Image forming device

a technology of image forming and forming sound, which is applied in the direction of electrographic process, instruments, transportation and packaging, etc., can solve the problems of difficult to confirm the presence of paper in the manual paper supply tray and the paper discharge tray, and difficult for a user located a long distance from the image forming device to operate by means of operation sounds, etc., to achieve the effect of easy confirmation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

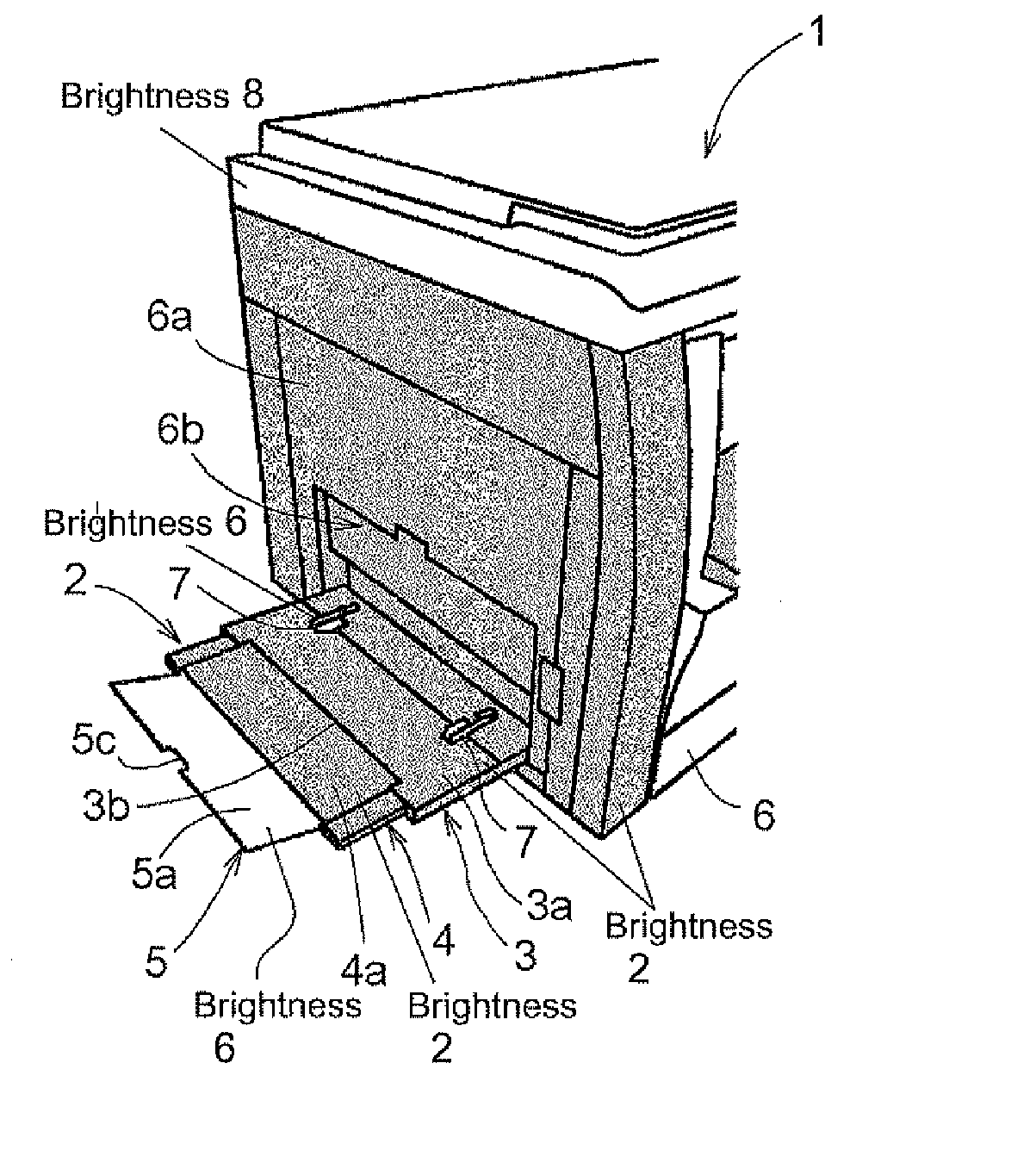

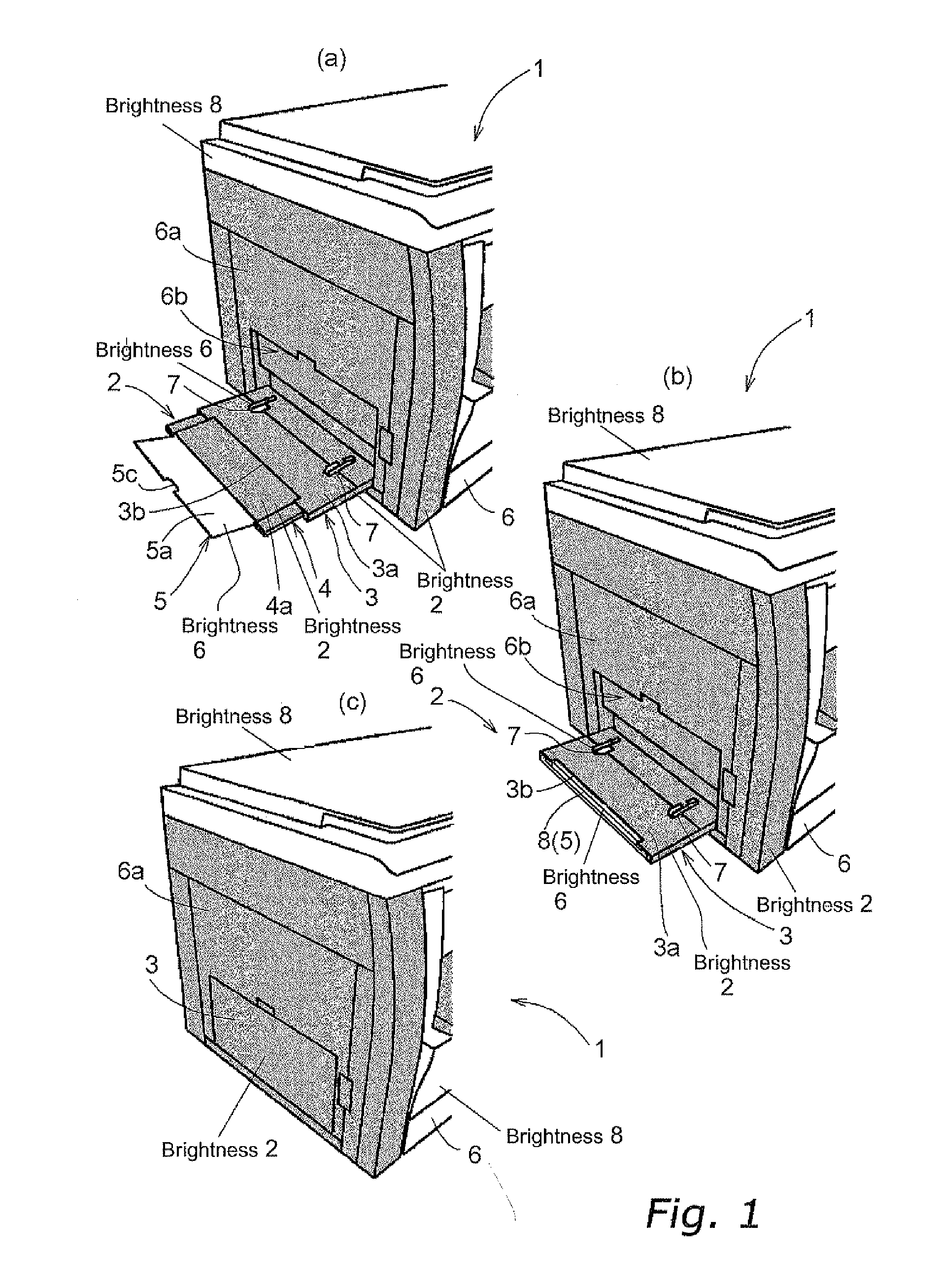

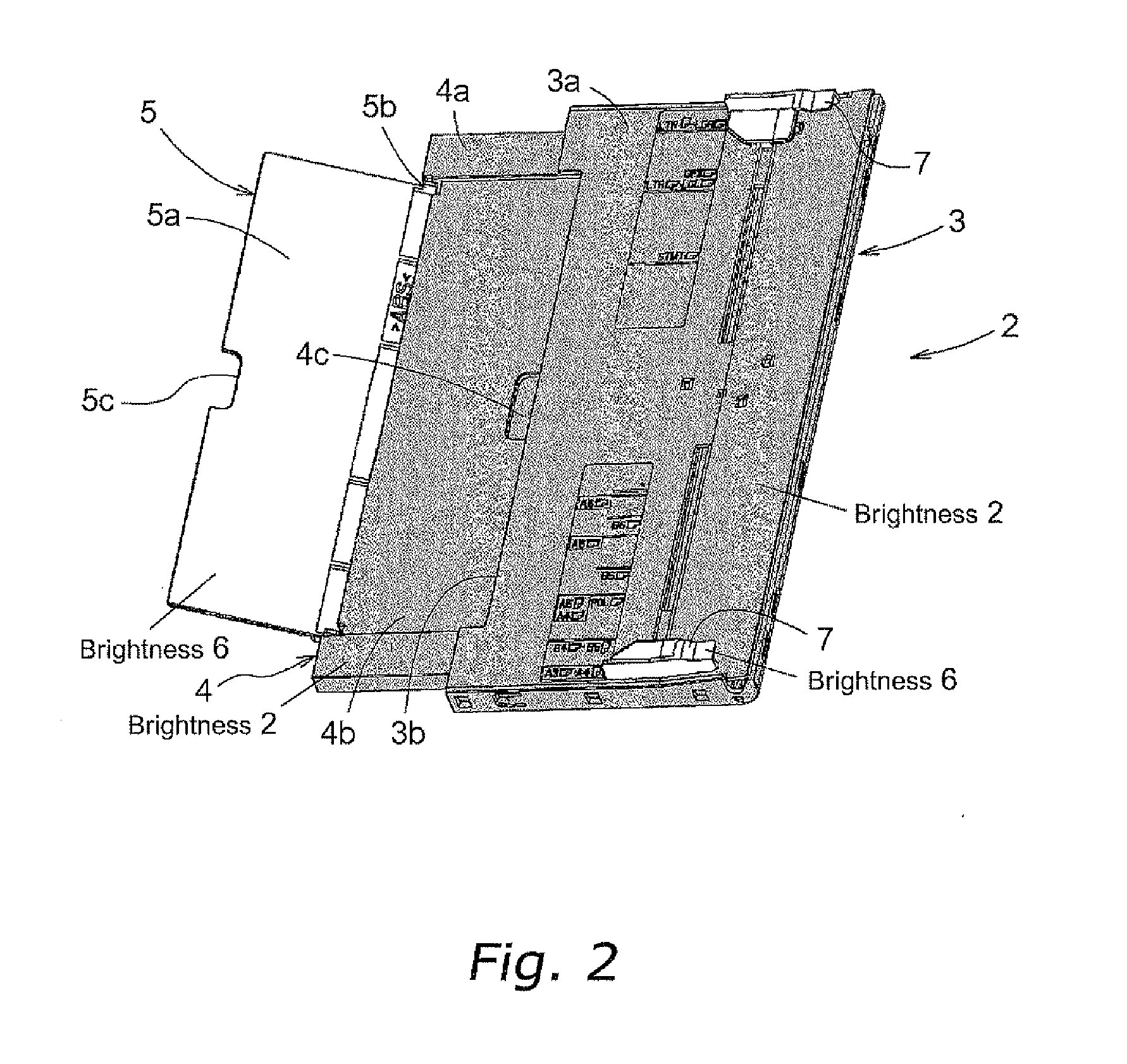

[0059]FIG. 3 is an oblique view showing the configuration of a manual paper supply tray 2 of the image forming device 1 according to a second embodiment of the present invention. The configuration of the device body 6 is the same as that shown in FIG. 1. In each of the embodiments below, the same components as those in the first embodiment have the same reference numbers, and a description thereof will be omitted. Like the first embodiment, the manual paper supply tray 2 of the second embodiment includes a first auxiliary mounting unit 4 and a second auxiliary mounting unit 5 configured to be deployable in two steps from the paper mounting unit 3. However, the specific configuration of the first auxiliary mounting unit 4 and the second auxiliary mounting unit 5 in the second embodiment is different. In other words, in the present embodiment, the second auxiliary unit 5 is configured so as to be stored in the first auxiliary mounting unit 4, and is pulled out horizontally with the fi...

third embodiment

[0061]FIG. 4 is an oblique view showing the configuration of a manual paper supply tray 2 of the image forming device 1 according to a third embodiment of the present invention. The configuration of the device body 6 is the same as that shown in FIG. 1. In each of the embodiments below, the same components as those in the first embodiment have the same reference numbers, and a description thereof will be omitted. Like the first embodiment, the manual paper supply tray 2 of the third embodiment includes a first auxiliary mounting unit 4 and a second auxiliary mounting unit 5 configured to be deployable in two steps from the paper mounting unit 3. However, the specific configuration of the second auxiliary mounting unit 5 in the third embodiment is different. In other words, in the third embodiment, the second auxiliary mounting unit 5 is arranged on top of the first auxiliary mounting surface 4a of the first auxiliary mounting unit 4, and can be deployed by pivoting around a rotation...

fourth embodiment

[0063]FIG. 5 is an oblique view showing the configuration of a manual paper supply tray 4 of the image forming device 1 according to a fourth embodiment of the present invention. The configuration of the device body 6 is the same as that shown in FIG. 1. In each of the embodiments below, the same components as those in the first embodiment have the same reference numbers, and a description thereof will be omitted. Like the first embodiment, the manual paper supply tray 2 of the fourth embodiment includes a first auxiliary mounting unit 4 and a second auxiliary mounting unit 5 configured to be deployable in two steps from the paper mounting unit 3. However, the specific configuration of the first auxiliary mounting unit 4 and the second auxiliary mounting unit 5 in the fourth embodiment is different. In other words, in the present embodiment, the second auxiliary unit 5 is configured so as to be stored in the first auxiliary mounting unit 4, and is pulled out horizontally with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com