300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and use method

A technology of gas turbines and nozzles, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as hula seal line and arc changes, failure to meet drawing requirements, and affect assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

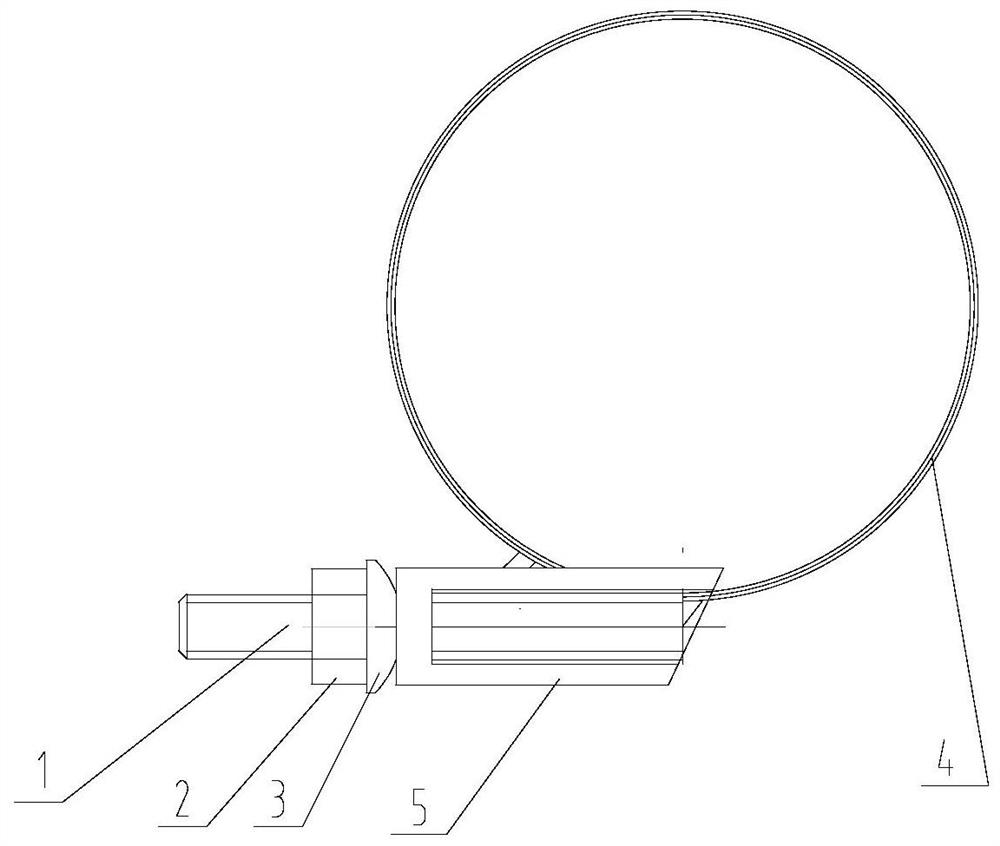

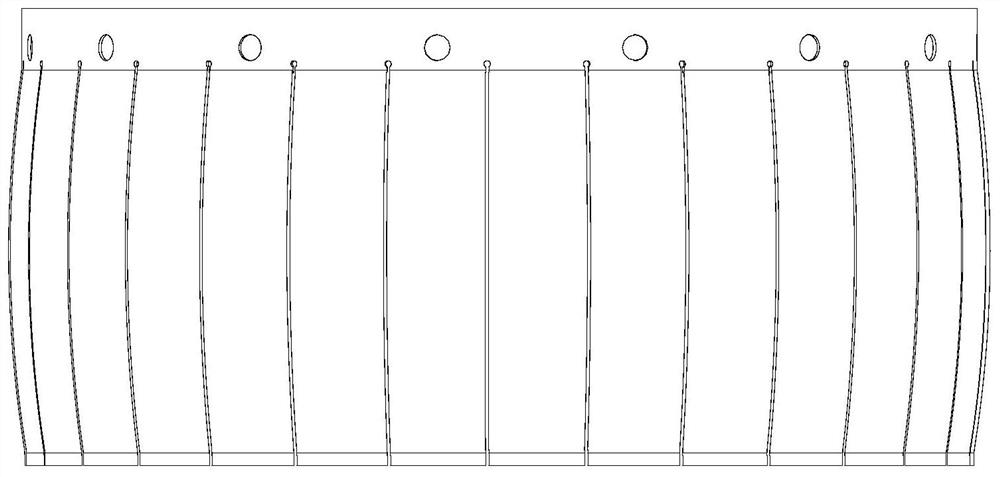

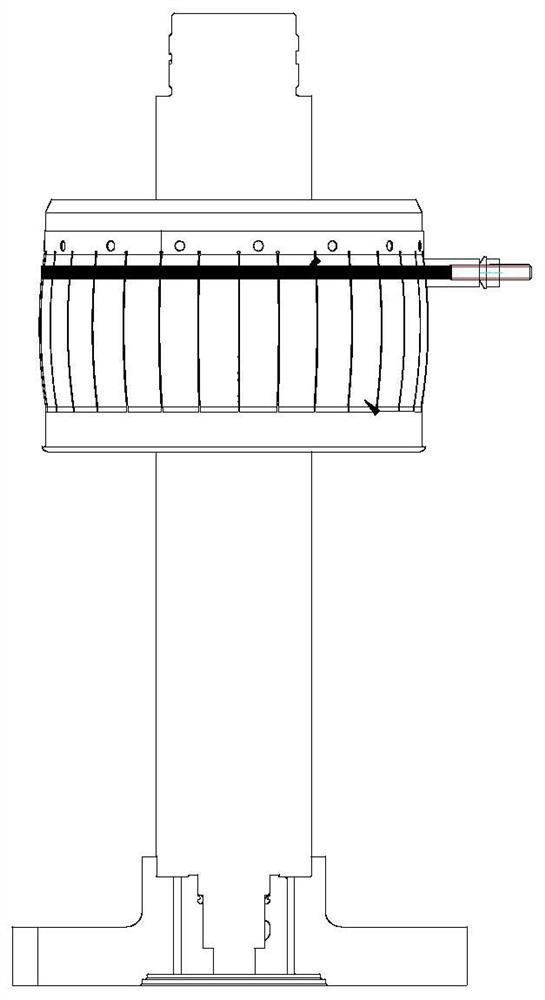

[0040] Specific implementation mode 1: 300MW heavy-duty gas turbine nozzle hula seal welding restraint tooling, which includes restraint force application part and restraint belt 4;

[0041] The restraint belt 4 is ring-shaped when working, one end of the restraint belt 4 is connected to the restraint application part, and the other end of the restraint belt 4 is tightened by the restraint application part.

specific Embodiment approach 2

[0042] Embodiment 2: The constraining force application part includes a threaded rod 1, a nut 2 and a cylinder 5;

[0043] The nut 2 is arranged on the threaded rod 1, one end of the threaded rod 1 is inserted into the inside of the cylinder 5, the nut 2 is adjacent to the outer wall of one end of the length direction of the cylinder 5, the cylinder 5 is connected with one end of the restraining band 4, and the threaded rod 1 One end is connected with the other end of restraining band 4.

[0044] Other specific implementations are the same as the first specific implementation.

specific Embodiment approach 3

[0045] Embodiment 3: The outer peripheral side wall of the other end of the cylinder (5) is connected to one end of the restraining band (4).

[0046] Other specific implementations are the same as the second specific implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com