Apparatus and method for printing corrugated cardboard sheets

一种印刷纸板、瓦楞纸板的技术,应用在用于印刷瓦楞型卡纸板的设备和方法领域,能够解决图像或颜色没有套准等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

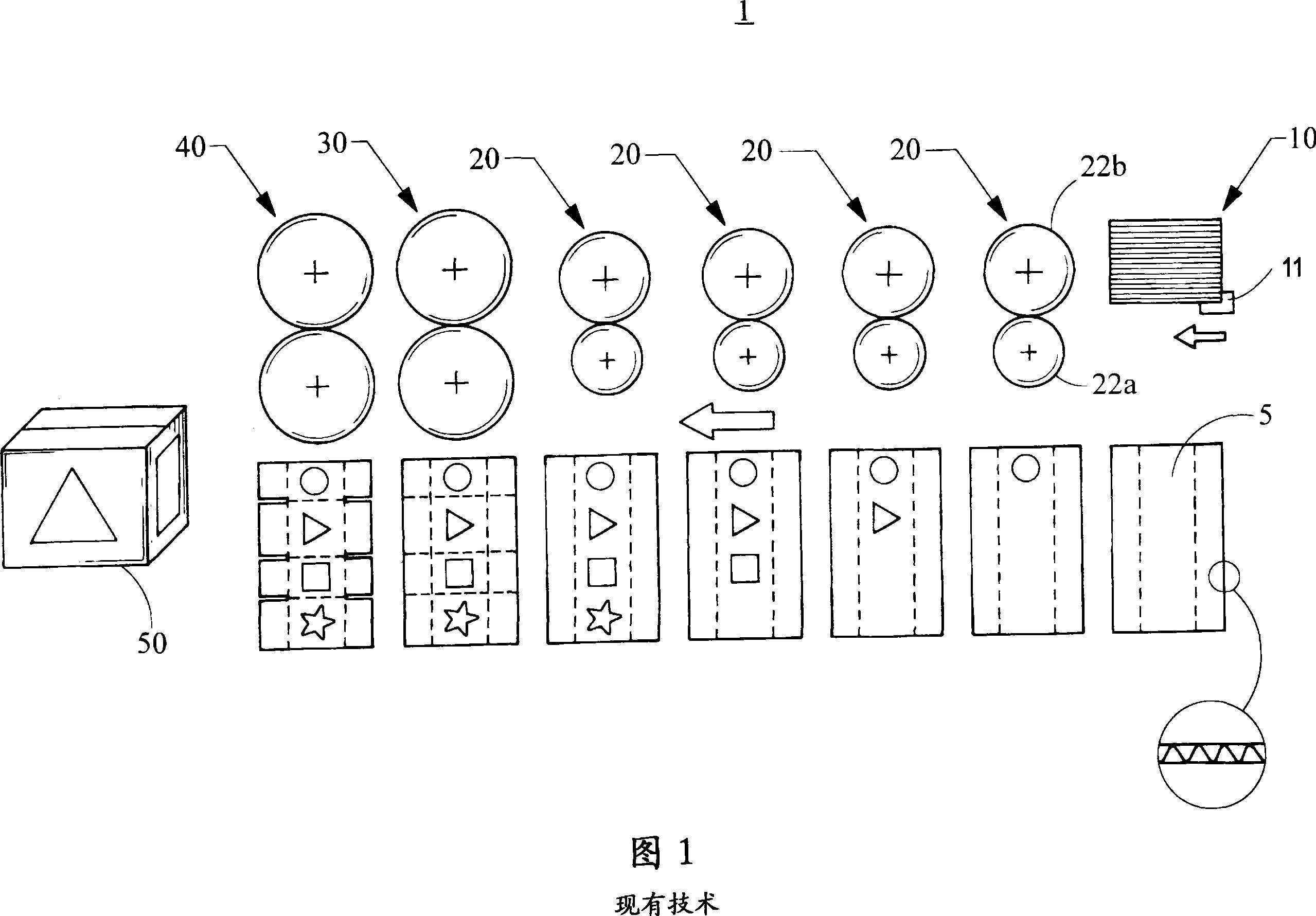

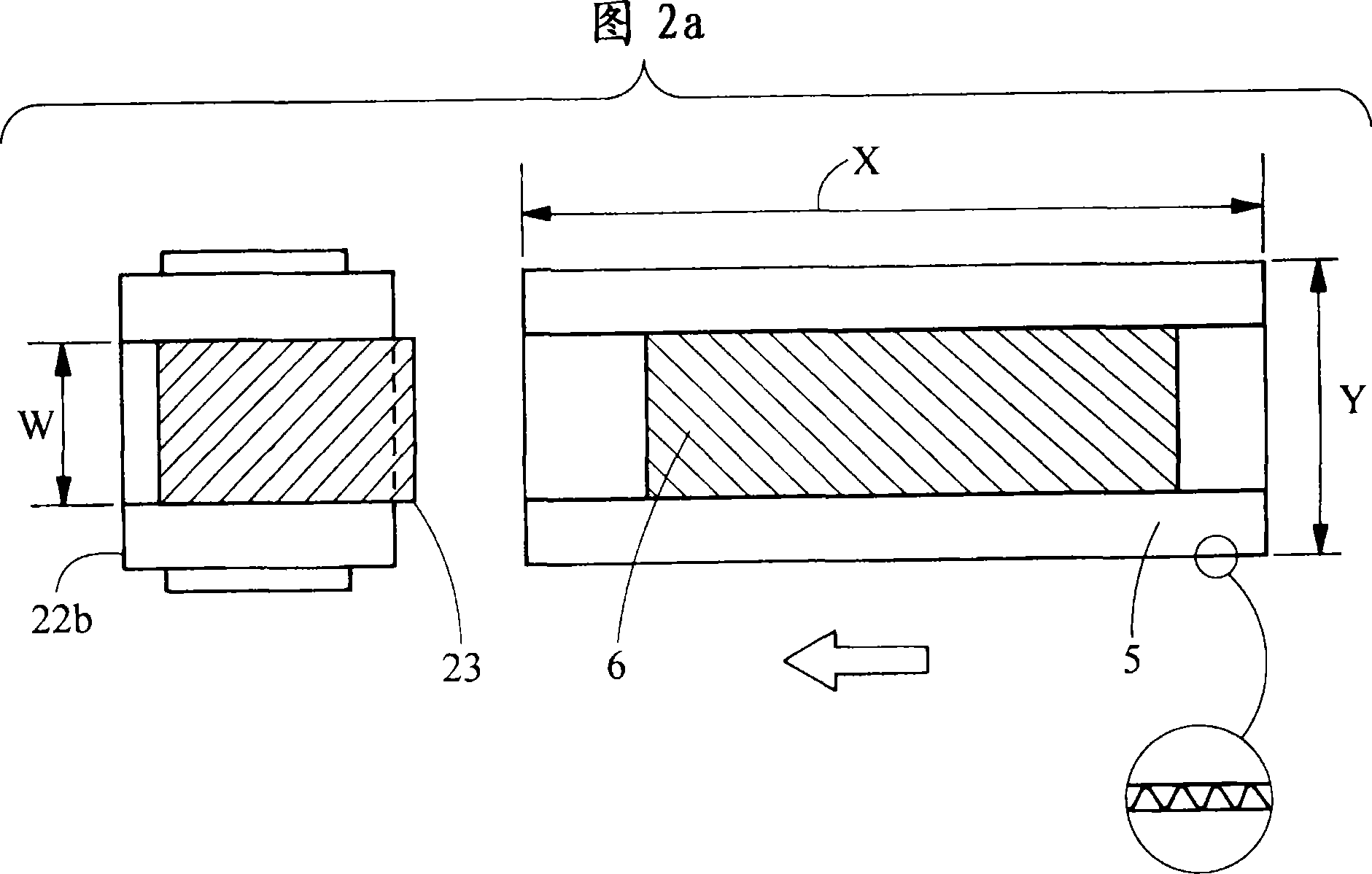

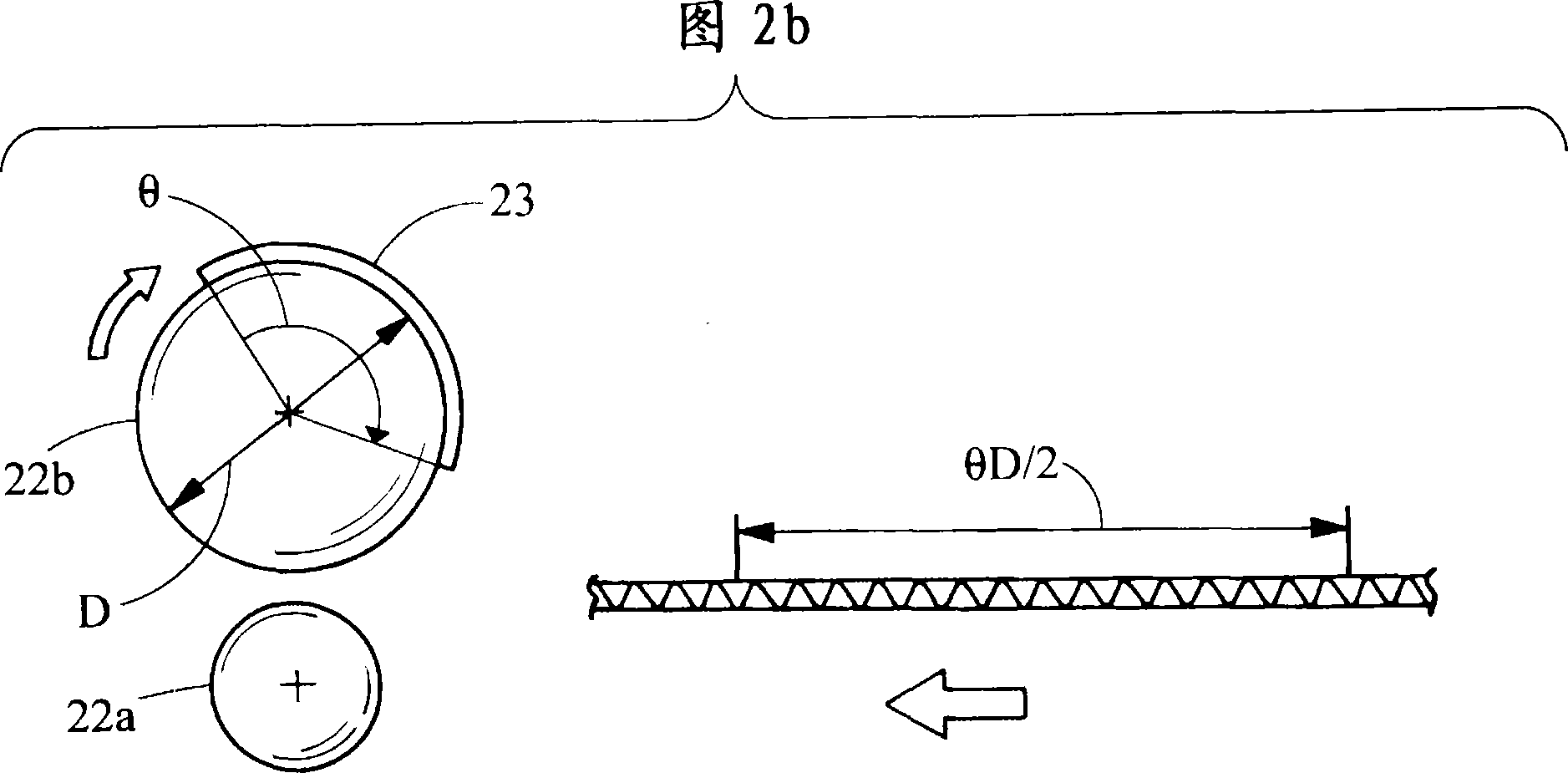

[0028] Typical, non-limiting embodiments can be better understood with reference to the accompanying drawings. Like numbered elements in the same or different drawings perform equivalent functions.

[0029] As used herein, corrugated board refers to any construction having at least one liner and corrugated structure that are integral or joined together by fastening means such as adhesives, interlayers, and the like. Such corrugated cardboard is usually made of cellulose-based material, but the term used herein does not exclude the use of other materials such as plastics, staple fiber or other combinations of materials from which cardboard can be made. Corrugated construction has at least lined and corrugated construction, but each type can contain multiple layers, and the layers can be joined together by various means.

[0030] The paperboard may be corrugated, flat, flat with corrugated secured on one side, corrugated secured on its opposite surface, and combinations of thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com