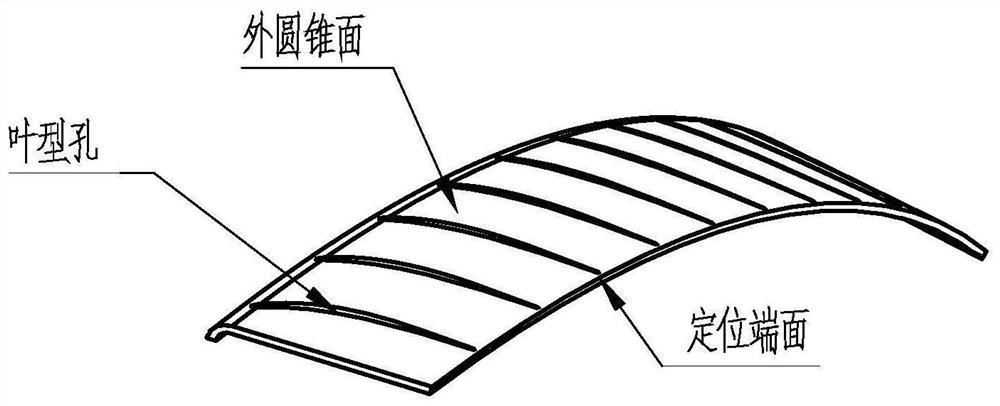

Device and method for detecting uniform distribution positions of blade-shaped holes in thin-wall fan-shaped section

A detection device and leaf-shaped hole technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., to achieve the effect of novel structure, ensuring assembly requirements, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

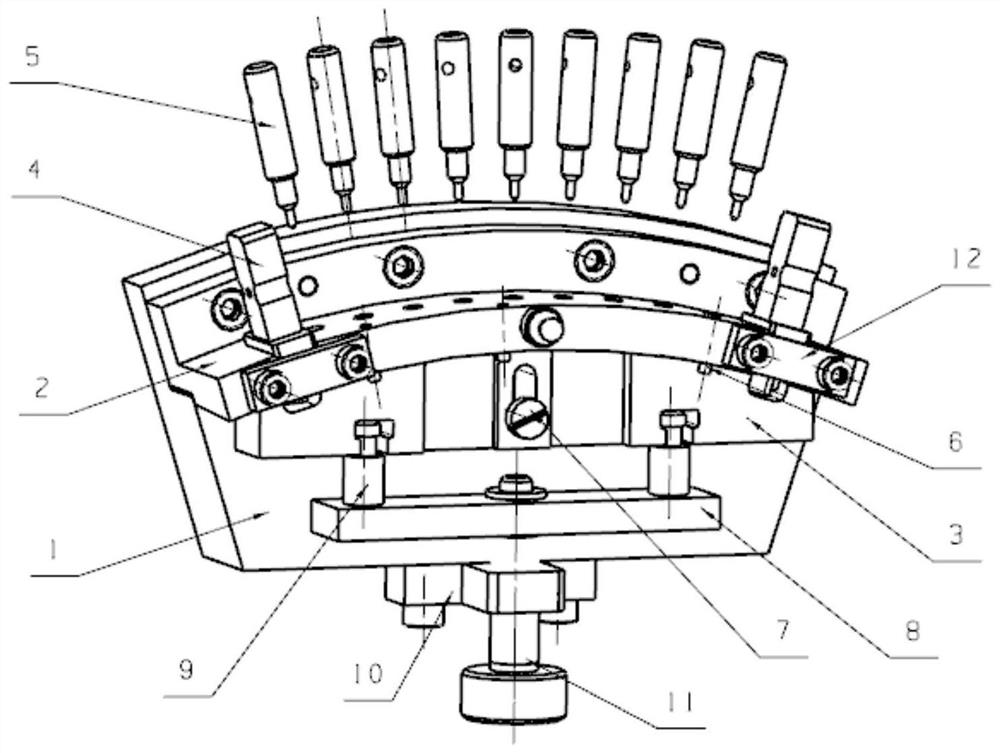

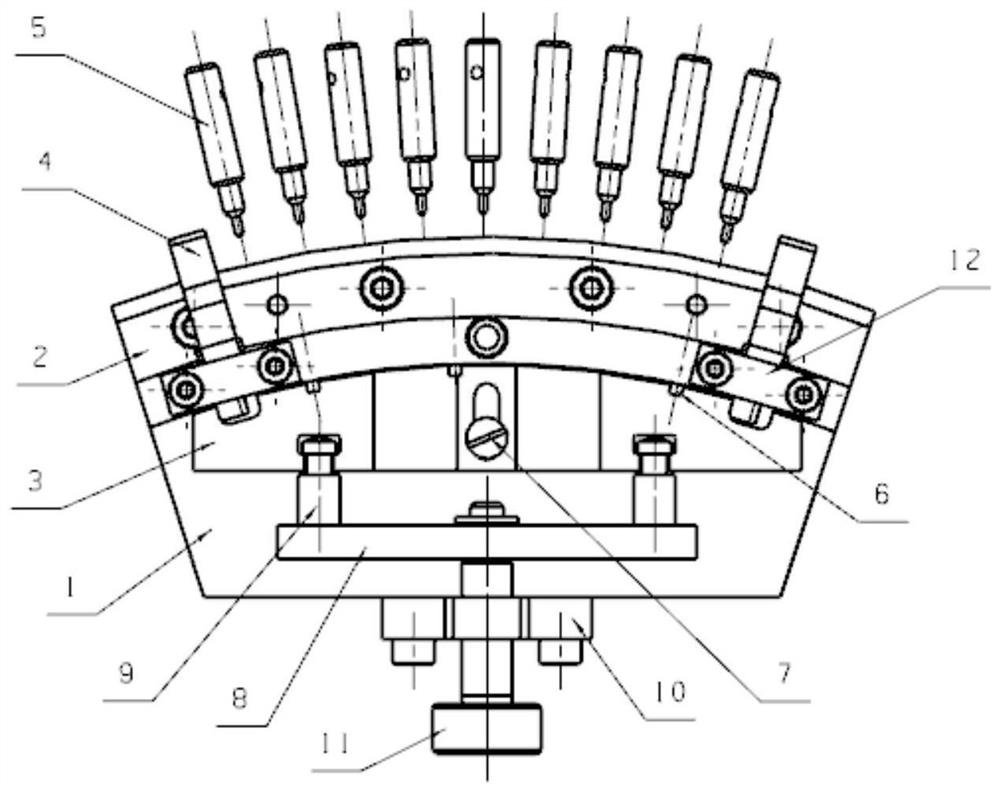

[0048] The inside of the arc-shaped positioning block 2 in the detection device is positioned in positioning the outer tapered surface of the part to be tested, and the end surface is positioned as the upper surface of the base 1, since the wall thickness of the part to be tested is too thin, the rigidity difference is large, and the end surface position is only width. 0.5mum loop must be designed with a limit device in both axial and radially direction to ensure that the thin-walled secting segment is accurate and reliable. The curved positioning block 2 is designed with a circular hole of 3 out of 3, and the positioning pin 6 is mounted in this circular hole, three positioning pin 6 minimum bus wires to the size of the upper surface of the base 1, axially size The maximum design (that is, the size of the lowest busbar of the positioning pin 6 to the upper end surface of the base 1 is equal to the maximum value of the axial dimension of the part to be tested), achieving an axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com