Paper feeding device and paper feeding method

A paper feeding device and paper feeding technology, applied in transportation and packaging, thin material handling, object separation, etc., can solve problems such as unstable overlapping conditions, falling, paper 60 posture deviation from the normal posture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

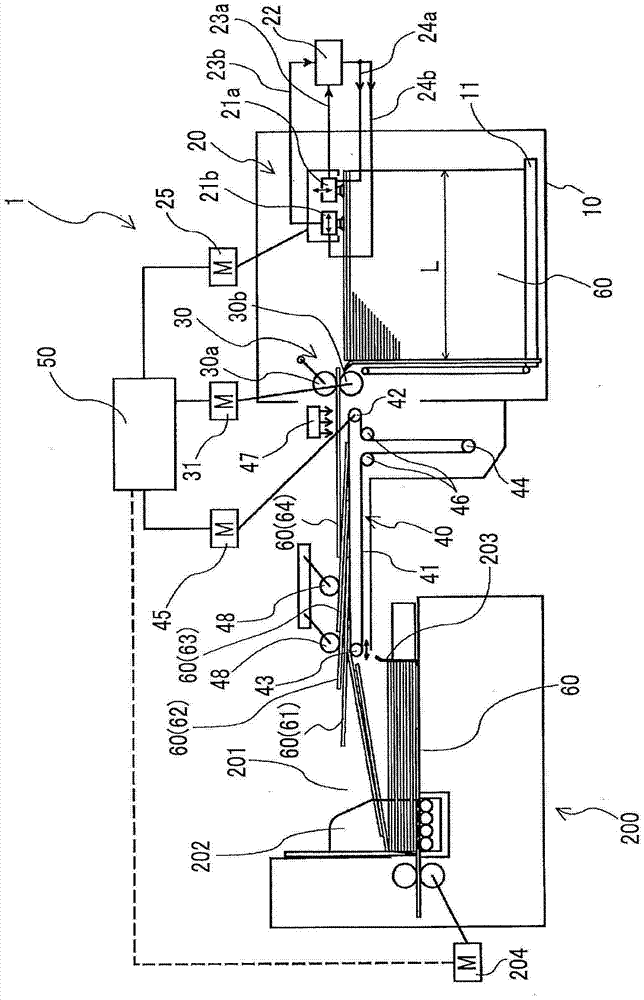

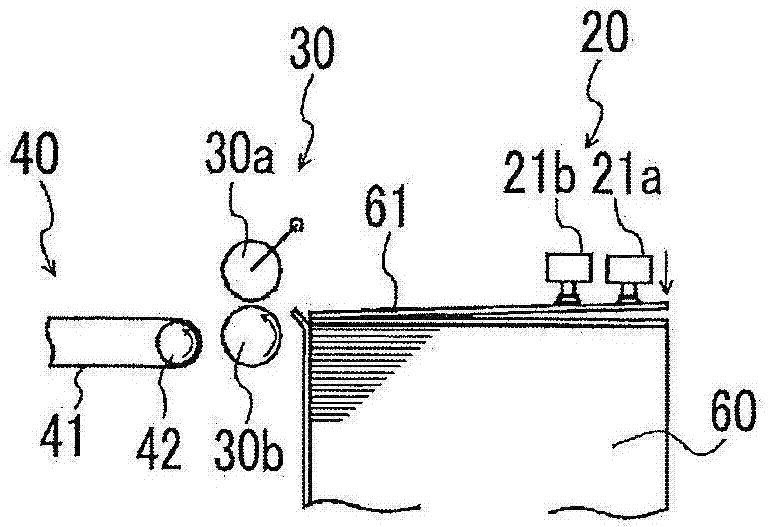

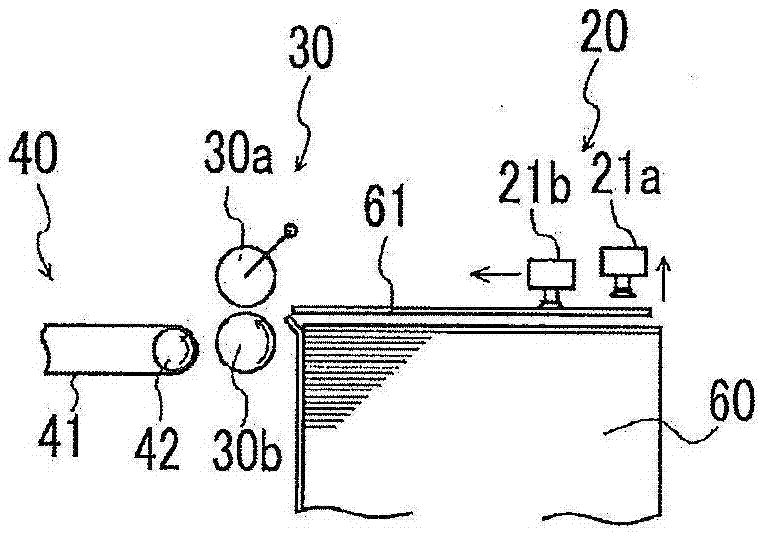

[0040] Hereinafter, an embodiment of the paper feeding device and the paper feeding method of the present invention will be specifically described with reference to the drawings.

[0041] like figure 1 As shown in the schematic front view of , the paper feeding device 1 of this embodiment is arranged adjacent to the paper feeding unit 200 of the printing machine. In addition, in figure 1 The description of the main body of the printing machine is omitted in . The paper feeding unit 200 of the printing machine is provided with a magazine 201, and is a mechanism that feeds paper sheets such as corrugated paper stacked in the magazine 201 one by one from the bottom. In the illustrated embodiment, the paper feeding device 1 is arranged adjacent to the paper feeding part 200 of the printing machine, but the paper feeding device 1 may also be arranged adjacent to the paper feeding part of the cardboard punching machine instead of being connected to the paper feeding part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com