Method of manufacturing a differentially heat treated catheter guide wire

a technology of heat treatment and guide wire, which is applied in the direction of guide wire, catheter, diagnostic recording/measuring, etc., can solve the problems of manual operation kinking of guide wires, easy plastic deformation, and rendering the smooth introduction operation of catheter impossibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Preferred embodiments of the present invention will be described with reference to the accompanying drawings.

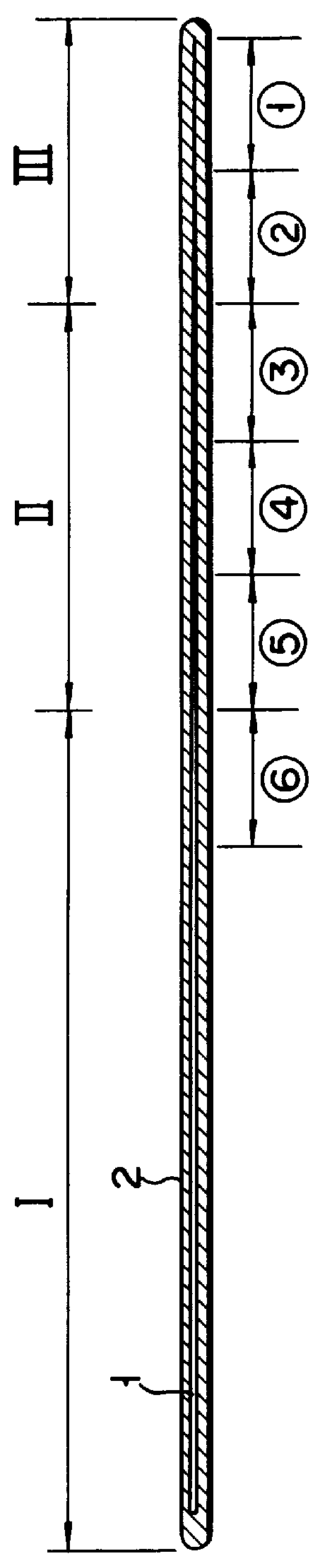

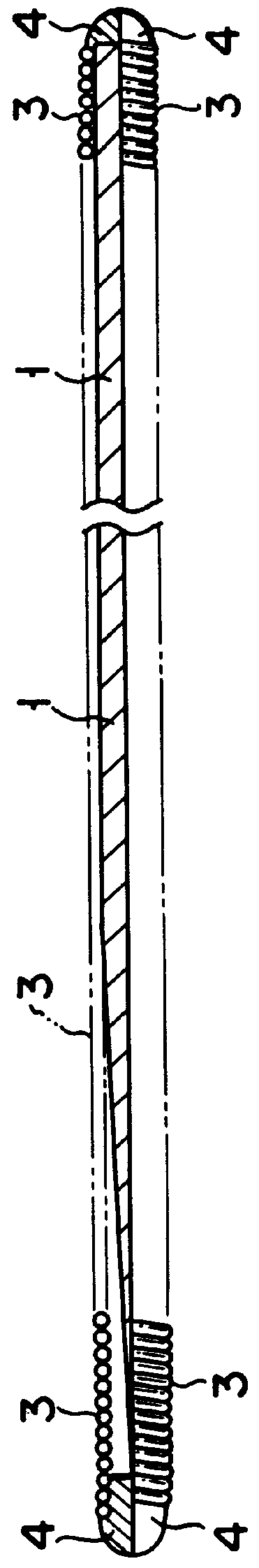

FIG. 1 is a sectional view of a catheter guide wire taken along the longitudinal direction according to an embodiment of the present invention. Referring to FIG. 1, reference numeral 1 denotes a core member; and 2, a thermoplastic resin layer entirely covering core member 1.

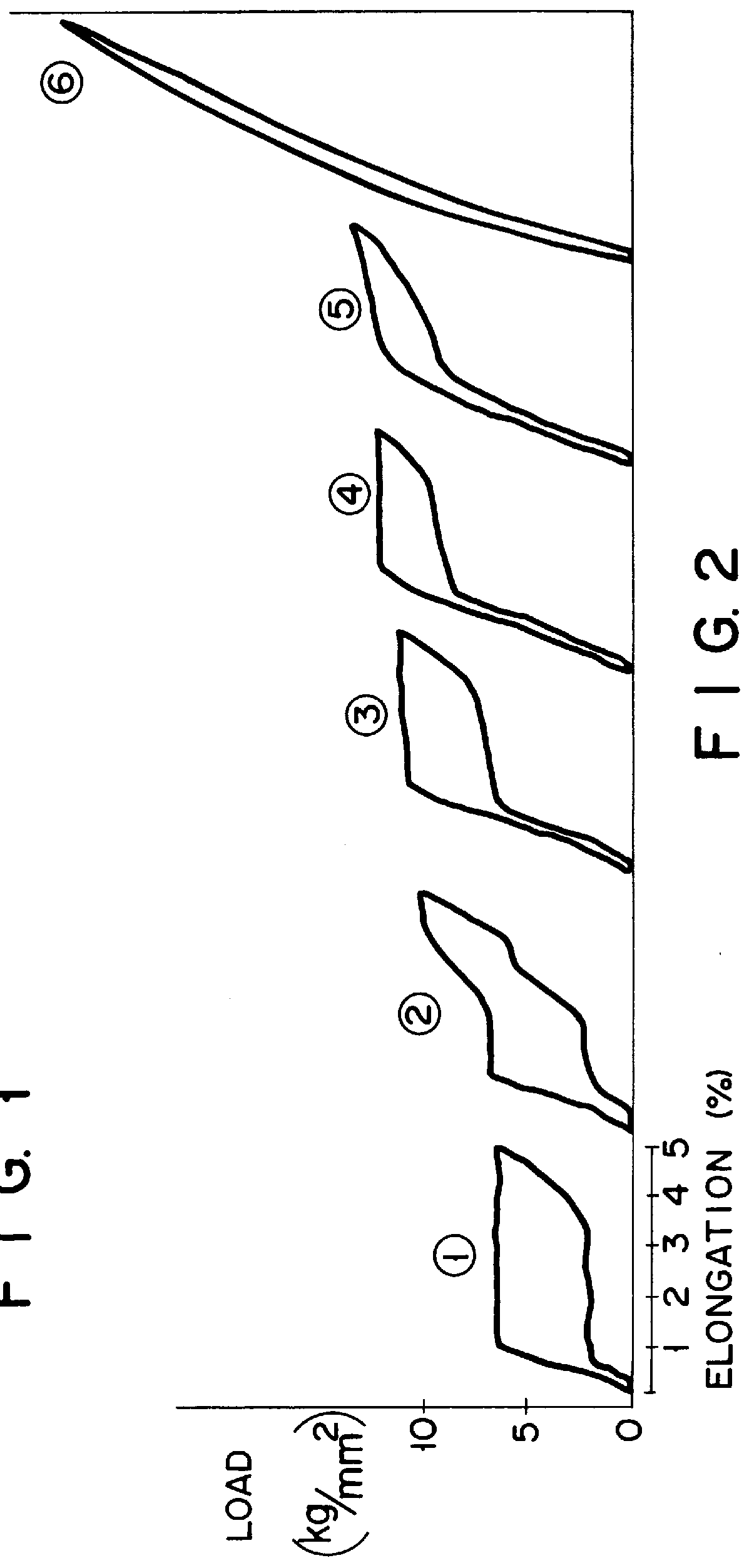

Core member 1 is a wire member made of an elastic alloy wire such as a piano wire, and preferably a very elastic alloy such as an Ni-Ti alloy. Core member 1 can have a uniform diameter of 0.2 to 0.4 mm, or can be tapered toward its distal end such that the diameter at its proximal end portion is 0.2 to 0.4 mm and the diameter at its distal end portion is 0.01 to 0.1 mm. In this specification, a very elastic alloy is defined as an alloy whose recoverable elastic strain is as large as several % to more than ten % and whose stress level does not exceed a predetermined value even if the strain is increased. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com