Injection molding product polishing machine capable of avoiding debris splashing

A technology for injection molding products and polishing machines, applied in the field of polishing machines, can solve the problems of occupying storage space, splashing, manual disassembly, etc., and achieve the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

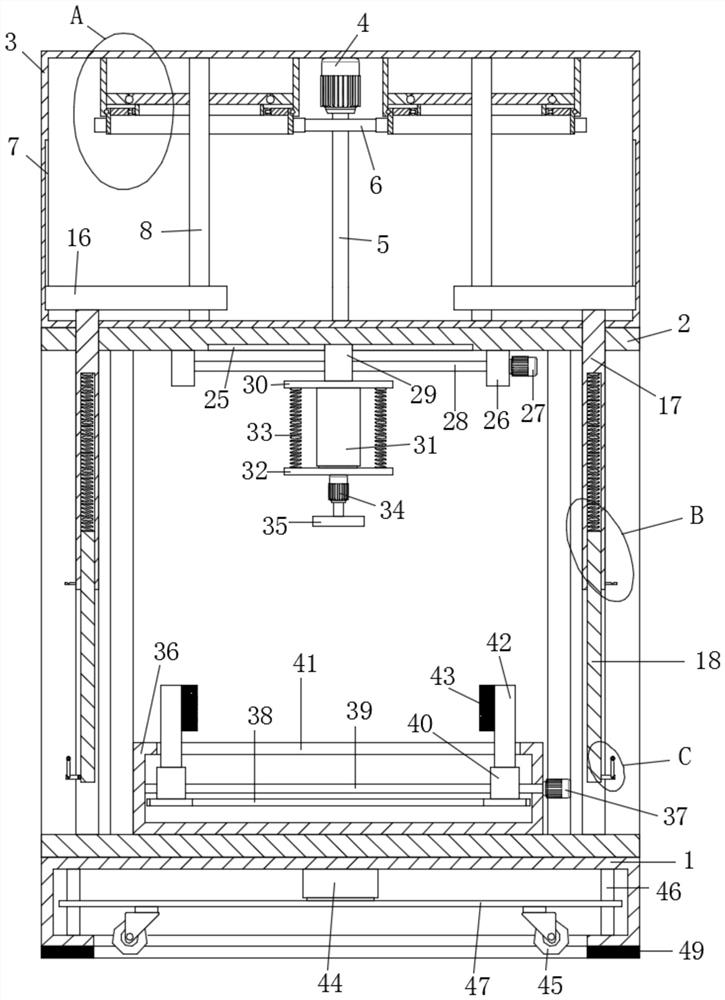

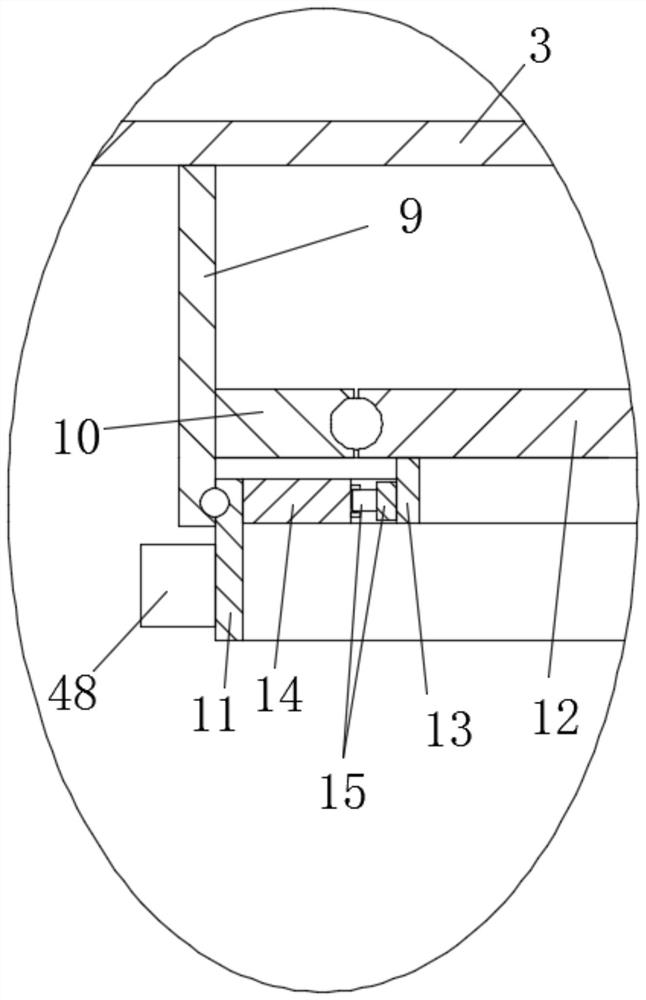

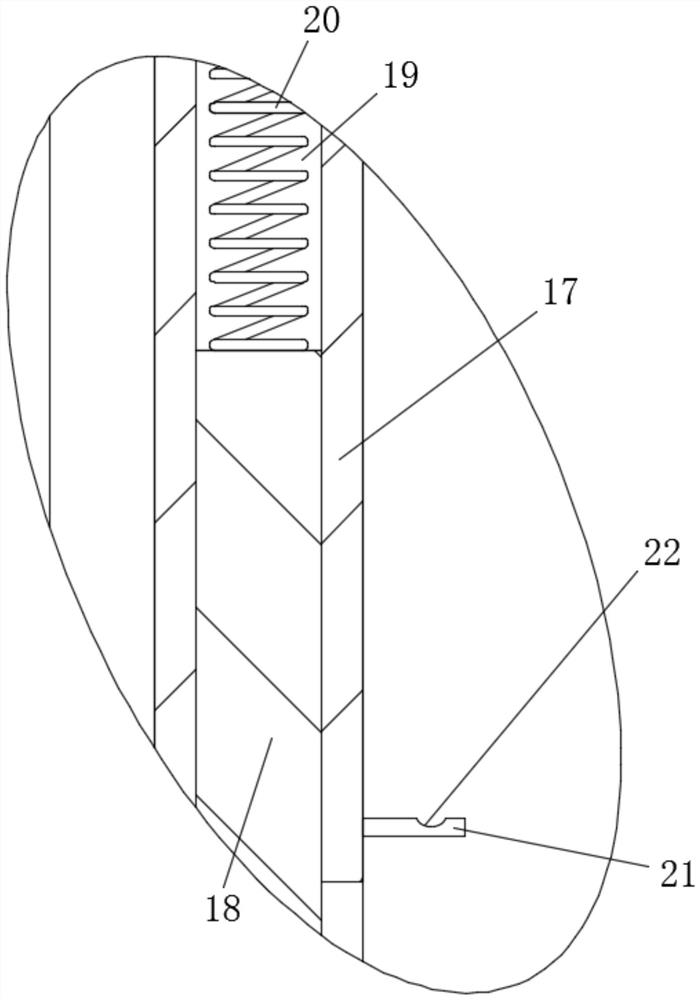

[0022] see Figure 1-4 , an injection molded product polishing machine that avoids debris splashing, including a base 1, a mounting bracket 2 hollowed out on both sides, a polishing piece clamping assembly and a polishing assembly arranged on the mounting bracket 2, and the mounting bracket 2 is fixedly installed on On the base 1, the polishing piece clamping assembly is arranged on the bottom inner wall of the mounting bracket 2, and the mounting bracket 2 is provided with a protective assembly that can be selectively raised and lowered asynchronously. The installation frame 3 on the top and the driving motor 4 fixedly installed on the inner wall of the top of the installation frame 3 and the protection units symmetrically arranged on both sides of the driving motor 4, the output end of the driving motor 4 is fixedly installed with the driving shaft 5, and the driving shaft 5 Rotationally installed on the installation frame 3, the driving gear 6 is fixedly installed on the ac...

Embodiment 2

[0030] This embodiment is further improved on the basis of the embodiment. The improvement is that: the base 1 is hollowed out, the bottom of the base 1 is provided with a second avoidance channel, and the base 1 is provided with a moving assembly. The mobile assembly includes a lift cylinder 44 fixedly mounted on the inner wall of the top of the base 1 and a number of moving rollers 45. Both sides of the lift cylinder 44 are symmetrically provided with guide shafts 46, and the guide shafts 46 are fixedly mounted on the base 1. The lift The telescoping end of the cylinder 44 is fixedly installed with a support mounting plate 47, the support mounting plate 47 is slidably mounted on the guide shaft 46, and the moving rollers 45 are evenly arranged on the bottom of the support mounting plate 47, and the lift cylinder 44 is positioned at the shortest stroke position. The lowest surface of the mobile roller 45 is higher than the lowest surface of the shock-absorbing anti-skid pad 49...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com