Patents

Literature

3692results about "Dowels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

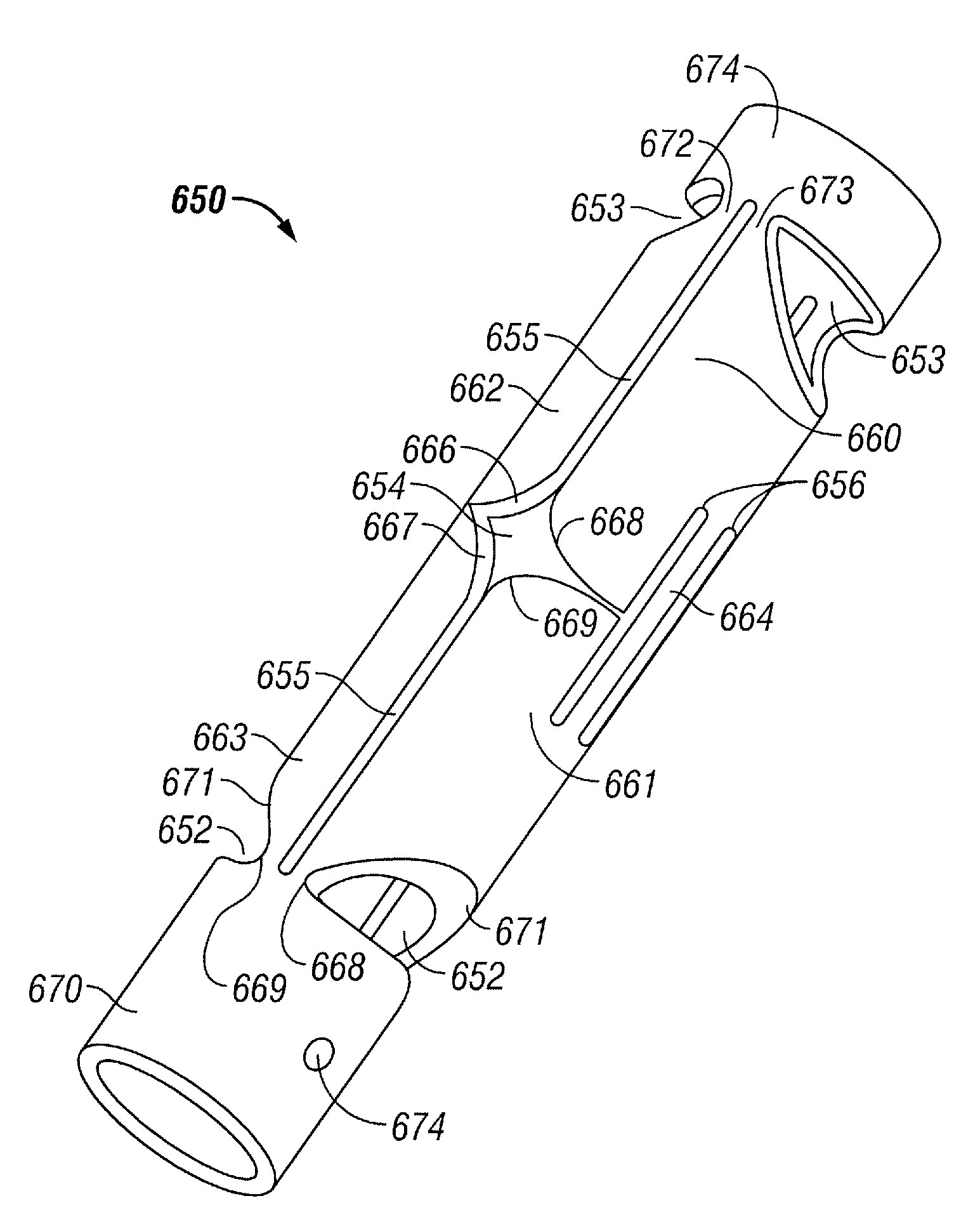

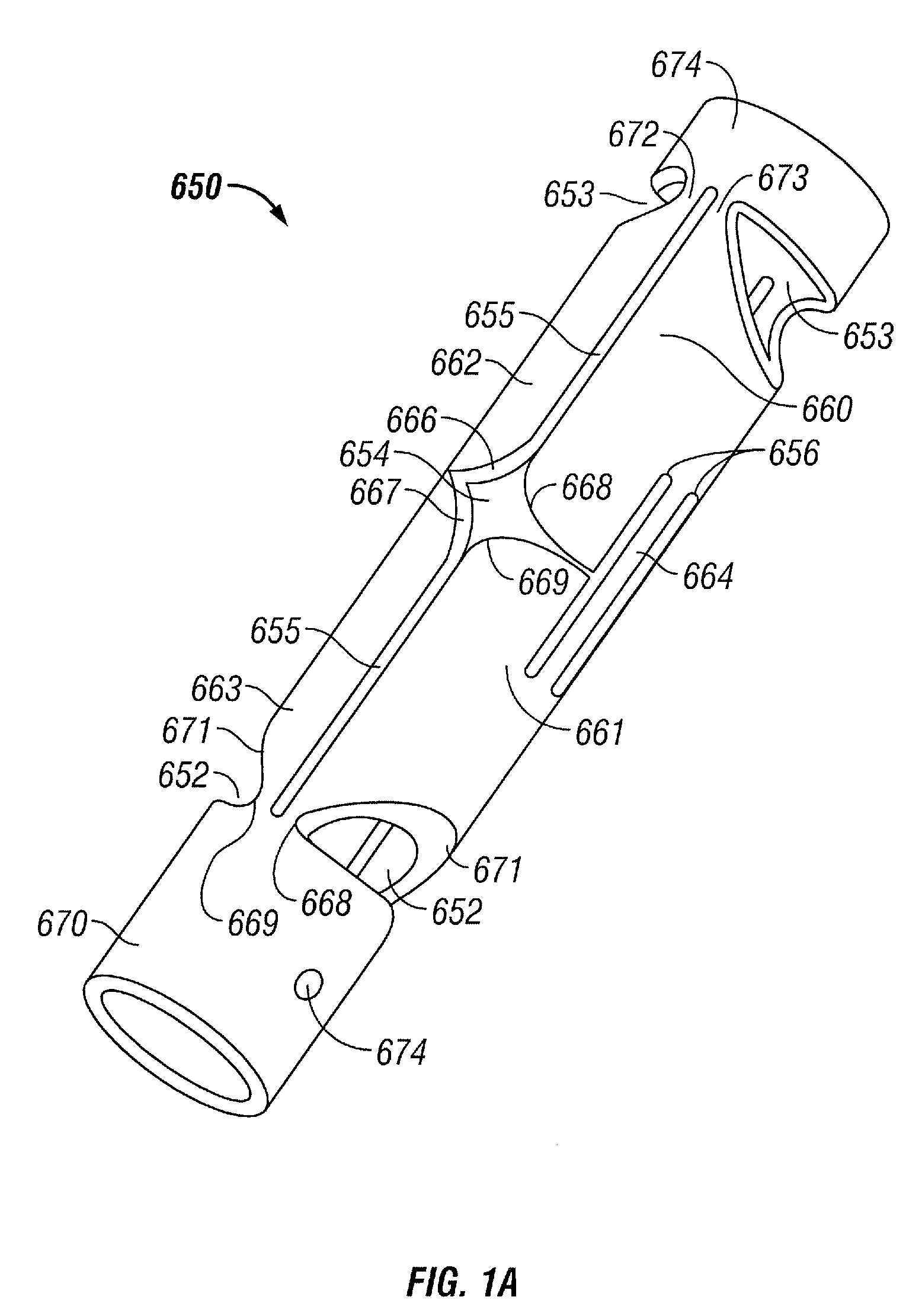

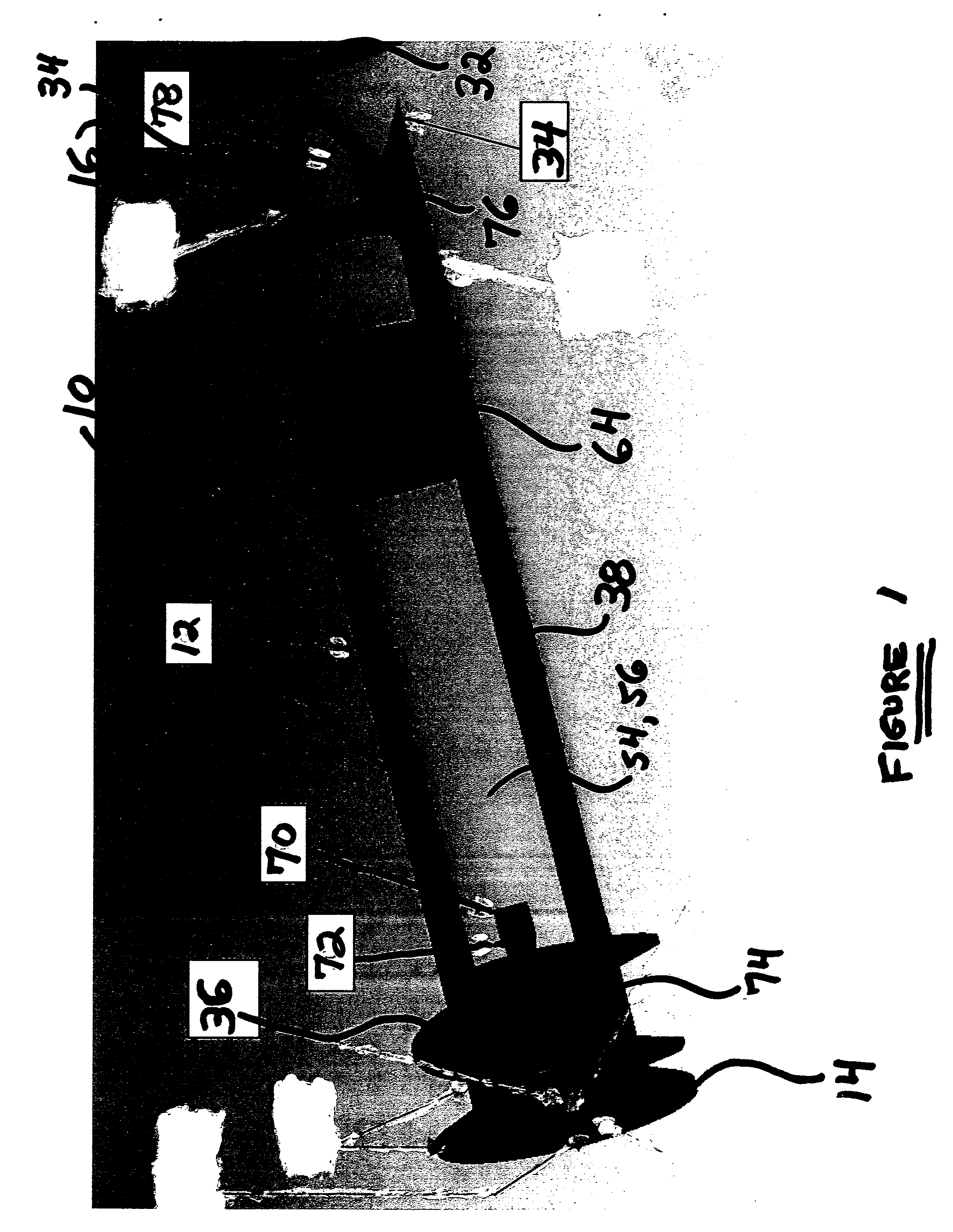

Methods and systems for material fixation

ActiveUS20080183290A1Easy to useHigh fixation of tendon-boneSuture equipmentsLigamentsTissue materialKnee Joint

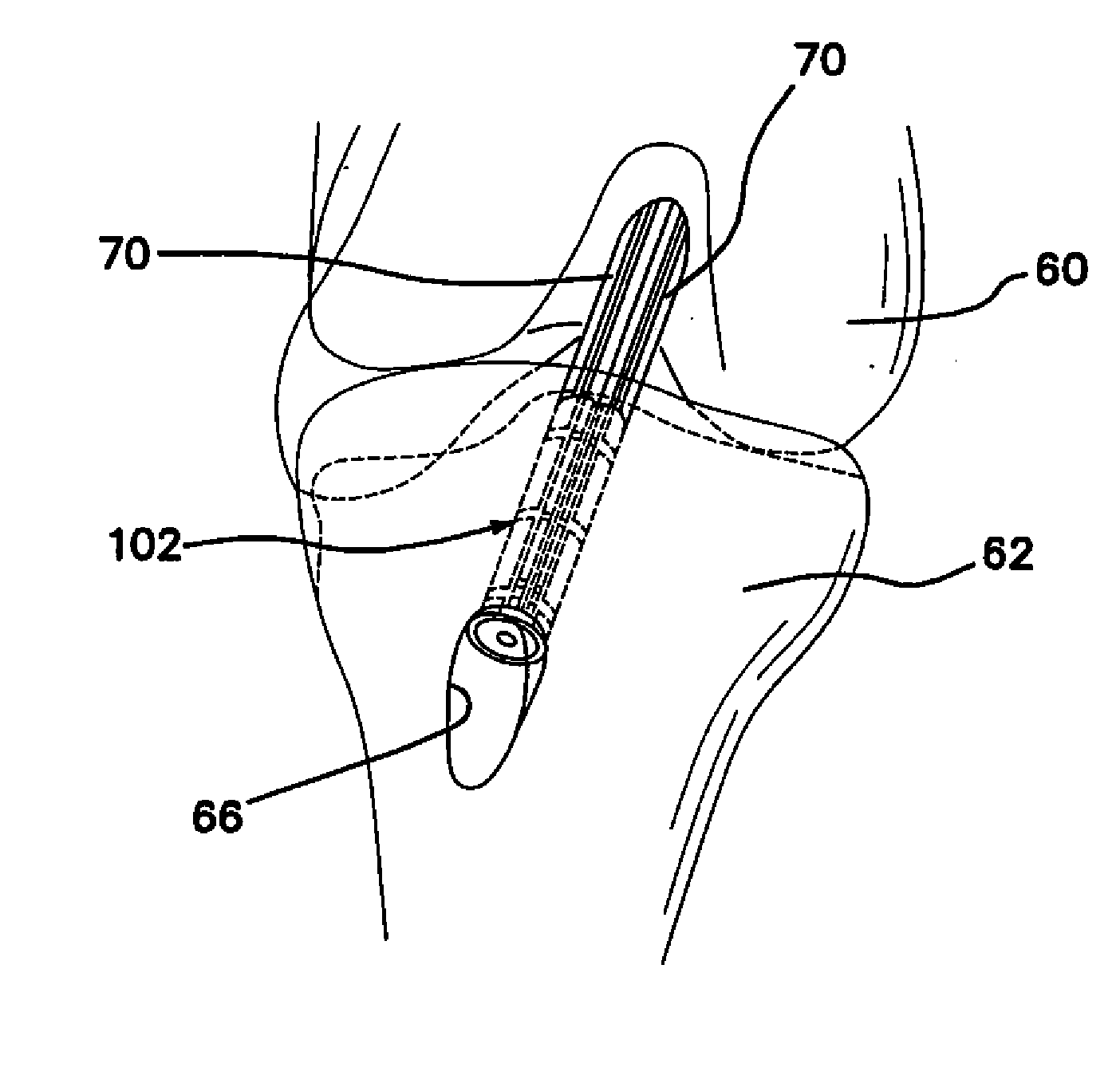

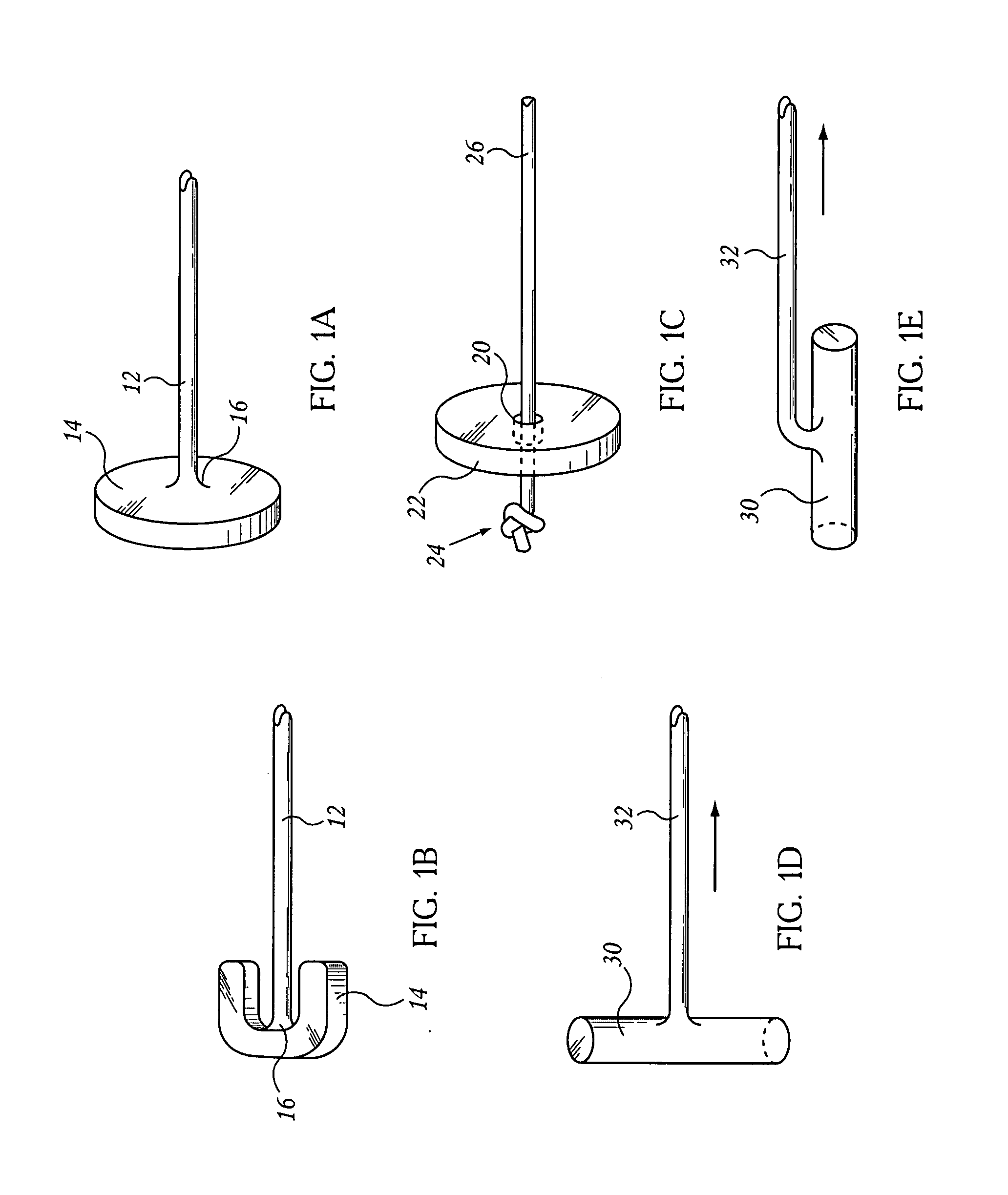

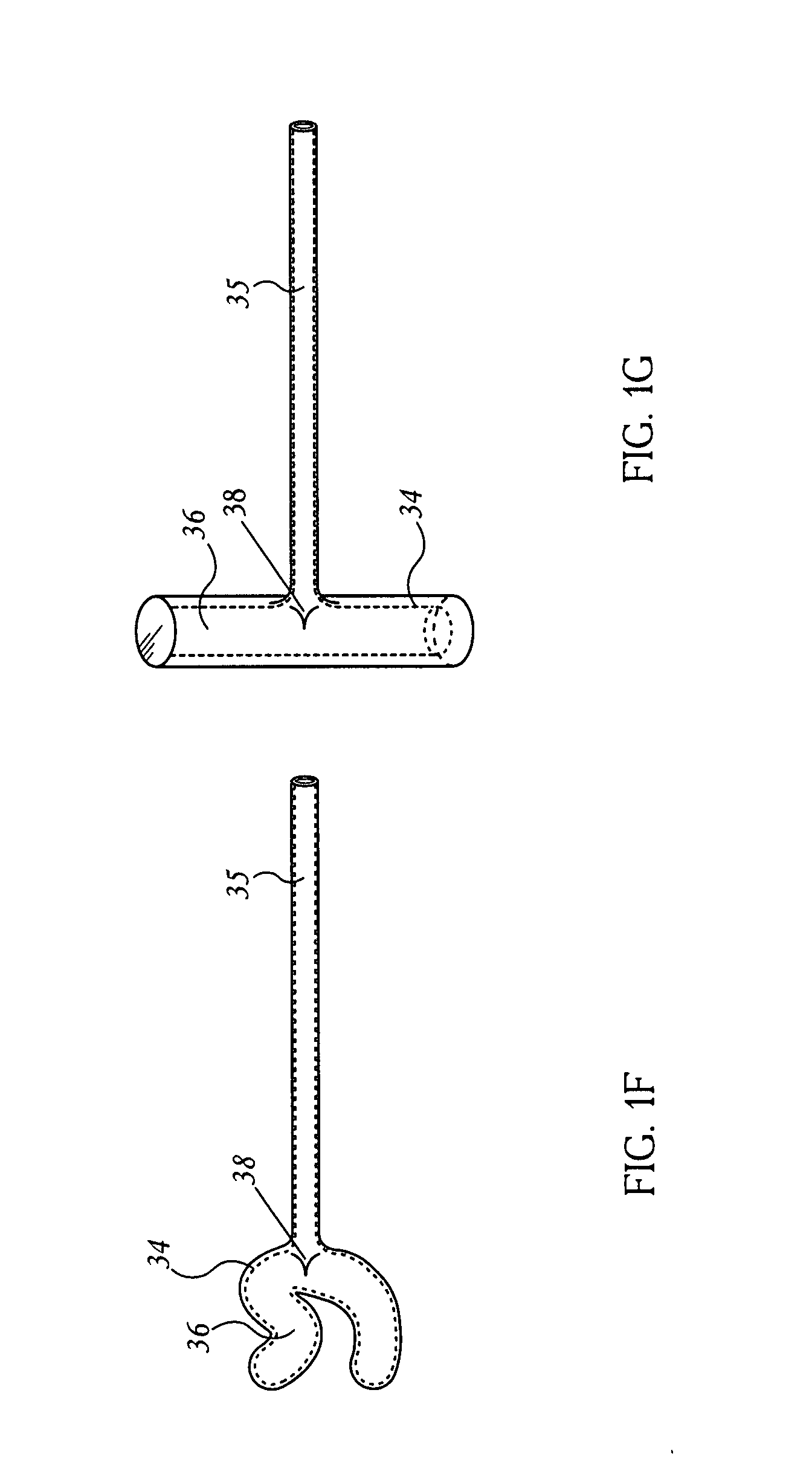

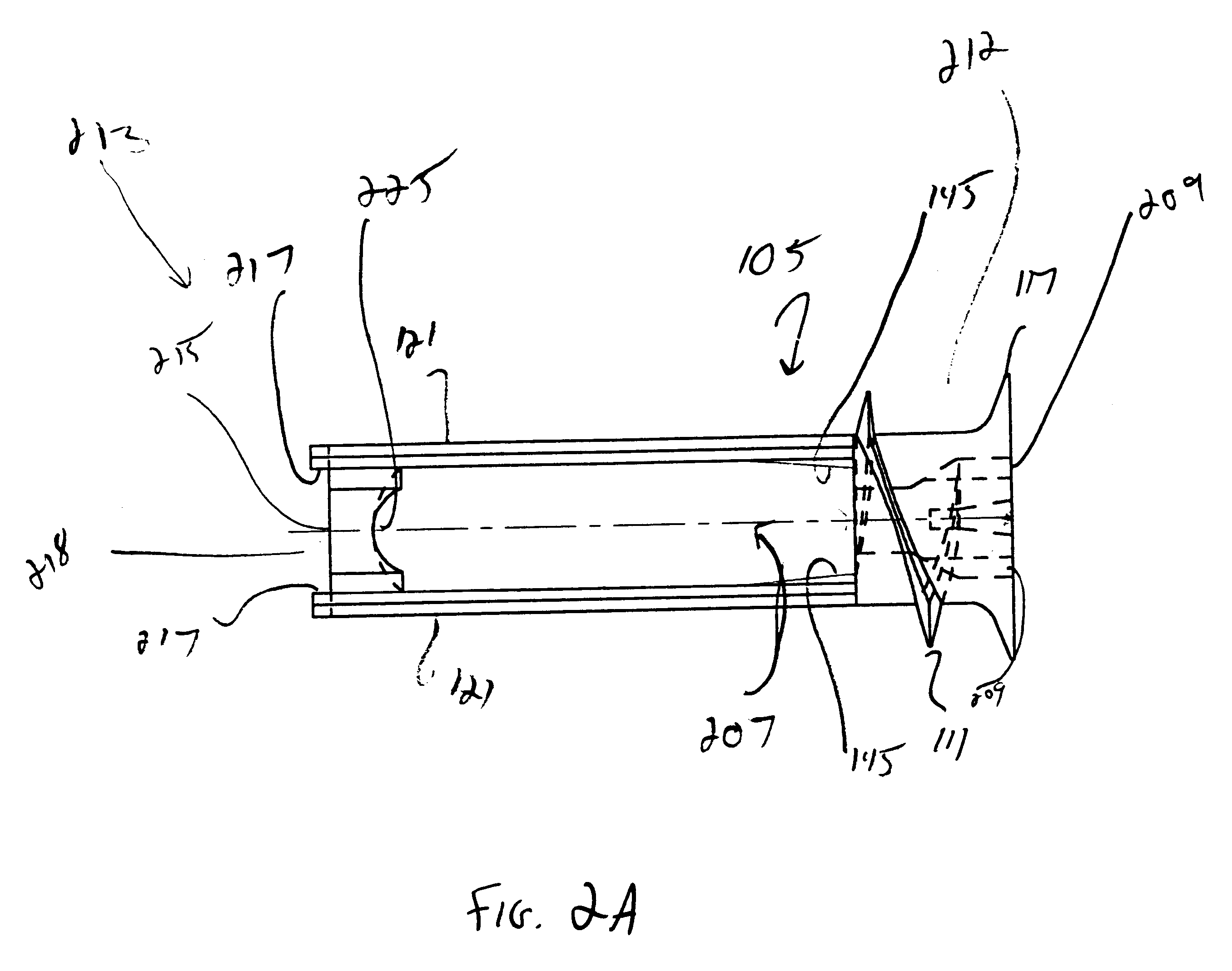

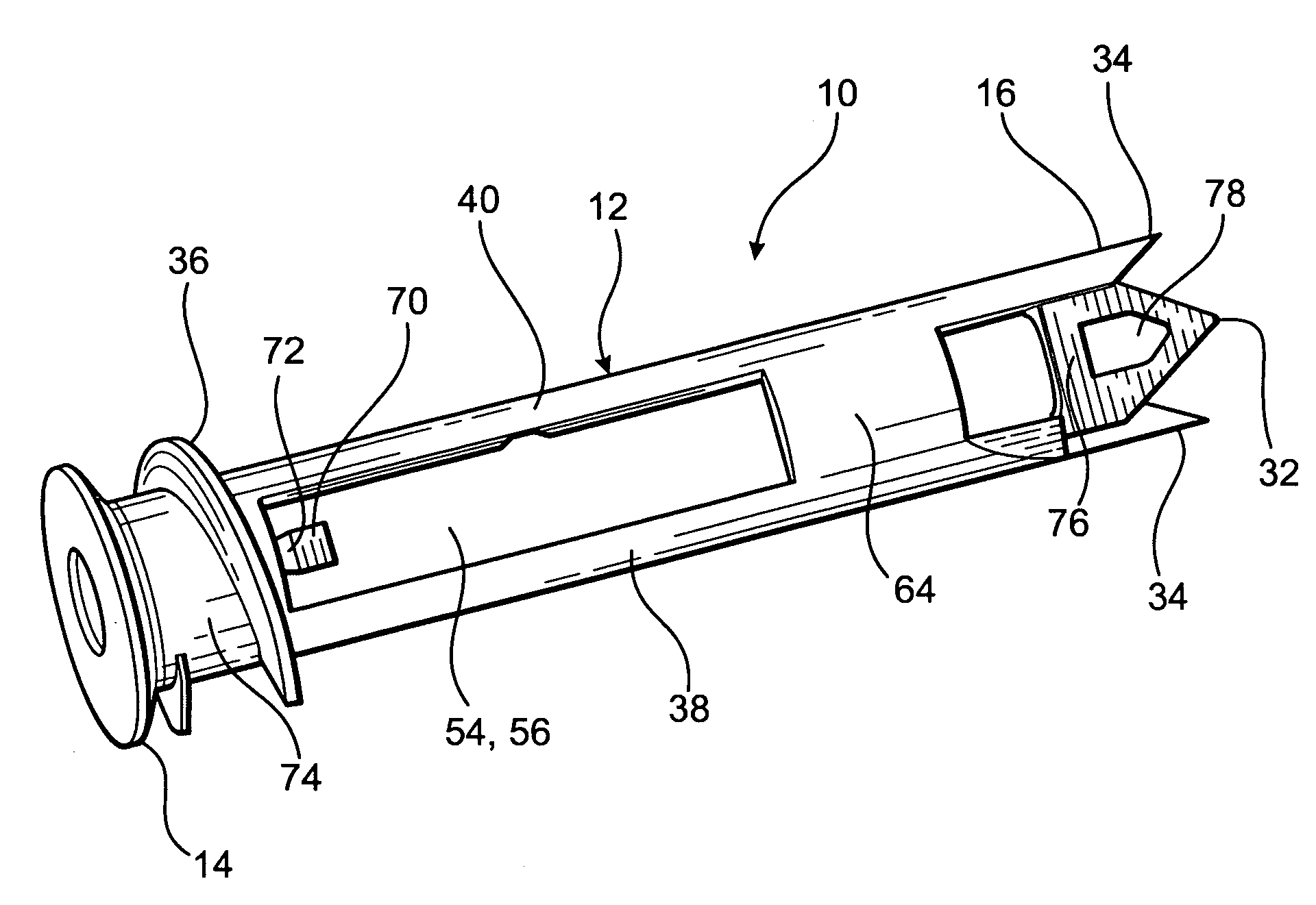

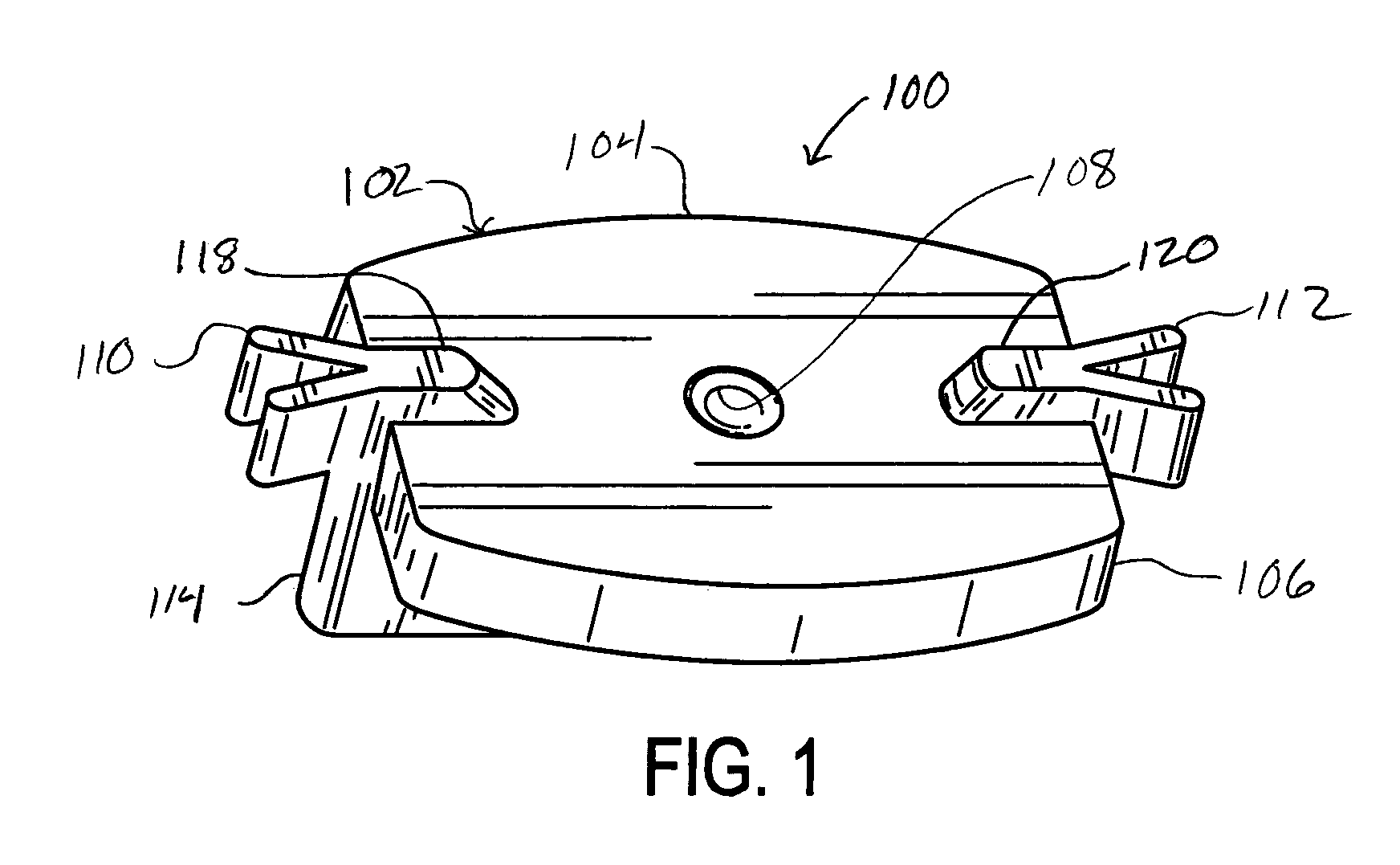

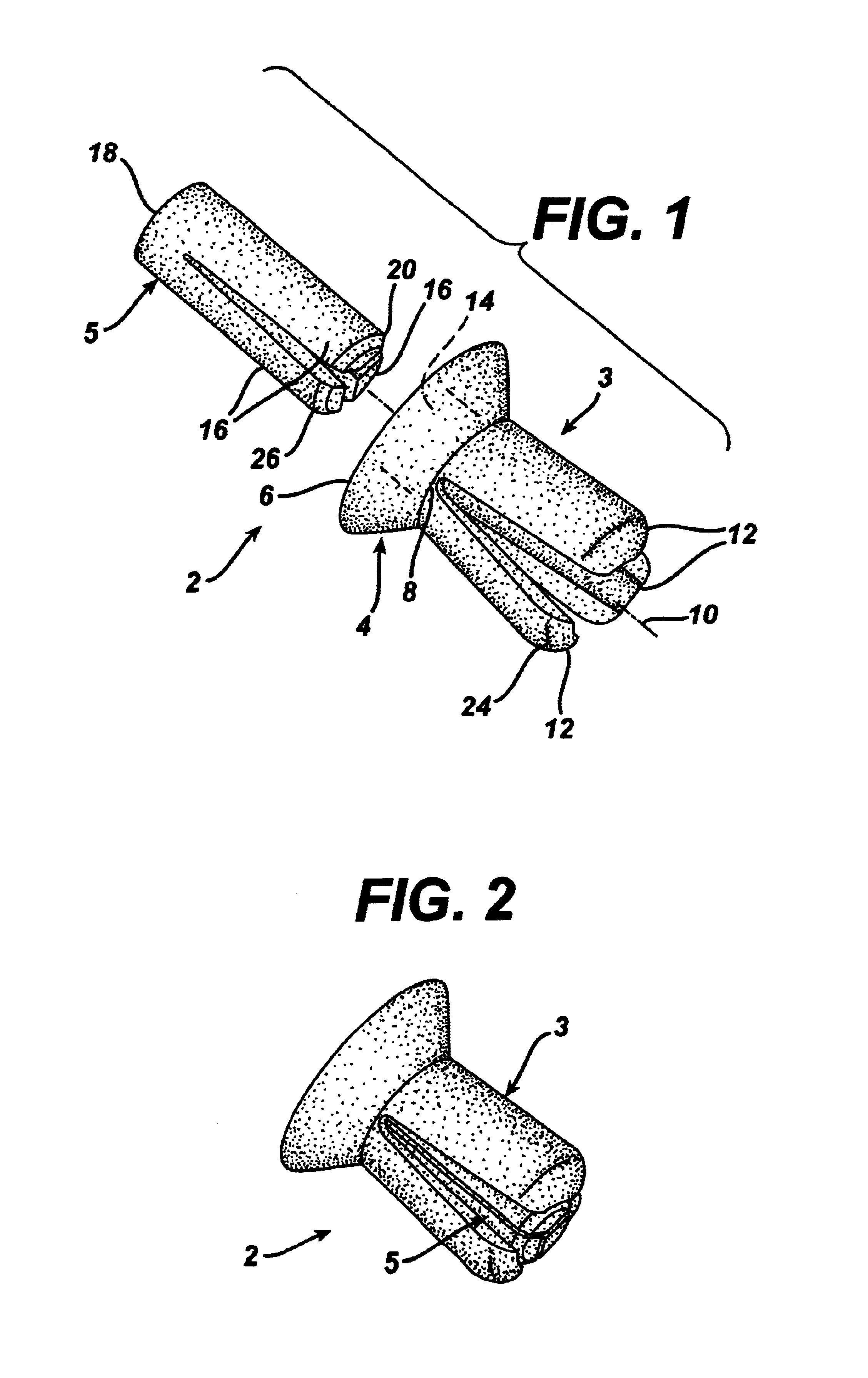

A soft tissue fixation system, most typically applicable to orthopedic joint repairs, such as anterior cruciate ligament (ACL) knee repair procedures, comprises an implant which is placeable in a tunnel disposed in a portion of bone, wherein the tunnel is defined by walls comprised of bone. A first member is deployable outwardly to engage the tunnel walls for anchoring the implant in place in the tunnel, and a second member is deployable outwardly to engage tissue material to be fixed within the tunnel. The second member also functions to move the tissue material outwardly into contact with the tunnel walls to promote tendon-bone fixation. Extra graft length is eliminated by compression of the tendon against the bone at the aperture of the femoral tunnel, which more closely replicates the native ACL and increases graft stiffness. The inventive device provides high fixation of tendon to bone and active tendon-bone compression. Graft strength has been found to be greater than 1,000 N (Newtons), which is desirable for ACL reconstruction systems.

Owner:CAYENNE MEDICAL INC

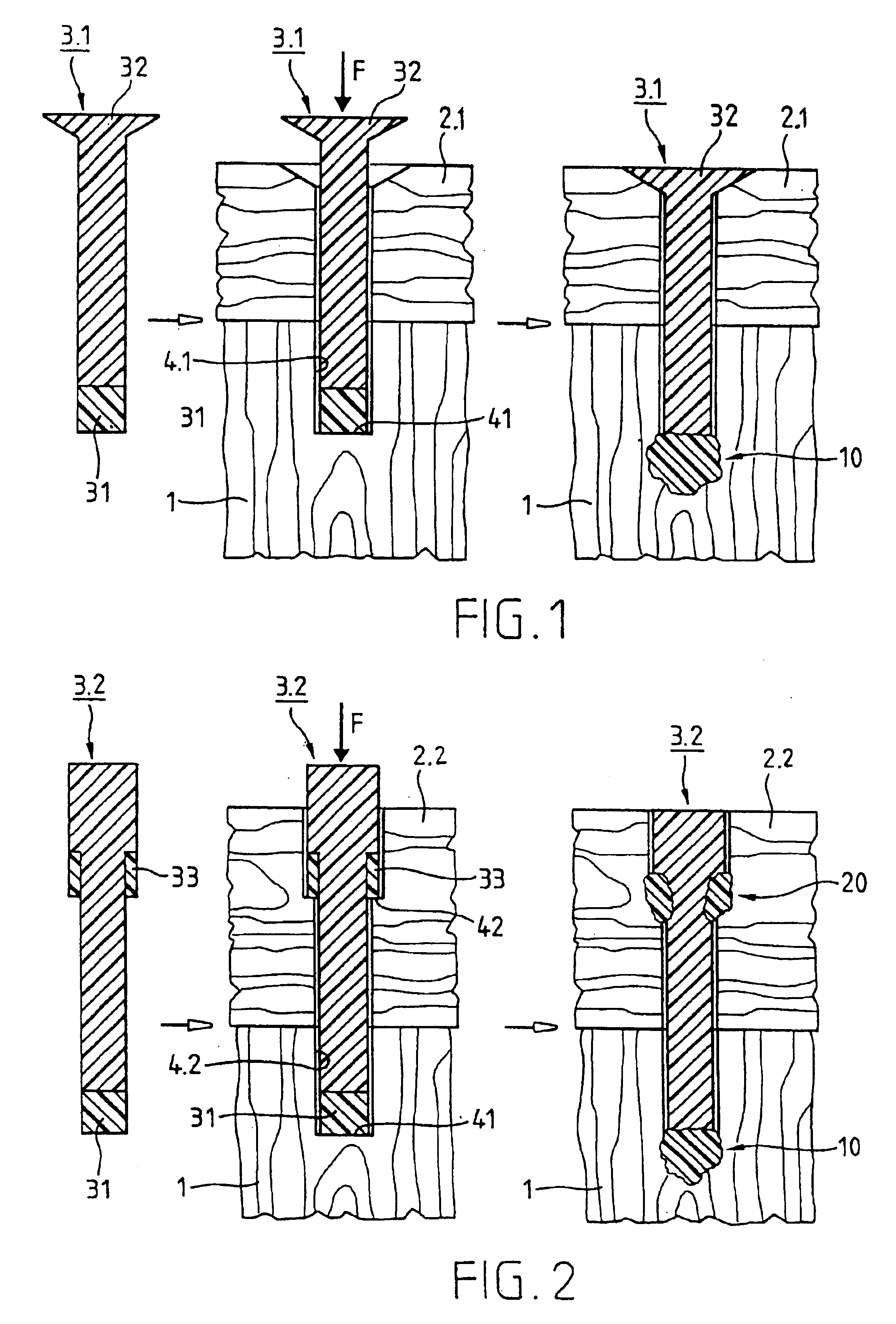

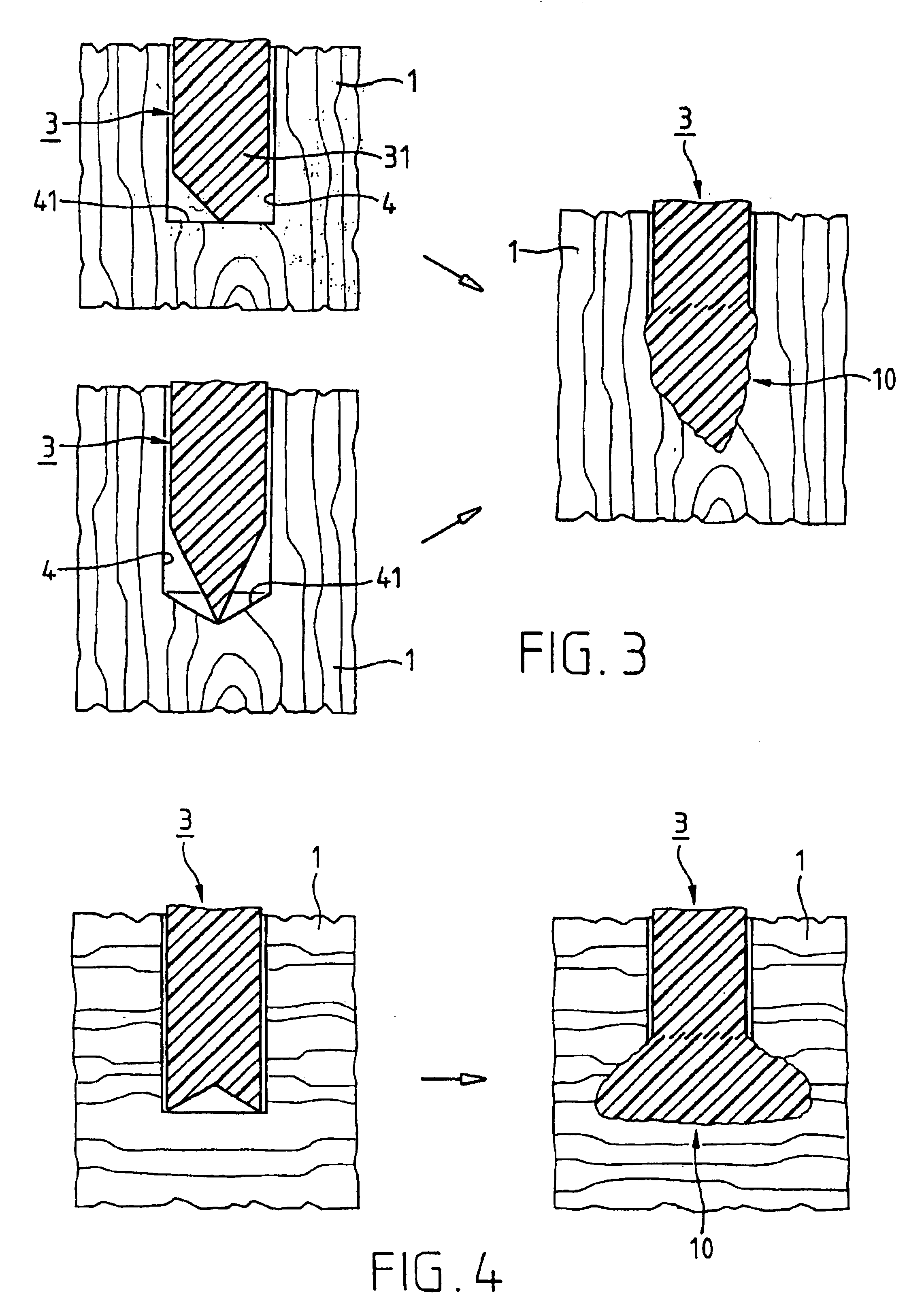

Process for anchoring connecting elements in a material with pores or cavities and connecting elements therefor

InactiveUS6913666B1Easy to reachReduce disadvantagesRivetsCylinder headsEngineeringUltrasonic vibration

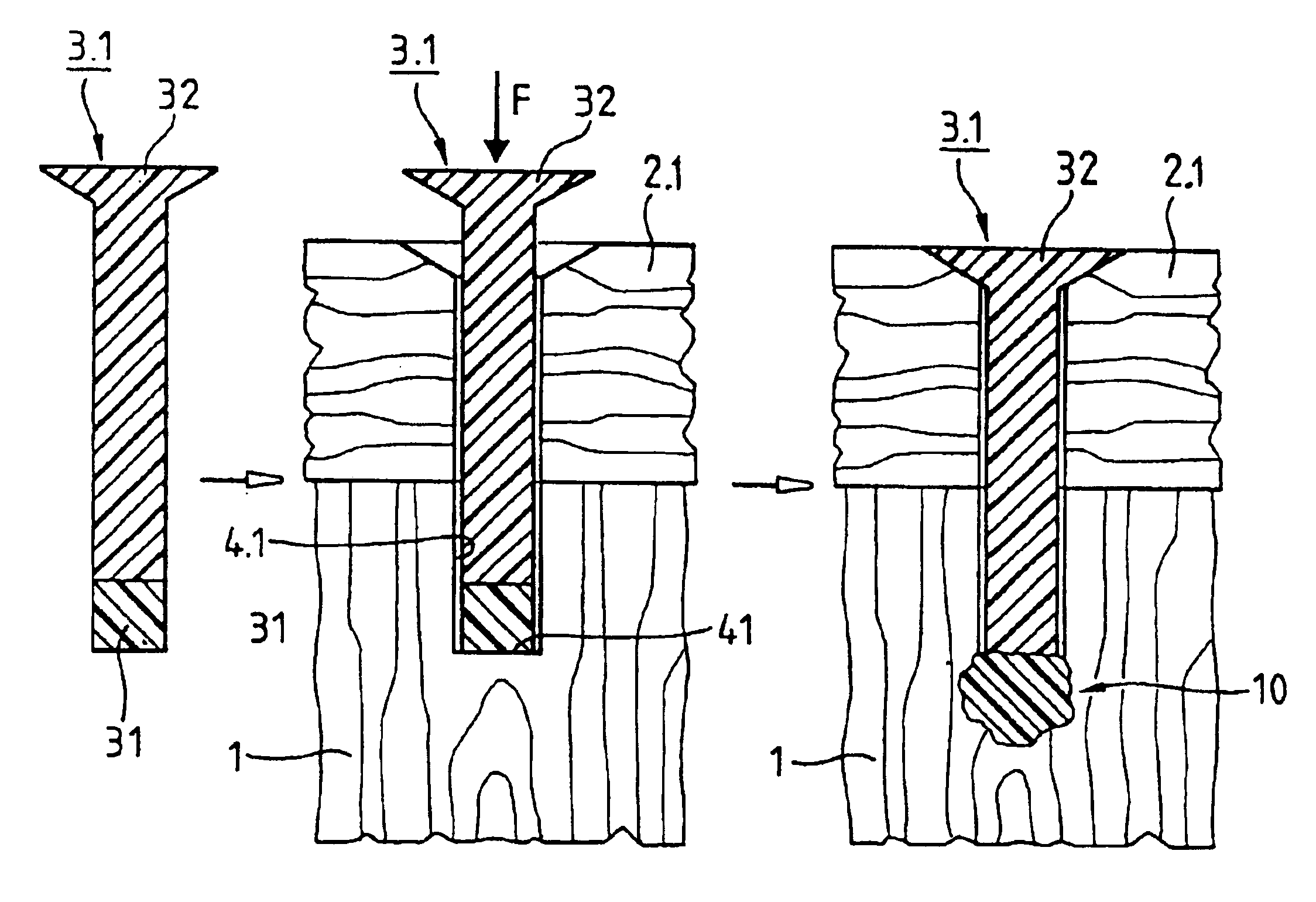

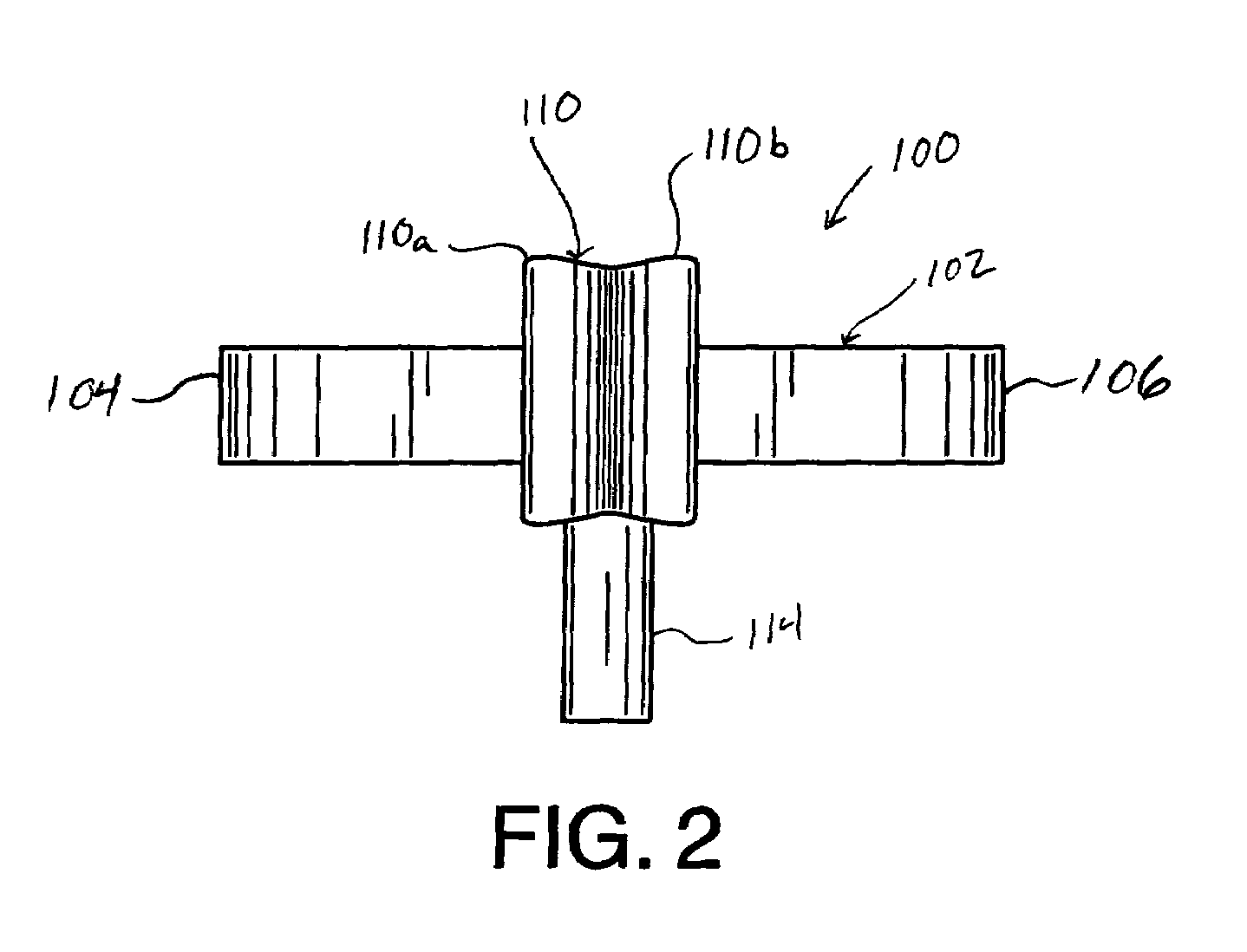

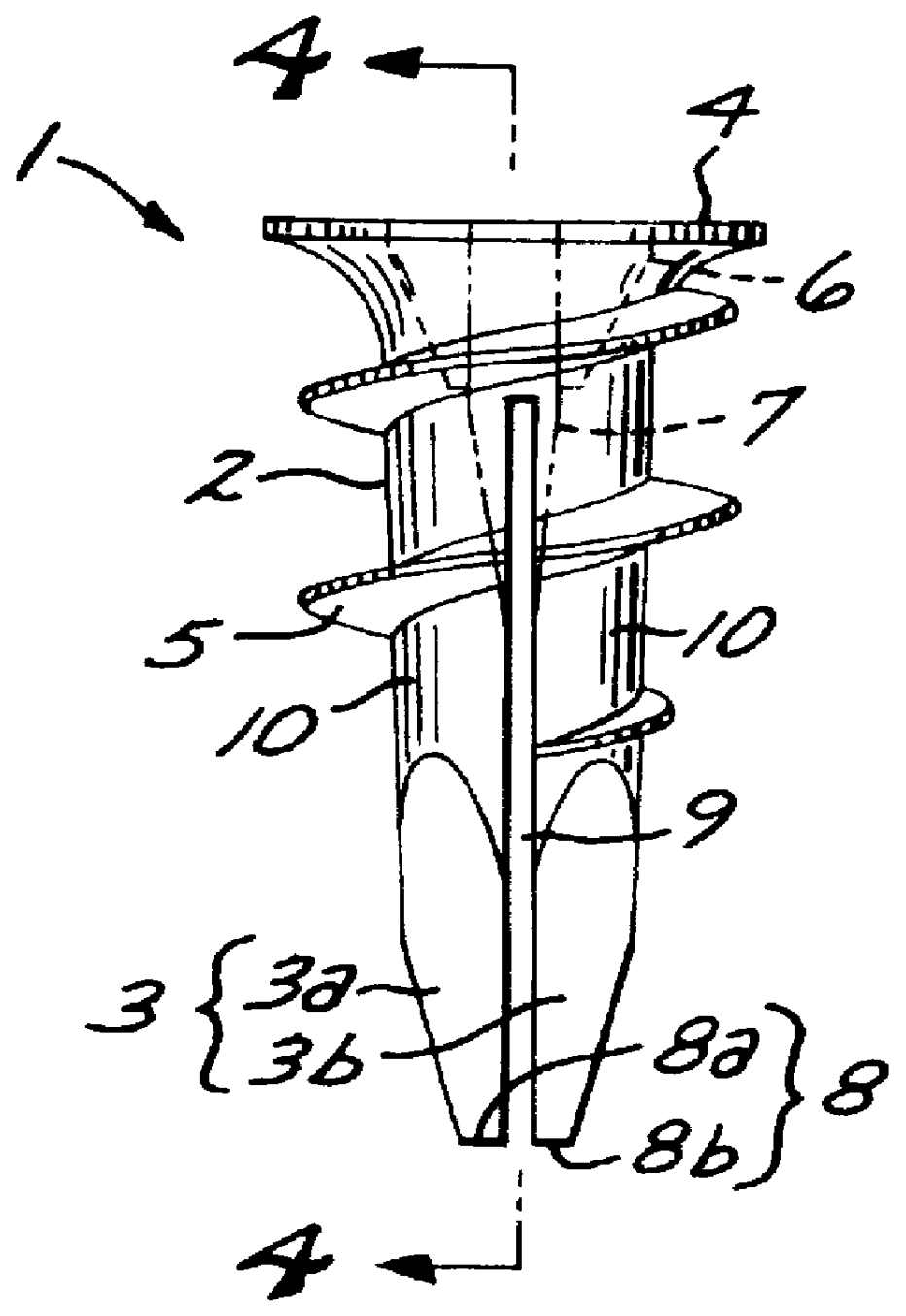

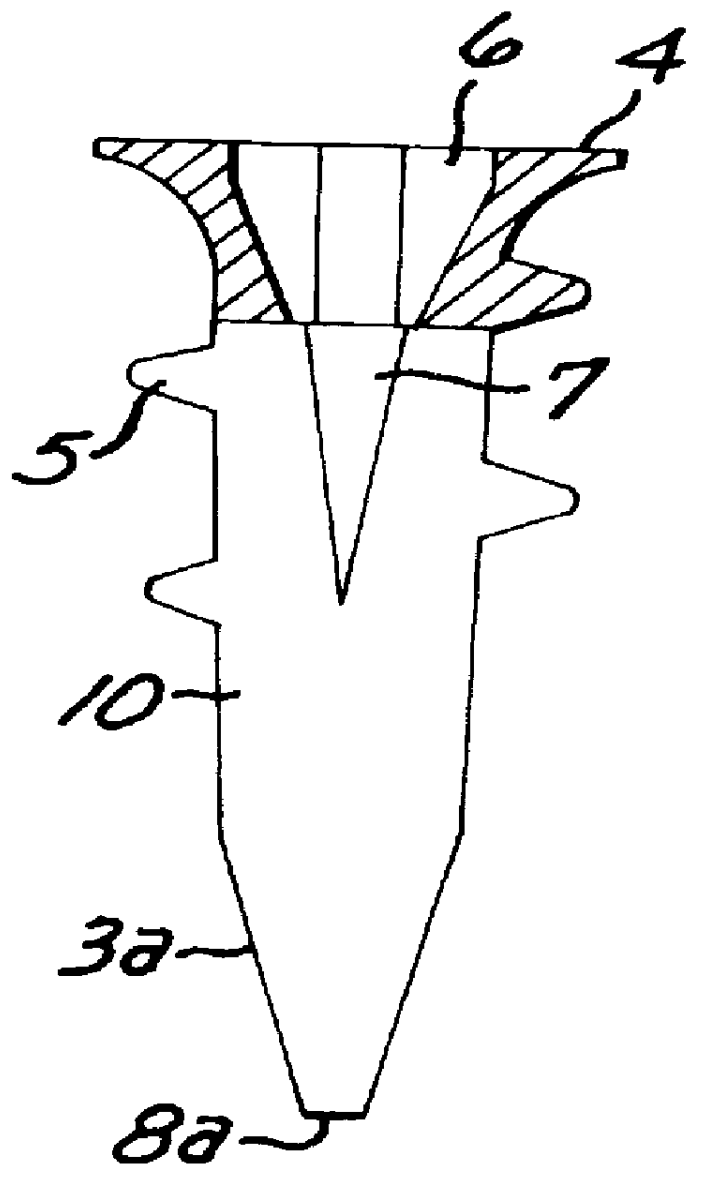

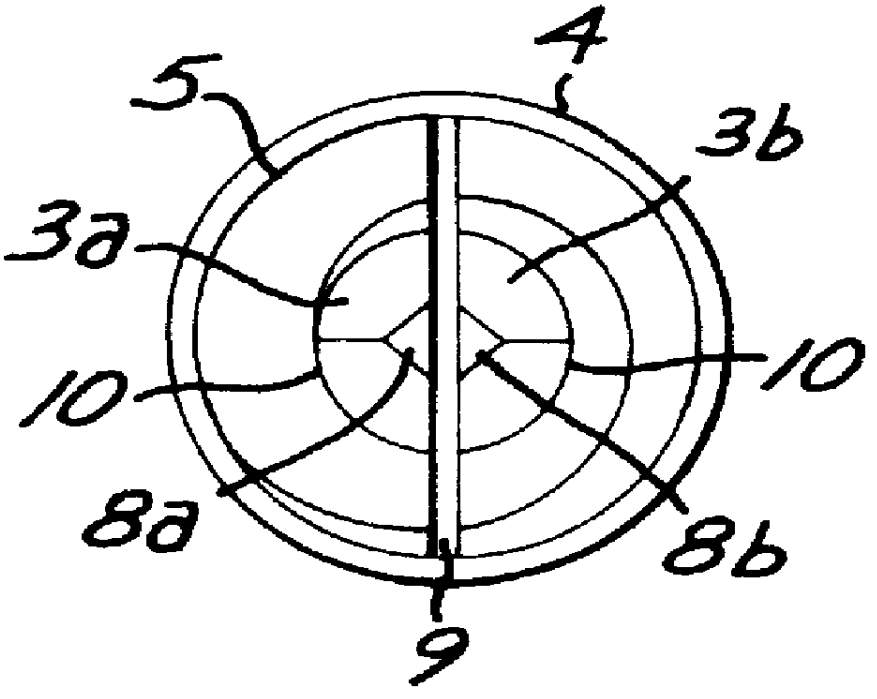

A joining pin (3.2) with which two parts (1 and 2) made from a porous material, particularly wood or a wood-like material, are to be joined together, is anchored in the porous material at predetermined anchoring points (31, 33). For this purpose, a bore (4.2) with a closed inner end (41) is made in the parts (1 and 2). The shape of this bore (4.2) is so matched to the joining pin (3.2) that it can be introduced substantially without force expenditure into the bore and is positionable in a first position. At least one predetermined anchoring point (31, 33) between the joining pin (3.2) and the wall of the bore (4.2) is formed when pressure is built up by pressing the joining pin (3.2) with a pressing force (F) more deeply into the bore to a second position. Energy is supplied in a planned manner to the joining pin (3.2) so that at the predetermined anchoring points (31, 33) the thermoplastic material of the joining pin (3.2) is plasticized. The locally plasticized plastic material is pressed by the local pressure into the porous material of the parts and forms local, macroscopic anchors (10, 20). The joining pin (3.2) is, e.g., made entirely from a thermoplastic material and the energy for plasticizing is supplied thereto by ultrasonic vibration.

Owner:WOODWELDING

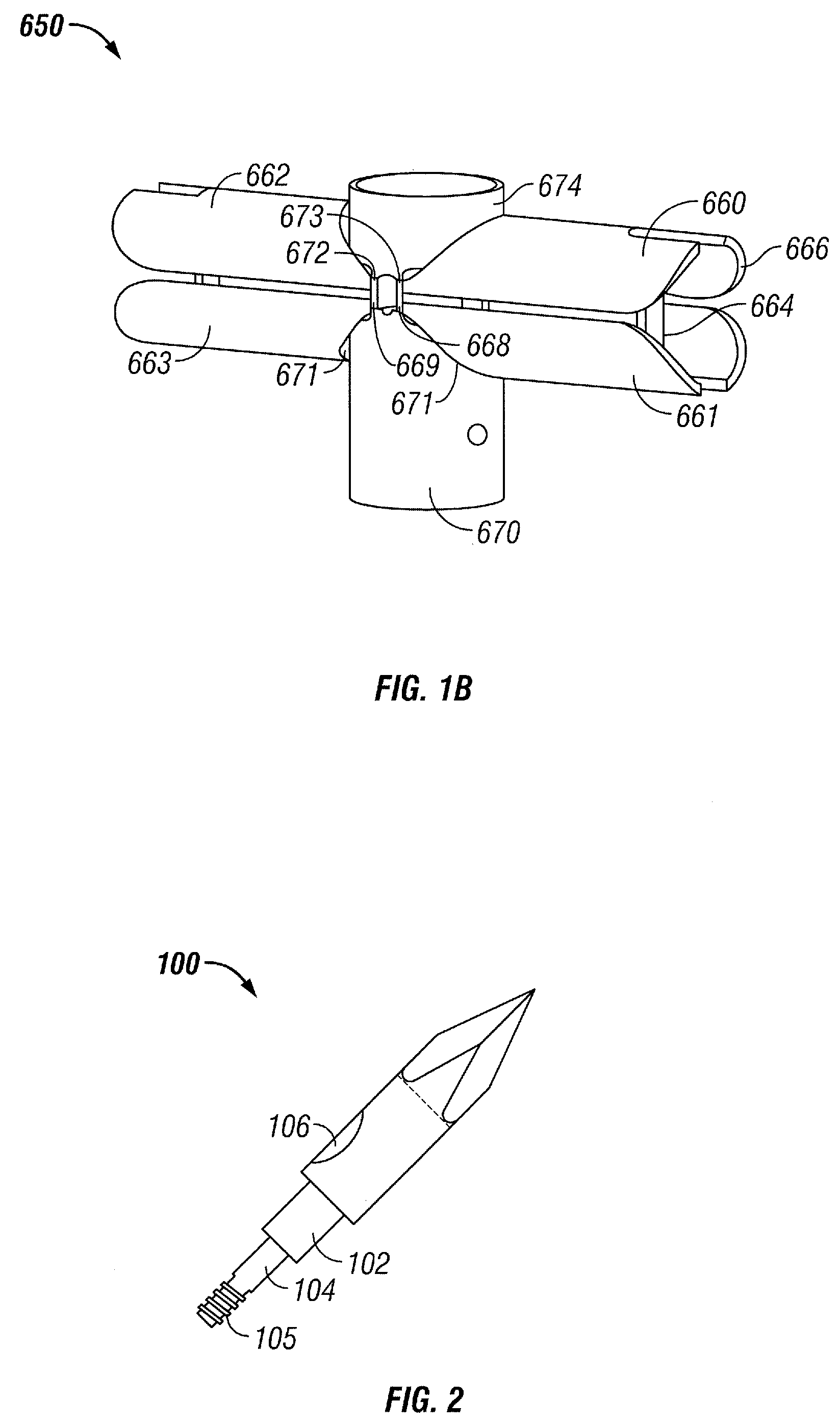

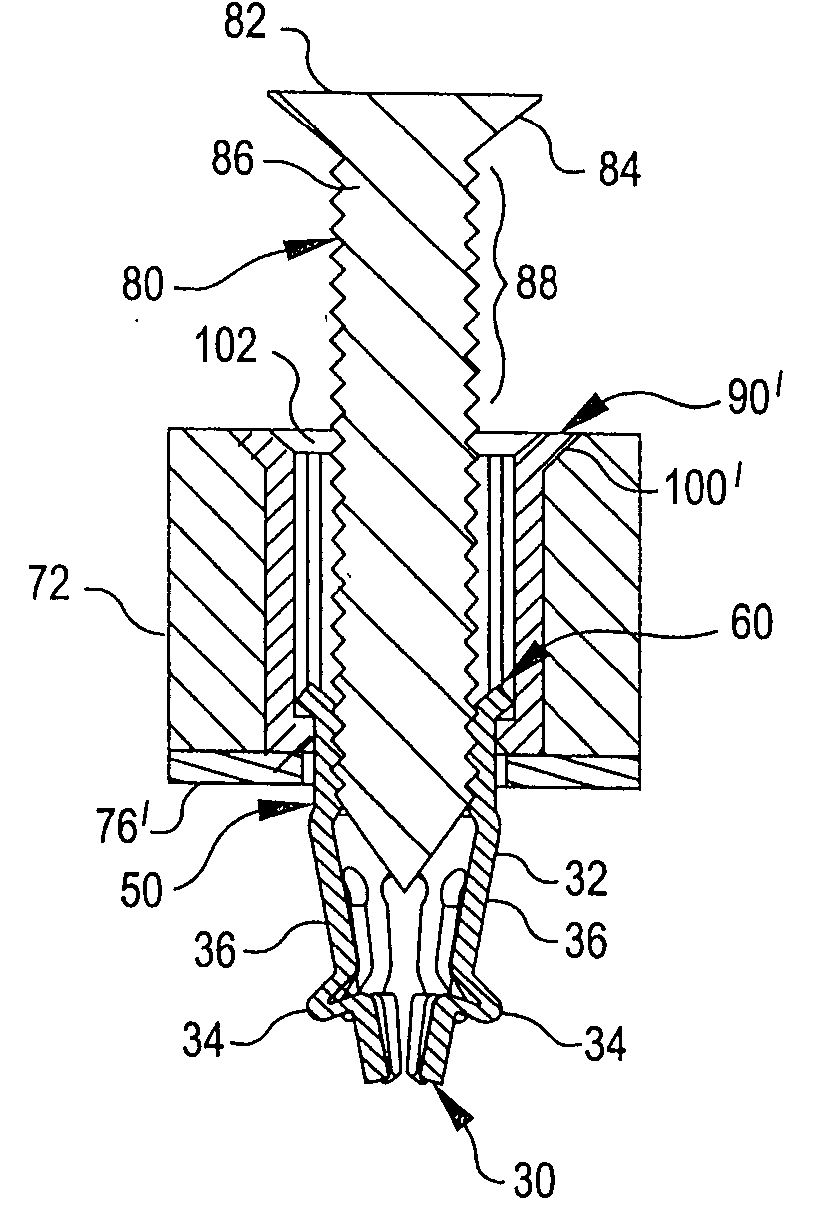

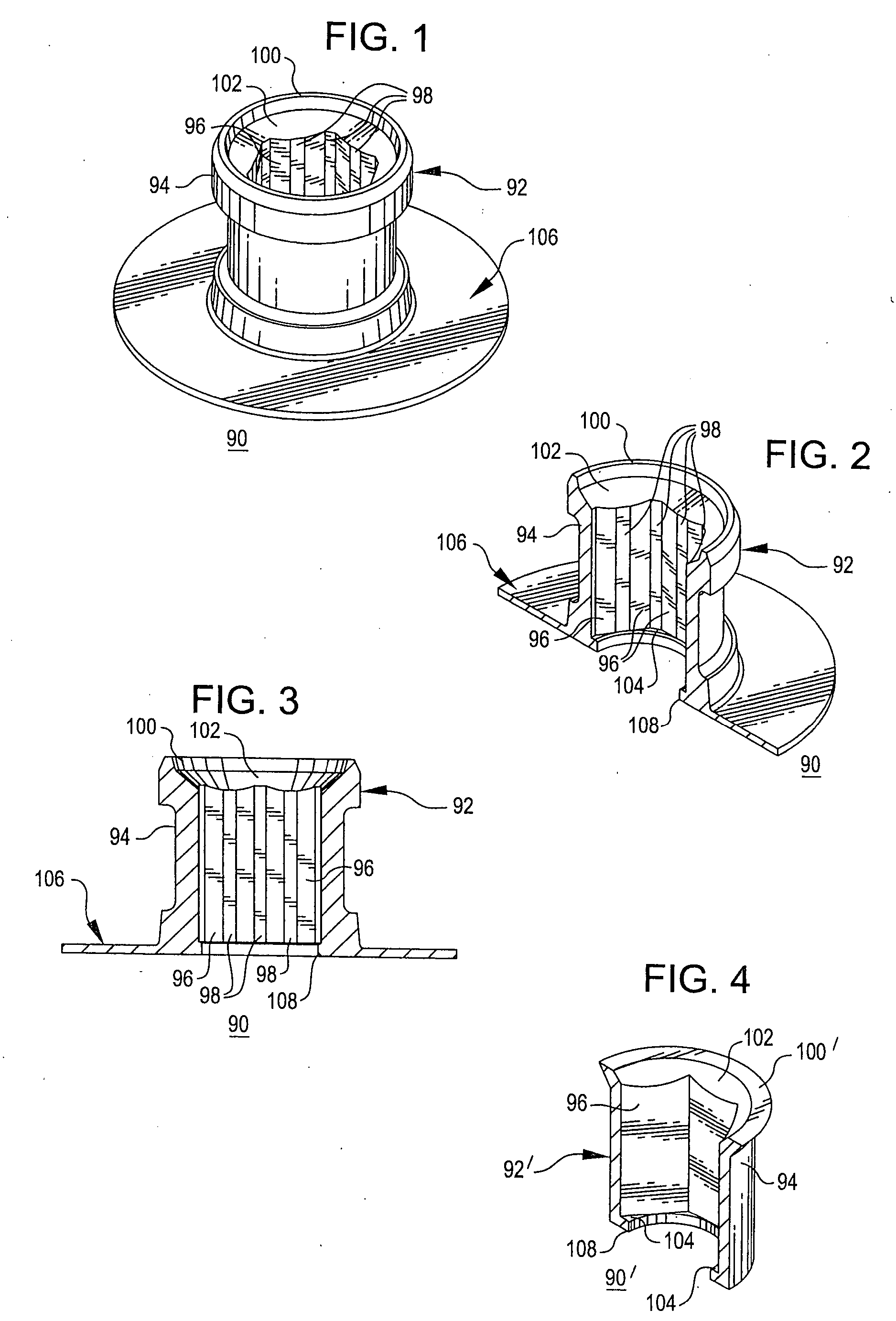

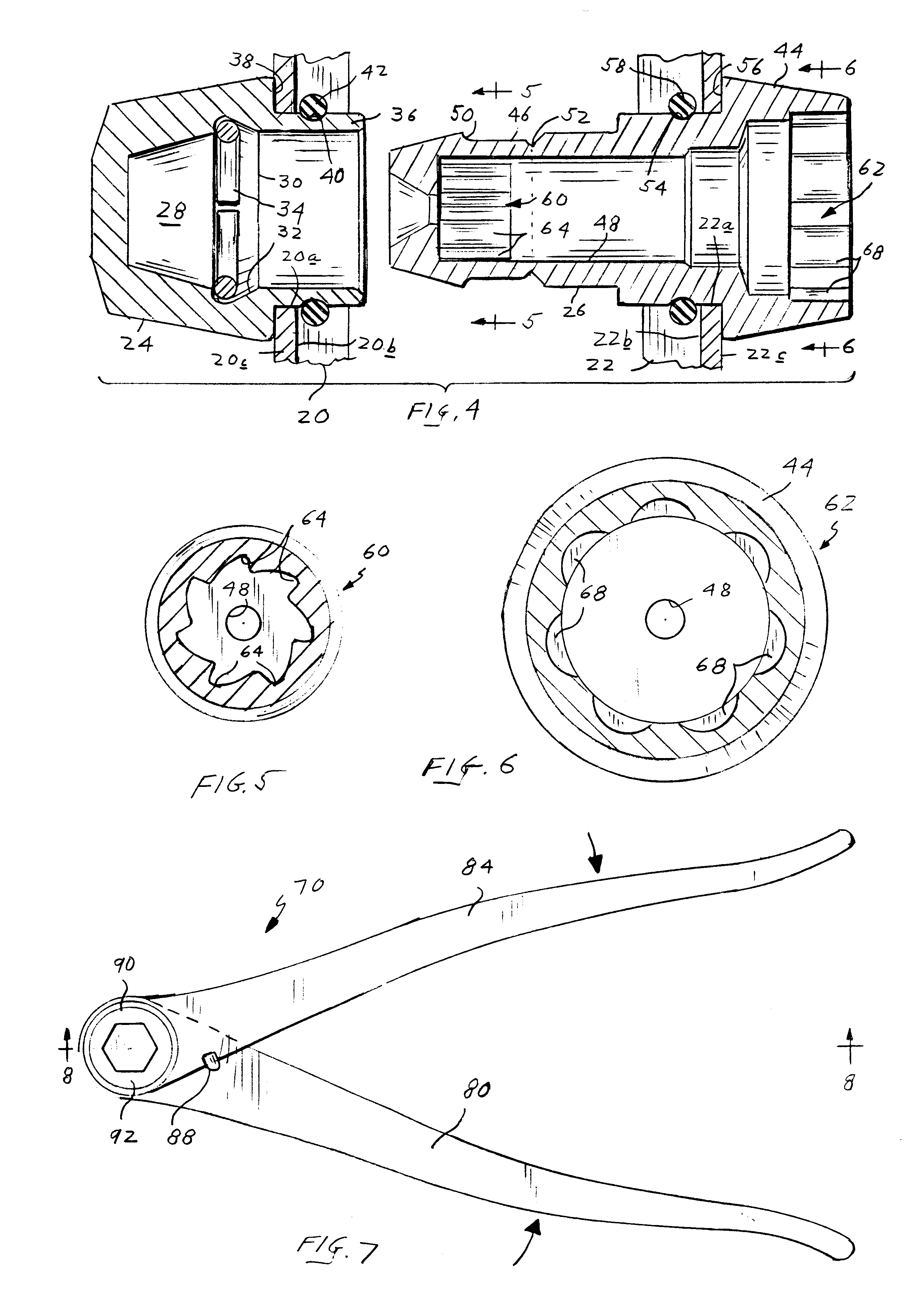

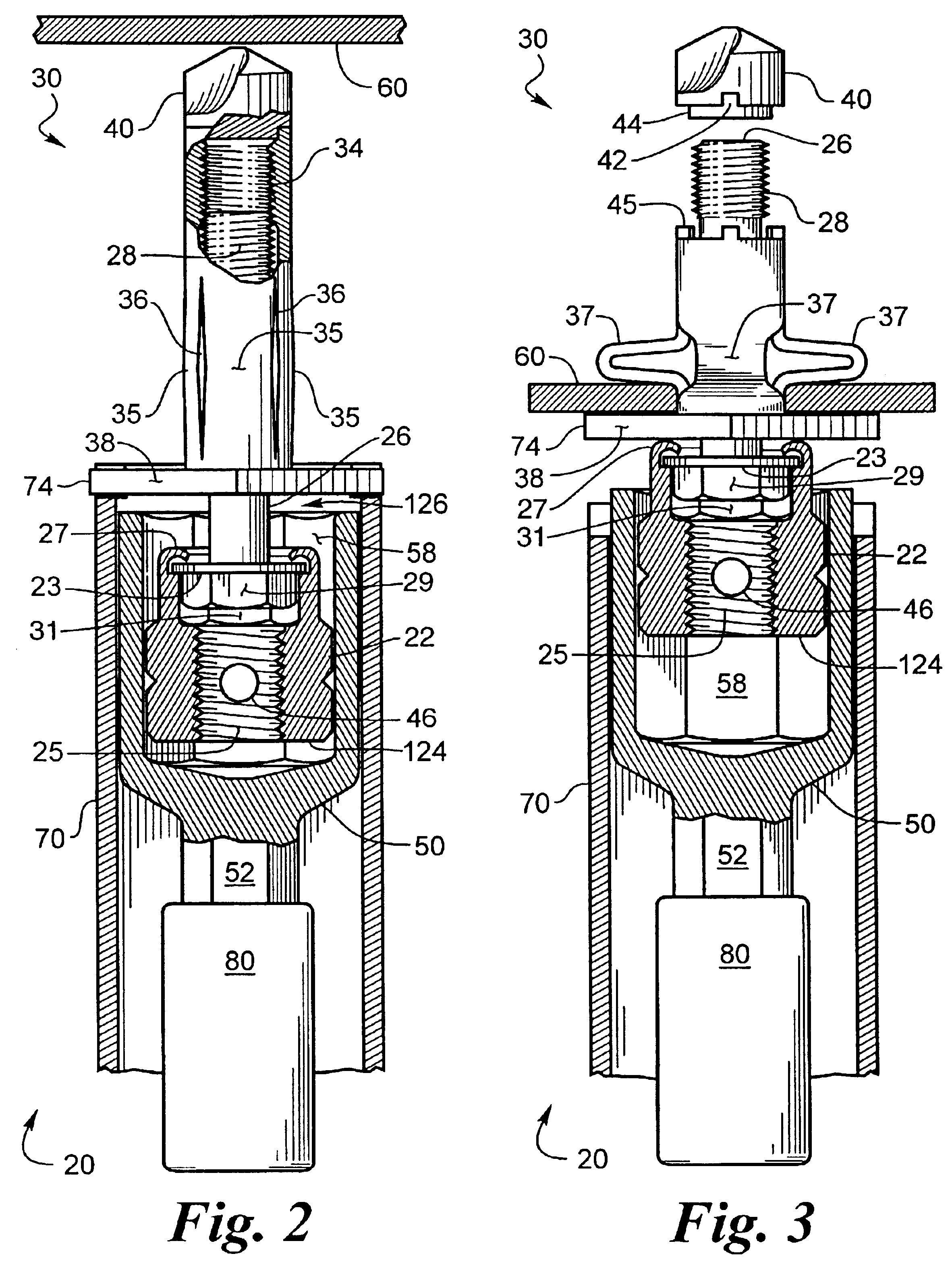

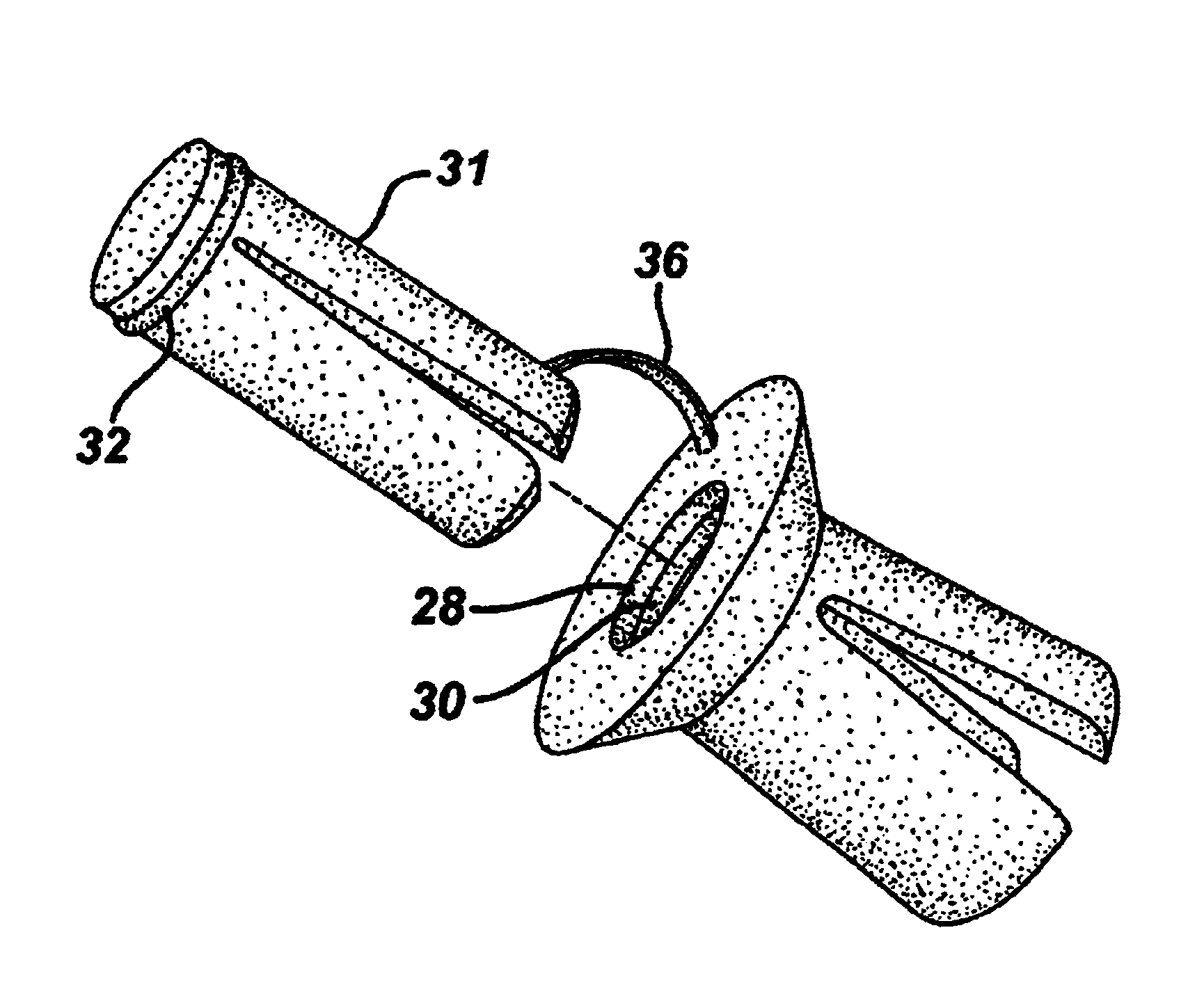

Bone anchor and deployment device therefor

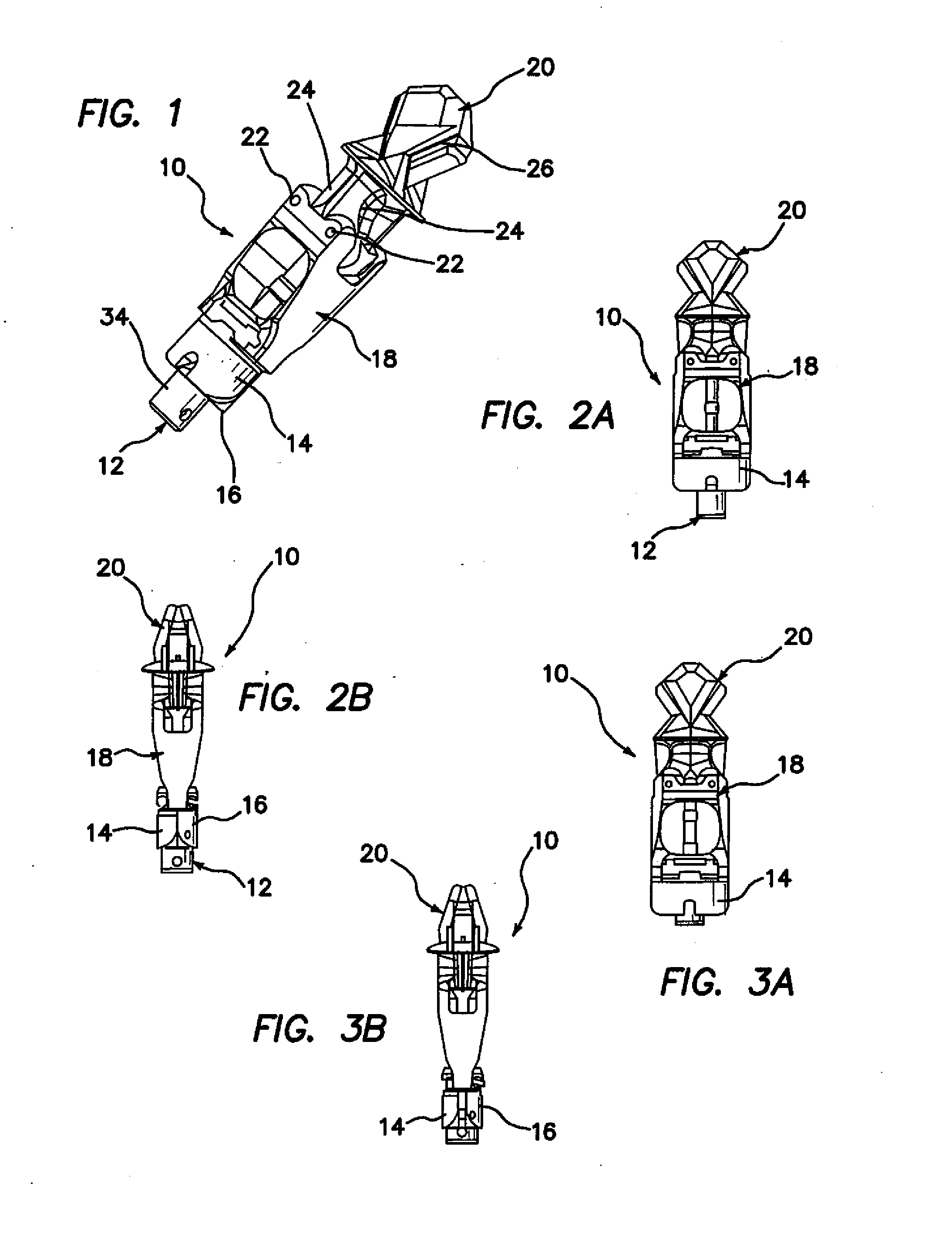

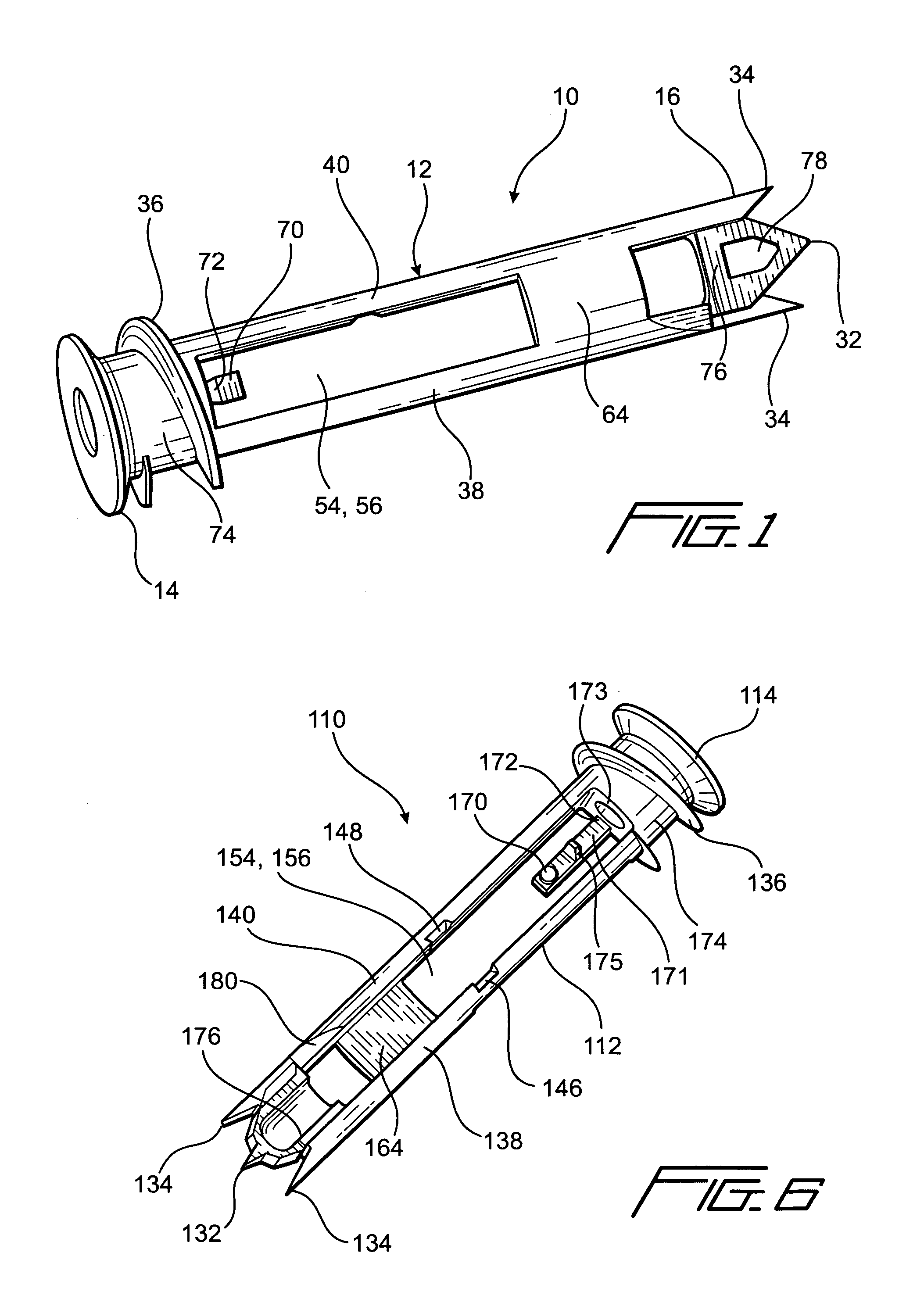

A rivet-like bone anchor has a floating washer at its head that can adapt to an angled bone surface and, thereby, better secure a tissue thereto. The anchor includes a rivet, an expandable sleeve, and a washer. The rivet includes a head and an elongate body having proximal and distal ends, the head being mounted on the proximal end of the elongate body. The expandable sleeve has an inner bore adapted to receive the rivet body. The washer “floats” at a proximal end of the sleeve. As the rivet is inserted into sleeve, the sleeve expands into an interference fit with the bone. The head of the rivet, moreover, forces the floating washer into contact with the tissue at an angle that conforms to that of the underlying bone surface. A deployment tool permits the anchor to be deployed without application of unnecessary counterforce. The tool includes an outer tube, the distal end of which can hold the anchor housing, e.g., via a screw fit. A rod, which is slidably disposed within the bore of the tube, can be used to push the rivet into the expandable sleeve so that the sleeve expands into the bone, so that the floating washer is forced into position against the bone surface, and so that anchor is broken away from the housing. This can be effected, for example, by squeezing the distal ends of the outer tube and the rod together, e.g., in the manner that the end of a syringe is squeezed.

Owner:INNOVASIVE DEVICES

Suture anchor

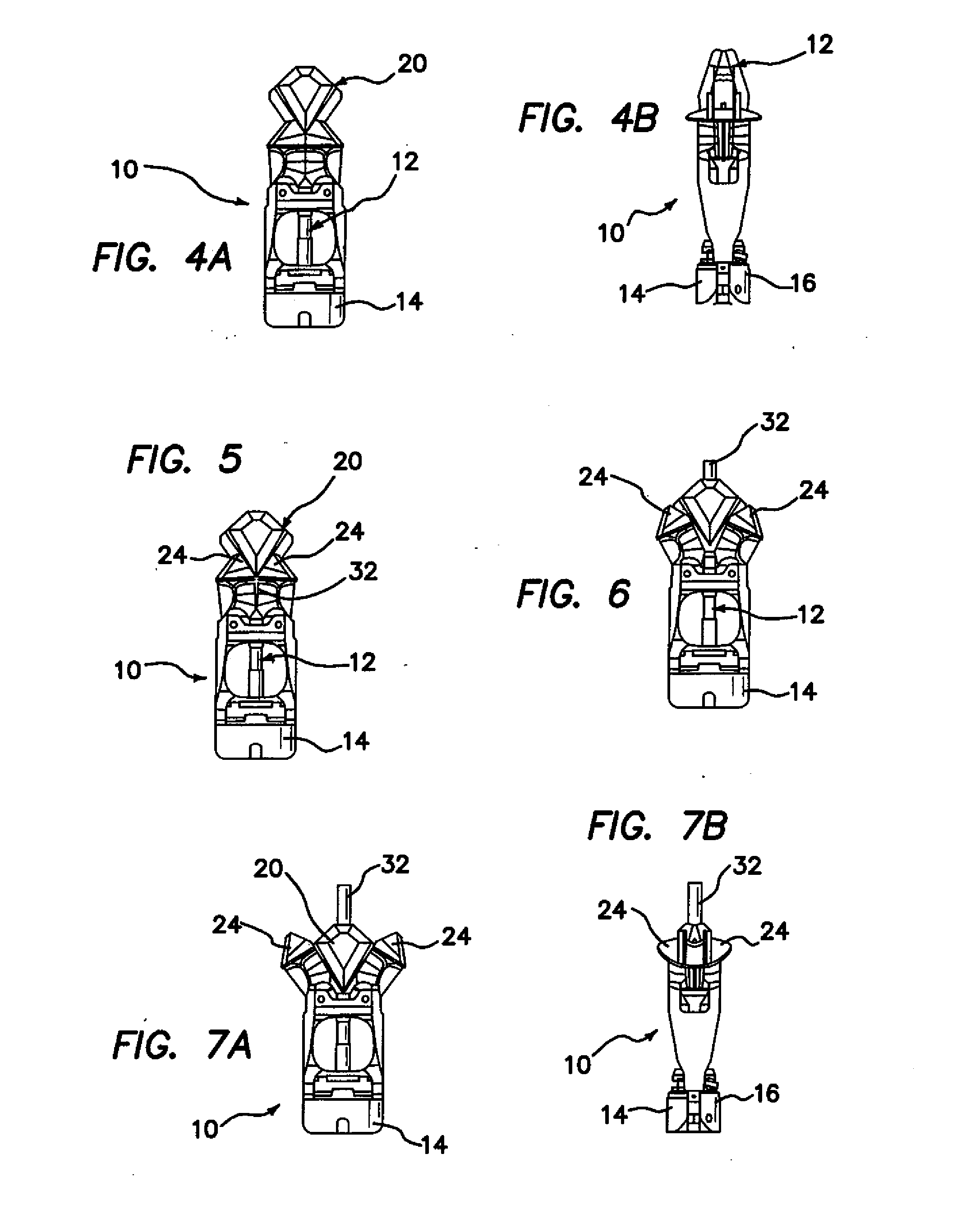

A bone anchor is described having pre-attached suture material. After insertion, lateral wings can be deployed on the bone anchor to prevent anchor pull-out. The suture may be attached at the tip of the anchor by tying it to a wire hook secured in a cavity in the anchor tip. The anchor may be inserted and deployed using an anchor inserter that is configured to apply an axial force to the anchor, thereby deforming the anchor to form the lateral wings.

Owner:SCOTT W TATE

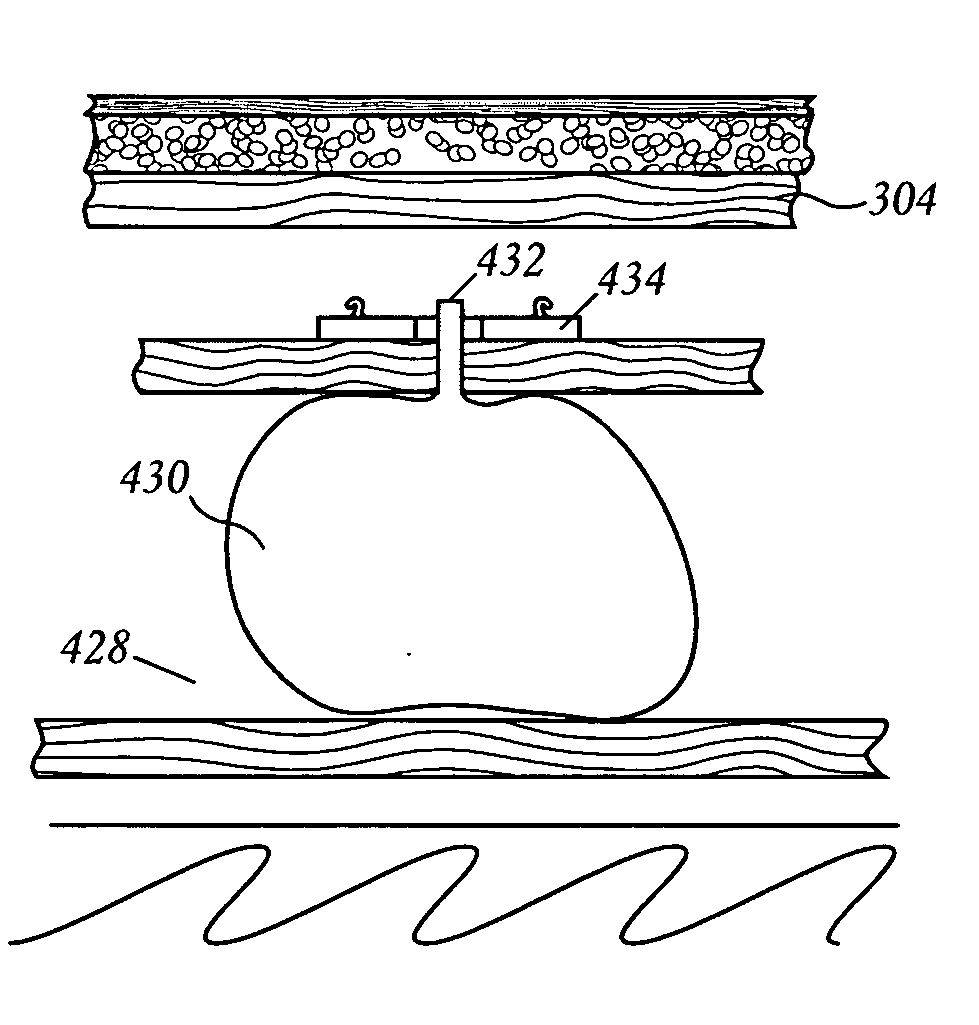

Extragastric Balloon With Attachment Tabs

InactiveUS20080071306A1Increase heightLonger-term implantationSurgeryDilatorsMedicineGeneral surgery

Disclosed are methods and devices to apply therapies to the walls of an organ such as the stomach. Visualization means and access means are disclosed as are devices and apparatus which can be used to perform the disclosed procedures and methods.

Owner:GERTNER MICHAEL

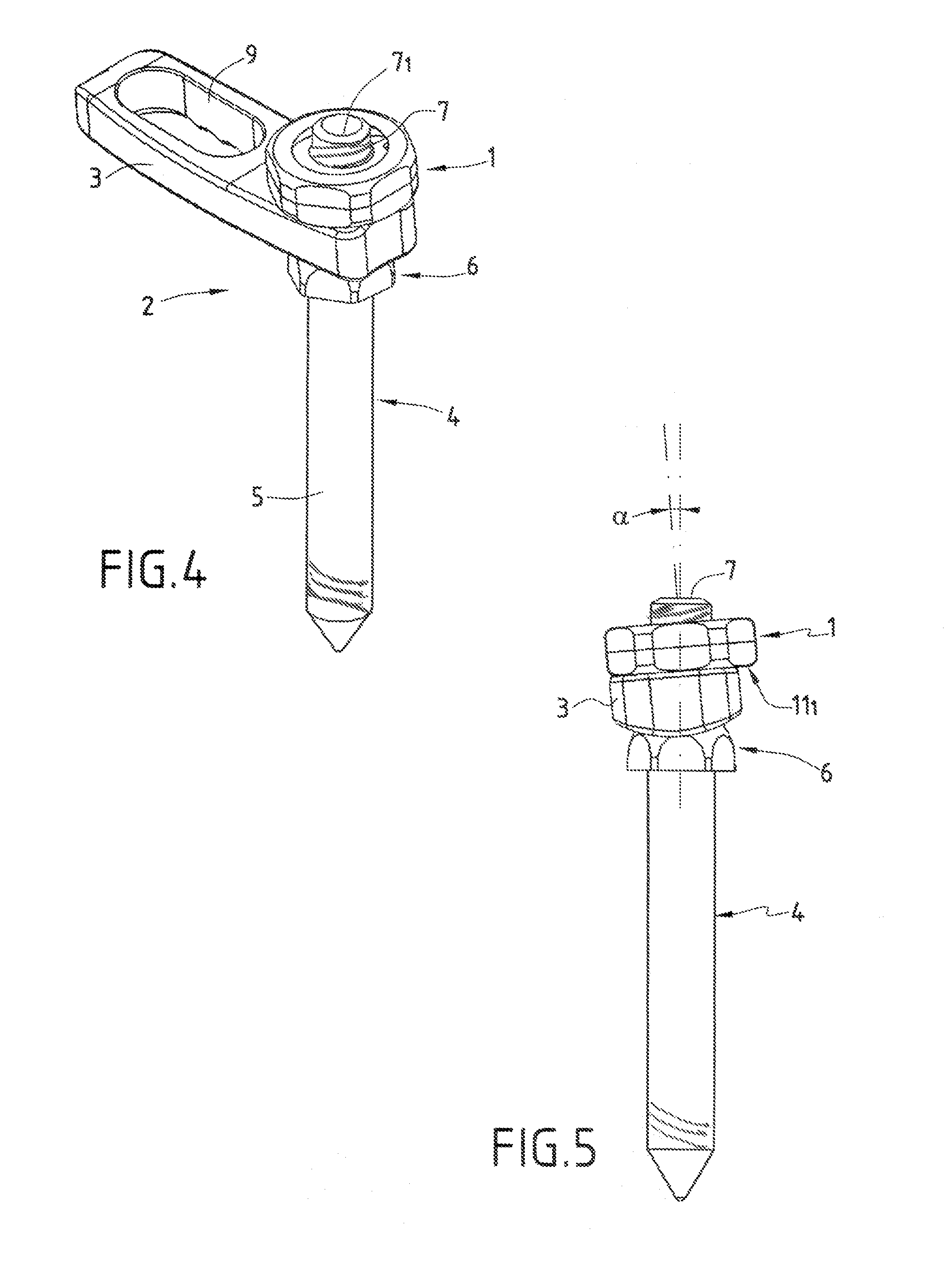

Device for fixing bone sections separated because of a fracture

InactiveUS6902567B2Readily and safely appliedSuture equipmentsInternal osteosythesisEngineeringIliac screw

Owner:VESE SILVANA

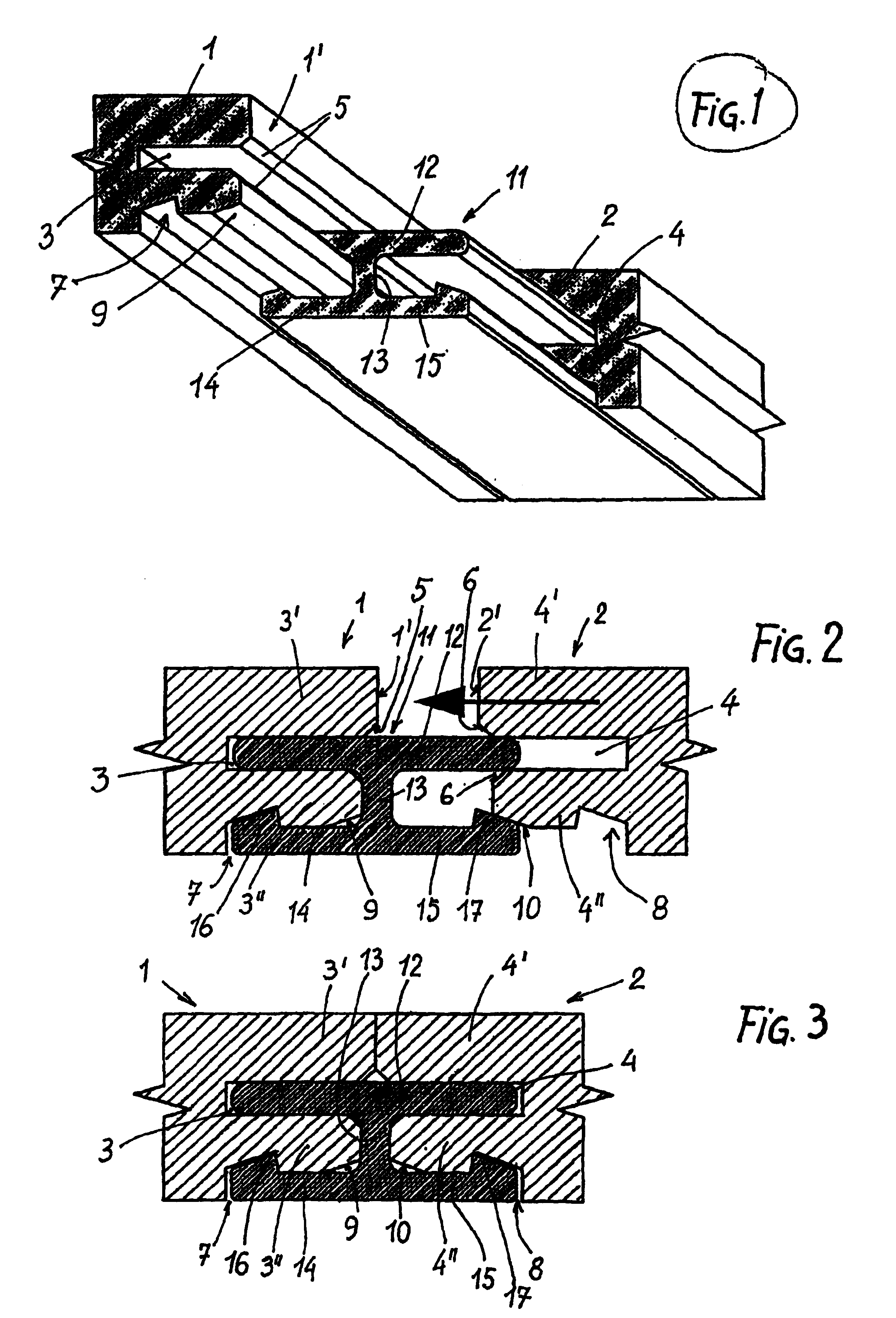

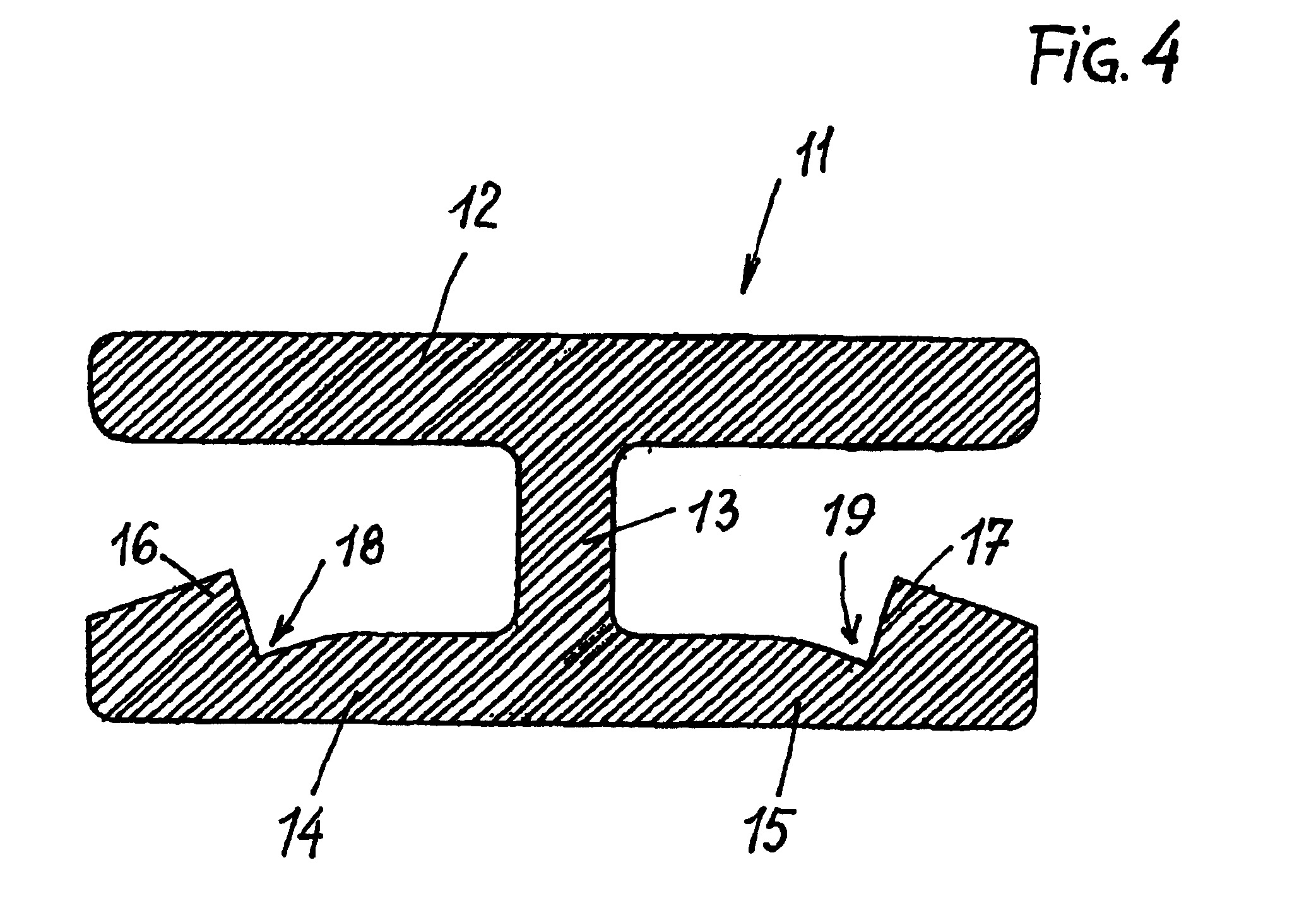

Device for joining flat, thin members that rest against another

The system relates to a system for joining flat, relatively thin members that adjoin one another along their narrow face, the members having grooves incorporated into the narrow faces that are parallel to the surface and have groove walls that are parallel to each other, and the joining element being inserted into the grooves of two adjacent members and bridging the partition gap between the members in the manner of an external tongue. In this context the joining element (11) has, on its part (12) that can be inserted in the manner of an external tongue in the longitudinal center on its side that faces away from the visible surface of the members, one continuous web or a plurality of aligned webs (13) that preferably protrude at a right angle, from which detent webs (14, 15) protrude on both sides, each of which has a detent projection (16, 17) that projects toward the external-tongue-like part (12), and on the bottom of the member (1, 2), which faces away from its visible surface, detent grooves (7, 8) being provided that run parallel to the adjacent edge at a distance corresponding to the width of the detent webs (14, 15).

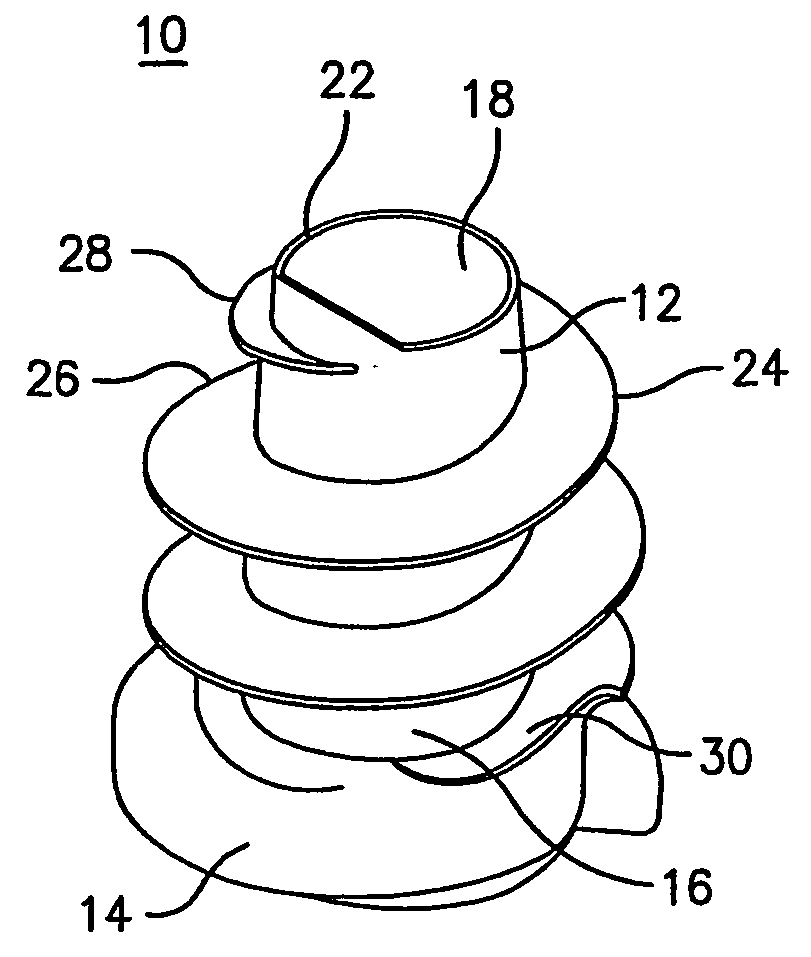

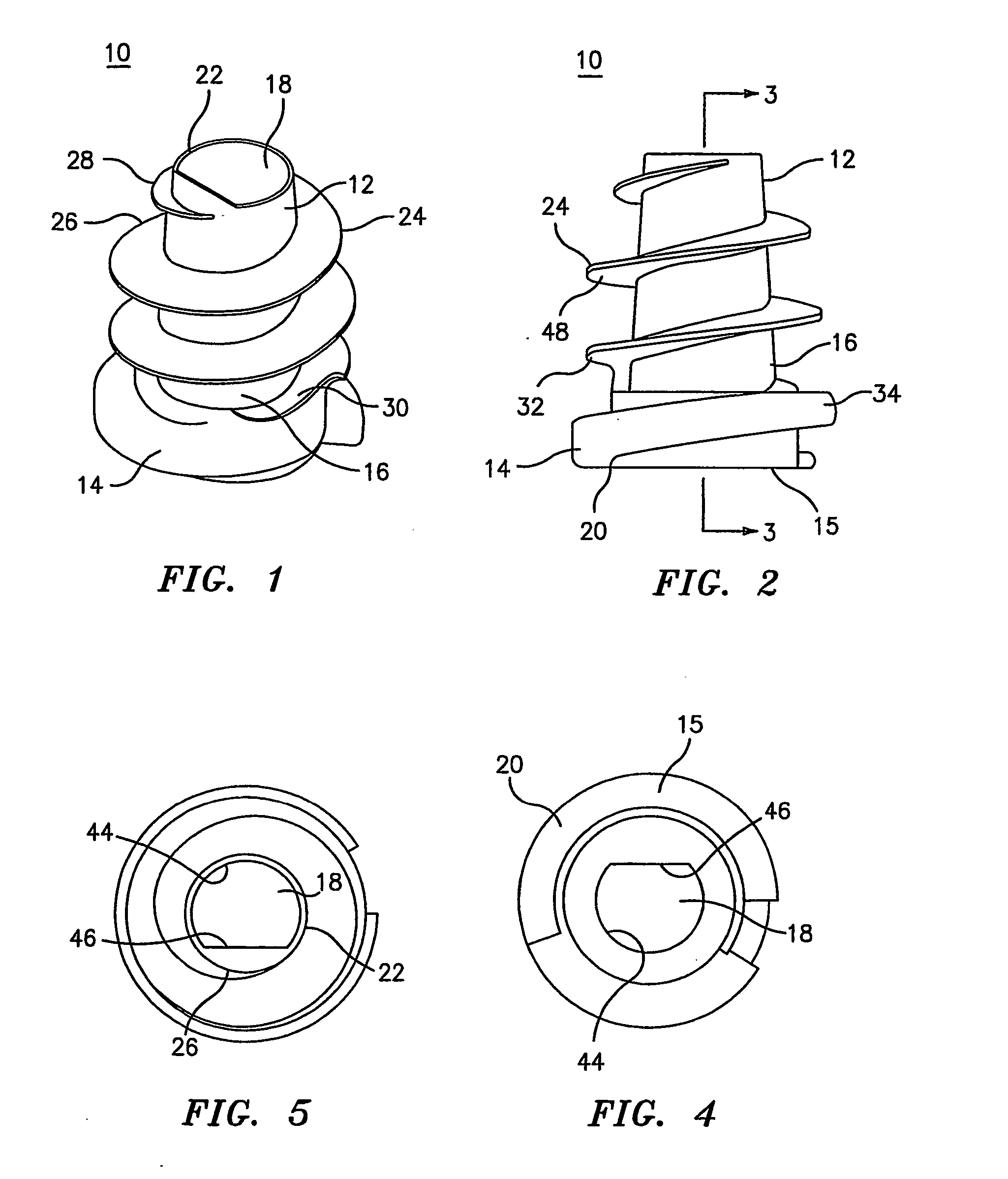

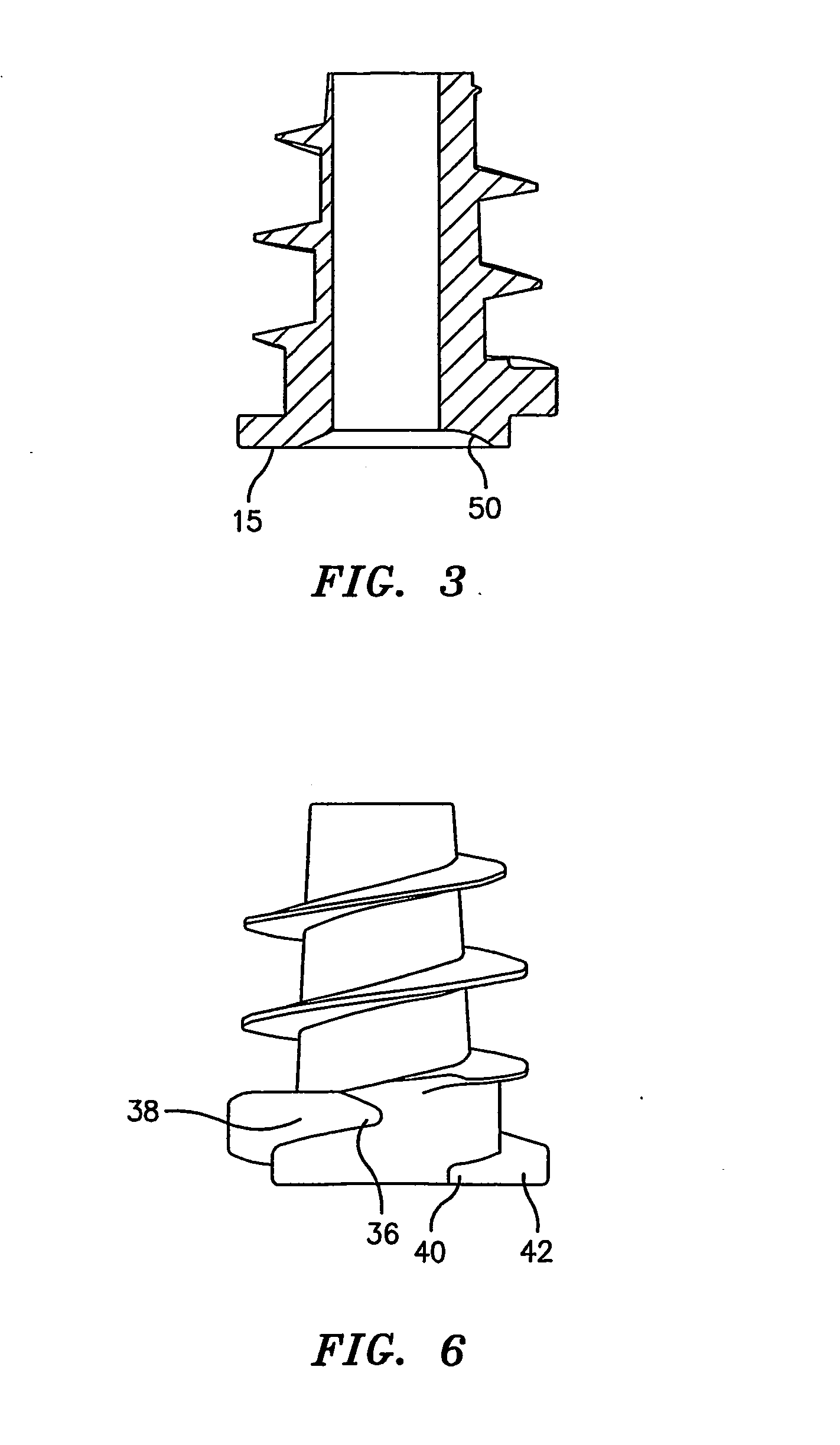

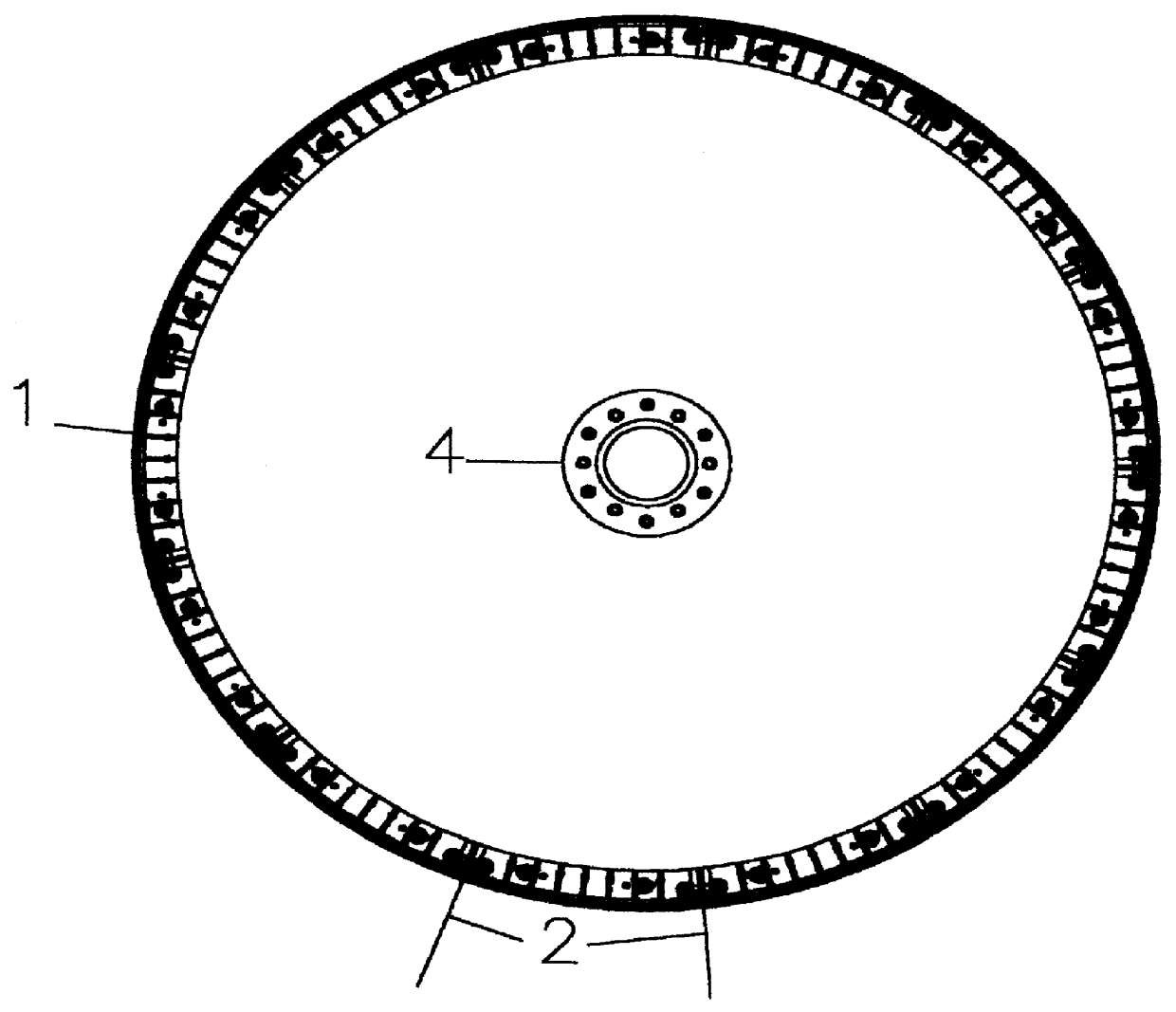

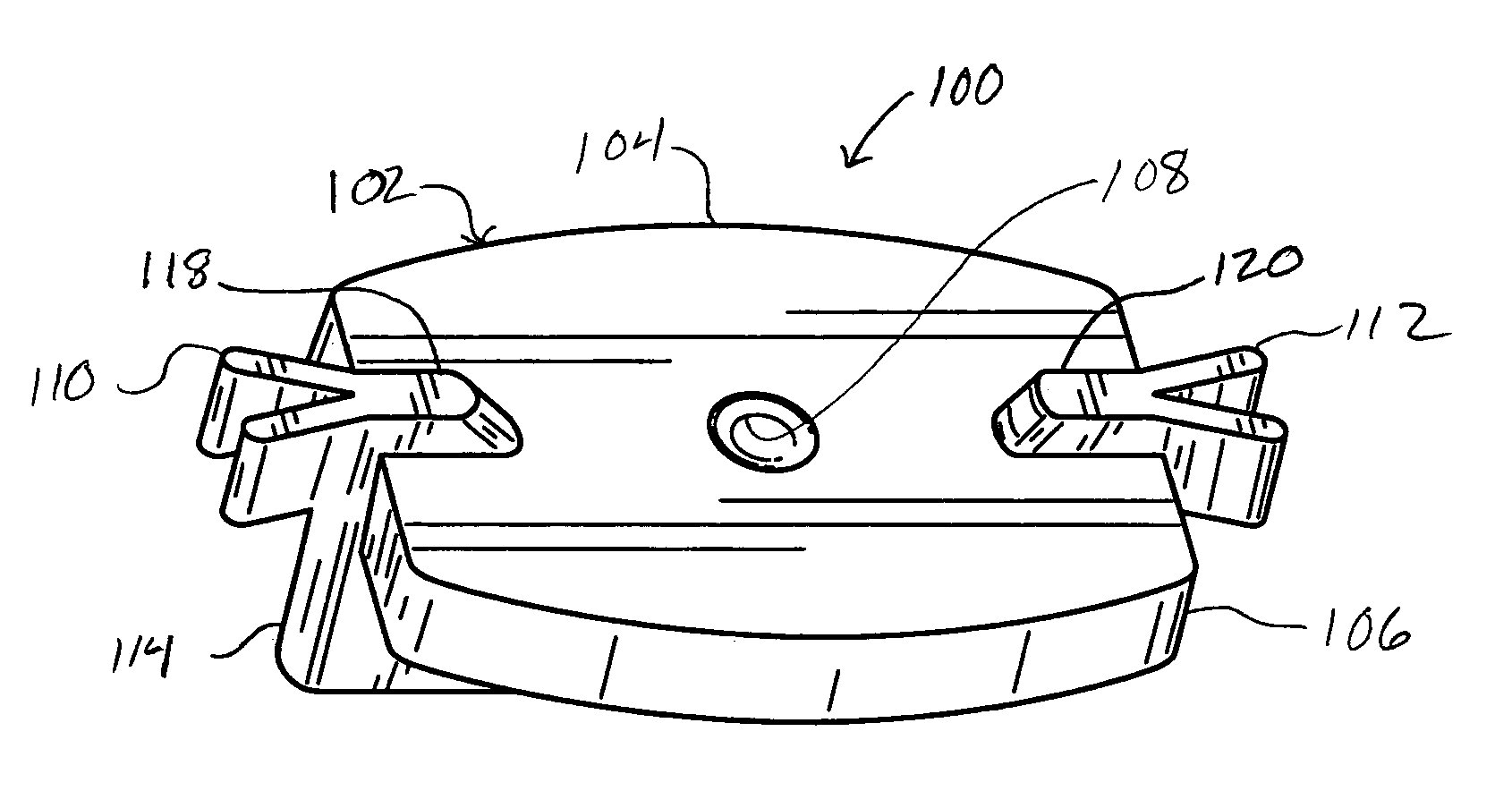

Hernia mesh tacks

InactiveUS20050171562A1Increase drive surface areaEasy to insertSuture equipmentsInternal osteosythesisEngineeringSurgical department

There are disclosed various embodiments of surgical tacks for use in surgical procedures. The tacks generally include a head and a barrel portion extending distally from the head. Preferably the head and the barrel portion define a throughbore for receipt of a drive instrument. A thread on the head is provided to engage threads in the installation tool. A tissue thread is provided on the barrel, portion to engage tissue. Distal and proximal surfaces of the tissue thread may be oriented at various angles relative to the barrel portion. There is also disclosed an insertion instrument to insert one or more tacks as well as a method of use. There is further disclosed a model device for use in explaining the operation of the instrument.

Owner:TYCO HEALTHCARE GRP LP

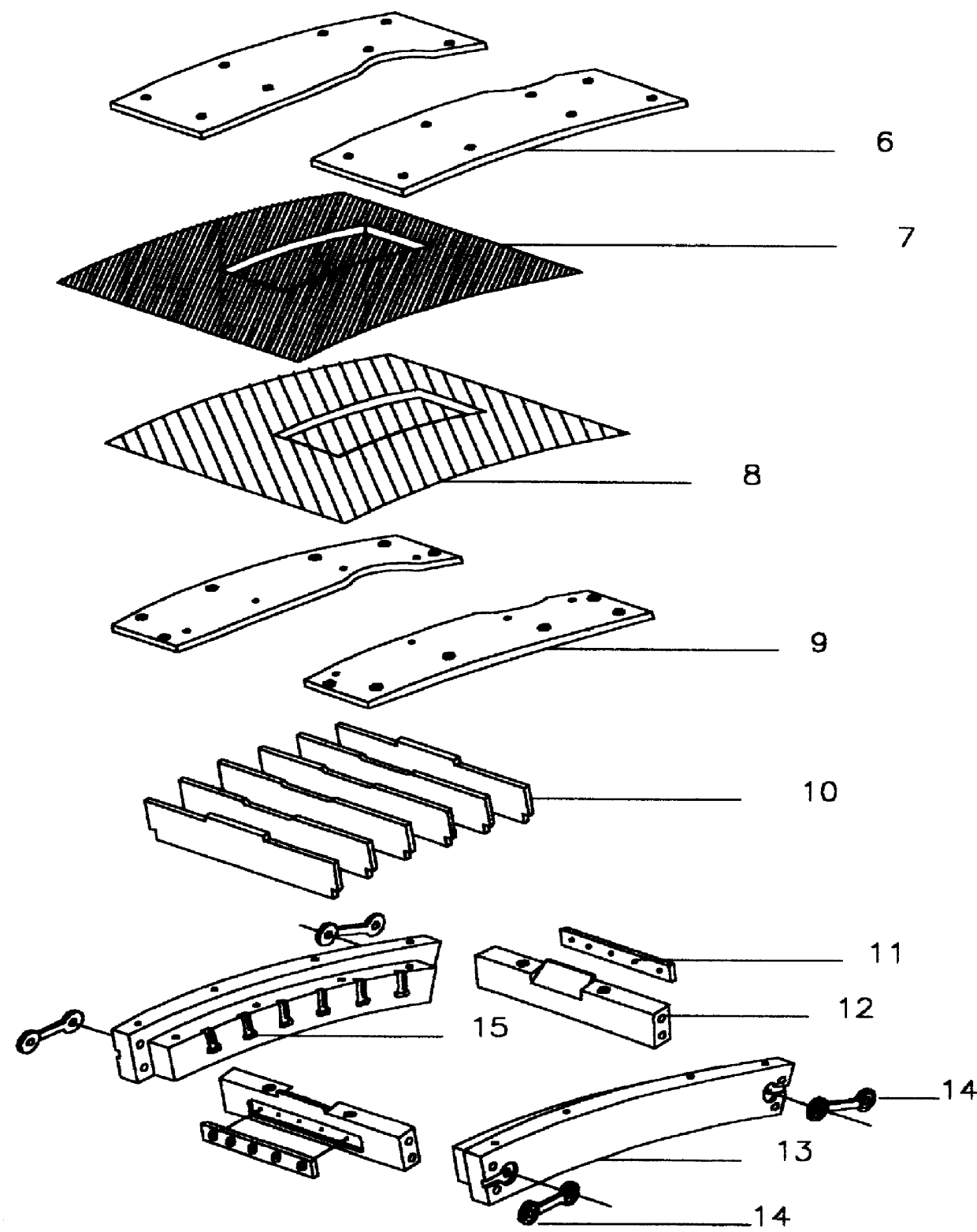

Apparatus for forming controlled density fibrous pads for diapers and the other absorbent products

The present invention provides an improved apparatus for forming a fibrous pad for absorbent products with improved density control. Fibers entrained in a high speed air flow are deposited onto the foraminous surface of a spaced, three-dimensional pad-forming pocket. The fine foraminous pad forming screen is supported on its periphery by two top plates, a coarse forming screen, two subplates and end rails which incorporate a device to hold the pad forming screen. A gas flow regulating system consisting of precisely placed cross directional fixed and adjustable airflow control louvers controls the air flow direction and reduces spill over and turbulence during the pad formation and especially during the transition of the forming pocket into and out of the air stream as the rotary former shell rotates through the filling position. Additional control of density and fiber placement is gained through the use of additional gas control innovations including a tapering the pocket ends such that the airflow is streamlined especially during pocket transition through forming sections.

Owner:TONEY JERRY L +3

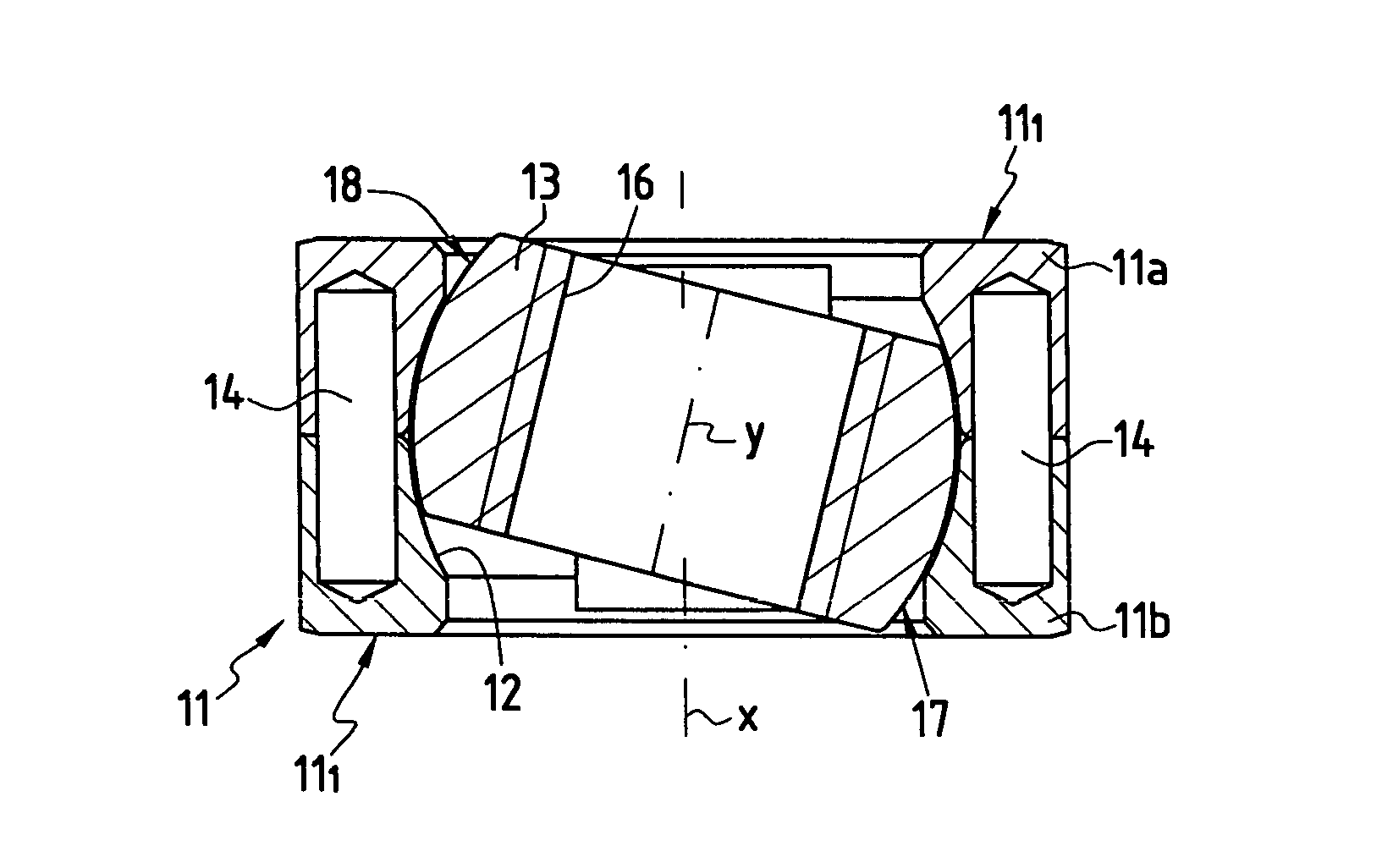

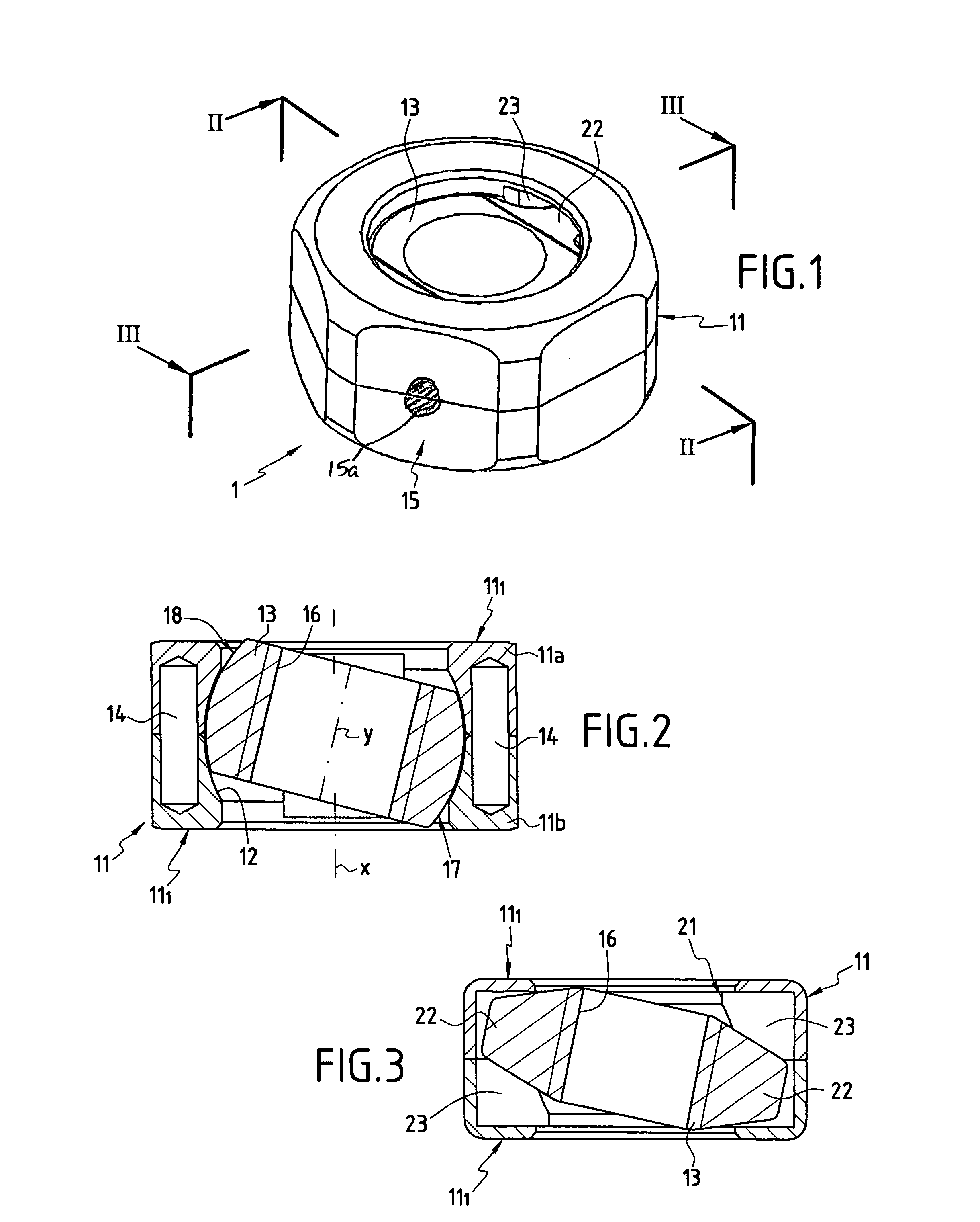

Clamping nut for an osteosynthesis device

A clamping nut suitable for co-operating with a threaded shank of an osteosynthesis appliance, the nut including an annular body and a tapped bore for cooperating with the threaded shank. The annular body is provided with a structure which enables turning the body and with a transverse bearing face. The osteosynthesis nut further includes a ring mounted in a housing of the annular body which is provided internally with the tapped bore, and which cooperates externally with the annular body.

Owner:SCIENTX

High performance sleeved interference fasteners for composite applications

A fastener adapted to pass through aligned holes through workpieces is disclosed. The fastener includes a pin member having a transition portion wherein the diameter of the transition portion decreases radially as it extends from the smooth cylindrical shank portion to the threaded portion. The fastener may also comprise a sleeve member and a clamping means. The clamping means includes a collar, a nut, or any other possible clamping means. In exemplary embodiments, the workpieces can be formed with a plurality of materials, the materials including composite, metallic, or composite / metallic structures, any combination thereof. In particular embodiments, the fastener has interference capability of 0.0005 to 0.0100 inches in composite structures without risk of composite delamination or damage. As a result of the fastener interference, gaps between the fastener and the structure are eliminated thereby providing good electrical conductivity between components. As a result, the potential for electrical sparks is reduced, providing a safer fastener for use with aerospace applications.

Owner:ALCOA GLOBAL FASTENERS

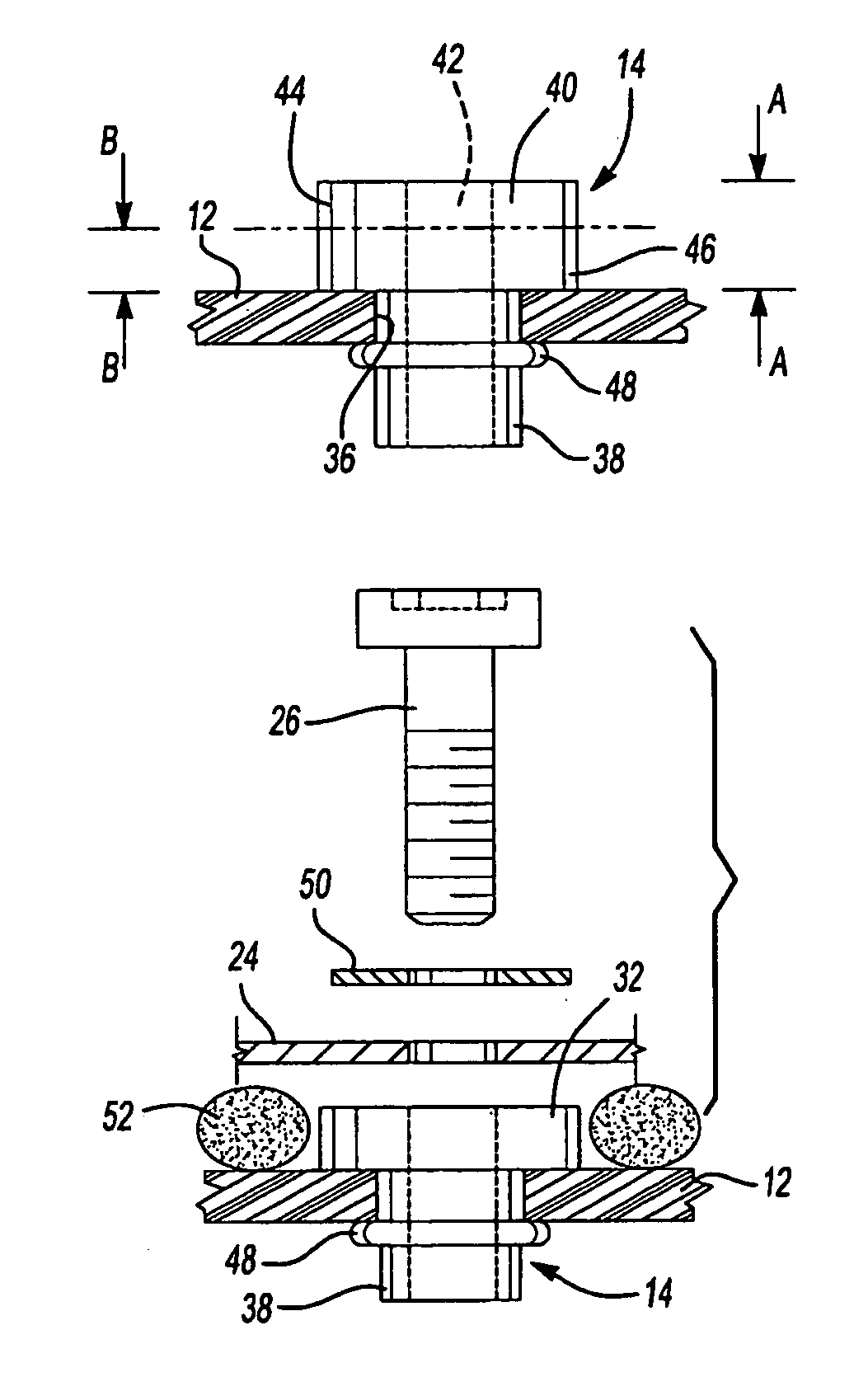

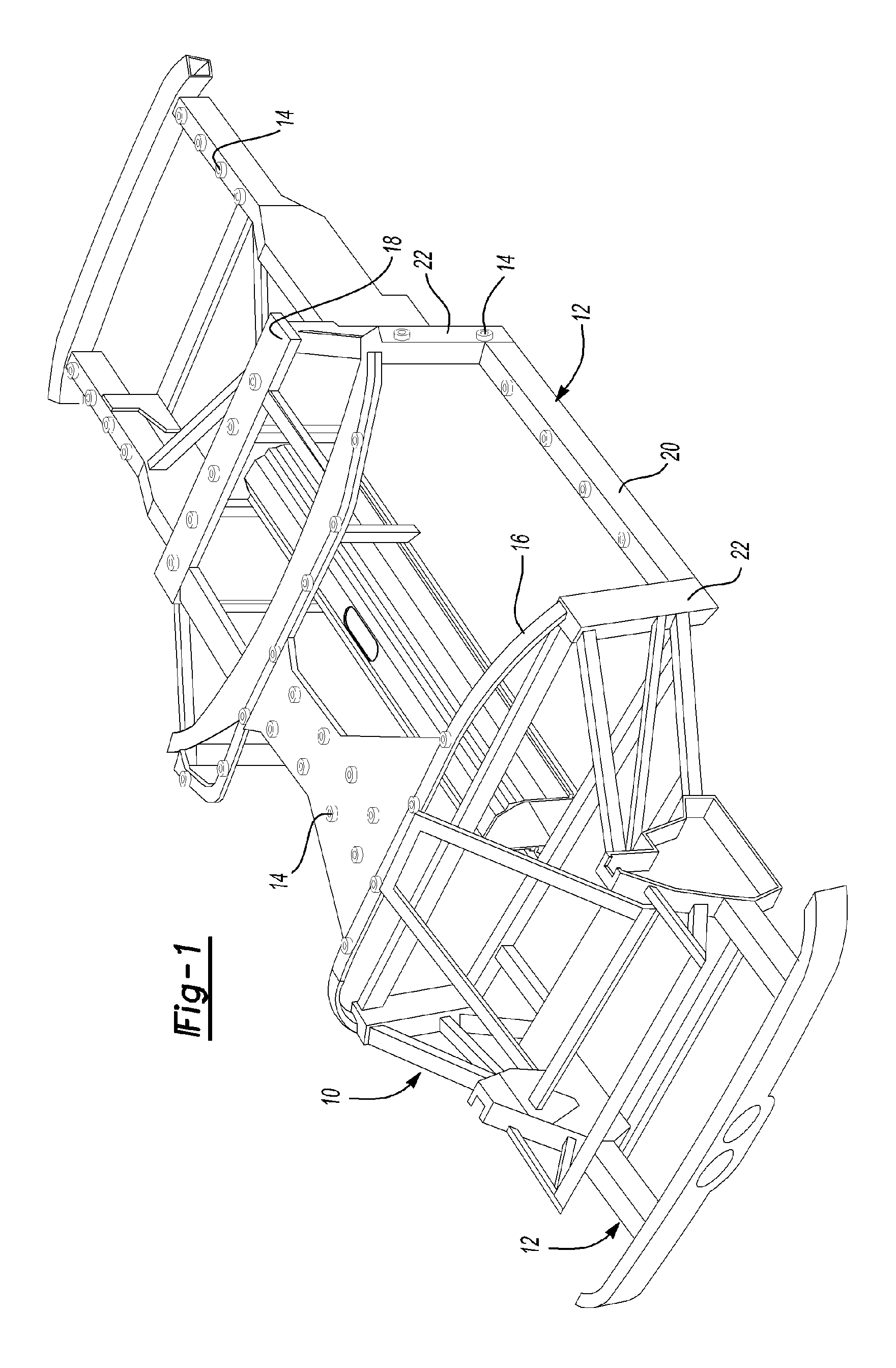

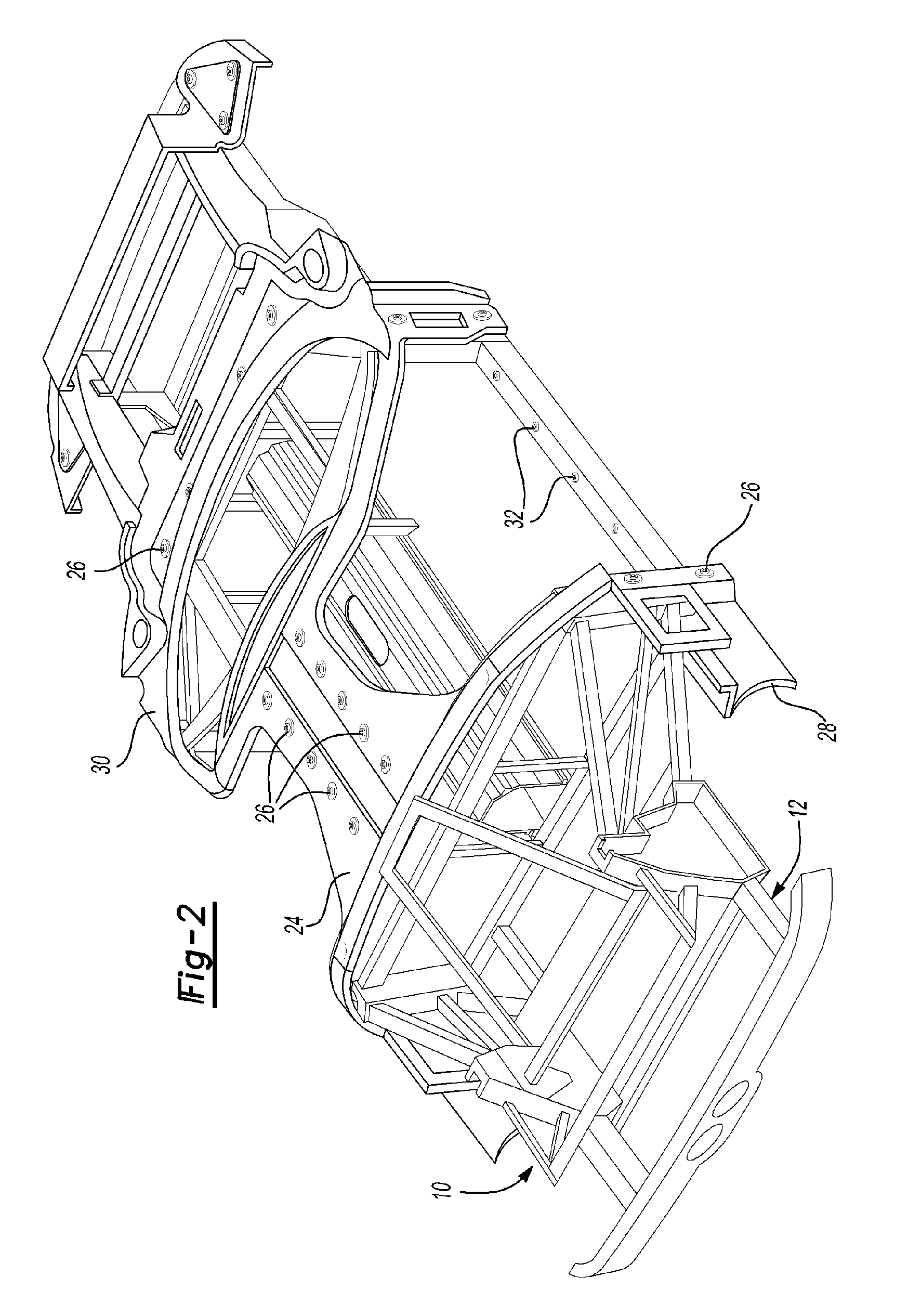

Rivet nut with machinable head and method of making a vehicle body

A method of securing body panels to a space frame of a vehicle is disclosed. Body panels are secured to rivet nuts that are assembled to frame members. The location of the rivet nuts or rivet nuts supporting surface is measured and the rivet nuts are milled or machined to correspond to reference body coordinates. The rivet nuts function as a integral shim pack and obviate the need for shims between the space frame and body panels. The rivet nuts may be milled or formed to predetermined thicknesses before or after assembly to the frame.

Owner:JAGUAR LAND ROVER LTD +1

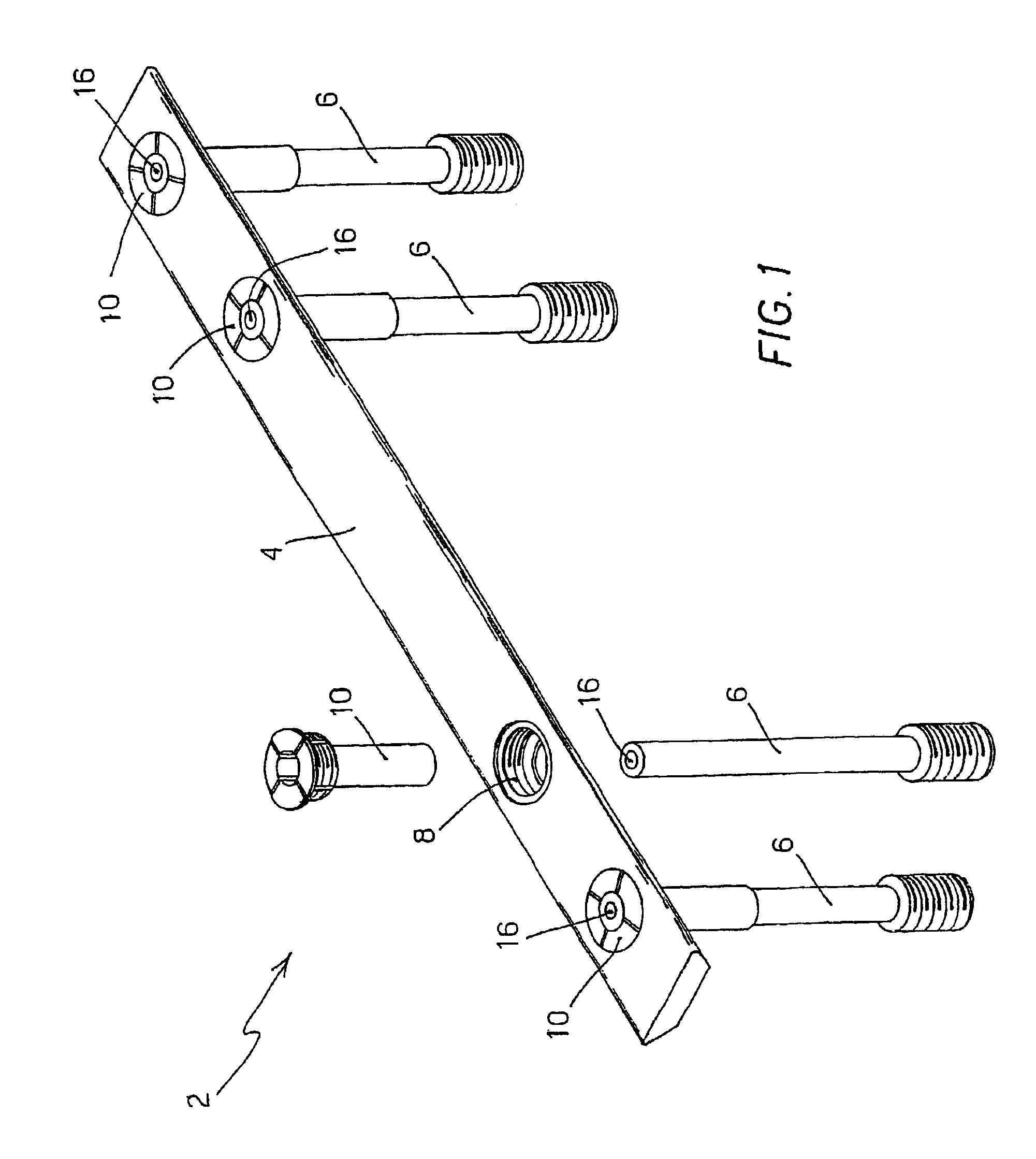

Fastener for variable mounting

A fastener assembly comprising a first wedge portion having an angled end, a second wedge portion having an angled end, and a fastener extending through the first wedge portion and the second wedge portion, wherein a portion of the fastener protrudes from one of the first and second wedge portions for interfacing with a component to be mounted, wherein the angled end of the first wedge portion and the angled end of the second wedge portion are interfaced when the fastener is extended through the first wedge portion and the second wedge portion.

Owner:HEWLETT PACKARD DEV CO LP

Self drilling swivel toggle anchor

Owner:BLACK & DECKER INC

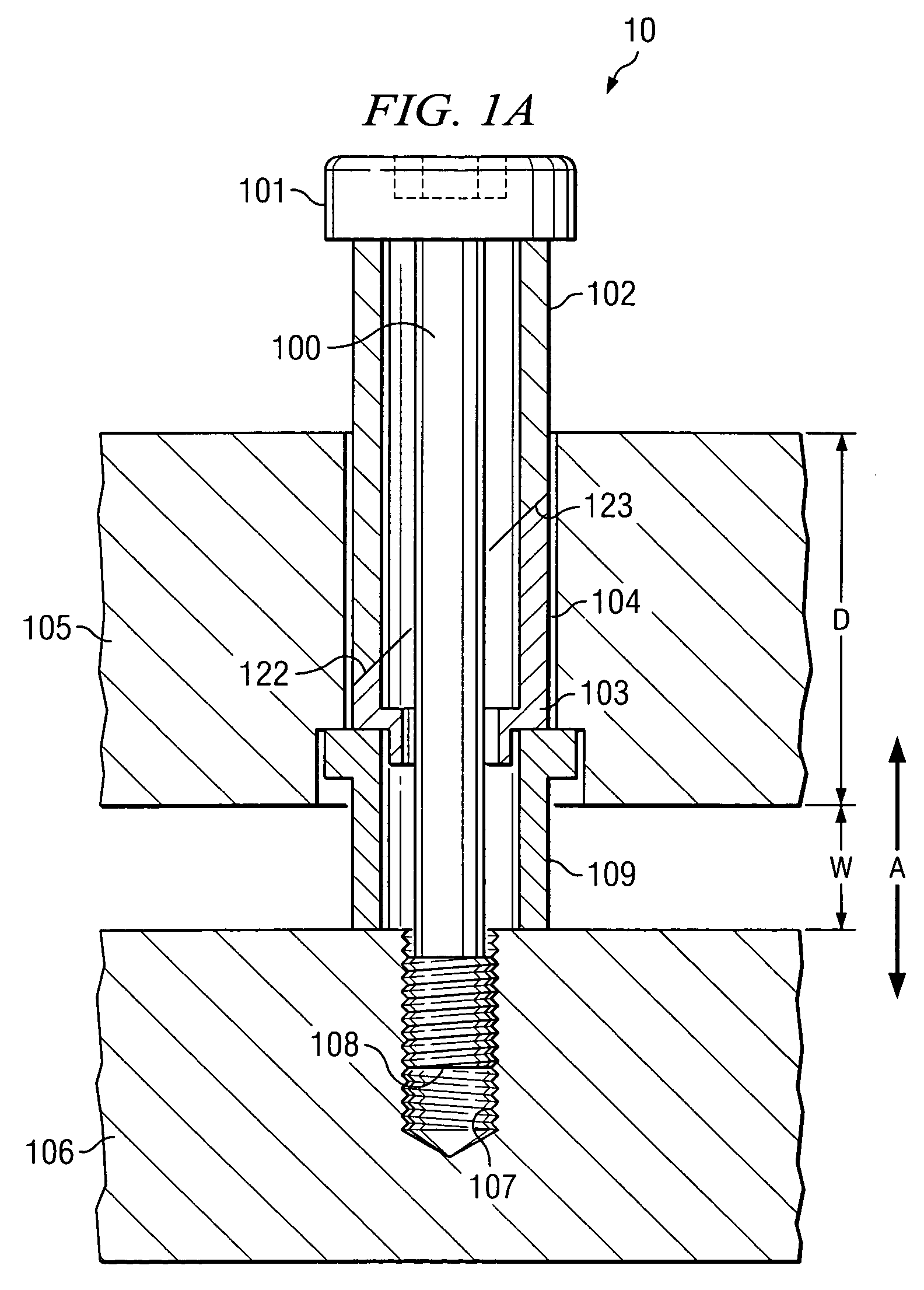

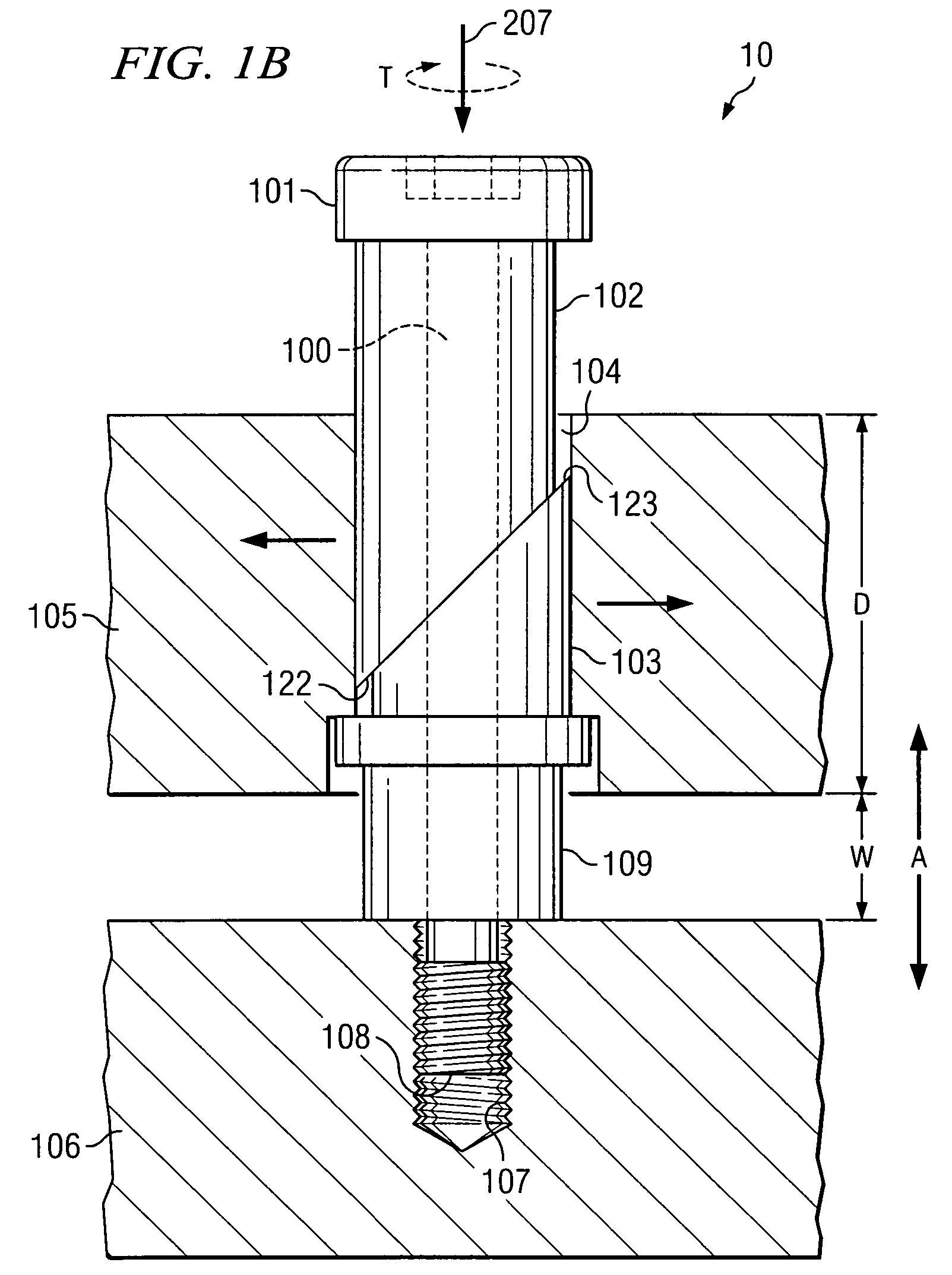

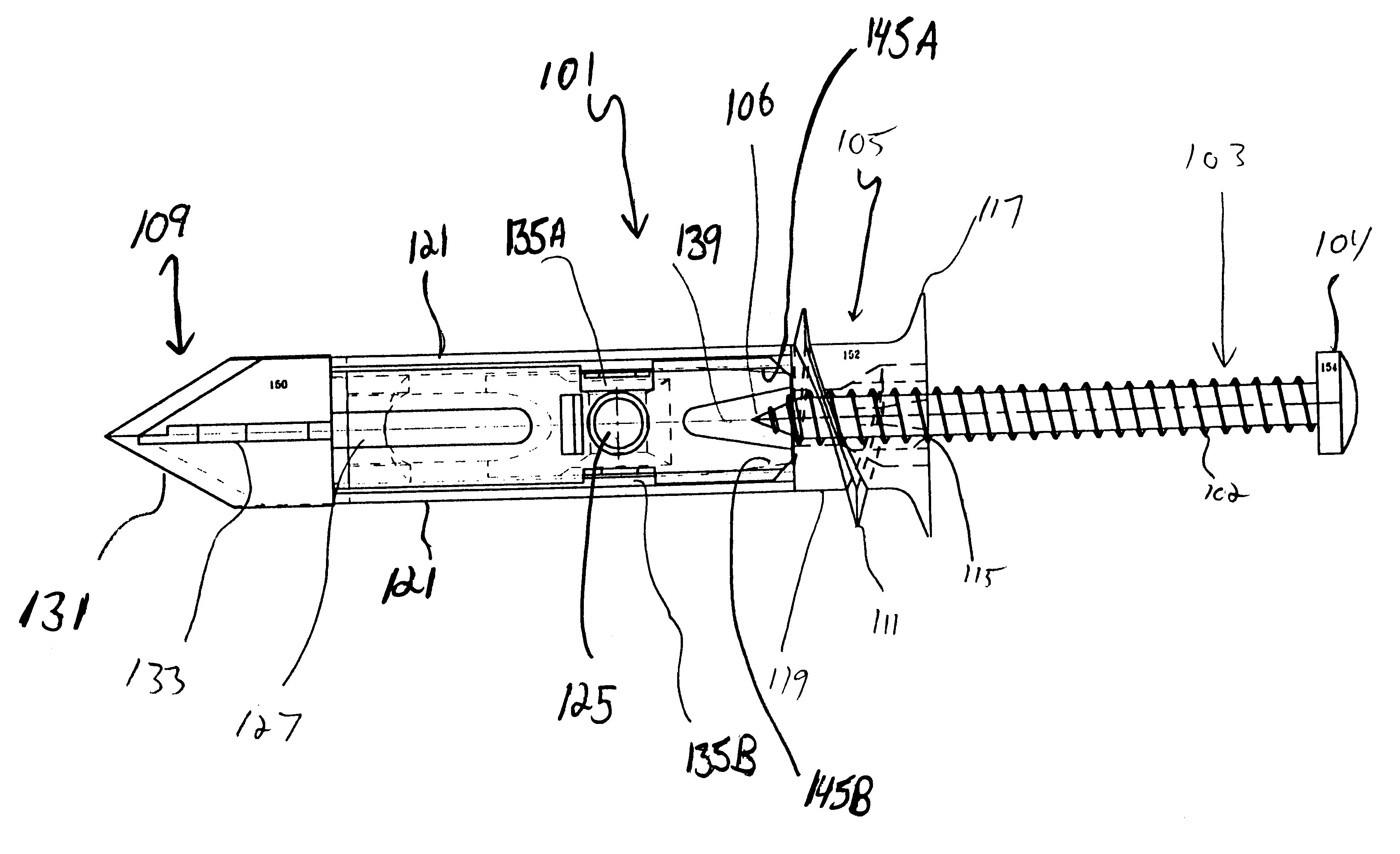

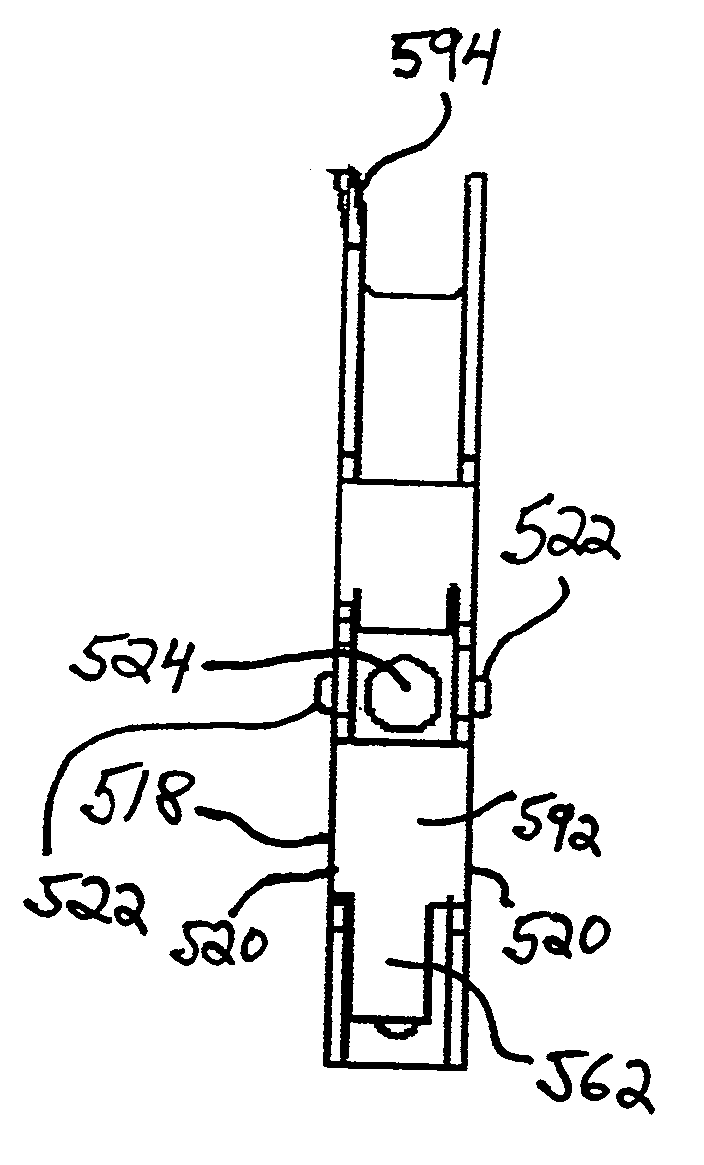

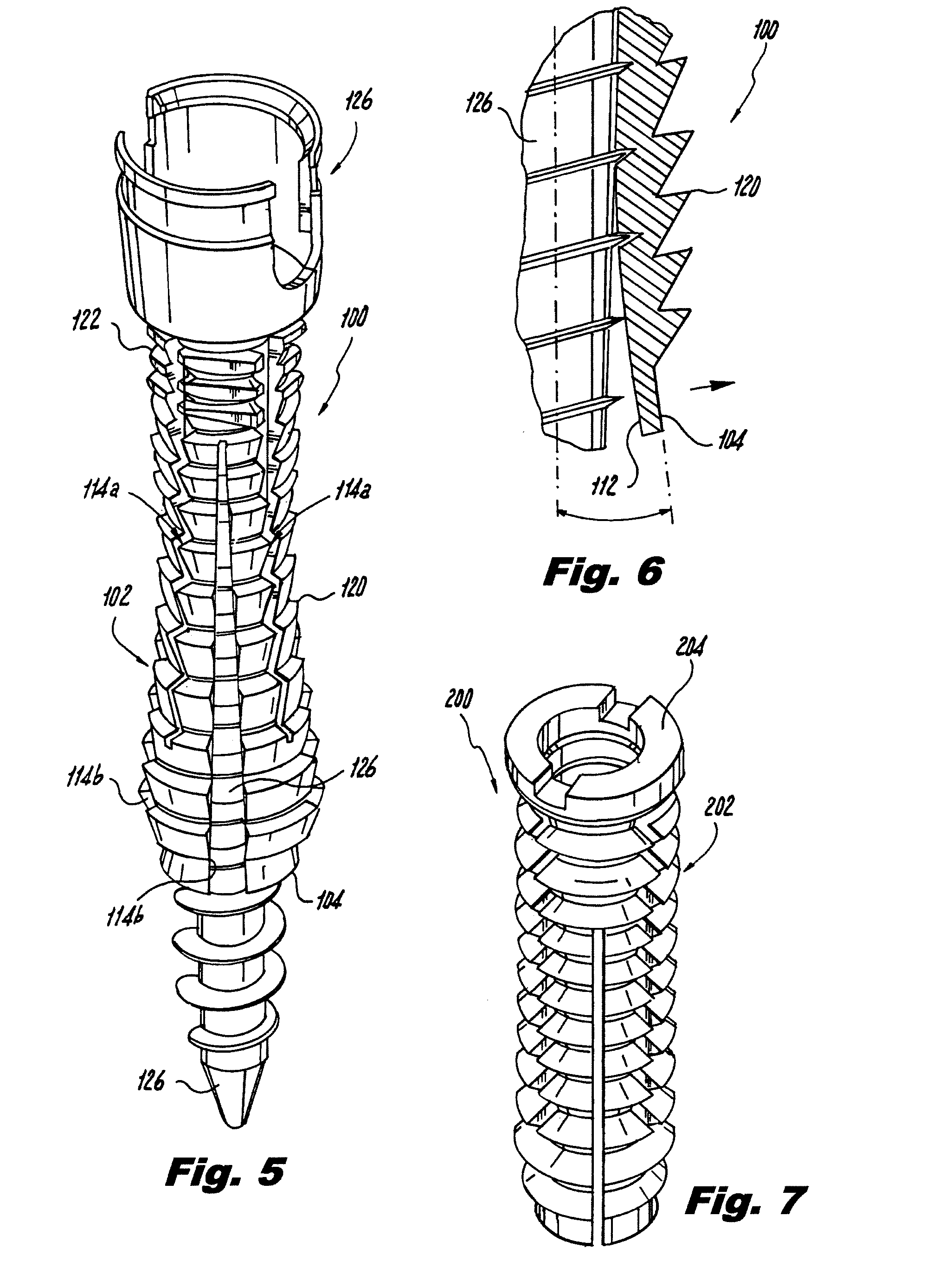

Heavy duty toggle bolt fastener for accommodating long screws and having properly positioned toggle nut component

A toggle-bolt type fastener has pocket structure incorporated therein for accommodating extra-long threaded bolt fasteners in a coaxial manner within the toggle-bolt type fastener. Alternatively, structure has been incorporated within the toggle-bolt type fastener which accommodates extra-long threaded bolt fasteners by causing the same to be slightly deflected from their coaxial disposition within the toggle-bolt type fastener so as to permit the same to bypass the pointed tip of the toggle-bolt type fastener. Still further, additional structure has been incorporated within the toggle-bolt type fastener for ensuring the fact that when the nut member is moved from its original, axially oriented, inoperative or non-deployed position, to its second, transversely oriented, operative or deployed position, the nut member will in fact be disposed substantially perpendicular to the longitudinal axis of the toggle-bolt type fastener so as to ensure the proper threaded engagement thereby by the threaded bolt fastener.

Owner:ILLINOIS TOOL WORKS INC

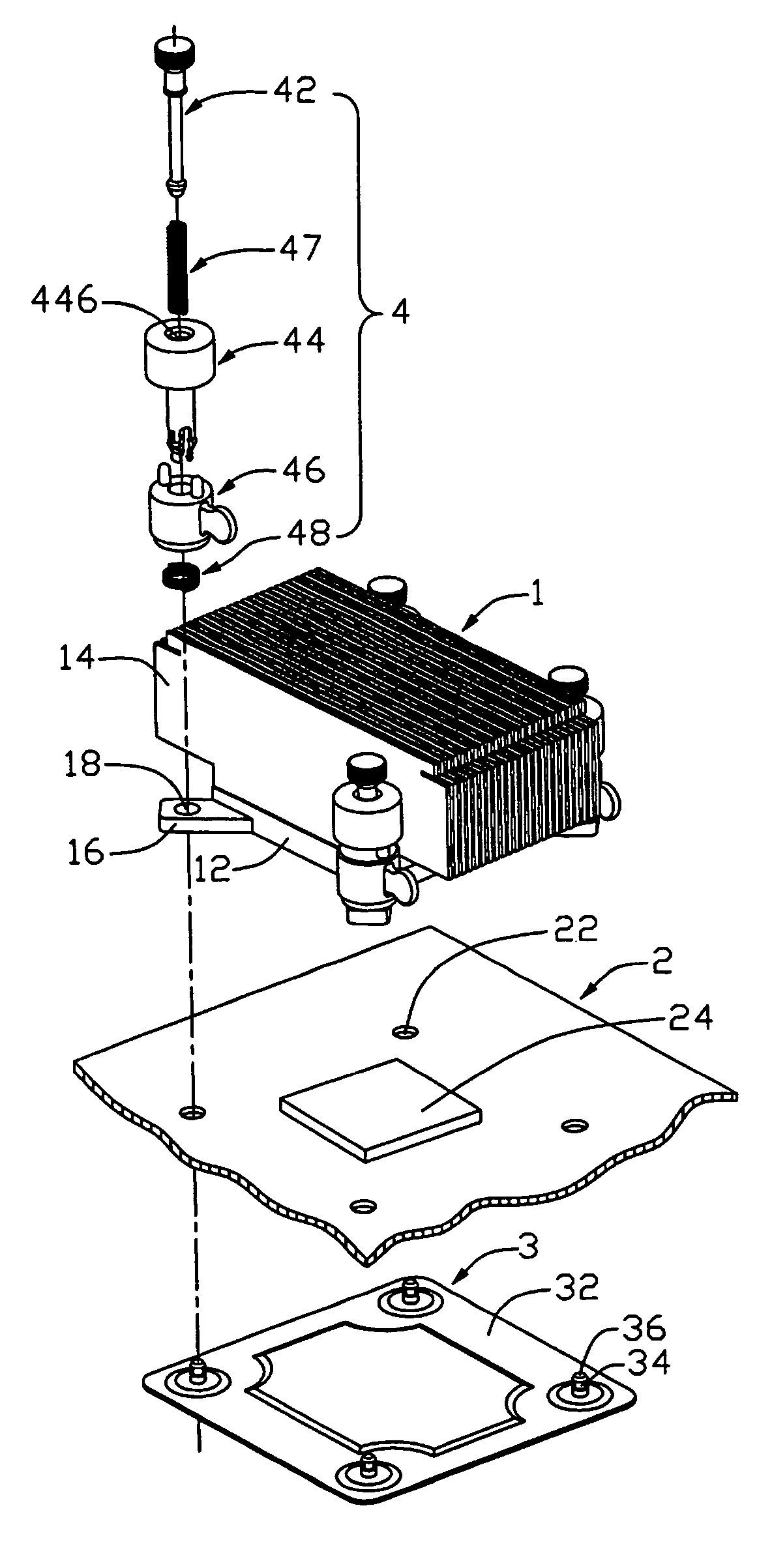

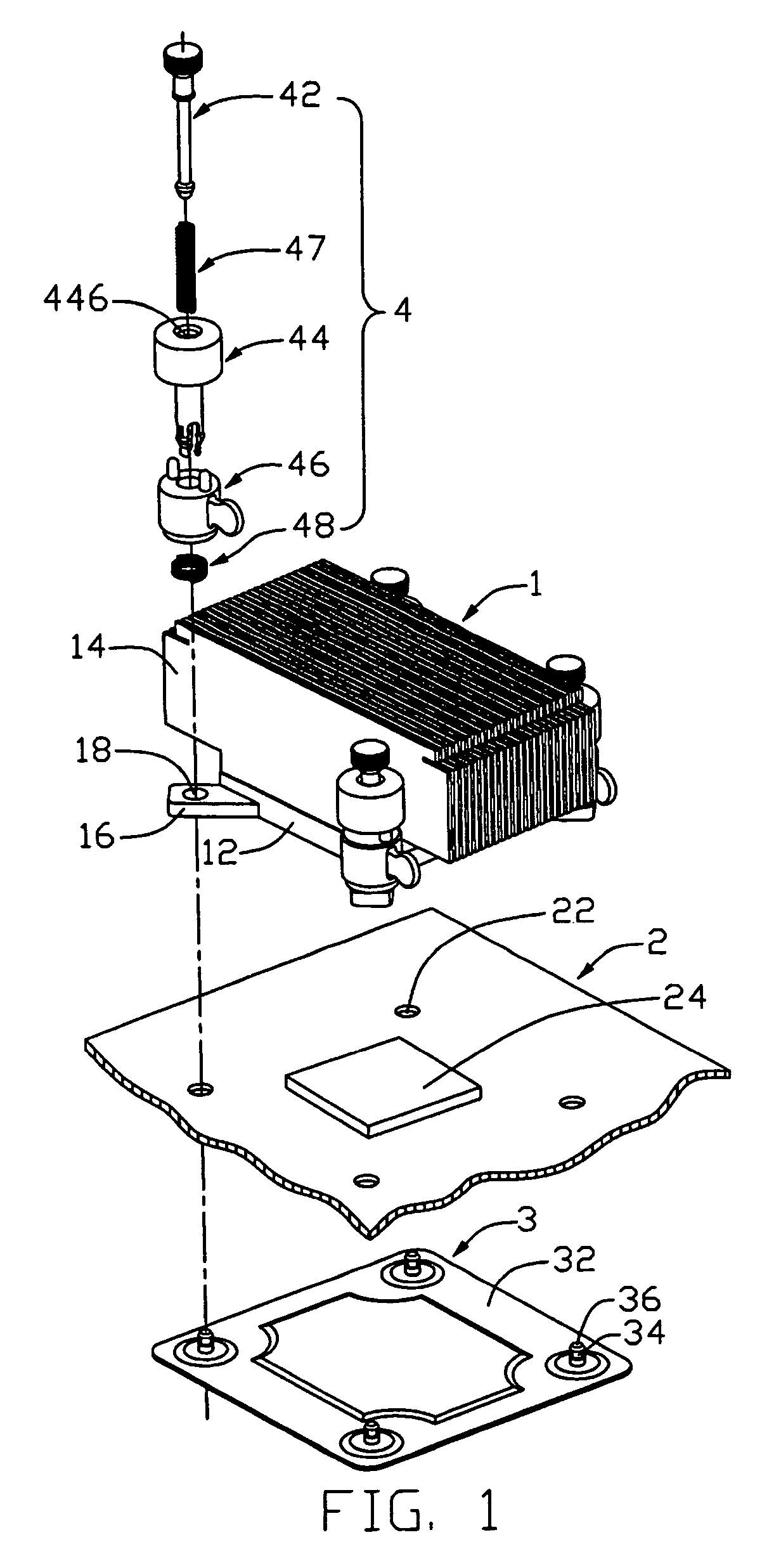

Locking device for heat dissipating device

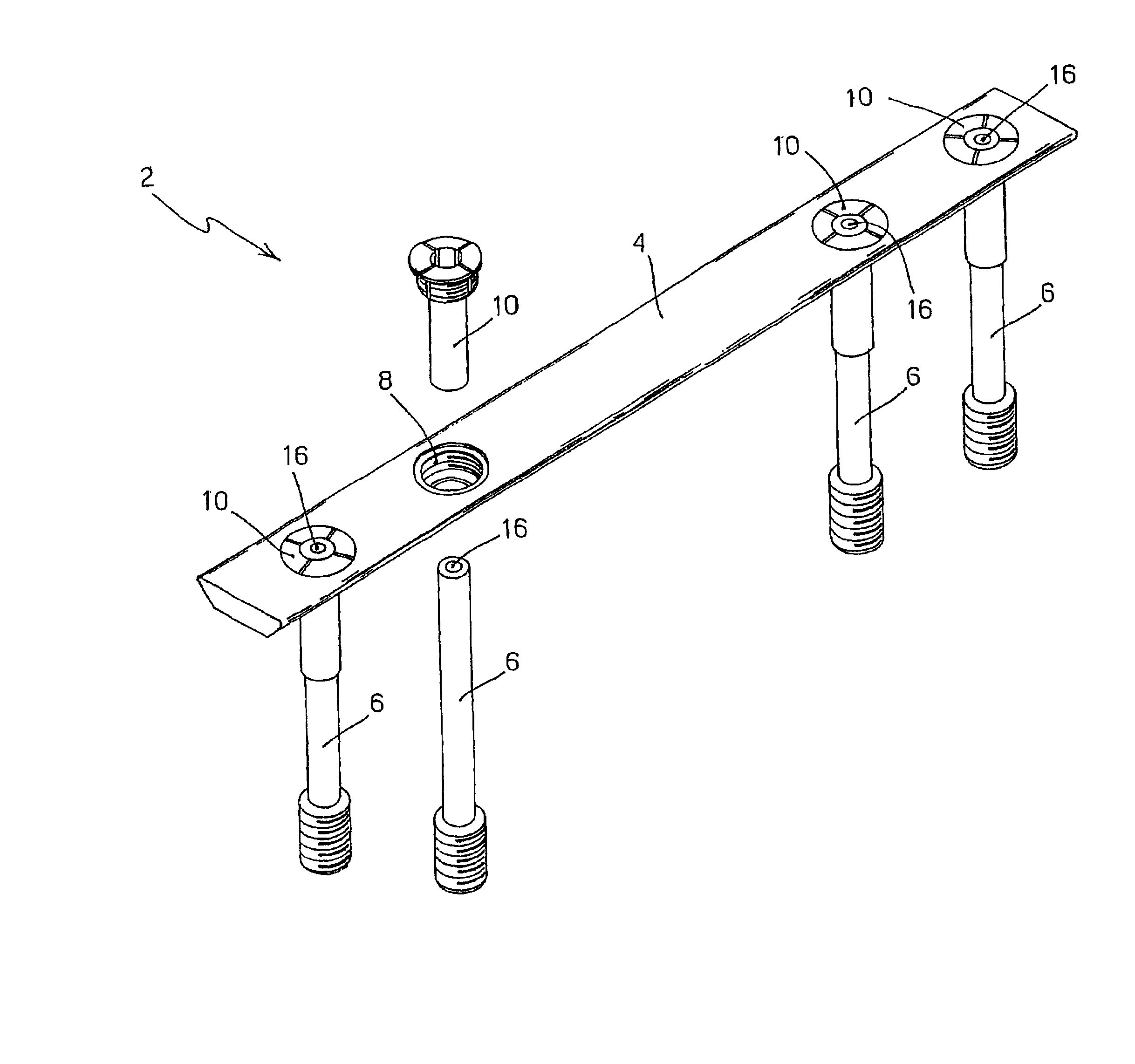

InactiveUS7126823B2Conveniently detachedEasy to installSnap fastenersSemiconductor/solid-state device detailsEngineeringPrinted circuit board

A locking device for mounting a heat sink to a CPU mounted on a printed circuit board, includes a back plate mounted below the circuit board and having a plurality of fasteners extending upwardly beyond the circuit board, and a plurality of retainers. Each retainer includes an operating member resting on a heat sink, a locking member extending through the operating member, and a pushing member extending through the locking member. The locking member includes a locking structure extending through the heat sink to engage with one of the fasteners. The pushing member includes a taper bottom portion. The pushing member is downward movable to cause the taper bottom portion to disengage the locking structure from the one of the fasteners.

Owner:HON HAI PRECISION IND CO LTD

Resilient deck board fastener

A fastener for securing deck boards to a support structure without the need for driving screws or nails through the deck boards. The fastener includes two horizontal flanges that fit into slots cut into the sides of adjacent deck boards, a center hole for securing the fastener to the support structure and deformable, resilient elements that bridge the gap between adjacent deck boards during fastening yet compress inward when the boards swell and expand.

Owner:SIMPSON STRONG TIE

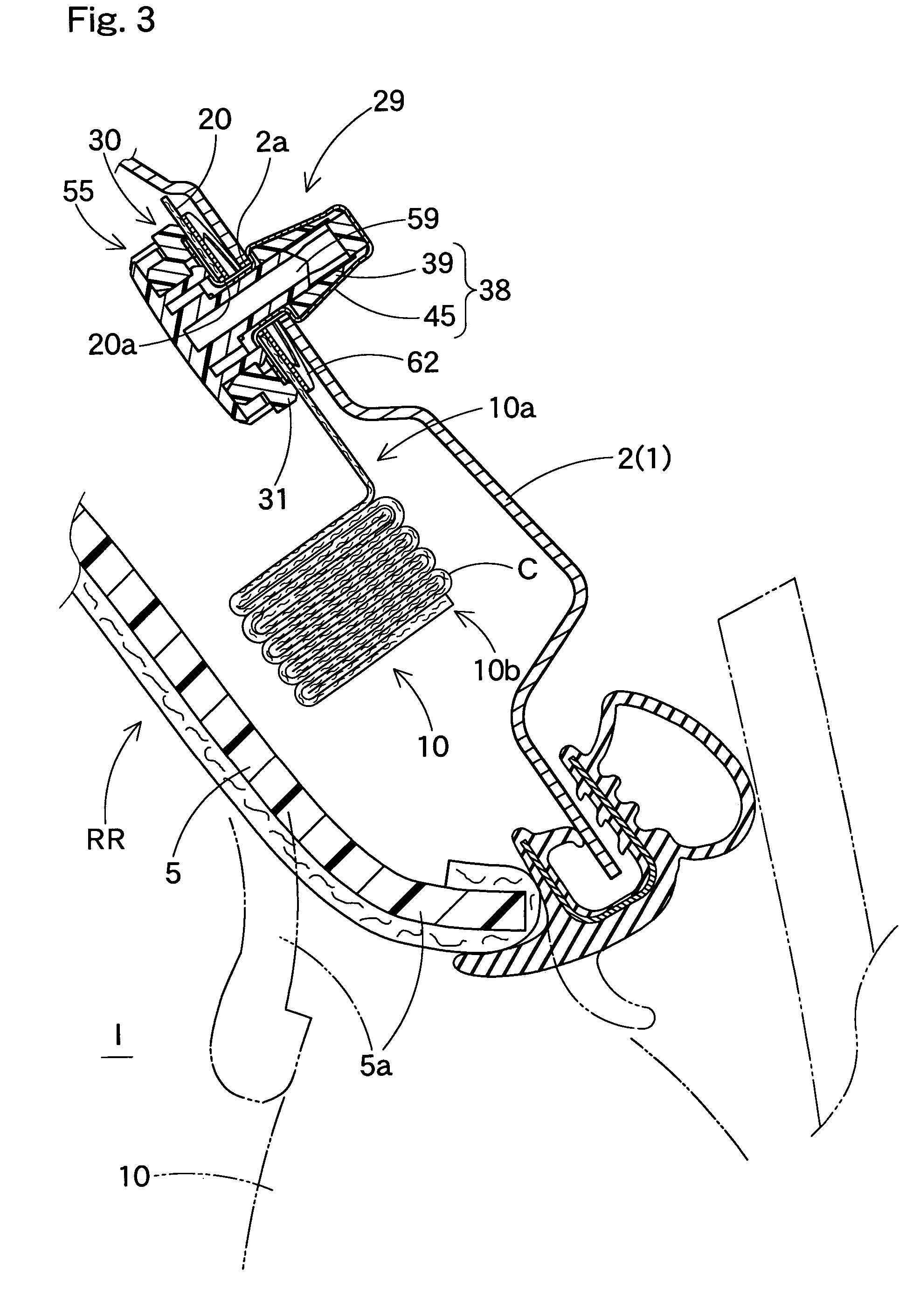

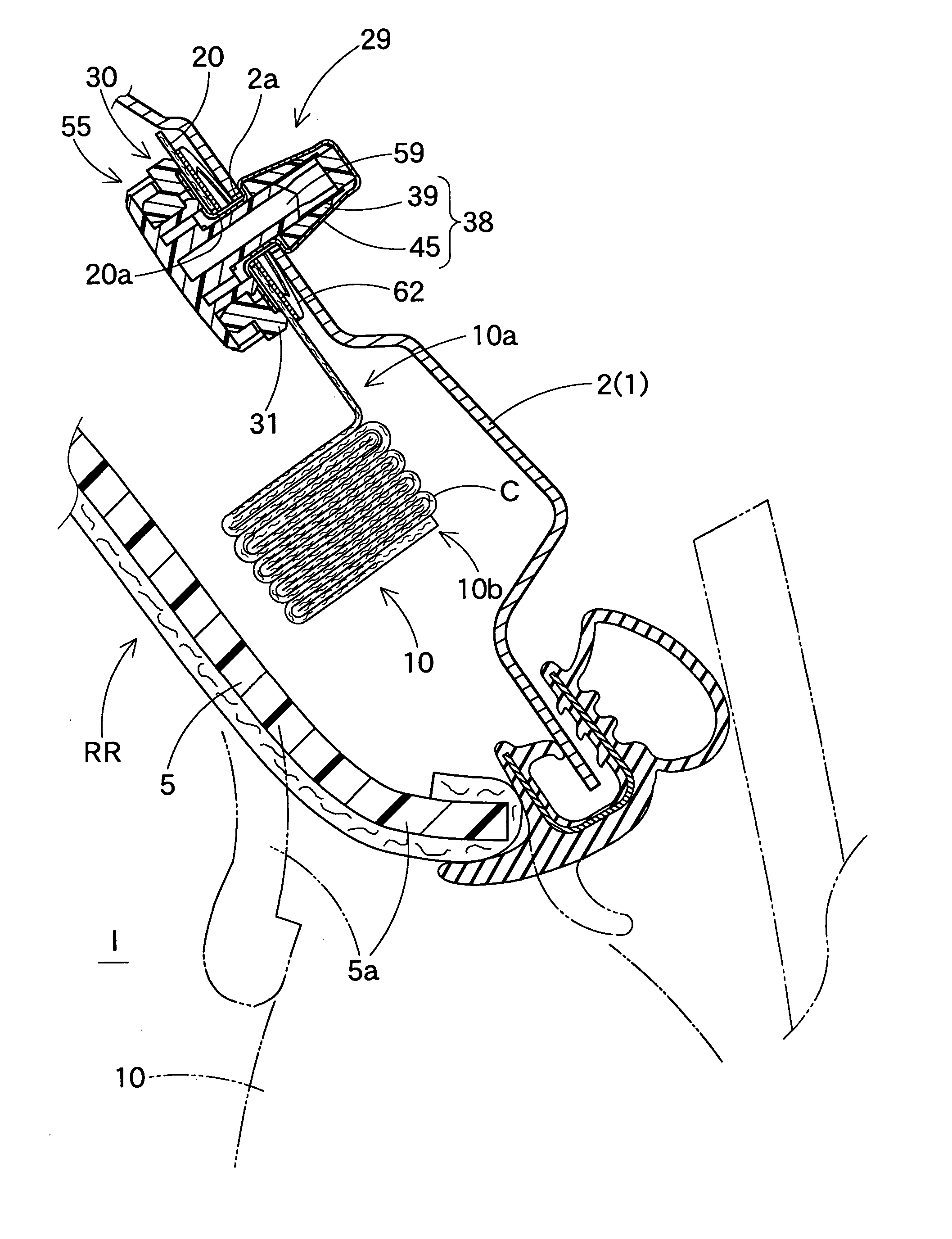

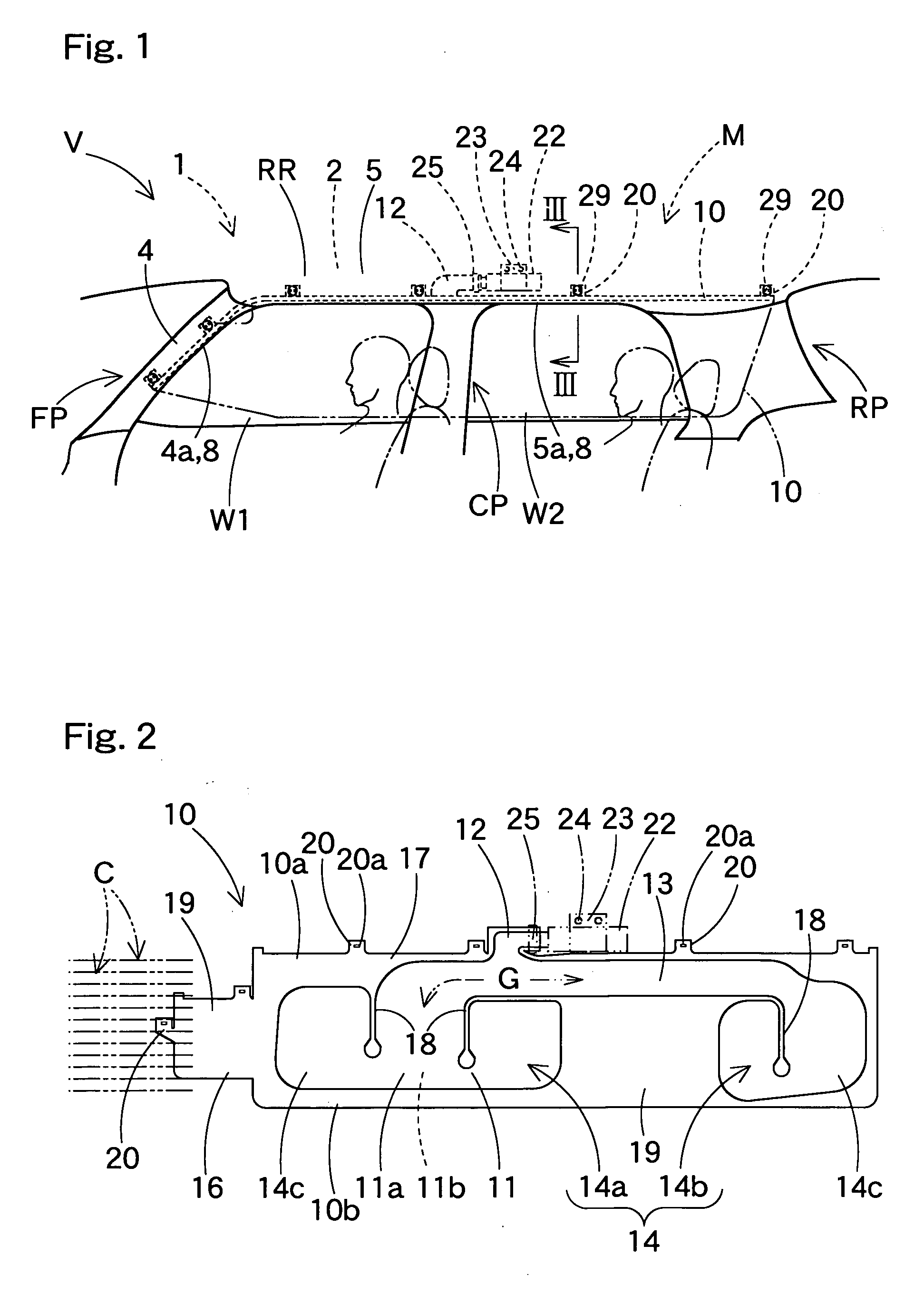

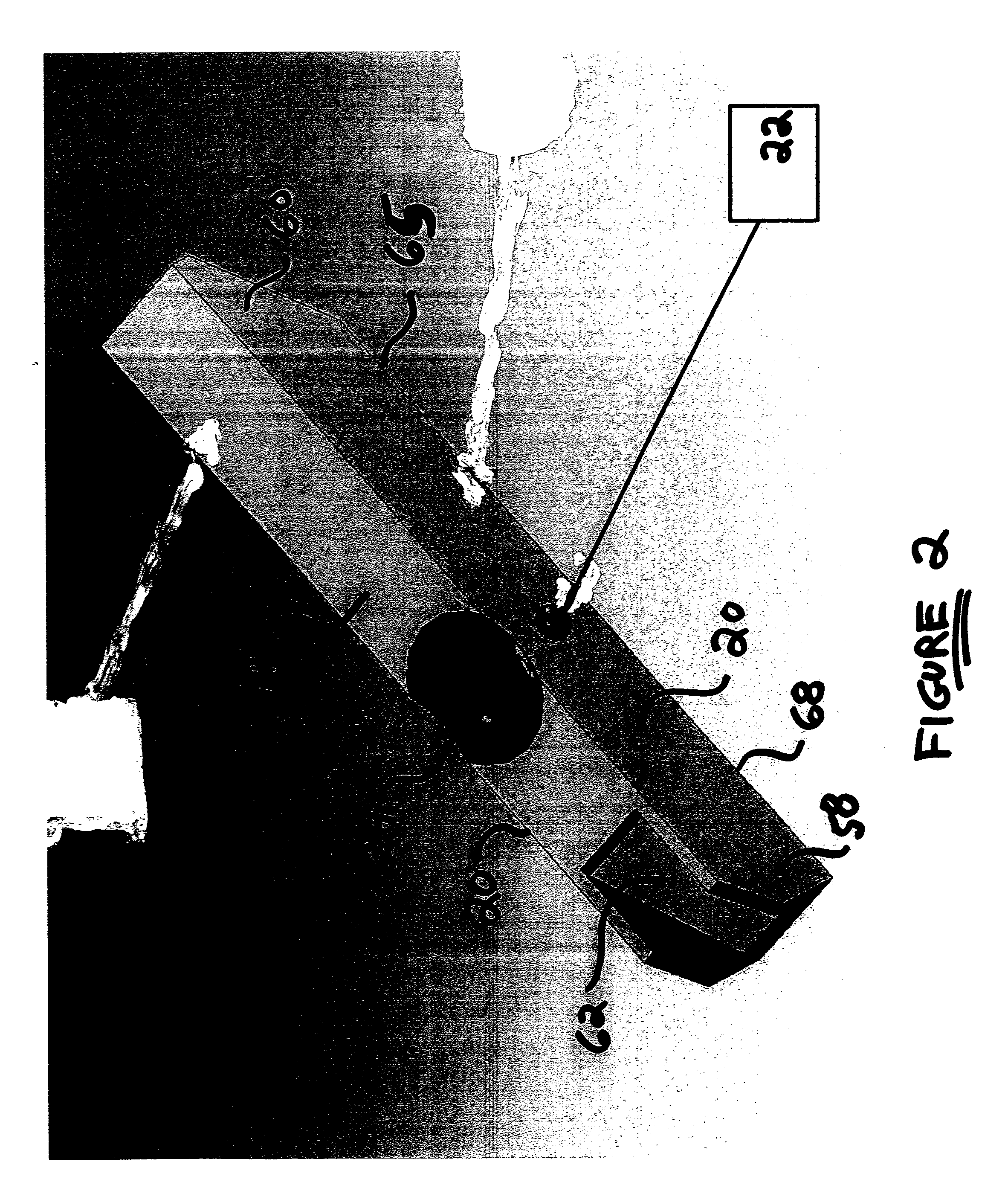

Head protecting airbag device

InactiveUS7374200B2Easily attaching attaching portionAssured attaching stabilitySnap-action fastenersPedestrian/occupant safety arrangementIn vehicleEngineering

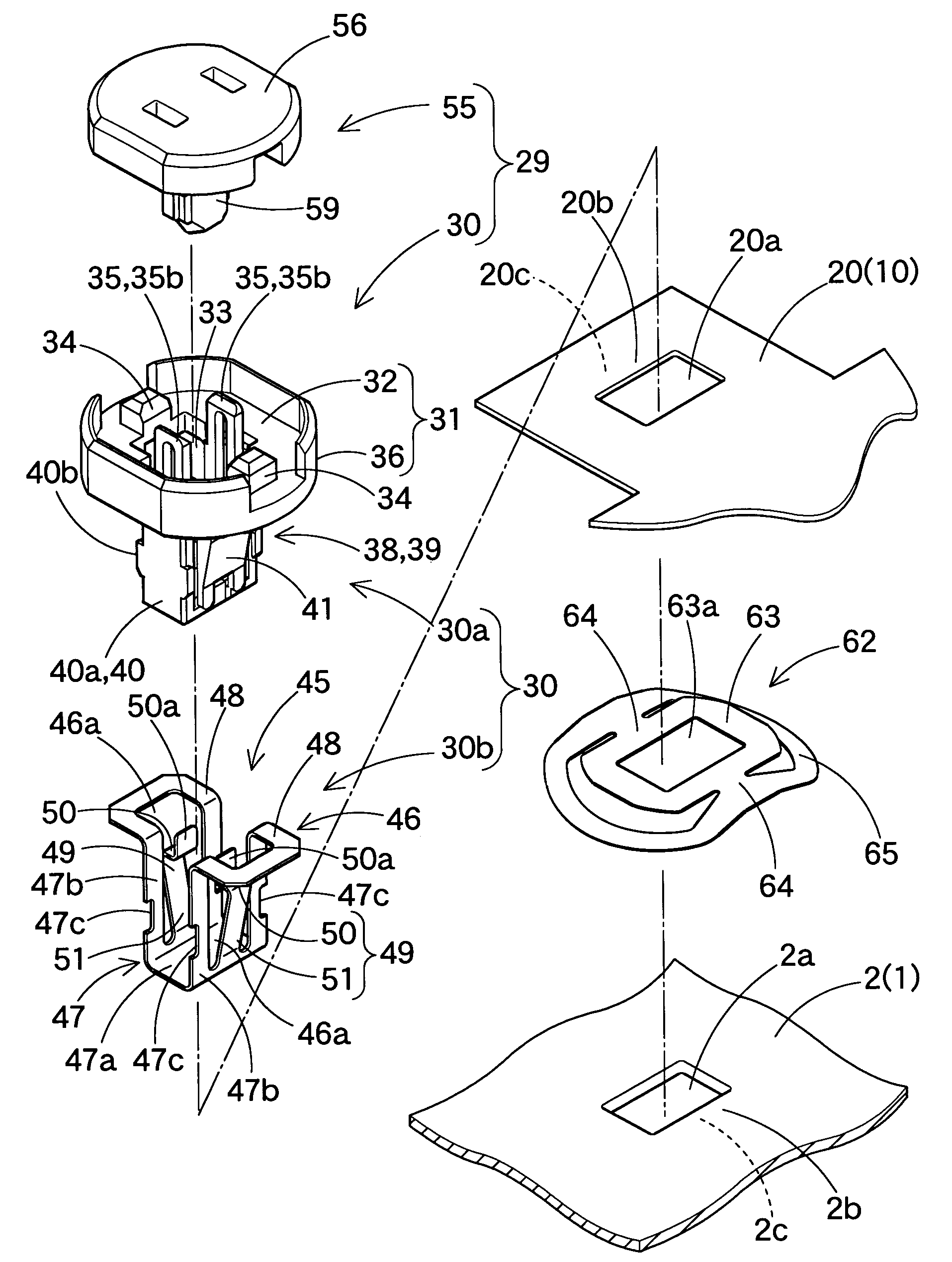

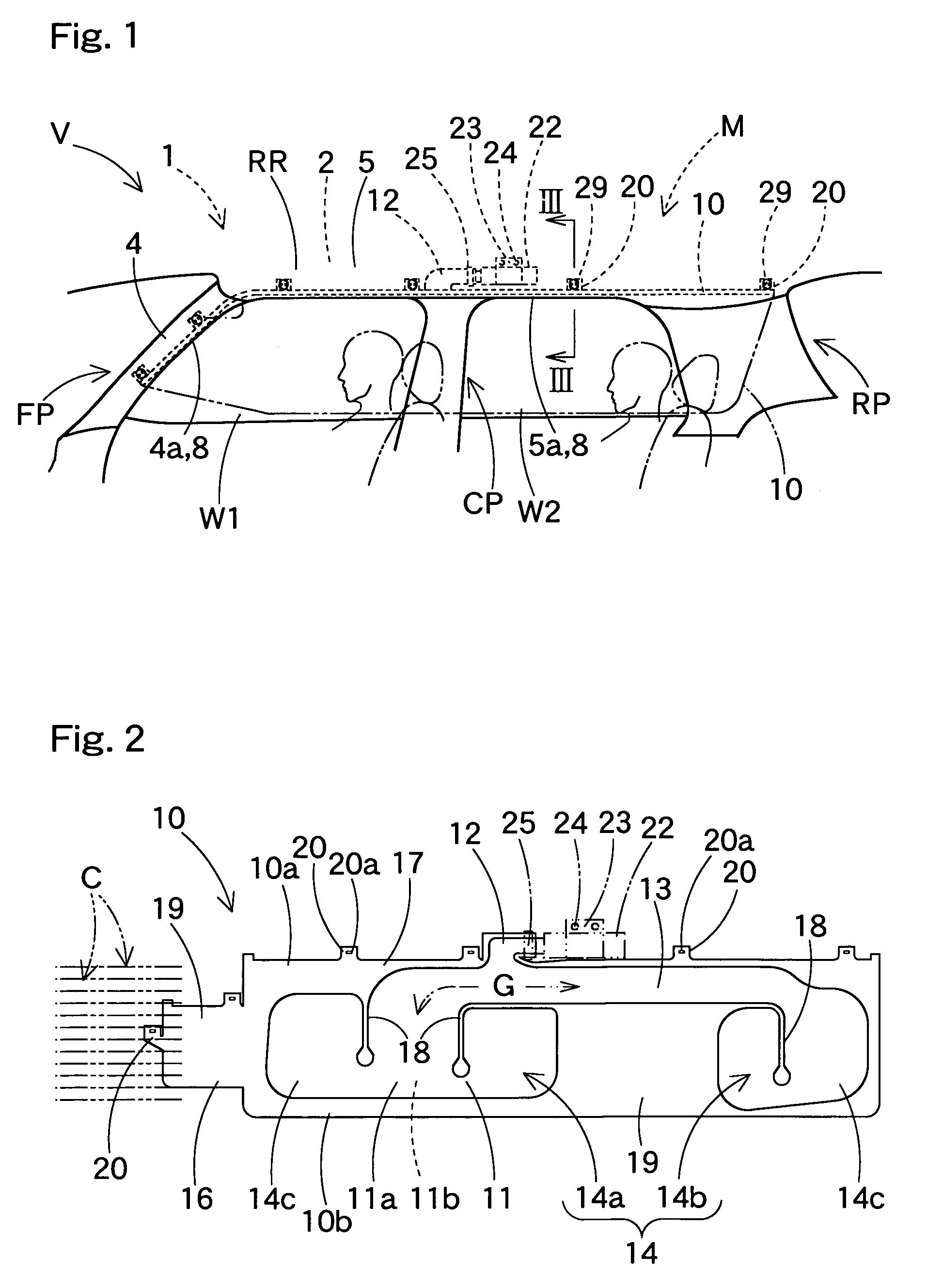

In a head protecting air bag device according to the present invention, a clip for attaching an attaching portion of an air bag to a fixing part on the side of a vehicle body includes a clip body and a locking part. The clip body has a shaft having a pair of securing legs protruded. The pair of securing legs are inserted in the fixing slot of the fixing part from an in-vehicle side via the attaching slot of the attaching portion and secured to the peripheral edge on an out-vehicle side of the fixing slot. The shaft is composed of a shell member of a metallic plate on the outer periphery and a core member of synthetic resin on the inner periphery. The core member is arranged on the opposite sides of a pair of securing lugs of the shell member. The core member has an inserting space in which a spacer of the locking part is inserted between the pair of securing lugs. The spacer limits the mutual approaching of the pair of securing legs. In the head protecting air bag according to this invention, using the clip, the attaching portion of the air bag can be easily attached to the vehicle body side with assured attaching stability.

Owner:TOYODA GOSEI CO LTD +1

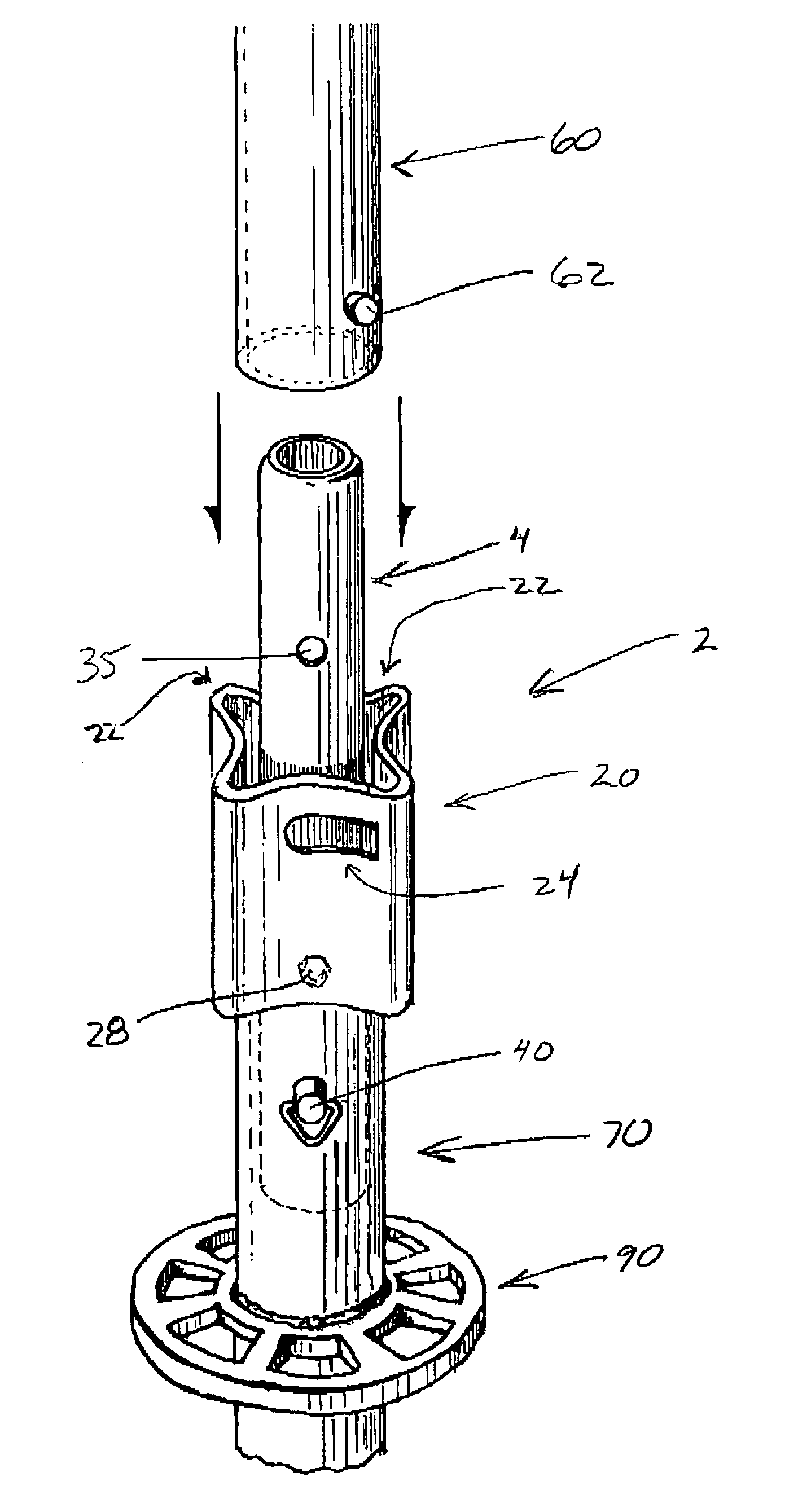

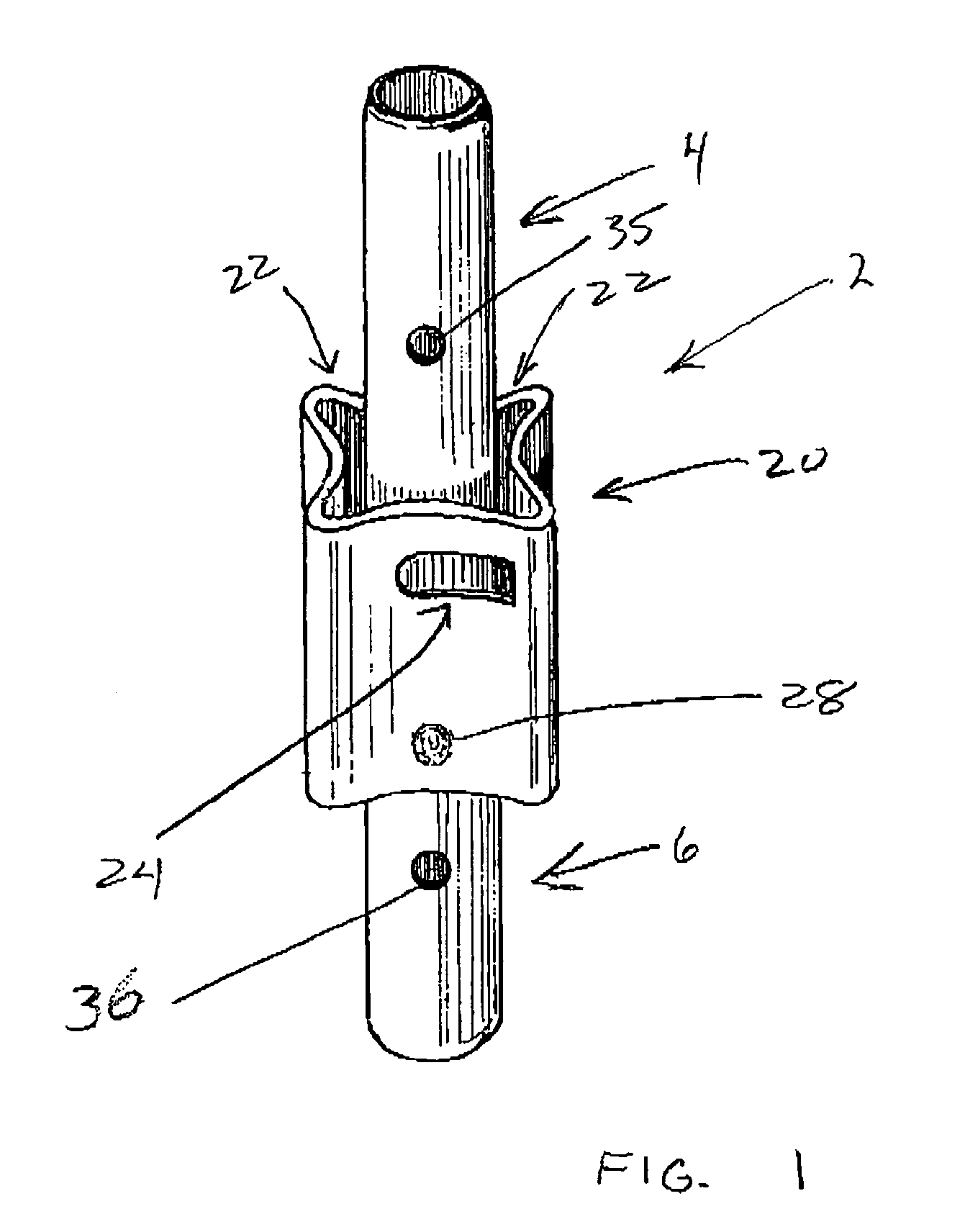

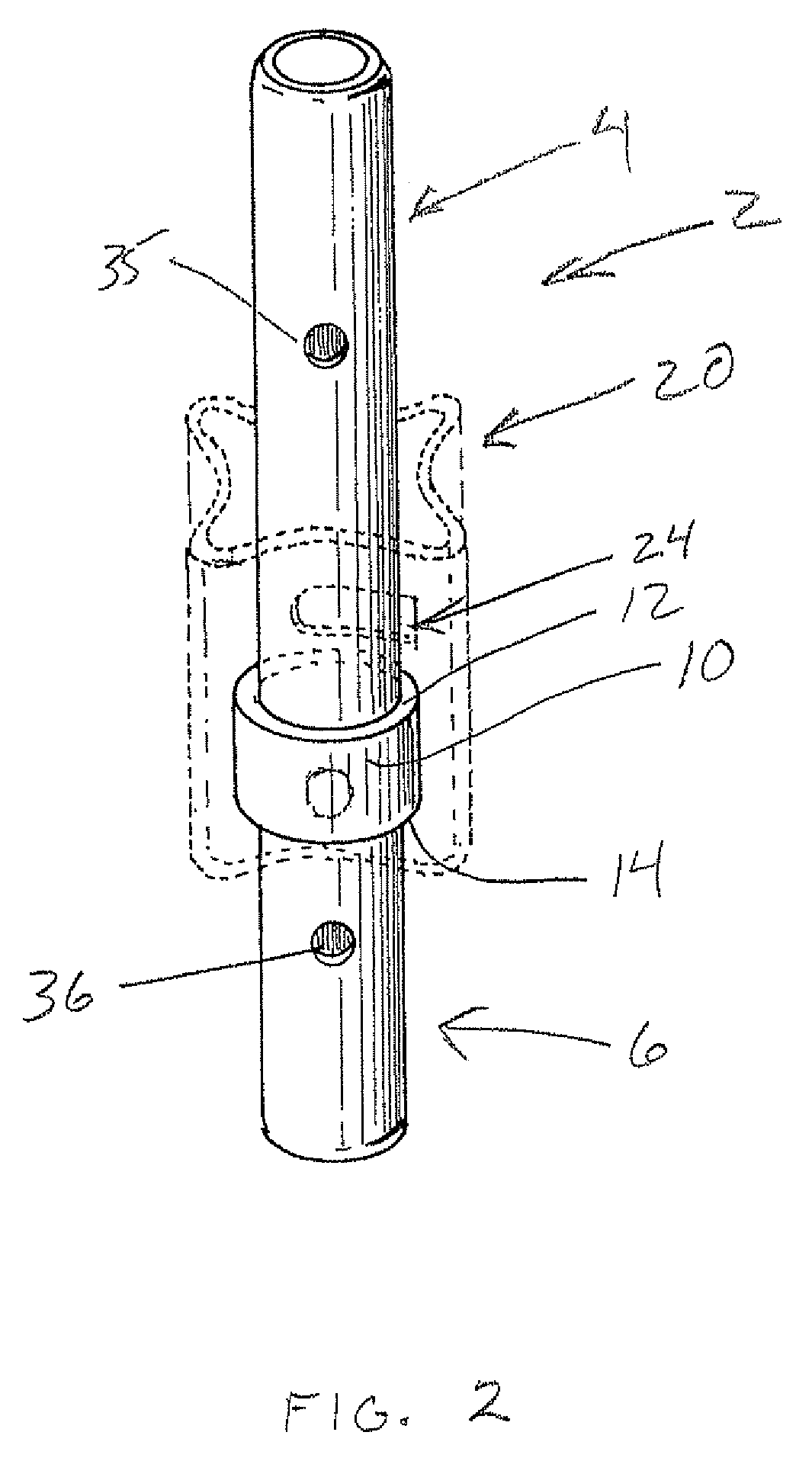

Twist lock coupling spigot

ActiveUS8132649B2Firmly connectedVisual simplicityScaffold connectionsRod connectionsEngineeringElectrical and Electronics engineering

A coupling spigot for connecting two scaffold legs one atop the other is designed to use a twist lock for securing the upper scaffold leg to the coupling spigot. A locking collar is fixed to a stop collar of the spigot. The locking collar includes receiving slots for receiving locking projections provided adjacent a bottom edge of the scaffold leg. Locking slots are connected to the receiving slots whereby an upper scaffold leg may be inserted on a coupling spigot of a lower scaffold leg and retained thereon by a twist lock.

Owner:ATHOS CONSTR PRODS

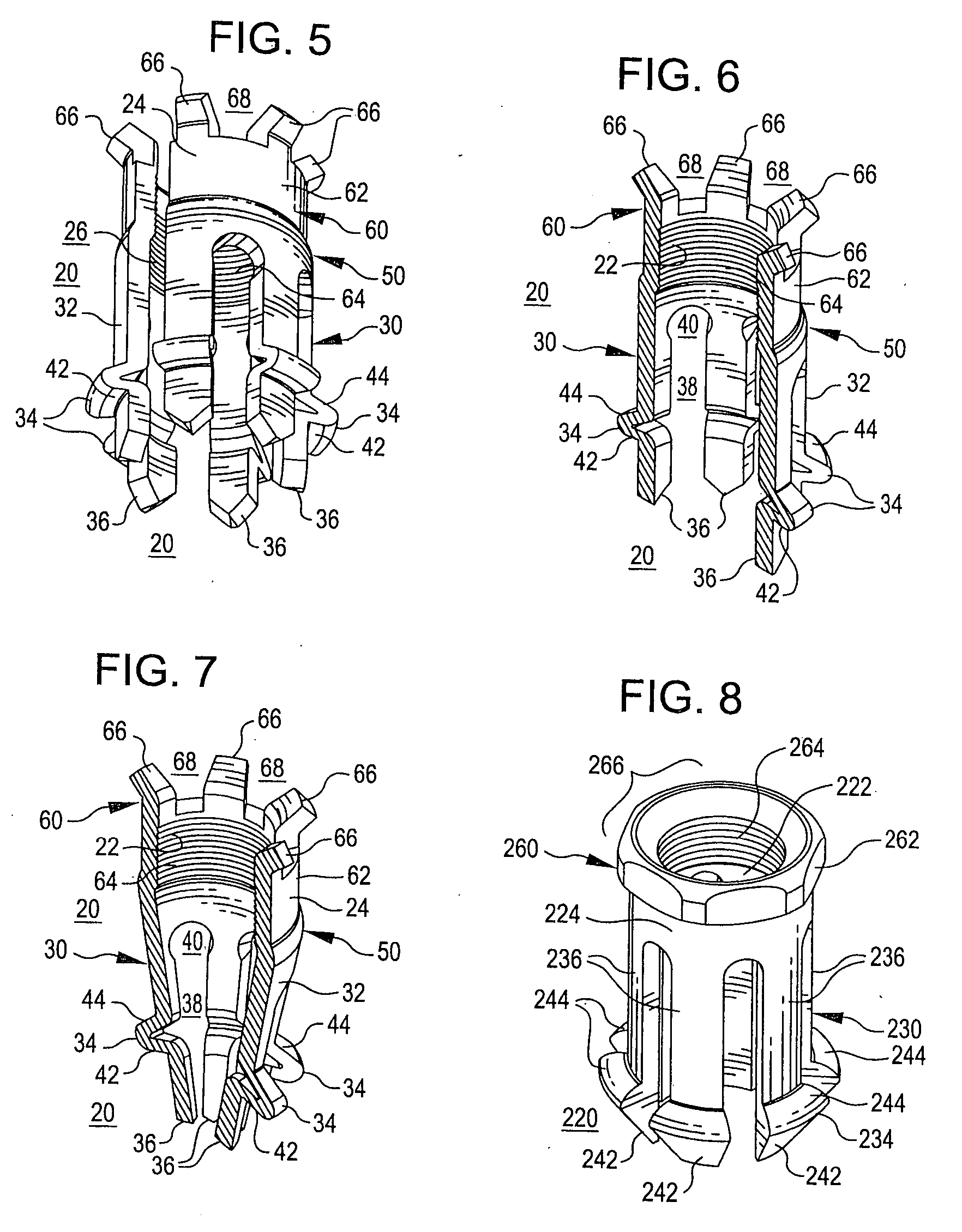

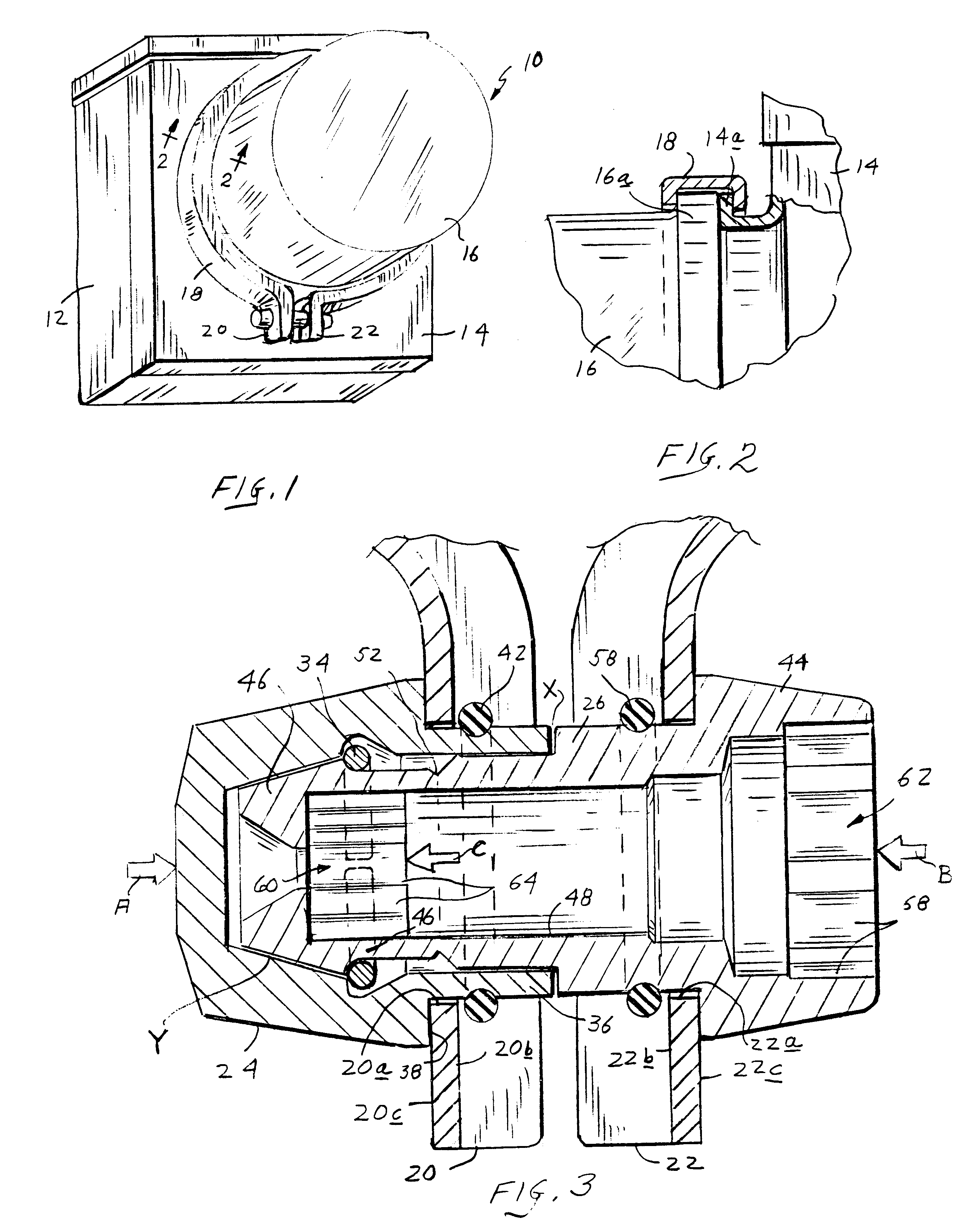

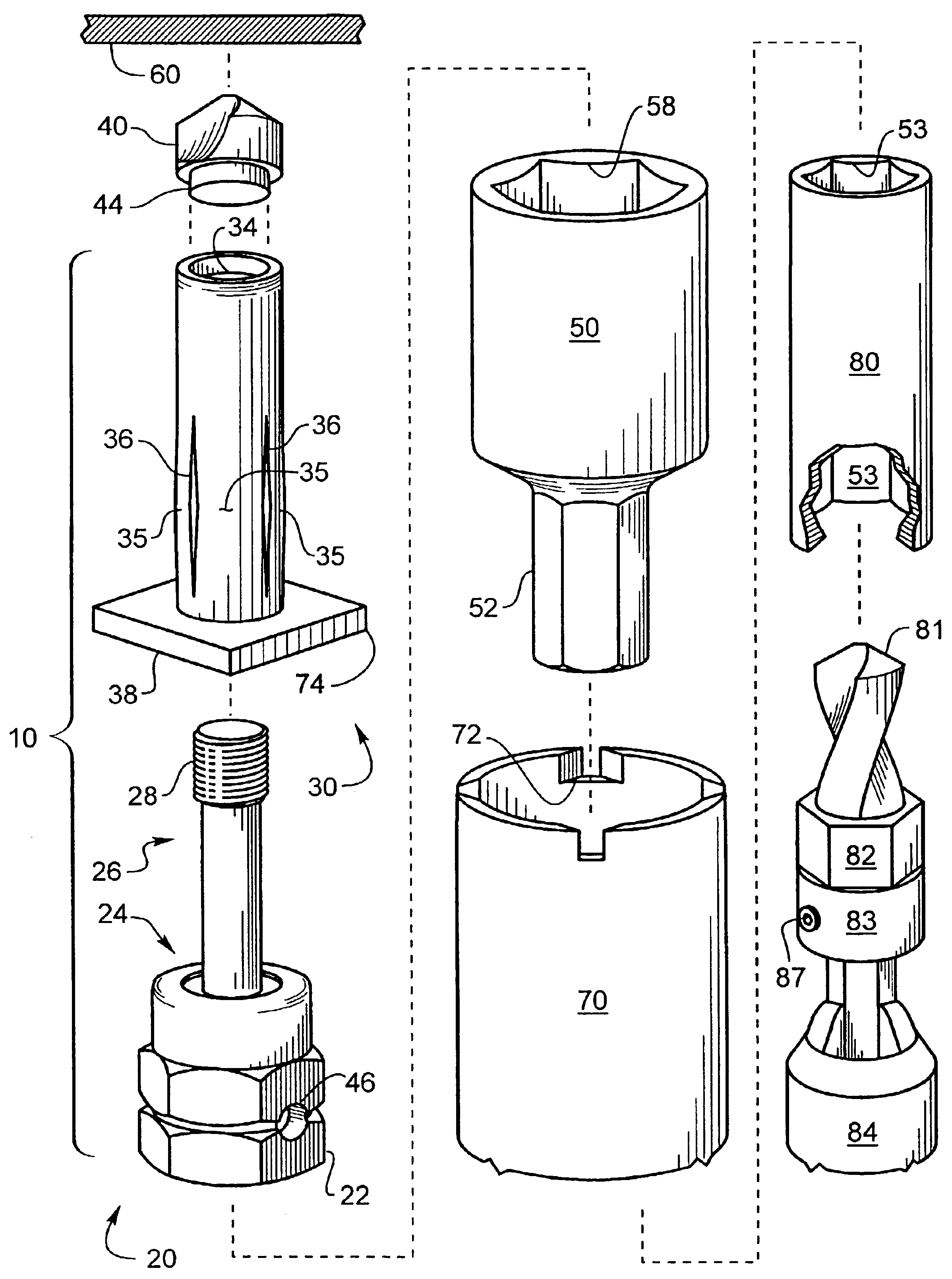

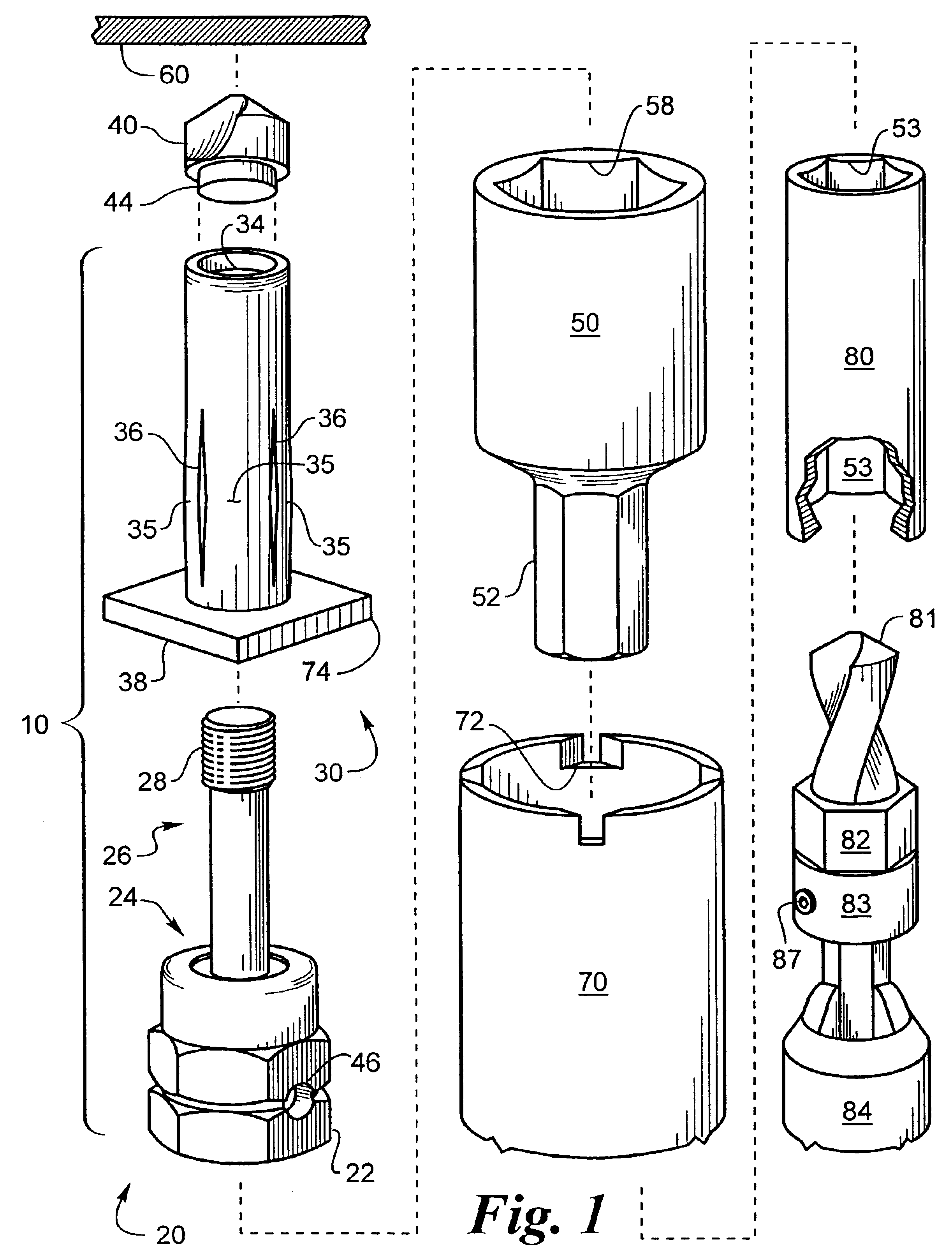

Expandable collet anchor system and method

An expandable collet body and anchor system incorporating a collet body anti-rotation feature and preferably collet body translation arresting means are disclosed. The collet body includes a first end, a first wall portion having at least two fingers, a second end including a head, a second wall portion, an annular protrusion and anti-rotation means where the anti-rotation means engages with an auxiliary structure defining a hole having an internal surface adapted to translationally accept the collet body and operatively function with the collet body anti-rotation means. The auxiliary may include a work piece to be optionally joined to another structure or a sleeve insert locatable in a hole defined by a work piece. Because the collet body is relatively free to translate within the auxiliary structure, a wide spectrum of work piece depths can be engaged with a single length collet body with the use of a stud to radially expand the fingers, thereby engaging a distal structure.

Owner:MCCLURE TRAVIS D

Destructible locking device

A locking device is disclosed for interlocking two members having aligned openings extending therethrough. The device includes a hollow cap and a pin with an enlarged head at one end and a nose at the opposite end. The pin is insertable through the aligned openings of the members, with its nose received in interlocked engagement within the cap, and with the two members captured between the cap and the enlarged head of the pin. A frangible portion of the pin is severable in response to relative rotation between its nose and enlarged head to thereby destructively disassemble the locking device.

Owner:INNER TITE A DIV OF YARA ENG

Head protecting airbag device

InactiveUS20060066080A1Easy to carryReduce insertion loadSnap-action fastenersPedestrian/occupant safety arrangementIn vehicleAirbag

In a head protecting air bag device according to the present invention, a clip for attaching an attaching portion of an air bag to a fixing part on the side of a vehicle body includes a clip body and a locking part. The clip body has a shaft having a pair of securing legs protruded. The pair of securing legs are inserted in the fixing slot of the fixing part from an in-vehicle side via the attaching slot of the attaching portion and secured to the peripheral edge on an out-vehicle side of the fixing slot. The shaft is composed of a shell member of a metallic plate on the outer periphery and a core member of synthetic resin on the inner periphery. The core member is arranged on the opposite sides of a pair of securing lugs of the shell member. The core member has an inserting space in which a spacer of the locking part is inserted between the pair of securing lugs. The spacer limits the mutual approaching of the pair of securing legs. In the head protecting air bag according to this invention, using the clip, the attaching portion of the air bag can be easily attached to the vehicle body side with assured attaching stability.

Owner:TOYODA GOSEI CO LTD +1

Heavy duty toggle bolt fastener for accommodating long screws and having properly positioned toggle nut component

ActiveUS20060182515A1Guarantees proper engagementEffectively bypassedDowelsEngineeringBiological activation

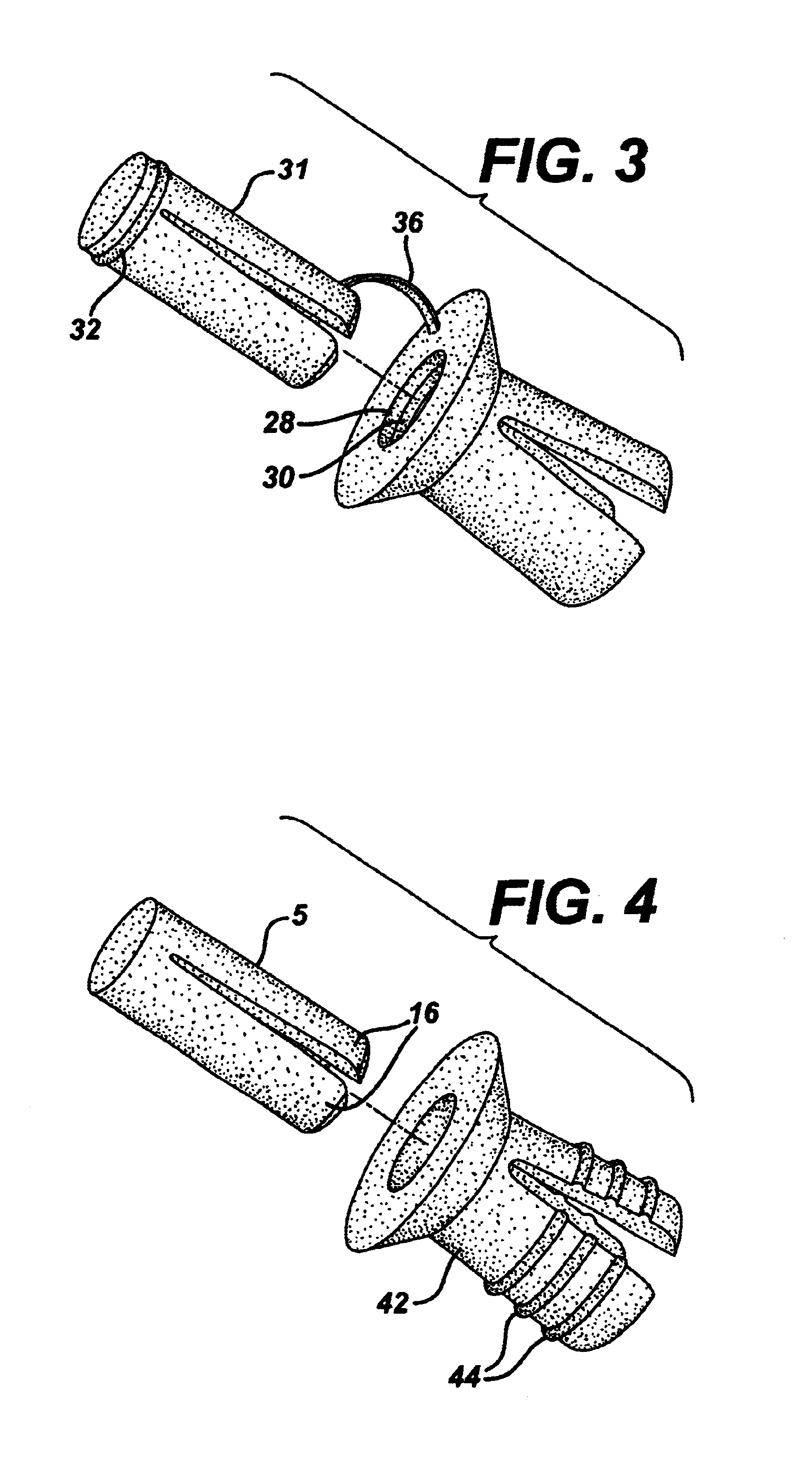

A new and improved toggle-bolt type fastener has pocket structure effectively incorporated therein so as to accommodate extra-long threaded activation screws or bolt fasteners in a coaxial manner within the toggle-bolt type fastener. Alternatively, structure has been incorporated within the toggle-bolt type fastener which effectively accommodates extra-long threaded activation screws or bolt fasteners by causing the same to be slightly deflected from their coaxial disposition within the toggle-bolt type fastener so as to permit the same to bypass the stab point of the toggle-bolt type fastener. Still further, additional structure has also been incorporated within the toggle-bolt type fastener for ensuring the fact that when the nut member is moved from its first or original, axially oriented, inoperative or non-deployed position, to its second, transversely oriented, operative or deployed position, the nut member will in fact be disposed substantially perpendicular to the longitudinal axis of the toggle-bolt type fastener so as to, in turn, ensure the proper threaded engagement thereby by the threaded activation screw or bolt fastener.

Owner:ILLINOIS TOOL WORKS INC

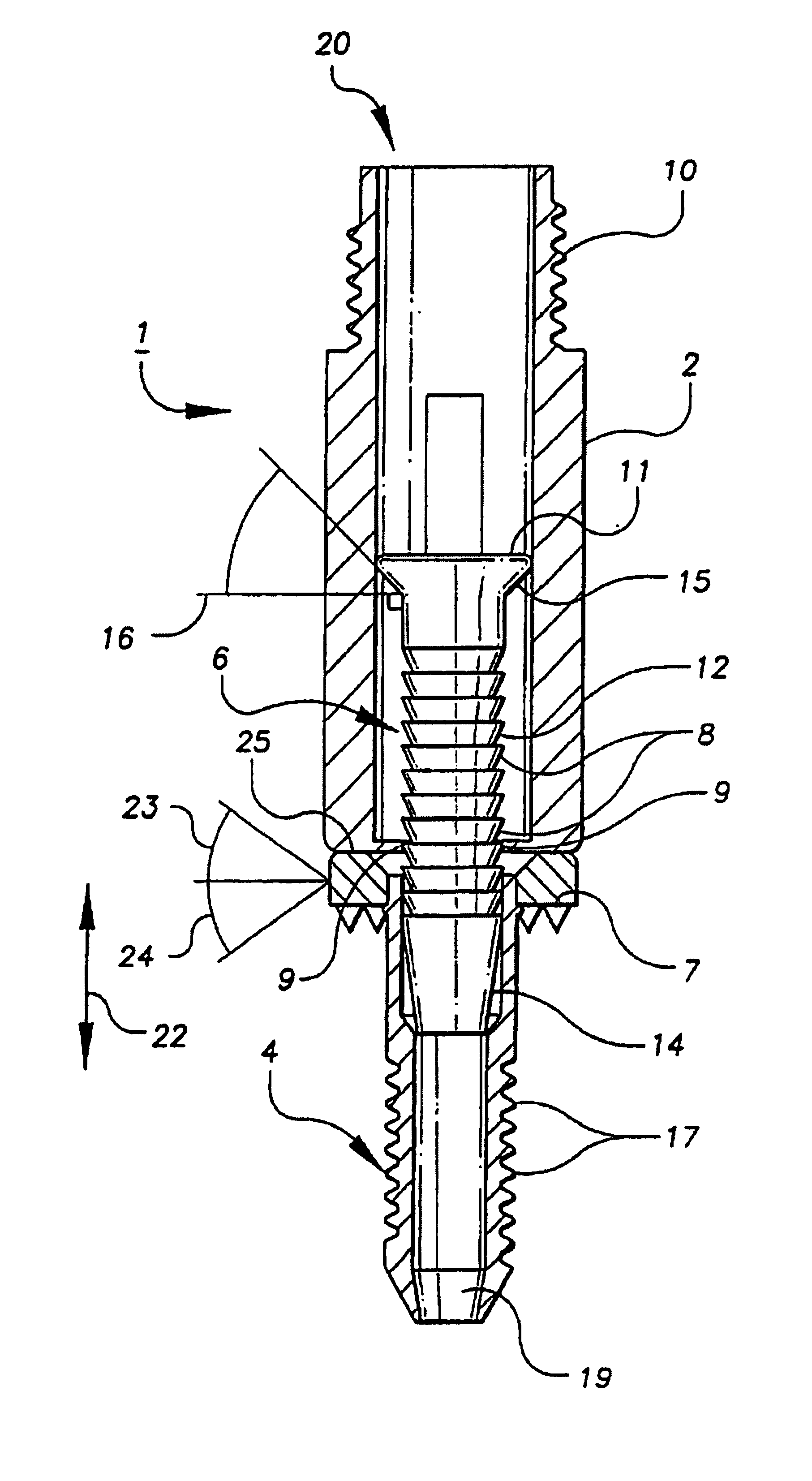

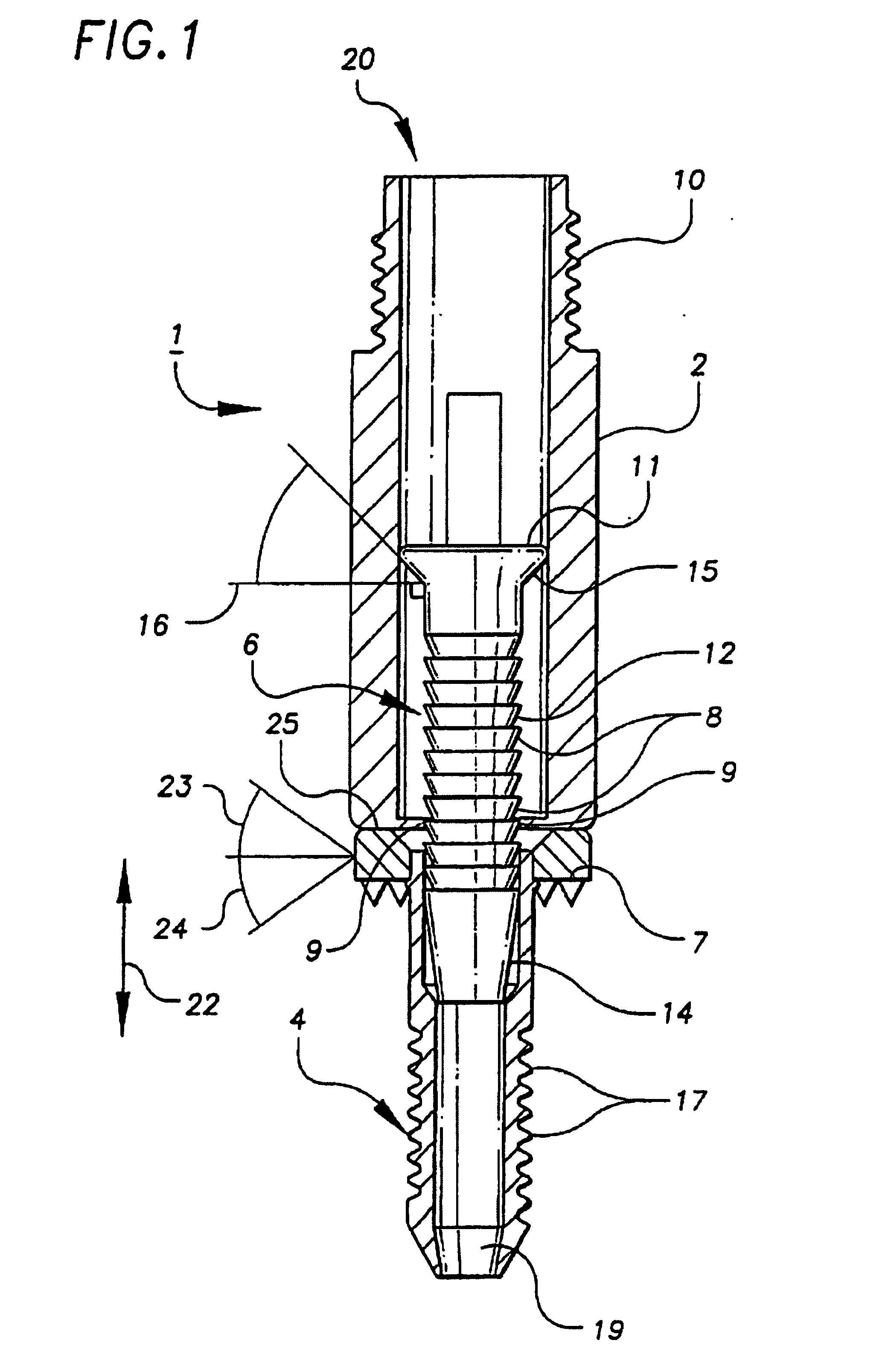

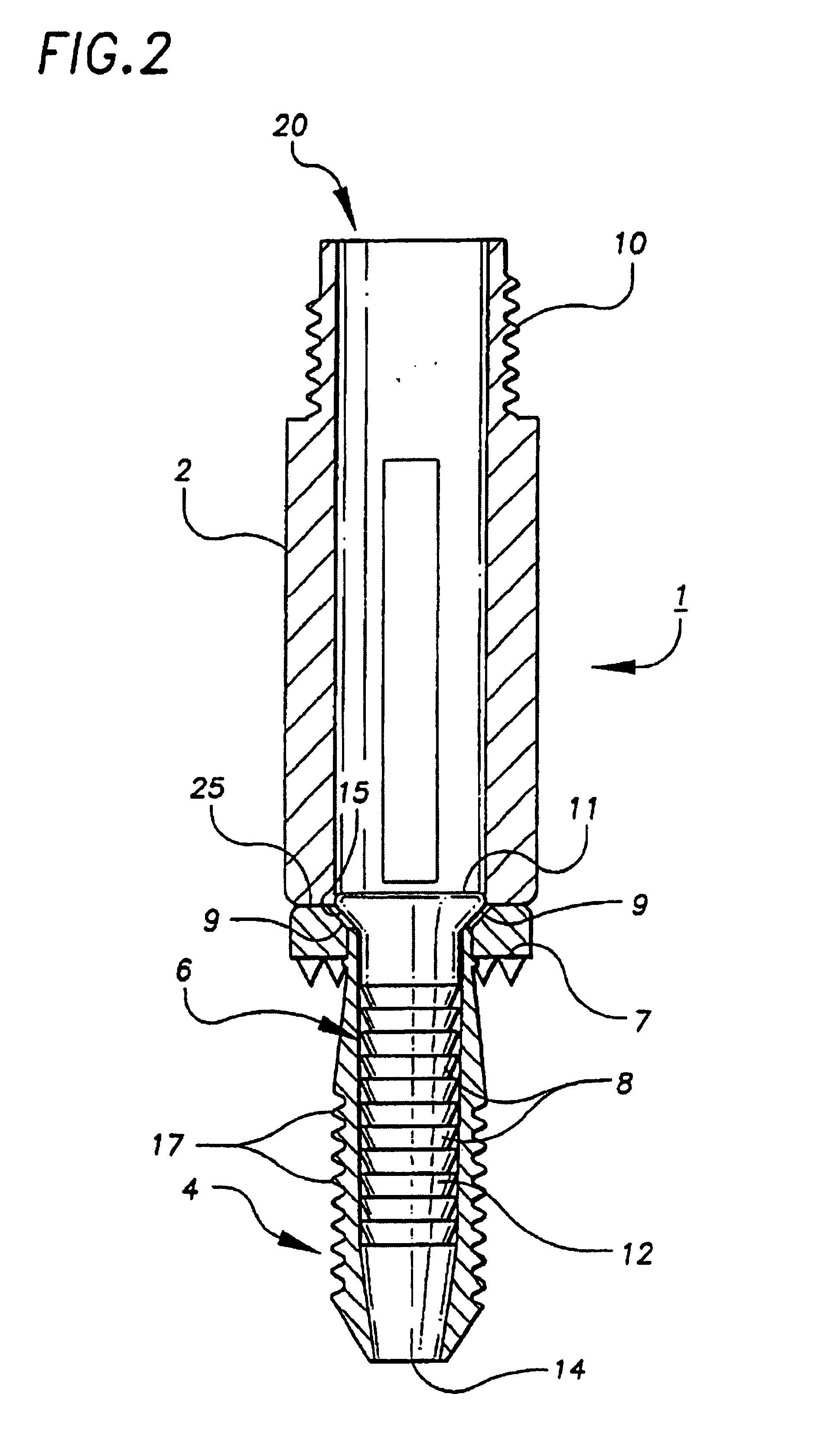

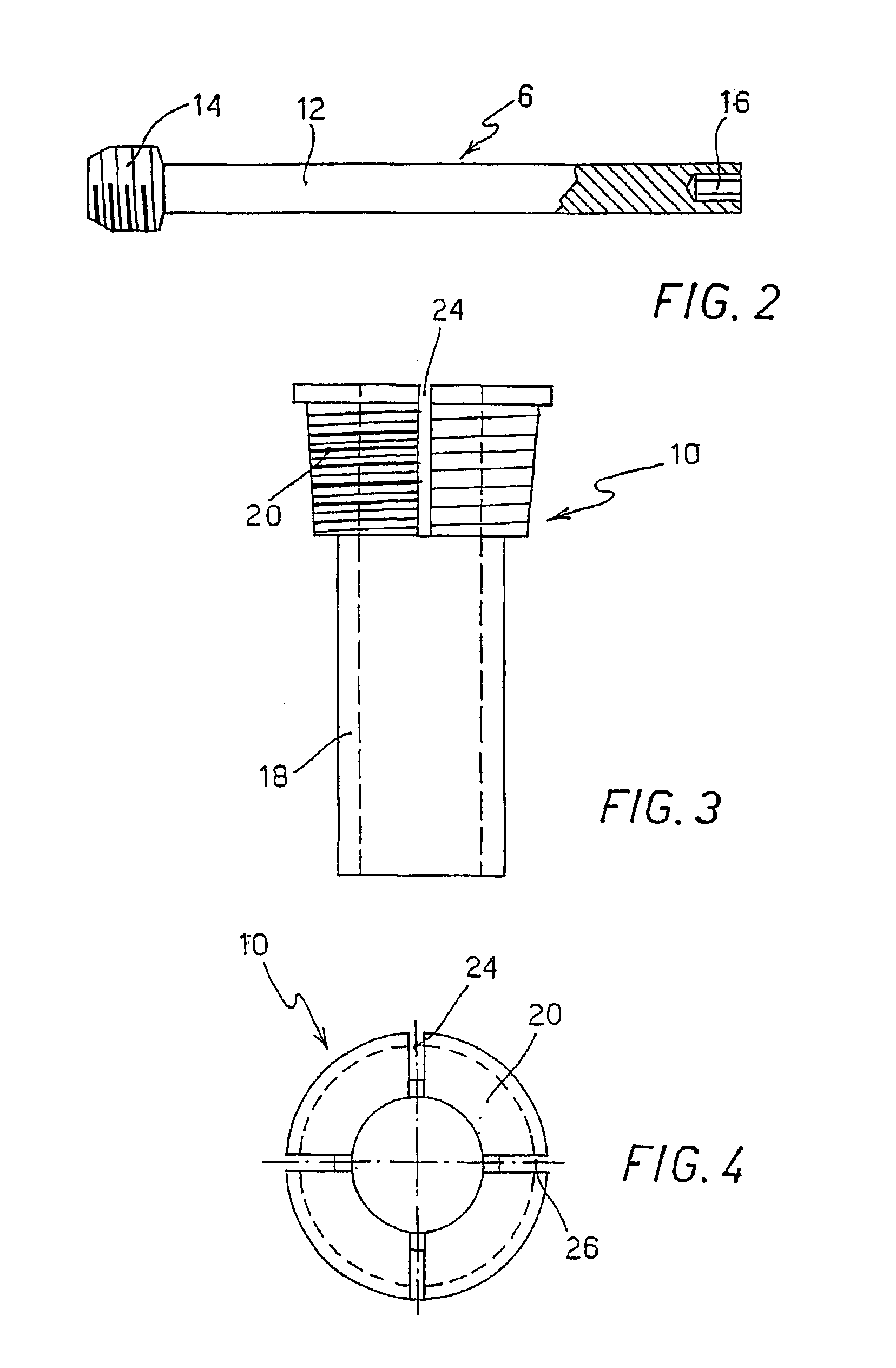

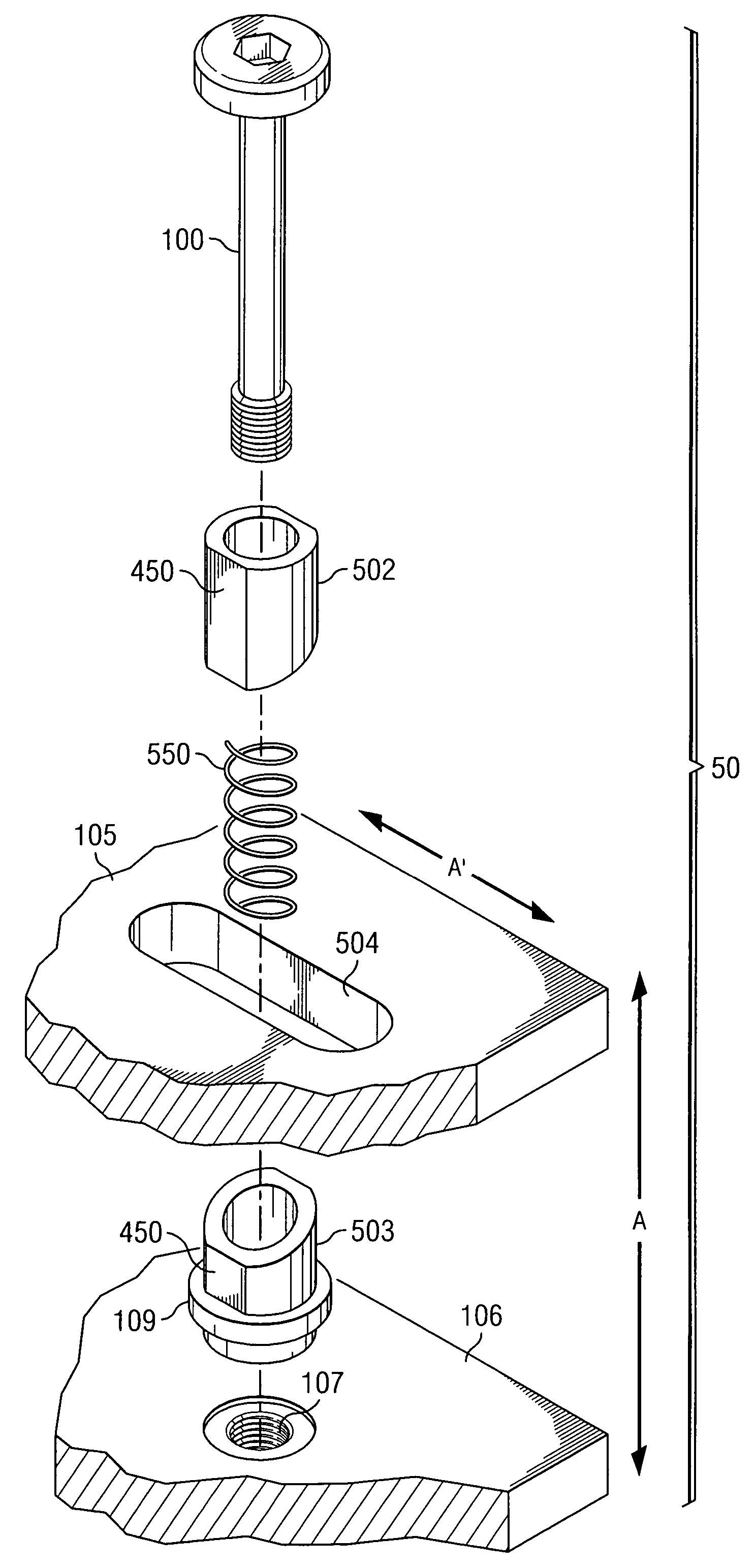

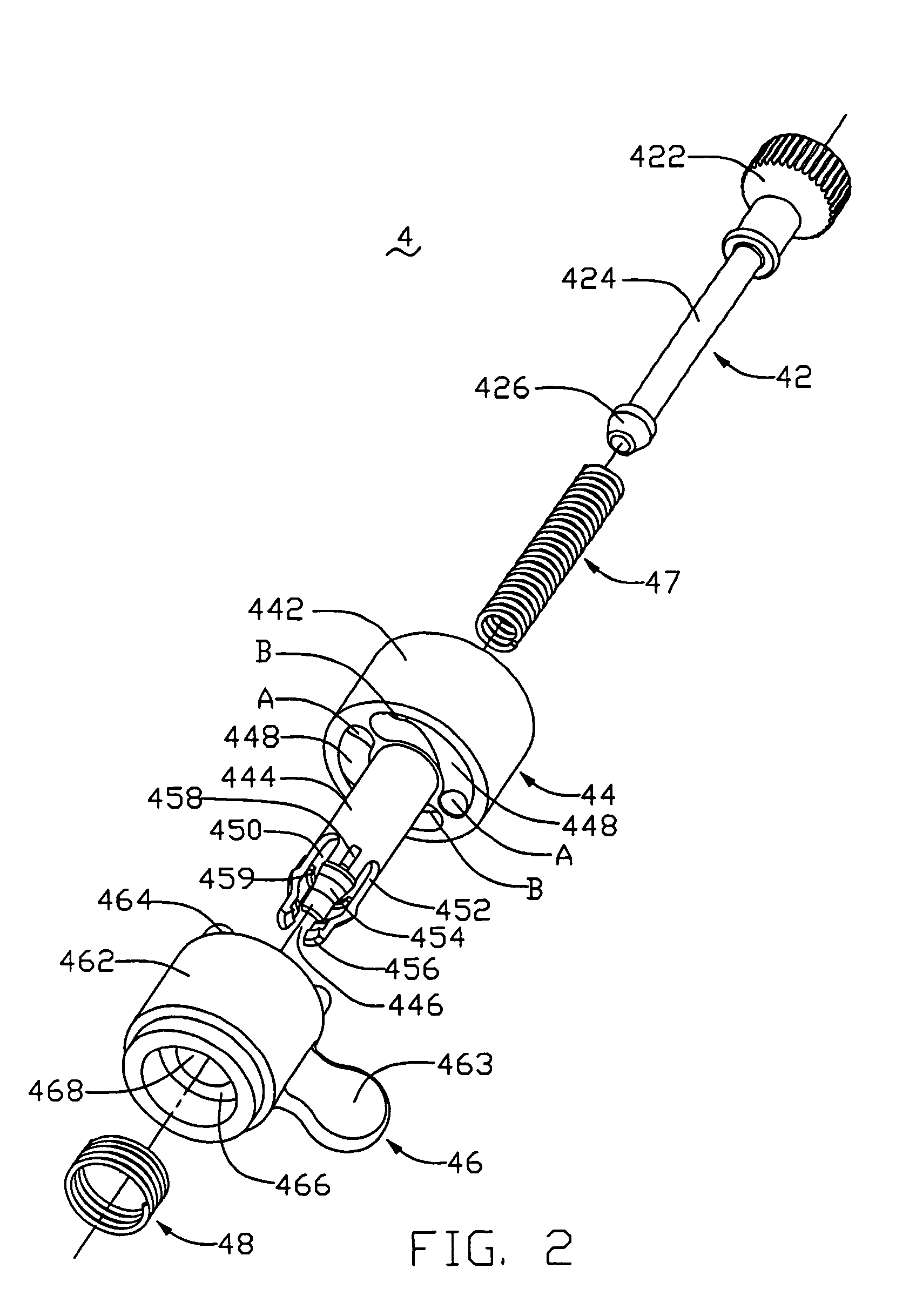

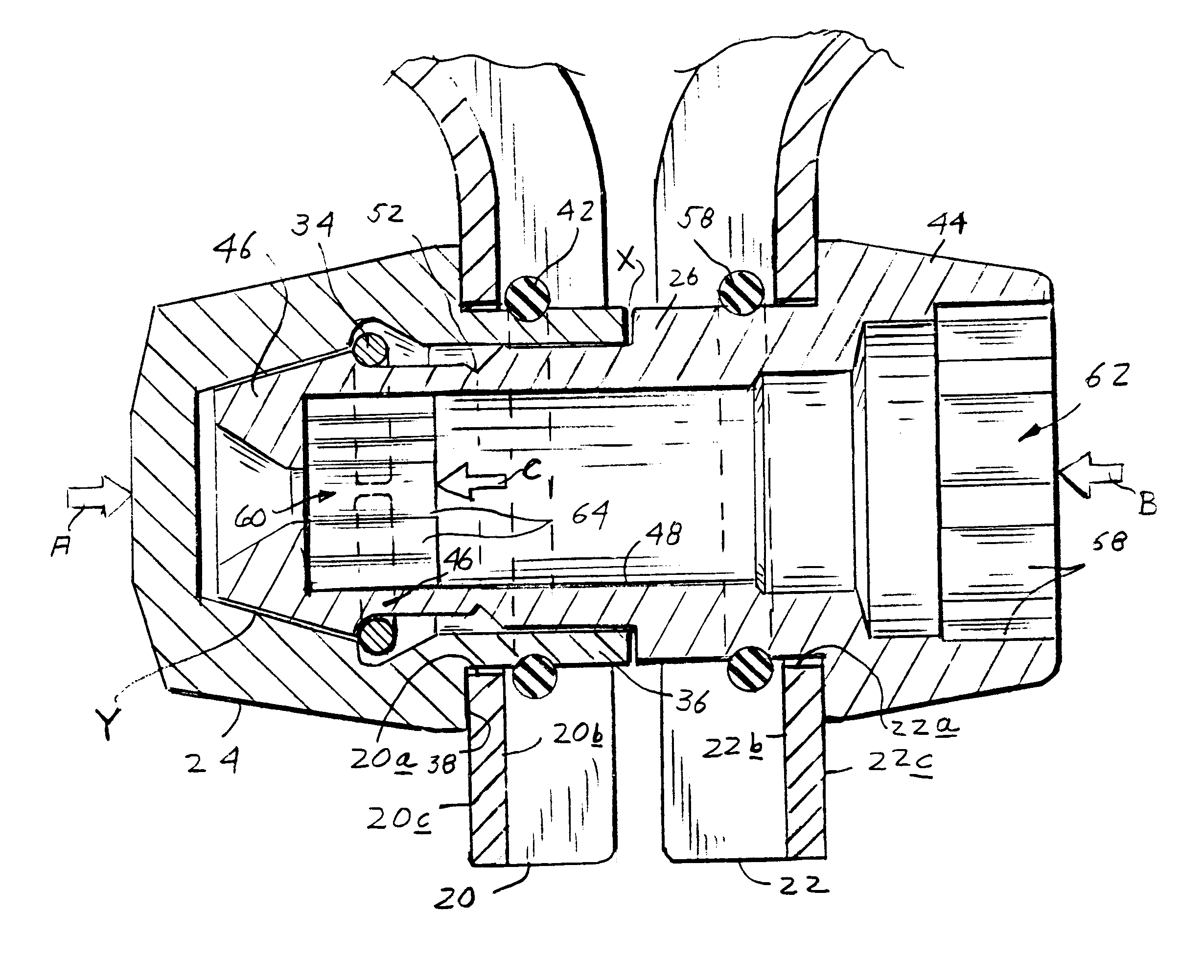

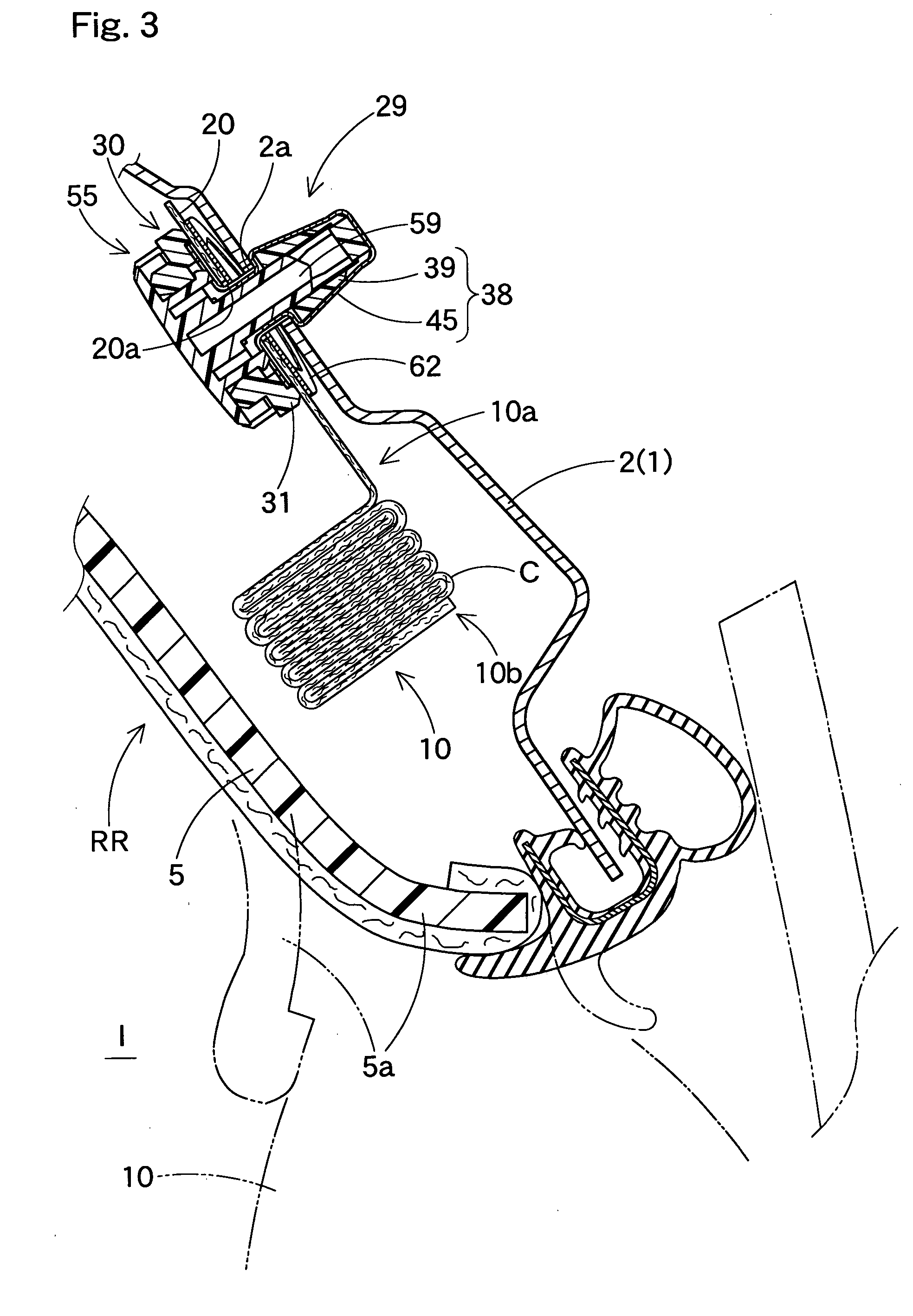

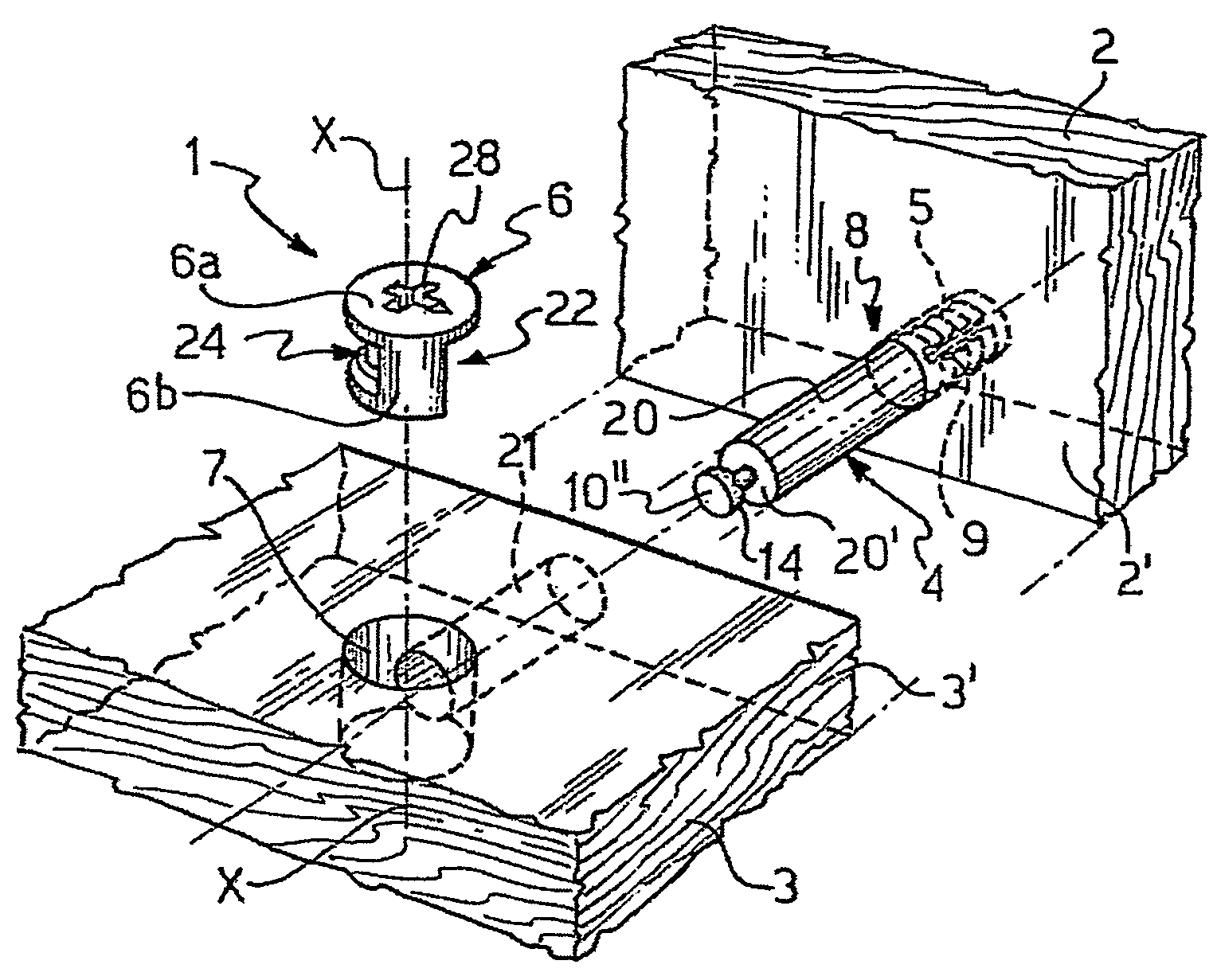

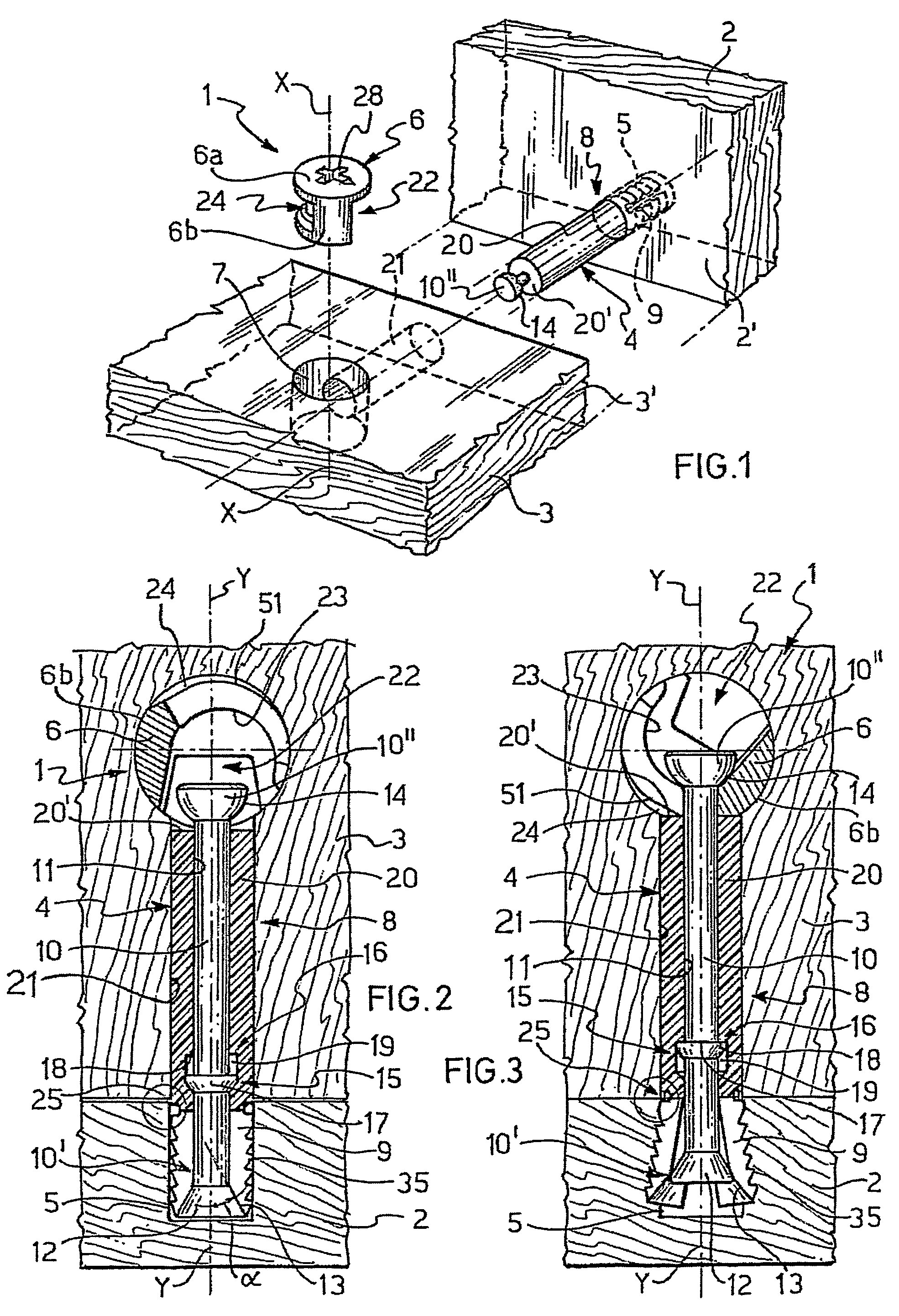

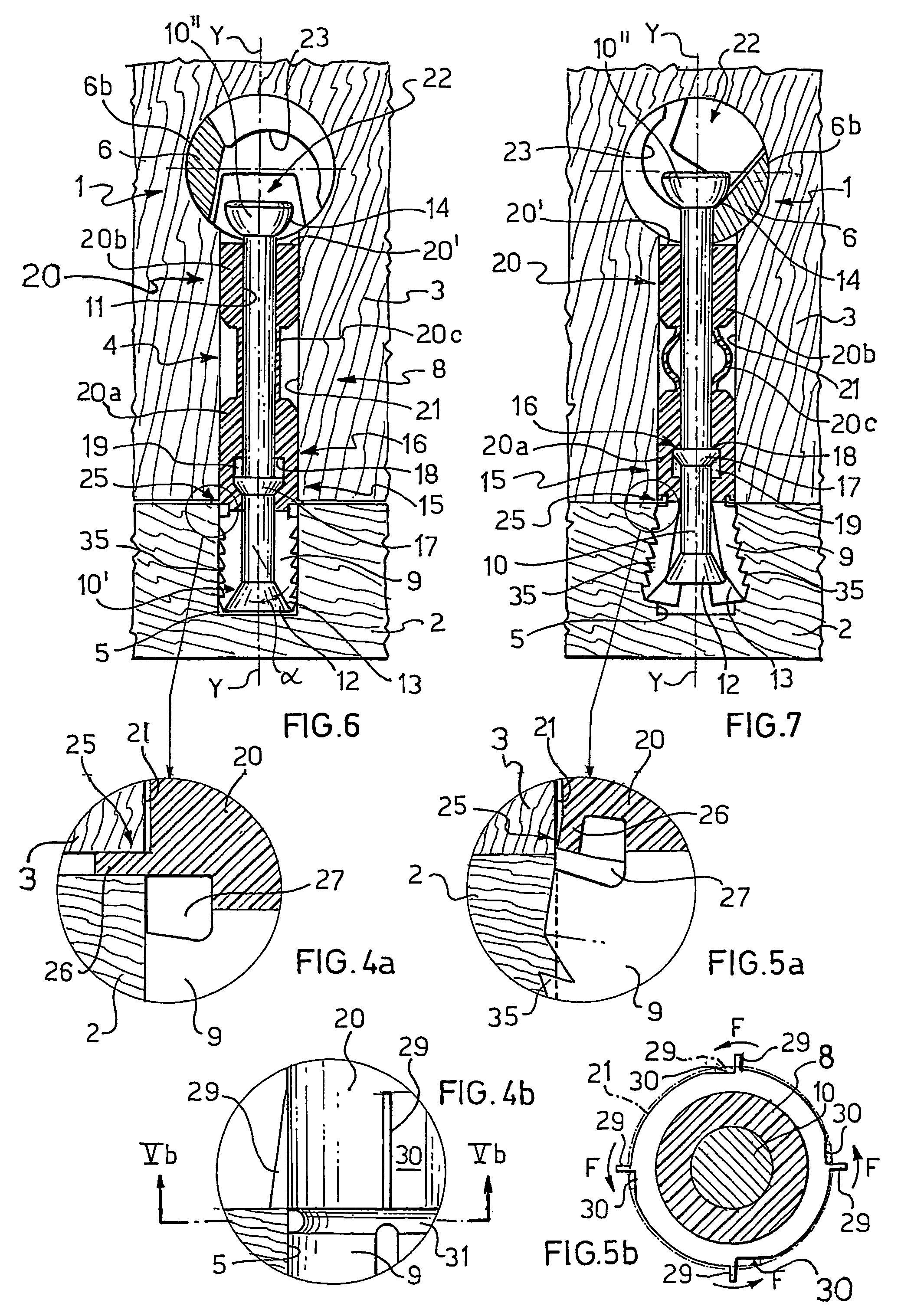

Device and method for detachably connecting abutting structural parts and tie member for use to form said device

InactiveUS7223045B2Reduced time and laborRopes and cables for vehicles/pulleyRod connectionsAbutmentEngineering

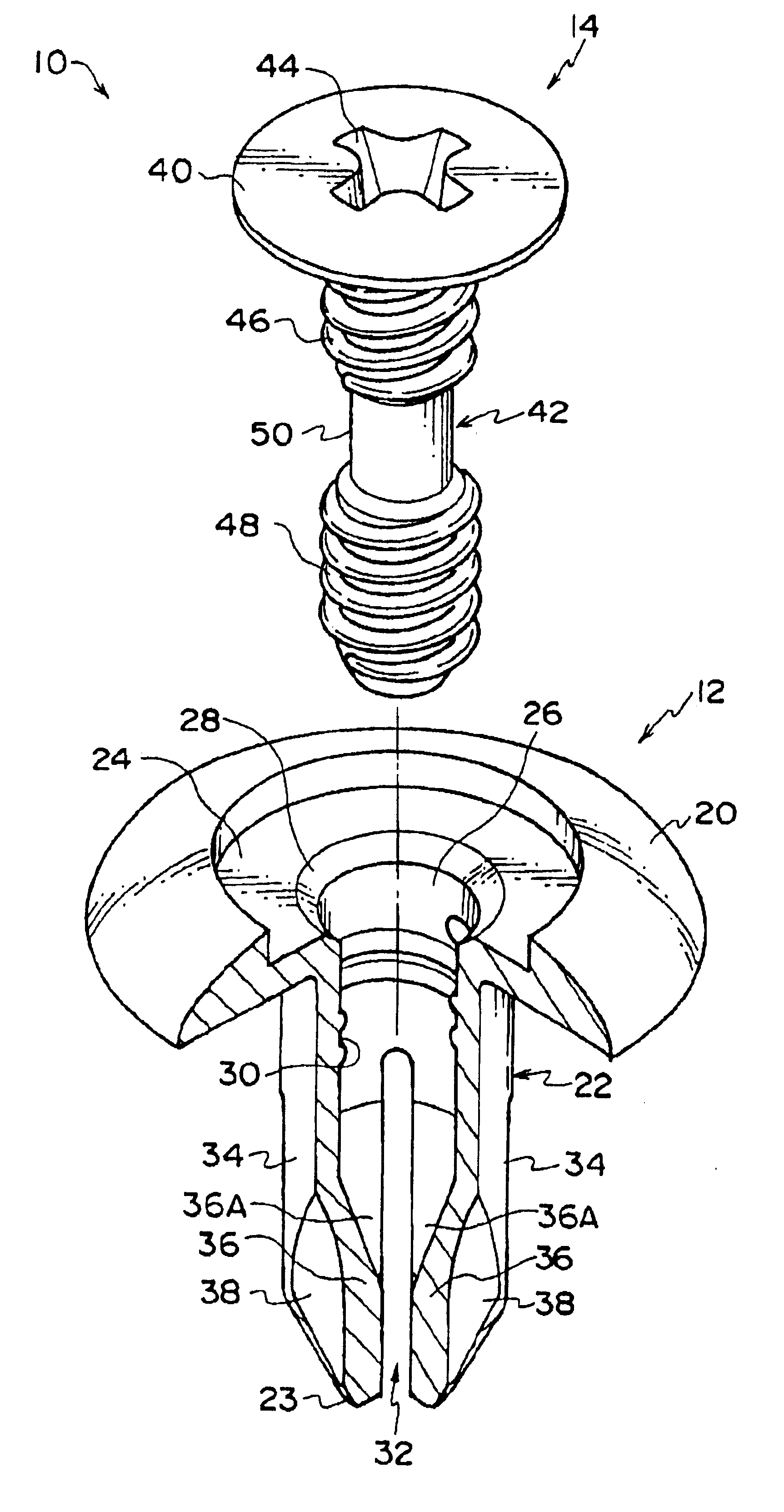

A device (1) for detachably connecting two abutting structural parts (2, 3) comprises a tie member (4), adapted to be at least partially inserted in a recess (5) formed in a first (2) of the structural parts (2, 3), and a locking element (6) operable to be disposed in a second (3) of the structural parts (2, 3) and to cooperate with an engagement surface (14, 45) of a rod member (10), slidably housed in a body (8) of the tie member (4), to pull the same towards the second structural part (3). The body (8) is provided with a first, expandable, portion (9) adapted to frictionally engage the recess (5) and with an engaging zone (13) cooperating with an expander region (12) of the rod member (10) operable to expand the first, expandable, portion (9) of the body (8) upon displacement of the rod member (10) relative to the same. The rod member (10) is provided with a traction portion (15) radially outwardly extending therefrom and adapted to cooperate with abutment means (16) radially formed in the body (8) of the tie member (4) at a predetermined axial distance from the engaging zone (13) to effect a substantially simultaneous displacement towards the second structural part (3) of the first, expandable, portion (9) of the body (8) of the tie member (4) and of the first structural part (2) in frictional engagement therewith.

Owner:TITUS D O O DEKANI

Board anchor

An anchor that screws directly into a board without requiring a tap drill hole. A male screw is provided around the shaft part of the anchor with a drill part at one end and a flange part at the other end; at the end where the flange part is provided, a turning tool engagement hole and a female screw formed hole part continuous therewith are provided. The drill part is formed into a tapered-pyramid shape, multiple split shaft parts being formed by providing a slit that extends from the end surface of the pyramid-shaped drill part to midway up the shaft part. The tip of the split shaft part incorporate connected multiple drill bits that are formed by splitting the pyramid-shaped drill part.

Owner:KOYOKIZAI

Mushrooming expandable anchor

A self-anchoring fastening device for installation in supports for hanging pipes wires or other articles in ceilings is shaped for a socket to drive the device for an easy installation process. The device comprises a collapsible anchoring portion having radially expanding anchoring strips, which will not pull out of a hole drilled in a support. A drill drills a hole in a support and an expandable anchor is inserted through the hole. Threads internal to the expandable anchor cooperate with threads on a screw inserted therein to collapse the expandable anchor, providing anchoring strips over the hole such that the expandable anchor cannot be pulled out of the hole. A threaded portion of the base of the screw is suitable for attaching the article to be hung. The base may be a swivel head type. The drill may be on the expendable anchor assembly.

Owner:ILLINOIS TOOL WORKS INC

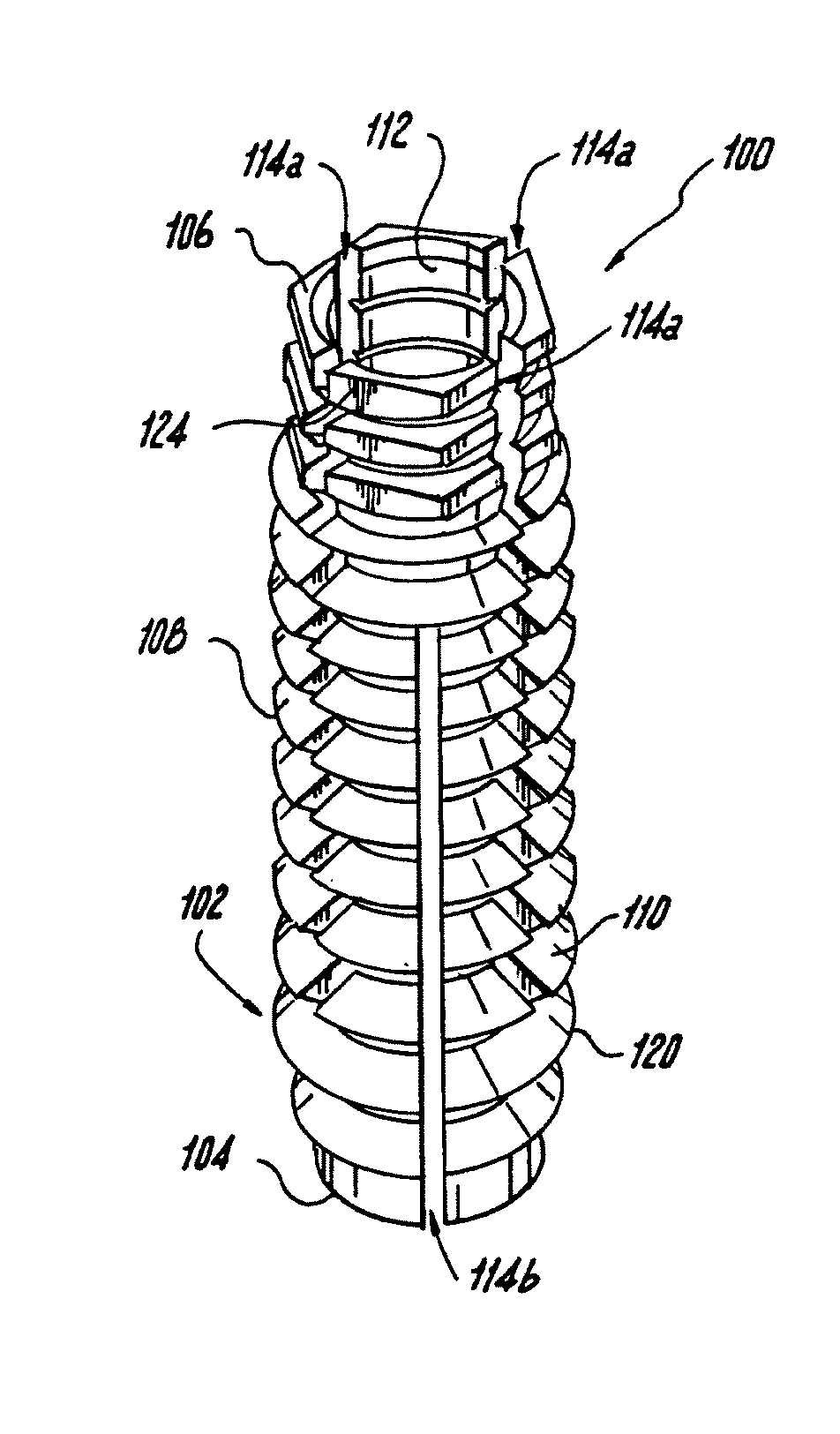

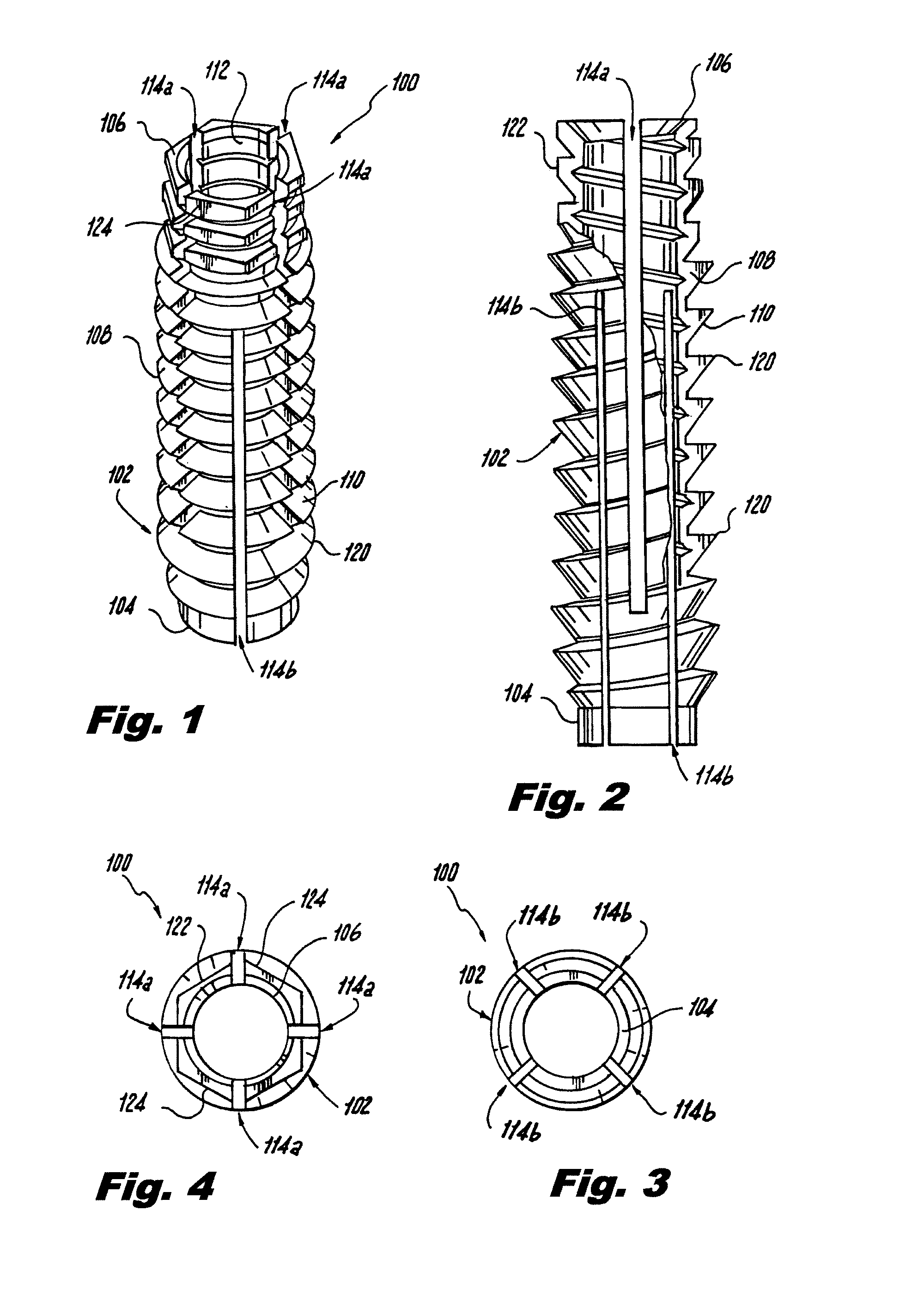

Orthopedic screw insert

An insert for receiving a bone screw includes an elongate sleeve having opposed proximal and distal ends and a wall defined by an outer peripheral surface configured for engaging bone and an inner peripheral surface configured for receiving a bone screw extended therethrough. At least one elongate slot is formed in the wall of the sleeve for promoting flexure of the insert. A tool for affixing an orthopedic screw insert within bone tissue includes a socket portion configured and adapted to engage a proximal section of an outer peripheral surface of an orthopedic screw insert. A driver extends distally from the socket portion. The driver is configured and adapted to engage a section of an inner peripheral surface of the orthopedic screw insert distal from the socket portion.

Owner:NUVASIVE

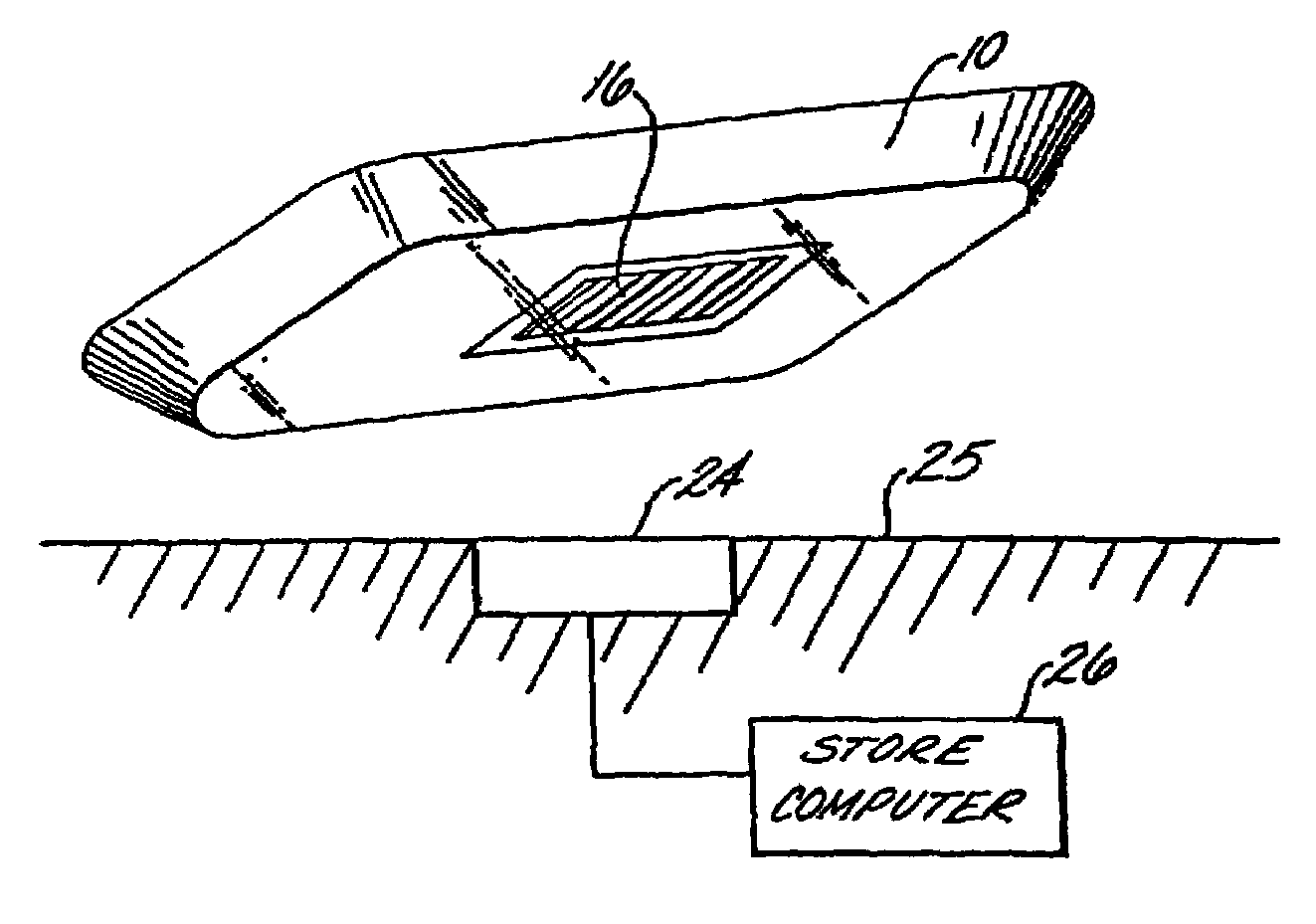

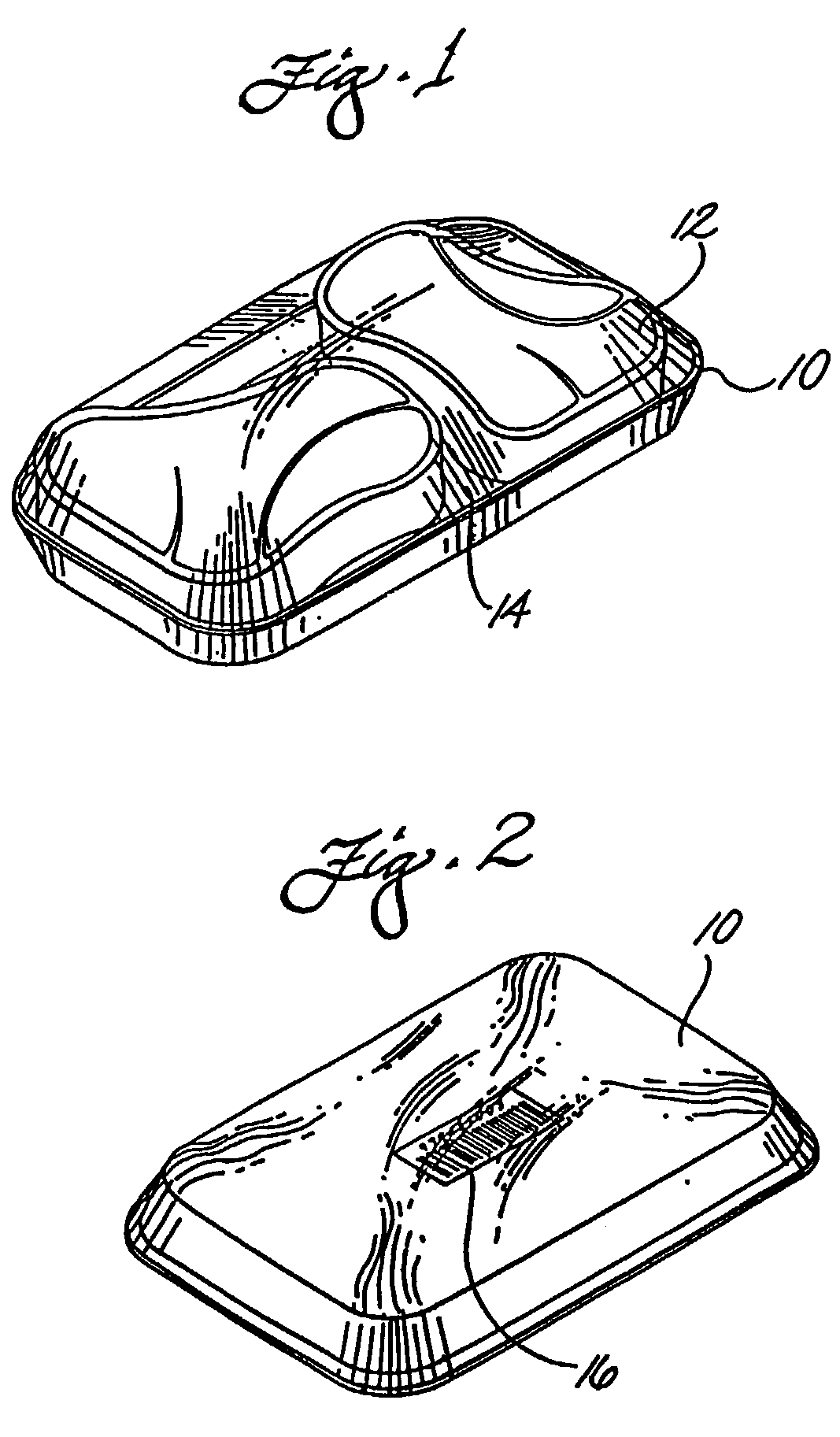

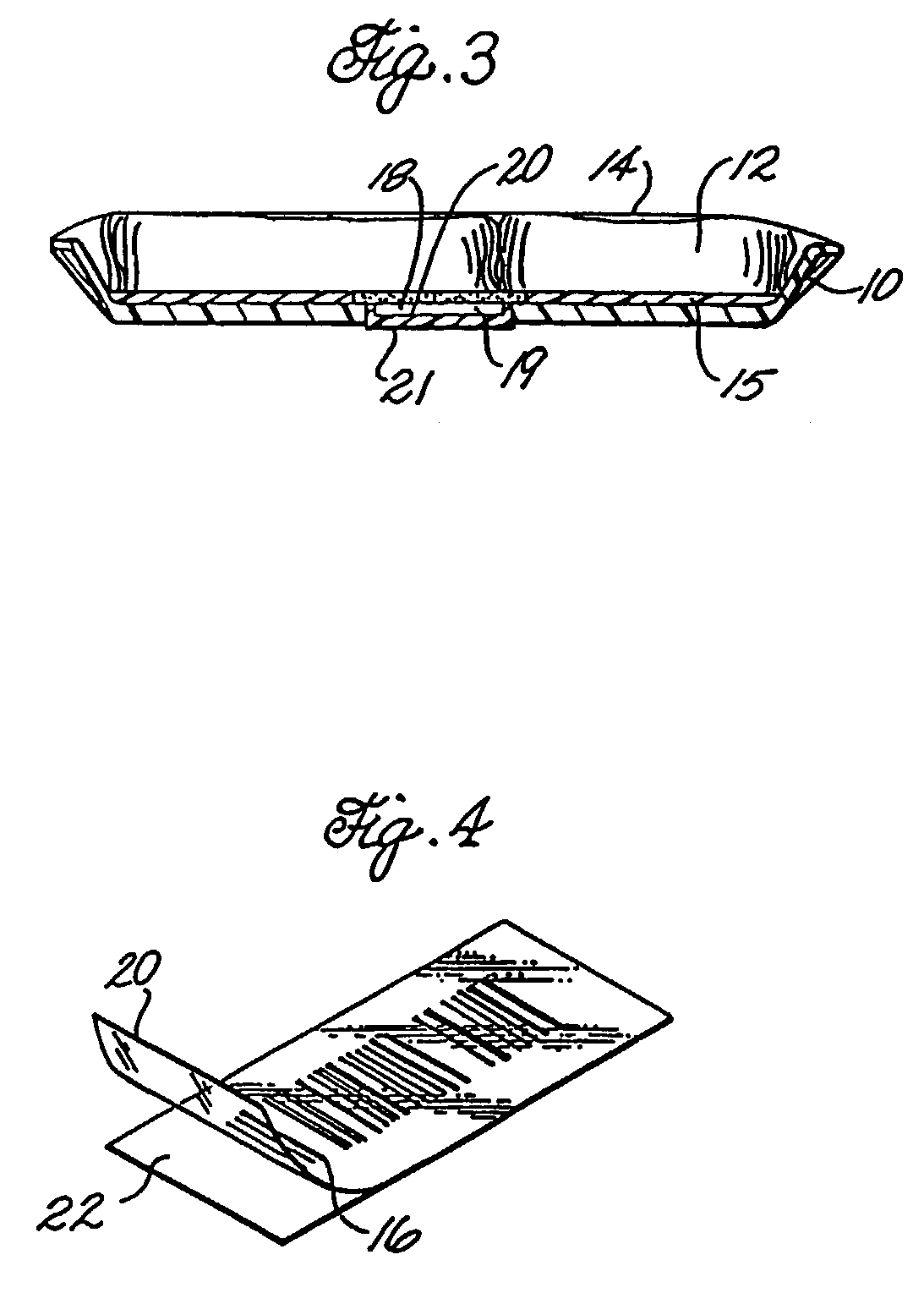

Contamination detection system

InactiveUS7156597B2Analysis using chemical indicatorsAnalysis by subjecting material to chemical reactionProgramming languageContamination

A dual bar code for detecting contamination. When no contamination is present, a first bar code identifies the product. When contamination is present a second bar code identifies the presence of contaminants.

Owner:SIRA TECH

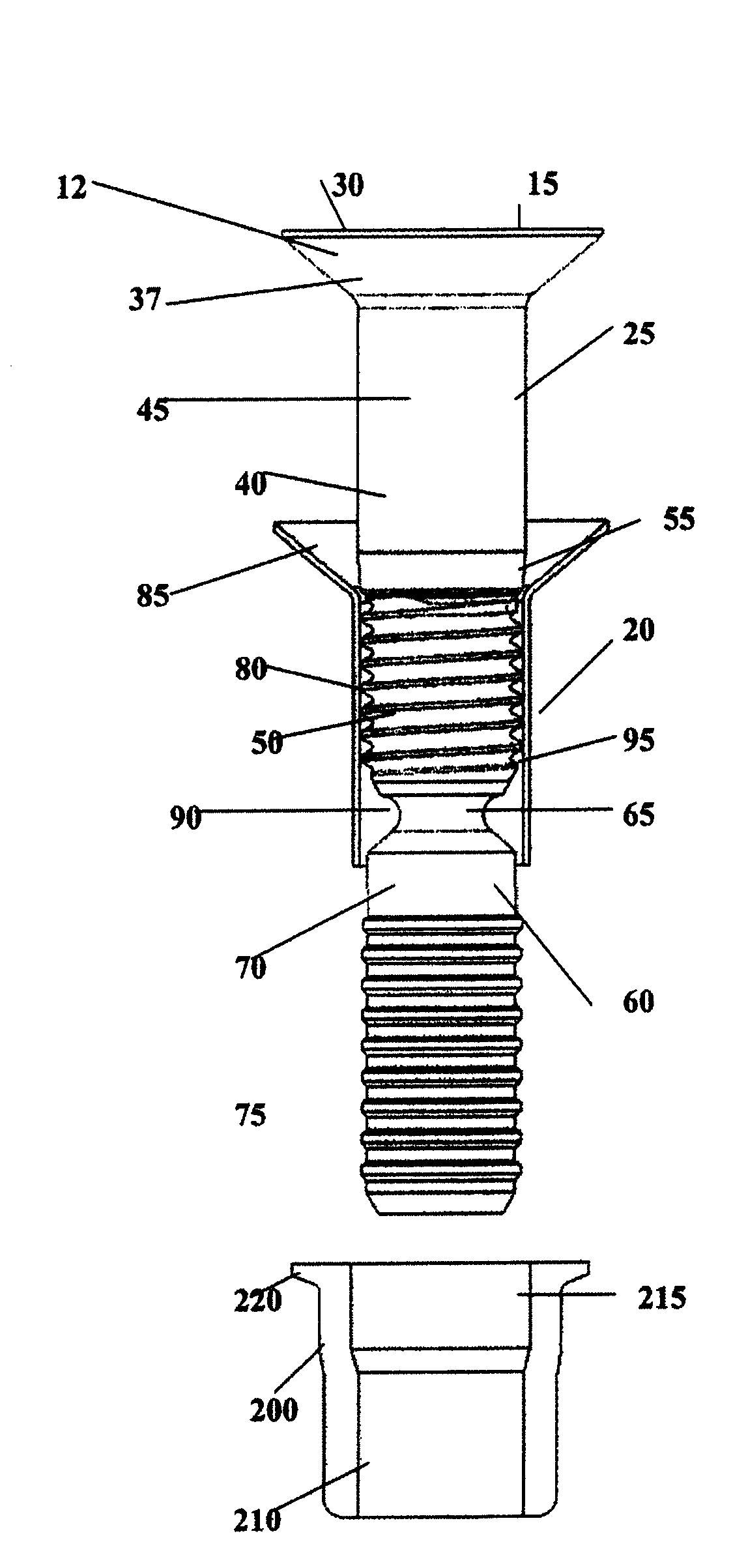

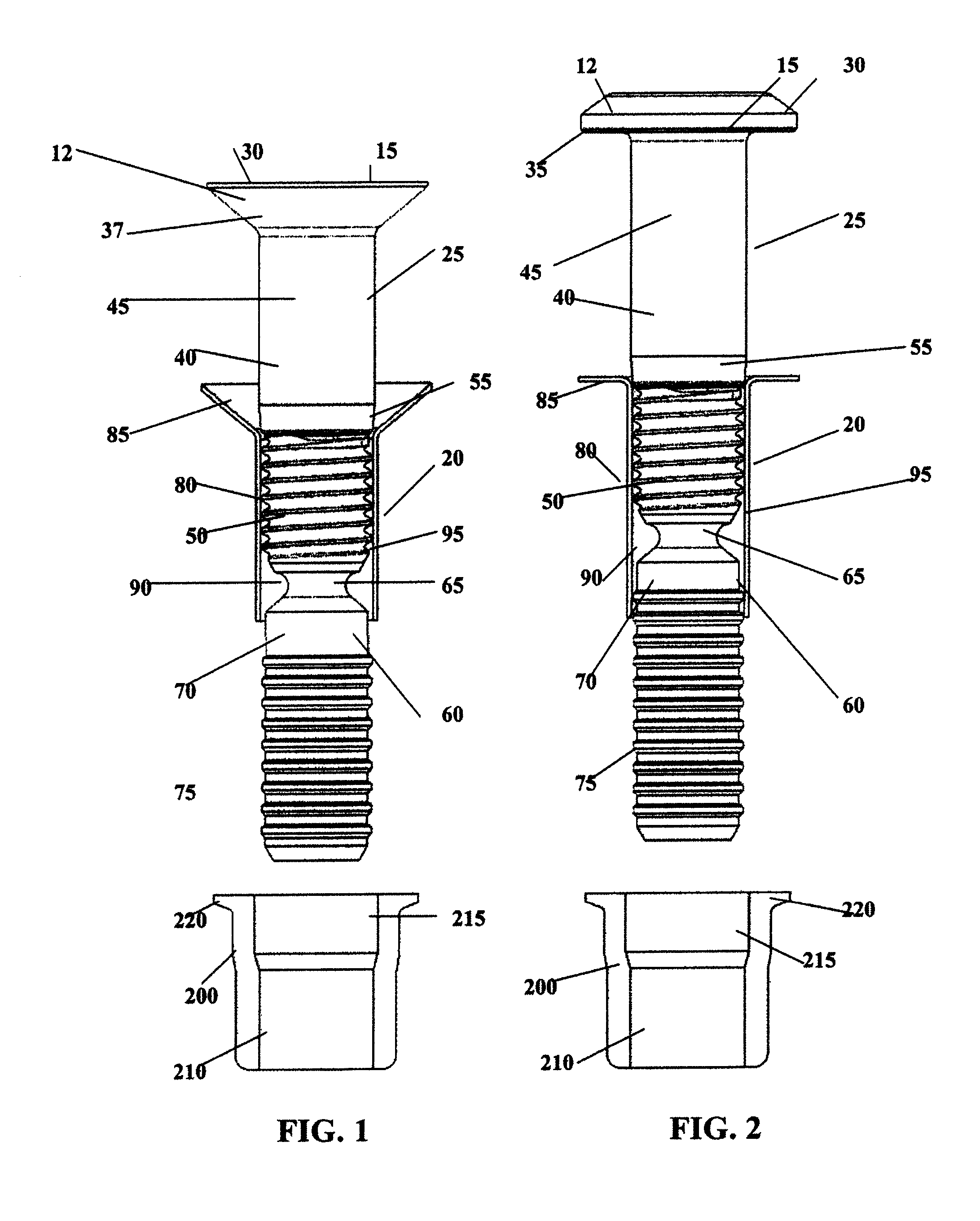

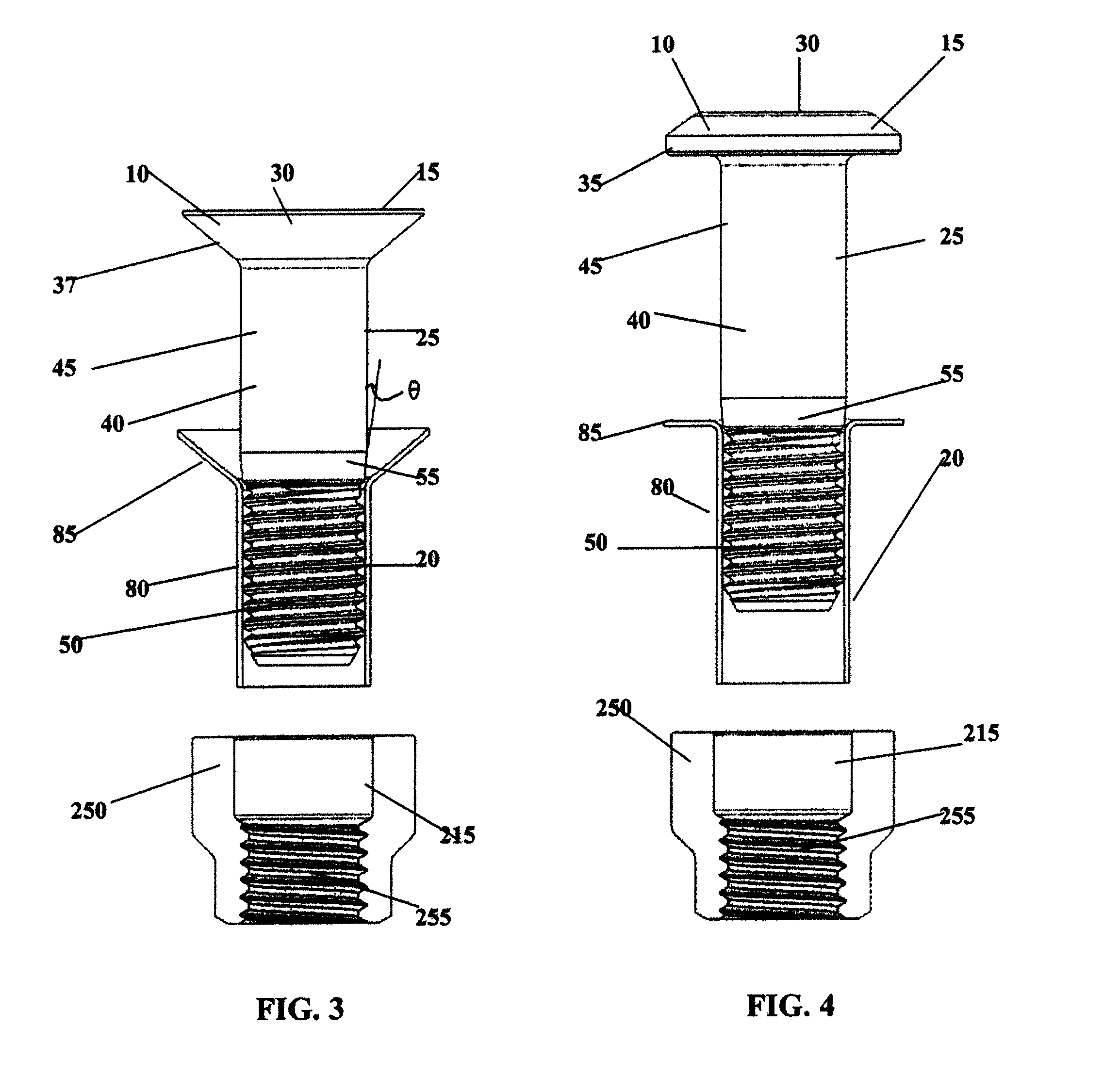

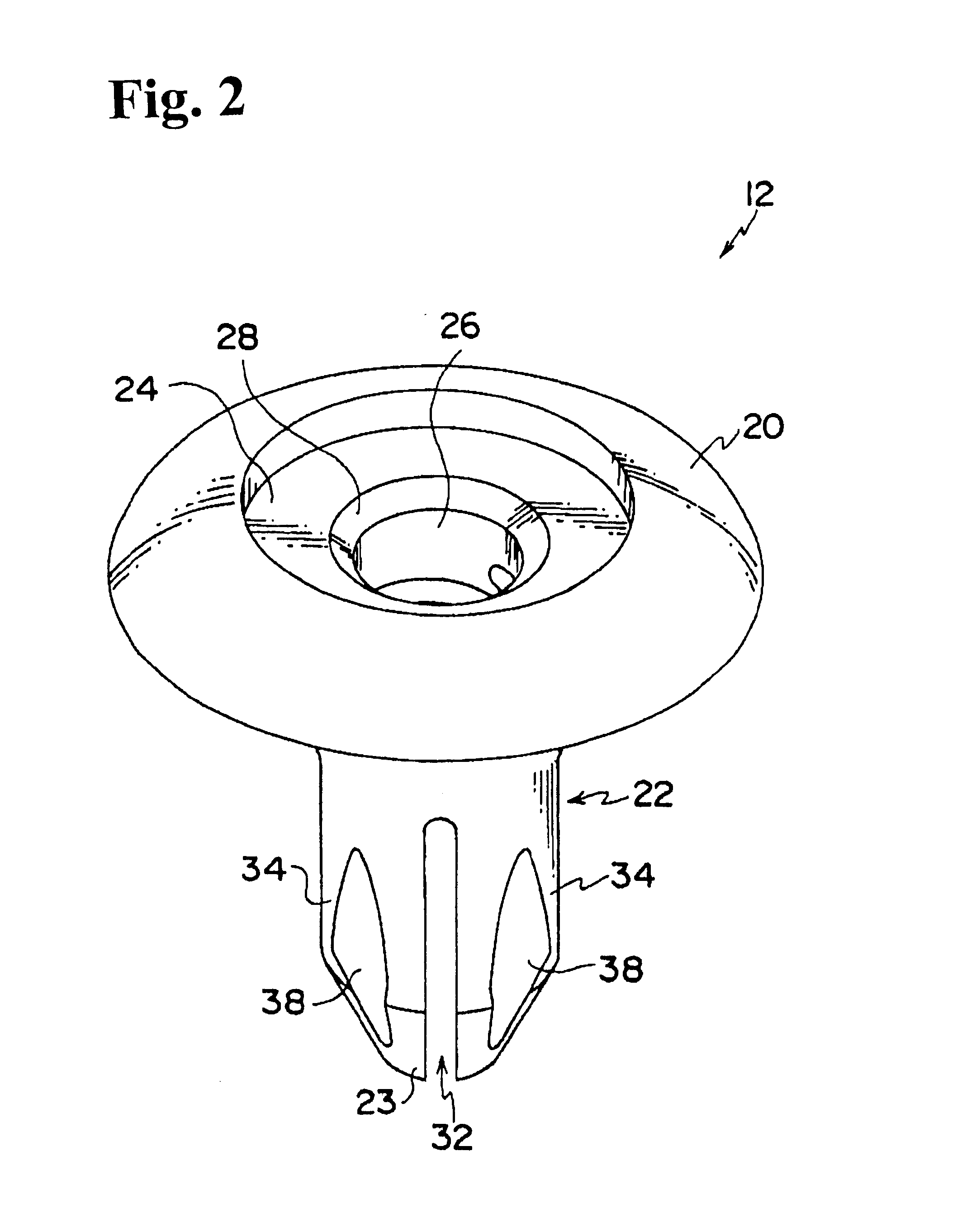

One-piece biocompatible absorbable rivet and pin for use in surgical procedures

InactiveUS6846313B1Easy to handleConveniently installedSuture equipmentsInternal osteosythesisEngineeringWeld line

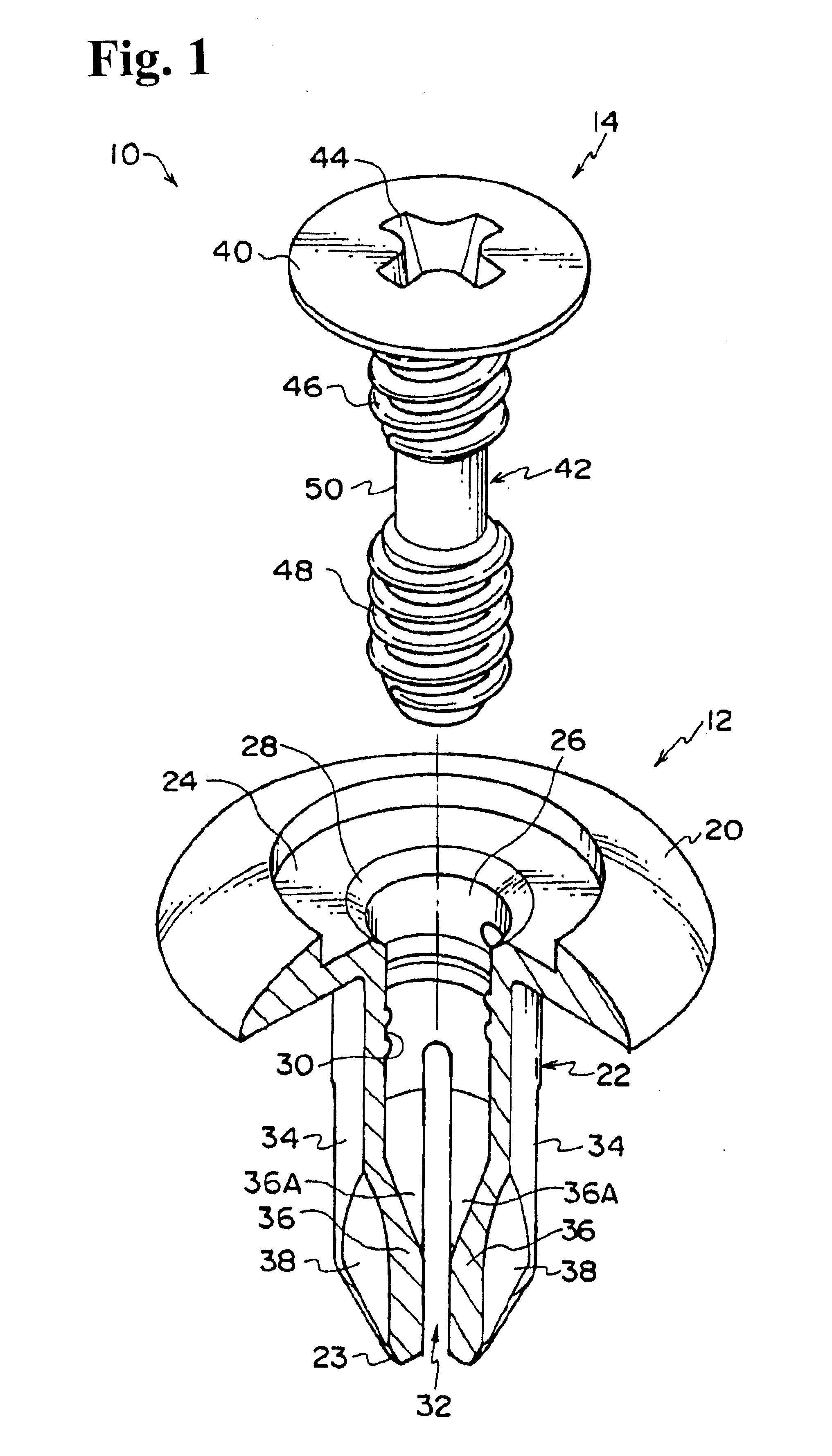

A bioabsorbable rivet and pin fastener is formed as an elongated unit that may be used for anchoring, or for attachment of a fixation plate. The rivet has a head mechanically connected to two or more legs that extend generally distally from the head and may flex outwardly from a central rivet axis. The pin is integral with the rivet and oriented along the central axis by a connection such as a web or a plurality of braces, forming an integral, aligned, one-piece assembly that may, for example, be molded as a single piece. The connection breaks under force as the pin is driven into the rivet, so that the pin contacts internal surfaces of the legs and pushes the legs outward into frictional engagement with the surrounding bone. The one-piece assembly may be formed in a gated mold having a central pin with a relief passage that defines the braces between upper and lower portions of the rivet. The braces so formed at the weld line readily part from the mold, and are easily sheared when the pin is advanced during installation of the rivet.

Owner:CODMAN & SHURTLEFF INC

Fastener

A fastener for connecting plate members includes a male member, and a female member to be inserted into mounting holes of the plate members. The female member includes a cylinder body for receiving the main body therein, a projecting portion formed on an outer periphery of the cylinder body at one end thereof, and protruding portions formed at the other end thereof. A first engaging portion is formed on an outer surface of a main body of the male member or an inner surface of the cylinder body, and a second engaging portion engaging the first engaging portion is formed on the inner surface or the outer surface. The second engaging portion has two engaging sections and a smooth surface portion interposed therebetween. When the male member is inserted into the female member, the male member can be easily engaged with the female member.

Owner:NIFCO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com