Winding structure

A technology of winding rollers and idlers, applied in the field of mechanical processing, can solve problems such as low efficiency and large space, and achieve the effects of ensuring smoothness, convenient implementation, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

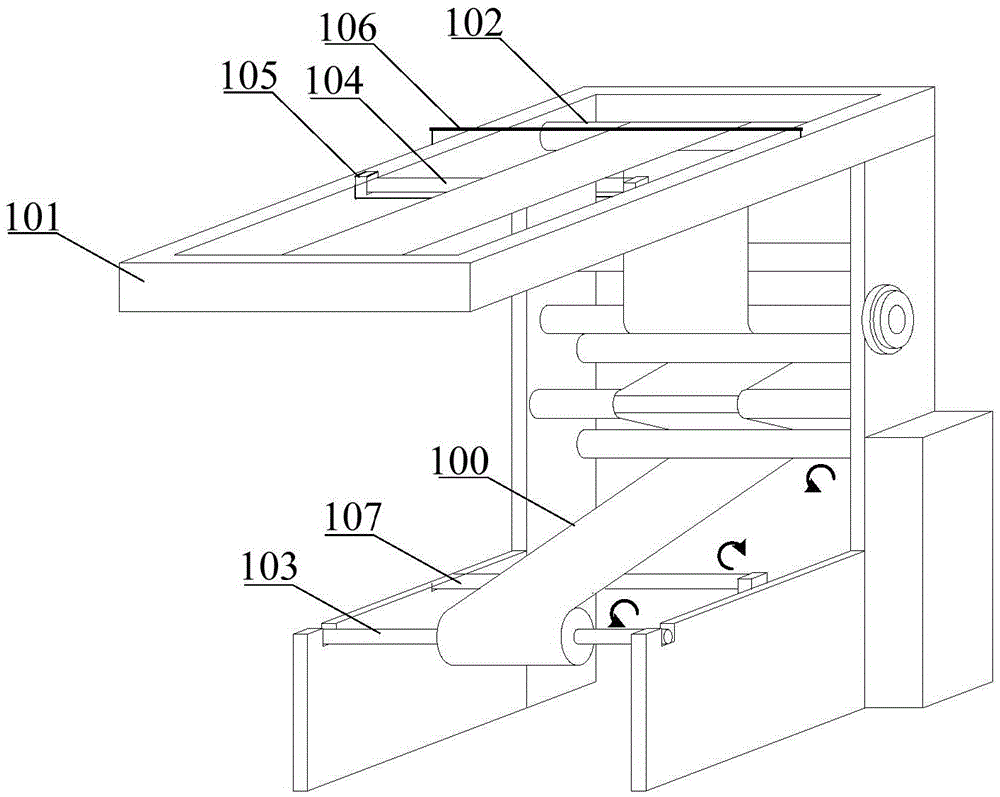

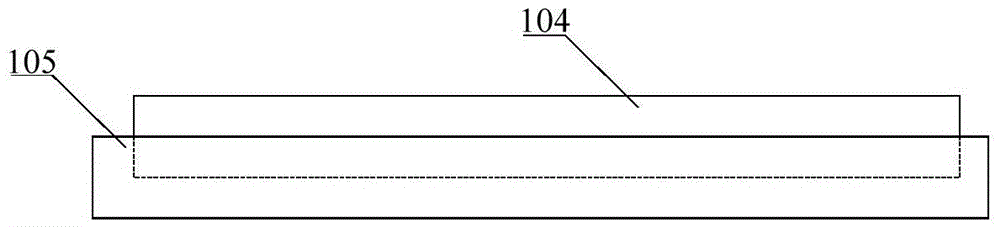

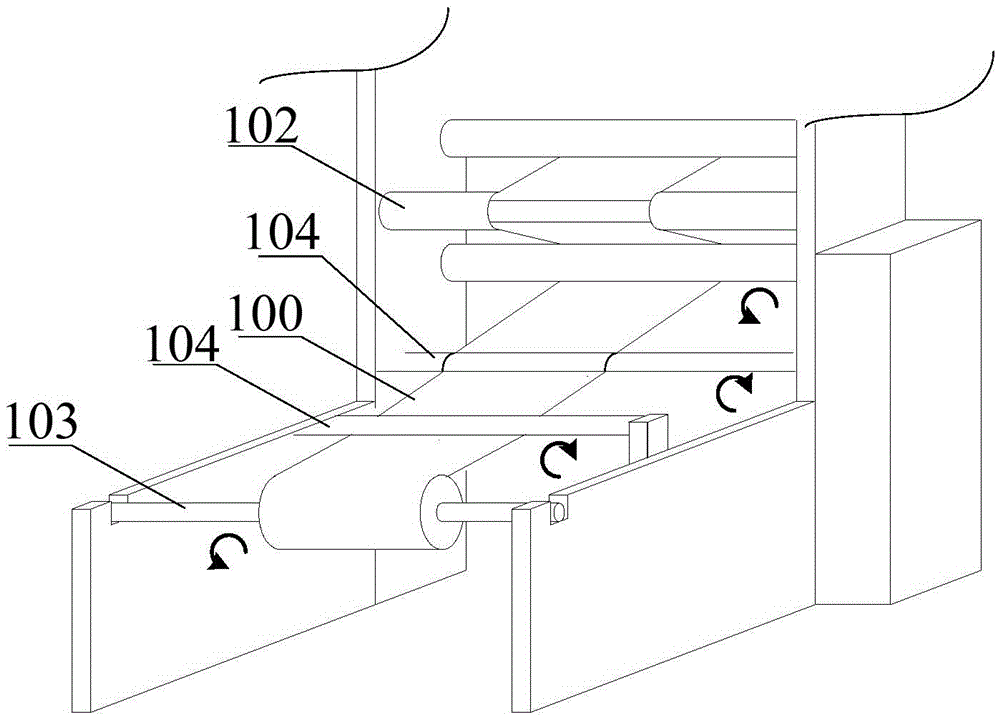

[0048] Such as figure 1 As shown, the embodiment of the present invention provides a winding structure, including a winding platform 101 , a plurality of supporting rollers 102 and a plurality of winding rollers 103 . The plurality of idler rollers 102 and the plurality of winding rollers 103 are installed on the winding platform 101 .

[0049] In order to ensure the reliability of the winding roller 103, in this embodiment, preferably, the plurality of idler rollers 102 and the plurality of winding rollers 103 are parallel to each other, and the plurality of idler rollers 102 and the plurality of winding rollers 103 are The winding platform 101 is installed staggeredly from top to bottom, and the idler roller 102 is located above the winding roller 103 .

[0050] Wherein, a plurality of idler rollers 102 and a plurality of winding rollers 103 are parallel to each other means that a plurality of idler rollers 102 and a plurality of winding rollers 103 are parallel to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com