Patents

Literature

775results about "Fastener tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

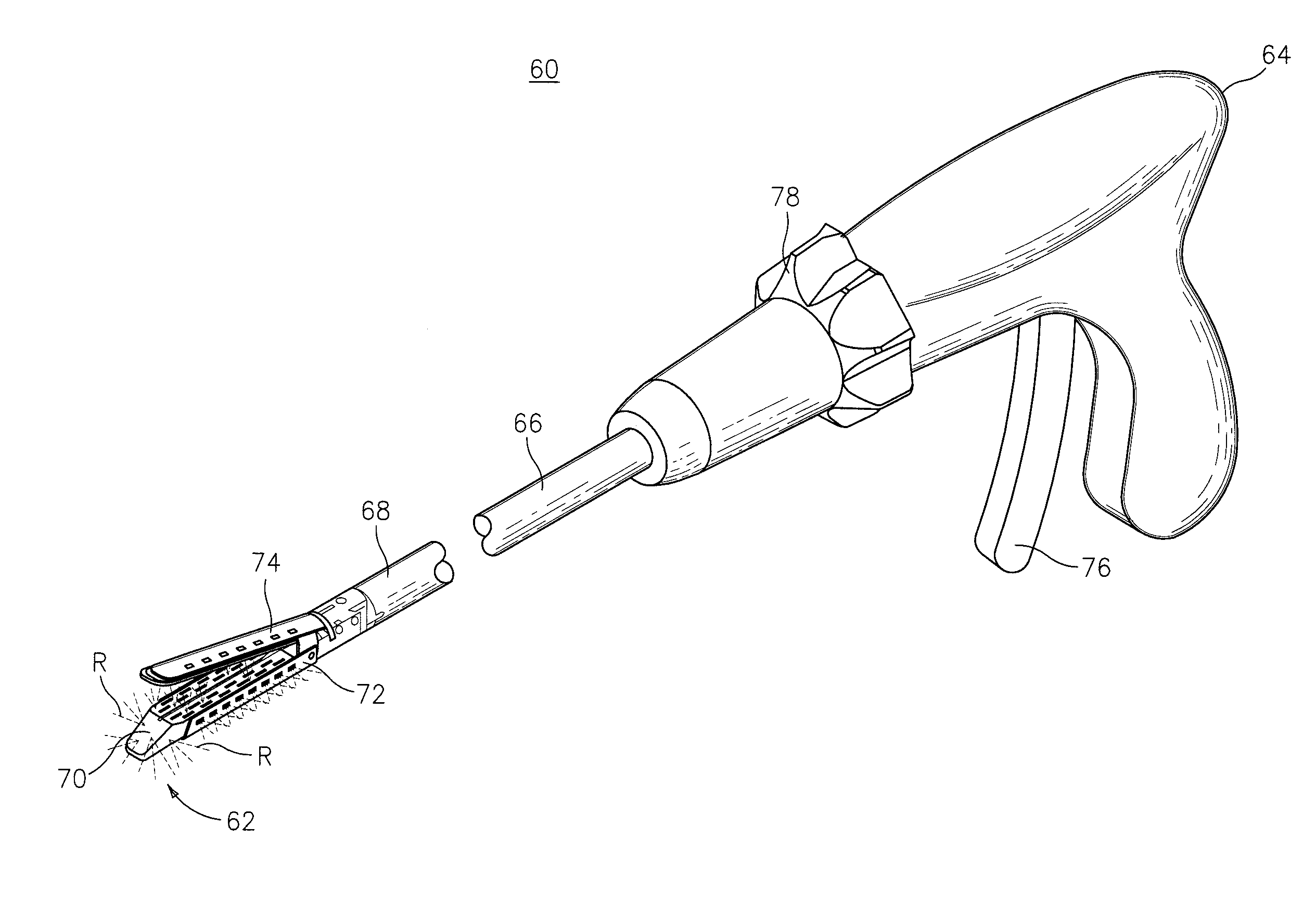

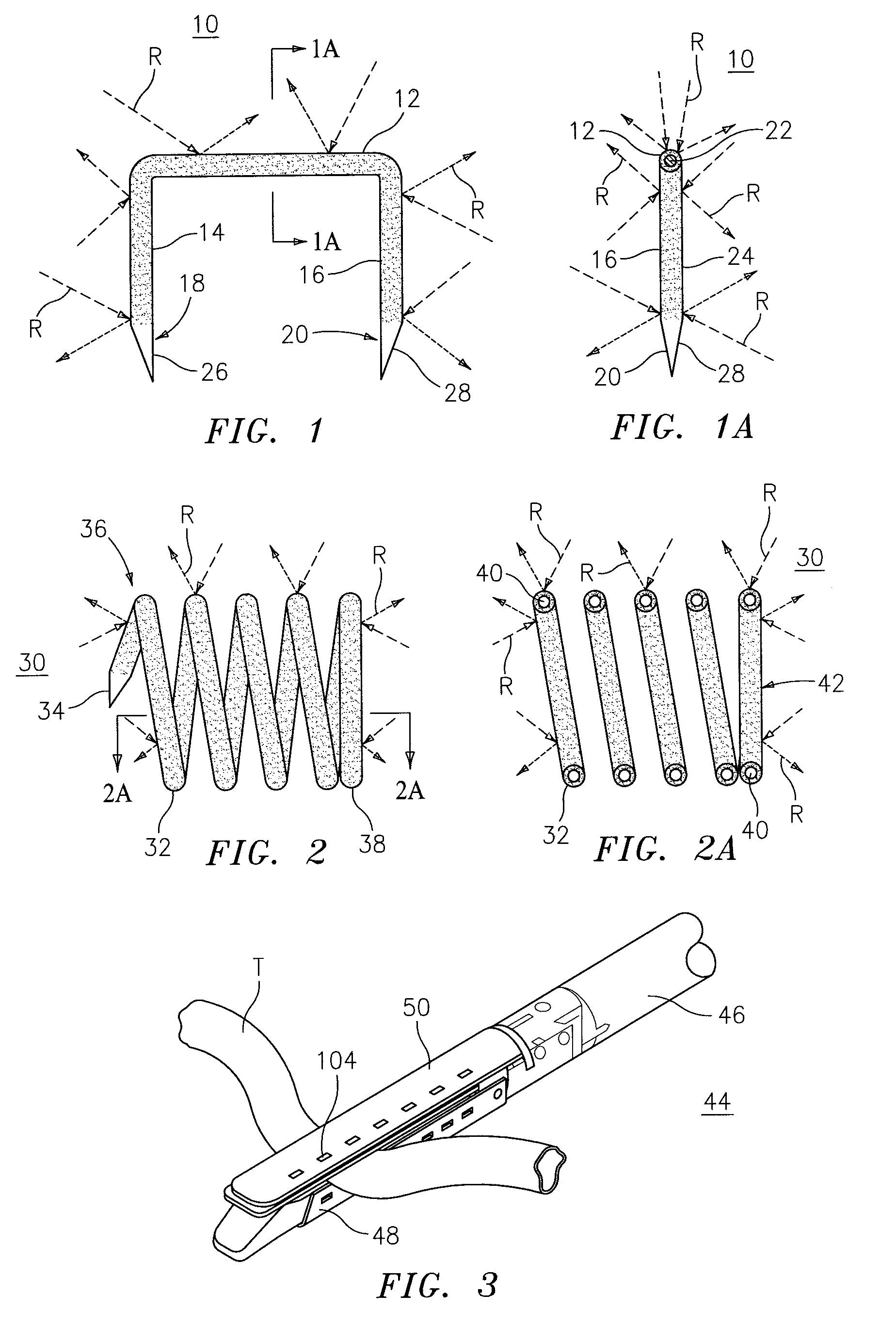

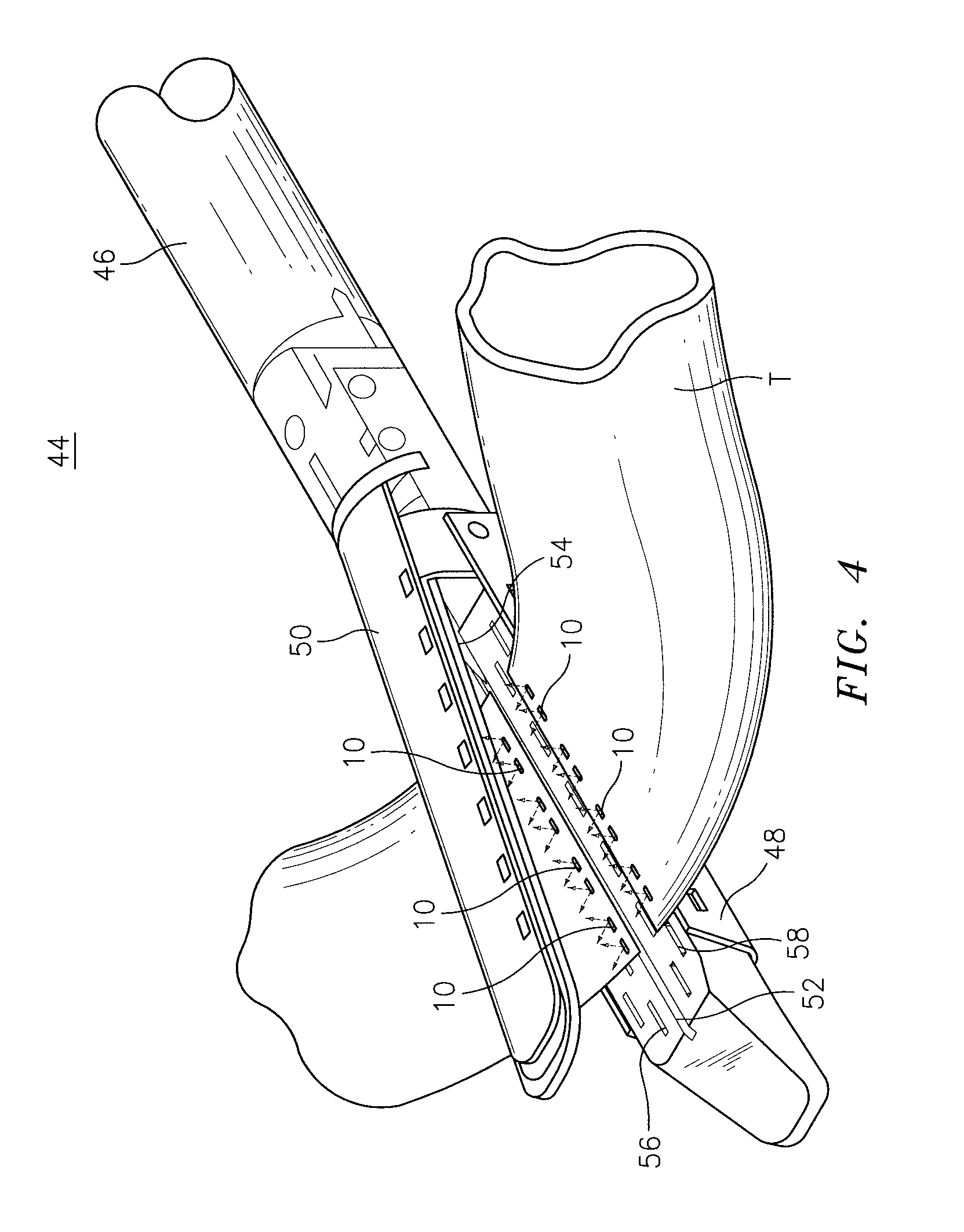

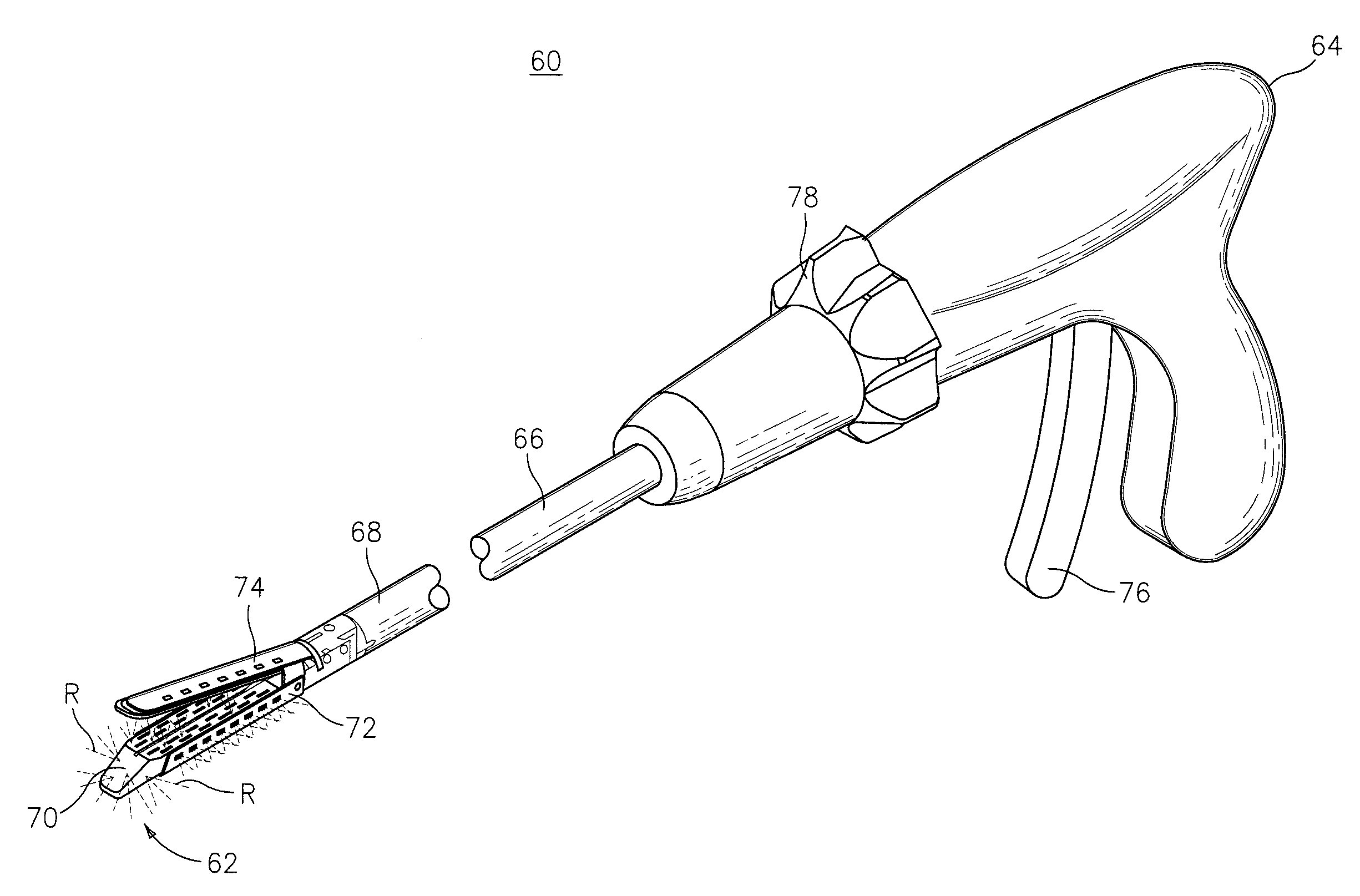

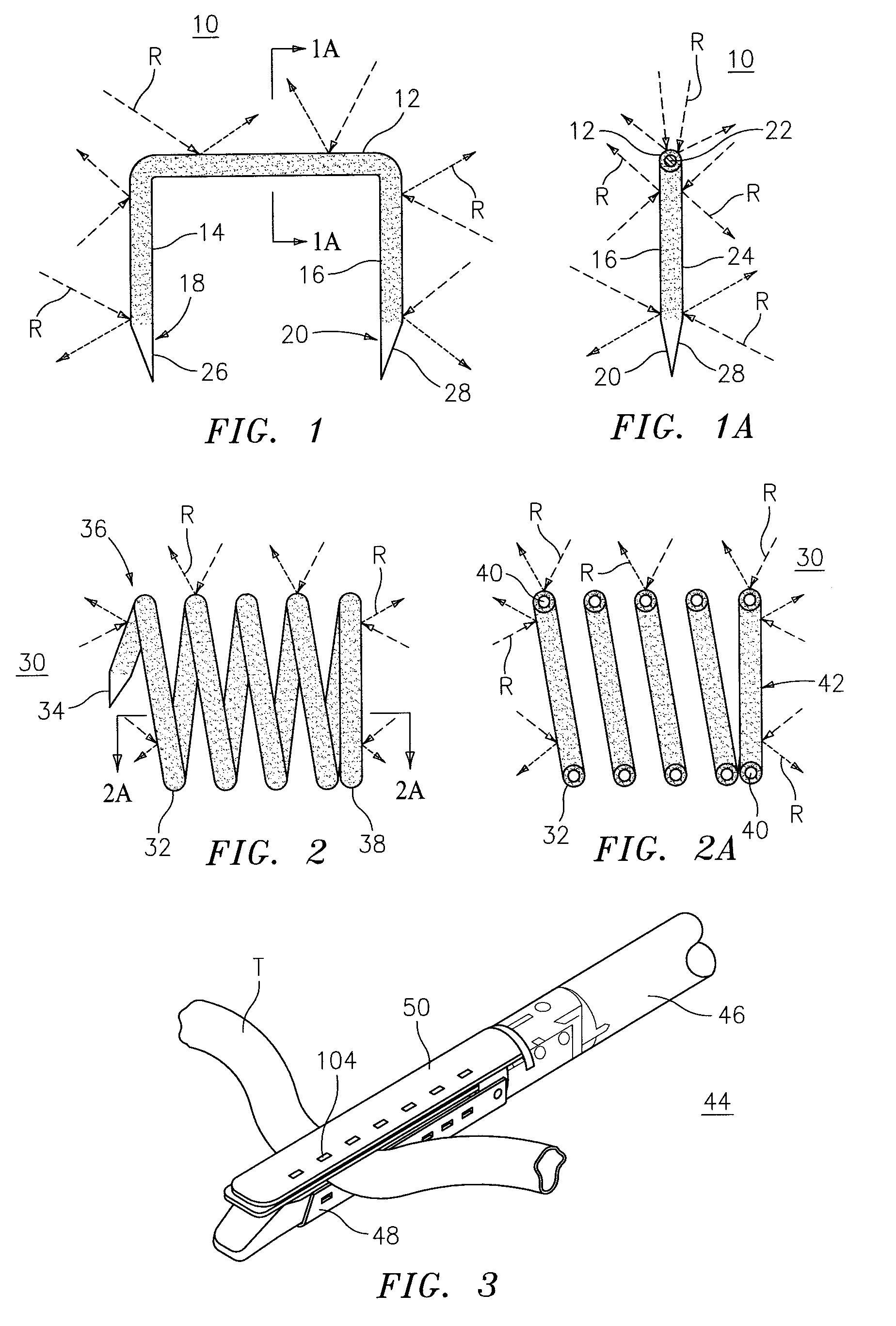

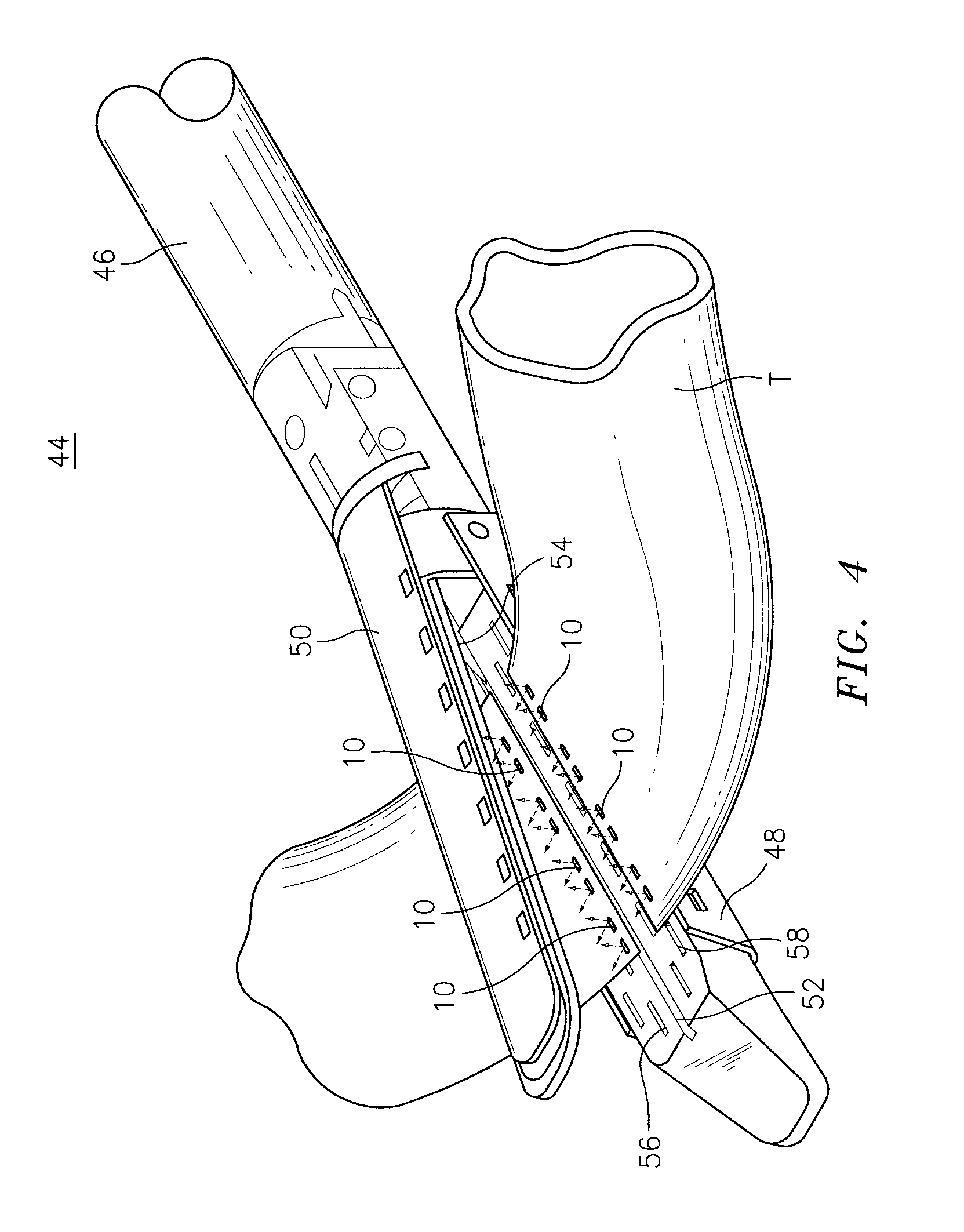

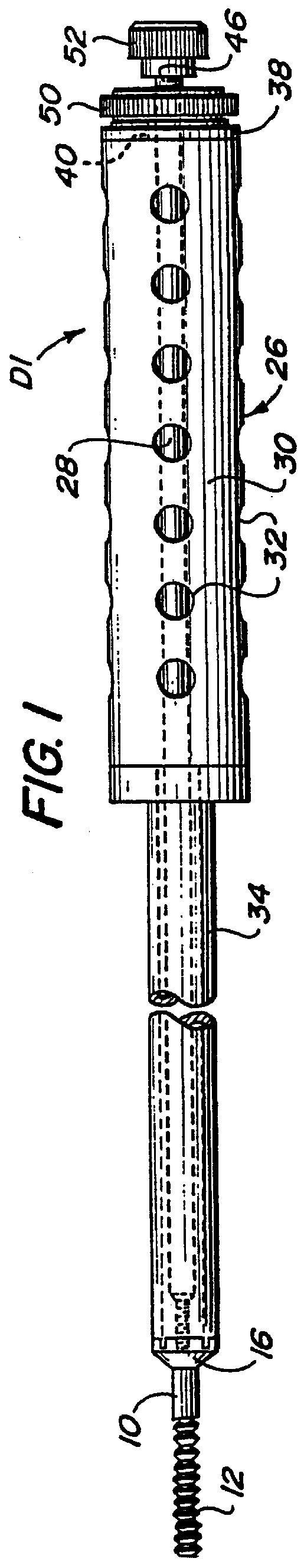

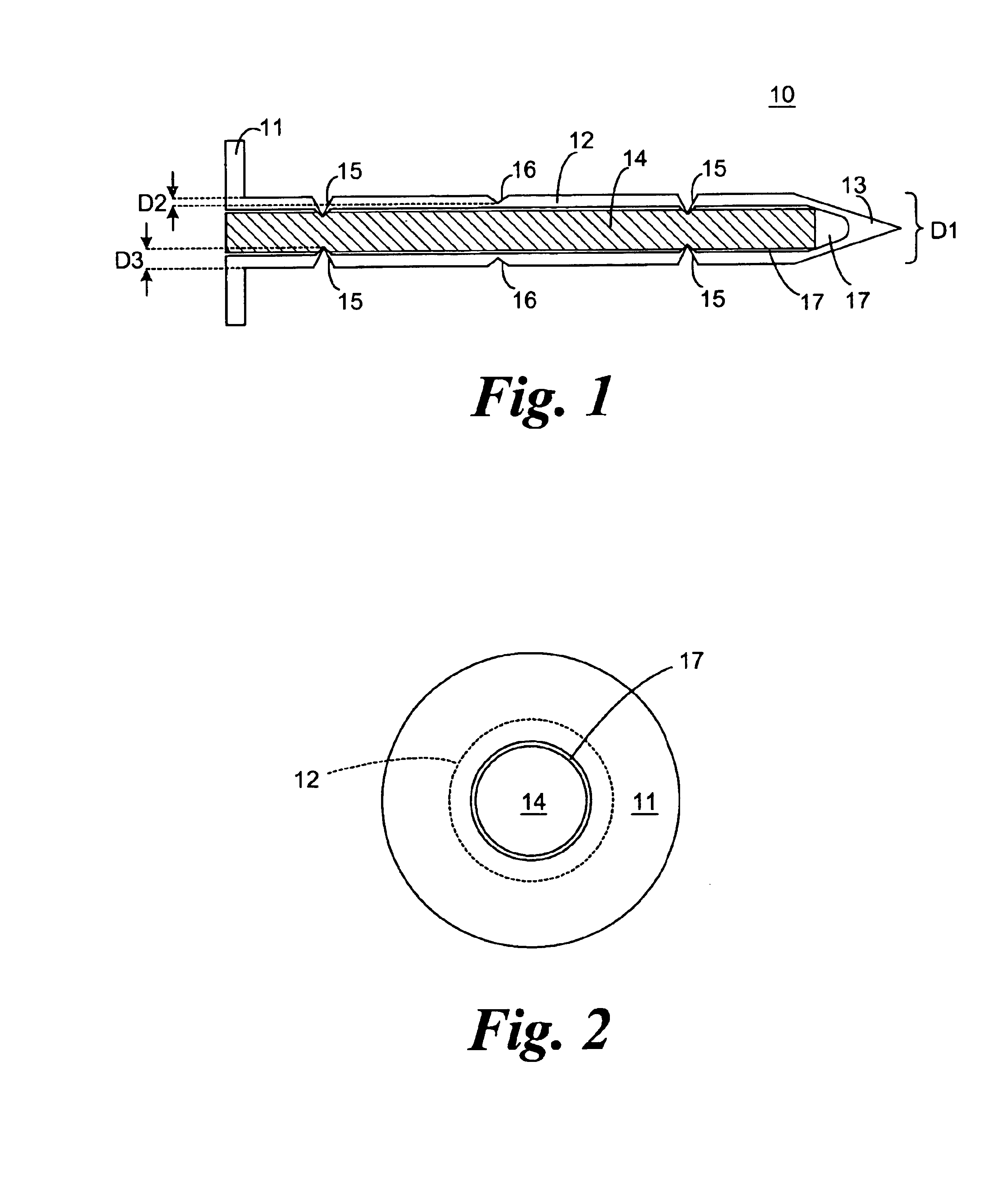

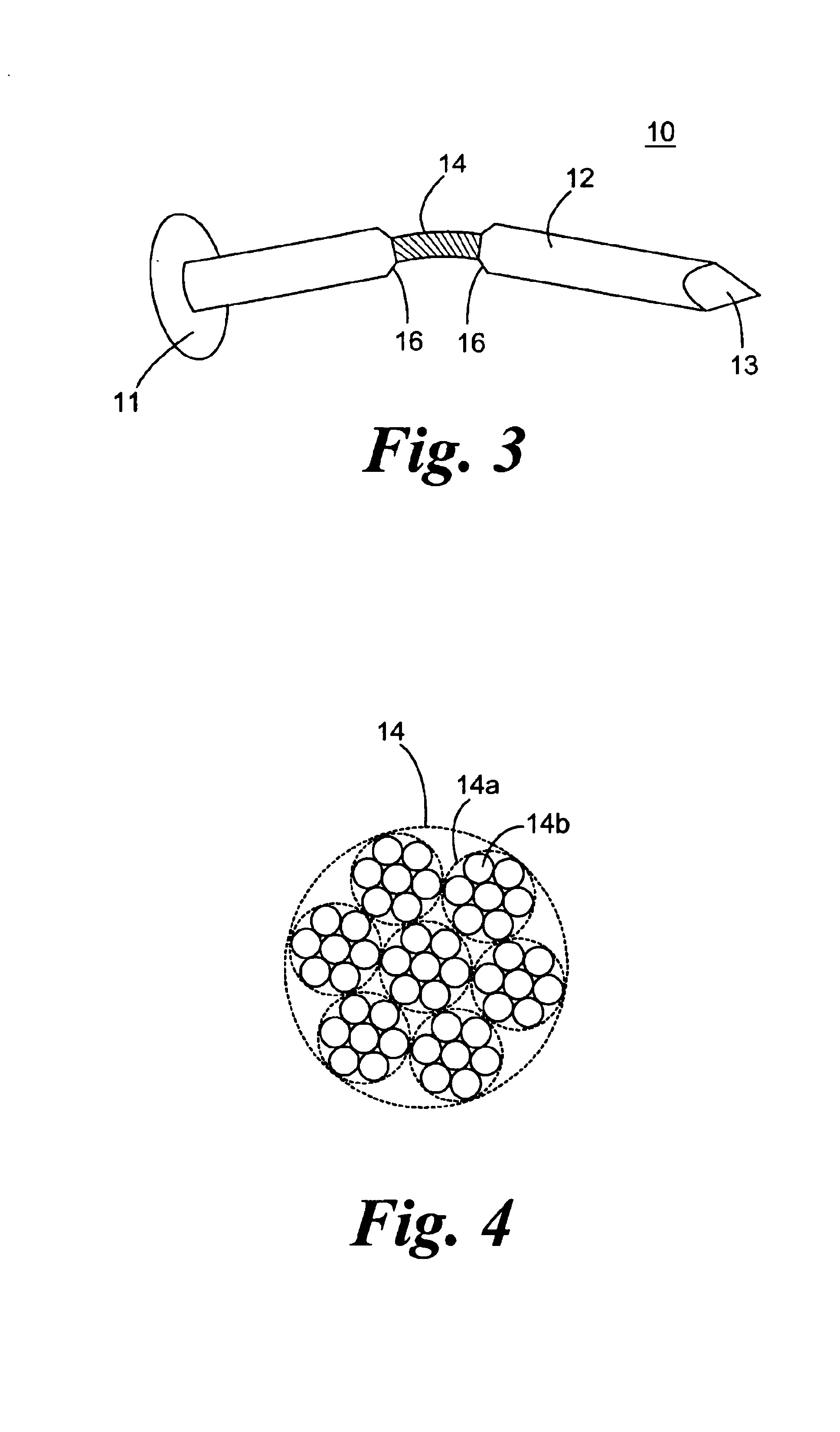

Coated surgical staples and an illuminated staple cartridge for a surgical stapling instrument

InactiveUS7954687B2Increase awarenessReduce reflectivitySuture equipmentsStapling toolsSurgical stapleEngineering

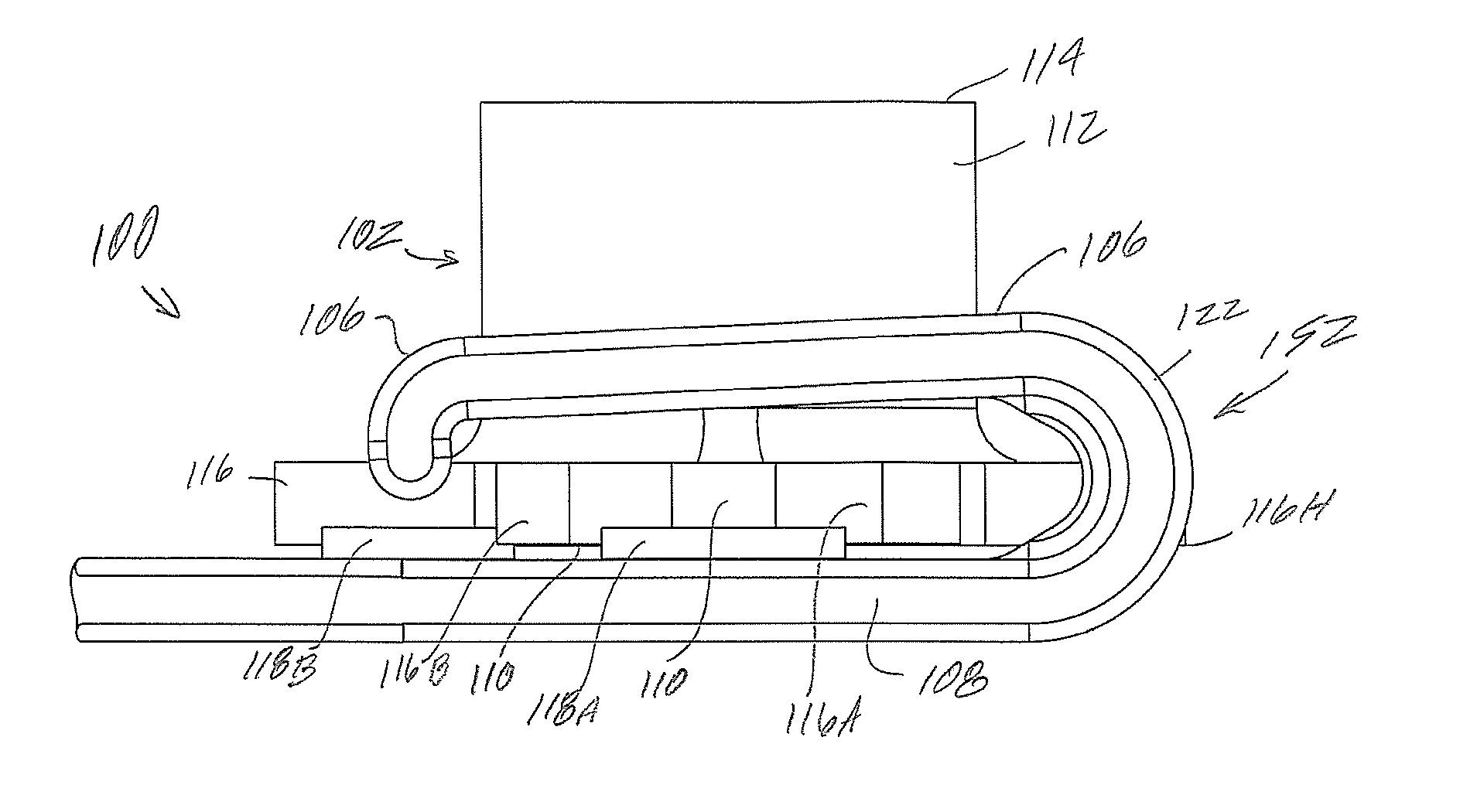

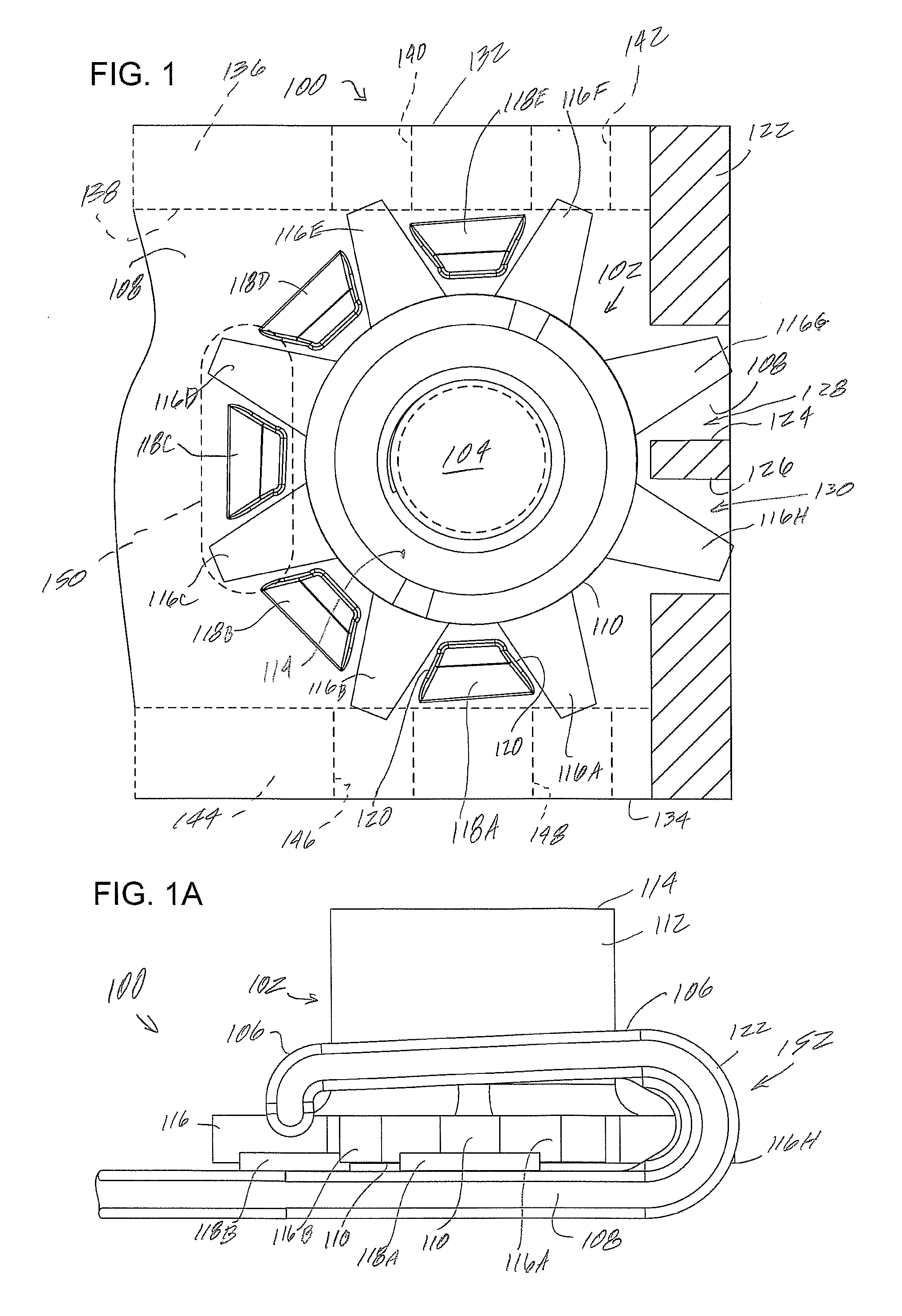

A coated surgical fastener is provided for an easy visualization within tissue. The coated surgical fastener includes a core and a relatively non-reflective coating applied about the core. There is also disclosed an illuminated staple cartridge for use with a surgical stapling device having a light source. The illuminated staple cartridge includes a transparent insert and a relatively nontransparent U-shaped outer channel at least partially surrounding the transparent insert. Windows formed in sides of the U-shaped outer channel allow defined amounts of light to project from the sides of the illuminated staple cartridge.

Owner:COVIDIEN LP

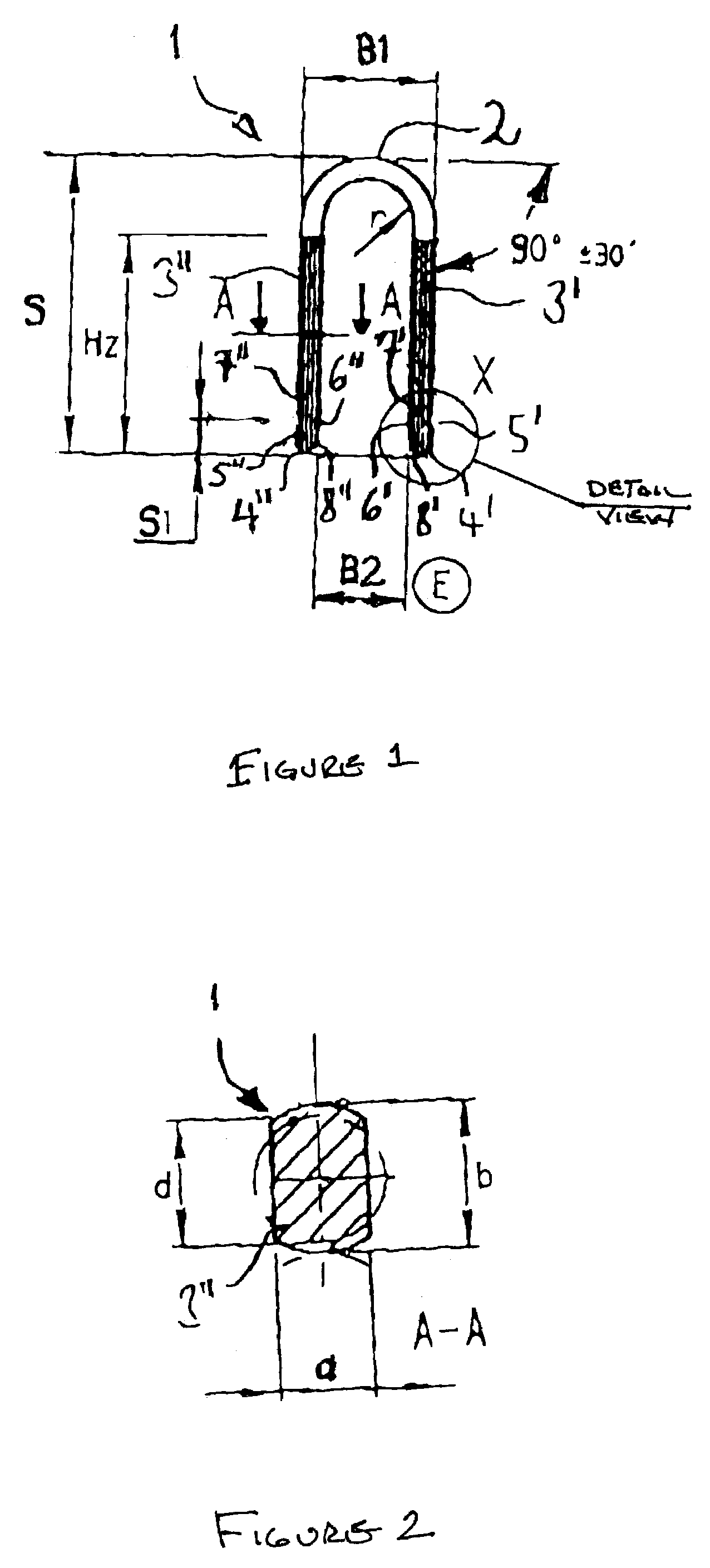

Fastening means and process for its manufacture

Owner:JOH FRIEDRICH BEHRENS AG

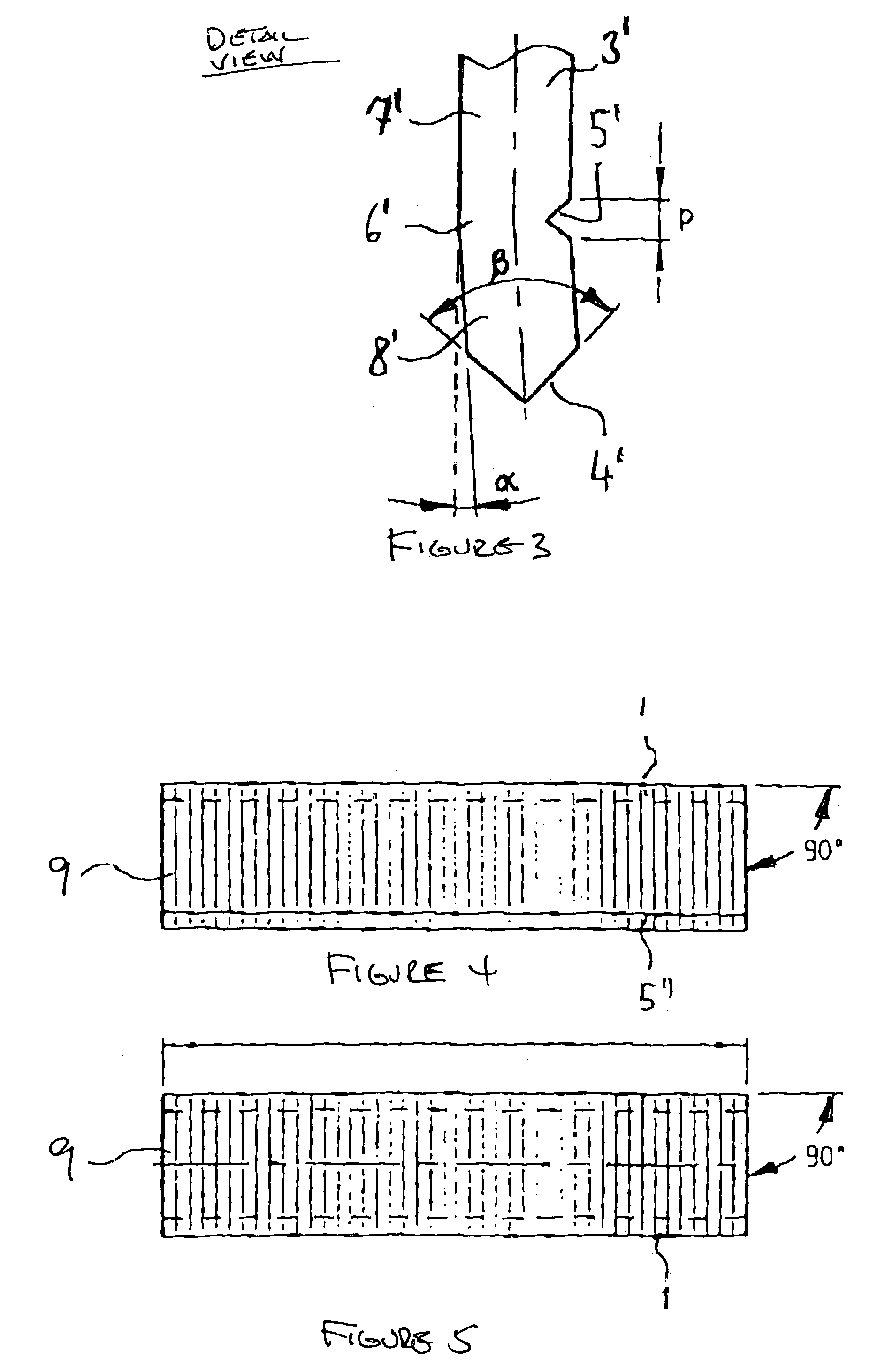

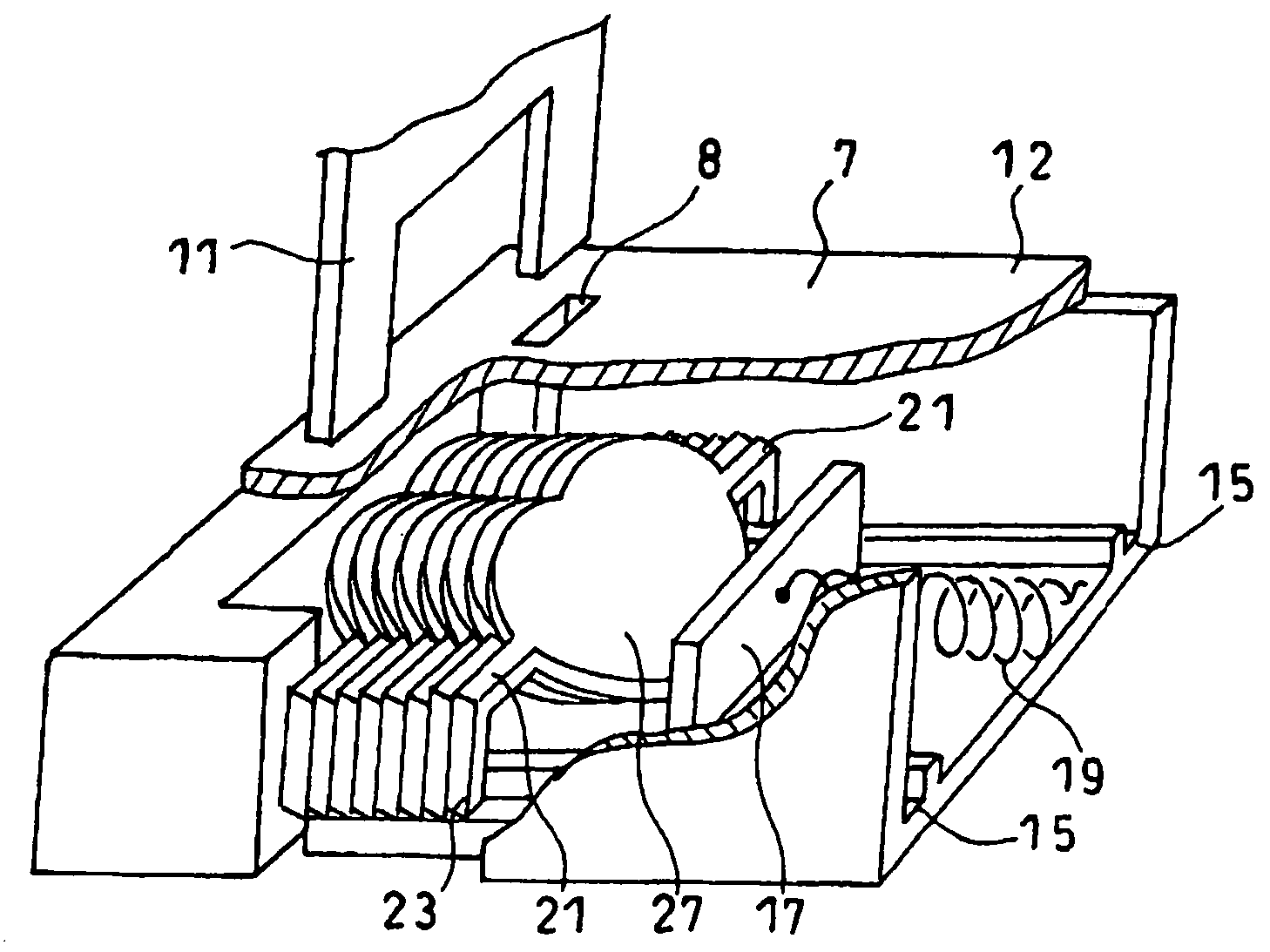

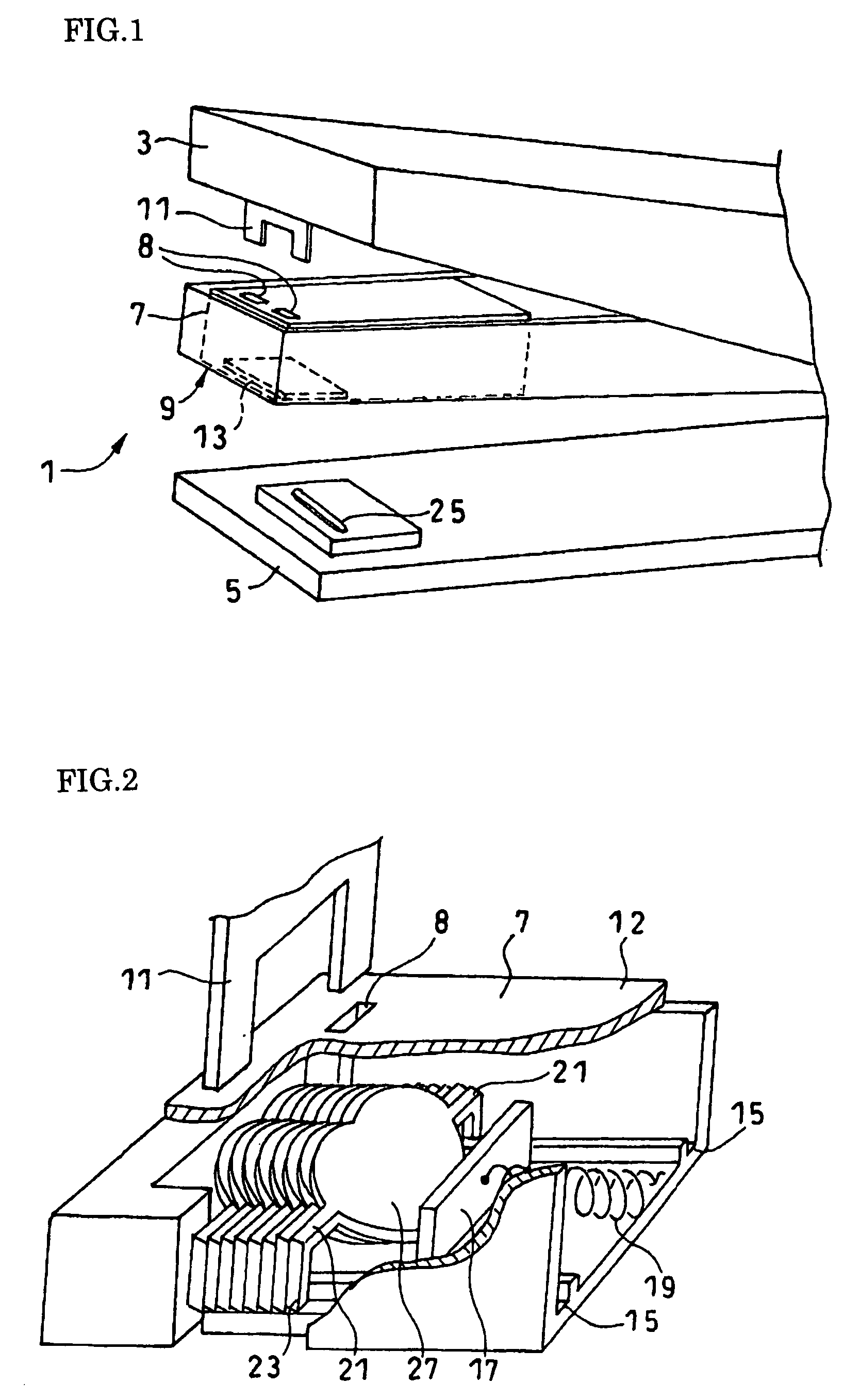

Cartridge for stapler and stapler

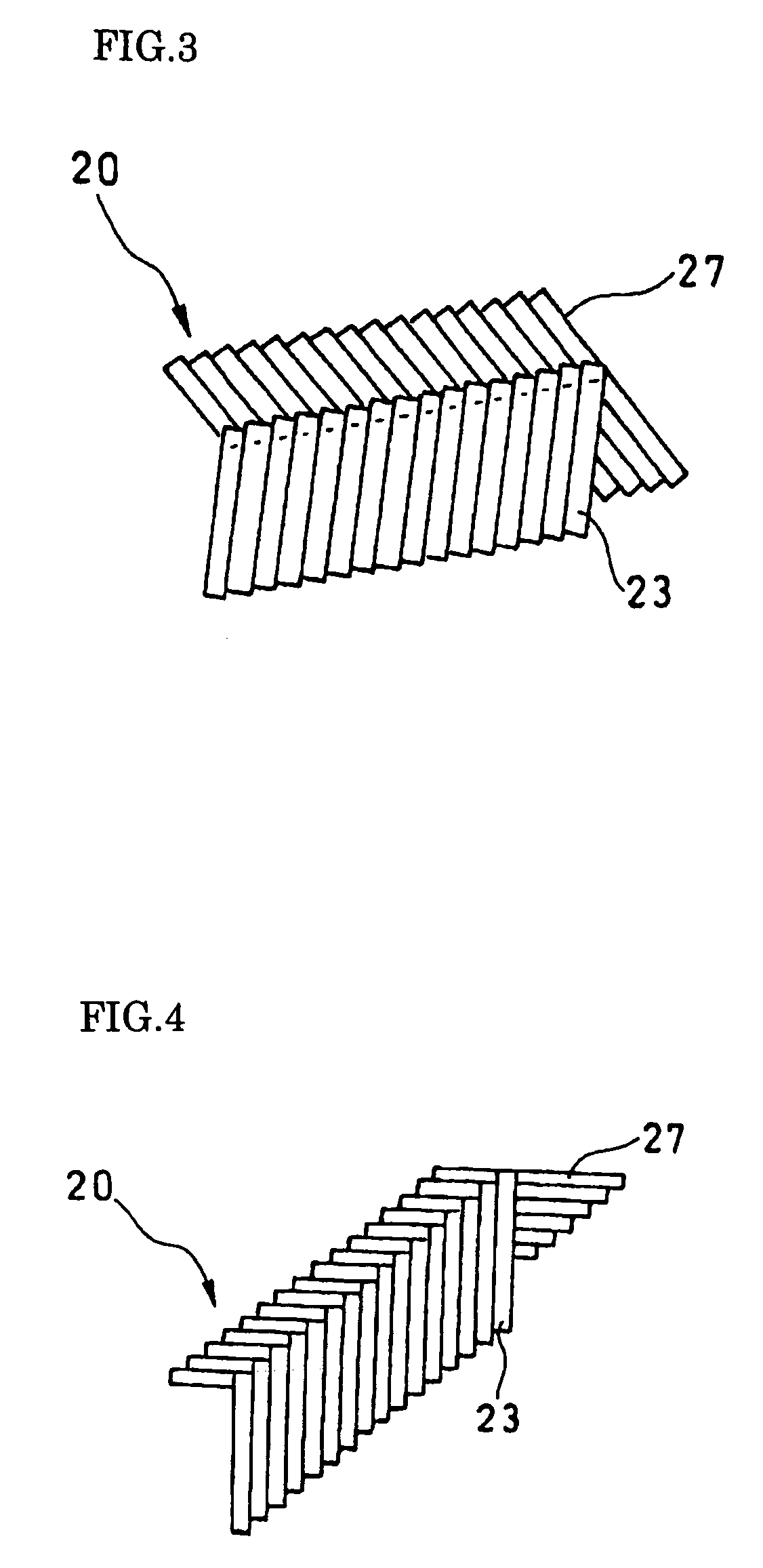

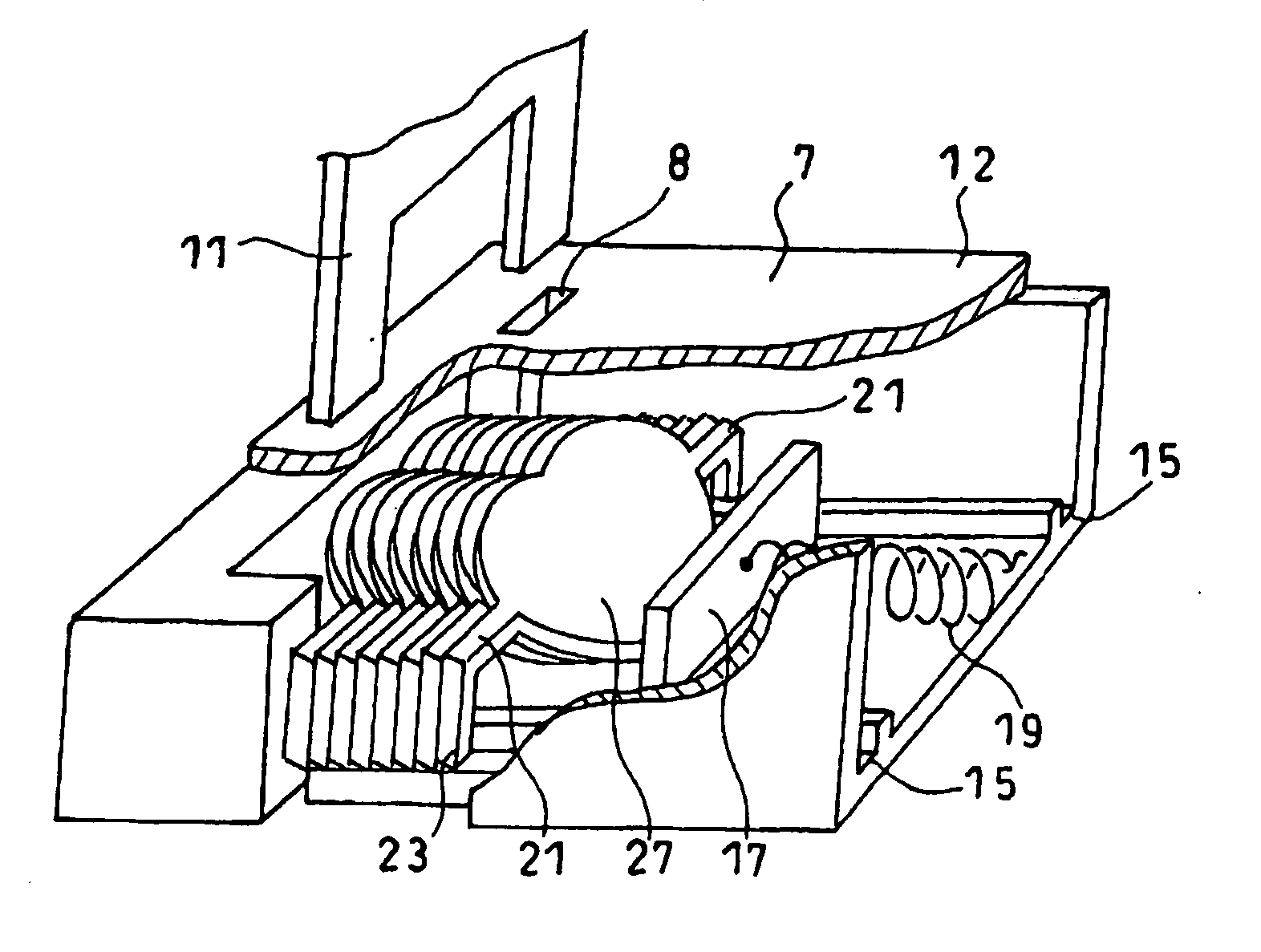

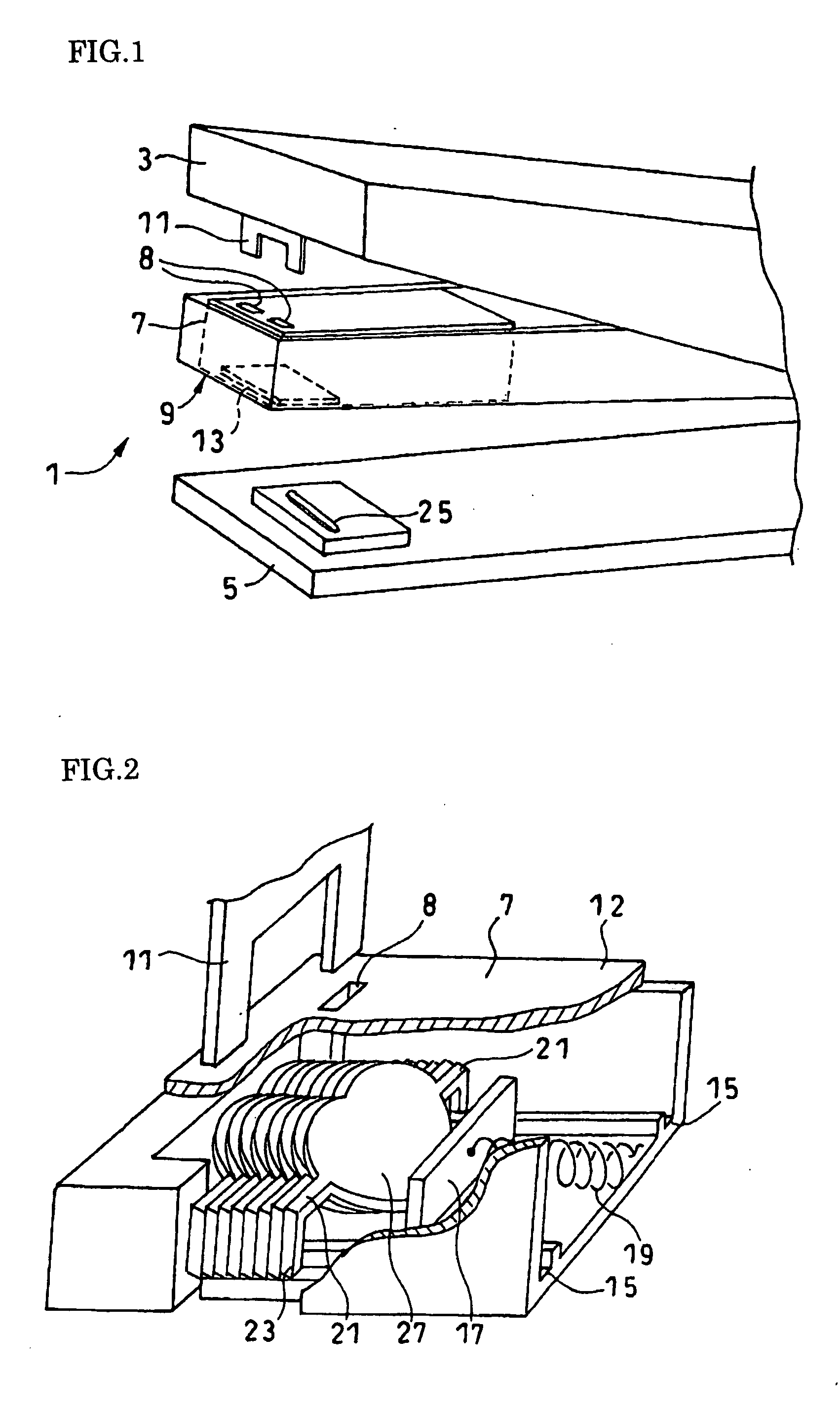

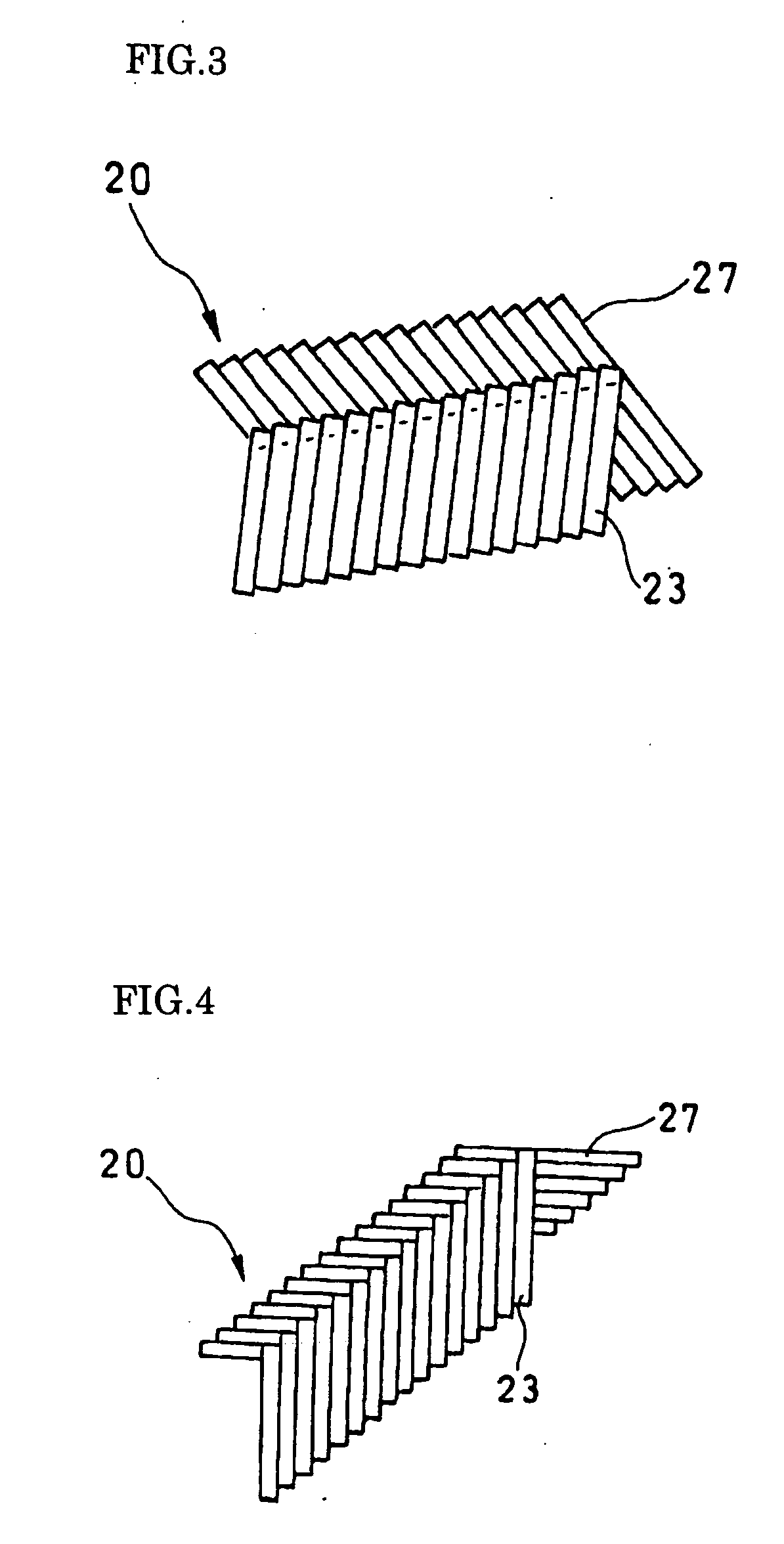

A stapler of the present invention includes a retaining part having a staple pusher, a storing section that stores a staple, and a receiving base that bends leg parts after piercing the staple pushed out by the staple pusher through a sheet material to bind the sheet material with the staple. The staple includes left and right shoulder parts against which the staple pusher abuts, leg parts extending substantially perpendicularly from the shoulder parts and a pattern part having an arbitrary shape and provided between the left and right shoulder parts. The pattern part is inclined against the leg parts and the storing section is provided, on one side thereof, with a take-out opening of the staple that is large enough to allow the pattern part to pass.

Owner:KAMEYAMA TOSHIYUKI

Cartridge for stapler and stapler

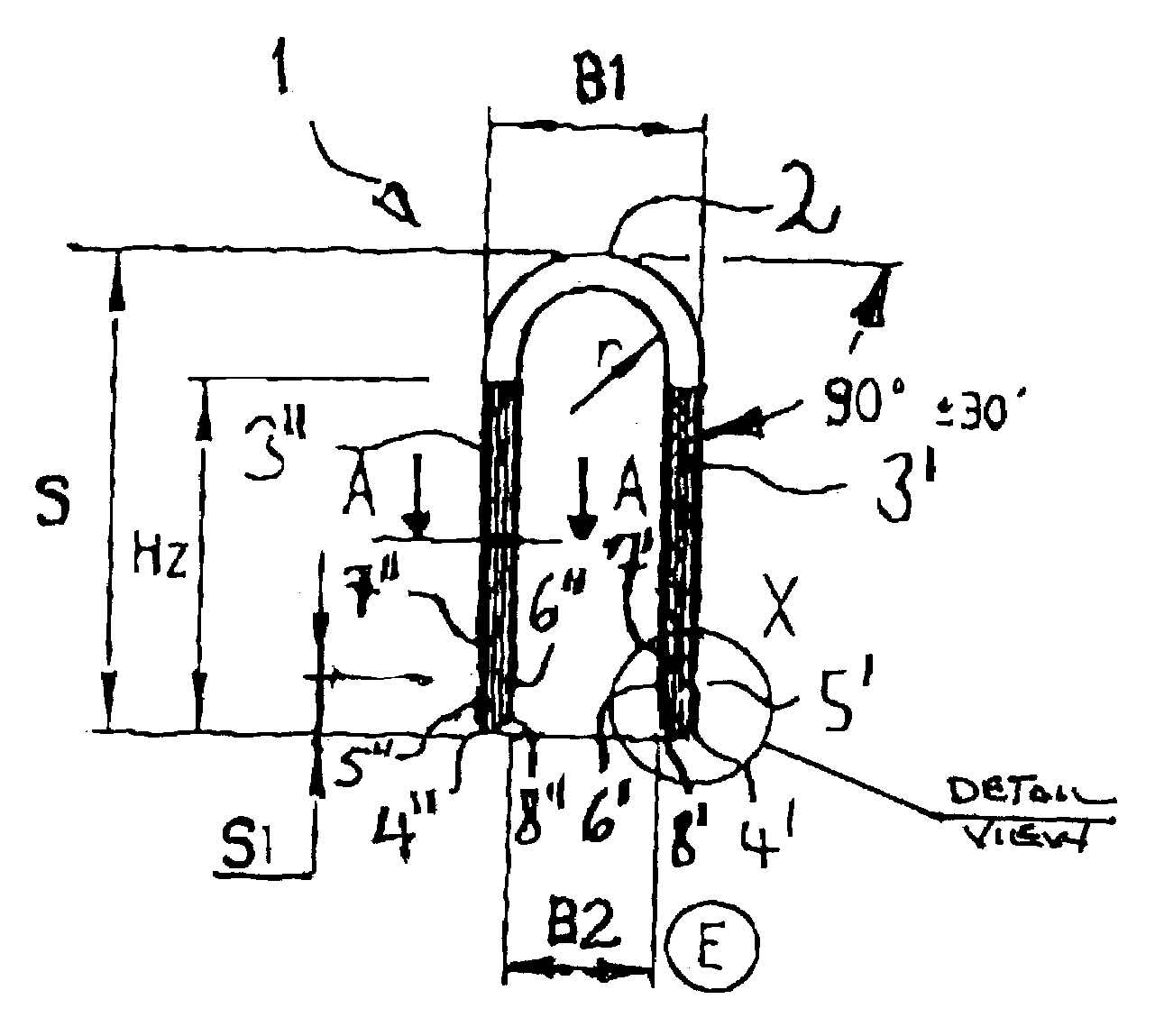

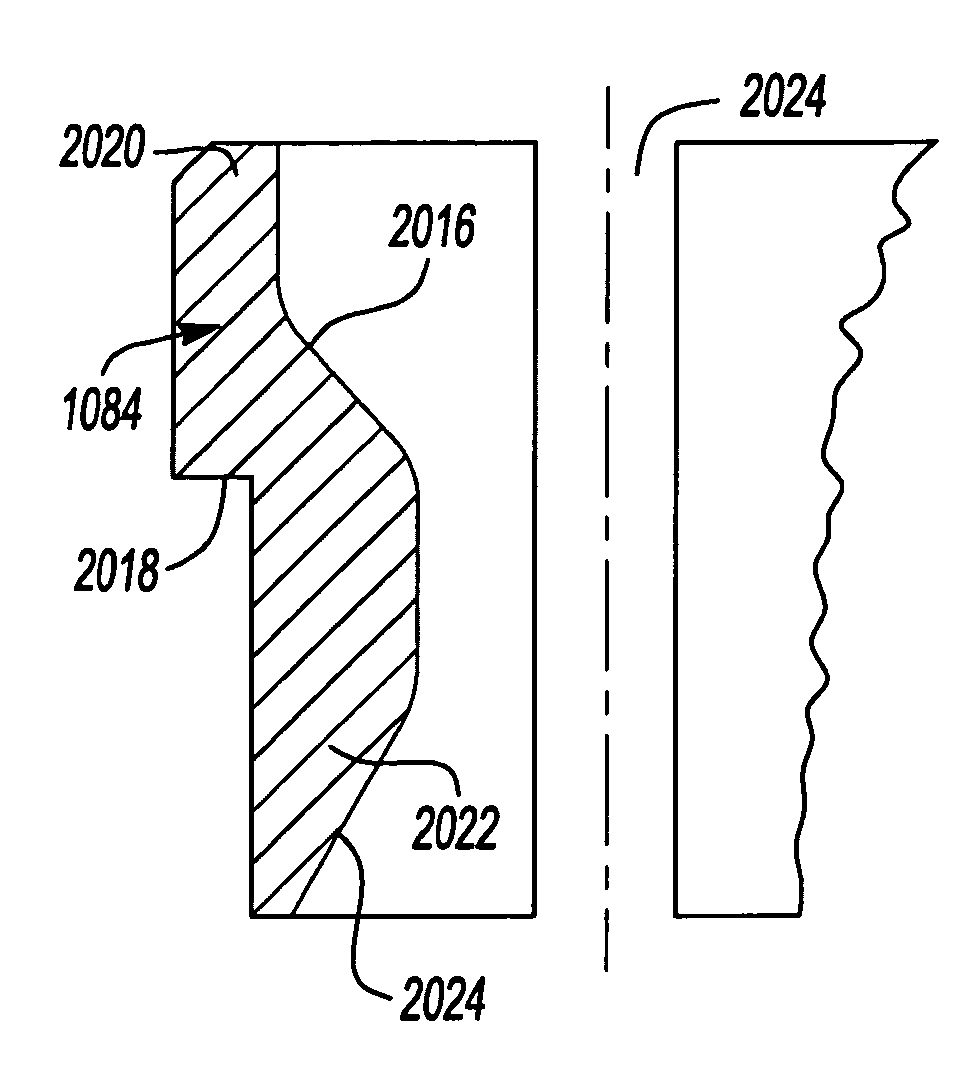

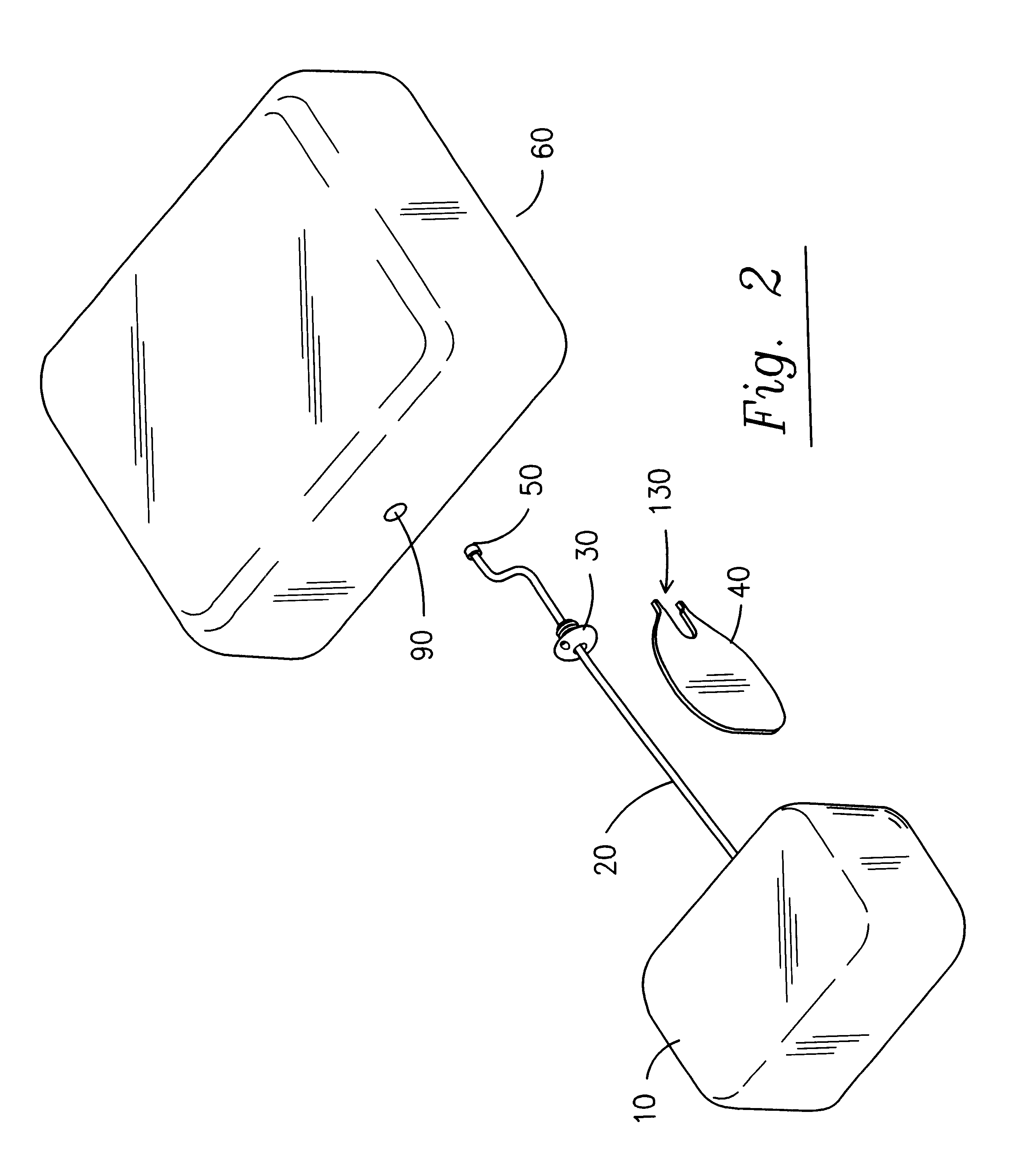

A stapler (1) of the present invention includes a retaining part (3) having a staple pusher (11), a storing section (9) that stores a staple (20), and a receiving base (5) that hat bents leg parts (23) after piercing the staple (2) pushed out by the staple pusher (11) through a sheet material to bind the sheet material (60) with the staple (20). The staple (20) includes left and right shoulder parts (21) against which the staple pusher (11) abuts, leg parts (23) extending substantially perpendicularly from the shoulder parts (21) and a pattern part (27) having an arbitrary shape and provided between the left and right shoulder parts (21). The pattern part (27) is inclined against the leg parts (23) and the storing section (9) is provided, on one side thereof, with a take-out opening (13) of the staple (20) that is large enough to allow the pattern part (27) to pass.

Owner:KAMEYAMA TOSHIYUKI

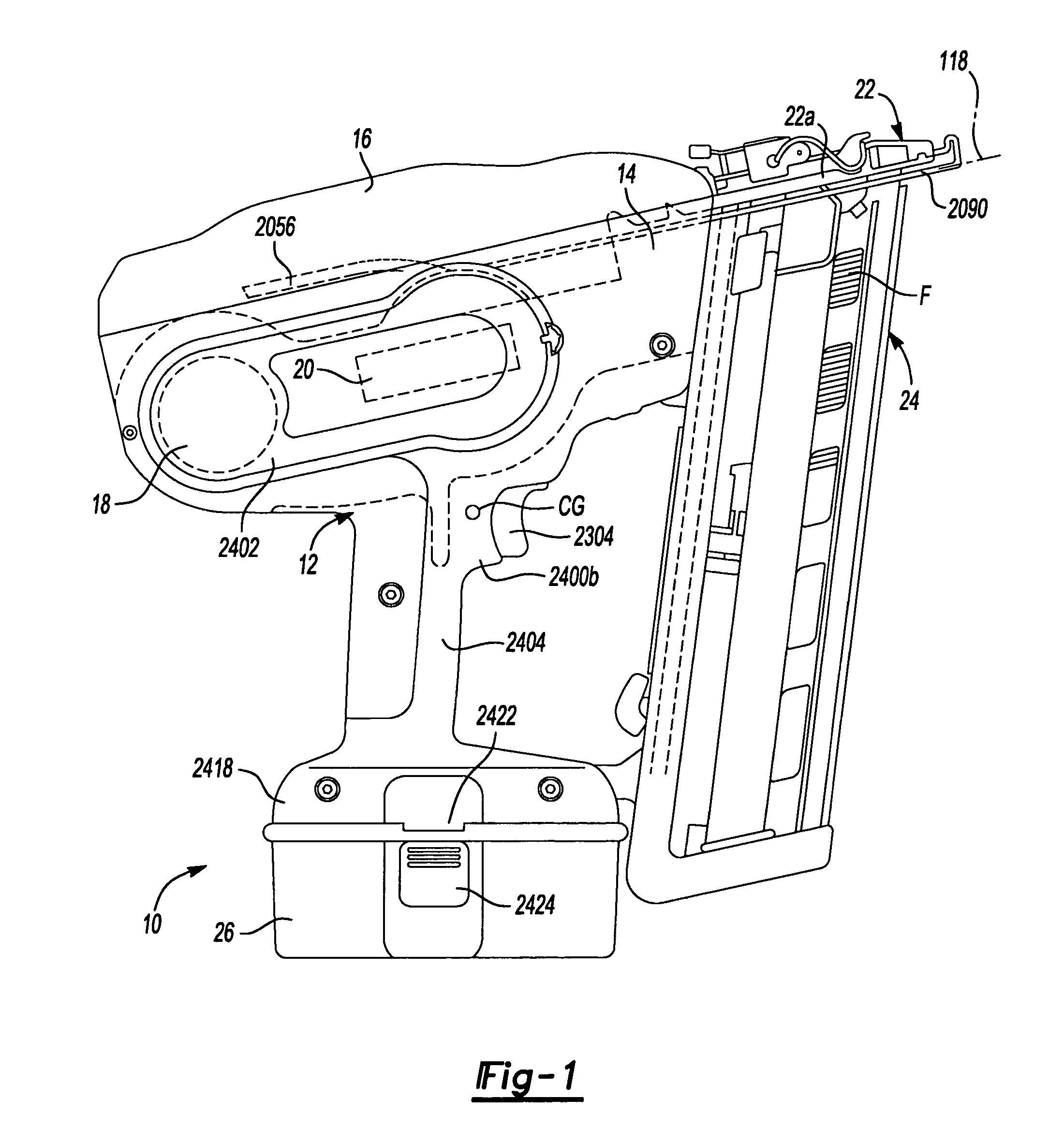

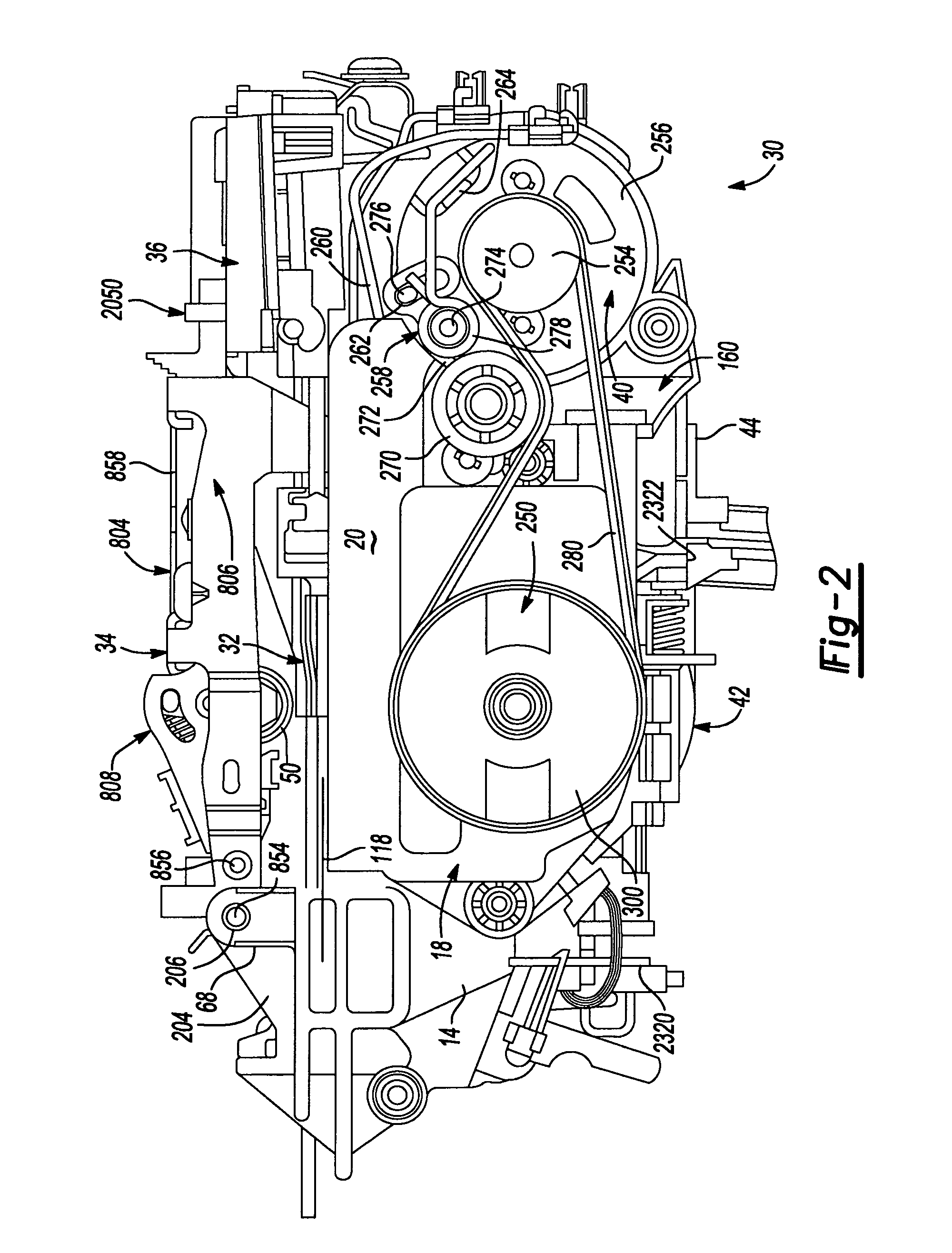

Lock-out for activation arm mechanism in a power tool

A power tool, such as a nailer, having a driver, a flywheel and an activation arm for selectively driving the driver into contact with the flywheel to transfer energy therebetween to cause the driver to translate. The power tool includes a bar that may be moved so as to resist movement of the activation arm in a direction that would bring the driver into contact with the flywheel. A method for operating a power tool is also provided.

Owner:BLACK & DECKER INC

Coated Surgical Staples and an Illuminated Staple Cartridge for a Surgical Stapling Instrument

ActiveUS20090114701A1Increase awarenessReduce reflectivitySuture equipmentsStapling toolsSurgical stapleEngineering

A coated surgical fastener is provided for an easy visualization within tissue. The coated surgical fastener includes a core and a relatively non-reflective coating applied about the core. There is also disclosed an illuminated staple cartridge for use with a surgical stapling device having a light source. The illuminated staple cartridge includes a transparent insert and a relatively nontransparent U-shaped outer channel at least partially surrounding the transparent insert. Windows formed in sides of the U-shaped outer channel allow defined amounts of light to project from the sides of the illuminated staple cartridge.

Owner:TYCO HEALTHCARE GRP LP

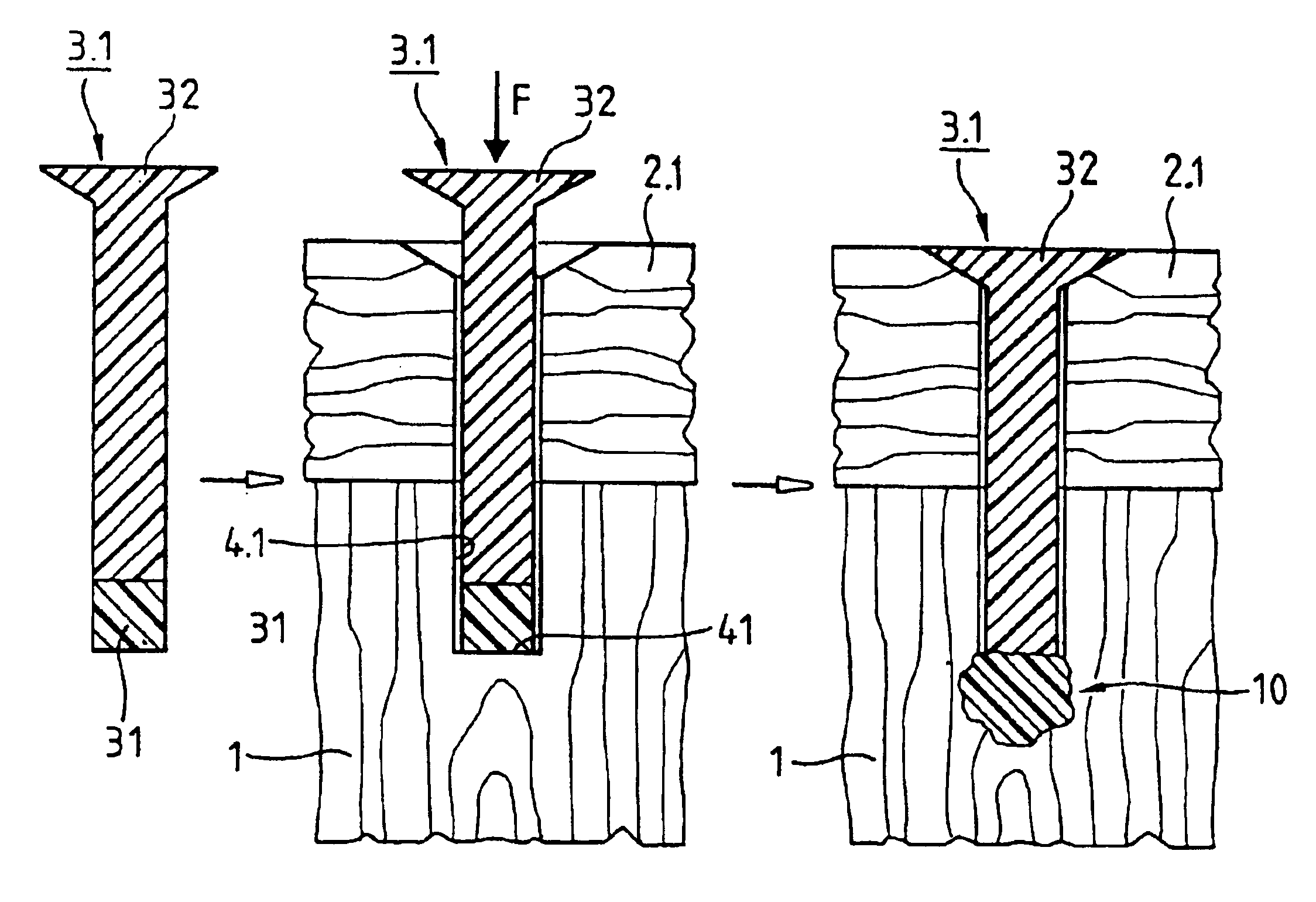

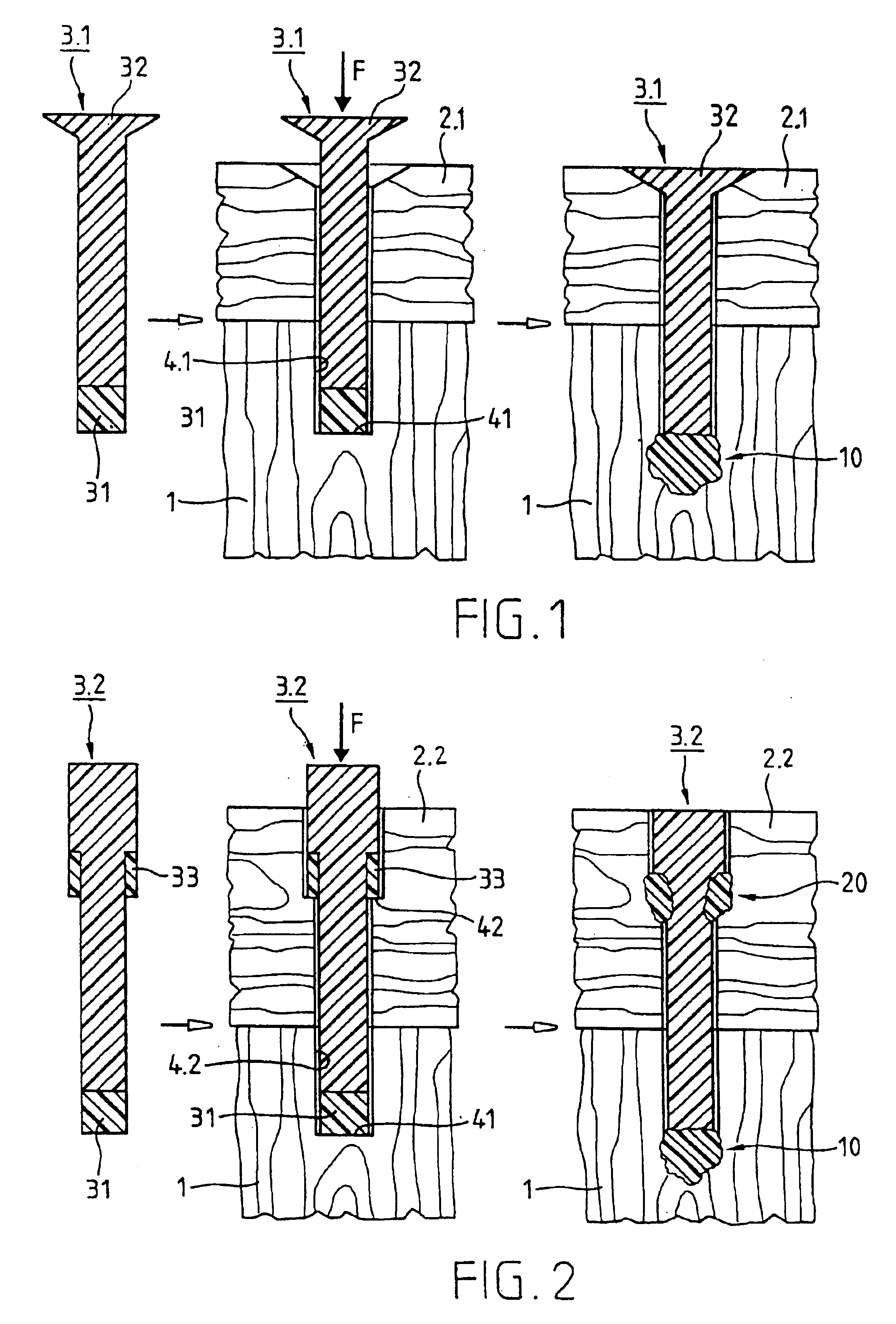

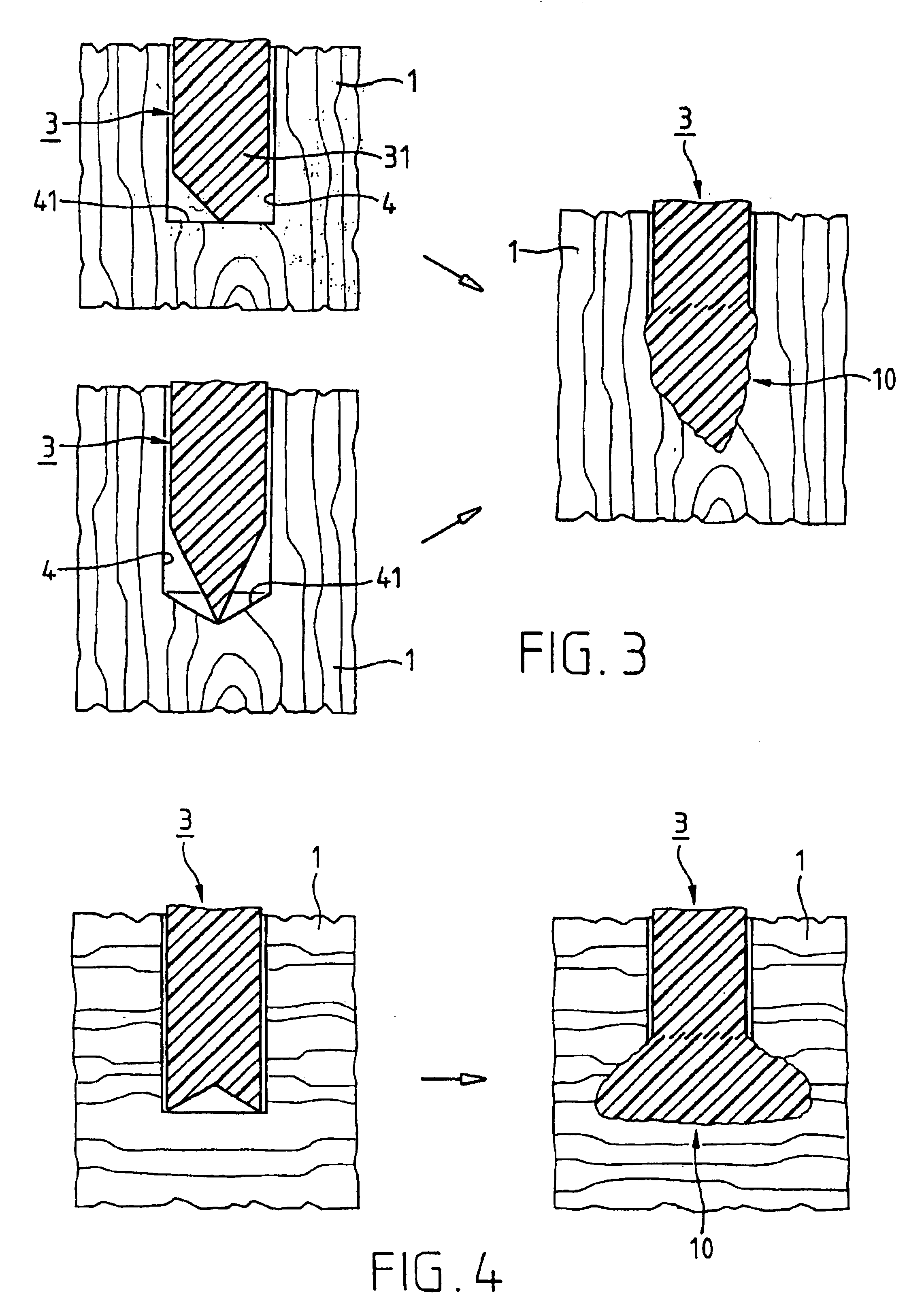

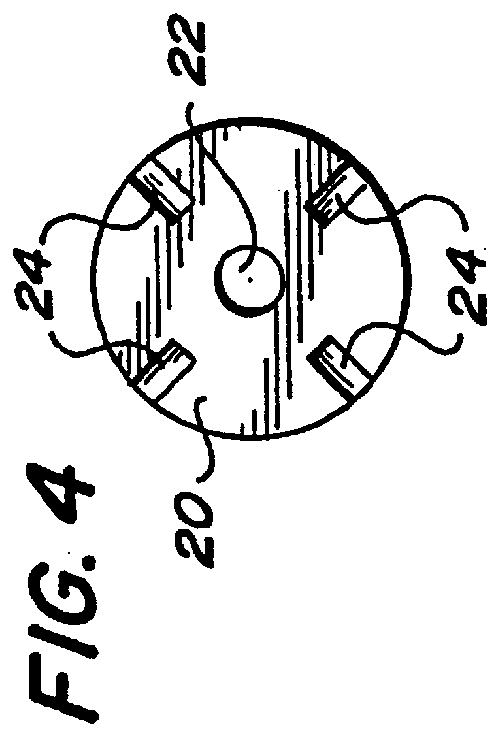

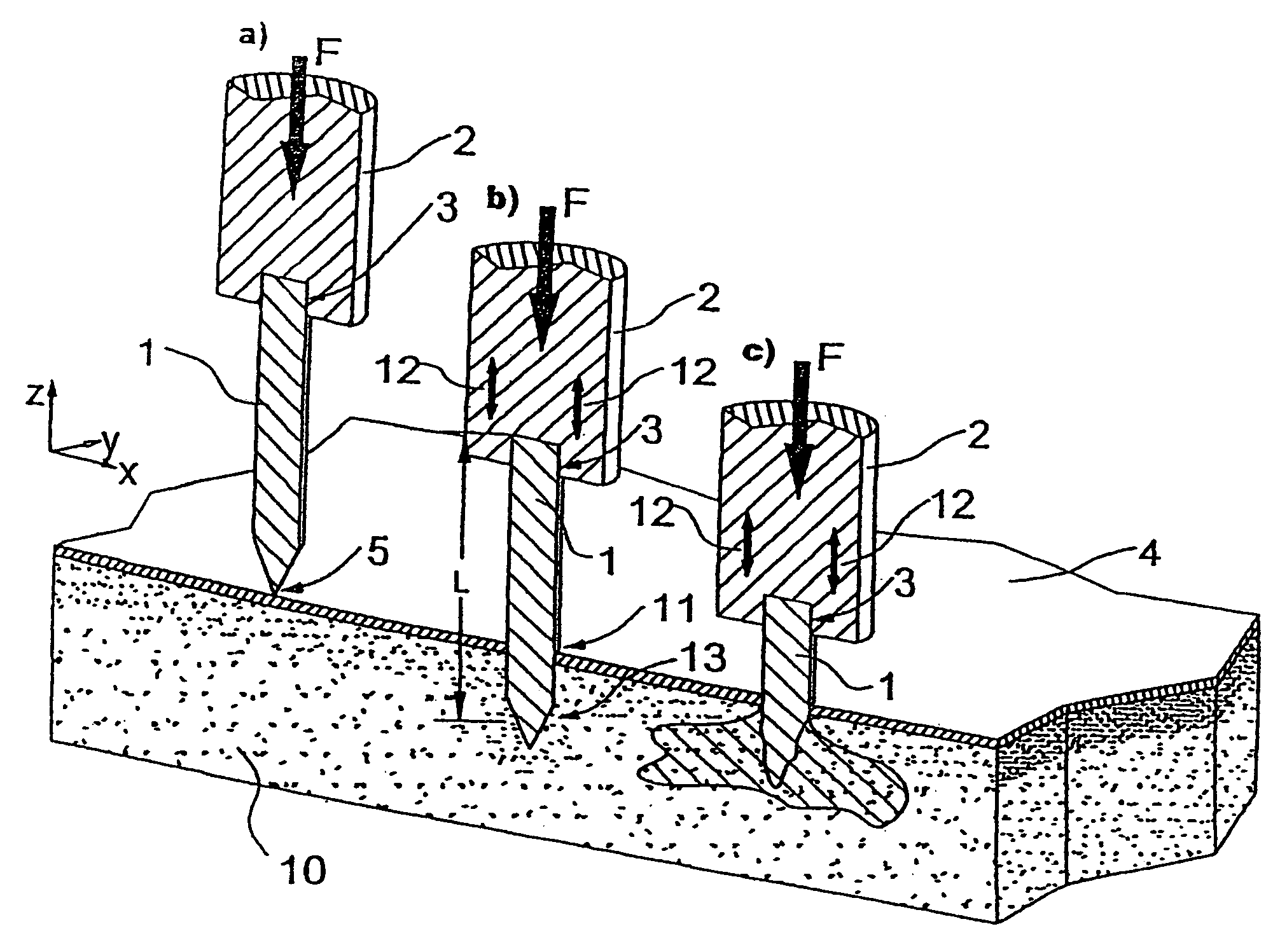

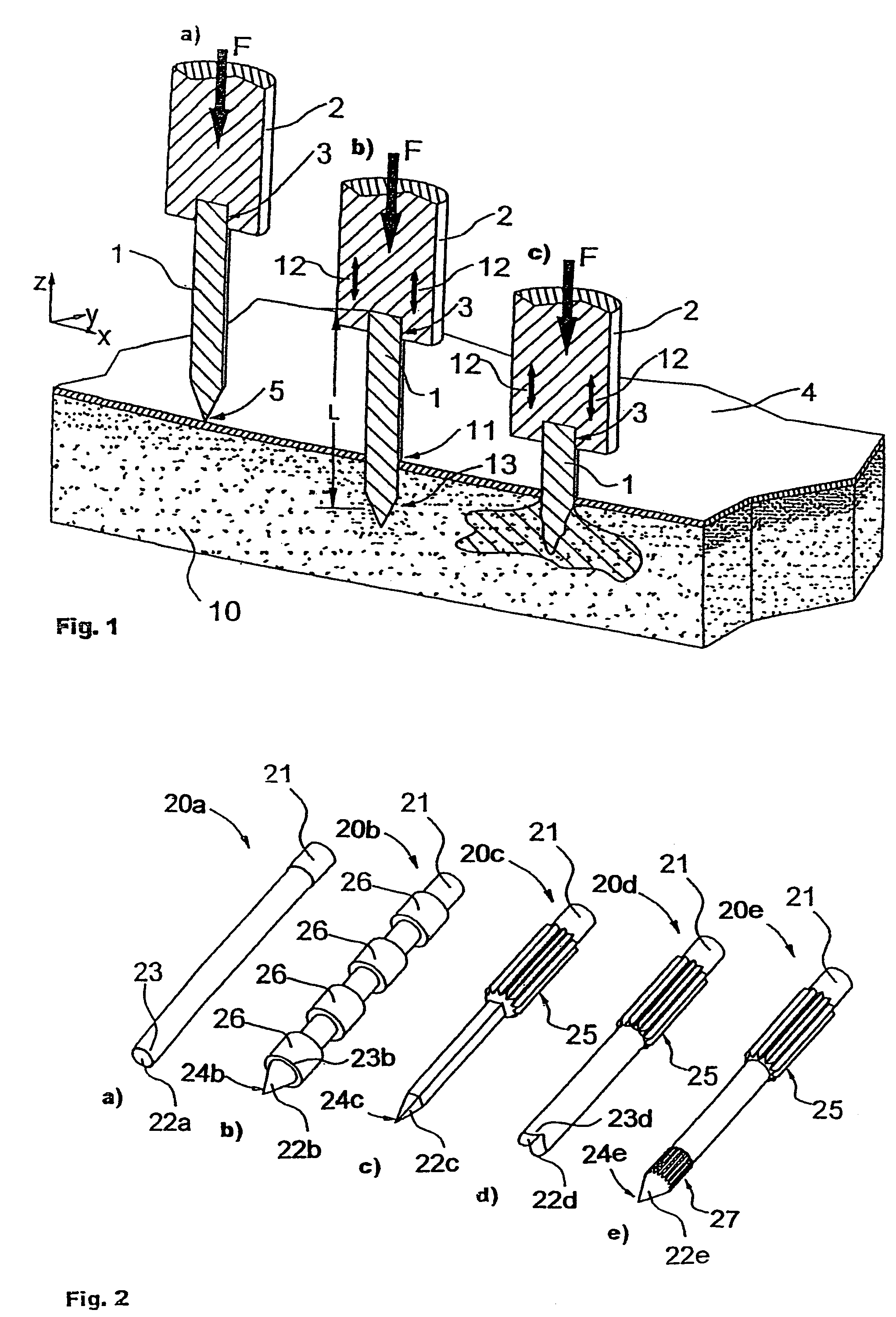

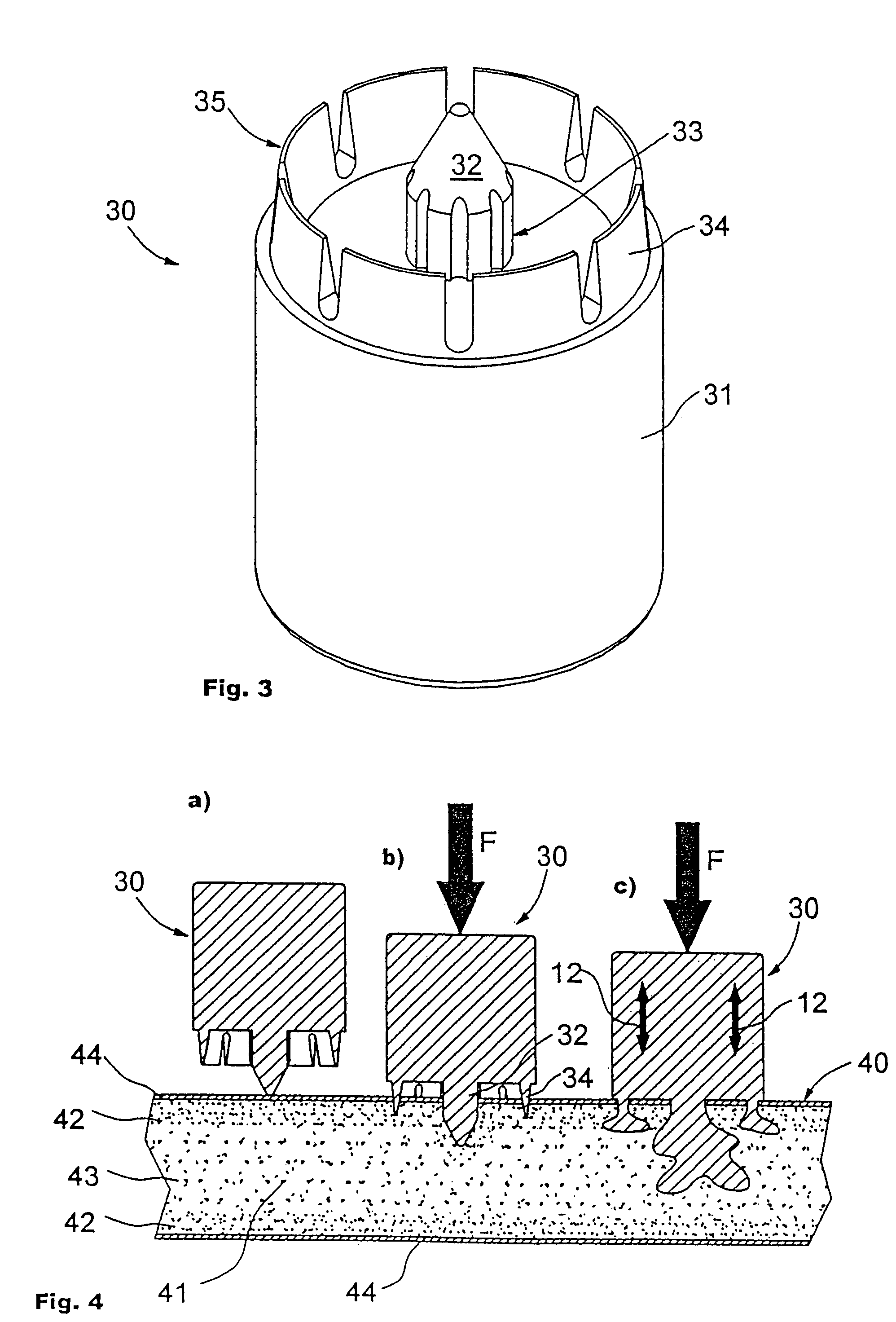

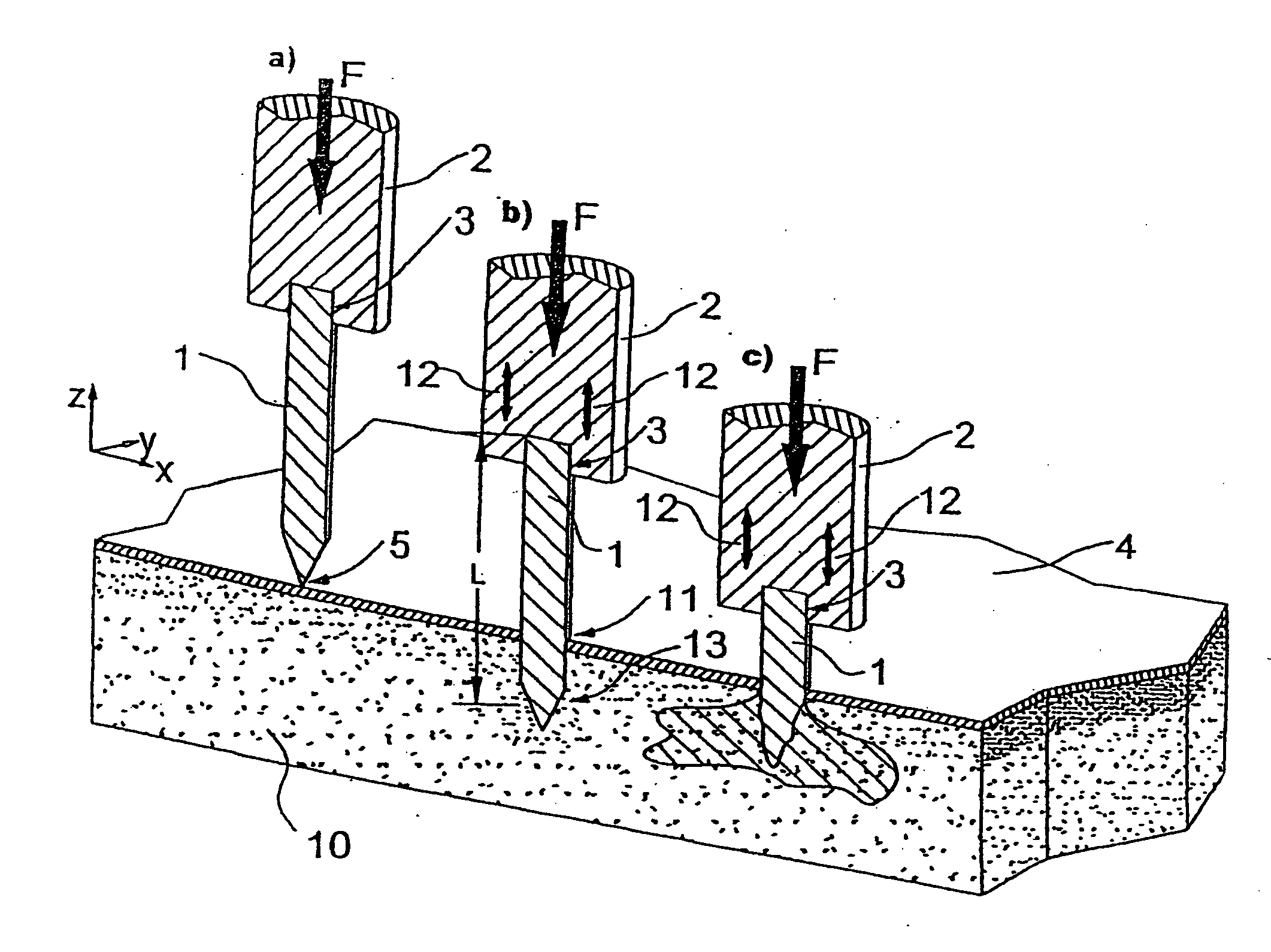

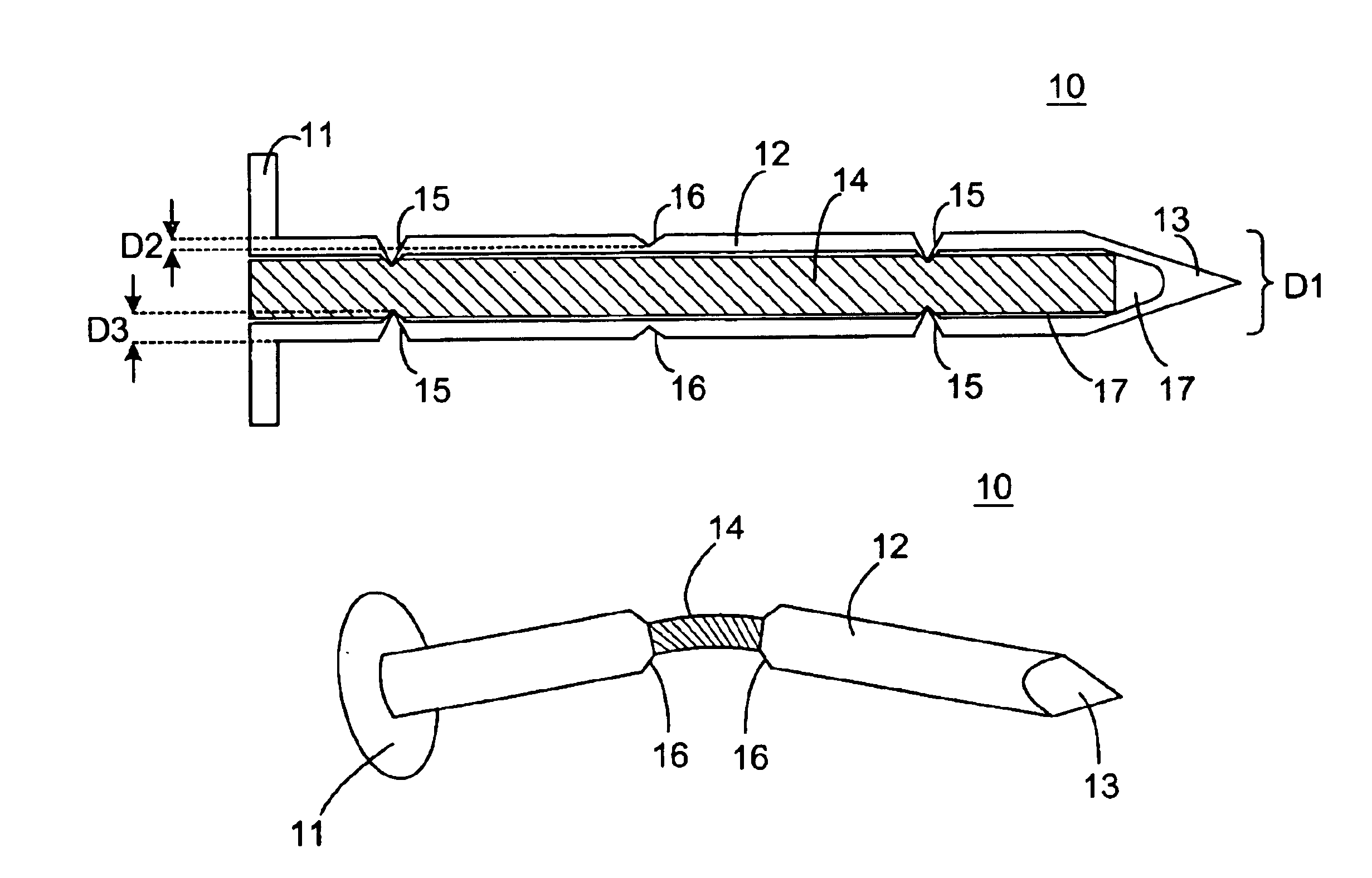

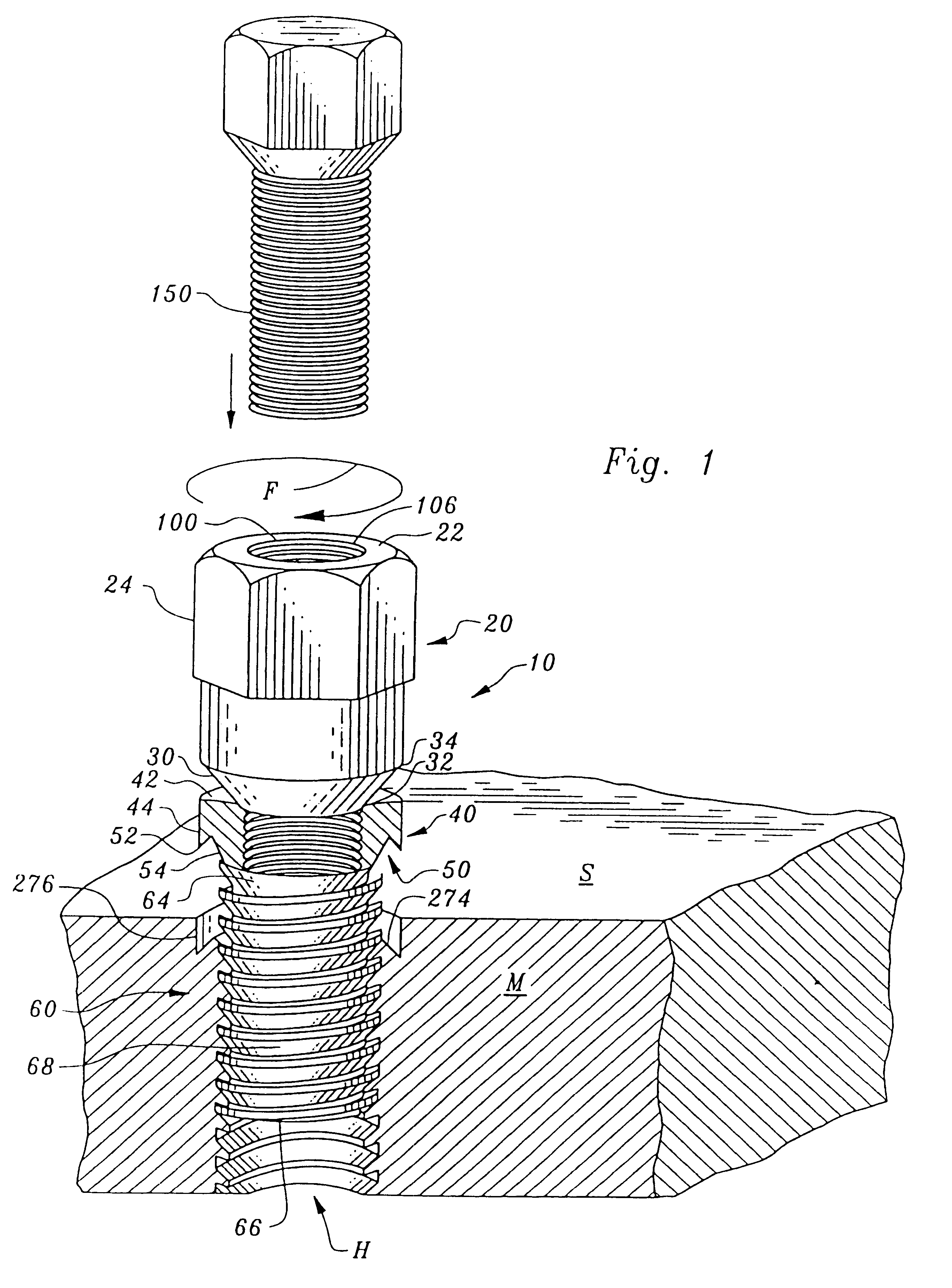

Process for anchoring connecting elements in a material with pores or cavities and connecting elements therefor

InactiveUS6913666B1Easy to reachReduce disadvantagesRivetsCylinder headsEngineeringUltrasonic vibration

A joining pin (3.2) with which two parts (1 and 2) made from a porous material, particularly wood or a wood-like material, are to be joined together, is anchored in the porous material at predetermined anchoring points (31, 33). For this purpose, a bore (4.2) with a closed inner end (41) is made in the parts (1 and 2). The shape of this bore (4.2) is so matched to the joining pin (3.2) that it can be introduced substantially without force expenditure into the bore and is positionable in a first position. At least one predetermined anchoring point (31, 33) between the joining pin (3.2) and the wall of the bore (4.2) is formed when pressure is built up by pressing the joining pin (3.2) with a pressing force (F) more deeply into the bore to a second position. Energy is supplied in a planned manner to the joining pin (3.2) so that at the predetermined anchoring points (31, 33) the thermoplastic material of the joining pin (3.2) is plasticized. The locally plasticized plastic material is pressed by the local pressure into the porous material of the parts and forms local, macroscopic anchors (10, 20). The joining pin (3.2) is, e.g., made entirely from a thermoplastic material and the energy for plasticizing is supplied thereto by ultrasonic vibration.

Owner:WOODWELDING

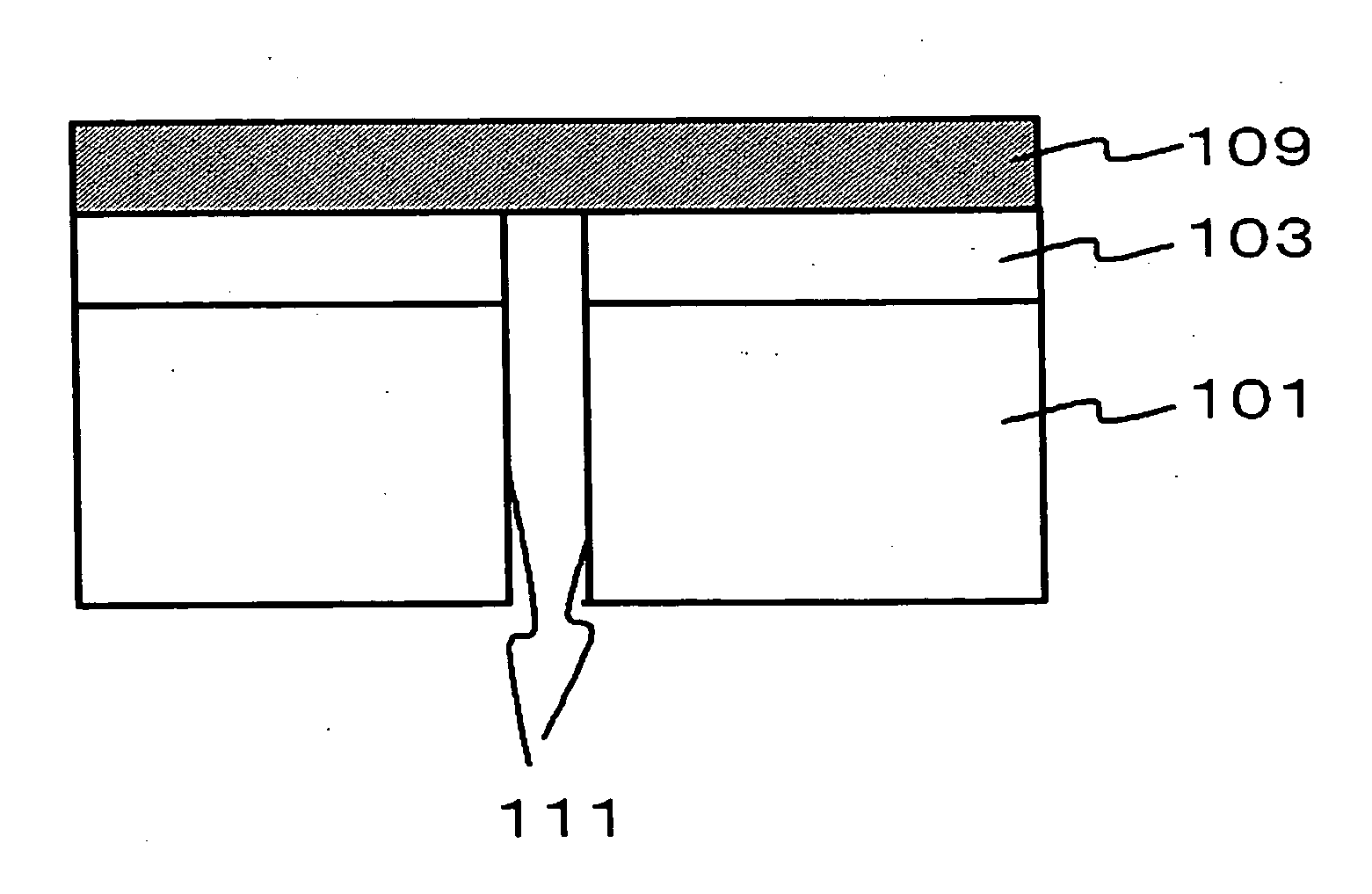

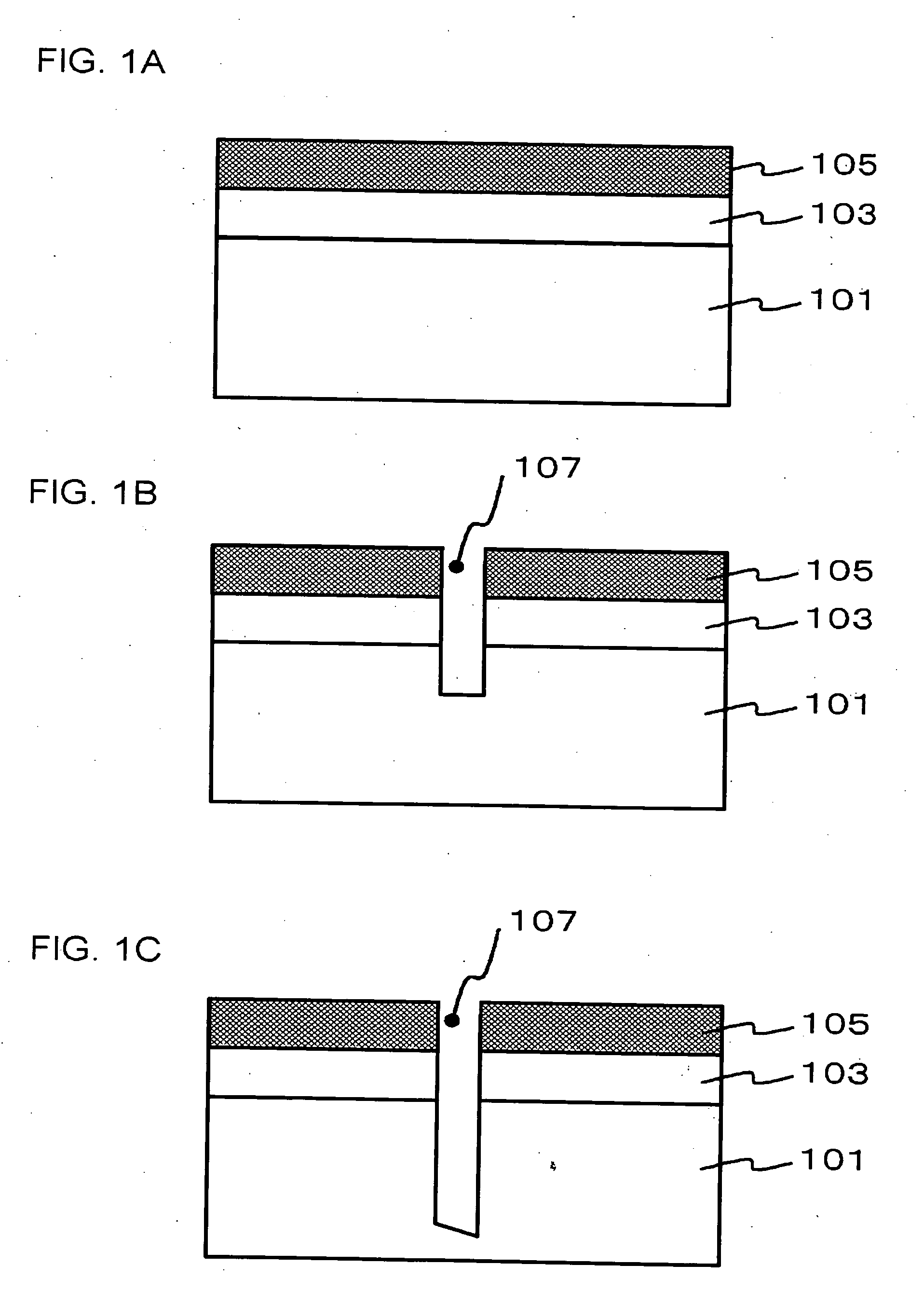

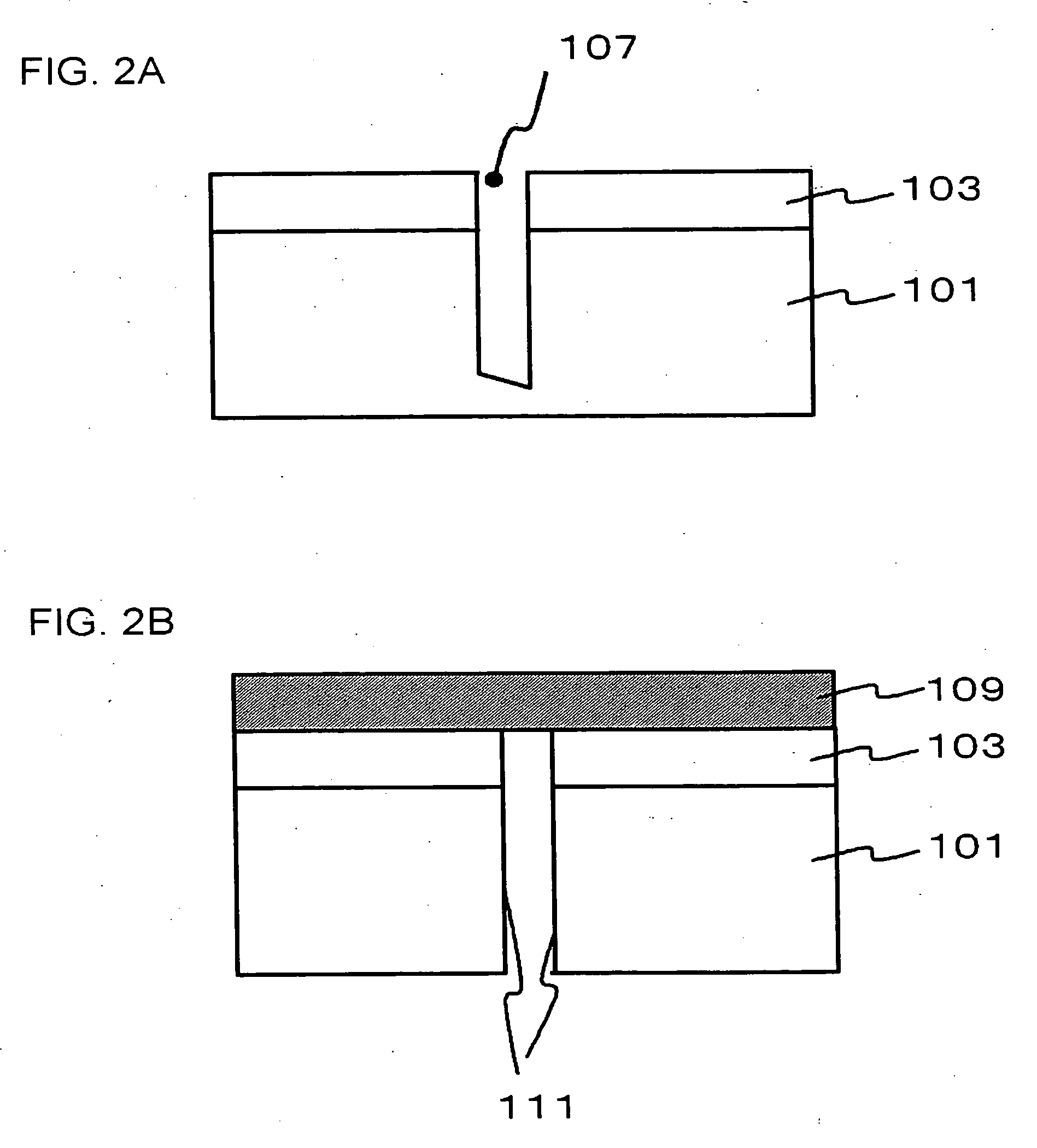

Method for manufacturing semiconductor device

InactiveUS20060205182A1Reduce widthRate of the processing for providing the trenched portion can beSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDevice form

A method of dicing a semiconductor wafer includes providing an interconnect layer providing a protective film on the interconnect layer on the side of a device-forming surface of a silicon wafer, irradiating the protective film with a laser beam to provide a trenched portion that extends through the interconnect layer from the protective film and reaches to an inside of the silicon wafer, removing a portion of the silicon wafer selectively in a depth direction from a bottom of the trenched portion, after irradiating with the laser beam to provide the trenched portion and dividing the silicon wafer along the portion where the trenched portion is provided into respective pieces of the silicon wafer, after removing a portion of the silicon wafer 101 selectively in the depth direction.

Owner:NEC ELECTRONICS CORP

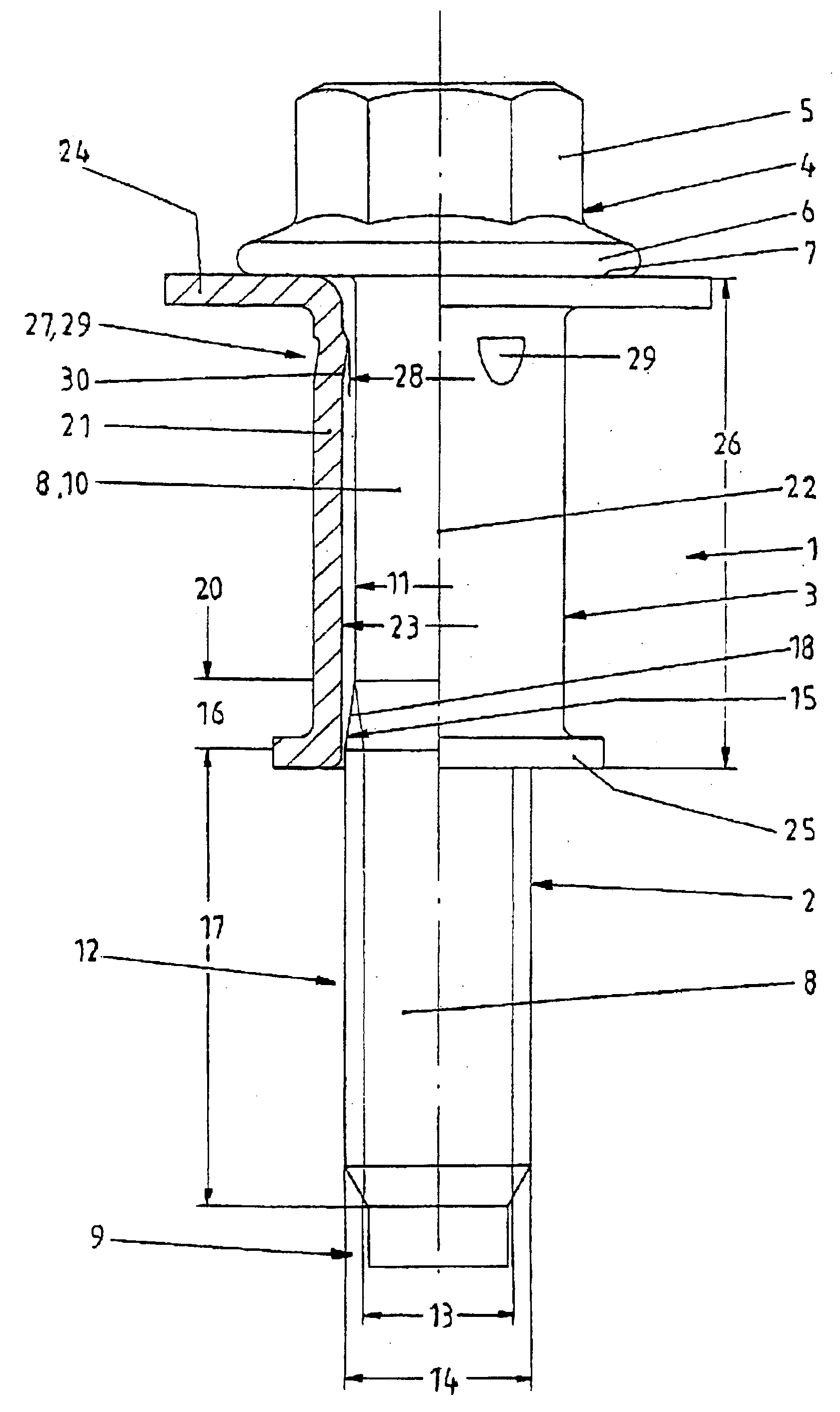

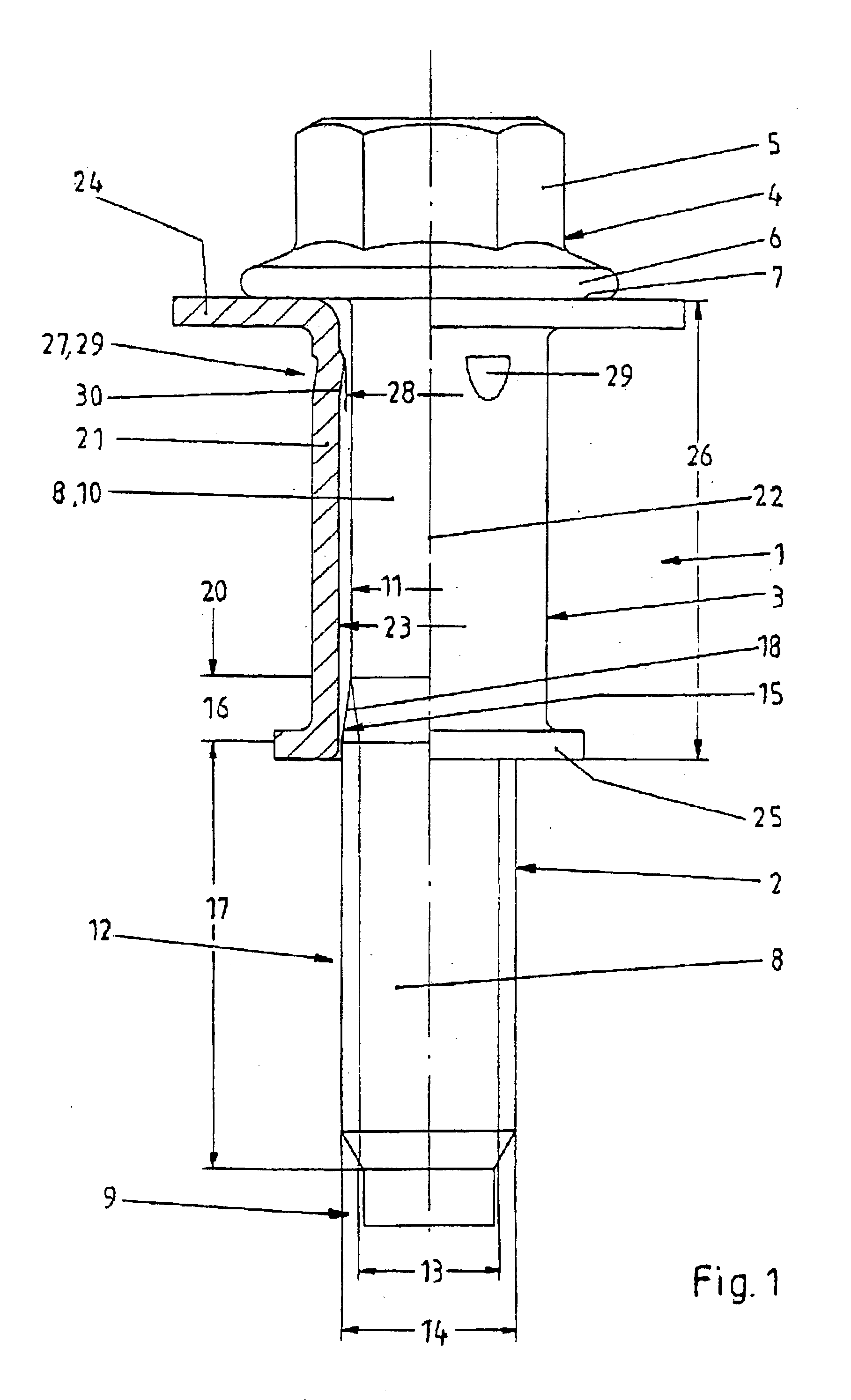

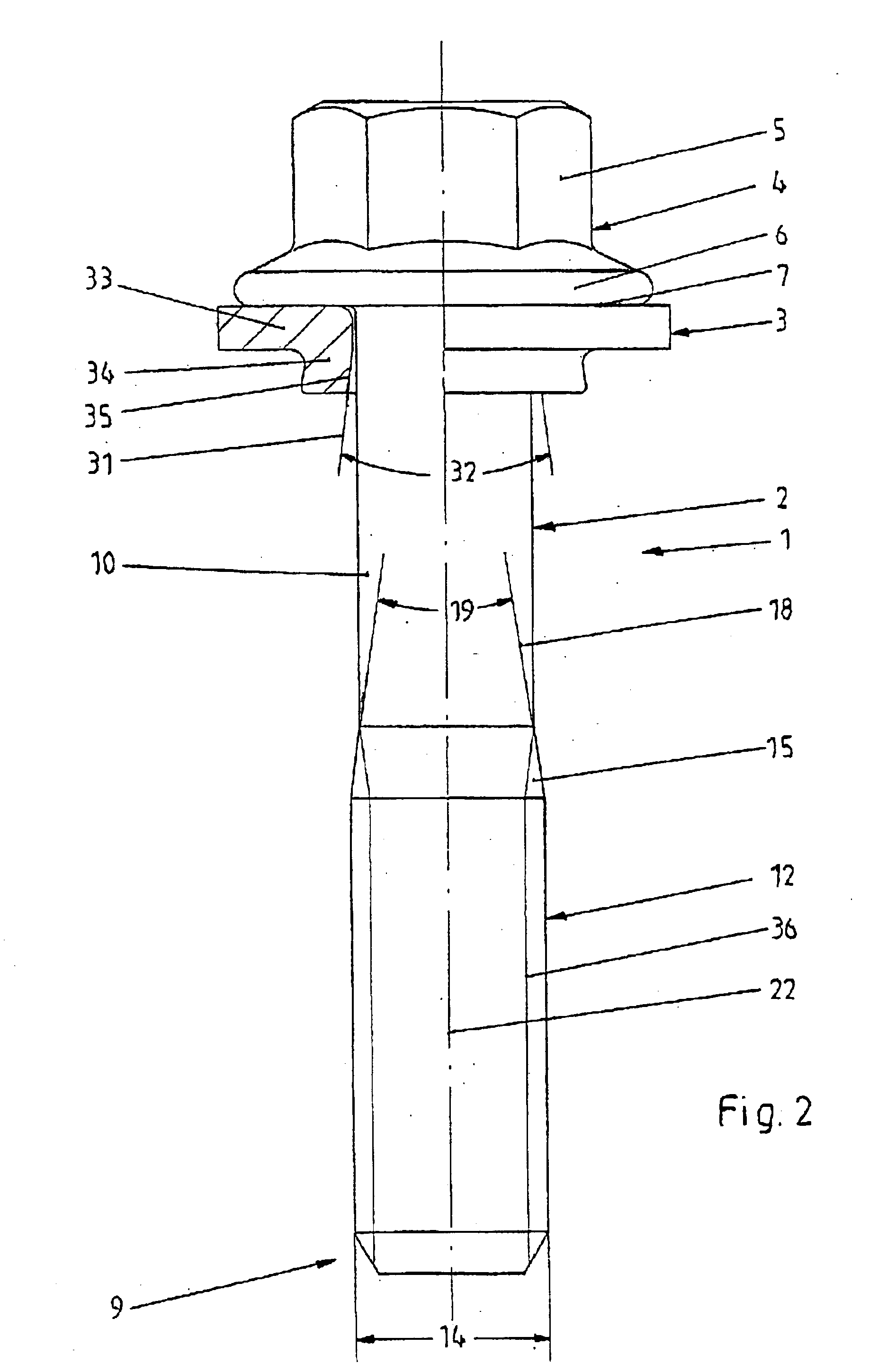

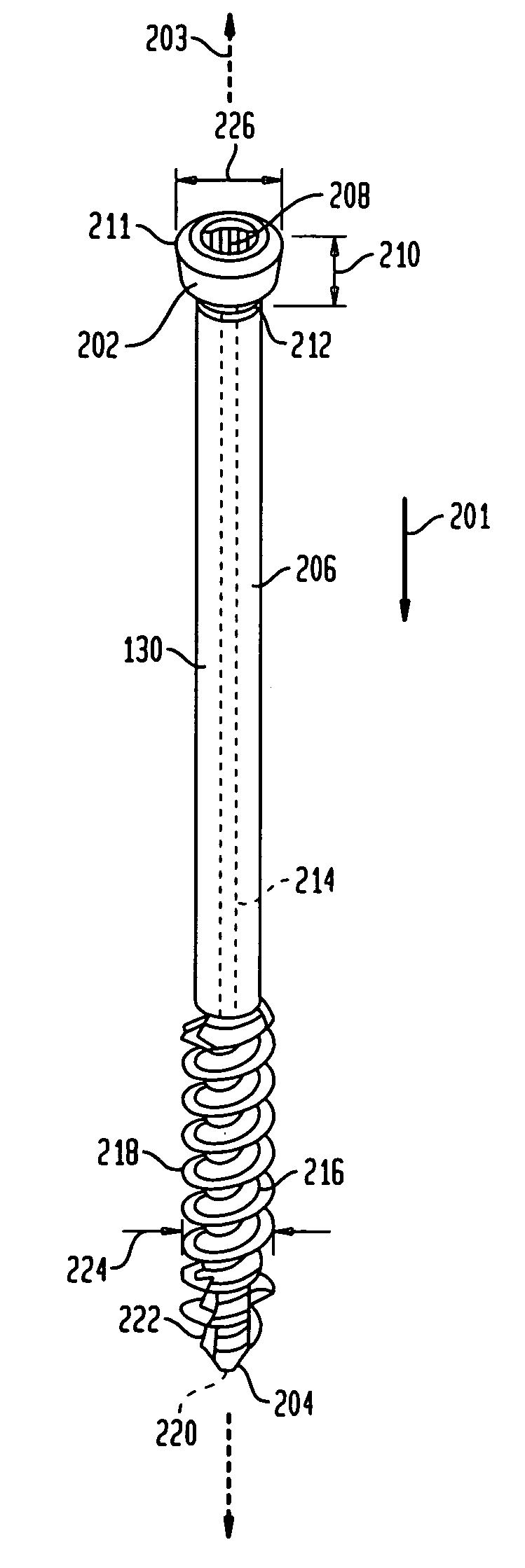

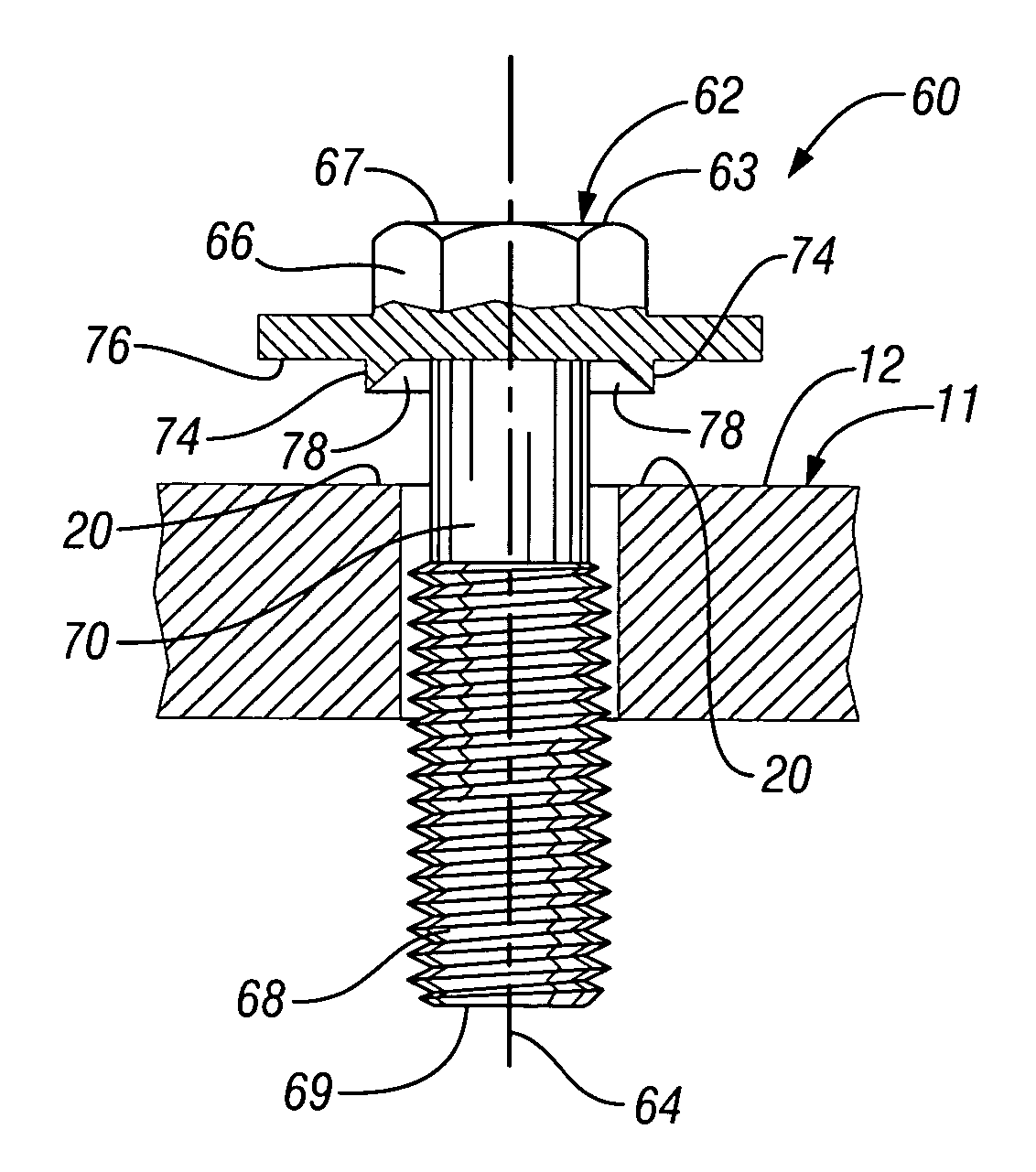

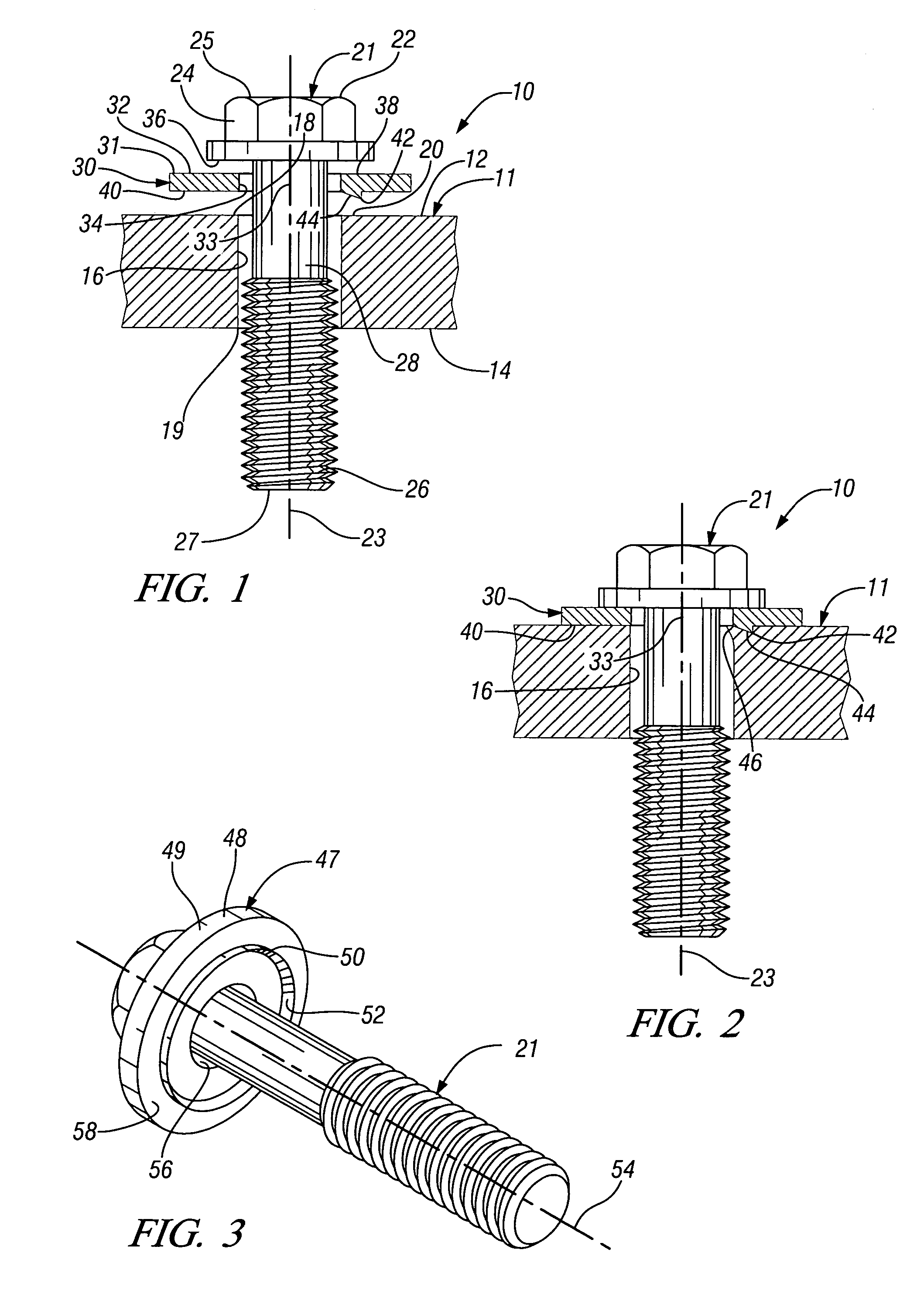

Fastener including a screw and a supporting element

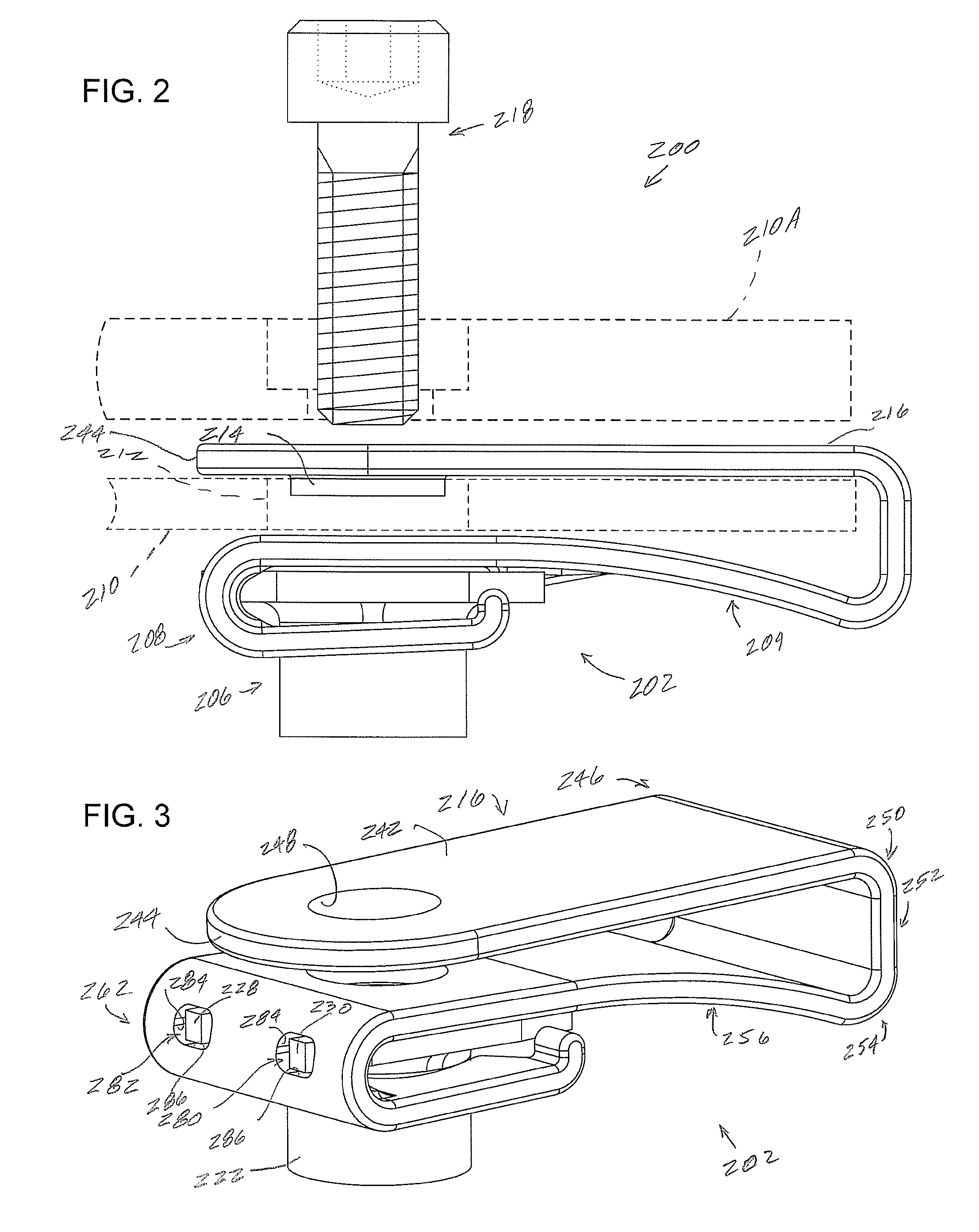

A fastener (1) includes a screw (2) and a supporting element (3). The screw (2) includes a head (4), a shank (8) and a threaded portion (12). The threaded portion (12) is located on the shank (8). The threaded portion (12) includes a thread having an outer diameter (14). The threaded portion (12) includes a thread runout (25) facing the head (4) of the screw (2). The shank (8) includes a shank portion (10) having a diameter (11) which is smaller than the outer diameter (14) of the thread. The supporting element (3) is captively connected to the screw (2), and it includes at least one narrow location (27). The narrow location (27) has a diameter (28) which is smaller than the outer diameter (14) of the thread. The narrow location (27) includes at least one surface element (30, 35) facing the thread runout (25) and forming an enveloping cone (31) enveloping the thread runout (25) to prevent the supporting element (3) from getting clamped at the thread runout (25) of the screw (2).

Owner:KAMAX HLDG

Absorbable bone screw and tool for its insertion

Owner:HUENE DONALD R

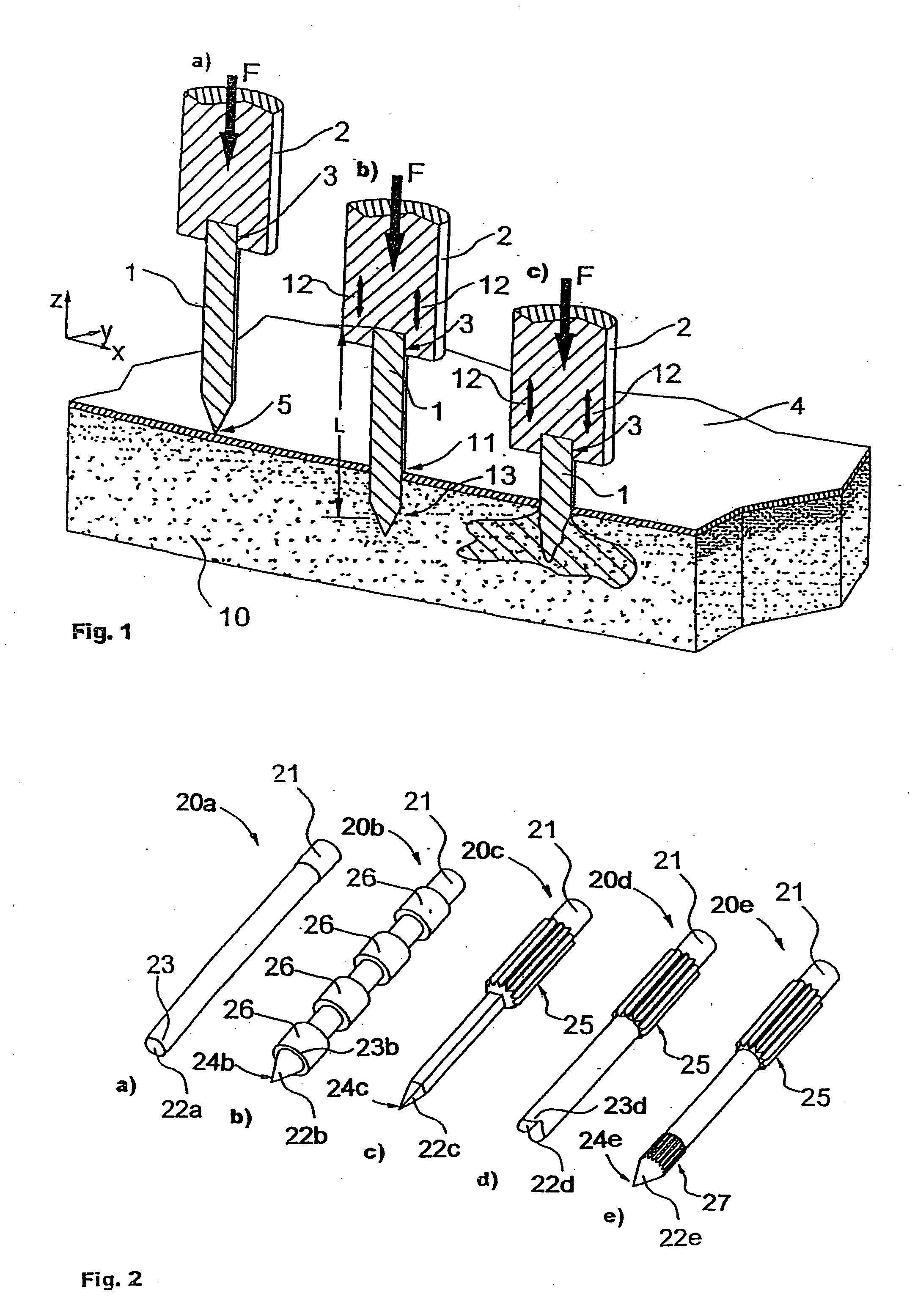

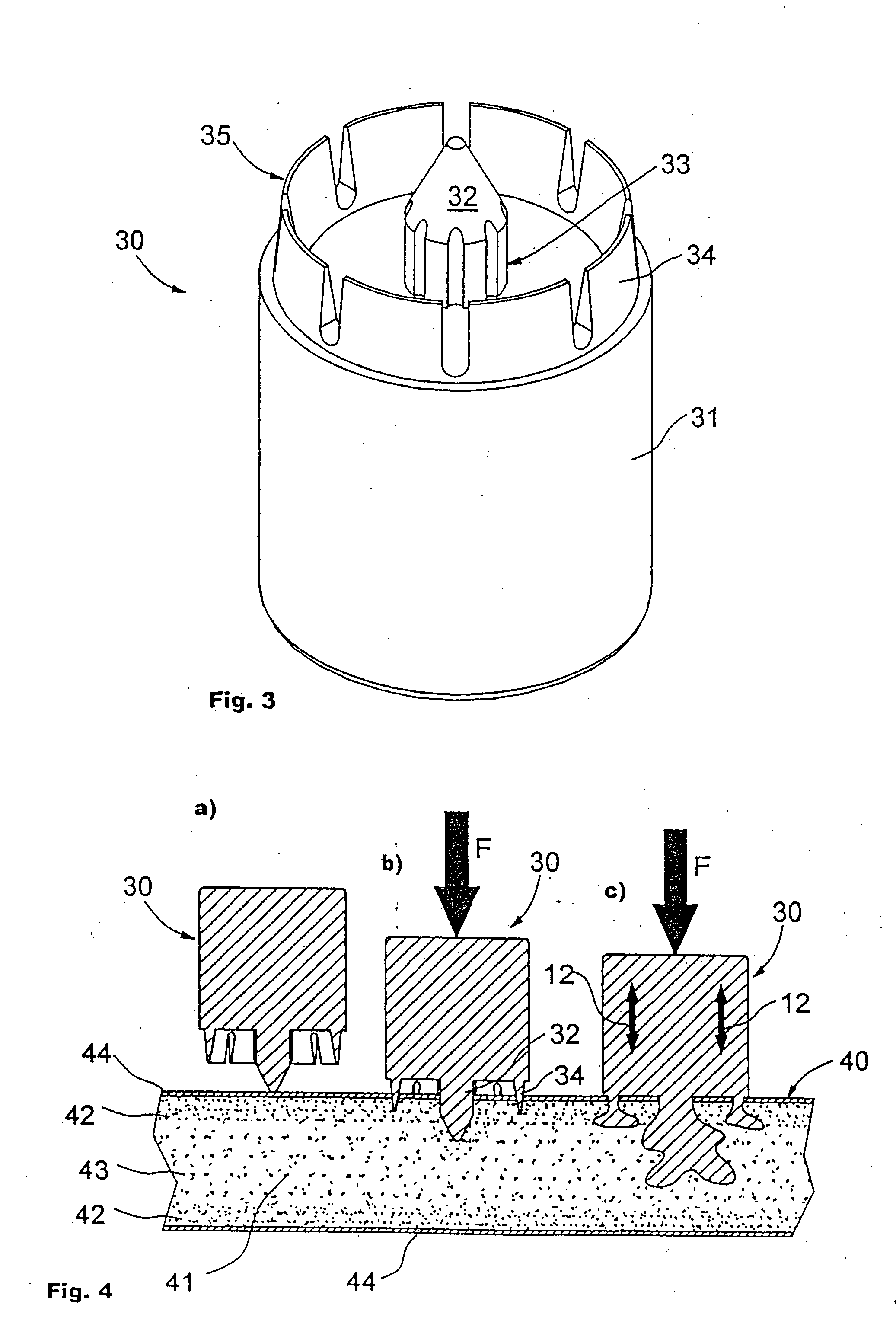

Integral joining

InactiveUS7160405B2Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

Integral joining

InactiveUS20050126680A1Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

Fastener and fastened assembly

A fastener for connecting a first component to a second component includes a first component connecting end allowing relative movement between a first component connected thereto and the fastener during assembly and during conditions of expansion and contraction. A second component connecting end of the fastener is configured for connecting to a second component.

Owner:ILLINOIS TOOL WORKS INC

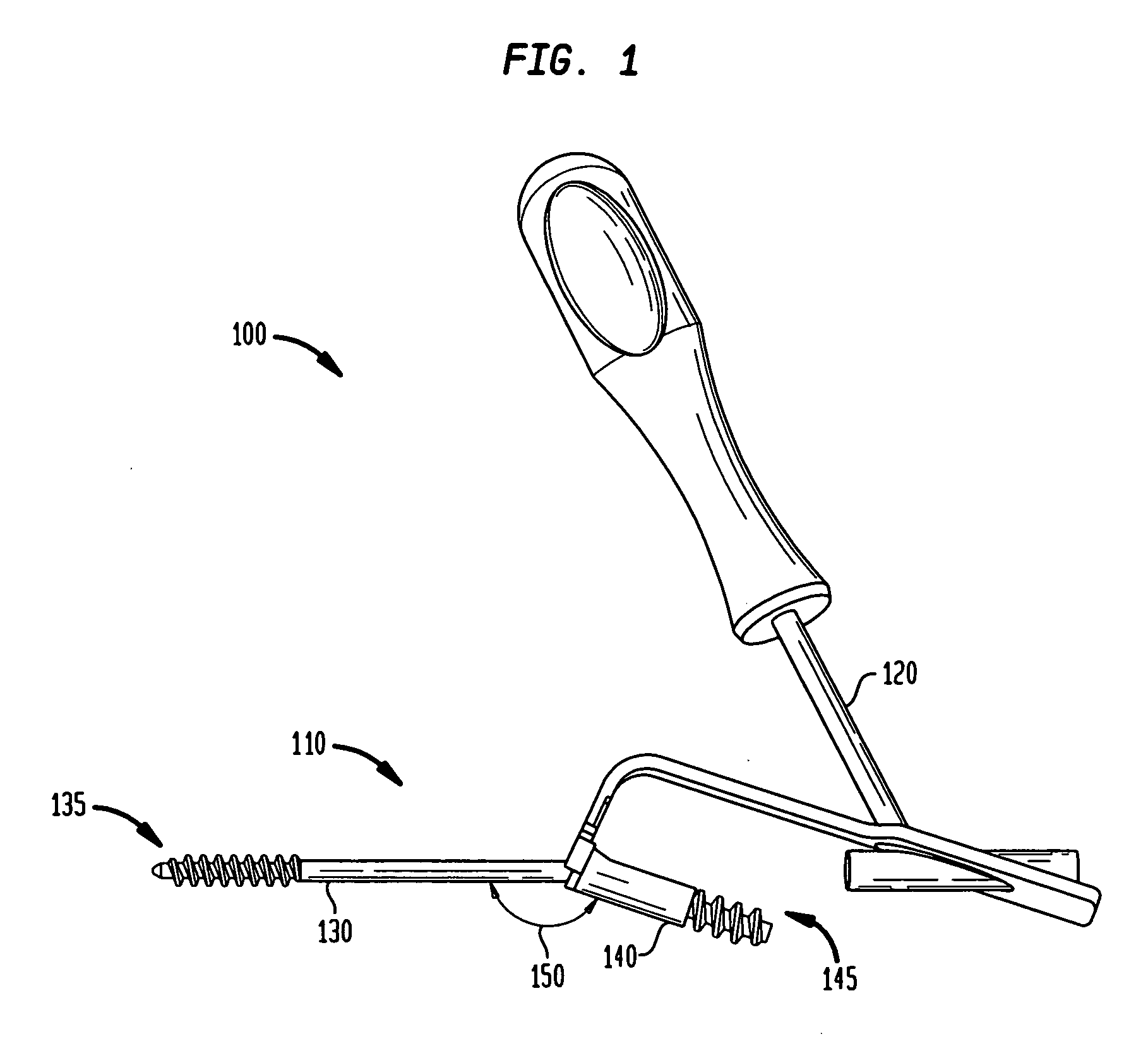

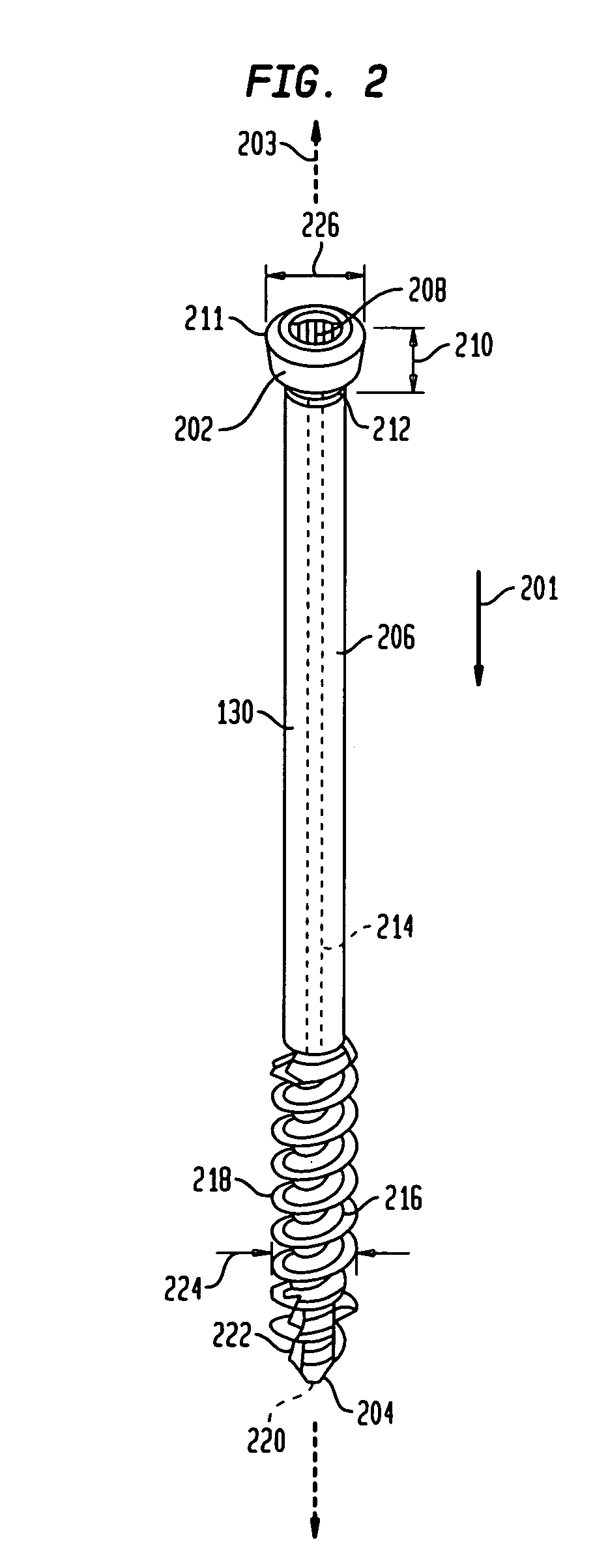

Intraosseous intramedullary fixation assembly and method of use

An intramedullary assembly for intraosseous bone fusion includes a lag screw member and a tapered screw member. The lag screw member includes a first elongated body, where the first elongated body includes a first threaded portion at a first end and a bulbous portion at a second end. The tapered screw member is coupled to the lag screw member, and the tapered screw member includes a second elongated body, where the second elongated body includes a second threaded portion at a third end, and an opening at a fourth end.

Owner:EXTREMITY MEDICAL

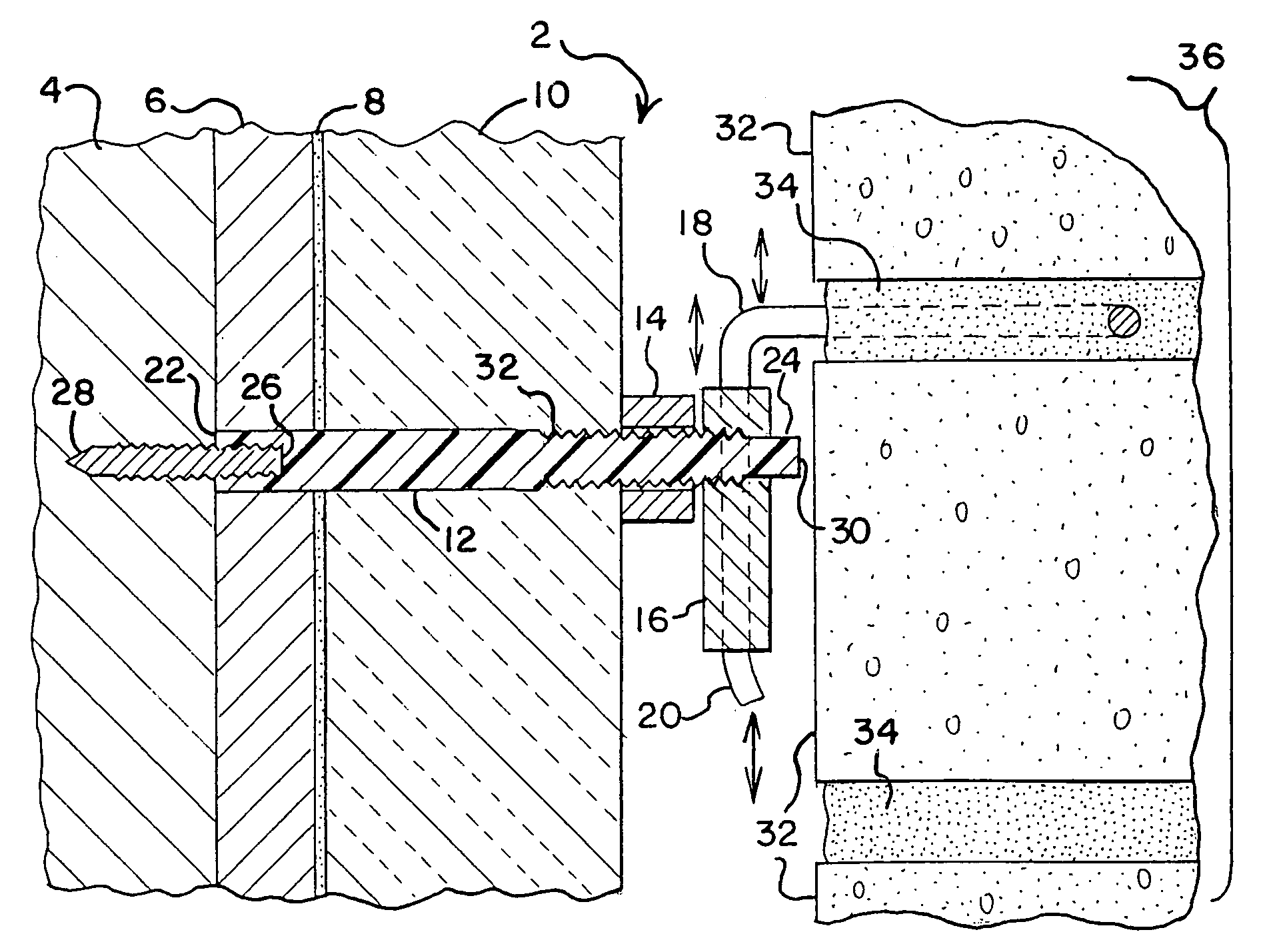

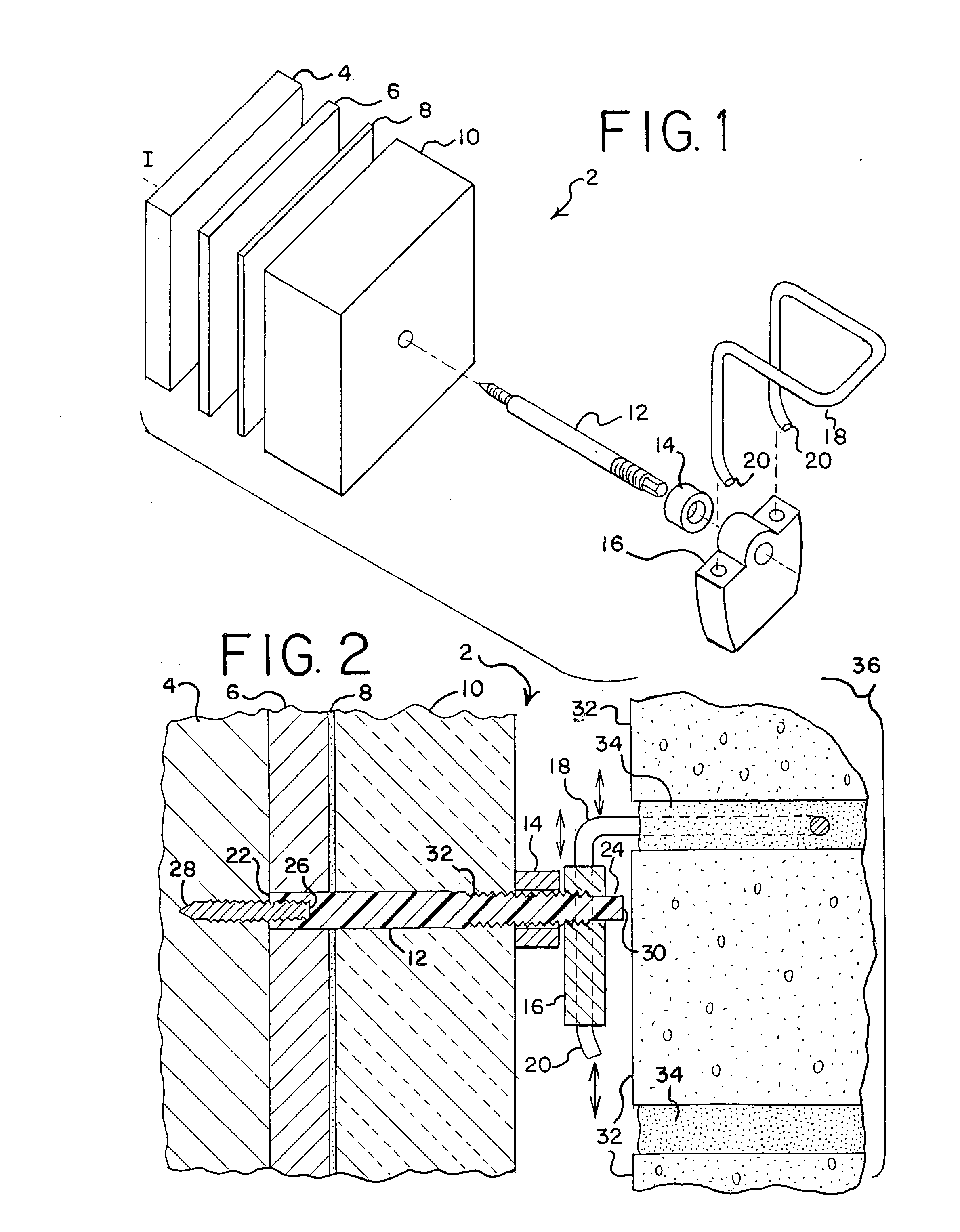

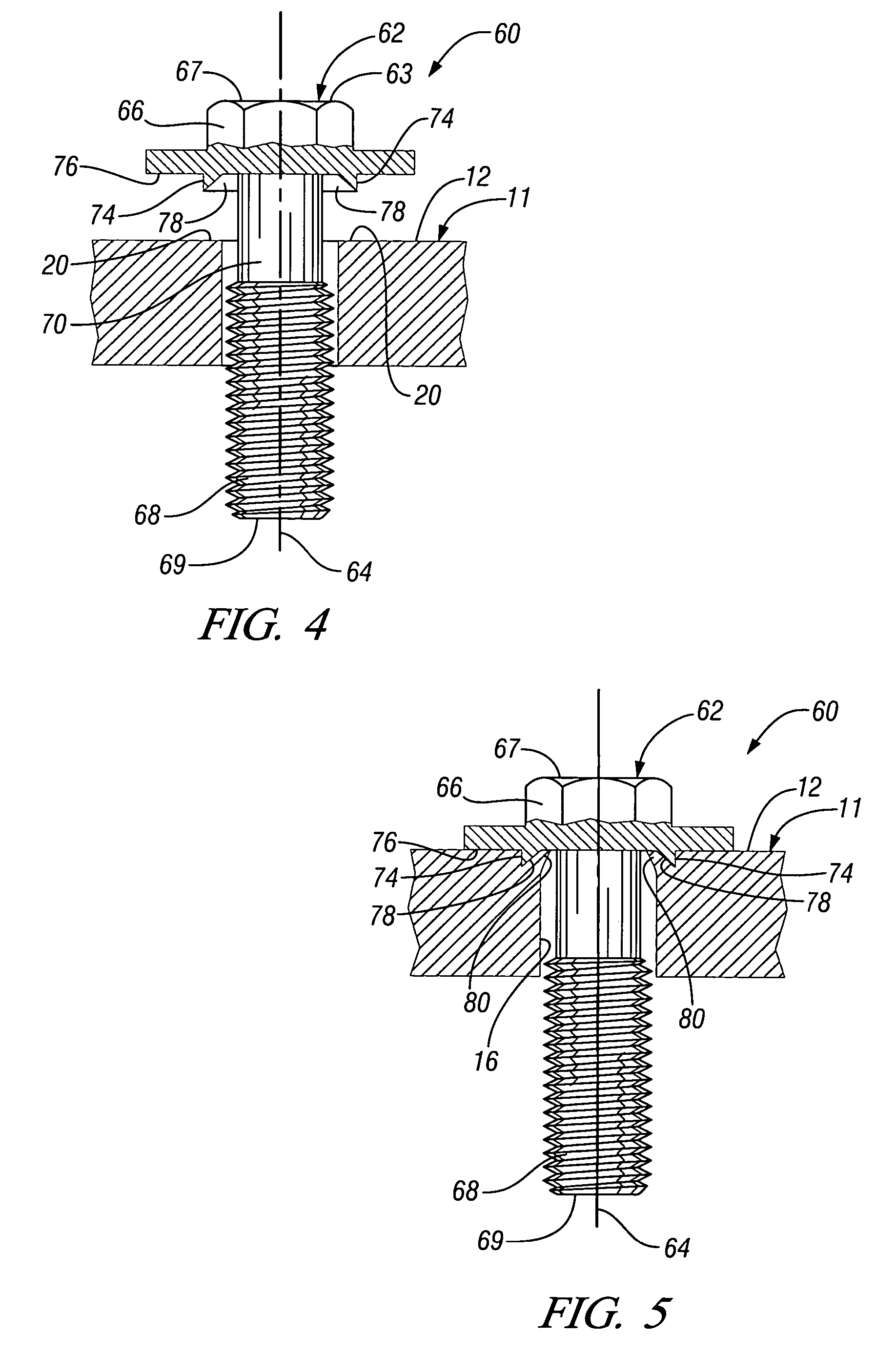

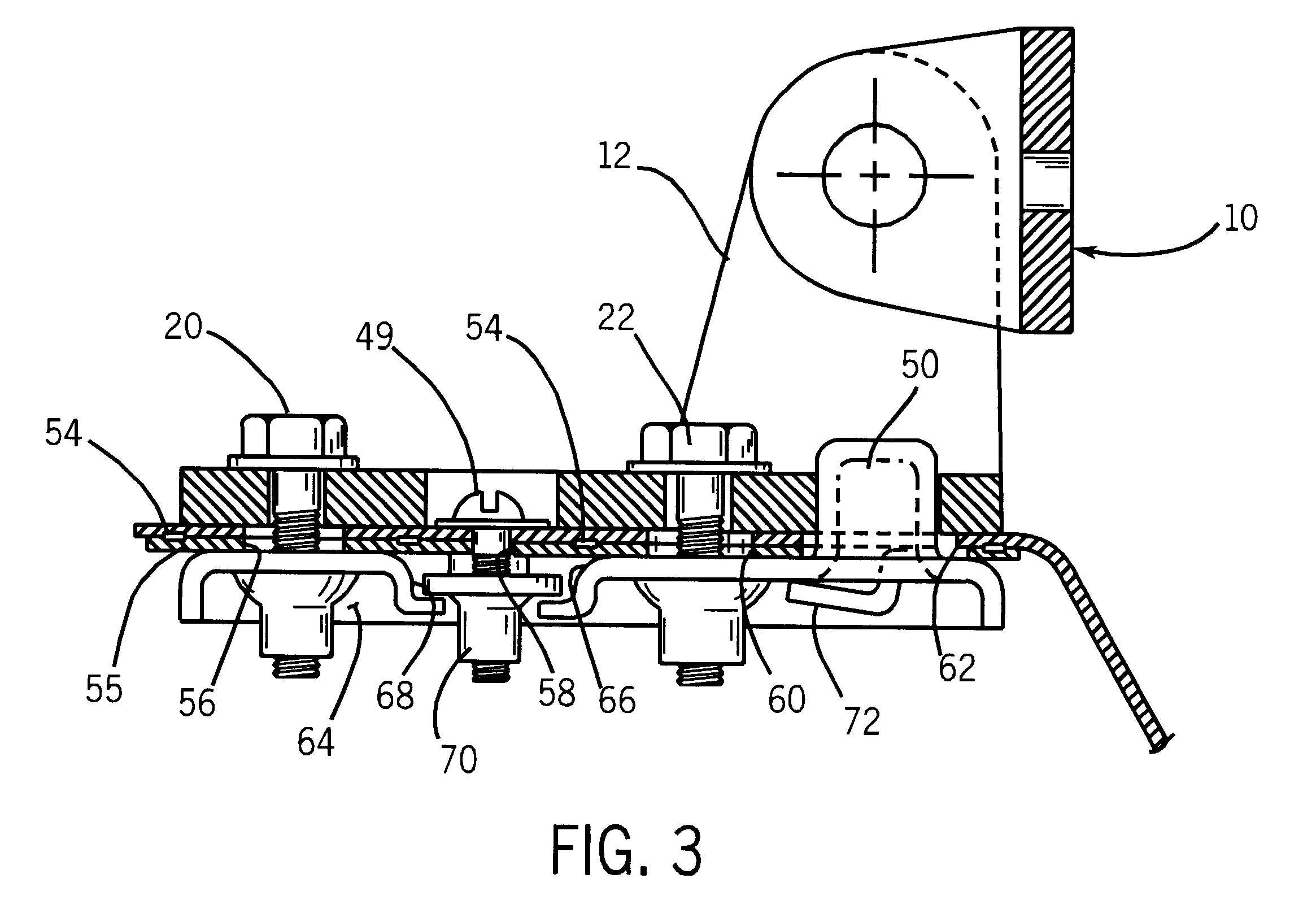

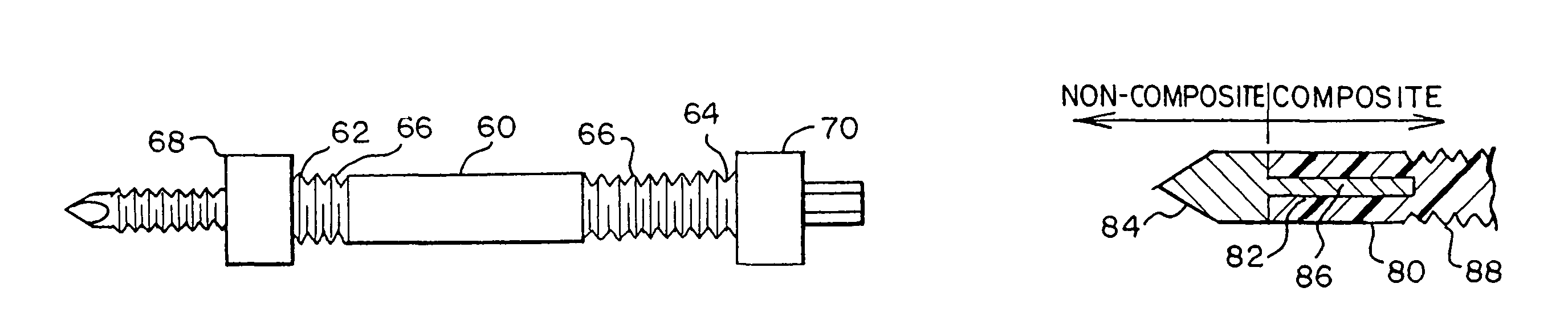

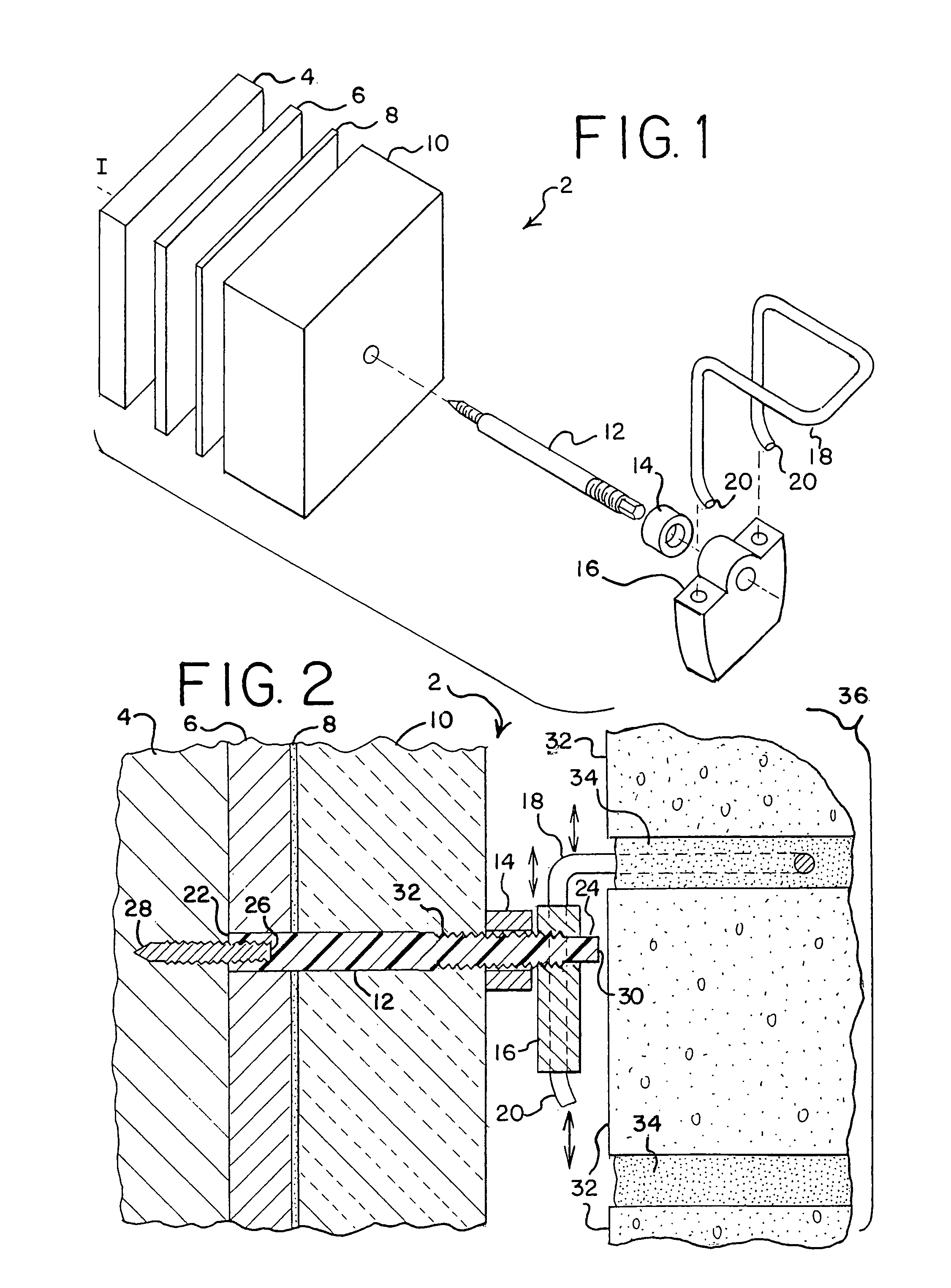

Composite fastener, belly nut, tie system and/or method for reducing heat transfer through a building envelope

InactiveUS20090133357A1Reduce heat transferLow thermal conductive valueWashersTransportation and packagingBuilding envelopePolymeric matrix

A composite fastener, a belly nut, a tie system and / or a method reduce heat transfer through a building envelope. The composite fastener, the belly nut, the tie system and / or the method secure a wall to a backup structure. The composite fastener is constructed from a fiber reinforced polymer that has fibers embedded in a polymeric matrix. The composite fastener has a low thermal conductive value (k-value) and has non-corrosive properties. The belly nut has a fastening hole on a first side of the belly nut to attach the composite fastener to the belly nut. Further, the belly nut has a pathway to receive a leg of a pintle from a top surface of the belly nut to a bottom surface of the belly nut. The pathway is sized to allow for greater vertical adjustment eccentricity between the belly nut and the pintle without creating large horizontal deflections of the tie system.

Owner:RICHARDS JOSEPH P

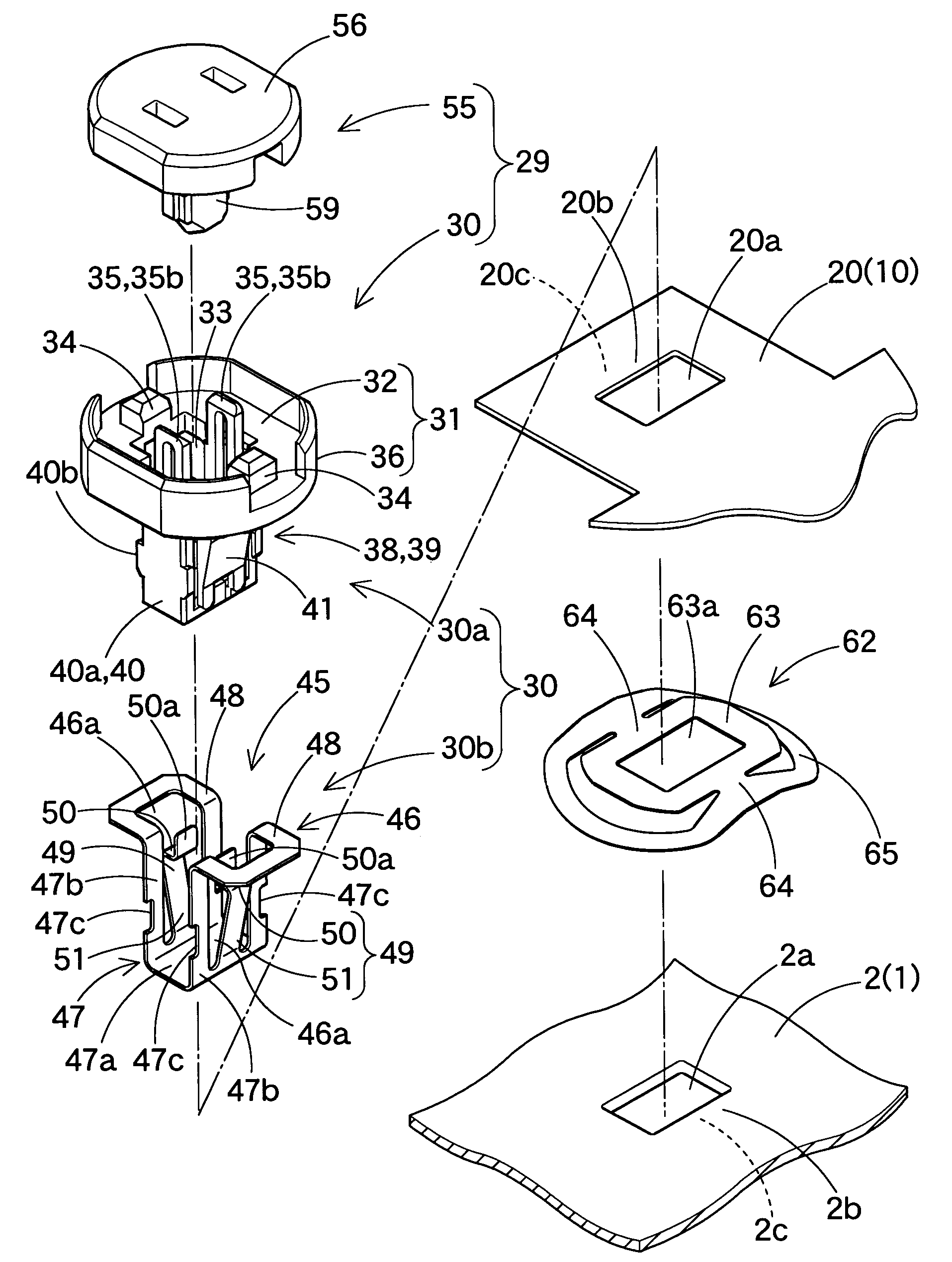

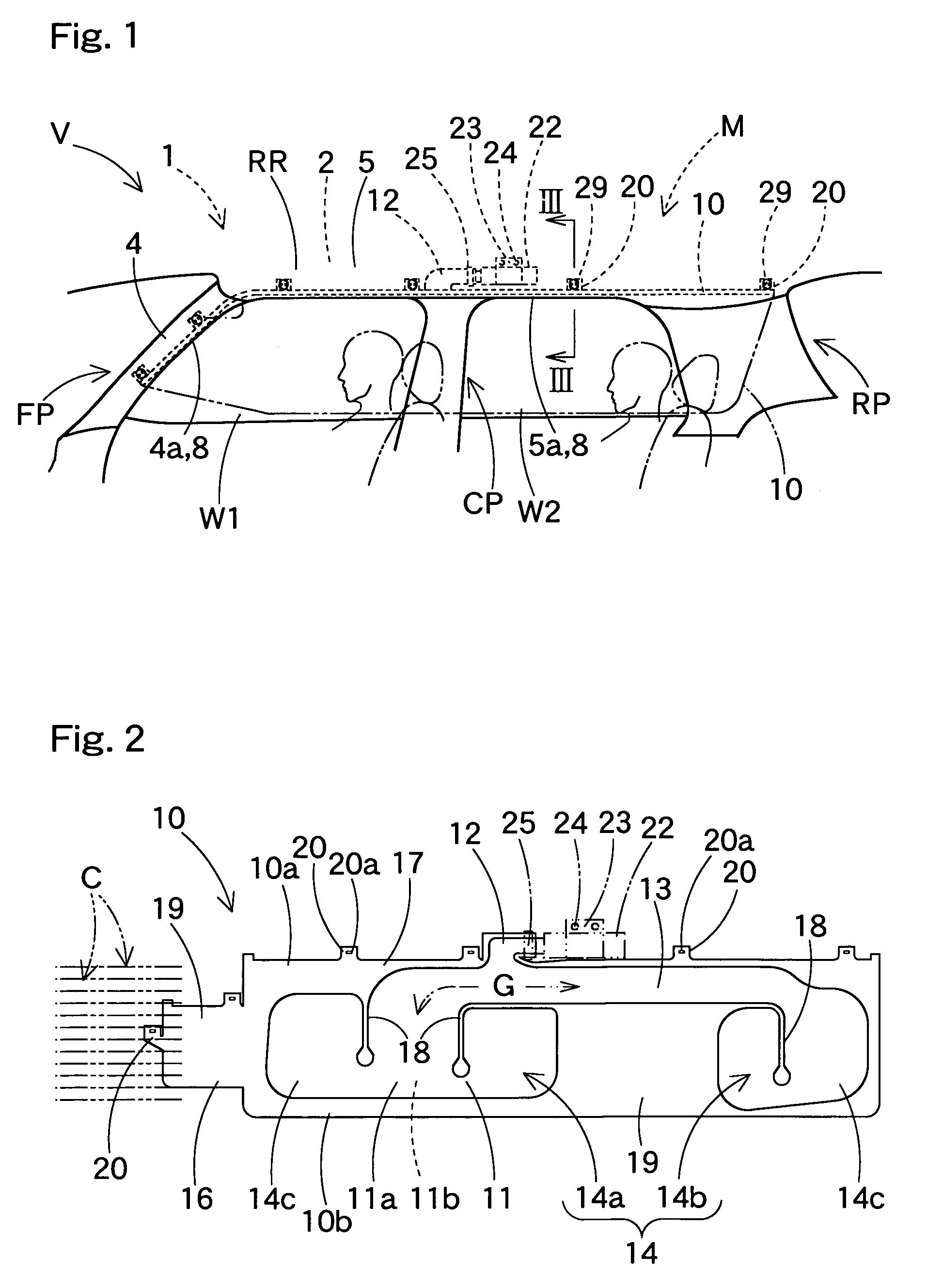

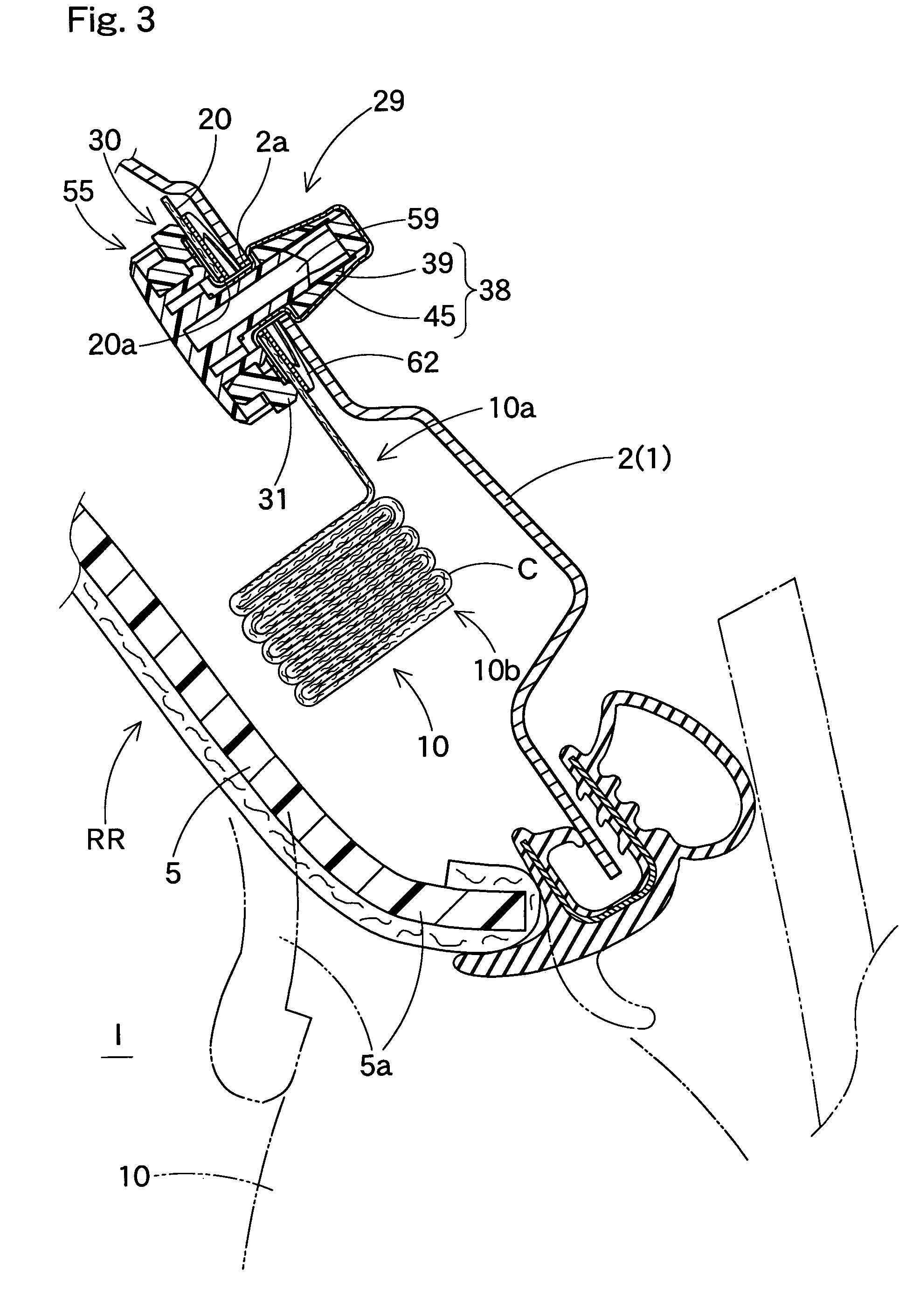

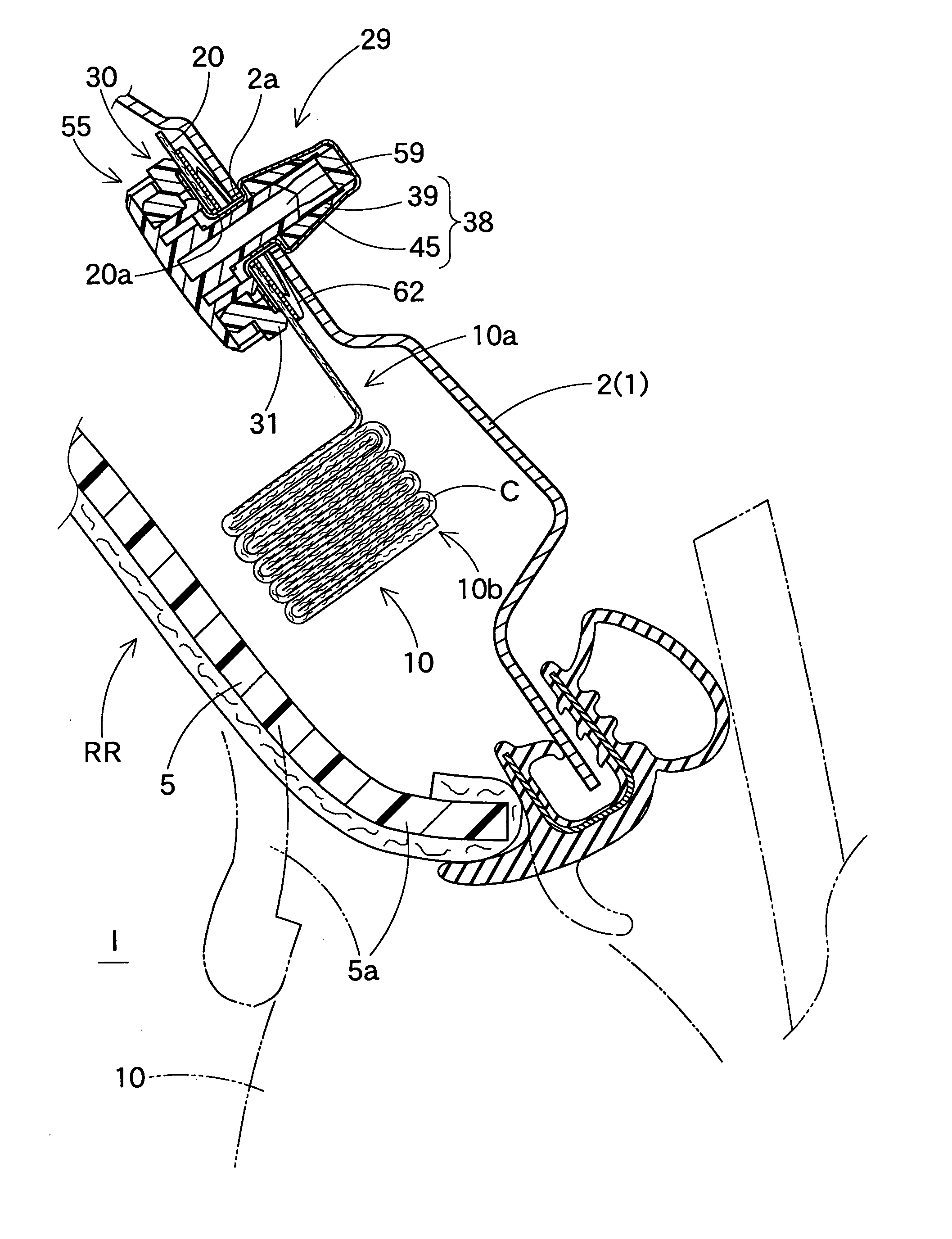

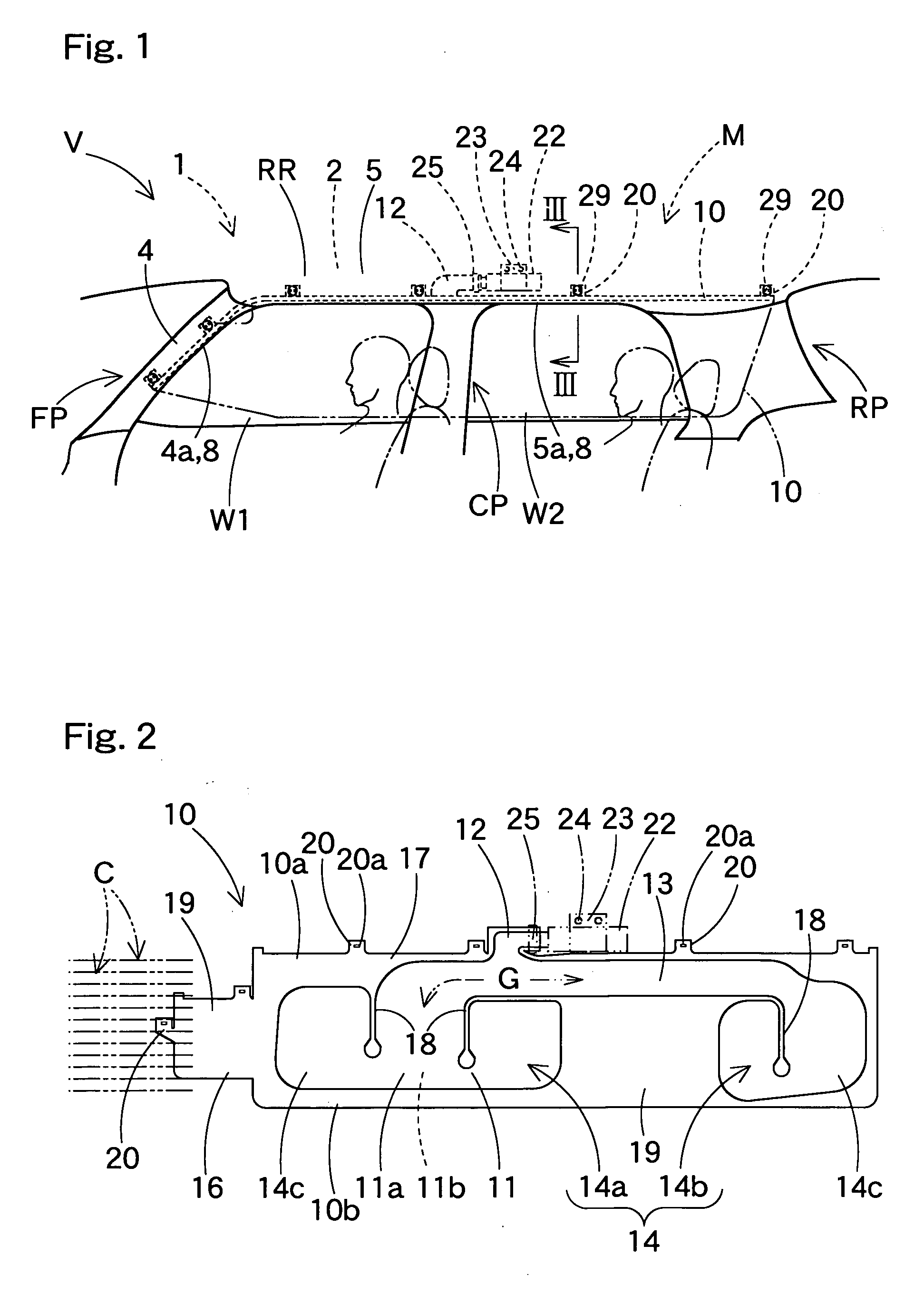

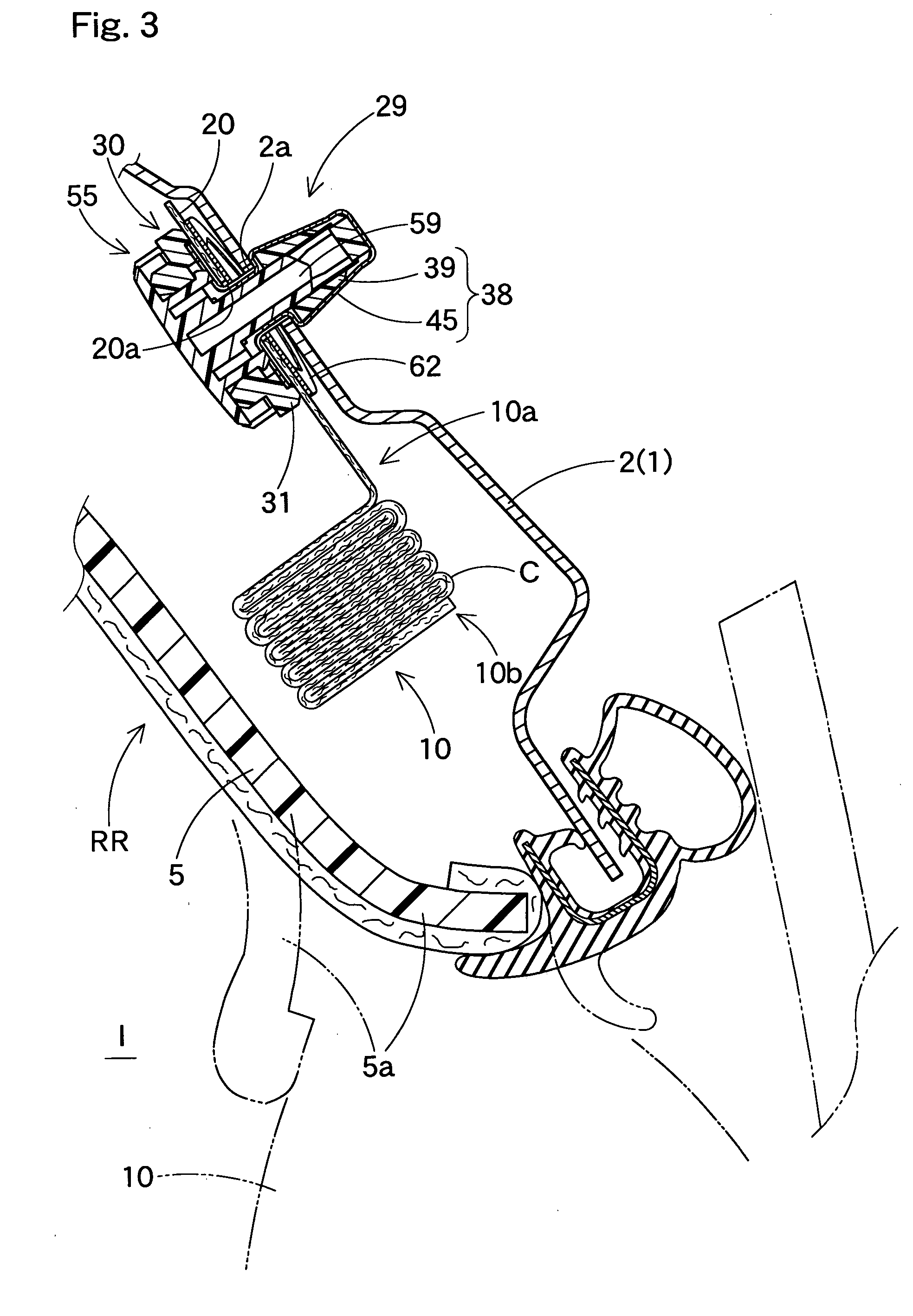

Head protecting airbag device

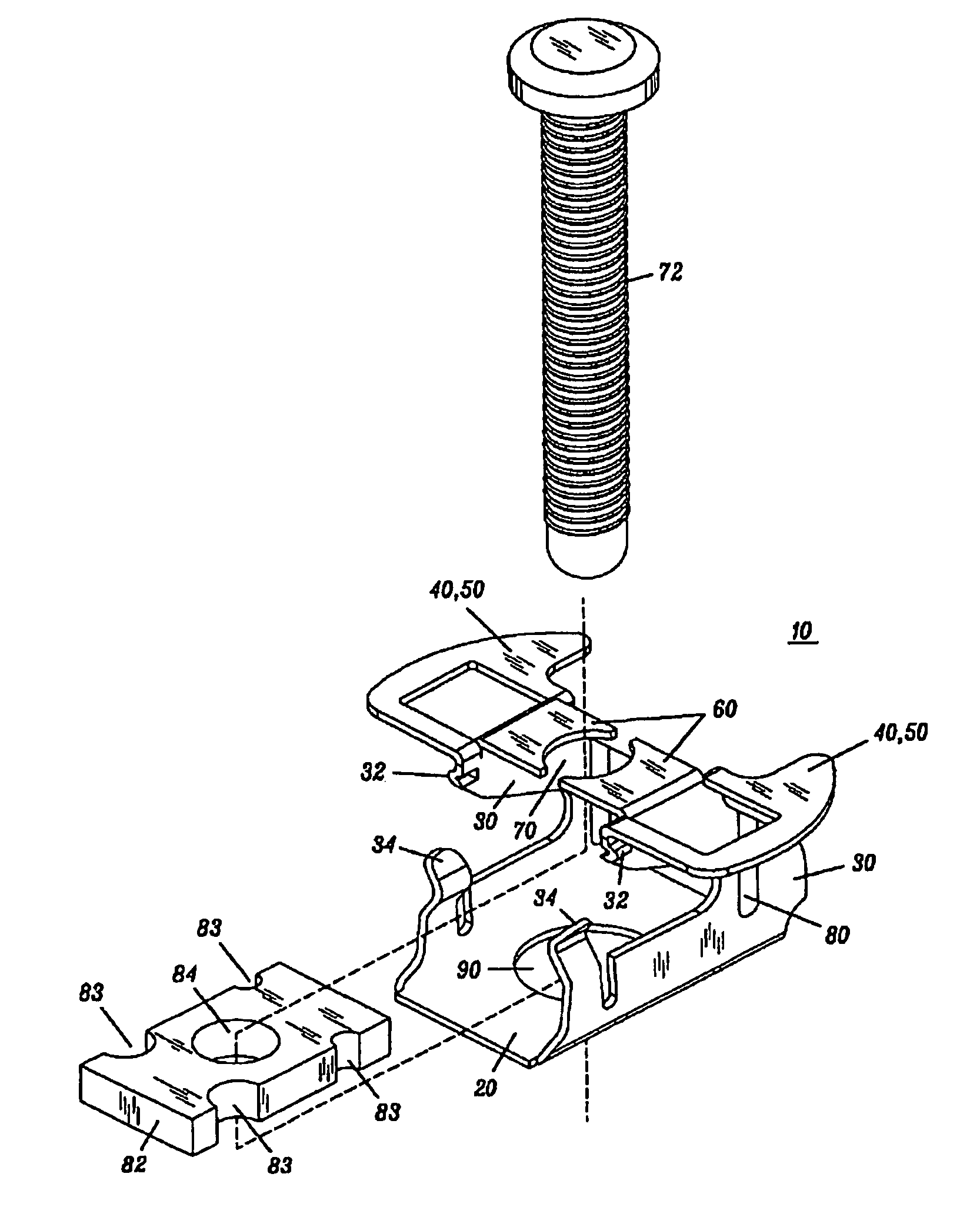

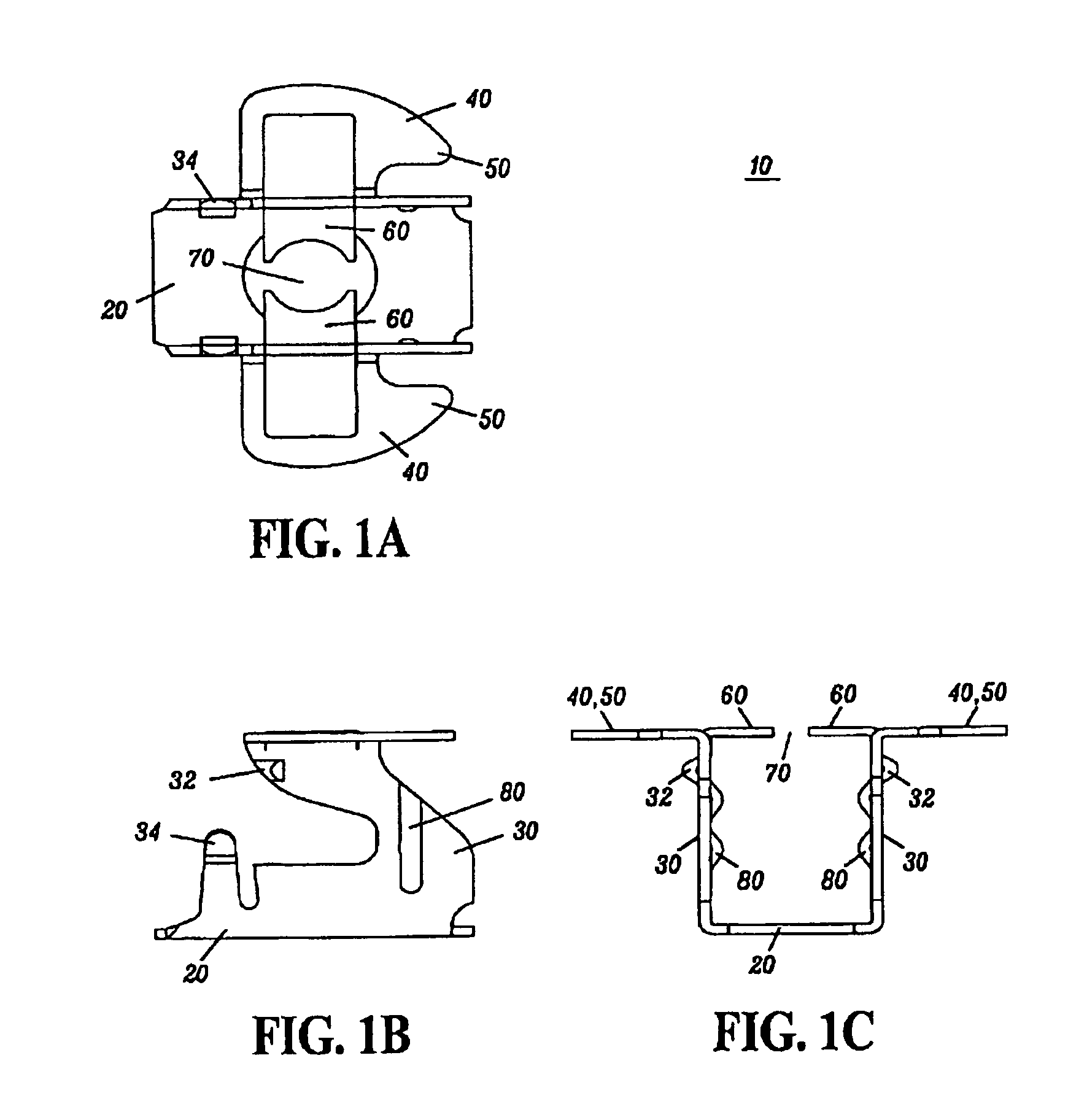

InactiveUS7374200B2Easily attaching attaching portionAssured attaching stabilitySnap-action fastenersPedestrian/occupant safety arrangementIn vehicleEngineering

In a head protecting air bag device according to the present invention, a clip for attaching an attaching portion of an air bag to a fixing part on the side of a vehicle body includes a clip body and a locking part. The clip body has a shaft having a pair of securing legs protruded. The pair of securing legs are inserted in the fixing slot of the fixing part from an in-vehicle side via the attaching slot of the attaching portion and secured to the peripheral edge on an out-vehicle side of the fixing slot. The shaft is composed of a shell member of a metallic plate on the outer periphery and a core member of synthetic resin on the inner periphery. The core member is arranged on the opposite sides of a pair of securing lugs of the shell member. The core member has an inserting space in which a spacer of the locking part is inserted between the pair of securing lugs. The spacer limits the mutual approaching of the pair of securing legs. In the head protecting air bag according to this invention, using the clip, the attaching portion of the air bag can be easily attached to the vehicle body side with assured attaching stability.

Owner:TOYODA GOSEI CO LTD +1

Head protecting airbag device

InactiveUS20060066080A1Easy to carryReduce insertion loadSnap-action fastenersPedestrian/occupant safety arrangementIn vehicleAirbag

In a head protecting air bag device according to the present invention, a clip for attaching an attaching portion of an air bag to a fixing part on the side of a vehicle body includes a clip body and a locking part. The clip body has a shaft having a pair of securing legs protruded. The pair of securing legs are inserted in the fixing slot of the fixing part from an in-vehicle side via the attaching slot of the attaching portion and secured to the peripheral edge on an out-vehicle side of the fixing slot. The shaft is composed of a shell member of a metallic plate on the outer periphery and a core member of synthetic resin on the inner periphery. The core member is arranged on the opposite sides of a pair of securing lugs of the shell member. The core member has an inserting space in which a spacer of the locking part is inserted between the pair of securing lugs. The spacer limits the mutual approaching of the pair of securing legs. In the head protecting air bag according to this invention, using the clip, the attaching portion of the air bag can be easily attached to the vehicle body side with assured attaching stability.

Owner:TOYODA GOSEI CO LTD +1

Fastener having supplemental support and retention capabilities

A fastener, such as a nail, screw, etc., which possesses supplemental support and / or retention capability is provided. The fastener includes an elongated auxiliary member secured interiorly to, exteriorly to, or along the shaft of the fastener. The auxiliary member is secured to the shaft at two or more portions of the shaft. The auxiliary member provides the shaft with additional support strength and / or enables fastened materials to be retained upon breakage or shearing of the shaft as a result of, for example, heavy tensile or shearing loads. To facilitate breakage or shearing of the shaft, the shaft may be provided with a deformation, such as a notch or reduced circumference, at one or more desired locations such that the shaft breaks or shears at the deformation(s), thereby allowing the auxiliary member to function as the sole member which retains the fastened materials. The auxiliary member may be sufficiently flexible and pliable such that, upon breakage or shearing of the shaft, retention of the materials is maintained but in a less stressed form.

Owner:NELSON CHARLES +2

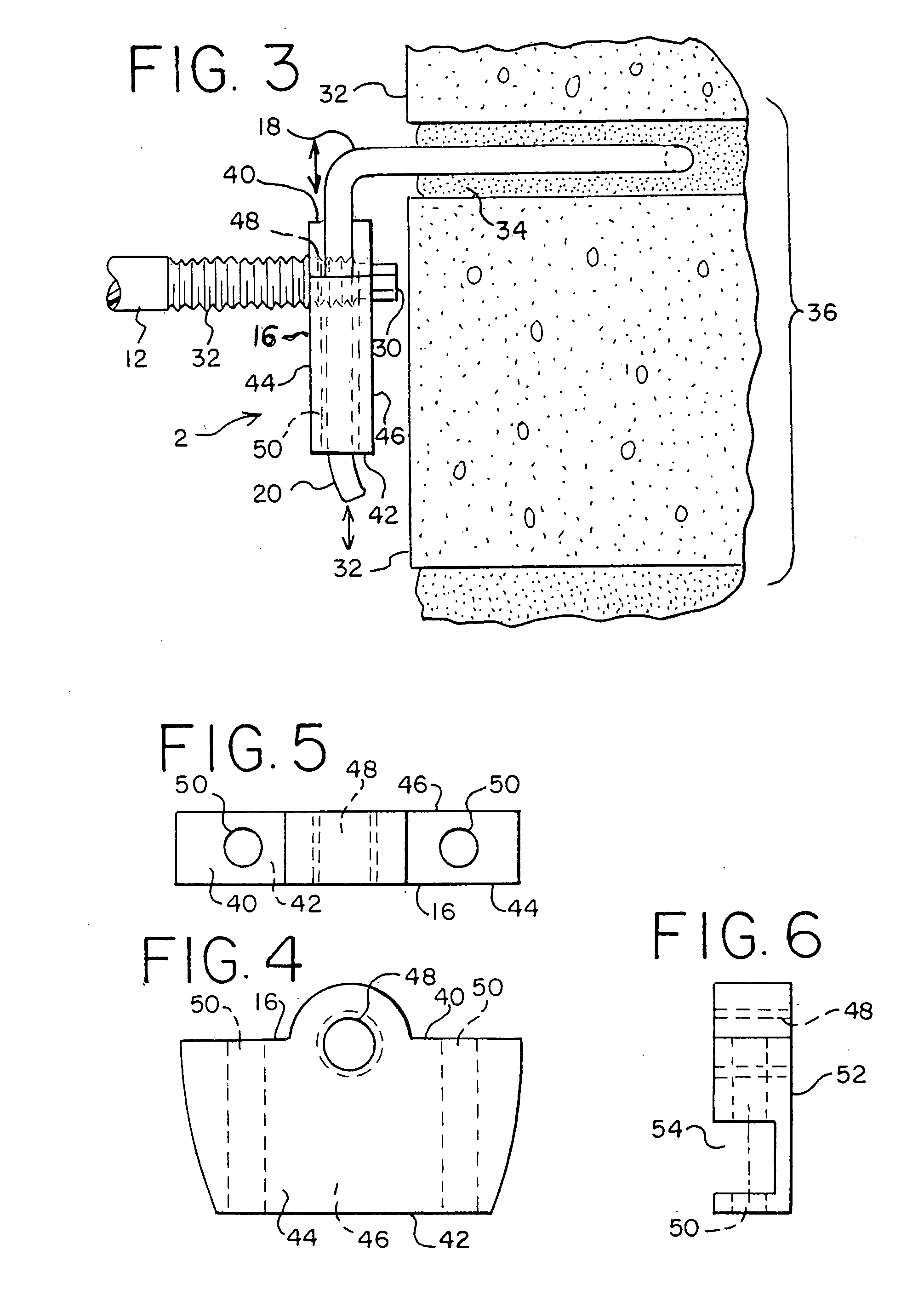

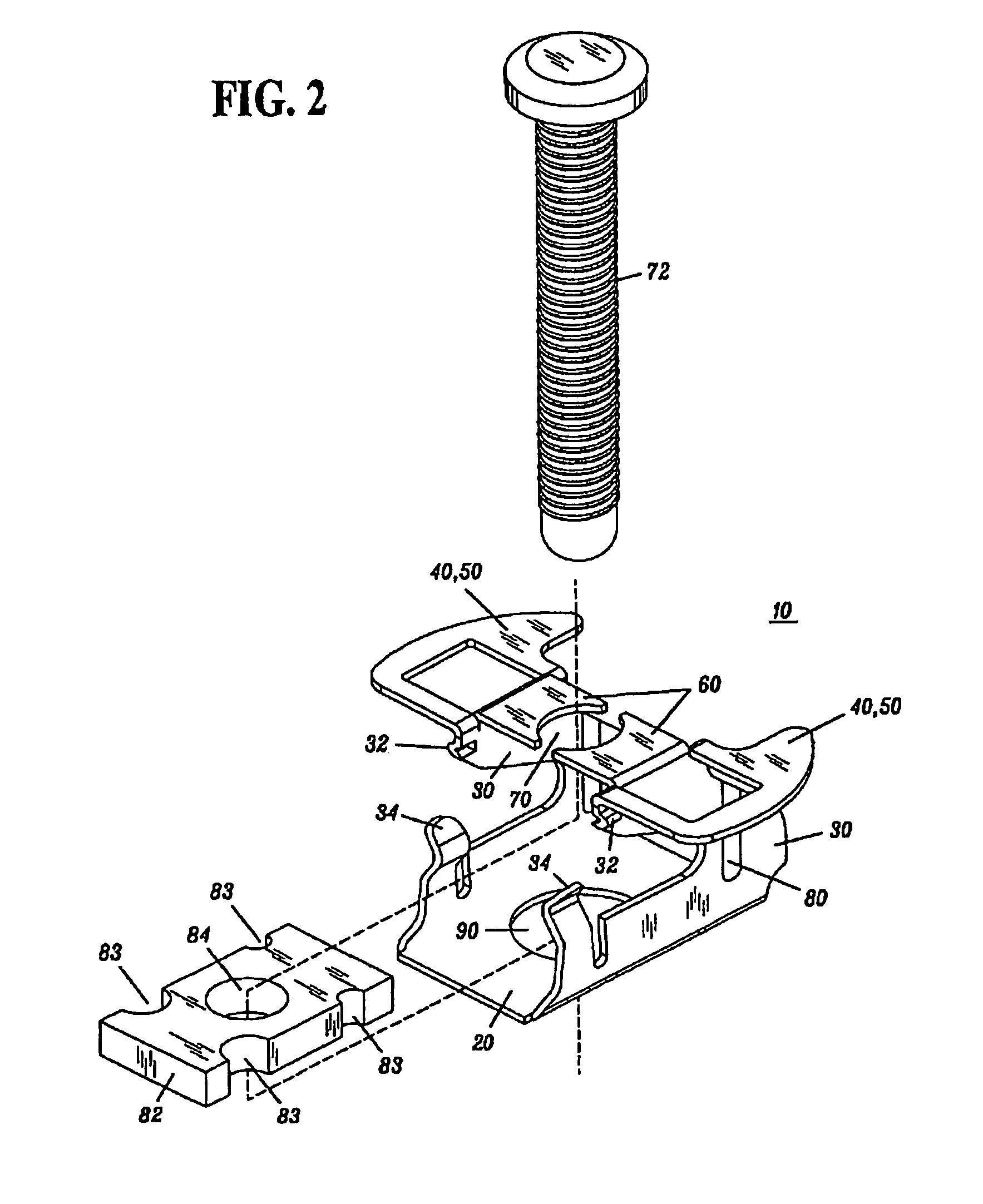

Removable anchor and fastener

An anchor facilitates blind engagement by a first fastener in order to connect an object to a wall. The anchor may be inserted into a cavity accessible through a hole defined in a hollow substrate to connect the object to the wall. The anchor includes a base plate and a pair of laterally offset arms extending from the base plate, such that each arm includes an engagement structure disposed at a distal end of each arm. The engagement structure of each arm cooperatively supports the anchor and complementarily engages the first fastener. The first fastener may be a bolt, a screw, or any suitable fastener such as a threaded fastener. The engagement structure includes a collar extending outwardly from each arm for engaging the hollow substrate upon insertion of the anchor into the cavity. Additionally, the engagement structure includes a tang extending inwardly from each arm, generally defining a portion of a first aperture for engaging the first fastener.

Owner:TERMAX CORP

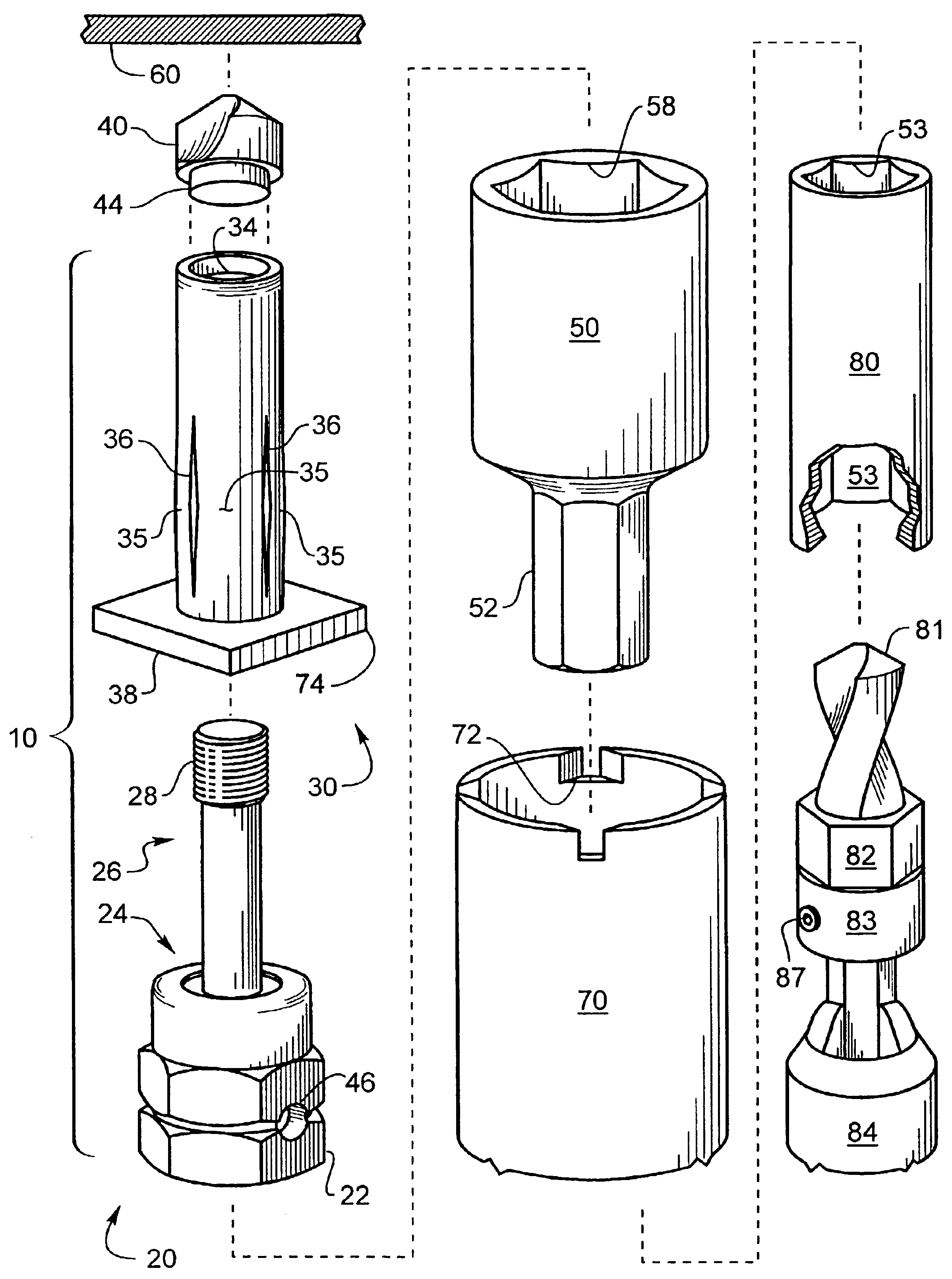

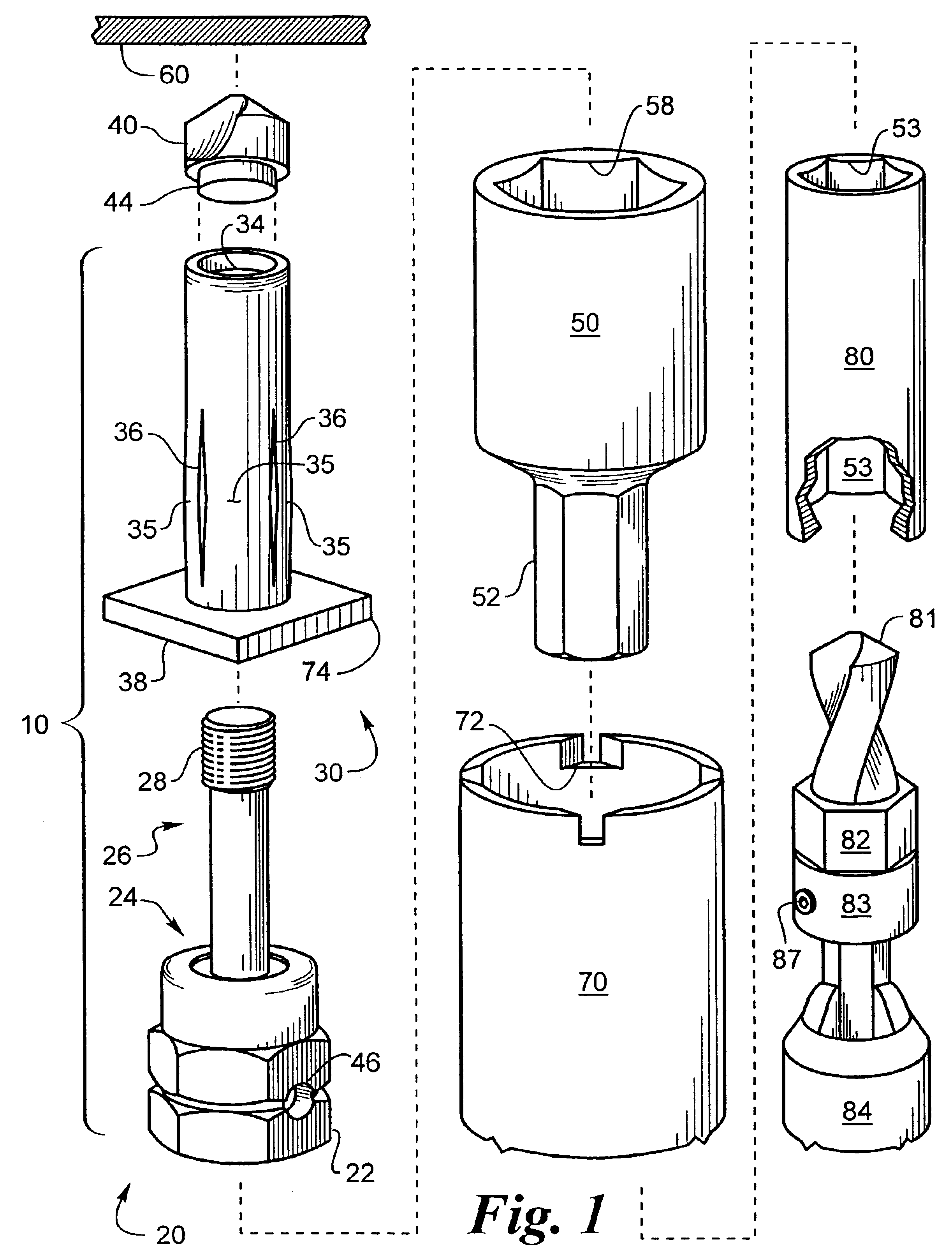

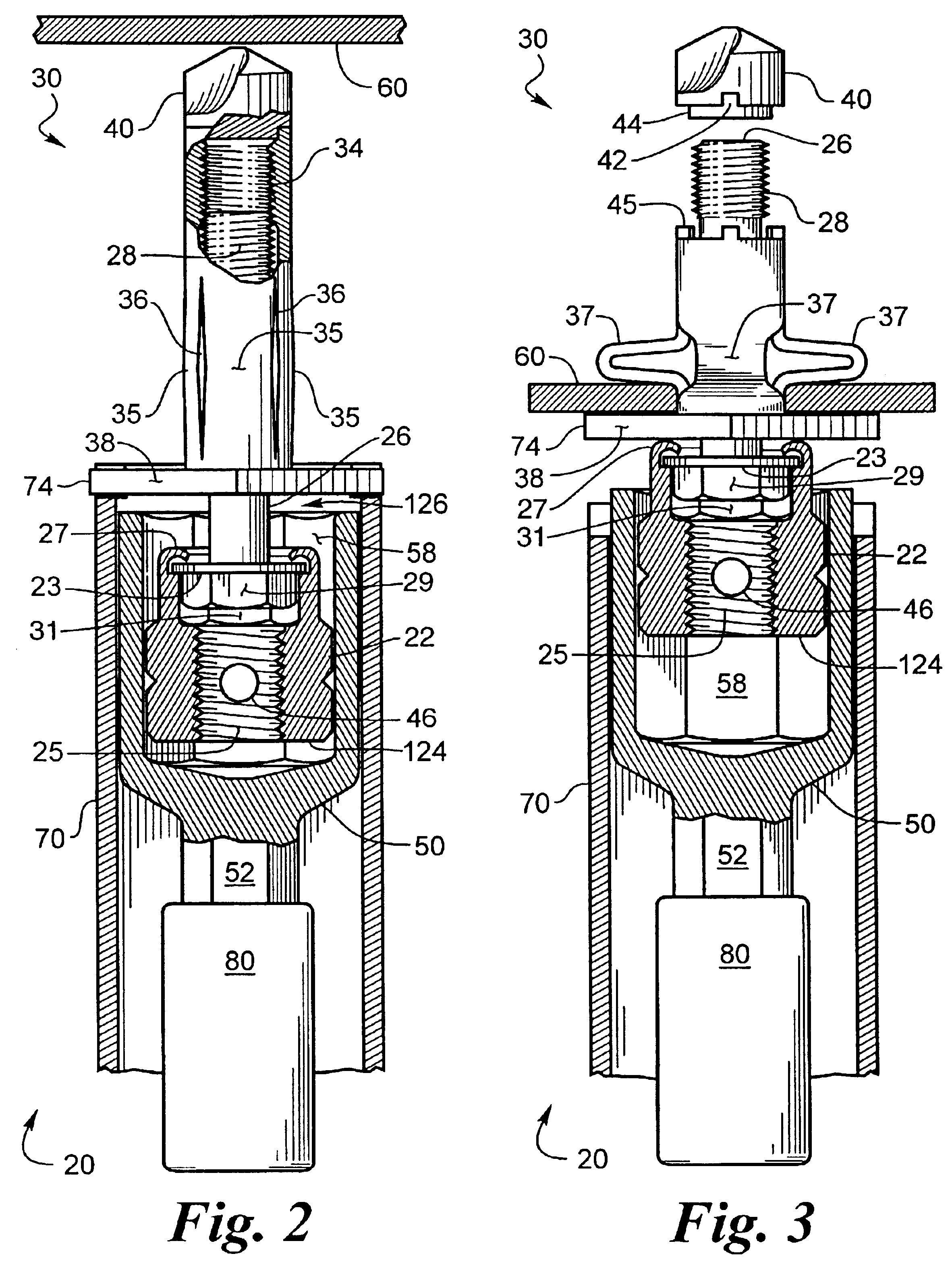

Mushrooming expandable anchor

A self-anchoring fastening device for installation in supports for hanging pipes wires or other articles in ceilings is shaped for a socket to drive the device for an easy installation process. The device comprises a collapsible anchoring portion having radially expanding anchoring strips, which will not pull out of a hole drilled in a support. A drill drills a hole in a support and an expandable anchor is inserted through the hole. Threads internal to the expandable anchor cooperate with threads on a screw inserted therein to collapse the expandable anchor, providing anchoring strips over the hole such that the expandable anchor cannot be pulled out of the hole. A threaded portion of the base of the screw is suitable for attaching the article to be hung. The base may be a swivel head type. The drill may be on the expendable anchor assembly.

Owner:ILLINOIS TOOL WORKS INC

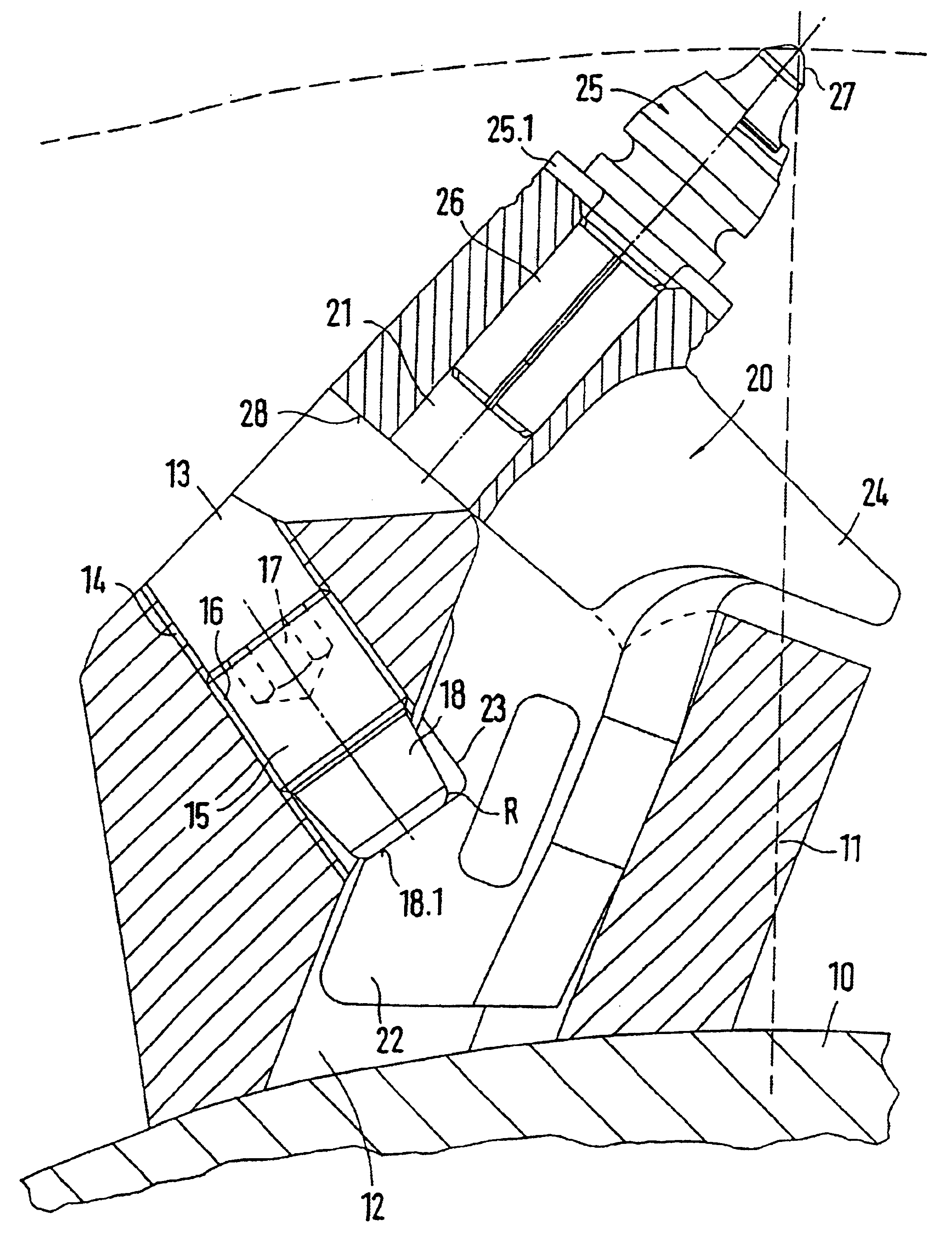

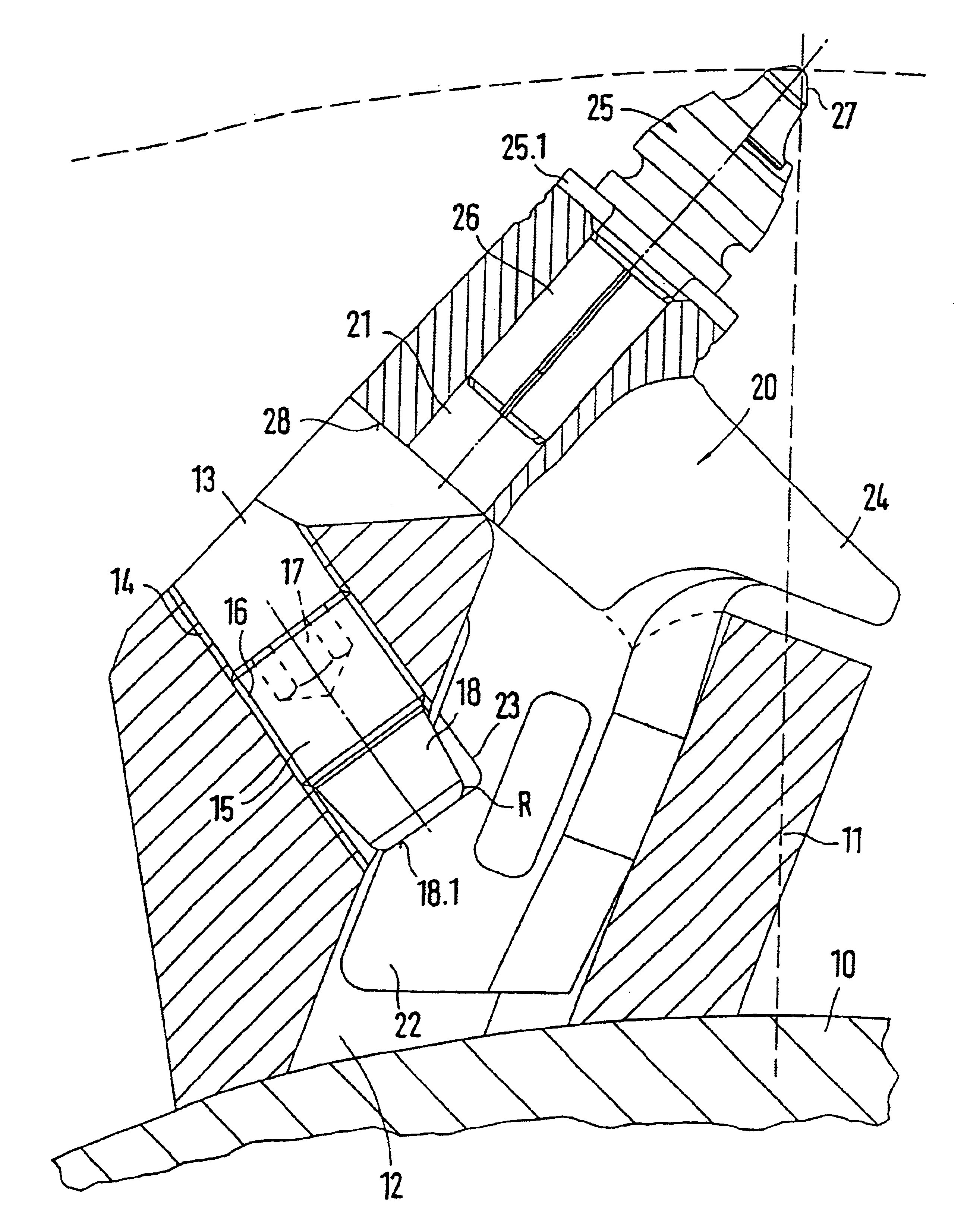

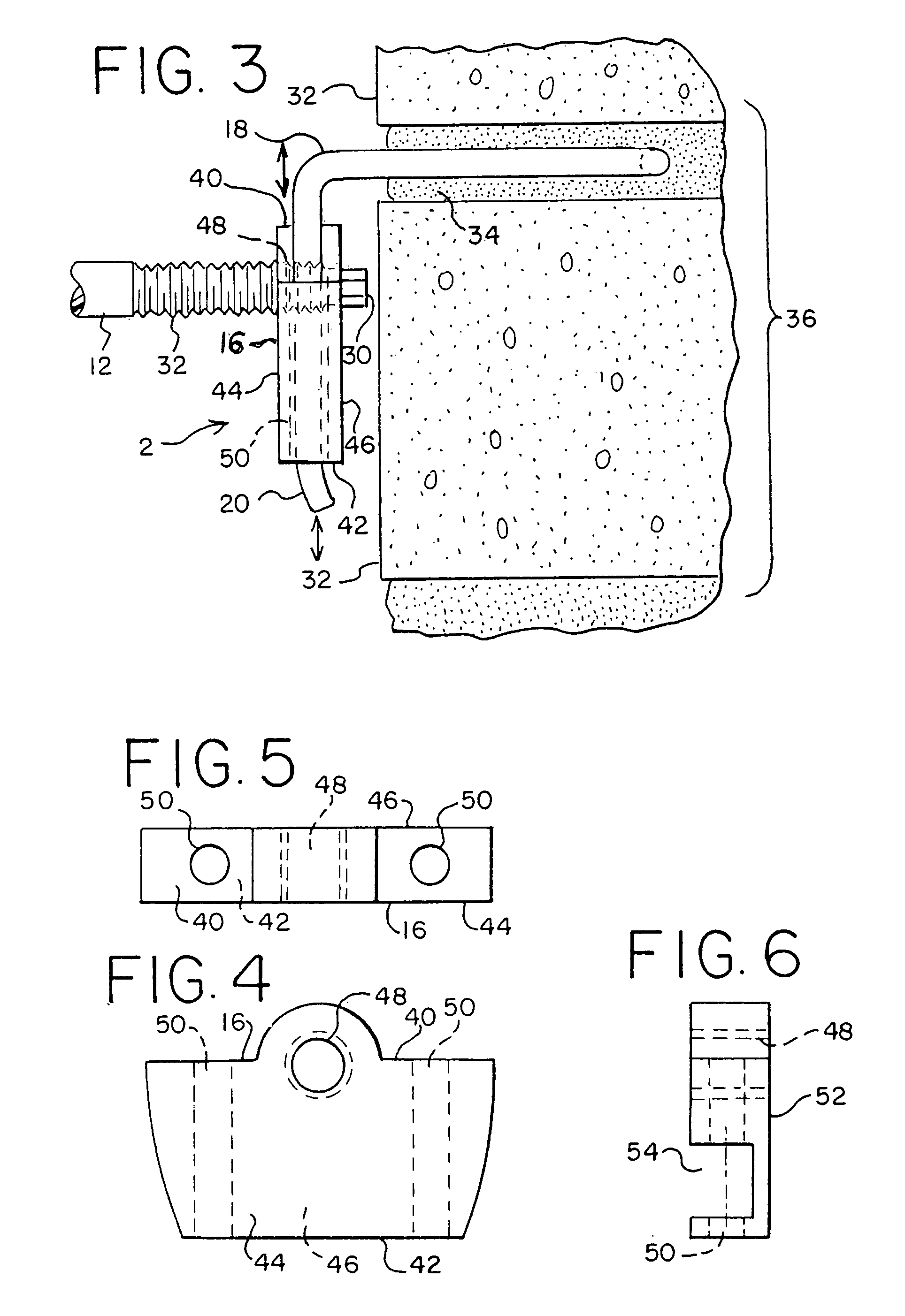

Chisel holder changing system with chisel holder receivers

A chisel holder changing system having a base element with a chisel holder receiver, into which a chisel holder equipped with a chisel can be inserted, wherein the chisel holder is inserted with a holder shaft into the chisel holder receivers and is maintained therein with the aid of bracing screws. Bracing screws can be screwed into a threaded receiver of the base element and during this are supported under tension in a bracing receiver of the holder shaft of the chisel holder. If in a chisel holder changing system in accordance with this invention the surfaces of the outer screw thread of the bracing screw and / or of the inner screw thread of the threaded receivers of the chisel holder receivers have a metallic layer of zinc and aluminum lamellas and a mineral chromium oxide bonding agent, which is burned in after the application, the screw connections are improved so that larger prestressing forces / tightening torques can be transmitted without damage to the screw connections.

Owner:WIRTGEN GMBH

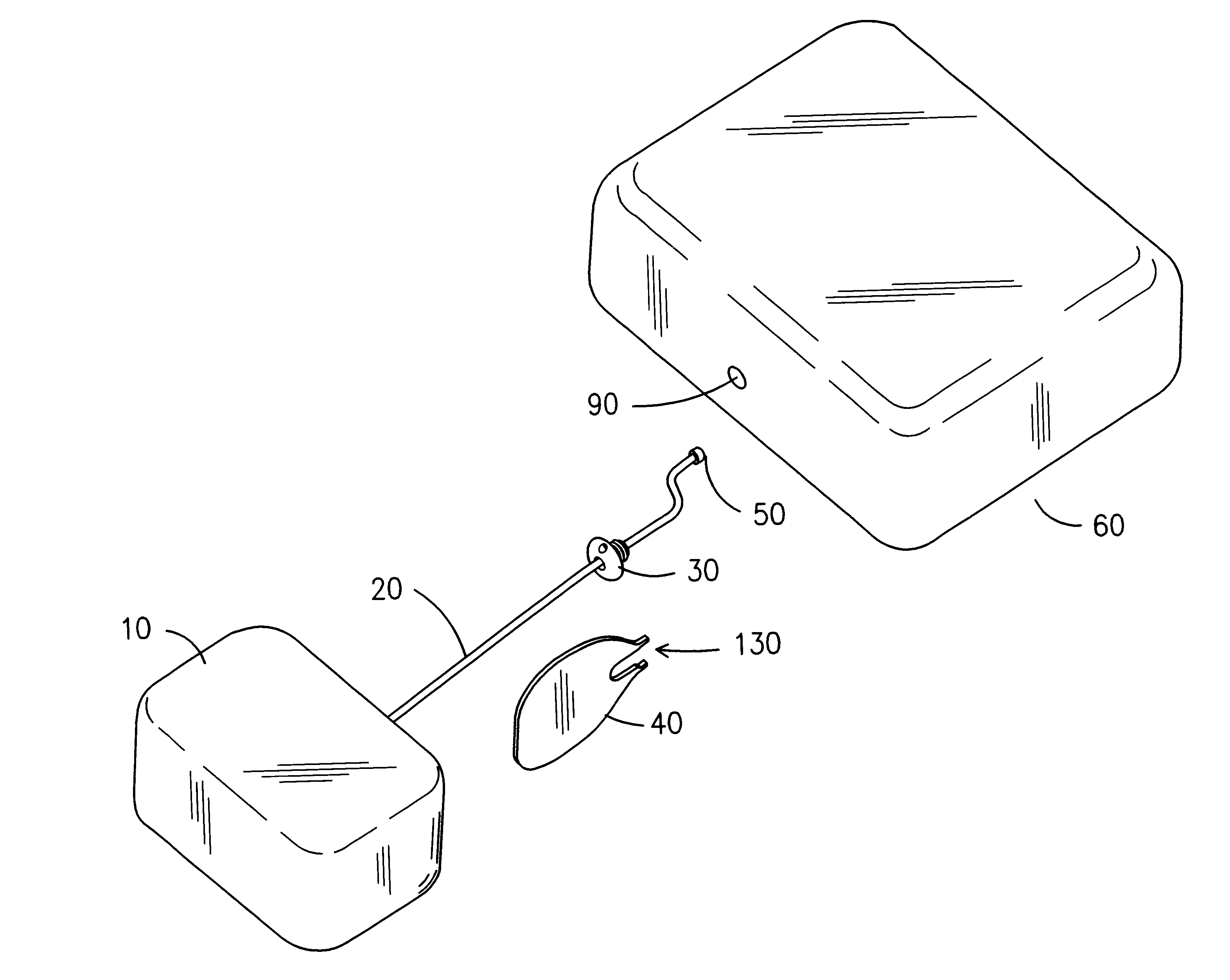

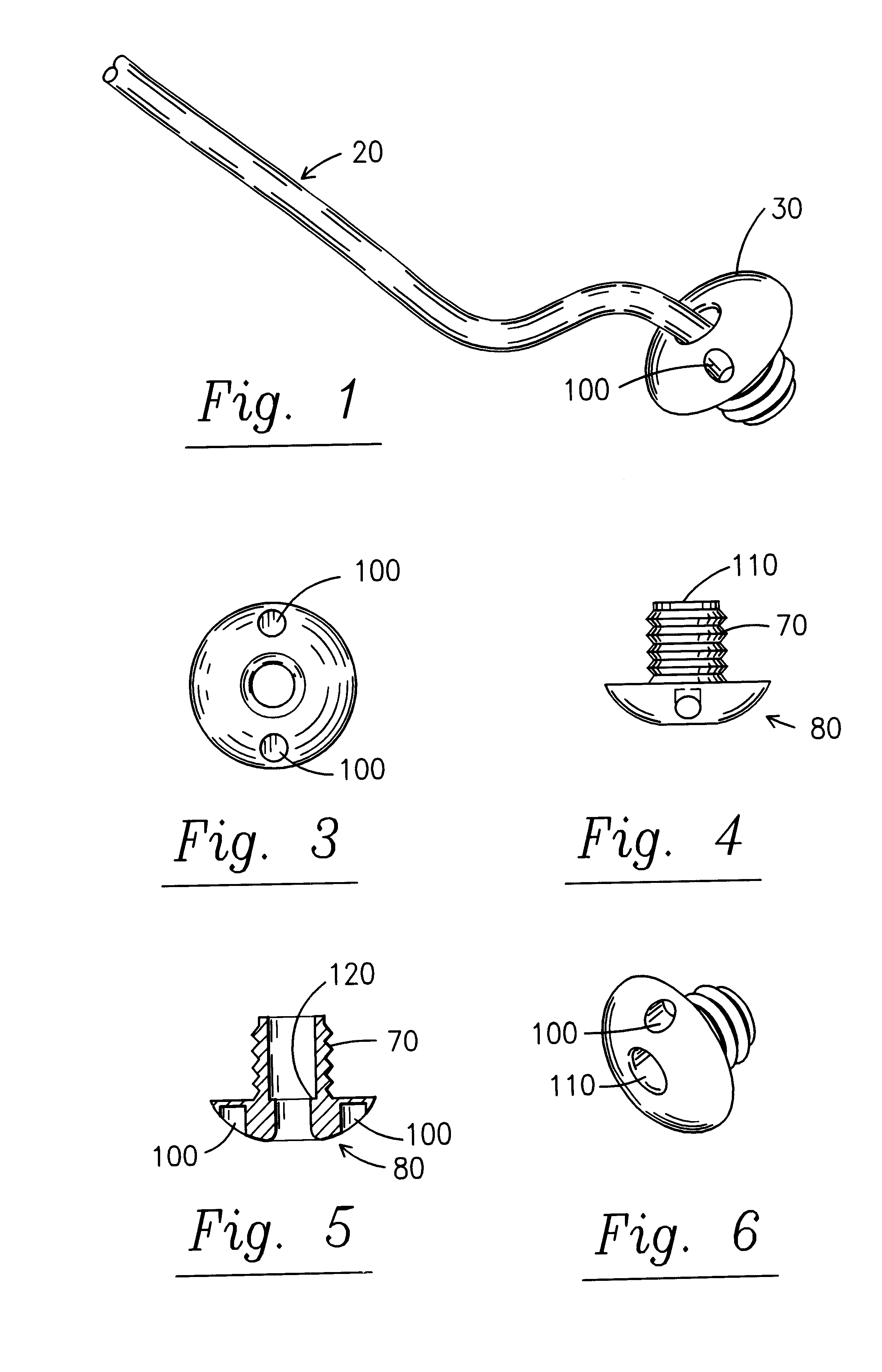

Security system

A security system for connecting a cable to consumer articles, such as cameras, and the like, to prevent unauthorized removal of the articles from a predetermined area while being displayed in retail establishments on open shelves. The system in its most basic form comprises a device including a security cable and a threaded fastener. The security cable is passed through the threaded fastener, and then the threaded fastener is attached into the body of the article. The threaded fastener head has a special configuration and cannot be removed without a special key, thereby preventing the unauthorized removal of the secured property. The threaded fastener also includes a circular borehole through the entire length of the threaded fastener to allow the cable to pass through the opening, and a step is provided inside the borehole to stop the cable from coming off the fastener. Optionally, a reel, an alarm, or a fastener cover can be added to the basic system to make more difficult the removal of the security cable from the article.

Owner:SENNCO SOLUTIONS INC

Deforming member and captive fastener retaining method

A fastener is retained within an opening of a workpiece by deforming a portion of an edge of the opening inwardly to prevent removal of the fastener. A deforming member associated with a head of the fastener includes a body having a clamping surface extending radially form a central axis. A wedge-like deforming element has a deforming member and having a deforming face angled axially and radially outward from the clamping surface. The deforming element, when pressed against a malleable edge of the workpiece, deforms at least a portion of the edge into the fastener opening thereby creating a stop which reduces the diameter of the opening and mechanically retains the fastener therein. The deforming member may be formed as a separate washer assembled on the fastener or may be made integral with the fastener head.

Owner:GM GLOBAL TECH OPERATIONS LLC

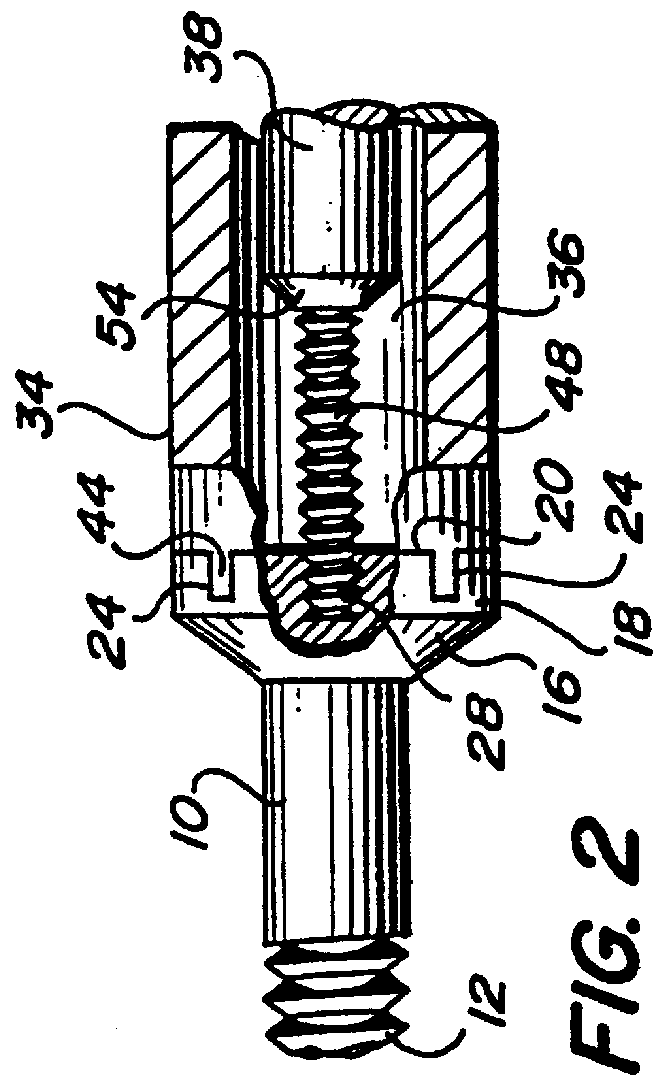

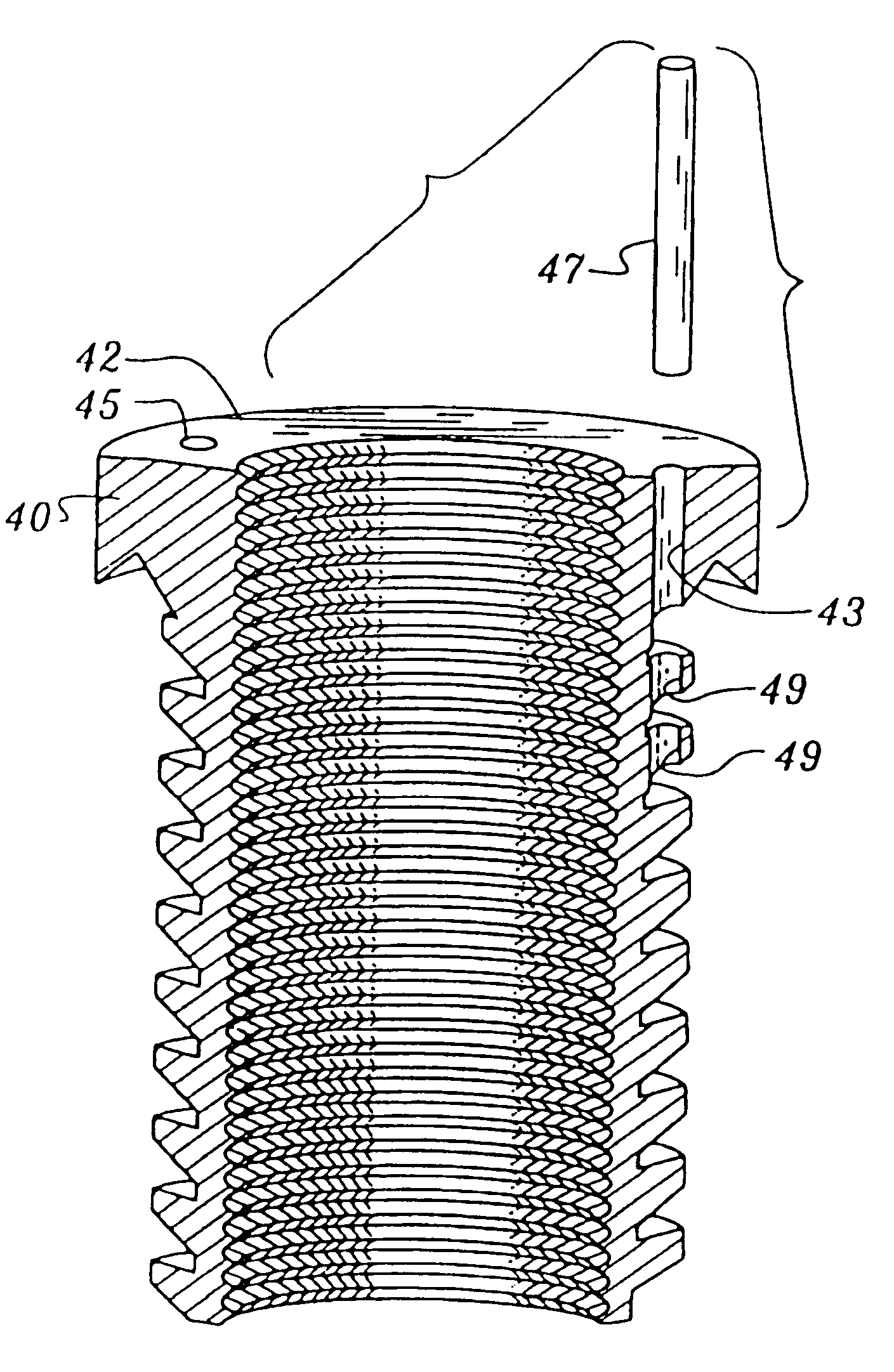

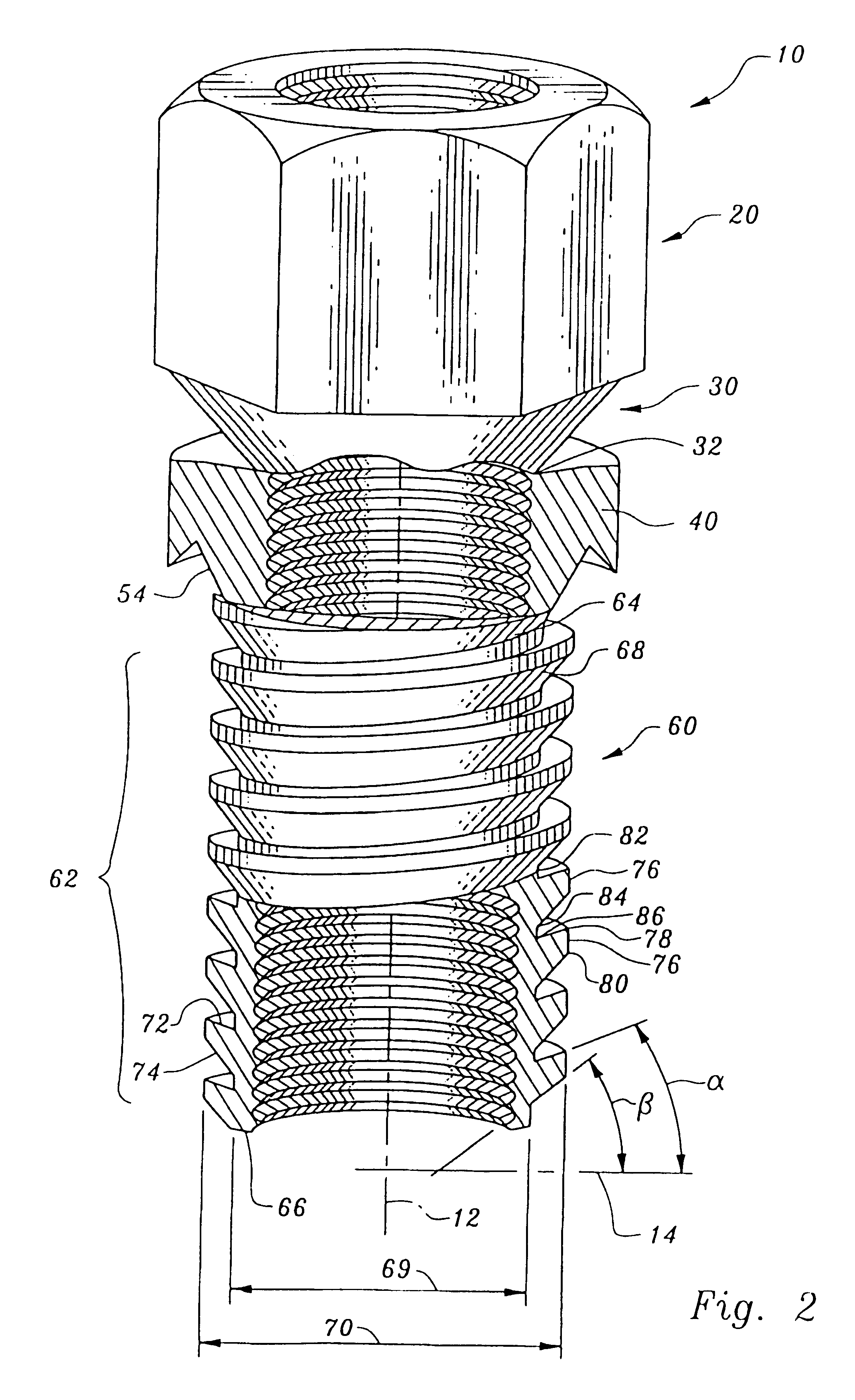

Insert retention mechanism

An insert for use in allowing spark plugs, fasteners, couplings for hydraulic fittings and pipe threads of a given dimension to be used in a material.

Owner:LOCK N STITCH INC

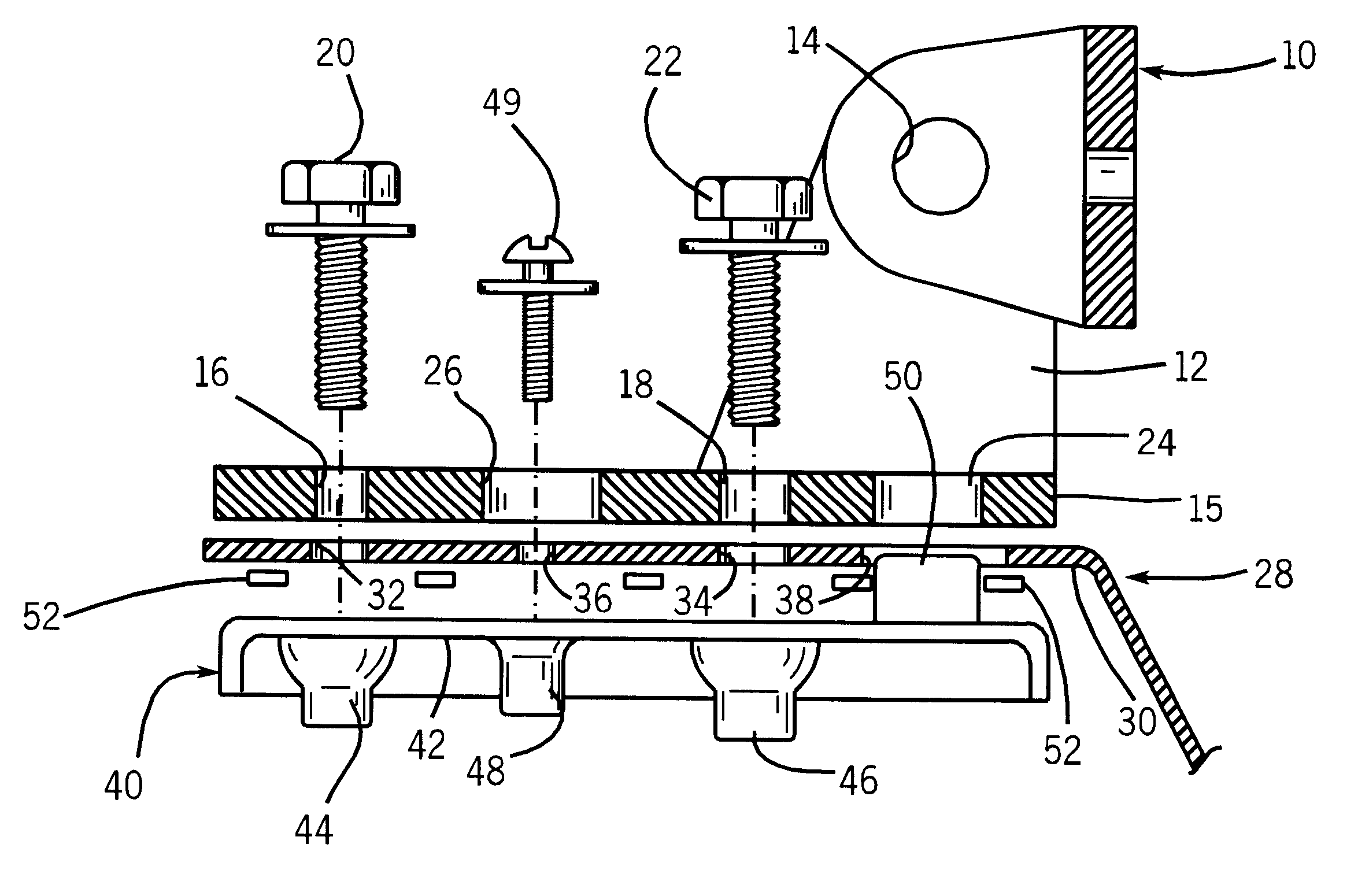

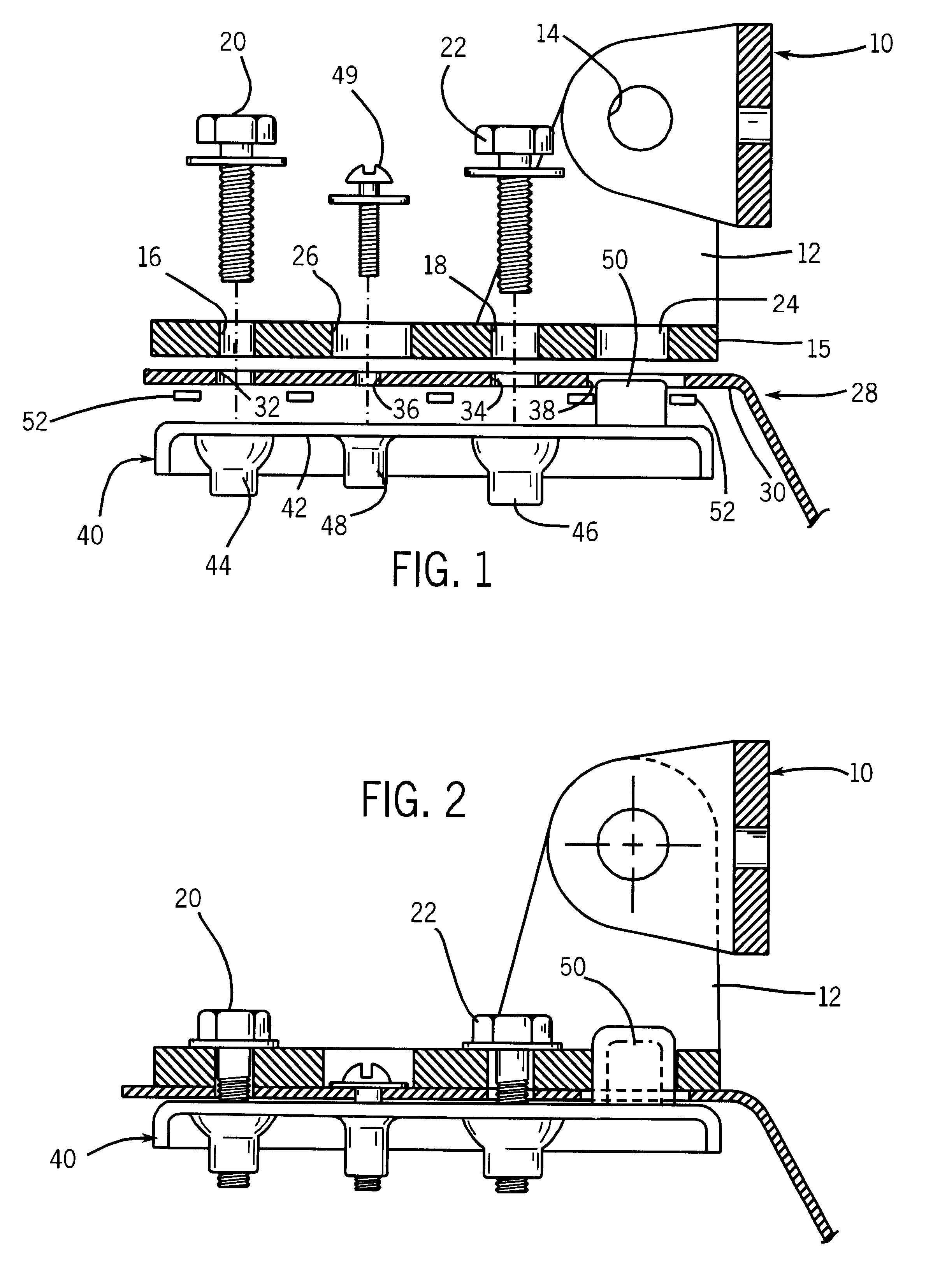

Vehicle door hinge attachment system and method

InactiveUS6511120B1Easy to disassembleImproving door fitmentVehicle seatsUnderstructuresEngineeringHot-melt adhesive

A reinforcing nut plate (40) contacts one surface of an automotive vehicle body pillar (28) with hot-melt adhesive bodies (52) therebetween. A door hinge plate (15) is secured to the pillar (28) and nut plate (40) by one or more bolts (20,22) providing a predetermined mounting arrangement. On rust-proofing or other manufacturing treatment raising the door temperature a significant amount, the adhesive bodies affix the nut plate to the pillar. Now, the door may be removed from the pillar and transported to another work site for accessories to be mounted, following which the door can be readily reinstalled to the predetermined arrangement with the pillar and nut plate.

Owner:ILLINOIS TOOL WORKS INC

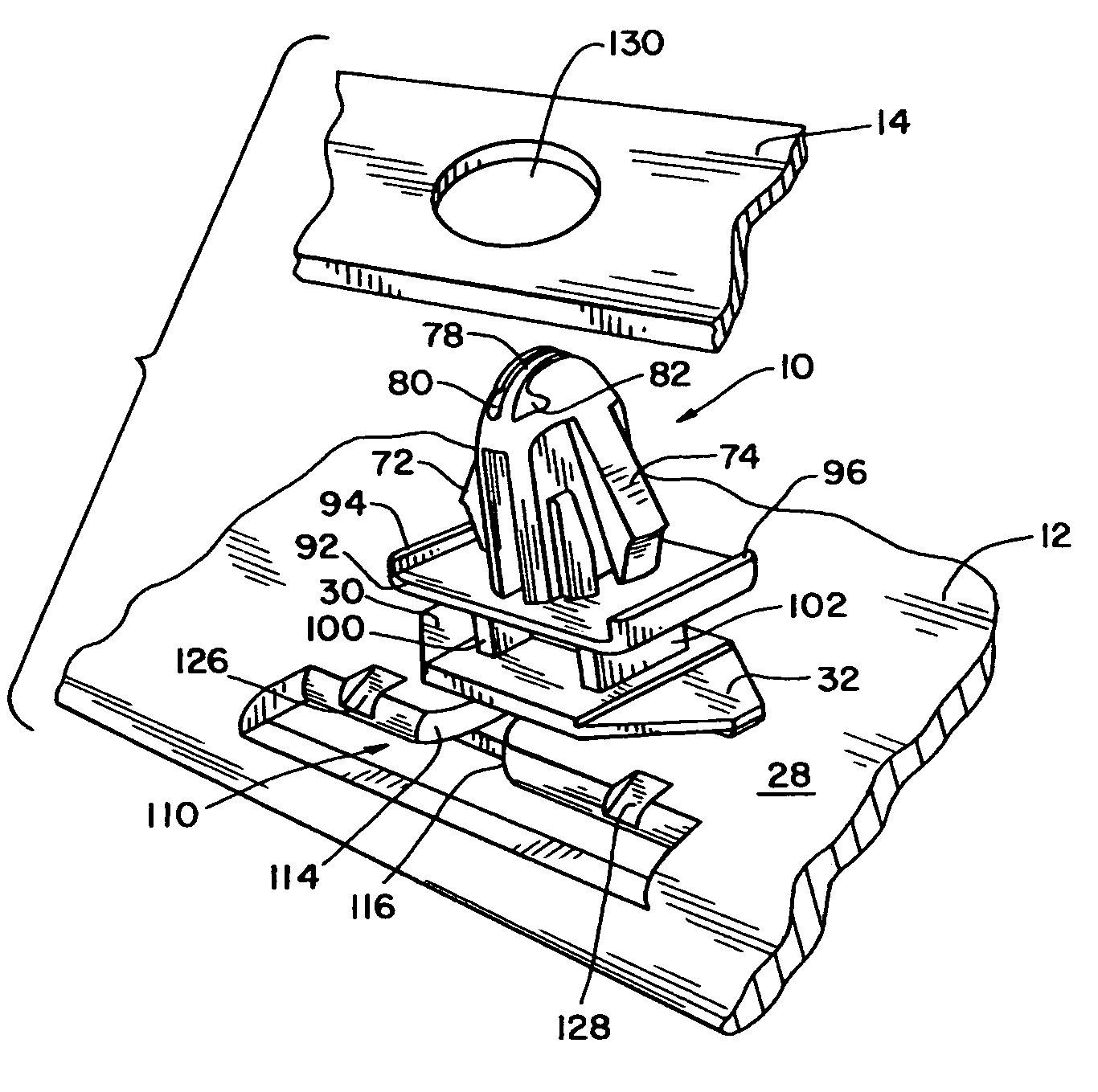

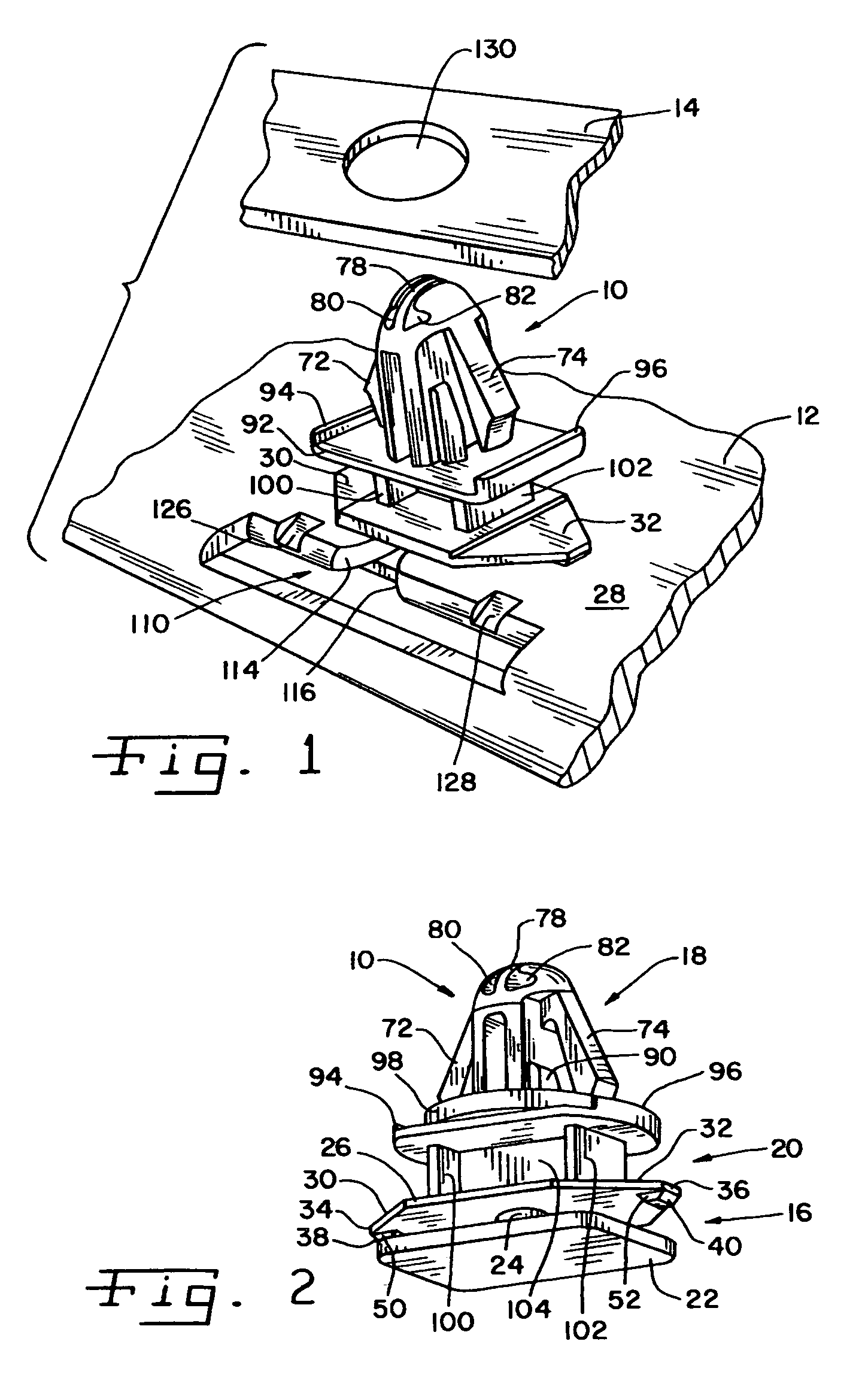

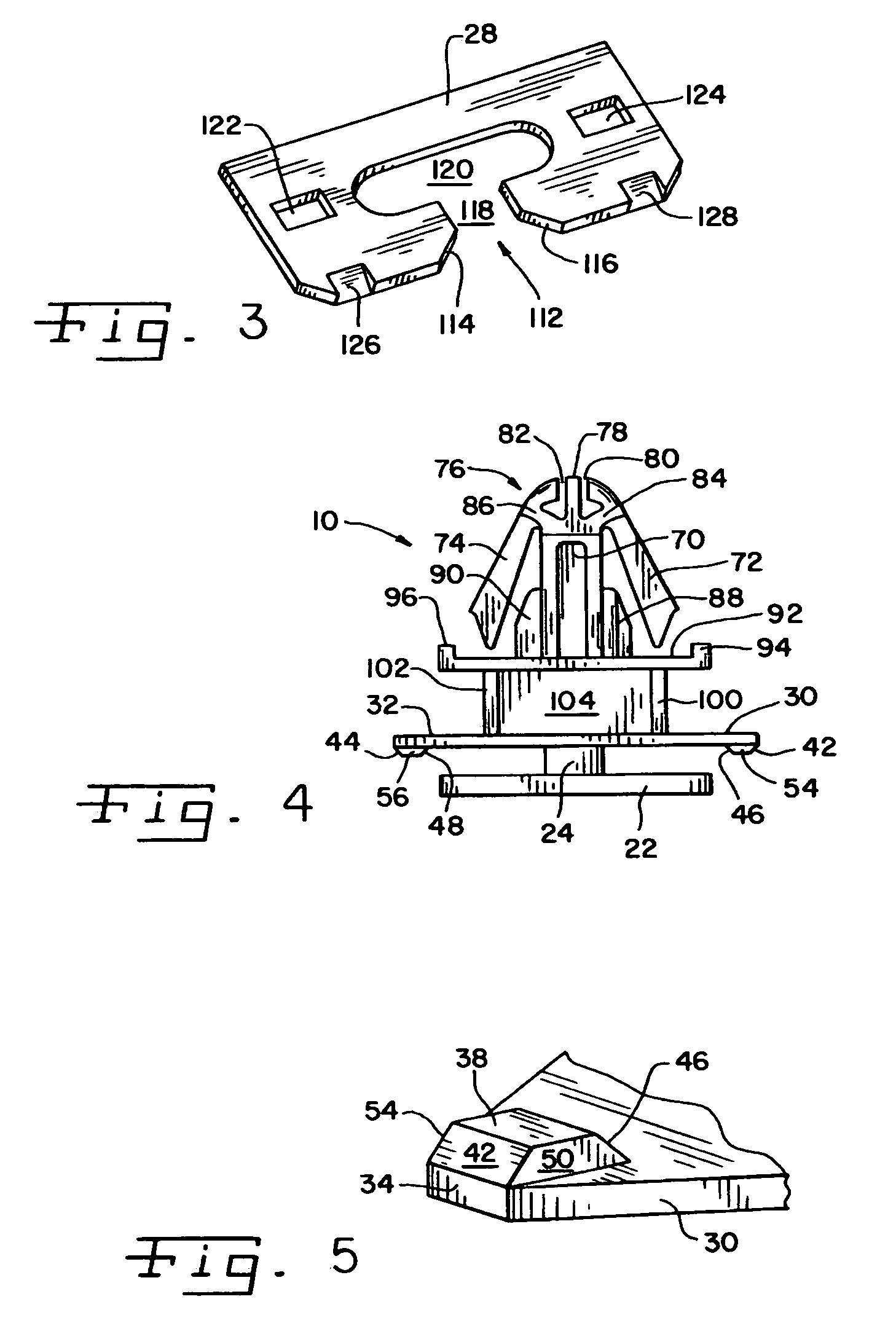

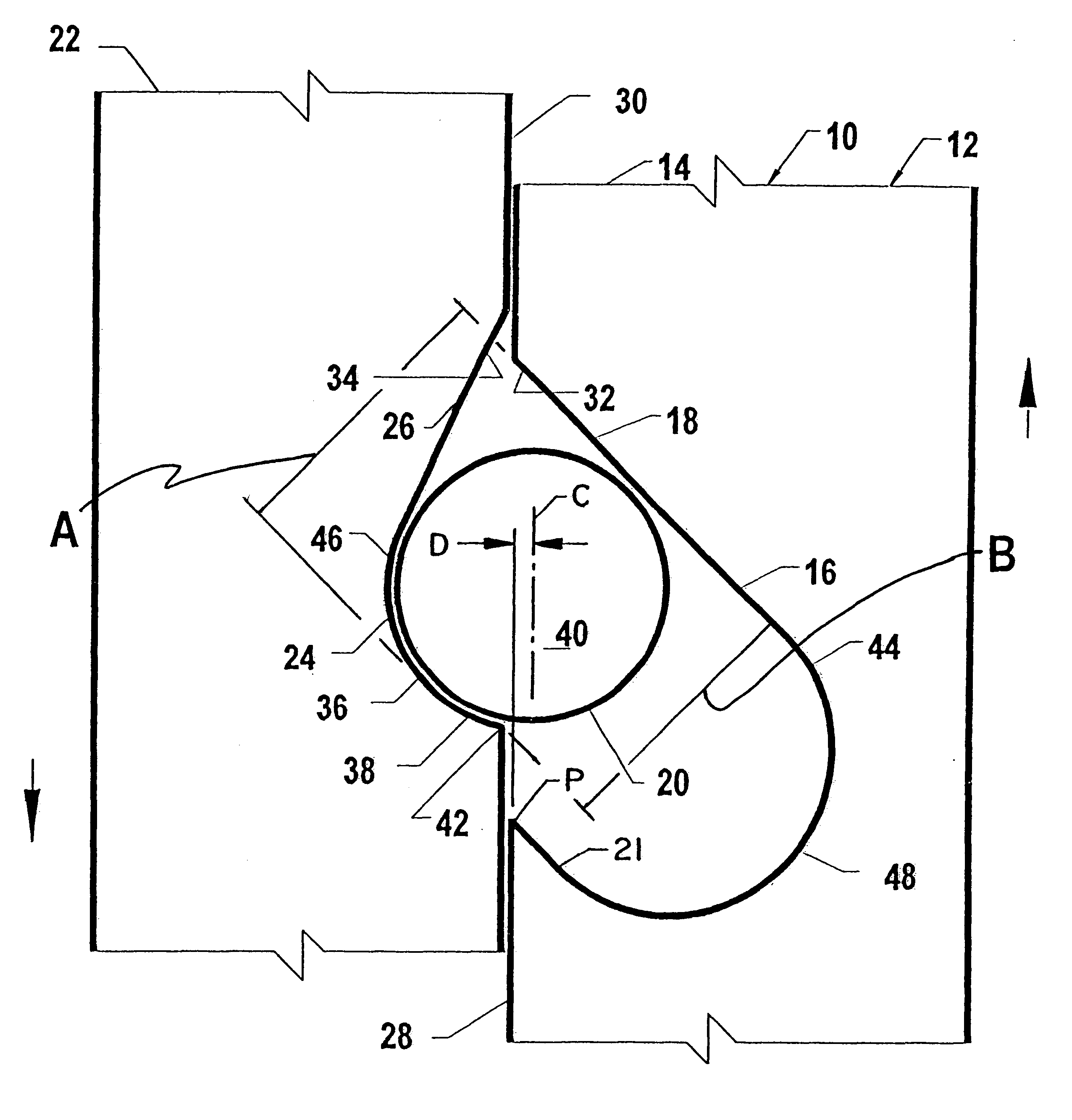

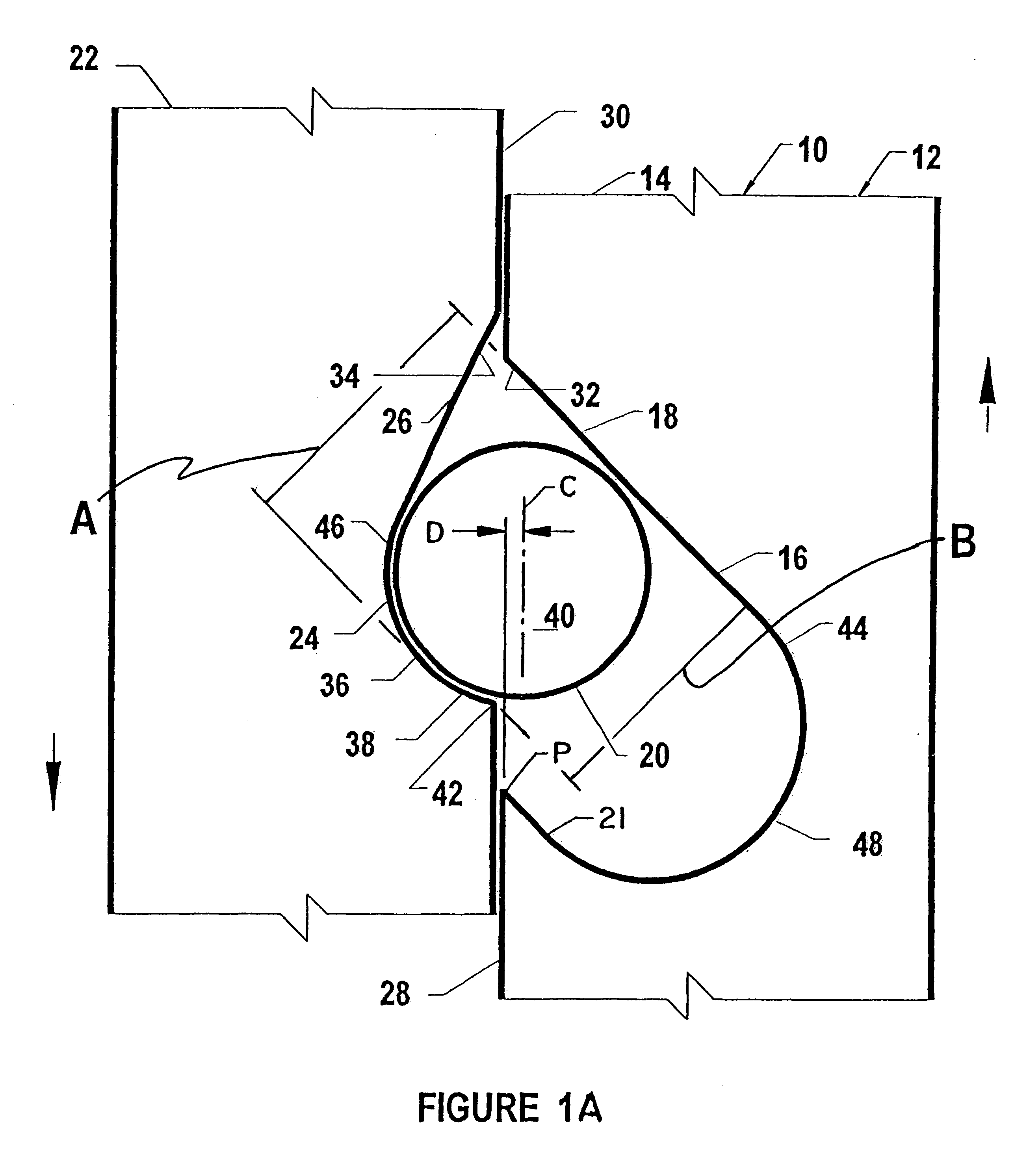

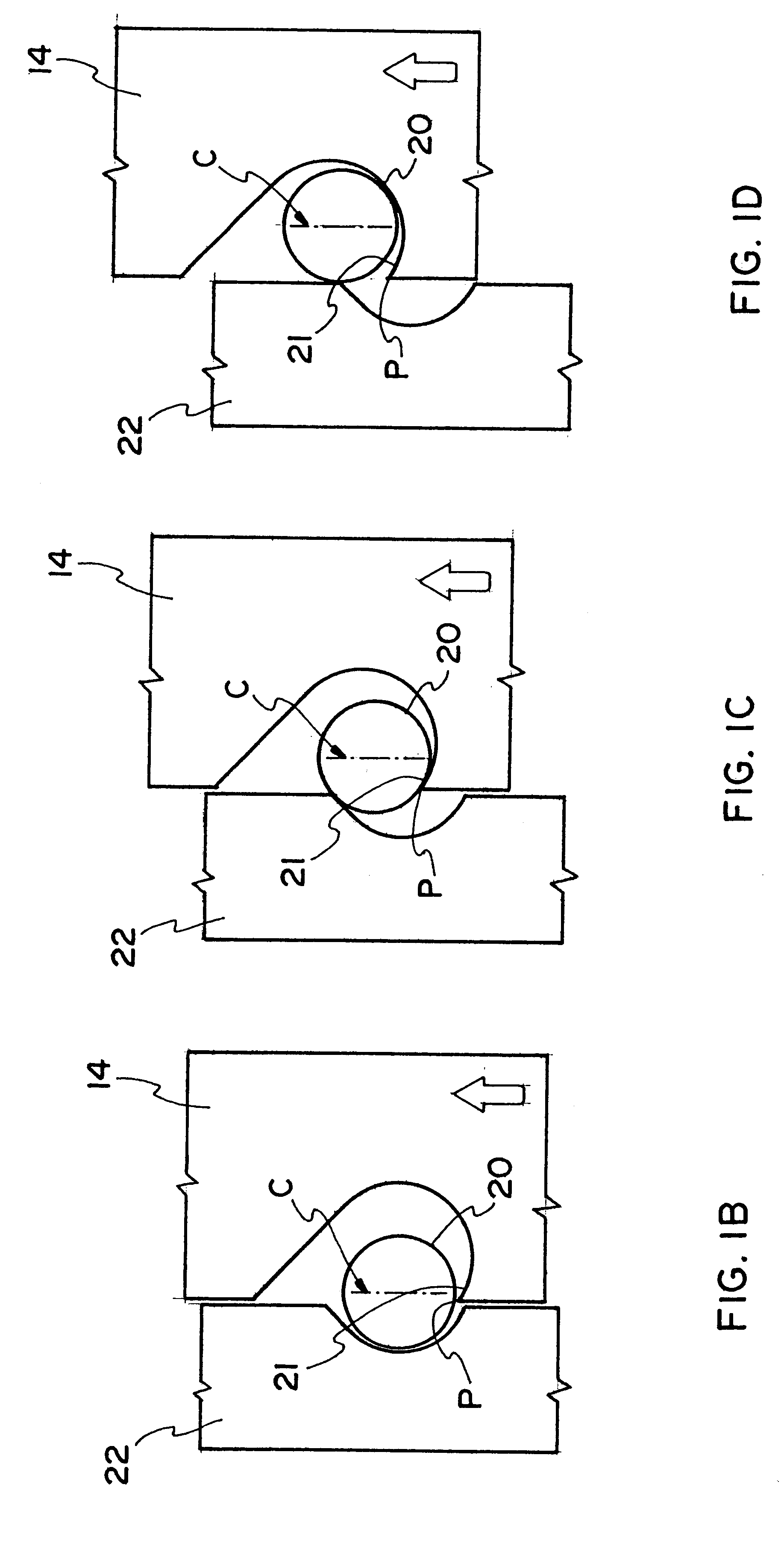

Tie down building, system tie down, and method

InactiveUS6494654B2Inexpensive and readily manufacturedEasy to assembleHuman health protectionNutsAuto regulationEngineering

A fastener assembly 10, in respect to forces which are subsequently applied, after the installation thereof, when forces is applied in one direction, this fastener assembly 10 is self adjusting incrementally, as needed in travel or actuation; yet when a force is applied in the opposite direction, this fastener assembly 10 is not self adjusting and there is no travel or actuation. The invention includes also the building structure and method.

Owner:ESPINOSA THOMAS M

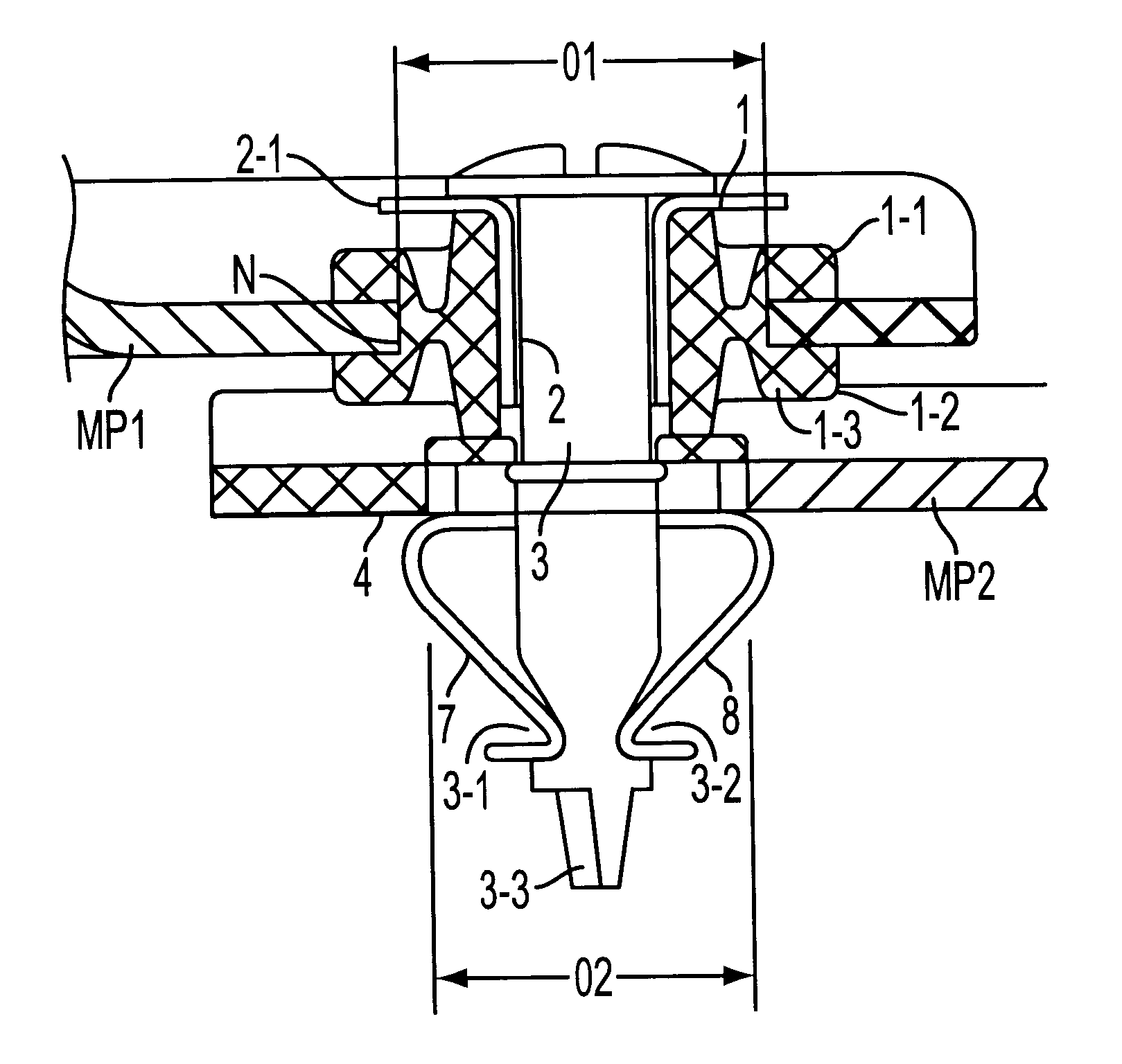

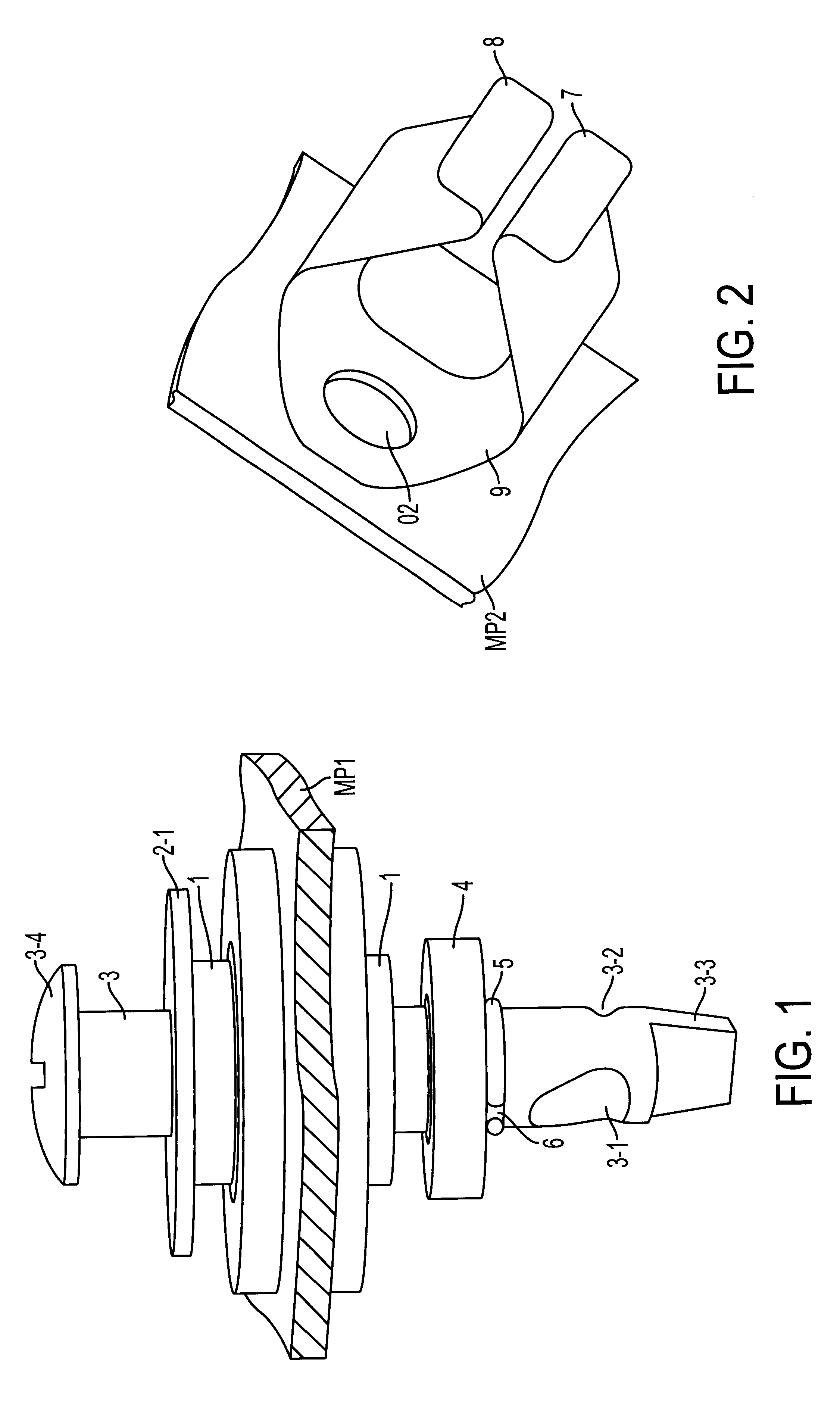

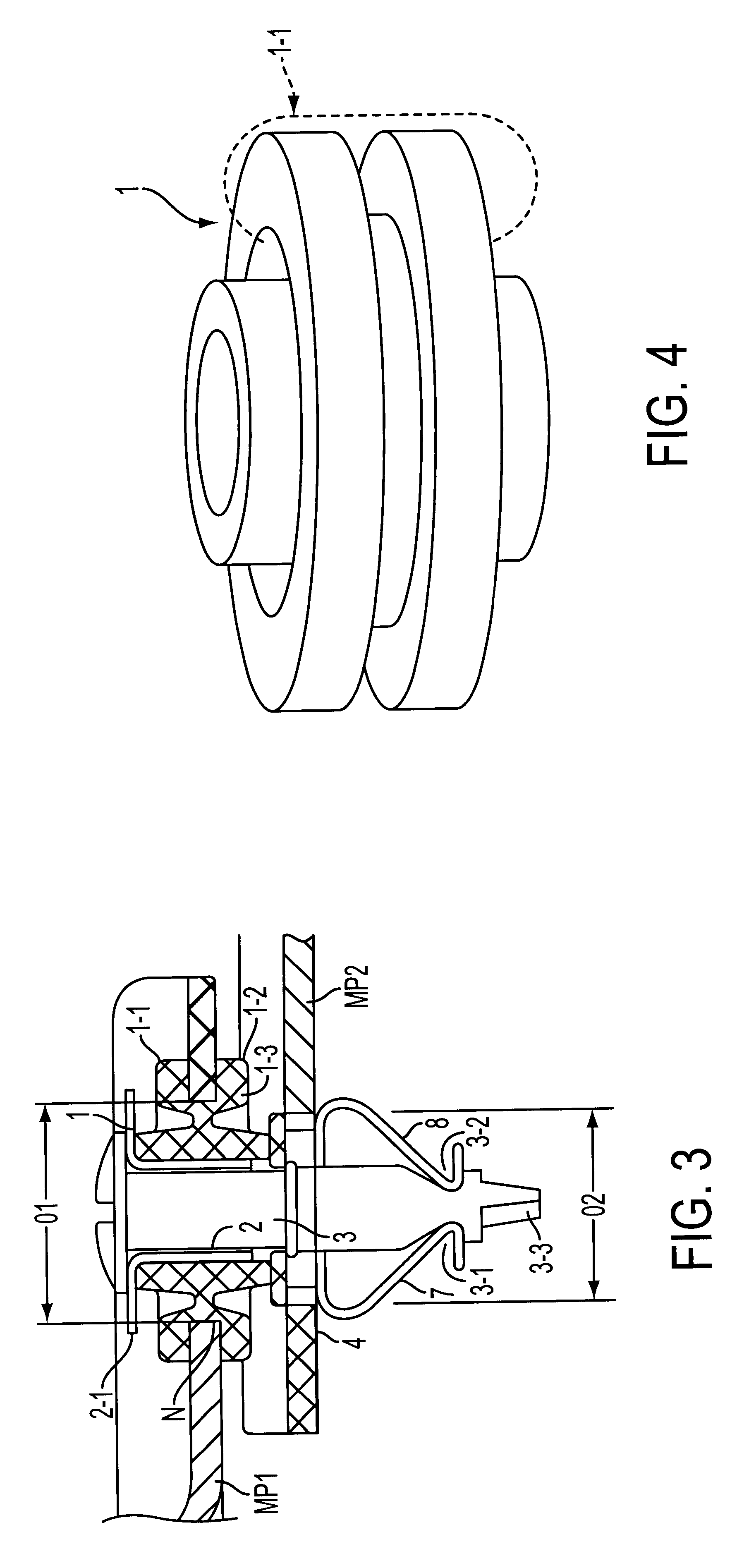

Vibration-damping detachable connection arrangement for two components with a rotating bolt, a retaining spring and a vibration-damping ring

Connection arrangement for detachable connection of components with aligned openings, includes a bolt, rotatable around its own axis, having tapered toward a free end, and at least two lateral notches, and retaining spring, including at least two spring-loaded ends, where spring-loaded ends are arranged to hook into lateral notches when first and second components are connected. At least lateral notches of bolt are arranged to project through opening of second component. Vibration-damping ring includes peripheral groove to receive edge of opening of first component and ring opening. Bush is located in ring opening to guide bolt. Movable ring, having outer diameter that is smaller than diameter of opening of first component and that is larger than diameter of opening of second component, is arranged on bolt. When first and second components are connected, movable ring is positioned between lower side of vibration-damping ring and upper side of second component.

Owner:SFS GRP INT AG

Composite fastener, belly nut, tie system and/or method for reducing heat transfer through a building envelope

InactiveUS8109706B2Reduce heat transferSolution value is not highWashersTransportation and packagingBuilding envelopeFibre reinforcement

Owner:RICHARDS JOSEPH P

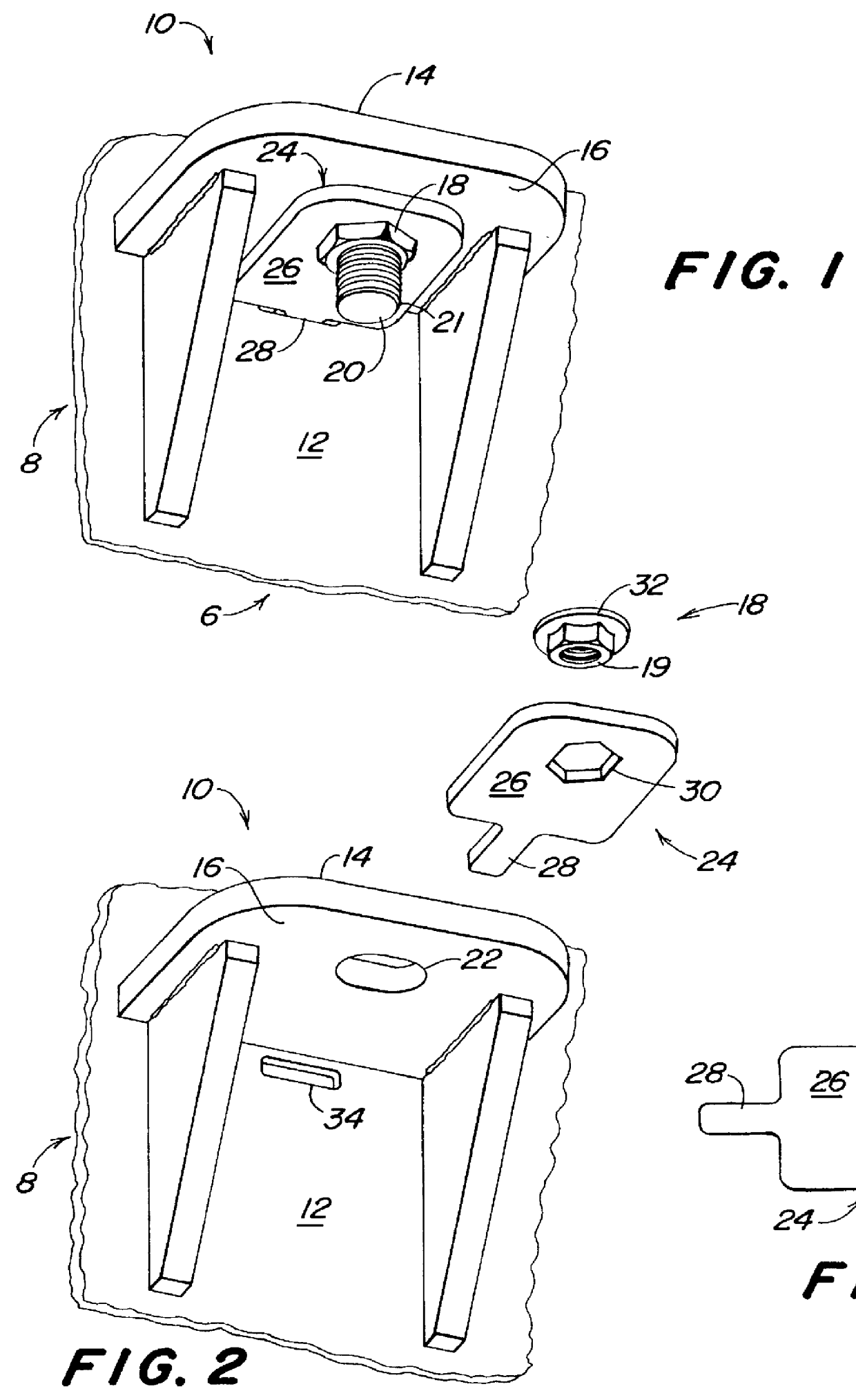

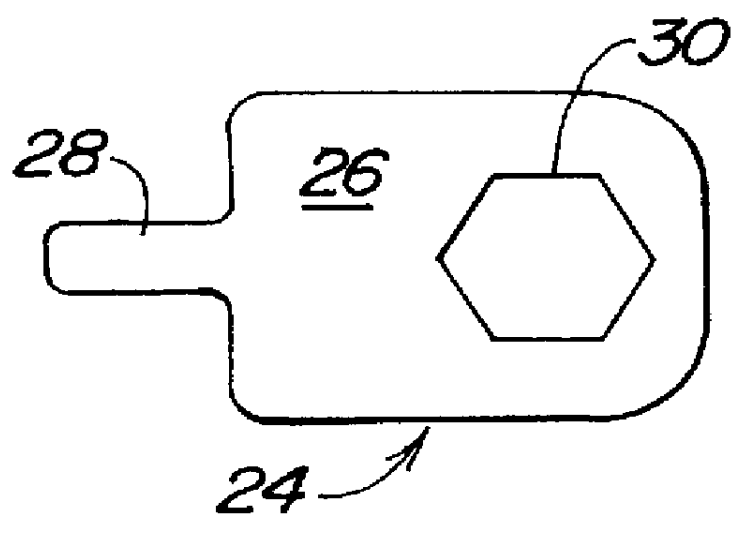

Nut retaining plate

A fastener assembly is adapted for attaching an article to a workpiece having a slot. The fastener assembly includes a flanged nut which has internal threads and a non-circular cross-section, and a bolt having a threaded shank for engagement with the internal threads of the nut. The fastener assembly also includes a plate which comprises a main body and a tab portion extending from the main body. The plate has an opening complementary to the non-circular cross-section of the nut for receiving the nut therein and for securing the nut against rotation relative to the plate when the nut is placed in the opening. Alternatively, a nut is fixed to an underside of the plate against rotation and the opening in the plate is adapted for receiving the bolt therethrough. The tab portion of the plate extends into the slot in the workpiece for retaining the plate and nut and allowing limited float of the plate and nut with respect to the workpiece.

Owner:DEERE & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com