Patents

Literature

65results about How to "Reduce clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

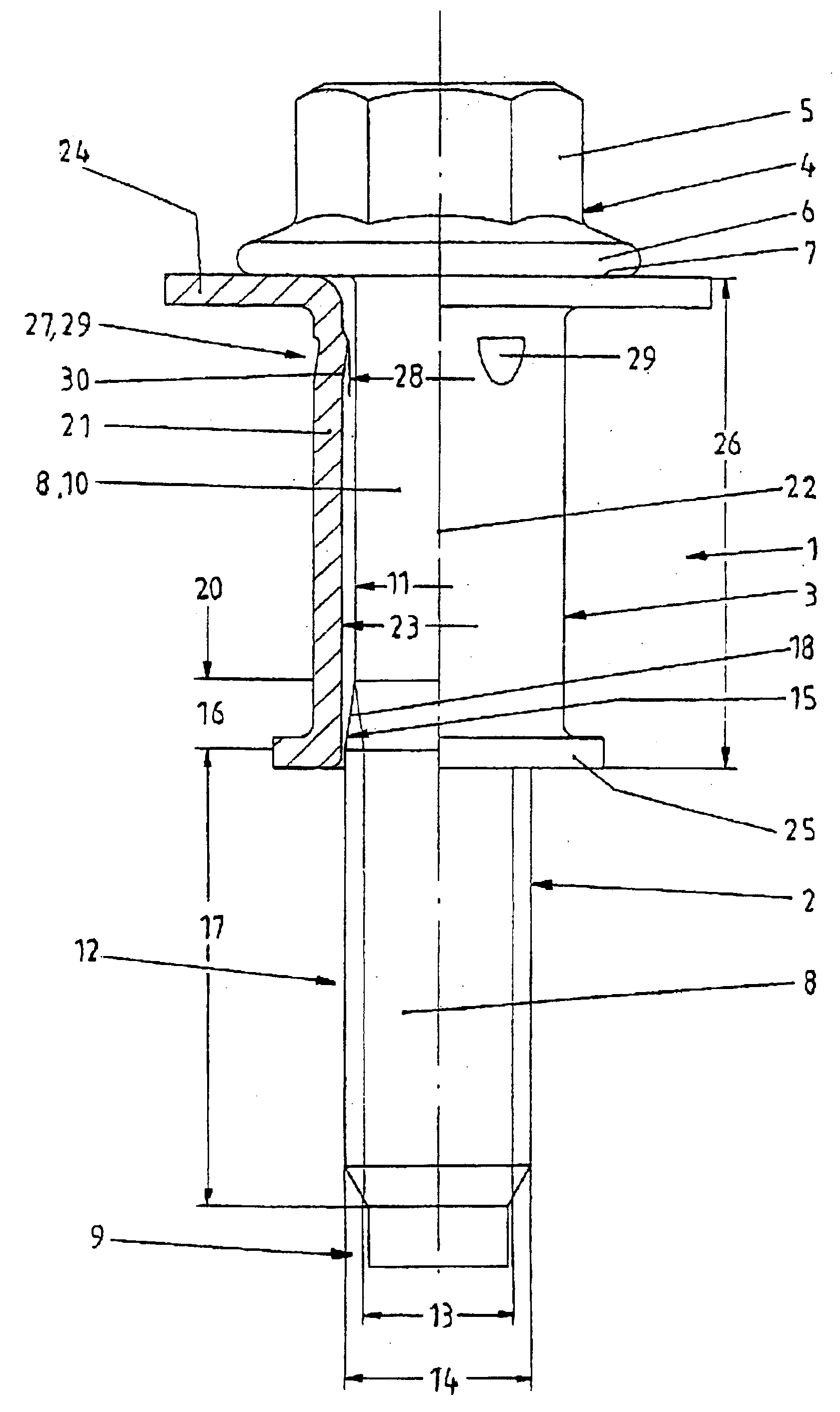

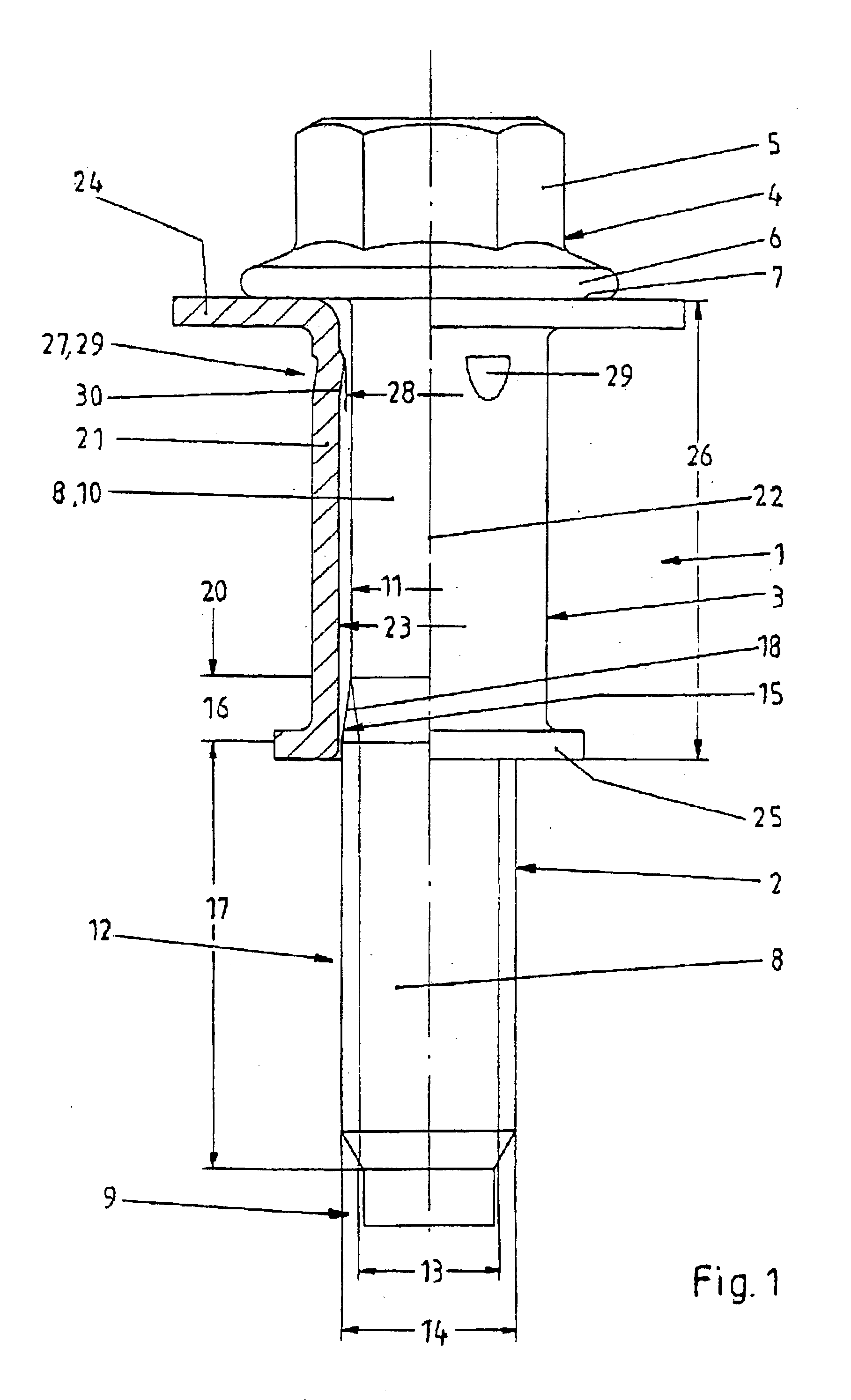

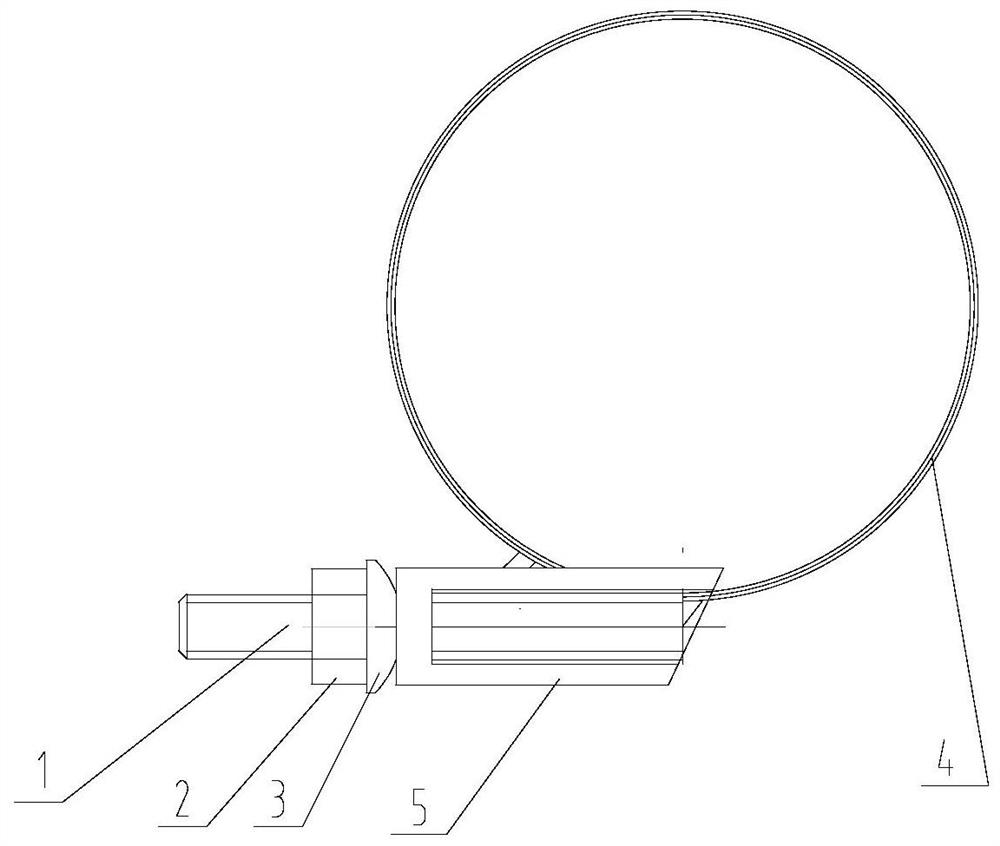

Fastener including a screw and a supporting element

A fastener (1) includes a screw (2) and a supporting element (3). The screw (2) includes a head (4), a shank (8) and a threaded portion (12). The threaded portion (12) is located on the shank (8). The threaded portion (12) includes a thread having an outer diameter (14). The threaded portion (12) includes a thread runout (25) facing the head (4) of the screw (2). The shank (8) includes a shank portion (10) having a diameter (11) which is smaller than the outer diameter (14) of the thread. The supporting element (3) is captively connected to the screw (2), and it includes at least one narrow location (27). The narrow location (27) has a diameter (28) which is smaller than the outer diameter (14) of the thread. The narrow location (27) includes at least one surface element (30, 35) facing the thread runout (25) and forming an enveloping cone (31) enveloping the thread runout (25) to prevent the supporting element (3) from getting clamped at the thread runout (25) of the screw (2).

Owner:KAMAX HLDG

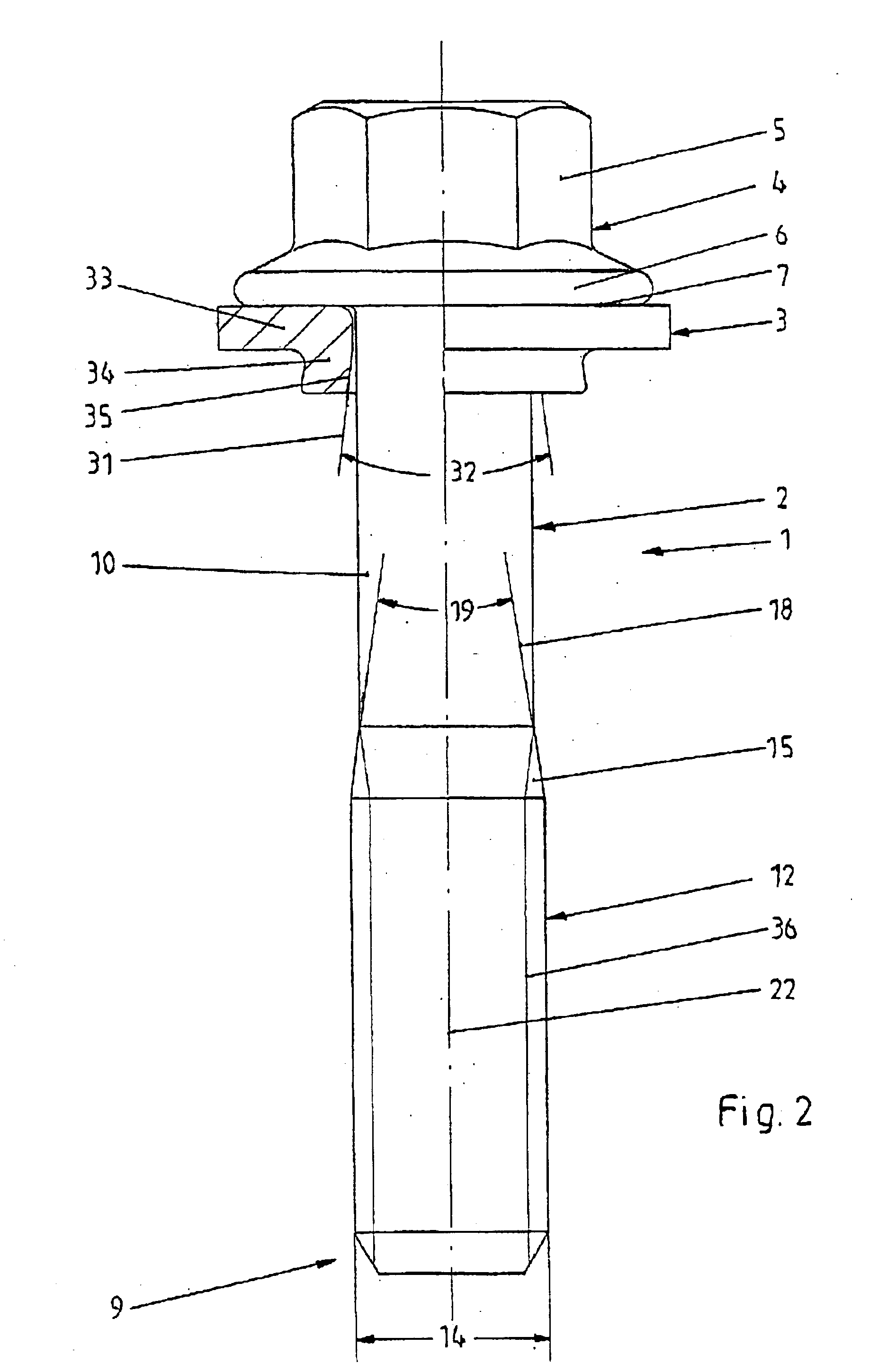

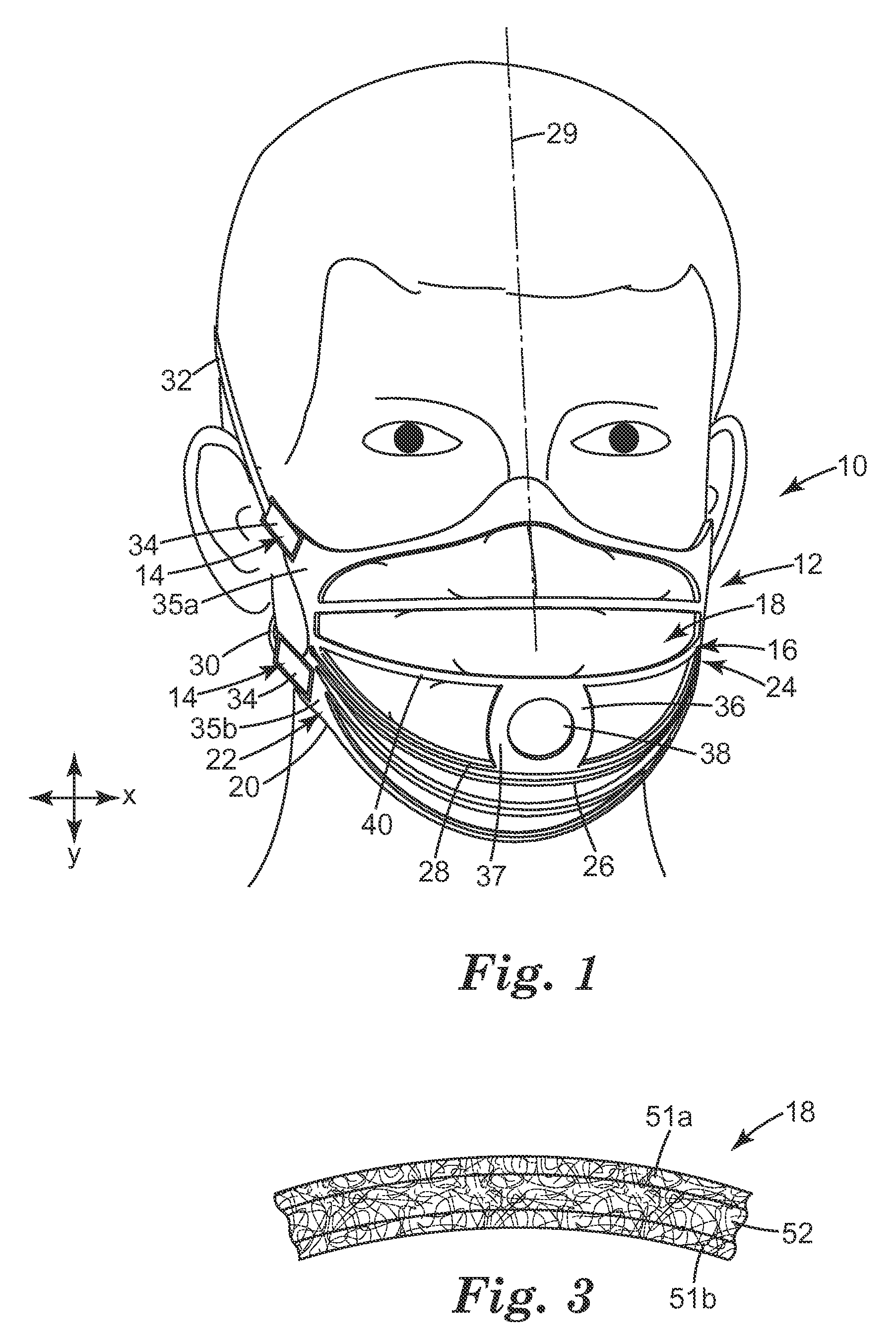

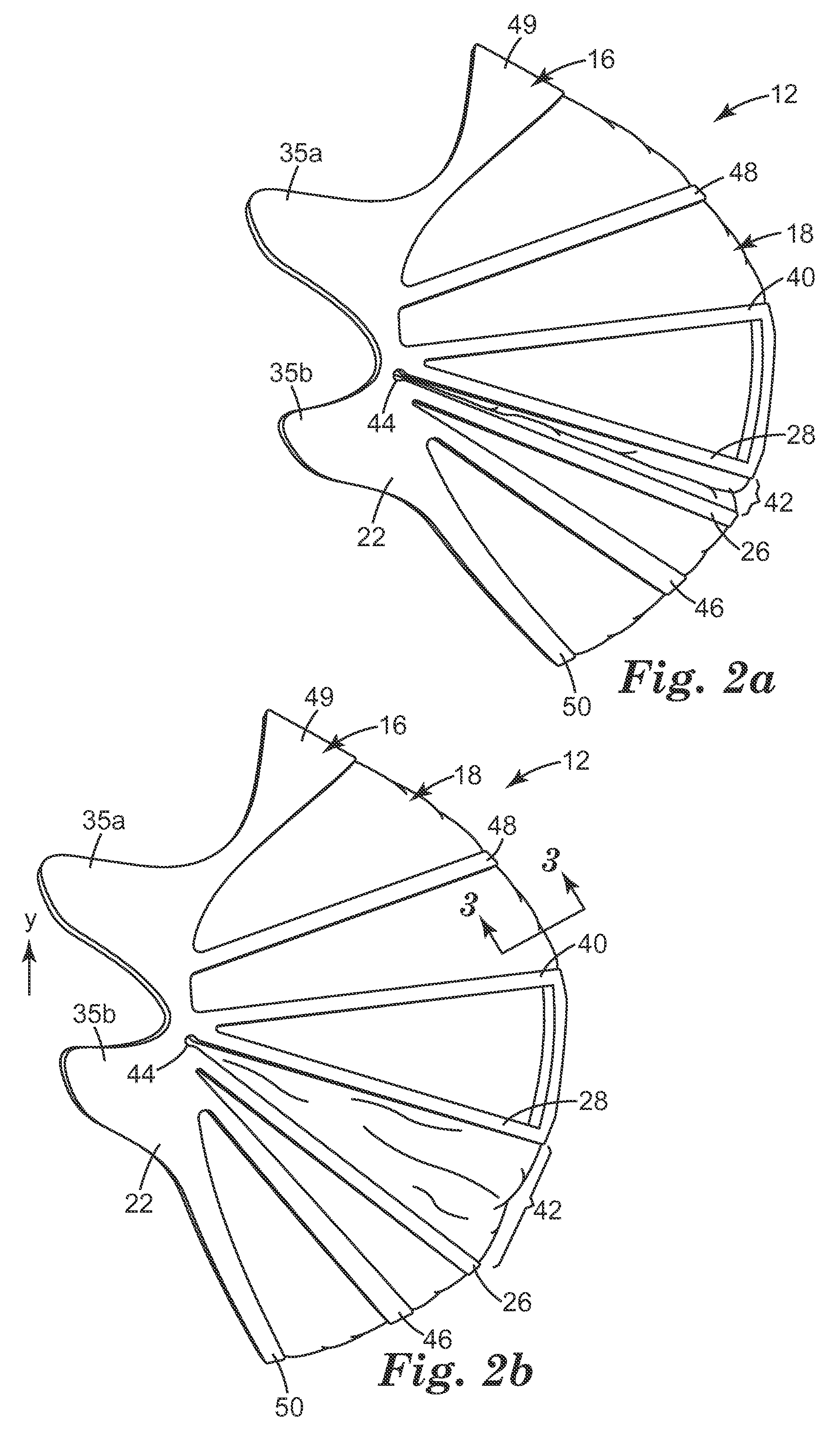

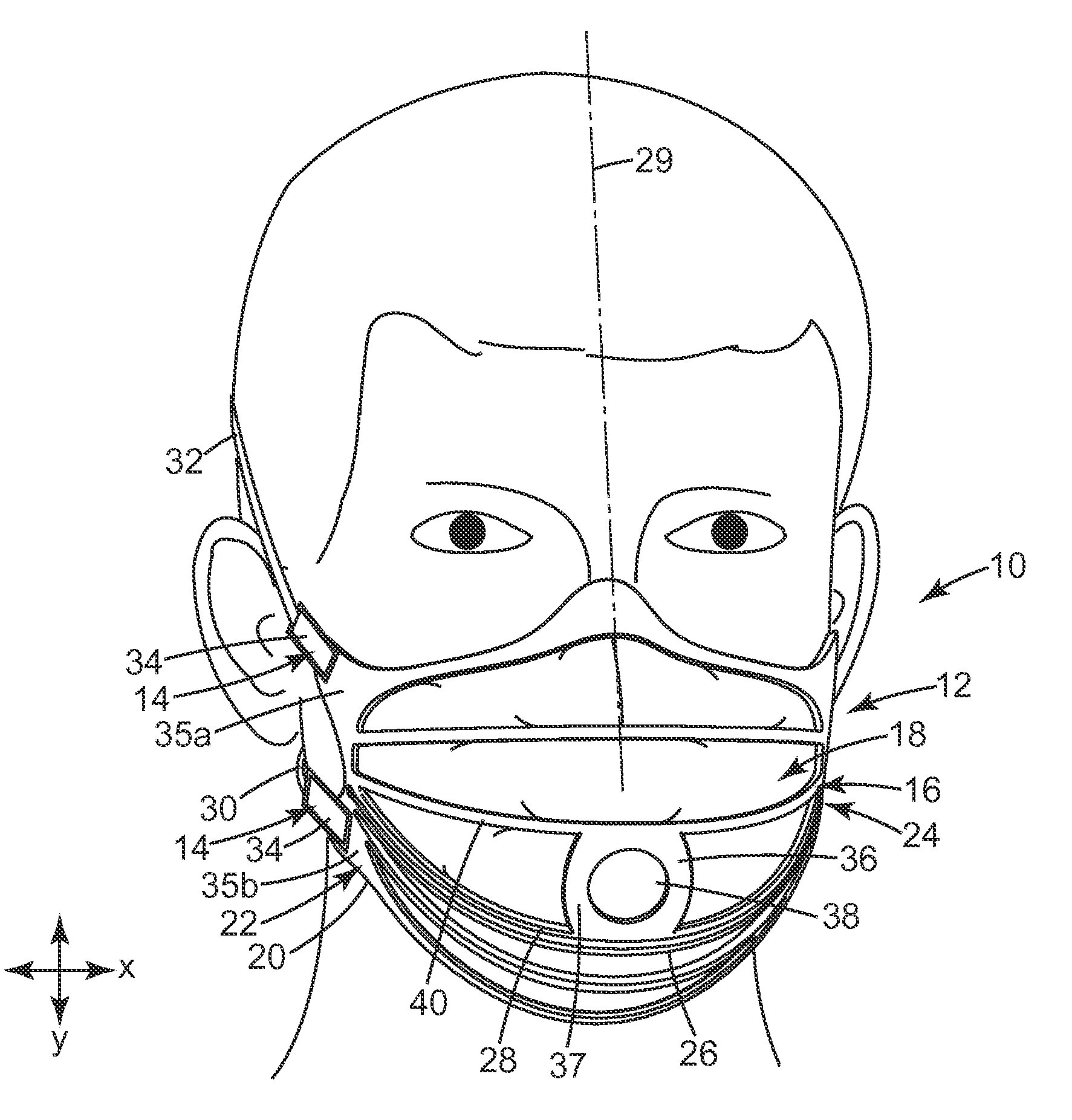

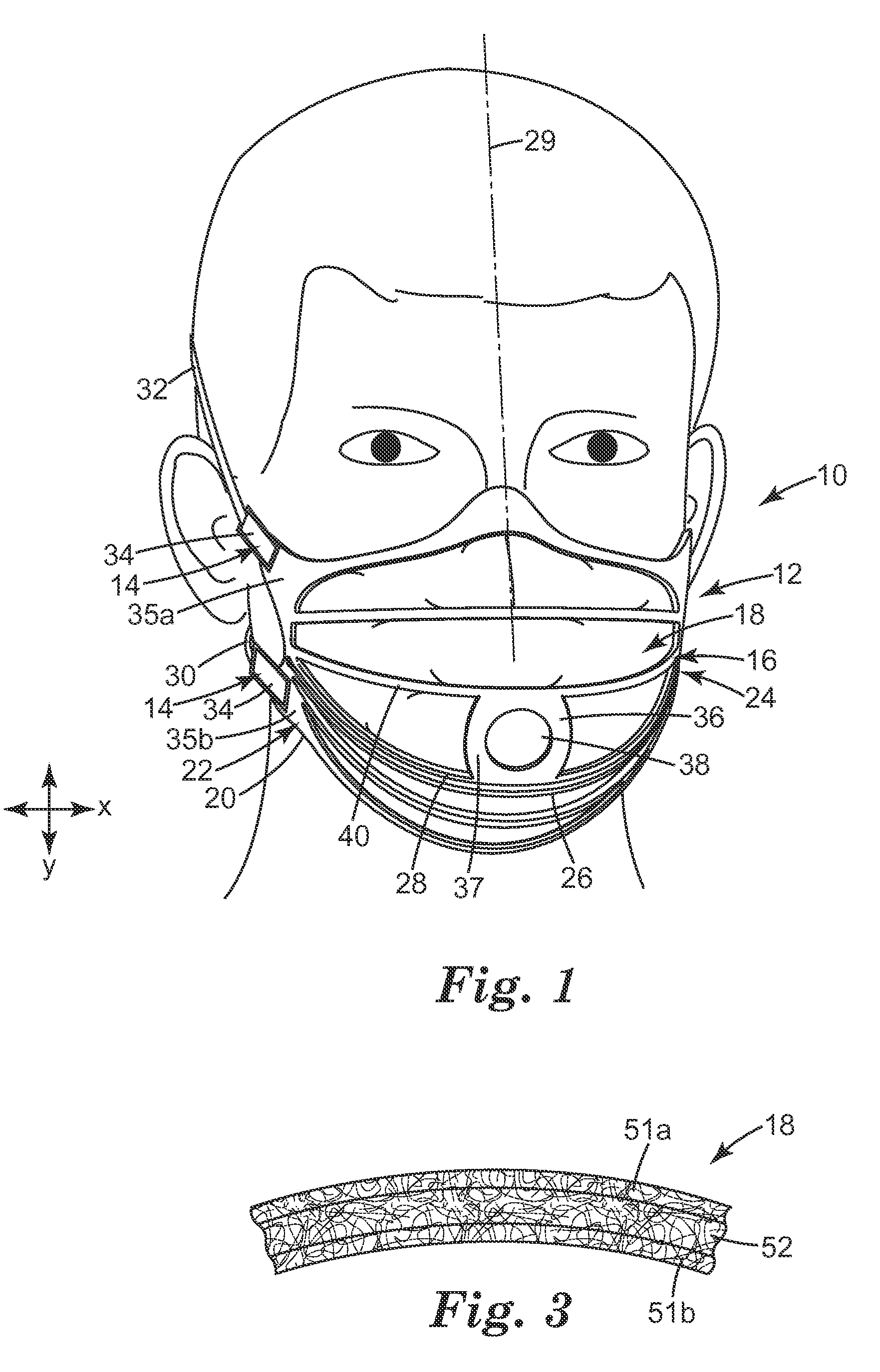

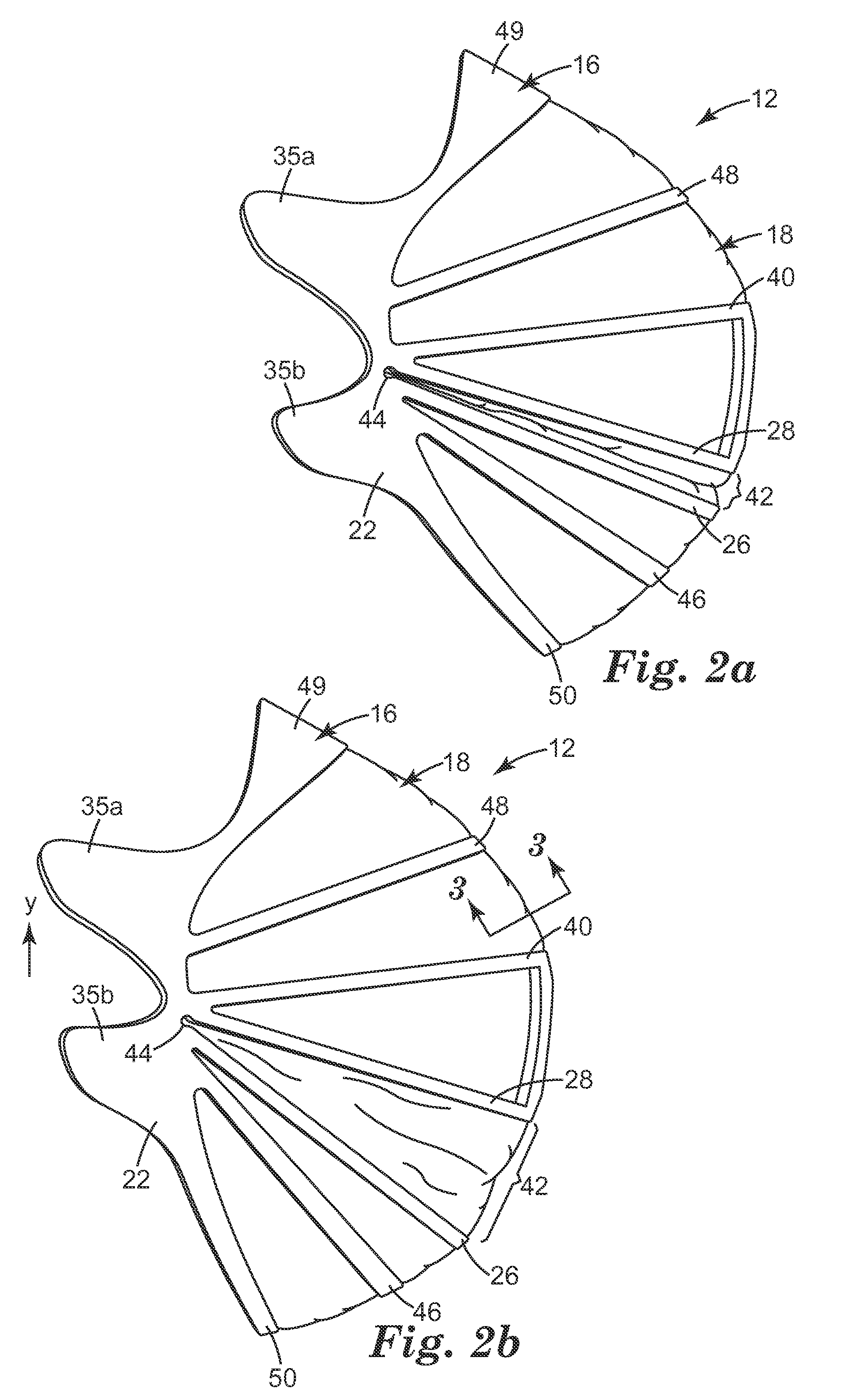

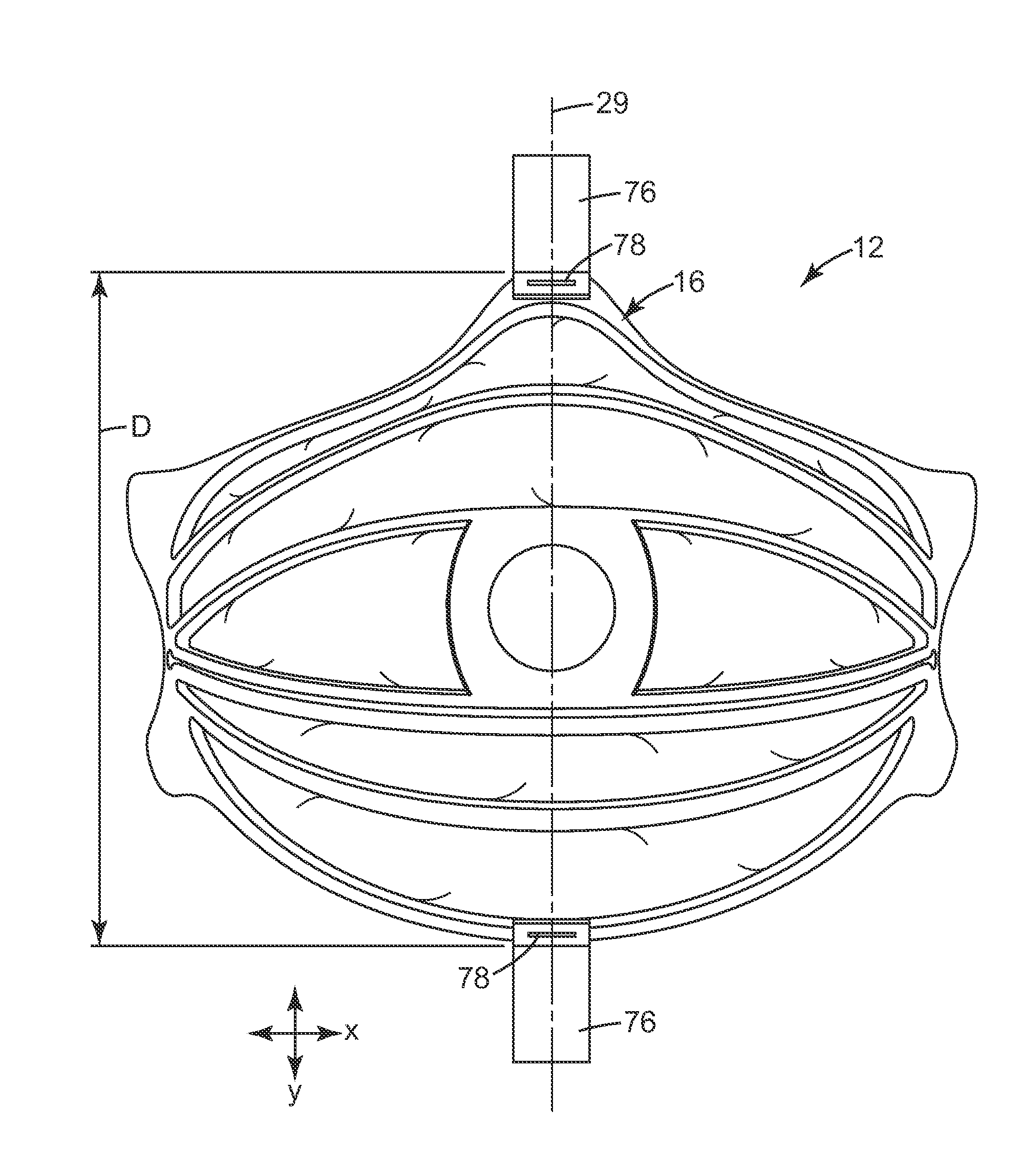

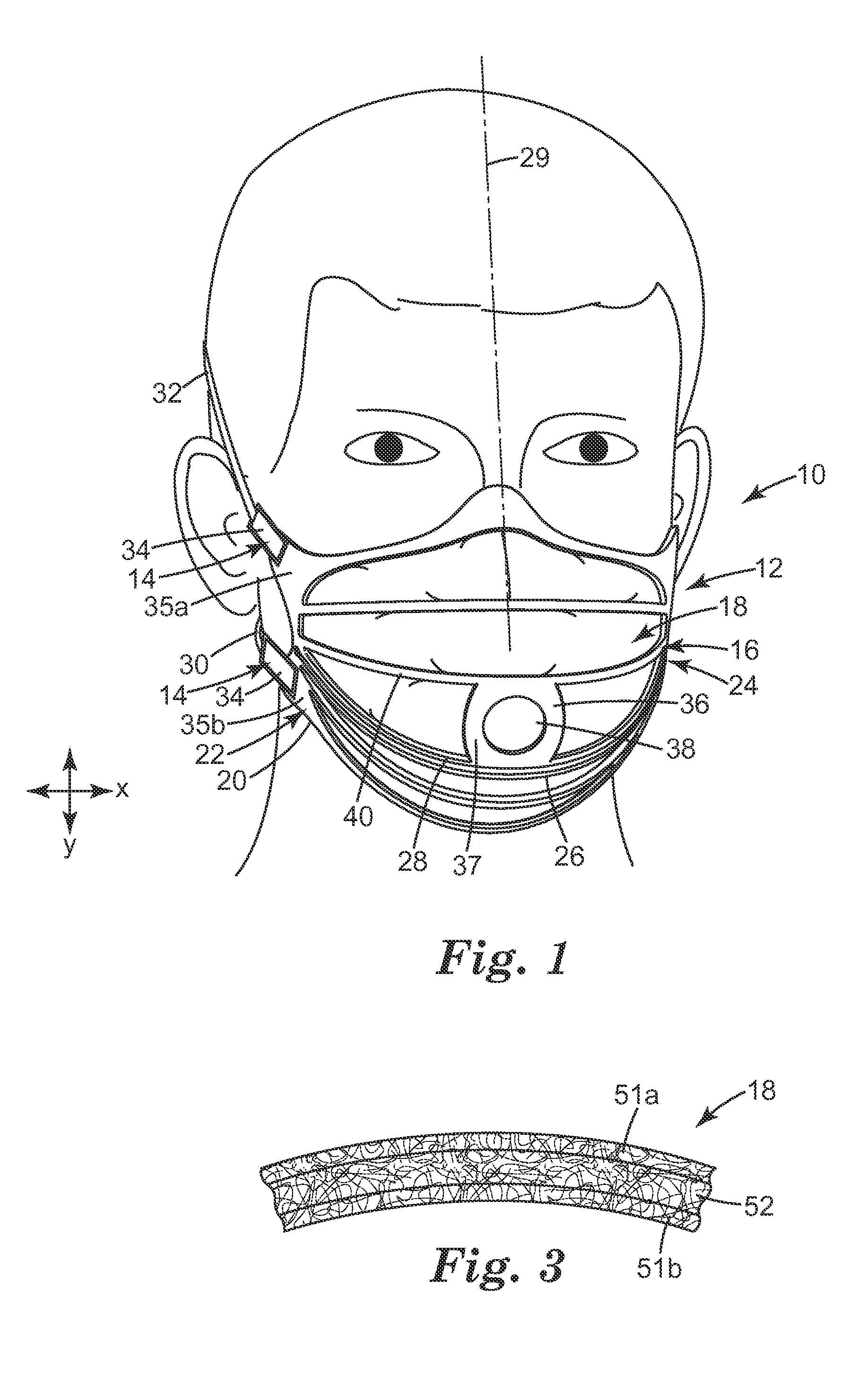

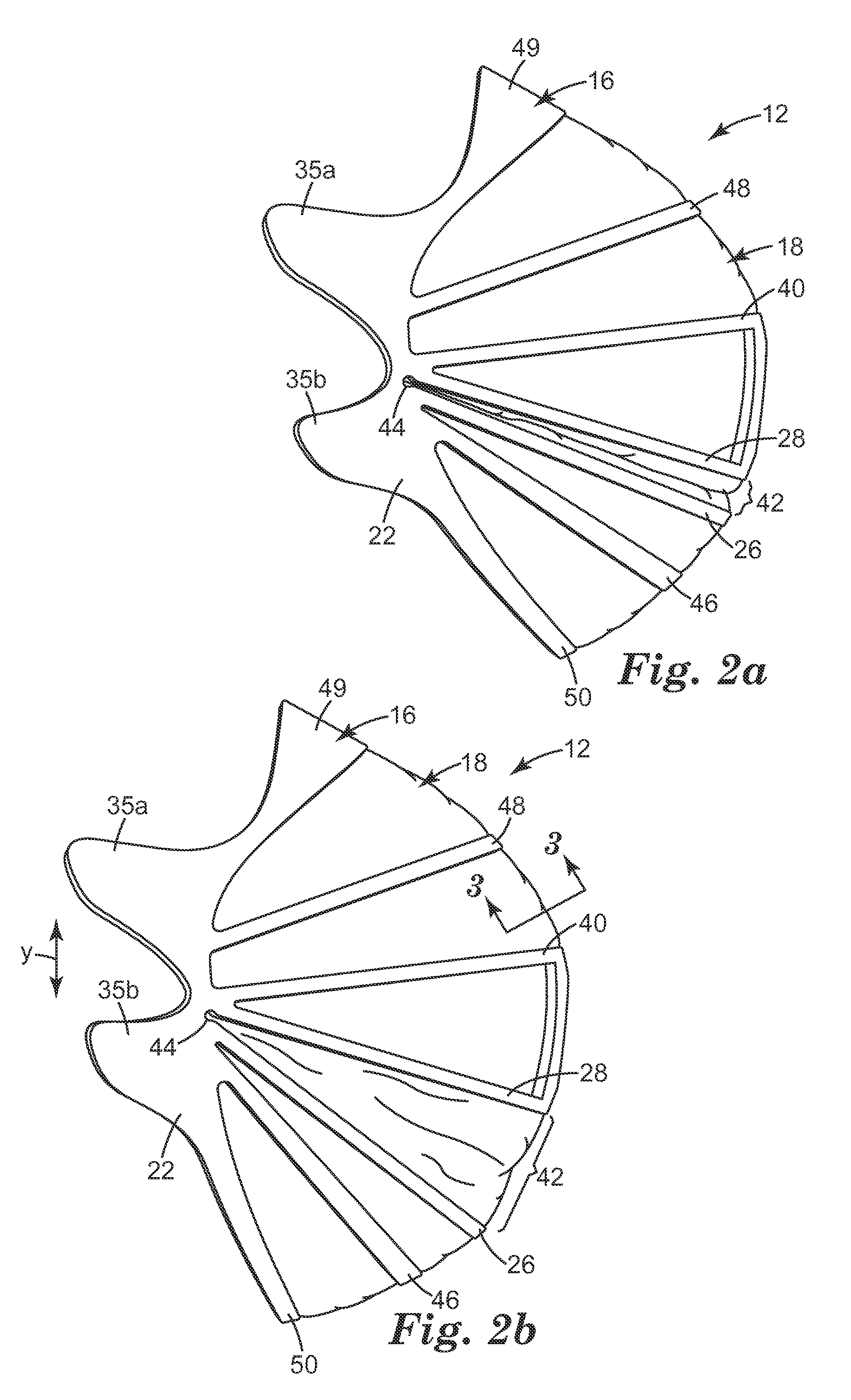

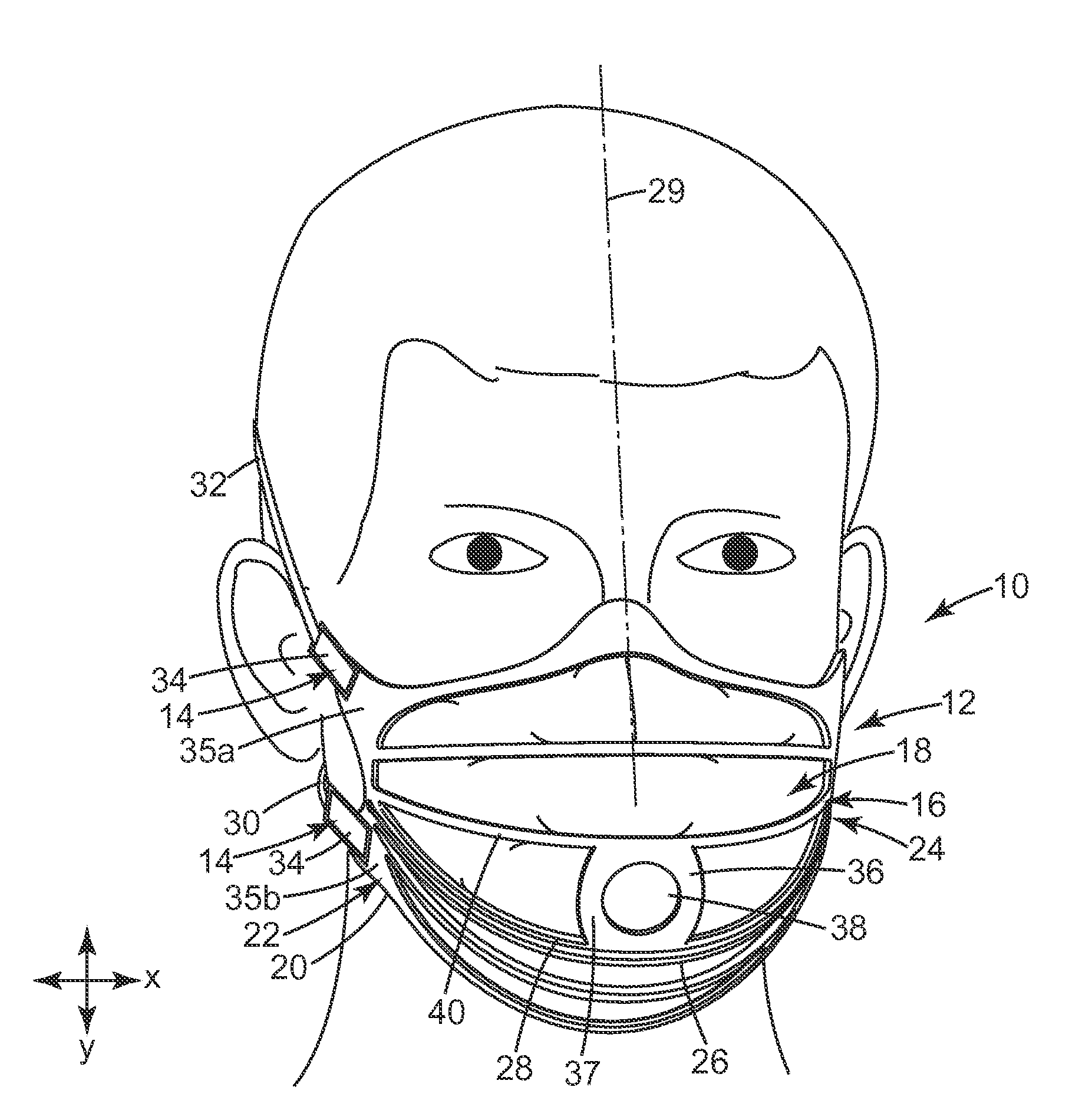

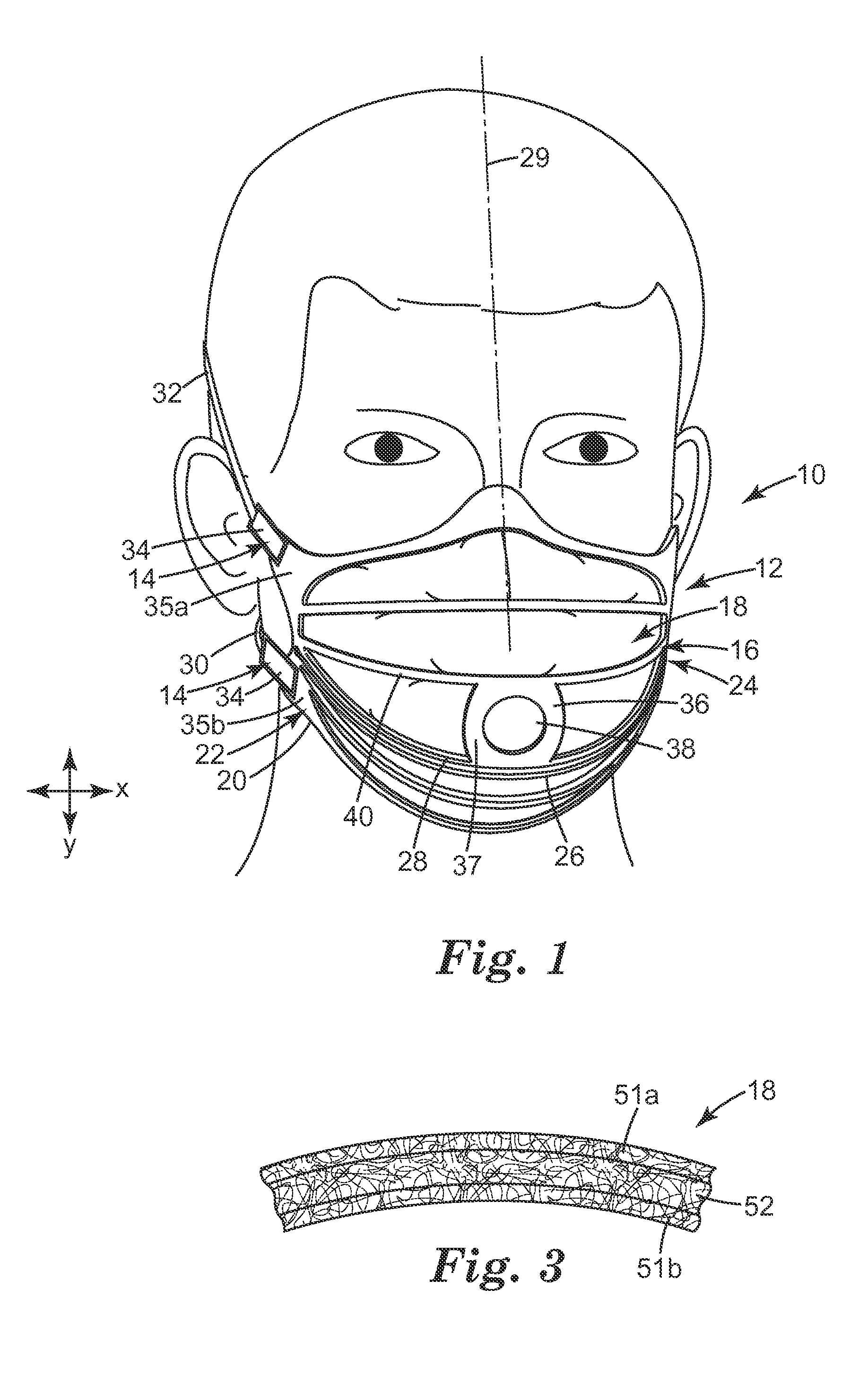

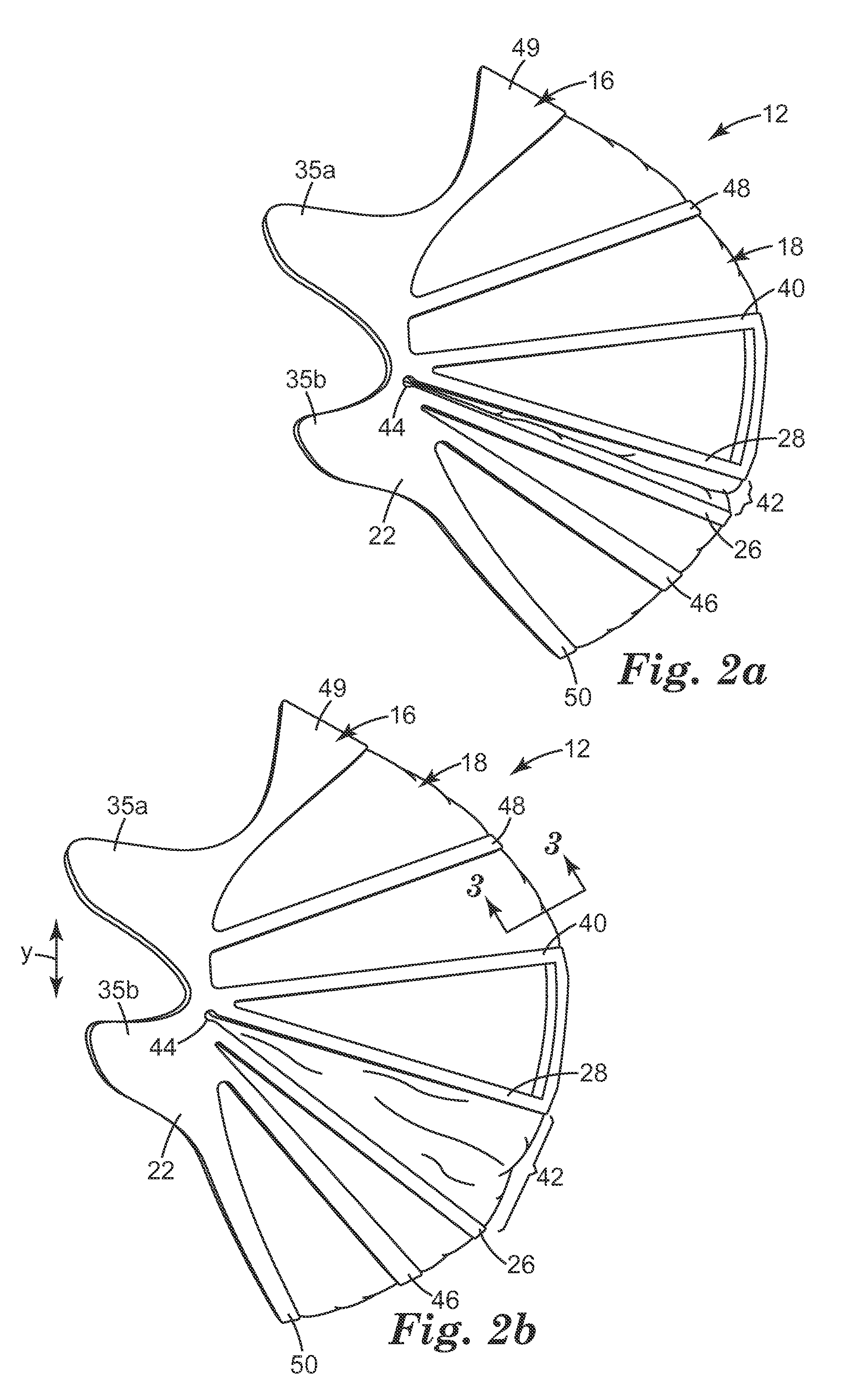

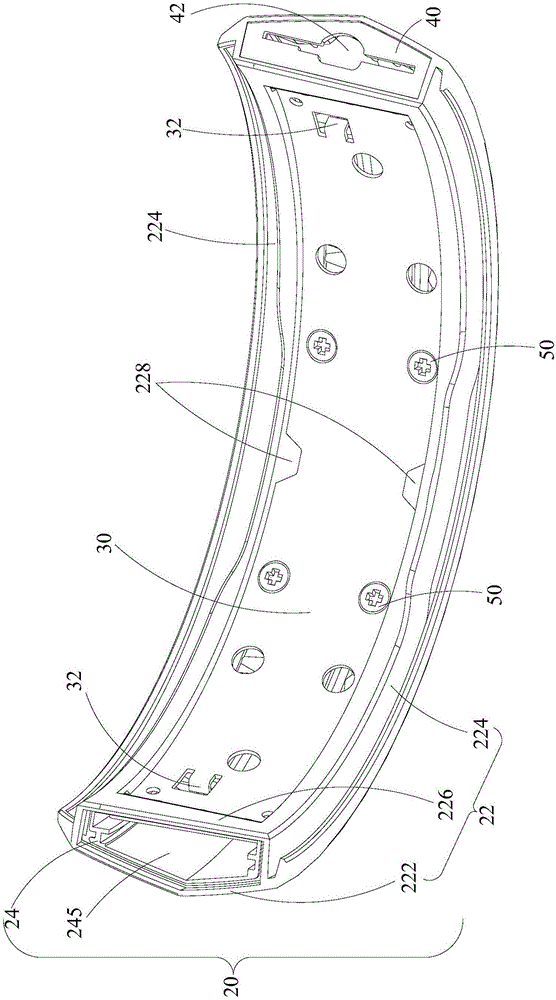

Respirator having dynamic support structure and pleated filtering structure

InactiveUS20090078265A1Better accommodateReduce clamping effectBreathing filtersBreathing masksRespiratorFiltration

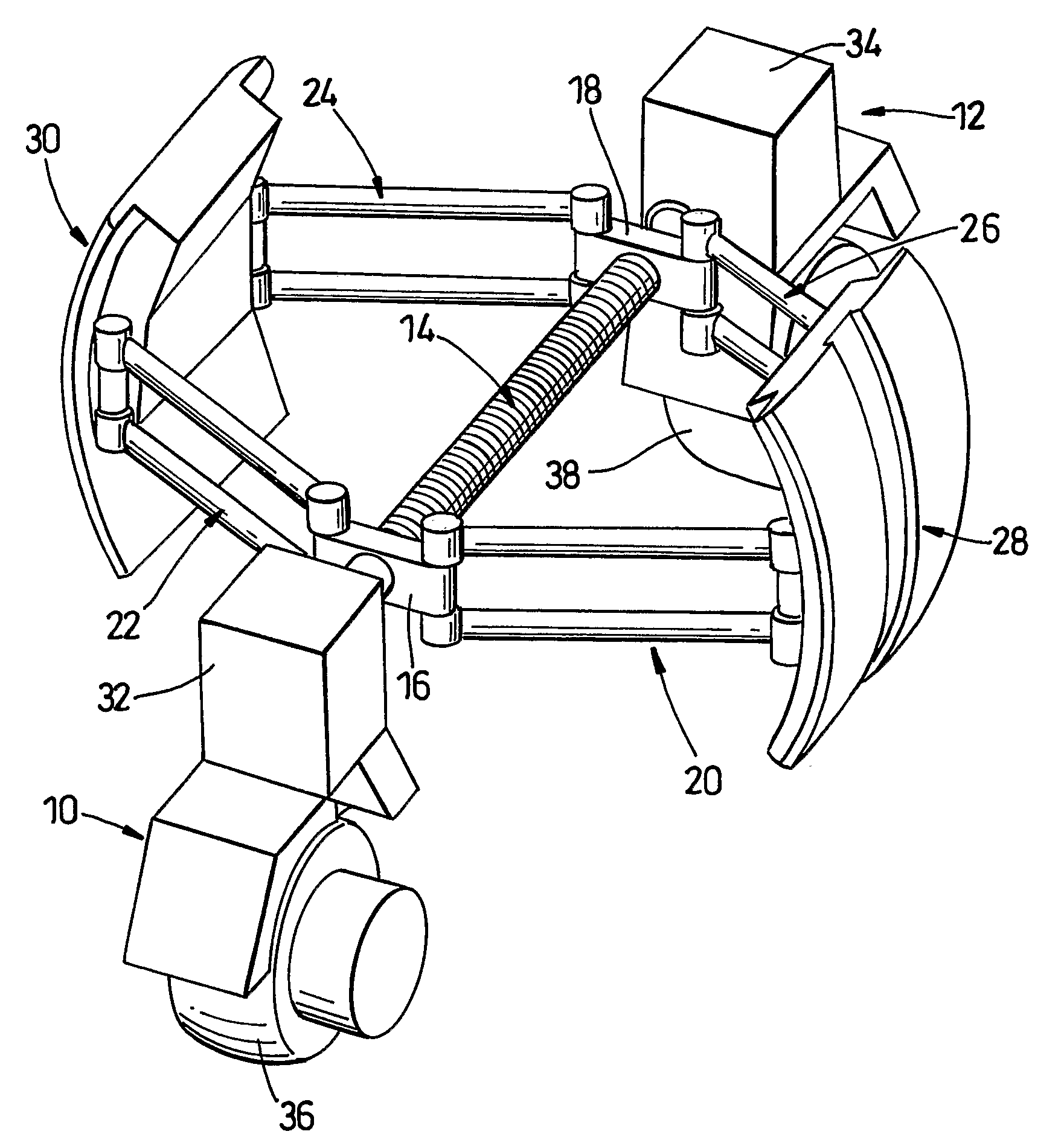

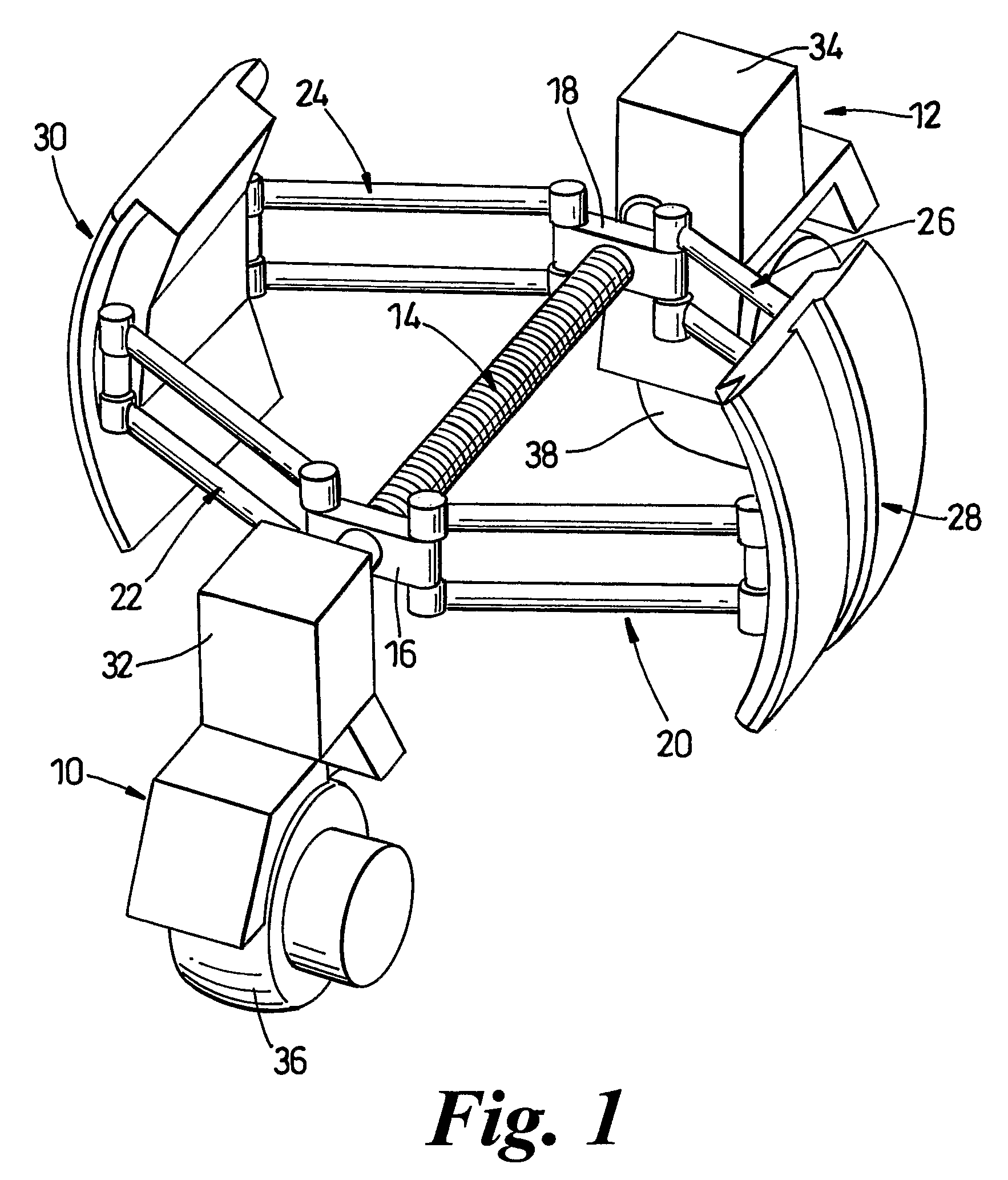

A filtering face-piece respirator 10 that has a support structure 16 and a filtering structure 18. The filtering structure 18 includes first and second transversely extending members 26, 28 that can move toward and apart from each other in the longitudinal direction. The filtering structure 18 has a filtration layer 52 and a pleat 58. The pleat 58 allows the filtering structure 18 to contract and expand when the first and second transversely-extending members 26, 28 move toward and apart from each other, respectively. This ability to expand and contract in an accordion-like manner enables the mask body to better accommodate wearer jaw movement.

Owner:3M INNOVATIVE PROPERTIES CO

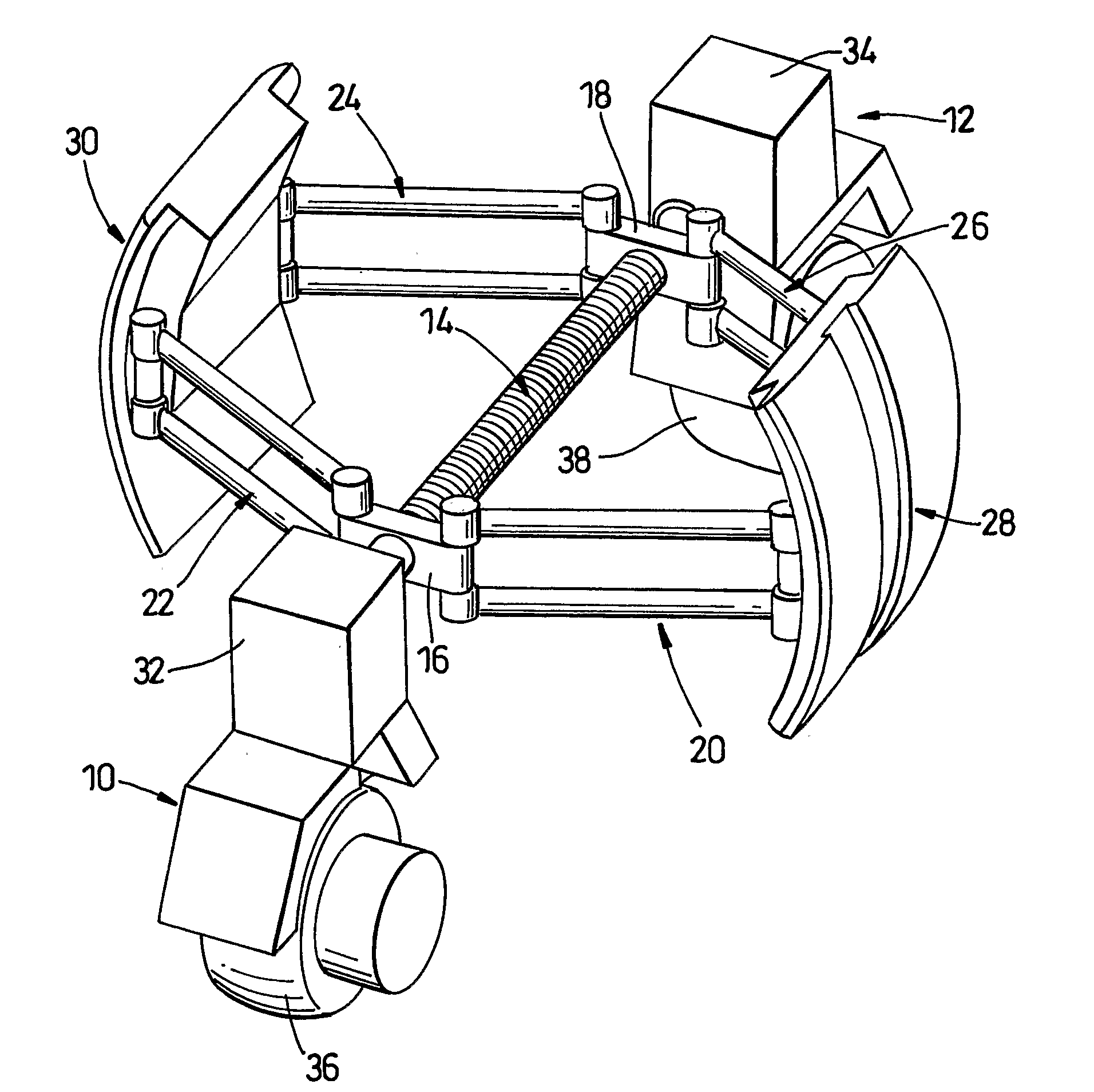

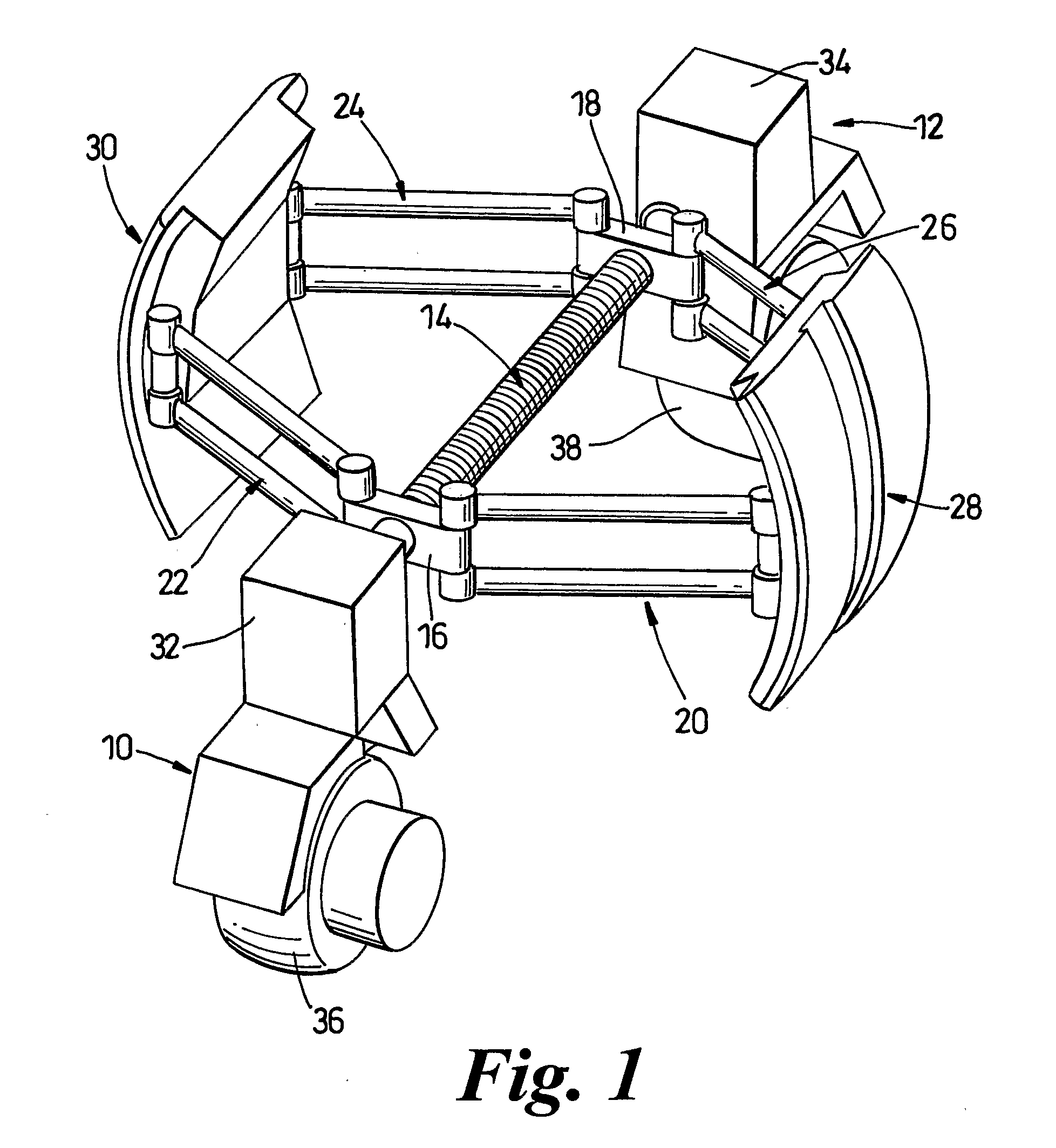

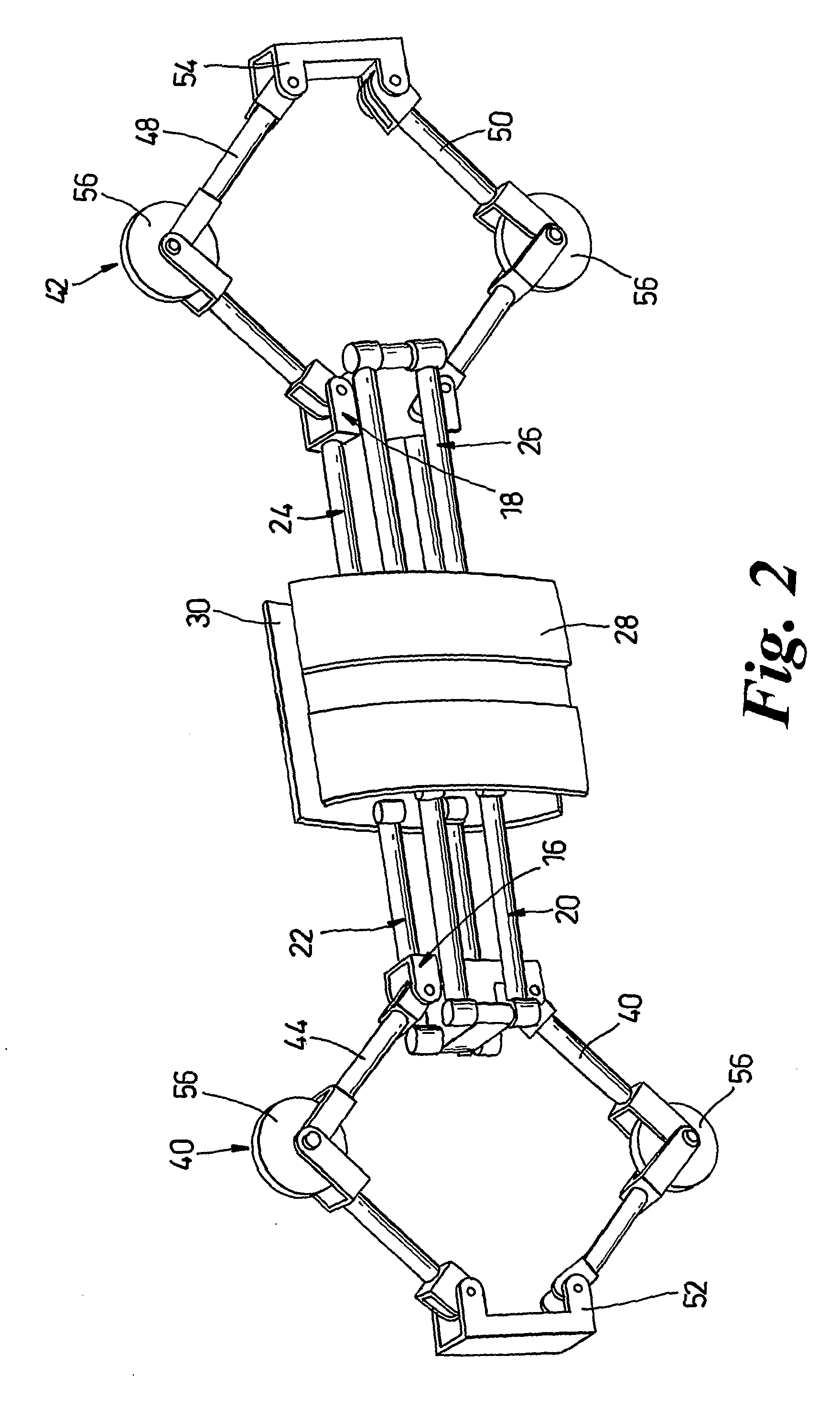

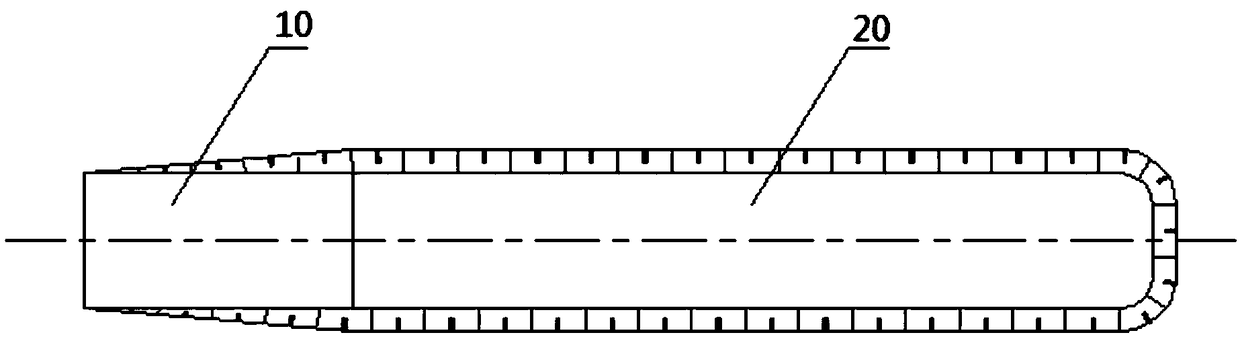

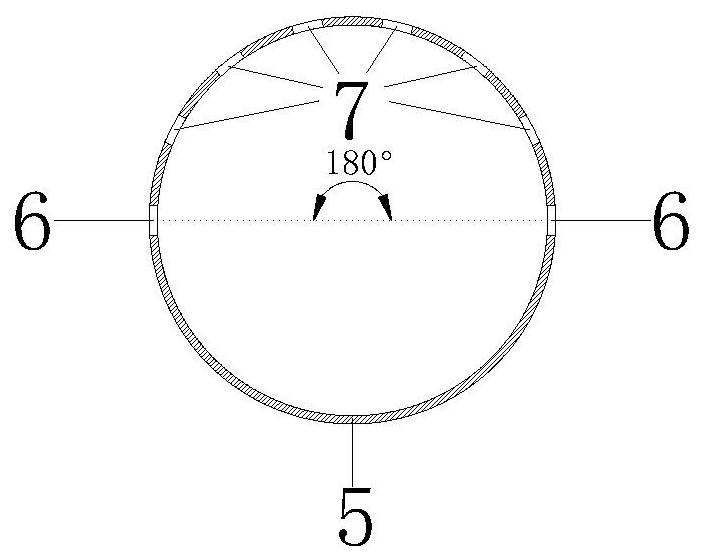

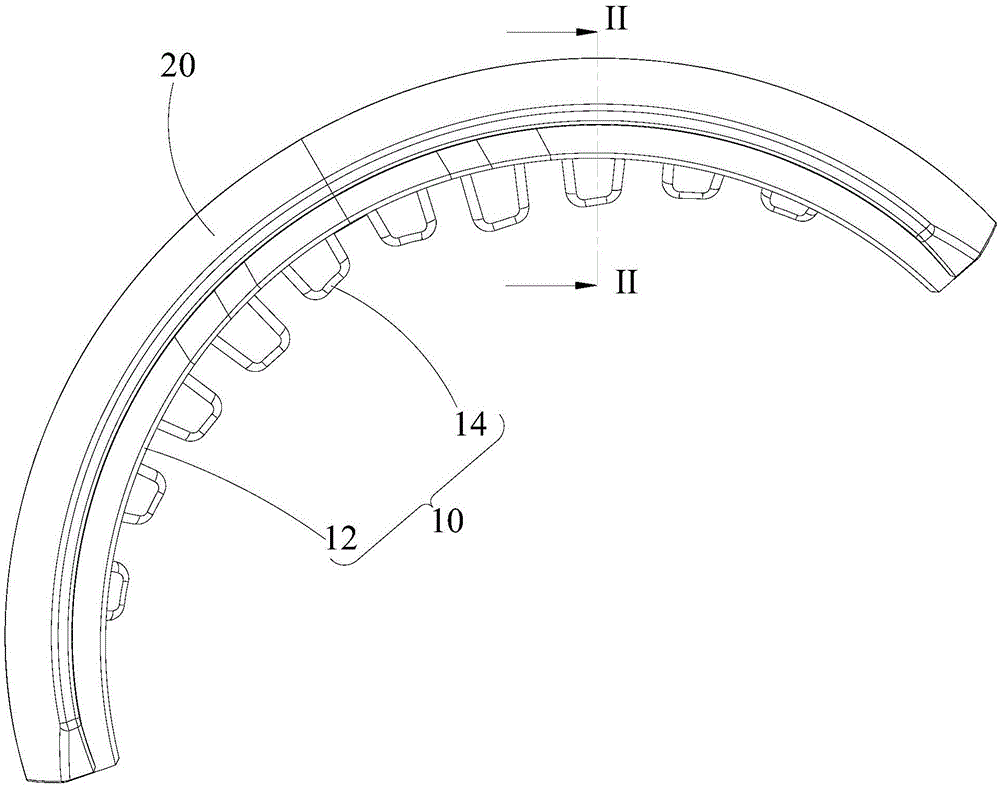

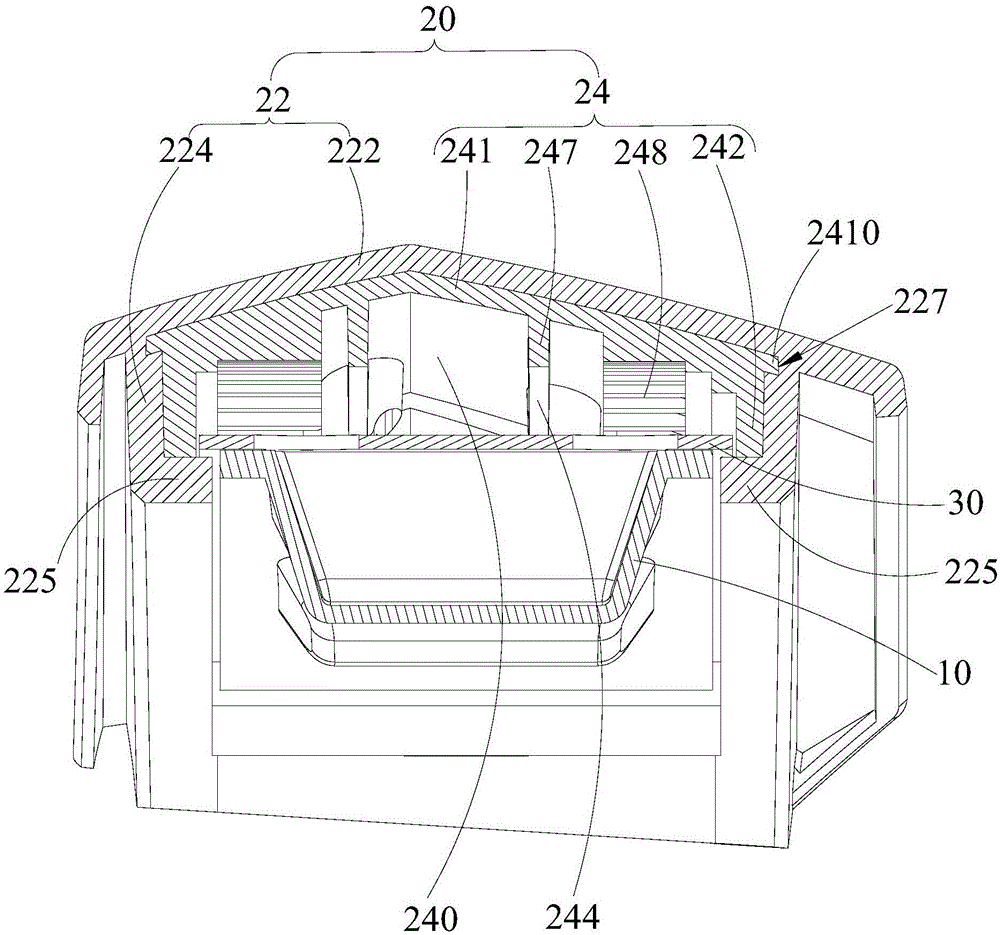

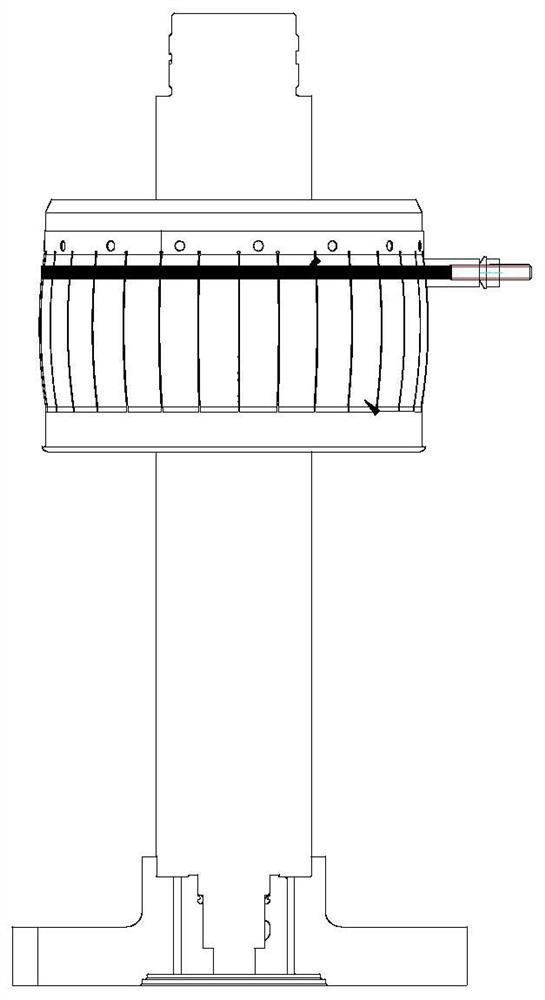

In-Line Pipe Inspection Tool

InactiveUS20080092672A1Inspection is accurateHigh fieldMagnetic property measurementsFluid-tightness measurementEngineeringMechanical engineering

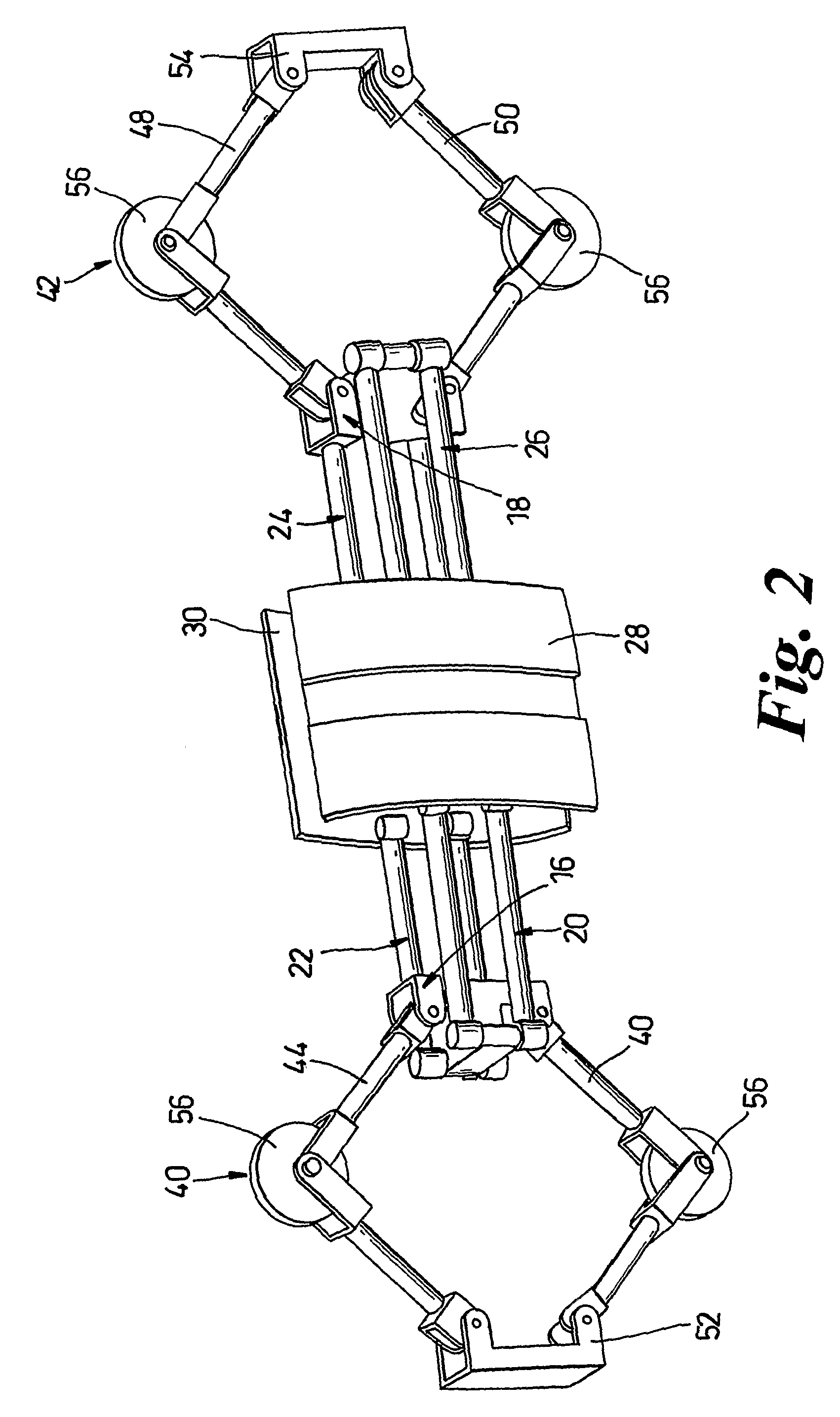

An in-line pipe inspection tool has one or more inspection platforms (28, 30) which are connected to an elongate wheeled trolley by link arms (20 to 26). The trolley unit (10, 12) has drive means for driving the point of connection of the first link arm (20, 22) to the trolley (10) relative to the point of connection of the second link arm (24, 26) to the trolley (12), thereby to move the inspection platforms (28, 30) in a direction perpendicular to the direction of elongation of the trolley (10, 12). Thus the inspection platforms (28, 30) are movable which is relative to the trolley (10, 12) to permit the tool to be adapted to pipelines of different diameters. Moreover, the platforms (28, 30) preferably have permanent magnets which contain a rotatable magnet. The rotatable magnet permits the net magnetic field generated by the platform to be varied.

Owner:PII LIMITED

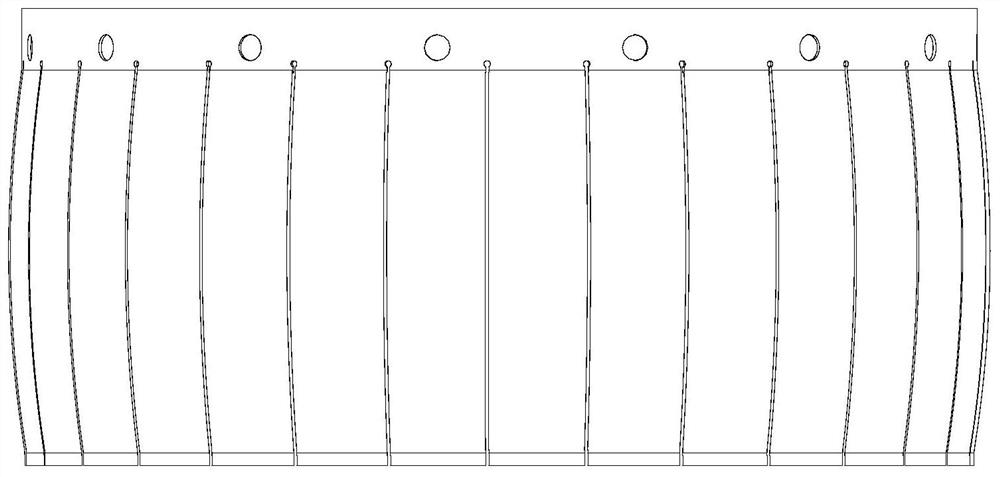

Filtering face-piece respirator that has expandable mask body

ActiveUS8342180B2Convenient to accommodateReduce clamping effectBreathing filtersBreathing masksRespiratorEngineering

A filtering face-piece respirator 10 that includes a mask body 12 and a harness 14. The mask body 12 contains a filtering structure 18 that is retained in position on the mask body 12 by a support structure 16 that includes a longitudinally-movable, centrally-spaced, transversely-extending member 26 that extends from a first side 22 of the structure 16 to a second side 24 without being joined together by any longitudinally-extending members that hinder movement of the transversely extending member 26 in the longitudinal direction. The transversely-extending members converge towards each other at east side 22, 24 of the mask body 12. A filtering face-piece respirator 10 of this construction can allow the mask body 12 to readily accommodate the motion of a person's jaw. Workers who use this filtering face-piece respirator may find it much easier to talk to other persons when working. A single mask size also may be able to properly fit to faces of various sizes.

Owner:3M INNOVATIVE PROPERTIES CO

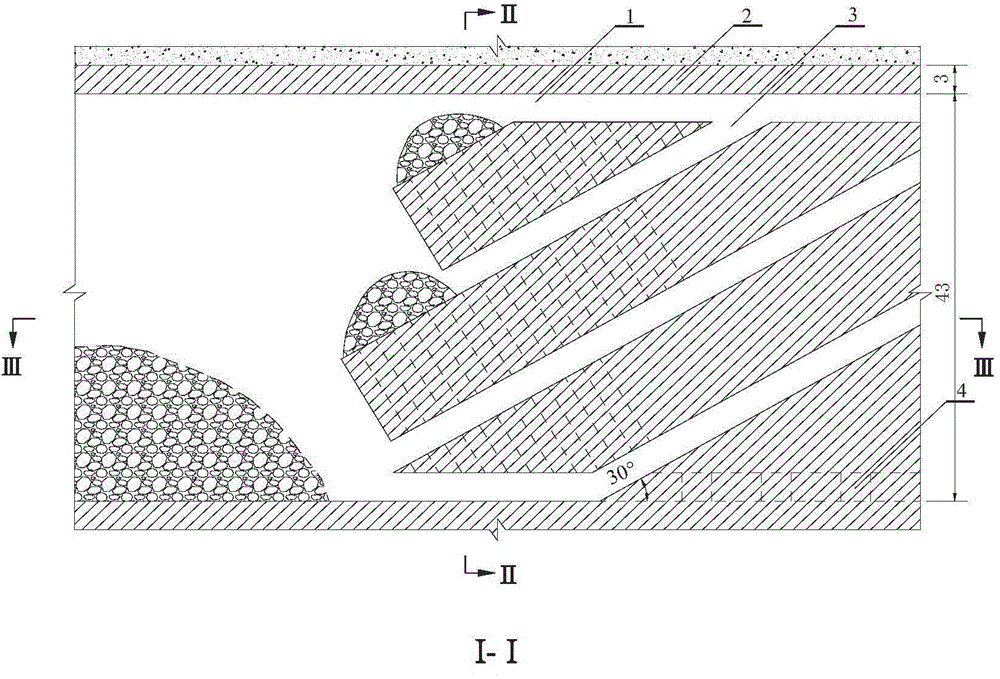

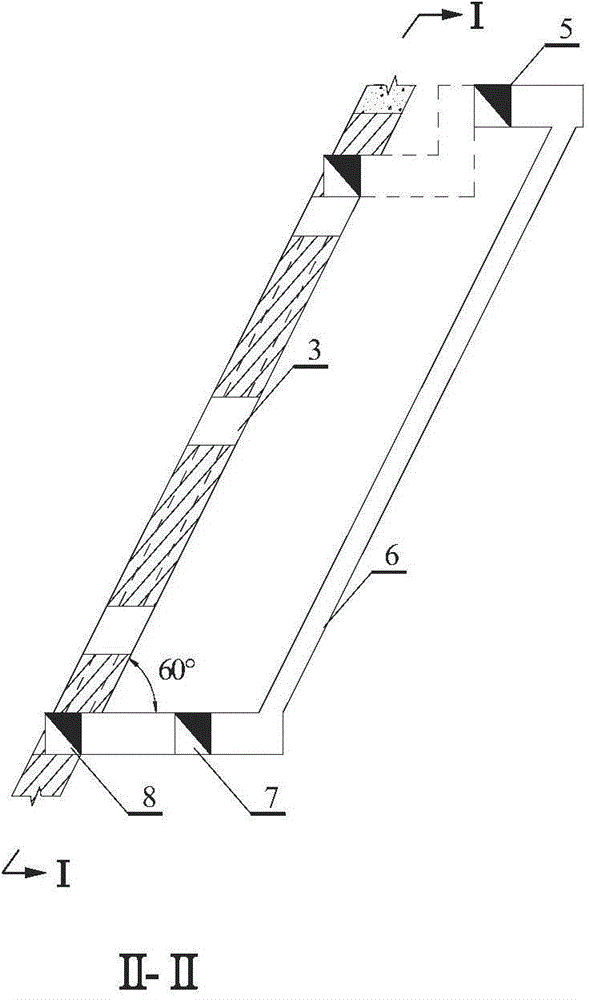

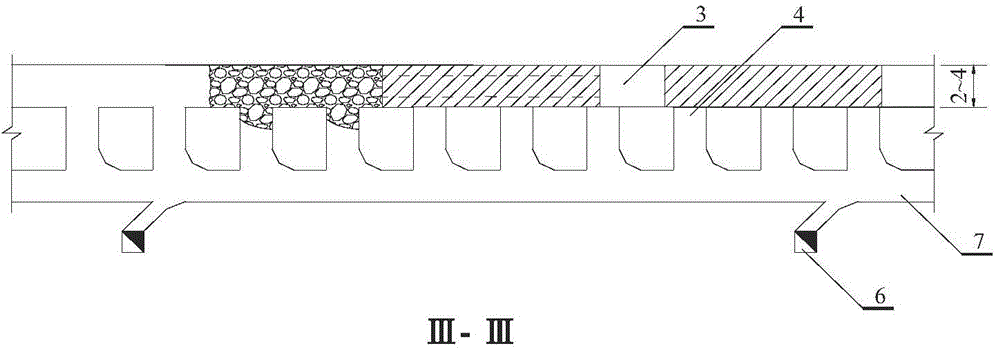

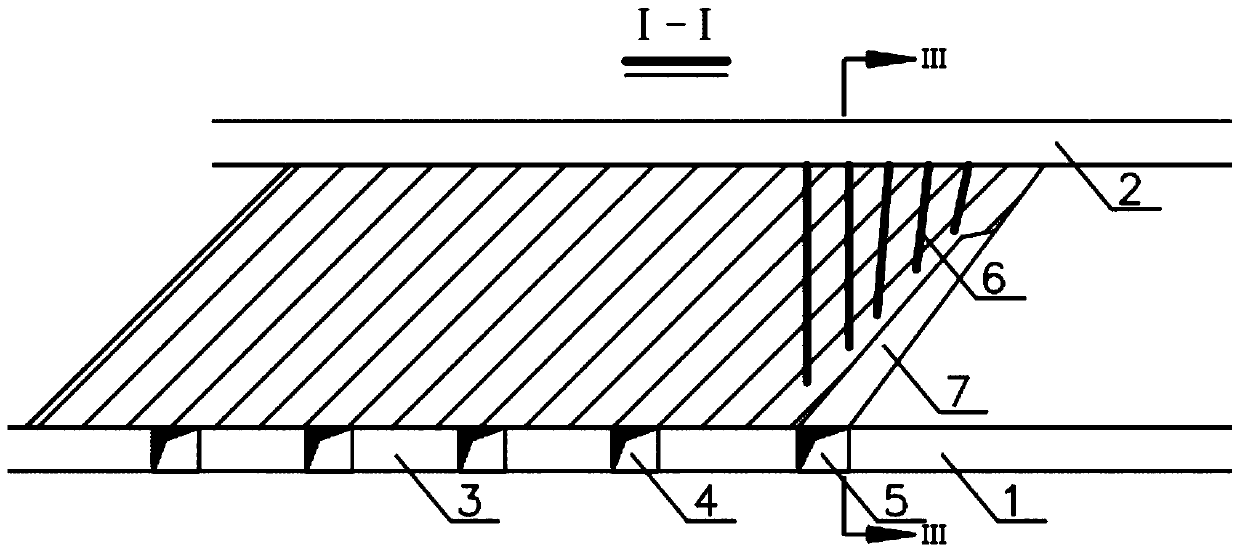

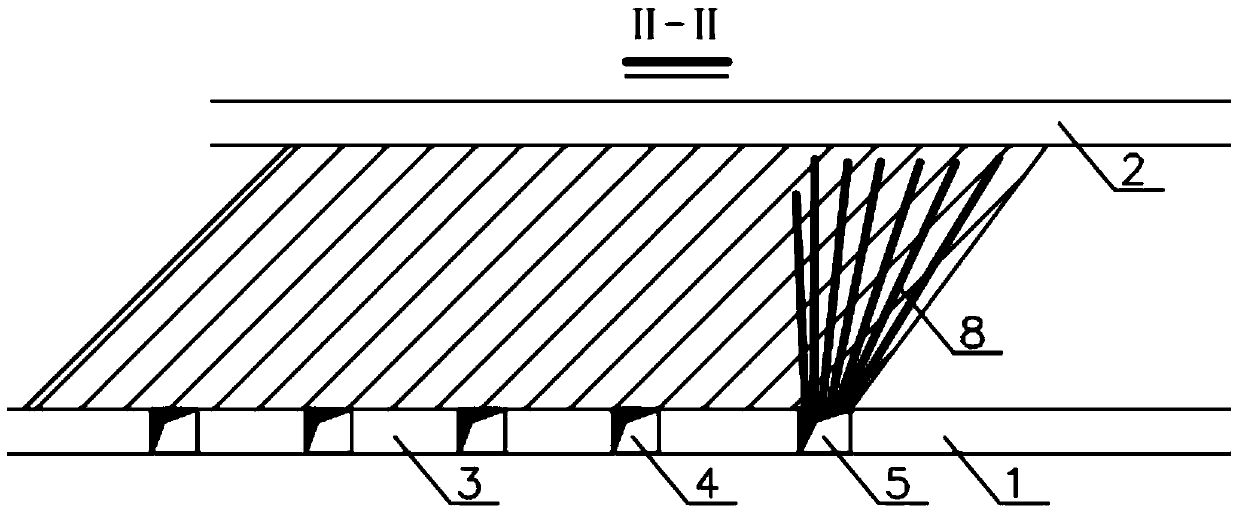

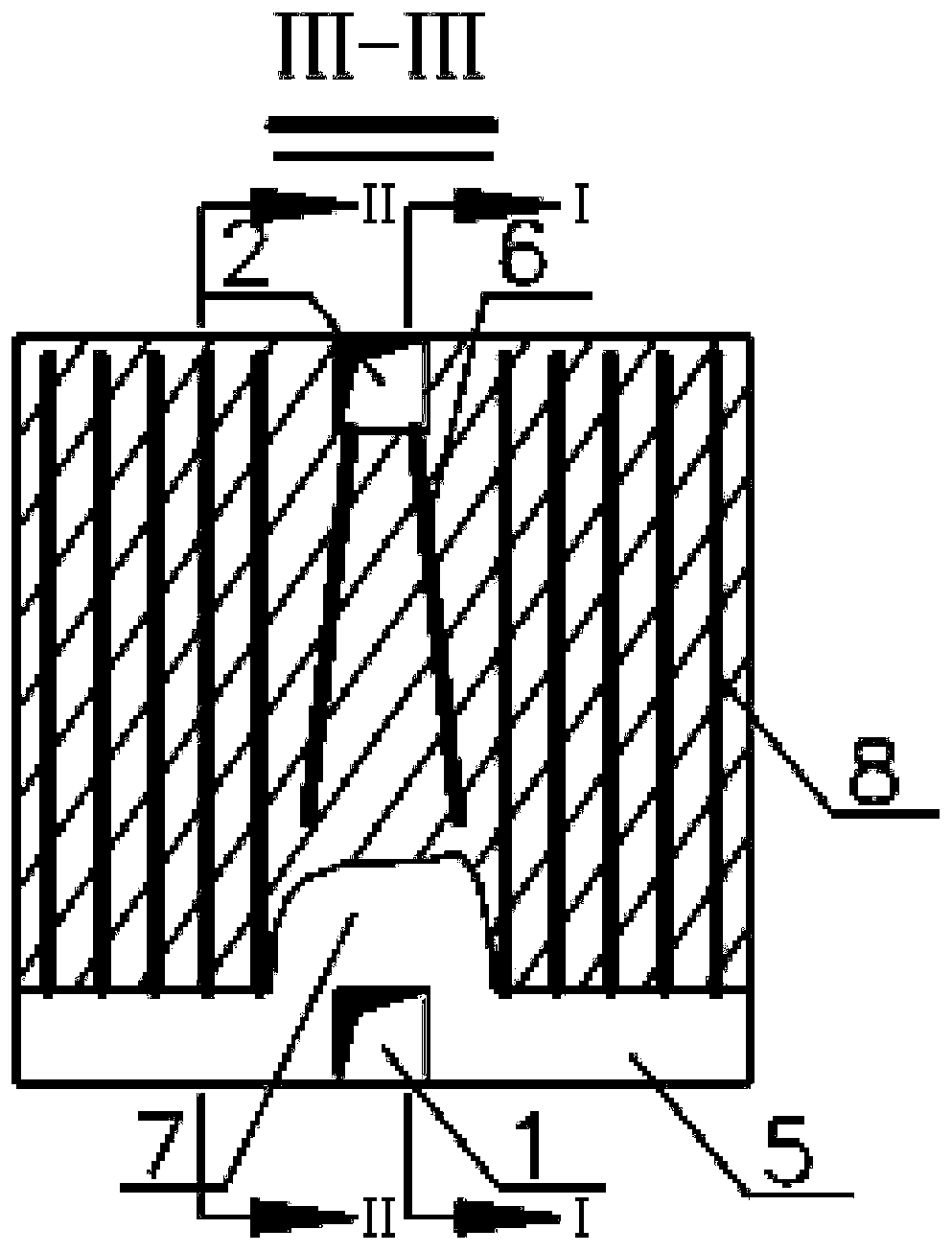

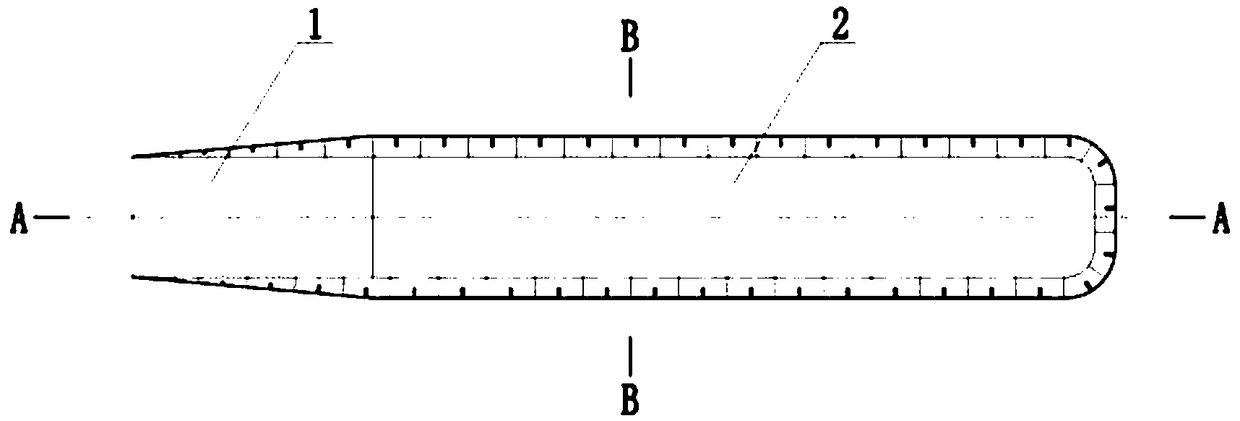

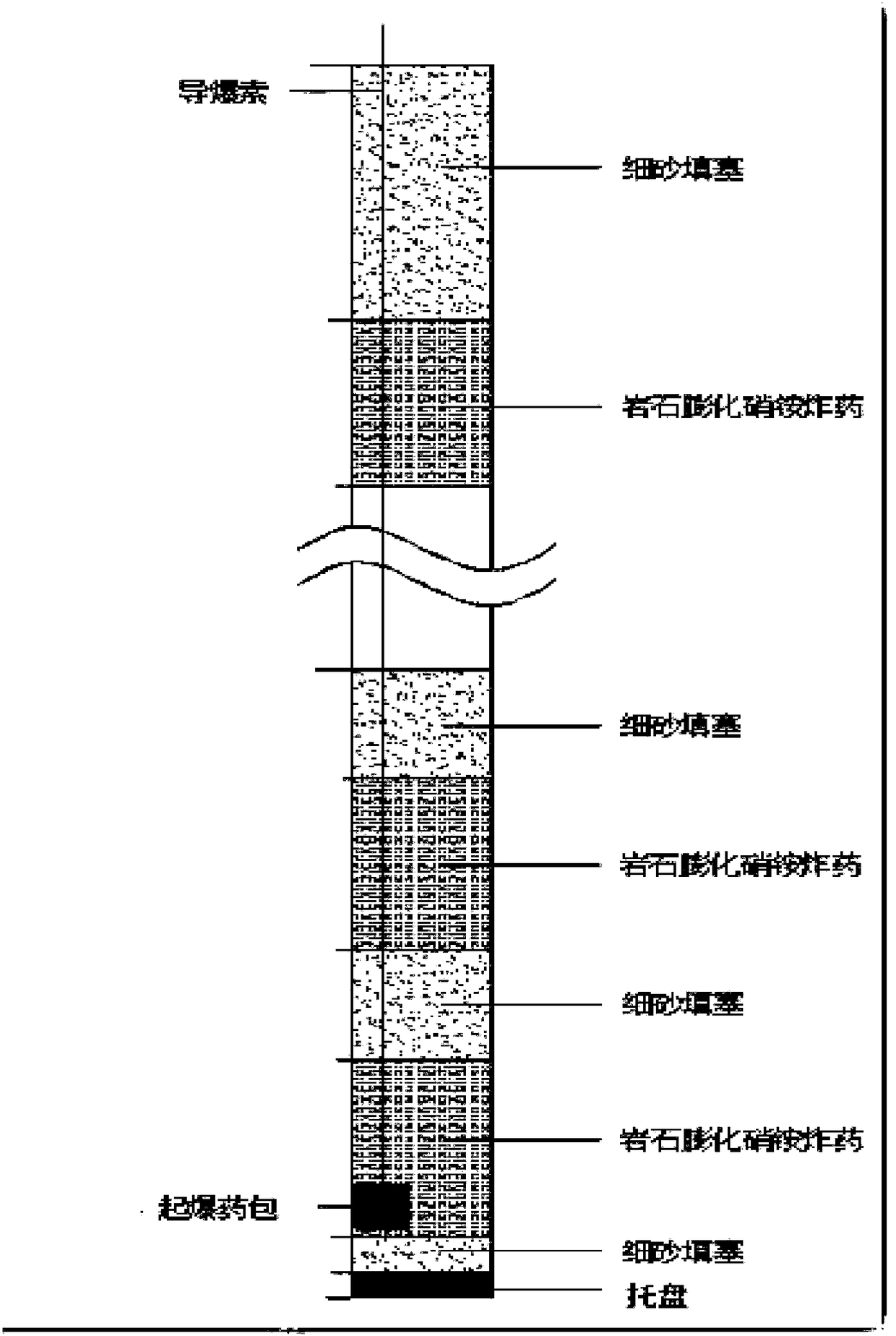

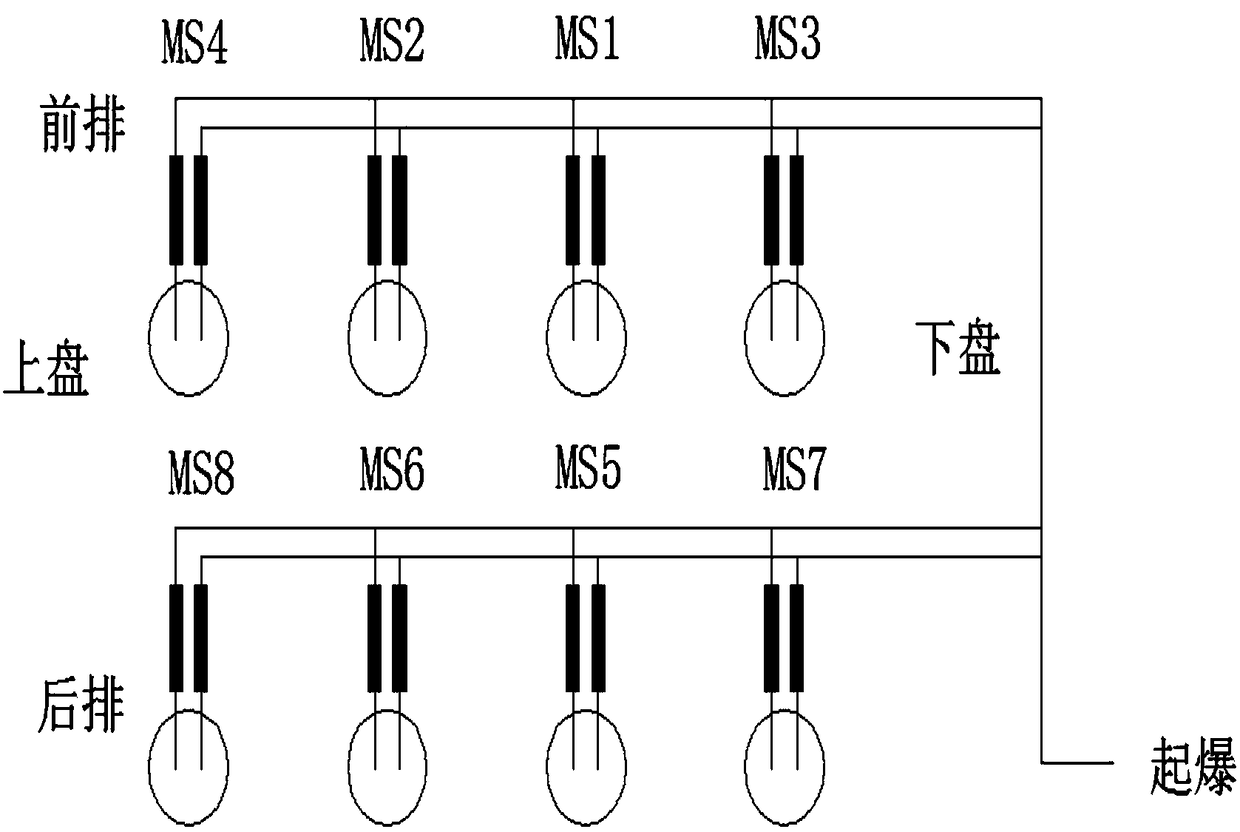

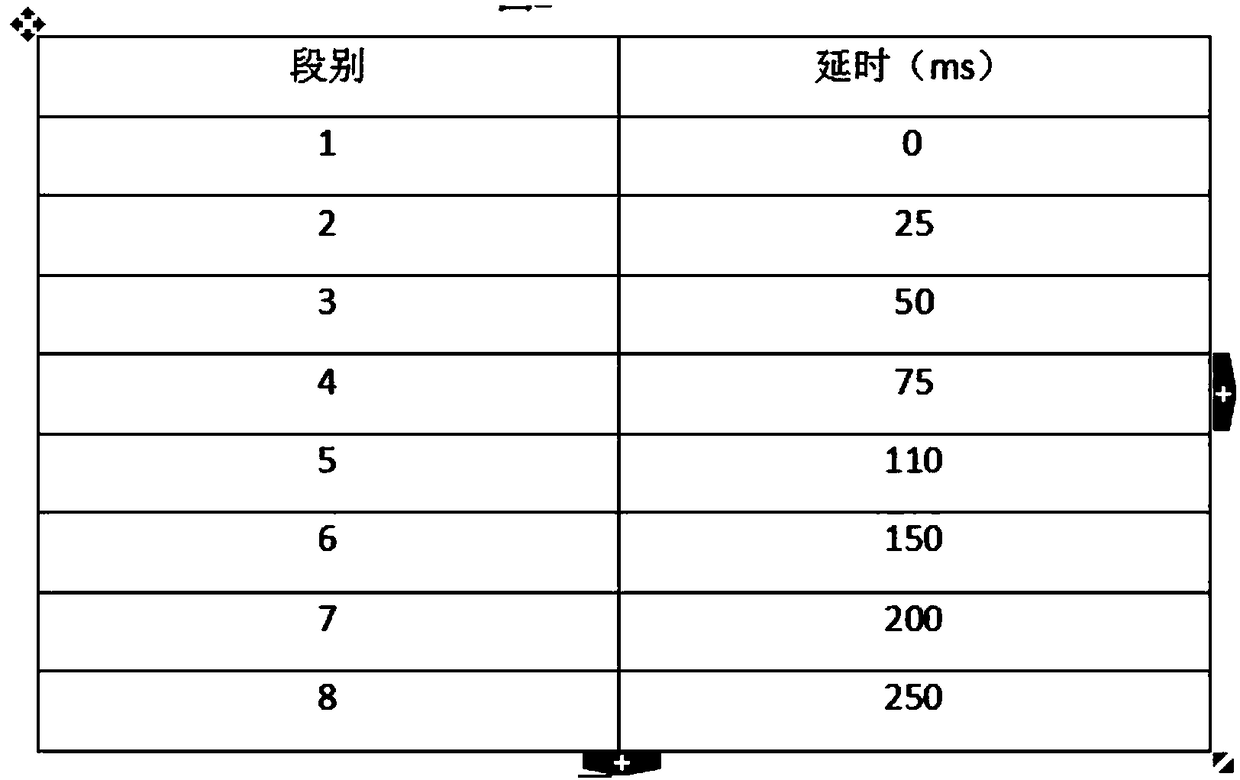

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

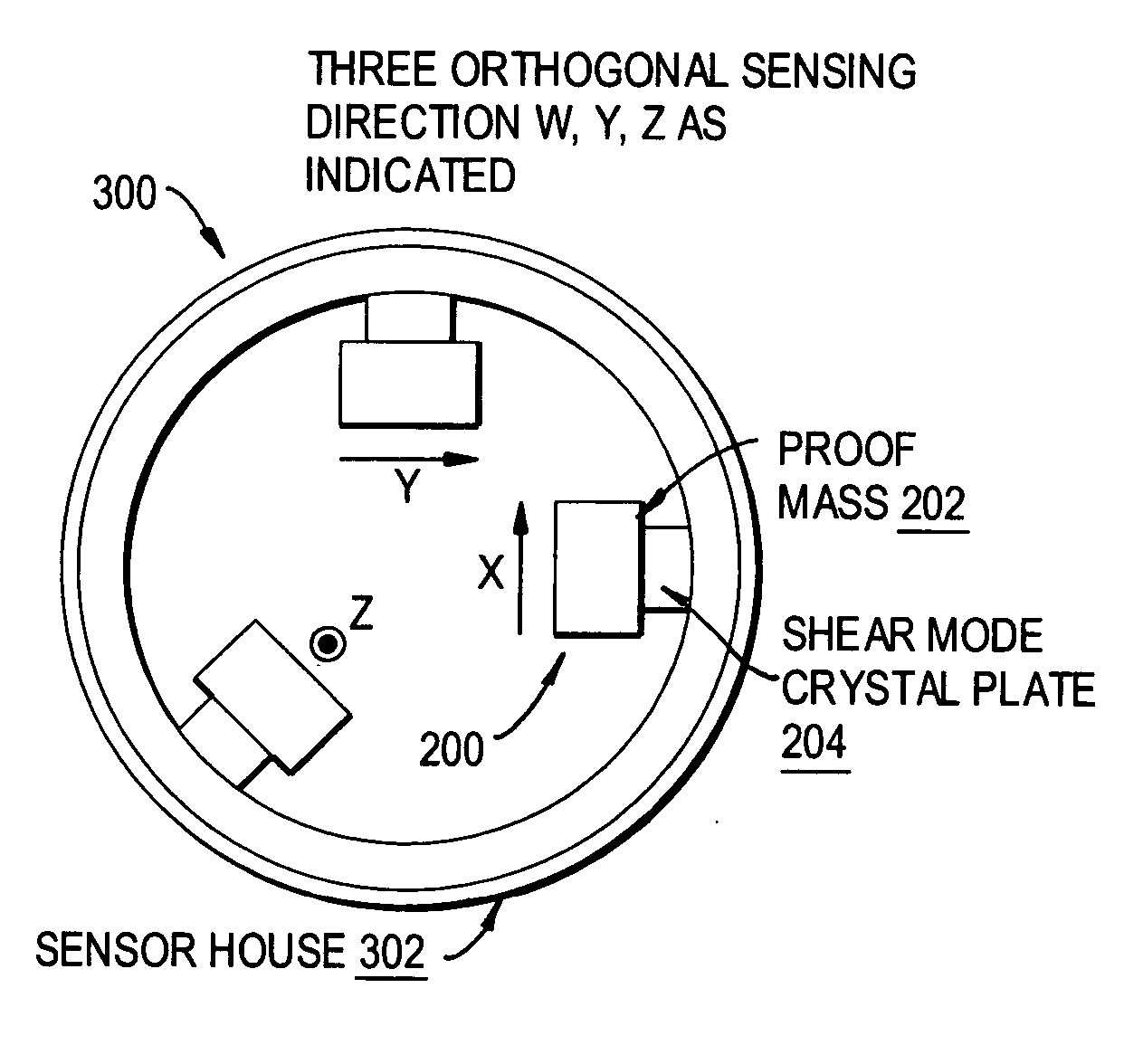

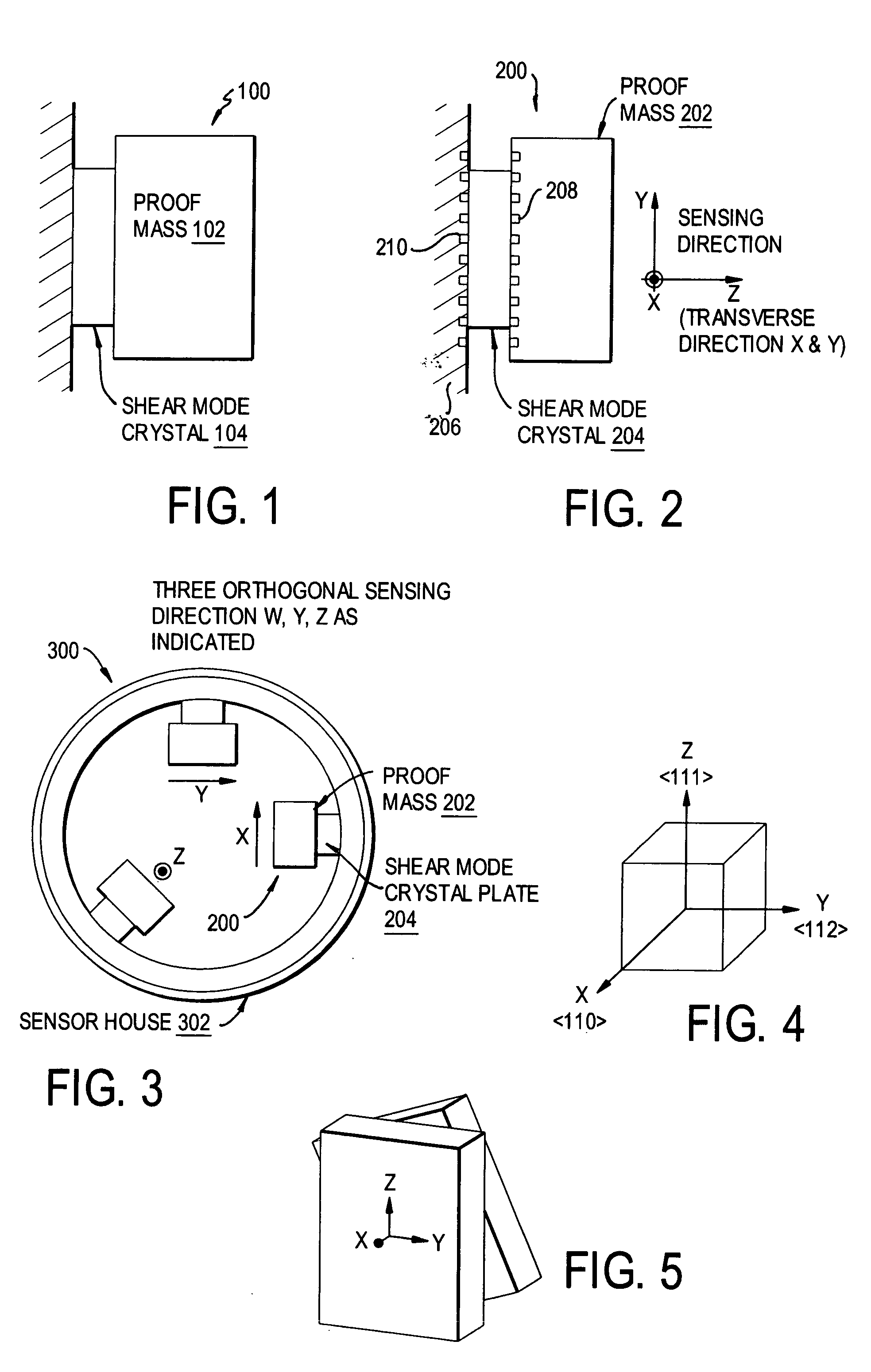

Acoustic vector sensor

InactiveUS20050034519A1Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityAcoustic energy

The present invention is directed to an acoustic vector sensor, specifically an underwater acoustic vector sensor. The acoustic vector sensor contains three piezoelectric sensors orthogonally mounted inside a rigid housing, where each of the piezoelectric sensors measures acoustic energy from one of the three different, orthogonal, axial directions (X, Y, and Z). The piezoelectric sensor contains a proof mass, a base, and a piezoelectric crystal sandwiched therebetween. The bonding surfaces of the proof mass and the base are preferably castellated; and the piezoelectric crystal is preferably a shear mode (d15) relaxor single crystal.

Owner:AMPHENOL MARYLAND INC

Filtering face-piece respirator support structure that has living hinges

InactiveUS8118026B2Reduce clamping effectConvenient to accommodateBreathing filtersBreathing masksPhysical medicine and rehabilitationEngineering

A filtering face-piece respirator 10 that comprises a harness 14 and a mask body 12. The mask body 16 includes a filtering structure 18 and a support structure 16. The support structure 16 has first and second opposing side portions 22, 24 that each include a living hinge 44. The use of living hinges allows the mask body to respond dynamically to wearer jaw movement.

Owner:3M INNOVATIVE PROPERTIES CO

Filtering face-piece respirator support structure that has living hinges

InactiveUS20090078262A1Damage is not causedReduce clamping effectBreathing filtersBreathing masksBiomedical engineeringRespirator

A filtering face-piece respirator 10 that comprises a harness 14 and a mask body 12. The mask body 16 includes a filtering structure 18 and a support structure 16. The support structure 16 has first and second opposing side portions 22, 24 that each include a living hinge 44. The use of living hinges allows the mask body to respond dynamically to wearer jaw movement.

Owner:3M INNOVATIVE PROPERTIES CO

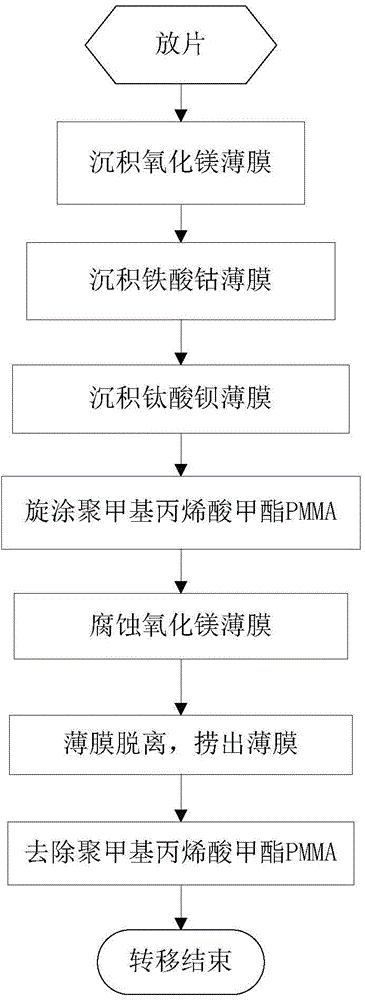

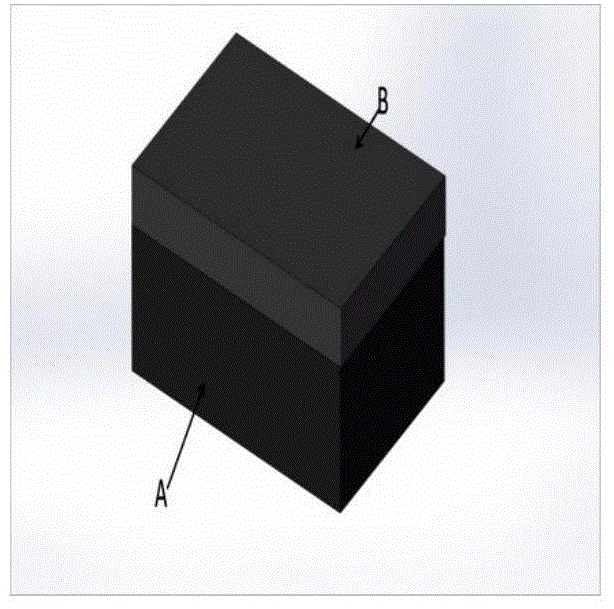

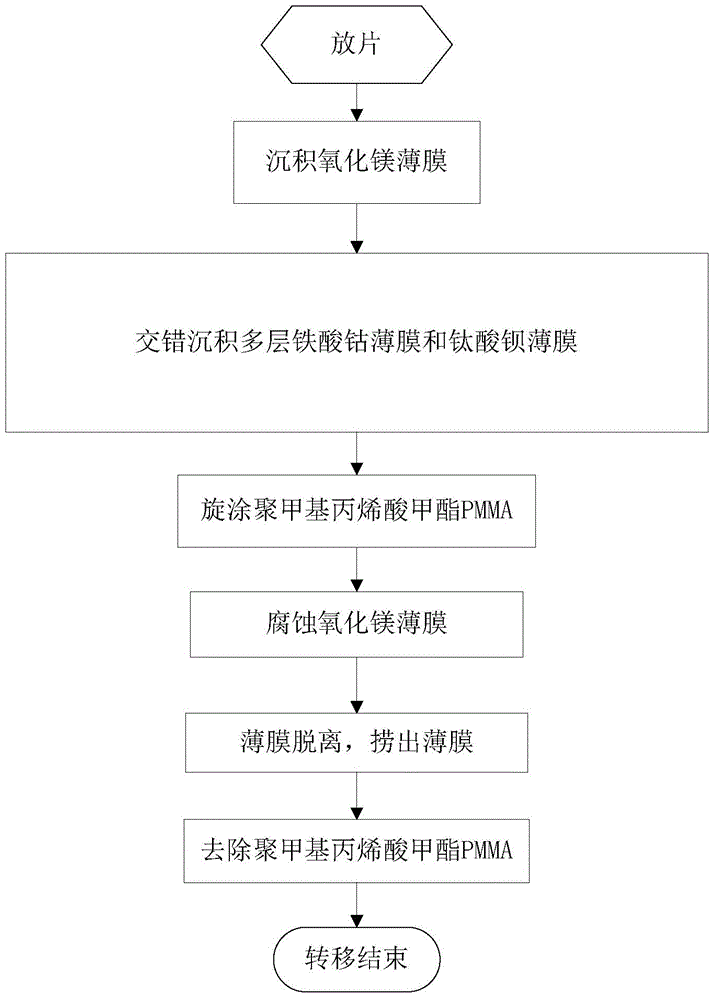

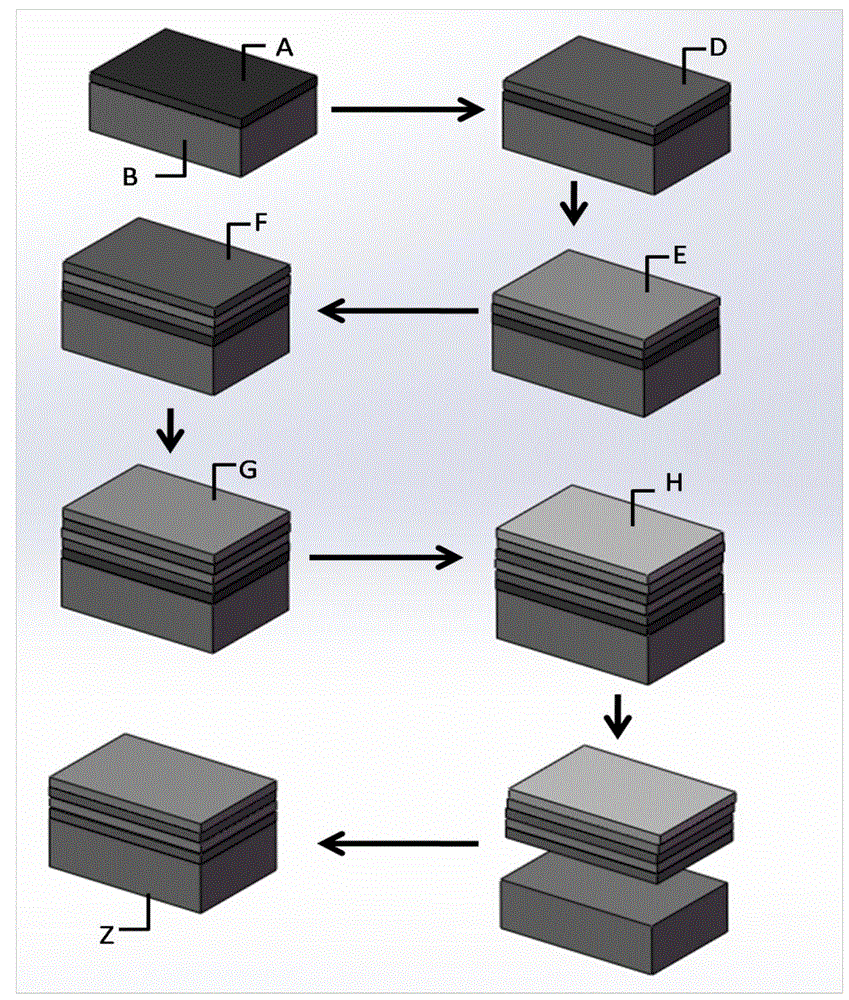

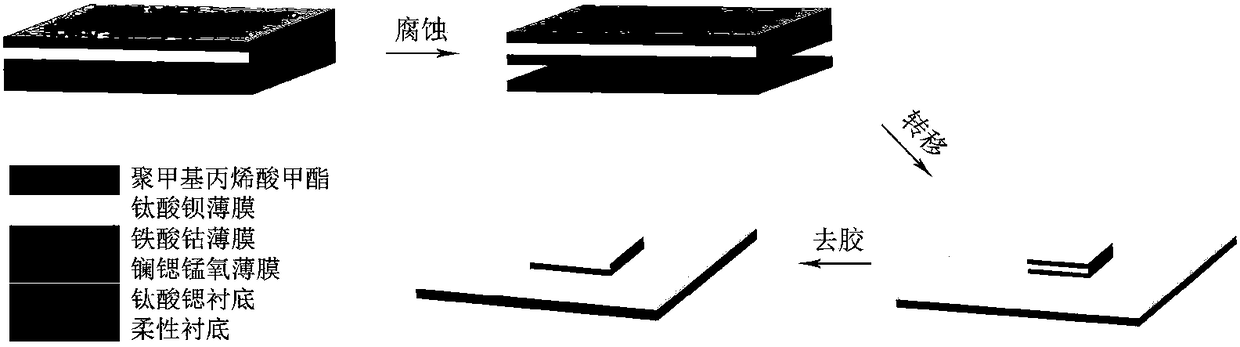

Preparation method of double-layer self-supporting magneto-electric composite thin film based on barium titanate and cobalt ferrite

ActiveCN104681715AAvoid breakingReduce clamping effectGalvano-magnetic material selectionGalvano-magnetic device manufacture/treatmentComposite filmBarium titanate

The invention discloses a preparation method of a double-layer self-supporting magneto-electric composite thin film based on barium titanate and cobalt ferrite and mainly solves the problem that an existing composite material with a 1-3 structure cannot reduce the substrate clamping effect and the electric leakage at the same time. The preparation method comprises the following realization steps: firstly depositing a layer of magnesium oxide thin film on a sapphire substrate and depositing cobalt ferrite and barium titanate thin films on the magnesium oxide thin film in sequence to obtain a double-layer magneto-electric composite thin film; then spin-coating the surface of the double-layer magneto-electric composite thin film with polymethyl methacrylate, removing a single crystal magnesium oxide thin film by using an ammonium sulfate solution to separate the magneto-electric composite thin film adhered with the polymethyl methacrylate from the sapphire substrate and transferring the magneto-electric composite thin film separated from the sapphire substrate to a substrate required subsequently to obtain the cobalt ferrite and barium titanate self-supporting magneto-electric composite thin film. Compared with the composite material with the 1-3 structure, the self-supporting magneto-electric composite thin film obtained by the preparation method can reduce substrate clamping, solve the electric leakage problem and be used for the preparation of a magneto-electric sensor.

Owner:XIDIAN UNIV

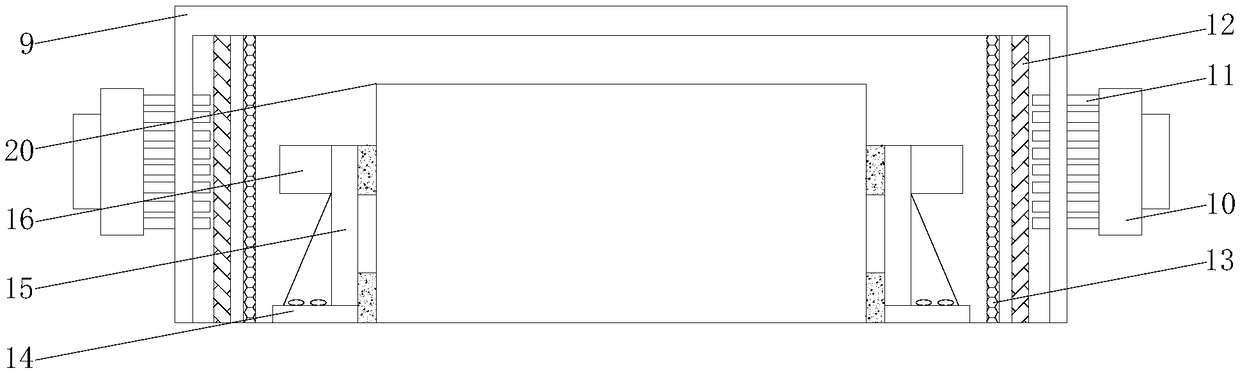

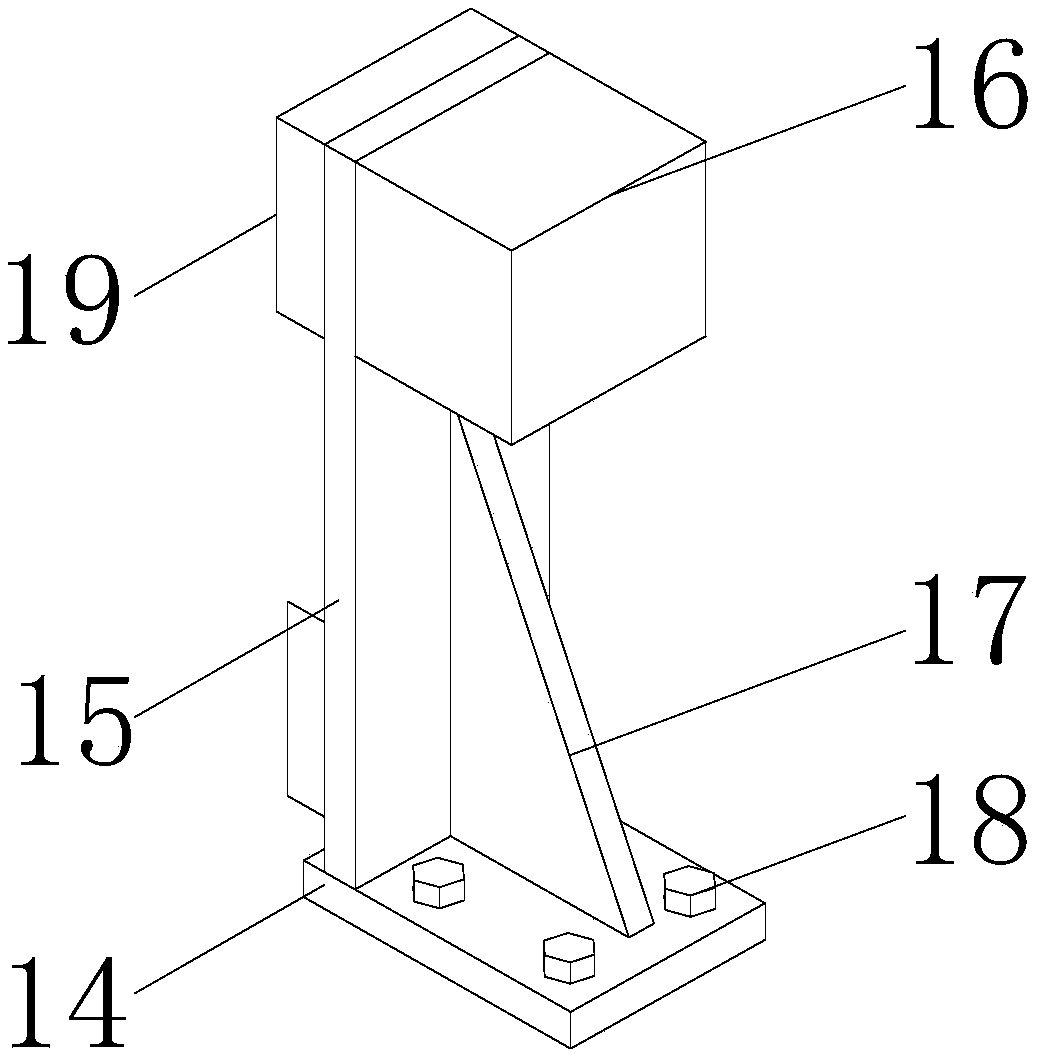

Steel structure welding and clamping device for building

ActiveCN111390470AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses a steel structure welding and clamping device for a building. The device comprises a protection cover and two supporting vertical plates, a driving mechanism and a lifting mechanism are mounted in the protection cover, a supporting plate is mounted on the top of the protection cover, a strip hole is formed in the supporting plate, the two supporting vertical plates penetrate through the strip hole, extend into the protection cover, and are matched with the driving mechanism, the lifting mechanism is mounted above the driving mechanism and is mounted between the two supporting vertical plates, the two ends of the lifting mechanism are mounted on the two supporting vertical plates, a clamping mechanism is mounted on the inner side of each supporting vertical plate, asteel structure can be clamped, welding precision is ensured, under the effect of the driving mechanism, the steel structure can be driven to rotate, a worker can conveniently weld the steel structure, the lifting mechanism can lift the steel structure required to be clamped to the same horizontal plane of the clamping mechanism, the clamping mechanism can conveniently clamp the steel structure, and the work efficiency can be improved.

Owner:BEIJING TIANHENG CONSTR

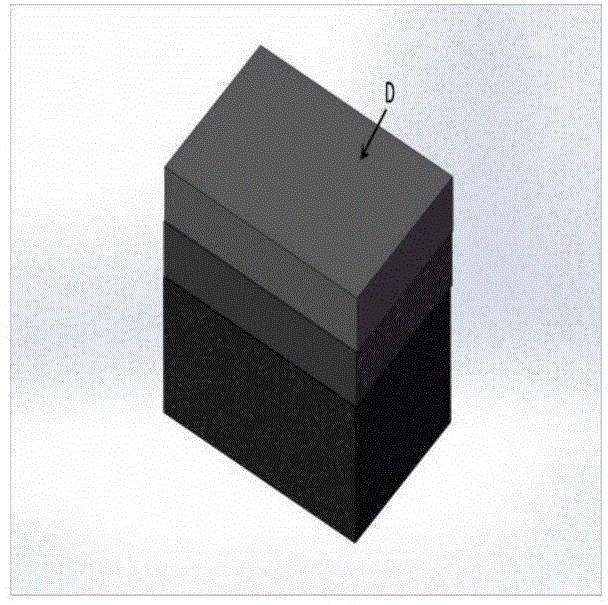

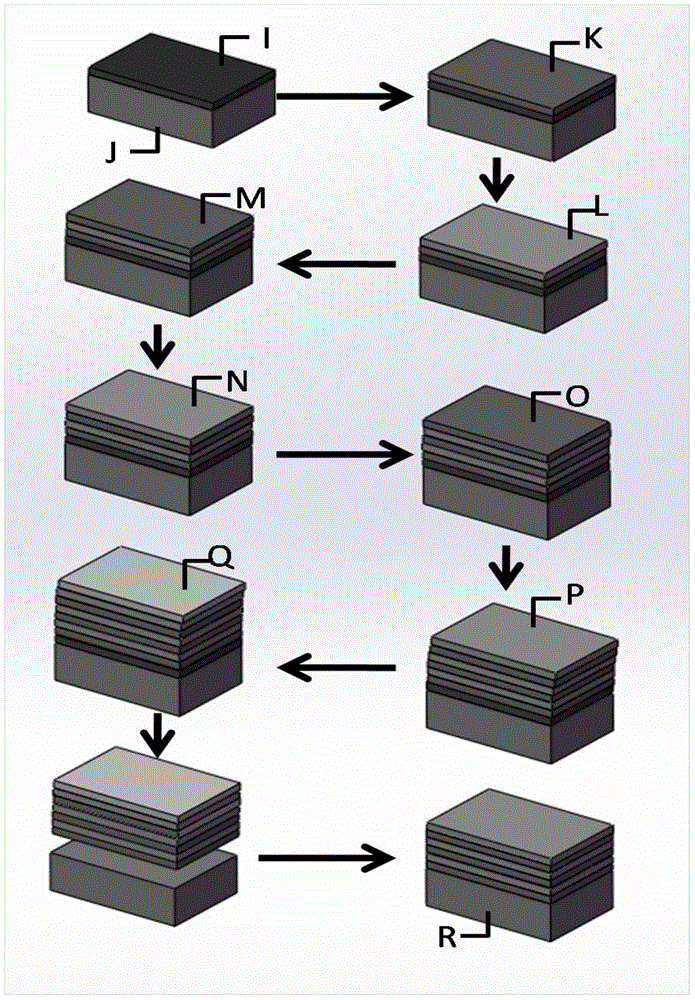

Method for preparing and transferring multilayer barium titanate and multilayer cobalt ferrite magnetoelectric composite film

The invention discloses a method for preparing and transferring a multilayer barium titanate and multilayer cobalt ferrite magnetoelectric composite film. The problems that the substrate clamping effect and electric leakage cannot be simultaneously reduced by the composite material of the conventional structures 1-3 are mainly solved. The method comprises the following implementation steps: depositing a magnesium oxide film on a sapphire substrate, and alternatively depositing a multilayer cobalt ferrite film and a multilayer barium titanate film on the substrate; spinning polymethyl methacrylate on the surface of the final barium titanate film, and removing a single crystal magnesium oxide film by using an ammonium sulfate solution, so that the magnetoelectric composite film attached to polymethyl methacrylate is separated from the sapphire substrate; and transferring the magnetoelectric composite film separated from the sapphire substrate onto a subsequent needed substrate, thereby obtaining a self-supported magnetoelectric film compounded by the multilayer cobalt ferrite film and the multilayer barium titanate film. The multilayer barium titanate and multilayer cobalt ferrite composite film disclosed by the invention is large in surface coupling property, the magnetic and electrical properties are enhanced, the substrate clamping and electric leakage problems are reduced, and the method can be used for preparing a magnetoelectric sensor.

Owner:XIDIAN UNIV

In-line pipe inspection tool

InactiveUS7784368B2Increase the lengthIncrease attractivenessAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsEngineeringMagnet

An in-line pipe inspection tool has one or more inspection platforms (28, 30) which are connected to an elongate wheeled trolley by link arms (20 to 26). The trolley unit (10, 12) has drive means for driving the point of connection of the first link arm (20, 22) to the trolley (10) relative to the point of connection of the second link arm (24, 26) to the trolley (12), thereby to move the inspection platforms (28, 30) in a direction perpendicular to the direction of elongation of the trolley (10, 12). Thus the inspection platforms (28, 30) are movable which is relative to the trolley (10, 12) to permit the tool to be adapted to pipelines of different diameters. Moreover, the platforms (28, 30) preferably have permanent magnets which contain a rotatable magnet. The rotatable magnet permits the net magnetic field generated by the platform to be varied.

Owner:PII LIMITED

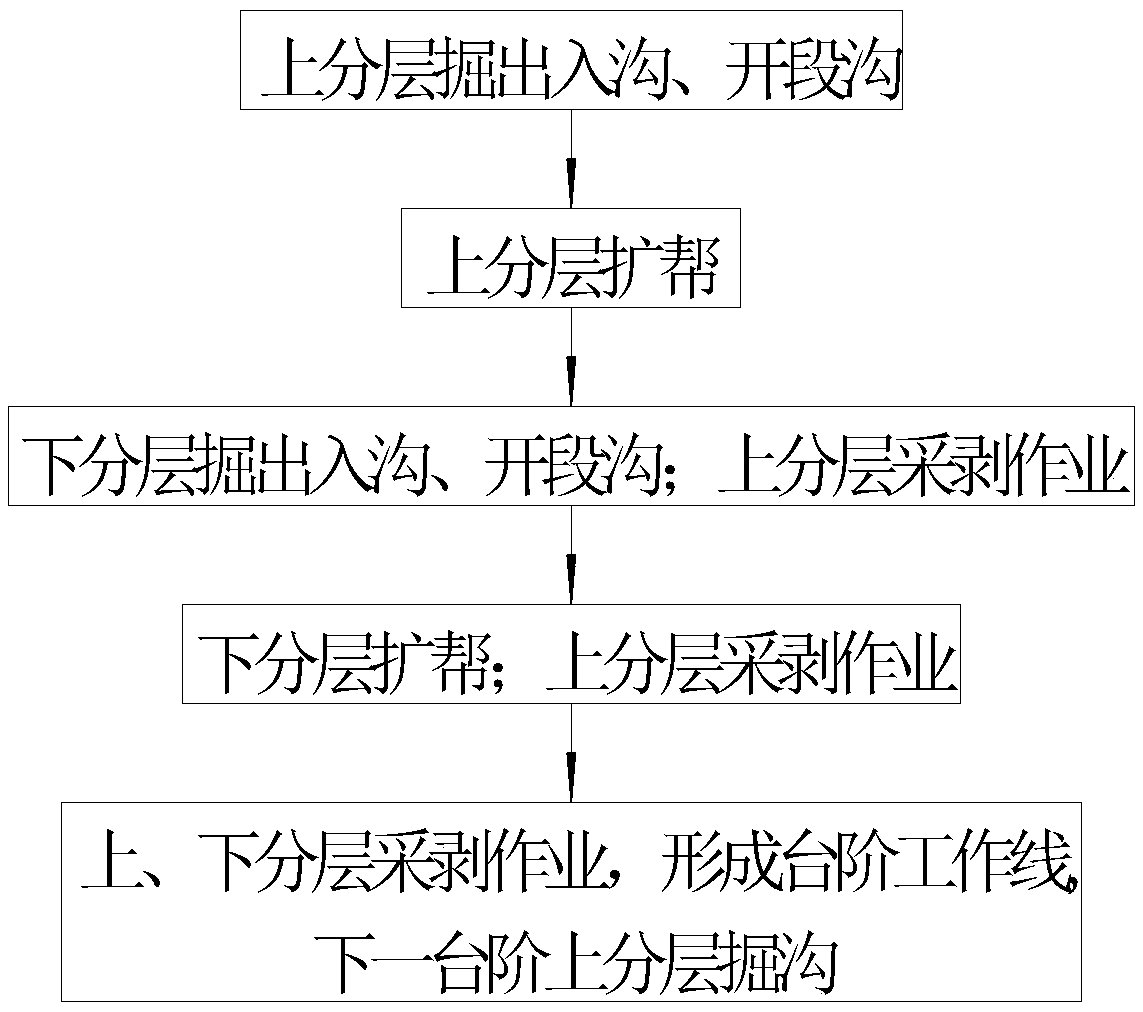

Strip mine trenching method

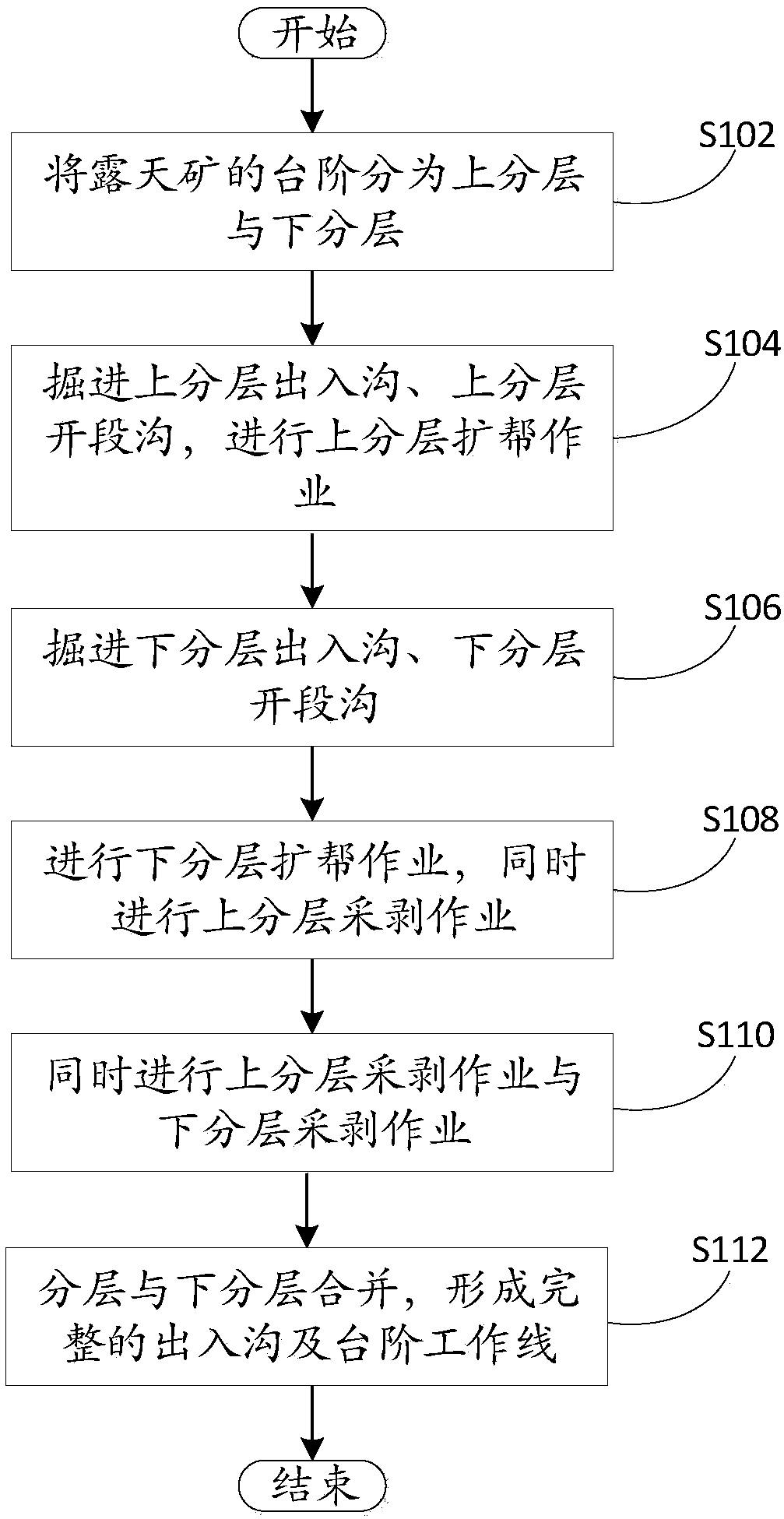

ActiveCN109162716AReduce preparation timeExtend stable production timeUnderground miningSurface miningComputer science

The invention provides a strip mine trenching method. The method comprises the following steps: dividing steps of a strip mine into a higher slice and a lower slice; tunneling a higher slice main access and a higher slice pioneer cut to carry out a higher slice expanding operation; tunneling a lower slice main access and a lower slice pioneer cut to carry out a lower slice expanding operation, andcarrying out a higher slice stripping operation at the same time; carrying out the higher slice stripping operation and a lower slice stripping operation at the same time; and combining the higher slice with the lower slice to form a complete step main access and a step work line. Through the technical scheme of the method, the trenching operation is implemented in two stages, so that the trenching work account is reduced by 20-40% and the new level preparation time is decreased; in the new level preparation process, a work surface can be formed to implement the stripping operation, so that the convention of carrying out trenching, expanding and stripping in sequence is broken through, a multi-work surface operation can be formed as soon as possible at the initial stages of mines, the mines can reach design capacities as soon as possible, and the stable yield time of the mines can be prolonged to avoid reduction of output untimely.

Owner:BAOTOU IRON & STEEL GRP

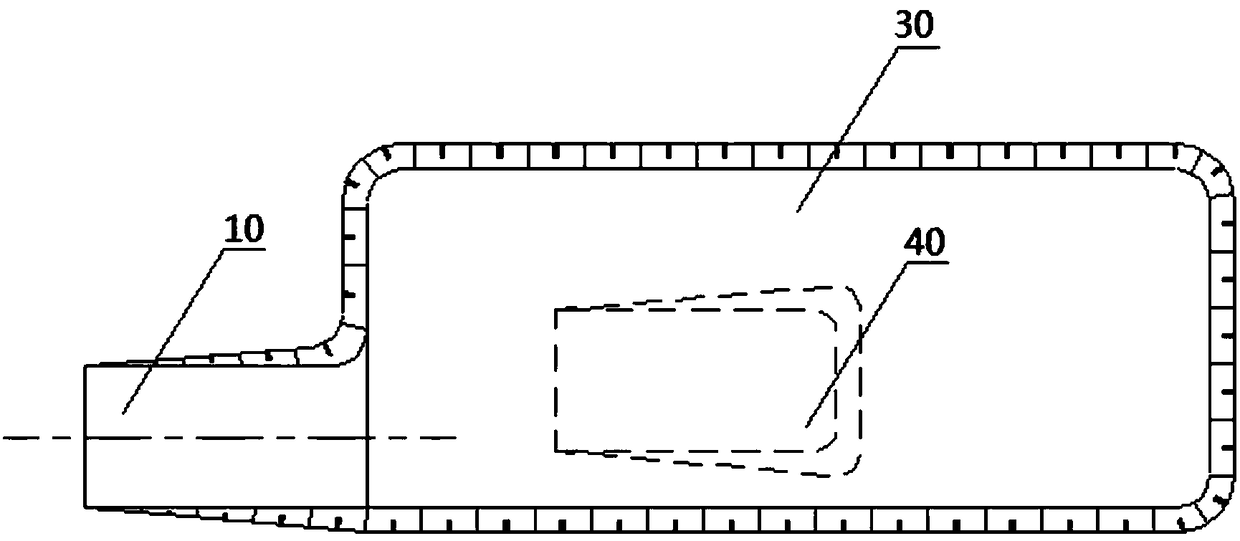

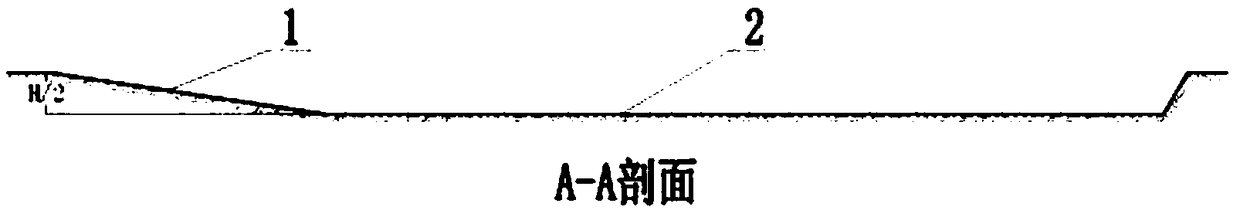

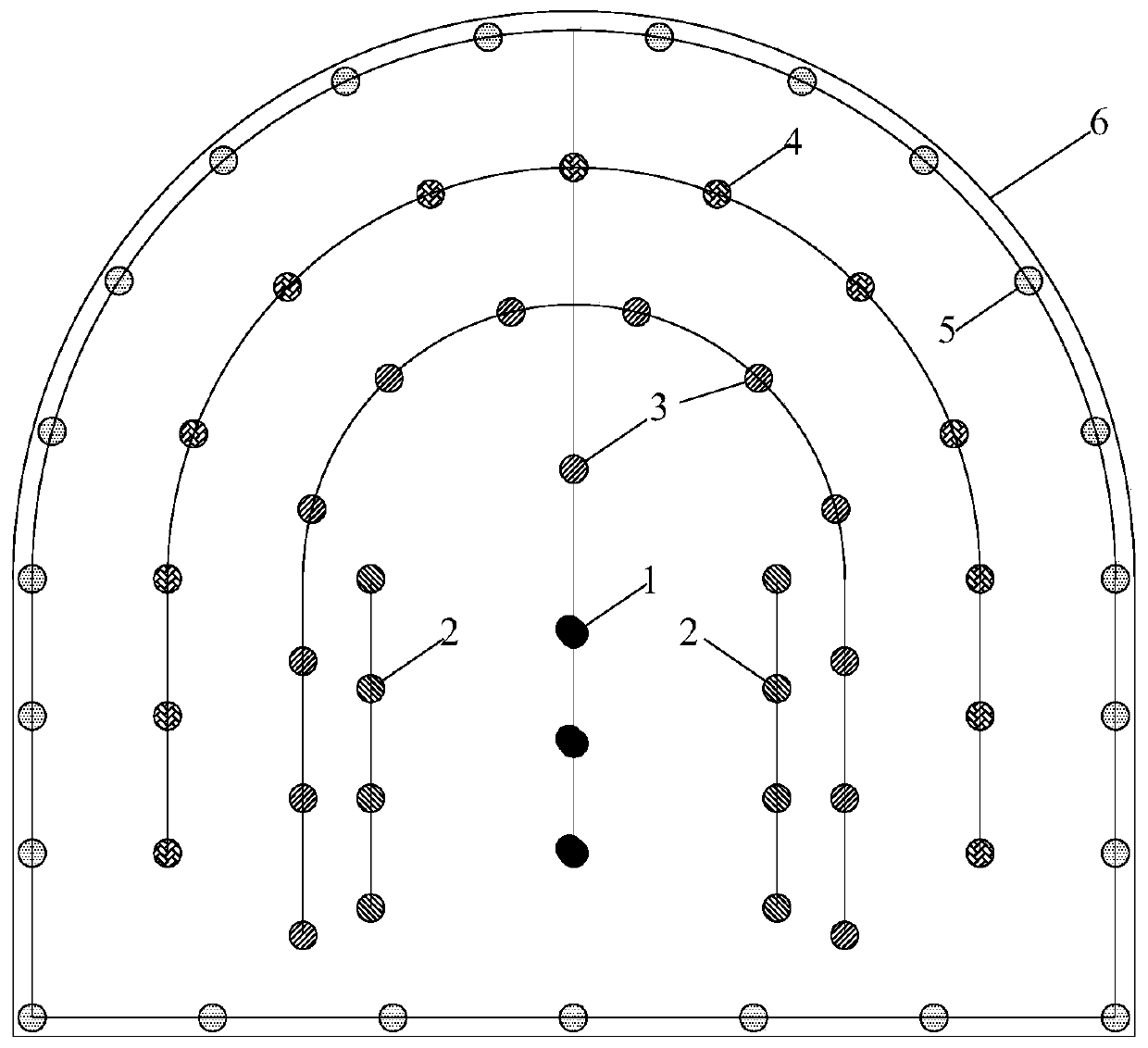

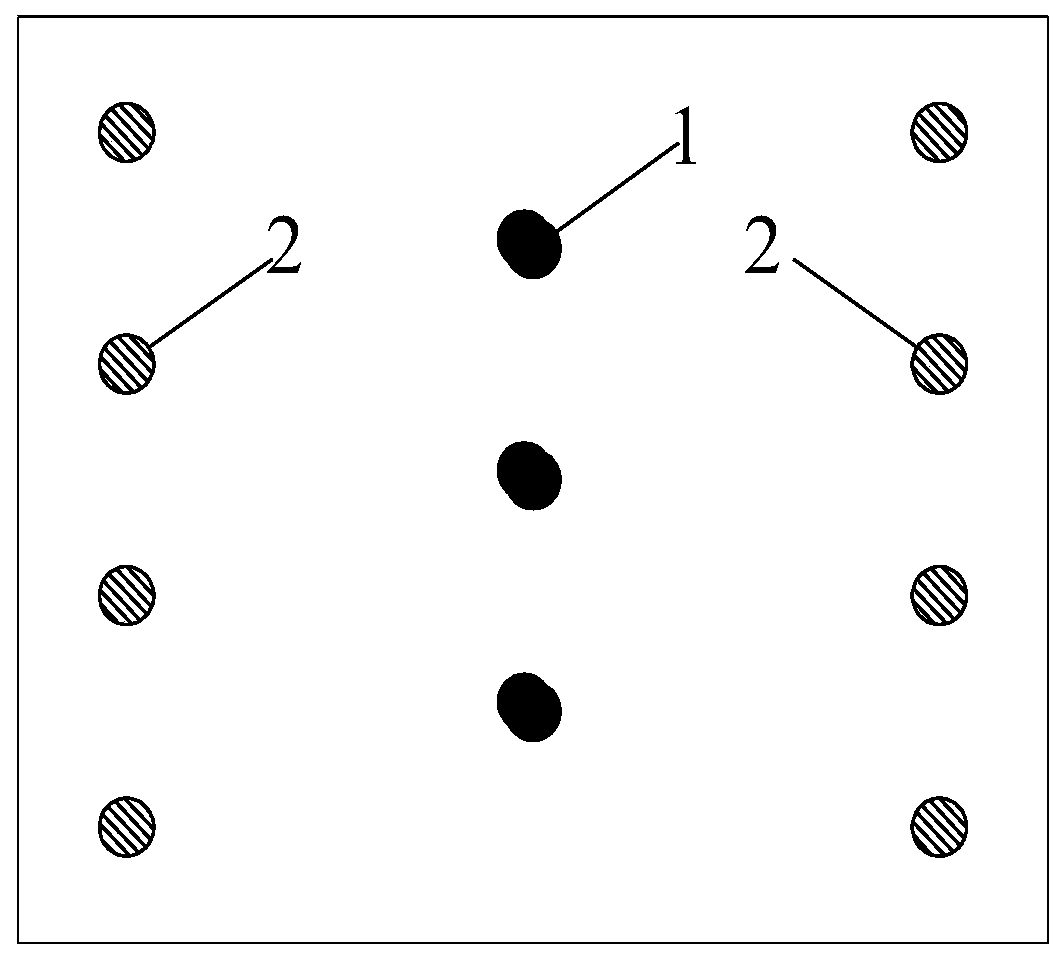

Cutting blasting method based on pre-blasting

The invention relates to a cutting blasting method based on pre-blasting. The cutting blasting method comprises the following steps: (1) a center charge hole is drilled in the center of a cut area, acircle of empty holes are drilled in the periphery of the center charge hole, main cutting holes and compensation cutting holes are drilled in the peripheries of the empty holes, and auxiliary holes,breaking holes and peripheral holes are sequentially drilled in the outer sides of the cutting holes; (2) the center charge hole is continuously filled with an explosive, the main cutting holes and the compensation cutting holes are continuously filled with 1 / 2 cumulative charge and 1 / 4 cumulative charge correspondingly, the auxiliary holes, the breaking holes and the peripheral holes are continuously filled with explosives, and blast holes are blocked by stemming; (3) the center charge hole is separately initiated to form a pre-blasted area; and (4) the remaining blast holes adopt micro-delayinitiation to achieve full-face one-time blasting. A large free face and rock breaking expansion space can be provided for cutting blasting, the surrounding rock clamping effect is overcome, the cutting effect is improved, and the overall blast hole utilization rate is increased.

Owner:ANHUI UNIV OF SCI & TECH

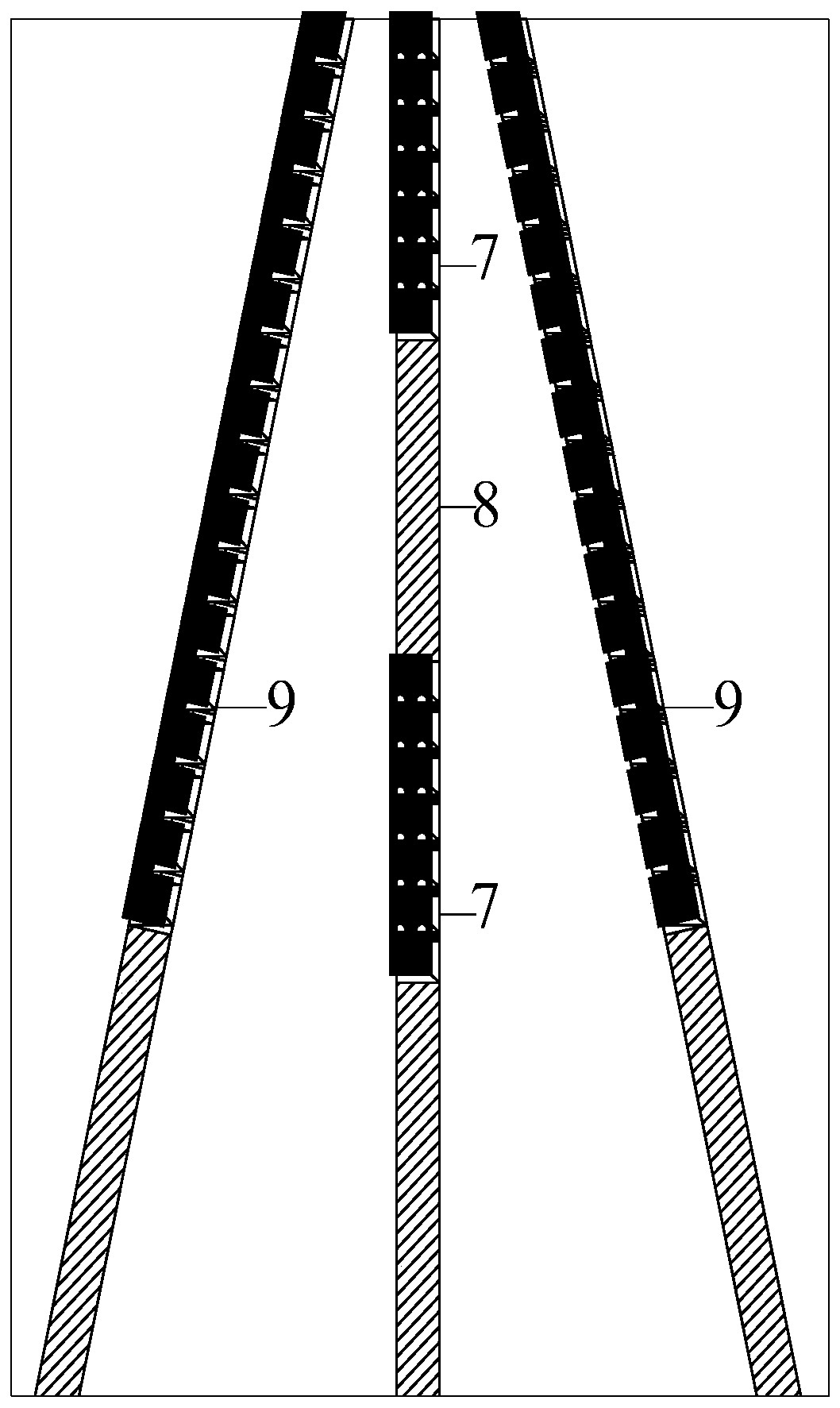

Up and down hole combined cutting-well-free slot broaching method

ActiveCN111441774AReduce clamping effectSufficient space for blasting compensationUnderground miningBlastingRock cuttingEngineering

The invention provides an up and down hole combined cutting-well-free slot broaching method. The method comprises the steps that inclined down holes are constructed in corresponding positions of an upper layering rock chiseling roadway and a lower layering cutting transverse roadway through a down-the-hole drill, after the down holes are arranged and constructed, a lower ore roof falling zone andthe lower layering cutting transverse roadway serve as blasting free faces, and blasting is carried out to obtain a first blasting space; up slot broaching holes are mounted and constructed in the lower layering cutting transverse roadway, first blasting space formed through down hole blasting and the lower layering cutting transverse roadway serve as free faces, and segmented blasting is carriedout to form a complete cutting vertical slot. The down holes and up holes are combined to carry out slot broaching, the up holes take the blasting space formed by the down holes as the free faces, segmented blasting is carried out, the process is simple and reliable, and the method is safe and economic. The method is suitable for breaking ores, construction of a cutting well is not needed, high danger and cost of construction of the cutting well in fractured ore rock can be reduced, and giant application prospects can be achieved.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

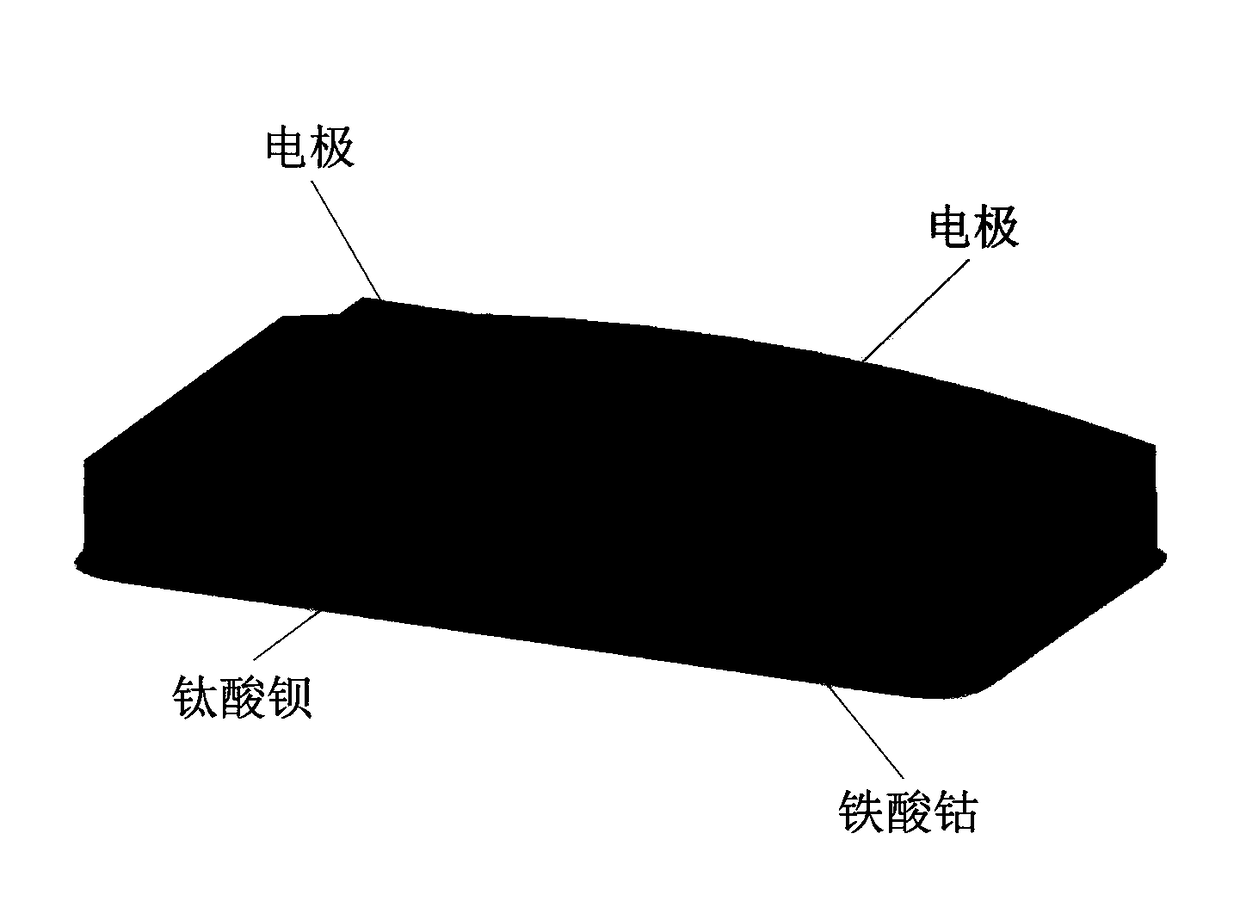

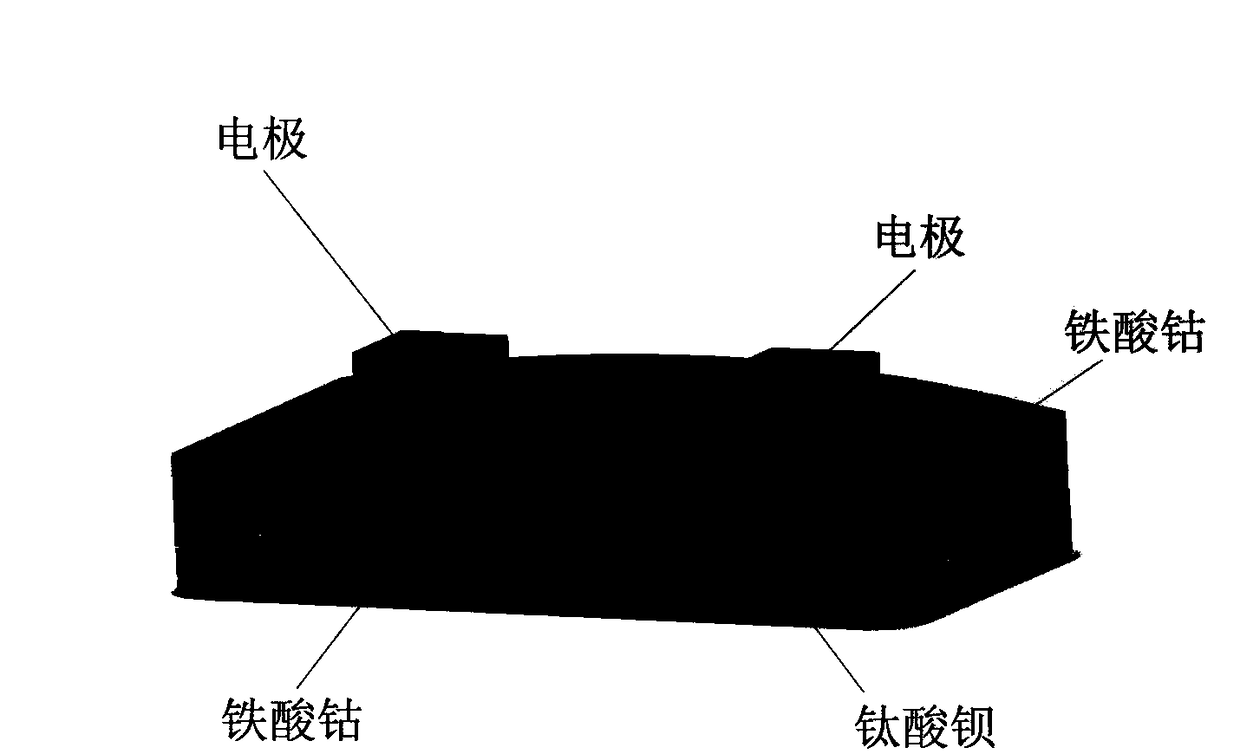

Flexible magnetic field strength sensor based on magnetoelectric composite film

ActiveCN108574043AAvoid breakingReduce clamping effectGalvano-magnetic material selectionGalvano-magnetic device manufacture/treatmentStrontium titanateBarium titanate

The invention discloses a manufacturing method of a flexible magnetic field strength sensor based on a magnetoelectric composite film. The problem that the existing magnetic field strength sensor haslow sensitivity and cannot be bent is solved. According to the implementation scheme, 1 a lanthanum strontium manganese oxide film is deposited on a strontium titanate substrate, and cobalt ferrite and a barium titanate film are successively deposited on the lanthanum strontium manganese oxide film to acquire a multilayer magnetoelectric composite film; 2 polymethyl methacrylate is spin-coated, and the lanthanum strontium manganese oxide film is removed with a potassium iodide solution; 3 the off-substrate magnetoelectric composite film is transferred to a subsequent needed flexible substrate;and 4 electrodes are added to left and right sides of the surface of the magnetoelectric composite film to complete the manufacturing of the magnetic field strength sensor. According to the invention, the magnetoelectric composite film is used as a sensing material, so that the sensor can be bent; the magnetoelectric characteristic of the bent film is remarkably enhanced; the sensitivity of the magnetic sensor is improved; the requirement of a flexible electronic device is satisfied; and the method can be used to prepare a semiconductor device.

Owner:XIDIAN UNIV

Novel level preparation method for improving annual declining speed of deep mining in open pit mines

ActiveCN109184696AReduce the amount of trenchingReduce preparation timeUnderground miningSurface miningEngineeringStructural engineering

The invention discloses a novel level preparation method for improving an annual declining speed of deep mining in open pit mines. The method comprises: dividing a deep step of an open pit mine into upper and lower layers, digging an upper layer inlet / outlet trench (1) and an upper layer working trench, after the upper layer rib expanding, digging a lower layer inlet / outlet trench (5) and a lowerlayer working trench so that an upper layer stripping work line (7) is formed, stripping the upper layer in advance, after the lower layer rib expanding (8), simultaneously stripping the upper and lower layers so that the upper and lower layers are combined into a complete step inlet / outlet trench and a step working line, and dipping the next step of an upper layer inlet / outlet trench and a working trench. The method realizes stripping work in the novel level preparation of the deep step of the open pit mine, reduces the trenching work intensity, reduces the new level preparation period, prolongs the years of stable production of the mine, prevents the premature production reduction of the mine, reduces the trenching cost and improves the mine capacity guarantee degree by two stages.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

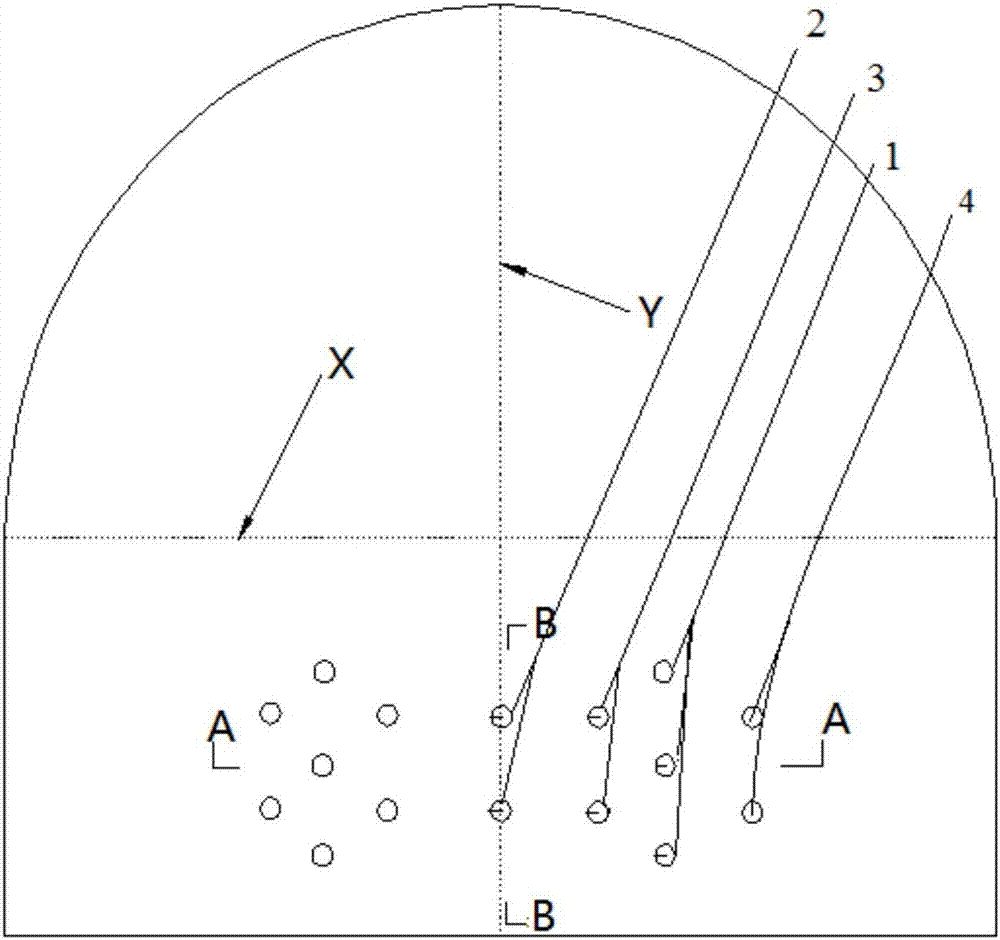

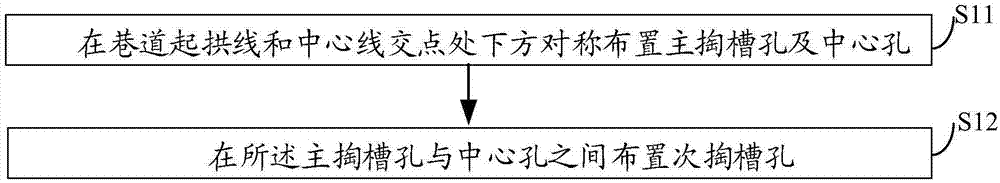

Hard rock stone head deep hole slotting and blasting method

The invention discloses a hard rock stone head deep hole slotting and blasting method, relates to the technical field of deading by drilling and blasting methods, and can effectively increase the utilization rate of slotting holes and blast holes to improve the blasting efficiency. The slotting method comprises the following steps: a main slotting hole and a center hole are symmetrically arranged below the intersection of a roadway springing line and a center line; and a secondary slotting hole is formed between the main slotting hole and the center hole. The blasting method comprises the following steps: the main slotting hole, the secondary slotting hole and the center hole are symmetrically arranged below the intersection of the roadway springing line and the center line; cartridges are loaded in the main slotting hole, the secondary slotting hole and the center hole; the main slotting hole, the secondary slotting hole and the center hole are blocked; the center hole and the secondary slotting hole are blasted firstly; and then, the main slotting hole is blasted. The hard rock stone head deep hole slotting and blasting method is suitable for such blasting tunneling engineering as hard rock stone heads, tunnels and caves.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

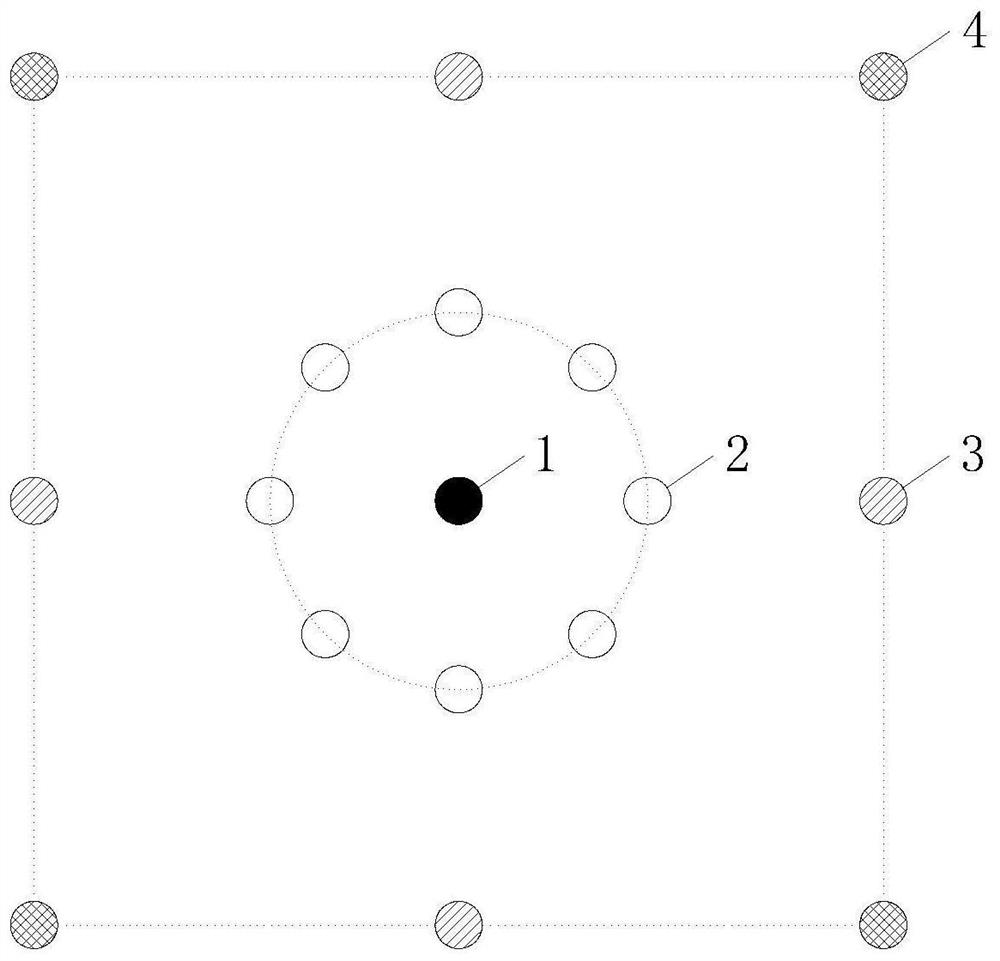

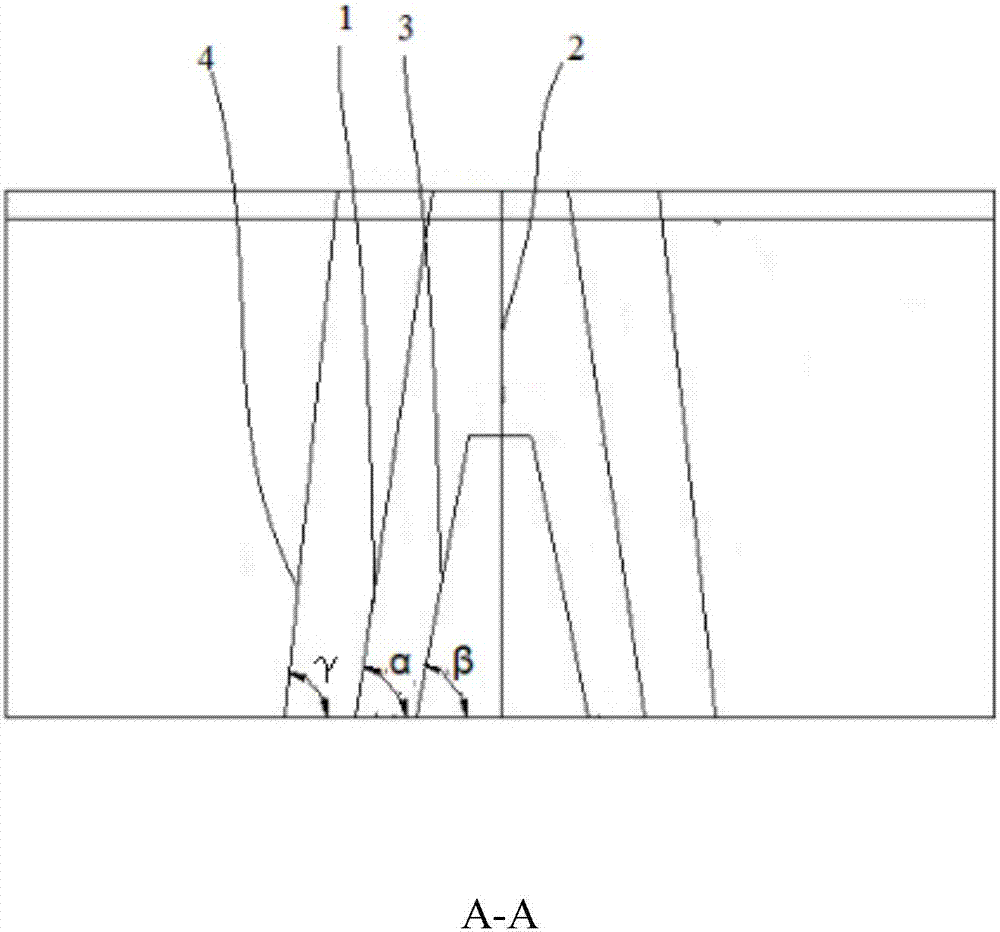

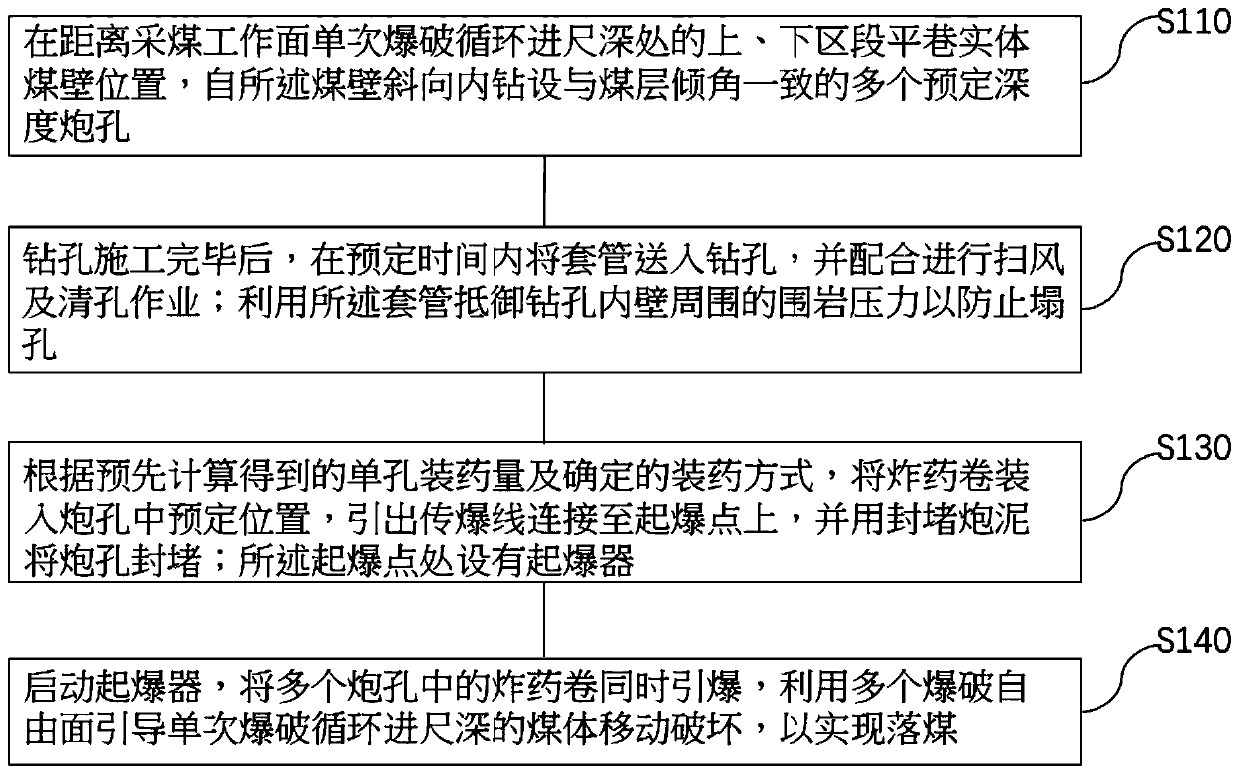

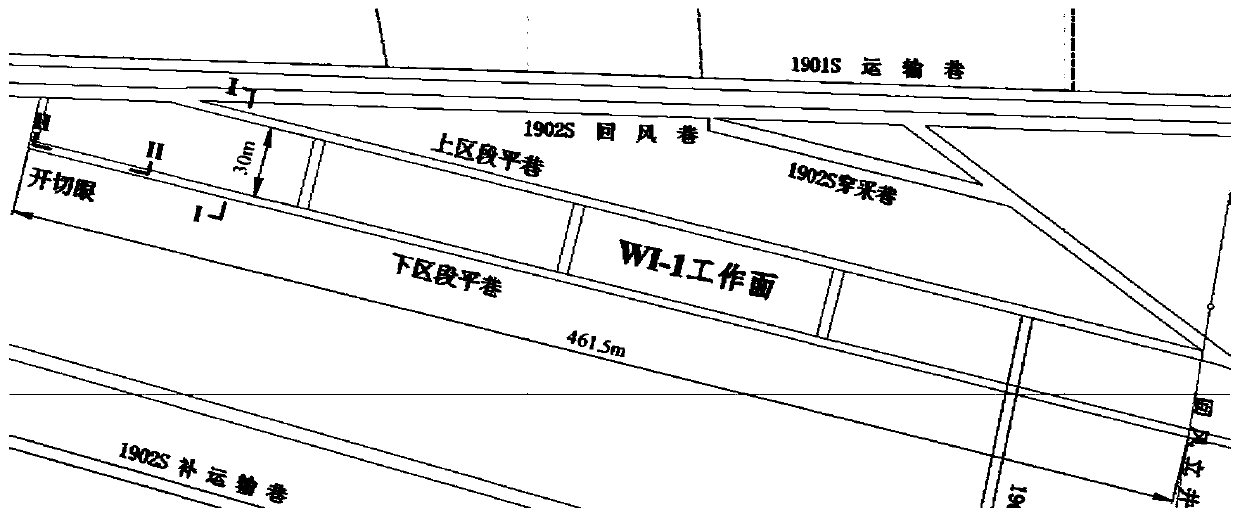

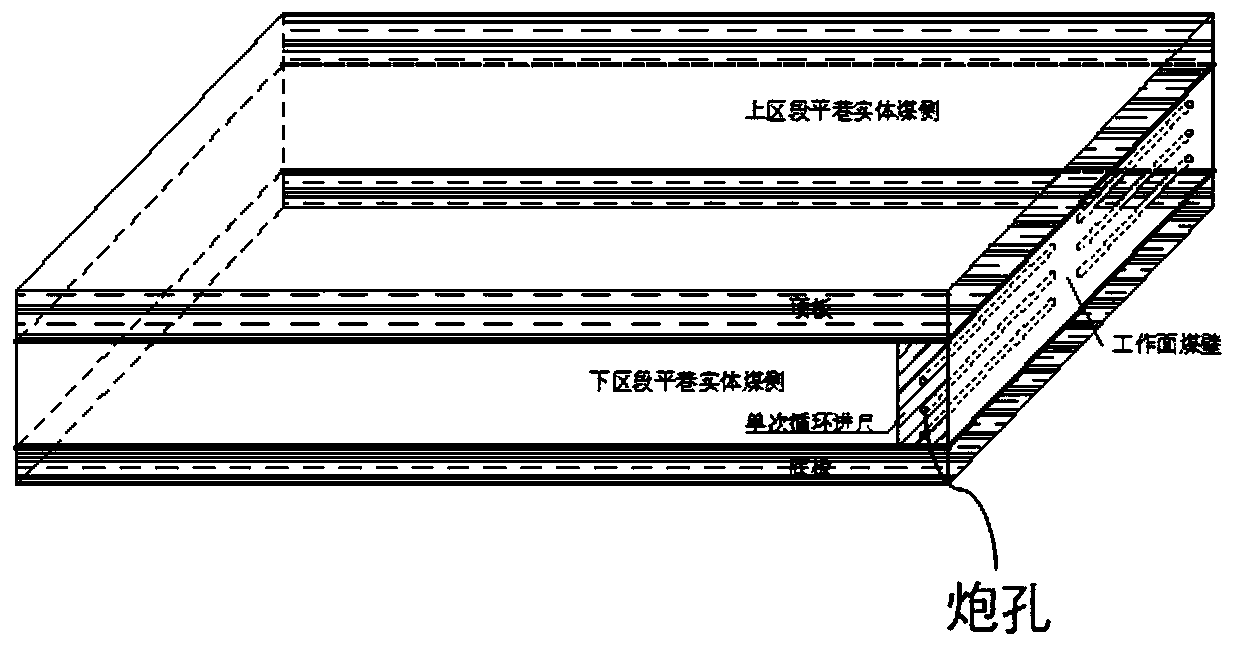

Deep-hole coal blasting method for steeply dipping coal seam

ActiveCN111551084AAvoid collapsing holesReduce clamping effectBlastingTEX-explosiveMining engineering

The embodiment of the invention relates to the technical field of coal mining engineering, in particular to a deep-hole coal blasting method for a manless working face of a steeply dipping coal seam.The deep-hole coal blasting method comprises the steps: at the positions of solid coal walls of an upper-zone roadway and a lower-zone roadway at the depth away from a coal working face by single-timeblasting cyclical footage, a plurality of blast holes with predetermined depths are drilled obliquely inwards from the coal walls, wherein the multiple blast holes are consistent with the dip angle of the coal seam; after drilling is completed, casings are sent into drill holes within the predetermined time; according to the pre-calculated single-hole explosive load and a determined explosive loading mode, explosive coils are loaded into predetermined positions of the blast holes, explosion propagation lines are led out to be connected to an initiation point, and the blast holes are blocked through blocking gun clay; and an initiator is started, the explosive coils in the multiple blast holes are initiated simultaneously, and coal bodies at the single-time blasting cyclical footage depthare guided to move to be broken through a plurality of blasting free faces to achieve coal dropping. The deep-hole coal blasting method can be suitable for mining the steeply dipping coal seam and provides a comprehensive theory and a practical guiding basis for later production and mining of the steeply dipping coal seam.

Owner:NORTH CHINA INST OF SCI & TECH

Piezoelectric plane horn

InactiveCN102625215AAdjust vibration behaviorReduce resonance phenomenonElectrical transducersResonancePiezoelectric actuators

The invention discloses a piezoelectric plane horn, comprising a framework, a piezoelectric actuator, and a vibration generating membrane arranged in the transparent assembling space of the framework, wherein two opposite sides of the vibration generating membrane are fixed to the piezoelectric actuator, with the other two sides thereof forming a spacing relationship with the framework; the piezoelectric actuator formed by utilizing a bimodal piezoelectric piece is fixed at two sides of the vibration generating membrane; the vibration generating membrane is made to generate the voice of high pitch voltage via the high deformation of a bimodal piezoelectric piece; the bimodal piezoelectric piece in the piezoelectric actuator can be independently driven by the drive circuit to cooperate with the phase control of different bimodal piezoelectric piece drive voltage, thus to adjust the vibration movement of the vibration generating membrane and reduce the resonance phenomenon of the vibration generating membrane, thereby making the vibration generating membrane produce relatively flat acoustic frequency response. The piezoelectric plane horn is applicable to sound equipment, TV, computer, and other electronic devices and is located in a preset installing space of the electronic device by utilizing the framework thereof.

Owner:HO HSIN PROGRESSIVE TECH

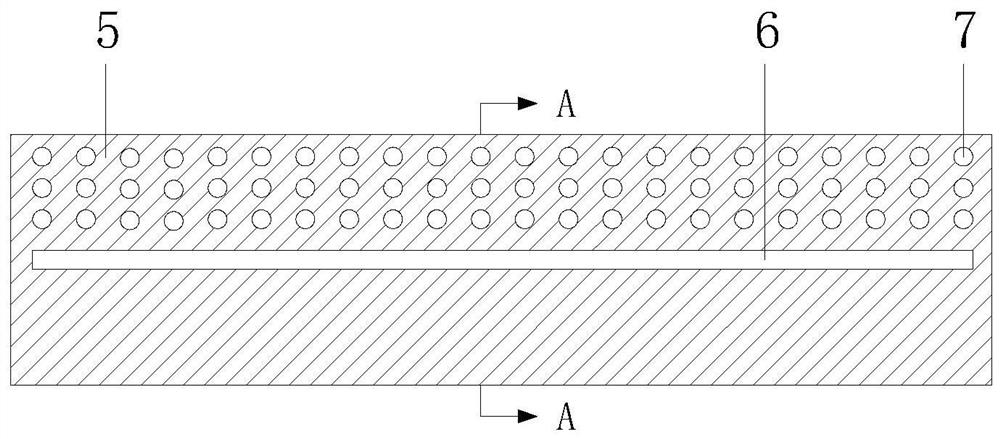

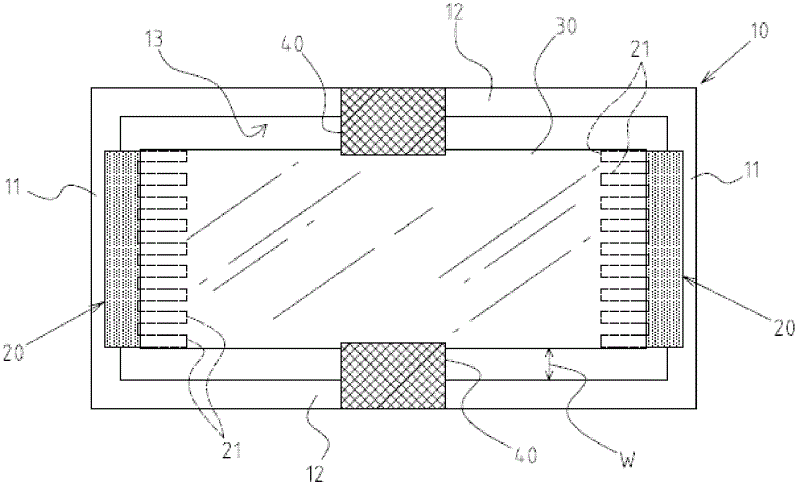

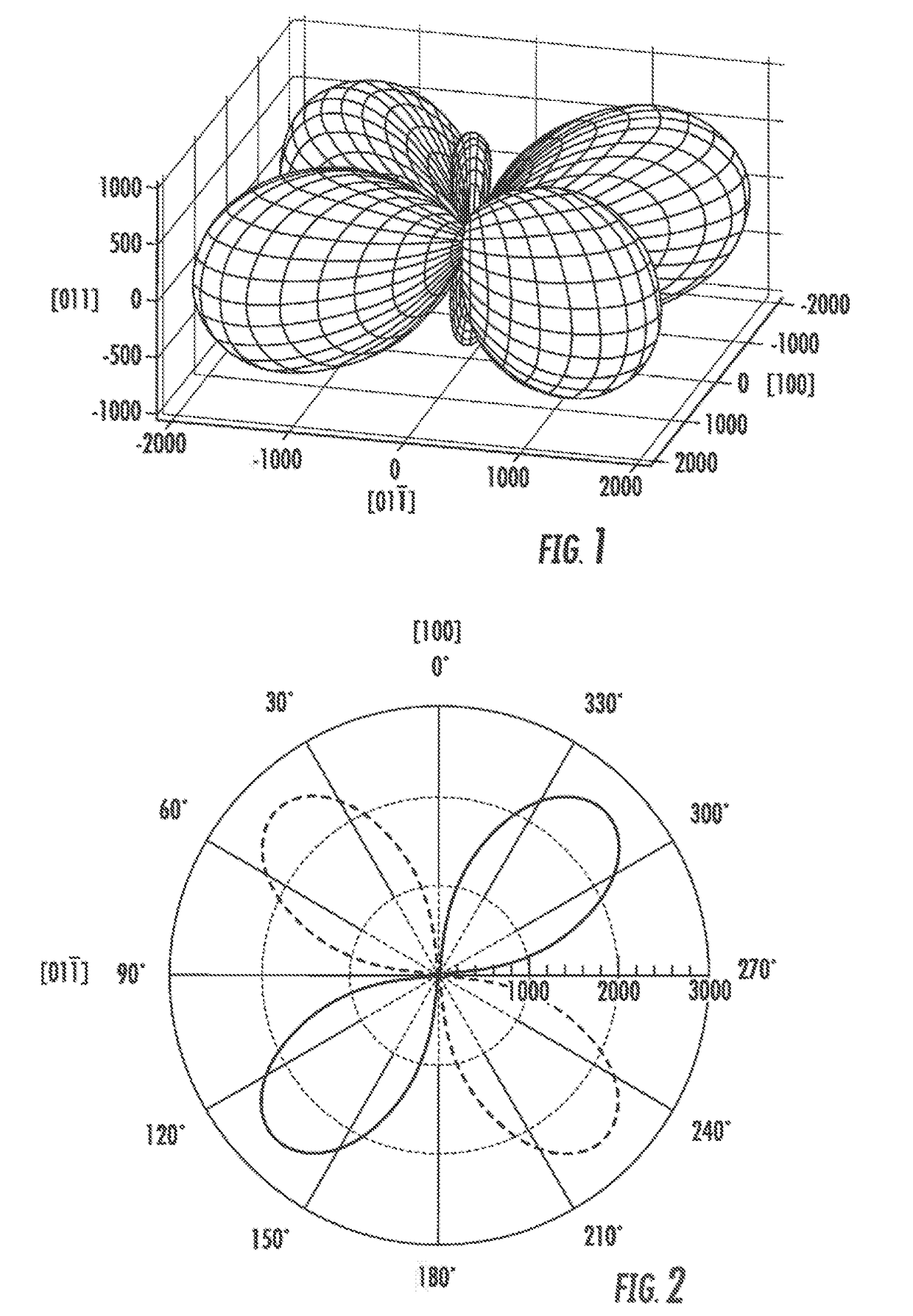

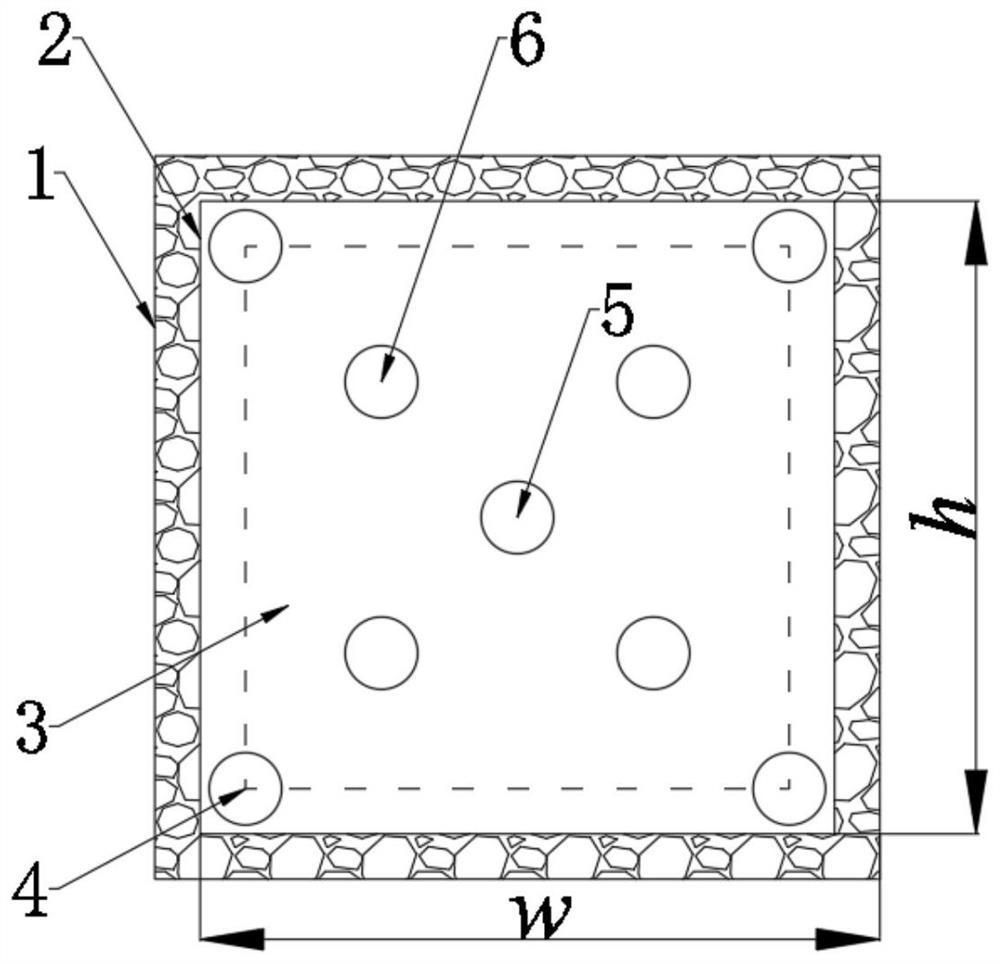

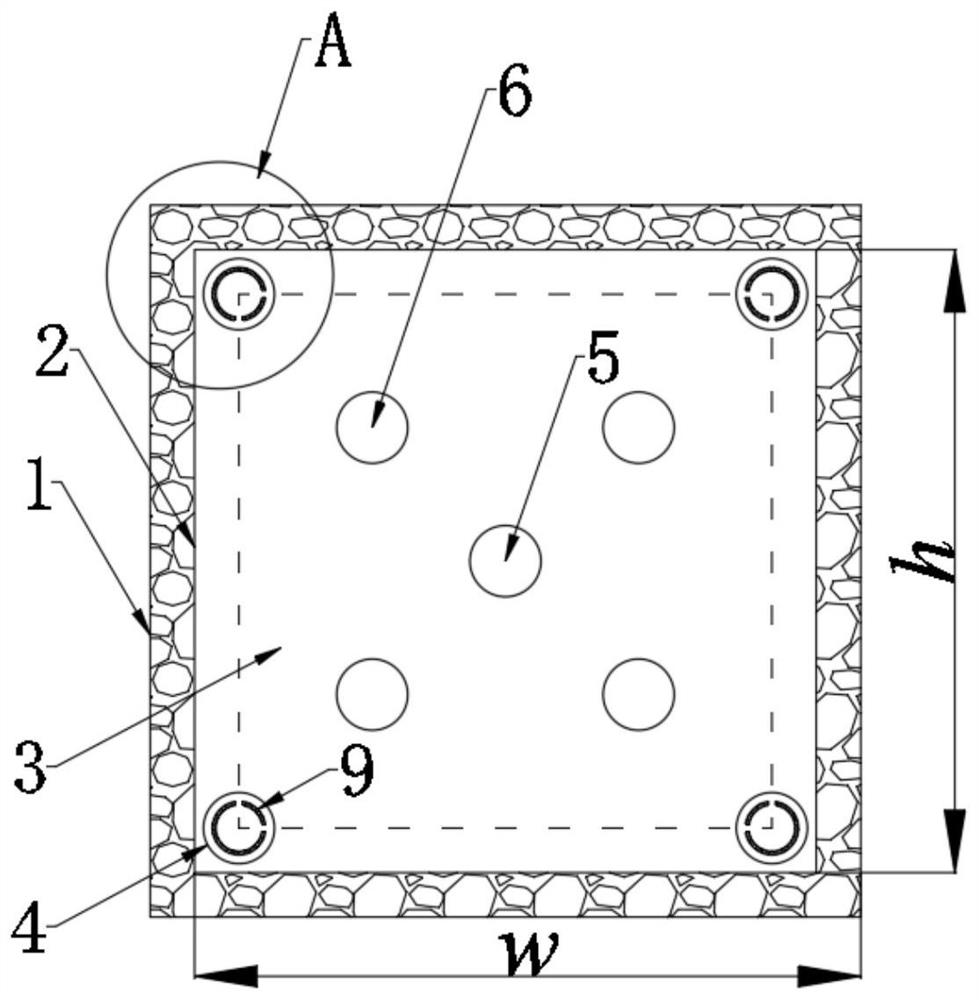

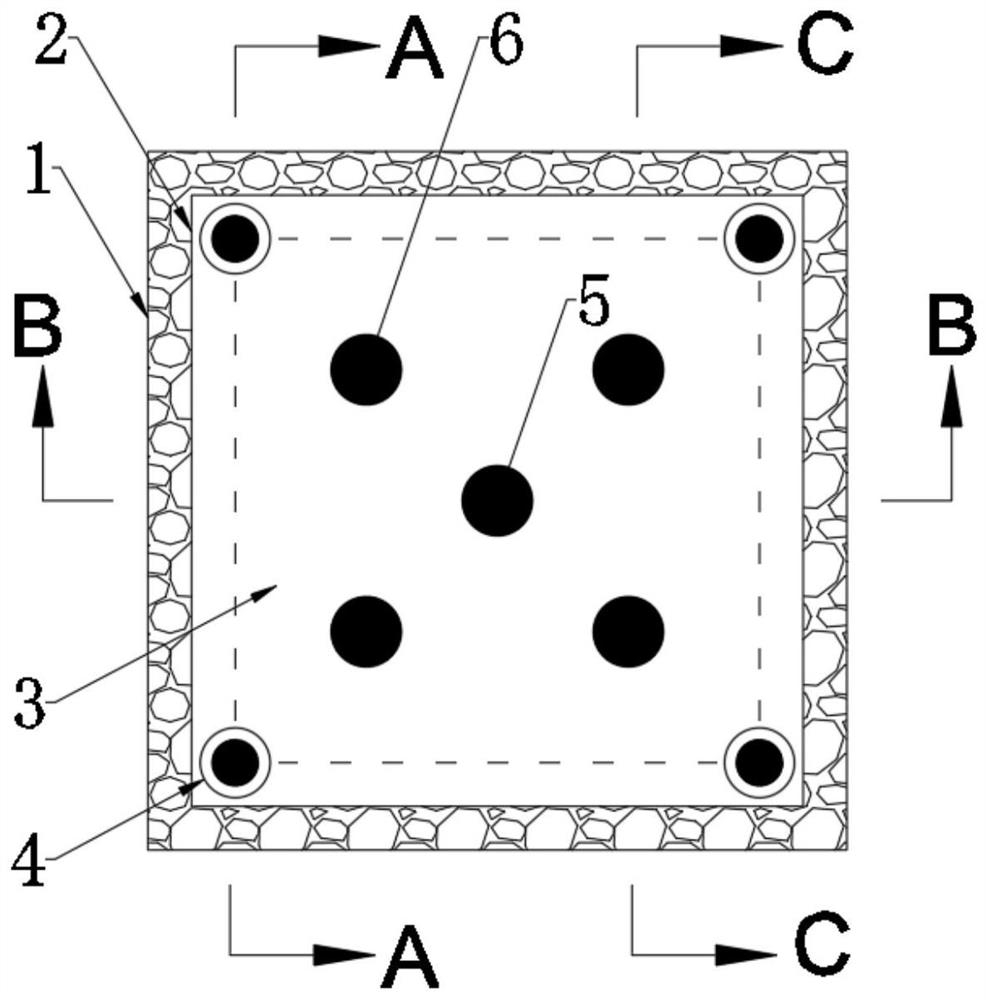

System and fabrication method of piezoelectric stack that reduces driving voltage and clamping effect

ActiveUS20170186937A1Reduce the driving voltageMaintaining driving levelAfter-treatment apparatusPolycrystalline material growthEngineeringSingle crystal

A system and method provides a piezoelectric stack arrangement for reduced driving voltage while maintaining a driving level for active piezoelectric materials. A stack arrangement of d36 shear mode <011>single crystals of both air X-cut and Y-cut ±1:45° (±20°) arrangement are bonded with discrete conductive pillars to form a shear crystal stack. The bonding area between the neighboring crystal parts is minimized. The bonding pillars are positioned at less than a total surface are of the single crystal forming the stack. The stack fabrication is facilitated with a precision assembly system, where crystal parts are placed to desired locations on an assembly fixture for alignment following the preset operation steps. With the reduced clamping effect from bonding due to lower surface coverage of the discrete conductive pillars, such a piezoelectric d36 shear crystal stack exhibits a reduced driving voltage while maintaining a driving level and substantial and surprisingly improved performance.

Owner:CTS CORP ELKHART

Headband structure and headphone

The invention is applicable to the technical field of headphones, and provides a headband structure. The headband structure comprises a headband pad leaning against the head, a headband body fixedly connected with the headband pad and a supporting sheet used for supporting the headband body, the headband body comprises a first body which is formed by flexible glue and is provided with a holding groove and a pair of second bodies, which is integrally formed with the first body and is formed by ebonite, the second bodies are symmetrically held in the holding groove and are located between the first body and the headband pad, and the supporting sheet is fixed on the second bodies and is located between the headband pad and the second bodies. The headband structure is integrally formed by the first body formed by the flexible glue and the second bodies formed by the ebonite, a headband body is obtained, the headband structure has certain elasticity, which greatly reduce the clamping function of the headband structure on the head to ensure comfortable wearing; and meanwhile, the supporting sheet plays a certain supporting role to perfect the outline and the wearing comfort of the entire headband structure.

Owner:SHENZHEN GRANDSUN ELECTRONICS CO LTD

Large-section-height multi-row micro-difference extrusion blasting method

The invention discloses a large-section-height multi-row micro-difference extrusion blasting method. A vertical deep hole is adopted as a blast hole, hole distribution is conducted according to the principle that explosive is evenly distributed in a to-be-blasted rock body, and the hole distribution manner is a rectangular hole distribution manner. Through determination on blasting parameters, anexplosive filling structure is designed, the multi-hole rowed hole distribution manner is selected on the vertical plane, a deflection center point is selected as a blasting point, and micro-difference sequential blasting is adopted between the adjacent holes and is adopted in holes between rows. The large-section-height multi-row micro-difference extrusion blasting method has the beneficial effects that a favorable free face is created for subsequent ore body rock blasting, and the rock clamping action is lowered; in the rock block motion process after rock body crushing, rock blocks are mutually in collision, mutual rubbing happens, impact pressure and shearing force are generated, the rock blocks are crushed again, a rock block diameter reducing blasting method is provided, the blastedrock body crushing degree can be improved, the blasting vibration effect is reduced, harm to ground buildings is lowered, and mine safety is maintained.

Owner:临沂会宝岭铁矿有限公司

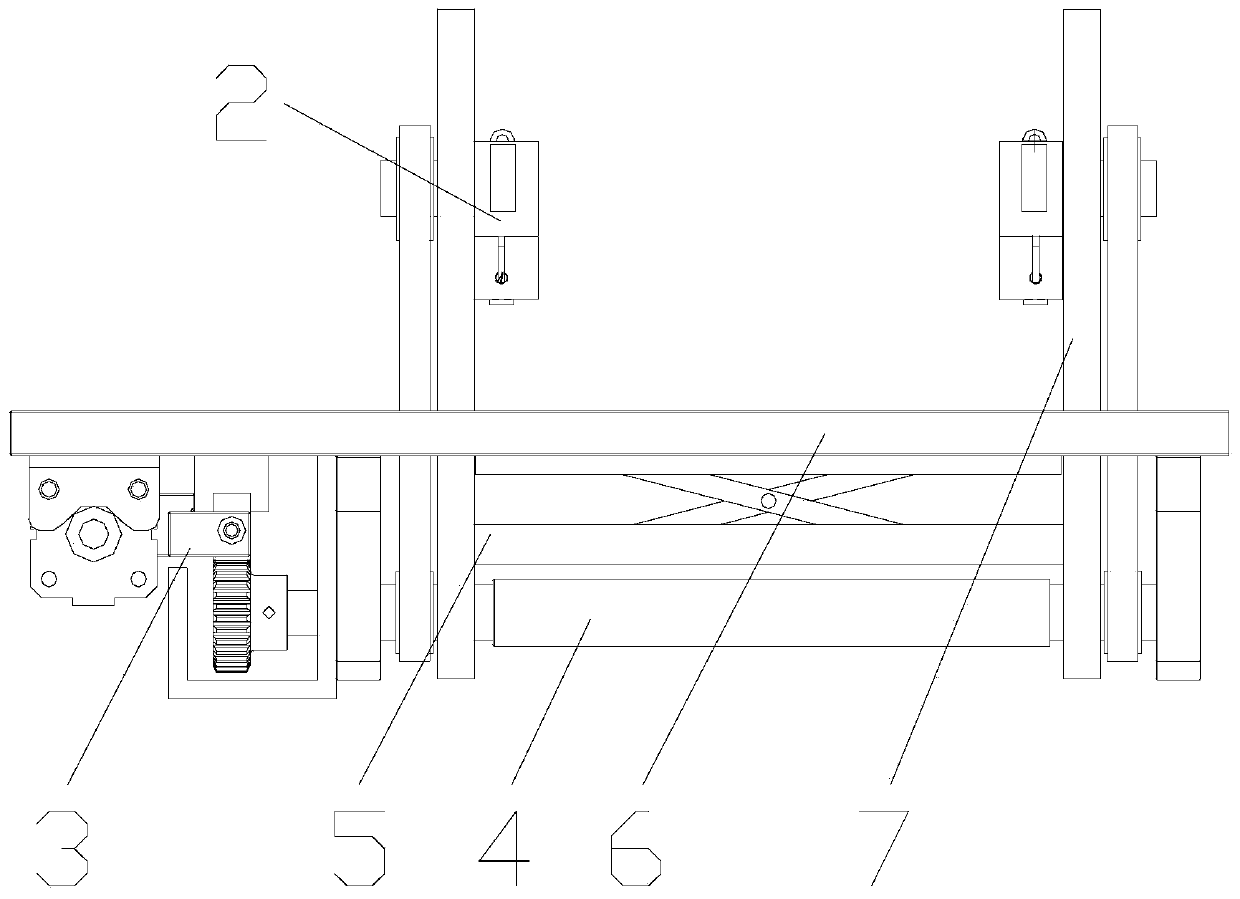

300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and use method

InactiveCN111687558AAvoid the phenomenon of free deformationGuaranteed Assembly RequirementsWelding/cutting auxillary devicesAuxillary welding devicesCombustion chamberEngineering

The invention relates to the field of welding, in particular to a 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and a use method. The 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and the use method aim at solving the problems that a hula seal molded line and radian are changed due to the fact that the unrestrained end of a 300MWheavy-duty gas turbine nozzle hula seal is deformed to release welding tensile stress, and the follow-up assembly is influenced. The 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool is designed and manufactured and comprises a restraining force application part and a restraining belt, wherein the restraining belt is annular when working, one end of the restraining belt is connected with the restraining force application part, the other end of the restraining belt is tightened through the restraining force application part, the hula seal is forcibly restrained byusing the restraining tool all the time in the high-temperature alloy hula seal and nozzle assembling and welding process, the temperature difference of different positions disappears after welding iscompleted, after a certain welding stress is released, the restraining tool is removed, it is guaranteed that the free end of the hula seal does not have larger free deformation, it is further guaranteed that the molded line and radian of a product meet drawing and design requirements, and the subsequent combustion chamber assembling requirement is met.

Owner:HARBIN TURBINE

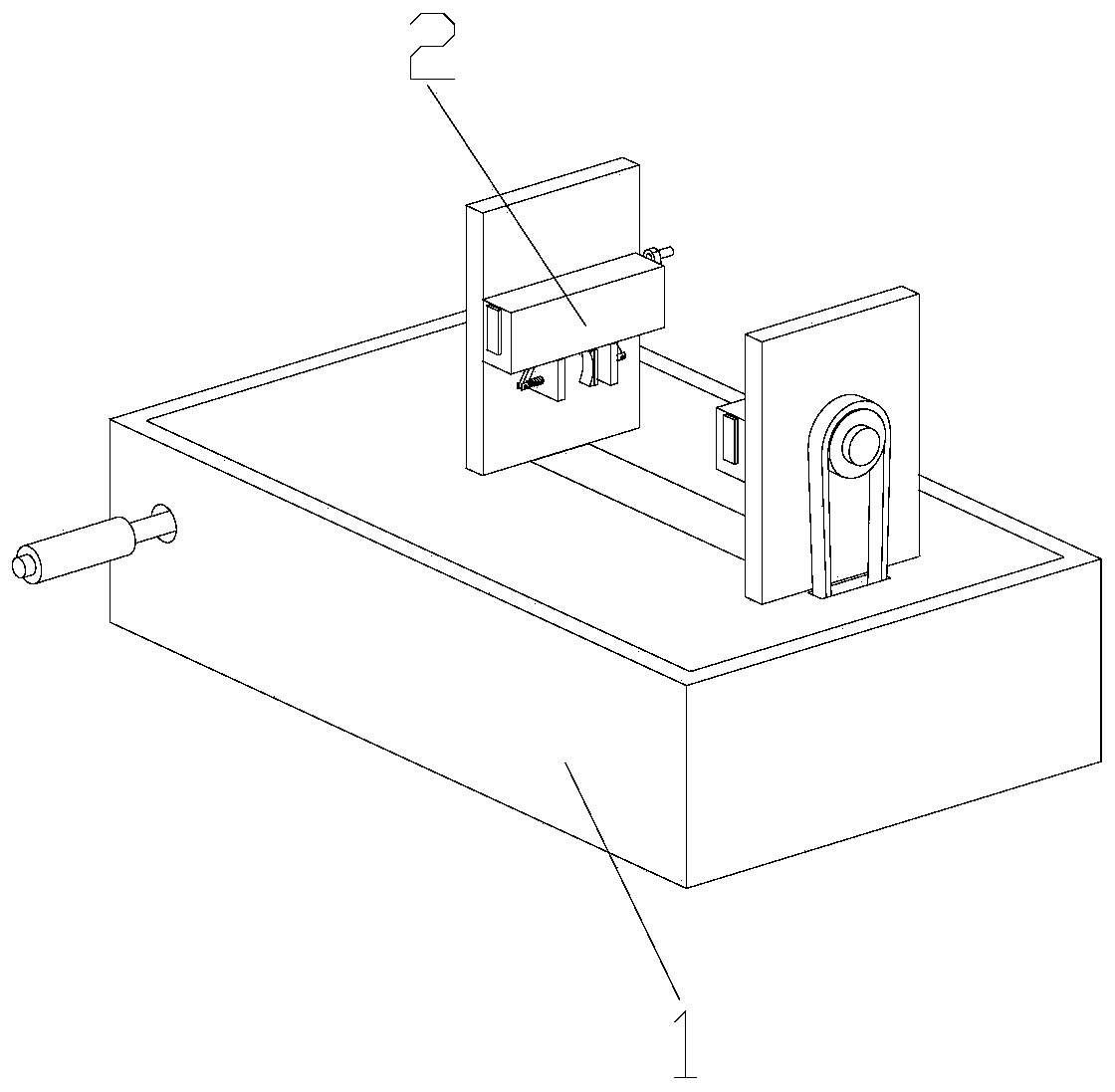

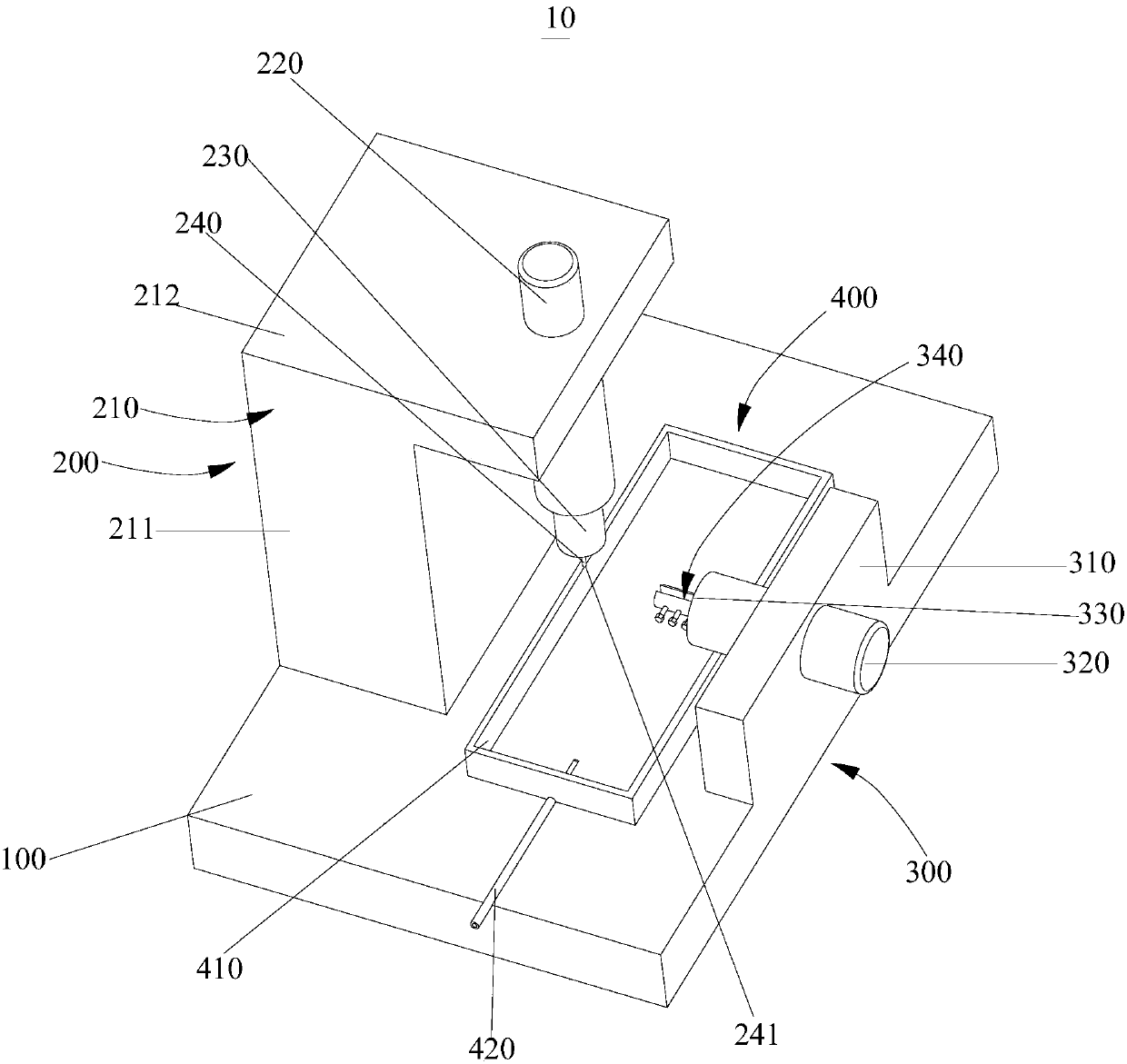

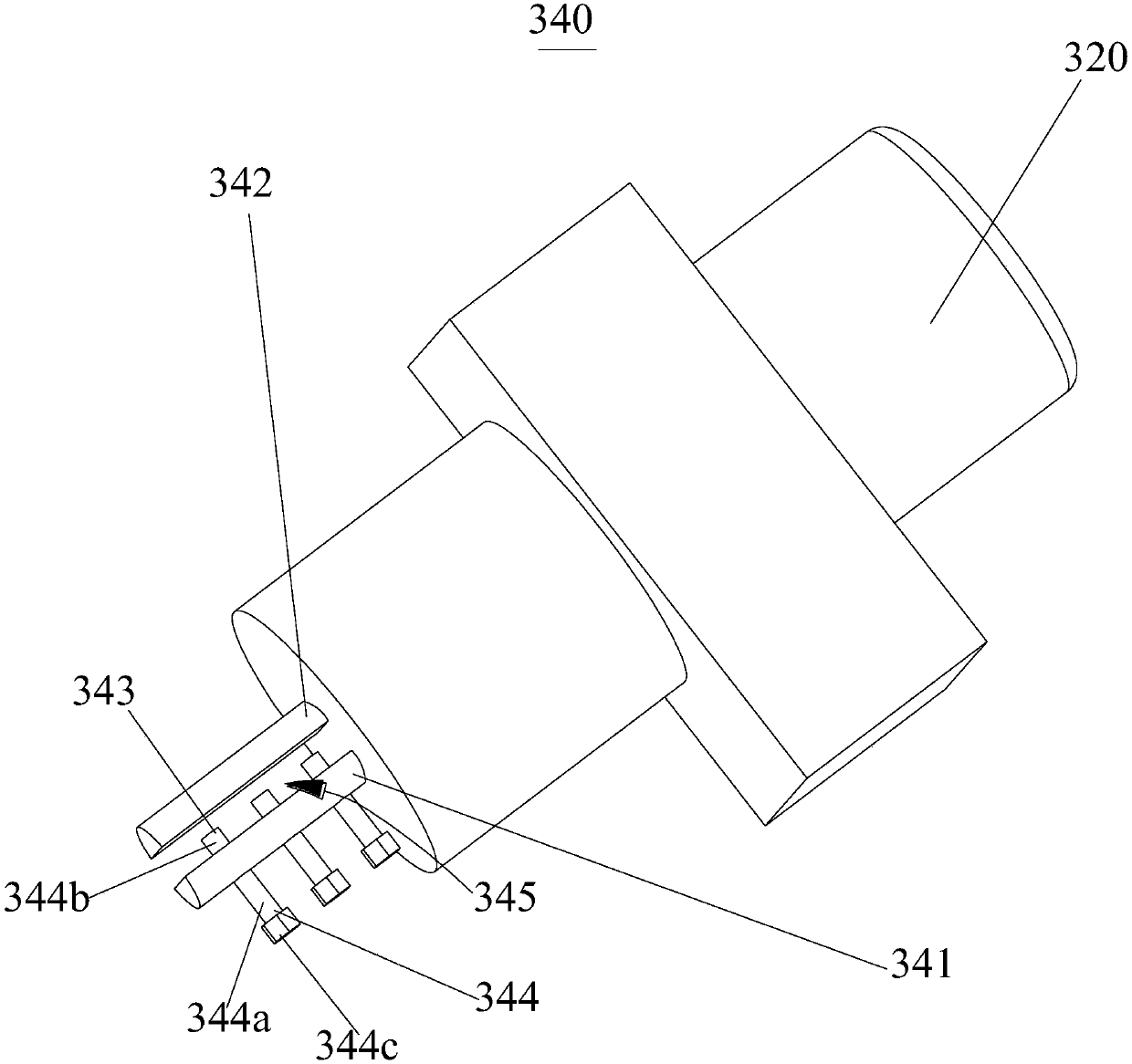

Dispensing device with positioning component

InactiveCN107755188AHigh precisionReduce clamping effectLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention relates to a dispensing device with a positioning component. The dispensing device includes a mounting base, a dispensing component, the positioning component and a glue receiving component. The dispensing component is installed on the mounting base, the positioning component is installed on the mounting base, and the glue receiving component is installed on the mounting base. According to the dispensing device with the positioning component provided by the invention, the mounting base, the dispensing component, the positioning component and the glue receiving component are disposed to replace the traditional manual dispensing way, the dispensing component can realize mechanical automatic dispensing to workpieces, thereby improving the dispensing efficiency and reducing the labor cost, the positioning component can have a clamping effect on workpieces, the dispensing component can improve the dispensing accuracy in a workpiece dispensing process, and the glue receiving component can avoid collecting leaking glue, thereby preventing glue from leaking to the mounting base in the dispensing process, so that the mounting base can be neater, and the glue collected by the glue receiving component can be recycled, thus saving cost.

Owner:惠州市佳德荣科技有限公司

Controlled blasting construction method of beam nest on vertical shaft wall

ActiveCN112432570ASafe and efficient control of blastingIncrease free surfaceBlastingShaft sinkingTEX-explosiveArchitectural engineering

The invention relates to a controlled blasting construction method of a beam nest on a vertical shaft wall. The method comprises the following steps that the beam nest outline boundary is determined on the vertical shaft wall; a set of corner blasthole is arranged and constructed in each corner of the beam nest according to the beam nest outline boundary, a central blasthole is arranged and constructed in the center of the beam nest, and at least one set of auxiliary blasthole is arranged and constructed between each corner blasthole and the central blasthole; 90-degree kerf explosive tubes are arranged in all the corner blastholes, and a first-section explosive and second-section explosives are arranged in the central blasthole and the auxiliary blastholes; and detonating is carried out according to the detonating sequence of corner blasthole explosives, central blasthole top explosives, auxiliary blasthole top explosives, central blasthole bottom explosives and auxiliary blasthole bottom explosives to finish controlled blasting construction of the beam nest. According to the method, 90-degree kerf explosive bags are arranged in the corner blastholes of peripheral holes of the beam nest to form vibration isolation pre-cracks, and a staged and sectioned blasting manner is adopted in a main blasting area, so that safe and efficient controlled blasting of the beam nest on the vertical shaft wall is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method

InactiveCN111595214ABig room for expansionIncrease free surfaceBlasting cartridgesBlastingTEX-explosiveStructural engineering

The invention discloses a small-hole reinforced fracturing grain and single-surface hoop slit grain combined cutting undermine method, which comprises the following steps of: 1) drilling; 2) charging:enabling central cutting undermine holes to use a decked charge structure and the small-hole reinforced fracturing grain, filling a second-decked small-hole reinforced fracturing grain into the bottom of each central cutting undermine hole, then, immediately filling tap-hole clay of which the length is 400-500 mm, then, filling a first-decked small-hole reinforced fracturing grain, finally, blocking by the tap-hole clay, filling a second-stage single-surface hoop slit grain into wedge-shaped cutting undermine holes, blocking by the tap-hole clay, filling third-decked common explosive in auxiliary holes, blocking by the tap-hole clay, filling four-decked common explosive in caving holes, blocking by the tap-hole clay, filling five-decked common explosive in surrounding holes, and blockingby the tap-hole clay; and 3) blasting. According to the method disclosed by the invention, the volume of a cutting undermine cavity can be enlarged, a free surface is increased, a surrounding rock clamping function is lowered, and a blast hole use ratio and an explosive energy use ratio are improved.

Owner:ANHUI UNIV OF SCI & TECH +1

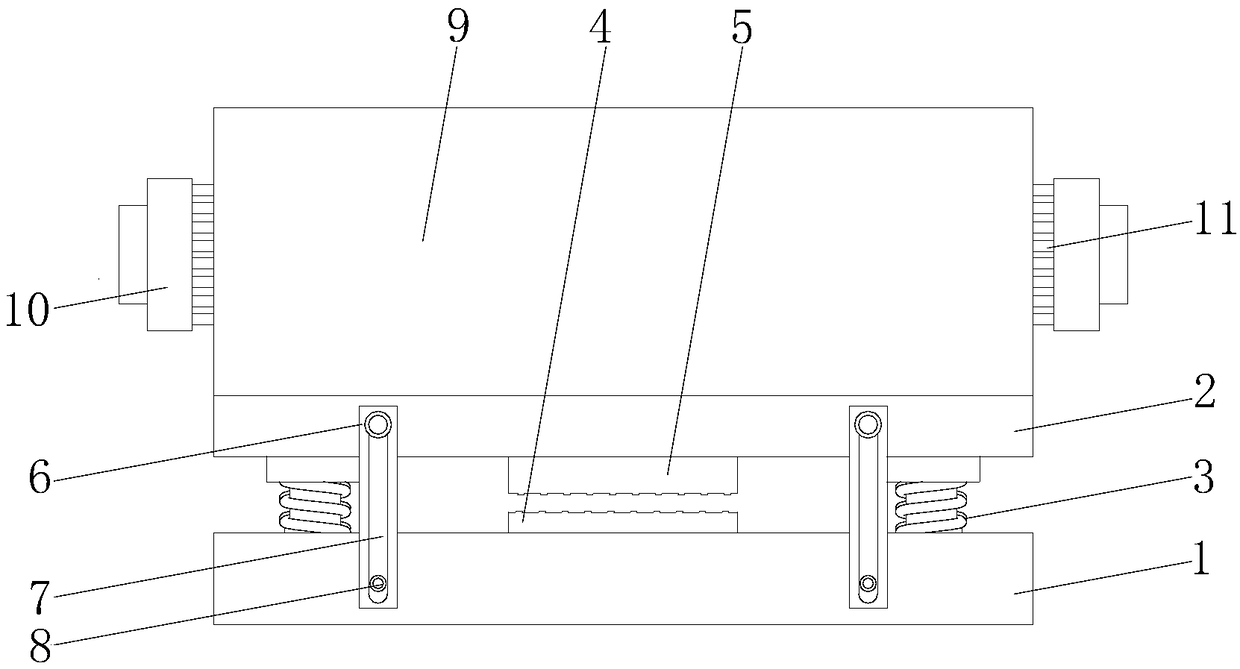

Programming numerical control machining center

PendingCN108772747AReduce vibrationPlay a shock absorbing roleLarge fixed membersMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a programming numerical control machining center. The programming numerical control machining center comprises a base and a machining table. The top of the base is fixedly connected with springs; the tops of the springs are fixedly connected with the bottom of the machining table; the top of the base is fixedly connected with a lower rubber pad; the bottom of the machiningtable is fixedly connected with an upper rubber pad; the top of the machining table is fixedly connected with a protection frame; two sides of the protection frame are fixedly connected with air blowers; the output ends of the air blowers are fixedly connected with air outlet pipes; the top of the machining table is fixedly connected with a base plate; and the top of the base plate is fixedly connected with stand plates. Through arrangement of the springs, the lower rubber pad, the upper rubber pad, fixing plates, strip-shaped grooves, fixing rods, the base plate, the stand plates, fixing blocks, reinforcing plates, bolts and rubber blocks, the problems that during operation of an industrial personal computer, self-shaking is generated, a damping mechanism is not achieved, and the servicelife of the industrial personal computer is shortened are solved.

Owner:遵义西密机电实业有限公司

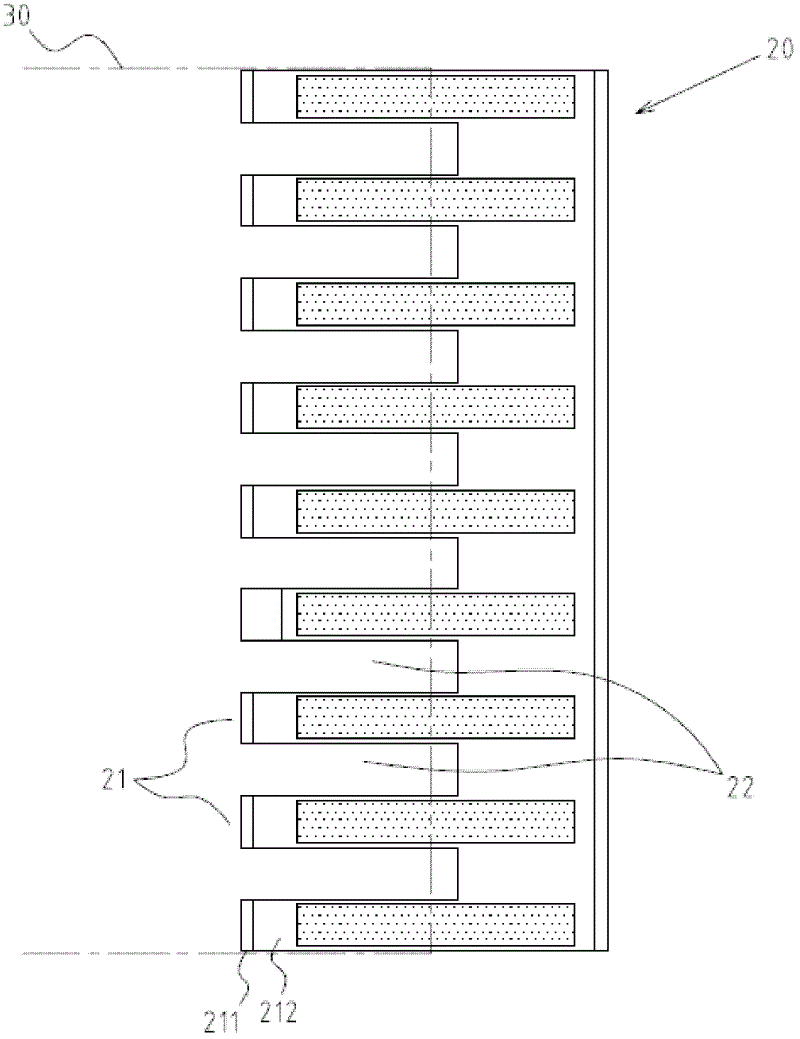

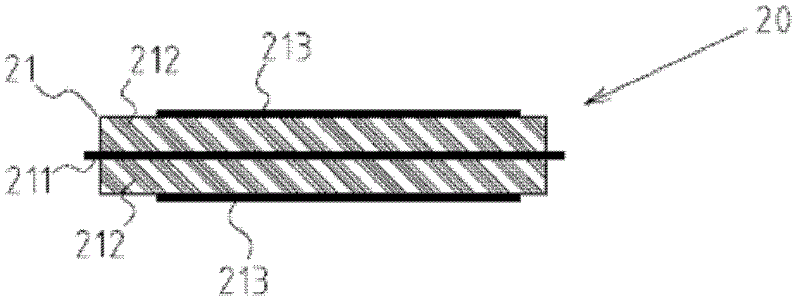

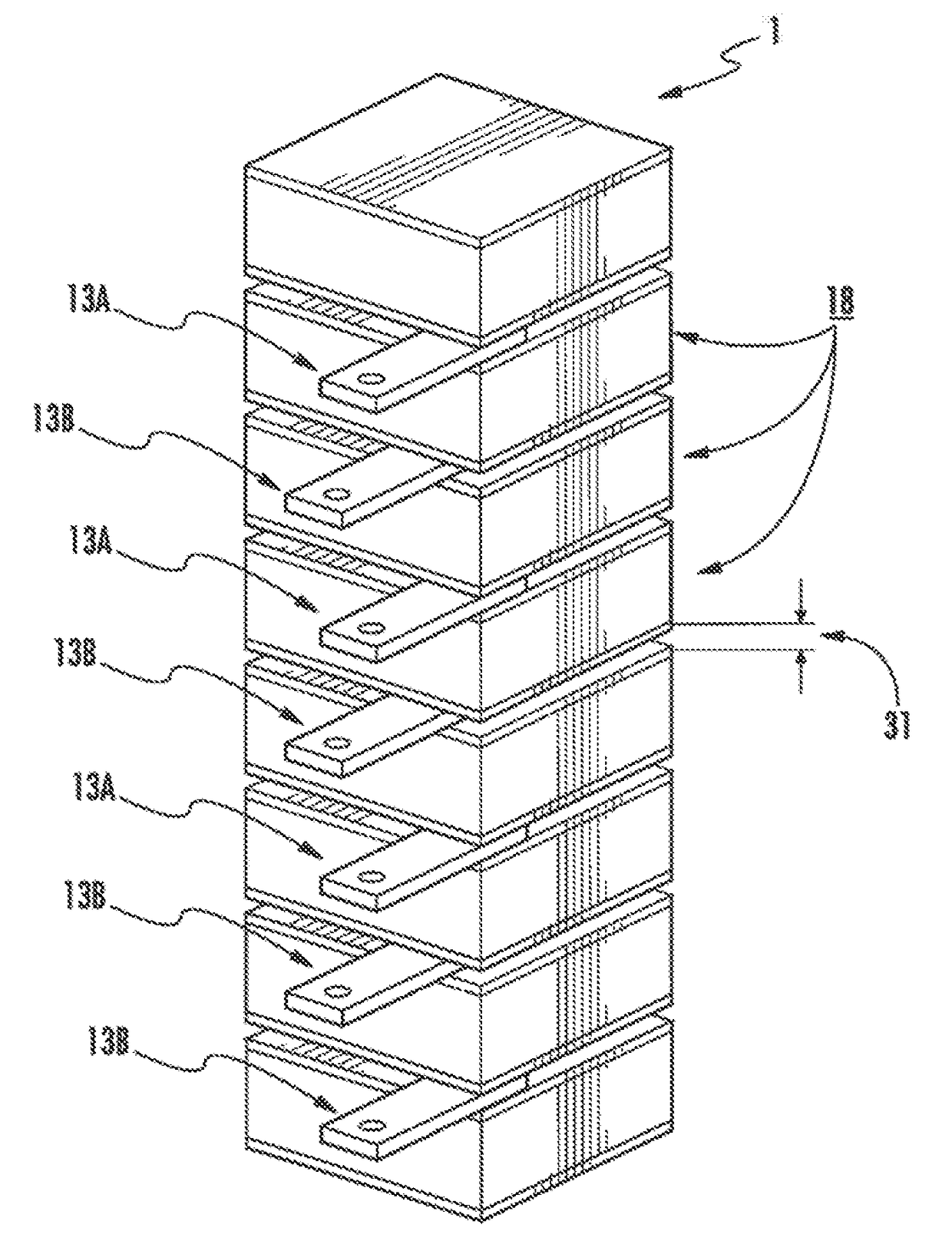

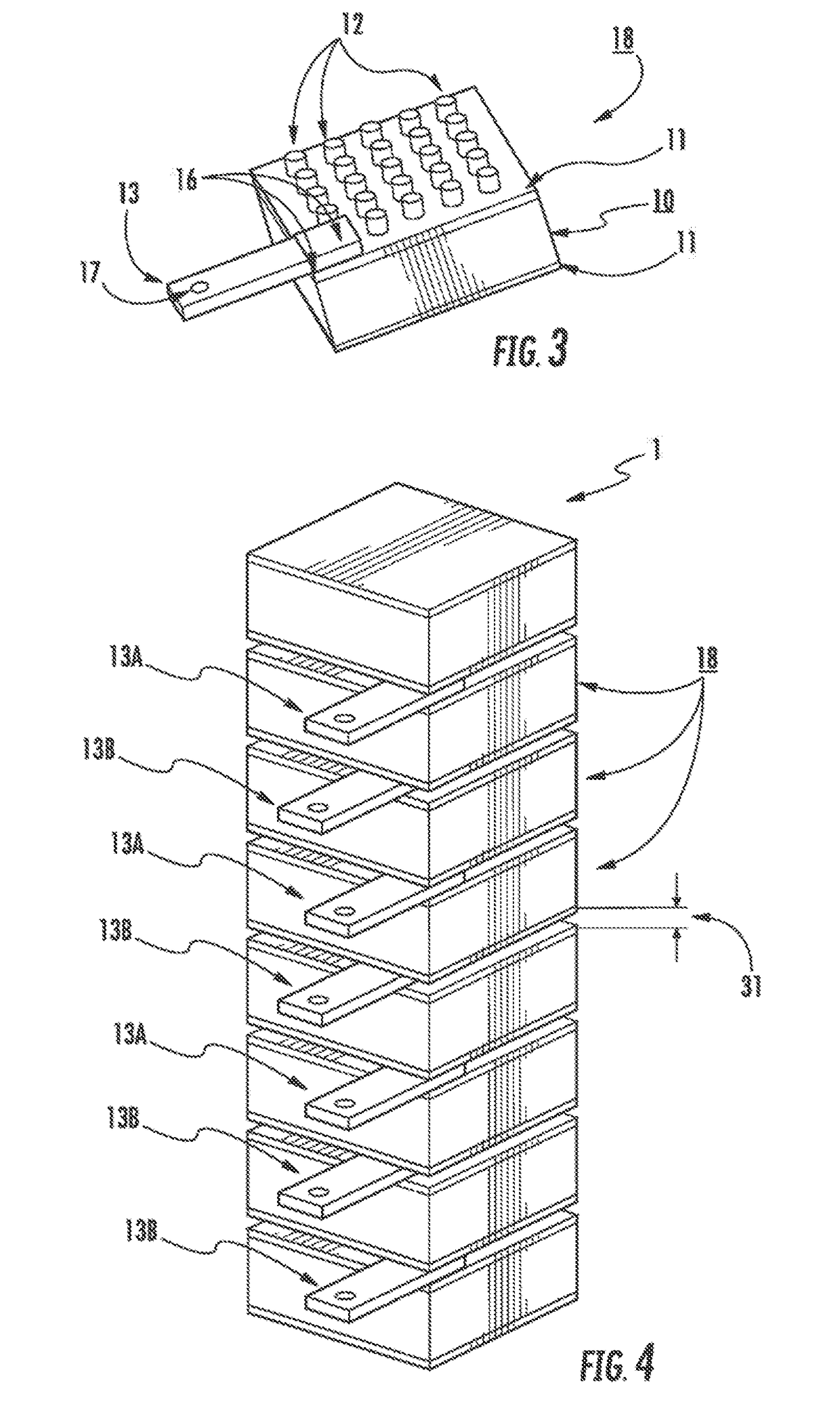

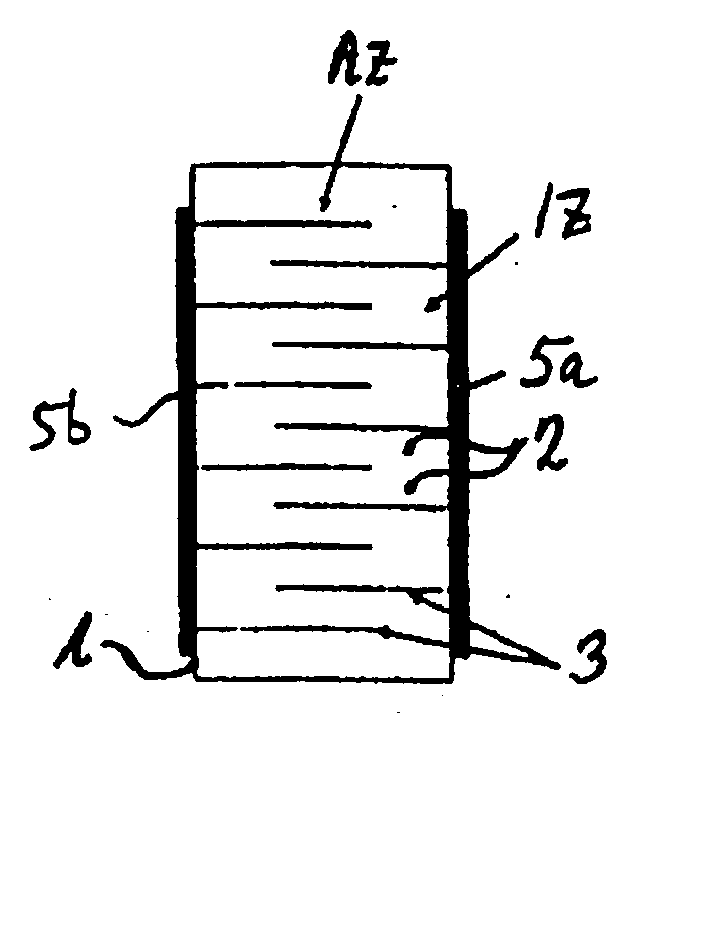

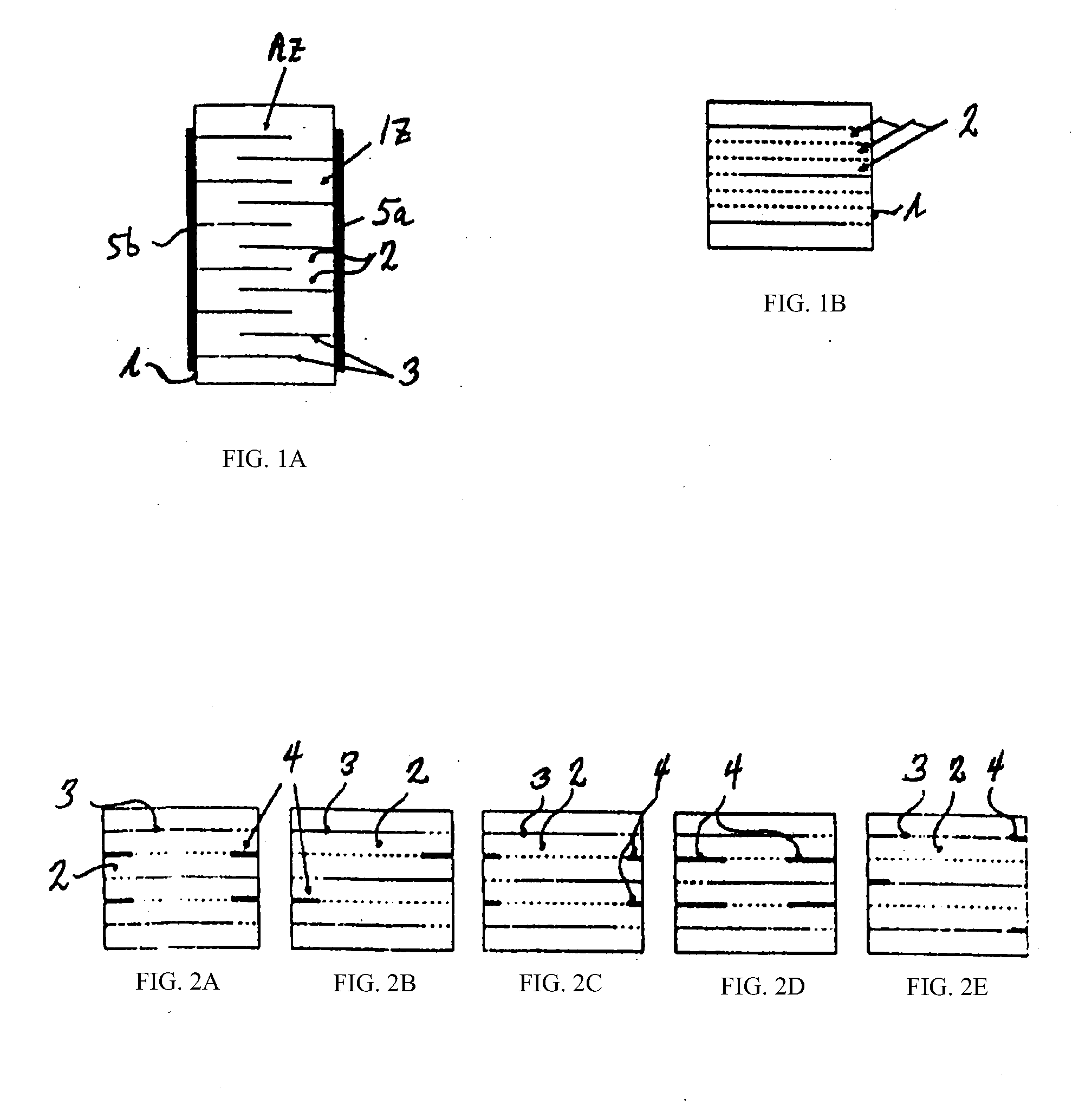

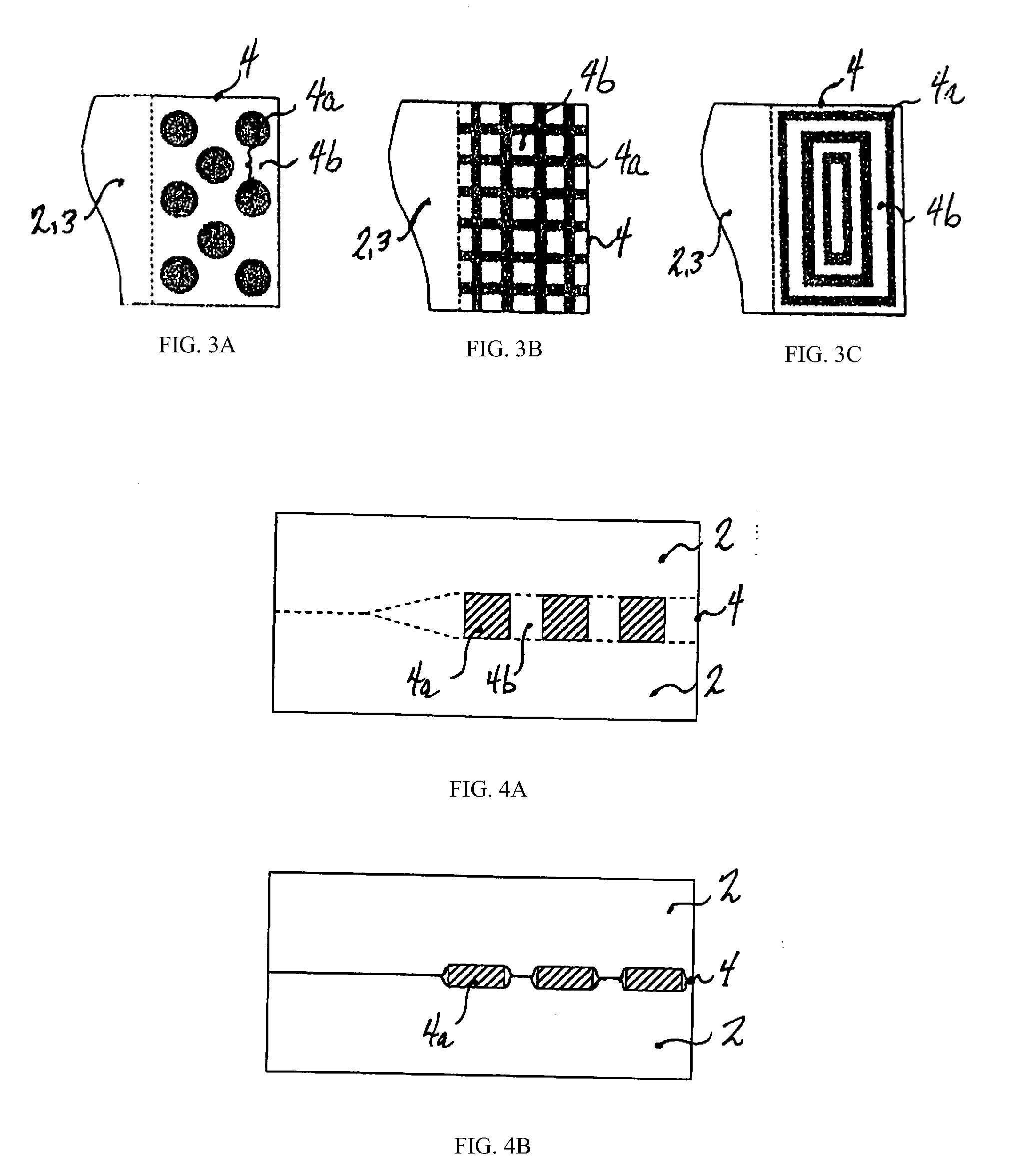

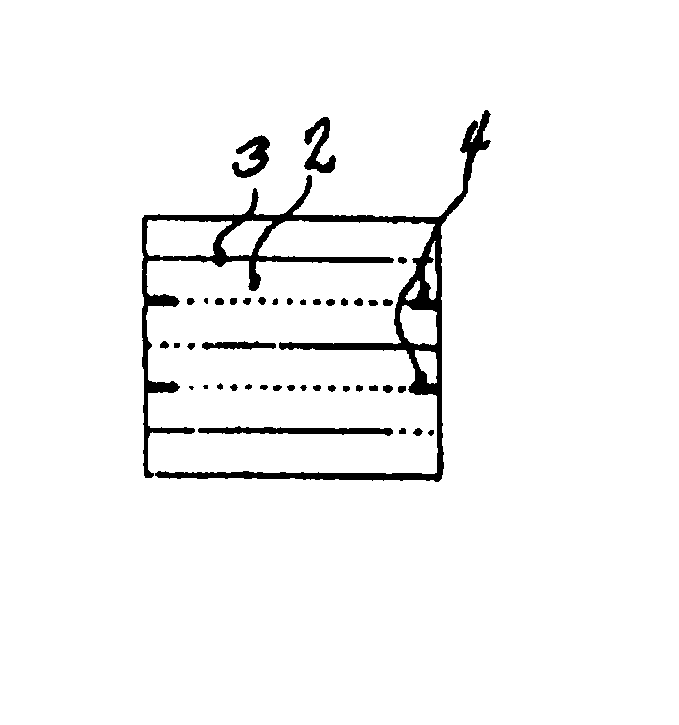

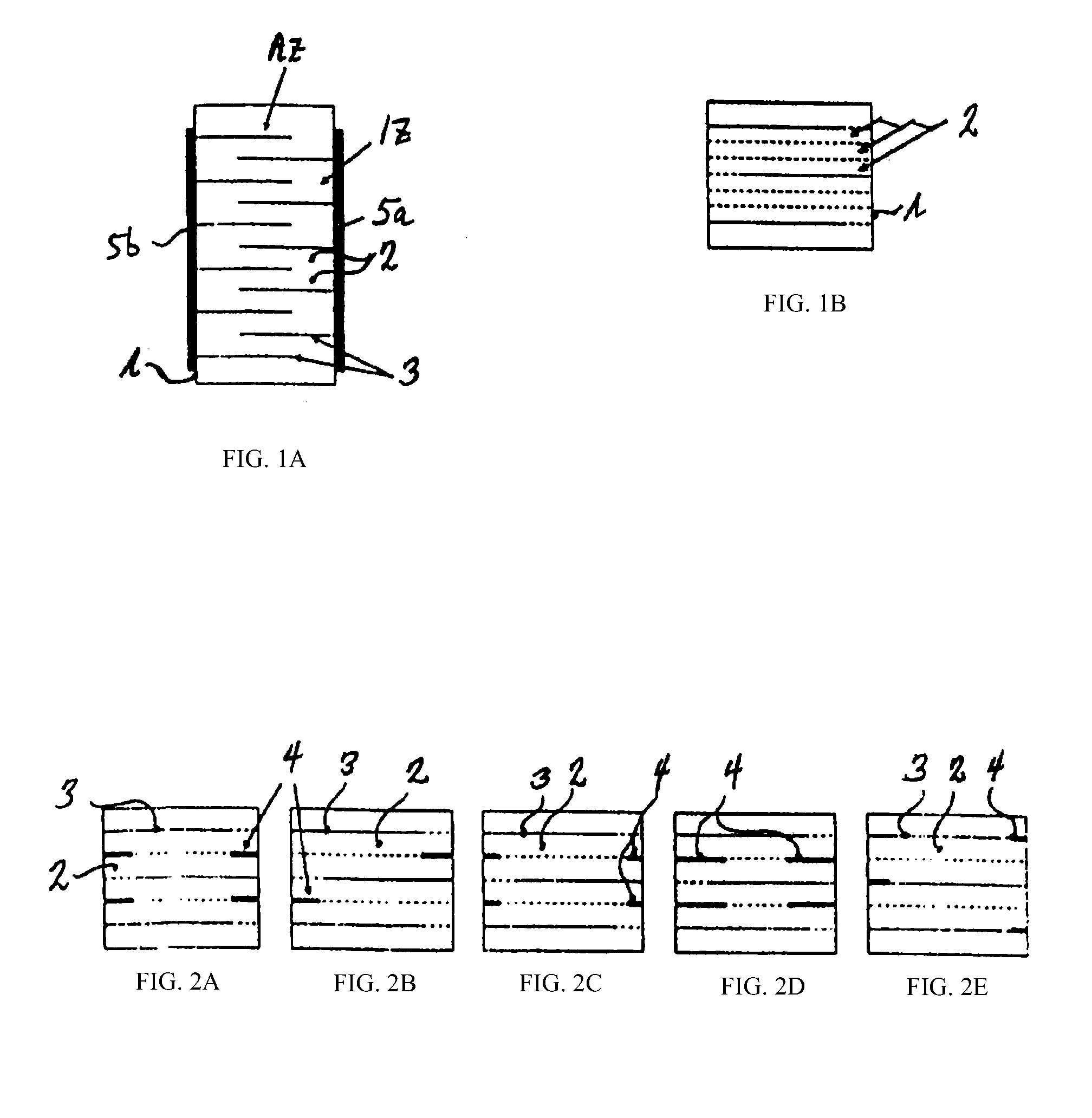

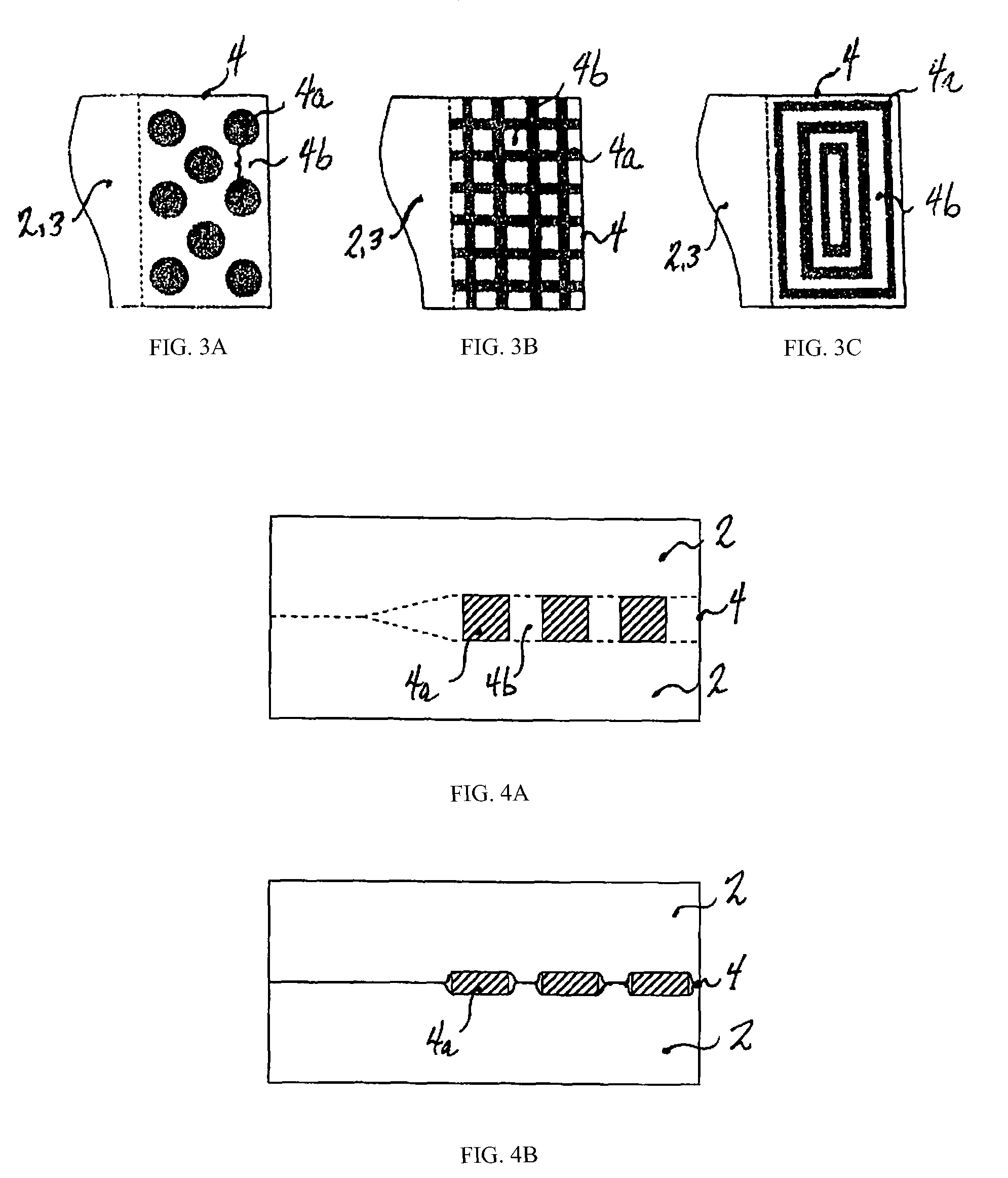

Piezoelectric Multilayer Component

InactiveUS20100225205A1Improved expansion distanceIncrease distancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPhysicsElectrode

A piezoelectric multilayer component includes a stack of piezoceramic layers and electrode layers arranged one above another. At least one piezoceramic layer is printed with a layer structured according to a predefined pattern in a piezoelectrically inactive zone of the stack. The structured layer has at least one connecting element by which piezoceramic layers that are adjacent in the stacking direction are mechanically connected to one another with a first strength. The structured layer has interspaces filled at least in part with piezoceramic material of the adjacent piezoceramic layers. The adjacent piezoceramic layers in the interspaces are mechanically connected to one another with a second strength, which is less than the first strength.

Owner:EPCOS AG

Piezoelectric multilayer component

InactiveUS8080919B2Increase distanceReduced strengthPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPhysicsElectrode

A piezoelectric multilayer component includes a stack of piezoceramic layers and electrode layers arranged one above another. At least one piezoceramic layer is printed with a layer structured according to a predefined pattern in a piezoelectrically inactive zone of the stack. The structured layer has at least one connecting element by which piezoceramic layers that are adjacent in the stacking direction are mechanically connected to one another with a first strength. The structured layer has interspaces filled at least in part with piezoceramic material of the adjacent piezoceramic layers. The adjacent piezoceramic layers in the interspaces are mechanically connected to one another with a second strength, which is less than the first strength.

Owner:EPCOS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com