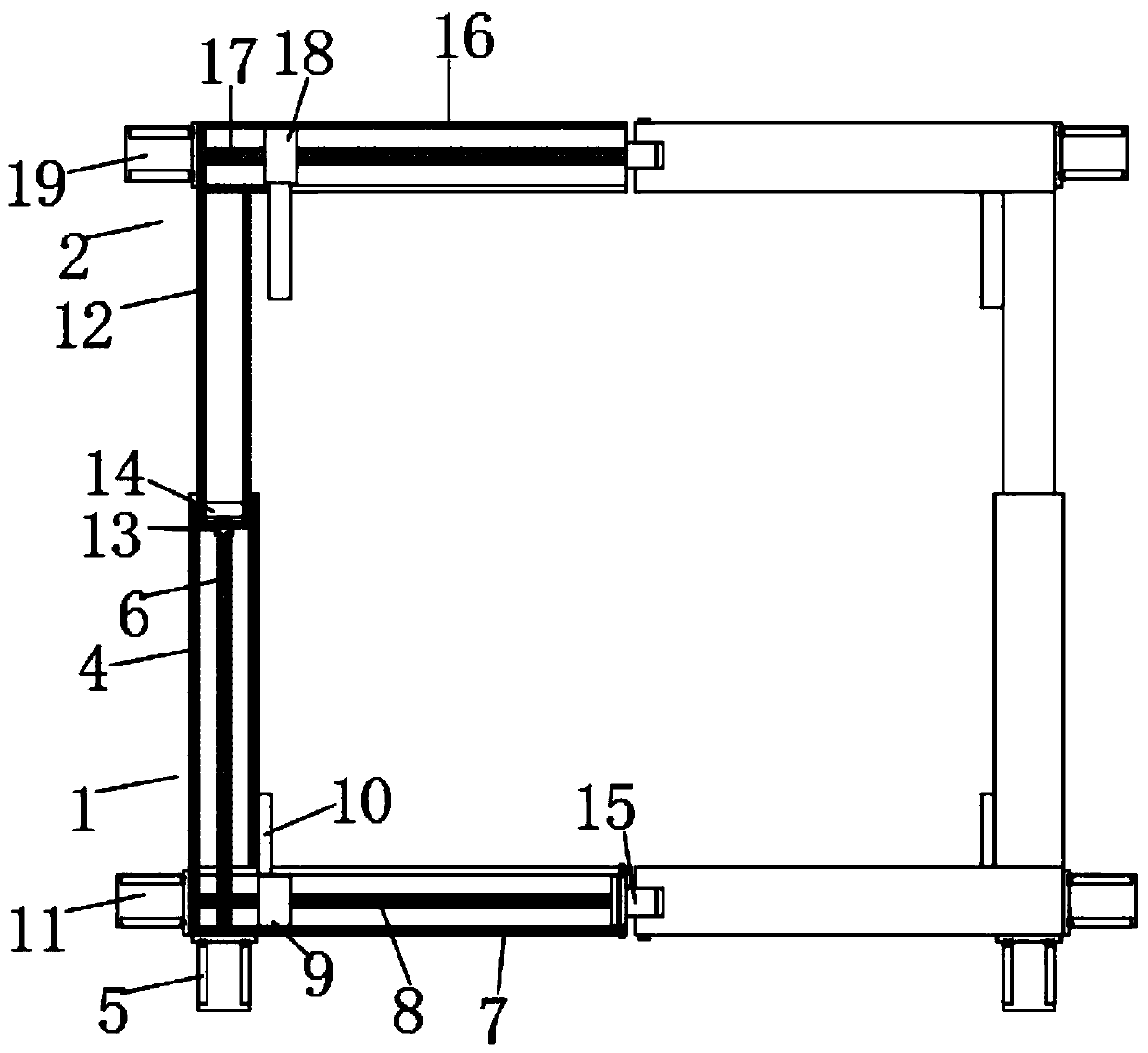

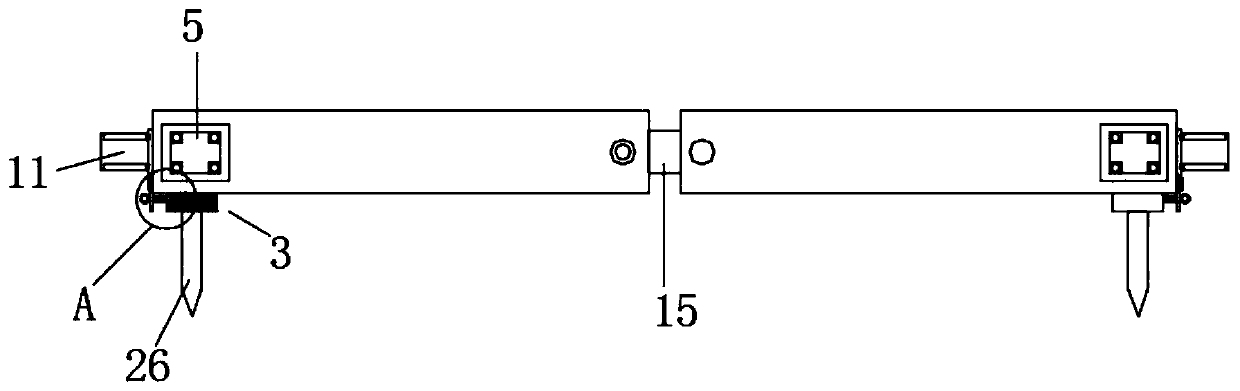

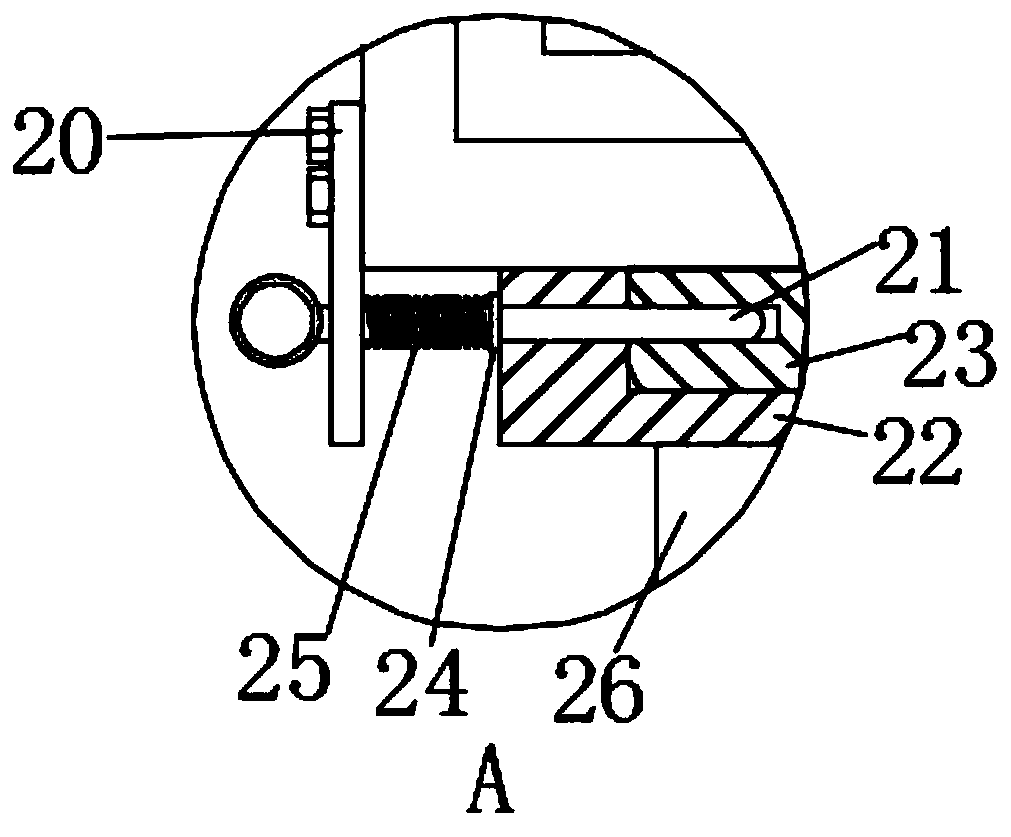

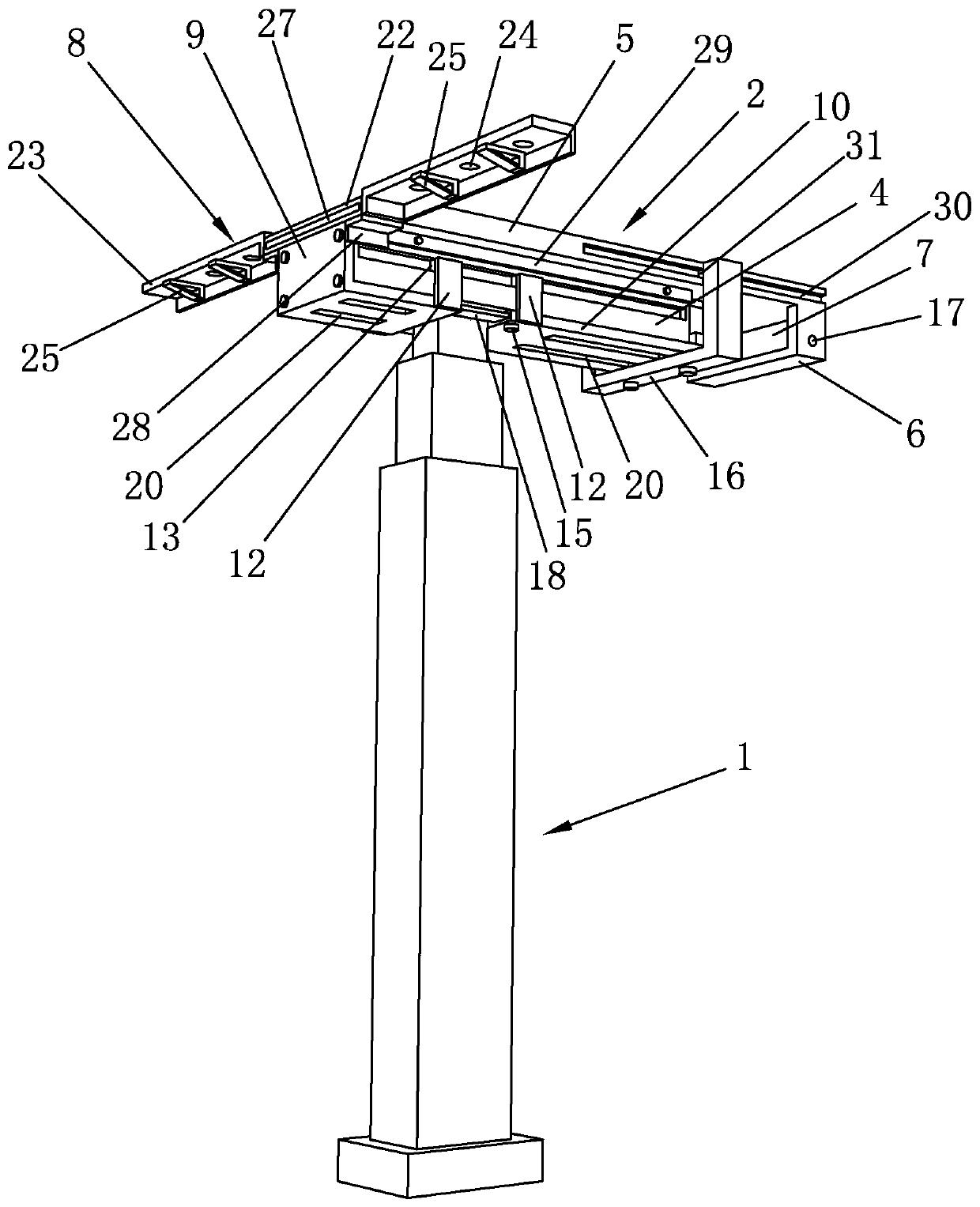

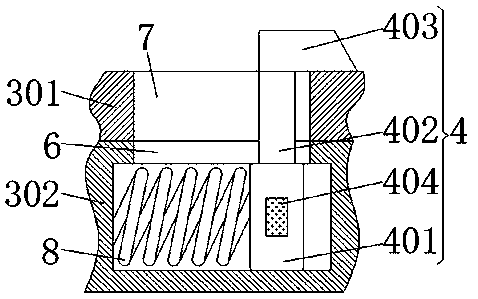

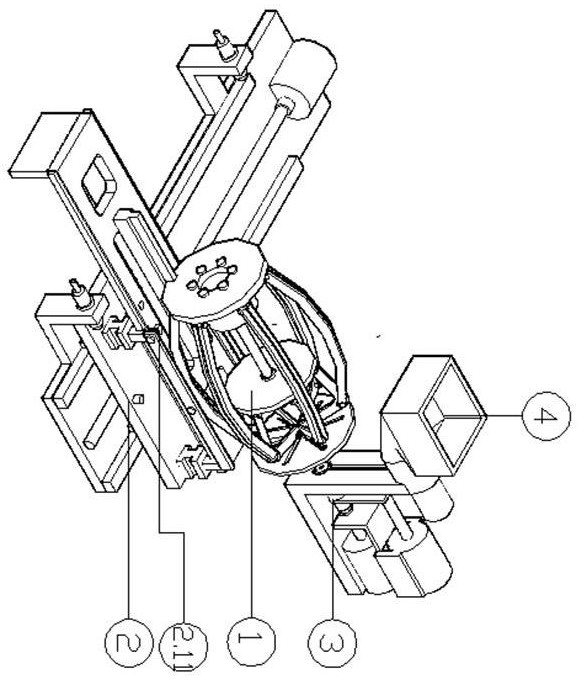

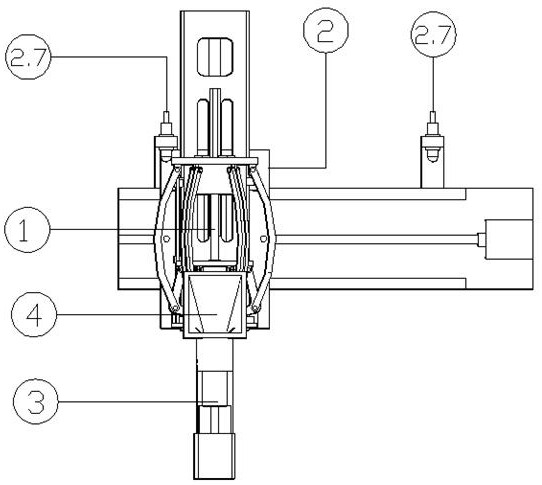

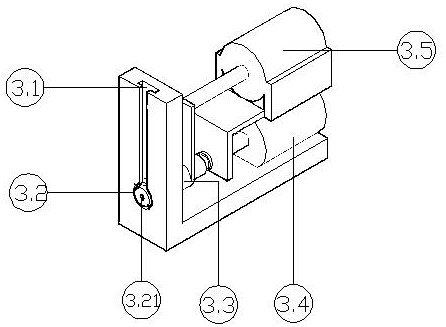

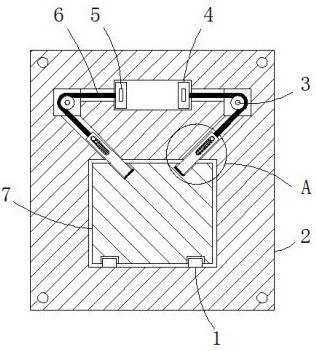

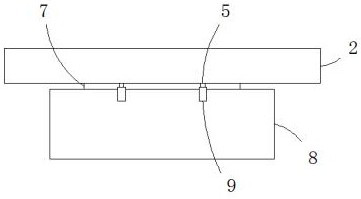

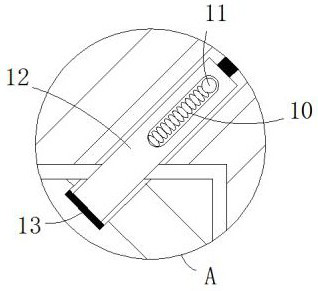

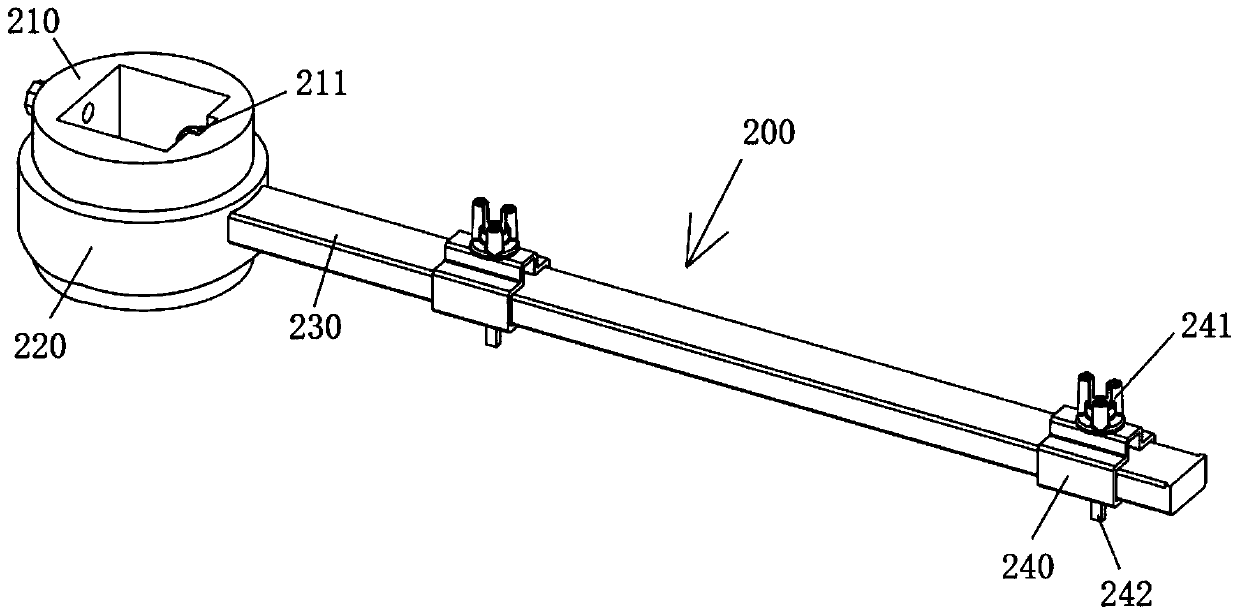

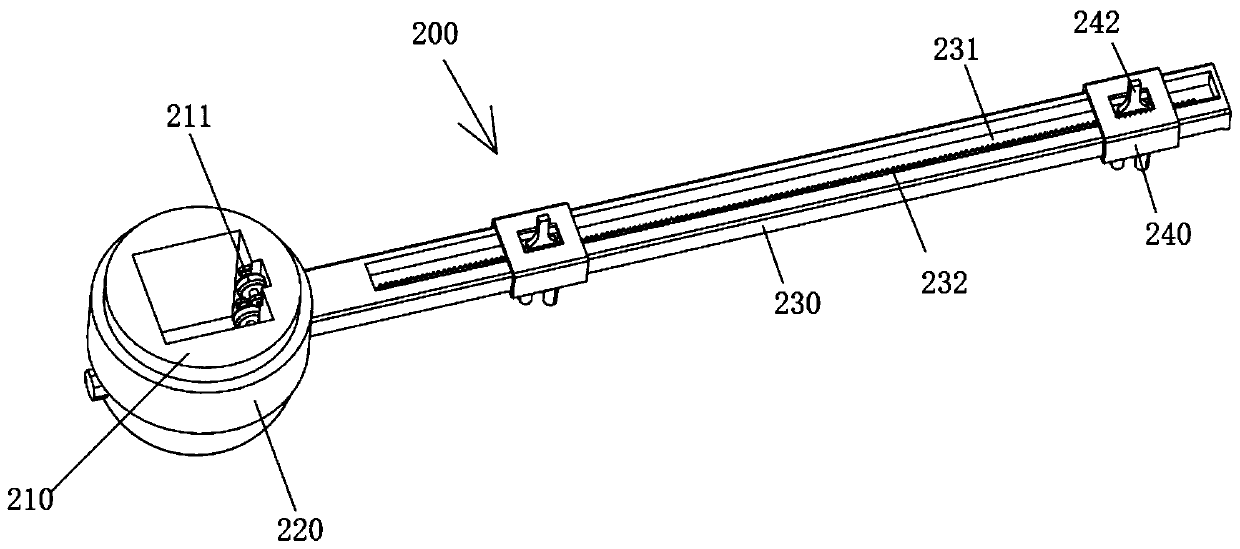

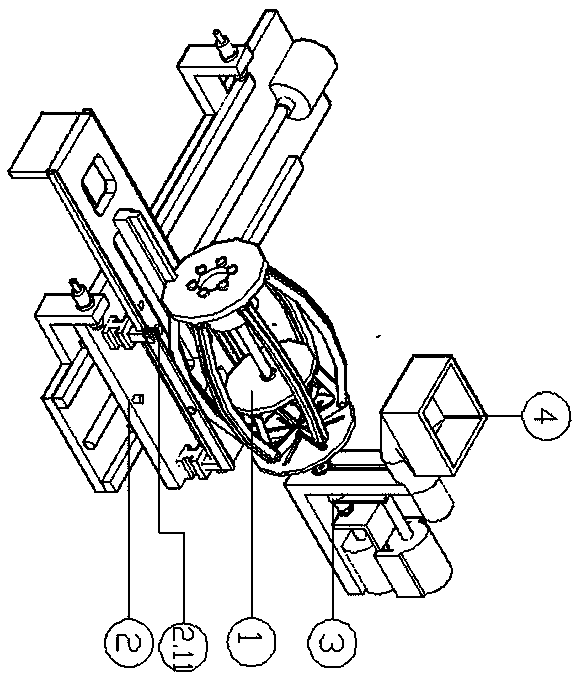

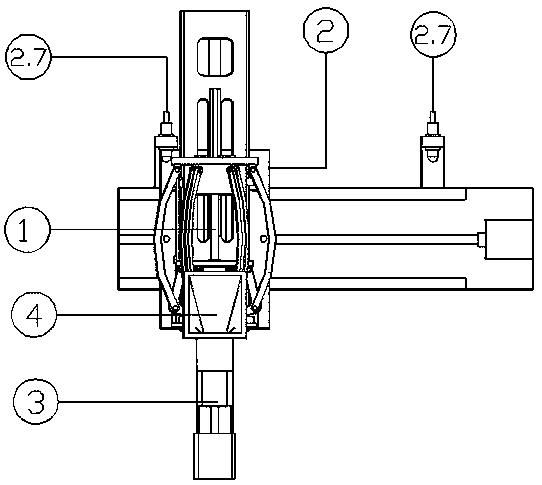

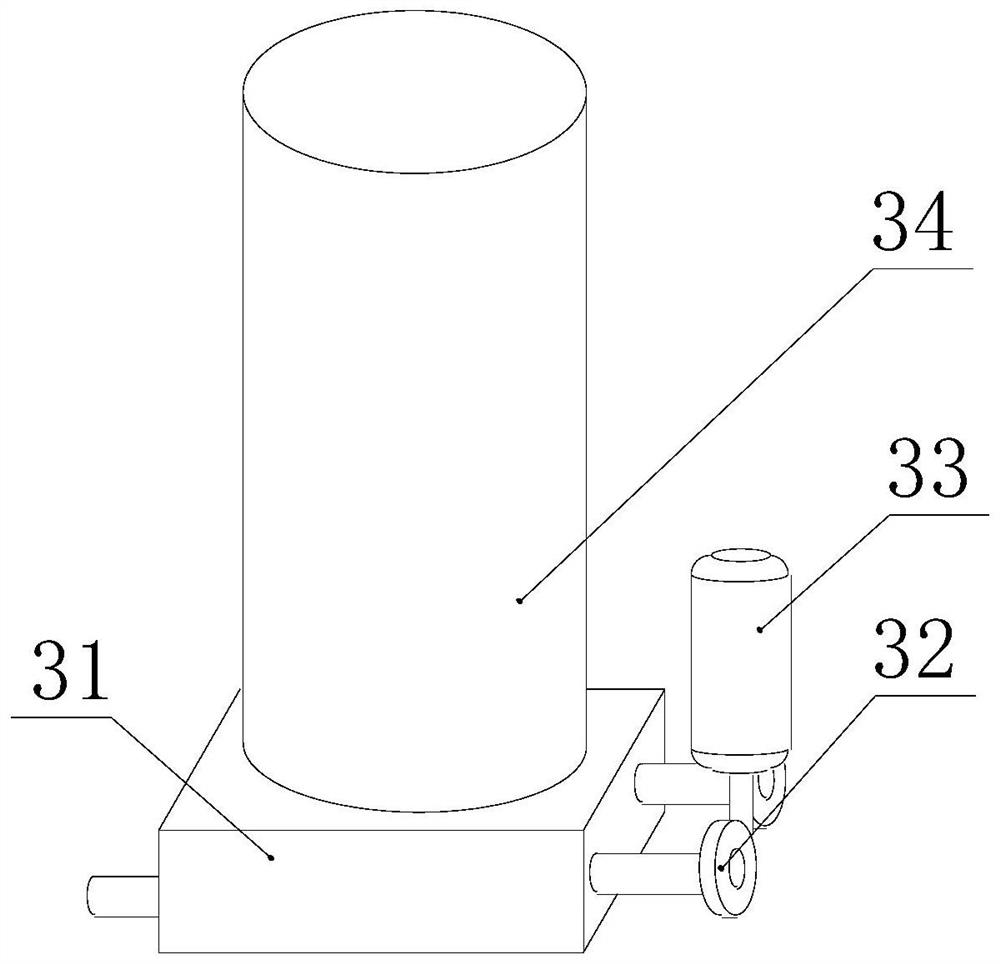

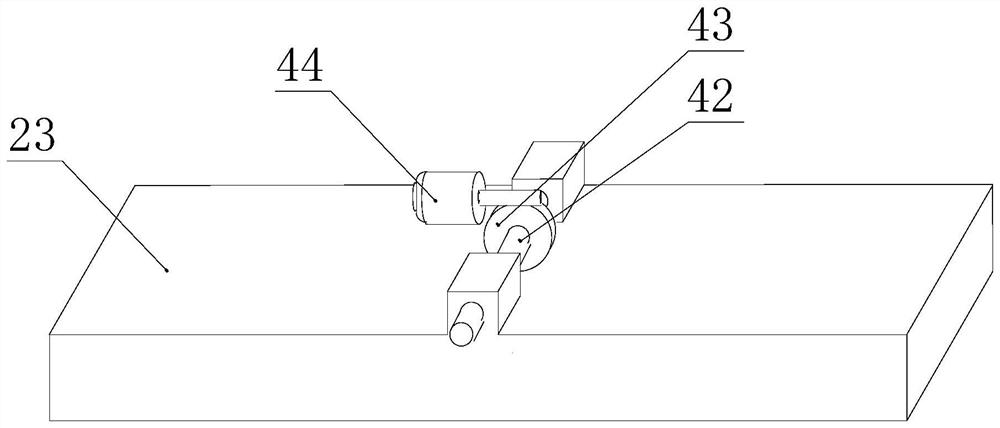

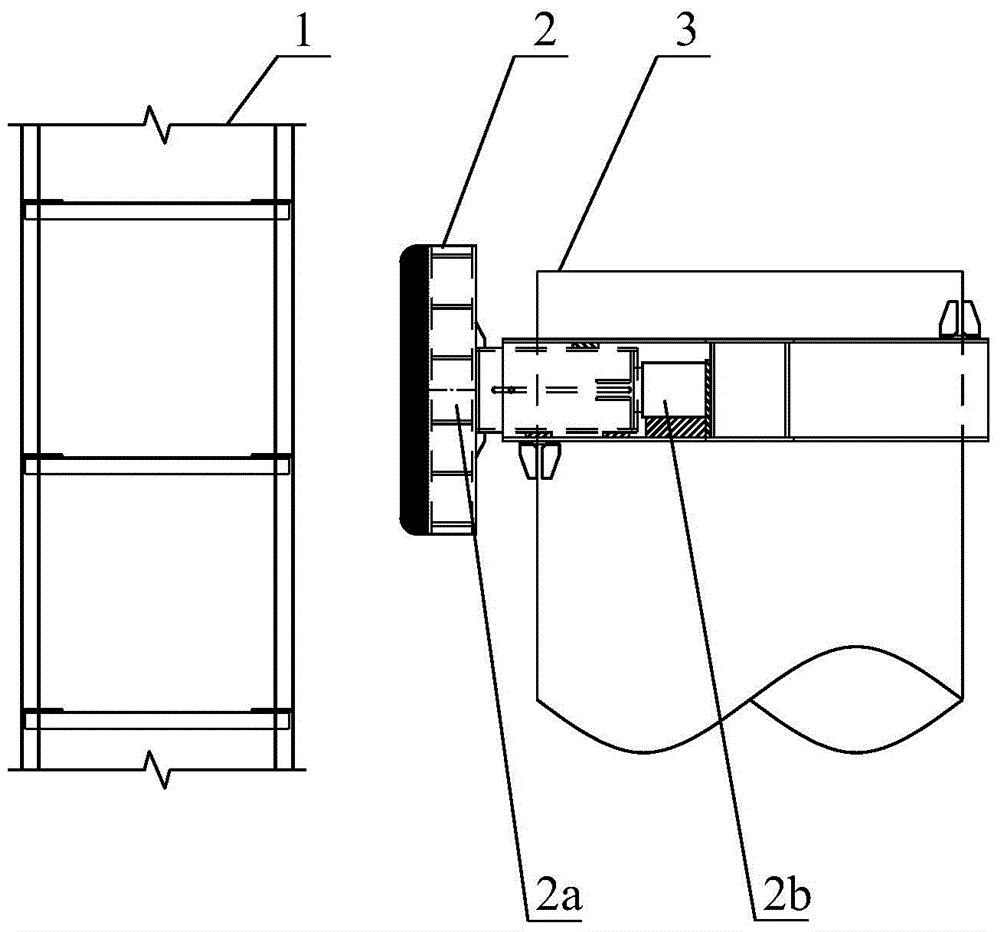

Robot welding system

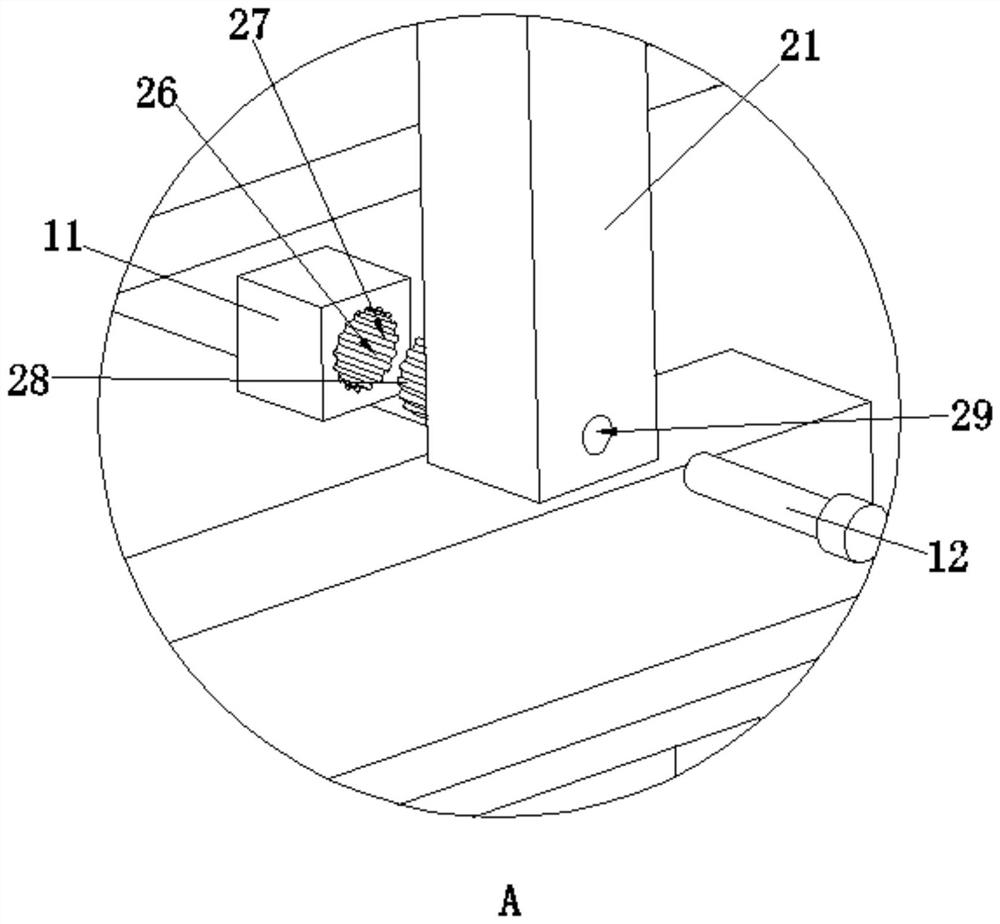

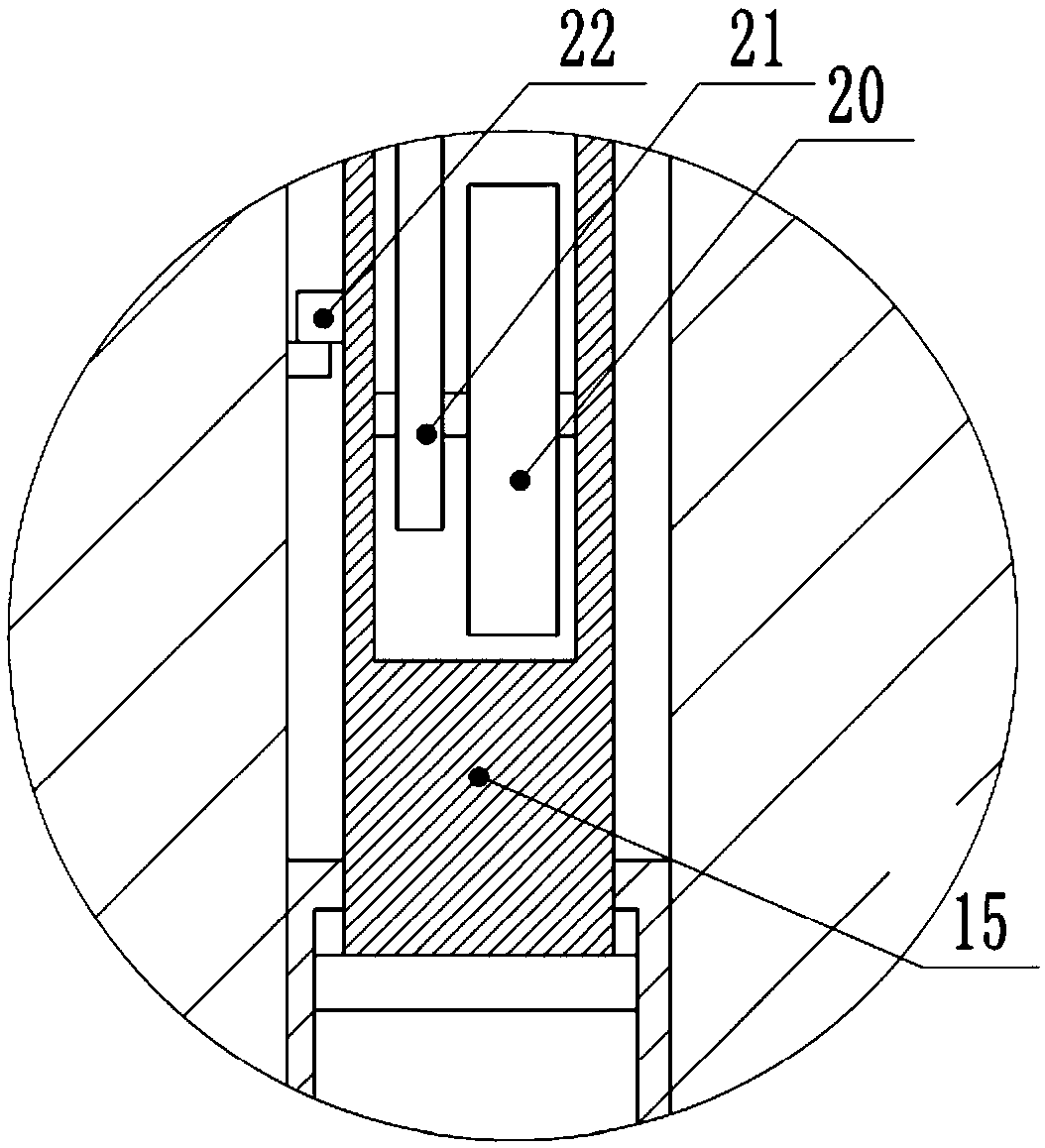

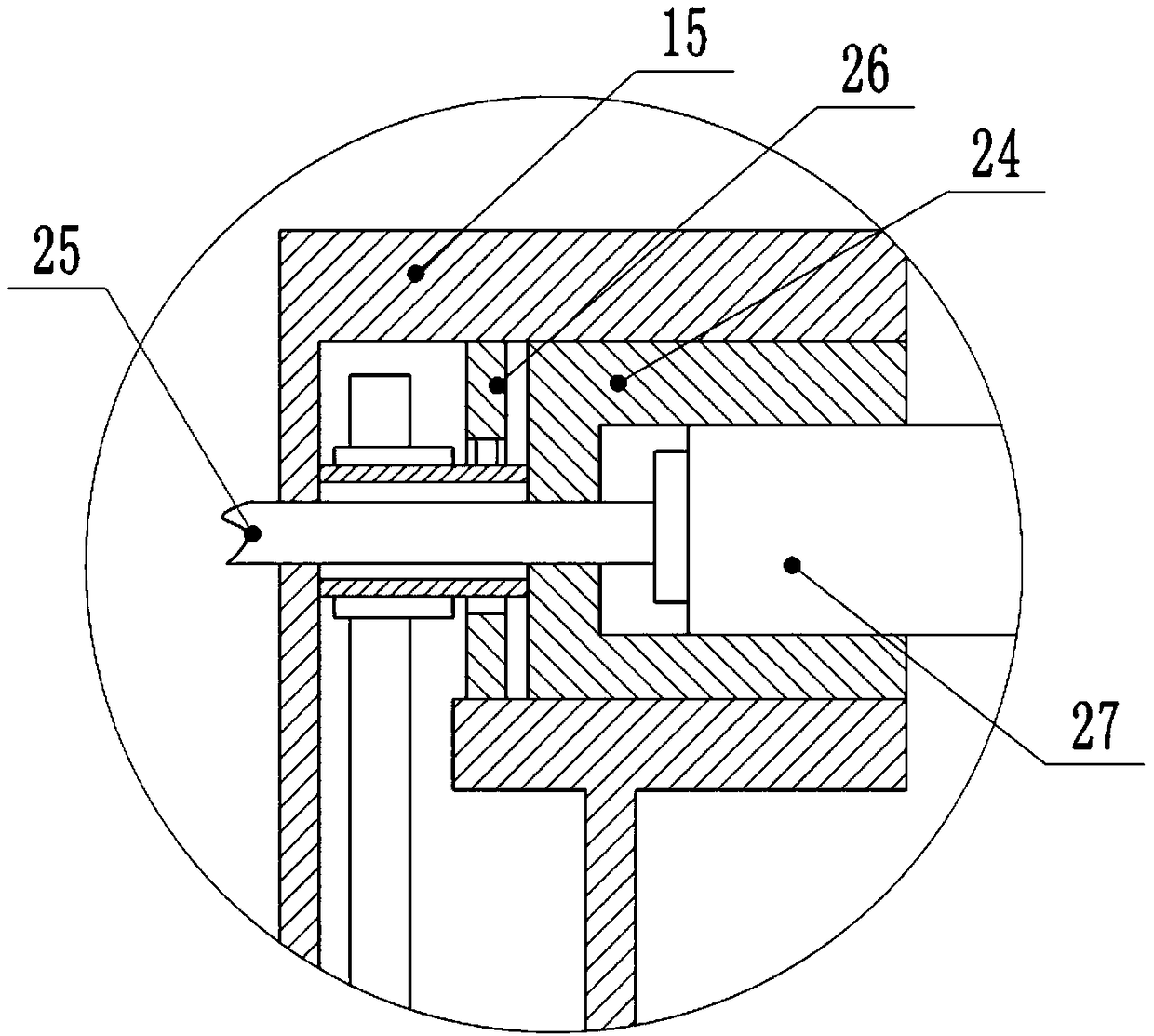

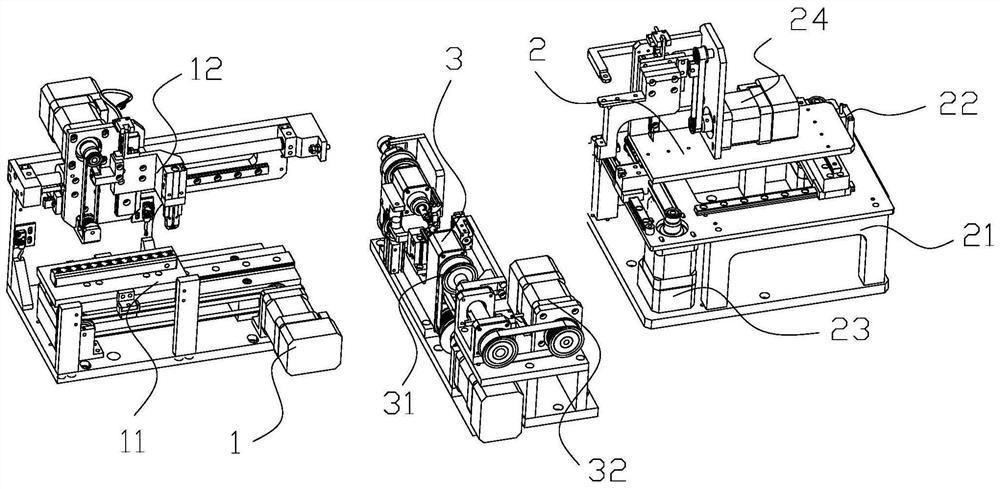

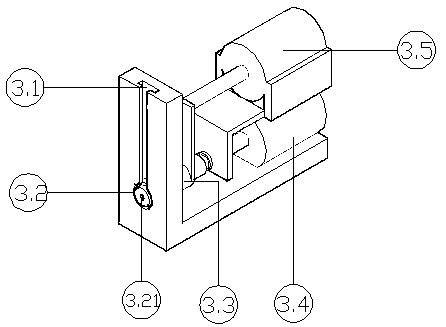

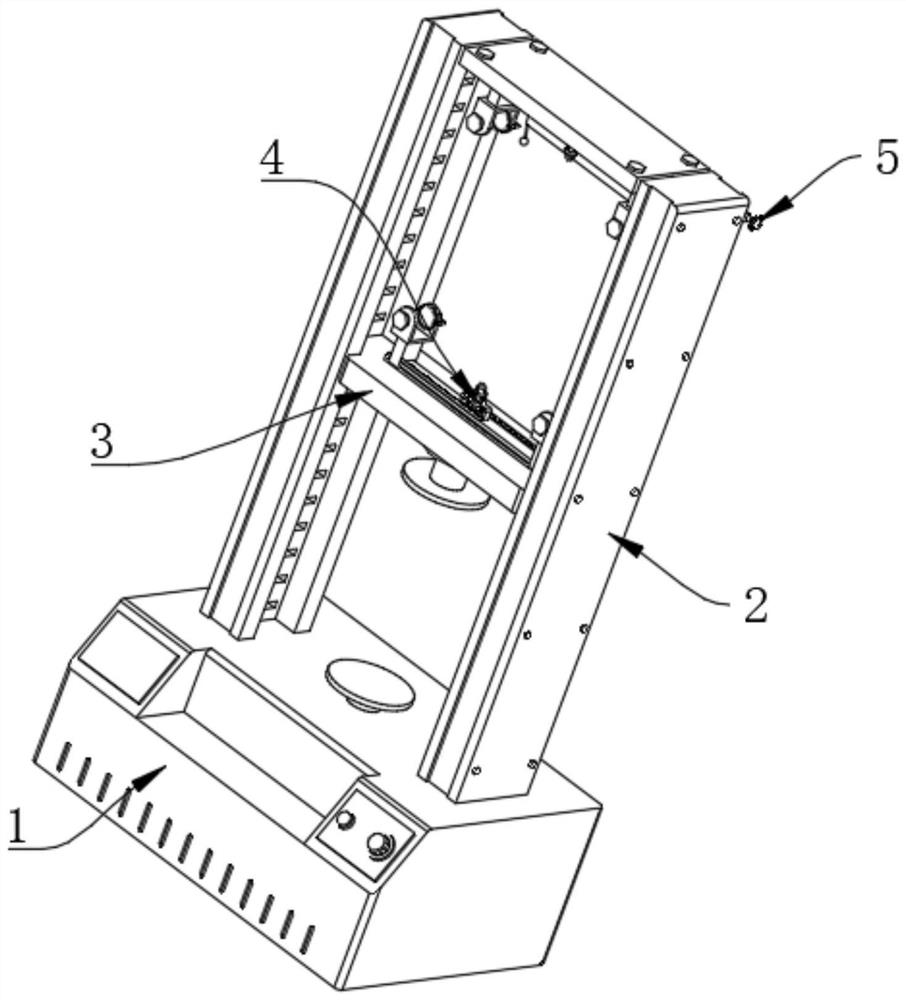

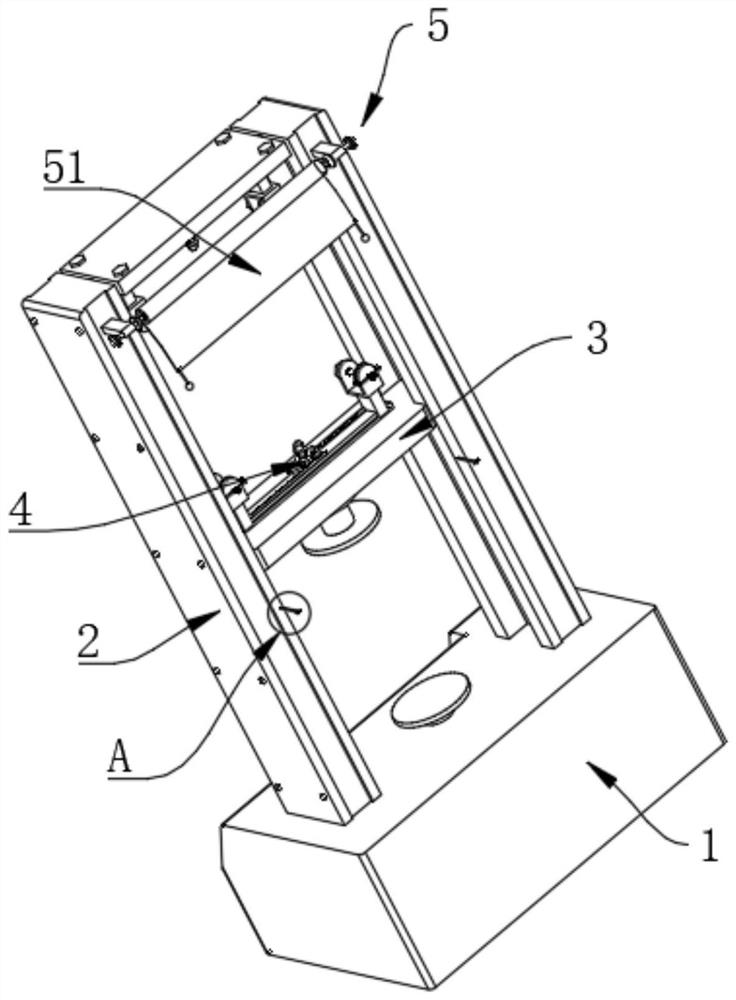

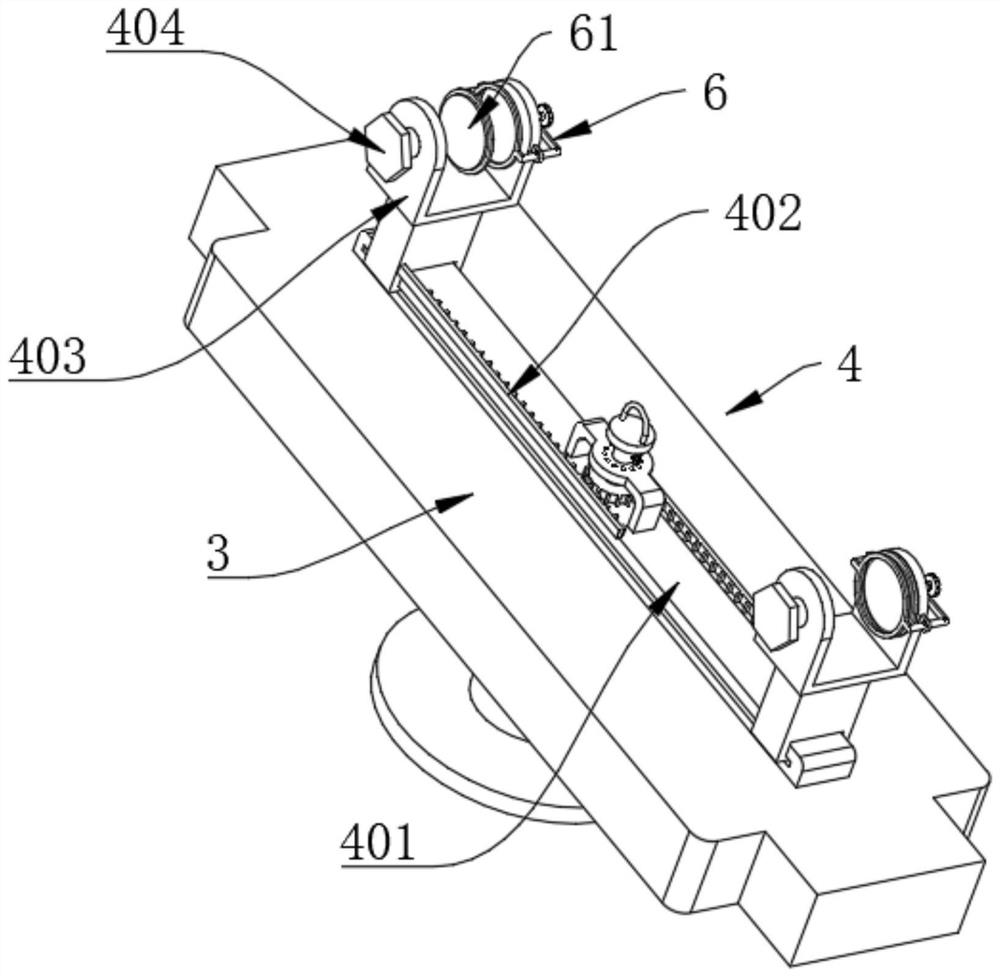

ActiveCN113770618AConvenient for initial positioningEasy to compressWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringRobot welding

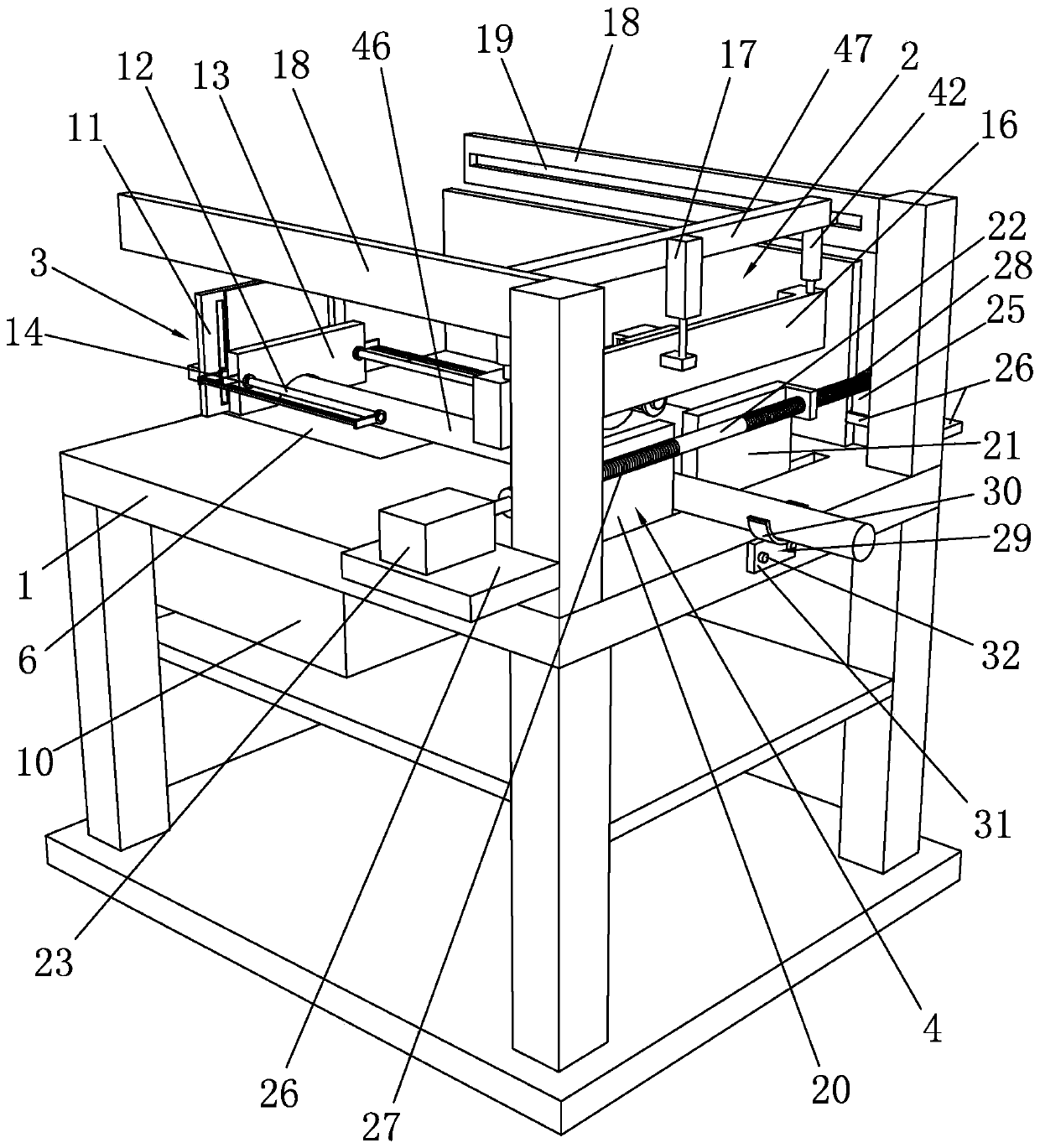

The invention discloses a robot welding system. The robot welding system comprises a welding support, wherein a clamping mechanism, a fixing framework, a welding mechanism and an angle adjusting mechanism are arranged on the welding support, and the clamping mechanism comprises a base rod, a clamping rod and a worm which are arranged at one side of the welding support; the fixing mechanism comprises a fixing rod arranged on the welding support, and an extension plate is arranged on the end face of the side, away from the welding support, of an abutting plate; the welding mechanism comprises a welding guide rail stretching across the upper portion of the welding support, a guide block horizontally arranged on the welding guide rail in a sliding mode and a welding head arranged on the guide block in an up-down sliding mode; and the angle adjusting mechanism comprises sliding blocks symmetrically arranged at the two sides of the welding support, and further comprises a locking bolt connected to the bottom of the welding guide rail in a threaded mode. The robot welding system can support, clamp and position a steel plate to be welded and correct the reference edge of the steel plate, so that multi-angle welding of the device is realized, and the device is more suitable for large-scale welding of small plates.

Owner:漳州恩得欣金属制品有限公司

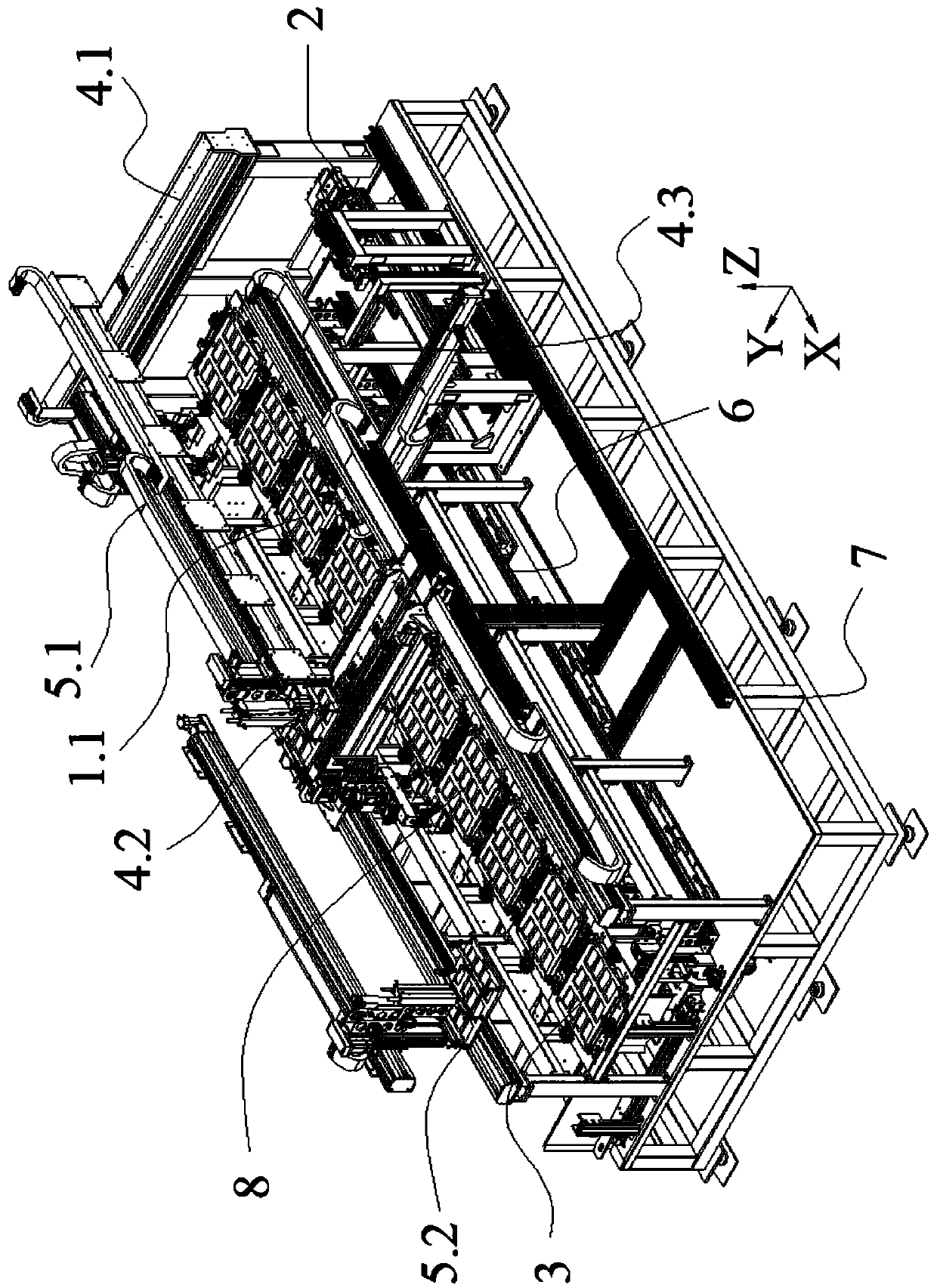

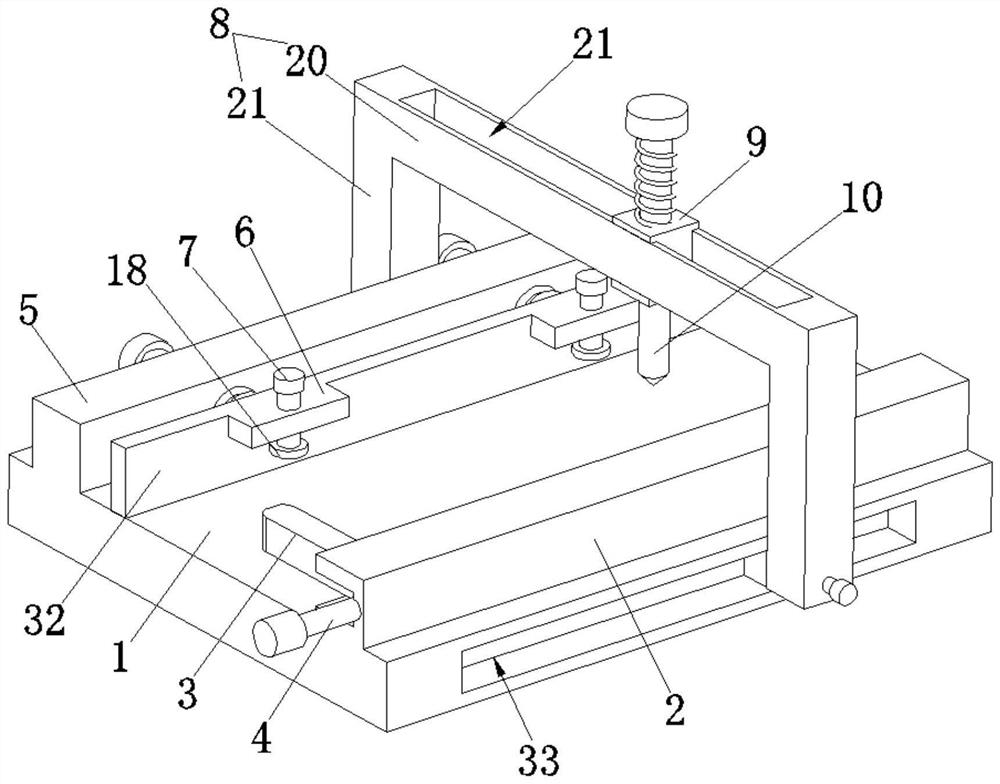

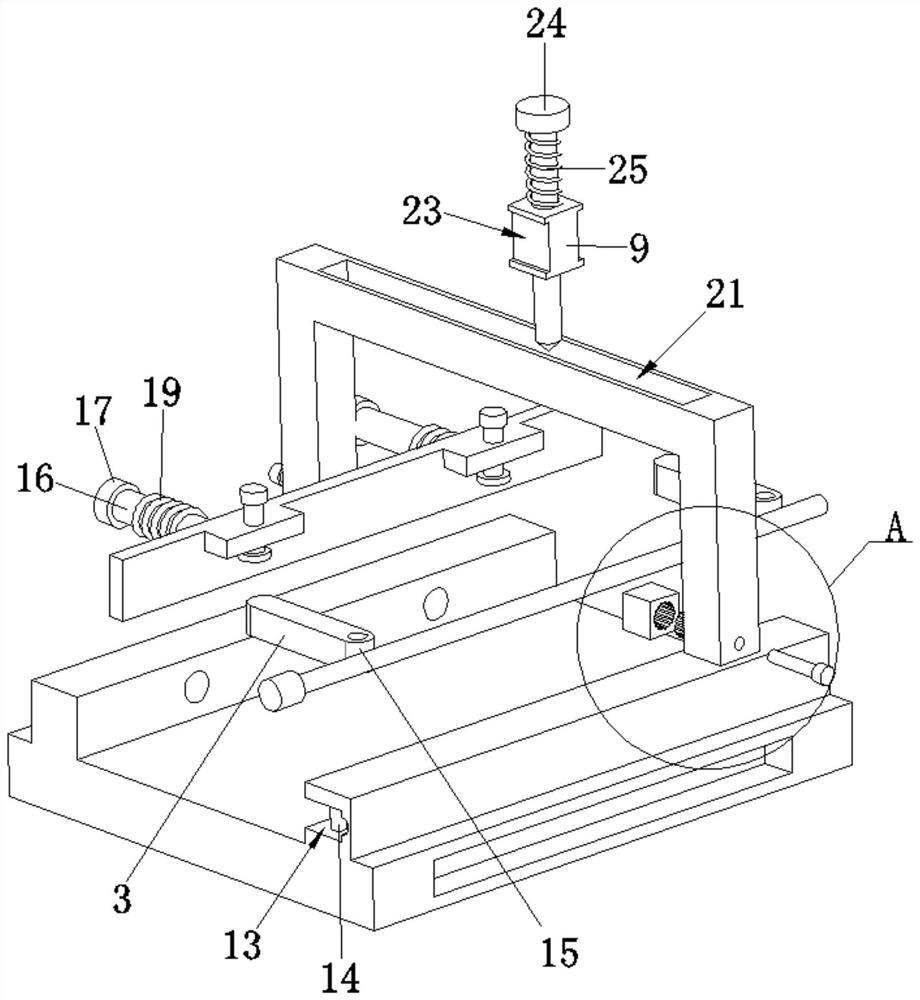

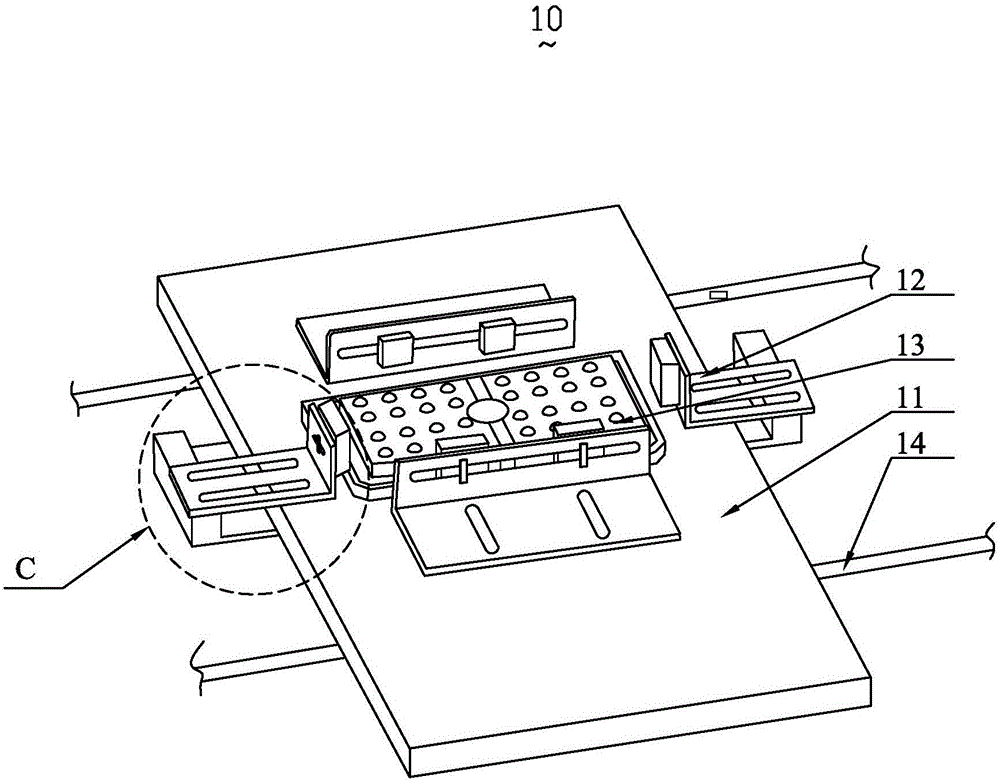

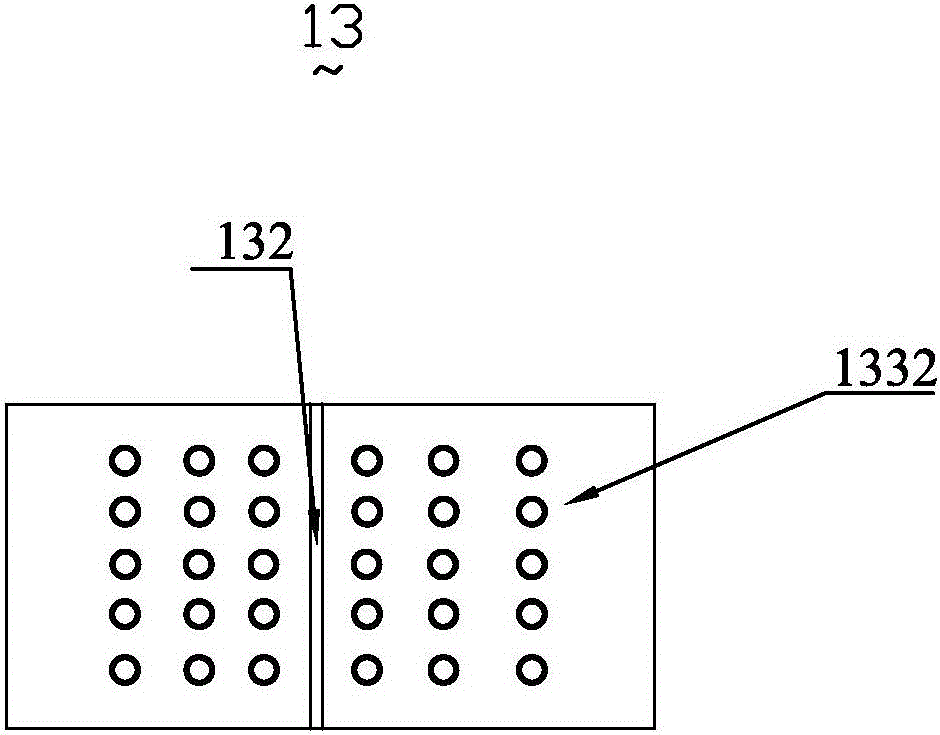

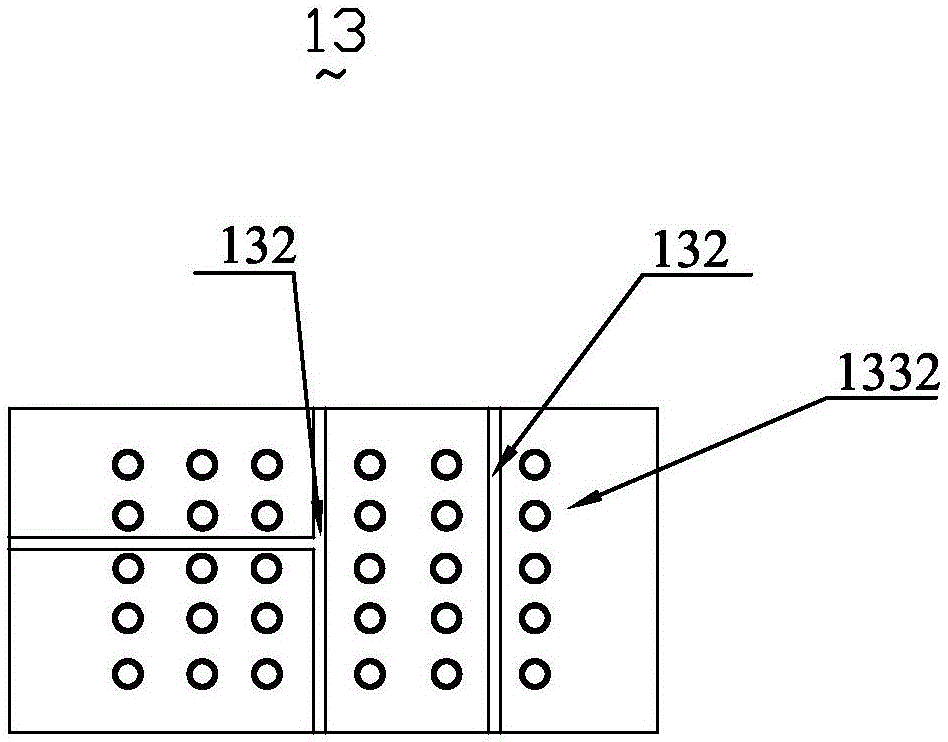

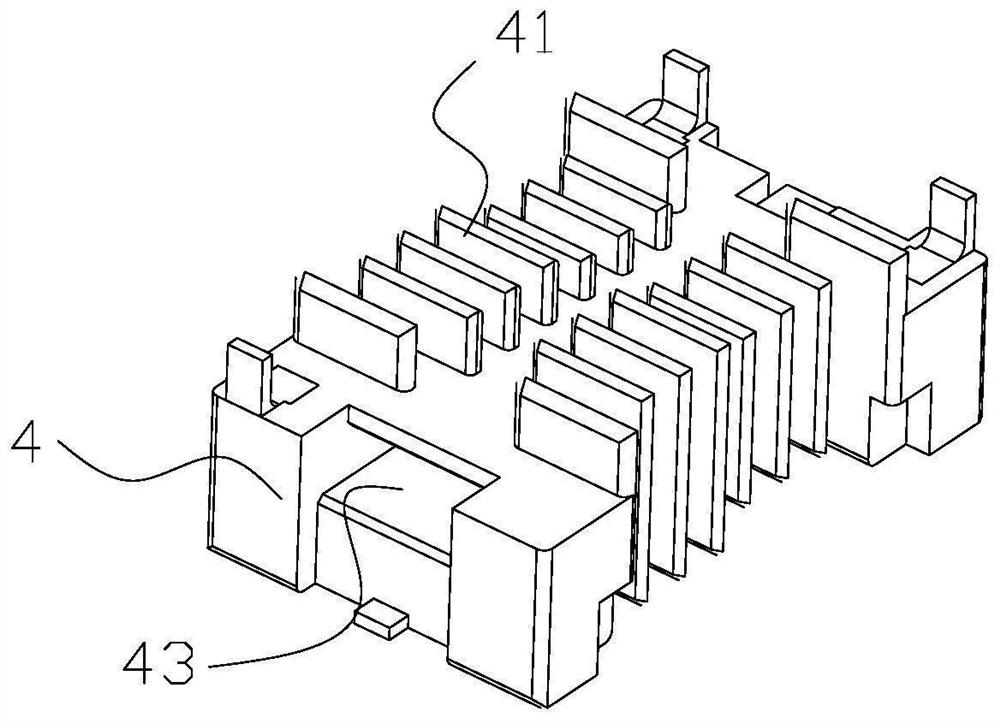

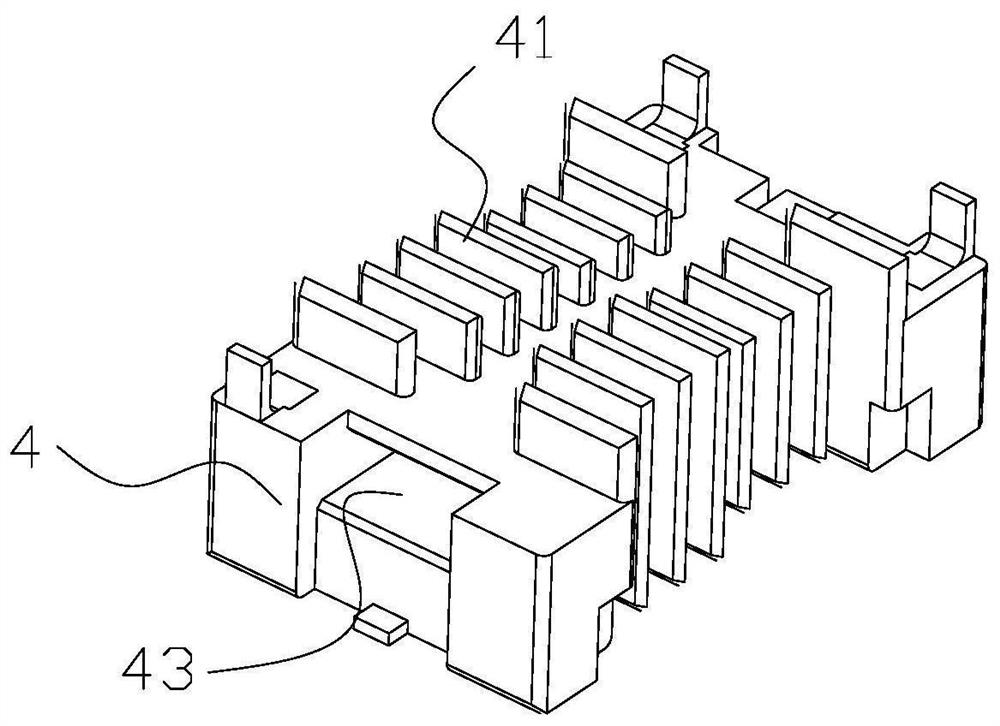

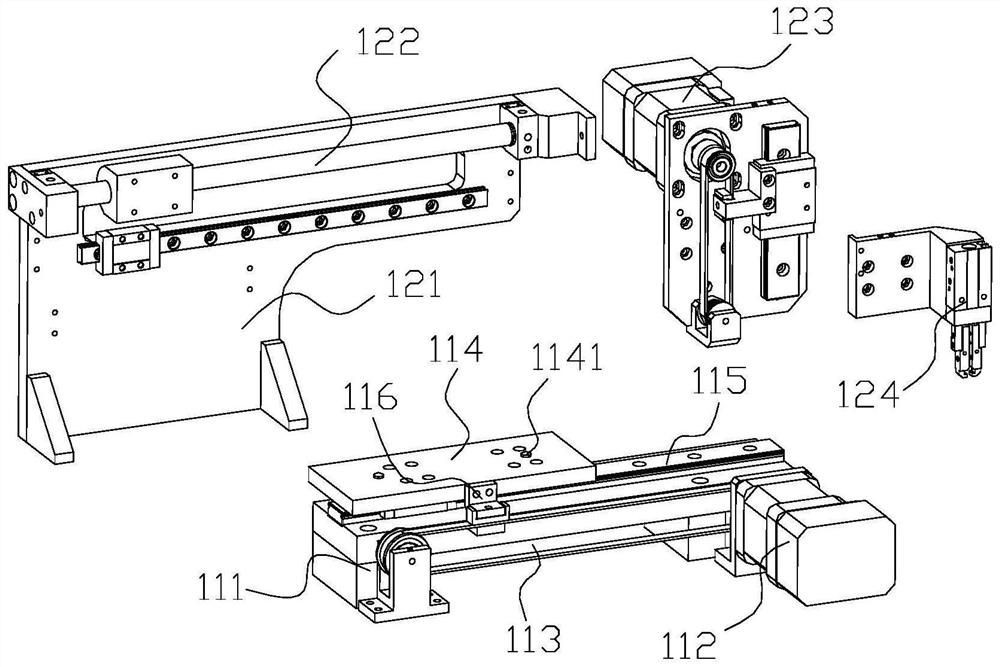

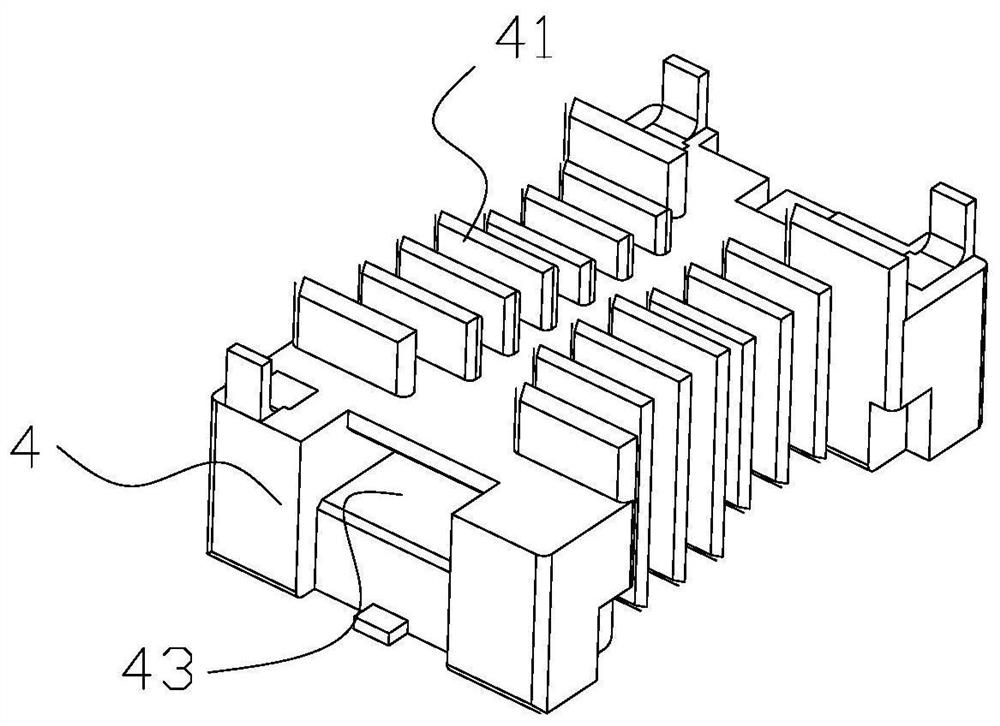

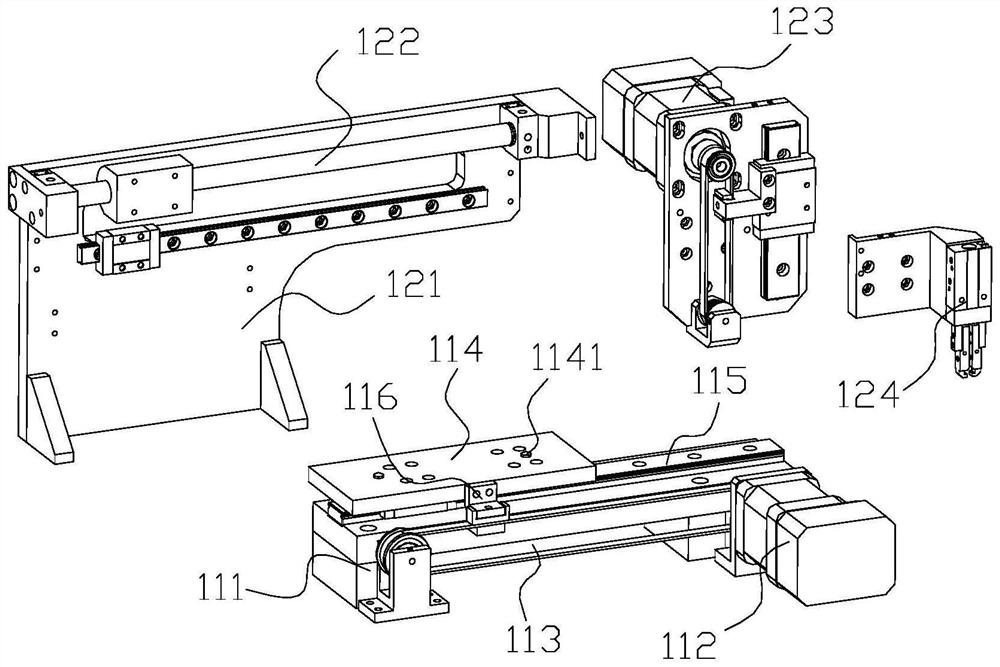

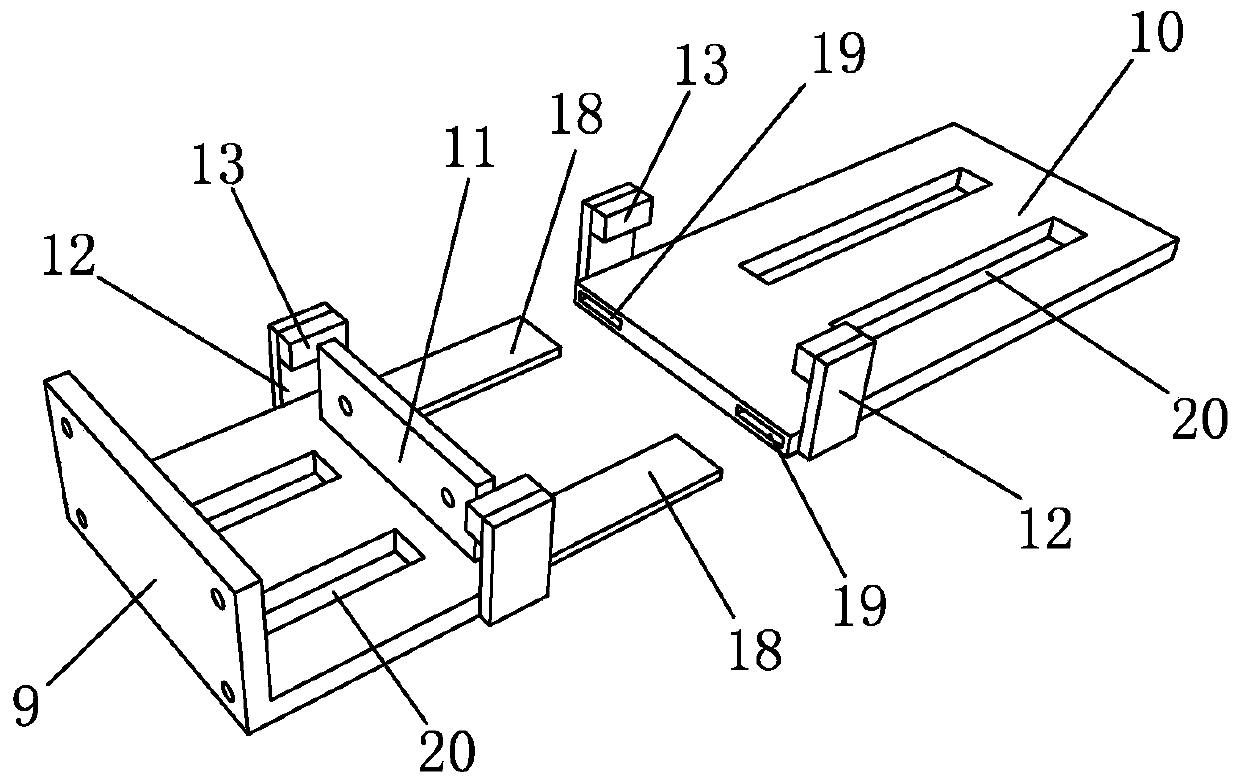

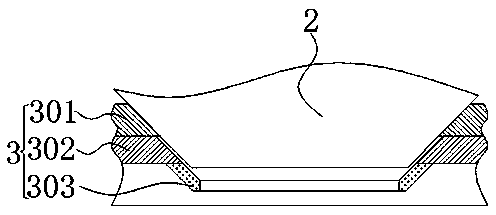

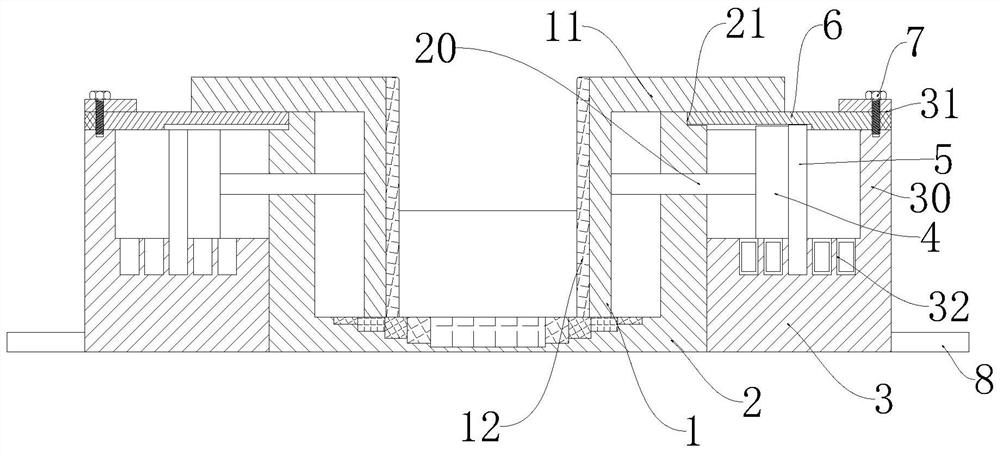

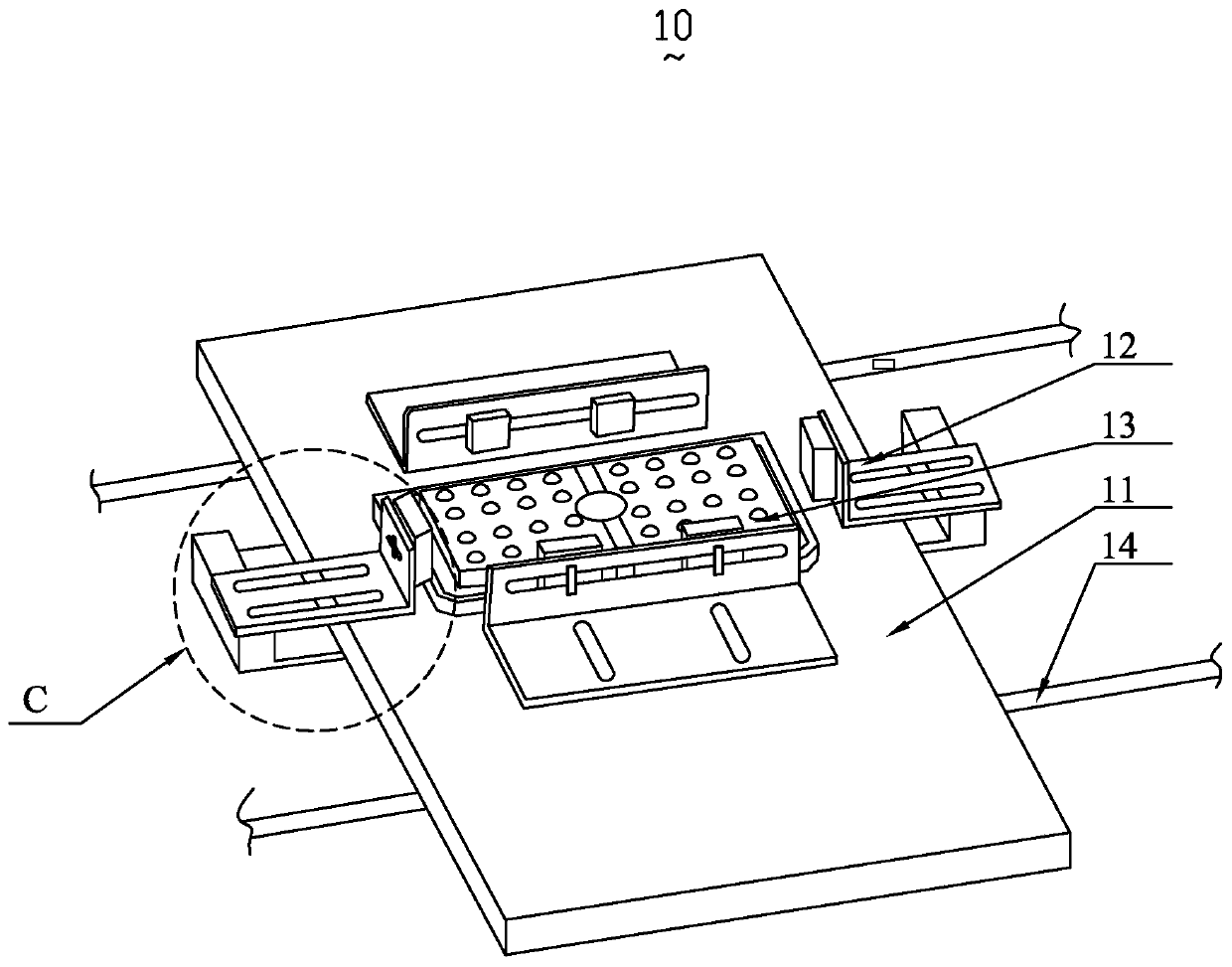

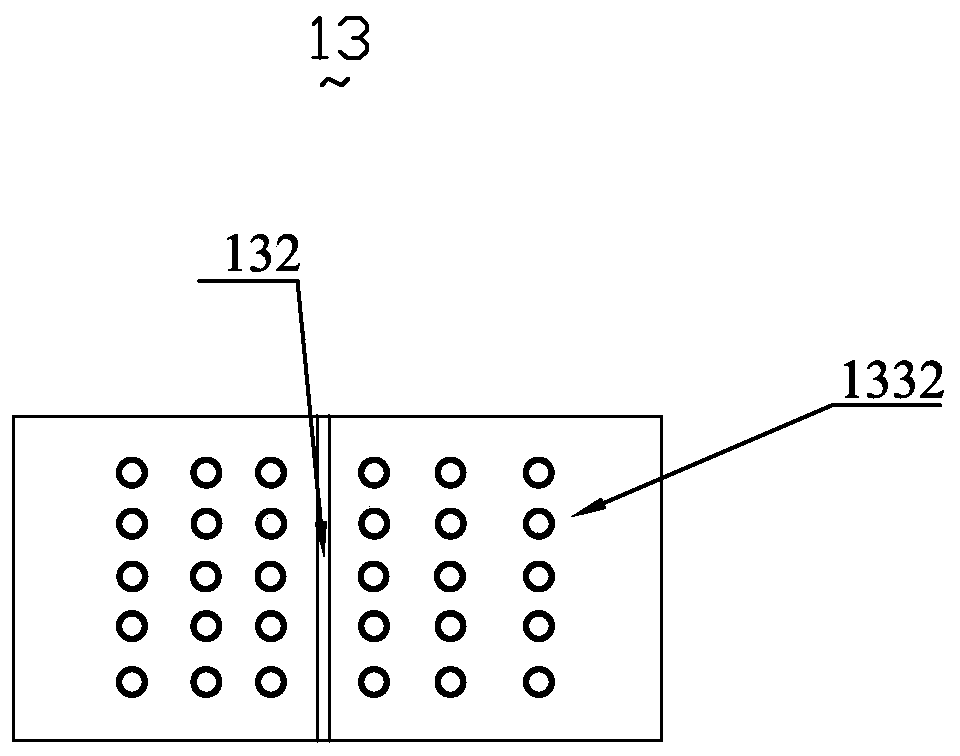

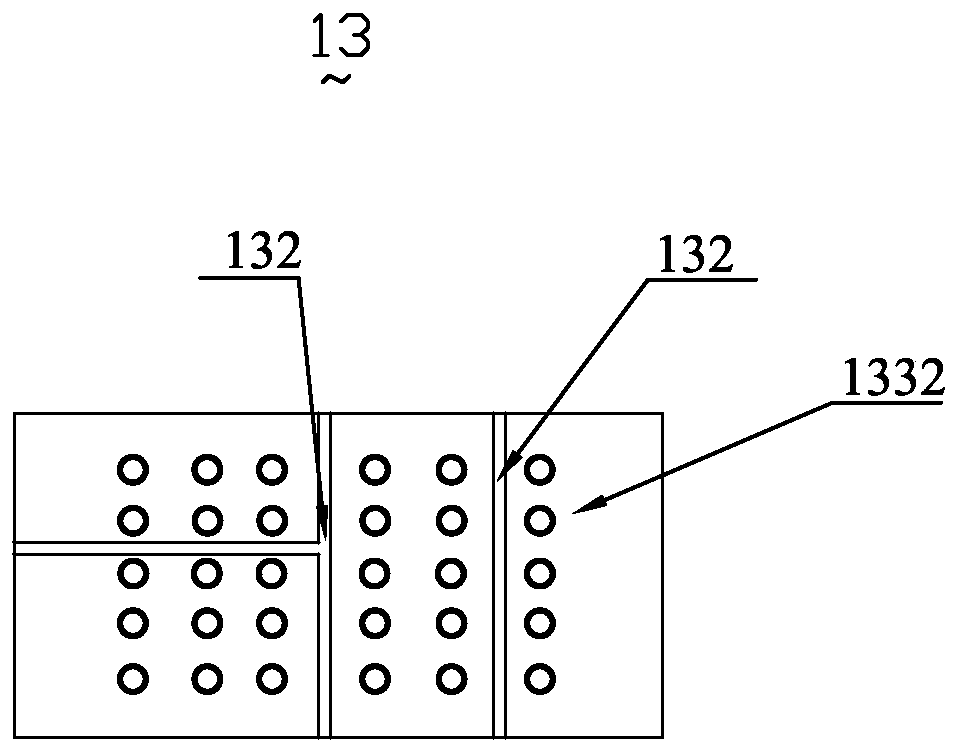

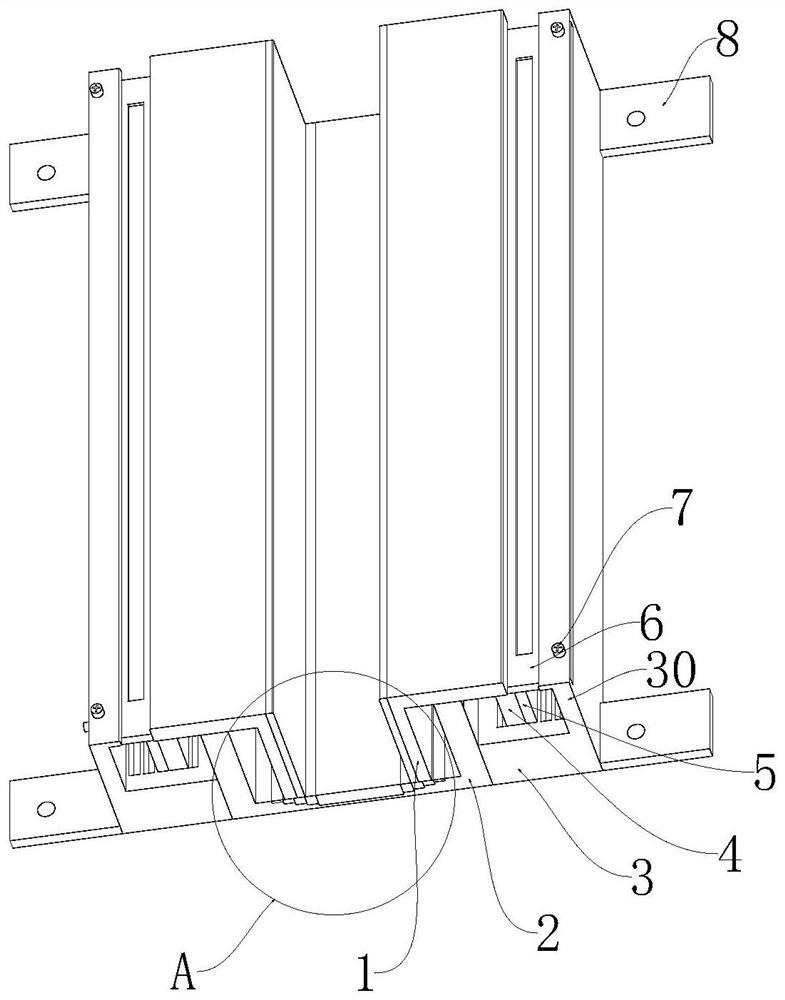

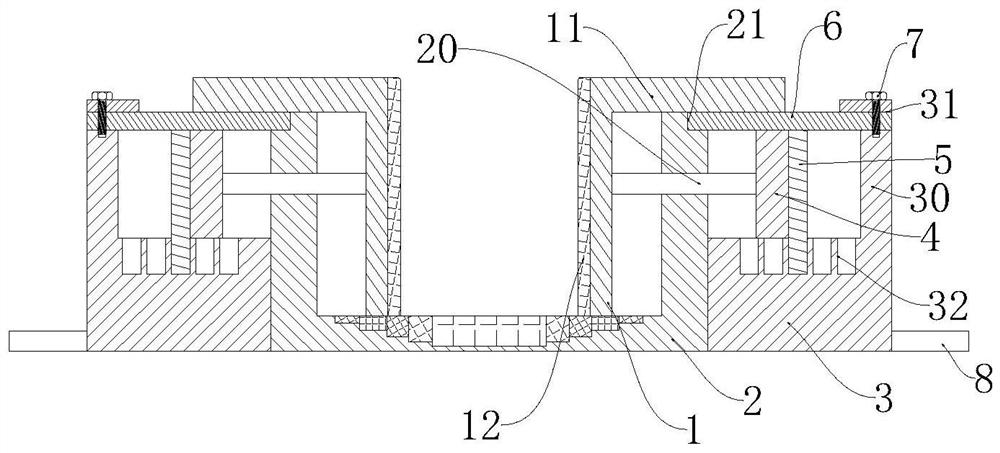

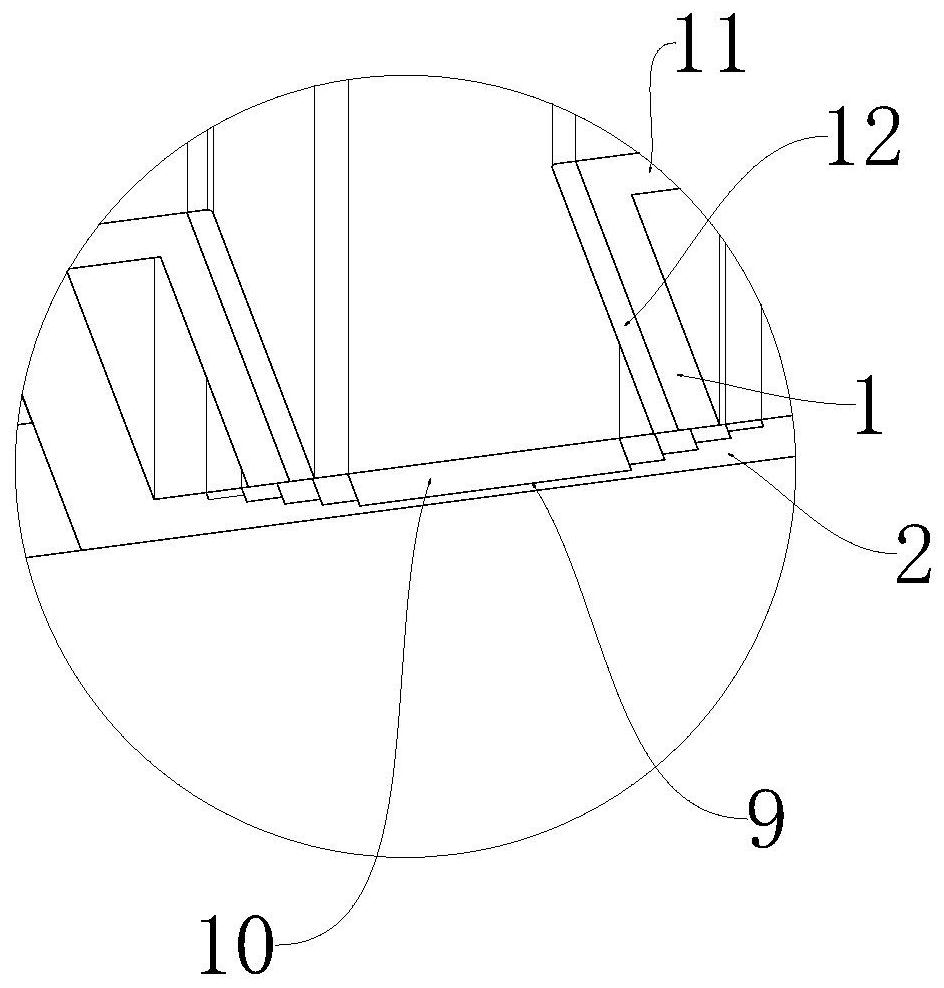

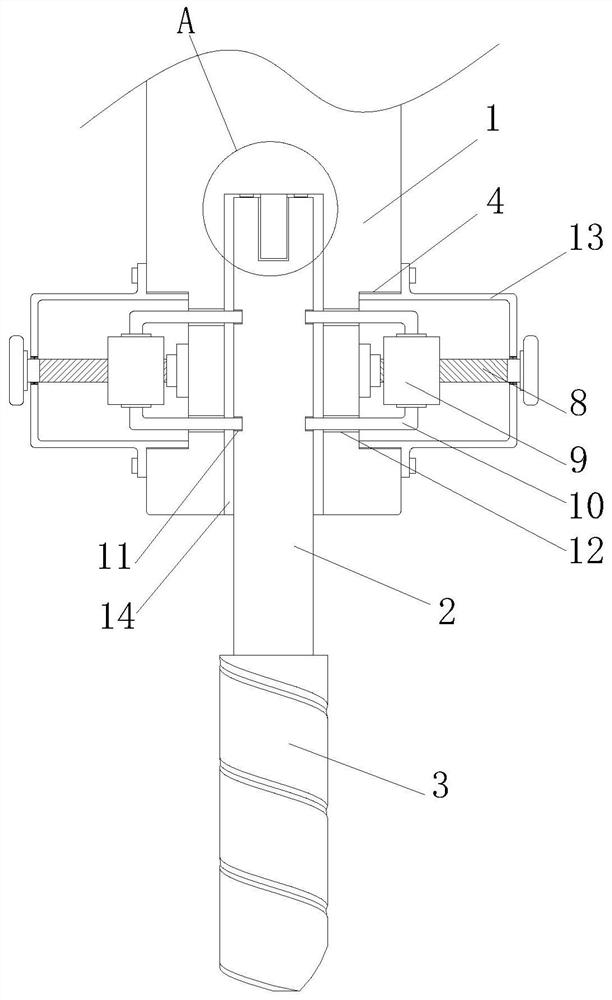

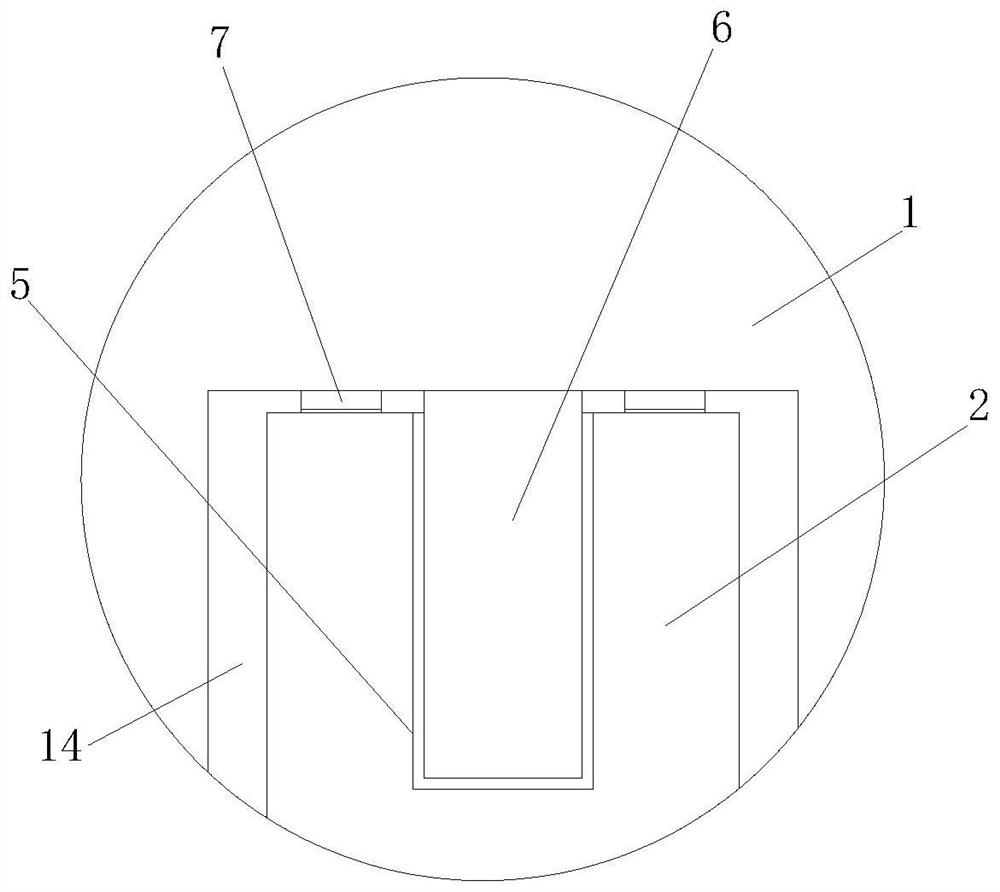

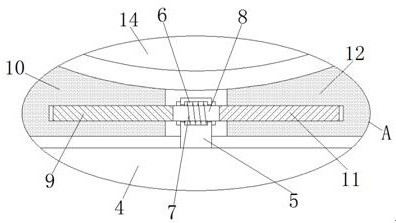

Pole plate positioning mechanism, lithium ion battery lamination device and lithium ion battery lamination method

ActiveCN106785076AReduce viscosityEfficient dischargeFinal product manufactureSecondary cellsViscous effectEngineering

The invention relates to the technical field of lithium ion batteries, and in particular relates to a polar plate positioning mechanism, a lithium ion battery lamination device and a lithium ion battery lamination method. The polar plate positioning mechanism is used for location of a polar plate, the polar plate positioning mechanism comprises a positioning placing plate, the upper surface of the positioning placing plate is used for placing the polar plate, the upper surface of the positioning placing plate is provided with a liquid guiding channel, and the liquid guiding channel is used for discharge of an electrolyte on the polar plate. The lithium ion battery lamination device and the lithium ion battery lamination method both adopt the polar plate positioning mechanism, the polar plate positioning mechanism and the lithium ion battery lamination device can improve the viscous effect of the polar plate in the process of positioning due to excess electrolyte, and have the advantages of good localization effect, the lithium ion battery lamination method can effectively pre discharge the excess electrolyte on the polar plate for preliminary positioning, and the lamination method is simple, and has good lamination effect.

Owner:山西能际智能科技有限责任公司

Transformer and production device and method thereof

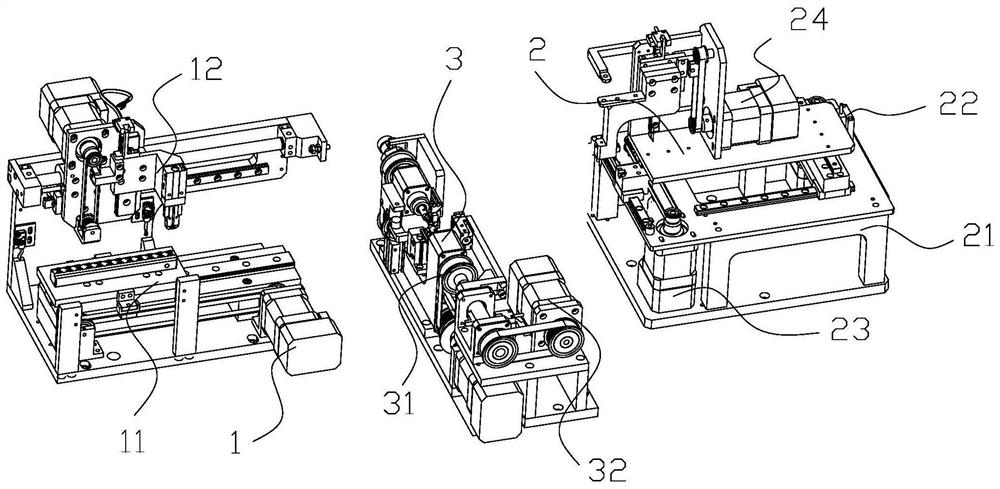

InactiveCN111627691AImprove winding positioning accuracyImprove stabilityTransformers/inductances coils/windings/connectionsCoils manufactureTransformerMechanical engineering

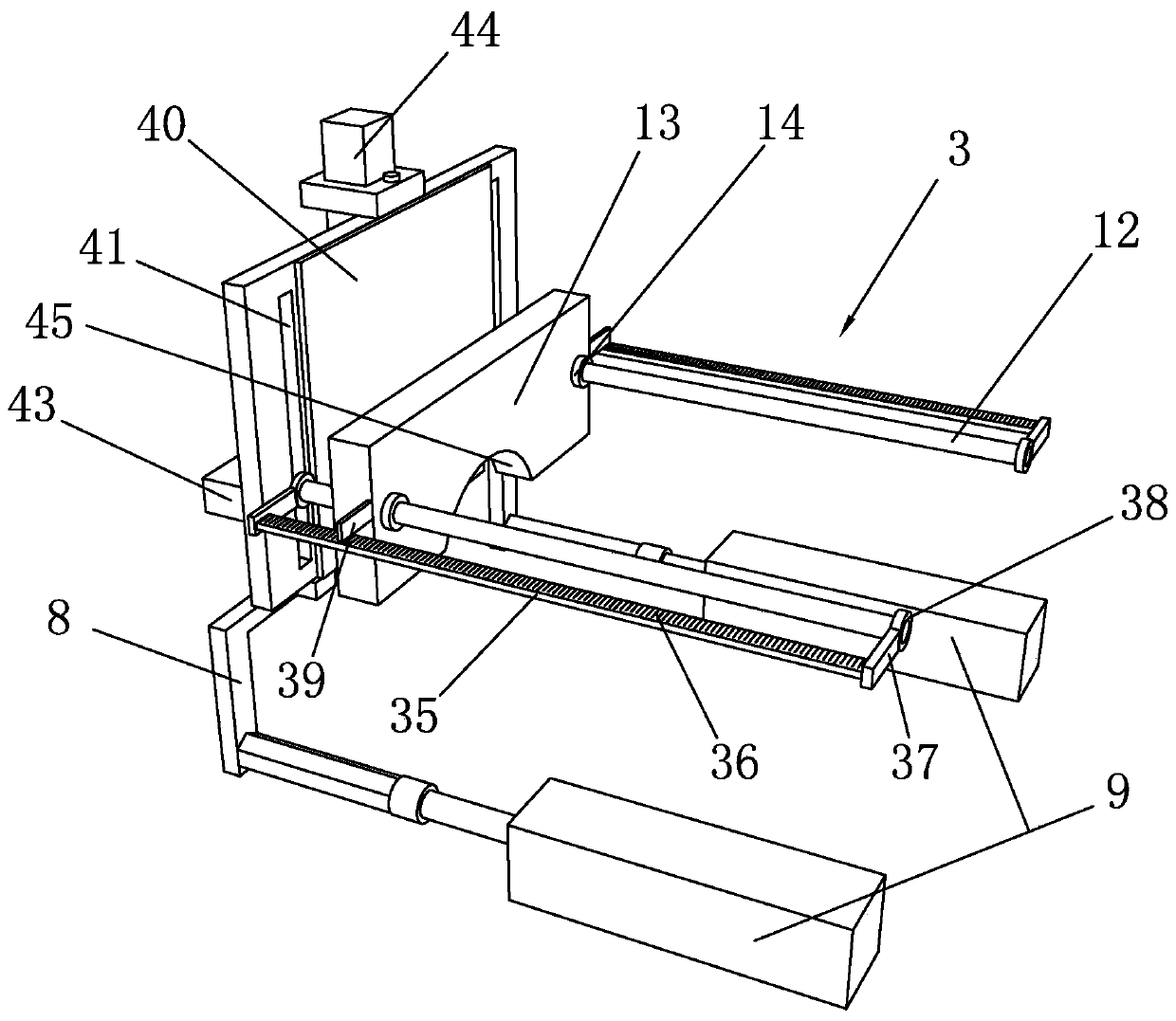

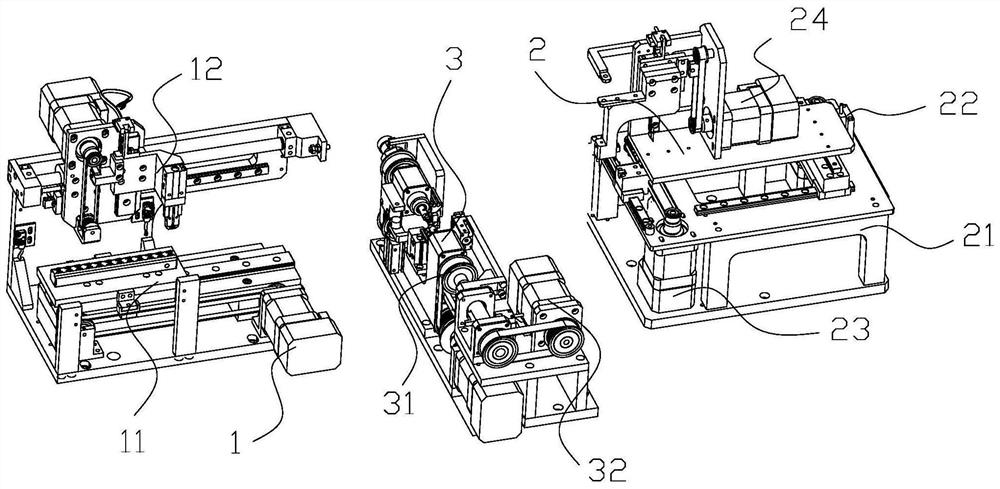

The invention belongs to the technical field of transformer production, and a transformer production device comprises a rack, and an iron core winding frame conveying device, a coil conveying device,a clamping winding device and a coil cutting-off device which are arranged on the rack. The clamping winding device is located between the iron core winding frame conveying device and the coil conveying device, the iron core winding frame conveying device is used for conveying an iron core winding frame to the clamping winding device, and the coil conveying device is used for conveying a coil to the clamping winding device. The clamping winding device is used for winding the coil to the iron core winding frame, and the coil cutting-off device is used for cutting off the coil after the iron core winding frame winds the coil. The advantages of the present invention are that the coil winding positioning precision is improved, the stability of the iron core winding frame in the winding processis improved, and the winding efficiency and the winding precision of the iron core winding frame are improved.

Owner:何国标

Machining process of end faces of gear

InactiveCN109382639AConvenient for initial positioningAvoid direct contactFeeding apparatusTurning machinesPunchingEngineering

The invention belongs to the technical field of gear machining and particularly discloses a machining process of the end faces of a gear. The process comprises the following steps of (1) forging; (2)normalizing, wherein forged pieces are subjected to normalizing treatment; (3) rough turning, wherein a large number of machining residues on the two end faces are removed, and preliminary molding ofthe two end faces is achieved; (4) finish turning, wherein finish turning is carried out on the two end faces in place, hard turning residues on the two end faces are reserved, and annular countersunkgrooves are formed in the two end faces through turning; (5) punching, wherein a plurality of through holes are formed in the annular countersunk grooves; (6) heat treatment, wherein carburizing andquenching are carried out; (7) shot blasting, wherein shot blasting is conducted on the forged pieces, the two end faces are cleaned, and the surface tissue and the surface strength are improved; (8)hard turning after heating, wherein hard turning is conducted on the two end faces in place, and the annular countersunk grooves are eliminated; (9) cleaning. According to the scheme, direct contact between a cutter and the through holes is avoided in the processes of rough turning, finish turning and hard turning, so that problems are avoided, the service life of the cutter is prolonged, there isno need to select the cutter with high hardness, and the production cost is reduced.

Owner:CHONGQING XINGJI GEAR

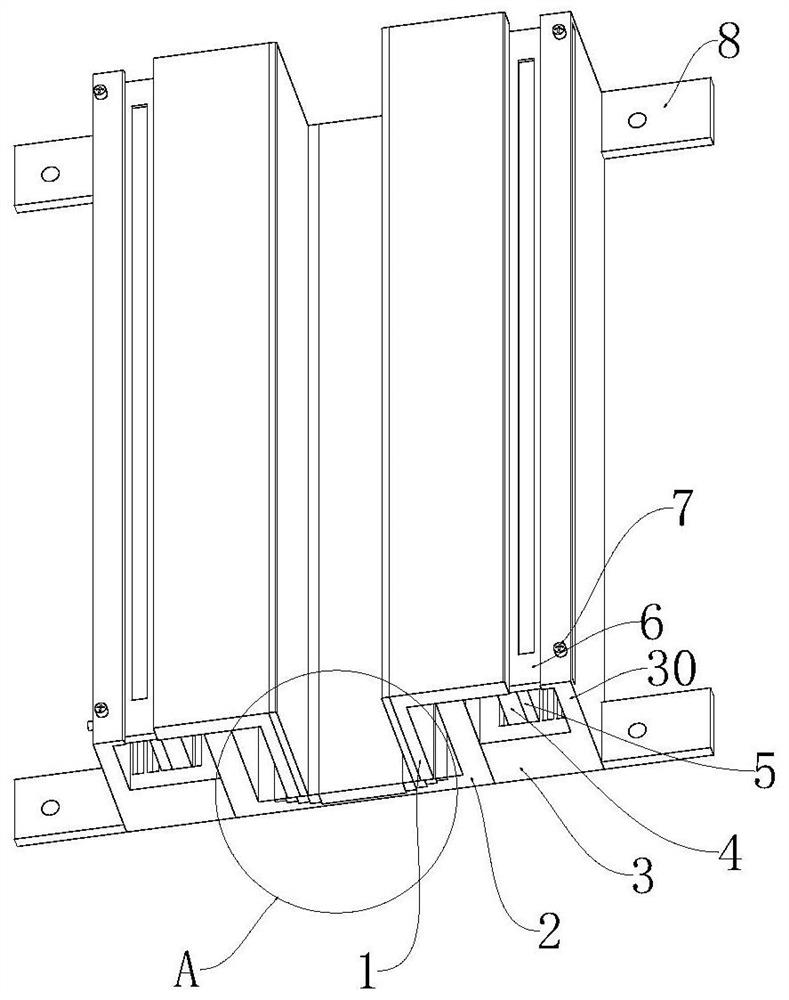

Clamping winding device for transformer production and method thereof

The invention belongs to the technical field of transformer production and discloses a clamping winding device for transformer production. The winding device comprises an iron core winding frame clamping and rotating assembly and a winding assembly, the iron core winding frame clamping and rotating assembly is used for clamping an iron core winding frame conveyed by an iron core winding frame conveying device, the winding assembly is used for preliminarily winding a coil on the coil conveying device onto the iron core winding frame, and the iron core winding frame clamping and rotating assembly cooperates with the winding assembly to wind the coil onto the iron core winding frame. The device has the advantages that the coil winding positioning precision is improved, the stability of the iron core winding frame in the winding process is improved, and the winding efficiency and the winding precision of the iron core winding frame are improved.

Owner:何国标

Iron core winding clamping and rotating mechanism for transformer production and method thereof

The invention belongs to the technical field of transformer production. The invention discloses an iron core winding frame clamping and rotating mechanism for transformer production. The iron core winding frame clamping and rotating mechanism comprises an iron core winding frame clamping bottom plate, an iron core winding frame rotating U-shaped frame, an iron core winding frame rotating driving motor, an iron core winding frame rotating driving rotating shaft, a first rotating module, a second rotating module and a supporting module. The iron core winding frame clamping bottom plate is arranged on a rack; the iron core winding frame rotating U-shaped frame is arranged on the iron core winding frame clamping bottom plate; the iron core winding frame rotating driving motor is arranged on the iron core winding frame clamping bottom plate, the winding frame rotating driving rotating shaft is connected with the iron core winding frame rotating driving motor, the first rotating module and the second rotating module are arranged at the two ends of the winding frame rotating driving rotating shaft respectively, and the supporting module is arranged at a notch of the iron core winding frame rotating U-shaped frame. The iron core winding frame clamping and rotating mechanism has the advantages that the clamping firmness of the iron core winding frame is improved, the stability of the iron core winding frame in the winding process is improved, and the winding efficiency and the winding precision of the iron core winding frame are enahnced.

Owner:何国标

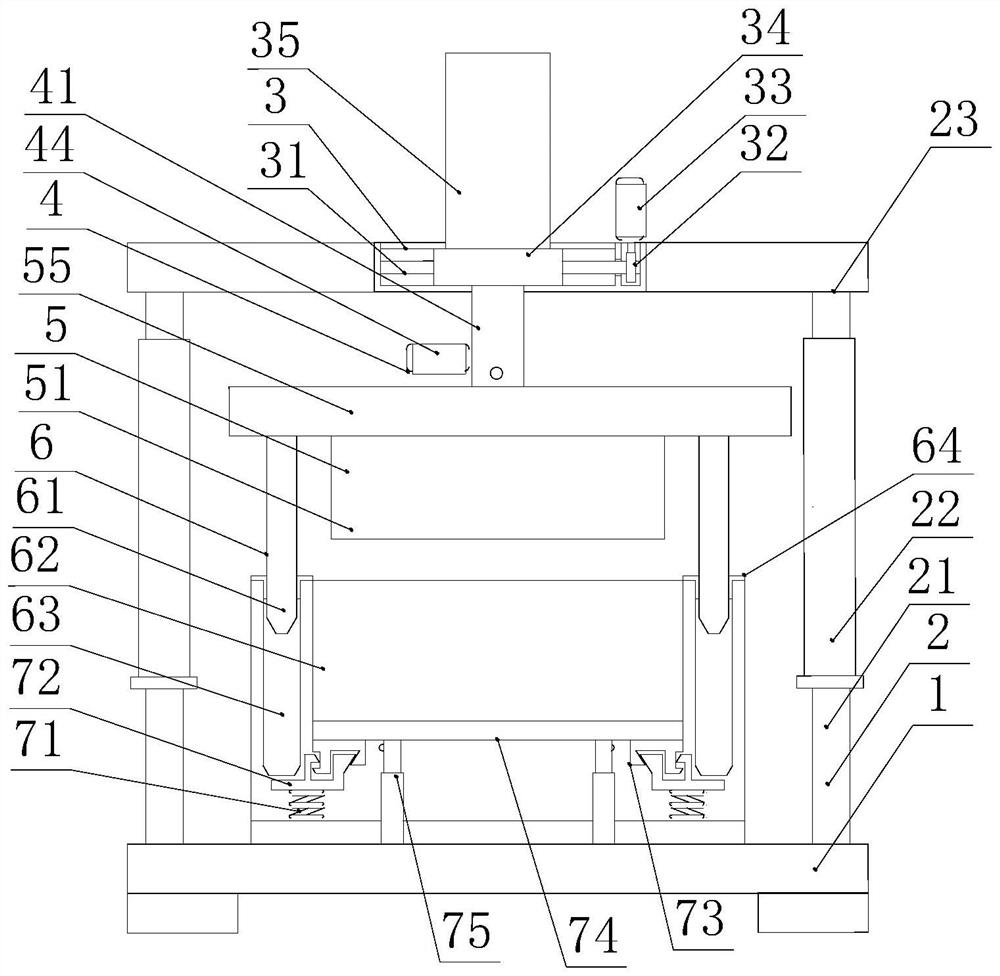

Positioning device for shock-proof bin safety bin base

InactiveCN111335474AConvenient for initial positioningEasy to transportBuilding constructionsProtective buildings/sheltersShock avoidanceLateral positioned

Owner:张峻华

High-thrust lifting upright structure and mounting method thereof

Owner:绍兴蒂尔莱特科技有限公司

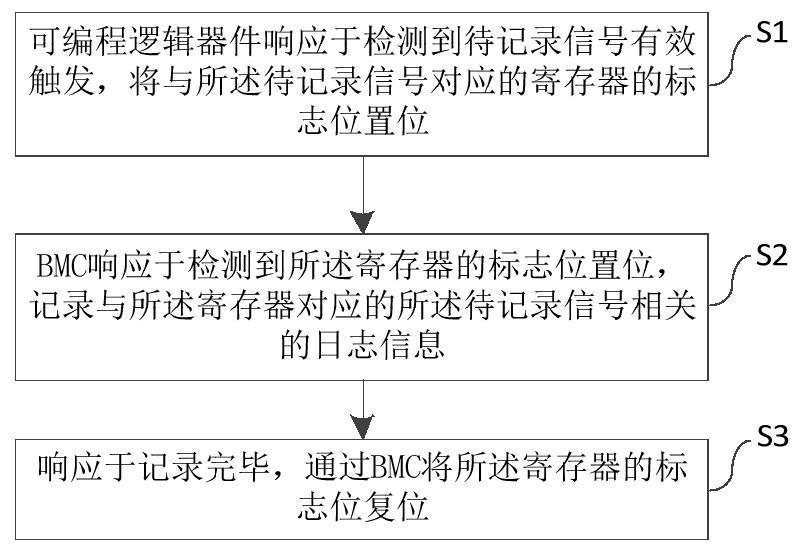

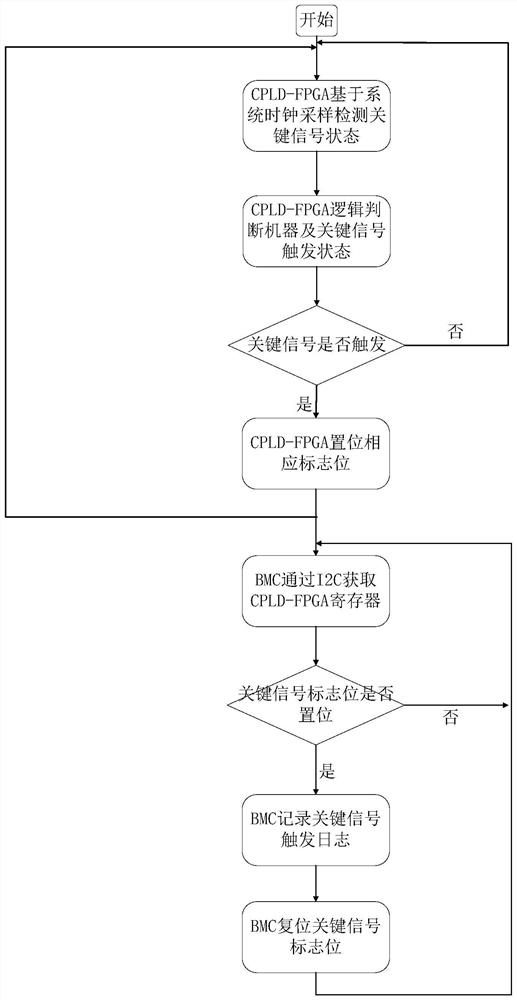

Signal detection recording method and system, equipment and medium

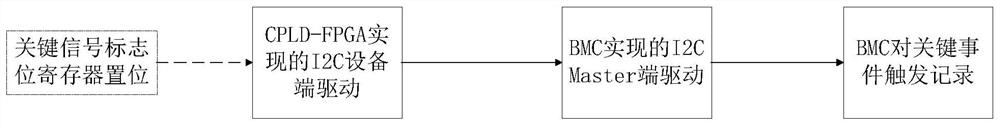

InactiveCN112445749AAchieve recordRealize the display effectDigital computer detailsElectric digital data processingProgrammable logic deviceLogisim

The invention discloses a signal detection recording method, which comprises the following steps that: a programmable logic device, in response to effective triggering of a to-be-recorded signal, setsa flag bit of a register corresponding to the to-be-recorded signal; a BMC records log information related to the to-be-recorded signal corresponding to the register in response to detection of setting of the flag bit of the register; and in response to completion of recording, the BMC resets the flag bit of the register. The invention further discloses a system, computer equipment and a readablestorage medium. According to the scheme provided by the invention, recording and display of the quick change signal are realized through the programmable logic device and the BMC, the problem that the key behavior of the system cannot be directly obtained due to slow BMC reaction is solved, the key event of the system is effectively recorded so as to comprehensively understand the system behavior, research and development of the positioning problem are facilitated, and customer preliminary positioning is facilitated.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

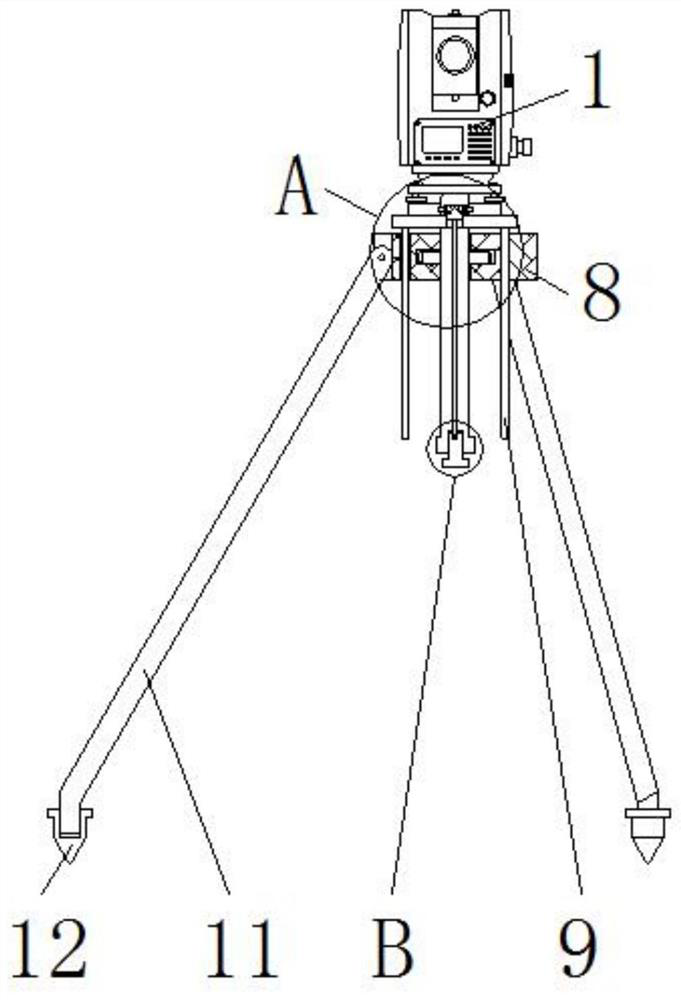

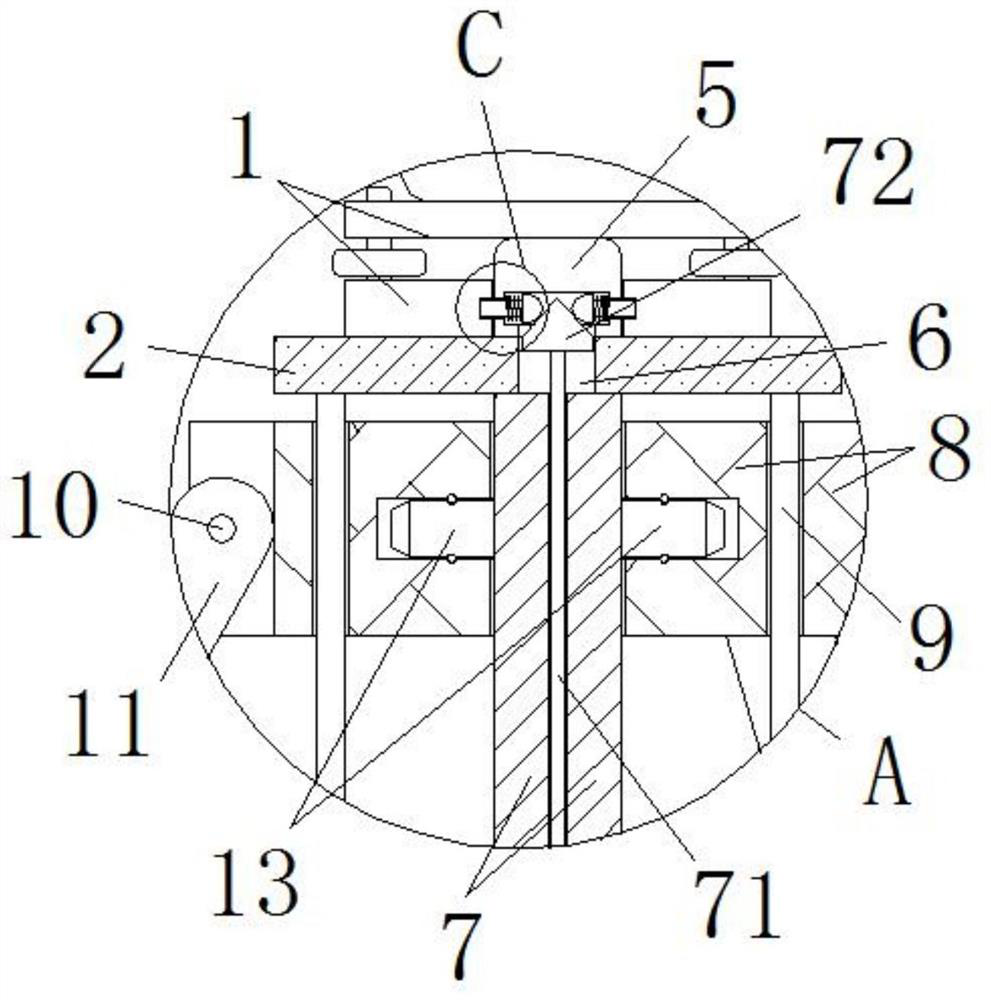

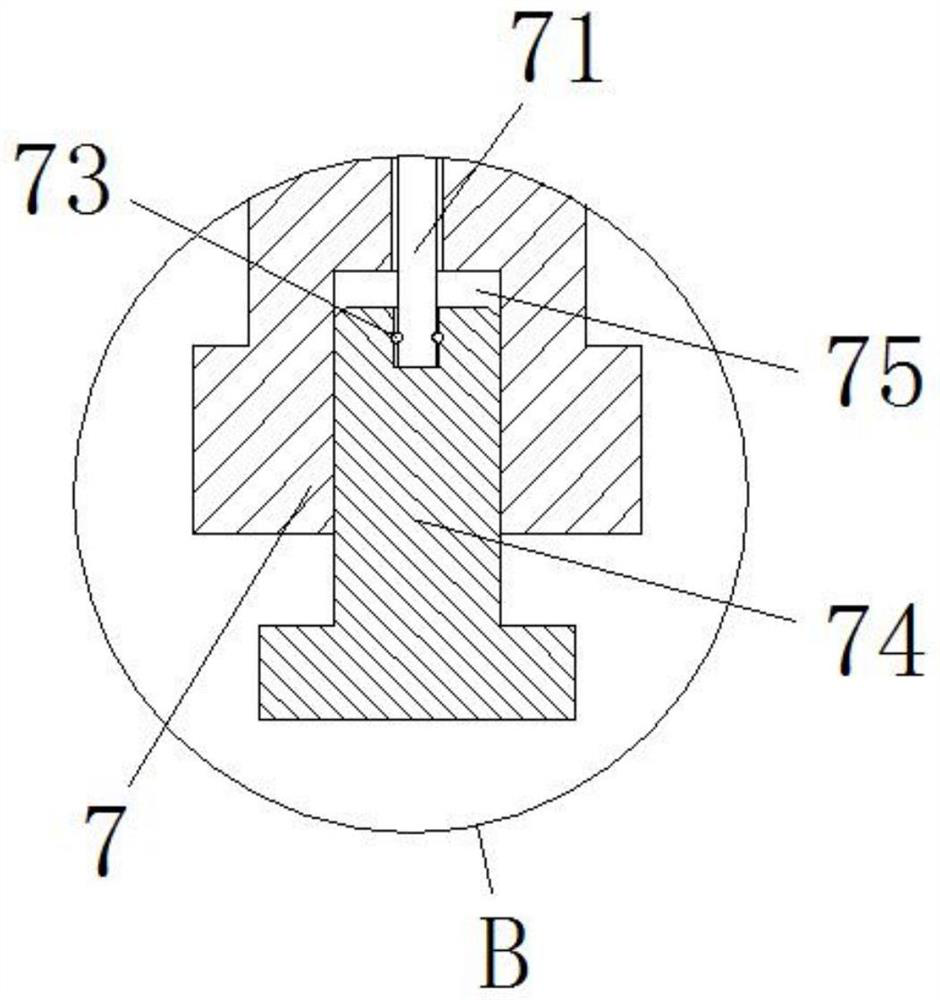

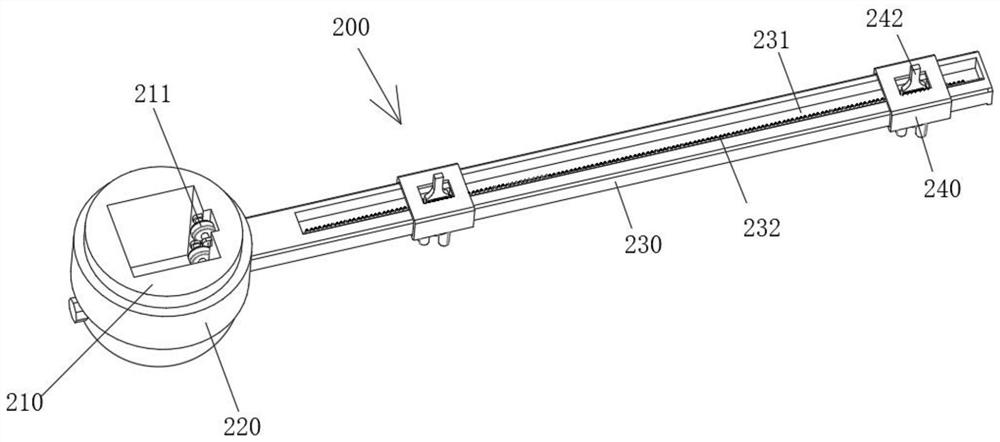

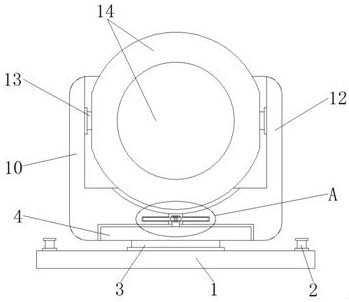

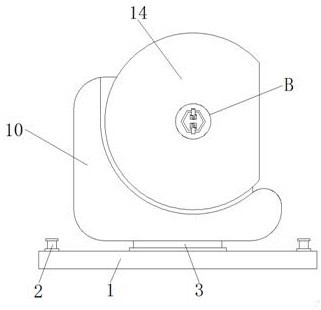

A kind of water conservancy and hydropower engineering surveying and mapping device and its surveying and mapping method

ActiveCN110701442BConvenient for initial positioningAvoid leaningSurveying instrumentsStands/trestlesGear wheelWater resources

The invention discloses a water resource and hydropower surveying and mapping device. The water resource and hydropower surveying and mapping device comprises a total station main body, a first rotating shaft, a supporting frame, a driving gear and a second rotating shaft. The total station main body is installed on the bottom face of a flat plate, and a connecting groove is formed in the center of the bottom face of the total station main body. A limiting hole is formed in the inner wall of the bottom end of the total station main body and further connected with the connecting groove. The connecting groove is connected with a fixed plate, and the fixed plate is fixedly installed on the top face of the flat plate. A limiting groove is formed in the flat plate, and a supporting shaft is fixedly installed on the bottom face of the flat plate. According to the water resource and hydropower surveying and mapping device and a surveying and mapping method thereof, the total station main bodyand the fixed plate are assembled in a clamped mode through the connecting groove, and the total station main body can be initially positioned conveniently; and meanwhile the overlook map of the fixed plate is a square, tilting of the total station main body can be effectively prevented, a limiting shaft and the limiting hole are connected in a clamped mode for fixation subsequently, and installation work can be facilitated.

Owner:温州江航建设有限公司

Bottom automatic valve mechanism of pumping hopper

InactiveCN111573314ASolve the inconvenience of cleaningEasy to disassembleLoading/unloadingStructural engineeringIndustrial engineering

Owner:QIYUAN HENGCHENG VALVE IND CO LTD

A wall positioning device for prefabricated buildings

ActiveCN111894291BReduce usageAchieving a position lockWallsBuilding material handlingStructural engineeringSplint device

The invention provides a wall body positioning device for a prefabricated building, which comprises a U-shaped frame with an opening on the upper end, and two compression splints are slidingly installed on the inner bottom of the U-shaped frame from left to right, and the two compression splints are symmetrically arranged on the left and right. The opposite ends of the compression splint are fixed with connecting shafts, and the connecting shafts on the left and right sides respectively run through the left end and the right end of the U-shaped frame. The upper ends of the two side plates are equipped with external connecting plates, and the end of the connecting shaft far away from the compression splint is fixedly connected with the external connecting plates. The lower end is inserted into one of the locking grooves, the upper baffle is installed on the upper limit plate, and the upper baffle is detachably installed on the upper side of the side plate. The invention has a reasonable structure, reduces the number of bolts used during connection, and improves work efficiency.

Owner:华临绿建科技股份有限公司

An energy-saving and environment-friendly building material processing equipment

ActiveCN111421086BConvenient for initial positioningFor precise tyingWire networkArchitectural engineeringMaterials processing

The invention belongs to the technical field of construction processing, and specifically relates to an energy-saving and environment-friendly building material processing equipment, a moving mechanism and a supporting mechanism; the moving mechanism includes a base plate 1 and a base plate 2; the number of the base plate 1 is two; the present invention Among them, by opening an embedding groove on the inner side of the first base plate, and clamping and fixing the second base plate on the inner side of the embedding groove, the position of the positioning claw can be adjusted by using the moving sleeve on the support rod, so that the steel bars can be placed in layers , the steel bar can be fixed by the positioning claw, so that it is convenient for the staff to initially locate the position of the steel bar, it is convenient for the staff to carry out precise binding of the steel bar, and it can avoid the situation that the steel bar falls off during the steel bar binding process, reducing the staff's work workload, and can reduce the amount of raw materials used for secondary binding of steel bars, reduce costs, and save energy and protect the environment.

Owner:安徽永利建设工程有限公司

Pole piece positioning mechanism, lithium ion battery stacking device and lithium ion battery stacking method

ActiveCN106785076BReduce viscosityEfficient dischargeFinal product manufactureSecondary cellsEngineeringPole piece

The invention relates to the technical field of lithium ion batteries, in particular to a pole piece positioning mechanism, a lithium ion battery stacking device and a lithium ion battery stacking method. The pole piece positioning mechanism is used to position the pole piece. The pole piece positioning mechanism includes a positioning and placing plate, the upper surface of the positioning and placing plate is used to place the pole piece, and the upper surface of the positioning and placing plate A liquid guiding channel is set up, and the liquid guiding channel is used to discharge the electrolyte on the pole piece. The pole piece positioning mechanism is adopted in the lithium-ion battery stacking device and the lithium-ion battery stacking method provided by the present invention, and the pole piece positioning mechanism and the lithium-ion stacking device of the present invention can improve the Due to the viscous effect of excess electrolyte in the positioning process, and has the advantage of better positioning effect, the stacking method of the lithium-ion battery can effectively discharge the excess electrolyte on the pole piece in advance for preliminary positioning, and the The lamination method is simple and the lamination effect is good.

Owner:山西能际智能科技有限责任公司

A prefabricated building wall positioning machine

ActiveCN111894290BReduce usageAchieving a position lockWallsBuilding material handlingArchitectural engineeringStructural engineering

Owner:华临绿建科技股份有限公司

Drill bit dismounting and mounting mechanism convenient to dismount and mount

InactiveCN112548169AEasy to assemble and disassembleFacilitate subsequent positioning operationsPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention relates to the related technical field of drill bit mounting, and discloses a drill bit dismounting and mounting mechanism convenient to dismount and mount. The drill bit dismounting andmounting mechanism comprises a mounting head, a drill handle and a drill bit are arranged below the mounting head, a vertical mounting groove matched with the drill handle is formed in the bottom ofthe mounting head, the drill handle and the drill bit are connected with each other, one end of the top of the drill hand is inserted in the inner side of the vertical mounting groove, an embedded block is installed at the top of the inner side of the vertical mounting groove, an embedded groove matched with the embedded block is formed in one end of the top of the drill handle, the embedded blockis inserted into the inner side of the embedded groove, and two magnetic pieces are symmetrically installed at the top of the inner side of the vertical mounting groove in the mode of penetrating through the embedded block. According to the drill bit dismounting and mounting mechanism convenient to dismount and mount, the drill handle and the mounting head are precisely mounted in a matched mode,operation can be completed without making contact with an external auxiliary tool, different from a traditional mounting mode with the help of an auxiliary tool, and meanwhile through limiting of thetransverse position of the drill handle, the drill handle is effectively prevented from loosening and disengaging from the inner side of the vertical mounting groove, and the mounting and using safety of the equipment drill bit is improved.

Owner:无锡秀研精密机械有限公司

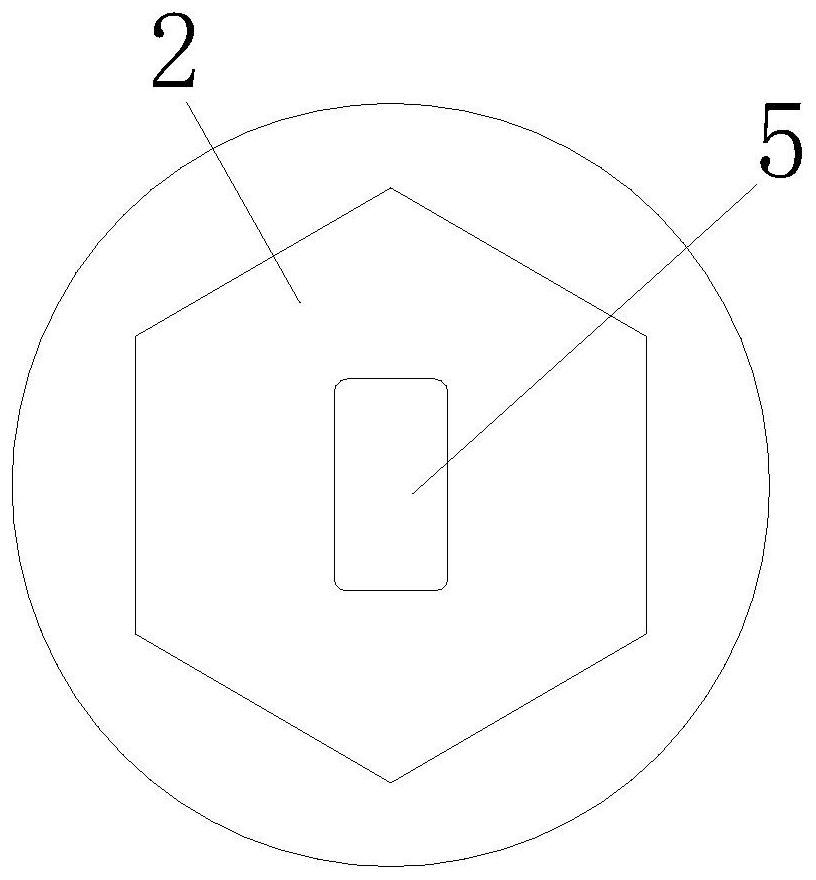

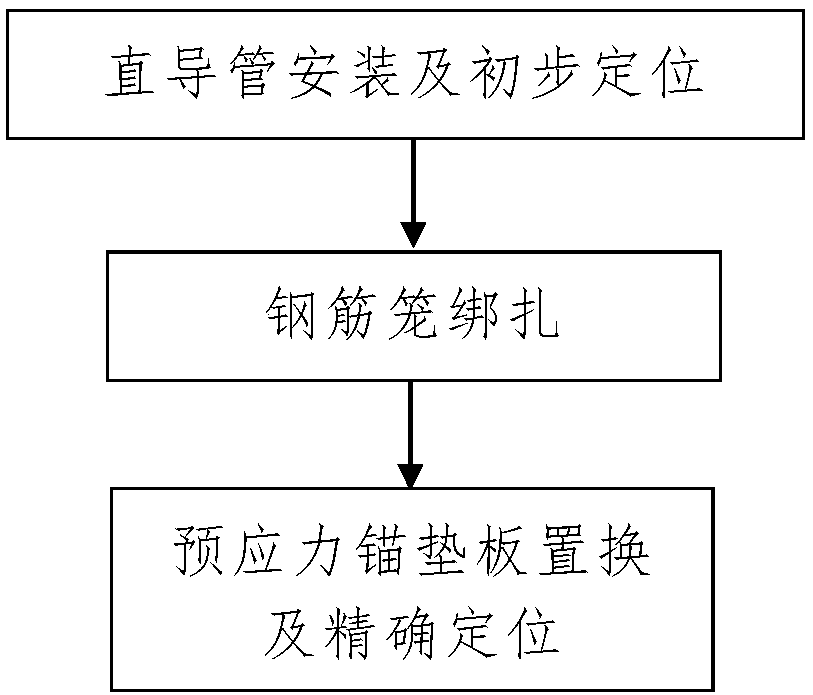

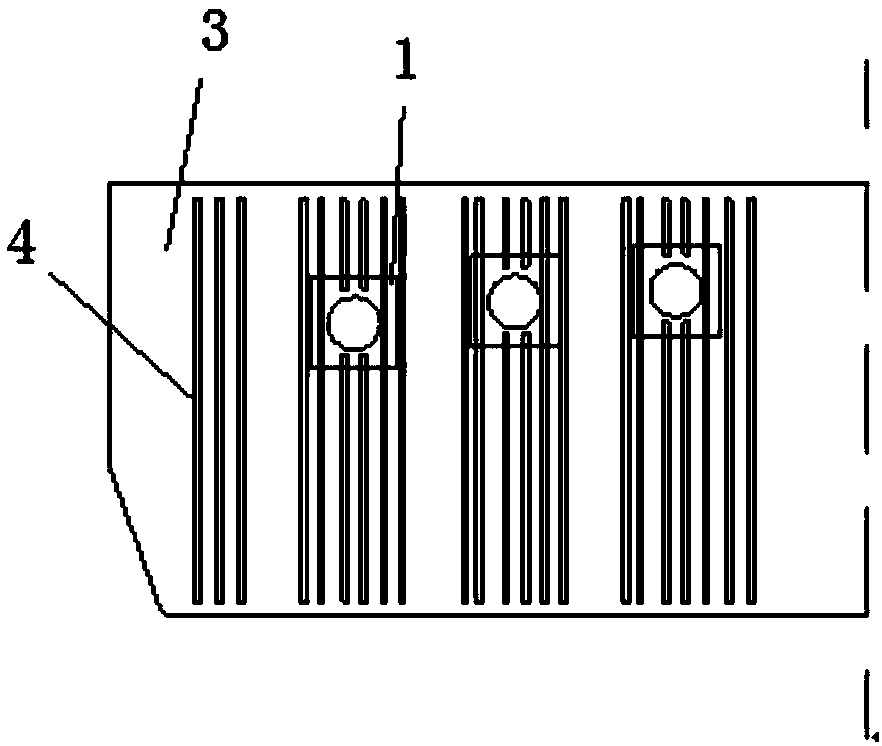

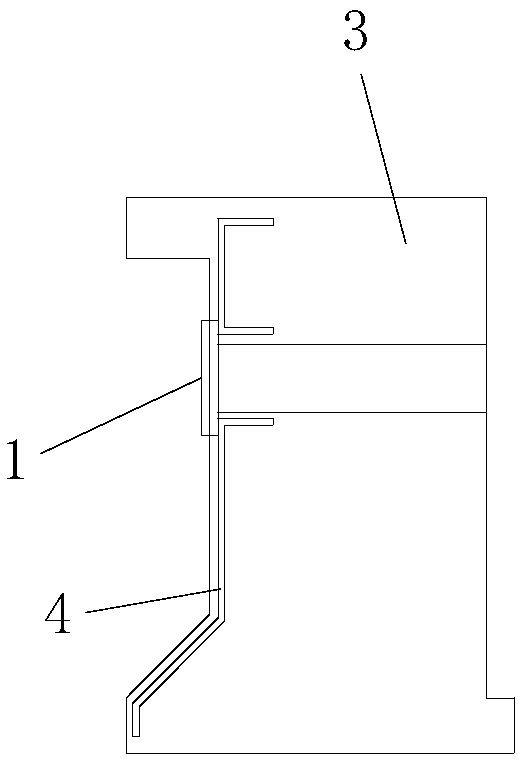

Replacement and location method of externally prestressed anchor pads for segmental beams

ActiveCN106192752BThe method steps are simpleReasonable designBridge structural detailsBridge erection/assemblyPre stressBuilding construction

The invention discloses a method for replacing and positioning an external prestressed anchor backing plate of a segmental beam, comprising steps: 1. Installation and preliminary positioning of a straight conduit: after the stiff skeleton used for construction of a segmental beam is installed, according to the pre-designed The installation position of the prestressed anchor backing plate at the end of the section beam is to install a straight conduit on the stiff skeleton; the inner diameter of the straight conduit is greater than the diameter of the installation hole opened on the prestressed anchor backing plate; two, steel cage binding ; 3. Replacement and precise positioning of the prestressed anchor backing plate: take out the straight pipe, install the prestressed anchor backing plate at the installation position of the straight pipe, and adjust the position of the prestressed anchor backing plate until the prestressed anchor backing plate is placed Backing plate installed in place. The method has the advantages of simple steps, reasonable design, convenient construction, and good application effect. It can easily and quickly complete the positioning process of the external prestressed anchor pad, and can effectively reduce the construction difficulty and greatly improve the construction efficiency.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Splicing type fixing device for automatic instrument

InactiveCN112413315AEasy to removeTime-saving and labor-saving efficiencyNon-rotating vibration suppressionStands/trestlesPhysicsMechanical engineering

Owner:XIAN ZHIYUEDA SOFTWARE CO LTD

Energy conservation and environmental protection type building material processing equipment

The invention belongs to the technical field of building processing, in particular to energy conservation and environmental protection type building material processing equipment. The energy conservation and environmental protection type building material processing equipment comprises a moving mechanism and a supporting mechanism, wherein the moving mechanism comprises two bottom plates I and a bottom plate II. In the energy conservation and environmental protection type building material processing equipment, an embedding groove is formed in the inner side of each bottom plate I, and the bottom plate II is buckled and fixedly arranged on the inner side of the embedding groove. The position of a positioning claw can be adjusted by a moving sleeve on a support rod, and therefore steel barscan be laid out in layers. The steel bars can be fixed through the positioning claw, and therefore workers can preliminarily position the position of the steel bars conveniently and precisely bind the steel bars conveniently. Moreover, the situation of the steel bars falling off in the process of steel bar binding can be avoided, and the workload of the workers is reduced. The amount of raw materials used in the second-time binding of the steel bars can be reduced, so the cost is reduced, and energy conservation and environmental protection are achieved.

Owner:安徽永利建设工程有限公司

Code scanner based on block chain technology

InactiveCN111985259AImprove convenienceVertical Angle AdjustmentSensing by electromagnetic radiationBlockchainEngineering

The invention discloses a code scanner based on a block chain technology. The code scanner comprises a mounting base, bolts and a code scanner main body, wherein the bolts and a supporting shaft are arranged on a surface of the mounting base, a lower end of the supporting shaft is rotationally connected with a surface of the mounting base, a supporting block is installed on a top face of the supporting shaft, a supporting rod is installed on a top face of the supporting block, a first storage groove is formed in the supporting rod, a volute spiral spring and a connecting rod are arranged in the first storage groove, and the volute spiral spring is fixedly connected with a surface of the connecting rod. The invention discloses a code scanner based on the block chain technology. A worker canstir the code scanner body to enable the code scanner body to rotate with the first positioning block through the limiting shaft, a longitudinal angle of the code scanner body can be conveniently adjusted, and meanwhile, the code scanner body can be stirred to enable the first positioning block to rotate on the mounting base through the supporting shaft.

Owner:吴发青

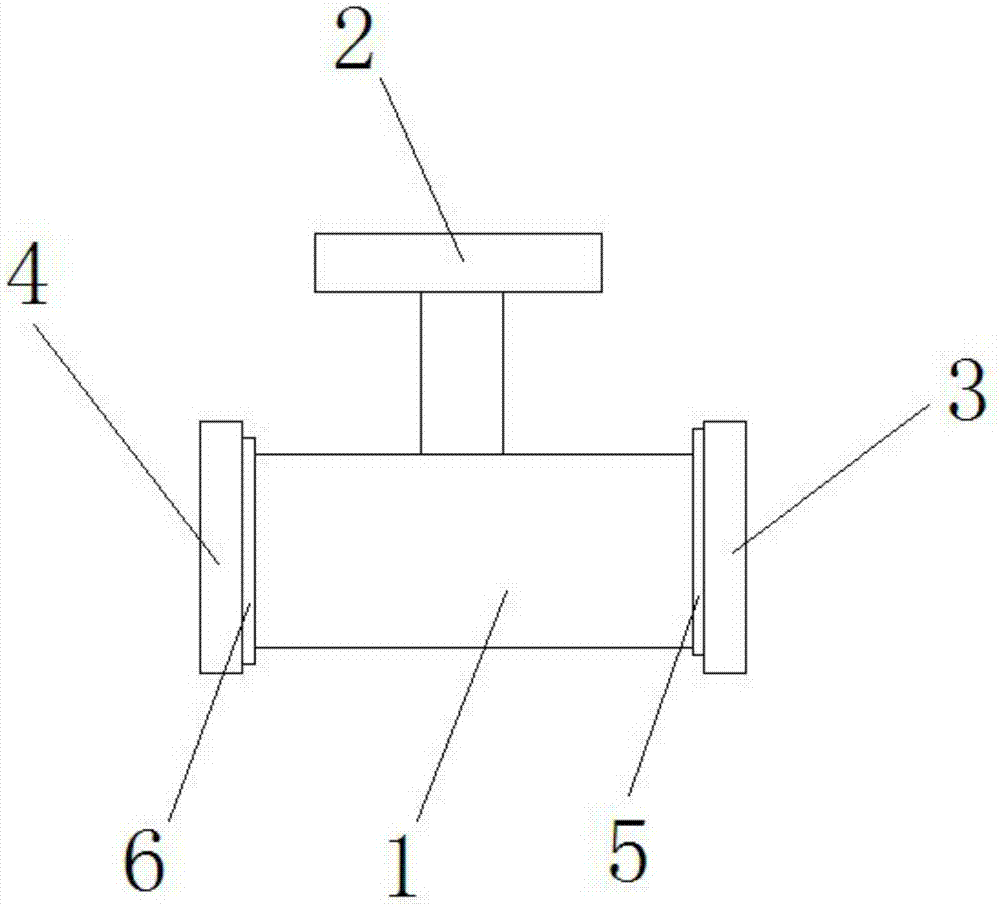

Convenient-to-assemble hydraulic valve

The invention discloses a convenient-to-assemble hydraulic valve which comprises a valve casing and an adjusting handle; a water inlet and a water outlet are formed in the two ends of the valve casing correspondingly; a first magnet ring is arranged at the rear end of the water inlet; a second magnet ring is arranged at the rear end of the water outlet; and the adjusting handle is arranged at the upper end of the valve casing. When the convenient-to-assemble hydraulic valve is mounted, pipe openings at the two ends can attract pipe openings to be connected, and preliminary location of a throttling valve is facilitated.

Owner:NINGBO HAIHONG HYDRAULICS

Composite insulation board detection equipment

ActiveCN114112672AEasy to pullEasy to fixMaterial strength using tensile/compressive forcesInsulation improvementStructural engineeringMechanical engineering

The invention provides composite insulation board detection equipment, and relates to the technical field of composite insulation board detection.The composite insulation board detection equipment comprises drawing equipment, a fixing frame is fixedly installed on the surface of the drawing equipment, a driving plate is slidably connected to the inner wall of the fixing frame, adjusting devices are arranged on the inner wall of the driving plate and the inner wall of the fixing frame, and each adjusting device comprises a limiting frame; the limiting frame is fixedly connected with the surface of the driving plate, the inner wall of the limiting frame is slidably connected with two clamping blocks, the two clamping blocks are slidably connected with the surface of the limiting frame, driving rods penetrate through the interiors of the two clamping blocks in a threaded mode, and the surfaces of the two clamping blocks are fixedly connected with racks; the surface of the limiting frame is fixedly connected with a fixing frame, and the projection plane of the fixing frame is in a U shape. According to the clamping device, the problem that due to the fact that clamping equipment on a fixing frame and a driving plate can only conduct clamping on the single position of the composite heat preservation plate, stress on the side positions of the composite heat preservation plate is not uniform is solved.

Owner:无锡振华建设工程质量检测有限公司

Positioning mold for engine ceramic core material development and positioning method thereof

PendingCN114669720AAccurate locationReduce wasteFoundry mouldsFoundry coresWaste productStress sensors

The invention discloses a positioning mold for engine ceramic core material development and a positioning method thereof.The positioning mold comprises a base, an adjusting mechanism is arranged at the top of the base, a left-right moving mechanism is arranged at one end of the top of the adjusting mechanism, a front-back moving mechanism is arranged at the bottom of the left-right moving mechanism, and a heating mechanism is arranged at the bottom of the front-back moving mechanism; the device has the beneficial effects that through cooperation of a positioning rod and a positioning groove, preliminary positioning is facilitated, then through detection of a pressure sensor, the front-back moving mechanism and the left-right moving mechanism are adjusted, and the positioning rod and the positioning groove are matched with each other, so that the positioning rod and the positioning groove are matched with each other; the position of the male die is more accurate, the device can machine parts conveniently, waste products are reduced, an ejection mechanism is used, the parts can be ejected out conveniently after machining is completed, part machining is prevented from being affected, and the bottom plate can be limited and prevented from moving.

Owner:无锡汉瓷特种陶瓷技术有限公司

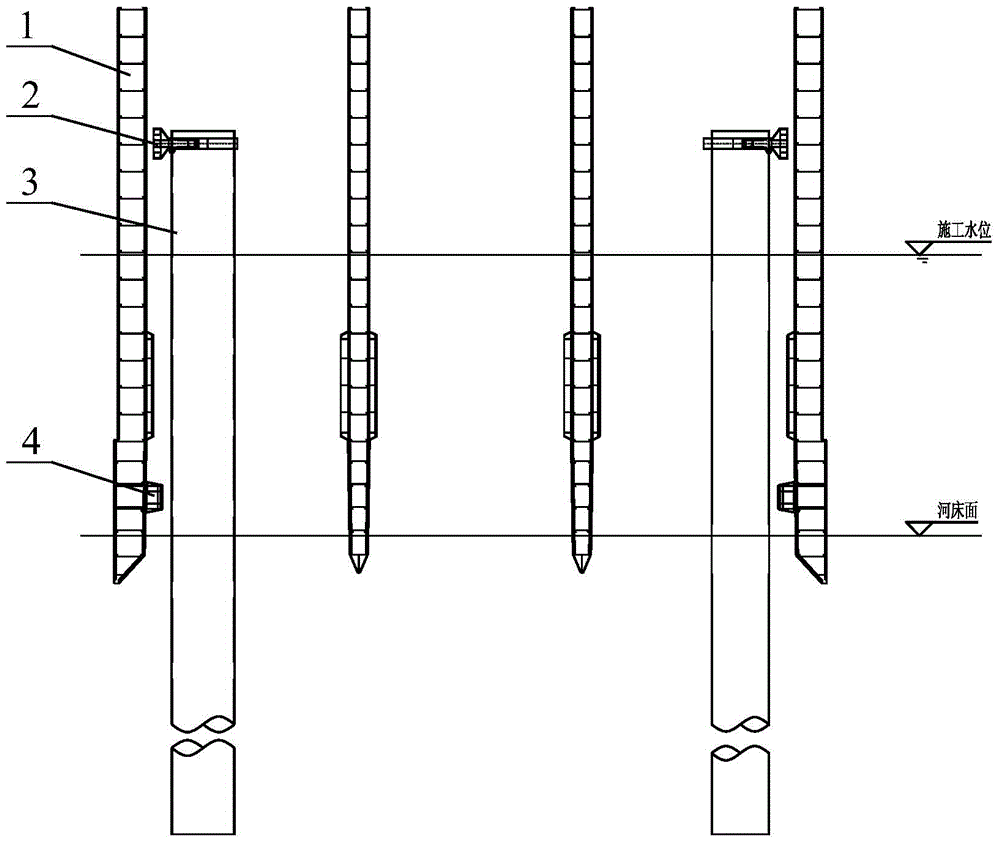

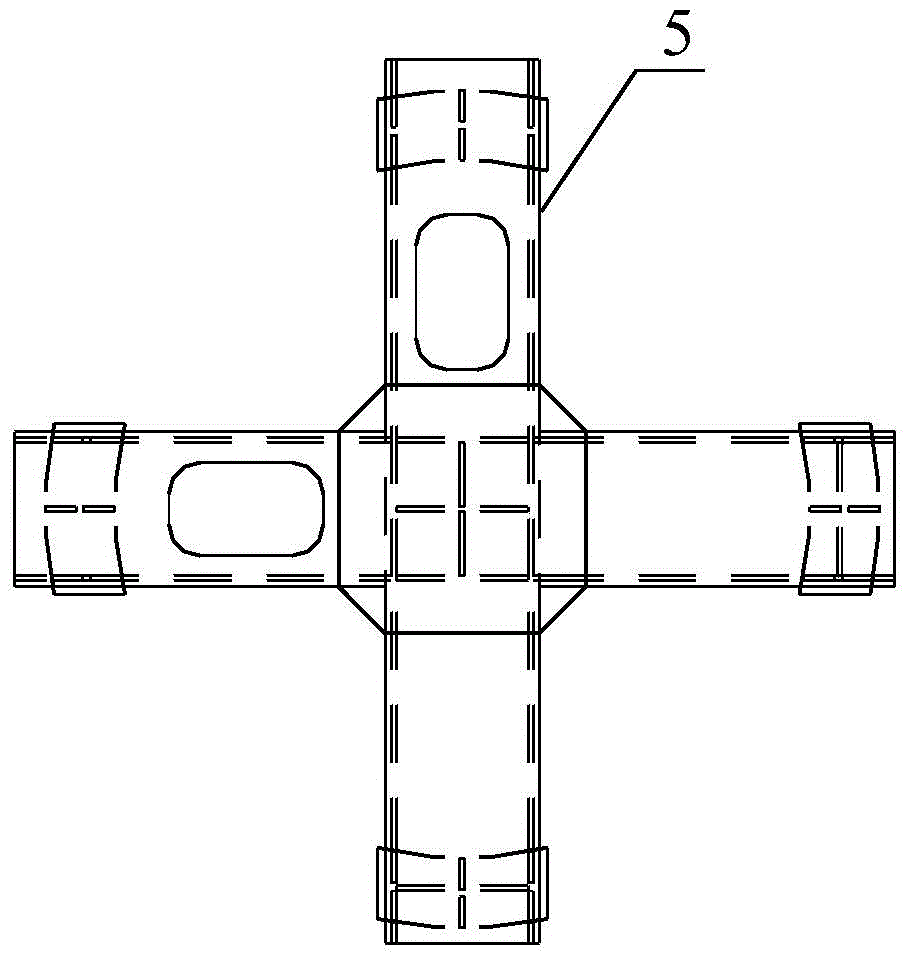

Guidance method and device for steel caisson positioning

ActiveCN104988940BMake sure to sink verticallyPrecise positioningCaissonsBridge engineeringEngineering

The invention discloses a guiding method and device used for positioning a steel open caisson, and relates to the field of bridge engineering construction. The guiding method comprises the following steps that at least four support anchoring piles and at least four cruciform beams are made, and each cruciform beam is provided with accommodating cavities; all support anchoring piles are vertically knocked and positioned into a pier well hole of the steel open caisson in a plug-in manner, the top of each support anchoring pile is fixed with one cruciform beam, and the interior of each accommodating cavity is provided with a top bracing device; and the steel open caisson is assembled in the pier well hole. Water is injected into a separation chamber of the steel open caisson, when the steel open caisson is in a vertical state, water injection is stopped, each top bracing device supports the inner wall of the steel open caisson, water injection is continued, the steel open caisson goes down, and the top bracing devices are dynamically adjusted to make the steel open caisson maintain a vertical state. According to the invention, the steel open caisson can vertically go down, and can be positioned accurately, synchronous operation can be achieved, process transformation is reduced, construction interference is reduced, water area occupied by construction is reduced, influence on river navigation is reduced, and the guiding method and device used for positioning the steel open caisson are beneficial to construction operations in narrow river areas.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

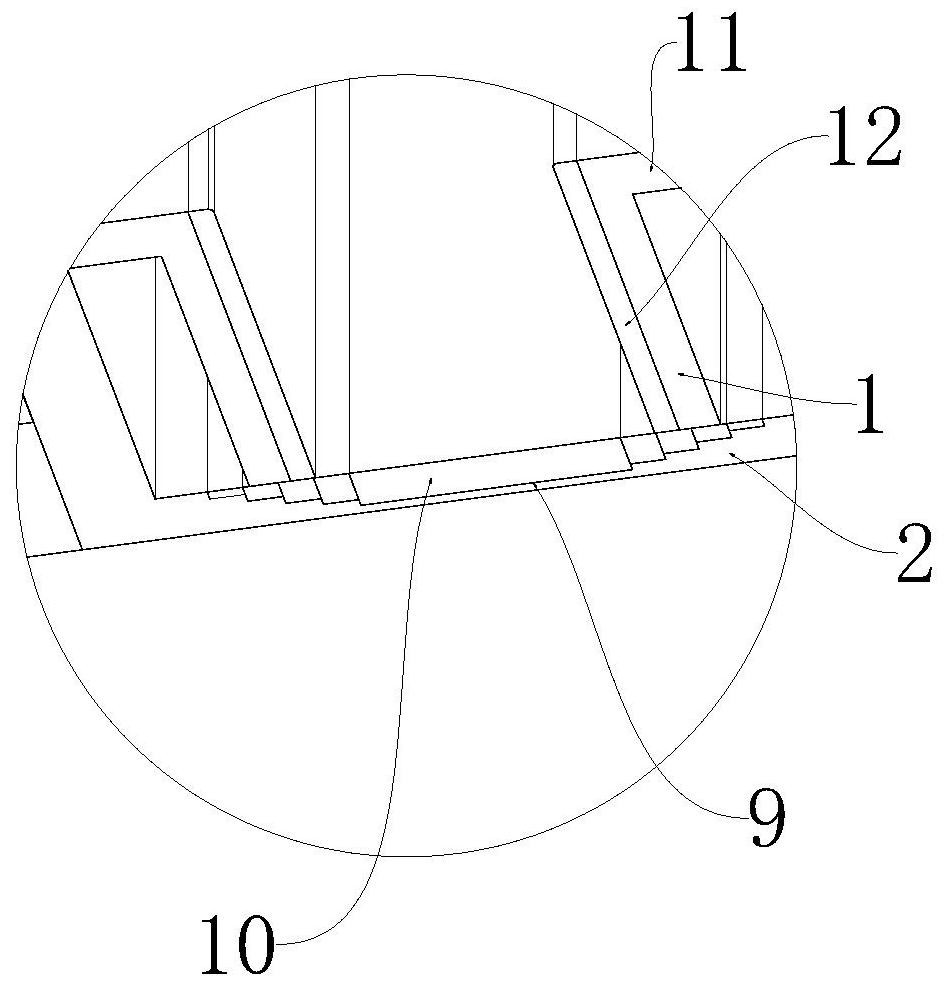

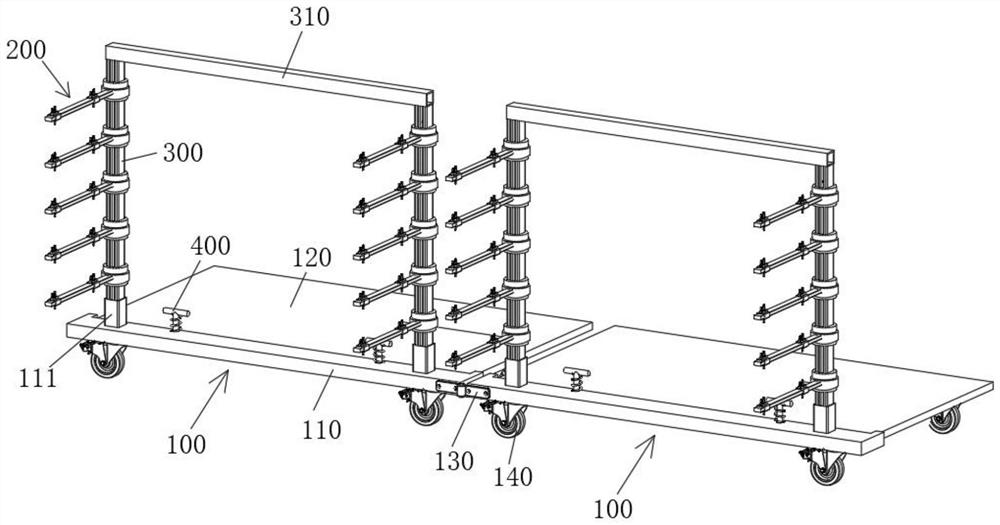

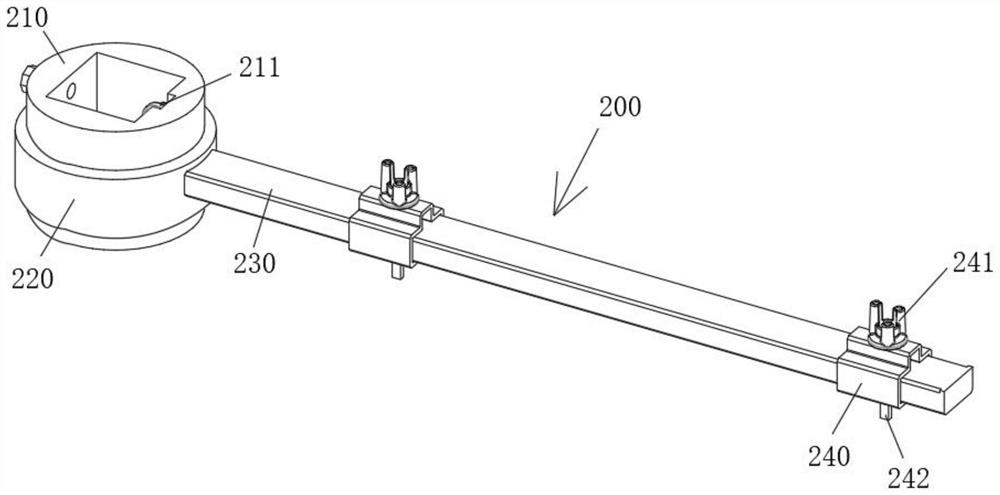

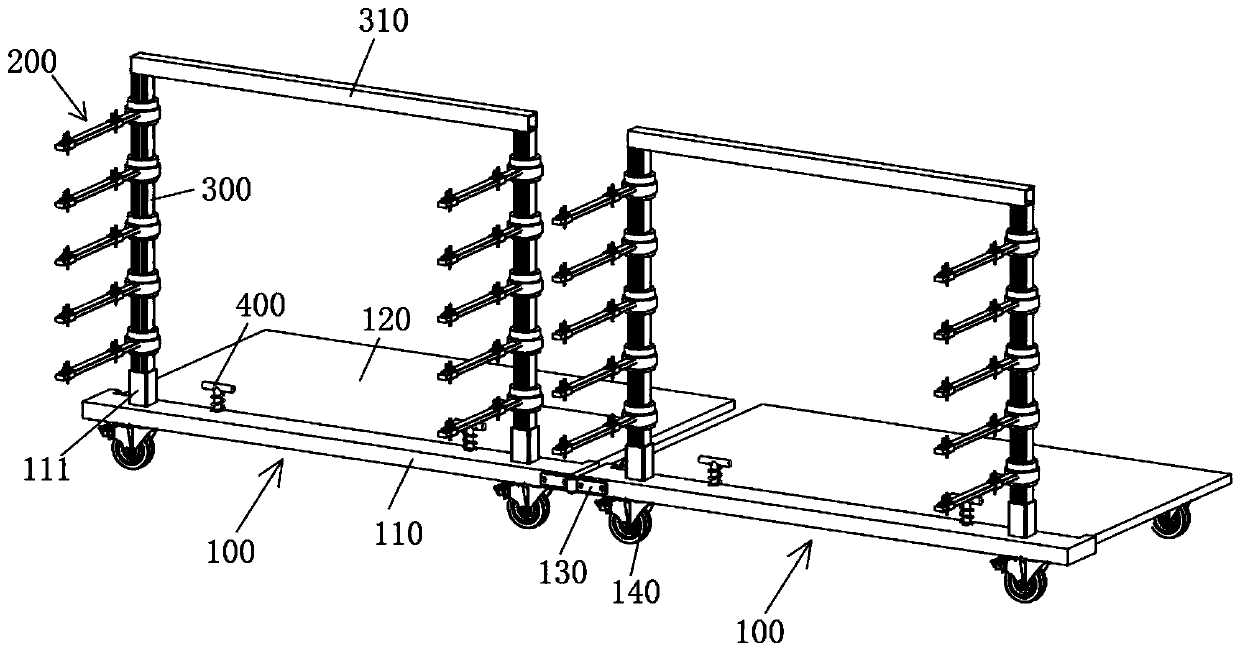

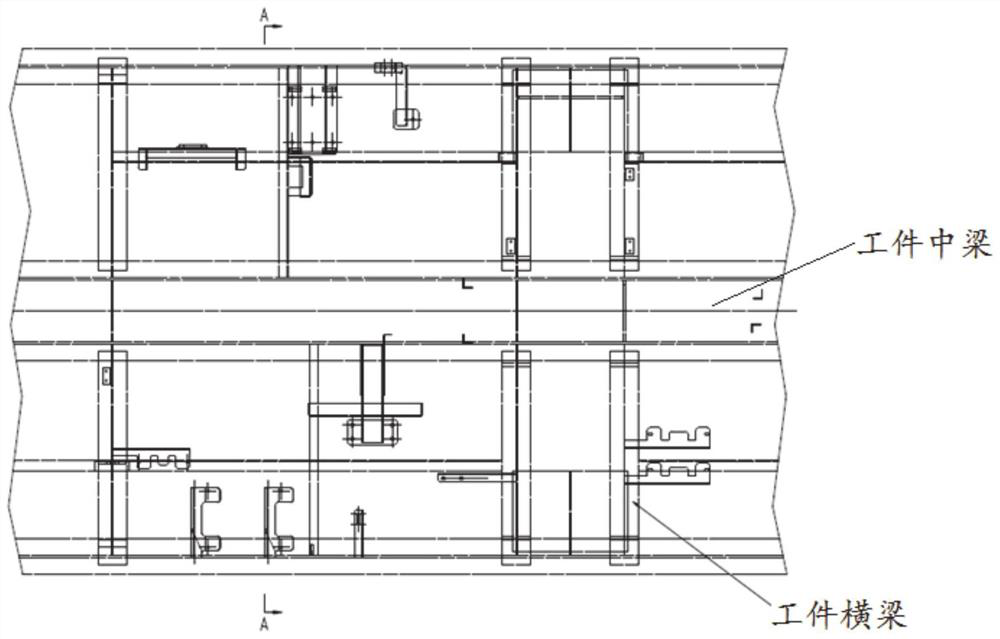

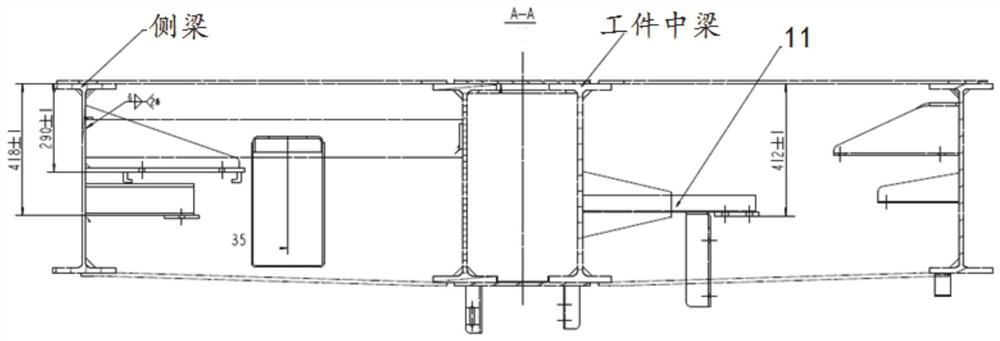

A modular assembly tooling for flat car underframe accessories and its use method

ActiveCN112428228BEasy to installEasy to operateWork benchesStructural engineeringMechanical engineering

The invention discloses a modular assembly and use method for attachments of flat car underframes, which solves the problem of limited installation space for the attachments of flat car underframes in the prior art, and has the beneficial effect of improving the installation efficiency of the attachments. The specific plan is as follows: a modular assembly tooling for the accessories of the flat car chassis, including a fixed lower platform, which is set on the ground or fixed on the frame; the upper and lower platform can be lifted and lowered, and the upper and lower platform can be lifted relative to the fixed lower platform. The lifting upper platform includes the tooling main beam, which fixes multiple tooling beams, and there is a set distance between two adjacent tooling beams to facilitate people's entry or exit. The lifting upper platform is set for multiple positioning of accessories Seats; supporting seats are arranged on both sides of the fixed lower platform, and the supporting seats on both sides are respectively used to support the two sides of the lower surface of the workpiece.

Owner:CRRC SHANDONG CO LTD

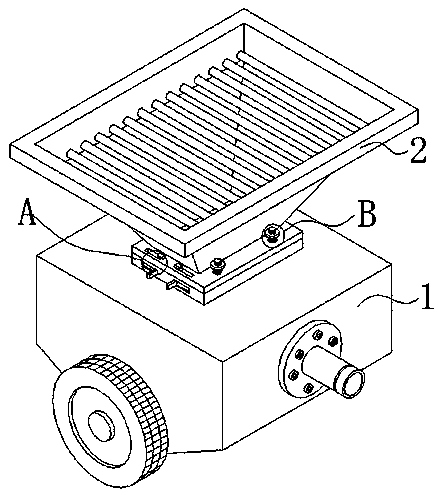

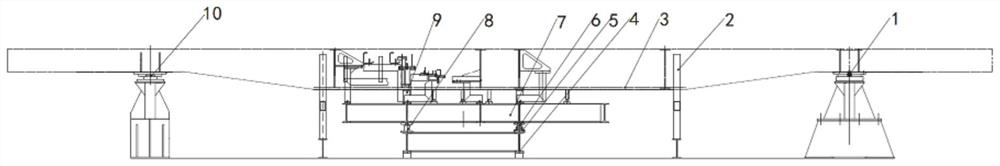

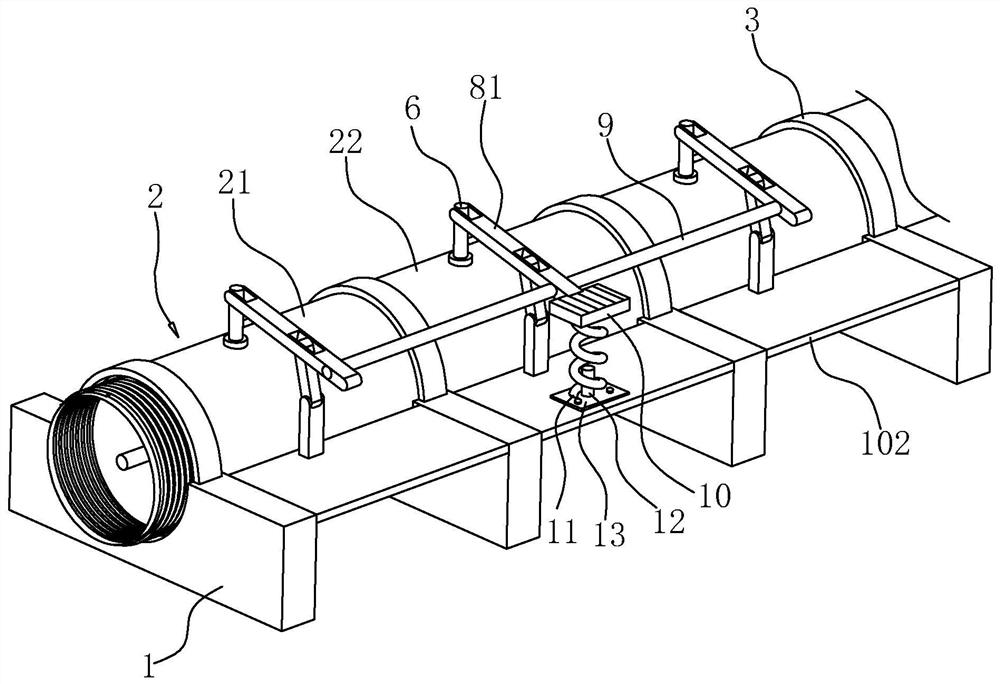

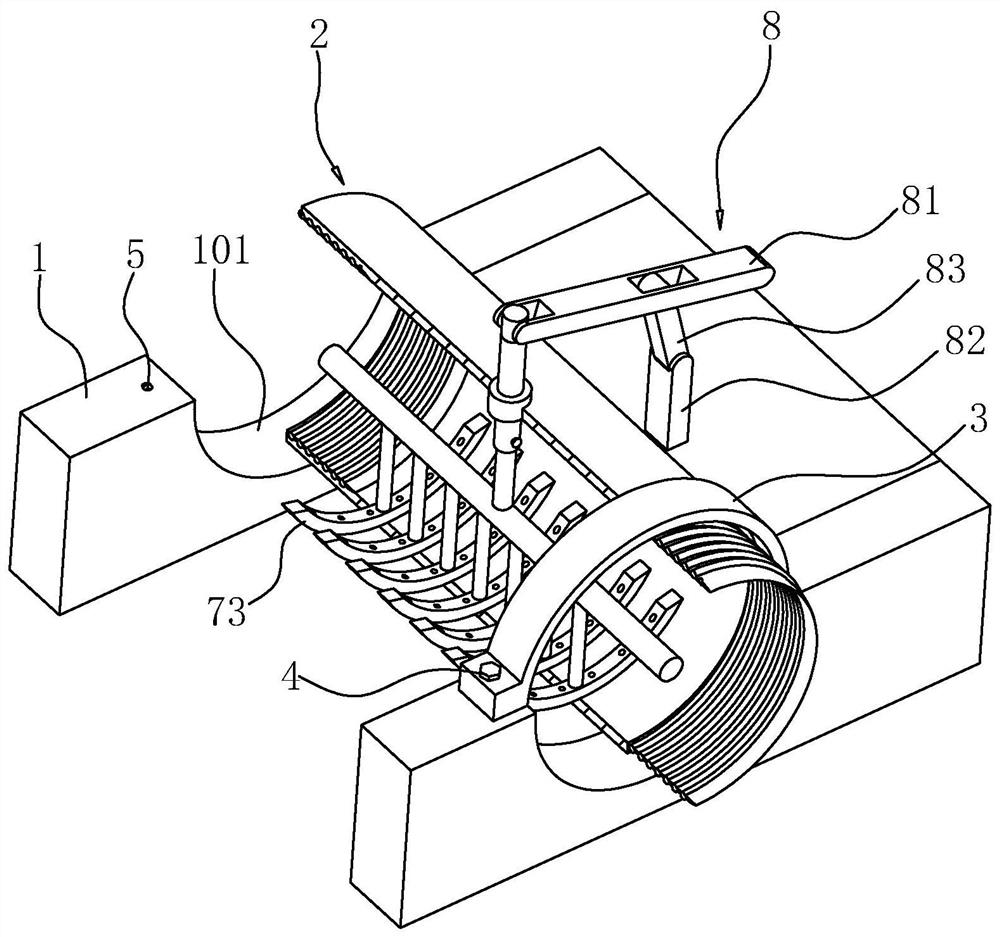

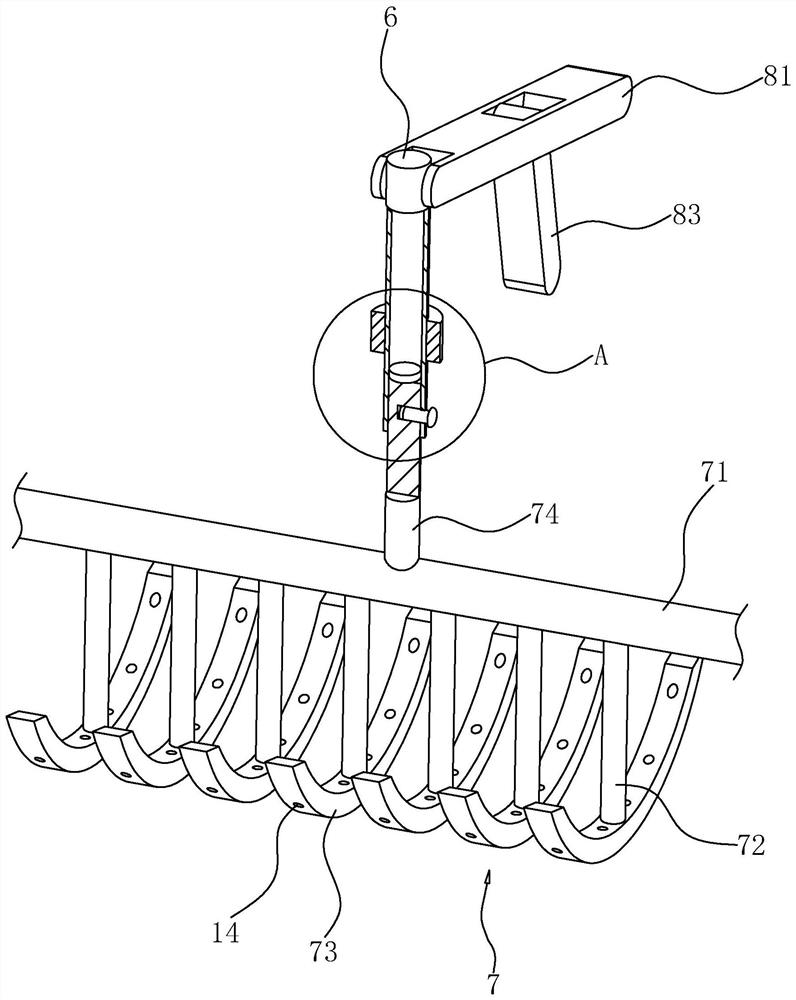

Sponge type urban rainwater pipeline drainage dredging system

InactiveCN111877503AAchieve initial positioningConvenient for initial positioningSewer cleaningGrain treatmentsSludgeWater resource management

The invention relates to the technical field of urban drainage, in particular to a sponge type urban rainwater pipeline drainage dredging system. The sponge type urban rainwater pipeline drainage dredging system is characterized by comprising a plurality of pipelines spliced in sequence and bases used for supporting the pipelines, wherein every two adjacent pipelines are detachably connected; fixing pieces used for fixing the pipelines to the base are arranged between the pipelines and the bases; dredging devices used for dredging pipeline sludge are arranged on the pipelines, each dredging device comprises a lifting sleeve movably penetrating through the inner wall and the outer wall of the top of the corresponding pipeline in the vertical direction and a dredging assembly connected to the lifting sleeve, and the dredging assemblies are located in the pipelines; and driving assemblies used for driving the lifting sleeves to ascend and descend are arranged between the bases and the pipelines. The sponge type urban rainwater pipeline drainage dredging system can reduce the situation that the pipelines are blocked due to the fact that a large amount of sludge deposits in the rainwater pipelines, and improves the drainage effect of the rainwater pipelines.

Owner:深圳市德嘉工程管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com