Cutting fluid centralized supply-discharge and recovery system

A recovery system and cutting fluid technology, applied in the field of cutting fluid supply and drainage and processing systems, can solve the problem of inability to realize the centralized supply and discharge of cutting fluid, the effective operation of cutting fluid and the centralized recovery of waste chips, and the inability to realize the centralized supply and drainage of cutting fluid and recycling Utilize and increase the site occupancy of auxiliary equipment for processing equipment, etc., to reduce cleaning time and labor intensity, reduce maintenance frequency, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

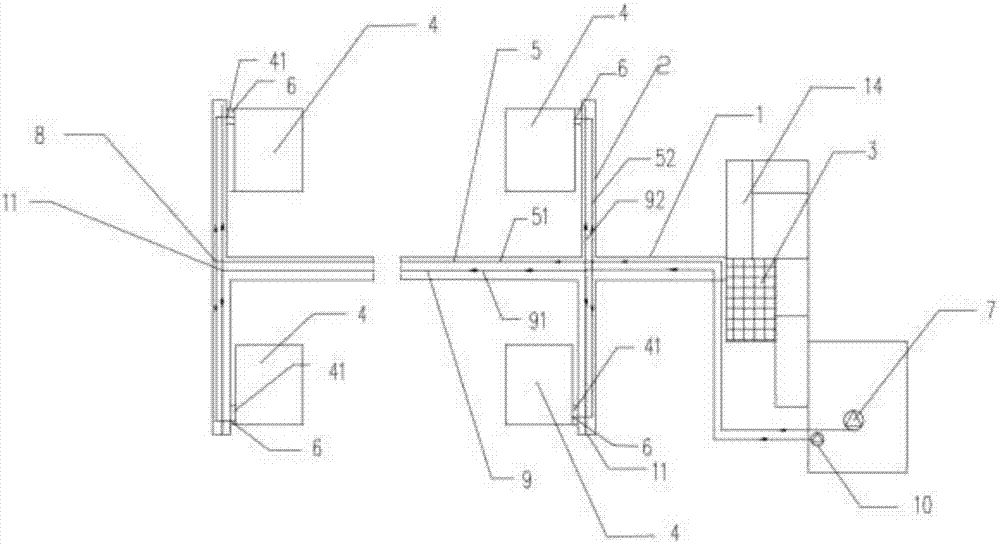

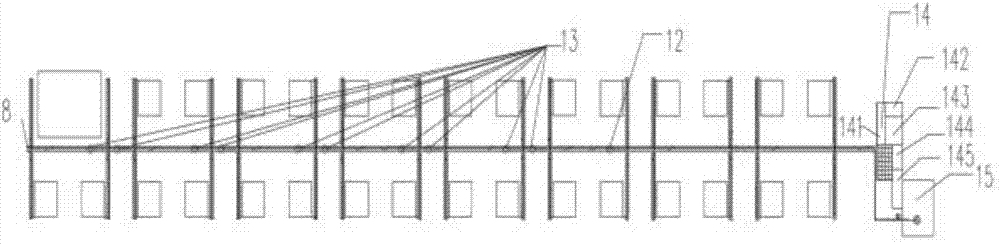

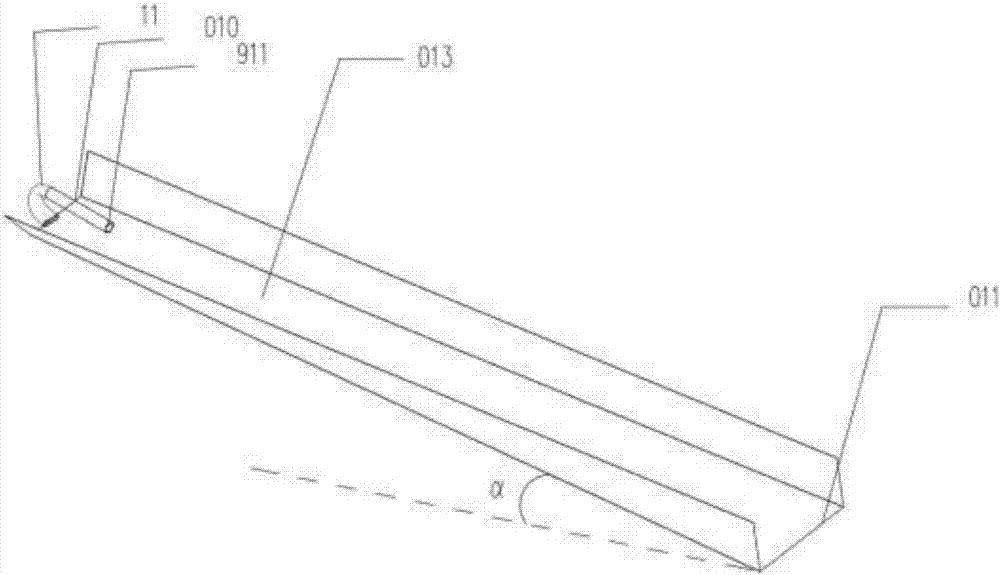

[0021] like Figures 1 to 4 As shown, a cutting fluid centralized supply and drainage and recovery system includes a main water tank 1 and several branch water tanks 2 connected to each other; the main water tank 1 communicates with the recovery pool 3; the recovery pool is lower than the main water tank; the starting end of the branch water tank 2 can be It communicates with the cutting fluid outlet 41 of the machine tool 4 .

[0022] The recovery tank is connected to the water supply pipeline 5, and the end of the water supply pipeline can be connected with the cutting fluid supply port 6 of the machine tool. The water supply pipeline includes a main water supply pipeline 51 and a branch water supply pipeline 52 that communicate with each other. Extending along the branch water tank 2; the first water pump 7 is arranged on the pipeline of the main water su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com