Patents

Literature

787results about "Stencilling apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

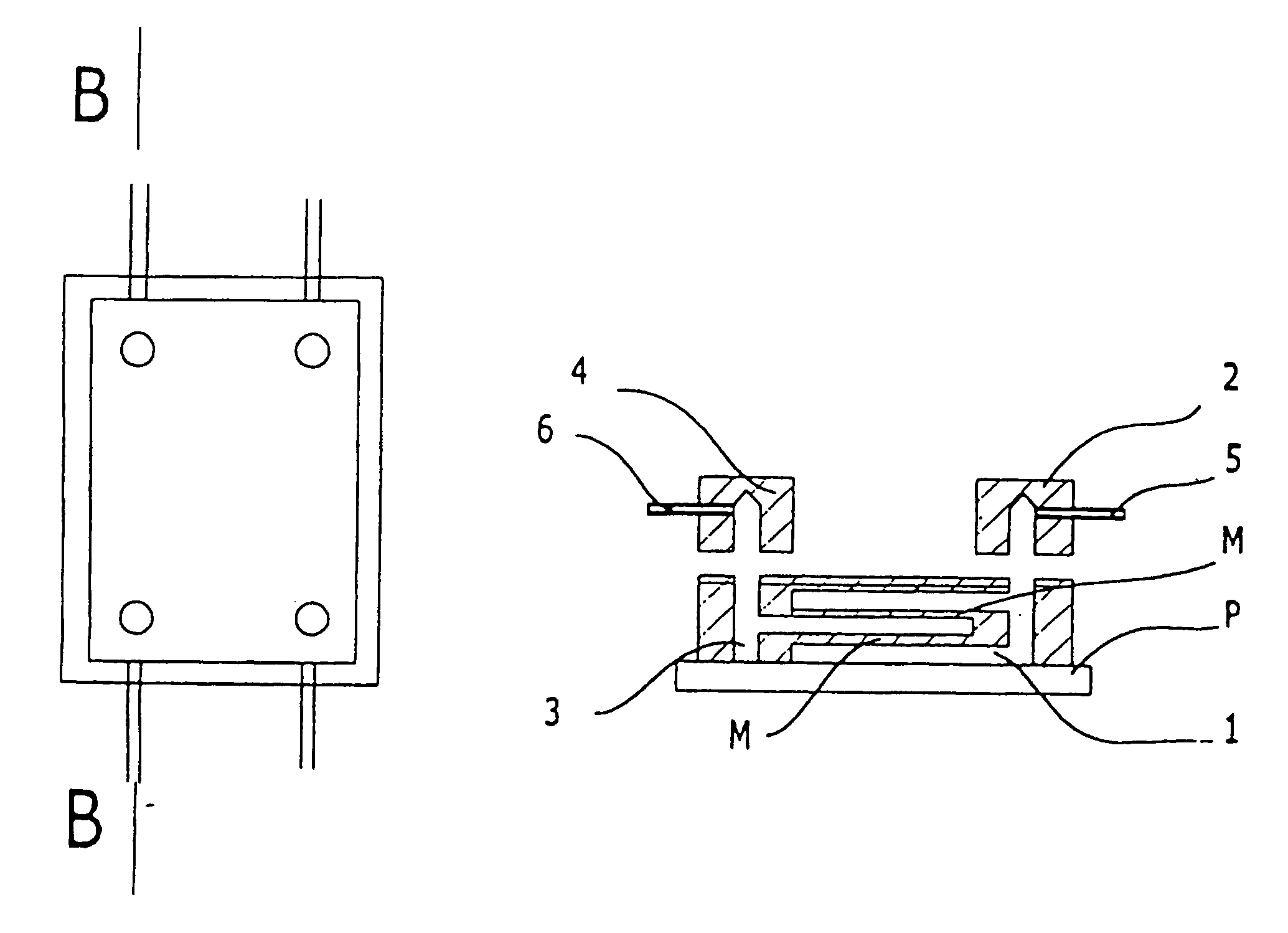

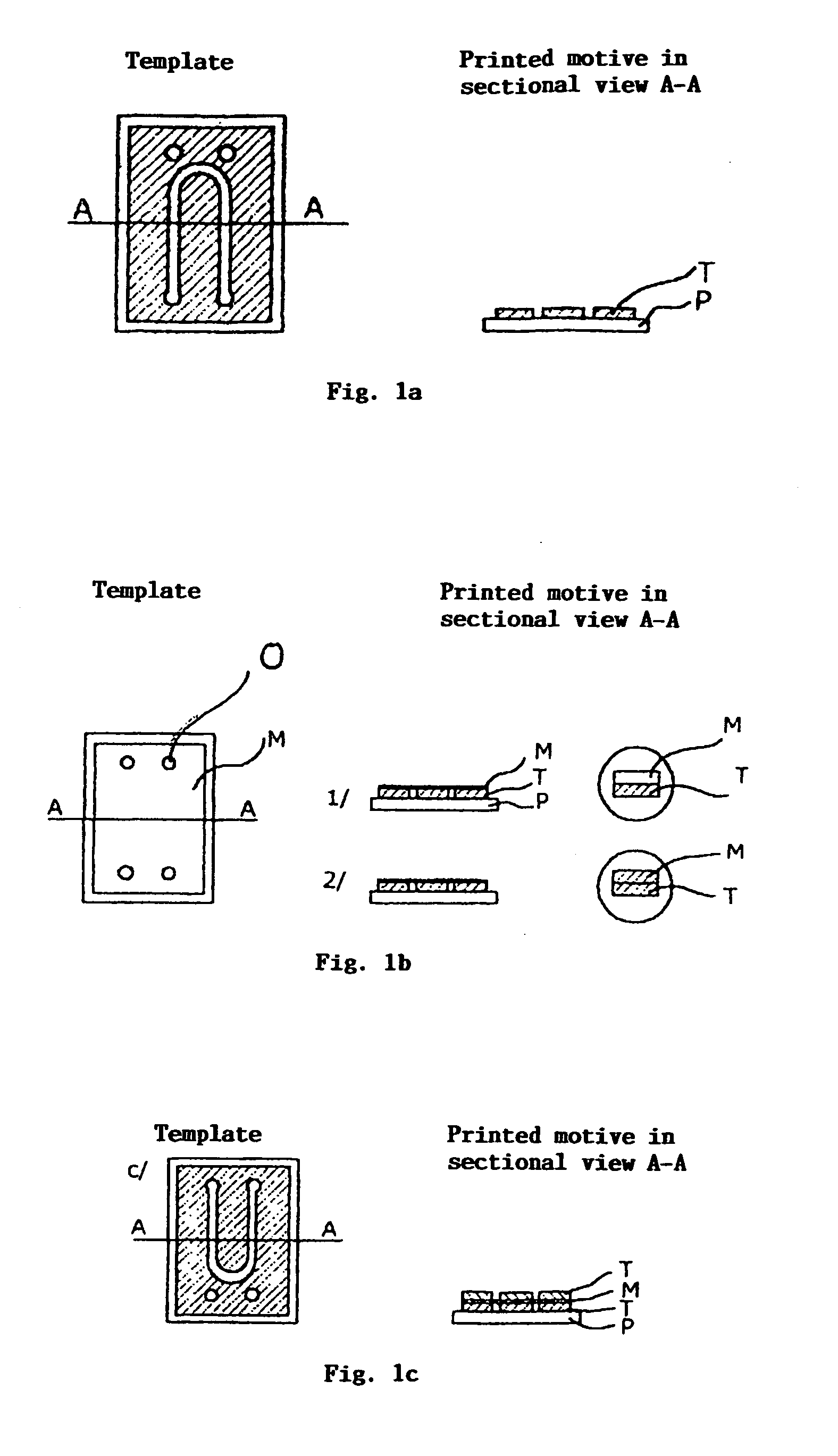

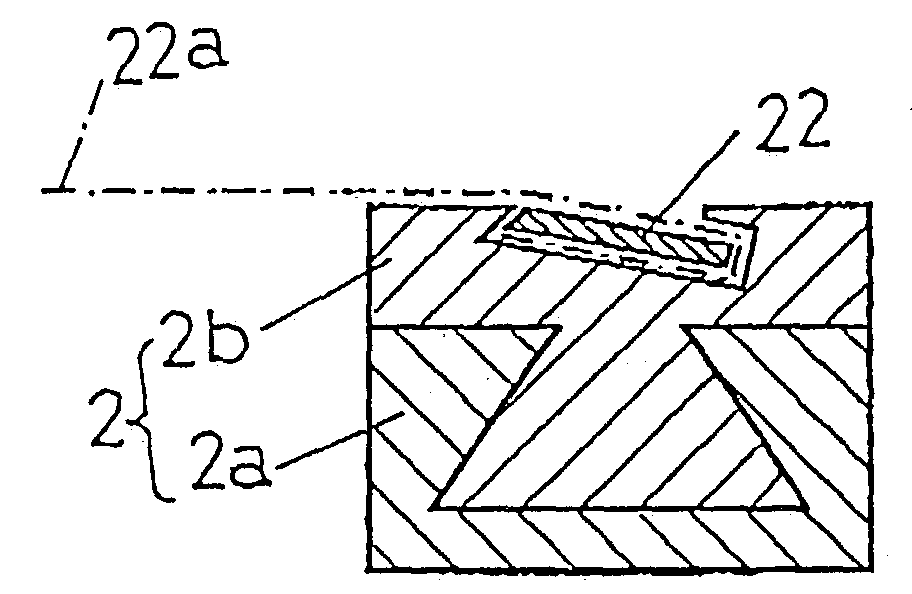

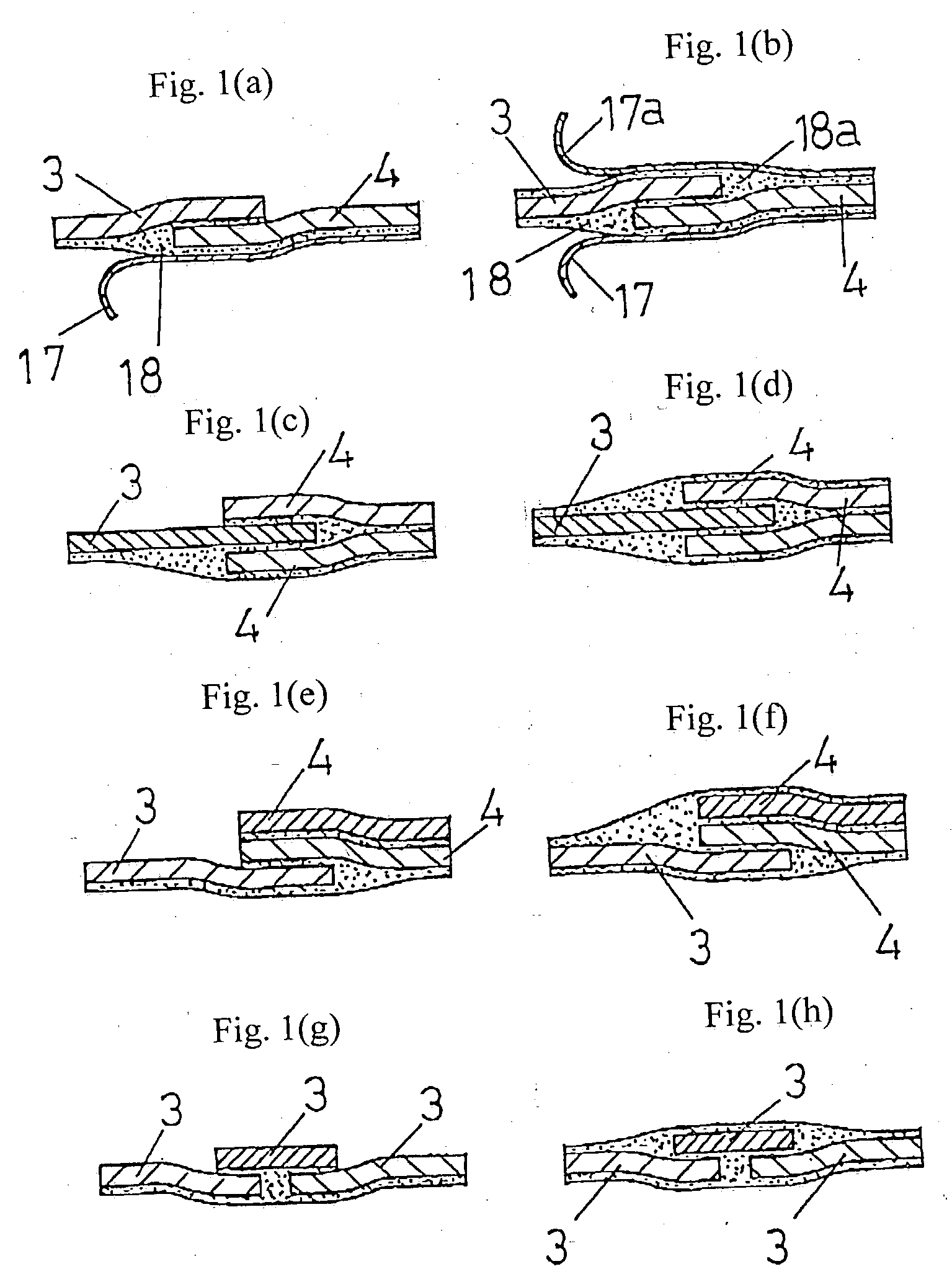

Three-dimentional components prepared by thick film technology and method of producing thereof

Object of the present invention are components with three dimensional structure prepared by thick film technology by print, where between the printed layers is inserted at least one membrane. The membrane is according to the present to invention at least in a part of the final product. The membrane can be provided with holes which are necessary for next technological steps. The inserted membranes can have pores of the size of 50˜tm to 10 nm and a thickness of 1 to 200˜tm. Method of producing of components with three-dimensional structure by thick film printing technology according to the invention lies in that between some of the printed layers is inserted a suitable membrane, which allows to lay on next layers without influence to previous layers. The printing can be done by screen-printing.

Owner:ING ILJA KREJCI ENG

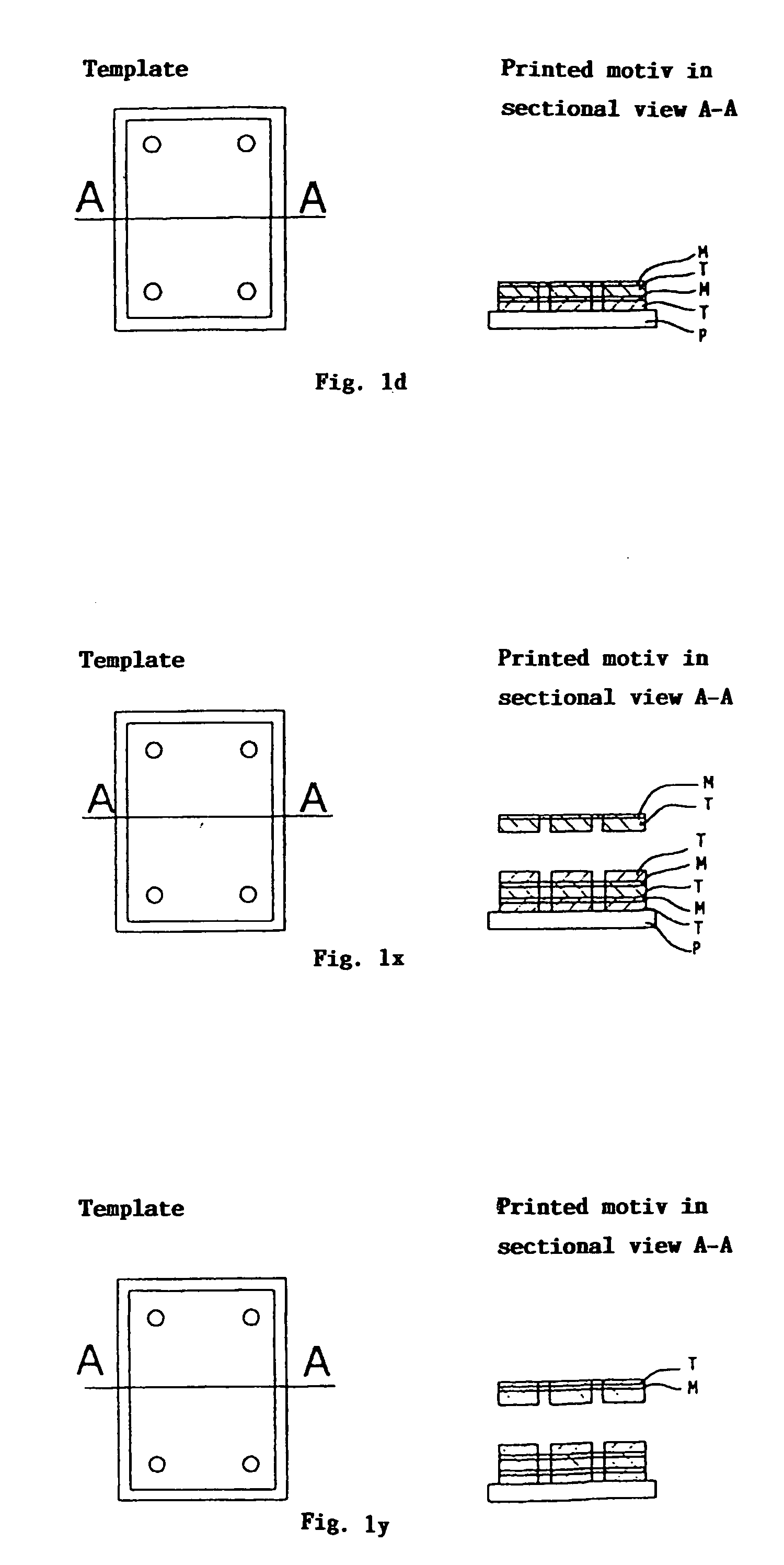

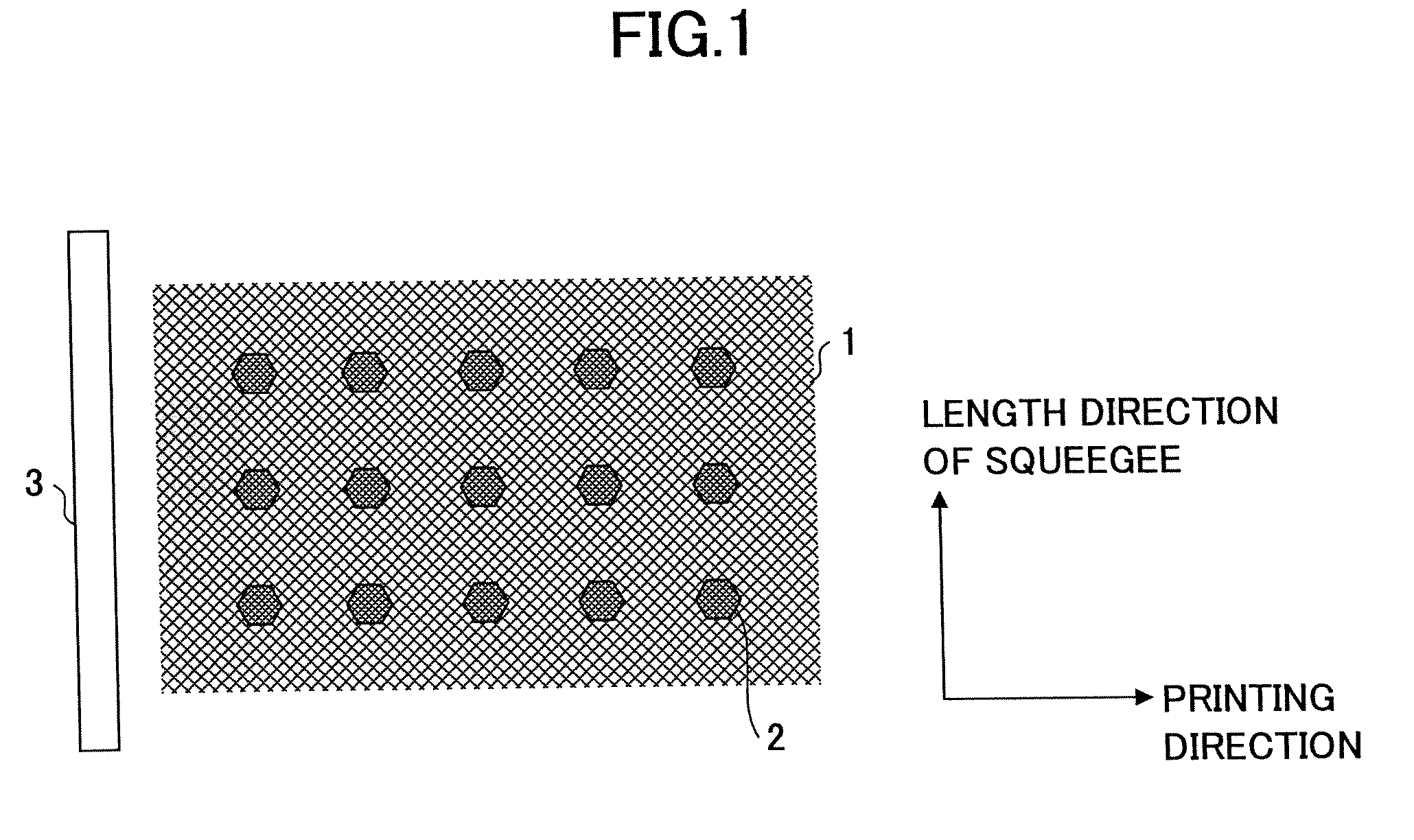

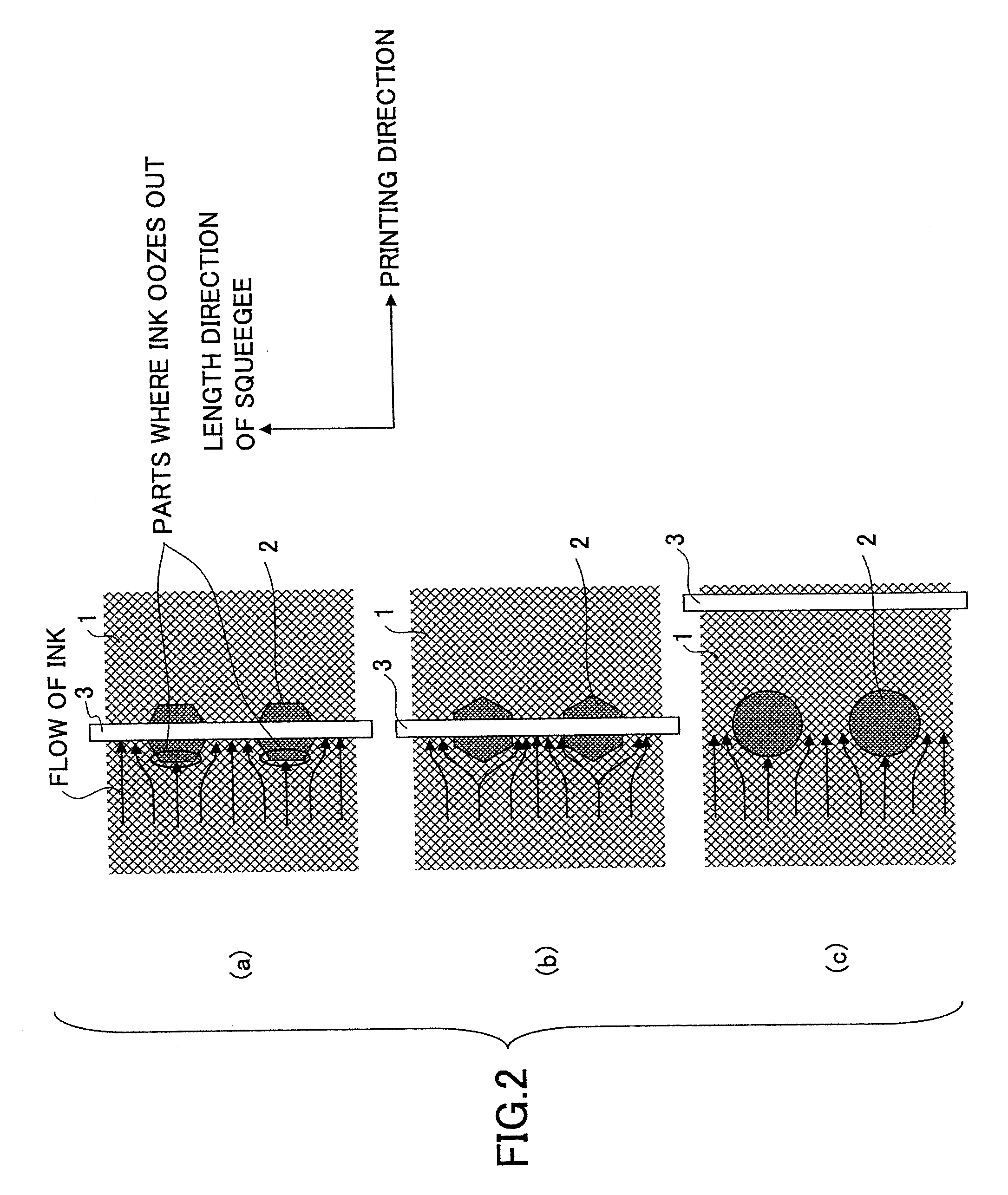

Screen printing plate

InactiveUS20080017053A1Way stableLiquid surface applicatorsPattern printingScreen printingMechanical engineering

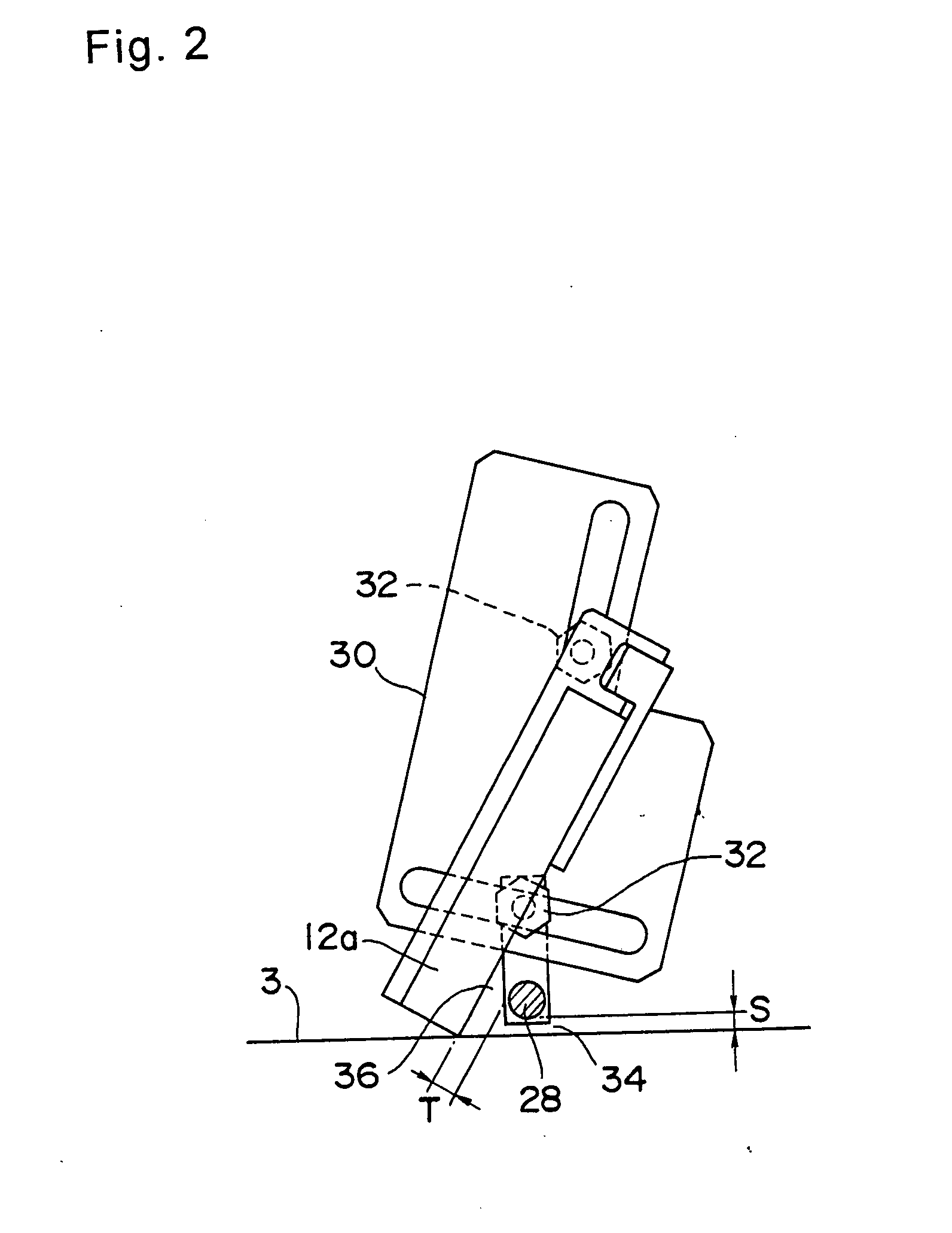

A screen printing plate includes a discharging area from which printing liquid is discharged and a non-discharging area from which no printing liquid is discharged. With the screen printing plate, a squeegee is slid to discharge the printing liquid so as to perform printing. The non-discharging area is of a polygonal shape having as an apex the point with which the squeegee first comes in contact when being slid, and a width of the non-discharging area in the length direction of the squeegee increases from the apex to the maximum of the width.

Owner:RICOH KK

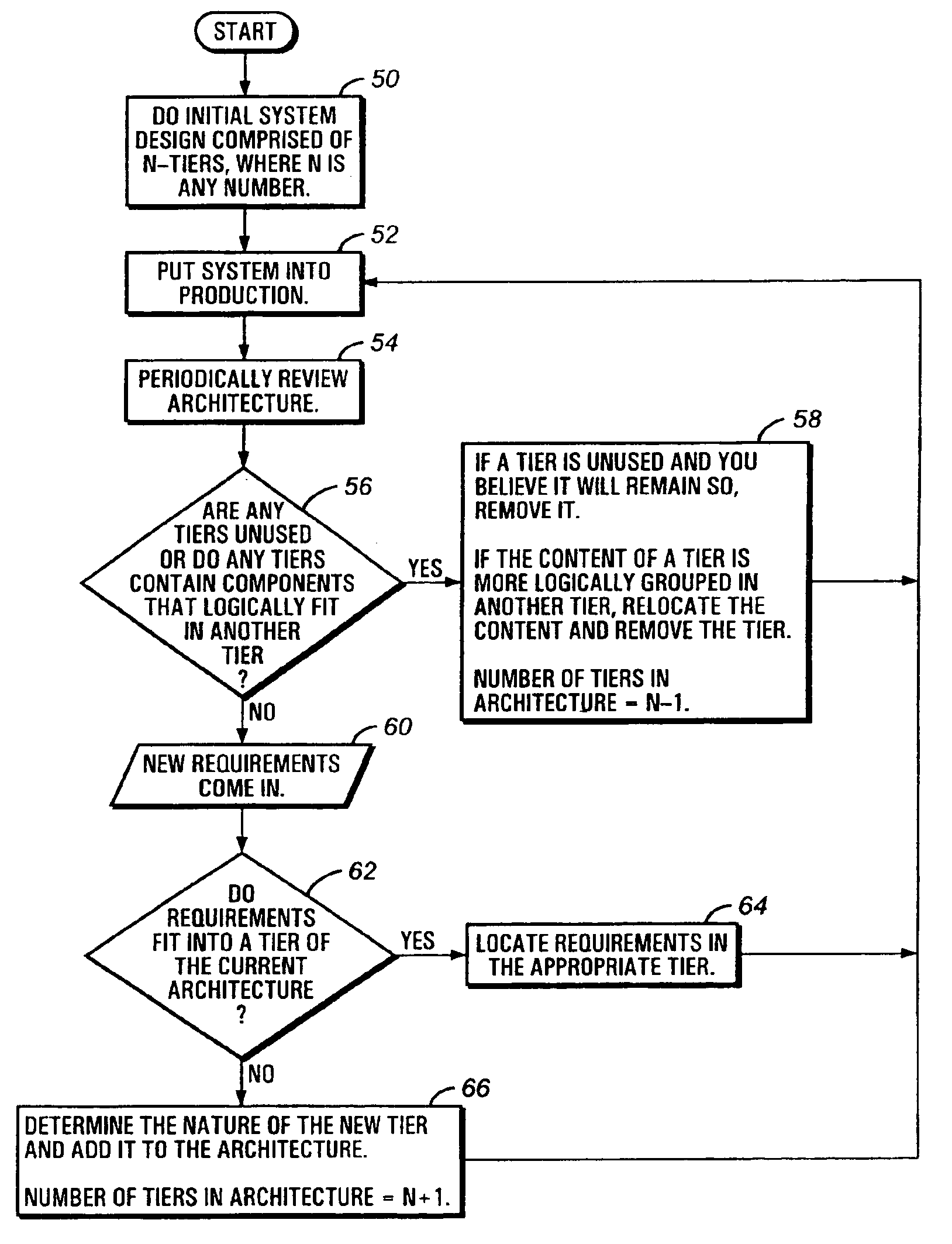

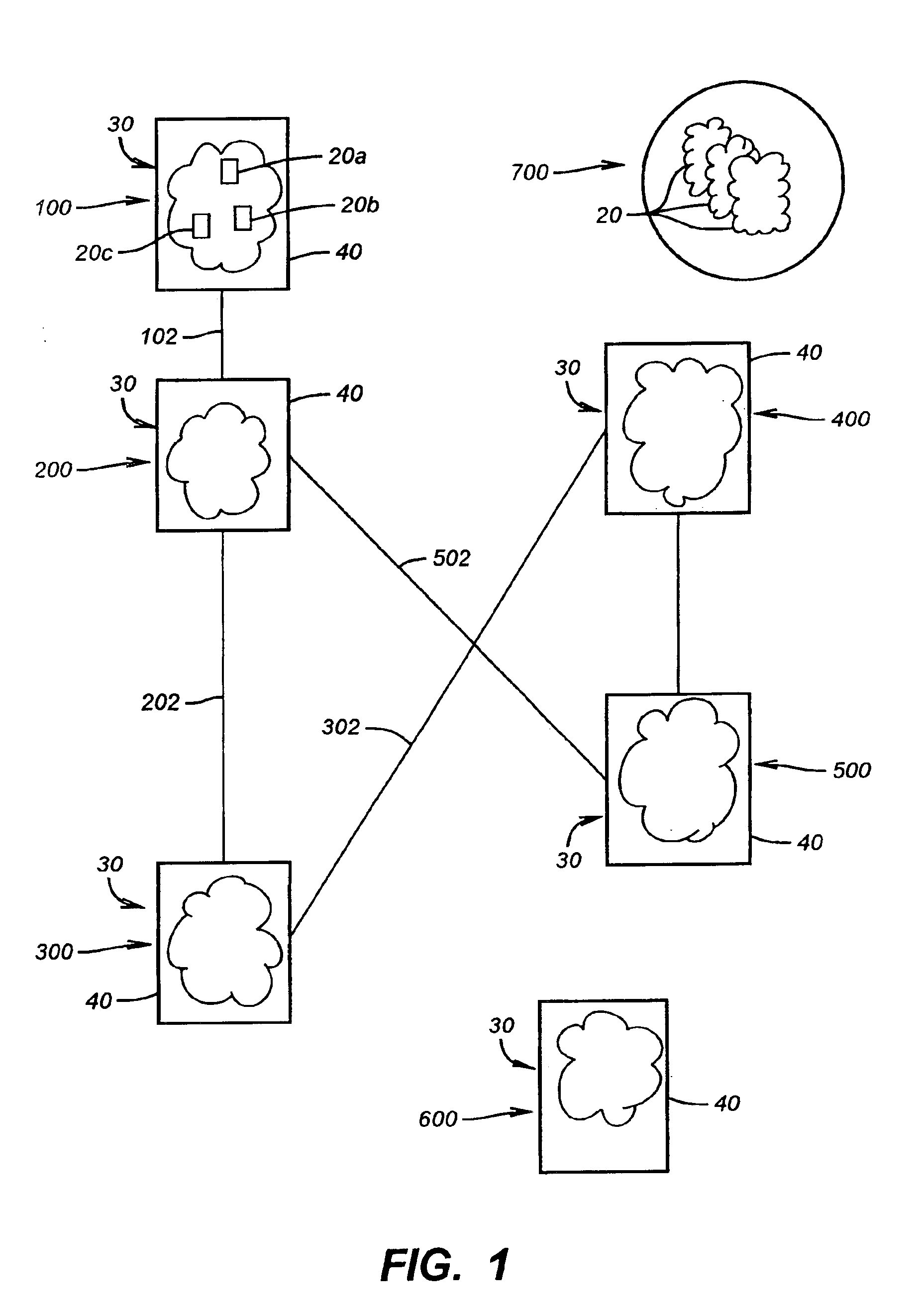

Method and system and article of manufacture for an N-tier software component architecture oilfield model

InactiveUS6931621B2Inking apparatusData processing applicationsComputer hardwareApplication software

A system and method for developing a software application for manipulating data associated with an asset are provided. The system includes at least one processing unit. The system further includes at least one memory store operatively connected to the processing unit. The system further includes an extensible N-tier software resident in and executable within the at least one processing unit, wherein N corresponds to a positive integer value. The system further includes an inventory of software components resident in the memory store wherein a plurality of tiers are generated from the inventory of a software components using the N-tier software, each tier being associated with at least one other tier, and each tier comprising a plurality of software components and performing a predetermined function relating to an asset.

Owner:BAKER HUGHES INC

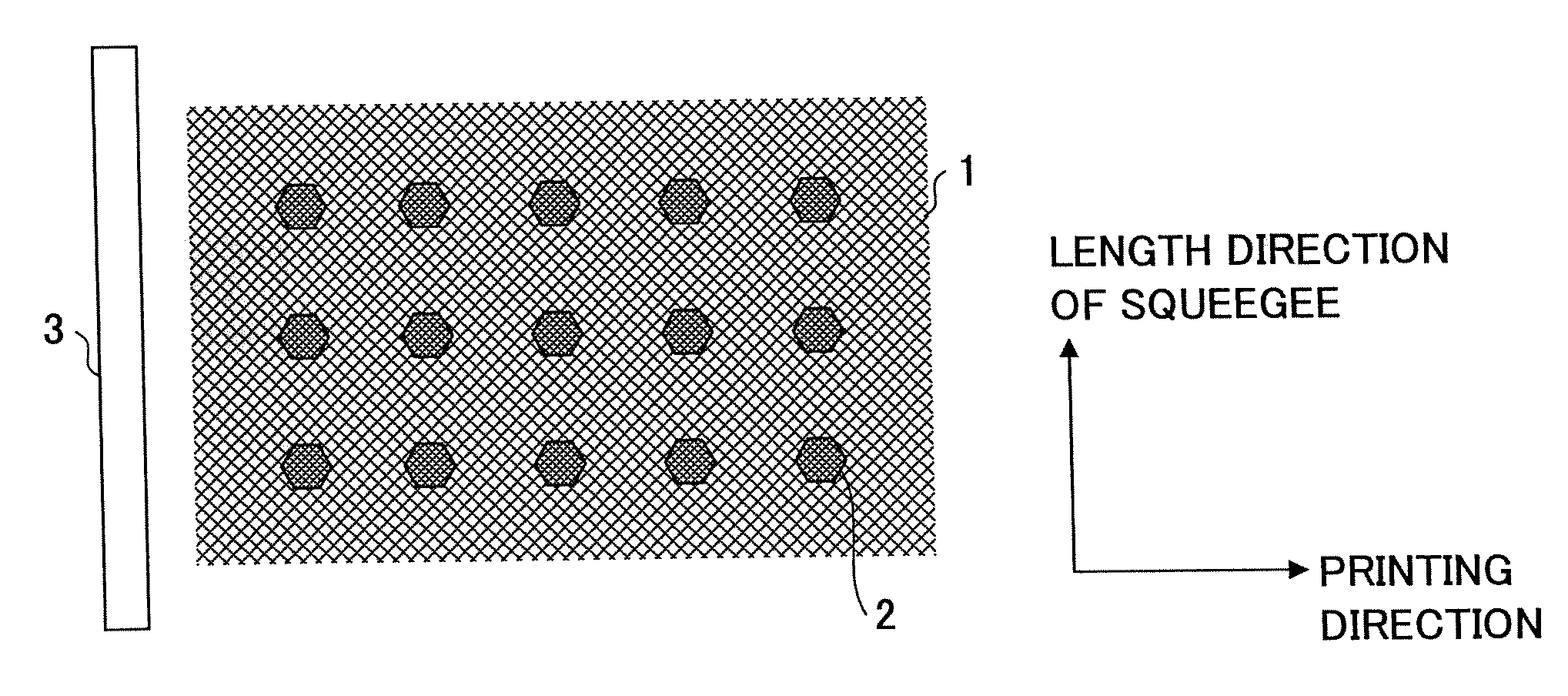

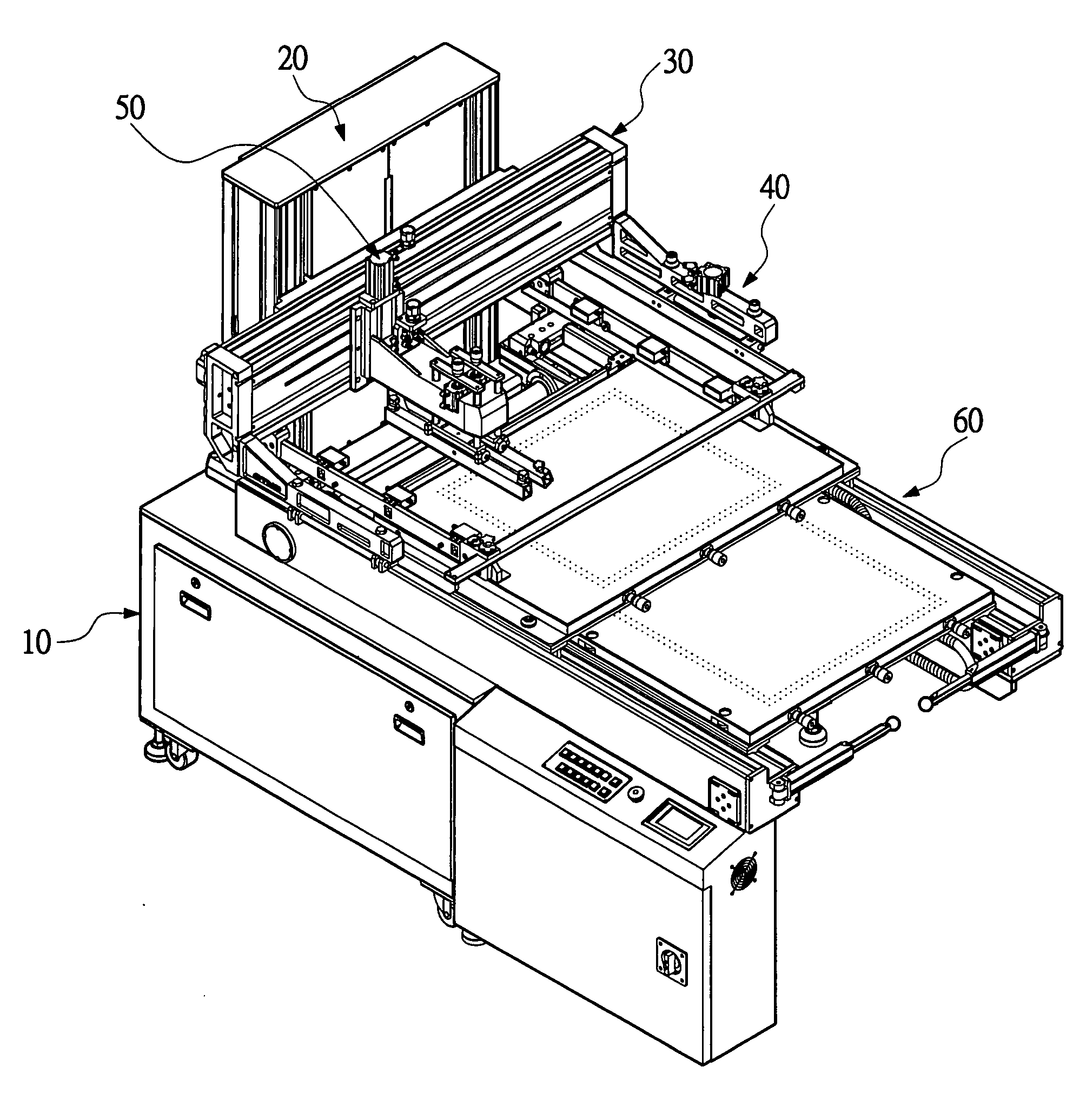

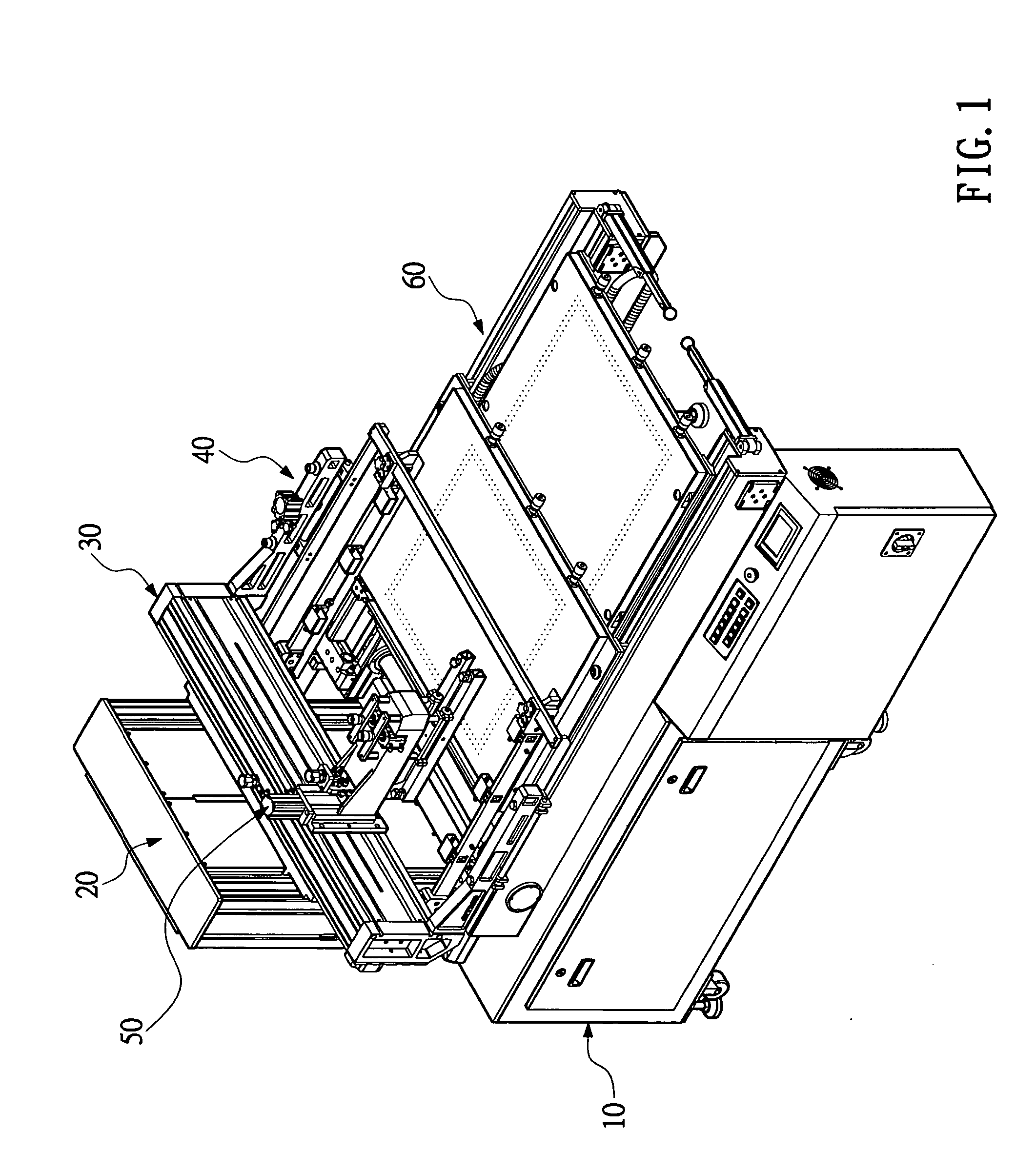

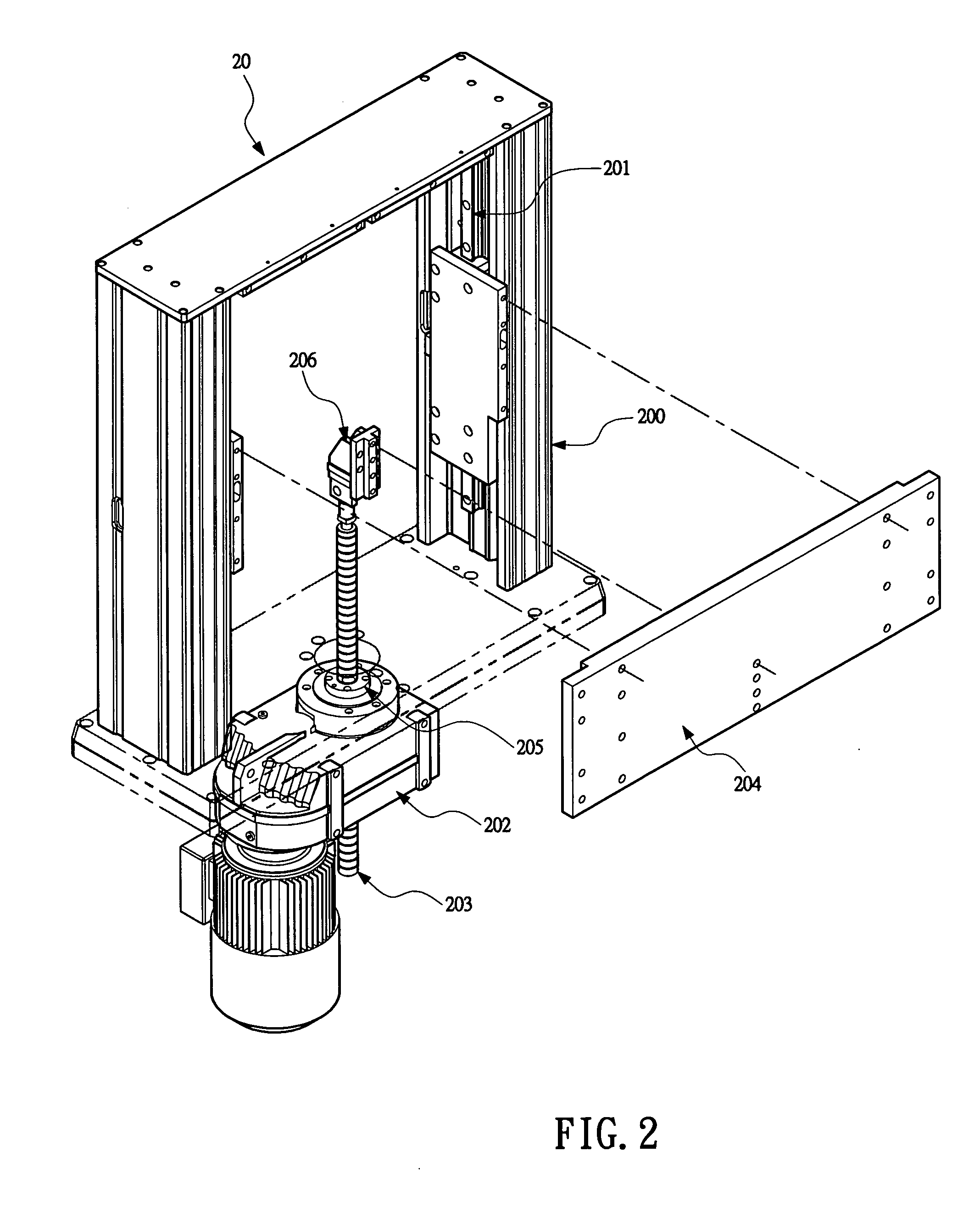

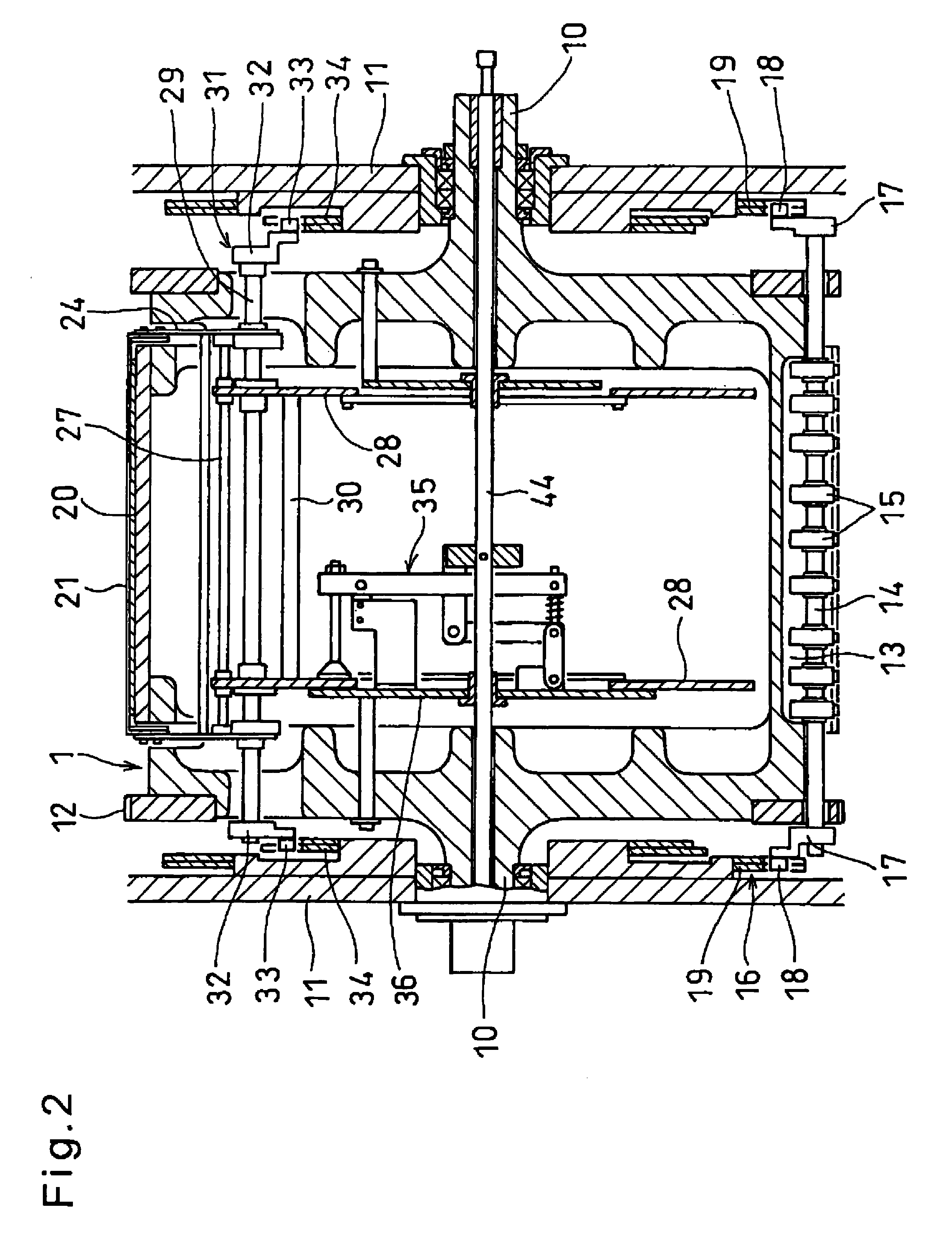

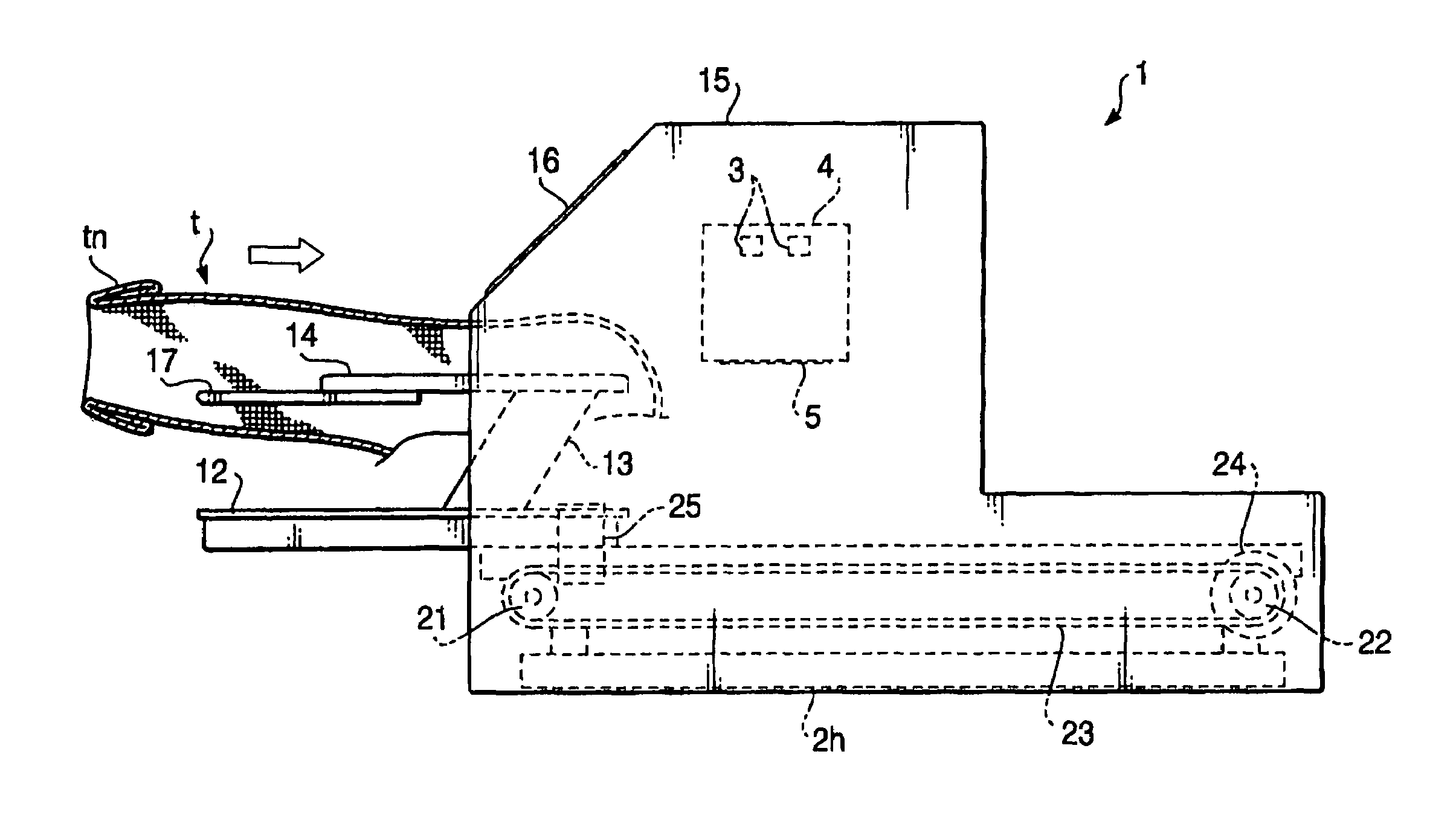

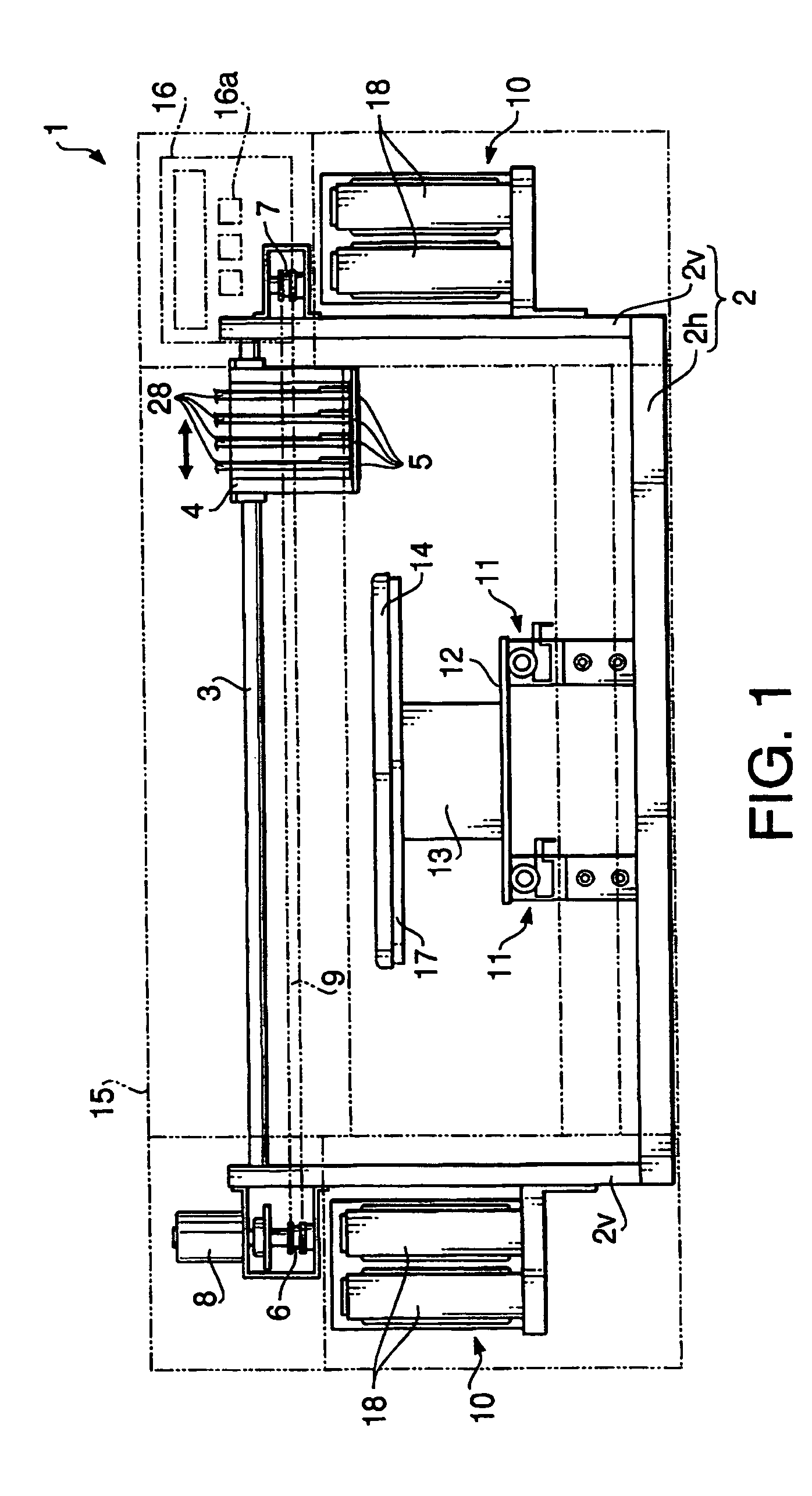

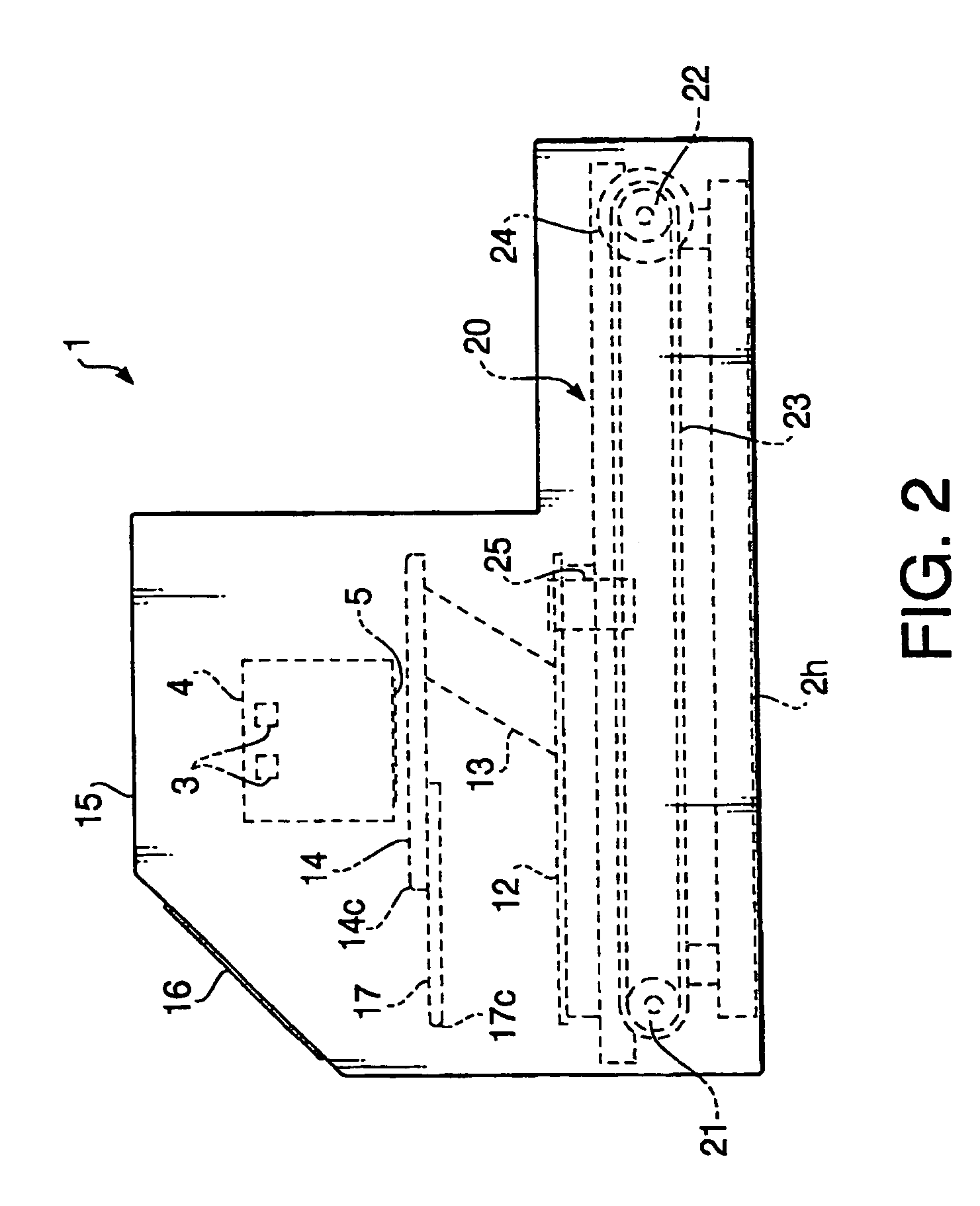

Cantilever type screen-printing machine with double platform

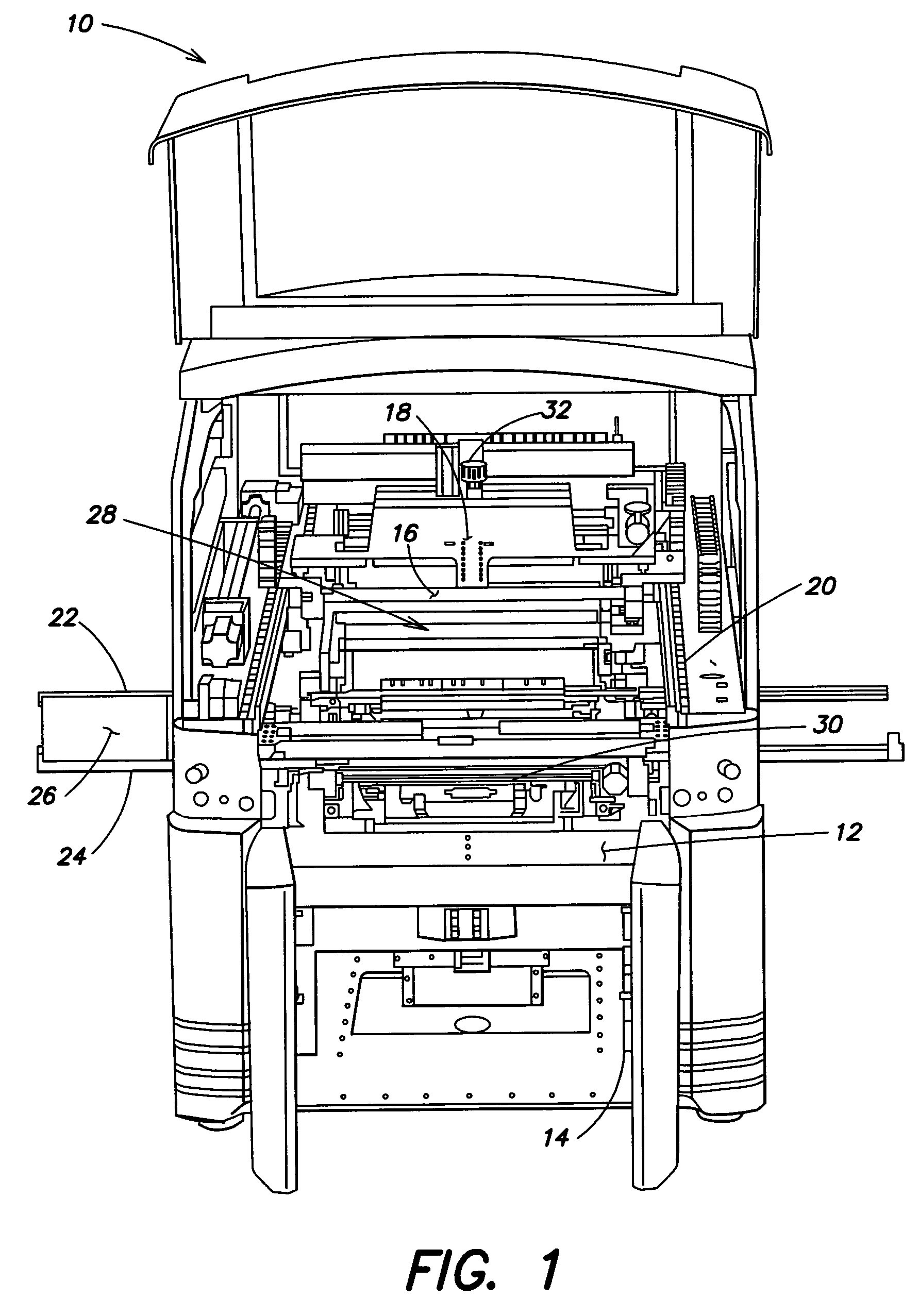

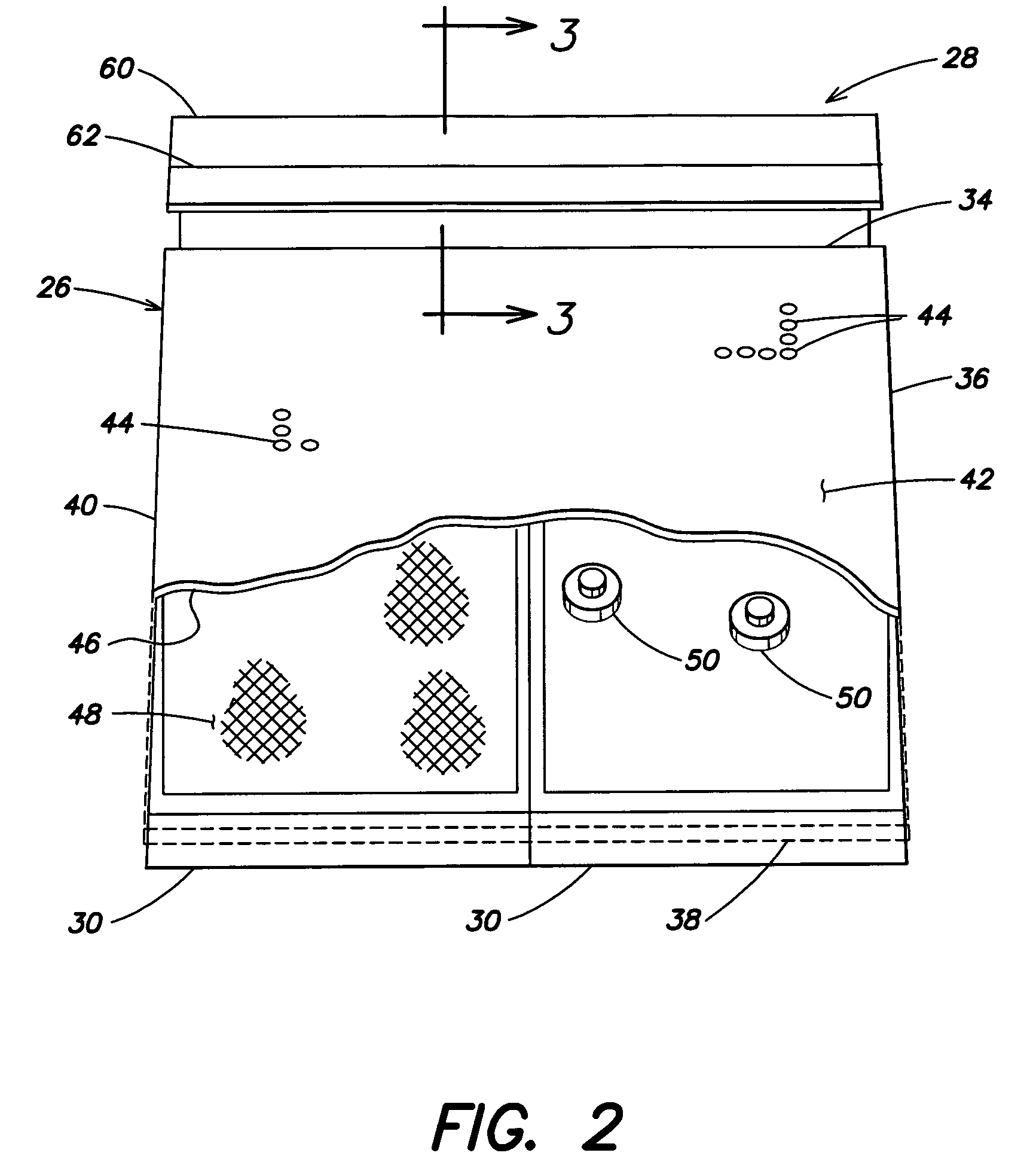

InactiveUS20050263017A1Prevent movementPrecise positioningLiquid surface applicatorsScreen printersGear wheelReducer

The present invention discloses a cantilever type screen-printing machine with double platforms that possess a gear reducer motor with a hollow shaft to rotate a screw of a threaded screw unit and further drive a threaded rod to move upward and downward without rotation inside the hollow shaft thus make a transverse sliding assembly move vertically and synchronously with the threaded rod. Moreover, by a rectangular frame and two sets of horizontal micro adjustable chase clamping mechanism transversely fixed on the rectangular frame, the relative position between the chase and the print materials is adjusted directly. The upper and the lower platforms are driven and powered by two gear reducer motors and a homocentric coaxial-type driving mechanism respectively. By the simplified driving mechanism, the printing efficiency and productivity are enhanced.

Owner:ATMA CHAMP ENTERPRISE

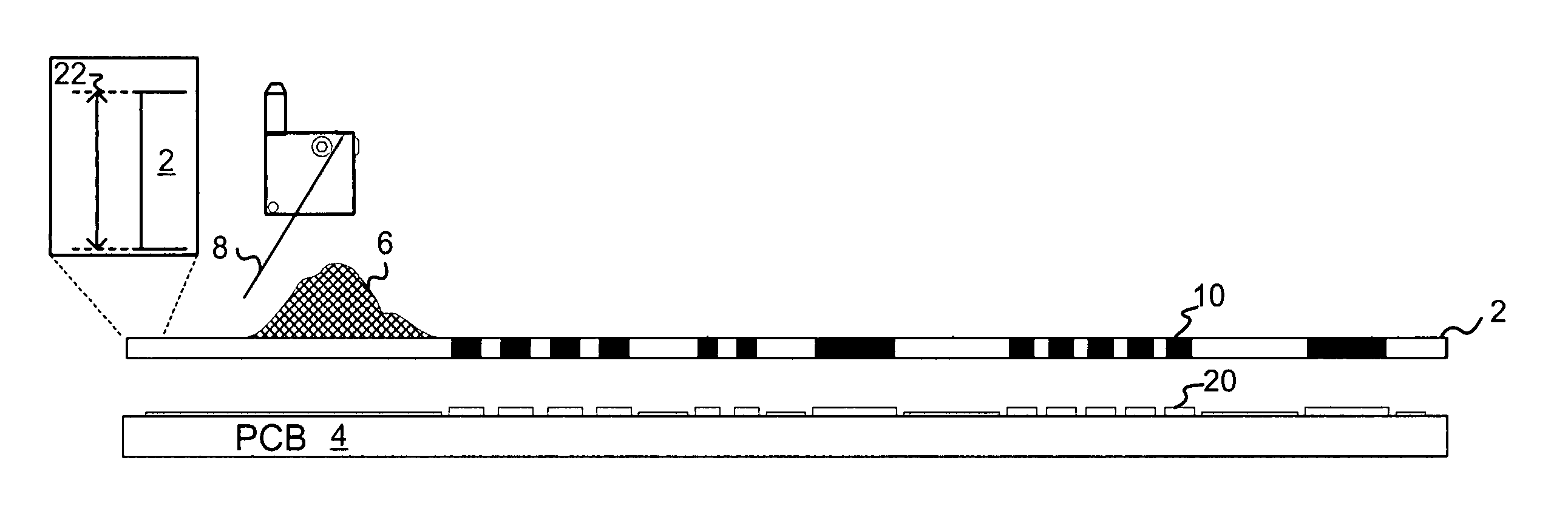

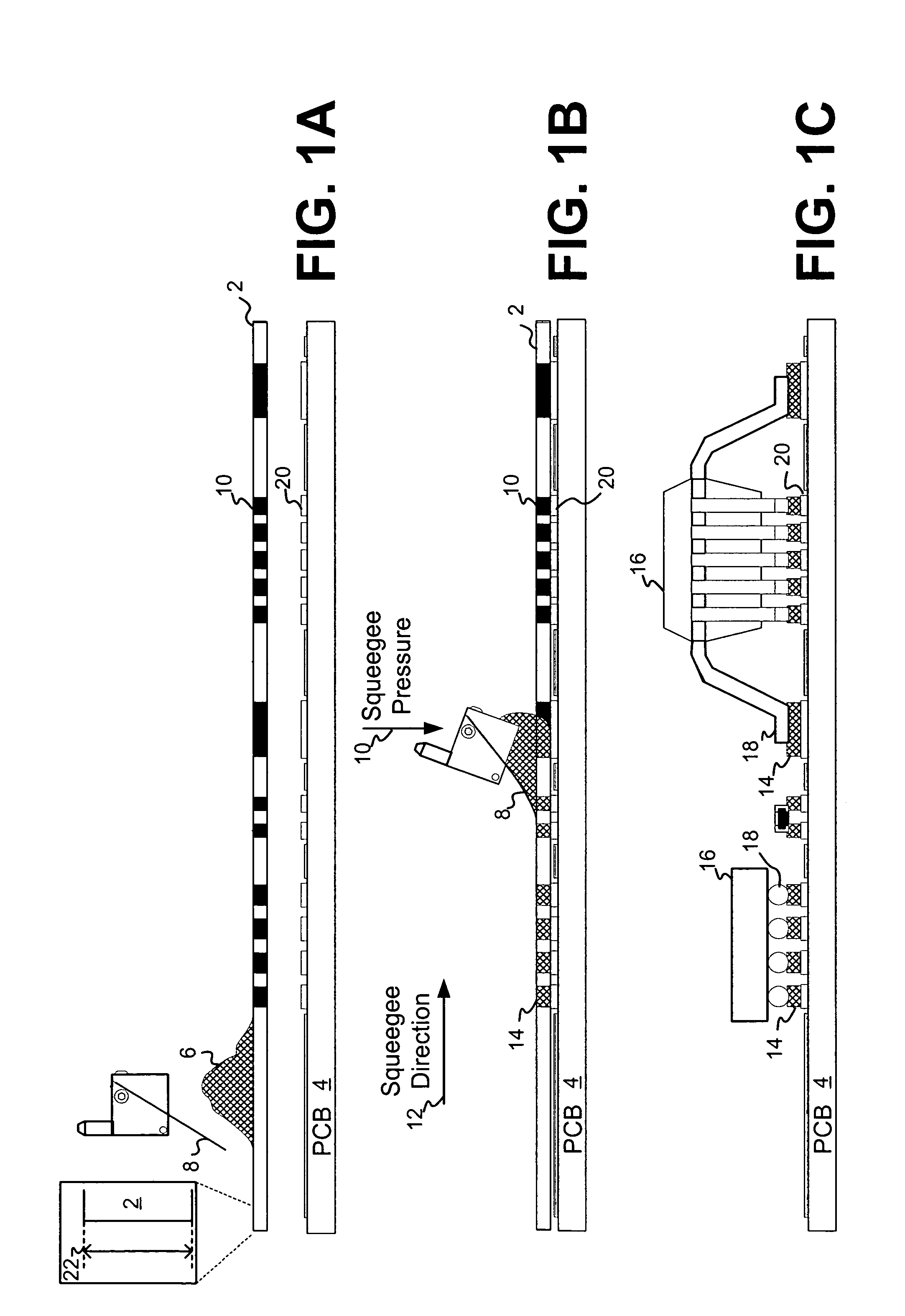

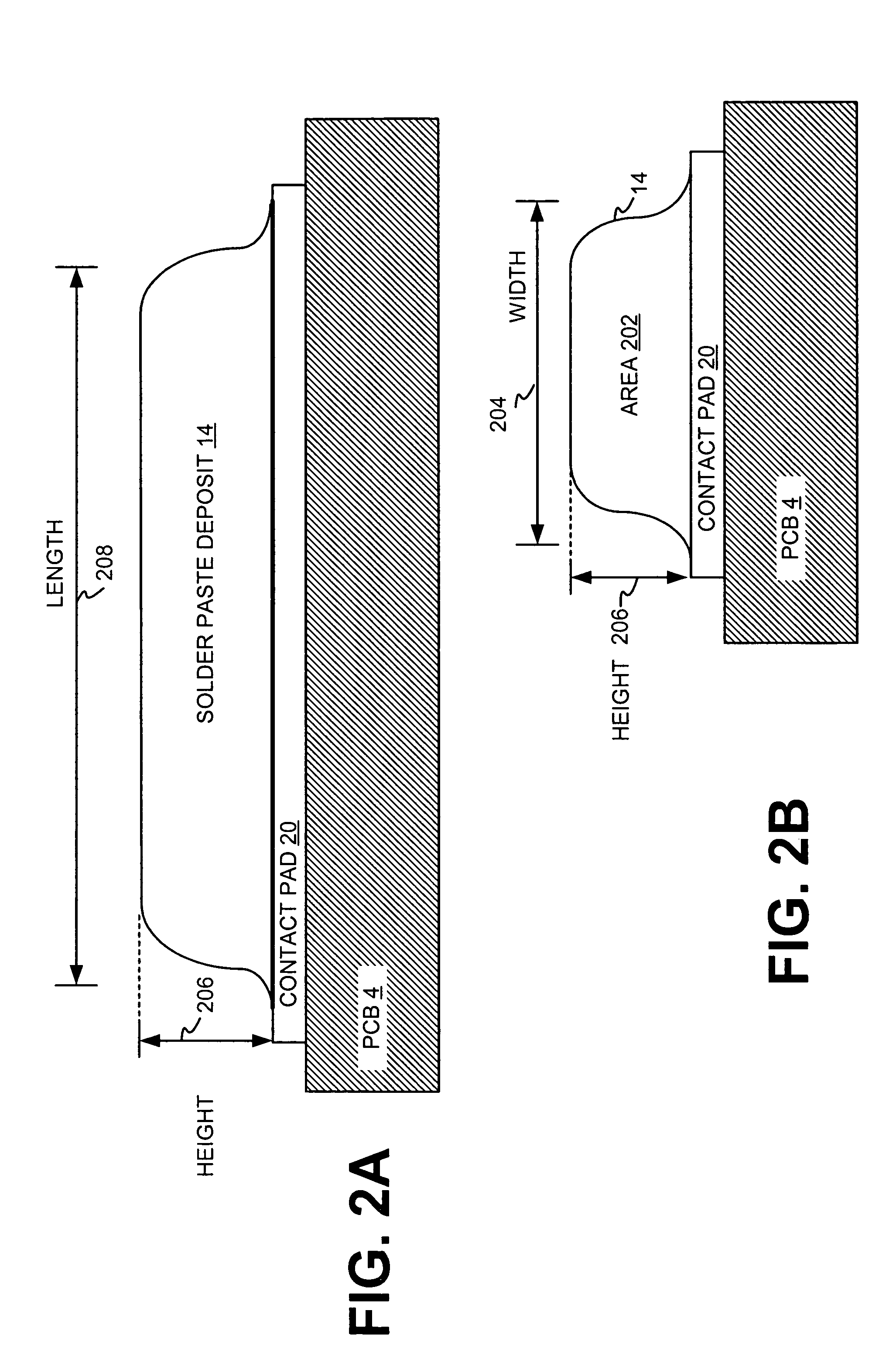

System and methods for data-driven control of manufacturing processes

Systems and methods for implementing hybrid, closed-loop control that generates control values for processes defined by a limited number of function evaluations and large amounts of process and measurement noise. The described control system is applied to a stencil printing process for applying solder paste to an electronic medium such as a printed circuit board or semiconductor wafer. The control system is defined by a hybrid approach. A first, coarse algorithm is used to rapidly produce the value of a stencil printer control value resulting in a solder paste deposit having a volume within predetermined acceptable limits. After the coarse algorithm no longer produces solder paste deposits closer to a desired volume, a second, more refined estimator is used to fine tune the process. An additional transitional algorithm may be added between the coarse algorithm and refined estimator. The coarse algorithm may be implemented with a constrained-conjugated gradient search, and the refined search may be a implemented using a least-squares affine estimator or a quadratic estimator. The transitional algorithm may be implemented using a block version of a least-squares affine estimator.

Owner:GEORGIA TECH RES CORP

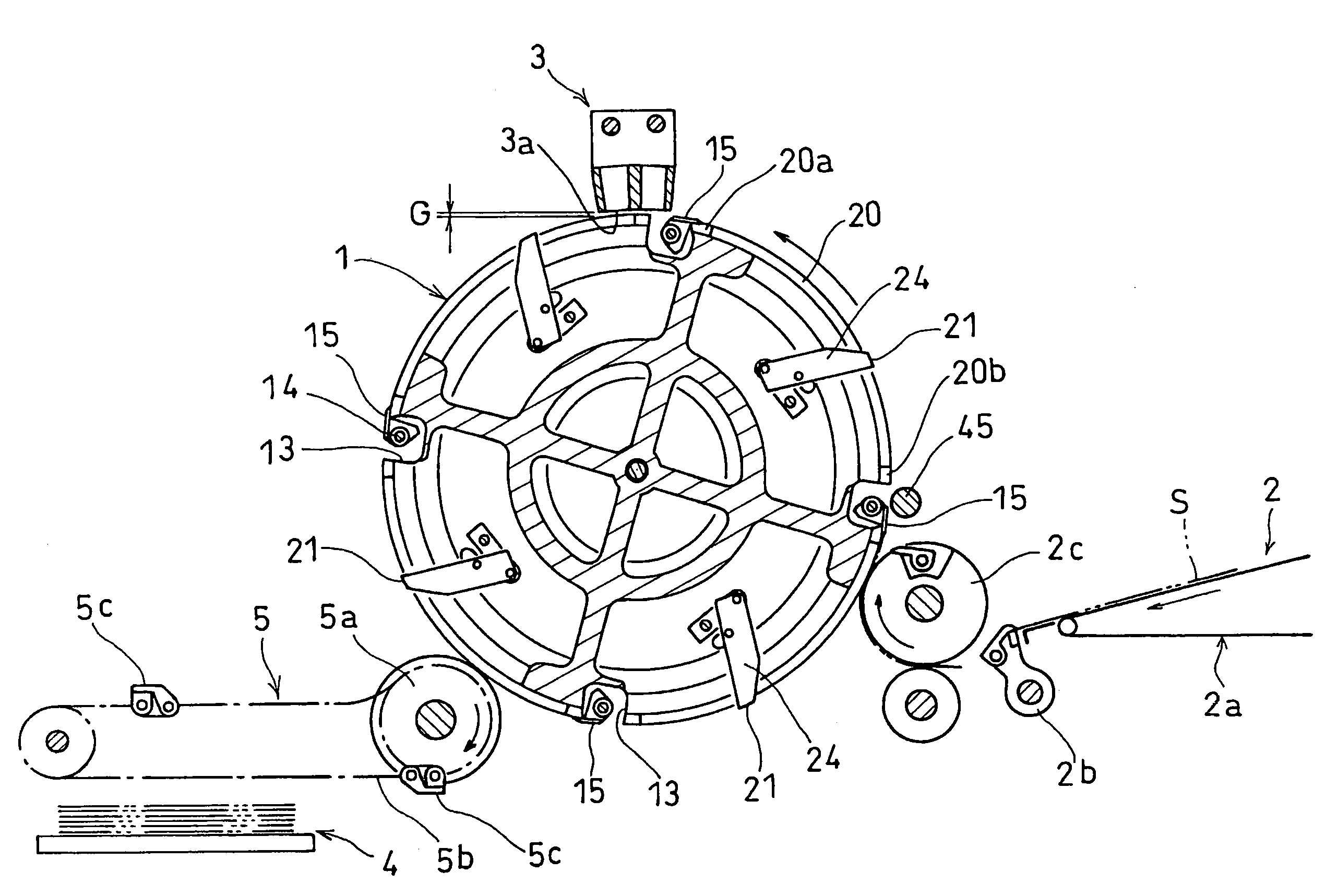

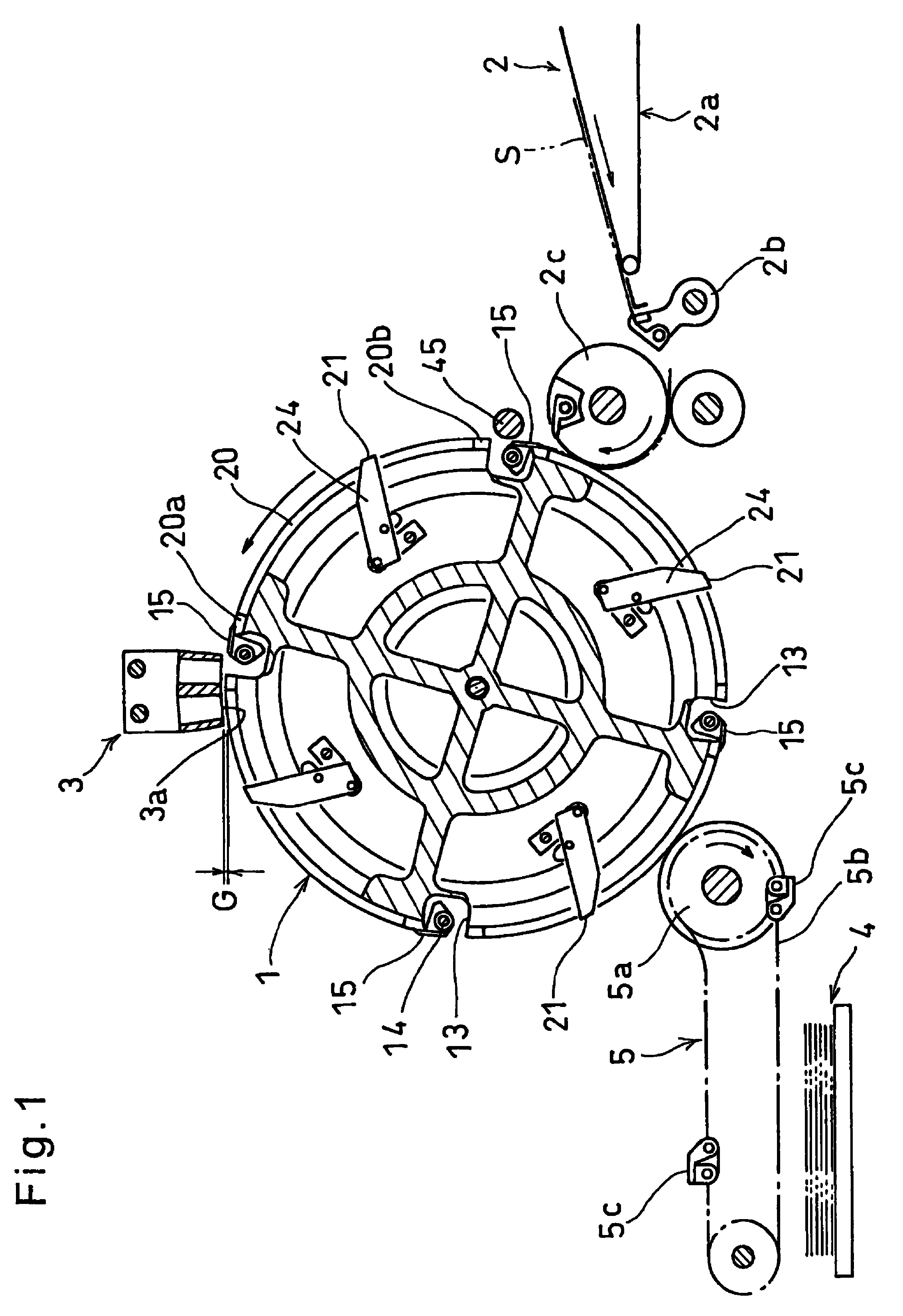

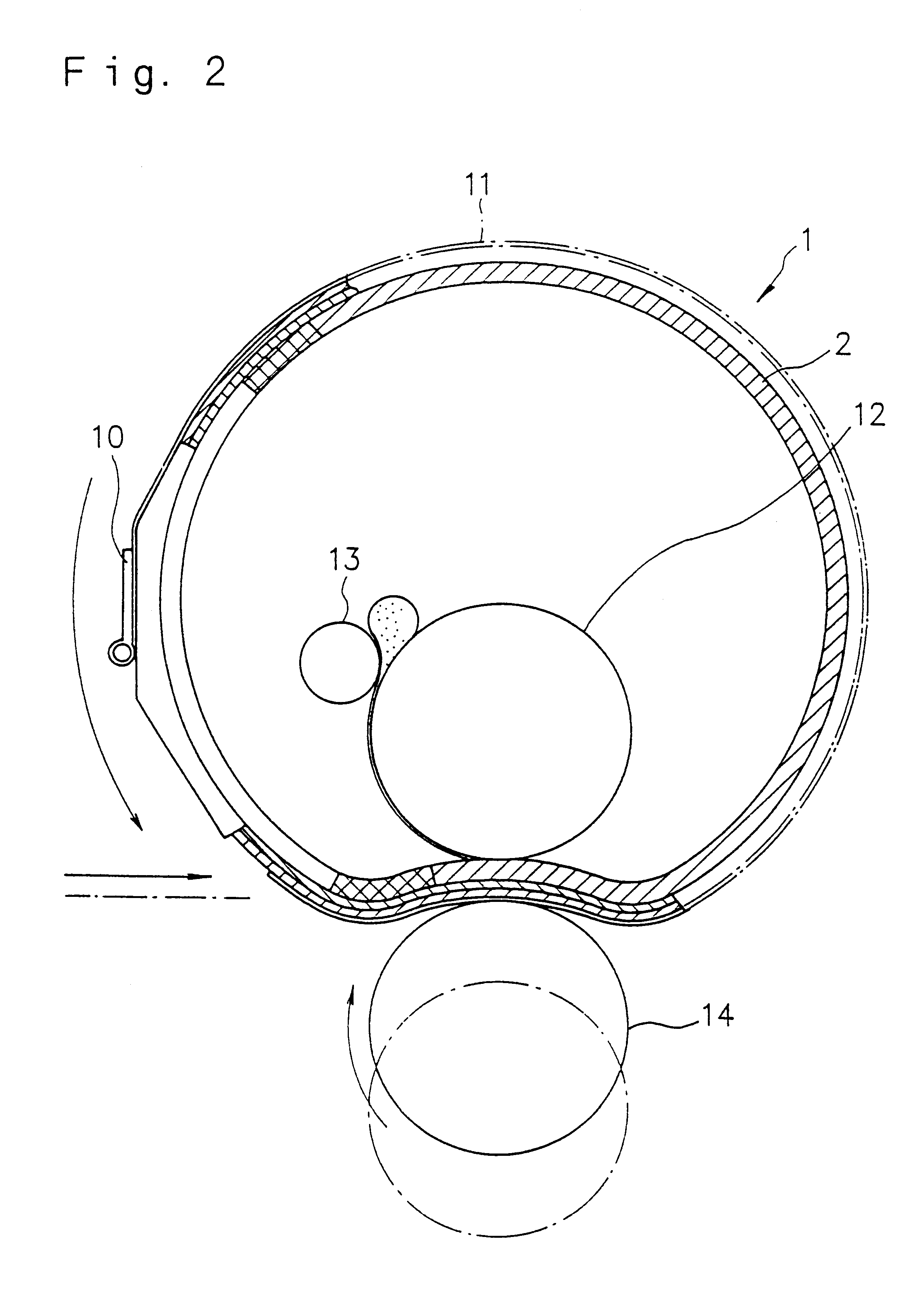

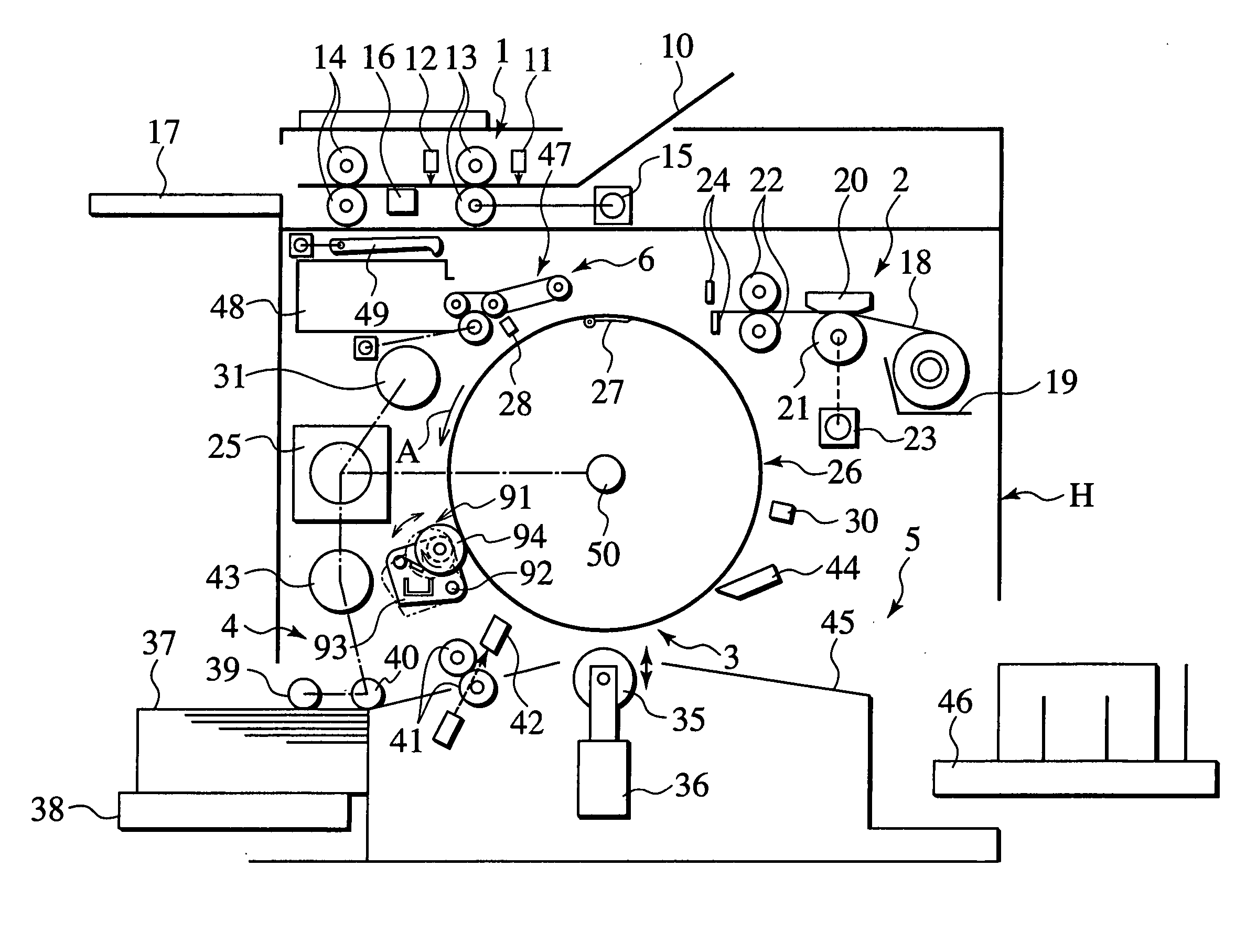

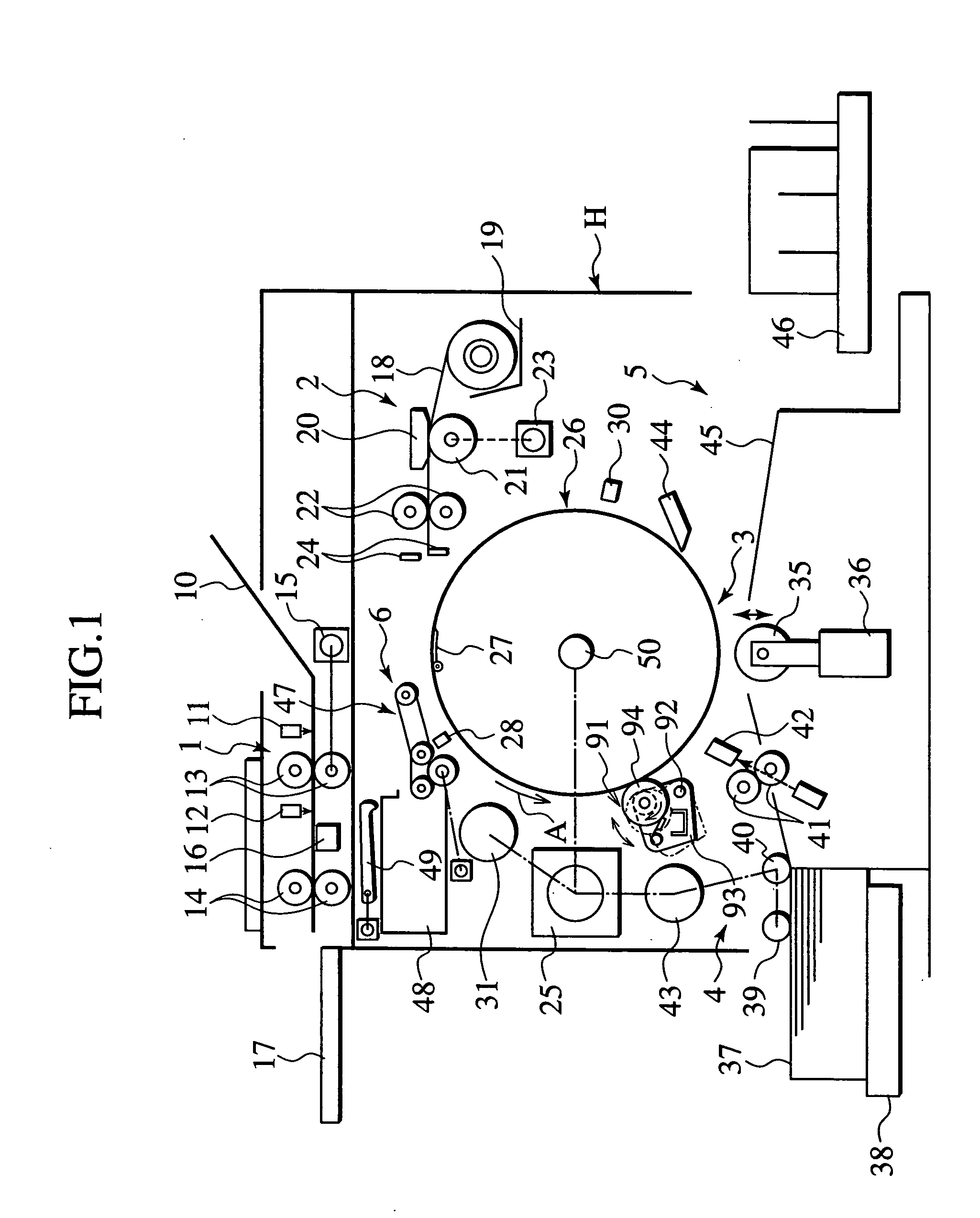

Inkjet printing press

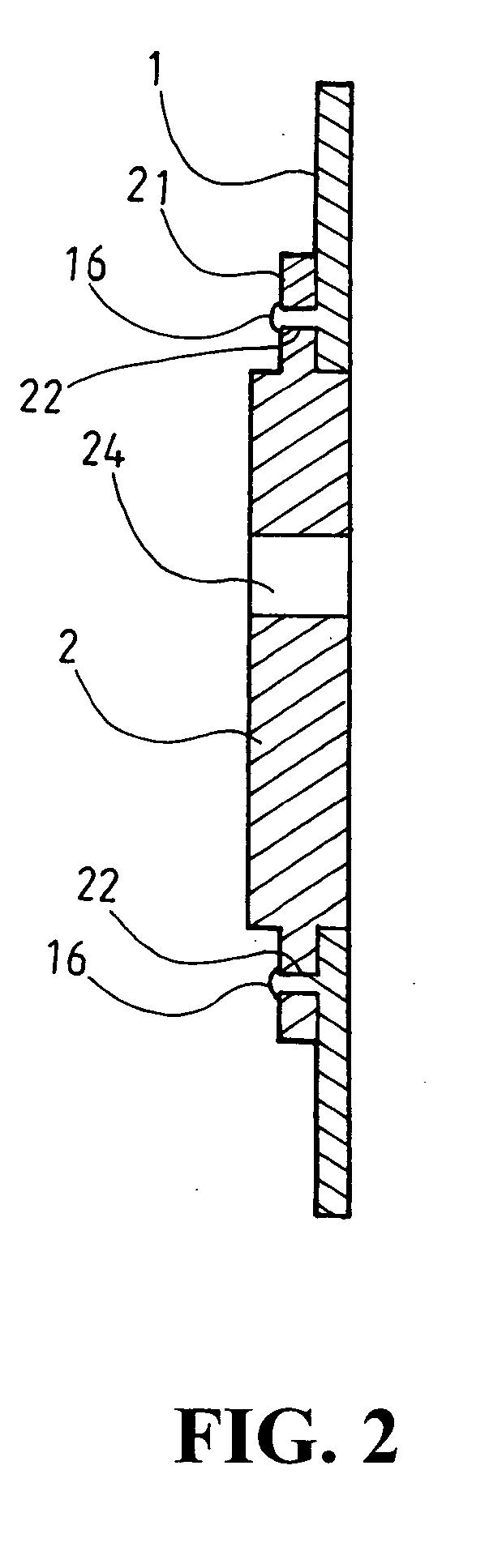

InactiveUS7909454B2Quality improvementImpart tensionStencilling apparatusOther printing apparatusEngineeringPrinting press

An inkjet printing press is provided which can hold sheets extremely stably. In an inkjet printing press, an inkjet head 3 is provided at the outer periphery of a printing drum 1 rotated in one direction. The printing drum 1 is provided with holding claws 15 which are opened and closed to hold the leading end of the sheet S, and clamps 21 which can be opened and closed for clamping the trailing end of the sheet S. When the clamps 21 are moved from their open positions to their closed positions, the clamps 21 are moved backward with respect to the rotating direction of the printing drum 1 to impart a tensile force to the trailing end of the sheet S and tighten the sheet so that the trailing end of the sheet is held by a clamp 21 with the sheet in its tight state. Also, the clamp 21 is brought into contact with the periphery of the printing drum 1 by an attracting device to assure the holding of the sheet.

Owner:KOTO HARUHIKO

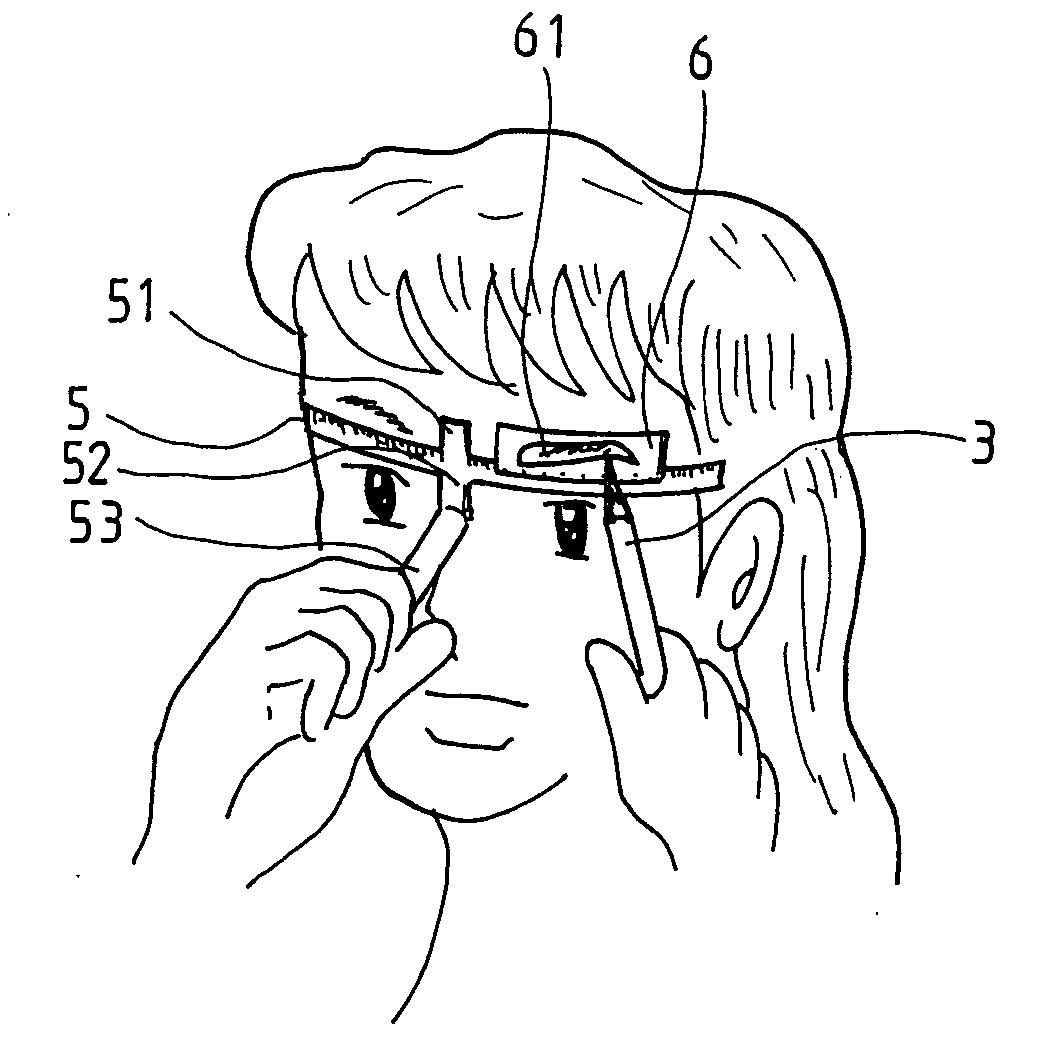

Stencil strap for eyebrow stenciling

InactiveUS20070006748A1Liquid surface applicatorsStencilling apparatusEngineeringMechanical engineering

A stencil strap for eyebrow-stenciling is disclosed. The strap comprises a strap body having two ends mounted with a male and female adhesive plate, and a central upper and lower edge provided with an eyebrow center and nose positioning plate, wherein the two lateral sides of the positioning plate are respectively provided with elongated opening and the upper and lower edge of the opening are provided with a plurality of engaging hooks; and a plurality of stencils having a circumferential edge provided with a stepped section, the stepped section being mounted with fastening hole corresponding to the engaging hooks of the strap body, wherein the surface of the stencil is stenciling opening of various shapes.

Owner:LIU CHEN HAI

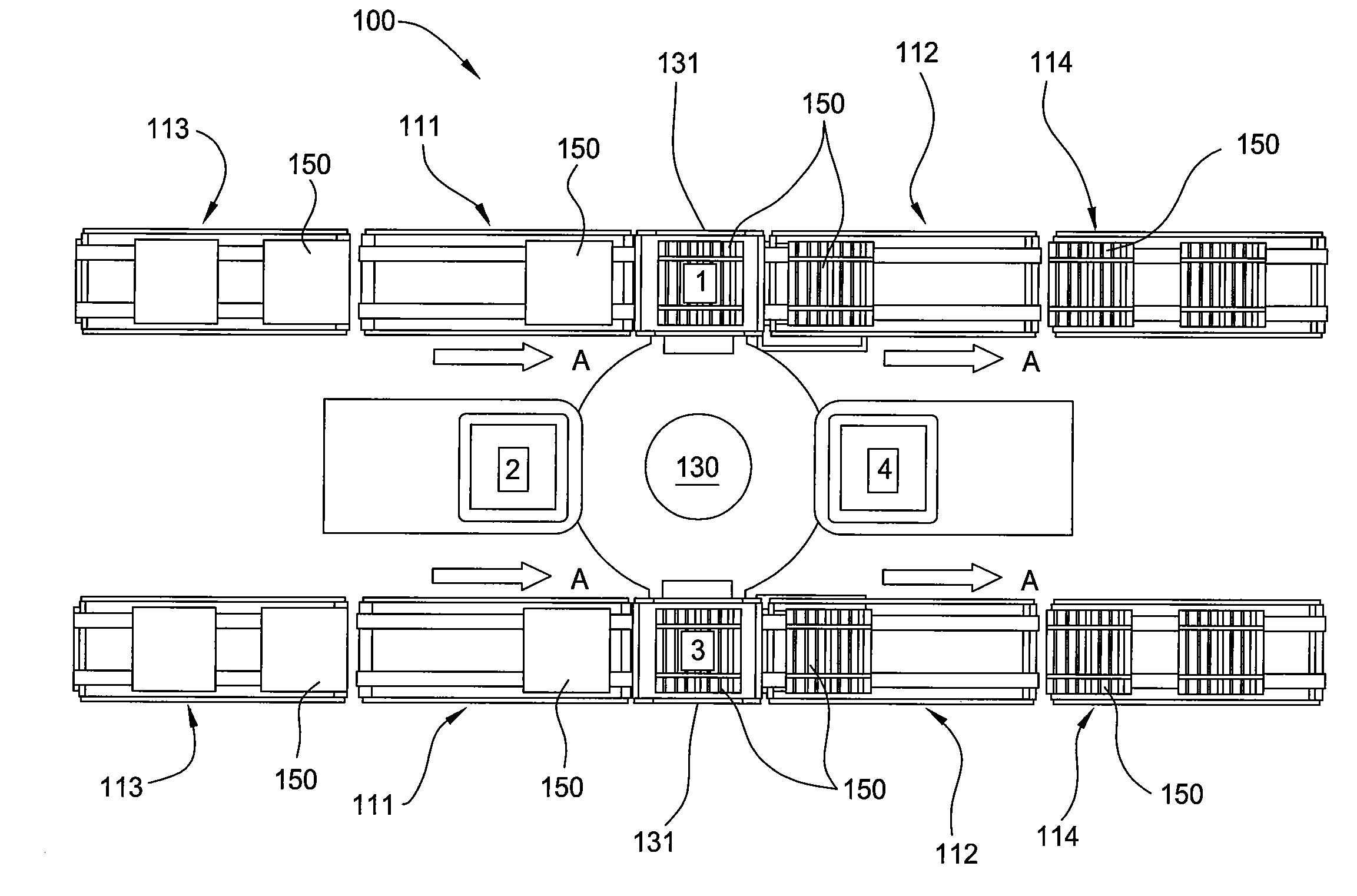

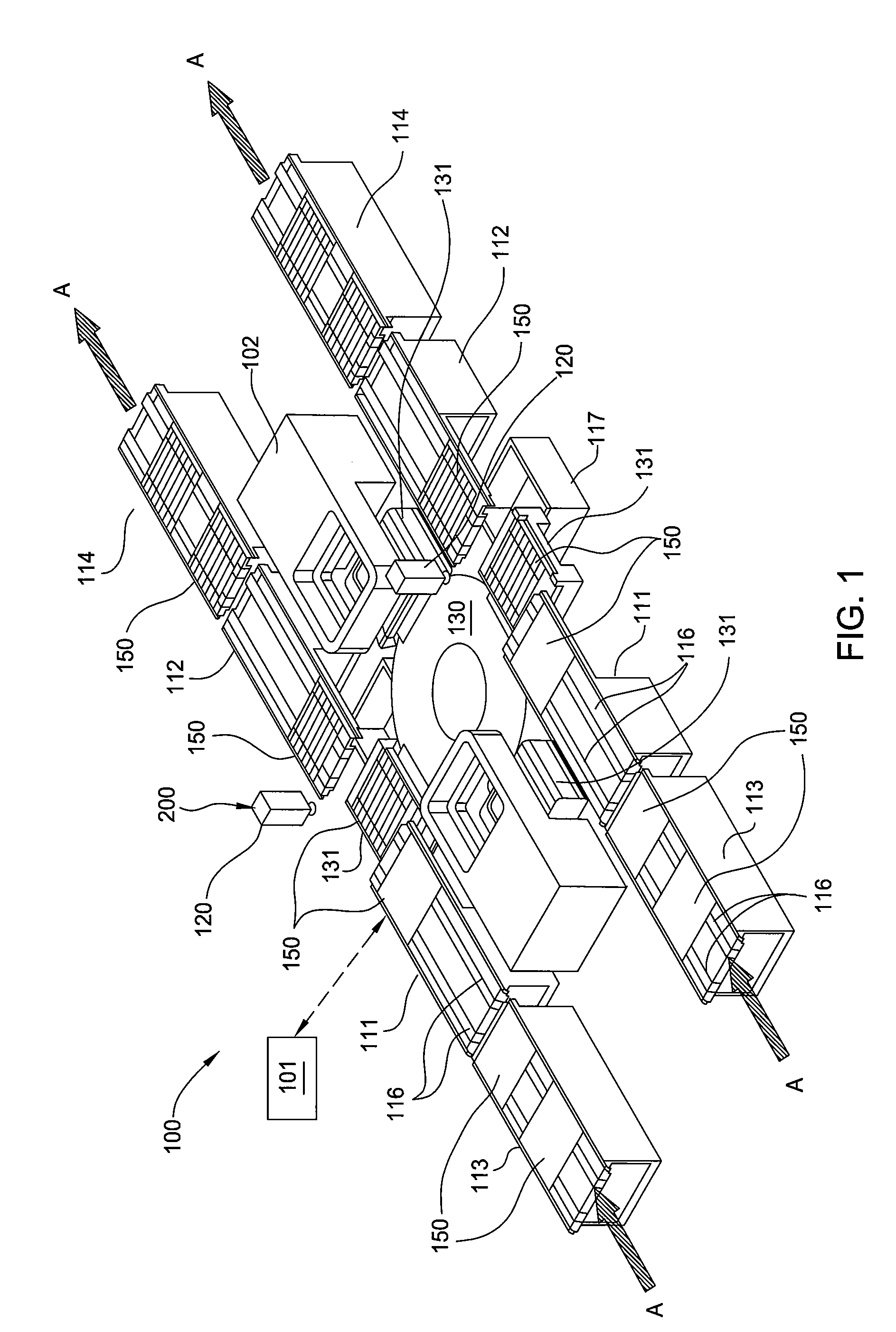

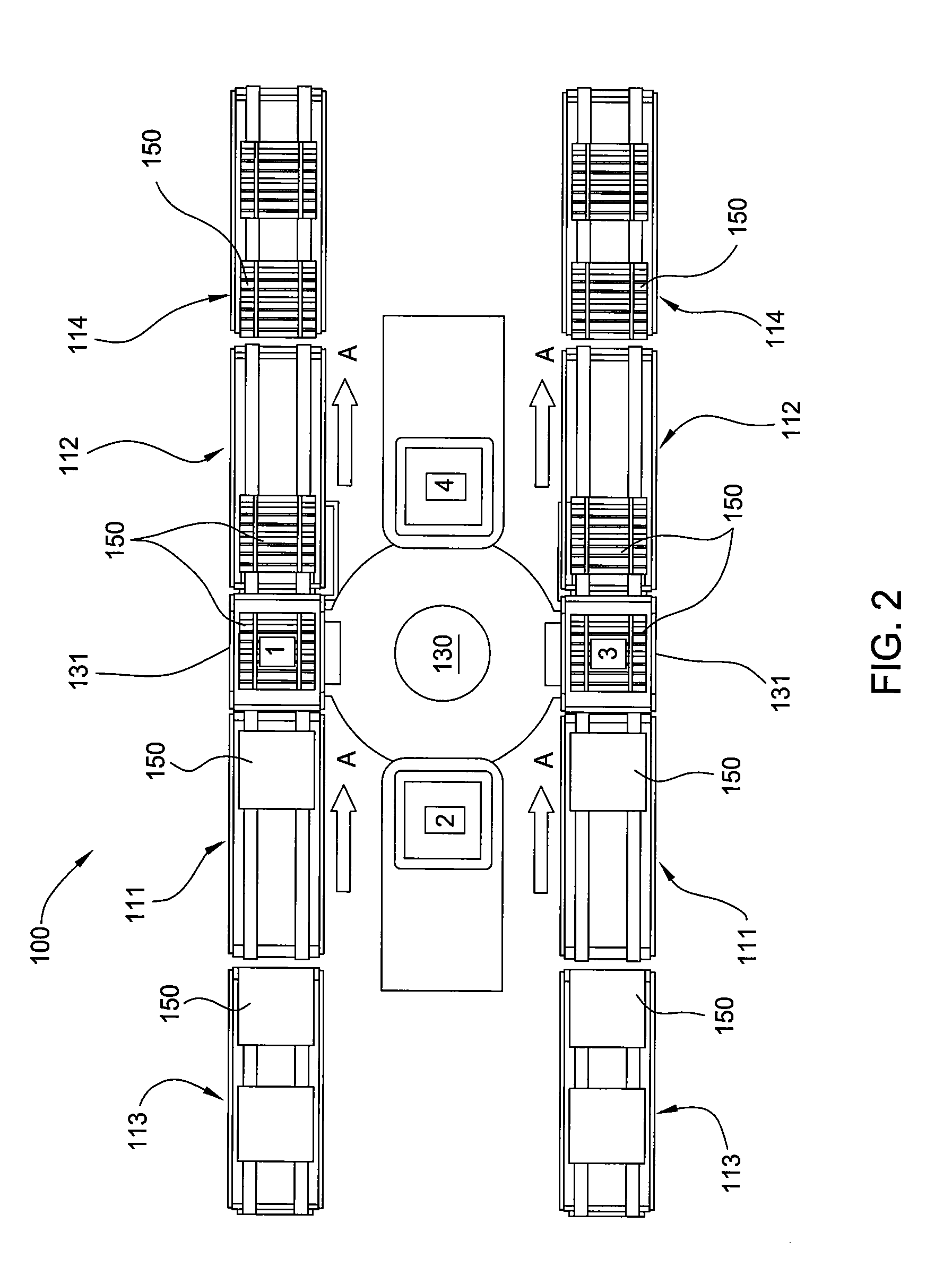

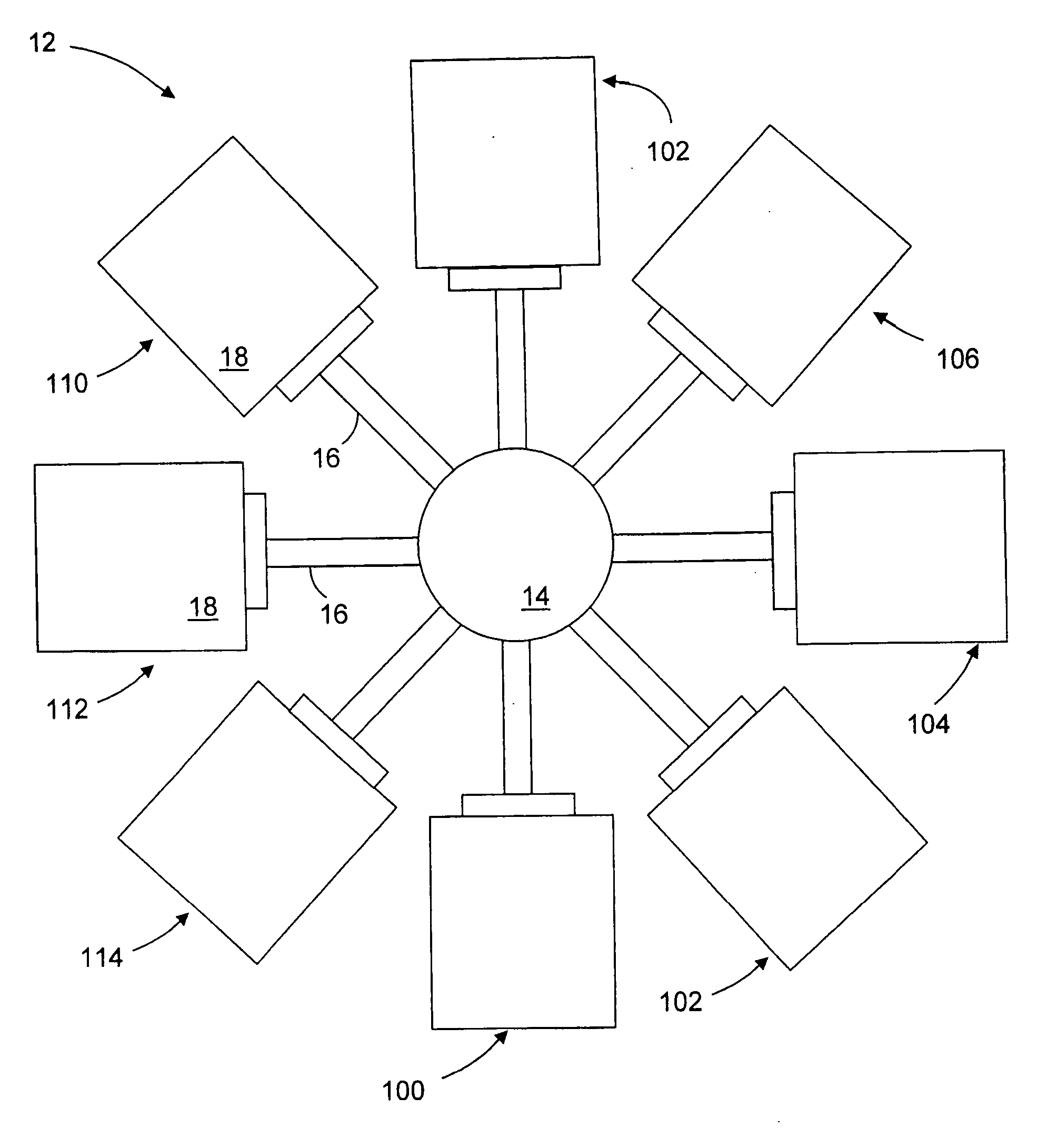

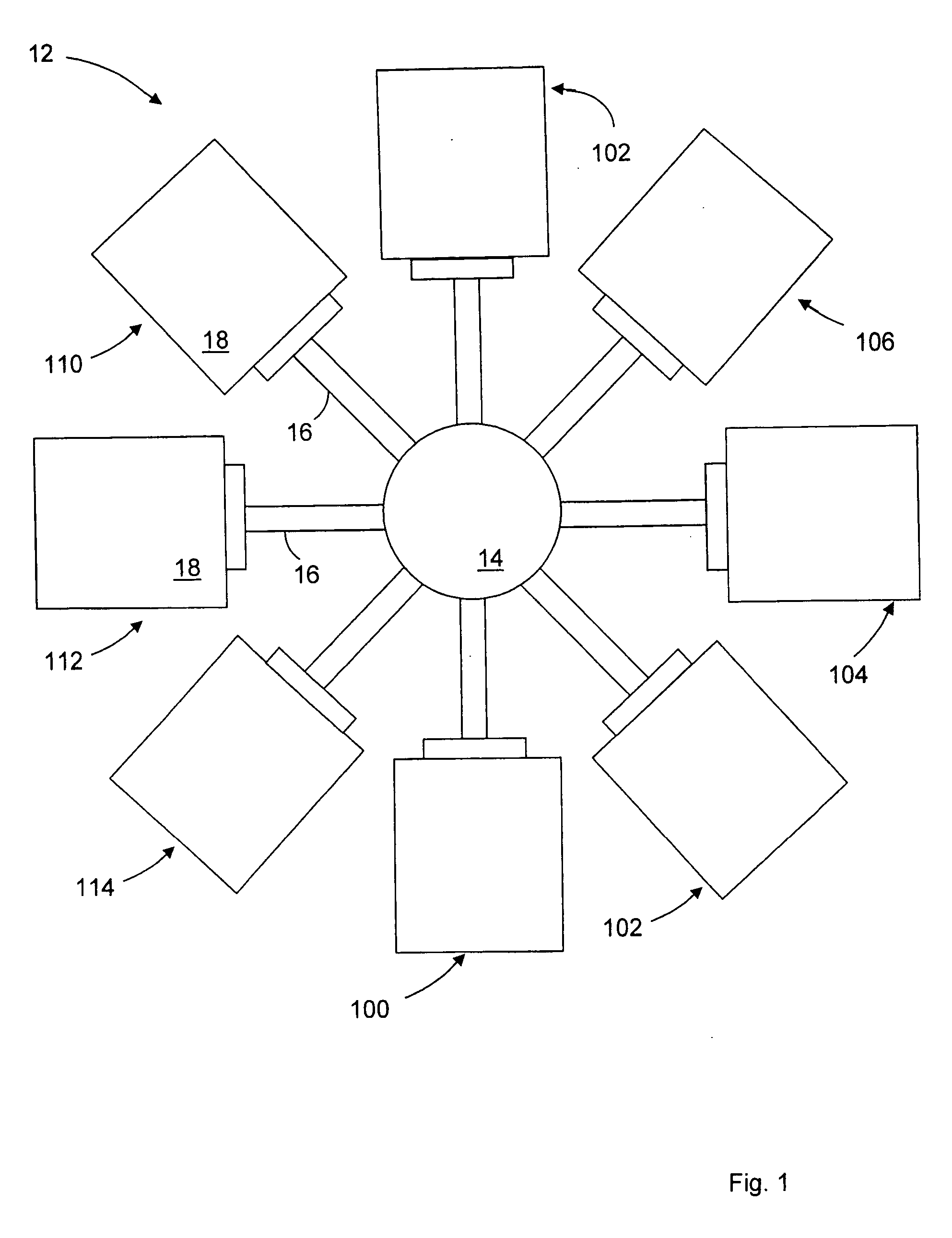

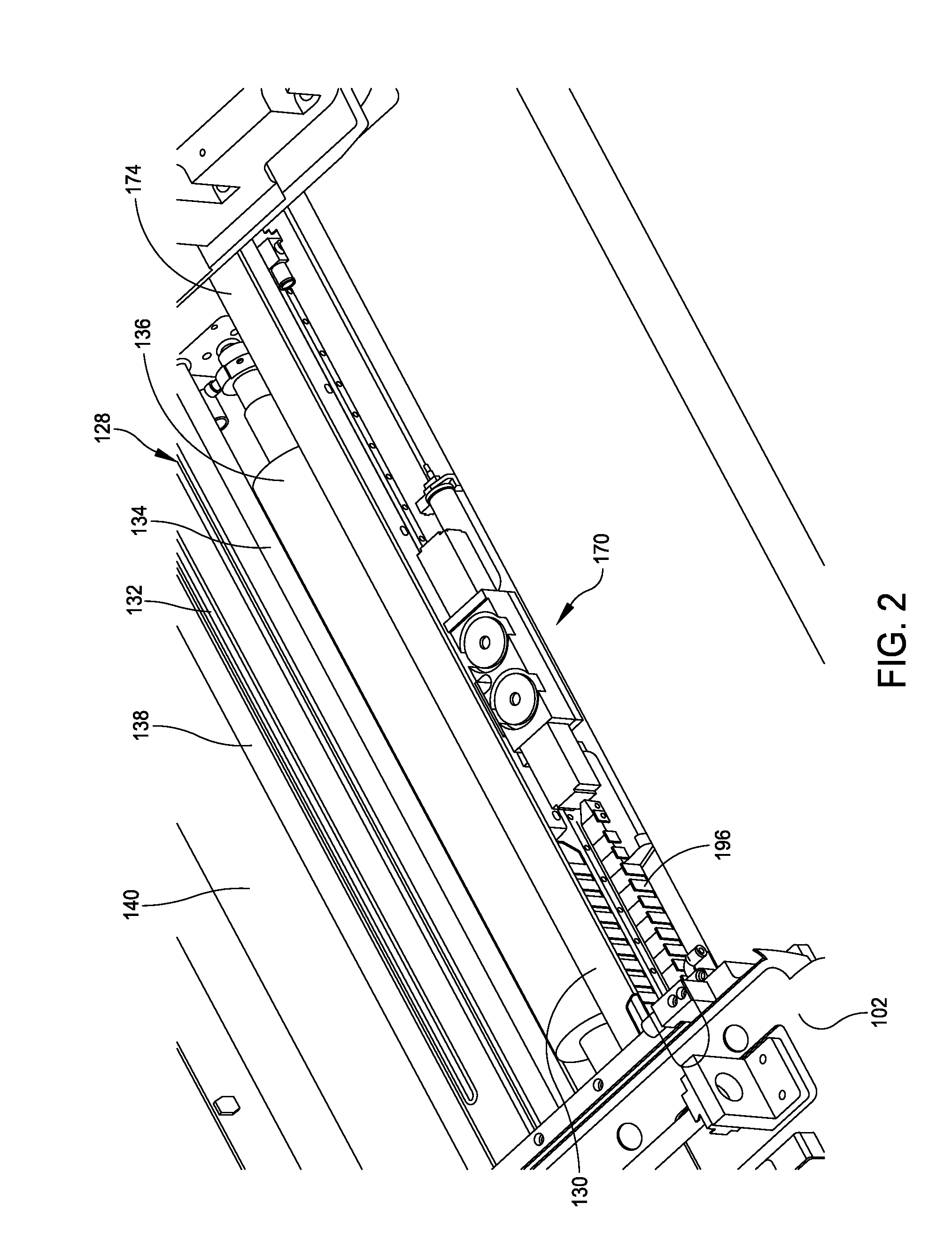

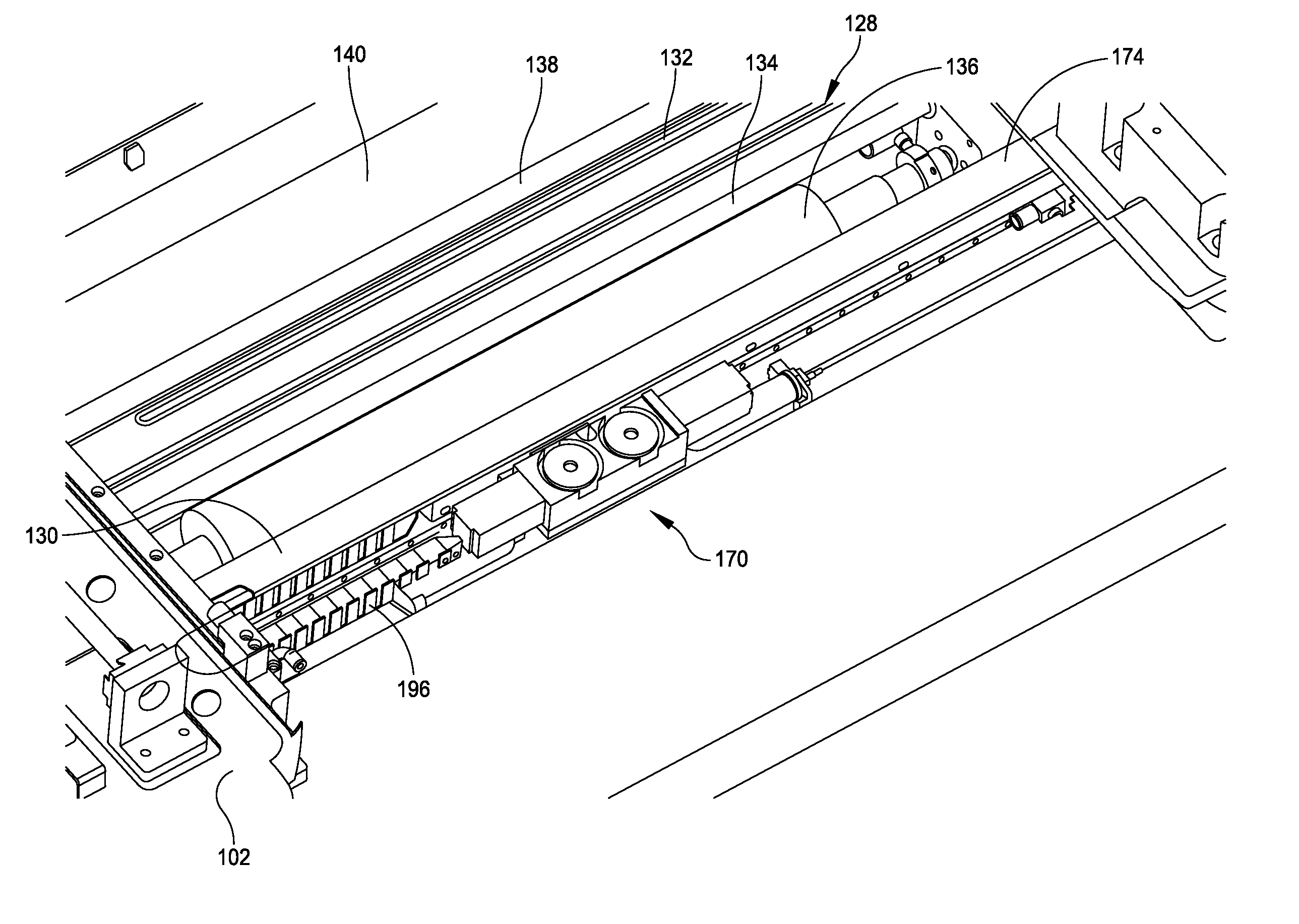

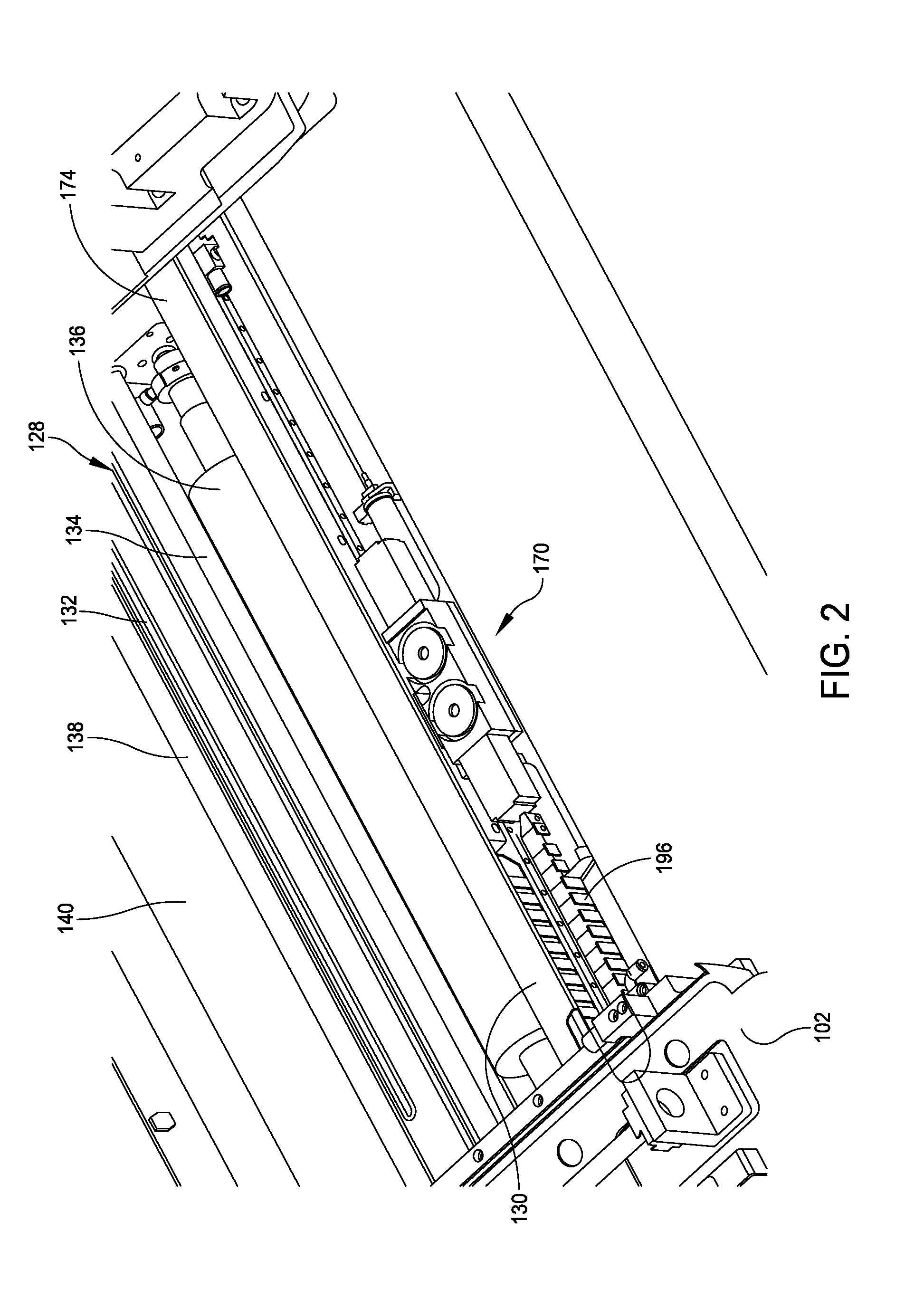

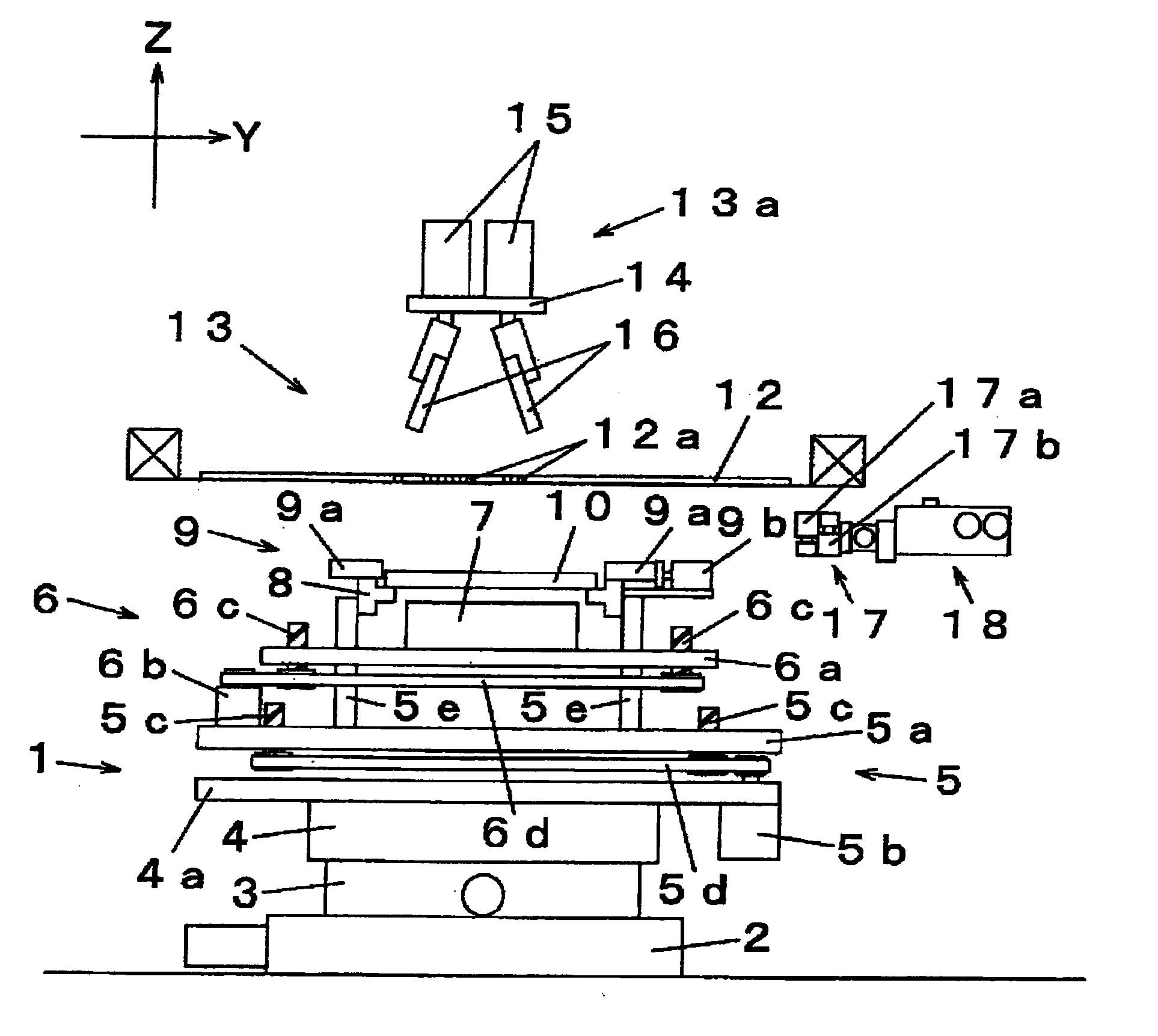

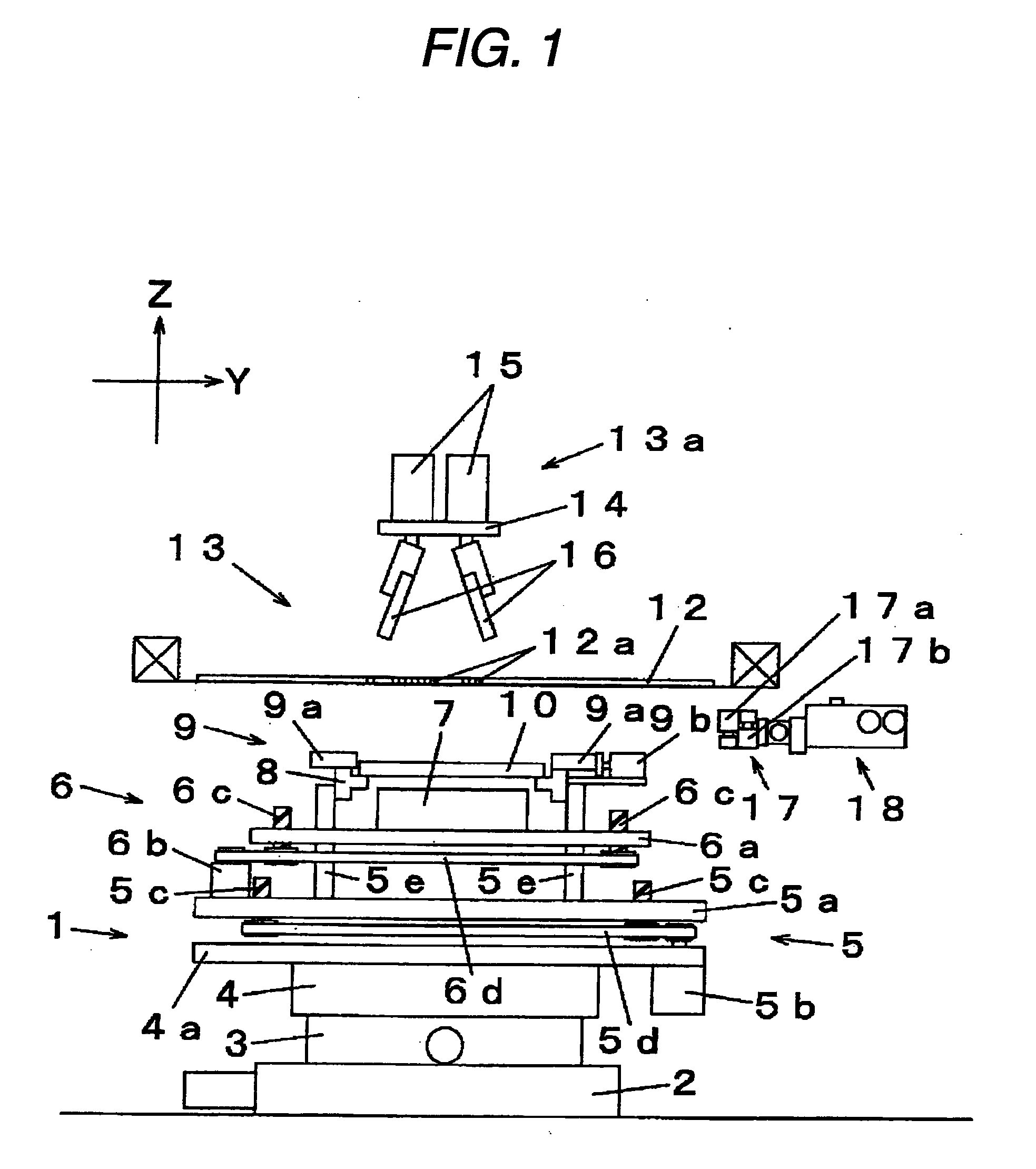

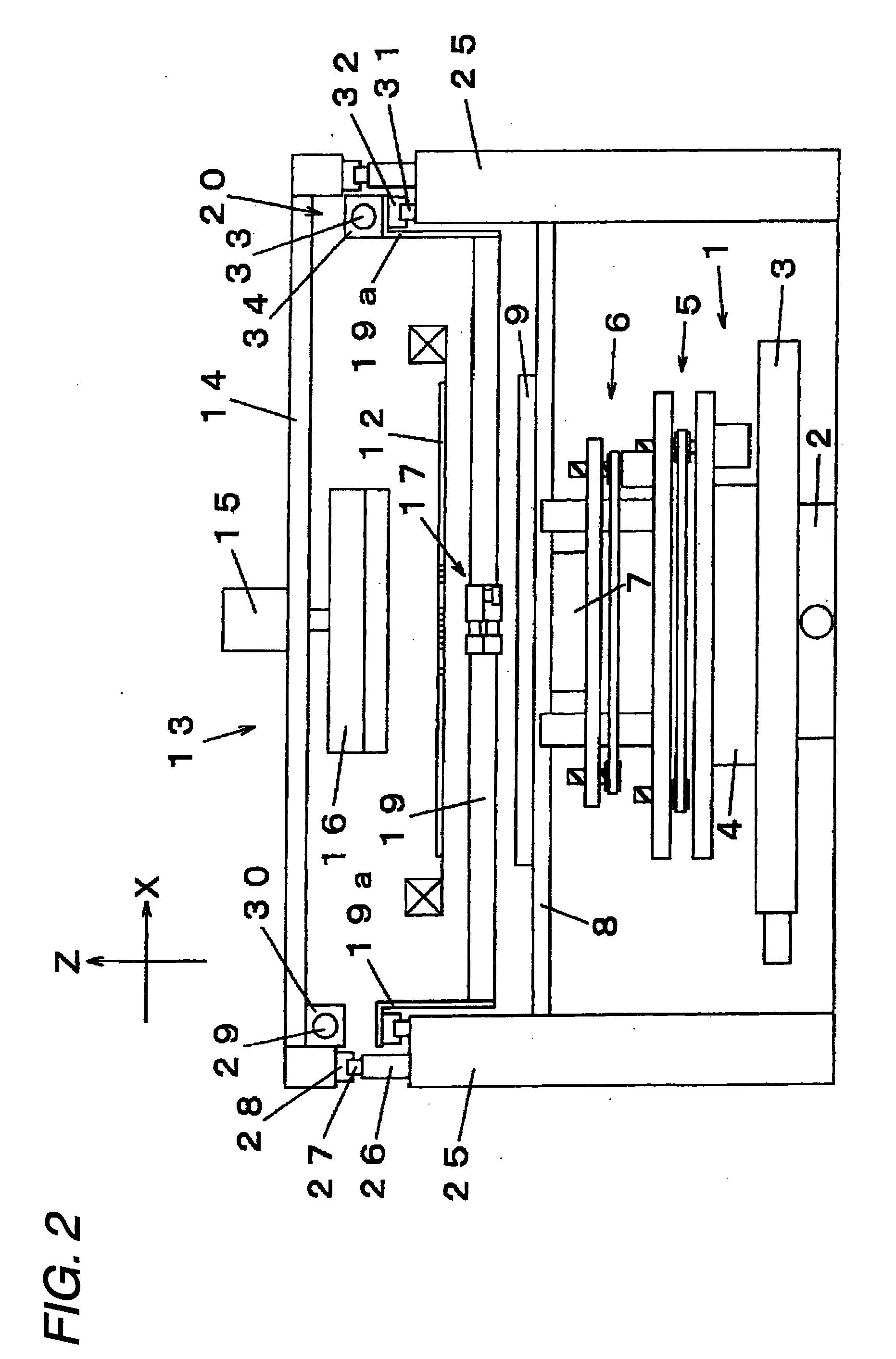

Accurate conveyance system useful for screen printing

The present invention(s) provide an apparatus and method for processing substrates in a screen printing chamber that can deliver a repeatable and accurate screen printed pattern on one or more processed substrates. In one embodiment, the screen printing chamber is adapted to perform a screen printing process within a portion of a crystalline silicon solar cell production line in which a substrate is patterned with a desired material. In one embodiment, the screen printing chamber is a processing chamber positioned within the Rotary line tool or Softline™ tool available from Baccini S.p.A., which is owned by Applied Materials, Inc. of Santa Clara, Calif.

Owner:APPLIED MATERIALS INC

Method for inkjet printing light colors on dark textiles

A method and apparatus for printing on dark textiles such as black t-shirts is disclosed. The method includes screen printing an underbase onto the textile and then using an inkjet printer to print an image over the underbase. In the preferred embodiment, a white, opaque image is screen printed onto a black t-shirt, followed by inkjet printing a white image on top of the screen-printed image.

Owner:GRAPHIC ARTS ACQUISITION

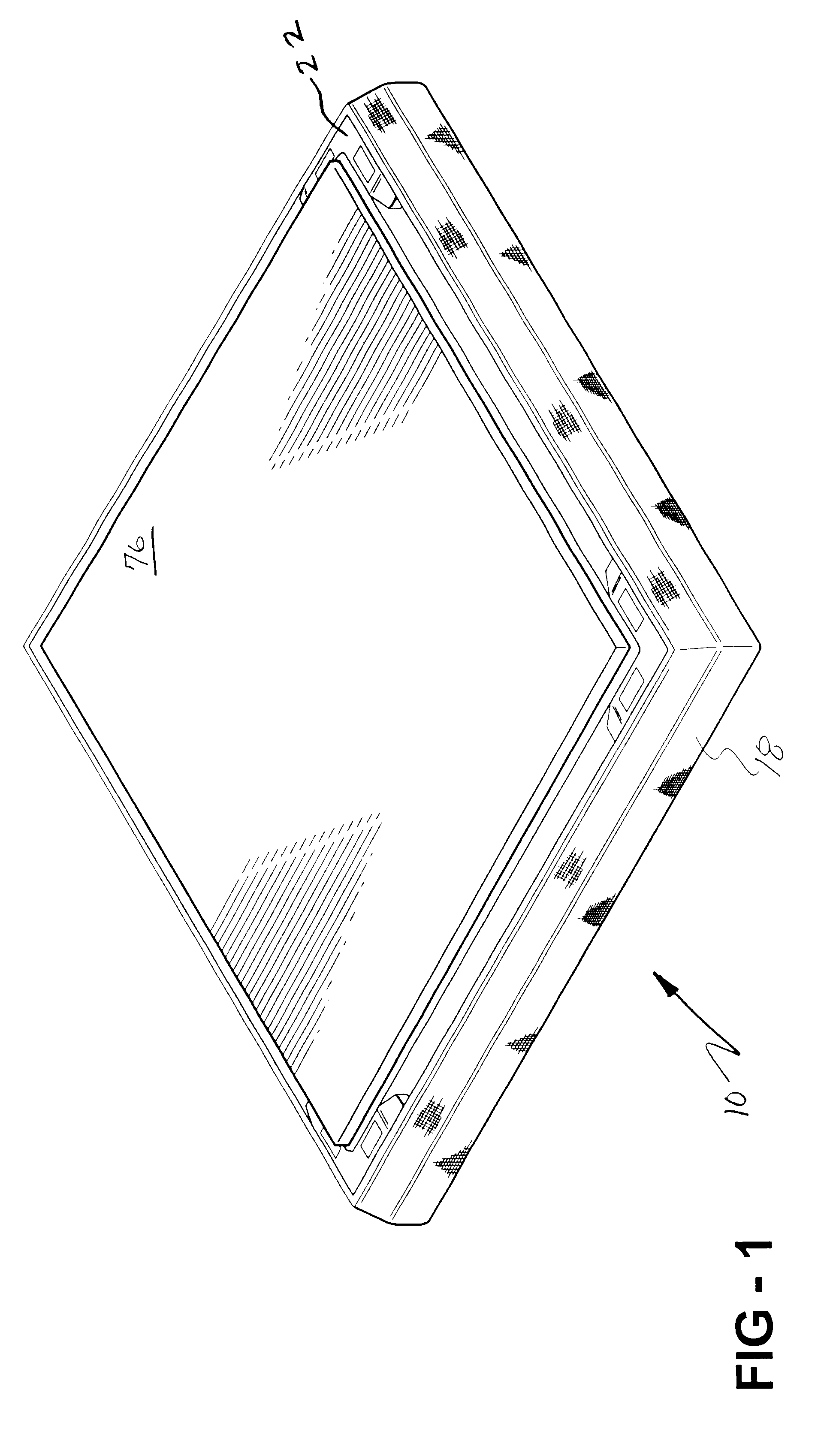

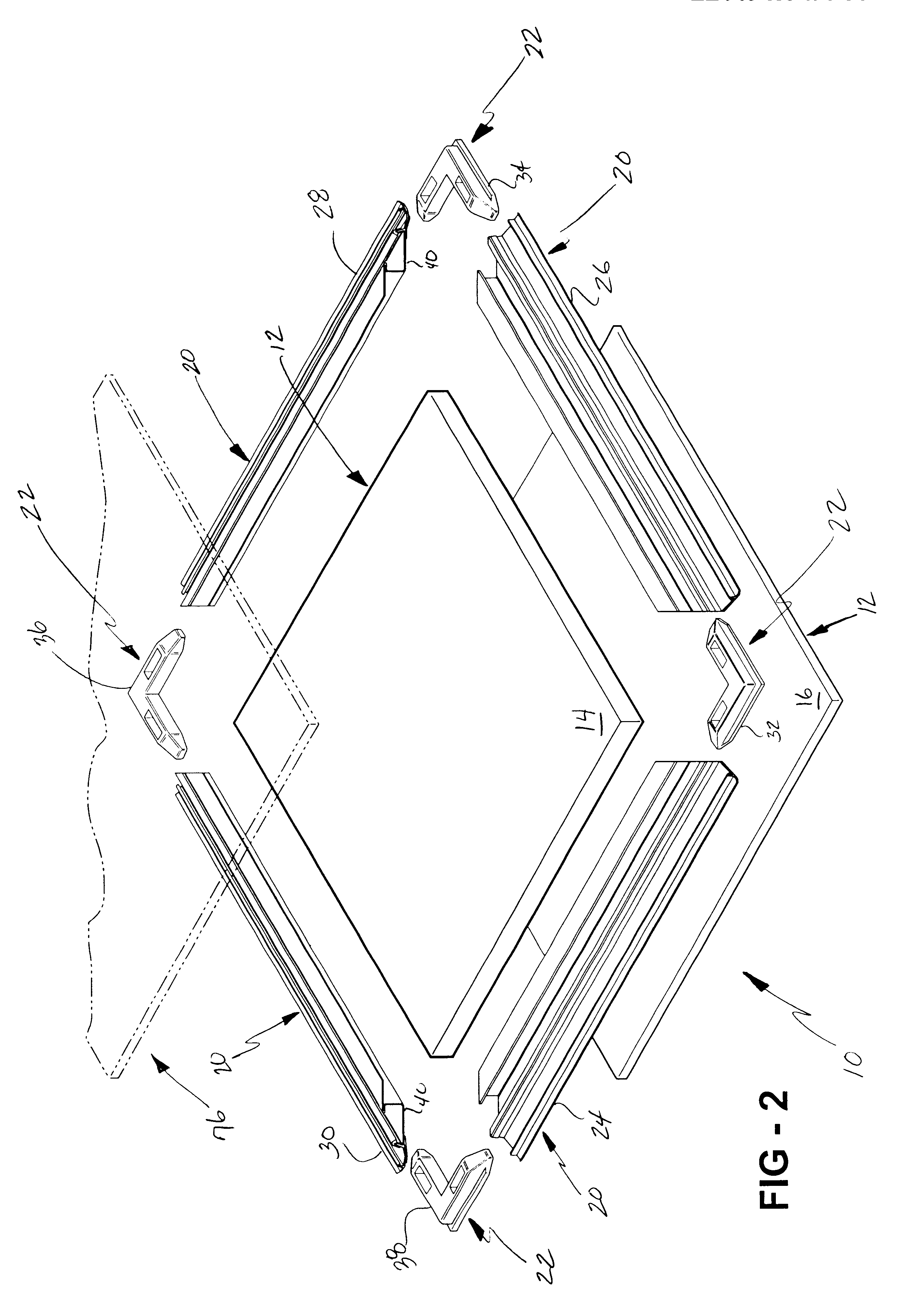

Method of assembling a frame assembly for a partition system

A method of assembling a frame assembly for a partition system is disclosed. The frame assembly includes a partition panel, a fabric covering the panel, and a frame component. The frame component automatically and evenly tensions the fabric about the panel. The frame component provided according to this method includes a support element, a lockable element, and an integral hinge defined between the support and lockable elements. The support element defines a cavity for receiving and supporting the panel. The lockable element extends from and is moveable relative to the support element. The panel is inserted into the cavity, and the fabric is mounted to the lockable element. Next, the lockable element is moved about the integral hinge such that the fabric mounted to the lockable element is automatically and evenly tensioned about the panel. A backing strip may be mounted to the frame component to protect the fabric from the integral hinge.

Owner:QUANEX HOMESHIELD LLC

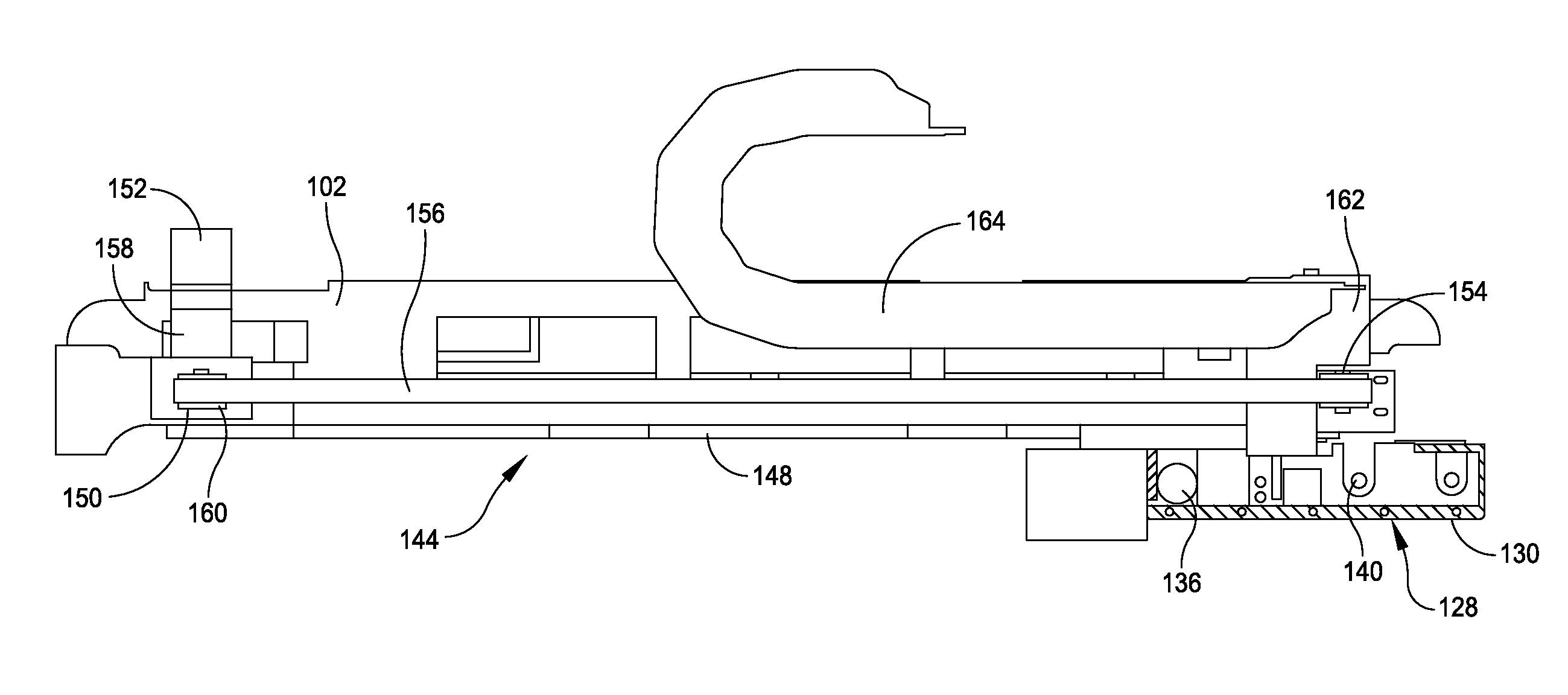

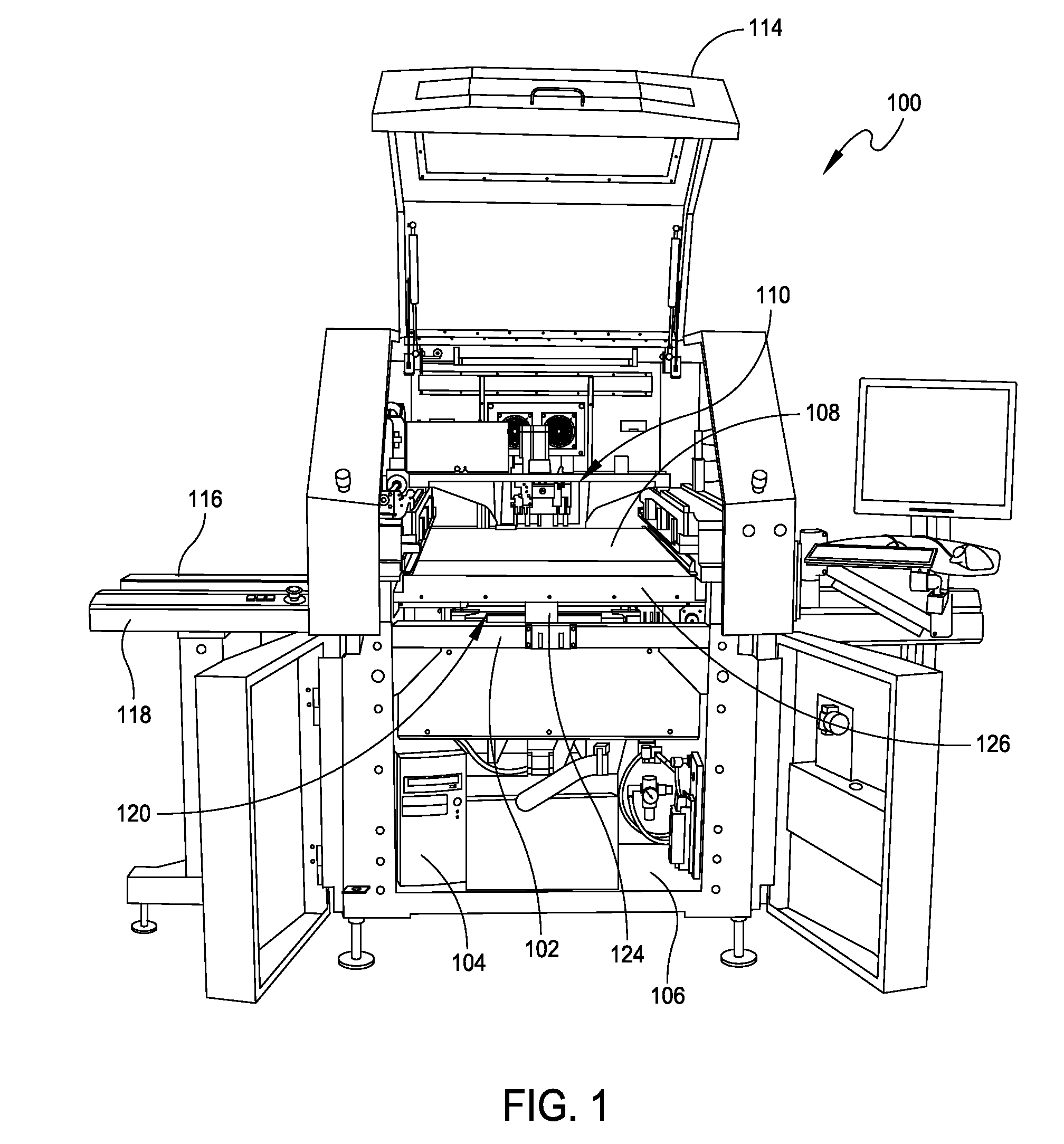

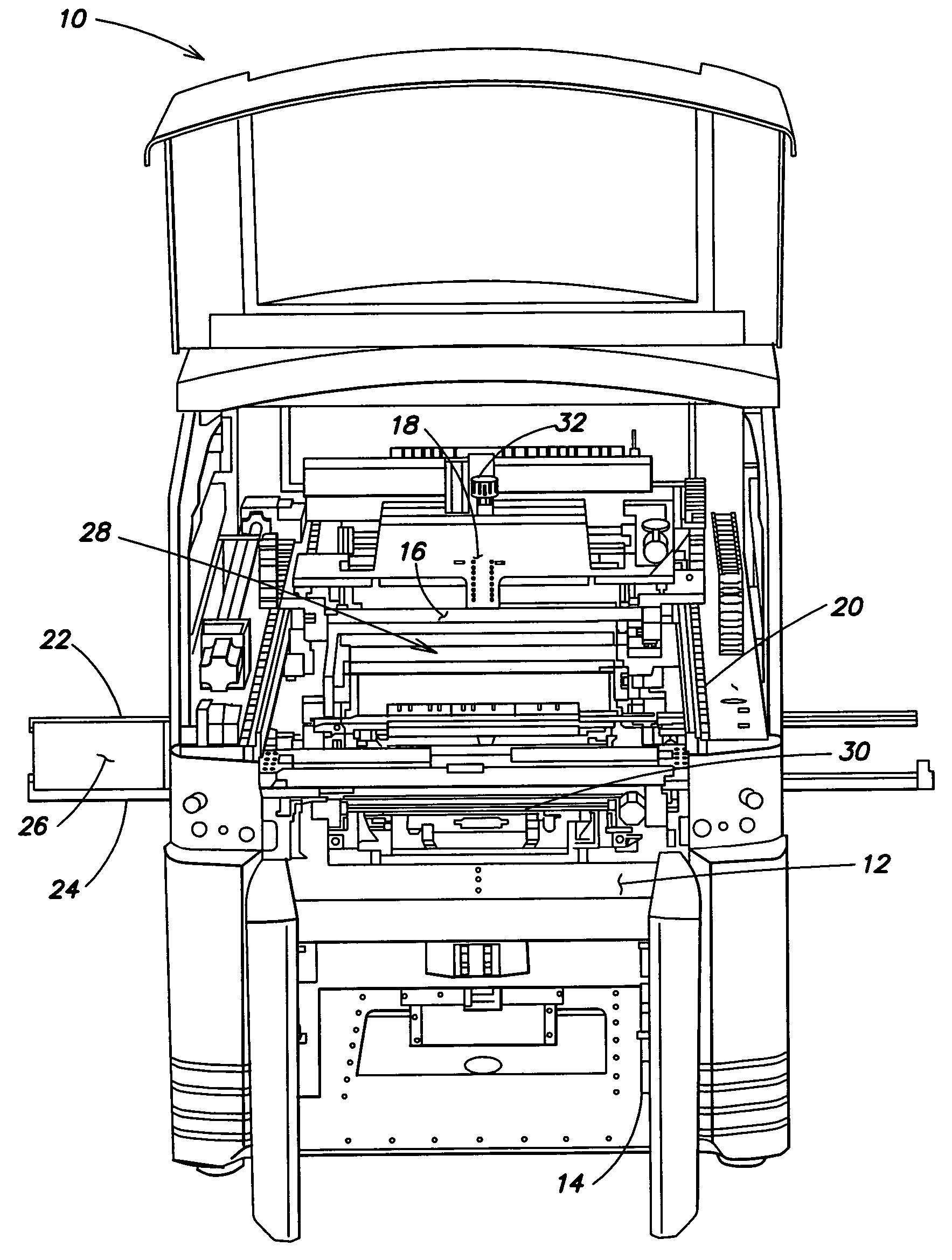

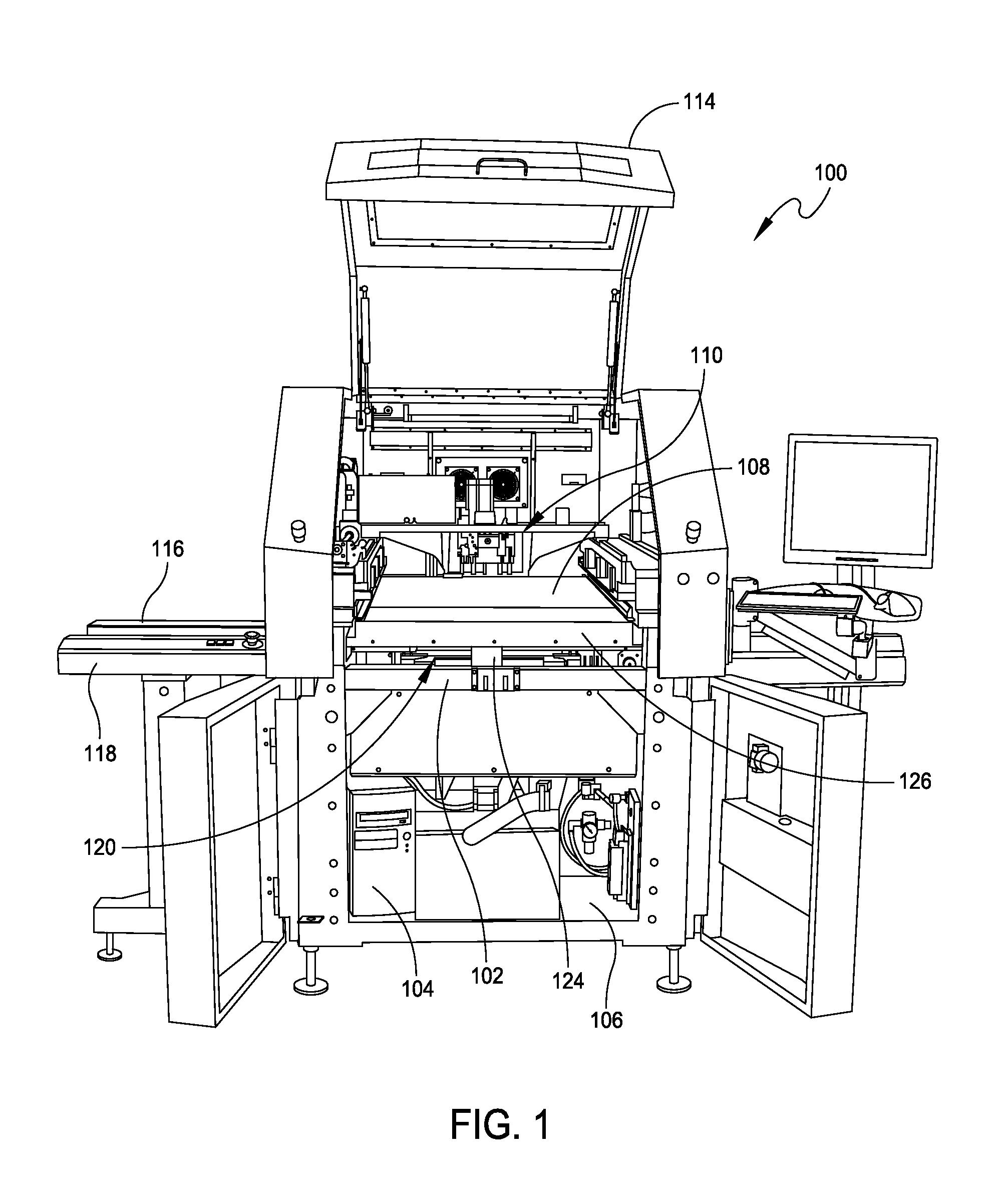

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100122633A1Printed circuit assemblingLiquid surface applicatorsProcess equipmentTransport system

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a material application position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including an upper track and a lower track disposed below the upper track.

Owner:ILLINOIS TOOL WORKS INC

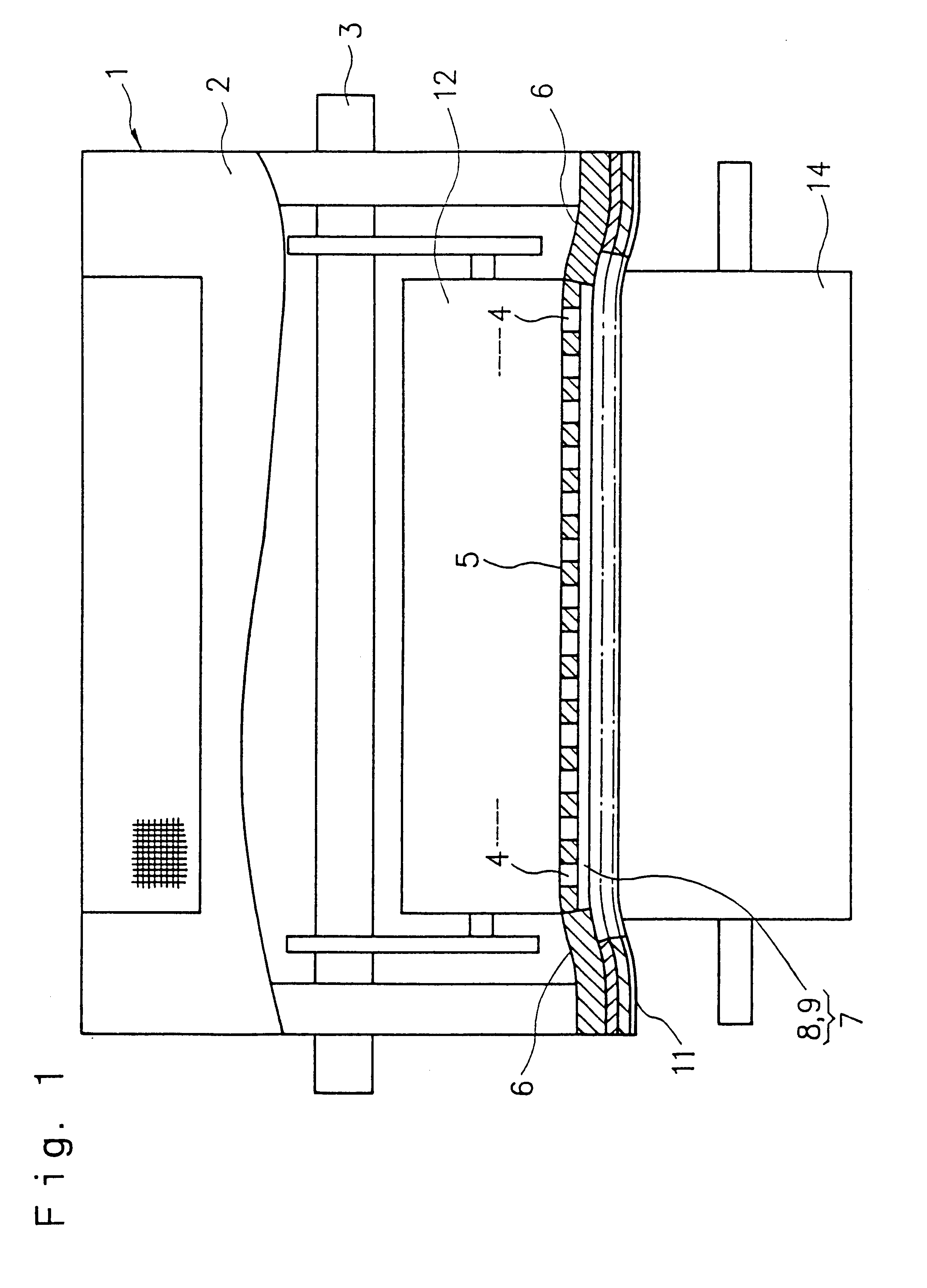

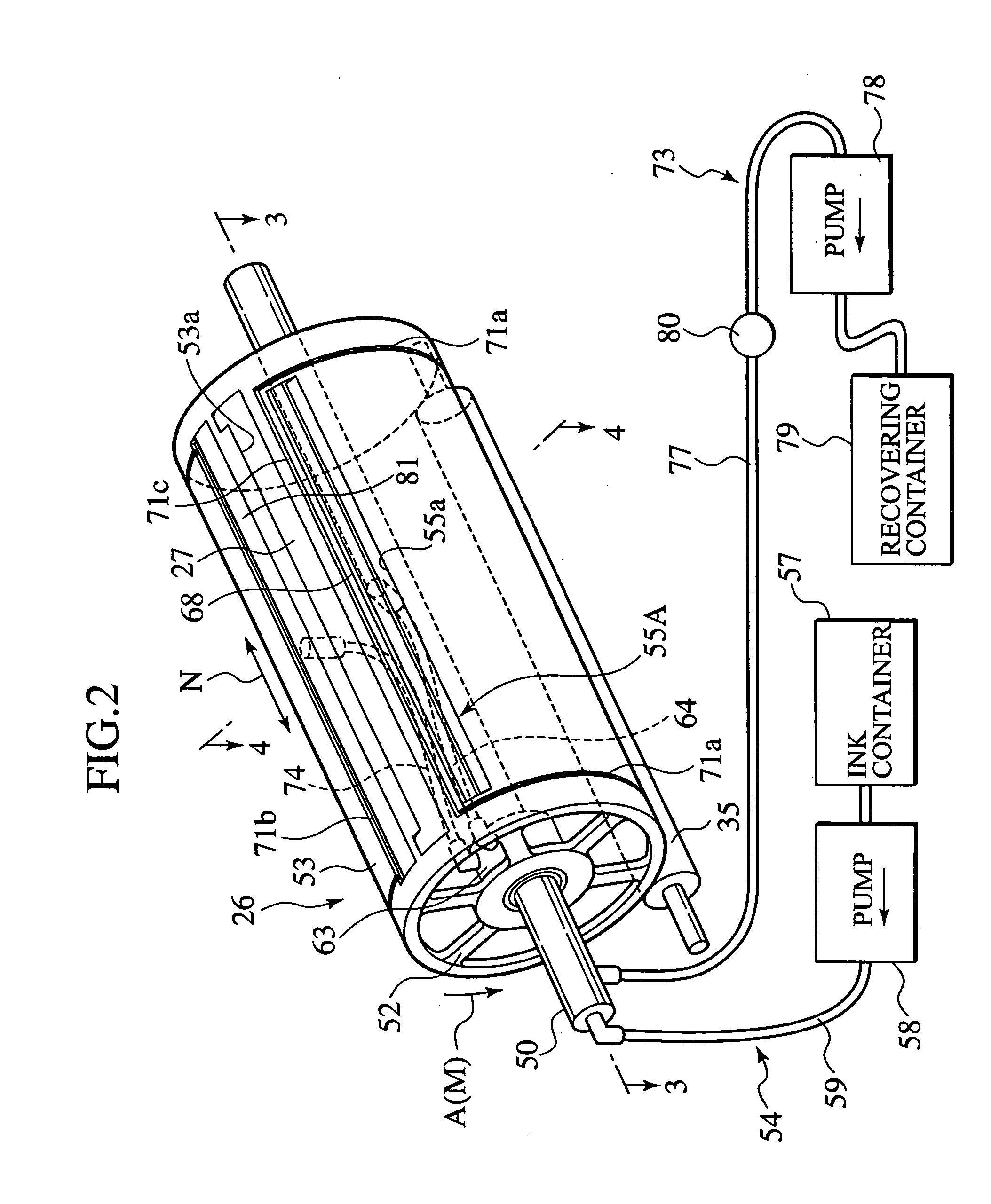

Stencil printing machine and stencil printing drum

A stencil printing machine has a printing drum having a cylindrical circumferential wall adapted to receive a perforated stencil sheet wrapped on an outer circumferential surface thereof and driven to rotate around a central axis thereof the circumferential wall having an opening portion with many through holes formed therein, a non-opening portion formed around the opening portion, and at least one recessed portion formed in at least one part of the opening portion adjacent to the non-opening portion in an axial direction of the circumferential wall; an ink supplying roller situated in the printing drum for supplying ink to an inner circumferential surface of the cylindrical circumferential wall of the printing drum; and a press roller situated adjacent to the printing drum and being urged against the outer circumferential surface of the cylindrical circumferential wall of the printing drum.

Owner:RISO KAGAKU CORP

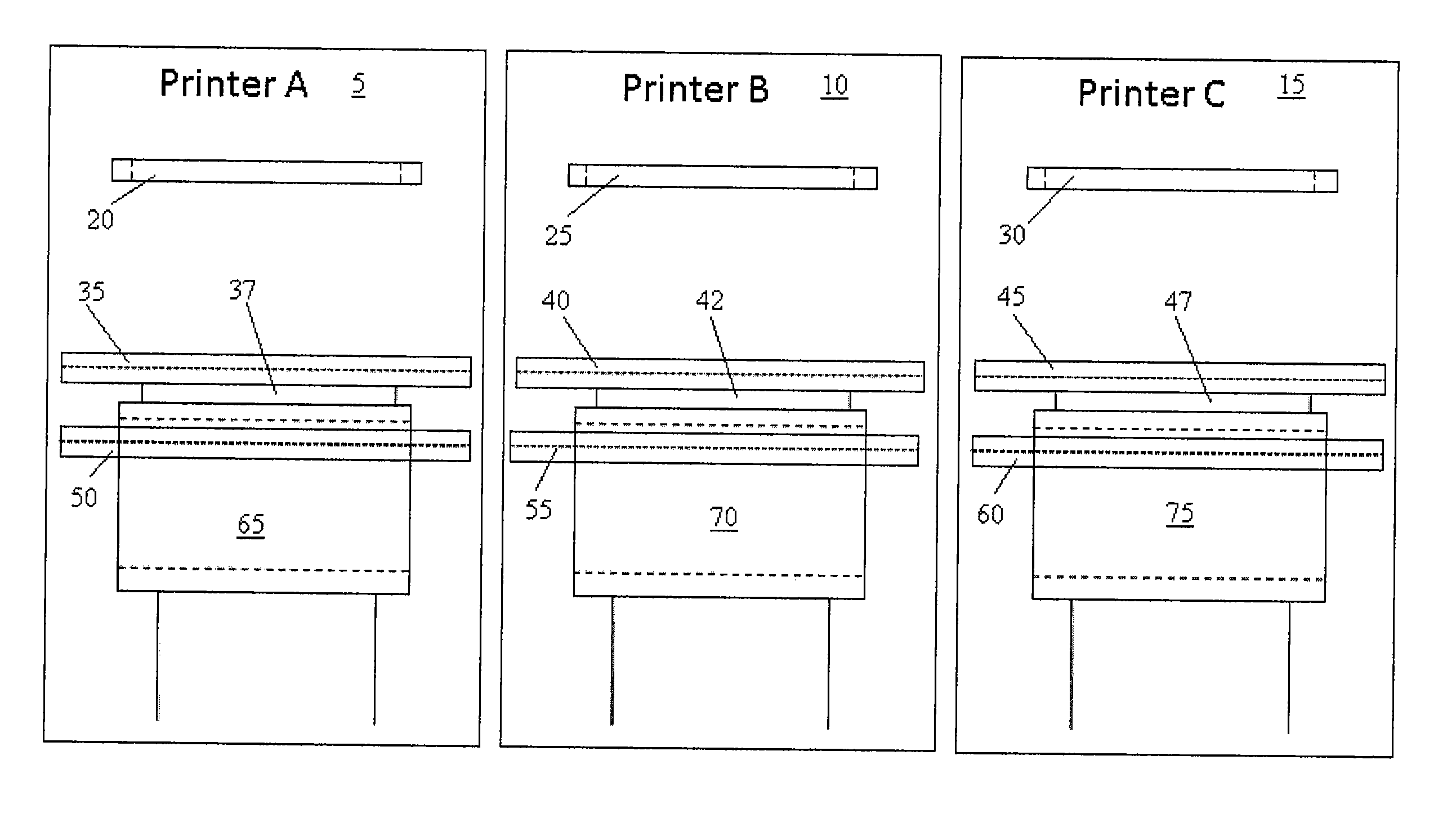

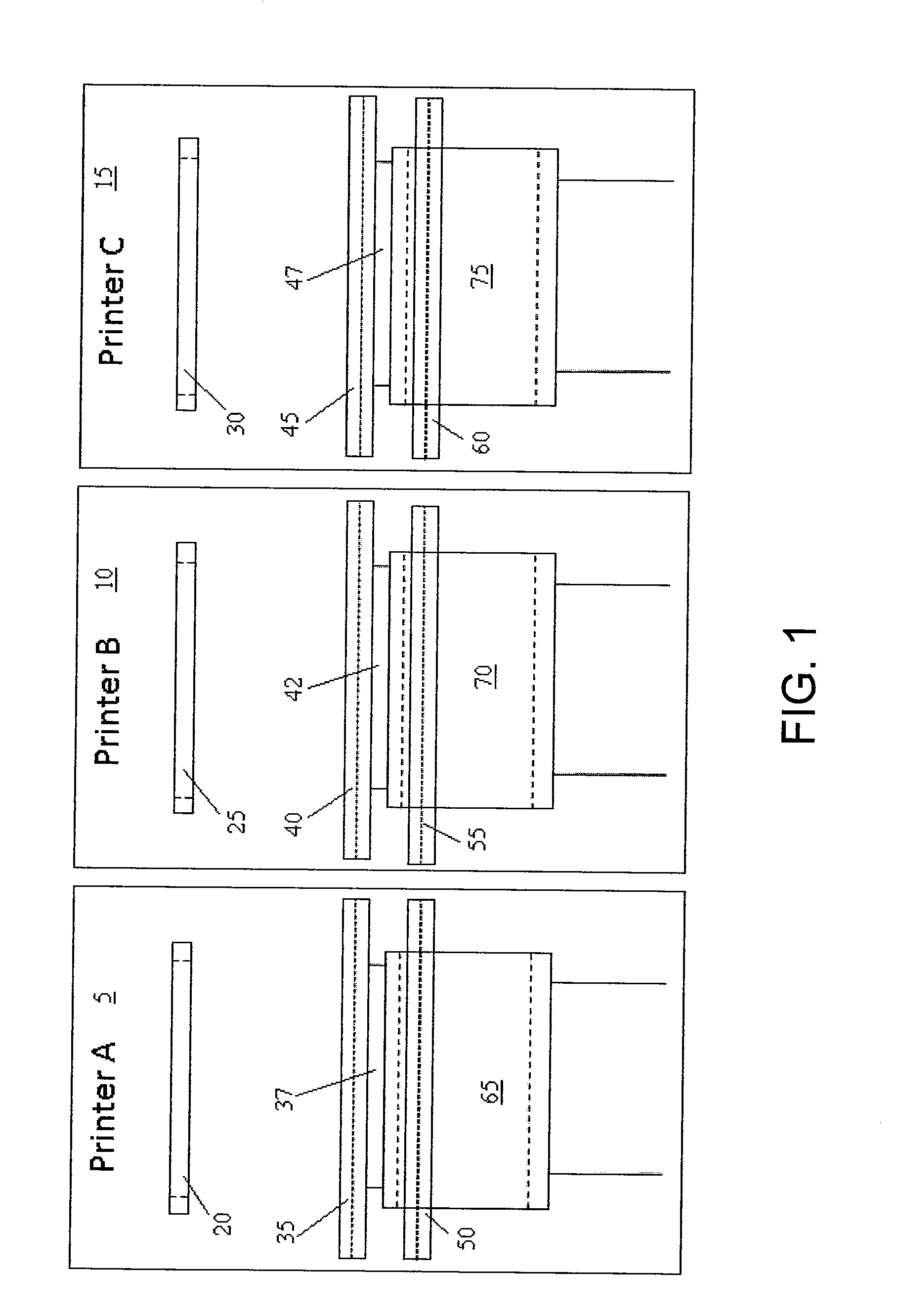

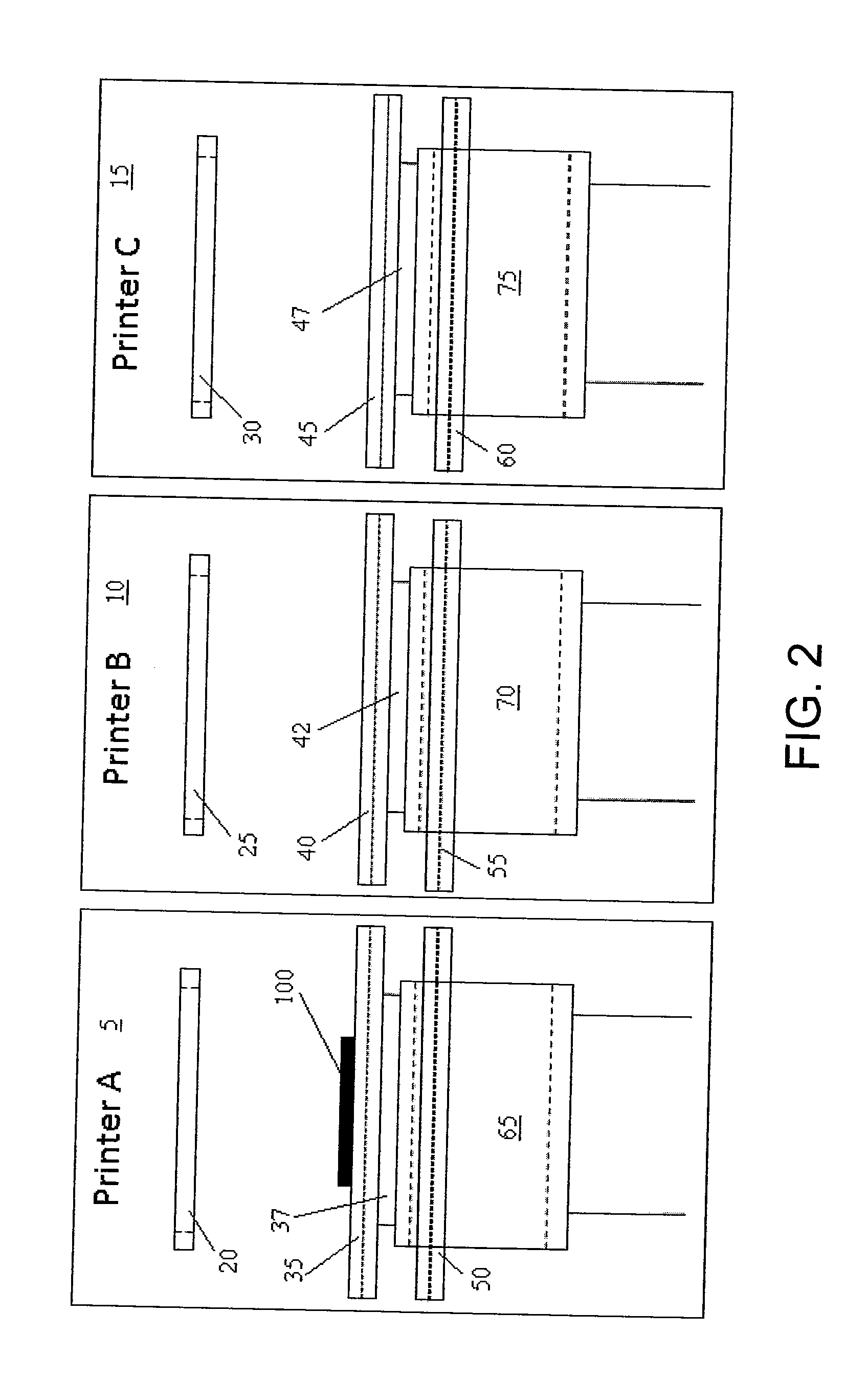

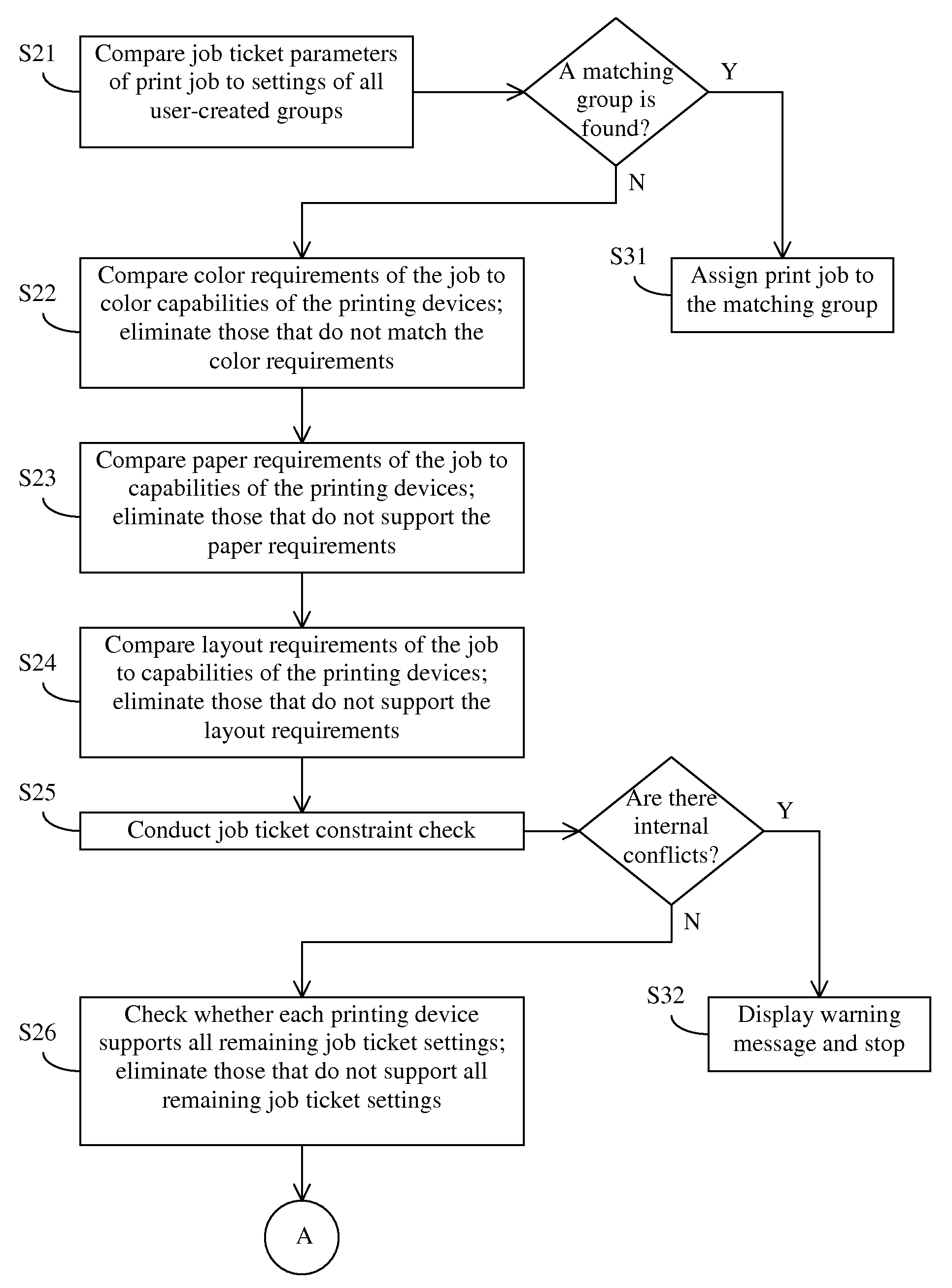

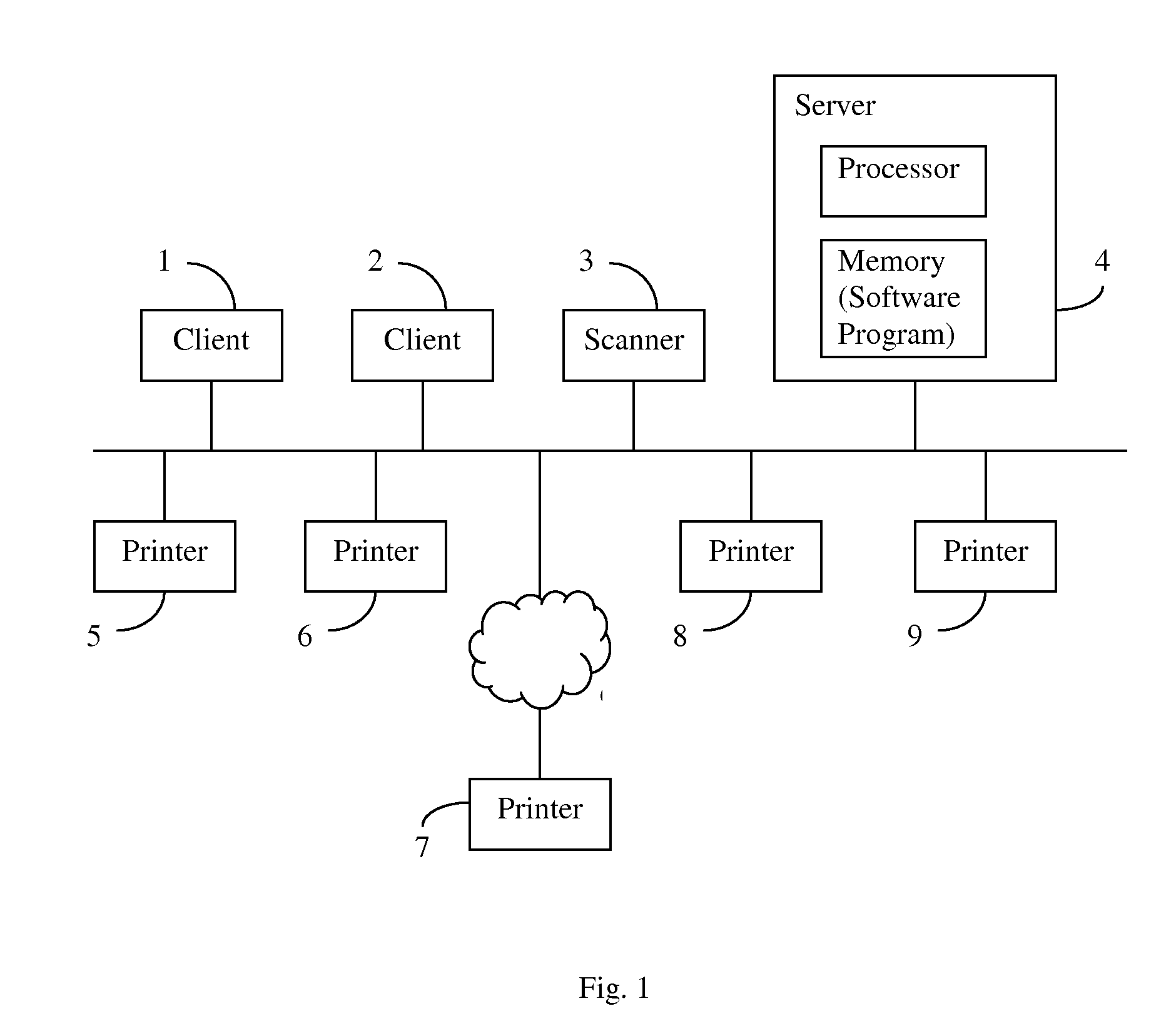

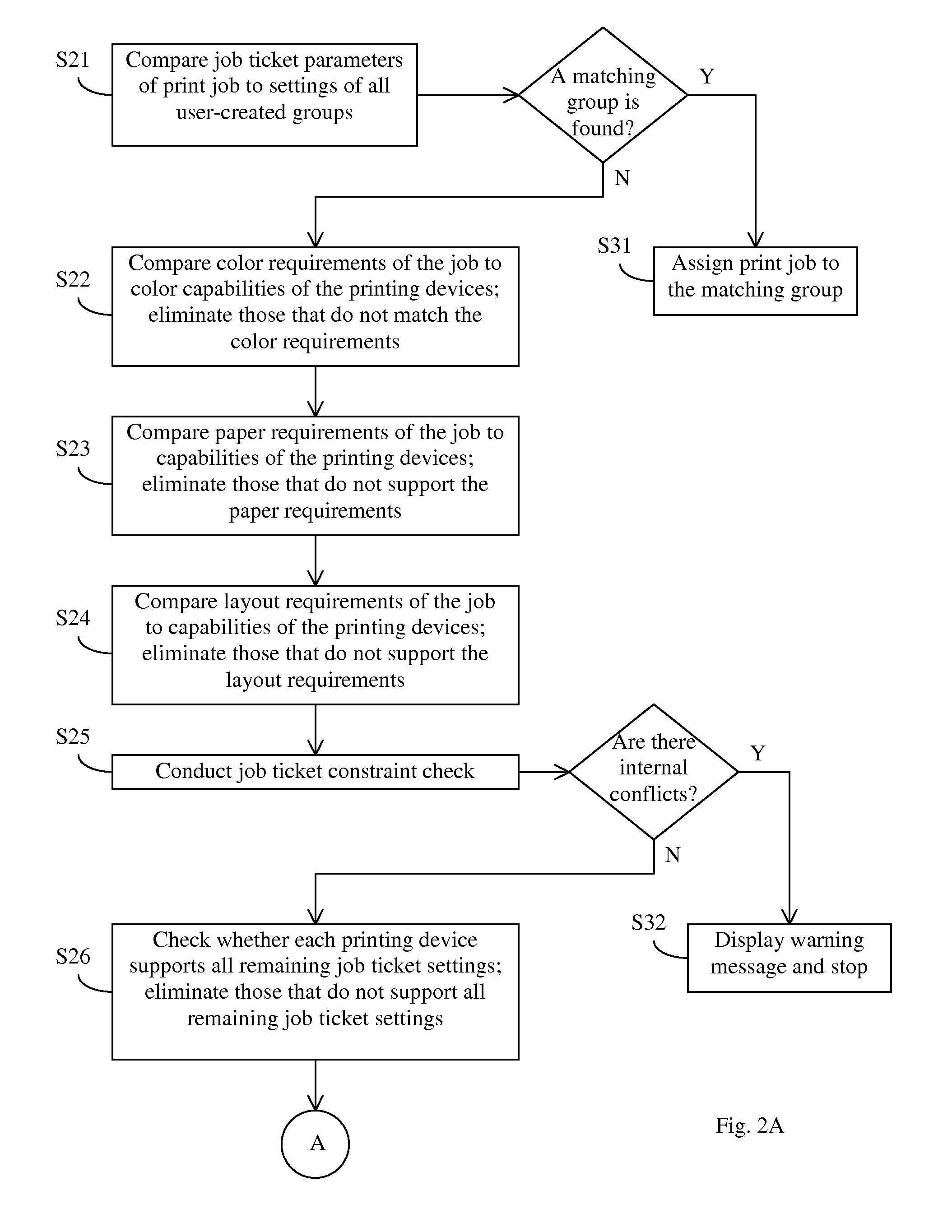

Print job assignment method allowing user-prioritization

ActiveUS20090201531A1Extended processing methodDigitally marking record carriersCharacter printing data arrangement from carrierComputer scienceJob assignment

A method implemented in a print job management apparatus for processing print jobs in a multiple-printer print shop environment is described. Each print job specifies job ticket parameters representing printing requirements. Each received job is processed by comparing the printing requirements of the job with capabilities of the printers. If a printer cannot satisfy all printing requirements of the job, it is eliminated as a candidate printer. Then, from all printers that can satisfy all printing requirements of the job, one printer is selected based on a pre-defined priority preference and the job is submitted to the selected printer. The printer priority preference is created by the operator based on cost and other factors. The operator can also select an alternative execution mode where, among all printers that can satisfy all requirements of the job, the one with minimum wait time is selected.

Owner:KONICA MINOLTA LAB U S A INC

Stencil printing machine, ink recovering method, image unevenness preventing method, and ink adapting method

InactiveUS20050056169A1Simple configurationRaise the ratioInking apparatusStencilling apparatusStencil printingRecovery method

A stencil printing machine has a rotatable printing drum including an outer peripheral wall of ink impermeable material. A stencil paper is mounted on the surface of the outer peripheral wall. An ink supplying mechanism includes an ink supplying unit in the outer peripheral wall of the printing drum. The ink supplying mechanism supplies ink from the ink supplying unit to the surface of the outer peripheral wall. A pressure roller presses a fed print sheet against the outer peripheral wall. An ink recovering mechanism recovers ink which has flown out of a maximum printing area of the outer peripheral wall of the printing drum. A pressing mechanism presses the stencil paper against the outer peripheral wall of the printing drum.

Owner:RISO KAGAKU CORP

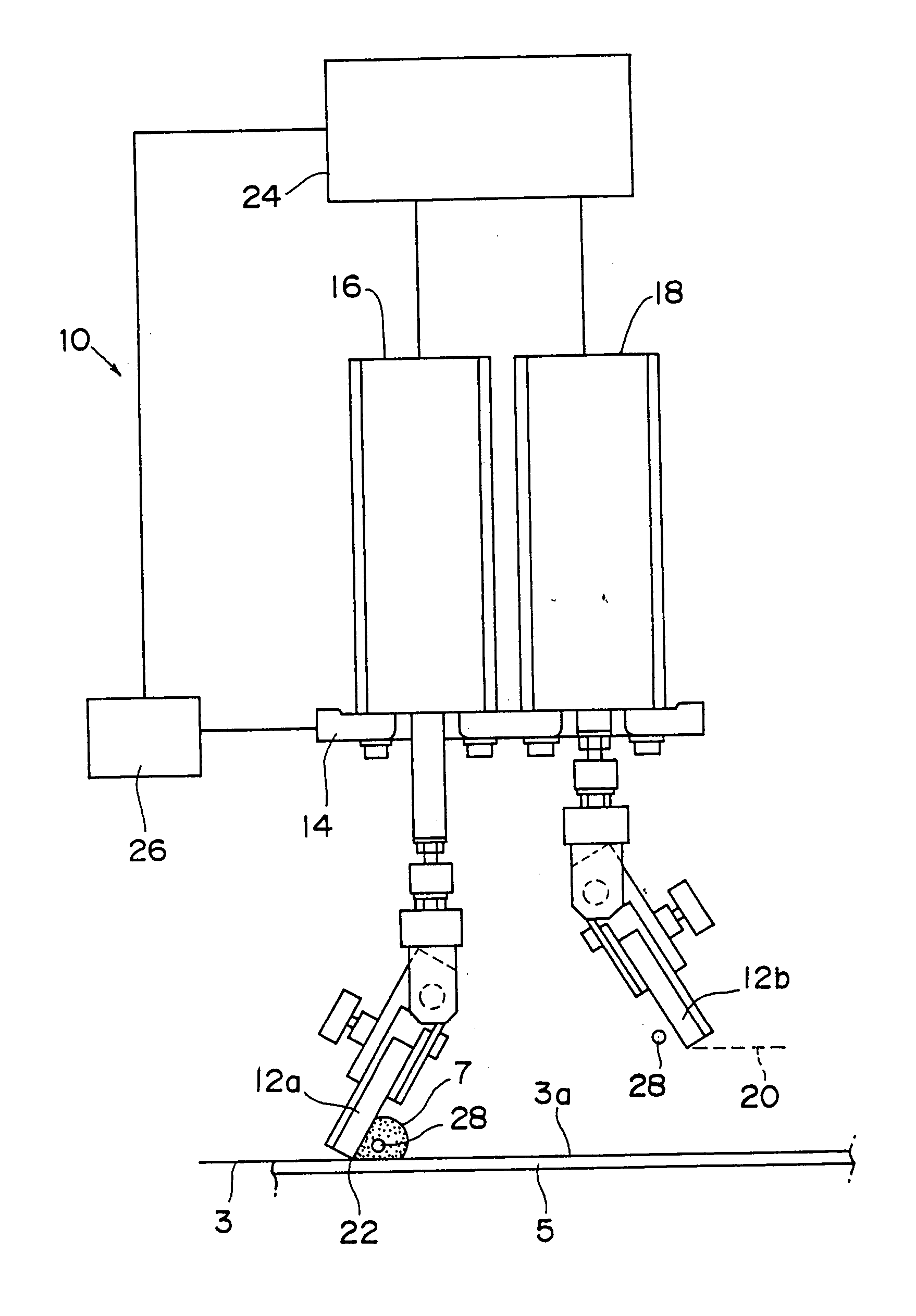

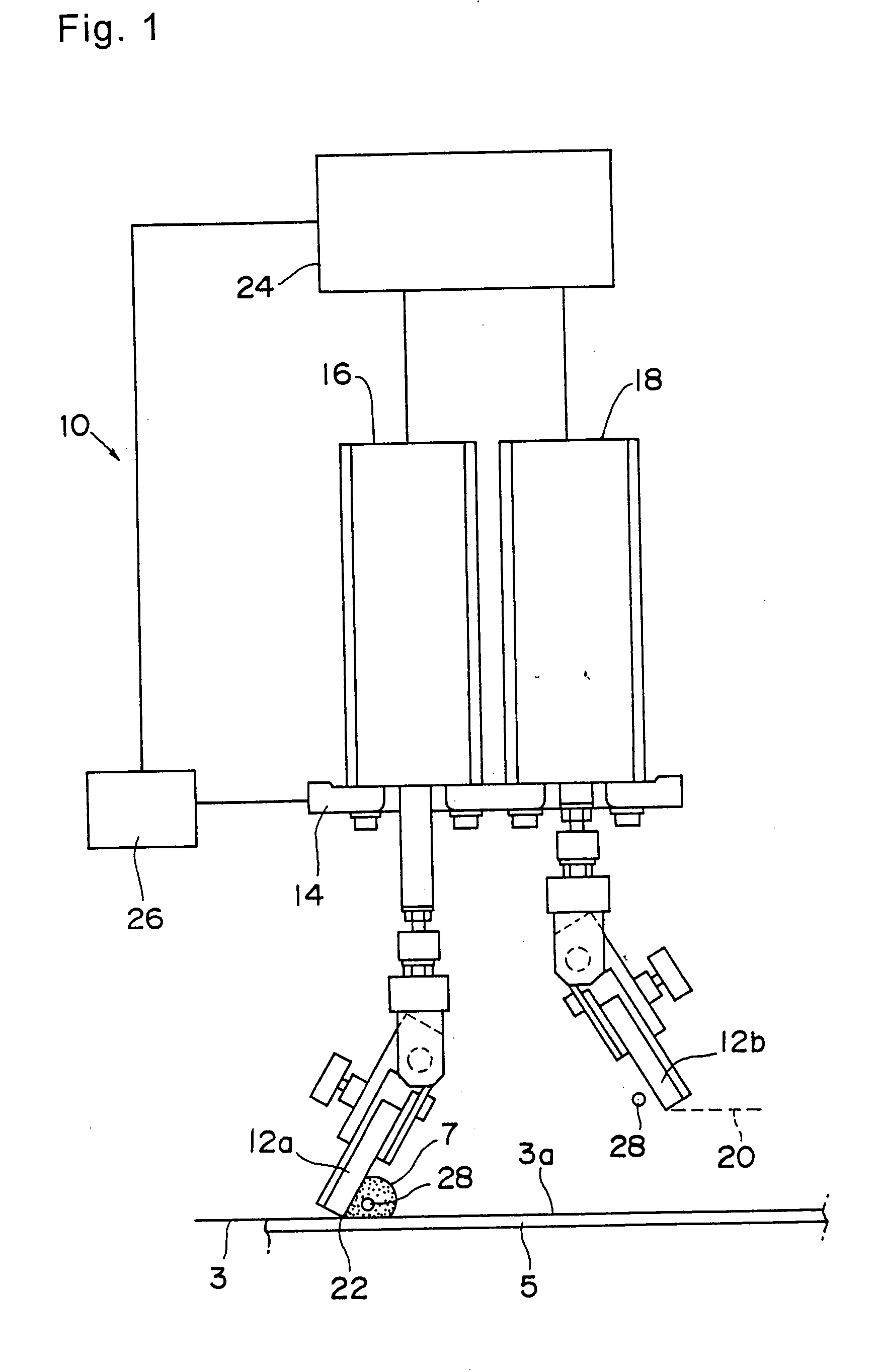

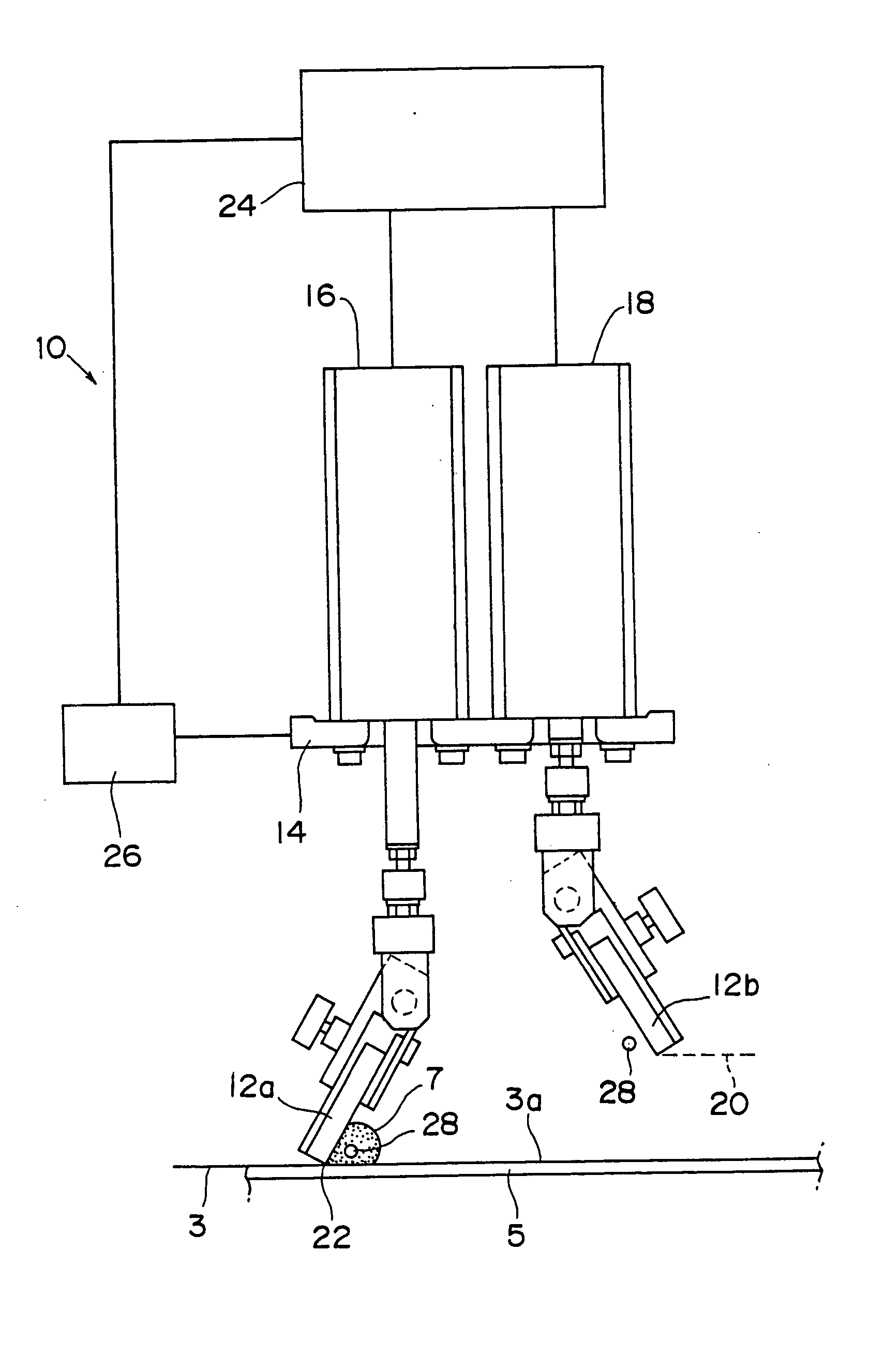

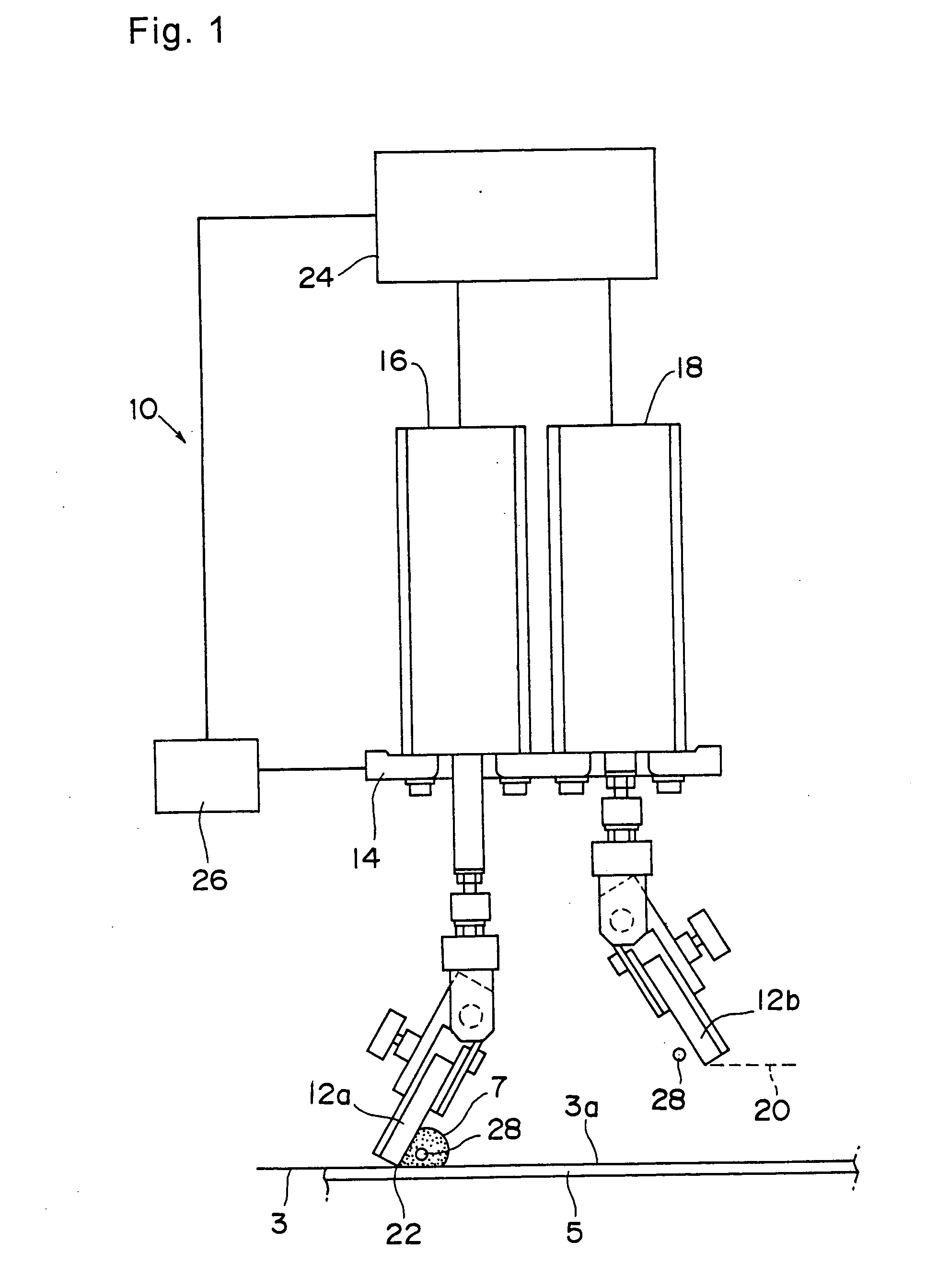

Solder past printing apparatus and printing method

InactiveUS20040108368A1Evenly filledTakingLiquid surface applicatorsScreen printersEngineeringSolder paste

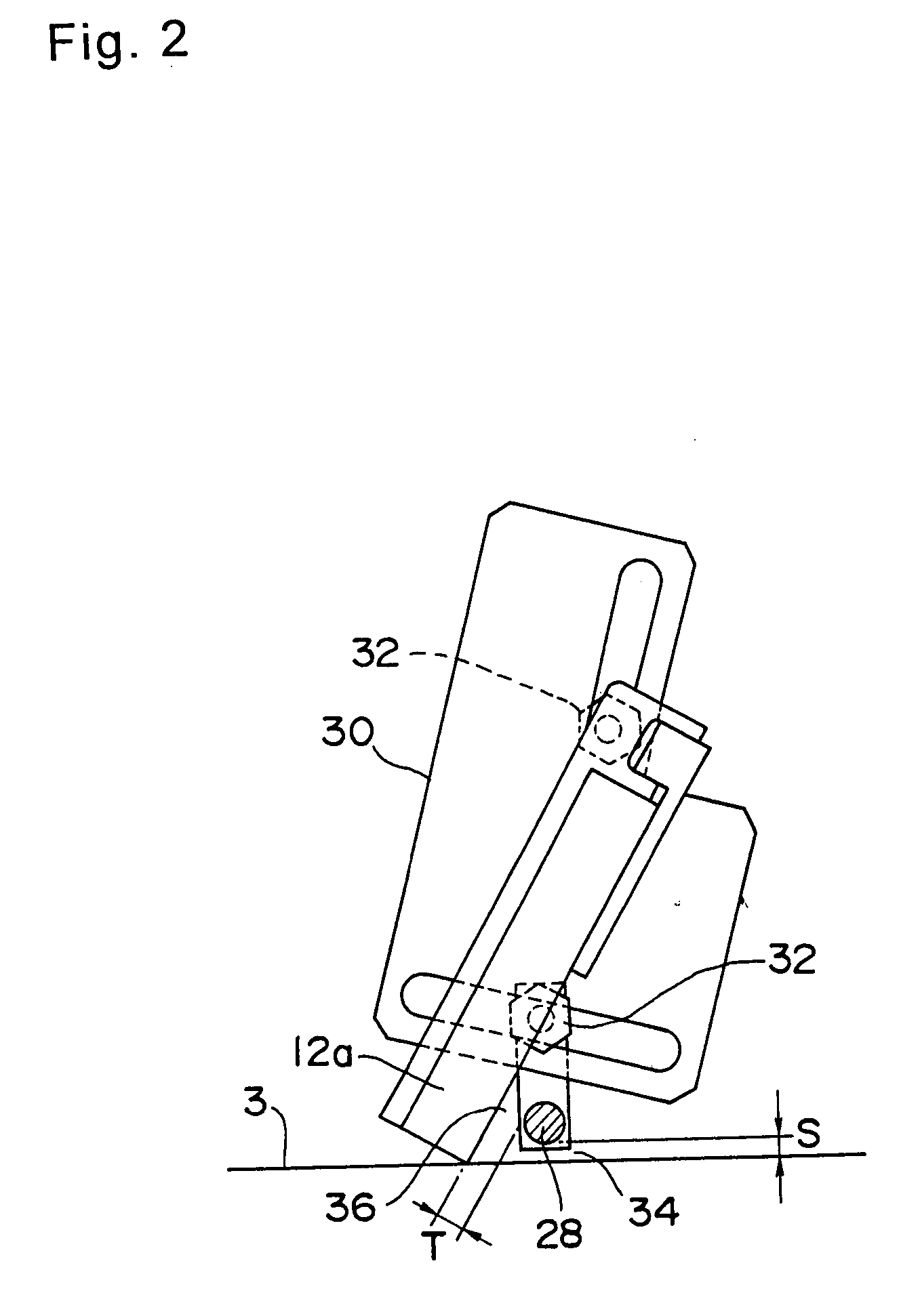

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

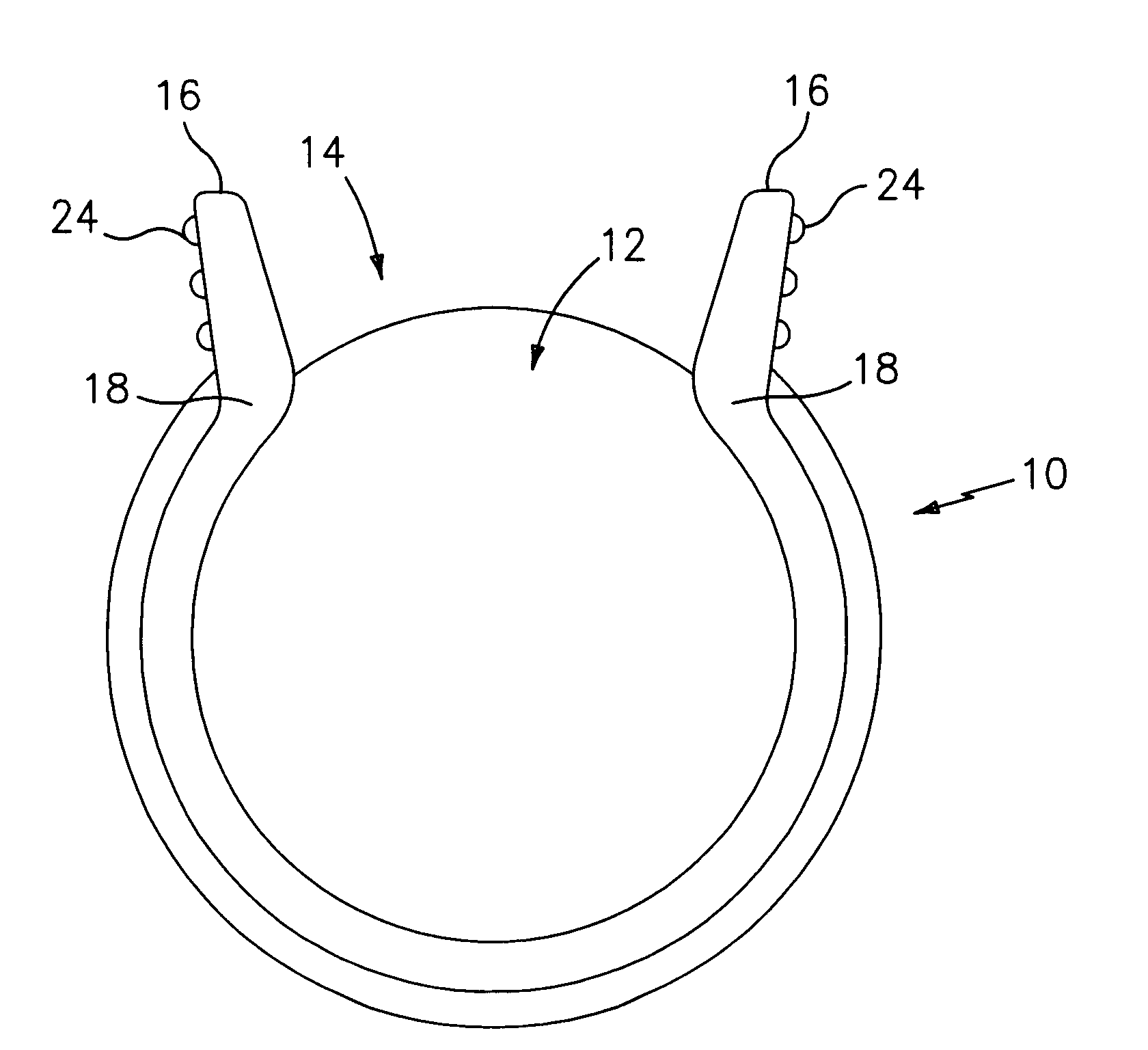

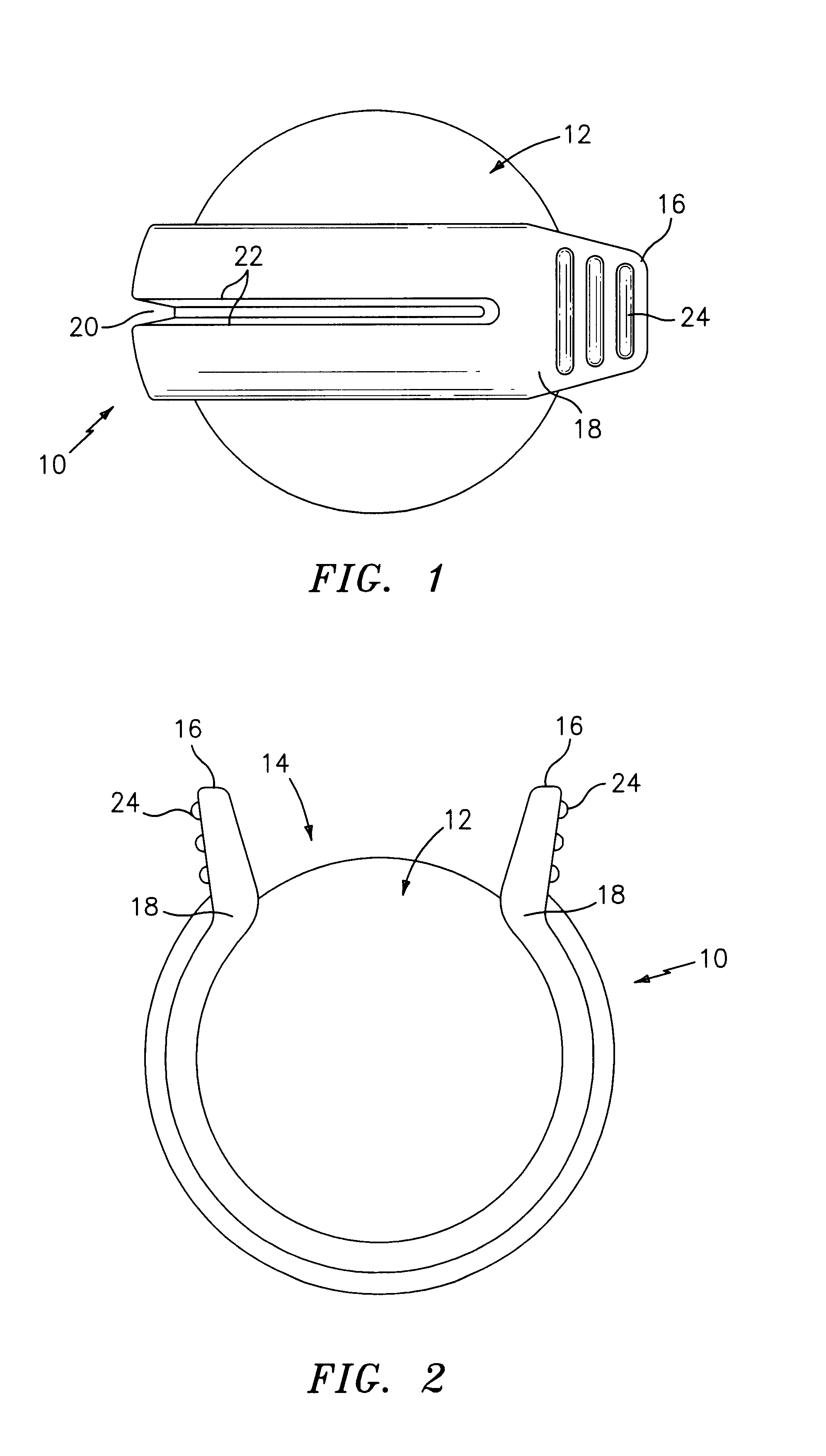

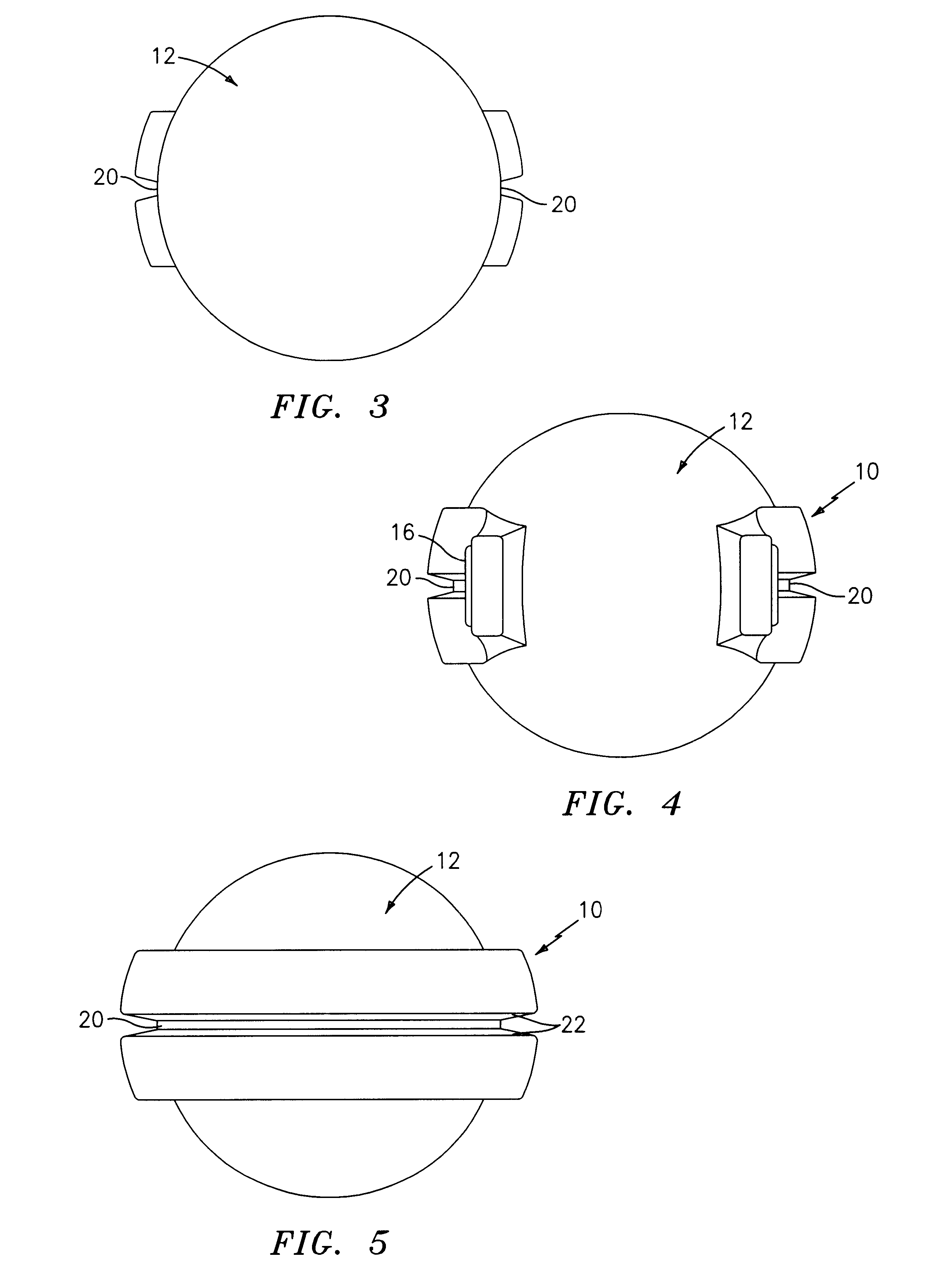

Golf ball stencil

InactiveUS6595128B2Prevent smudging poolingPrevent rotationLiquid surface applicatorsSpraying apparatusEngineeringGolf Ball

Owner:PARKS CASEY D

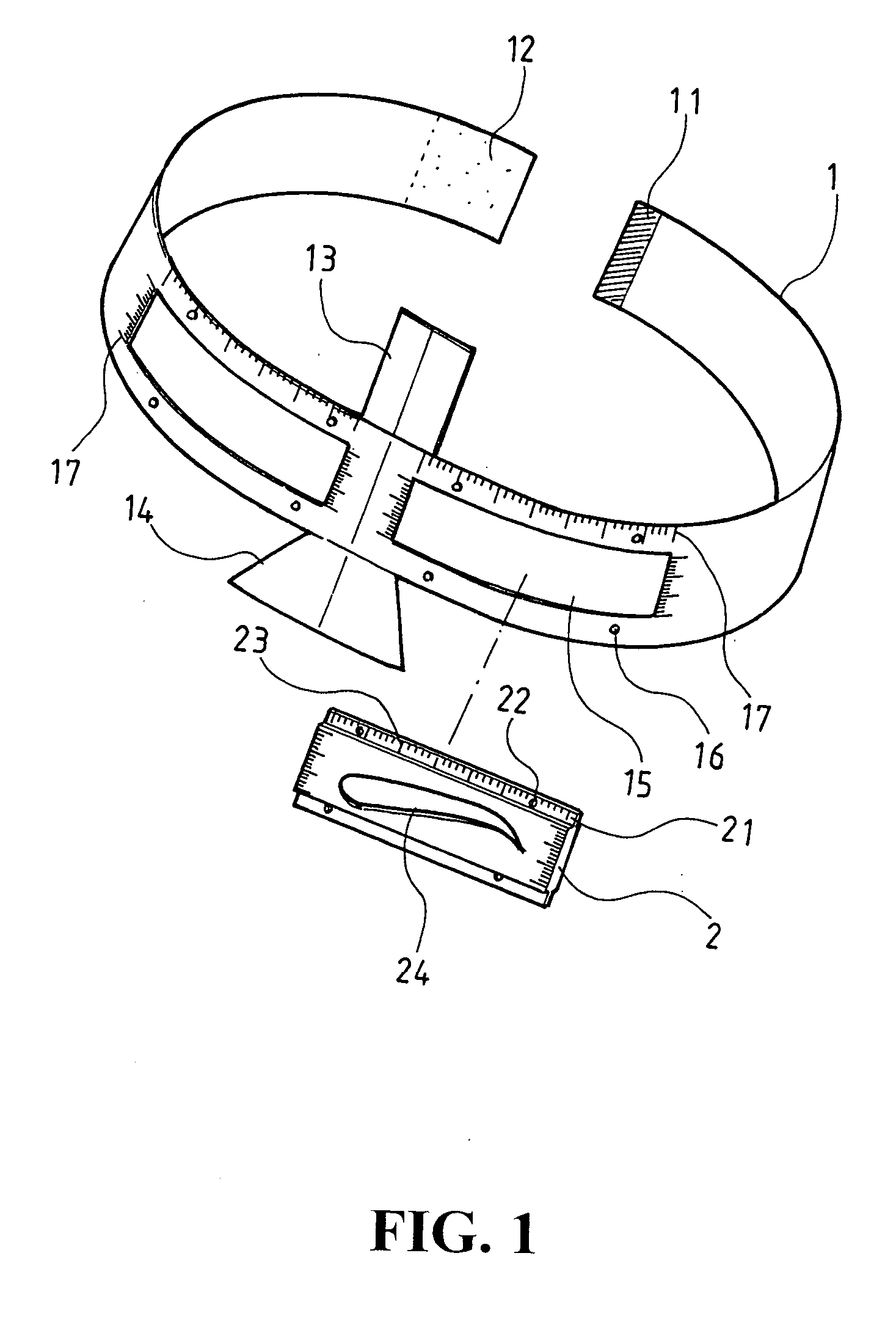

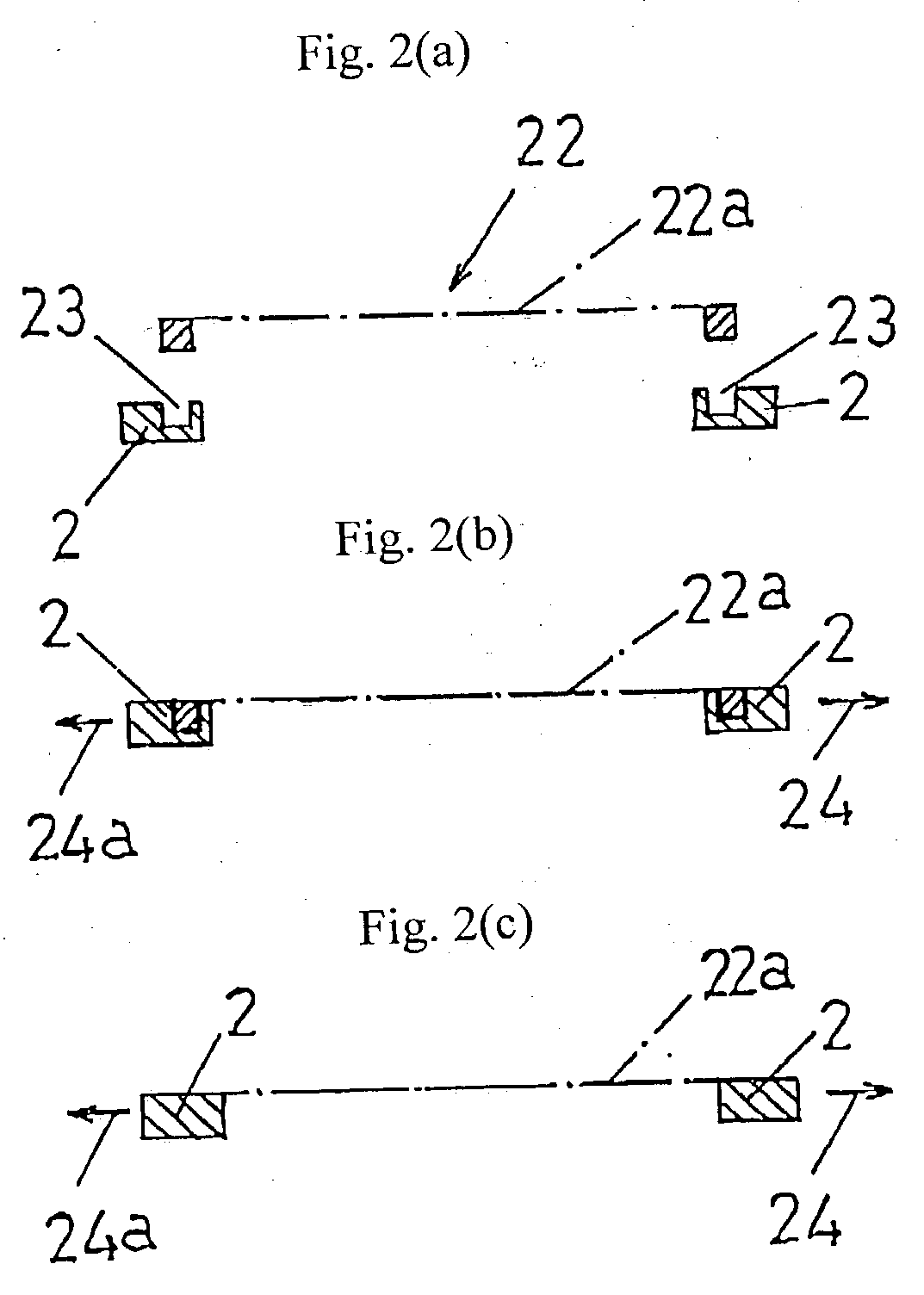

Screen printing screen, screen, screen frame, screen joining method, screen spreading method, painting canvas, advertisement sheet, and planer mirror

InactiveUS20050034614A1Easy to useControl tensionScreensLiquid surface applicatorsScreen printingTypes of mesh

The present invention relates to a screen for screen printing. More particularly, the structure of the screen can have different types of mesh or sheets joined together. The present invention also relates to a method of detachably spreading a screen to a screen frame.

Owner:KASUYA FURETABU

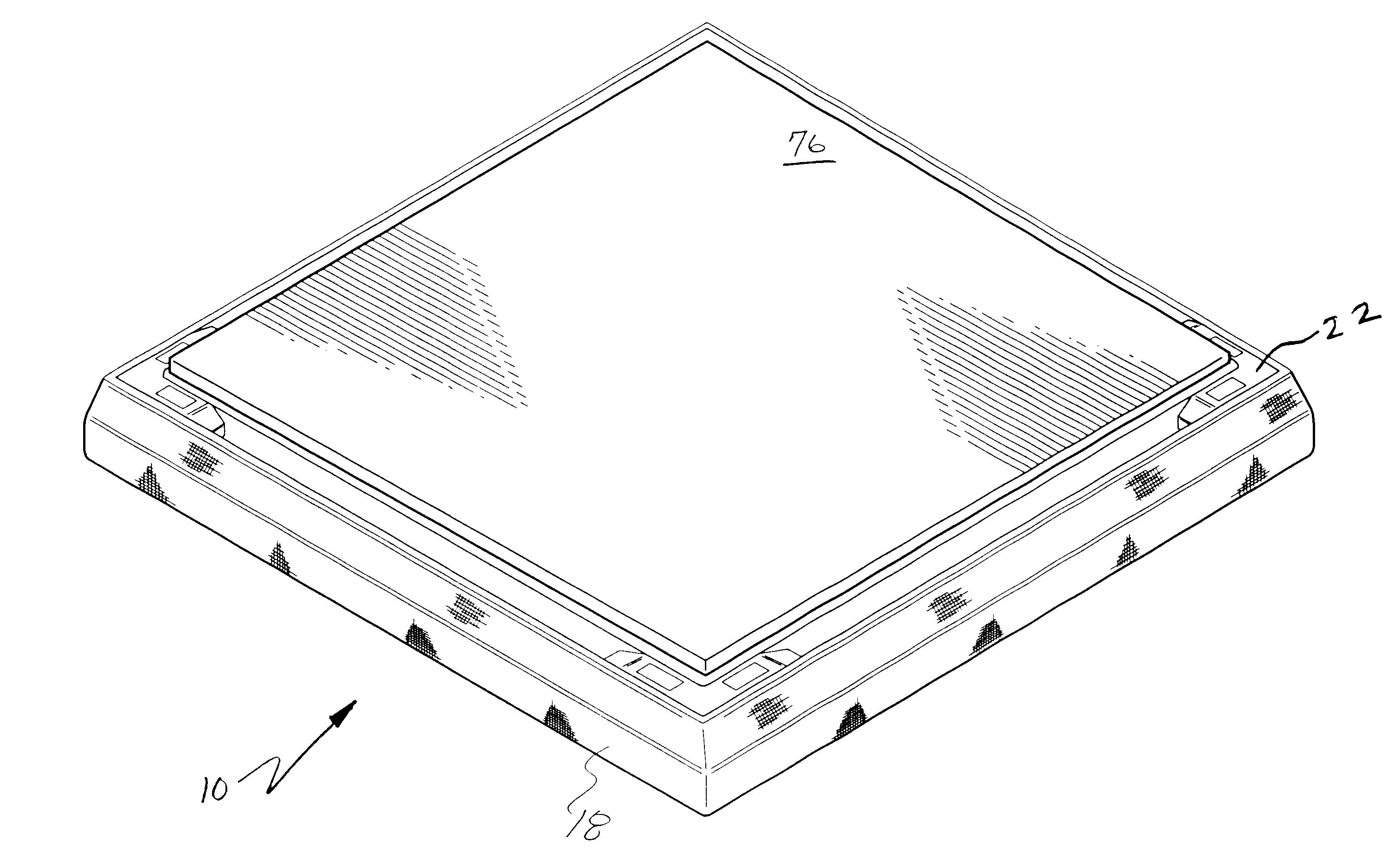

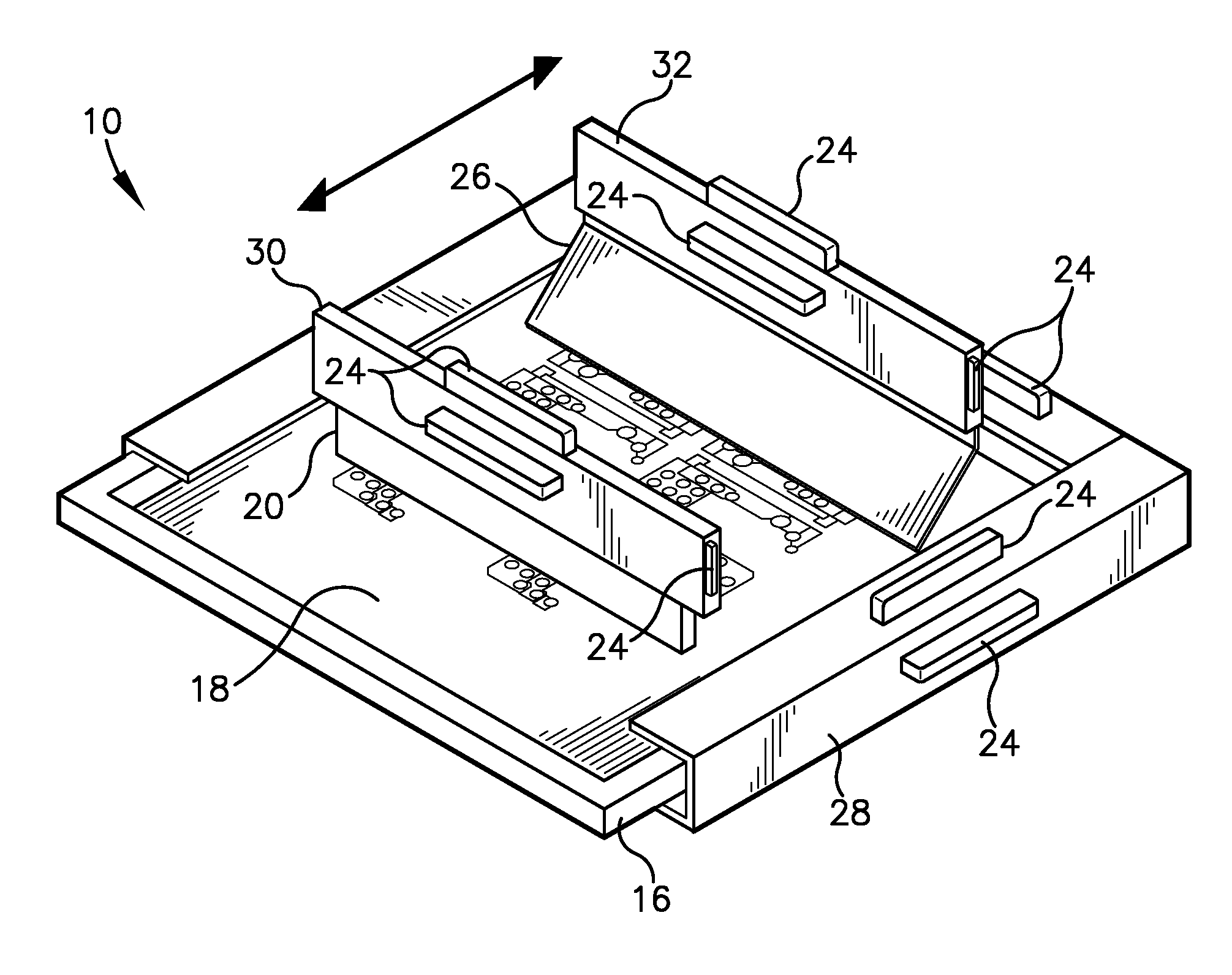

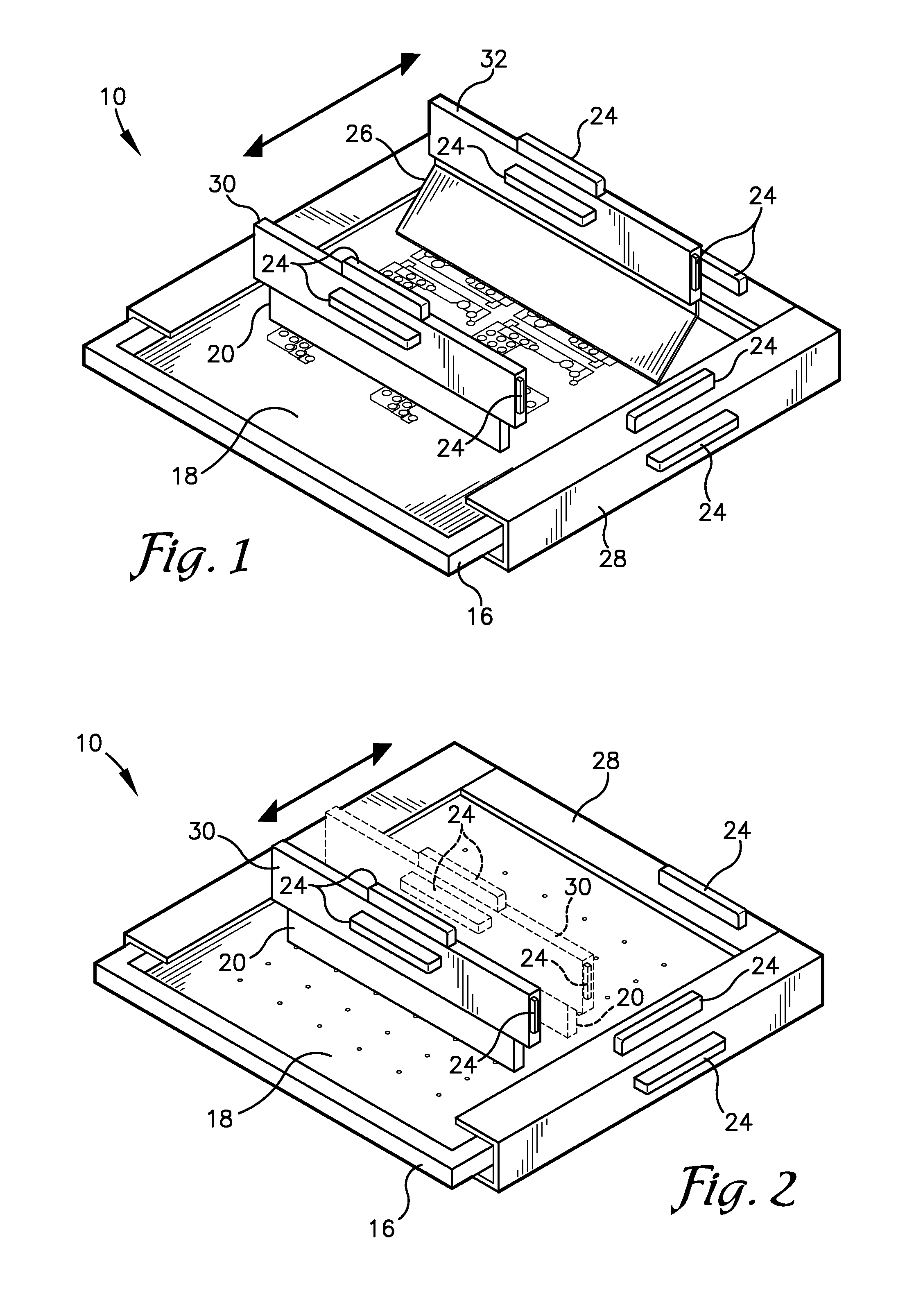

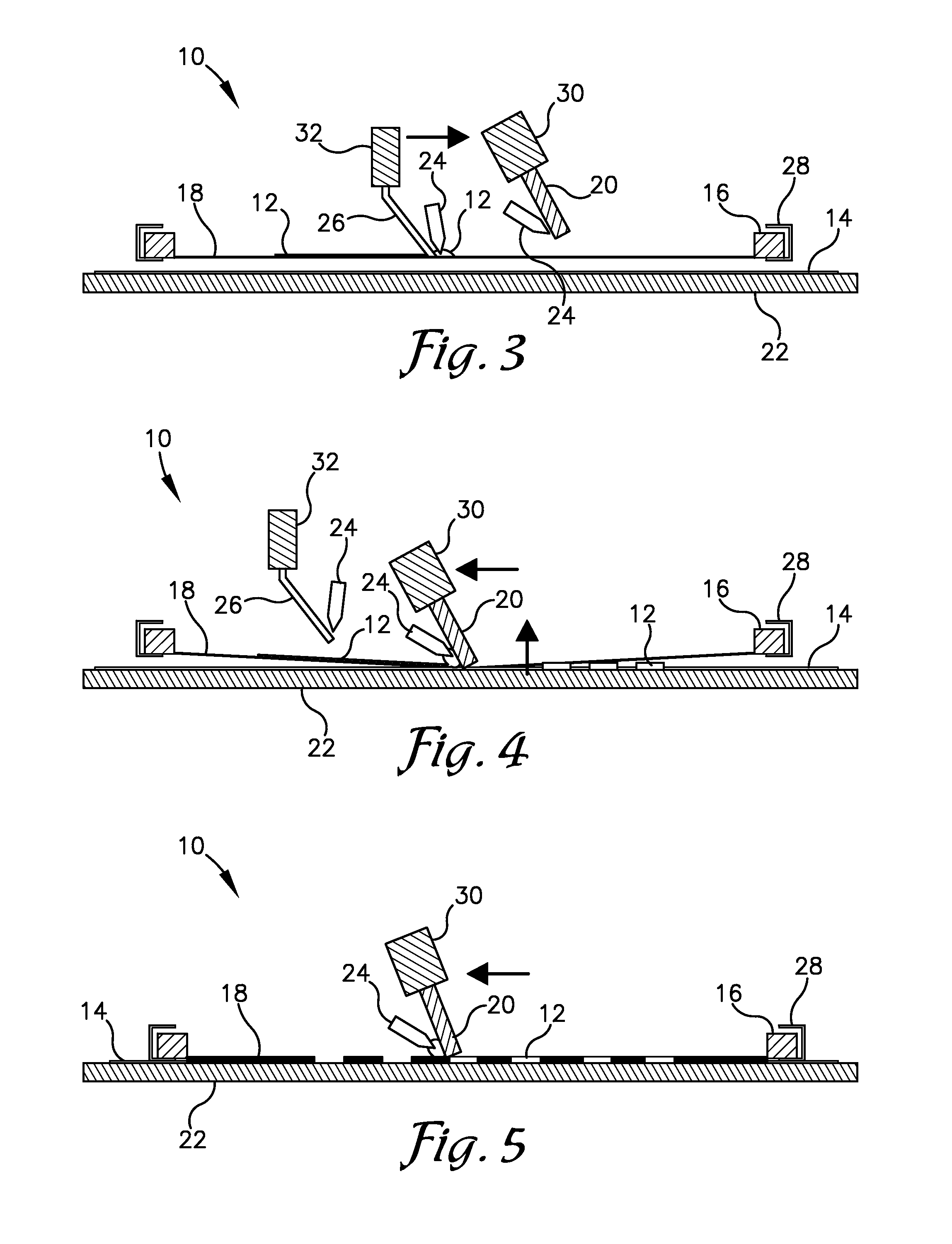

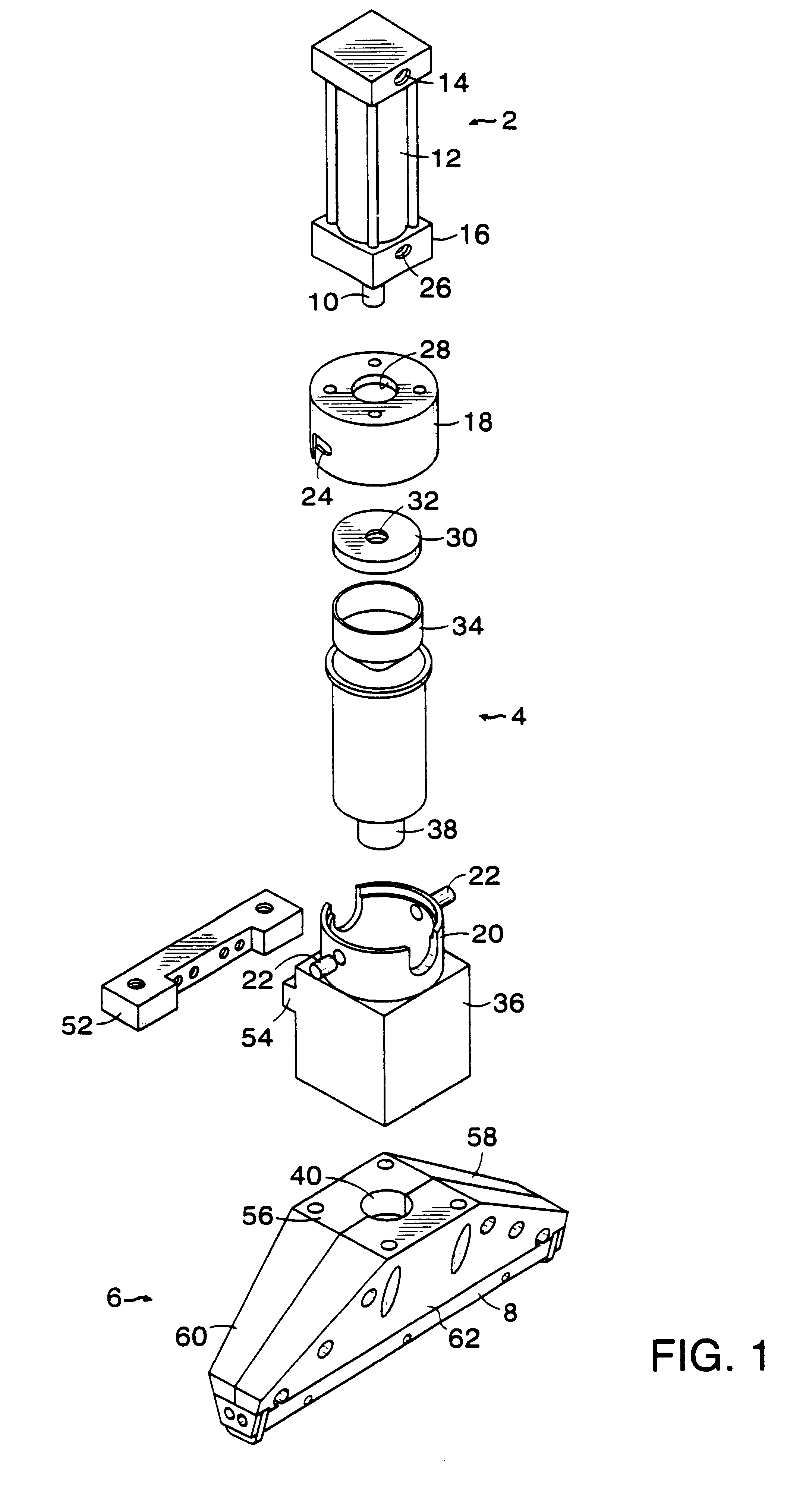

Combination stencil printer and dispenser and related methods

A combination stencil printer and dispenser includes a frame, a movable stencil coupled to the frame, a substrate support coupled to the frame to support a substrate in a print position, and a print head coupled to the frame to deposit and print viscous material over the stencil. The combination stencil printer and dispenser further includes a dispenser mounted on the movable stencil to dispense viscous material on the substrate when the substrate is in the print position. In other embodiments, the dispenser can be mounted on a stencil wiper or on an independent gantry provided within the combination stencil printer and dispenser.

Owner:ILLINOIS TOOL WORKS INC

Solder paste printing apparatus and printing method

InactiveUS20040035306A1TakingReduce printing timeMechanical cleaningInking apparatusEngineeringPrinting ink

When solder paste passes through a first gap (34) located between a pressurizing member (28) and a printing mask (3) during solder paste printing, a pressure directed toward the printing mask is applied from the pressurizing member to the solder paste.

Owner:PANASONIC CORP

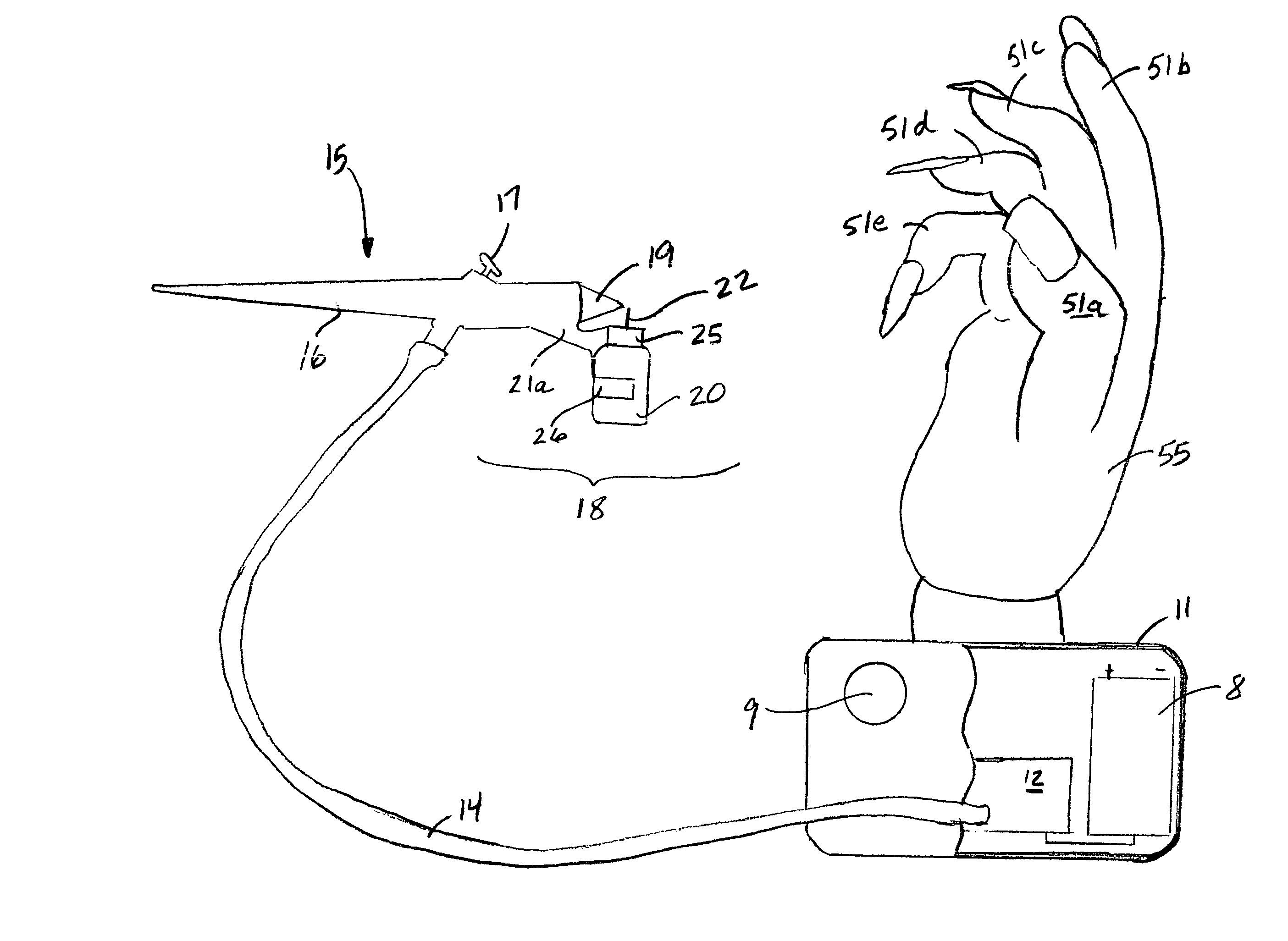

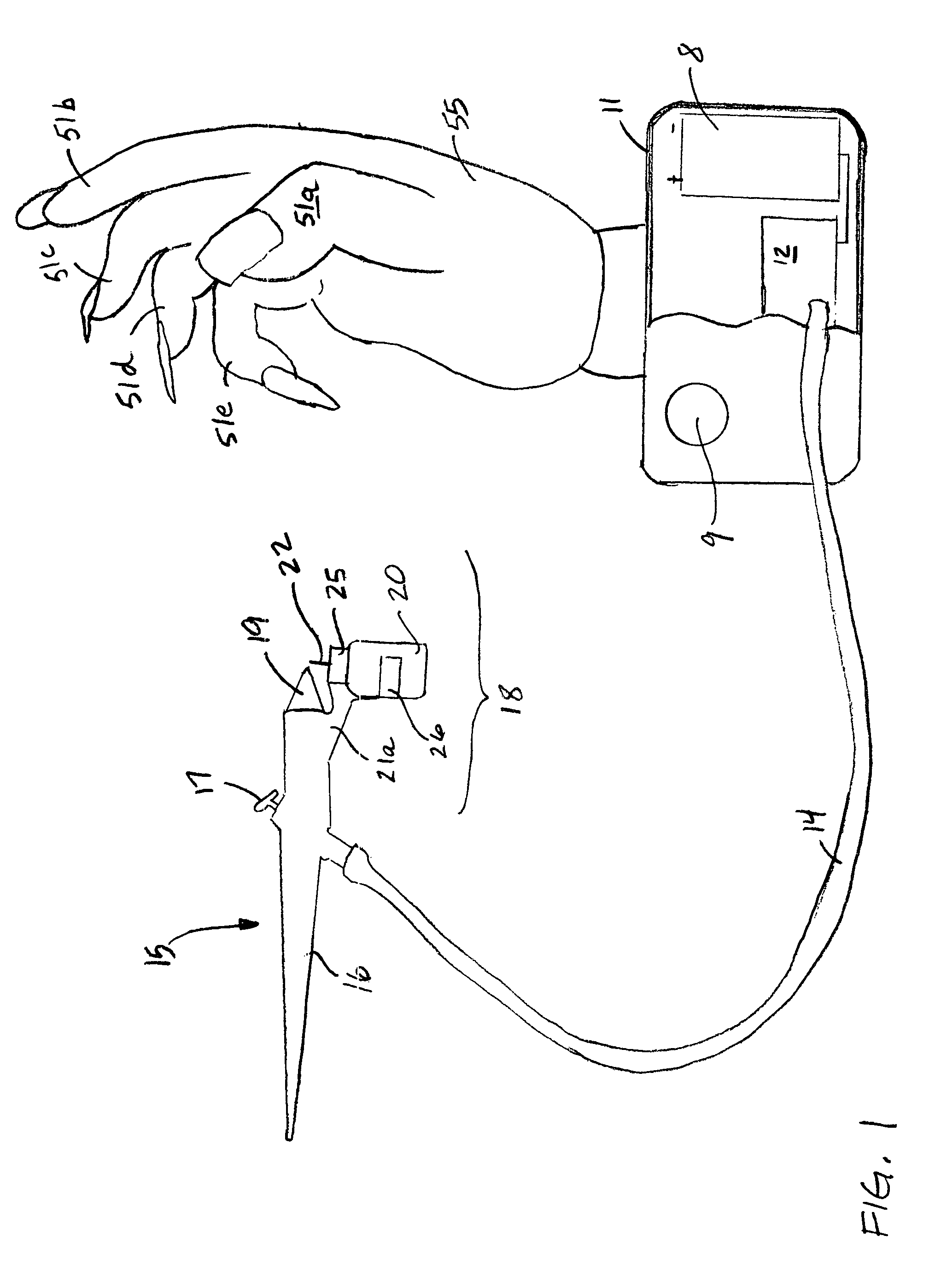

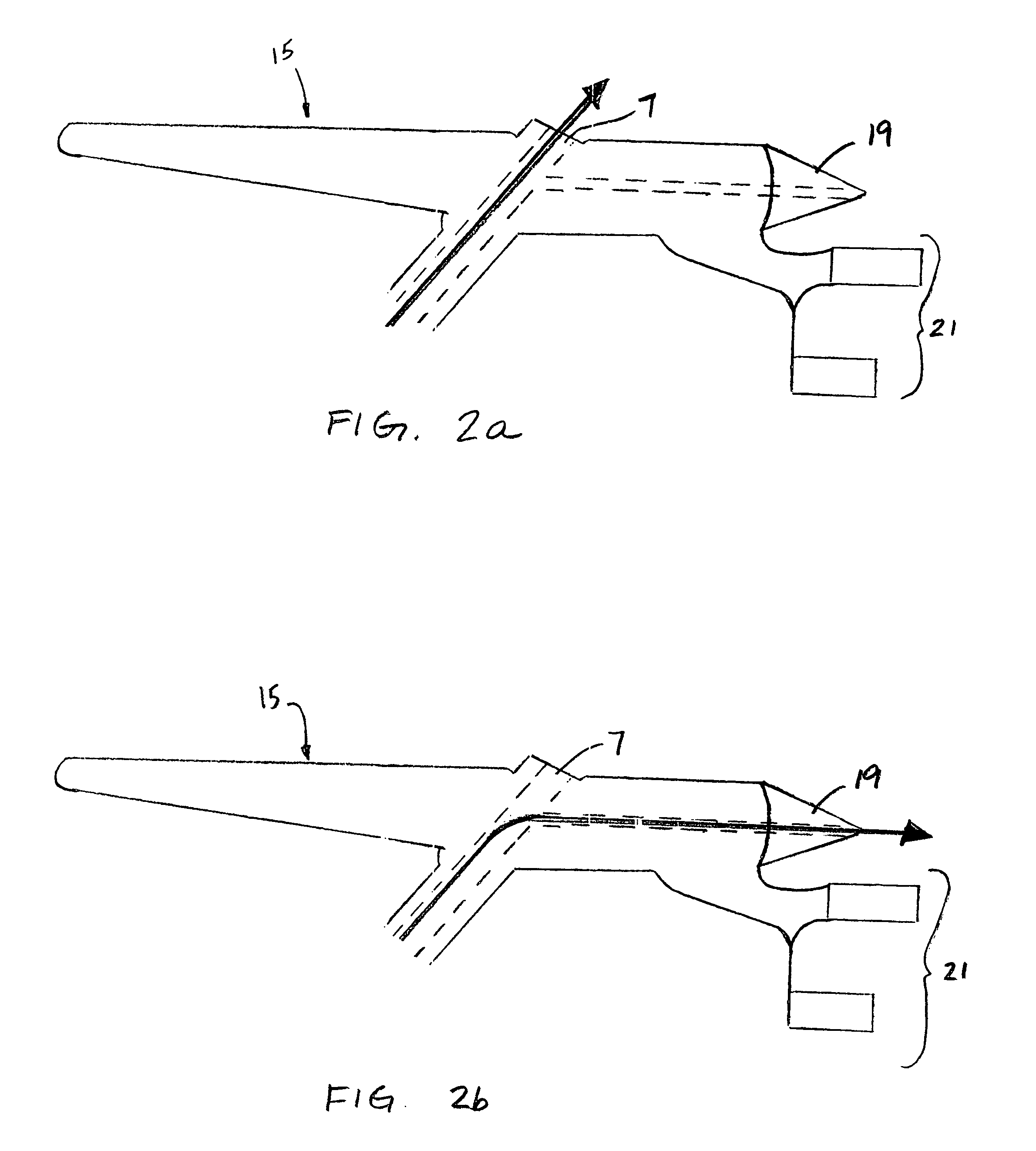

Portable airbrush with improved paint mechanism and stencil assembly

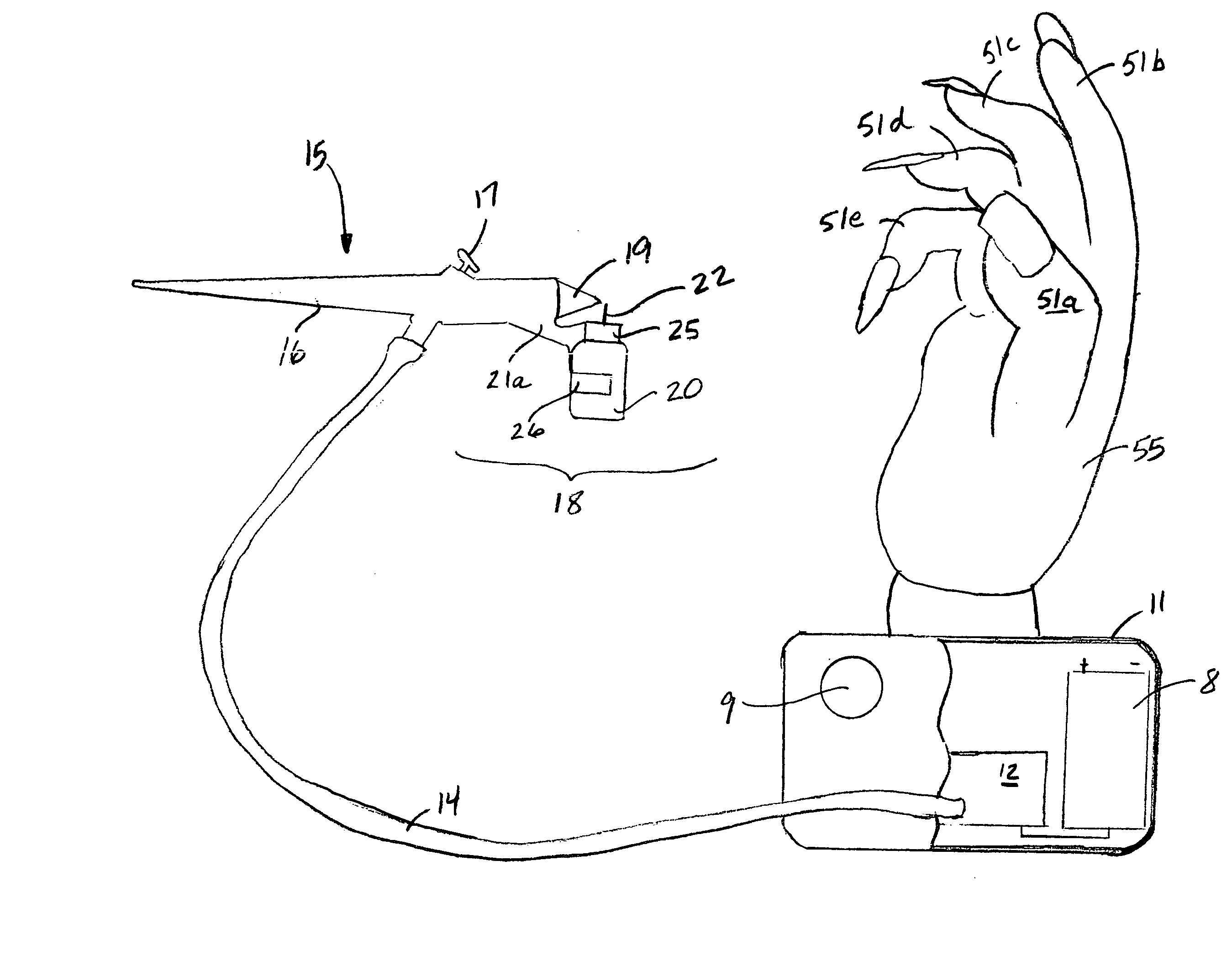

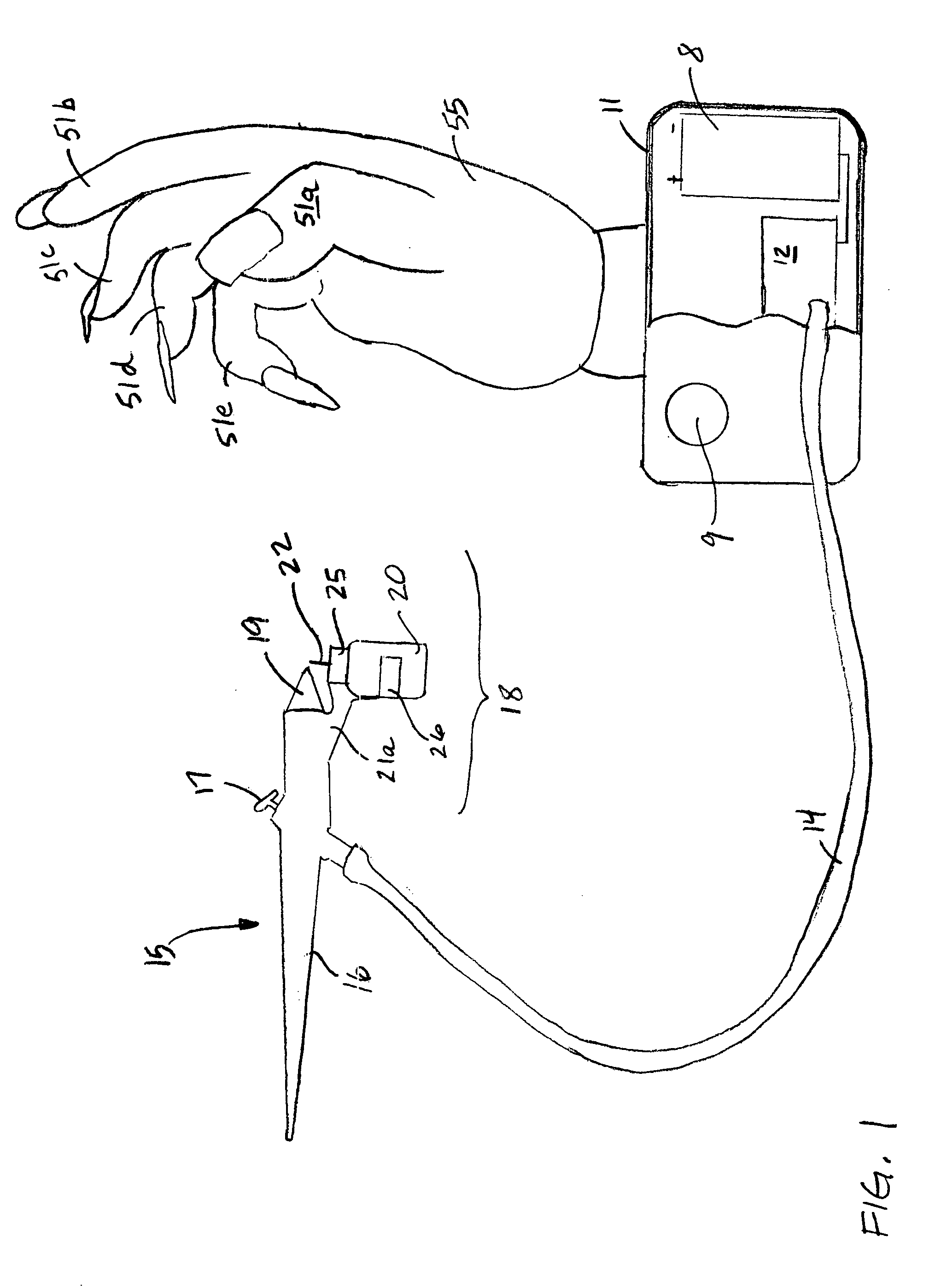

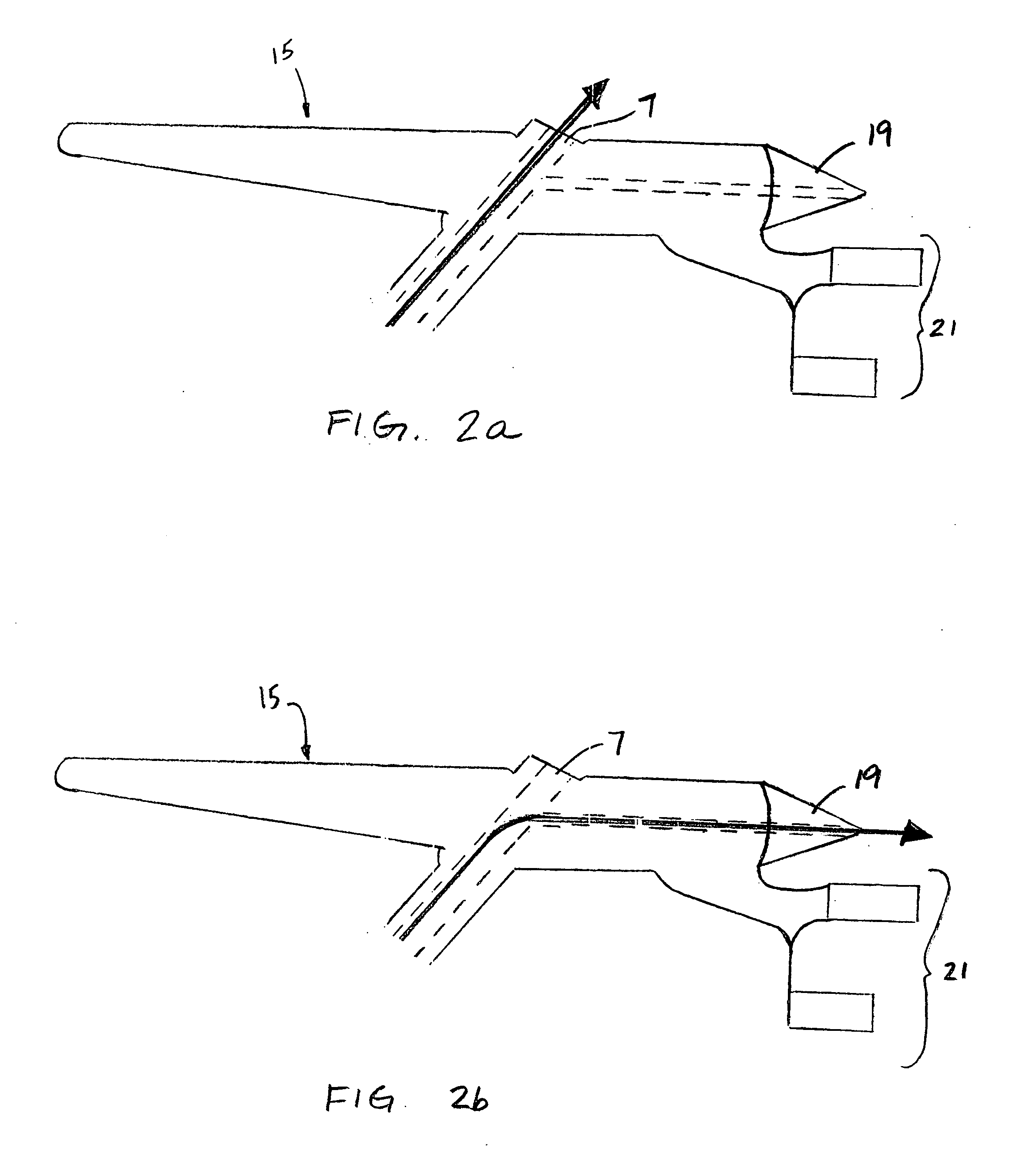

InactiveUS20050016448A1Optimization mechanismFacilitating stencilingLiquid surface applicatorsFire rescueEngineeringBottle

A portable airbrush with improved mechanisms for aerosolizing paint and for facilitating stenciling. The device utilizes an air compressor that is compact, portable and relatively lightweight. The air compressor is housed in a base that has projections to hold stencils in positions that make it easier for a person to spray his or her own nails. The stencils are removably attached to the projections with stencil fasteners. The mechanism for aerosolizing the paint arranges an air-emitting nozzle, a paint-emitting needle, and its attached paint reservoir in such a way that when the nozzle and paint reservoir are removed from the wand, substantially no residual paint remains in the wand. The air compressor may be battery-powered or powered by house current, and the device may be packaged in a case with numerous stencils and refillable bottles of paint.

Owner:DILOU CAROLIN

Method and apparatus for printing on a substrate

InactiveUS20120042795A1Inking apparatusLiquid surface applicatorsScreen printingBiomedical engineering

A screen printing apparatus and method for applying paste to a substrate while agitating the paste through vibration or pulsating of one or more pulse sources. The screen printing apparatus may comprise a support structure including a frame, a stencil supported by the frame, a squeegee configured to contact the stencil and transfer the paste through apertures of the stencil, and at least one pulse source attached to the support structure and configured to agitate the paste on the stencil. The pulse sources may be configured to attach to and vibrate the frame, squeegee, or other components contacting the paste. Some of the pulse sources may vibrate in different directions relative to each other. In some embodiments of the invention, the pulse source may be configured to be directly inserted or immersed in the paste resting on the stencil during various steps of the printing method.

Owner:PRECO

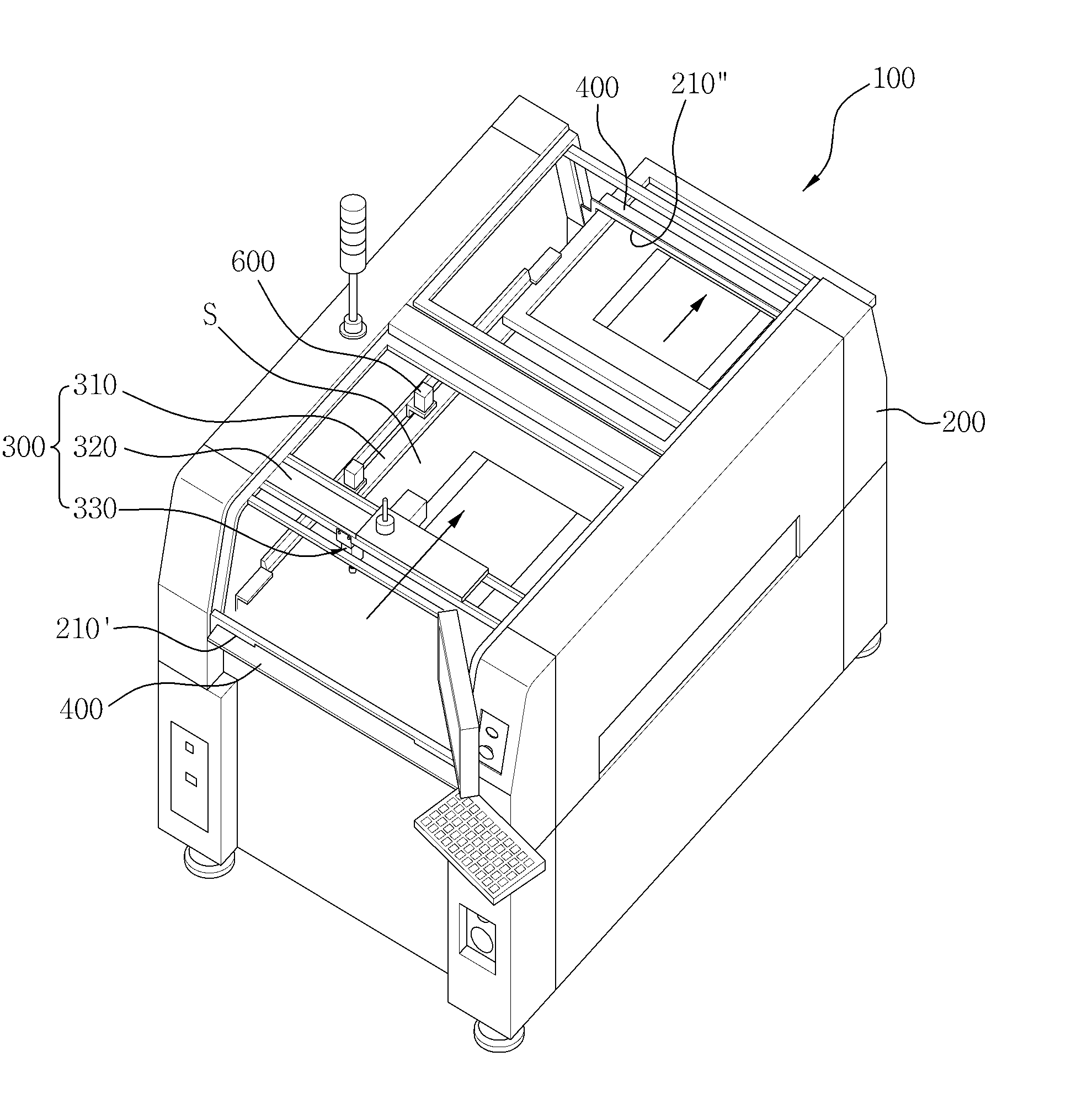

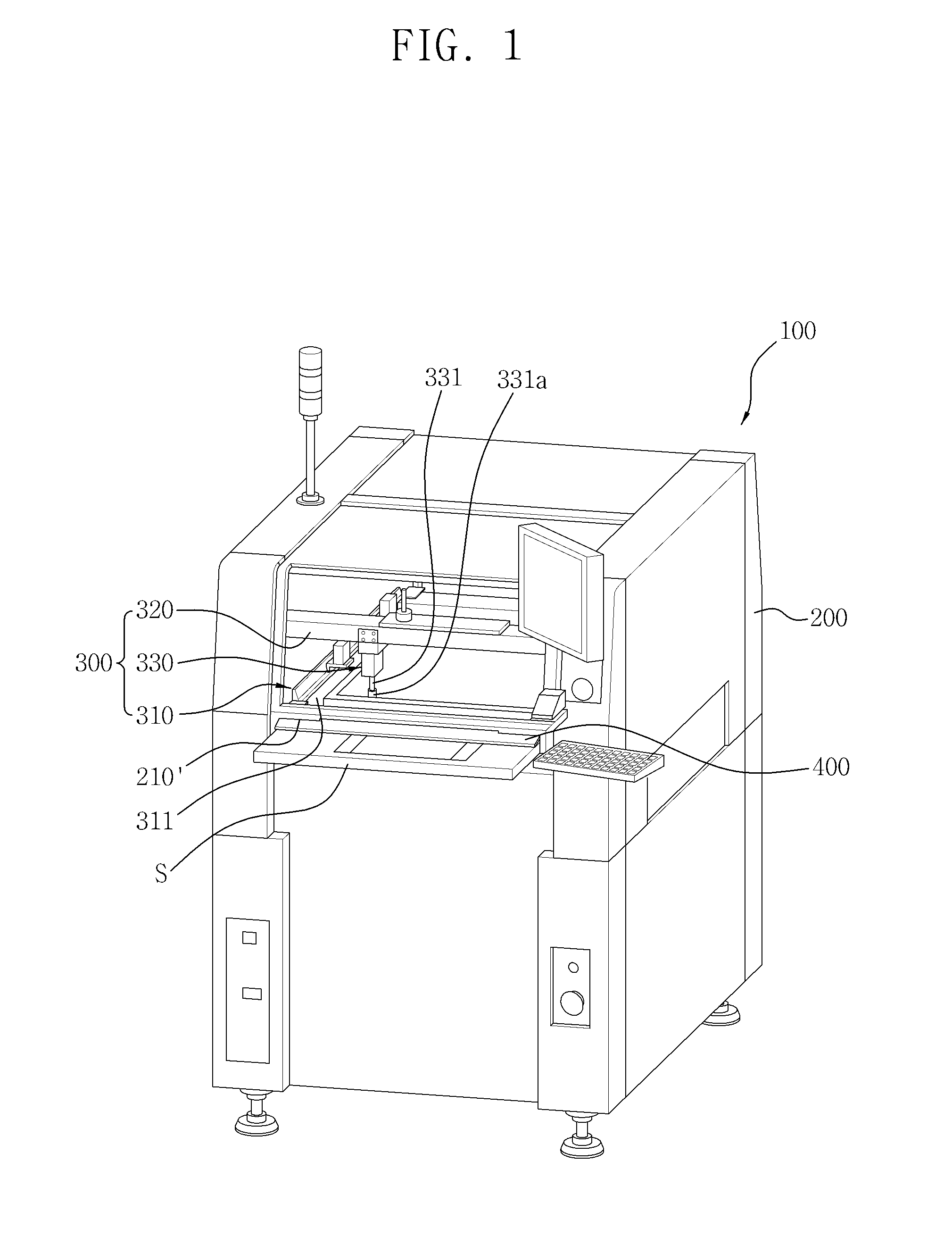

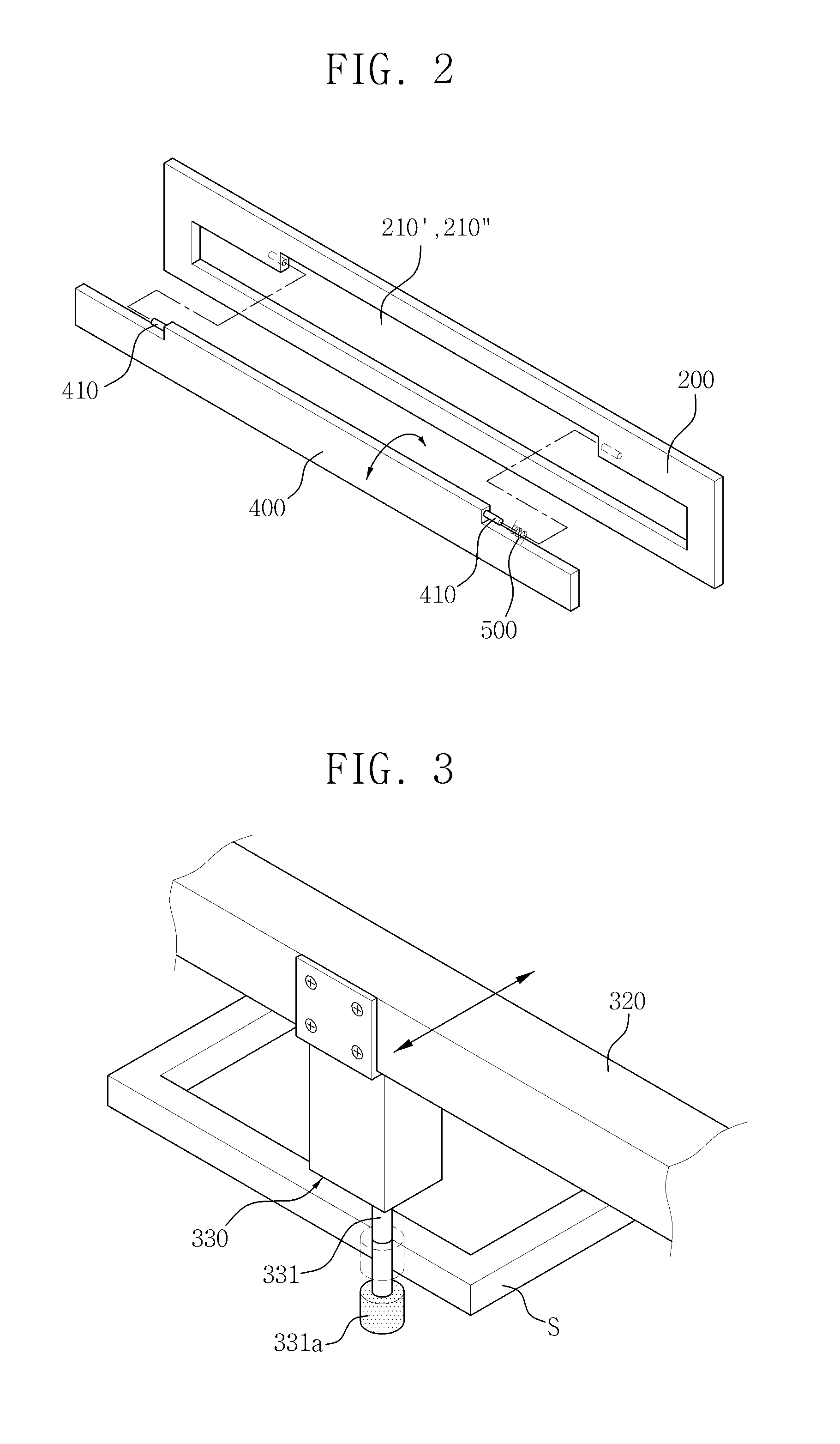

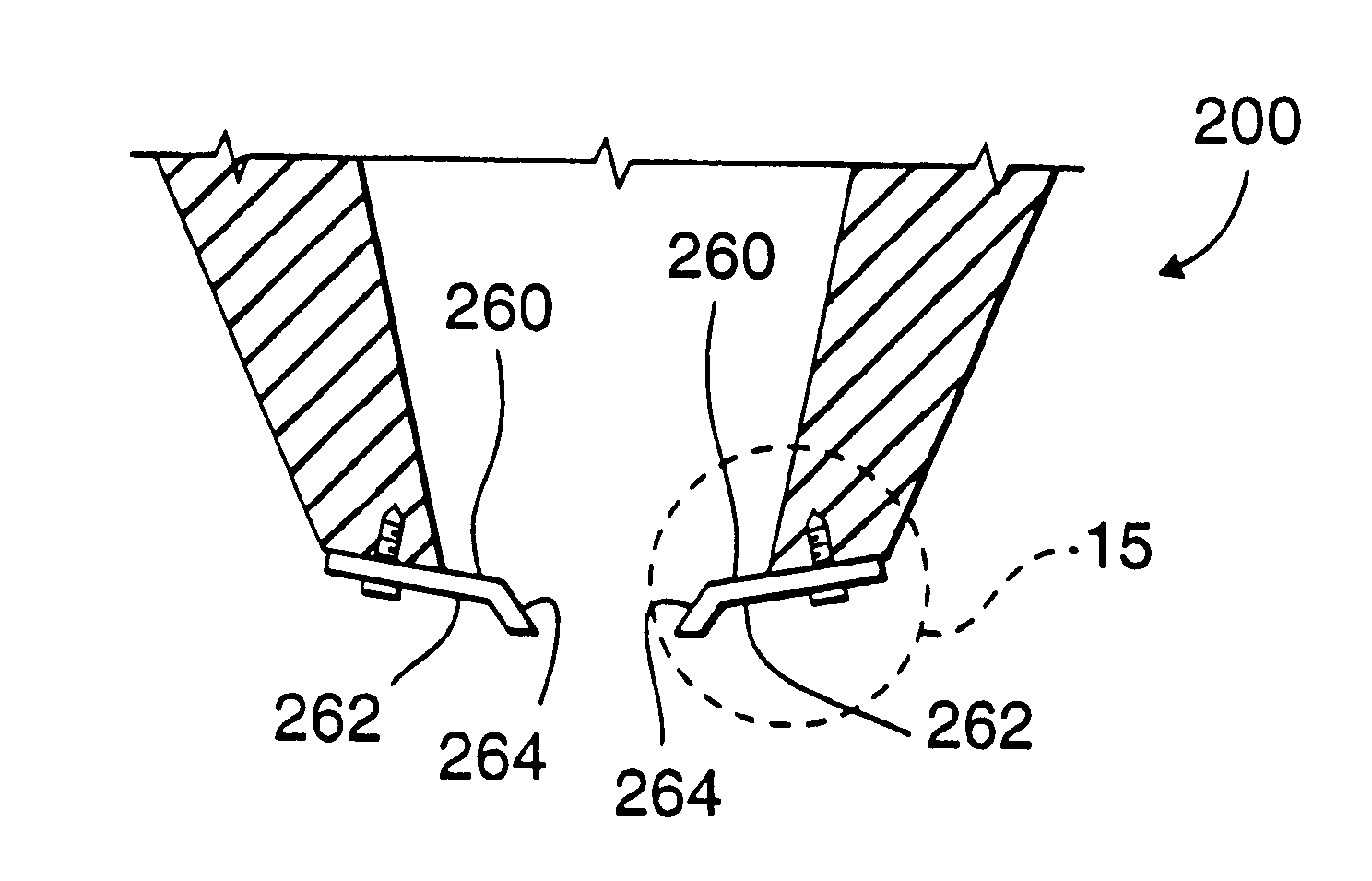

Method and apparatus for supporting and clamping a substrate

A stencil printer for printing viscous material on a substrate includes a frame, a stencil coupled to the frame, and a print head, coupled for the frame, to deposit and print viscous material over the stencil. The stencil printer further includes a substrate supporting and clamping assembly to support and clamp a substrate in a print position. The substrate supporting and clamping assembly includes at least one support member to support the substrate in a print position, a pair of rail members, coupled to the frame, adapted to engage opposite edges of the substrate, and a clamping mechanism, coupled to the frame, to move at least one of the rail members against the substrate to clamp the substrate. The clamping mechanism includes at least one piston to move the at least one of the rail members between a first position in which the rail member is spaced away from one of the opposite edges of the substrate and a second position in which the rail member engages one of the opposite edges of the substrate to clamp the substrate between the rail members during a print operation. The clamping mechanism further includes a pressure regulator to control a clamping force applied by the piston to the rail member against the edge of the substrate. A method for supporting and clamping a substrate in a print position is further disclosed.

Owner:SPEEDLINE TECH

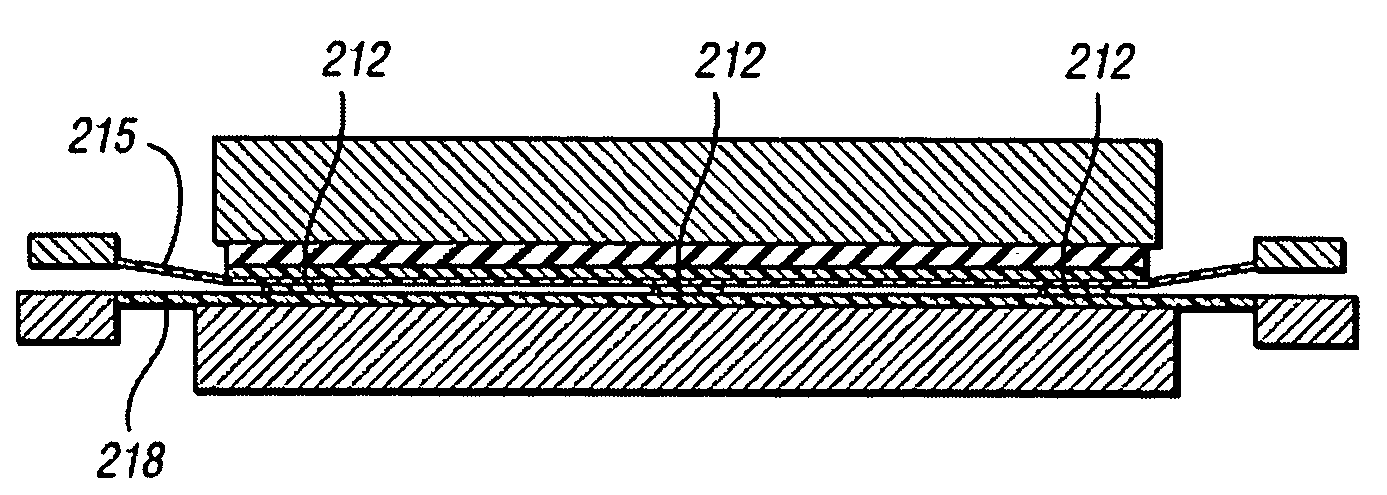

Method of transferring a membrane image to an article in a membrane image transfer printing process

The present invention involves a method of transferring a membrane image to an article. The method comprises providing a printed decoration to be applied onto a low surface energy membrane. The low surface energy membrane has a hardness level of greater than 70 durometer Shore A and a surface energy of up to 25 mJ / m2. The method further includes applying a predetermined pressure with a pressure device to force the printed decoration through a screen onto the low surface energy membrane. The pressure device has a hardness of up to 70 durometer Shore A. The method further includes forming the low surface energy membrane to the geometry of the surface of the article and applying pressure between the membrane and the article to transfer the membrane image from the membrane to the article.

Owner:EXATEC LLC

Screen printer

ActiveUS20110192296A1Reduce in quantityLiquid surface applicatorsStencilling apparatusPrinting pressBiomedical engineering

Provided is a screen printer including a main body in which an operation region and at least one introduction and extraction portion are formed, wherein the operation region includes an installation position of a stencil mask therein, and, through the at least one introduction and extraction portion, the stencil mask is introduced into the operation region and is extracted from the operation region to an outside of the main body; and a conveyance unit which conveys the stencil mask introduced into and disposed at the operation region to the at least one introduction and extraction portion when the stencil mask is replaced by a new stencil mask introduced through the at least one introduction and extraction portion, and conveys the new stencil mask to the operation region.

Owner:HANWHA AEROSPACE CO LTD

Inkjet printing apparatus

ActiveUS7040748B2Accurate printingLiquid surface applicatorsPlaten pressesDistance spaceMechanical engineering

An inkjet type fabric printing apparatus is provided with an inkjet head, a platen and a positioning member. The inkjet head reciprocally moves in main scanning direction and auxiliary scanning direction relative to a fabric (e.g., clothes). The platen holds the fabric to extend on a plane parallel with the main scanning direction and the auxiliary scanning direction with a first predetermined distance spaced from the inkjet head. On the positioning member, the fabric is set. The fabric is positioned on the platen in place in a direction parallel with the main scanning direction and the auxiliary scanning direction. The positioning member supports at least one of a neck portion and a shoulder portion of the fabric such that the neck portion and / or a shoulder portion is spaced from the inkjet head by a second predetermined distance.

Owner:BROTHER KOGYO KK

Portable airbrush with improved paint mechanism and stencil assembly

InactiveUS7798061B2Optimization mechanismEasier for a person to spray his or her own nailsLiquid surface applicatorsFire rescueGas compressorEngineering

A portable airbrush with improved mechanisms for aerosolizing paint and for facilitating stenciling. The device utilizes an air compressor that is compact, portable and relatively lightweight. The air compressor is housed in a base that has projections to hold stencils in positions that make it easier for a person to spray his or her own nails. The stencils are removably attached to the projections with stencil fasteners. The mechanism for aerosolizing the paint arranges an air-emitting nozzle, a paint-emitting needle, and its attached paint reservoir in such a way that when the nozzle and paint reservoir are removed from the wand, substantially no residual paint remains in the wand. The air compressor may be battery-powered or powered by house current, and the device may be packaged in a case with numerous stencils and refillable bottles of paint.

Owner:DILOU CAROLIN

Combination stencil printer and dispenser and related methods

A combination stencil printer and dispenser includes a frame, a stencil coupled to the frame, a substrate support coupled to the frame to support a substrate in a print position, and a print head coupled to the frame to deposit and print viscous material over the stencil. The combination stencil printer and dispenser further includes a dispenser mounted on an independent gantry to dispense viscous material on the substrate when the substrate is in the print position. In other embodiments, the dispenser can be mounted on a stencil wiper assembly or a movable stencil provided within the combination stencil printer and dispenser.

Owner:ILLINOIS TOOL WORKS INC

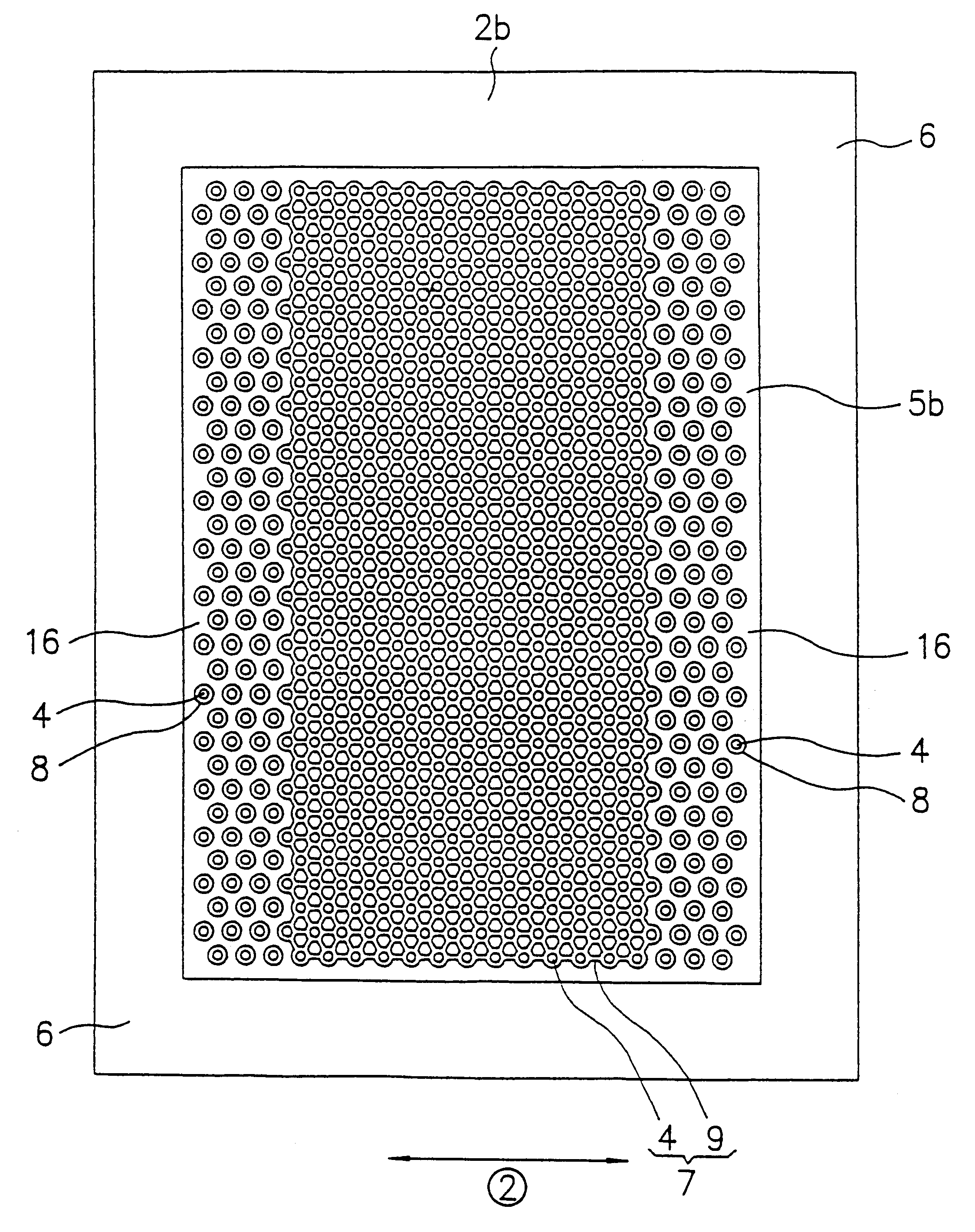

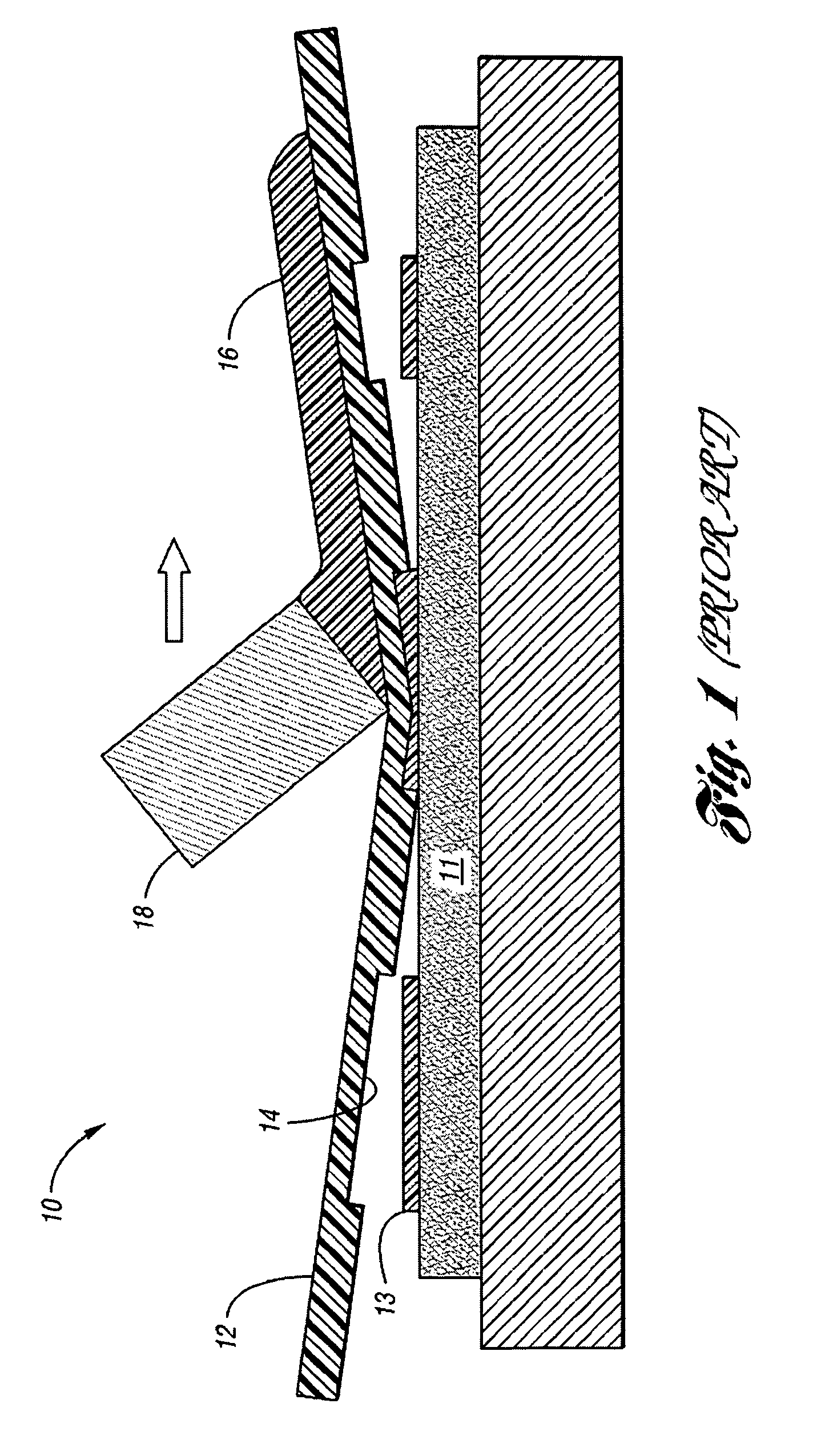

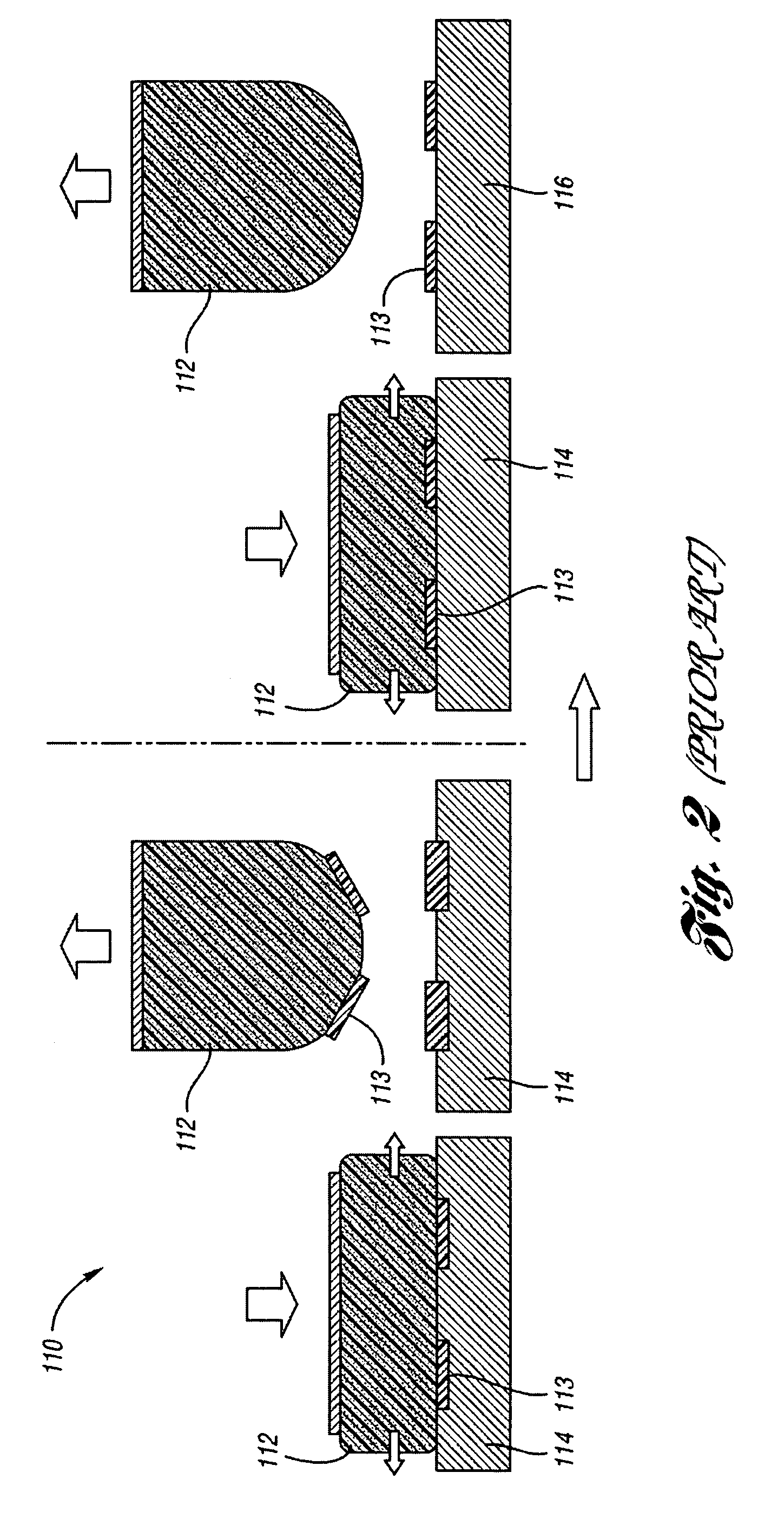

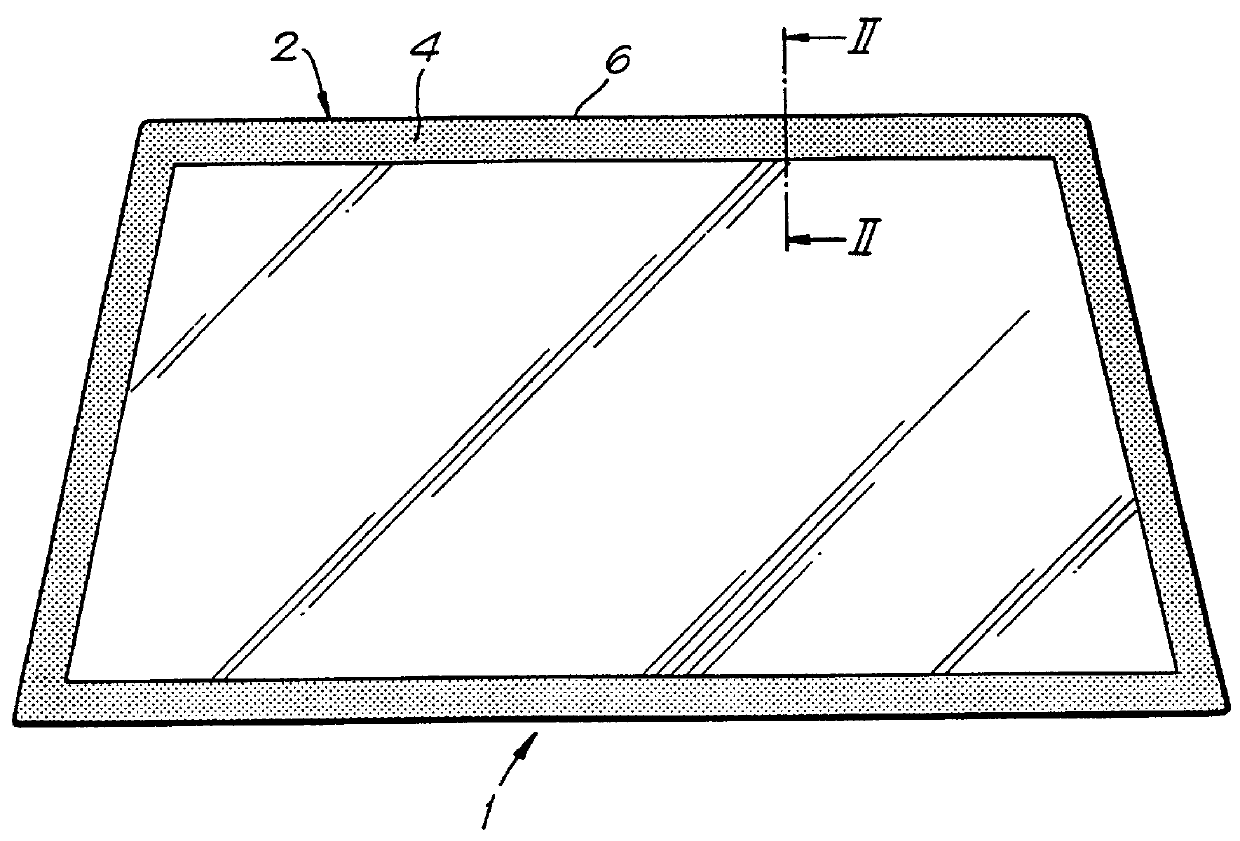

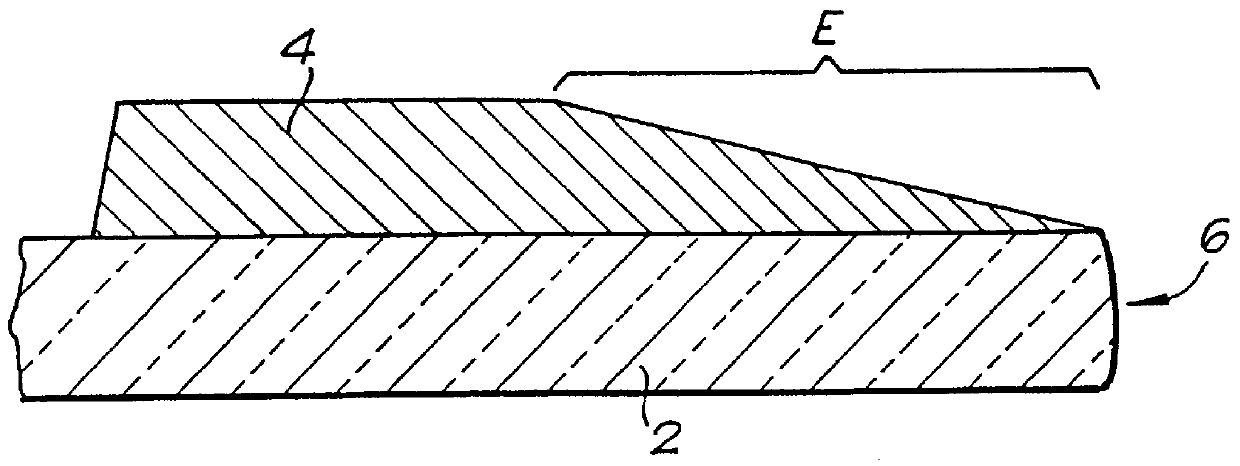

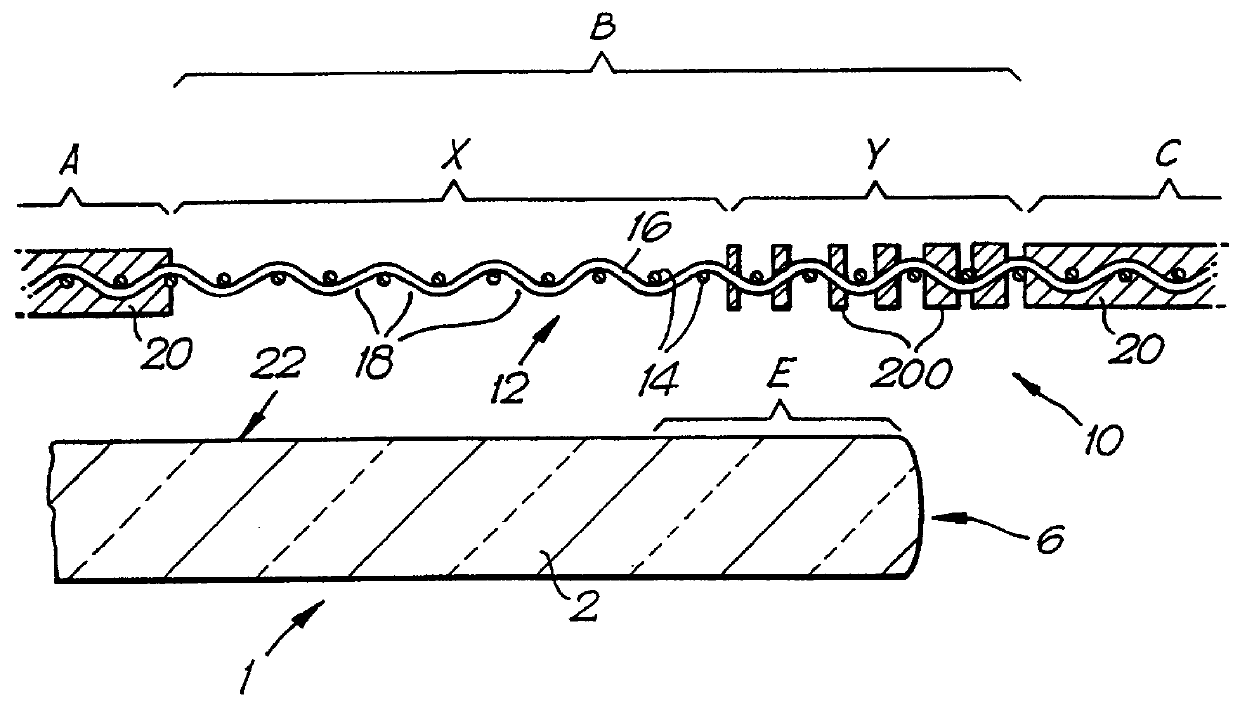

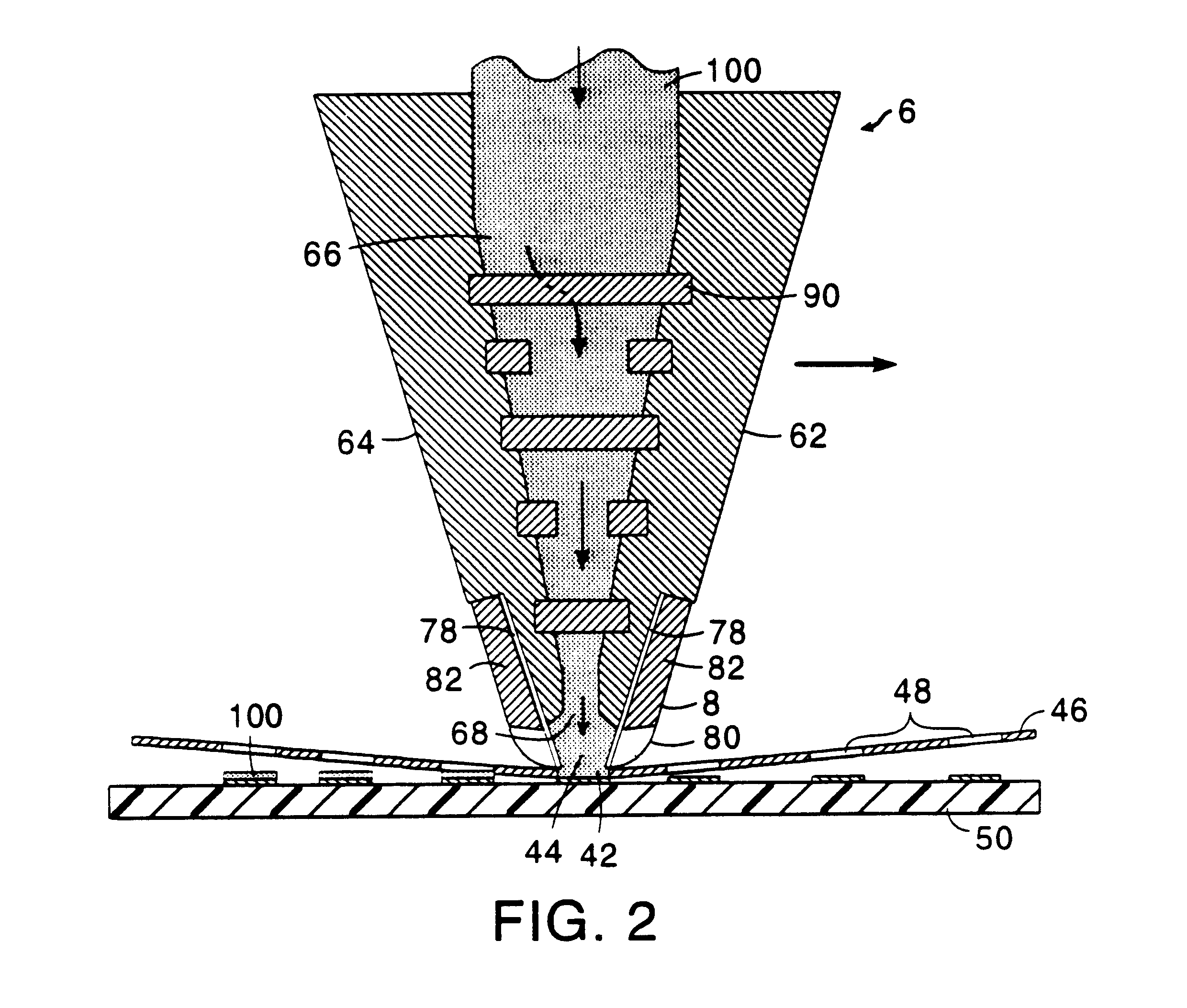

Method and apparatus for screen printing on a hard substrate

InactiveUS6032576AReduce processing timeReduced carrying capacityLiquid surface applicatorsScreen printersScreen printingEngineering

PCT No. PCT / GB96 / 01215 Sec. 371 Date Jan. 27, 1998 Sec. 102(e) Date Jan. 27, 1998 PCT Filed May 21, 1996 PCT Pub. No. WO96 / 40525 PCT Pub. Date Dec. 19, 1996A method of screen printing on to a hard non-absorbent substrate (1) involves using a screen (10) which has an ink permeable area (B) whose pattern corresponds to whatever is to be printed. The area B is divided into two parts (X and Y). Part X is of normal, maximum, ink carrying capacity and part Y is of reduced ink carrying capacity. The ink carrying capacity of the reduced ink carrying capacity part Yis determined by the extent to which it is coated with ink / impenetrable emulsion (20), the size of the pores (18) in the screen (10) and the type of ink used. The ink carrying capacity of the part Y reduces with distance away from part X. The emulsion coating (20) may be in the form of dots (200), with the dots (200) increasing in diameter with distance away from part X. During printing, the reduced ink carrying capacity part Y is located over the edge region (E) of the substrate (1), and the substrate is printed up to but not on to its edge (6).

Owner:PILKINGTON AUTOMOTIVE UK

Method and apparatus for dispensing viscous material

InactiveUS6286422B1Printed circuit assemblingLiquid surface applicatorsBiomedical engineeringViscous material

A novel apparatus for compressing viscous material through openings in a stencil is disclosed. The novel apparatus has a compression head cap which provides a contained environment to direct and to aid the flow of pressurized viscous material through the openings in the stencil.

Owner:VISTEON GLOBAL TECH INC

Screen printing apparatus and screen printing method

ActiveUS20080289518A1Improve positional deviation stateLiquid surface applicatorsInking apparatusScreen printingEngineering

In supply of feedback data to improve a positional deviation quantity and a deviation state of a soldering paste printed on individual substrates held on the carrier, a plurality of average values of individual positional deviation for each of the individual substrates are obtained, and then, if the deviation value ΔM indicating a difference between the maximum value Mmax and the minimum value Mmin of the plurality of average values M of individual positional deviation is less than or equal to the tolerance value Δ(t), an intermediate value of the maximum value Mmax and the minimum value Mmin is obtained, and the positioning parameters of the mask plate and the carrier are corrected based on the intermediate value (Mmax+Mmin) / 2.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com