Method for preparing polyurethane rubber granule mixture for pavement self-stress icebreaking

A technology of polyurethane rubber and mixture, which is applied in the field of rubber mixture, and can solve problems such as damage, ice layer fracture, and poor road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

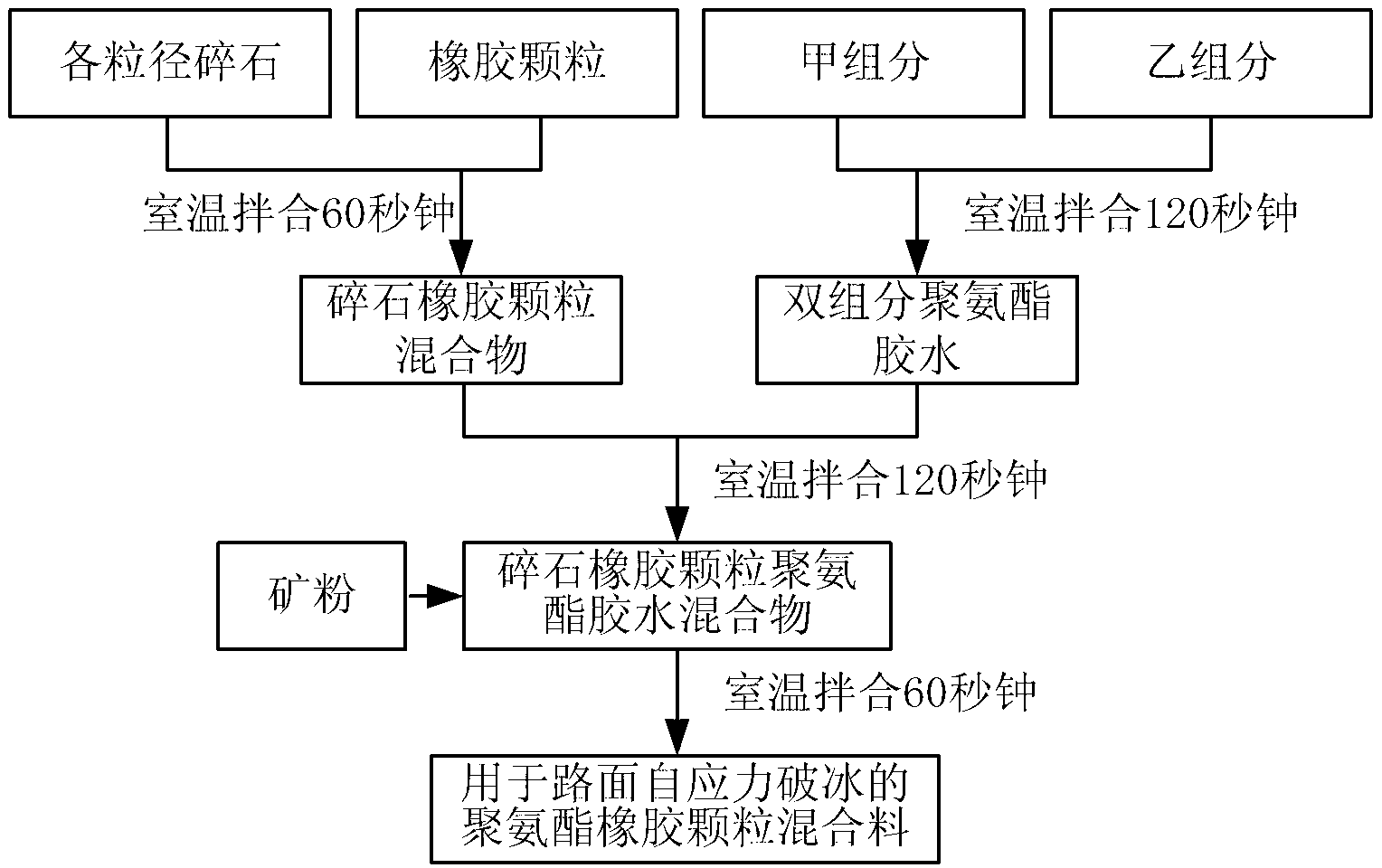

Method used

Image

Examples

Embodiment 1

[0084] The first step is to prepare two-component polyurethane glue

[0085] Ⅰ. Preparation of A component

[0086] The raw materials for preparing component A are shown in the table below,

[0087] raw material

Pure MDI

Liquefied MDI

Polyether diol

95

5

60

[0088] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0089] Dehydrate the polyether diol at 100°C and a vacuum of 0.08MPa for 1 hour to constant weight. After cooling to 40°C, add the melted measured pure MDI and liquefied MDI, and react at 75°C for 2 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0090] Ⅱ. Preparation of component B

[0091] The raw materials for preparing component B are shown in the table below,

[0092]

[0093] The composite polyether in the above table is prepared by adjusting the mass ratio, trihyd...

Embodiment 2

[0106] The first step is to prepare two-component polyurethane glue

[0107] Ⅰ. Preparation of A component

[0108] The raw materials for preparing component A are shown in the table below,

[0109] raw material

Pure MDI

Liquefied MDI

polyether triol

95

5

80

[0110] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0111] Dehydrate the polyether triol at 105°C and a vacuum of 0.08MPa for 1 hour to constant weight, cool to 45°C, then add the melted measured pure MDI and liquefied MDI, react at 78°C for 2.5 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0112] Ⅱ. Preparation of component B

[0113] The raw materials for preparing component B are shown in the table below,

[0114]

[0115] The composite polyether in the above table is prepared by adjusting the mass ratio, trihydroxy...

Embodiment 3

[0128] The first step is to prepare two-component polyurethane glue

[0129] Ⅰ. Preparation of A component

[0130] The raw materials for preparing component A are shown in the table below,

[0131] raw material

Pure MDI

Liquefied MDI

Polyether diol

95

5

100

[0132] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0133] Dehydrate the polyether diol at 110°C and a vacuum of 0.08MPa for 1 hour to constant weight. After cooling to 50°C, add the melted measured pure MDI and liquefied MDI, and react at 80°C for 3 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0134] Ⅱ. Preparation of component B

[0135] The raw materials for preparing component B are shown in the table below,

[0136]

[0137] The composite polyether in the above table is prepared by adjusting the mass ratio, trihy...

PUM

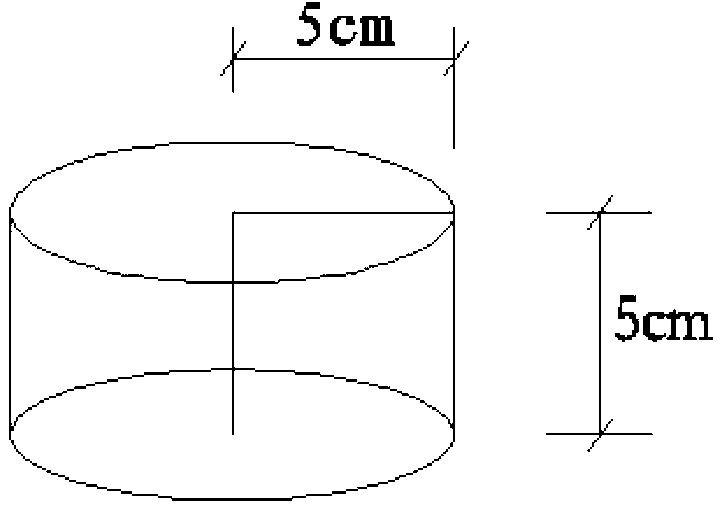

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com