Patents

Literature

2933results about How to "Easy to pull" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

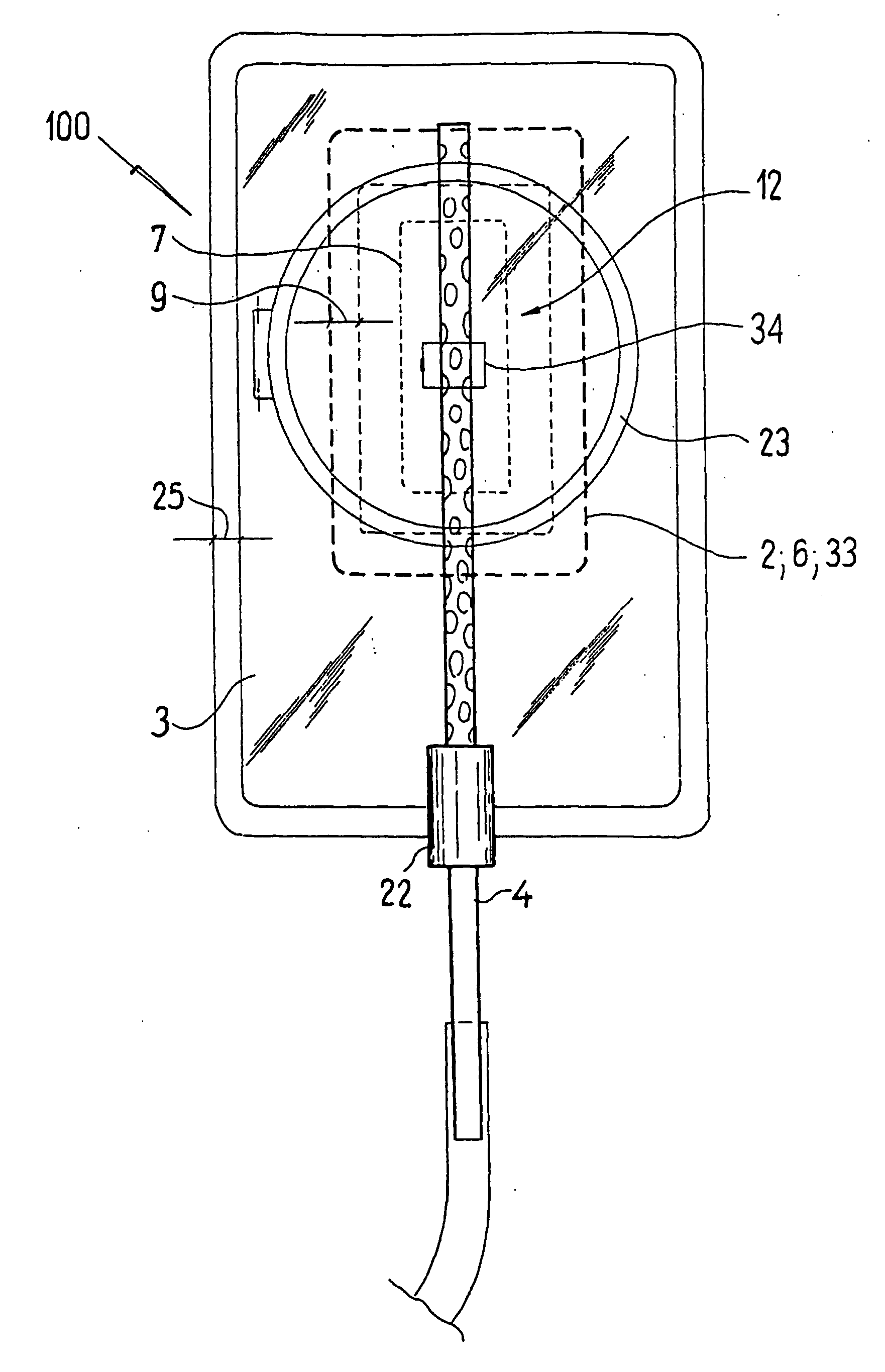

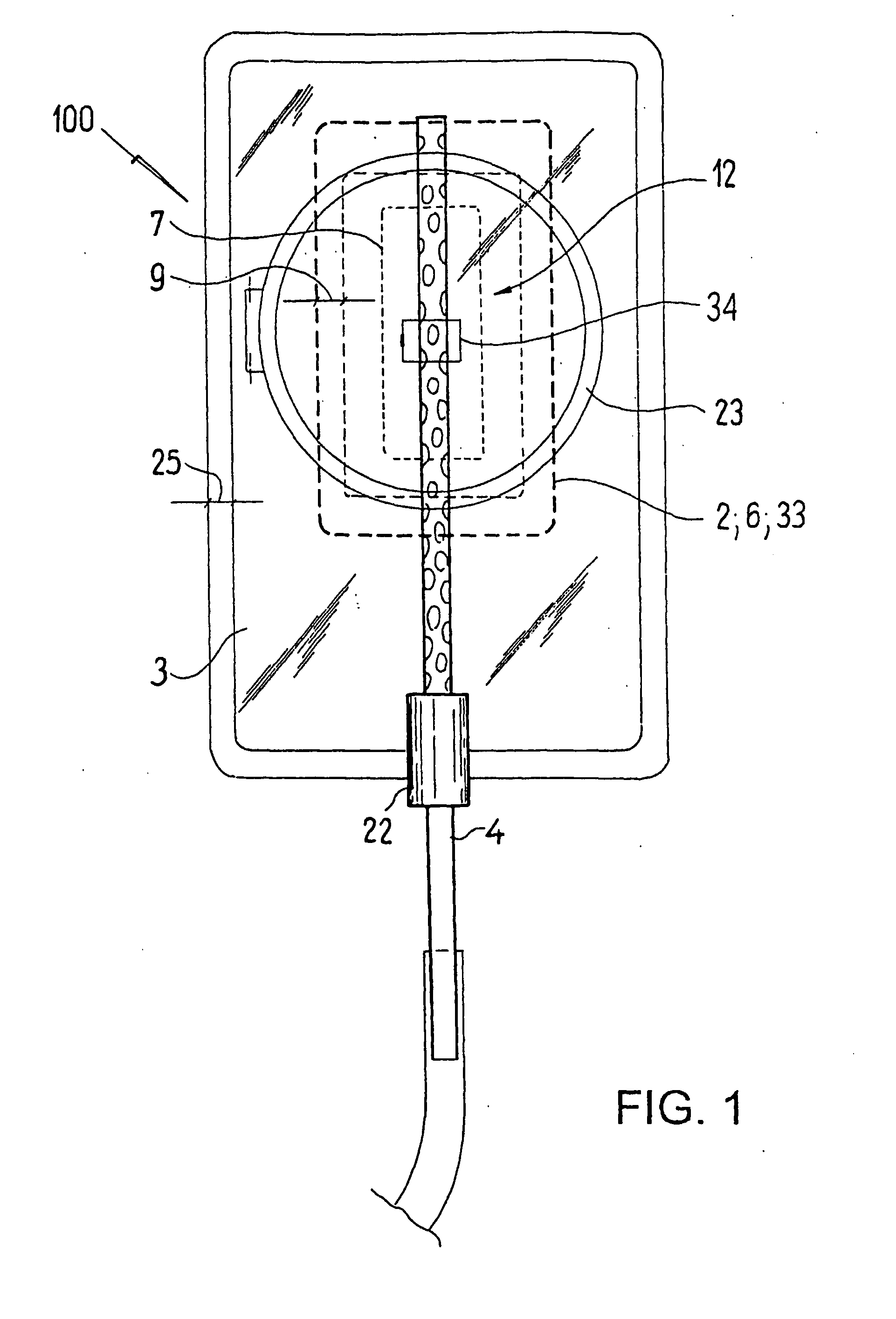

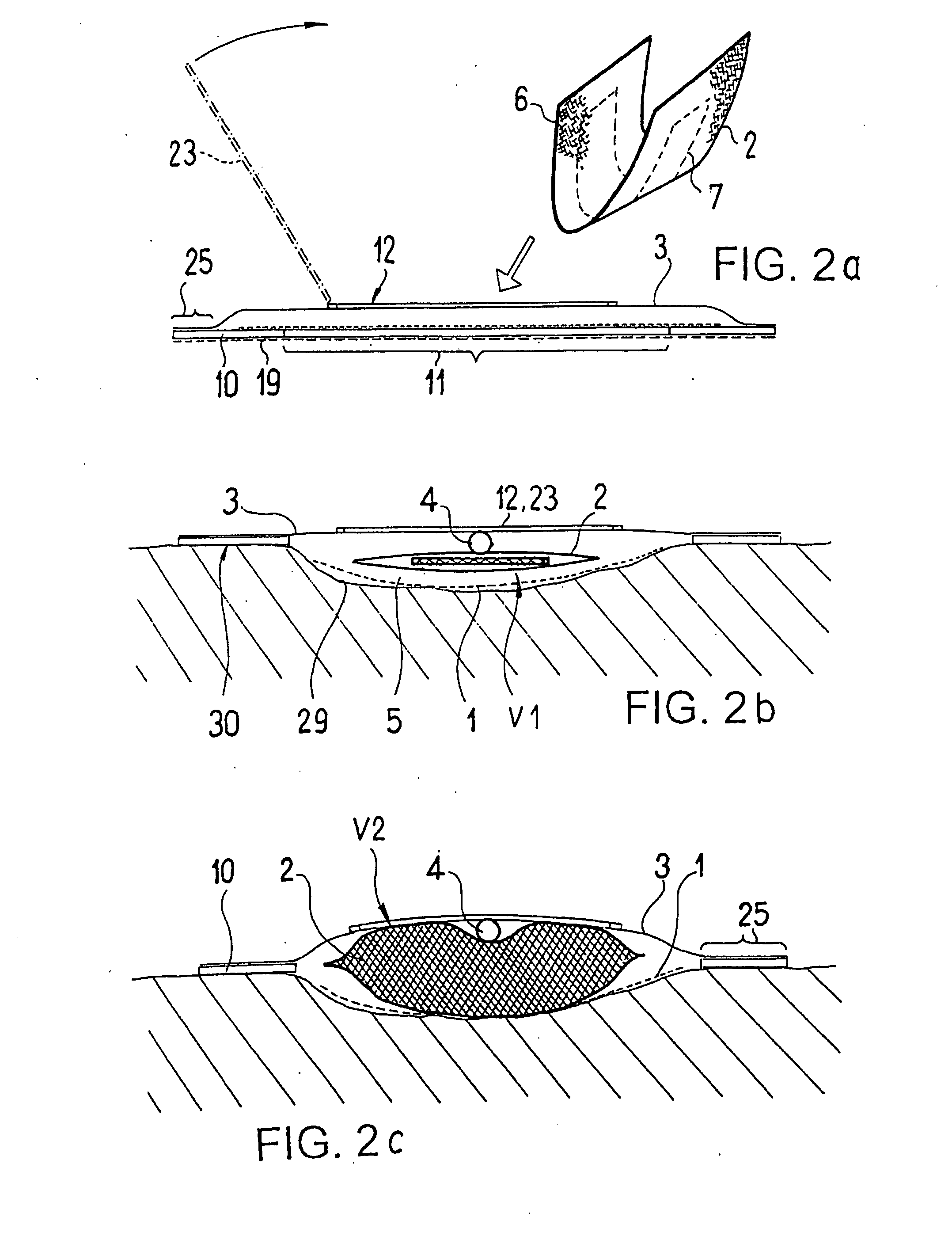

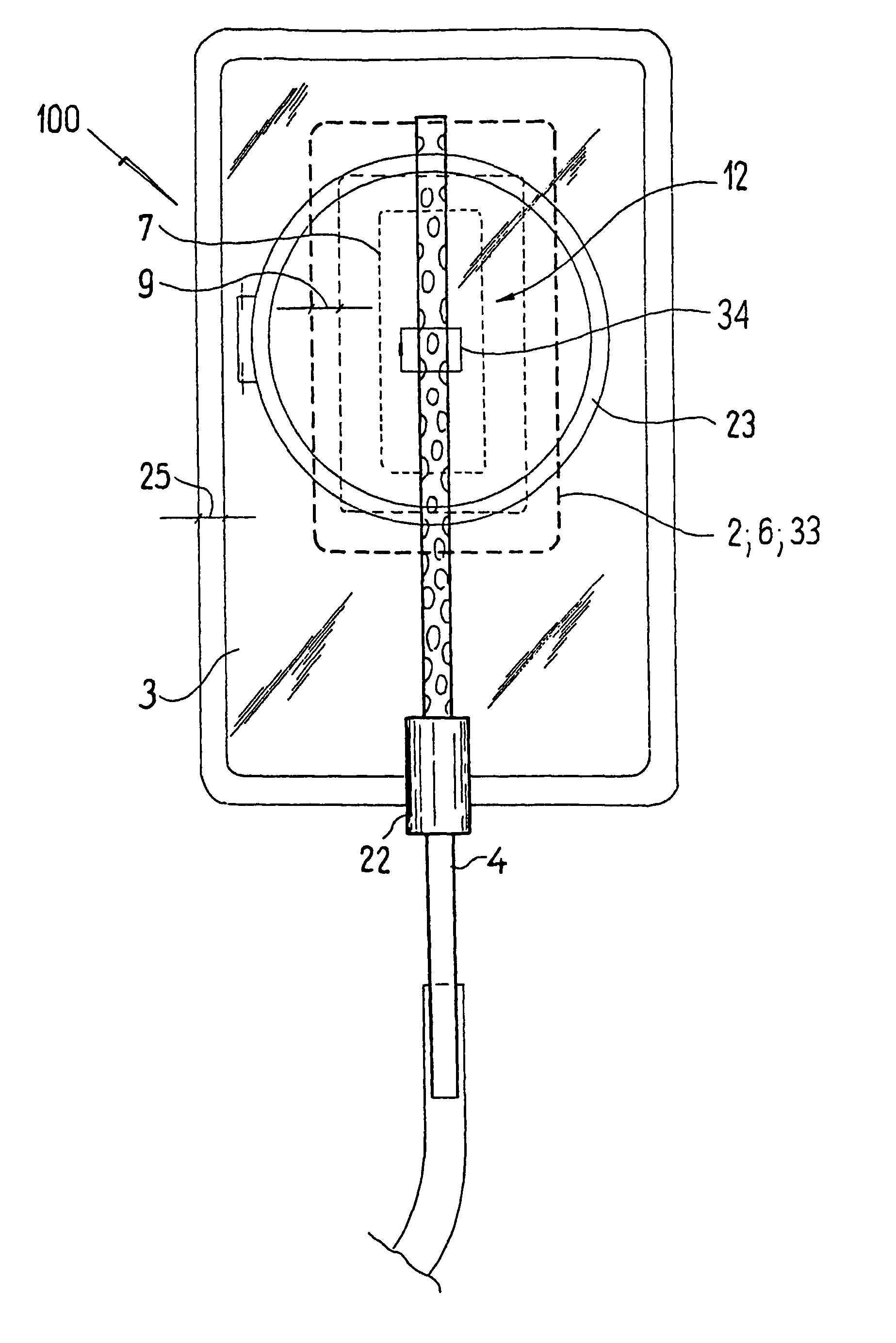

Drainage Device for the Treating Wounds Using a Reduced Pressure

ActiveUS20080119802A1Cost-effectiveSimple designSurgical needlesWound drainsSkin surfaceDrainage tubes

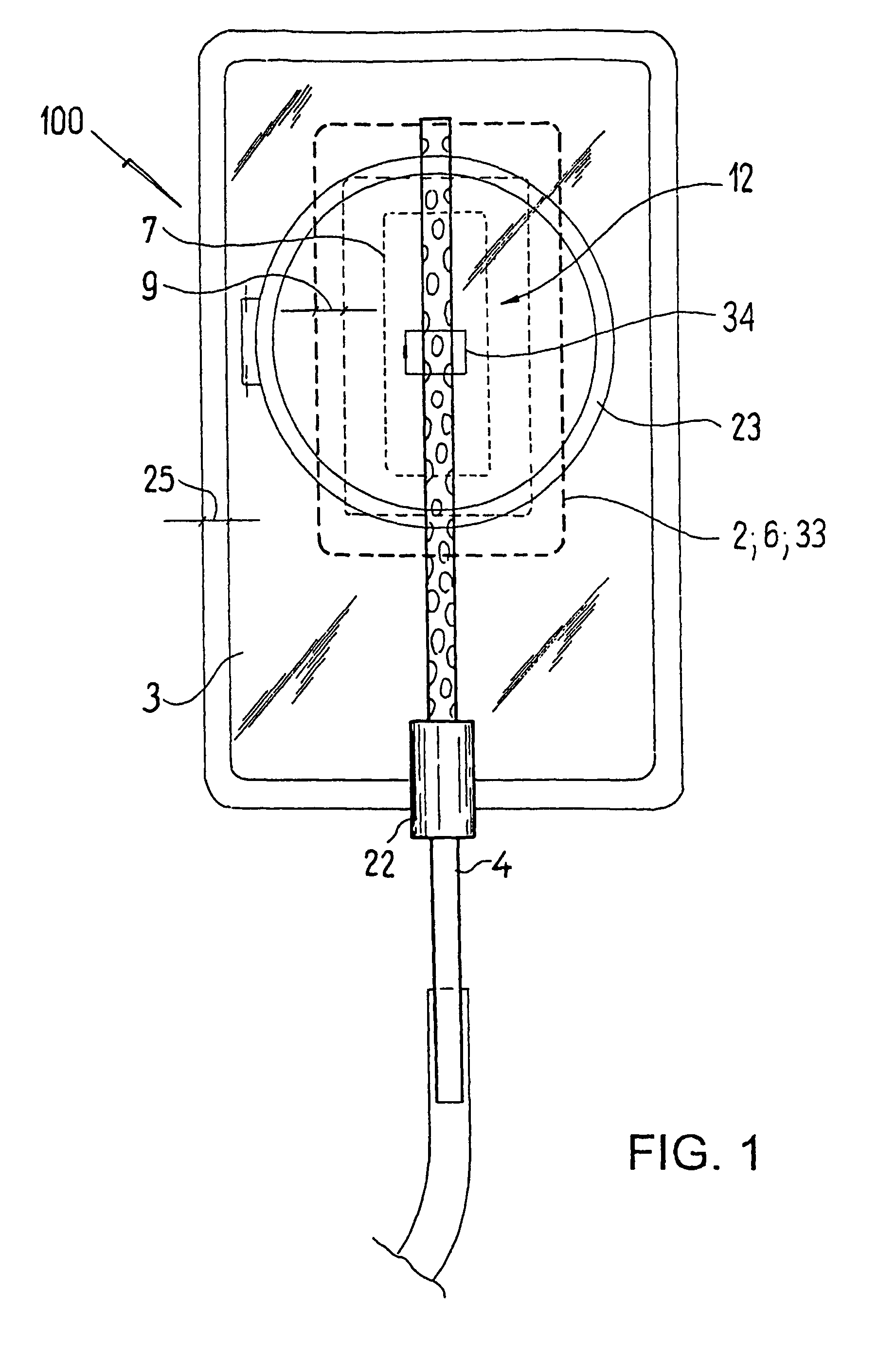

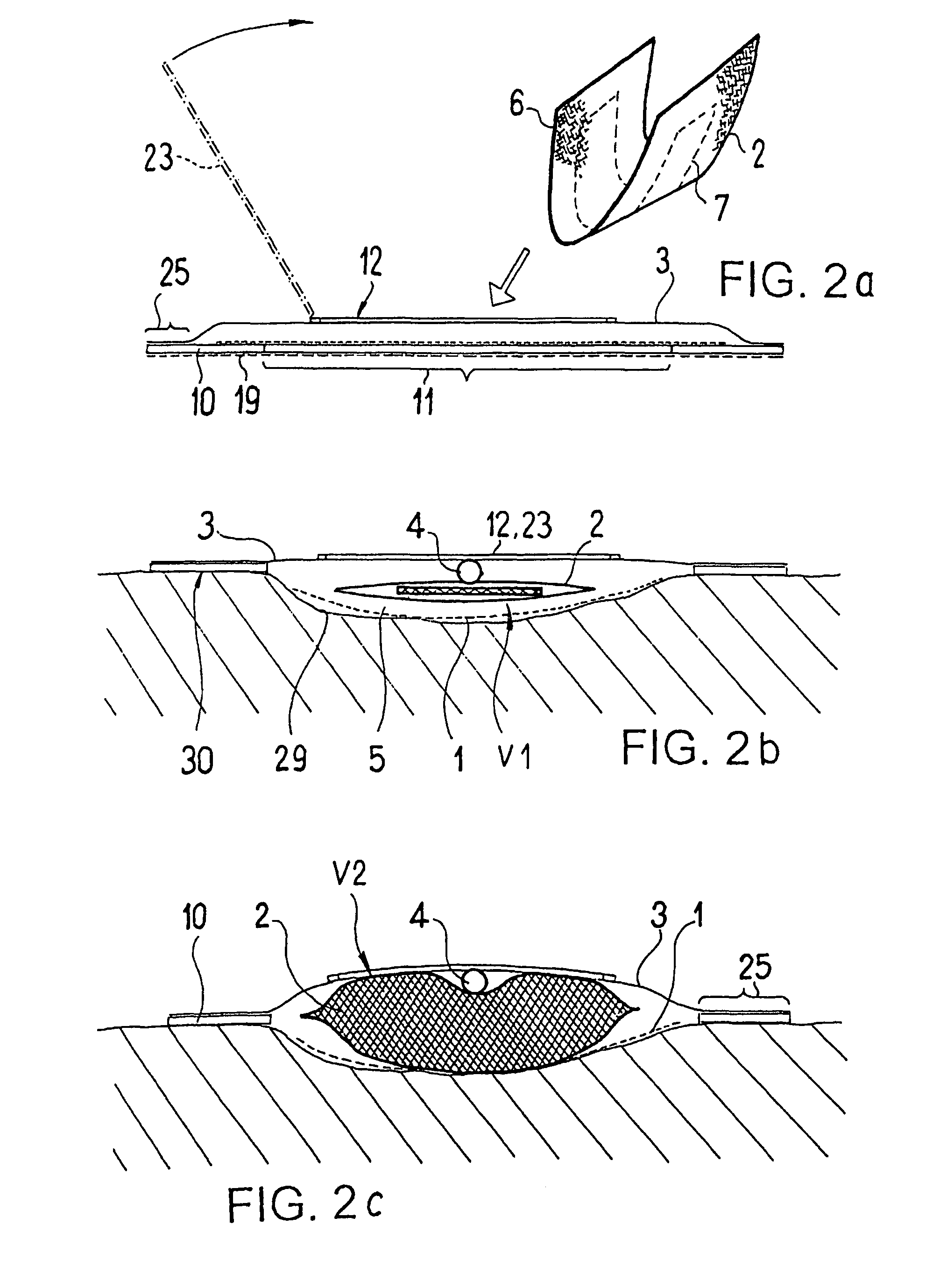

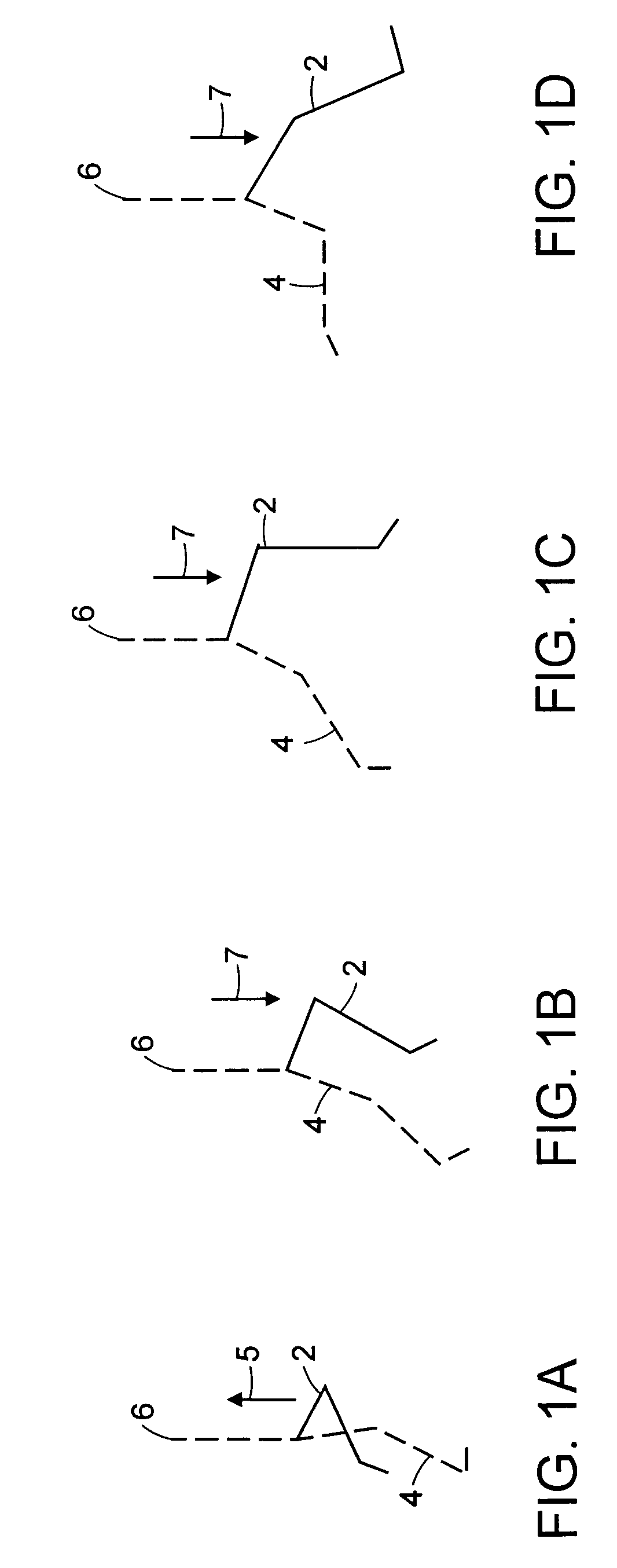

The invention relates to a drainage device (100) for the treatment of wounds using reduced pressure, comprising (a) a gas-type wound-covering element (3), which, in the state in contact with the body of the patient, is fastened cohesively at the skin surface around the region of the wound and forms a sealed wound space, remaining between the respective wound and the wound-covering element (3); (b) at least one drainage tube (4), which can be connected to means generating the reduced pressure and can be inserted into the wound space approximately parallel to the wound-covering element (3); and (c) at least one absorption body (2) in the form of at least one layer (7) of a textile section (33), which is interspersed with super-absorbing particles and enclosed in an envelope. Due to the size of the pores of the envelope, the absorbed wound secretions remain within the absorption body (2) and, with that, underneath the wound-covering element (3) until the absorption body is removed from the wound space. An air opening (34) is provided for the wound-covering element (3).

Owner:BR ENTWICKLUNGS

Drainage device for treating wounds using a reduced pressure

The invention relates to a drainage device (100) for the treatment of wounds using reduced pressure, comprising (a) a gas-type wound-covering element (3), which, in the state in contact with the body of the patient, is fastened cohesively at the skin surface around the region of the wound and forms a sealed wound space, remaining between the respective wound and the wound-covering element (3); (b) at least one drainage tube (4), which can be connected to means generating the reduced pressure and can be inserted into the wound space approximately parallel to the wound-covering element (3); and (c) at least one absorption body (2) in the form of at least one layer (7) of a textile section (33), which is interspersed with super-absorbing particles and enclosed in an envelope. Due to the size of the pores of the envelope, the absorbed wound secretions remain within the absorption body (2) and, with that, underneath the wound-covering element (3) until the absorption body is removed from the wound space. An air opening (34) is provided for the wound-covering element (3).

Owner:BR ENTWICKLUNGS

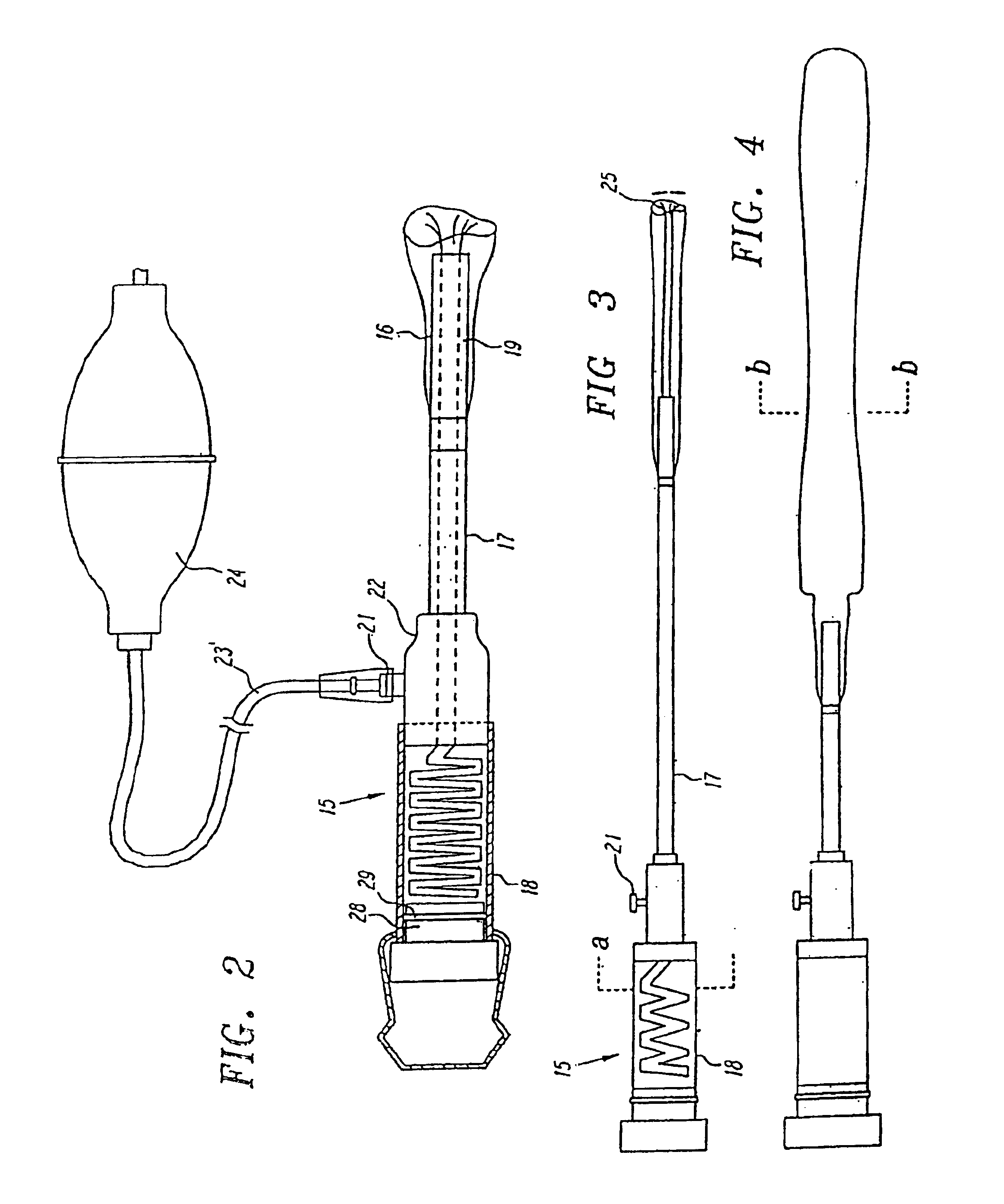

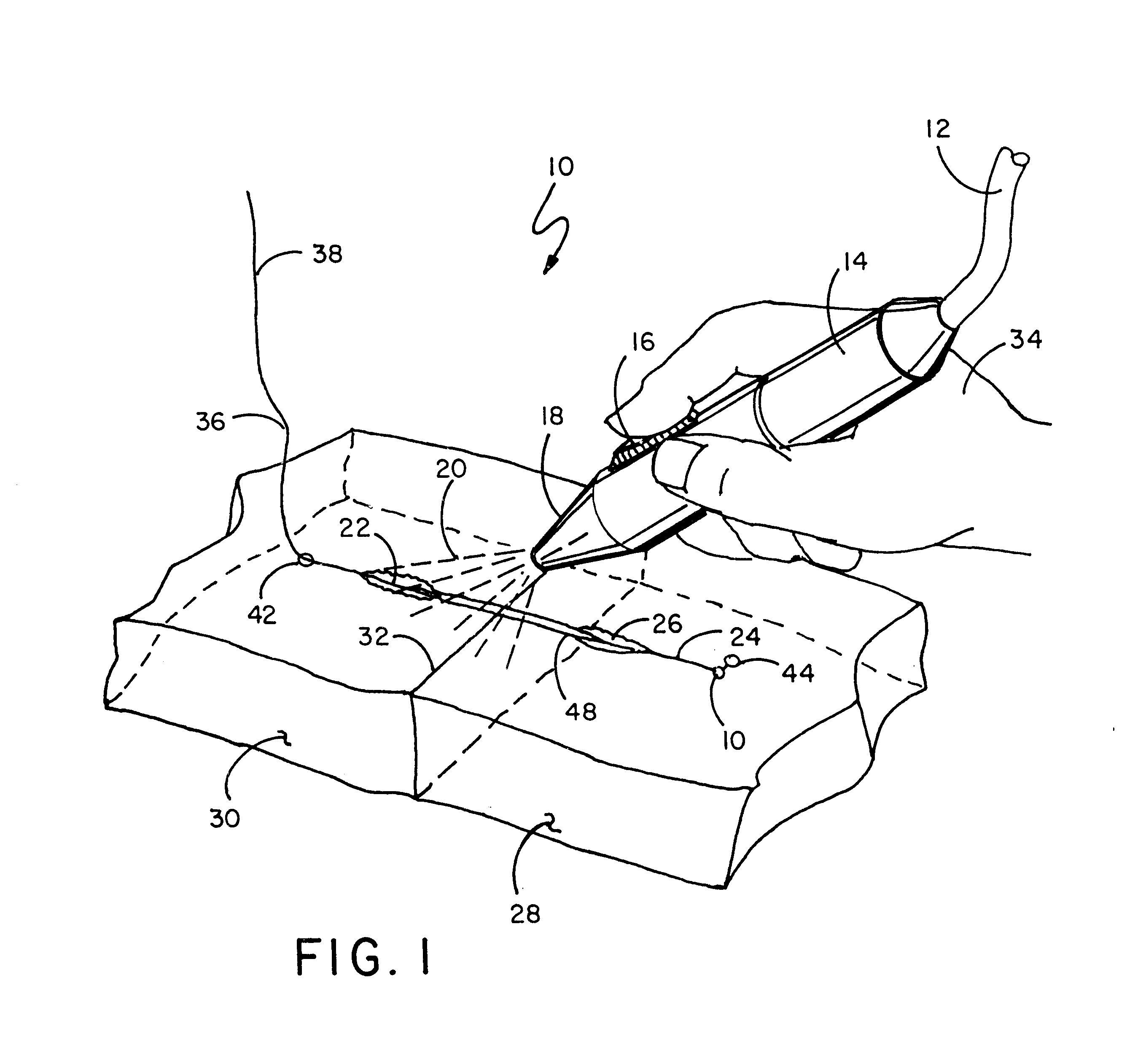

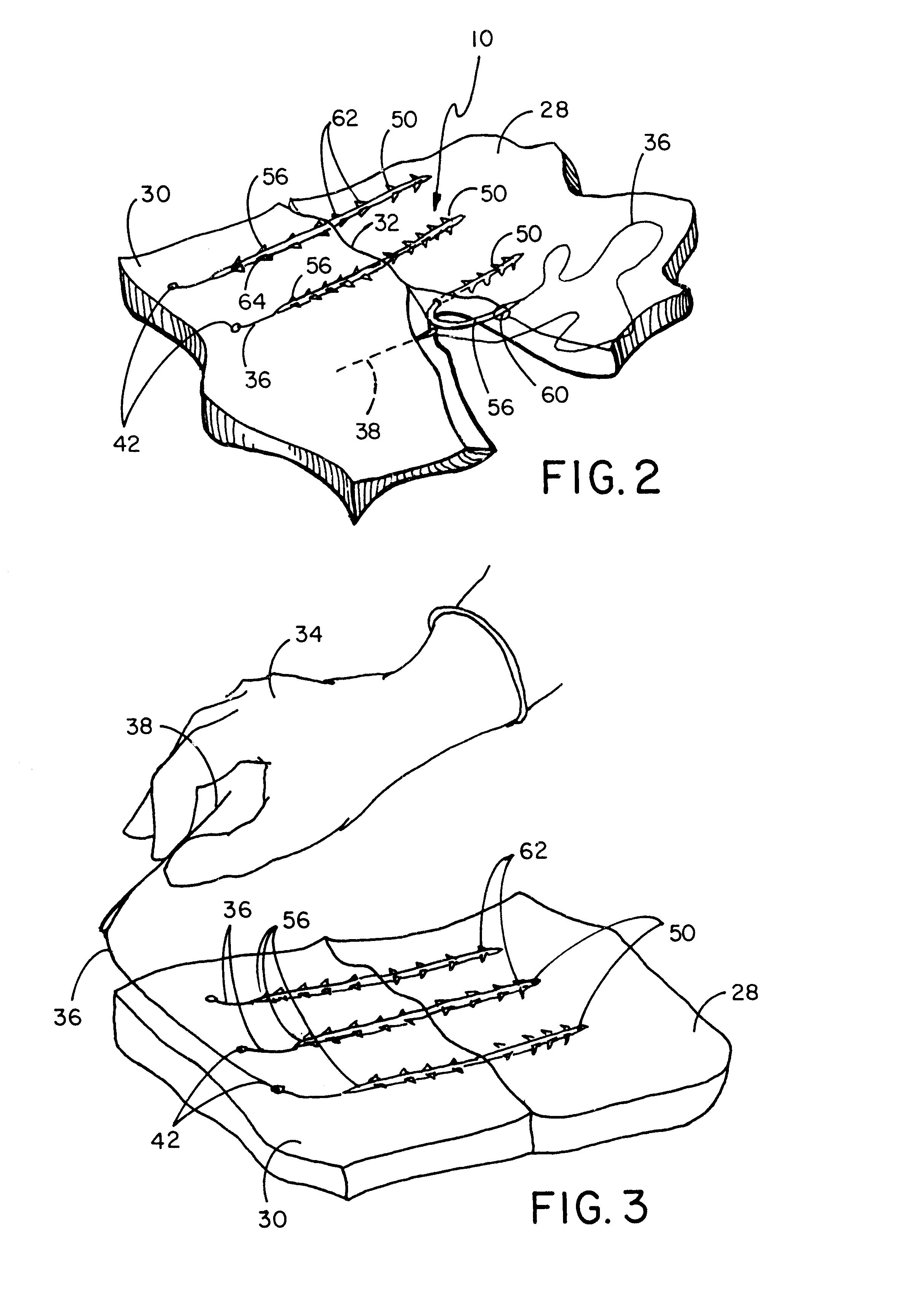

Methods and devices for blood vessel harvesting

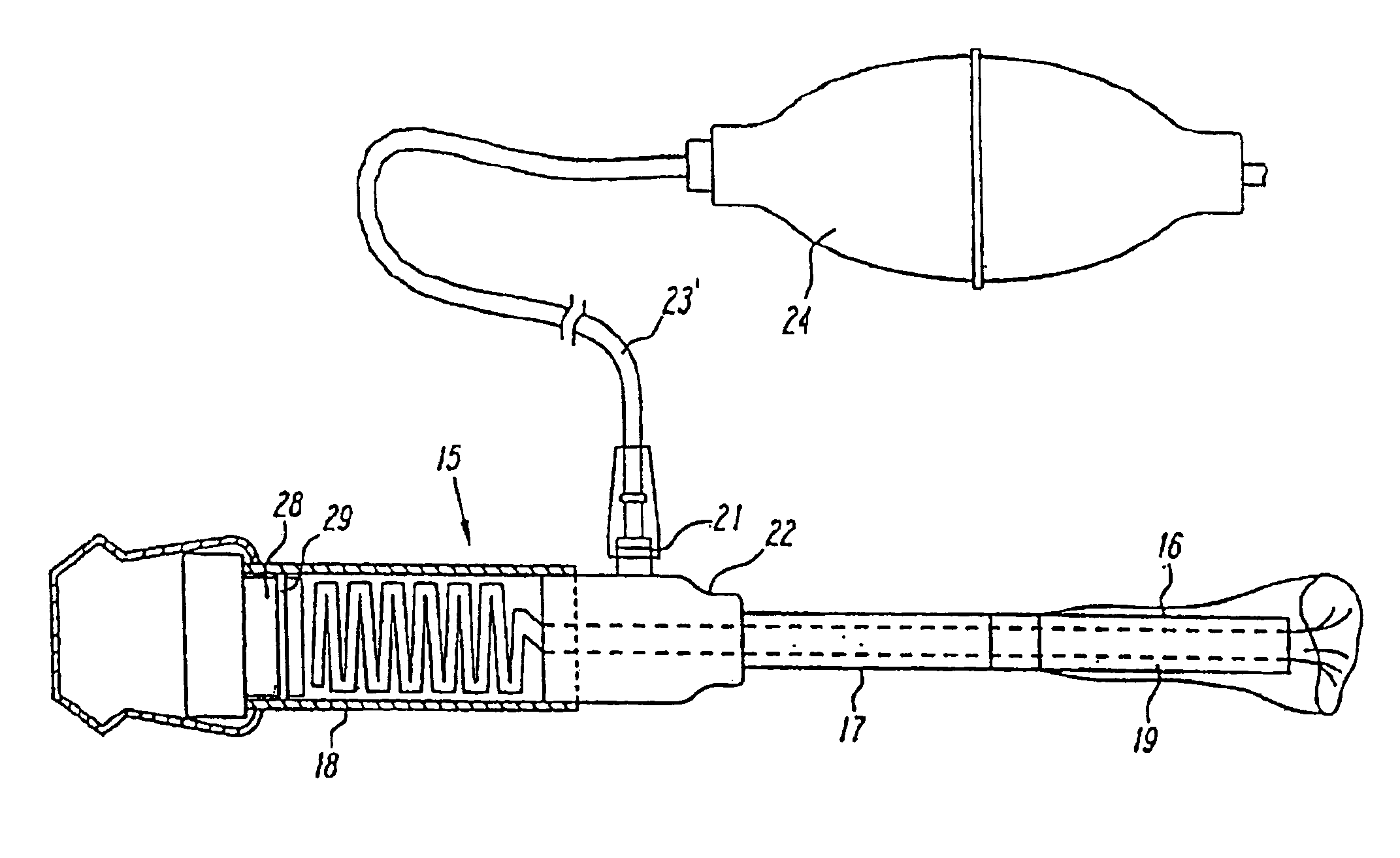

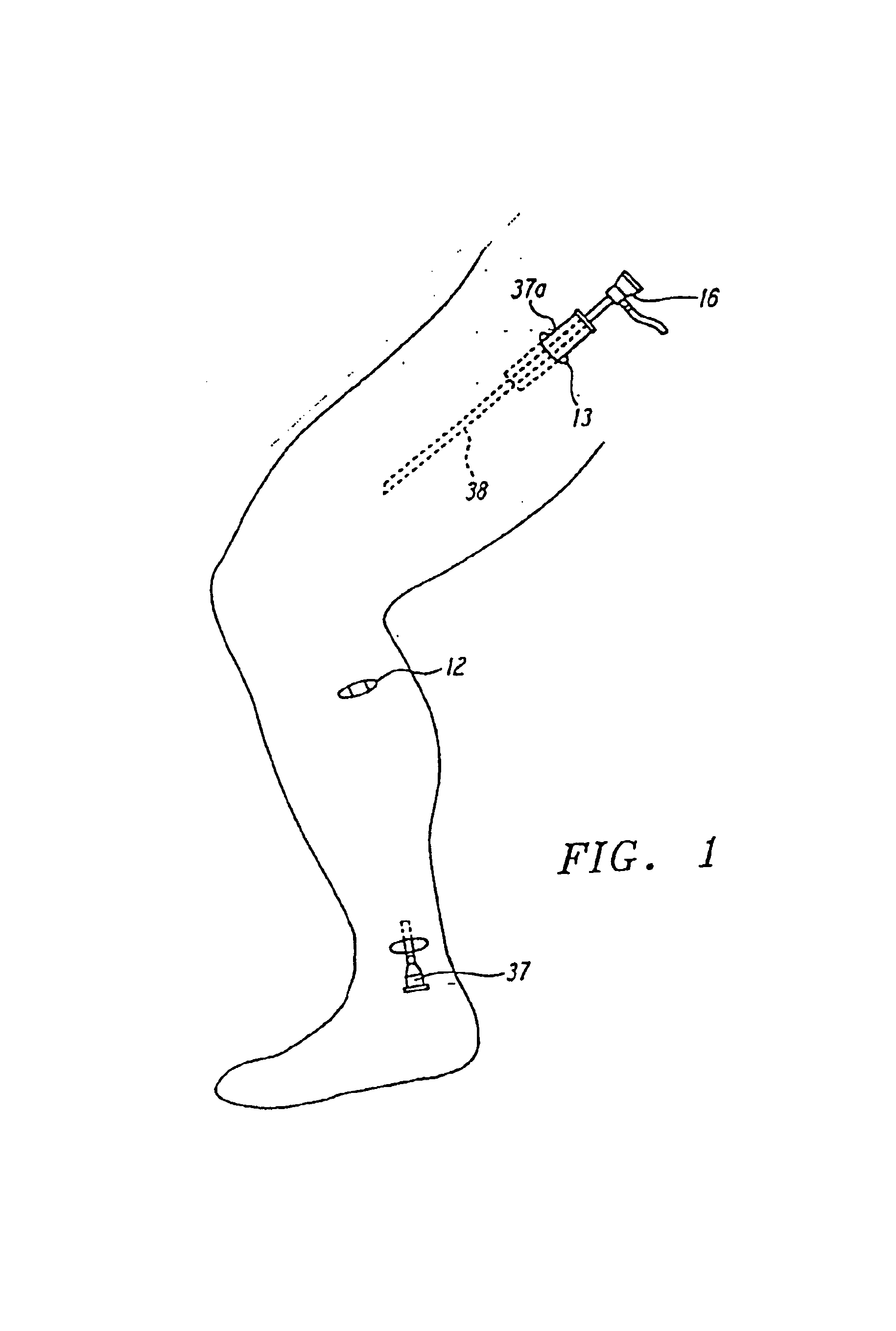

Methods and devices for harvesting veins from the body. The methods and devices allow vein harvesting using laparoscopic procedures. A working space is created over the vein using standard laparoscopic procedures and a side-hooked wire is inserted into the working space and twisted to insert the side-hook under the vein. The wire is then pulled or drawn along the vein to separate the vein from the surrounding tissue. In an alternative embodiment, vein separation is accomplished by threading a soft rubber tube under the vein, grasping the ends of the tube so as to surround the vein, and then pulling the tube along the vein. In other embodiments, the working space is created with everting balloons.

Owner:GEN SURGICAL INNOVATIONS

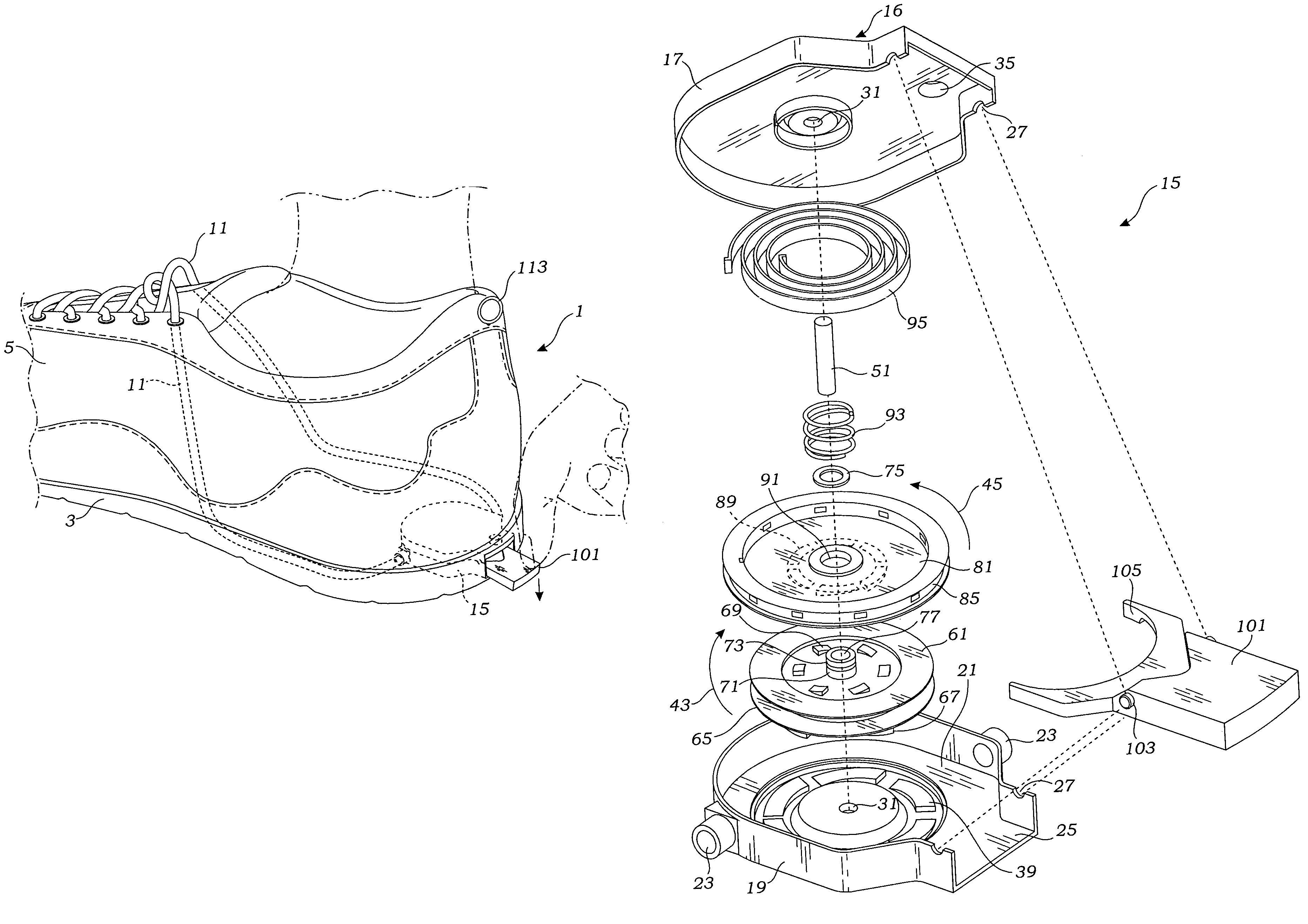

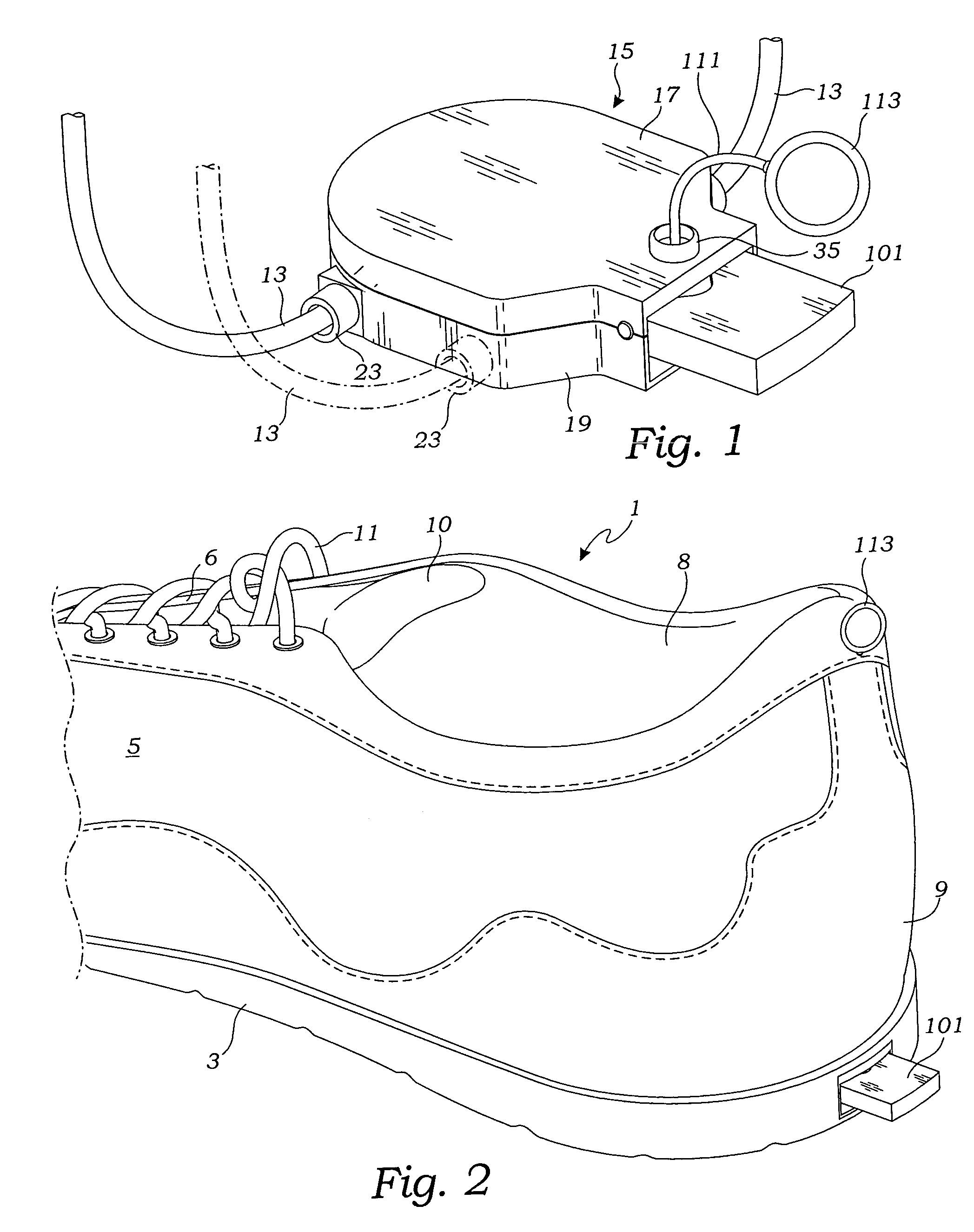

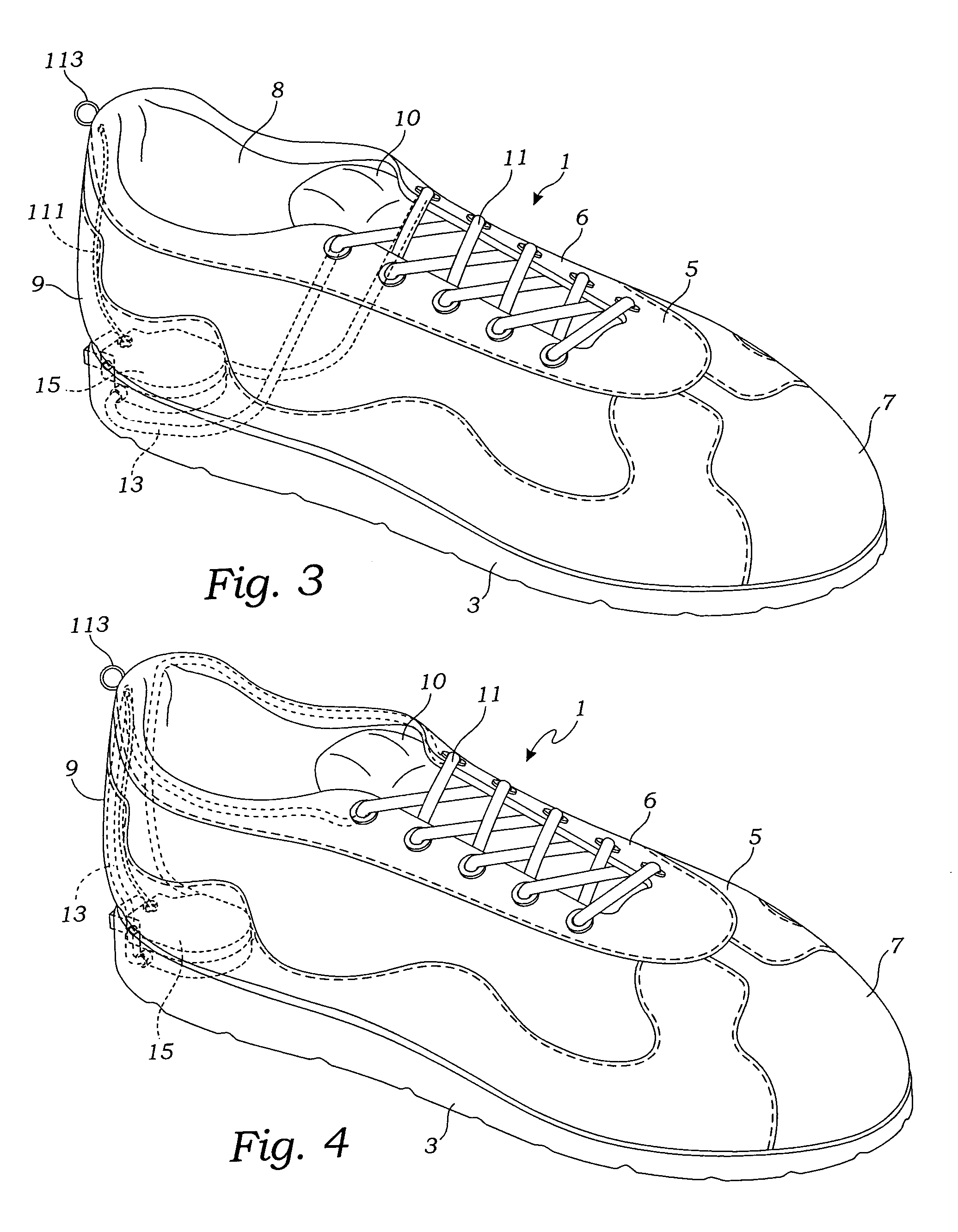

Tightening shoe

ActiveUS7721468B1Easy to pullSimple and inexpensive and easy to useShoe lace fasteningsShoe lacesGear wheel

A tightening shoe is provided with a sole, an upper and crisscrossing laces. The lace ends project into the shoe structure where they are received by a tightening mechanism. The tightening mechanism includes a winding gear for winding the lace ends about its perimeter to withdraw the laces into the tightening mechanism's interior chamber. In addition, the tightening mechanism includes a drive gear which is rotated by a pre-wound tightening cable which is positioned immediately adjacent to the winding gear. Preferably, the winding gear and drive gear are positioned within the shoe's sole so as to rotate about a vertical axis relative to the shoe's structure.

Owner:GREGORY G JOHNSON +1

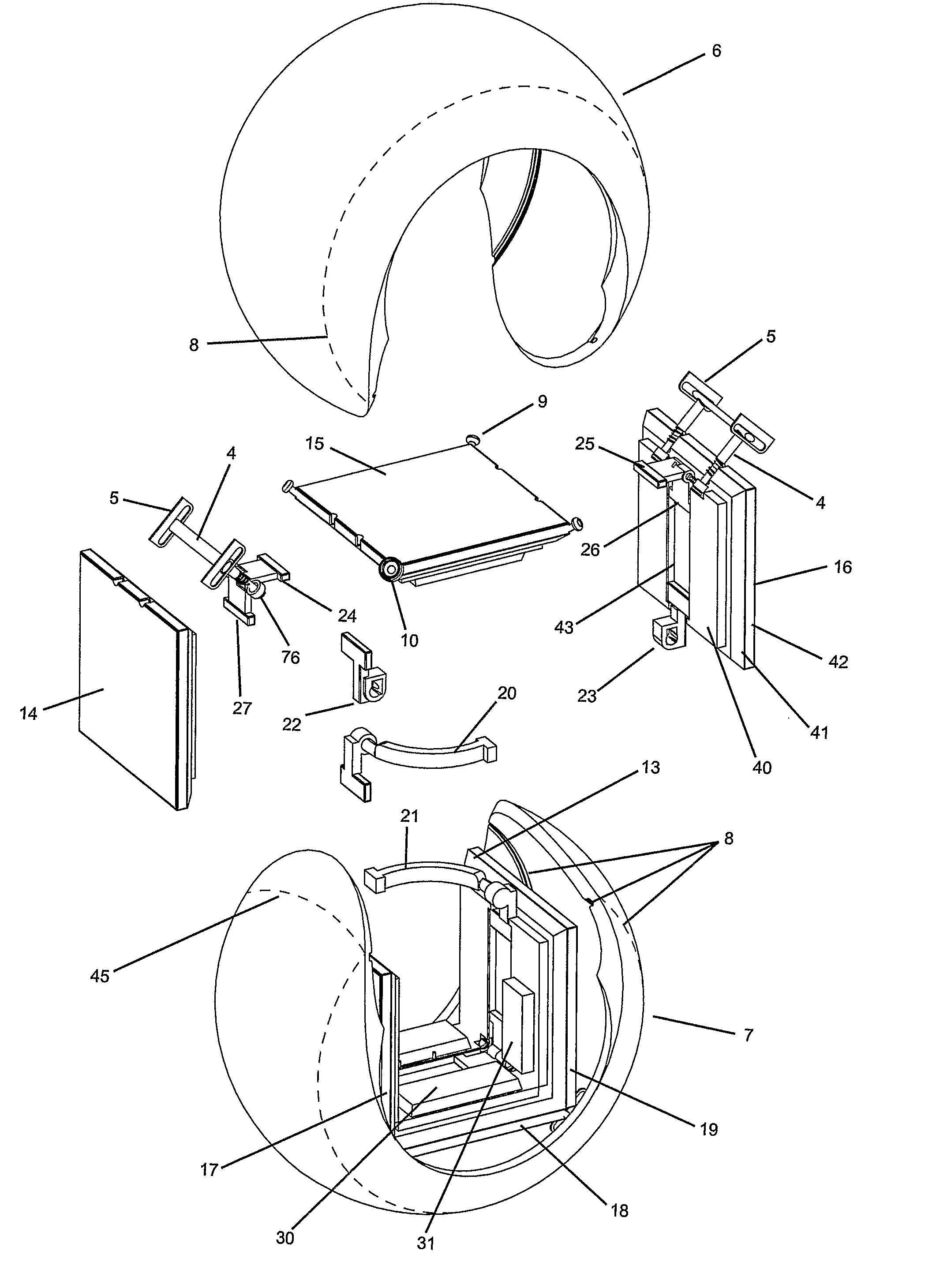

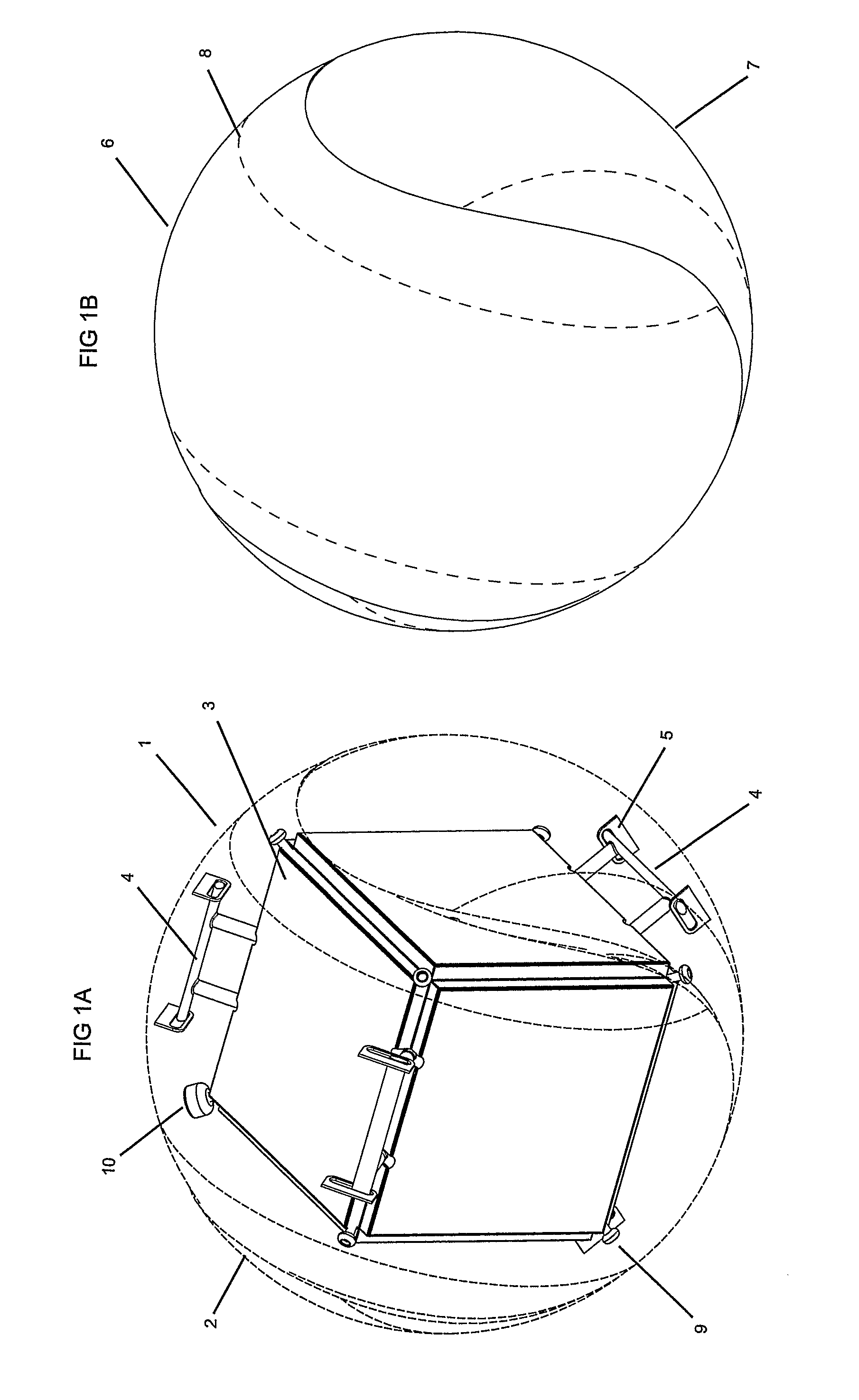

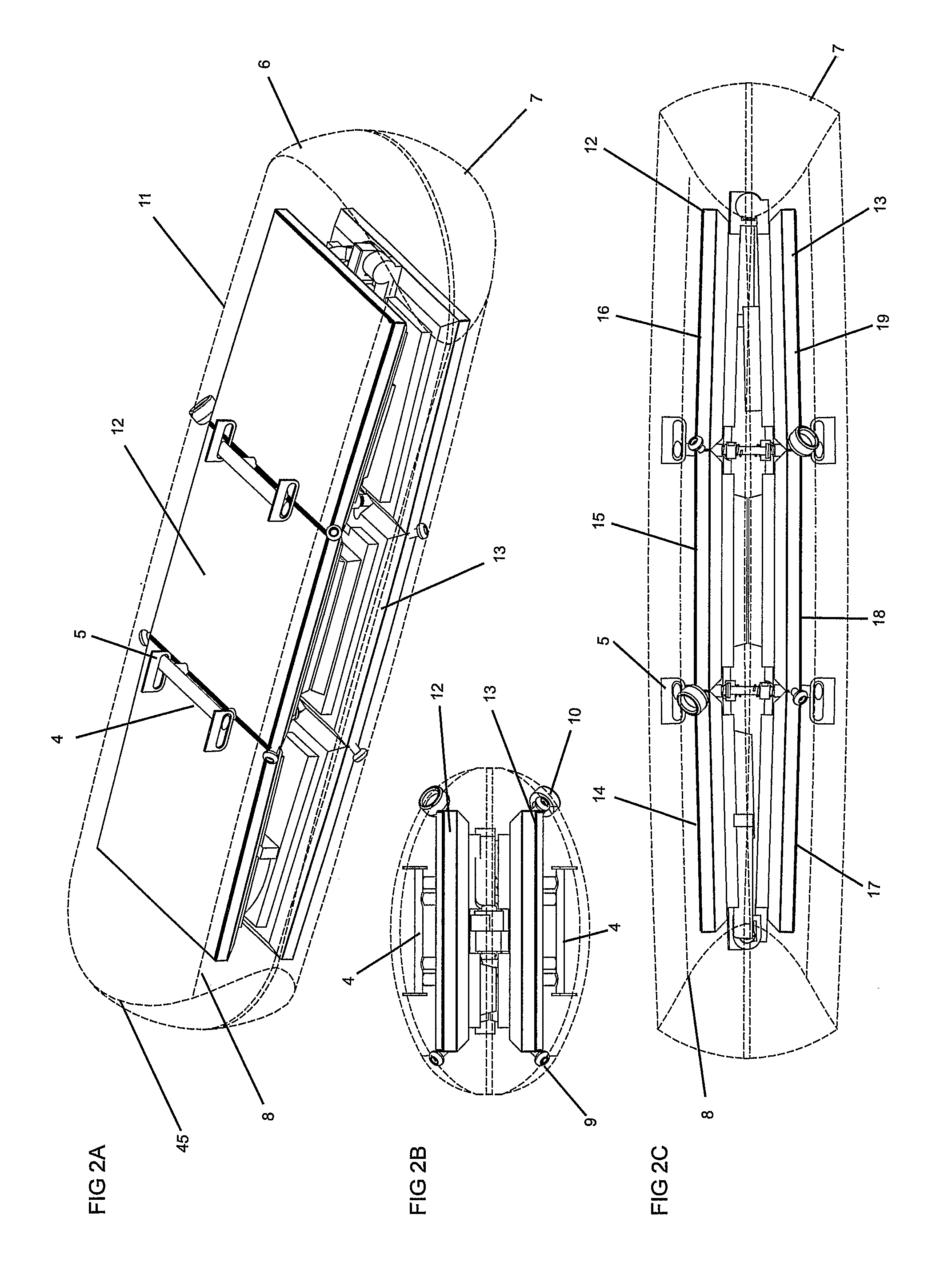

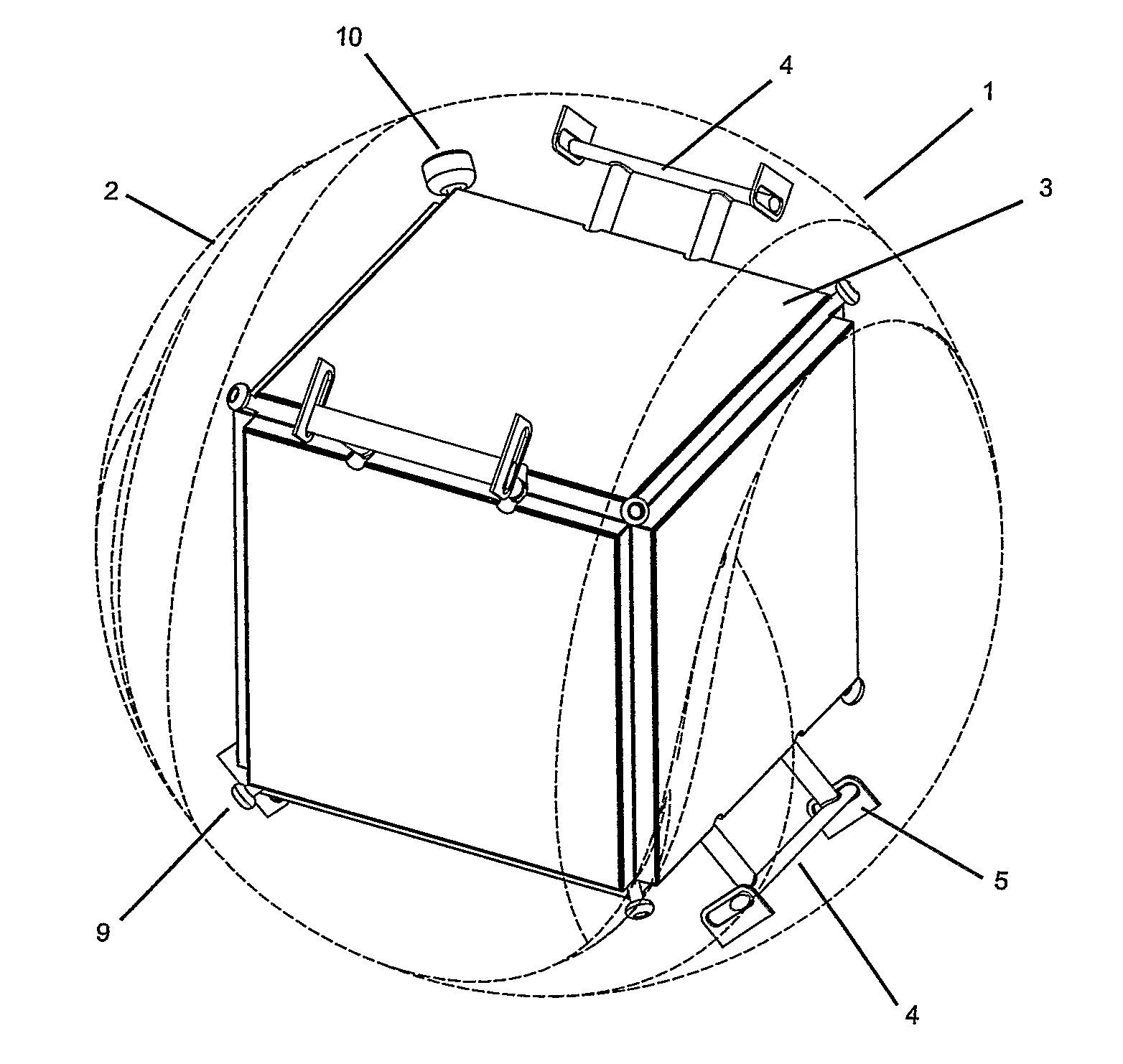

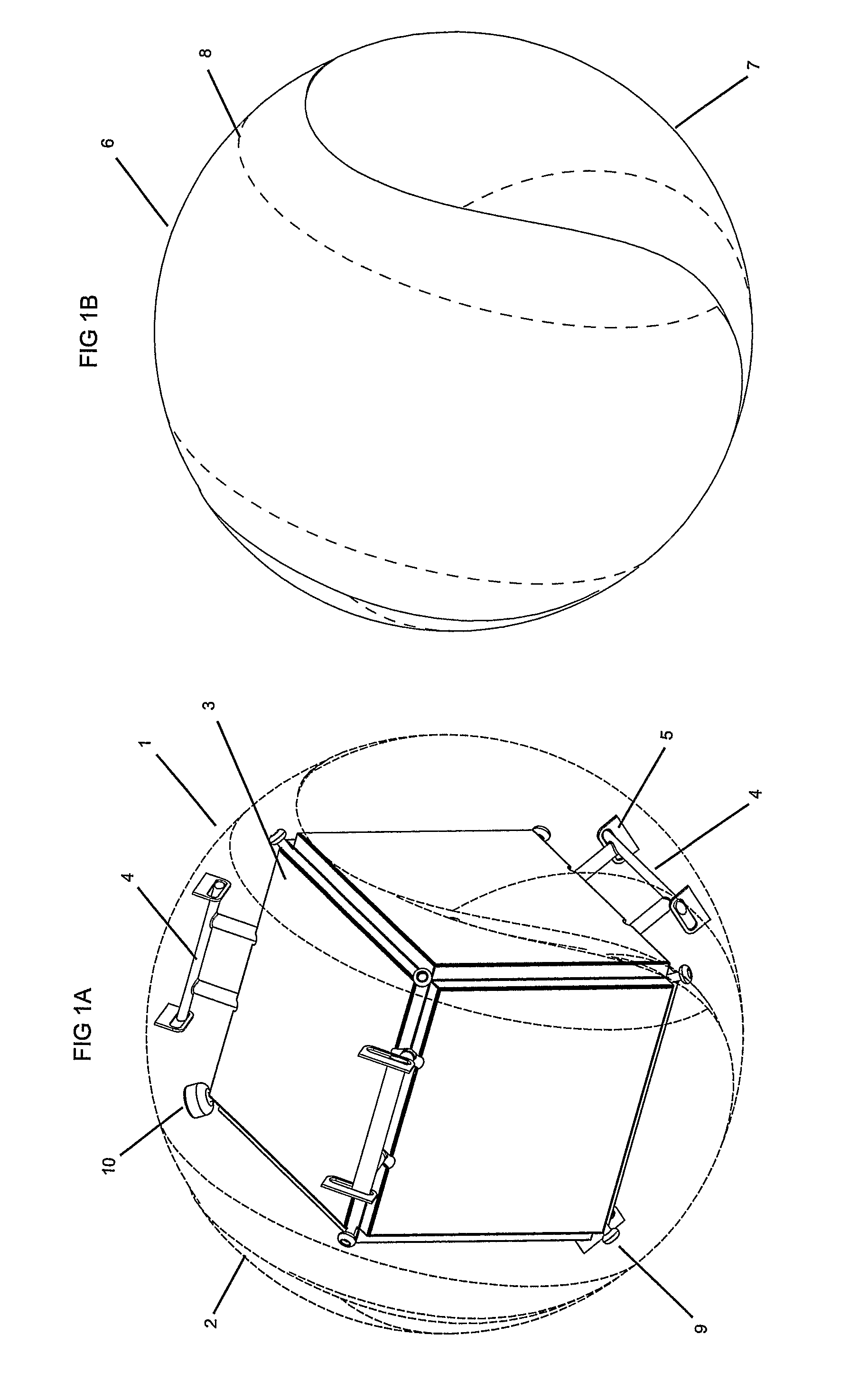

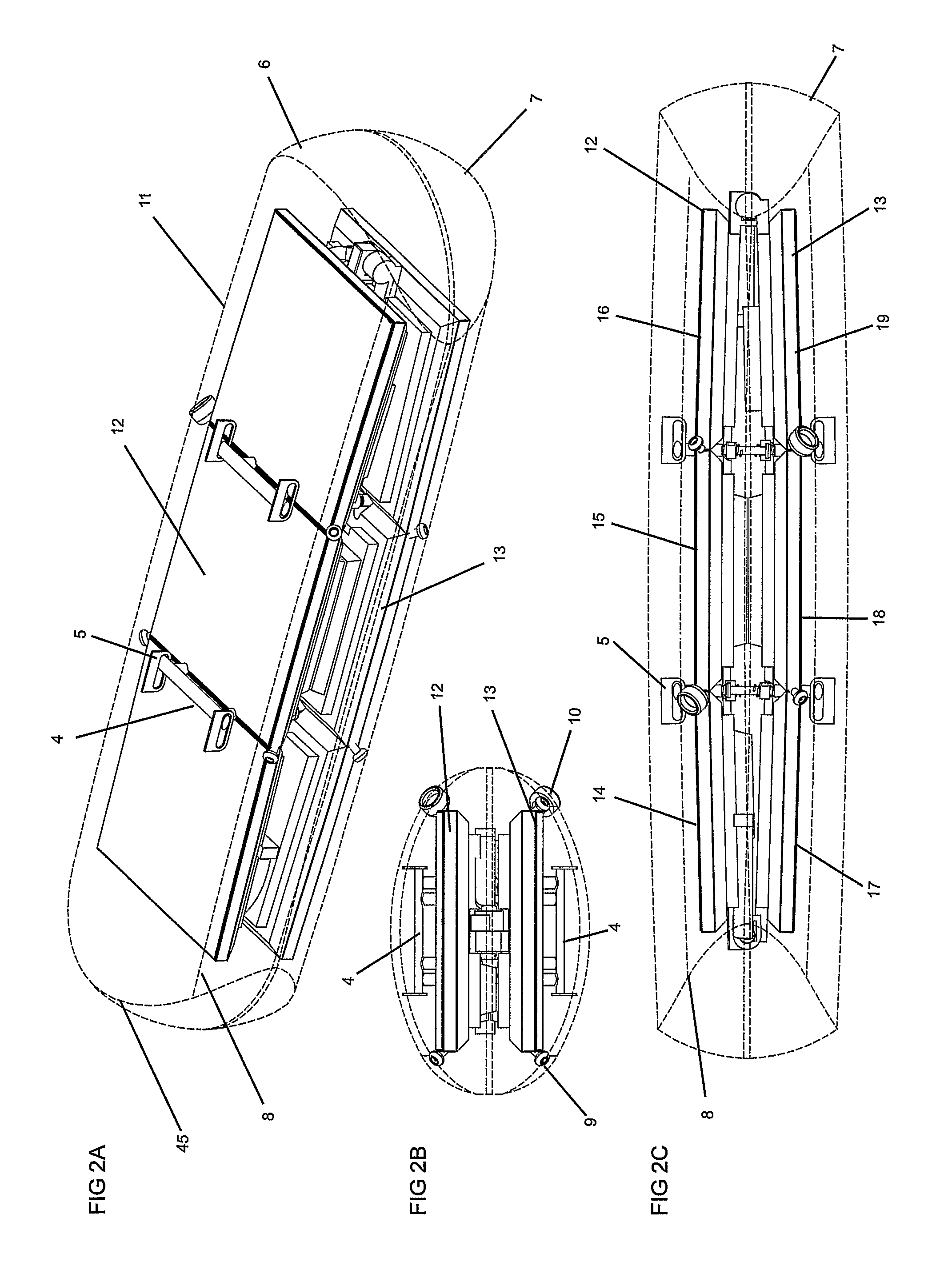

Spherical Display and Control Device

InactiveUS20070247439A1Rapid drill-downQuick selectionCathode-ray tube indicatorsDetails for portable computersGyroscopeDisplay device

A spherical display and control device, that is preferably collapsible between a spherical configuration and a collapsed generally cylindrical ellipsoid configuration, comprising a flexible transparent spherical surface sprung attached to a central hinged modular cube assembly that contains digital displays on outward faces, and circuitry, battery units and electronic modules on inward surfaces, where said sphere surface contains surface position sensing layers and said central cube contains gyroscopic and inertial sensing devices to provide spherical rotation, and physical displacement data for three dimensional control applications, where said displays preferably have curved polarizer lenses such that the overall device appears as a spherical display or are flat to form an overall Cuboid display or are combined with a flexible spherical display surfaces. The overall device being mechanically biased such that it is Bi-stable between the spherical and collapsed configuration via the action of pulling open and rotating the central cube halves.

Owner:DANIEL SIMON +2

Suture and method of use

InactiveUS6478809B1Easily manipulableEasy to pullSuture equipmentsSurgical needlesAdhesiveBody tissue

A suture member for joining the first and second sides of a cut in body tissue, such suture member having an elongated body member in one embodiment with a needle and thread member disposed at one end thereof and with externally activatable adhesive disposed on the suture member. The adhesive is activated by application of high-frequency radiation directed through the body tissue to retain the suture member securely in the body tissue.

Owner:BROTZ GREGORY R

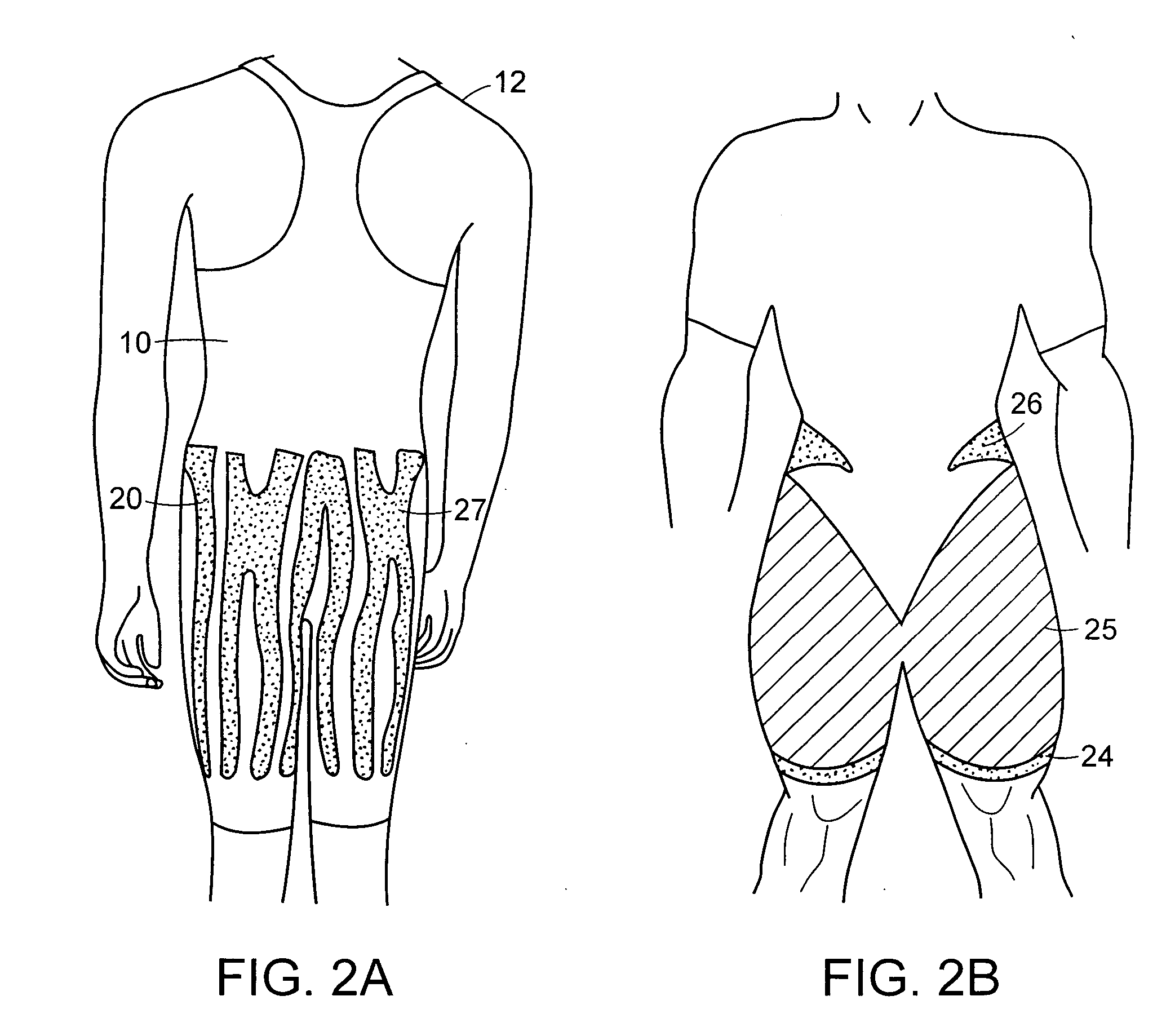

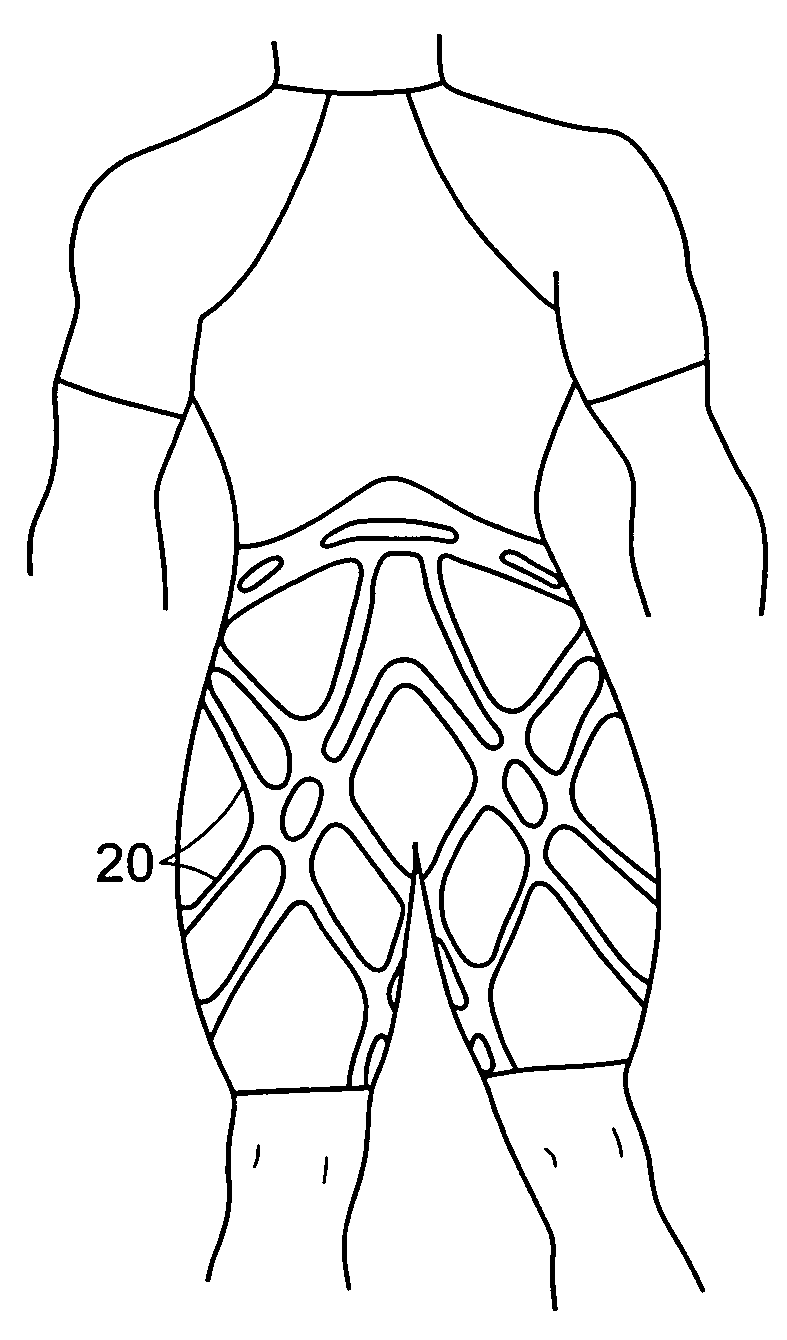

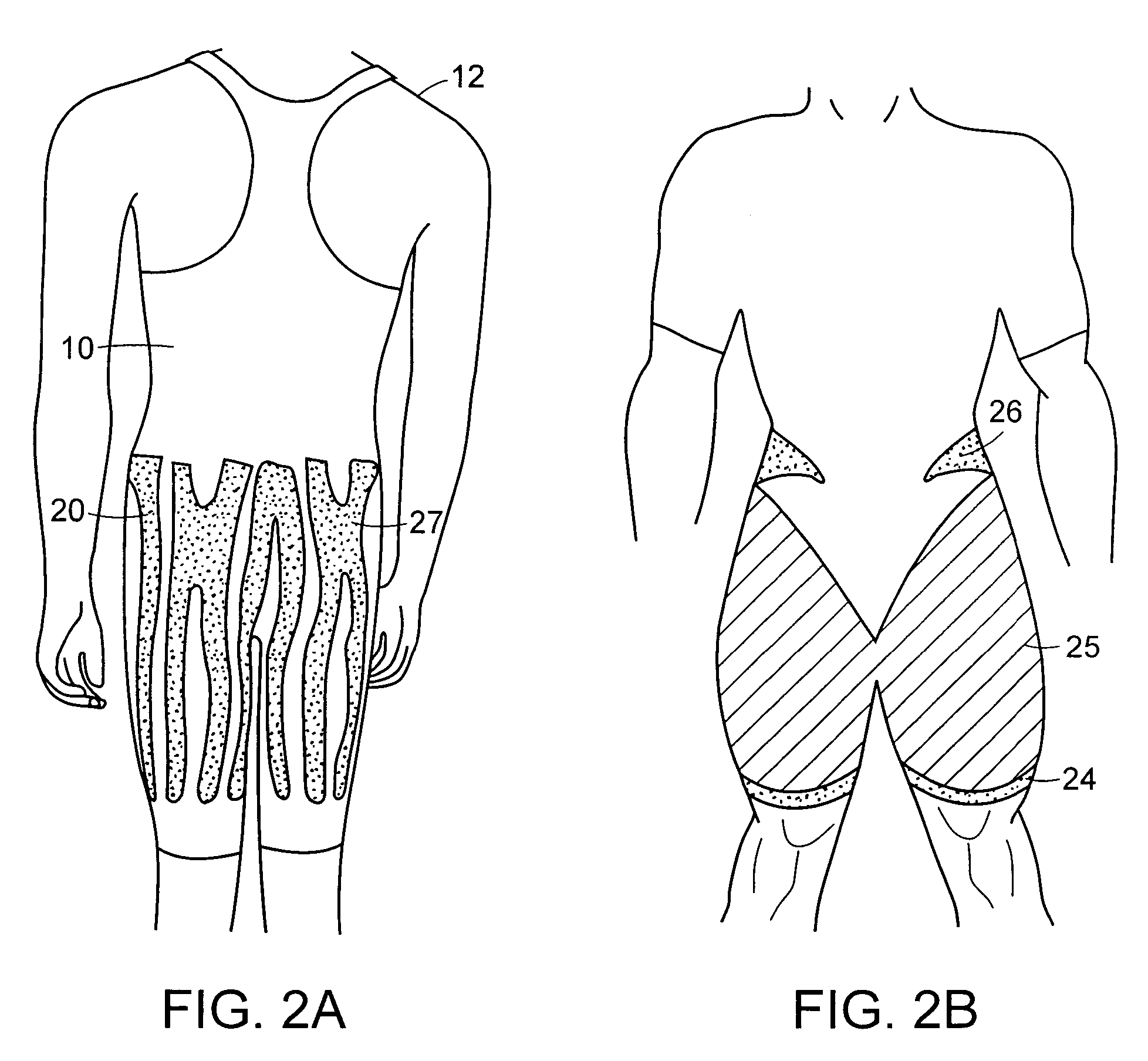

Garment

ActiveUS20050193461A1Improve performanceFaster movementTrousersProtective garmentEngineeringEnergy analysis

Owner:ADIDAS

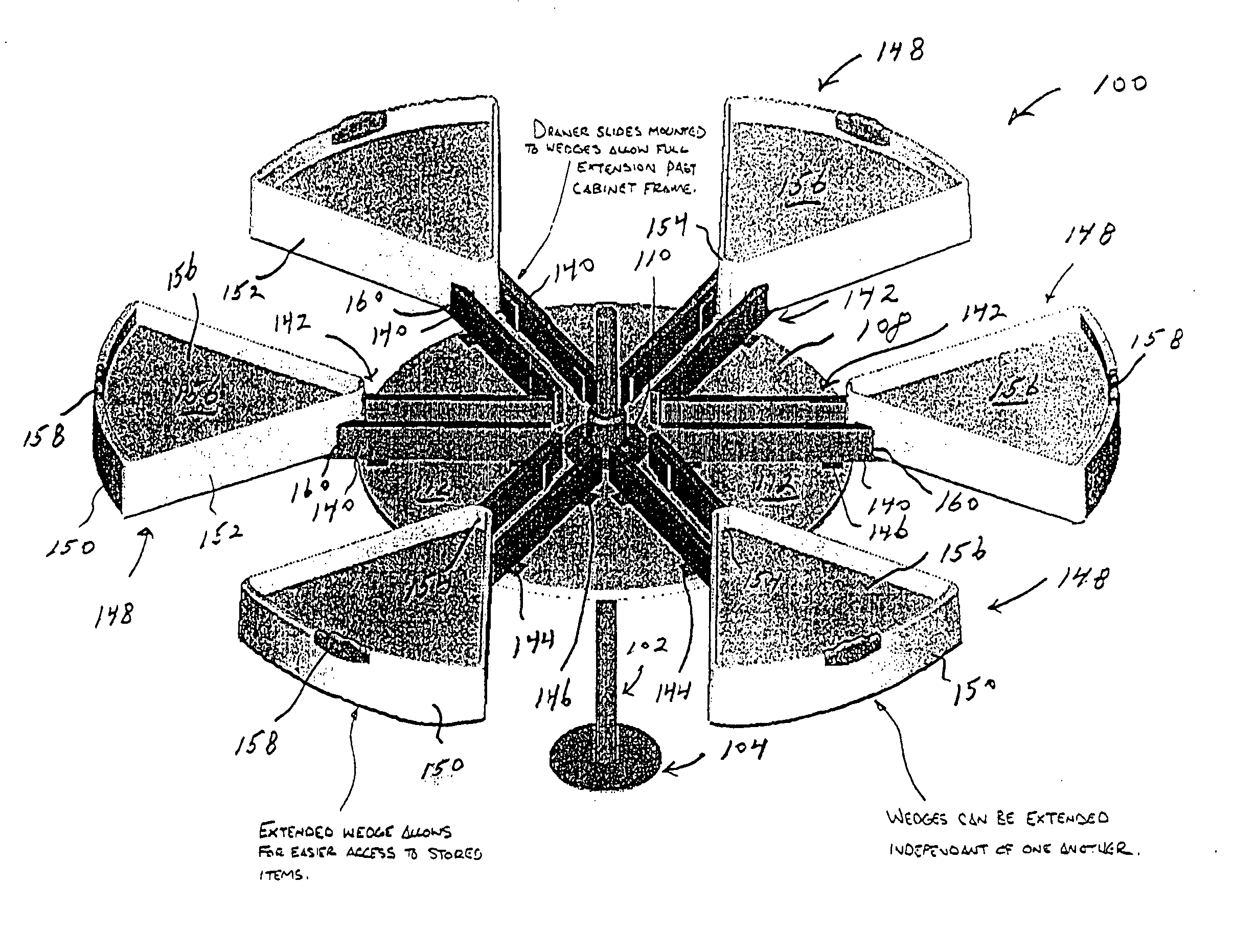

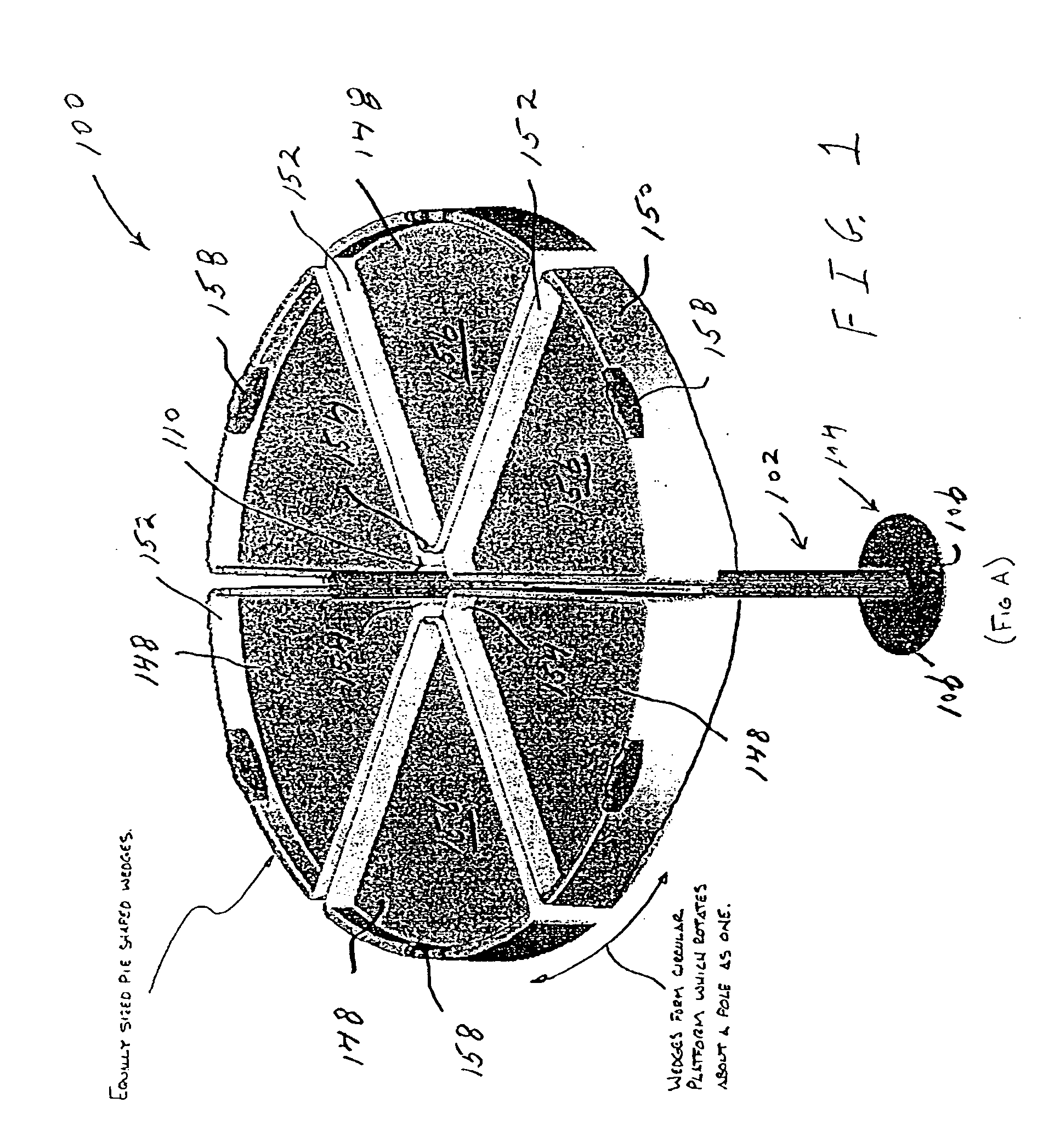

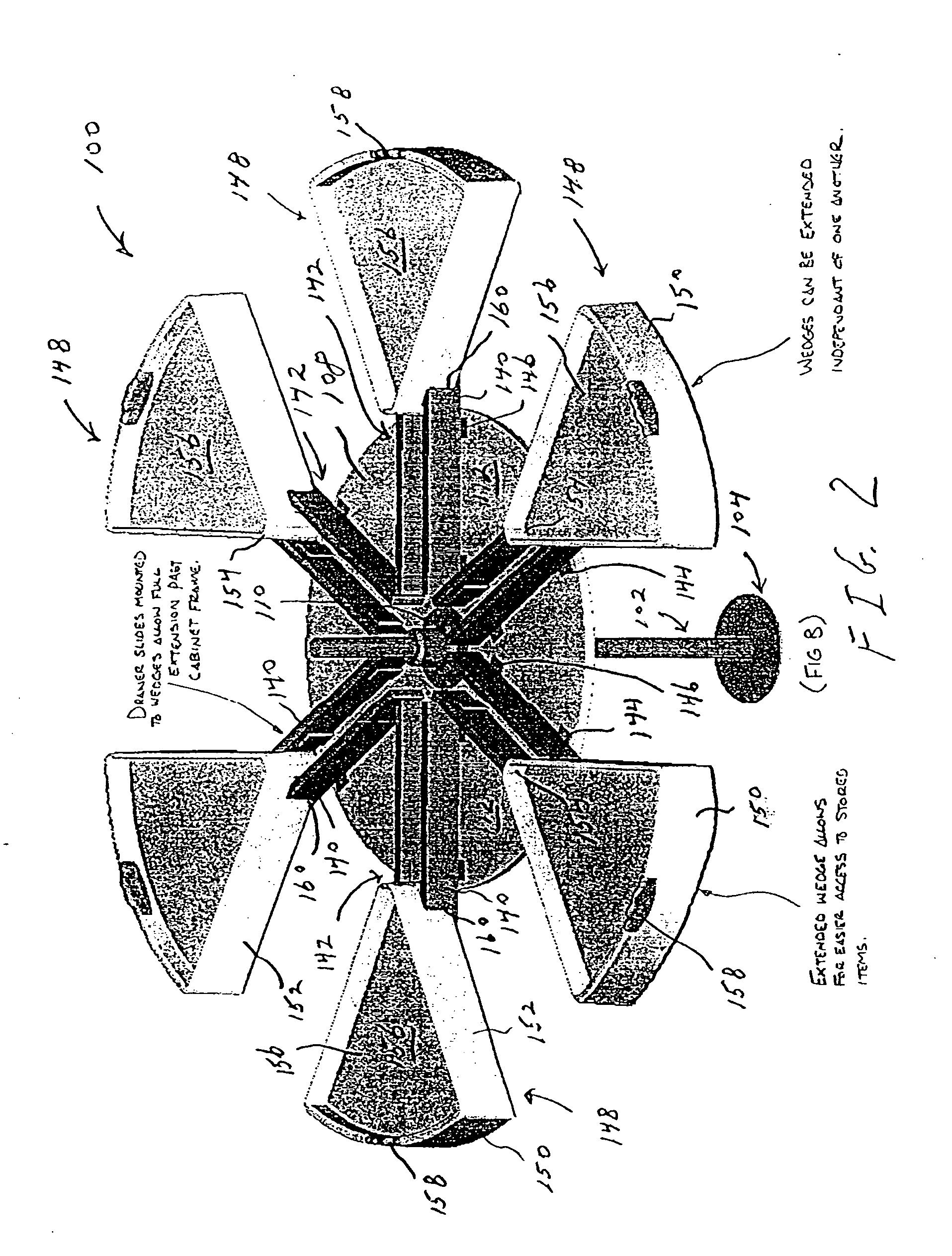

Lazy susan with pull-out shelving

Owner:KNAPE & VOGT MFG

Spherical display and control device

InactiveUS7755605B2Reduce vibrationEasy to pullCathode-ray tube indicatorsDetails for portable computersDisplay deviceModularity

A spherical display and control device, that is preferably collapsible between a spherical configuration and a collapsed generally cylindrical ellipsoid configuration, comprising a flexible transparent spherical surface sprung attached to a central hinged modular cube assembly that contains digital displays on outward faces, and circuitry, battery units and electronic modules on inward surfaces, where said sphere surface contains surface position sensing layers and said central cube contains gyroscopic and inertial sensing devices to provide spherical rotation, and physical displacement data for three dimensional control applications, where said displays preferably have curved polarizer lenses such that the overall device appears as a spherical display or are flat to form an overall Cuboid display or are combined with a flexible spherical display surface. The overall device being mechanically biased such that it is Bi-stable between the spherical and collapsed configuration via the action of pulling open and rotating the central cube halves.

Owner:DANIEL SIMON +2

Garment

Owner:ADIDAS

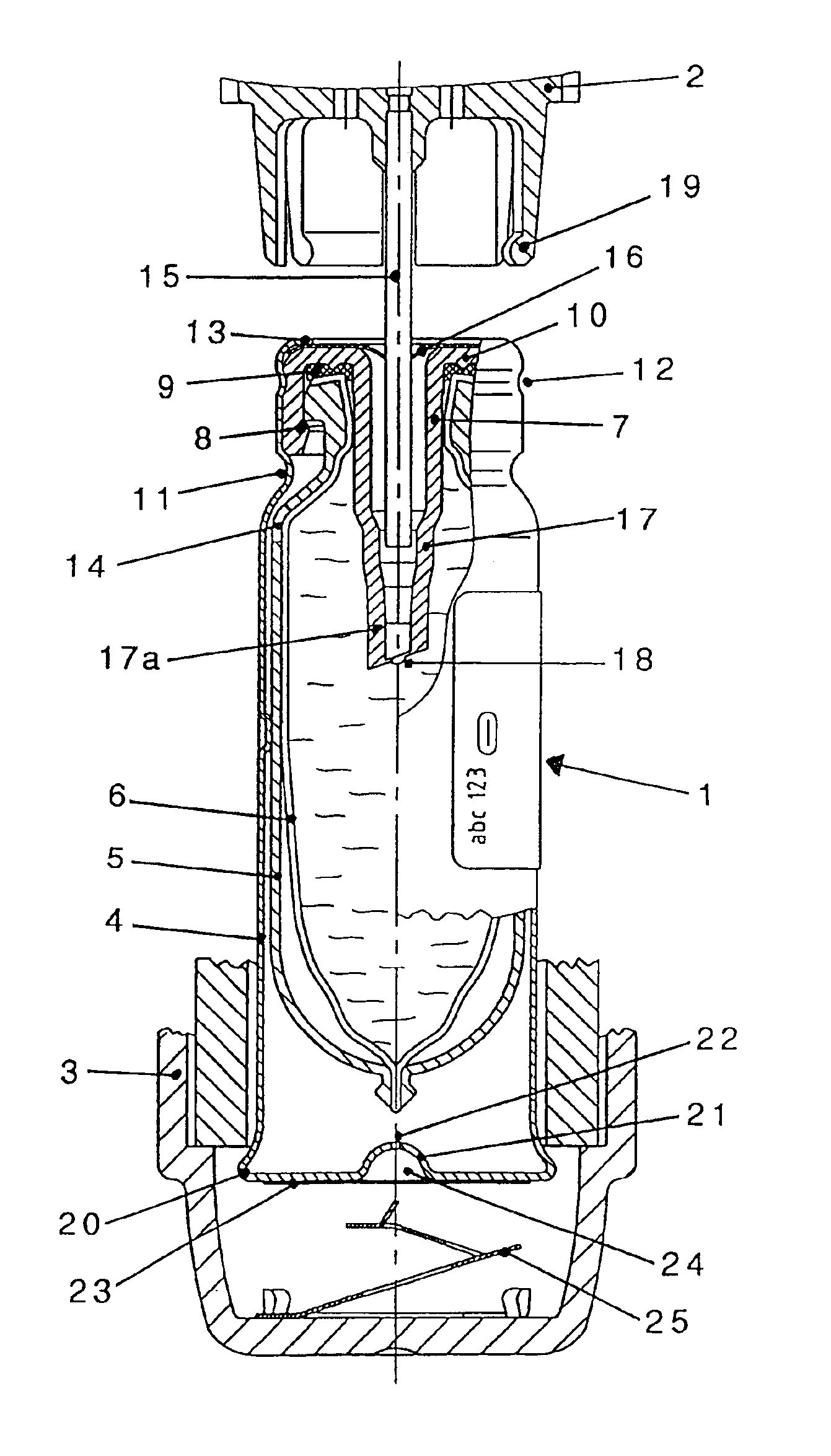

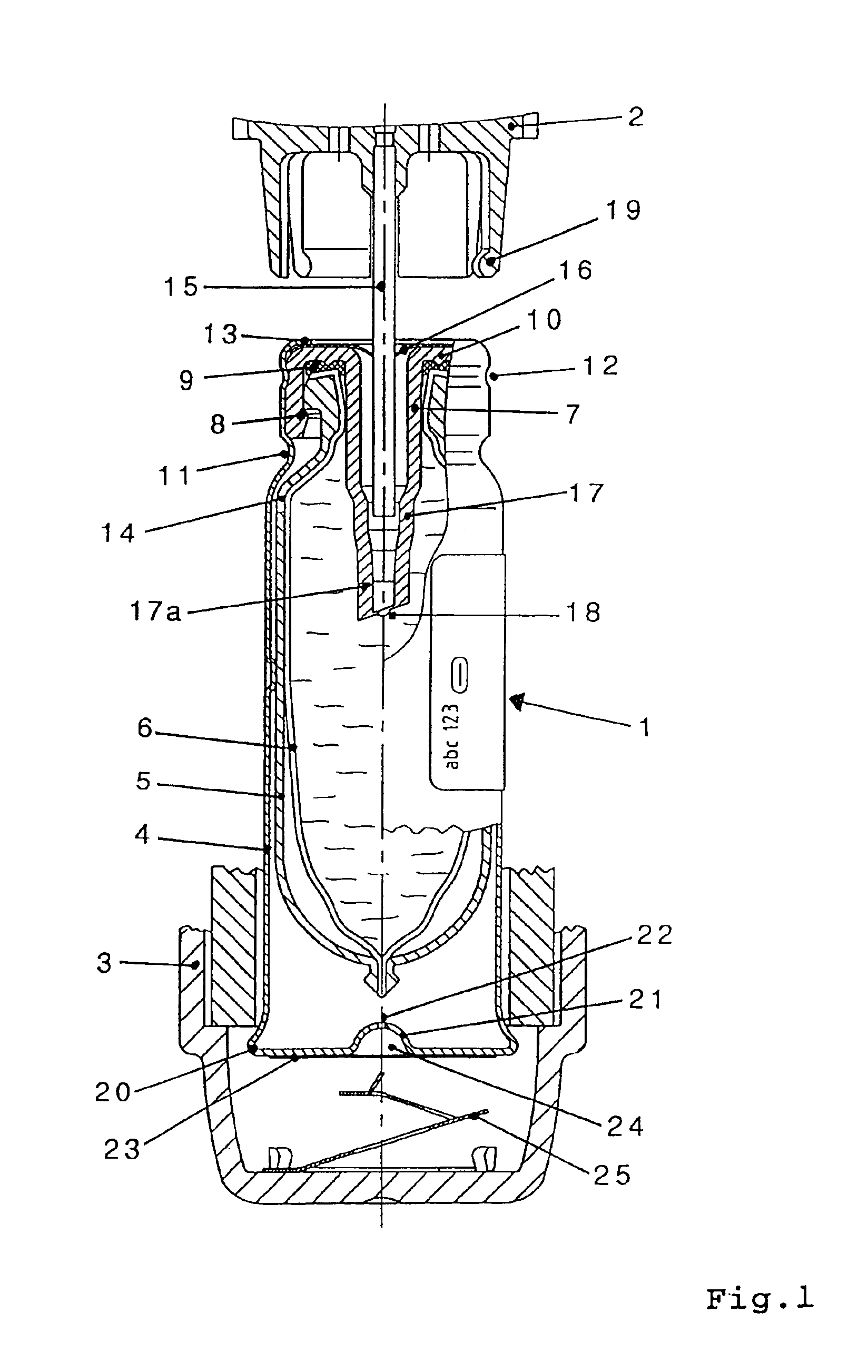

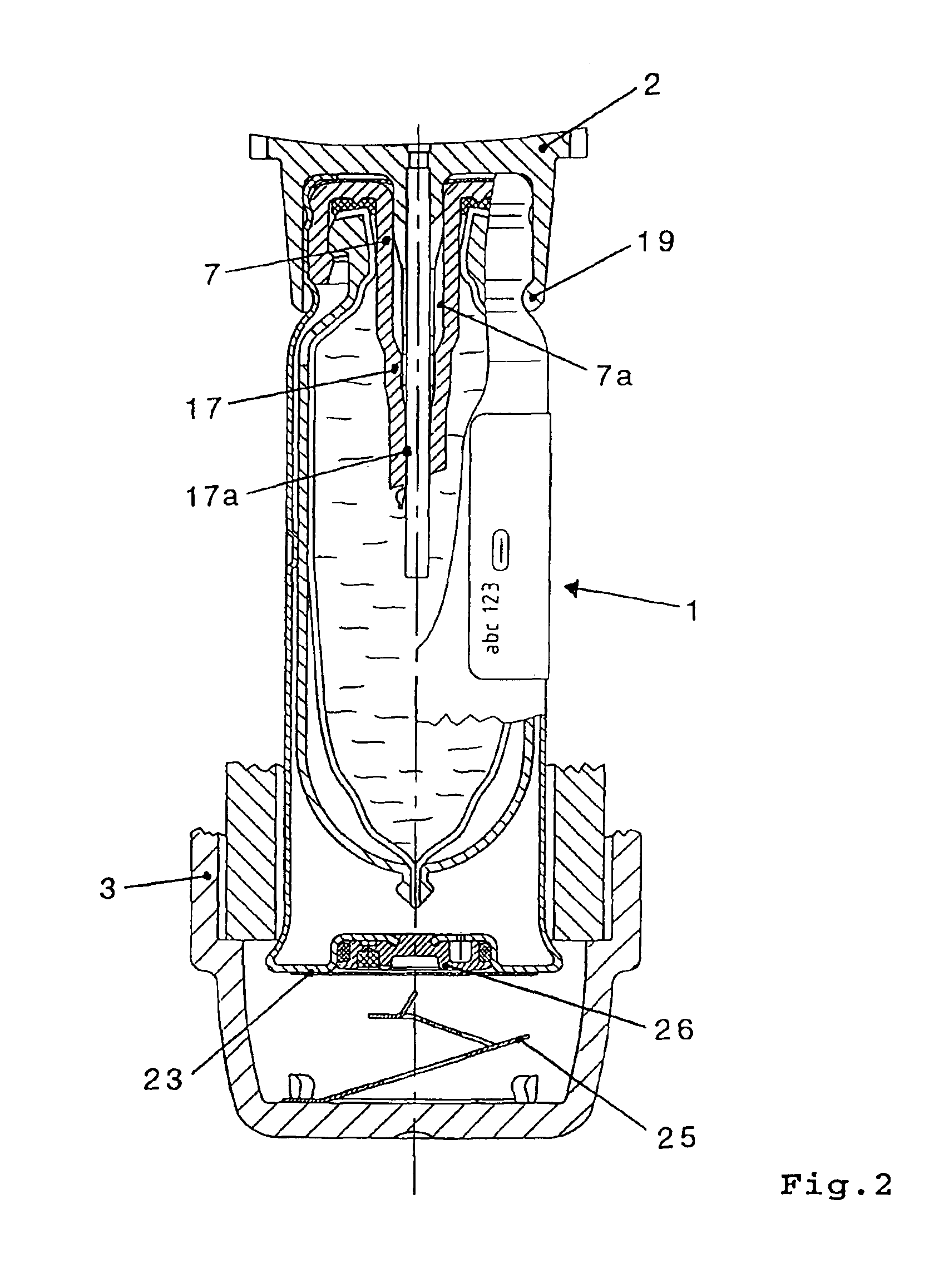

Cartridge for a liquid

InactiveUS6988496B1Lower the volumeReduce pressureWatering devicesRespiratorsBiomedical engineeringMonths time

For meteredly dispensing a liquid over a period of several months from a container which can be stored over a long period of time, the need is for a container which is practically diffusion-tight and in which the liquid does not come into contact with the ambient atmosphere.The cartridge according to the invention is a three-shell container comprising a collapsible bag which contains the liquid, a container which is stable in respect of shape and a stiff metal casing. The cartridge can be releasably connected to a dispensing device. The cartridge can be provided with a micro-opening with which the time for pressure equalisation between the cartridge and the ambient atmosphere can be adjusted. The cartridge is suitable for aqueous and for alcoholic liquids which contain a pharmacologically active substance. The liquid in the cartridge is protected from external influences.The cartridge can be used in an atomiser for producing an inhalable aerosol for the treatment of illnesses.

Owner:BOEHRINGER INGELHEIM INT GMBH

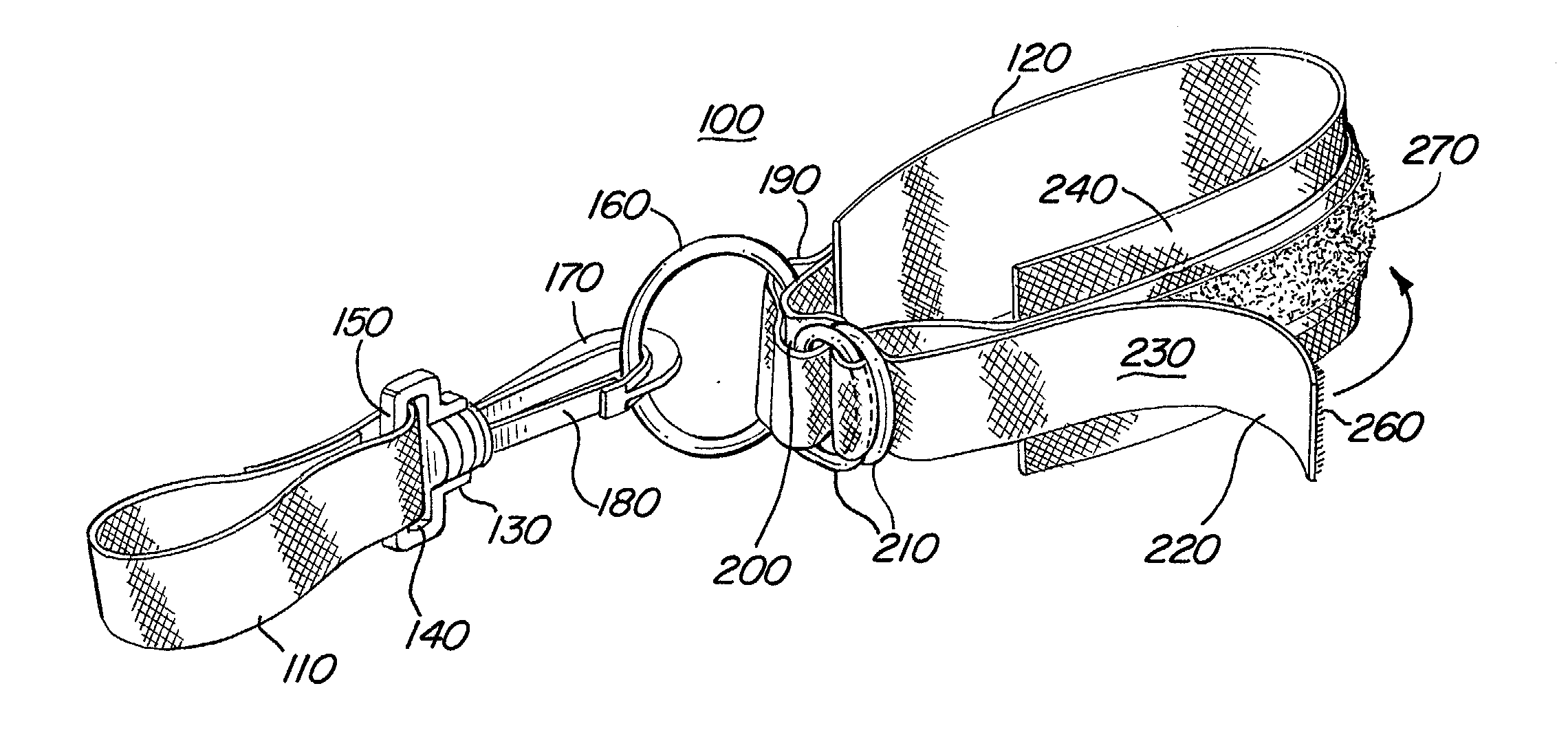

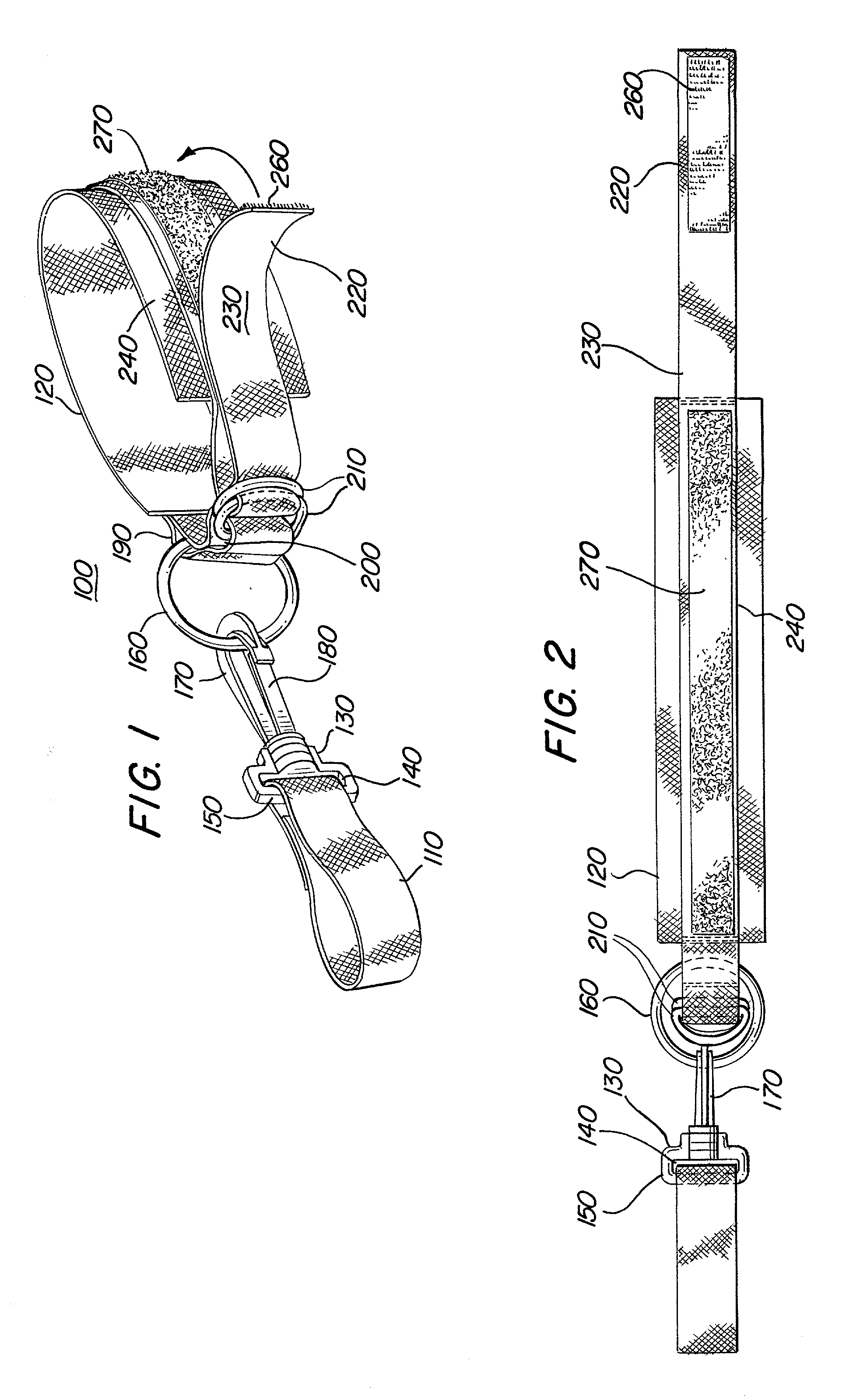

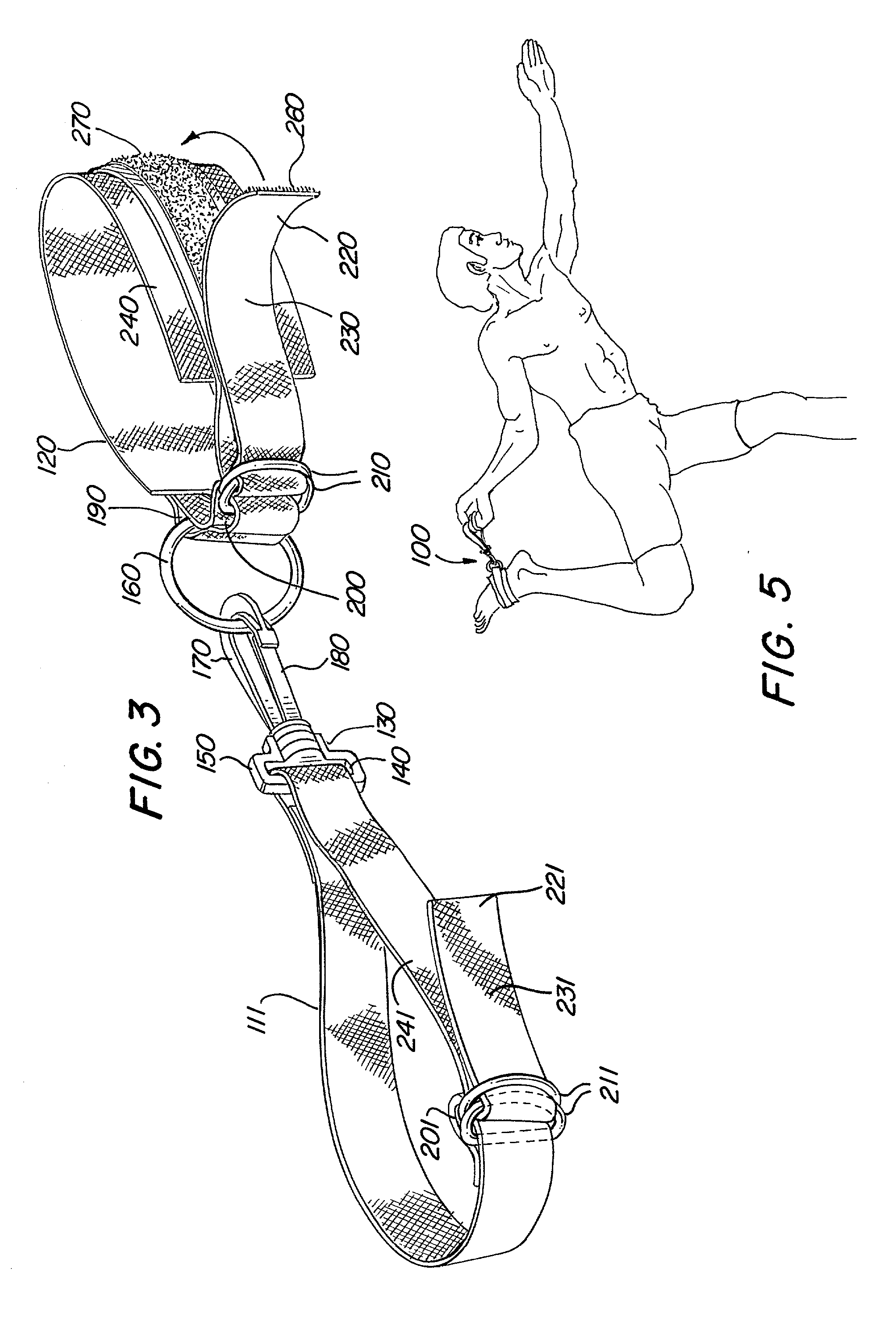

Swiveling exercise strap for stretching

An exercise device is disclosed for enabling various stretching exercises comprising an adjustable loop connected to a handle element by a swivel connector. The adjustable loop can be placed about a foot, ankle, or other body part, and the handle grasped in one hand. The swivel connector allows a user to stretch in multiple positions and postures without readjusting the exercise device. In a preferred embodiment, the handle comprises either a handle loop sized to accommodate a user's finger, fingers, or hand, or a series of loops to allow the user to gradually increase the tension in the stretch by grasping successive loops in the series. Alternatively, the handle can comprise a hand support member that allows the user to easily and firmly grasp the handle and apply a steady tension. In addition, the handle can comprise an adjustable loop to facilitate various lengths of stretching and levels of difficulty.

Owner:SHEN CHARLES

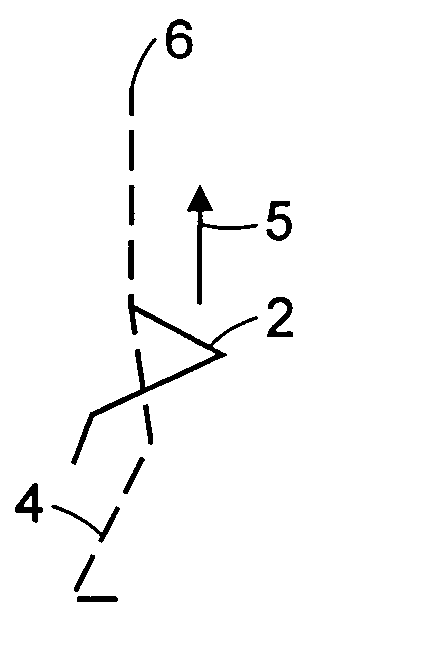

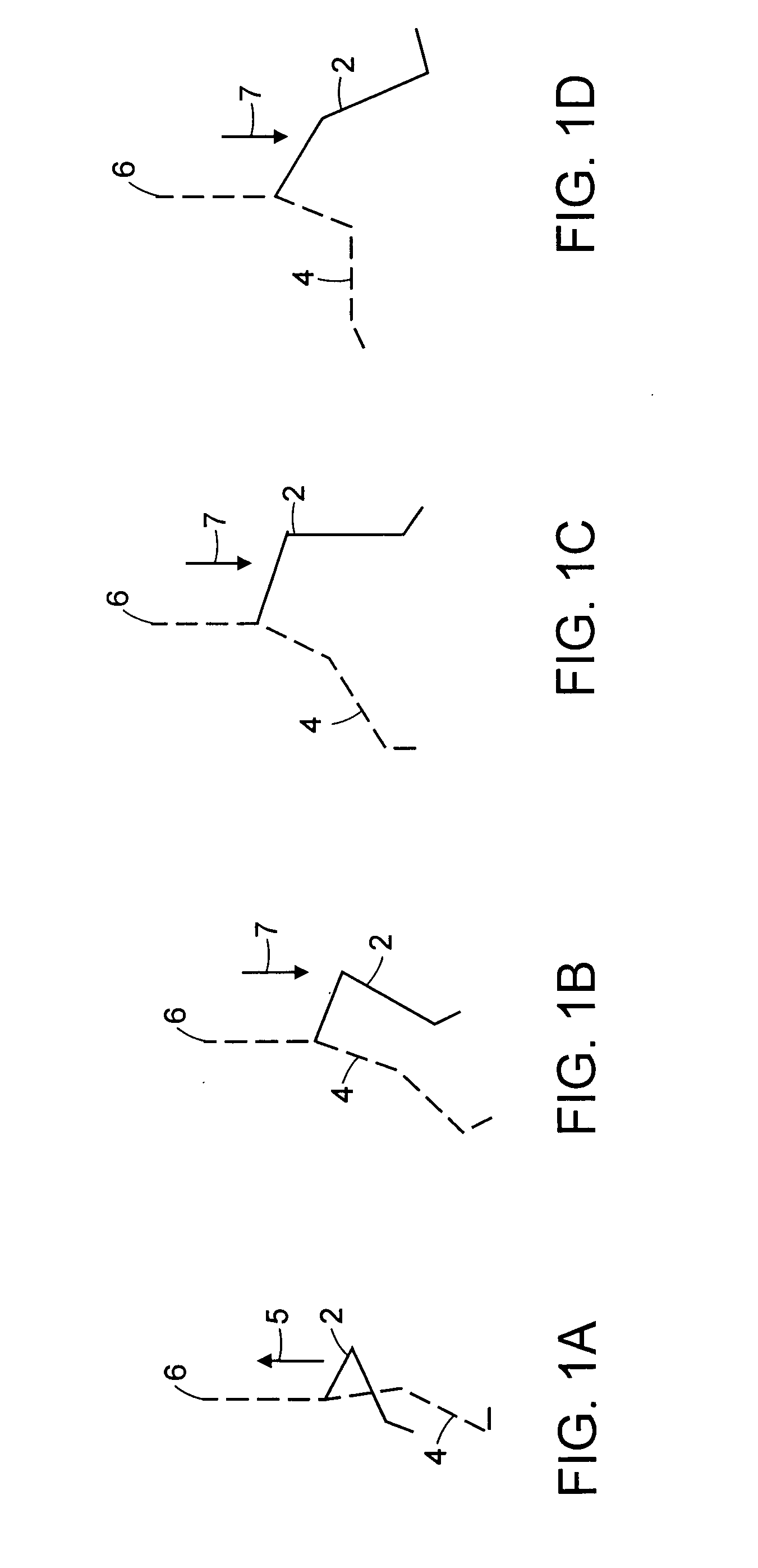

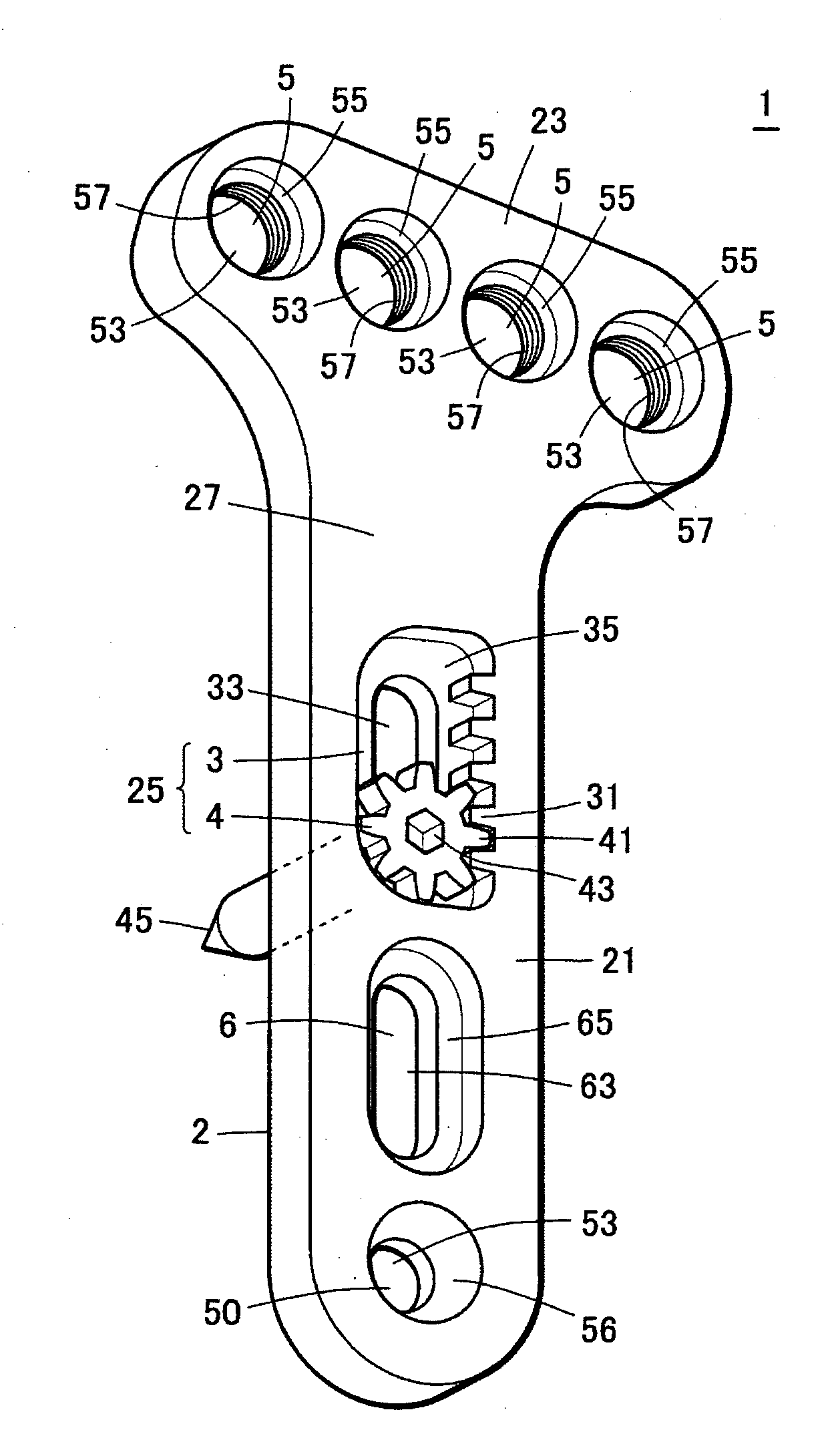

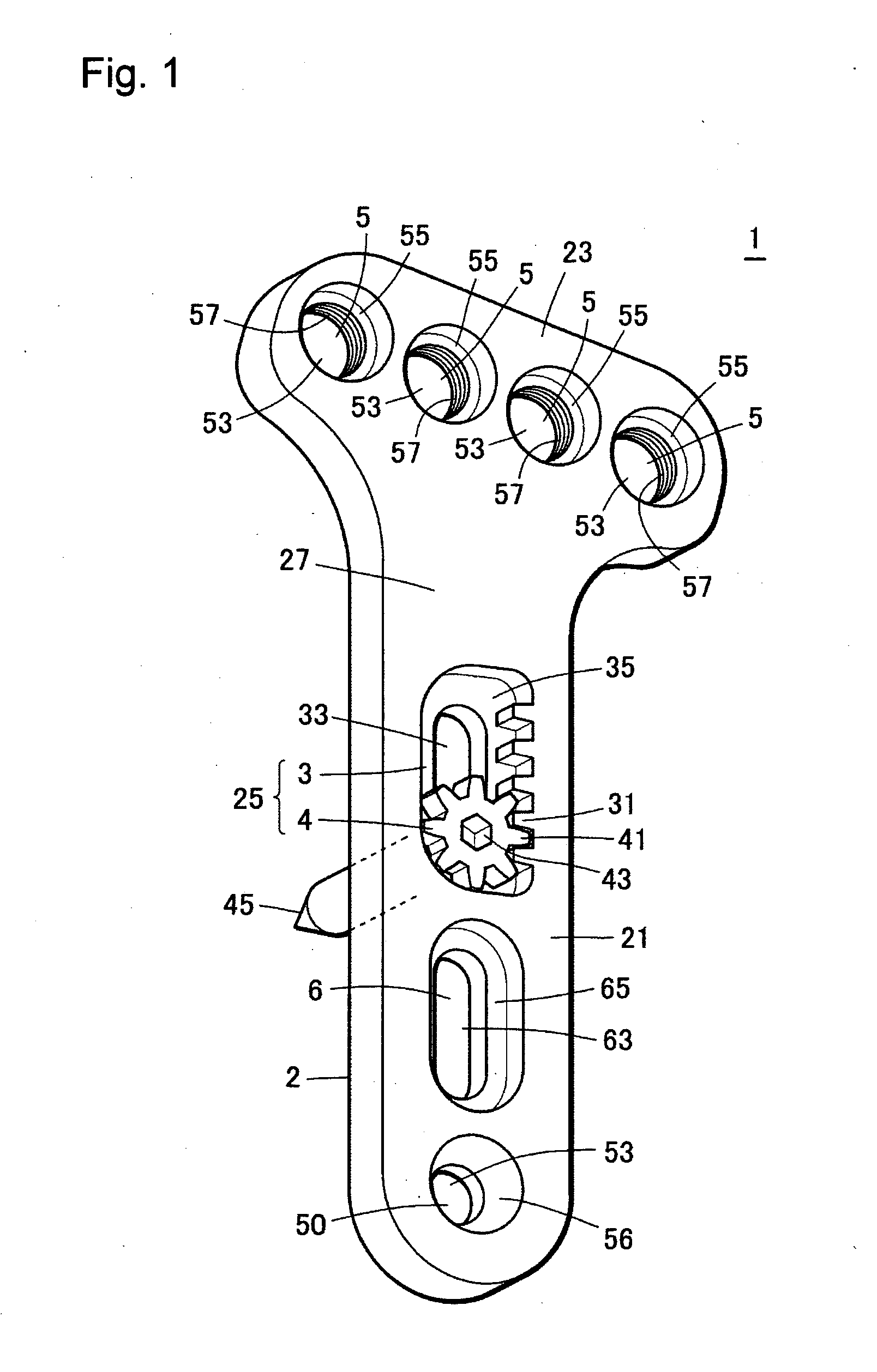

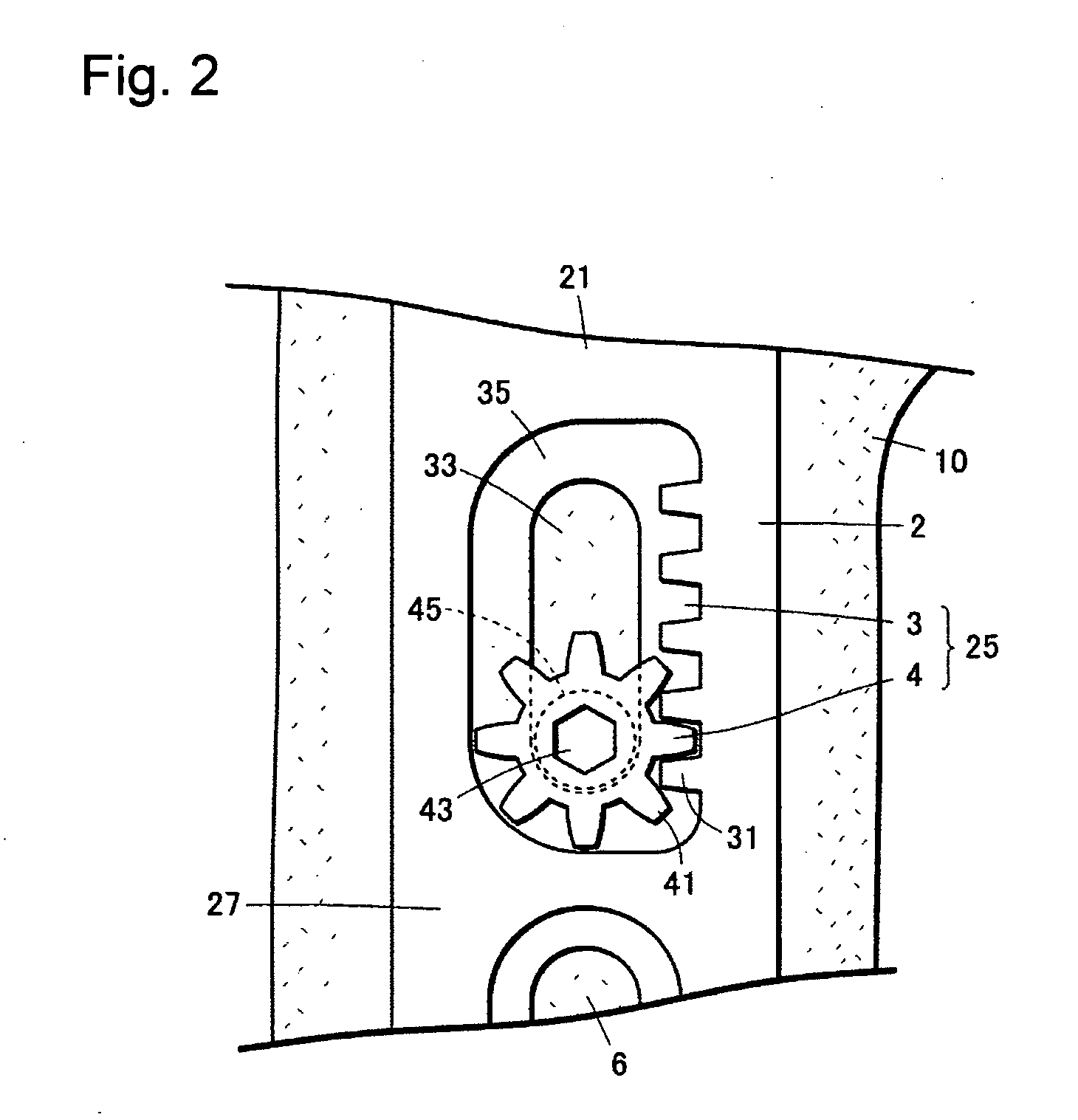

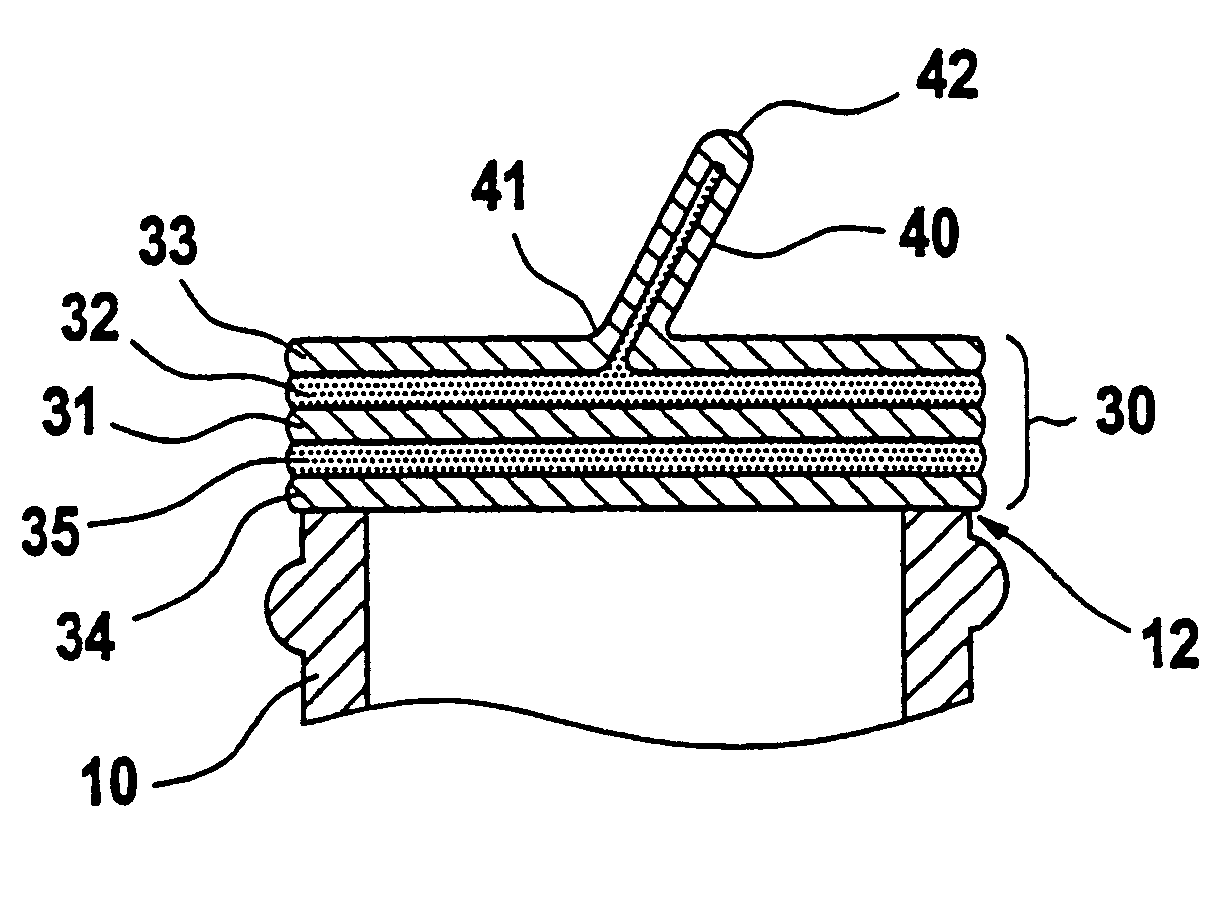

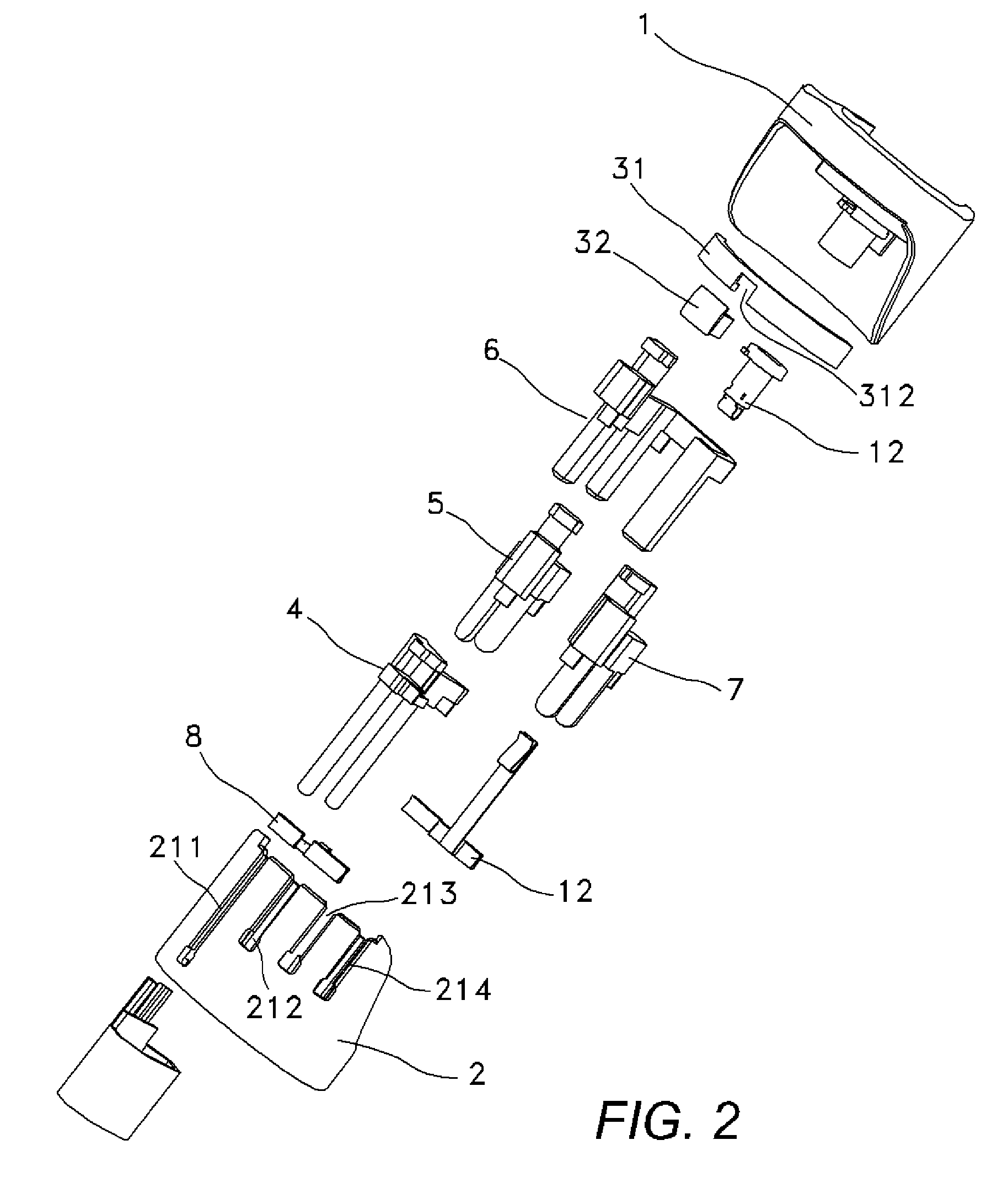

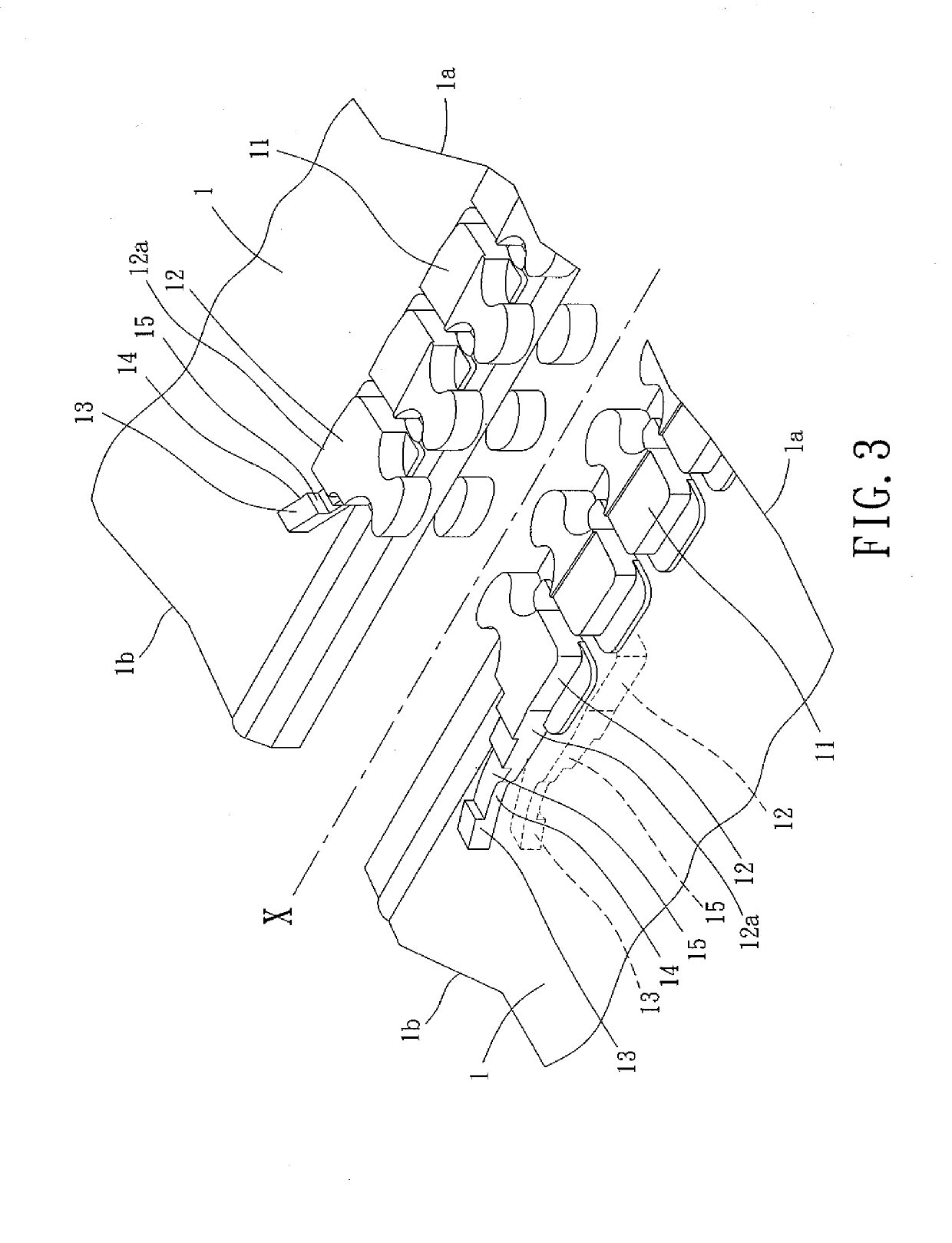

Mechanism for Osteosynthesis

InactiveUS20090234359A1Manufacturing cost be reduceSimple structureJoint implantsFastenersEngineeringOsteosynthesis

A mechanism for osteosynthesis 1 is provided that is capable of finely adjusting the amount of movement of a fractured bone, quantifying the amount of the movement and can be used both in pulling the fractured bones apart from each other and pulling the fractured bones nearer toward each other. A first mechanism for osteosynthesis 1 of the present invention comprises a plate part 2 for reducing two or more fractured bones monolithically by fixing at least both ends of the plate part 2 on the fractured bones and a sliding part 25 for moving one fractured bone along a sliding elongate hole 3 formed in the plate part 2 so as to elongate from the one fractured bone toward another fractured bone, the sliding part 25 comprising a rack 31 formed on an inner surface of the sliding elongate hole so as to extend along a sliding direction and a pin inserted in the sliding elongate hole 3, the pin 4 having a head portion 41 having a pinion for engaging with the rack 31 and a base portion 45 to be inserted into the one fractured bone, wherein the sliding part 25 moves the one fractured bone slidably along the sliding elongate hole 3 by rotating the pin 4.

Owner:HIDETOSHI ONOUE +1

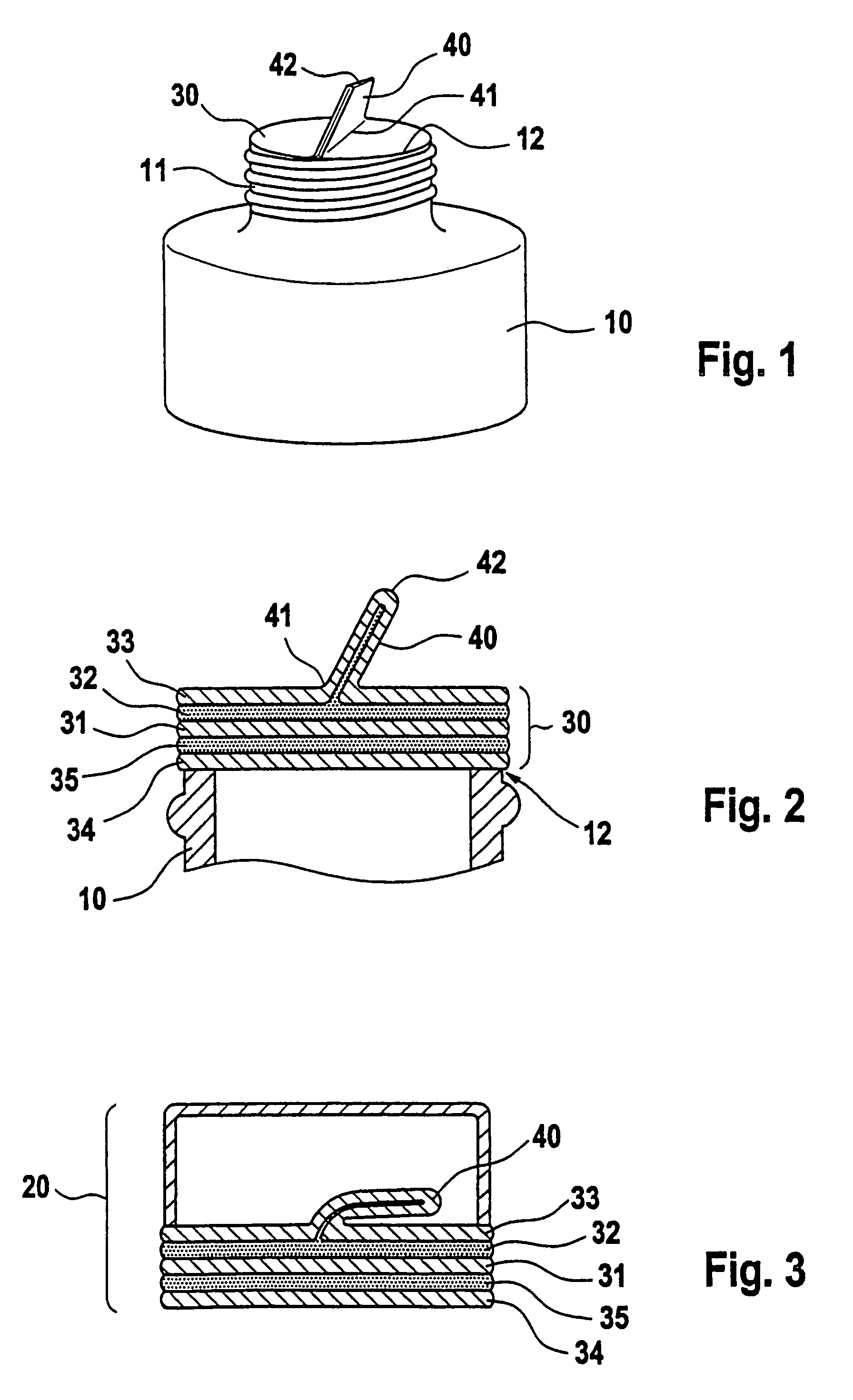

Sealing disc and film composite for a closure of a container

InactiveUS6974045B1Improve stabilityImprove adhesionCapsClosure using stoppersThin membraneMechanical engineering

A sealing disc and a film composite for a container closure is provided, for use on a container with an opening bounded by a peripheral edge. The film composite includes a plurality of layers. An adhesive layer is arranged at least over a joining surface between the upper layer and the underlying layer.

Owner:ALFELDER KUNSTWERKE HERM MEYER

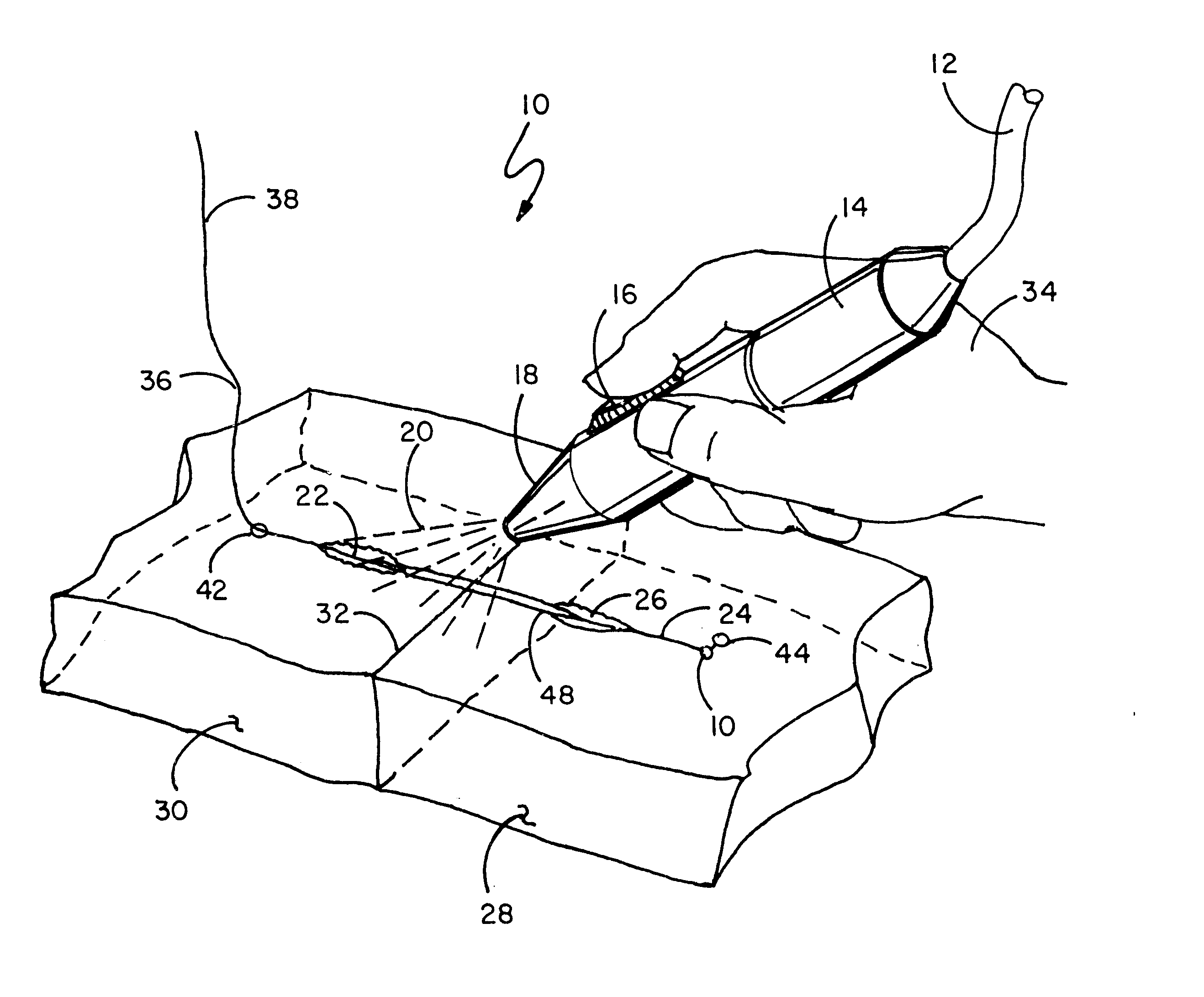

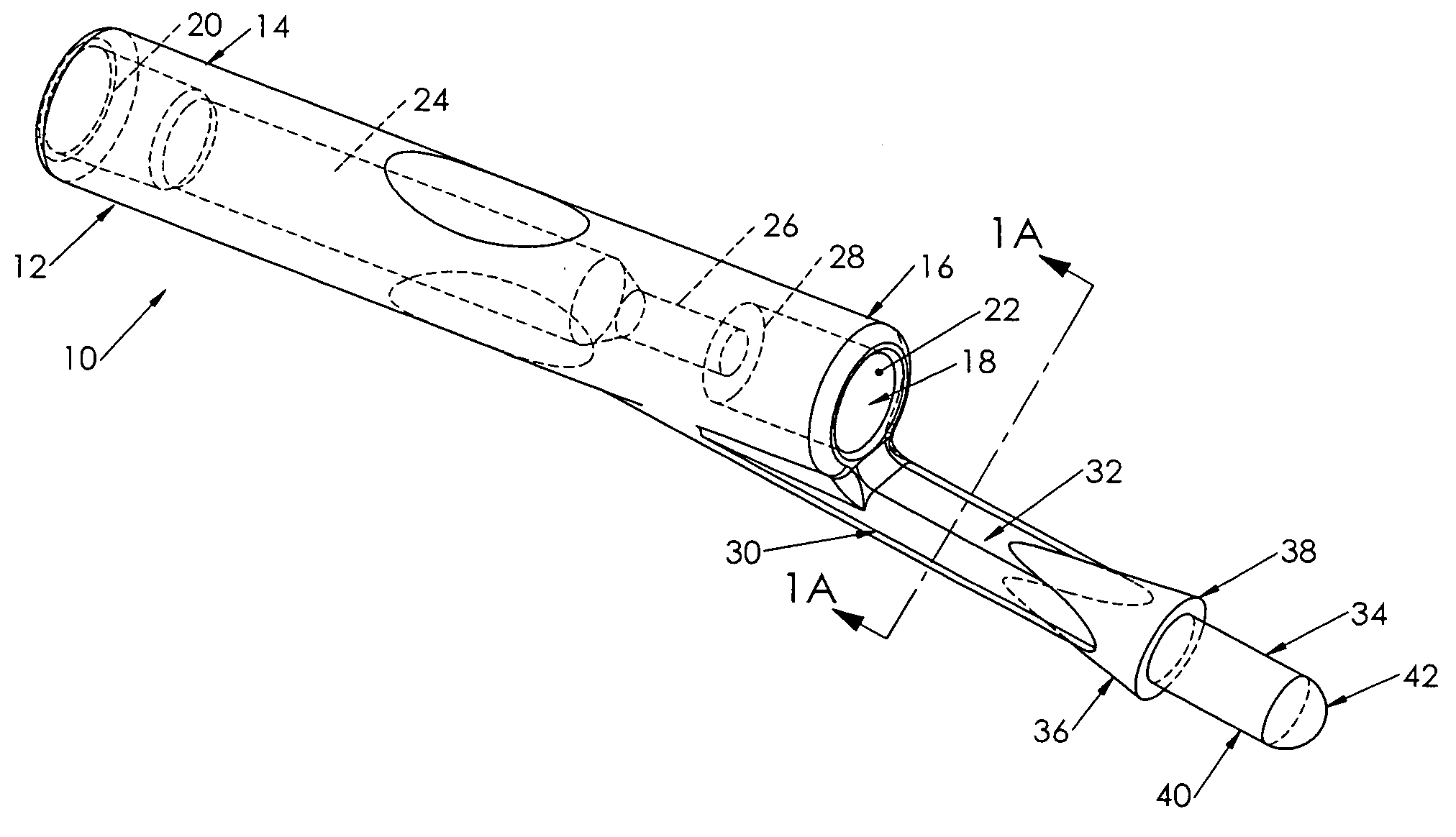

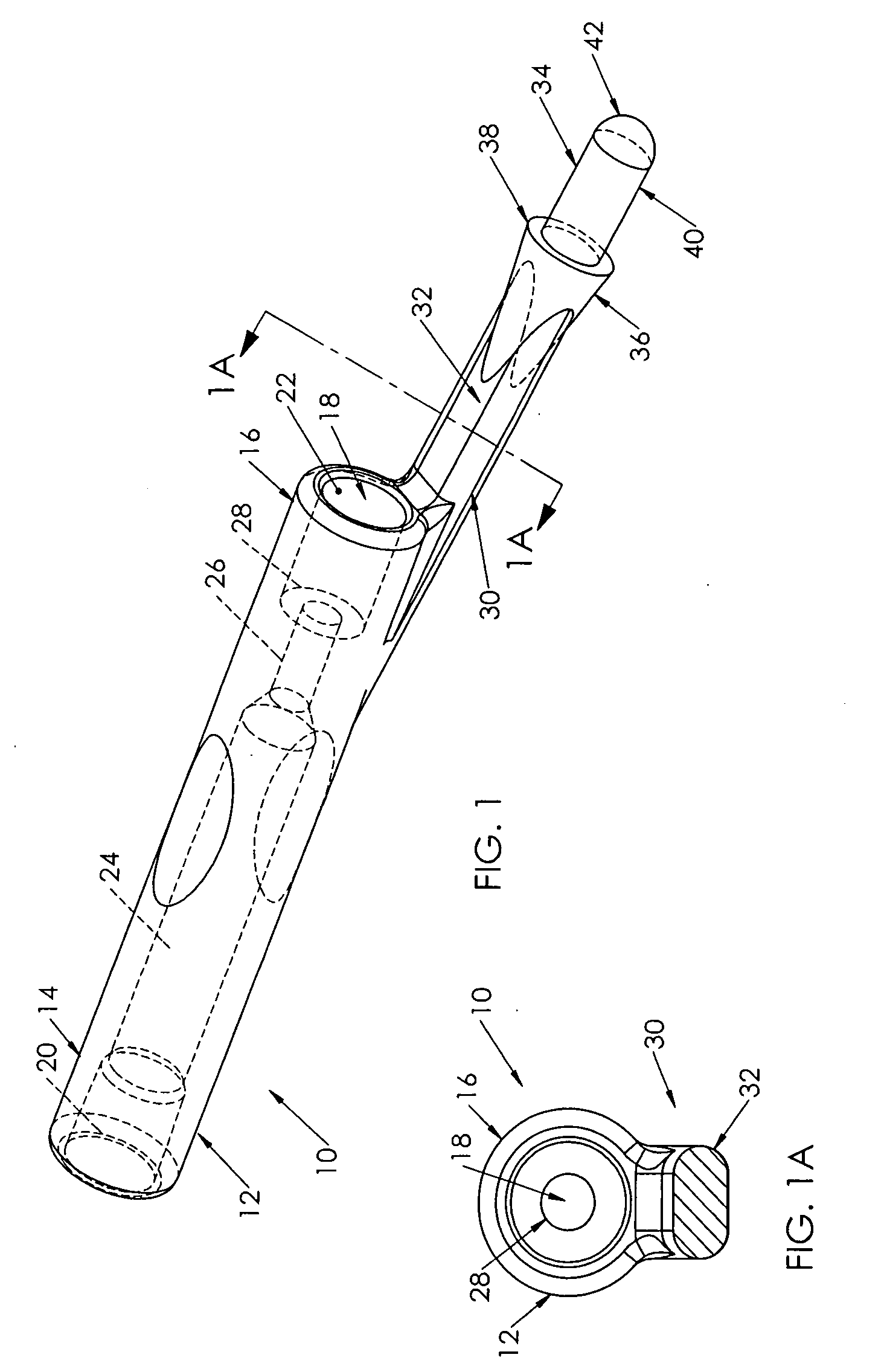

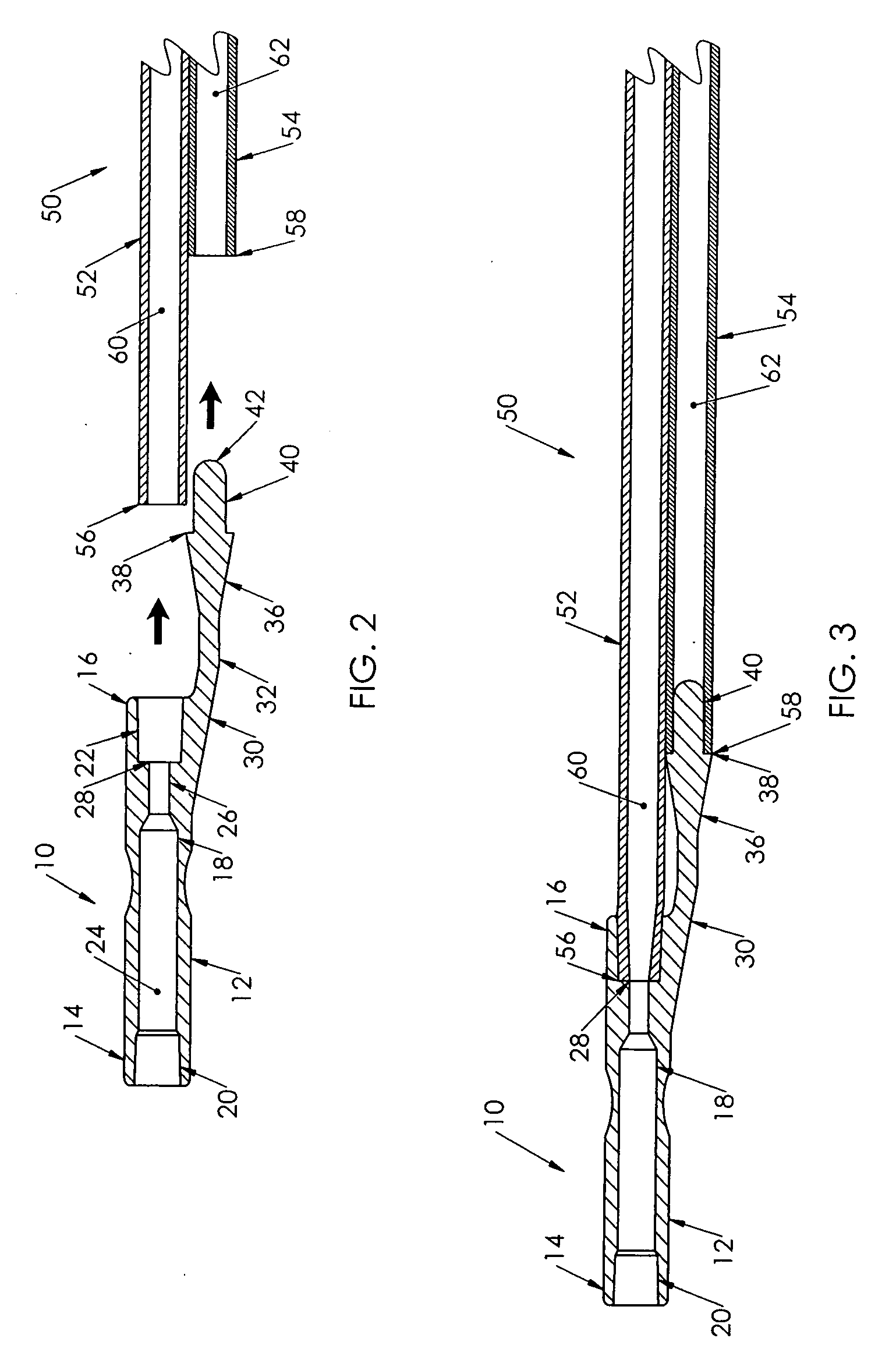

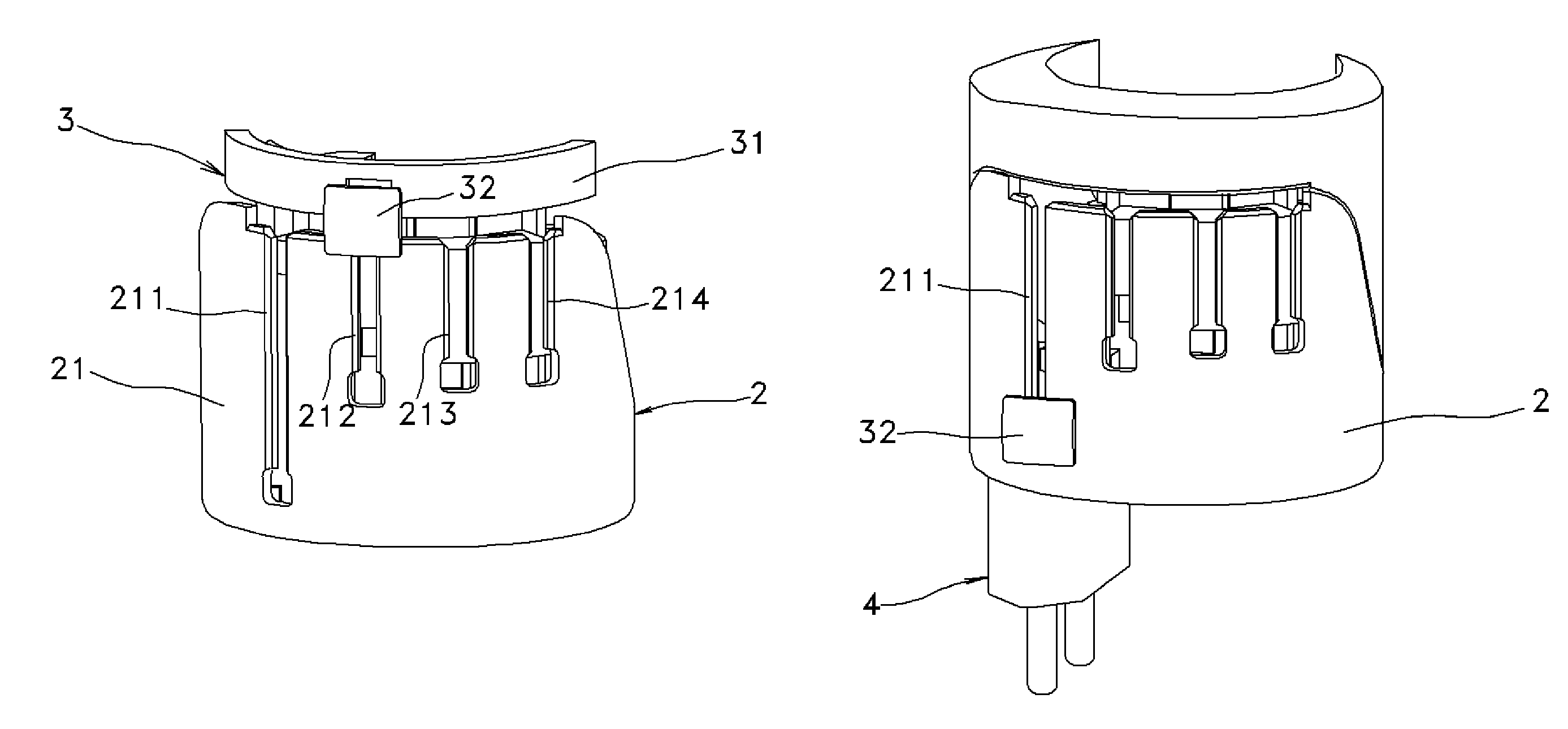

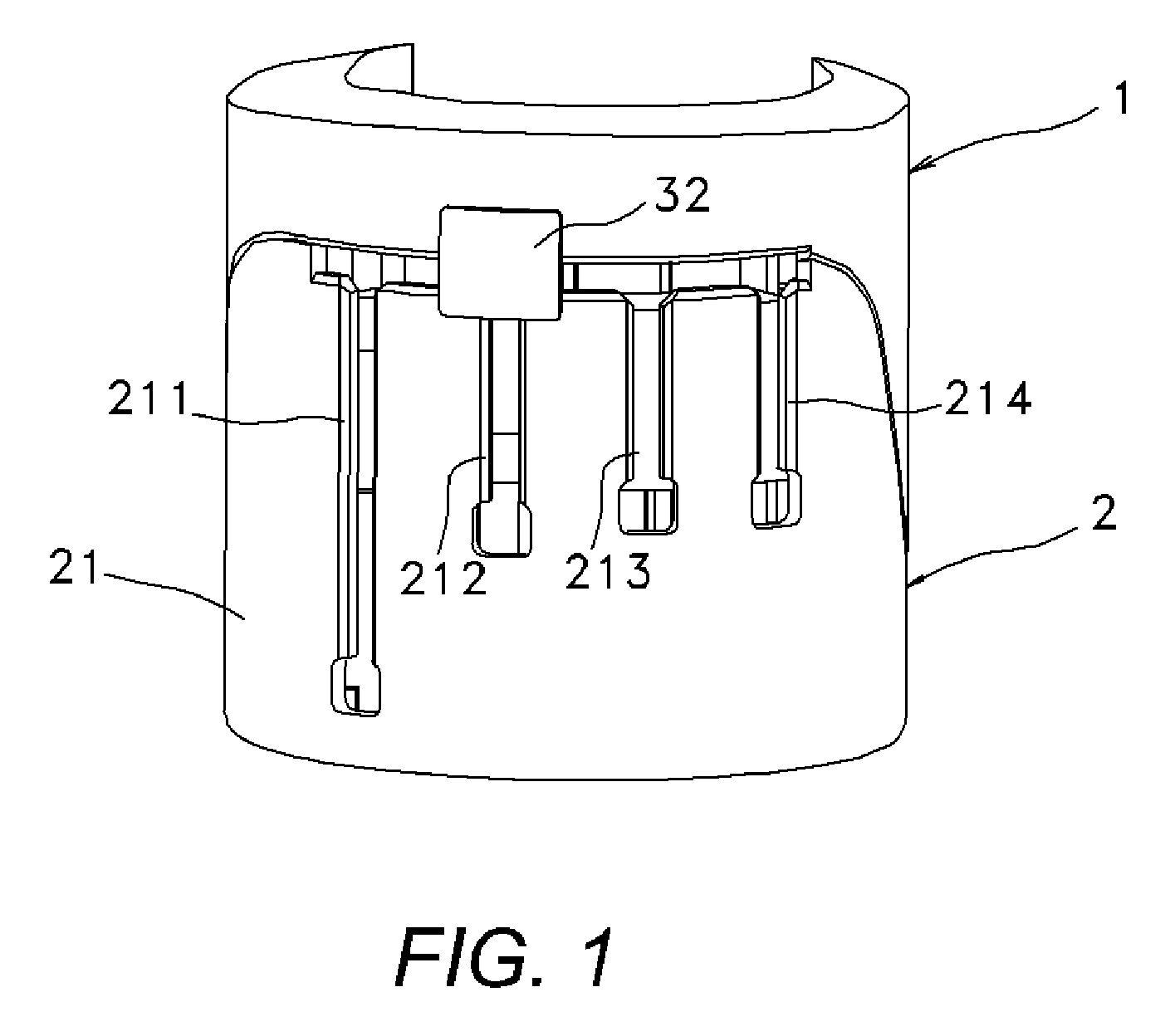

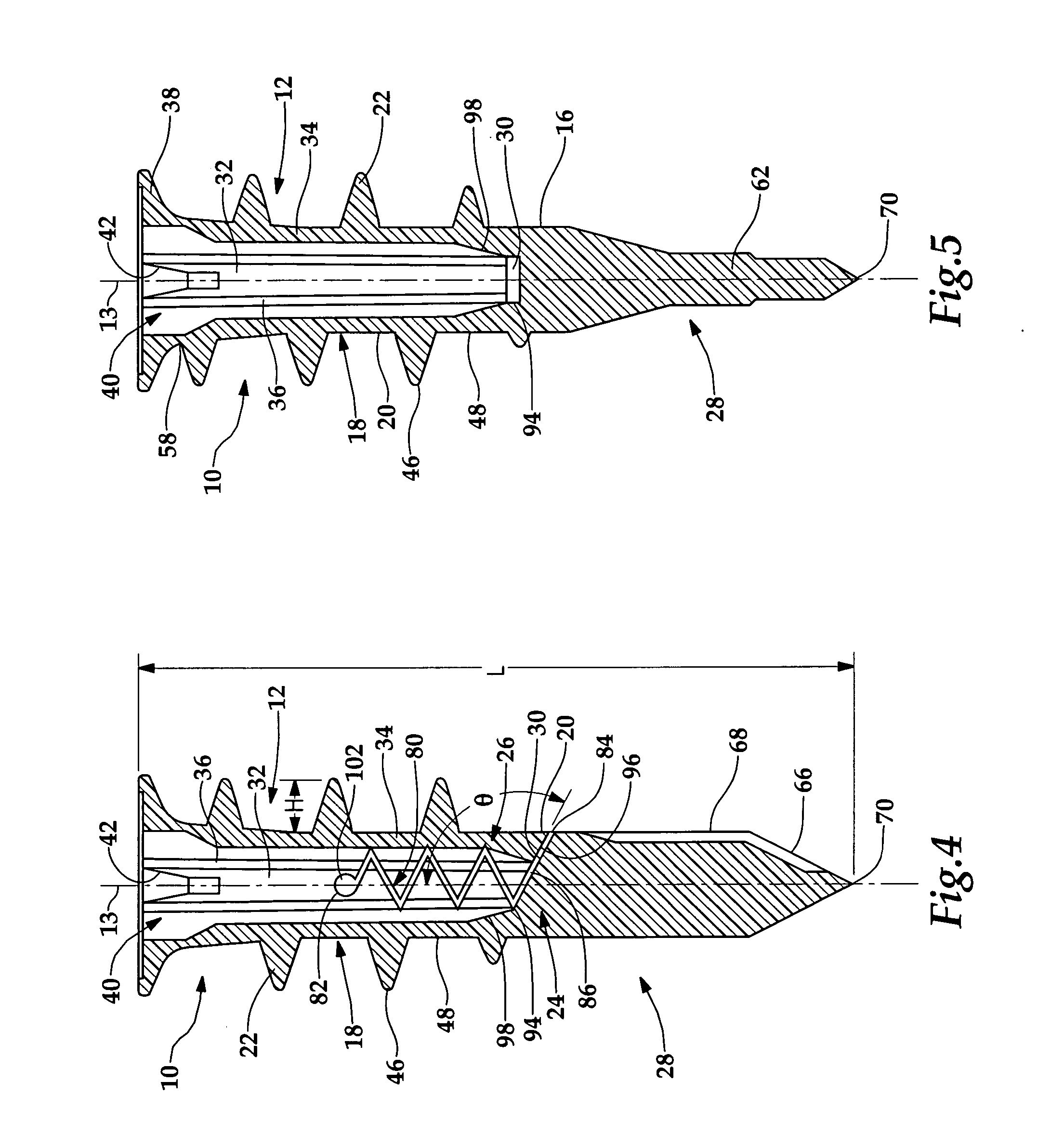

Catheter tunneler adapter and methods of assembly to a catheter and use

ActiveUS20080097409A1Facilitate implantationEasy to pullEar treatmentMulti-lumen catheterCatheter insertionCatheter tunneler

A catheter tunneling adapter (10) including a generally elongated body (12) having a proximal end (14), a distal end (16) and a through passageway (18) extending therethrough between the proximal and distal end. The proximal end (14) of the adapter (10) is connectable both to a proximal hub of a stylet (70) and subsequently to the distal end (84,94) of a tunneler (80,90). The distal end (16) of the adapter (10) comprises a connector for connecting a plurality of proximal catheter tubes (52,54) thereto, wherein the proximal end of one tube (52) is affixed within the passageway at the adapter's distal end (16) and the proximal end of the second tube (54) is plugged by a plug (40) extending distally from a free end of an elongate flexible arm (30) that also extends distally of the adapter's distal end (16), such that the plug is offset laterally therefrom. The flexible arm (30) and the affixed second tube end (58) are deflectable toward the first tube (52) to reduce the profile of the assembly during tunneling. Methods of affixing an adapter to a catheter, of inserting a catheter into a patient, and of subcutaneously tunneling a catheter under a patient's skin using the tunneling device, are also disclosed.

Owner:MEDICAL COMPONENTS INC

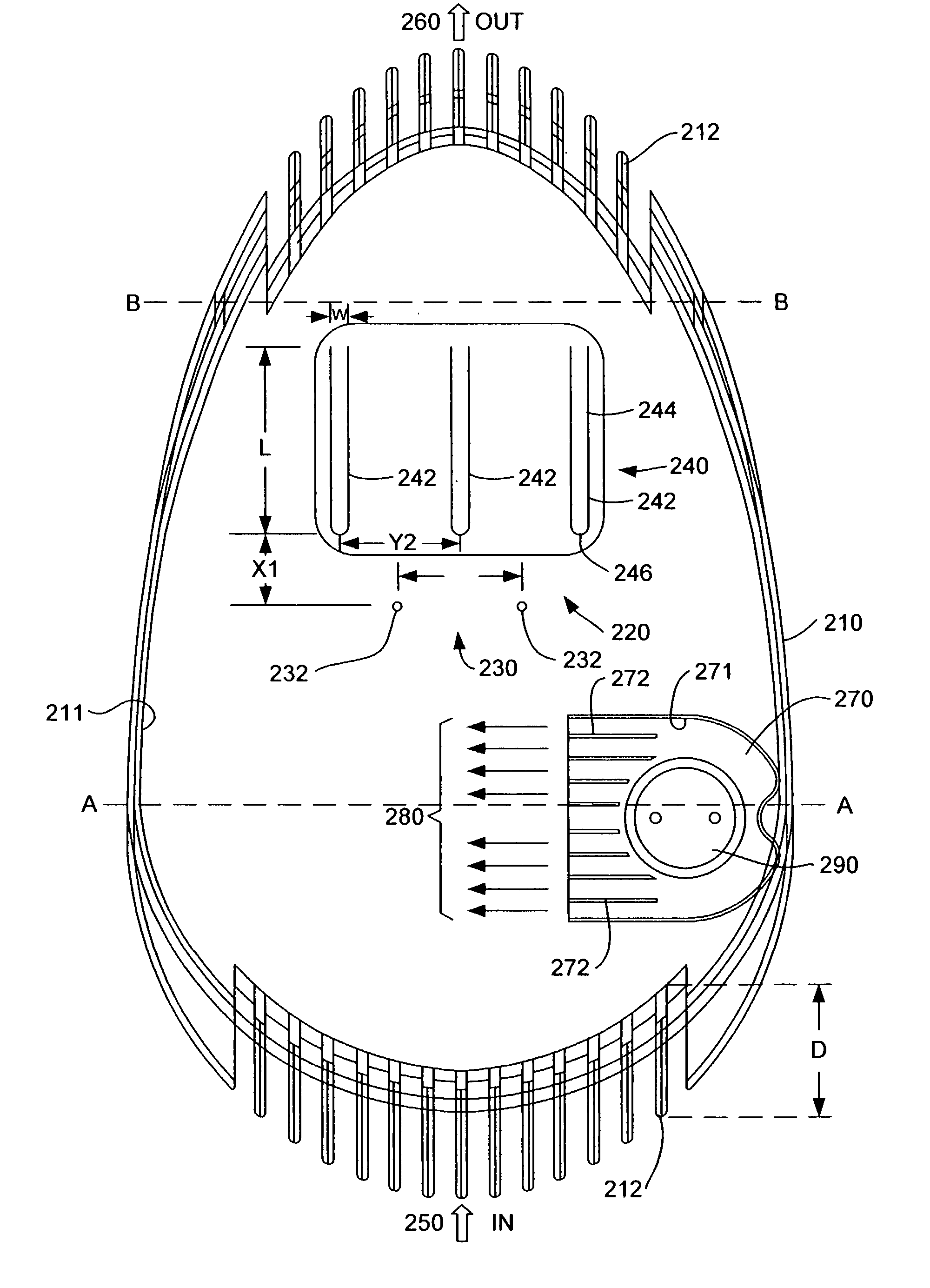

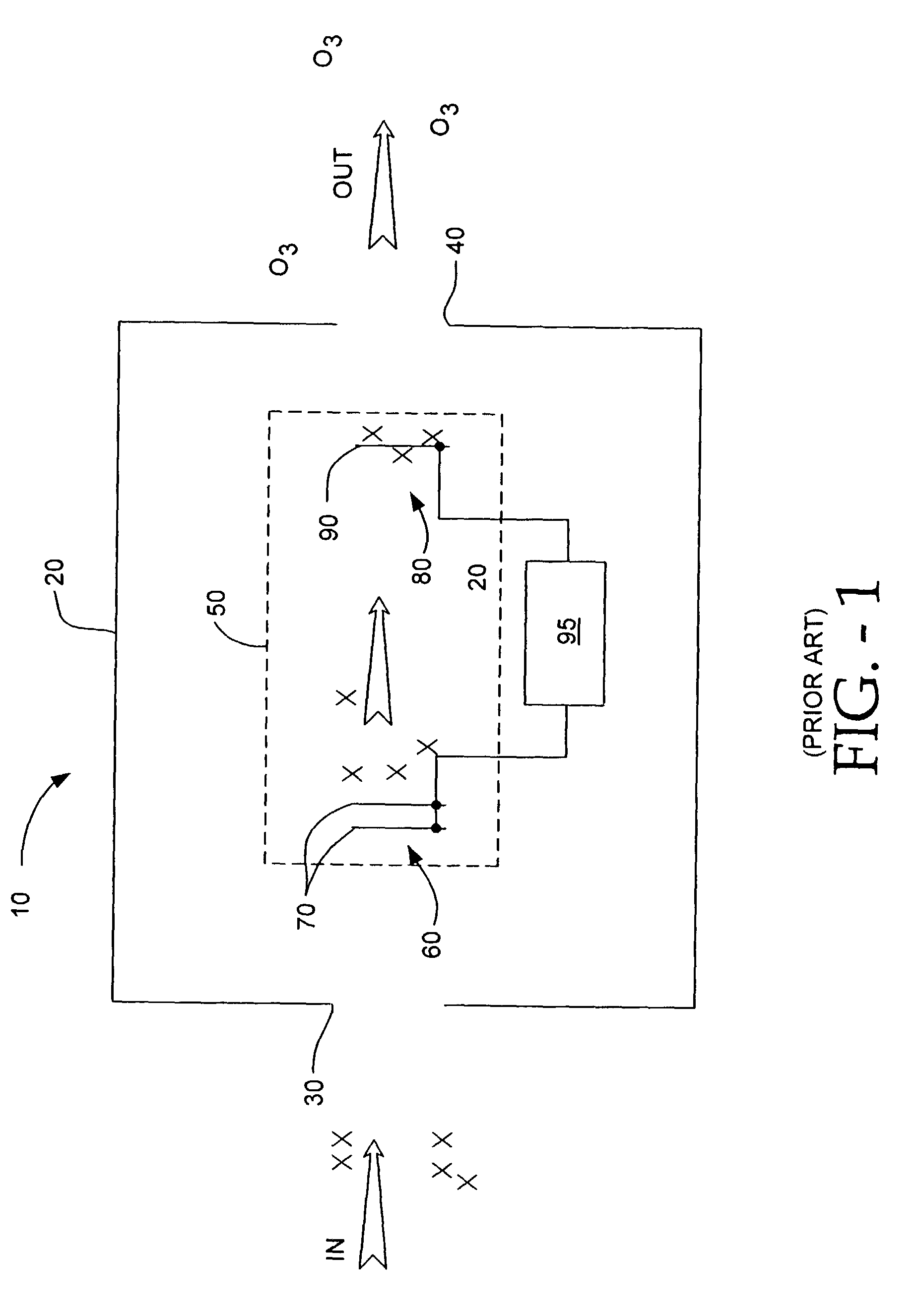

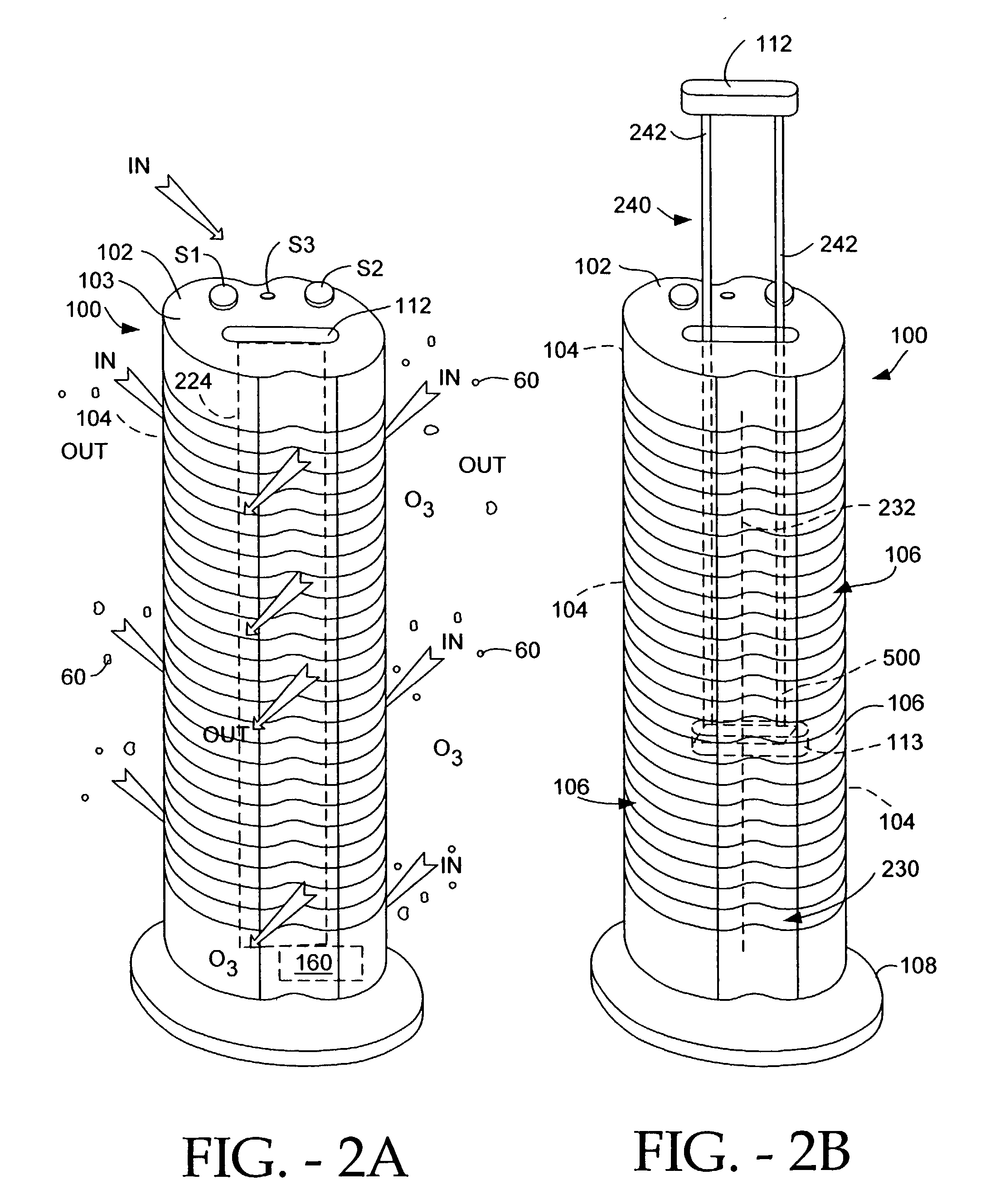

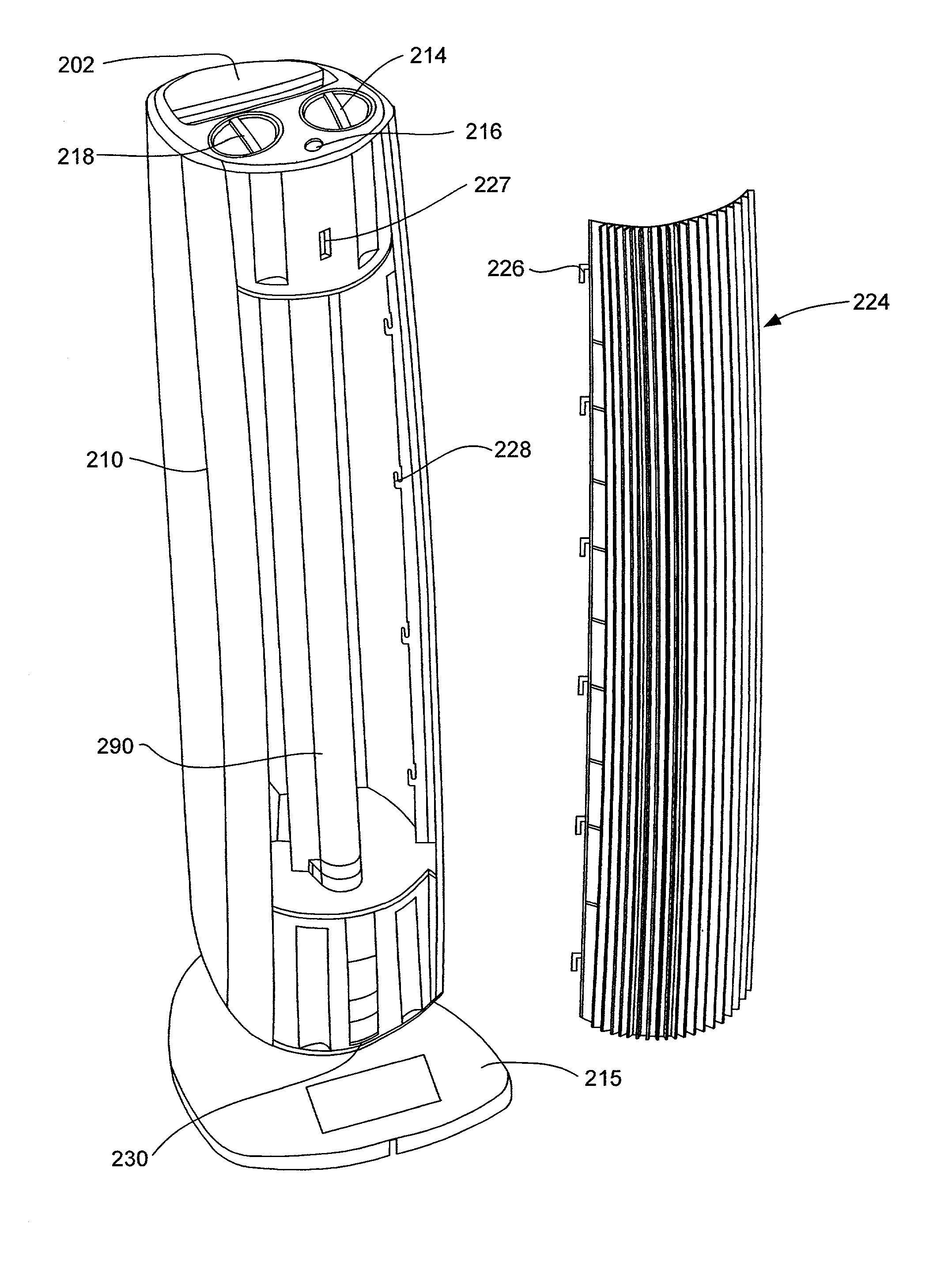

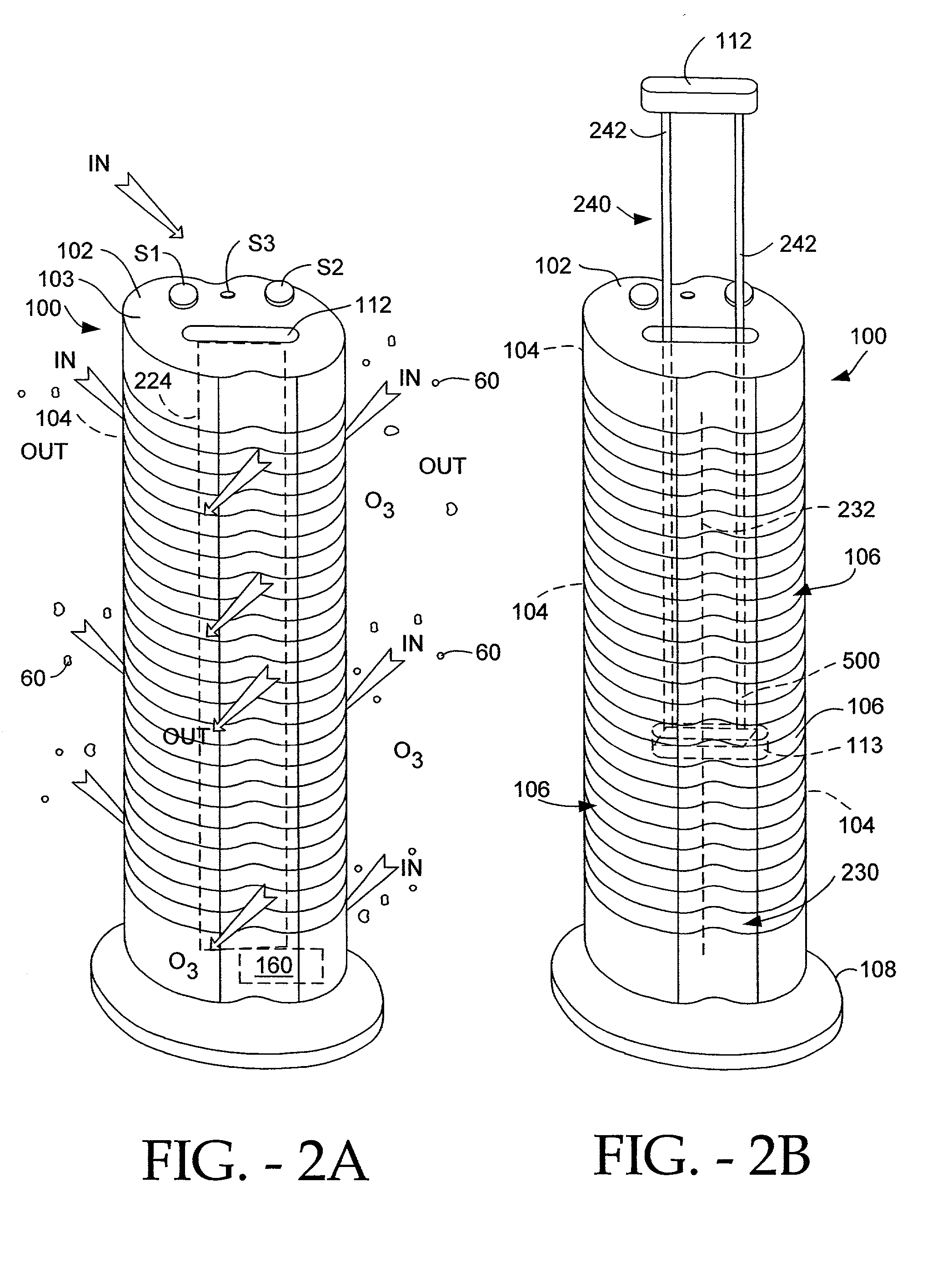

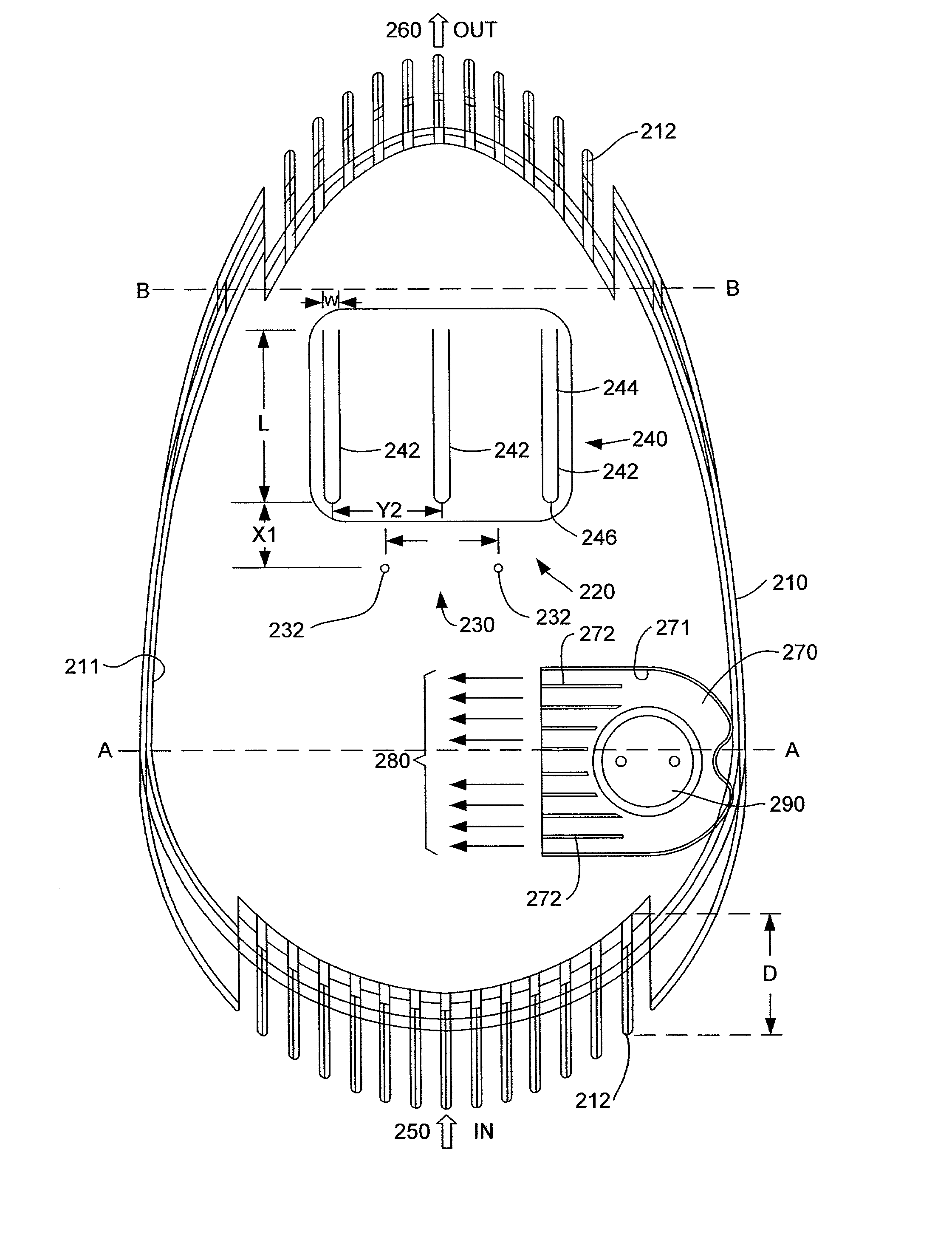

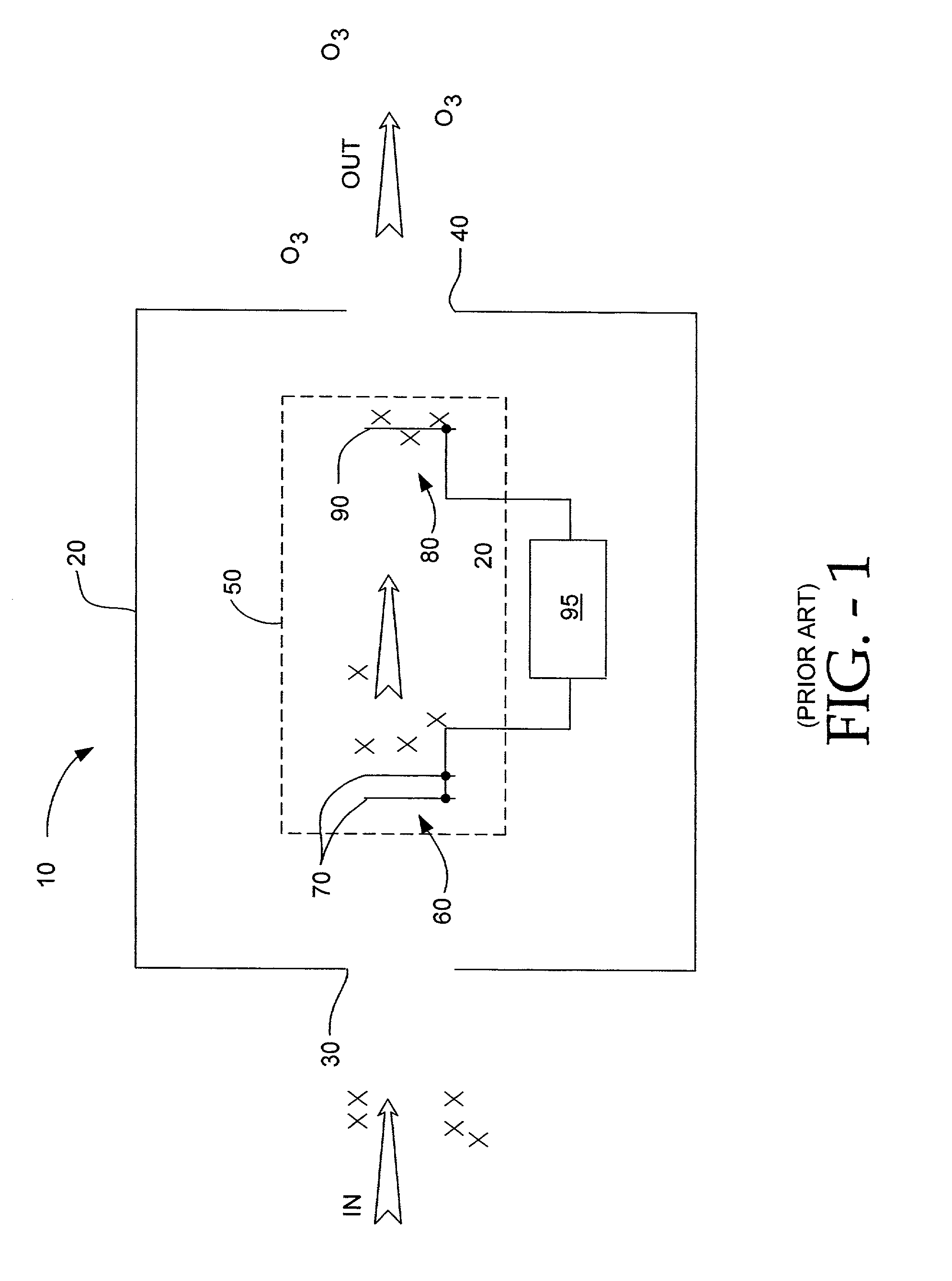

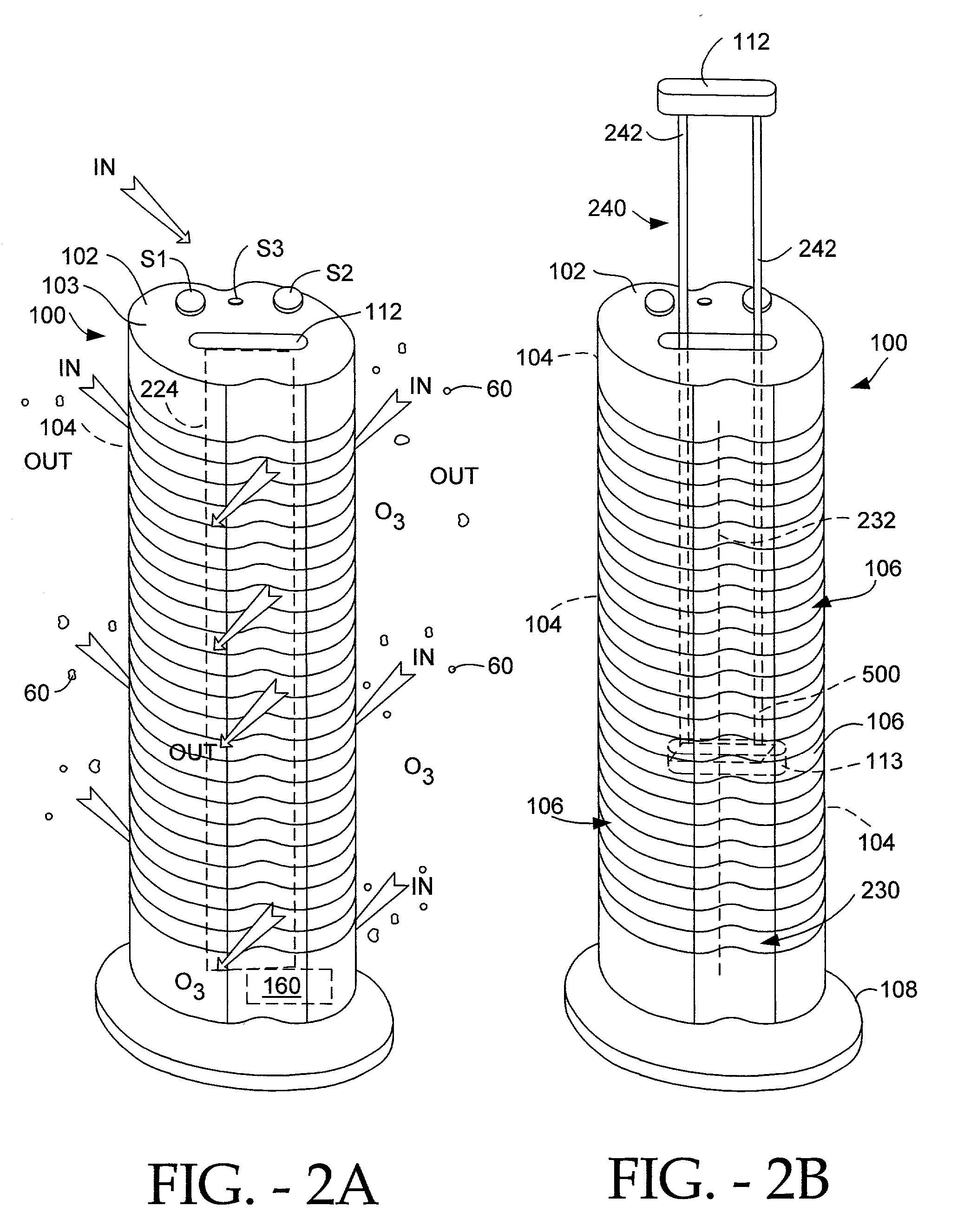

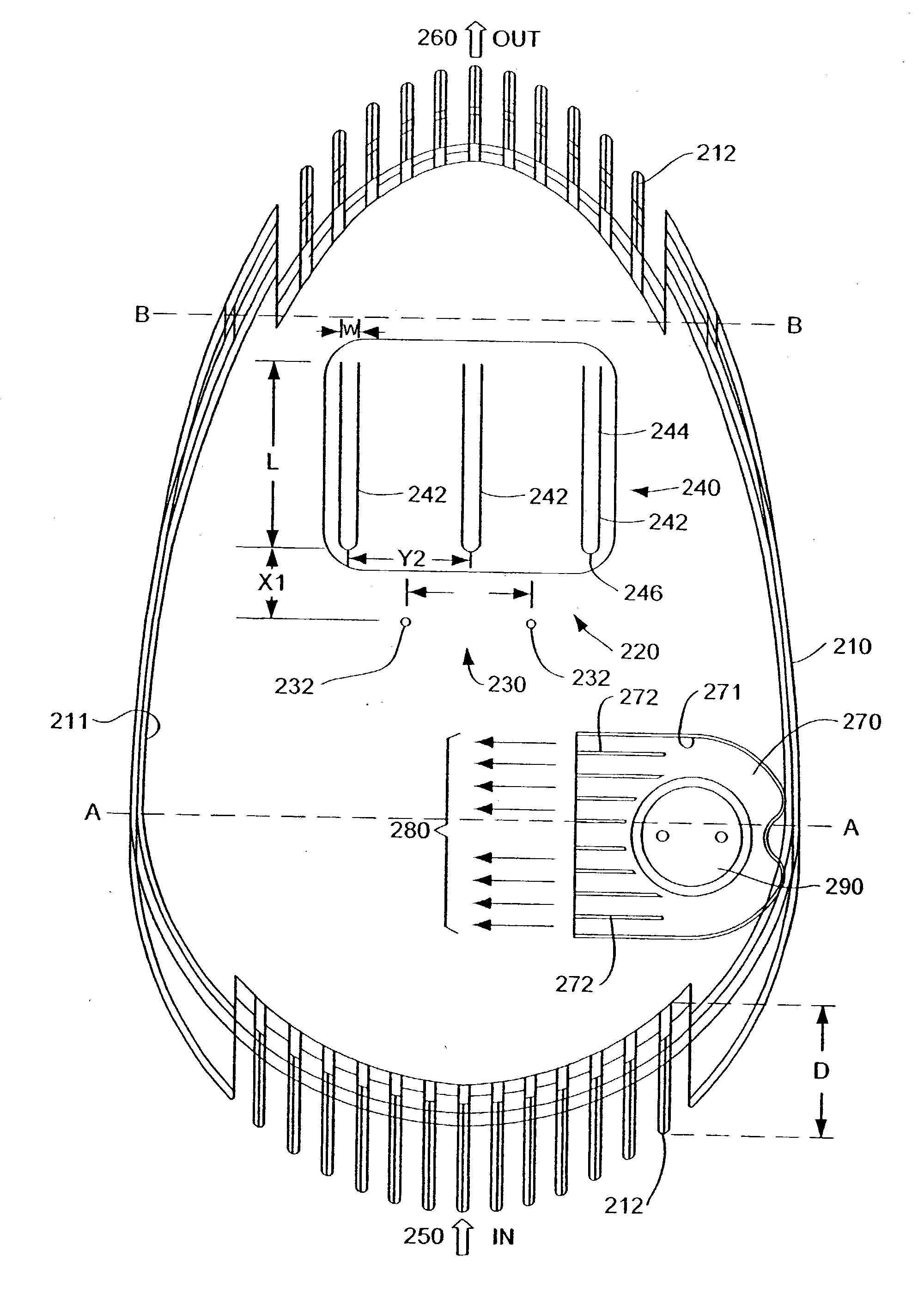

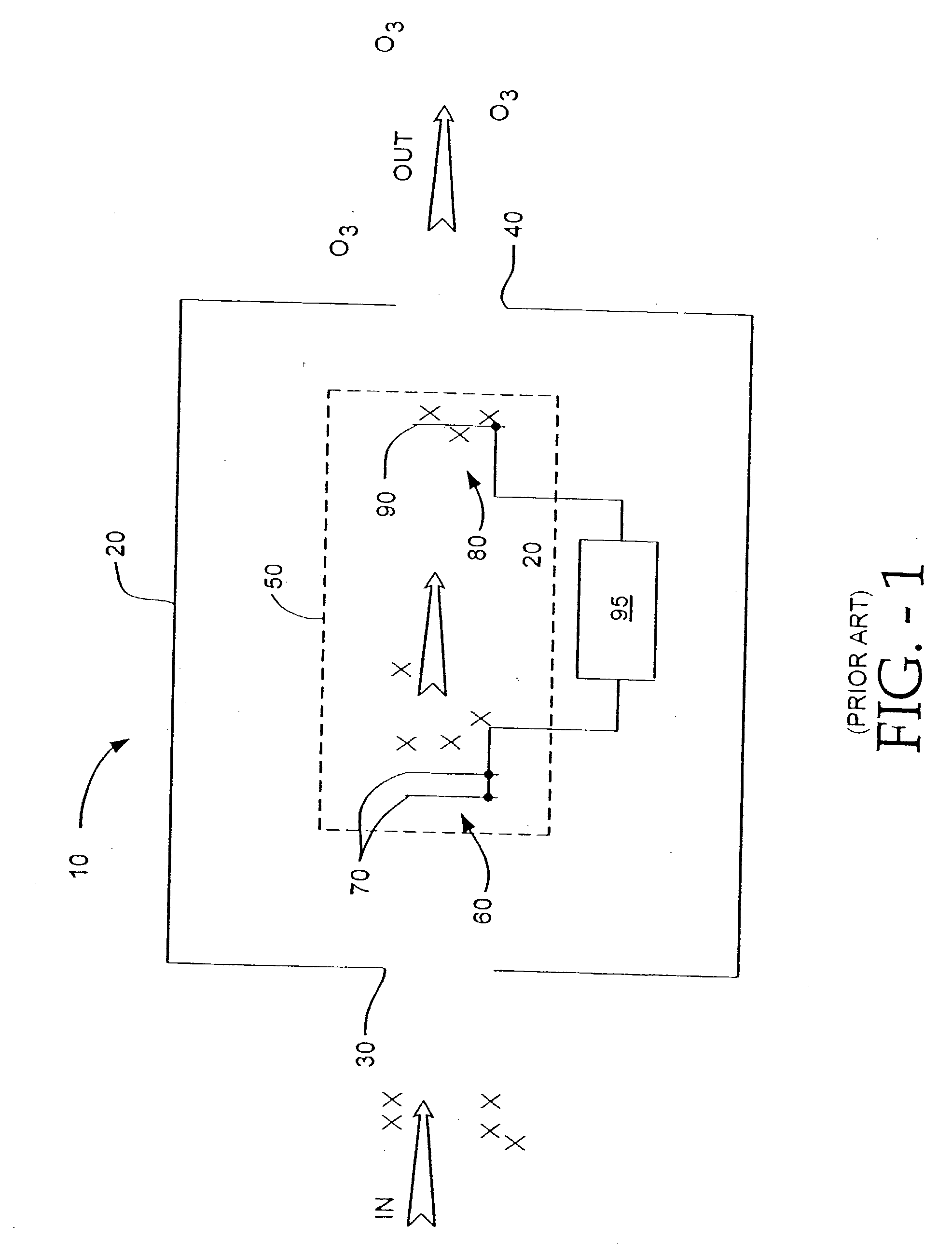

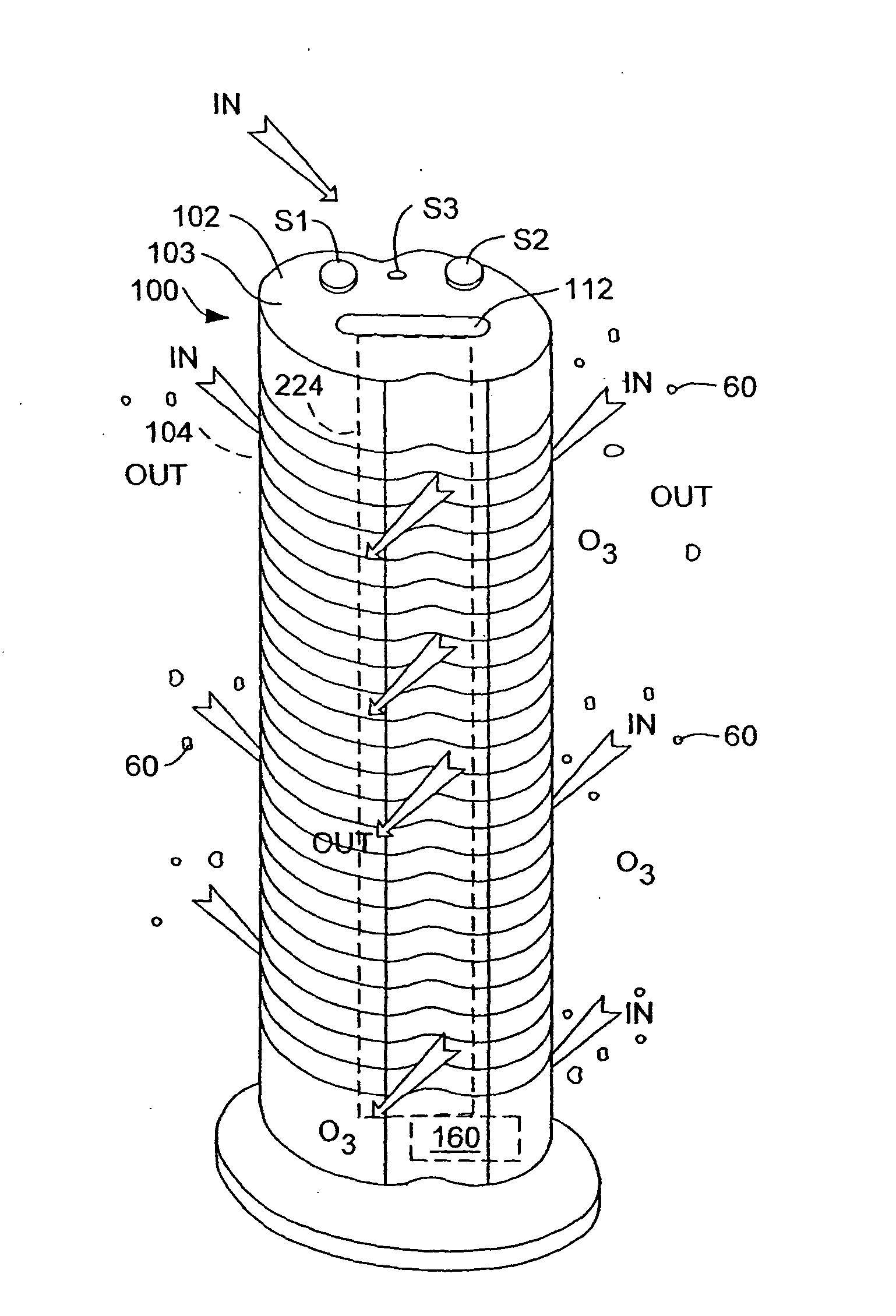

Electro-kinetic air transporter and conditioner device with enhanced housing configuration and enhanced anti-microorganism capability

InactiveUS20030206840A1Reduce the amount requiredSlow airflow rateMechanical apparatusLighting and heating apparatusParticulatesEmissivity

An electro-kinetic air conditioner for removing particulates from the air creates an airflow using no moving parts. The airflow is subjected to UV radiation from a germicidal lamp within the device. The conditioner includes an ion generator that has an electrode assembly including a first array of emitter electrodes, a second array of collector electrodes, and a high voltage generator. The device can also include a third or leading or focus electrode located upstream of the first array of emitter electrodes, and / or a trailing electrode located downstream of the second array of collector electrodes, and / or an interstitial electrode located between collector electrodes, and / or an enhanced emitter electrode with an enhanced length in order to increase emissivity.

Owner:SHARPER IMAGE ACQUISITION LLC A DELAWARE LIMITED LIABILITY

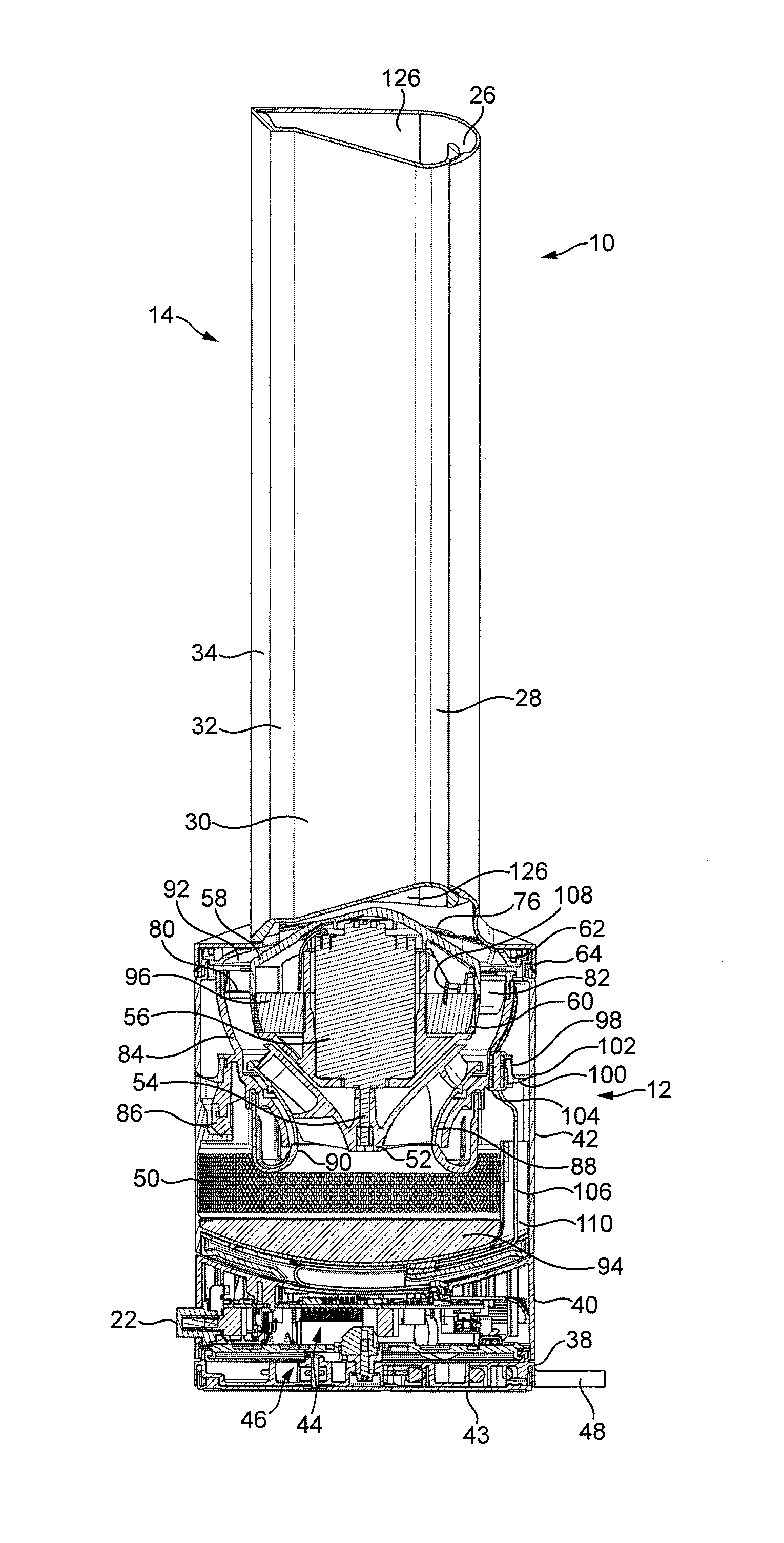

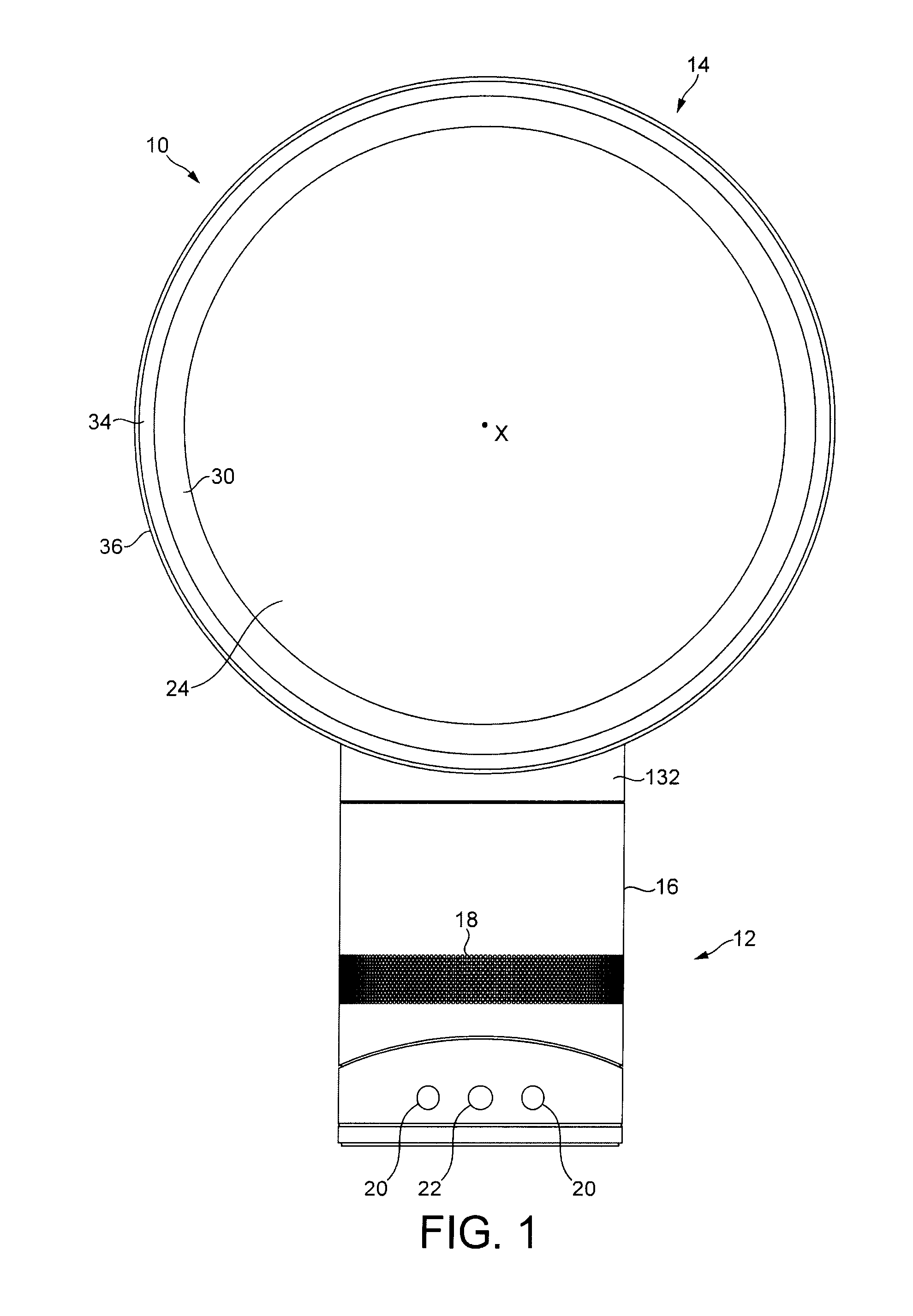

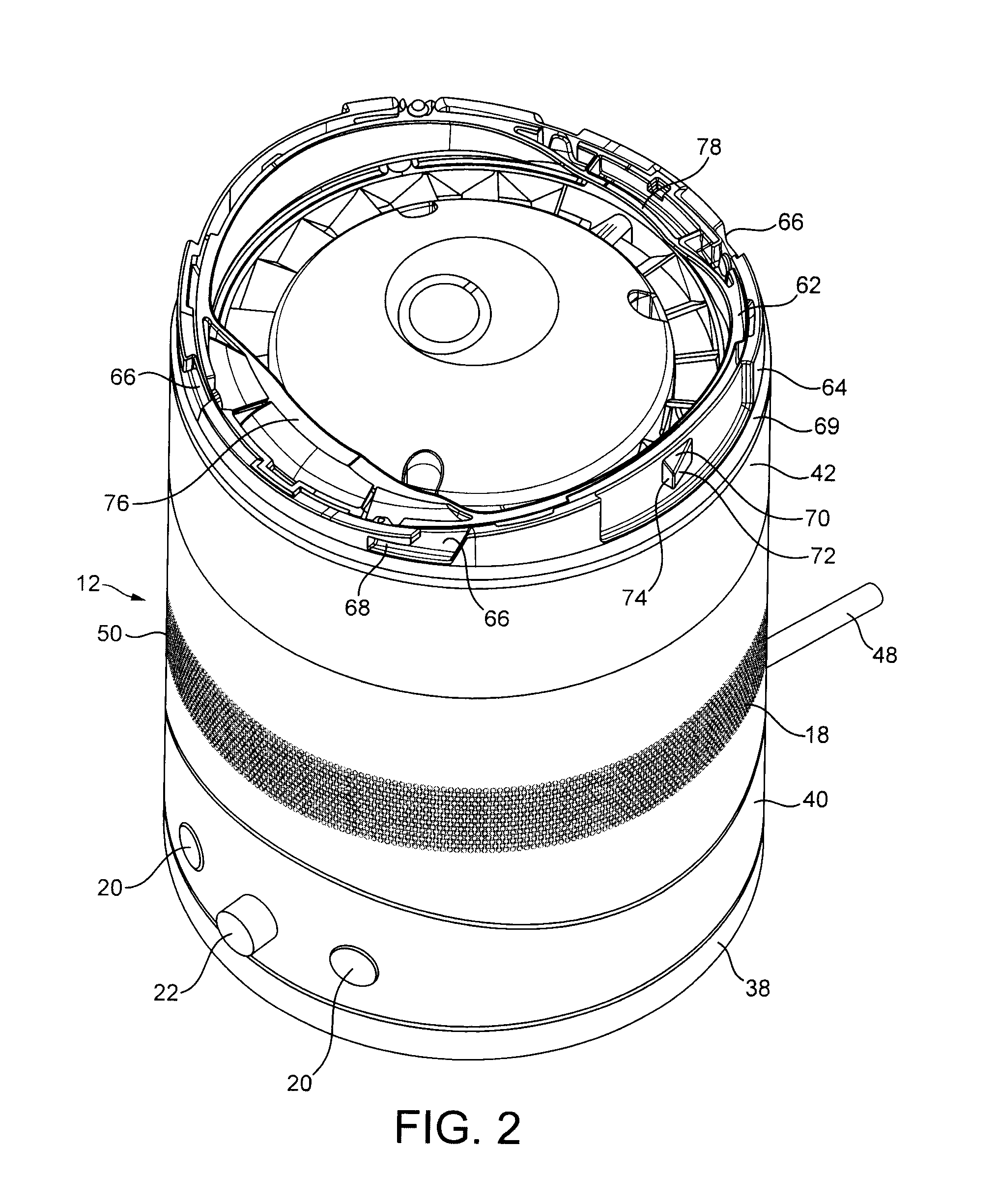

Fan

InactiveUS20110236228A1Increase contactLow costPositive displacement pump componentsLighting and heating apparatusImpellerEngineering

A portable fan includes a casing having an air inlet, and an air outlet having an interior passage for receiving an air flow, and a mouth for emitting the air flow, the interior passage extending about an opening through which air is drawn by the air flow emitted from the mouth. The fan includes an impeller and a motor for rotating the impeller to generate an air flow between the air inlet and an air outlet which has a static pressure of at least 150 Pa downstream from the impeller. A filter unit is detachably connected to the casing. A filter of the filter unit is located upstream of the air inlet to remove airborne particulates from the air flow before it enters the casing.

Owner:DYSON TECH LTD

Electro-kinetic air transporter and conditioner device with enhanced anti-microorganism capability

InactiveUS20030206839A1Reduce the amount requiredSlow airflow rateMechanical apparatusLighting and heating apparatusParticulatesEmissivity

An electro-kinetic air conditioner for removing particulates from the air creates an airflow using no moving parts. The airflow is subjected to UV radiation from a germicidal lamp within the device. The conditioner includes an ion generator that has an electrode assembly including a first array of emitter electrodes, a second array of collector electrodes, and a high voltage generator. The device can also include a third or leading or focus electrode located upstream of the first array of emitter electrodes, and / or a trailing electrode located downstream of the second array of collector electrodes, and / or an interstitial electrode located between collector electrodes, and / or an enhanced emitter electrode with an enhanced length in order to increase emissivity.

Owner:SHARPER IMAGE ACQUISITION LLC A DELAWARE LIMITED LIABILITY

Universal power adapter

InactiveUS7220139B1Easy constructionEasy to operateCoupling device connectionsRotary switchEngineering

A universal power adapter to allow only the plug desired to stick out smoothly in a simple construction and allowing convenient operation is comprised of a lid, a base, a rotary switch, and multiple plugs; multiple channels being disposed on the external wall of the base, a standardized plug being inserted to each channel; a rotary switch containing a bar sliding block and a braking pushbutton; the bar sliding block containing a bar slide and a gap; the pushbutton being inserted into the gap; a protruding block and a slot below being disposed to the top of the plug; the slot receiving the insertion end of the braking pushbutton; and the pushbutton sliding in the channel on the external wall of the base; and the protruding block of each plug being inserted into the bar slide of the bar sliding block to slide against the protruding block.

Owner:CHANG HSI FAN

Electro-kinetic air transporter and conditioner device with enhanced maintenance features and enhanced anti-microorganism capability

InactiveUS20030206837A1Reduce the amount requiredSlow airflow rateMechanical apparatusLighting and heating apparatusParticulatesEmissivity

An electro-kinetic air conditioner for removing particulates from the air creates an airflow using no moving parts. The airflow is subjected to UV radiation from a germicidal lamp within the device. The conditioner includes an ion generator that has an electrode assembly including a first array of emitter electrodes, a second array of collector electrodes, and a high voltage generator. The device can also include a third or leading or focus electrode located upstream of the first array of emitter electrodes, and / or a trailing electrode located downstream of the second array of collector electrodes, and / or an interstitial electrode located between collector electrodes, and / or an enhanced emitter electrode with an enhanced length in order to increase emissivity.

Owner:THE SHARPER IMAGE

Electro-kinetic air transporter and conditioner devices with special detectors and indicators

InactiveUS20030209420A1Easy to pullMechanical apparatusLighting and heating apparatusElectrode arrayTimer

Owner:SHARPER IMAGE ACQUISITION

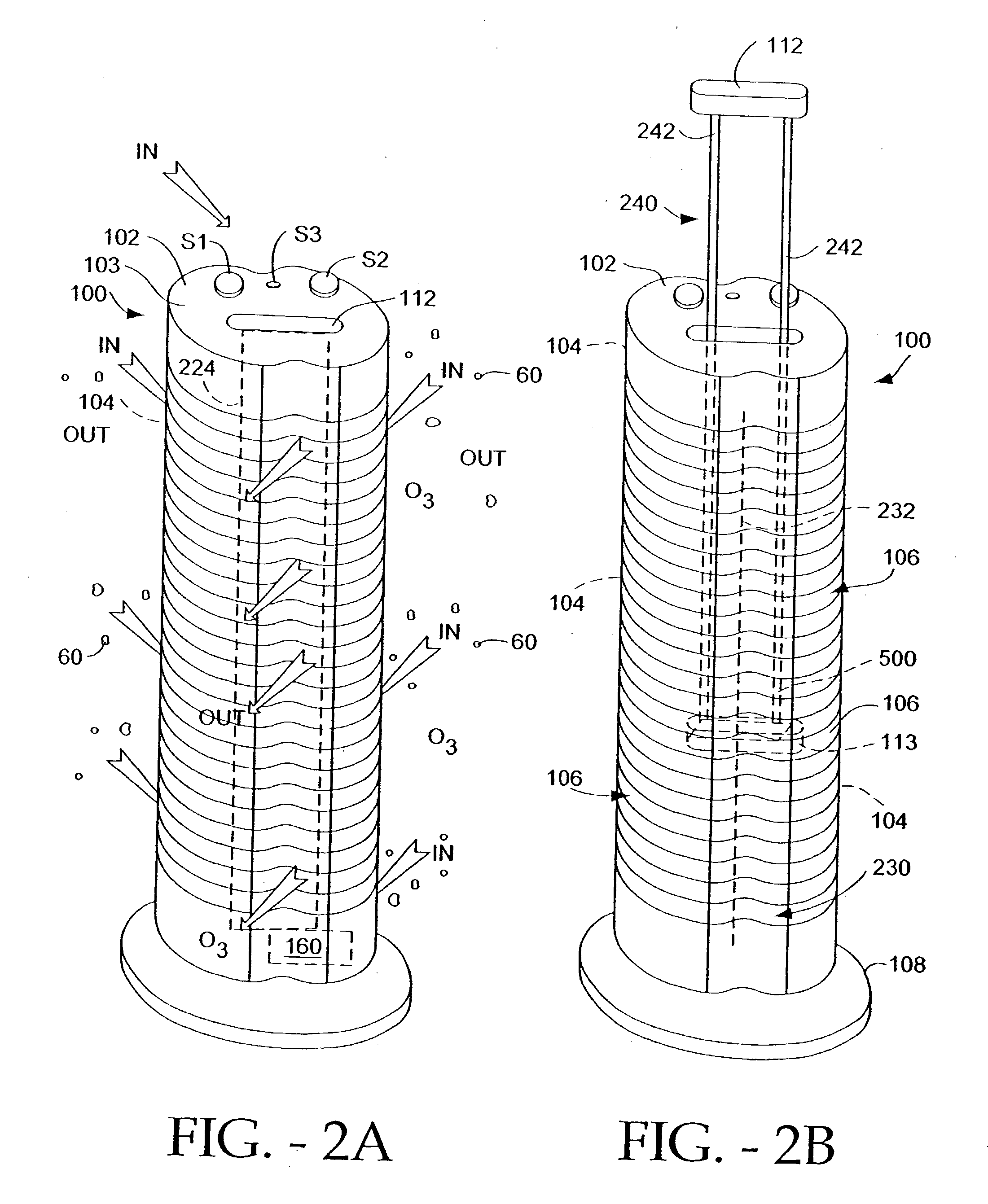

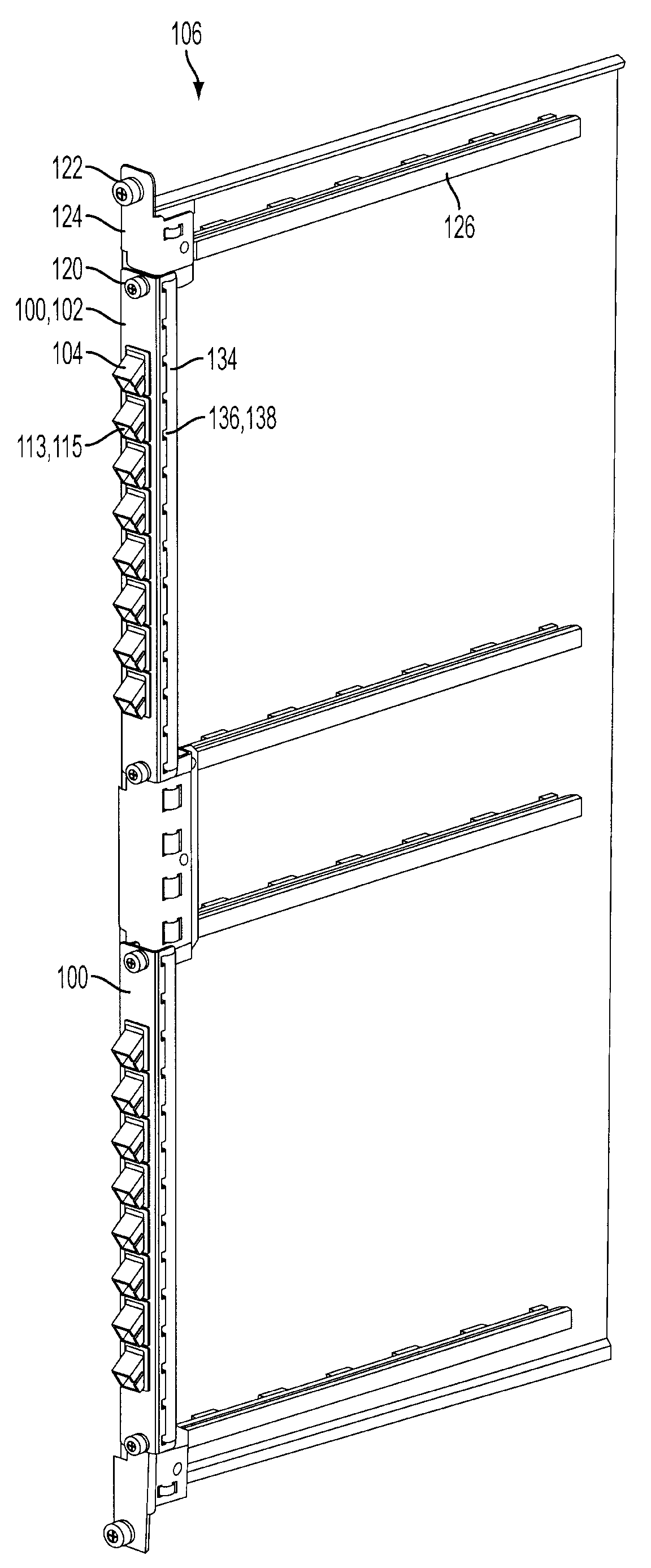

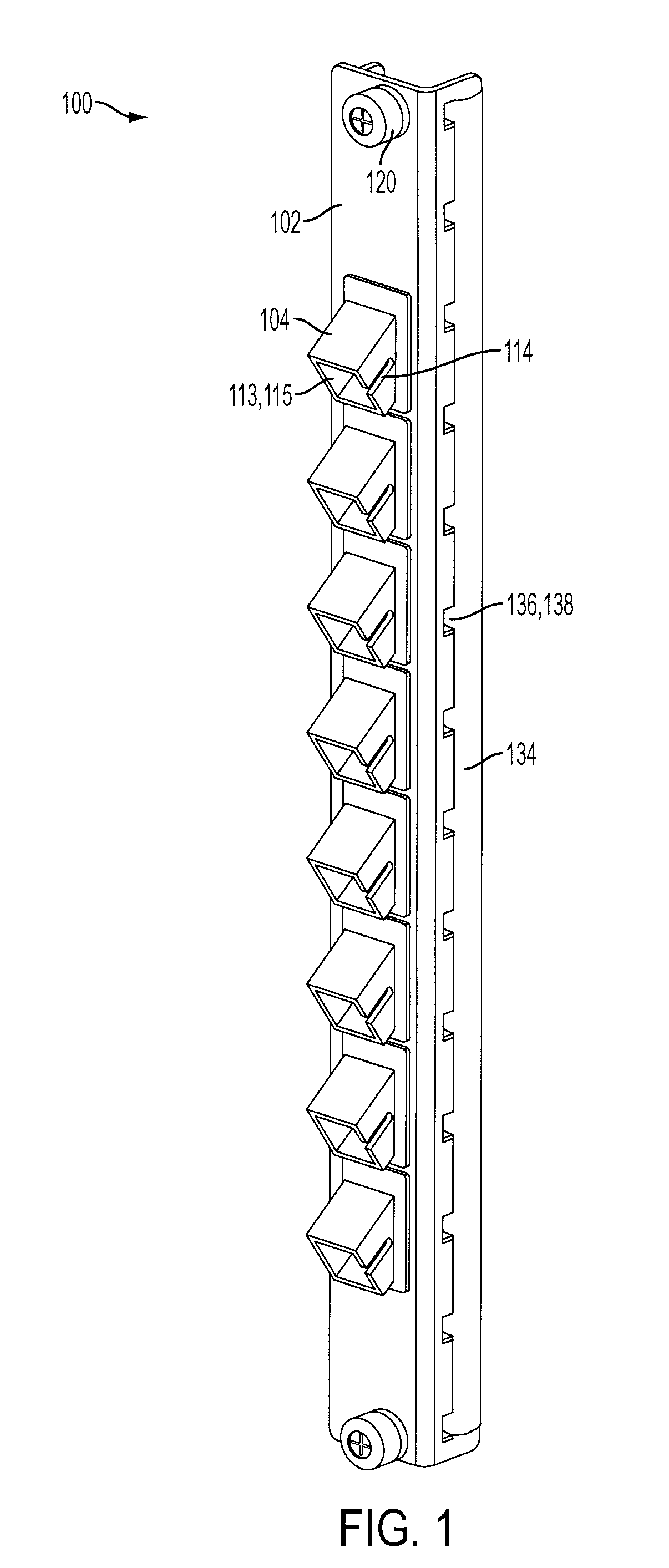

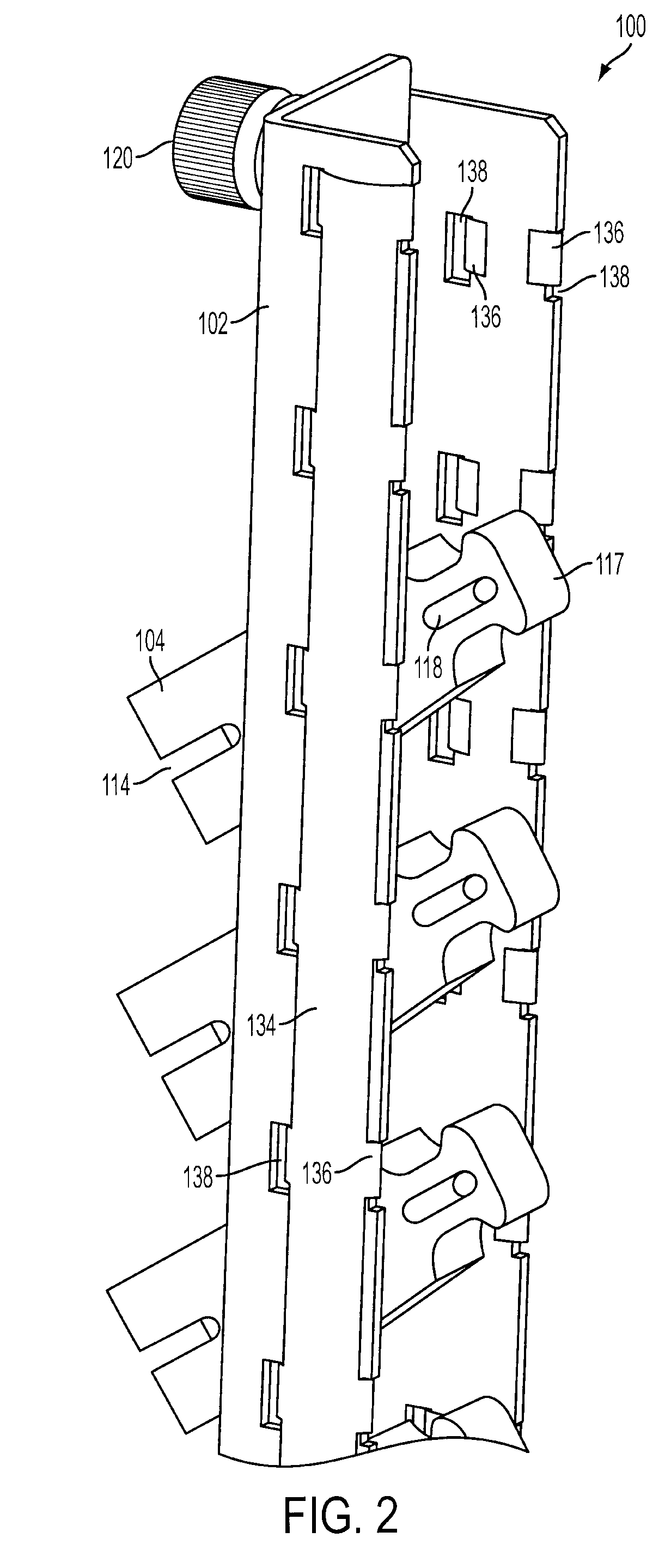

Blank plate for managing cables

A blank or parking plate for managing cables, particularly fiber optic cables, having a planar base, removably securable to a chassis, and at least one resilient holder removably inserted through an aperture in the base, for securing and enclosing an end portion of a cable. The blank plate with at least one holder is arranged so as not to extend substantially within the chassis. The holder may secure a male cable connector end in substantially the same position and orientation that it will occupy when inserted into a female connector of an active circuit board, which replaces the blank plate. A distensible opening to an enclosure inside the holder may protect the cable end from dust or contact damage with foreign objects by defining an inner space behind an inlet for the cable, but no further opening serving as an outlet for the cable.

Owner:TELLABS PETALUMA

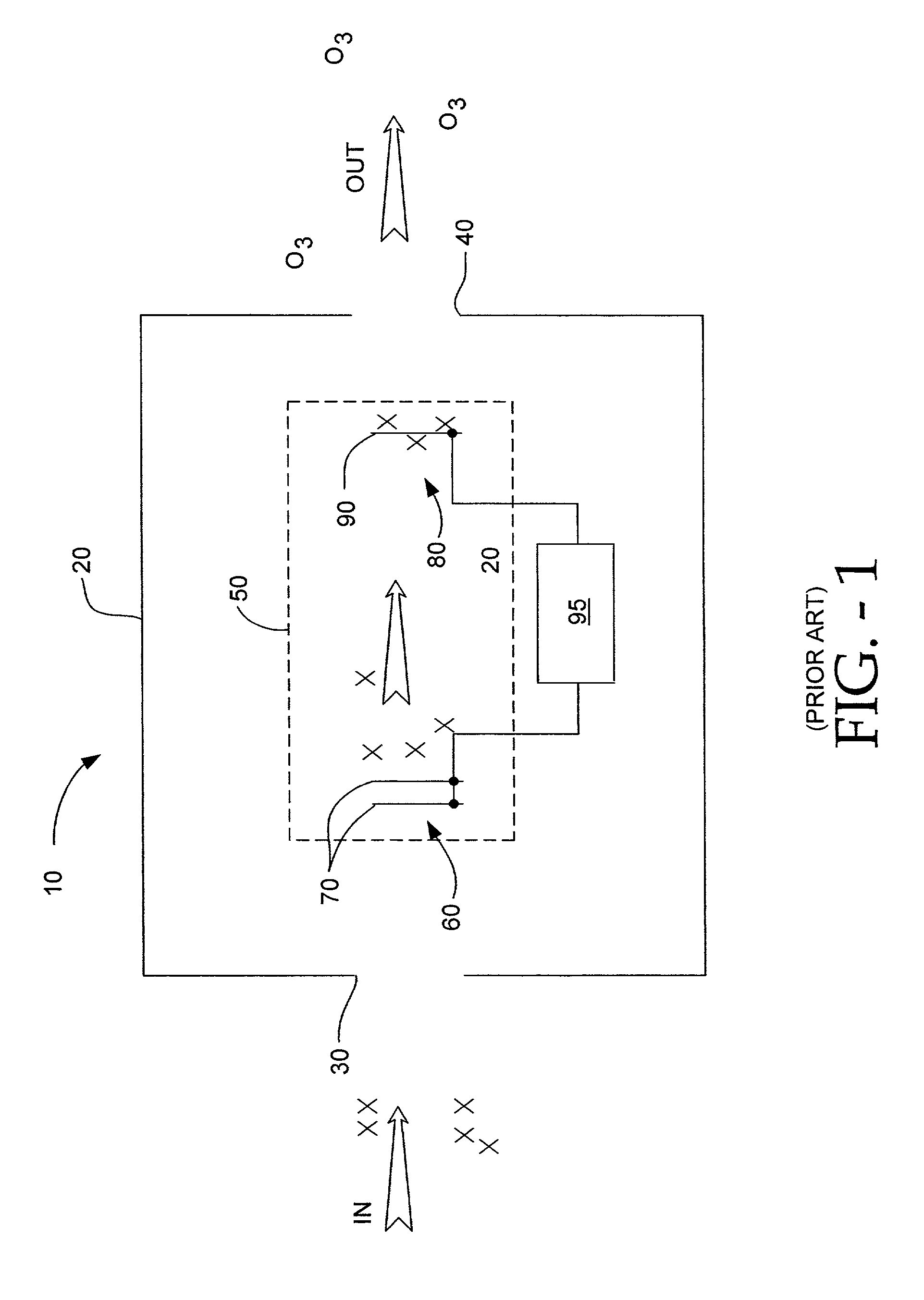

Electro-kinetic air transporter and conditioner devices with features that compensate for variations in line voltage

InactiveUS20040251124A1Increase airflowDrag minimizationMechanical apparatusLighting and heating apparatusRegulators (device)Voltage sensing

Systems and methods are provided for compensating for variations in line voltages the power an electro-kinetic air transporter and conditioner device. The electro-kinetic air transporter and conditioner device includes a high voltage generator that provides a potential difference between at least one emitter electrode and at least one collector electrode. The high voltage generator is driven by both a DC voltage obtained from an AC voltage source, and a low voltage pulse signal. The DC voltage is stepped down to produce a voltage sense signal indicative of a level of AC voltage source. The voltage sense signal is monitored. At least one of a pulse width, duty cycle and frequency of the low voltage pulse signal is adjusted, based on the monitored voltage sense signal, in order to substantially maintain the potential difference at a desired level.

Owner:SHARPER IMAGE ACQUISITION

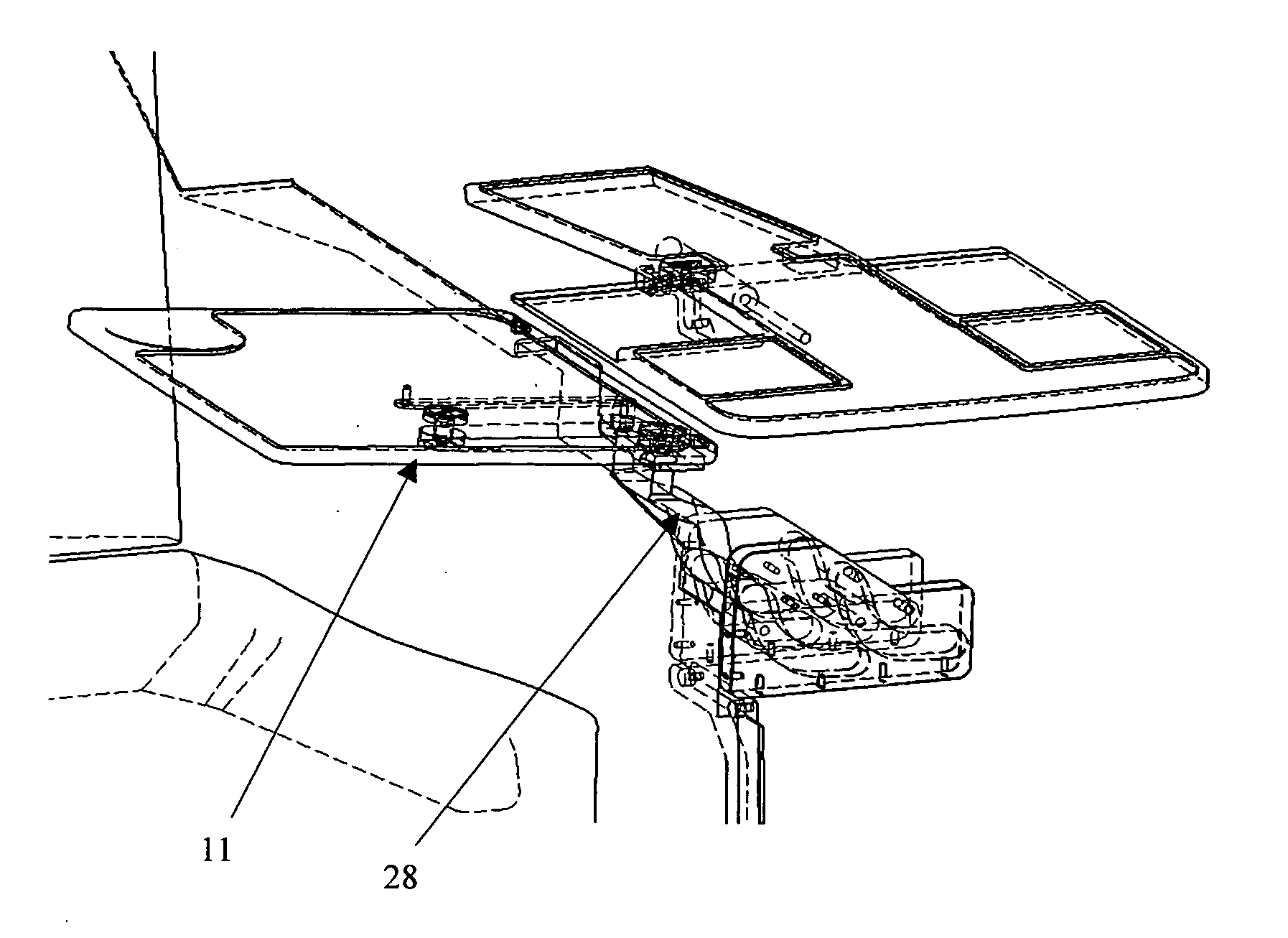

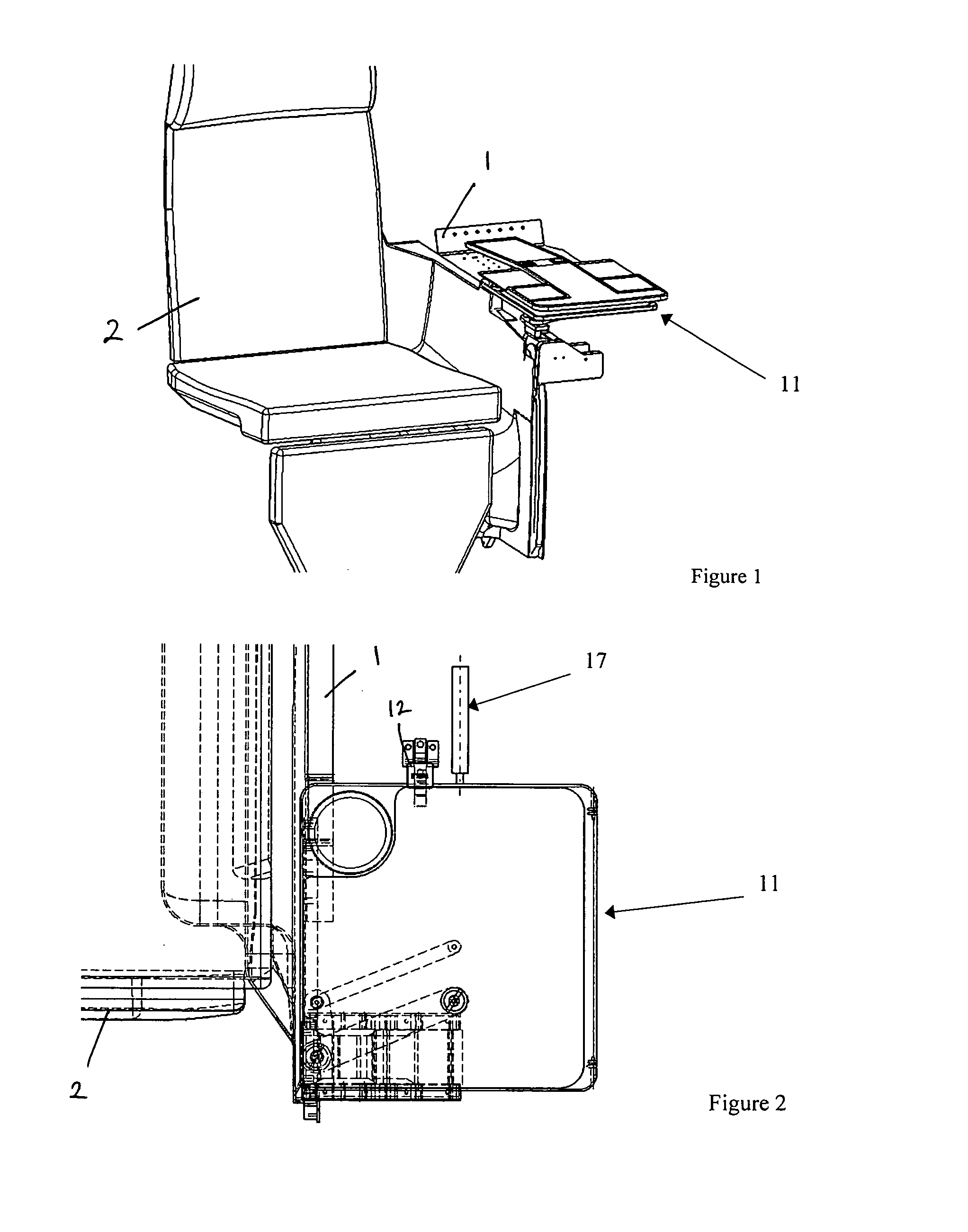

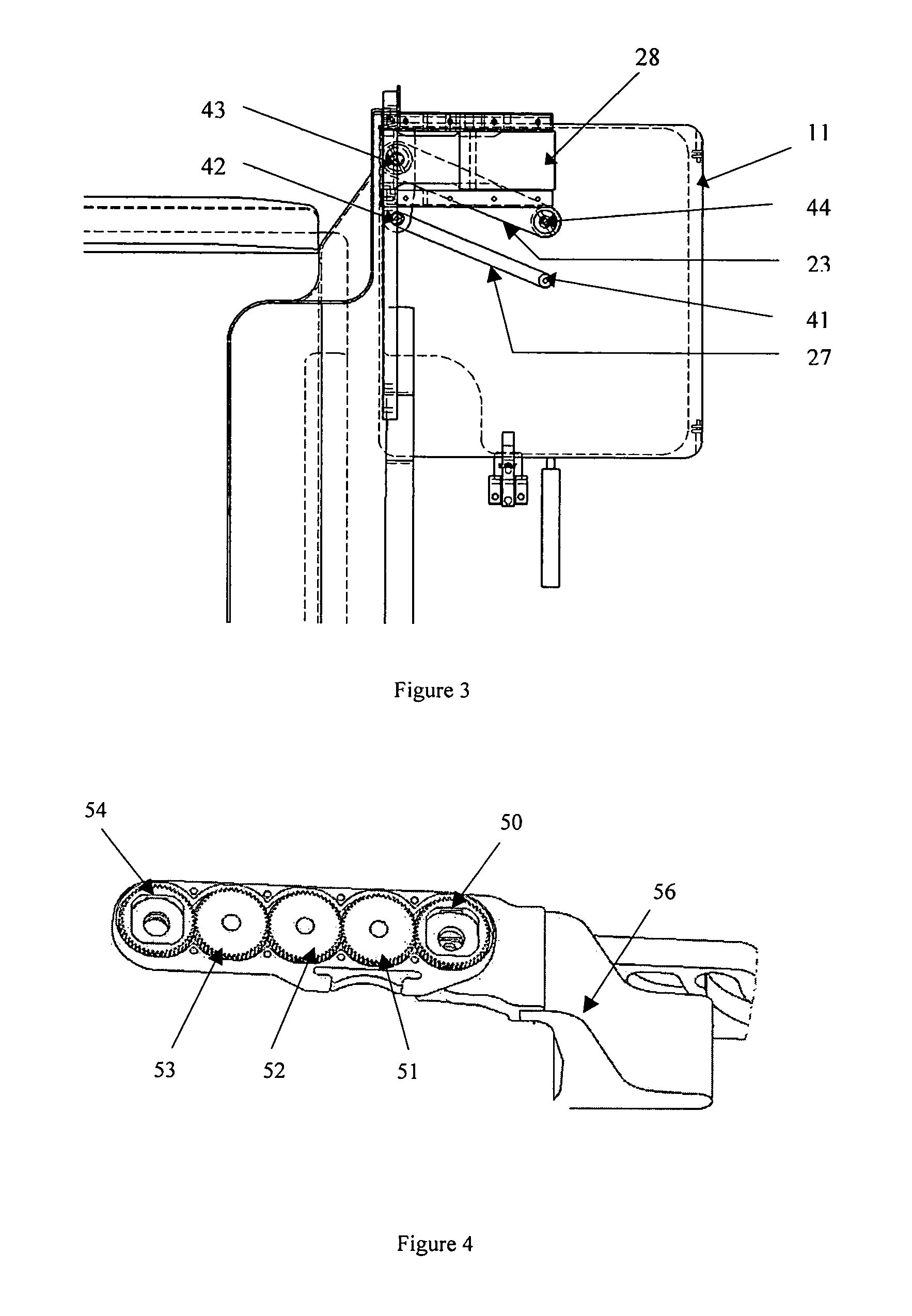

Table apparatus for a vehicle seat

ActiveUS20100319588A1Simpler intuitive kinematicsReduce in quantityVehicle arrangementsSeating arrangementsEngineeringLinkage concept

Owner:THOMPSON AERO SEATING

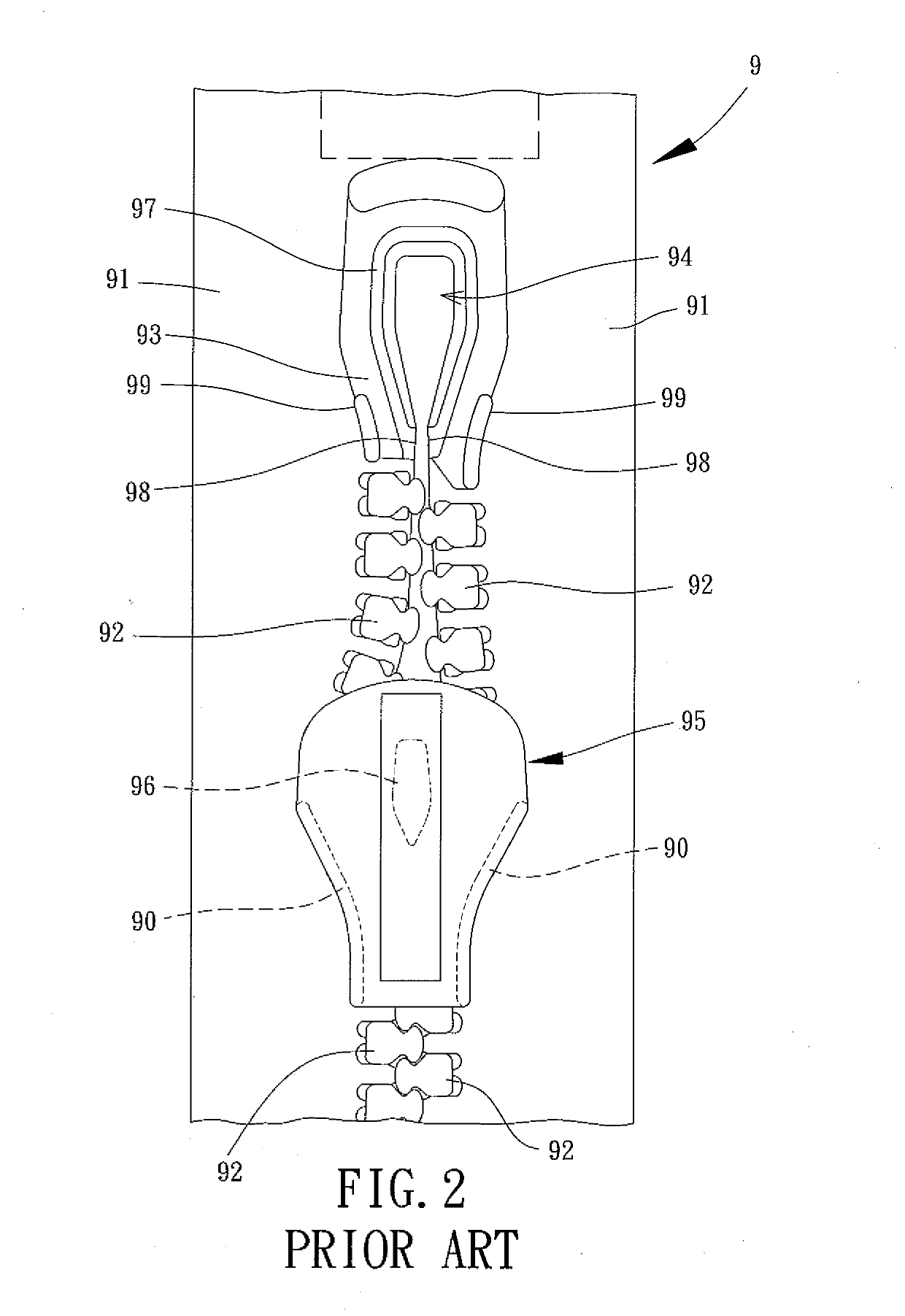

Watertight Slide Fastener

A watertight slide fastener includes two tapes each having a waterproof layer. Each of the two tapes includes an inner edge on which a plurality of consecutively disposed scoops and an upper stopper scoop made of a rigid plastic are mounted. A first end of each upper stopper scoop is contiguous to the last one of the plurality of scoops. A second end of each upper stopper scoop has an extension. A top end stop is formed on upper and lower faces of each of the two tapes by an elastomer and envelops an upper face and a lower face of each extension. Each of two outer sides of the top end stop has a shoulder. A slider includes an upper body and a lower body interconnected to the upper body by a diamond. Each of two sides of the upper and lower bodies has a flange.

Owner:TAIWAN UNITED OUTDOOR GRP INC

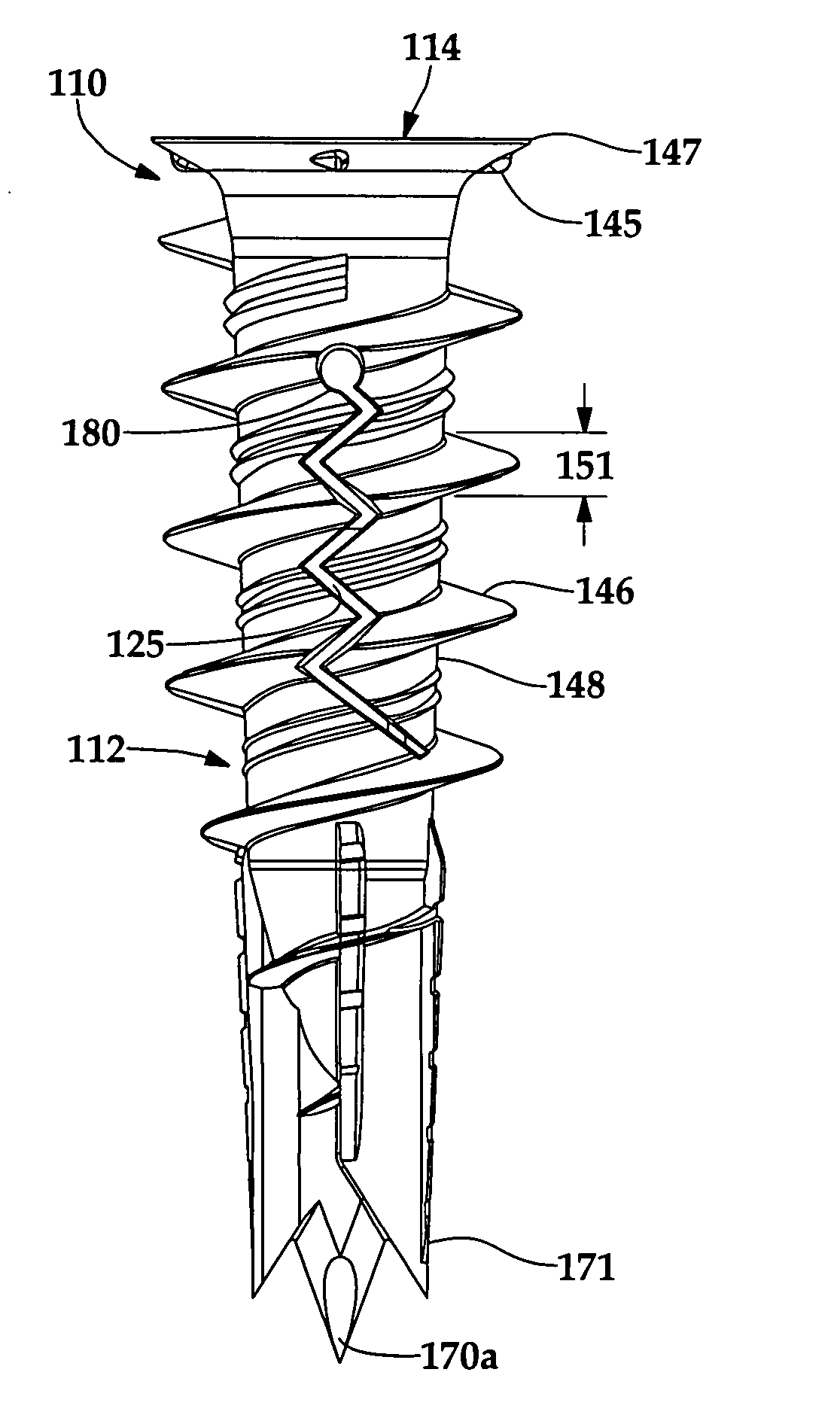

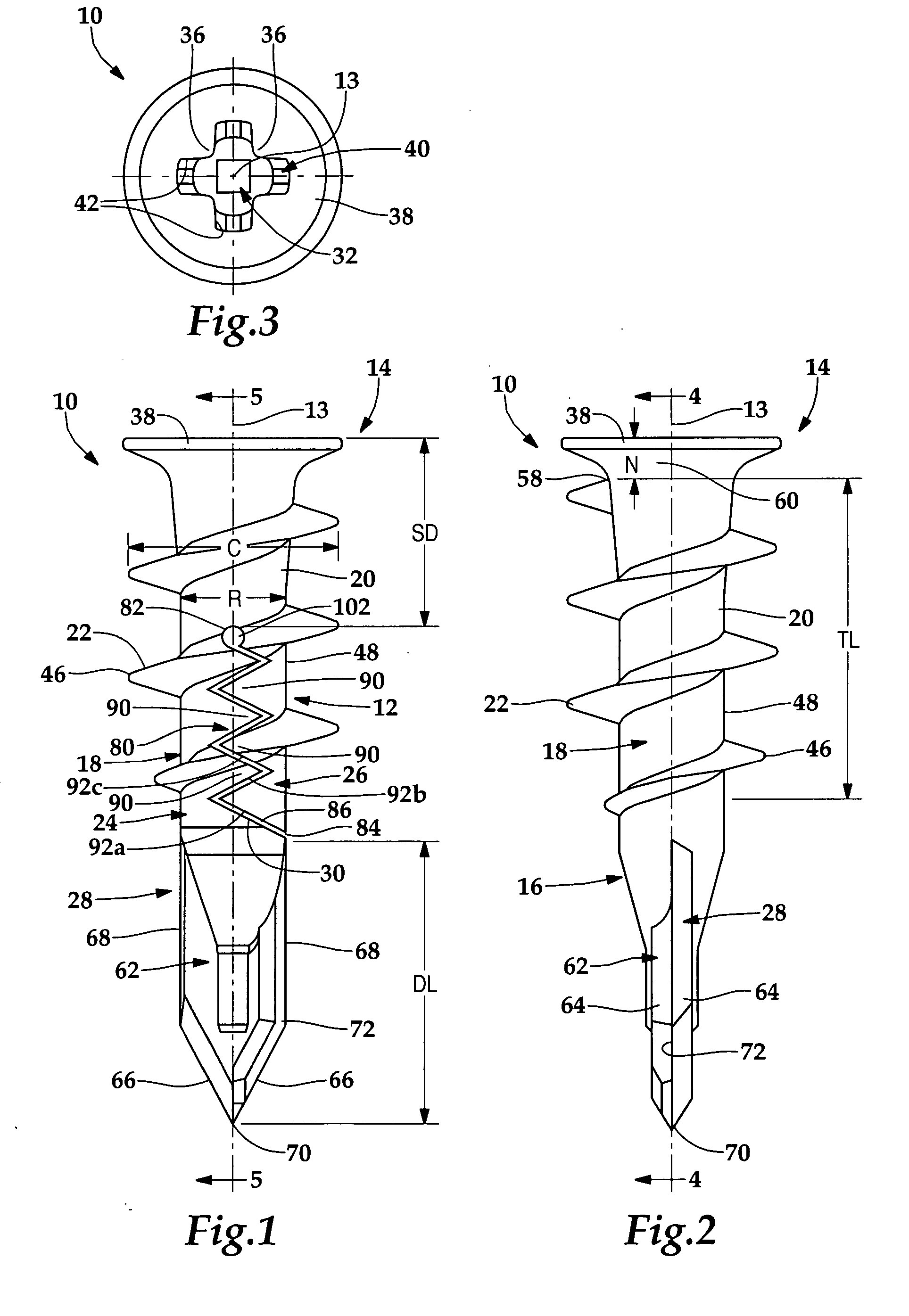

Anchor

A self-drilling anchor for use in a friable material comprises a body having an axis, a flanged rear end, a drilling front end and a generally cylindrical portion therebetween having an outer surface with a thread disposed thereon, wherein the body forks, beginning at a predetermined distance from the flanged rear end, into a first leg and a second leg, the first leg extending forwardly into a drilling tip and having a generally rearward facing shoulder angled obtusely outwardly with respect to the axis, wherein the body has an axial bore for receiving an elongate fastener, the axial bore extending substantially through the flanged end and the generally cylindrical portion and leading to the generally rearward facing shoulder, wherein the anchor has a drilling mode wherein the second leg nests behind the generally rearward facing shoulder of the first leg, and an anchoring mode wherein the legs are pivoted apart from one another.

Owner:ILLINOIS TOOL WORKS INC

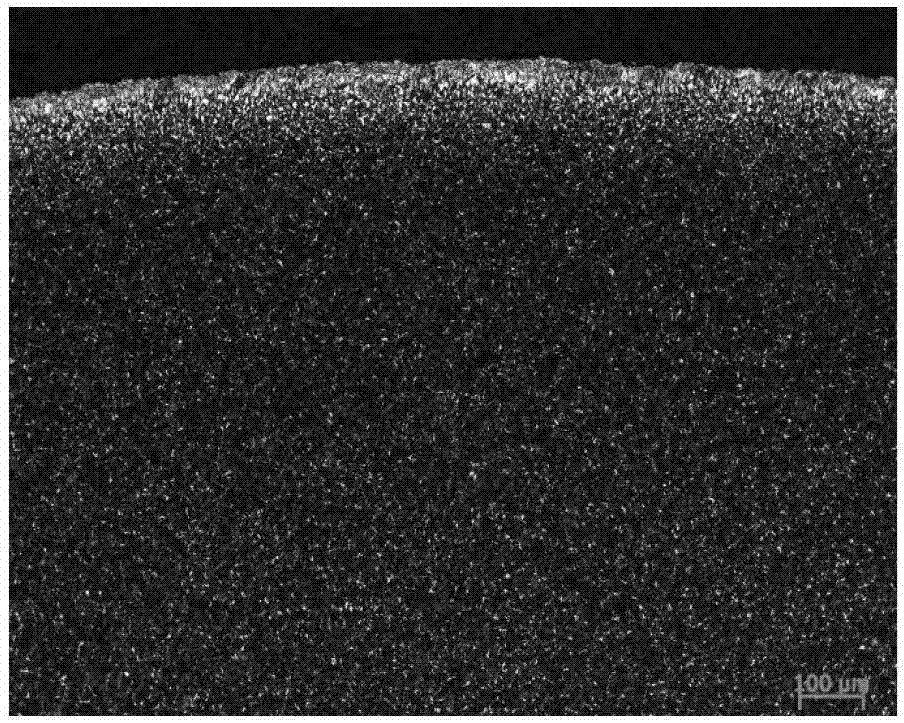

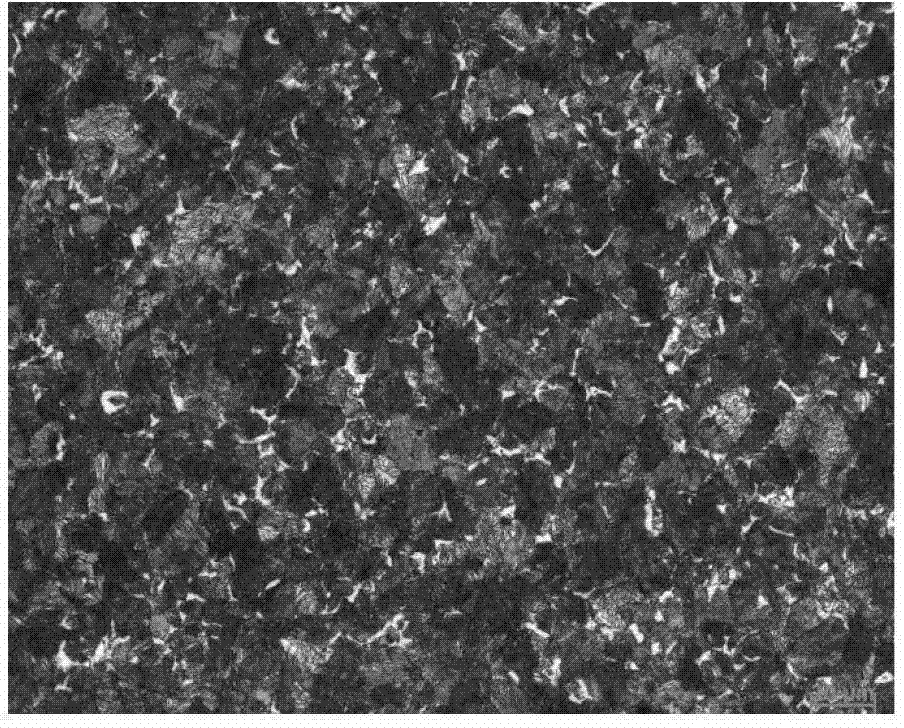

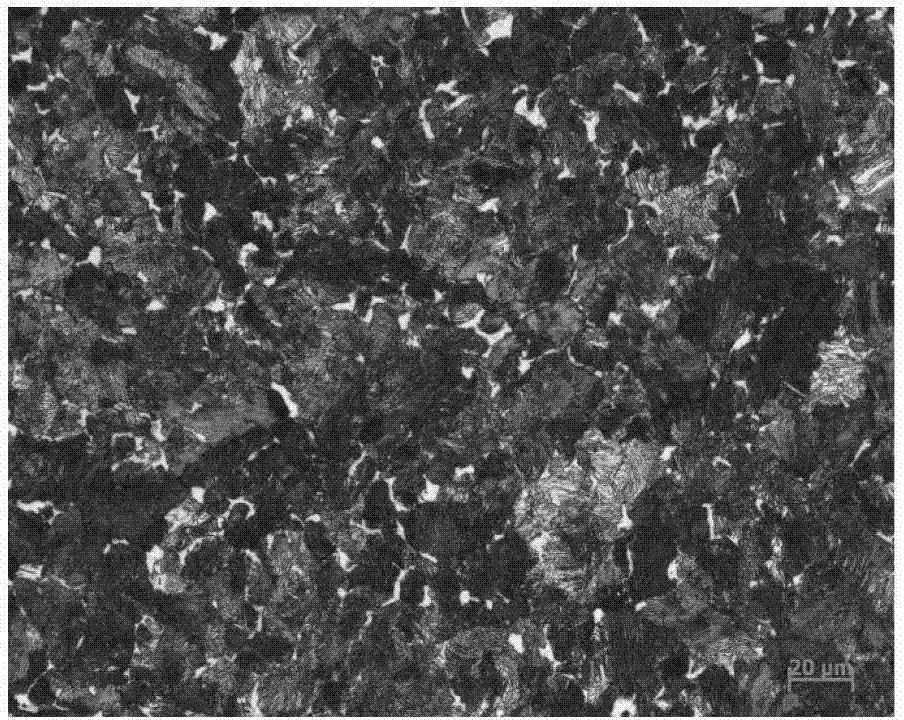

Control method for surface decarburization and ferrite distribution of steel disc bar of spring

ActiveCN103045935AReduce manufacturing costReduce intensityManufacturing convertersWire rodSpring steel

The invention relates to a control method for surface decarburization and ferrite distribution of a steel disc bar of a spring. The method comprises the steps of raw material preparation,smelting in a converter, LF (Ladle Furnace), VD (Vacuum Degassing) treatment, continuously casting, flaw detection and coping, heating, rolling, spinning, wind cooling by stelmor, intensively coiling, detecting and putting in a storeroom, rolling wire rods to be 8-18 mm in diameter, ensuring that the tensile strength (ob) is 950-1100MPa and the percentage reduction of area (Z) is 30-50 percent after aging treatment, and organizationally adding a small amount of dispersedly distributed into sorbite. Compare with other processes, the strength is decreased to a certain extent, the reduction of area is improved to a certain extent, the variation range of the strength and reduction of area is smaller, the performance is more stable, pulling and reeding operation is facilitated, the production cost of spring steel is lowered, and the service life of the spring steel is prolonged.

Owner:TIANJIN IRON & STEEL GRP

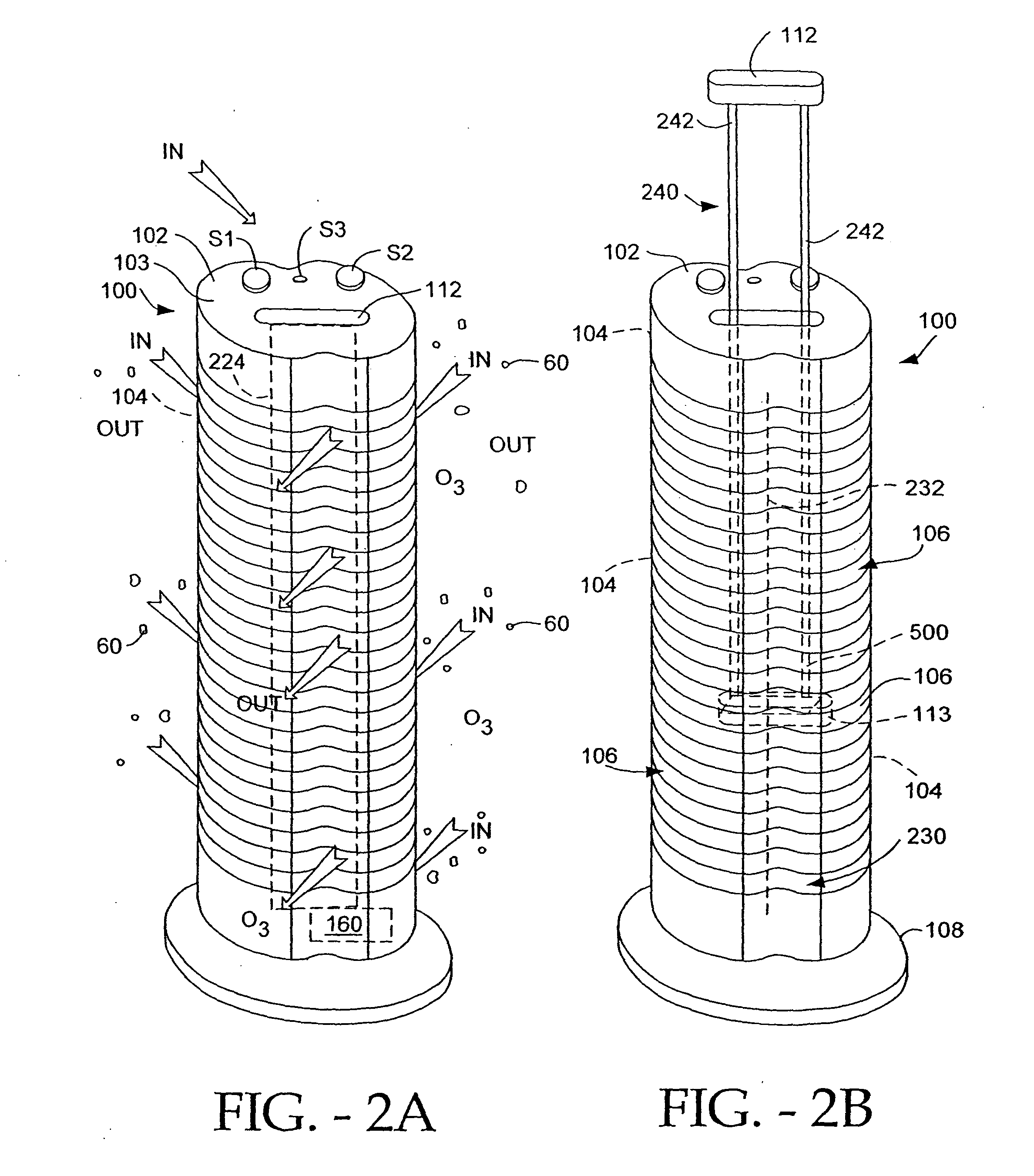

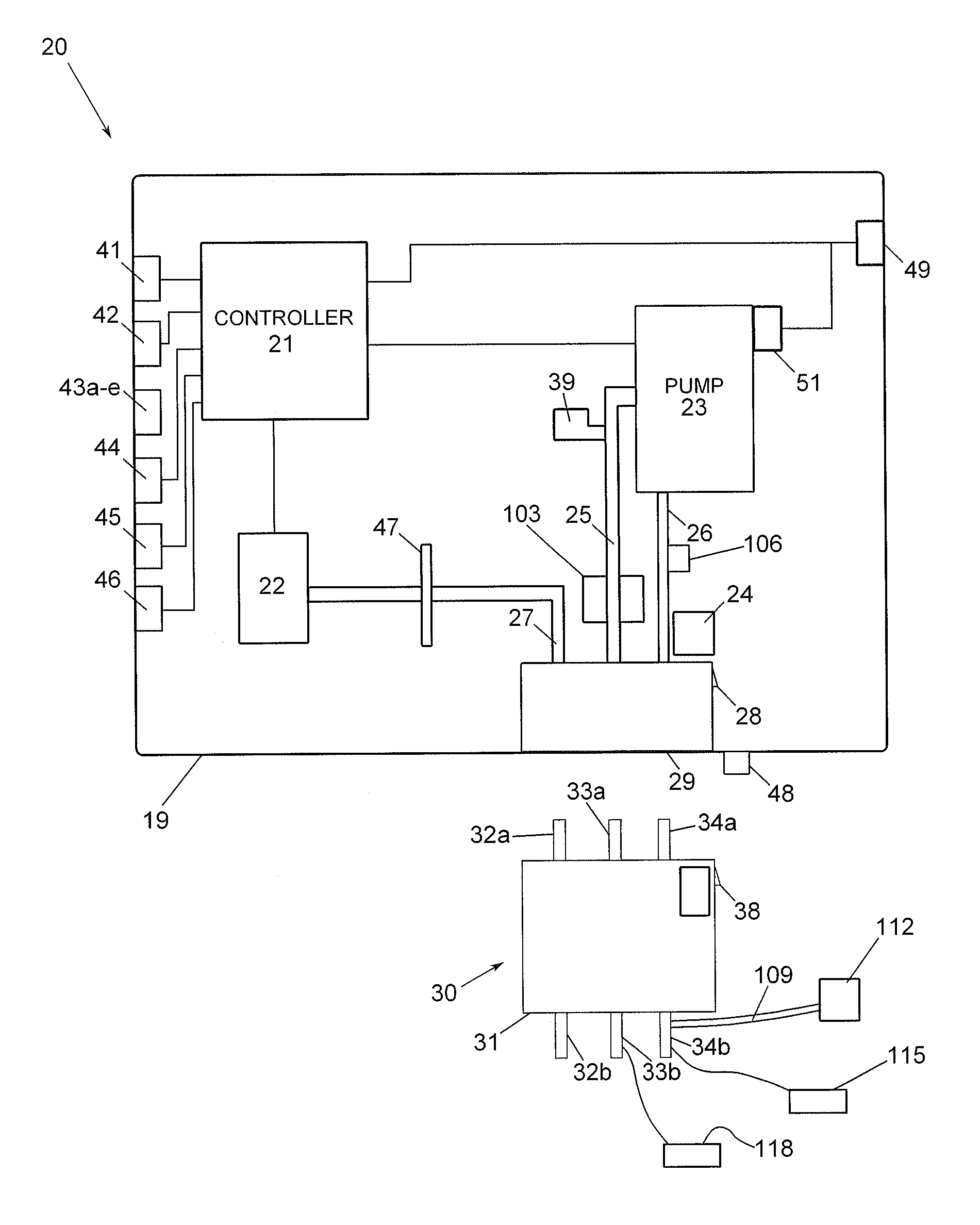

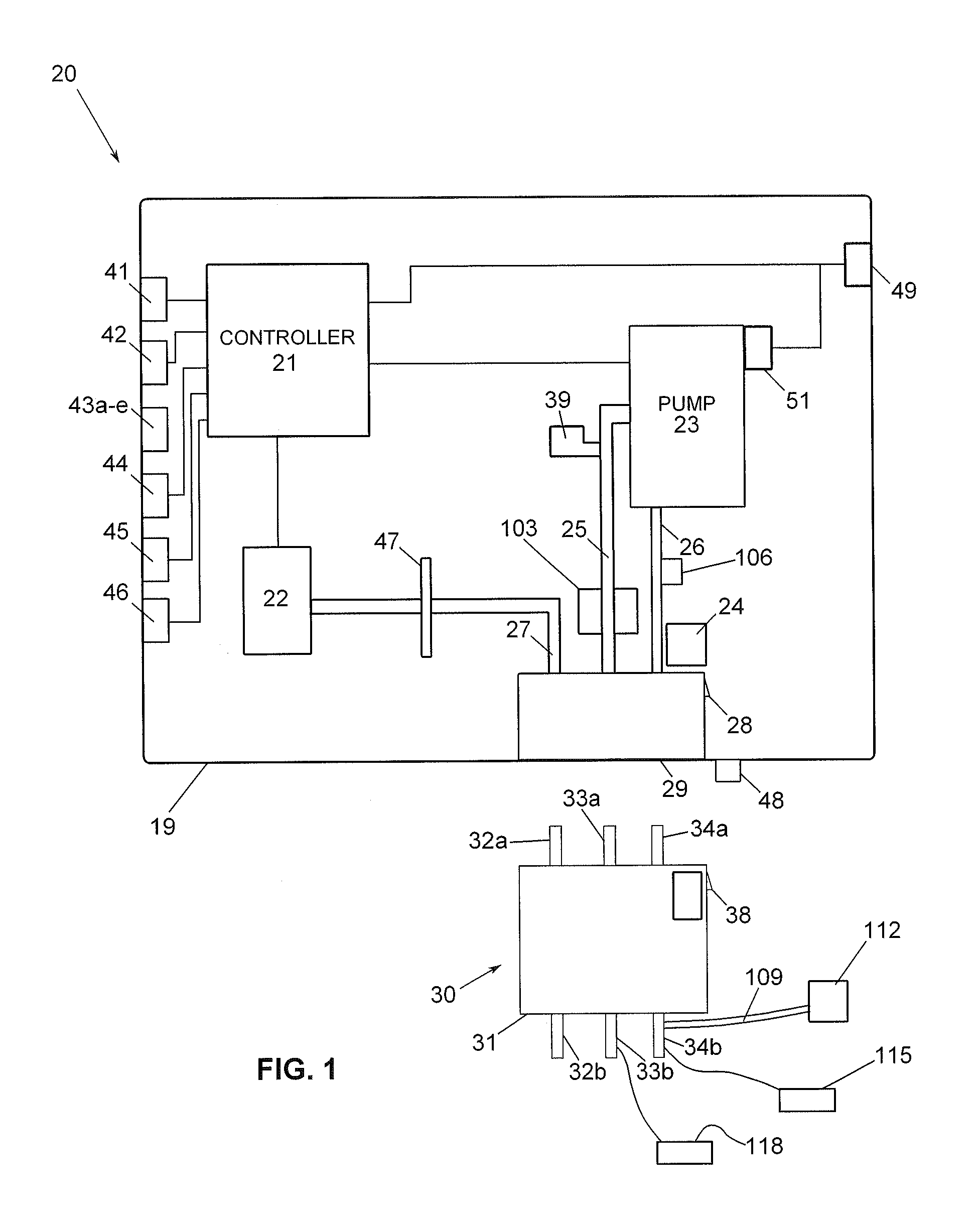

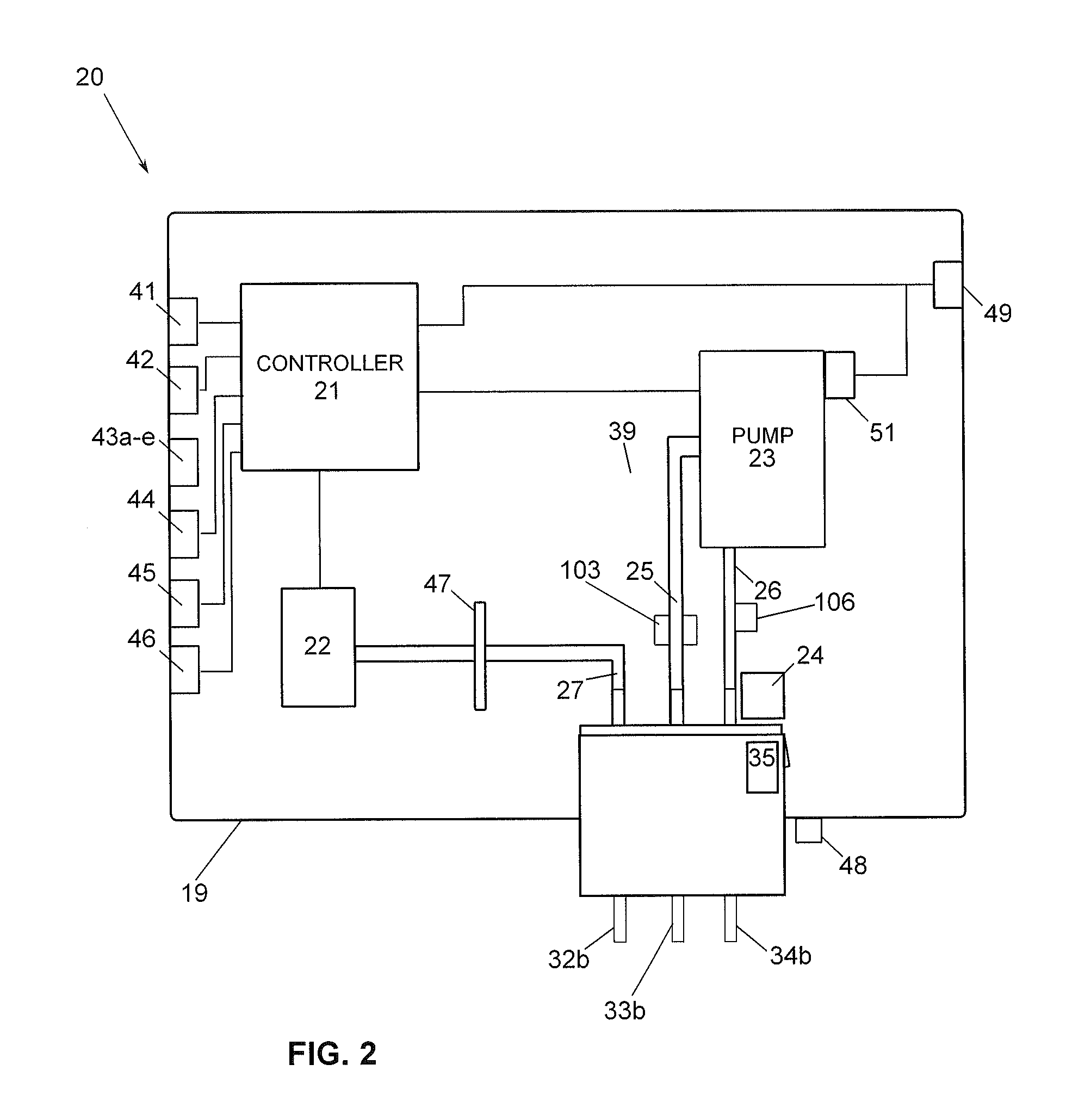

Filtration System and Method

ActiveUS20150112246A1Accurate estimateEasy to pullCombination devicesAuxillary pretreatmentFilter mediaPressure sense

A laparoscopic filter system having a main unit having an inflow port, an outflow port, a pressure sensing port, a user interface having a power switch, a controller, a pump, and an interface for receiving a detachable filter cartridge, and a detachable filter cartridge configured and arranged to reversibly attach to the interface, the detachable filter cartridge having an inflow pass-through line, an outflow pass-through line, a pressure sensing pass-through line, and a filter media arranged in series with the inflow pass-through line.

Owner:BUFFALO FILTER

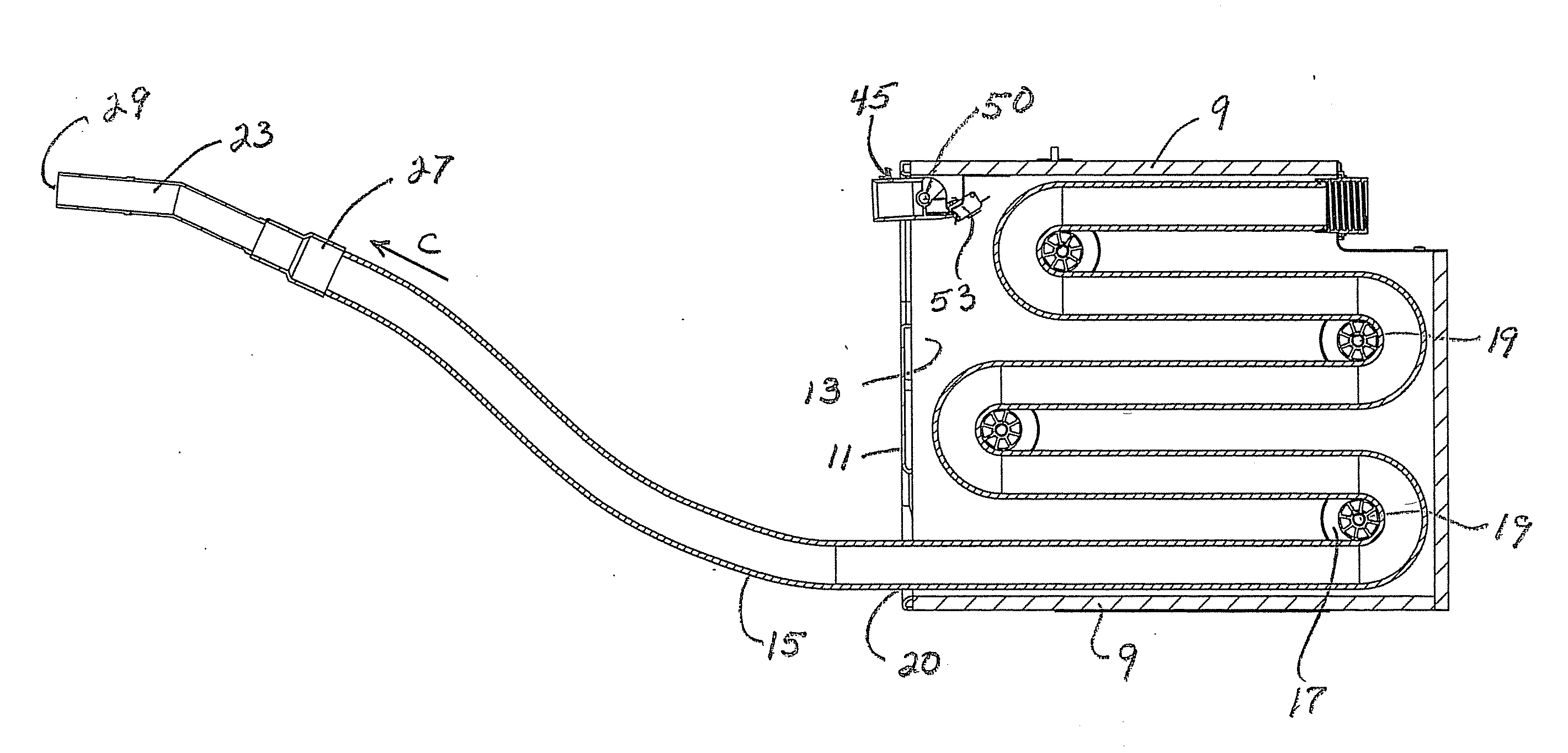

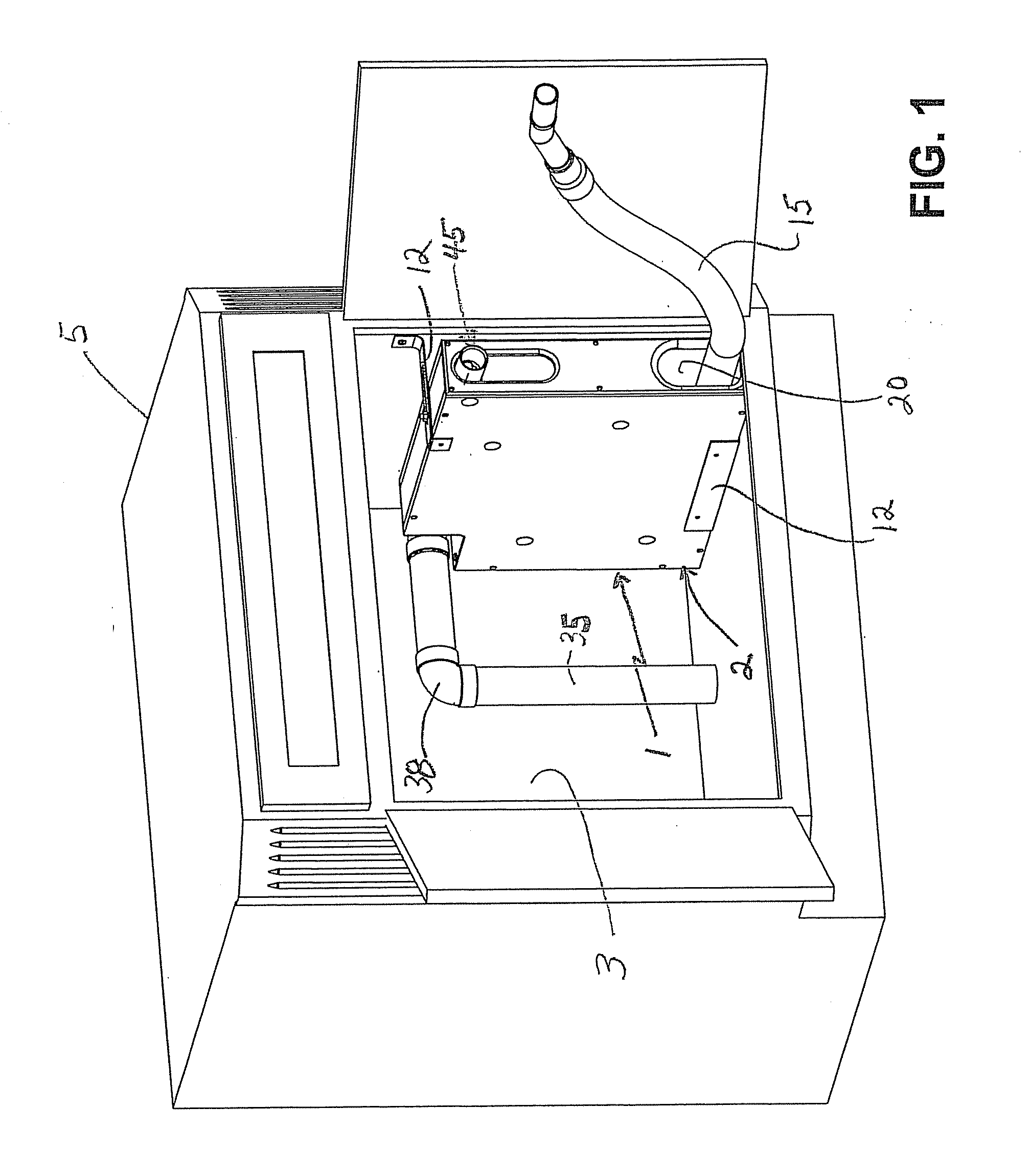

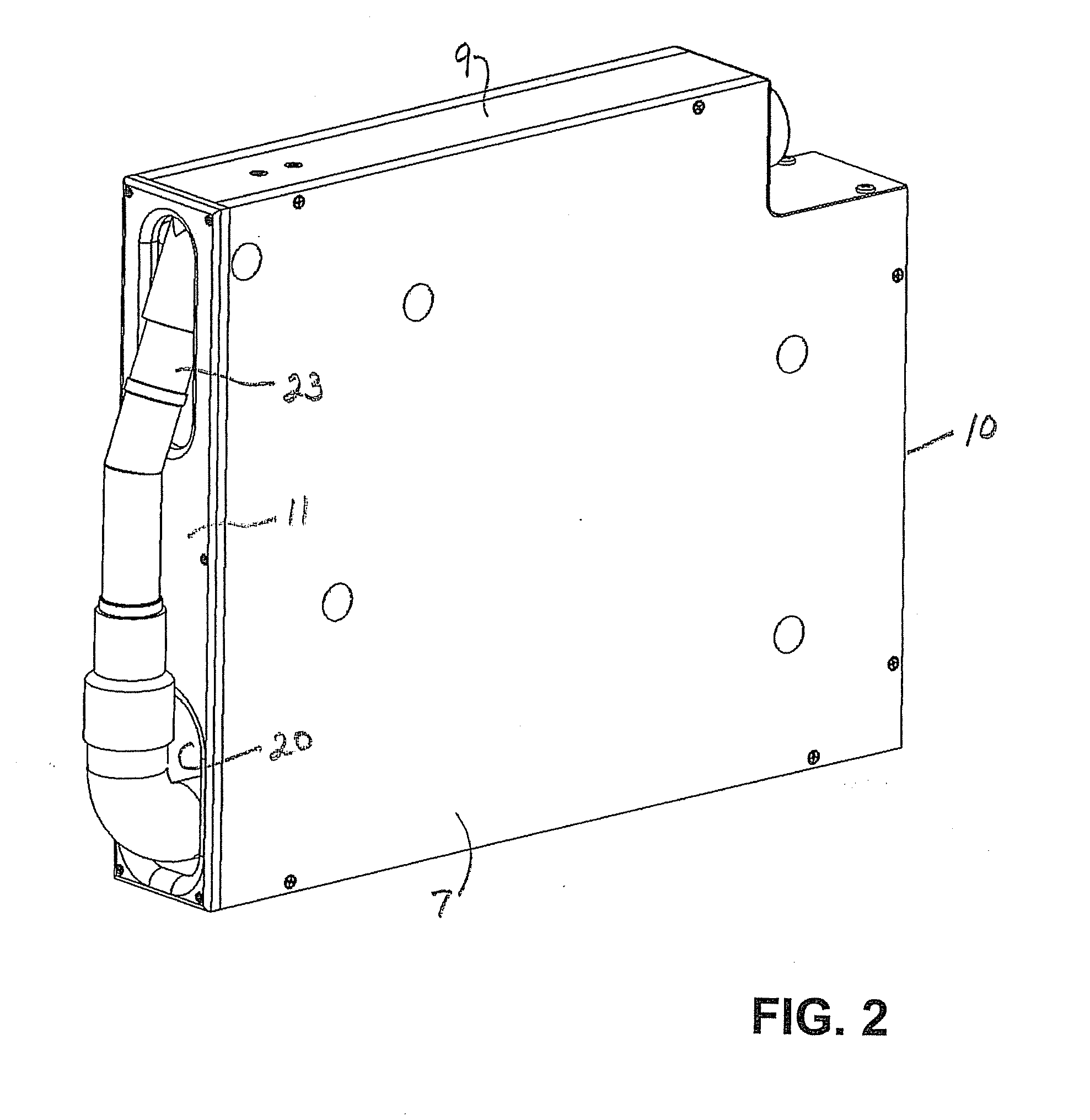

Vacuum hose storage system

ActiveUS20110041282A1Easy to disassembleLow production costSuction cleaner storing devicesFire rescueCoil springVacuum tube

A vacuum hose storage system includes a housing which is mounted in a storage area of a dwelling or vehicle and connected to a vacuum source. A length of flexible, expandable cleaning hose is mounted in a looped fashion about a plurality of spaced rollers rotatably mounted within the housing. A handle is attached to one end of the hose and is seated in a cradle formed in the housing when the hose is in a fully retracted position within the housing. The cradle is mounted in the housing and receives the open end of the hose when not in use and enables other vacuum tubes in the structure to be operational without shutting off the vacuum to the stored hose. An ON / OFF switch is located in the cradle for controlling the vacuum source and is actuated when the handle is placed in or removed from the cradle. The hose has an internal helical spring which biases the hose toward a retracted position about the spaced rollers within the housing. In an alternate embodiment, the hose is slidably extendable from within a rigid serpentine tubing mounting within the housing.

Owner:H P PROD

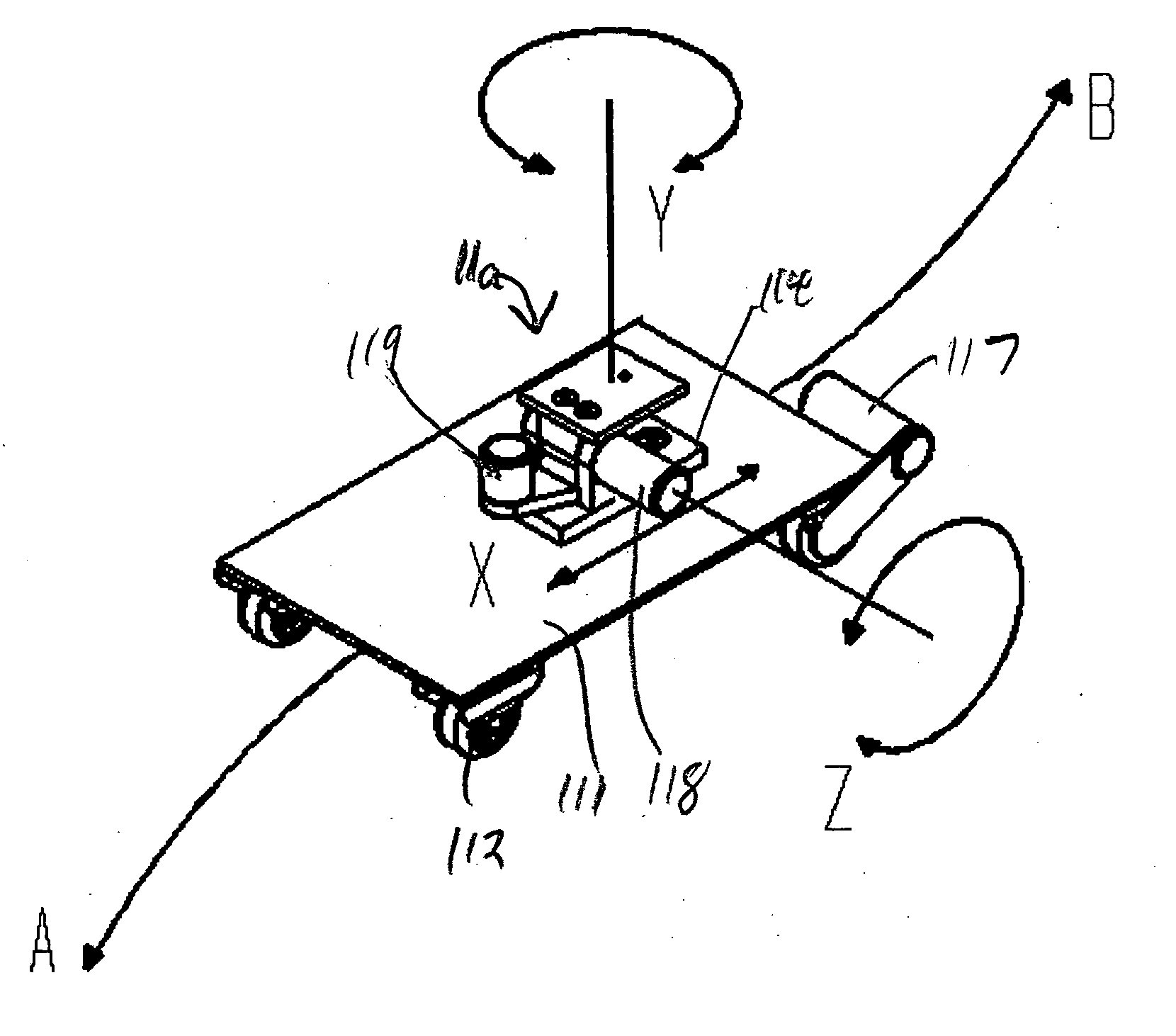

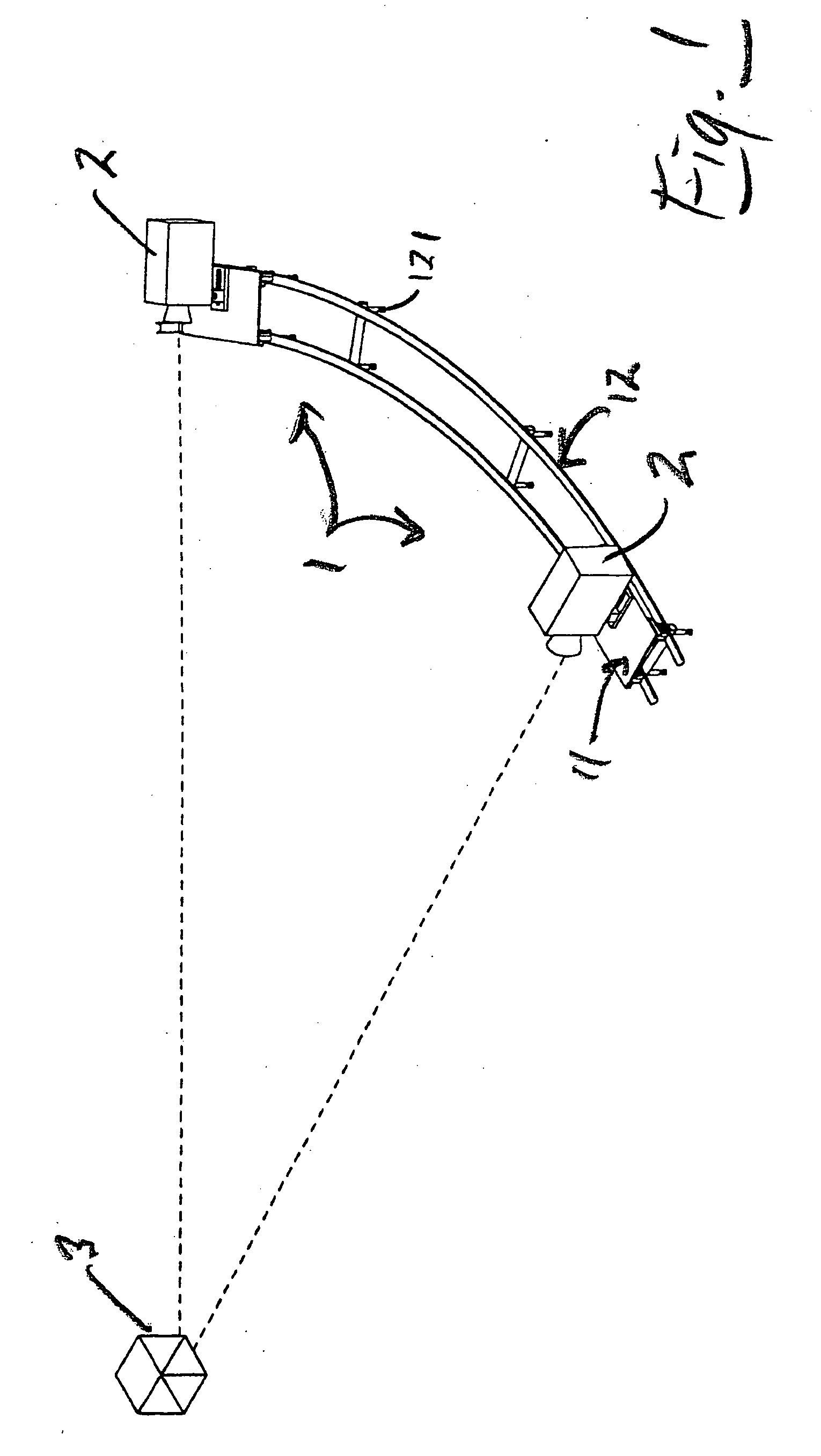

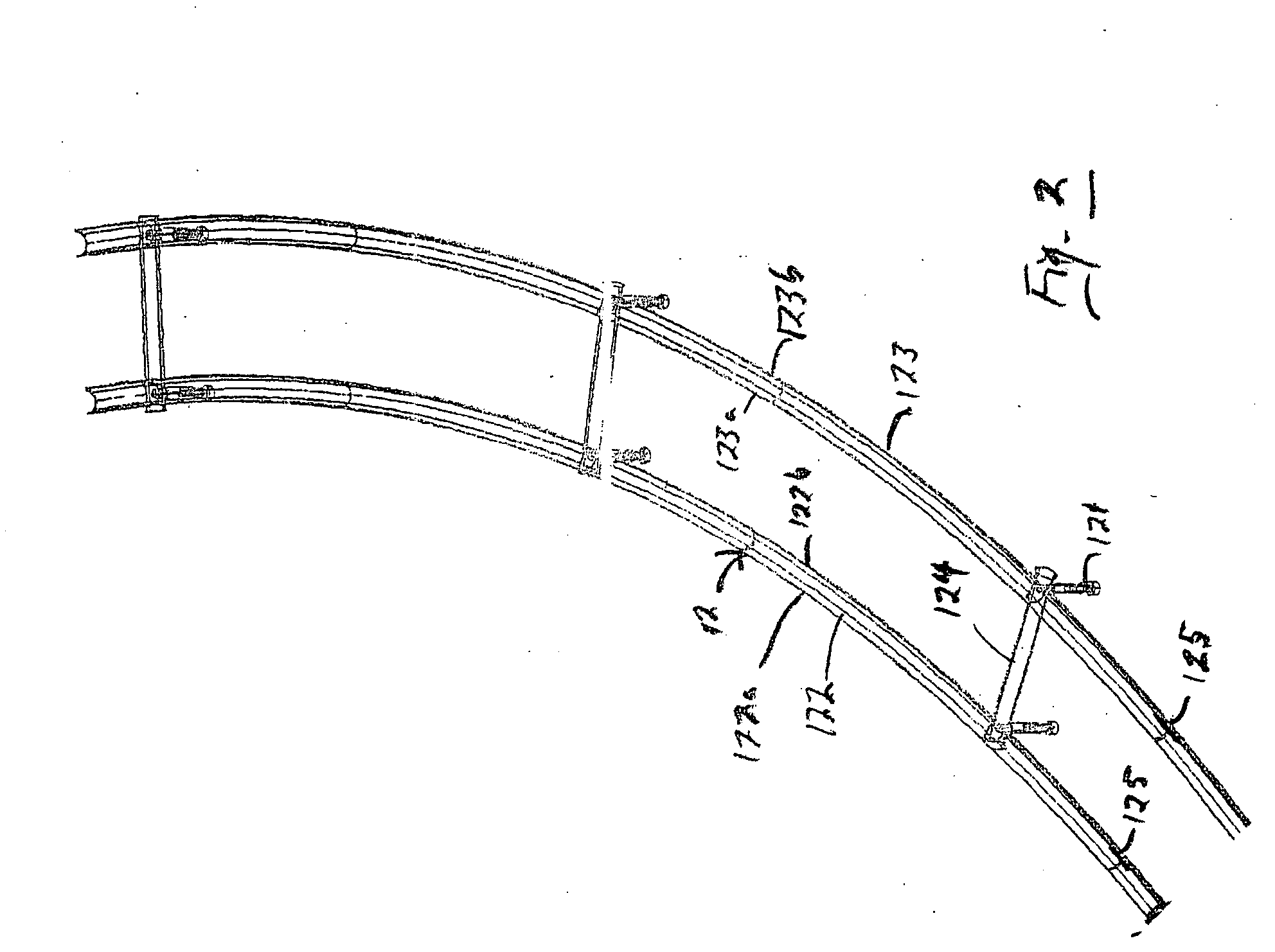

Economical camera-support-and-movement track-and-dolly system providing high stability and precision to camera movement

InactiveUS20050231689A1Cheap constructionEasy to useProjectorsStands/trestlesEngineeringAngular orientation

A system for moving a camera in space has a track with two spaced-parallel rails, each rail having two upward-extending spaced-parallel lips, and a dolly holding the camera and riding upon both rails of the track. The track is preferably segmented with each elongate rail segment preferably in the cross-section of half of a tube, while the dolly has wheels that contact only, and that ride upon, the upward-extending spaced-parallel lips of each half-tubular rail. The camera is mounted close upon the support platform of the generally rectangular wheeled dolly, which is itself squat and low to the track's two spaced-parallel rails. According to the geometries of construction, the camera is relatively insensitive in space and in angular orientation to such irregularities in track and moving dolly as are in any case minor by design, and the camera can be moved along complex paths with great precision for purposes of motion pictures and movies.

Owner:LONGLEY BRIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com