A battery pack installation structure and vehicle

A technology for installing structures and battery packs, applied in structural parts, vehicle components, electric power devices, etc., can solve problems such as inability to maintain, and achieve the effects of easy replacement or maintenance, reduced space and weight, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

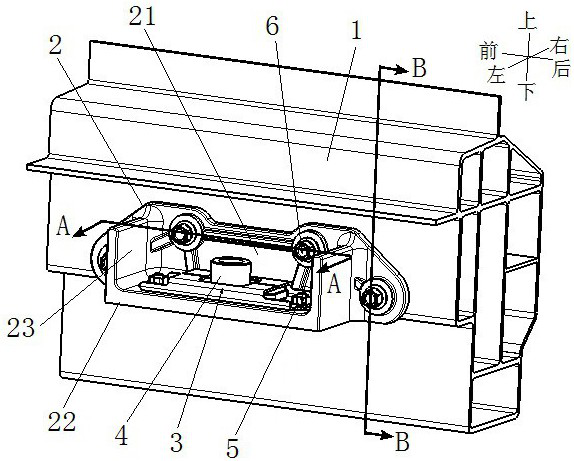

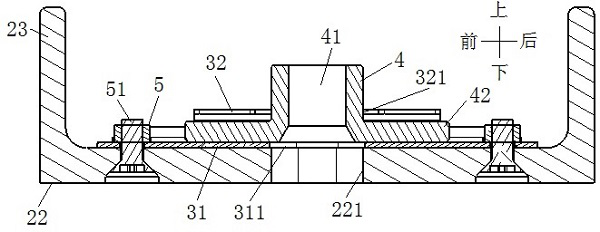

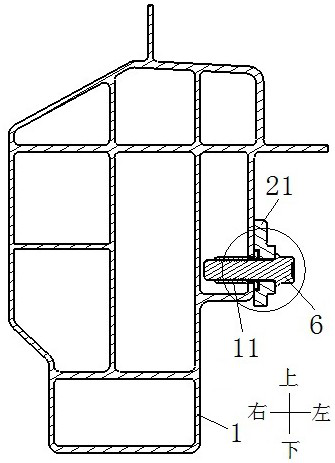

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

[0023] see Figure 1 to Figure 6 , The battery pack installation structure shown includes a plurality of aluminum mounting brackets 2 fixed on the aluminum body longitudinal beam 1 at intervals, and the battery pack is installed on the aluminum body longitudinal beam 1 through a plurality of spaced mounting brackets 2 , compared with the integral mounting structure, the arrangement of multiple mounting brackets 2 reduces the occupied space and weight of the mounting structure, and the assembly and fixation of different types of battery packs can be realized only by changing the number and arrangement spacing of the mounting brackets 2 , the generality is good.

[0024] The mounting bracket 2 includes a longitudinal mounting plate 21 and a lateral mounting plate 22. The longitudinal mounting plate 21 is provided with four first mounting holes 211 connected to the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com