Patents

Literature

423results about "Feed tables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

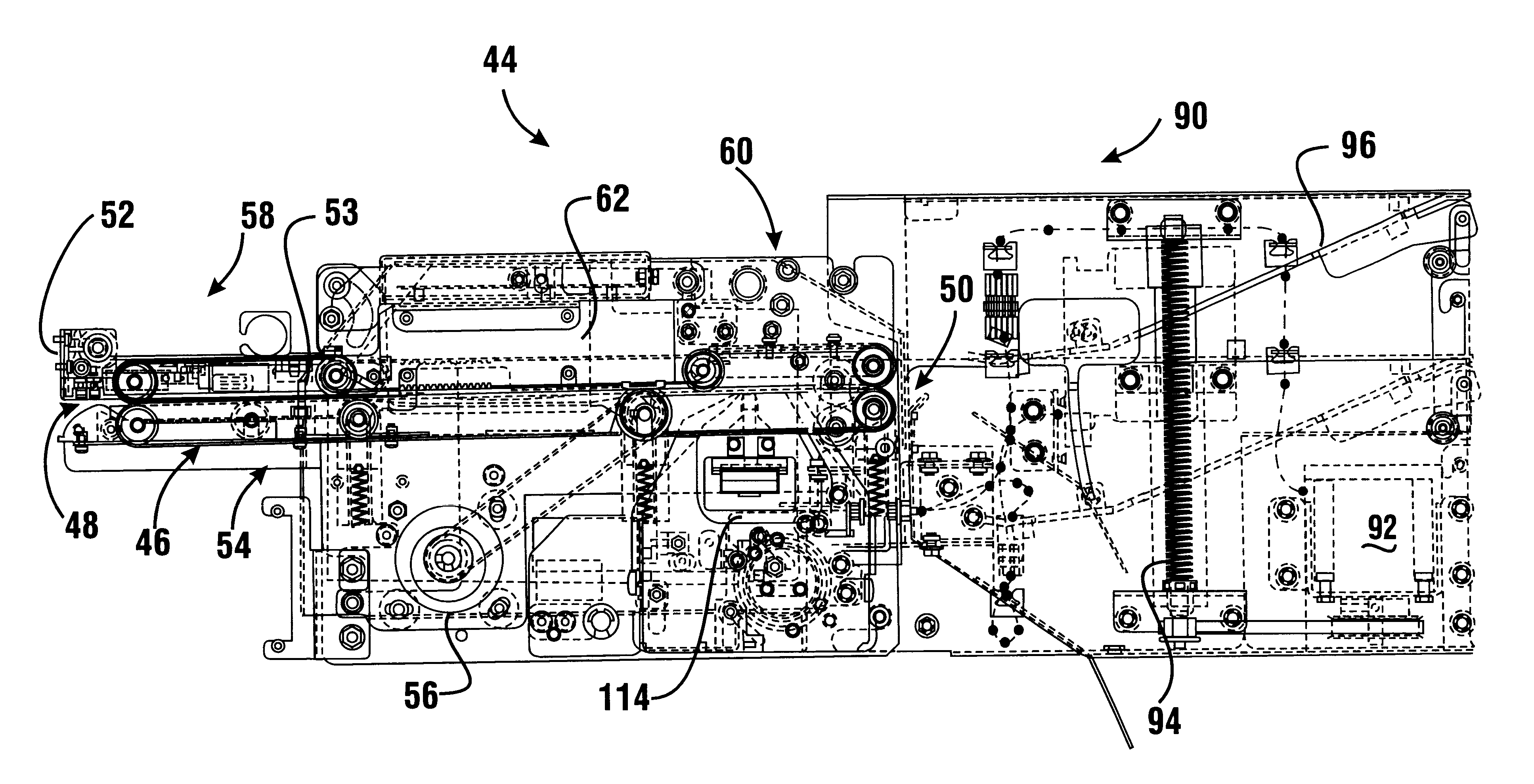

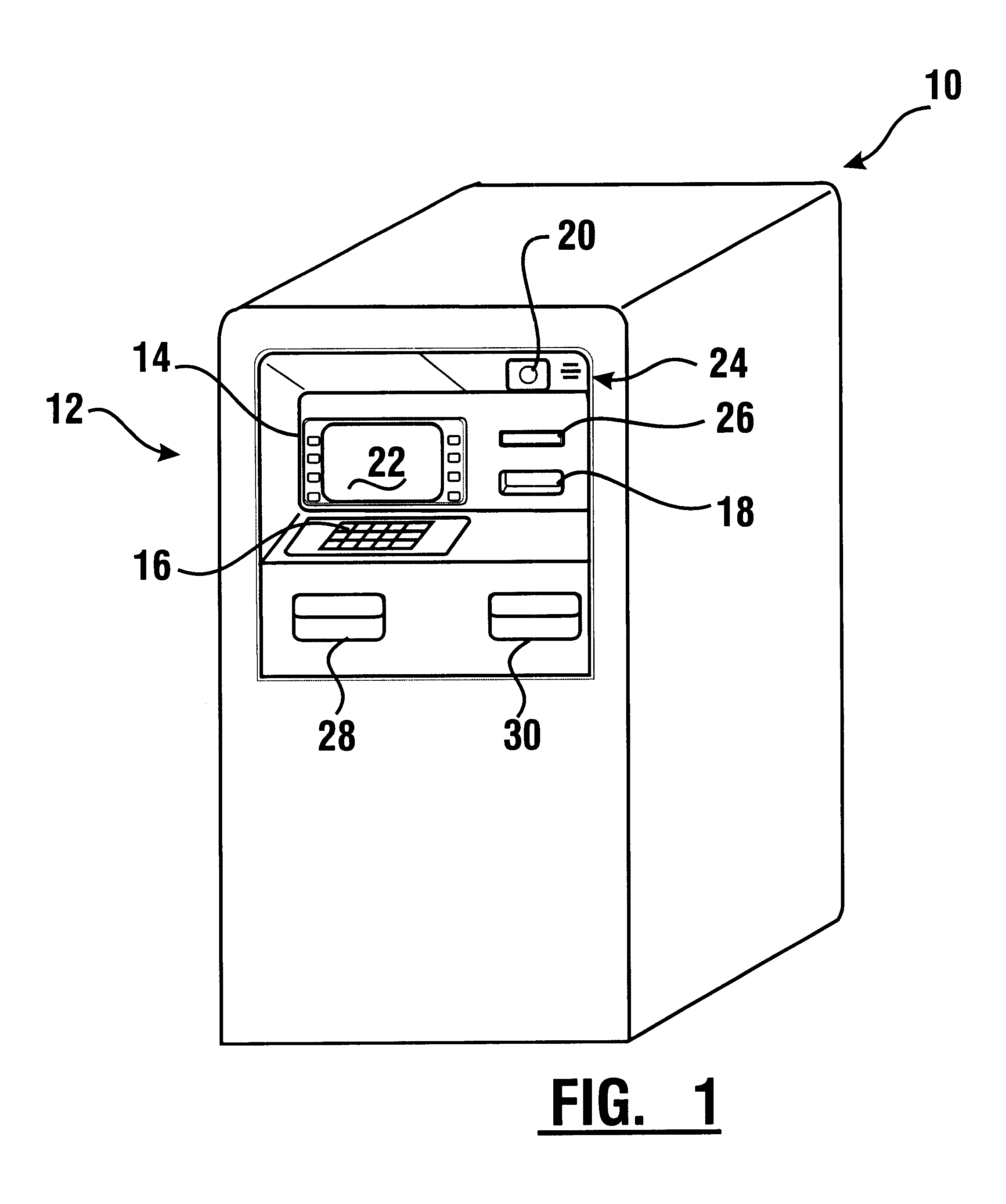

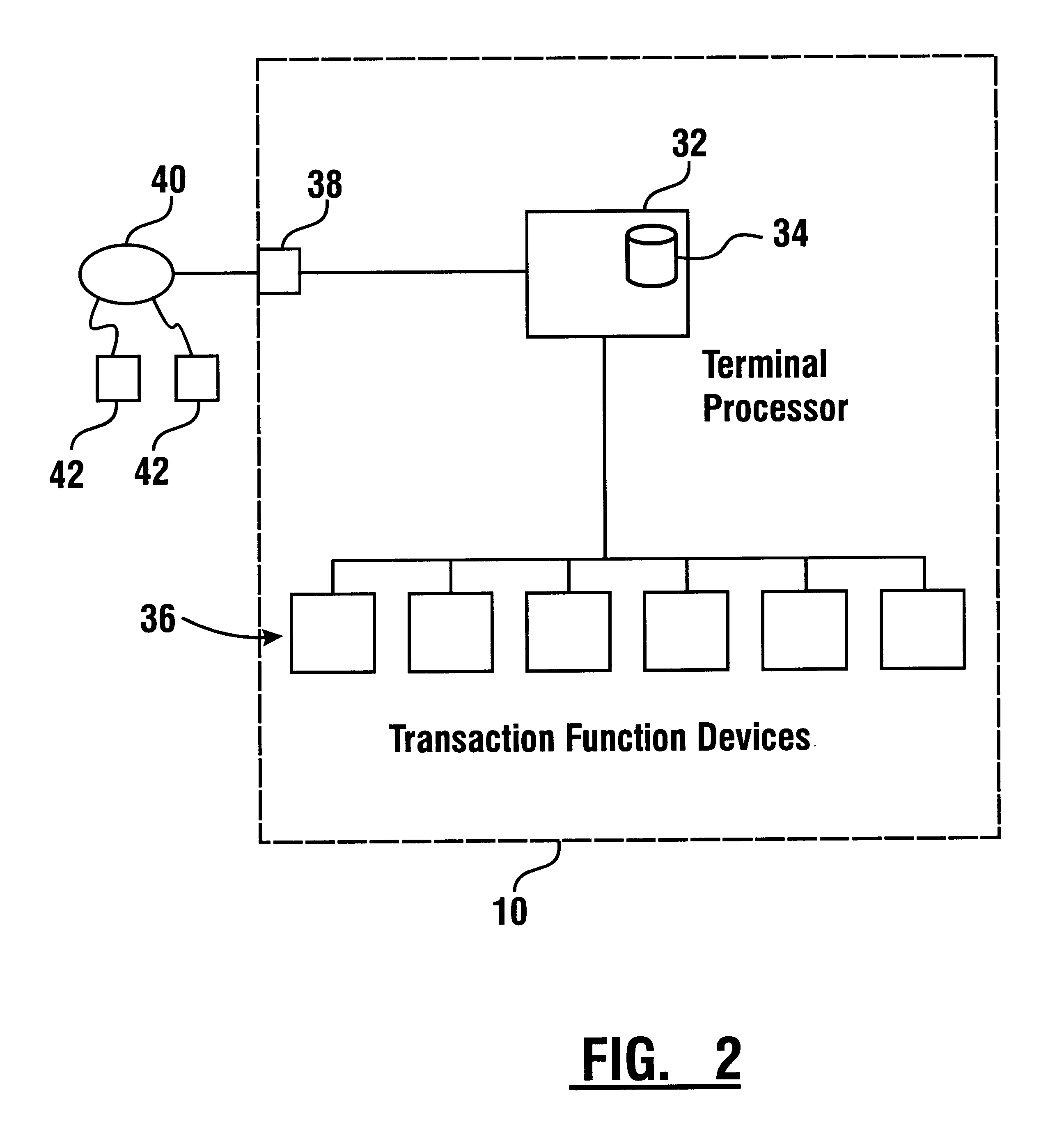

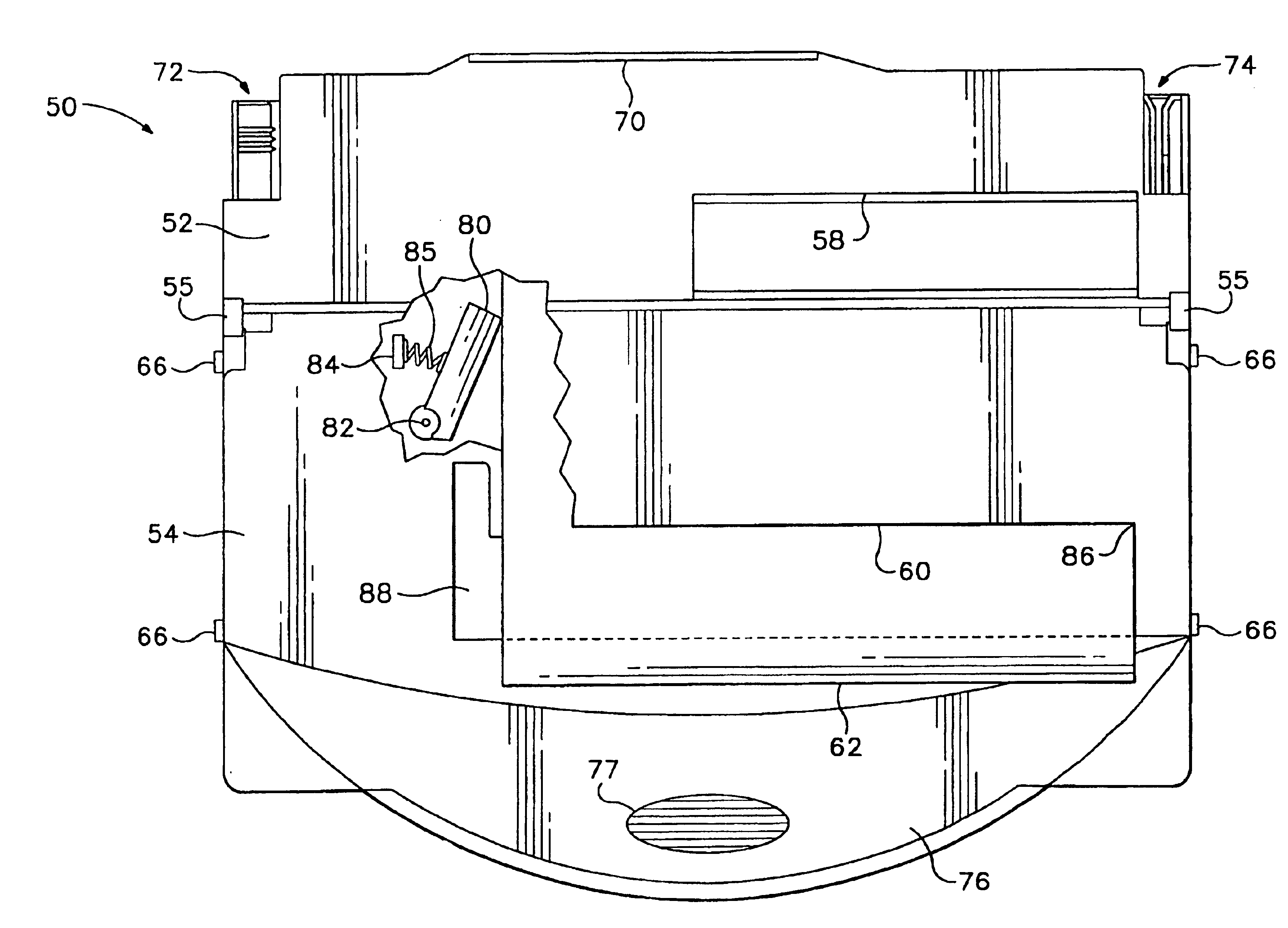

Deposit accepting and storage apparatus and method for automated banking machine

InactiveUS6474548B1Minimize the risk of damageReduce the possibilityComplete banking machinesRegistering devicesEngineeringInstrumentation

An automated banking machine (10) includes a deposit accepting apparatus (44) which is capable of accepting and authenticating instruments, as well as accepting envelopes deposited into the machine by a user. A transport section (46) is operative to engage and transport deposited items selectively from an inlet (48) to an outlet (50). A deposit holding module (90) includes compartments (98, 106) which are operative to hold different types of deposits. The machine operates to selectively move a compartment into communication with the outlet based on the particular type of item being deposited. The depository apparatus is further operative to acquire image and magnetic profile data from deposited instruments, to manipulate the image and profile data and to analyze and resolve characters in selected areas thereof. The data from deposited instruments is used for determining if a user is authorized to conduct certain requested transactions at the machine.

Owner:DIEBOLD NIXDORF

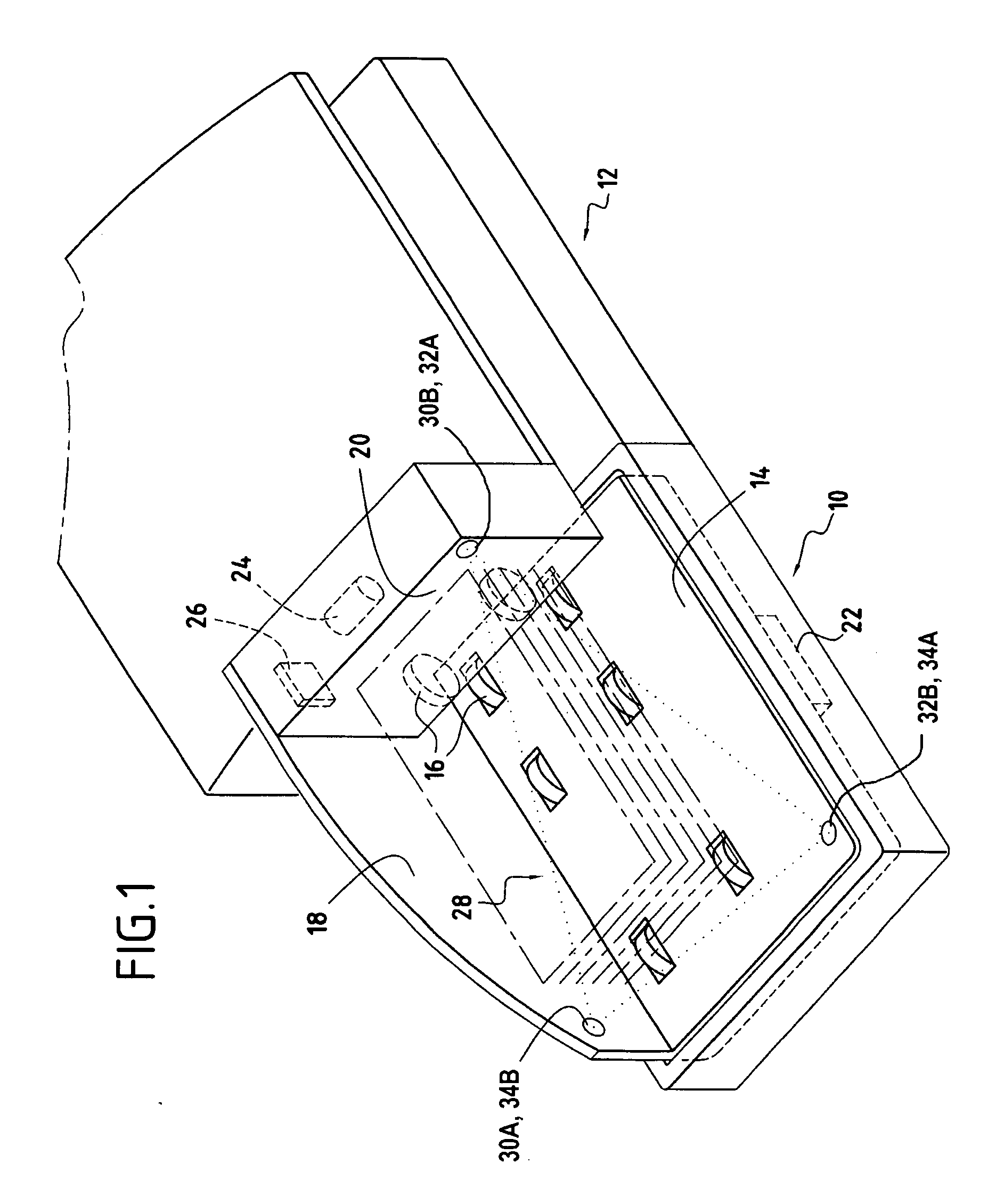

Greeting card feeder module for inkjet printing

InactiveUS6848844B2Easy to useClear imagingPrinting mechanismsRegistering devicesCard stockInk printer

A hardcopy printing mechanism and a greeting card feeder retrofit kit therefor, along with a retrofitting method are provided for printing images on a first-sized media, and on both surfaces a second-sized greeting card media without removing the first-sized media from its normal supply tray. The hardcopy device may be an electrophotographic or inkjet printer preferably equipped with a duplexer module which inverts media from a printed first surface to an opposing second surface for printing an image thereon. For a printer having an alignment surface, and a width adjuster to push the first-sized media against the alignment surface, the greeting card feeder includes a biasing member which pushes the card stock against the alignment surface. The retrofit kit includes a supply of pre-scored greeting card stock and a software program with a group of greeting card images for a consumer to select from to print store-bought quality greeting cards.

Owner:HEWLETT PACKARD DEV CO LP

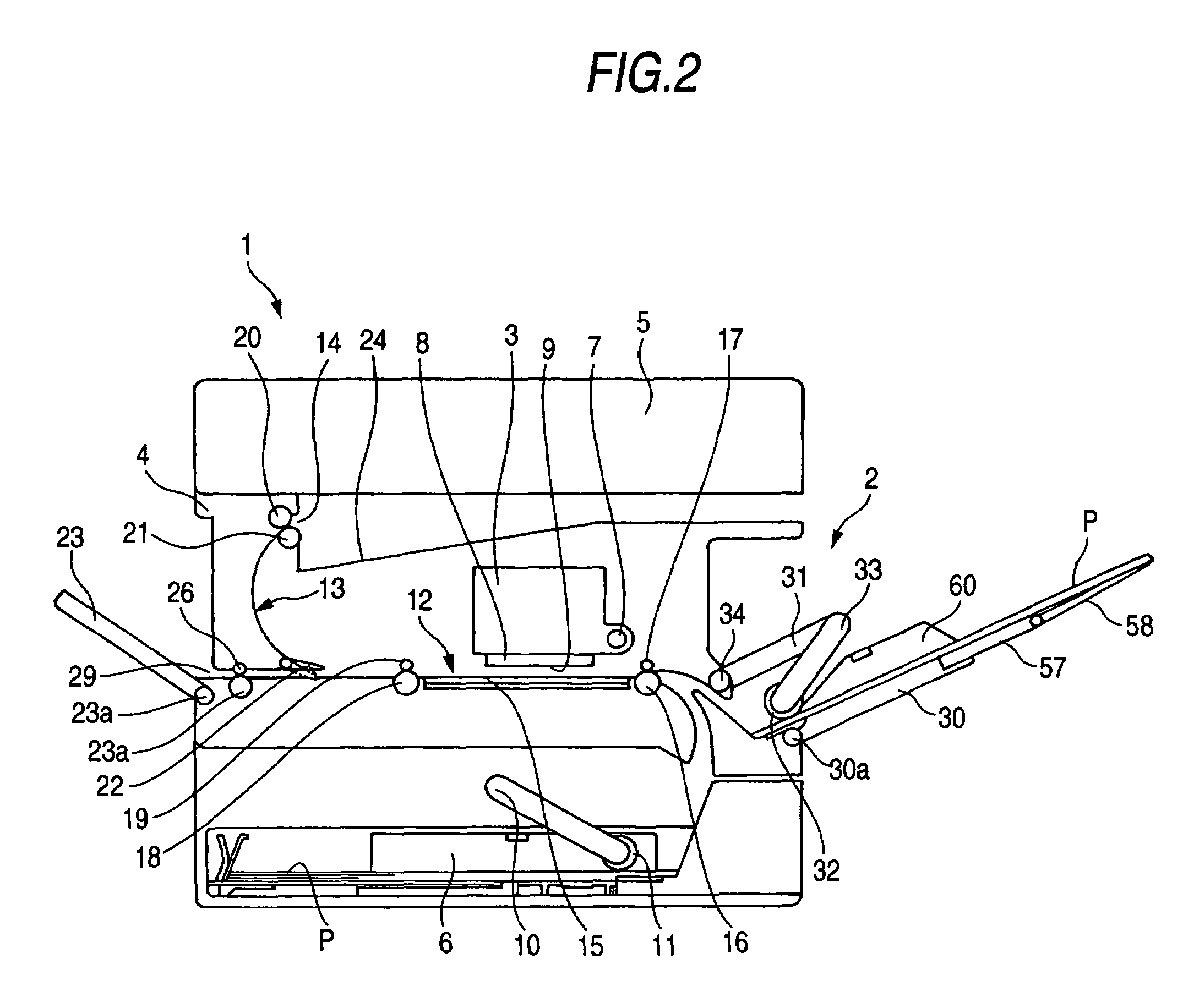

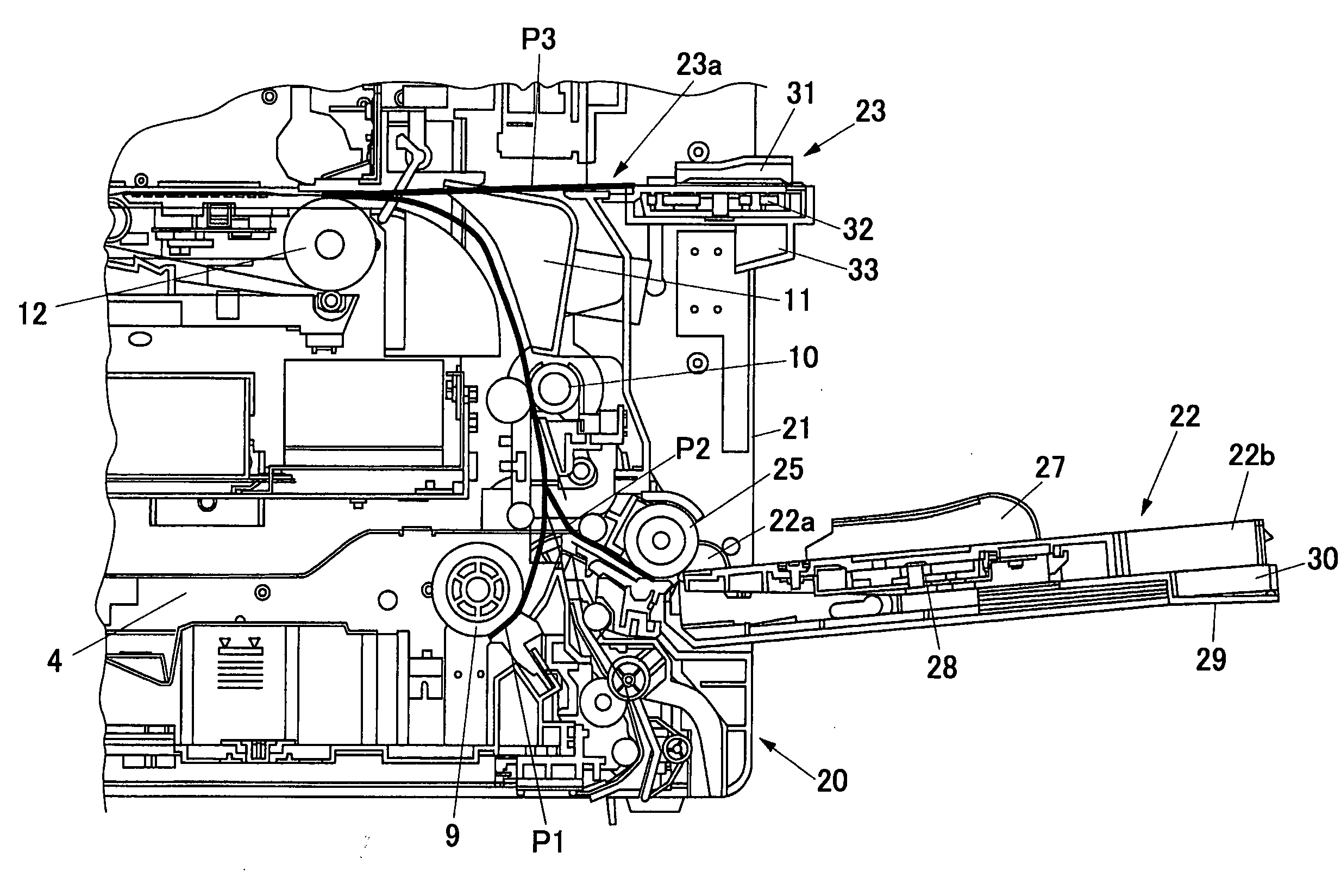

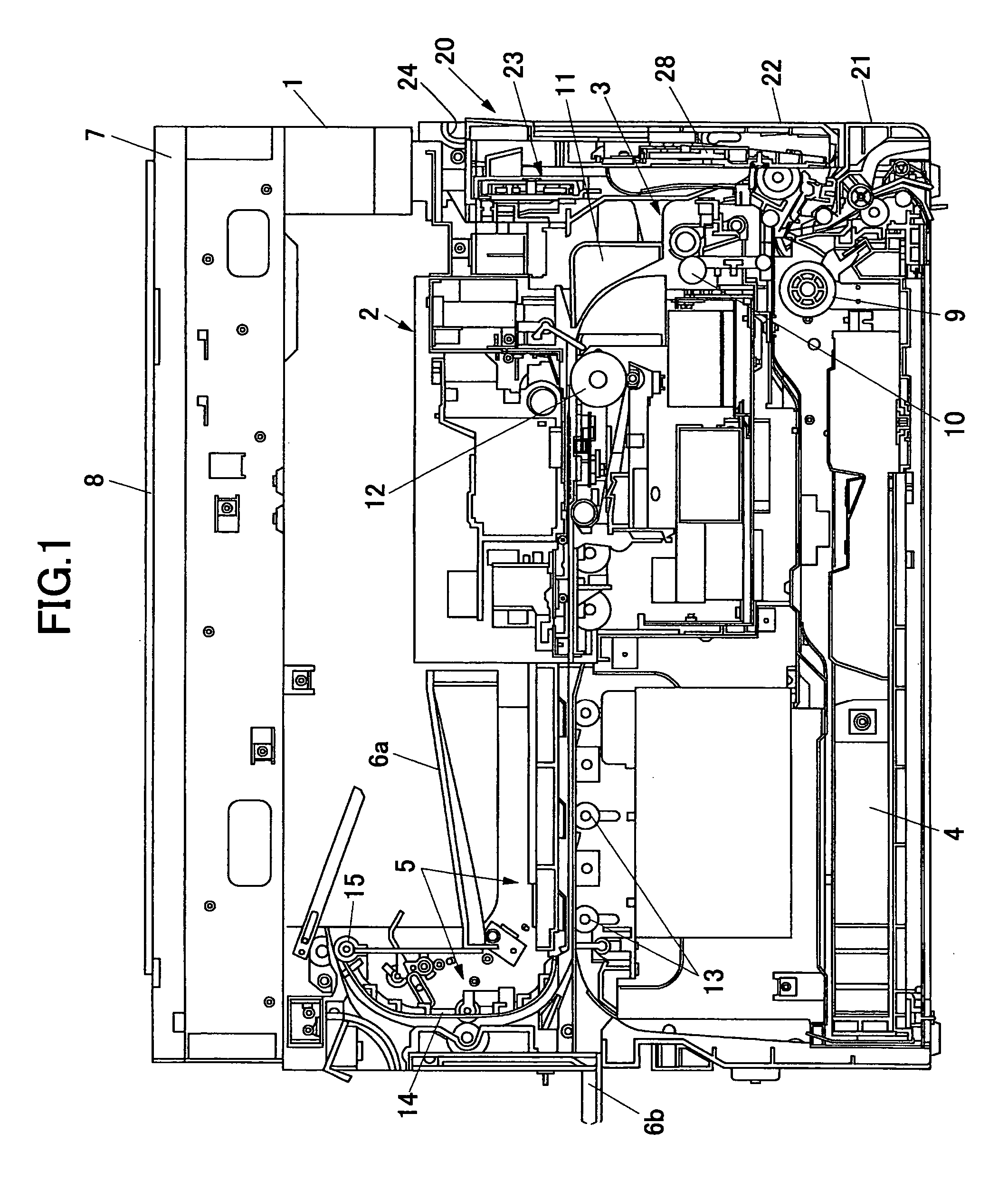

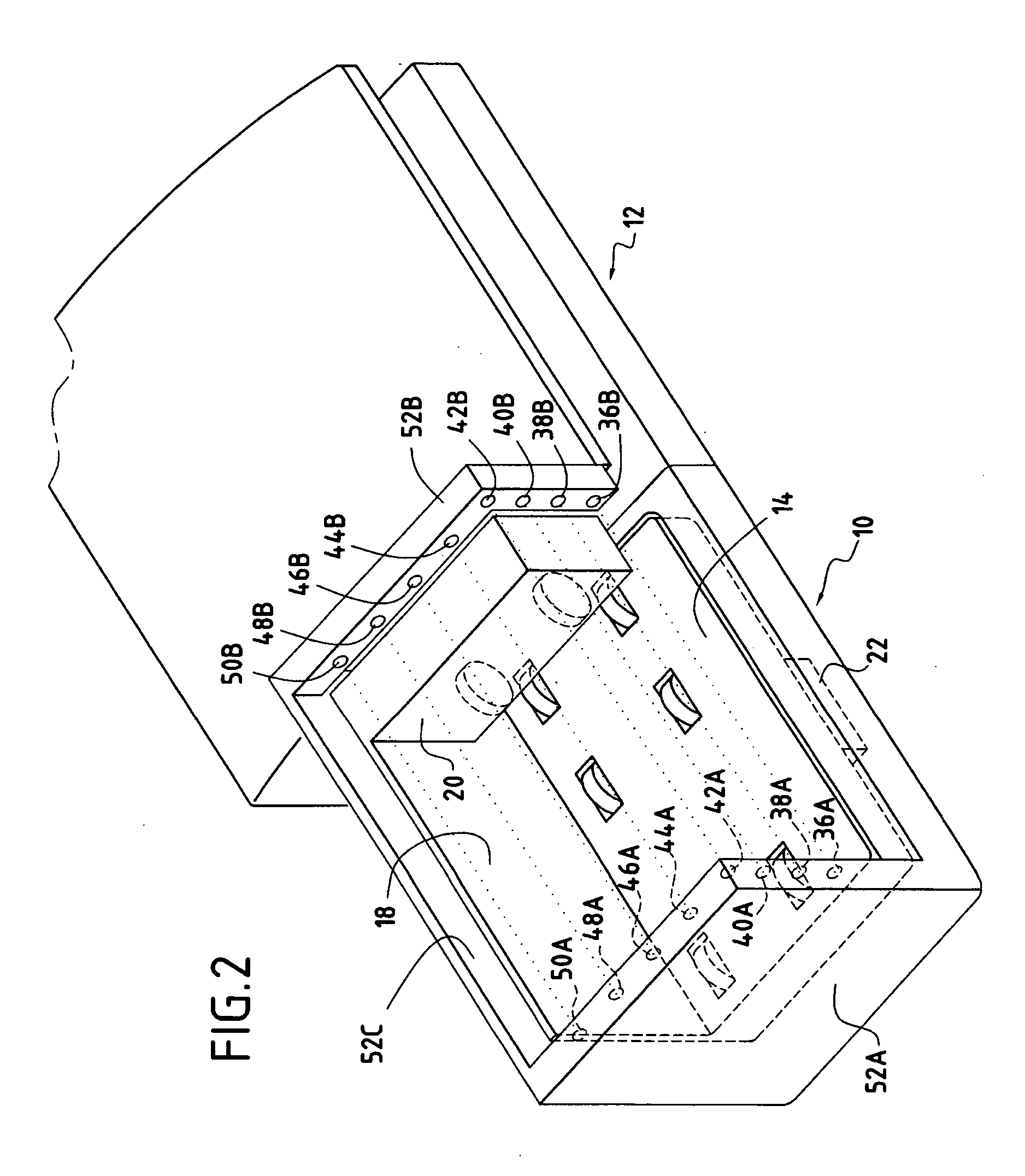

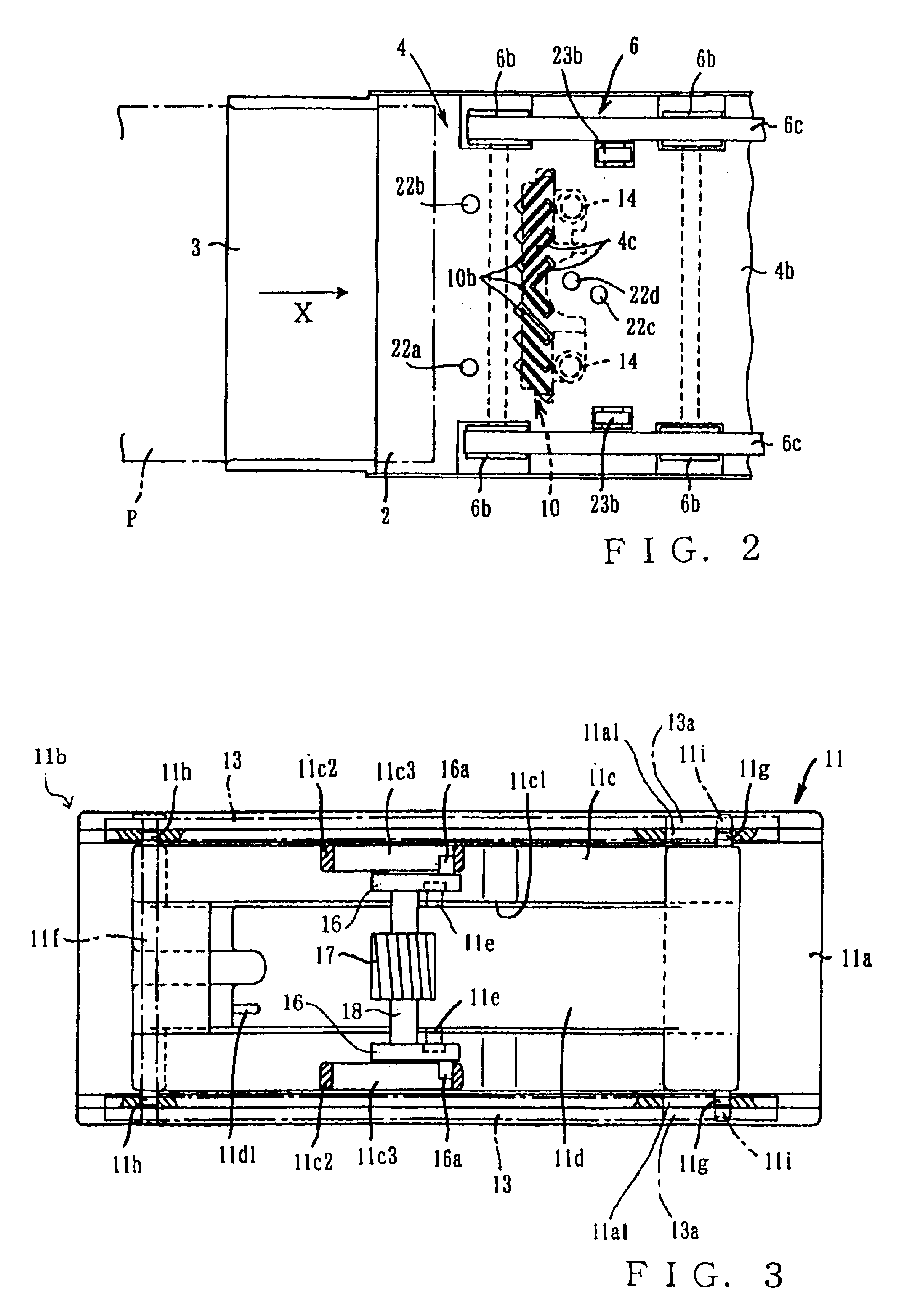

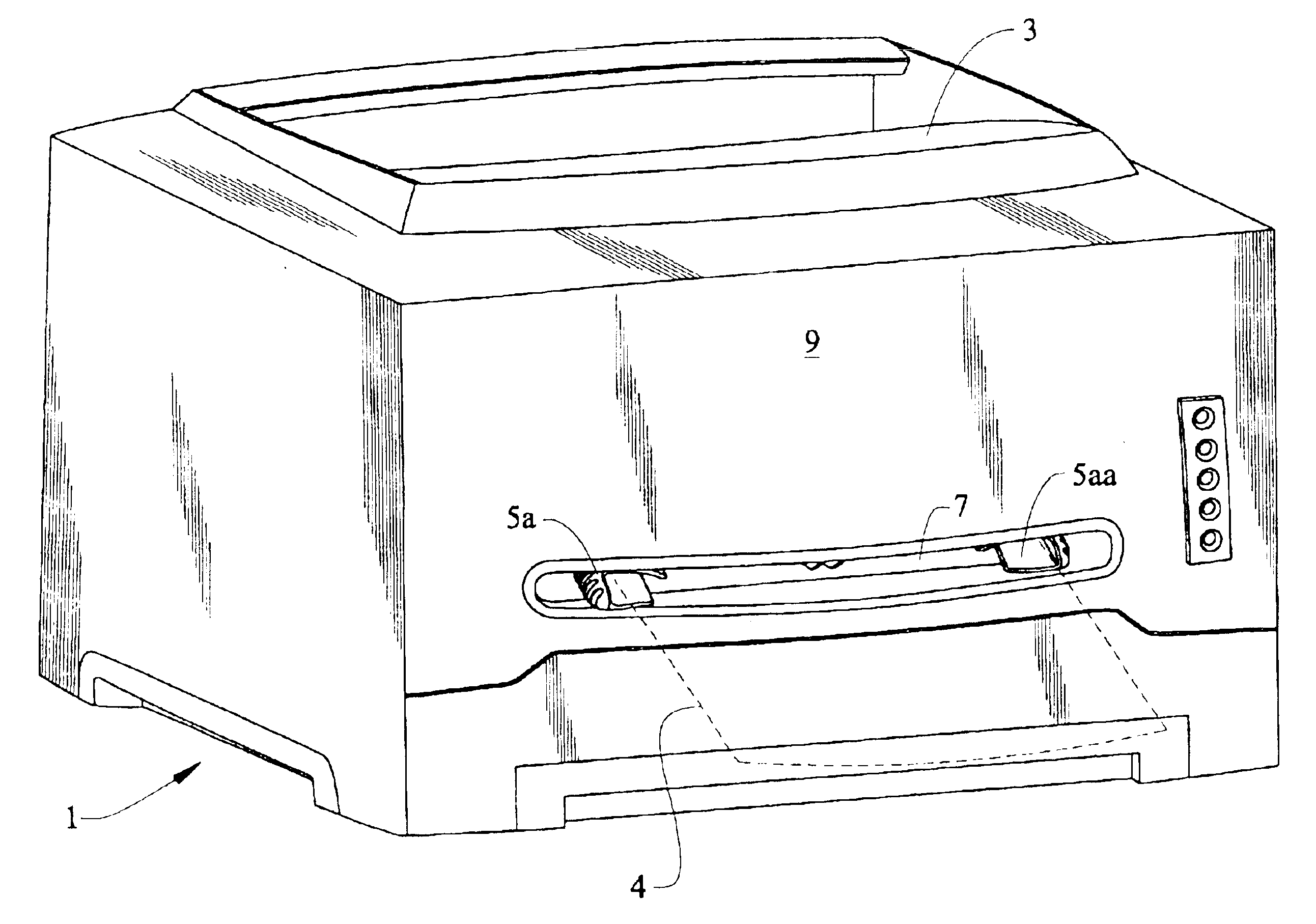

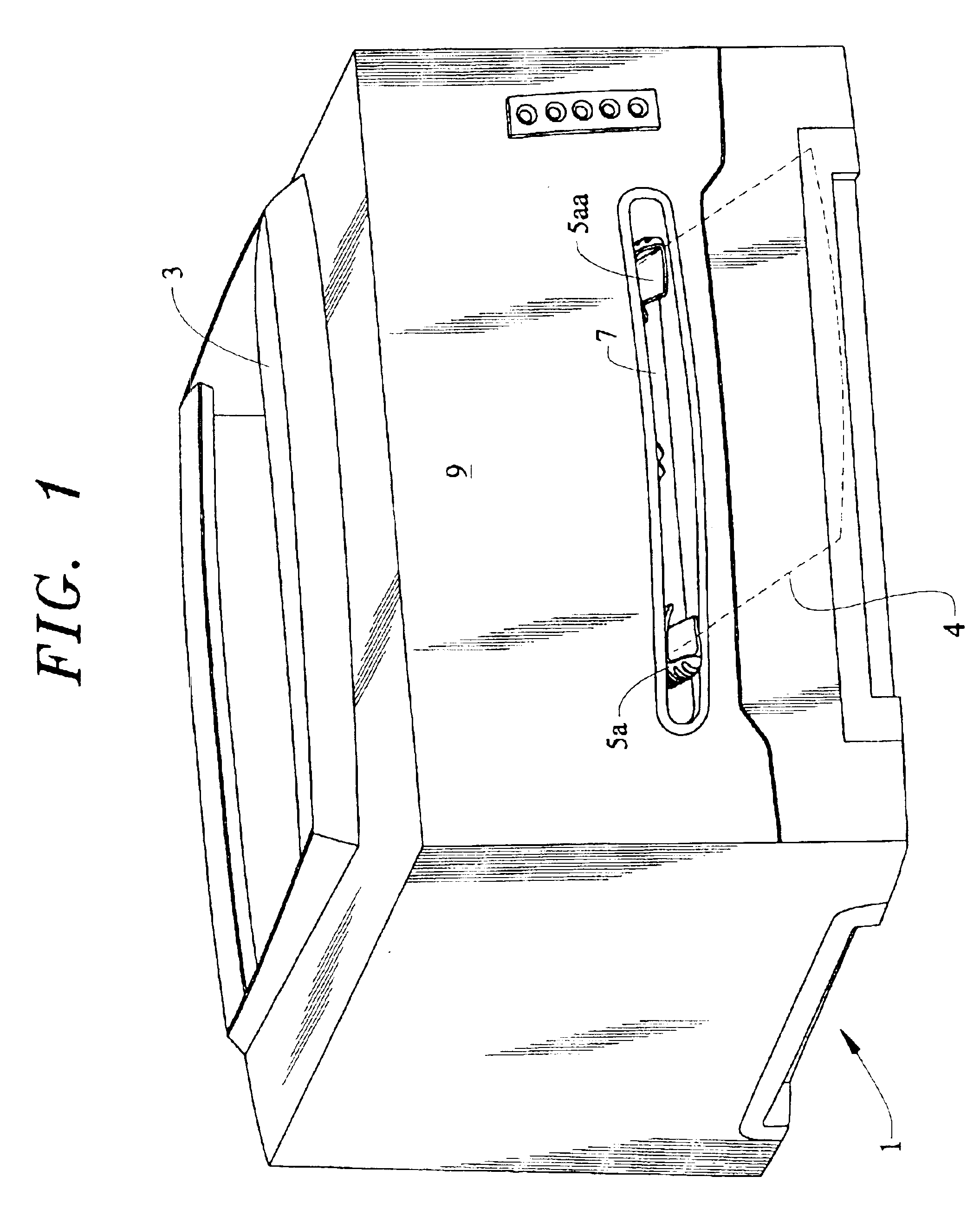

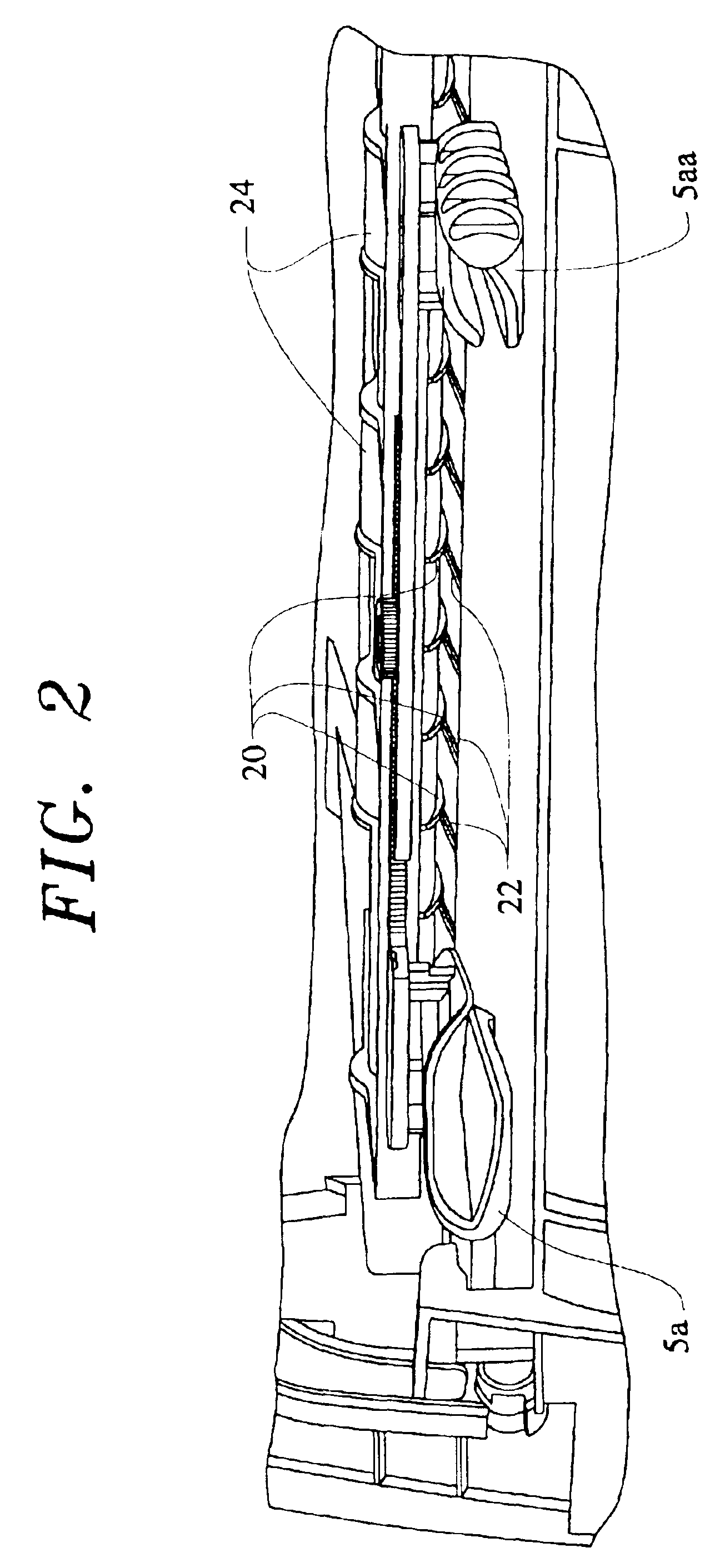

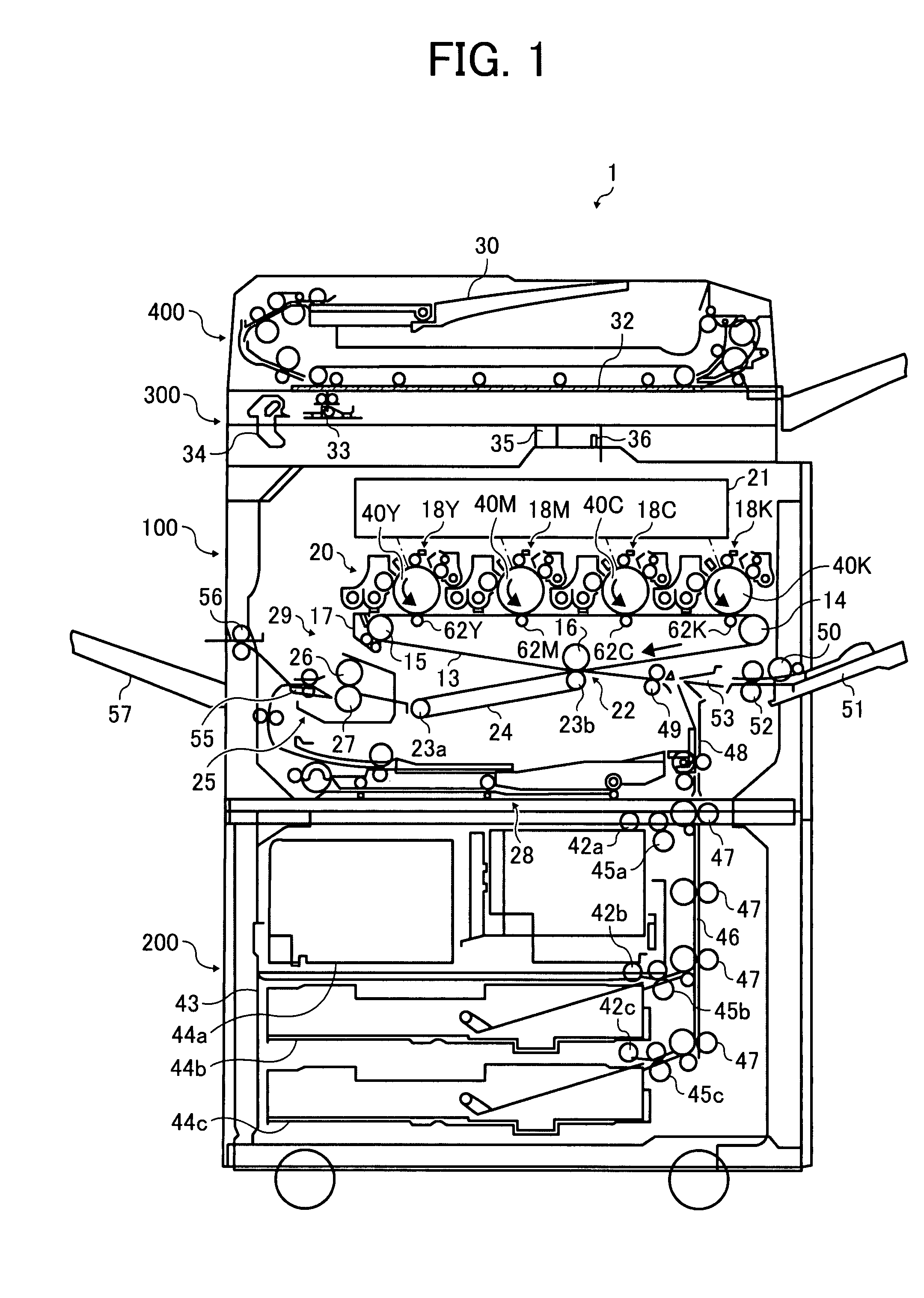

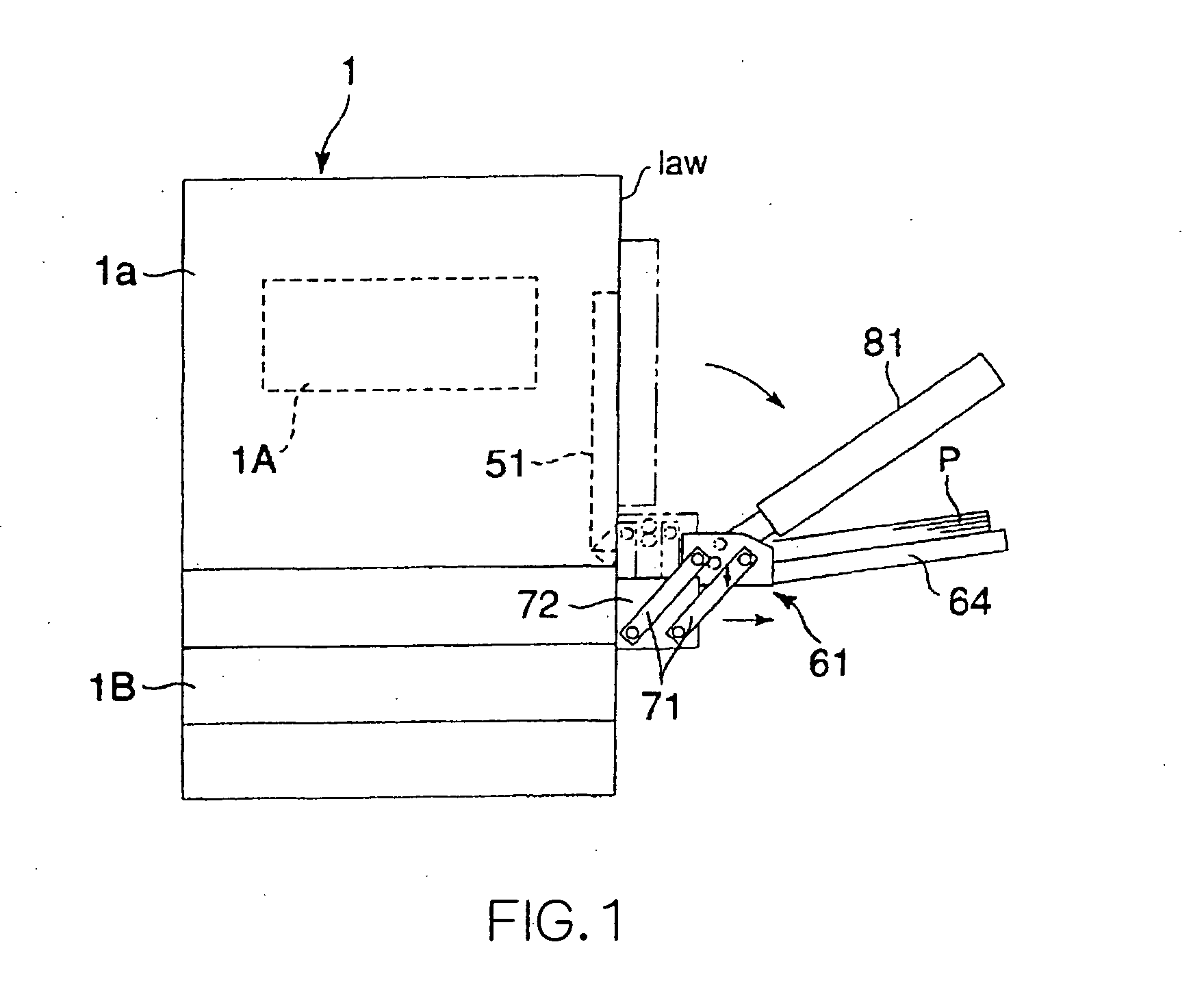

Recording medium feed apparatus

ActiveUS7036813B2Easy to insertReduce extra spaceArticle feedersFeed tablesEngineeringRecording media

A recording medium feed apparatus has a manual feed tray provided in open or closed state, a feed roller feeding a recording portion a recording medium on the manual feed tray, an arm body having a first end portion rotatably attached to a housing and a second end portion, a feed roller unit having a front end portion provided with the feed roller and a base end portion rotatably attached to the second end portion, and a driving source transferring driving force to the feed roller, wherein the arm body and the feed roller unit are vertically housed inside the housing when the manual feed tray is closed, and as the manual feed tray changes from closed to opened state, the arm body tilts toward outside, while a folding angle of the feed roller increases so that the feed roller abuts against a recording medium on the manual feed tray.

Owner:BROTHER KOGYO KK

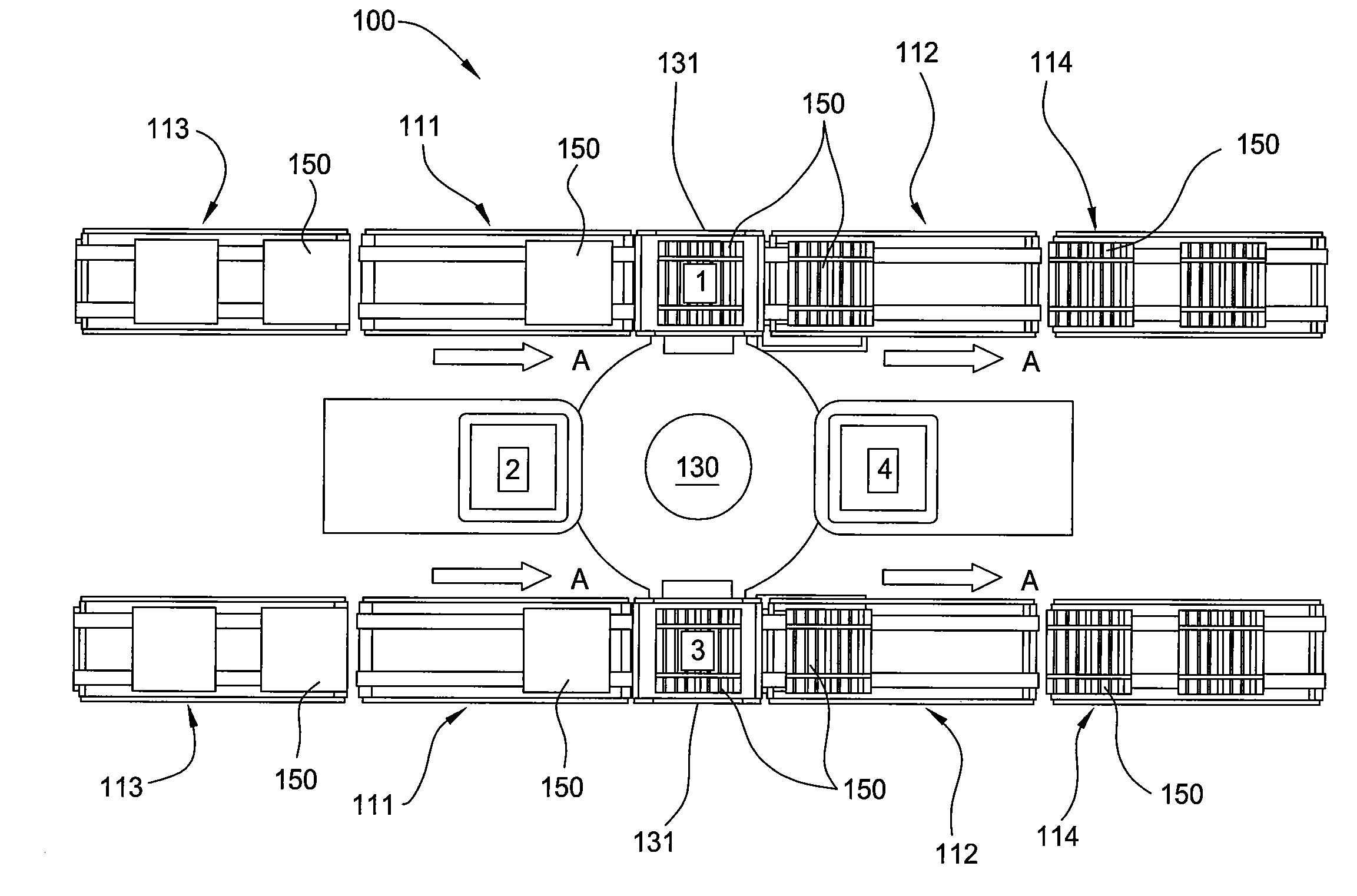

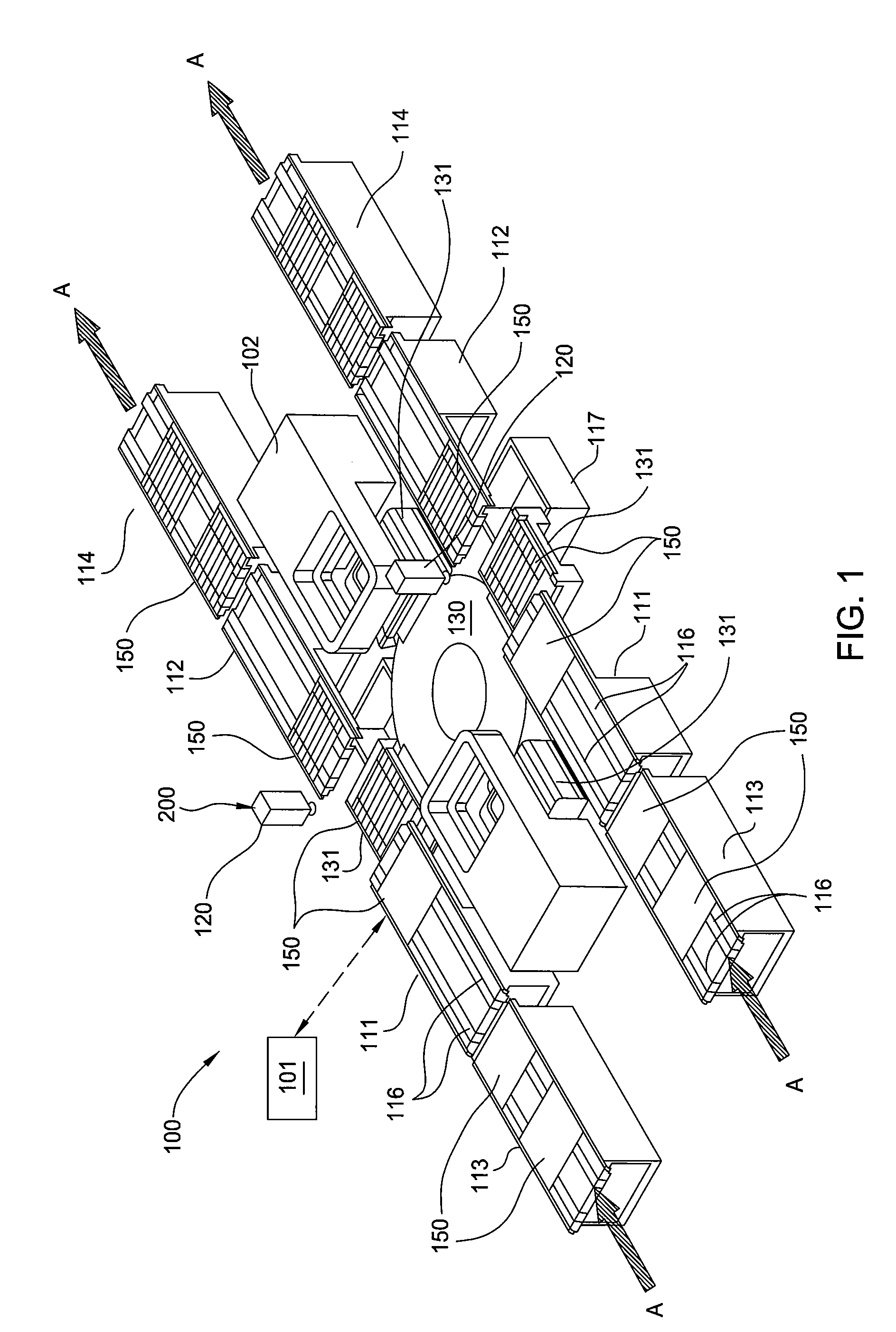

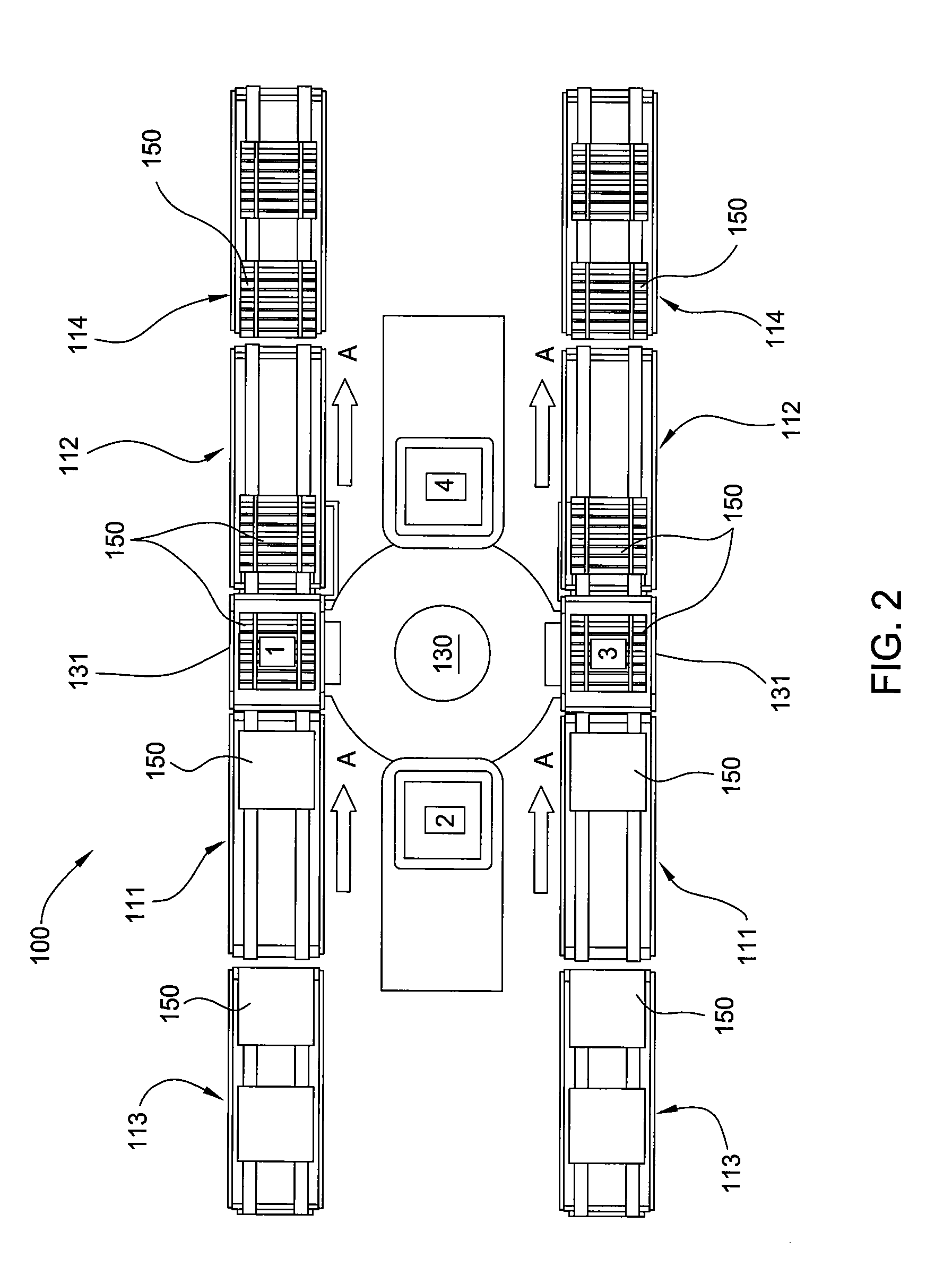

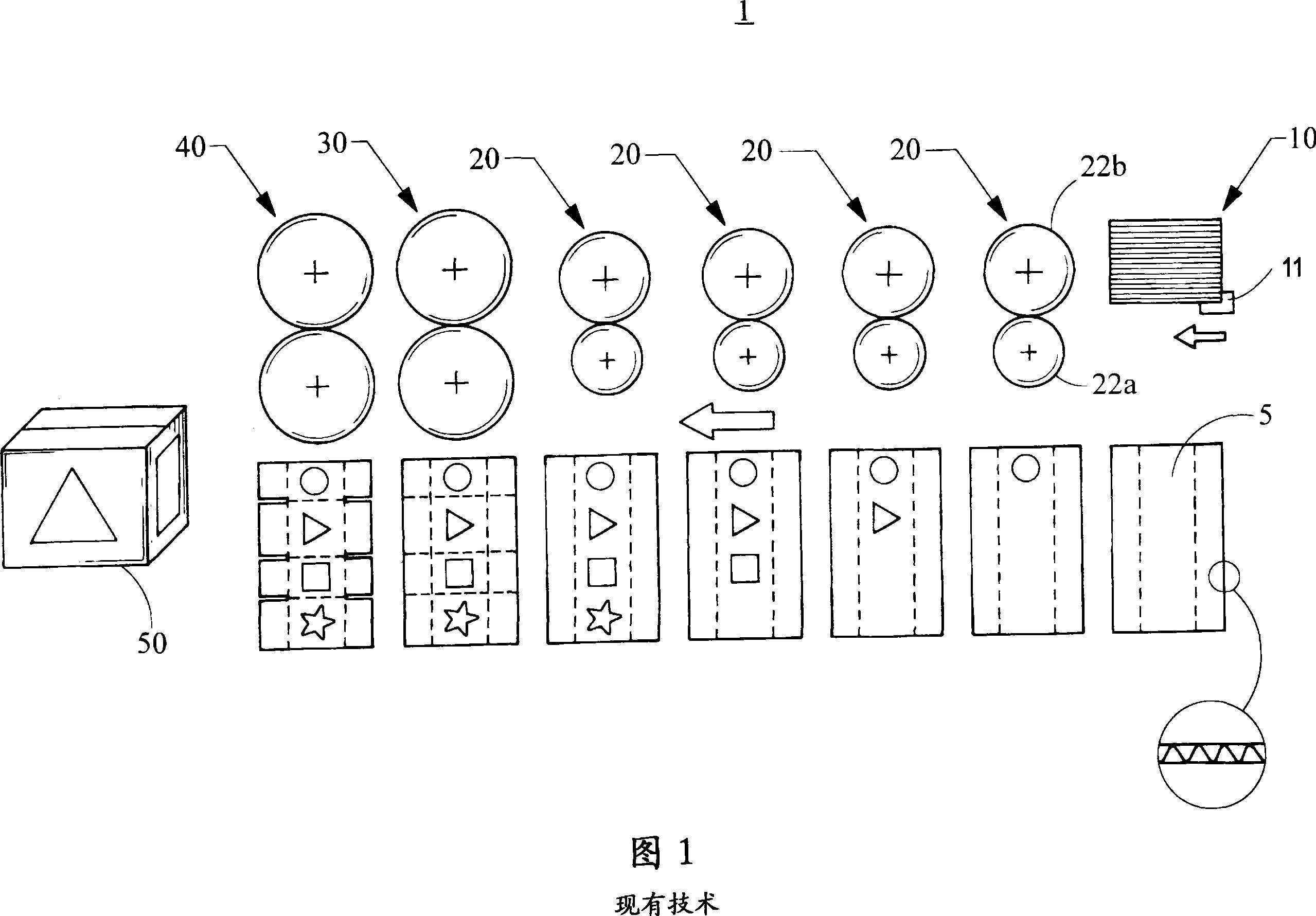

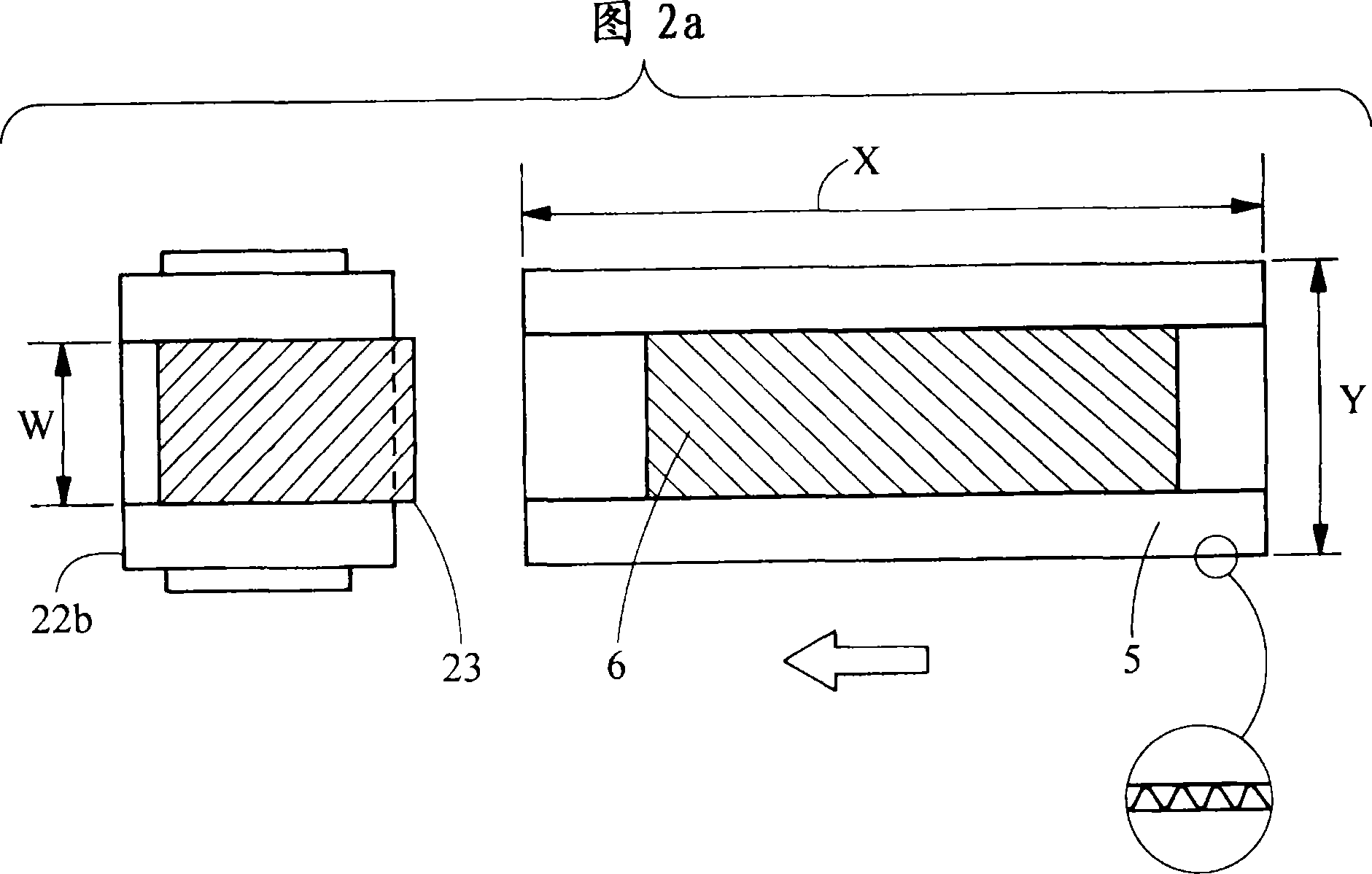

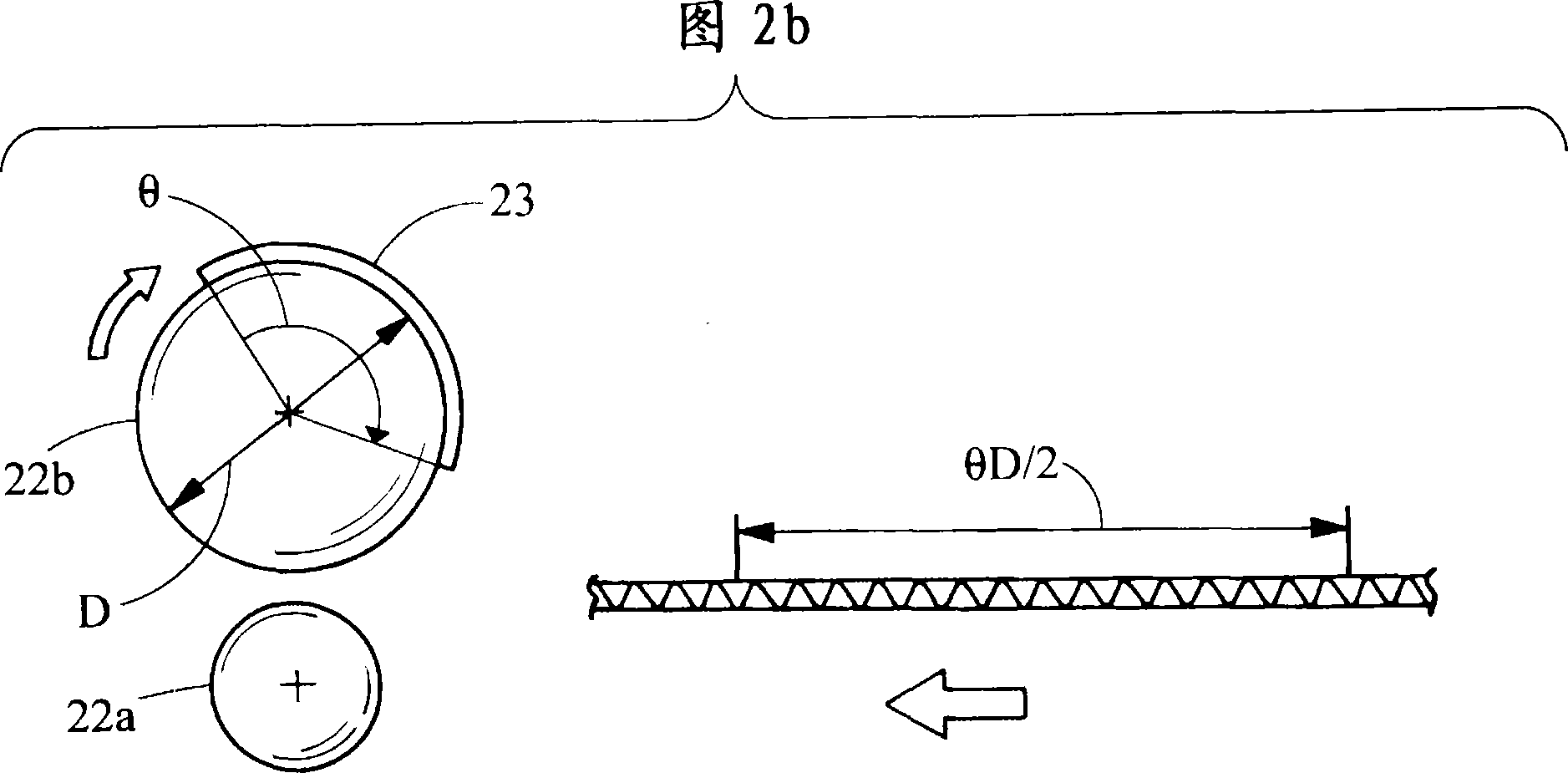

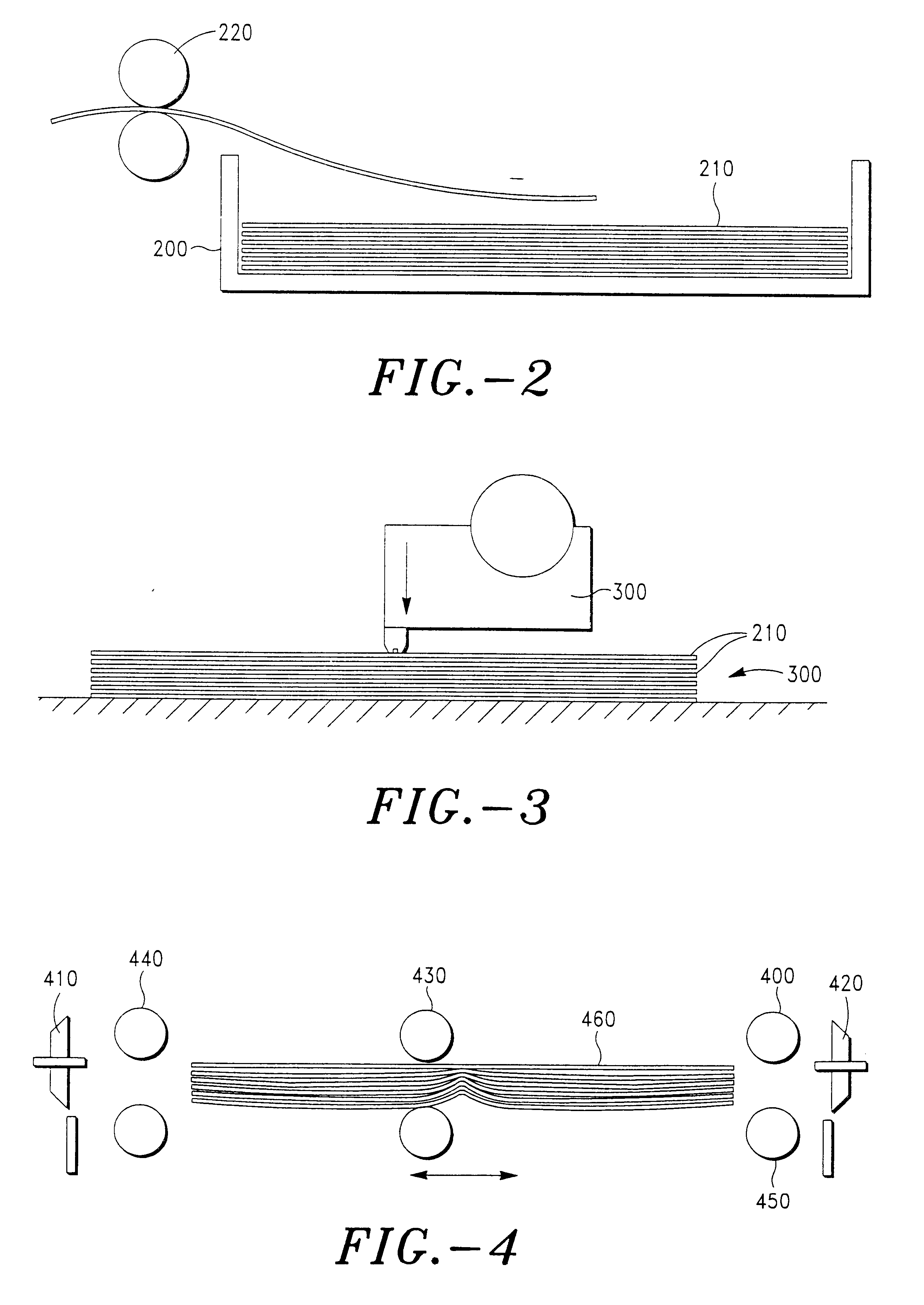

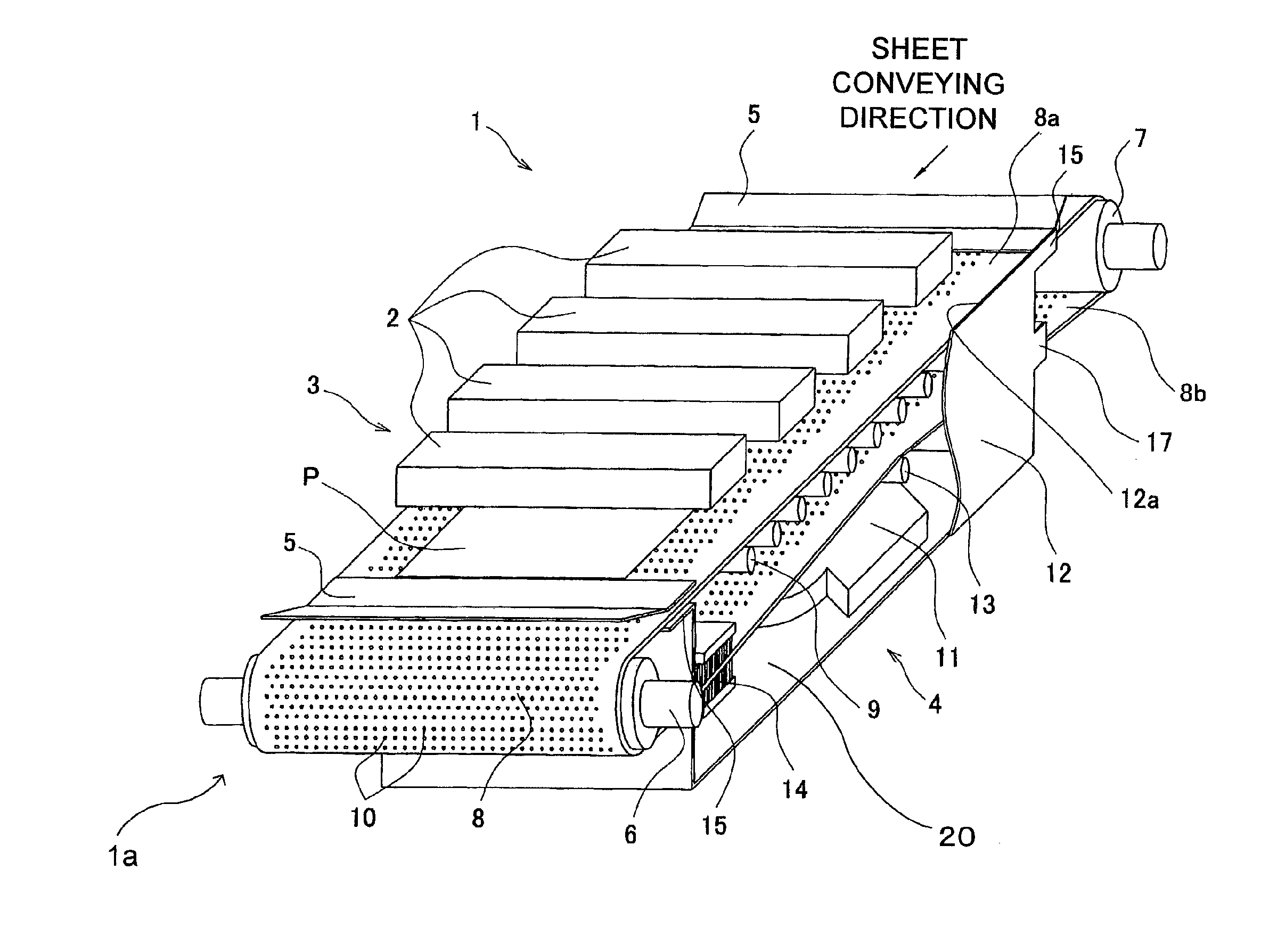

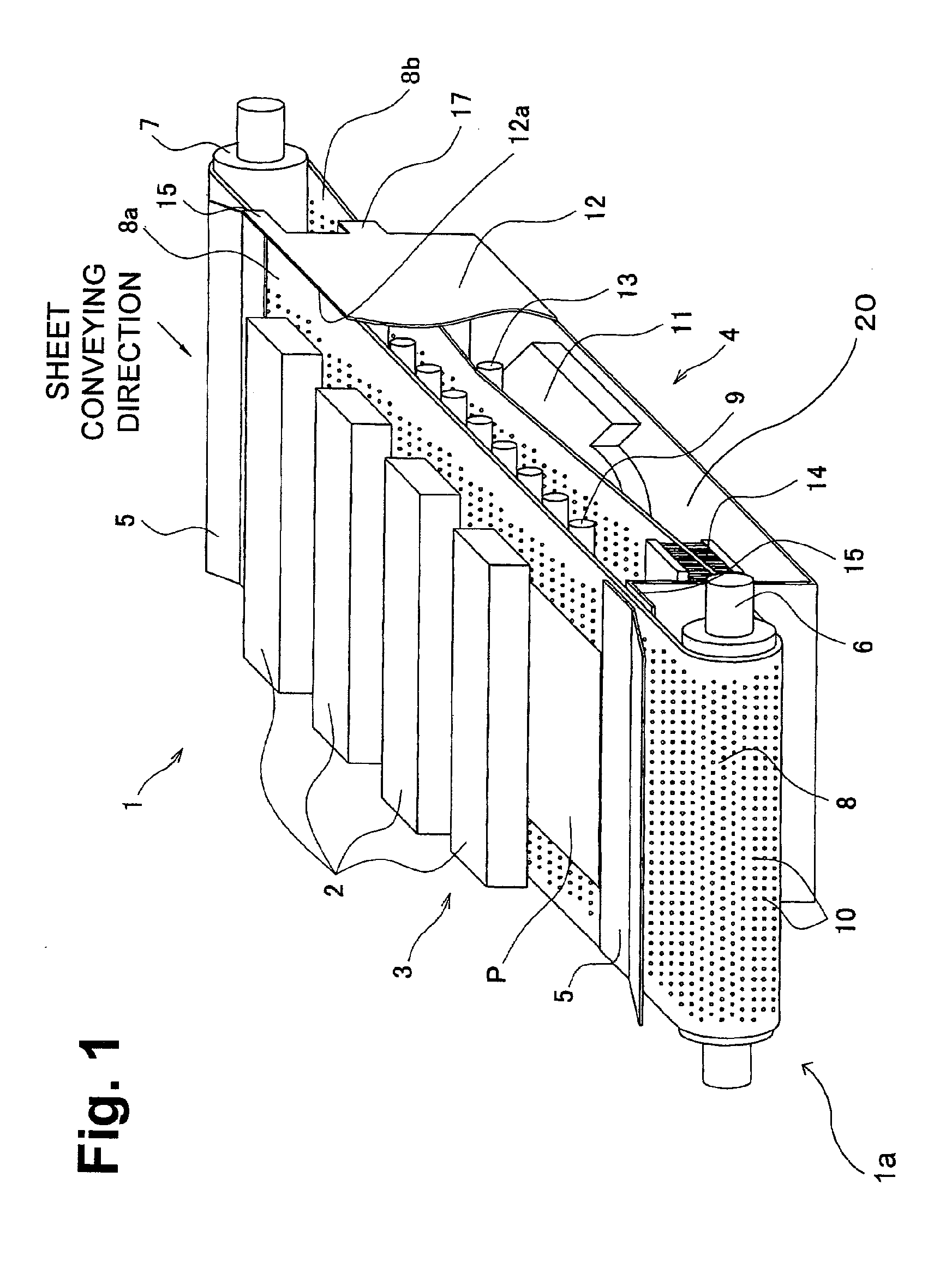

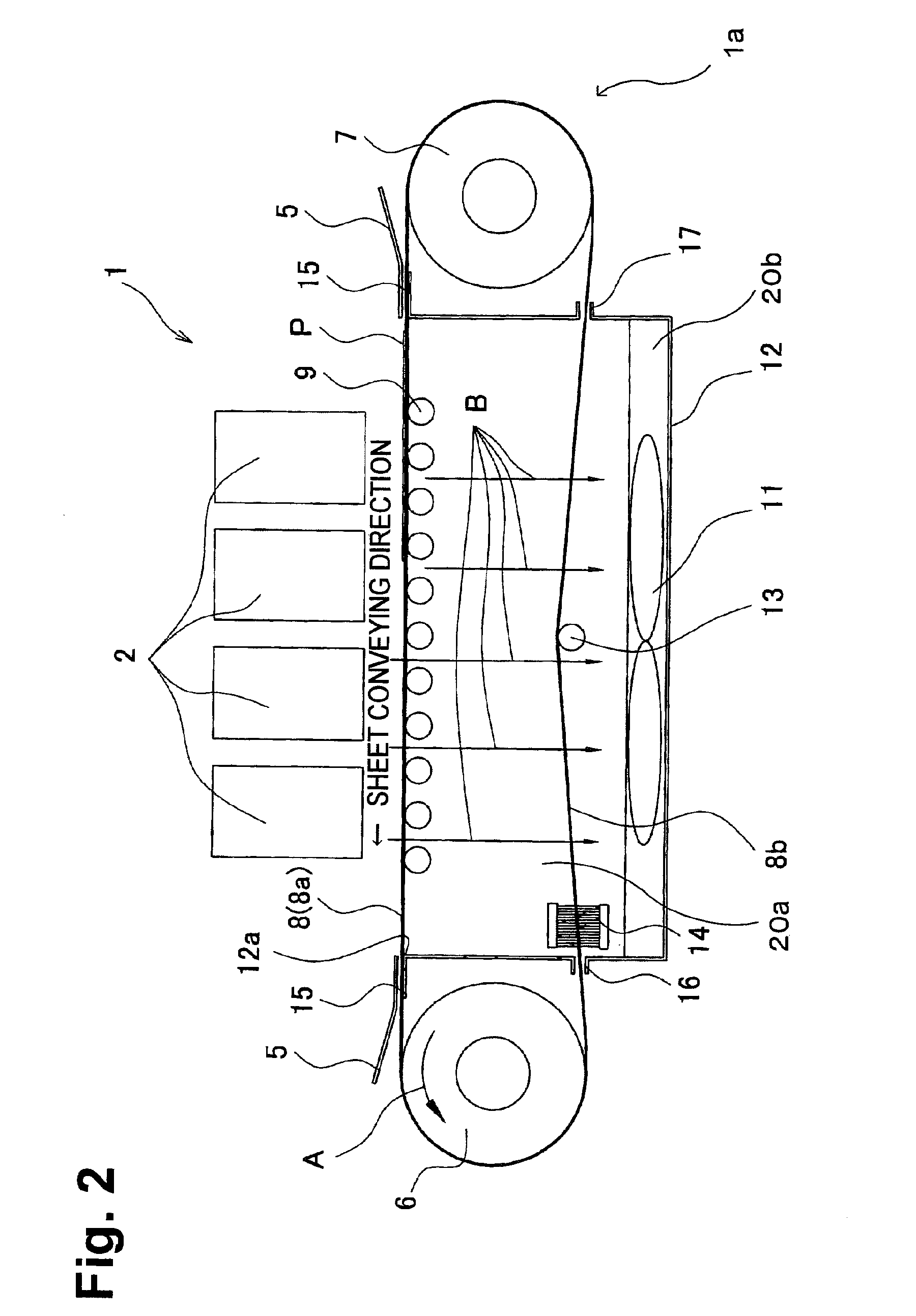

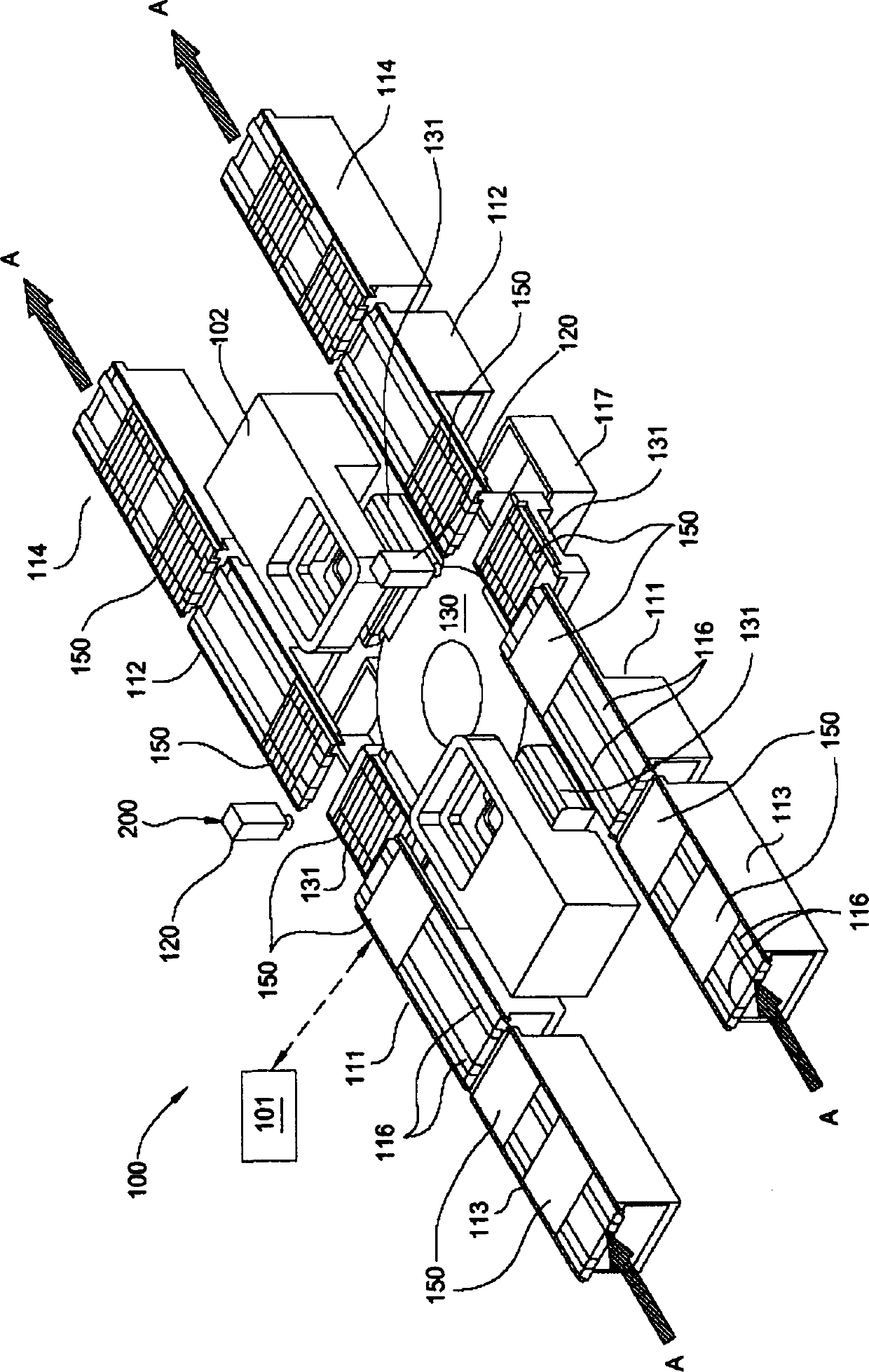

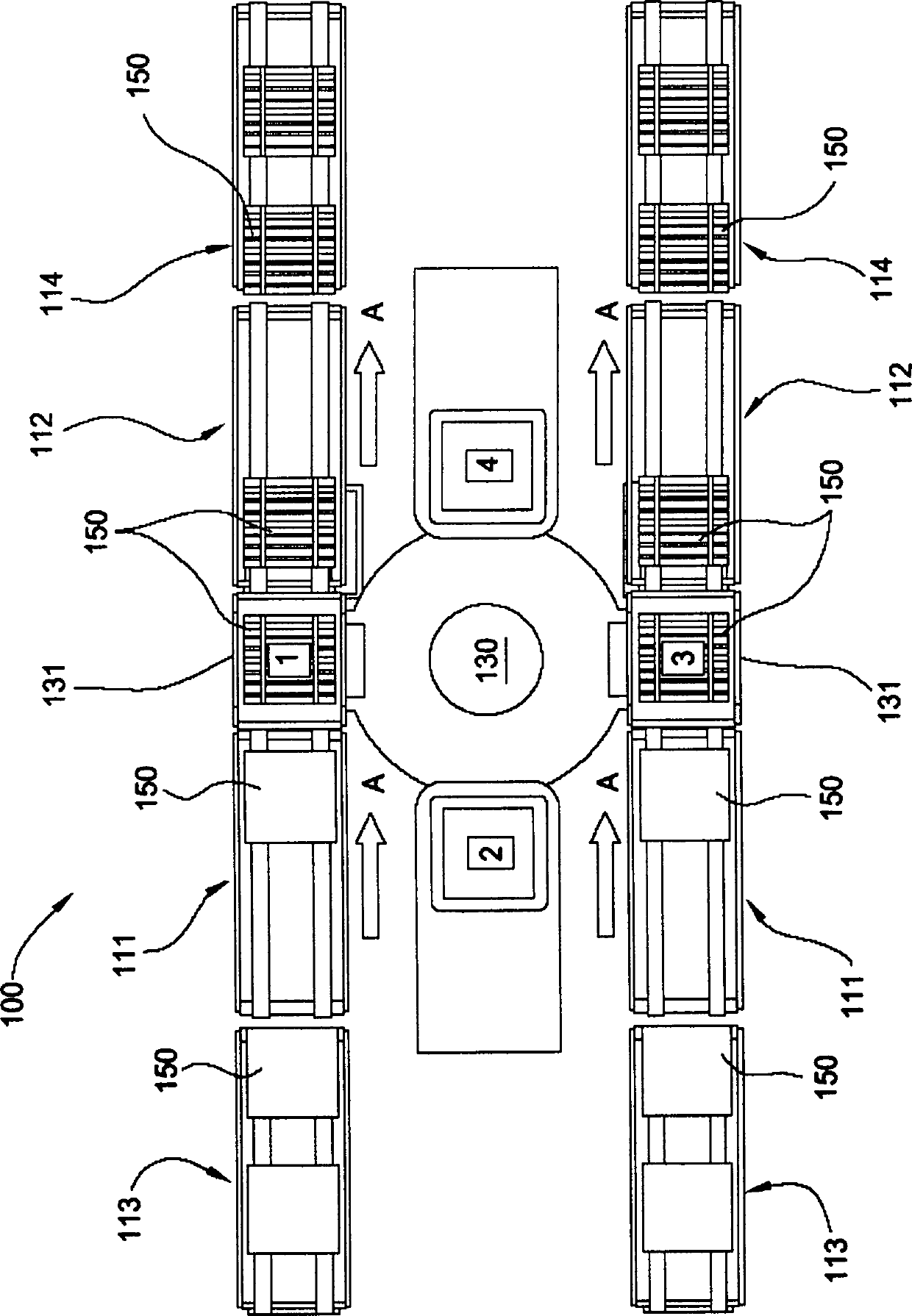

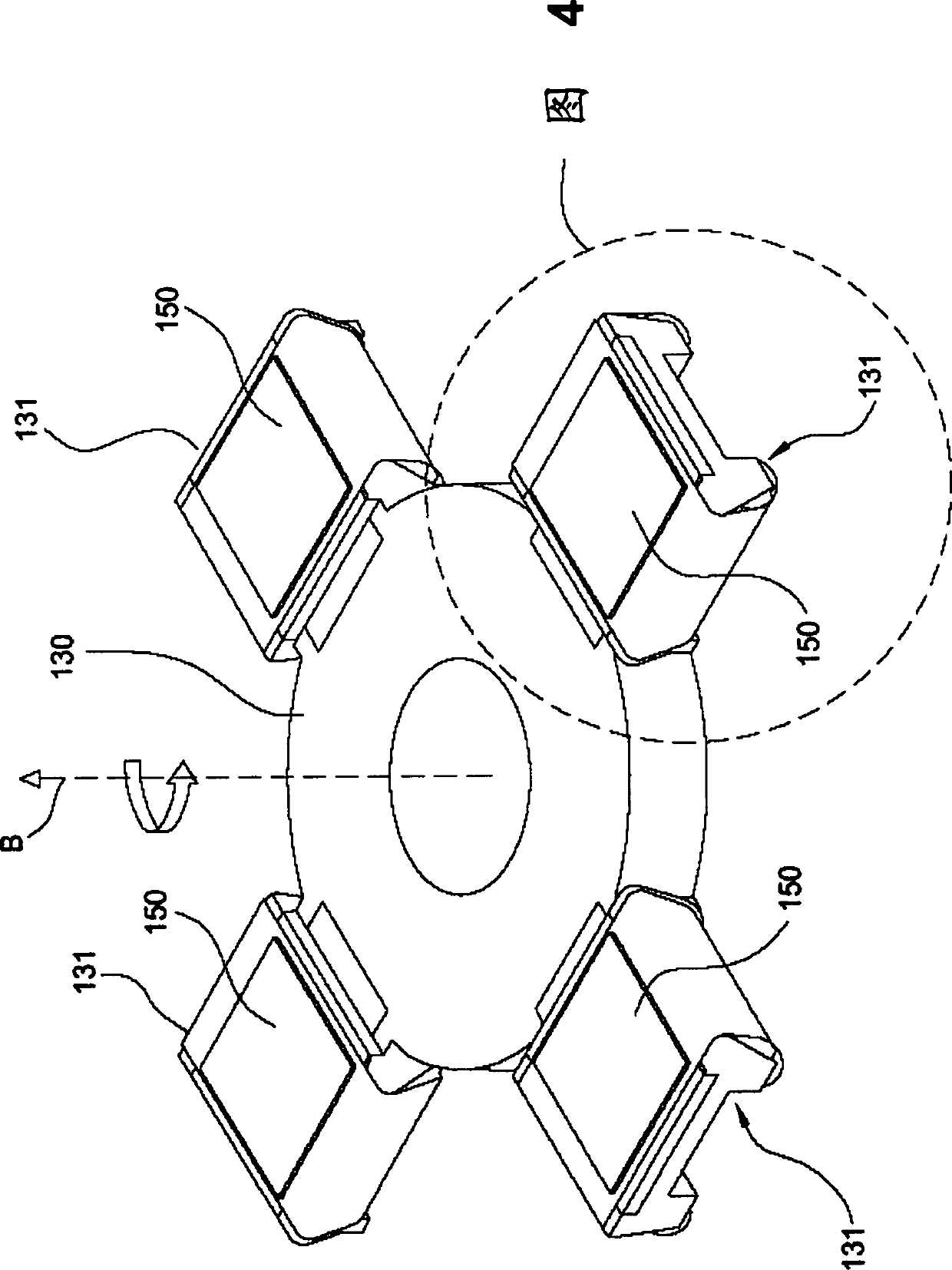

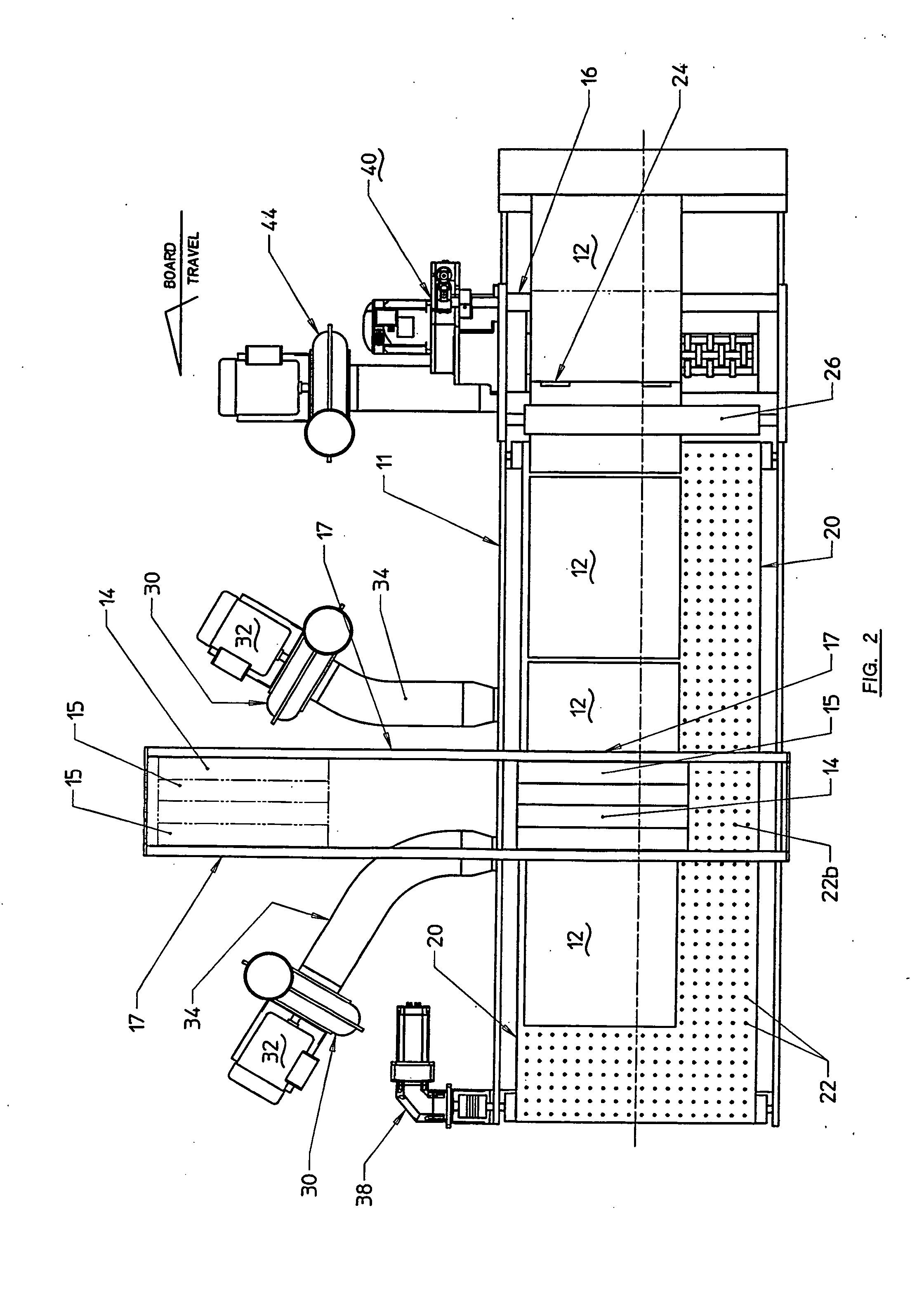

Accurate conveyance system useful for screen printing

The present invention(s) provide an apparatus and method for processing substrates in a screen printing chamber that can deliver a repeatable and accurate screen printed pattern on one or more processed substrates. In one embodiment, the screen printing chamber is adapted to perform a screen printing process within a portion of a crystalline silicon solar cell production line in which a substrate is patterned with a desired material. In one embodiment, the screen printing chamber is a processing chamber positioned within the Rotary line tool or Softline™ tool available from Baccini S.p.A., which is owned by Applied Materials, Inc. of Santa Clara, Calif.

Owner:APPLIED MATERIALS INC

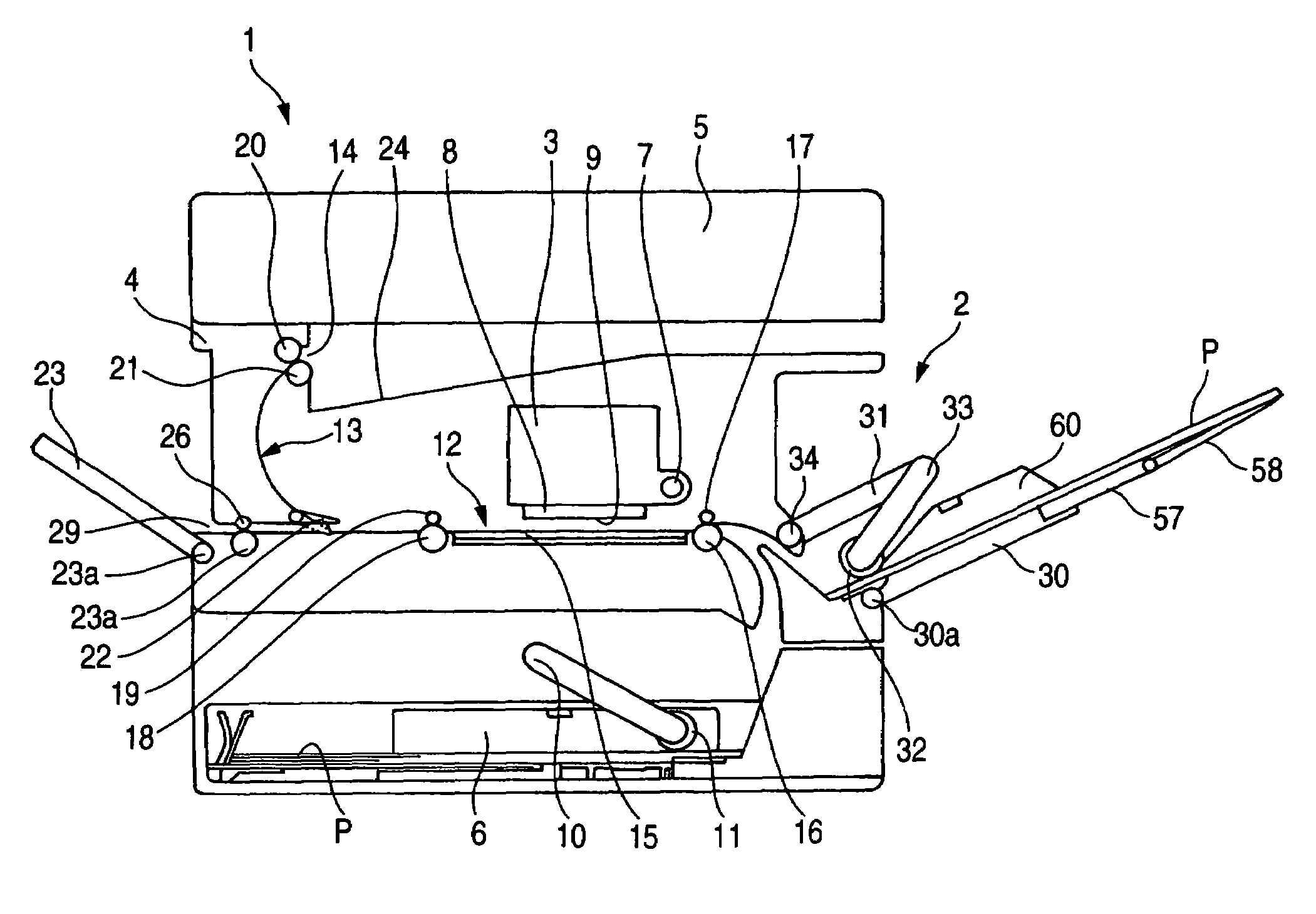

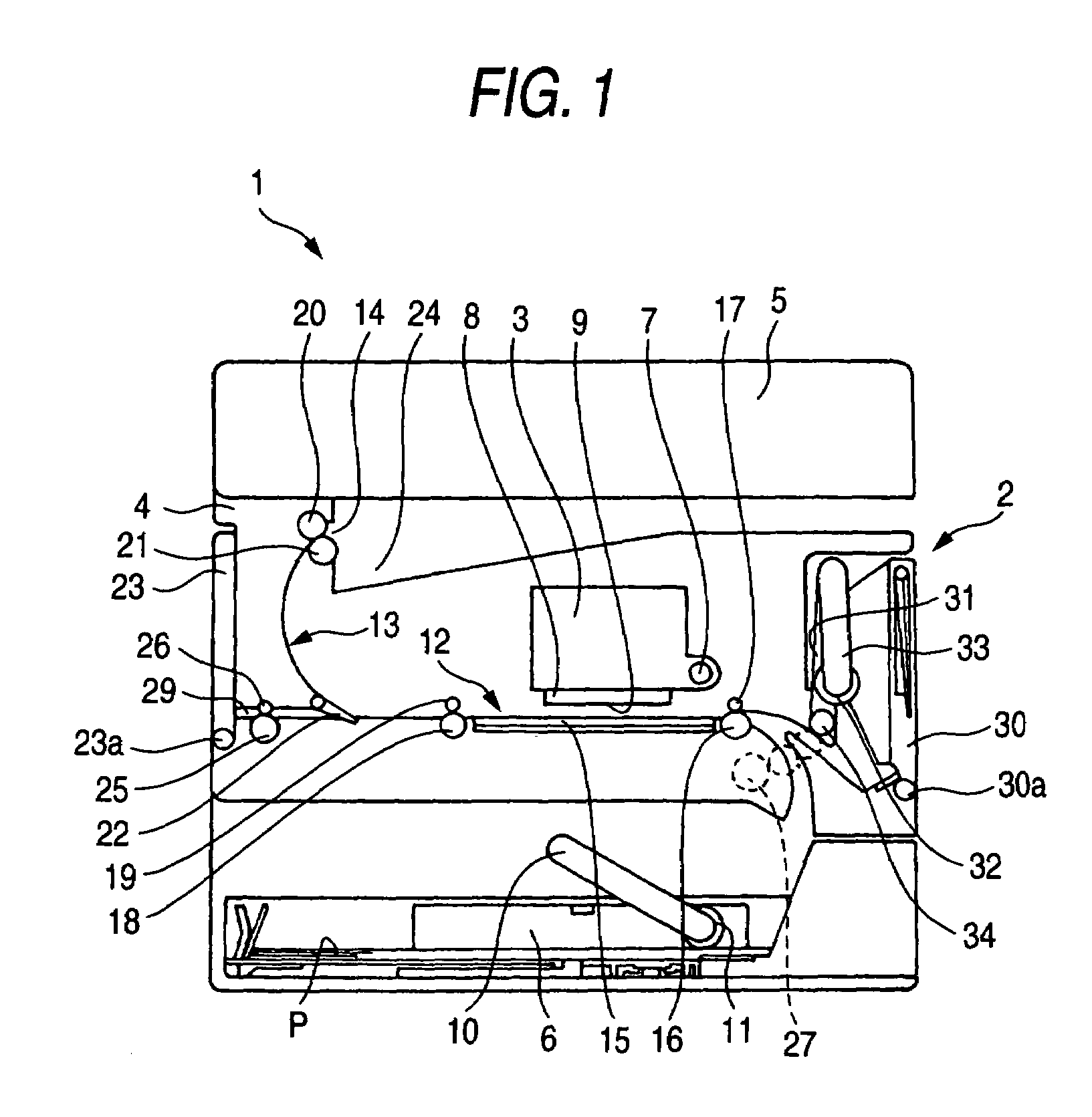

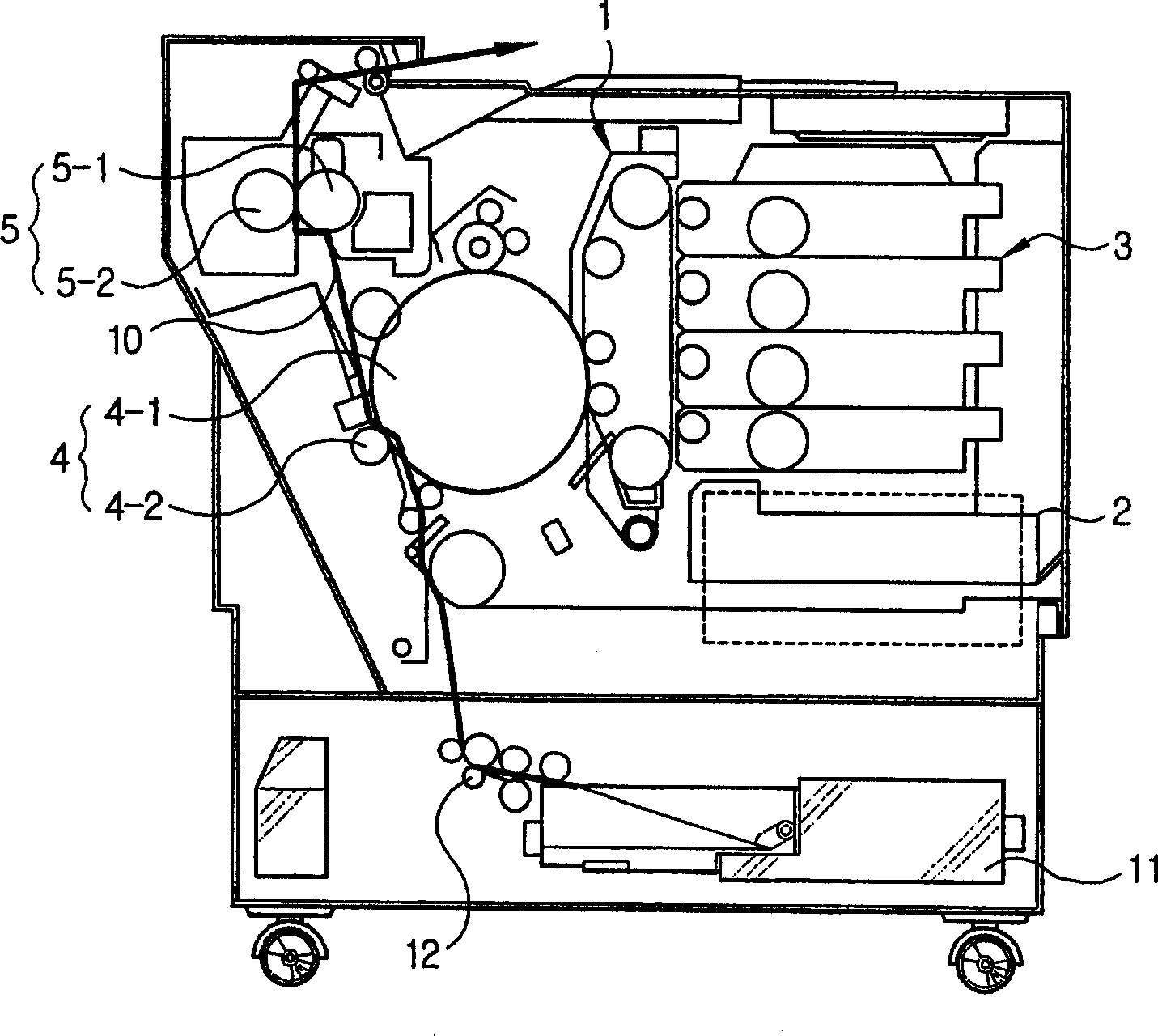

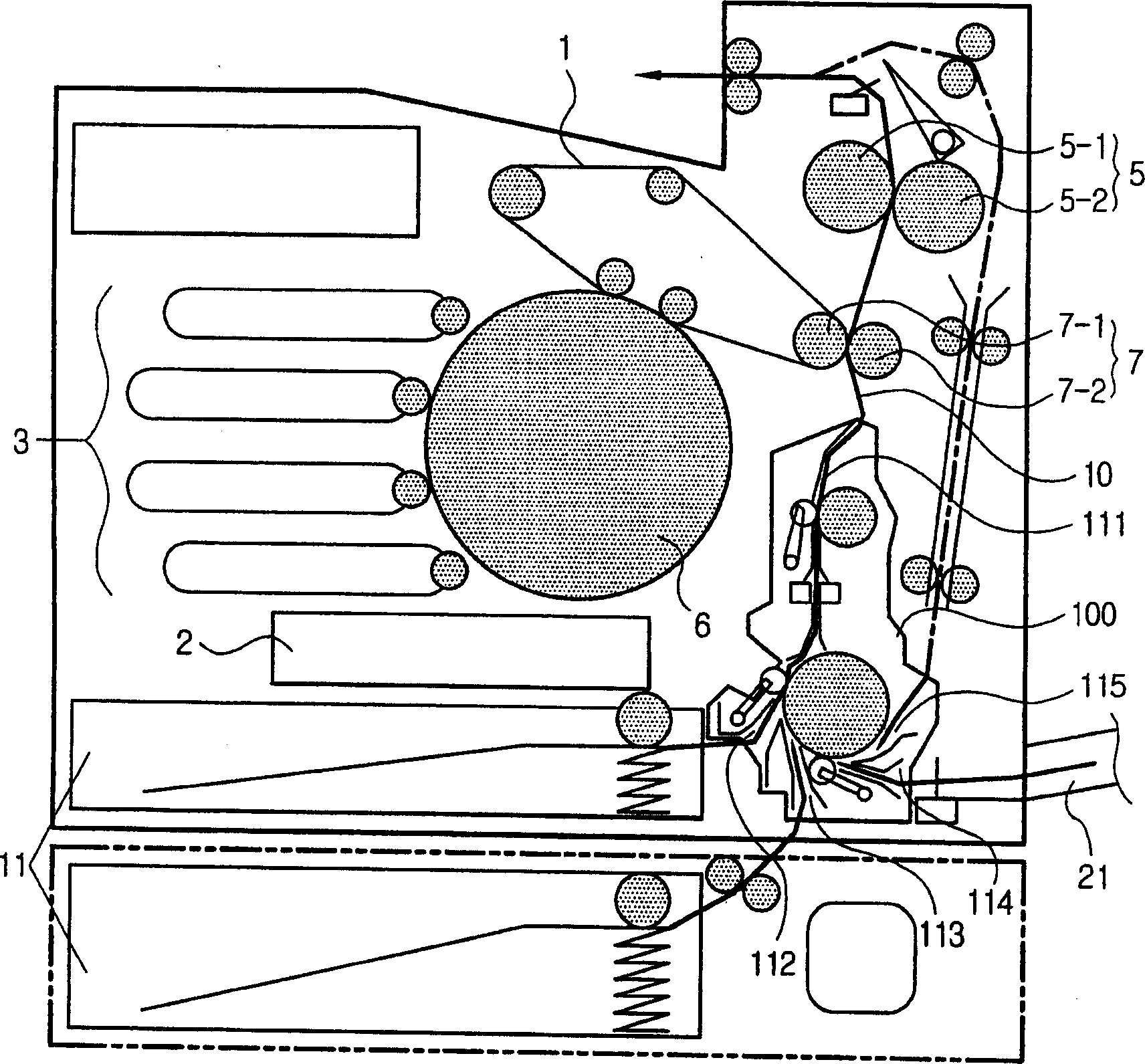

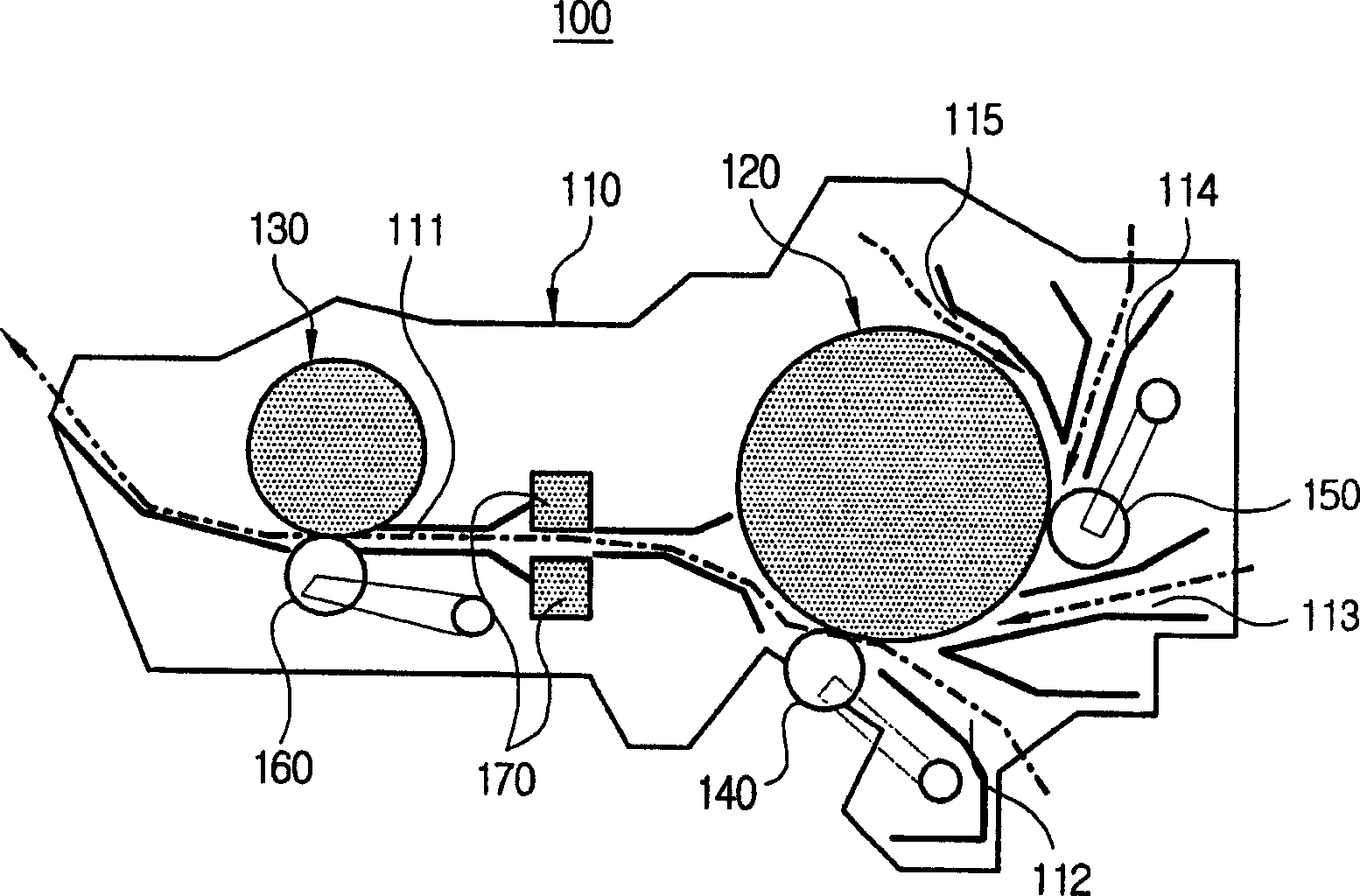

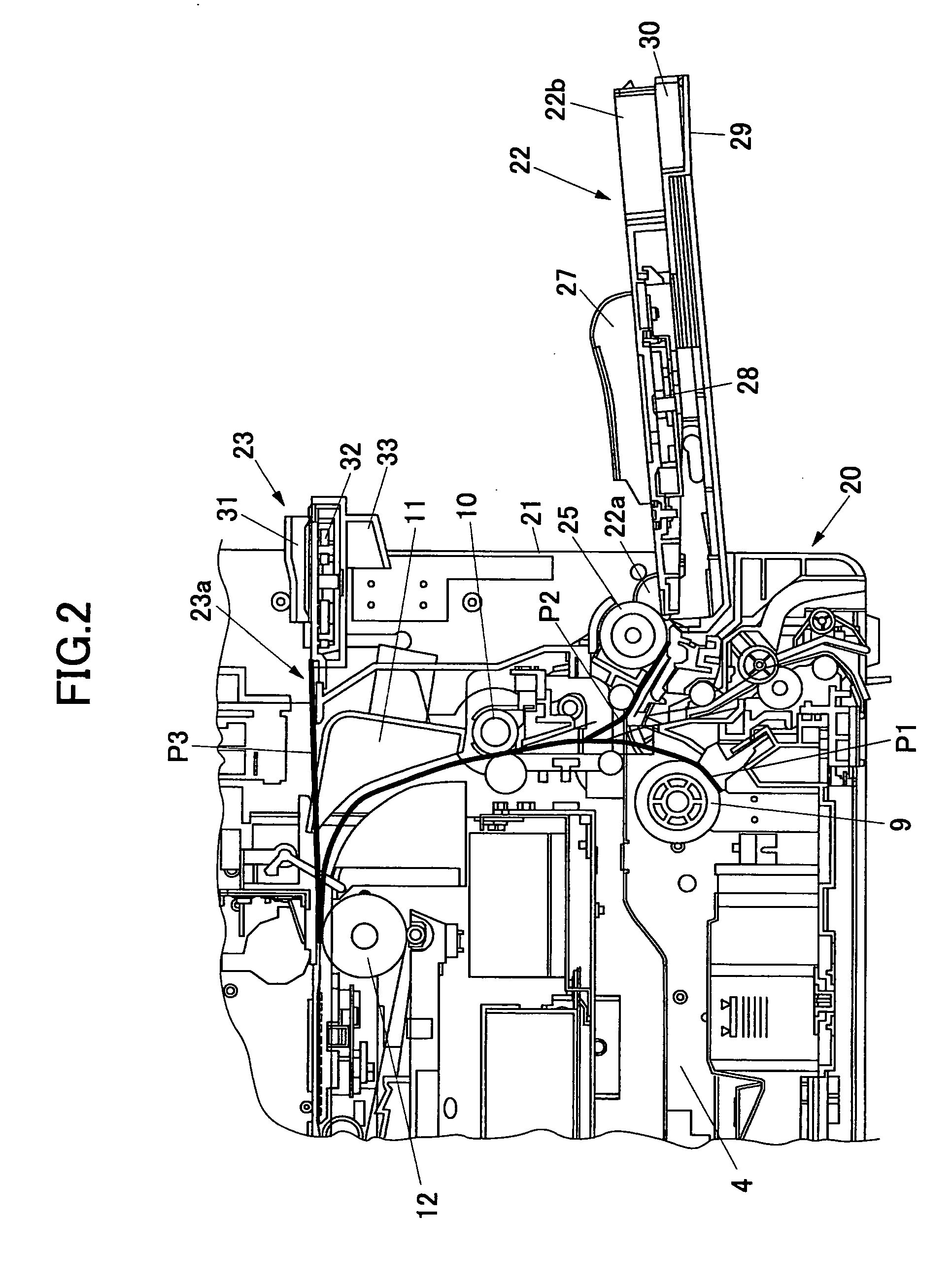

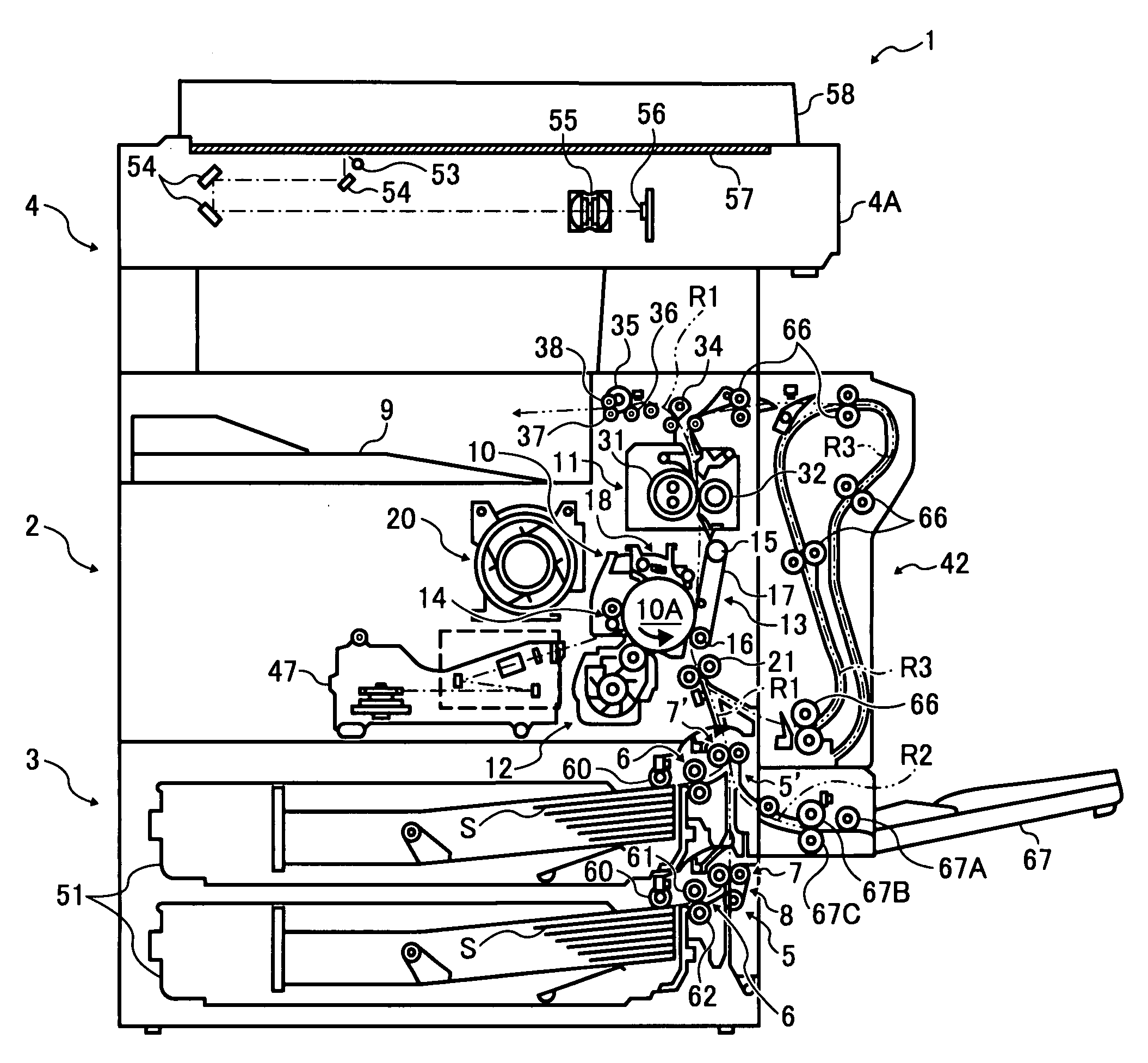

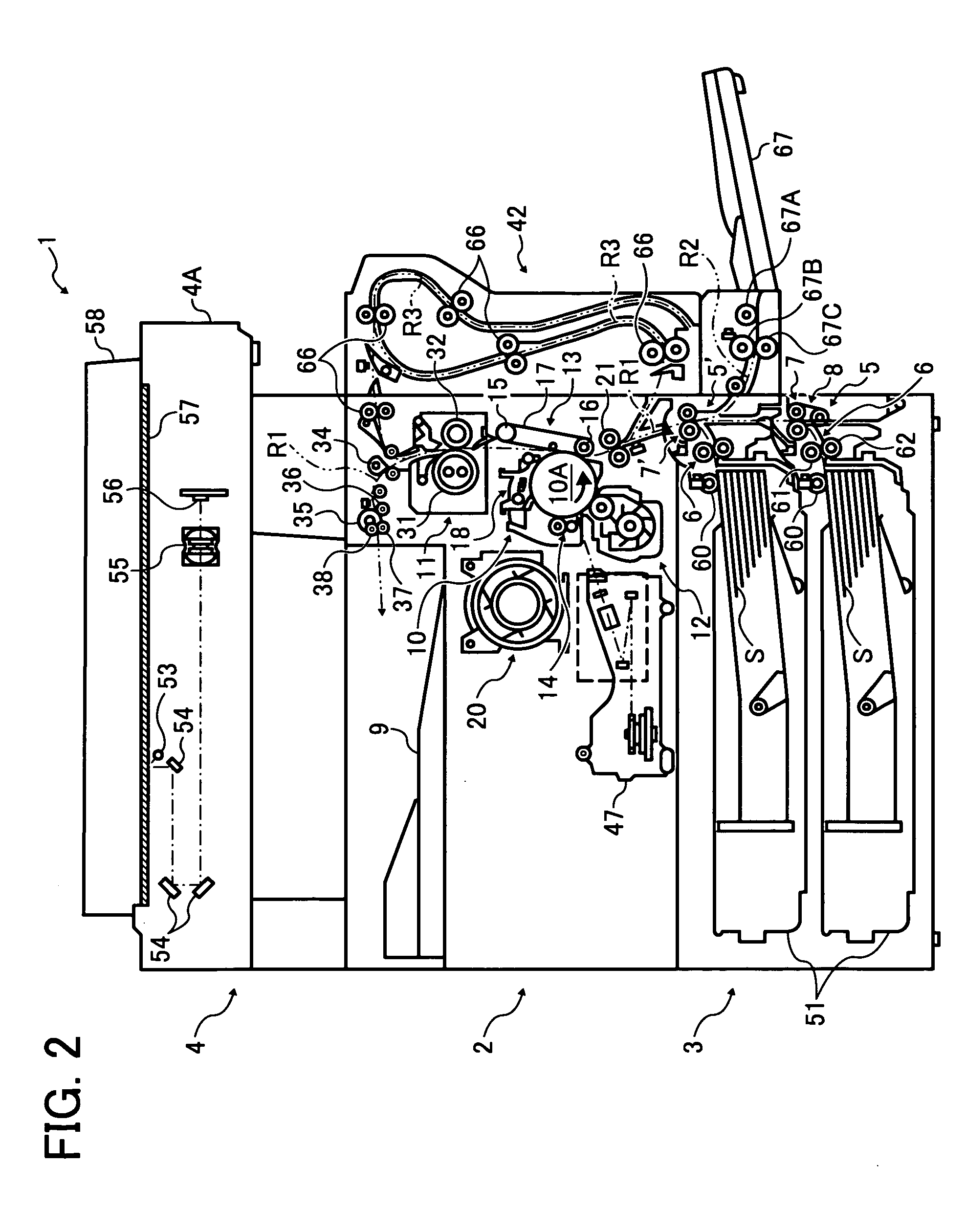

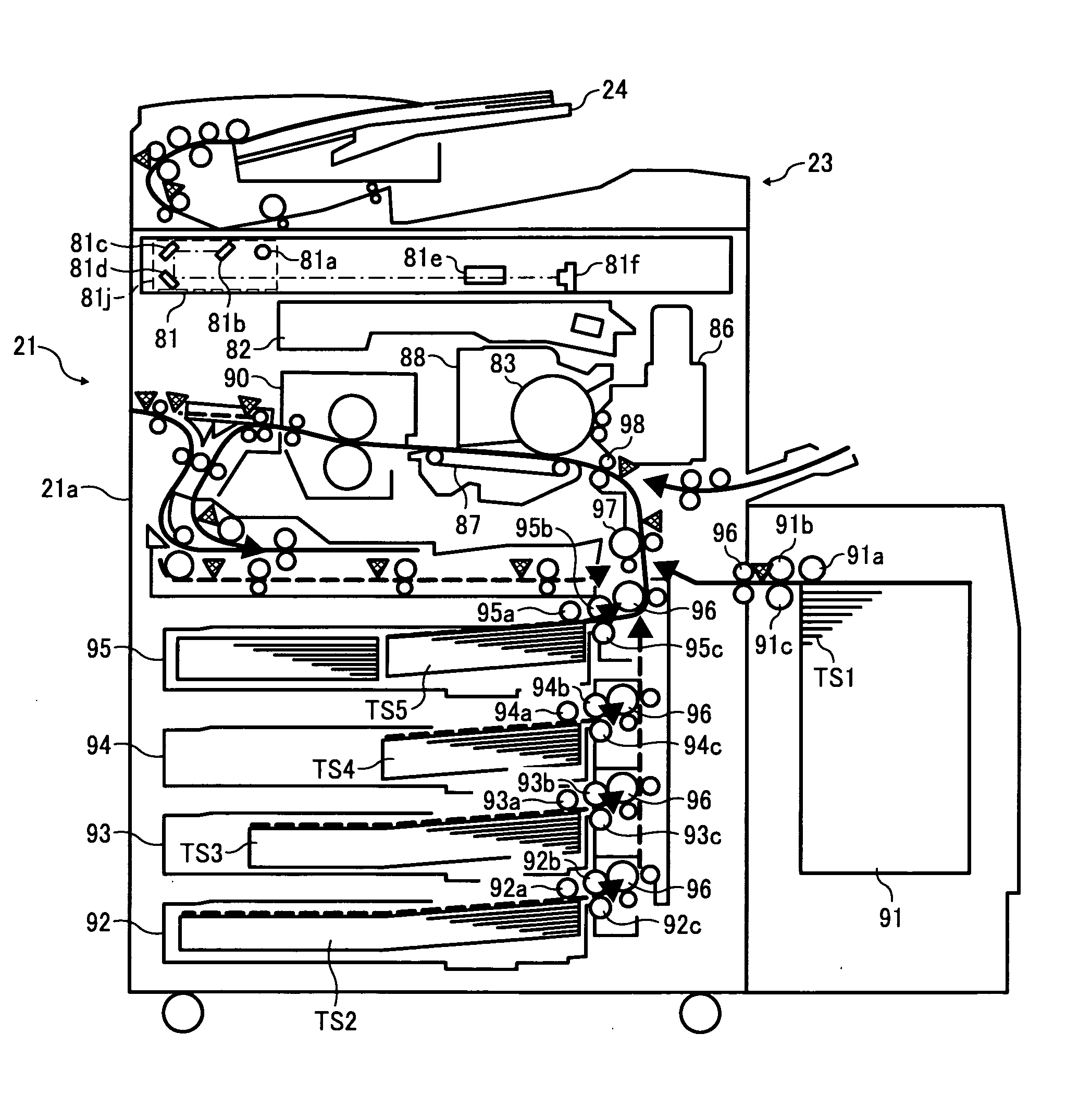

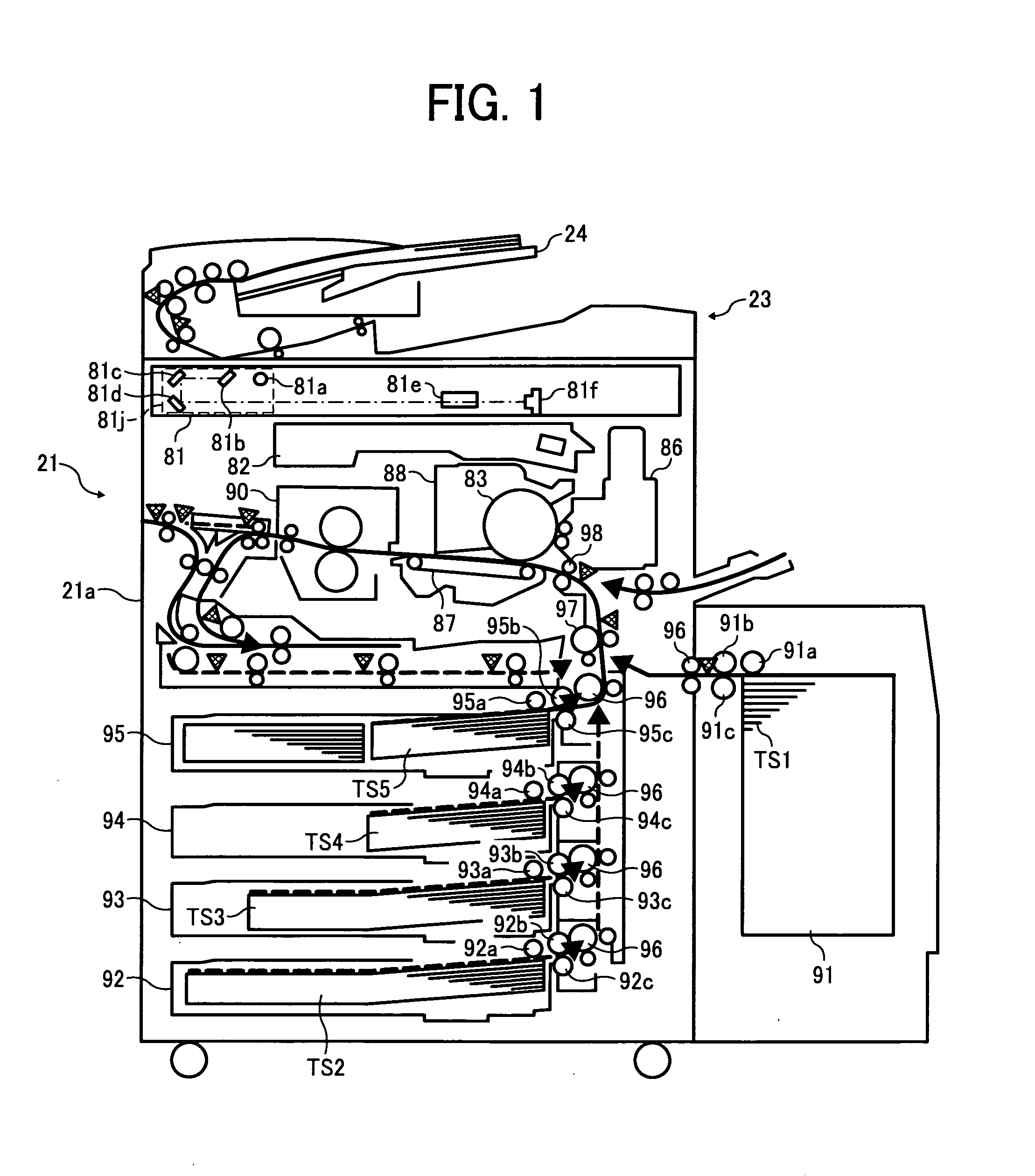

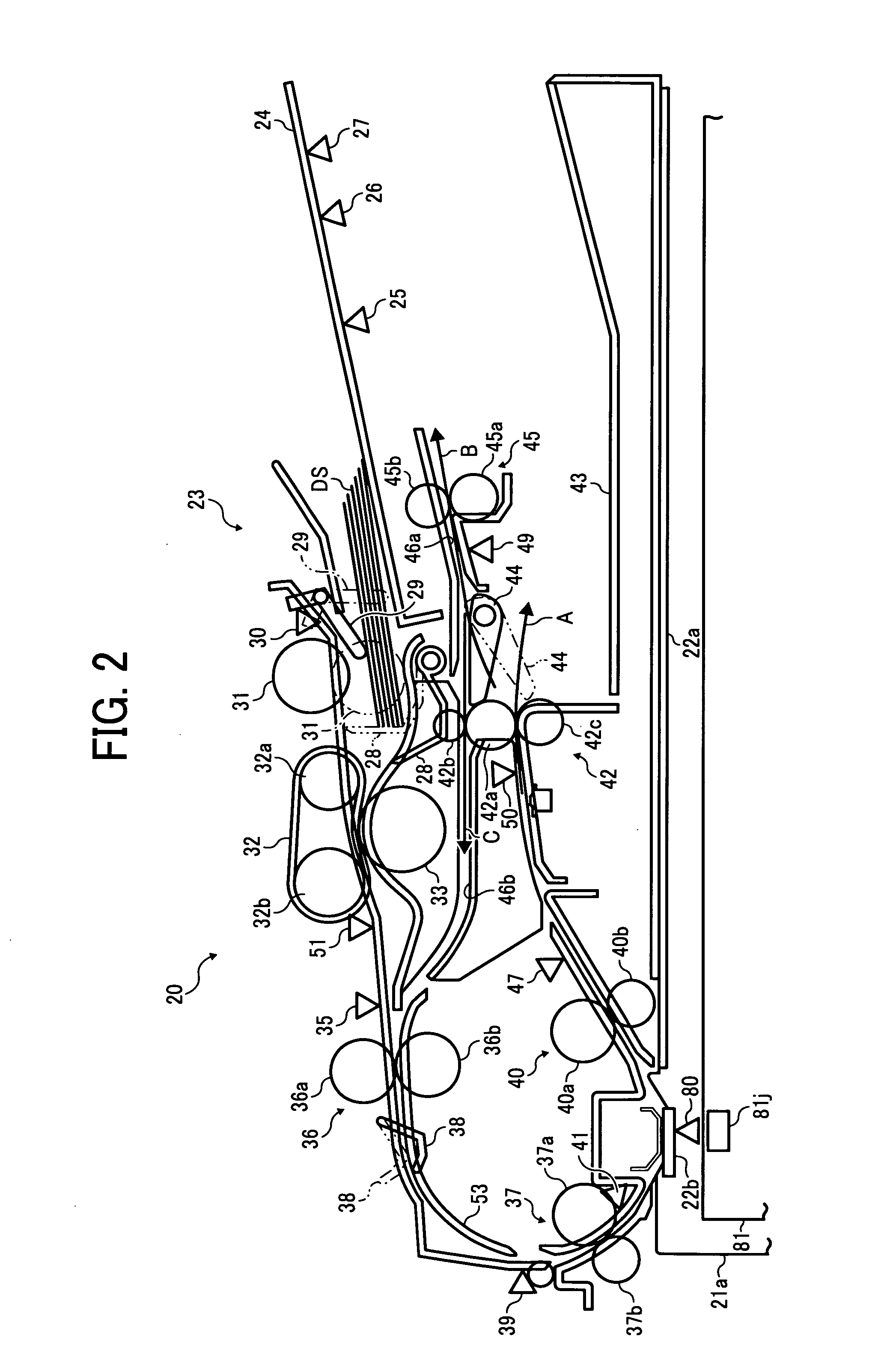

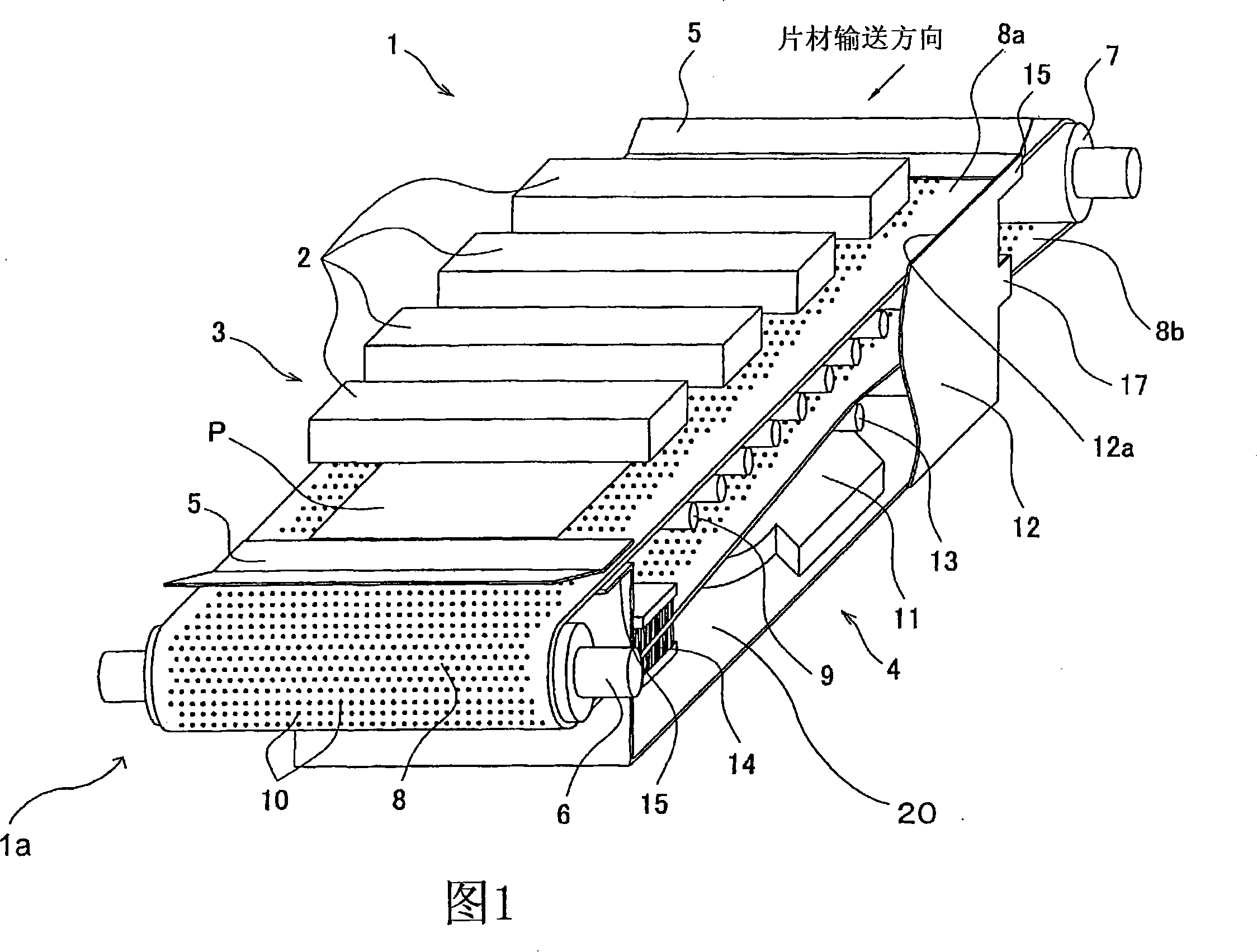

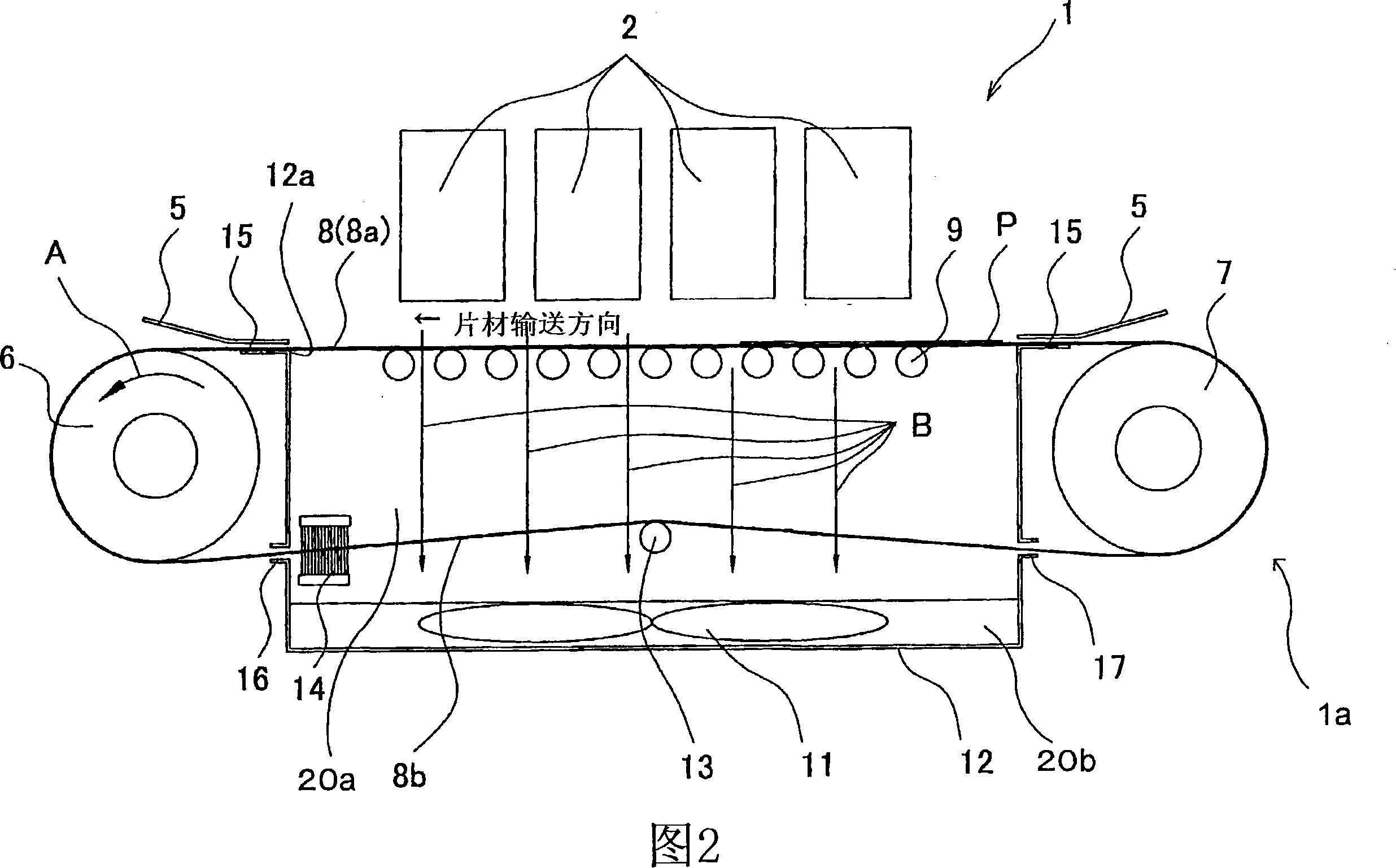

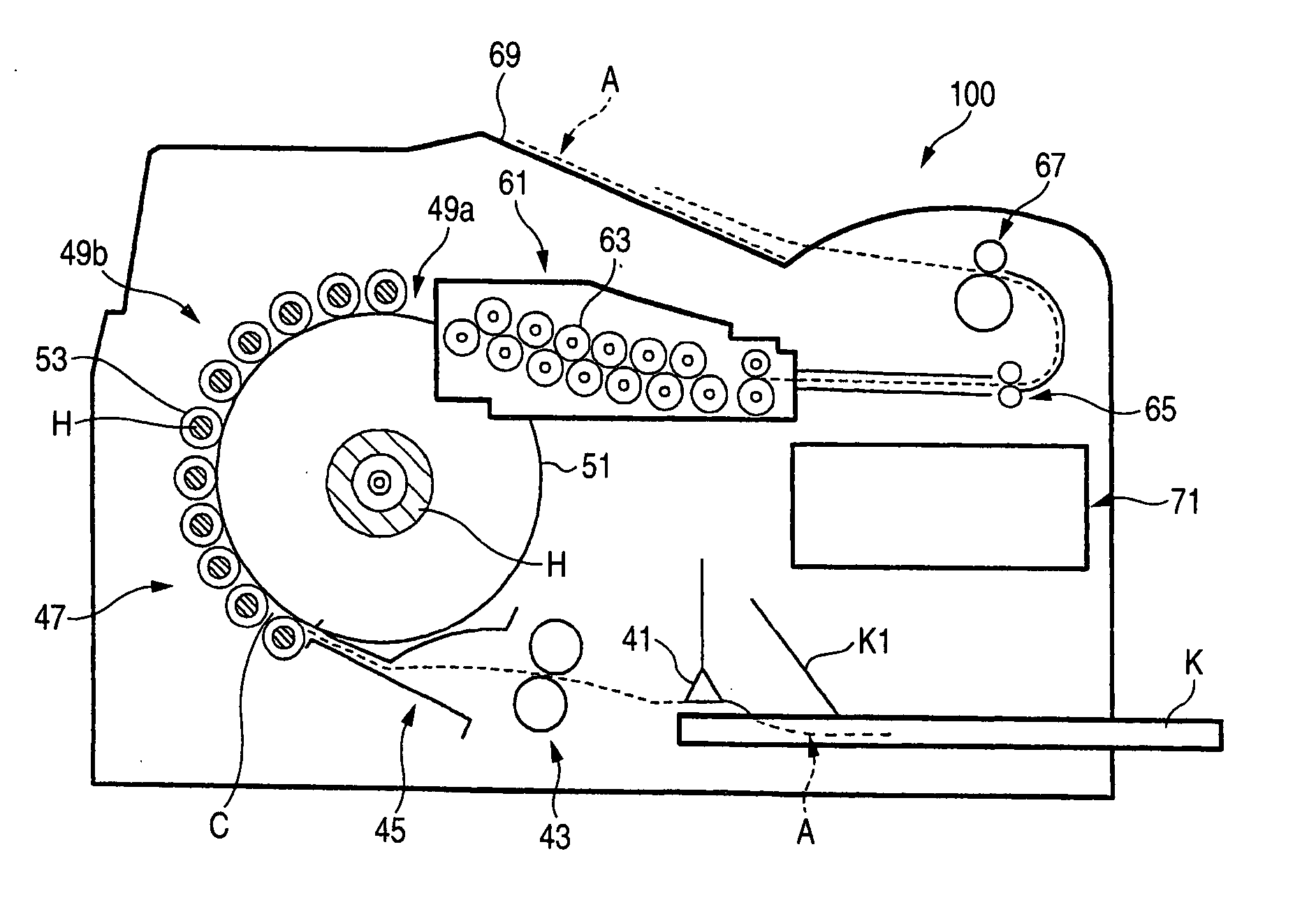

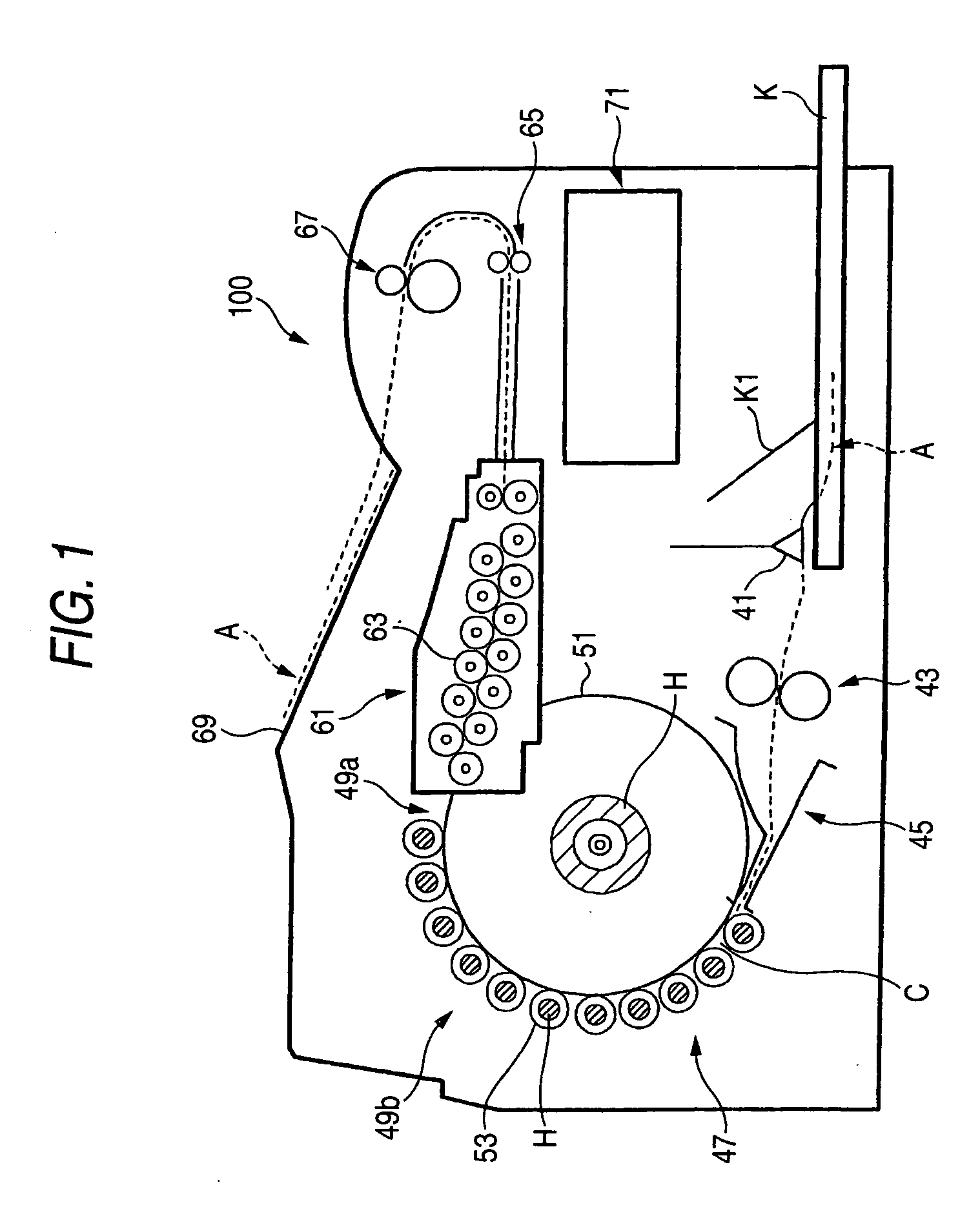

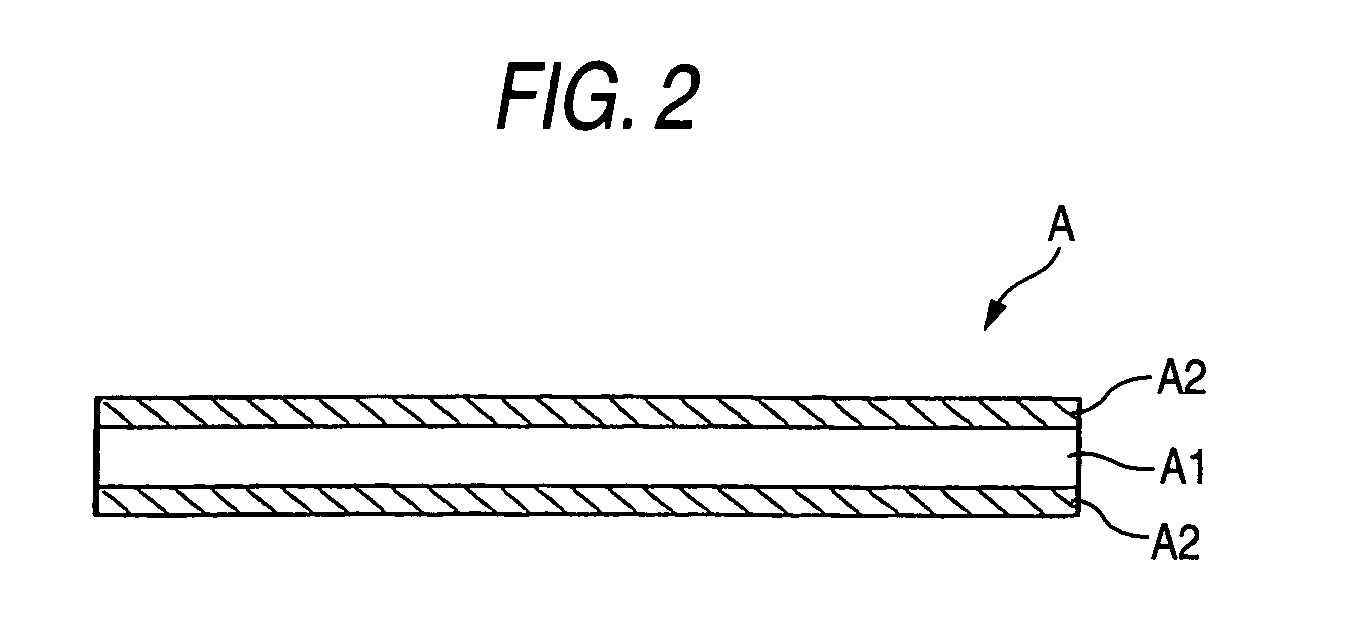

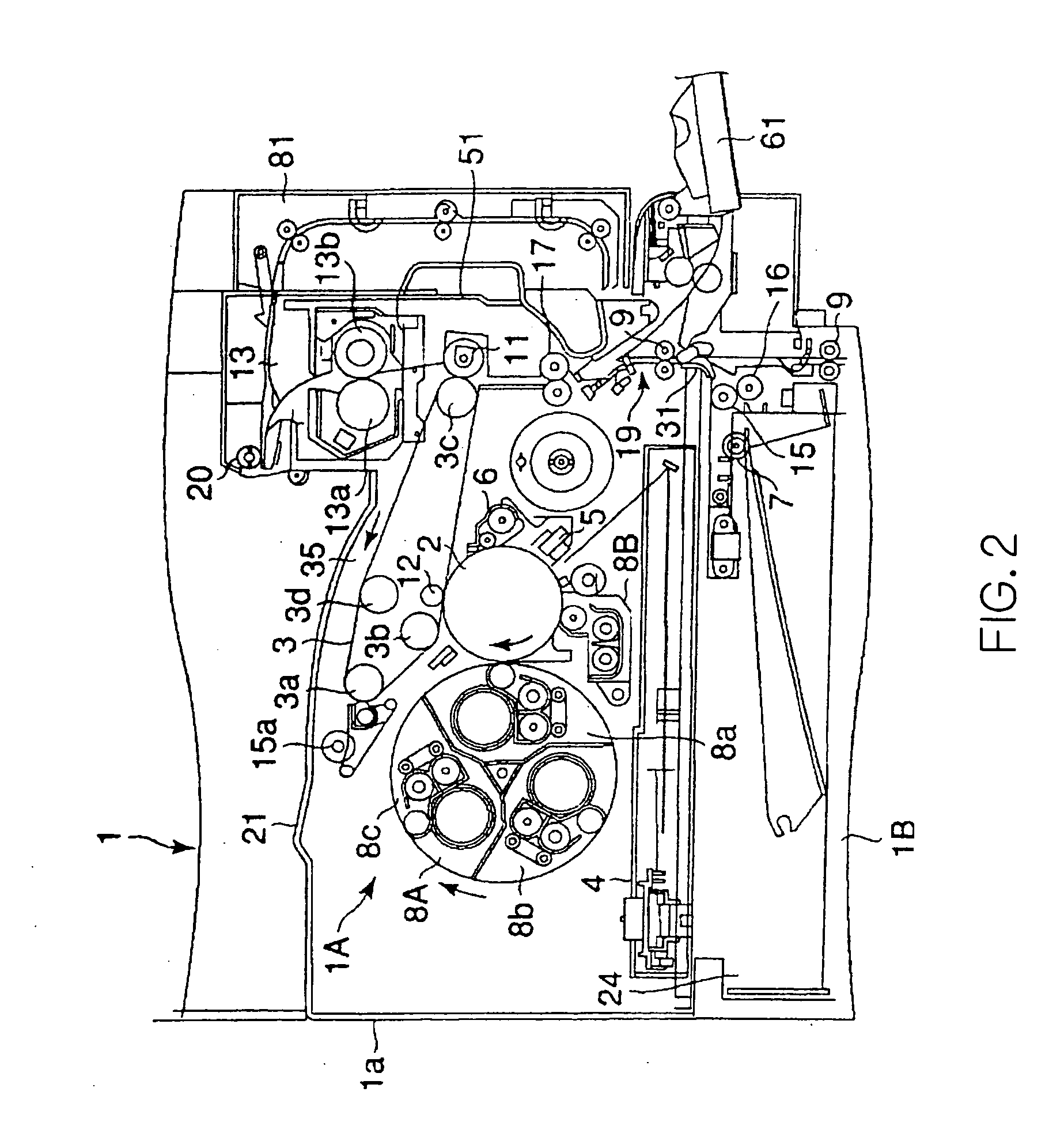

Paper feeder and a printer employing the same

InactiveCN1501185ACompact structureReduce manufacturing costRegistering devicesElectrographic process apparatusComputer printingPulp and paper industry

A paper feeder of a printer has a plurality of paper feeding paths to feed a printing paper, and a main fed roller feeding the printing paper to an image forming unit of an image forming apparatus. The paper feeding paths are disposed along an outer circumference of the main fed roller and confluent along a connecting conveyance path by the main feed roller. The connecting conveyance path is connected with a main conveyance path which guides the printing paper to the image forming unit of the image forming apparatus. By a single feed roller, the printing paper from the paper feeding cassette in an automatic paper feeding mode, the printing paper from a manual paper feeding tray in a manual paper feeding mode, and the printing paper being inverted and returned in double-sided printing, can be fed to the paper conveyance path efficiently. Because there is no need to prepare a separate feeding apparatus to convey the printing paper according to the respective printing modes, a structure of the printer can be simplified, and an internal space of the printer is reduced. As a result, a compact-sized printer requiring less manufacturing costs can be provided.

Owner:HEWLETT PACKARD DEV CO LP

Apparatus and method for printing corrugated cardboard sheets

Owner:ISOWA IND CO LTD

Image forming device

ActiveUS20050141936A1Easy to confirmIncrease awarenessElectrographic process apparatusOther printing apparatusImage formationPulp and paper industry

Owner:KYOCERA DOCUMENT SOLUTIONS INC

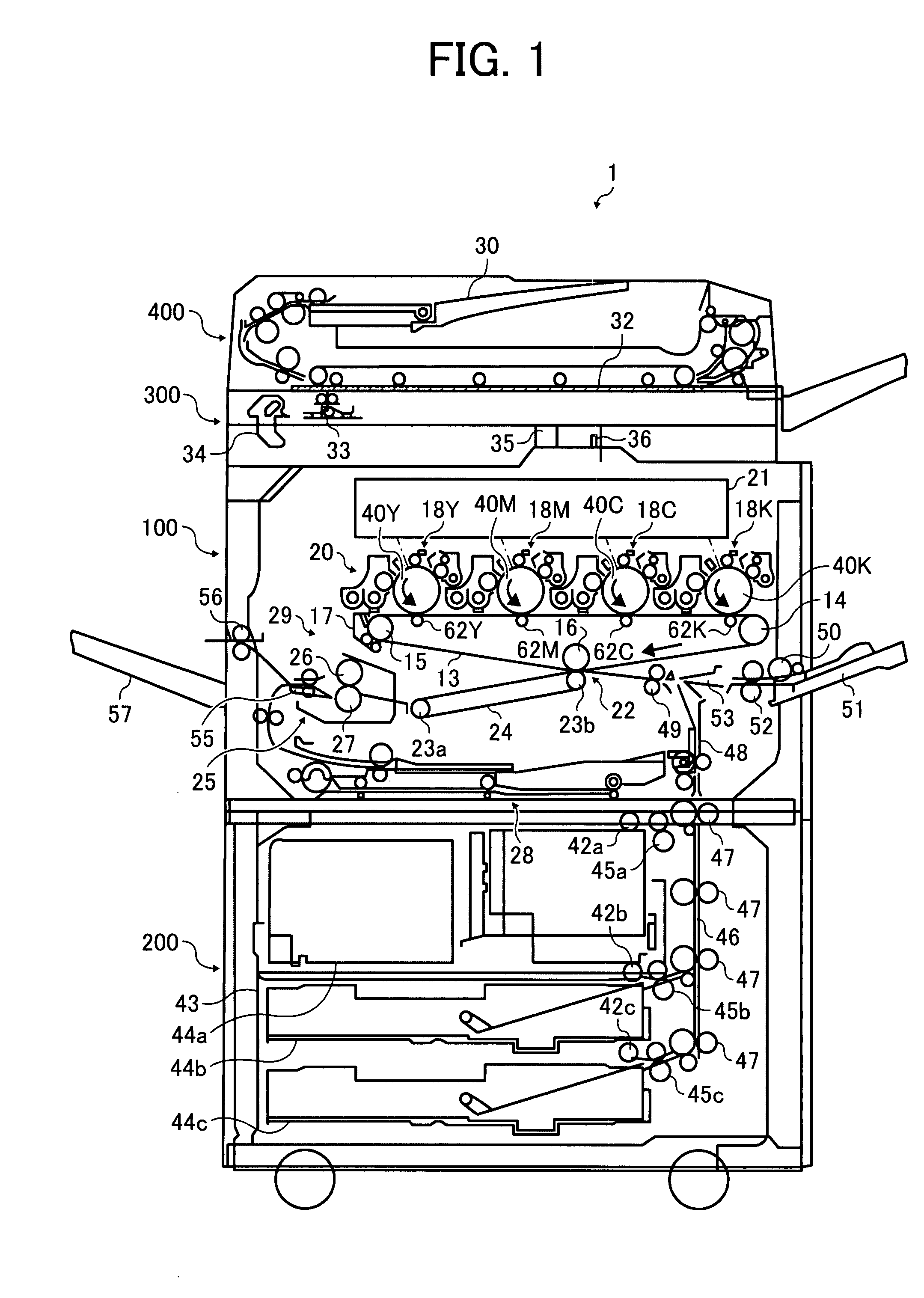

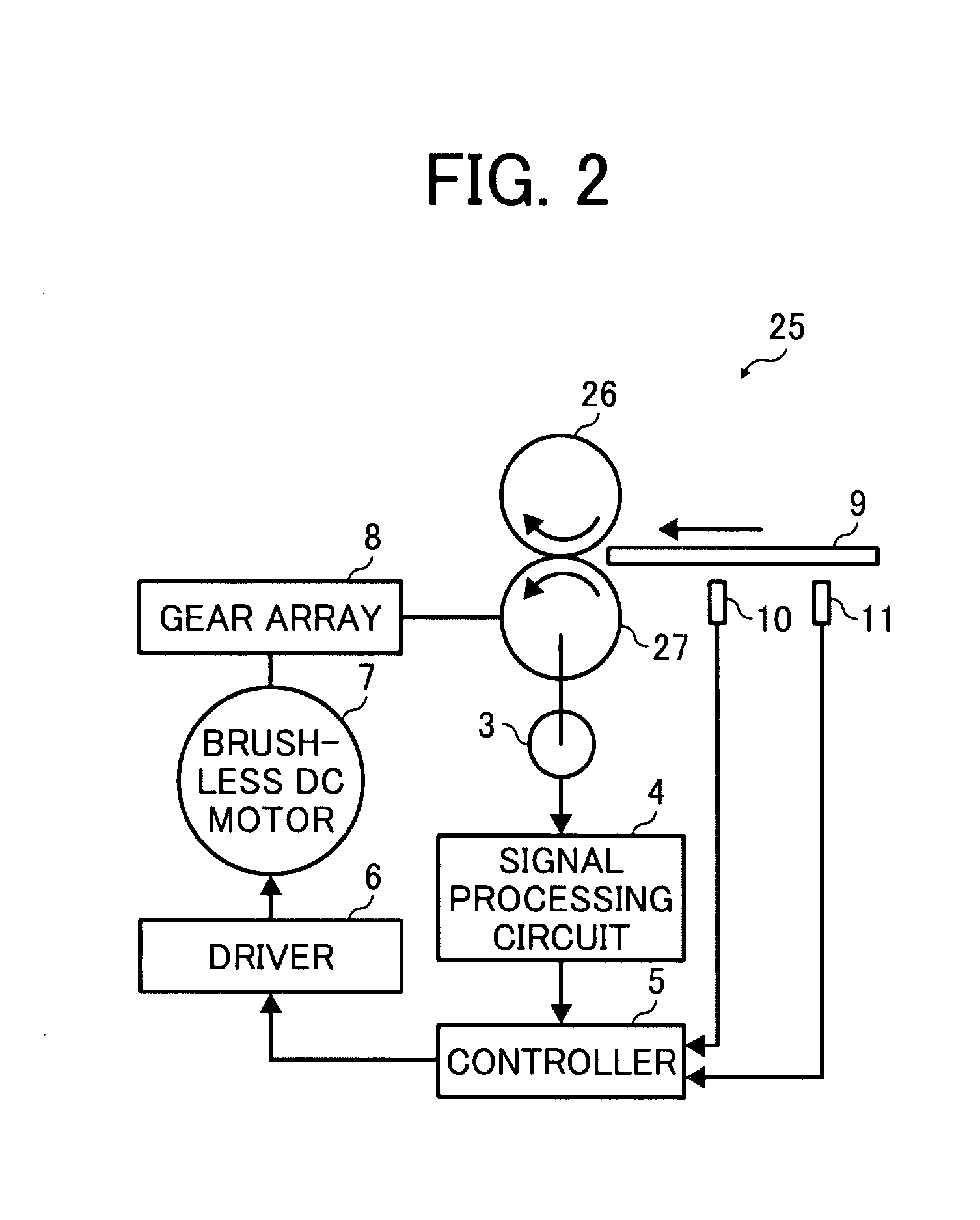

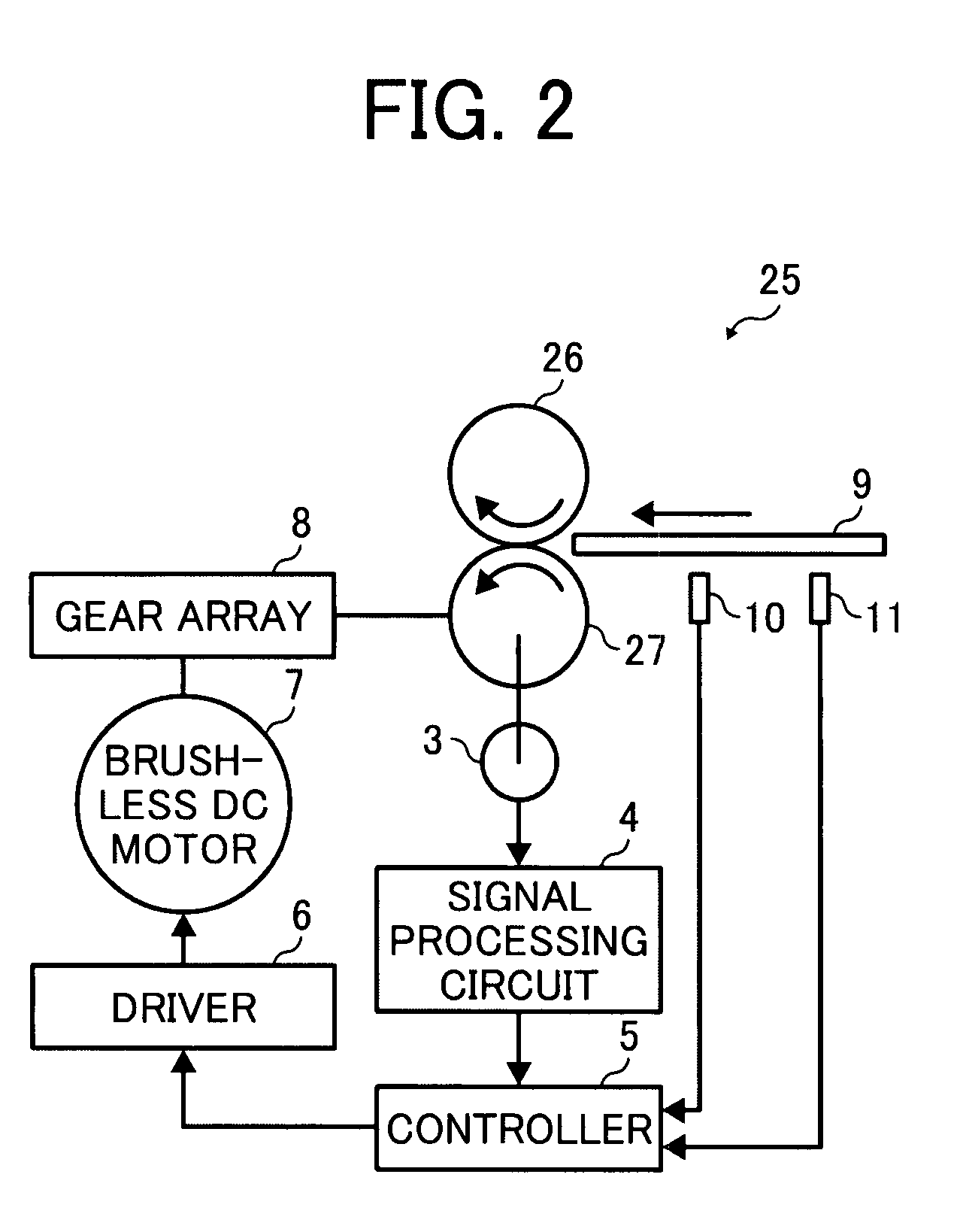

Sheet conveying device, and image forming apparatus including same

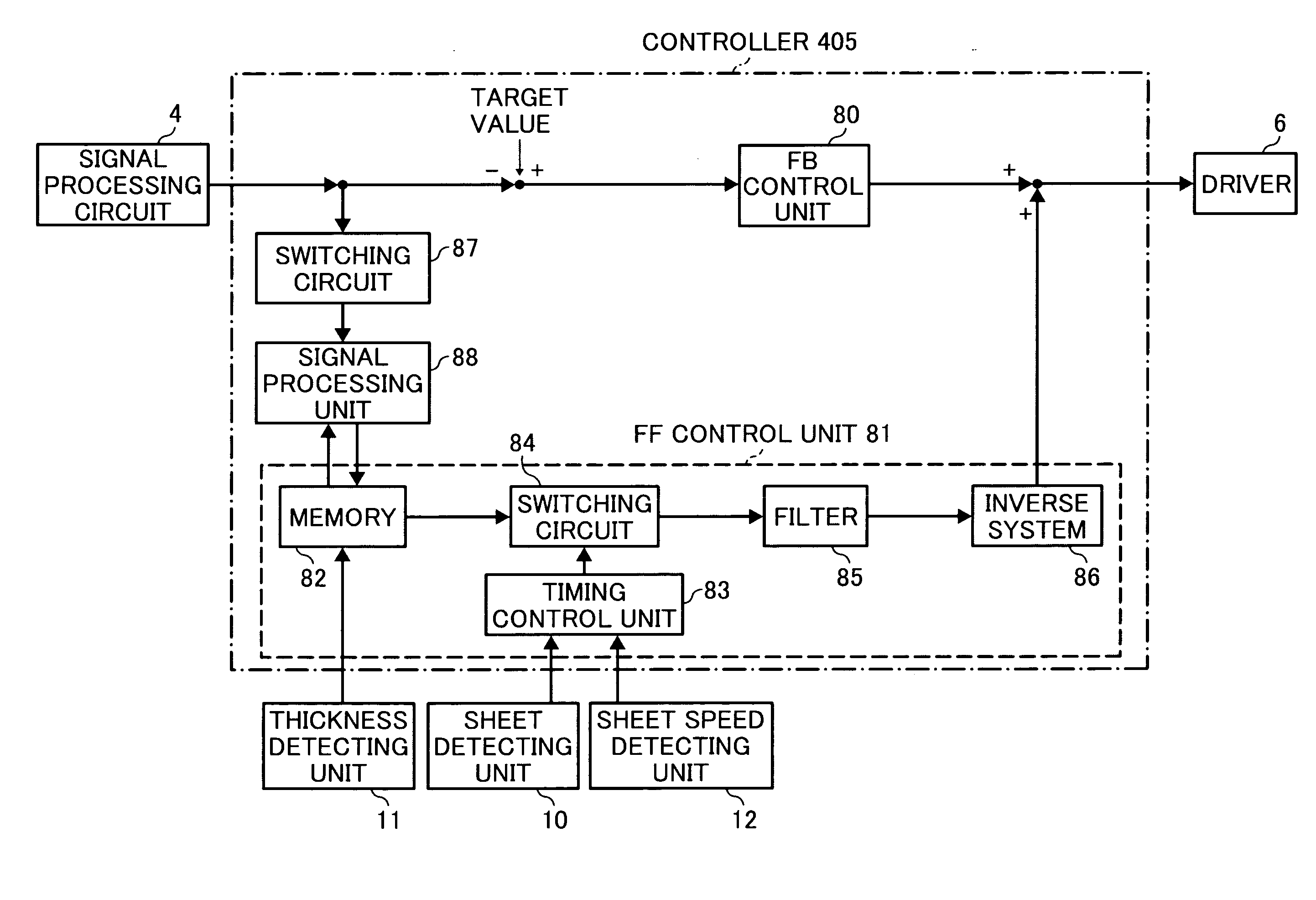

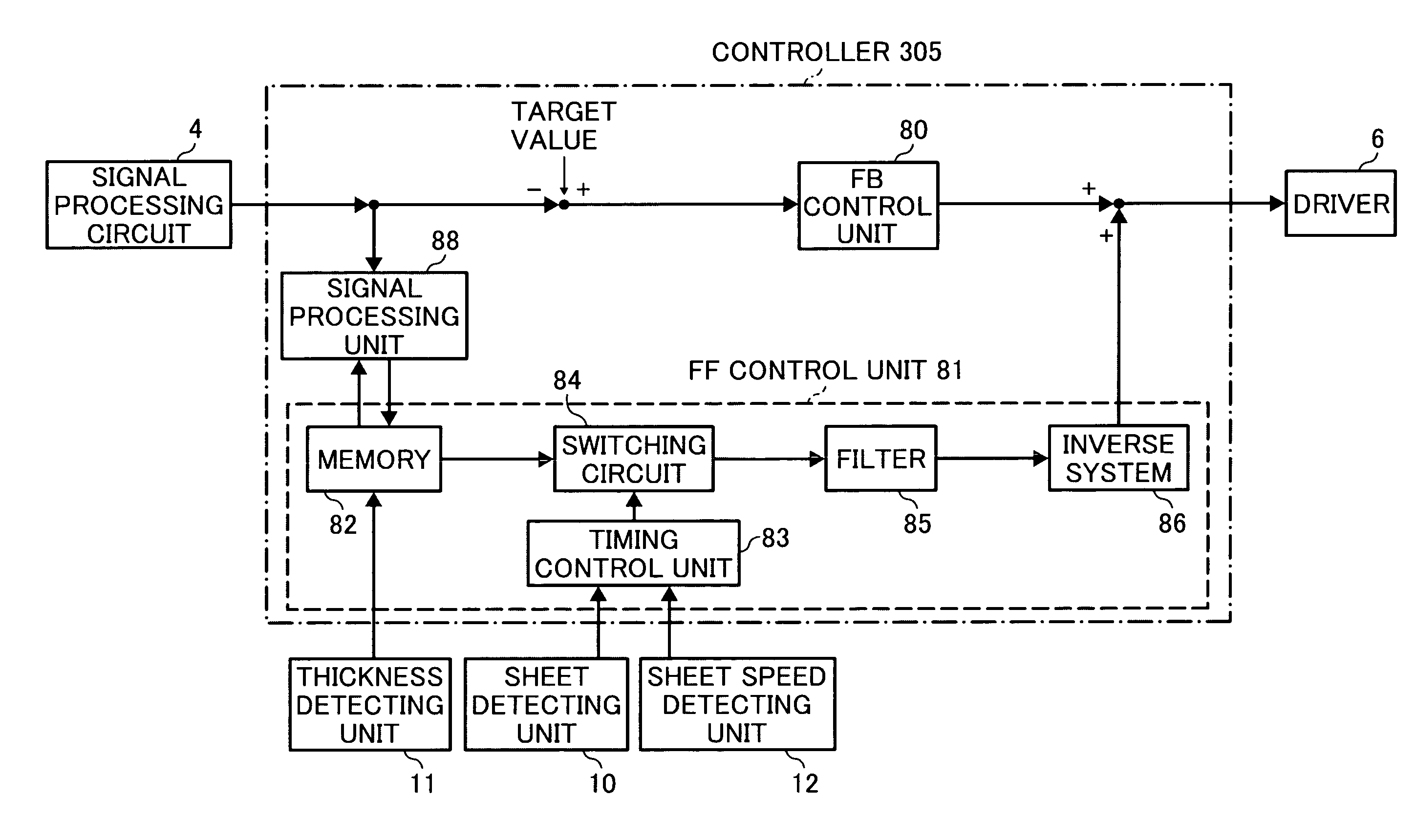

InactiveUS20090026689A1Simple configurationLow costRegistering devicesFunction indicatorsImage formationAngular velocity

A sheet conveying device, that can be included in an image forming apparatus, includes a drive source, a drive roller driven by the drive source, a driven roller to press against the drive roller and rotate with the drive roller, an angular velocity detector to detect an angular velocity of the drive roller, a timing estimation unit to estimate a timing when a sheet-type recording medium enters between the drive roller and the driven roller, and a controller to control the drive source based on detection results obtained by the angular velocity detector. The controller includes a feedback control unit to perform feedback control based on data obtained by the angular velocity detector, and a feed-forward control unit to perform feed-forward control based on data obtained by the timing estimation unit.

Owner:RICOH KK

Paper feeder and image forming apparatus using the same

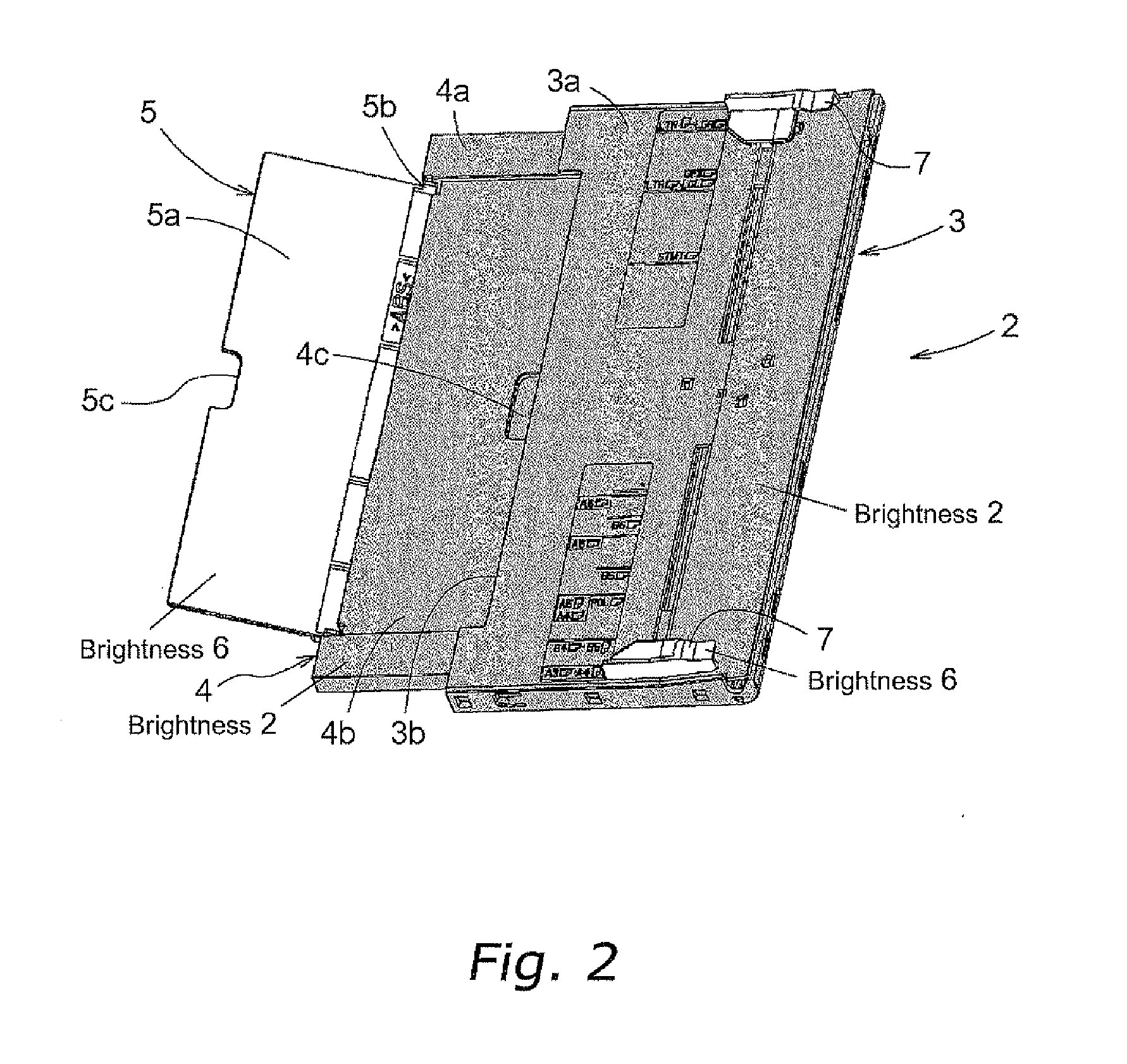

ActiveUS20050253323A1Eliminate disadvantagesSave spaceArticle feedersFeed tablesImage formationPulp and paper industry

Owner:RICOH KK

Feeder device with an integrated differential weigh module

InactiveUS20060000648A1Increase chanceProvide informationRegistering devicesFunction indicatorsElectrical and Electronics engineering

A mail article feeder device comprises a support housing receiving a weighing cell for delivering a weighing signal, a receiver tray having longitudinal and transverse walls for jogging mail articles, and for receiving a stack of mail articles, automatic extractor means for ejecting mail articles from said stack one by one, the automatic extractor means and the receiver tray being carried by the weighing cell, the feeder device further including intrusion detector means for detecting any intervention by an operator on the elements carried by the weighing cell, including on the stack of mail articles.

Owner:NEOPOST TECH SA

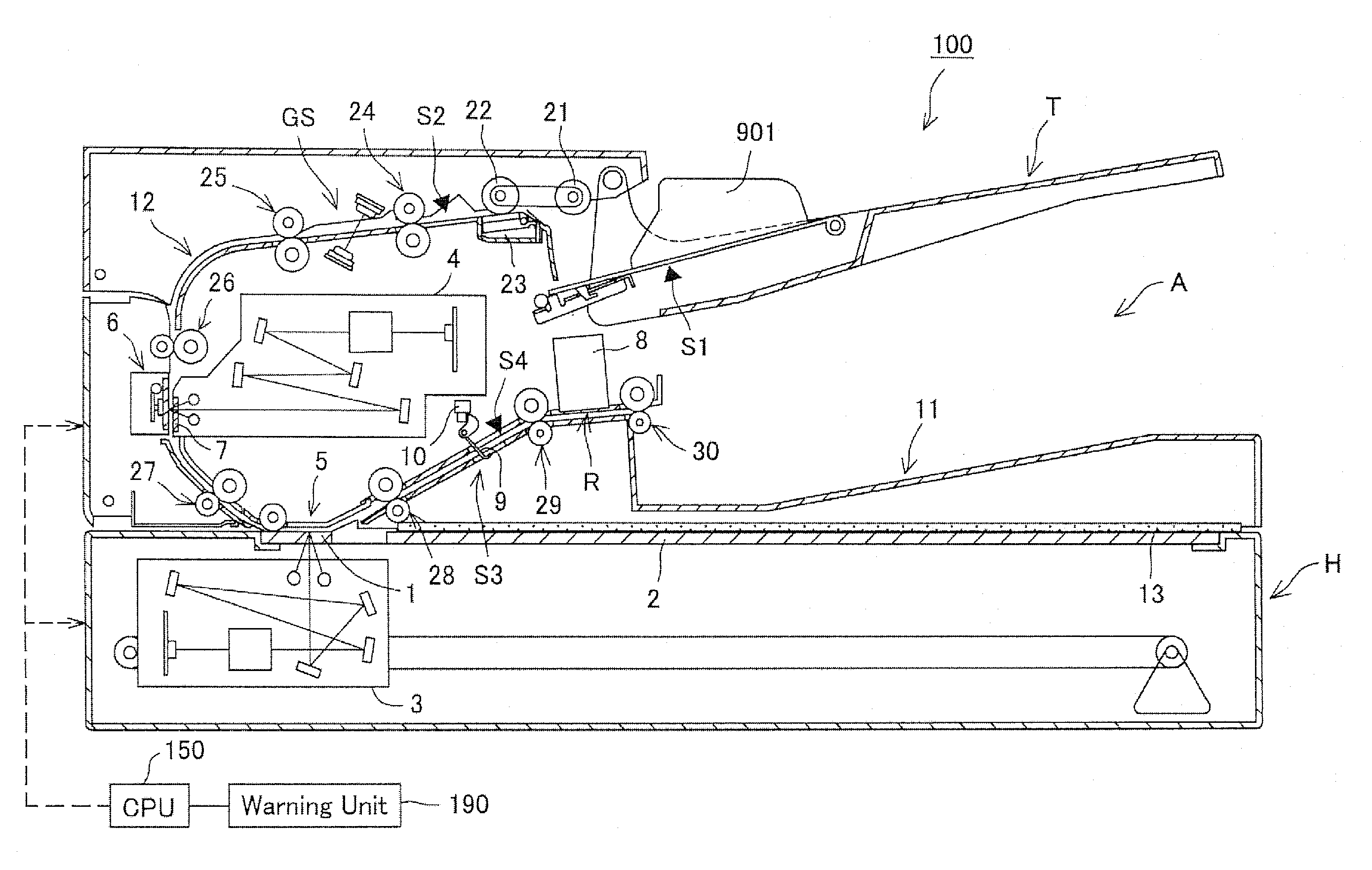

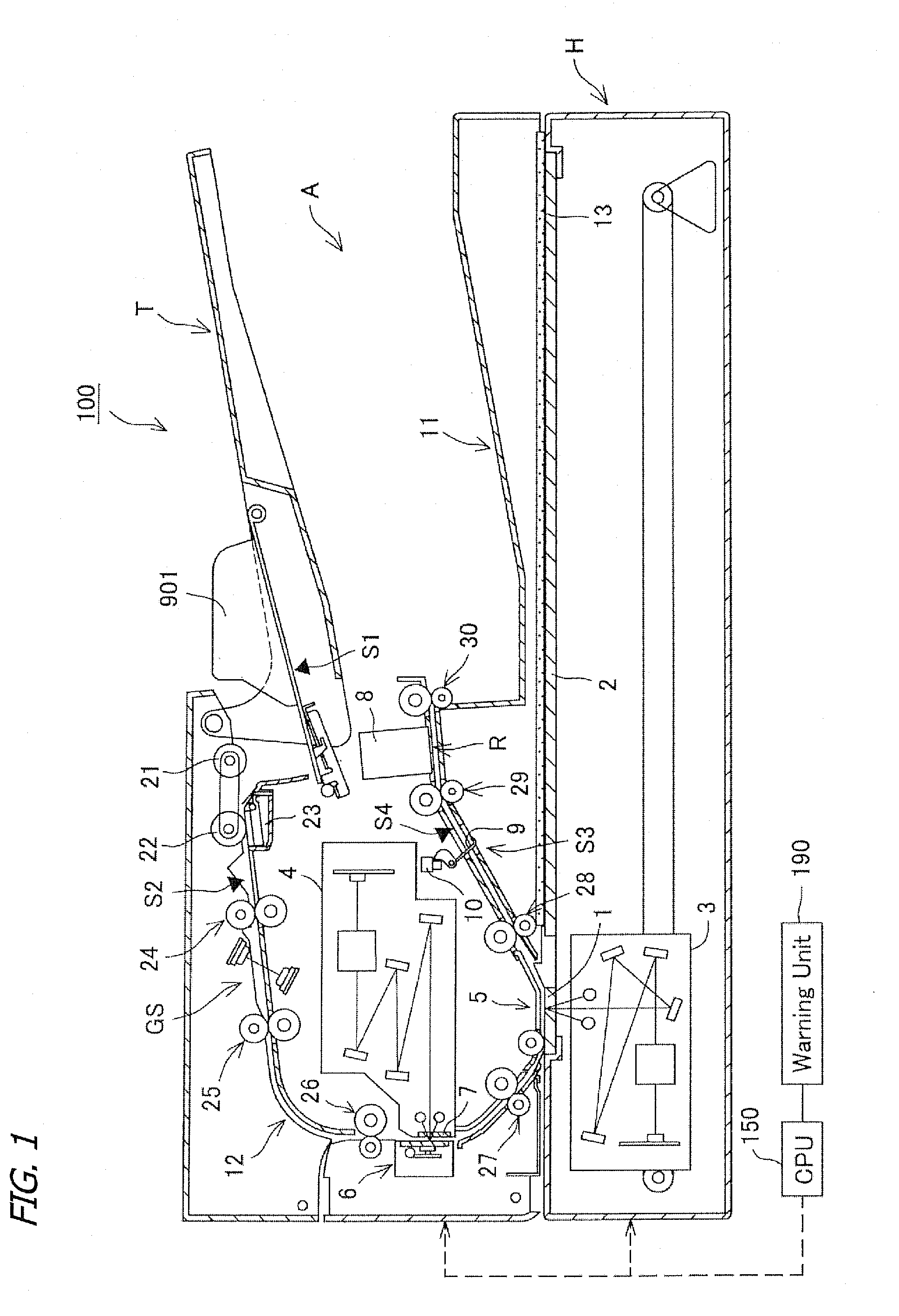

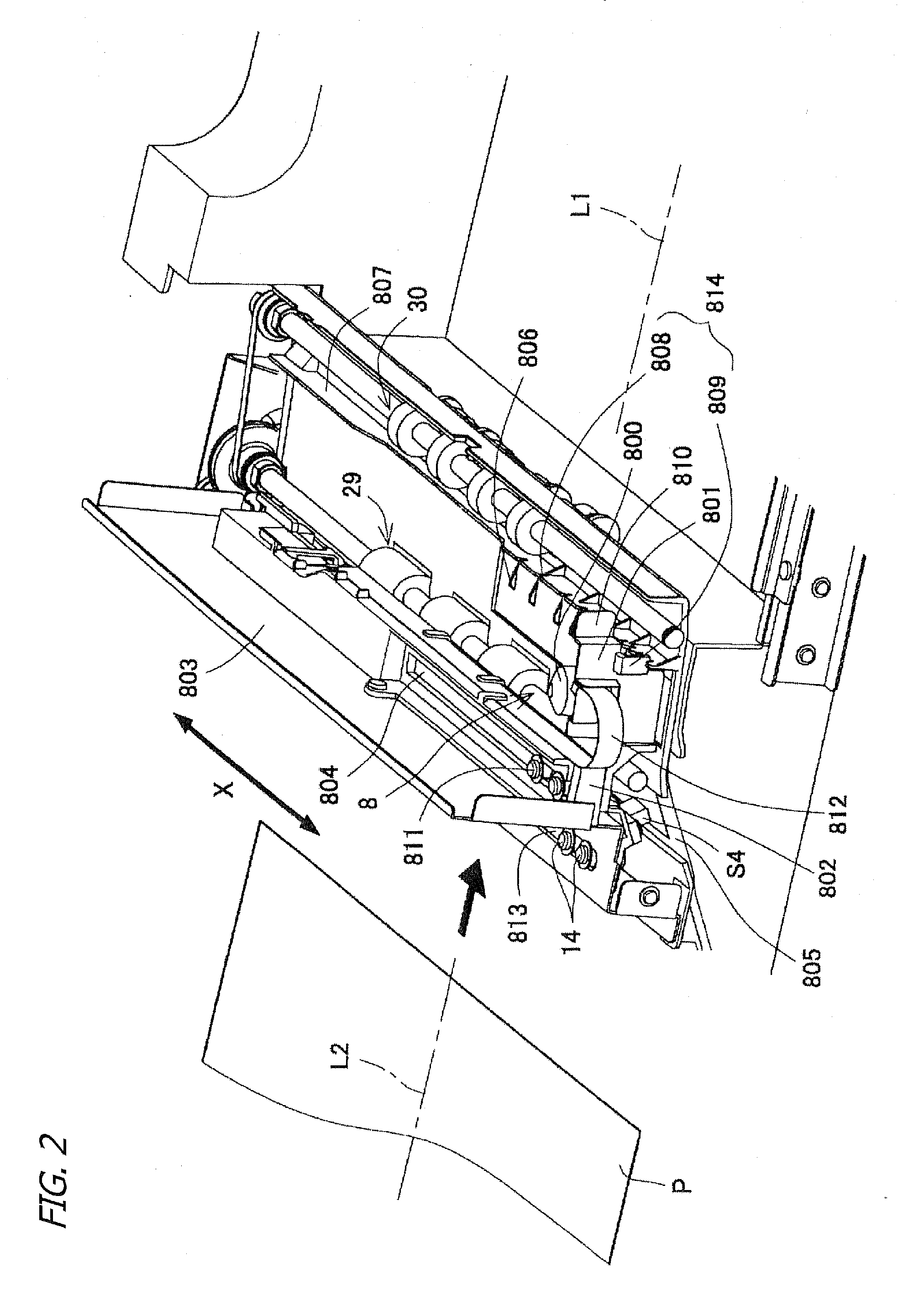

Document Feeder and Image Capturing Device

InactiveUS20080158621A1Solve precise positioningRegistering devicesArticle feedersElectrical and Electronics engineering

Document feeder and image capturing device preventing empty stamping associated with improper positioning of printing unit. Document feeder A, conveying document originals from a document placement location, along a predetermined conveyance path (12), and to a document information-capturing location (5, 6), is furnished with: a printing unit (8), which is shiftable along the document widthwise direction approximately orthogonal to the document conveyance direction, and is for carrying out predetermined printing onto conveyed documents; and a detection unit (S4), provided in the conveyance path further upstream in the conveyance direction than the printer unit (8), that detects whether a conveyed document will pass inside the limits of the range in which the printer unit (8) prints.

Owner:NISCA KK

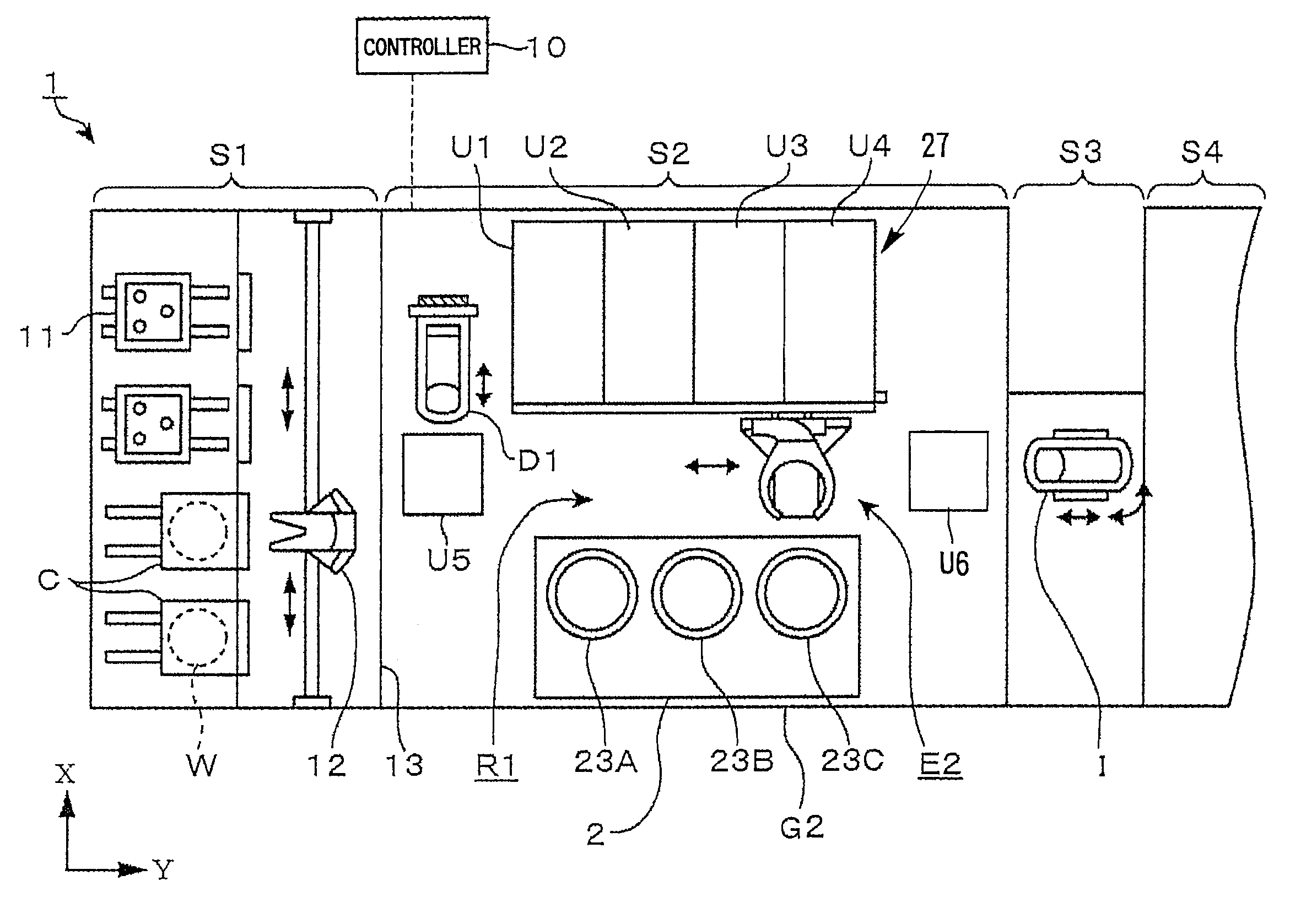

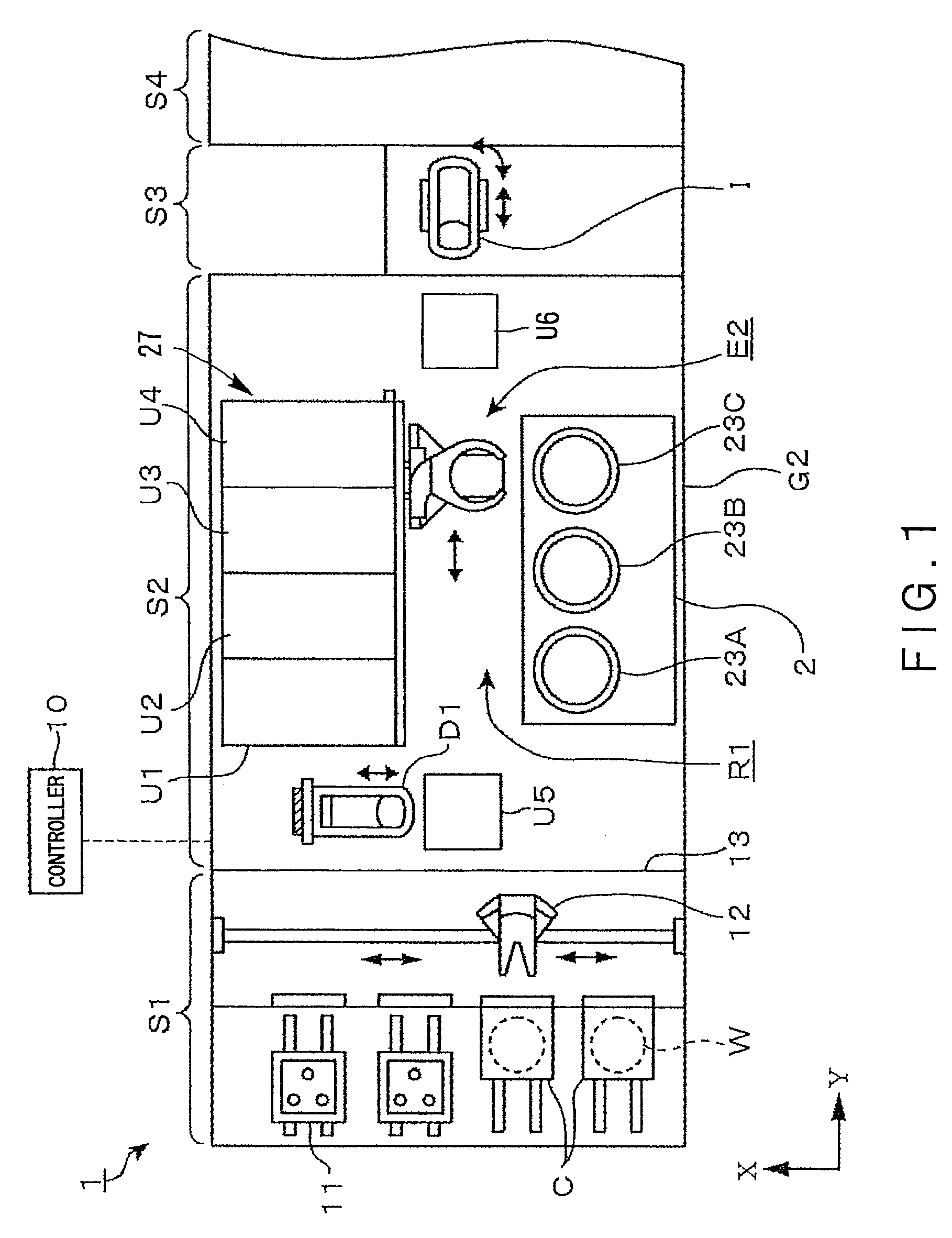

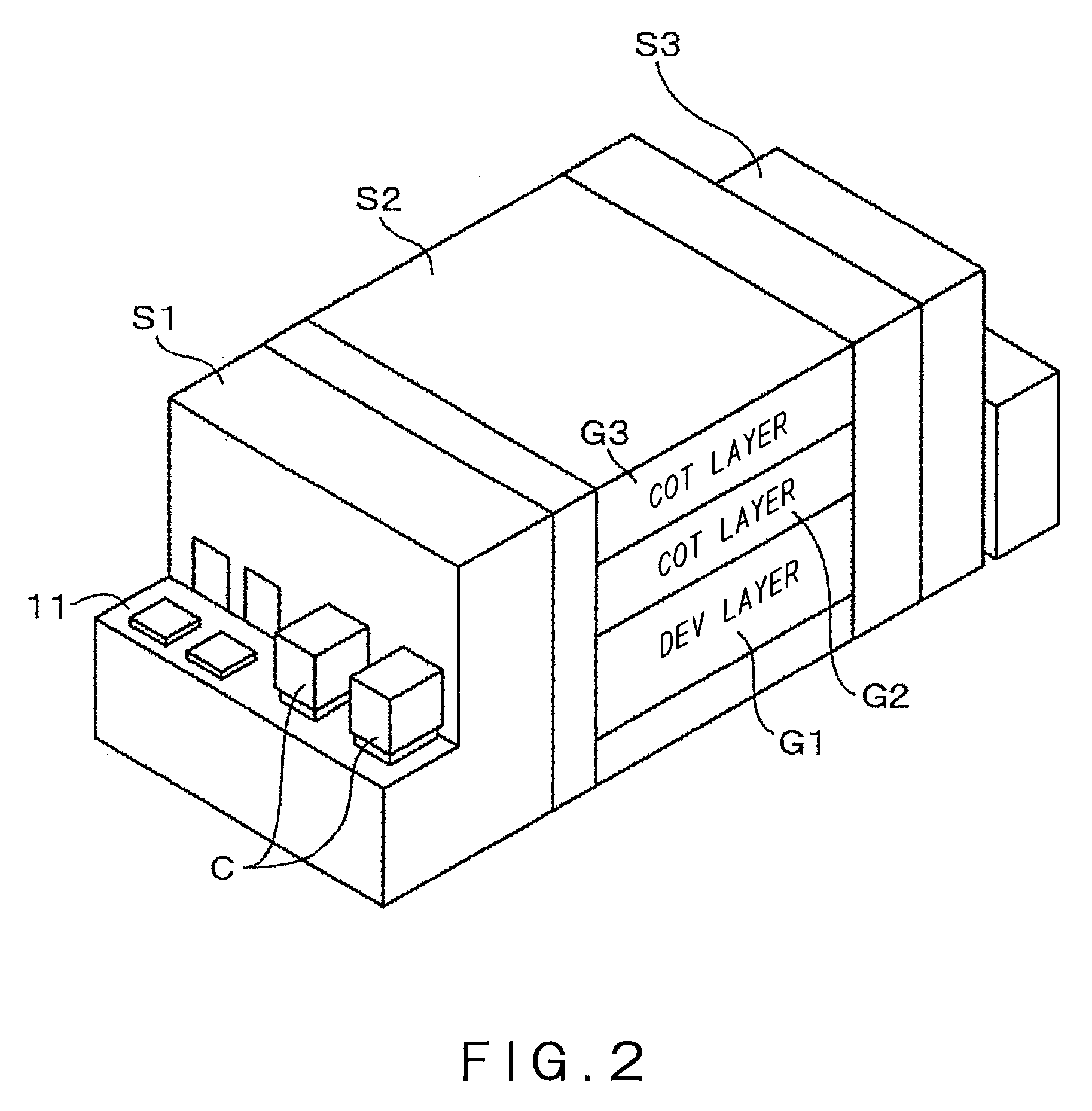

Coating and developing apparatus, coating and developing method, and storage medium

ActiveUS7645081B2Improve accuracySuppressing decrease in wafer-conveying accuracyLiquid surface applicatorsLiquid processingResistEngineering

Disclosed herein is a coating and developing apparatus 1 whose decreases in substrate-conveying accuracy can be suppressed. A processing block S2 of the coating and developing apparatus 1 includes multiple resist-film forming blocks G2, G3, and a developing block G1. A conveyance element 12 for substrate loading into the processing block S2 is provided to convey substrates W from a carrier C to the resist-film forming blocks G2, G3. Also, a conveyance element I for substrate loading into an exposure apparatus S4 is provided in an interface block S3 to load the substrates W into the exposure apparatus S4 and after unloading the substrates W from the exposure apparatus S4, convey the substrates W to the developing block G1. The processing block loading conveyance element 12 conveys the substrates W, one at a time, from the carrier C to each resist-film forming block G2, G3, sequentially and periodically, and the exposure apparatus loading conveyance element I loads the substrates W from each resist-film forming block G2, G3 into the exposure apparatus S4 in the sequence that each has been conveyed to the resist-film forming block G2, G3 by the processing block loading conveyance element 12.

Owner:TOKYO ELECTRON LTD

Paper feeding device and paper feeding method

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

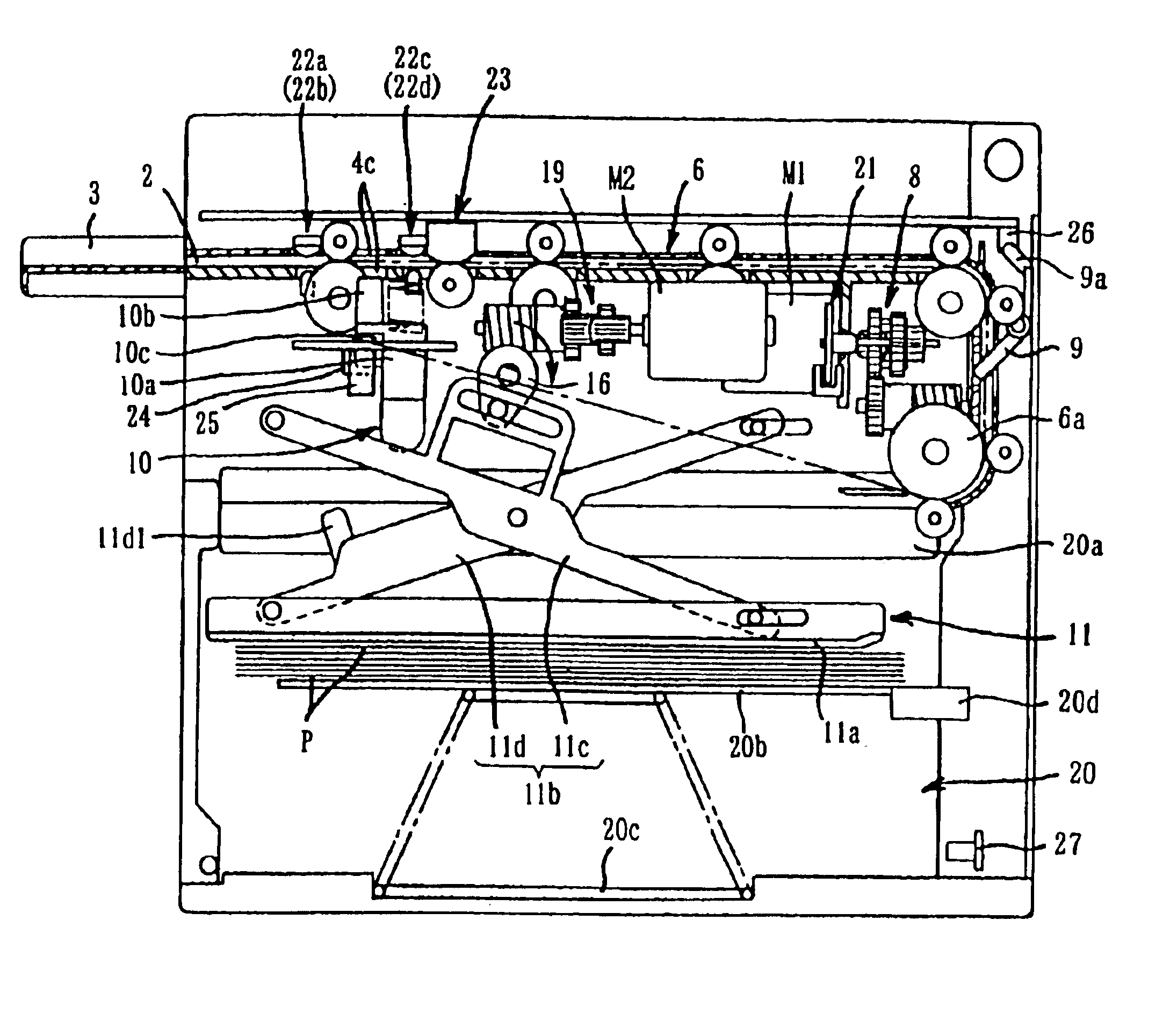

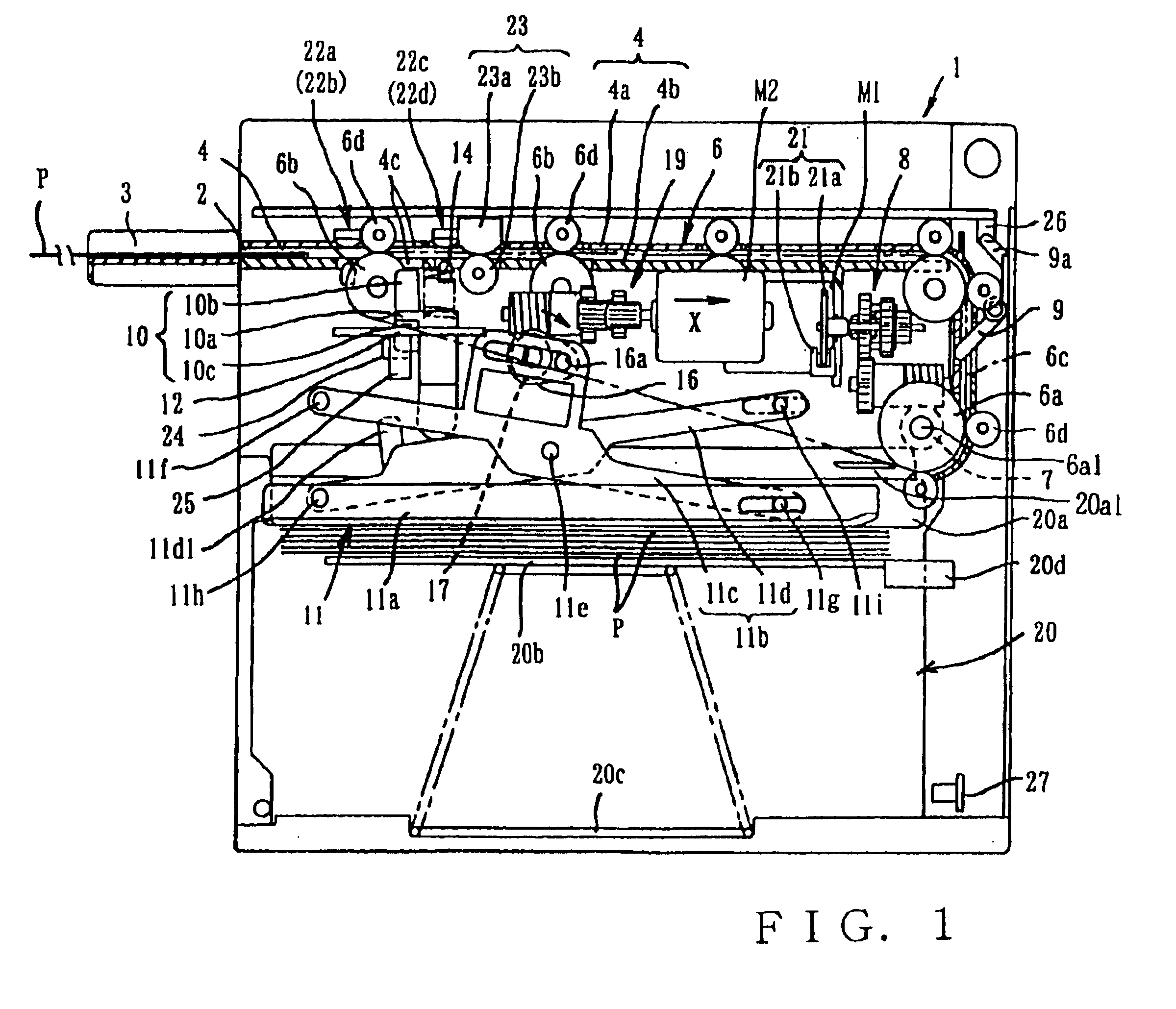

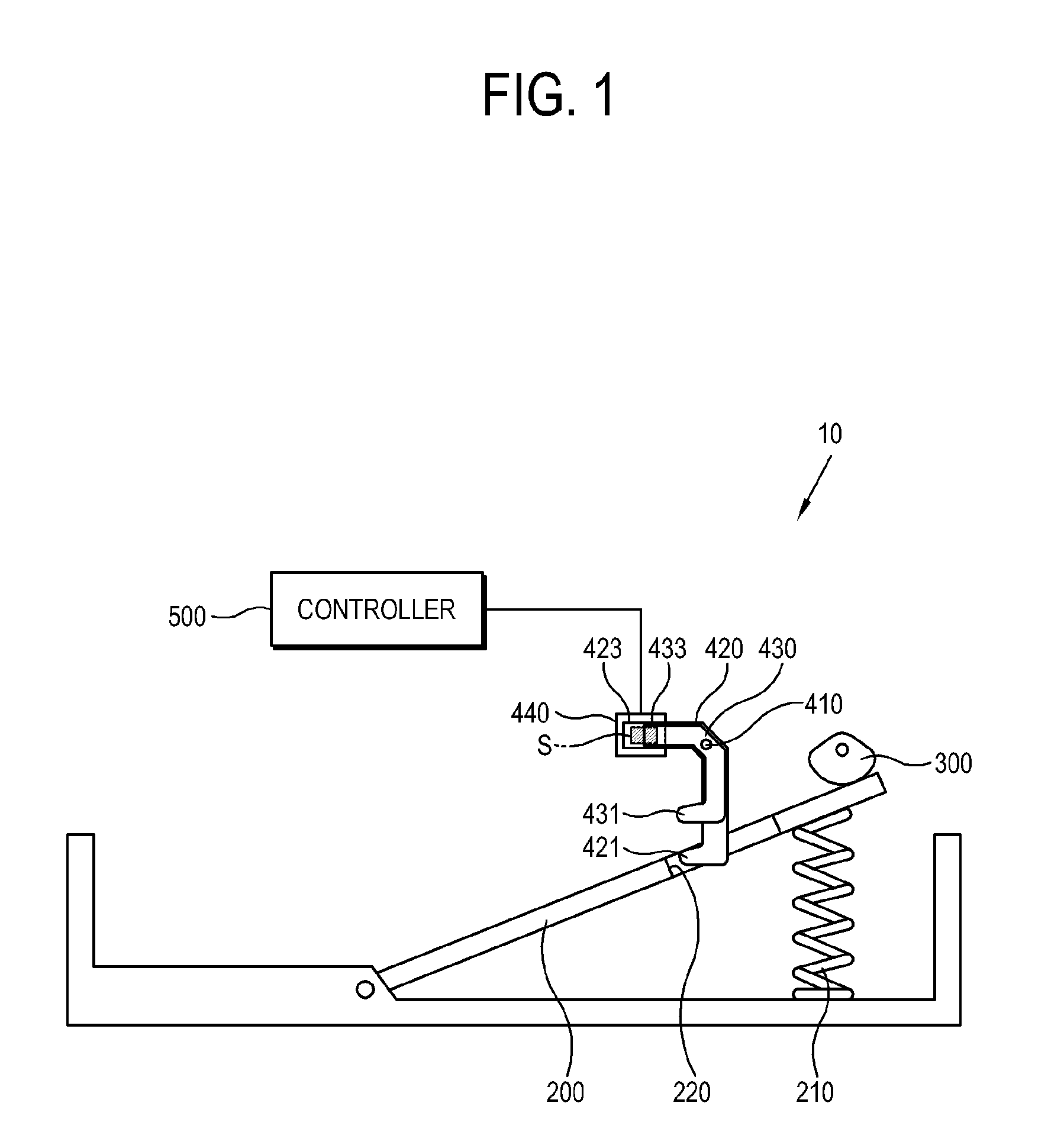

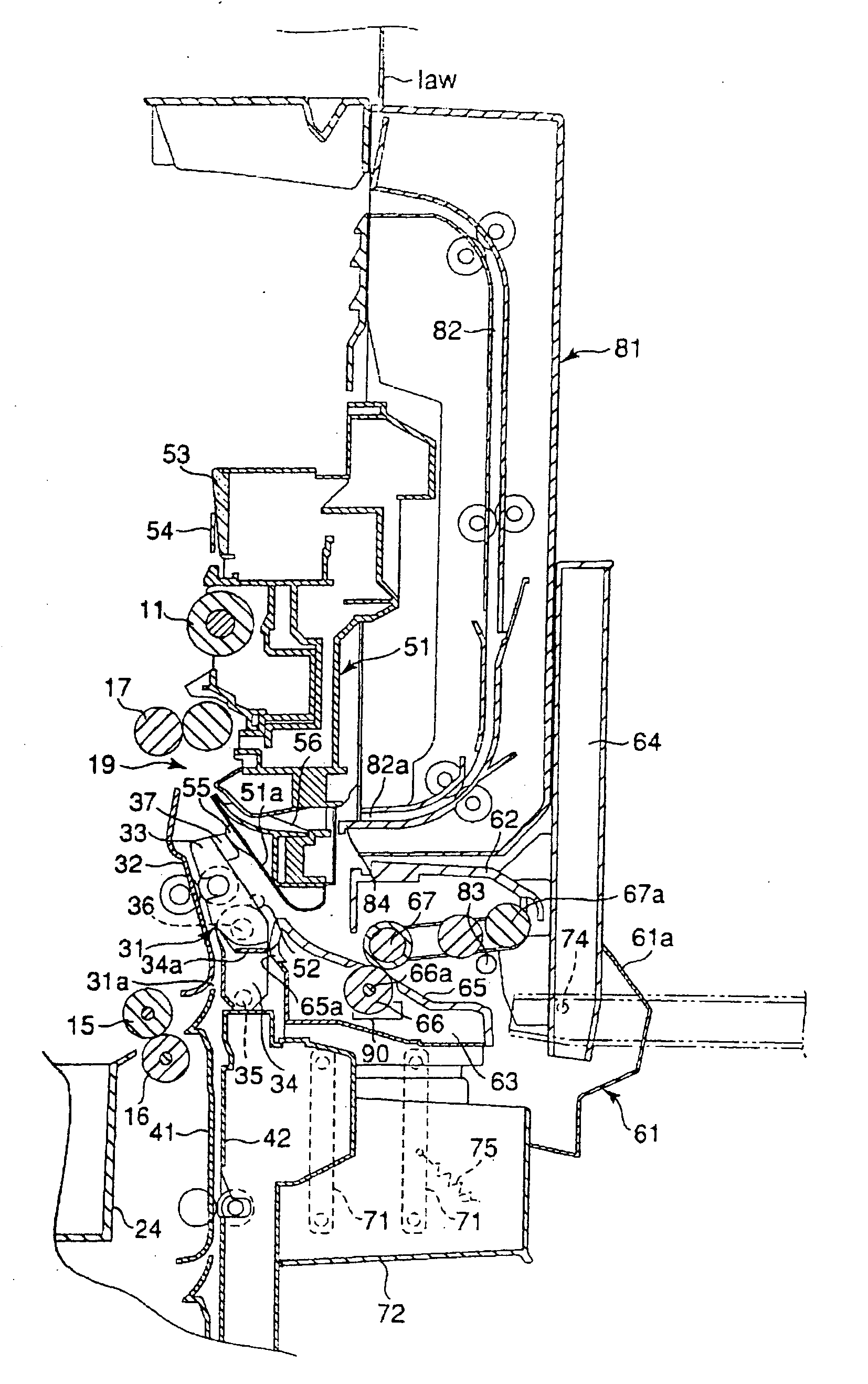

Sheet handling apparatus and method for opening/closing sheet transport path in the handling apparatus

InactiveUS6948607B2Reduce the number of partsCost of apparatus can be reducedPaper-money testing devicesCoin countersEngineeringStacker

In a paper-like piece handling apparatus, a same drive (M2) is shared between a stacker mechanism (11) for storing an inserted paper-like piece (P) into a cumulative paper-like piece storage section (20) and a shutter (10) for opening / closing a predetermined transport path (4). The shared use of the drive (M2) can reduce the number of necessary component parts and overall cost of the apparatus.

Owner:NIPPON CONLUX

Sheet feeder avoiding sheet sag

InactiveUS6902161B2Inhibit functioningIncrease beam intensityRegistering devicesFunction indicatorsCircular segmentSheet material

Owner:BRADY JOHN A +1

Automatic document feeder, image reading system including same, and image forming apparatus including same

ActiveUS20080308995A1Small and cost-effectiveReduce consumptionRegistering devicesElectrographic process apparatusImage formationPaper document

An automatic document feeder, included in an image reading system that can be included in an image forming apparatus, is configured to transfer an original document to an image reader included in the image reading system, and includes a first drive unit configured to include a first motor to drive the document separation and feed unit, a second drive unit configured to include a second motor to drive the document conveyance unit, a third drive unit configured to include a third motor to drive the document discharging unit, where at least two motors of the first, second, and third motors disposed in a substantially in-line arrangement, and a cooling member configured to supply a coolant to the at least two motors disposed in a substantially in-line arrangement, to the first, second, and third motors, in that order.

Owner:RICOH KK

Booklet maker with sheet wise trim

InactiveUS6632061B2More compactLess expensiveOther printing matterRegistering devicesWood veneerEngineering

A trimming apparatus for a booklet maker is described which provides a compact and low cost booklet maker for desktop publishing. The booklet maker includes a sheet receiving tray for receiving a stack of sheets to be stapled into a booklet, a stapler unit arranged to staple the stack of sheets, and a trimming system for trimming the sheets in a sheet wise manner. The trimming system includes first and second pick and separate mechanisms arranged to separate each of the sheets in the stack of sheets and first and second cutters arranged to cut each of the separated sheets after the have been separated by the first and second pick and separate mechanisms. A controller positions the sheets and controls the trimming system to cut each of the separated sheets at a location determined based on a trimming schedule. The trimming schedule varies the position of the cut depending on a position of the sheet in the booklet and a thickness of the sheets.

Owner:HEWLETT PACKARD DEV CO LP

Sheet conveying device

Owner:BROTHER KOGYO KK

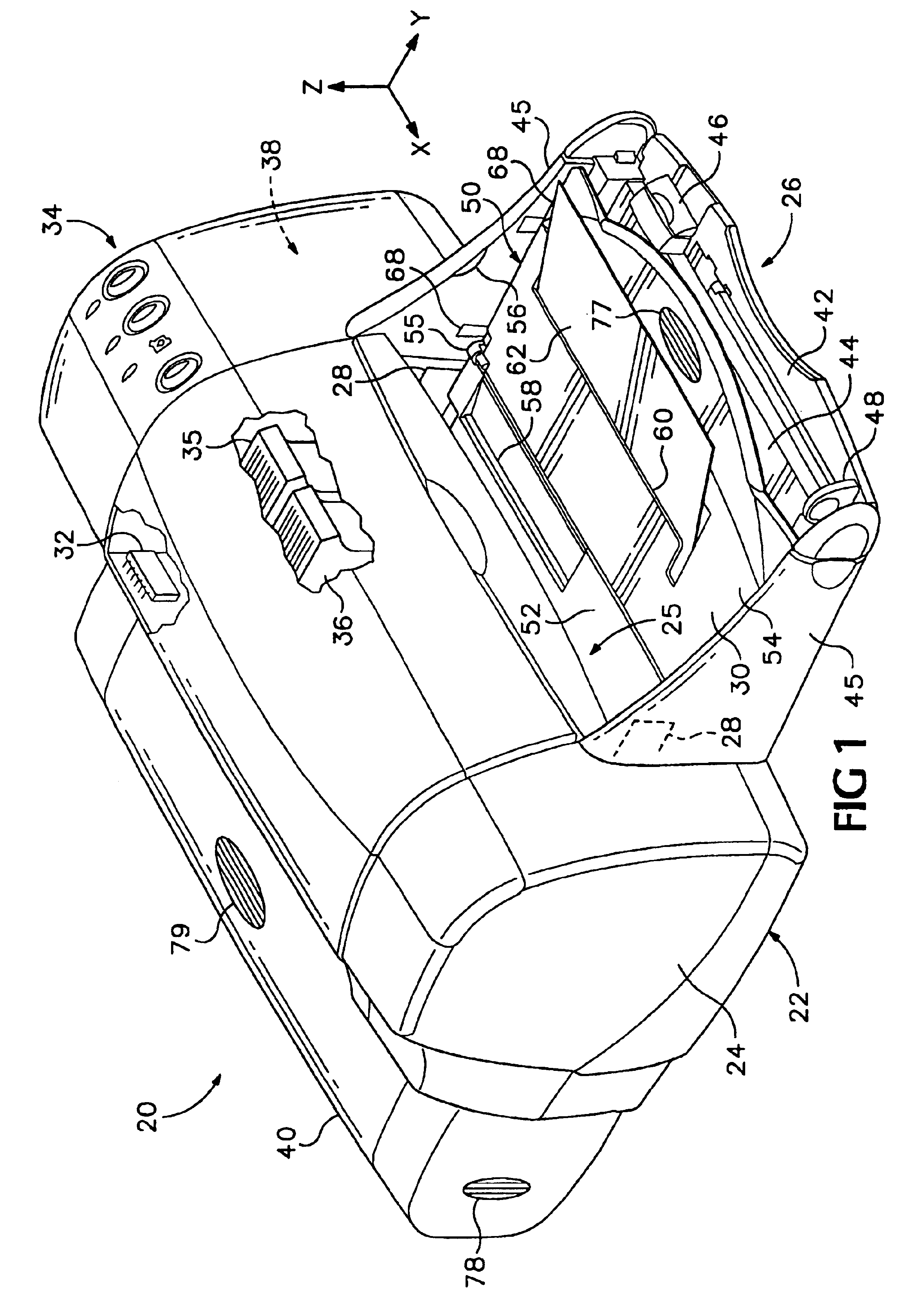

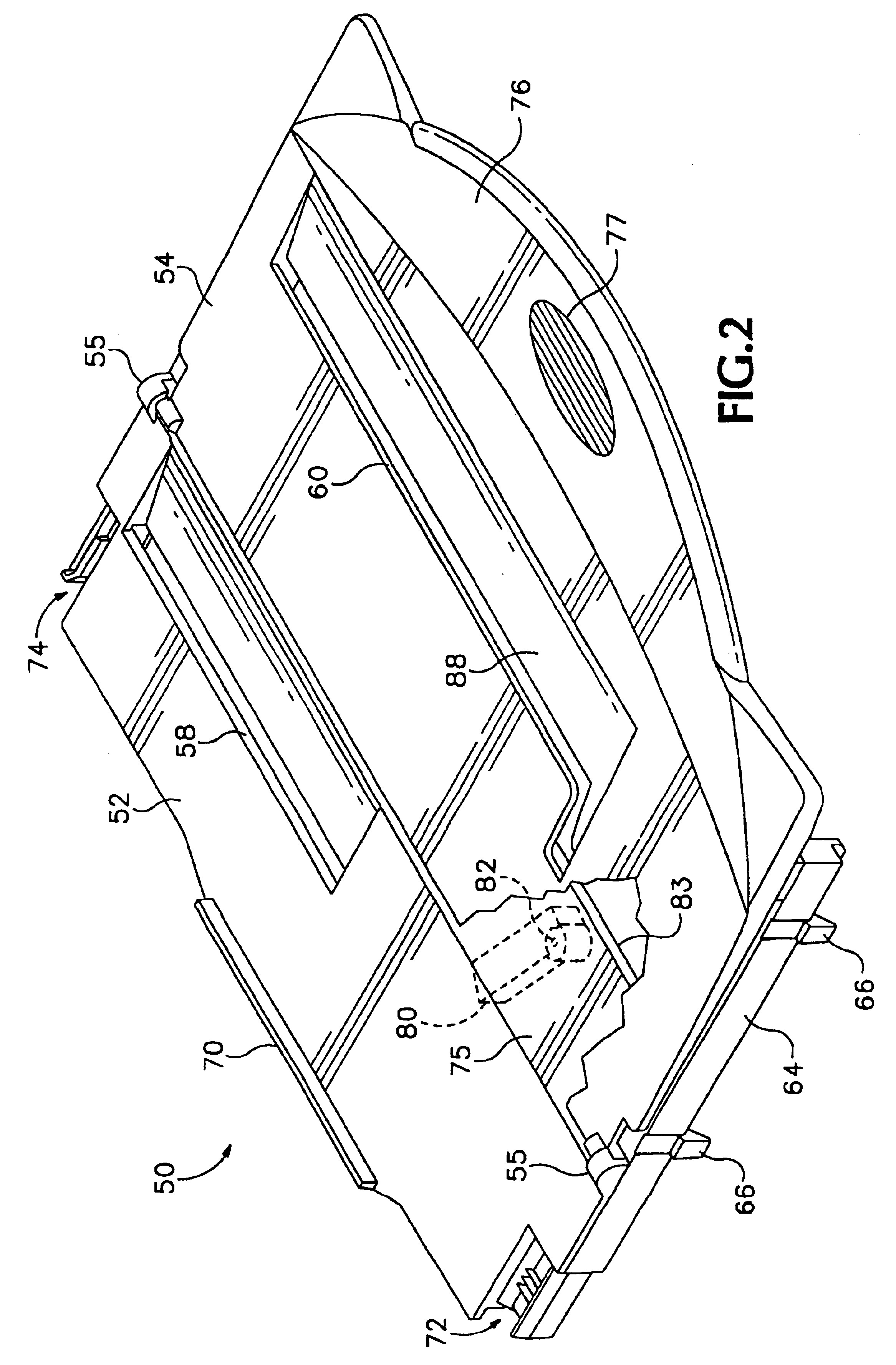

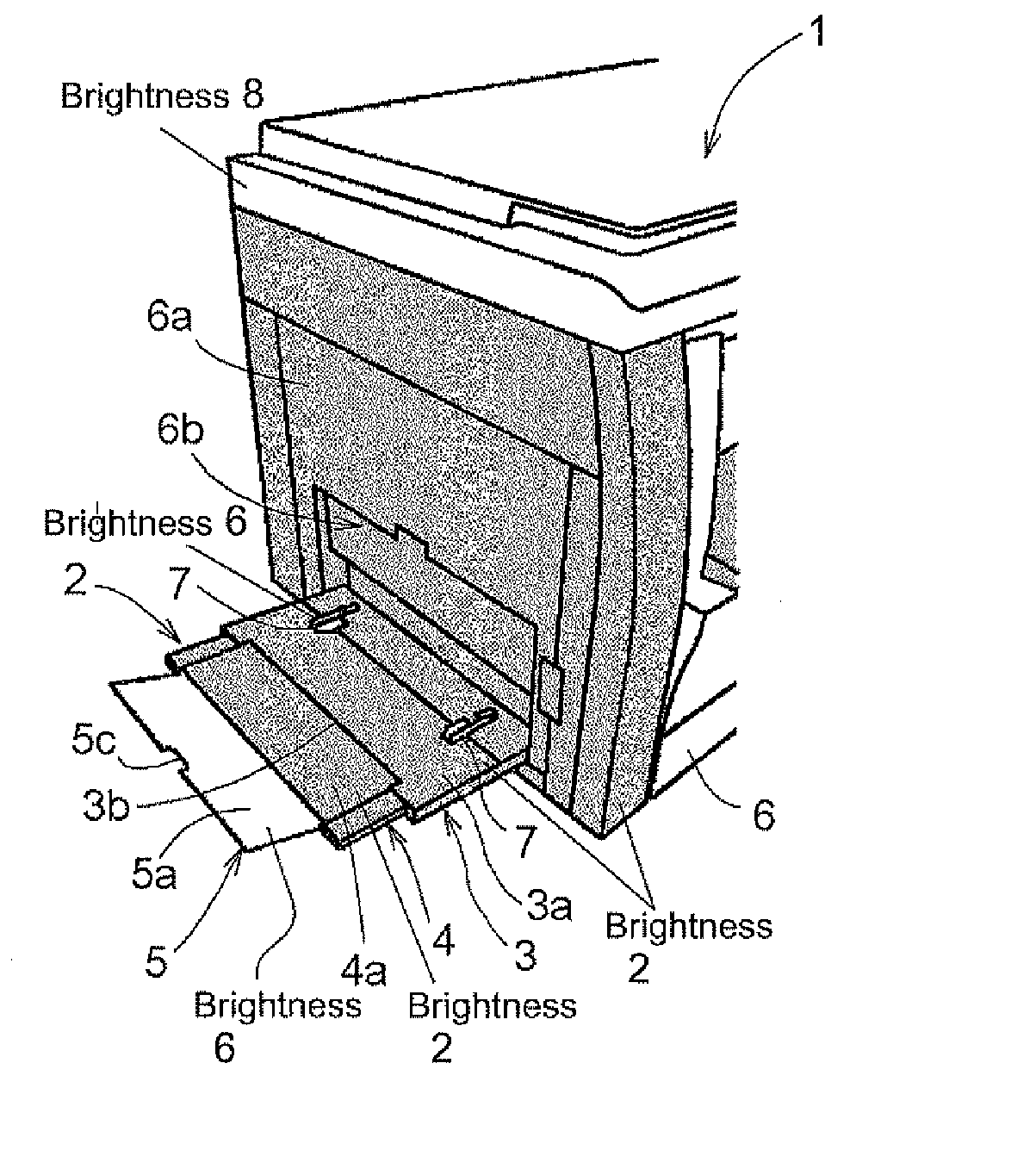

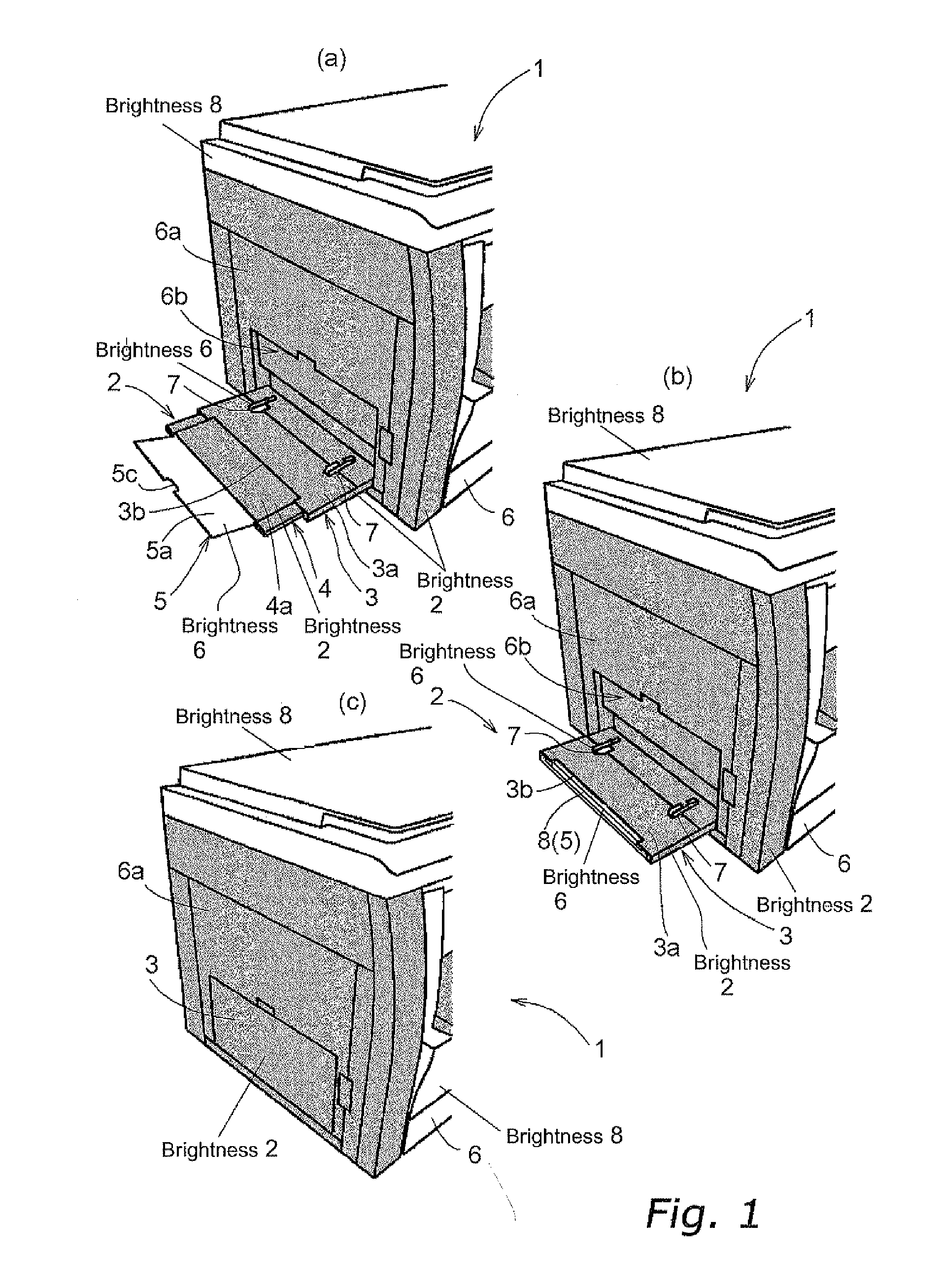

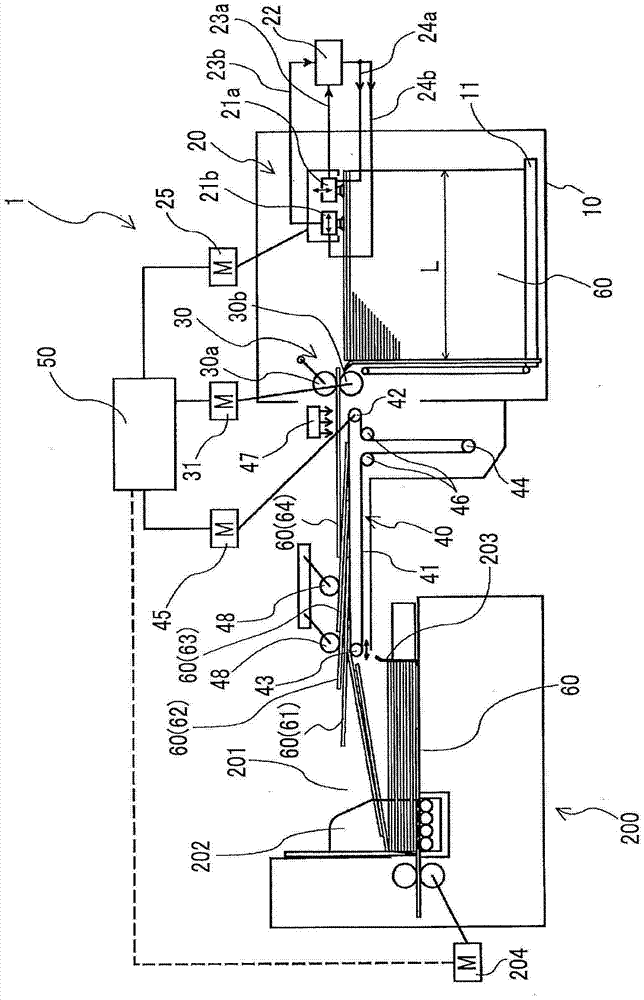

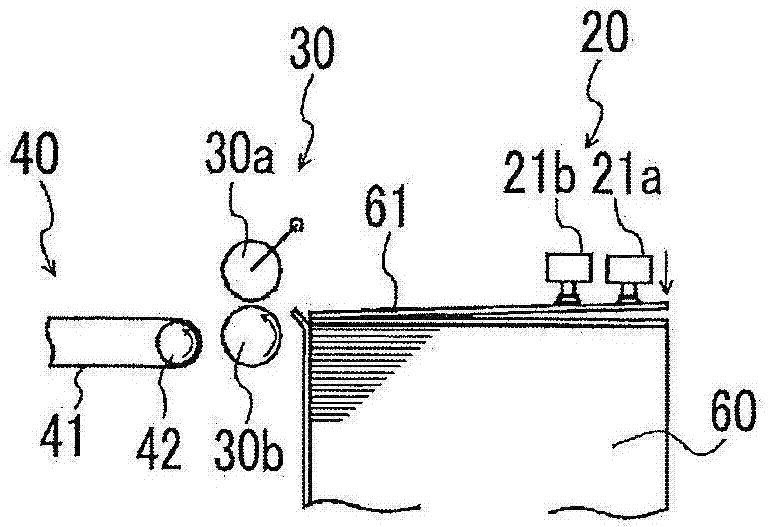

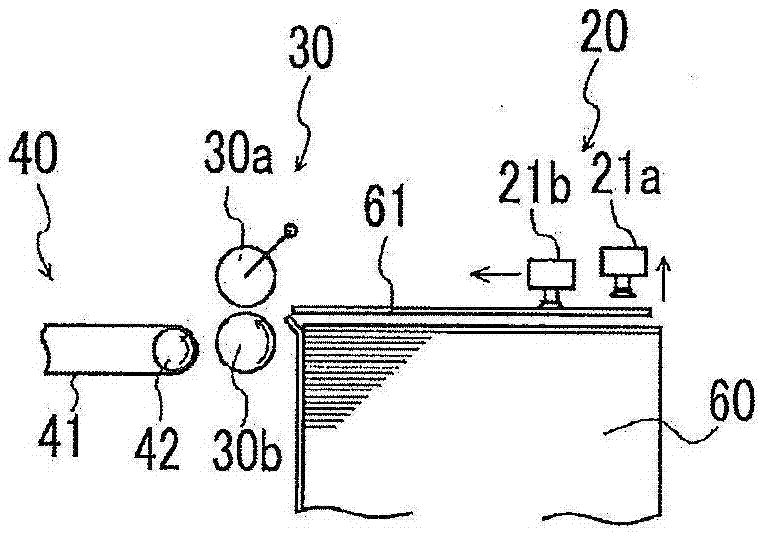

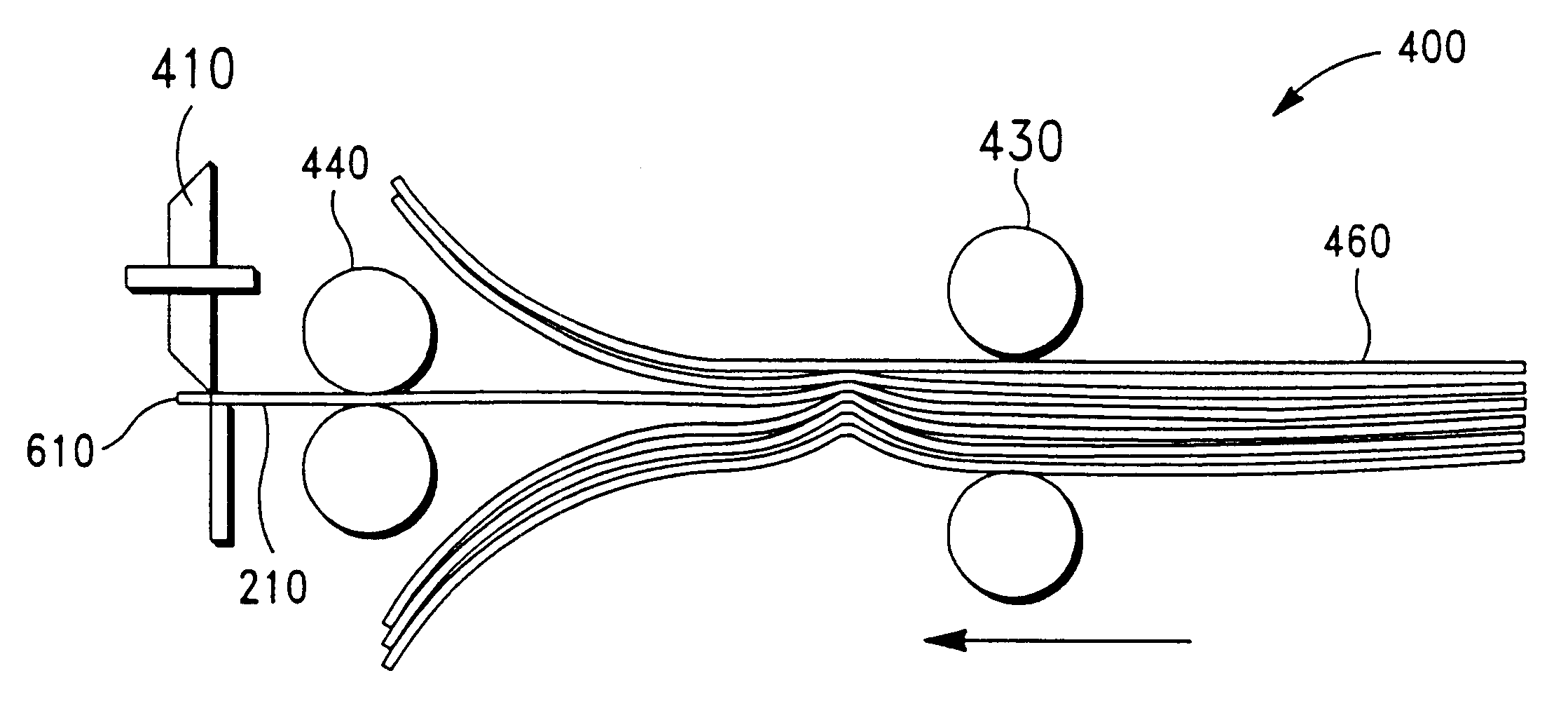

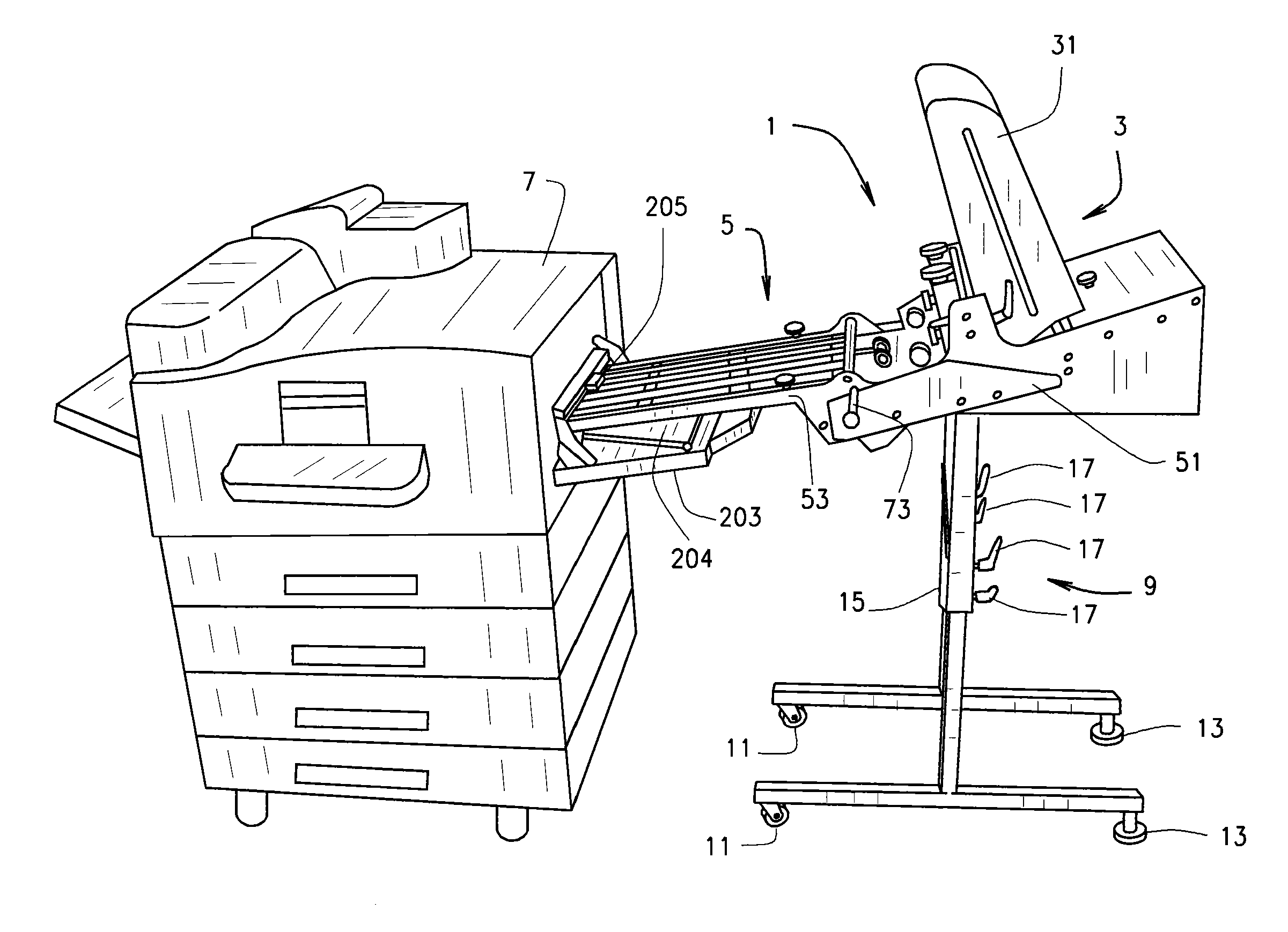

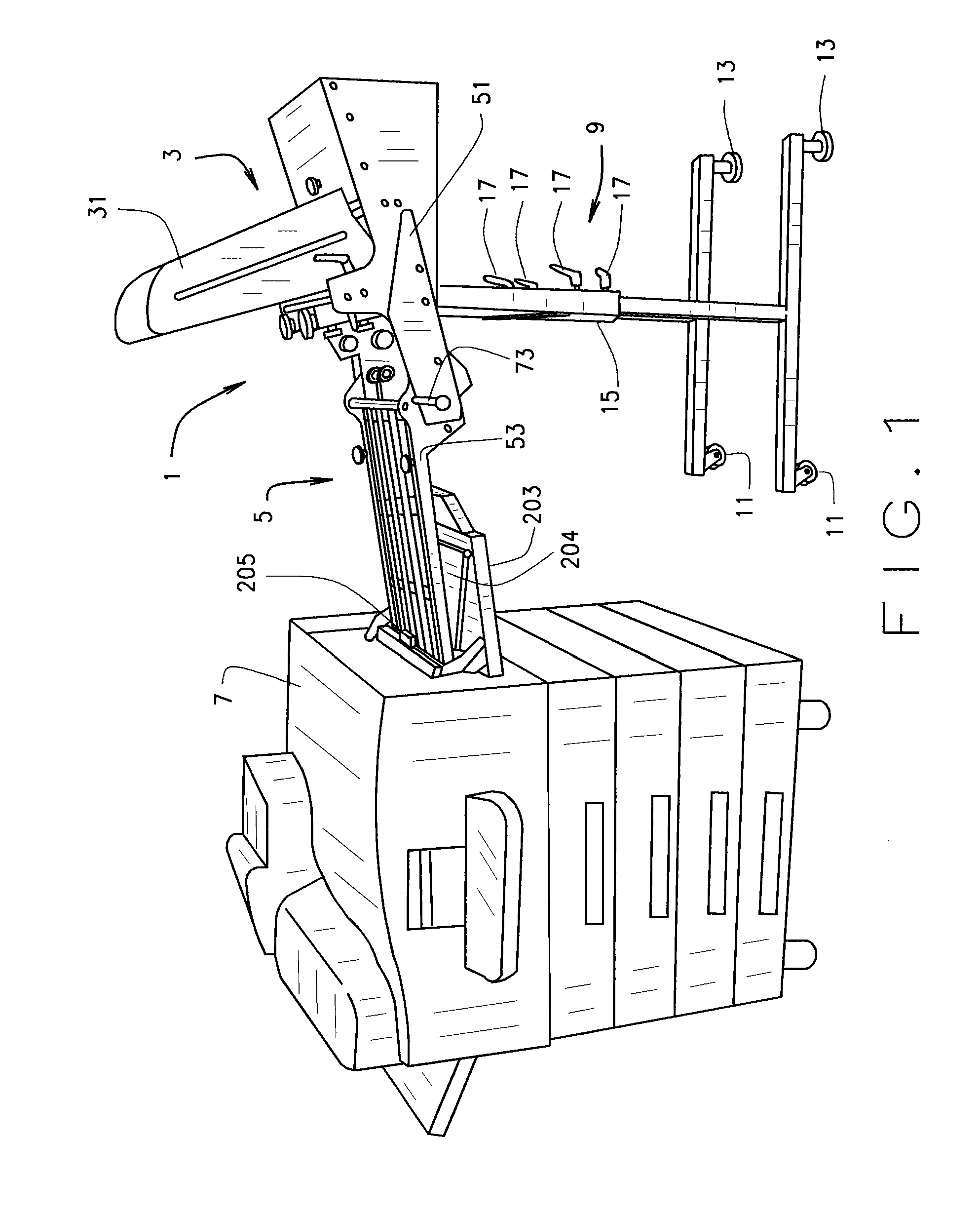

Document feeder with pivoting delivery table, particularly for digital printers

ActiveUS20110291348A1Improve abilitiesRich varietyElectrographic process apparatusArticle feedersEngineeringPaper document

A sheet feeder assembly (1) includes a bottom-feed sheet feeder (3) and a delivery table (5) positioned to receive sheets from the sheet feeder and deliver the sheets one at a time to a top-feed mechanism (205) designed to feed the top sheet of a stack of sheets in a manual feed tray of a printer (7) or the like. The top-feed mechanism includes a lifting support (204) for a stack of sheets. An exit end of the delivery table rests on and moves with the lifting support and delivers sheets one at a time to the top-feed mechanism. A balance mechanism (75) reduces the effective weight of the delivery table.

Owner:KAIPING JAMES C

Sheet conveying device, and image forming apparatus including same

InactiveUS7871073B2Simple configurationLow costRegistering devicesFunction indicatorsImage formationAngular velocity

Owner:RICOH KK

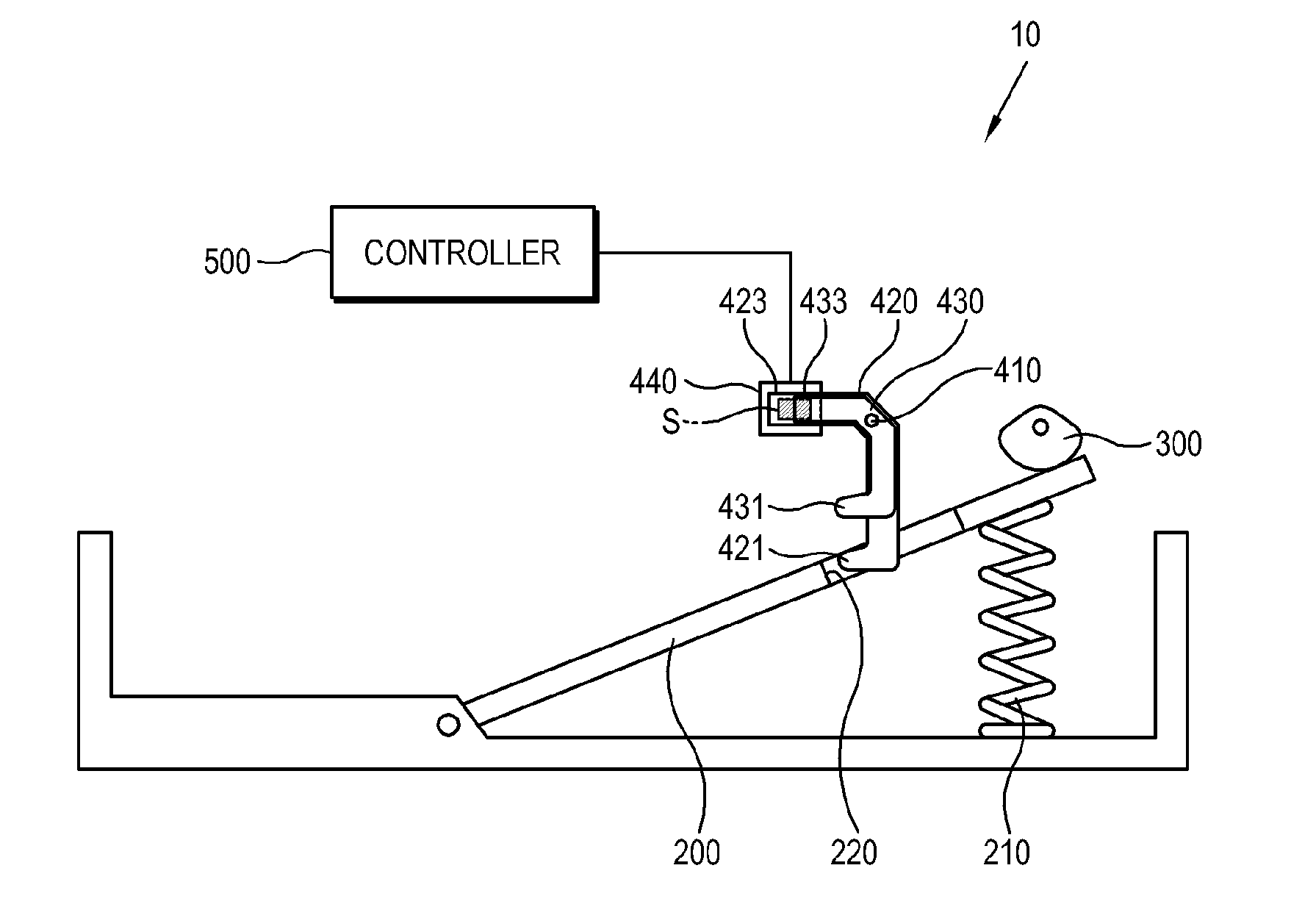

Medium feeding unit and image forming apparatus having the same

ActiveUS20090066006A1Simple structureRegistering devicesFunction indicatorsPrint mediaImage formation

A medium feeding unit having an improved structure for sensing that the number of print media loaded onto a loading plate is equal to or exceeds a predetermined remaining number, and an image forming apparatus having the same. The medium feeding unit includes a sensor that outputs sensing signals having different voltages according to quantities of received light. The medium feeding unit also includes a plurality of actuators that sense the number of print media on a loading plate, differentially intercept the sensing area of the sensor thus changing the voltage level of the sensing signal, and therefore signal the medium feeding unit when the number of print media on the loading plate falls below the predetermined remaining number.

Owner:HEWLETT PACKARD DEV CO LP

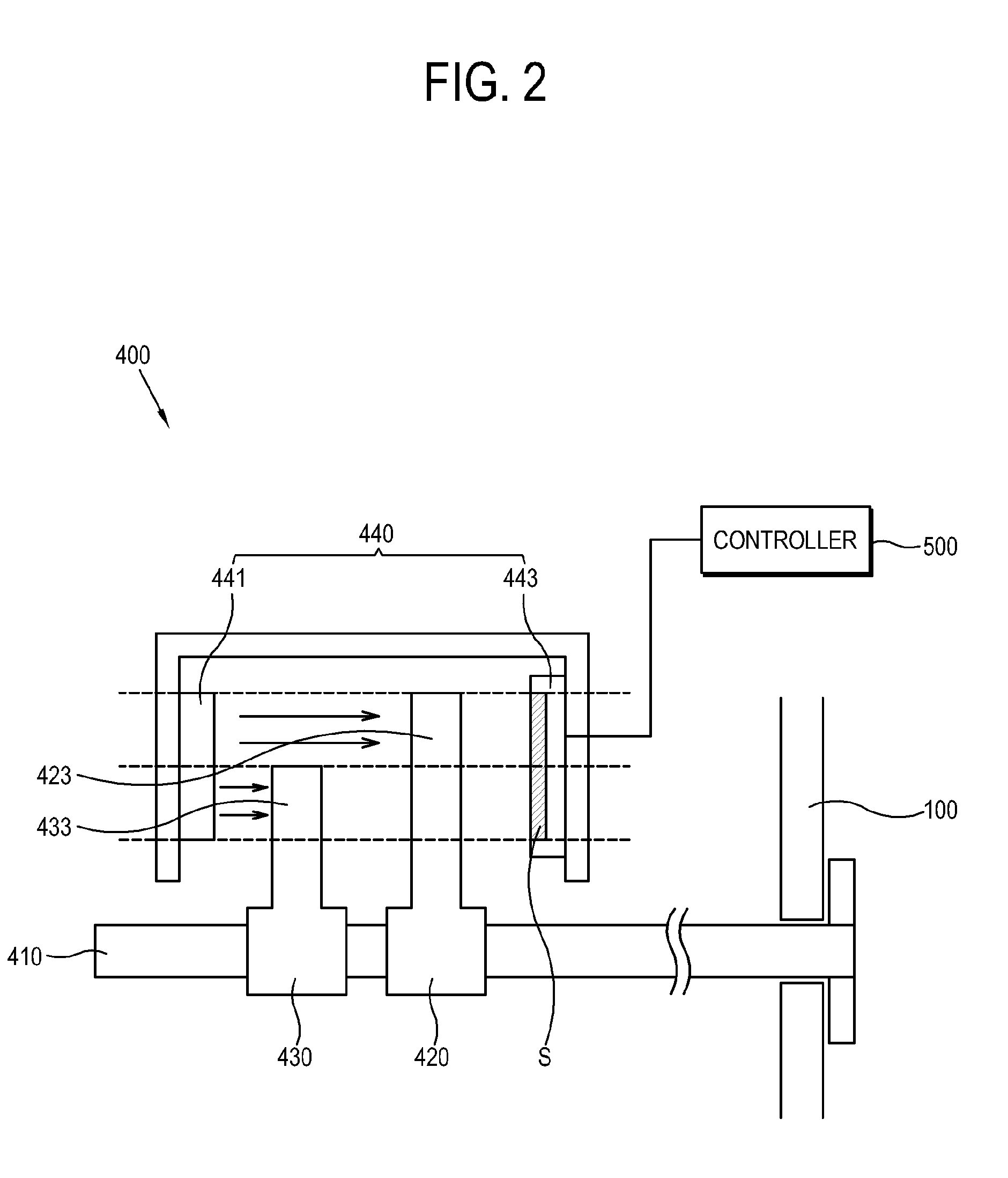

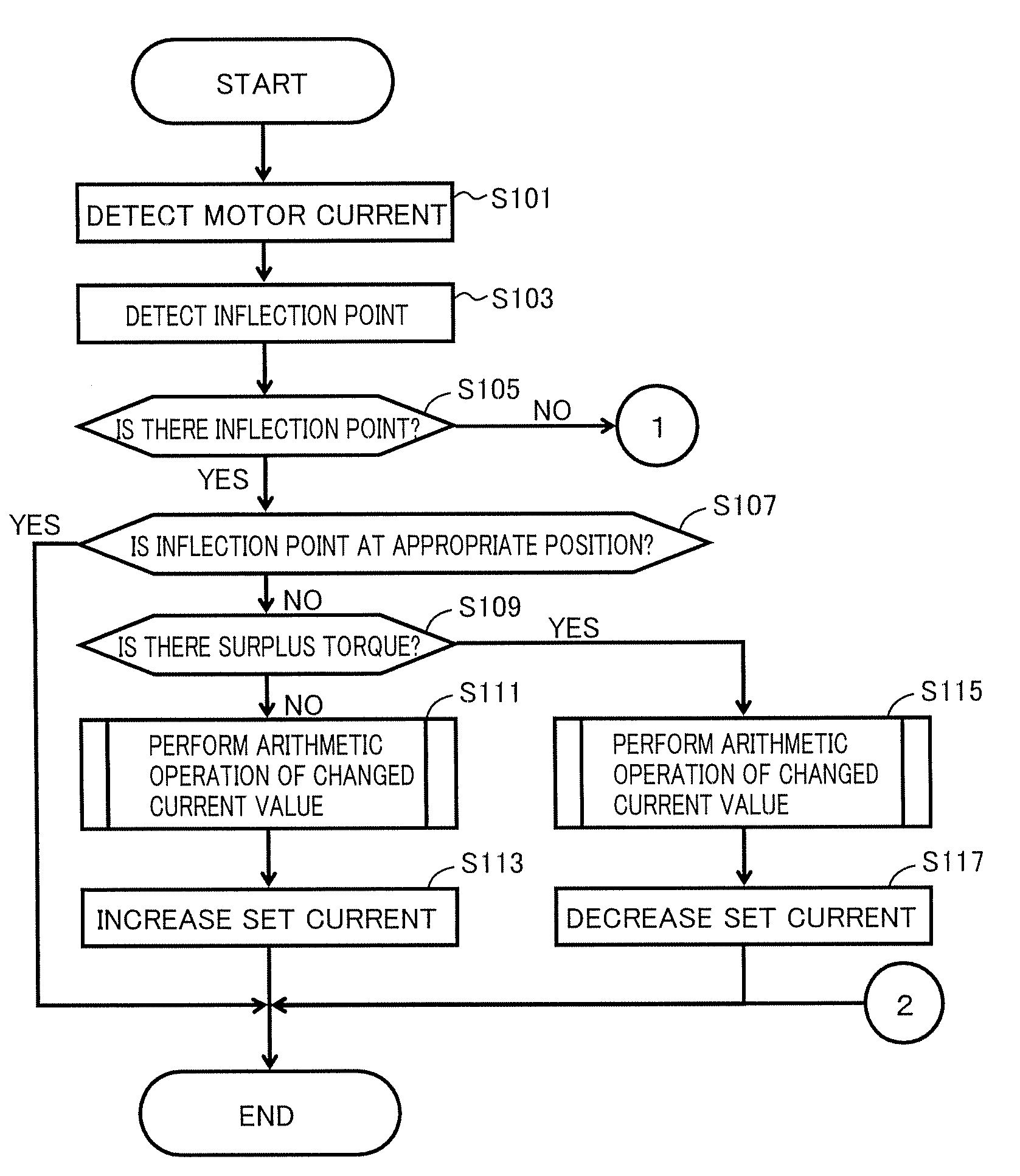

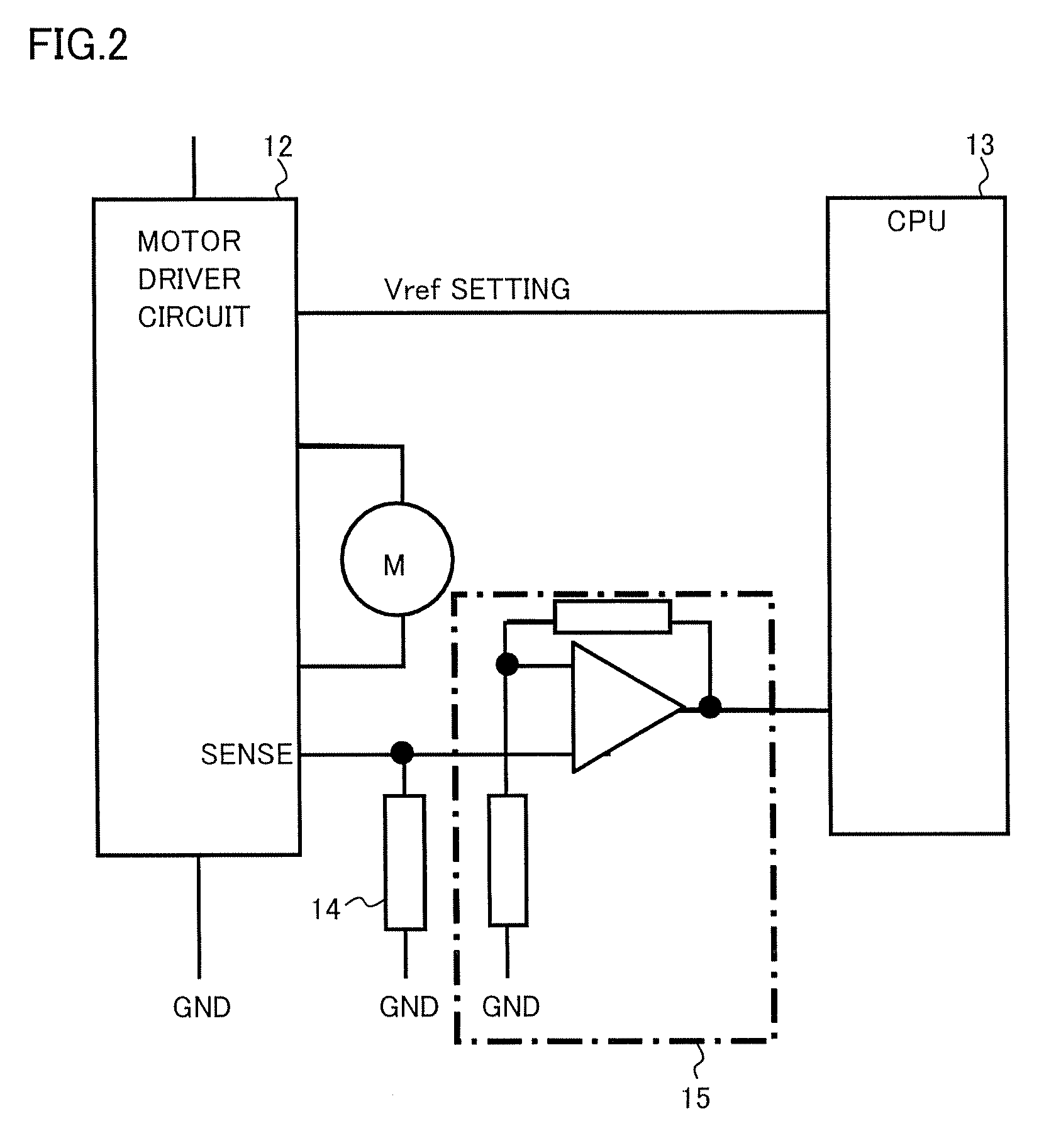

Image Forming Apparatus Appropriately Setting Current Value for Driving Motor

InactiveUS20080231220A1Low costReduce device sizeDC motor speed/torque controlEmergency protective circuit arrangementsDisplay deviceImage formation

When a printing instruction is provided, a CPU causes a stepping motor M to drive a developer and calculates the value of a load of the stepping motor M before printing operations are performed. Then, CPU determines whether the value of the load is within a predetermined range stored in advance. If the value is not within the predetermined range, CPU causes a display to display an error message.

Owner:KONICA MINOLTA BUSINESS TECH INC

Sheet Conveying Device

InactiveUS20080073838A1Efficient removalChange in speed can be preventedOther printing apparatusArticle feedersEngineeringSheet material

A sheet conveying device may include a belt having a plurality of throughholes, a fan disposed so as to interpose a portion of the belt placed in a return run position between the fan and a portion of the belt placed in the forward run position, and a case that defines a chamber with a portion of the belt placed in the forward run position. The fan creates a negative pressure within the chamber by drawing air through the throughholes of the endless belt, thereby removing dust and other unwanted particles and debris from the endless belt. In one or more examples, a brush may also be included to provide further removal of unwanted dust and particles. Further, in one or more configurations, the sheet conveying device may also include belt rollers and / or supporting members.

Owner:BROTHER KOGYO KK

Thermal developing apparatus

InactiveUS20050195271A1Reduced space required for installationConvey evenlyRecording apparatusElectrode and associated part arrangementsLatent imageEngineering

A thermal developing apparatus for visualizing a latent image recorded on a photosensitive thermal developing recording material by heating the photosensitive thermal developing recording material with heating unit while conveying the photosensitive thermal developing recording material with conveying unit along a conveying path having the heating unit equipped therewith, the thermal developing apparatus containing a manual feeding tray for manually feeding the exposed photosensitive thermal developing recording material into the thermal developing apparatus.

Owner:FUJIFILM CORP +1

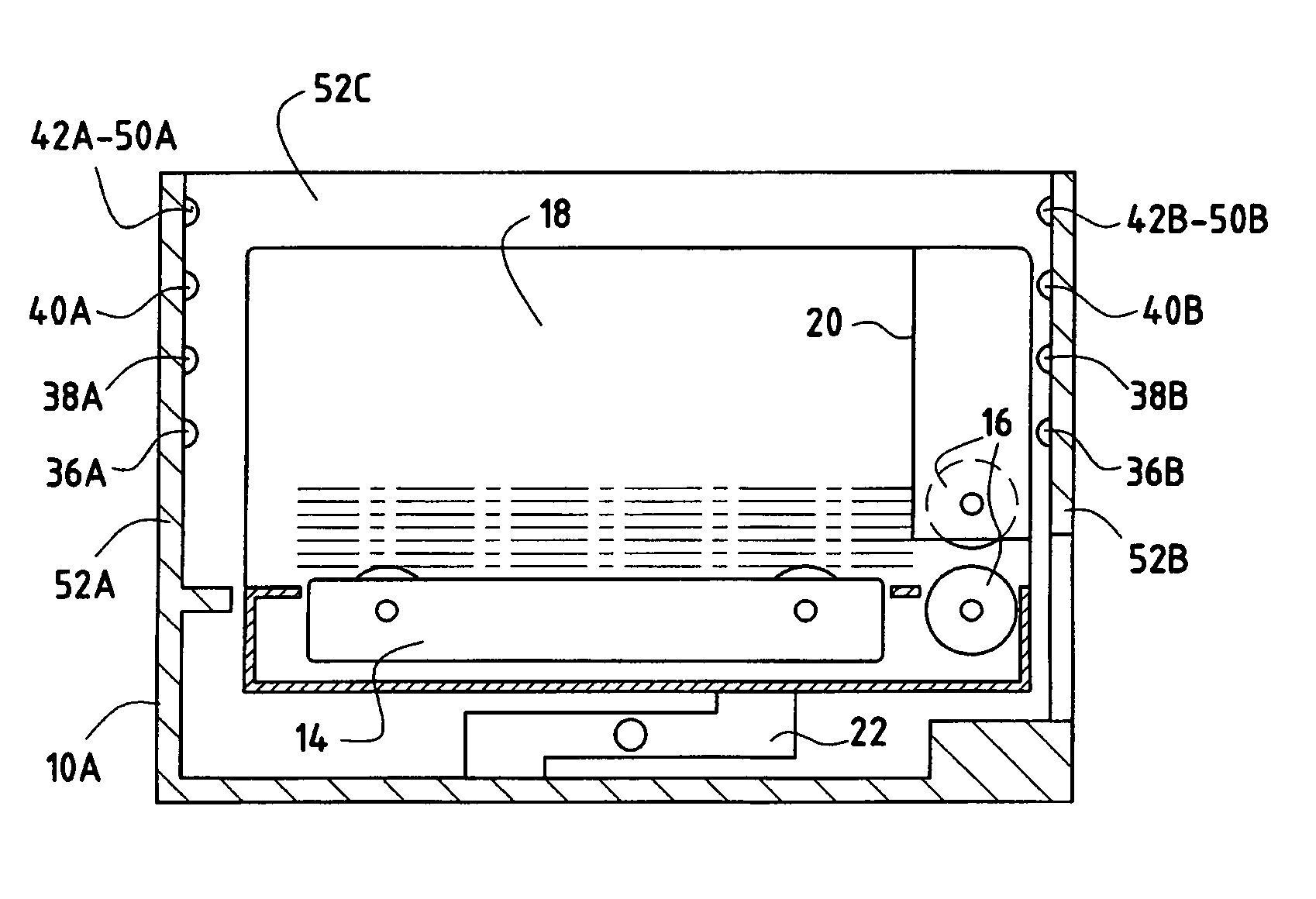

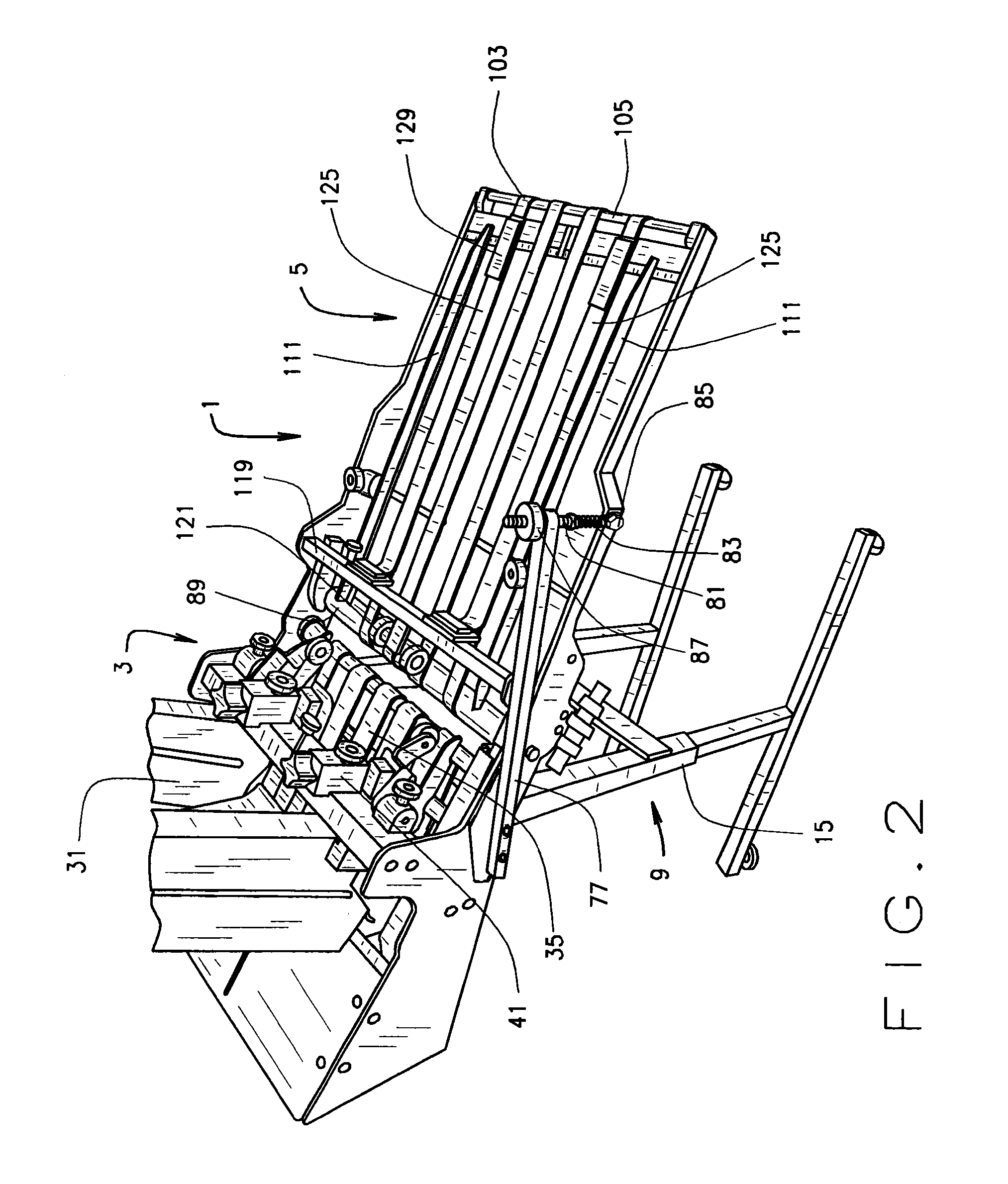

Precise transfer system for screen printing

The present invention presents apparatus and methods for processing substrates (150) of a screen printing chamber (102) whereby repeatable and accurate screen printing patterns are delivered on one or more processed substrates. In one embodiment, the screen printing chamber is used to perform a screen printing process for a production line of partially crystalline silicon solar cells, wherein the substrate is patterned with a predetermined material. In one embodiment, the screen printing chamber is a processing chamber located within a rotary line tool or a Softline™ tool from Baccini S.p.A., Applied Materials, Inc., Santa Clara, CA.

Owner:APPLIED MATERIALS ITALIA SRL

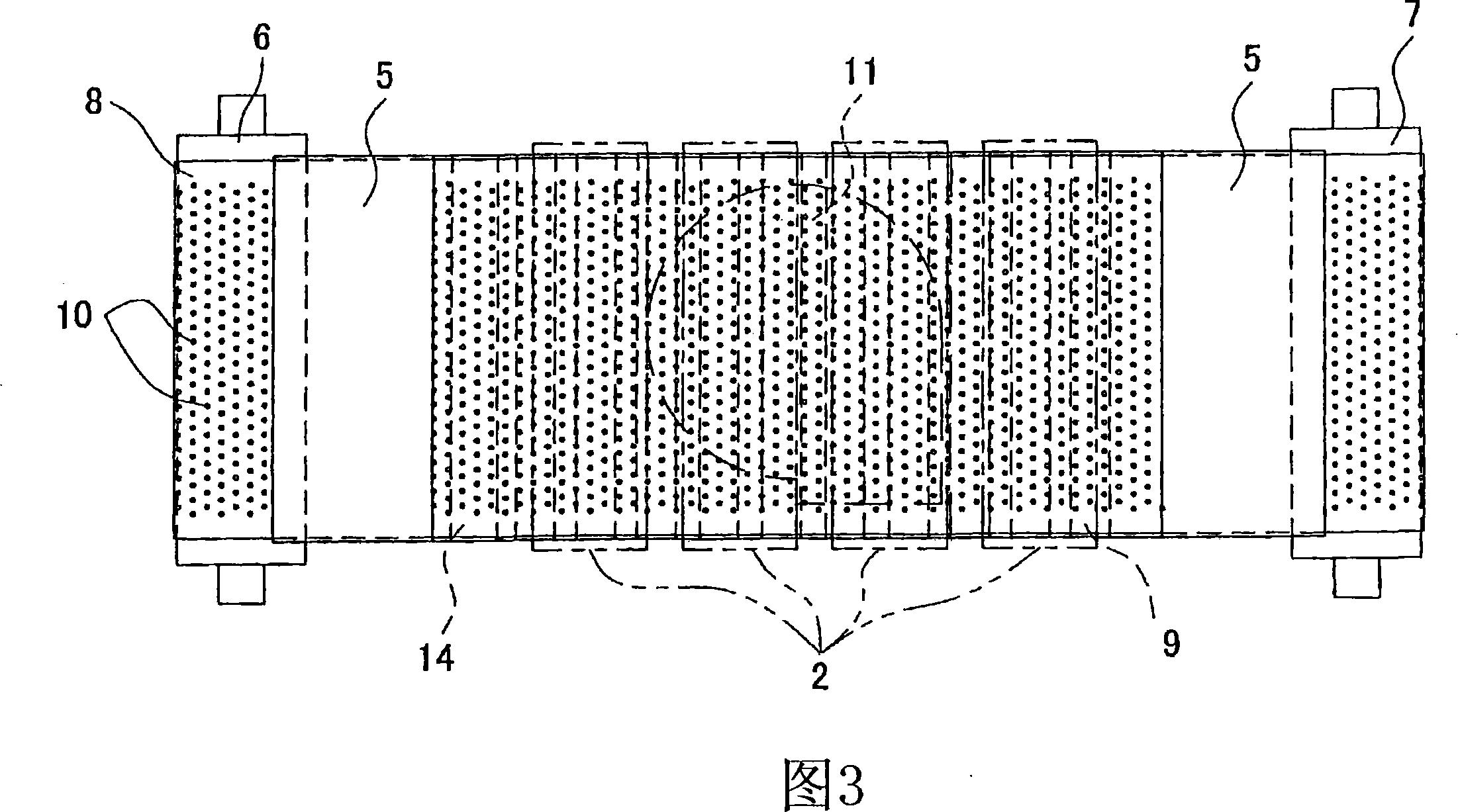

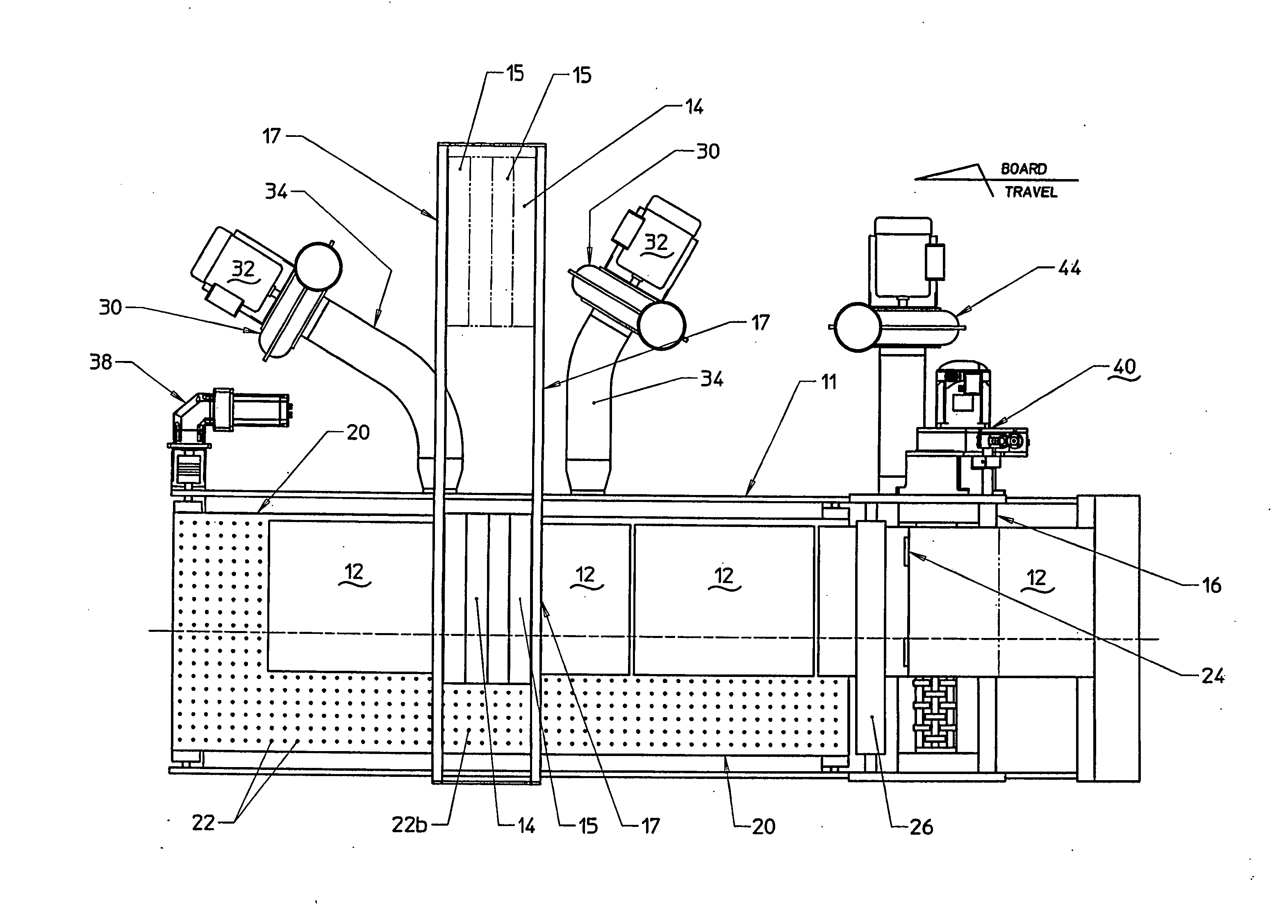

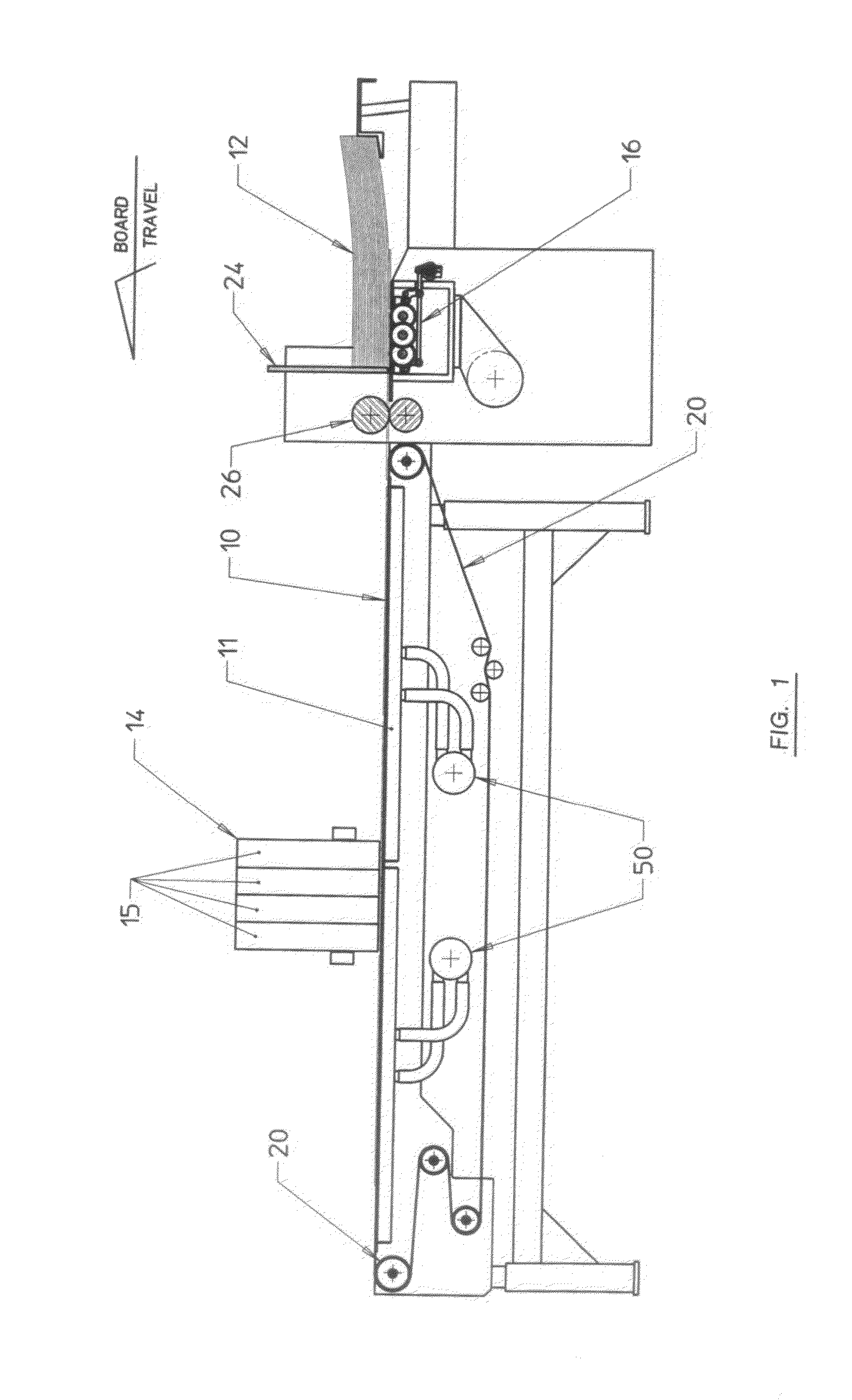

Conveyors for box making machines

ActiveUS20150259144A1Adversely affecting qualityAdversely affecting digital printingBox making operationsPaper-makingEngineeringPlenum chamber

A vacuum belt conveyor sequentially delivers sheet articles to a digital printer. The sheets are held in position by vacuum on the underside of the sheets through apertures in the belts and covered by the sheets. A plurality of independent plenums on the underside of the belt have chambers respectively communicating with rows of apertures extending along the belt. Vacuum is selectively applied from a manifold only to the plenum chambers that supply apertures that are covered by the sheets so that the ink from the printer will not be directed from its intended position on the sheet by vacuum from adjacent uncovered belt apertures. The sheets are fed to the conveyor in synchronism with the conveyor speed by a timed feeder so that the sheets are carried by the conveyor with a predetermined gap between the sheets and no belt apertures in the gap. A sensor counts the apertures in the belt and activates the feeder at predetermined time intervals.

Owner:SUN AUTOMATION

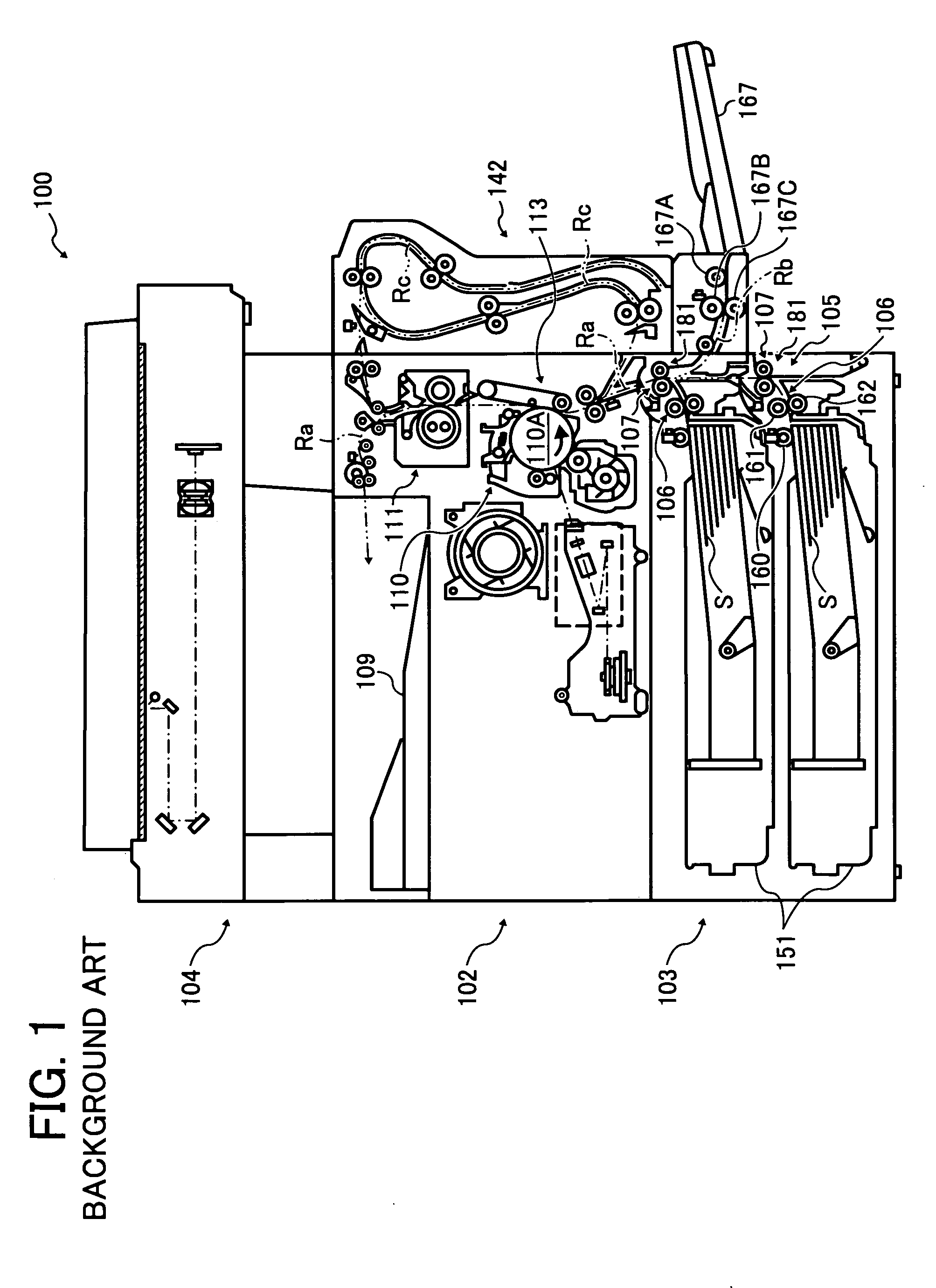

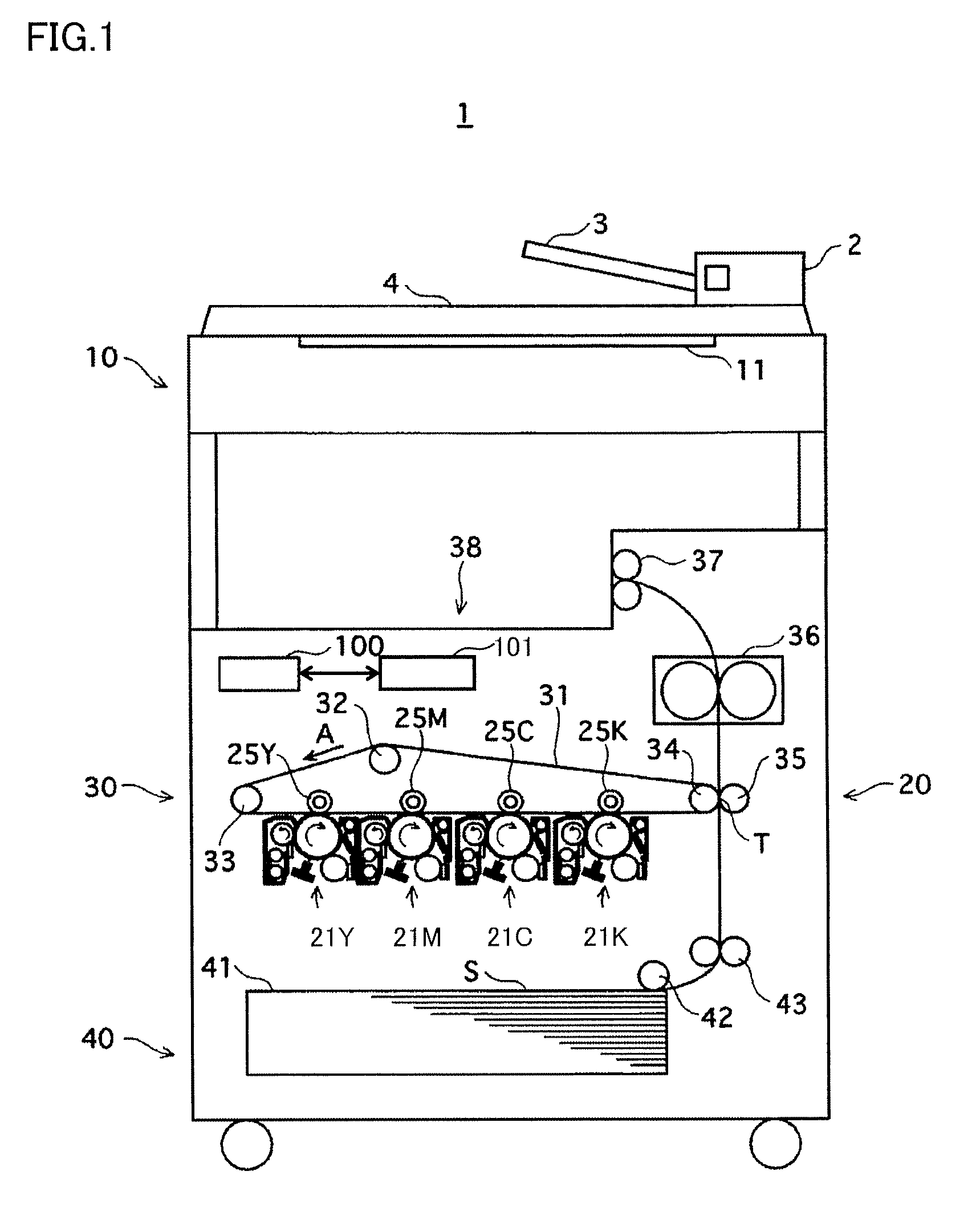

Image forming apparatus

InactiveUS20050040583A1Less laborSimple working processElectrographic process apparatusFeed tablesImage formationEngineering

Owner:KK TOSHIBA +1

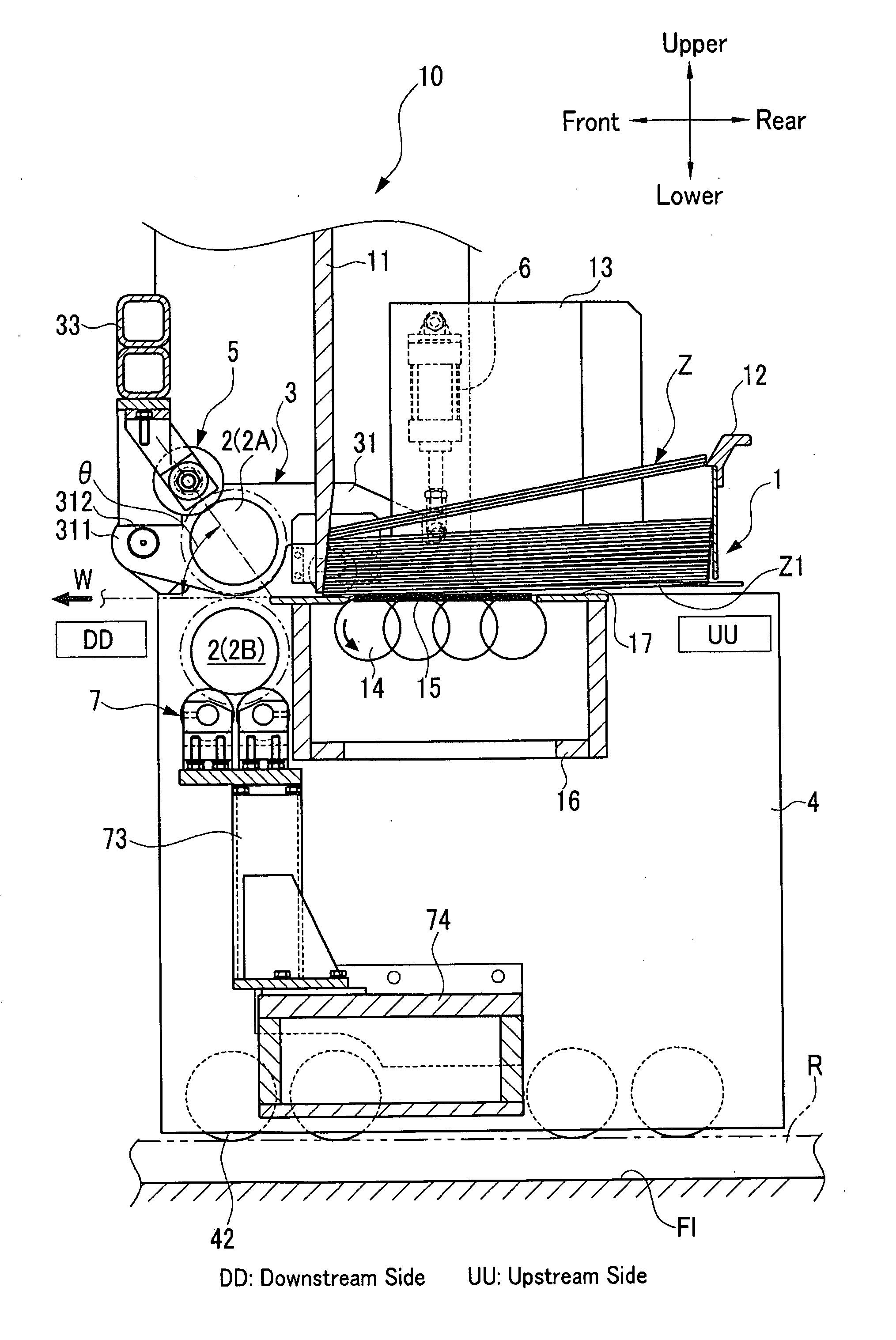

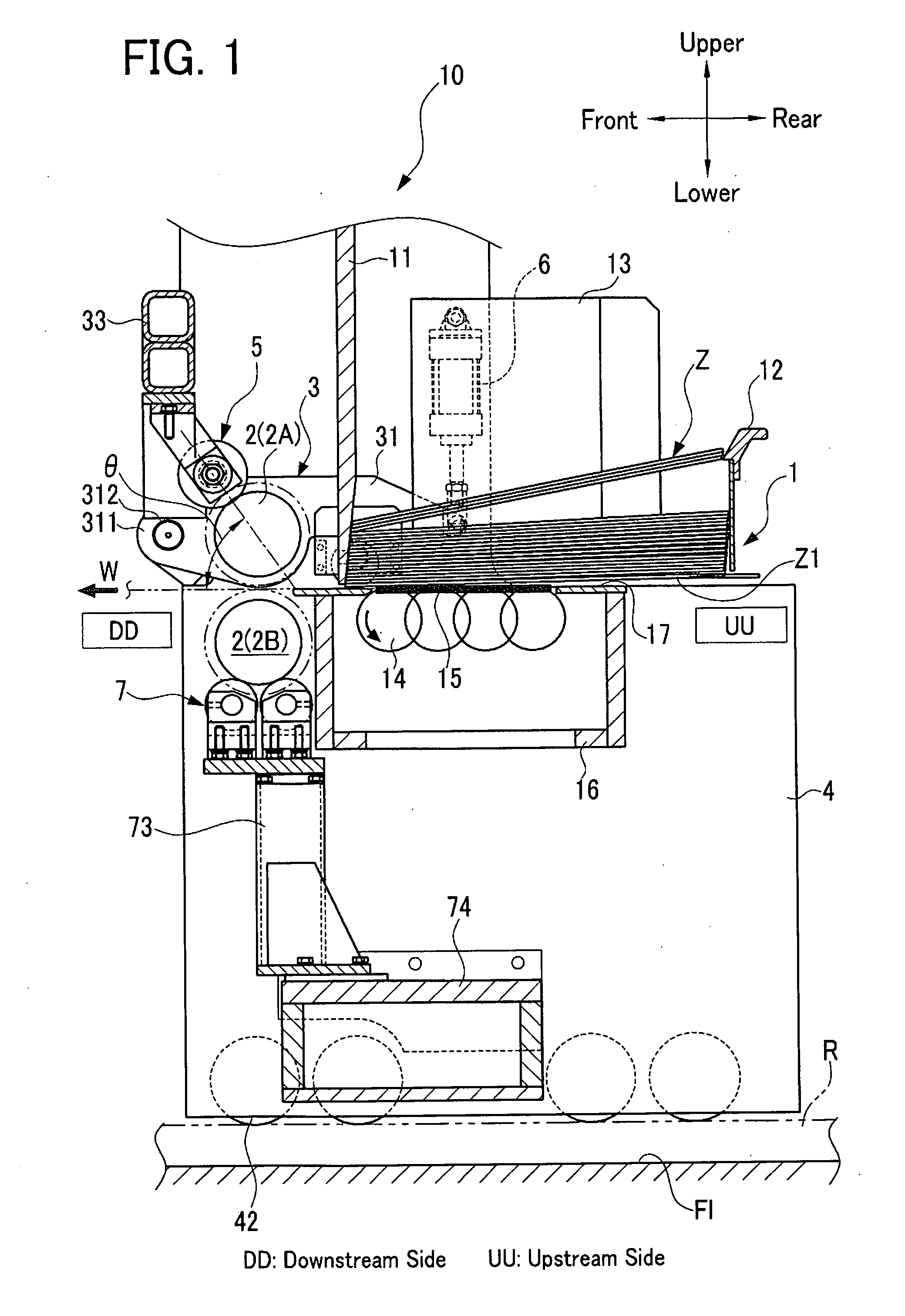

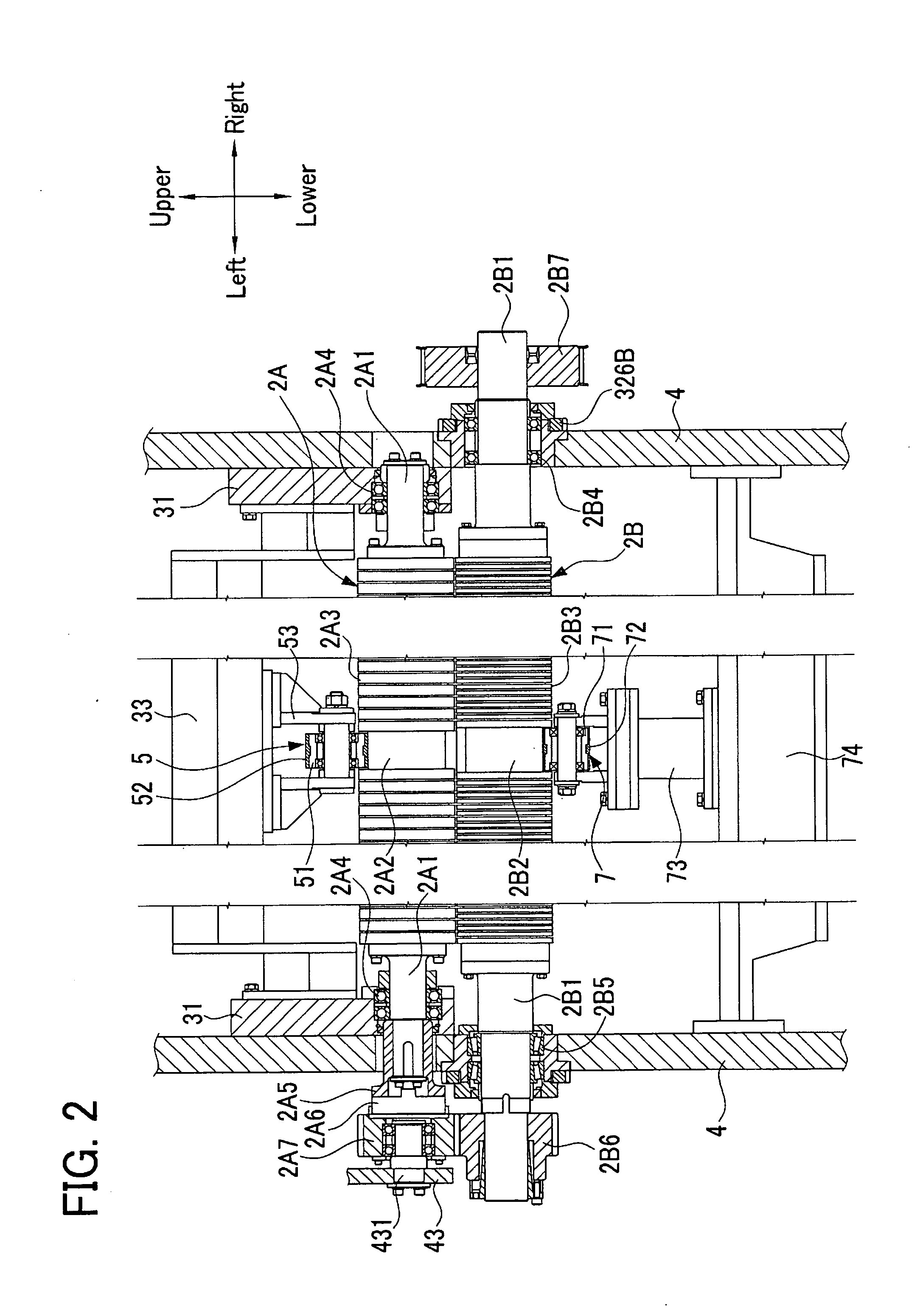

Sheet feeder of corrugated cardboard sheet box making machine

ActiveUS20150084275A1Reduce warpageBoxes/cartons making machineryBox making operationsCardboardEngineering

A sheet feeder of a corrugated paperboard box making machine includes a sheet feed table, feed rolls, an adjusting mechanism, a main unit, and a backing roller. The adjusting mechanism holds support plates pivotally supporting both ends of a first feed roll opposed to a second feed roll having an axis fixed to the main unit so as to allow an axis of the first feed roll to move with respect to the main unit. The support plates support a first backing roller via a connecting member connecting the support plates so that the first backing roller contacts with an outer peripheral surface of the first feed roll.

Owner:ISOWA IND CO LTD

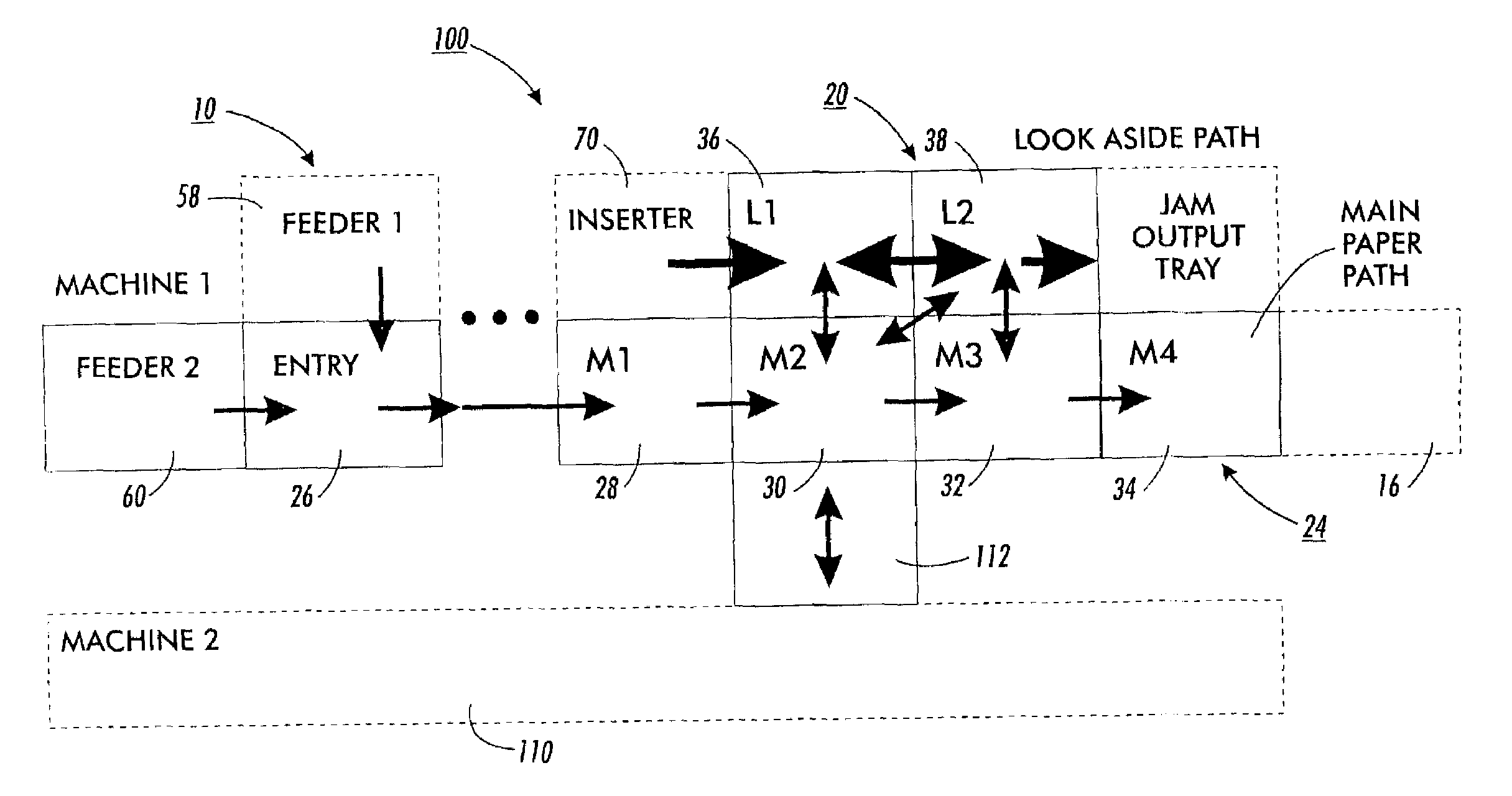

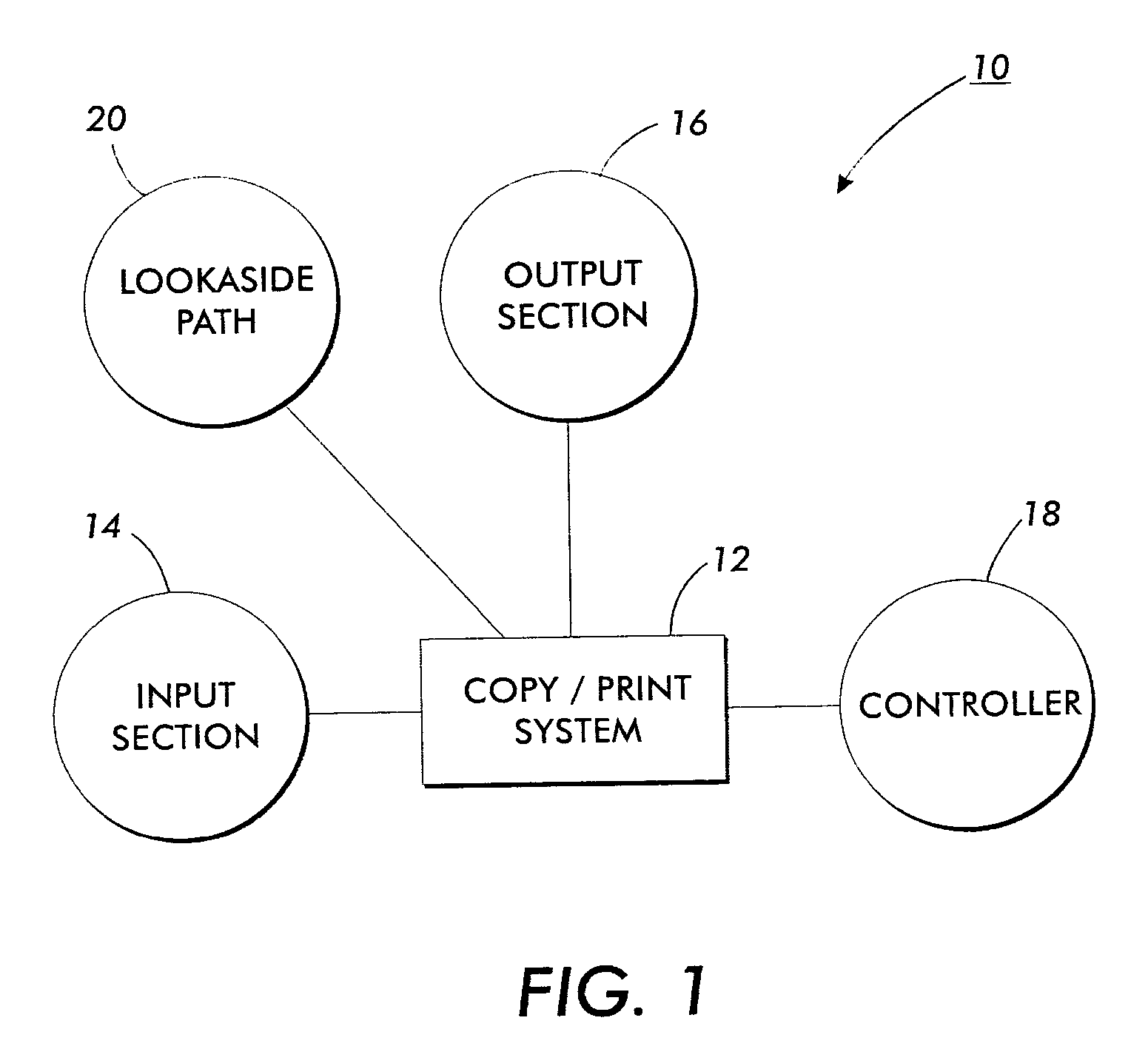

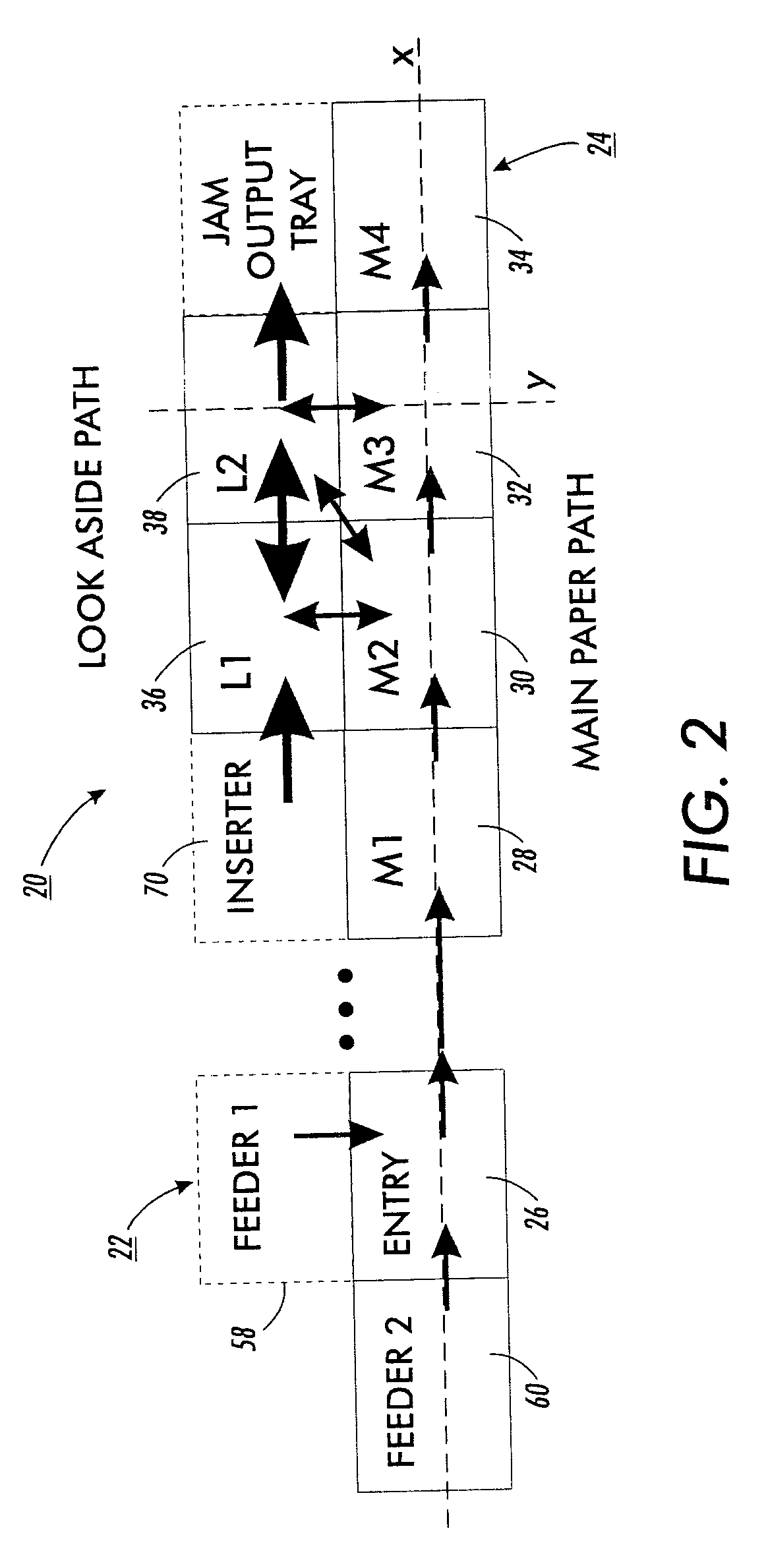

Flexible paper path using multidirectional path modules

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com