Patents

Literature

64results about How to "Reduce occupied space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

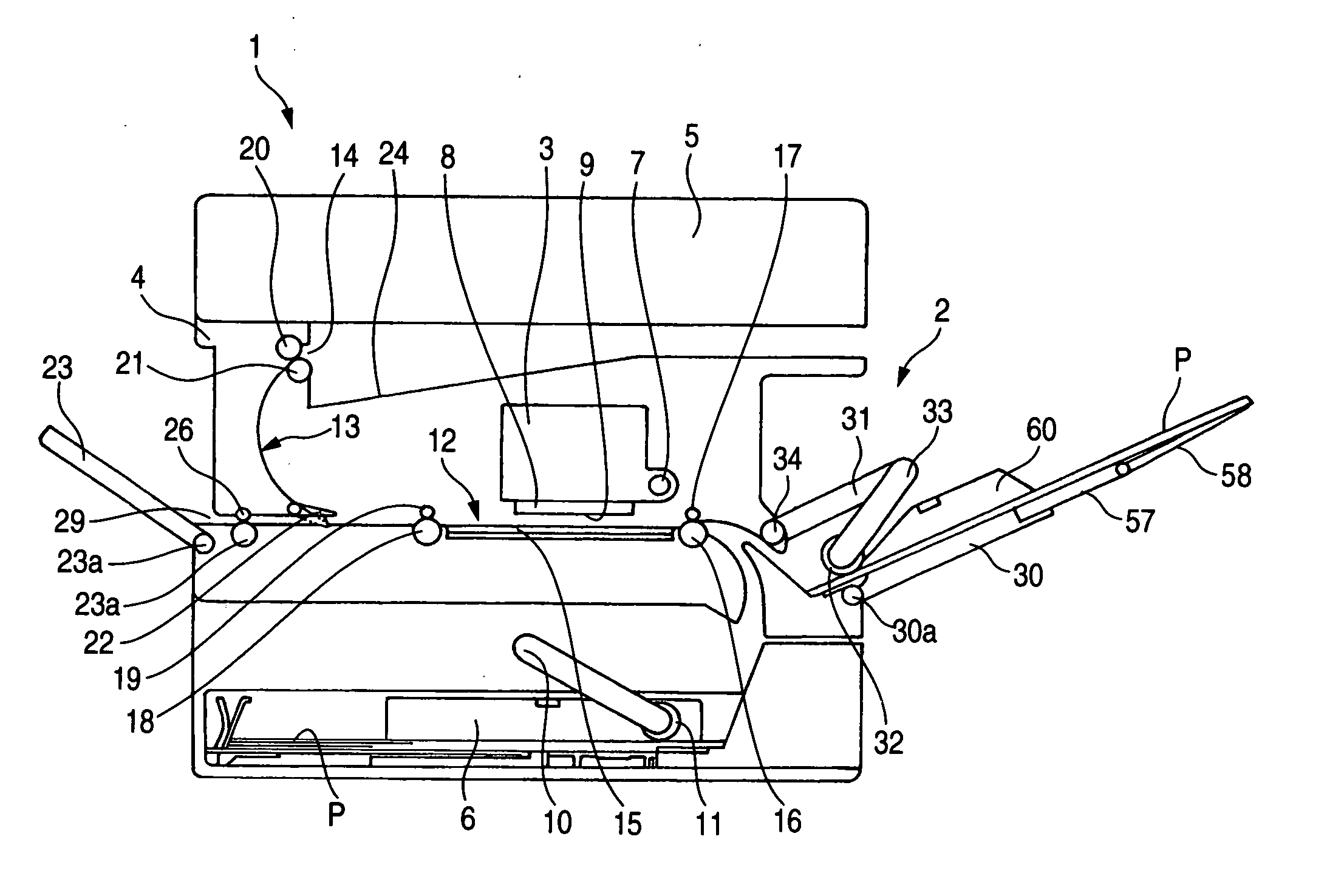

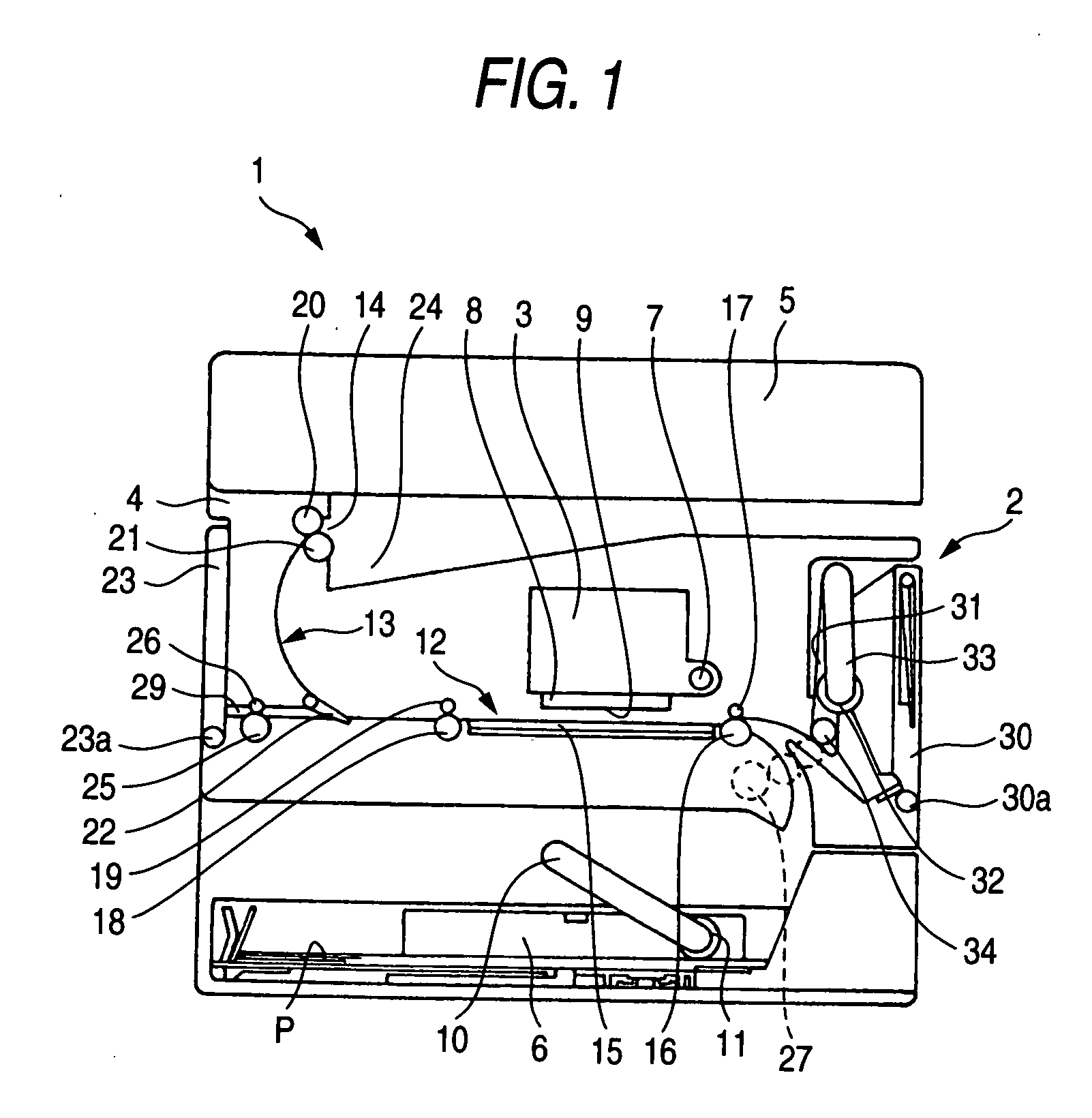

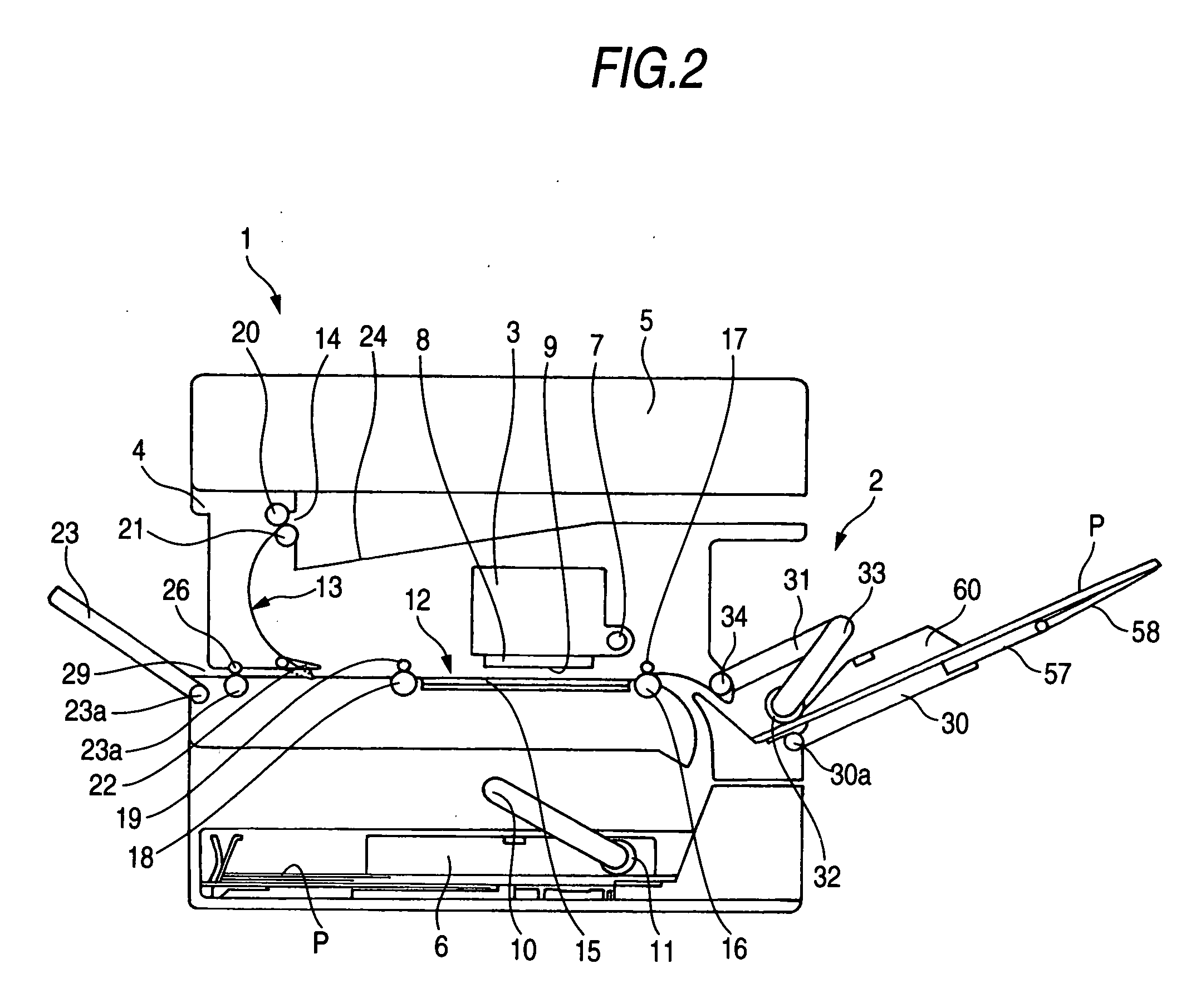

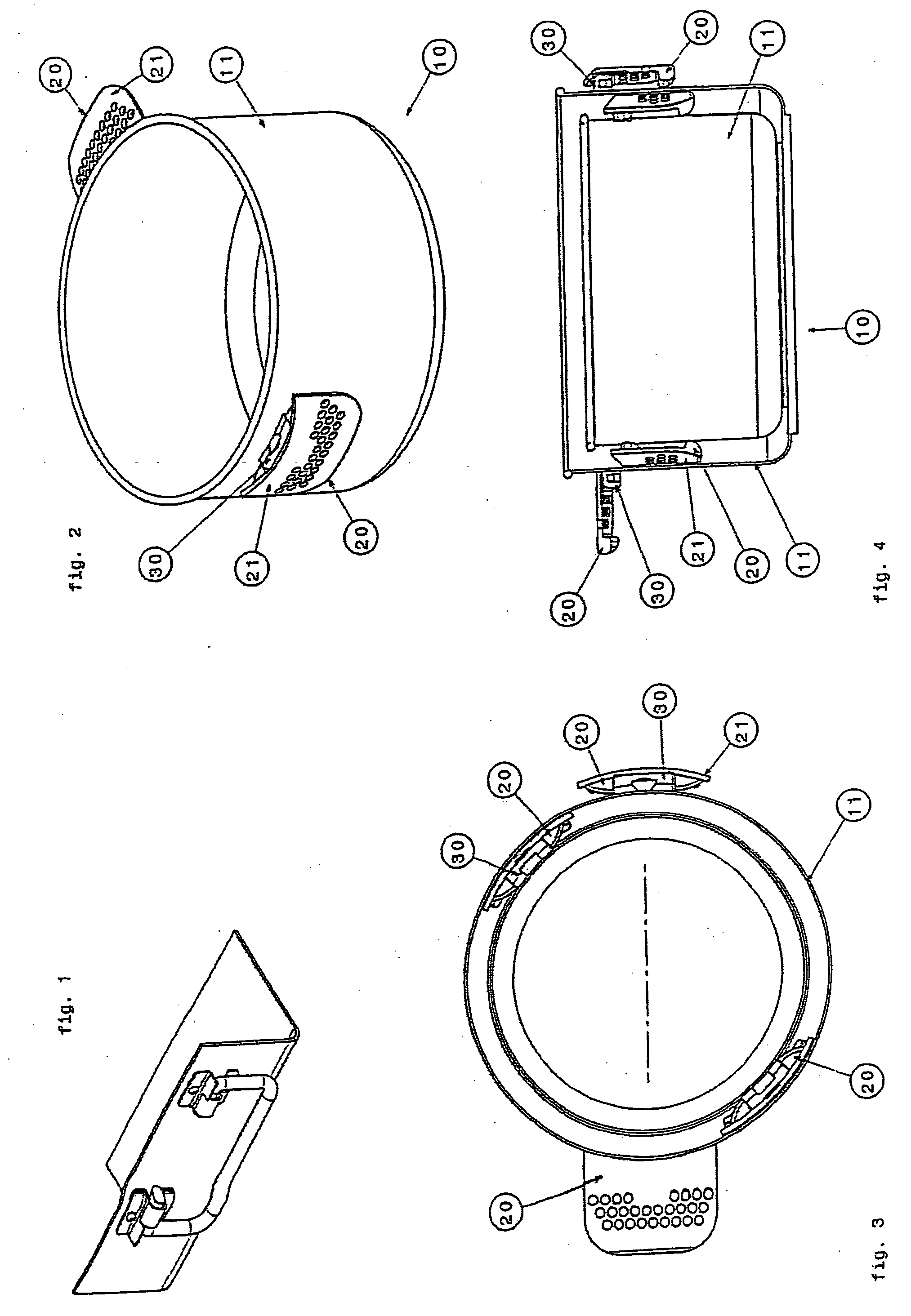

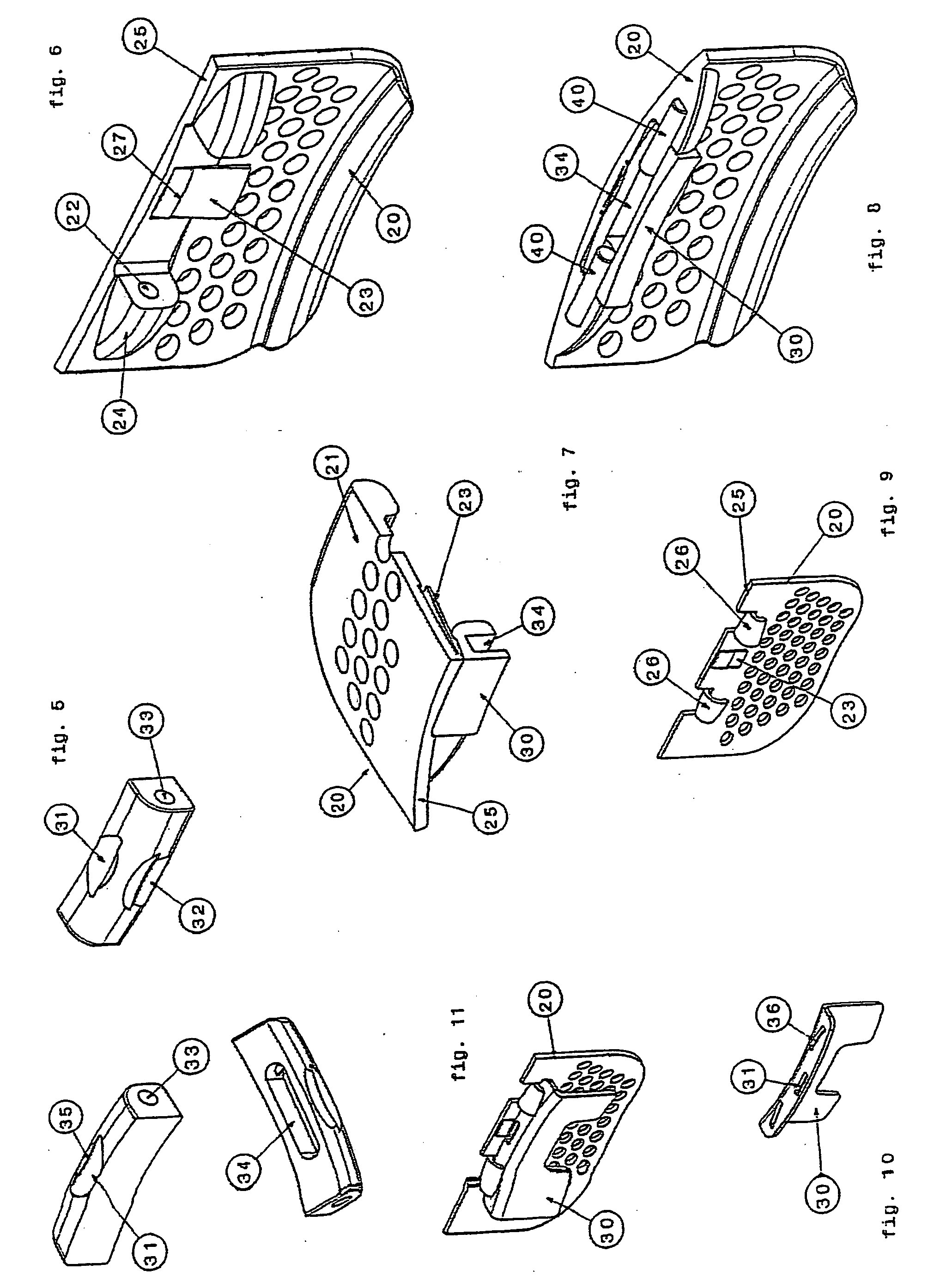

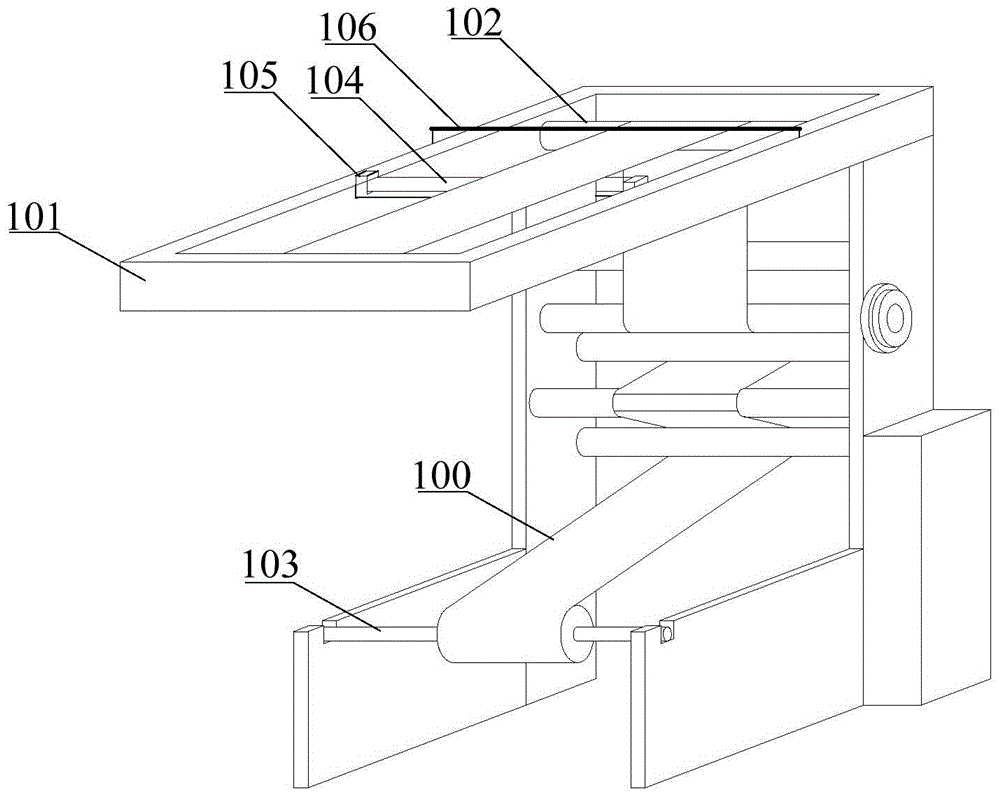

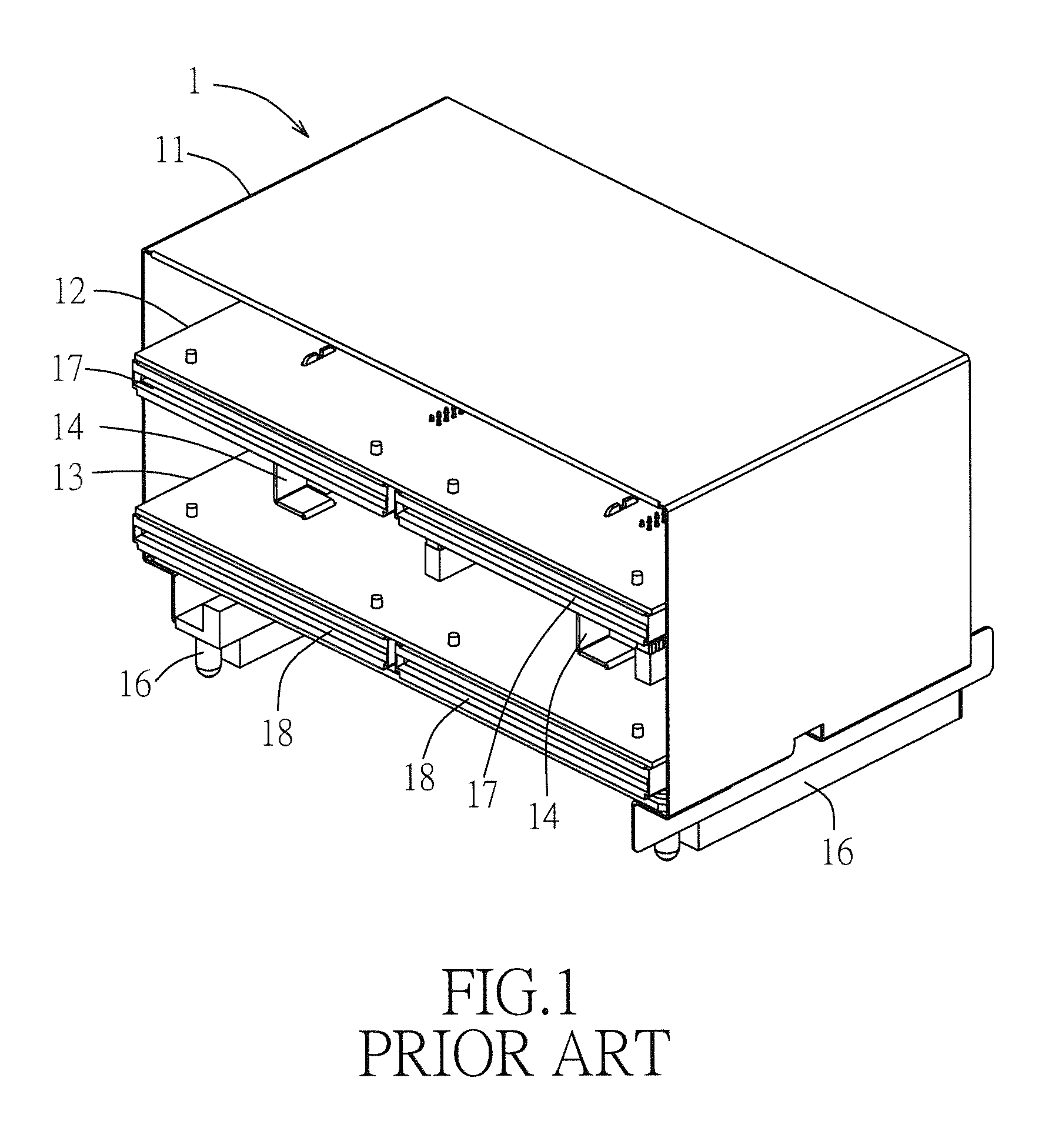

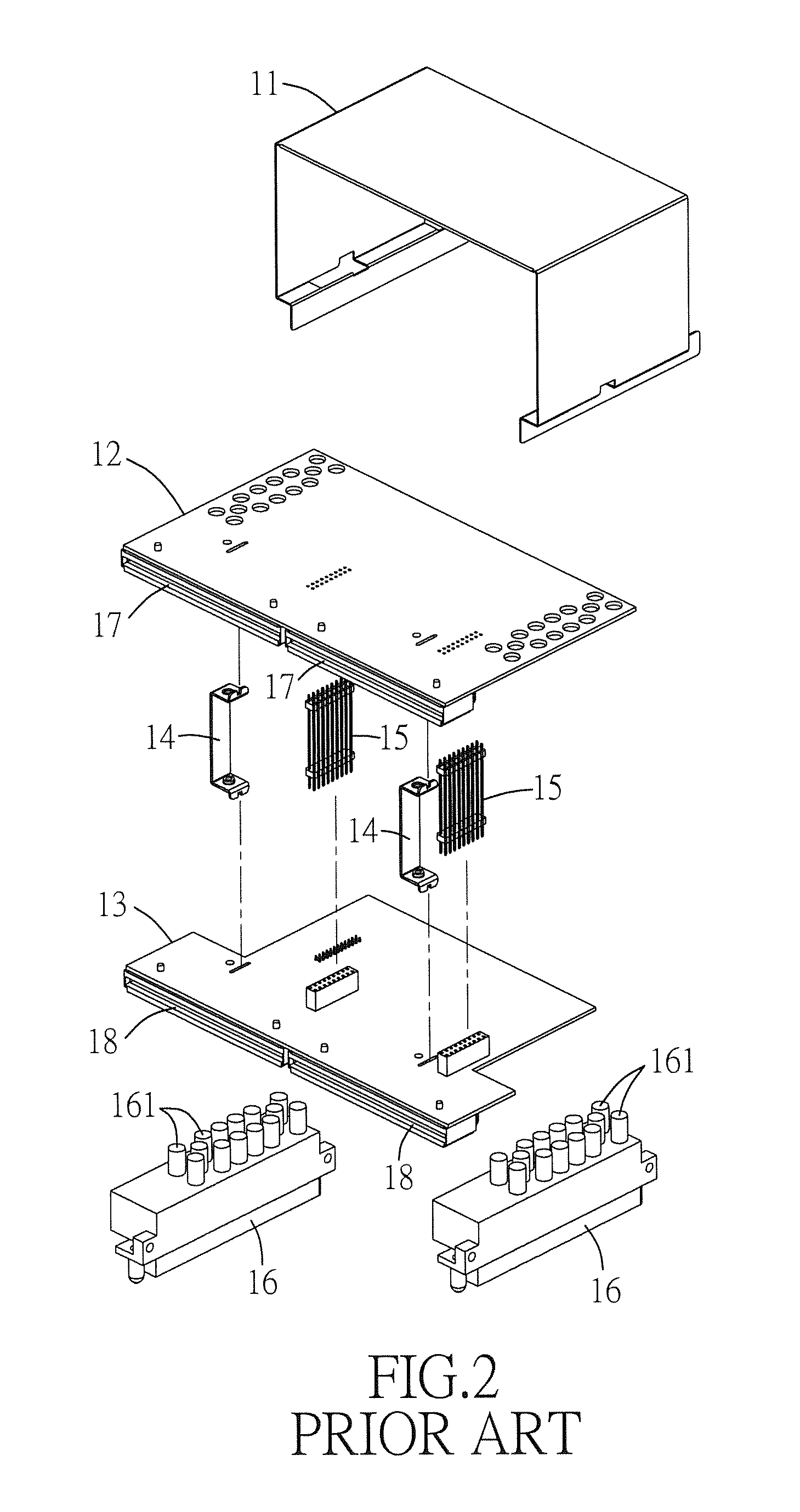

Recording medium feed apparatus

ActiveUS20050062217A1Reduce occupied spaceEasy to insertArticle feedersFeed tablesEngineeringRecording media

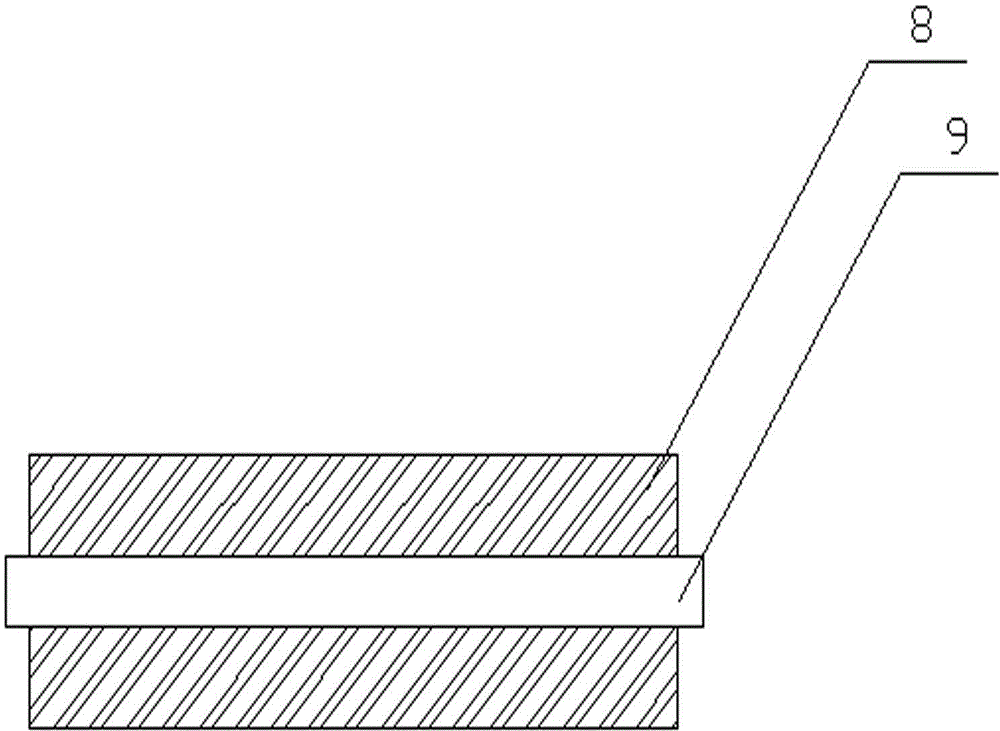

A recording medium feed apparatus has a manual feed tray provided in open or closed state, a feed roller feeding a recording portion a recording medium on the manual feed tray, an arm body having a first end portion rotatably attached to a housing and a second end portion, a feed roller unit having a front end portion provided with the feed roller and a base end portion rotatably attached to the second end portion, and a driving source transferring driving force to the feed roller, wherein the arm body and the feed roller unit are vertically housed inside the housing when the manual feed tray is closed, and as the manual feed tray changes from closed to opened state, the arm body tilts toward outside, while a folding angle of the feed roller increases so that the feed roller abuts against a recording medium on the manual feed tray.

Owner:BROTHER KOGYO KK

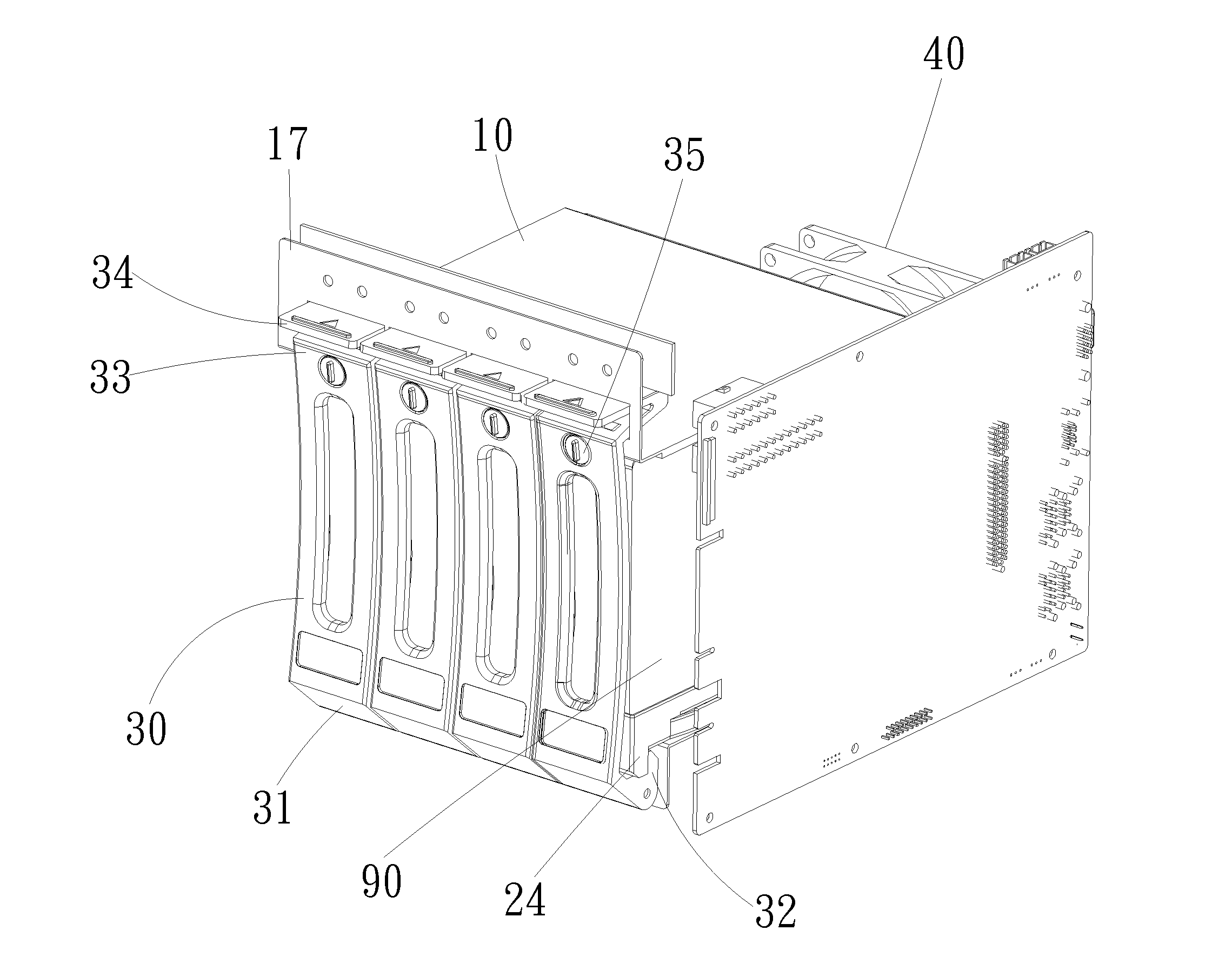

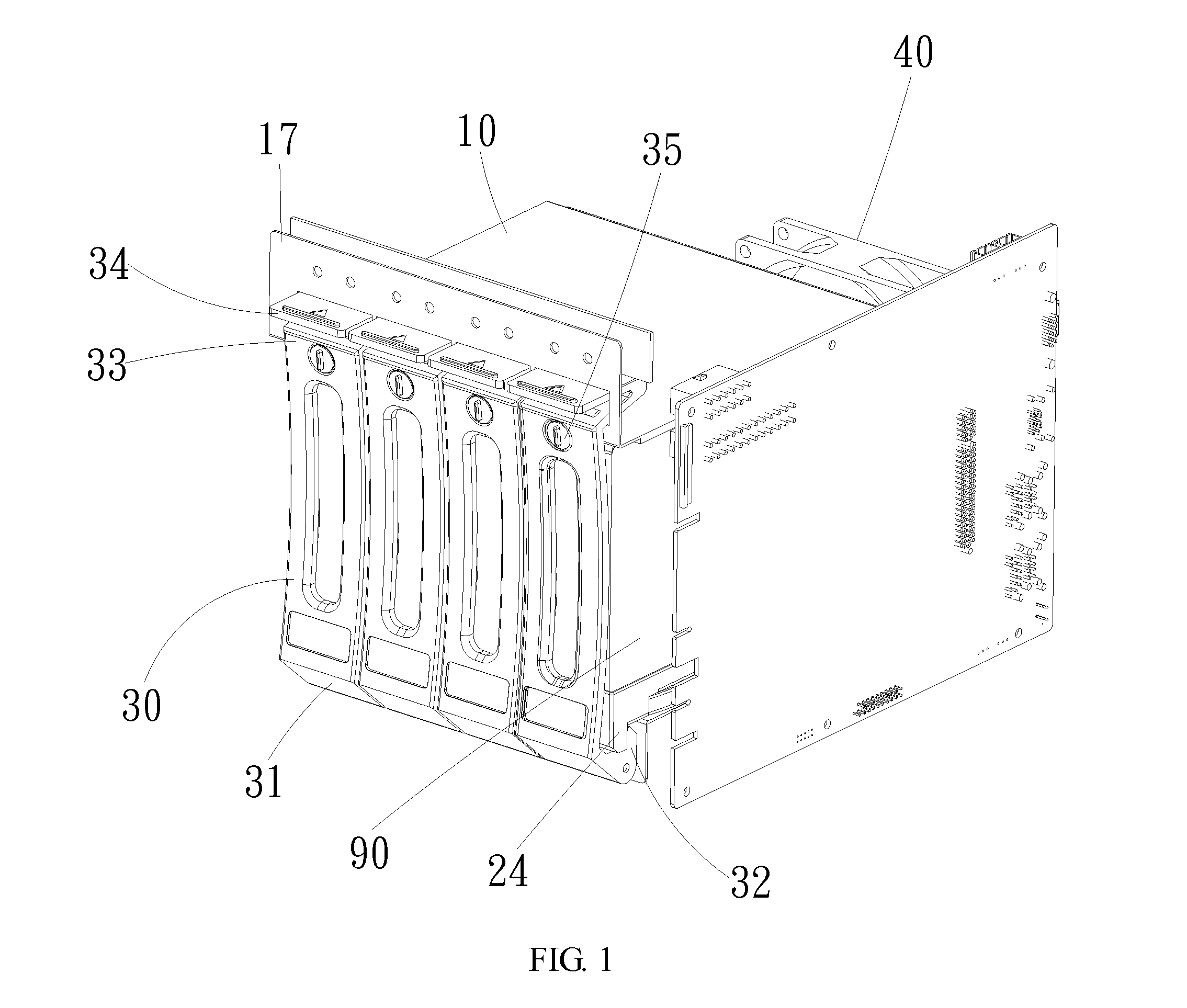

Hard Disk Carrying Apparatus

InactiveUS20120113583A1Reduce occupied spaceReduce weightDigital data processing detailsFurniture partsVALVE PORT

Owner:PROMISE TECHNOLOGY

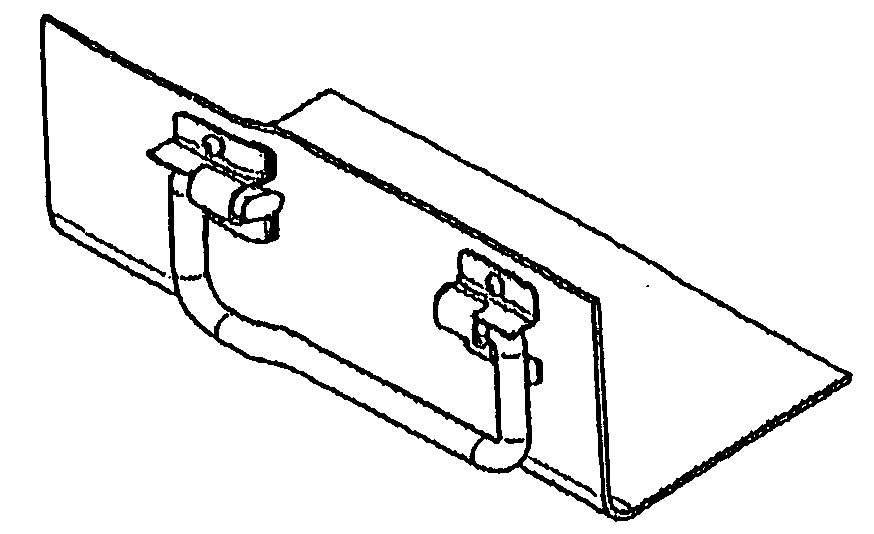

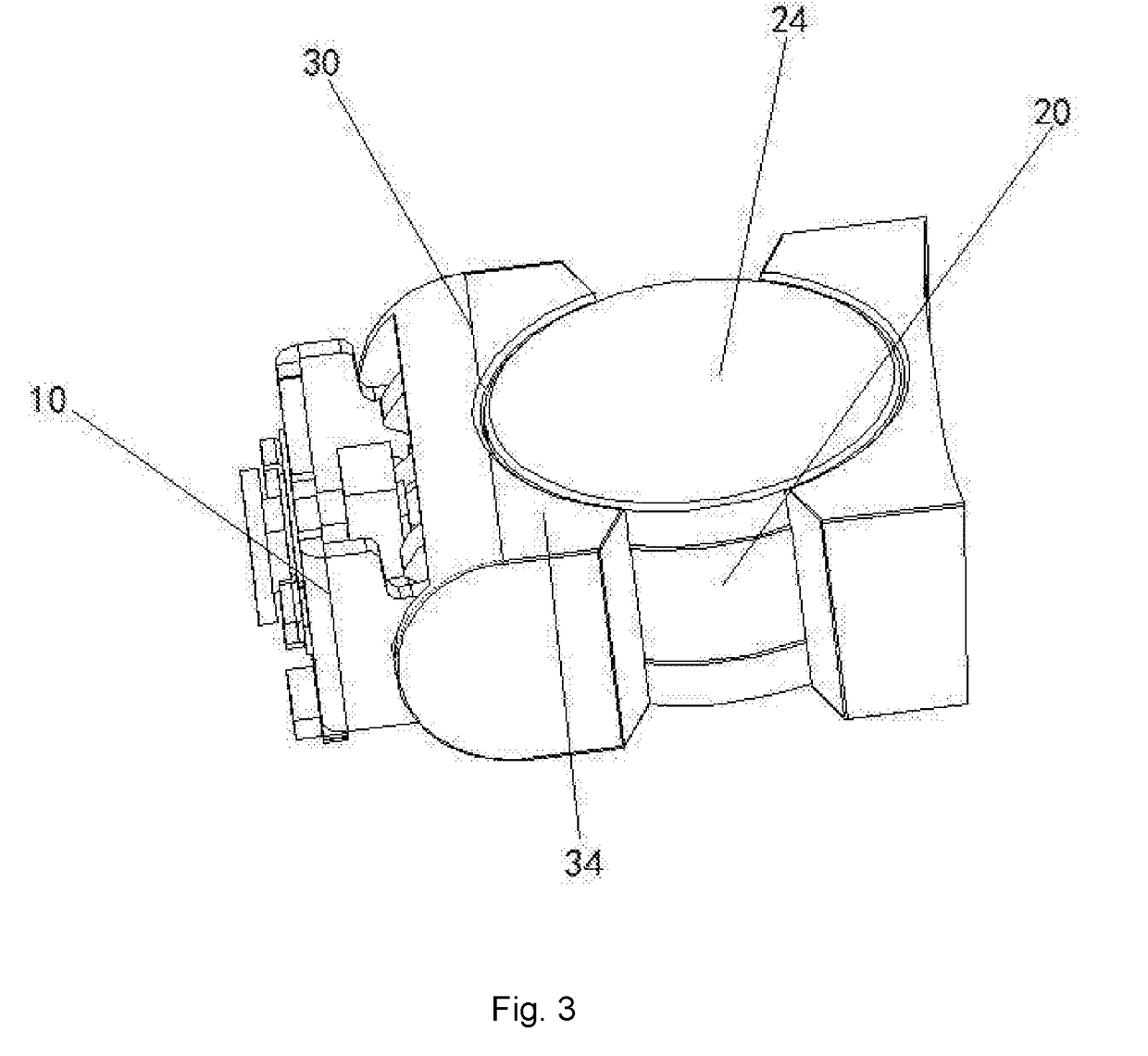

Container for gastronomic use

InactiveUS20050188857A1Comfortable and safe grippingReduce extra spaceDeep fat fryersEngineeringCoupling system

A container for gastronomic use includes a substantially cylindrical receptacle; at least two attachment lugs, connected to the walls of the container; at least two handles, coupled to the attachment lugs through an articulated coupling system. The handles are arranged, in a simple manner, in at least two positions of which one is a raised position, in which the handles radially extend from the walls of the receptacle and the other is a lowered position, in which the handles are arranged near the walls, to allow the container to be located inside another container having a like shape and a slightly larger size. A locking device locks the handles in the raised position.

Owner:BALLARINI PAOLO E FILI SPA

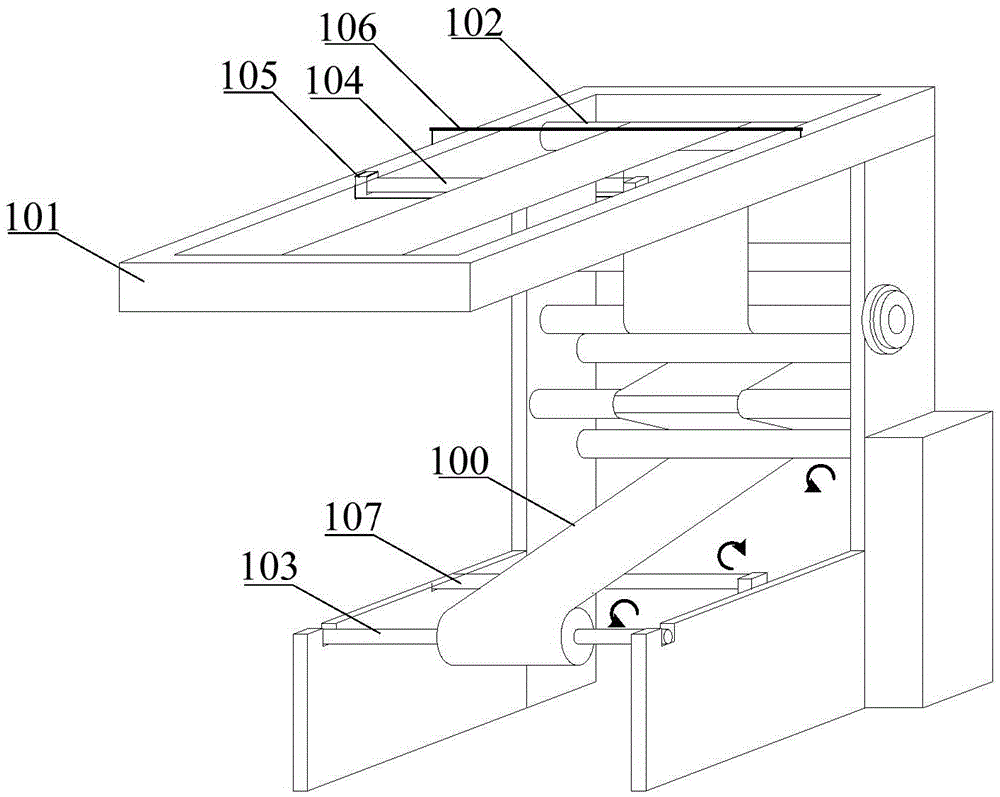

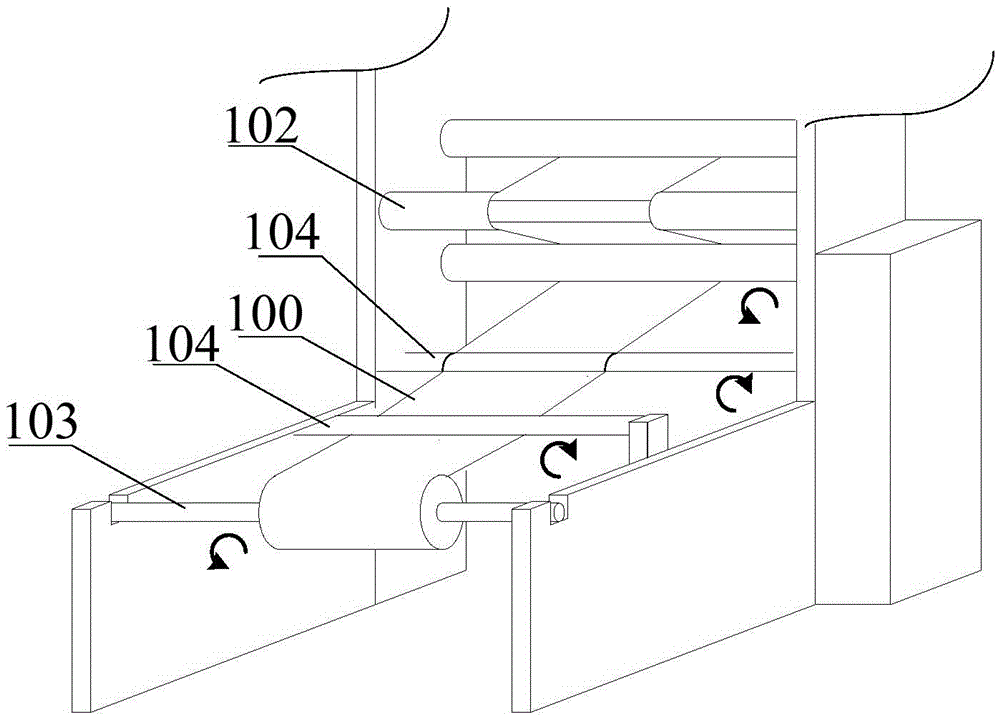

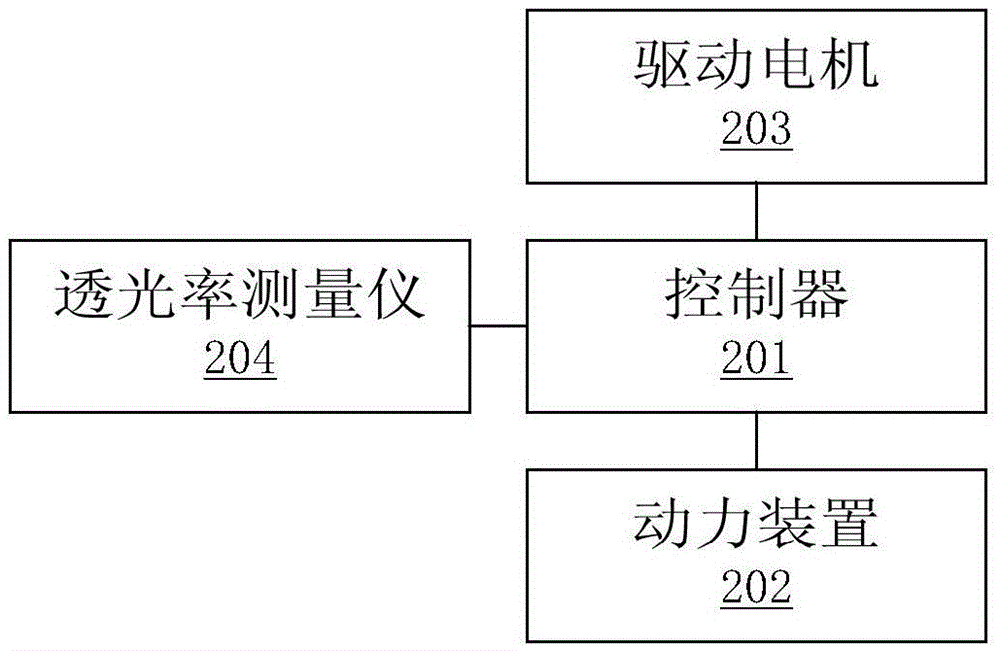

Winding structure

ActiveCN105460653AGuaranteed flatnessSimple structureChemical fixing of textilesTextile treatment carriersMeasuring instrumentTransmittance

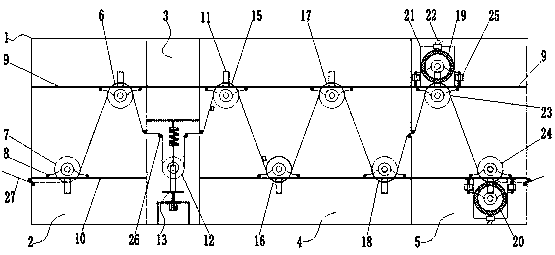

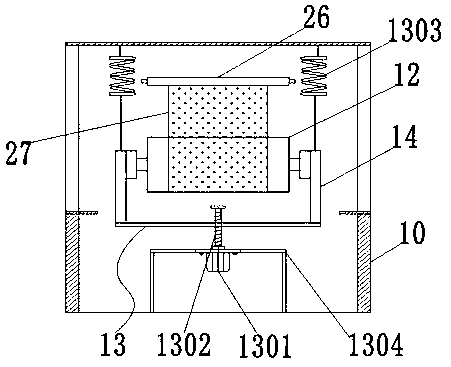

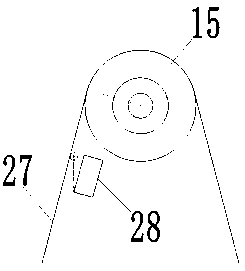

The embodiment of the invention provides a winding structure. The problem that the cost performance and the working efficiency of an existing winding structure need to be improved is solved. The winding structure comprises a controller, a power device, a winding platform, a plurality of carrier rollers and a plurality of winding rollers. The multiple carrier rollers and the multiple winding rollers are installed on the winding platform. Tensioning shafts, dyeing devices and color fixing devices are further installed on the winding platform, wherein the dyeing devices and the color fixing devices are connected with the controller. The dyeing devices and the color fixing devices are located between the two adjacent carrier rollers. The outer surfaces of the winding rollers are coated with elastic layers. The tensioning shafts are located at the positions adjacent to the winding rollers. Each dyeing device comprises a rotating shaft which is coated with a color absorbing material and is parallel to the corresponding carrier roller, wherein a dye storage groove is arranged below the rotating shaft, the lower portion of the rotating shaft is located in the dye storage groove, the rotating shaft and the corresponding tensioning shaft are connected with a driving motor, the driving motor and the power device are connected with the controller, and the controller is connected with a transmittance measuring instrument. The winding structure is high in cost performance and winding efficiency and easy to apply and popularize.

Owner:CHONGQING KEXIN PLASTIC

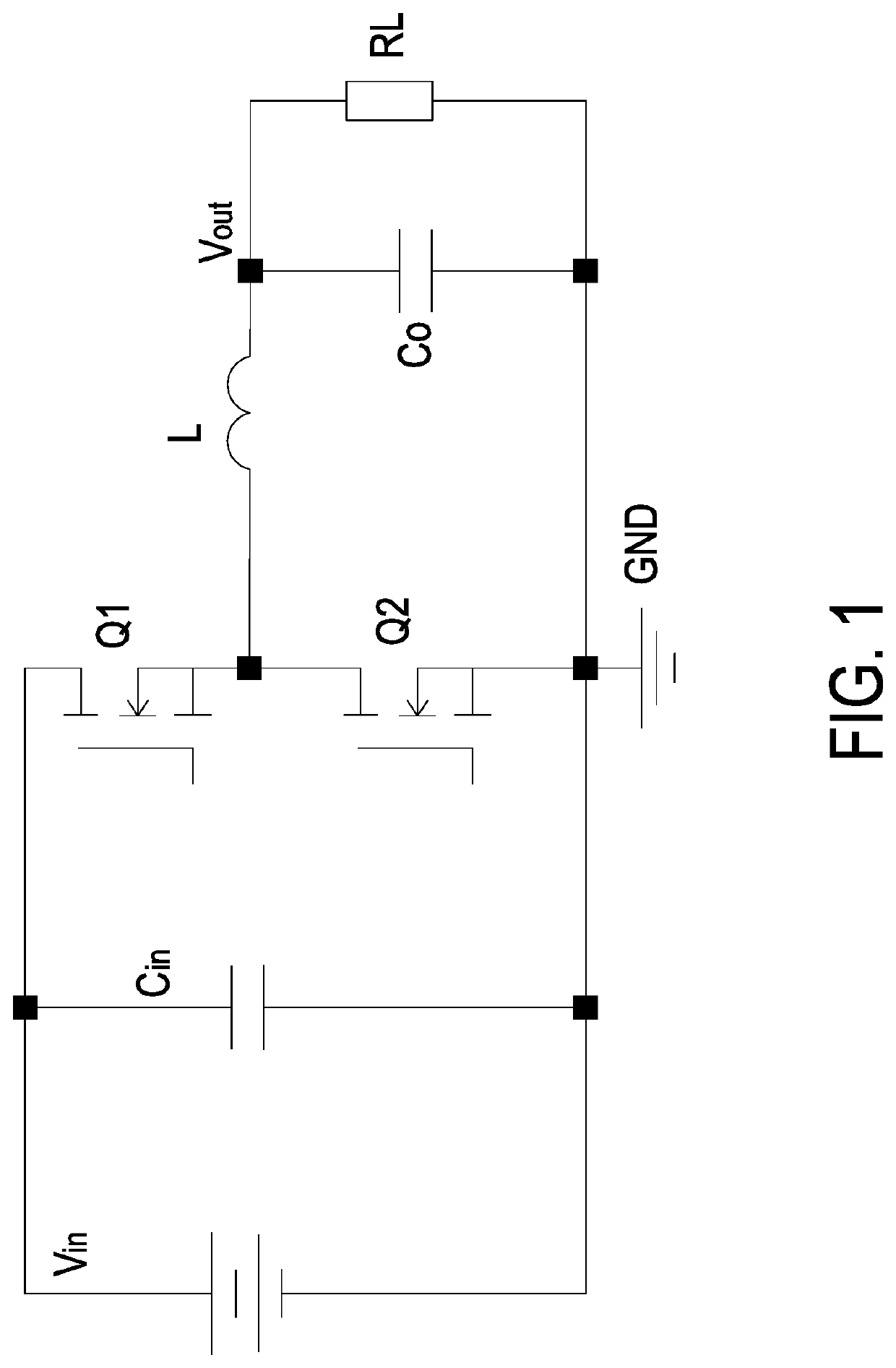

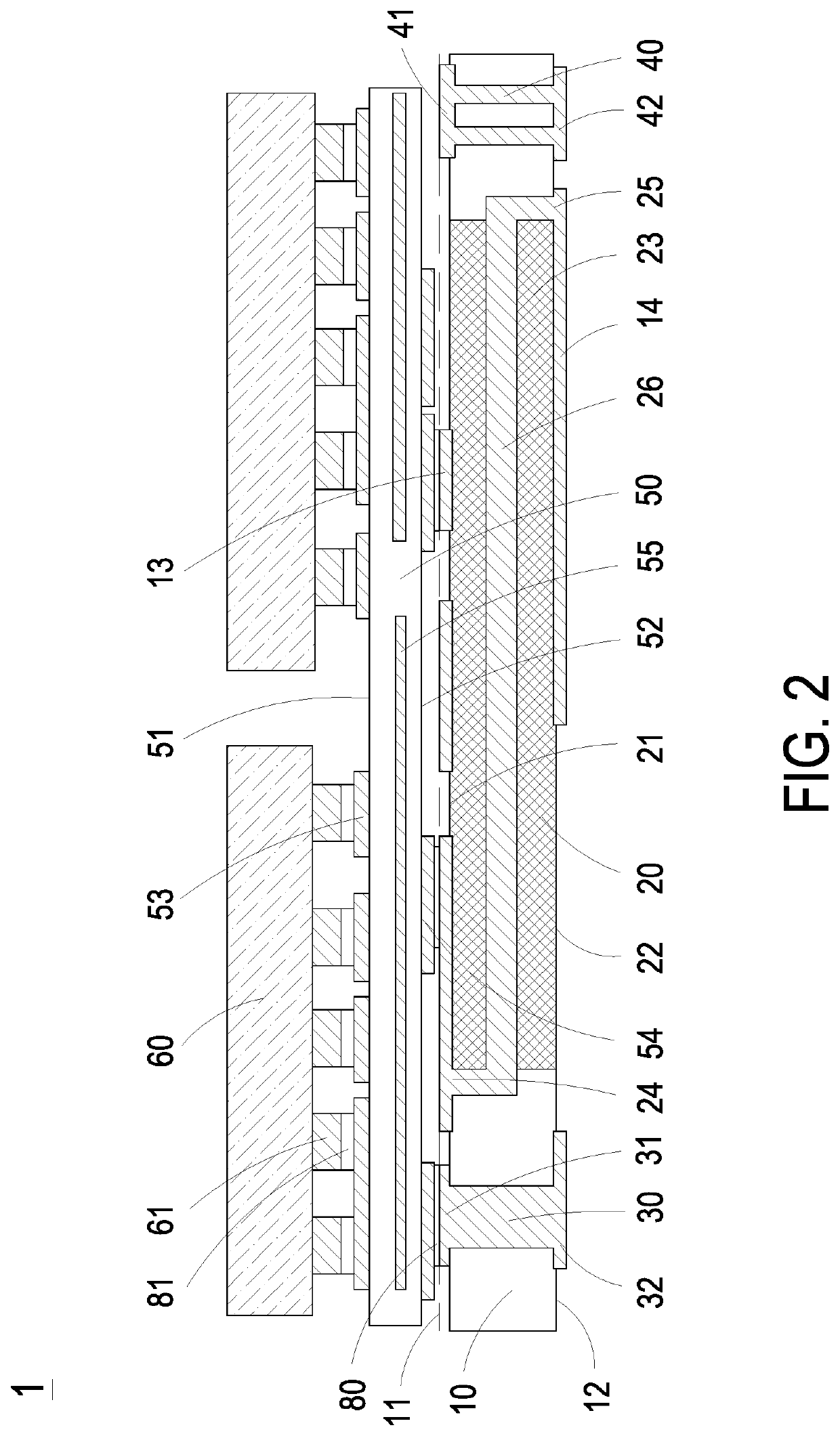

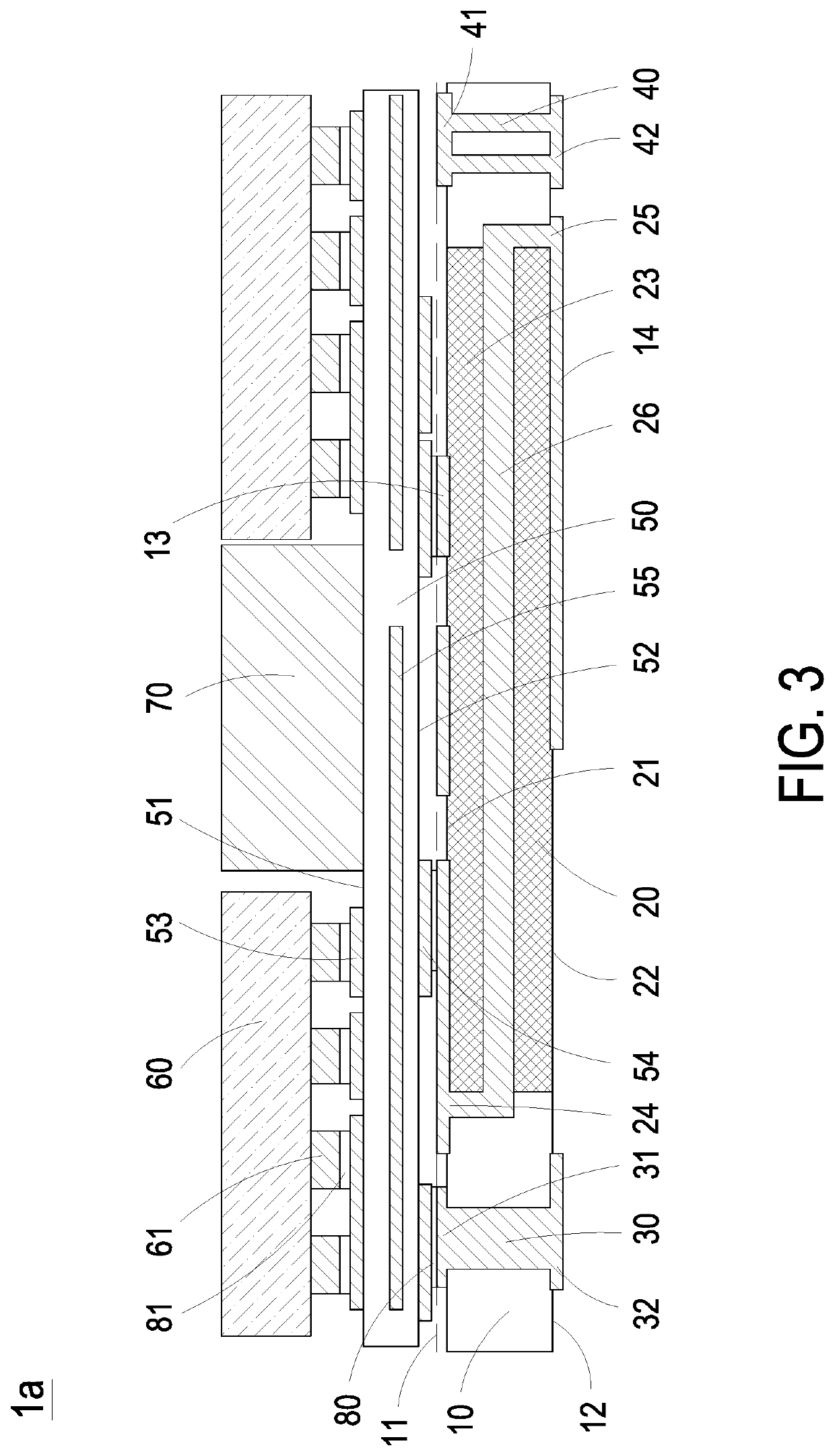

Power module and manufacturing method thereof

PendingUS20200260586A1Improve efficiencyIncrease flexibilityPrinted circuit assemblingTransformers/inductances coils/windings/connectionsElectrical connectionPower module

A power module and a manufacturing method thereof are disclosed. The power module includes a first board, a magnetic component, a second board and a power device. The first board includes a conductive component disposed between a first side and a second side opposite to each other. The magnetic component is disposed between the first side and the second side and includes a magnetic core and a winding. A first conductive terminal and a second conductive terminal are led out on the first side and the second side, respectively. The second board is disposed on the first board and includes a third side and a fourth side opposite to each other. The fourth side faces the first side. The power device is disposed on the third side of the second board and electrically connected to the first board.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

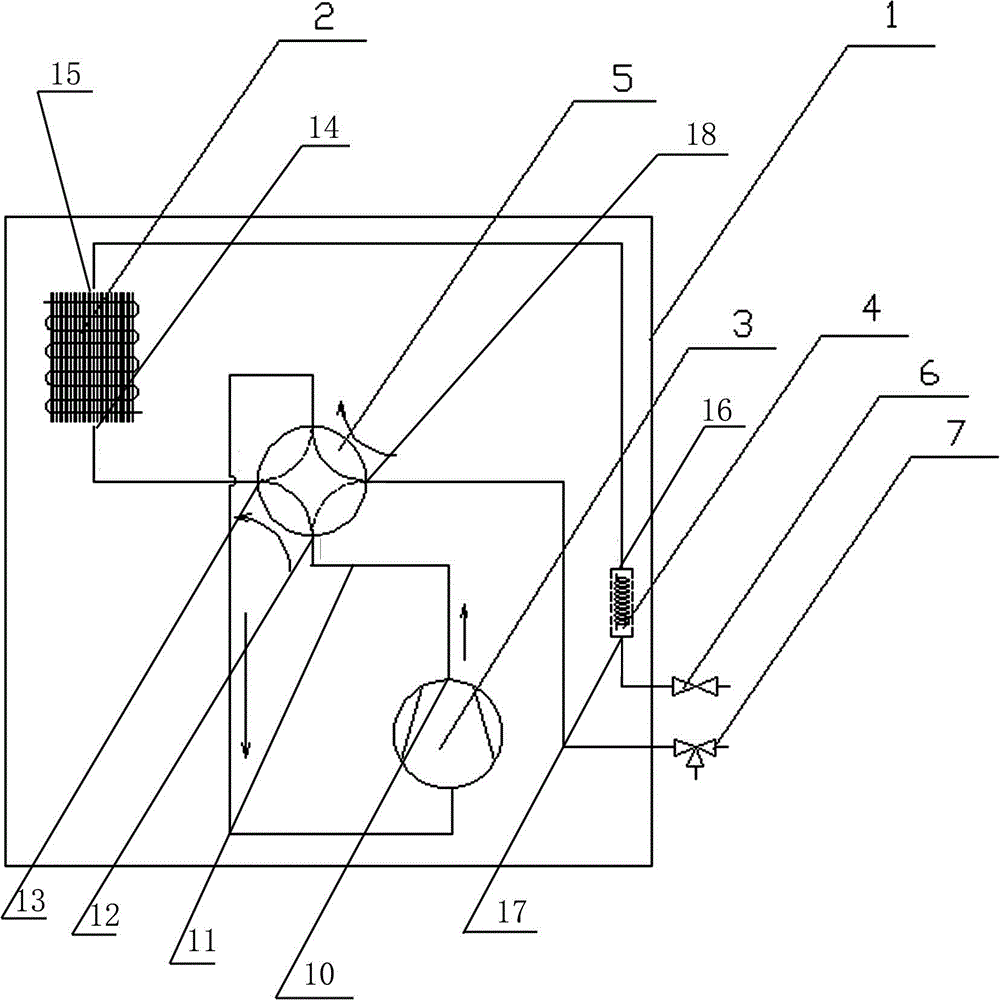

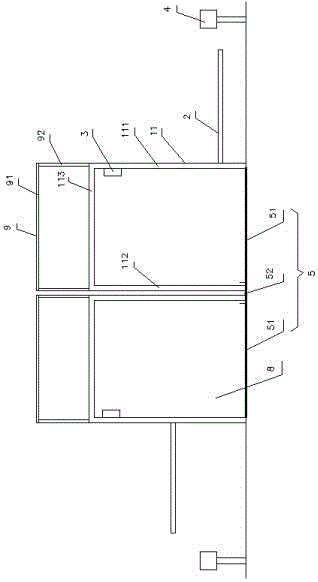

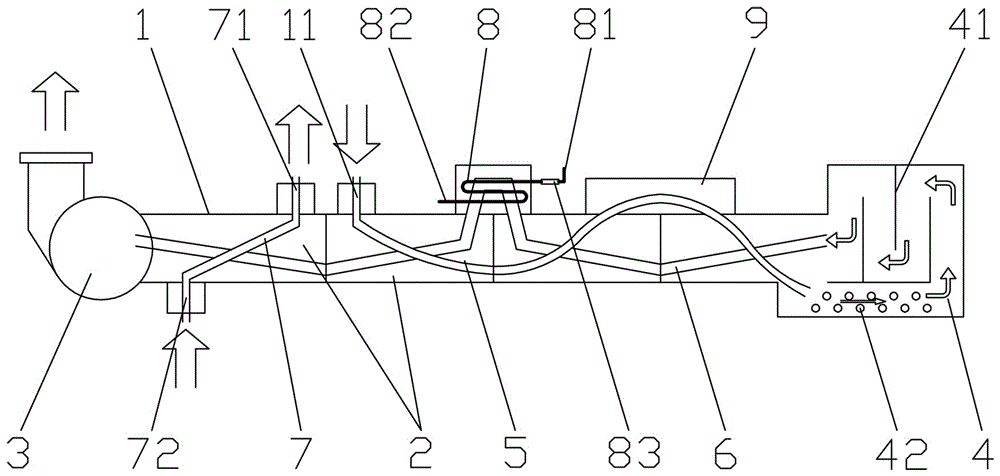

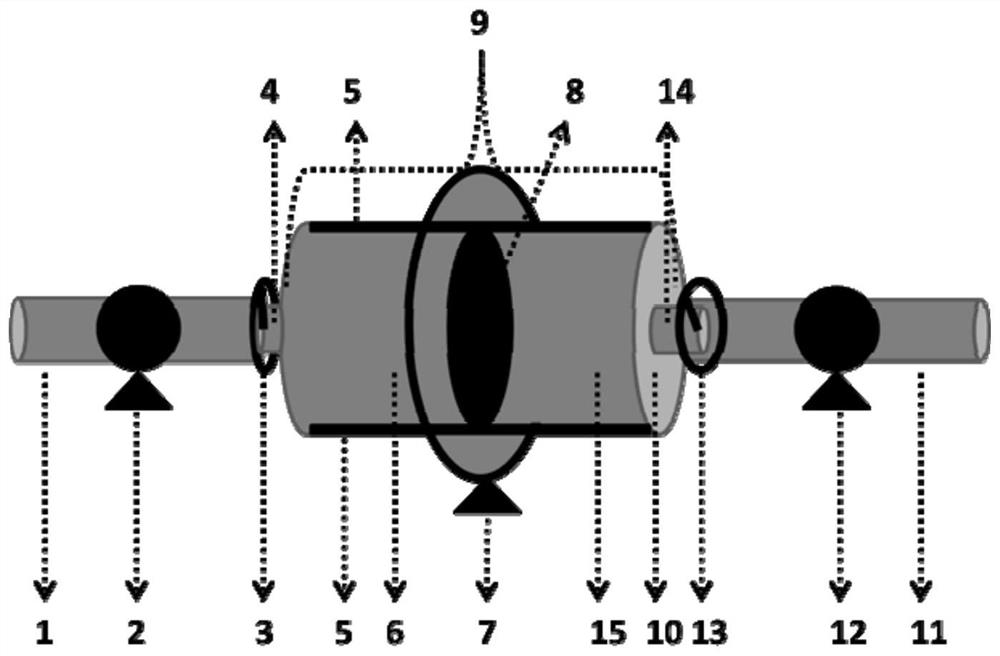

Air conditioning unit without outdoor draught fan system

PendingCN104976700AReduce volumeReduce the occupied spaceLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

The invention discloses an air conditioning unit without an outdoor draught fan system. The air conditioning unit without the outdoor draught fan system is provided with a shell (1), and a heat exchanger (2), a compressor (3), a throttling device (4), a reversing valve (5), a liquid valve (6) and a steam valve (7) are arranged in the shell (1). An exhaust port I end (10) of the compressor (3) is connected with a port II (12) of the reversing valve (5) through a connecting pipe (11). A port III (13) of the reversing valve (5) is connected with an inlet end IV (14) of the heat exchanger (2), an outlet end V (15) of the heat exchanger (2) is connected with an inlet end VI (16) of the throttling device (4), an outlet end VII (17) of the throttling device (4) is connected with the liquid valve (6), and the steam valve (7) is connected with a port VIII (18) of the reversing valve (5).

Owner:JIANGSU CHUNLAN REFRIGERATING EQUIPMENT CO LTD

High-efficiency textile oven

ActiveCN110375532ADry evenlyFully dryMechanical cleaningPressure cleaningWrinkle skinWorking environment

The invention discloses a high-efficiency textile oven which comprises a box body. The box body comprises a drying room, an adjusting room, a de-wrinkling room and a dust collecting room. An upper drying roller and a lower drying roller are arranged in the drying room, an adjusting roller and a tensioning device are arranged in the adjusting room, an upper ironing roller, a lower ironing roller and an upper heating roller and a lower heating roller are arranged in the de-wrinkling room, an upper hairbrush roller, a lower hairbrush roller and an upper supporting roller and a lower supporting roller are arranged in the dust collecting room, dust collecting hoods and dust collecting pipes are arranged on the upper and lower hairbrush rollers, anti-deviation carrier rollers are separately arranged on two sides of the upper and lower supporting rollers, the drying room dries a textile, the adjusting room tensions the textile to prevent deviation, the de-wrinkling room de-wrinkles the textile and heats and dries the textile, and the dust collecting room collects dust of the textile, so that the drying quality is improved and wrinkles are reduced. A good working environment is created forstaff, places and equipment are saved, the drying efficiency is improved, and the labor intensity is reduced.

Owner:江西嘉丰纺织有限公司

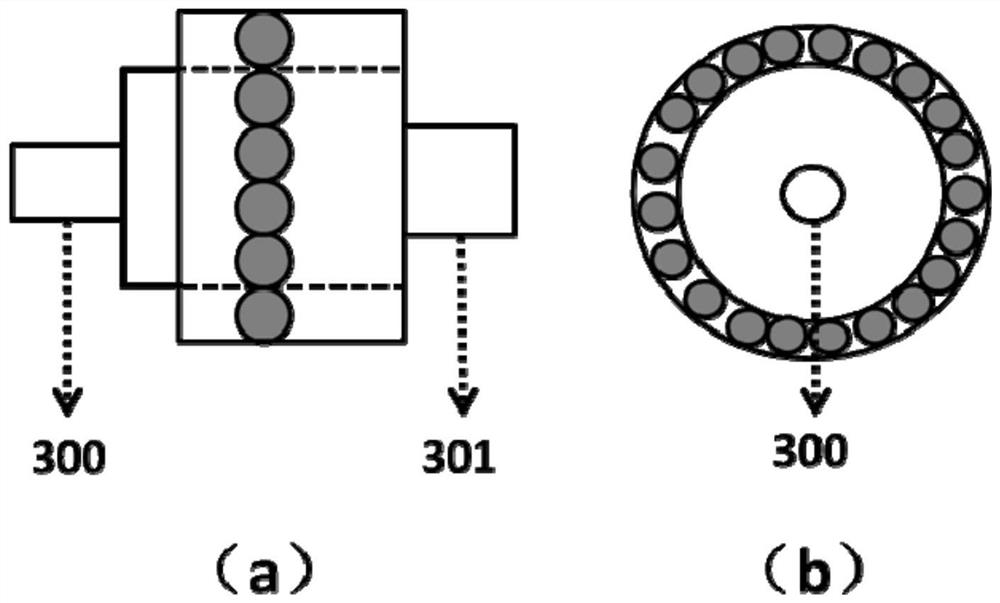

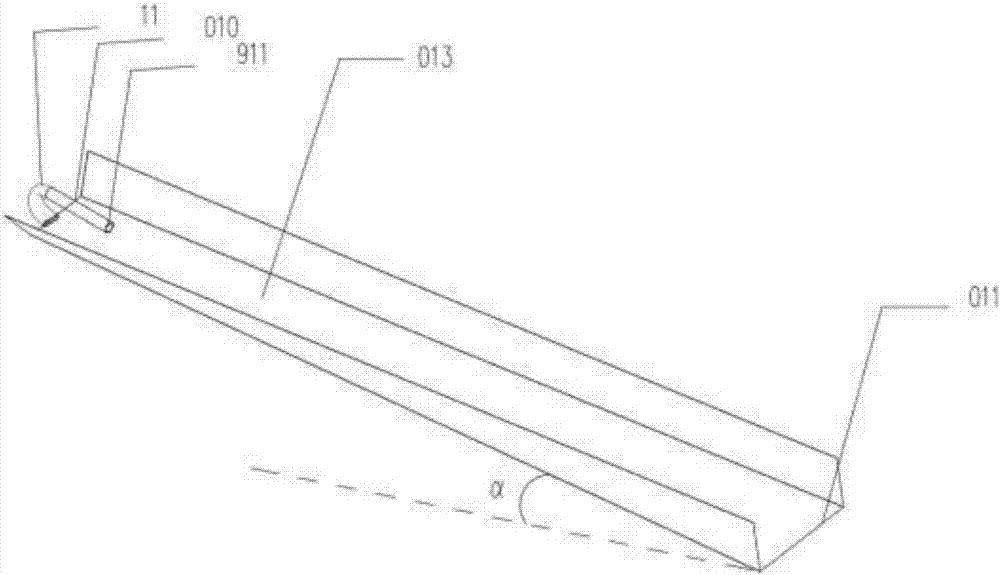

Rolling machine and control method thereof

ActiveCN105460658AReduce the occupied spaceImprove processing efficiencyLiquid surface applicatorsCoatingsBand shapeTransmittance

The embodiment of the invention provides a rolling machine and a control method thereof. The problem that in the prior art, treatment, machining and rolling on strap-shaped thin materials belong to different treatment procedures, and consequently the efficiency of finally achieving rolling is low is solved. The rolling machine comprises a controller, a power device, a rolling platform, a plurality of carrier rollers and a plurality of wind-up rollers. The carrier rollers and the wind-up rollers are arranged on the rolling platform and connected with the power device, and dyeing devices and color fixation devices are arranged on the rolling platform and connected with the controller. The dyeing devices comprise rotary shafts coated with color absorption materials, and the rotary shafts are parallel to the carrier rollers. A dye storage tank is arranged below the rotary shafts, and the lower portions of the rotary shafts are located in the dye storage tank. The rotary shafts are connected with a drive motor, and the drive motor and the power device are connected with the controller. The controller is connected with light transmittance measurement instruments. By means of the rolling machine, rolling efficiency can be improved, and application and popularization are easy.

Owner:CHONGQING KEXIN PLASTIC

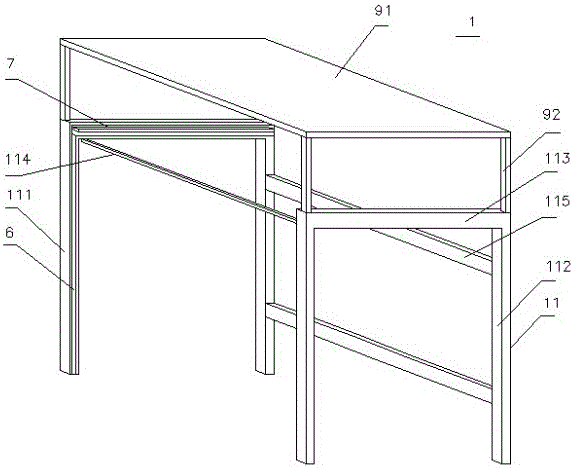

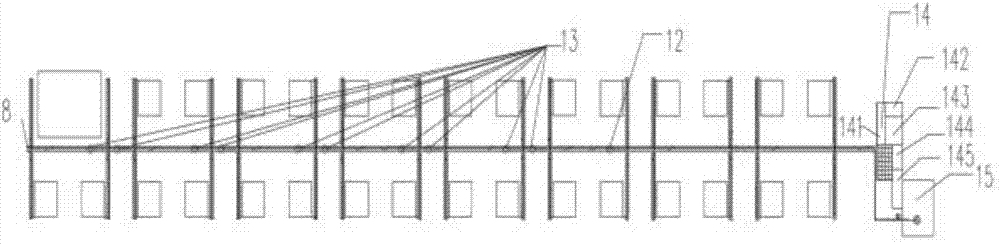

Road crossing type stereo garage for lateral-position parking

ActiveCN106401248AIncrease the number of buildsSolve parking problemParkingsControl systemSingle vehicle

The invention relates to a road crossing type stereo garage for lateral-position parking. The road crossing type stereo garage for lateral-position parking comprises a garage frame, vehicle carrying plates, a transmission system and a control system. The road comprises single lanes located on the left side and the right side and a greenbelt arranged between the single lanes on the two sides. The garage frame is located above the single lanes and includes inverted-U-shaped garage supports located at the front end and the rear end. Each garage support comprises first vertical frames vertically fixed to the roadside of the road, second vertical frames vertically fixed in the greenbelt, cross frames and a supporting frame. One side of each vehicle carrying plate extends upwards to be provided with a connecting plate, wherein two layers of walking wheels are fixed to the side faces of the two ends of the connecting plate. Vertical sliding ways are formed in the inner side faces of the two first vertical frames in each garage support, and two transverse sliding ways corresponding to the corresponding two layers of walking wheels are formed in the inner side faces of the two cross frames in each garage support, wherein the two transverse sliding ways communicate with the vertical sliding ways. According to the road crossing type stereo garage for lateral-position parking, the space above the existing road is sufficiently used for building the stereo garage, occupied space is greatly reduced, and the problem of difficult parking in a city is better solved.

Owner:合肥博仕达汽车技术服务有限公司

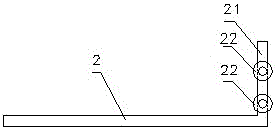

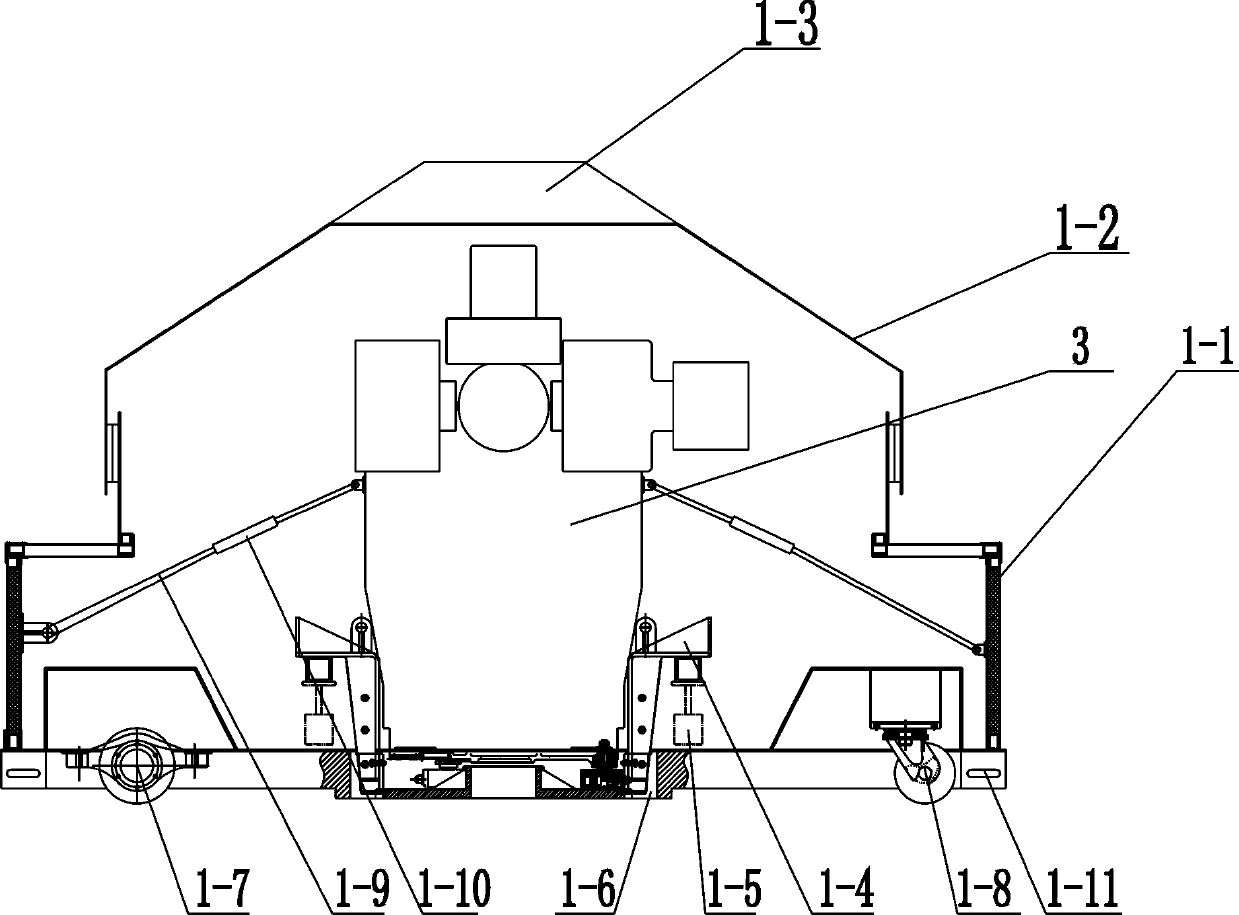

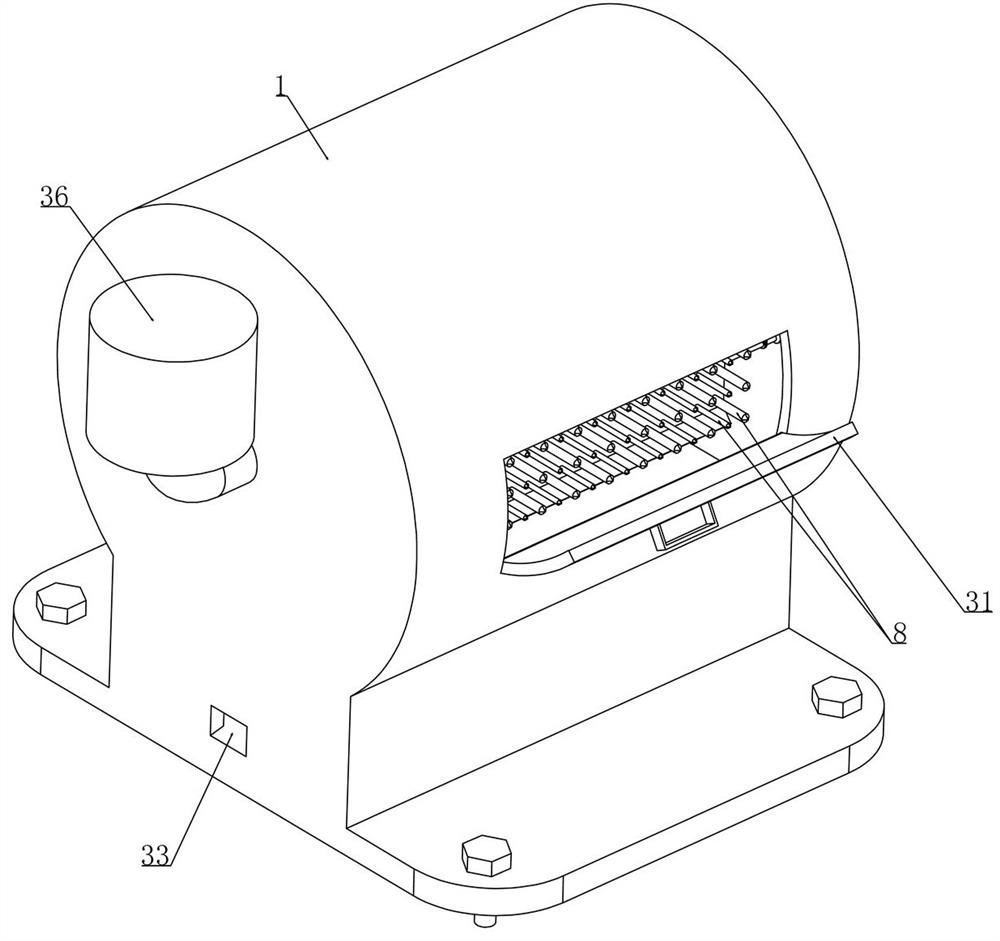

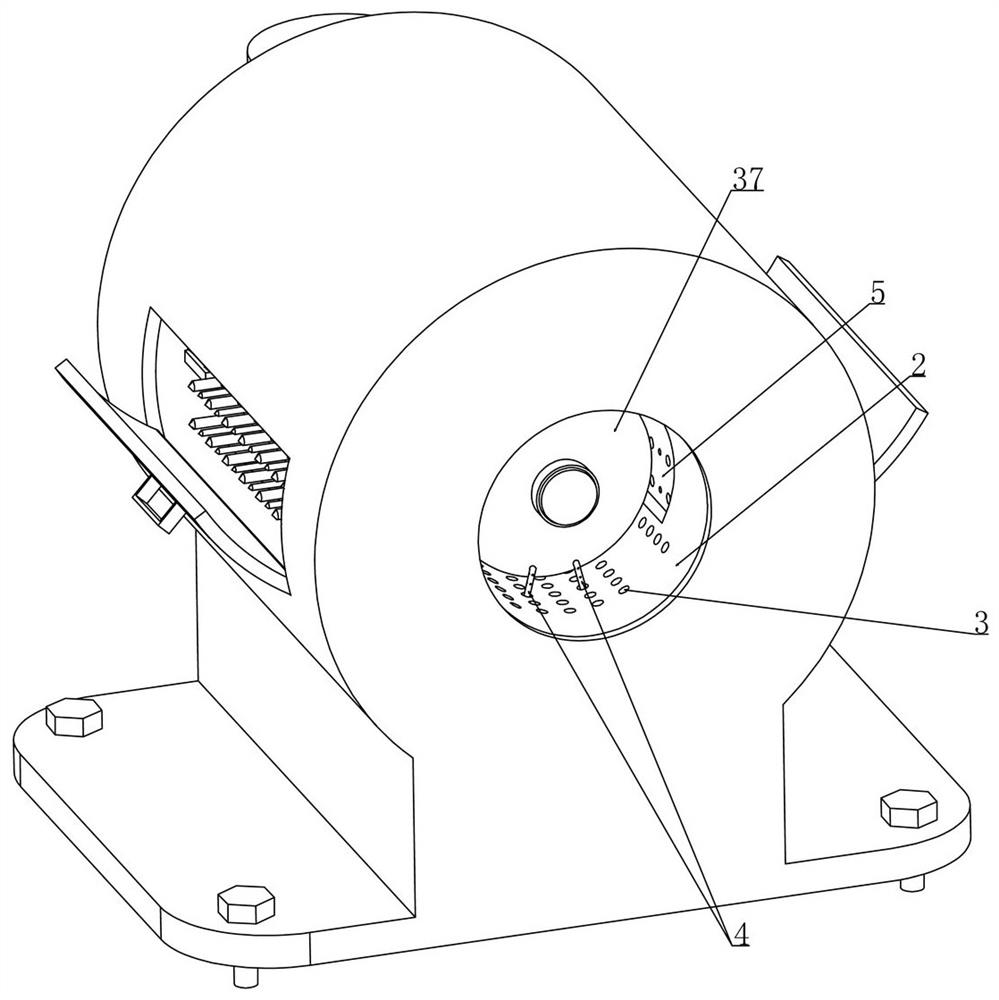

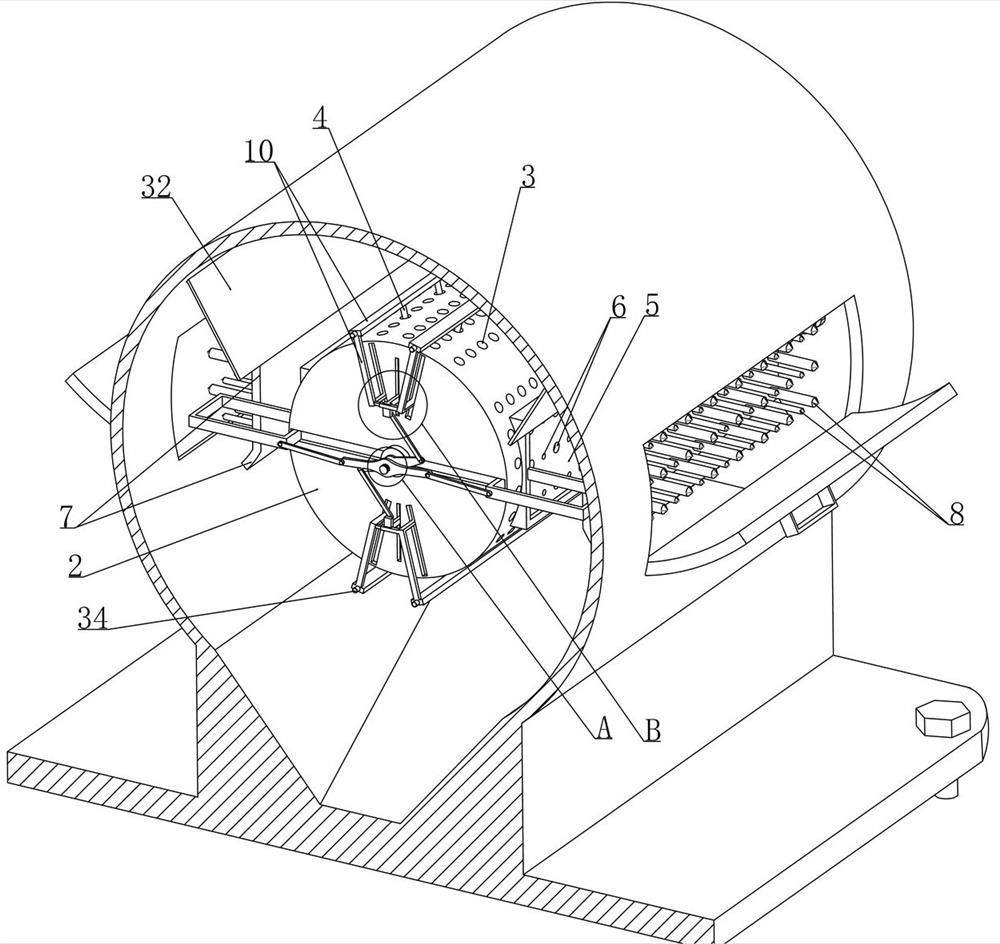

On-board theodolite cabin self boarding and alighting structure

PendingCN110562114ASimple structureEasy to assembleVehicle fittings for liftingLoad securingTheodoliteOn board

The invention relates to an on-board theodolite cabin self boarding and alighting structure, and belongs to the technical field of on-board theodolites. The on-board theodolite cabin self boarding andalighting structure is characterized in that the structure comprises a theodolite cabin, an on-board leveling platform and a chassis; the top surface of the chassis is provided with the on-board leveling platform, and the top surface of the on-board leveling platform is provided with the theodolite cabin; a theodolite body is arranged in the theodolite cabin, and the four corners of the theodolite cabin are provided with folding supporting structures correspondingly; and the folding supporting structures do not interfere and influence the on-board leveling platform; the chassis, a platform body, telescopic supporting legs and horizontal sensors are included; the platform body is arranged at the top of the chassis; the four corners, corresponding to the platform body, of the chassis are provided with connection flanges used for limiting moving of the platform body in the horizontal direction, and the two sides, corresponding to the platform body, of the chassis are each provided with two lock catches in a spaced mode. According to the on-board theodolite cabin self boarding and alighting structure, the problems that a traditional theodolite on-board structure is complex, and a lotof manpower and material resources need to be consumed are solved.

Owner:洛阳安驰汽车制造有限公司 +1

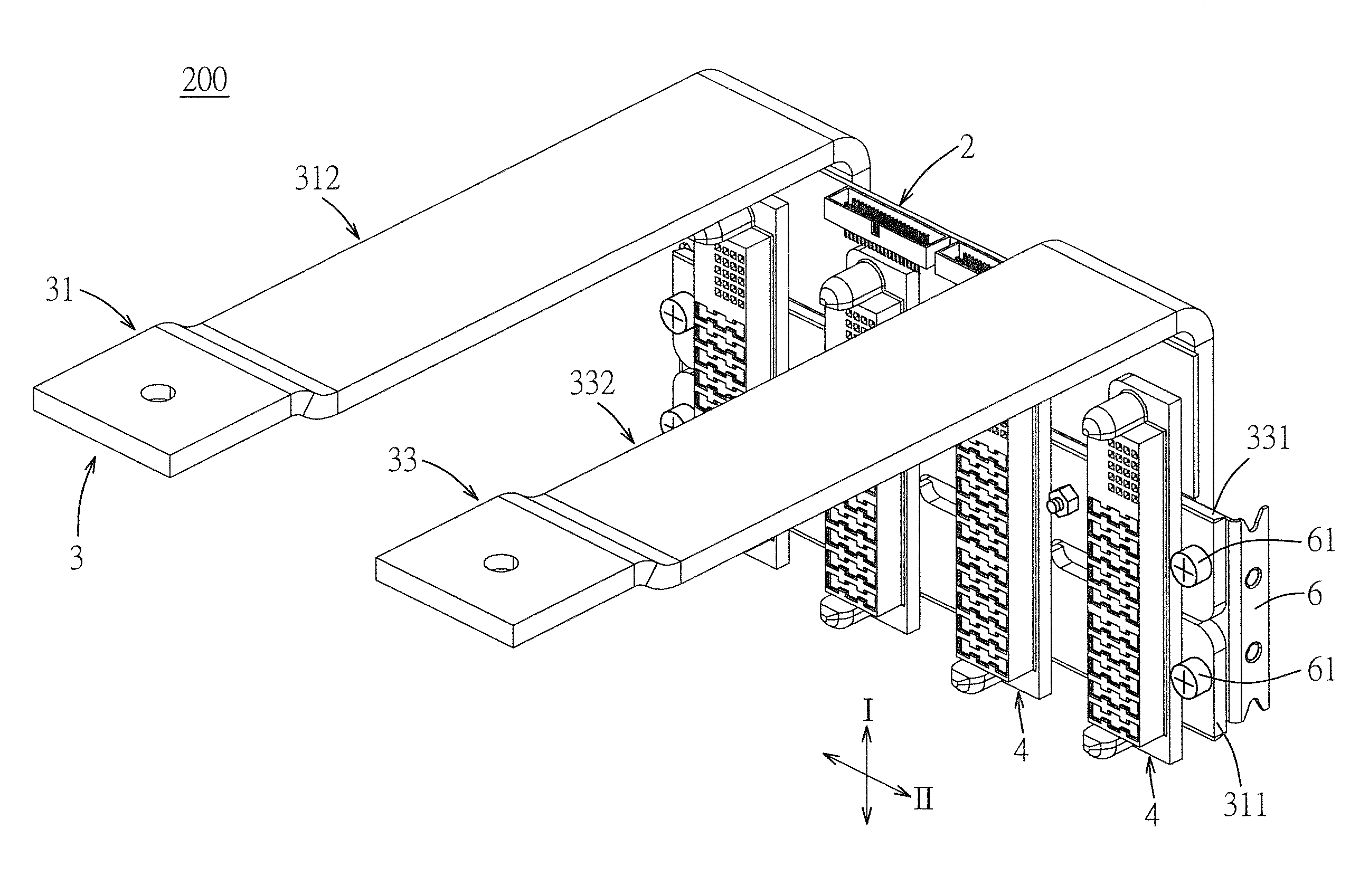

Power distribution device and assembling method thereof

ActiveUS9538685B2Shorten the transmission pathReduce lossesServersSubstation/switching arrangement casingsElectricityEngineering

A power distribution device for connection with a plurality of power supply units includes a signal control element, a transmission mechanism including a current transmission unit and a ground transmission unit, and a plurality of electrical connectors respectively adapted for insertion of and connection with the power supply units. Each electrical connector includes a first conductive terminals electrically connected to the signal control element for transmitting an electrical signal to the signal control element, and a plurality of second conductive terminals electrically connected to the current and ground transmission units for transmitting current to the current and ground transmission units.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

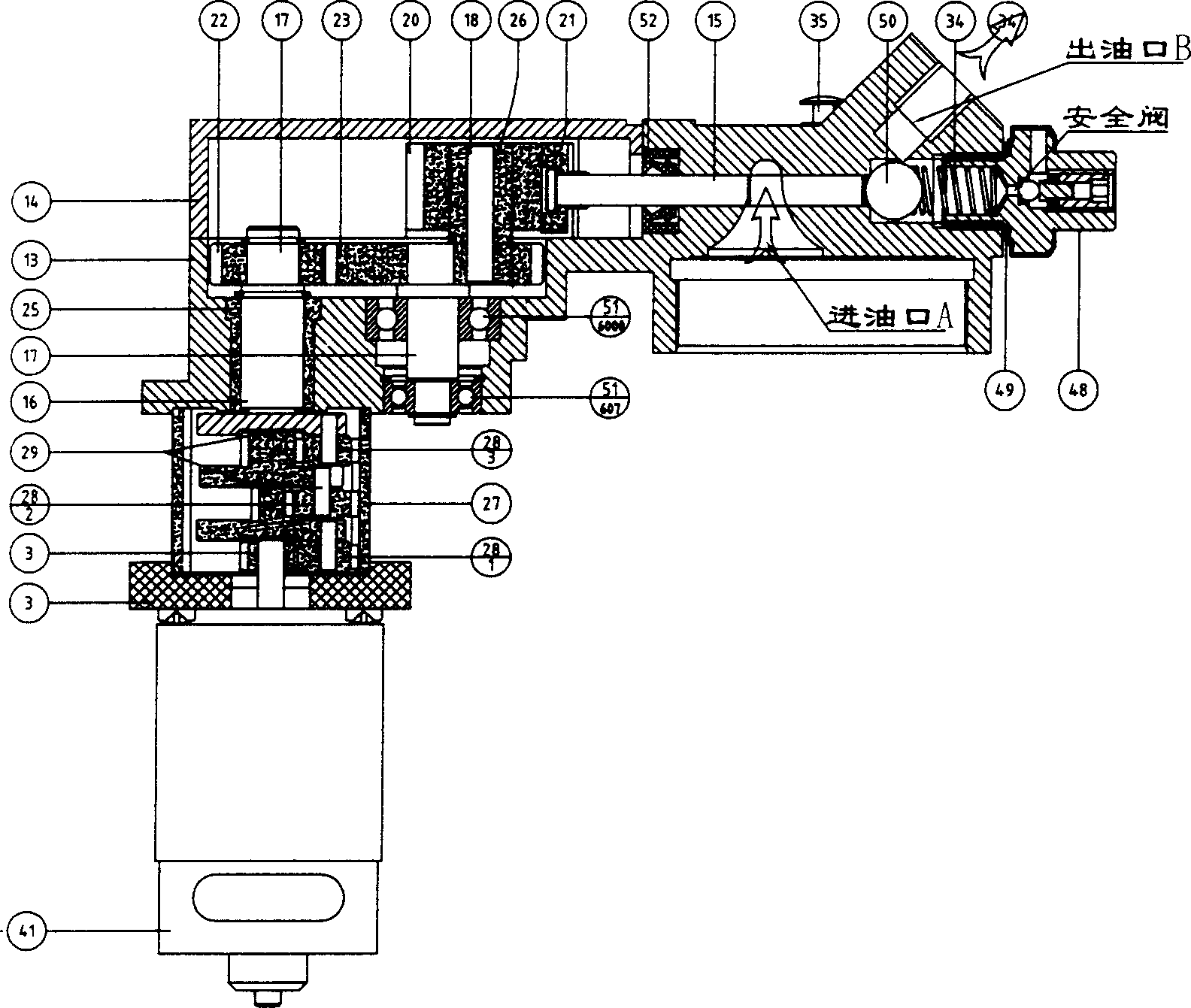

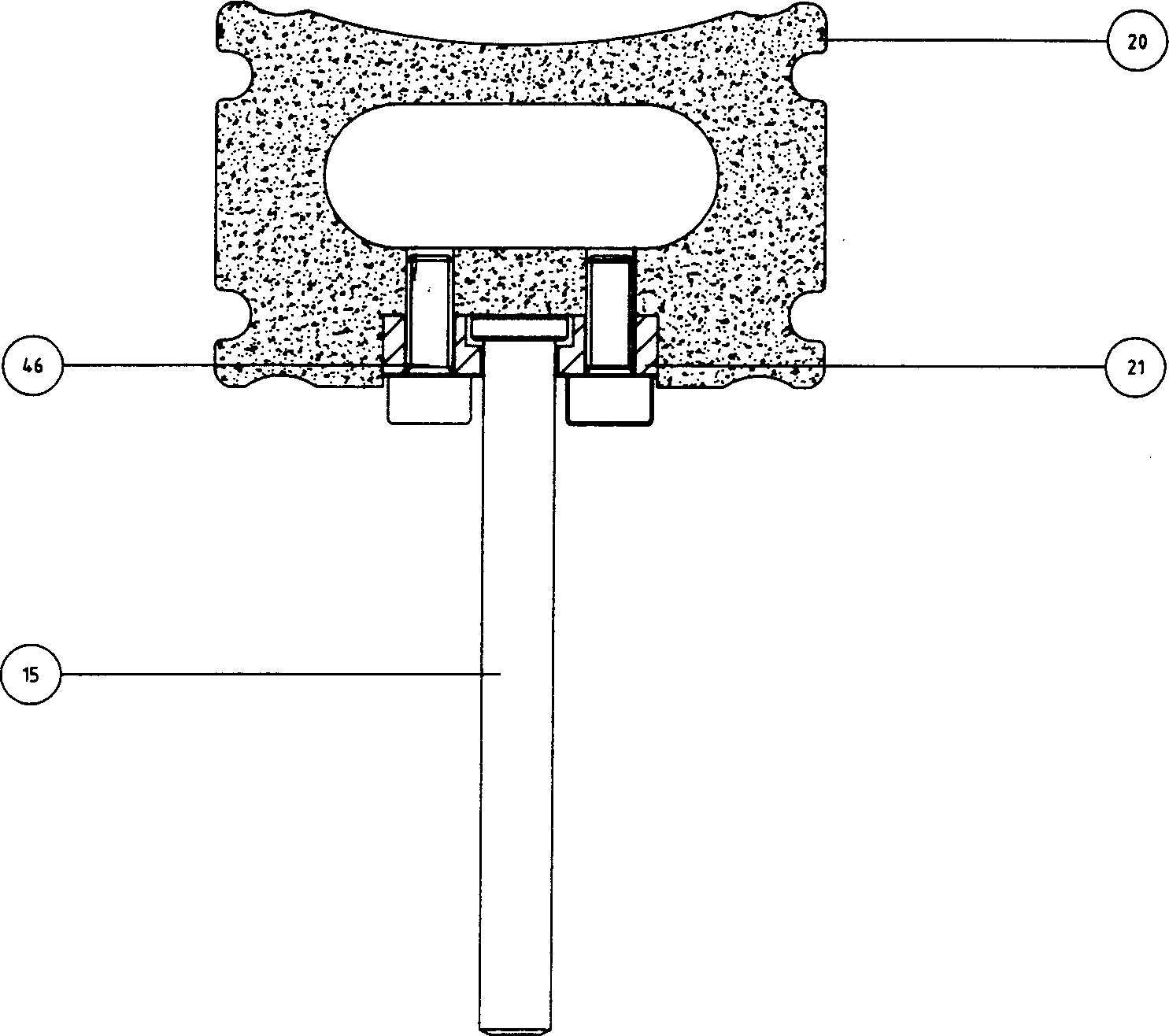

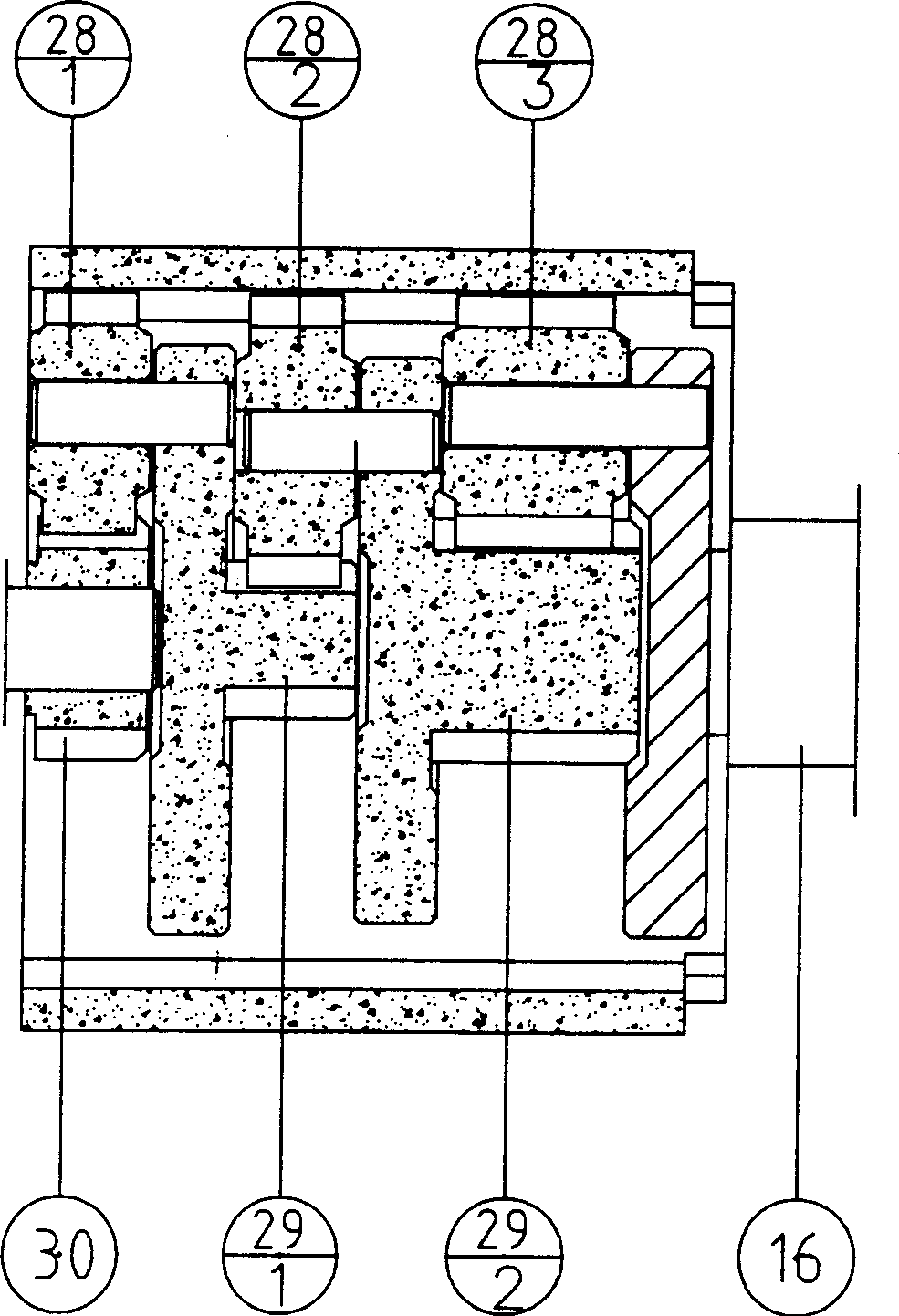

Straight-through heavy type greaser

The present invention relates to grease gun, and is especially one kind of electrically driven 18 V DC heavy grease gun. It has plug-in battery package to provide DC power source to drive great power DC motor, three stage planetary gear and straight gear for reducing speed to increase the output torque of the motor, and sliding crank mechanism to convert the rotation of motor to the linear reciprocation of block and drive the reciprocating plunger to complete high pressure grease injection via cooperation with the grease supplying system. The present invention has high pressure, great flow rate and other advantages.

Owner:赵宏武 +1

Light emitting element, light emitting element manufacturing method and illuminating device

InactiveCN101766059AWell formedEasy to manufactureElectroluminescent light sourcesSolid-state devicesOptoelectronicsPhysics

Owner:SUMITOMO CHEM CO LTD

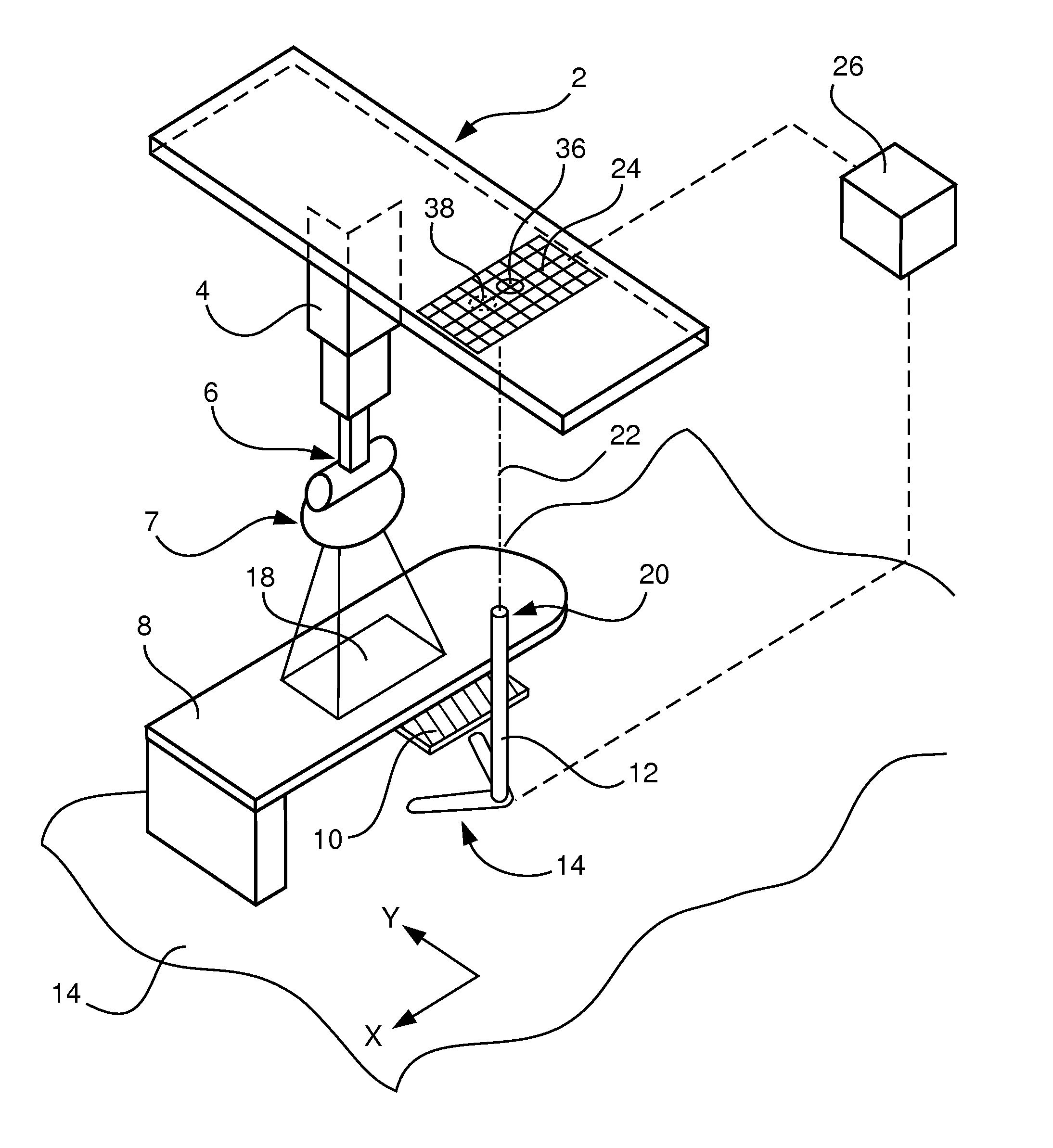

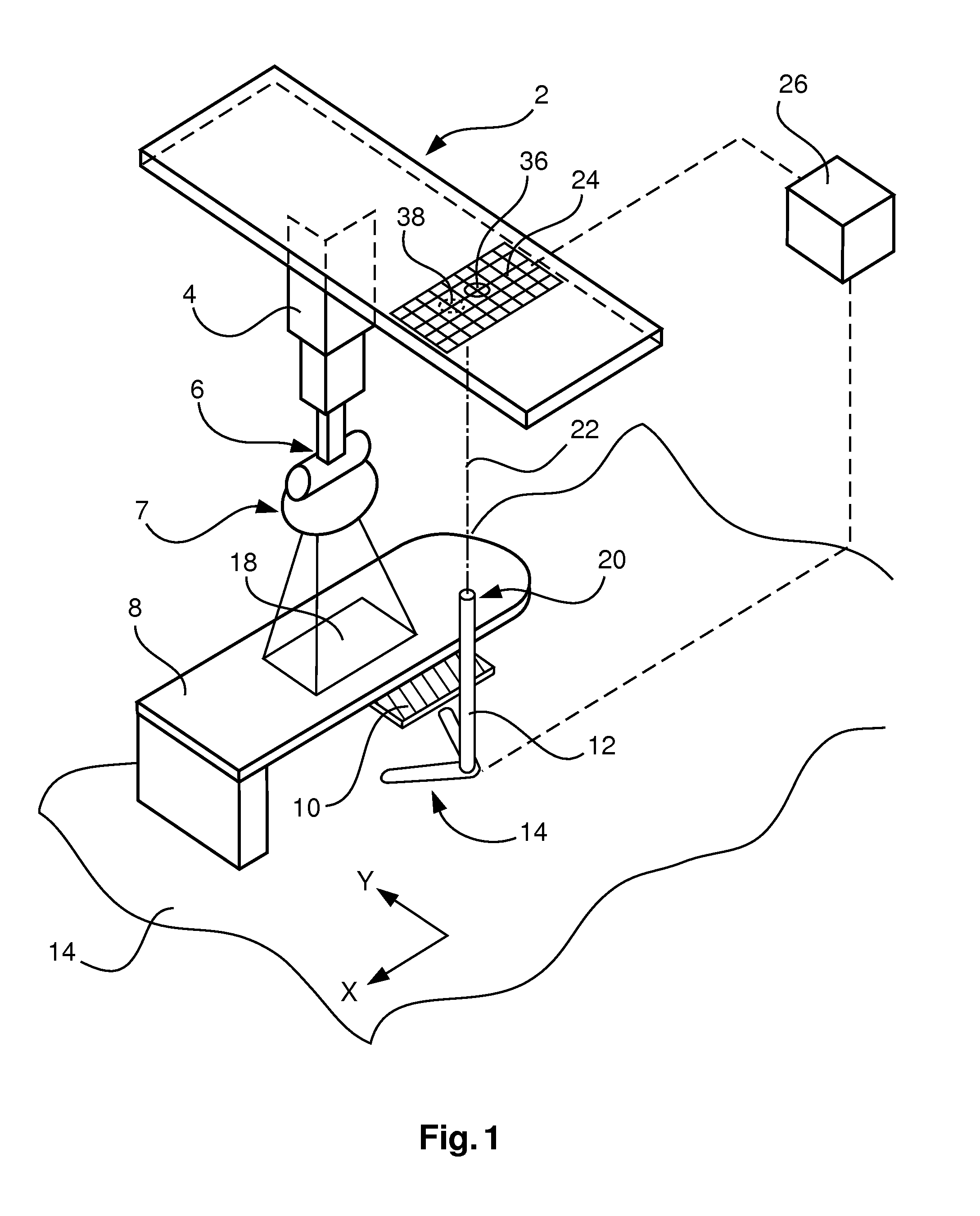

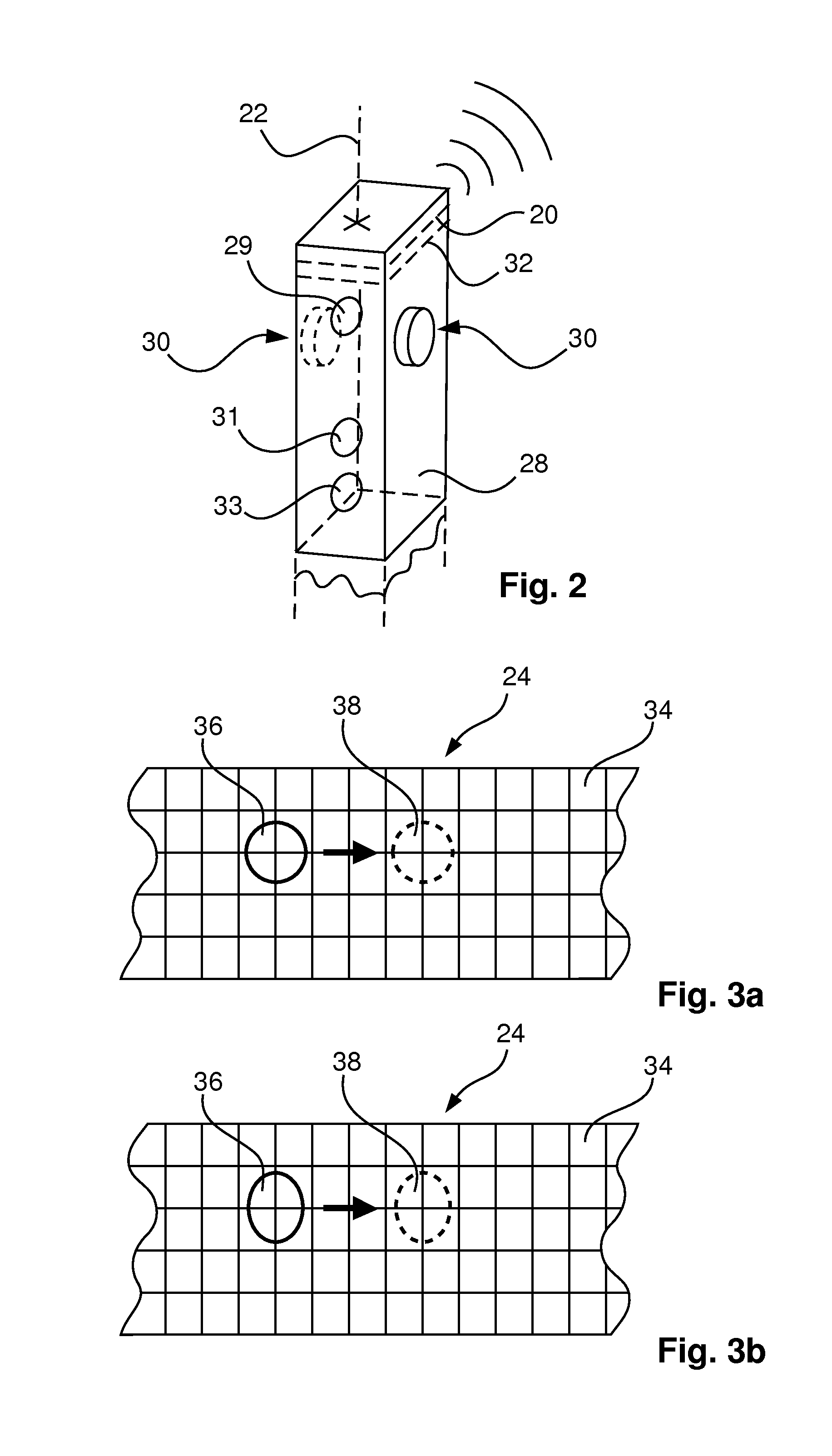

Medical imaging system and method for providing an x-ray image

ActiveUS20140341356A1Reduce occupied spaceEasily positionElectric discharge tubesFree-space transmissionMedical imagingX ray image

An X-ray imaging system comprises an X-ray tube (6), a ceiling suspension (2) for the X-ray tube, a detector trolley (12) with an X-ray detector (10) mounted thereon, an active sensor matrix (24), an optical indication unit (20) and a control unit (26). The active sensor matrix (24) is fixedly mounted on the ceiling suspension (2), the optical indication unit (20) is fixedly mounted to the detector trolley (12) and is adapted for emitting an optical indication (22) onto the active sensor matrix (24). The control unit (26) is connected to the active sensor matrix (24) and is adapted for acquiring the position of the optical indication (22) on the active sensor matrix (24) and to create control signals for aligning the detector trolley position and the ceiling suspension position relative to each other such that the optical indication is present on a predetermined spot on the active sensor matrix. This eliminates the need of a mechanically fixed arm carrying a detector unit at a fixed spatial relationship to an X-ray arm as the detector and the X-ray tube are be linked by a position following process.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

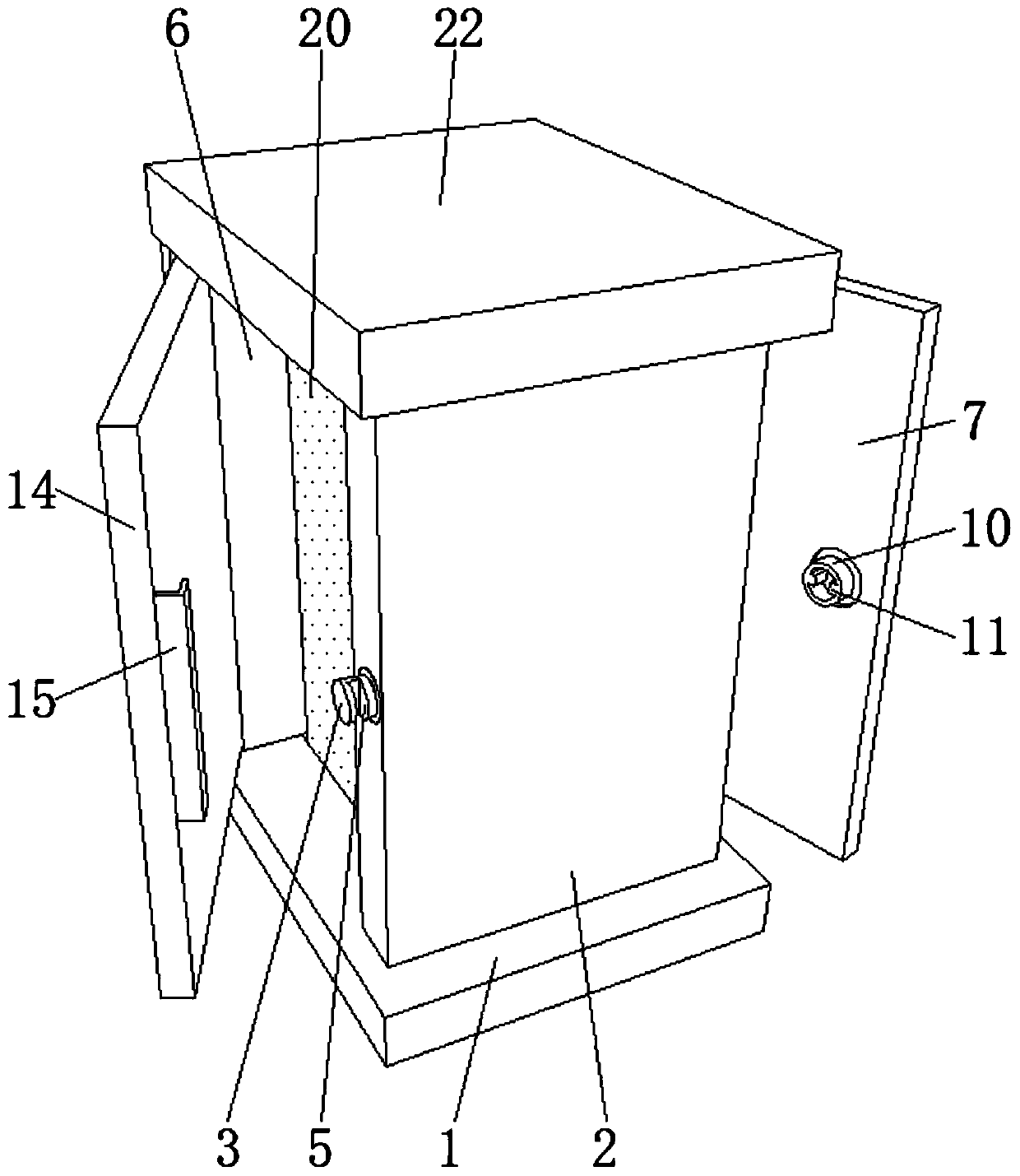

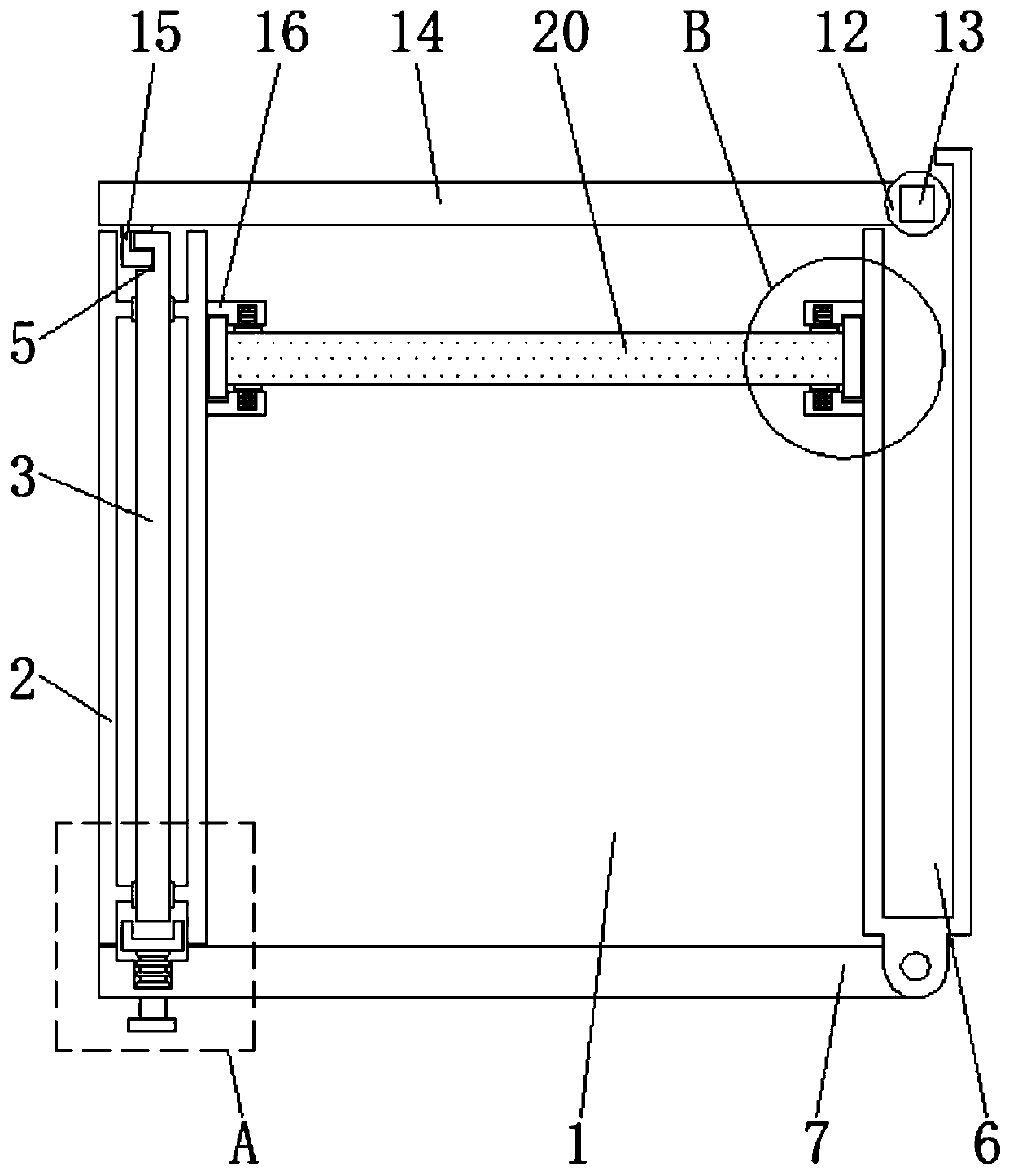

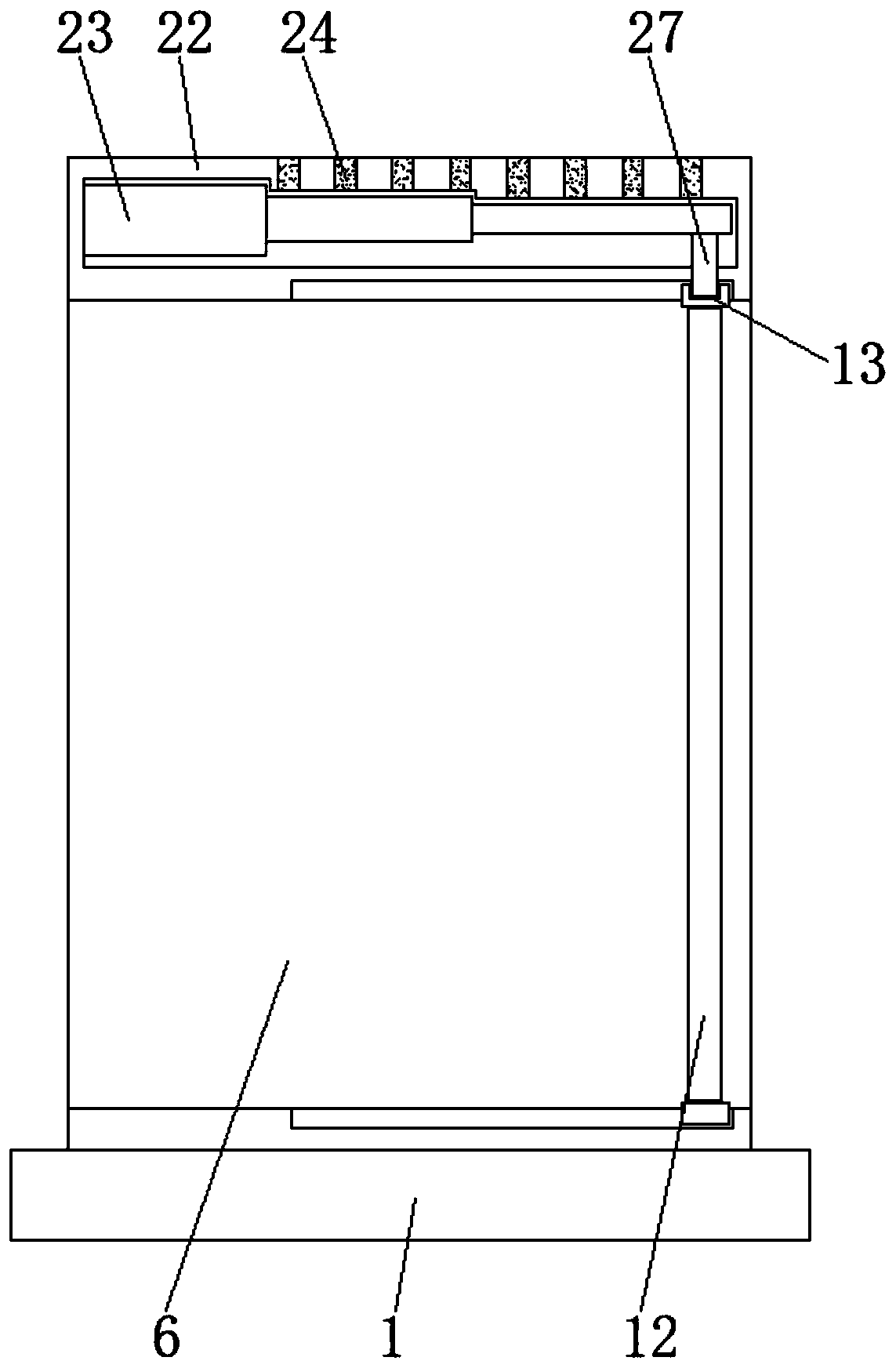

Front-rear double-door type electrical cabinet convenient to overhaul and high in stability

ActiveCN111405785AEasy maintenanceImprove stabilityCasings/cabinets/drawers detailsEngineeringBack door

The invention discloses a front-rear double-door type electrical cabinet convenient to overhaul and high in stability. The electrical cabinet comprises a base, a front door and a rear door, a first side plate is fixed to the upper portion of the left side of the base. And a second side plate is fixed to the upper portion of the right side of the base, the rear end of the pull rod penetrates through the interior of a first spring, a guide rod is installed in the rear portion of the second side plate, the rear door is located in the rear portion of the first side plate, a second spring is installed in a fixing block, and clamping blocks are installed on the left side and the right side of a bearing plate correspondingly. According to the invention, by setting the front door and the rear door, when the electrical element is installed and debugged, the installation position of the electrical element can be quickly found by opening the front door or the rear door in different directions, the installation and potential connection of the electrical element are facilitated, the convenience of workers in the use and operation process is improved, and the overhaul and maintenance efficiencyof the electrical element in the electrical cabinet is greatly improved.

Owner:宁波仁泽电气有限公司

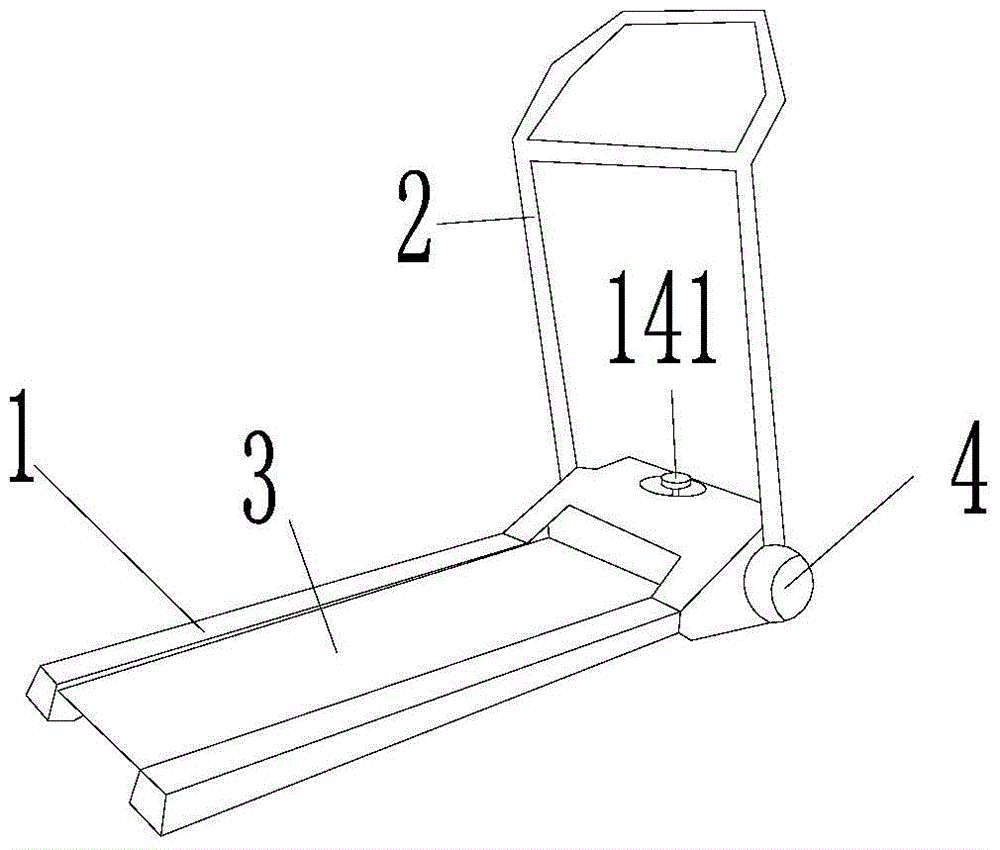

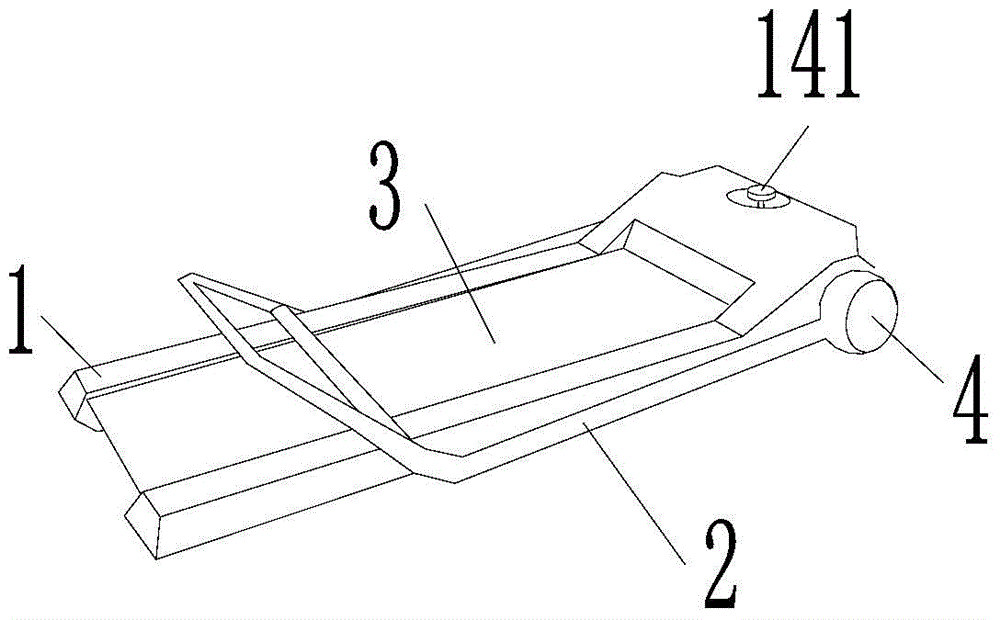

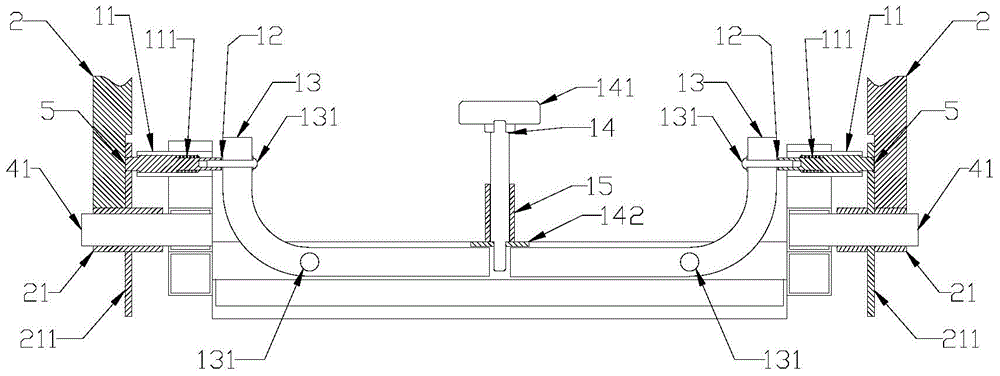

Foldable indoor fitness treadmill

InactiveCN104645553ASimple structureEasy to operateMovement coordination devicesCardiovascular exercising devicesEngineeringTread

The invention discloses a foldable indoor fitness treadmill. The foldable indoor fitness treadmill comprises a seat, an armrest and a tread platform. The tread platform is mounted on the seat; the front end of the seat is provided with a folding mechanism and connected with the lower end of the armrest; through action of the folding mechanism, the armrest can rotate to be folded with the seat when in a storage state and rotate to be perpendicular to the seat and to be positioned when in a use state; the folding mechanism comprises a rotating shaft which is arranged on one side surface of the seat; the lower end of the armrest is provided with a shaft matched with the rotating shaft. The foldable indoor fitness treadmill is simple in structure and convenient to use; when the foldable indoor fitness treadmill is not in use, the armrest can be folded to reduce indoor space occupation and facilitate storage, so that the foldable indoor fitness treadmill is an ideal indoor fitness device for people without sufficient living space.

Owner:陈素洁

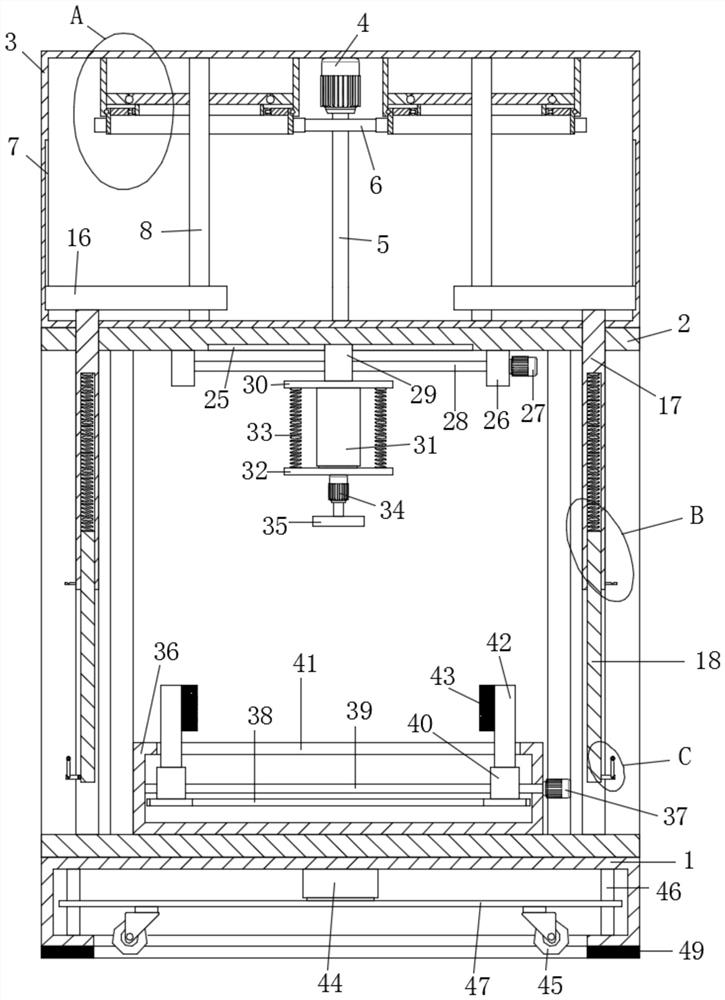

Disinfecting, recycling and pretreating device for environment-friendly medical utensils

InactiveCN113894969AReduce contactReduce the risk of infectionPlastic recyclingLavatory sanitoryMedicineEnvironmental engineering

The invention relates to a disinfecting, recycling and pretreating device for environment-friendly medical utensils. The disinfecting, recycling and pretreating device effectively solves the problems that existing waste infusion bottles are inconvenient to disinfect and clean and inconvenient to transfer in the storage and recycling processes. According to the technical scheme, a medical worker can disinfect, recycle and pretreat the waste infusion bottles temporarily stored in a hospital through the device, the medical worker does not need to participate too much in the whole disinfection process, the number of times of direct contact between the medical worker and the infusion bottles is reduced, and the characteristics of the materials of the plastic infusion bottles can be utilized to synchronously compact and adhere the infusion bottle bodies, so that the space occupied by the infusion bottle bodies is greatly reduced, more infusion bottles can be stored at a time, and the frequency that recovery personnel go back and forth to the hospital is reduced.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

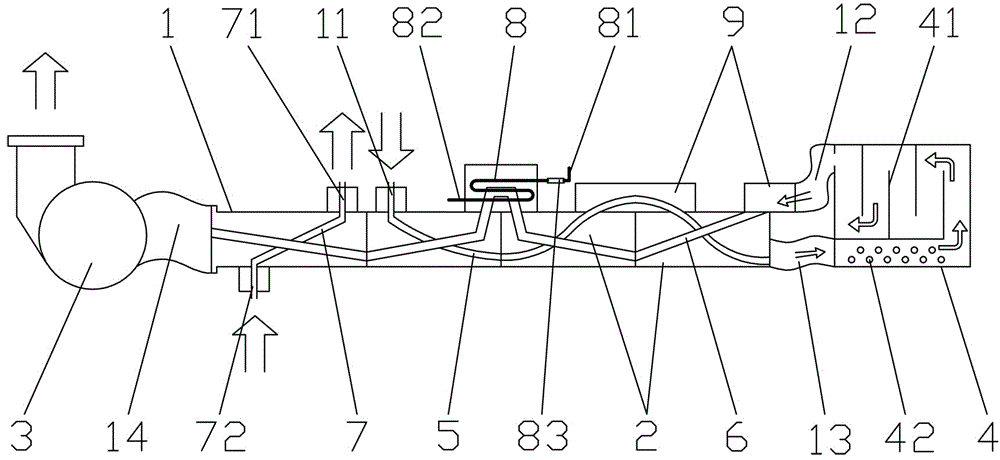

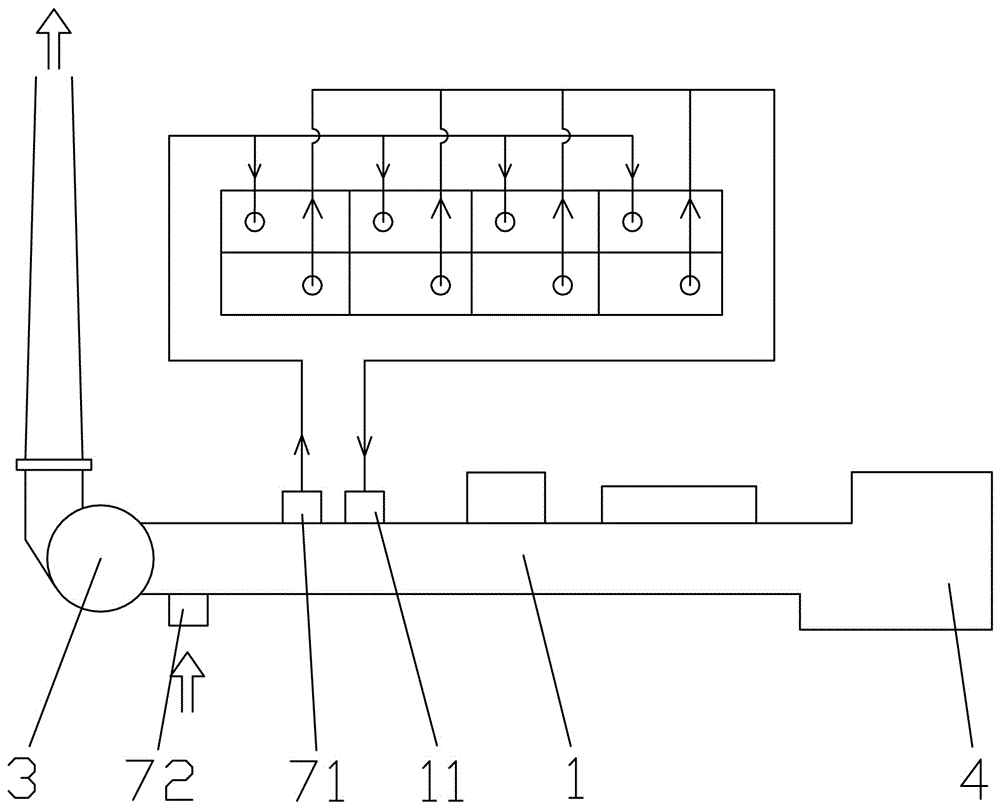

Waste gas treatment structure applied to incineration unit

ActiveCN106196125AImprove heat exchange efficiencyReduce occupied spaceDrying gas arrangementsCombustion technology mitigationThermal energyIncineration

The invention discloses a waste gas treatment structure applied to an incineration unit. The waste gas treatment structure comprises a heat exchange body which comprises gas-gas heat exchanger units arranged in the horizontal direction; an air exhaust fan is arranged at the left end of the heat exchange body, and a pyrolyzation chamber is arranged at the right end of the heat exchange body; and channels between adjacent gas-gas heat exchanger units of the heat exchange body are communicated and form a waste gas go passage and a gas return passage, and fresh channels are arranged in the gas-gas heat exchanger units close to the left side of the heat exchange body. As the waste gas treatment structure adopts the design that the multiple gas-gas heat exchanger units are connected in series to improve the heat exchange efficiency, the occupation space and the installation difficulty of equipment can be greatly reduced; preceding-stage high-temperature waste heat of smoke exhausted by the pyrolyzation of waste gas is used for preheating organic waste gas to be subject to pyrolyzation so that compensatory thermal energy for pyrolyzation can be saved; and later-stage high-temperature waste heat of the smoke directly generates clean and hot air which is returned to and used by a drying system of the equipment.

Owner:FOSHAN ANJIEBAO ENERGY SAVING EQUIP CO LTD

Rotation Mechanism and Display Supporter

InactiveUS20180368588A1Facilitate adjustmentReduce occupied spaceStands/trestlesShow shelvesEngineeringDisplay device

Owner:TAIZHOU STRONKIN ELECTRONICS

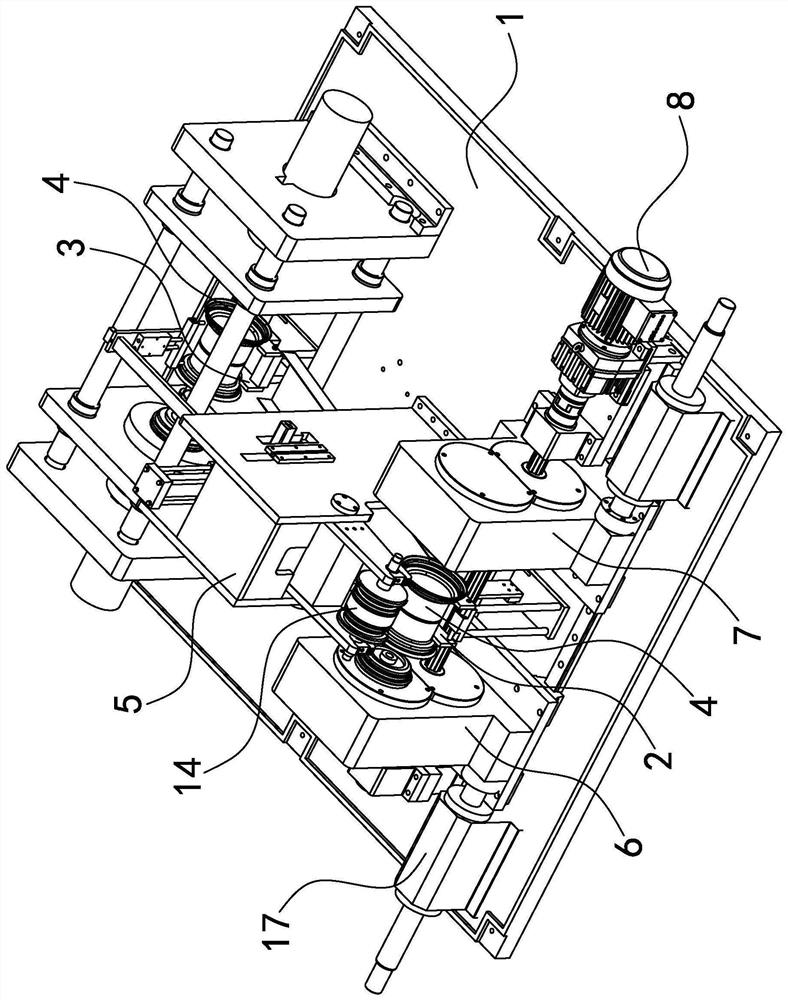

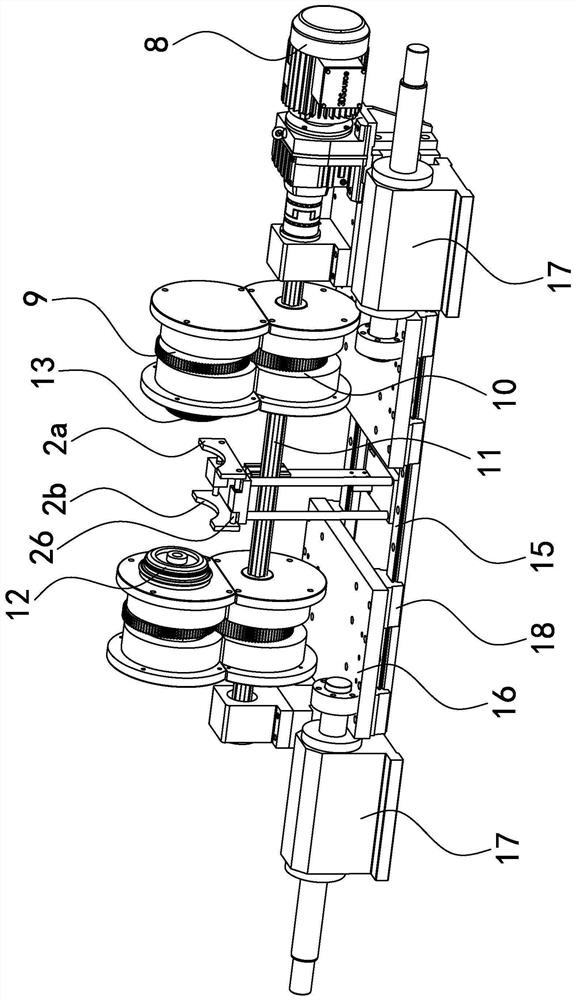

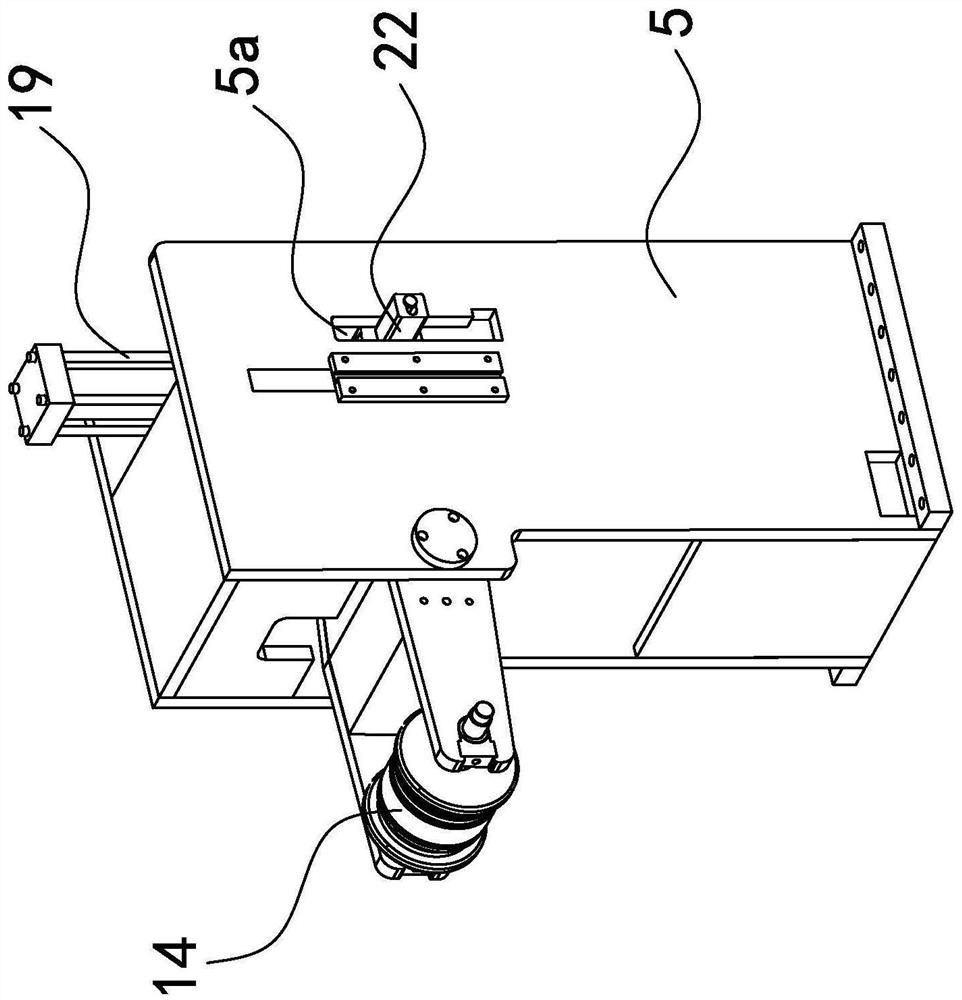

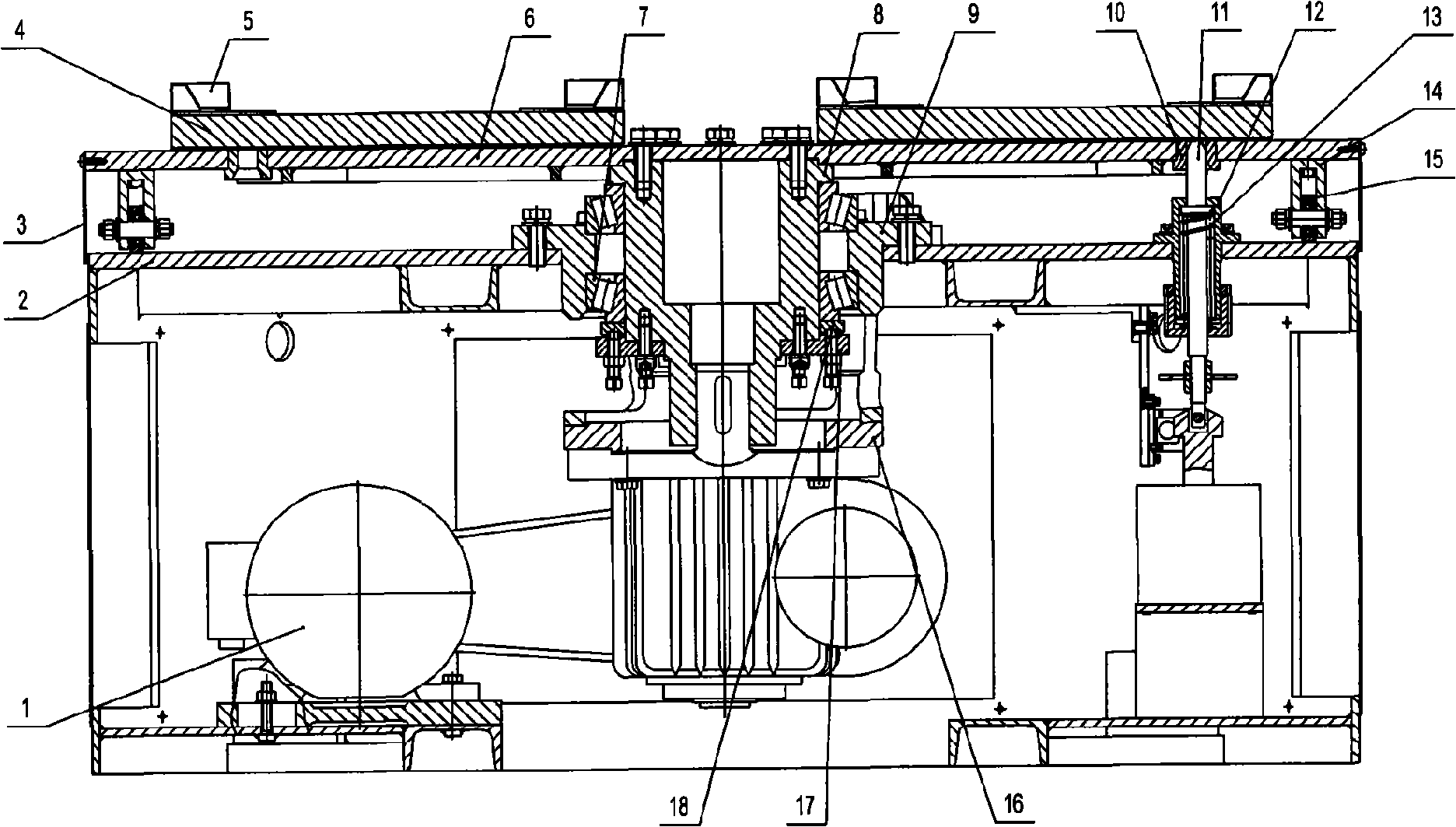

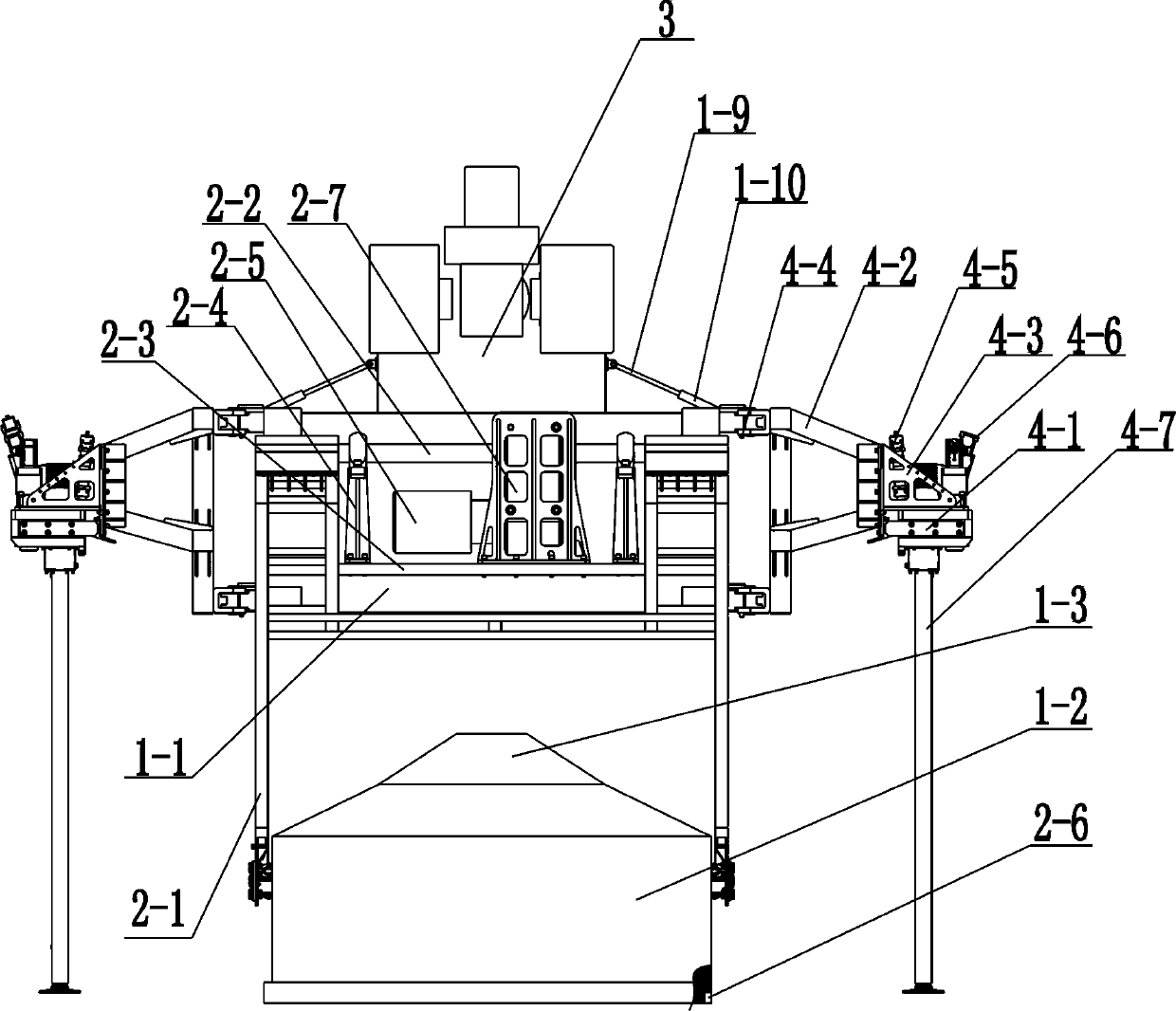

Rim spinning and shaping all-in-one machine

PendingCN112517752AHigh degree of automationIncrease productivityShaping toolsMetal-working feeding devicesMachineMachining

The invention provides a rim spinning and shaping all-in-one machine, and belongs to the technical field of rim manufacturing. The problems that existing rim machining is low in production efficiencyand low in percent of pass are solved. The rim spinning and shaping all-in-one machine comprises a base, an external rotation forming device, a cold-molding shaping device, a controller and a conveying device; the conveying device comprises a rolling ring positioning frame and a shaping positioning frame; and the rolling ring positioning frame and the shaping positioning frame are both used for supporting a rim; The controller is used for controlling the external rotation forming device to work so as to conduct external rotation forming on a to-be-machined rim on the rolling ring positioning frame, used for controlling the conveying device to work so as to automatically convey the rim which is located on the rolling ring positioning frame and subjected to external rotation forming to the shaping positioning frame, and used for controlling the cold-molding shaping device to work so as to carry out cold-molding shaping on the rim which is positioned on the shaping positioning frame and subjected to external rotation forming. The rim spinning and shaping all-in-one machine has the advantages of high automation degree and accurate finished product size.

Owner:ZHEJIANG FENGCHI MECHANICAL

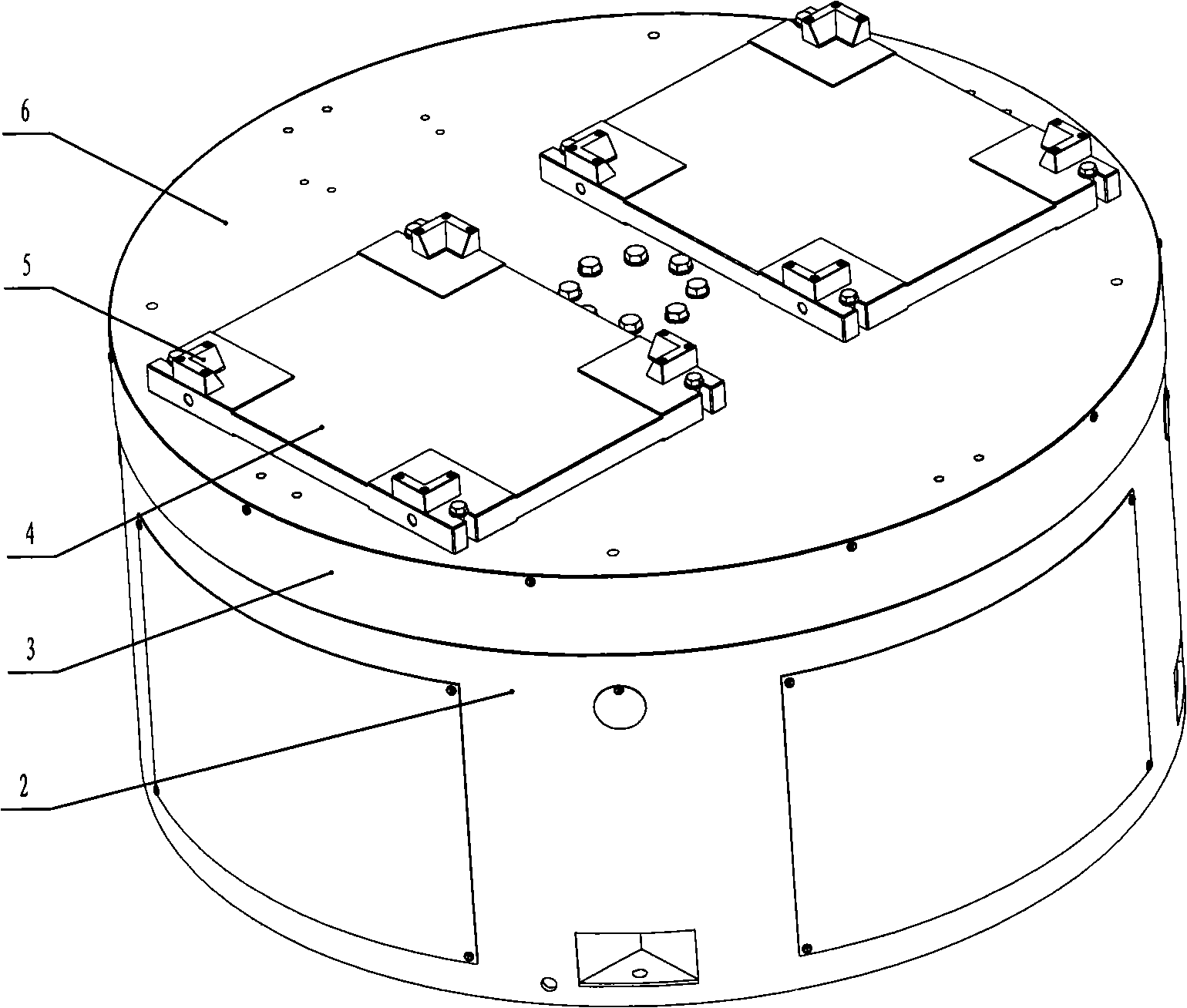

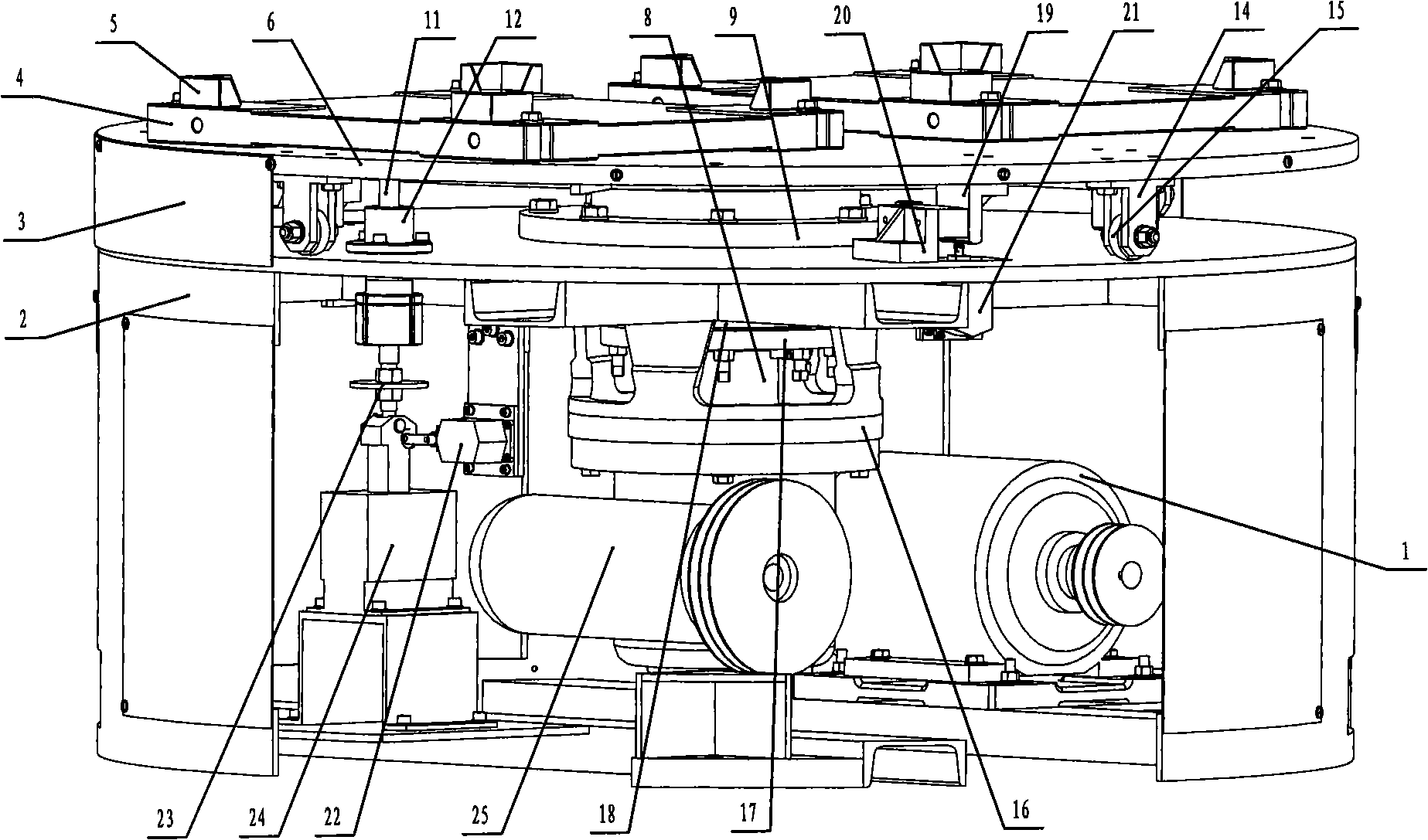

Automatic revolving table for robot teeming line

The invention relates to an automatic revolving table structure for a robot casting line, which comprises a motor, a pedestal, a main revolving shaft, a worm and gear speed reducer, a revolving table revolution surface and an outer table cover. The automatic revolving table structure for the robot casting line is characterized in that the motor and the worm and gear speed reducer are connected with each other through gearing down by a V-type belt; a tractive electromagnet is connected with the pedestal through a tractive electromagnet pedestal; a buffer block support is arranged on the revolving table revolution surface; a buffer block is arranged on the buffer block support; a positioning guide sleeve is sleeved on a positioning guide rod which is arranged inside the pedestal through a positioning guide rod seat; a spring is arranged inside the positioning guide rod seat; an auxiliary support is arranged under the revolving table revolution surface; an auxiliary support roller is arranged inside the auxiliary support; and a box body positioning pedestal is symmetrically arranged on the revolving table revolution surface. The automatic revolving table structure for the robot casting line not only can guarantee the accuracy of placement and positioning of a manipulator clamping position and a casting die shell but also can guarantee the improvement of the production efficiency during operation and the capability of improving the safety factor of operations.

Owner:鹰普(中国)有限公司

Injection molding product polishing machine capable of avoiding debris splashing

InactiveCN112318342AReduce occupied spaceImprove applicabilityGrinding carriagesPolishing machinesRatchetGear wheel

The invention discloses an injection molding product polishing machine capable of avoiding debris splashing. The injection molding product polishing machine comprises a base, a polishing part clampingassembly and a polishing assembly, wherein a protection assembly is arranged on a mounting bracket; the protection assembly comprises a mounting frame, a driving motor and a protection unit; the protection unit comprises protection plate assemblies, a reciprocating screw rod, a first mounting ring, a second mounting plate, a third mounting ring, a fourth mounting plate, a fifth mounting ring anda sixth mounting plate; and the sixth mounting plate and the fifth mounting ring are in transmission connection through a ratchet wheel and pawl pair. According to the injection molding product polishing machine disclosed by the invention, the driving motor is arranged; under the mutual matching effect of a driving gear and a driven gear and the common effect of the ratchet wheel and pawl pair, the protection plate assemblies, which are symmetrically arranged, are driven to hoist through driving a guide block, so that debris splashing is avoided and a placement space, which is additionally occupied by the protection plate assemblies, is reduced; and meanwhile, the protection plate assemblies, which are symmetrically arranged, do not need to be hoisted synchronously, so that the applicability of the protection plate assemblies of the whole device is improved.

Owner:陈明友

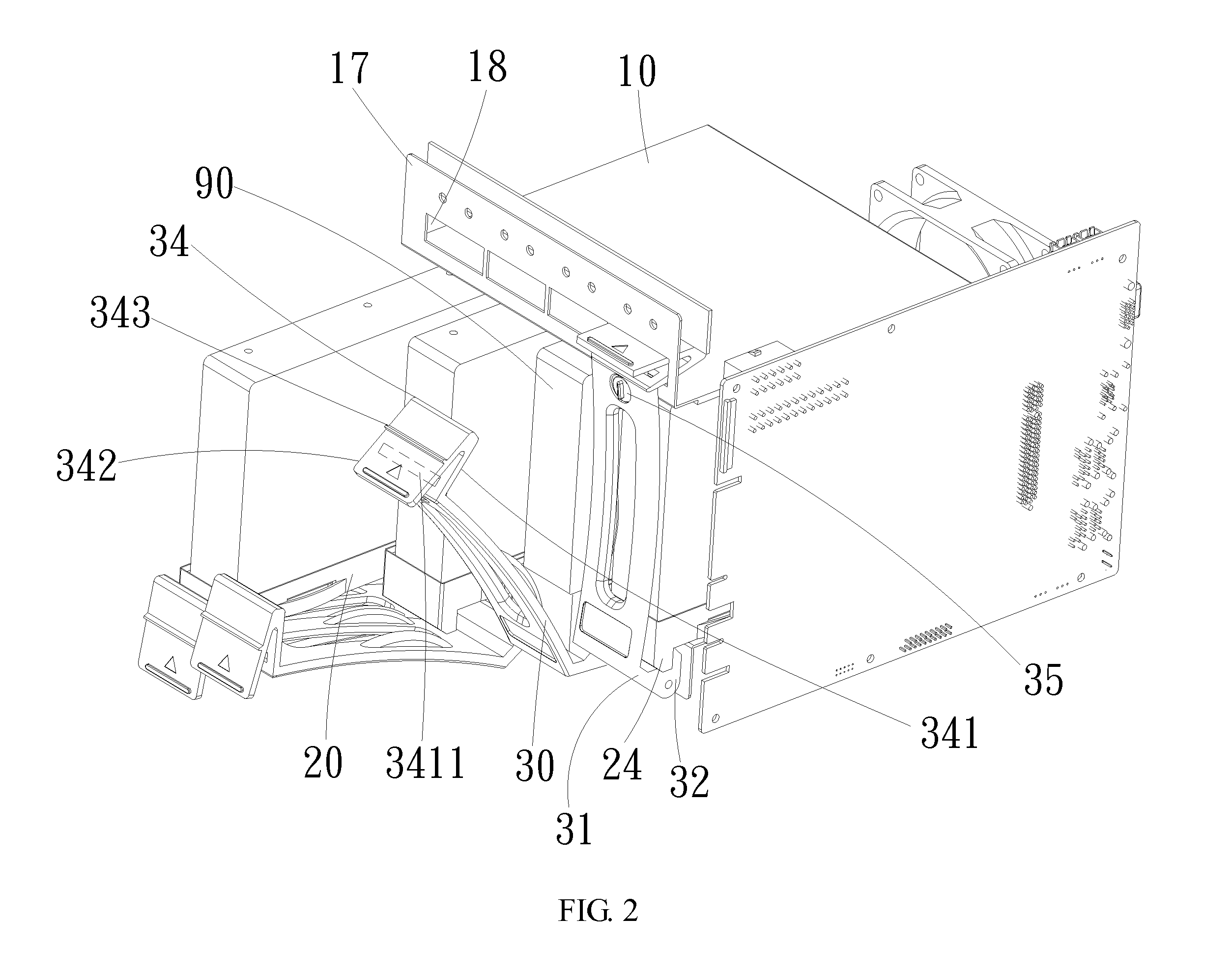

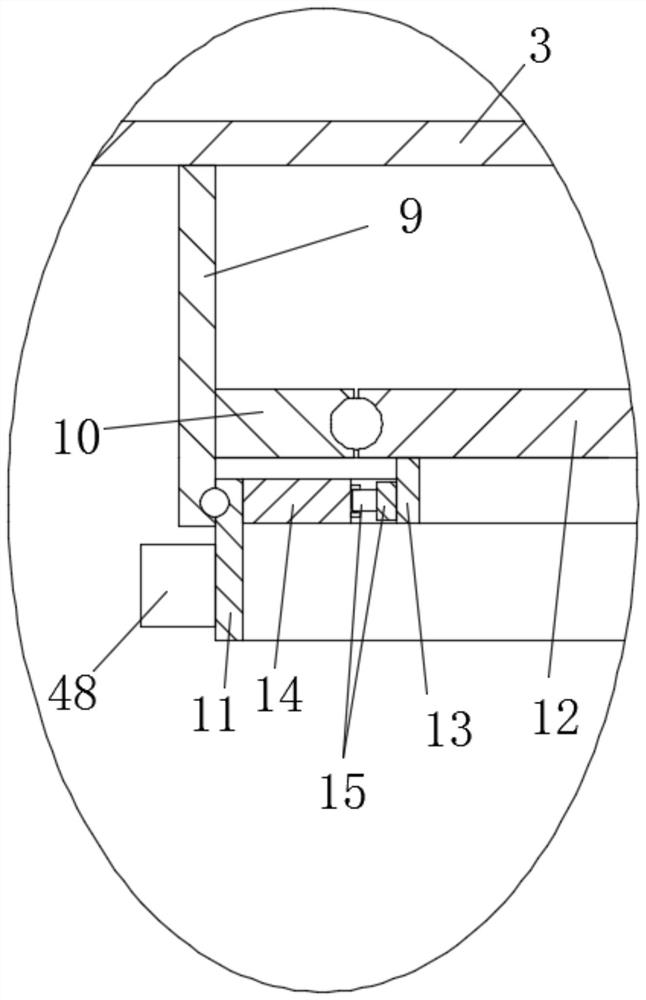

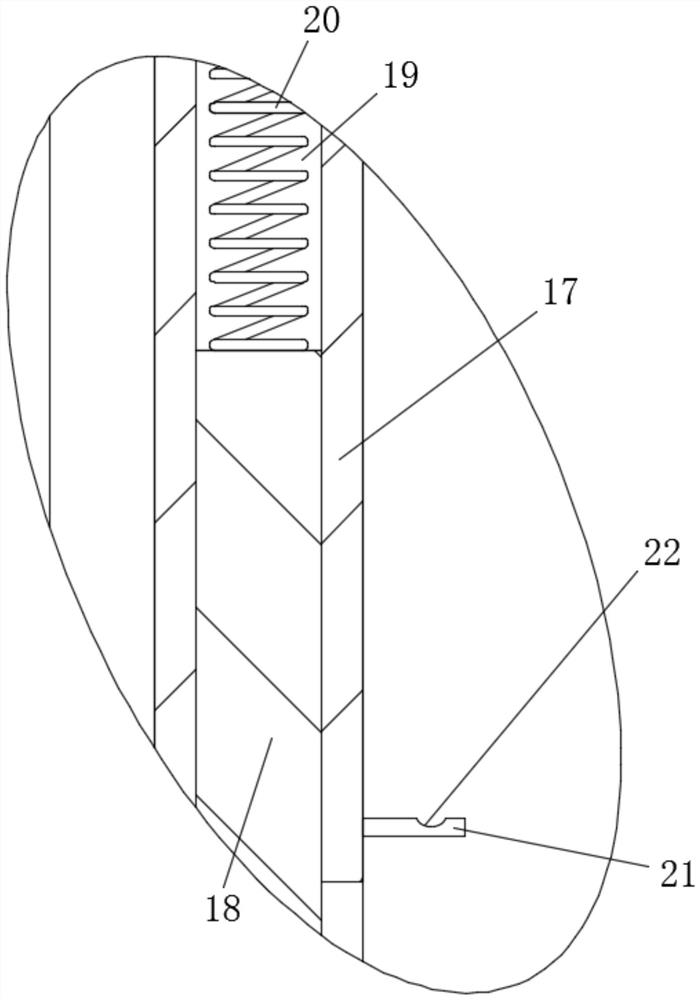

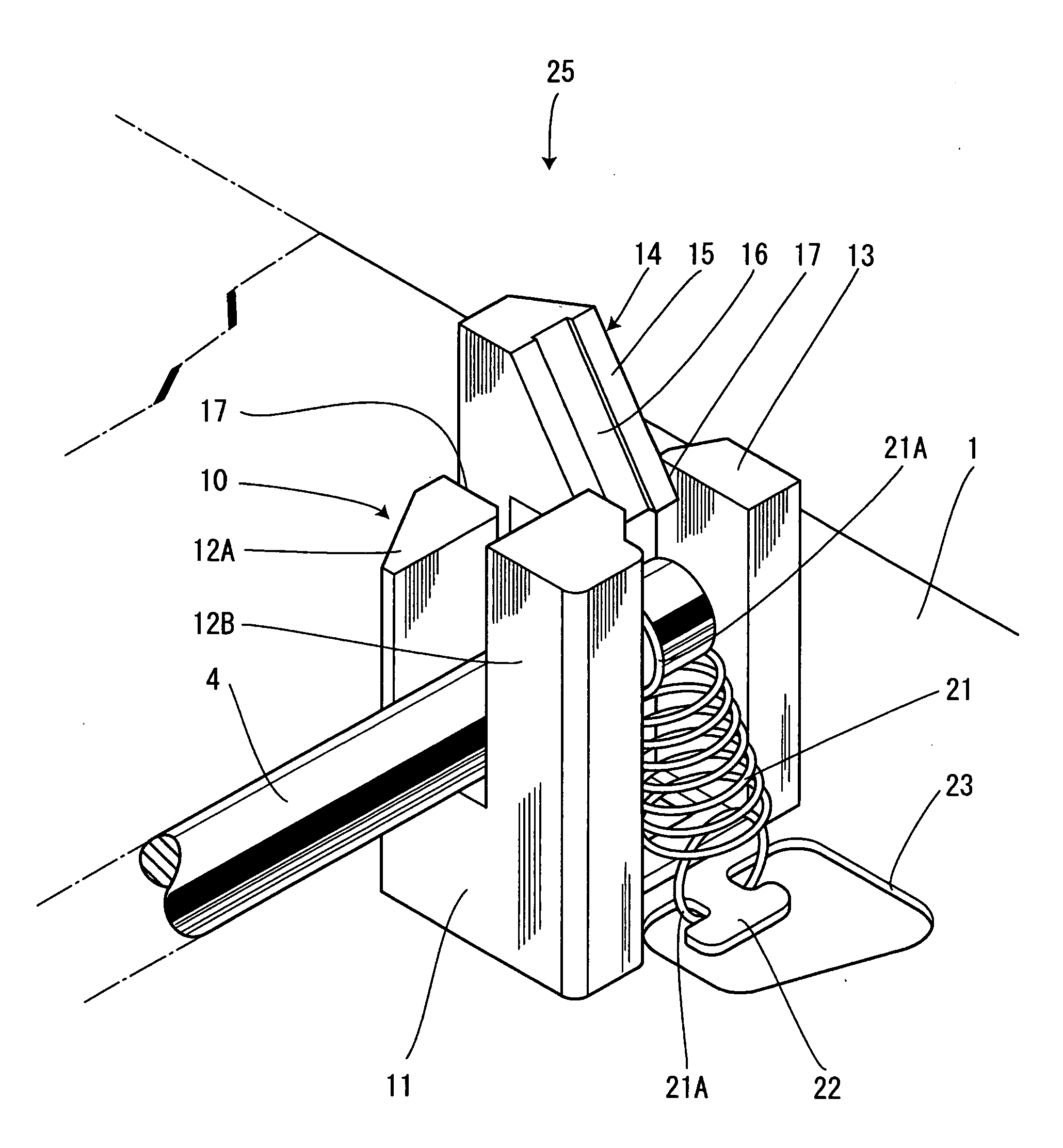

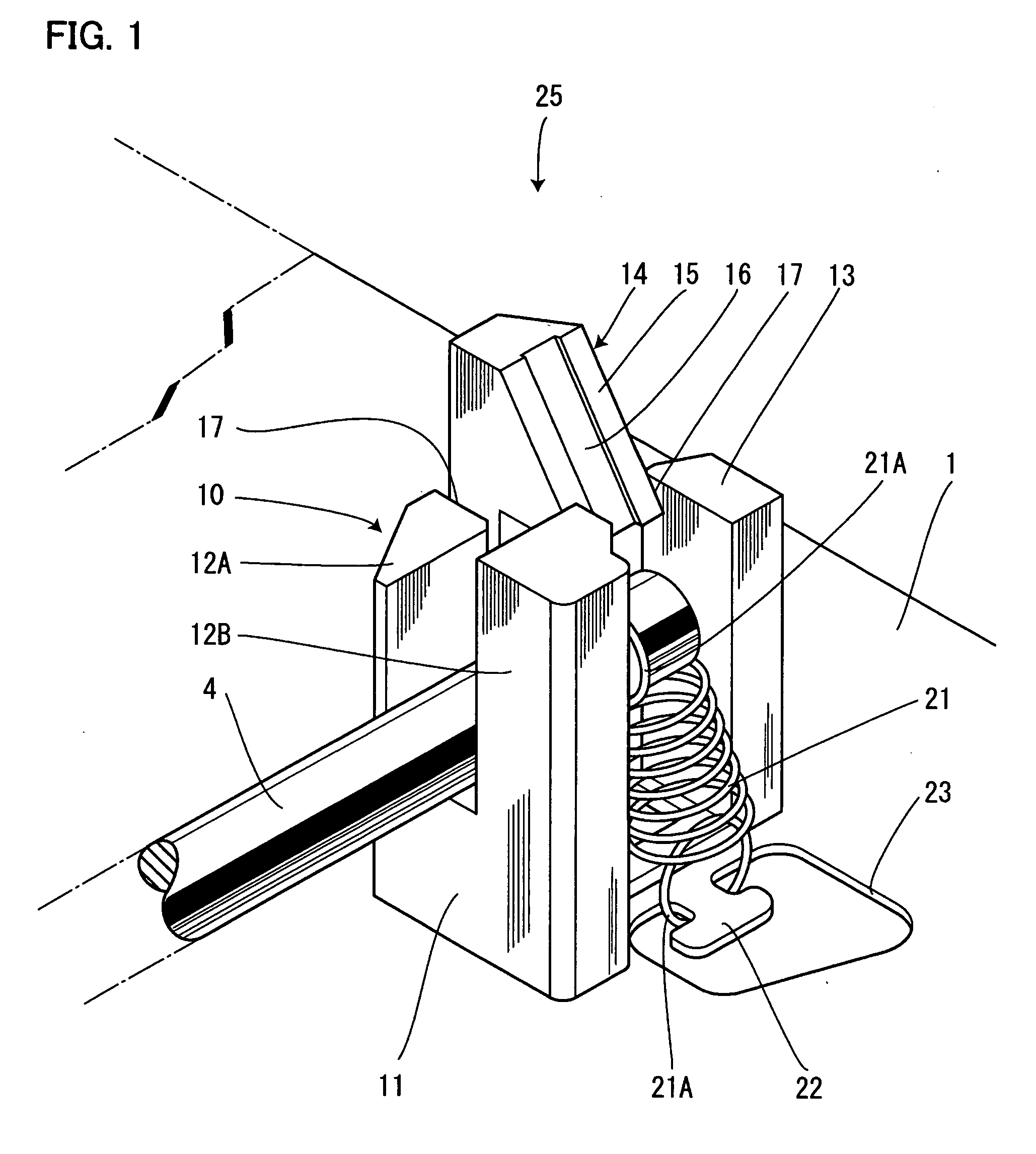

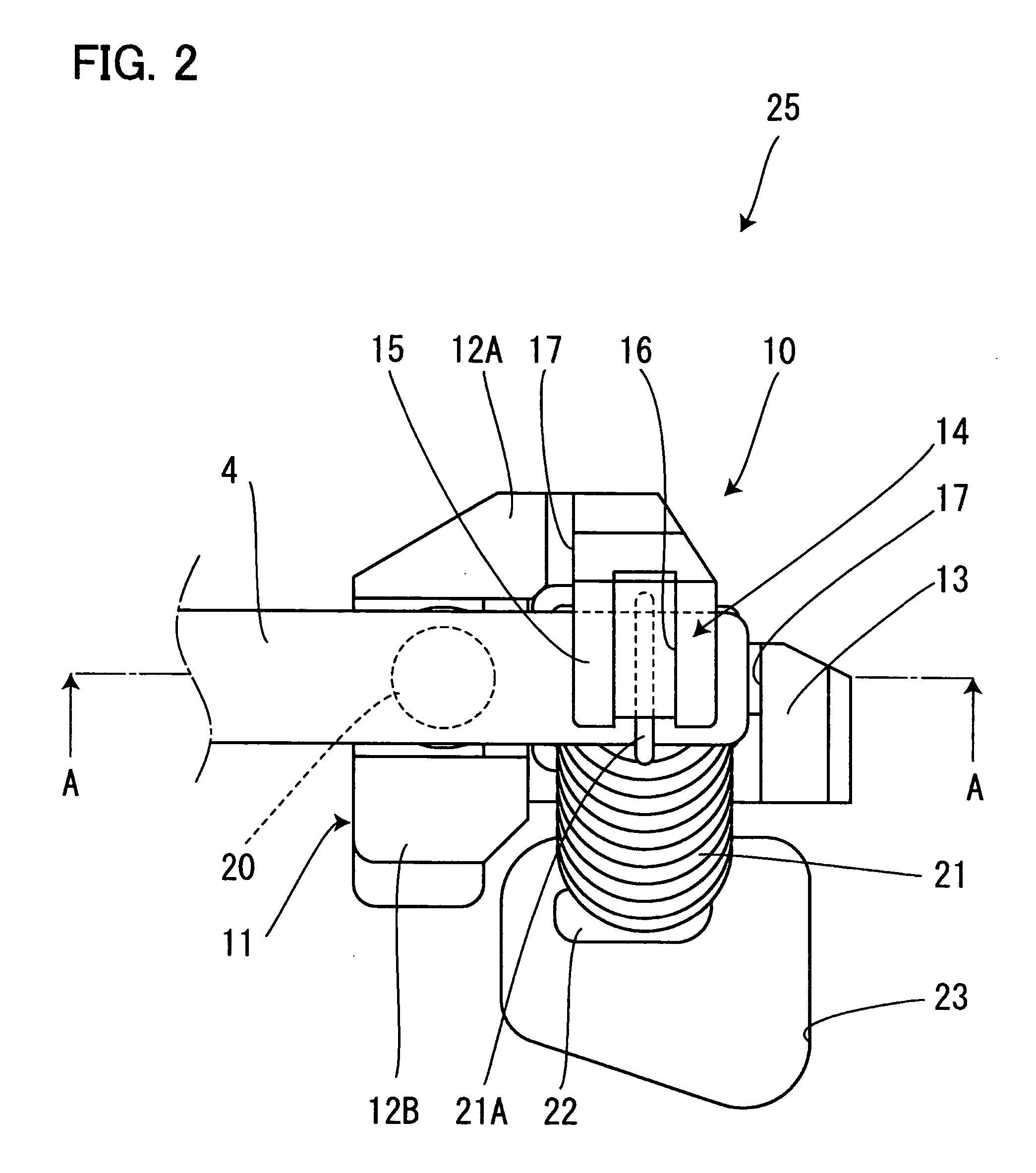

Guide shaft holding mechanism and disk device including the guide shaft holding mechanism

InactiveUS20060117327A1Reduce occupied spaceDownsize and miniaturize deviceRecord information storageRecording head arrangementsEngineeringCoil spring

To make it possible to downsize a device by reducing an occupied space on a chassis occupied by a holding mechanism of a guide shaft as much as possible. A support part 10 is constructed by integrally molding guide walls 12A, 12B which restrict movement of a guide shaft 4 in a radial direction, a stopper part 13 which restricts movement of the guide shaft in a thrust direction and a hook part 14 which restricts slipping-off of the guide shaft 4. A coil spring 21 is provided at a position opposed to the hook part 14 disposed between the guide walls 12A and 12B and the stopper part 13. Thereby, the holding mechanism 25 of the guide shaft 4 including the support part 10 and the coil spring 21 is organized to be compact, and the occupied space of the holding mechanism 25 in a chassis 1 is reduced.

Owner:ORION ELECTRIC CO LTD

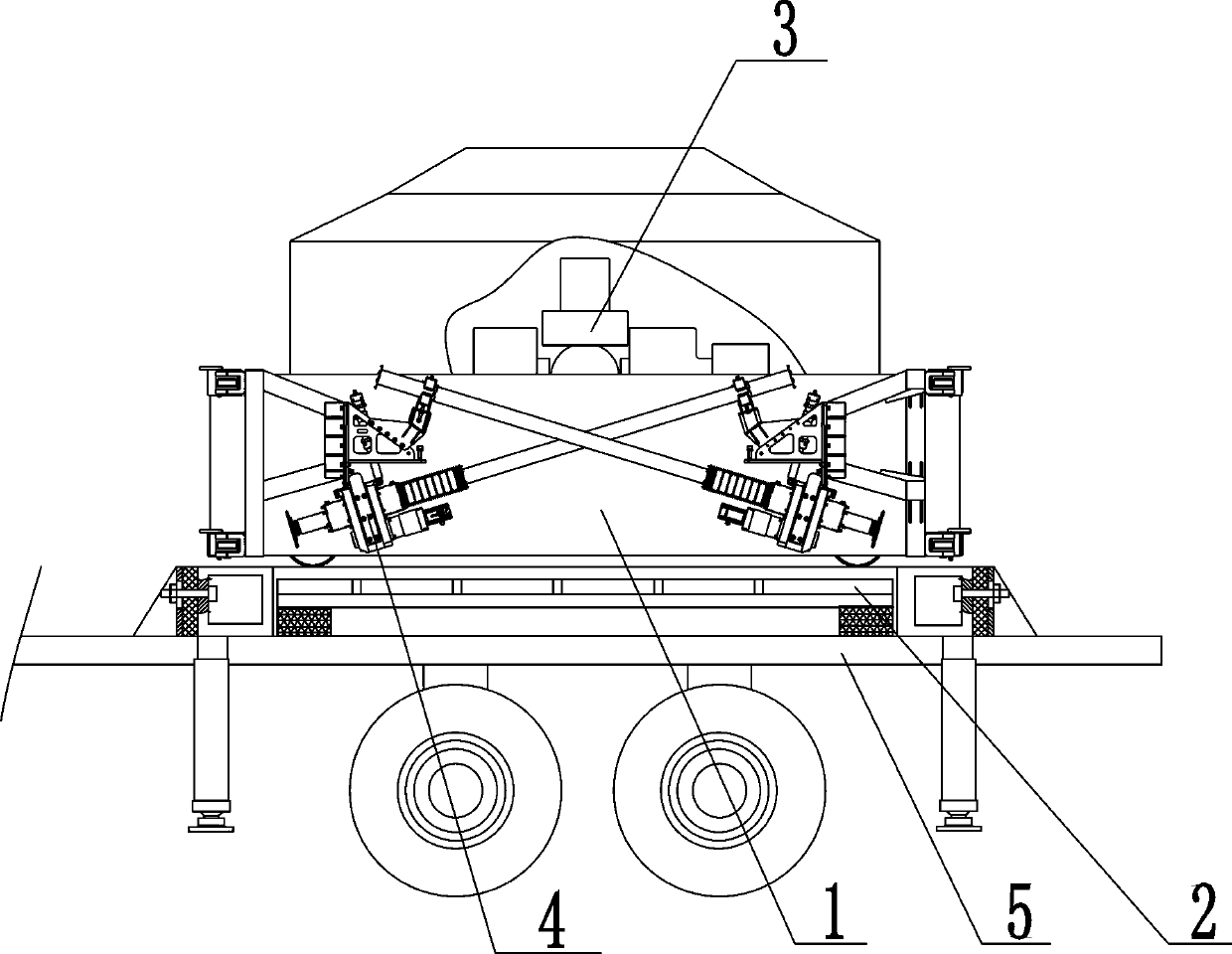

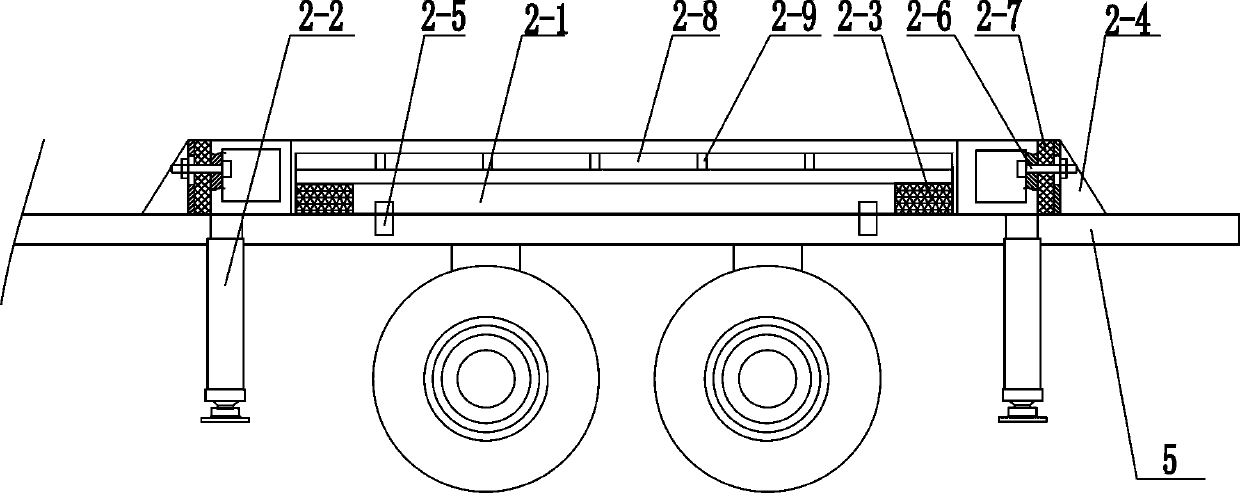

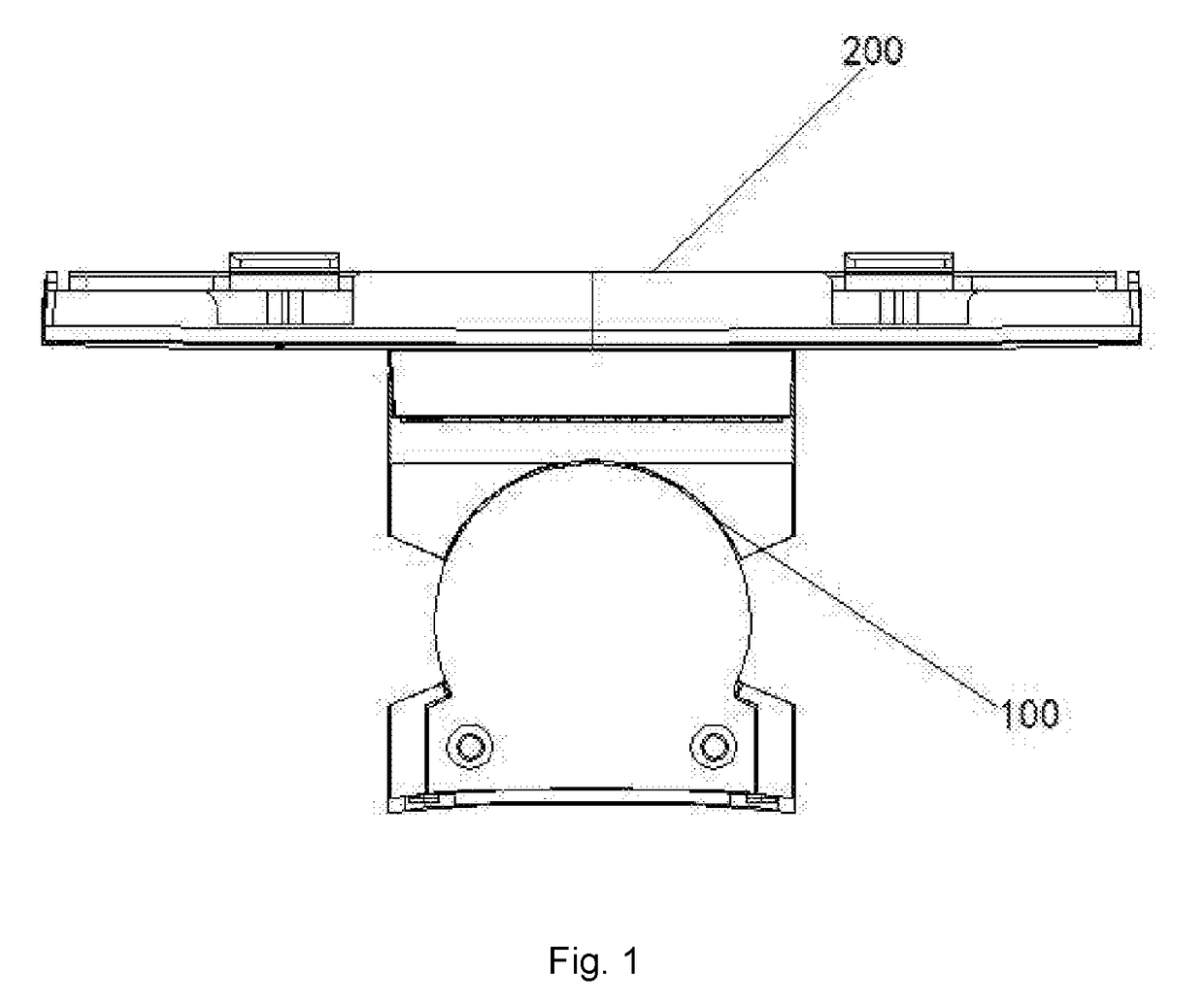

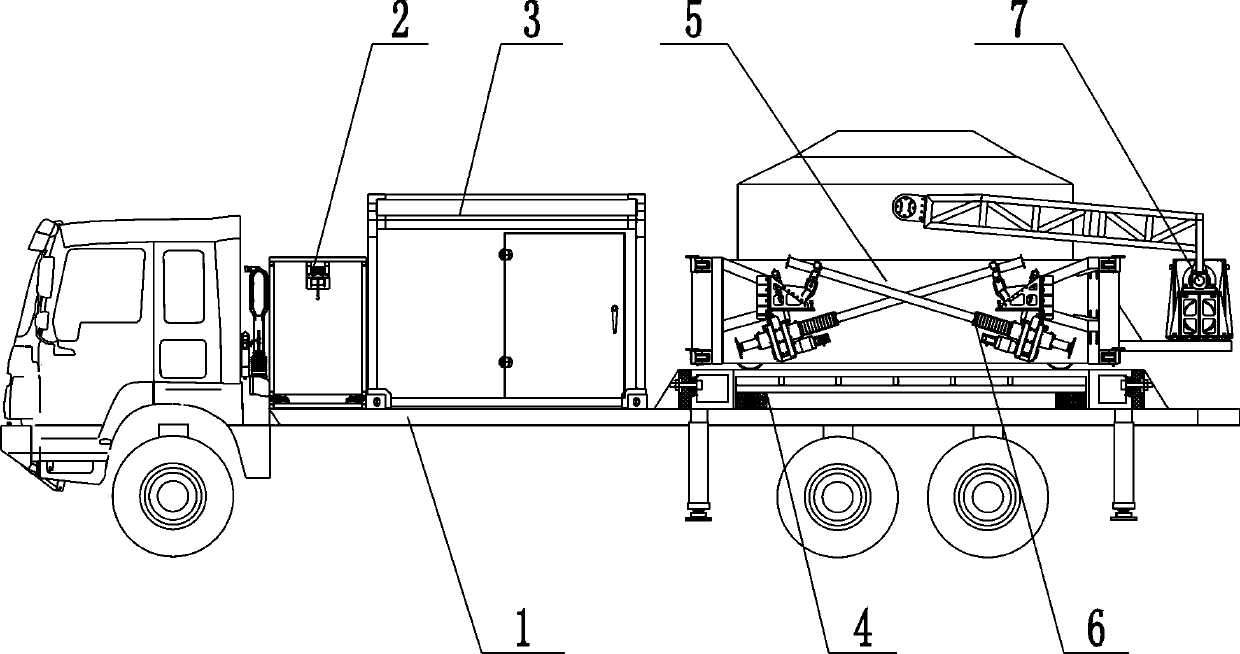

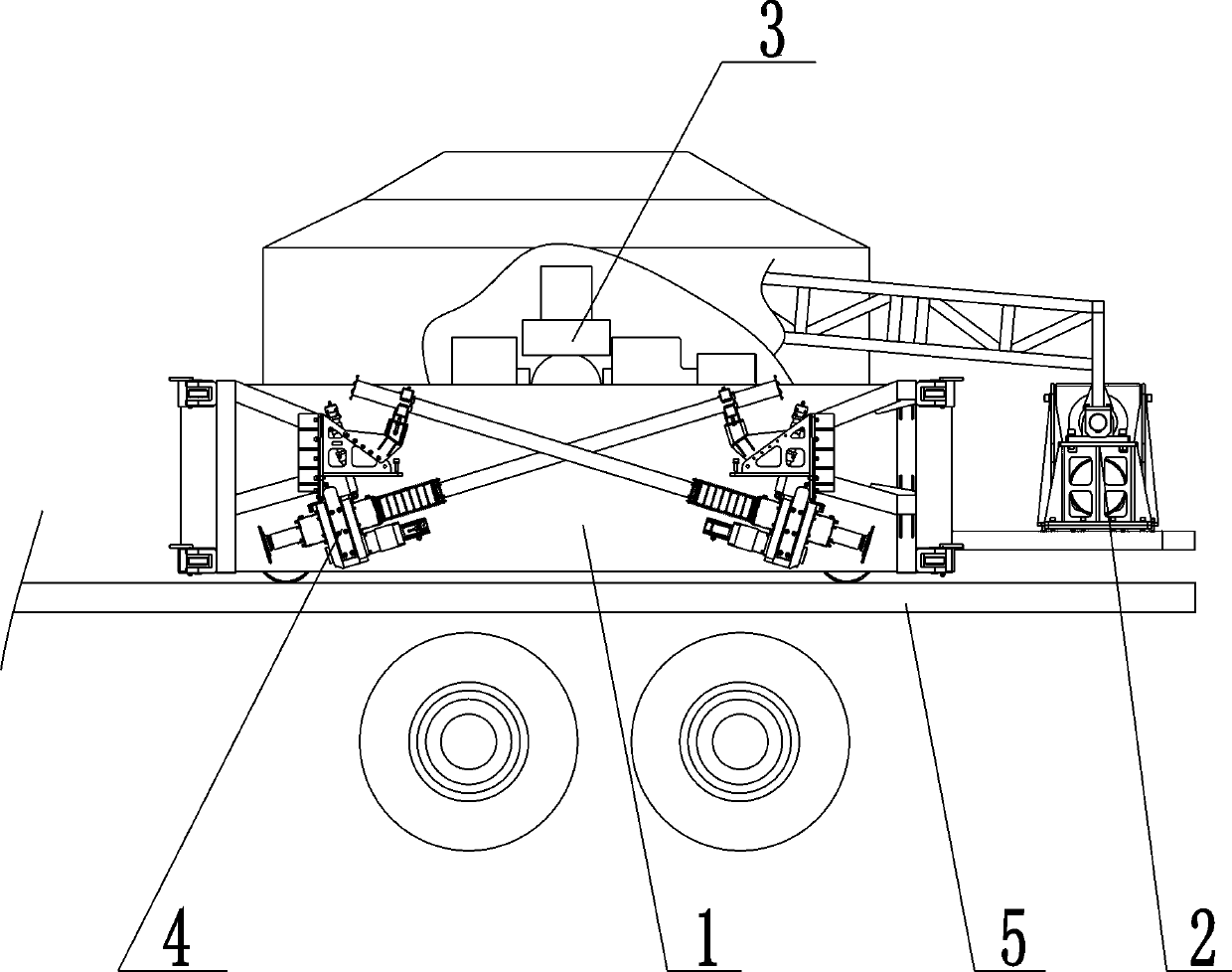

Integrated carrier vehicle body of theodolite carrier vehicle

PendingCN110588483AAvoid influenceSimple structureVehicles with cranesBase supporting structuresAutomotive engineeringMaterial resources

The invention provides an integrated carrier vehicle body of a theodolite carrier vehicle. The integrated carrier vehicle body of the theodolite carrier vehicle is characterized by comprising a chassis, a generator hoisting structure, an operation chamber, a vehicle-mounted leveling platform, a vehicle-mounted theodolite cabin and a flip cover structure of the vehicle-mounted theodolite cabin. Thehead of the chassis is provided with the generator hoisting structure, and the vehicle-mounted leveling platform is arranged at the tail end of the chassis. The vehicle-mounted theodolite cabin is erected on the top face of the vehicle-mounted leveling platform. The operation chamber for operating the theodolite body is arranged between the vehicle-mounted leveling platform and the generator hoisting structure. The integrated carrier vehicle body of the theodolite carrier vehicle effectively solves the problem that a traditional theodolite carrier vehicle is complicated in structure and needsto consume a large quantity of manpower and material resources.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI +1

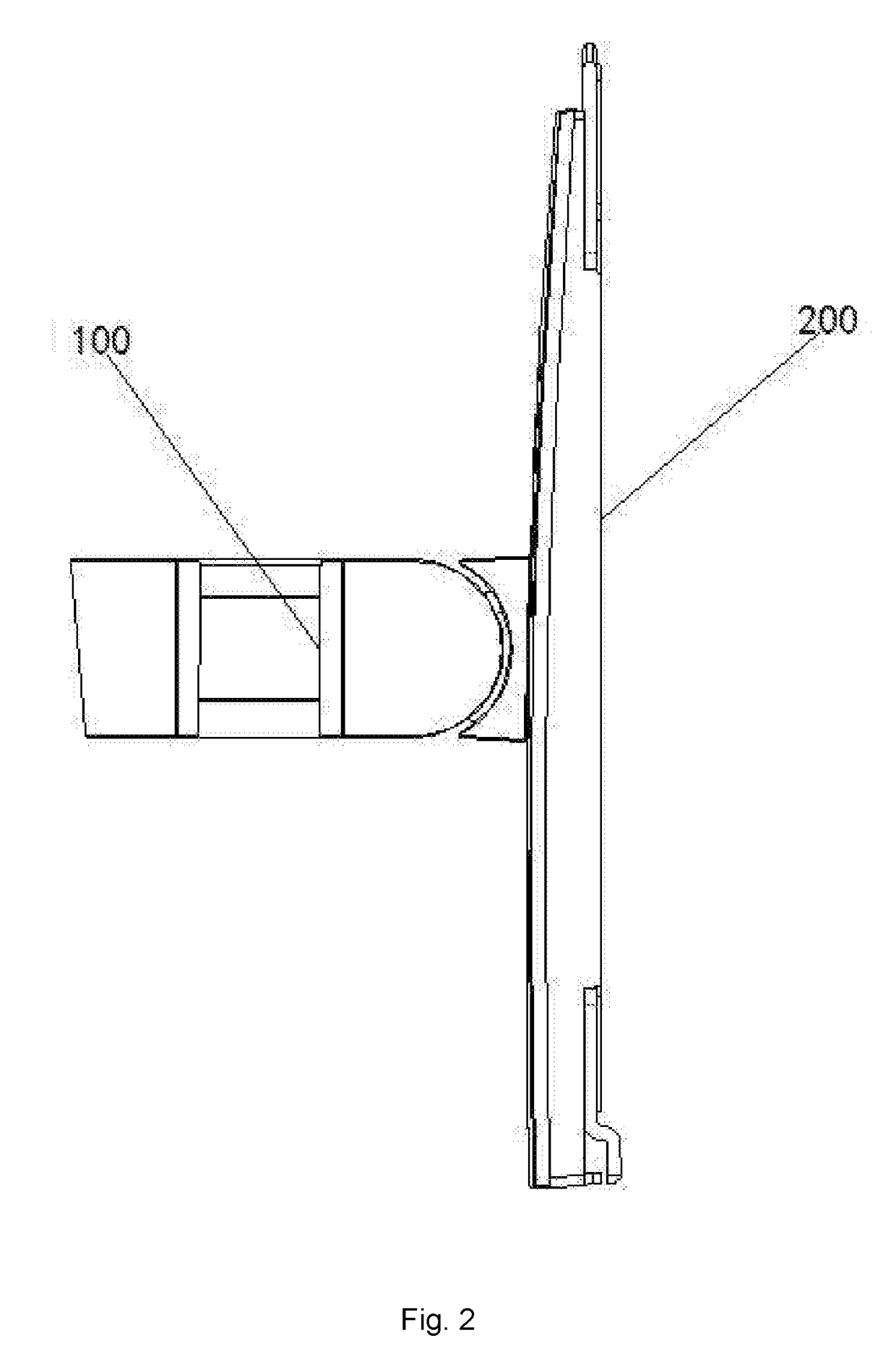

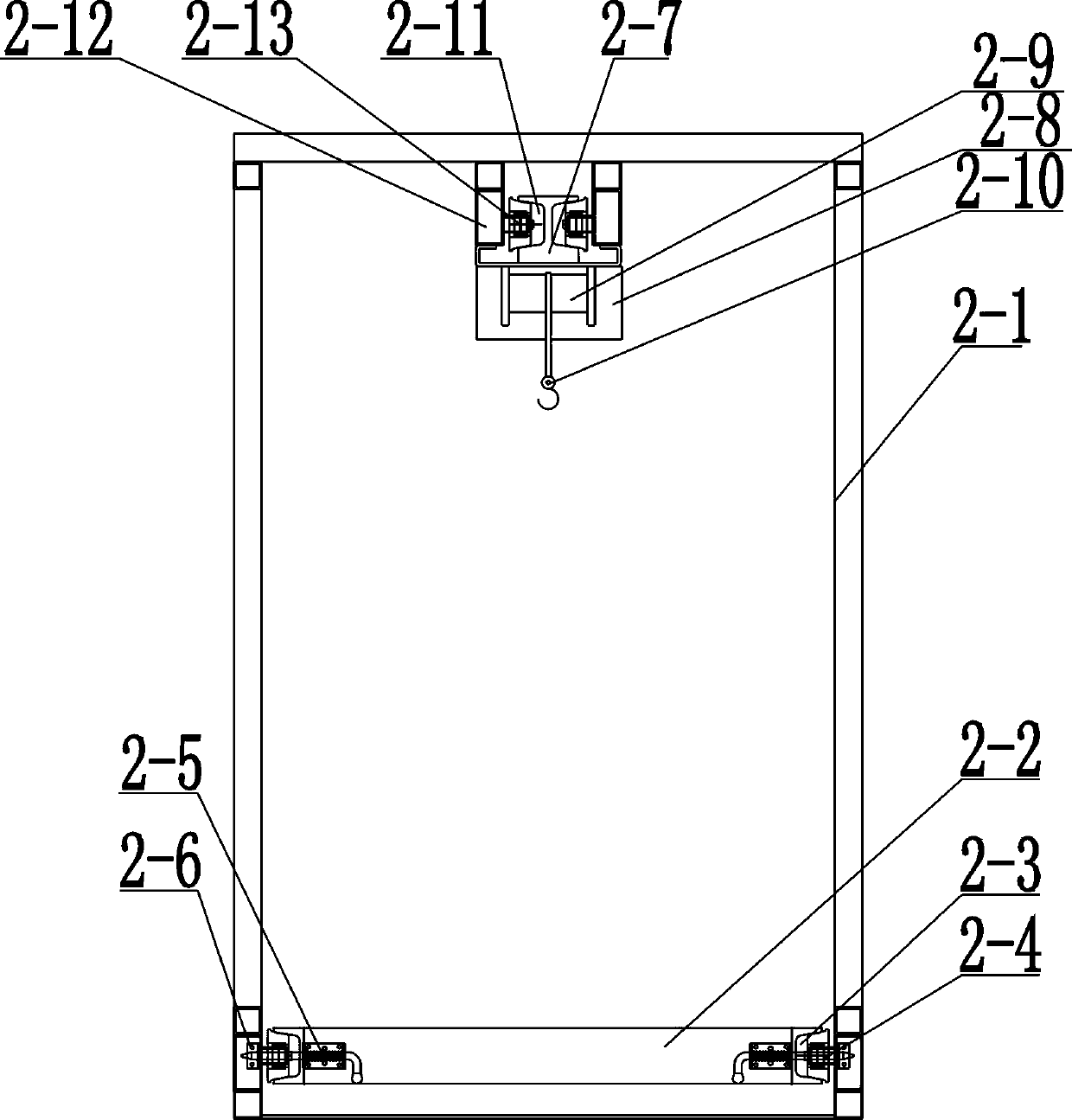

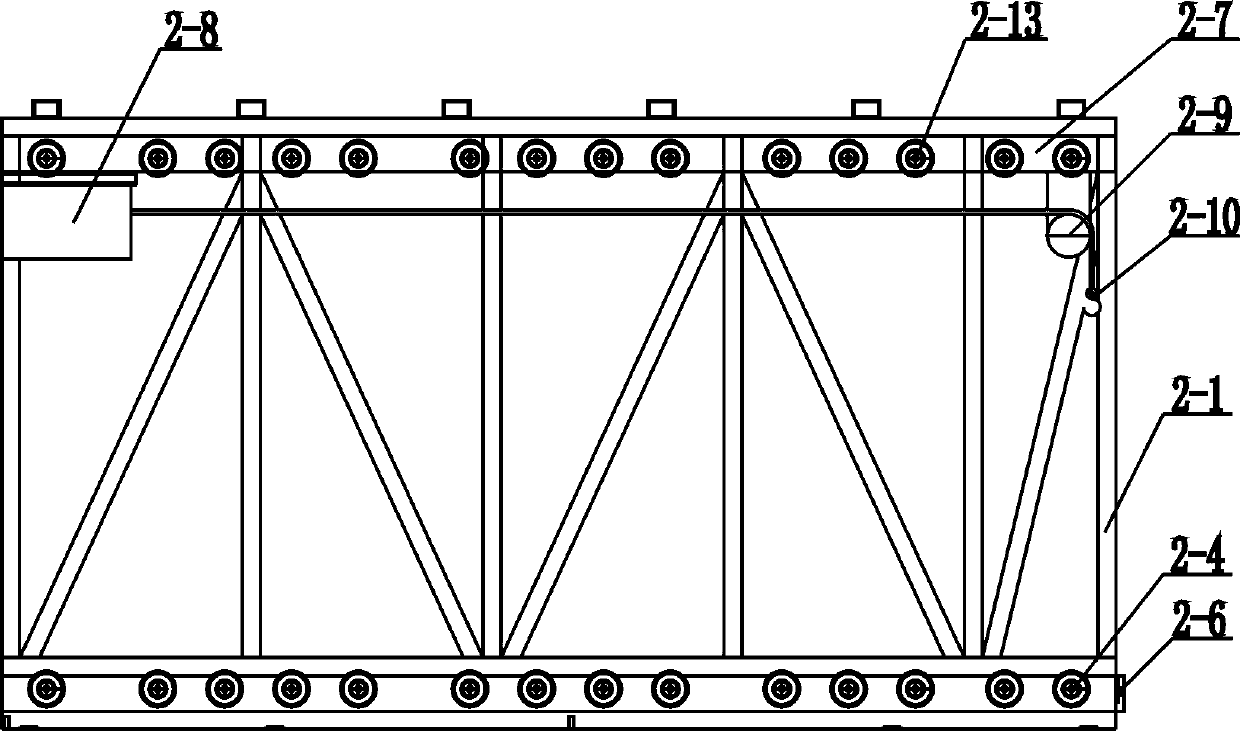

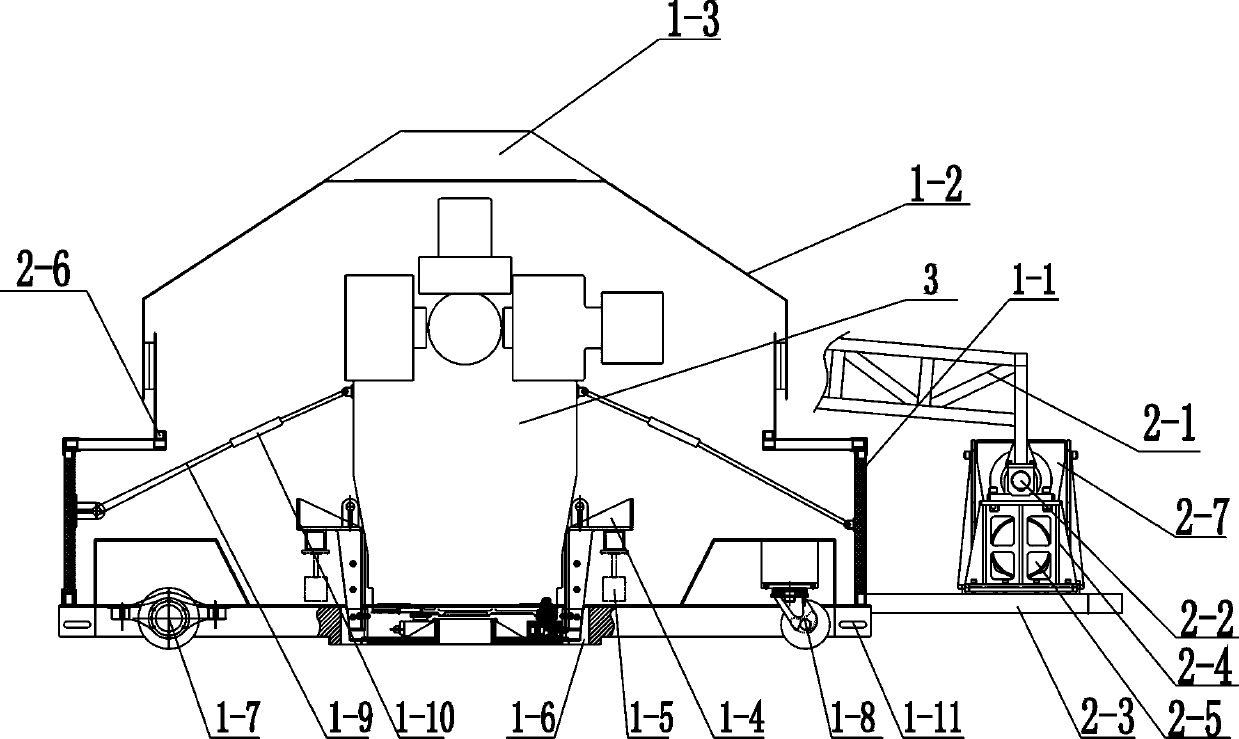

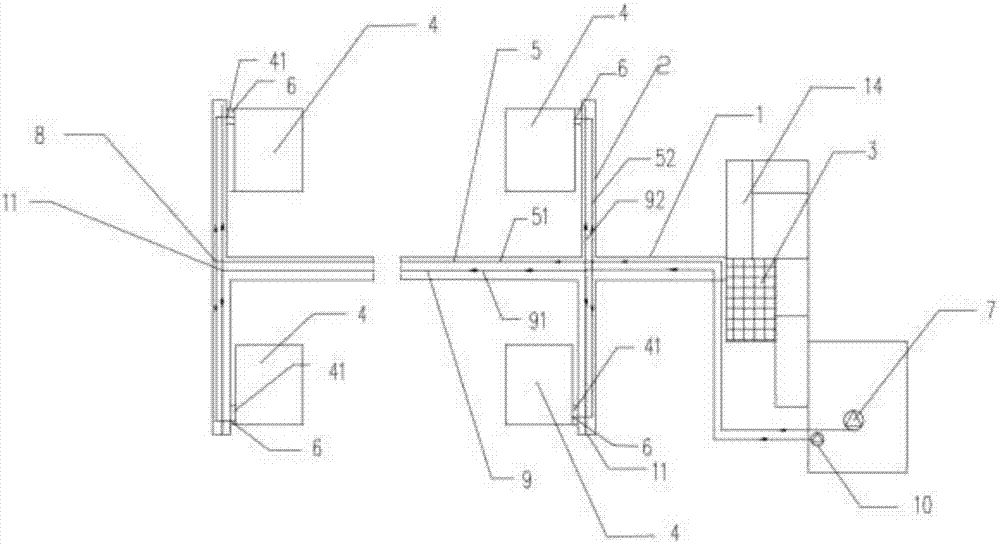

Vehicle-mounted theodolite cabin for theodolite carrier vehicle

PendingCN110562149ASimple structureEasy to assembleVehicle componentsItem transportation vehiclesDrive wheelTheodolite

The invention relates to a vehicle-mounted theodolite cabin for a theodolite carrier vehicle, and belongs to the technical field of theodolite carrier vehicles. The vehicle-mounted theodolite cabin ischaracterized by comprising a theodolite cabin body, an overturning cover structure and a chassis; the theodolite cabin body is arranged on the top face of the chassis, a theodolite body is arrangedin the theodolite cabin body, folding supporting structures are arranged at the four corner ends of the theodolite cabin body, the overturning cover structure is arranged at one end of the theodolitecabin body, and the folding supporting structures and the overturning cover structure do not interfere or affect; the vehicle-mounted theodolite cabin comprises a cabin body and a cabin cover; the cabin cover is arranged on the top of the cabin body, a drive wheel is arranged at one end of the bottom of the cabin body, and a steering wheel is arranged at the other end of the bottom of the cabin body; and the theodolite body is located at the middle position in the cabin body, and multiple transition connecting parts are evenly distributed on the side wall of the lower portion of the theodolitebody at intervals in a surrounding manner. The problems that a traditional theodolite carrier vehicle is complex in structure, and a large quantity of manpower and material resources need to be wasted are effectively solved.

Owner:洛阳安驰汽车制造有限公司 +1

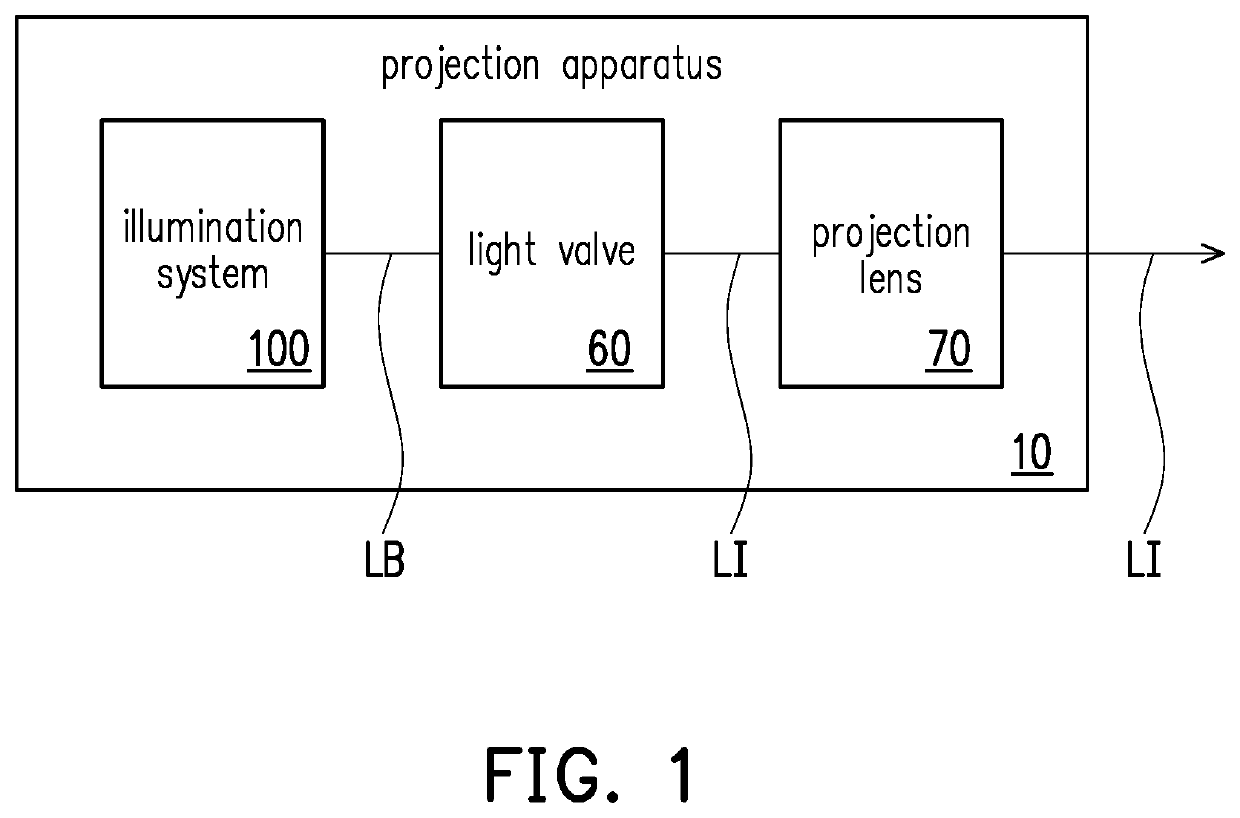

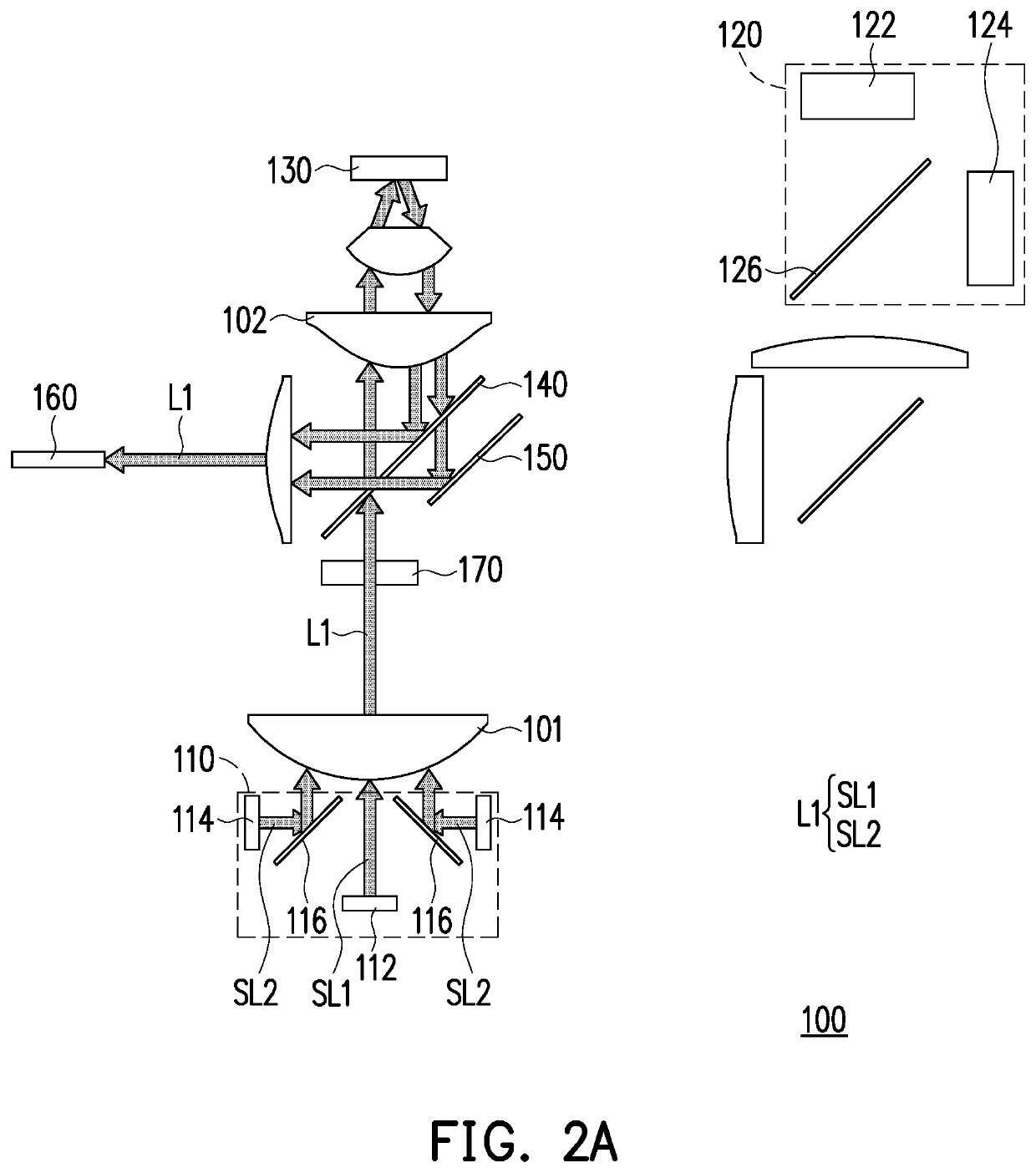

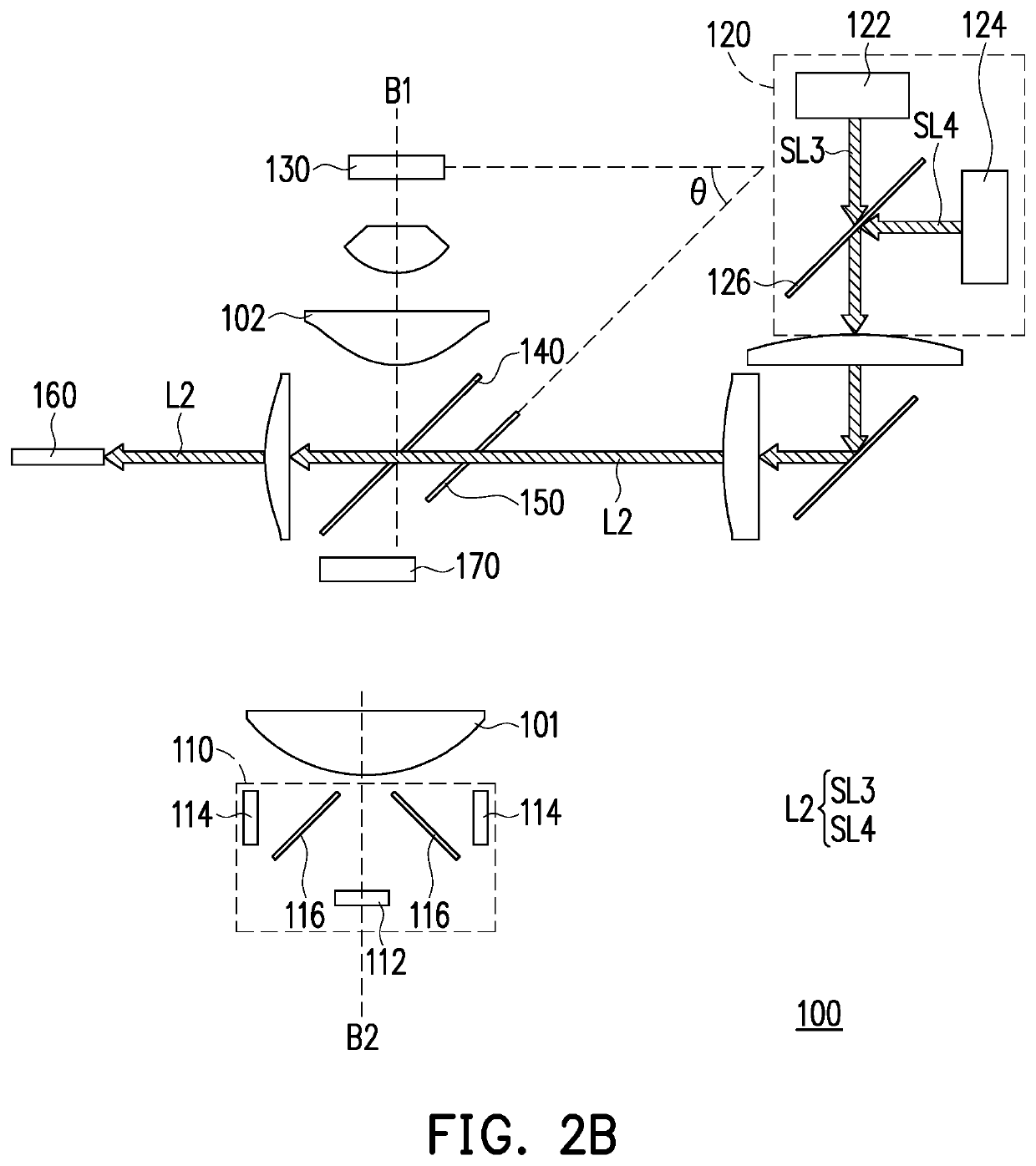

Illumination system and projection apparatus

ActiveUS20210247677A1Improve uniformityReduce occupied spaceProjectorsOptical elementsLighting systemFirst light

An illumination system, including a first light source for providing a first beam; a second light source for providing a second beam; a wavelength conversion element having a reflection region and a conversion region, wherein the reflection region is for reflecting the first beam and the conversion region is for converting the first beam into a third beam; a first light splitting element for allowing the second beam to pass; a second light splitting element for reflecting the first beam penetrated by the first light splitting element and allowing the second beam to pass, wherein the first light splitting element is disposed between the wavelength conversion element and the second light splitting element; and a light homogenizing element for receiving the first beam, the second beam, and the third beam, and generating an illumination beam, is provided. A projection apparatus including the illumination system is also provided.

Owner:CORETRONIC

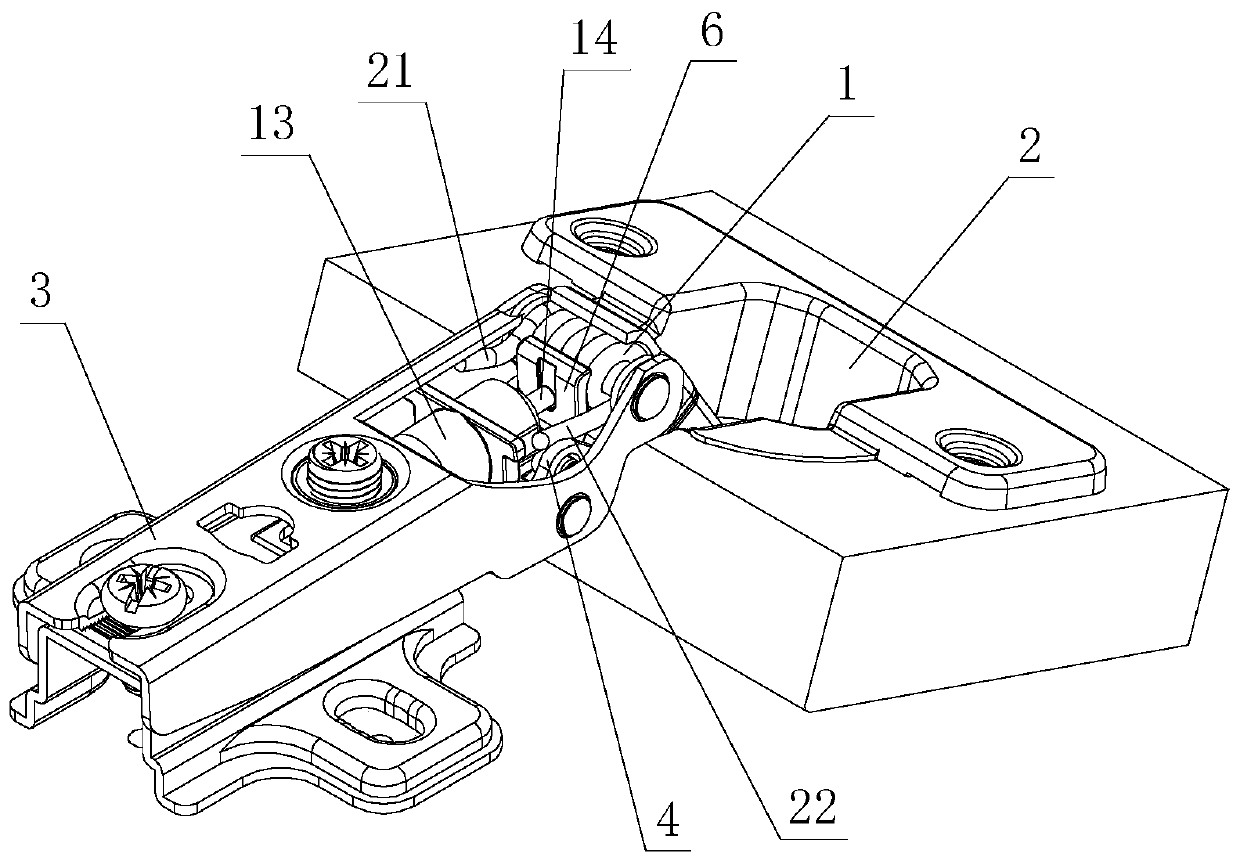

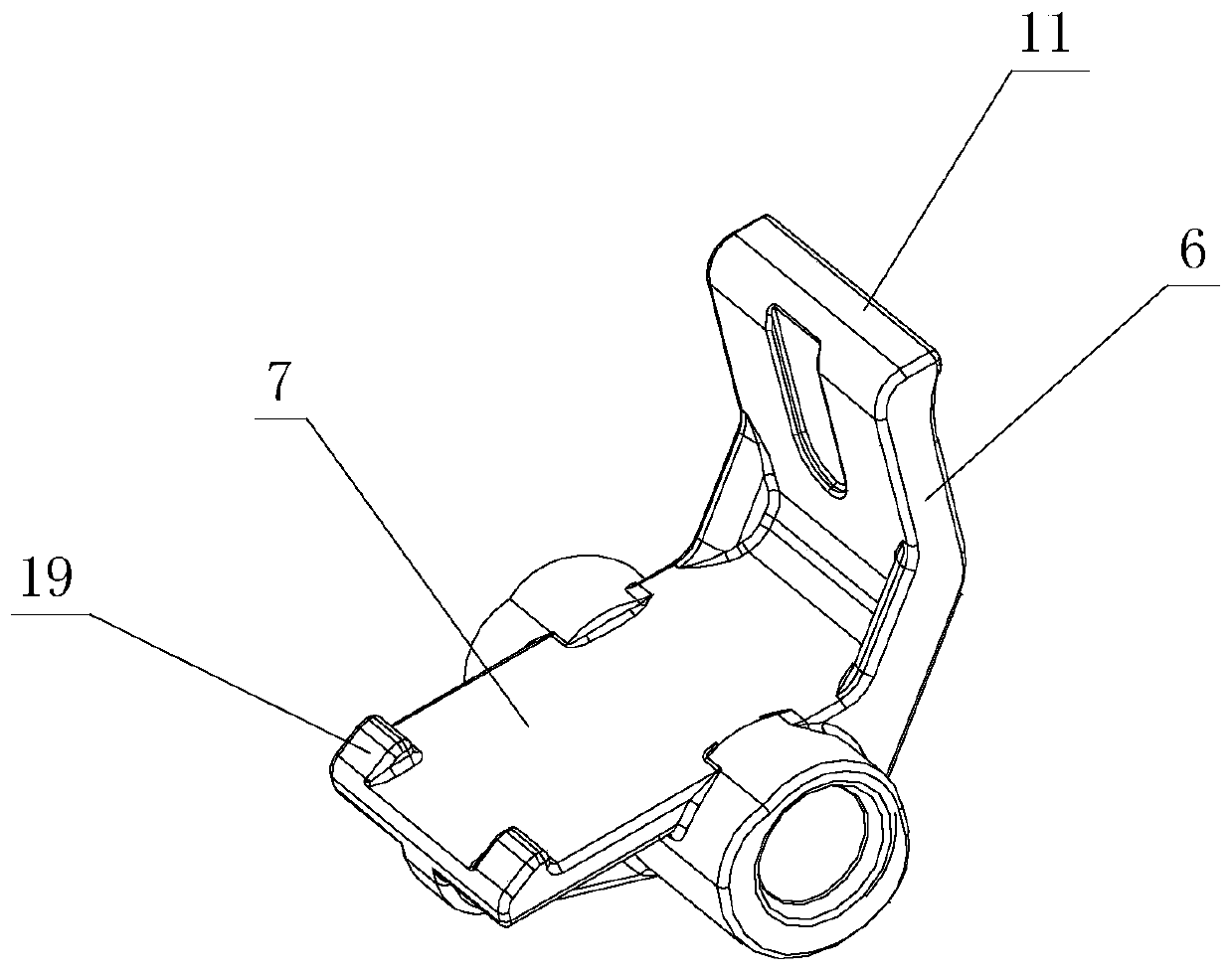

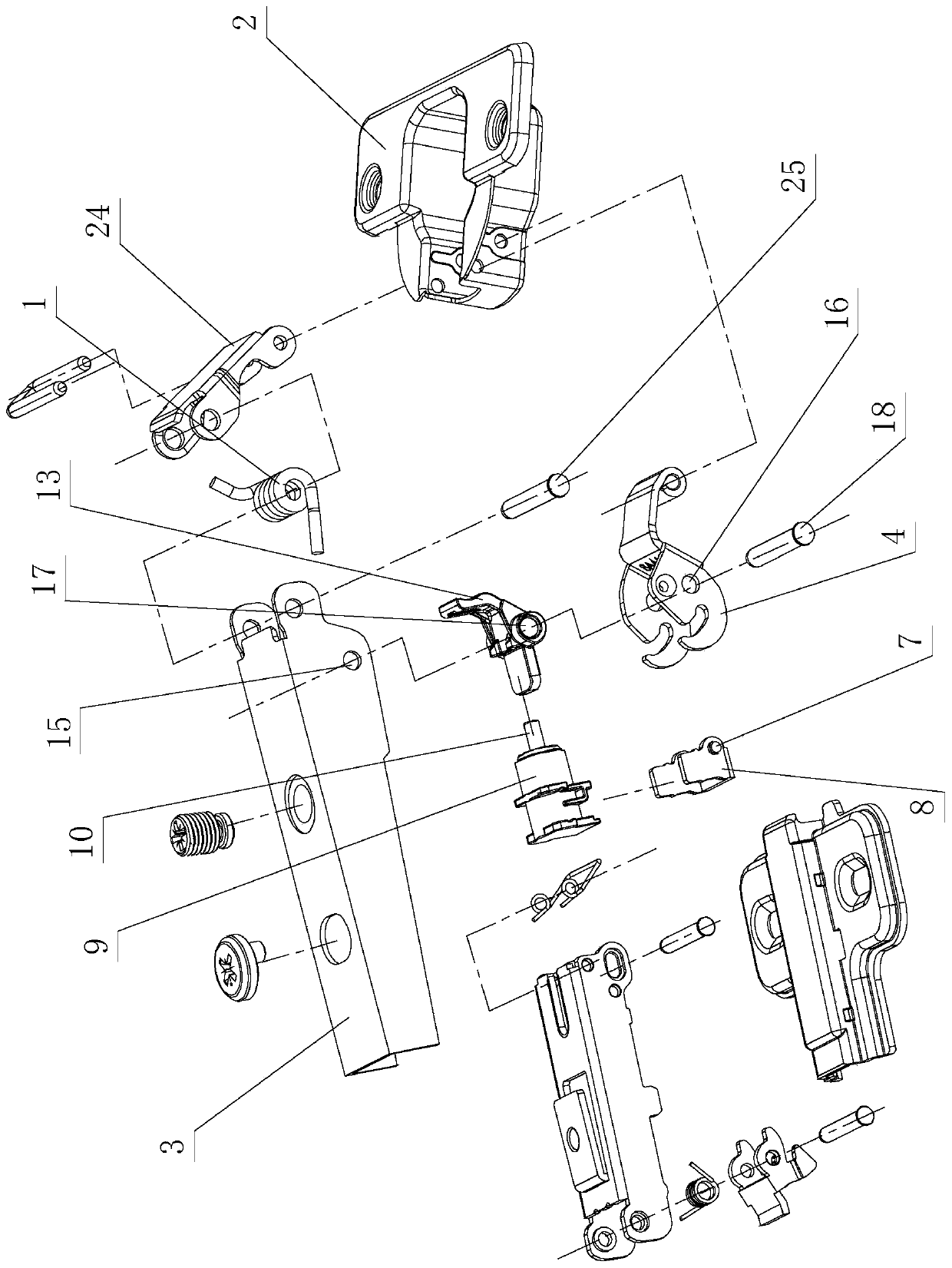

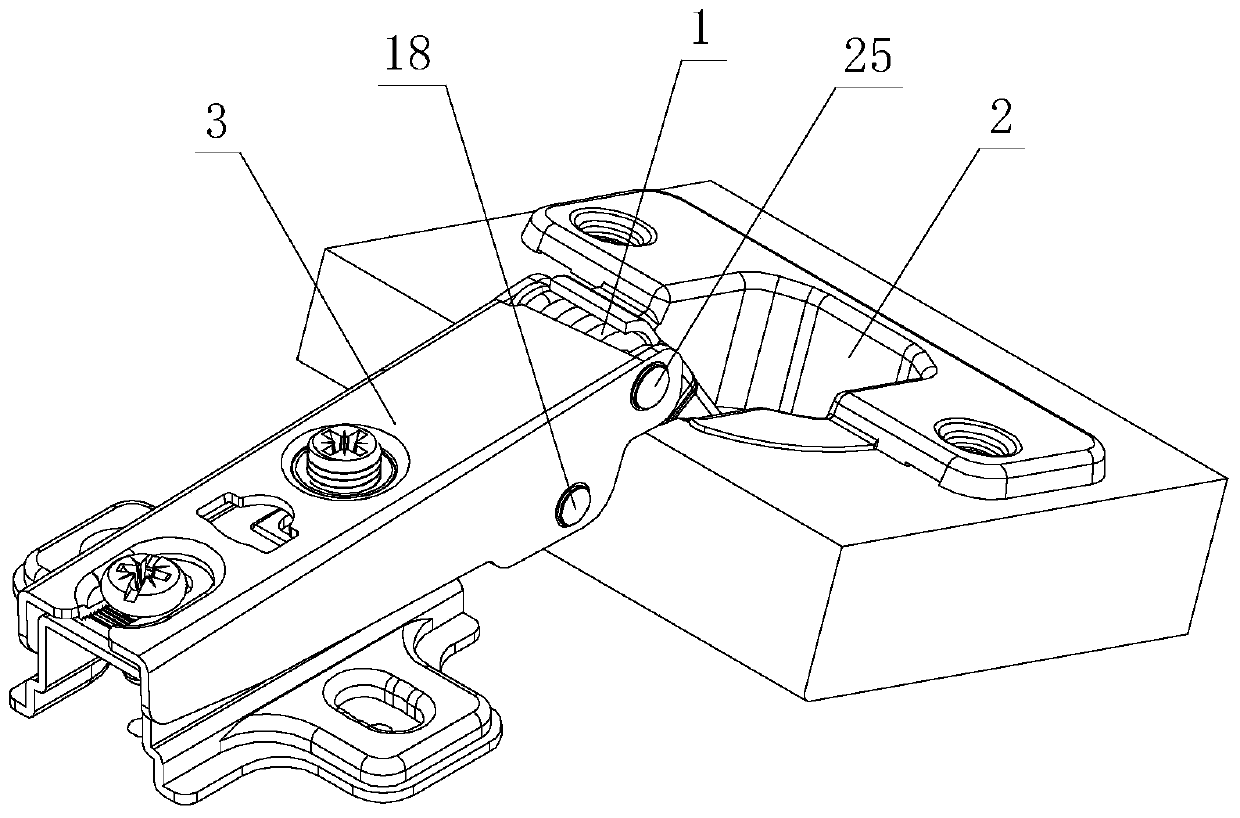

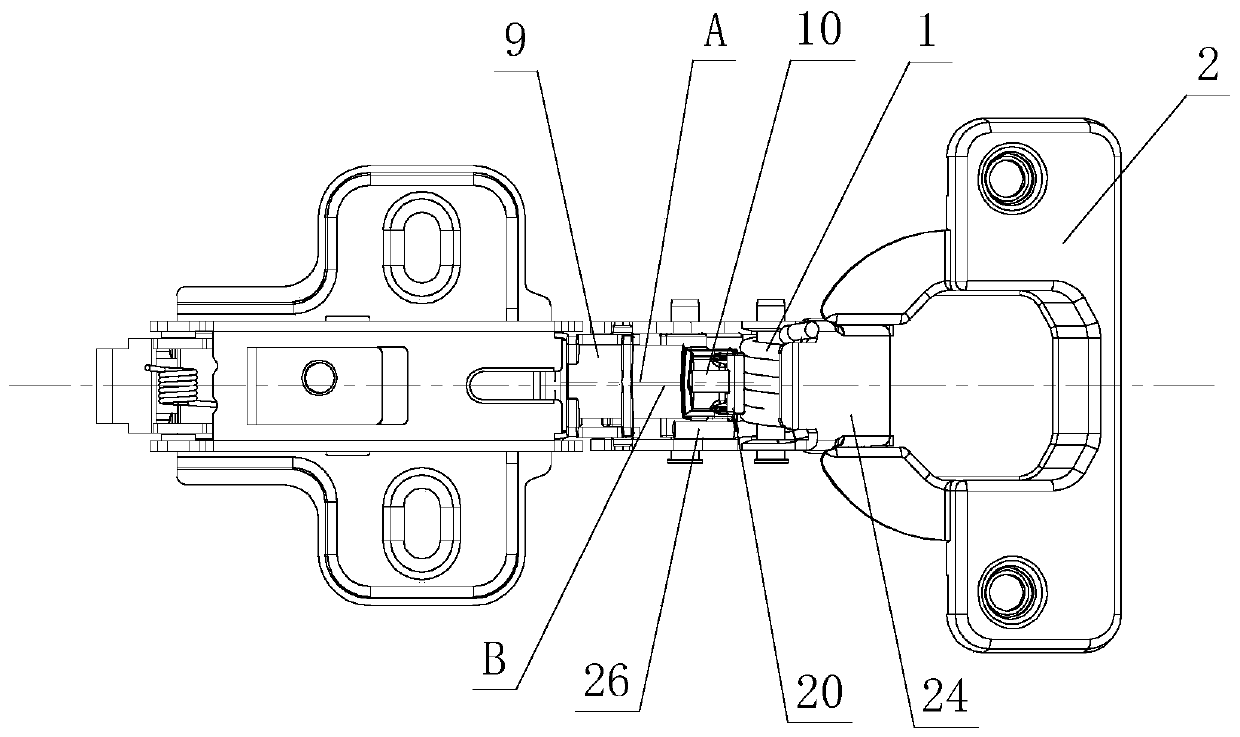

Integrated optimized damping structure of furniture hinge

PendingCN111058709ADrawbacks of reduced assemblyReduce manufacturing costBuilding braking devicesPin hingesDamperMechanical engineering

The invention discloses an integrated optimized damping structure of a furniture hinge. The integrated optimized damping structure comprises a hinge cup and a connecting arm which are elastically hinged to each other through a hinge arm assembly and a hinge arm elastic piece to be opened and closed in a matched mode, wherein the hinge arm assembly at least comprises an inner hinge arm, the inner hinge arm is hinged to the hinge cup and the connecting arm; a positioning piece is arranged on the inner hinge arm; the positioning piece is positioned on the inner hinge arm; an extending part is arranged on the positioning piece; the positioning piece is positioned on the hinge arm elastic piece or the hinge arm assembly at least through the extending part when being stressed; a damper is arranged between the connecting arm and the positioning piece; and the inner hinge arm acts and drives the damper to reset and slide and / or to be compressed and slide between the connecting arm and the positioning piece when the hinge cup is elastically hinged to the connecting arm to be opened and closed, so that automatic reset of the damper and / or damping closing of the furniture hinge are / is realized. The integrated optimized damping structure has the characteristics of being simple and reasonable in structure, reliable in performance, high in use flexibility, low in manufacturing cost, long inservice life, easy to produce and realize, exquisite in appearance, high in safety and the like, and is high in practicability.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

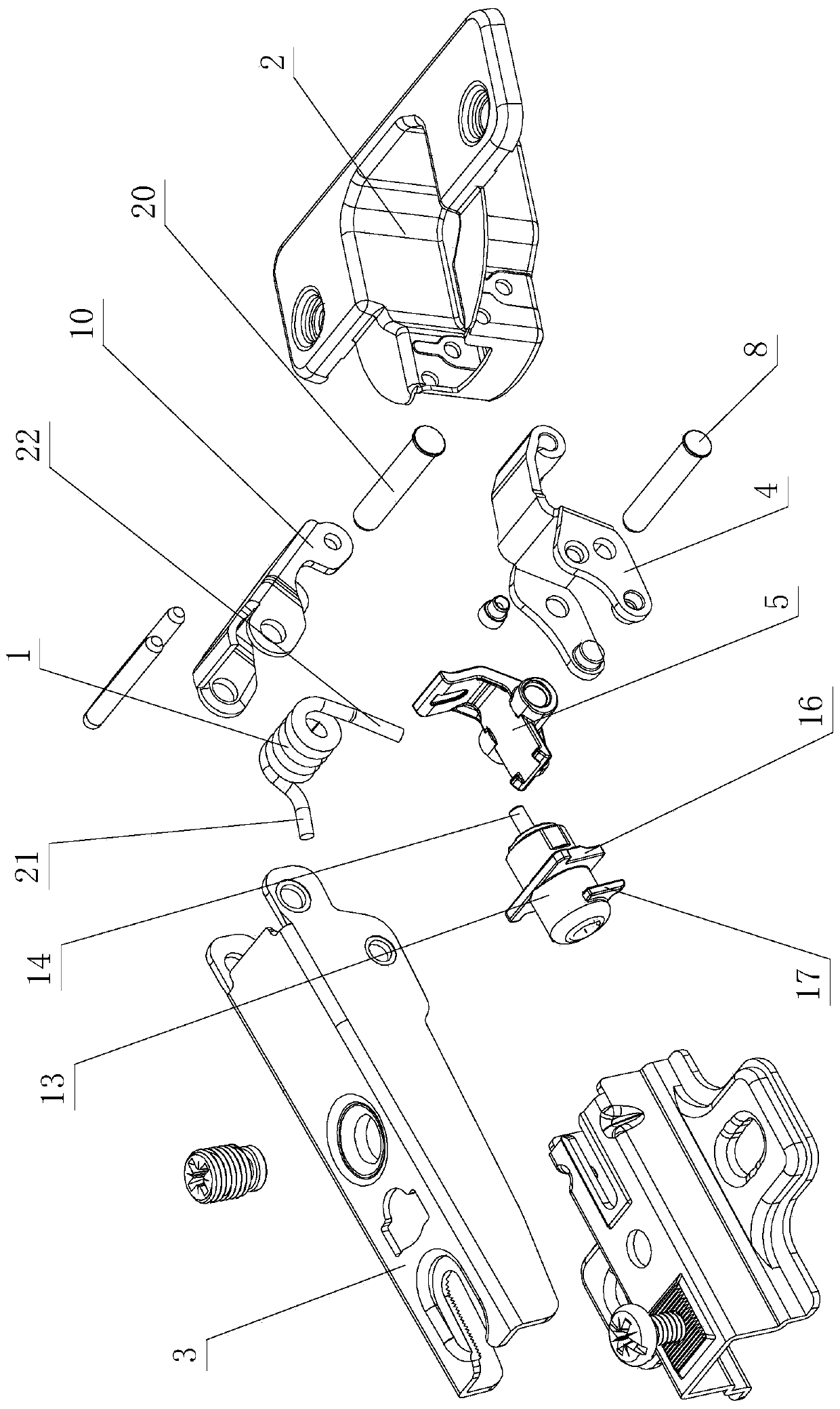

Integrated optimization structure of damping hinge

PendingCN111456577AReduces the space taken up by the hingeDrawbacks of reduced assemblyBuilding braking devicesWing accessoriesEngineeringControl theory

The invention discloses an integrated optimization structure of a damping hinge. The integrated optimization structure comprises a hinge cup and a connecting arm which are hinged to each other in an elastic damping mode and matched in opening and closing through a damper, a hinge arm assembly and a hinge arm elastic part, the hinge arm assembly at least comprises an inner hinge arm, the inner hinge arm is correspondingly hinged to the hinge cup and the connecting arm, a guiding groove and an inner arm action part are arranged on the inner hinge arm, the hinge arm elastic part is arranged between the hinge cup and the connecting arm, and is correspondingly and elastically connected with the inner arm action part and the connecting arm, the damper is located in the connecting arm, one end ofthe damper acts on the hinge arm elastic part, and the other end of the damper is provided with a damping action part; and when the hinge cup is elastically hinged and opened and closed relative to the connecting arm, the inner hinge arm acts on the damping action part through the guide of the guiding groove, and drives reset sliding and / or compression sliding of the damper on the connecting arm,so as to achieve the automatic reset of the damper and / or the elastic damping closing of a hinge. The integrated optimization structure has high practicability through the improvement of the structure.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

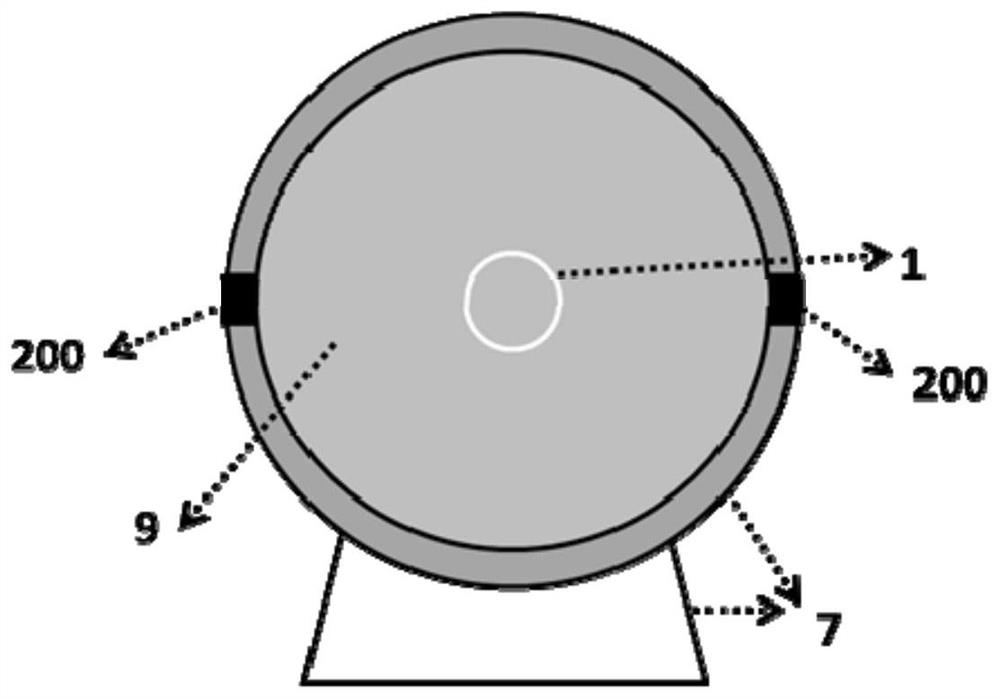

A lithium slurry battery storage tank system

ActiveCN111266055BGuaranteed uniformityImprove cycle stabilityRotating receptacle mixersTransportation and packagingThermodynamicsElectrical battery

The invention discloses a structure and a method of a lithium slurry battery material storage tank system, belonging to the field of large-scale energy storage. The present invention uses a traditional lithium slurry battery system with two storage tanks, namely a positive electrode slurry tank and a negative electrode slurry tank. Compared with the traditional slurry tank, the slurry tank of the present invention has a rotatable storage tank to avoid slurry settlement; and has a movable partition to allow positive / negative electrodes to enter the slurry of the storage tank and output the slurry of the storage tank Separate, reduce the concentration polarization, self-discharge and safety problems caused by the difference in charge state of the slurry in the lithium slurry battery reactor and the storage tank, improve the utilization rate of active materials and charge and discharge capacity, and realize four storage tanks The operating effect of the system is improved and the cost and space occupied by two storage tanks are saved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Cutting fluid centralized supply-discharge and recovery system

ActiveCN106925029AReduce maintenance frequencyShorten cleaning timeTreatment involving filtrationNature of treatment waterProcess equipmentCooling effect

The invention discloses a cutting fluid centralized supply-discharge and recovery system. The system is characterized in that: it comprises a main water tank and several branch water tanks that are communicated with each other; the main water tank is communicated with a recovery pool; the recovery pool is lower than the main water tank; and starting ends of the branch water tanks can be communicated with cutting fluid outlets of machine tools. The system provided by the invention has the advantages of simple structure and obvious economic benefits, can achieve no chip and water on a workshop site, takes the lead to realize clean production of the machining industry, is conducive to processing equipment maintenance, reduces maintenance frequency, and lowers the maintenance cost, reduces the occupation of processing accessory equipment, and is convenient for operation. The system provided by the invention enables recycling of cutting fluid, a cutting fluid mother pool is underground and does not spoil or deterioriate easily; the cutting fluid has better cooling effect, and is more conducive to machining; also the waste chips generated by machining are subjected to centralized recovery, the cutting fluid recycling, cutting fluid filtration treatment, cutting fluid cyclic utilization, cutting fluid storage and other functions are uniformly realized in one system, energy sources are saved, and the cost is lowered.

Owner:重庆雷联汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com