Patents

Literature

51results about How to "Guaranteed Assembly Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

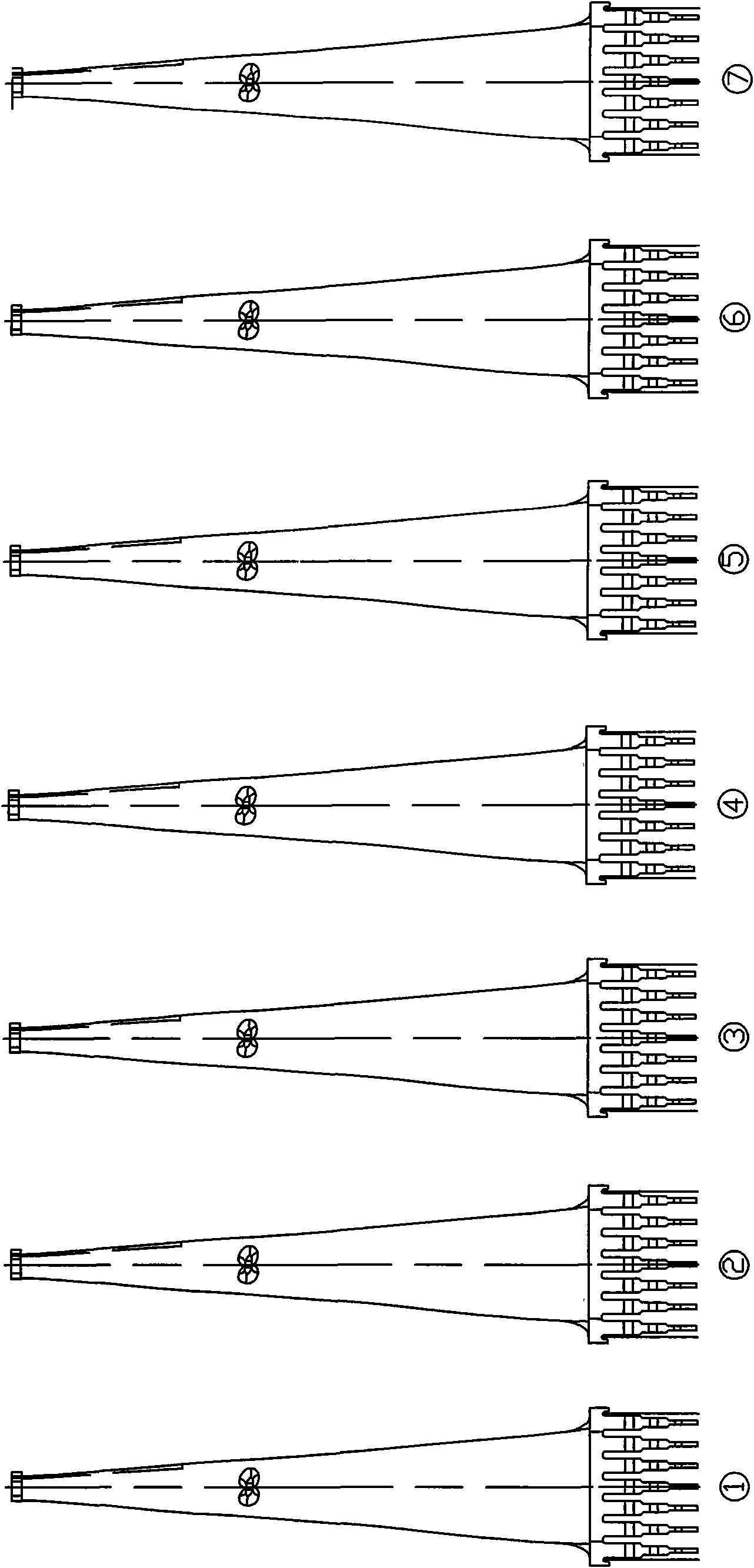

Method for machining gas compressor fixed blade ring of gas turbine

ActiveCN103801912AImprove machining accuracySmall thermal deformationNumerical controlGas compressor

The invention provides a method for machining a gas compressor fixed blade ring of a gas turbine. The method comprises the steps that a fixed blade ring blank is placed on a permanent magnetic chuck workbench of a machine tool, and clamped by the permanent magnetic chuck workbench, and the outer circumferential surface, the annular inner conical surface and the upper end face of the fixed blade ring are turned at a time; the bottom plane is machined; the turned fixed blade ring blank is placed on a working platform of a five-axis numerical control wire cutting machine, the cutting inclination of the five-axis numerical control wire cutting machine ranges from 0 degree to 60 degrees, and is adjustable, and the axis of the fixed blade ring blank coincides with the axis of a rotary platform of the five-axis numerical control wire cutting machine; the cut portion of a wire electrode of the five-axis numerical control wire cutting machine is made to be opposite to a molded line inclined groove in the annular inner conical surface in position by adjusting the rotary platform on a machine tool body, the inclination angle of the cut portion of the wire electrode is equal to the inclination angle of the molded line inclined groove, and the molded line inclined groove is machined; the rotary platform on the machine tool body is adjusted repeatedly, and machining of all the molded line inclined grooves is accomplished. According to the method for machining the gas compressor fixed blade ring of the gas turbine, the machining cost is low, the machining speed is high, the degree of thermal deformation is low, machining stability is good, and machining precision is high.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

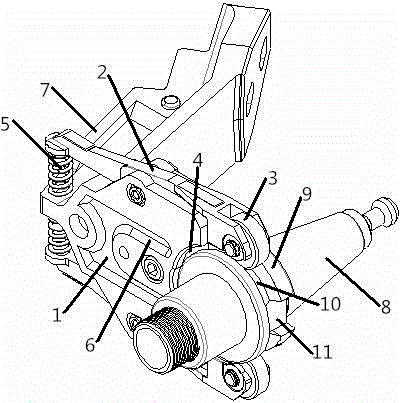

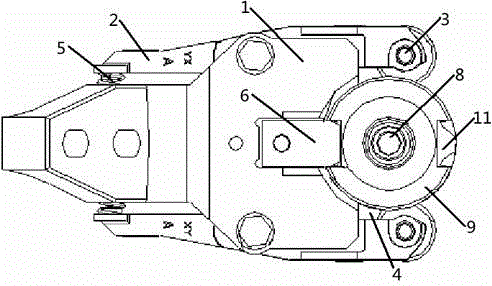

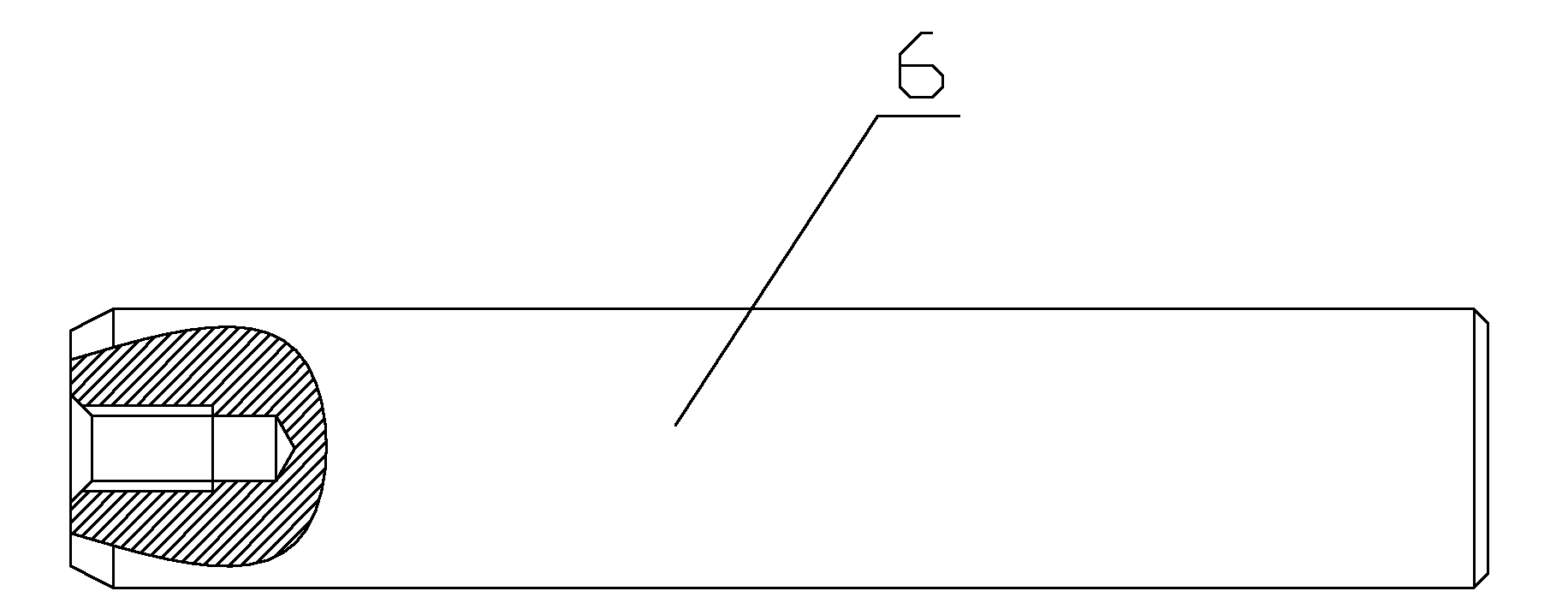

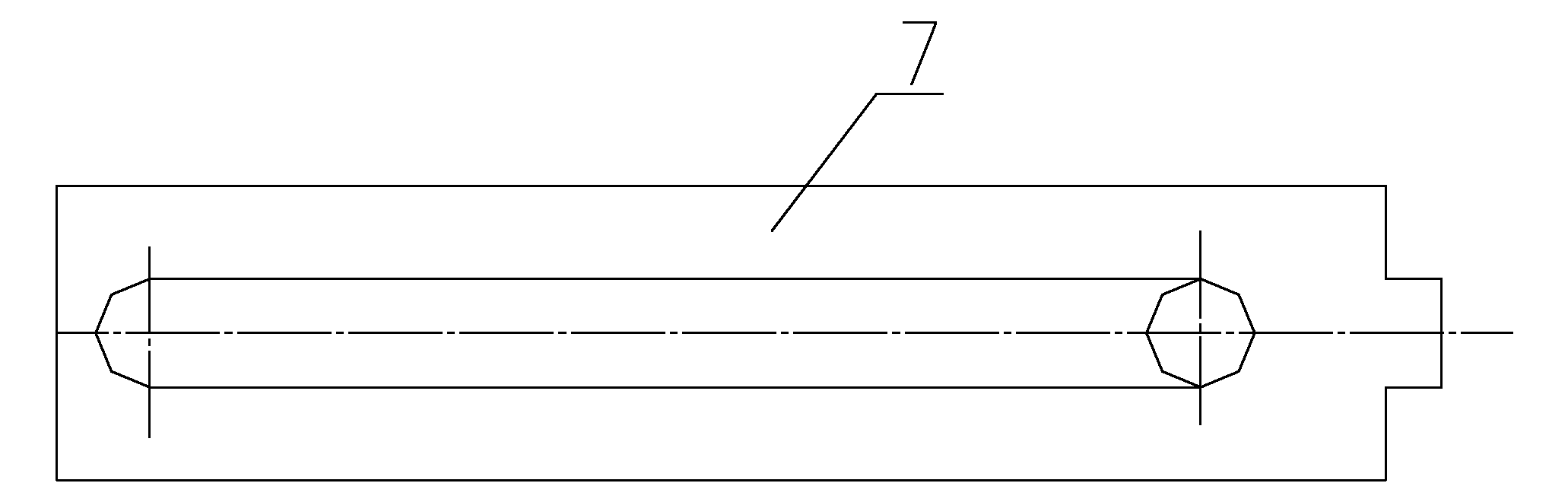

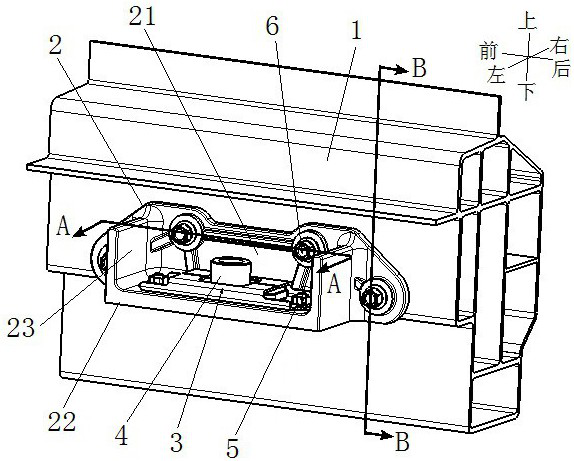

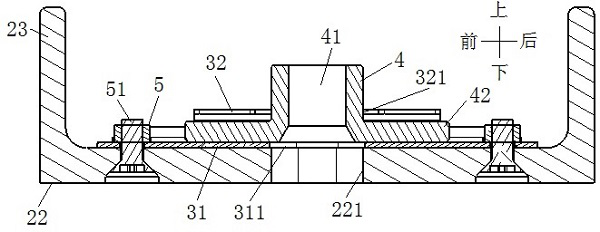

Tool magazine tool clamping device

InactiveCN104551807AAvoid damageExtended service lifePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a tool magazine tool clamping device comprising a clamping seat. Lever mechanisms are arranged at the upper end and the lower end of the clamping seat symmetrically, each lever mechanism is fixed on the clamping seat through bolts, a roller is mounted at one end of the lever mechanism, and a clamping seat groove is formed among the rollers and the clamping seat. The tool magazine tool clamping device is characterized in that a spring is mounted on the clamping seat, located between the lever mechanisms and fixedly connected with the lever mechanisms, and the spring and the rollers are located at two ends of the lever mechanism respectively. The spring is arranged between the lever structures, collision force between the clamping seat and a tool is buffered through the spring during tool changing, so that damage to the clamping seat due to tool changing collision is reduced, service life of the clamping seat is prolonged, and frequency of maintenance of the clamping seat is lowered.

Owner:HUBEI YIXING INTELLIGENT EQUIP CO LTD

Processing technology of steam turbine seven-fork blade root pin holes and special fixture

ActiveCN101837482AGuaranteed accuracyGuaranteed roughnessDrilling/boring measurement devicesBlade accessoriesEngineeringRadial line

The invention relates to a processing technology of steam turbine seven-fork blade root pin holes and a special fixture. A blade root is provided with seven forks for installation, wherein the two forks in the middle side of the seven forks are staggered with the five forks in the inner part; the five forks in the inner part are successively provided with three pin holes along the radial line direction of a steam turbine; the two forks on the outer side are successively provided with three first semicircle pin holes on the same axis with the above three pin holes and are provided with other three second semicircle pin holes on the same axis with the pin holes on the inner five forks on the adjacent blade; the first semicircle pin holes and the second semicircle pin holes on the two forks on the outer side of adjacent two seven-fork blades are spliced into a full circle pin hole; and multiple blades are radially arranged on the circumstance of the steam turbine. The fixture is providedwith a cavity capable of containing the roots of the seven forks of the two adjacent blades and is provided with a device which makes two blade roots to be jointly installed on the steam turbine position relation status and makes the two blade roots to be fixed on the fixture; and the fixture is provided with a drilling guide hole correspondingly on the axis of the full circle pin hole spliced bythe first semicircle pin holes and the second semicircle pin holes on the two blade roots.

Owner:常州市三维技术成套设备有限公司

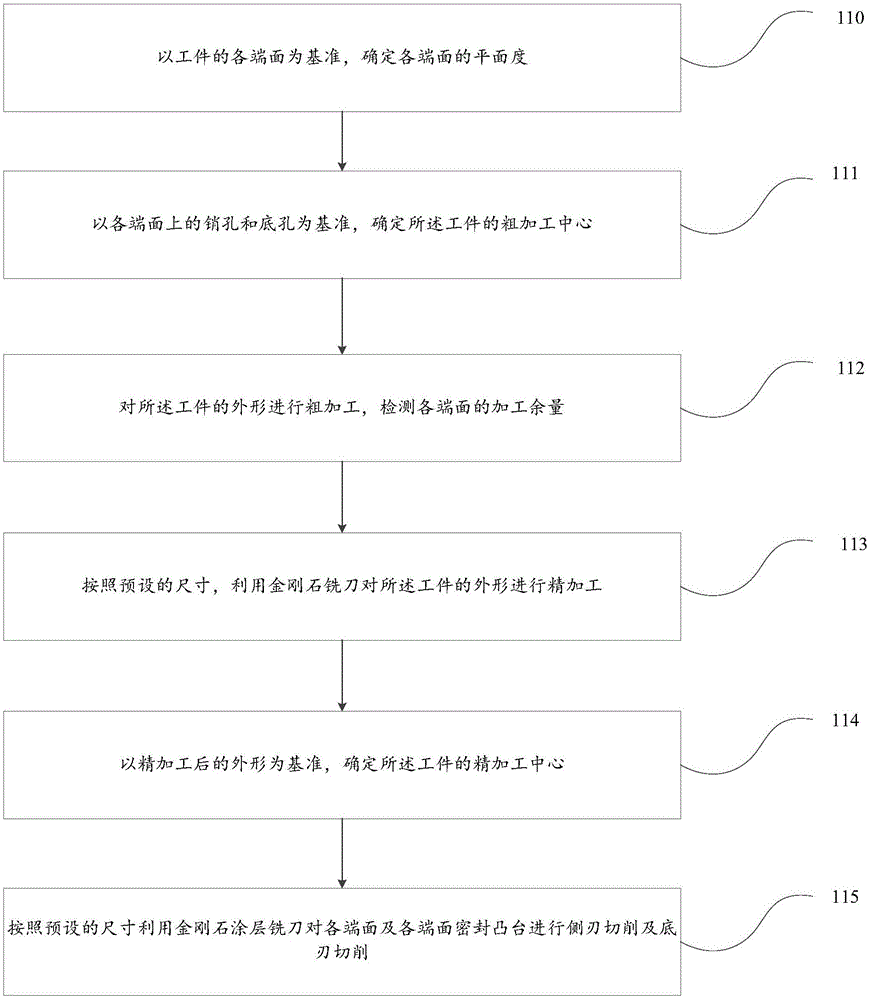

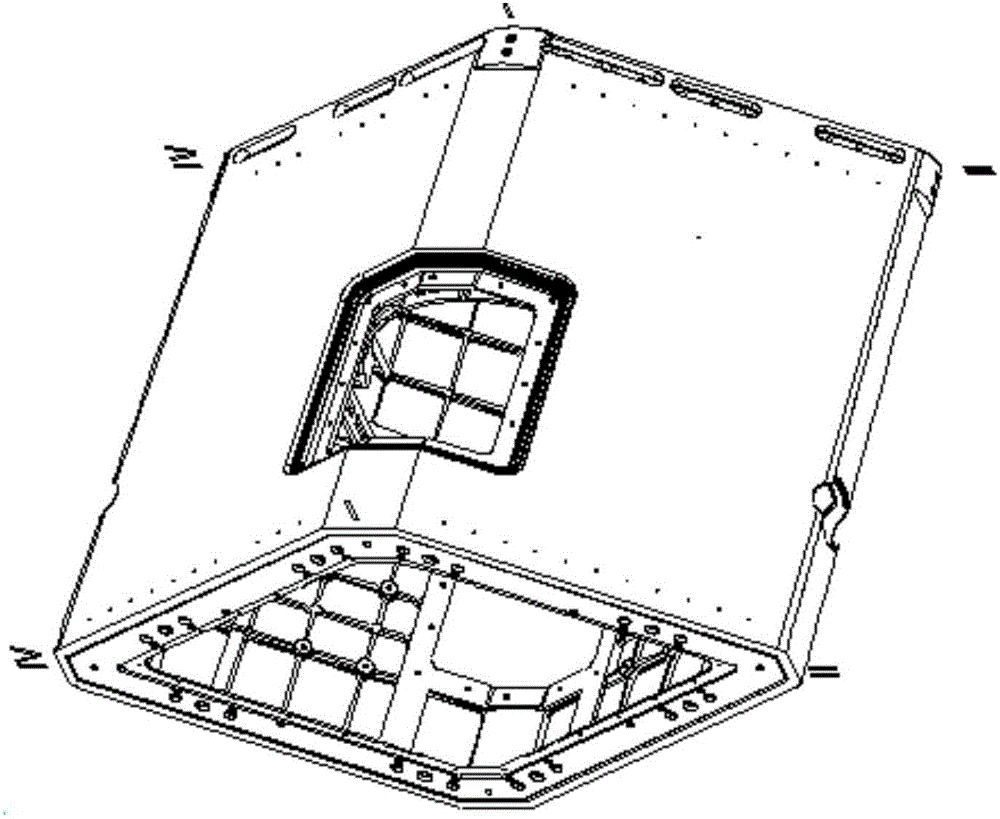

Machining method of cabin section work-piece

ActiveCN106239066AAvoid uneven wall thicknessSolve the problem of out-of-tolerance distance between butt pin holesAircraft componentsMilling cutterCoating

The invention provides a machining method of a cabin section work-piece. The work-piece comprises end faces. The method comprises the steps of: determining the planeness of the end faces by taking the end faces of the work-piece as benchmarks; determining a rough machining center of the work-piece by taking pin holes and bottom holes in the end faces as benchmarks; carrying out rough machining on a profile of the work-piece and detecting a machining allowance of each end face; carrying out finish machining on the profile of the work-piece by using a diamond milling cutter according to a preset size; determining a finish machining center of the work-piece by taking the finish-machined profile as a benchmark; carrying out side-edge cutting and bottom-edge cutting on the end faces and end face sealing lug bosses by using a diamond coating milling cutter; carrying out boring-machining on the pin holes in the end faces; pressing out notch edges of a notch by using a pressing plate; and carrying out segmental machining and layered machining on the notch with a preset cutting step length by using a spiral cutting method. Thus, by using a benchmark conversion machining method, the problem of non-uniform wall thicknesses caused by machining deformation in a single benchmark is solved, and the phenomena of scaling-off, breaking-up and delaminating appearing during machining are avoided.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

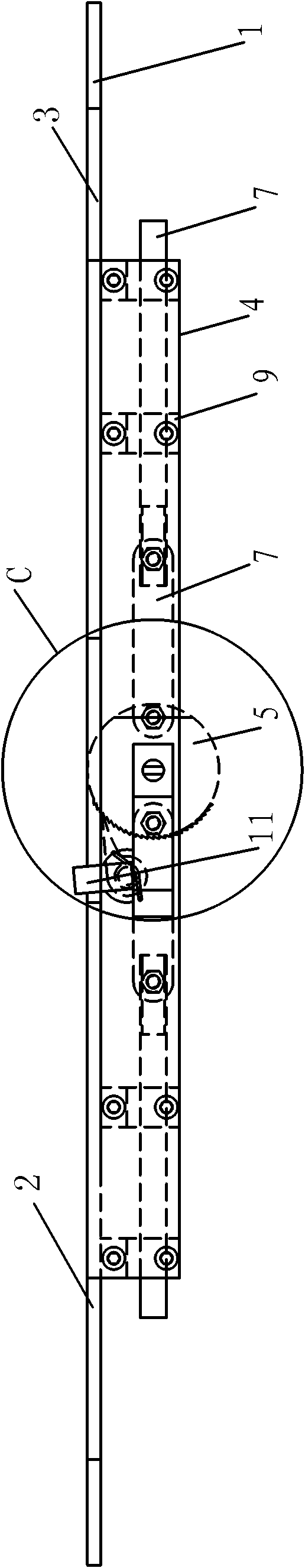

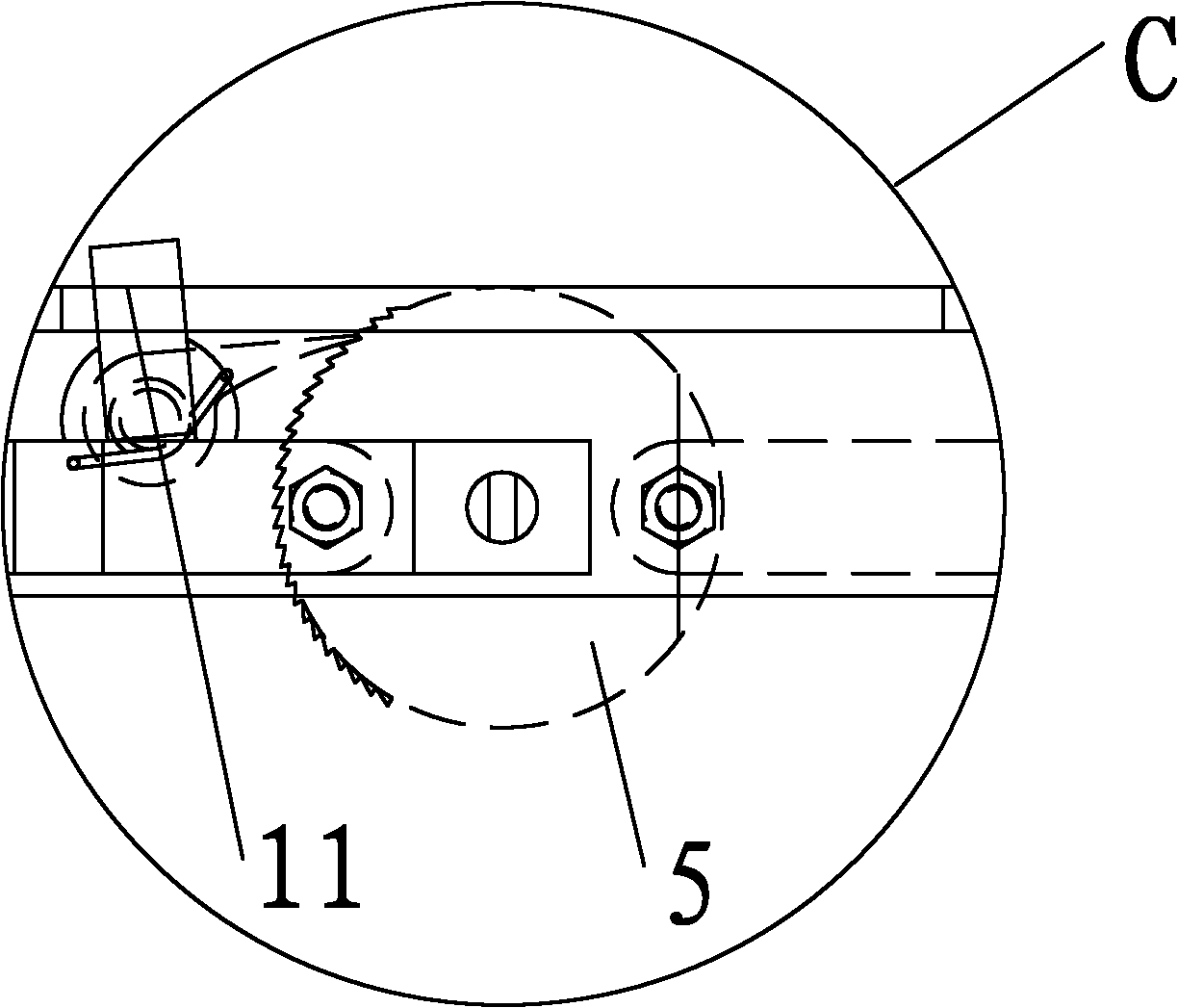

Feeding type cylinder side edge strip wing drilling fixture

InactiveCN107262782AFast realization of clampingFast disassemblyDrilling/boring measurement devicesDrill jigsEngineeringMachining

The invention discloses a feeding type cylinder side edge strip wing drilling fixture, and belongs to the field of fixtures. The drilling fixture comprises parts such as a fixture body, a drilling jig plate, a rotation shaft, an adjustable positioning plate, a blanking cap, a pressing disc, a limiting block, a compression screw, a knurled thumb screw, a positioning plug pin a, a positioning plug pin b, quick-changing drilling bushings and a bolt washer assembly. By adopting the drilling fixture, the hole machining precision can be greatly improved, the assembling requirement of a corresponding product is guaranteed, occupation of a machining center can be reduced, the machining cost is reduced, and the working efficiency is improved. Through actual detection, when drilling and reaming machining is conducted on sixteen holes formed in four side edge strip wings of a cylindrical product with the diameter of 400 mm and the length of 500 mm by adopting the drilling fixture, the position degree can meet the requirement of 0.1 mm.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Device for measuring rotor bracket of hydrogenerator oblique stud support arm structure

ActiveCN102141363AMeet the technical requirements of assemblySolving Detection ChallengesMechanical clearance measurementsEngineeringDynamo

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

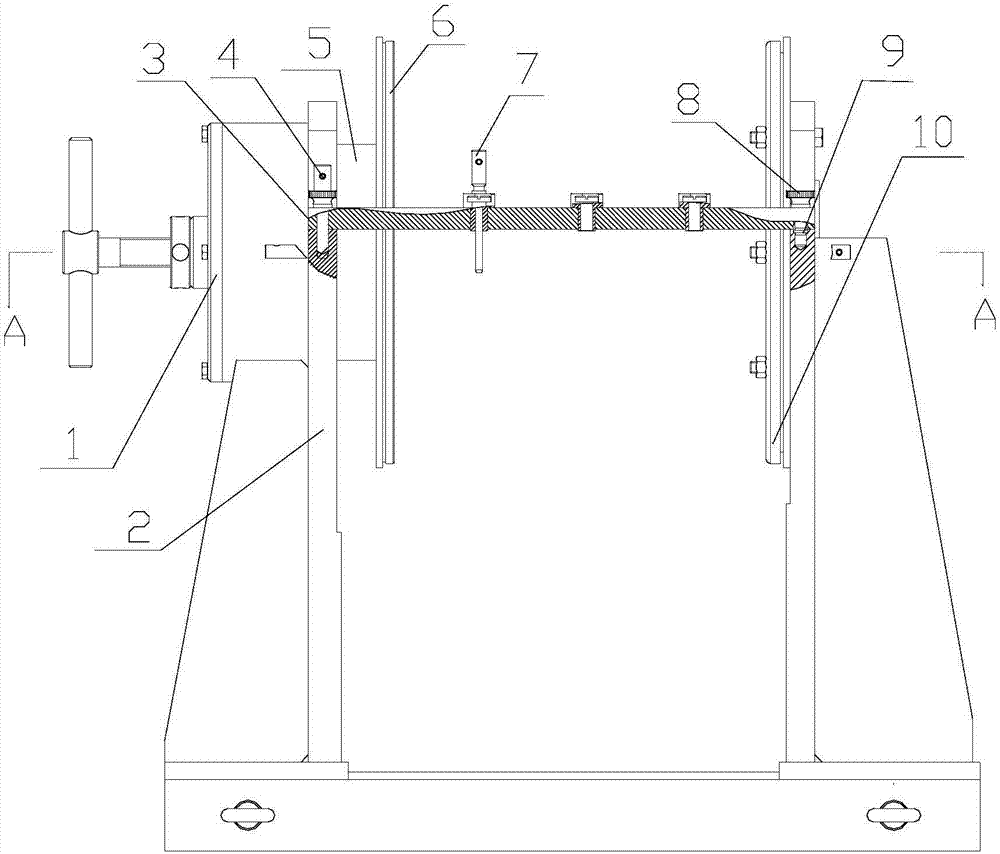

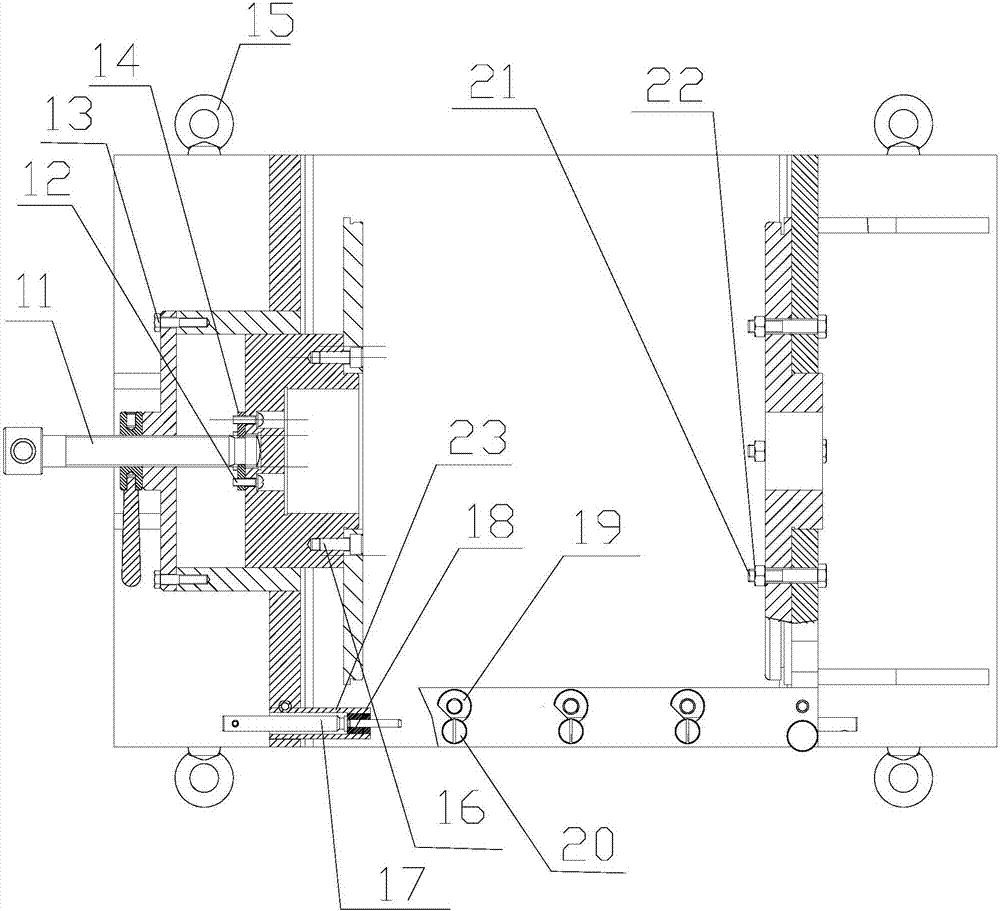

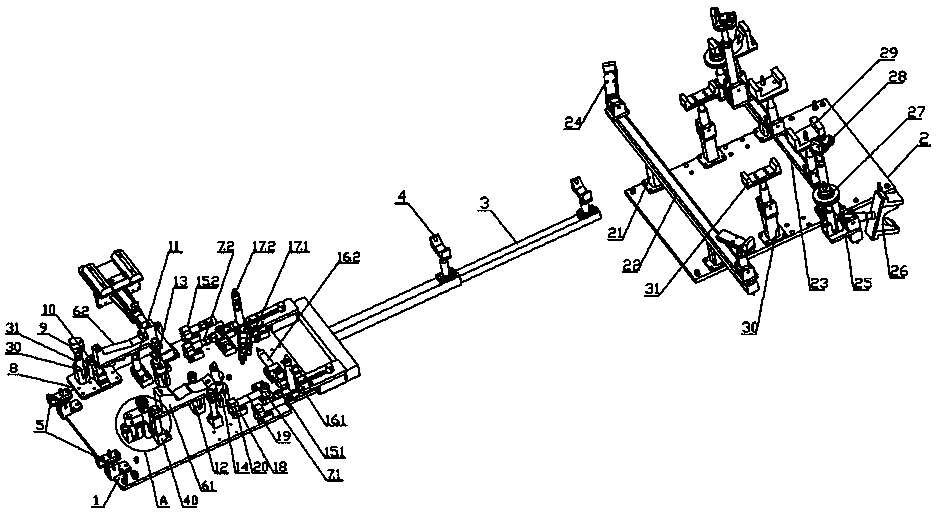

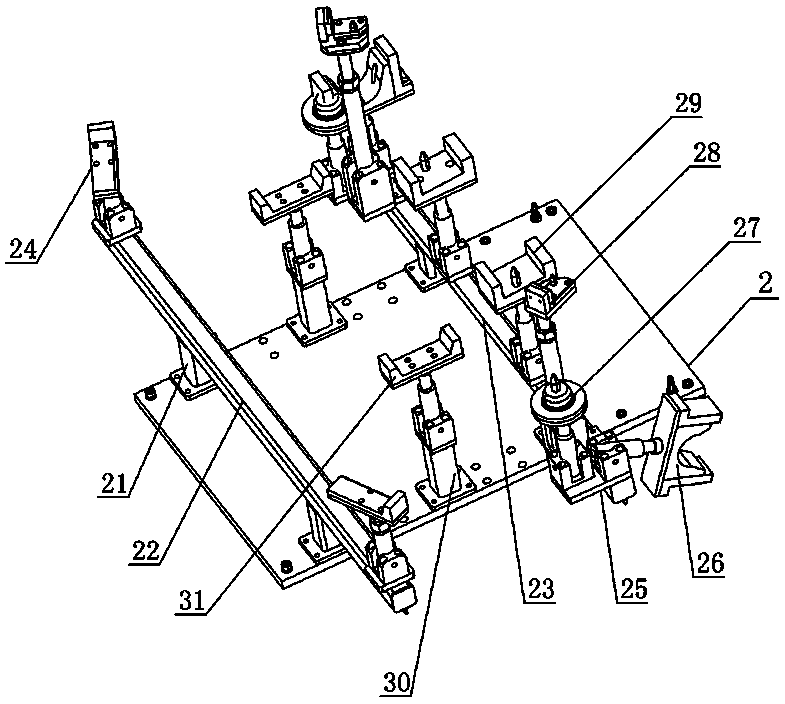

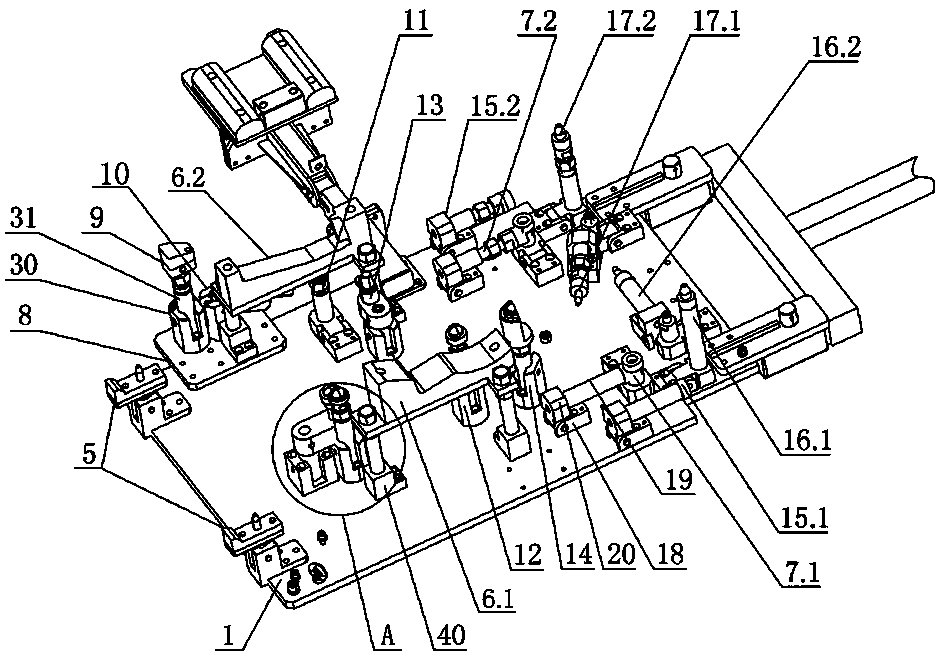

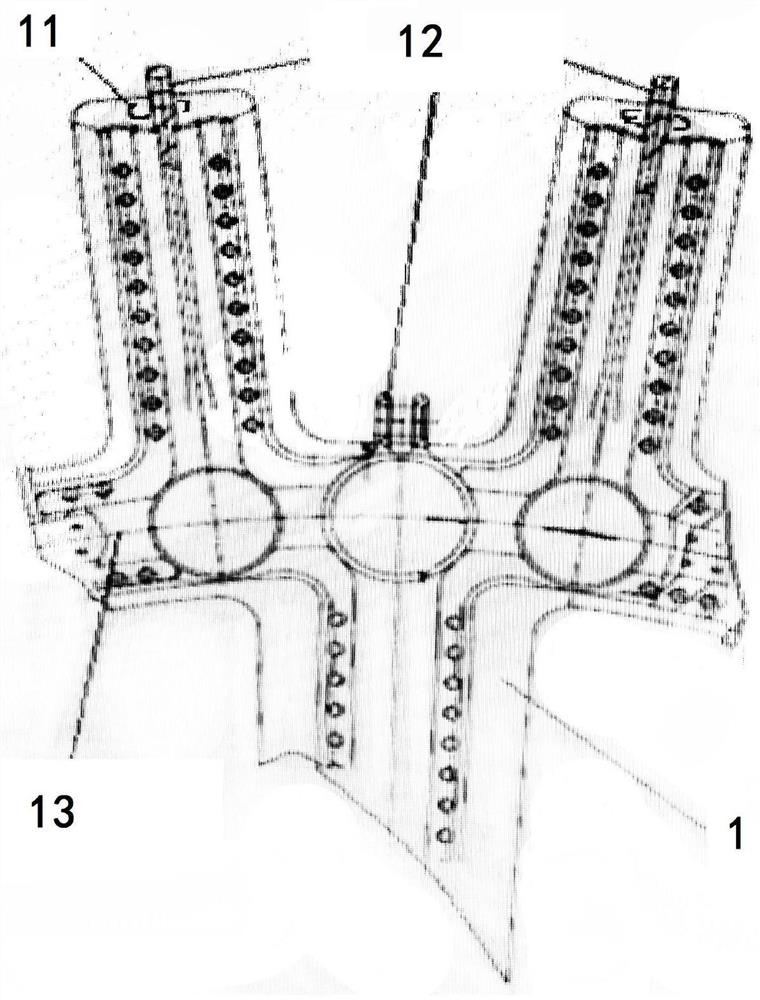

Flexible support device suitable for multiple model powertrain assemblies

PendingCN107584276AReduce manufacturing costSave storage spaceAssembly machinesPowertrainEngineering

The invention discloses a flexible support device suitable for multiple model powertrain assemblies. The support device comprises a left mounting base and a right mounting base, a first positioning support mechanism for supporting an engine is arranged on the left mounting base, and a second positioning support mechanism for supporting a rear axle is arranged on the right mounting base. The flexible support device suitable for the multiple model powertrain assemblies has the advantages that supporting bases and positioning bases of multiple model engines are integrated on the first positioningsupport mechanism, the supporting bases and the positioning bases of multiple model rear axles are integrated on the second positioning support mechanism, the production cost is effectively reduced,and the storage space is saved; the assembly needs of different sized powertrains can be met by switching between the supporting bases during an assembling and switching between the positioning bases,the assembly efficiency is effectively improved, the intensity of work is reduced, under the premise of ensuring the production demand, an operator can easily complete all the assembly tasks; meanwhile the positioning bases have positioning and supporting functions, the assembly accuracy of powertrains is ensured, and the skill requirements of the operator are reduced.

Owner:郑州日产汽车有限公司

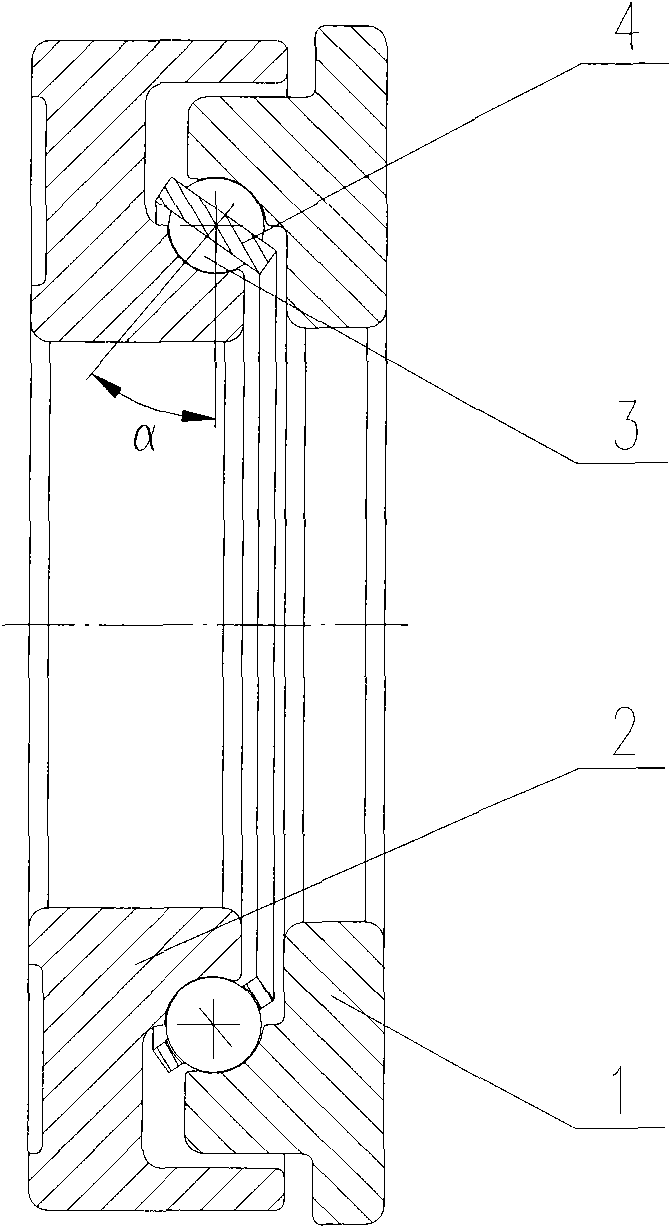

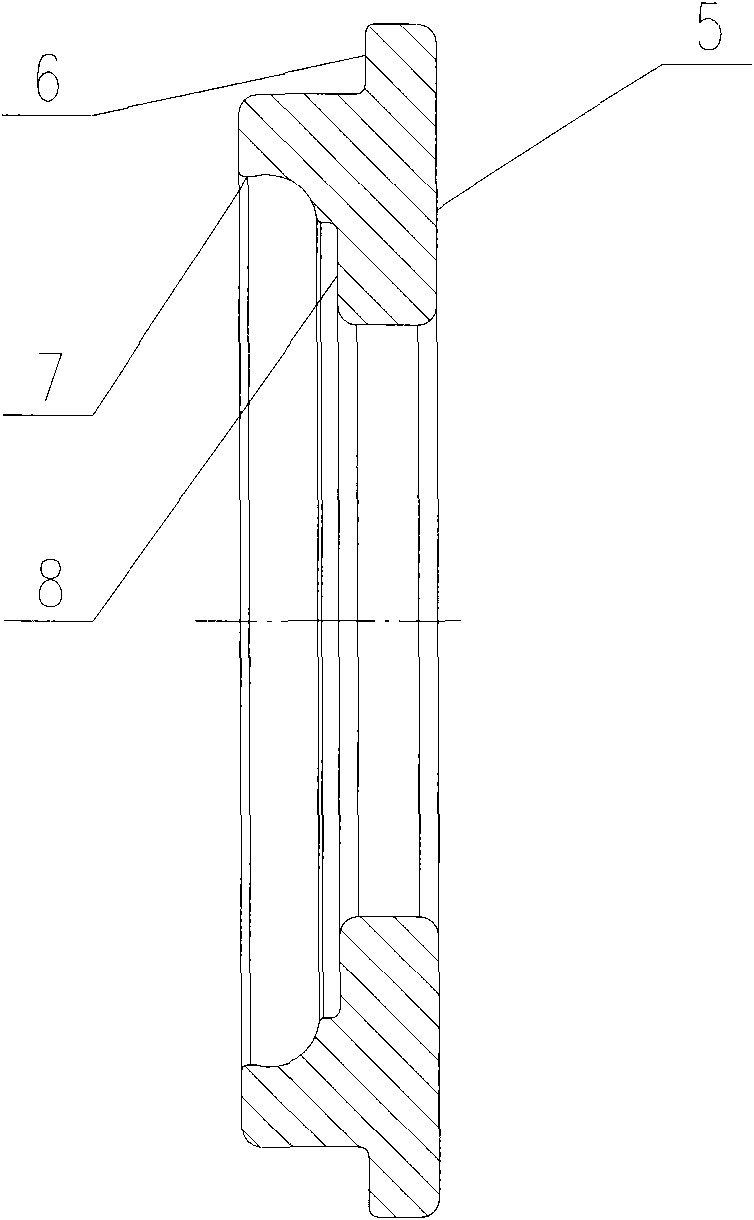

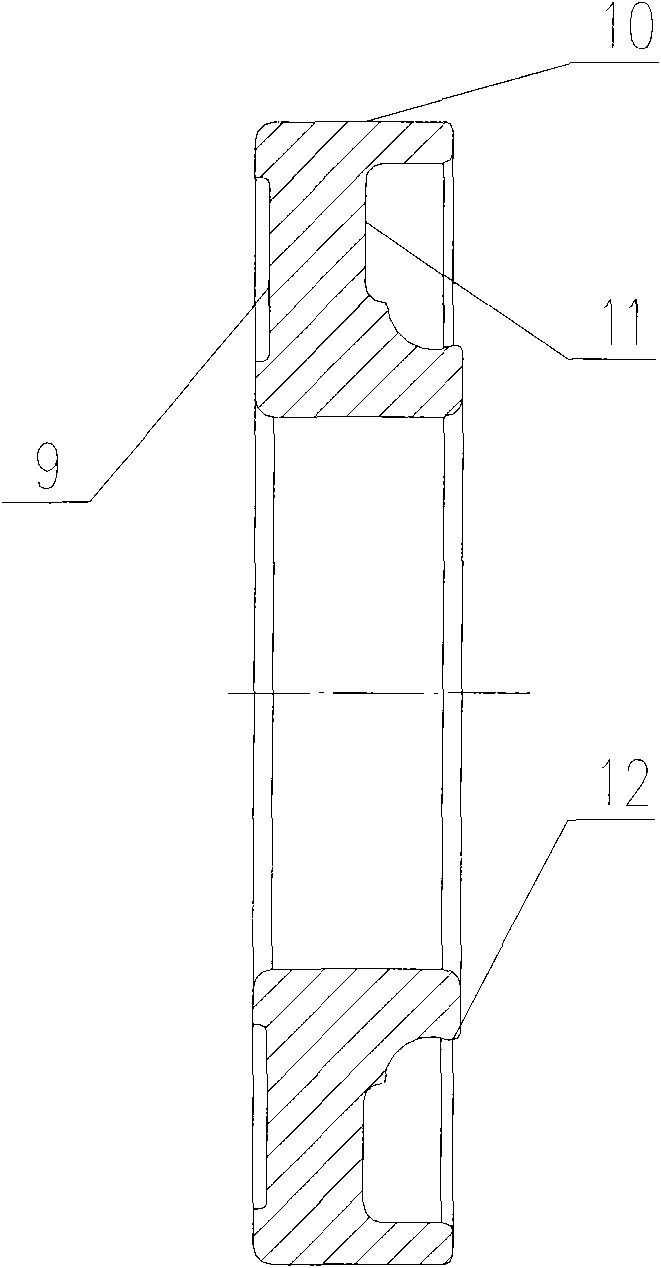

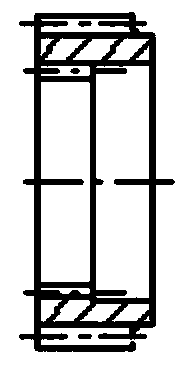

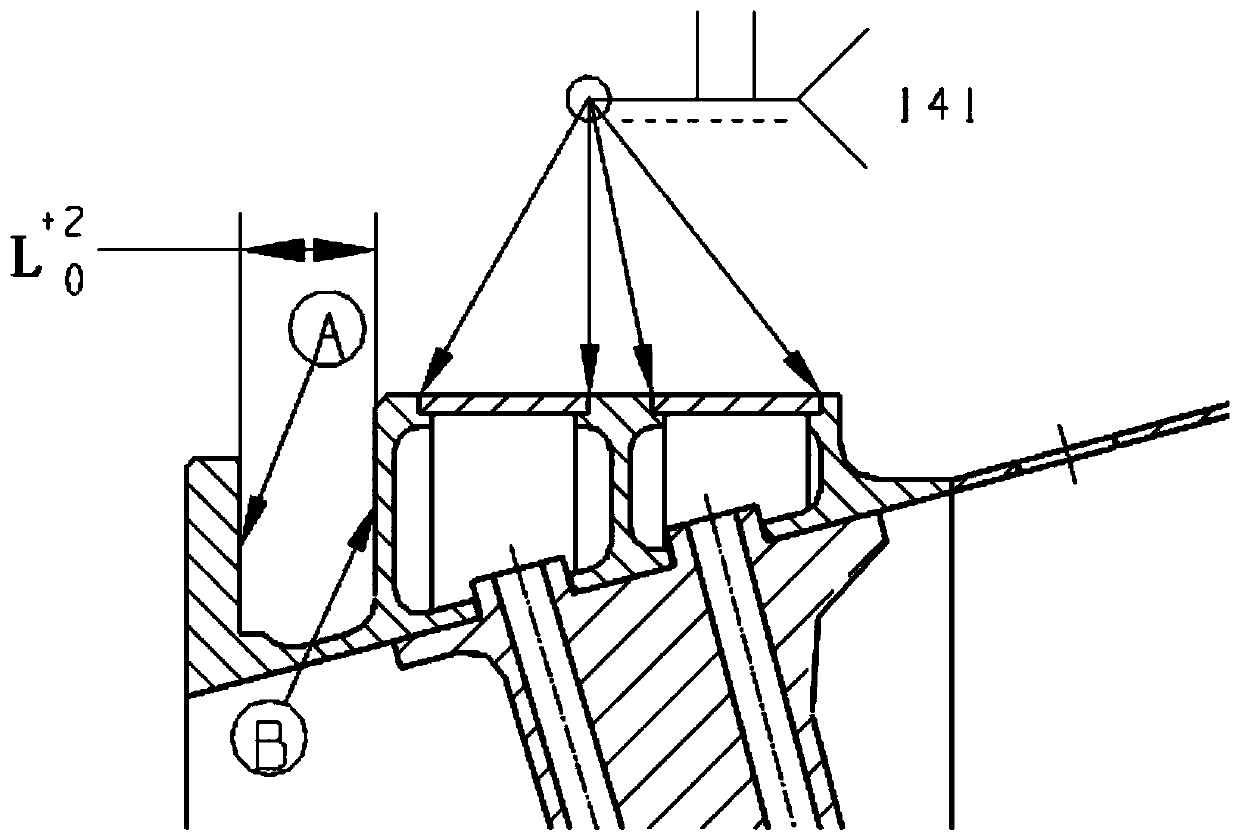

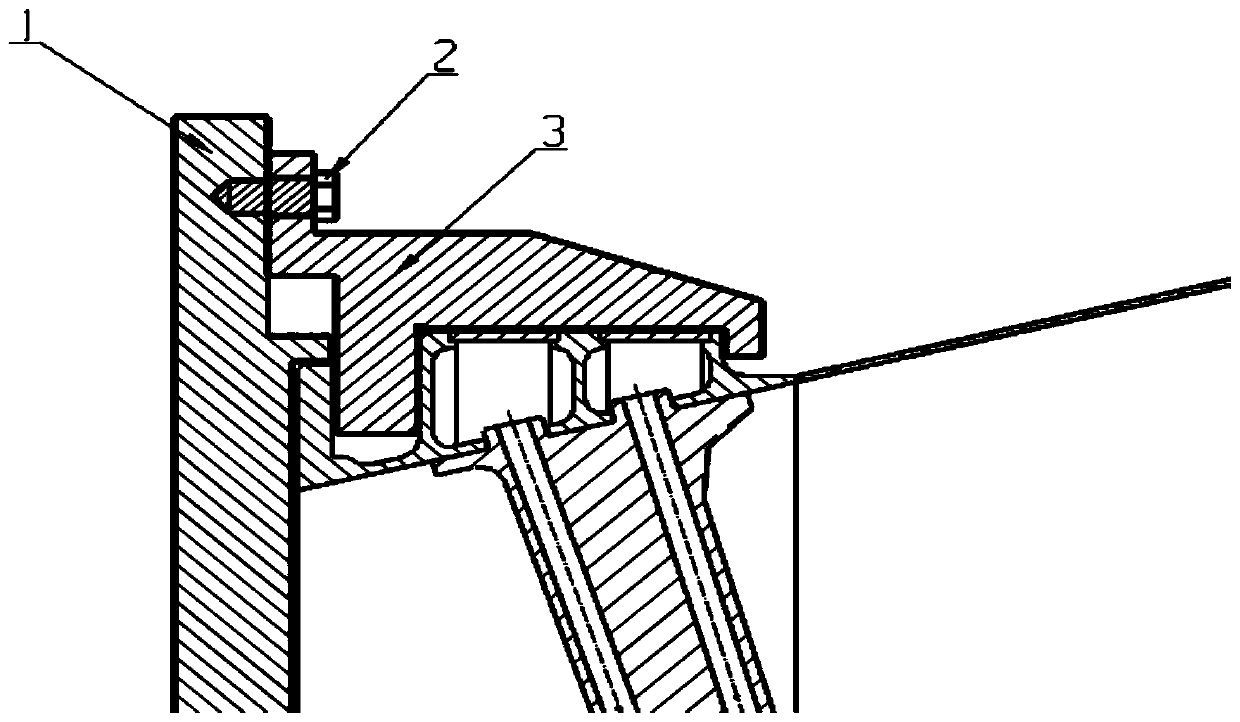

Special angular contact ball bearing for liquid vortex flow retarder

InactiveCN101571159AIncrease frictionGuaranteed rotationBall bearingsBearing componentsPistonEngineering

The invention discloses a special angular contact ball bearing for a liquid vortex flow retarder, comprising an outer ring (1), an inner ring (2), a steel ball (3) and a holder (4). The special angular contact ball bearing is characterized in that a bearing contact angle alpha is 40 DEG; the small end surface of the outer ring (1) is provided with an upper step (6) and a lower step (8), and a roller path of the outer ring (1) is provided with a lock dot (7); the end surface of the inner ring (2) is provided with an annular groove (9), the outside diameter surface (10) of the inner ring (2) can be used as a piston for sealing a cylinder, a step (11) is arranged above a roller path of the inner ring (2), and a lock dot (12) is arranged below the roller path of the inner ring (2); the holder (4) is led by the steel ball (3), and an angle (beta) of the holder (4) is 30 DEG. The invention has the advantages of compact structure, high rotation speed, long service life, good lubricating property, flexible rotation and steady operation, can simultaneously bear the jointed load of a radial direction and an axial direction and can especially bear heavier axial load. The special angular contact ball bearing can not be heated when urgently stopping at the speed of 2800 rotations / minute and has low manufacture cost and convenient installation.

Owner:洛阳斯意特轴承制造有限公司

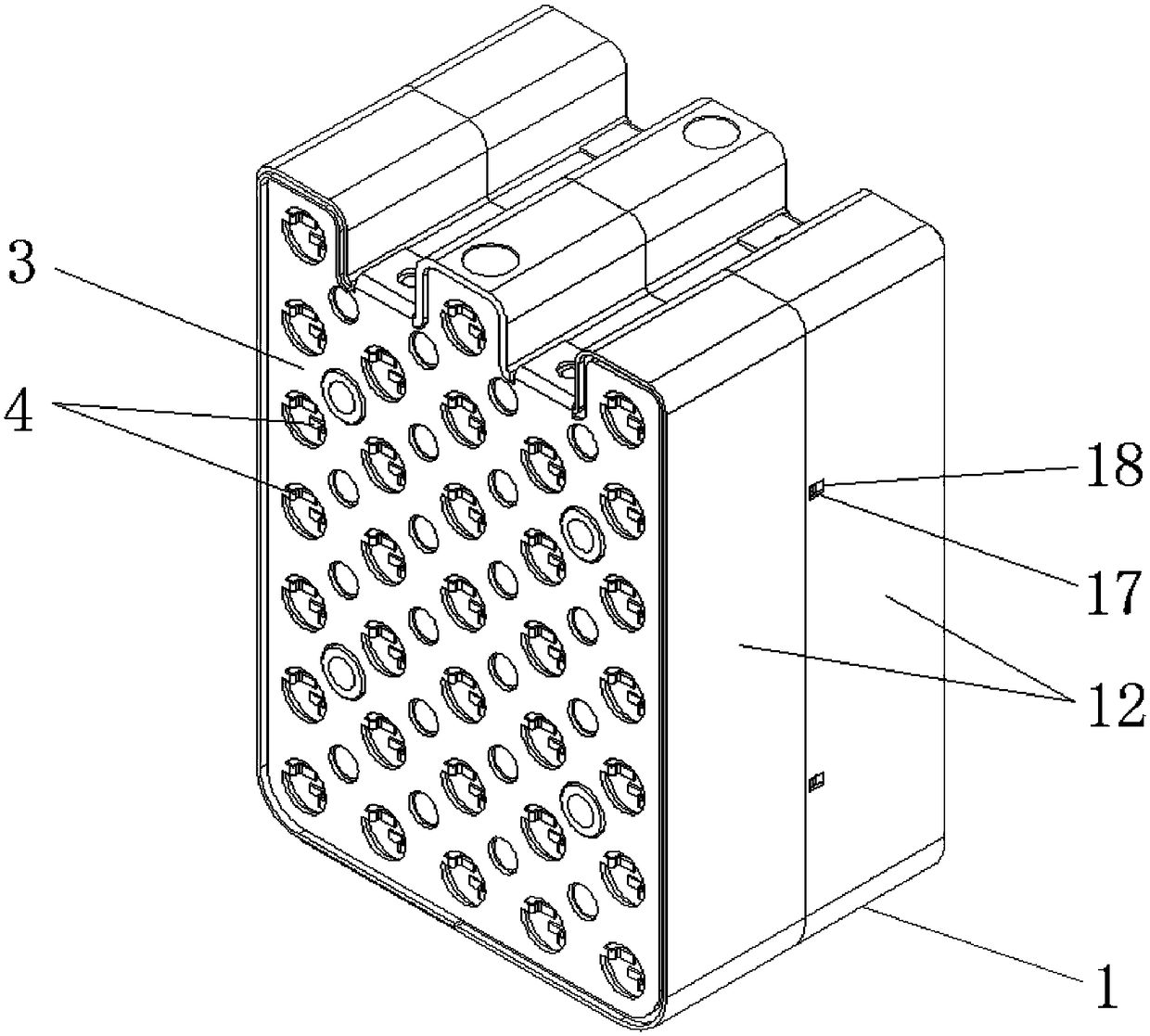

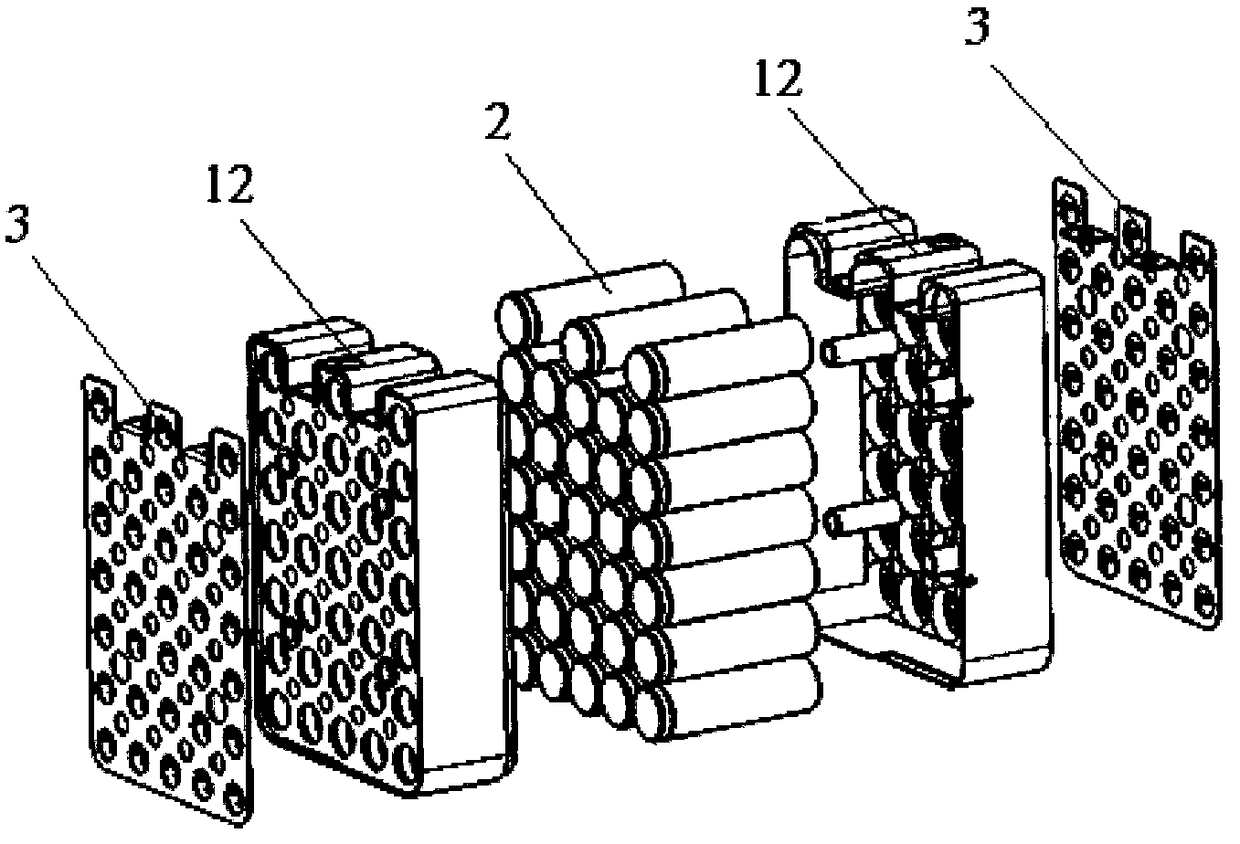

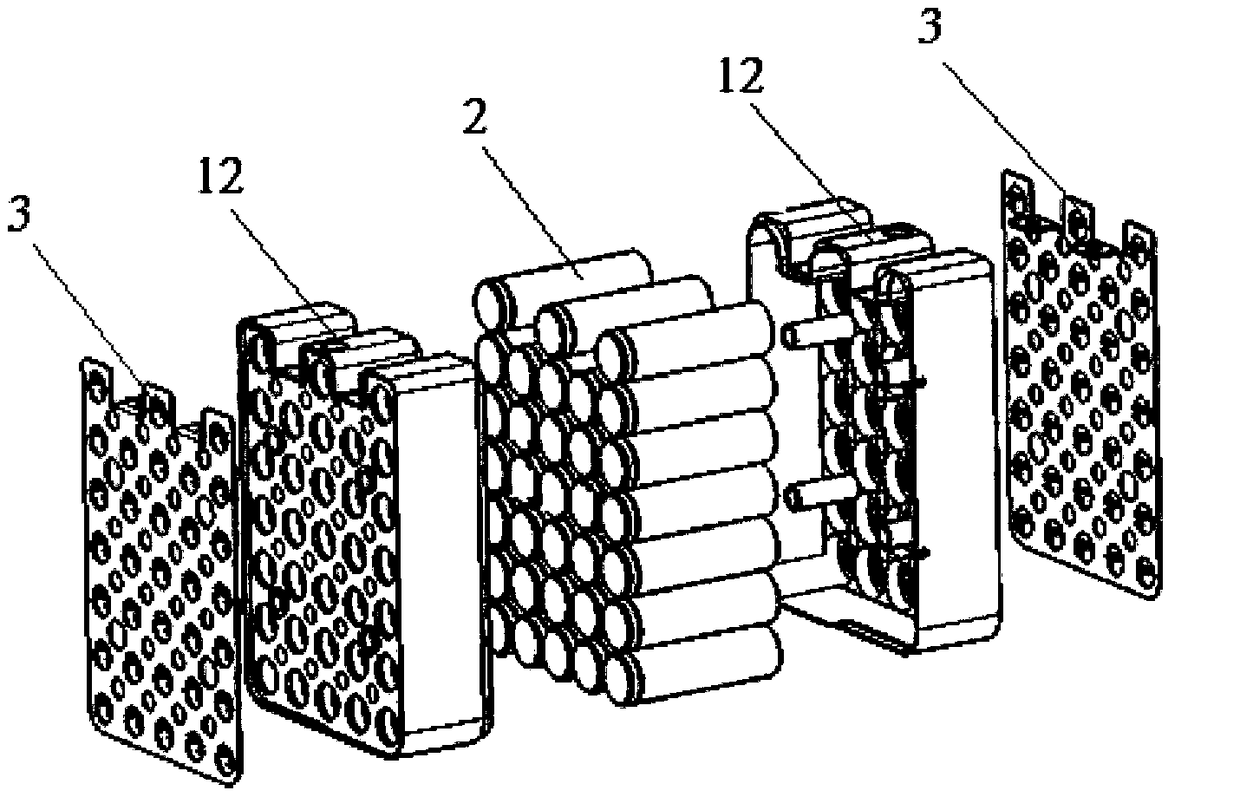

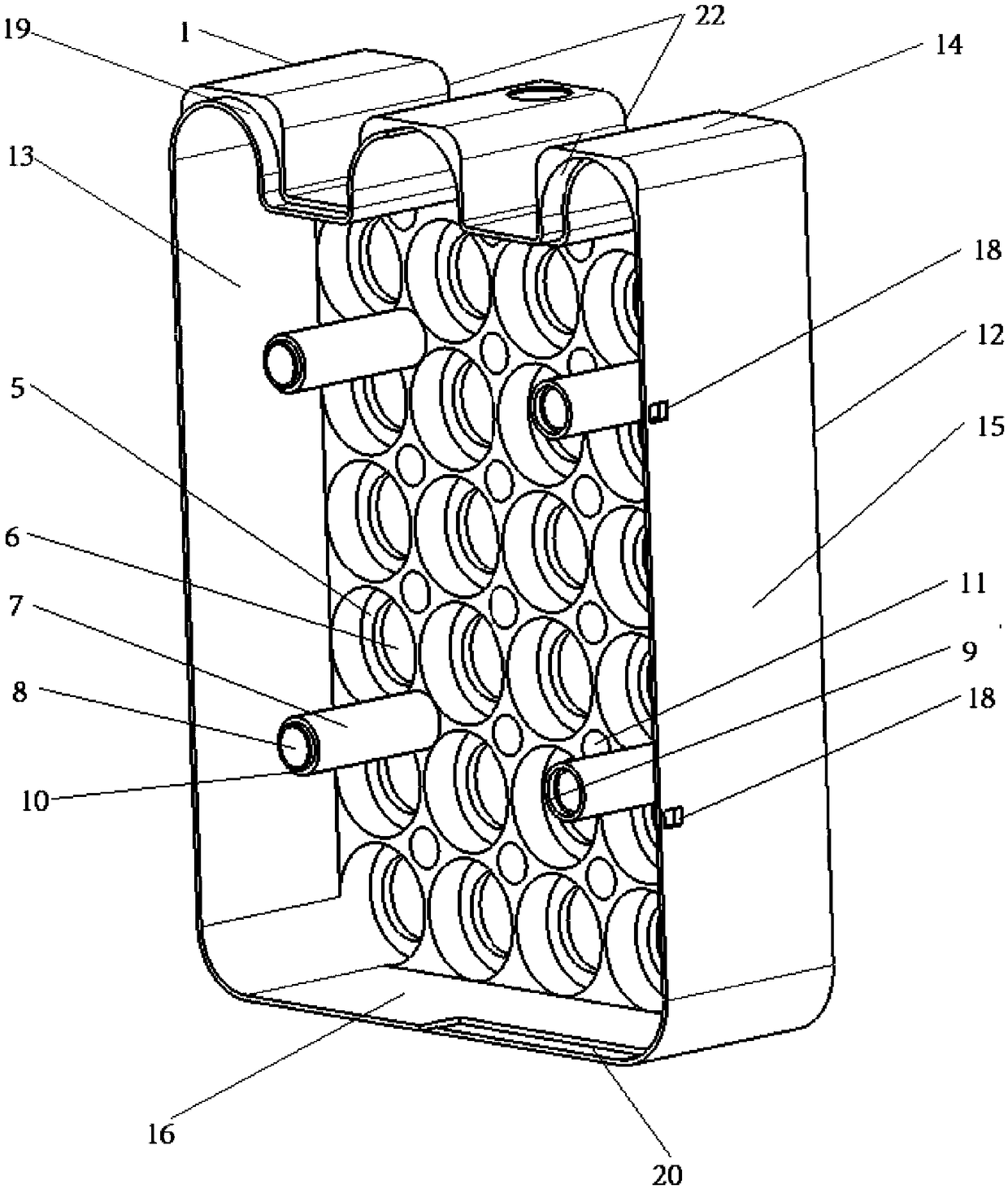

21700 cell series-parallel battery module

PendingCN108511659AGood cooling functionImprove use reliabilitySecondary cellsCell component detailsElectrode insertionHigh intensity

The invention relates to the technical field of cell parallel battery modules, in particular to a 21700 cell series-parallel battery module. The 21700 cell series-parallel battery module comprises a plurality of 21700 battery module units arranged in sequence, and the 21700 battery module units penetrate through a fixed part in sequence and are fixed into a whole; each 21700 battery module unit comprises a module housing and a plurality of 21700 single cells, parallel confluence plates are mounted on two outer walls of the module housing, and a plurality of insertion slots and electrode insertion through holes are provided in two inner walls of the module housing. According to the 21700 cell series-parallel battery module, the 21700 single cells are fixed in the module housing by insertingand clamping, and the 21700 battery module units are correspondingly clamped and limited and penetrate through bolt nut connectors, which can meet the high-strength structure required for the series-parallel battery module composed of 21700 single cells with large capacity, the structure is simple, and the manufacturing cost is low.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

Tailor-welding method of excavator main platform

InactiveCN102248348AImprove welding quality and efficiencyReduce the amount usedWelding/cutting auxillary devicesAuxillary welding devicesCentre of rotationManufacturing engineering

The invention provides a tailor-welding method of an excavator main platform. The tailor-welding method comprises the following steps: hanging a main bottom plate in a fixture, pressing the fixture after positioning with a centre of rotation; hanging a left side plate assembly on the main bottom plate to be fixed by spot welding; hanging a front closing plate on the main bottom plate to be fixed by spot welding; hanging a beam on the fixture to be fixed by spot welding; hanging a right side plate assembly on the main bottom plate to be fixed by spot welding; sectionally welding the joints among the left side plate assembly, the right side plate assembly, the front closing plate and the beam; then arranging a left plug plate and right lug plate in the fixture to be fixed by spot welding. The tailor-welding method of the excavator main platform provided by the invention comprises the following steps: firstly positioning with the centre of rotation of the main bottom plate, orderly combining other parts at a positioned left side plate assembly, and sectionally welding the joints among the left side plate assembly, the right side plate assembly, the front closing plate and the beam, thereby improving the welding quality and efficiency; and the welding can achieve the assembling requirement.

Owner:龙工(上海)挖掘机制造有限公司

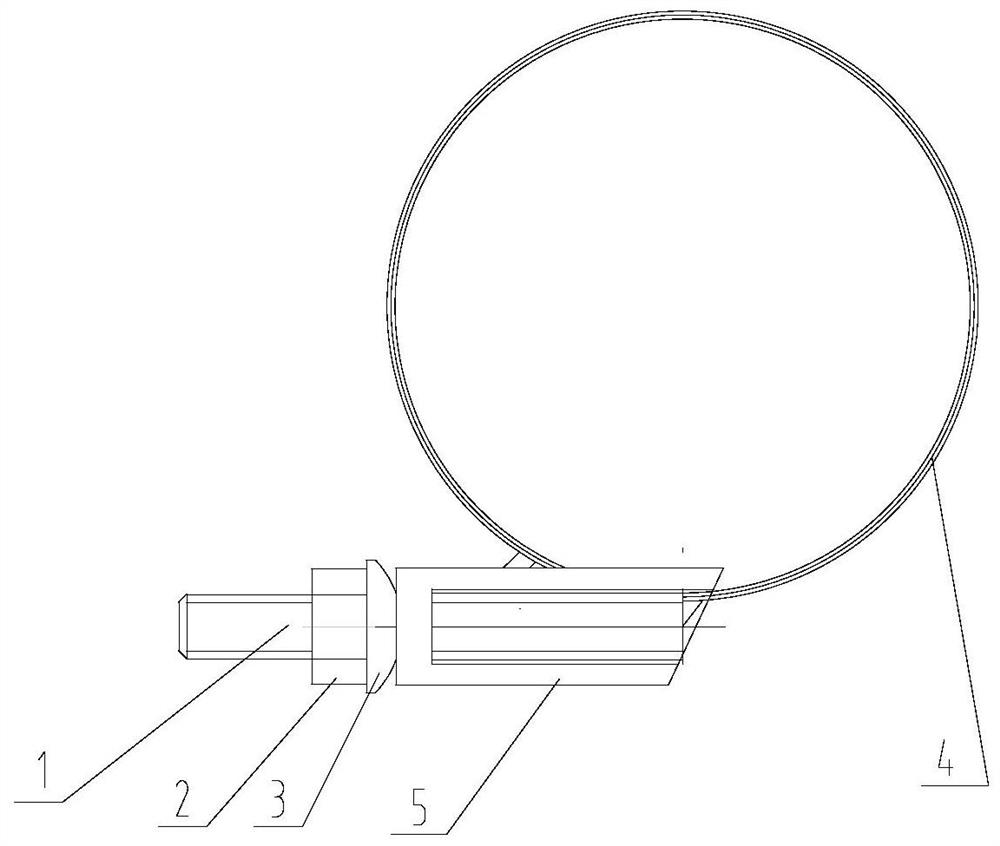

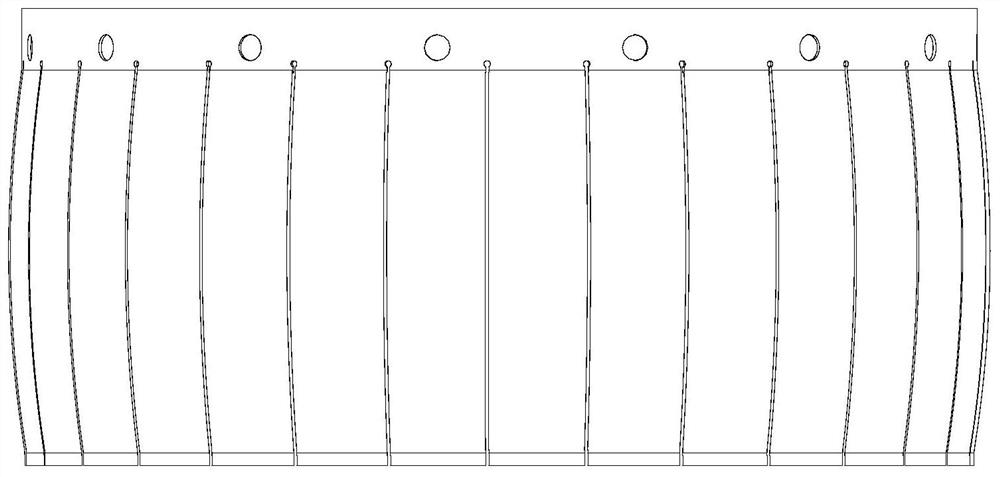

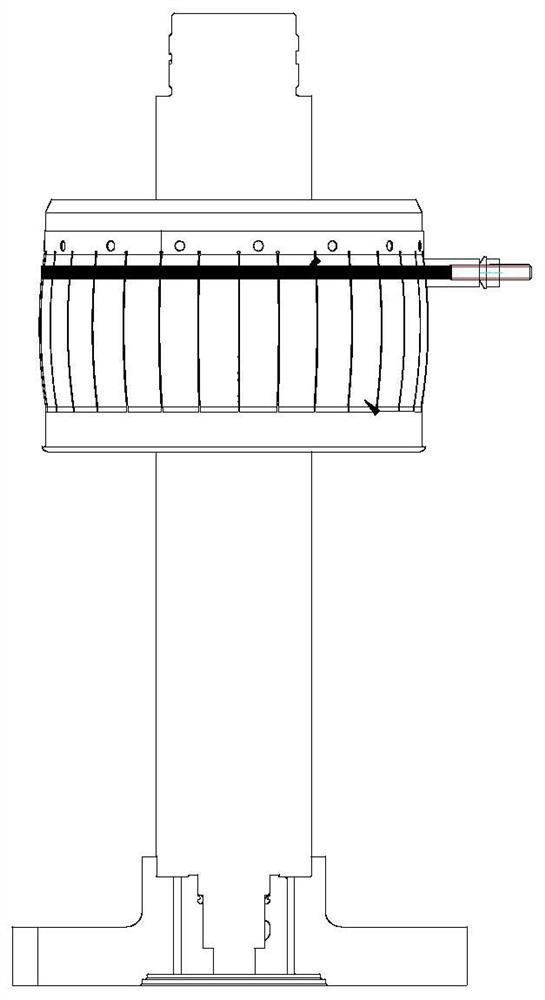

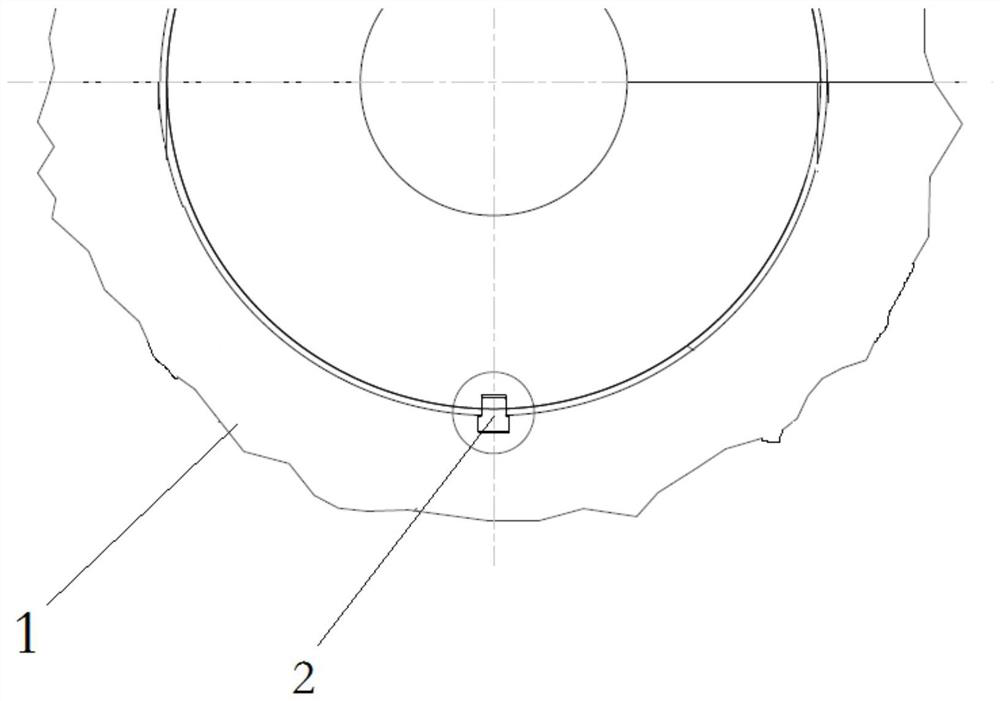

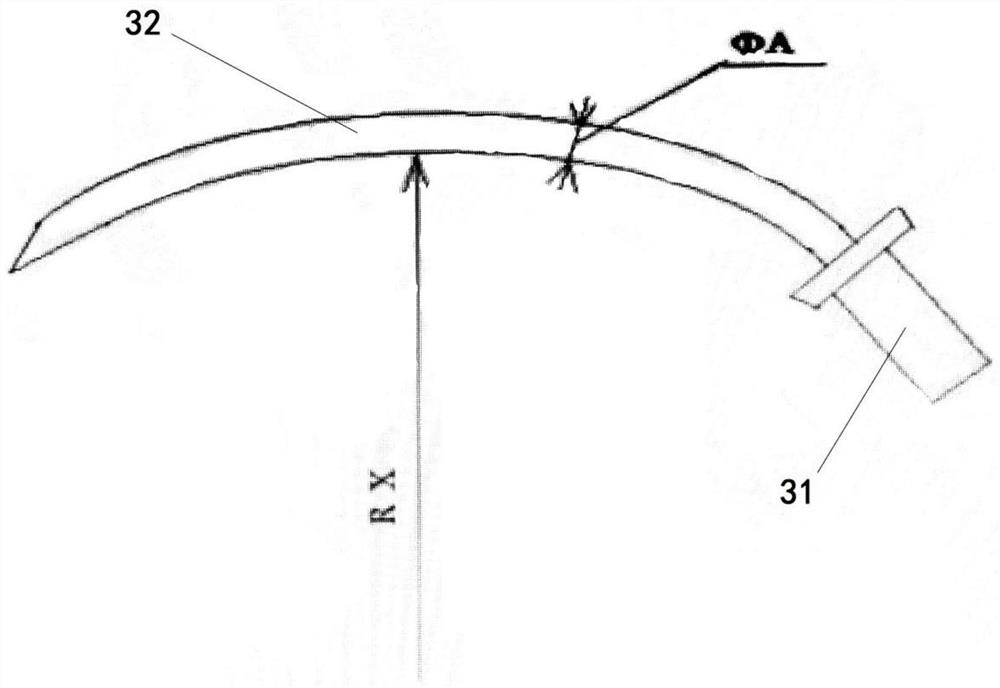

300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and use method

InactiveCN111687558AAvoid the phenomenon of free deformationGuaranteed Assembly RequirementsWelding/cutting auxillary devicesAuxillary welding devicesCombustion chamberEngineering

The invention relates to the field of welding, in particular to a 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and a use method. The 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool and the use method aim at solving the problems that a hula seal molded line and radian are changed due to the fact that the unrestrained end of a 300MWheavy-duty gas turbine nozzle hula seal is deformed to release welding tensile stress, and the follow-up assembly is influenced. The 300MW heavy-duty gas turbine nozzle hula seal assembly welding restraining tool is designed and manufactured and comprises a restraining force application part and a restraining belt, wherein the restraining belt is annular when working, one end of the restraining belt is connected with the restraining force application part, the other end of the restraining belt is tightened through the restraining force application part, the hula seal is forcibly restrained byusing the restraining tool all the time in the high-temperature alloy hula seal and nozzle assembling and welding process, the temperature difference of different positions disappears after welding iscompleted, after a certain welding stress is released, the restraining tool is removed, it is guaranteed that the free end of the hula seal does not have larger free deformation, it is further guaranteed that the molded line and radian of a product meet drawing and design requirements, and the subsequent combustion chamber assembling requirement is met.

Owner:HARBIN TURBINE

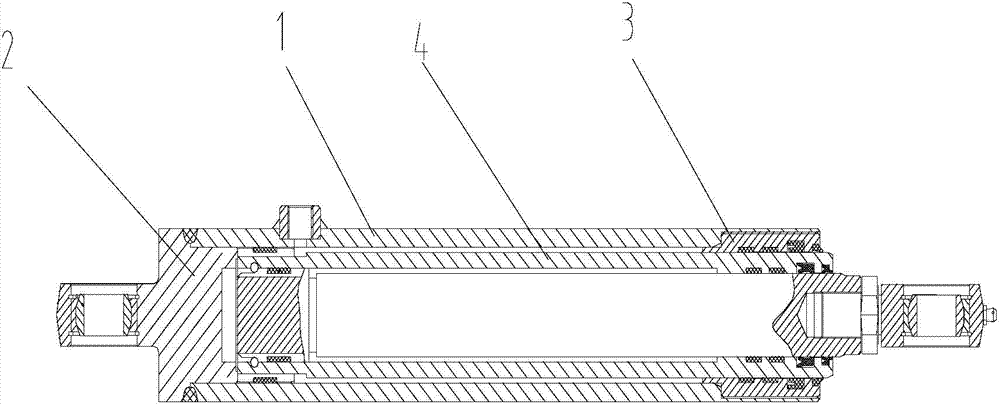

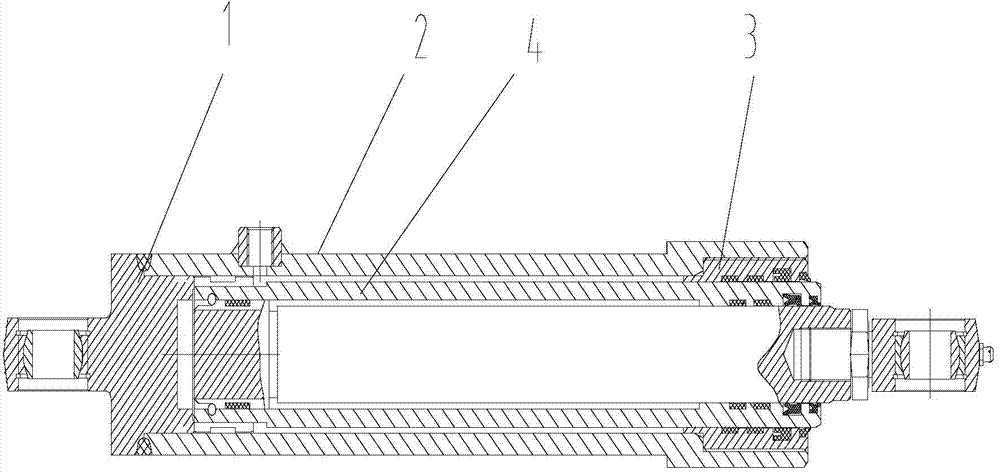

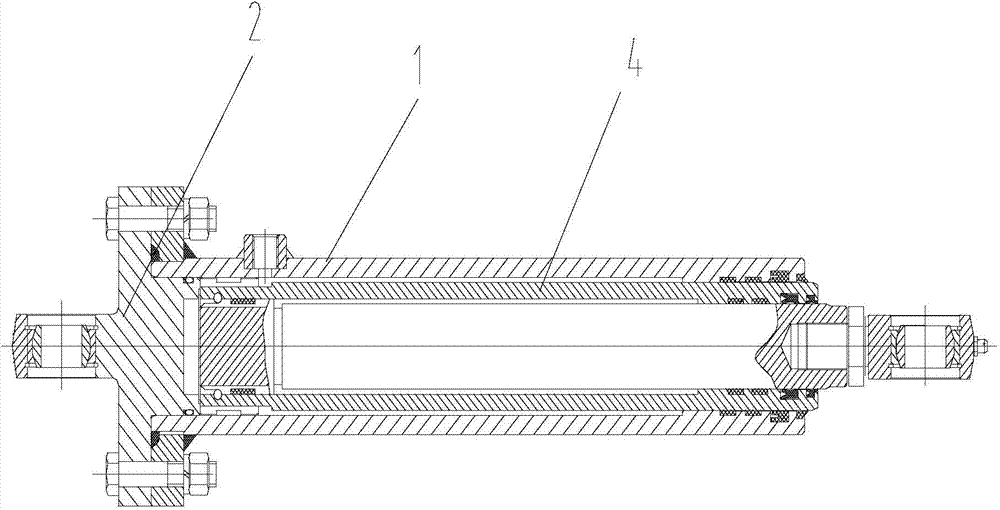

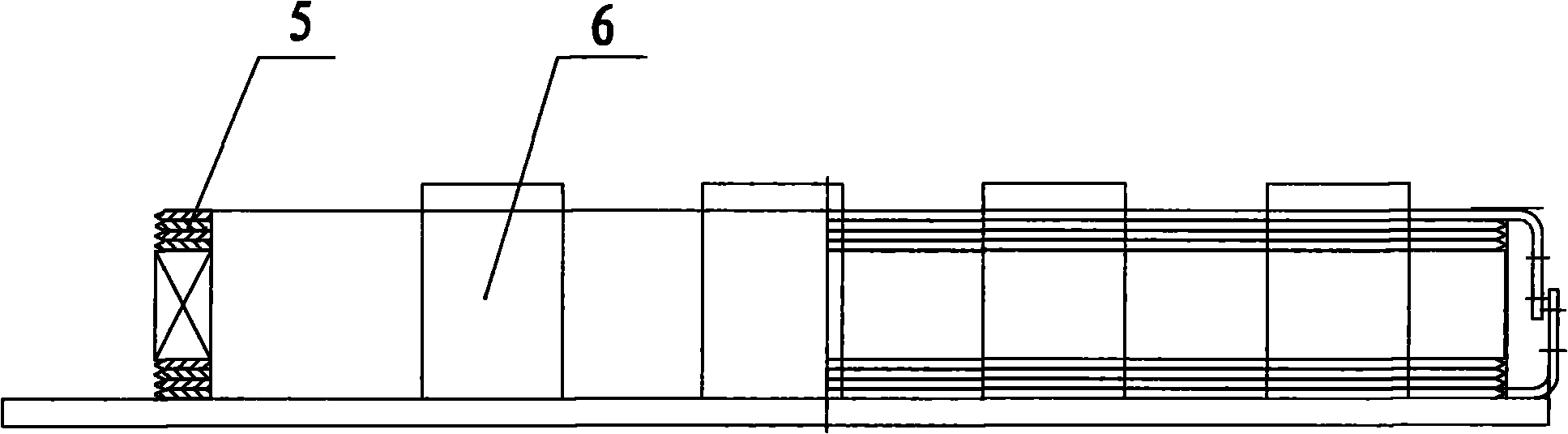

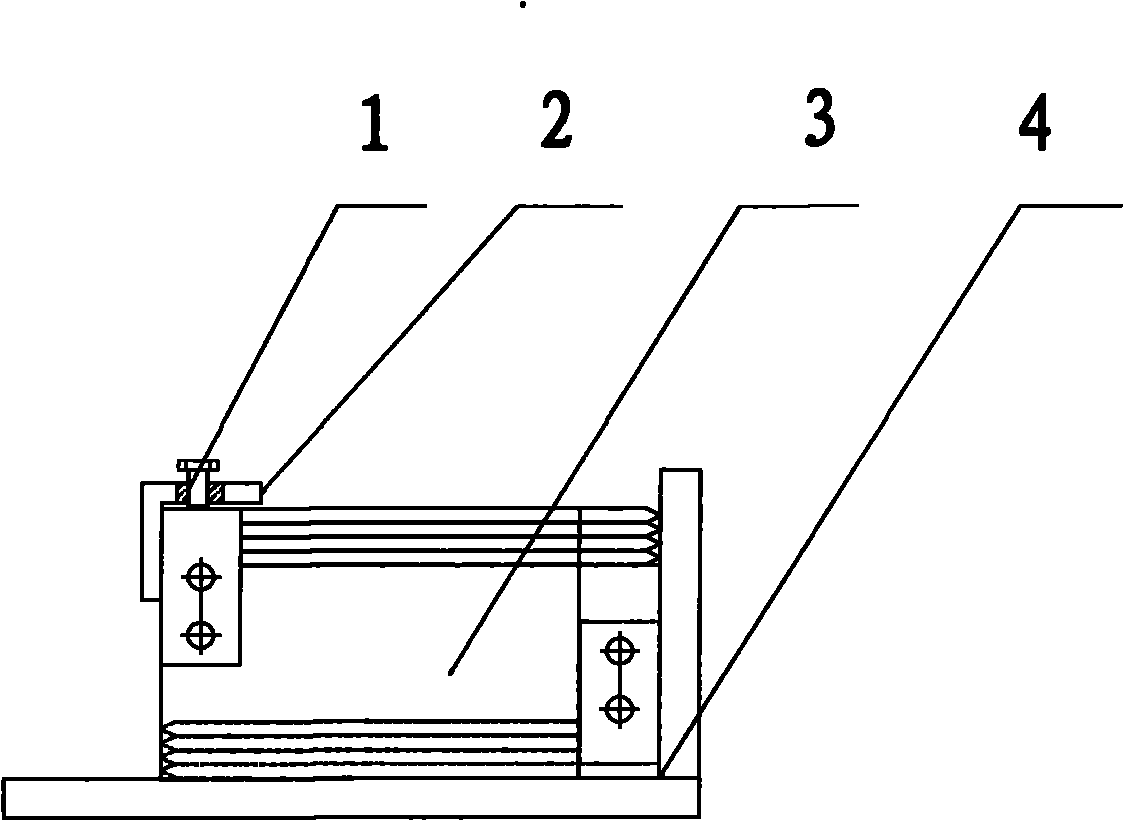

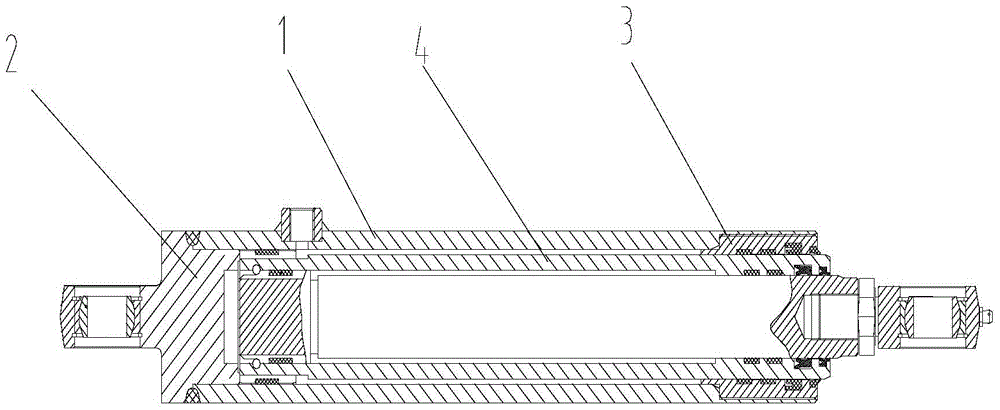

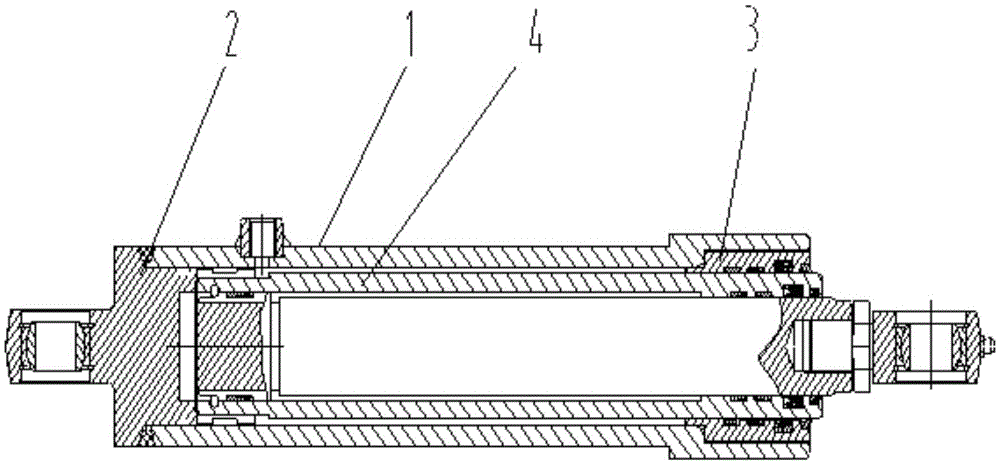

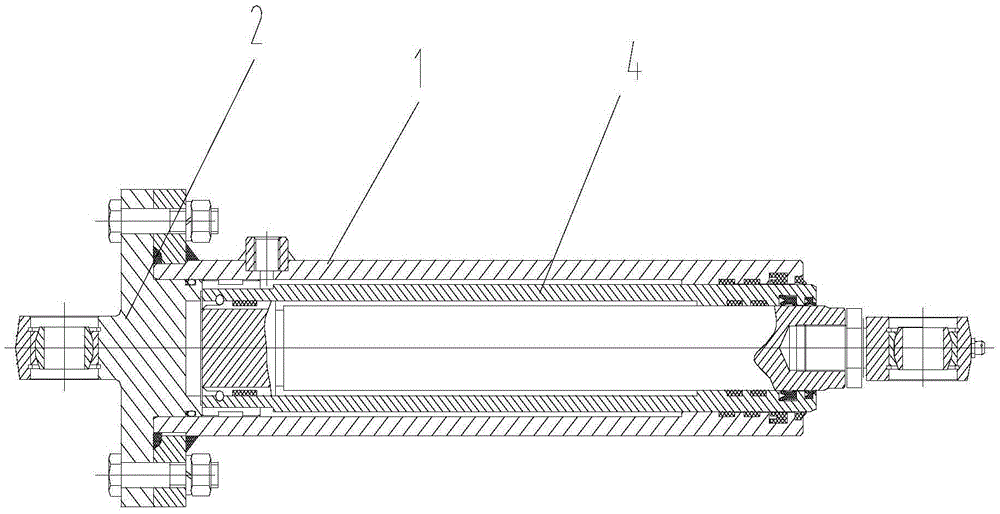

Hydraulic cylinder

ActiveCN104514767AMeet strength requirementsMeet form factor constraintsFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a hydraulic cylinder, including a cylinder barrel (1), wherein one end of the cylinder barrel (1) is connected with a cylinder bottom (2) while the other end forms a cylinder rod extending end, a first sealing member (5) is arranged on the inner peripheral surface of the cylinder rod extending end, the cylinder barrel (1) and the cylinder bottom (2) are fixed with each other by a positioning member positioned in the cylinder barrel (1) and simultaneously stopping the cylinder barrel (1) and the cylinder bottom (2). The hydraulic cylinder can simultaneously meet the requirements on strength, assembly and dimensional limit.

Owner:HUNAN TELI HYDRAULIC +1

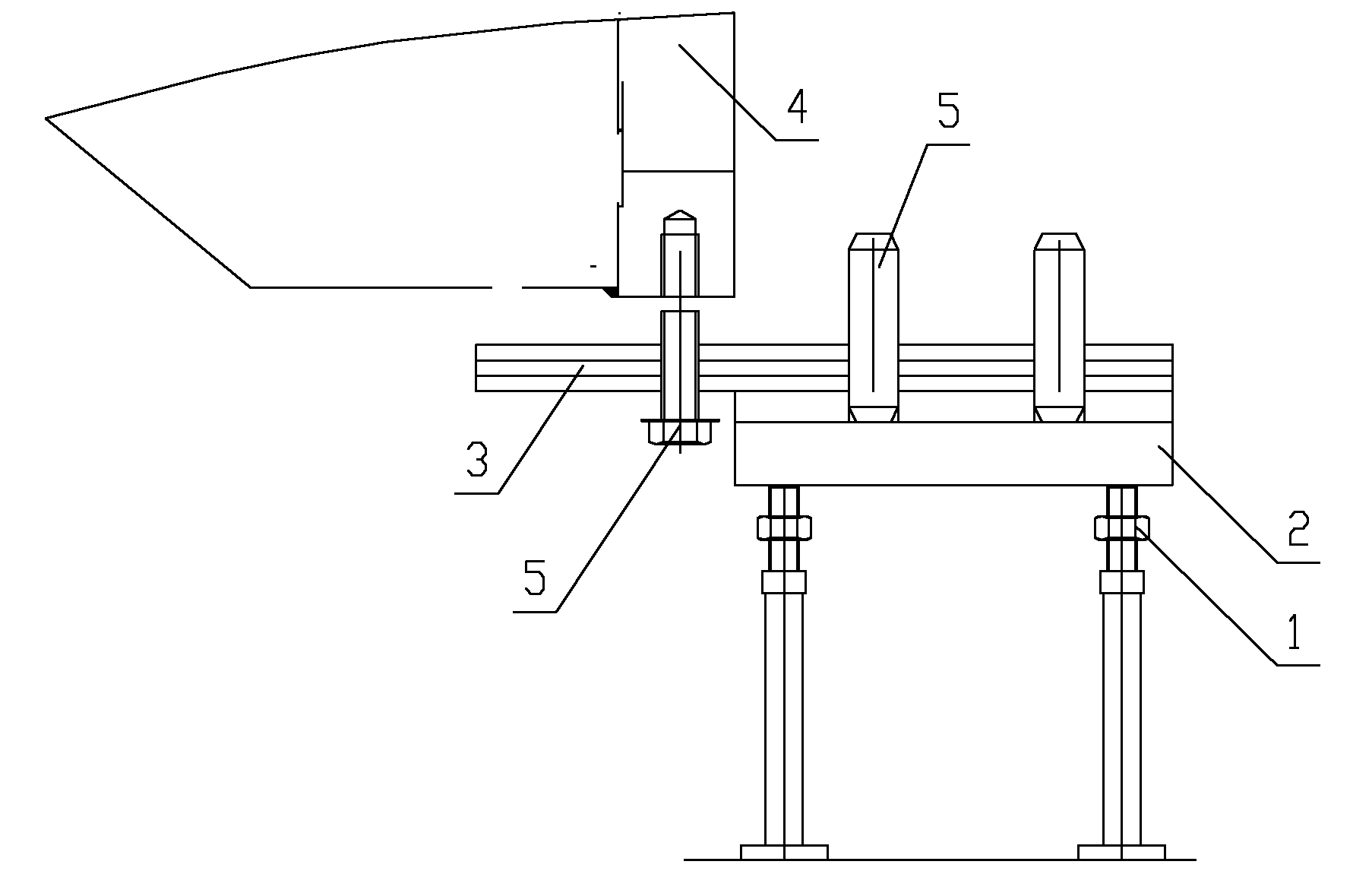

Lead bending die of rotor winding and processing method

InactiveCN101917098AAccurate processing methodPrecise processingManufacturing dynamo-electric machinesConductor CoilCopper

The invention relates to a lead bending die of a rotor winding and a processing method, belonging to the technical field of hydraulic generators. The lead bending die of a rotor winding is provided with a soleplate, a line-pressing plate, a positioning plate and a supporting plate, wherein the soleplate and the supporting plate are vertically fixed together, the positioning plate is fixed on the soleplate and provided with a notch in a position where a lead is pressed to be bent at the bottom, and the line-pressing plate is fixed on the positioning plate which is used for positioning and bending the end of the rotor winding. The lead bending processing method of the rotor winding comprises the following steps of: annealing the rotor winding through a copper bar, edgewise winding, secondarily annealing, cold pressing, scribing the lead, dipping tin and drilling holes and carrying out the lead bending treatment of the rotor winding; and putting the rotor winding on a bending die, firmly clamping the copper bar lead by a compressing bolt through the line-pressing plate and bending the lead by adopting shape-beating mode of an iron hammer. The invention has the advantages of simple structure, rapid operation, time and labor saving, less working hour consumption, high production efficiency, high winding lead bending quality, and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Double-layer composite plastic floor

InactiveCN103074988AFast and easy plug-in connectionTo achieve a plug-in connectionFlooringManufacturing cost reductionManufacturing technology

The invention discloses a double-layer composite plastic floor. The double-layer composite plastic floor comprises a floor surface layer and a floor cushion layer which is arranged under the floor surface layer, wherein the floor surface layer and the floor cushion layer are paralleled to each other and are horizontally and longitudinally connected together in a dislocation adhesion way, bulge parts between the floor surface layer and the floor cushion layer are formed into connecting strips and connecting lap strips, and adhesive sticker is coated on connecting surfaces opposite to the connecting strips and / or the connecting lap strips; and the floor cushion layer is formed by connecting a left floor cushion layer and a right floor cushion layer through connecting rabbets in a clamping way, the connecting rabbets are just arranged at long sides of the floor cushion layer and are formed by convex tenons and concave mortises, the convex tenons and the concave mortises are respectively arranged at long edges at two sides of the floor cushion layer and can form inserting connection, the convex tenons and the concave mortises are of parallelograms, and the convex tenons and the concave mortises are matched. According to the double-layer composite plastic floor disclosed by the invention, the inserting connection of the tenons and the mortises can be easily and quickly realized, and thus the assembly and the disassembly of a floor can be easy and efficient; and through an optimization structure, the manufacturing technology difficulty can be reduced, the manufacturing cost can be reduced, and the structural strength of a connecting tenon can be increased.

Owner:TAIZHOU HUALI PLASTIC

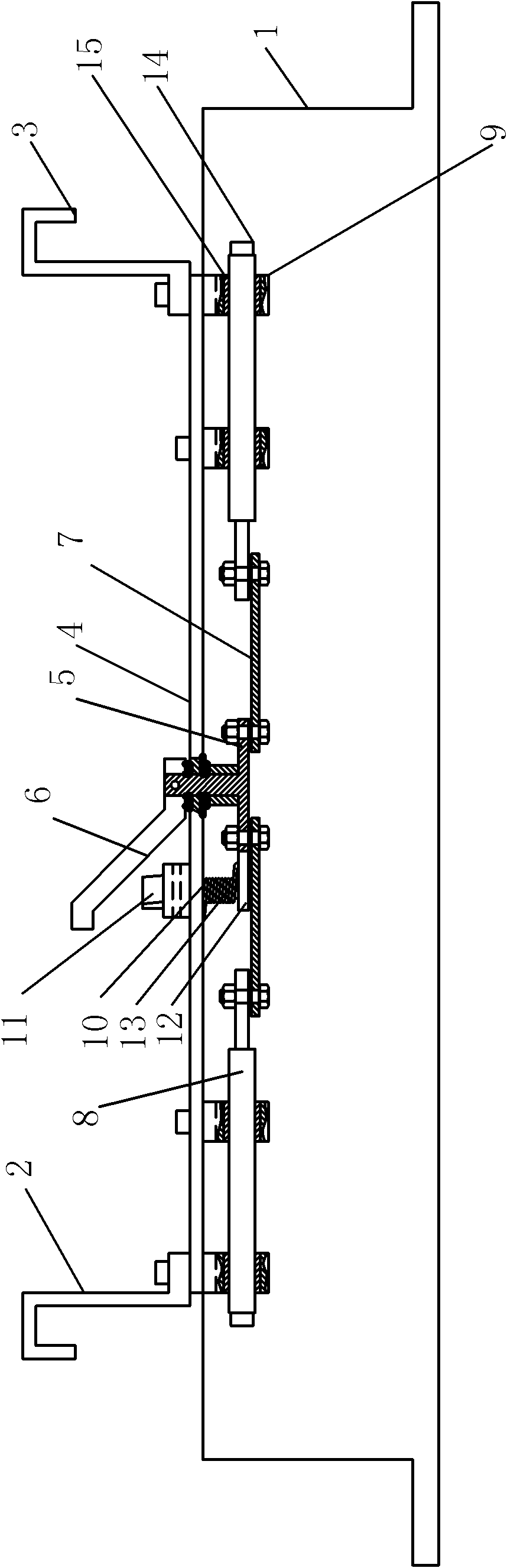

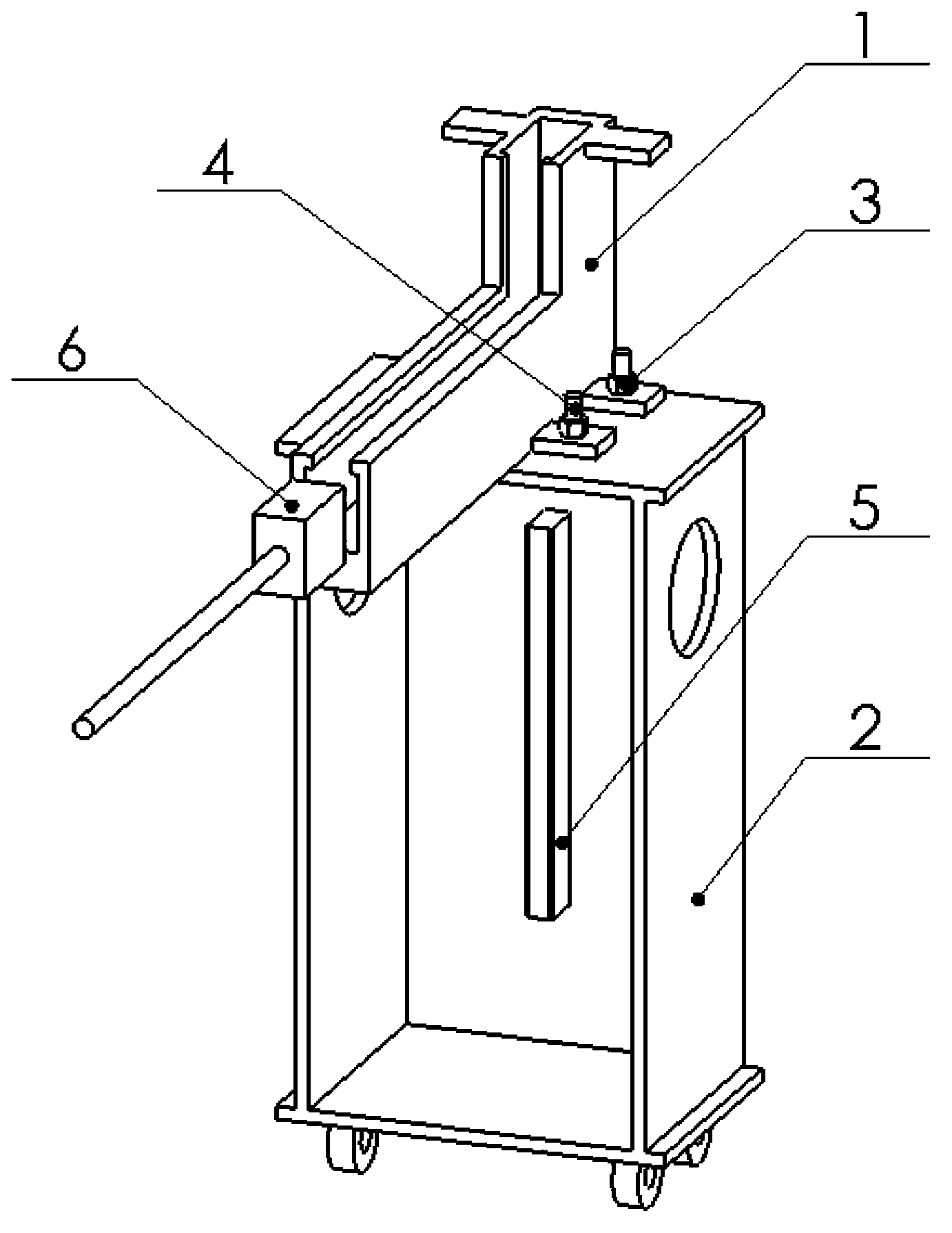

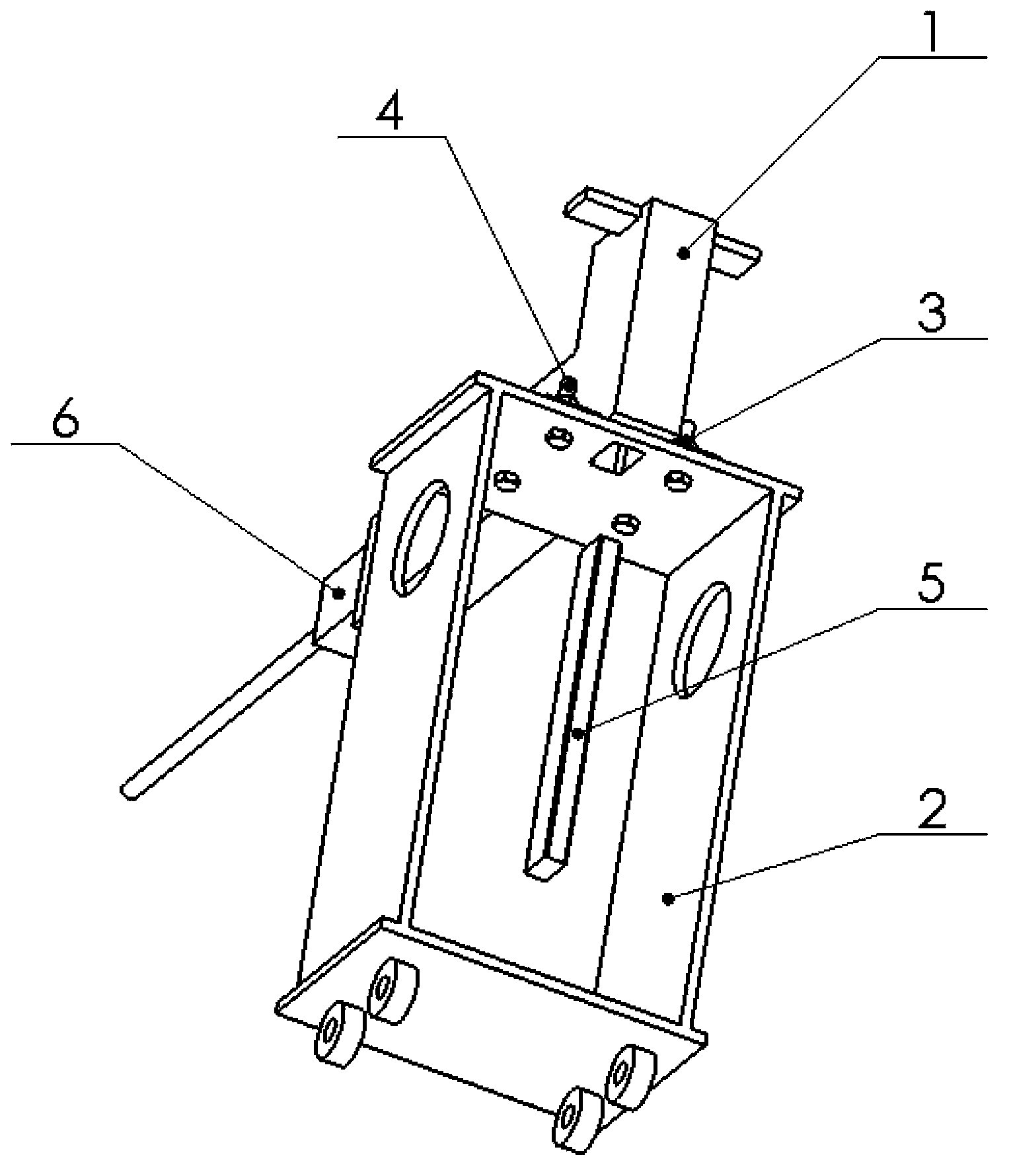

Quick positioning and mounting device of screen armrest support seat of metro vehicle guest room

ActiveCN102030012AGuaranteed Assembly RequirementsGuaranteed assembly qualityRailway componentsEngineeringHandrail

The invention discloses a quick positioning and mounting device of a screen armrest support seat of a metro vehicle guest room, comprising a special positioning plate for a support seat, wherein the steps of the screen armrest support seat are arranged on two sides of the special positioning plate for the support seat; a left-side hanging arm and a right-side hanging arm are respectively arranged above two sides of the special positioning plate for the support seat; a fixed plate is arranged on the special positioning plate for the support seat; a rotatable circular rotating disk is arranged in the middle of the fixed plate; a rotating handle is arranged on the circular rotating disk; two connecting arms are respectively hinged with two sides of the circular rotating disk; two stay bars are respectively hinged with the other ends of the connecting arms; and stay bar support seats are externally and hollowly sleeved on the stay bars and are fixed on the fixed plate. The invention effectively solves the problems that the screen armrest support seat is inaccurately positioned and the screen glass stress and the gap between the bottom surface of an armrest rod and a side plate of a chair have quality problems in the screen armrest assembly process of the metro vehicle guest room. The invention ensures the assembly requirement of the screen armrest support seat, lays a foundation for the subsequent installation of a vehicle body wall board and the assembly of the screen glass and ensures the assembly quality of the quick positioning and mounting device.

Owner:CSR HANGZHOU RAIL TRANSIT

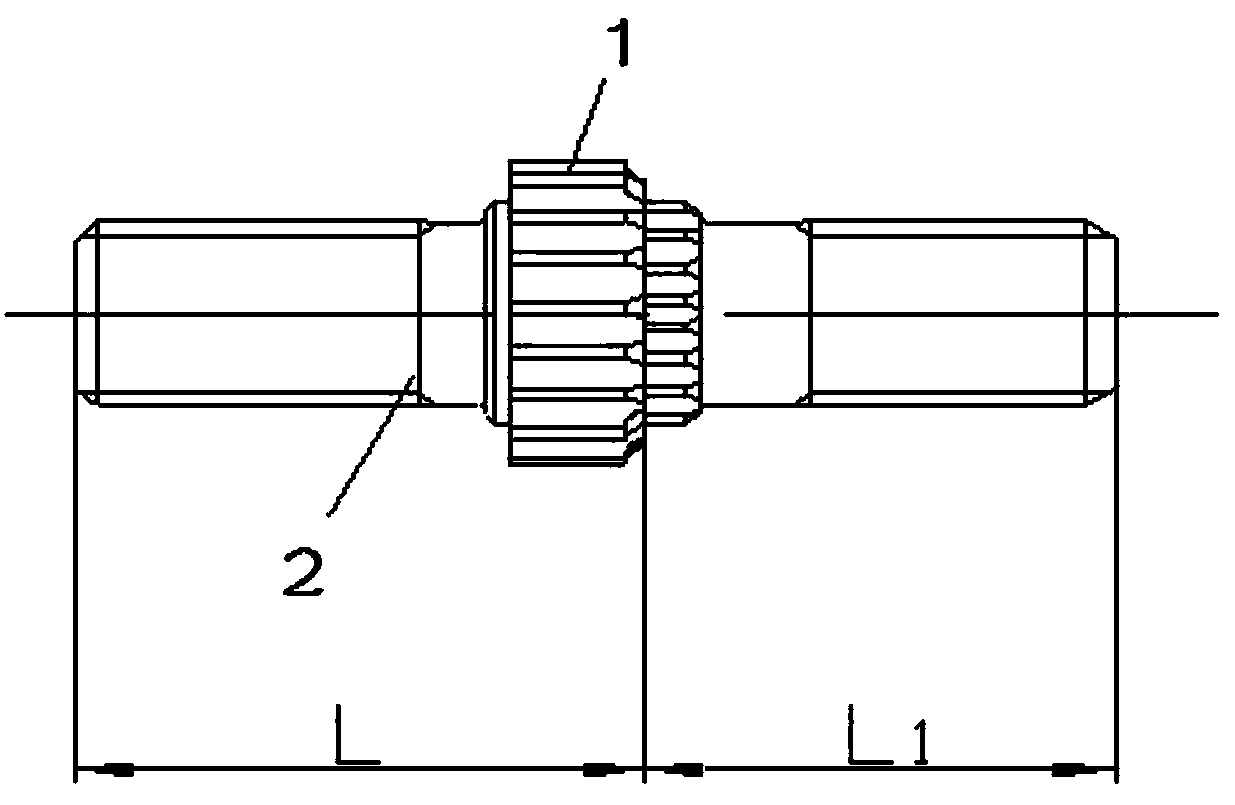

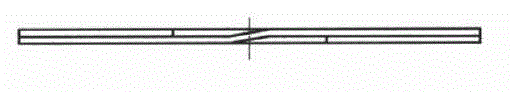

Locking double-end stud assembly structure with stopping station

The invention belongs to the field of fasteners special for connection and looseness-proof of aerospace, and provides a locking double-end stud assembly structure with a stopping station. The lockingdouble-end stud assembly structure with the stopping station includes a locking ring and a double-end stud, straight teeth are arranged on the middle of the double-end stud in the circumferential direction, the stopping station is arranged at one ends of the straight teeth, a tool withdrawal groove is formed in the root of the joint of the stopping station and the straight teeth, the width of therelief escape is 0.4-0.5mm, and the groove bottom size of the tool withdrawal groove is 0.05-0.1mm smaller than the small diameter of the straight teeth. The problems that existing fasteners special for connection and looseness-proof of aerospace are not reasonable in structure design and high-probability scrapping is caused during installation are solved.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

High-medium-pressure dummy-shaft-free final assembly method for modified unit

ActiveCN112360582AGuaranteed Assembly RequirementsShorten the timeMachines/enginesEngine componentsStructural engineeringMechanical engineering

The invention discloses a high-medium-pressure dummy-shaft-free final assembly method for a modified unit, and relates to the field of assembling processes of large equipment. The method aims to solvethe problems that when an existing assembly method is used for assembling a high-medium-pressure inner cylinder and inner sleeves of a modified unit, the assembling period is too long, the working efficiency is low, and delay is possibly caused. By the adoption of the novel high-medium-pressure part dummy-shaft-free final assembly method, a dummy shaft does not need to be used for centering all the sleeves, the time for centering the inner cylinder and all the inner sleeves through the dummy shaft is saved, due to the fact that the dummy shaft needs to be hoisted in again and calibrated in the centering process of each inner sleeve, the dummy shaft needs to be in place again when a product pin is replaced, the novel final assembly process scheme also meets all assembly requirements of final assembly, a large amount of assembly time is saved, the maintenance period of owners can be met, and the working efficiency is improved. The method is suitable for high-medium-pressure dummy-shaft-free assembly of the modified unit.

Owner:国能(泉州)热电有限公司 +1

Bonded permanent magnet for large direct-drive permanent-magnet generator

InactiveCN102738910AReduce eddy currentReduce heatMagnetic circuit shape/form/constructionMetal layered productsEpoxyElectricity

The invention relates to a bonded permanent magnet for a large direct-drive permanent-magnet generator. The permanent magnet is formed by bonding a plurality of small permanent magnets. Since each permanent magnet group is formed by bonding a plurality of permanent magnets, the surface eddy, heat and thermal loss of the permanent magnets can be effectively reduced; in consideration of the requirements for salt-fog resistance and humidity-heat resistance in the overall operating environment of a wind-driven generator set, the coating thereof can ensure that the permanent magnets can meet the operating requirements under severe environmental conditions and can not cause the inter-layer conduction of the permanent magnets; and epoxy glue used for bonding the permanent magnets has fine insulating properties such as high temperature resistance, convenient curing process, high dielectric property, surface creepage resistance and arc resistance. In use, the invention can effectively ensure assembling requirements, can achieve the technical requirement effect and can be widely used for permanent magnets of various large permanent-magnet generators.

Owner:GUODIAN UNITED POWER TECH

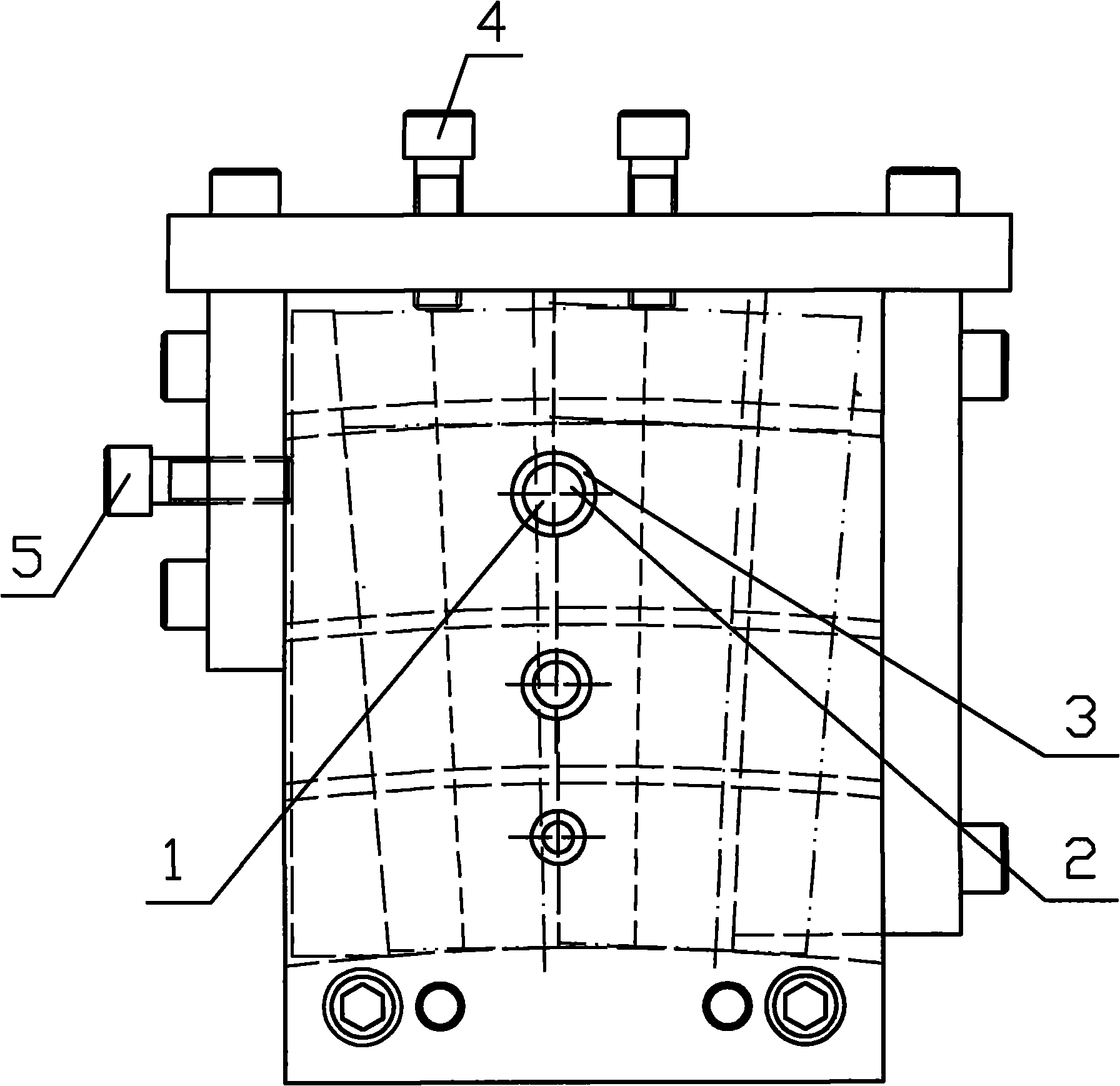

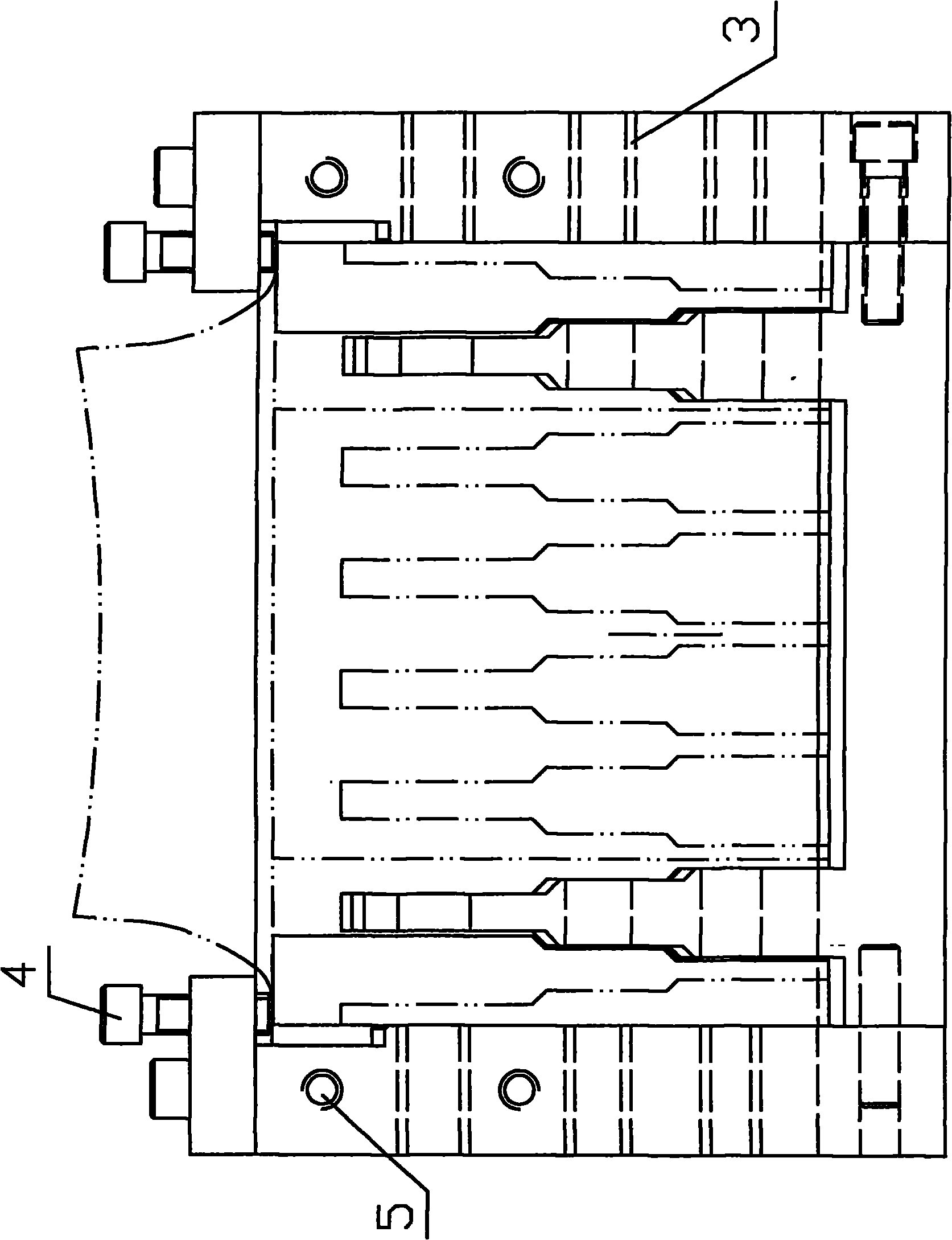

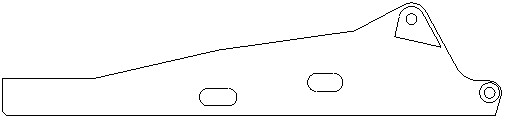

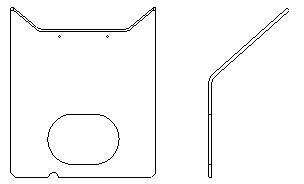

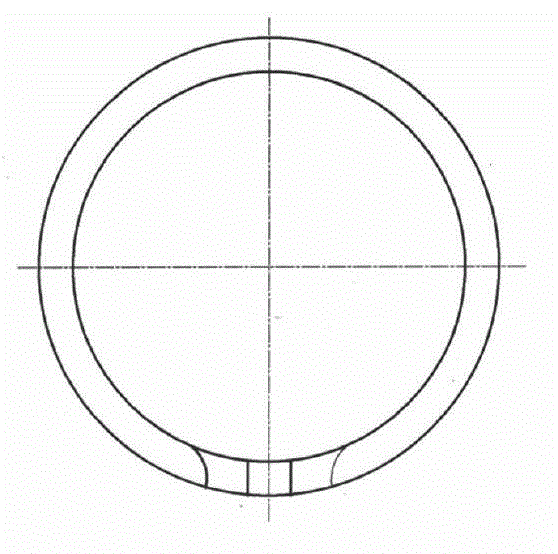

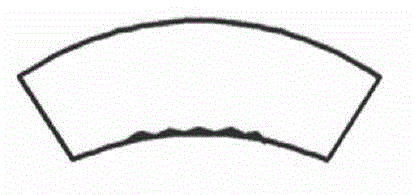

Manufacturing method of locking ring and used fixtures

InactiveCN102941297AGuaranteed flatness requirementsGuaranteed Assembly RequirementsWire ringsConductor CoilScrew thread

The invention relates to a manufacturing method of a locking ring and used fixtures, which belong to the technical field of aircraft engines. By using the manufacturing method and the used fixtures, the technical problems of easiness in deformation and difficulty in tight winding and forming due to the fact that a flat wire is used for winding the locking ring are successfully solved. The manufacturing method has the technical scheme that the manufacturing method of the locking ring comprises the following steps of preparation of raw materials, preparation of winding, winding of the flat wire, forming of the locking ring and heat treatment for forming. An auxiliary winding fixture special for the locking ring comprises a base, wherein a shell is arranged on the base, and an outer roller and an inner roller are arranged in the shell. A rectangular thread slot winding fixture special for the locking ring comprises a core rod, wherein a core rod step is arranged on the core rod, a step rectangular slot is formed in the core rod step, a bolt is arranged on one side of the step rectangular slot, and a washer is arranged between the bolt and the core rod step. A forming fixture special for the locking ring comprises a forming base, wherein an inner step is arranged inside the forming base, and a pressure plate is arranged above the forming base.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A battery pack installation structure and vehicle

ActiveCN112959879BReduce extra spaceReduce weightElectric propulsion mountingCell component detailsElectrical batteryMechanical engineering

The invention discloses a battery pack installation structure and a vehicle, comprising a plurality of installation brackets fixed on a longitudinal beam of a vehicle body at intervals, the installation bracket includes a longitudinal installation plate and a transverse installation plate, and the longitudinal installation plate is provided with a plurality of The first mounting hole connected to the longitudinal beam of the vehicle body, the lateral mounting plate is provided with a mounting seat, the mounting seat includes a bottom plate, a top plate and a side plate connecting the bottom plate and the top plate, and the top plate is provided with an accommodating bush passing through The bottom end of the bushing extends horizontally outward to form a limit plate, the limit plate is located between the top plate and the bottom plate, and the bushing is provided with a second mounting bolt corresponding to the battery pack mounting bolt A second via hole and a third via hole coaxial with the second mounting hole are respectively provided on the bottom plate and the lateral mounting plate. The structure is simple and the tolerance is good, and the risk of wrong holes in the overall installation of the battery pack can be avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

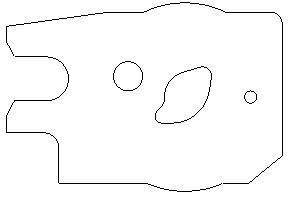

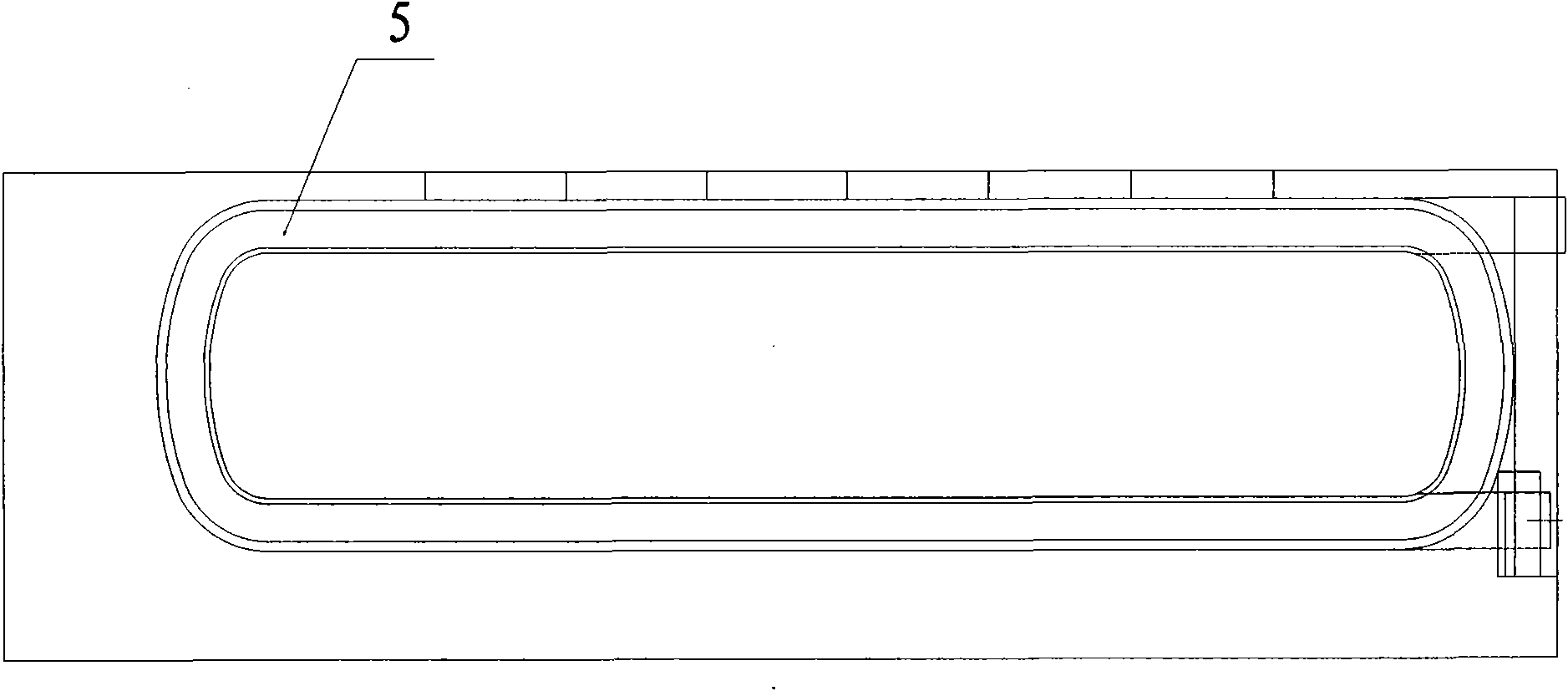

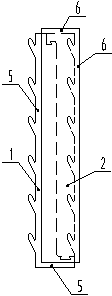

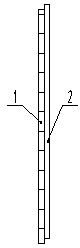

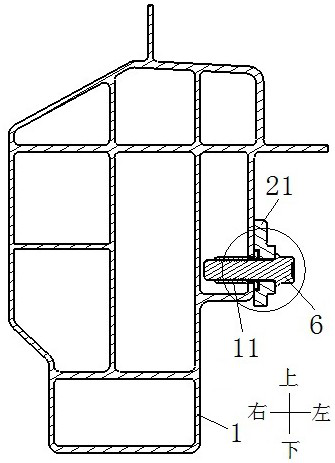

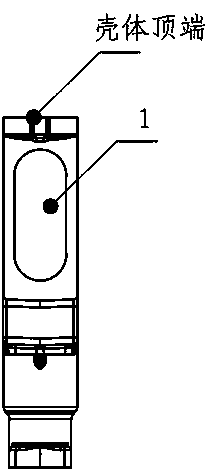

12 kV solid insulation single-phase and single-cavity sealed type shell

InactiveCN104466708AGuaranteed Assembly RequirementsSave man hoursSubstation/switching arrangement casingsArrangements with resin casingEngineeringSilica gel

The invention discloses a 12 kV solid insulation single-phase and single-cavity sealed type shell. The 12 kV solid insulation single-phase and single-cavity sealed type shell comprises a shell body made of solid epoxy resin, wherein a cavity 5 is formed in the shell body, an opening communicated with the cavity 5 is formed in the top of the shell body, an elliptic hole 1 is formed in the upper portion of the outer wall of the front face of the shell body, and a cylinder cavity 2 is formed in the lower portion of the rear face of the shell body. The 12 kV solid insulation single-phase and single-cavity sealed type shell is characterized in that a silica gel layer 3 is arranged between the cylinder cavity 2 and the shell body, an electric conductor 8 is embedded in the bottom of the cavity 5, the electric conductor 8 and the cylinder cavity 2 are isolated through the silica gel layer 3, a hole 7 is formed in the bottom of the cavity 5, and the electric conductor 8 is arranged between the cylinder cavity 2 and the hole 7.

Owner:ZHUHAI KELI ELECTRIC

A precision machining method and detection device for a flame stabilizer

ActiveCN110732850BPassabilitySimple structureMechanical counters/curvatures measurementsEngineeringMachining

A precision machining method and a detection device for a flame stabilizer, including processes such as argon arc welding and high-temperature coating spraying, and after each step of heat treatment process, the shaping and correction of the parts are carried out, and finally the annular channel is carried out by the detection device. Detection, the invention fundamentally solves the influence of the spraying high temperature coating process on the size of the precision ear seat hole, and the precision castings are machined after the high temperature thermal process such as the high temperature coating to remove the allowance, which improves the delivery of the precision ear seat hole size of the parts. The pass rate of the annular channel can be effectively detected, the channel interference points can be removed in time during the product processing process, the product technical requirements and assembly requirements are guaranteed, the product quality is stable, and the consistency is good. It is popularized and used in various parts that need to be processed by annular channel parts.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

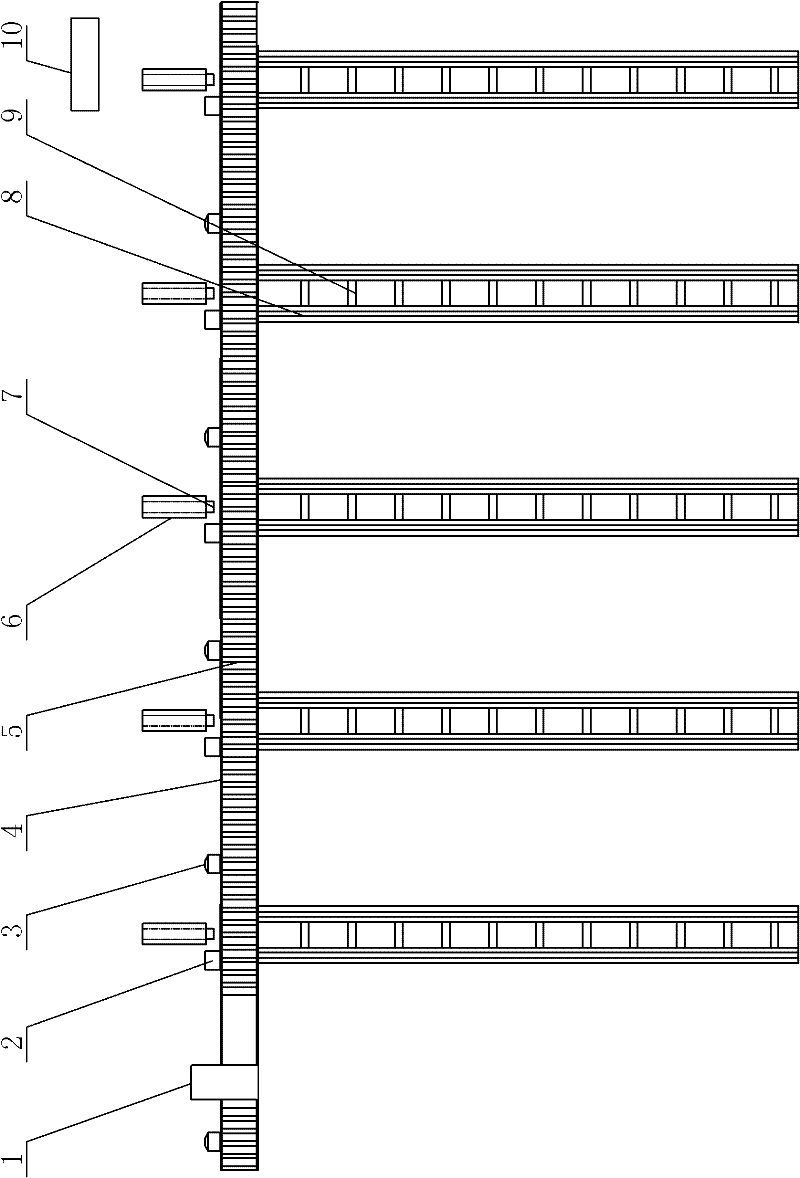

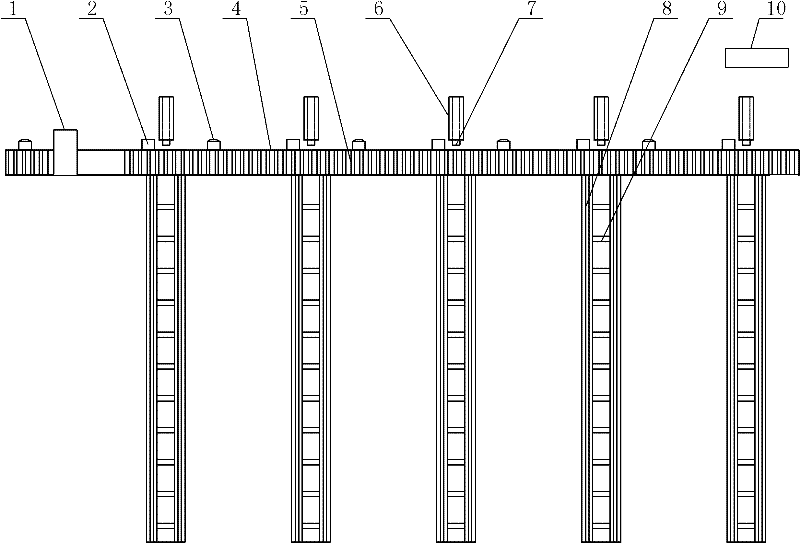

Production line for hydraulically assembling valve guide rod of cylinder cover

ActiveCN101913071BStable punching forceReduce labor intensityMetal working apparatusProduction lineAssembly line

Owner:ZICHAI POWER CO LTD

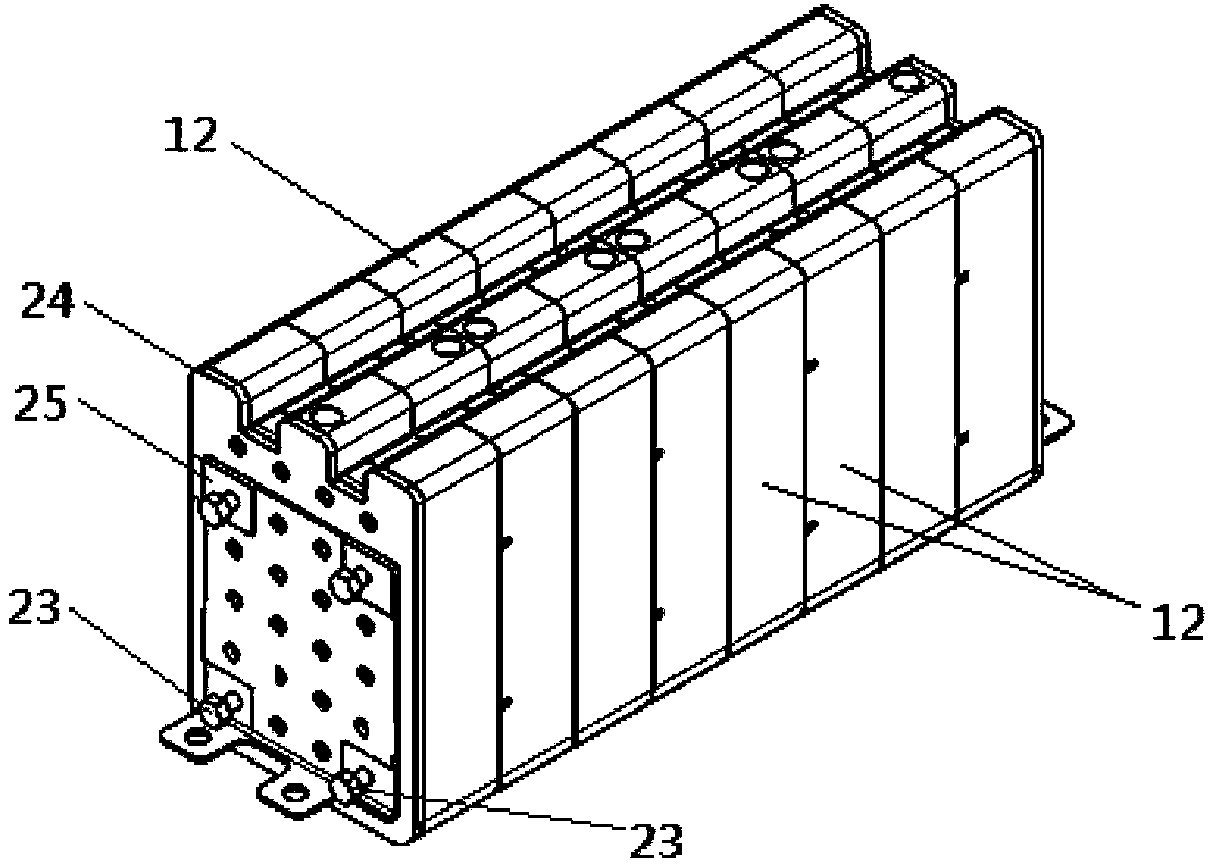

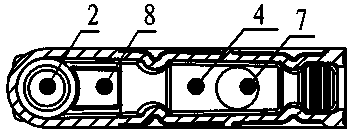

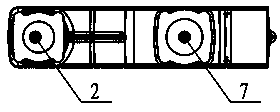

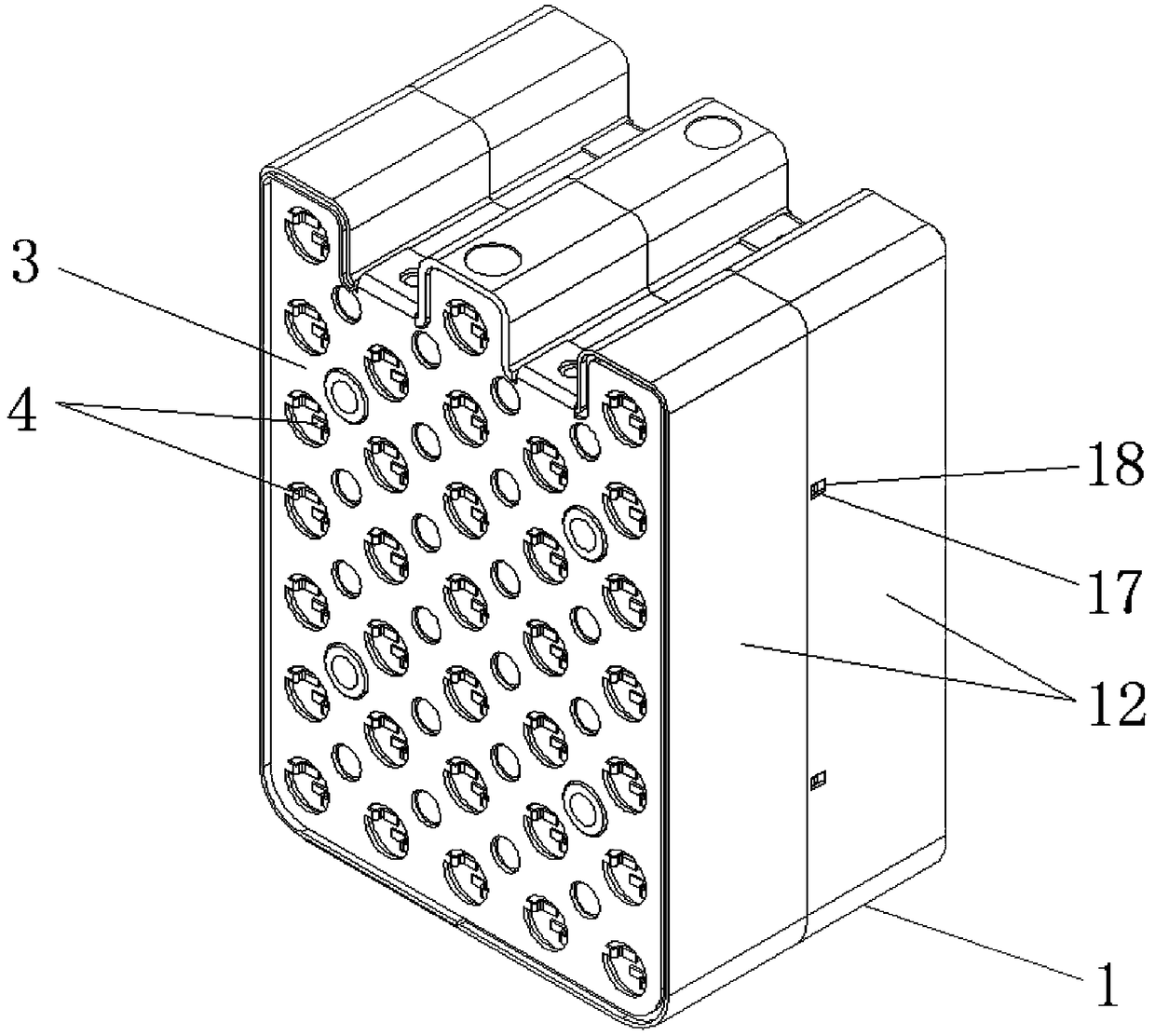

21700 cell parallel battery module

PendingCN108832047AGood cooling functionImprove use reliabilityCurrent conducting connectionsSecondary cellsHigh intensityEngineering

The invention relates to the technical field of cell parallel battery modules, in particular to a 21700 cell parallel battery module. The battery module comprises a module housing and a plurality of 21700 single cells. A confluence plate is installed on the outer walls of two sides of the module housing, a plurality of insertion slots are arranged on the inner walls of two sides of the module housing, through holes for electrode piercing are mounted on the two side walls of the module housing, the through holes of the electrode piercing correspond to the positions of the insertion slots one byone, and a plurality of confluence pieces on each confluence plate are connected with the electrodes at both ends of the 21700 single cells one by one, respectively. According to the 21700 cell parallel battery module disclosed by the invention, the 21700 single cells is fixed in the module housing in an inserting and clamping manner by installing the plurality of insertion slots for installing the 21700 single cells in the module housing, and the 21700 cell parallel battery module can meet the high-strength structure required for the parallel battery module composed of the 21700 single cellswith large capacity, and has a simple structure and is low in manufacturing cost.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

Processing technology of steam turbine seven-fork blade root pin holes and special fixture

ActiveCN101837482BGuaranteed accuracyGuaranteed roughnessDrilling/boring measurement devicesBlade accessoriesPilot holeEngineering

The invention relates to a processing technology of steam turbine seven-fork blade root pin holes and a special fixture. A blade root is provided with seven forks for installation, wherein the two forks in the middle side of the seven forks are staggered with the five forks in the inner part; the five forks in the inner part are successively provided with three pin holes along the radial line direction of a steam turbine; the two forks on the outer side are successively provided with three first semicircle pin holes on the same axis with the above three pin holes and are provided with other three second semicircle pin holes on the same axis with the pin holes on the inner five forks on the adjacent blade; the first semicircle pin holes and the second semicircle pin holes on the two forks on the outer side of adjacent two seven-fork blades are spliced into a full circle pin hole; and multiple blades are radially arranged on the circumstance of the steam turbine. The fixture is provided with a cavity capable of containing the roots of the seven forks of the two adjacent blades and is provided with a device which makes two blade roots to be jointly installed on the steam turbine position relation status and makes the two blade roots to be fixed on the fixture; and the fixture is provided with a drilling guide hole correspondingly on the axis of the full circle pin hole spliced by the first semicircle pin holes and the second semicircle pin holes on the two blade roots.

Owner:常州市三维技术成套设备有限公司

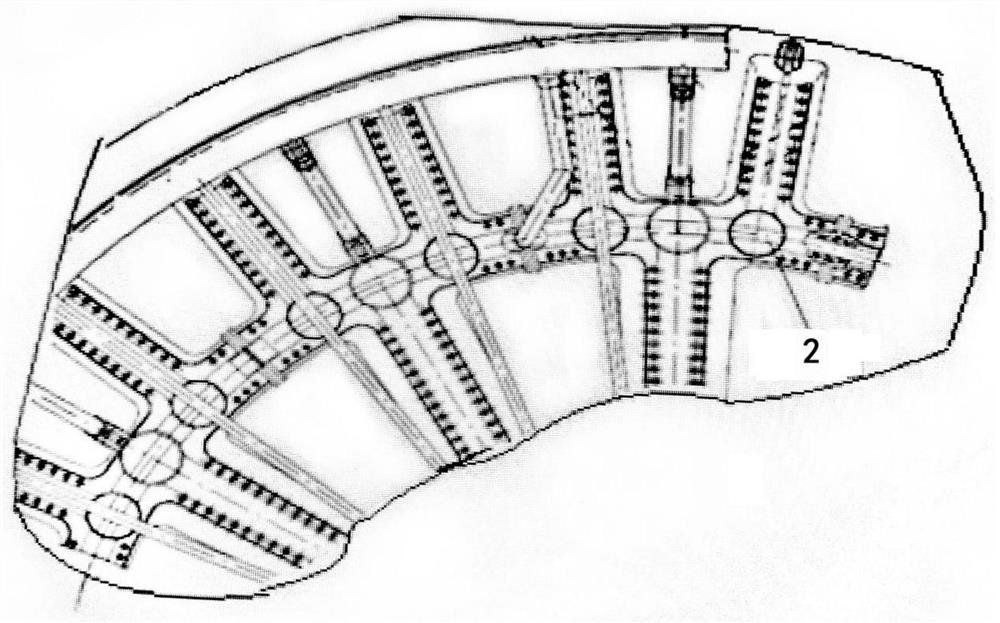

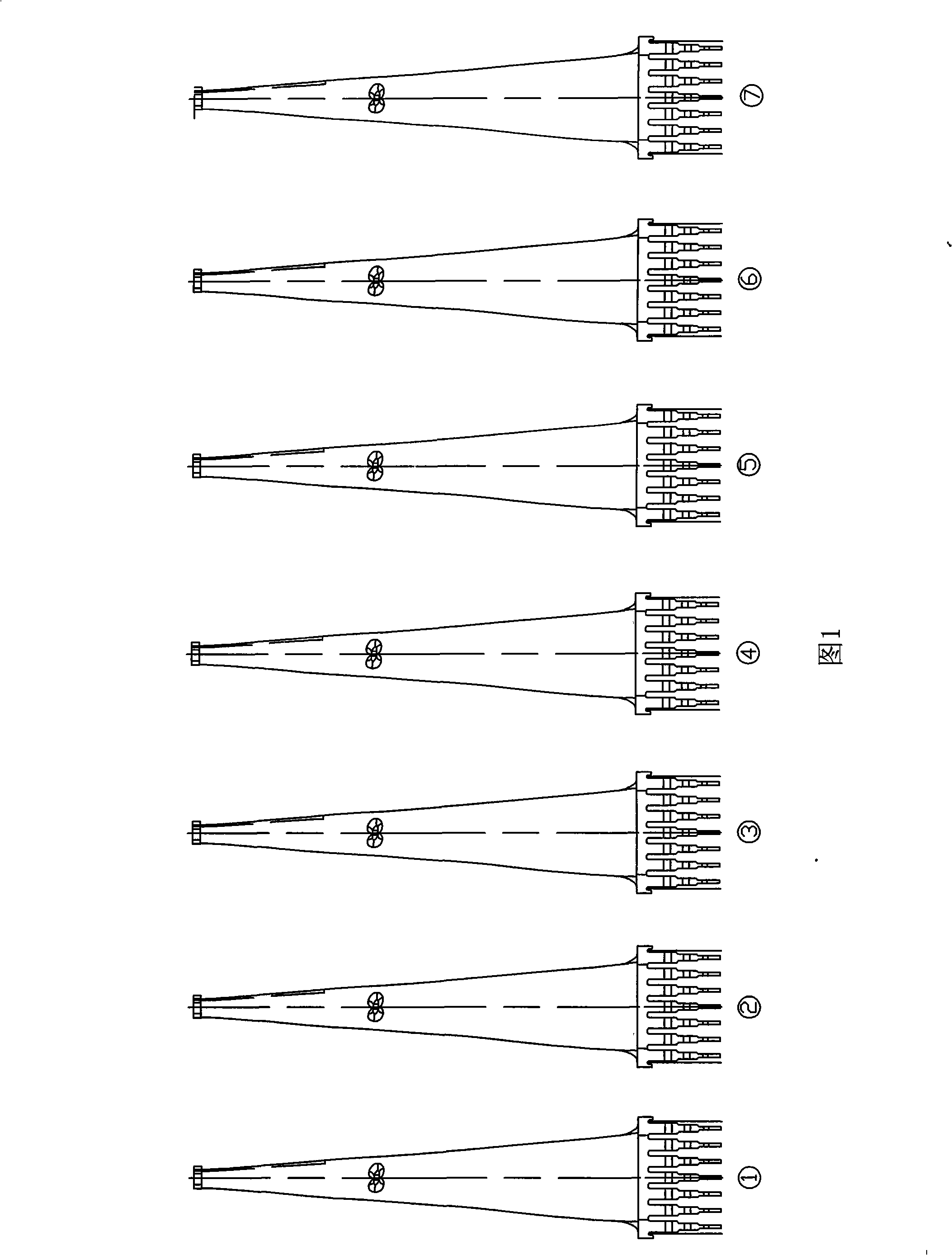

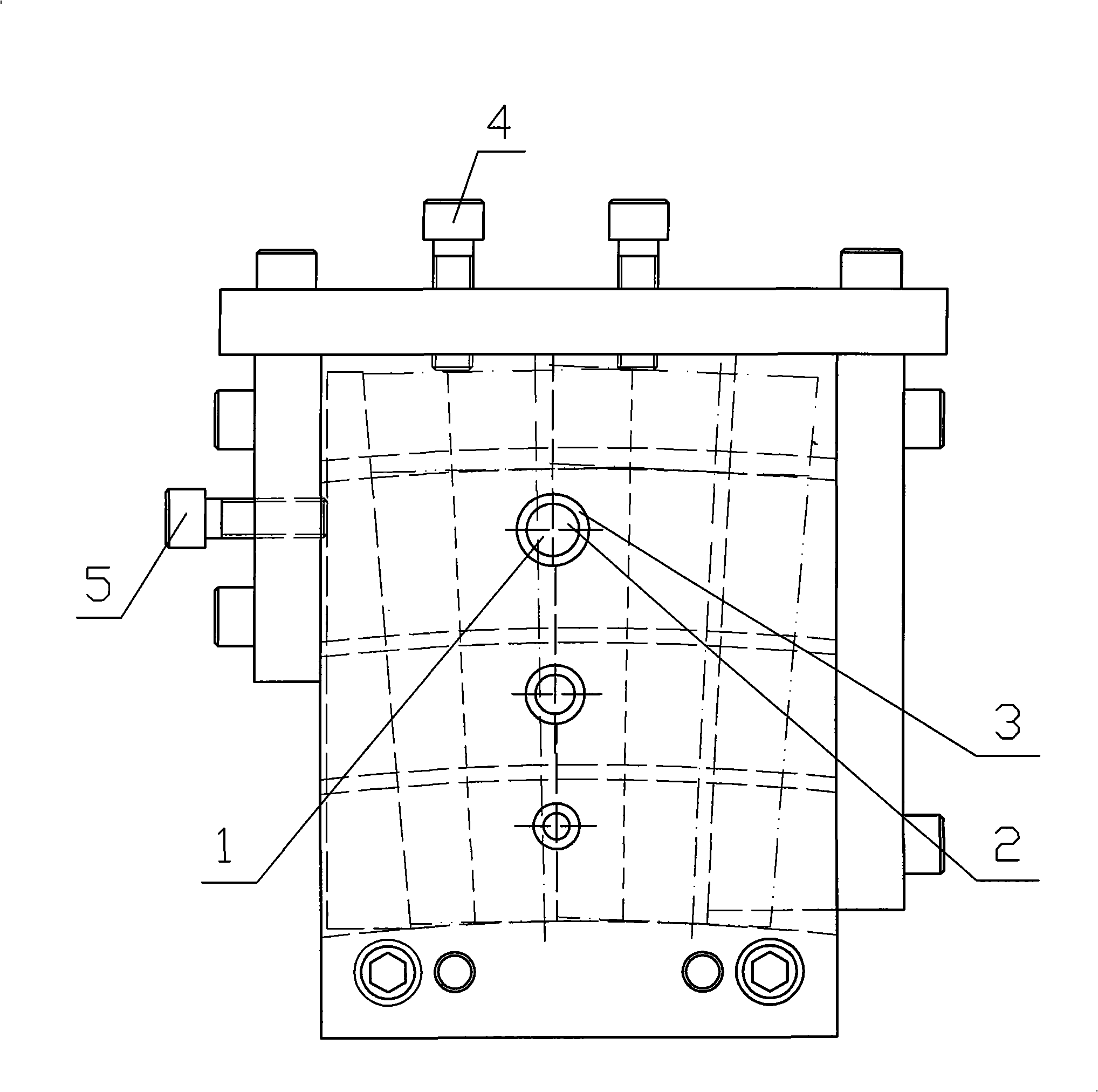

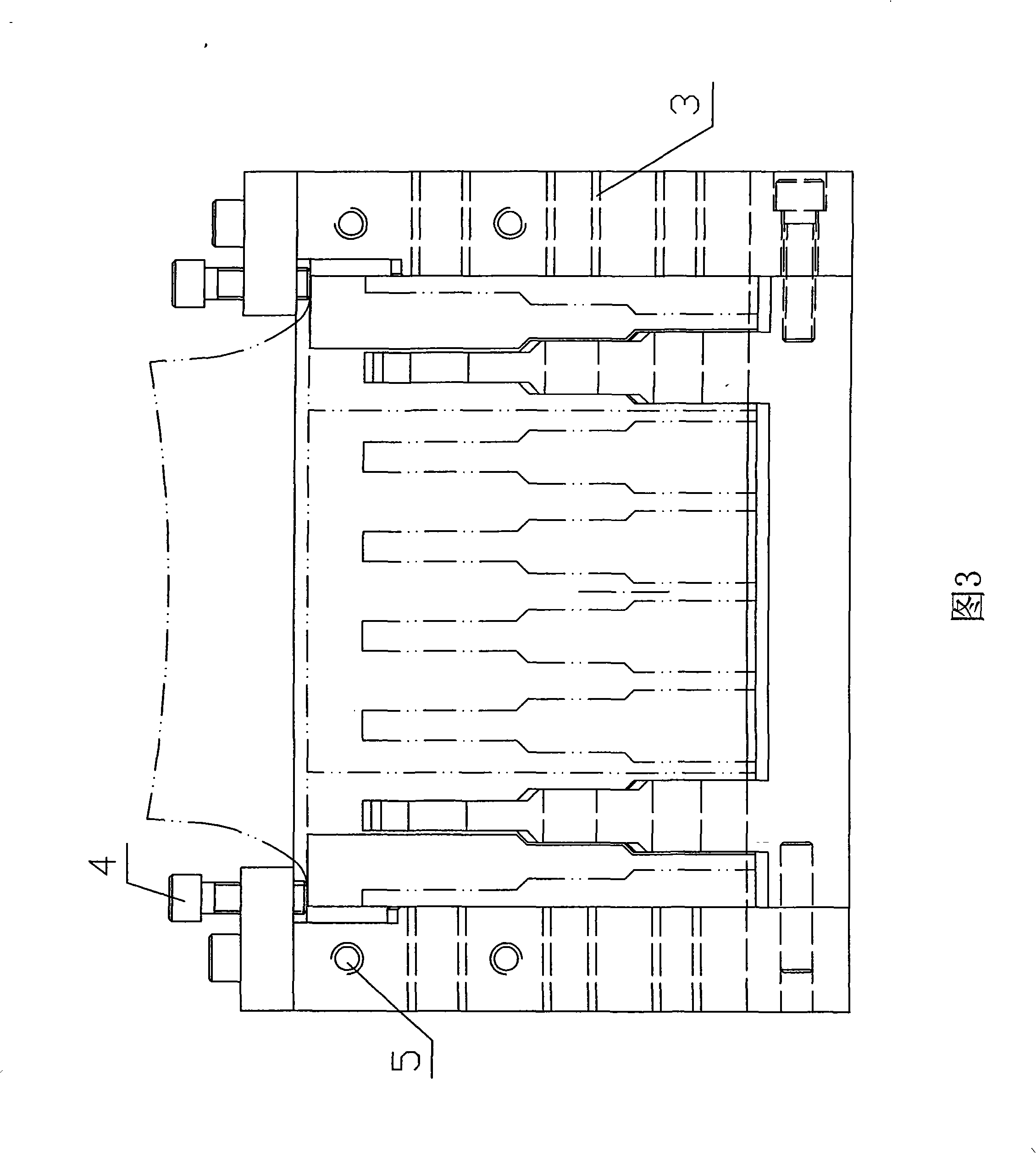

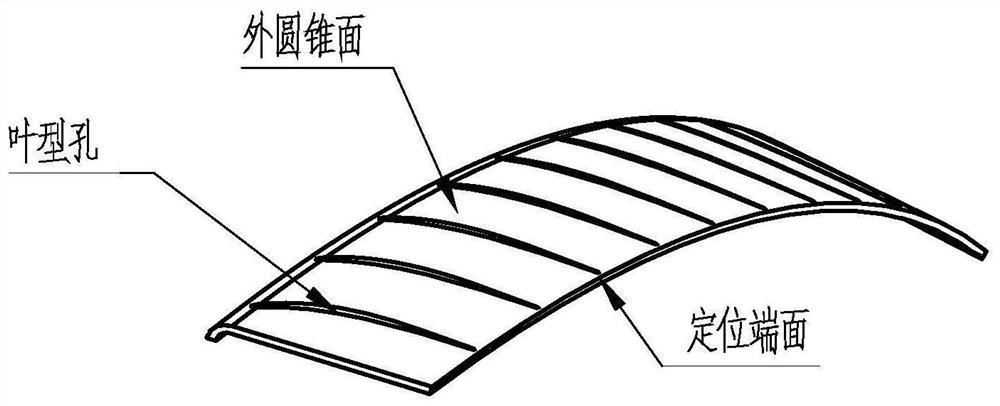

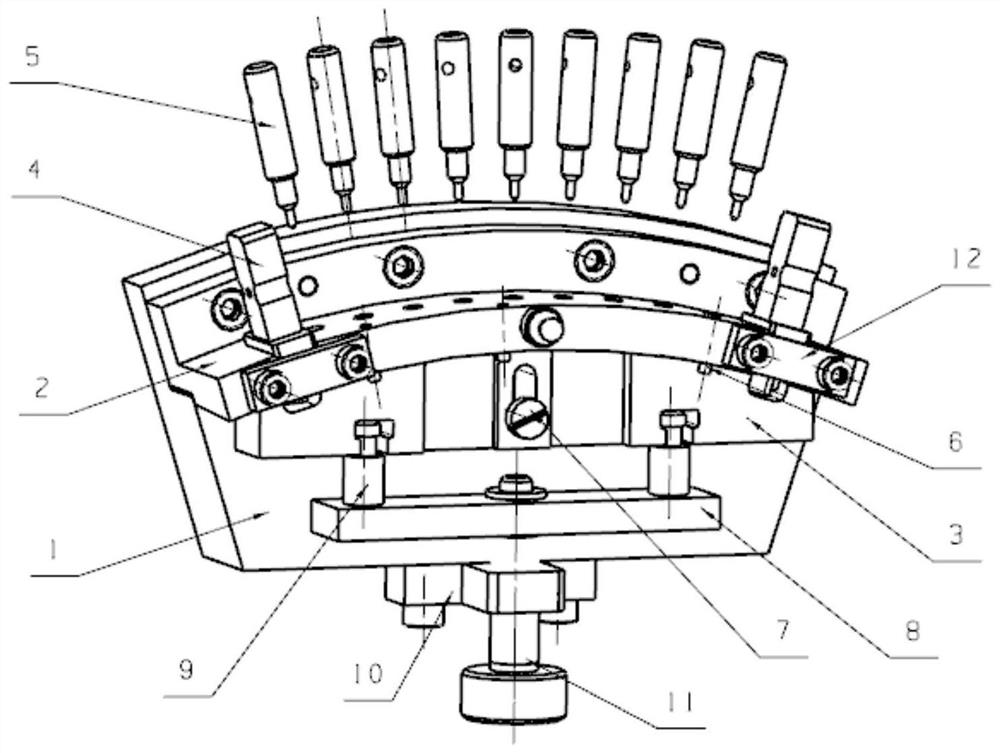

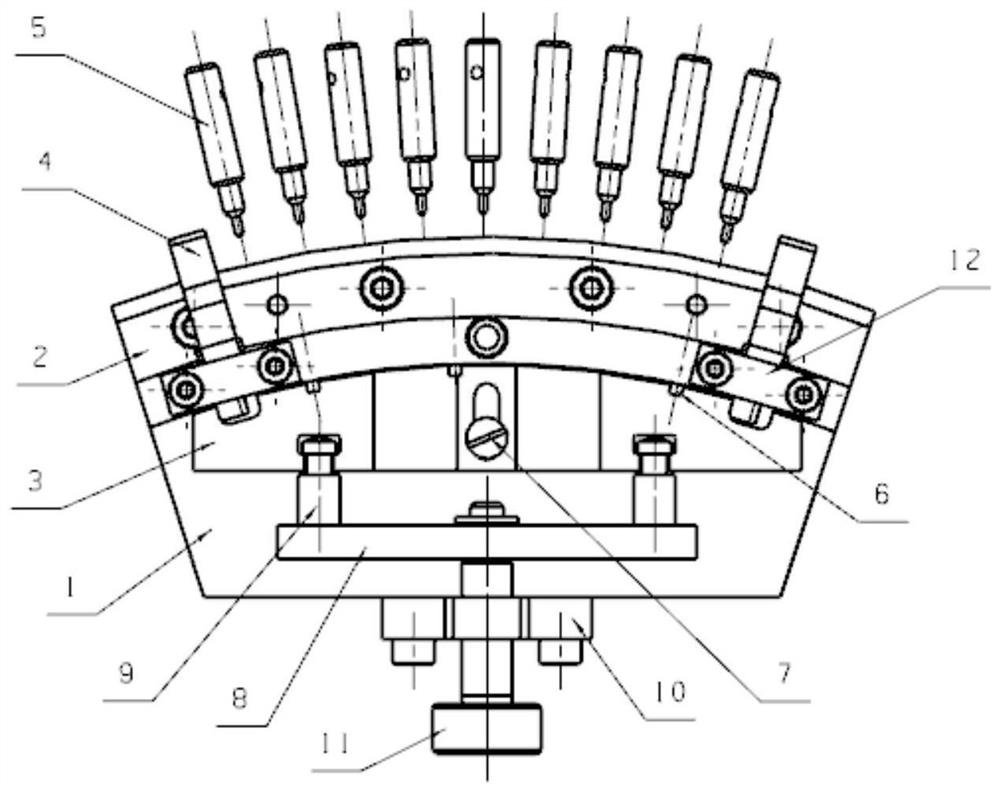

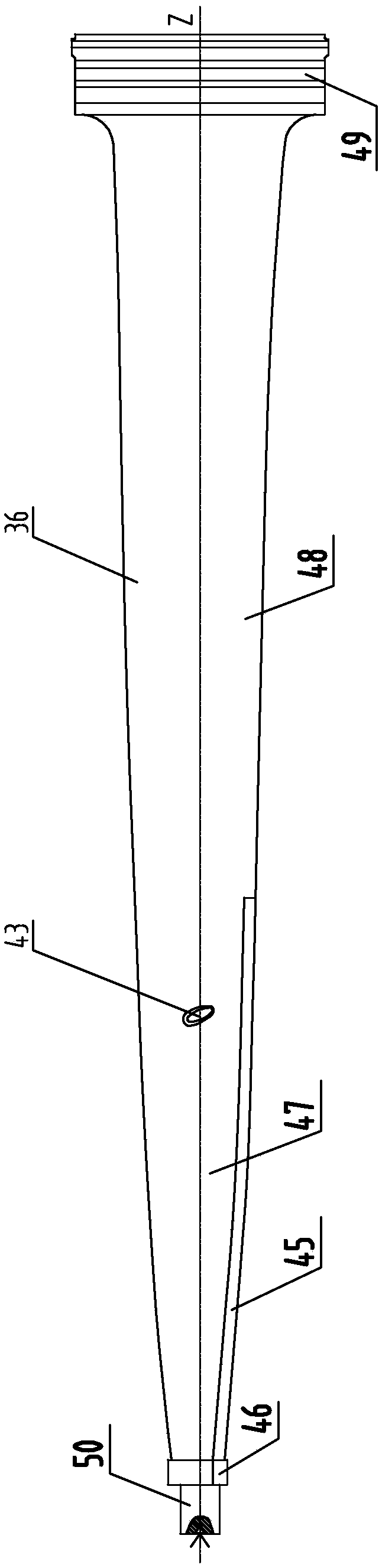

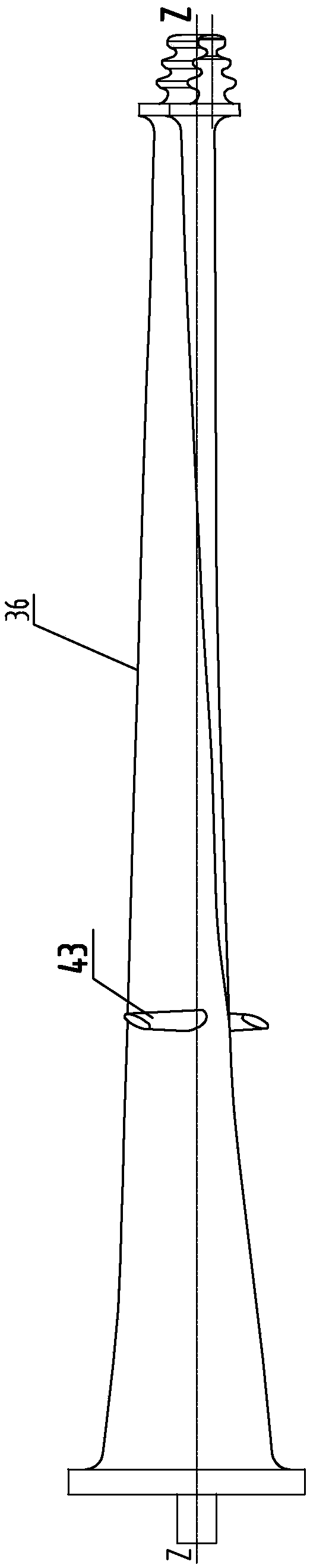

Device and method for detecting uniform distribution positions of blade-shaped holes in thin-wall fan-shaped section

PendingCN113899279AImprove detection efficiencyNovel structureMechanical measuring arrangementsEngineeringThin walled

The invention discloses a device and method for detecting the uniform distribution positions of blade-shaped holes in a thin-wall fan-shaped section. The inner conical surface of an arc-shaped positioning block can be attached to the outer conical surface of a to-be-detected part, and the positions, close to the two ends, of the arc-shaped positioning block are provided with through grooves which are consistent with the theoretical uniform distribution positions of blade-shaped holes in the two ends of a to-be-measured part, a measuring block is arranged in each through groove in a sliding manner, the measuring end of each measuring block is the same as the theoretical shape of the blade-shaped holes of the to-be-measured part, and the size of the measuring end is equal to the result of the difference of the minimum entity of the blade-shaped holes and the uniform distribution position degree; guide holes consistent with the theoretical uniform distribution positions of the remaining blade-shaped holes of the to-be-measured part are formed in the arc-shaped positioning block and located between the two through grooves, a measuring pin is arranged in each guide hole in a sliding mode, and the diameter of the measuring end of each measuring pin is obtained by subtracting the uniform distribution position degree from the diameter of thesmallest blade-shaped hole inscribed circle in the corresponding position; and a movable pressing block is slidably arranged on the upper end face of a base. According to the device and method of the invention, the measurement of the uniform distribution positions of the blade-shaped holes of the thin-wall fan-shaped section can be rapidly and accurately realized.

Owner:AECC AVIATION POWER CO LTD

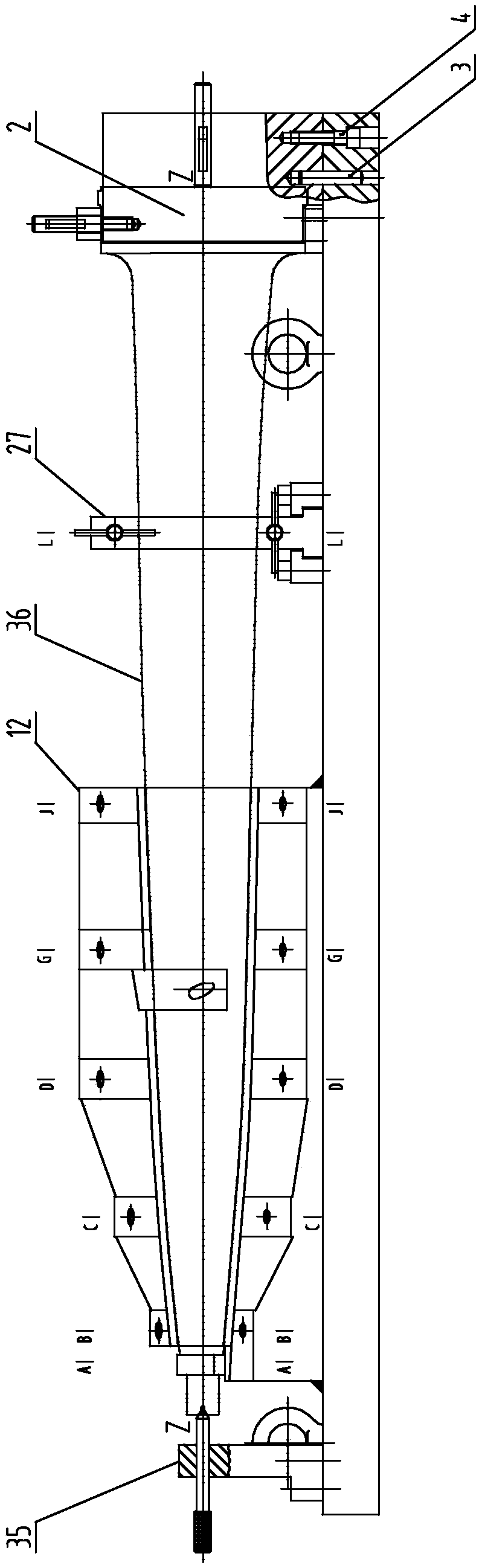

A tool for heat treatment and shaping of large blades

ActiveCN107674959BNo deformationSmall overall deformationFurnace typesHeat treatment furnacesEngineeringAlloy

The invention discloses a shaping tool for large blade heat treatment. Large blades of a steam turbine can generate deformation and internal stress in machining of air way molded lines and welding ofStellite alloy sheets, so that the quality requirements of the blades are difficult to meet, no working allowance caused by appearance of steam ways in the blades in finishing is generated, the rebound caused by internal stress in the blades in blade assembly is generated, and the blade crown assembly requirements cannot be met in blade assembly. Blade crown parts of the large blades are ejected against blade crown thimble bases; molded line segments of the large blades are matched with molded line positioning bases; air way molded line segments of the large blades are arranged on L-gear molded line positioning blocks; blade root parts of the large blades are clamped on blade root positioning bases; and molded line positioning end surfaces matched with tiepiece molded line segments of thelarge blades are formed among A# molded line pressing end surfaces, B# molded line pressing end surfaces, C# molded line pressing end surfaces, D# molded line pressing end surfaces, G# molded line pressing end surfaces, J# molded line pressing end surfaces and split positioning end surfaces. The shaping tool for large blade heat treatment is used for positioning the large blades.

Owner:HARBIN TURBINE +1

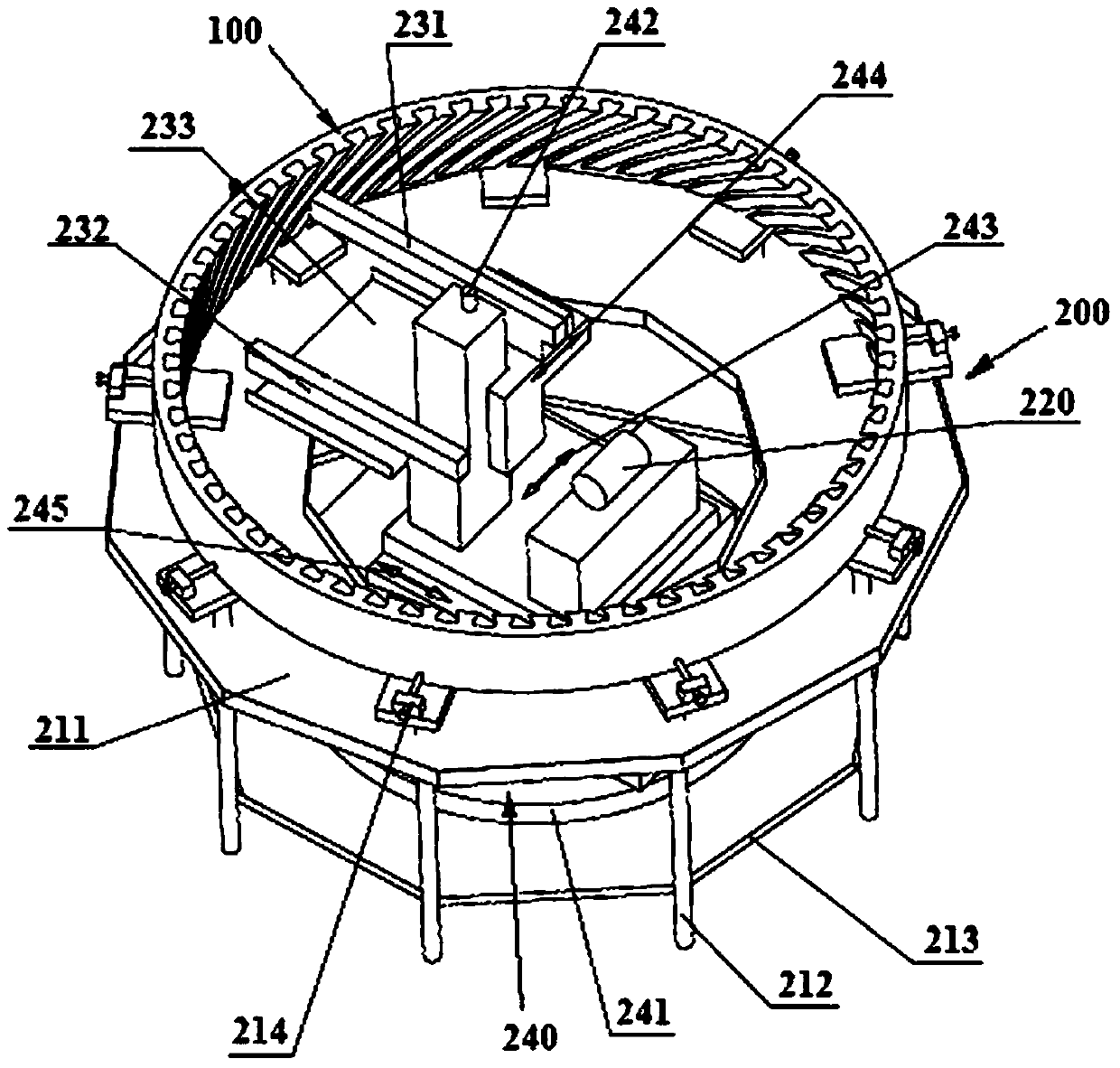

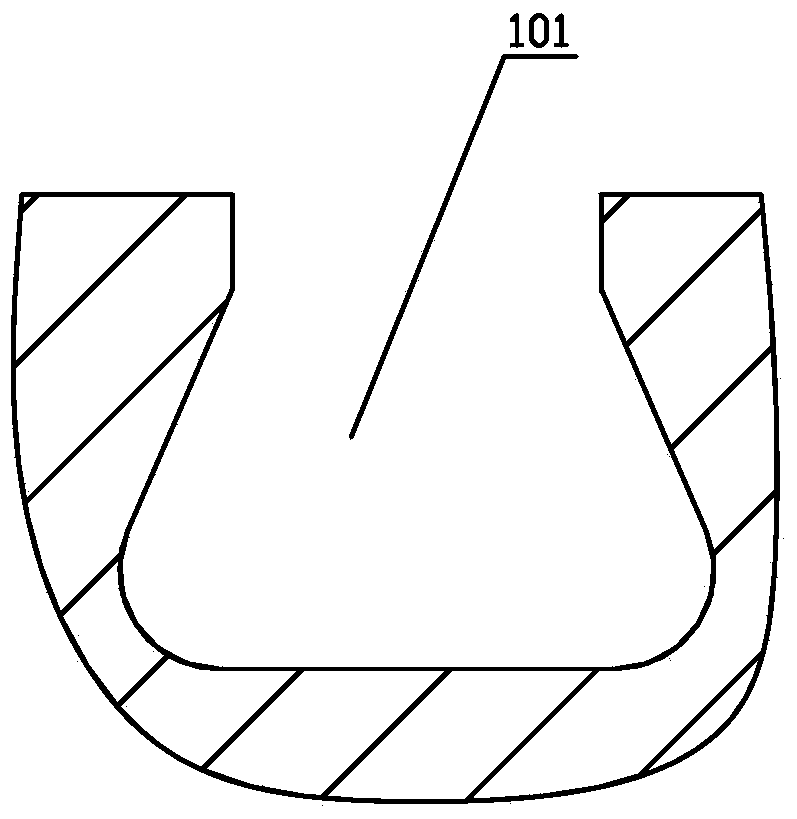

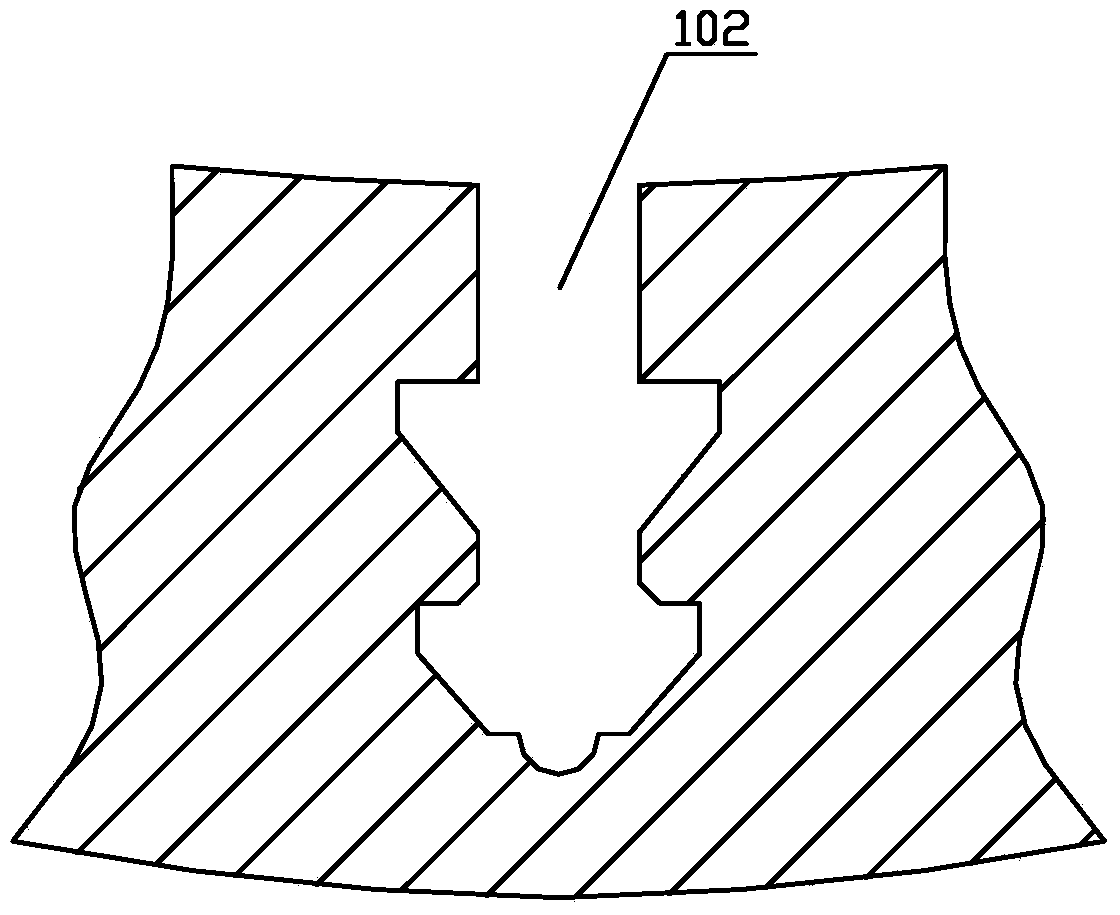

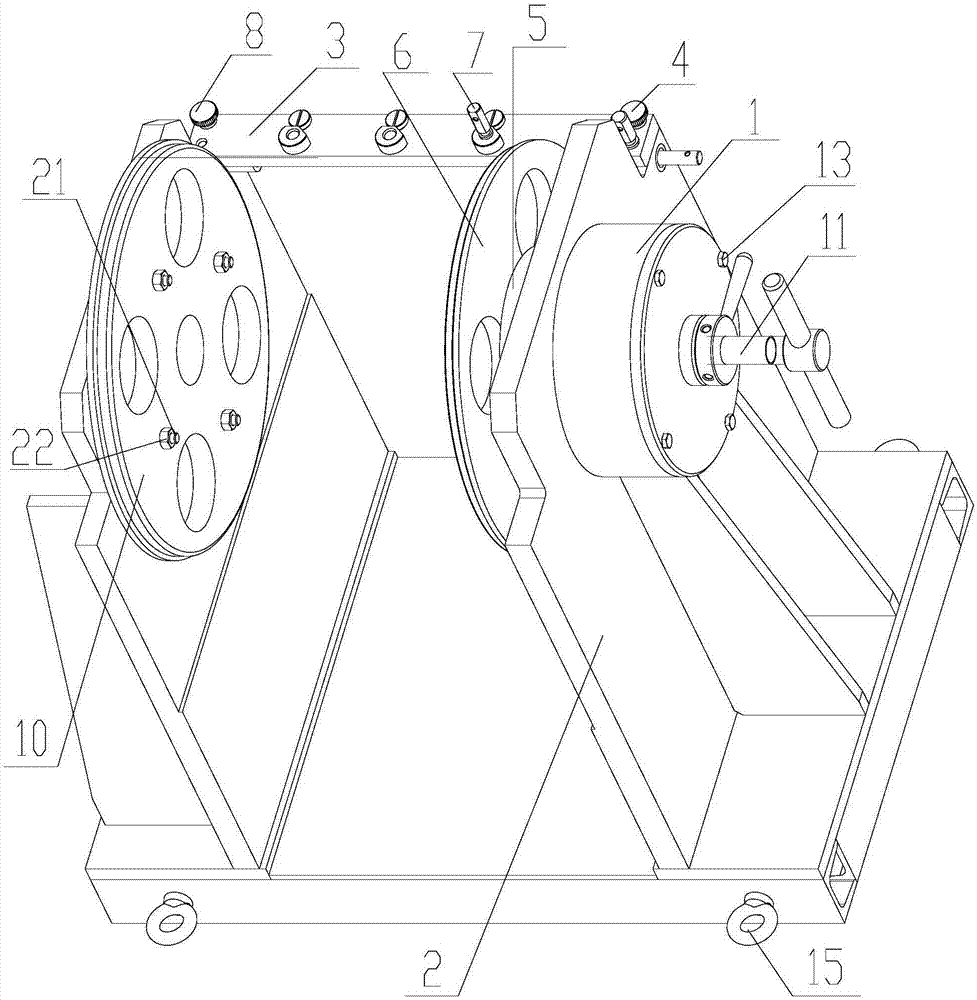

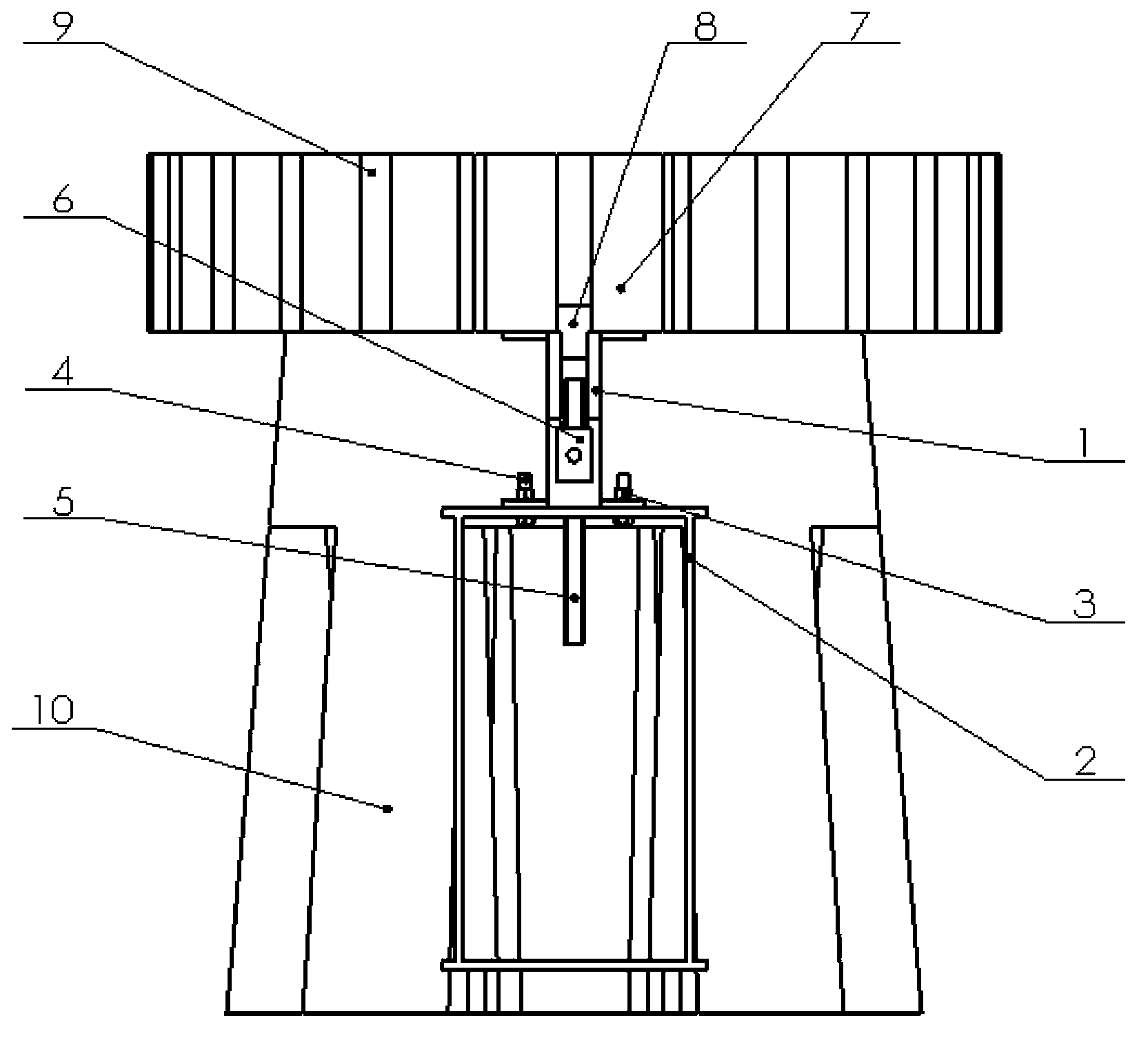

Permanent magnet assembly fixture for large permanent magnet direct-driven wind generator and assembly method of permanent magnet assembly fixture

ActiveCN102756345BGuaranteed smooth assemblySimple conditions of useWork holdersMetal working apparatusPole pieceDynamo

The invention relates to a permanent magnet assembly fixture for a large permanent magnet direct-driven wind generator and an assembly method of the permanent magnet assembly fixture, wherein the fixture comprises a bracket, a permanent magnet guide groove and a conducting rod; the permanent magnet guide groove is L-shaped, and is fixedly arranged above the bracket; the conducting rod is slidably arranged inside the bracket up and down; and conducting holes corresponding to the top end of the conducting rod are formed on the bracket and the permanent magnet guide groove. The method comprises the following steps of: placing the rotor of the generator on a mounting platform so that the assembly port of a permanent magnet faces downwards; arranging the fixture below the rotor of the generator, wherein the outlet of the vertical section of the permanent magnet guide groove is opposite to the assembly port of the permanent magnet; feeding in the permanent magnet from the inlet of the horizontal section of the permanent magnet guide groove, and pushing till reaching the bottom of the vertical section of the permanent magnet guide groove; pushing the conducting rod to slide upwards, and pushing the permanent magnet to enter the middle of pole terminals along the vertical section of the permanent magnet guide groove; and taking out the conducting rod. The permanent magnet assembly fixture for a large permanent magnet direct-driven wind generator and the assembly method of the permanent magnet assembly fixture can realize the direct assembly of the permanent magnet between two sets of pole terminals, and the operation is convenient, safe and reliable.

Owner:GUODIAN UNITED POWER TECH

A device and method for controlling heat treatment deformation of non-machined surface of welding part installation side

ActiveCN109439881BSimple structureEasy to useFurnace typesHeat treatment furnacesMachined surfaceMechanical engineering

The invention discloses a welding part mounting side unfinished surface heat treatment deforming control device and method. The control device comprises a bottom plate (1) and a positioning ring (3);a stop opening is formed in one end face of the bottom plate (1), the inner diameter of the stop opening is equal to the outer diameter of a mounting side on the end, with the small diameter, of a welding part, and the positioning ring (3) comprises a pair of semi-circular-ring parts, a pair of parallel upper protrusions and lower protrusions are arranged on the inner ring faces of the semi-circular-ring parts, and connecting sides are arranged on outer ring faces of the semi-circular-ring parts. The device is simple in structure, convenient to use and capable of being repeatedly used, meanwhile, deforming of the groove width position mounting side and the unfinished surface in the part heat treatment process can be effectively controlled, the product technical needs and the assembling needs are ensured, the product yield is effectively ensured while the production efficiency is improved, the machining period of the part is shortened, the product quality is stable, and consistency is good.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

hydraulic cylinder

ActiveCN104514767BMeet strength requirementsMeet form factor constraintsFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a hydraulic cylinder, including a cylinder barrel (1), wherein one end of the cylinder barrel (1) is connected with a cylinder bottom (2) while the other end forms a cylinder rod extending end, a first sealing member (5) is arranged on the inner peripheral surface of the cylinder rod extending end, the cylinder barrel (1) and the cylinder bottom (2) are fixed with each other by a positioning member positioned in the cylinder barrel (1) and simultaneously stopping the cylinder barrel (1) and the cylinder bottom (2). The hydraulic cylinder can simultaneously meet the requirements on strength, assembly and dimensional limit.

Owner:HUNAN TELI HYDRAULIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com